Hydrodynamic retarder

A hydraulic retarder and oil technology, applied in the direction of hydraulic resistance brakes, brake types, mechanical equipment, etc., can solve the casting and processing difficulties of oblique straight blades, the low working efficiency of hydraulic retarders, and the waste products generated by demoulding. It can increase the braking effect, take up less space and have a solid structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with accompanying drawing:

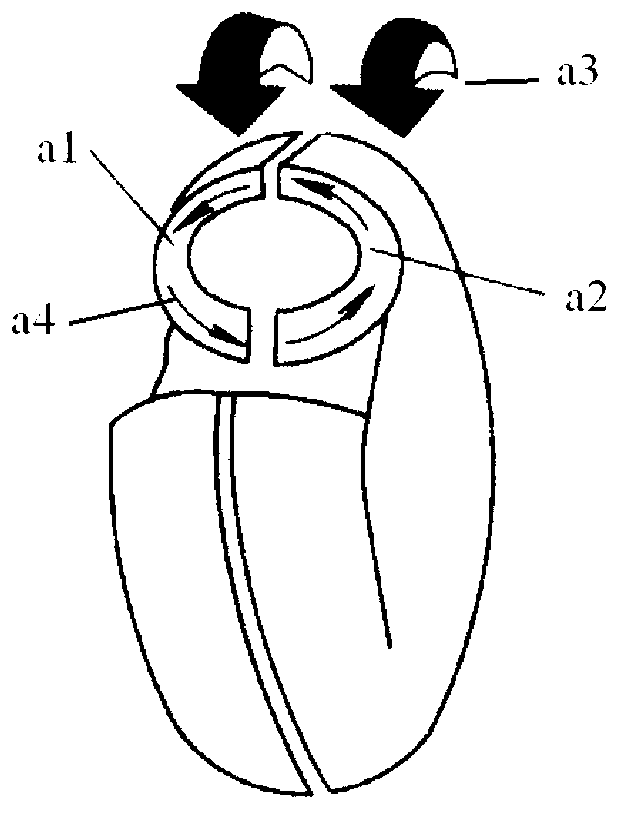

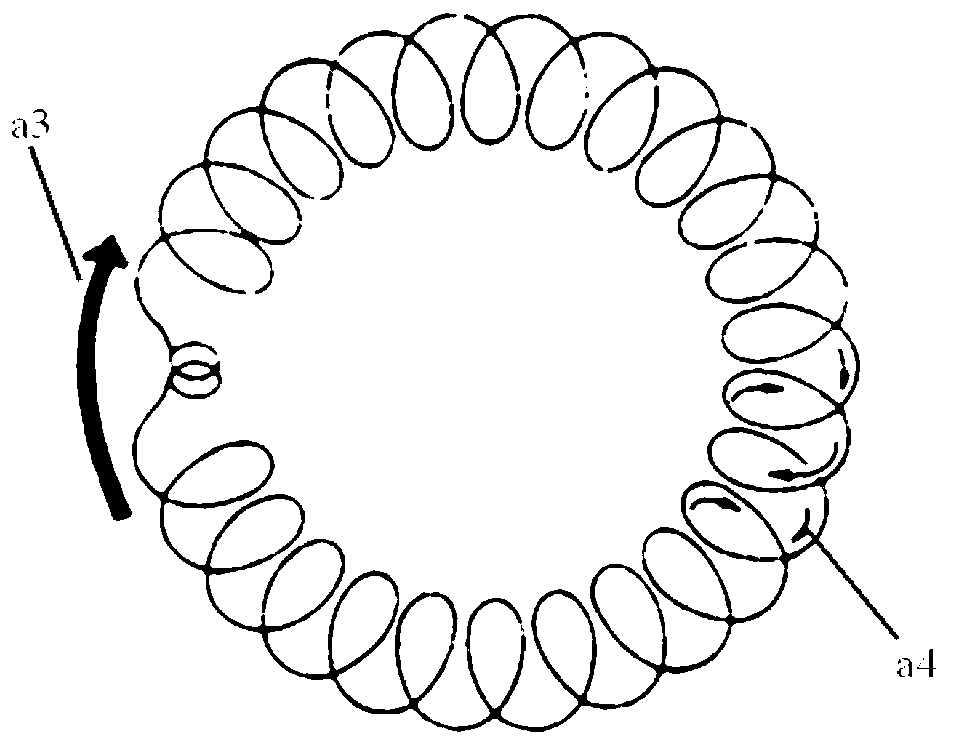

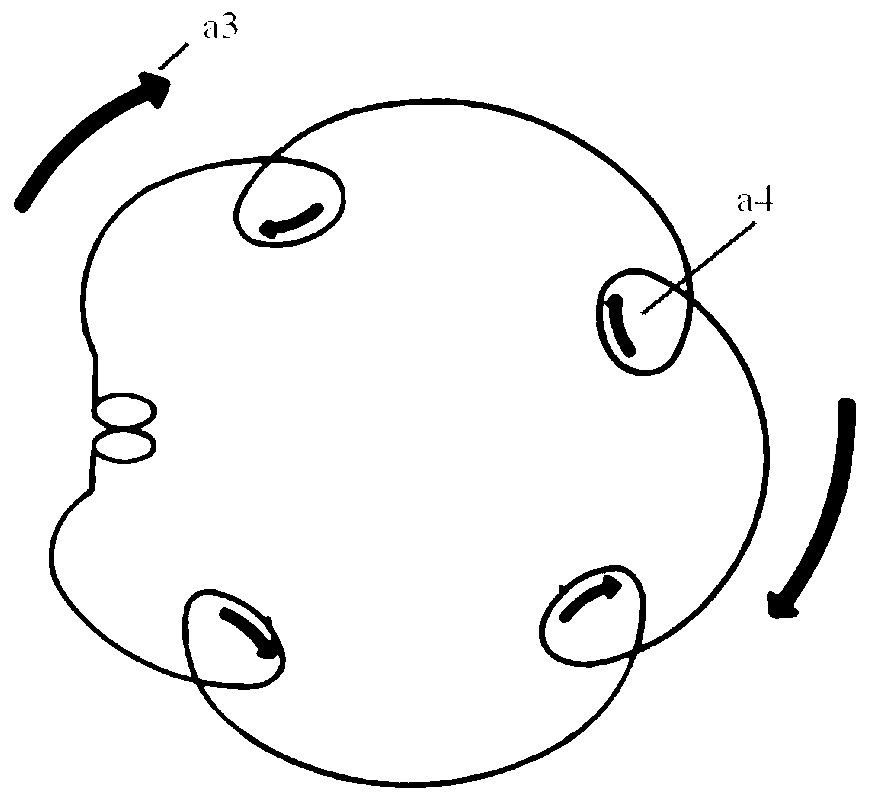

[0051] Such as Figure 5 and Figure 6As shown, the present invention discloses a hydraulic retarder, which includes a runner and a fixed wheel. The blades of the runner and the fixed wheel are arranged along the radial direction of the runner and the fixed wheel, and the two sides of the straight blades are inclined to collect oil. The U-shaped blades of the runner and the fixed wheel are set opposite to each other. The thickness of the front end of the blade is small and the middle thickness is large, and the front end is provided with a draft angle 4. The blades are divided into upper surface 2, front surface 1 and rear surface 3. The surface that impacts on the front of the liquid flow is the front surface 1, the surface opposite to the front surface 1 is the rear surface 3, and the upper part of the blade is the upper surface 2; the upper surface 2 of the blade is an arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com