Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Effective transmission torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

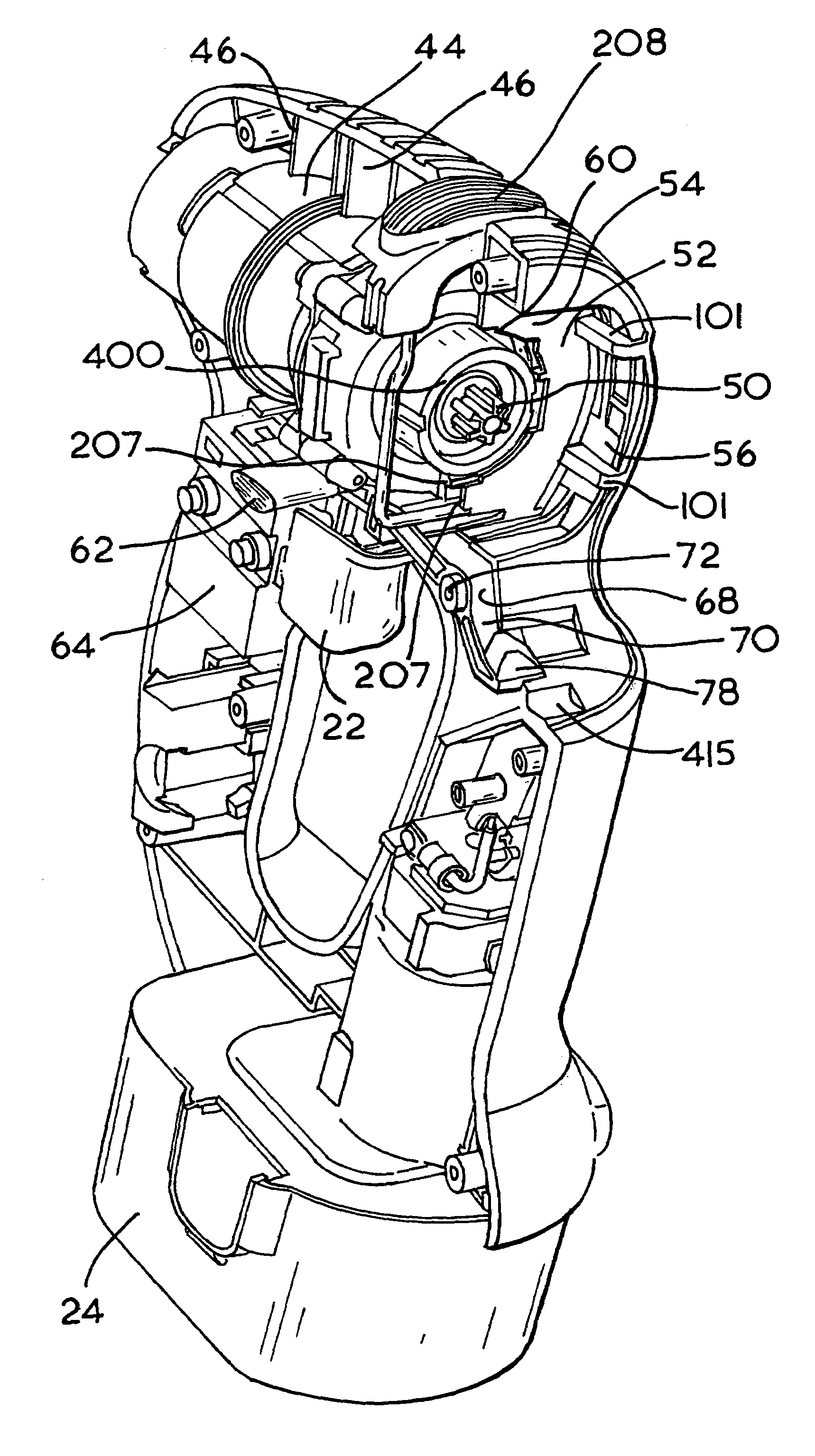

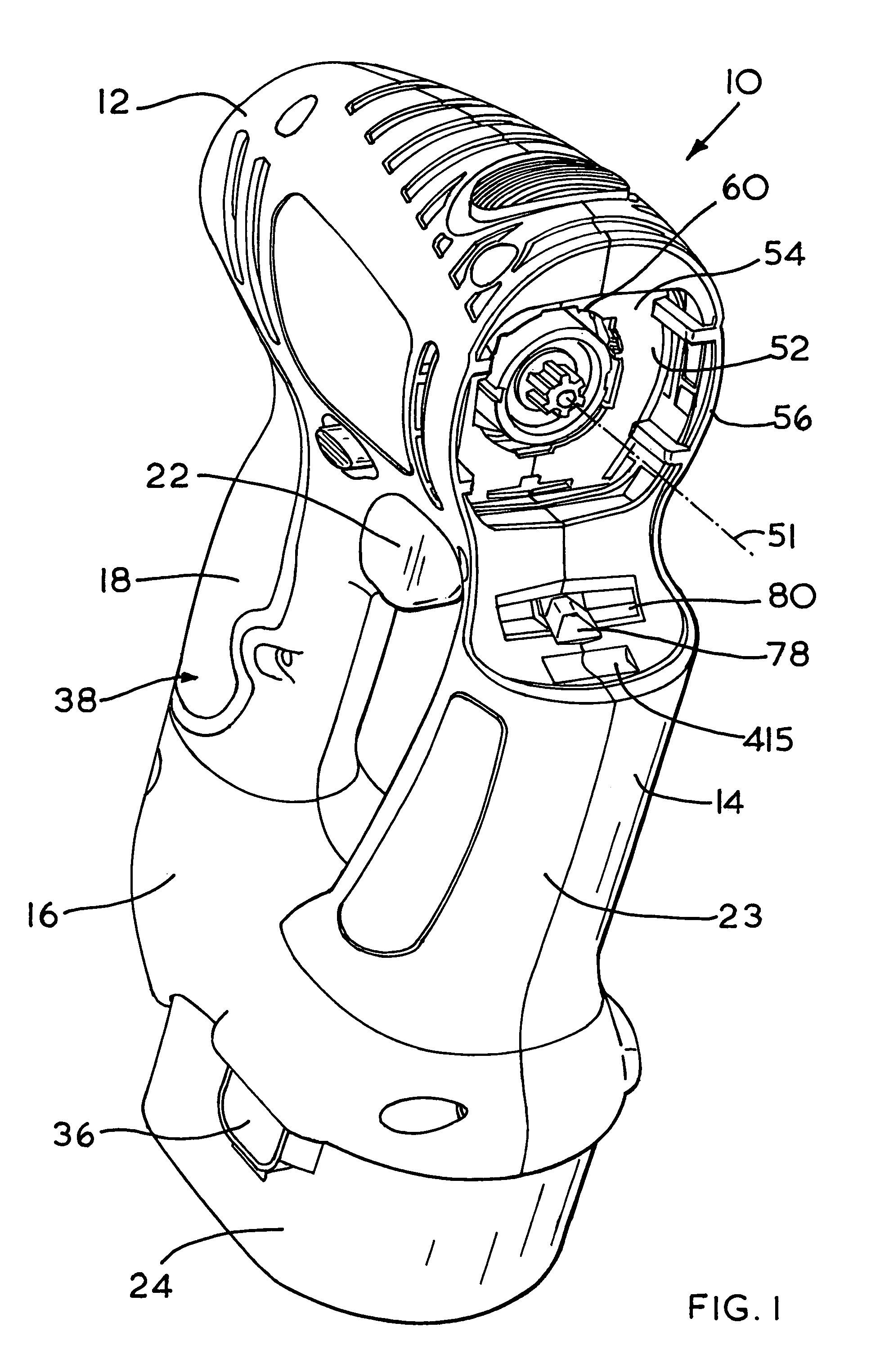

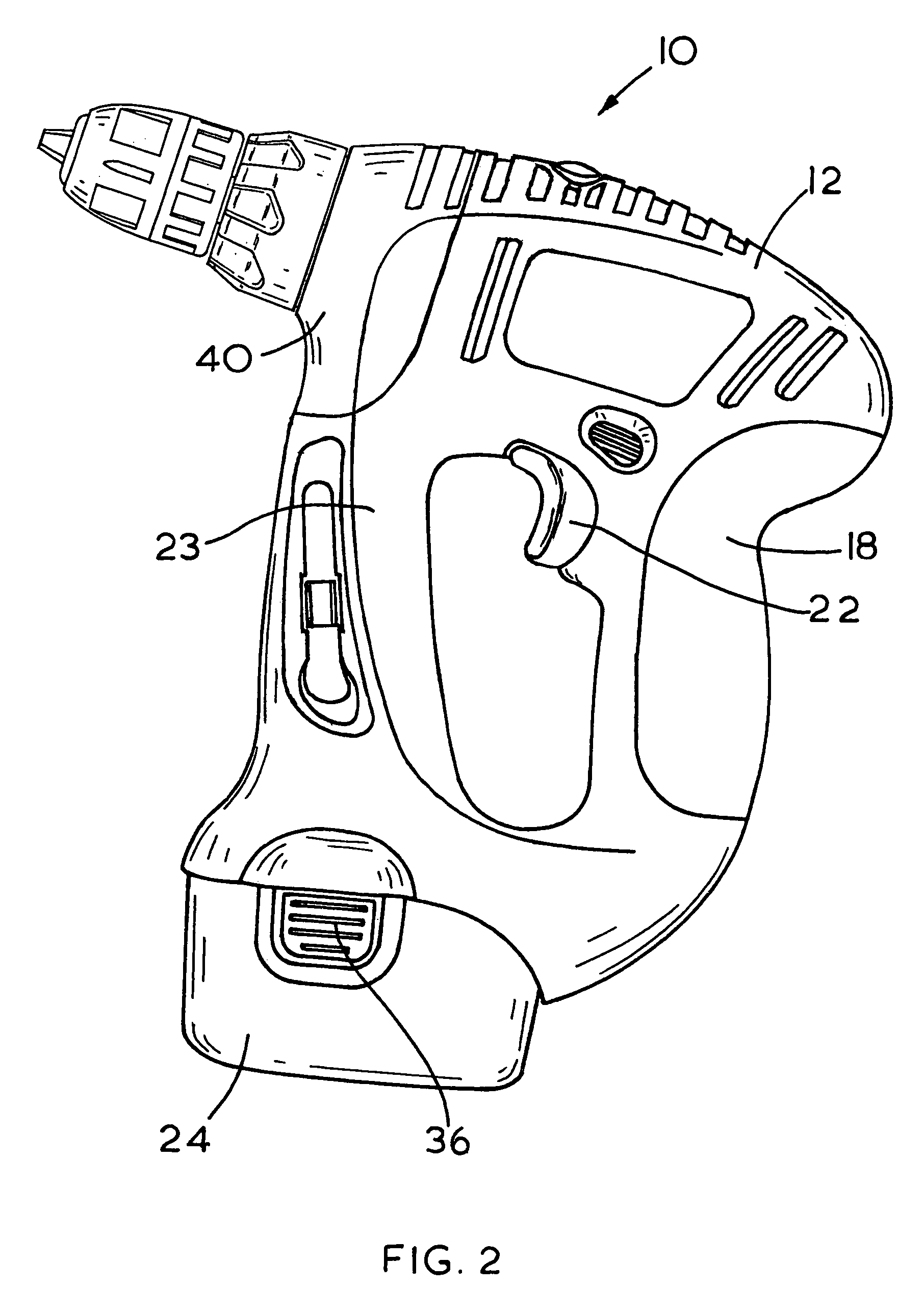

Power tool

A power tool includes a body housing a motor with a first output shaft and an attachment for engagement with the output shaft. The attachment includes an output shaft which transmits rotational motion derived from the rotational motion of the motor and further includes a gear mechanism enabling a gear change in rotational speed between its input and output. A combination of the body and the attachment thereby provides a plurality of serially-coupled gear mechanisms.

Owner:BLACK & DECKER INC

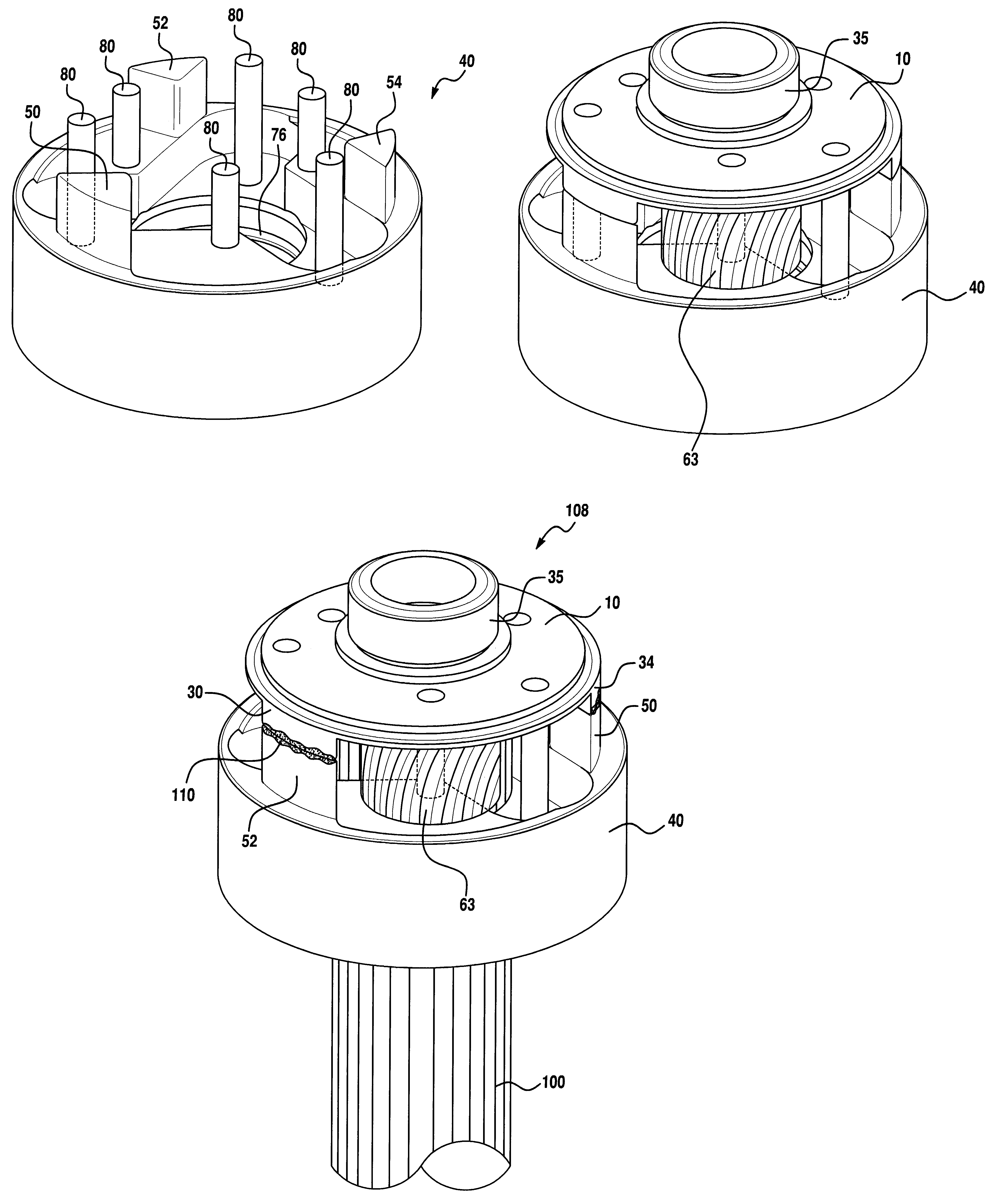

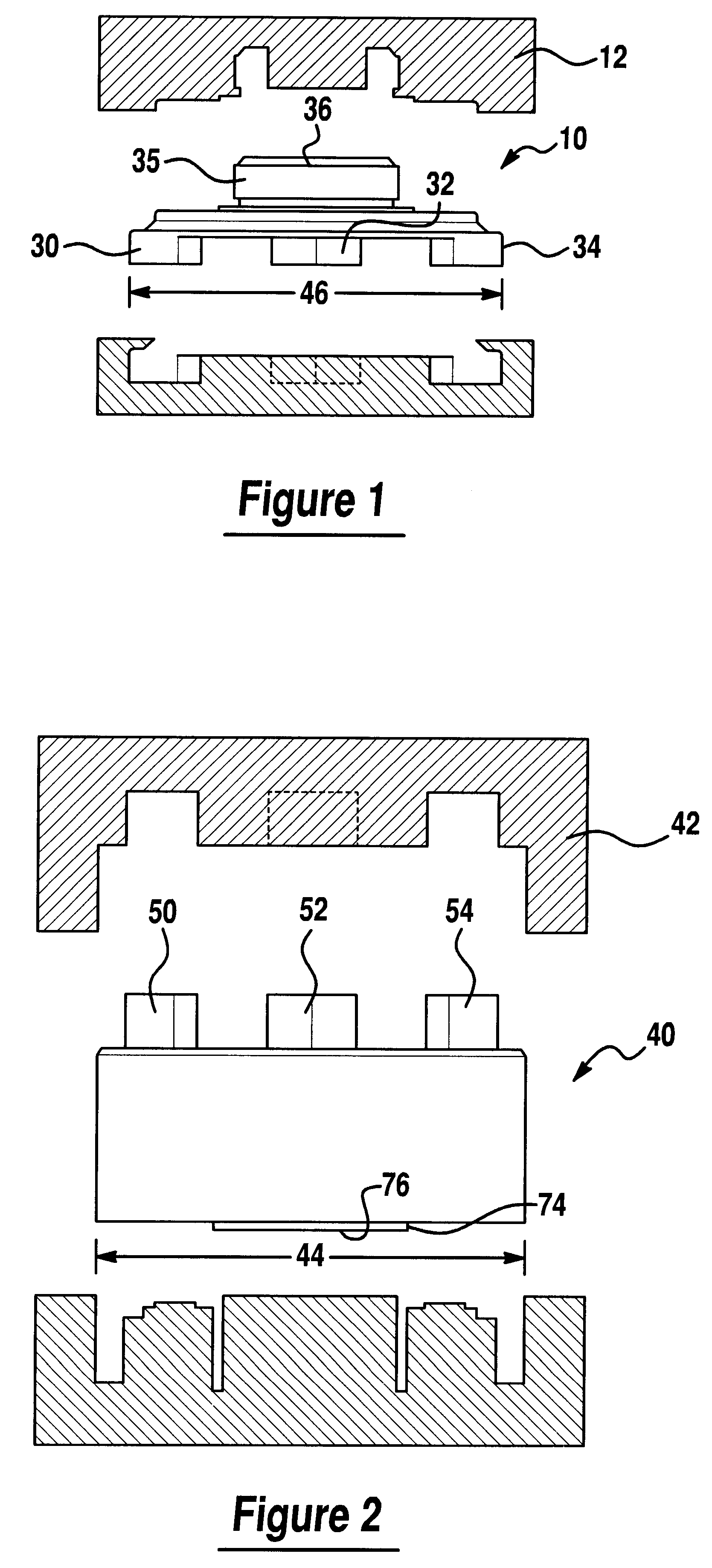

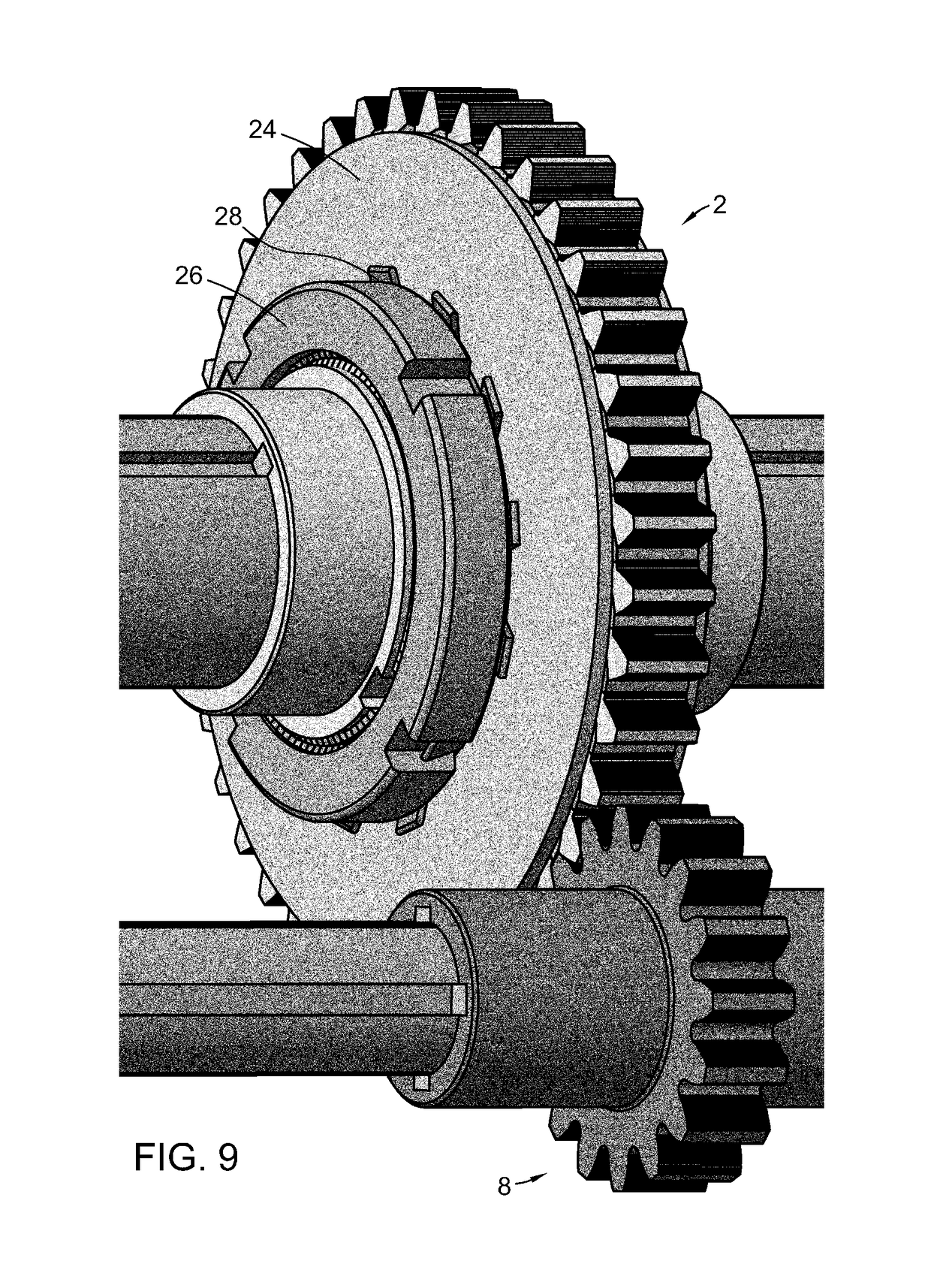

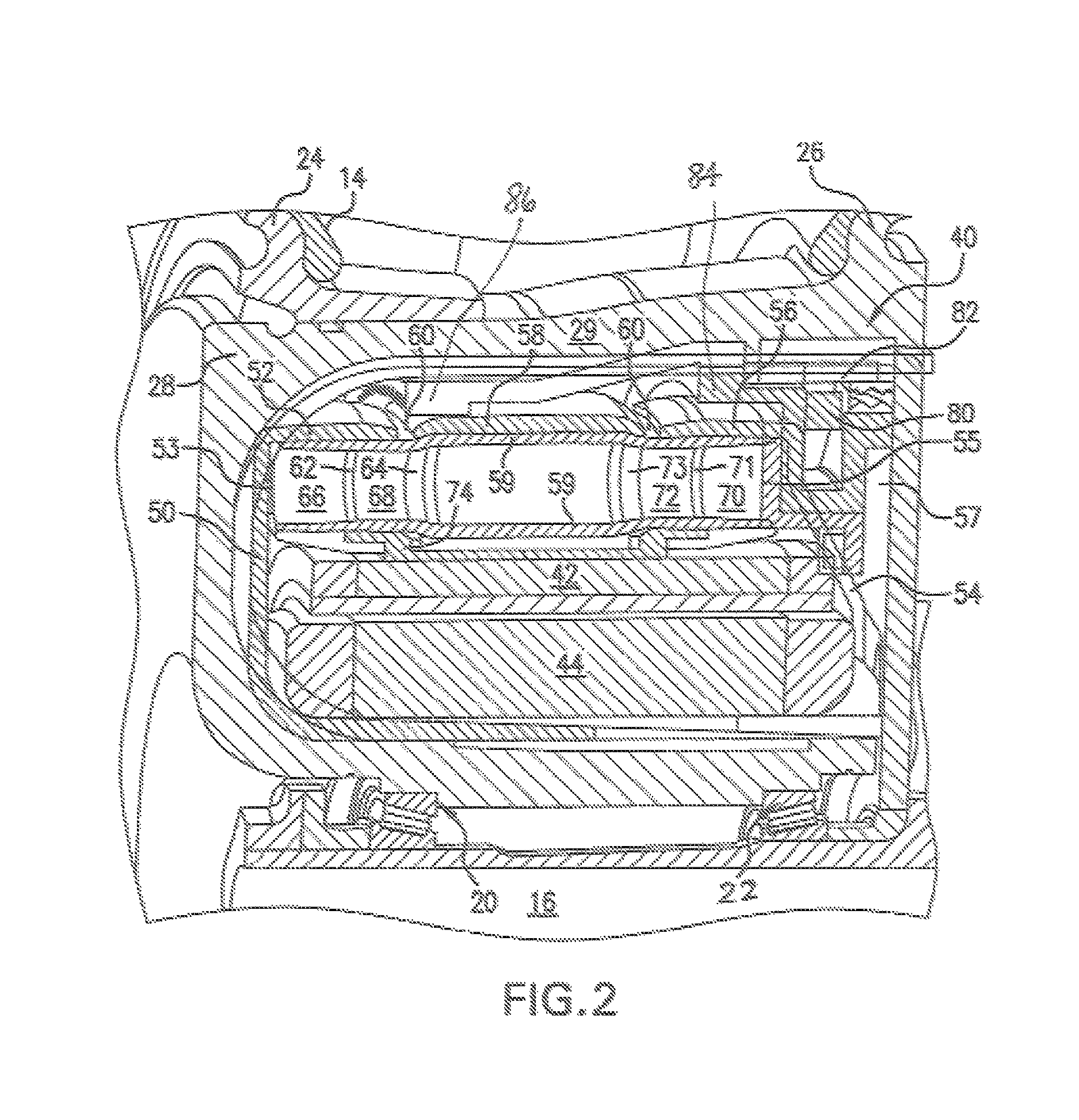

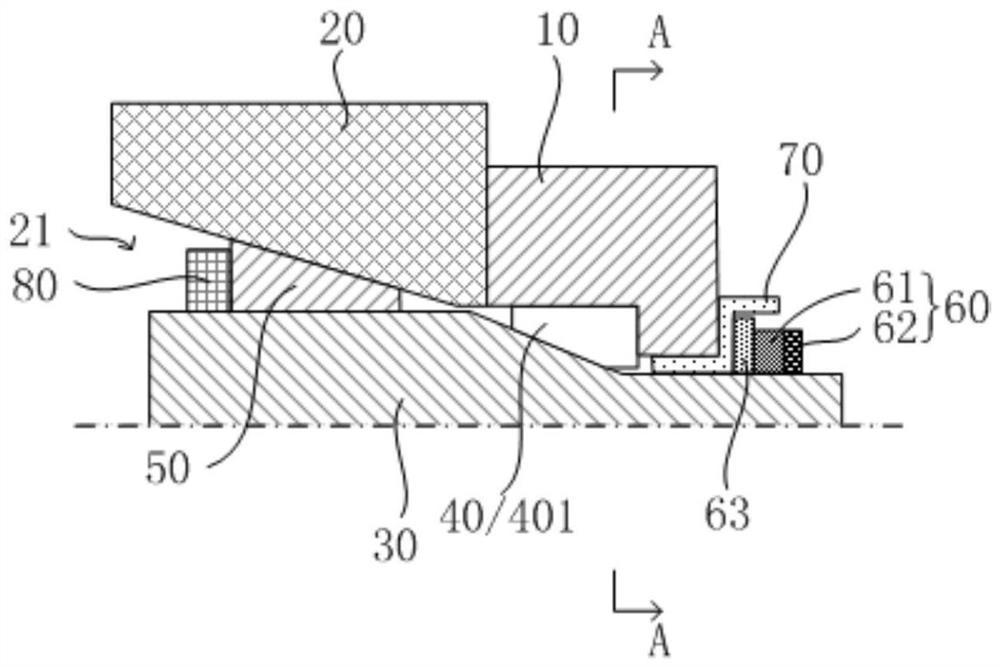

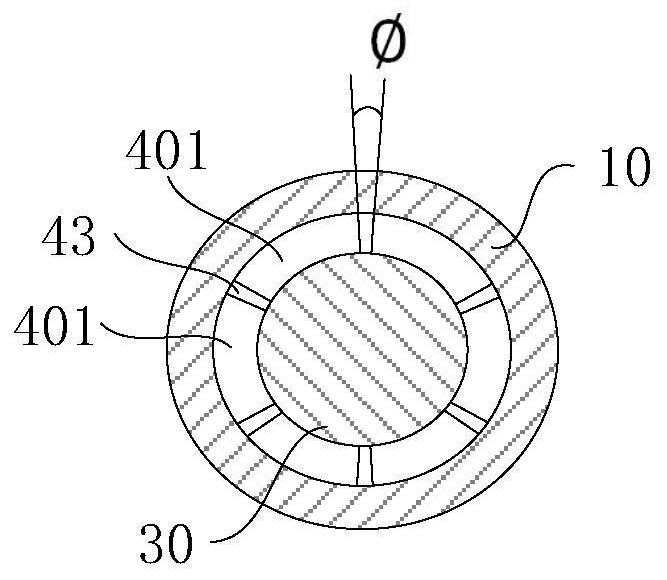

Method for creating a gear assembly

InactiveUS6434827B1Effective transmission torqueOvercomes drawbackMetal-working apparatusToothed gearingsEngineeringPinion

A method for producing a gear assembly 108 which allows for the relatively efficient transfer of energy. Assembly 108 is created by forming a first member 10 and a second member 40, by placing pinion support members 80 within the second member 40, by placing gear assemblies or pinions 63 upon each of the pinion support members 80, and by coupling the pinion support members 80 to the first member 10, thereby forming gear assembly 108.

Owner:FORD GLOBAL TECH LLC

Articulation joints for torque transmission

InactiveUS20120197241A1Easy to operateSufficient flexibilitySurgeryEndoscopesTorque transmissionEngineering

The invention can include an articulation link having a body with a first surface located proximate a first end of the body and a second surface located proximate a second end of the body opposite the first end. A cavity can extend from the first surface to a cavity contact surface located between the first surface and the second surface. A protrusion can extend from the second surface away from the first surface to a protrusion contact surface. The protrusion contact surface can be generally curved to engage a cavity contact surface of an adjacent link. A protrusion sidewall can engage a cavity sidewall of the adjacent link.

