Carbon brush for electric machine

A carbon brush and mechanical technology, which is applied in the field of carbon brushes for electric machinery, can solve the problems of not being able to ensure good sliding properties of carbon brushes and commutators, unevenness, and inability to ensure rectification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

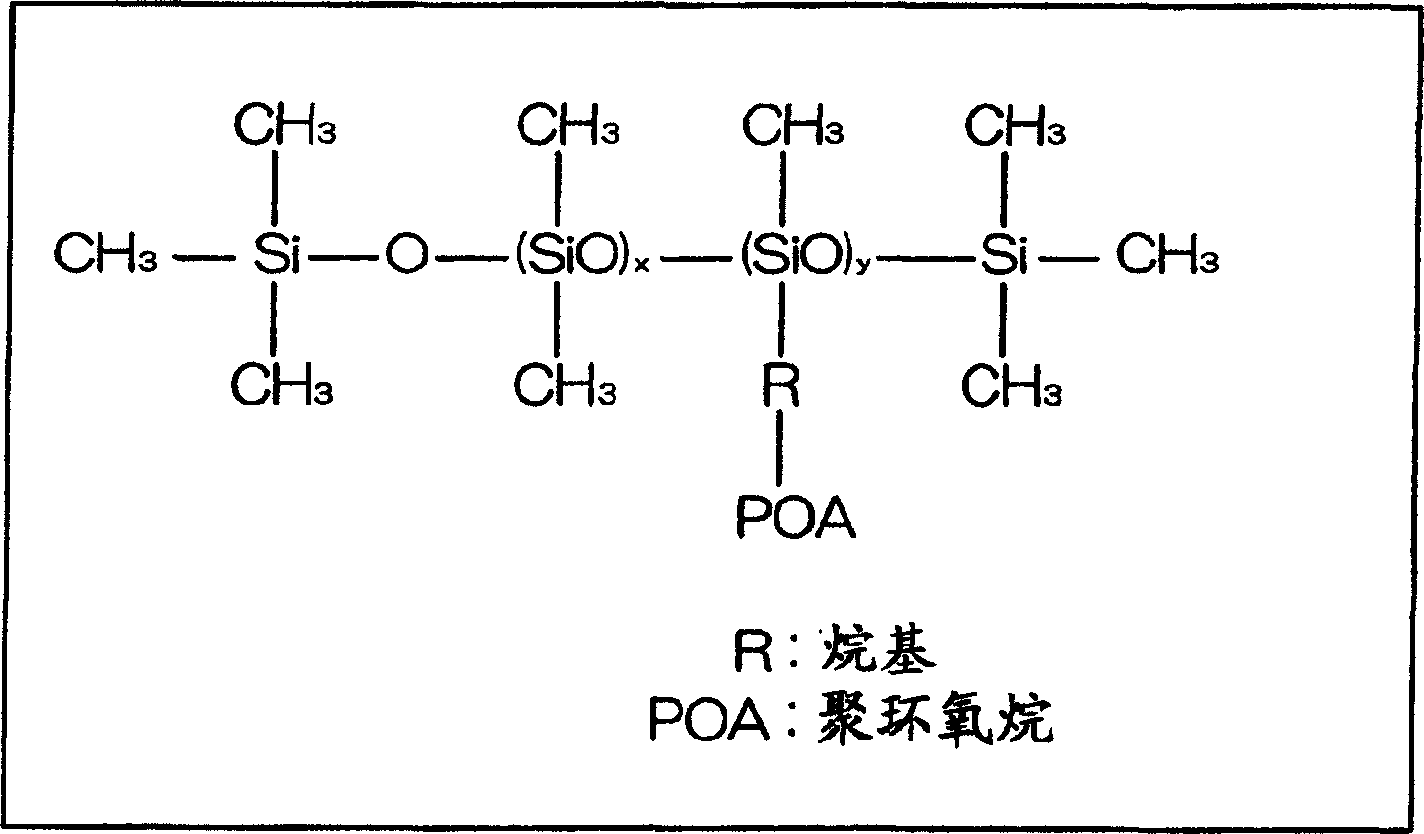

[0079] In the implementation, there will be figure 2 A water-soluble silicone oil having the chemical structure shown above was impregnated into pores of the resin-bonded carbon brush substrate produced as described above. Furthermore, the kinematic viscosity of the water-soluble silicone oil used at 20°C is 100mm 2 / s.

