Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Increase braking torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

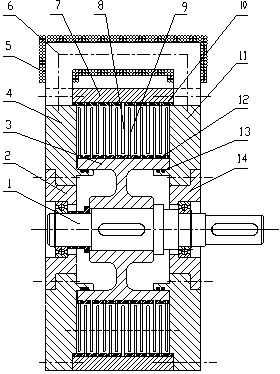

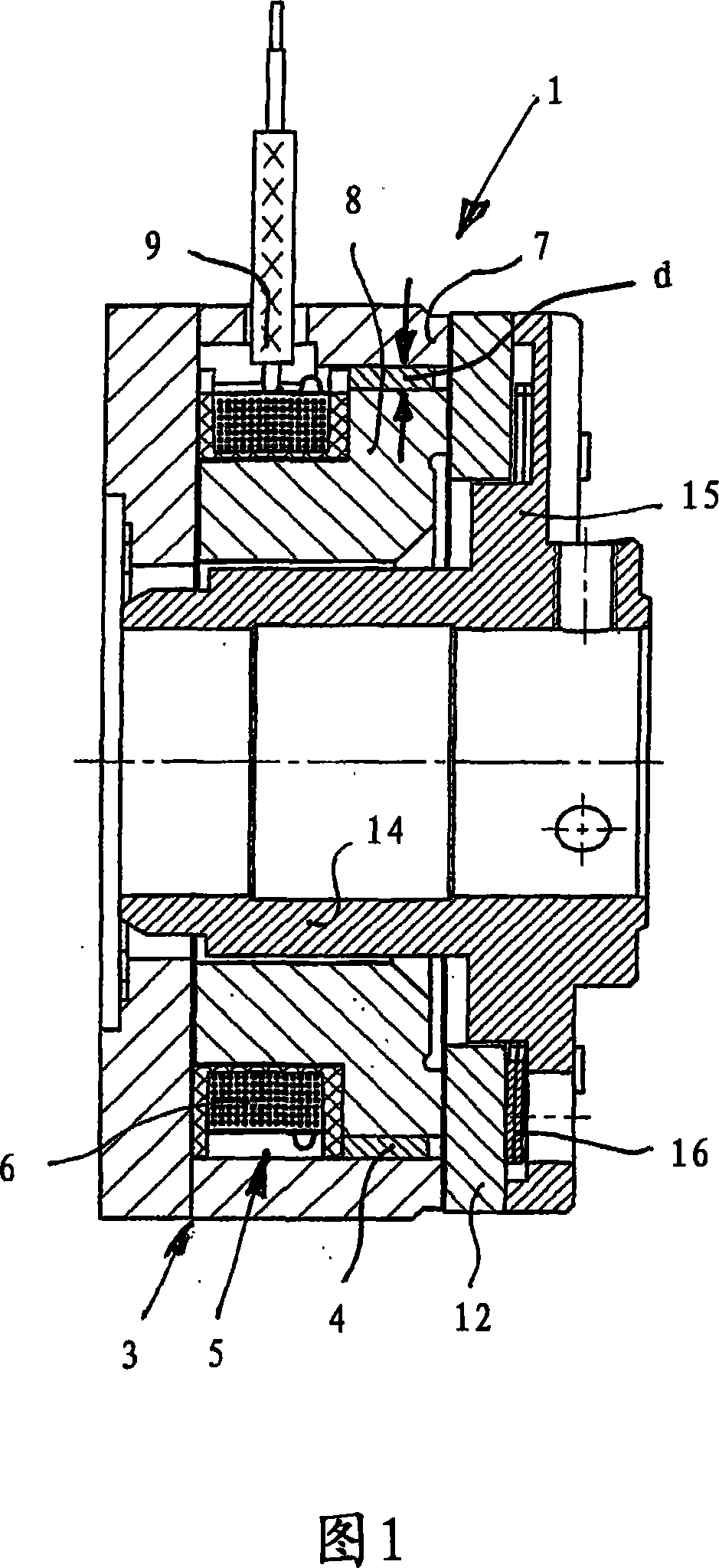

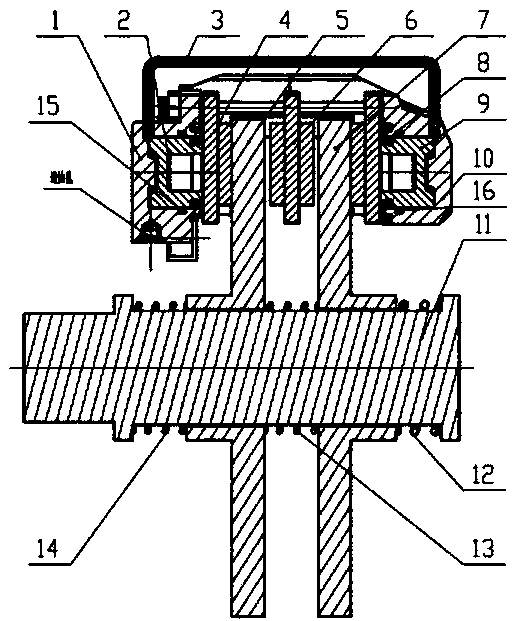

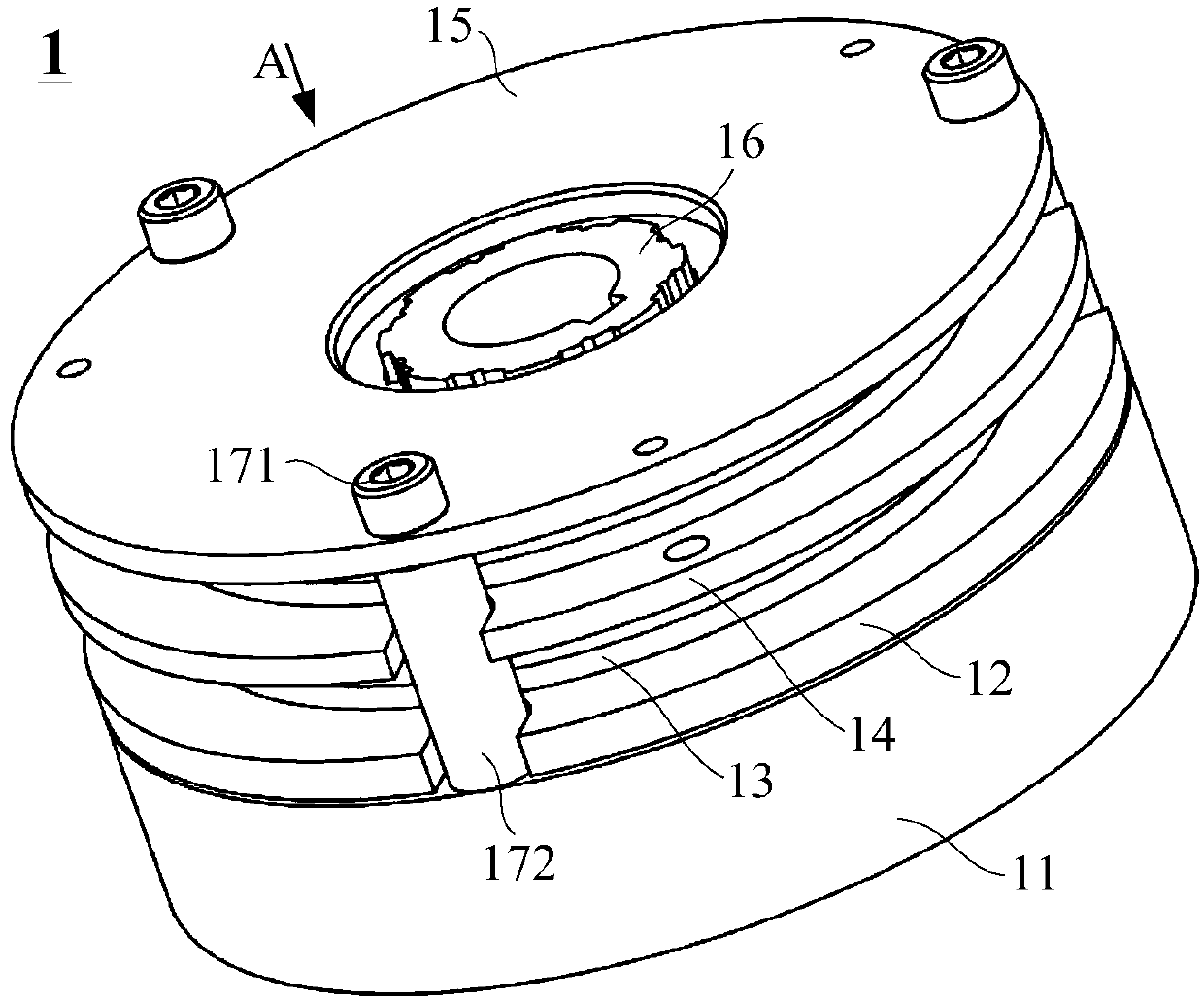

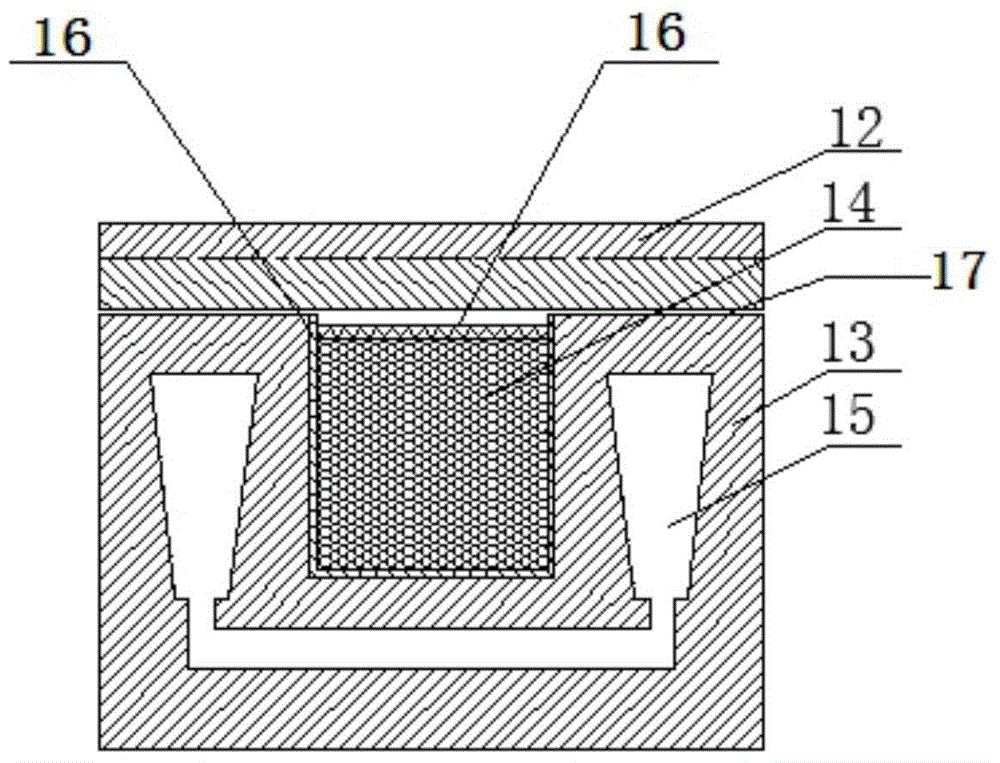

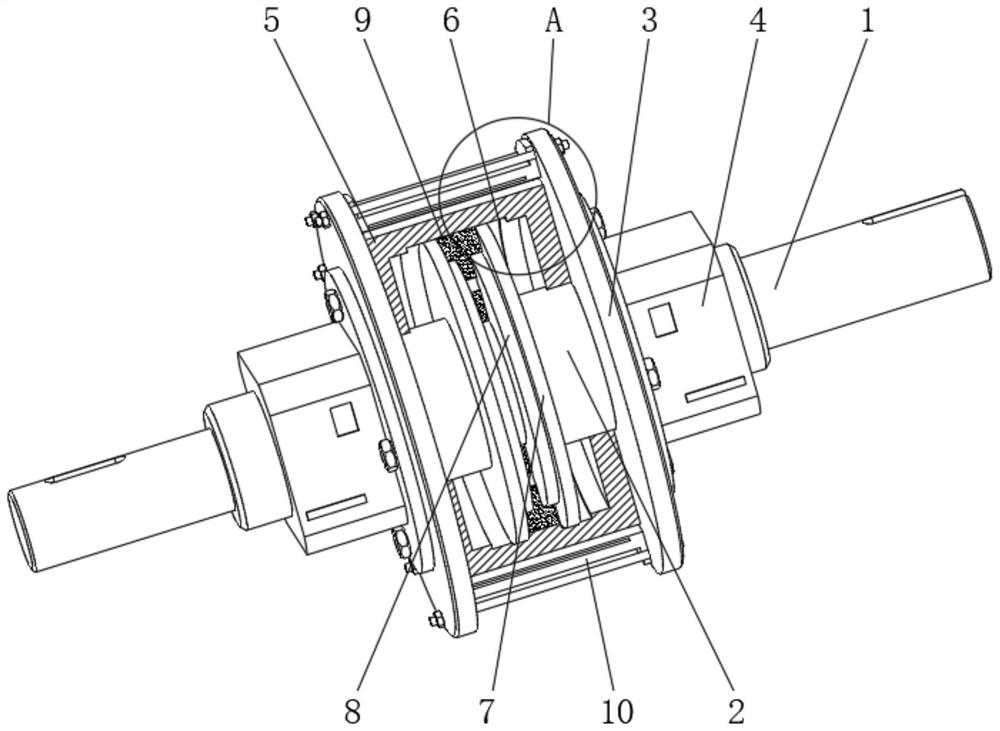

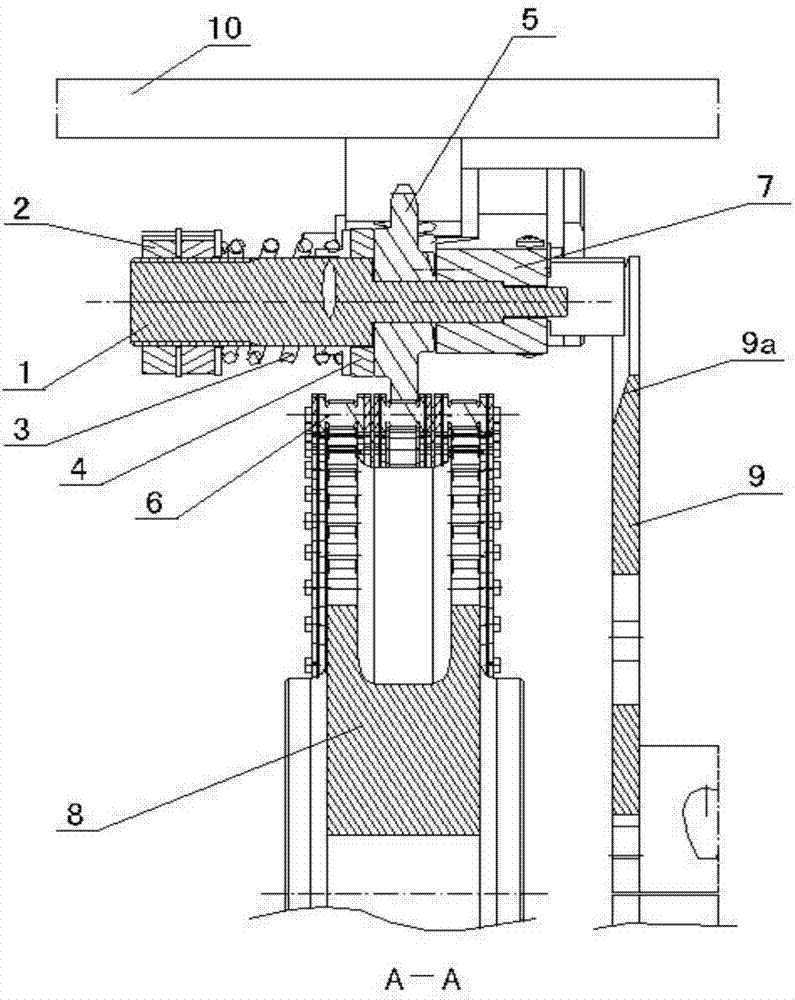

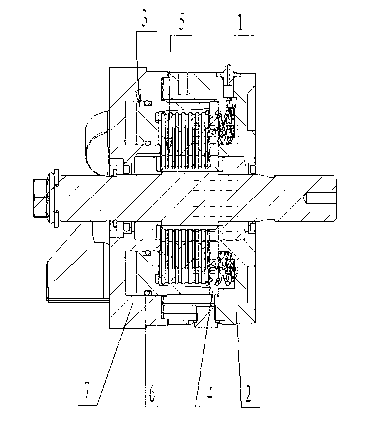

Multiple-disc type magnetorheological brake

InactiveCN102146968AGood heat dissipationImprove cooling effectLiquid resistance brakesMagnetic currentBrake torque

The invention relates to a multiple-disc type magnetorheological brake which mainly comprises a transmission shaft, a wheel hub, a drive friction plate group, a driven friction plate group, inner and outer magnetic isolation rings, an exciting coil with a U-shaped iron core, magnetic-conducting side plates and a magnetic isolation casing. A sealing ring is used for sealing magnetorheological fluid between the drive friction plate group and the driven friction plate group; the drive friction plate group and the driven friction plate group are respectively sleeved on the magnetic isolation rings and the wheel hub through splines; the drive friction plate group is separated from the driven friction plate group by the inner magnetic isolation ring and the outer magnetic isolation ring; the exciting coil with the U-shaped iron core is directly spliced in iron core jacks of the magnetic conducting side plates; and the braking torque can be changed through changing the current intensity of the coil. When the braking torque is not enough, the quantity of friction plates can be increased or the quantity of the exciting coil with the U-shaped iron core can be increased to adapt to the big torque braking. The multiple-disc type magnetorheological brake has the advantages that the structure is compact, the braking torque is big, the assembly and the disassembly are convenient, the coil is easily used for radiating the heat, and the number of turns wounded by the coil is more.

Owner:CHINA UNIV OF MINING & TECH

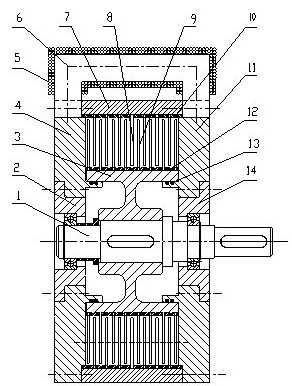

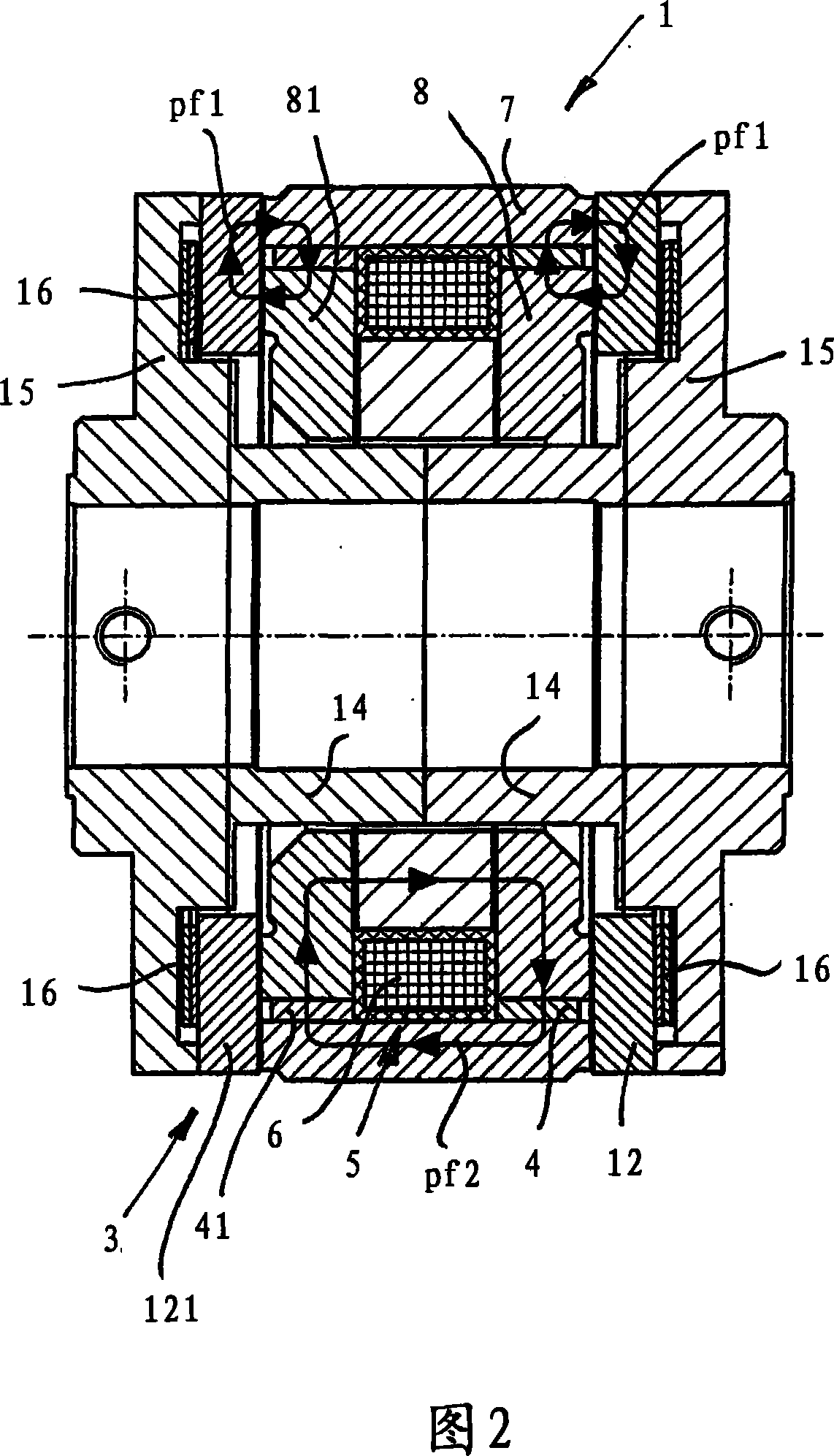

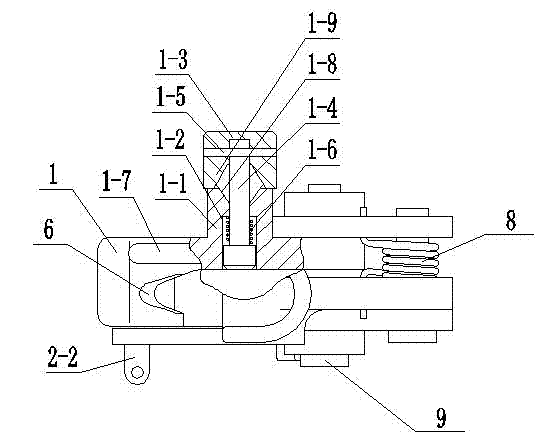

Radial extrusion type magnetorheological fluid brake

InactiveCN103089863AIncrease shear stressImprove reliabilityLiquid resistance brakesDrive shaftMagnetorheological fluid

The invention discloses a radial extrusion type magnetorheological fluid brake, and belongs to the field of hydraulic resistance brakes. On the basis of an existing device, a right guiding magnetic brake outer shell, a pressurization device, a coil fixing ring, pressurization channels, a right magnet exciting coil and a separation magnet ring are added to the brake, wherein the right guiding magnetic brake outer shell is arranged on the right of a left guiding magnetic brake outer shell, a gap is reserved between the right guiding magnetic brake outer shell and the left guiding magnetic brake outer shell, and the pressurization device is arranged on the outer circumference of the right guiding magnetic brake outer shell; a magnetorheological fluid gap is formed between a driving shaft and the right guiding magnetic brake outer shell, the other magnetorheological fluid gap is formed between the driving shaft and the left guiding magnetic brake outer shell, and a left magnet exciting coil, the right magnet exciting coil and the separation magnet ring are arranged in the gap formed between the right guiding magnetic brake outer shell and the left guiding magnetic brake outer shell; and the left magnet exciting coil and the right magnet exciting coil are fixed through the coil fixing ring, the pressurization channels are respectively arranged on the right guiding magnetic brake outer shell, the coil fixing ring and the separation magnet ring. The radial extrusion type magnetorheological fluid brake is simple in assembling and compact in structure, provides large braking torque, meanwhile enhances device reliability, and reduces energy consumption.