Owner:BOSTON SCI SCIMED INC

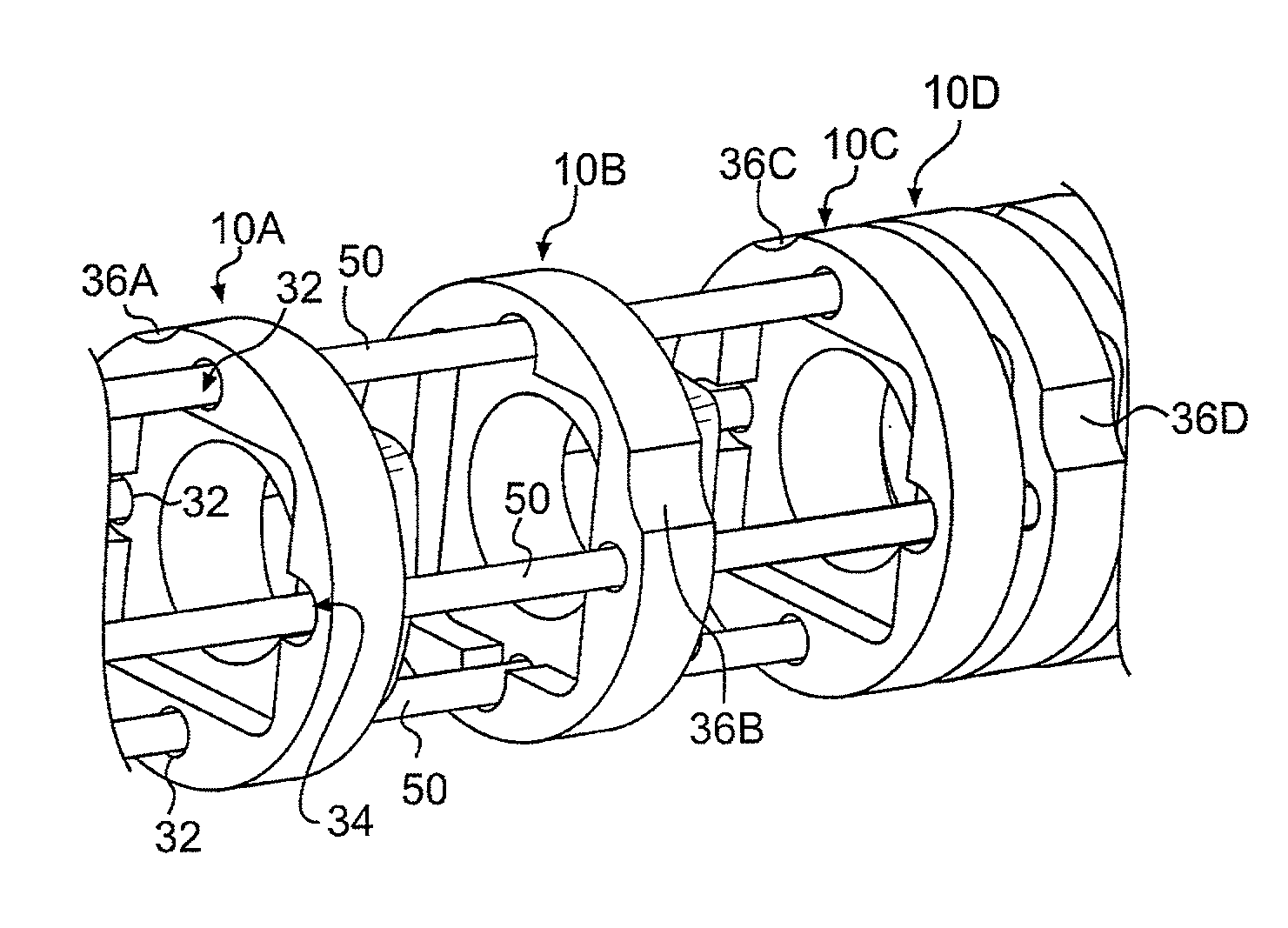

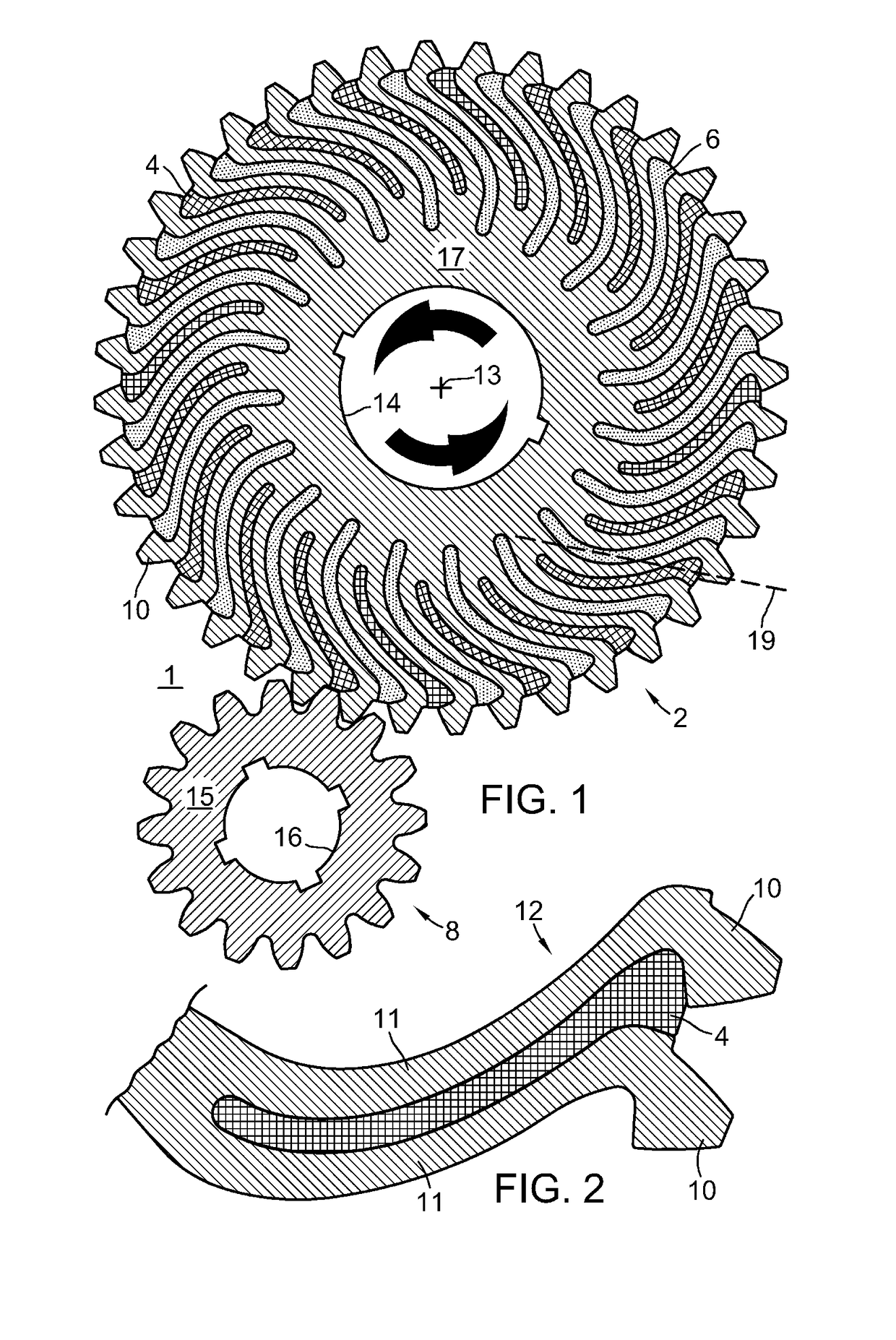

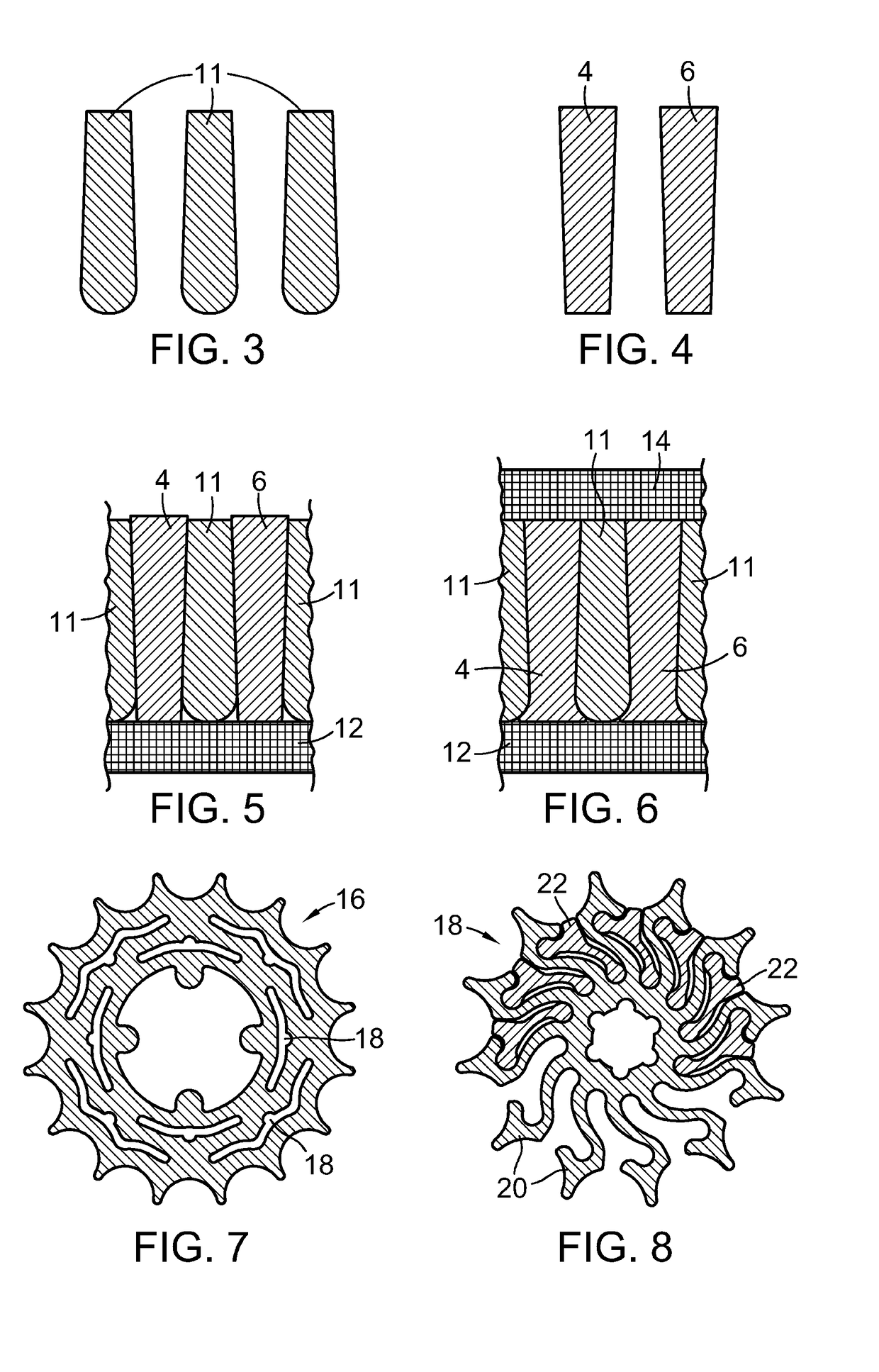

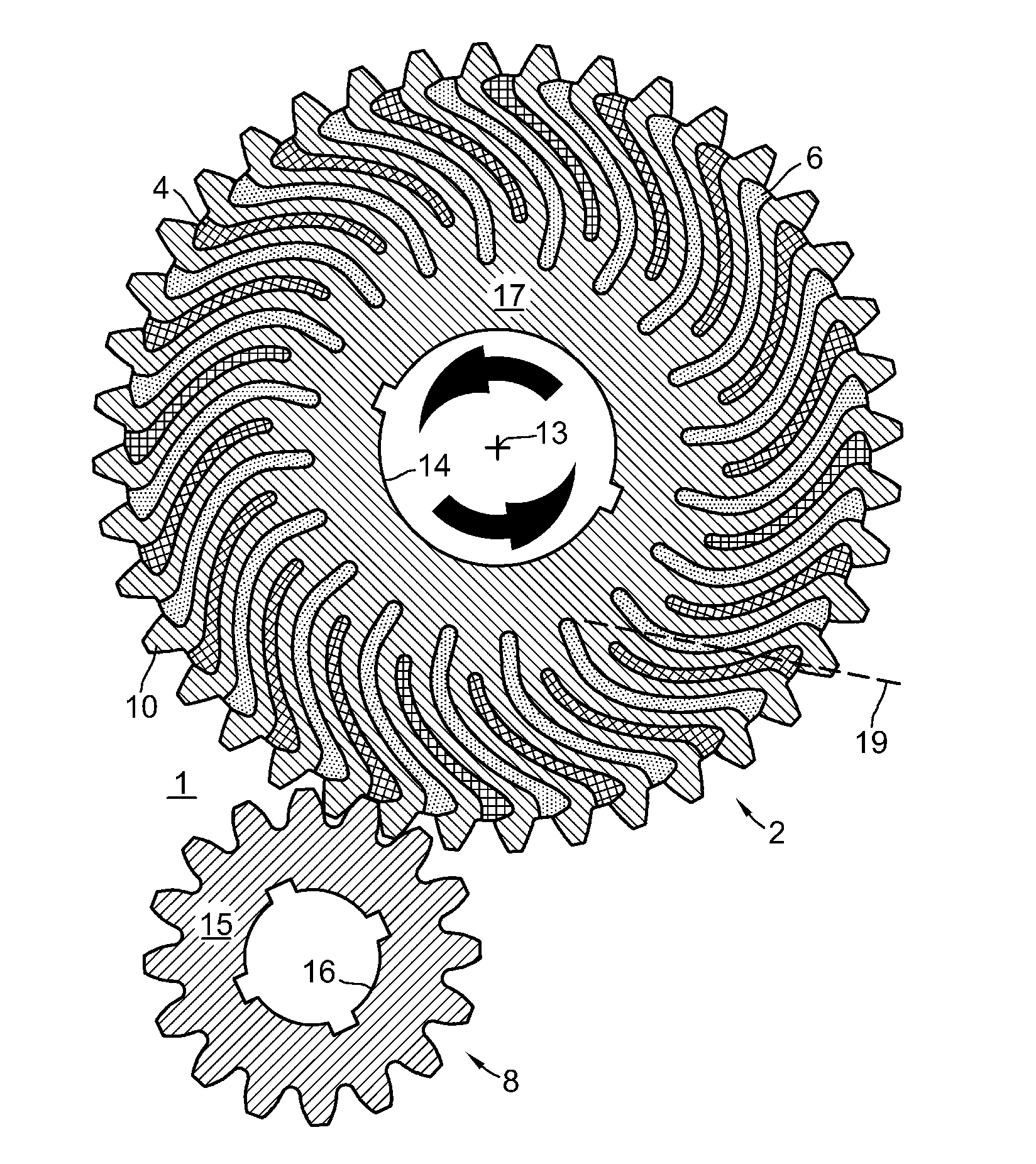

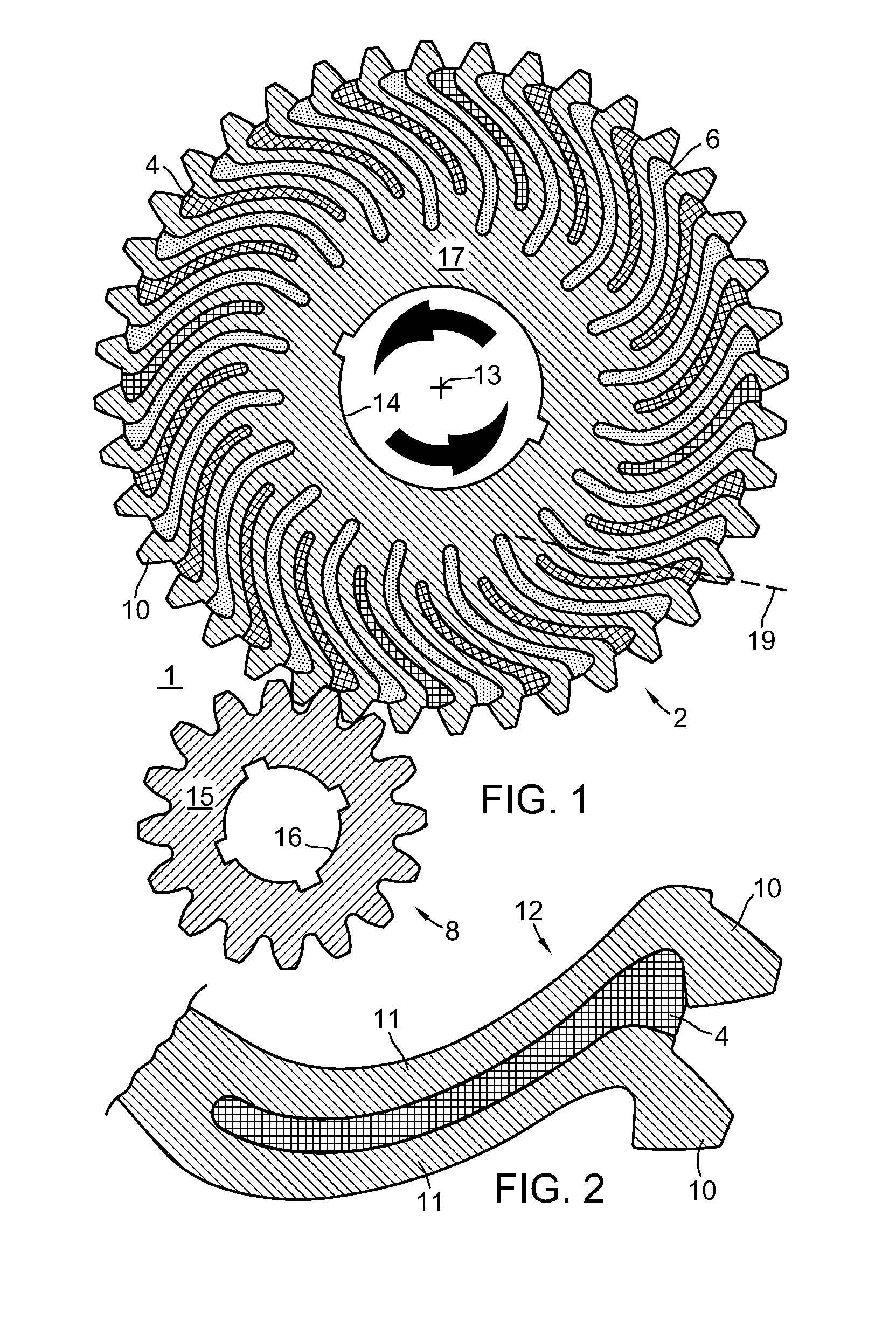

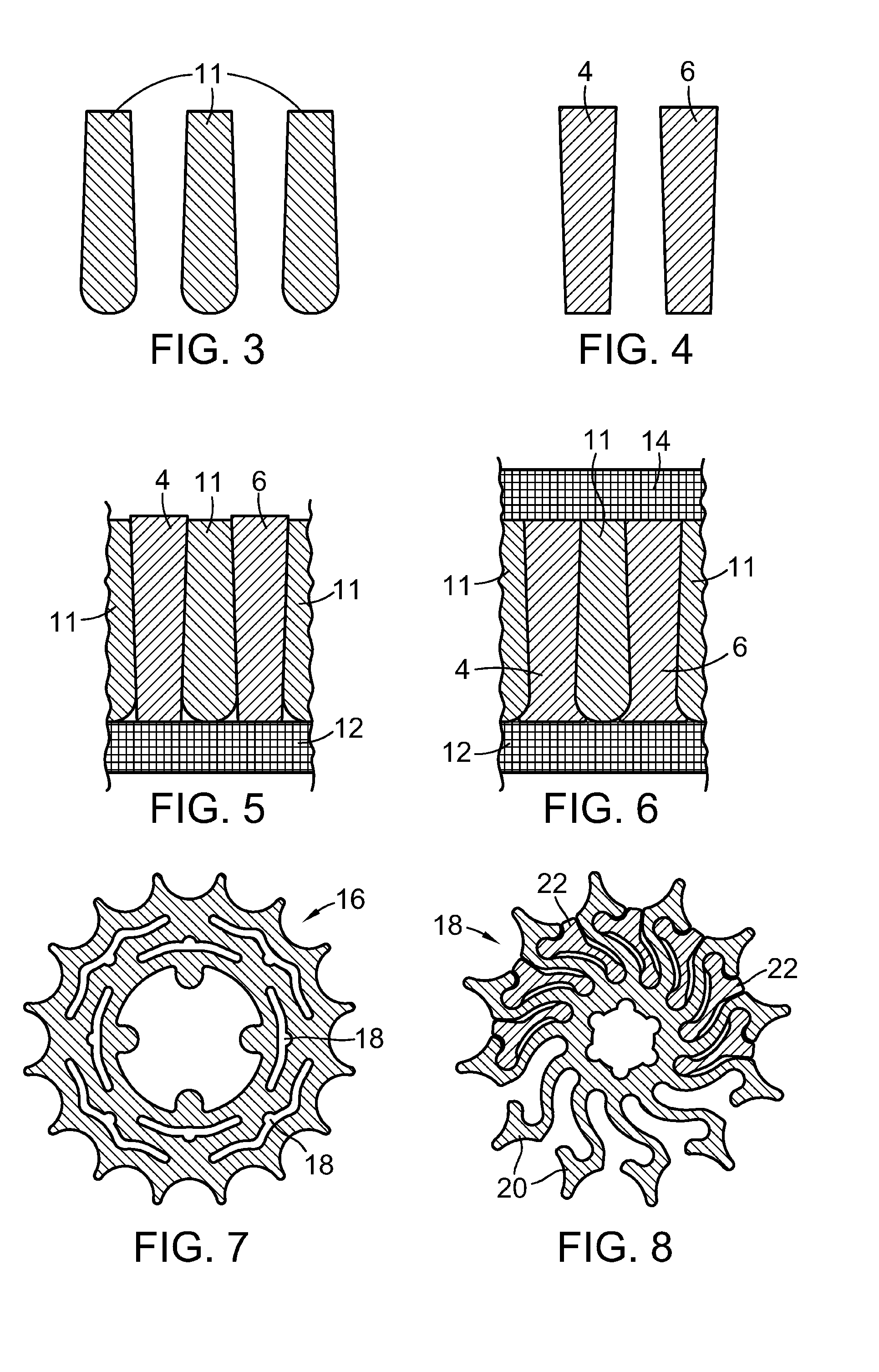

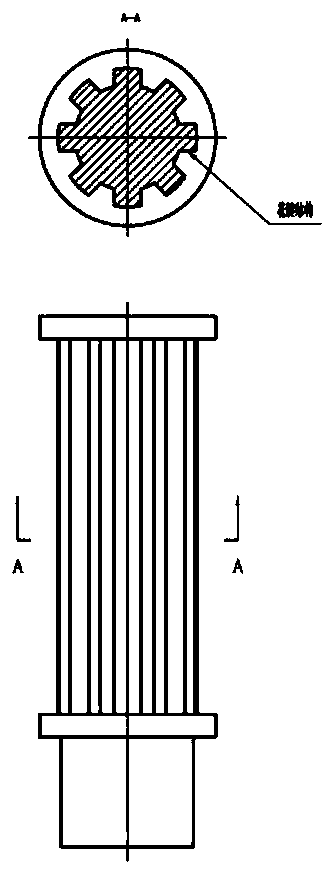

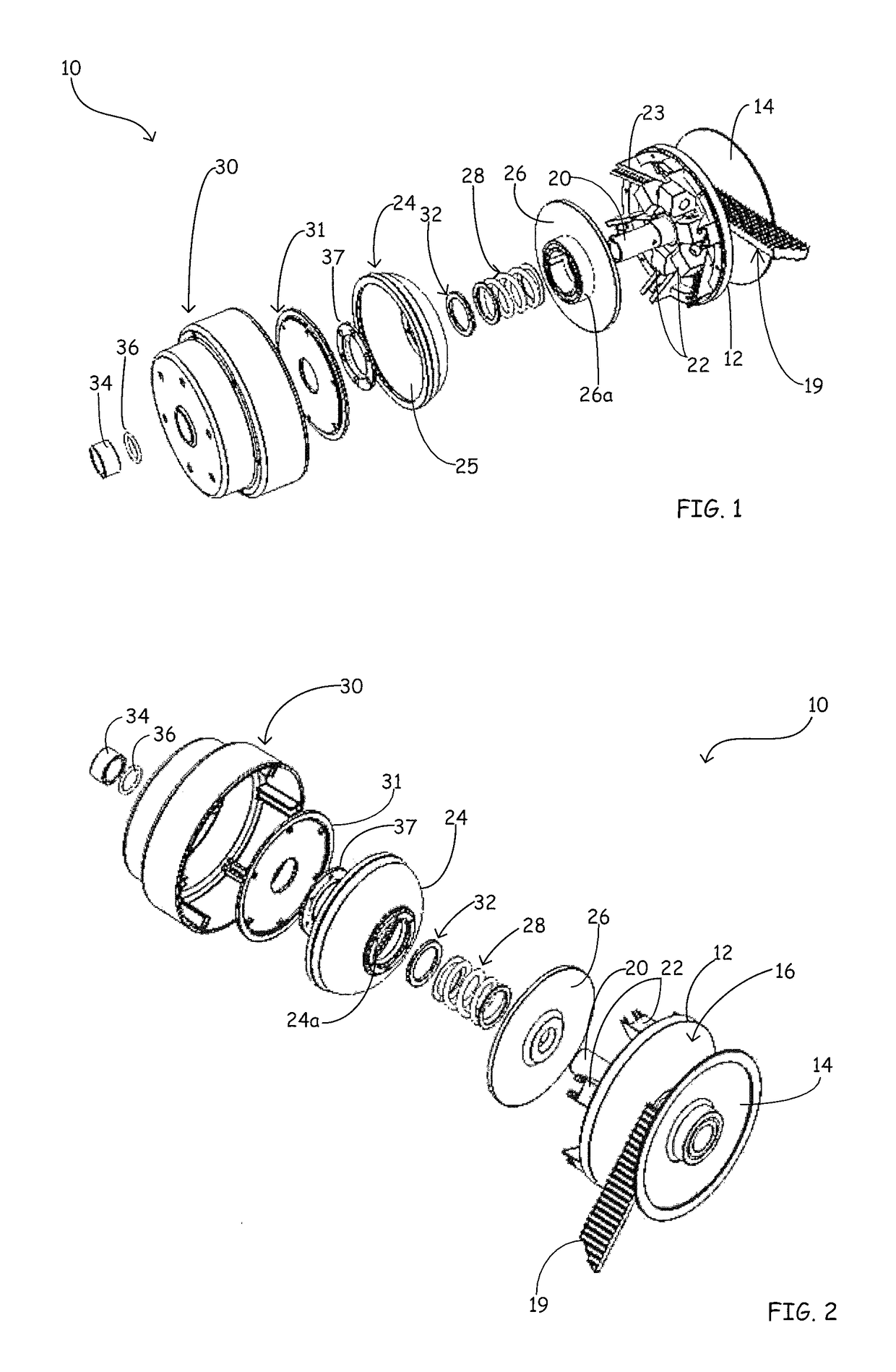

Torque-handling gear with teeth mounted on flexible arms

ActiveUS8468904B2Effective transmission torquePrecise functionMetal-working apparatusPortable liftingCantilevered beamDistributor

First gear for use in a gear set including a second gear has a hub to which are attached a plurality of arms made of an elastic material. Each pair of adjacent arms defines a slot between them into which the arms may bend. The arms can deflect elastically in the plane as a cantilevered beam. Each arm has on the end thereof, a tooth for meshing with a tooth on the second gear to allow transfer of force between the first gear's tooth and the meshing second gear's tooth. A load distributor in contact with at least first and second arms distributes to the second arm at least a portion of force received by the first arm's tooth while the first arm's tooth meshes with a tooth on the second gear. In one embodiment, the load distributor comprises an insert within the slot between the first and second arms.

