Electric locomotive braking control method and system

A technology for braking control and electric locomotives, which is applied to electric braking systems, electric vehicles, vehicle components, etc., and can solve problems such as commutator damage, wheel scratches, and wheel irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

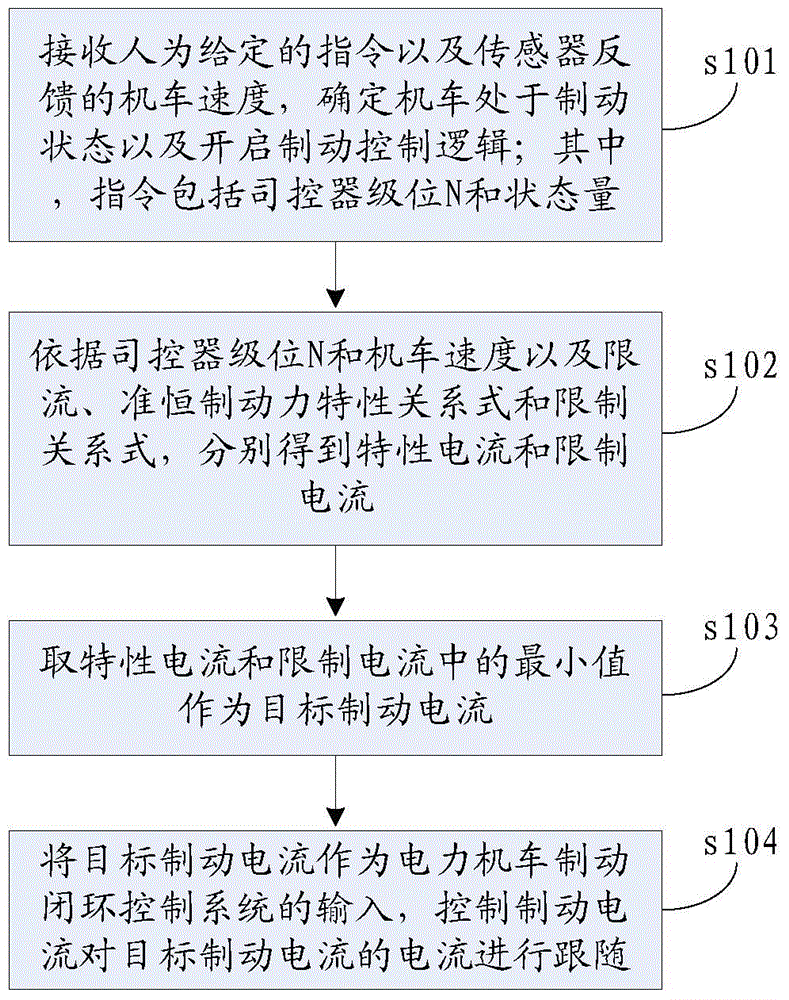

[0047] Please refer to figure 1 , figure 1 It is a flow chart of the process of a braking control method for an electric locomotive provided by the present invention, the method comprising:

[0048] Step s101: Receive the artificially given instruction and the locomotive speed v fed back by the sensor, determine that the locomotive is in the braking state and start the braking control logic; where the instruction includes the controller level N and the state quantity;

[0049] It can be understood that the logic determination module in the control cabinet of the electric locomotive first receives the artificially given command and the locomotive speed v fed back by the locomotive sensor, and determines that the locomotive is in the braking state according to the command and the locomotive speed v, and then the micro-cabinet is opened Brake control logic.

