Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1217 results about "Motor efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Motor efficiency is the ratio between the amount of mechanical work the motor performs and the electrical power it consumes to do the work, represented by a percentage. A higher percentage represents a more efficient motor. Electric motor efficiency is dependent on (but not limited to) design, materials, construction, rating,...

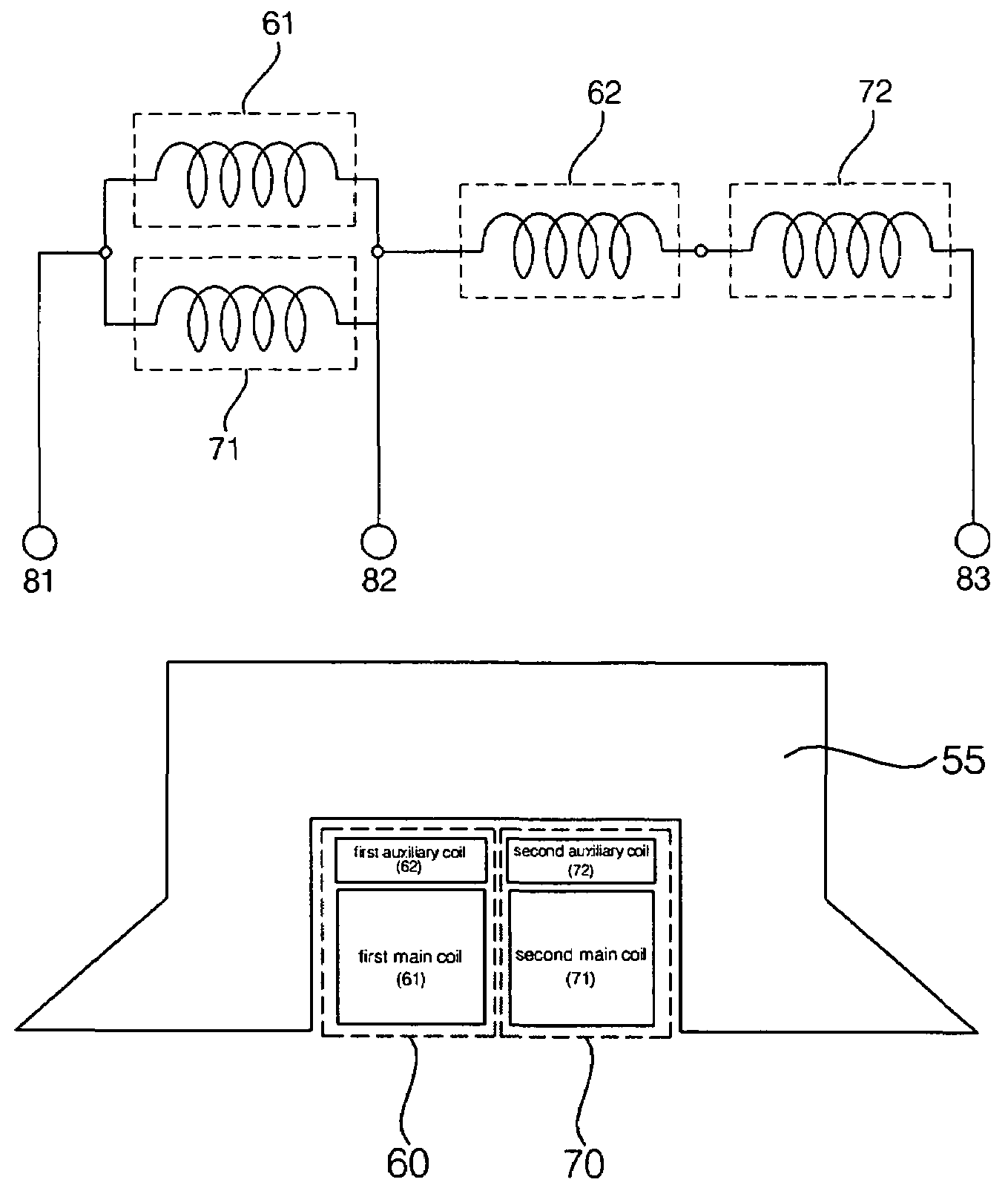

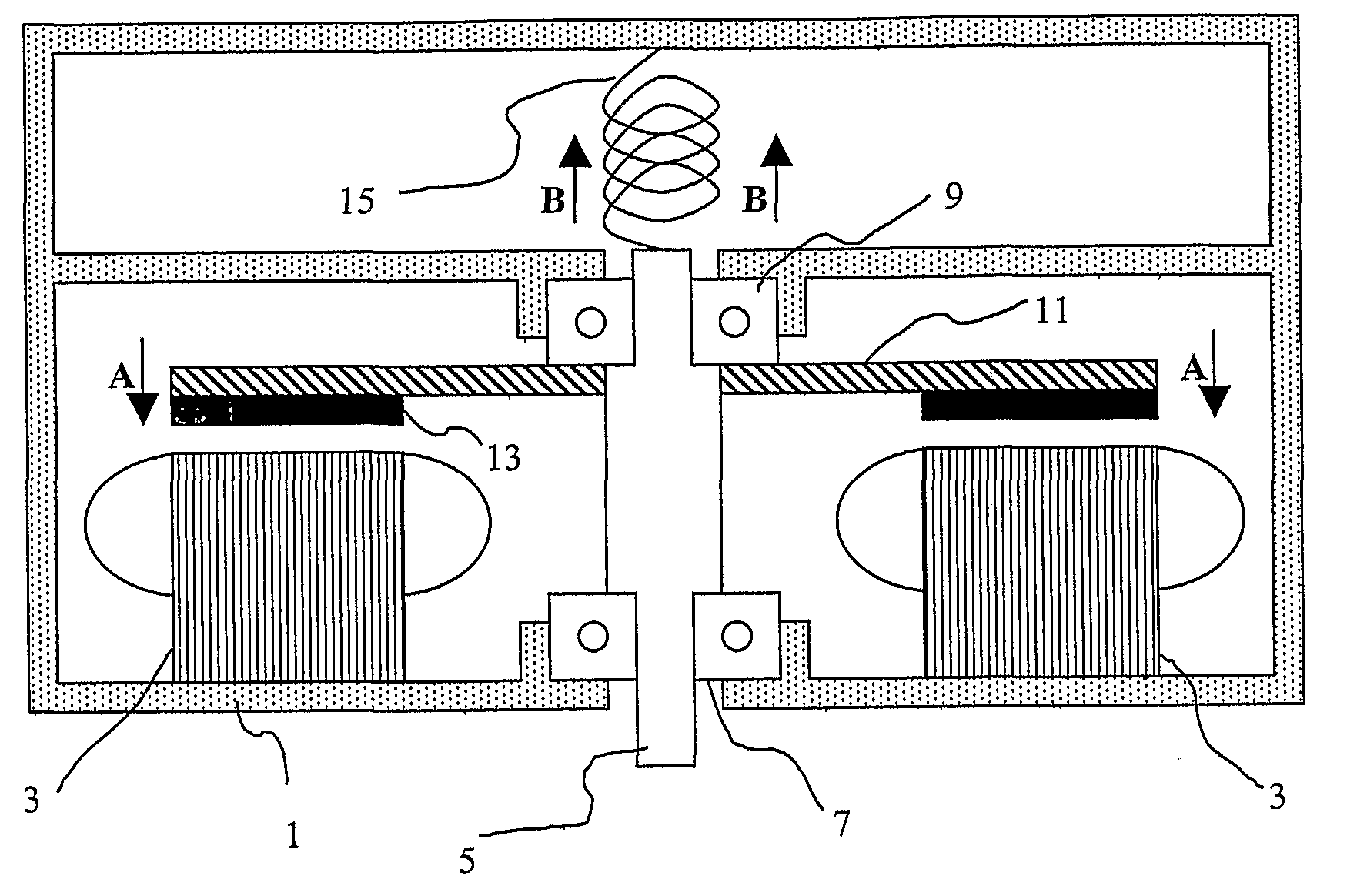

Linear motor and linear compressor using the same

ActiveUS7489055B2Improve efficiencySmall sizeAC motor controlDC motor speed/torque controlBobbinElectrical conductor

Disclosed herein is a linear motor in which a plurality of coil groups are connected in series or in parallel and driving power is applied to part or all of the coil groups according to load applied to the linear motor, thereby achieving improved motor efficiency with a reduced motor size. The linear motor includes a bobbin, the plurality of coil groups wound on the bobbin, the plurality of coil groups being connected in series or in parallel to allow the driving power to be applied to part or all of the coil groups, and a magnet adapted to be linearly reciprocated by a magnetic field produced by the coil groups depending on load current flowing through the coil groups. As a result of connecting the plurality of coil groups, which are formed of a plurality of coil conductors, in series or in parallel, the capacity of the coil groups is variable depending on the load of the motor, resulting in improved motor efficiency. Also, using the coil conductors having a small cross sectional area enables reduction in the size of the motor.

Owner:LG ELECTRONICS INC

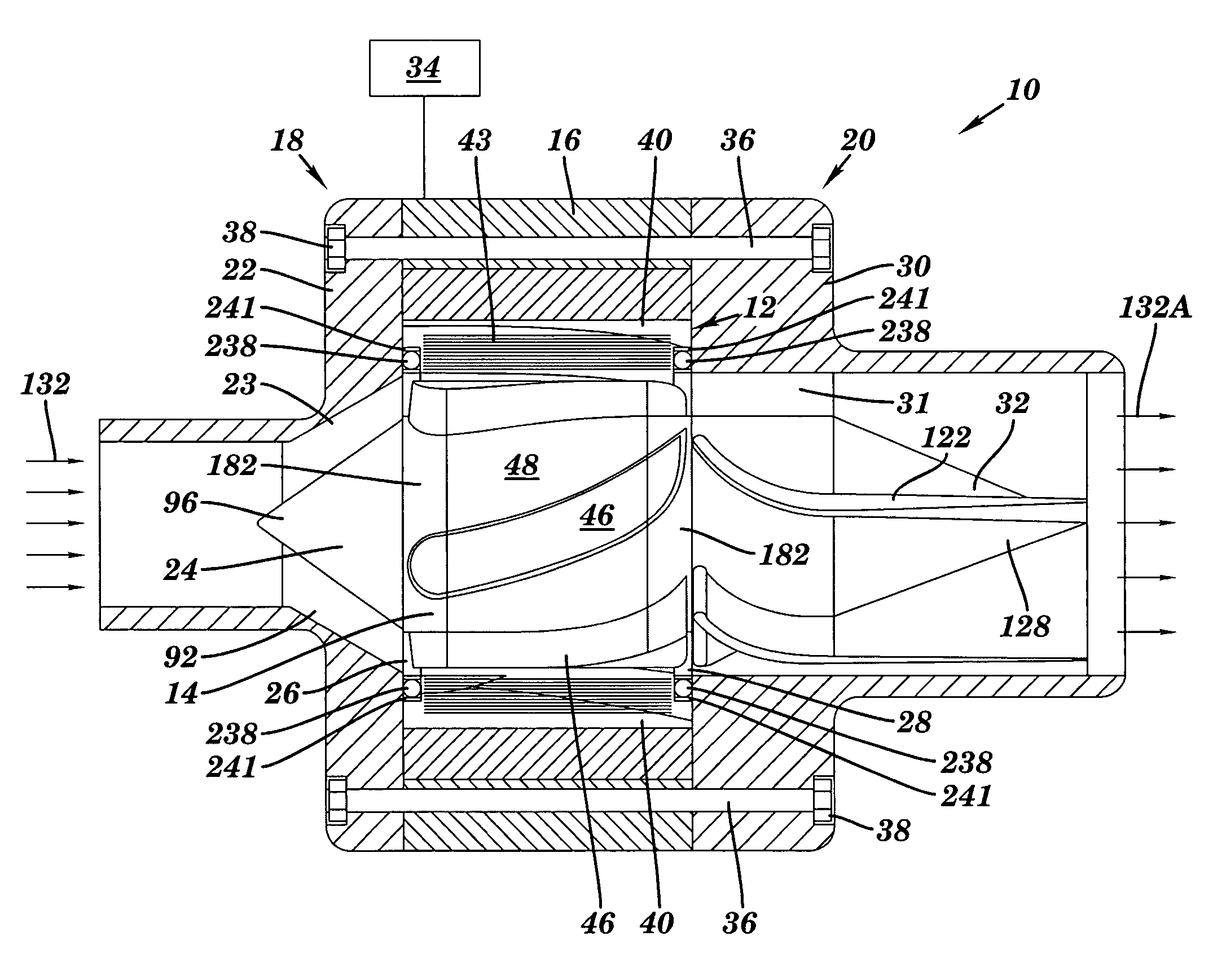

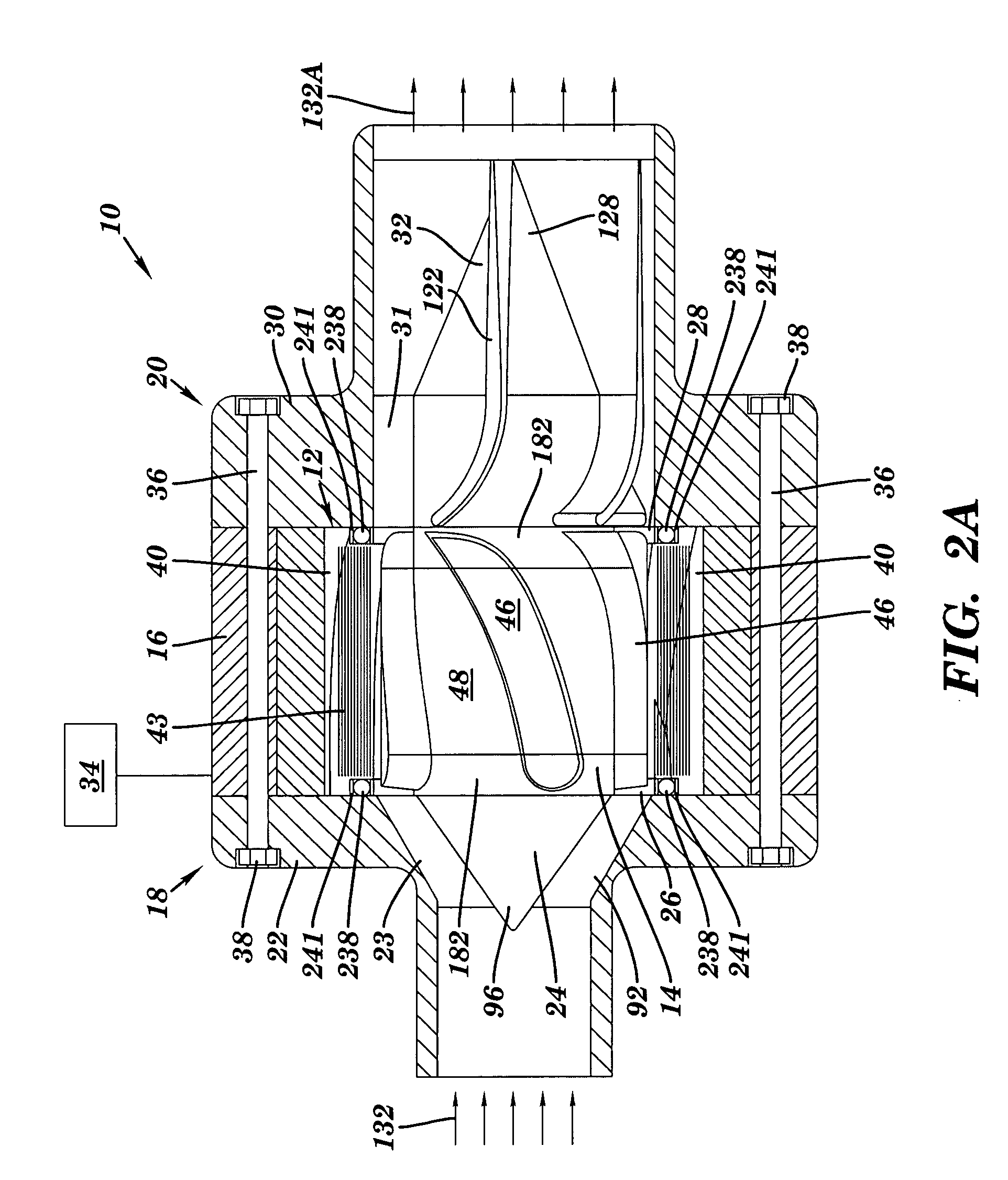

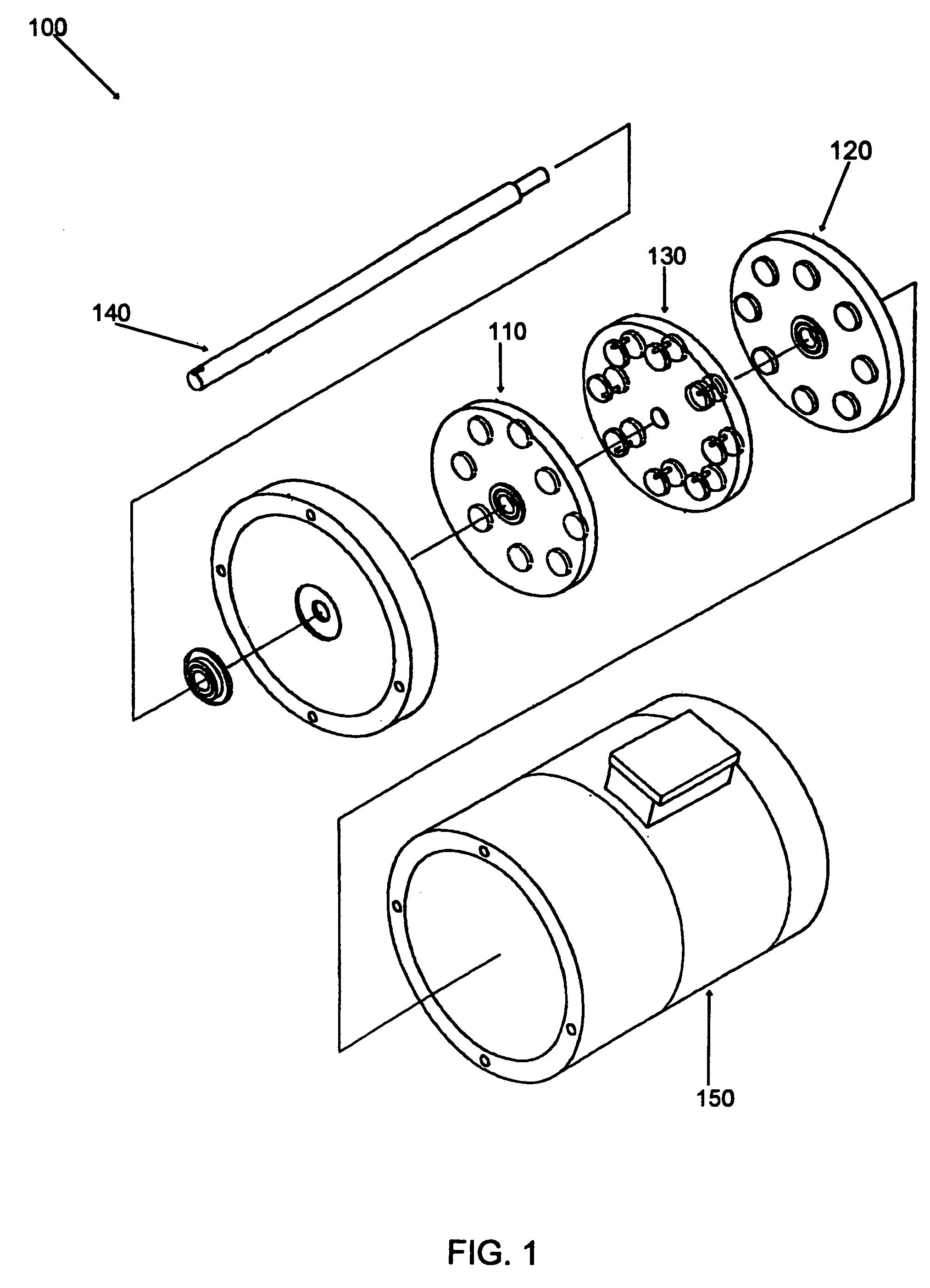

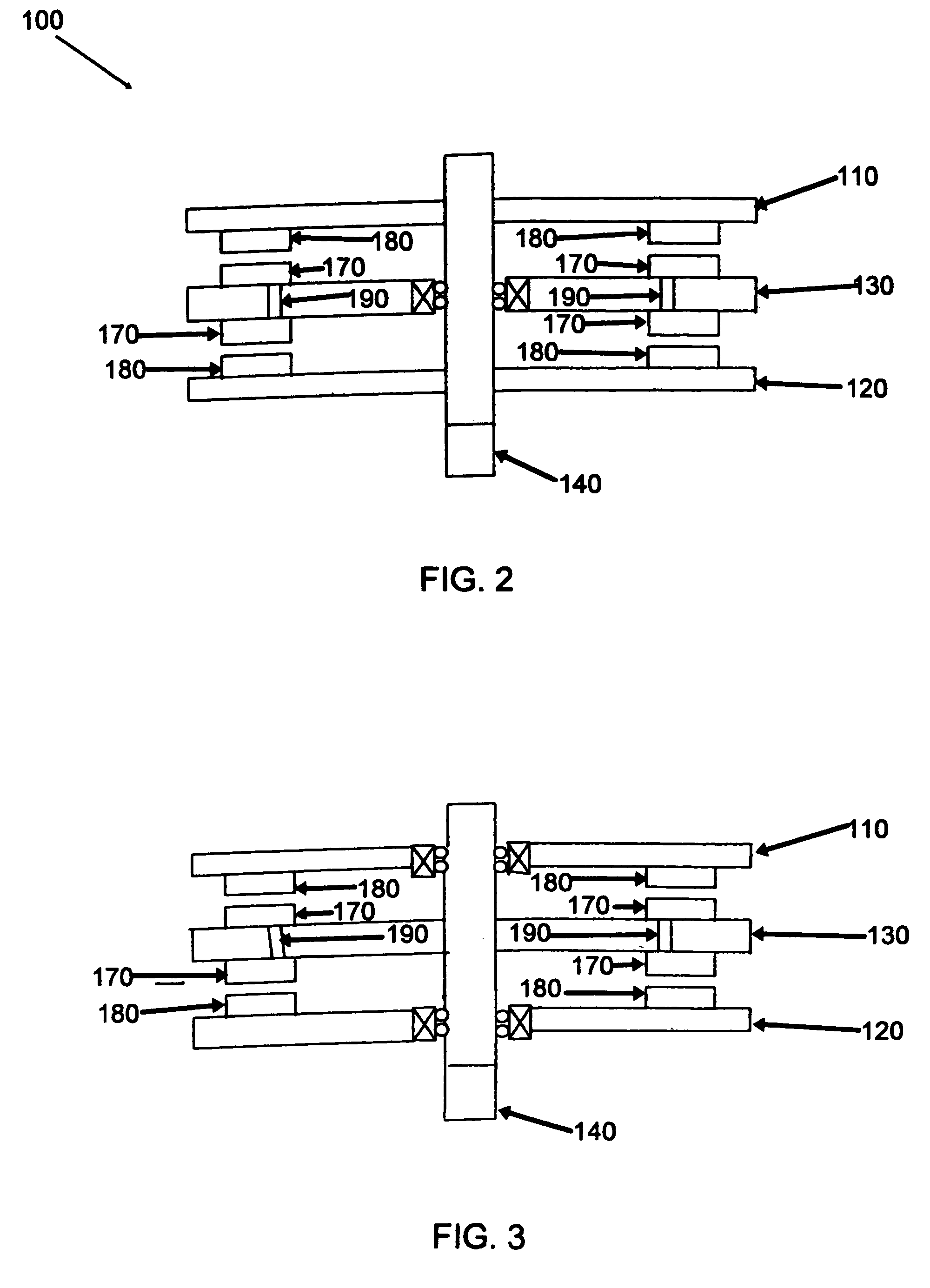

Fluid pump/generator with integrated motor and related stator and rotor and method of pumping fluid

InactiveUS7021905B2Small sizeReduce the number of partsGas turbine plantsRotary piston pumpsImpellerElectric machine