Owner:CHINA UNIV OF MINING & TECH

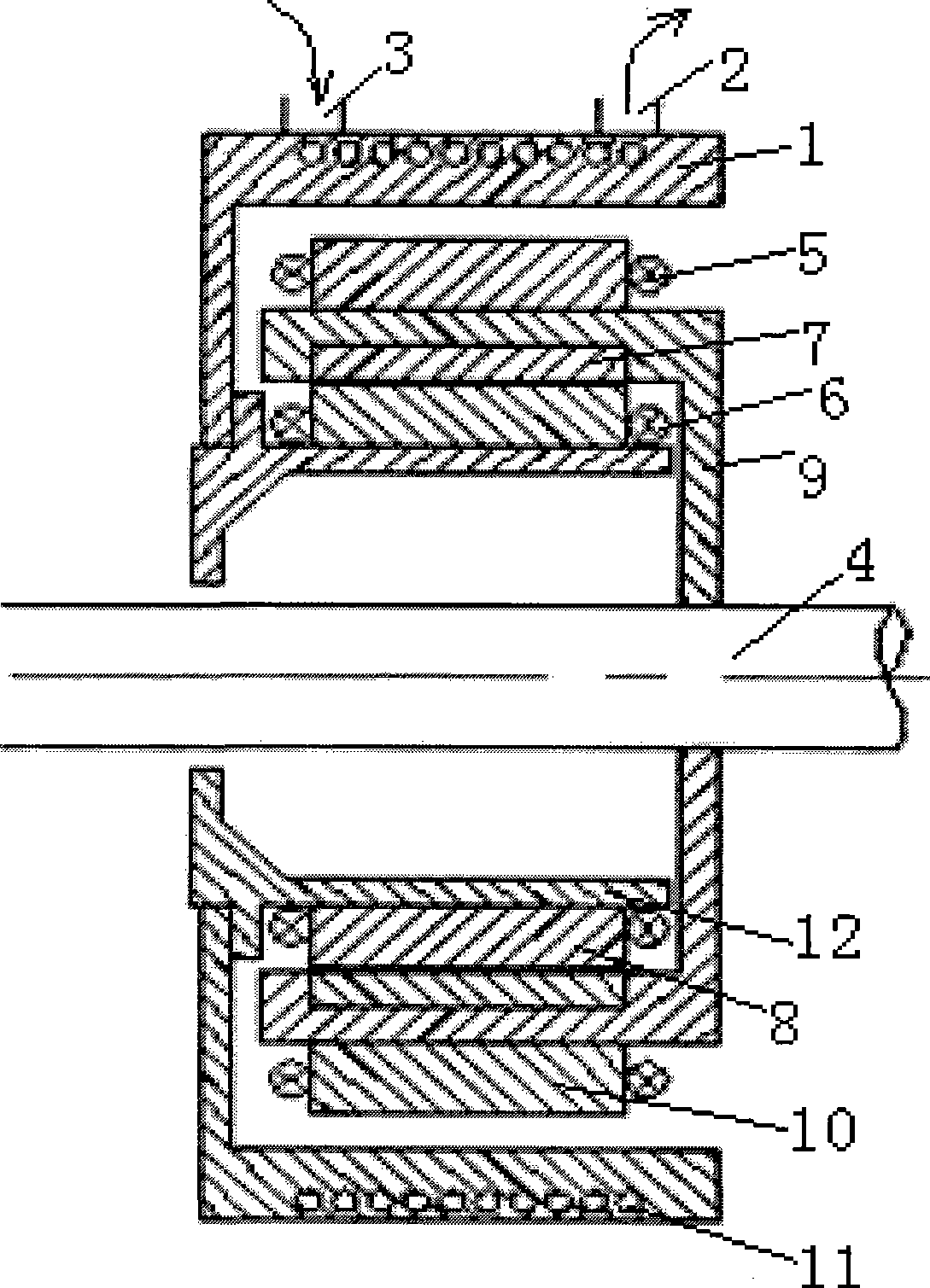

Electromagnetic permanent magnet brake

ActiveCN101115937AConstant torqueRaise or enlarge the magnet surfaceAxially engaging brakesBrake actuating mechanismsMagnetic tension forceSpring force

An electromagnetic brake (20), in particular for an electric drive is provided, having a brake body (3), which is provided with a sleeve-shaped permanent magnet (4), an electromagnet (5) with an exciting coil (6), an external ring in the form of an external pole and an internal ring (8) in the form of an internal pole, wherein an armature disc (12) rotatably connected to a shaft is attractable against the brake body (3) or the external or internal ring surfaces by the permanent magnet (4) force acting against a return spring force. When the exciting coil is powered, the permanent magnet (4) magnetic field is compensated in such a way that the armature disc (12) is lifted up from the brake body (3) by the spring force, thereby allowing the brake to be released. A radial cross-sectional dimension or cross-sectional thickness d of the permanent magnet (4) is smaller than the axial dimension thereof and a spatial arrangement, viewed in the axial direction, is provided between the armature disc (12) and the exciting coil (6) in the area radially external with respect to the exciting coil (6) or the housing thereof.

Owner:KENDRION VILLINGEN GMBH

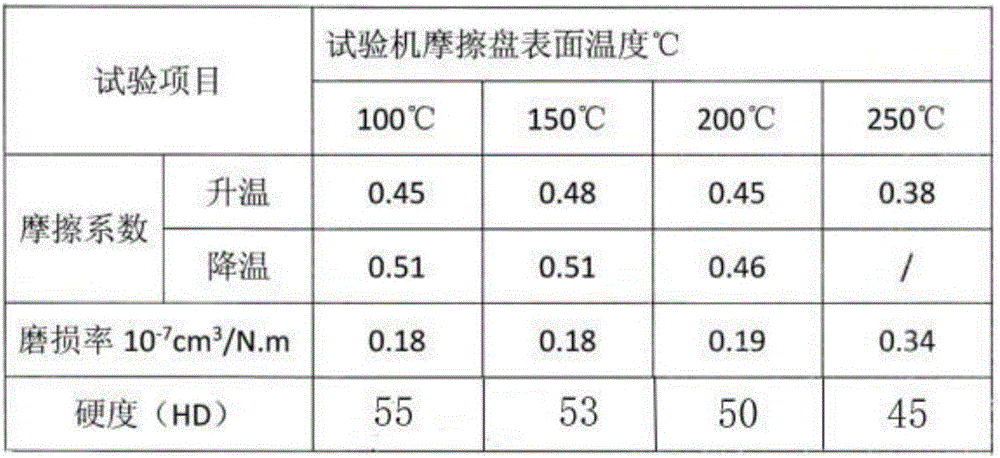

Copper-base powder metallurgical brake pad material for sea-base wind turbine generator system and preparation process thereof

InactiveCN102002609AMeet the performance requirementsIncrease coefficient of frictionFriction liningFerrochromeSeawater

The invention provides a copper-base powder metallurgical brake pad material for a sea-base wind turbine generator system, which comprises the following components in percentage by weight: copper, FWCuZn30 brass, graphite, sea sand, silicon carbide, ferrochrome and tin. The preparation process of the brake pad material comprises the following five steps: blending materials, pressing blank, making support steel backing, pressurizing and sintering in sections, and machining for molding. In the invention, by adopting the seawater corrosion resistant brass as a material matrix and high-content nonmetal components the weight ratio of which is more than 30%, excellent corrosion resistance, high friction coefficient and high brake moment can be obtained, and the stability of friction coefficient is good; the obtained powder metallurgical brake pad material conforms to the service performance requirements for a high-speed shaft braking device of the sea-base high-power wind turbine generator system; the material has the advantages of rational component proportion, simple machining process, good corrosion resistance, high friction coefficient, good friction coefficient stability and high strength, and is suitable for industrialized production; and the copper-base powder metallurgical brake pad material can be taken as a high-speed shaft braking material for the sea-base high-power wind turbine generator system with the power of more than 3.5MW.

Owner:CENT SOUTH UNIV

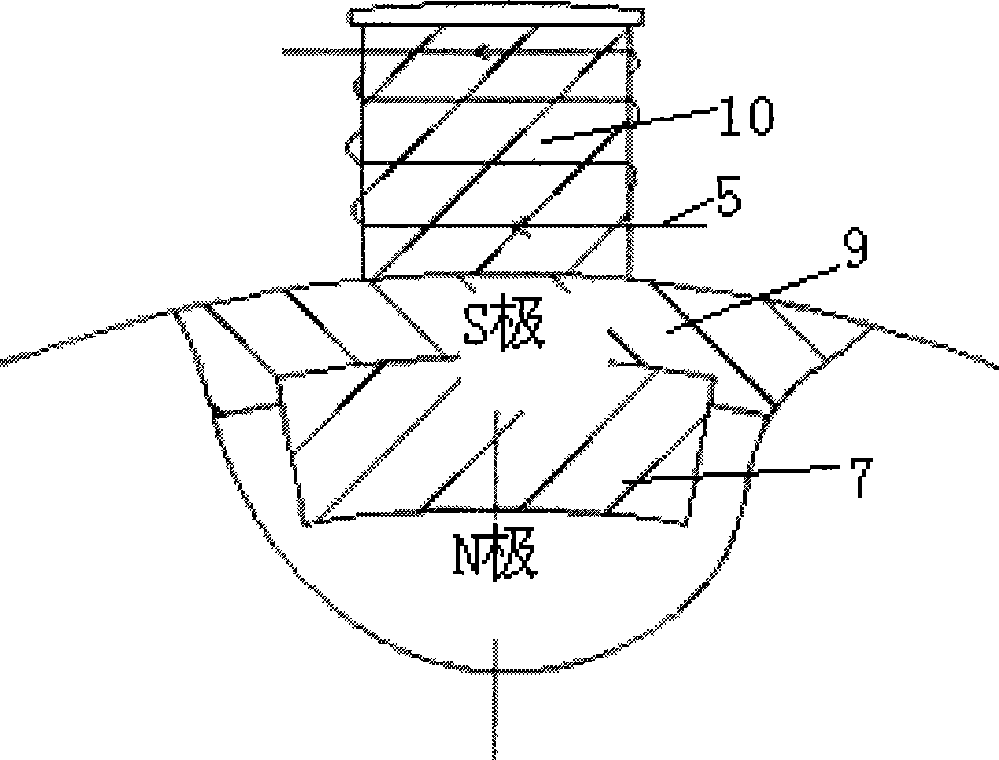

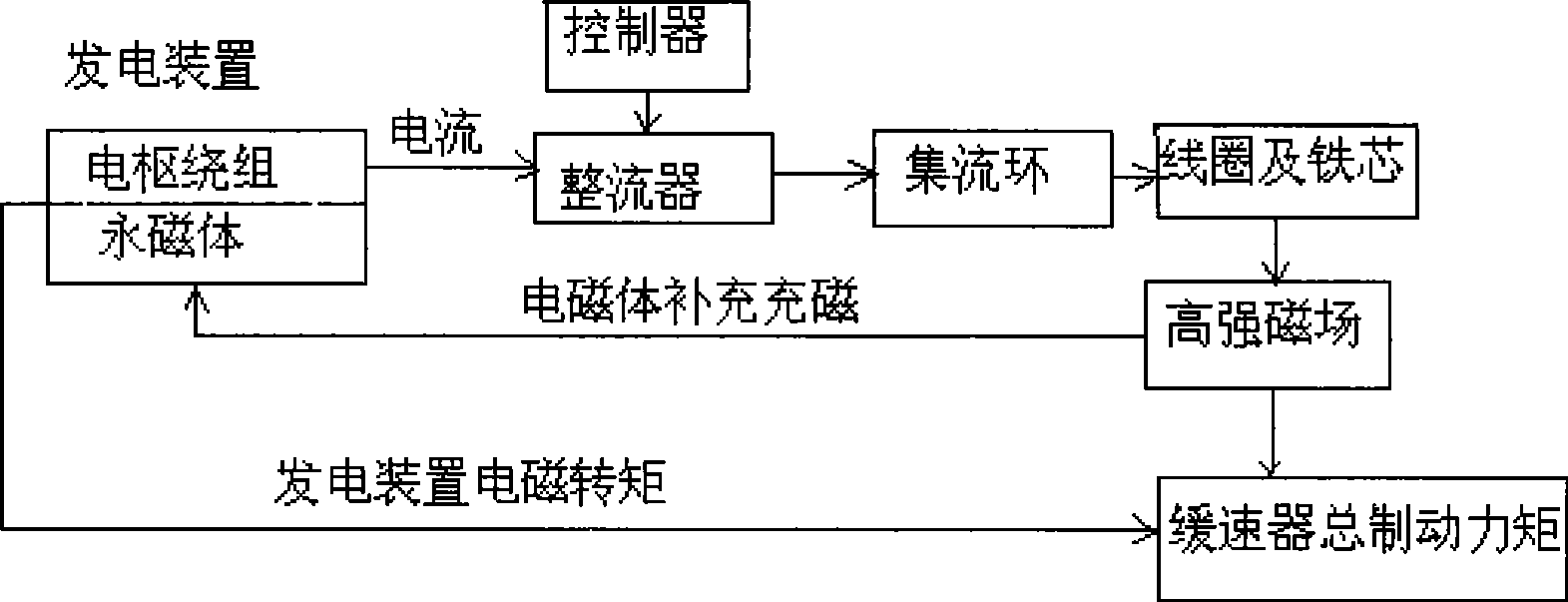

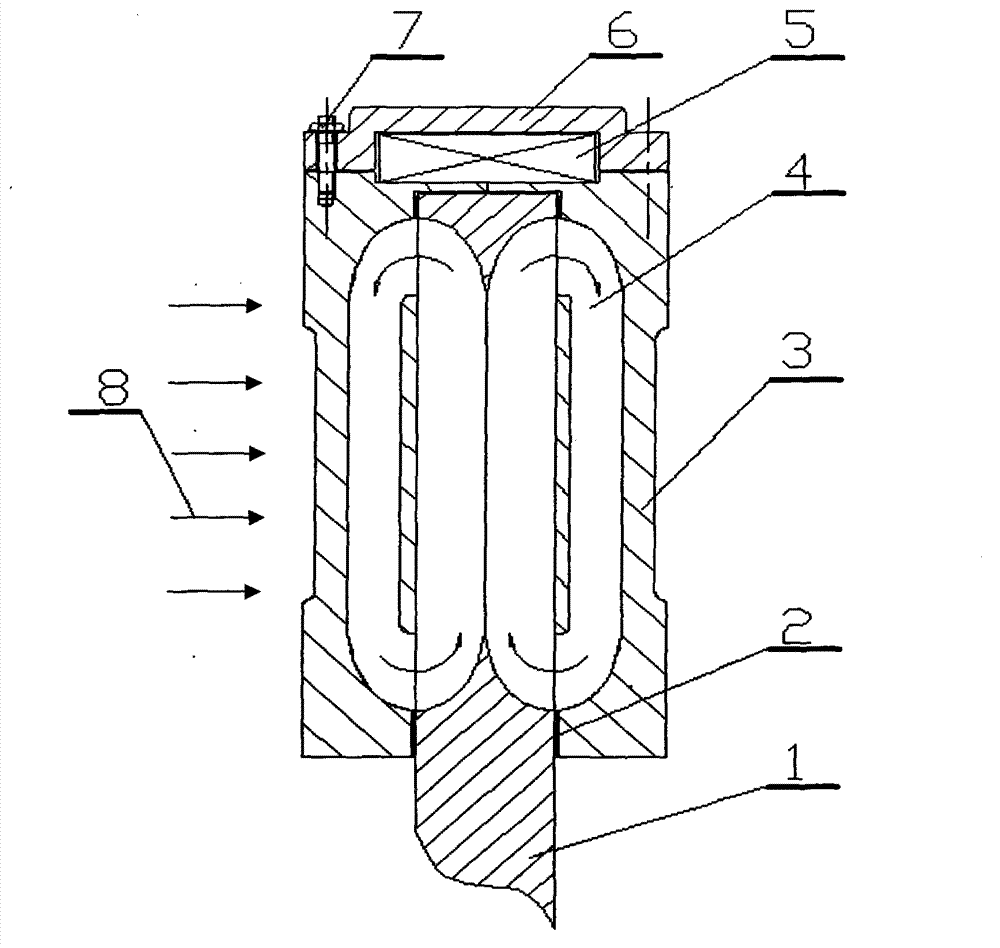

Self-excitation type speed inhibitor having water cooling system

InactiveCN101425737AIncrease the excitation currentIncrease braking torqueMagnetic circuit stationary partsAsynchronous induction clutches/brakesMagnetic polesGenerators (Apparatus)

The invention discloses an auto-excitation type retarder with a water-cooling system, which comprises a vortex induction cylindrical stator, a rotor, an iron core and a transmission axle, wherein the transmission axle is connected with the rotor, the stator is positioned on the outer layer of the rotor, the iron core and an exciting coil thereof are arranged outside the rotor, the permanent magnetic pole of an electric generator is arranged at the inner side of the rotor, and an armature and a coil thereof of a generating set are connected to a stator fixing frame; a cooling water channel is arranged inside the stator, a water channel outlet and a water channel inlet are arranged on the surface of the stator, and the cooling water channel is communicated with the outside via the water channel outlet and the water channel inlet. When a vehicle brakes at moderate speed, the load of the engine is reduced, the requirement for the heat dispersion is also lowered, therefore, the cooling fluid in the cooling water channel can be directly adopted for cooling for the retarder. The invention has the advantages of simple structure, saved energy resources, enhanced generating capacity of the generating set for the retarder, increased exciting current of the retarder and increased braking torque and retarded braking effect of the retarder.