Owner:NOWICKI ANDREW

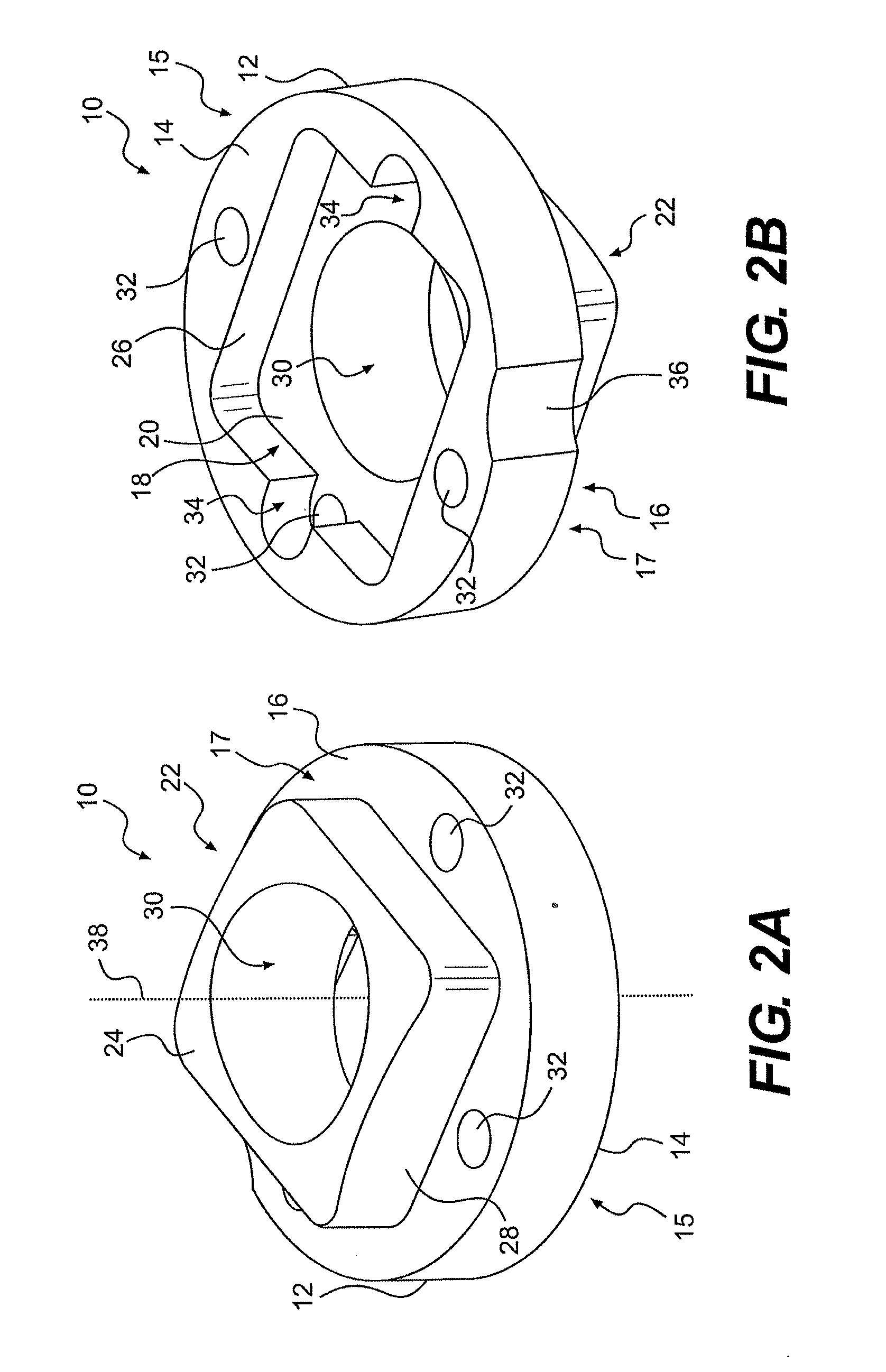

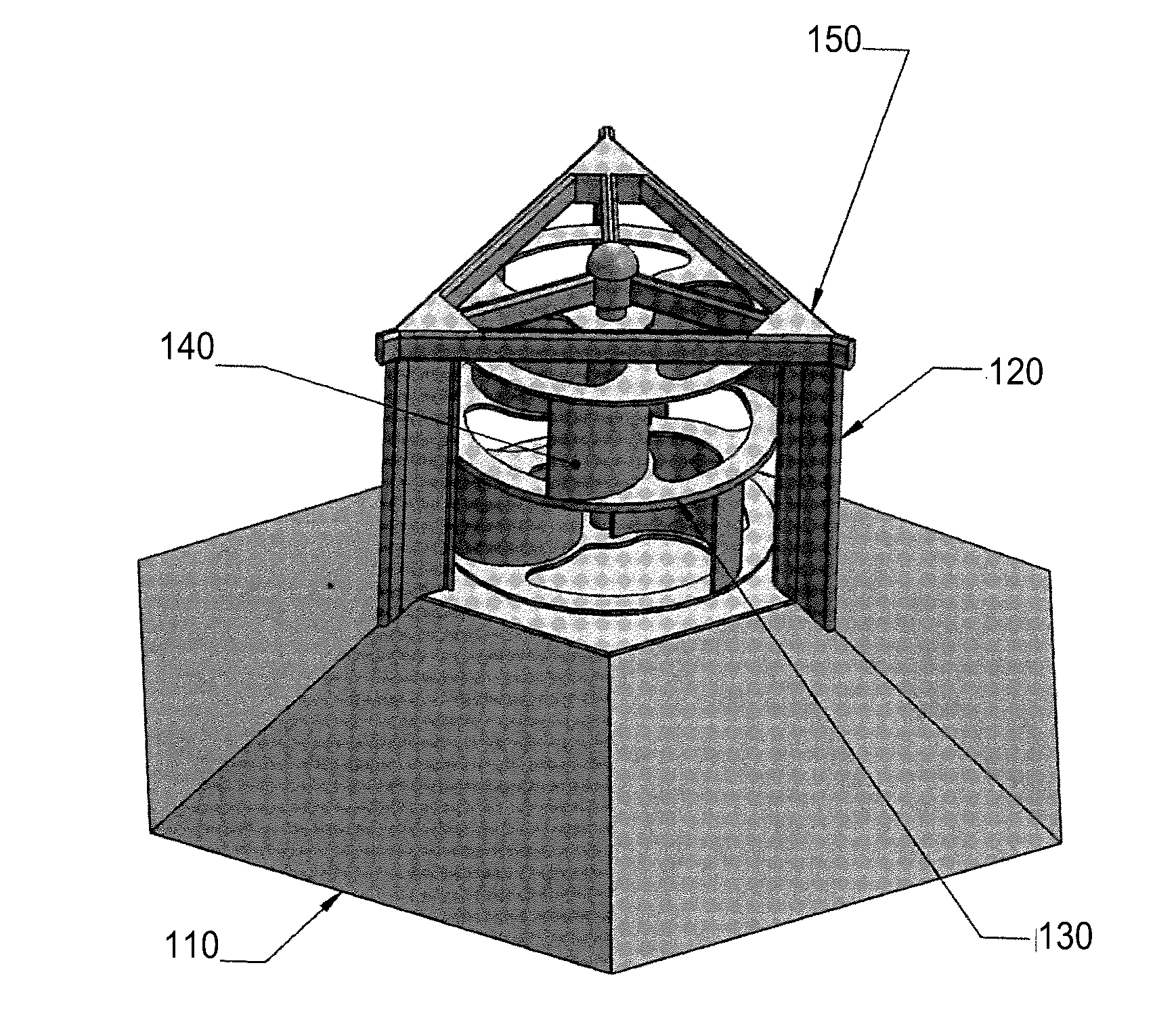

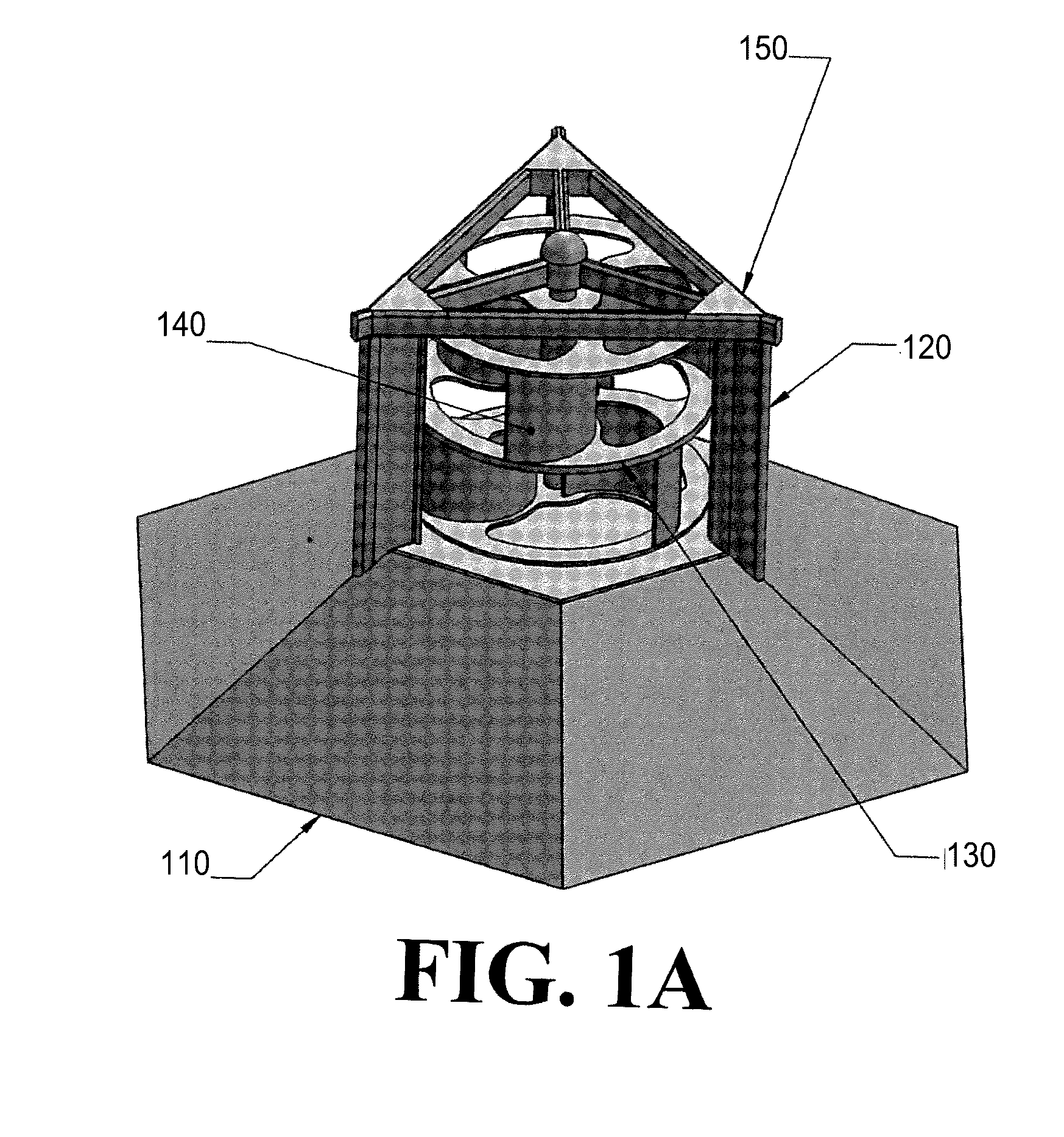

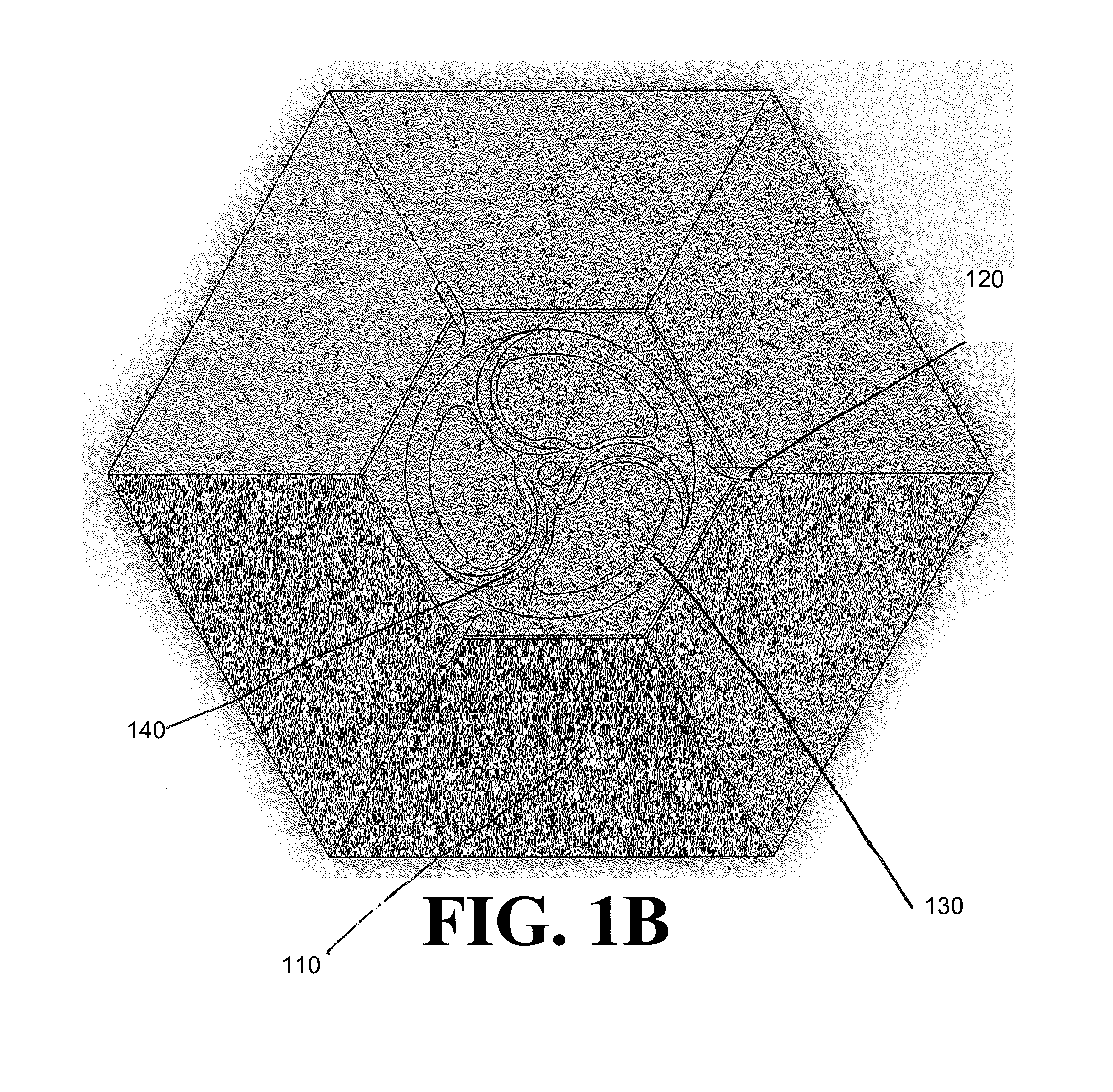

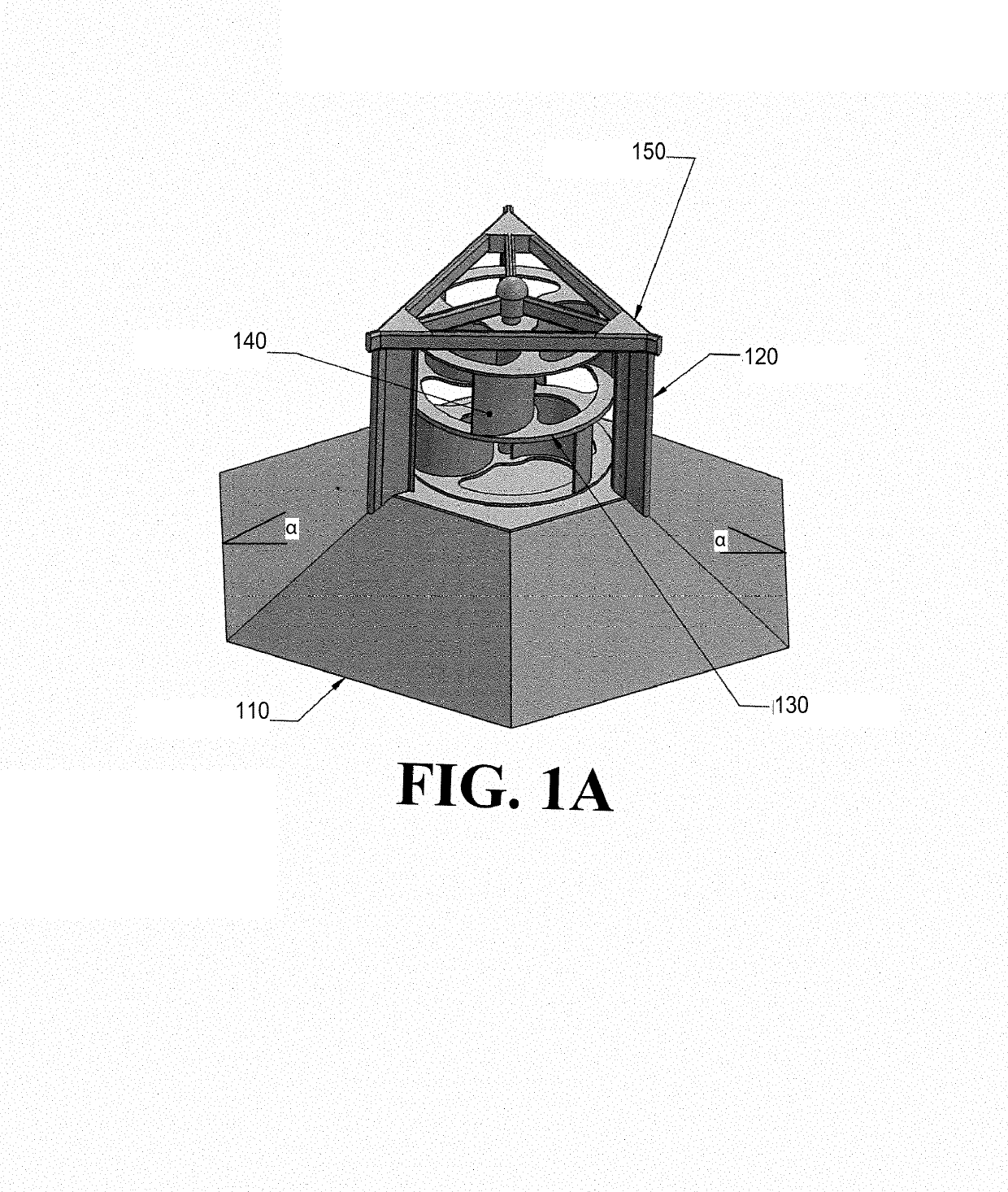

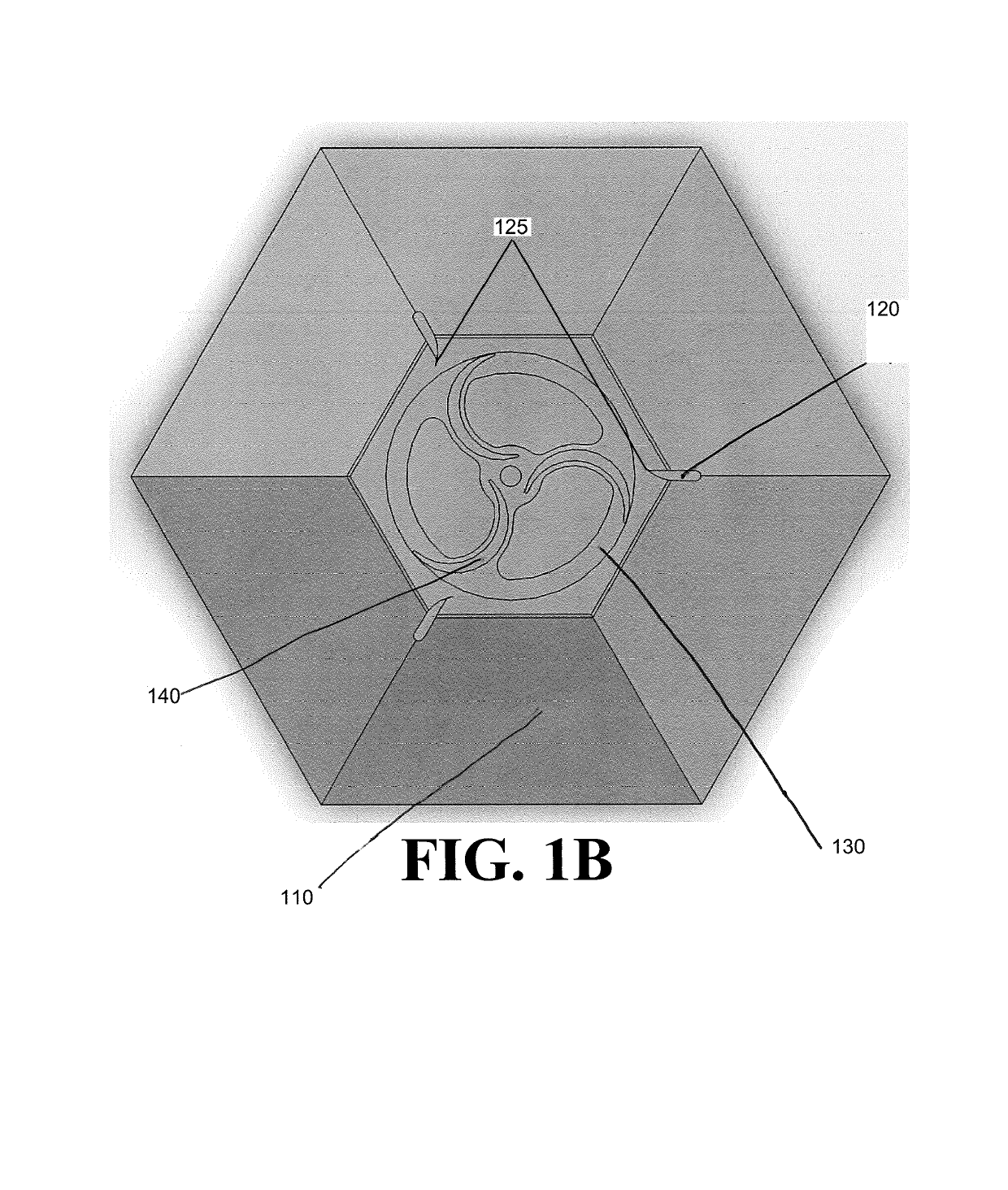

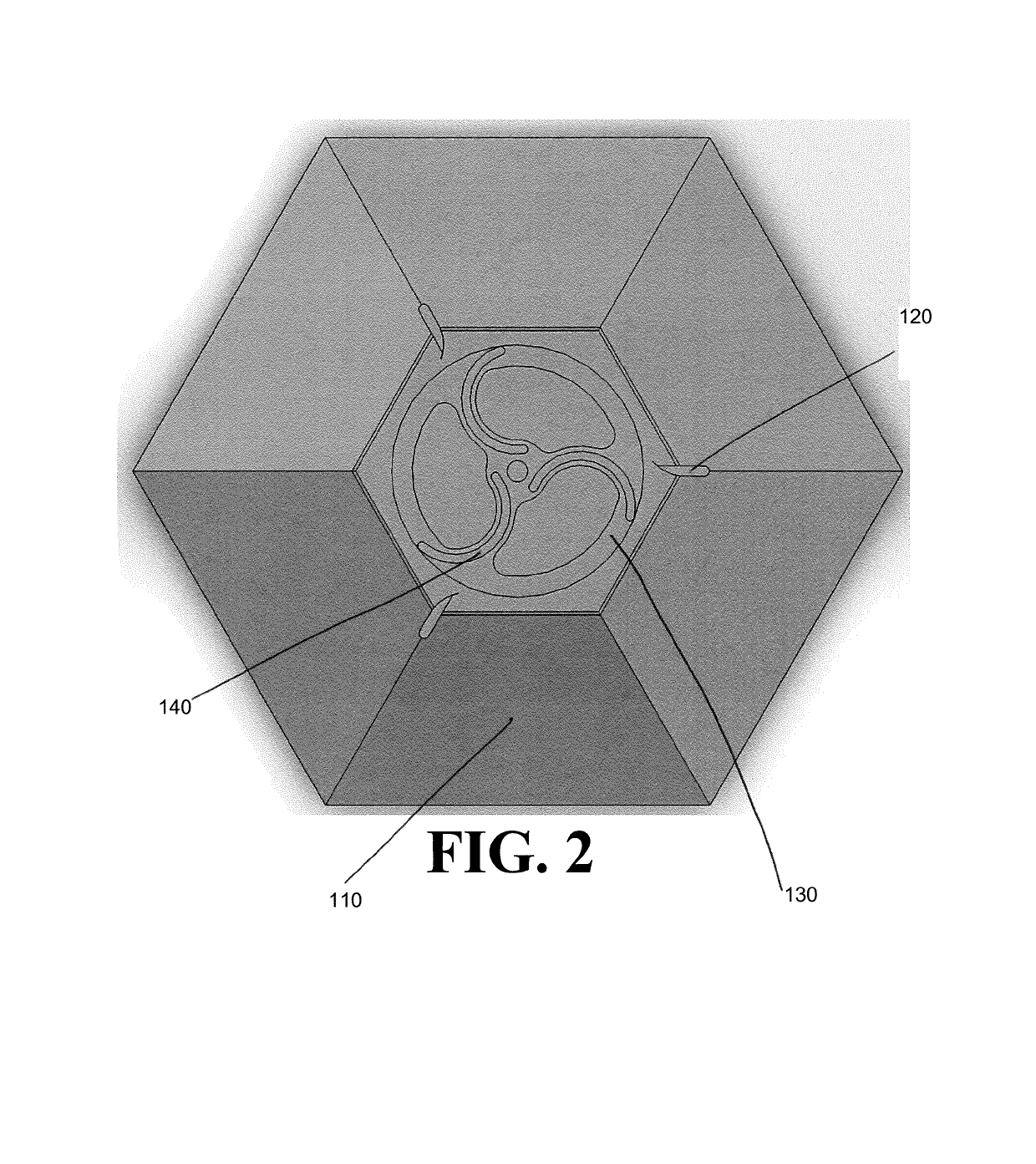

Vertical axis wind turbine

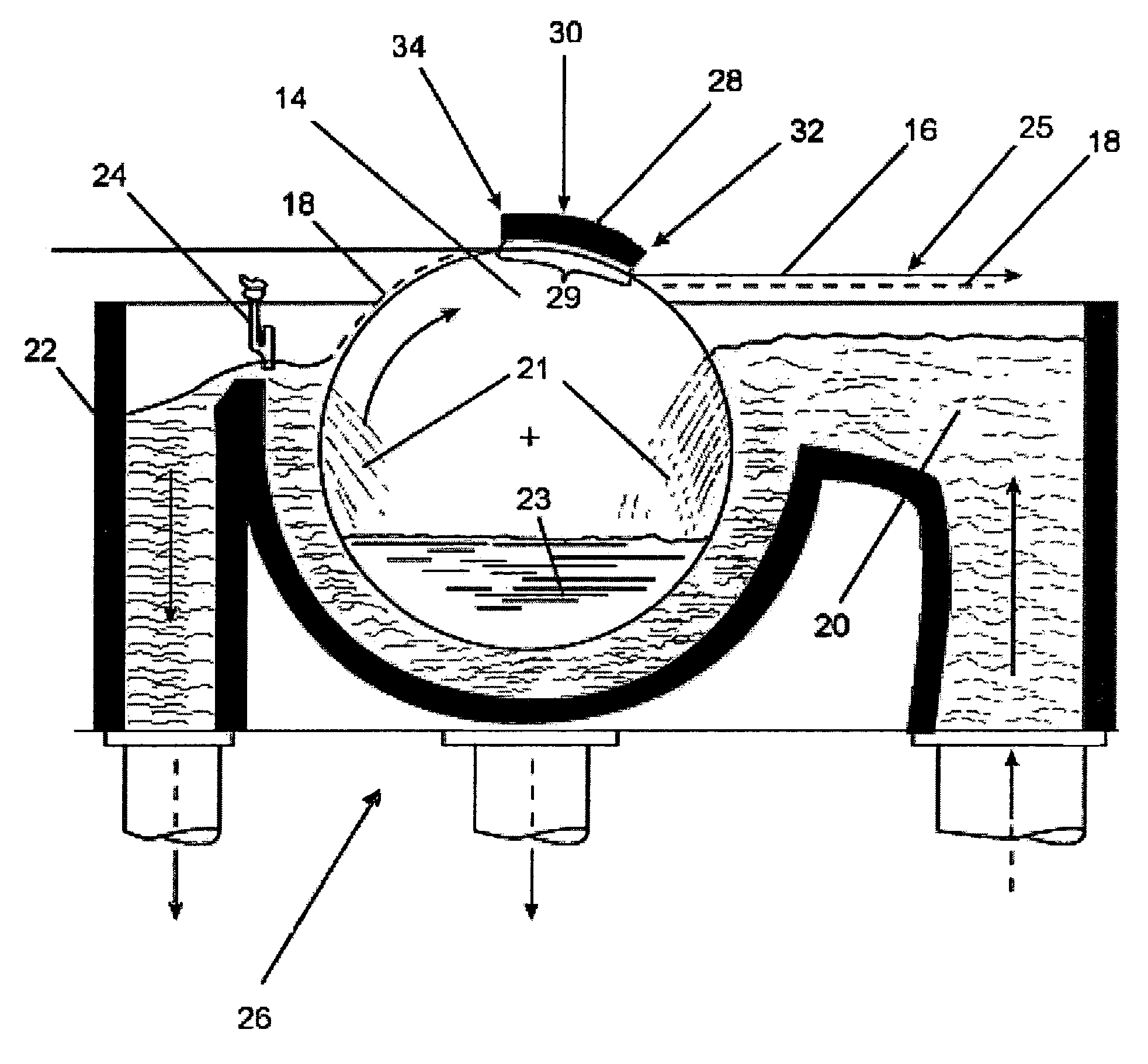

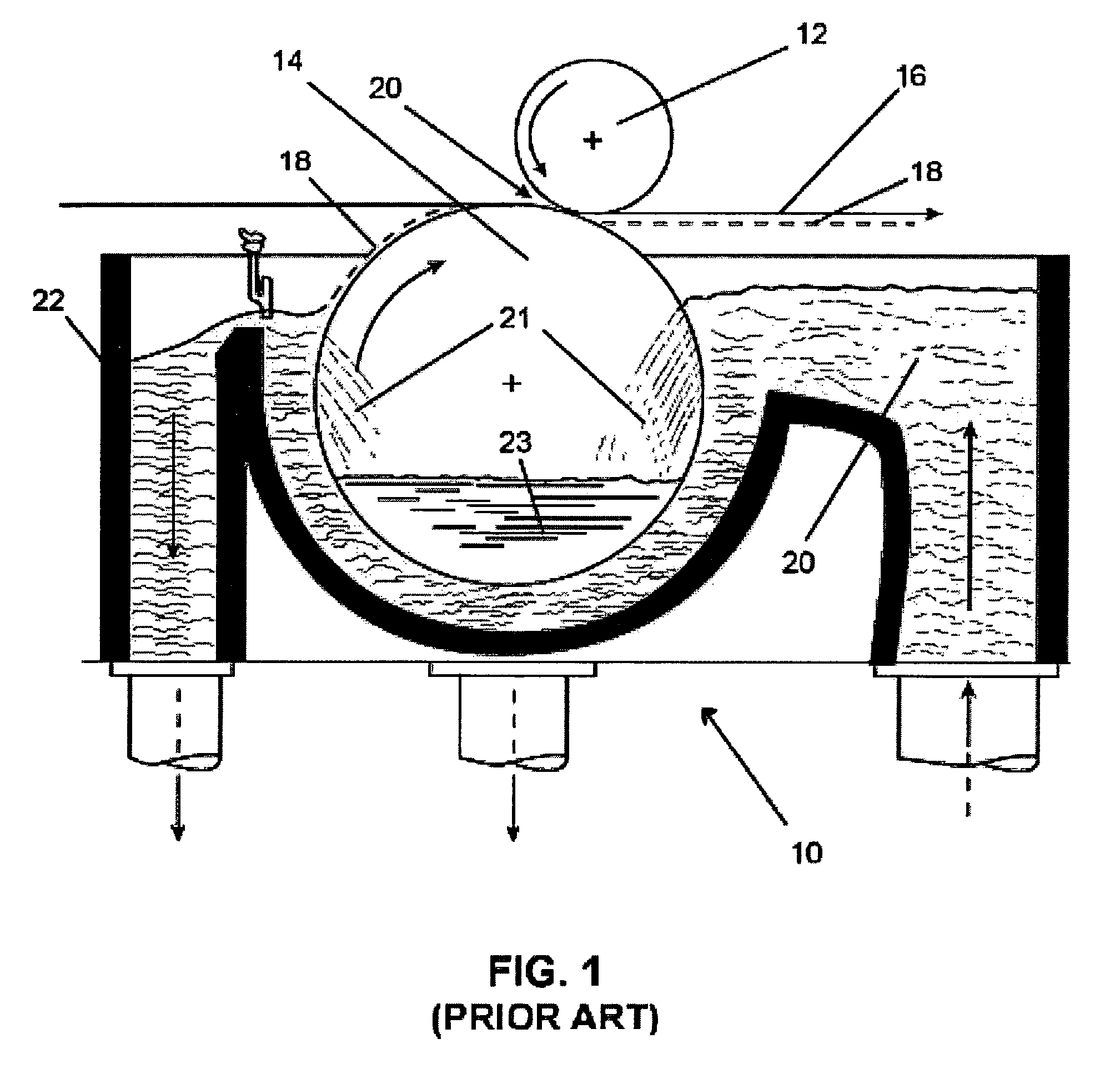

ActiveUS20160377053A1Increase wind speedAvailable powerWind motor controlPump componentsWind forceDynamo

A vertical axis wind turbine (VAWT) with improved and optimized wind-directing, wind-shaping, and wind-power conversion features is disclosed. The shapes of these features directly affect the ability of the VAWT to use the power of moving air, such as wind, to spin a rotor and create torque on a rotor shaft to generate electricity. The wind-power-conversion mechanical efficiency of the invention is significantly improved over previous efforts, to the point that the invention can convert wind energy into electrical power at a price-to-performance ratio that competes with or surpasses existing alternative energy technologies.

Owner:DME WIND ENERGY CORP

Torque-handling gear with teeth mounted on flexible arms

ActiveUS20110079098A1Effective transmission torquePrecise functionMetal-working apparatusPortable liftingCantilevered beamMechanical engineering

First gear for use in a gear set including a second gear has a hub to which are attached a plurality of arms made of an elastic material. Each pair of adjacent arms defines a slot between them into which the arms may bend. The arms can deflect elastically in the plane as a cantilevered beam. Each arm has on the end thereof, a tooth for meshing with a tooth on the second gear to allow transfer of force between the first gear's tooth and the meshing second gear's tooth. A load distributor in contact with at least first and second arms distributes to the second arm at least a portion of force received by the first arm's tooth while the first arm's tooth meshes with a tooth on the second gear. In one embodiment, the load distributor comprises an insert within the slot between the first and second arms.

Owner:NOWICKI ANDREW

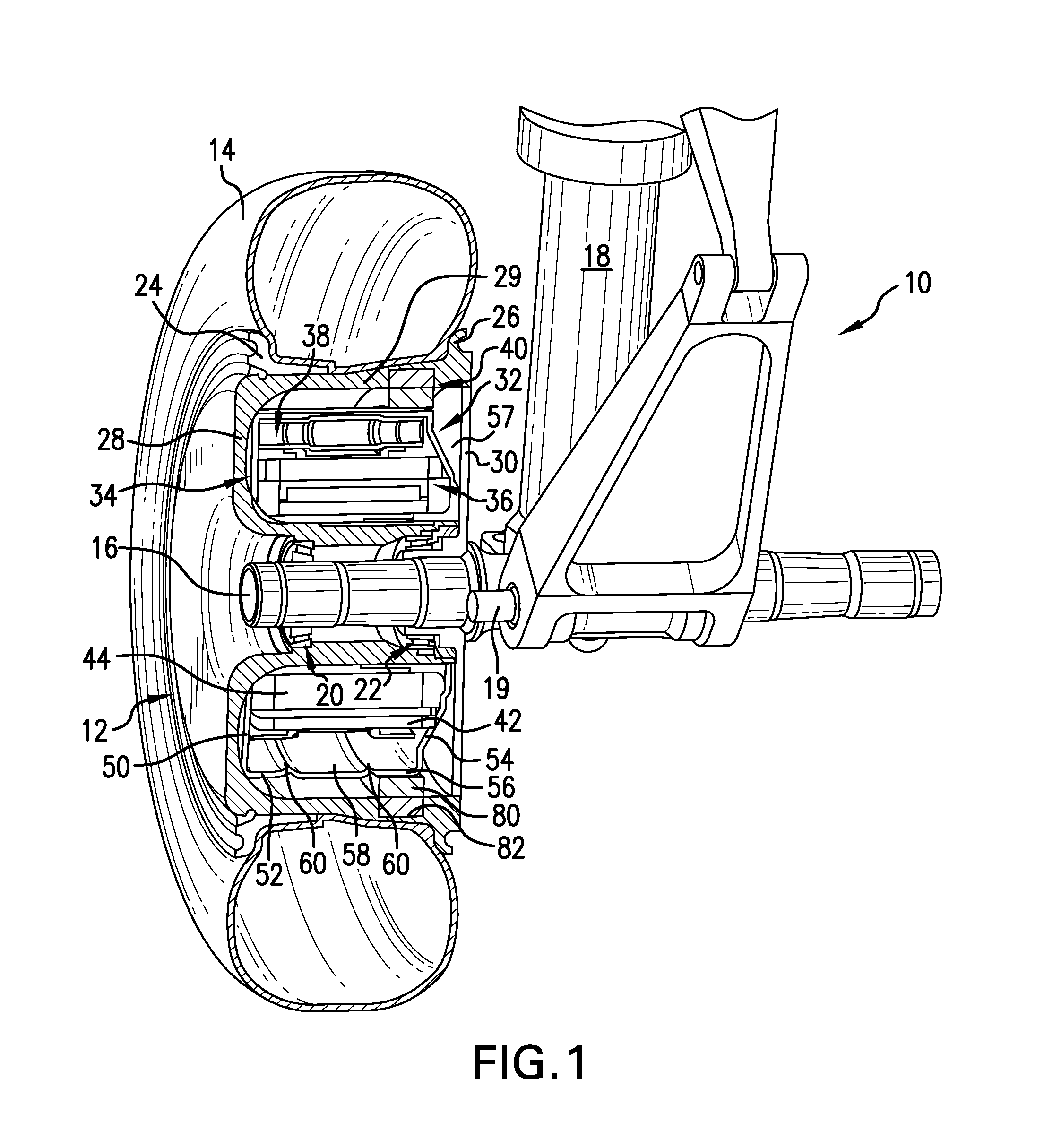

Roller Traction Drive System for an Aircraft Drive Wheel Drive System

InactiveUS20160122008A1Improve efficiencyEfficient integrationEnergy efficient operational measuresAlighting gearDrive wheelMaterial Design

A roller traction drive system integral with a non-engine drive means and a clutch assembly in an aircraft drive wheel drive system capable of moving an aircraft autonomously on the ground is provided. The roller traction drive system is selectively activated by the clutch assembly into and out of actuating contact with the non-engine drive means to drive the aircraft drive wheel. Roller traction drive system components are made of materials designed to enable dry running and operation at the torques, drive means speeds, and reduction ratios required to actuate a drive means and drive a drive wheel for autonomous aircraft ground movement. Roller traction drive materials may be selected to maintain effective torque transfer between roller traction drive system components and the non-engine drive means as well as to minimize undesirable thermal expansion.

