Electromagnetic permanent magnet brake

A technology of electromagnetic brake and permanent magnet, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problems of braking torque limitation, impossible installation space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

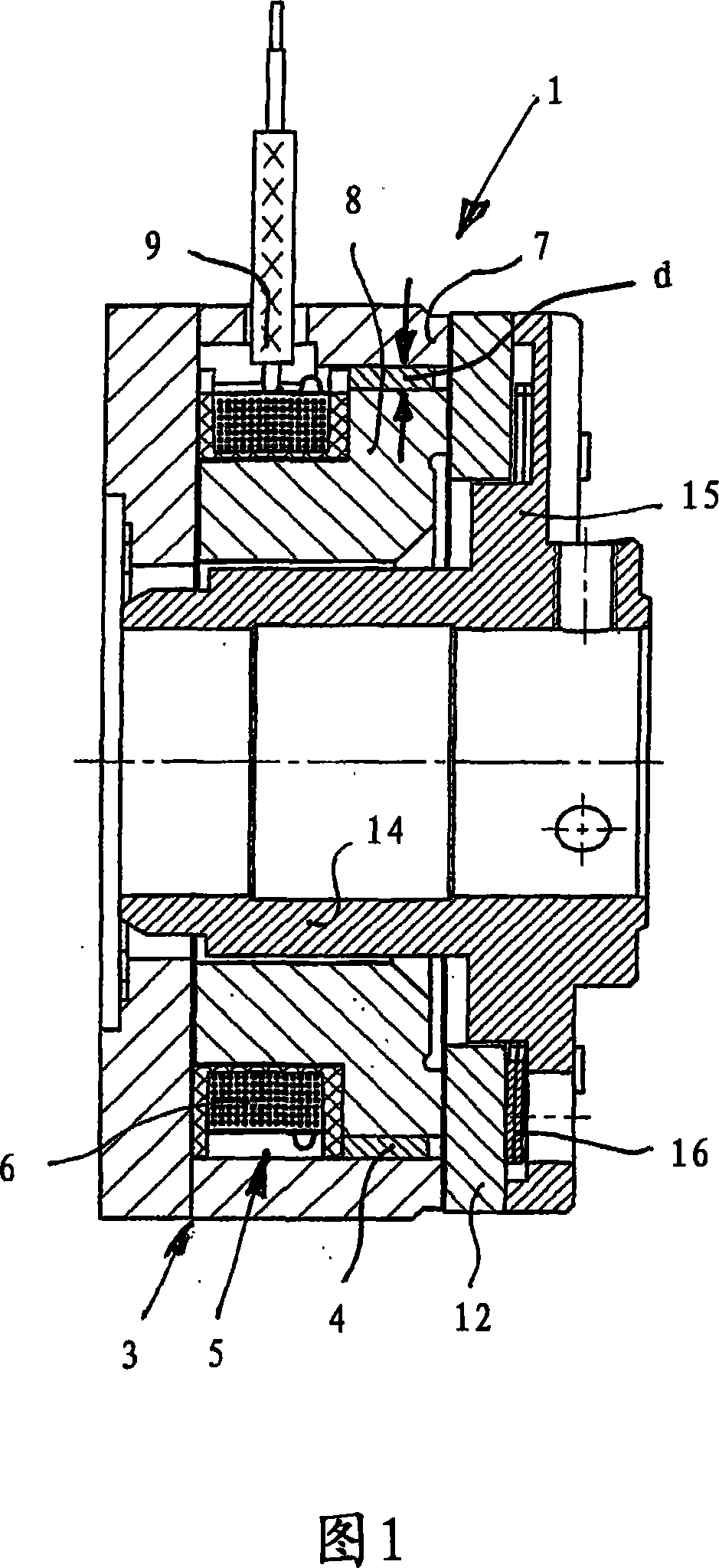

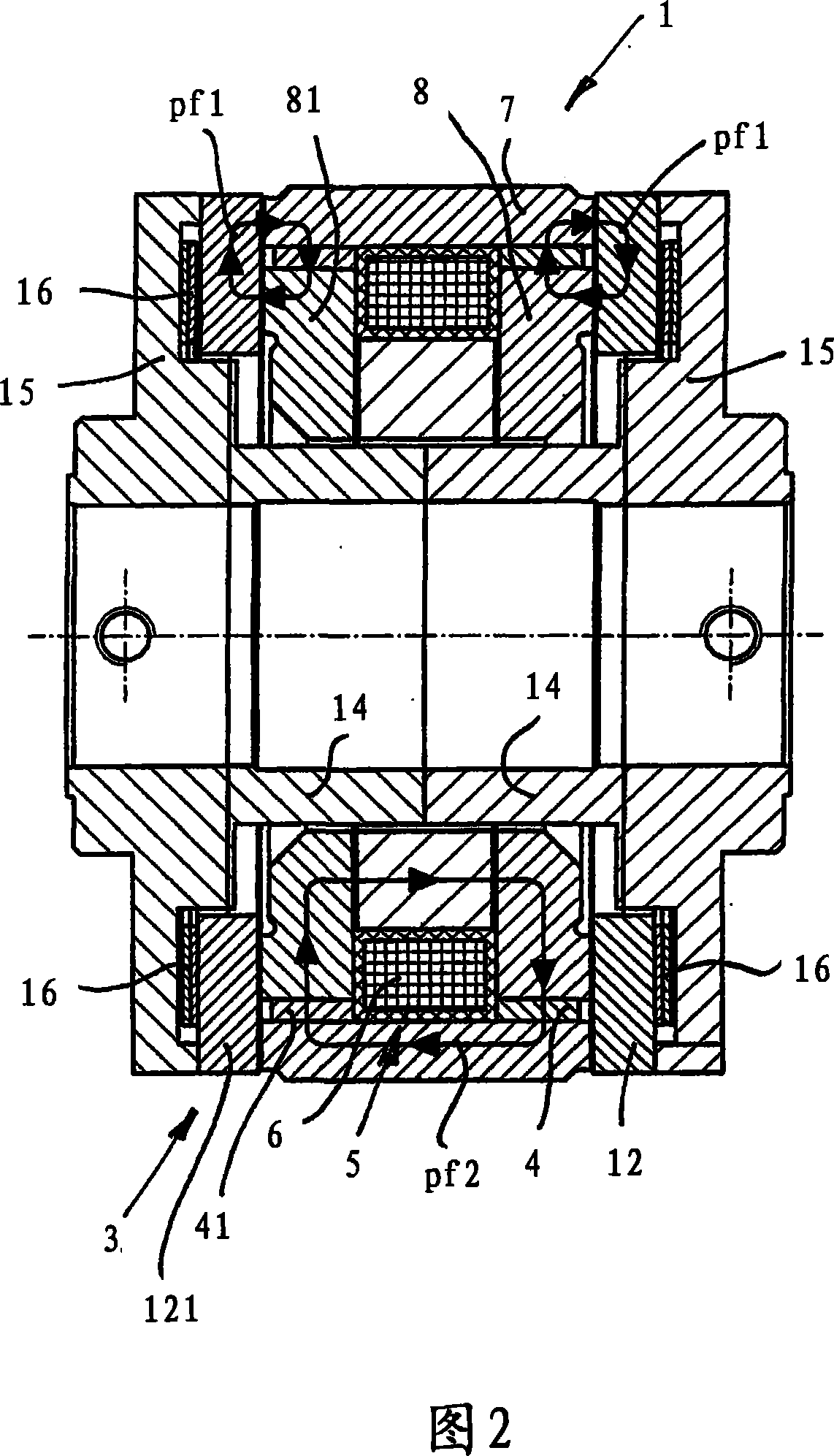

[0032] In the following description of the two exemplary embodiments, parts that are identical in terms of their function are provided with identical reference symbols even if their design and structure differ slightly.

[0033] An electromagnetic brake generally indicated by 1 is considered for an electric drive not shown in detail and has a brake body 3 comprising a permanent magnet 4, at least one electromagnet 5 with an electromagnetic excitation coil 6, a An outer pole of the outer ring 7 and an inner pole of the inner ring 8. The litz wires or plugs 9 connected to the field coil 6 can be seen here from above in FIG. 1 .

[0034] In the position of use, the brake body 3 is connected in a rotationally fixed manner to the frame or housing of the electric drive, for example via a bearing cover in a known manner.

[0035] According to FIG. 1, the electromagnetic brake 1 comprises an armature disc 12, which is connected in a rotationally fixed manner to the rotatable shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com