Owner:JIANGSU UNIV

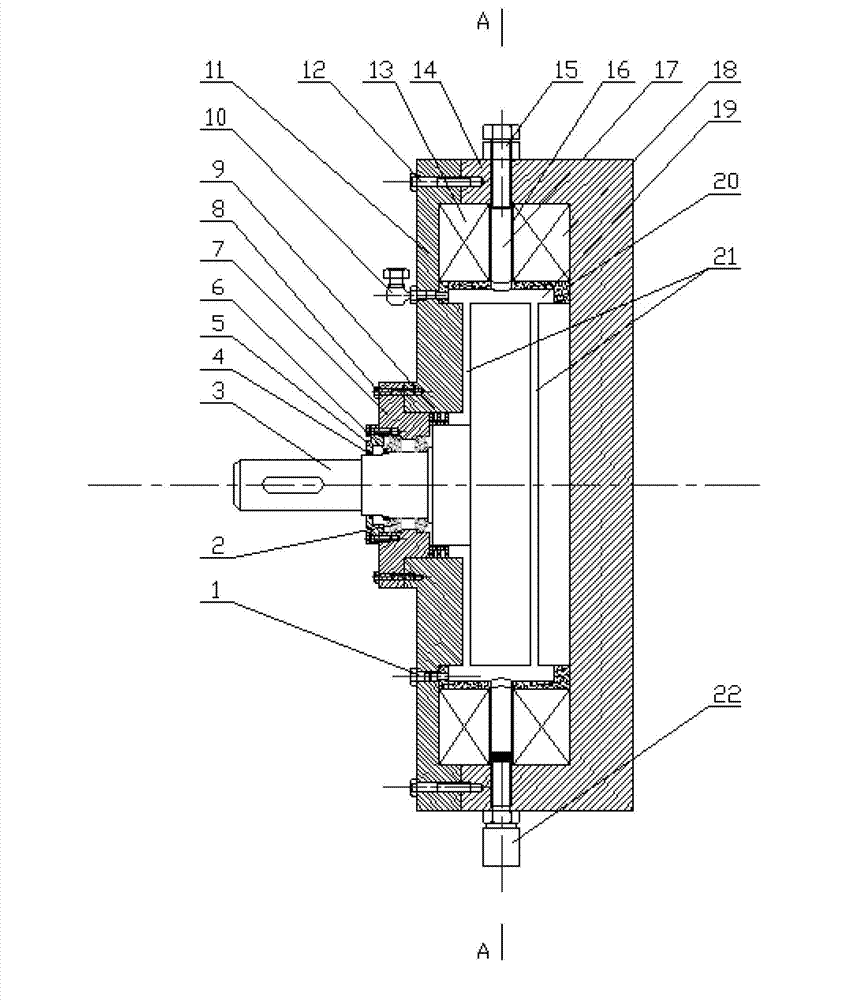

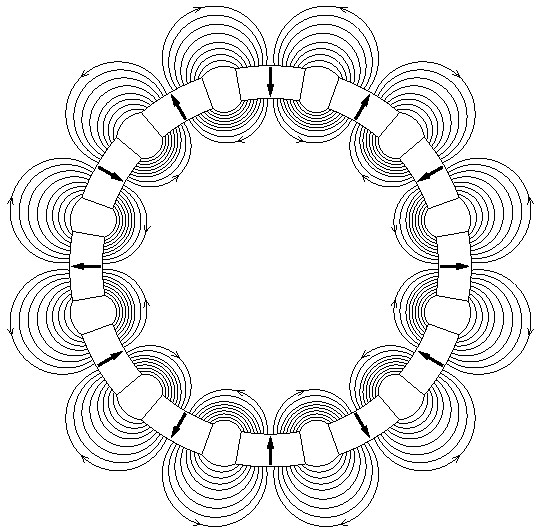

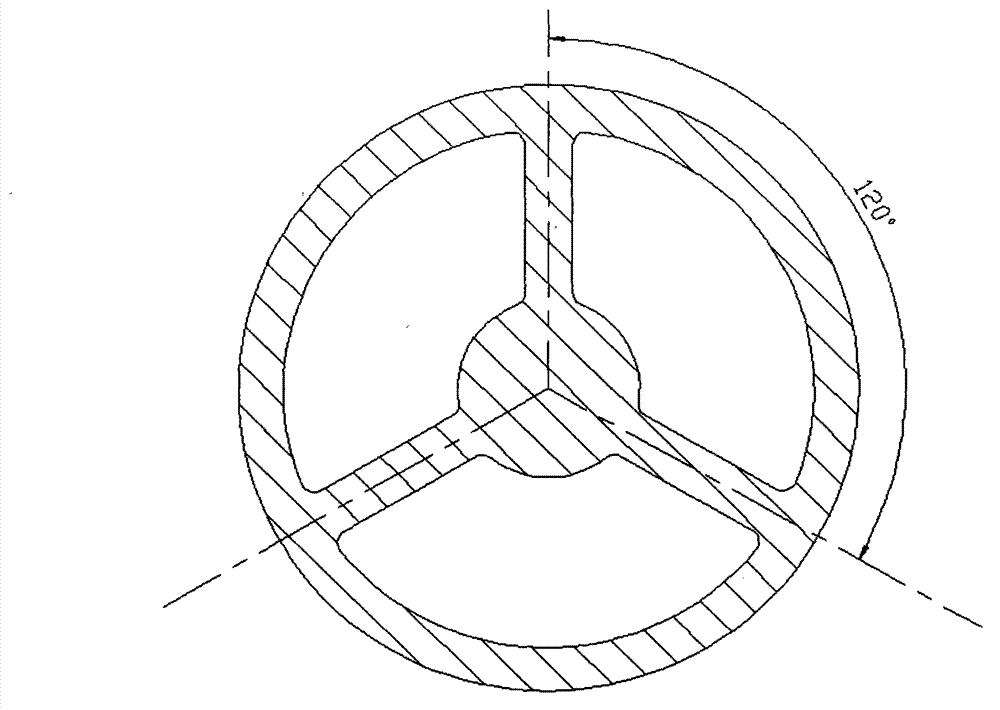

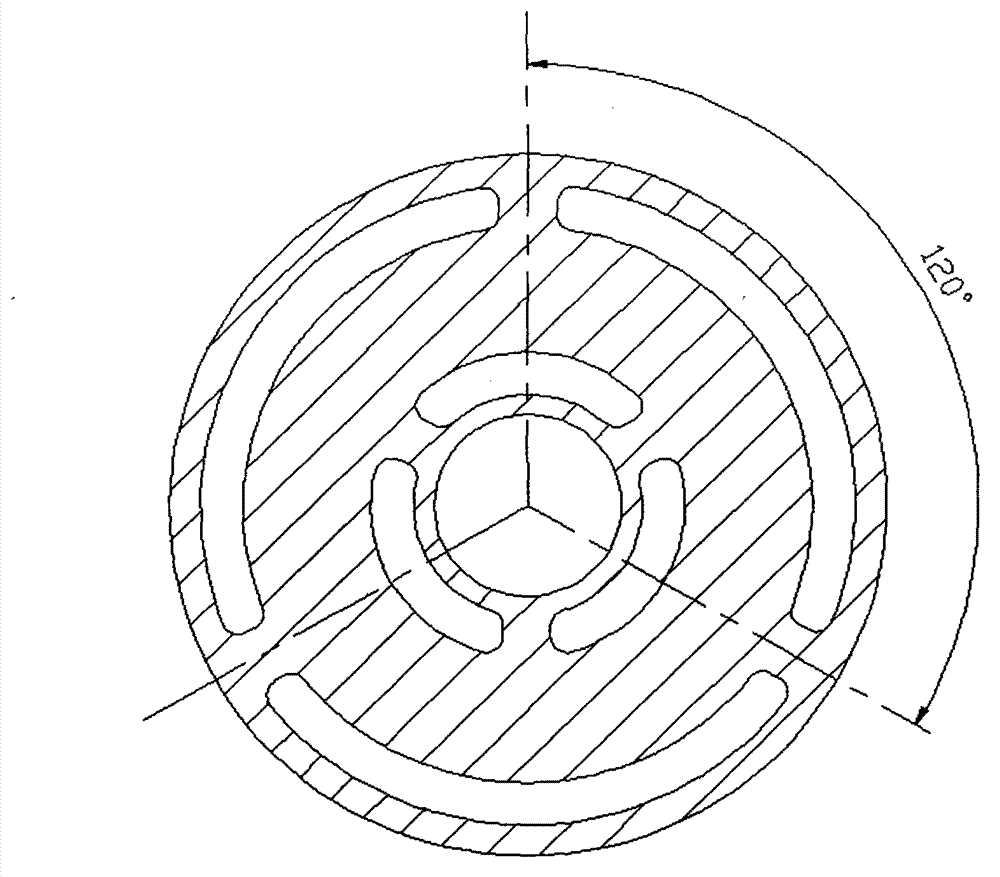

Radial-array permanent-magnet eddy current retarder

InactiveCN102497084AIncrease profitIncrease braking torquePermanent-magnet clutches/brakesOptical axisDrive shaft

The invention discloses a radial-array permanent-magnet eddy current retarder. Rotors are installed on a transmission shaft; the transmission shaft is installed in a central hole of a fixing plate; two ends of a bidirectional screw shaft are installed inside holes above the central hole of the fixing plate; two ends of each of three linear optical shafts are fixed into holes in front of, behind and below the central hole of the fixing plate; each of the two rotors consists of a radial-array permanent-magnet ring and a retaining rack; an end surface of one side of the permanent-magnet ring is fixed on an end surface of the retaining rack through bolts; radial clearances are formed between an inner cylindrical surface and an outer cylindrical surface of the permanent-magnet ring and an inner cylindrical surface and an outer cylindrical surface of an annular groove of each rotor; four installing holes are uniformly distributed on the retaining rack; an upper installing hole is matched with the bidirectional screw shaft through a screw nut; the other three installing holes are matched with the linear optical shafts through linear bearings; and a servo motor is connected whit the bidirectional screw shaft through a shaft coupler. In the radial-array permanent-magnet eddy current retarder, the utilization ratio of a magnet is high, the brake moment is large, the response is quick, and the stepless regulation of the brake moment is realized.

Owner:ZHEJIANG UNIV

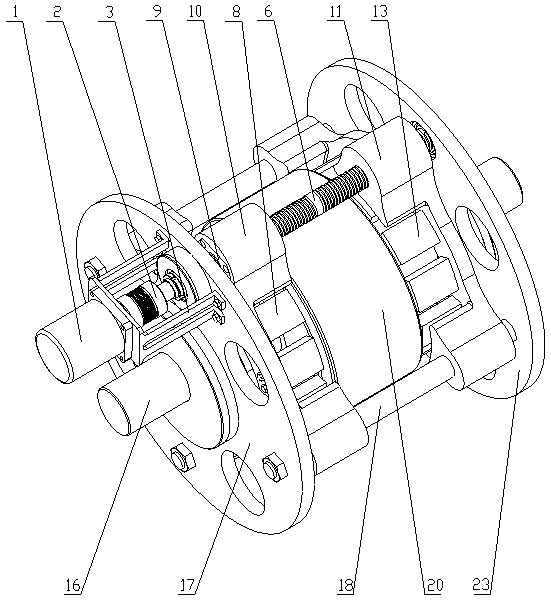

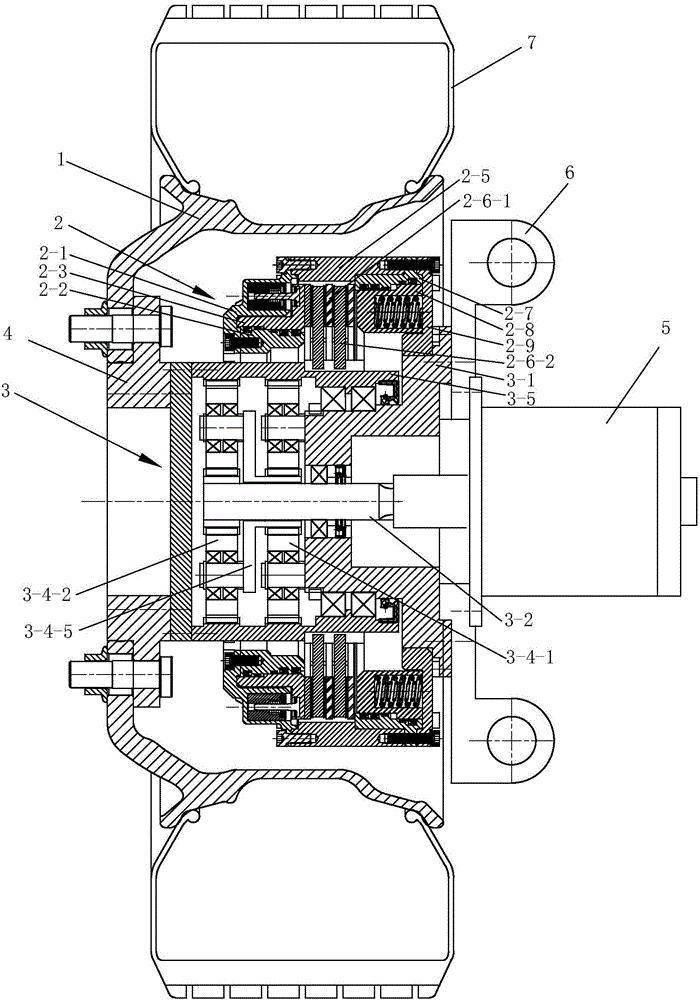

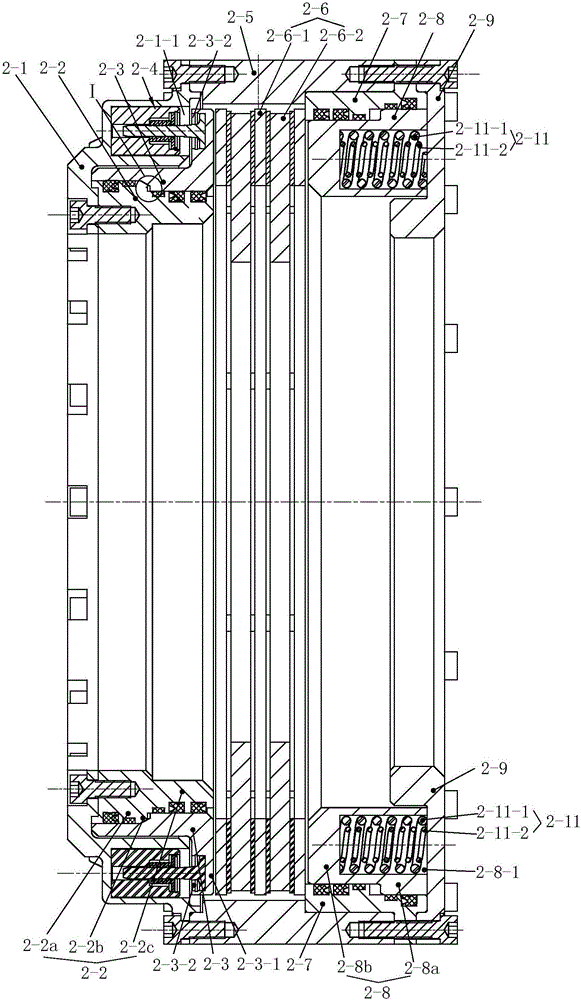

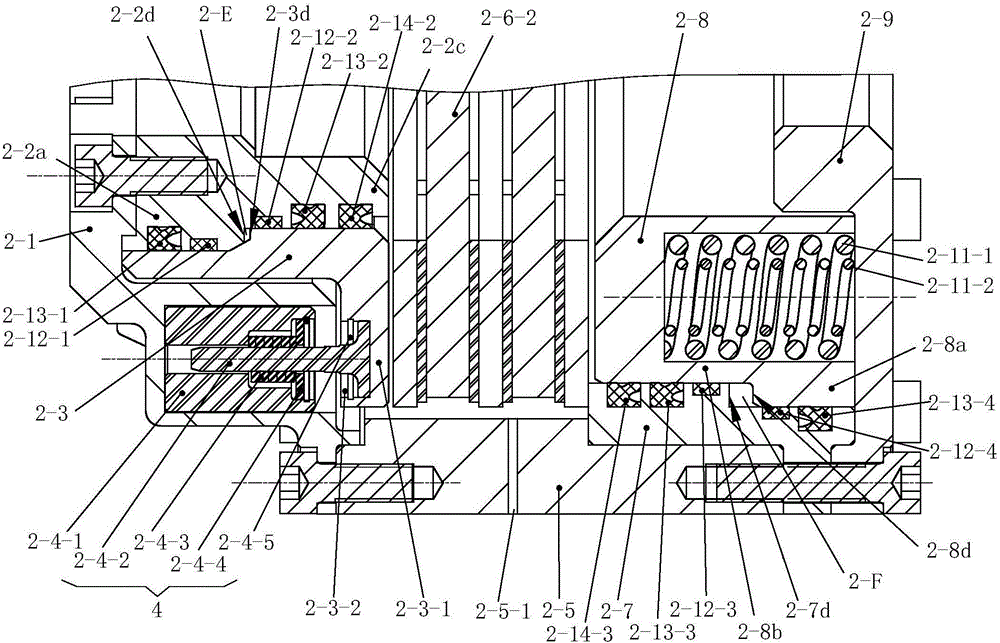

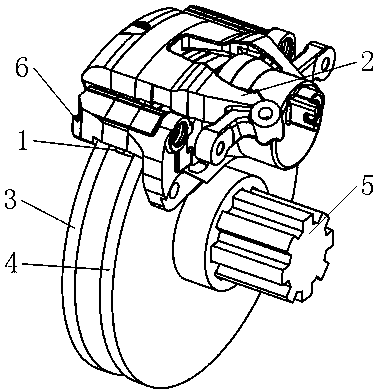

Transmission and braking integrated device for vehicle

ActiveCN106015406ACompact structureReduce volumeToothed gearingsBrake actuating mechanismsVehicle frameReducer

The invention discloses a transmission and braking integrated device for a vehicle. The transmission and braking integrated device comprises a wheel rim, a brake, a speed reducer and a motor. The brake comprises a vehicle end cover, a traveling cylinder body, a traveling piston, a cylindrical intermediate body, a braking friction pair assembly, a parking cylinder body, a parking piston, a parking end cover and a parking spring. The traveling cylinder body is sleeved with the traveling piston in a movable fit manner. An annular gap exists between the traveling piston and the traveling cylinder body, wherein the annular gap is a traveling braking oil cavity. The parking piston is arranged in the parking cylinder body in a movable fit manner. An annular gap exists between the parking cylinder body and the parking piston, wherein the annular gap is a parking braking oil cavity. The traveling piston and the parking piston can abut against the friction pair assembly from the two sides correspondingly. The parking piston is provided with the parking spring abutting against the parking end cover. By means of the transmission and braking integrated device for the vehicle, the motor, the brake and the speed reducer are integrated, the brake is arranged in the wheel rim, the speed reducer is arranged in a cavity of the brake, the structure is compact, the size is small, the space of a vehicle frame is greatly saved, and the transmission and braking integrated device is very suitable for flexible configuration with various vehicles narrow in structure space.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

