Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

456results about "Brushes manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

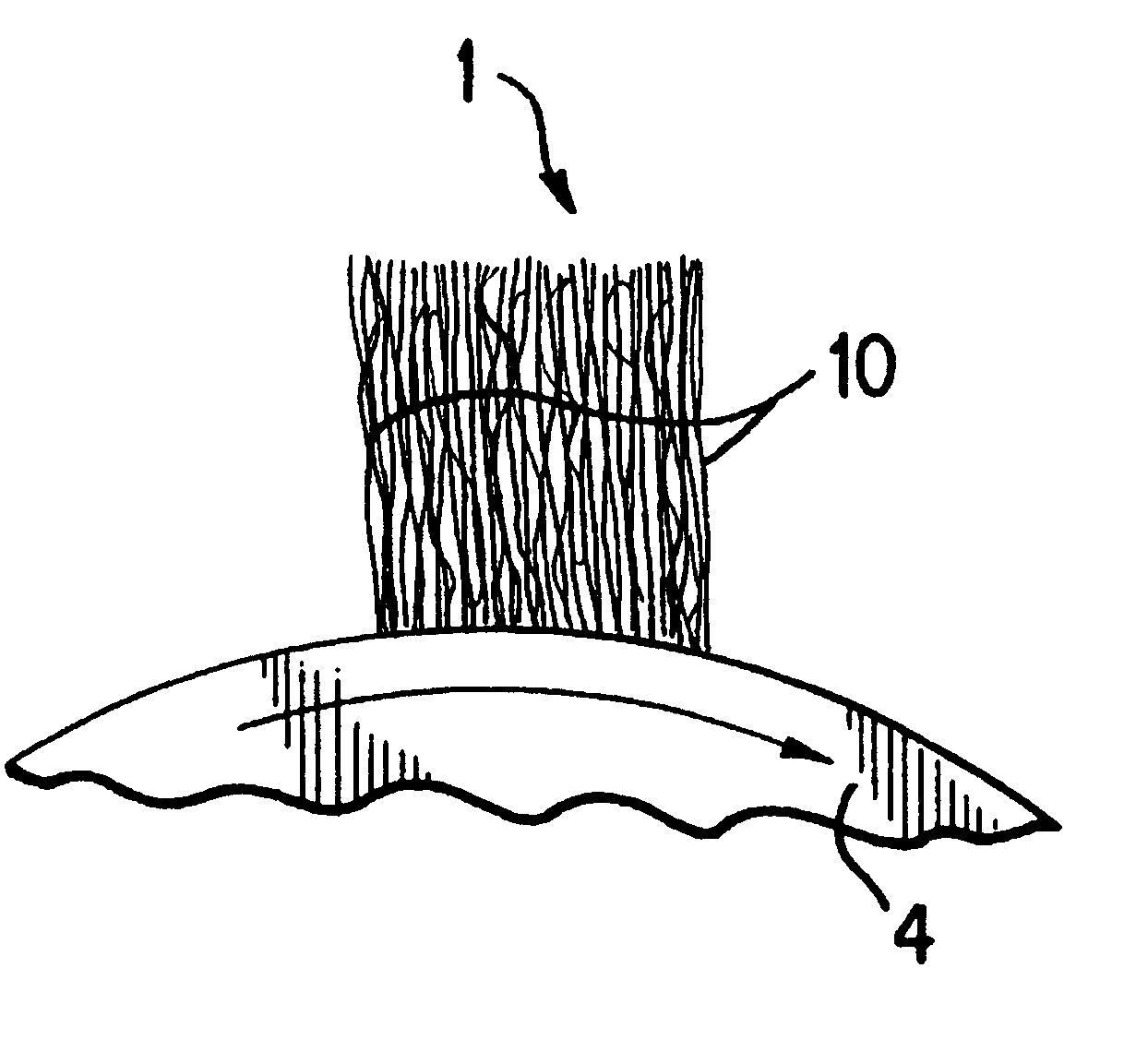

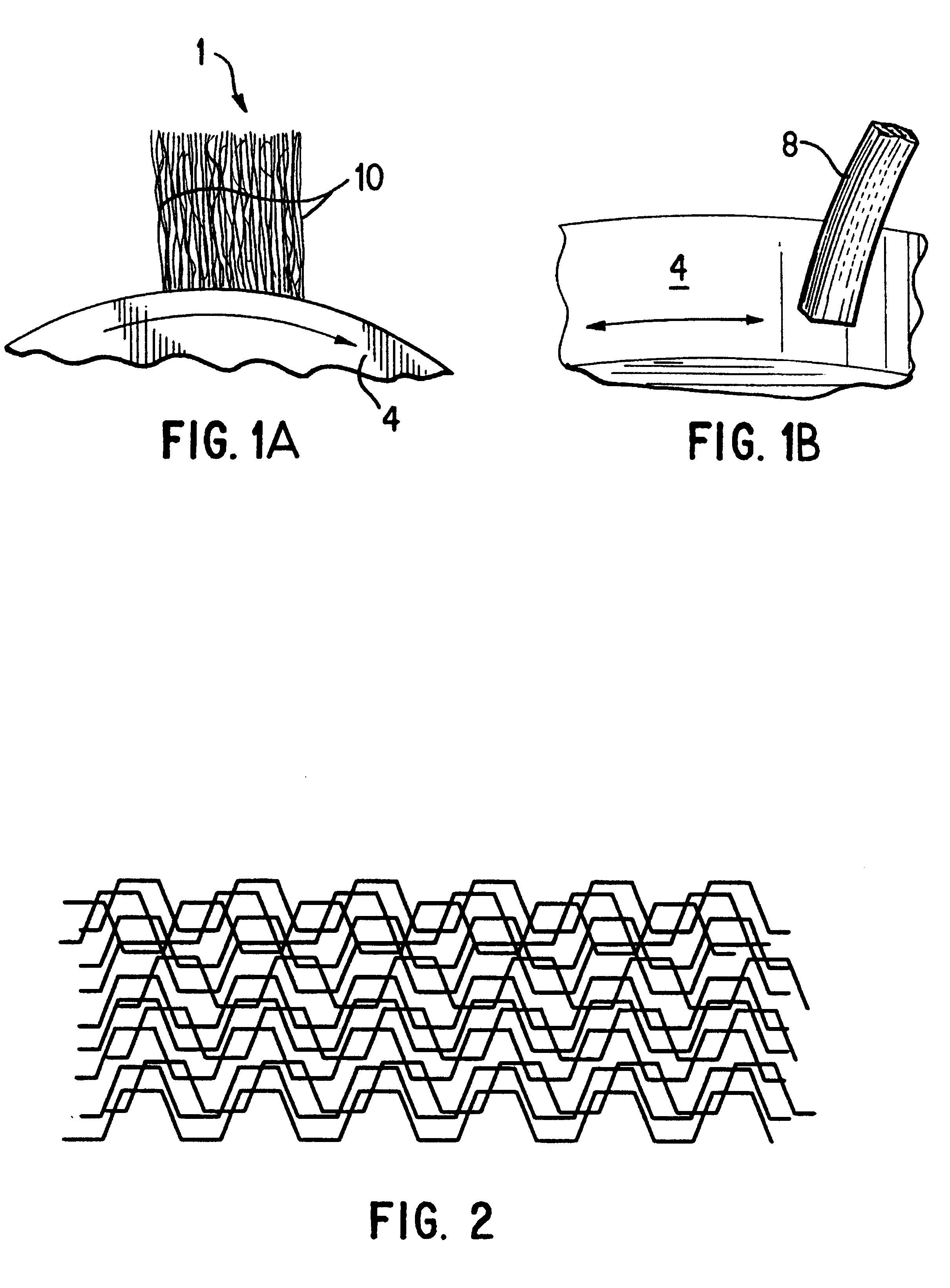

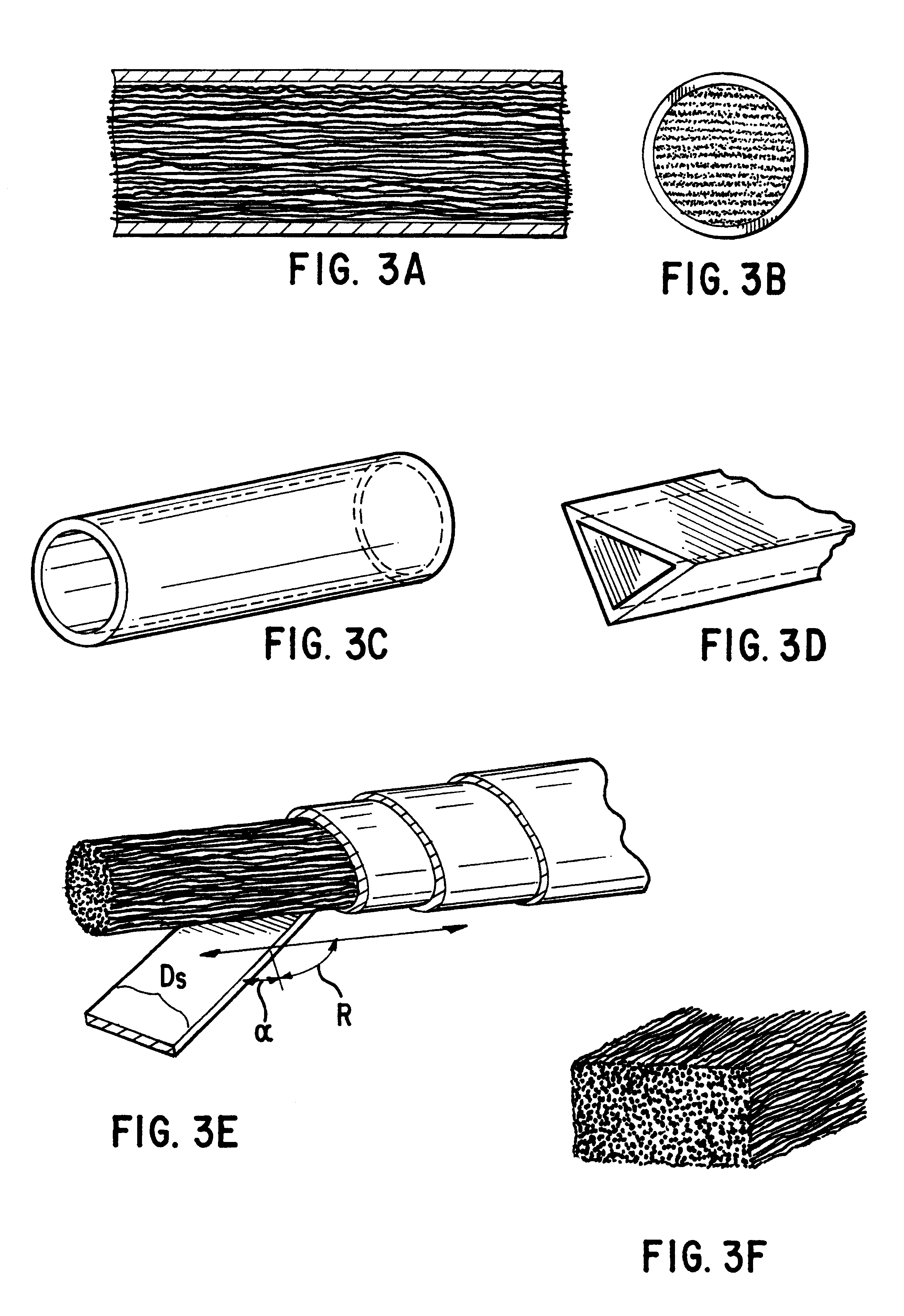

Continuous metal fiber brushes

InactiveUS6245440B1Avoid large gapsSuppressing advanceRotary current collectorMagnetic materialsMetal fiberLubrication