Owner:ADVANCED ENERGY CONVERSION

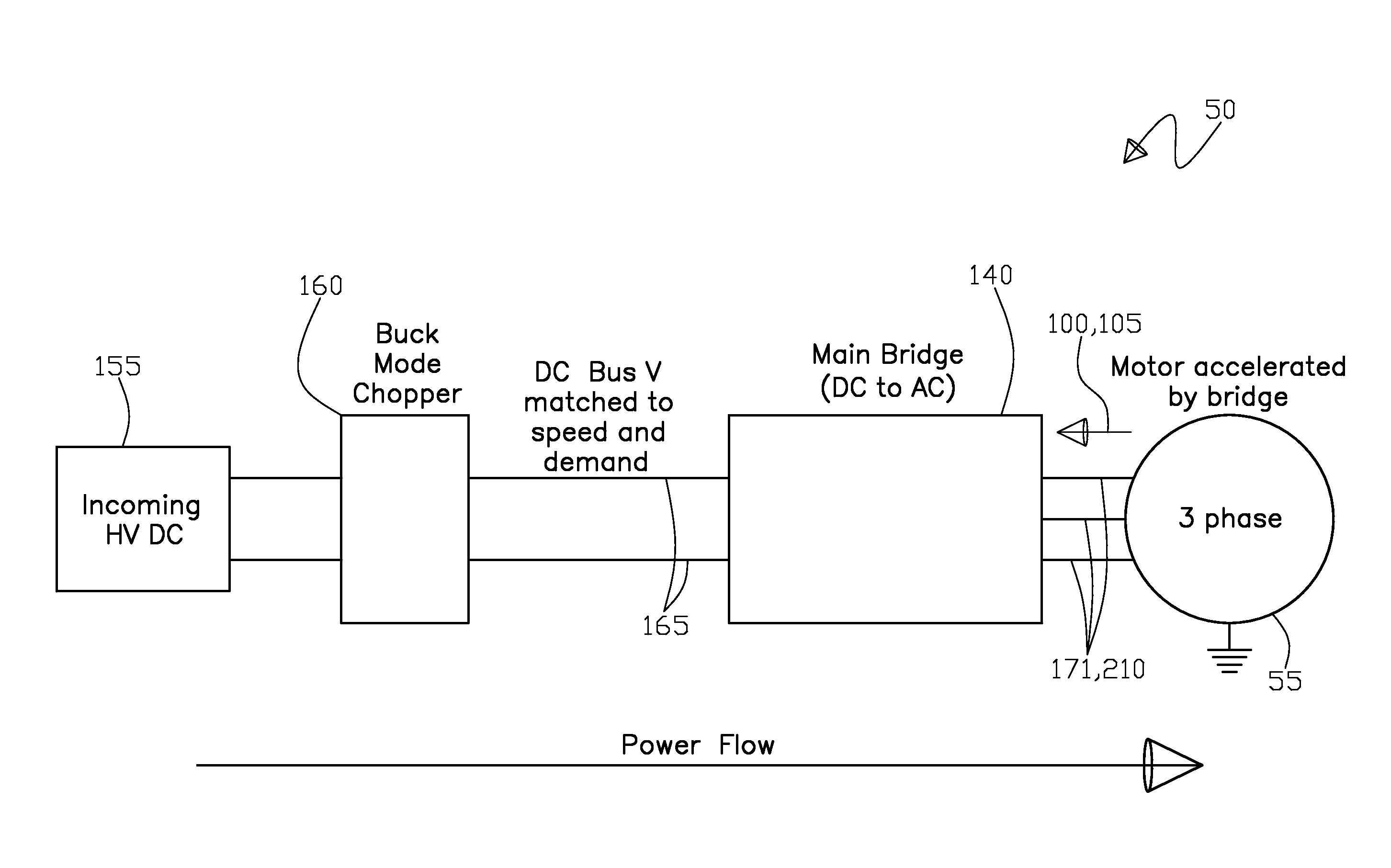

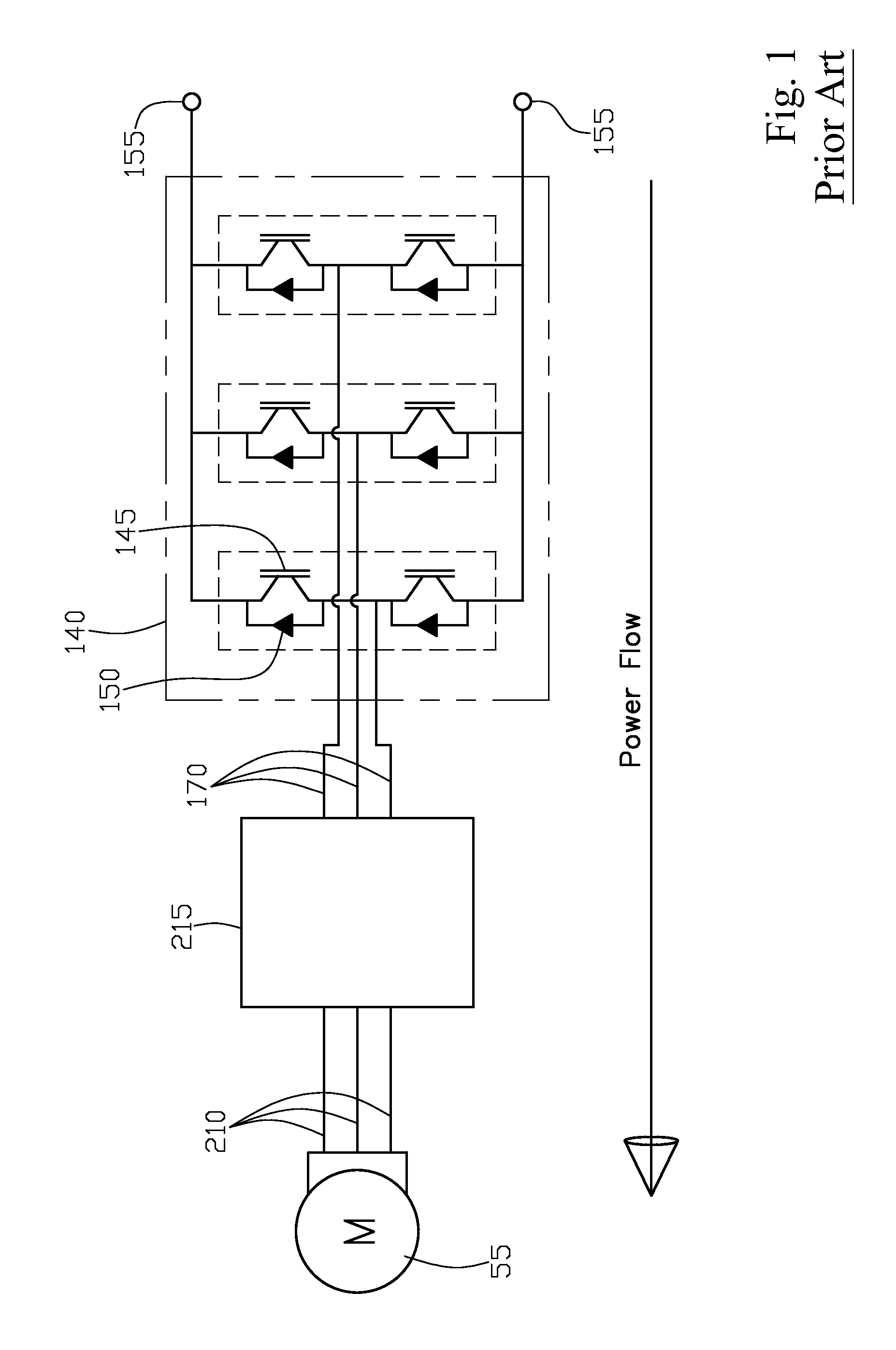

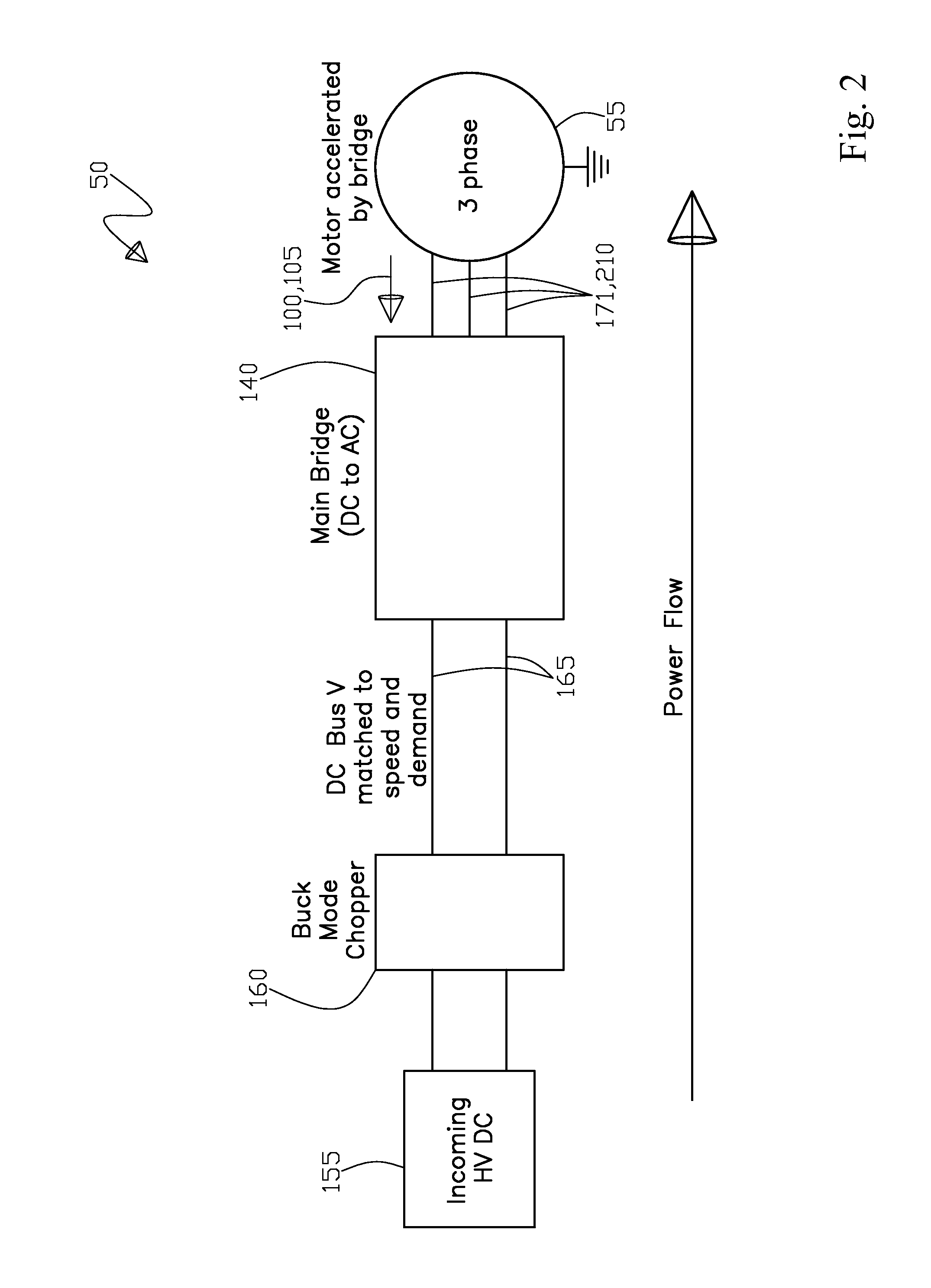

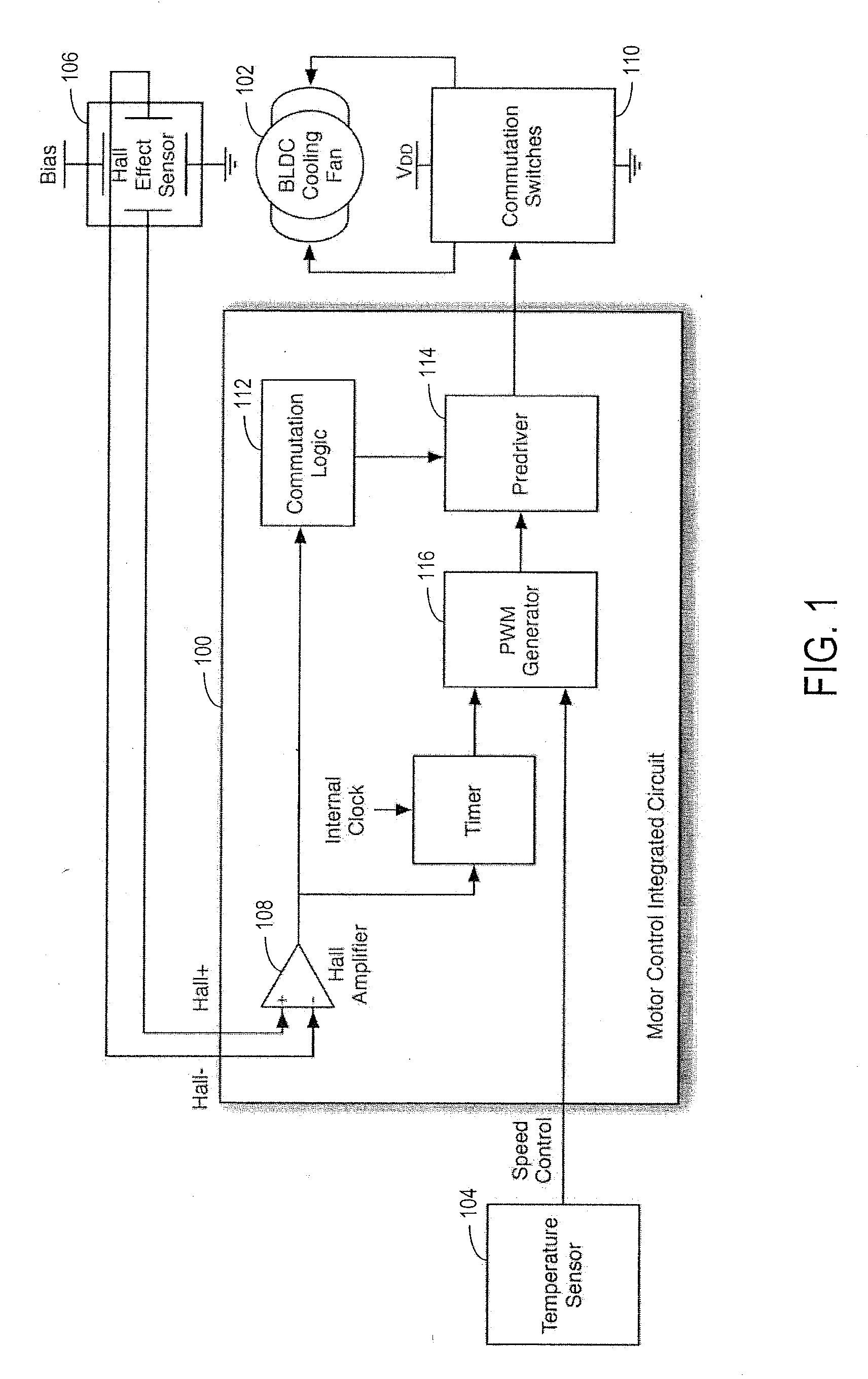

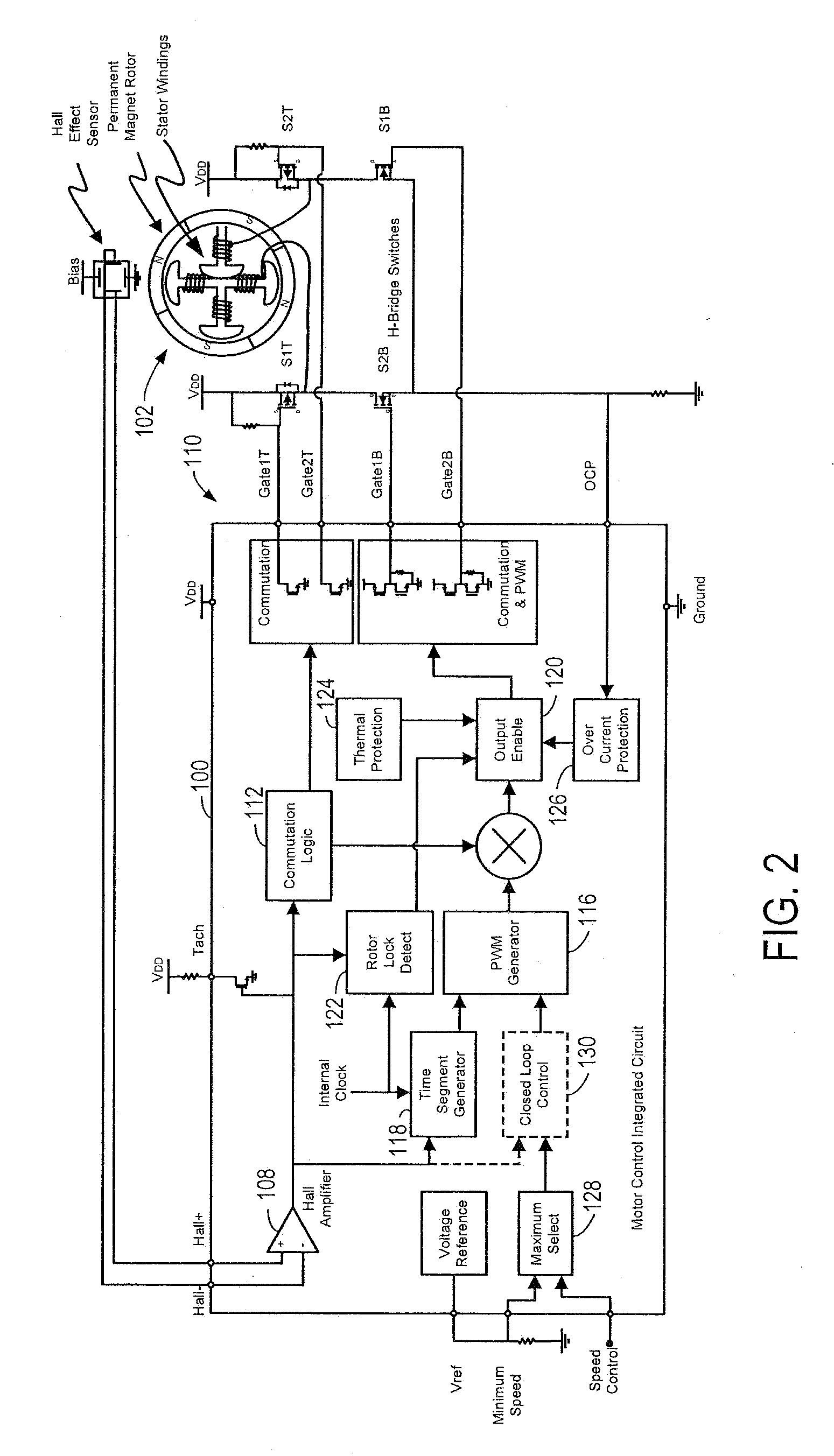

Electrical Control System

ActiveUS20130307450A1Reduce switching frequencyImprove motor efficiencyTorque ripple controlAC motor controlSwitching frequencyAlternating current

An electrical control system having a direct current to direct current regulator receiving a direct current supply input, wherein the regulator outputs a controlled voltage direct current inverter power feed. Included is an inverter in electrical communication with the regulator and receives the controlled voltage direct current inverter power feed, the inverter outputs an alternating current motor power feed to a permanent magnet brushless direct current motor that outputs a shaft rotational speed and a back electromotive force. Also, a control is provided for regulating the controlled voltage direct current inverter power feed based upon criteria utilizing the back electromotive force or an auxiliary motor stator wire loop signal in conjunction with an optional voltage look-up table to substantially make the controlled voltage result in a reduction of a pulse width modulation switching frequency to further smooth and reduce harmonic of the alternating current waveform to increase motor efficiency.