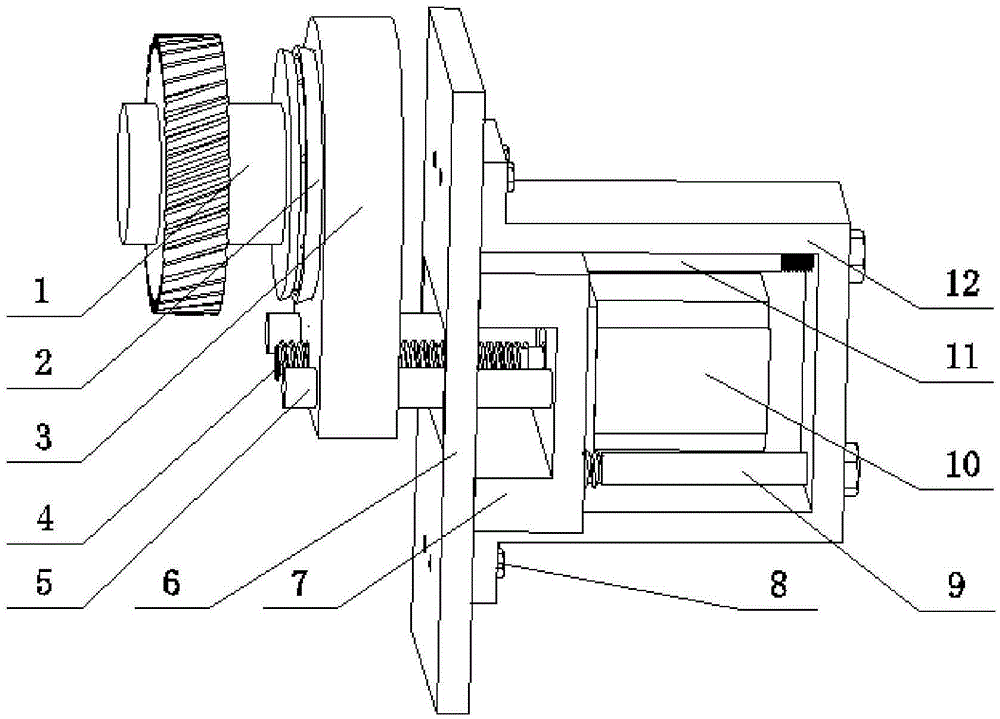

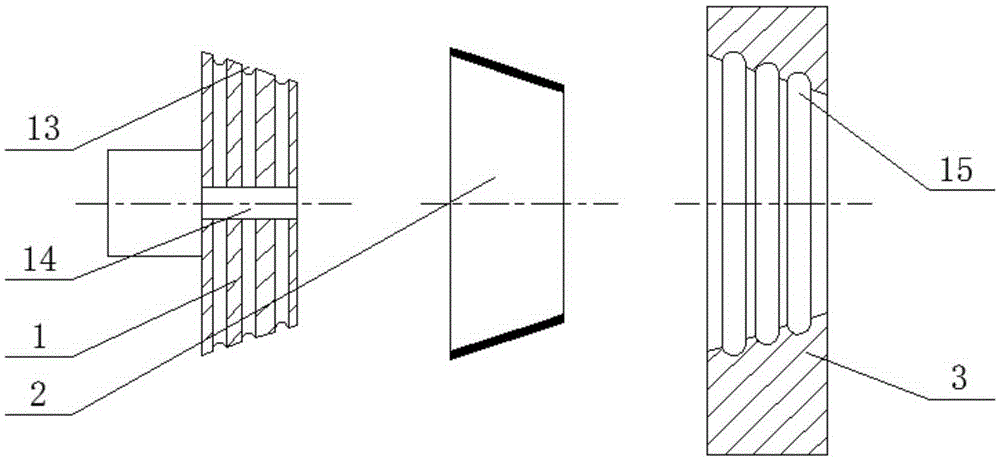

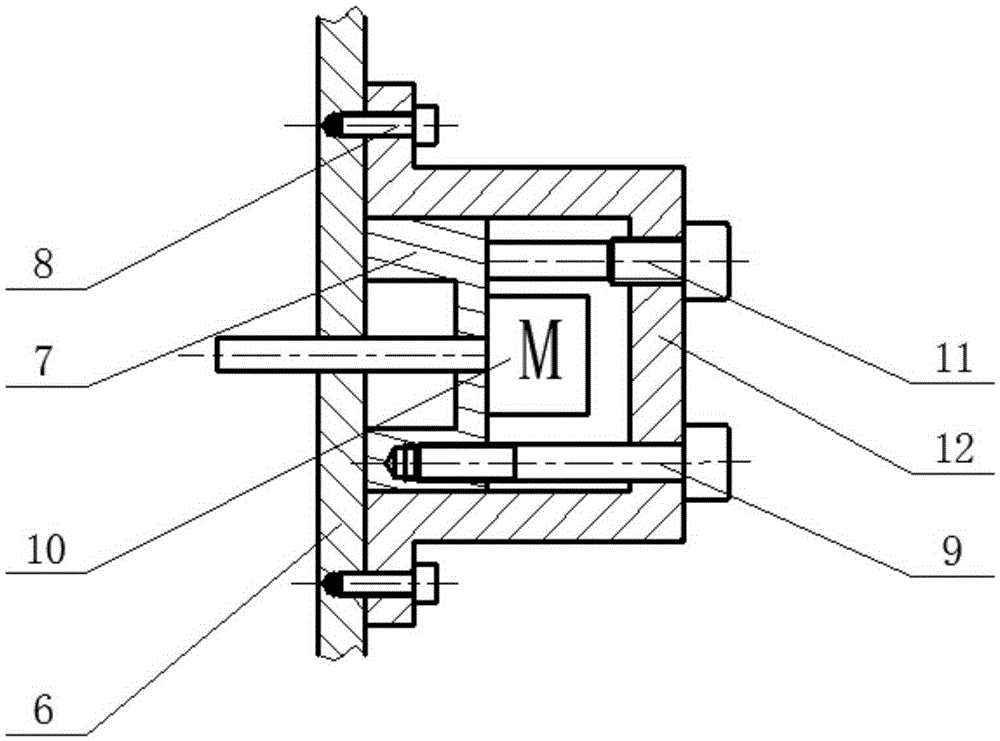

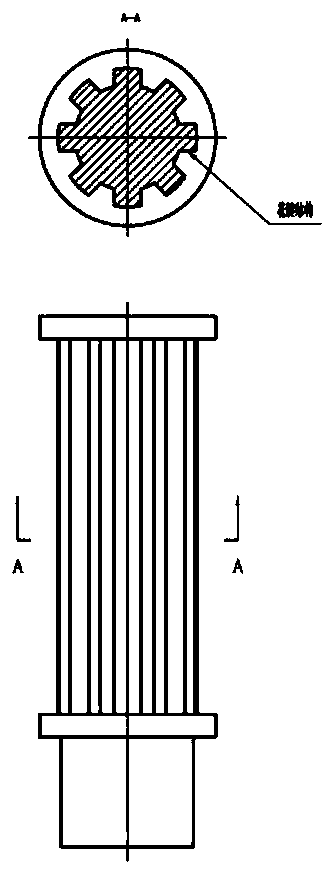

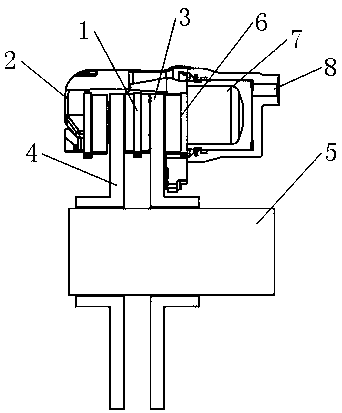

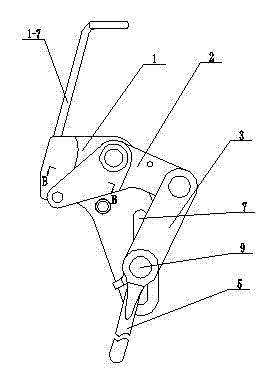

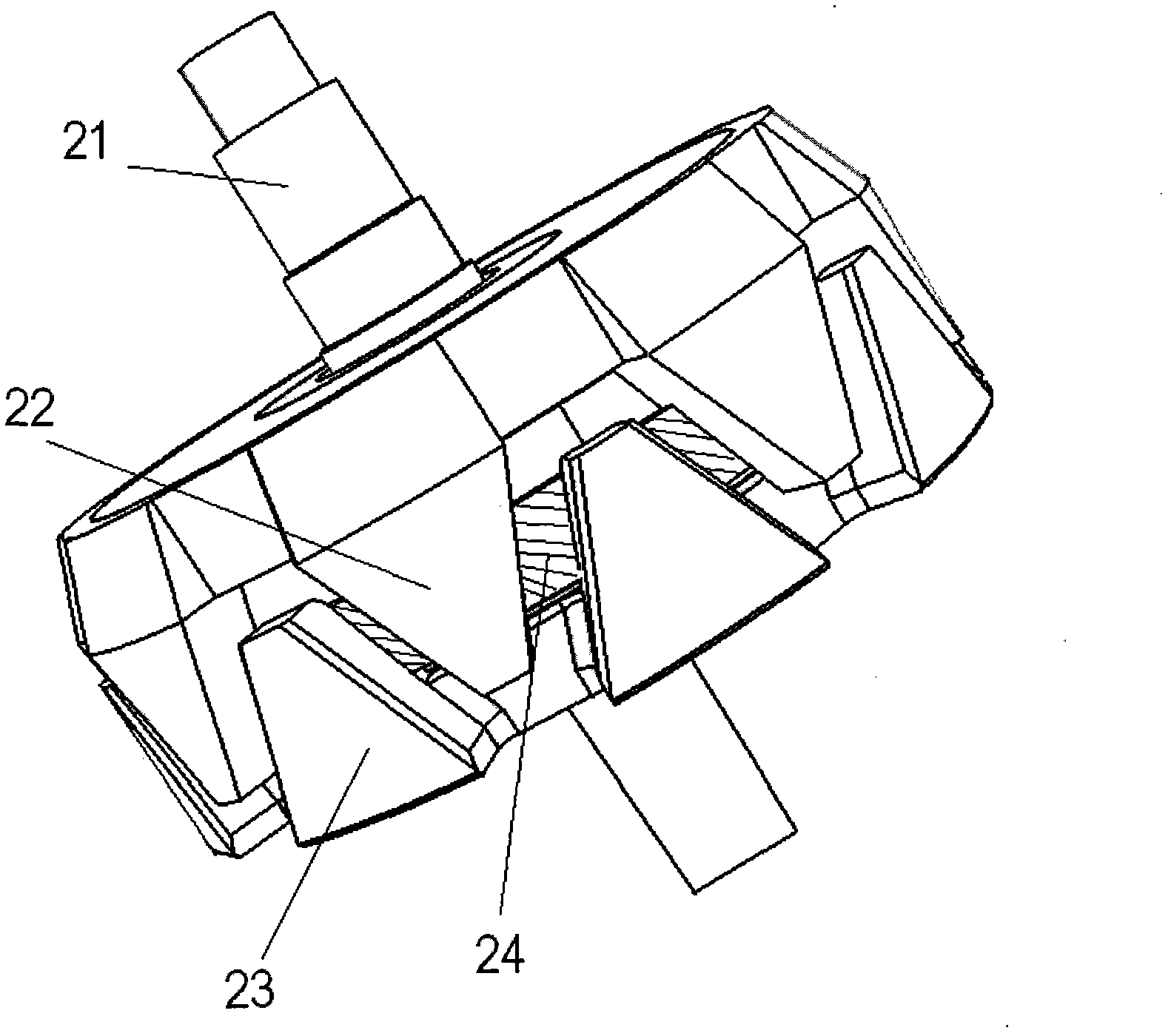

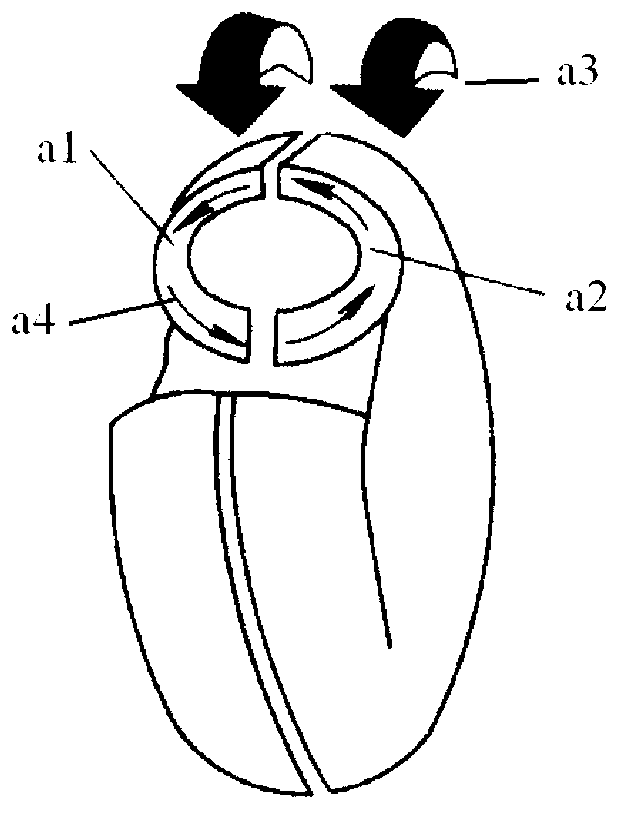

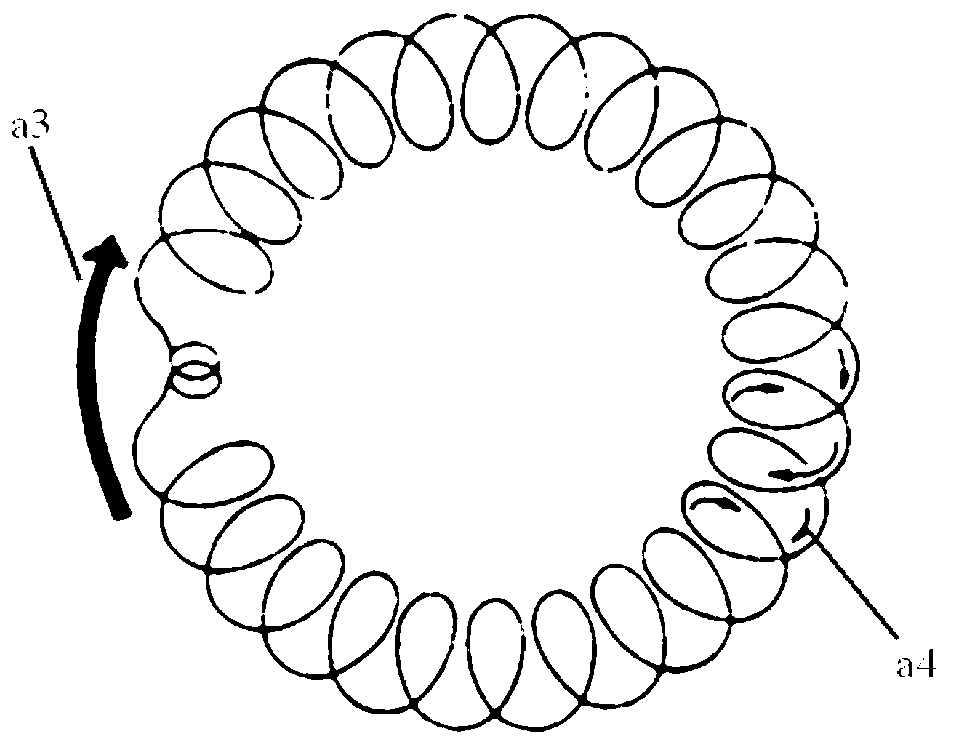

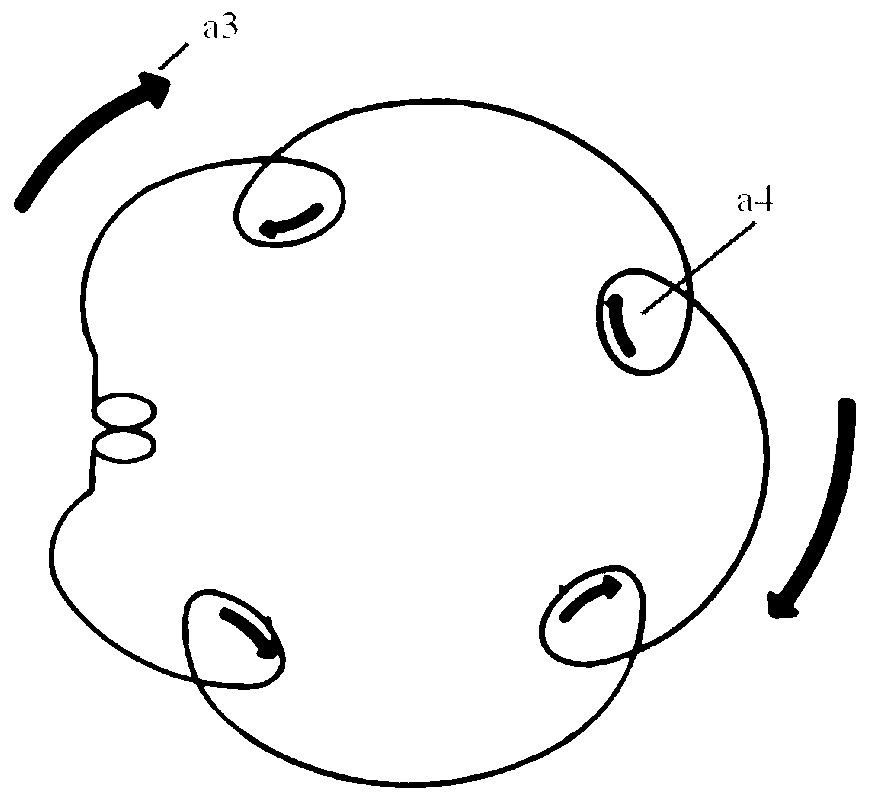

Parking locking mechanism for automobile speed changer

ActiveCN105333140AIncrease braking torqueImprove braking effectGearing controlLocking mechanismEngineering

The invention discloses a parking locking mechanism for an automobile speed changer. The parking locking mechanism for the automobile speed changer is characterized in that the parking locking mechanism comprises a locking mechanism body and a manual unlocking mechanism; the locking mechanism body is composed of a conical surface intermediate shaft, a friction ring, a conical surface locking ring, a lead screw, a guide rod and a motor; the shaft end of the conical surface intermediate shaft is in a conical surface shape, and the periphery of the conical surface intermediate shaft comprises multiple rows of oil discharge grooves which are connected with a through hole in the shaft center; an inner hole of the conical surface locking ring is conical and comprises multiple oil return grooves; the motor is controlled to rotate to drive the conical surface locking ring, the friction ring and the conical surface intermediate shaft for combination so as to achieve braking of the speed changer; the concentricity of three conical surfaces of the conical surface intermediate shaft, the friction ring and the conical surface locking ring can be guaranteed during mounting of the parking locking mechanism, so that braking accuracy is guaranteed and automobile sliding is avoided. Power-off self-locking and power-on unlocking are achieved; the control operation is simple; the structure is compact; comprehensive functions are achieved; the reliability and the stability of parking braking are effectively improved.

Owner:黄山市开发投资集团有限公司

Yaw mechanical locking device of wind turbine generator set

The invention discloses a yaw mechanical locking device of a wind turbine generator set. The mechanical locking device of the wind turbine generator set comprises a cabin chassis, a yaw bearing arranged on the lower side of the cabin chassis and a locking pin, wherein the yaw bearing is a bearing with teeth on the outer ring, the locking pin comprises a shaft body, axial teeth extended on the radial side of the shaft body are meshed with the teeth of the outer ring of the yaw bearing, the cabin chassis is provided with a locking pin hole, and the locking pin hole corresponds to the position of the teeth of the outer ring of the yaw bearing. When a yaw system is locked, the locking pin is inserted into the locking pin hole, and the axial teeth on the side of the locking pin are inserted between two neighboring teeth of the outer ring of the yaw bearing. The mechanical locking device of the wind turbine generator set increases the braking torque when a yaw reducer is replaced or under bad meteorological conditions, and increases safety factors of yaw braking.

Owner:JIANGSU WENDE NEW ENERGY

Braking control method, device and equipment and storage medium

ActiveCN110332054AImprove reliabilityIncrease air intakeElectrical controlMachines/enginesControl theoryBrake control

The invention provides a braking control method, device and equipment and a storage medium. The method comprises the steps that when it is determined that an engine is in the braking working condition, the current rotation speed of the engine is acquired; whether the current rotation speed is higher than preset critical rotation speed or not is determined, wherein the critical rotation speed is the critical speed between a middle-low rotation speed area and a high rotation speed area, the rotation speed in the middle-low rotation speed area is the braking rotation speed commonly used by a user, and the rotation speed in the high rotation speed area is not lower than the maximum rotation speed in the middle-low rotation speed area; if not, the deflation opening degree of a supercharger is controlled to be zero; and if yes, the deflation opening degree of the supercharger is adjusted to a first opening degree value, wherein the first opening degree value is larger than a second opening degree value, the first opening degree value is the deflation opening degree corresponding to the current rotation speed when the engine is in the braking working condition, the second opening degree value is the deflation opening degree corresponding to the current rotation speed when the engine is in the positive work working condition, and the first opening degree value is larger than zero. According to the scheme, variable adjustment of the braking power can be achieved, and then the reliability of the engine is improved.

Owner:WEICHAI POWER CO LTD

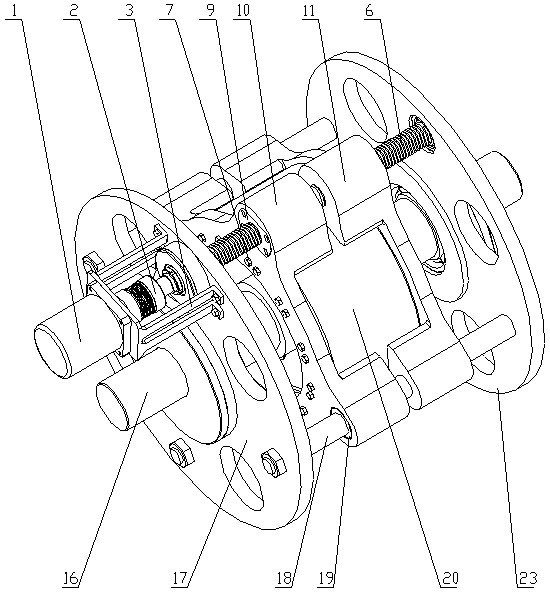

Double-brake disc type brake and automobile braking method

ActiveCN110242689AEffective transmission torqueImprove axial sliding abilityAxially engaging brakesBraking discsMobile vehicleBrake torque

The invention relates to the field of motor vehicle braking, in particular to a double-brake disc type brake. The brake comprises a first brake disc (5), a second brake disc (7), a first friction plate (4), a second friction plate (8), a friction plate with friction materials on the two sides (6), and a driving assembly for driving the friction plate to rub with the corresponding brake disc; and the driving assembly comprises a first brake clamp body (1), a second brake clamp body (10), a first piston (2) and a second piston (9). According to the double-brake disc type brake, the double brake discs can move in two directions at the same time, so that the abrasion of the friction plate is reduced, and the service life is prolonged; and meanwhile, on the premise that conventional problems are avoided, the braking torque is improved, and the braking torque is increased by 1.8 times under the condition that parameters are unchanged.

Owner:QI AUTOMOTIVE CO LTD

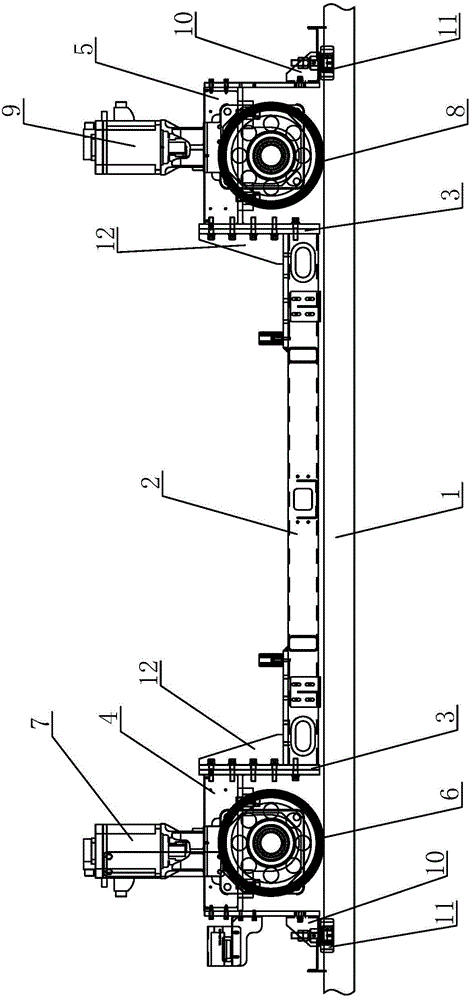

Dual-drive horizontal drive mechanism of stacking machine

The invention discloses a dual-drive horizontal drive mechanism of a stacking machine. The dual-drive horizontal drive mechanism comprises a rail and a travelling mechanism of the stacking machine; the travelling mechanism disposed on the rail comprises a lower beam; two ends of the lower beam are connected with a first drive rack and a second drive rack through connecting plates, respectively; a first drive wheel and a first drive motor are disposed on the first drive rack; the first drive motor drives the first drive wheel to travel; a second drive wheel and a second drive motor are disposed on the second drive rack; the second drive motor drives the second drive wheel to travel. The dual-drive horizontal drive mechanism is in a dual-drive mode, and thus, weight of all devices is on the drive wheels; the use of synchronous control leads to increase in friction and more than double of increase in acceleration, with the wheels never skidding; additionally, single-drive power is equaled to two motors, and thus, drive friction is increased, start acceleration is increased and brake torque is increased.