Owner:WARNER ELECTRIC TECH +1

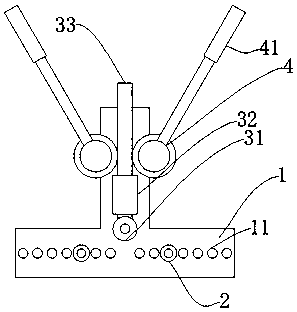

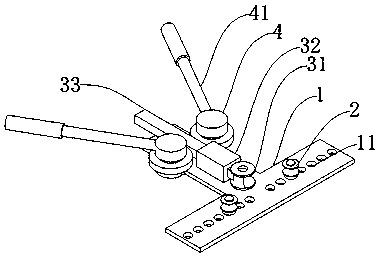

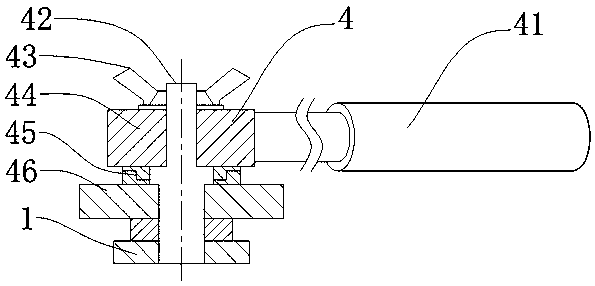

Manual cable bending machine

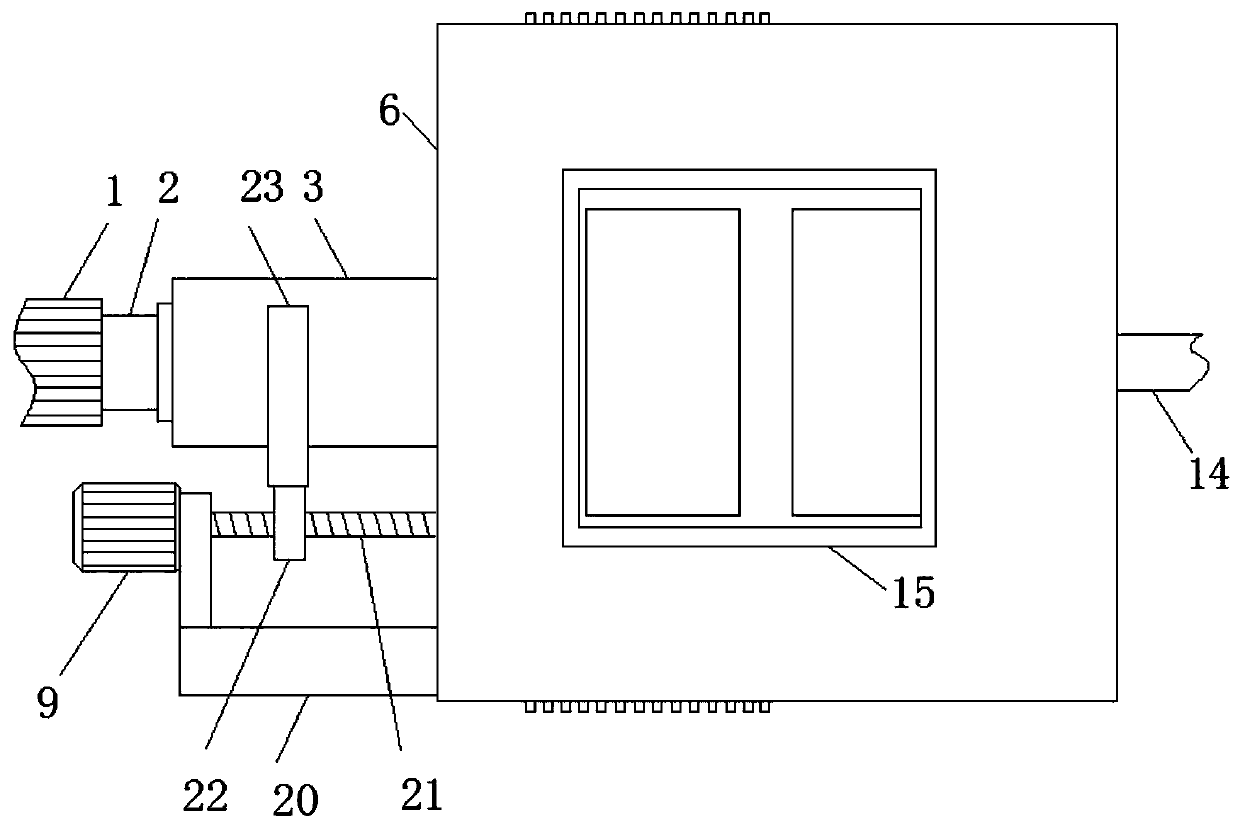

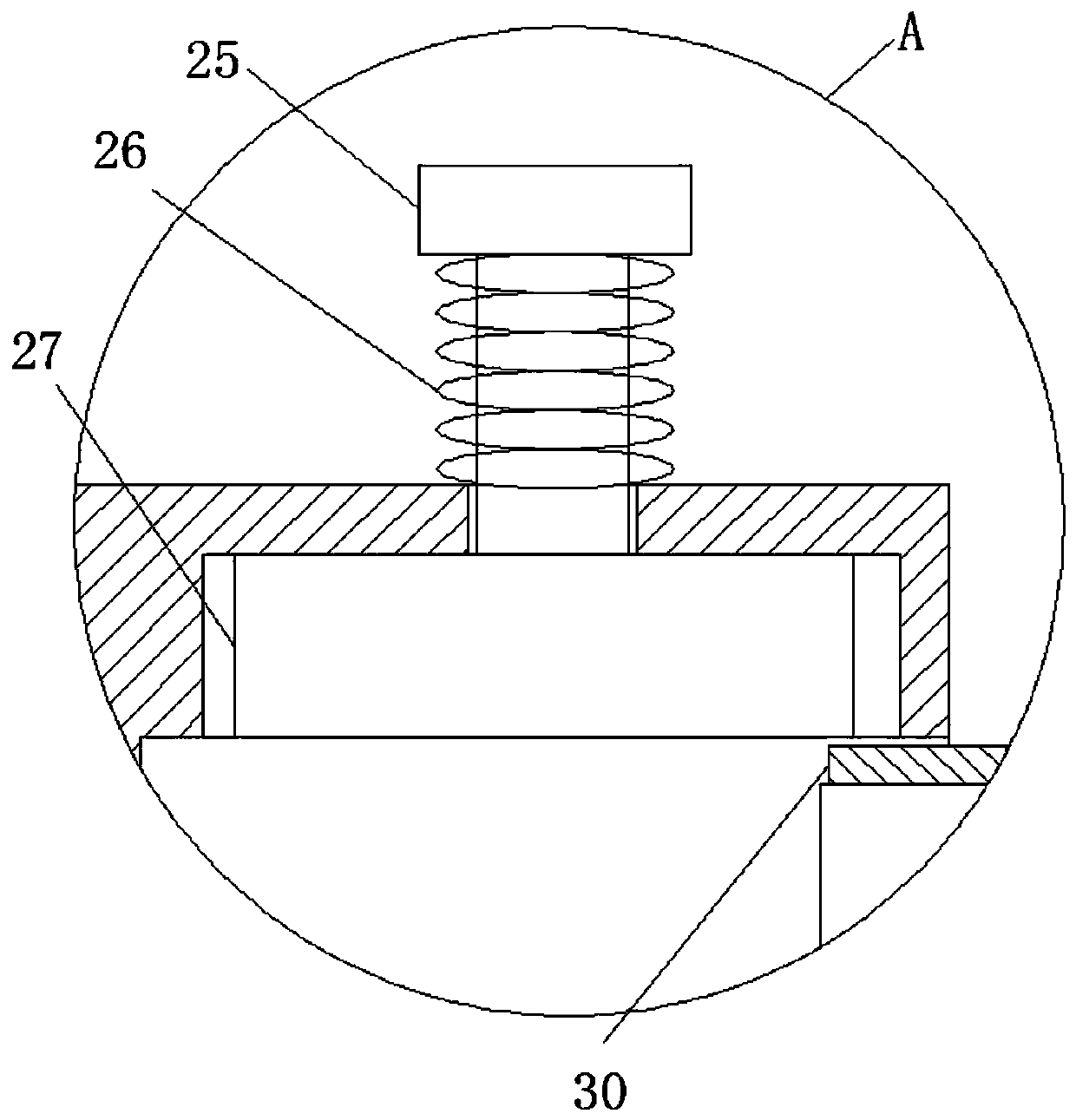

PendingCN107623281ASemi-mechanizedAvoid damageApparatus for overhead lines/cablesRelative motionEngineering

The invention relates to a manual cable bending machine. The manual cable bending machine is characterized by comprising a body, a bending mechanism, a feeding mechanism and driving mechanisms, wherein the bending mechanism is arranged on the body and is fixedly connected with the body, the feeding mechanism is arranged on the body and on a side surface of the bending mechanism, a bottom surface of the feeding mechanism is fixedly connected with the body, an end is fixedly connected with the bending mechanism, the driving mechanisms are arranged on the body and at two sides of the feeding mechanism, a bottom surface of each driving mechanism is fixedly connected with the body, and a middle part of each driving mechanism is in contact with the feeding mechanism. The application method comprises the steps of calculating minimum bending diameter of a cable, placing fixed rollers in through holes at appropriate positions of the body, fixedly connecting the fixed rollers, placing the cablein the bending mechanism, locking the driving mechanism, simultaneously rotating handles of the driving mechanisms by two hands, driving a gear to rotate by the driving assembly, driving a rack and apush plate to move by the gear, wherein the push plate moves relative to the two fixed roller so that the cable is bent and is plastically deformed to achieve cable bending.

Owner:STATE GRID CORP OF CHINA +1

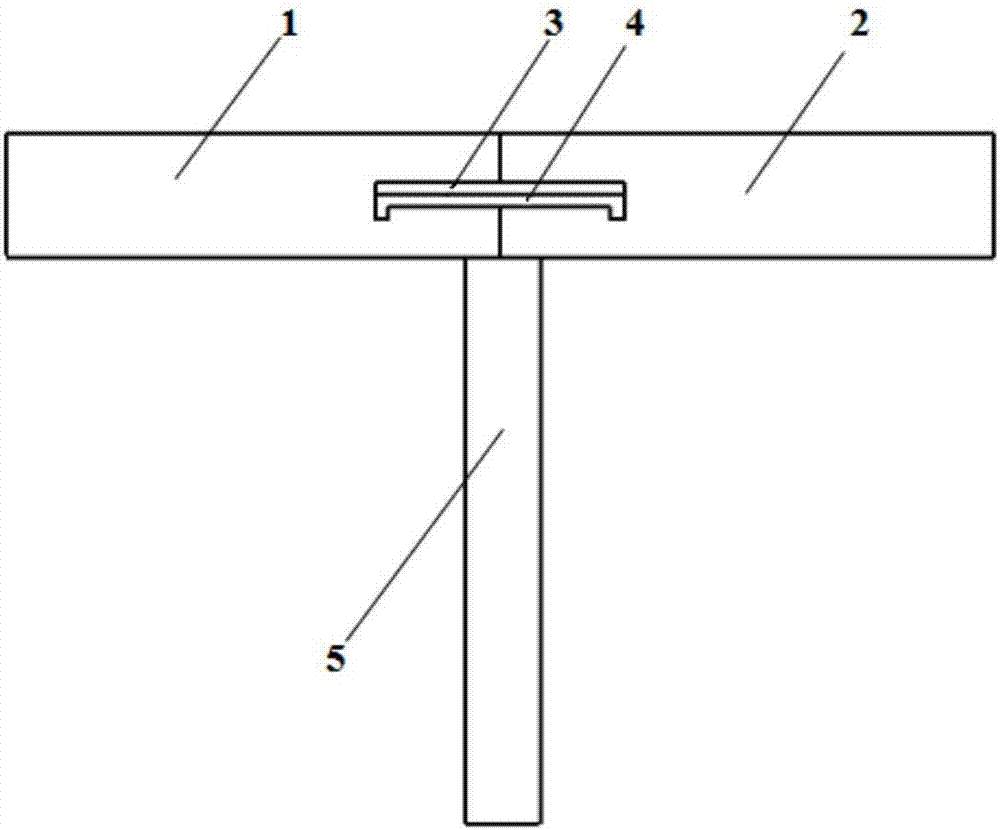

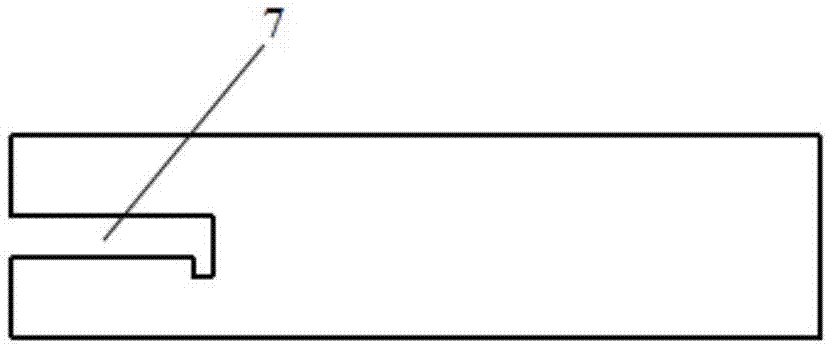

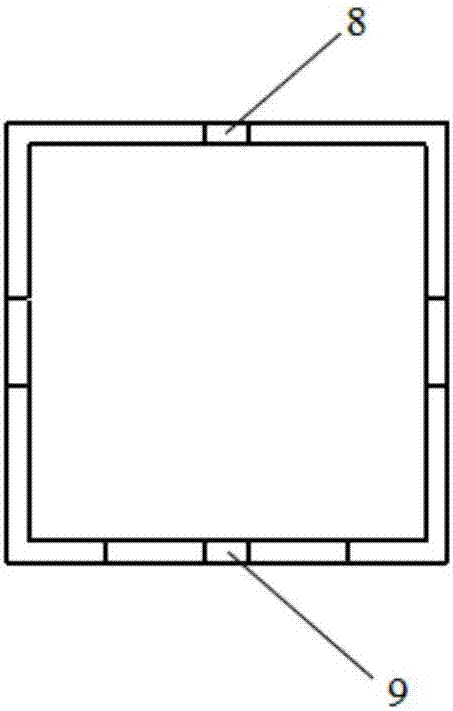

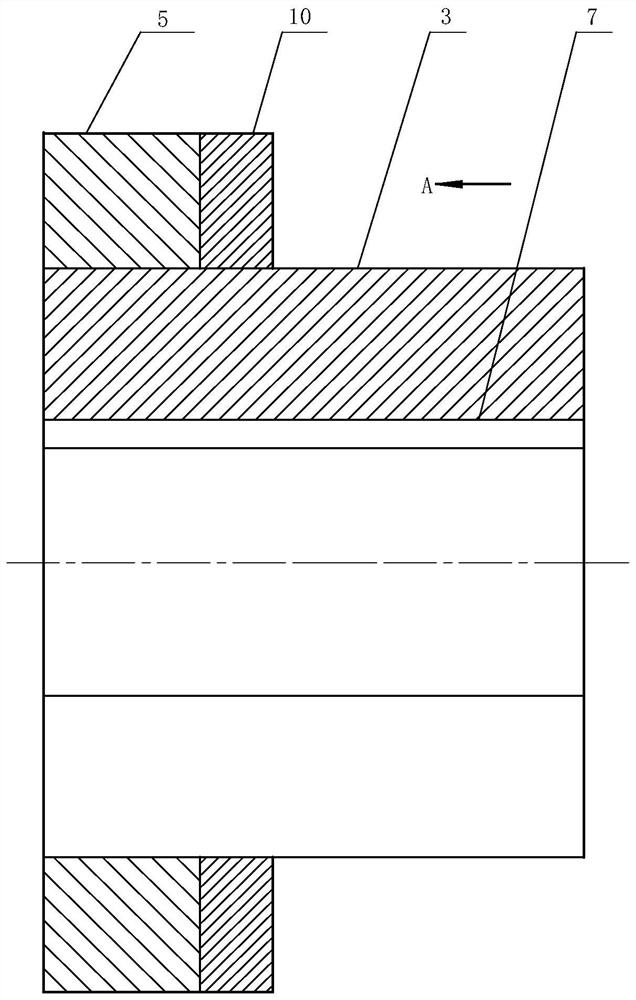

Energy-saving environment-friendly type permanent magnet speed regulation device

ActiveCN109861496AEffective transmission torqueSave electricityPermanent-magnet clutches/brakesCooling/ventillation arrangementElectrical conductorControl engineering

The invention relates to the technical field of driving speed regulation, and discloses an energy-saving environment-friendly type permanent magnet speed regulation device; the energy-saving environment-friendly type permanent magnet speed regulation device comprises a shell, wherein a rectangular pipe is transversely connected with the left of the shell through a rectangular through hole in a sliding and sleeving mode, and an output shaft is arranged in the rectangular pipe, and two first rolling shafts are fixedly connected to the shaft wall of the output shaft; the outer rings of two firstrolling bearings are fixedly connected with the inner wall of the rectangular pipe, and one end of the output shaft penetrates through the rectangular pipe and is fixedly connected with a mounting block; an annular groove is formed in the right side of the mounting block; a plurality of first magnets are uniformly and fixedly connected to one side of the annular groove, wherein the plurality of first magnets are annularly distributed; and a transverse plate is fixedly connected to the lower end of the left side of the shell. According to the device, the transmission torque between a permanentmagnet rotor and a conductor rotor in the speed regulation device can be effectively increased, so that the driving device is not easy to perform idle rotation, electric energy is saved, and when thepermanent magnet speed regulation device works, the clothes of workers are not prone to being wound so as to avoid dangers.

Owner:MAANSHAN LANXIN ENVIRONMENTAL PROTECTION TECH CO LTD

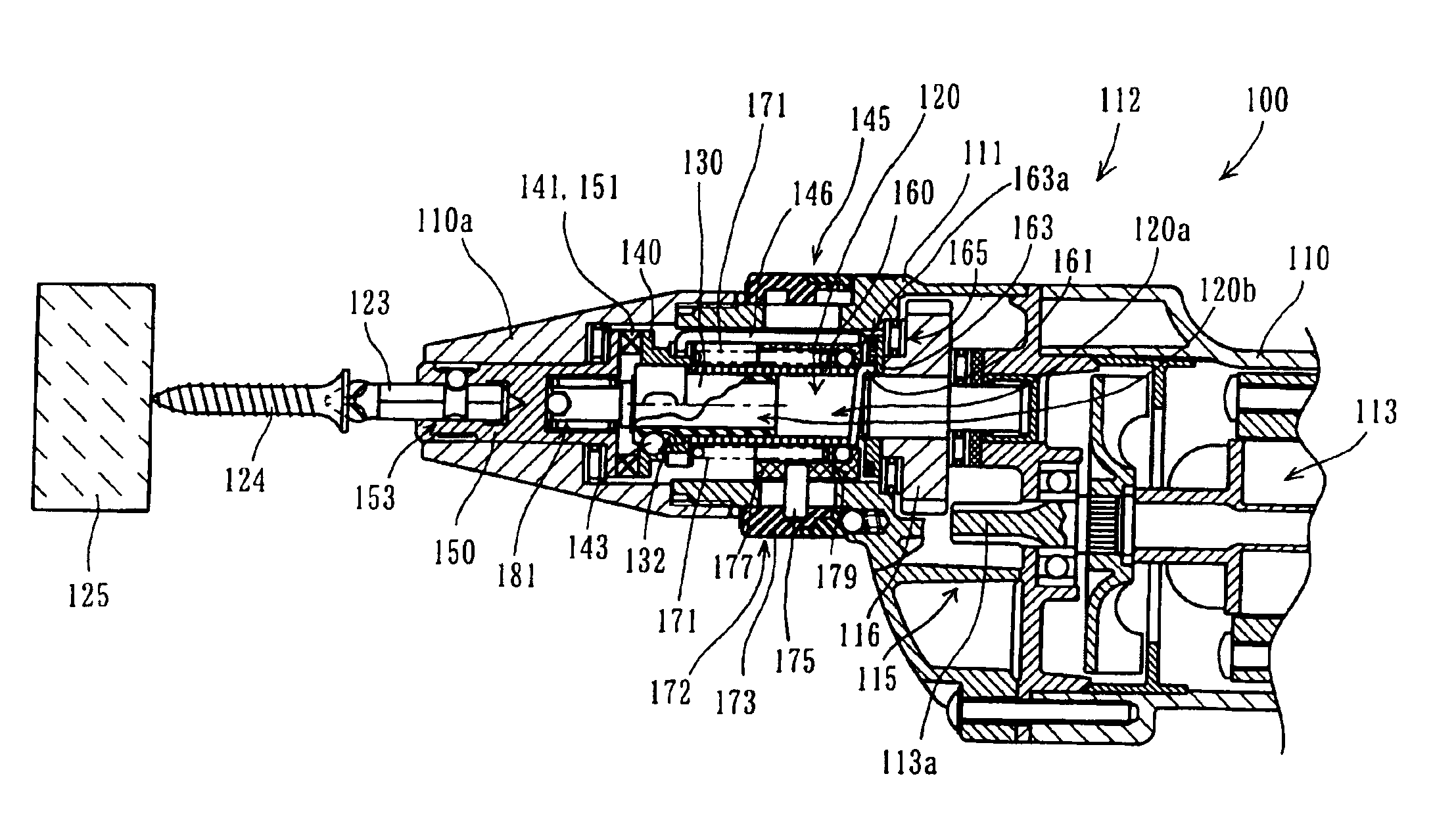

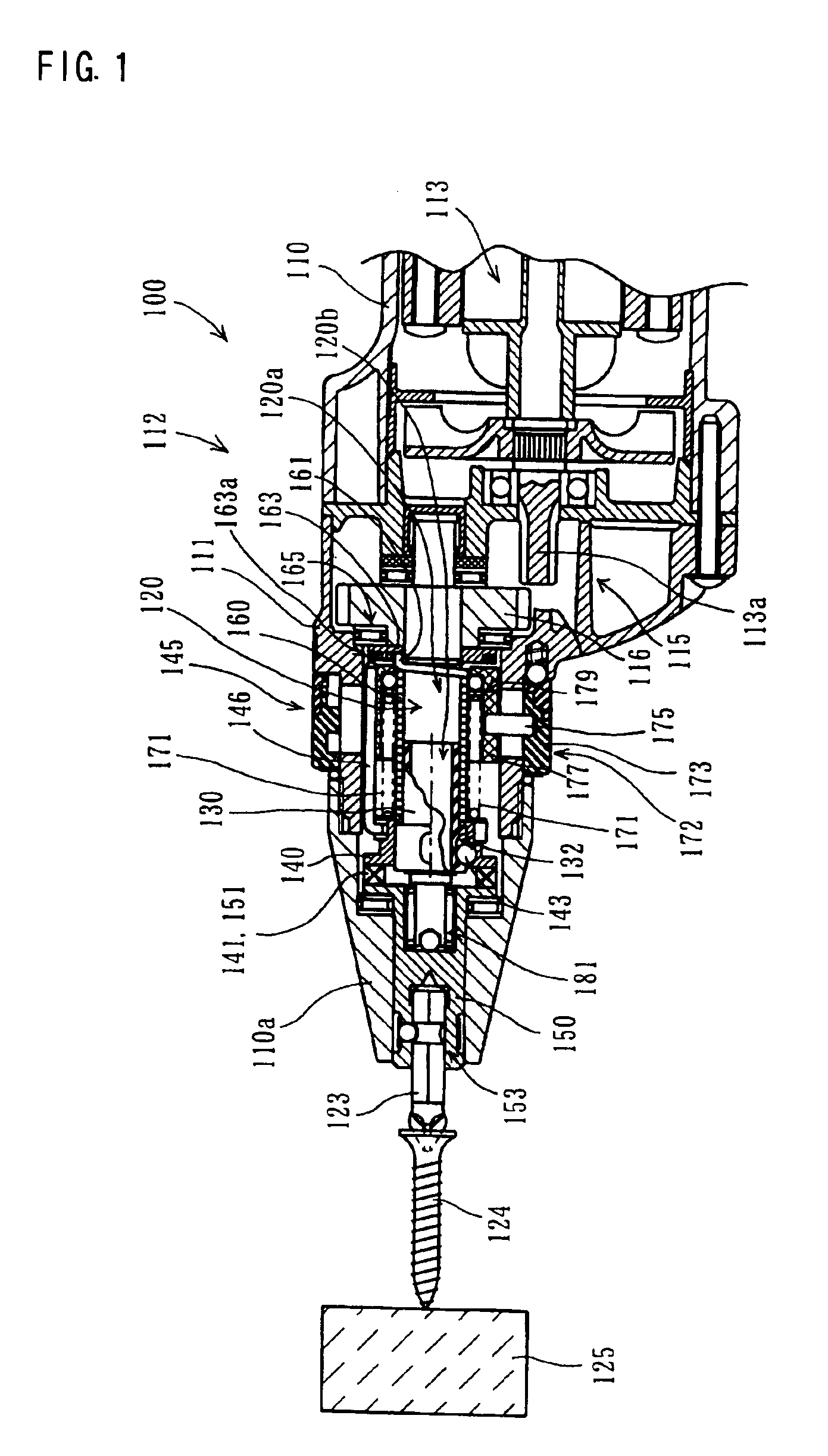

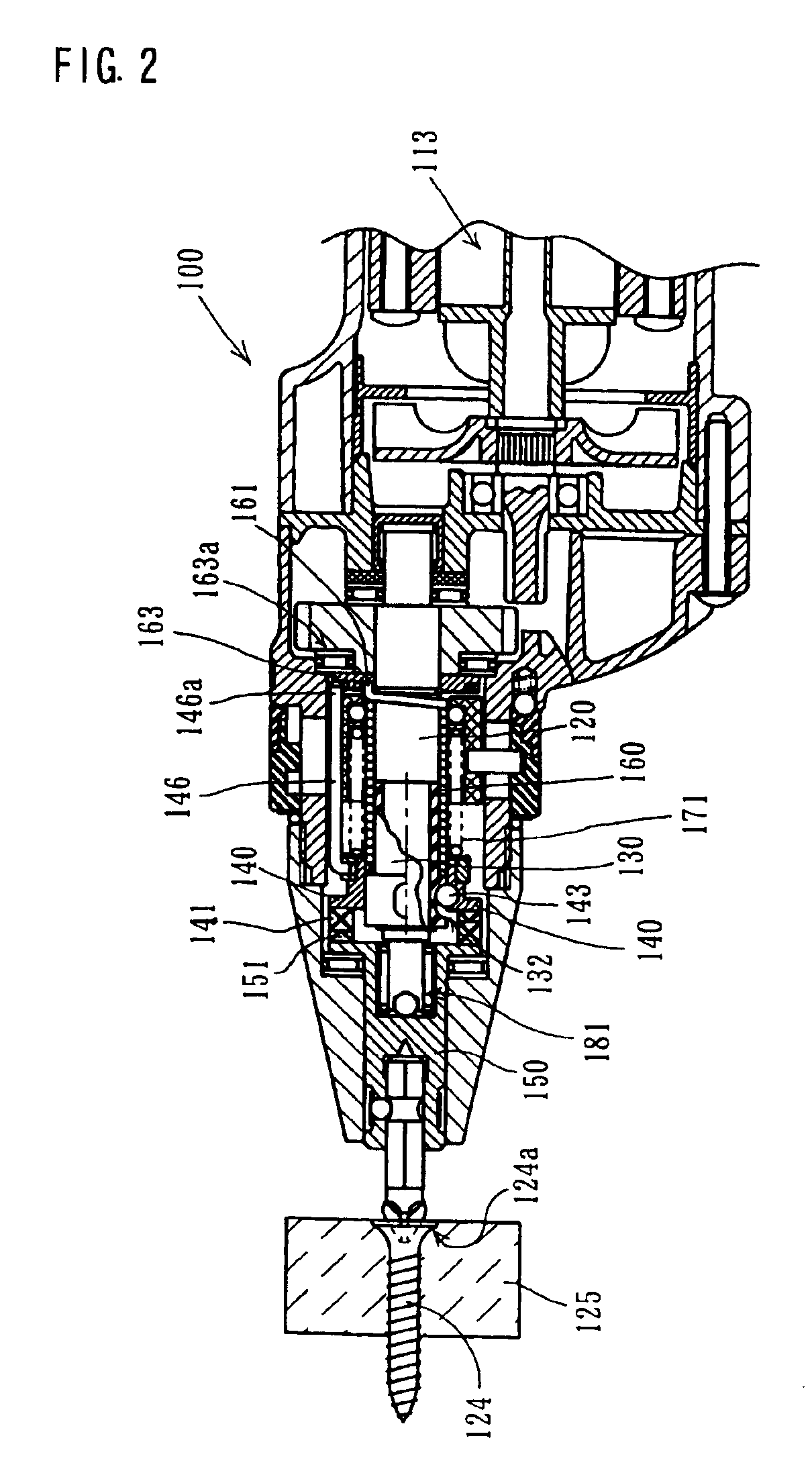

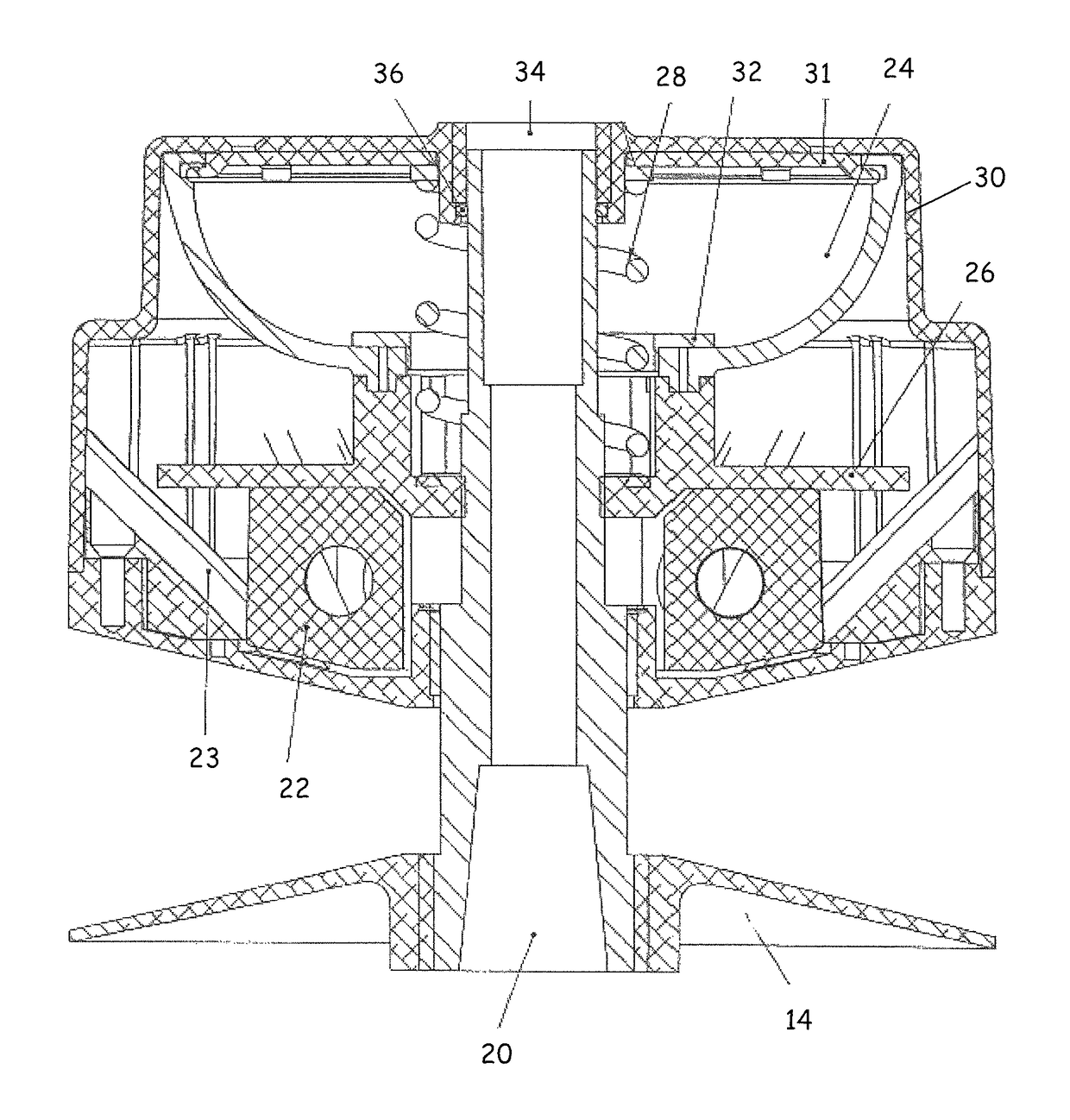

Screwdriver

InactiveUS6892611B2Guaranteed normal transmissionStop transmissionSpannersWrenchesControl theoryConductor Coil

It is an object of the invention to provide an electric screwdriver that can efficiently transmit torque for tightening a screw and stop the torque transmission. A representative screwdriver may include a motor, first and second rotating members, a tool, a torque transmission spring and a torque transmission releasing device. The torque transmission spring transmits the rotating torque of the motor from the first rotating member to the second rotating member in order to drive the tool by closely winding around the first rotating member and the second rotating member when the motor drivingly rotates the first rotating member in a predetermined rotating direction. Further, the torque transmission releasing device moves in the axial direction of the first rotating member or the second rotating member in response to the screw-tightening torque. By such movement, the torque transmission releasing device releases the close winding of the torque transmission spring around at least one of the first rotating member and the second rotating member and releases the transmission of the rotating torque of the motor to the tool.

