Floating tong type bipushing rod pneumatic disk brake based on rectangular torsional spring single dicrection clutch

A disc brake and torsion spring technology, which is applied to the axial direction of the brake, brake type, brake components, etc., can solve the problem of poor synchronization of double push rod compensation, and the automatic compensation mechanism of brake friction plate wear and clearance is unstable and has poor reliability. and other problems, to achieve the effect of improved transmission efficiency, efficient and accurate double push rod movement synchronization, and stable braking torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with accompanying drawing and embodiment describe in detail:

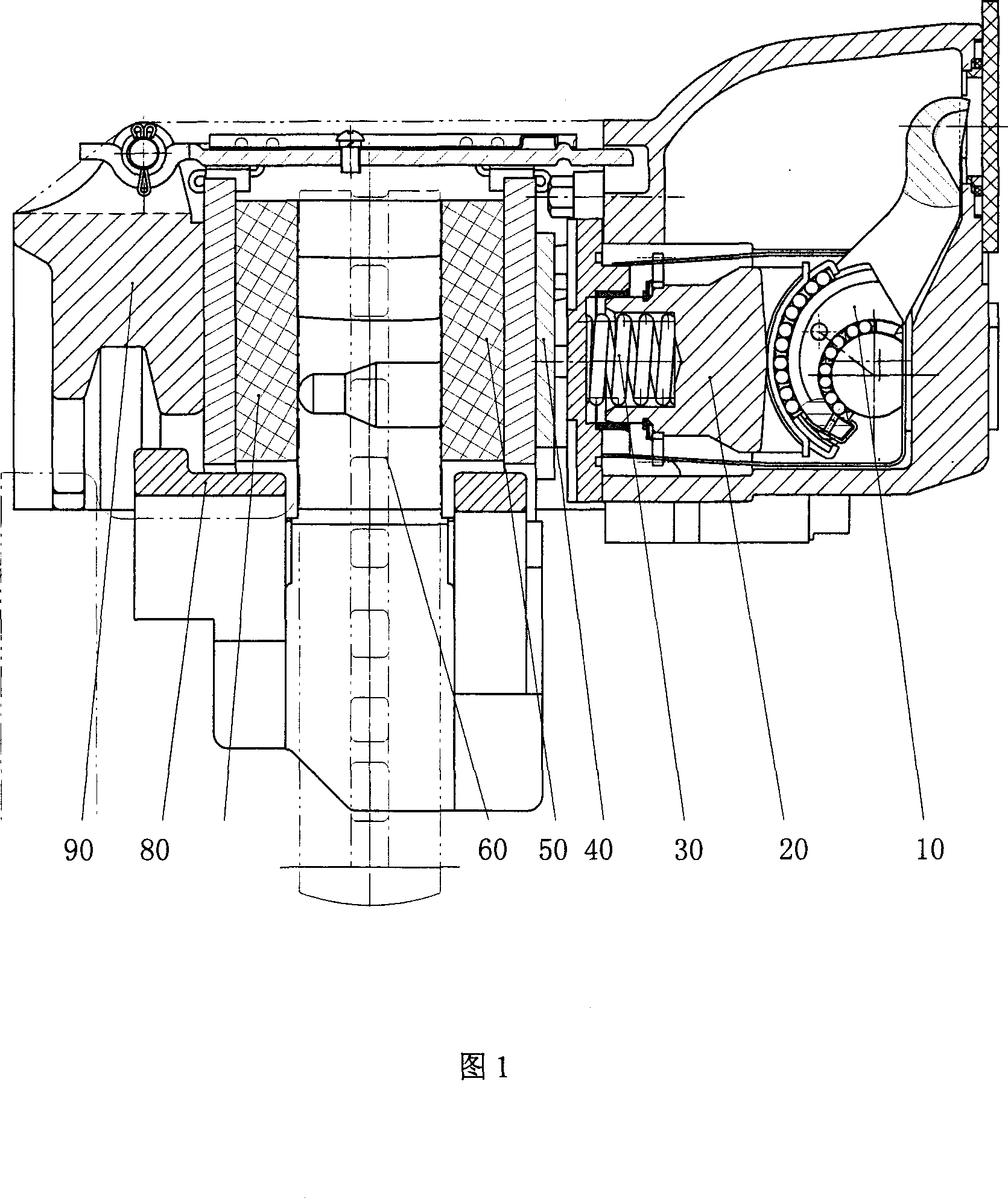

[0064] 1. Pressure arm assembly 10

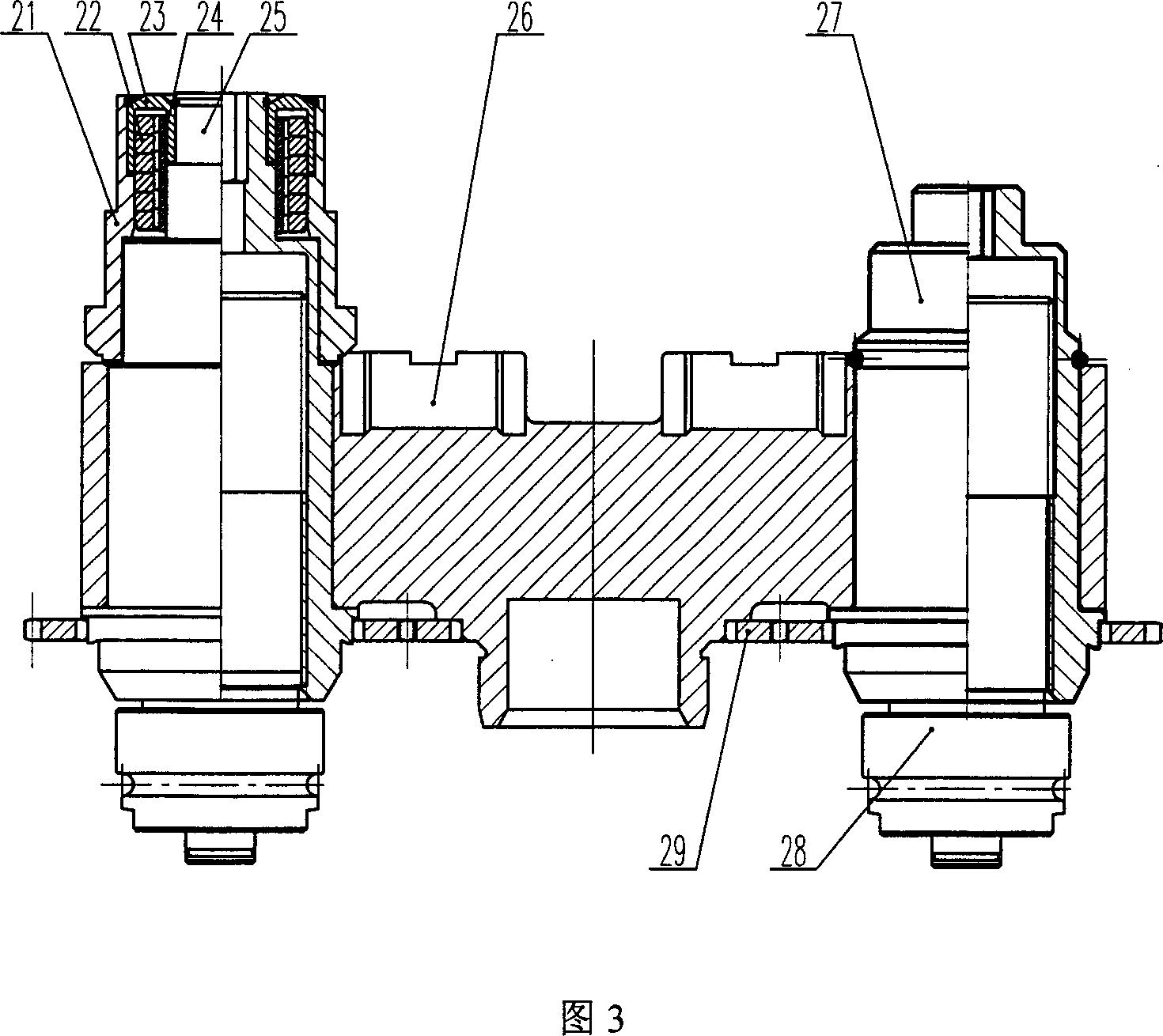

[0065] As mentioned above, the pressure arm assembly 10 includes a pressure arm 11, a fulcrum cylinder 12, a small needle roller pair 13, a large needle roller pair 14, and a shift fork 15, as shown in Figure 2;

[0066] The pressure arm 11 is a force-increasing lever, and constitutes a cam mechanism with the fulcrum cylinder 12, as shown in FIG. 4 .

[0067] The fulcrum cylinder 12 is a cylinder cut off in one piece longitudinally, and its function is to provide a fulcrum for rotation, as shown in Figure 5 .

[0068] The small needle roller pair 13 is a semicircular cylindrical needle roller pair, and its function is to reduce the friction between the rotating pairs, as shown in Figure 2.

[0069] The large needle roller pair 14 is a semicircular cylindrical needle roller pair whose function is to reduce the friction between the rotating pairs, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com