Owner:BARBER NICHOLS

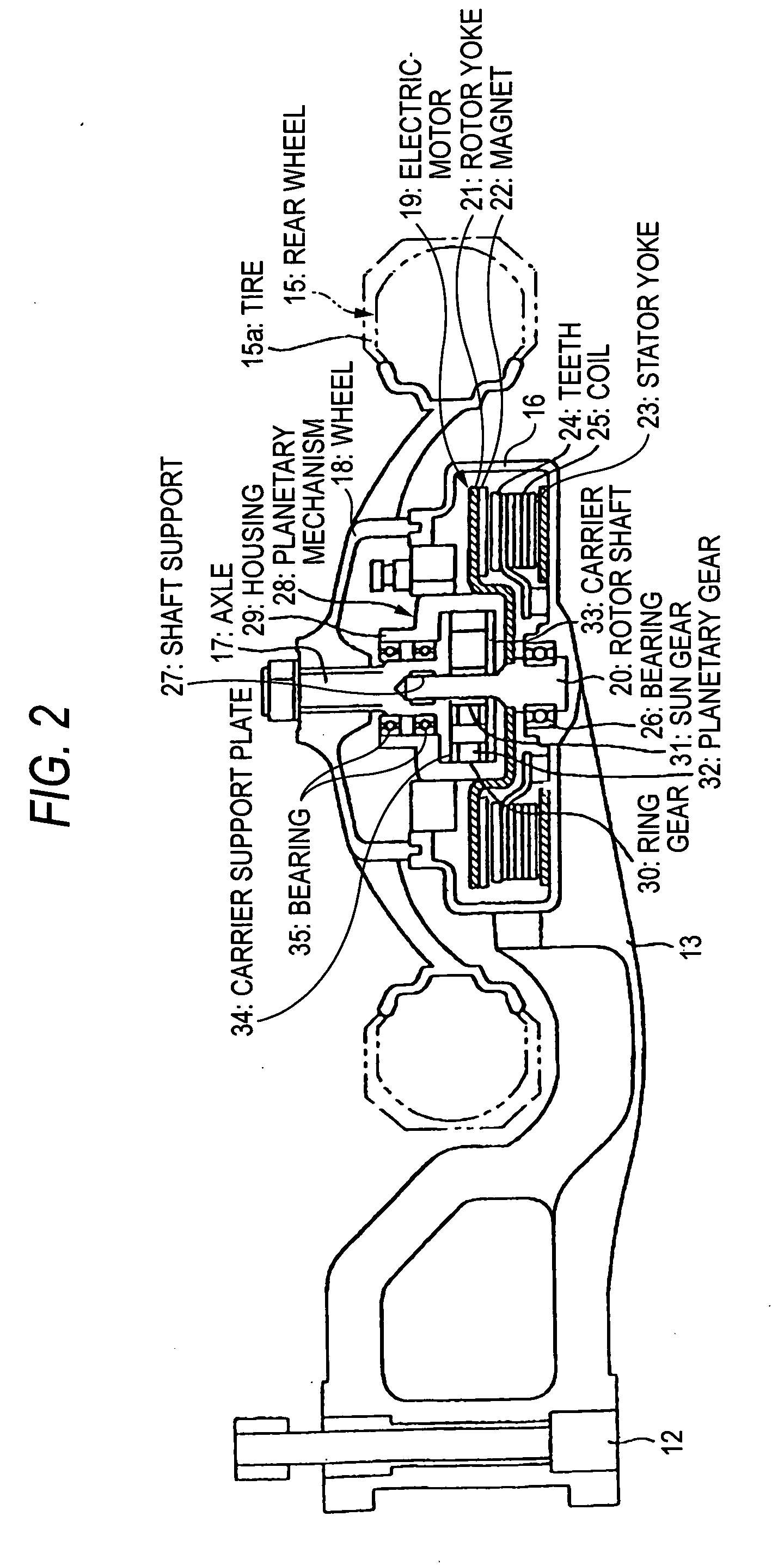

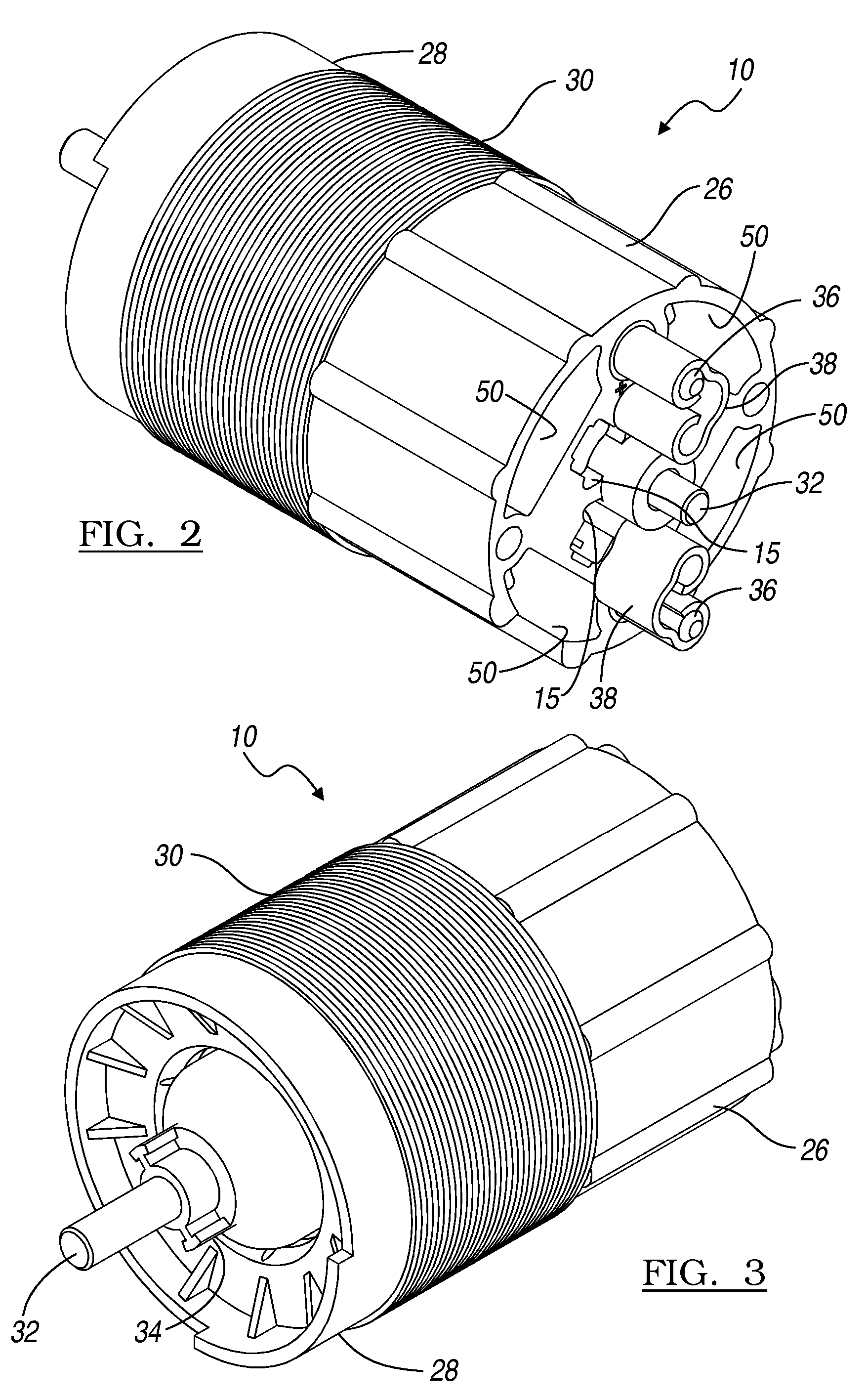

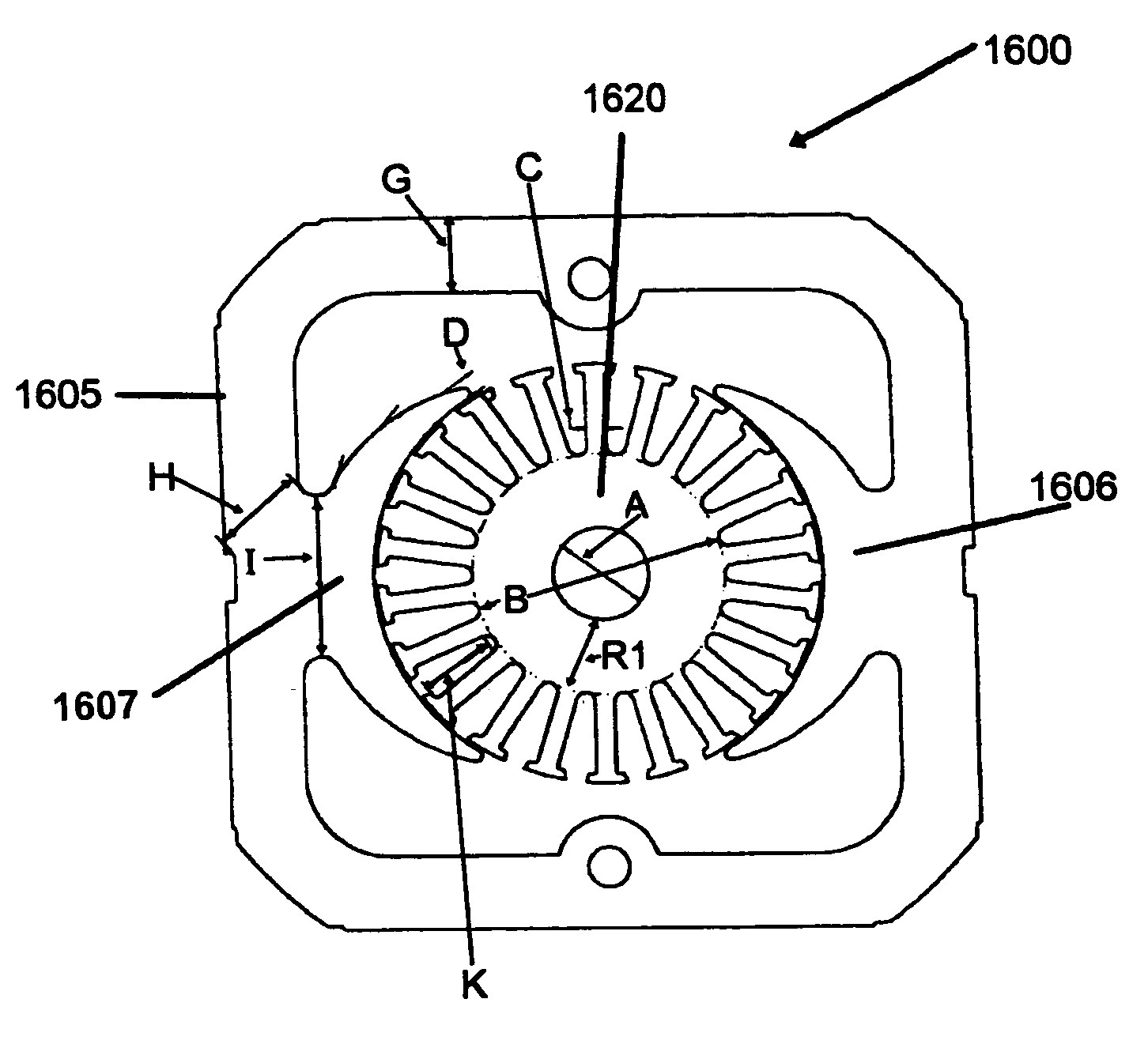

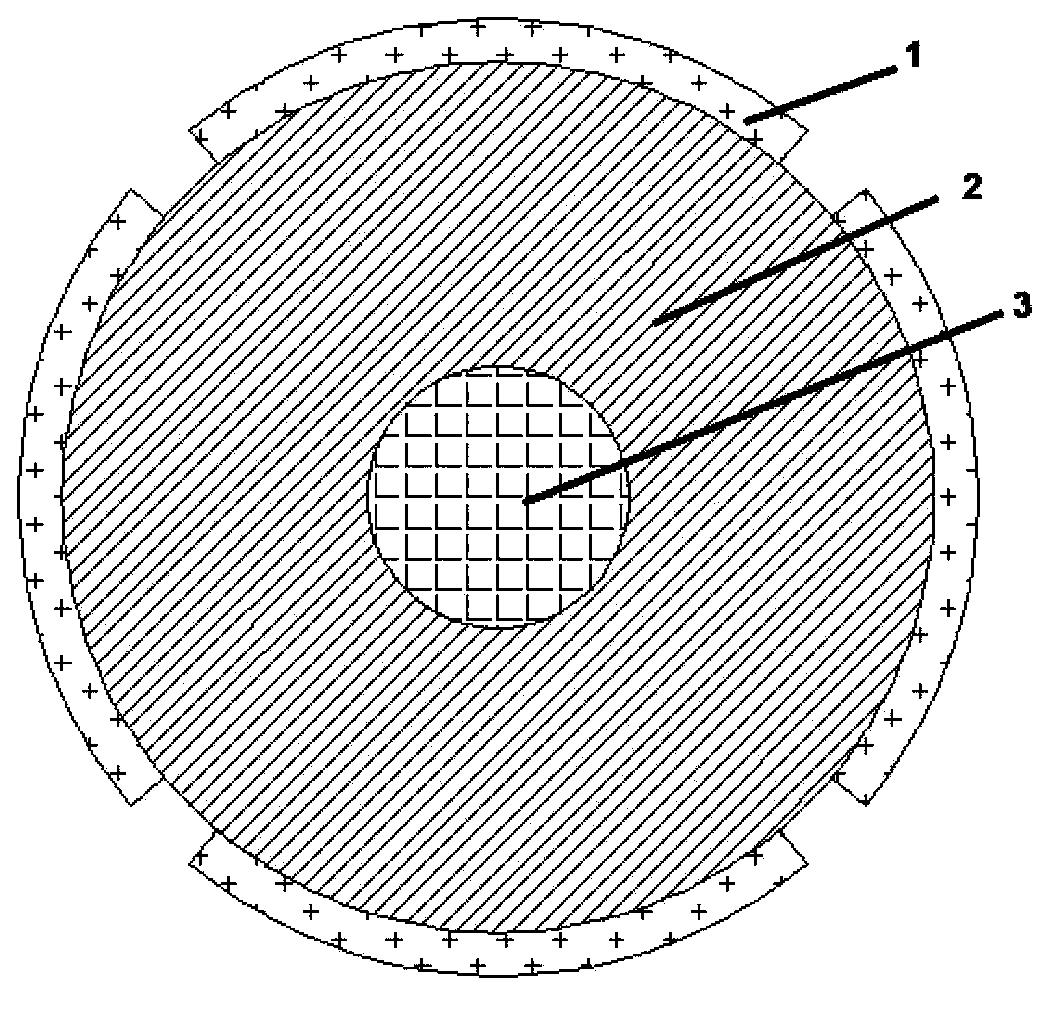

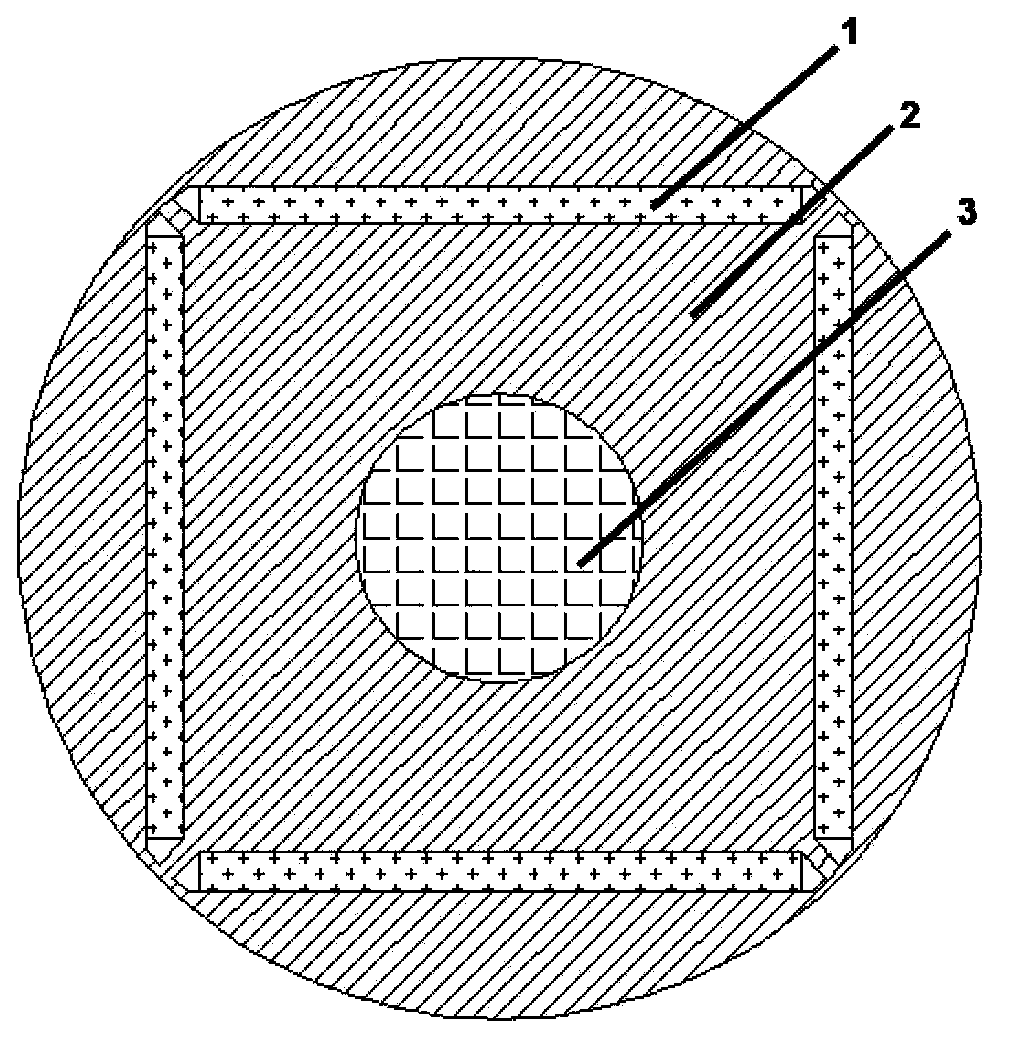

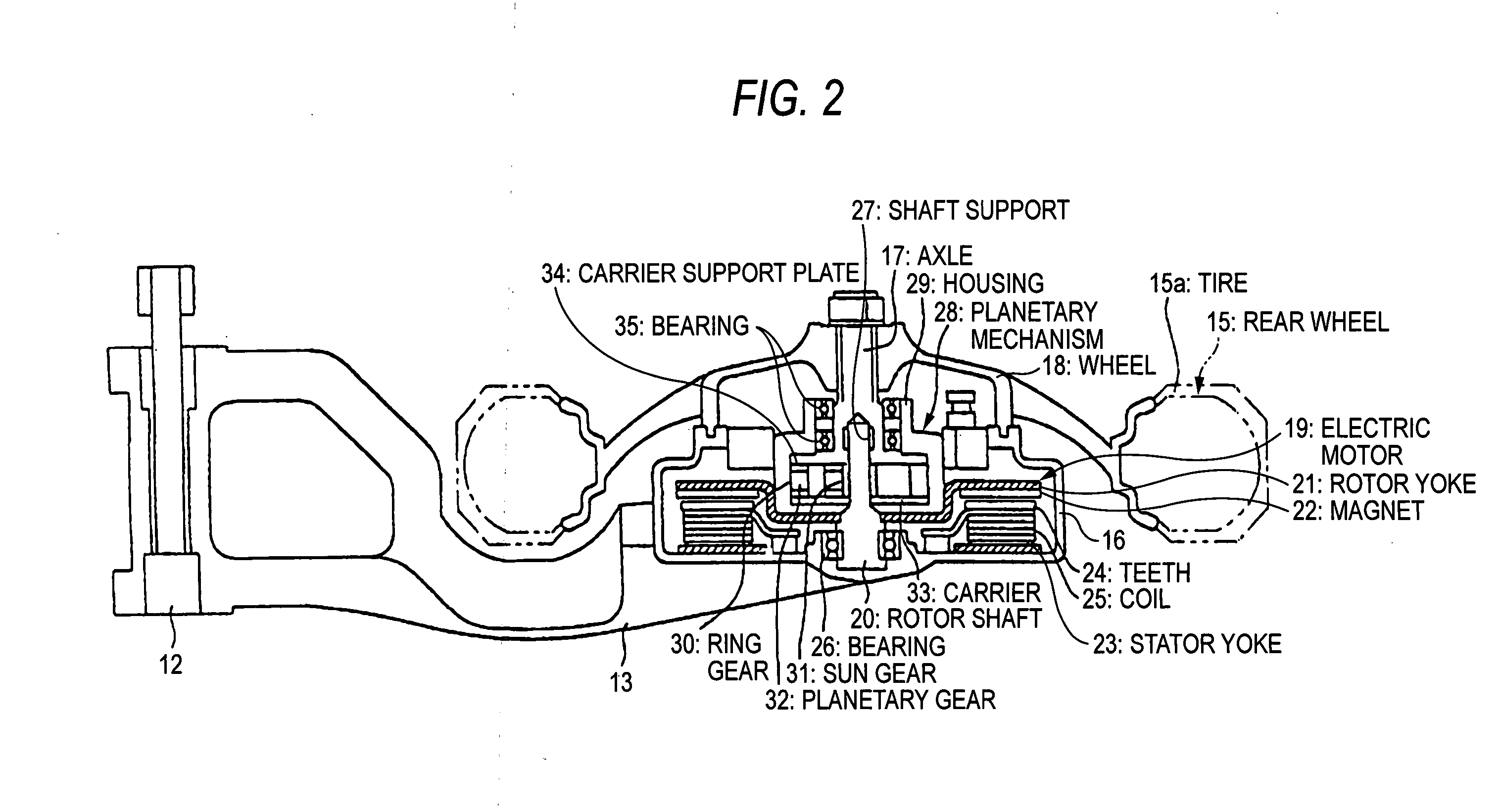

High-efficiency wheel-motor utilizing molded magnetic flux channels with transverse-flux stator

InactiveUS7492074B1Improve efficiencyTotal current dropMagnetic circuit rotating partsSynchronous machinesTransverse fluxPole piece

A motor including a mounting shaft having a hollow channel and a bearing attached to each end, a cylindrical hub having a hollow core for the mounting shaft, and plural rows of plural Molded Magnetic Flux Channels with a hollow core and a channel forming a U-shaped recess and mounted the surface of the hub, each row corresponding to a motor phase. Each magnetic flux channel forms two pole pieces divided by the channel. The motor also includes plural phase windings, one passing through each row of plural Molded Magnetic Flux Channels, a rotating drum having plural rows of permanent magnets on an inner surface, each row pair corresponding to and aligned with one of the plural rows of Molded Magnetic Flux Channels. The rotating drum connected with the bearing, and drive electronics for driving the plural phase windings, wherein the plural Molded Magnetic Flux Channels increases torque and motor efficiency.