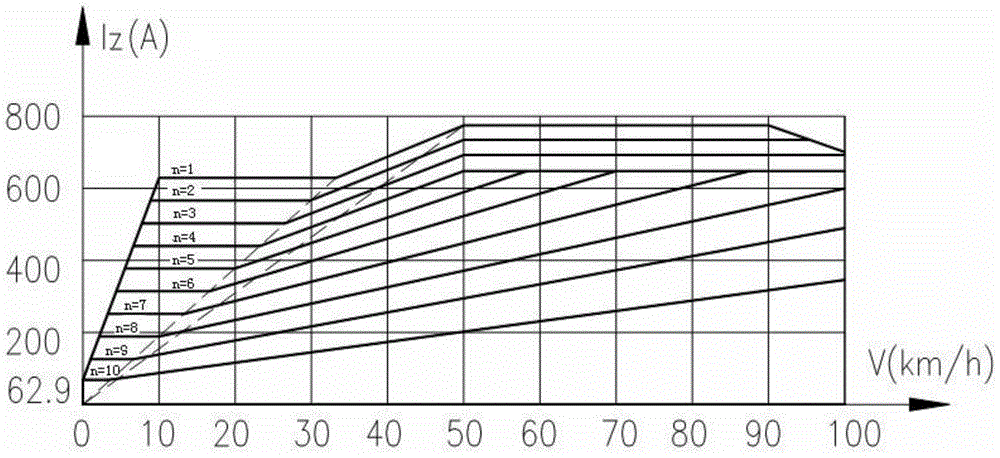

[0050] Step s102: According to the level N of the controller, the speed v of the locomotive, and the current limiting, q...

Embodiment 2

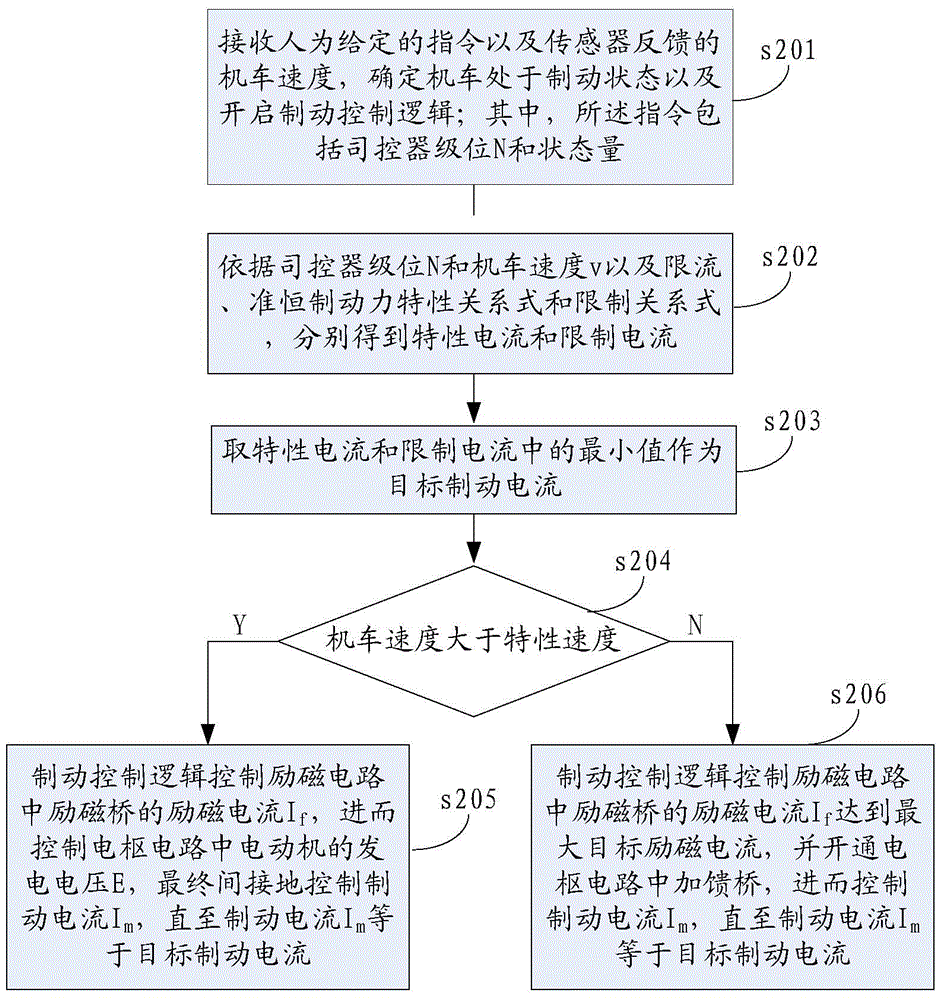

[0138] This embodiment is based on Embodiment 1, please refer to image 3 , image 3 A flow chart of the process of another electric locomotive braking control method provided by the present invention, the method includes:

[0139] Step s201: Receive an artificially given instruction and the locomotive speed fed back by the sensor, determine that the locomotive is in the braking state and start the brake control logic; wherein, the instruction includes the level N of the controller and the state quantity;

[0140] Step s202: According to the level N of the controller, the speed v of the locomotive, and the current limiting, quasi-constant braking force characteristic relation and limit relation, respectively obtain the characteristic current I 1 and limit the current I 2 ,in:

[0141] The characteristic relation is I 1 = 1197.1 · ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com