Owner:WUXI ZHONGDING INTEGRATION TECH CO LTD

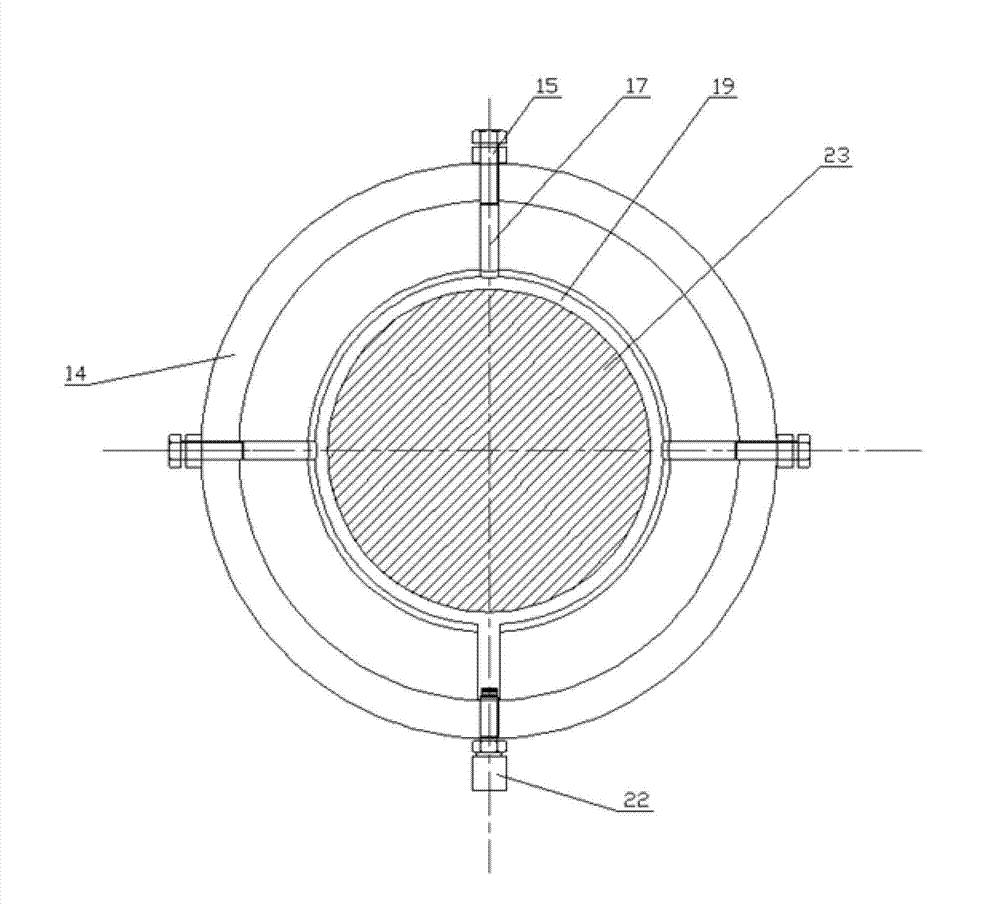

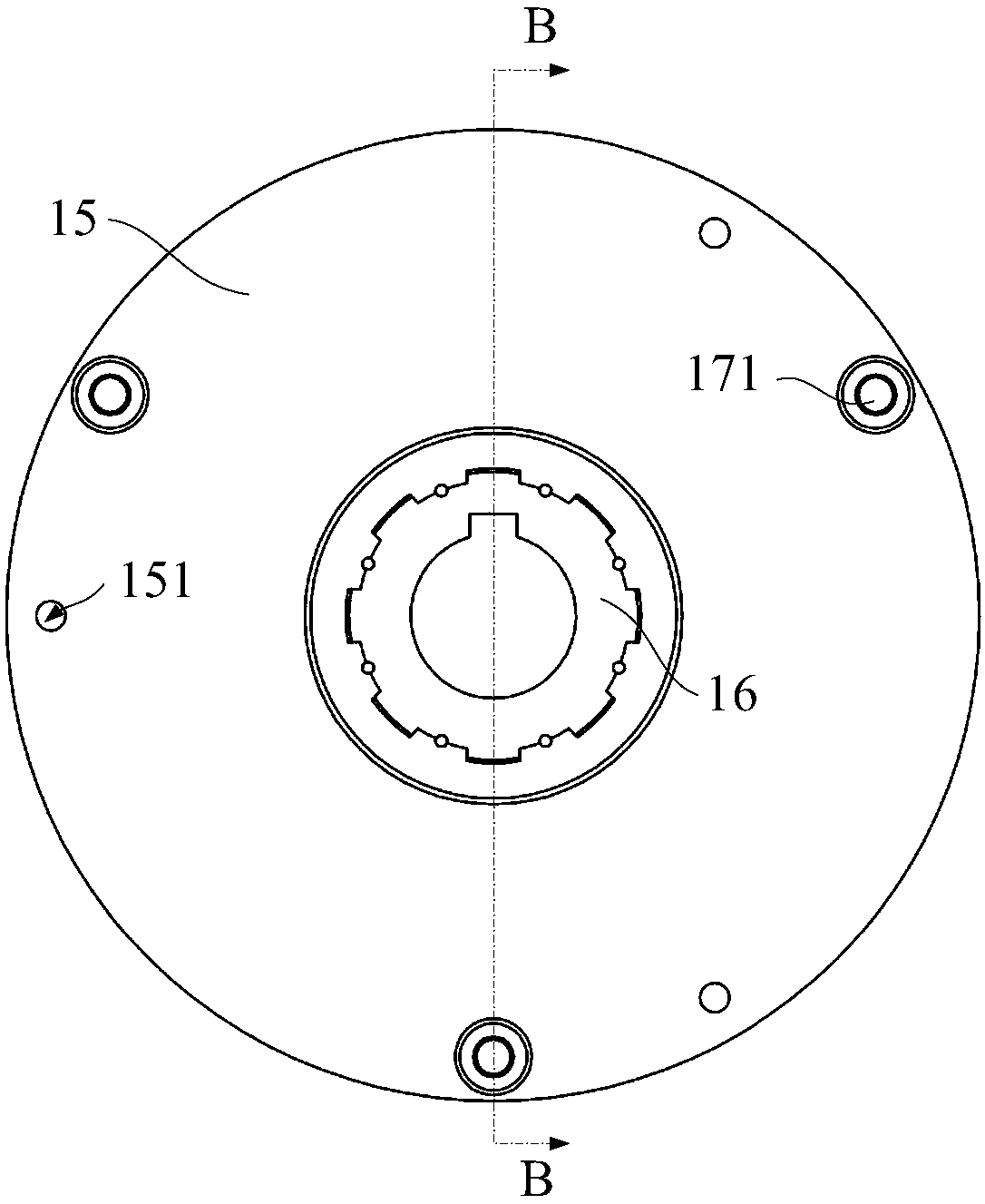

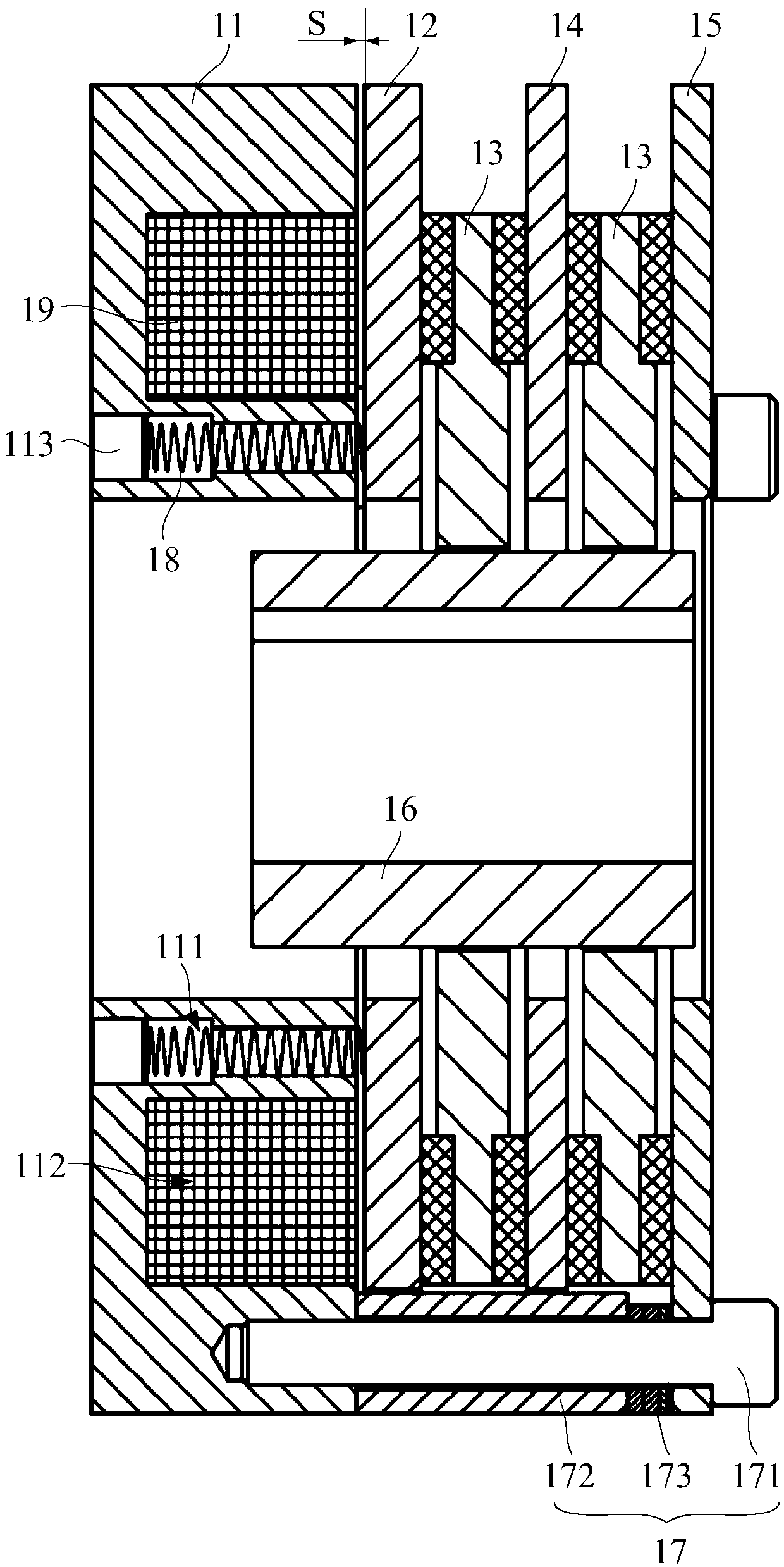

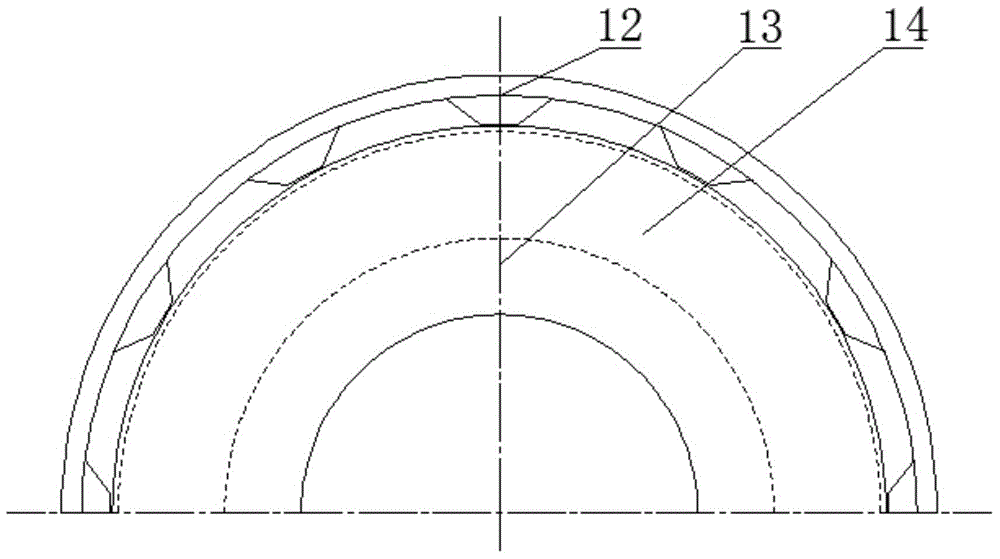

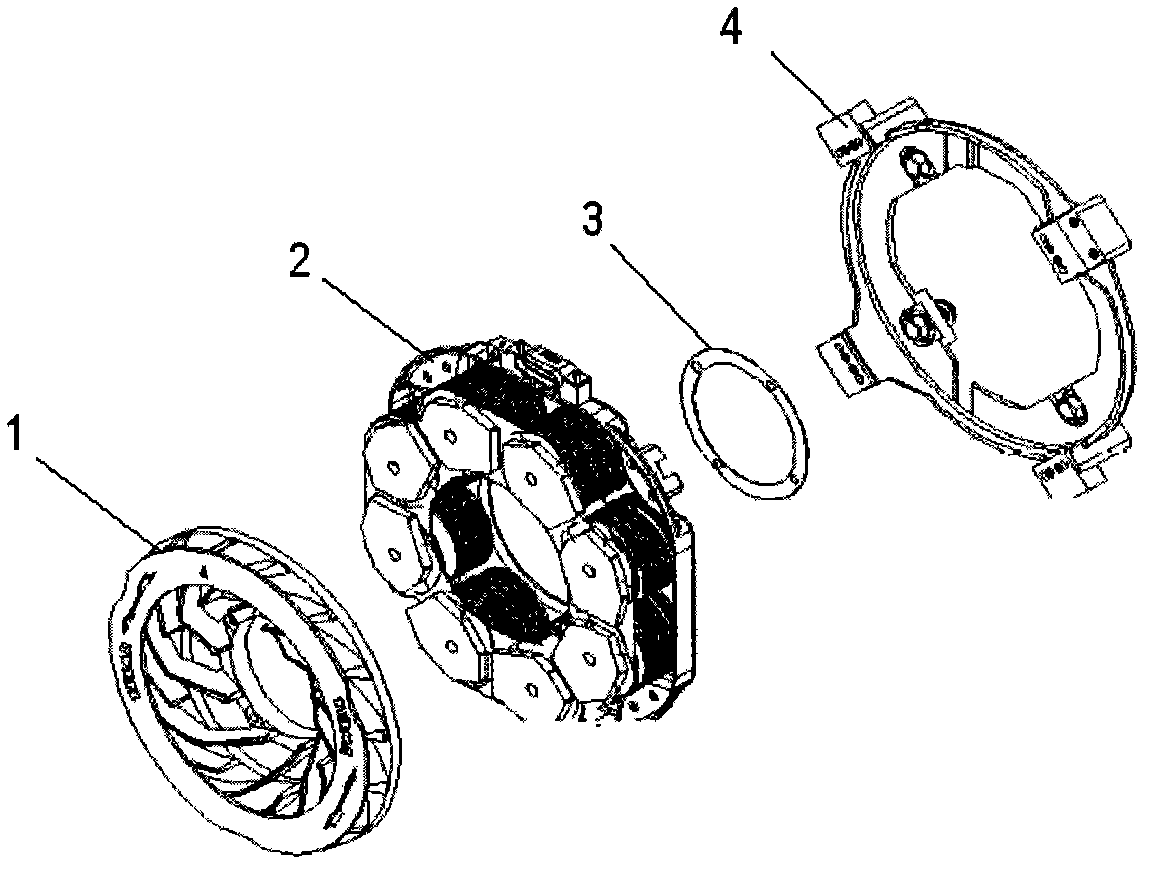

Magnetorheological reflux type complete disc brake

InactiveCN103047321ACompact structureIncrease braking torqueLiquid resistance brakesBrake torqueMagnetorheological fluid

The invention relates to a magnetorheological reflux type complete disc brake which comprises a shearing disc, a seal ring, a shell, magnetorheological fluid, an exciting coil, an end cover and a stud. The shell is arranged on the peripheral side of the shearing disc, and the seal ring is arranged on a portion, contacting with the shearing disc, of the lower portion of the shell. A gap between the shell and the shearing disc is filled with the magnetorheological fluid, the end cover is fittingly arranged on the upper portion of the shell, the exciting coil is wound between the end cover and the shell, and the end cover and the shell are fixedly connected through the stud. The flowing direction of the magnetorheological fluid is changed by means of refluxing, the defects of sedimentation of magnetorheological fluid particles and failure of the magnetorheological fluid under centrifugal action are overcome, and the brake is compact in structure of the magnetorheological fluid particles during braking, large in shearing area, high in braking torque and convenient to demount. In addition, the magnetorheological reflux type complete disc brake improves reliability in magnetorheological fluid braking and has wide practical value.

Owner:王剑 +1

Micro-rail vehicle and electromagnetic brake thereof

InactiveCN110873135ALarge braking forceSolve the problem that the braking performance requirements of micro-rail vehicles cannot be metAxially engaging brakesBrake actuating mechanismsBrake torqueEngineering

The invention relates to the technical field of rail traffic, in particular to a micro-rail vehicle and an electromagnetic brake thereof. The electromagnetic brake comprises a magnetic yoke, an armature, an excitation coil, a fixing sleeve, a fixing disc, an elastic piece, two or more braking discs and movable discs; the two or more braking discs can all slide in the axial direction of the fixingsleeve, and sleeve the peripheral face of the fixing sleeve in a relatively fixed mode in the circumferential direction of the fixing sleeve; and each movable disc is sandwiched between every two adjacent corresponding braking discs. According to the electromagnetic brake, the friction area of the braking discs can be increased through the arranged two or more braking discs and the movable discs arranged between the braking discs, then braking friction force and braking torque are increased, and thus the electromagnetic brake has the characteristic of large braking force so as to solve the problem that an existing electromagnetic brake cannot meet the braking performance requirement of the micro-rail vehicle due to the small braking force.

Owner:CRRC TANGSHAN CO LTD

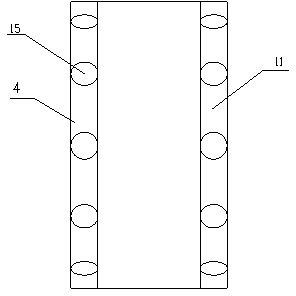

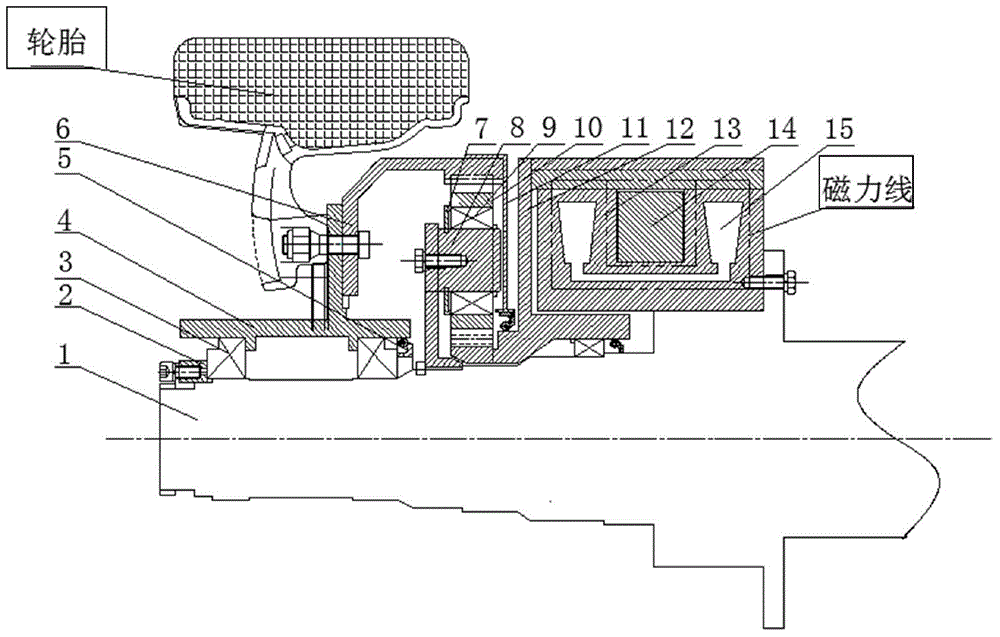

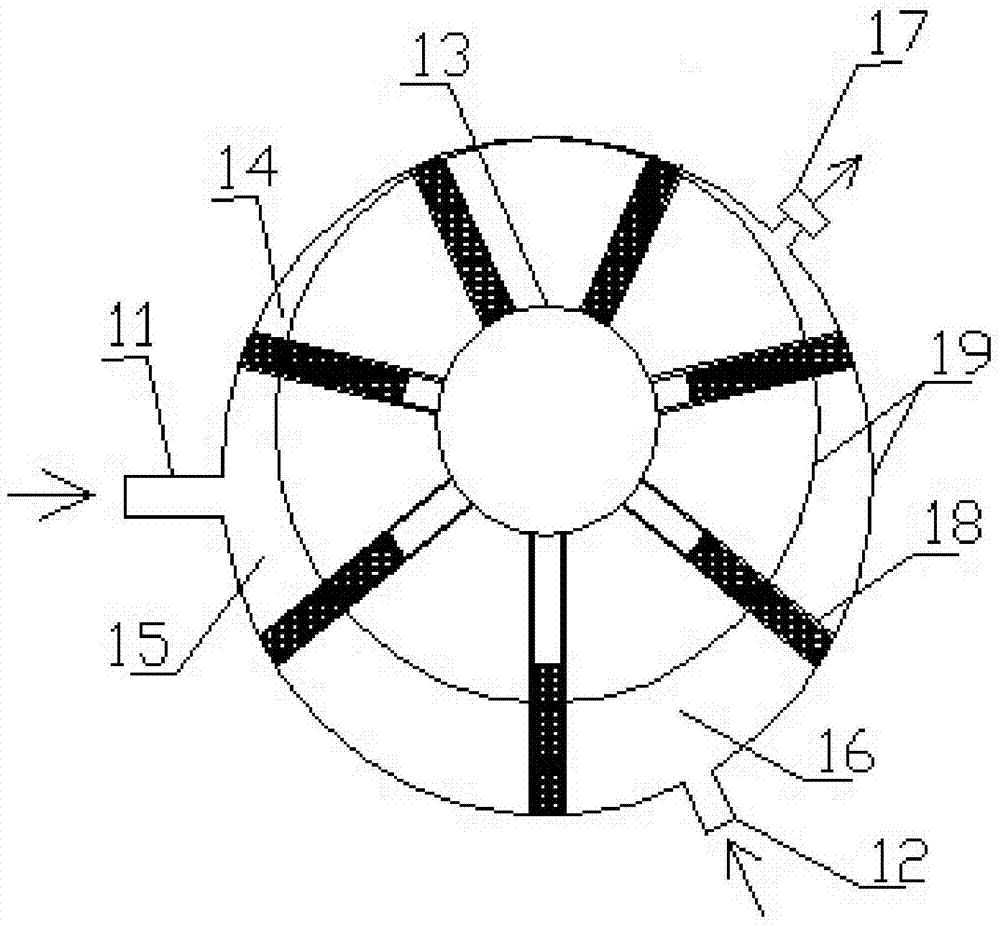

Hub-type electromagnetic liquid cooling retarder

ActiveCN104578685ASimple winding processIncrease braking torqueAsynchronous induction clutches/brakesMechanical energy handlingBrake torqueEngineering

The invention relates to a hub-type electromagnetic liquid cooling retarder which comprises a hub (4), an accelerating device, an oil liquid sealing device, a stator (13) and an excitation coil (14), wherein the hub (4) is connected with the rear axle (1) of an automobile; the accelerating device is connected with the hub (4); the oil liquid sealing device is connected with the accelerating device; the stator (13) is fixed on the rear axle (1) through a bolt; an internal groove is formed in the stator (13); the excitation coil (14) is coiled in the internal groove of the stator (13). The hub-type electromagnetic liquid cooling retarder has the advantages that an automobile brake drum is reformed into a gear ring serving as a part of an accelerating mechanism; the structure is simple; the braking torque and the braking power of the retarder can be improved; a rotor is light, so that the rotary inertia is low; the stator is directly fixed on the rear axle, so that the coiling of the excitation coil is simple.