Owner:RITTENHOUSE NORMAN

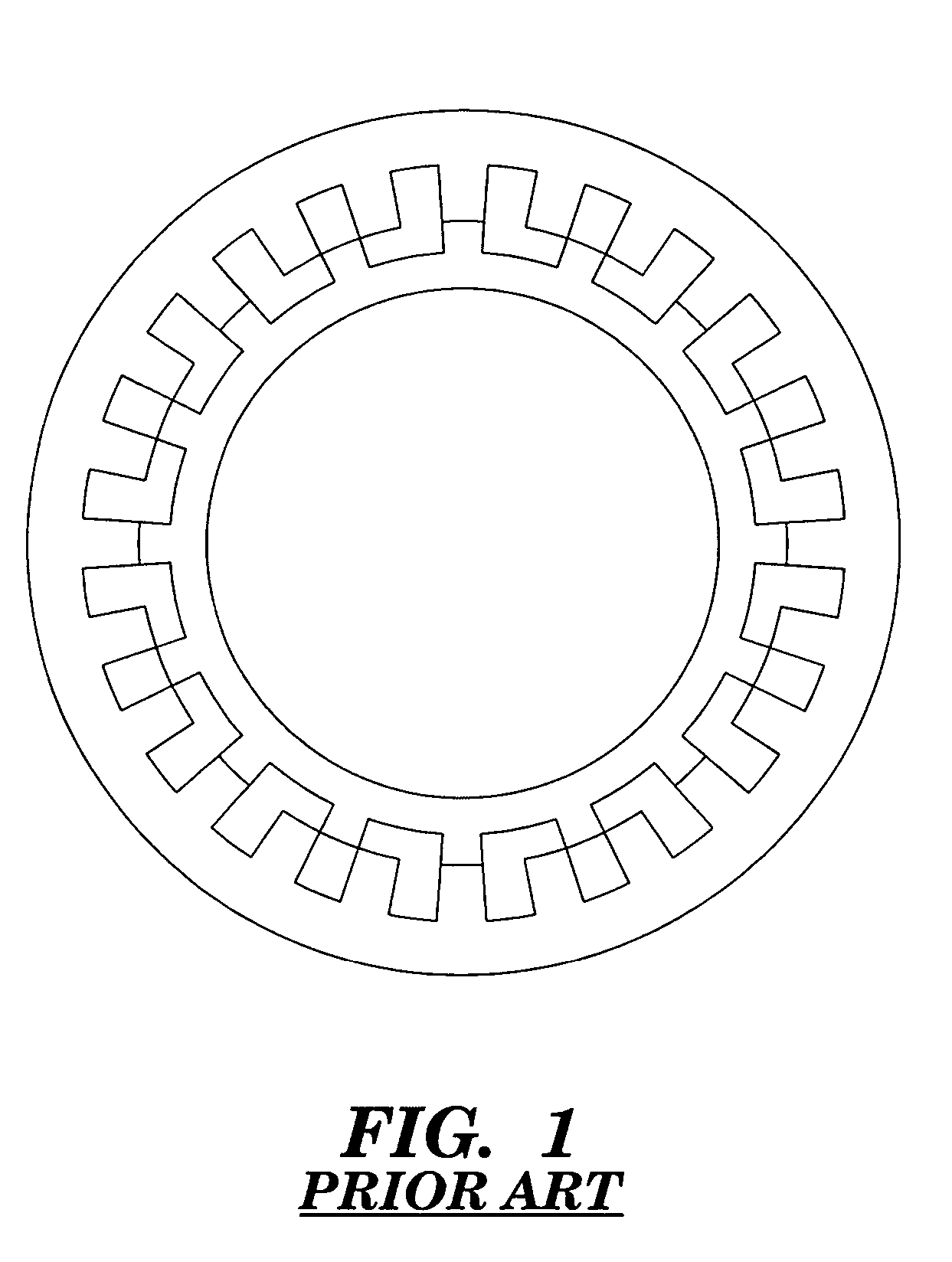

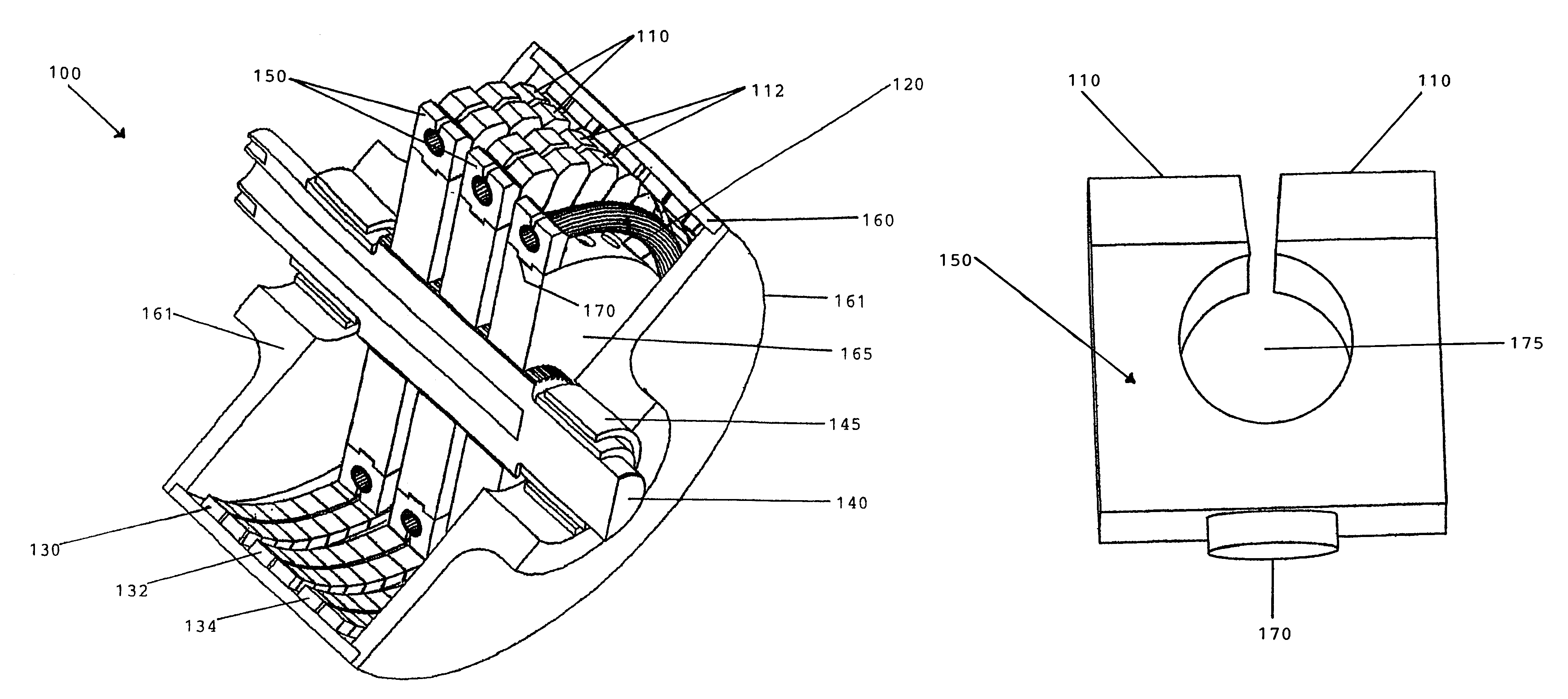

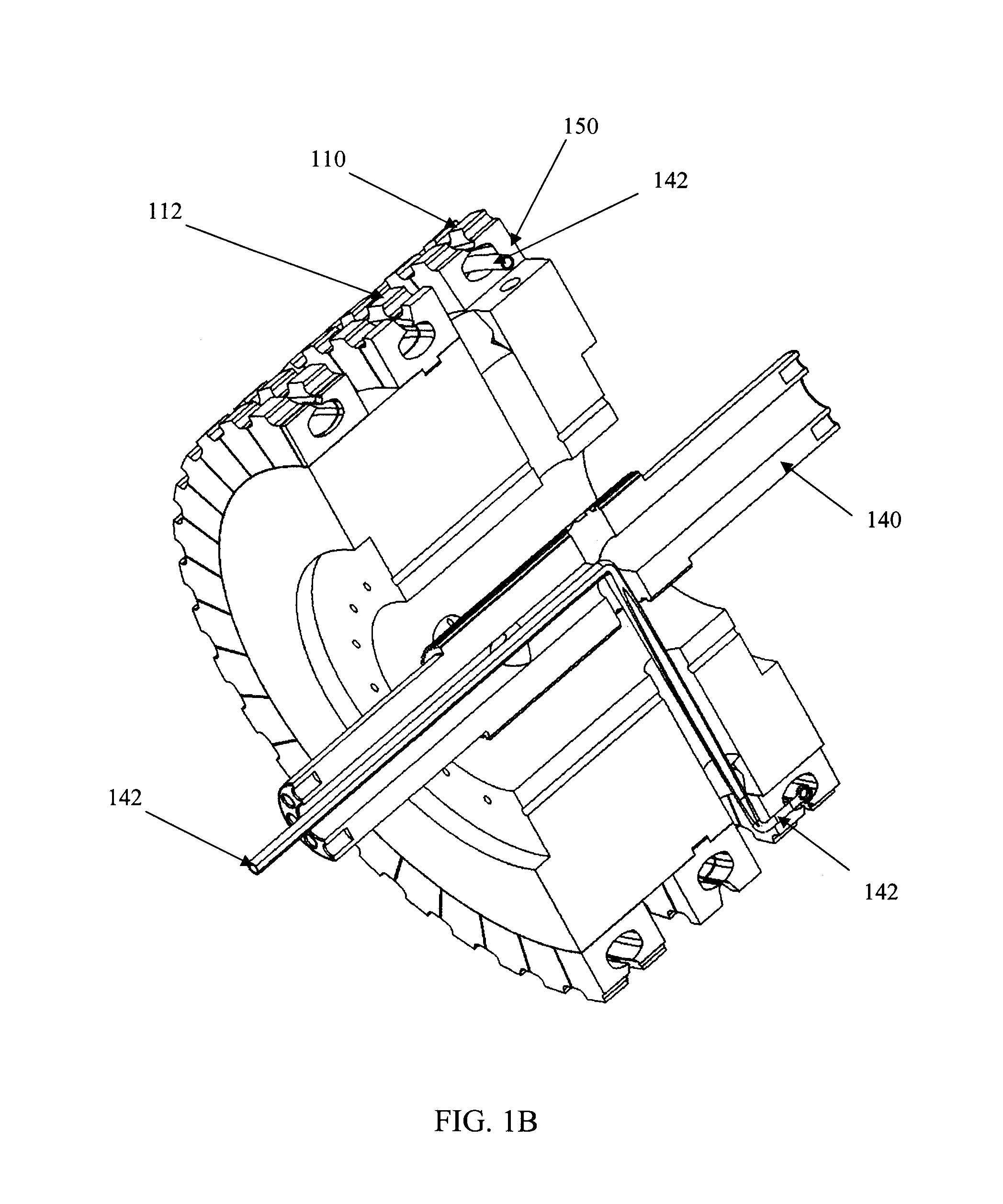

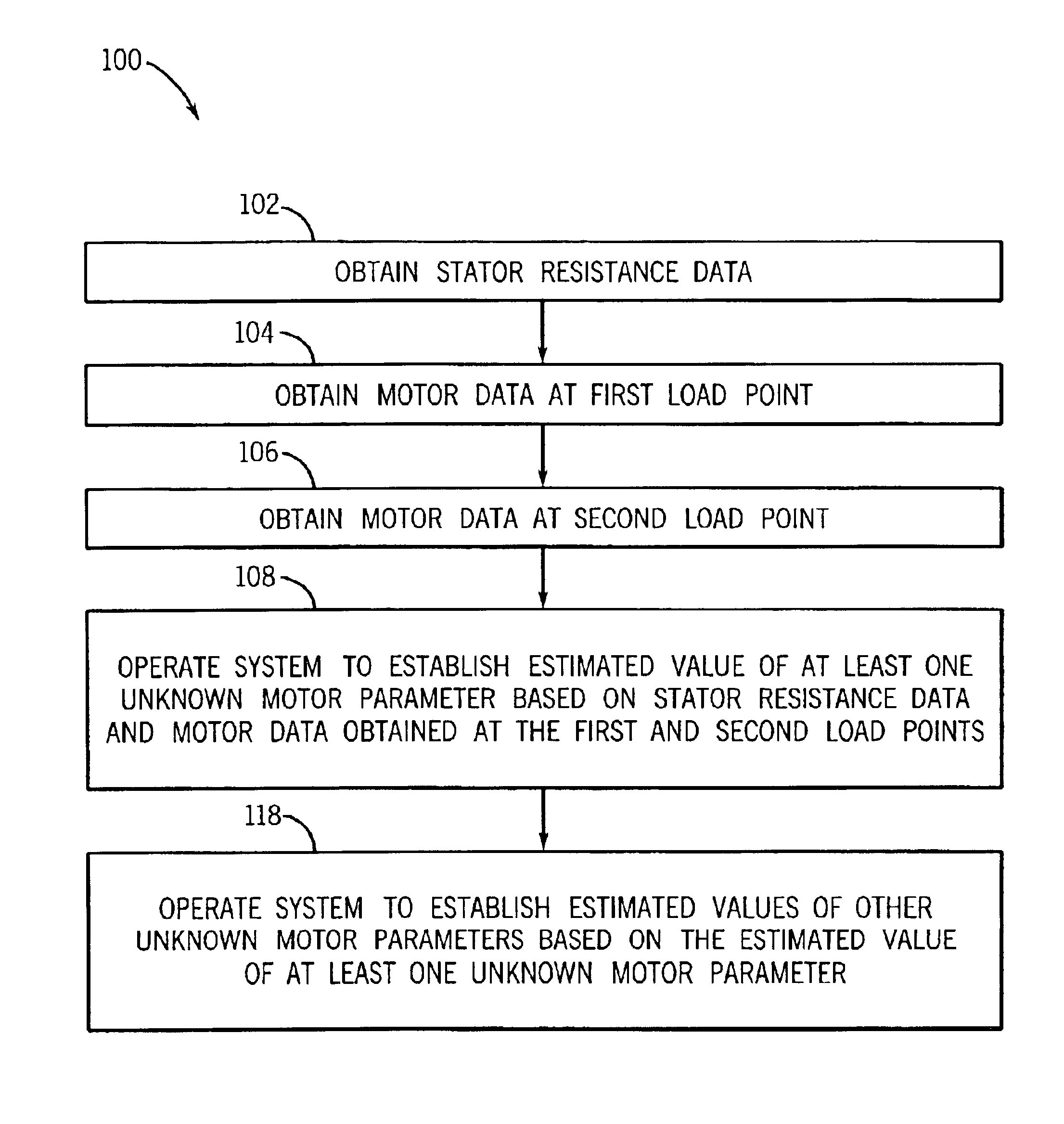

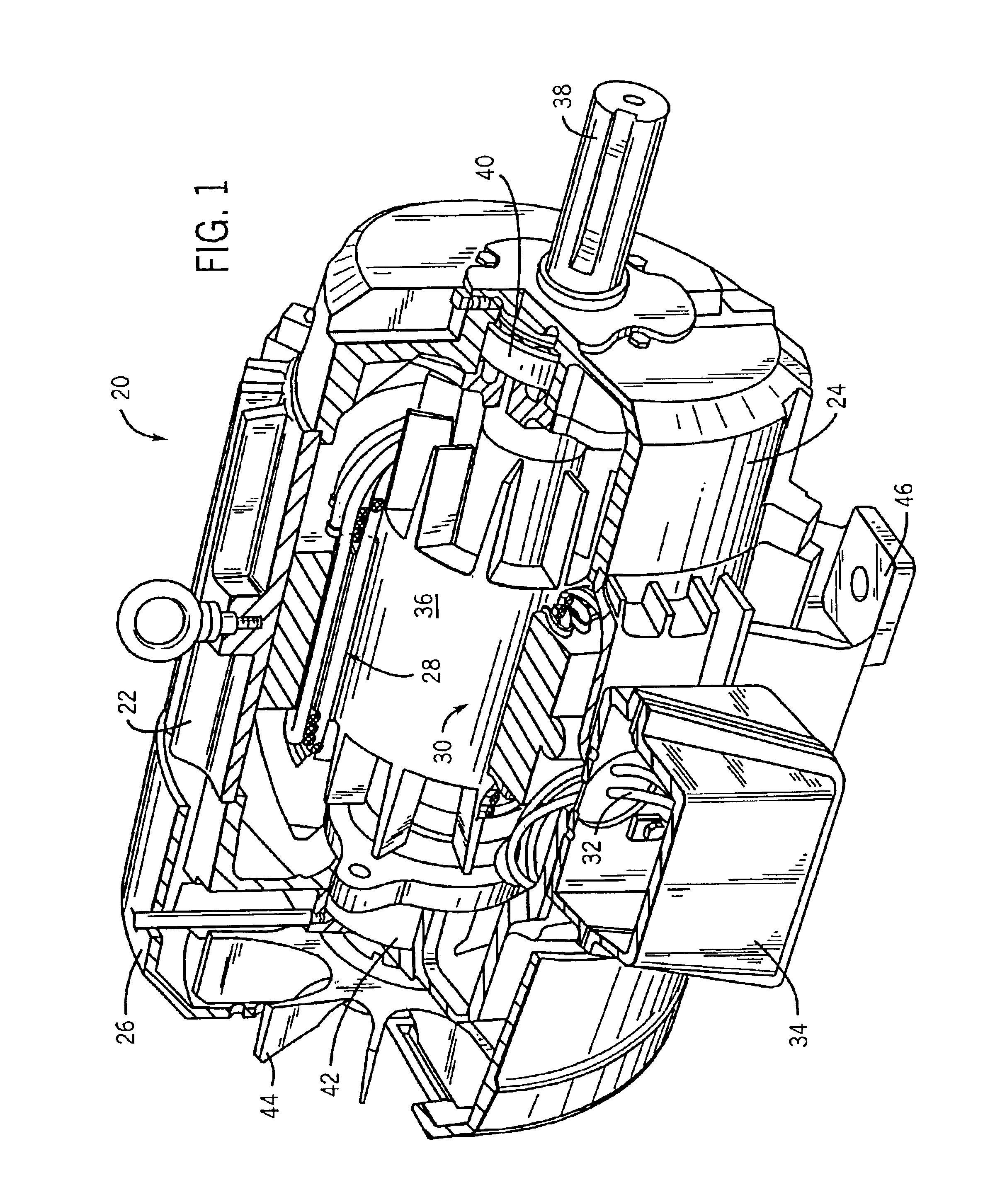

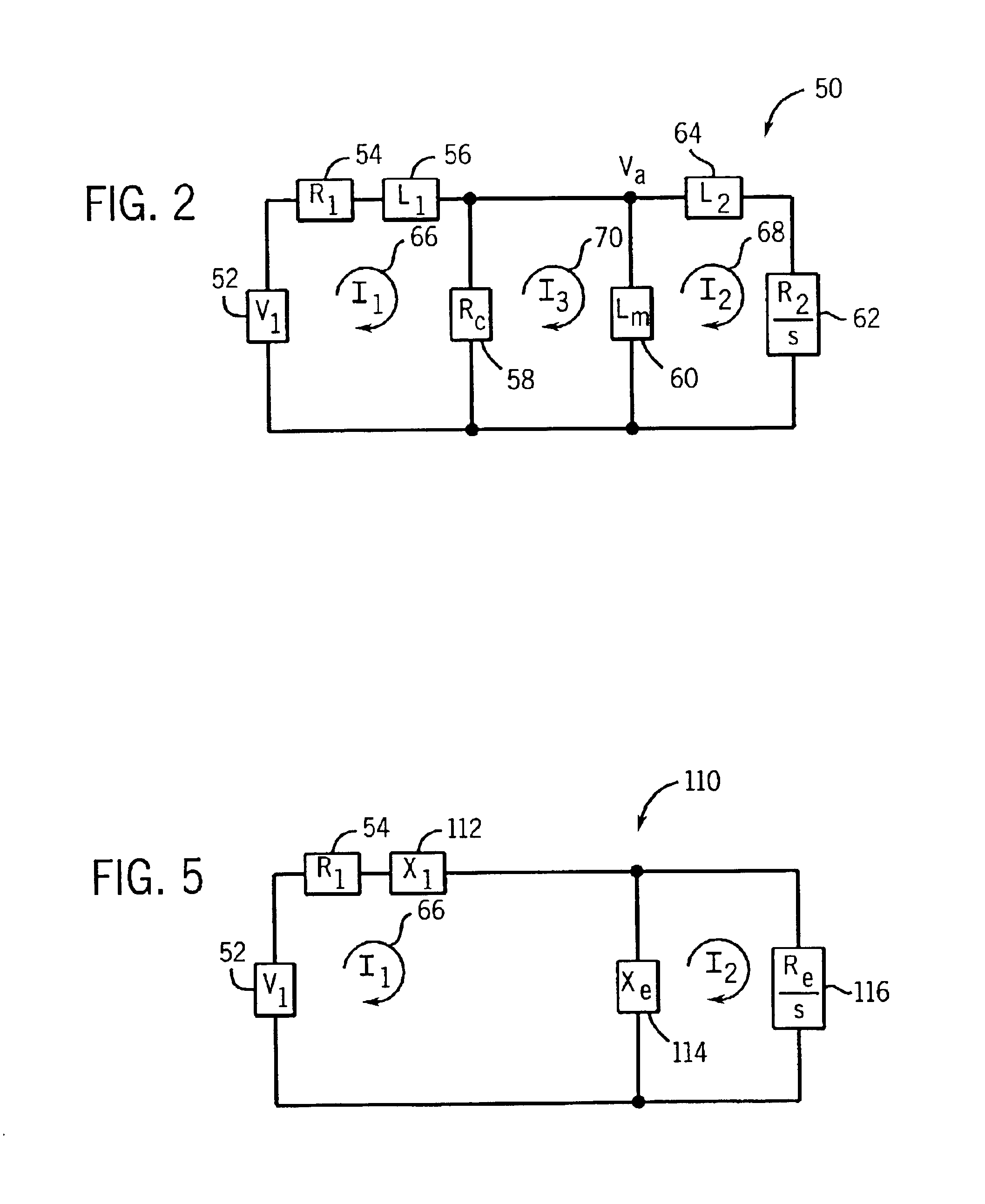

Induction motor module and motor incorporating same

InactiveUS6862538B2Electric motor controlMotor parameters estimation/adaptationElectricityMotor efficiency

A system and method for establishing estimated values of a plurality of electrical parameters of a motor. The plurality of electrical parameters may be established from stator resistance data and electrical input data obtained with no load on the motor. The plurality of electrical parameters may also be established from stator resistance data, electrical input data, and motor speed data obtained at at least two load conditions of the motor. The plurality of electrical parameters may comprise rotor resistance. The system and method may also be used to estimate a plurality of operating parameters of the motor based on the estimated values of a plurality of electrical parameters of the motor. The plurality of operating parameters of a motor may comprise rotor temperature, motor torque, and motor efficiency.