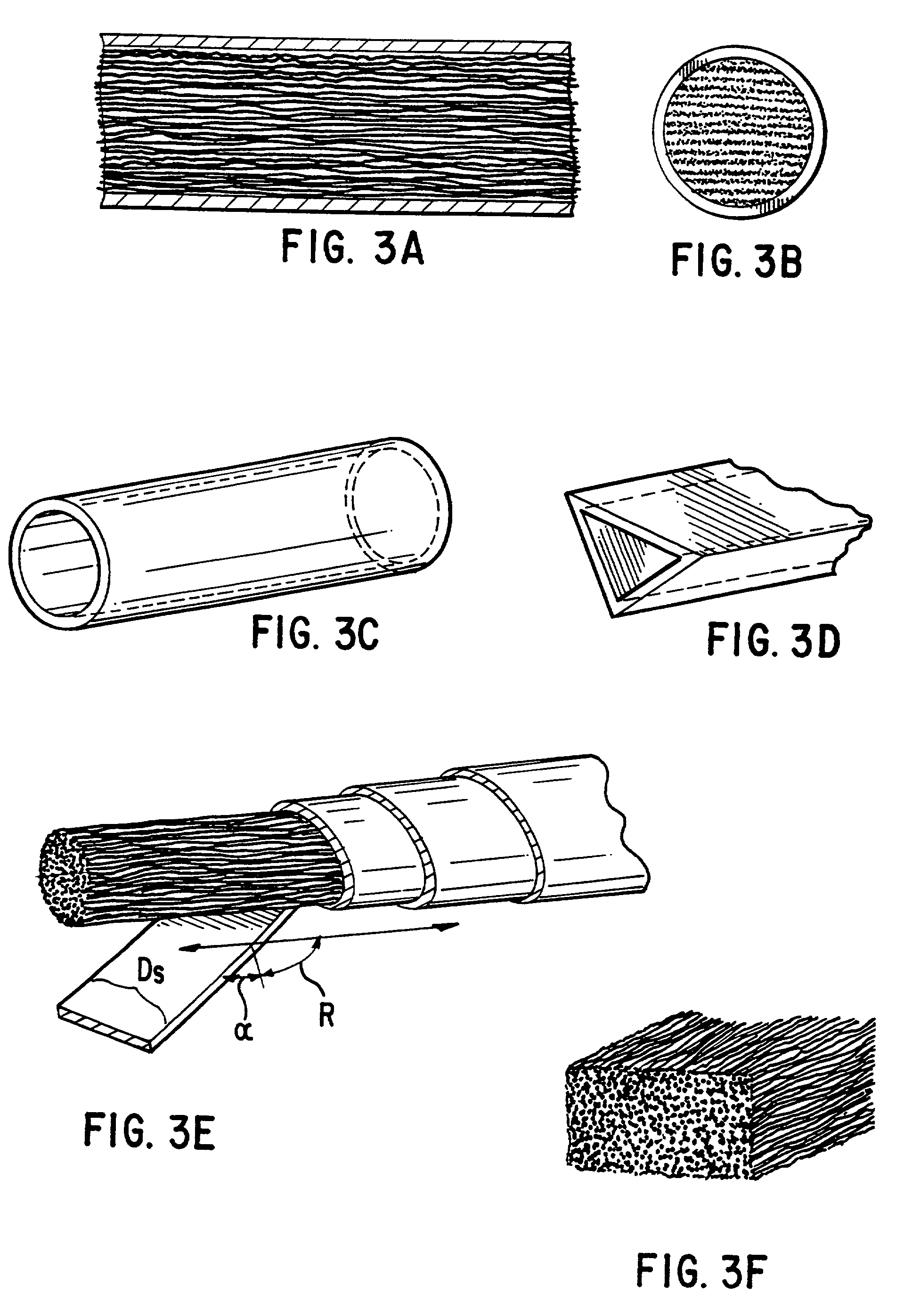

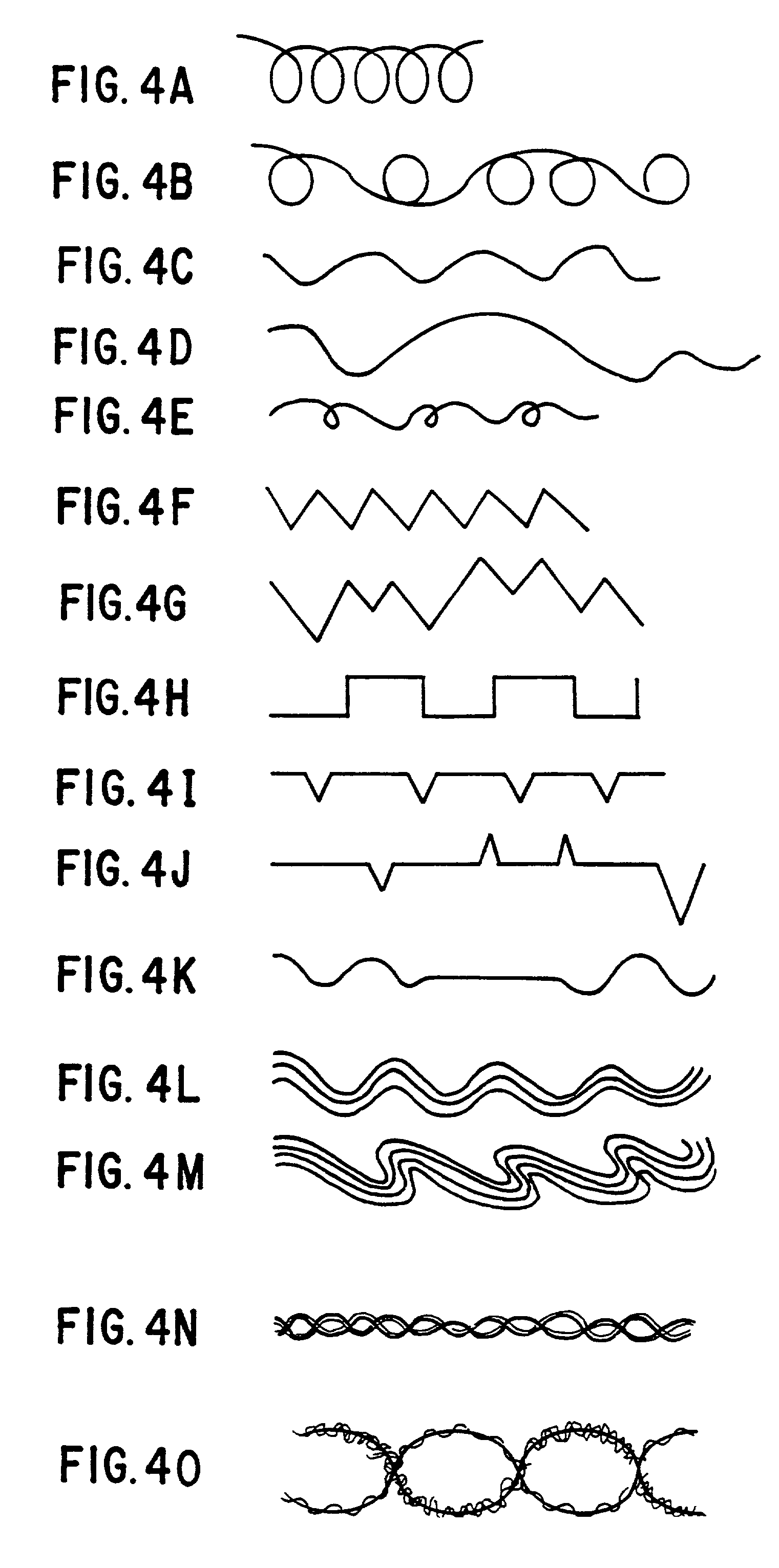

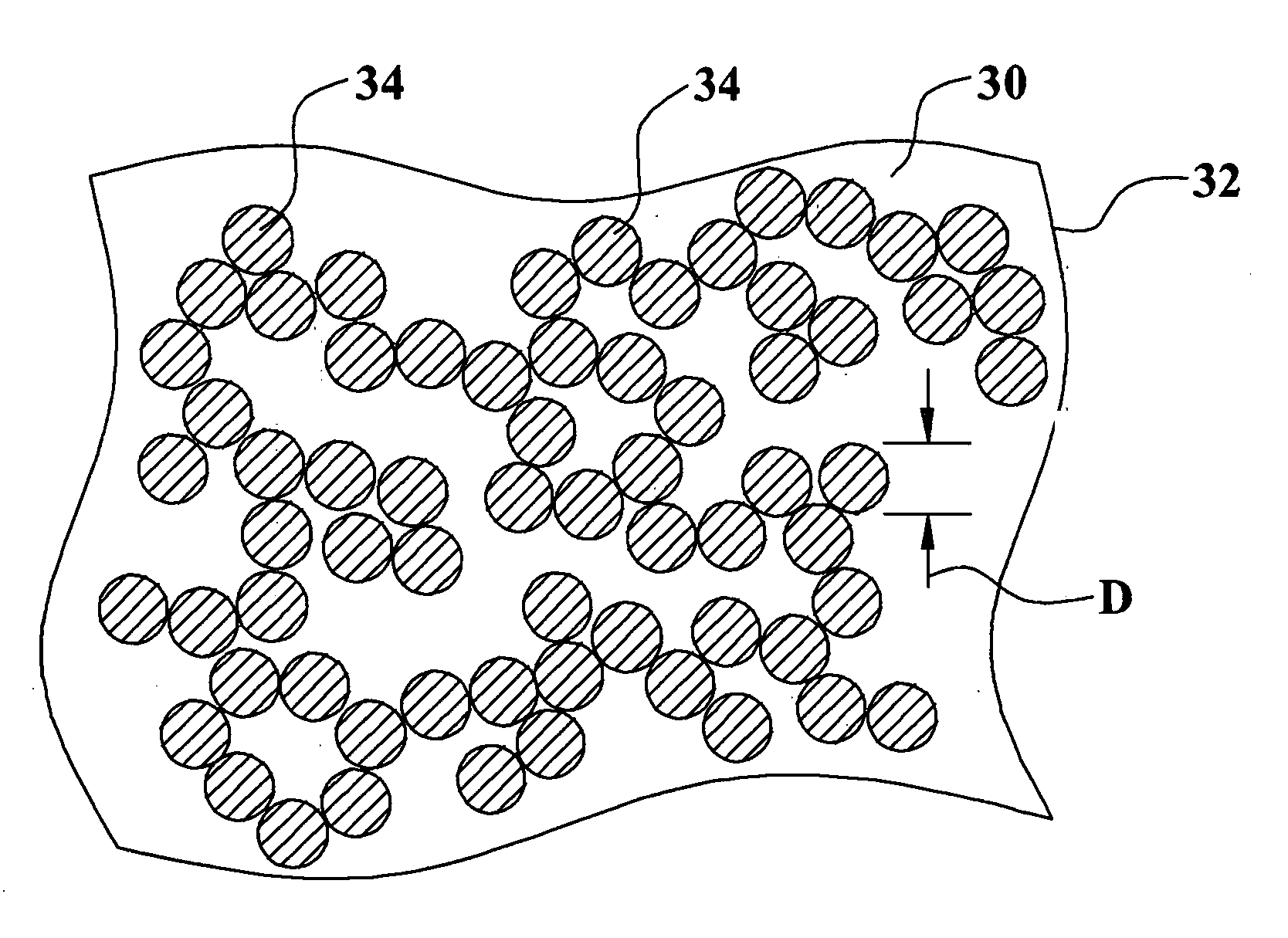

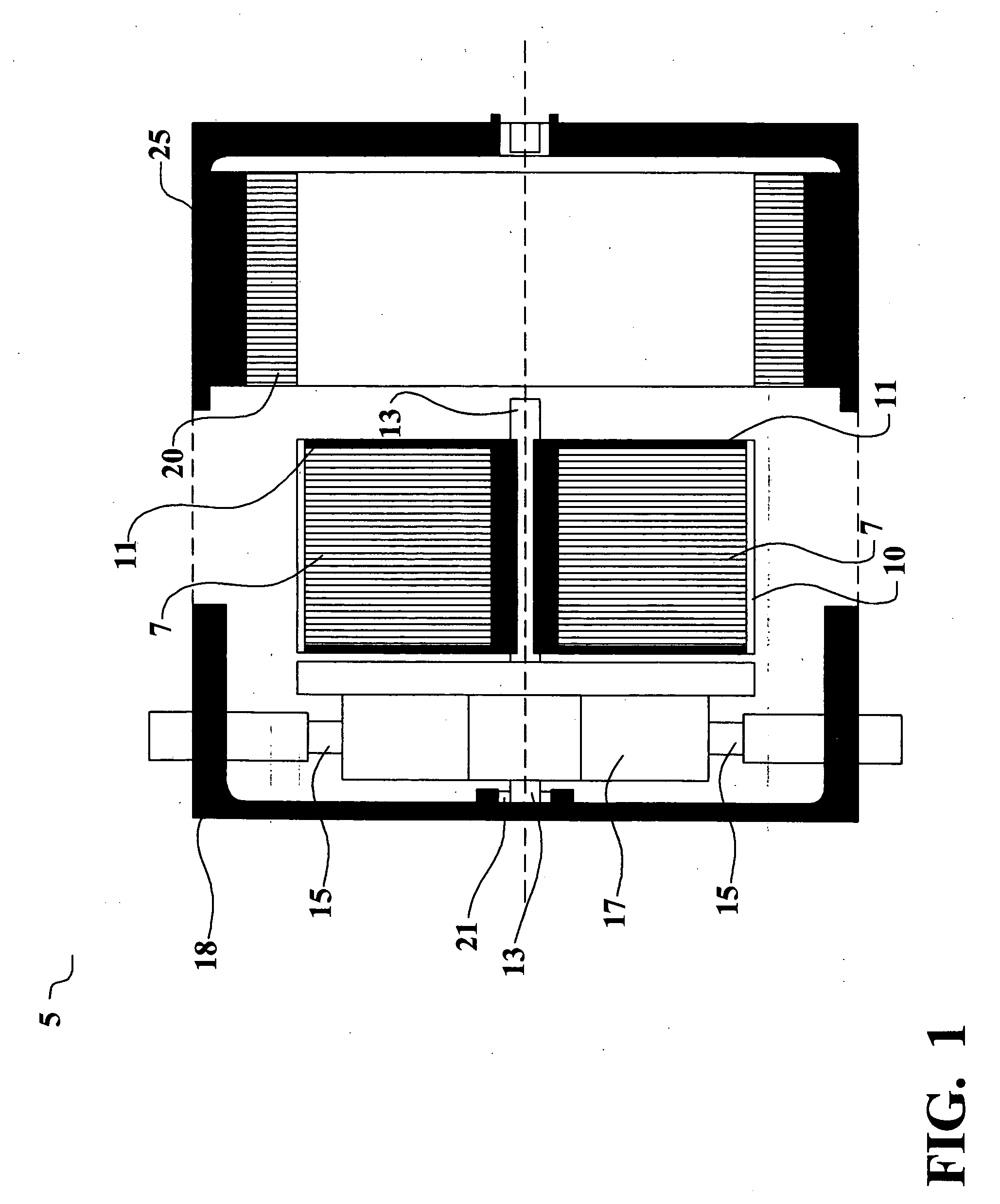

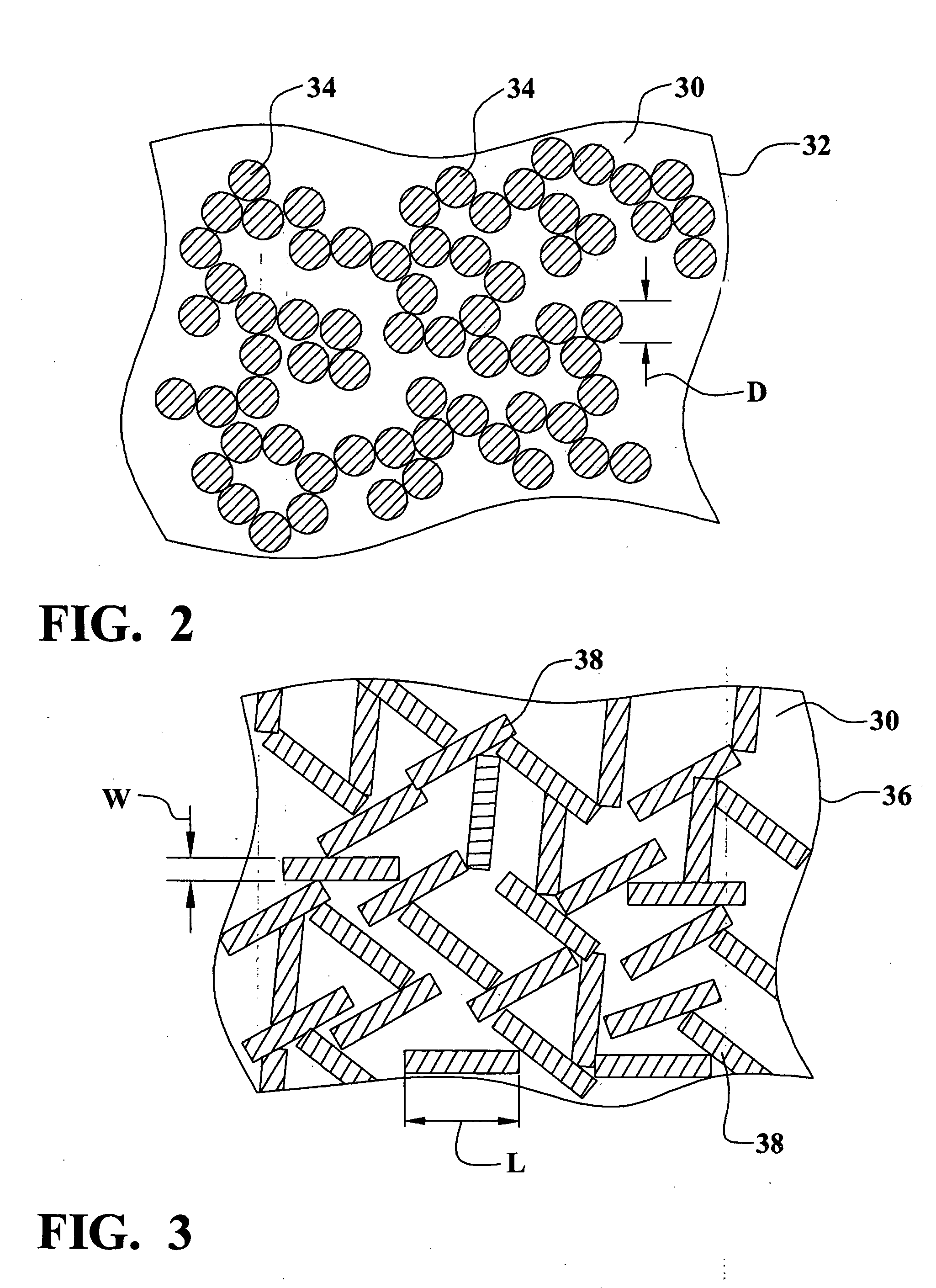

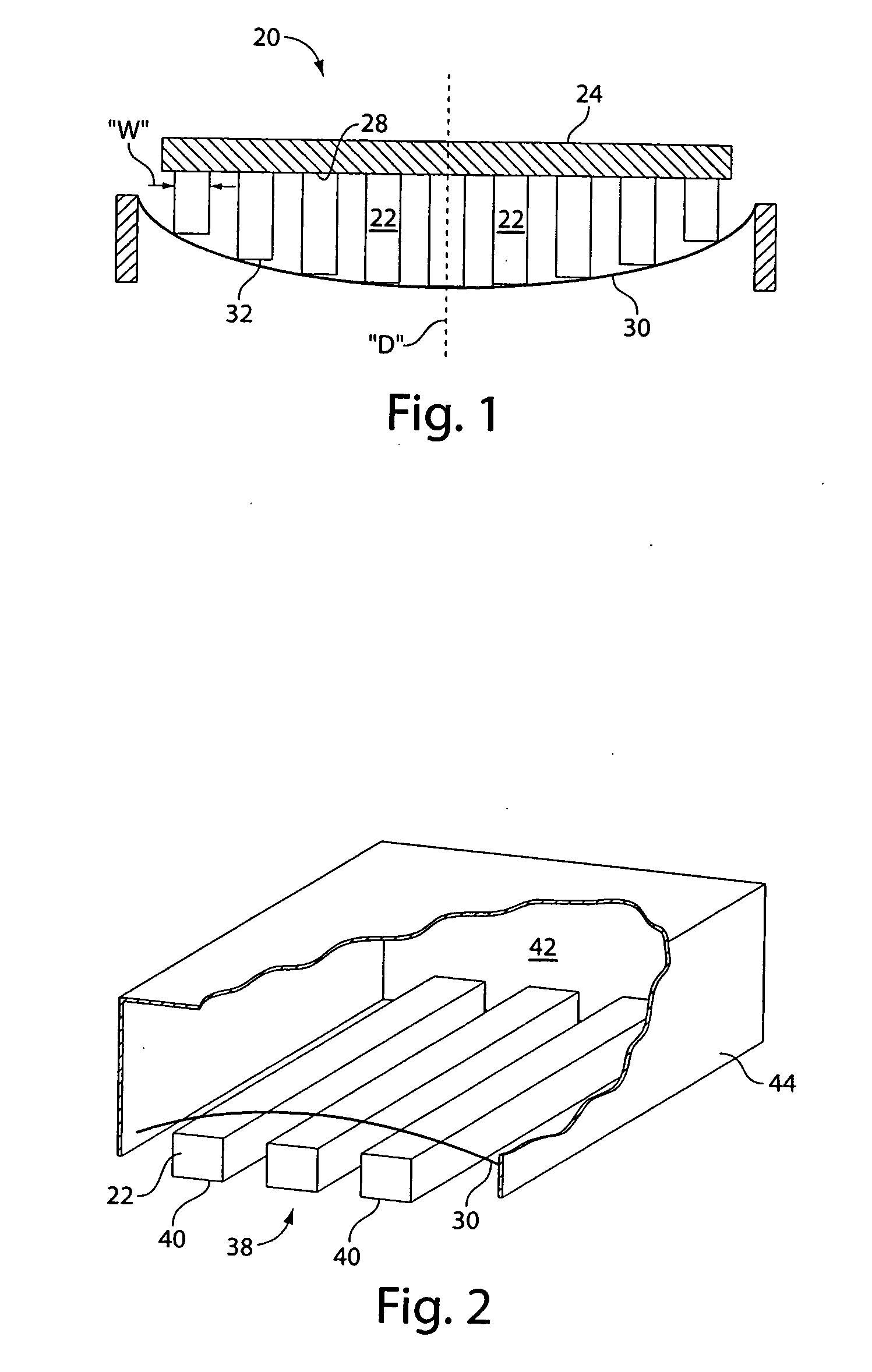

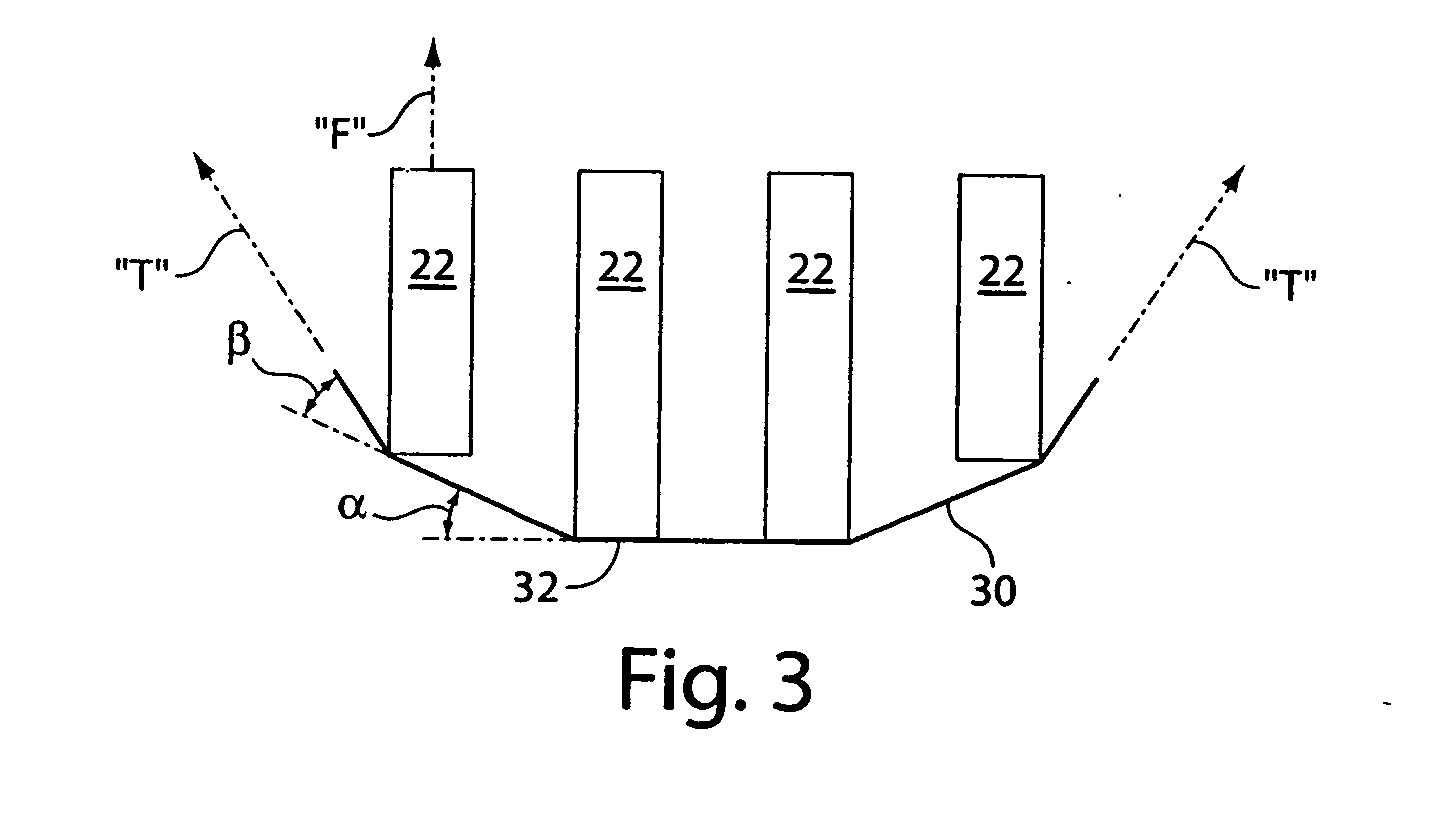

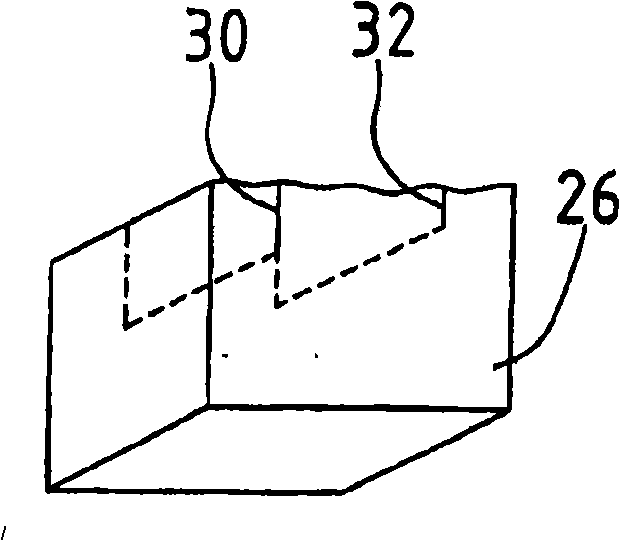

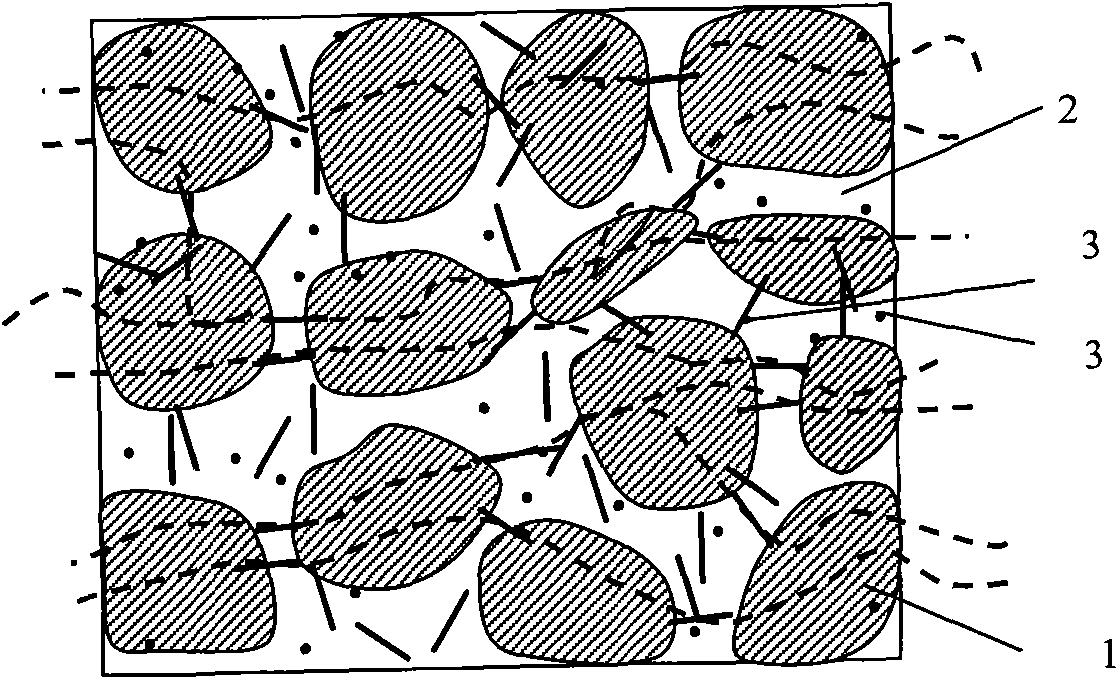

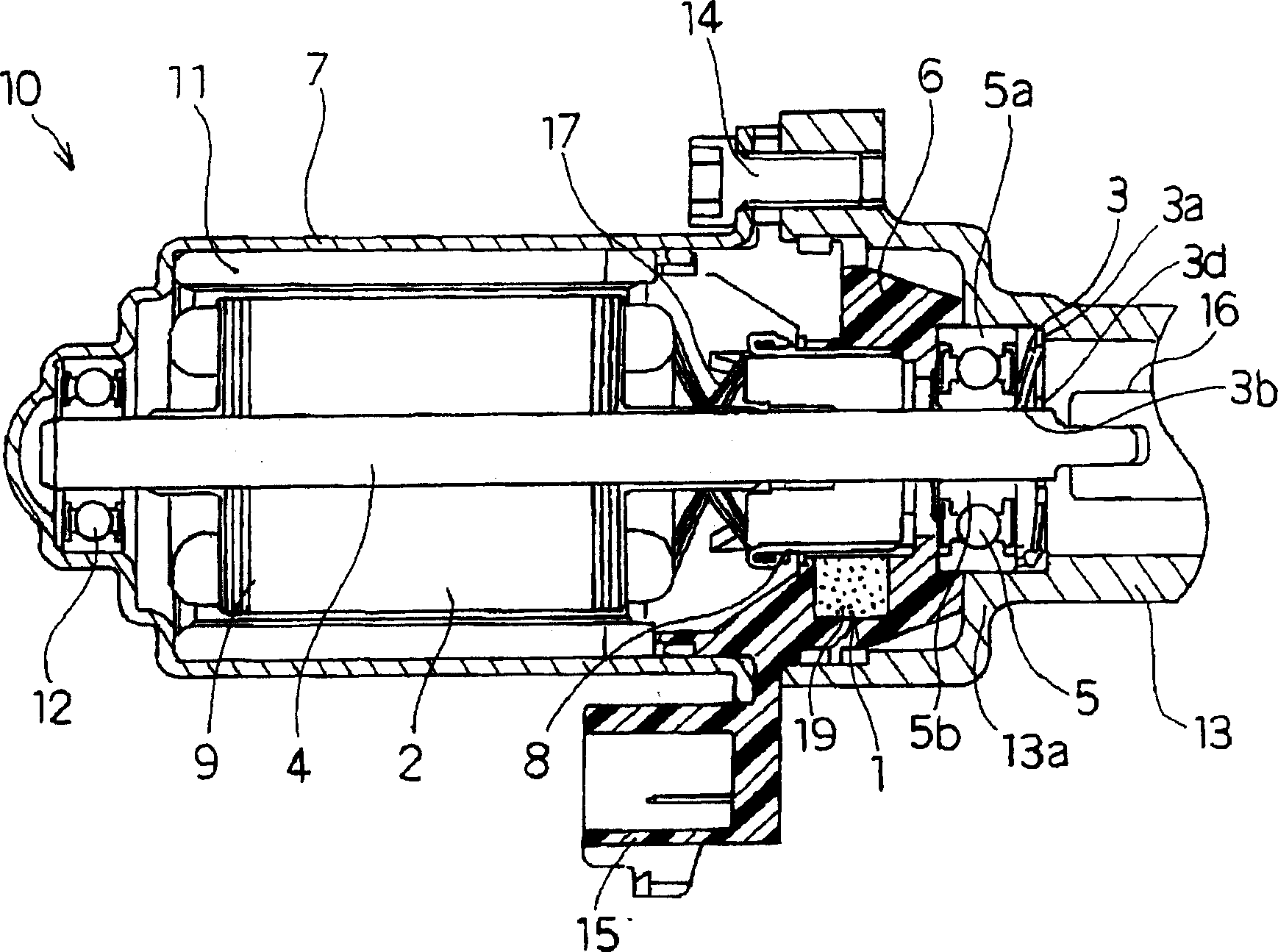

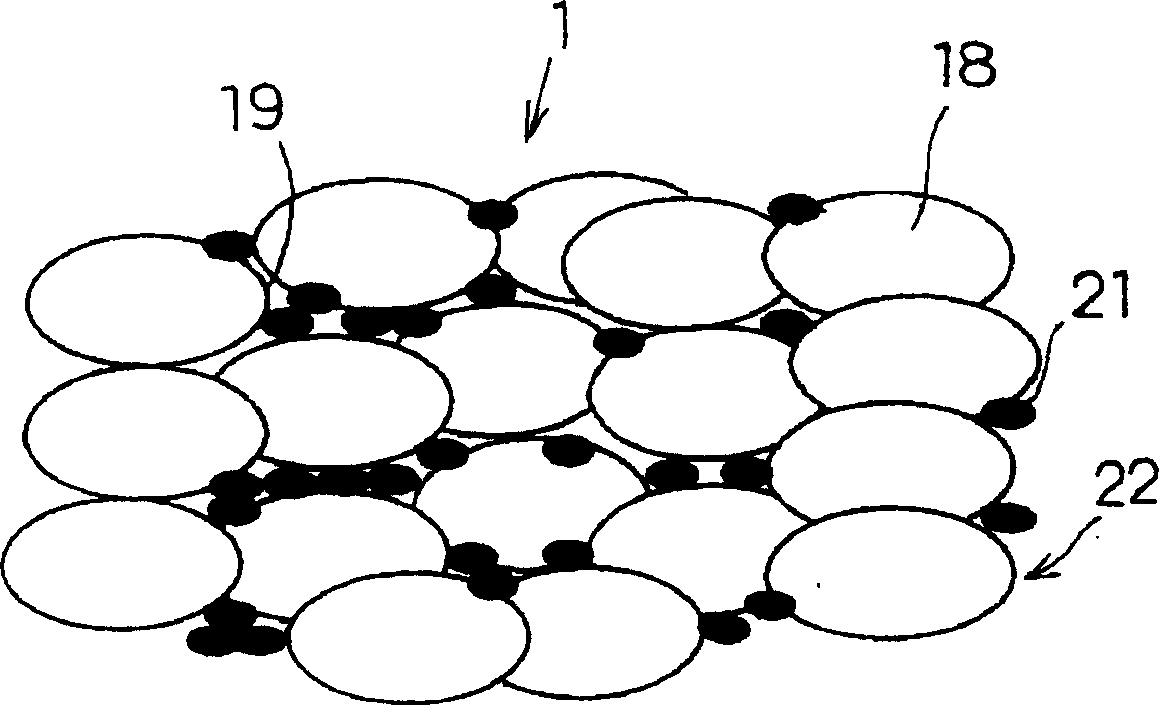

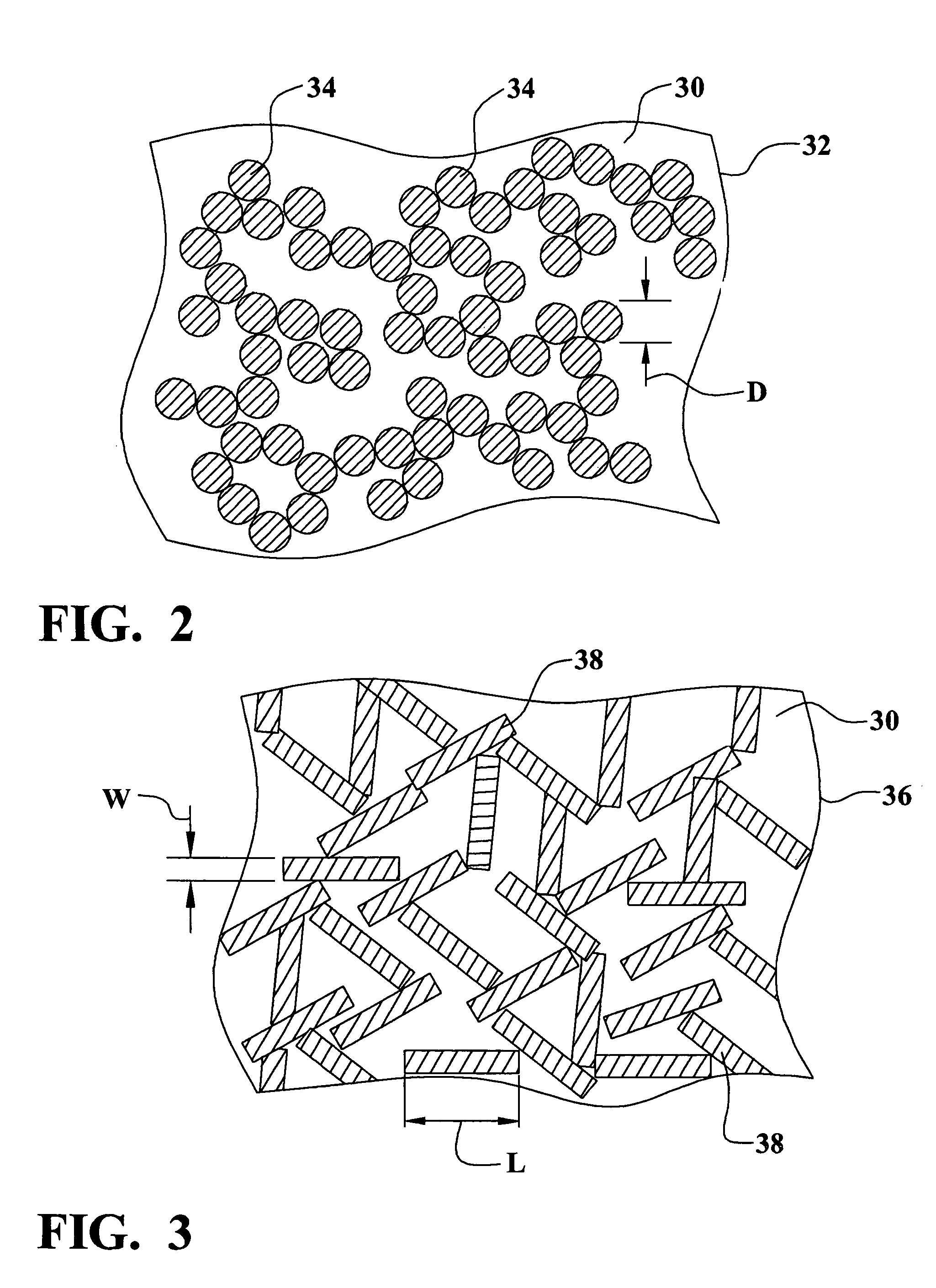

A conductive fiber brush including a brush stock composed of plural conductive fibers or strands of fibers at least some of which may have plural bends along the leg of the fibers or strands. The fibers may have a diameter less than 0.2 mm and are arranged in contacting engagement with each other with the touching points among the fibers or strands maintaining elastic tension between the fibers or strands and thereby maintaining voids between the fibers or strands to produce a packing fraction between 1 and 50% and in extreme cases up to 70% but generally between 10-20% depending on the various factors, including the materials used, the current densities to be conducted, and the sliding speeds under operation. The plural bends are implemented by producing fibers or strands having a regular or irregular spiral, wavy, saw-tooth, triangular, and / or rectangular pattern, or other undulating pattern. Optionally, the voids in brush stock may be partially filled with a strengthening, lubricating, abrasive, and / or polishing material, and may be wrapped in an outer sheath, slid into a casing, or provided with an other covering of all or part of the area of the brush stock, be infiltrated or sprayed at the surface with some material, have an increased packing fraction at the surface and / or have some or all of the touching points between the fibers or strands soldered, welded or otherwise thermally joined. Optionally also, the friction among the fibers may be reduced through light lubrication applied by rinsing the brush or brush stock in a lubricant. In one embodiment, the fiber brush is employed in a brush loading device having a hydrostatically controlled brush holder wherein the force exerted on the brush is controlled by a metallic or other conductive hydrostatic fluid which at the same time conducts the current to the brush.