Owner:YANGZHOU ANXING ELECTROMECHANICAL TECH

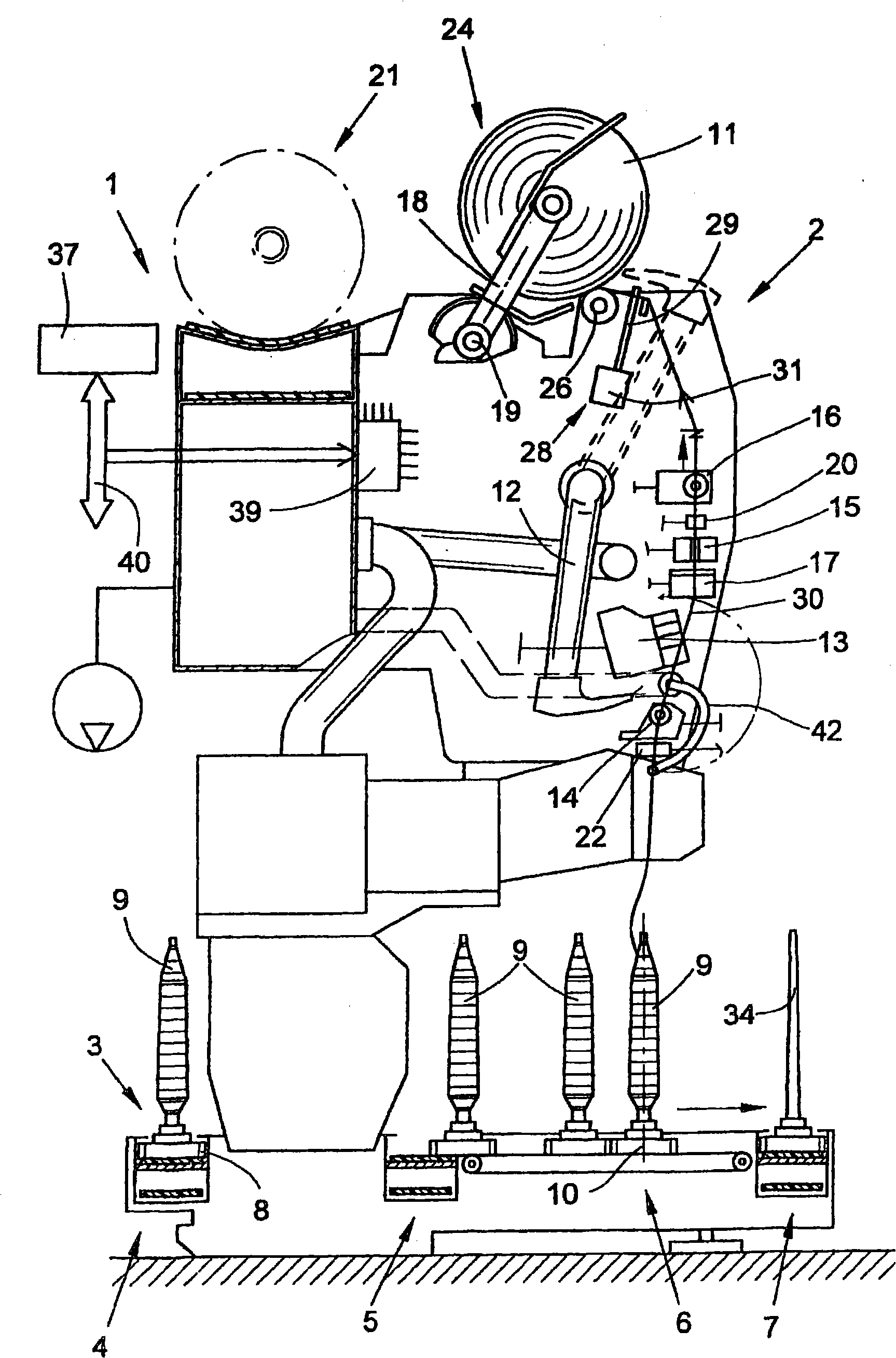

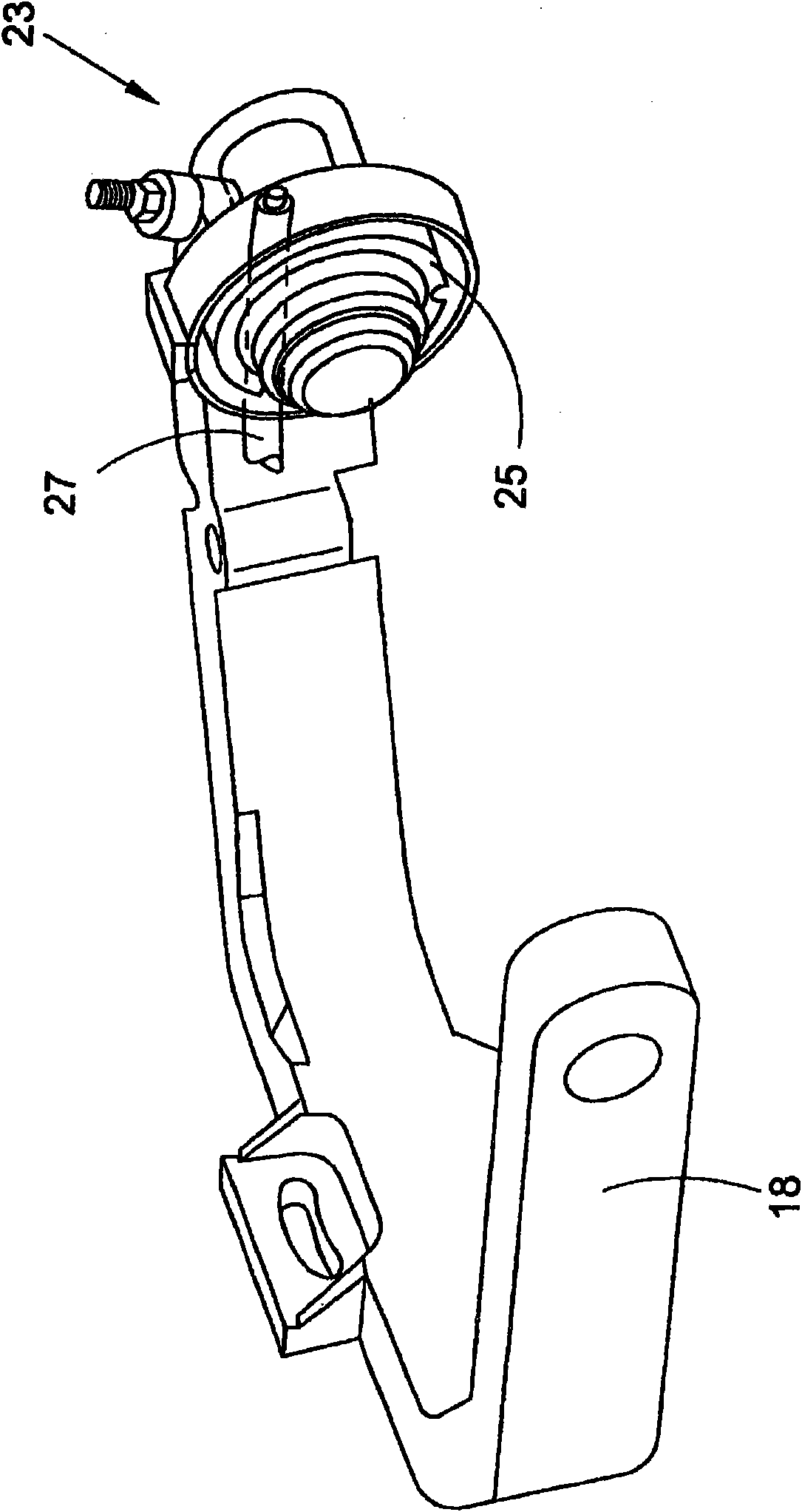

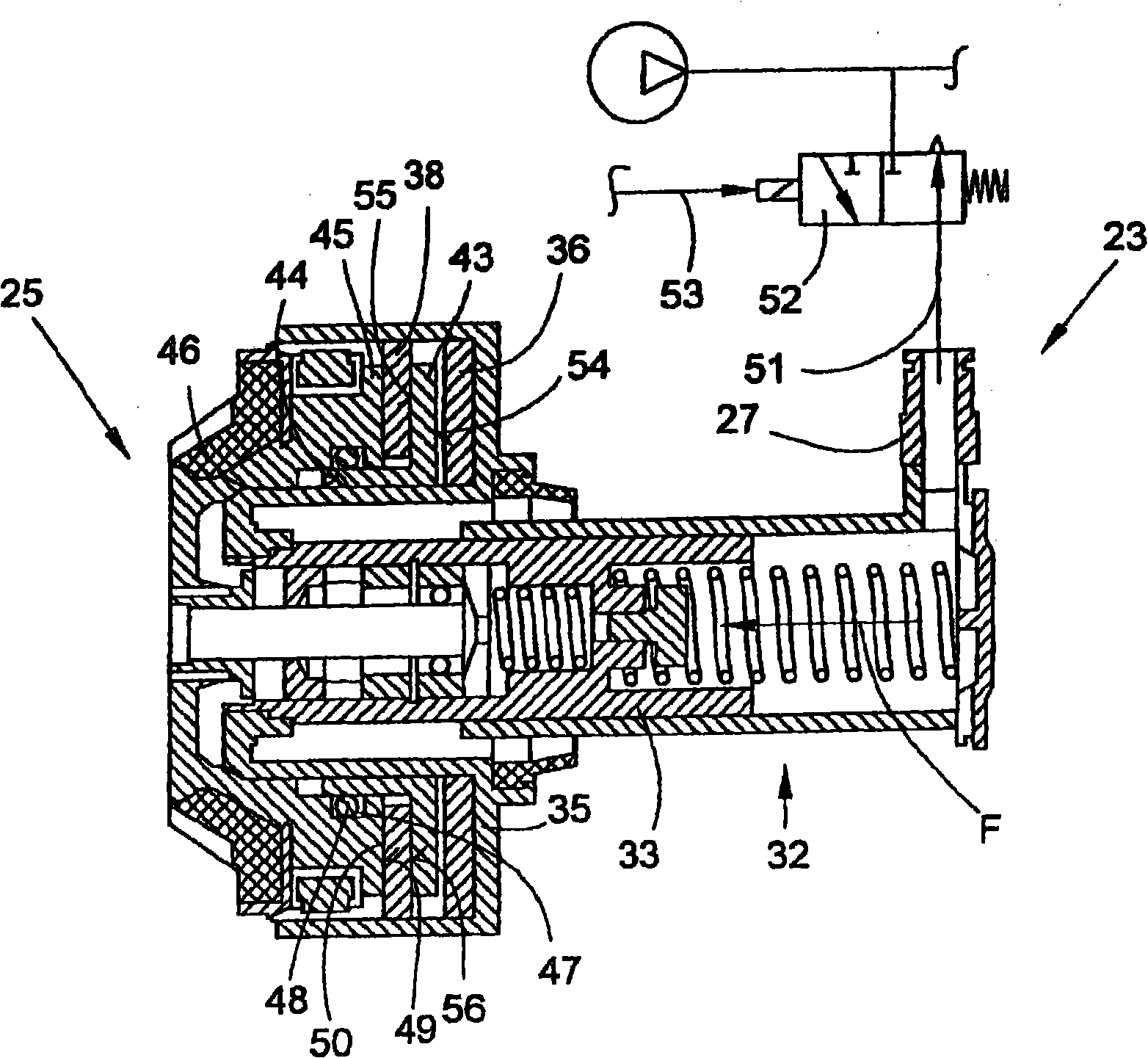

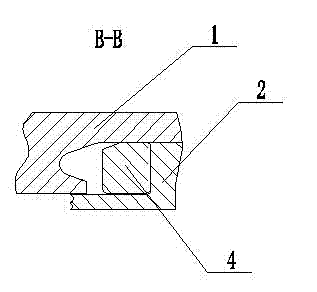

Bobbin brake for a winding apparatus of a textile machine which produces crosswound bobbins

InactiveCN101528575AIncrease braking torqueNot easy to wearFilament handlingBraking discsBobbinBrake lining

The invention relates to a bobbin brake (23) for a winding apparatus (24) of a textile machine (1) which produces crosswound bobbins having a rotatably mounted empty-bobbin receiving plate (25) which is provided with a rear-side brake face (49), an axially displaceably mounted brake housing (35) which is equipped with a brake lining (36), and a device (32) for moving the brake housing (35) into a braking position, wherein the brake housing (35) is moved towards the empty-bobbin receiving plate (25). There is provision according to the invention for the brake housing (35) to have, in addition to the brake lining (36) which is arranged fixedly on the brake housing (35), a brake ring (38) which is connected fixedly in terms of rotation to the brake housing (35) but is mounted such that it can be displaced axially with regard to the brake housing (35), and for a sleeve-like brake disc (43) to be installed between the brake lining (36) and the brake ring (38), which sleeve-like brake disc (43) is arranged fixedly in terms of rotation but axially displaceably in a rotatably mounted receiving housing (45) of the empty-bobbin receiving plate (25), which receiving housing (45) has a brake face (49) which is arranged on the end side.

Owner:SAURER GERMANY GMBH & CO KG

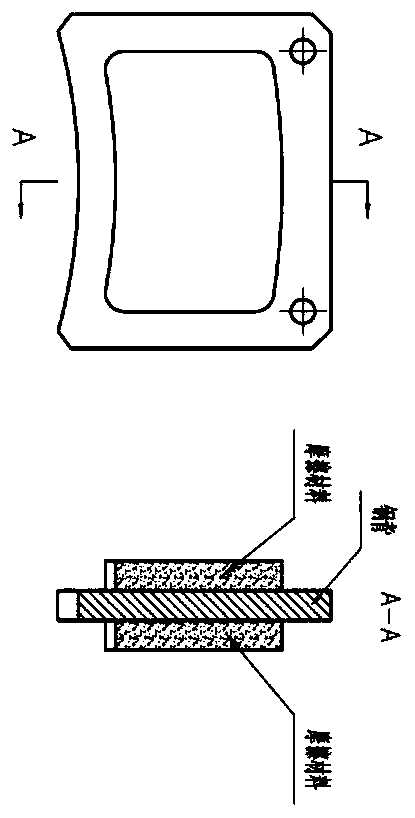

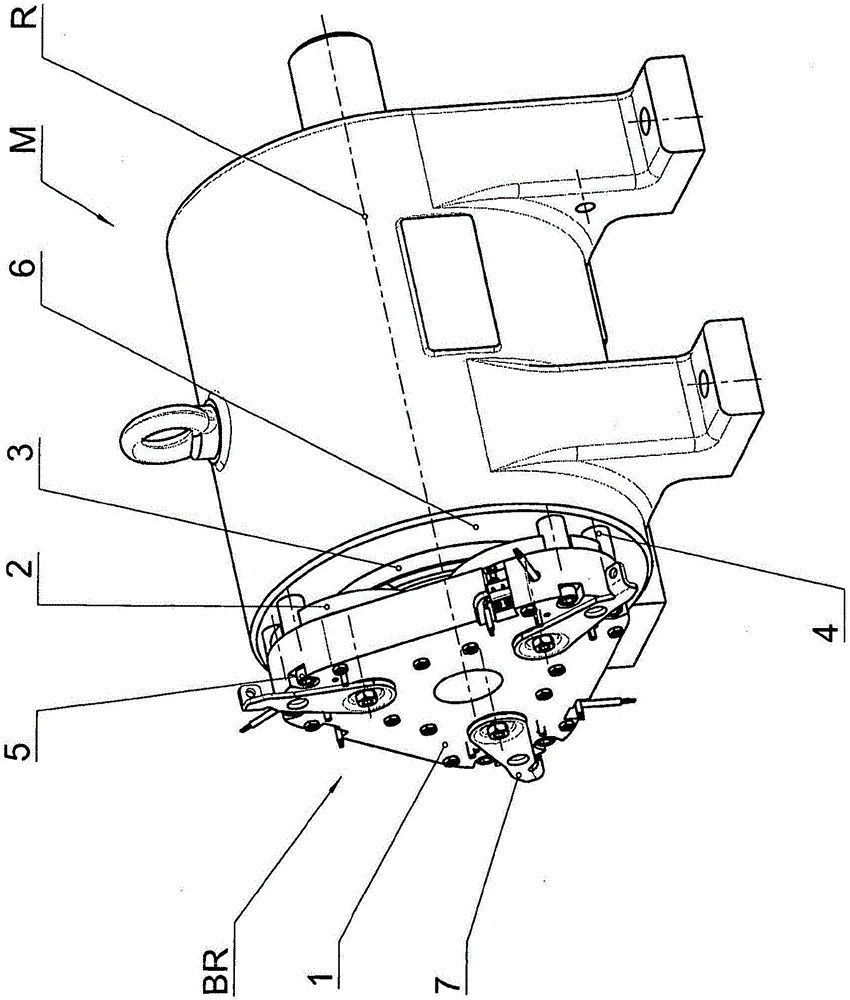

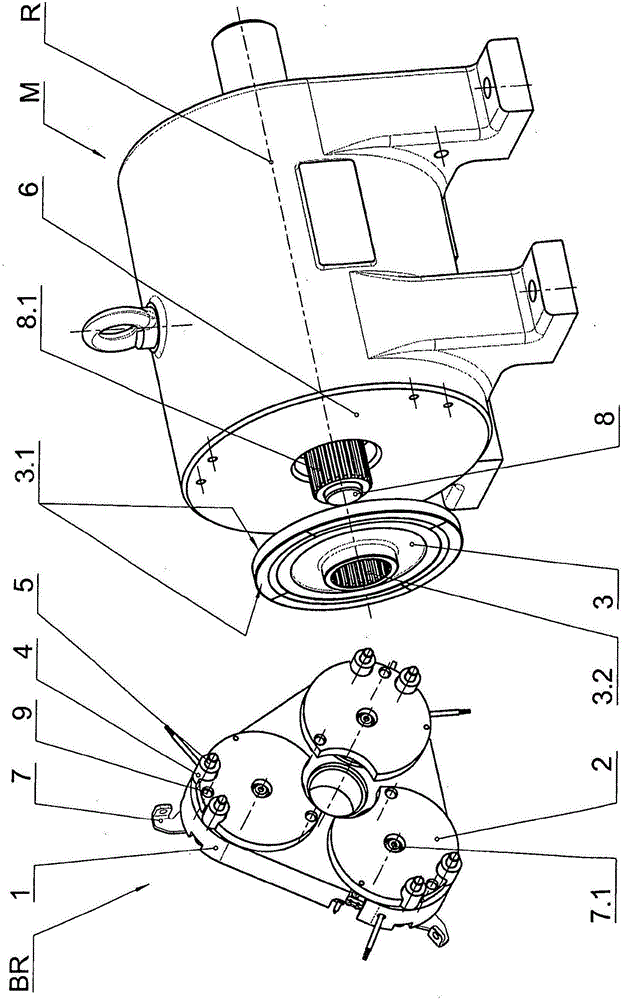

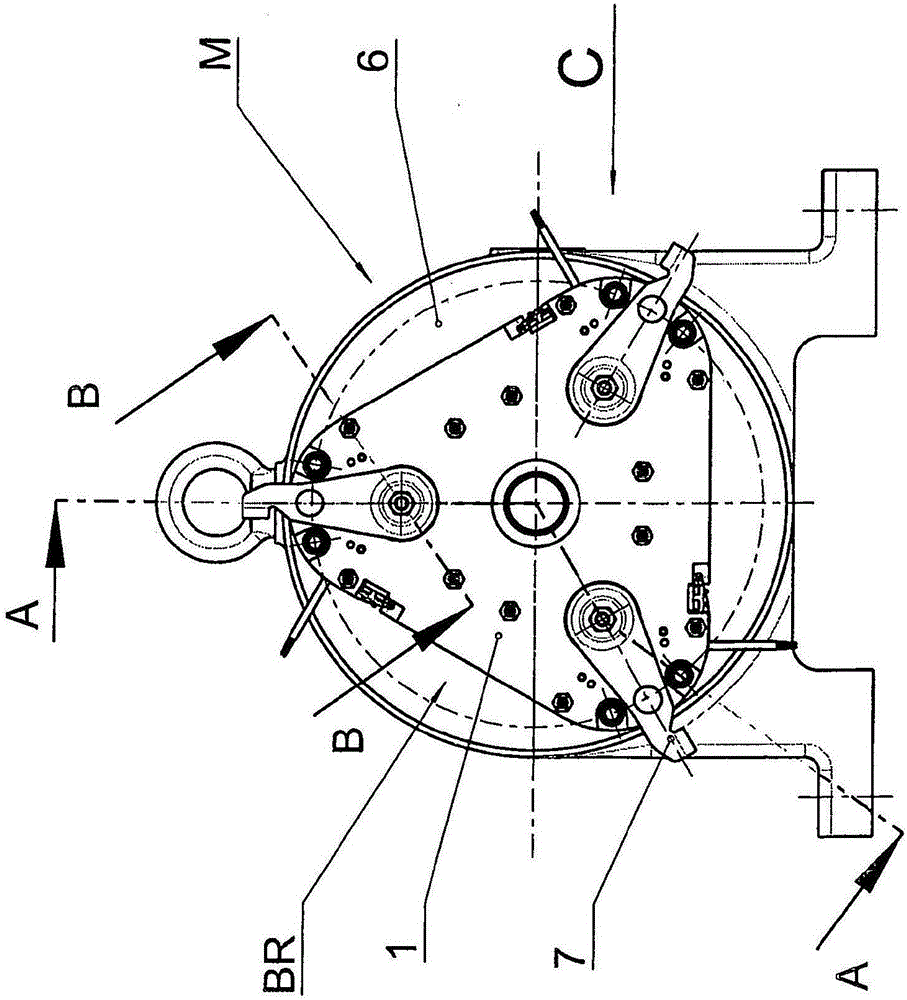

Electromagnetically ventilating spring pressure brake in the form of a multi-circle triangular brake

ActiveCN106763323ACompact structureReduce manufacturing costSelf acting brakesBraking elementsEngineeringMechanical engineering

The invention relates to an electromagnetically ventilating spring pressure brake (BR). The pressure brake is installed on a machine wall plate or a similar structure and comprises an axially movable brake rotor (3). The brake rotor comprises friction linings (3.1) which are continuous on two sides, i.e., the left side and the right side. The pressure brake (BR) comprises a coil rack (1) and multiple armature discs (2) disposed to the coil rack (1). In order to achieve the braking function, the brake rotor (3) is allowed to press the machine wall plate (6) or the similar structure on one side (left side) and press the armature discs (2) on the other side (right side). The pressure brake (BP) comprises the coil rack (1) with a triangular basic cross section. Three armature discs (2) are disposed to the coil rack (1).