Owner:MAKITA CORP

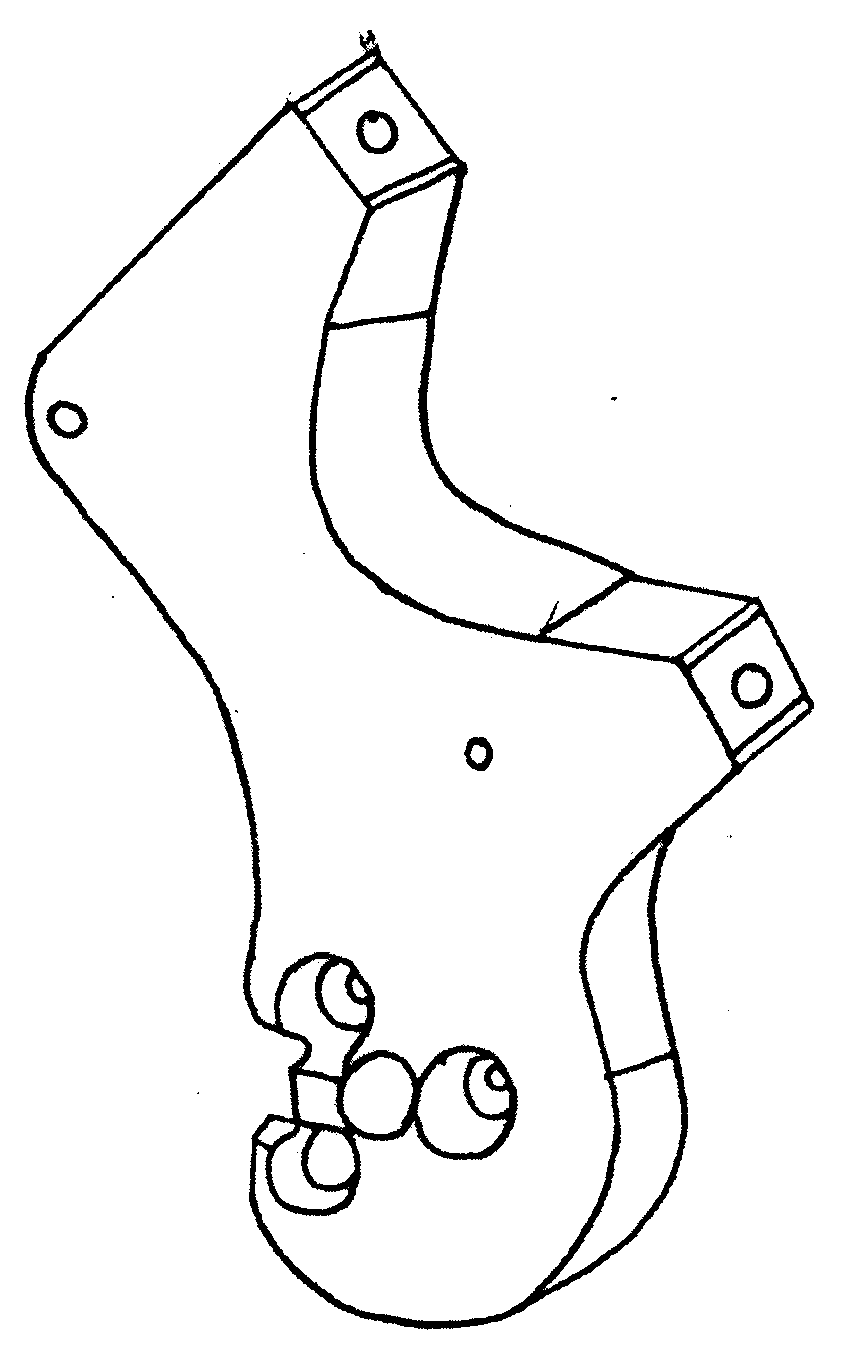

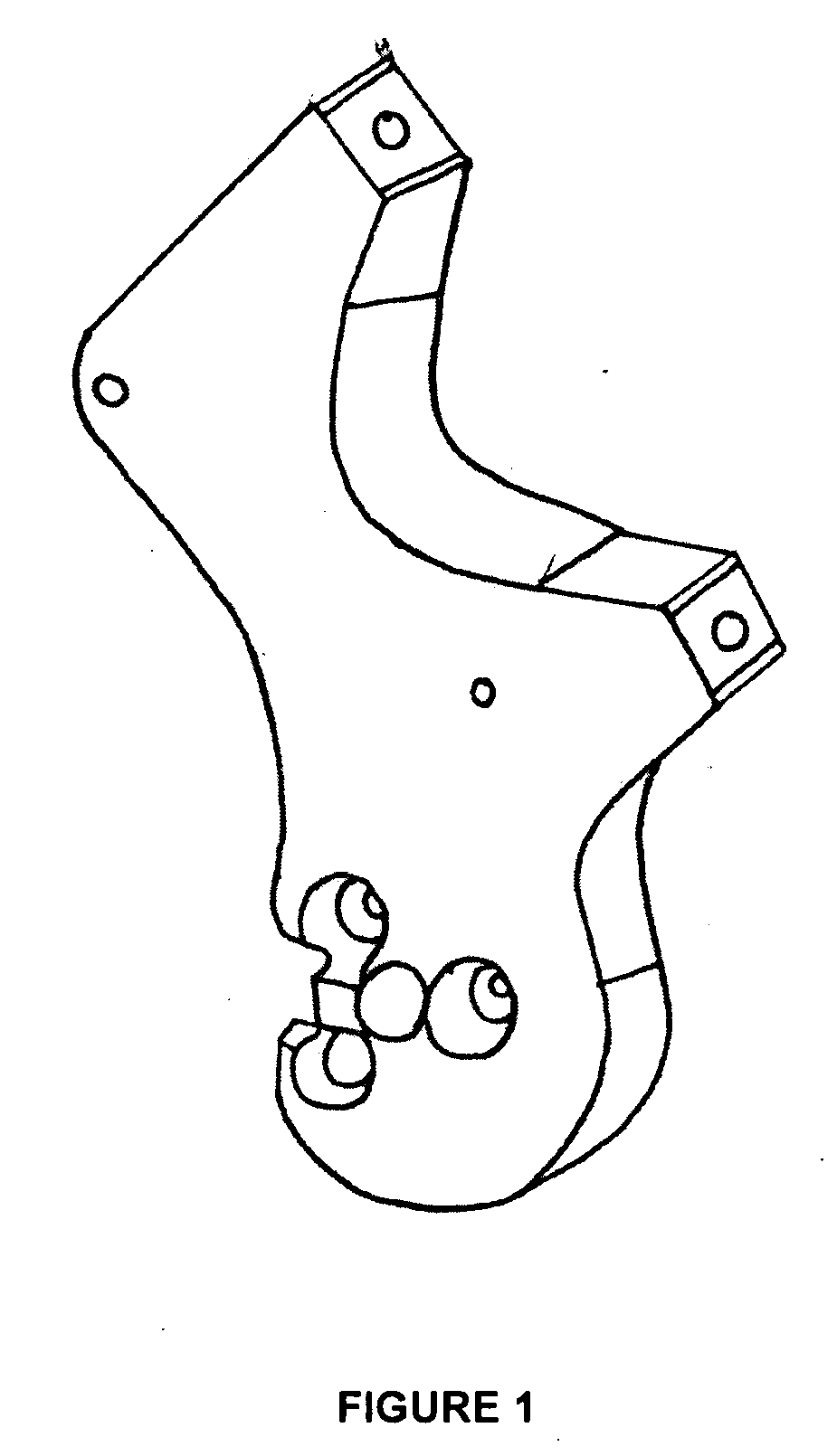

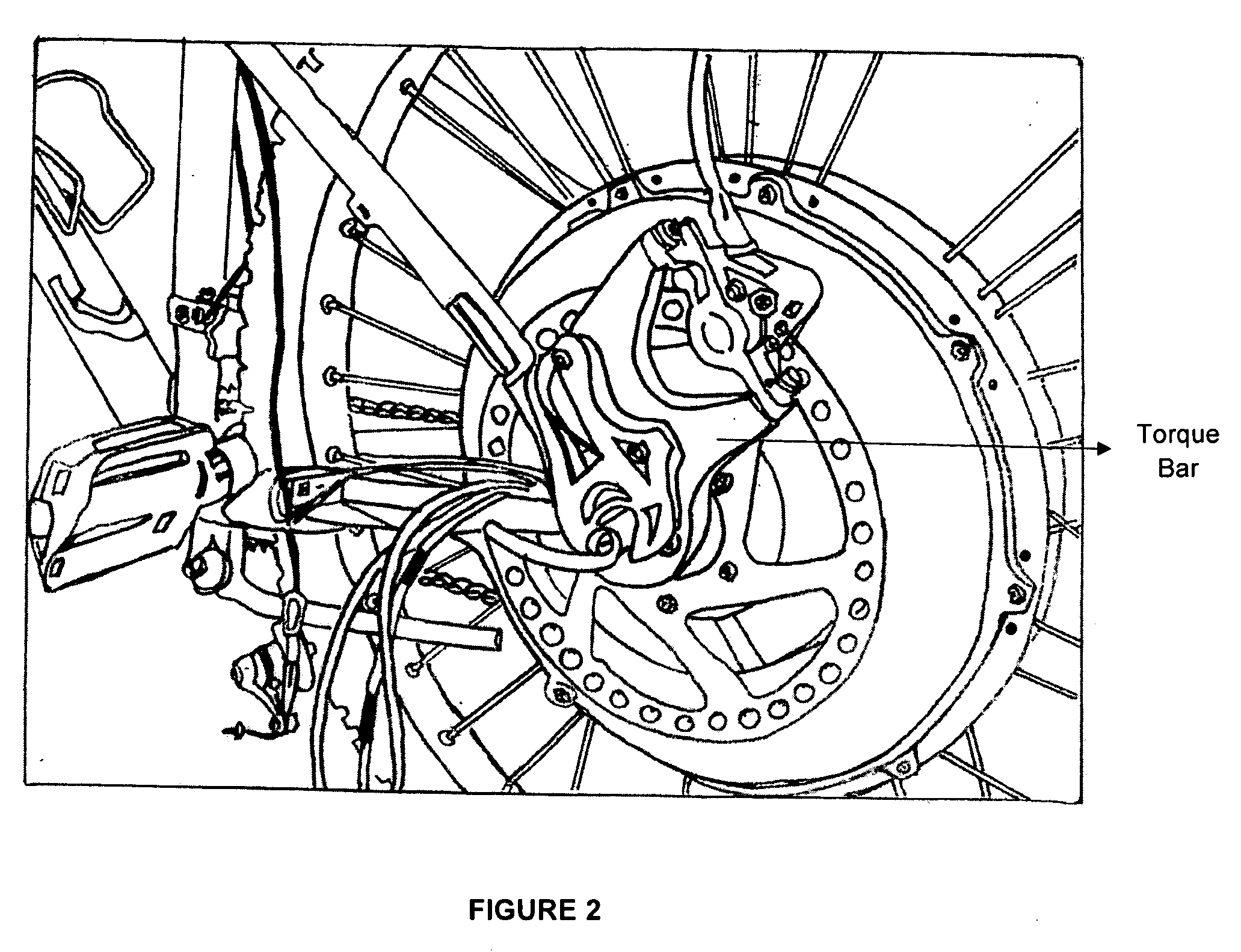

Torque bar with integrated disc brake caliper mounting

InactiveUS20100170757A1Simple and easilyHigh of effectivenessAxially engaging brakesBraking membersVehicle frameCalipers

Owner:DHAWAN RAKESH KUMAR +4

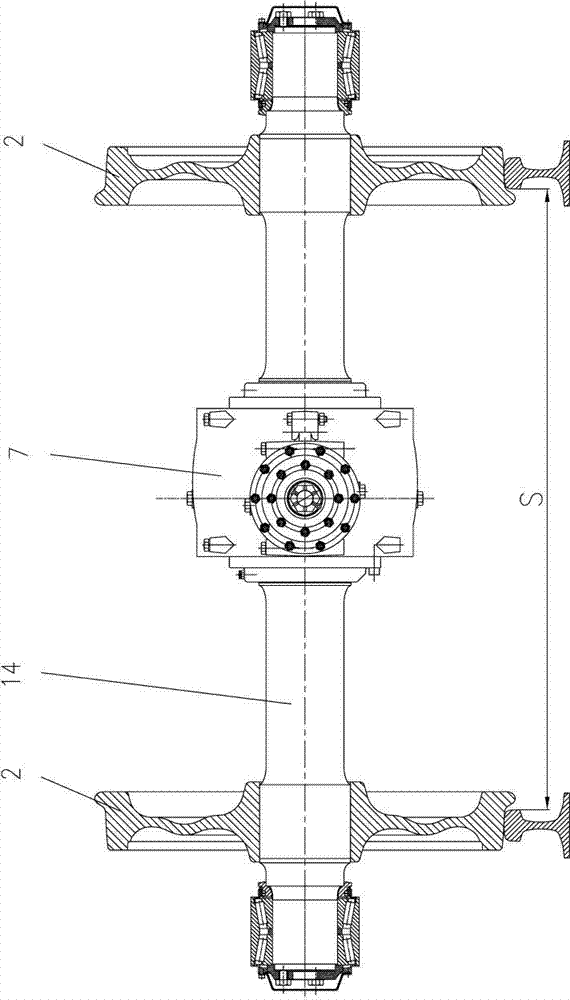

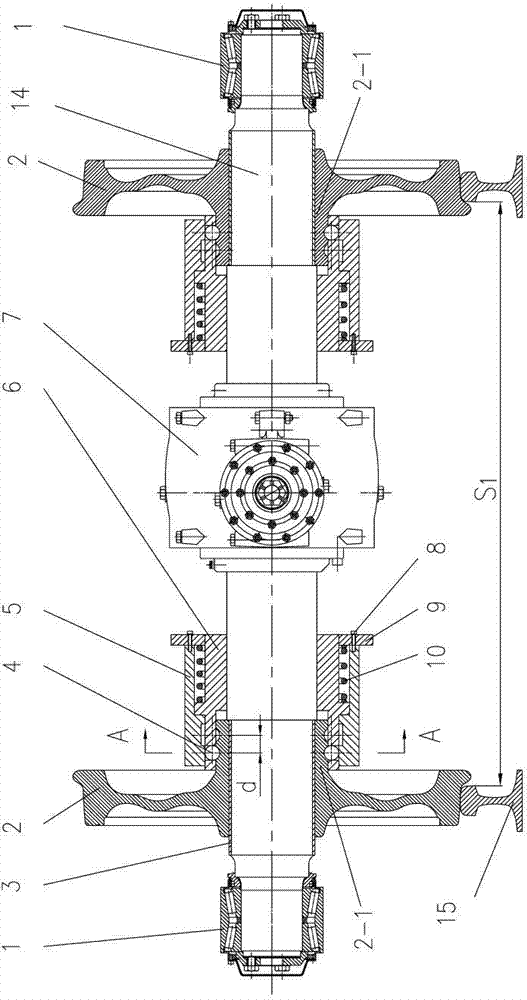

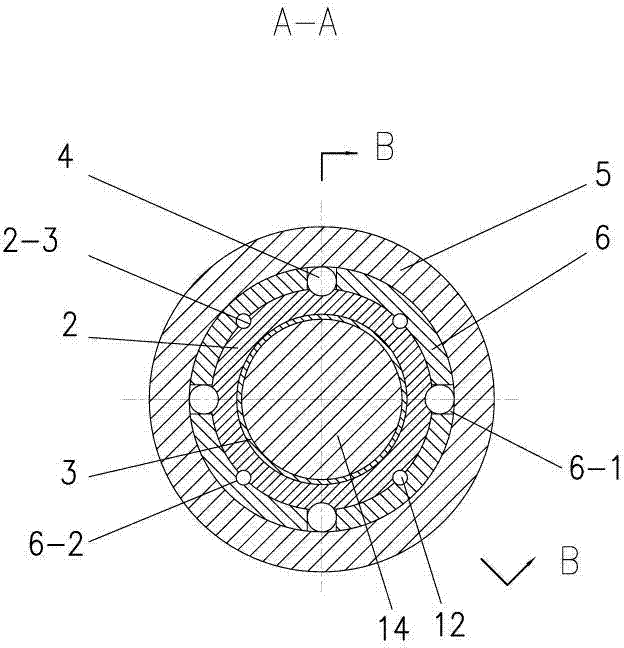

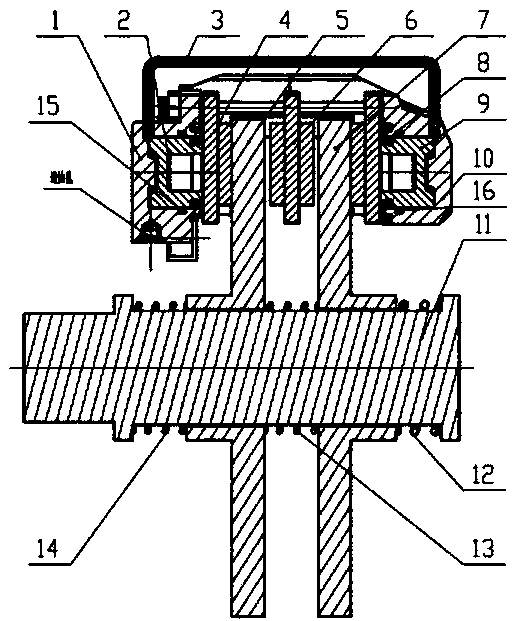

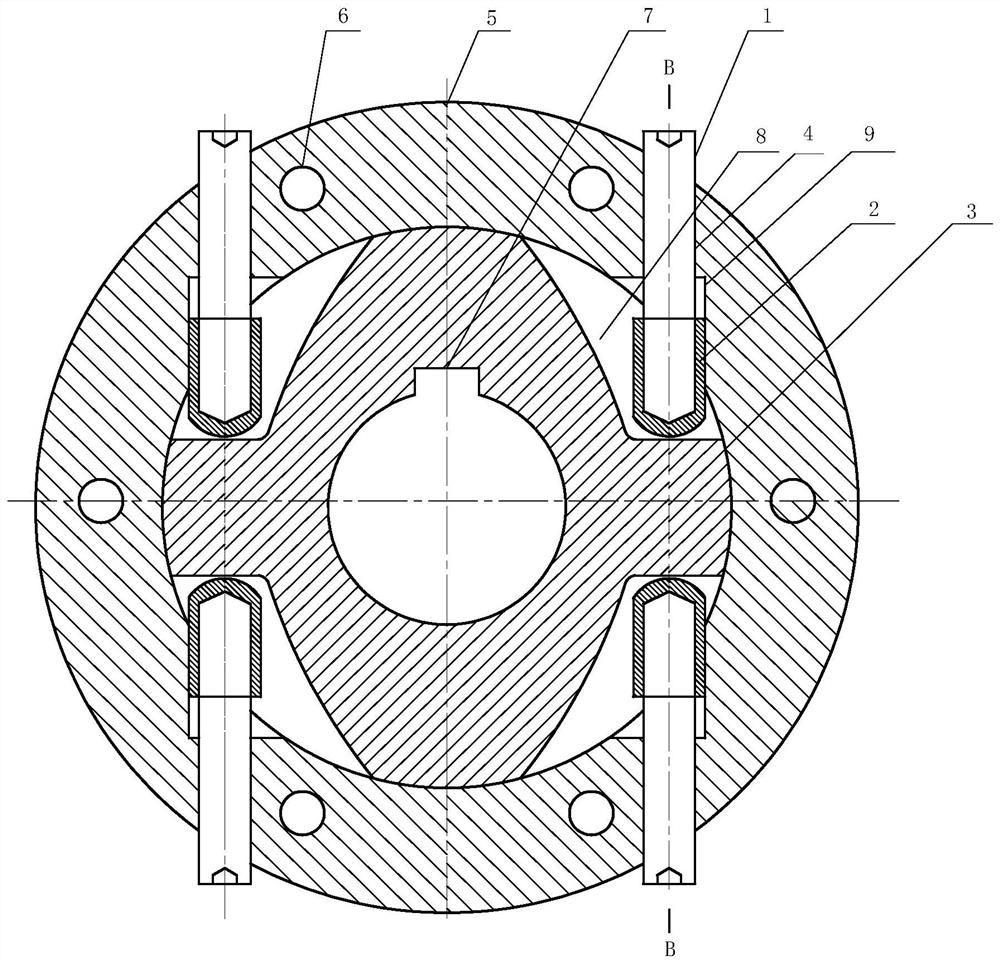

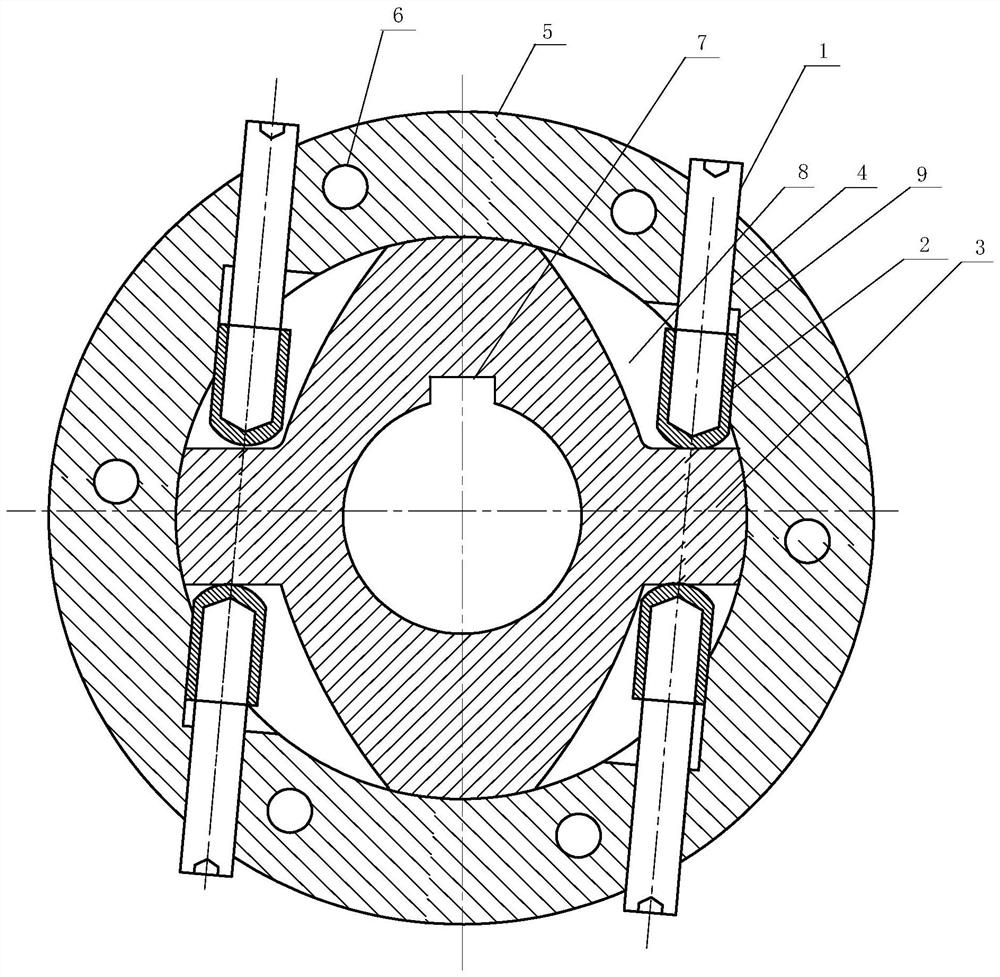

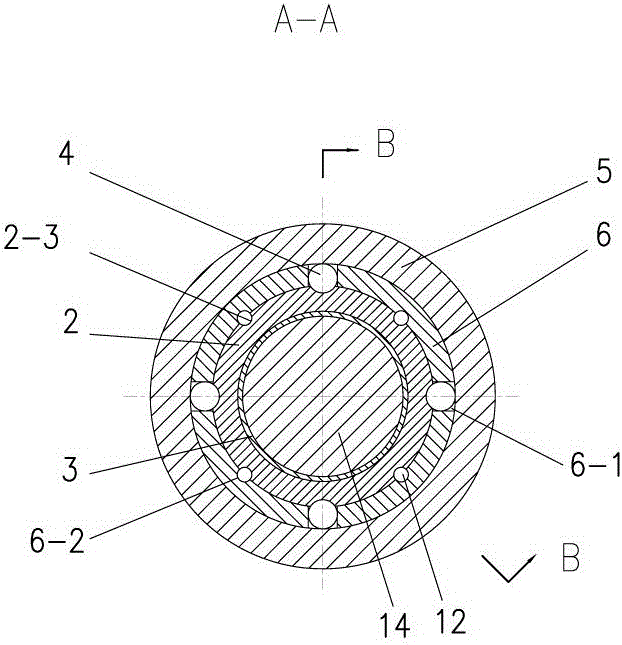

Drive axle gearbox wheel set for large railway maintenance machinery

ActiveCN104494366AEffective transfer of movementEffective transmission torqueHubsAxle-boxesLocking mechanismEngineering

The invention discloses a drive axle gearbox wheel set for large railway maintenance machinery. The drive axle gearbox wheel set comprises an axle, two wheels, a sliding bearing, a locking steel ball, an inner sleeve, an outer sleeve, a rolling steel ball, an axle retainer ring, a hole retainer ring, a spring and an end cover. The two wheels are positioned on wheel seats at two ends of the axle respectively. The locking steel balls, spherical grooves, a radial cylindrical hole of the inner sleeve and the outer sleeve form a locking mechanism; the rolling steel balls, first semicircular grooves and second semicircular grooves are matched to form a rolling ball key mechanism; the end cover is fixed to the end face of one side, away from the wheels, of the outer sleeve, a gap is reserved between the end cover and the circumference of the inner sleeve, the end cover is capable of axially moving left and right along the inner sleeve, and the springs are mounted in a closed annular inner cavity formed by the outer sleeve, the end cover and the inner sleeve. The drive axle gearbox wheel set for large railway maintenance machinery is simple in structure, convenient to operate and capable of fitting different rail gauges.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

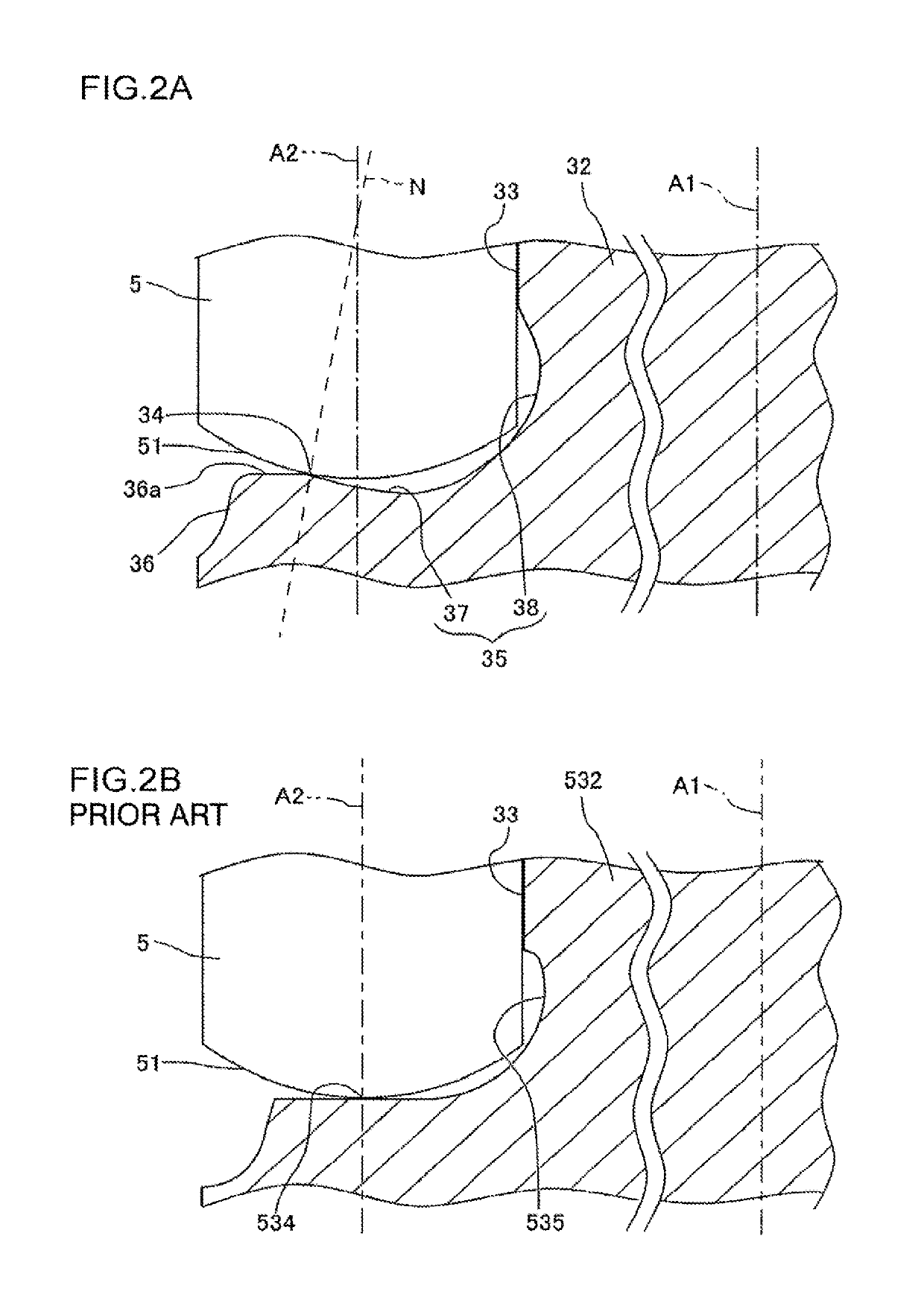

Double-brake disc type brake and automobile braking method

ActiveCN110242689AEffective transmission torqueImprove axial sliding abilityAxially engaging brakesBraking discsMobile vehicleBrake torque

The invention relates to the field of motor vehicle braking, in particular to a double-brake disc type brake. The brake comprises a first brake disc (5), a second brake disc (7), a first friction plate (4), a second friction plate (8), a friction plate with friction materials on the two sides (6), and a driving assembly for driving the friction plate to rub with the corresponding brake disc; and the driving assembly comprises a first brake clamp body (1), a second brake clamp body (10), a first piston (2) and a second piston (9). According to the double-brake disc type brake, the double brake discs can move in two directions at the same time, so that the abrasion of the friction plate is reduced, and the service life is prolonged; and meanwhile, on the premise that conventional problems are avoided, the braking torque is improved, and the braking torque is increased by 1.8 times under the condition that parameters are unchanged.