Owner:BALDOR ELECTRIC COMPANY

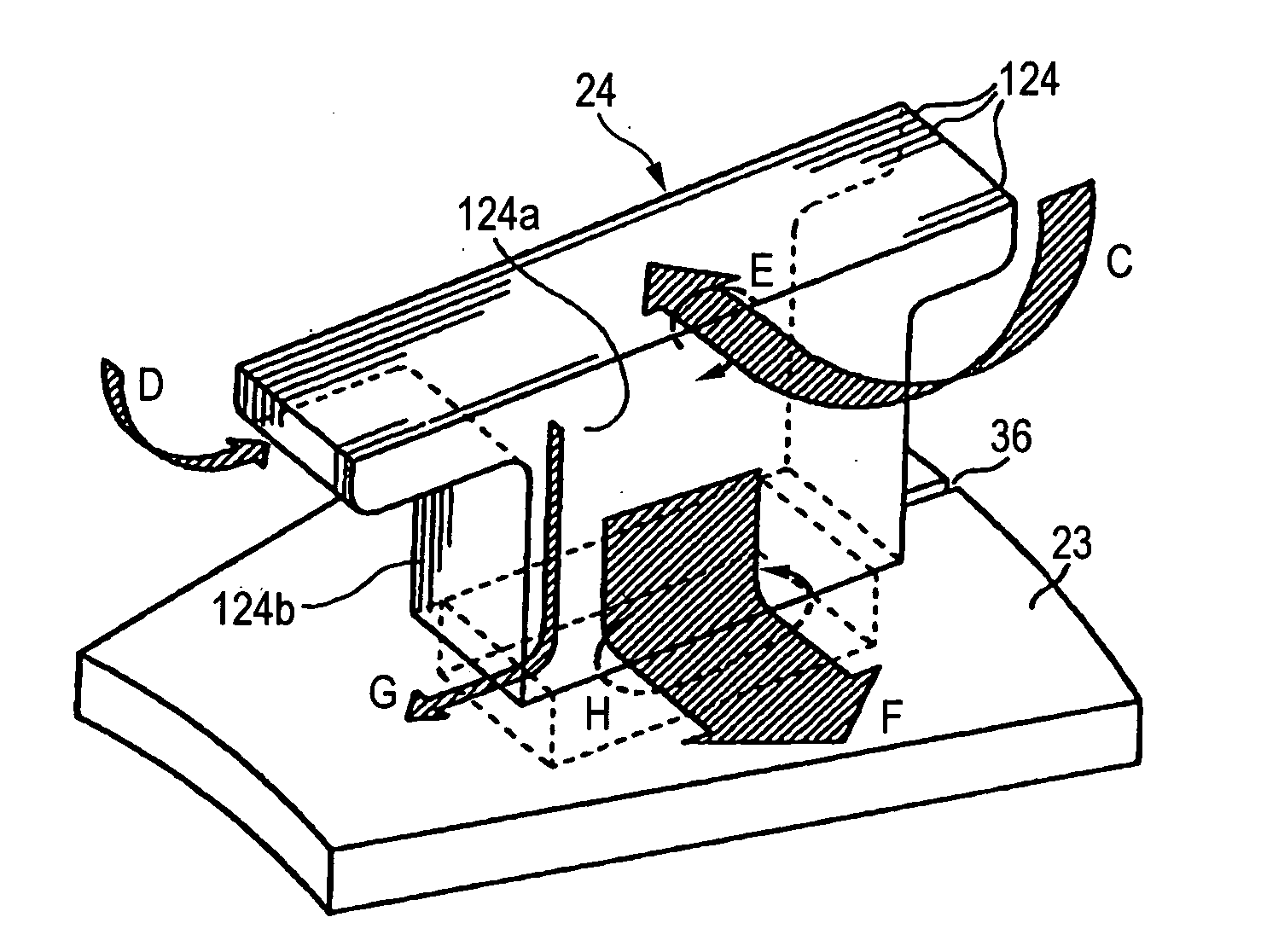

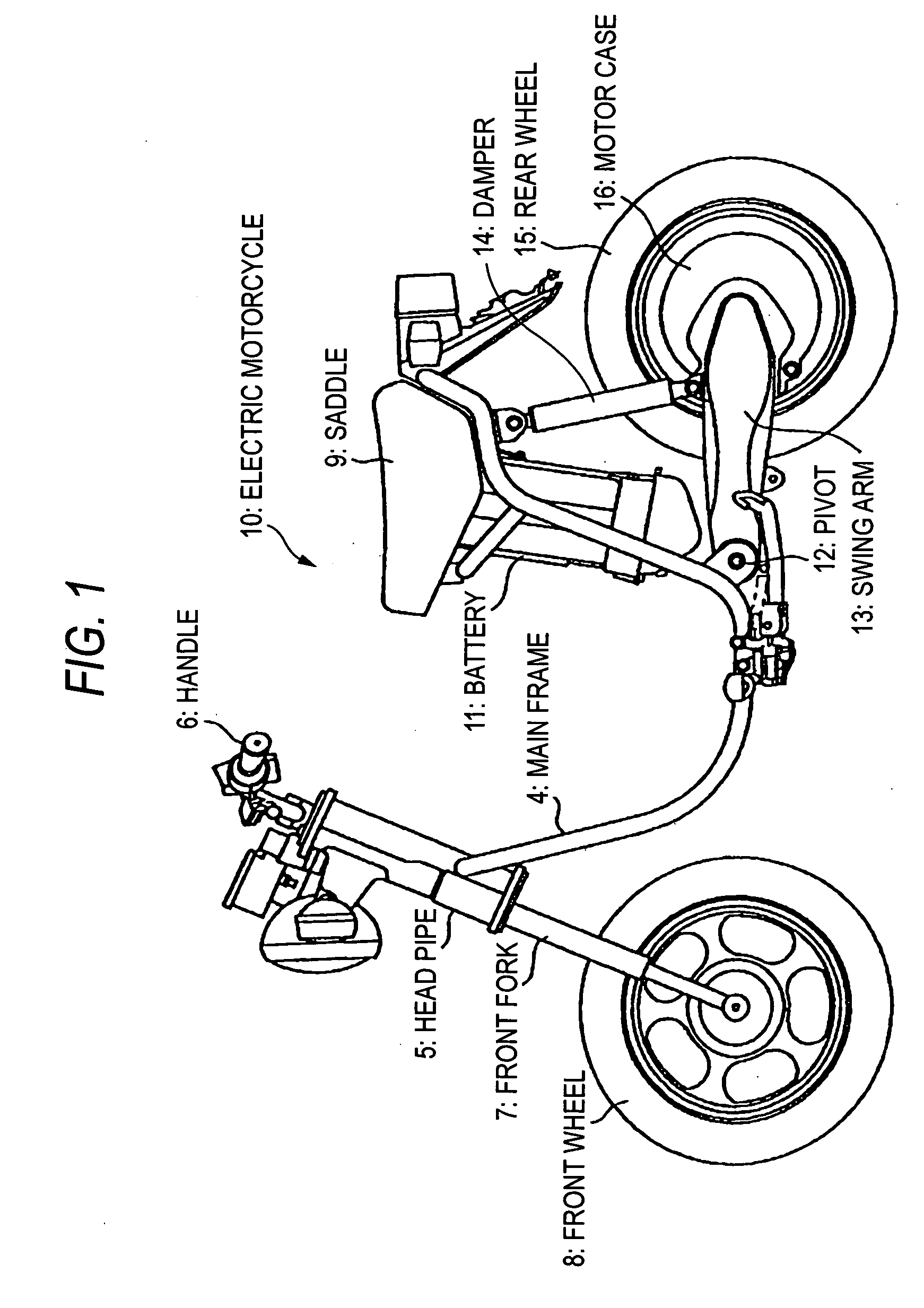

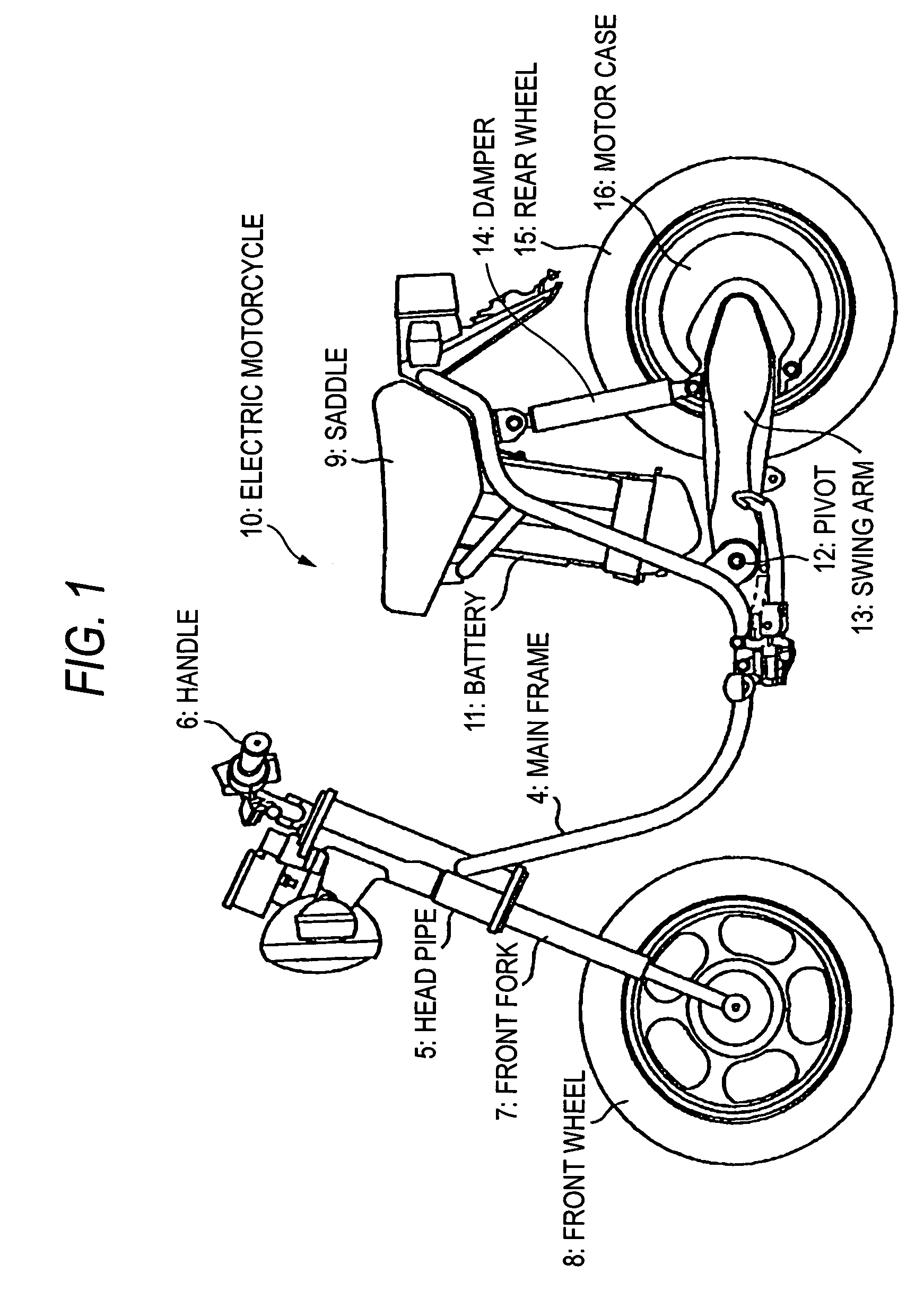

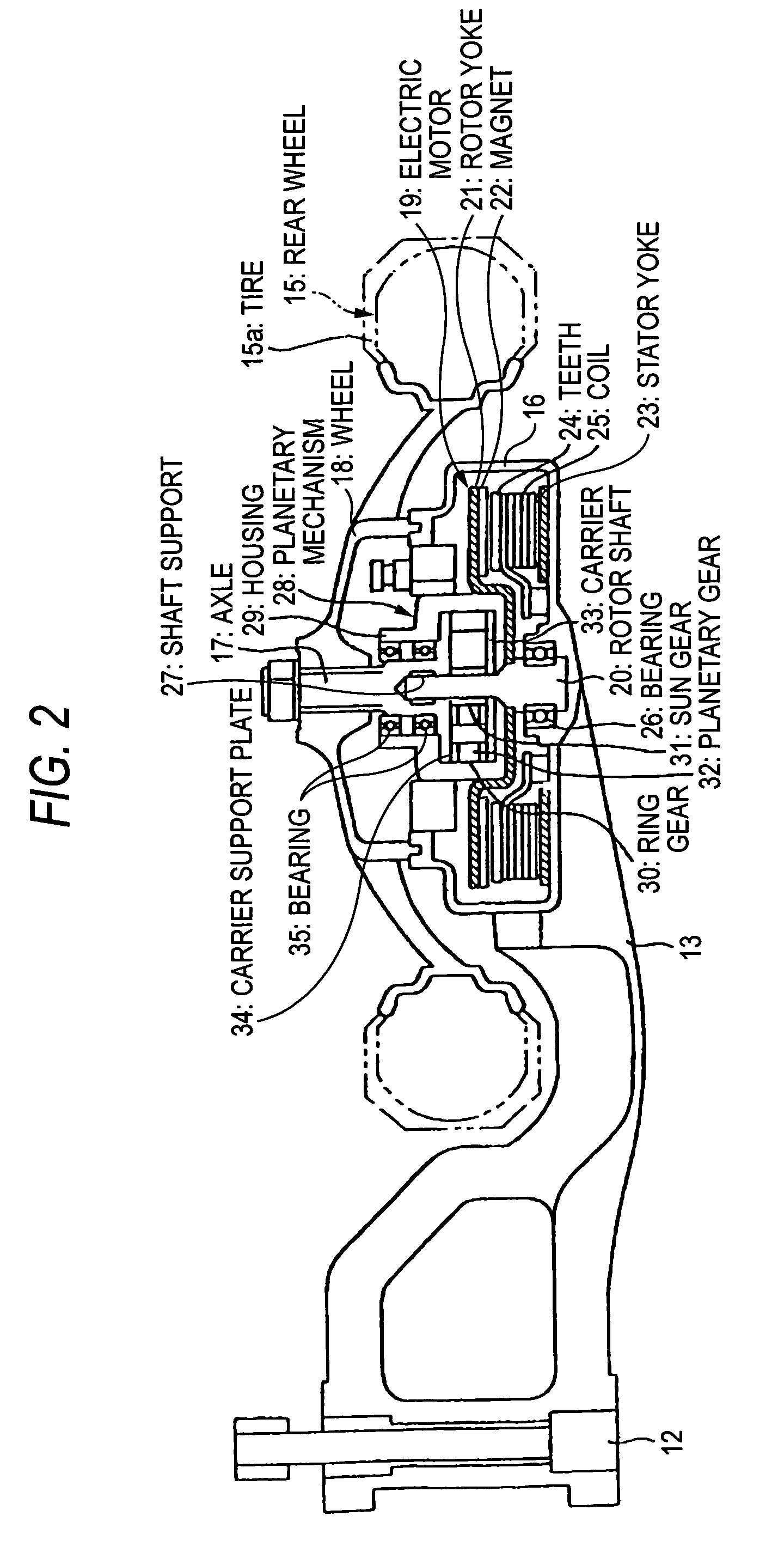

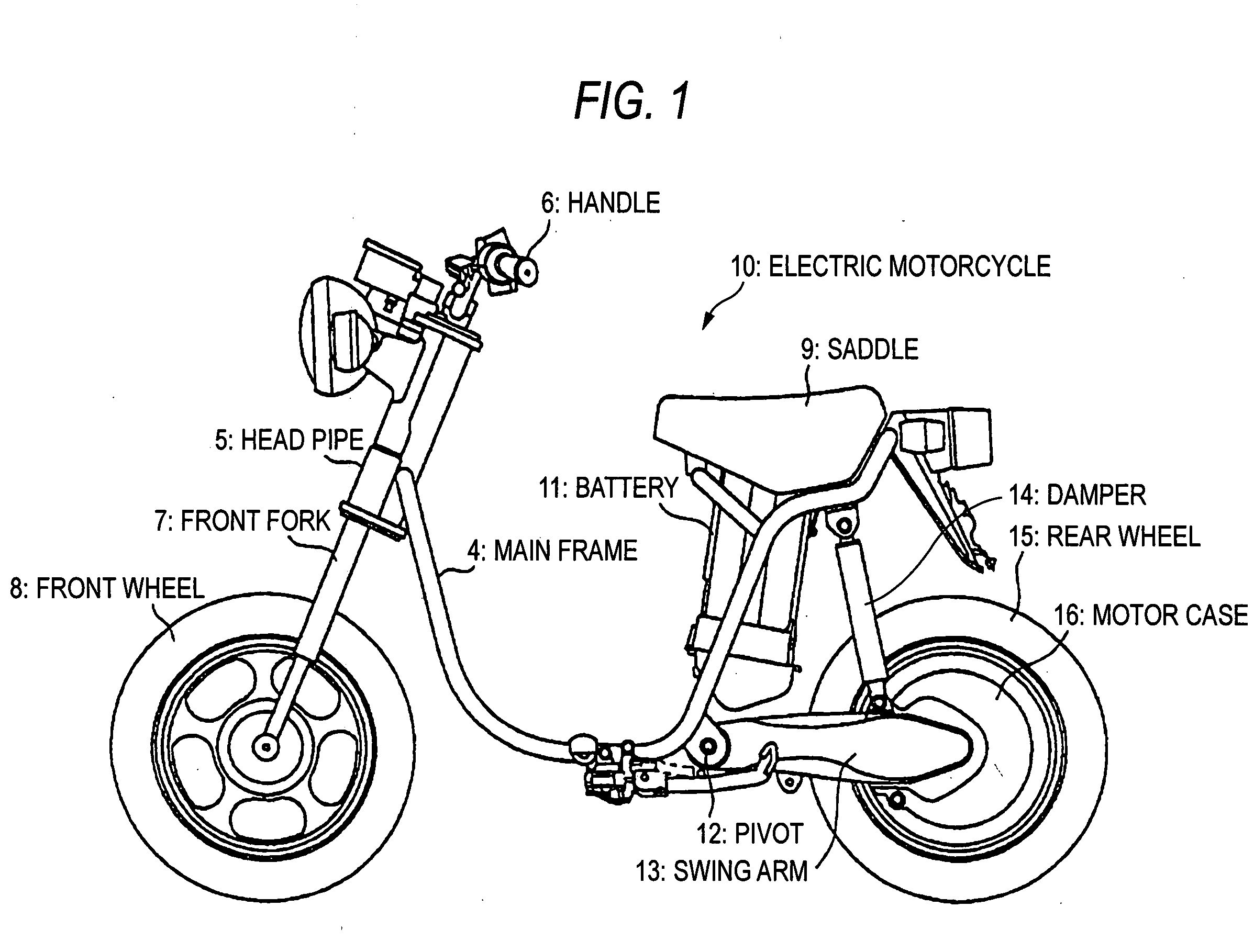

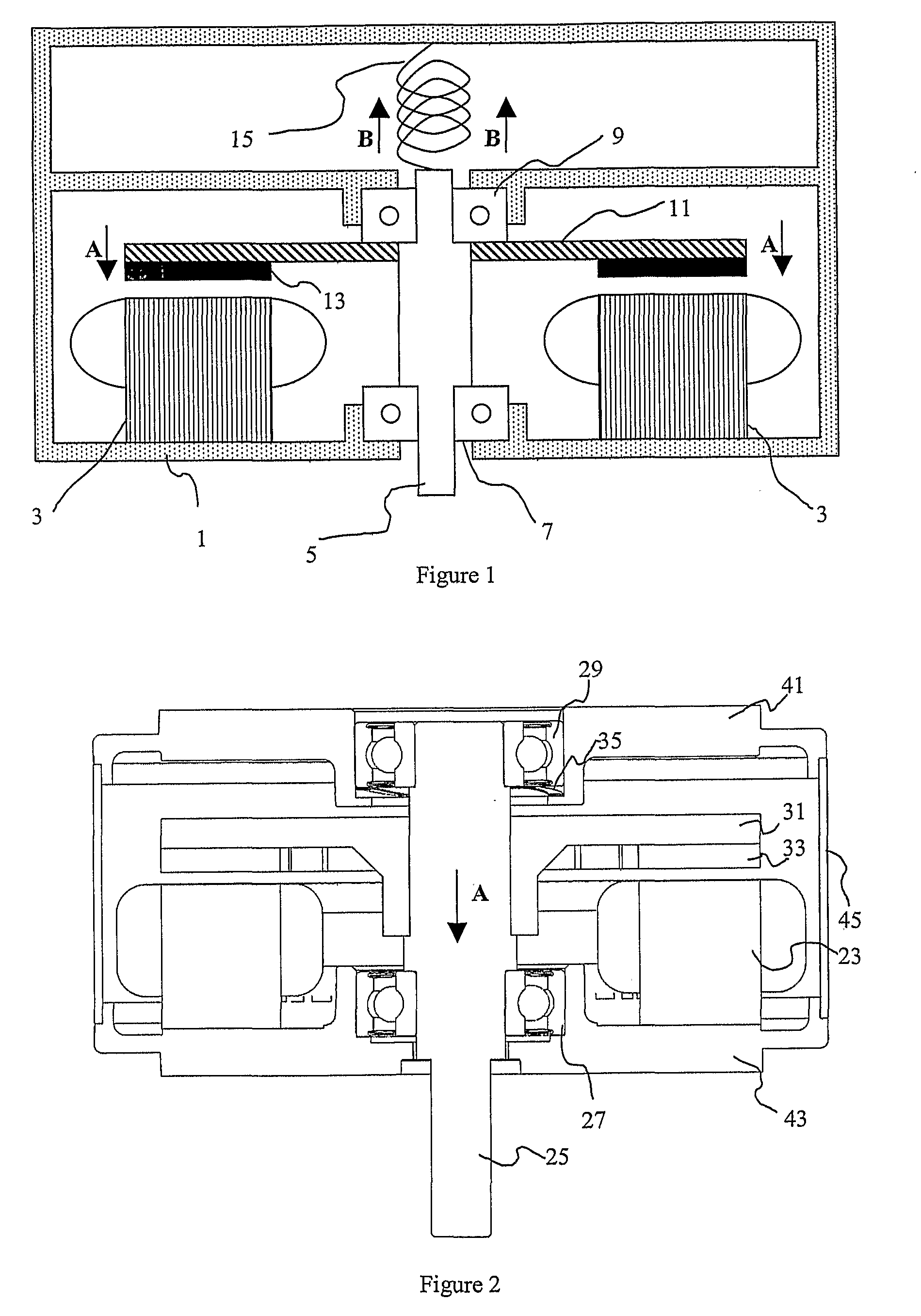

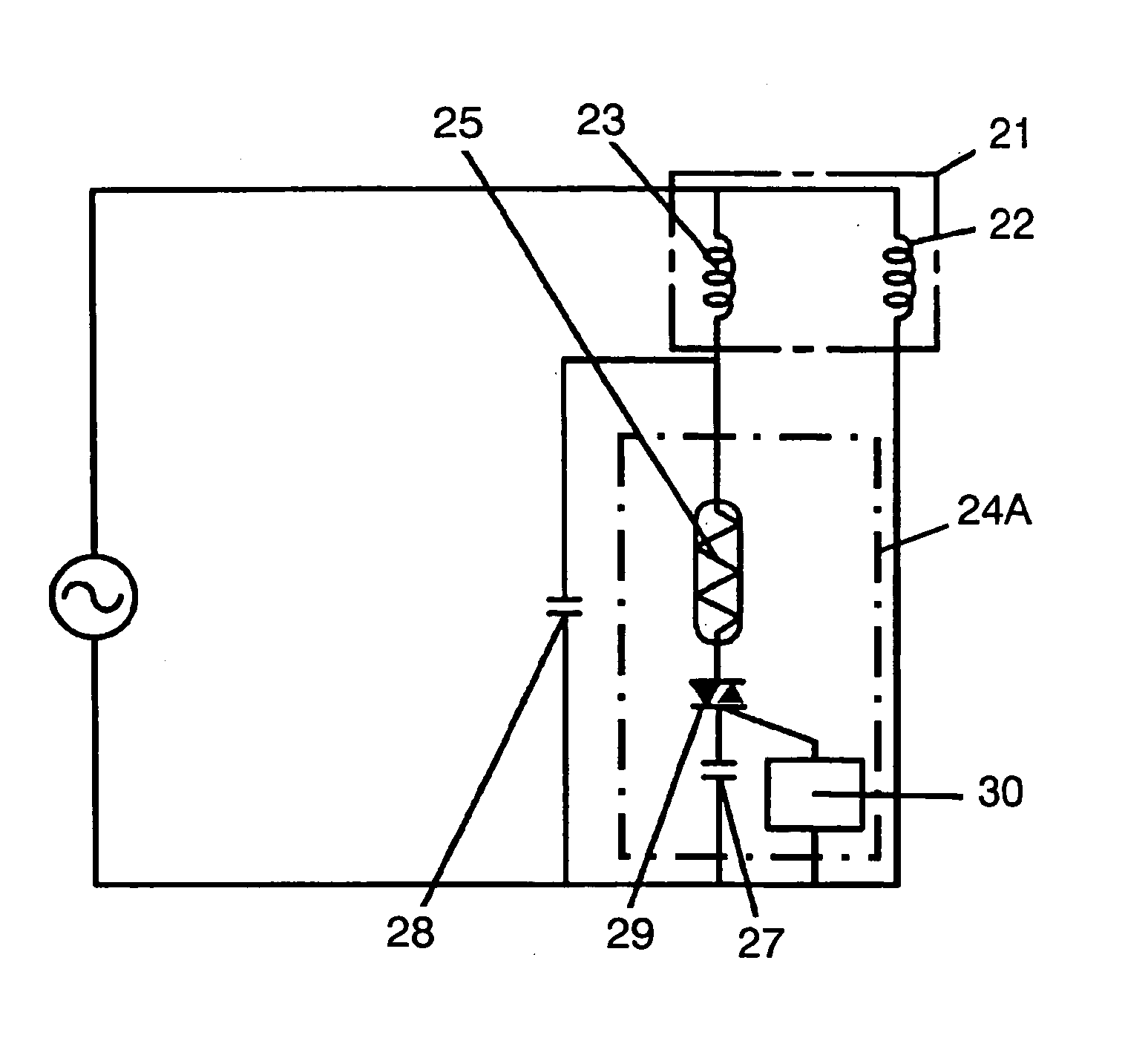

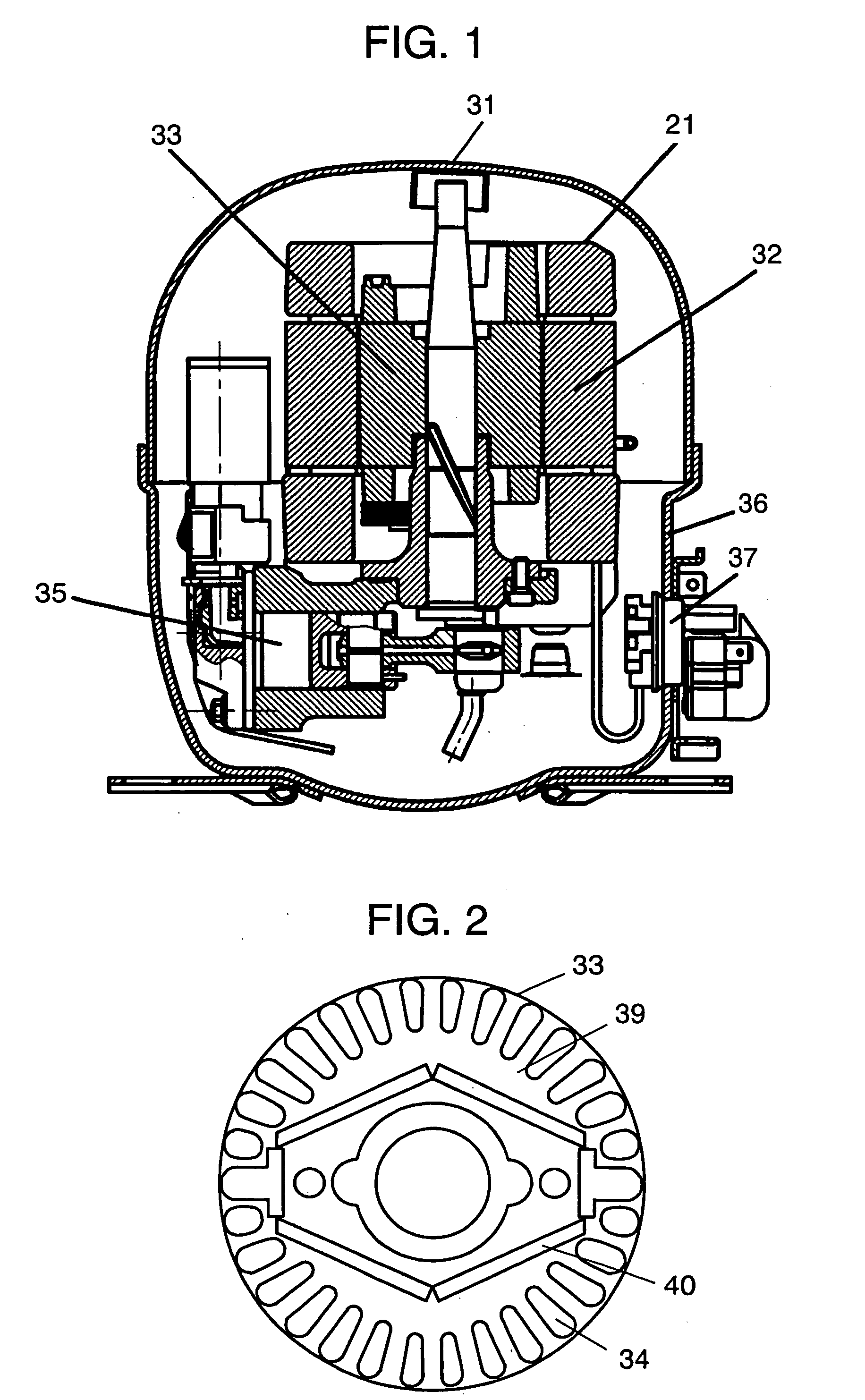

Axial gap type dynamo-electric machine

InactiveUS20050073213A1Total current dropImprove electrical resistanceSuspensionsMagnetic circuit rotating partsElectric machineHigh torque

There is provided an axial gap type rotating electric machine which is small-sized and achieves a high motor efficiency as a drive source having a high torque using, for example, a strong magnet by reducing an energy loss by an induced current. An axial gap type rotating electric machine having a yoke on a side of a rotor in a circular plate shape fixed to a rotating shaft, a yoke 23 on a side of a stator in a circular plate shape opposed to the yoke on the side of the rotor, a magnet fixed to a side of an opposed face of either one of the yokes on the side of the rotor or the side of the stator, a plurality of teeth 24 arranged on a side of an opposed face of other yoke on the side of the rotor or the side of the stator radially and opposedly to the magnet and fixed to the yoke 23, and a coil wound around each of the plurality of teeth, in which the teeth 24 has a laminated member of plate members 124 for the teeth and faces 124a to be superposed of the plate members 124 for the teeth are arranged in a circumferential direction.