Owner:CHRISTIAN MAYR GMBH & CO KG

Main shaft brake mechanism based on magnetorheological fluid

InactiveCN111911565AIncrease braking torqueShorten deceleration braking timeLiquid resistance brakesBrake actuating mechanismsBrake torqueMagnetorheological fluid

The invention relates to the technical field of main shaft brake devices, and discloses a main shaft brake mechanism based on magnetorheological fluid. The main shaft brake mechanism comprises a transmission main shaft, wherein transmission spacer bushes movably sleeve two sides of the outer surface of the transmission main shaft, a connecting baffle plate fixedly sleeves one side of the outer surface of each transmission spacer bush, a hydraulic mechanism is in threaded connection with the outer side of each connecting baffle plate, one ends of the transmission spacer bushes is in transmission connection with the interiors of the hydraulic mechanisms, brake shells are fixedly installed on the inner sides of the connecting baffle plates, and intercepting grooves are formed in the inner walls of the brake shells. According to the main shaft brake mechanism based on the magnetorheological fluid, due to the arrangement of an intercepting through hole and the inclination angle of the intercepting through hole, the tangent angle of the intercepting through hole to the magnetorheological fluid can be increased, and therefore braking of the transmission main shaft is achieved not only through friction between the surface of the intercepting through hole and the magnetorheological fluid; and meanwhile, the cutting torque of the magnetorheological fluid is increased by utilizing the intercepting through hole, so that the braking torque generated by the main shaft brake mechanism during braking is further increased.

Owner:许飚

Engagement and disengagement overturning mechanism for accumulation conveyor

The invention discloses an engagement and disengagement overturning mechanism for an accumulation conveyor. The mechanism is characterized in that a friction plate is pressed against the inner end face of a friction wheel through a pressure spring by a compression nut to provide friction force, wherein chain teeth on the friction wheel are engaged with a driving chain; the driving chain, the friction wheel and a trolley are driven to synchronously advance by a chain wheel; an end face fluted disc is arranged on the outer end face of the friction wheel; a pressure plate coaxial with the chain wheel is fixedly arranged on the outer side of the chain wheel, and rotates synchronously with the chain wheel; an engagement and disengagement inserted pin is arranged at the bottom of the trolley; an engagement and disengagement fluted disc is arranged on the front end face of the engagement and disengagement inserted pin; the engagement and disengagement inserted pin is engaged with the end face fluted disc of the friction wheel after the pressure plate is pressed against the tail part of the engagement and disengagement inserted pin, and is disengaged from the end face fluted disc of the friction wheel when the tail part of the engagement and disengagement inserted pin is freed from the pressing of the pressure plate. The engagement and disengagement overturning mechanism for the accumulation conveyor is functionally reliable, low in noise and cost and stable in running.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

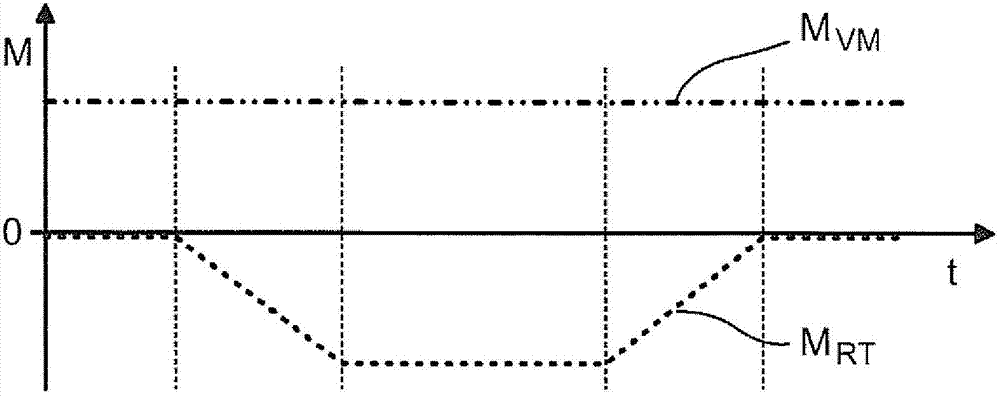

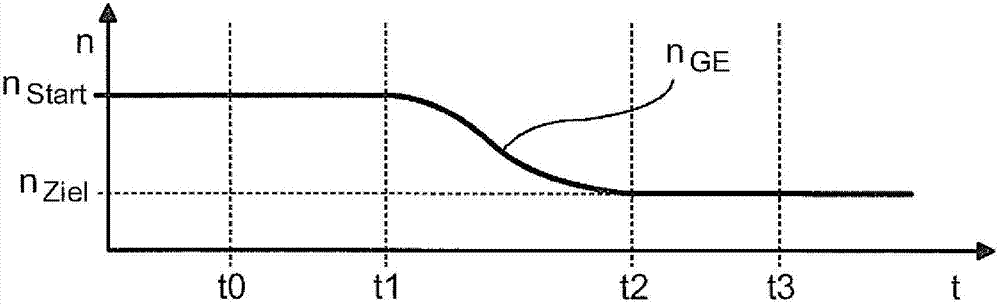

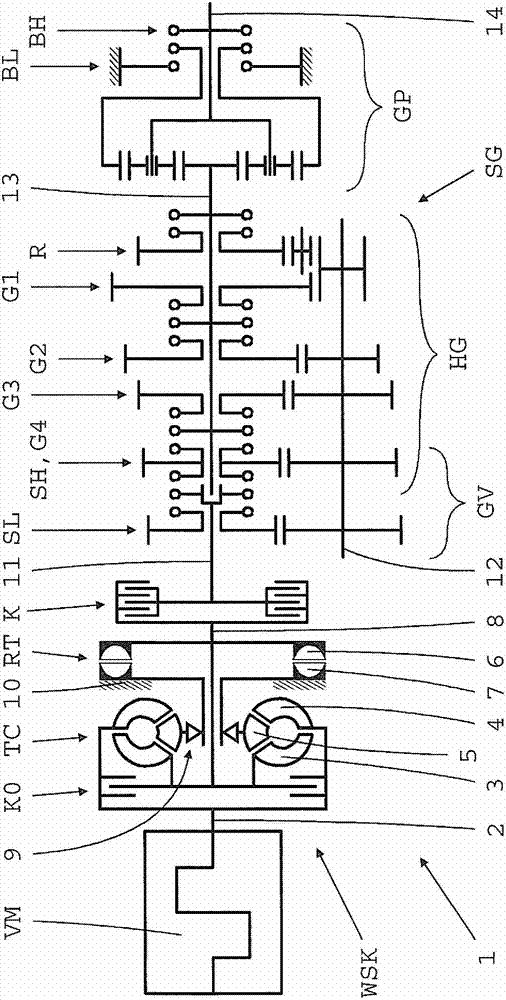

Method for performing gear shifting control on automated gear shifting transmission

InactiveCN102889376AReduce pulling forceIncrease braking torqueBraking element arrangementsHydrodynamic brakesImpellerDrive shaft

A method for performing gear shifting control on an automated gear shifting transmission. A torque conversion clutch device is placed in front of the transmission and includes: a hydraulic torque converter which has a pump impeller connected with a transmission shaft of a driving motor of an internal combustion engine configured for turbocharging, and a turbine connected with a middle shaft; a retarder of a rotor which is in transmission connection with the middle shaft; and a cut-off clutch configured to be an automated friction clutch and arranged between the middle shaft and an input shaft of the transmission, during traction and gear shafting, the input shaft of the transmission remains torque-free as far as possible through reduction of a load when gear shifting begins. To prevent weakening of motive force of the driving motor when traction and gear shifting finish and the load is established, the arrangement is that: in the circumstance of maintaining motor torque output by the driving motor, the reduction of the load on the input shaft is caused by absorbing correspondingly high retarding torque in the retarder, and the retarding torque absorbed from the retarder increases to above the motor torque of the driving motor at the beginning of traction and gear shifting, and reduces to zero when traction and gear shifting finish.

