Magnetorheological reflux type complete disc brake

A magnetorheological and brake technology, applied in the direction of brake type, hydraulic resistance brake, mechanical equipment, etc., to achieve the effect of overcoming failure, wide practical value, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

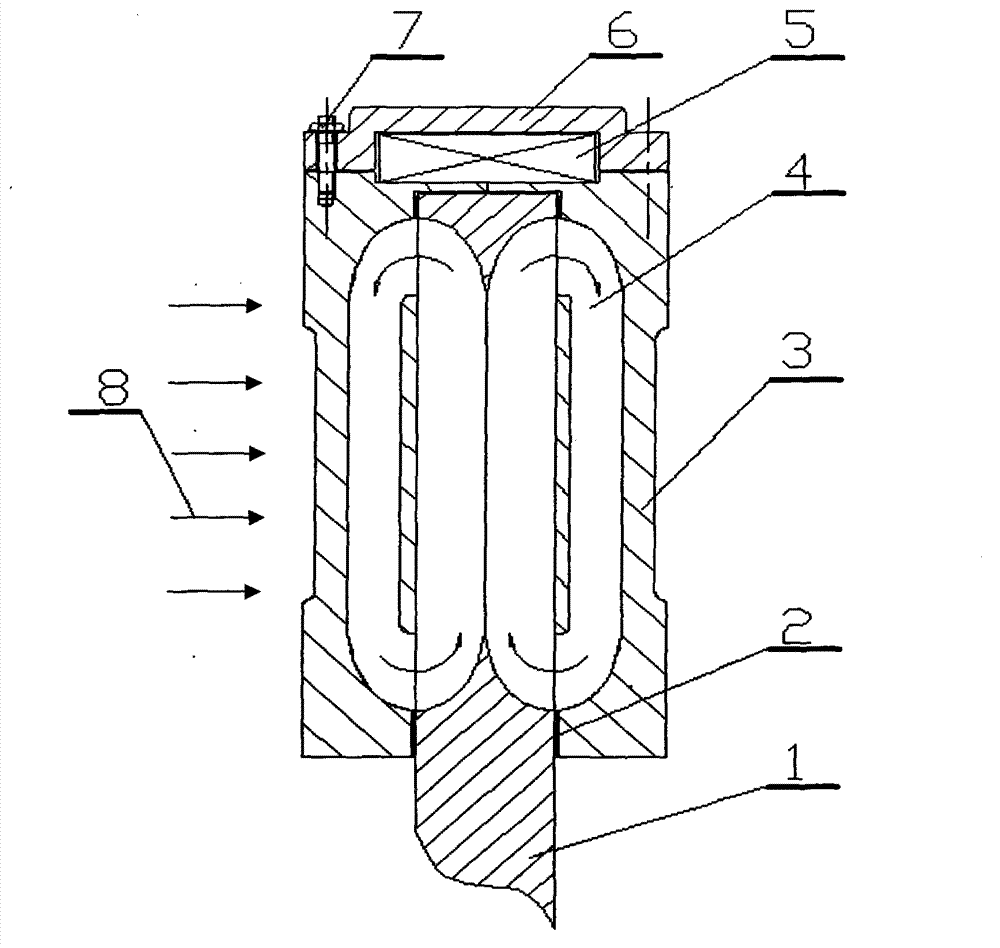

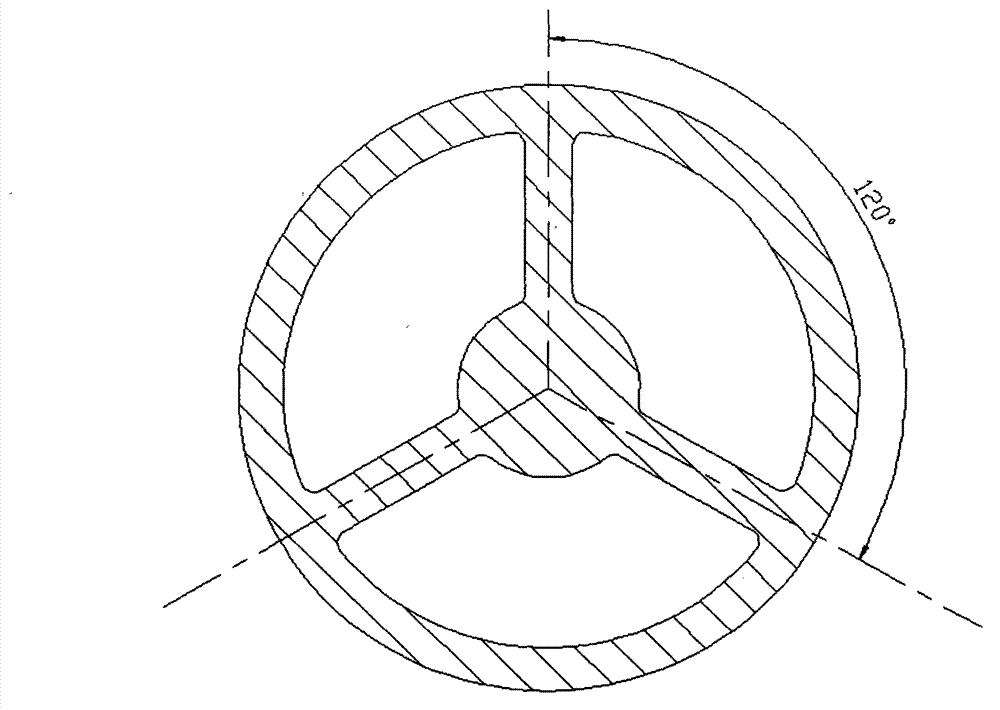

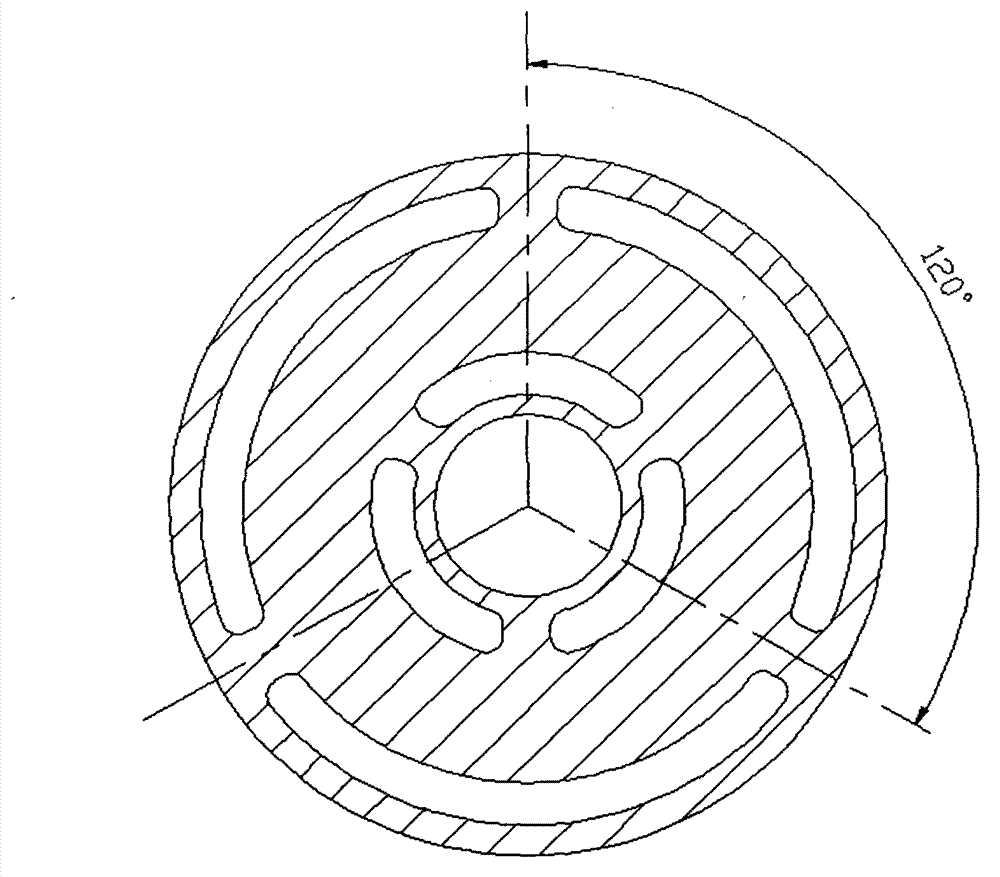

[0012] In the figure, the full-disc reflux magnetorheological brake includes a shear disc 1, a sealing ring 2, a housing 3, a magnetorheological fluid 4, an excitation coil 5, an end cover 6 and a stud 7. A casing 3 is provided around the side of the disk 1, and a sealing ring 2 is provided at the lower part of the casing 3 in contact with the shearing disk 1. The gap between the casing 3 and the shearing disk 1 is filled with a magnetorheological fluid 4. The upper part of 3 is fitted with an end cover 6, and an excitation coil 5 is wound between the end cover 6 and the housing 3, and the end cover 6 and the housing 3 are fixedly connected by studs 7; There are three grooves, each distributed at 120°, the inside of the housing 3 is hollow, and three channel openings are arranged inside and outside the contact surface with the shear disk 1, each distributed at 120°, after the magnetic field lines pass through the center of the excitation coil, they pass through the Through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com