Owner:YAMAHA MOTOR CO LTD

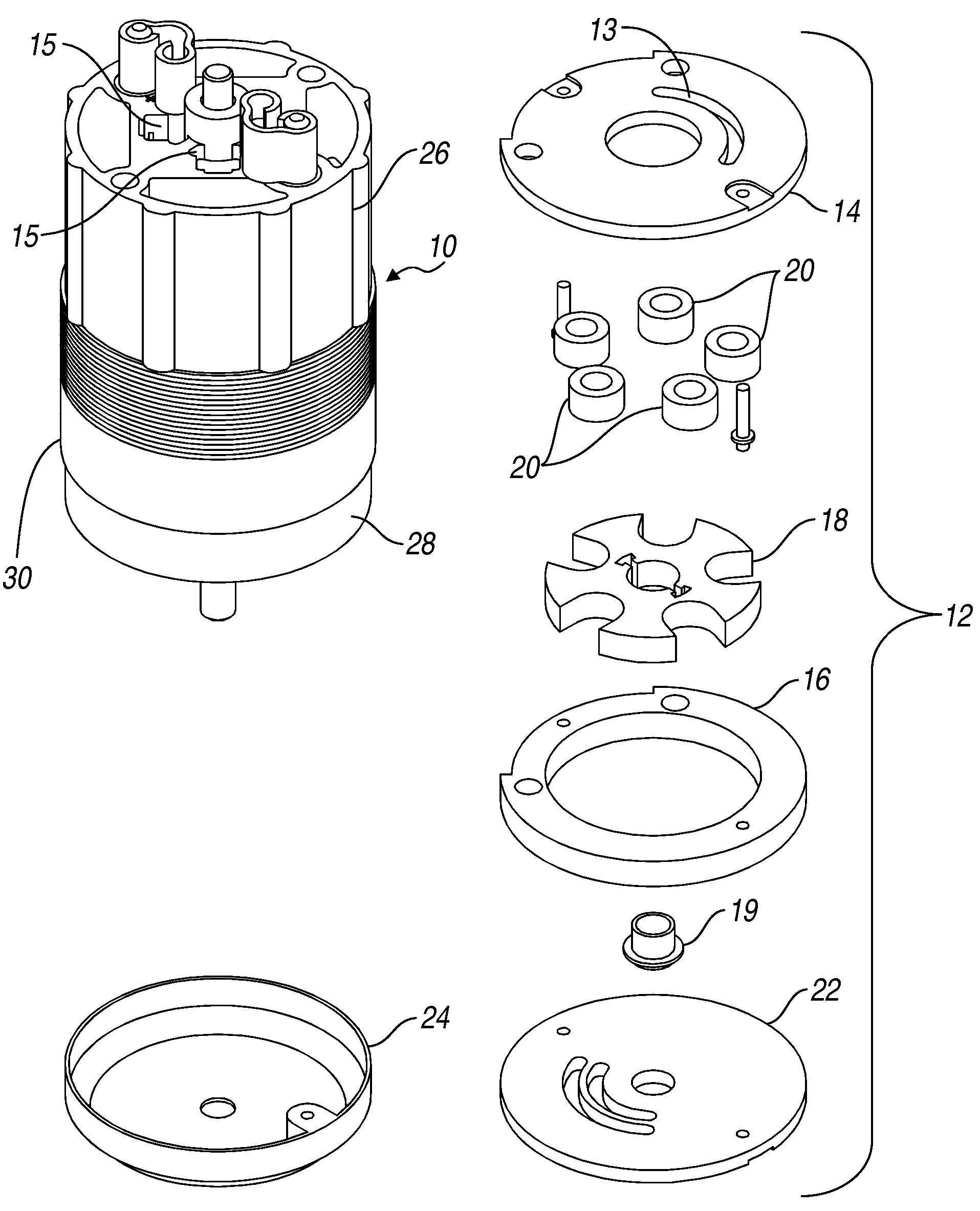

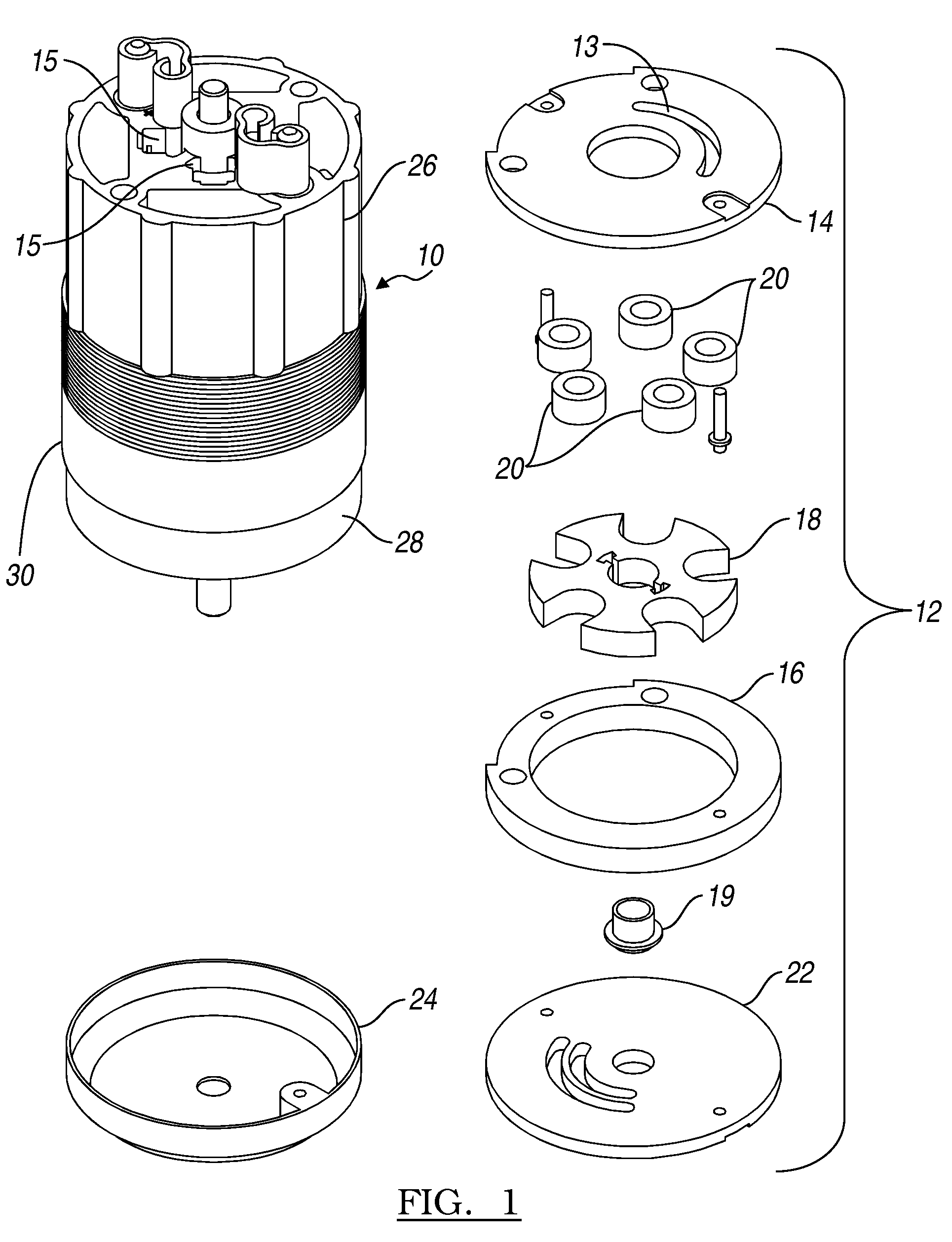

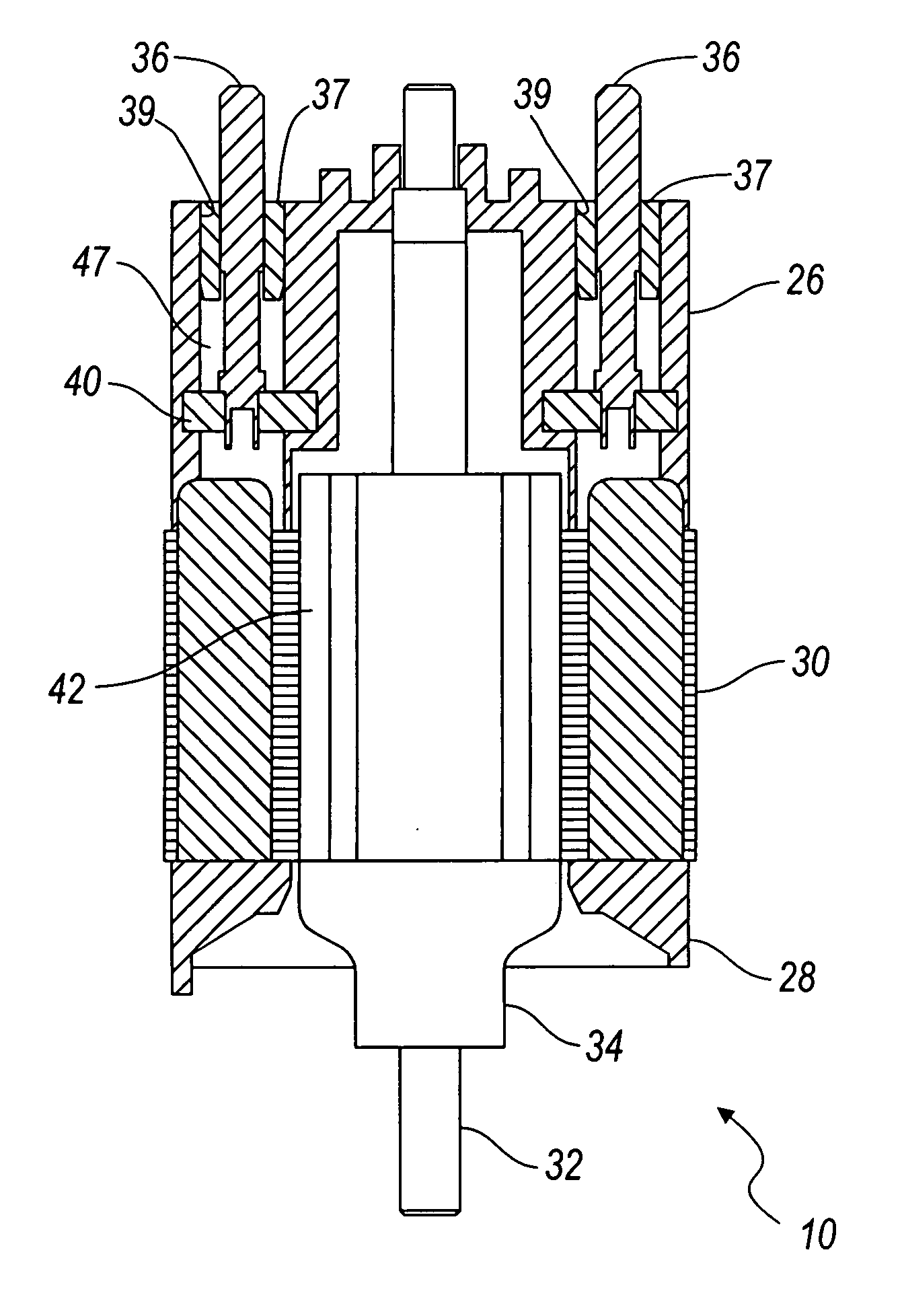

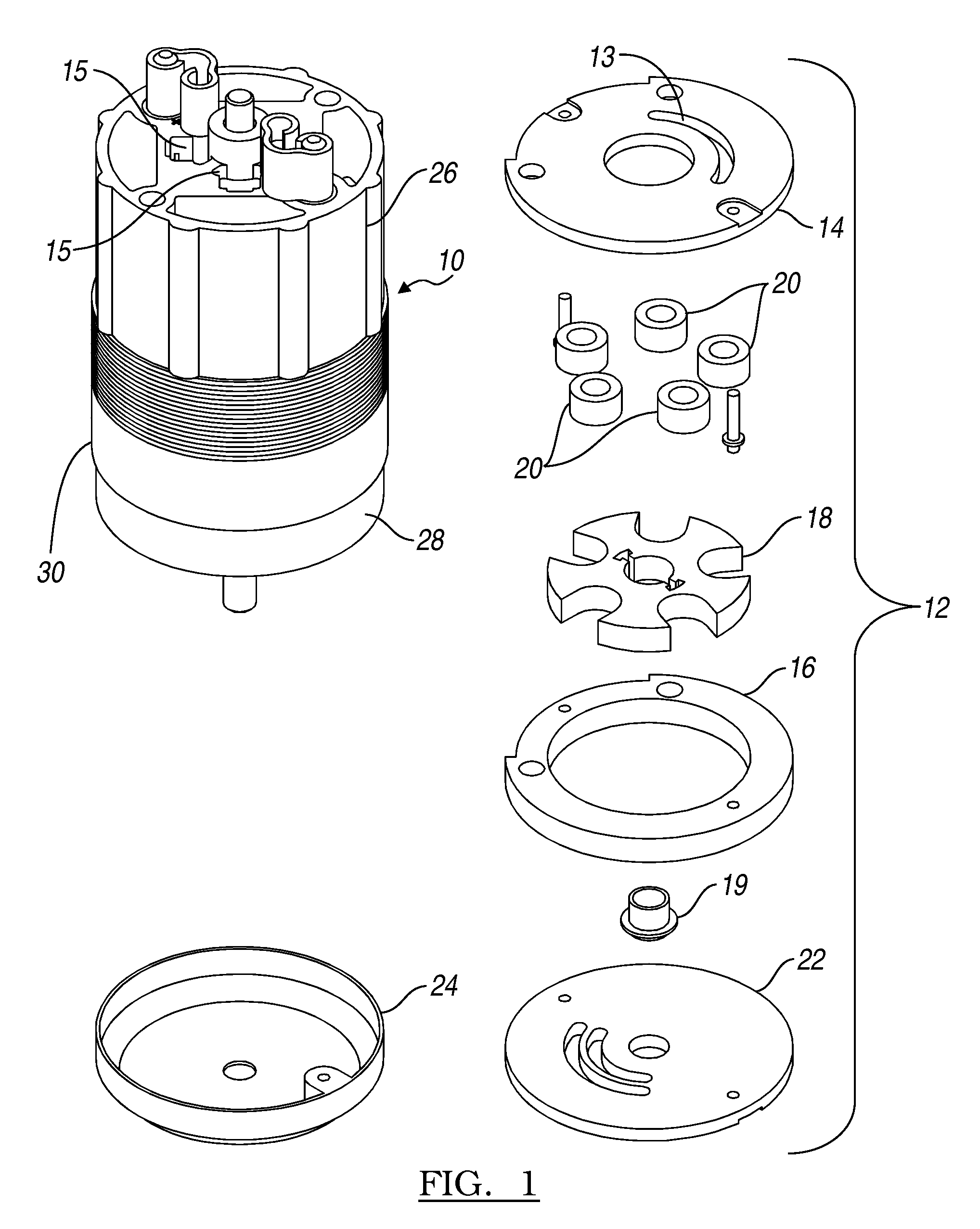

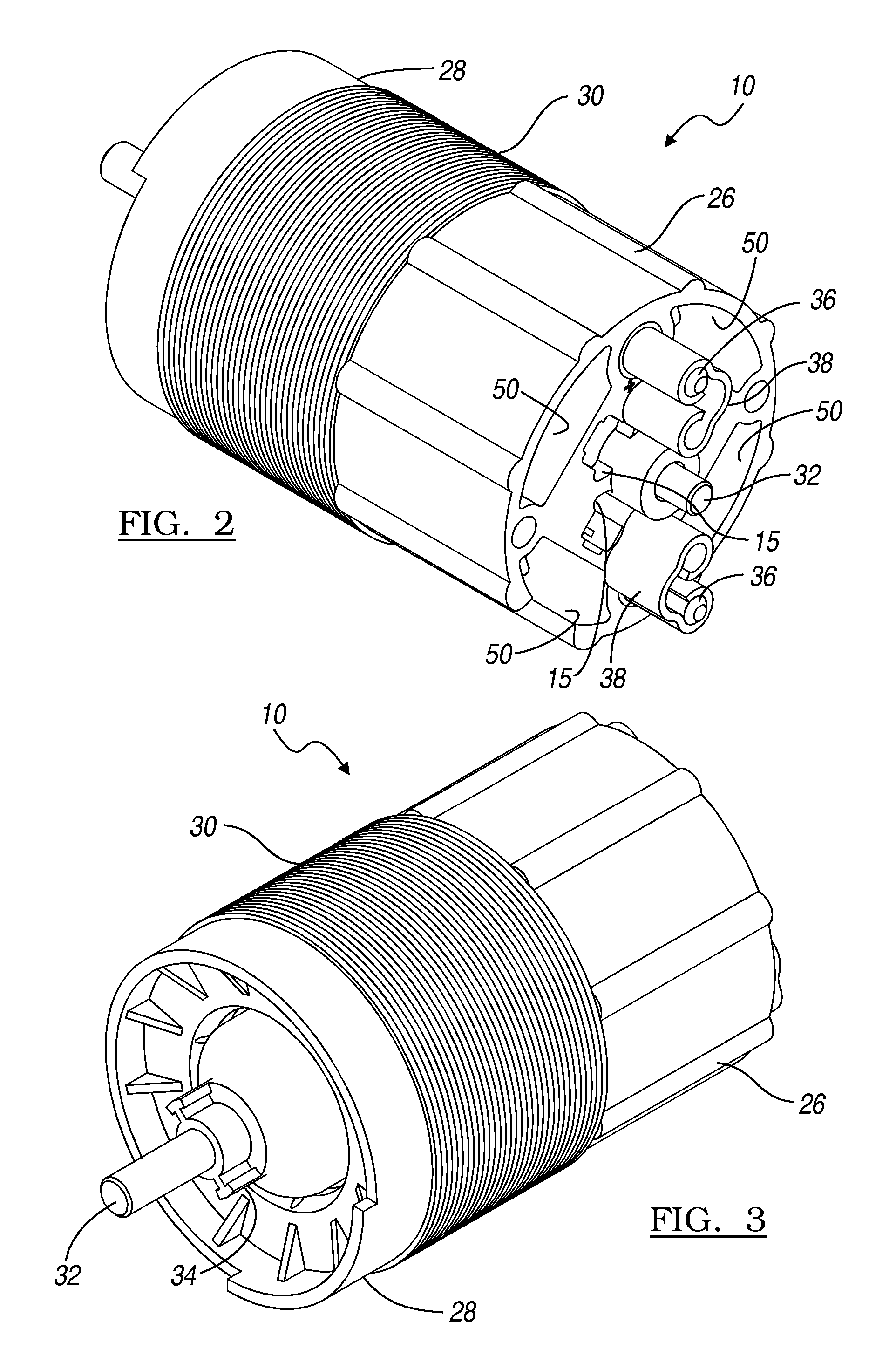

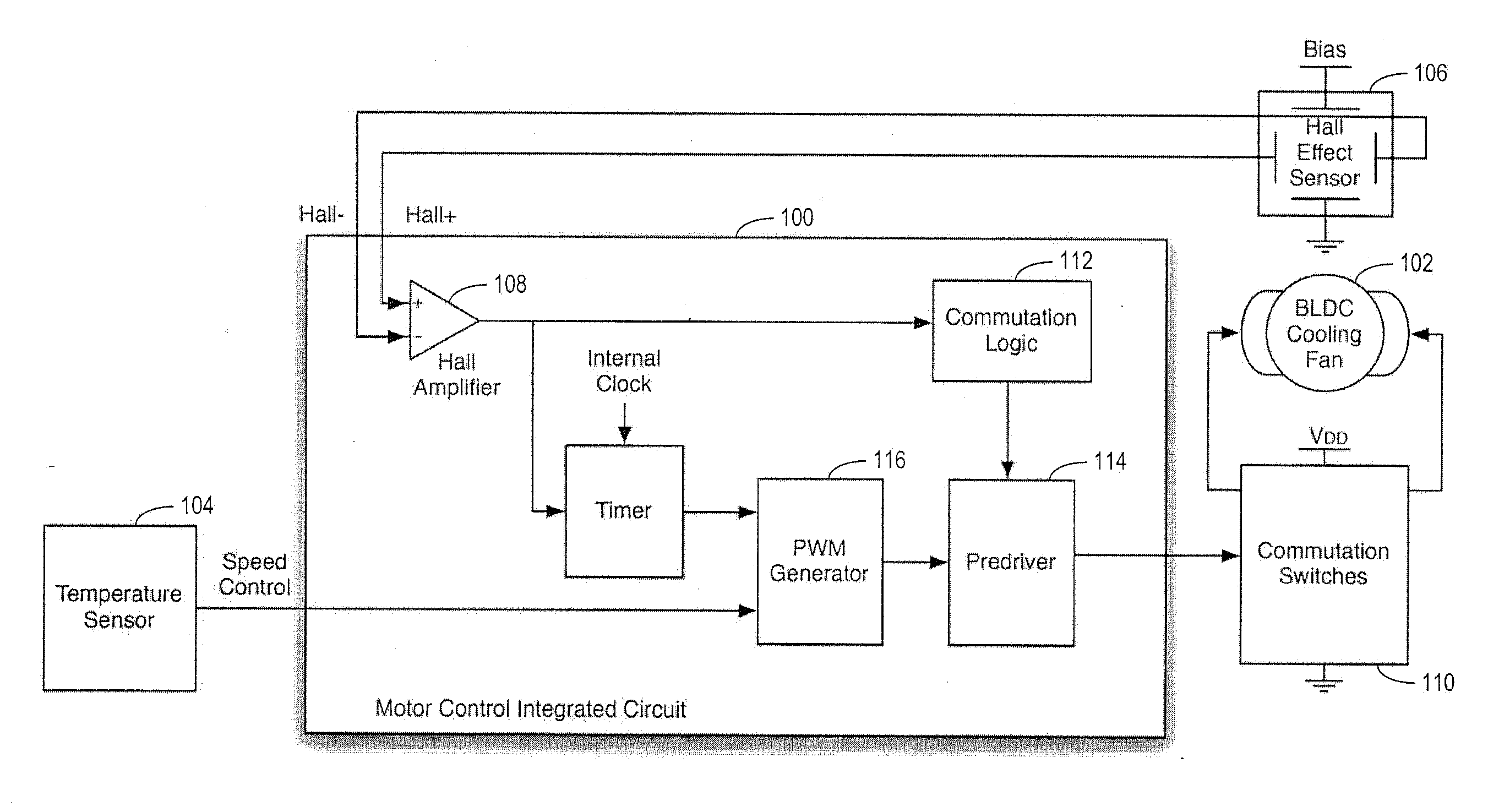

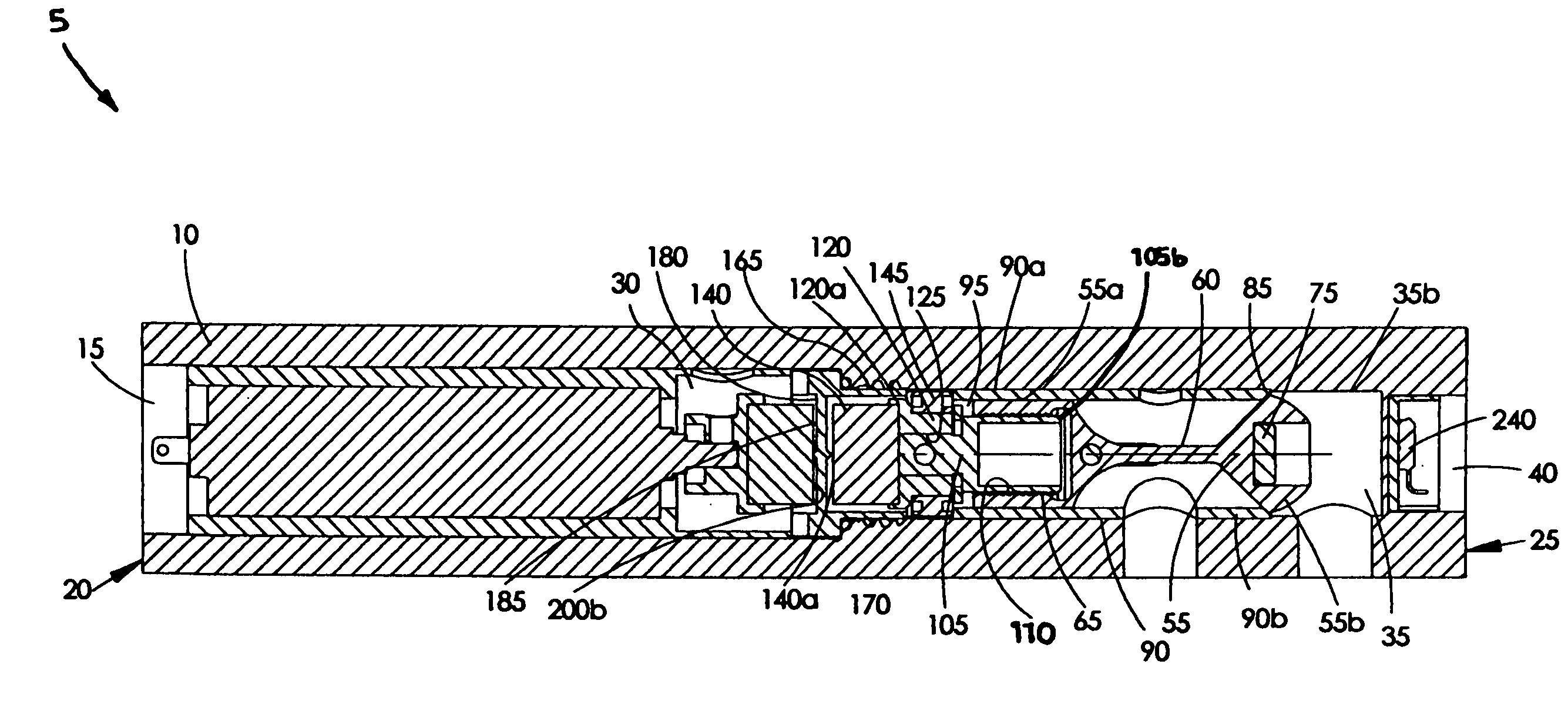

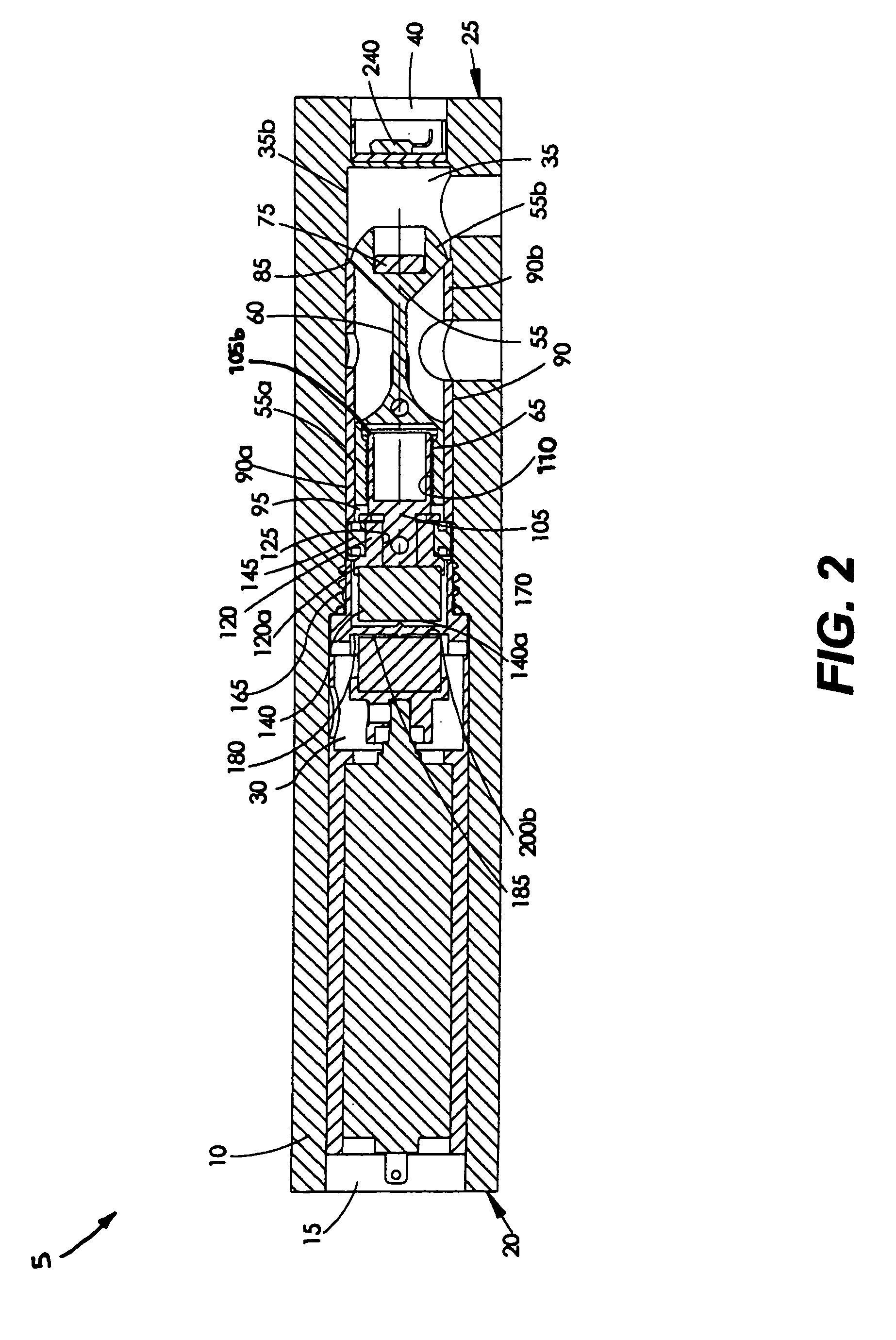

BLDC motor and pump assembly with encapsulated circuit board

ActiveUS7411326B2Increased Design FreedomImprove efficiencyAssociation with control/drive circuitsManufacturing dynamo-electric machinesElectrical devicesEngineering

A BLDC motor assembly and method for manufacturing same is disclosed. The motor has a housing, a shaft supported for rotation within the housing, a stator disposed within the housing for generating an electro-magnetic field, a rotor operatively coupled to the shaft and disposed for powered rotation within the stator in response to the electro-magnetic field, at least one temperature sensitive electronic device (TSED) disposed within the housing and electrically connected to the stator for controlling or measuring an aspect of the electro-magnetic field, and a fuel resistant and electrically insulated polymeric material encapsulating the TSED so that the TSED is protected from adverse temperature and chemical agents without the need for a separate internal container or a pre-potting operating. The TSED, which may be carried on a printed circuit board within the housing, is thus overmolded with polymeric material so that the polymeric material fills, or substantially fills, a space within the housing. Not only is the cost and weight associated with a prior art dedicated container for the electronics eliminated, but this invention allows greater design freedom in the location or placement of the various electrical devices within the housing for better motor efficiency and / or protection.

Owner:CARTER FUEL SYST

BLDC motor and pump assembly with encapsulated circuit board

ActiveUS20060279162A1Increased Design FreedomImprove motor efficiencyAssociation with control/drive circuitsRotary current collectorElectrical devicesEngineering

A BLDC motor assembly and method for manufacturing same is disclosed. The motor has a housing, a shaft supported for rotation within the housing, a stator disposed within the housing for generating an electro-magnetic field, a rotor operatively coupled to the shaft and disposed for powered rotation within the stator in response to the electro-magnetic field, at least one temperature sensitive electronic device (TSED) disposed within the housing and electrically connected to the stator for controlling or measuring an aspect of the electro-magnetic field, and a fuel resistant and electrically insulated polymeric material encapsulating the TSED so that the TSED is protected from adverse temperature and chemical agents without the need for a separate internal container or a pre-potting operating. The TSED, which may be carried on a printed circuit board within the housing, is thus overmolded with polymeric material so that the polymeric material fills, or substantially fills, a space within the housing. Not only is the cost and weight associated with a prior art dedicated container for the electronics eliminated, but this invention allows greater design freedom in the location or placement of the various electrical devices within the housing for better motor efficiency and / or protection.

Owner:CARTER FUEL SYST

Position Corrected Pulse Width Modulation for Brushless Direct Current Motors

ActiveUS20120326643A1Increased torque outputReduce motor noiseTorque ripple controlMotor/generator/converter stoppersPosition dependentDirect current

A method of operating a brushless direct current motor is provided that generates a rotor position dependent pulse width modulation waveform. The waveform can improve motor efficiency and reduce torque variation.

Owner:AGAVE SEMICON

Magnetically-coupled actuating valve assembly

ActiveUS7159842B1Maximum power and efficiencyEliminate riskOperating means/releasing devices for valvesValvesWorking fluidCoupling

A magnetically-coupled actuating valve assembly. The actuating valve can be used to control the action of an actuator, such as a hydraulic or pneumatic cylinder. The valve assembly is especially well-suited to use with a damping cylinder of an electronically controlled prosthetic knee. A drive motor is coupled to and actuates a valve body portion of the assembly by means of magnetic attraction and, therefore, the valve assembly operates without the need to physically couple the drive motor to the valve body. The design of the present invention can reduce or eliminate working fluid leaks typically associated with a physical coupling. The design of the present invention may also obviate the need to submerge the drive motor in the working fluid, which typically reduces motor efficiency and may pose a fire hazard.

Owner:WILLOWWOOD GLOBAL LLC

Efficient motor

InactiveUS7081698B1Improve motor efficiencyReduce wind resistanceMagnetic circuit rotating partsDC commutatorAmpereEngineering

The present invention is directed to a method and system for improving motor efficiency. The motor of the present invention may provide at least 1.9 Horsepower (HP) while drawing 15–16 Amperes at 120 Volts. The motor of the present invention may provide at least 75% efficiency and the speed of 12,000 to 14,000 RPM. A small size and low weight motor may be provided by the present invention. Further, it is contemplated that the motor of the present invention may be produced at a low cost per unit with a volume of 500,000 to 1,000,000 units per year. It is also contemplated that the motor may be suitable for use in consumer and professional products by complying with recognized safety standards such as U.L., CSA, CEE and the like.