Owner:ZF FRIEDRICHSHAFEN AG

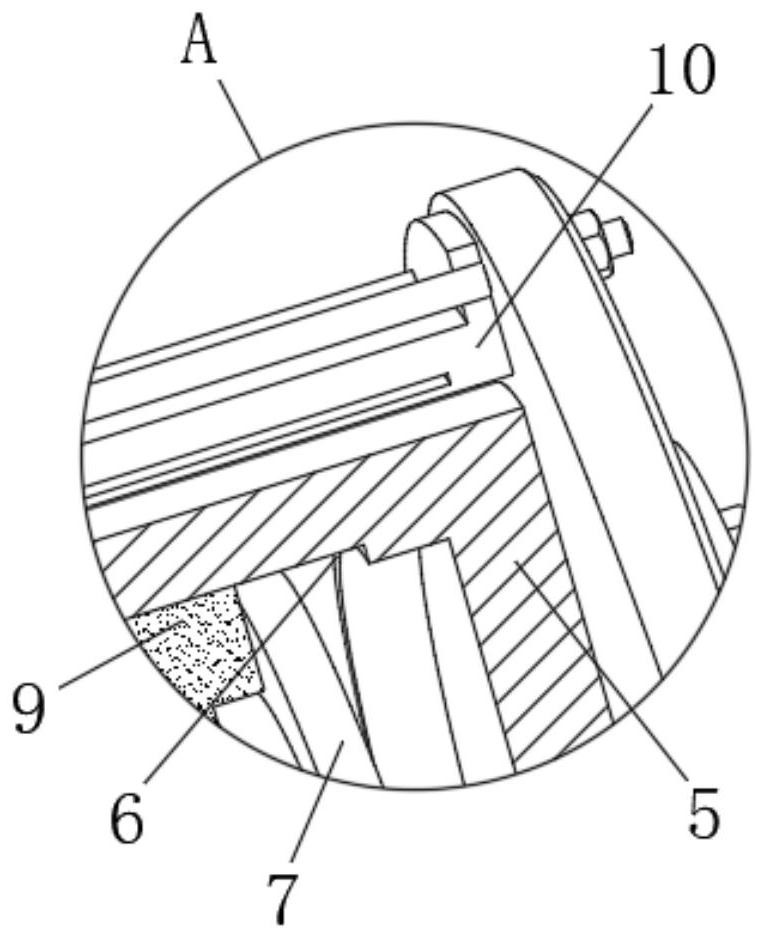

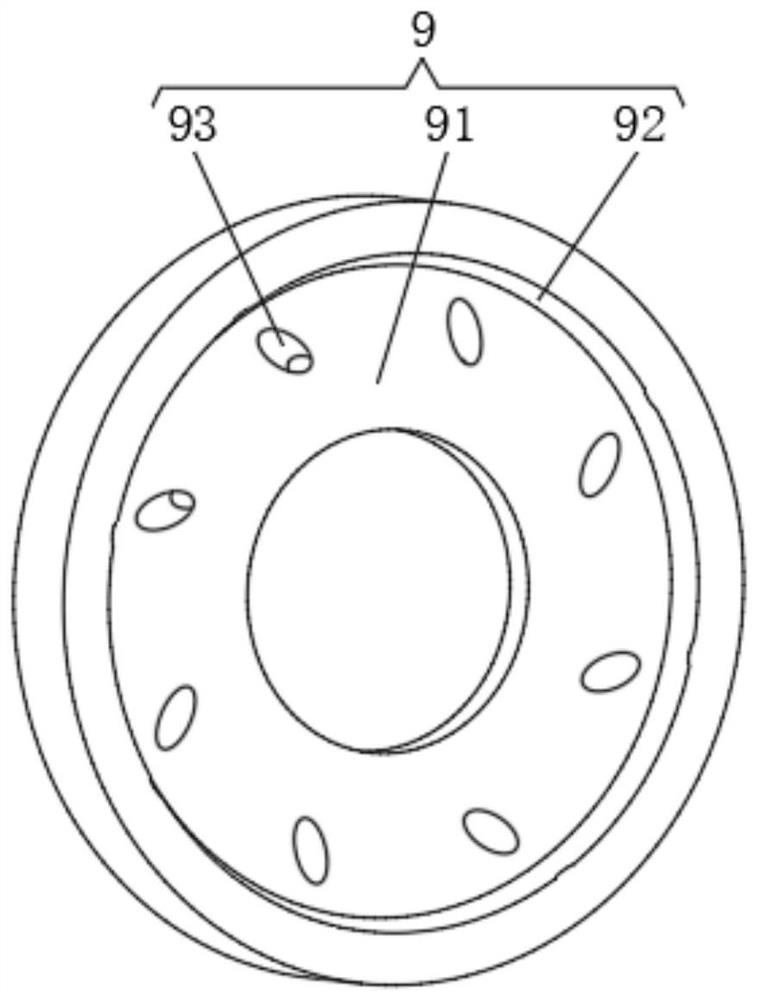

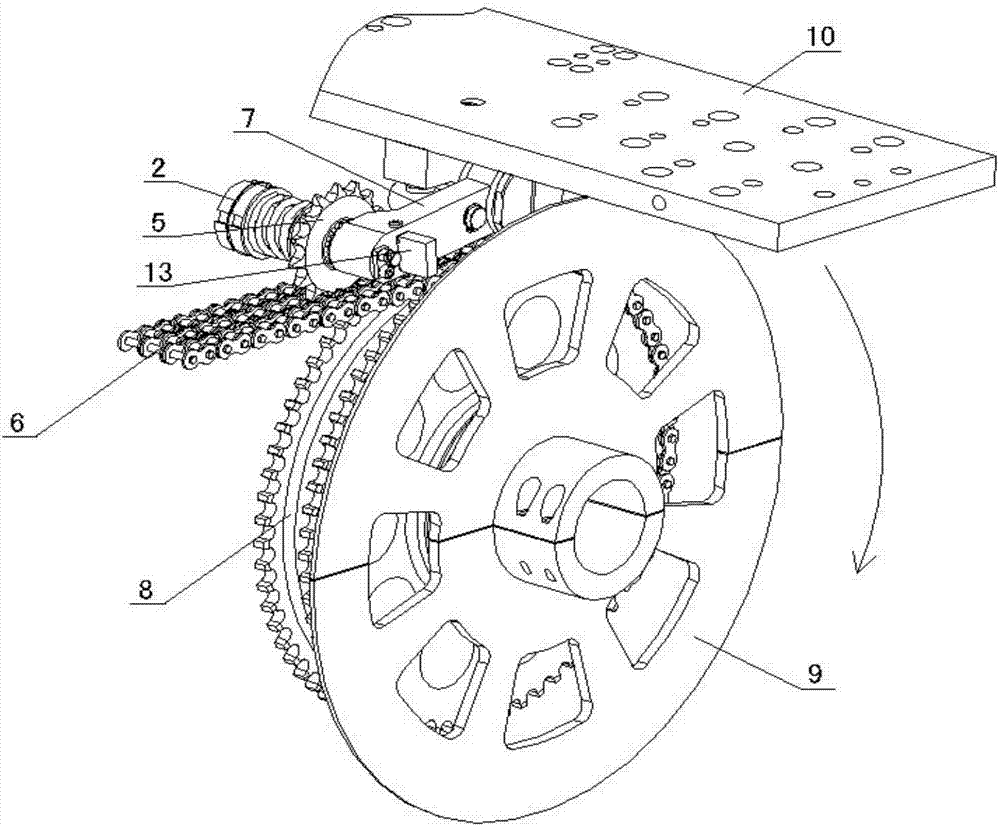

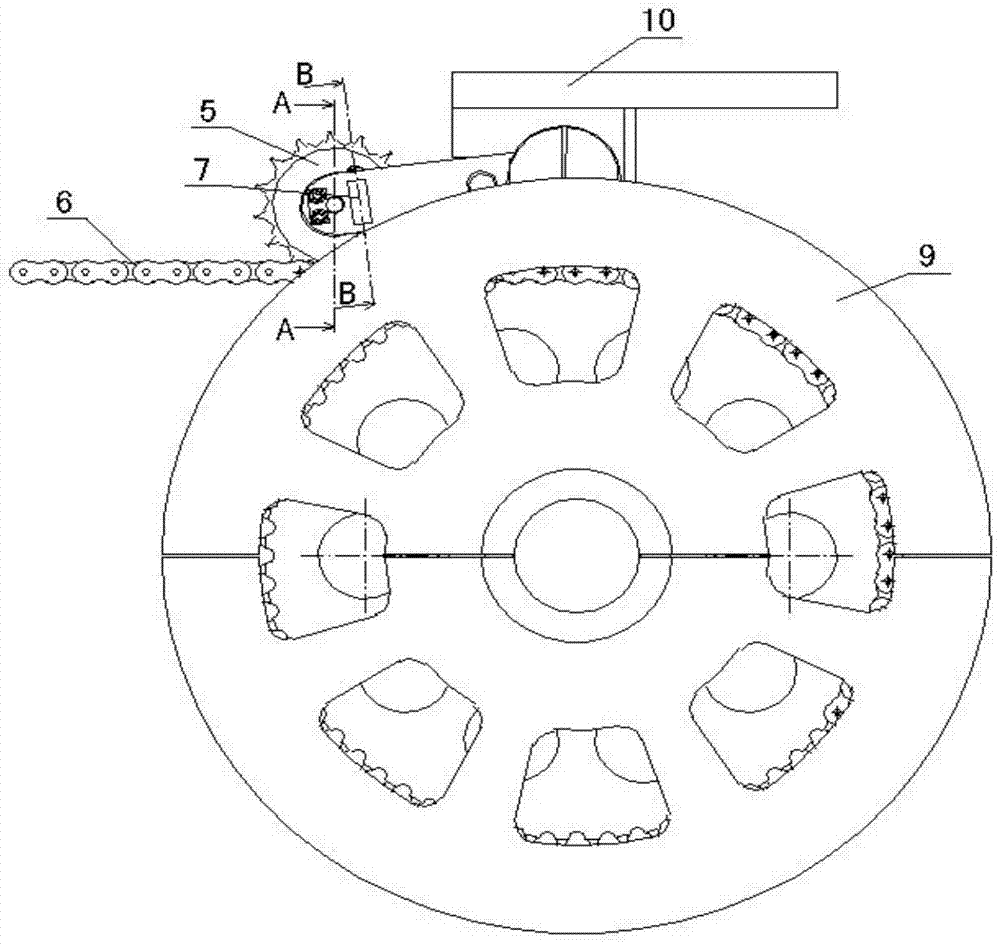

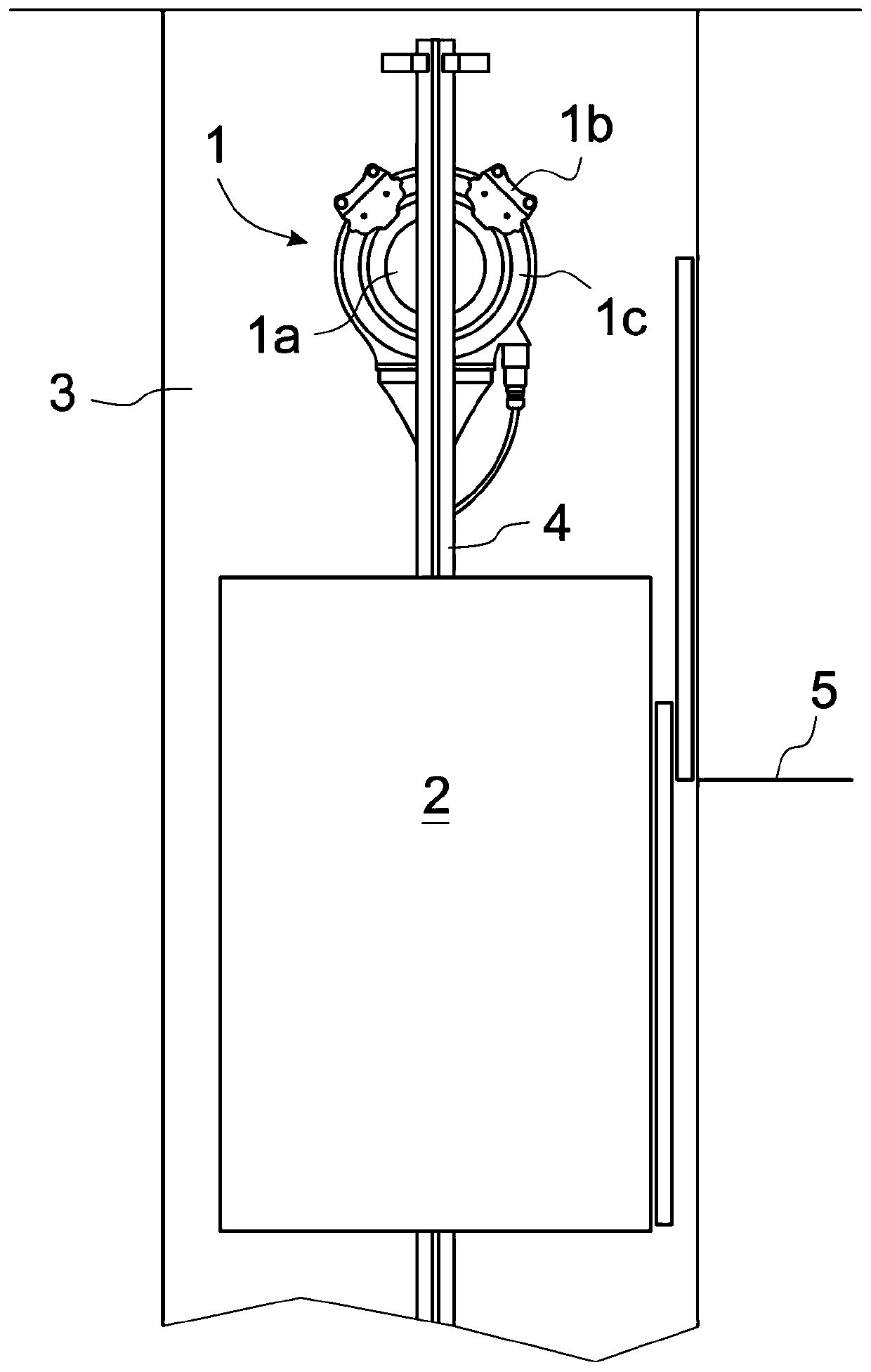

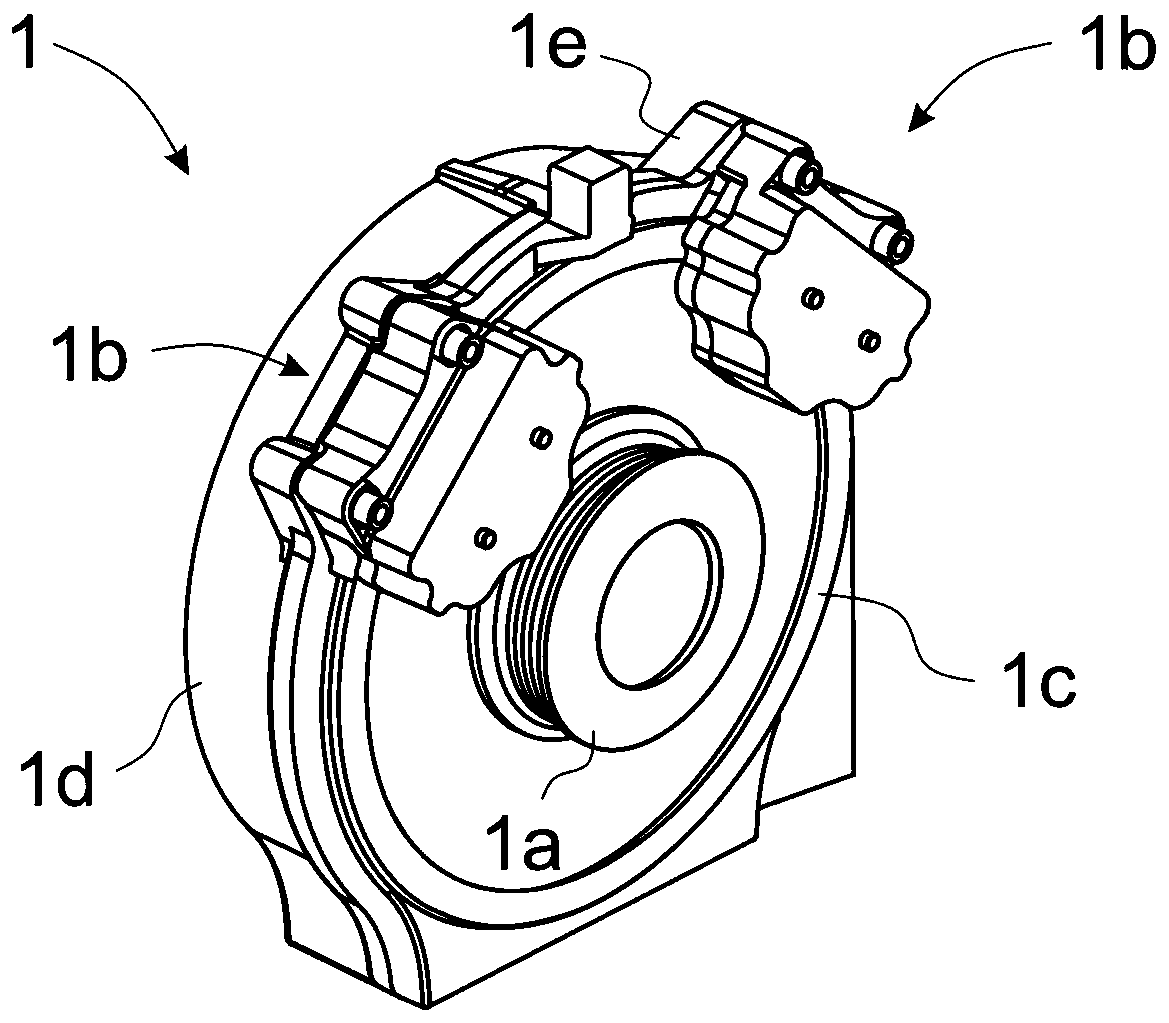

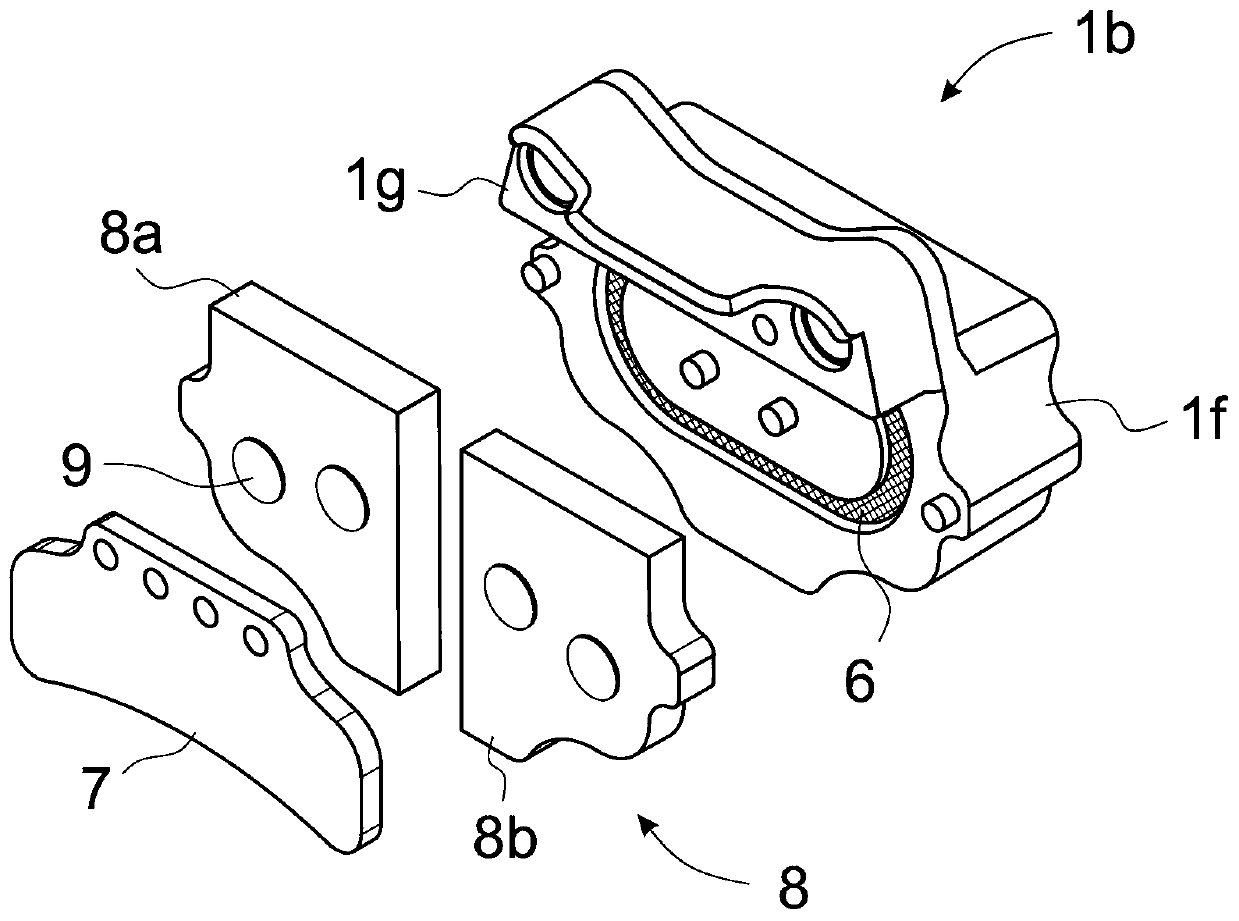

Dual-disc type brake

PendingCN108119578AIncrease braking torqueImprove securityAxially engaging brakesBrake actuating mechanismsCalipersPiston

The invention belongs to the field of vehicle braking and discloses a dual-disc type brake which is provided with a two-sided friction plate, wherein the two-sided friction plate is fixedly mounted with brake calipers through bolts; a brake disc I and a brake disc II are respectively arranged at two sides of the brake calipers; the middle parts of the brake disc I and the brake disc II are sleevedwith a spline half shaft; a single friction plate matched with the brake disc I and the brake disc II is also arranged at the upper end of the two-sided friction plate; the rear ends of the brake calipers are communicated with a brake pipeline; a piston is mounted at the tail end of the brake pipeline; and an oil inlet is formed between the brake pipeline and the piston. The dual-disc type brakeis provided with two friction surfaces, thereby increasing the brake moment of a vehicle and improving the safety performance.

Owner:QI AUTOMOTIVE CO LTD

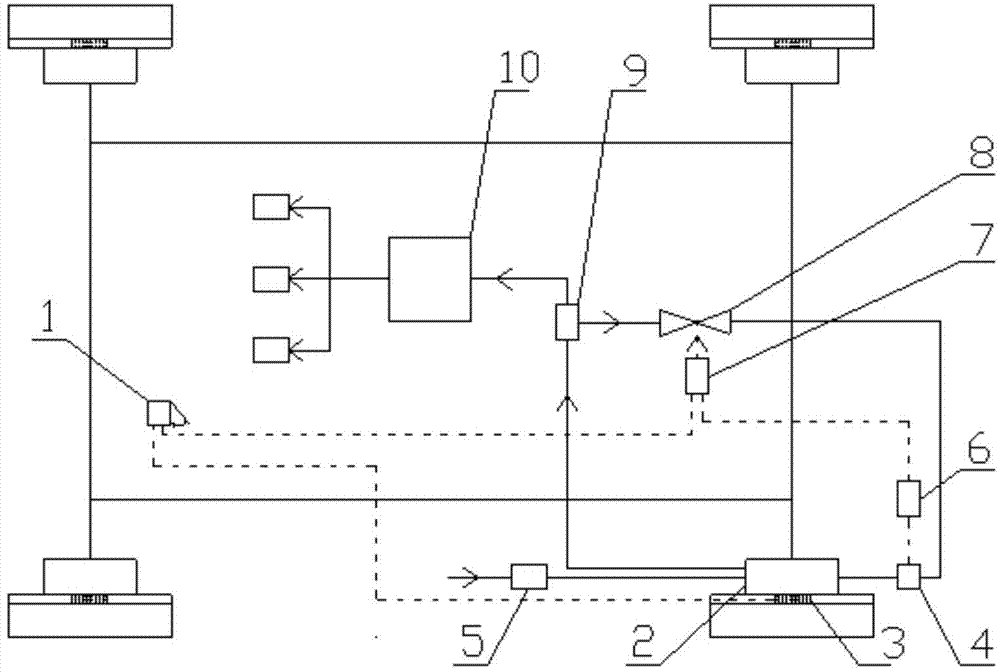

Automobile air rotary compression energy storage type braking system

InactiveCN104709265AEcho operating habitsIncrease braking torqueBraking action transmissionEnergy recoveryHabit

The invention relates to an automobile air rotary compression energy storage type braking system and belongs to the technical field of automobile control. The system mainly comprises a sliding vane type air compression device, a pedal and angle displacement inductor, an electromagnetic clutch, a pressure feedback transducer, a voltage comparator, an electromagnetic valve, a low-pressure air inflow device, a high-pressure air inflow device, a buffer box and an air storage tank. By the adoption of the system, force is acquired from rotation of an axle in the automobile braking process, the sliding vane type air compression device installed in the position of a brake disc is driven, air compression energy storage is conducted, power is adjusted and controlled by adjusting the initial pressure of air before the air is compressed, high-intensity air compression is achieved, and the large counter torque is output to stop an automobile from moving forwards continuously. By the adoption of the automobile air rotary compression energy storage type braking system, energy can be recycled and stored immediately under the common braking condition, braking operation is conducted on the brake disc through small-size high-intensity rotary air compression design, the system accords with a traditional braking operation habit, and the safety performance and the economic performance of the air rotary compression energy storage type braking system are improved.

Owner:CHONGQING UNIV

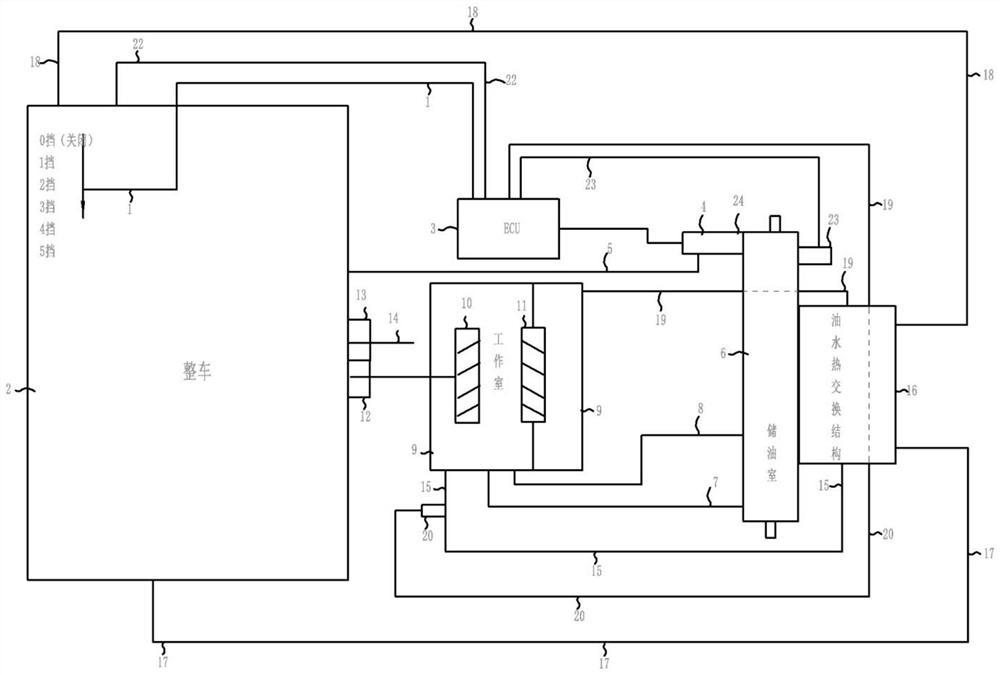

Hydraulic retarder control system

PendingCN113525315AEasy gear shiftingLow costLiquid resistance brakesHydrodynamic brakesBrake torqueControl system

The invention relates to the technical field of hydraulic retarders, and discloses a hydraulic retarder control system. The system comprises a retarder controller, a retarder handle switch, a main vehicle braking system and a whole vehicle cooling system; the main vehicle braking system sends braking information to the retarder controller, and the retarder controller controls the braking torque of the hydraulic retarder based on the braking information; the retarder controller acquires liquid temperature information of the hydraulic retarder, and based on the water temperature information, the retarder controller controls a whole vehicle cooling system; and the retarder handle is provided with a plurality of gears, and the retarder controller controls the braking torque of the hydraulic retarder based on gear information. The hydraulic retarder is cooled, and the braking torque of the hydraulic retarder is improved.

Owner:吉林省中誉信德科技有限公司

Elevator safety brake, elevator and method for testing elevator safety brakes

ActiveCN110857210ASmall sizeReduce manufacturing costBraking membersBrake actuating mechanismsBrakeControl theory

The invention relates to an elevator safety brake unit (10b), to an elevator comprising at least two of the aforementioned safety brake units, and to a method for testing the safety brake units. Eachsafety brake unit comprises a frame part (11); a movable composition movably supported on the frame portion; a compression spring assembly associated with the movable composition and adapted to activate braking by pushing the movable composition forward; and a coil assembly (16) of an electromagnet disposed in the frame portion and adapted to release braking by pulling the movable composition rearwardly. Wherein each movable composition comprises at least two movable elements (12); a compression spring (17) for each movable element; and at least one coil assembly (16) adapted to deactivate braking by pulling the at least two movable elements rearwardly.

Owner:KONE CORP

Fall-preventing device for ropes and round bars

The invention discloses a fall-preventing device for ropes and round bars. The fall-preventing device comprises a body, a rotating arm, two connecting plates, a movable block and a pull ring, wherein a V-shaped through groove is formed in one end of the body; a strip sliding chute is formed in the other end of the body; the rotating arm is rotationally connected with the body at the middle position; the movable block is arranged between the rotating arm and the body and is positioned on one side of an opening of the V-shaped through groove; the two connecting plates are oppositely arranged on two sides of the body; one end of each connecting plate is rotationally connected with one end of the rotating arm; a spring is arranged at the rotationally-connecting part; the other end of each connecting plate is rotationally connected with the pull ring through a pin roll; and the pin roll penetrates through the strip sliding chute in the body. According to the fall-preventing device disclosed by the invention, due to the adoption of a cam type five-link mechanism, a brake torque is increased; by adopting a V-shaped through groove structure, the fall-preventing device is more suitable for fixing the ropes and the round bars; by adopting a rotary movable block structure, the size of the rotating arm and the size of an integral structure are reduced and meanwhile, the brake torque is increased; and by adopting a spring locking structure, the mechanism is always positioned in a locking state.

Owner:中国能源建设集团南京线路器材厂有限公司 +1

Parking brake

InactiveCN103277434AReliable and Safe Downhole OperationsSafe and reliable downhole operationFluid actuated brakesEngine sealsDrive shaftParking brake

The invention discloses a parking brake, and belongs to the technical field of brakes. The parking brake comprises a spring, an end cover, a brake piston, a brake puck, a friction plate and a brake shell, wherein the brake puck and the friction plate are matched for use in a cavity formed by the brake piston and a transmission shaft. The brake piston and the brake puck are both connected with one end of the spring, the other end of the spring is fixed on the end cover, and the brake shell connected with the end cover is arranged on the periphery of the brake piston. The brake puck is connected with the brake shell through an outer spline, the friction plate is connected with the transmission shaft through a spline shaft, the brake shell is of a full-seal structure, and cooling oil liquid is filled in the brake shell. The brake not only avoids influence of water, dust, impurities and the like, but also is rapid and stable in a brake process, improves brake moment of force, and reduces wastage and maintaining costs of equipment.

Owner:江苏科意达机械有限公司

Powder metallurgy brake pad material for high speed multiple unit and preparation thereof

InactiveCN100591785CGuaranteed densificationIncrease coefficient of frictionTurbinesOther manufacturing equipments/toolsFerrosiliconJet fuel

The invention discloses powder metallurgy braking disc material used for the high speed train set. The powder metallurgy braking disc material is characterized in that the raw material comprises copper-based powder which is adulterated with stannum and ferroalloy component and alpha silicon carbide, all components have the following mass percent: stannum occupies 1 to 8 percent, iron occupies 1 to10 percent, copper occupies 50 to 80 percent and alpha silicon carbide occupies 1 to 3 percent. The invention also provides a process used to prepare the material, the process is characterized in that the process comprises the following steps: various powder is weighed according to the following mass percent: 4 to 10 percent of iron, 6 to 12 percent of graphite, 1 to 8 percent of sea sand, 1 to 3percent of alpha silicon carbide, 1 to 8 percent of stannum, 1 to 4 percent of alumina, 1 to 10 percent of ferroboron, 1 to 5 percent of supramoly, 2 to 8 percent of ferrosilicon, the residual is copper; after being mixed uniformly, aviation kerosene and emulsion are admixed and mixed to be uniformly; the mixture is compressed to obtain the green compact; the green compact is fixed on a supporting steel back, and thus the powder metallurgy braking disc material can be obtained through sintering. If the braking disc made by the invention is used, the service life and the braking performance can meet the braking demand of high speed train set that the speed can be up to 250 km / h and above.

Owner:CENT SOUTH UNIV

Retarder for transport equipment

InactiveCN103166369AIncrease braking torqueIncrease power generation functionMechanical energy handlingDrive shaftTransport engineering

The invention provides a retarder for transport equipment. The retarder for the transport equipment comprises a retarder transmission shaft, a first stator, and a first rotor which is placed outside the first stator. The retarder transmission shaft is in coupling with a transmission shaft of the transport equipment through a gear unit.

Owner:TELMA AUTOMOBILE BRAKING SYST SHANGHAI

Low-noise friction plate for brake

InactiveCN106321696AImprove braking effectReduce wear rateOther chemical processesFriction liningLow noiseFiber

The invention discloses a low-noise friction plate for a brake. The low-noise friction plate for the brake comprises, by weight, 33-35 parts of buna-n rubber, 7-9 parts of thermosetting phenolic resin, 24-26 parts of enhanced non-asbestos fibers, 14-16 parts of granulated cork, 4-6 parts of metal powder, 4-6 parts of artificial graphite, 4-6 parts of barium sulfate and 2-4 parts of other impurities. According to the low-noise friction plate for the brake, the formula is advanced, the braking torque is high and stable, the temperature resistance can reach 250 DEG C, the abrasion rate is low, a high friction coefficient and the low abrasion rate can still be guaranteed while the hardness is reduced, braking noise is effectively lowered by 20 dB, the problem that the friction plate adheres when encountering water is completely eradicated, and promotion of the braking performance of a horizontal type main machine is facilitated.

Owner:CEG MOTOR SUZHOU

Hydrodynamic retarder

InactiveCN103185085AImprove braking effectIncrease braking torqueLiquid resistance brakesEngineeringOblique angle

The invention provides a hydrodynamic retarder. The hydrodynamic retarder comprises a turning wheel and a fixed wheel, wherein blades of the turning wheel and the fixed wheel are U-shaped and are arranged along the radial directions of the turning wheel and the fixed wheel; the U-shaped blades of the turning wheel and the fixed wheel are arranged in opposite directions; oil fluids in an inner ring and an outer ring of a hydrodynamic circulating cavity are fully centralized to a place with the largest axial hydrodynamic circulating circle for impacting and stirring; the front end of each blade is thin and the middle part of each blade is thick; a taper oblique angle is formed at the front end of each blade; the upper surface of each blade is an arc-shaped; the semicircular arc-shaped surface on the upper surface of the two U-shaped blades arranged in opposite directions forms another circulating circle between the turning wheel and the fixed wheel; stirring circulating impact can be carried out on the upper part of the blade to further enhance mutual impact of liquid flow; the casting connection area between the U-shaped blades, the fixed wheel and the turning wheel is large; the two sides of eawch blade are similar to two support ribs so as to enhance the rigidity of the blades; the structure is firm and unlikely to be damaged; and by increasing the diameter of the circulating circle, the axial size of the whole transmission is reduced, the occupation space is small, and the casting difficulty is low.

Owner:西安双特智能传动有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com