Motor brush for small household appliances and manufacturing method thereof

A manufacturing method and technology for small electrical appliances, applied in the manufacture of brushes, current collectors, rotary current collectors, etc., can solve the problem of product instability affecting the wear resistance and other properties of brushes, poor performance of brushes, and hidden dangers of environmental protection, etc. problems, to achieve the effect of simple manufacturing process, good commutation performance and reduced wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

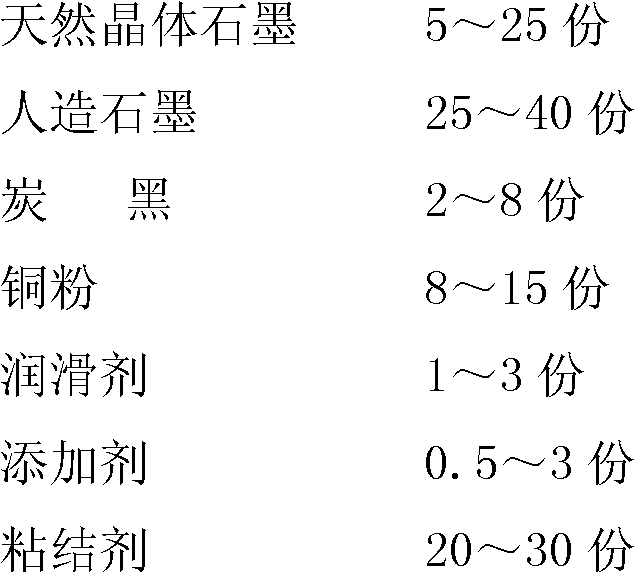

[0026] A motor brush for small household electrical appliances, the composition ratio of raw materials in parts by weight is:

[0027]

[0028] The manufacture method of above-mentioned electric motor electric brush for small household appliances, it comprises the following steps:

[0029] 1. Add natural crystal graphite, artificial graphite, carbon black, tungsten disulfide, and refined table salt into the container according to the above formula, and mix for 70 minutes while heating.

[0030] 2. When the temperature of the above materials reaches 120±10°C, add the formulated amount of medium-temperature asphalt, continue to heat to 190±10°C and knead evenly.

[0031] 3. Freely cool and granulate the uniformly kneaded pasty material during the kneading process. When the temperature of the material is ≤100°C, unload it from the container and allow it to cool freely to room temperature.

[0032] 4. Grind the above-mentioned cooled granular material into powder, pass through...

Embodiment 2

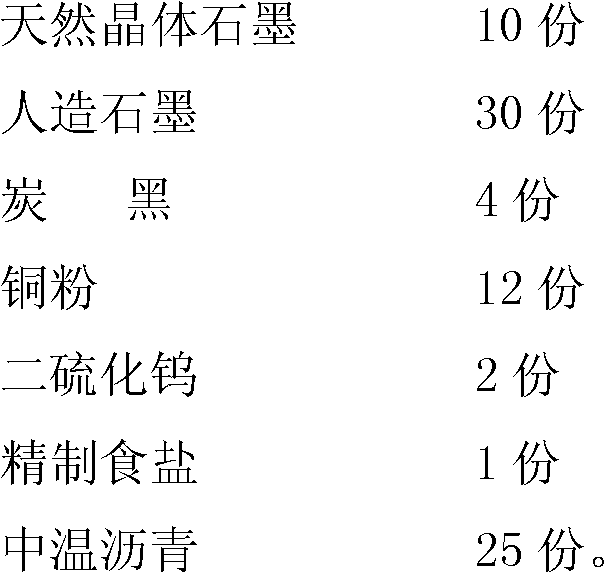

[0035] A motor brush for small household electrical appliances, the composition ratio of raw materials in parts by weight is:

[0036]

[0037] The manufacture method of above-mentioned electric motor electric brush for small household appliances, it comprises the following steps:

[0038] 1. Add natural crystal graphite, artificial graphite, carbon black, tungsten disulfide, and refined table salt into the container according to the above formula, and mix for 60 minutes while heating.

[0039] 2. When the temperature of the above materials reaches 120±10°C, add the formulated amount of medium-temperature asphalt, continue to heat to 190±10°C and knead evenly.

[0040] 3. Freely cool and granulate the uniformly kneaded pasty material during the kneading process. When the temperature of the material is ≤100°C, unload it from the container and allow it to cool freely to room temperature.

[0041] 4. Grind the above-mentioned cooled granular material into powder, pass through...

Embodiment 3

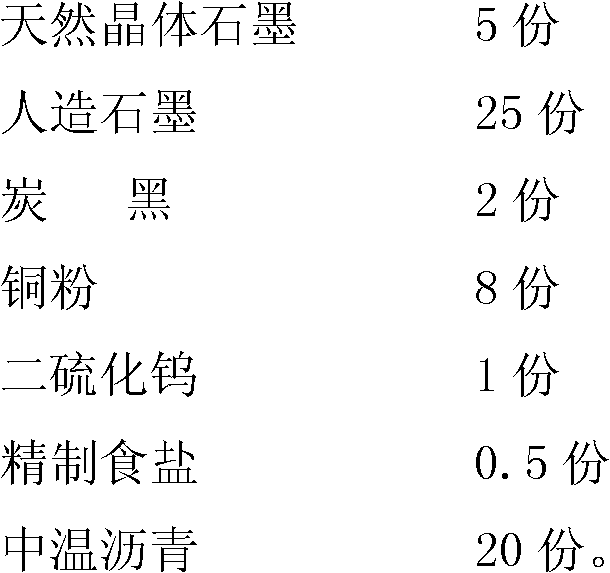

[0044] A motor brush for small household electrical appliances, the composition ratio of raw materials in parts by weight is:

[0045]

[0046]

[0047] The manufacture method of above-mentioned electric motor electric brush for small household appliances, it comprises the following steps:

[0048] 1. Add natural crystal graphite, artificial graphite, carbon black, tungsten disulfide, and refined table salt into the container according to the above formula, and mix for 70 minutes while heating.

[0049] 2. When the temperature of the above materials reaches 120±10°C, add the formulated amount of medium-temperature asphalt, continue to heat to 190±10°C and knead evenly.

[0050] 3. Freely cool and granulate the uniformly kneaded pasty material during the kneading process. When the temperature of the material is ≤100°C, unload it from the container and allow it to cool freely to room temperature.

[0051] 4. Grind the above-mentioned cooled granular material into powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com