Owner:HITACHI HOME & LIFE SOLUTIONS INC +1

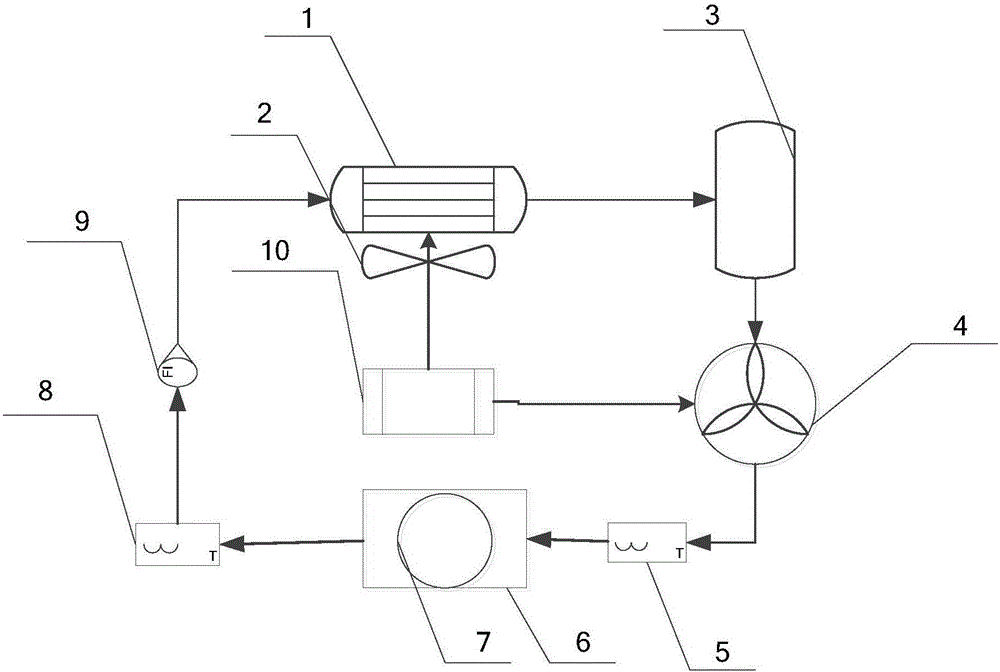

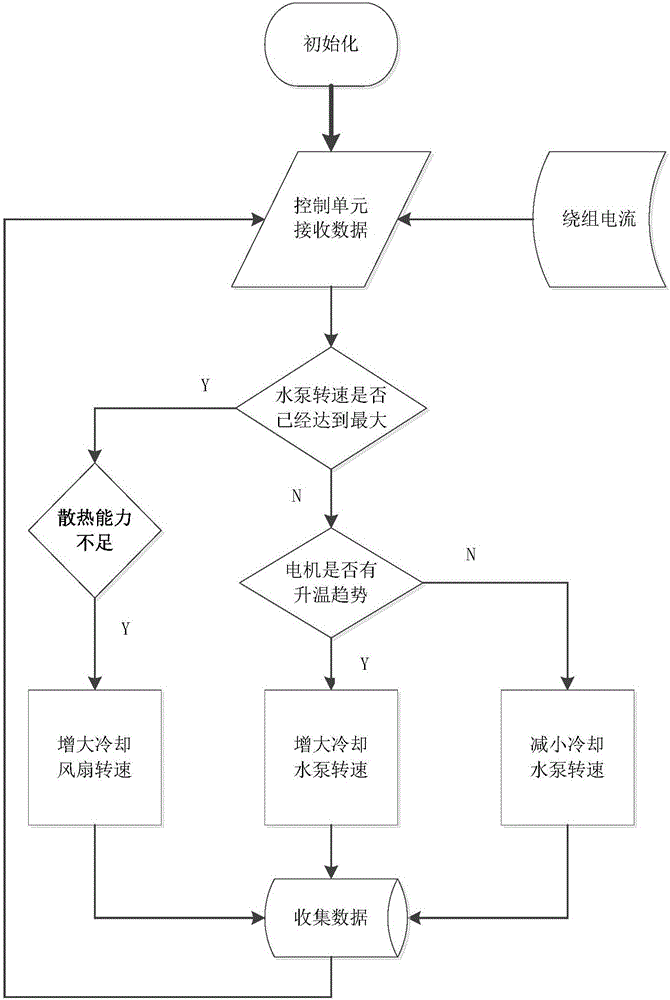

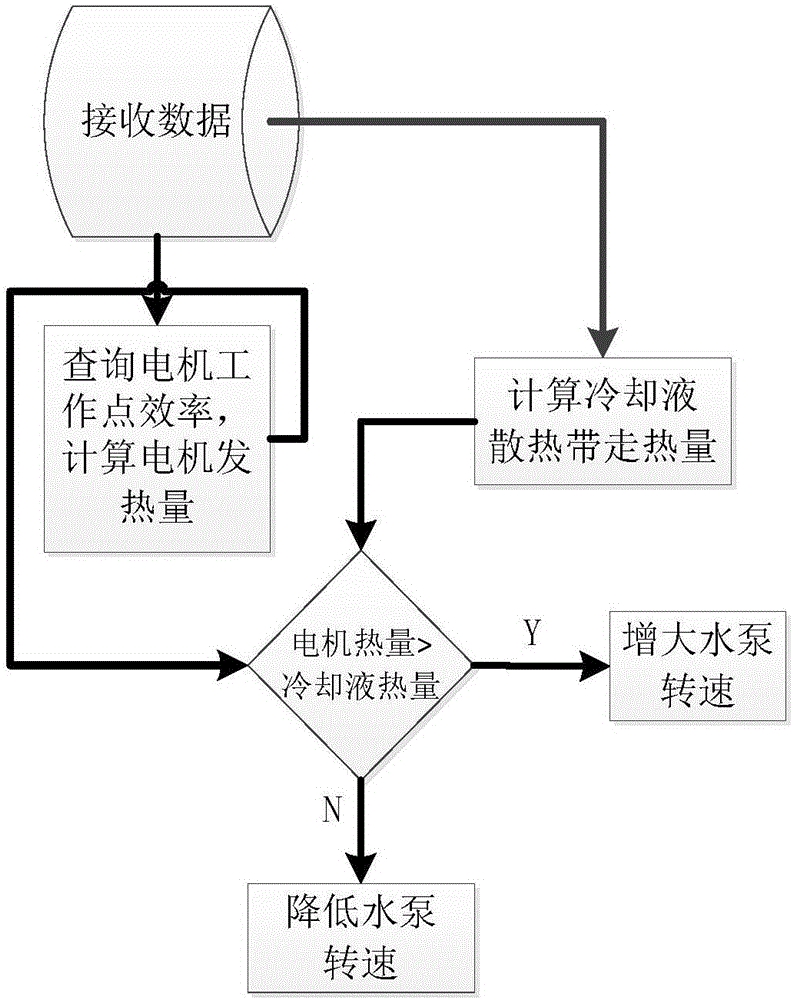

Permanent magnet synchronous motor cooling system for electric automobile and control method thereof

ActiveCN106240341ASpeed coordinationIntelligent controlElectric machinesCooling/ventillation arrangementPermanent magnet synchronous motorWater jacket

The invention discloses a permanent magnet synchronous motor cooling system for an electric automobile and a control method thereof. The cooling system comprises a control unit, a motor winding ammeter, a cooling water pump, a cooling water jacket, a cooling water temperature sensor, a cooling liquid flow meter, a heat radiator and a cooling fan. The control method comprises the following steps: judging whether a permanent magnet synchronous motor has a temperature rising trend or a temperature lowering trend under the working condition through detecting current of a motor stator winding, and adjusting a cooling capability of the cooling system so as to realize active adjustment of the cooling system; meanwhile, introducing auxiliary feedback adjustment and inquiring a working point of a motor through a motor efficiency MAP graph, so as to obtain the efficiency of the motor under the corresponding working condition; calculating the heat productivity of the motor; then feeding a difference value of the heat productivity of the motor and a heat radiation amount of the heat radiator back to the control unit, so as to correct the adjustment of the cooling system. The cooling system is subjected to active cooling control before the temperature of the motor is changed; energy sources are saved while a sufficient heat dissipation capability of the motor is guaranteed.

Owner:WUHAN UNIV OF TECH

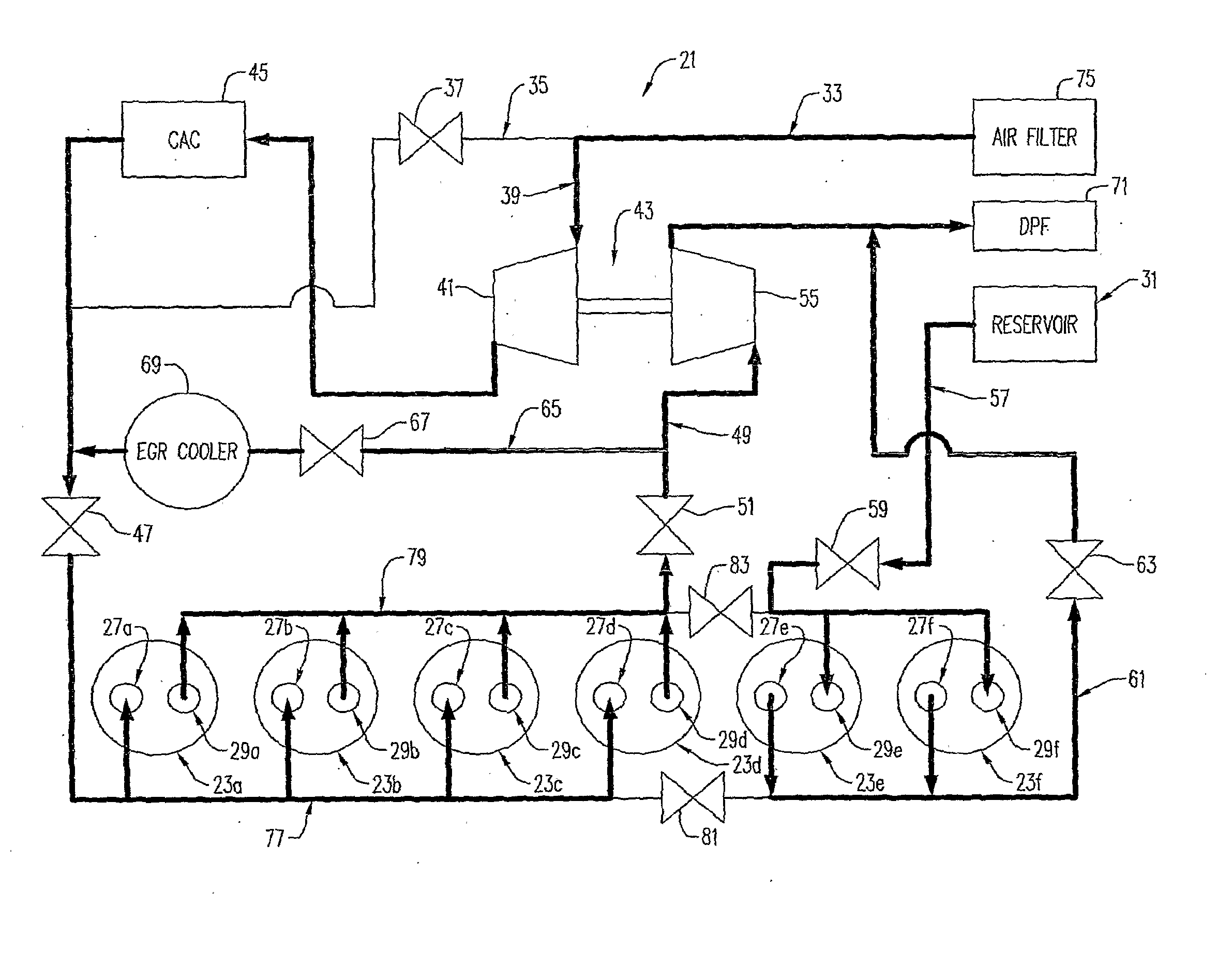

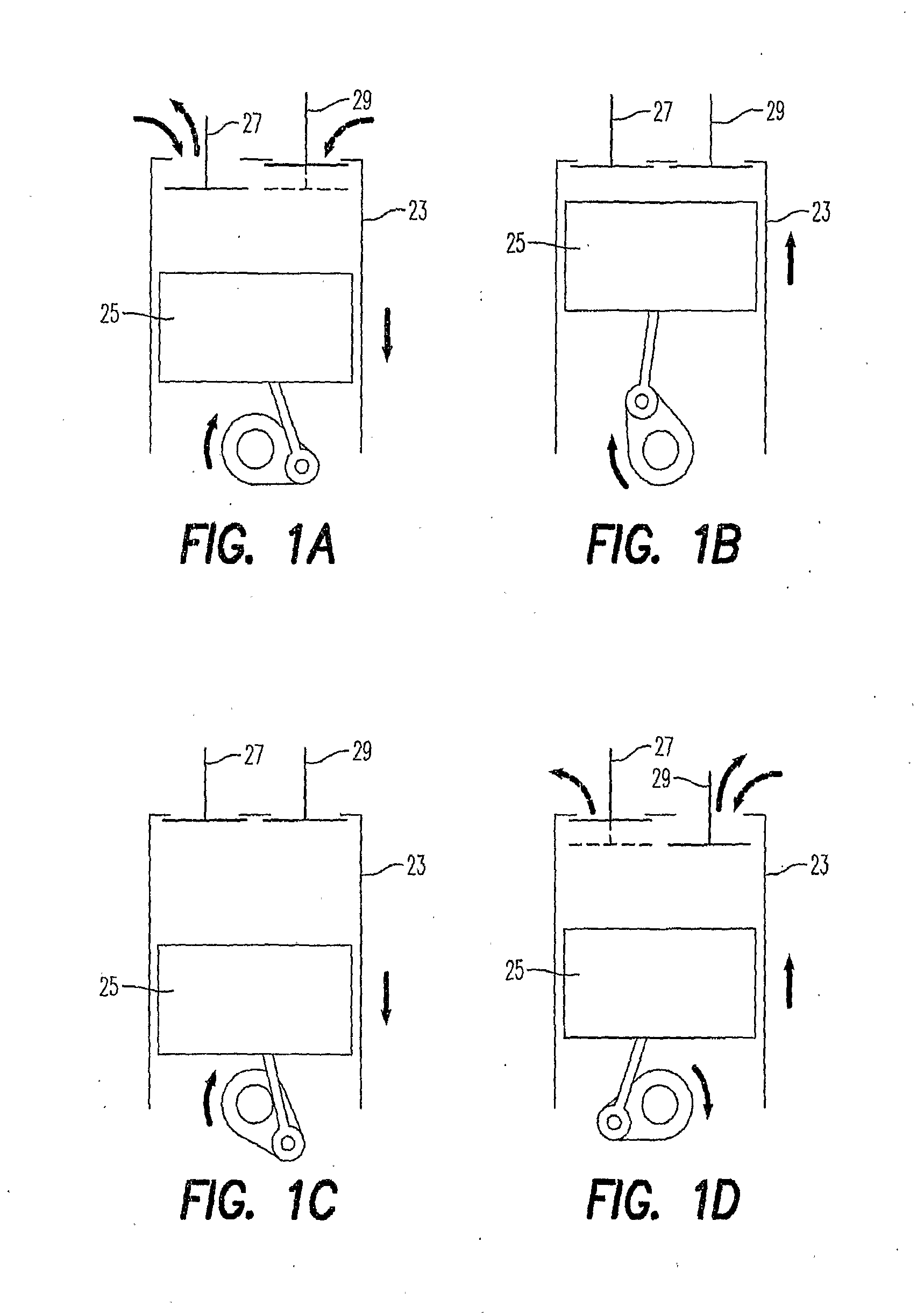

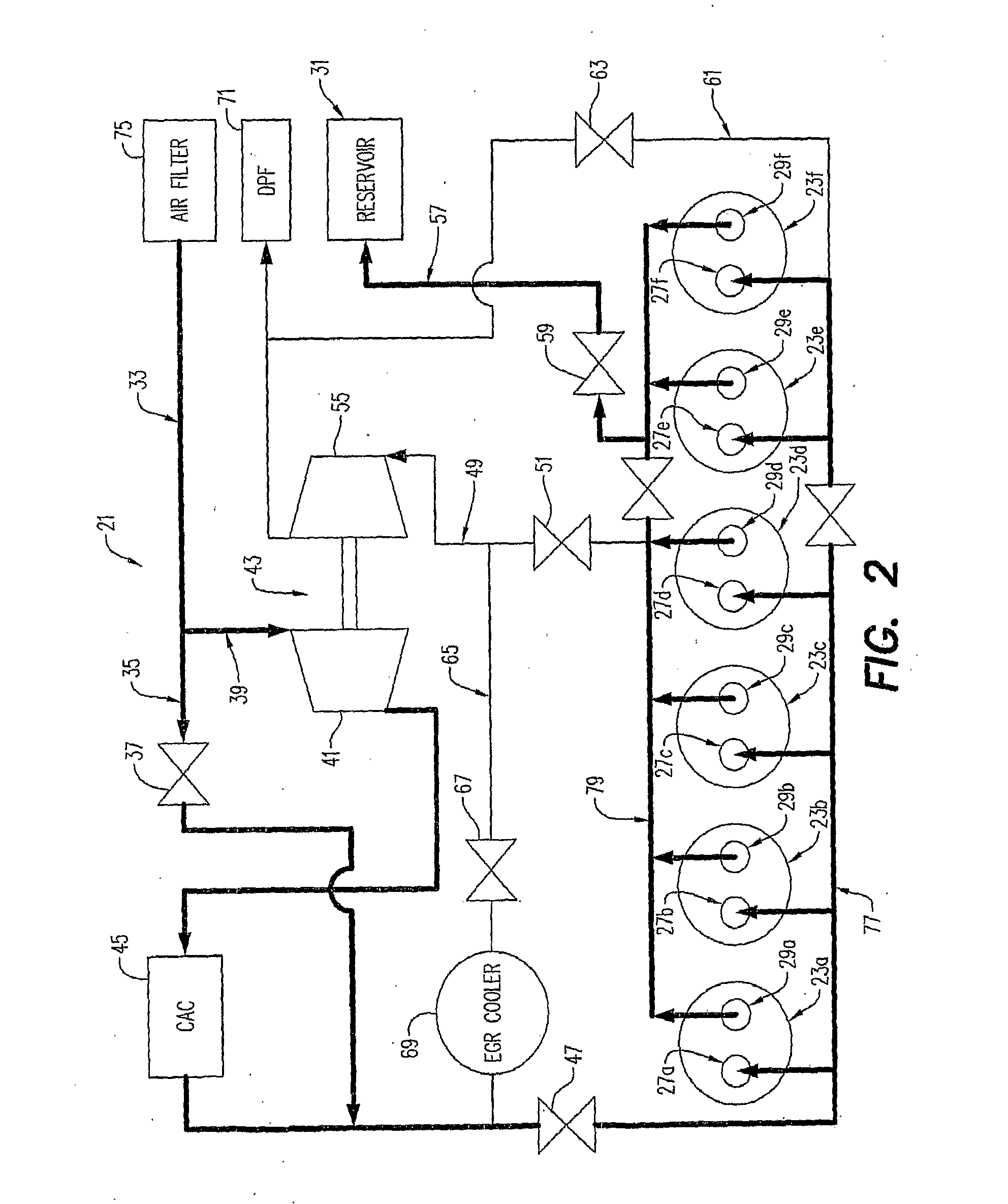

Hybrid internal combustion engine and air motor system and method

ActiveUS20100086414A1Maximizing air compressor efficiencyMaximizing air motor efficiencyValve arrangementsBraking element arrangementsExhaust valveExternal combustion engine

A hybrid internal combustion engine and air motor system is provided and includes at least one chamber having a drivable member and at least one intake valve and at least one exhaust valve, and a reservoir connected to the chamber through at least one of the intake valve and the exhaust valve. The system further comprises a computer configured to calculate air compressor efficiency during an air compressor mode of operation and select an intake and exhaust valve opening and closing timing sequence for maximizing air compressor efficiency and / or a computer configured to calculate air motor efficiency during an air motor mode of operation and select an intake and exhaust valve opening and closing timing sequence for maximizing air motor efficiency.

Owner:VOLVO LASTVAGNAR AB

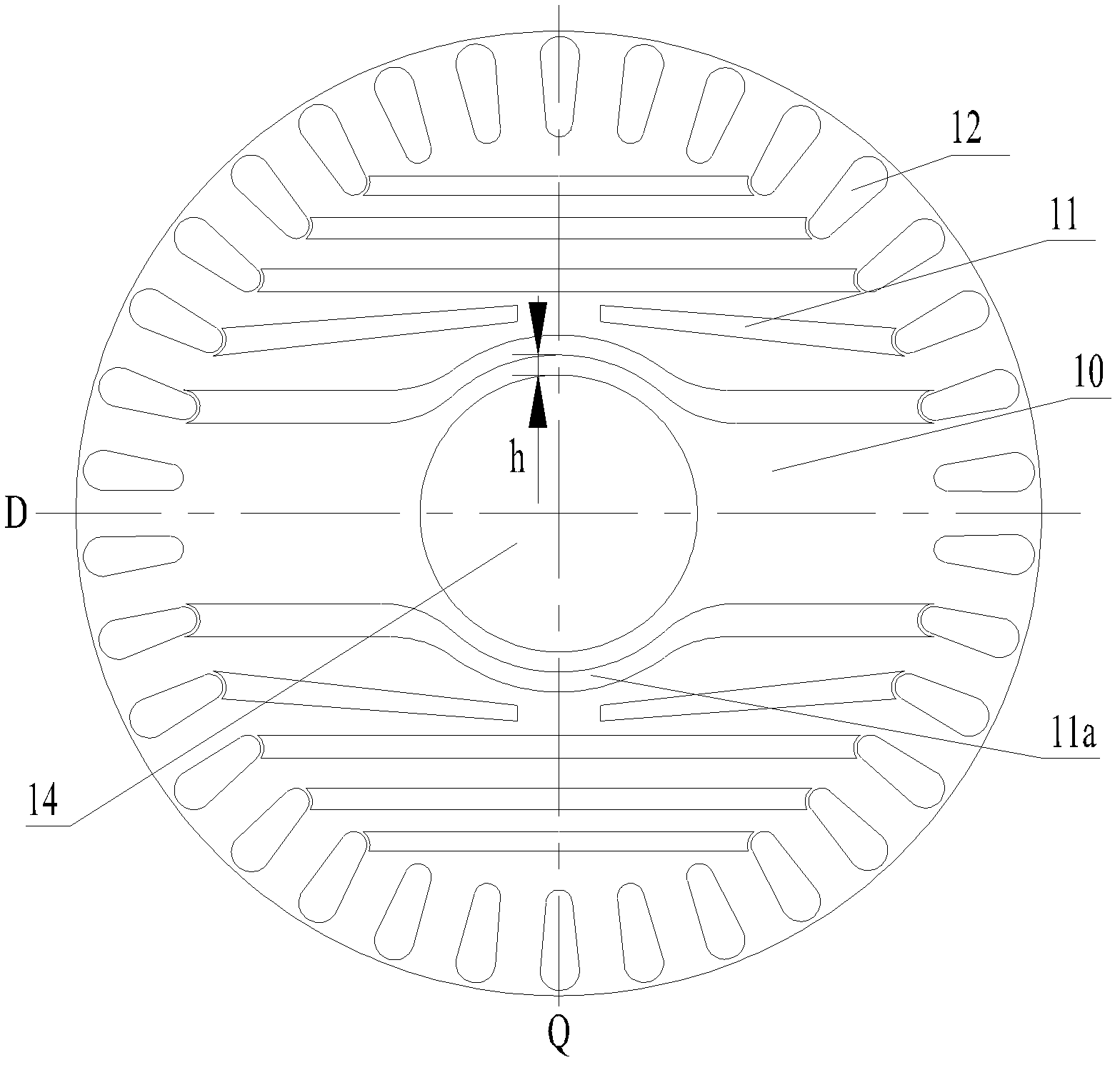

Self-starting synchronous reluctance motor and rotor thereof

ActiveCN103208894ARaise the saliency ratioImprove efficiencySynchronous machinesAsynchronous induction motorsSynchronous reluctance motorInductance

The invention provides a self-starting synchronous reluctance motor and a rotor thereof. The rotor of the self-starting synchronous reluctance motor comprises an iron core and squirrel-cage grooves, wherein magnetic flux separation grooves are arranged on the iron core, and the squirrel-cage slots are distributed along the periphery of the iron core. In the cross section of the rotor, the center line of the cross sections of the squirrel-cage slots deviates from the center circle of the iron core. The self-starting synchronous reluctance motor comprises a stator and the rotor of the self-starting synchronous reluctance motor. According to the self-starting synchronous reluctance motor and the rotor, the center line of the cross sections of the squirrel-cage grooves is led to deviate from the center circle of the iron core by adjusting the angle of the squirrel-cage grooves arranged on the rotor, magnetic permeability in the direction of the D axis is improved, magnetic permeability in the direction of the Q axis is reduced, inductance Ld in the direction of the D axis is increased and inductance Lq in the direction of the Q axis is reduced, namely salient pole ratio (Ld / Lq) of the motor is improved, and further motor efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