Owner:QI AUTOMOTIVE CO LTD

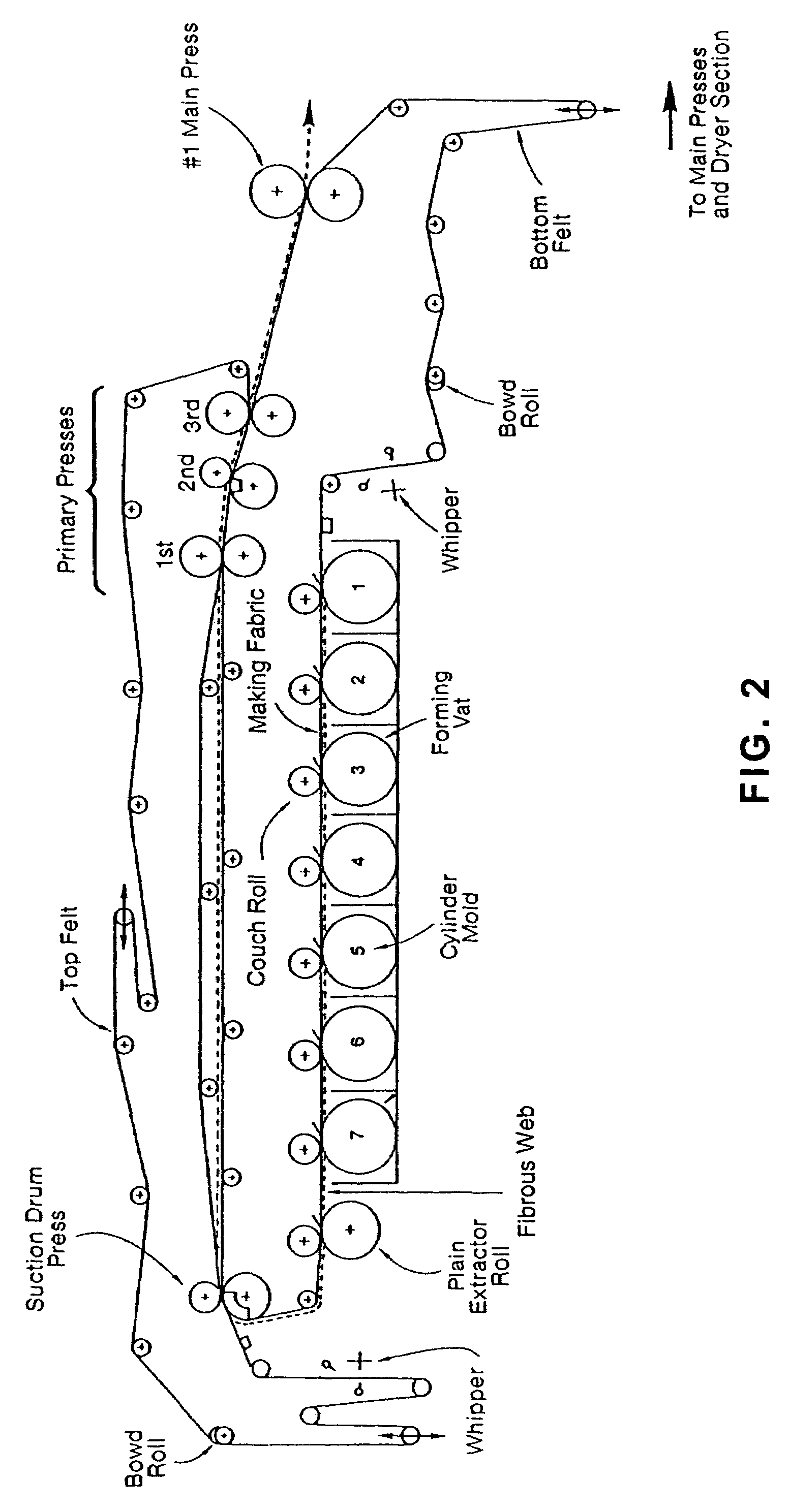

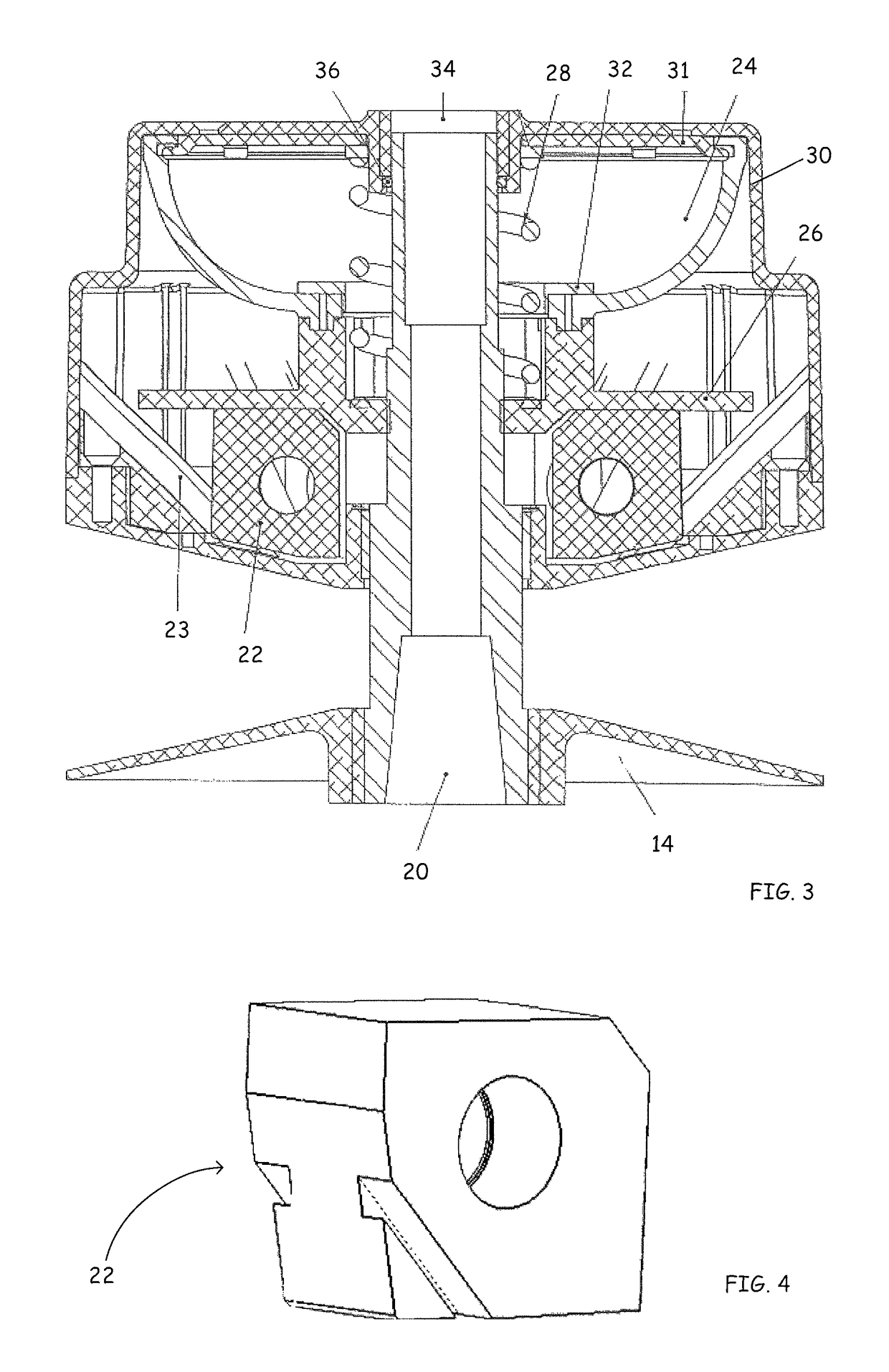

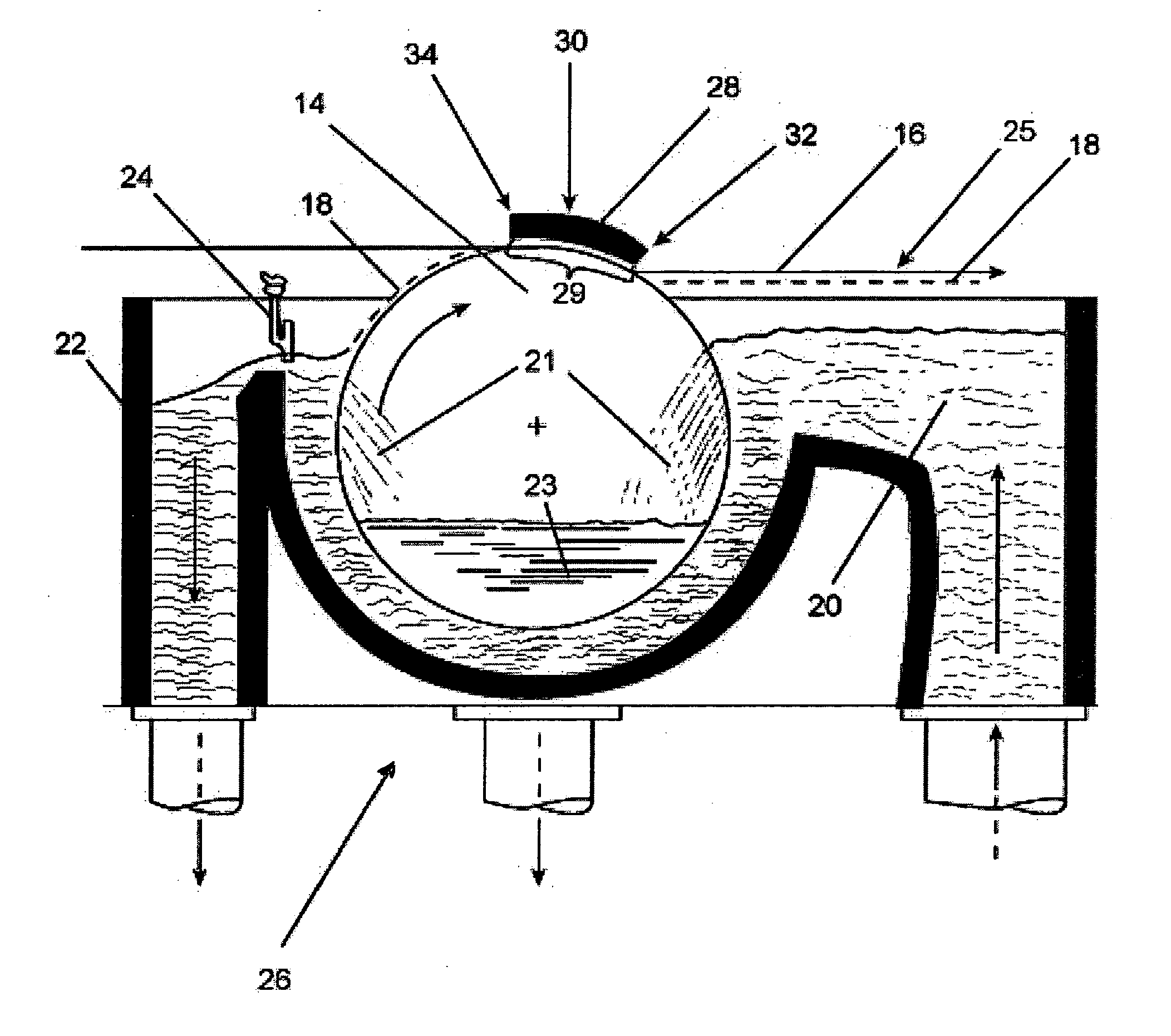

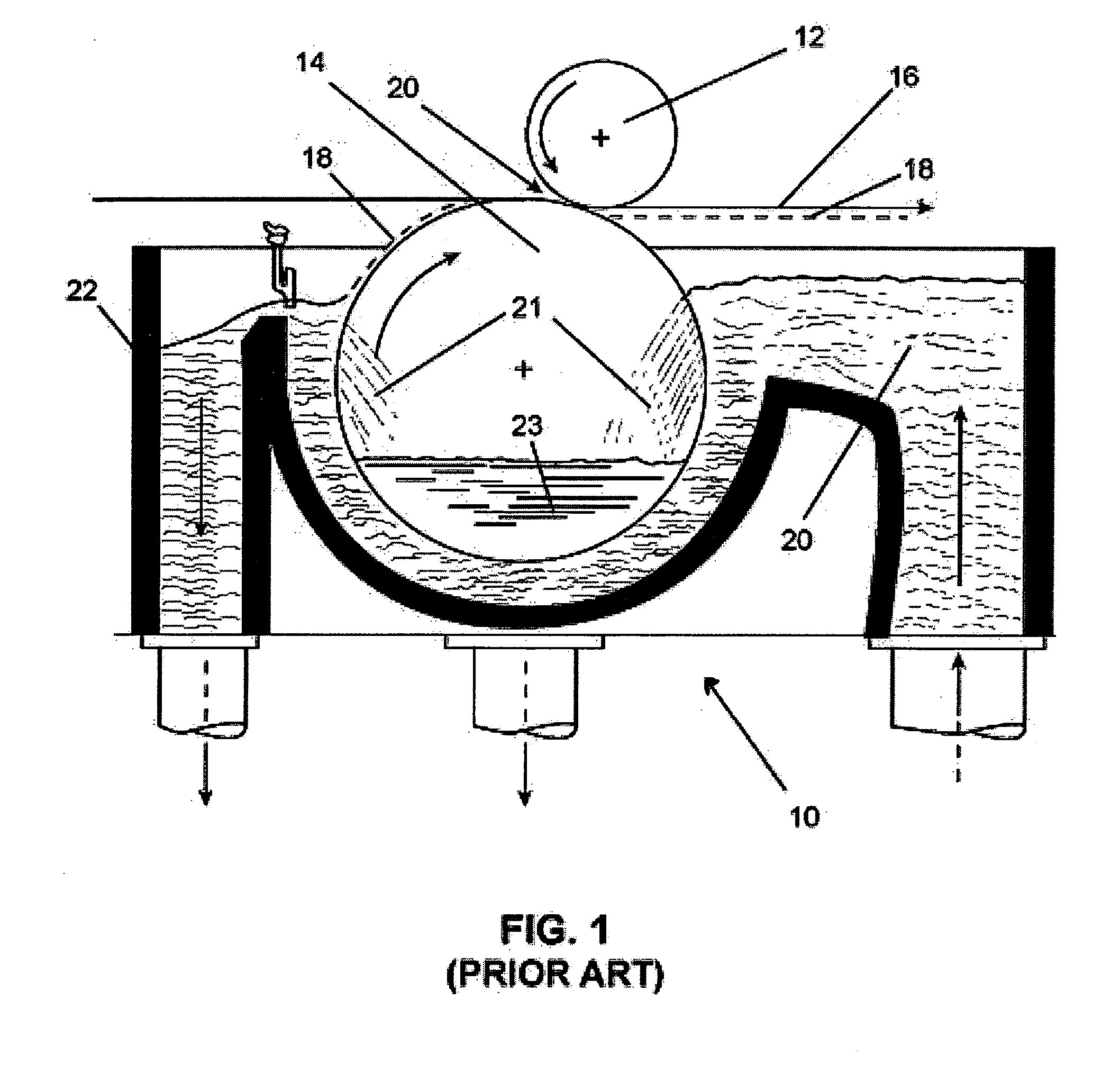

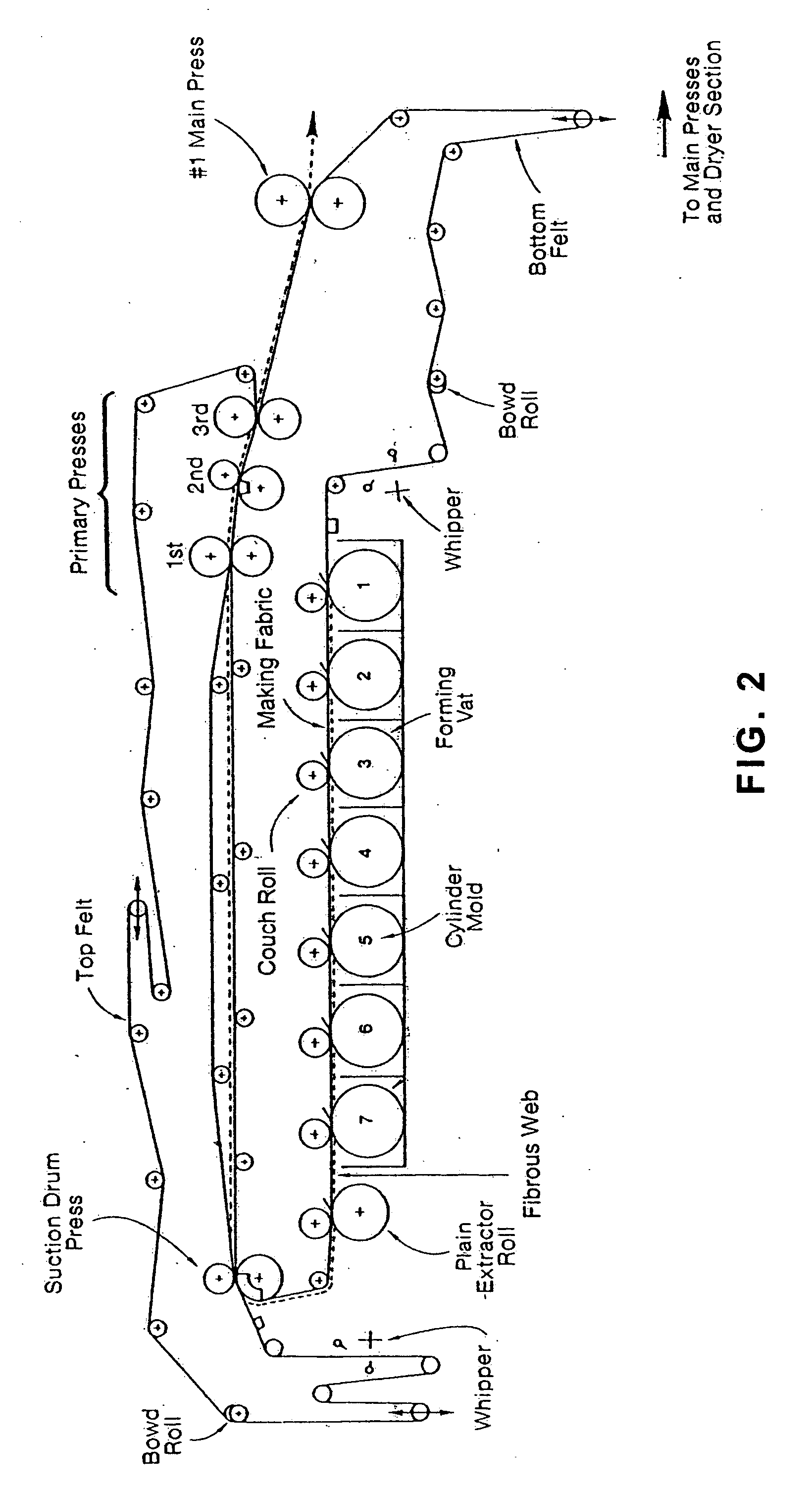

Extended couch nip on cylinder former

InactiveUS7510630B2Effective transmission torqueIncrease the amount of wrap a making fabricFibreboardMachine wet endEngineeringMechanical engineering

An apparatus for use in a cylinder machine having a shoe with a concavely-shaped pressure surface that forms a substantially mating relationship with a cylinder mould or sieve. The concavely-shaped pressure surface of the shoe increases the amount of wrap that a making fabric has on a cylinder mould or sieve thereby increasing the amount of friction generated between the making fabric and the cylinder mould or sieve. The increased friction results in an improved torque transfer between the making fabric and the cylinder mould or sieve.

Owner:JAMES HARDIE TECH LTD

Vertical axis wind turbine

ActiveUS10612515B2Increase capacityEffective transmission torqueMachines/enginesRenewable energy generationEnergy technologyEngineering

A vertical axis wind turbine (VAWT) with improved and optimized wind-directing, wind-shaping, and wind-power conversion features is disclosed. The shapes of these features directly affect the ability of the VAWT to use the power of moving air, such as wind, to spin a rotor and create torque on a rotor shaft to generate electricity. The wind-power-conversion mechanical efficiency of the invention is significantly improved over previous efforts, to the point that the invention can convert wind energy into electrical power at a price-to-performance ratio that competes with or surpasses existing alternative energy technologies.

Owner:DME WIND ENERGY CORP

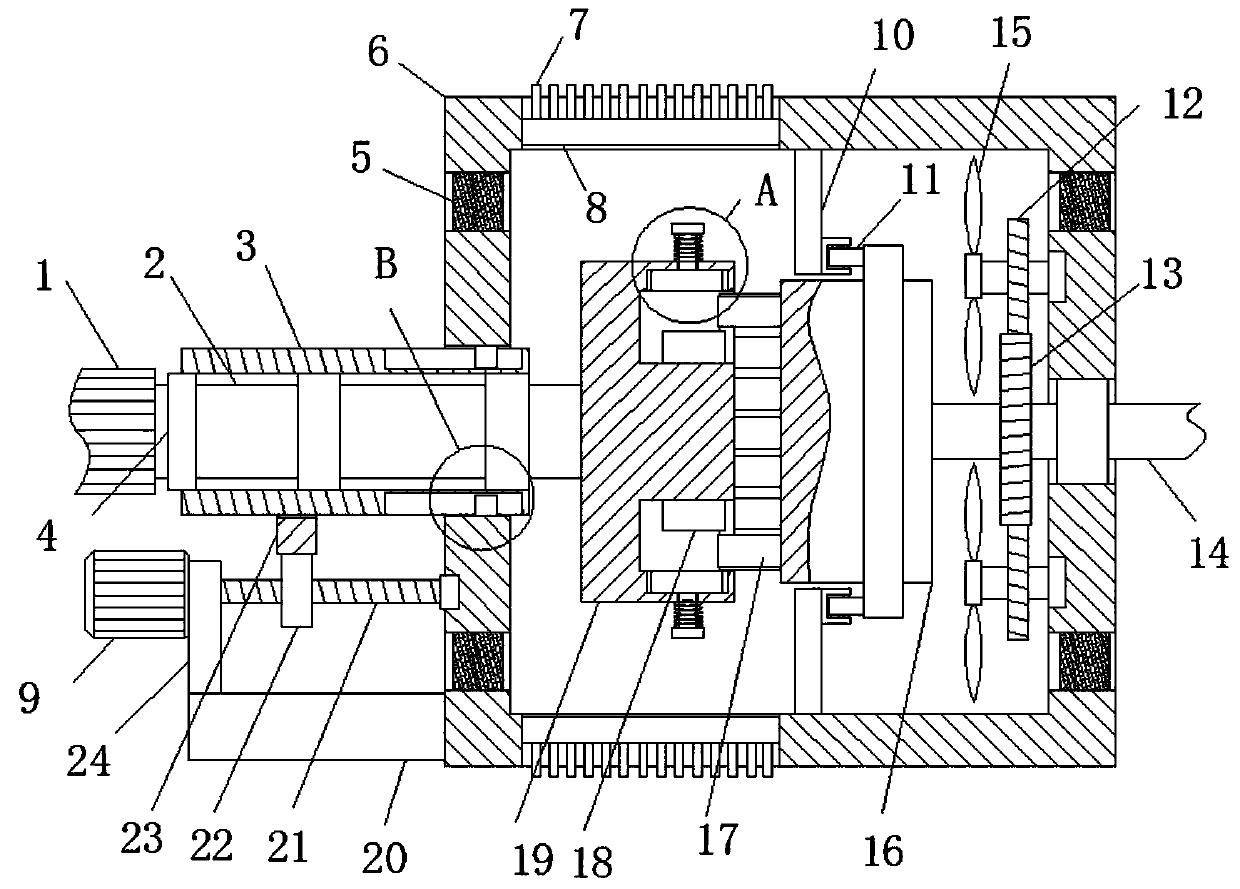

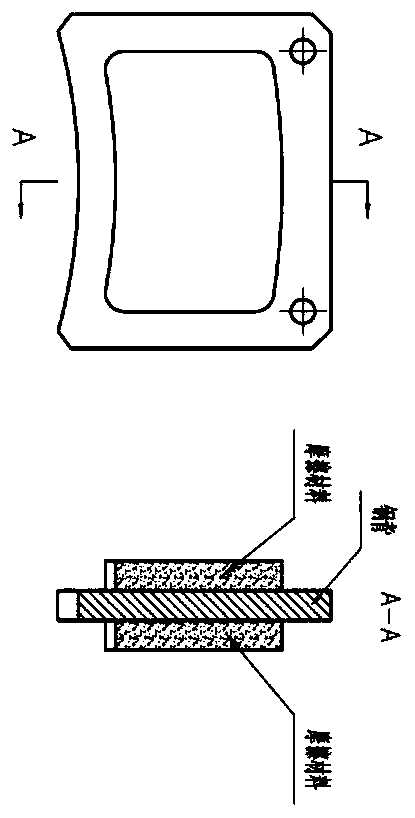

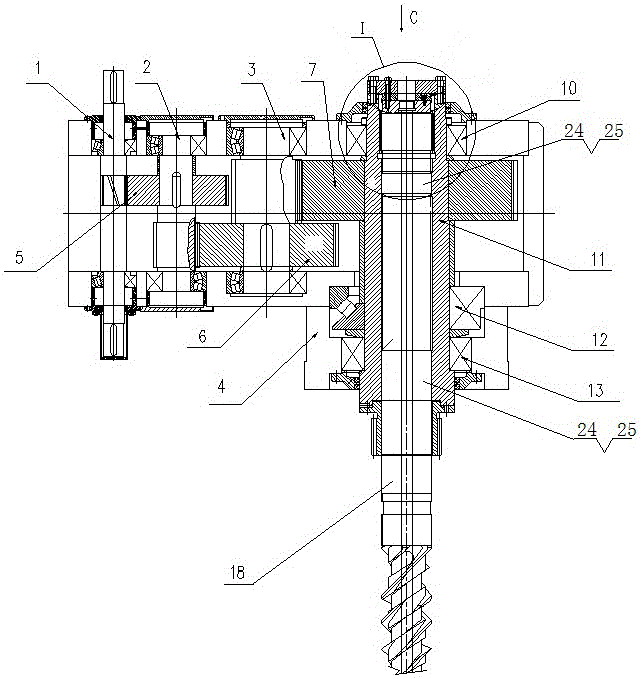

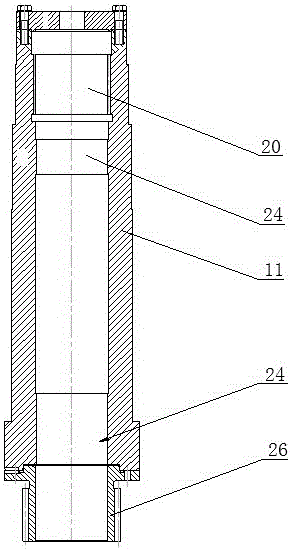

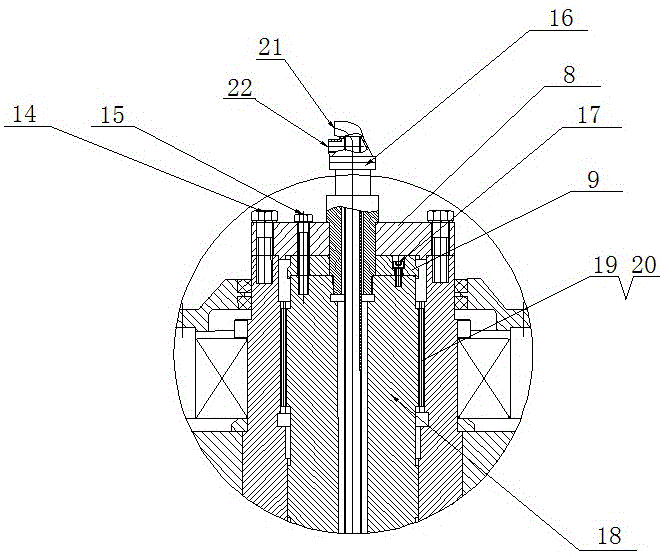

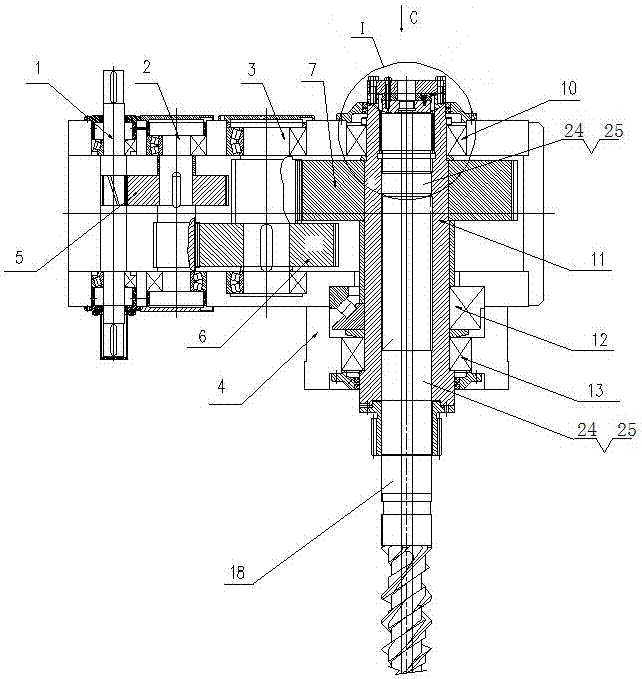

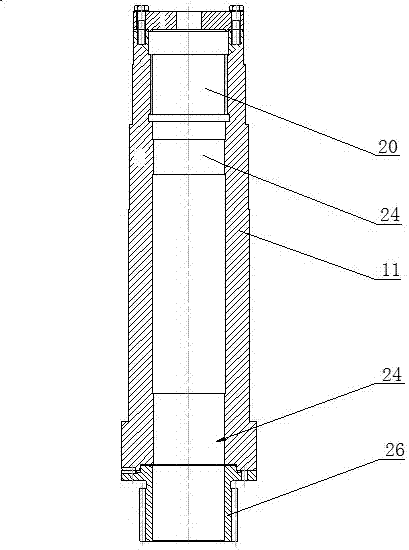

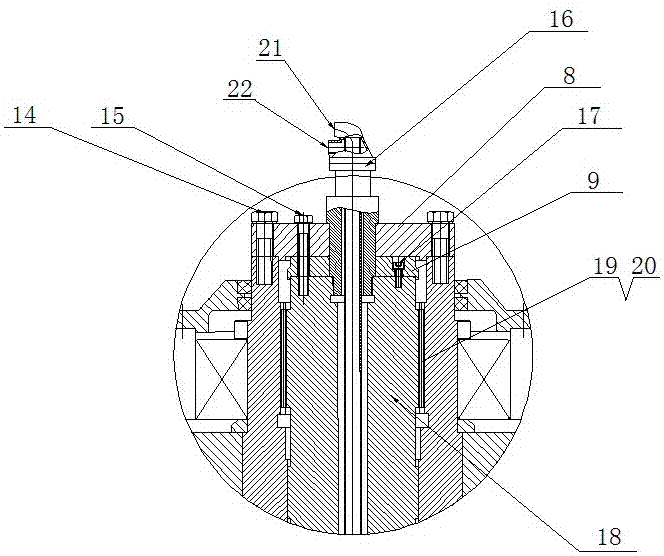

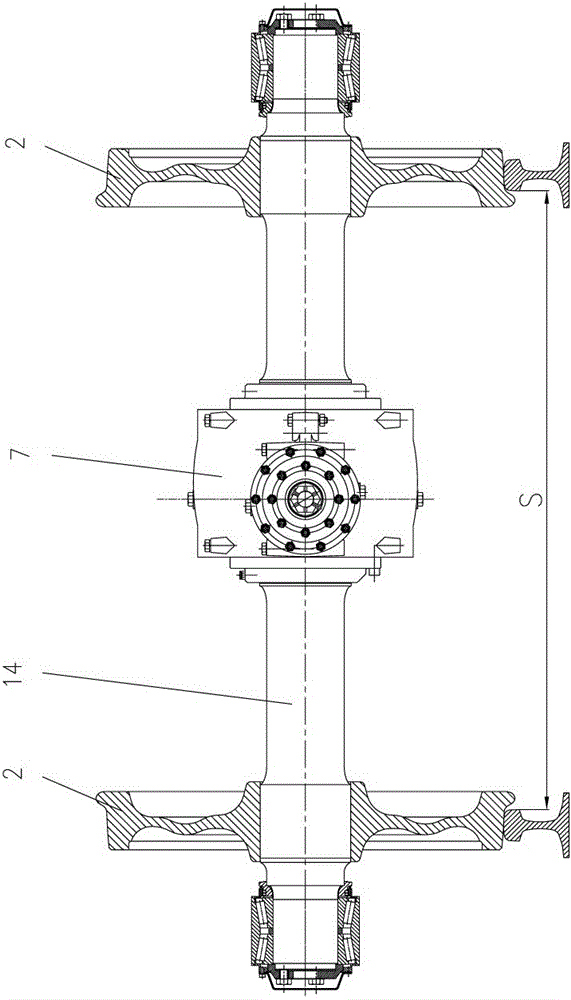

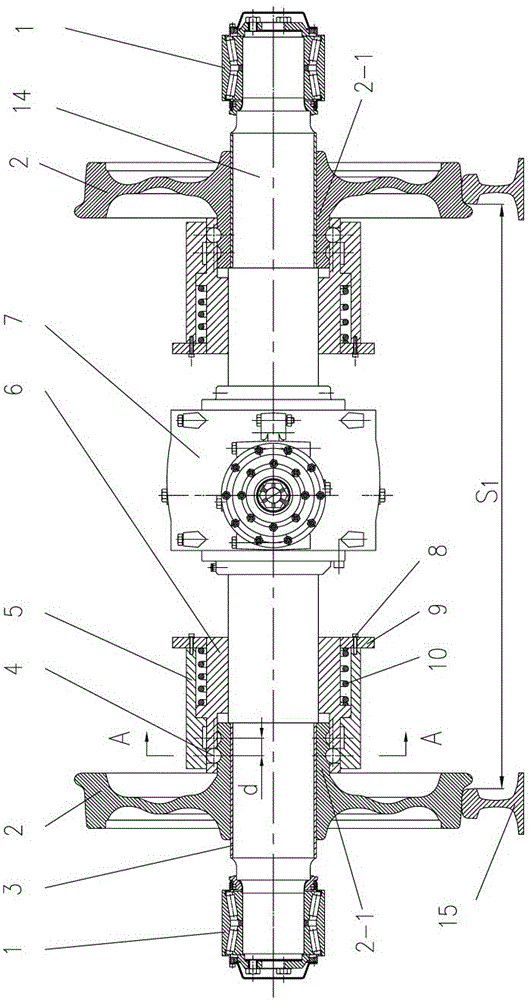

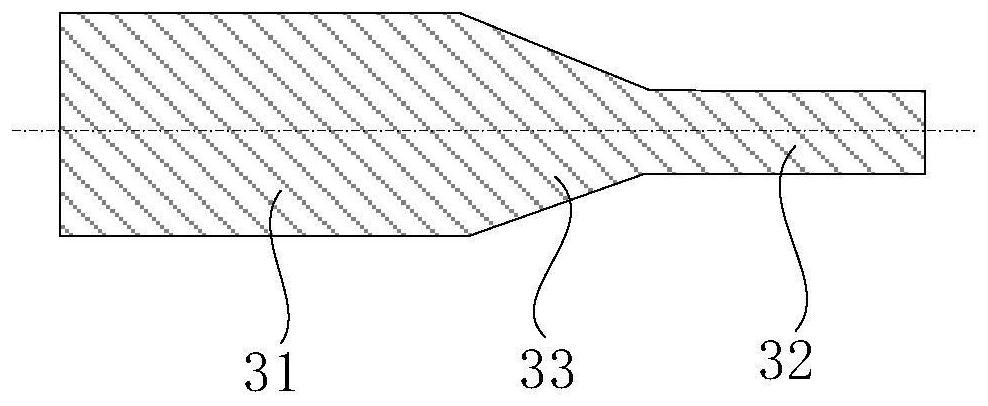

Main gearbox assembly of single-screw extruder and application of main gearbox assembly

ActiveCN105673818APrecise positioningEffective transmission torqueGearing detailsAerospace engineering

The invention relates to a main gearbox assembly of a single-screw extruder and application of the main gearbox assembly. The main gearbox assembly comprises a main gearbox and a thrust screw, wherein the main gearbox is a hollow output shaft, an internal spline is arranged at the tail end of the main gearbox, and two locating holes are formed in the tail end at the same time; a thrust spiral is arranged at the front part of the thrust screw, a locating neck is arranged at the rear part, an external spline and bulged shaft necks are arranged on the locating neck, the diameters of the bulged shaft necks are larger than that of the thrust spiral, and smaller than that of the external spline at the tail end; the hollow output shaft is equipped with an adjusting pad and a rear pressing cover on the surface of the tail end, and equipped with an external gear sleeve at the front end, the external gear sleeve is provided with an internal hole, and the diameter of the internal hole in the external gear sleeve is larger than that of the thrust spiral; after the thrust spiral at the front end of the thrust screw penetrates the inner hole in the external gear sleeve, the bulged shaft necks are placed in the locating holes of the hollow output shaft, and the external spline is engaged with the internal spline; a rotation joint penetrates the rear pressing cover and the adjusting pad, and is connected with the thrust screw and communicated with a circulating water channel in the thrust screw. During use, a rubber extruding unit is equipped with at least one material conveyor containing the gearbox assembly of the single-screw extruder.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