Owner:VIRGINIA UNIV PATENT FOUND OF

Contact woven connectors

A contact connector is provided that has at least one loading fiber and a plurality of conductors. Each conductor may have at least one contact point. Each conductor may contact a single loading fiber, and each loading fiber may be capable of delivering a contact force at each contact point. In one example, the connector may be a power connector having a power circuit and a return circuit. In another example, the connector may be a data connector having at least one signal path.

Owner:METHODE ELETRONICS INC

Continuous metal fiber brushes

InactiveUS20010024735A1Improve the immunityMore rigidRotary current collectorMagnetic materialsMetal fiberLubrication

A conductive fiber brush including a brush stock composed of plural conductive fibers or strands of fibers at least some of which may have plural bends along the length of the fibers or strands. The fibers may have a diameter less than 0.2 mm and are arranged in contacting engagement with each other with the touching points among the fibers or strands maintaining elastic tension between the fibers or strands and thereby maintaining voids between the fibers or strands to produce a packing fraction between 1 and 50% and in extreme cases up to 70% but generally between 10-20% depending on the various factors, including the materials used, the current densities to be conducted, and the sliding speeds under operation. The plural bends are implemented by producing fibers or strands having a regular or irregular spiral, wavy, saw-tooth, triangular, and / or rectangular pattern, or other undulating pattern. Optionally, the voids in brush stock may be partially filled with a strengthening, lubricating, abrasive, and / or polishing material, and may be wrapped in an outer sheath, slid into a casing, or provided with an other covering of all or part of the area of the brush stock, be infiltrated or sprayed at the surface with some material, have an increased packing fraction at the surface and / or have some or all of the touching points between the fibers or strands soldered, welded or otherwise thermally joined. Optionally also, the friction among the fibers may be reduced through light lubrication applied by rinsing the brush or brush stock in a lubricant. In one embodiment, the fiber brush is employed in a brush loading device having a hydrostatically controlled brush holder wherein the force exerted on the brush is controlled by a metallic or other conductive hydrostatic fluid which at the same time conducts the current to the brush.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Ultra-abrasion resistant multifunctional nano carbon brush and preparation method thereof

ActiveCN101656385ANo difference in conductivityNo difference in lubricityRotary current collectorBrushes manufactureNano siliconLow noise

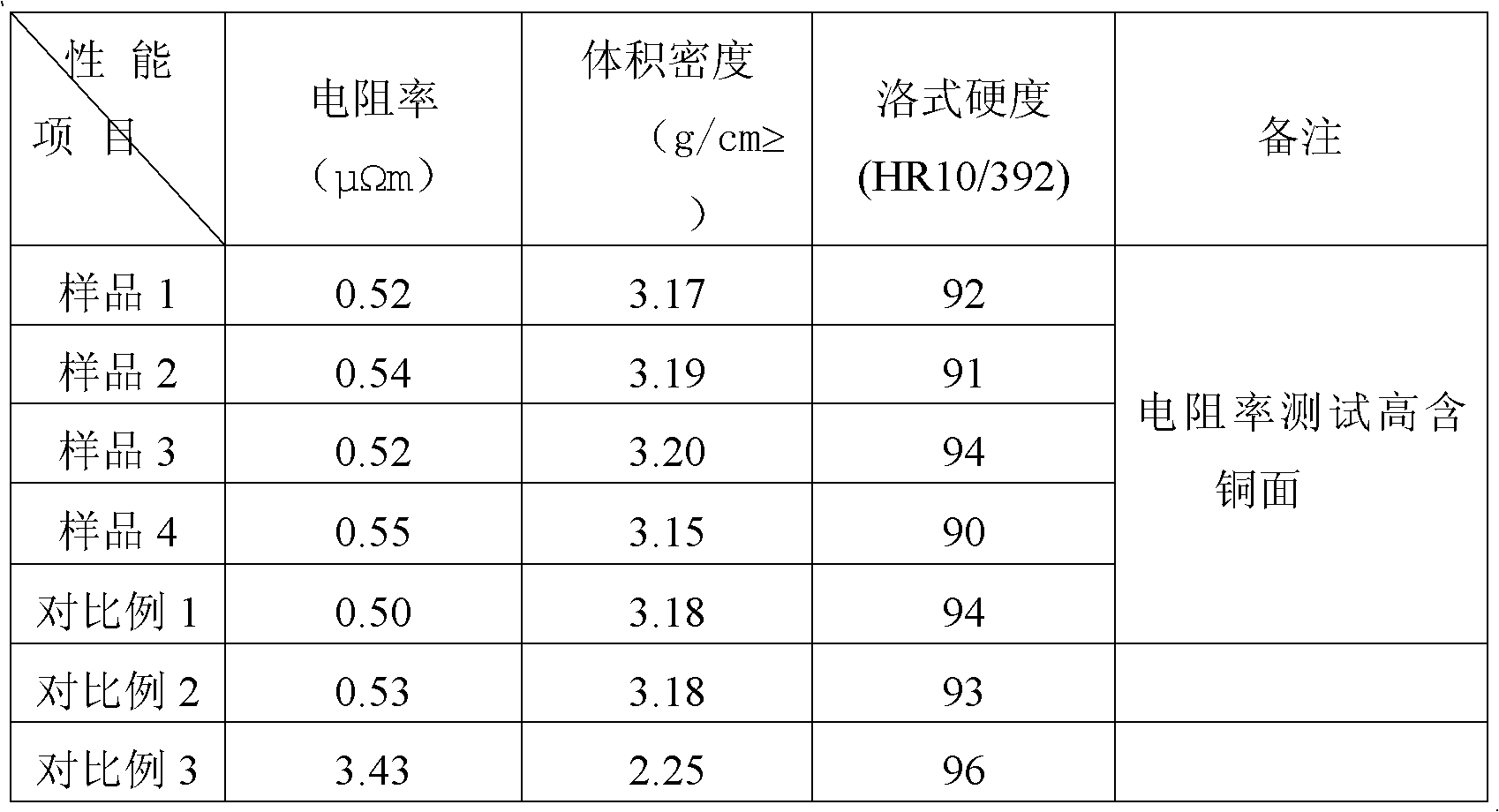

The invention relates to an ultra-abrasion resistant multifunctional nano carbon brush which comprises the following components in parts by weight: 40-60 parts of copper powder and 60-40 parts of cementing graphite powder. The cementing graphite powder comprises the following components in parts by weight: 0.7-1.5 parts of nano silicon oxide, 8.0 parts of subnano graphite powder, 70.5-71.3 parts of flake graphite powder and 45 parts of phenolic resin solution with concentration of 45 percent. The invention has the advantages that the abrasion resistance of the carbon brush is obviously reinforced, and the service life of a single carbon brush reaches 920 hours; and the working contact surface is stably run, the reversing performance is excellent and the spark is tiny, the noise is greatlylowered and the start power is improved by more than 30 percent. The overlong service life is realized by adding the nano silicon oxide; the low noise and the favorable reversing performance are realized by adding the subnano graphite powder; and the favorable conductive performance is realized by adding the copper powder.

Owner:丽水市长新电器制造有限公司

Motor brush for small household appliances and manufacturing method thereof

InactiveCN102280790AConductiveImprove conductivityRotary current collectorBrushes manufactureLow noiseAgricultural engineering

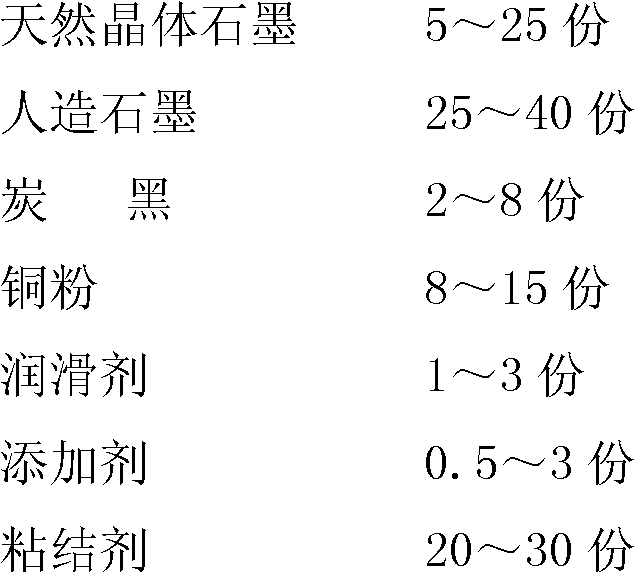

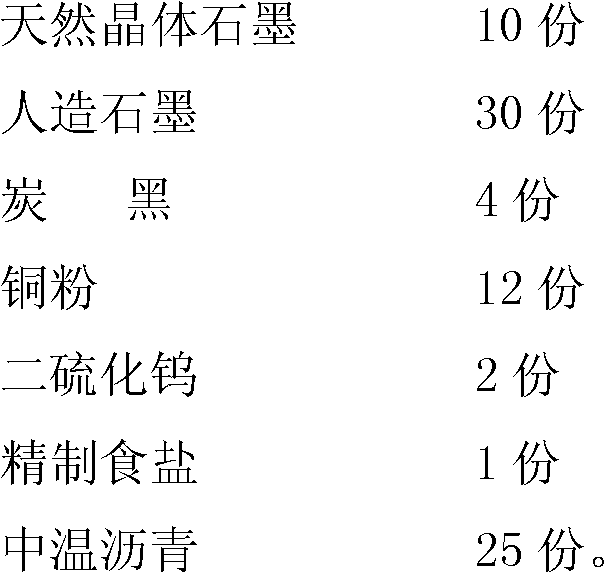

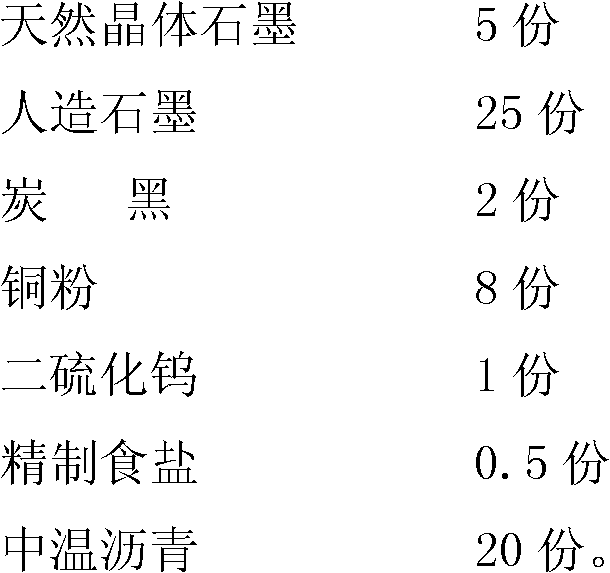

The invention discloses a motor brush for small household appliances and a preparation method thereof. The brush uses natural crystal graphite, artificial graphite, copper powder and carbon black as the main material of the brush, and is equipped with lubricants, additives, adhesives, etc. The agent is made by mixing, molding and roasting. The invention is suitable for small household electrical appliances such as soybean milk machines, juicers, shavers, hair dryers, and small irons. The motor brush for small household electrical appliances of the present invention adopts special raw materials and proportions, and has the advantages of low resistivity, good commutation performance, low running noise, excellent wear resistance, long service life, and environmental protection. Its manufacturing process is simple, Easy to implement, stable product performance and high yield.

Owner:SUZHOU DONON CARBON PRODS

Electric brush for electric tool motor and preparation method thereof

ActiveCN103259150ALow resistivityImprove wear resistanceRotary current collectorBrushes manufactureElectric machineryEngineering

The invention discloses an electric brush for an electric tool motor and a preparation method thereof. Electric brush mixture is roasted and then compressed to form the electric brush. The electric brush mixture comprises, part by weight, 30-60 parts of natural graphite, 25-40 parts of binder, 10-15 parts of amorphous carbon, 10-25 parts of solvent and 4-8 parts of additive. According to the electric brush for the electric tool motor and the preparation method thereof, preparation technologies are simple, operation is easy, the electric brush is low in resistivity, good in abrasion resistance, good in reversing performance, strong in anti-interference capability and long in service life, various requirements of the electric tool motor for the electric brush can be met better, and application ranges are wide.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Low cost electrical motor components manufactured from conductive loaded resin-based materials

InactiveUS20050204544A1Characteristic can be alteredTransformers/inductances coolingRadiating elements structural formsElectrical conductorMetal fibers

Electric motor components are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are metals or conductive non-metals or metal plated non-metals. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:INTEGRAL TECHNOLOGY INC

Carbon brush for truck starting motor as well as manufacture method and application thereof

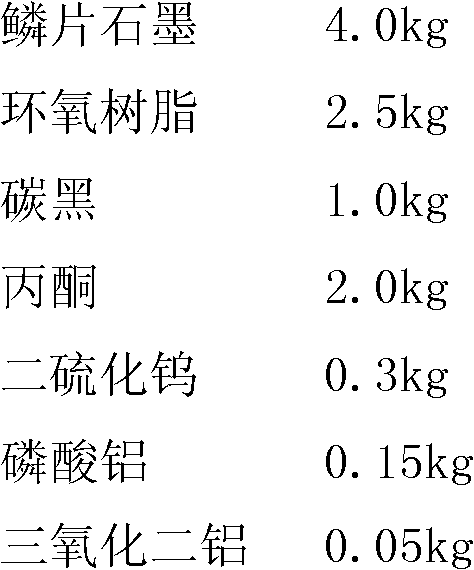

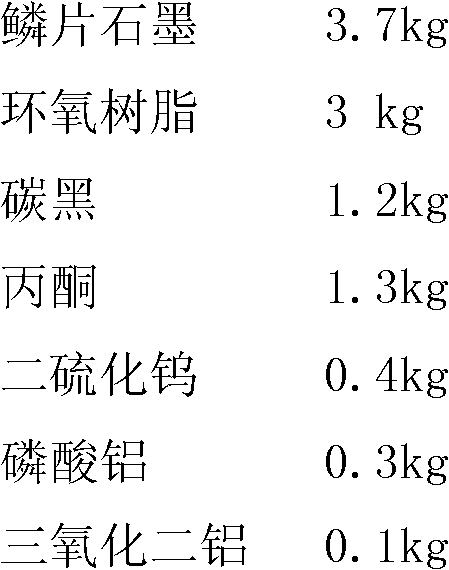

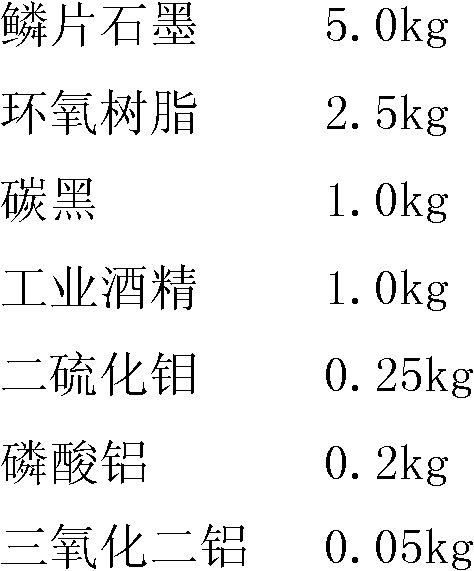

ActiveCN102130407AForm evenlyExtended service lifeRotary current collectorBrushes manufacturePhosphoric acidGraphite

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Process for producing low-noise and high-performance electric brushes by using copper-coated graphite powder

InactiveCN102694329AReduce energy consumptionImprove efficiencyRotary current collectorBrushes manufacturePhysical chemistryGraphite

The invention discloses a process for producing low-noise and high-performance electric brushes by using substitutional copper-coated graphite powder, and the process comprises the following steps: 1) kneading graphite powder and a bonding agent together so as to obtain colloidal graphite powder; 2) mixing the colloidal graphite powder, additives and a release agent so as to obtain mixed powder; 3) adding methanol or a gasoline low-carbon-residue binder dilute-solution in the mixed powder, mixing and then adding copper coated graphite powder into the obtained mixture; and 4) airing the material powder mixed in the step 3), pressing the material powder, and finally, sintering the material powder, thereby obtaining a low-noise and high-performance electric brush. According to the process disclosed by the invention, through adopting chemical substitutional copper coated graphite powder which can be industrialized as raw materials, and overcoming the defects that a chemical substitutional copper coated graphite powder coating is loose, porous and poor in binding force, and in the process of application, a copper plating layer is easy to fall off, a low-noise and high-performance electric brush is prepared. According to the process, a product can be obtained just through one-step molding and low-temperature heat treatment, therefore, the process is simple in working procedure, low in energy consumption, high in efficiency and short in production cycle, and the cost of the process is lower than that of a process implemented by using electrographite.

