Self-homogeneity wearproof resin type carbon brush and preparation method thereof

A technology of resin type and carbon brush, which is applied in the manufacture of brushes, current collectors, electrical components, etc., and can solve problems such as rough wear surfaces, large electric sparks, and high self-heating temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Sulfonated graphene oxide 20wt%,

[0039] Thermosetting resin 40wt%.

[0040] In addition, 1 wt% aminosilane coupling agent, accounting for the total mass of the above components, is added to the mixed powder of graphite powder and sulfonated graphene oxide.

[0041] Add 2wt% polyethylene glycol accounting for the total mass of sulfonated graphene oxide, graphite powder and thermosetting resin to the mixture and resin alcohol solution.

[0042] 3. Dry mix, wet mix, flake, crush, sieve, press the above materials, and then solidify at a final temperature of 190°C to obtain the required samples.

[0043] 4. Make the sample into a carbon brush of the desired shape, and put it into a 1400W stone cutting machine for performance testing.

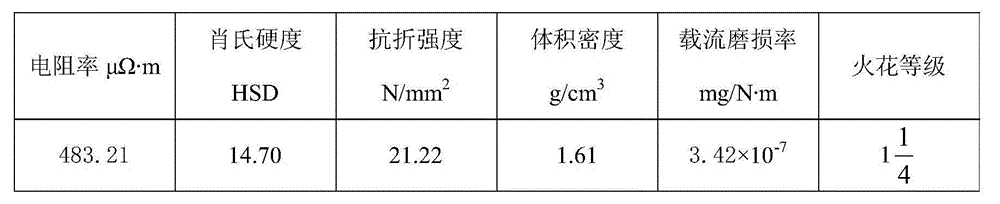

[0044] The test data is shown in the table below:

[0045]

Embodiment 2

[0047] Sulfonated graphene oxide 15wt%,

[0048] Graphite powder 45wt%,

[0049] Thermosetting resin 40wt%.

[0050] In addition, 1 wt% aminosilane coupling agent, accounting for the total mass of the above components, is added to the mixed powder of graphite powder and sulfonated graphene oxide.

[0051] Add 2wt% polyethylene glycol accounting for the total mass of sulfonated graphene oxide, graphite powder and thermosetting resin to the mixture and resin alcohol solution.

[0052] 3. Dry mix, wet mix, flake, crush, sieve, press the above materials, and then solidify at a final temperature of 190°C to obtain the required samples.

[0053] 4. Make the sample into a carbon brush of the desired shape, and put it into a 1400W stone cutting machine for performance testing.

[0054] The test data is shown in the table below:

[0055]

Embodiment 3

[0057] Sulfonated graphene oxide 15wt%,

[0058] Graphite powder 55wt%,

[0059] Thermosetting resin 30wt%.

[0060] Adding 1wt% of the total mass of aminosilane coupling agent to the mixed powder of graphite powder and sulfonated graphene oxide;

[0061] Add 2wt% polyethylene glycol accounting for the total mass of sulfonated graphene oxide, graphite powder and thermosetting resin to the mixture and resin alcohol solution.

[0062]3. Dry mix, wet mix, flake, crush, sieve, press the above materials, and then solidify at a final temperature of 190°C to obtain the required samples.

[0063] 4. Make the sample into a carbon brush of the desired shape, and put it into a 1400W stone cutting machine for performance testing.

[0064] The test data is shown in the table below:

[0065]

[0066] The above embodiments are only some preferred groups of preferred solutions in the present invention, and are not intended to limit the present invention; within the spirit and principle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com