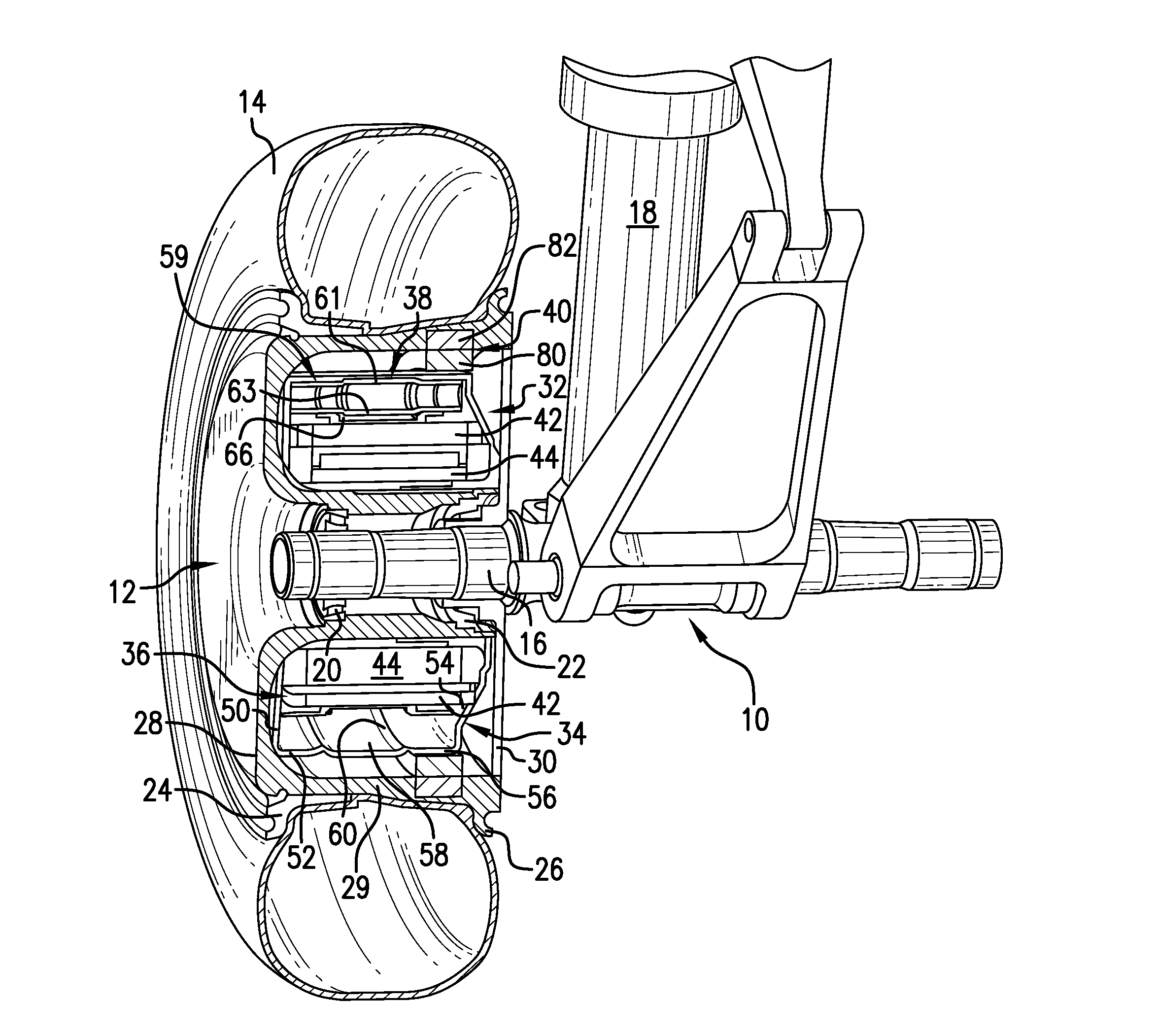

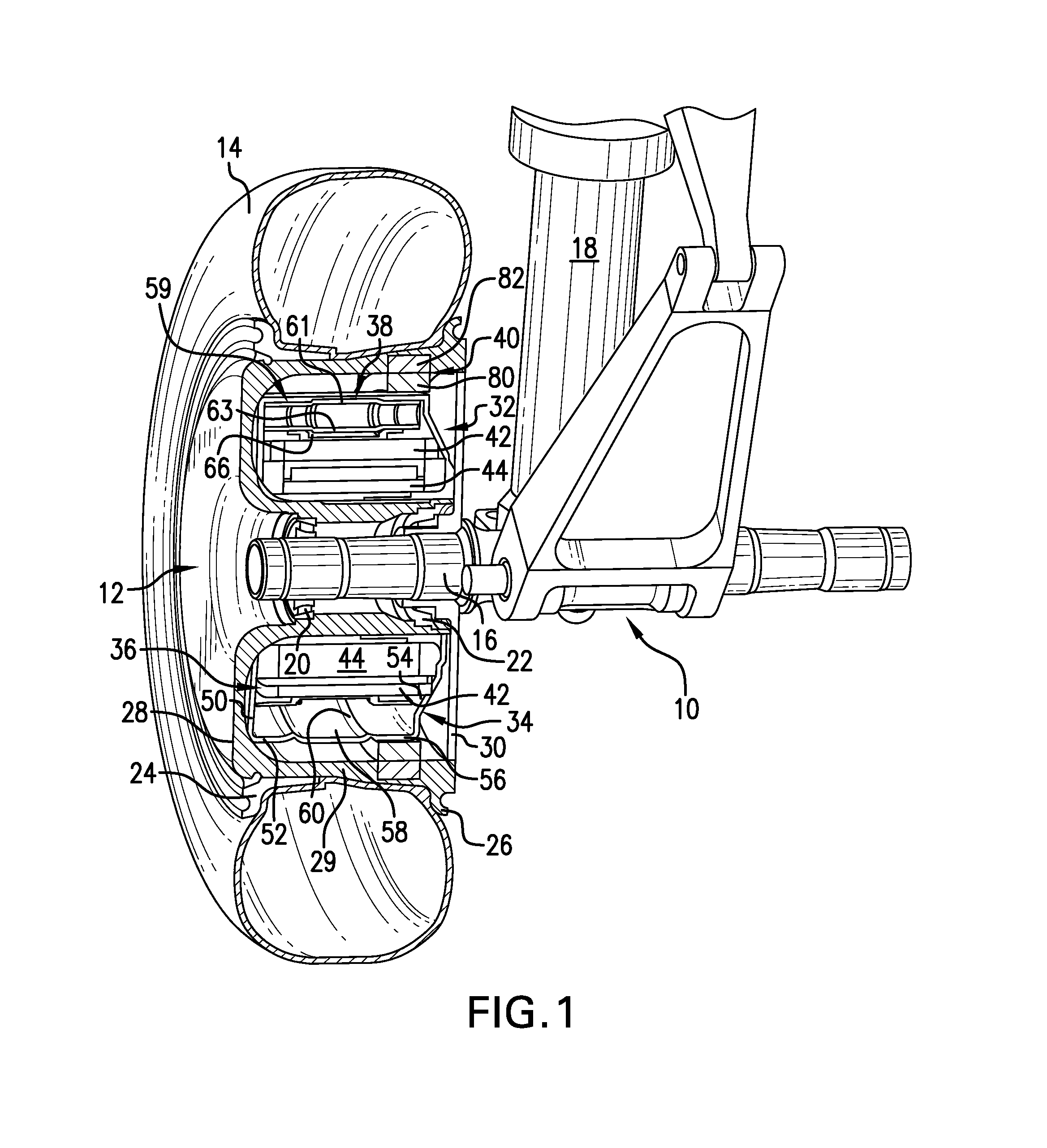

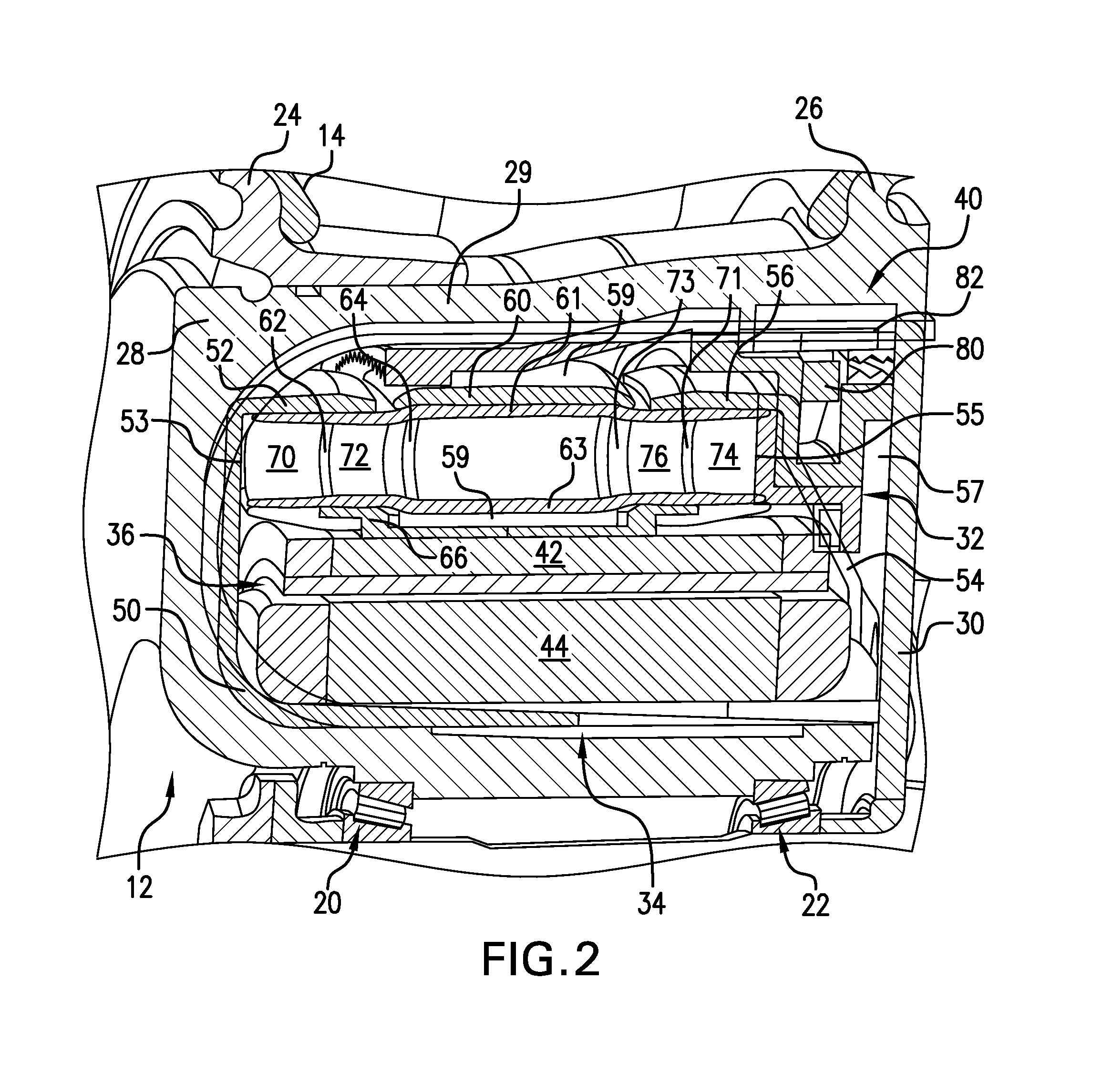

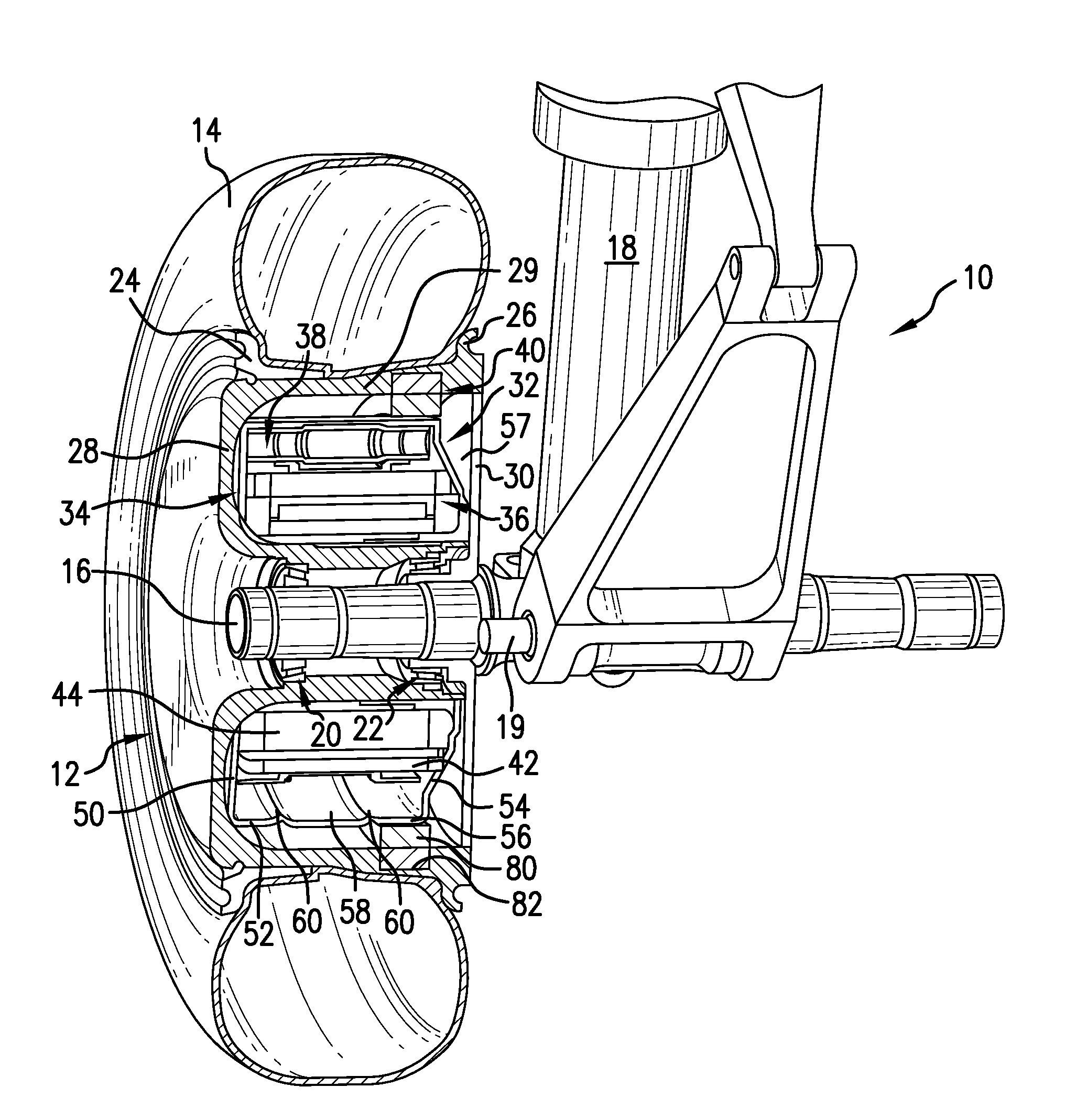

Torque Transmission in an Aircraft Drive Wheel Drive System

ActiveUS20160200425A1Efficient transferEffective transmission torqueEnergy efficient operational measuresAlighting gearMaximum torqueDrive wheel

A torque transmission system is provided for an aircraft drive wheel drive system mounted on nose or main landing gear wheels to move the aircraft autonomously on the ground that effectively transmits torque through drive system components. The drive system includes a drive means capable of generating sufficient torque to move the aircraft, a drive system capable of generating a high torque capacity that activates the drive means, a clutch assembly that can be selectively engaged to control torque transmission to the drive system and activate the drive means, and a landing gear torque takeout element. The clutch assembly is configured to be inactivated and prevented from transmitting torque to other drive wheel drive system components when an overtorque event occurs. Aircraft drive wheel drive system components in the present torque transmission system are designed to withstand torque in excess of a determined maximum for the system.

Owner:BOREALIS TECH LTD

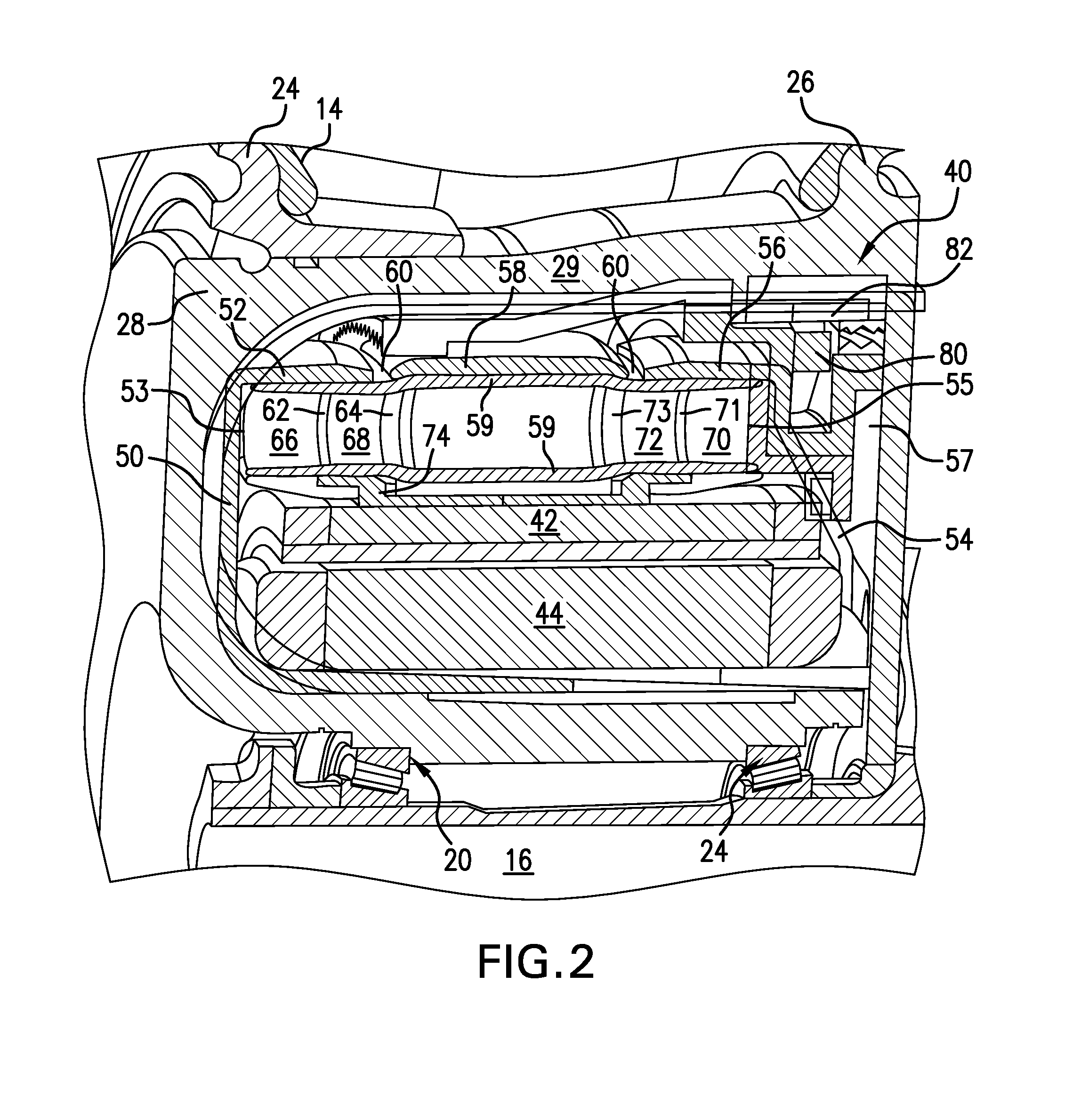

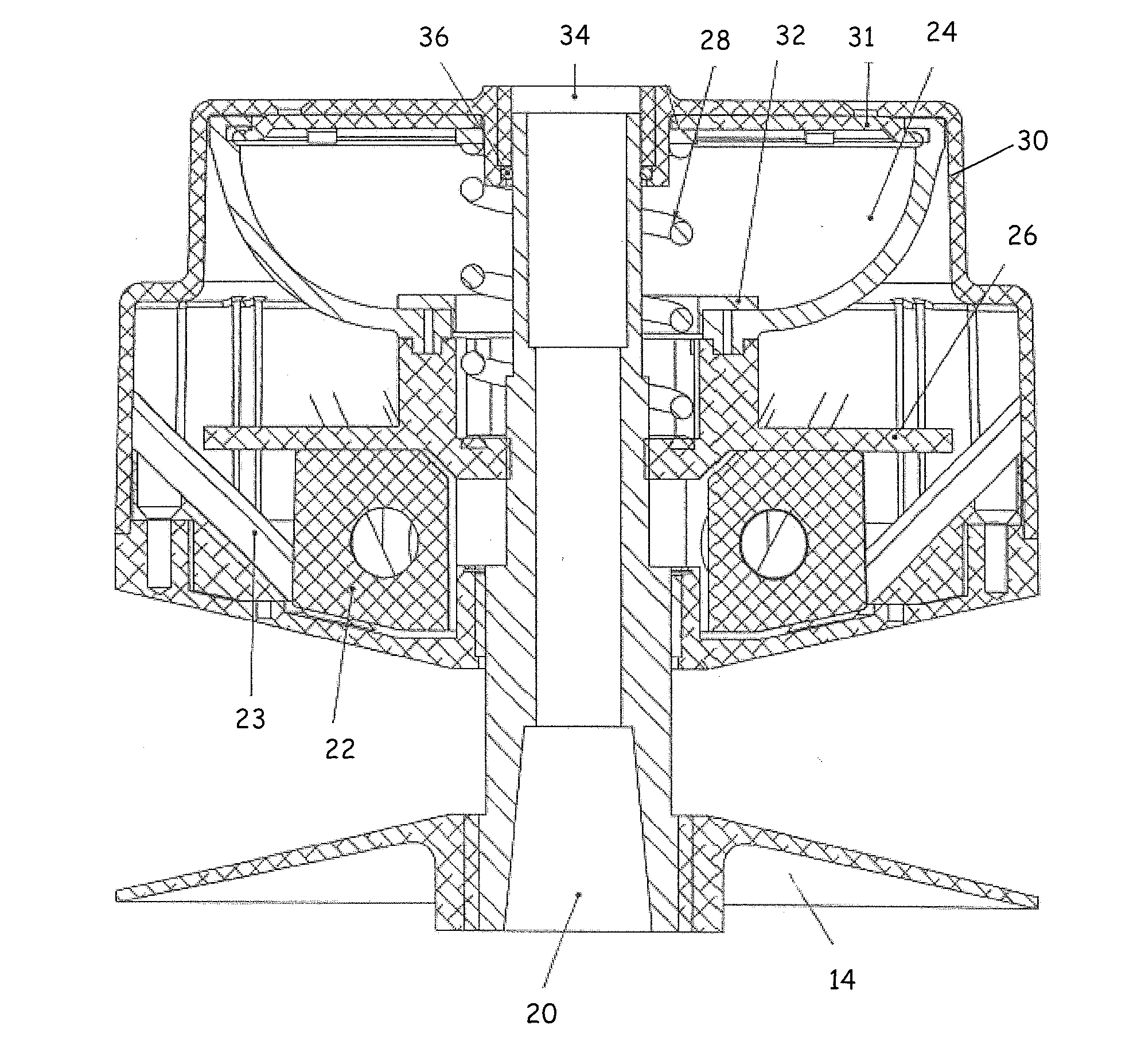

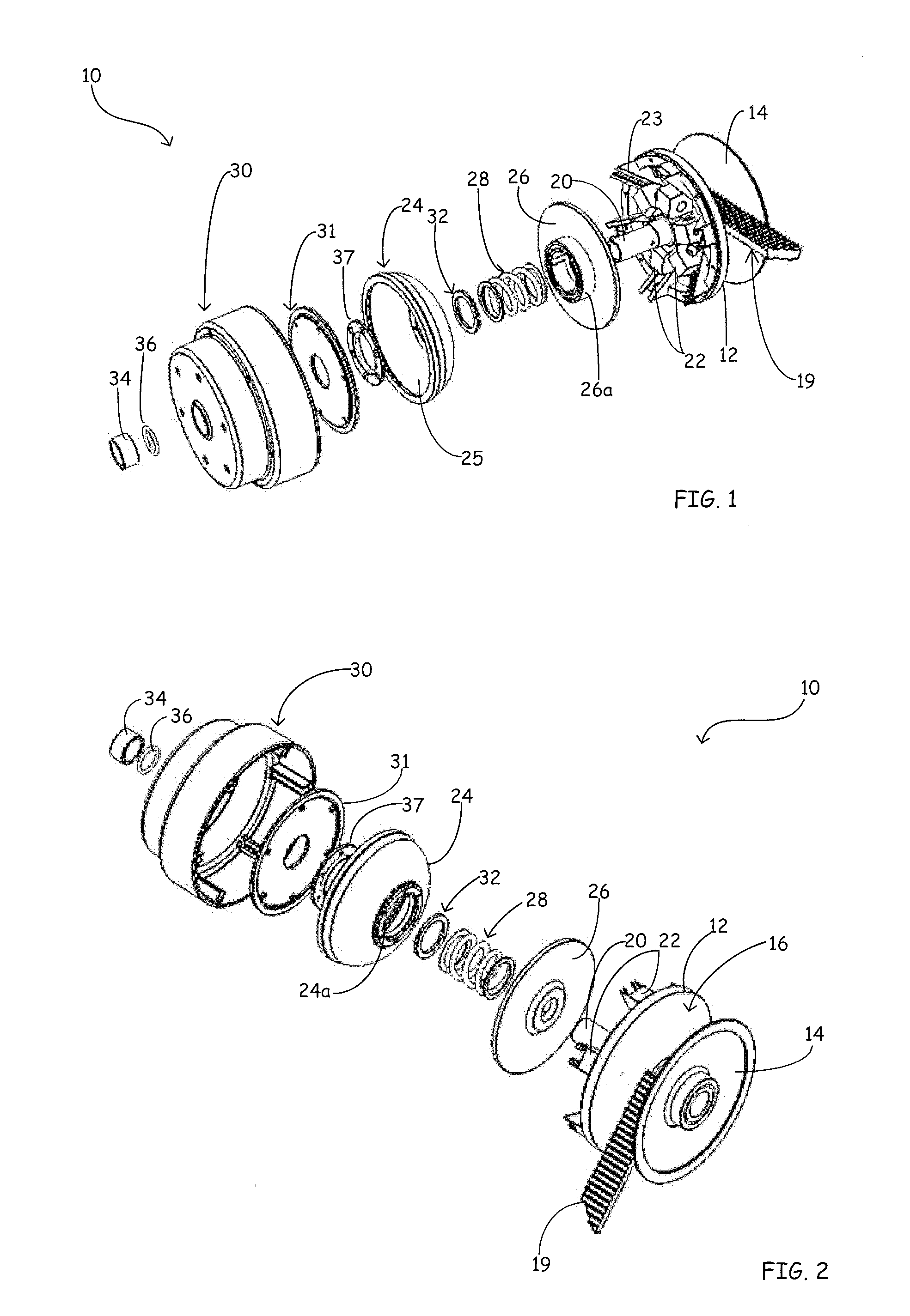

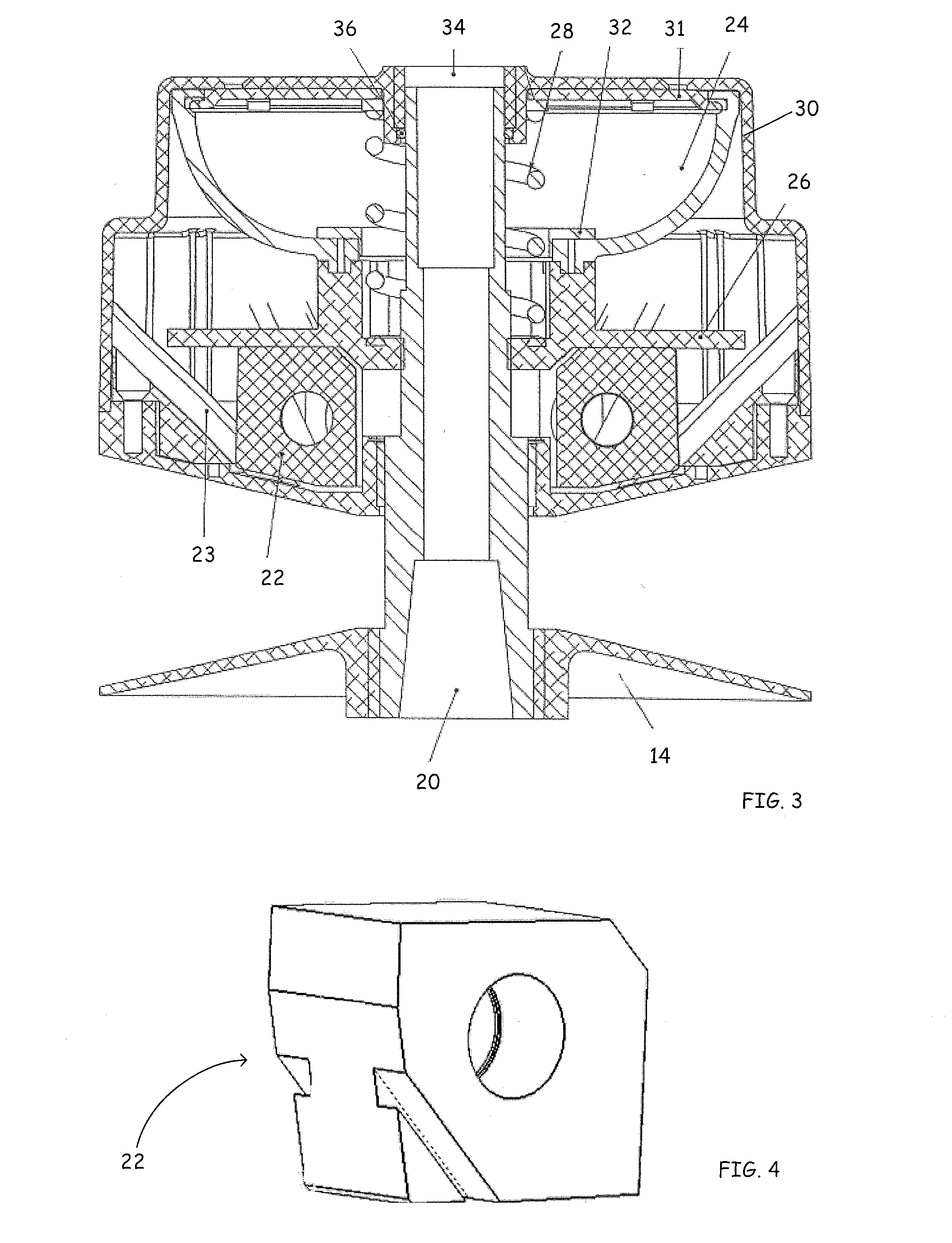

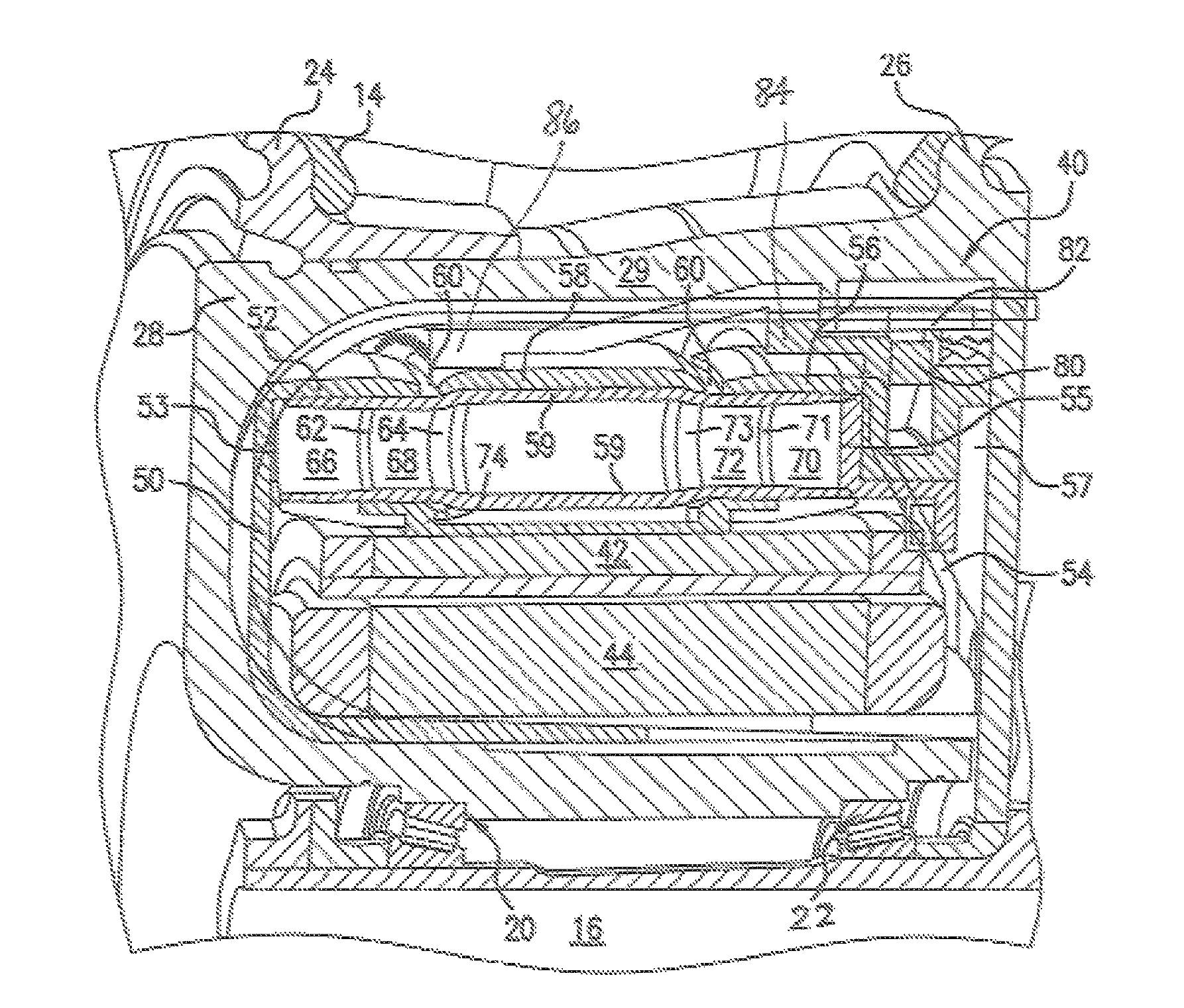

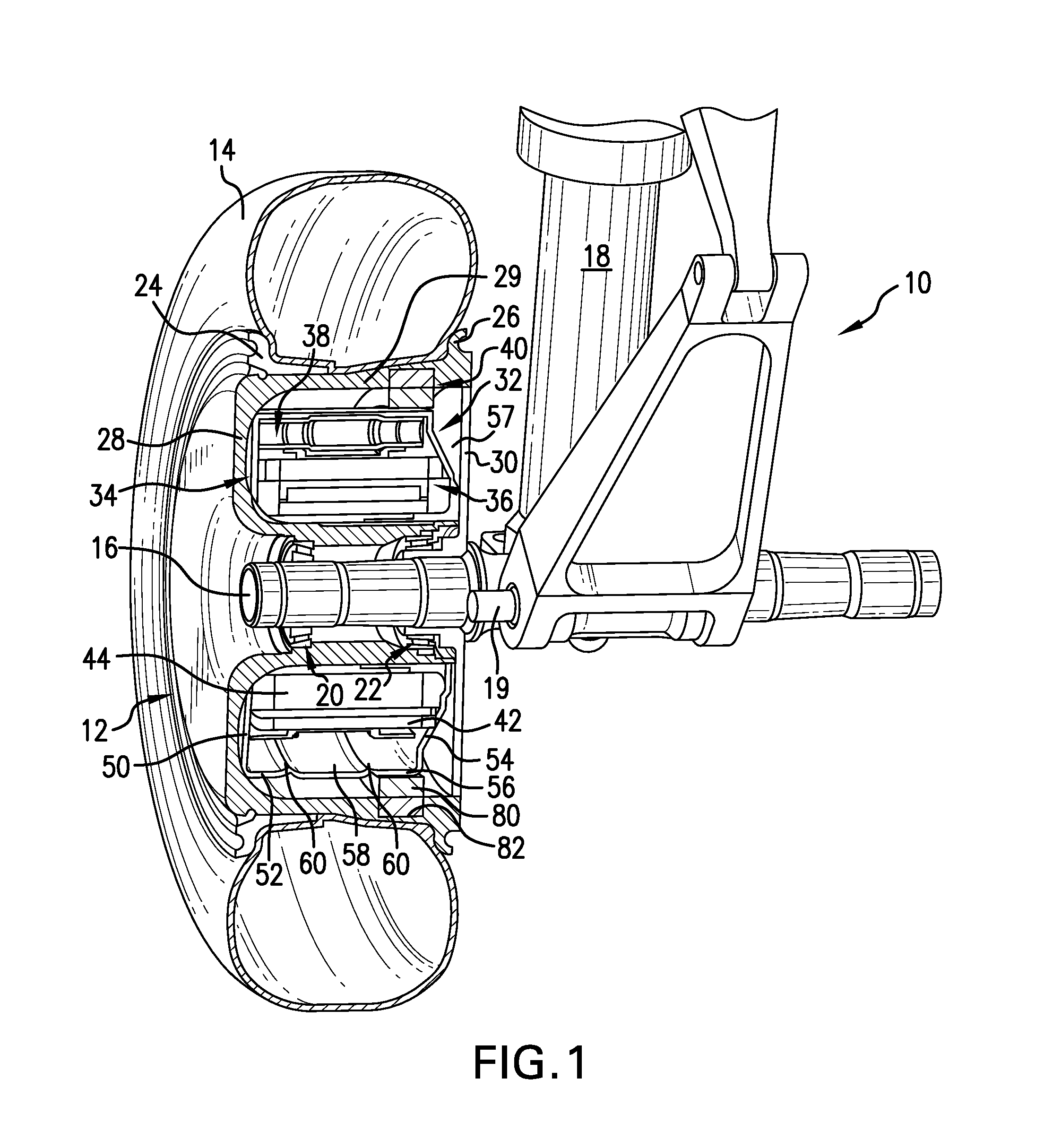

Drive clutch

A drive clutch having a compressible torque transfer mechanism configured to transfer torque from an engine or motor to a moveable sheave and configured to reduce wear on components of the drive clutch by eliminating sliding contact between surfaces to transfer torque and change the gear ratio. The torque transfer mechanism increases efficiency and reduces wear and may comprise a torque bellows, which is configured to transfer torque from the engine to the moveable sheave upon radial compression of the torque bellows. Sliding blocks and corresponding slide tracks are concentrically positioned between the moveable sheave and the shift plate and centrifugal force provides a force for linear movement for the sliding blocks, which results in movement of the moveable sheave and the cover, which can act to compress the torque bellows. This configuration reduces costs because precise machining is not needed and reduces premature wear and tear on the drive clutch.