Owner:自贡恒基电碳厂

Method for manufacturing electric brush used for industrial motor

InactiveCN102074875AGuaranteed uniformityImprove the lubrication effectBrushes manufactureEpoxyCopper

The invention discloses a method for manufacturing an electric brush used for an industrial motor. In the method, a main material is formed by proportioning 52 kilograms of copper powder, 5 kilograms of tungsten disulfide, 2 kilograms of surfactant oleic acid, 41 kilograms of rubber powder, 15 kilograms of phenolic resin, 5 kilograms of epoxy resin and 80 kilograms of industrial alcohol. The invention also discloses a preparation process for the electric brush used for the industrial motor. The method has the advantages of high abrasion resistance, prolonged service lives of the electric brush and a motor slip ring and the like.

Owner:杨长根

Carbon brush used for low-abrasion motor and mixed with nanocopper and preparation method thereof

InactiveCN104901116AImprove performanceImprove conductivityRotary current collectorBrushes manufactureEpoxyLow noise

The invention relates to the field of carbon brush technology, in particular to a carbon brush used for a low-abrasion motor and mixed with nanocopper and a preparation method thereof. In the carbon brush, middle-temperature coal tar pitch, conductive silica gel and epoxy resin are mixed and used as a bonding agent. The composite bonding agent has higher comprehensive performance and electrical conducting performance, and is anti-abrasion and not liable to crack. Via the mixed nanocopper, oxidized grapheme and nanocarbon sol, electrical conductivity of materials is effectively improved, frictional coefficient is reduced, and flexibility of materials is improved. The prepared carbon brush has high electrical conducting performance, is low in abrasion rate, operates stably, generates low noise and small sparks, has stable size, and will not damage a rotator and a stator.

Owner:ANHUI A NAIL TRADE

Self-homogeneity wearproof resin type carbon brush and preparation method thereof

ActiveCN104917020AImprove toughnessLimit thermal vibrationRotary current collectorBrushes manufactureGraphiteHigh wear resistance

The invention discloses a self-homogeneity wearproof resin type carbon brush and a preparation method thereof. The carbon brush comprises the following components: 5wt%-30wt% of sulphonated and oxidized graphene, 20wt%-65wt% of scale graphite powder and isopressing graphite powder (one or mixture of the two), 30wt%-50wt% of thermosetting resin and an additive. The self-homogeneity wearproof resin type carbon brush has the characteristics of self homogeneity and high wear resistance, is applicable to a motor for a high-power electric tool, in particular to a motor for a high-power cutter. Compared to an existing carbon brush with the same type, the carbon brush is excellent in homogeneity and wear resistance, and the commutation spark is stabilized at the level defined in the specification; The current-carrying wear rate of the carbon brush is 1 / 5-1 / 2 of that of the motor for the conventional high-power electric tool with the same type.

Owner:HUNAN UNIV

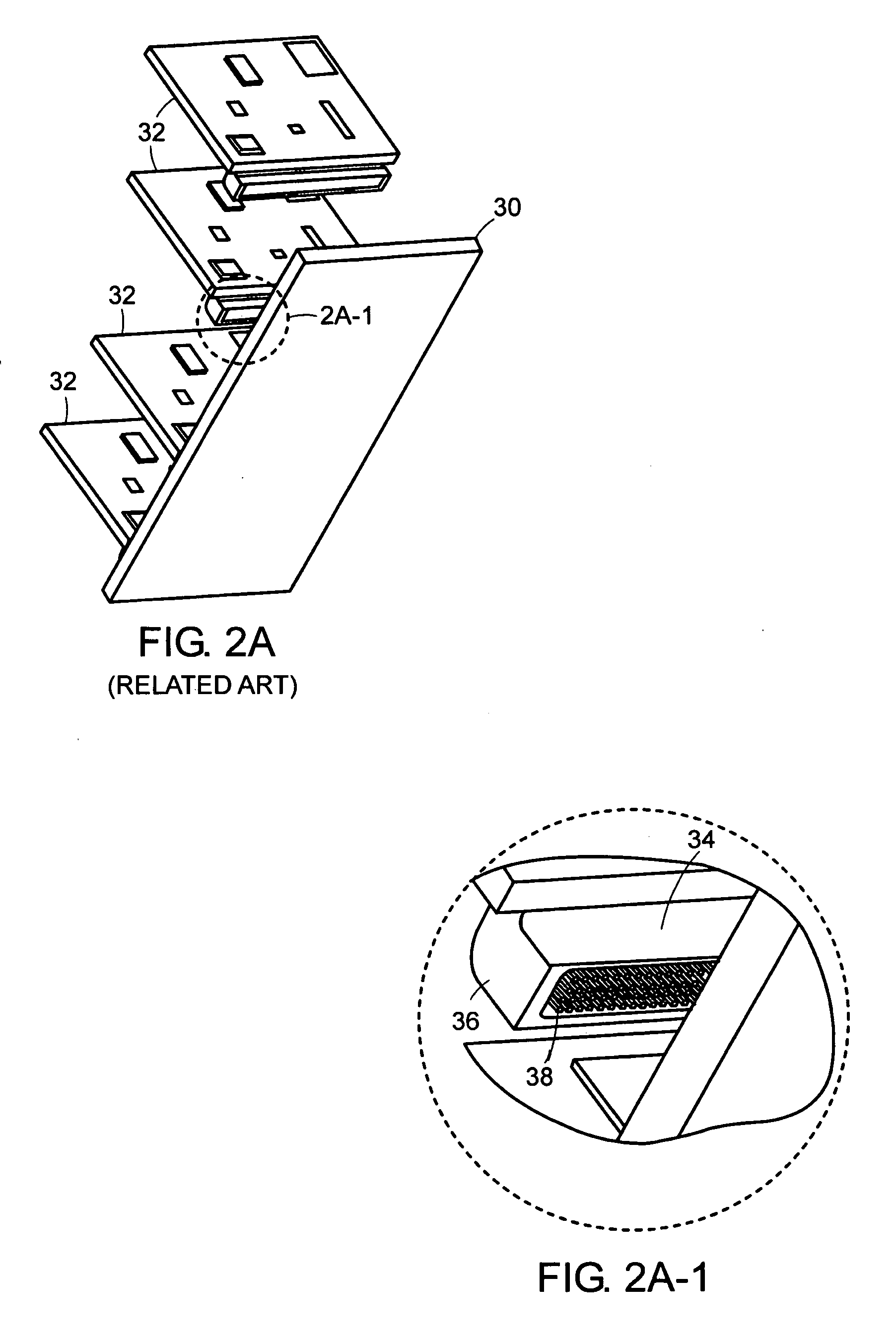

Electrical connector

InactiveUS20050202695A1Engagement/disengagement of coupling partsPretreated surfacesFiberElectrical conductor

An electrical connector that has an array of conductors each having a contact point to make contact with a mating conductive surface. Upon engaging the contact points in a sliding manner with the mating surface, the conductors are displaced, which, in turn, tensions a loading fiber within the connector. Tensioning of the loading fiber provides a contact force between the contact points and the mating surface.

Owner:METHODE ELETRONICS INC

A vacuum cleaner motor brush preparation method and a brush prepared by the method

ActiveCN105322410ALight in massConductiveRotary current collectorBrushes manufactureRoom temperatureAgricultural engineering

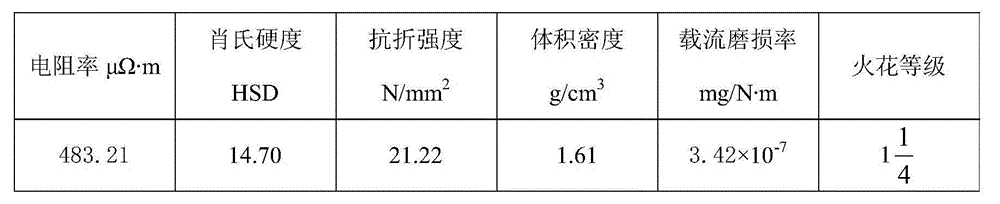

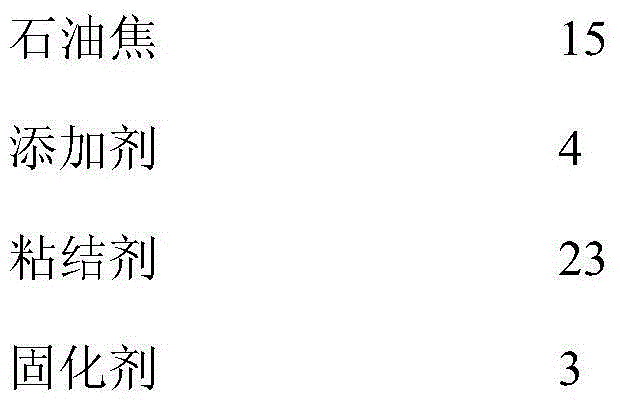

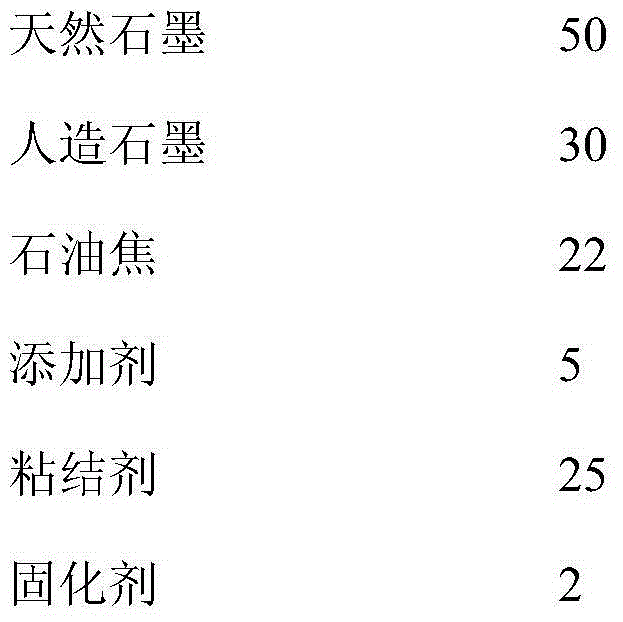

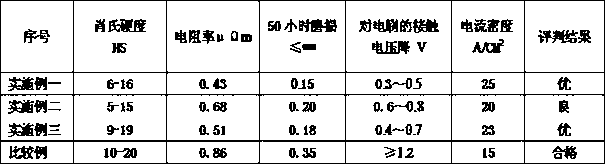

The invention discloses a vacuum cleaner high-speed high-efficiency motor brush preparation method and a brush prepared by the method. Constituent materials of the motor brush belong to the field of material science. The brush preparation method comprises, to begin with, mixing graphite, petroleum coke, additive, binders and curing agents uniformly under an ambient temperature condition, smashing the mixture and then, placing the smashed mixture into a die; carrying out compression moulding; and then, carrying out curing processing, cutting, grinding machine, hole drilling and line filling. The vacuum cleaner high-speed high-efficiency motor brush prepared by the method is low in resistance in the using process, good in commutating performance and long in service life, and more importantly, has high wear resistance, low spark grade and good product stability.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Electric brush for ABS system and preparation method thereof

ActiveCN102856758AFrictional stabilityStable service lifeRotary current collectorBrushes manufactureFiberElectrolysis

An electric brush for ABS (Anti-skid Brake System) comprises a brush body and a lead-out wire, wherein the brush body comprises 46 to 52 parts by weight of superfine electrolytic copper powder, 52 to 46 parts by weight of cementing powder and 2 parts by weight of modifier at; the cementing powder comprises 1.0 to 3.0 parts of high-purity carbon fiber powder, 23 to 27 parts of artificial graphite powder, 25 to 35 parts of high-purity sub-nanometer graphite powder, 18 to 22 parts of crystal graphite powder, 3 to 8 parts of graphitized carbon black powder, 2.5 to 4.5 parts of rare-earth tungsten disulfide composites and 5 to 15 parts of high-temperature resistant phenolic resin; and the modifier comprises 0.20 to 1.30 parts of vulcanization silver powder, 0.20 to 1.5 parts of stibonium powder and 0.5 to 1.5 parts of zinc powder. The chemical stability, the lubricating property, the electrical conductivity, the high-temperature resistance and the abrasion resistance of the electric brush provided by the invention are much better than that of the existing products.

Owner:丽水市长新电器制造有限公司

Series-excitation AC (Alternating Current) motor brush for soybean milk maker/juice extractor

ActiveCN102468587ADetailed instructionRotary current collectorBeverage vesselsEngineeringHigh resistivity

The invention relates to a series-excitation AC (Alternating Current) motor brush for a soybean milk maker / a juice extractor. The series-excitation AC motor brush is characterized by comprising the following components of: natural crystal graphite, electrochemical graphite, carbon black, polytetrafluoroethylene, graphite fluoride, table salt and asphalt. The series-excitation AC motor brush disclosed by the invention has the advantages of high resistivity, good reversing performance, small sparkles during operation, good sliding contact characteristic, high mechanical strength, good abrasion performance, long service life and the like; and the series-excitation AC motor brush makes a bonder fully be cracked and makes a broken chain of an organic annular structure of the bonder form an organization structure of inorganic carbon when the bonder is roasted at the temperature of 600-700 DEG C, thus the series-excitation AC motor brush is safe and reliable.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Electirc sliding contact and method for processing the same

The present invention relates to an electric sliding connect terminal such as carbon brushes, which is provides with a base body prepared with artificial graphite materials and by processes such as pressing, heat treatment and subsequent processing when necessary. The base body(10)of the sliding connect terminal is processed with laser for realizing a process with a high precision by a simple measure.

Owner:GERHARD PRAZISIONSPRESSTECHN

Graphite brush and preparation method thereof

InactiveCN101651281AHigh thermal conductivityHigh densityRotary current collectorBrushes manufactureCopper wireCarbon nanotube

The invention discloses a graphite brush, which comprises graphite, resin, carbon nano tubes which are mixed in the graphite and the resin, and a copper wire. The invention also provides a method forpreparing the graphite brush, which comprises the following steps of: performing surface treatment on the carbon nano tubes; adding the carbon nano tubes into solvent for pre-dispersion; slowly addingthe carbon nano tube suspension into resin solution for dispersion; mixing the resin solution containing the carbon nano tubes with the graphite and an additive; cold pressing and sintering the mixture to prepare a blank; and fixedly connecting a lead in the solidified and sintered blank to prepare the brush. Due to the fact that the carbon nano tubes are added in the graphite brush, the graphitebrush of the invention has high thermal conductivity, carrier density and abrasion resistance, can effectively reduce the contact resistance between the brush and a commutator to prolong the servicelife.

Owner:JOHNSON ELECTRIC SHENZHEN

Carbon brush and copper plating technology of carbon brush

InactiveCN102931561ASimple conditionsEasy to implementRotary current collectorBrushes manufactureCopper platingPunching

The invention discloses a carbon brush. The carbon brush is characterized by comprising the following constituents in percentage by weight: 80-90% of graphite powder, 10-15% of resin and 1-8% of asphalt. The copper plating technology is characterized by comprising the following steps of: mixing the constituents of the carbon brush in a mixer, and drying; then, smashing the mixture, screening, carrying out compression moulding on a press by a die, sintering, grinding the surface after sintering; and then, placing the grinded workpiece in a copper plating container for executing the copper plating reaction, and after the copper plating reaction, making the needed carbon brush by punching, wire embedding and arc grinding. The carbon brush and the copper plating technology have the advantages that the technological conditions are simple and easy to realize, the carbon brush is convenient to produce, the production cost is lowered, the working efficiency is improved, the service life is prolonged, and the carbon brush can be used for high-power electric tools or dust collector equipment.