[0080] In the immersion step, the water-soluble silicone oil is dissolved in a predetermined amount of water to form an aqueous silicone oil solution, and the carbon brush base material is immersed in the aqueous solution for a predetermined period of time.

[0081] In order to produce various carbon brushes with different impregnation rates of silicone oil in the carbon brush base material, an aqueous silicone oil solution with a silicone oil concentration of 1 to 80% by weight was prepared, and the impregnation rate was adjusted using the difference in the silicone oil concentration. In addition, the time for immersing the carbon brush base material in the...

Embodiment 2

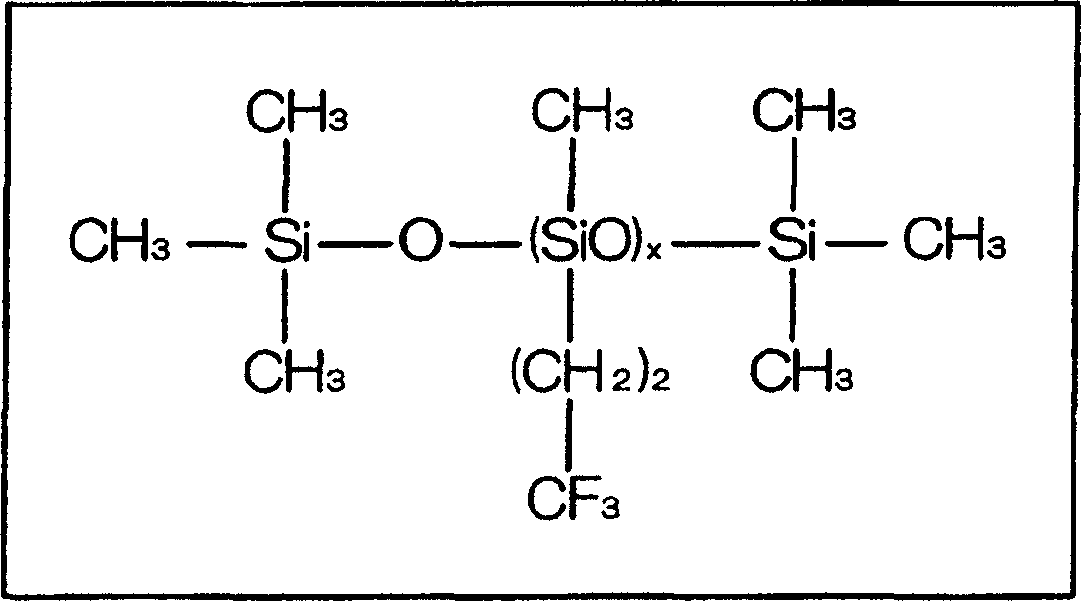

[0097] In this embodiment 2, at first to the carbon brush base material that embodiment 1 makes, dipping has image 3 Fluorine-modified silicone oil with the chemical structure shown. Here, the kinematic viscosity of fluorine-modified silicone oil is 100mm 2 / s.

[0098] Impregnation of fluorine-modified silicone oil, immersing the carbon brush base material in fluorine-modification silicone oil at room temperature of 25° C. for a certain period of time. Then take out the carbon brush and wipe it with a soft cloth to remove the fluorine-modified silicone oil stuck on the surface of the carbon brush.

[0099] Change the time of impregnating the carbon brush substrate in the fluorine-modified silicone oil to obtain a carbon brush with the same impregnation rate as in Example 1, that is, the impregnation rates are respectively 0.2% by weight, 1.2% by weight, 2.7% by weight, and 4.0% by weight. Carbon brushes with fluorine-modified silicone oil (4 types). In addition, the impr...

Embodiment 3

[0105] To the carbon brush substrate of the making of embodiment 1, impregnation has such as figure 2 Mixture of water-soluble silicone oil with the chemical structure shown and metal complex Cu(edta). Here, the kinematic viscosity of the water-soluble silicone oil and the metal complex is 100mm 2 / s.

[0106] For the impregnation of the water-soluble silicone oil and the metal compound, the carbon brush substrate was immersed in the mixture at a liquid temperature of 50° C. for 15 minutes. Then, after taking out the carbon brush base material from the mixture, the carbon brush was placed in a desiccator maintained at 100° C. to remove the water impregnated with the water-soluble silicone oil and the metal compound.

[0107] The impregnation ratios of the water-soluble silicone oil and the metal compound were shown in Table 3 to obtain respective carbon brushes. In addition, the impregnation rate was calculated|required by the method similar to the case of Example 1.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com