Owner:ZULAWSKI DENNIS

Extended couch nip on cylinder former

InactiveUS20060237157A1Effective transmission torqueIncrease the amount of wrap a making fabricFibreboardMachine wet endPulp and paper industryCylinder mould

An apparatus for use in a cylinder machine having a shoe with a concavely-shaped pressure surface that forms a substantially mating relationship with a cylinder mould or sieve. The concavely-shaped pressure surface of the shoe increases the amount of wrap that a making fabric has on a cylinder mould or sieve thereby increasing the amount of friction generated between the making fabric and the cylinder mould or sieve. The increased friction results in an improved torque transfer between the making fabric and the cylinder mould or sieve.

Owner:JAMES HARDIE TECH LTD

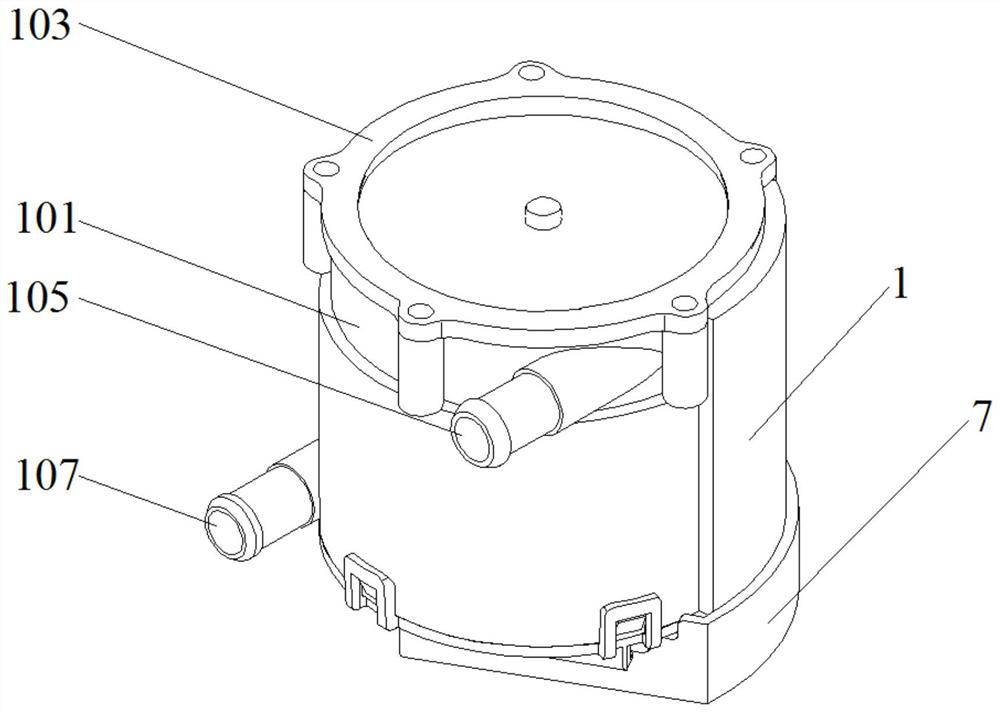

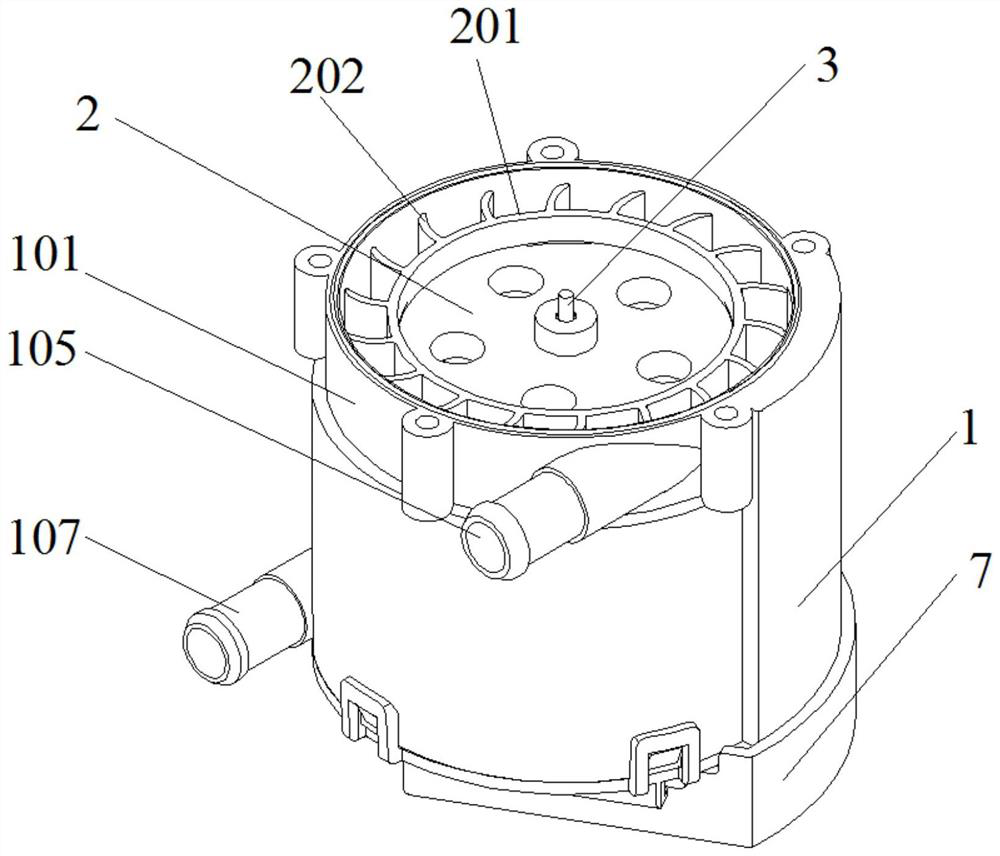

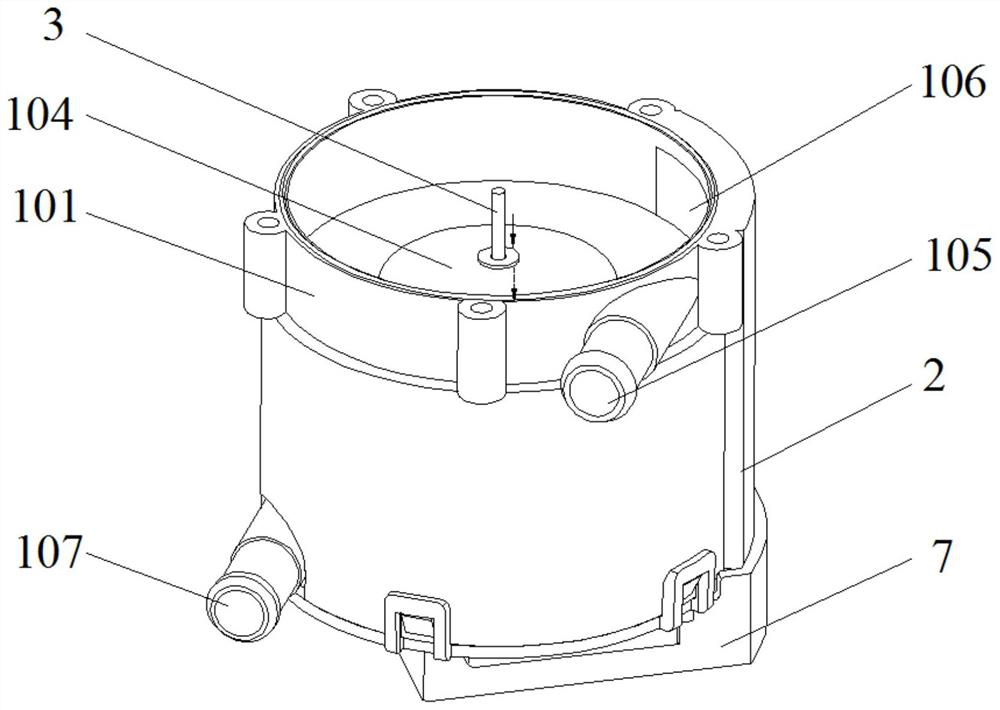

Treating agent feeding device and washing equipment

PendingCN112553841AImprove reliabilityOvercoming influences on power transmissionOther washing machinesTextiles and paperImpellerWater wheel

The invention discloses a treating agent feeding device and washing equipment. The treating agent feeding device comprises a water wheel bin, a distribution bin, a partition plate, a transmission shaft and an anti-overflow structure, wherein an impeller driven by water flow to rotate is arranged in the water wheel bin; the distribution bin is located below the water wheel bin, and a distribution mechanism is arranged in the distribution bin; the partition plate is arranged between the water wheel bin and the distribution bin; the input end of the transmission shaft is connected with the impeller, and the output end of the transmission shaft penetrates through the partition plate, extends into the distribution bin and is used for outputting power to the distribution mechanism; the transmission shaft is in clearance fit with the partition plate to form a first overflow gap; and the anti-overflow structure is located on the side, facing the distribution bin, of the partition plate and used for guiding water overflowing from the first overflow gap. Water overflowing into the distribution bin from the first overflow gap in the water wheel bin is drained and discharged through the anti-overflow structure, so that the operation reliability of the treating agent feeding device is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Drive clutch

A drive clutch having a compressible torque transfer mechanism configured to transfer torque from an engine or motor to a moveable sheave and configured to reduce wear on components of the drive clutch by eliminating sliding contact between surfaces to transfer torque and change the gear ratio. The torque transfer mechanism increases efficiency and reduces wear and may comprise a torque bellows, which is configured to transfer torque from the engine to the moveable sheave upon radial compression of the torque bellows. Sliding blocks and corresponding slide tracks are concentrically positioned between the moveable sheave and the shift plate and centrifugal force provides a force for linear movement for the sliding blocks, which results in movement of the moveable sheave and the cover, which can act to compress the torque bellows. This configuration reduces costs because precise machining is not needed and reduces premature wear and tear on the drive clutch.

Owner:ZULAWSKI DENNIS

Torque transmission in an aircraft drive wheel drive system

ActiveUS9567068B2Effective transmission torqueEfficient transferEnergy efficient operational measuresAlighting gearMaximum torqueDrive wheel

A torque transmission system is provided for an aircraft drive wheel drive system mounted on nose or main landing gear wheels to move the aircraft autonomously on the ground that effectively transmits torque through drive system components. The drive system includes a drive means capable of generating sufficient torque to move the aircraft, a drive system capable of generating a high torque capacity that activates the drive means, a clutch assembly that can be selectively engaged to control torque transmission to the drive system and activate the drive means, and a landing gear torque takeout element. The clutch assembly is configured to be inactivated and prevented from transmitting torque to other drive wheel drive system components when an overtorque event occurs. Aircraft drive wheel drive system components in the present torque transmission system are designed to withstand torque in excess of a determined maximum for the system.

Owner:BOREALIS TECH LTD

Rotary type cutting and fishing integral fisher

InactiveCN105781465APrevent chargebackThe effect of structure anti-regression is obviousBorehole/well accessoriesNeedle roller bearingEngineering

The invention discloses a rotary type cutting and fishing integral fisher. The rotary type cutting and fishing integral fisher comprises an upper connector provided with an internal thread. The upper connector is connected with a lower connector provided with an external thread. The inner side of the lower end of the upper connector is provided with L-shaped tracks. The lower connector is sequentially sleeved with an upper bearing ring, a slip cone body and a lower bearing ring from top to bottom. The part between the slip cone body and the lower connector is sequentially sleeved with an upper roller pin sealing sleeve, an upper roller pin bearing, a lower roller pin bearing and a lower roller pin sealing sleeve from top to bottom. The upper end and the lower end of the upper roller pin bearing are provided with upper roller pin bearing spacer rings correspondingly. The upper end and the lower end of the lower roller pin bearing are provided with lower roller pin bearing spacer rings correspondingly. The slip cone body is sleeved with a slip. The outer side of the upper end of the slip is provided with L-shaped keys. The rotary type cutting and fishing integral fisher is simple in structure, convenient to use, long in service life, capable of descending a well along with a cutter and conducting one time of cutting milling and fishing operation on a pipe column to be cut and milled, and suitable for cutting milling and fishing of the pipe column.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Main gearbox assembly of single screw extruder and its application

ActiveCN105673818BPrecise positioningEffective transmission torqueGearing detailsAerospace engineering

The invention relates to a main gearbox assembly of a single-screw extruder and application of the main gearbox assembly. The main gearbox assembly comprises a main gearbox and a thrust screw, wherein the main gearbox is a hollow output shaft, an internal spline is arranged at the tail end of the main gearbox, and two locating holes are formed in the tail end at the same time; a thrust spiral is arranged at the front part of the thrust screw, a locating neck is arranged at the rear part, an external spline and bulged shaft necks are arranged on the locating neck, the diameters of the bulged shaft necks are larger than that of the thrust spiral, and smaller than that of the external spline at the tail end; the hollow output shaft is equipped with an adjusting pad and a rear pressing cover on the surface of the tail end, and equipped with an external gear sleeve at the front end, the external gear sleeve is provided with an internal hole, and the diameter of the internal hole in the external gear sleeve is larger than that of the thrust spiral; after the thrust spiral at the front end of the thrust screw penetrates the inner hole in the external gear sleeve, the bulged shaft necks are placed in the locating holes of the hollow output shaft, and the external spline is engaged with the internal spline; a rotation joint penetrates the rear pressing cover and the adjusting pad, and is connected with the thrust screw and communicated with a circulating water channel in the thrust screw. During use, a rubber extruding unit is equipped with at least one material conveyor containing the gearbox assembly of the single-screw extruder.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

Connecting part and method for abutting-joint and supporting of steel pipes

ActiveCN107386459AImprove mechanical performanceEffective transmission of axial forceRailway tracksBuilding constructionsArchitectural engineeringAxial force

The invention relates to abutting-joint and supporting of steel pipes, and aims to provide a connecting part and method for abutting-joint and supporting of single-rail steel pipes. The connecting part comprises a first steel pipe, a second steel pipe, a supporting pipe, an inserting plate and a backing plate. The two ends of the inserting plate are correspondingly embedded into axial troughs of the two abutting-joint steel pipes for solid joint, the backing plate is inserted into a gap of the two sides, and the supporting pipe is inserted into the gap from a bottom groove of the abutting-joint position. According to the connecting part, the two steel pipes are in solid joint through the inserting plate, a variety of internal force such as axial force, bending moment and torque can be transmitted effectively, connecting of the supporting pipe and abutting-joint of the steel pipes are combined, construction is convenient and safe, the process is simple, dependence of connecting quality on technical level of welders is got rid of, and fire hazards can be avoided through a non-welding abutting-joint mode.

Owner:JIANGSU UNIV

Rotary phase adjusting coupling and application method thereof

The invention relates to a rotary phase adjusting coupling which comprises a coupling stator, a coupling rotor, adjusting bolts, four adjusting ejector heads and a coupling pressure ring. Four rotor grooves and four stator grooves are separately formed in a coupling stator and a coupling rotor at a contact end of the coupling stator and the coupling rotor, the four rotor grooves are symmetricallyformed along the center line of the coupling stator, the four stator grooves extend in the corresponding stator grooves, the four adjusting ejector heads are separately mounted in the stator grooves and the rotor grooves, the shapes of the adjusting ejector heads are square cylinders, cylindrical holes are formed in the square cylinders, one ends of the adjusting ejector heads are mounted in the stator grooves, the cylindrical holes of the adjusting ejector heads are aligned to the stator grooves, the adjusting bolts leading to outside of the coupling stator are formed in the stator grooves along the length directions of the adjusting ejector heads, the adjusting bolts penetrate the adjusting bolt holes from outside of the coupling stator and are fixed in the corresponding cylindrical holes of the adjusting ejector heads to fix the coupling stator and the coupling rotor together, and the coupling pressure ring is mounted on the circumference of the coupling rotor in a sleeving manne and is fixed to the coupling stator.

Owner:宁波赛乐福板材成型技术有限公司

Drive axle gearbox wheel set for large railway maintenance machinery

ActiveCN104494366BEffective transmission torqueGuaranteed uptimeHubsAxle-boxesDrive wheelLocking mechanism

The invention discloses a drive axle gearbox wheel set for large railway maintenance machinery. The drive axle gearbox wheel set comprises an axle, two wheels, a sliding bearing, a locking steel ball, an inner sleeve, an outer sleeve, a rolling steel ball, an axle retainer ring, a hole retainer ring, a spring and an end cover. The two wheels are positioned on wheel seats at two ends of the axle respectively. The locking steel balls, spherical grooves, a radial cylindrical hole of the inner sleeve and the outer sleeve form a locking mechanism; the rolling steel balls, first semicircular grooves and second semicircular grooves are matched to form a rolling ball key mechanism; the end cover is fixed to the end face of one side, away from the wheels, of the outer sleeve, a gap is reserved between the end cover and the circumference of the inner sleeve, the end cover is capable of axially moving left and right along the inner sleeve, and the springs are mounted in a closed annular inner cavity formed by the outer sleeve, the end cover and the inner sleeve. The drive axle gearbox wheel set for large railway maintenance machinery is simple in structure, convenient to operate and capable of fitting different rail gauges.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

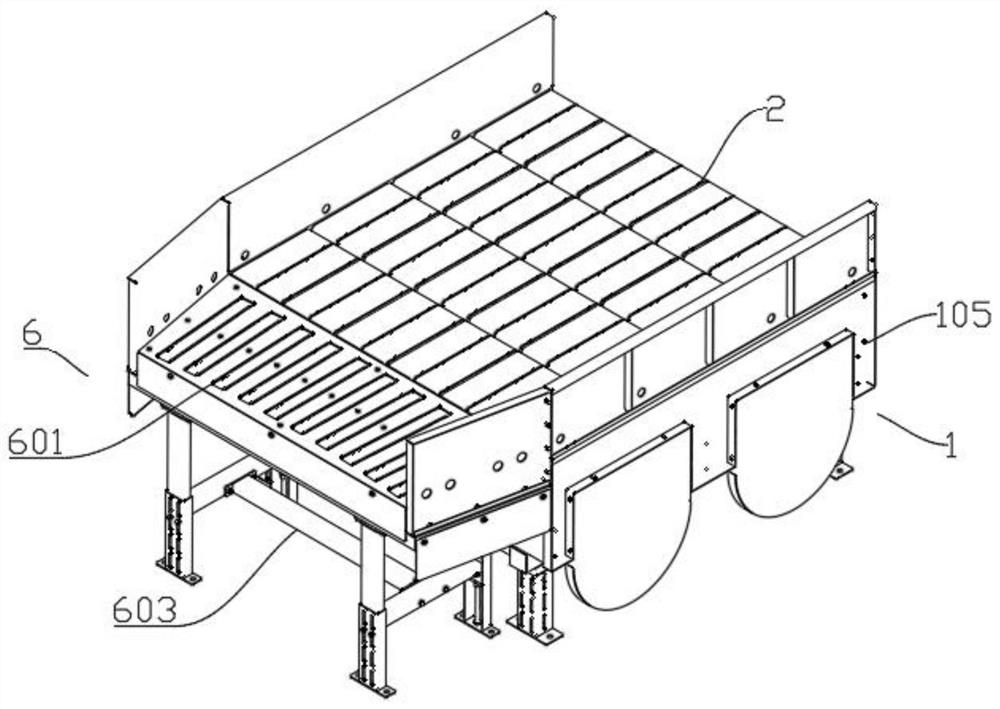

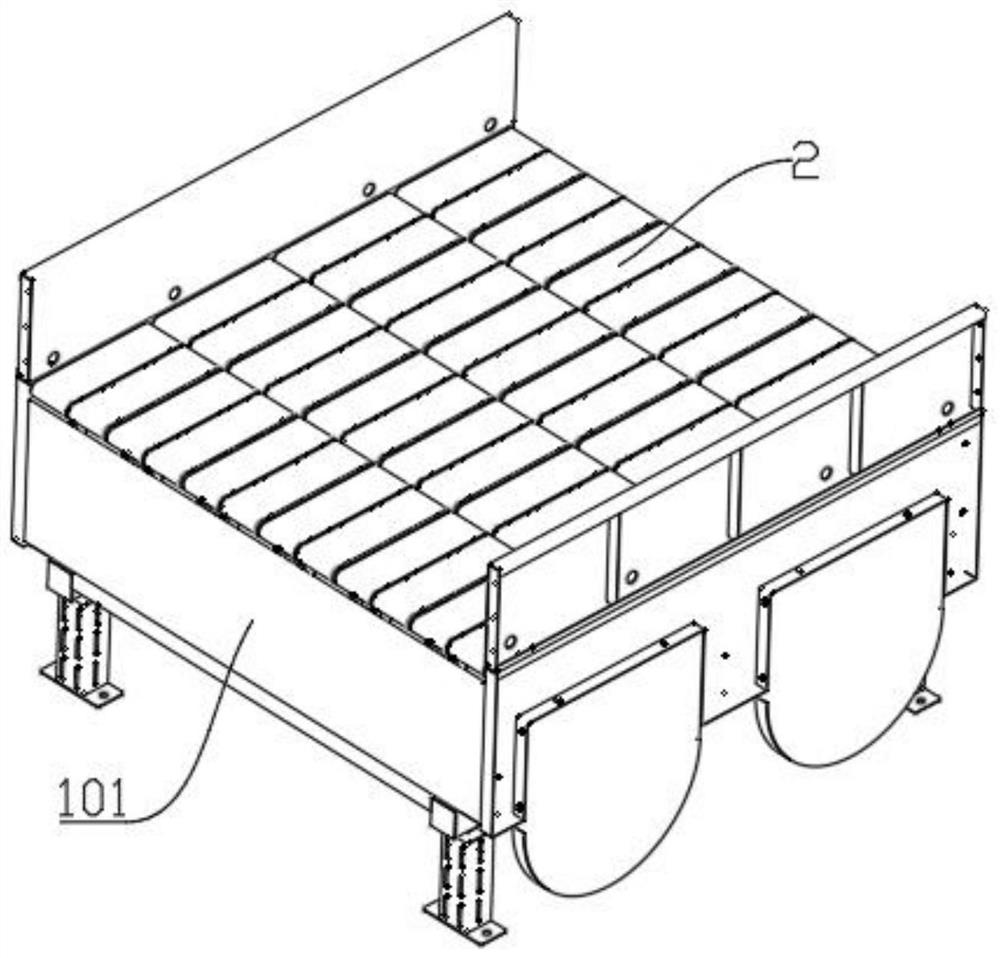

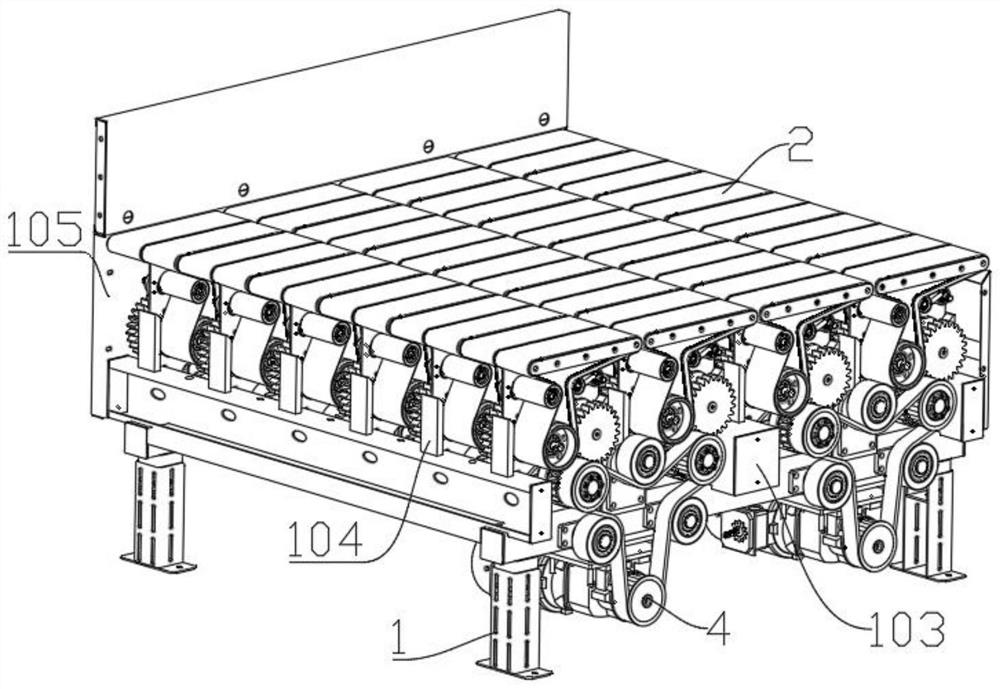

Modular single-piece separation system

PendingCN113979091AMinus the risk of blocking stopsImprove fluencyConveyorsControl devices for conveyorsDrive wheelLogistics management

The invention discloses a modular single-piece separation system which comprises a frame body, a mounting cavity is arranged in the frame body, a plurality of transmission units which are arranged in a matrix form is arranged in the mounting cavity; an electronic clutch is arranged on a driving wheel of each transmission unit, so that each transmission unit operates independently; a transmission part is arranged on the bottom surface of the mounting cavity and is positioned between every two rows of transportation units, so that the driving wheel of each transportation unit is meshed with the transmission part; and a power assembly is fixedly arranged below the mounting cavity, so that the power assembly is matched with the transmission part. The risk that a conveying system is blocked and stopped due to large package throughput in the peak period of the logistics industry is reduced, and the smooth degree of the whole logistics system is improved. The modular design is adopted, the transportation units are integrated in the installation cavities and installed on the frame body in a clamping mode by means of tolerance zone matching and gravity, interchangeability is high, assembly and disassembly are convenient, and maintenance and management are convenient.

Owner:苏州旷特智能科技有限公司

Connection structure and connection system

ActiveCN110985489BFacilitates the transfer of vibration loadsAchieve positioningWashersNutsFlight vehicleStructural engineering

The invention provides a connection structure and a connection system, the connection structure includes a first connection body, which is provided with a connection through hole and a limiting through hole; a second connection body, which is provided with a tapered hole, a tapered hole, a limiting through hole Bit through holes and connecting through holes are distributed sequentially; tapered studs pass through the tapered holes, limiting through holes and connecting through holes, and the tapered studs have a first cylindrical part, a tapered part and a second connected in sequence. Cylindrical part; a conical fitting structure arranged in the limiting through hole, the conical fitting structure is provided with a first conical surface matched with the tapered part, and a limiting cylindrical surface matched with the inner wall of the limiting through hole; The tapered nut screwed on the first cylindrical part, the tapered nut is provided with a second tapered surface matching the tapered hole; the set nut screwed on the second cylindrical part, the set nut and the first connecting body The end surface facing away from the second connecting body abuts. Through the present invention, the technical problem that it is difficult to effectively transmit the vibration load to the aircraft or its sections in the vibration test of the large aircraft is alleviated.

Owner:BEIJING AEROSPACE TECH INST

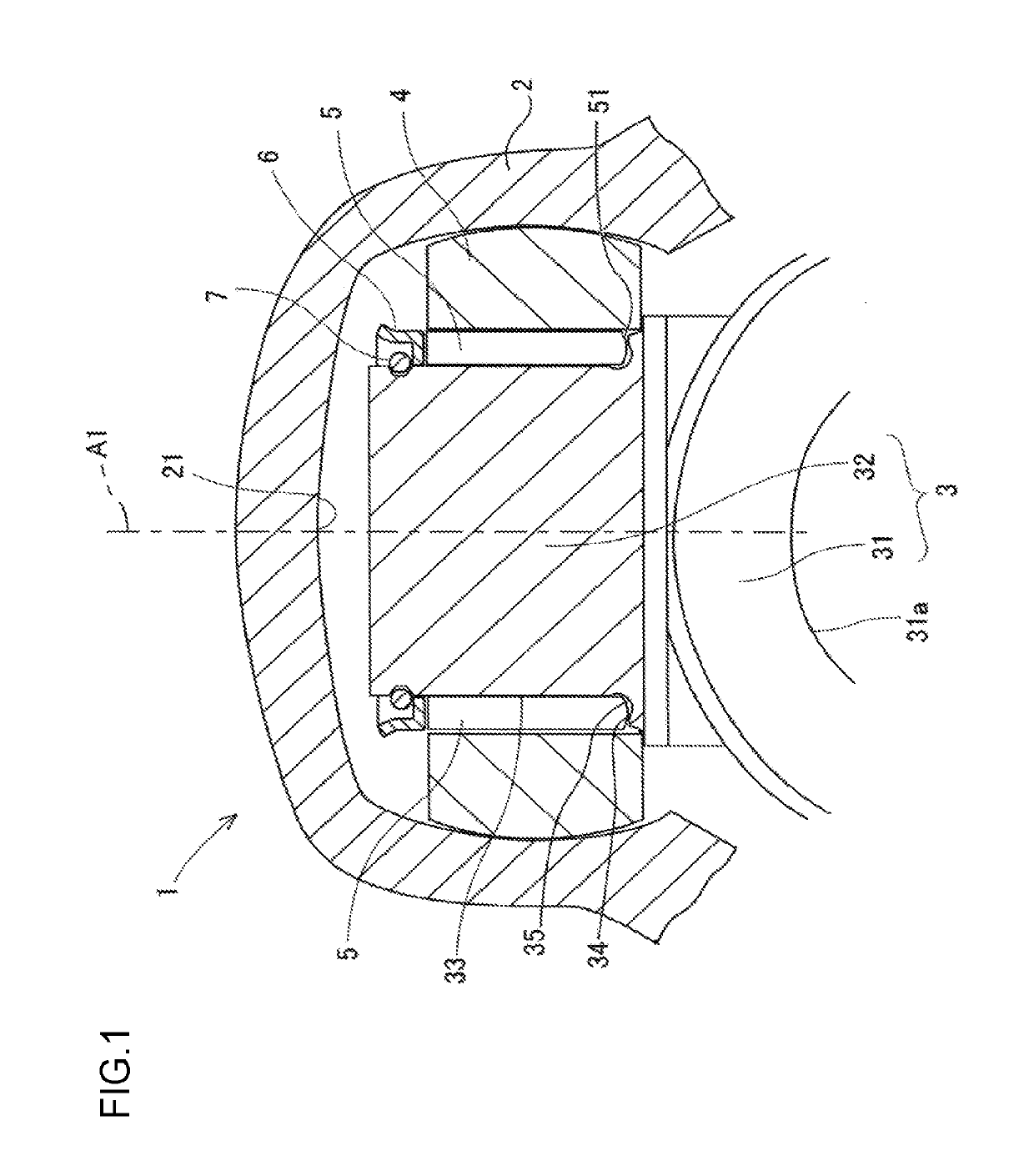

Constant velocity joint

ActiveUS10393186B2Effective transmission torqueReduce deteriorationYielding couplingRolling contact bearingsConstant-velocity joint

A constant velocity joint includes: an outer joint member having a raceway groove; an inner joint member having a leg shaft; a roller that is able to roll on the raceway groove; and a needle bearing that supports an inner periphery of the roller such that the inner periphery of the roller is able to rotate with respect to the leg shaft. The leg shaft includes: a roll portion that supports the needle bearing; a contact portion that is able to contact an end face of the needle bearing, the end face facing a first side in the direction of a central axis of the needle bearing; and a recess portion formed between the roll portion and the contact portion, in a position where the recess portion is recessed from a space in which the needle bearing is disposed.

Owner:JTEKT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com