Owner:JIANGSU HUAYU CARBON

Metal-graphite brush

InactiveCN1897418AEliminate Grinding LossIncrease contact areaRotary current collectorDynamo-electric machinesEmulsionBoiling point

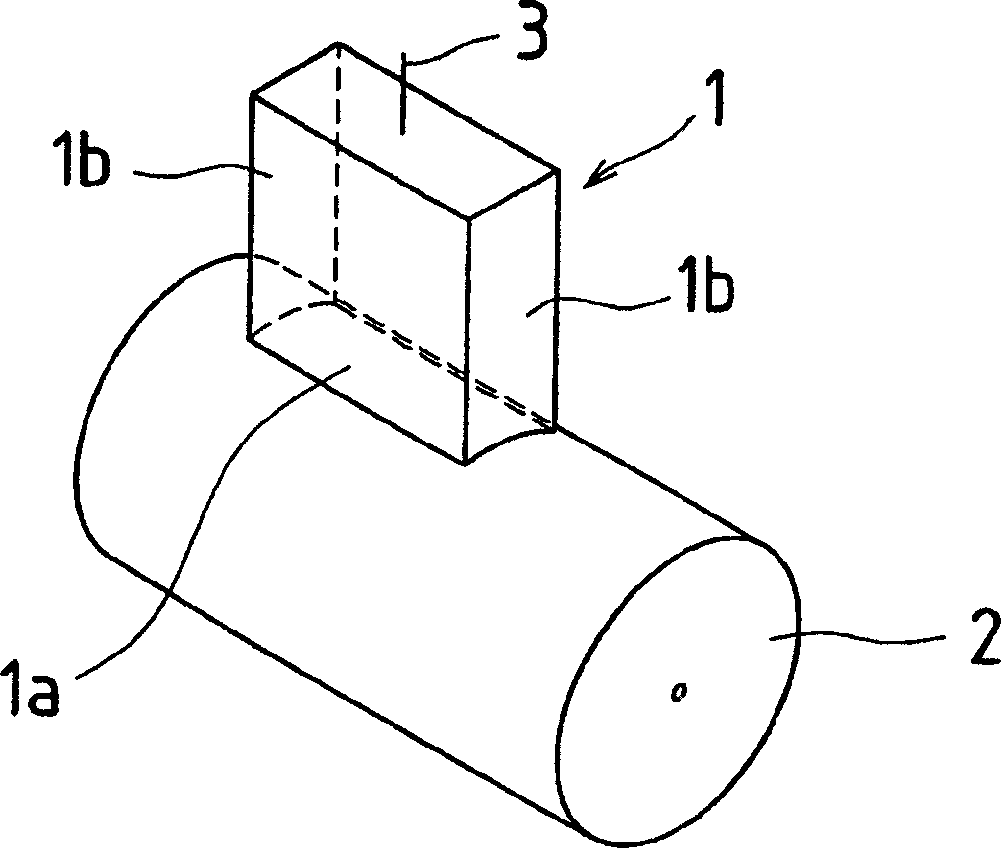

The present invention provided a metal graphite brush in which any spark discharge is hardly produced. A metal graphite brush 1 is made up of a sintered body having pores 19 on its surface and interior, and feeds a coil 17 in such a manner that the coil 17, wound around a core 9 provided on a rotor 2 of a motor, comes slidably into contact with an electrically connected commutator8 at a slidably contacting surface. Emulsion containing liquid that is vaporized in response to temperature rise due to contacting with the commutator 8 when a motor is operating, and solvent having a higher boiling point than that of liquid as well as causing the liquid to disperse is included within the pore 19.

Owner:AISIN SEIKI KK

Brush in composite material of carbon fiber and graphite based on silver

InactiveCN1874080AImprove performanceImprove friction and wear performanceRotary current collectorBrushes manufactureFiberCopper plating

Being related to electric contact material, i.e. brush, the invention discloses brush prepared from carbon fiber, graphite, silver based composite material in optimal adaptation among conduction, intensity, and wear resistance. Characters are that raw materials of the brush include silver powder, copper powder, graphite, and copper coated carbon fiber. Comparing with products in same domestic designation, the disclosed product increases performance of frictional wear remarkably, and raises service life to 2-3 times. Controlling pressure, and pressing time, the invention controls falling over direction of carbon fiber so as to low resistivity of brush, and increase density of carrying current. The invention raises electrical and mechanical performances of composite material (resistivity 0.06-0.09 micro ohm .m), and manufactures moderated, stable thickness of oxide film on surface of collector ring.

Owner:HEFEI UNIV OF TECH

Carbon brush for electric machine

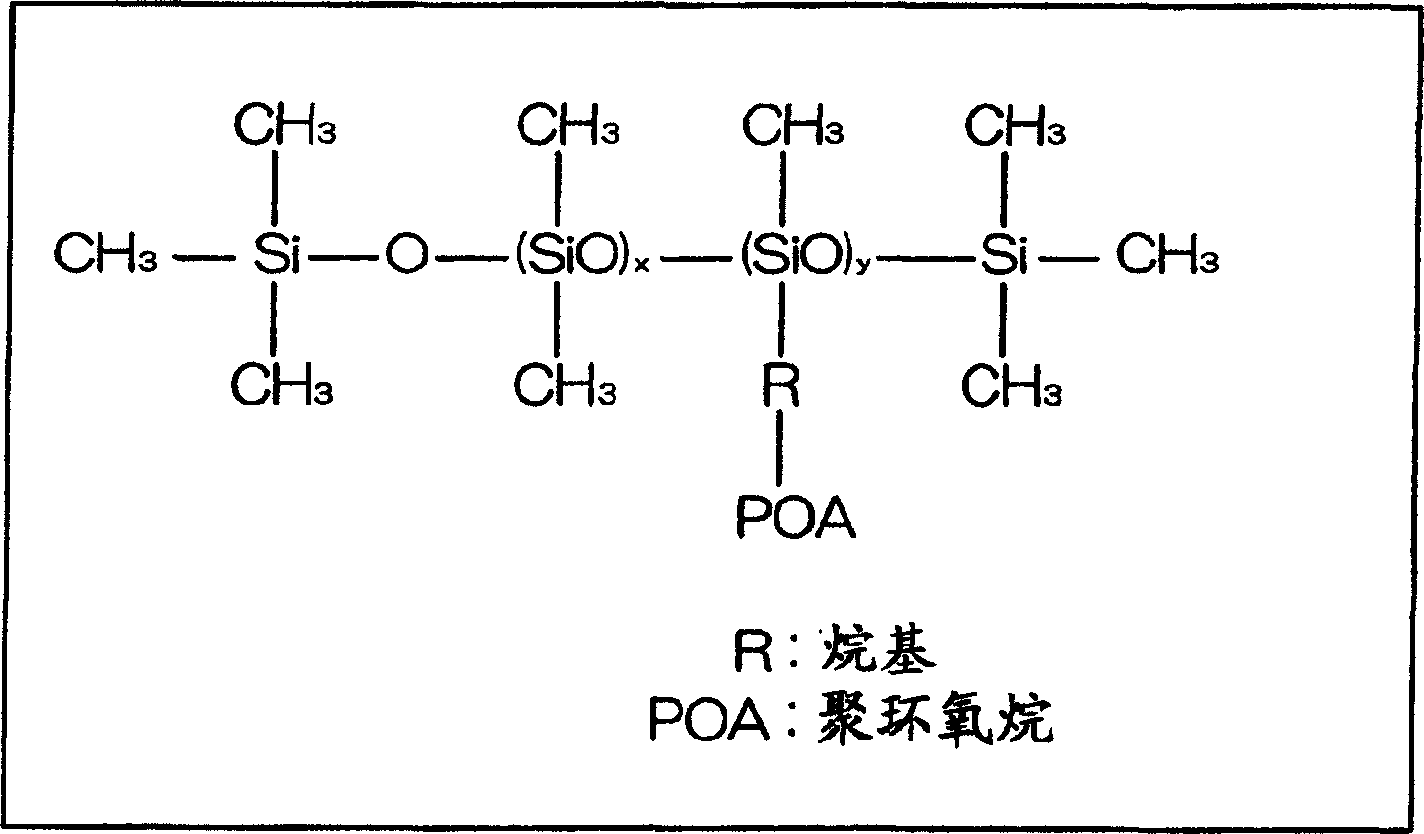

InactiveCN1701487AImprove efficiencyRotary current collectorDynamo-electric machinesElectric machineWater soluble

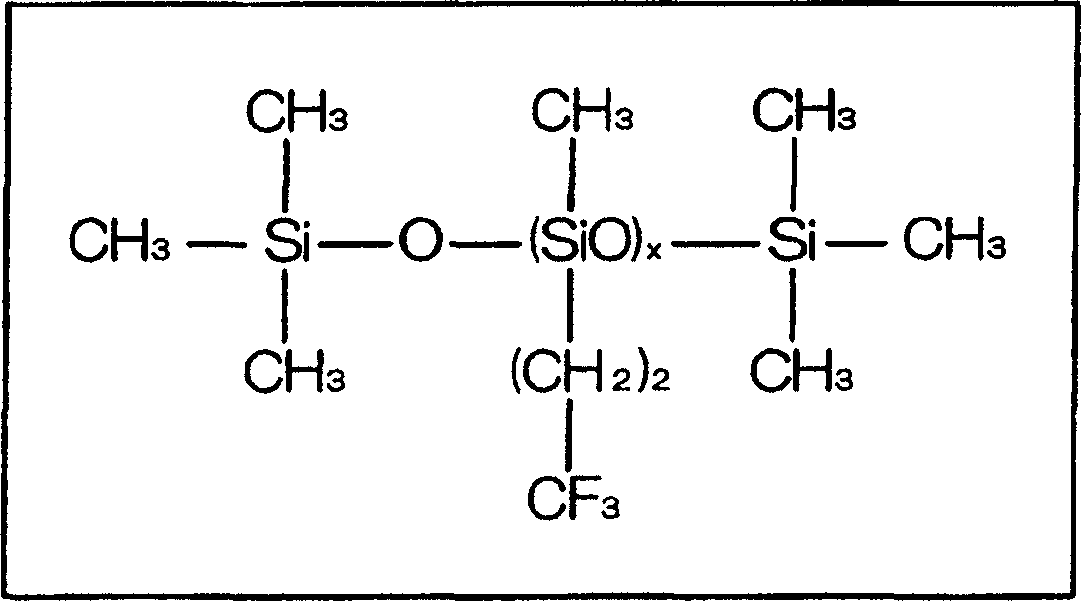

An electromechanical carbon brush 1 applied against a conductive rotating body 2 has a brush base material which is a material made of an aggregate including carbon as at least one (1) ingredient and of a binder, the electromechanical carbon brush 1 containing 0.2 to 10 % by weight of a water-soluble lubricant, 0.2 to 3 % by weight of fluorine denatured silicone oil or 0.2 to 10 % by weight of the water-soluble lubricant and a metallic compound, relative to the brush base material.

Owner:TOTANKAKO

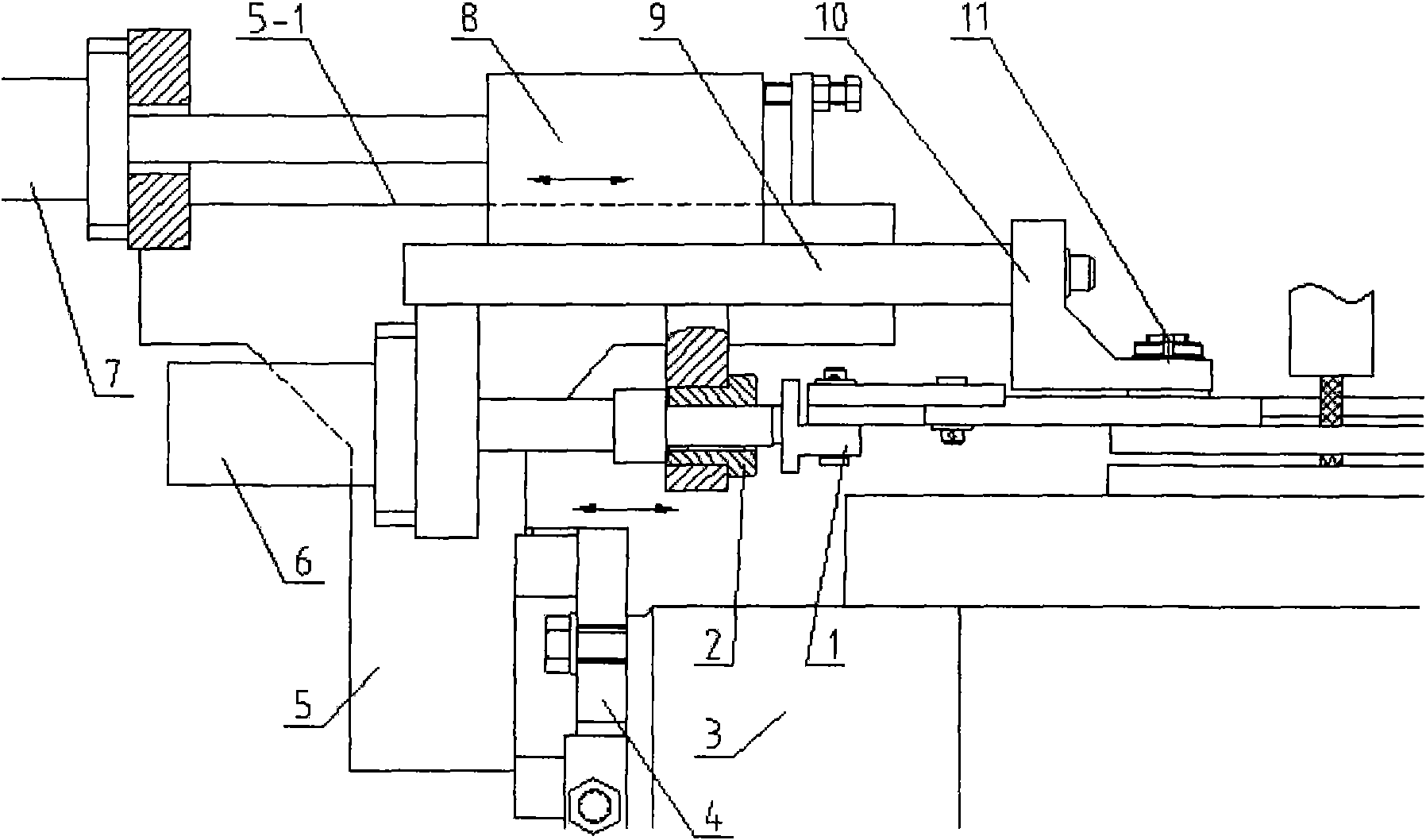

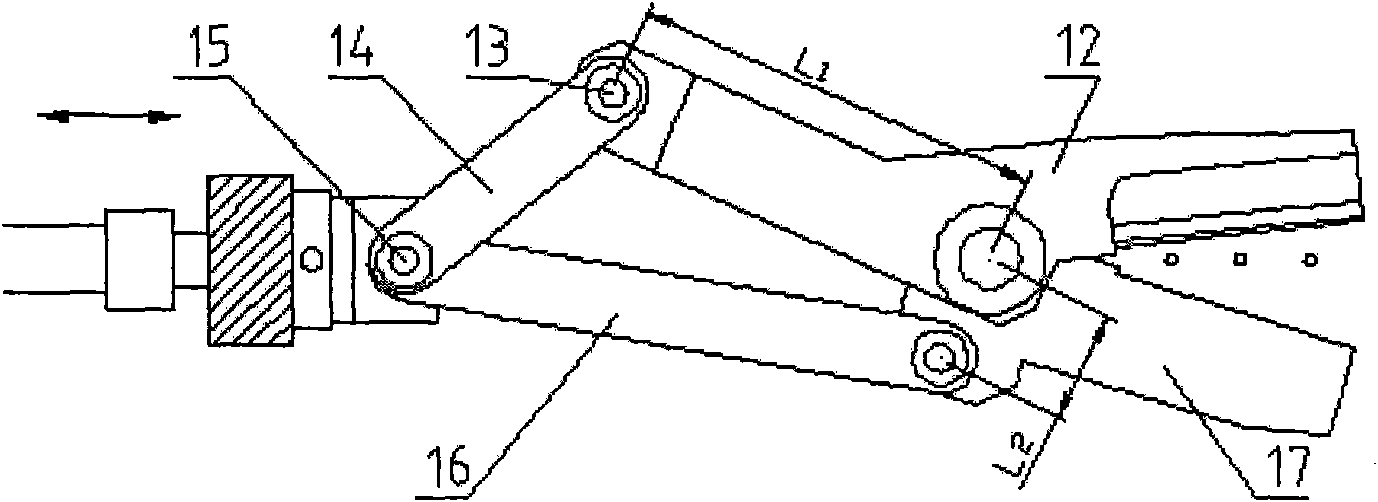

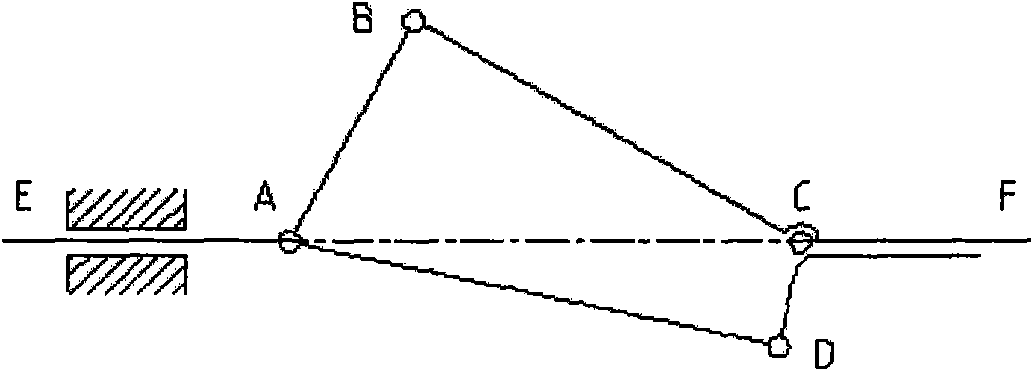

Automatic scissors apparatus of eletricity stranded wire

The present invention disclose an automatic scissors apparatus of eletricity stranded wire, including scissors position sender driving device, the scissors position sender driving device is provided with shearing device, the upper blade and bottom blade of the crank arm of the shearing device and two connecting bar together with another driving device connecting to form general slipper block parallel connection four-bar mechanism; the crank arm of the upper blade and the bottom blade applies arms of different size. The automatic scissors eletricity stranded wire apparatus can shear thread end without hairpin, possessing great universality, never affected by linetype and quantity, operational safety, knife edge easily redressing, long service life, saving energy sources and providing support for full-automatic ] pressing lined brush.

