Radial extrusion type magnetorheological fluid brake

A magneto-rheological fluid and brake technology, which is applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., can solve the problems of increased difficulty in brake processing, insufficient compact structure, and inconspicuous effects, achieving compact structure, simple assembly, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

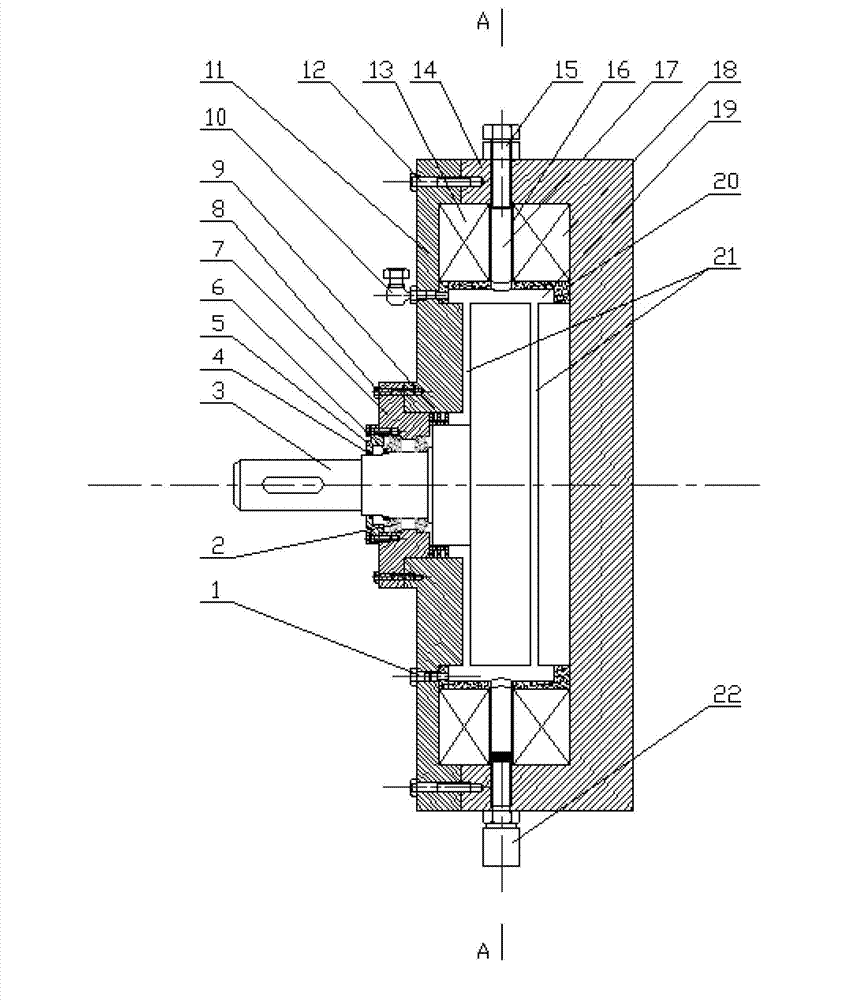

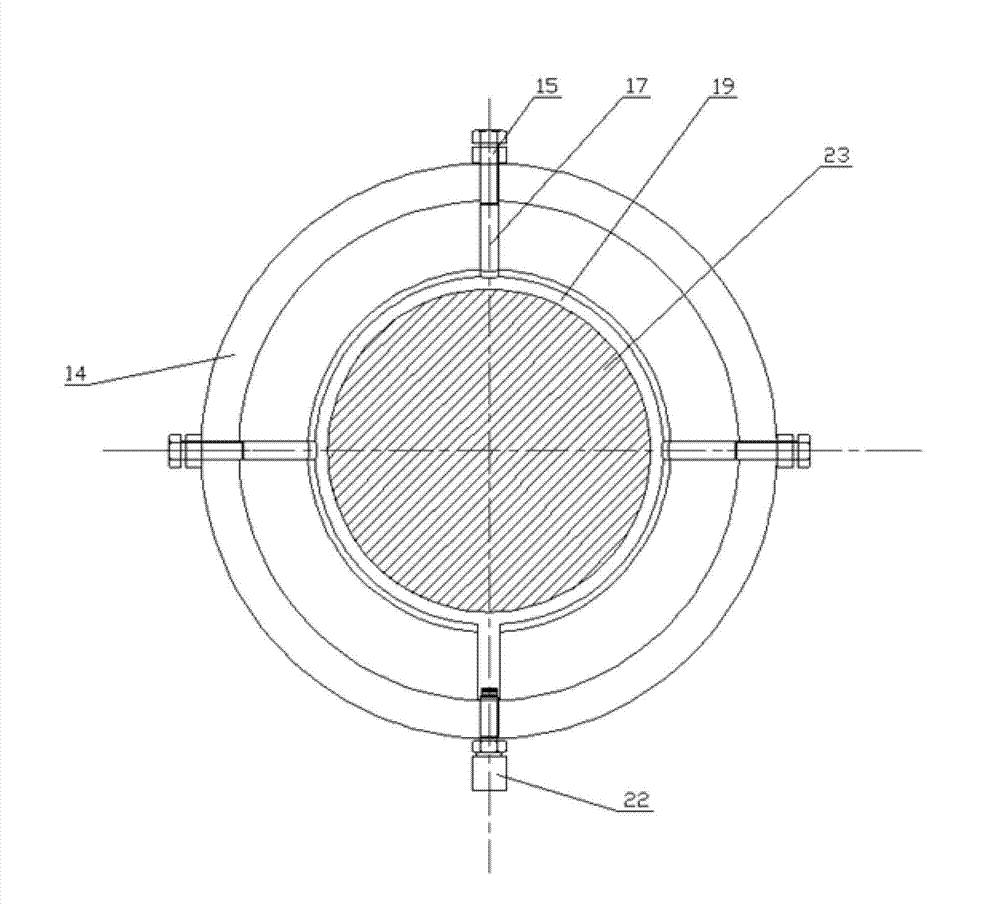

[0013] Such as figure 1 As shown, the radial extrusion magneto-rheological fluid brake includes liquid outlet 1, tapered roller bearing 2, transmission shaft 3, sealing ring 4, left end cover 5, lock nut 6, bearing seat 7, and fixing screws 8. Rotating sealing ring 9, liquid inlet 10, left magnetically conductive shell 11 and left excitation coil 13, transmission shaft 3 is connected with bearing housing 7 through paired tapered roller bearings 2, and lock nut 6 connects the tapered roller bearings 2 Locked on the transmission shaft 3, the bearing seat 7 is fastened on the left magnetic shell 11 through the fixing screw 8 and the rotating sealing ring 9, and the sealing ring 4 is fixed on the fixed left end cover 5, and is fixed on the bearing by the fastening screw On the left end of the seat 7, the left magnetic conduction shell 11 is provided with a liquid inlet 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com