Owner:湖南赛诺精密机器有限公司

Metal-graphite brush

InactiveUS20030127941A1Prevent drop in outputEffect can be obtainedRotary current collectorDynamo-electric machinesPhosphate ionPhosphoric acid

Owner:TRIS +1

Methods of making electrical motor components from conductive loaded resin-based materials

InactiveUS8268222B2Transformers/inductances coolingRadiating elements structural formsMetal fibersMetallizing

Electric motor components are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are metals or conductive non-metals or metal plated non-metals. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:INTEGRAL TECHNOLOGY INC

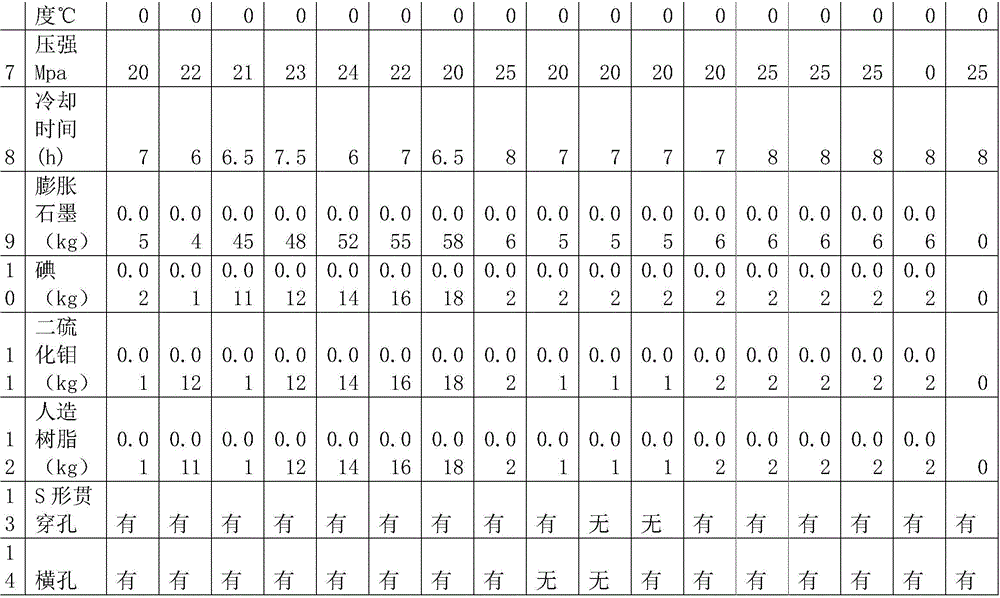

Manufacturing method of electric brush

The invention discloses a manufacturing method of an electric brush. The manufacturing method includes the steps that raw materials are selected and smashed into powder according to the ratio, and prepressing is carried out on the powder to form a prefabricated part with S-shaped grooves and transverse grooves; the prefabricated part is pressed again to obtain a preliminary processed product, wherein multiple S-shaped through holes are formed in the preliminary processed product, and transverse holes are communicated between the through holes; burrs on the surface of the preliminary processed product are ground off, then the preliminary processed product is sintered in a high-temperature and high-pressure environment, dipped and cooled after sintering, after cooling, filler prepared by mixing expanded graphite, iodine, binder and lubricant is injected into the S-shaped through holes and the transverse holes, and a finished product is obtained through compaction. Compared with the prior art, the manufactured electric brush reduces noise and heat productivity and increases heat dissipating channels in the operation process.

Owner:CHONGQING HEHAI CARBON PROD

Self-Lubricating Slipring

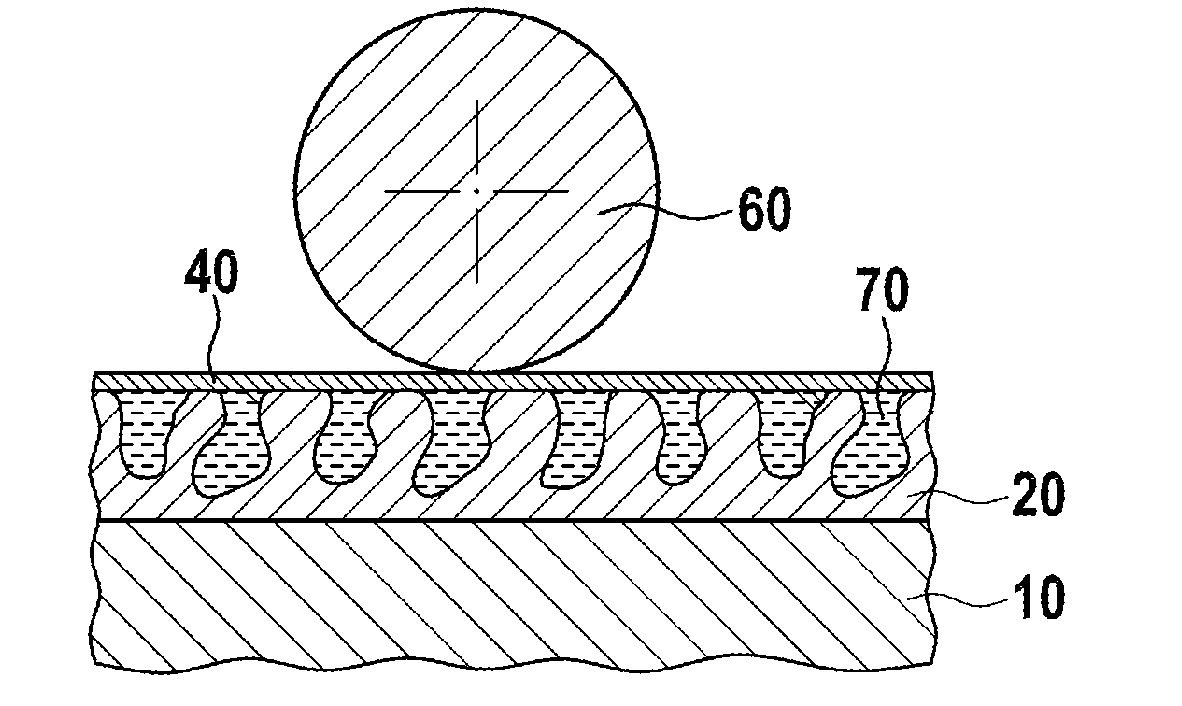

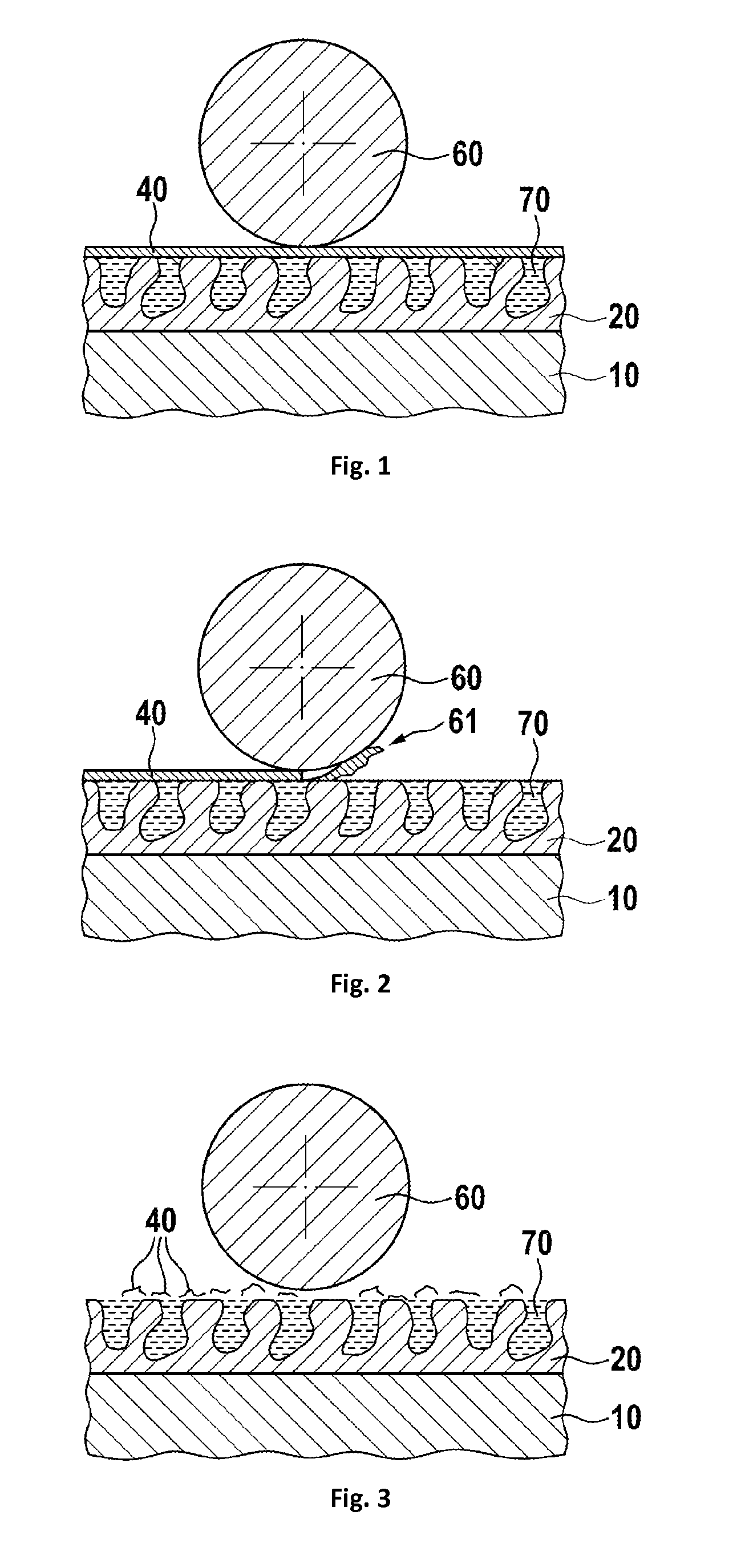

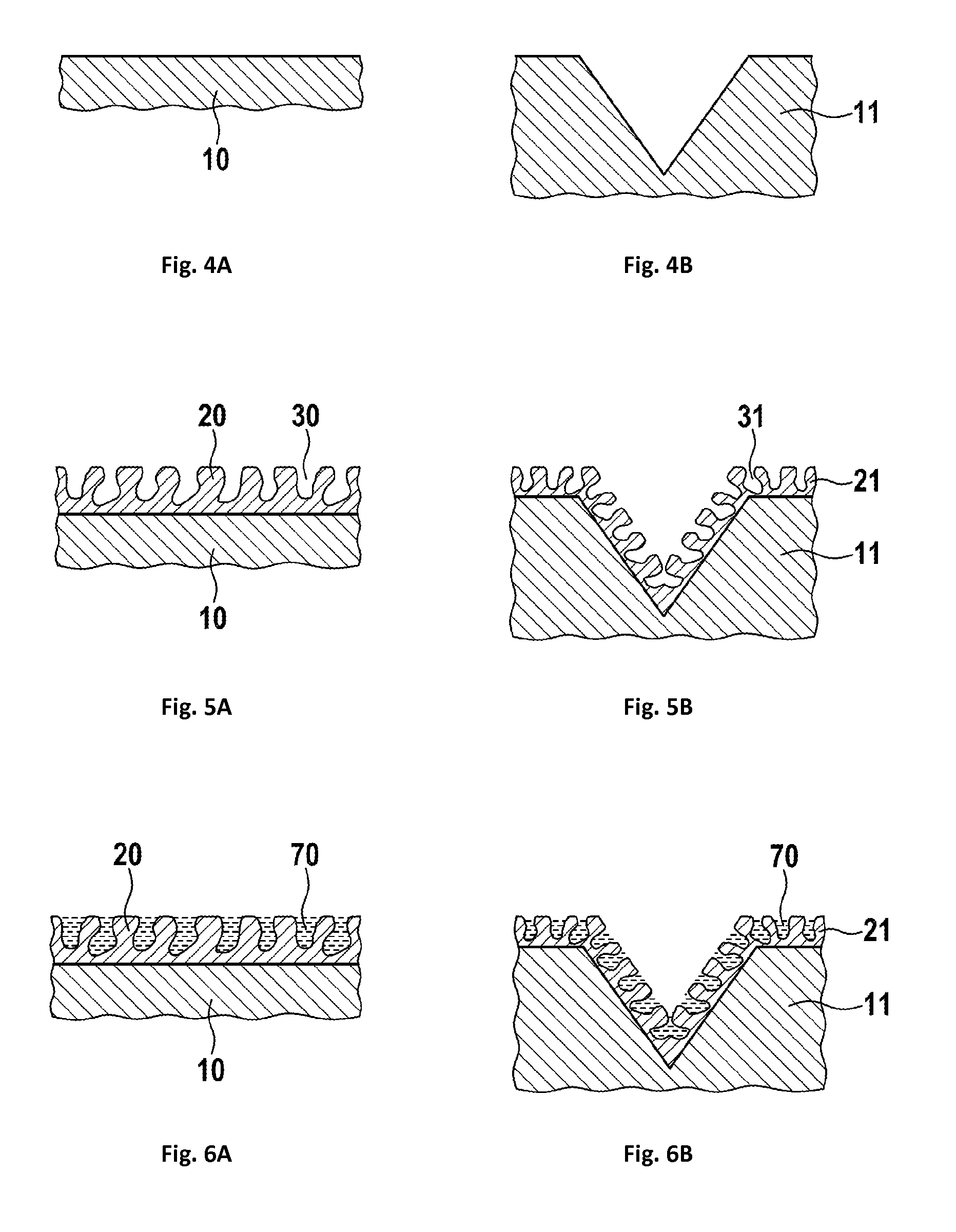

ActiveUS20150288121A1Extended service lifeSafe storageRotary current collectorNon-rotary current collectorLubricantSlip ring

A slip ring has a slip ring track with a contact area, the contact area containing a plurality of pores or cavities. A lubricant is held within these pores and cavities and is enclosed by a top coating. When a slip ring brush is sliding over the slip ring track, it rubs off particles of the top coating, therefore opening some of the pores or cavities which release parts of the lubricant contained therein. This lubricant reduces surface friction of the slip ring brush at the slip ring track and therefore further wear, which results in an extended lifetime.

Owner:SCHLEIFRING & APPBAU

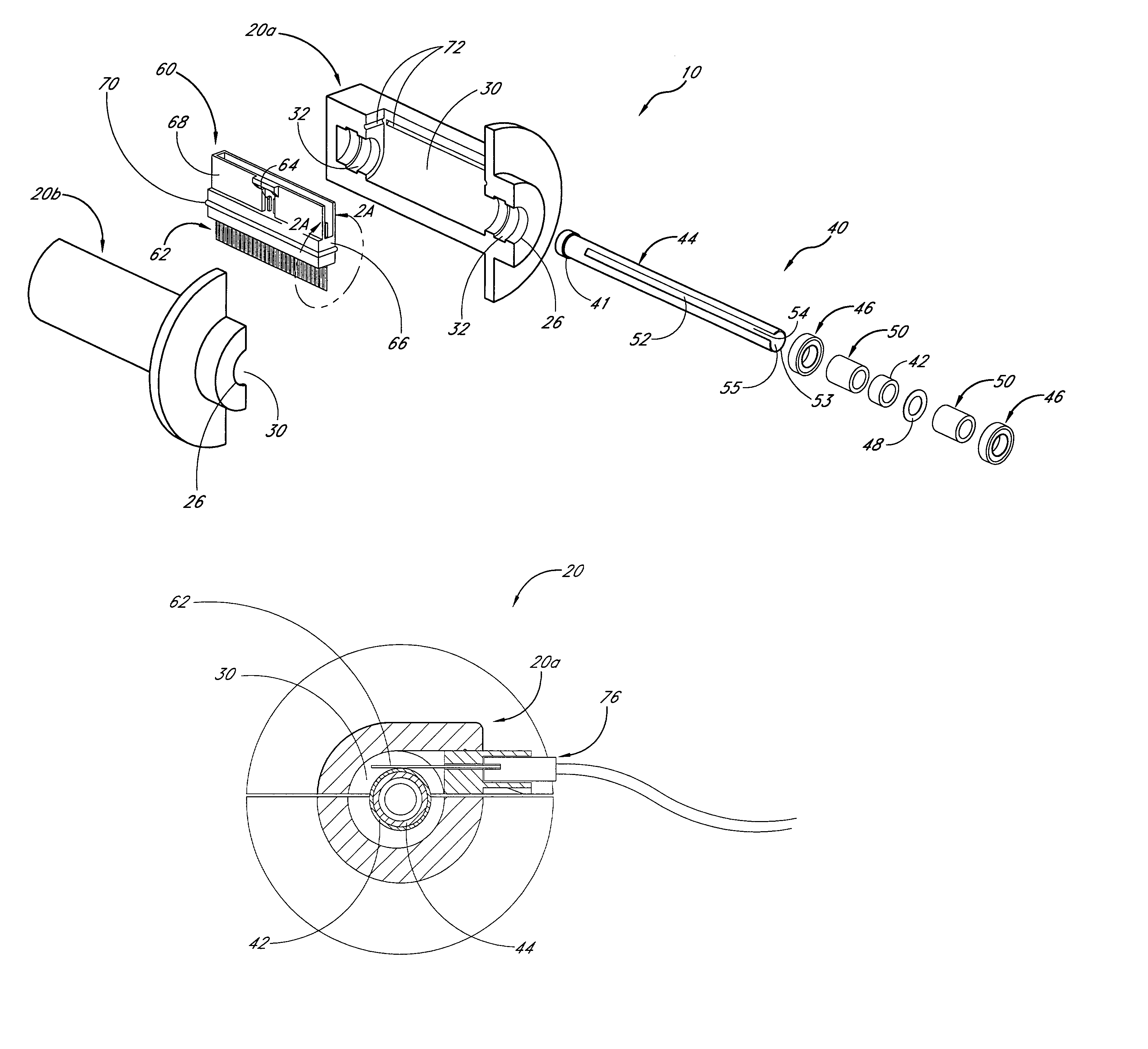

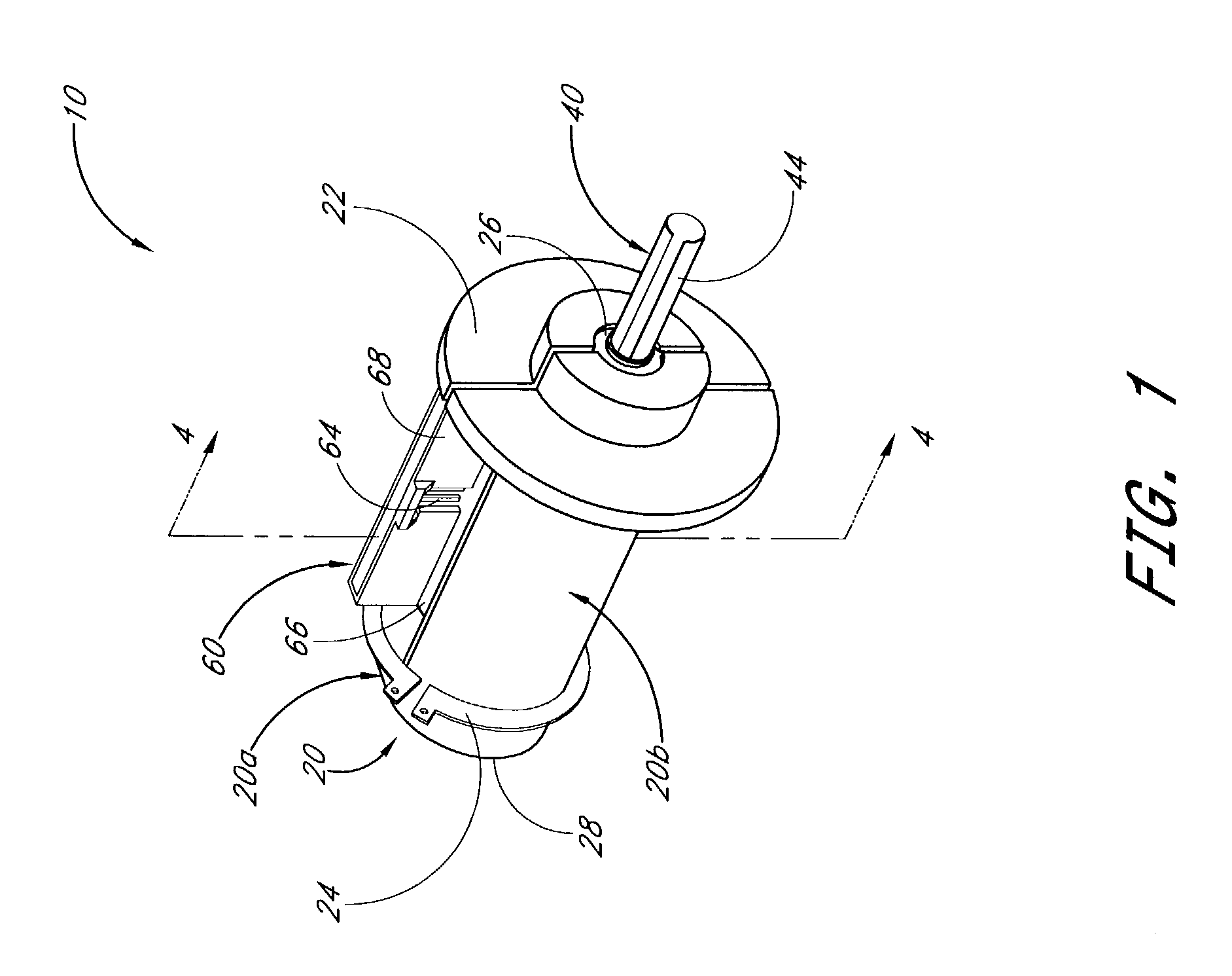

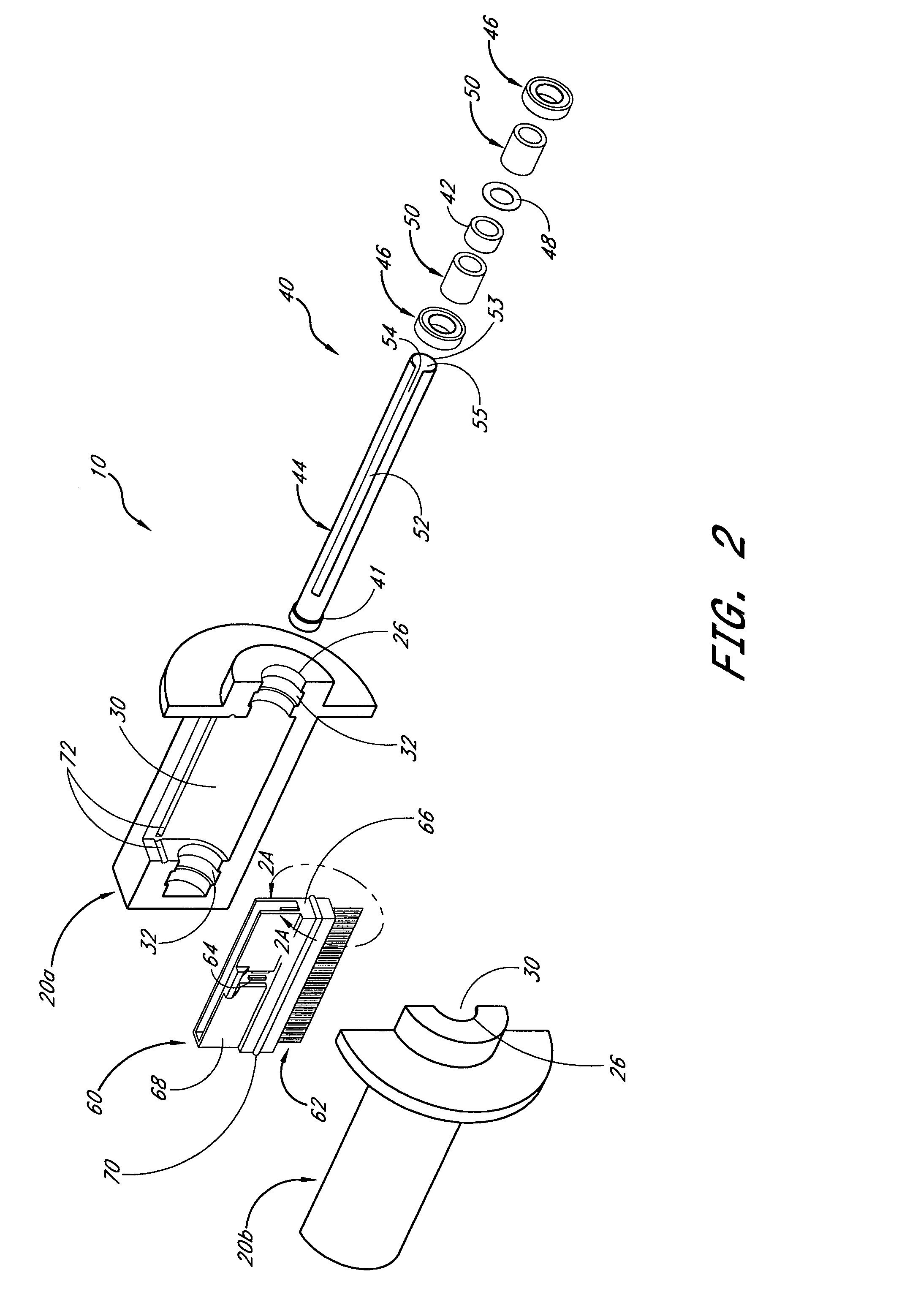

Slip ring with connector pins

A slip ring assembly for allowing electrical or electronic signal transfer between a stationary device and a rotating device includes a ring assembly and a brush assembly. The ring assembly comprises a plurality of assembled rings and spacers of selected widths positioned on a longitudinal tube having a slot and a hollow center. The tube may be provided with one or more bearings to allow the tube to be smoothly rotatable in a housing. A plurality of brushes unitarily formed with a plurality of connector pins are held by a brush holder which is removably received in the housing. The connector pins are configured to receive a standard male or female connector. The housing is typically incorporated into a body of a stationary device, and the tube may be attached to or incorporated into a rotating component of an electronic or electrical device.

Owner:UNIT INDS

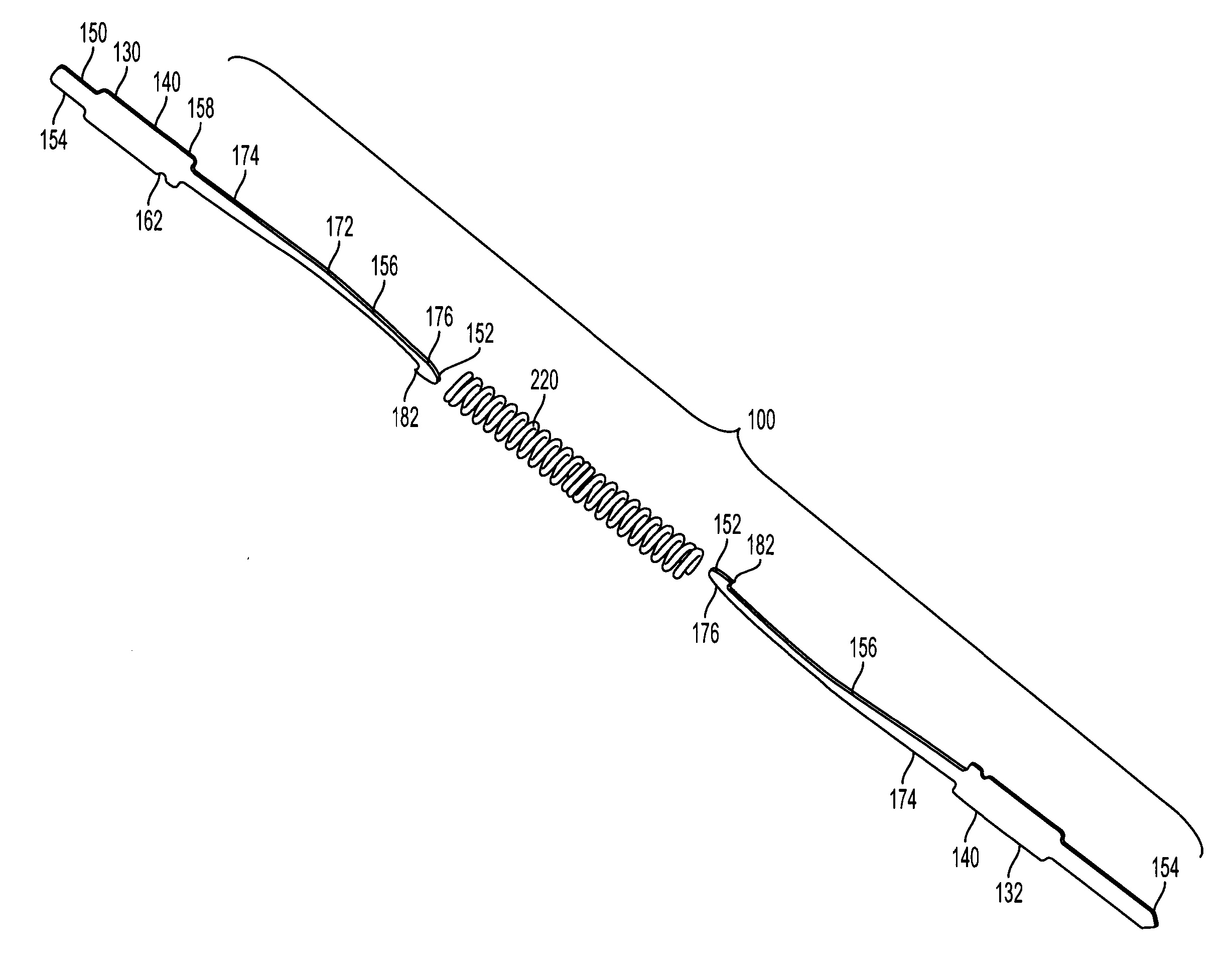

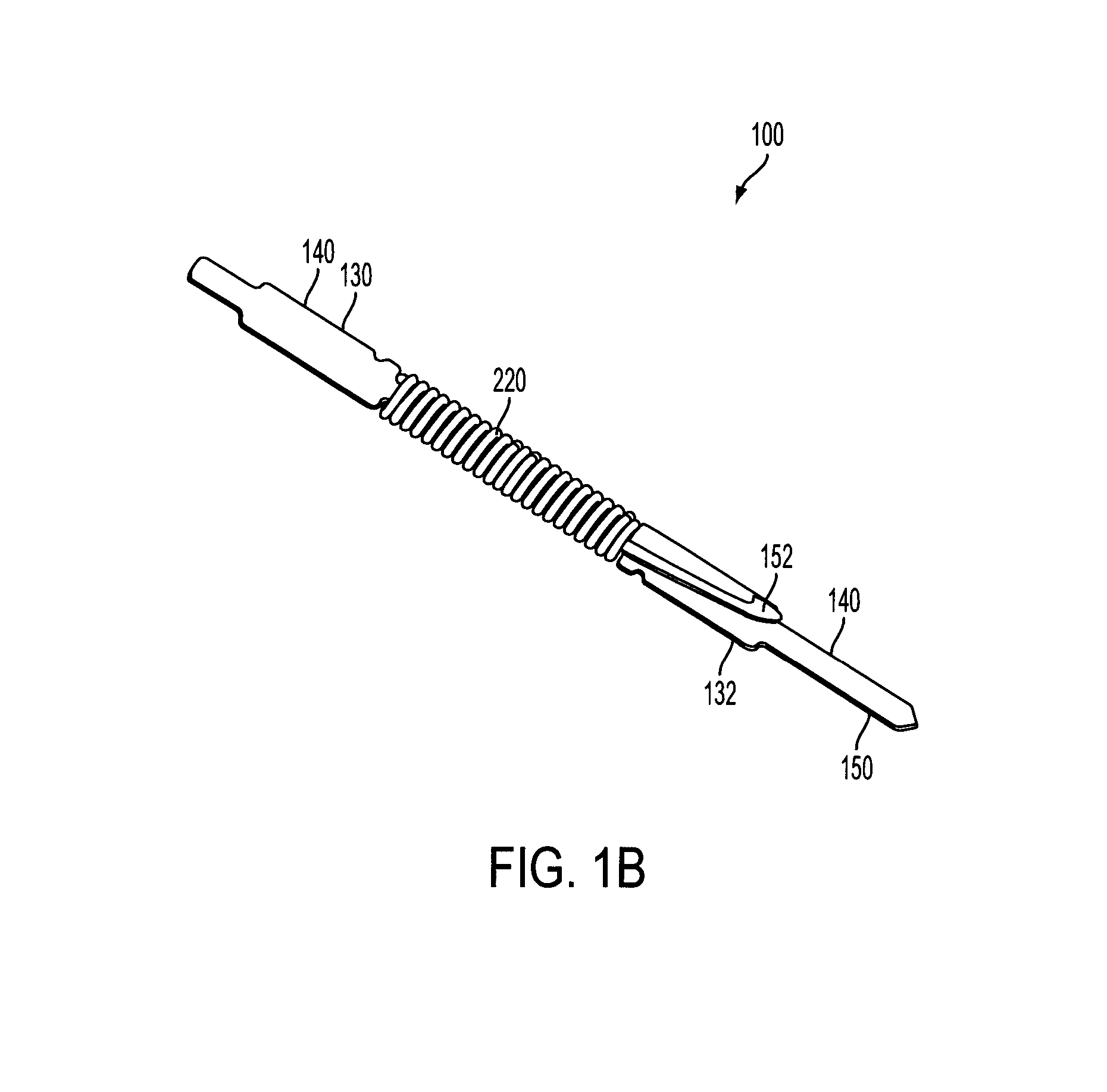

Test probe assembly and related methods

ActiveUS20150070040A1Electrical testingManufacture of electrical instrumentsMechanical engineeringPlunger

A test probe assembly includes a first elongate electrically conductive plunger that extends from a proximal first plunger end to a distal first plunger end, and is defined in part by a central longitudinal axis. The first plunger has a first spring latch at the distal first plunger end. At least a portion of the first plunger has an arc with a first plunger outer contact point opposite the first spring latch relative to the longitudinal axis. The first plunger is disposed in a spring. The first plunger outer contact point in contact with the inner diameter of the spring, and the first spring latch engages at least a portion of the spring. A method includes disposing a first plunger within a spring along a spring longitudinal axis, disposing a second probe within the spring along the spring longitudinal axis, and engaging the spring latch and the second plunger spring latch with the spring, for instance by capturing an end coil of the spring with the spring latch of at least one of the spring latch or the second plunger spring latch.

Owner:XCERRA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com