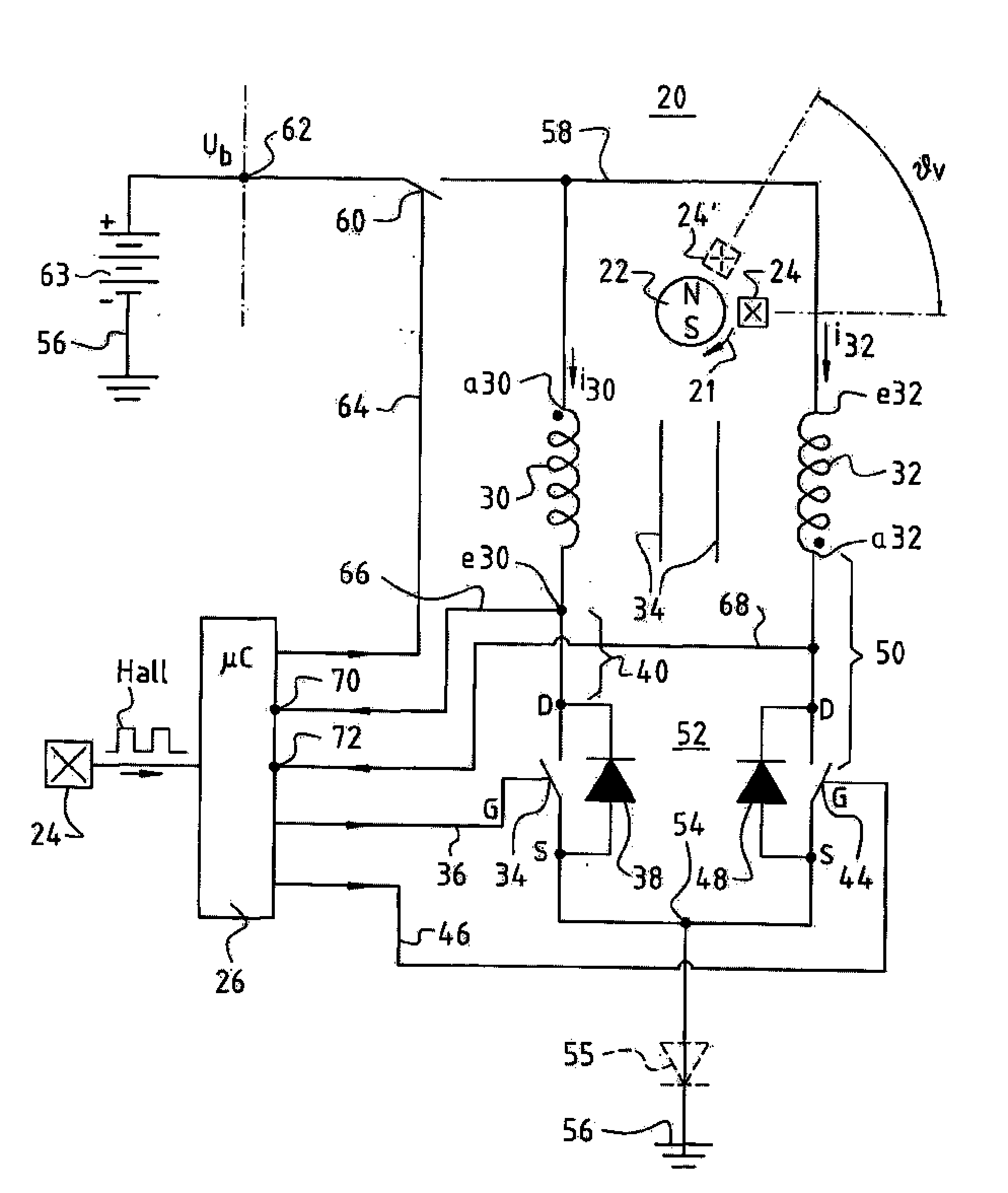

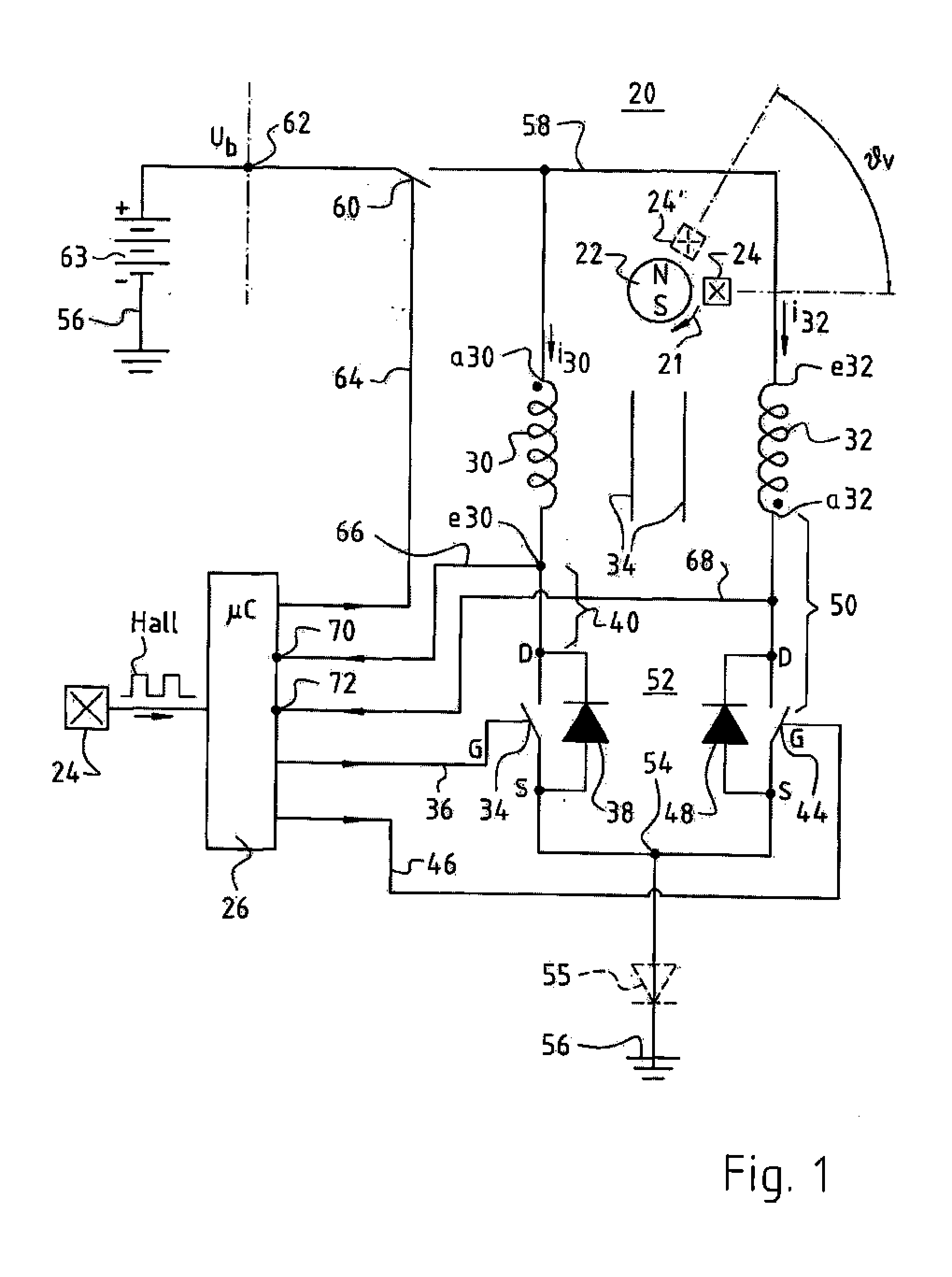

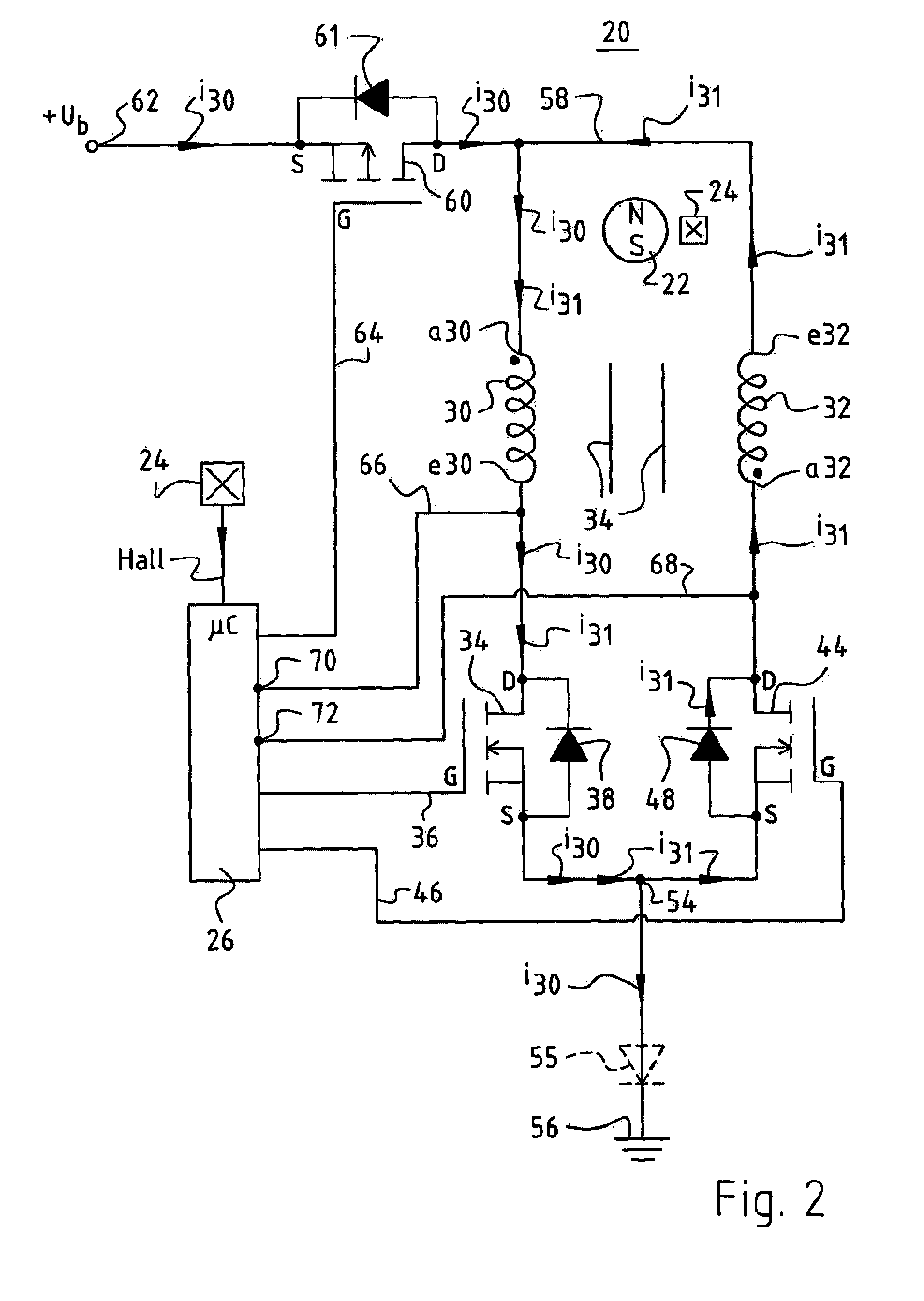

Method for Operating an Electronically Commutated Motor, and Motor for Carrying Out a Method Such as This

ActiveUS20080315807A1Low efficiencyImprove efficiencyMotor/generator/converter stoppersAC motor controlPermanent magnet rotorPower application

An electronically commutated motor (ECM 20) has terminals (56, 62) for connection to a DC power source (63). It has a permanent-magnet rotor (22), also a first and a second series circuit (40, 50) in each of which a stator winding strand (30, 32) is connected in series with a controllable semiconductor switch (34, 44), which two series circuits are connected in parallel to form a parallel circuit (52). In addition to the strand-connected switches (34, 44) typically found in an ECM, in a supply lead to said parallel circuit (52), a third controllable semiconductor switch (60) controls energy supply from the DC power source (63). In order to increase motor efficiency and minimize the size of any motor capacitor required, special switching steps are performed so that electromagnetic energy, remaining in the winding(s) after shutoff of power application, is converted into motor torque, instead of being dissipated as heat.

Owner:EBM PAPST ST GEORGEN & -

Novel magnetic flux adjustable permanent magnet synchronous motor

InactiveCN103441592AChange the state of magnetizationThe state of magnetization does not affectMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsPermanent magnet synchronous motorConductor Coil

The invention discloses a novel magnetic flux adjustable permanent magnet synchronous motor. Traditional magnetic flux weakening speed regulation has a lot of defects such as reduction of motor efficiency, risks of out of control of magnetic flux weakening and limited magnetic weakening capability. According to the novel magnetic flux adjustable permanent magnet synchronous motor, a permanent magnet is arranged under each pole of a rotor iron core, the permanent magnets are distributed in a U shape, wherein the permanent magnets with high coercivity are distributed at the bottom end of the U shape, the permanent magnets with low coercivity are distributed on the two sides of the U shape, a trapezoidal opening groove is formed above the permanent magnets with the high coercivity, and arc-shaped opening grooves are formed in the two sides of the trapezoidal opening groove. According to the novel magnetic flux controllable permanent magnet synchronous motor, due to the fact that a direct-axis current is applied to a stator winding, the magnetized state of the permanent magnets with the low coercivity can be changed, while the magnetized state of the permanent magnets with the high coercivity is not affected, thereof, the magnetic path inside the rotor is changed, the purpose of adjusting air gap magnetic flux is achieved, and the speed regulation range of the motor can be improved greatly.

Owner:ZHEJIANG UNIV

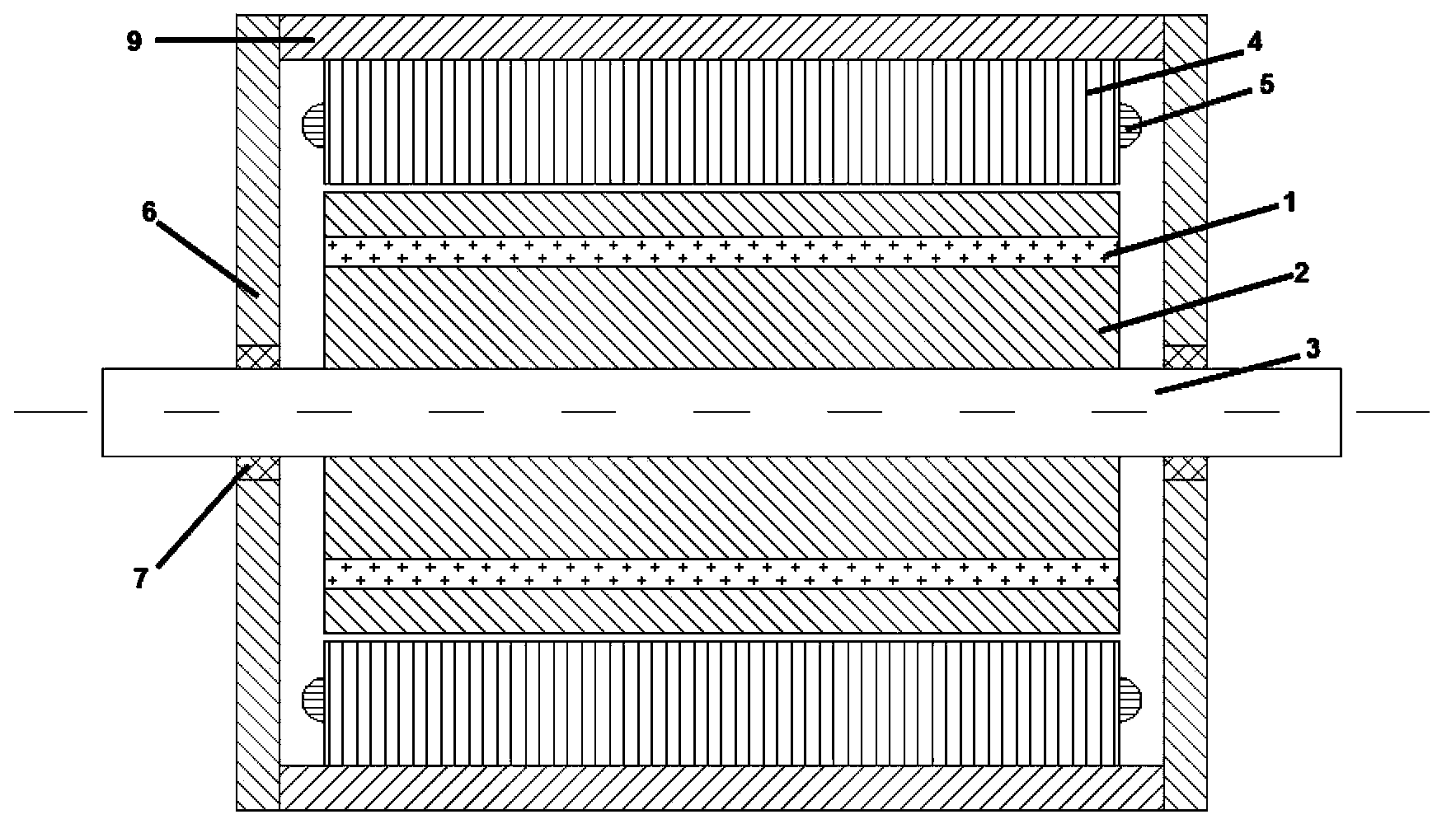

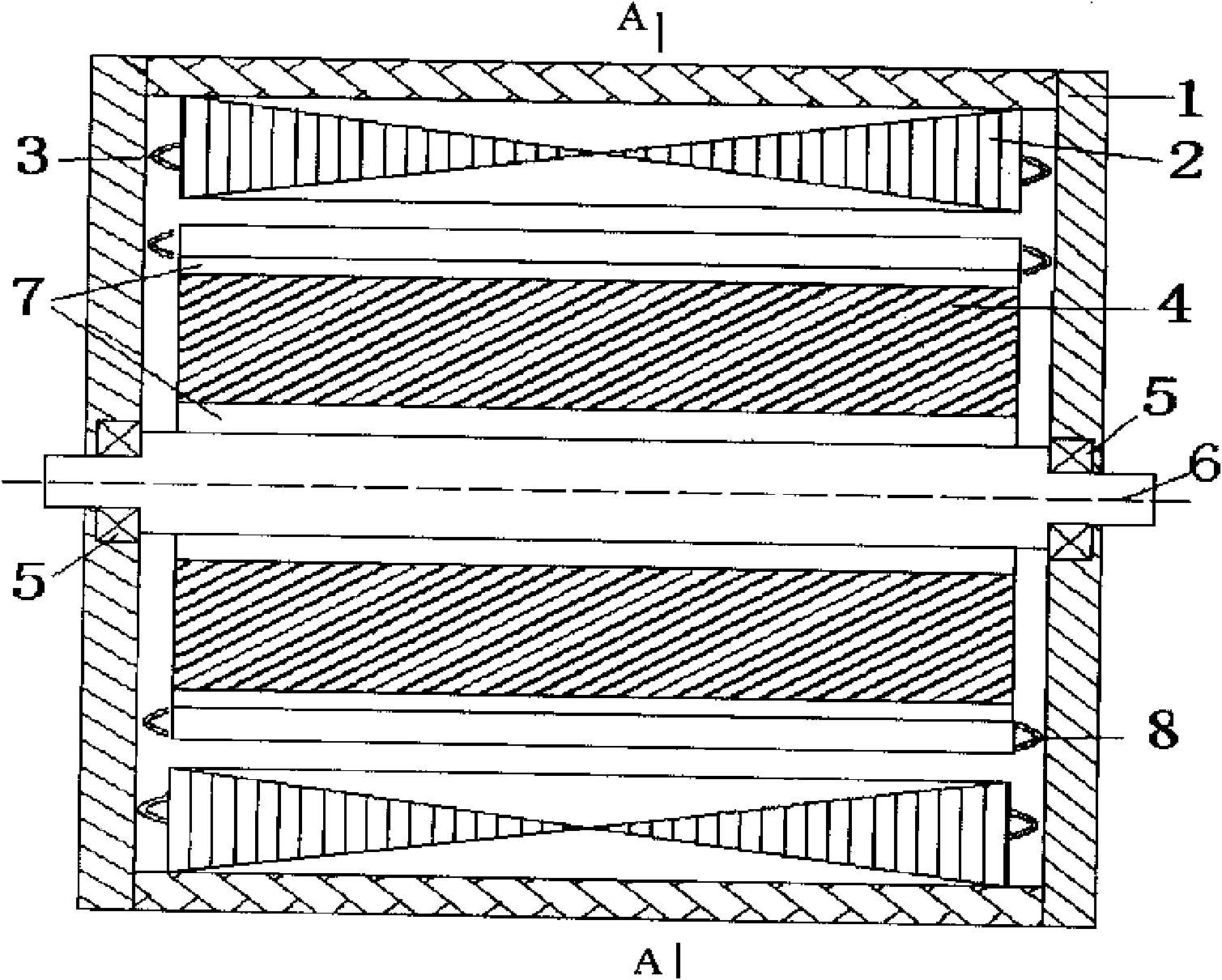

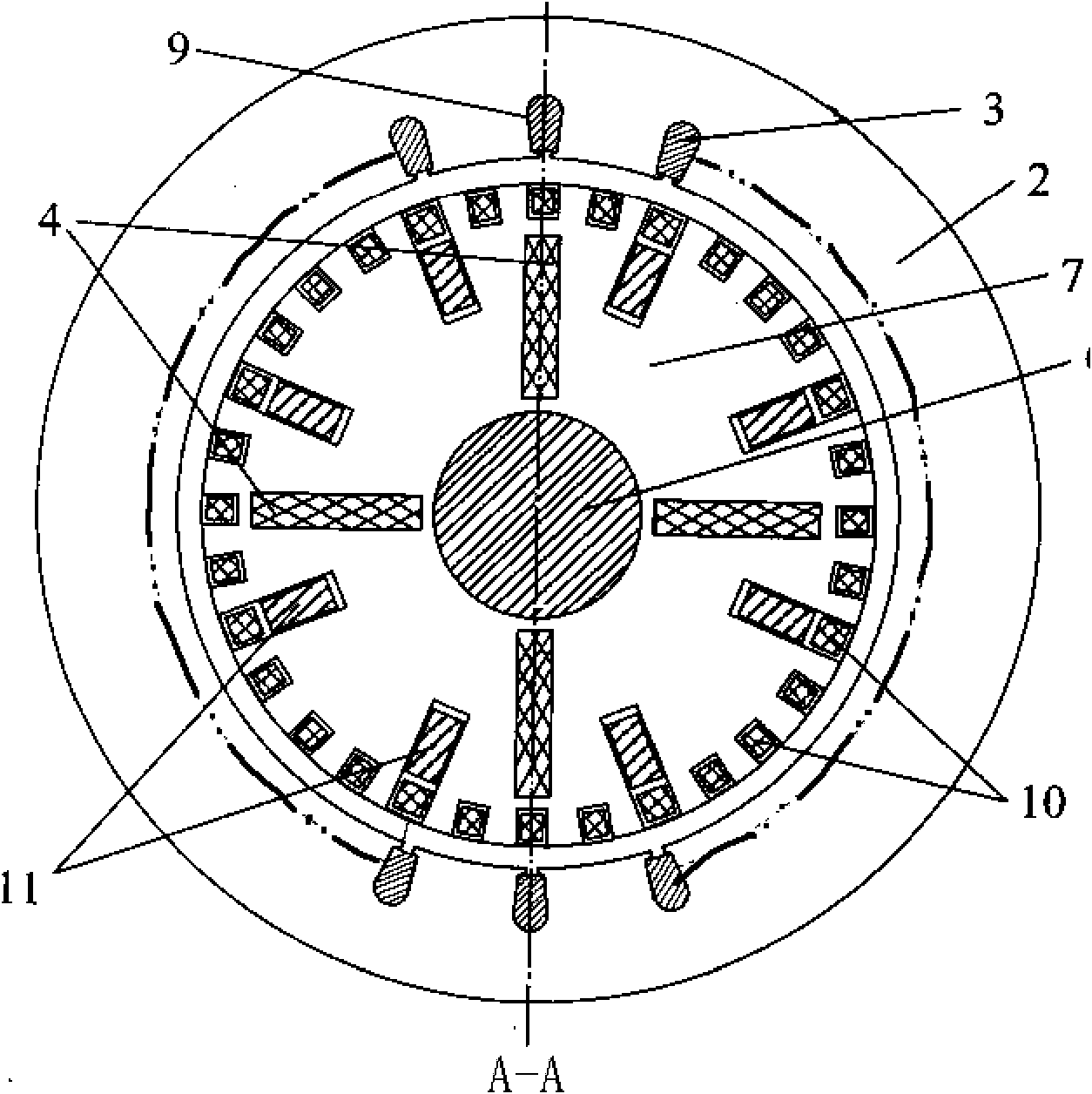

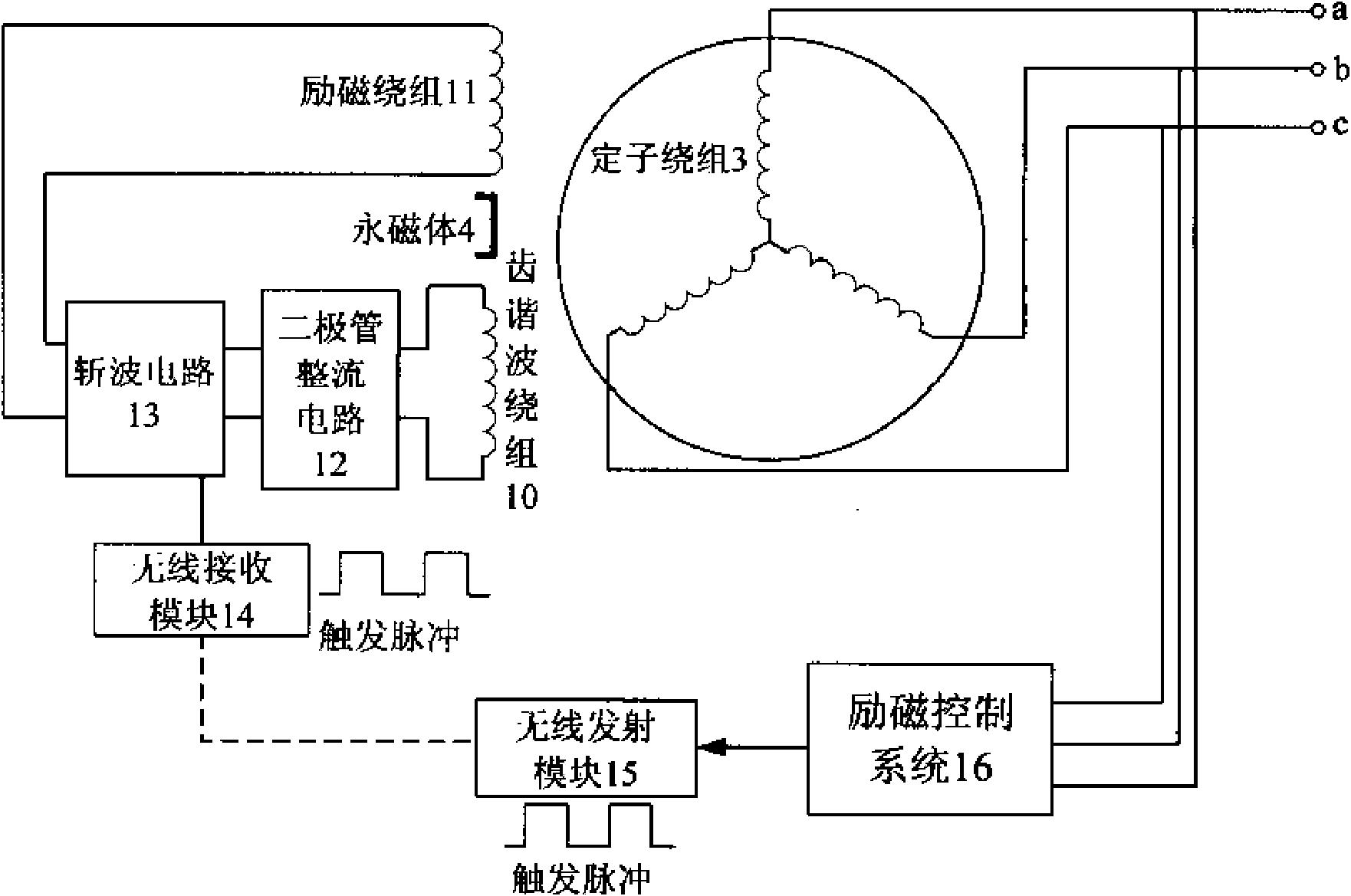

Hybrid excitation permanent magnet motor for wireless transmission and tooth harmonic excitation

ActiveCN102185448ASimple structureReduce maintenanceMagnetic circuit rotating partsStructural associationConductor CoilHarmonic excitation

The invention discloses a hybrid excitation permanent magnet motor for wireless transmission and tooth harmonic excitation in the technical field of motors. A stator and a rotor are arranged in a shell; a rotating shaft passes through a central hole of a rotor core and is fixed with the rotor core; the rotating shaft is connected with the shell through a bearing; a stator winding corresponds to apermanent magnet and a rotor exciting winding to generate electromagnetic induction; a rotor tooth harmonic winding and the rotor exciting winding are connected with a chopper circuit through a dioderectifying circuit; a driving signal of a switching element in the chopper circuit is acquired through a wireless receiving module; an excitation control system outputs a pulse signal to a wireless transmitting module, transmits the pulse signal to the wireless receiving module on the rotor through the wireless transmitting module, controls the on / off of the switching element in the chopper circuit and provides the needed exciting current for the rotor exciting winding; therefore, an air-gap field and the output voltage of the stator winding are adjusted. Compared with the prior art, the hybrid excitation permanent magnet motor has no electric brush, collecting ring, additional air gap or axial magnetic circuit, is simple in structure, low in flux leakage, low in electric excitation loss and high in motor efficiency, and has high capacity of adjusting a main field.

Owner:TSINGHUA UNIV

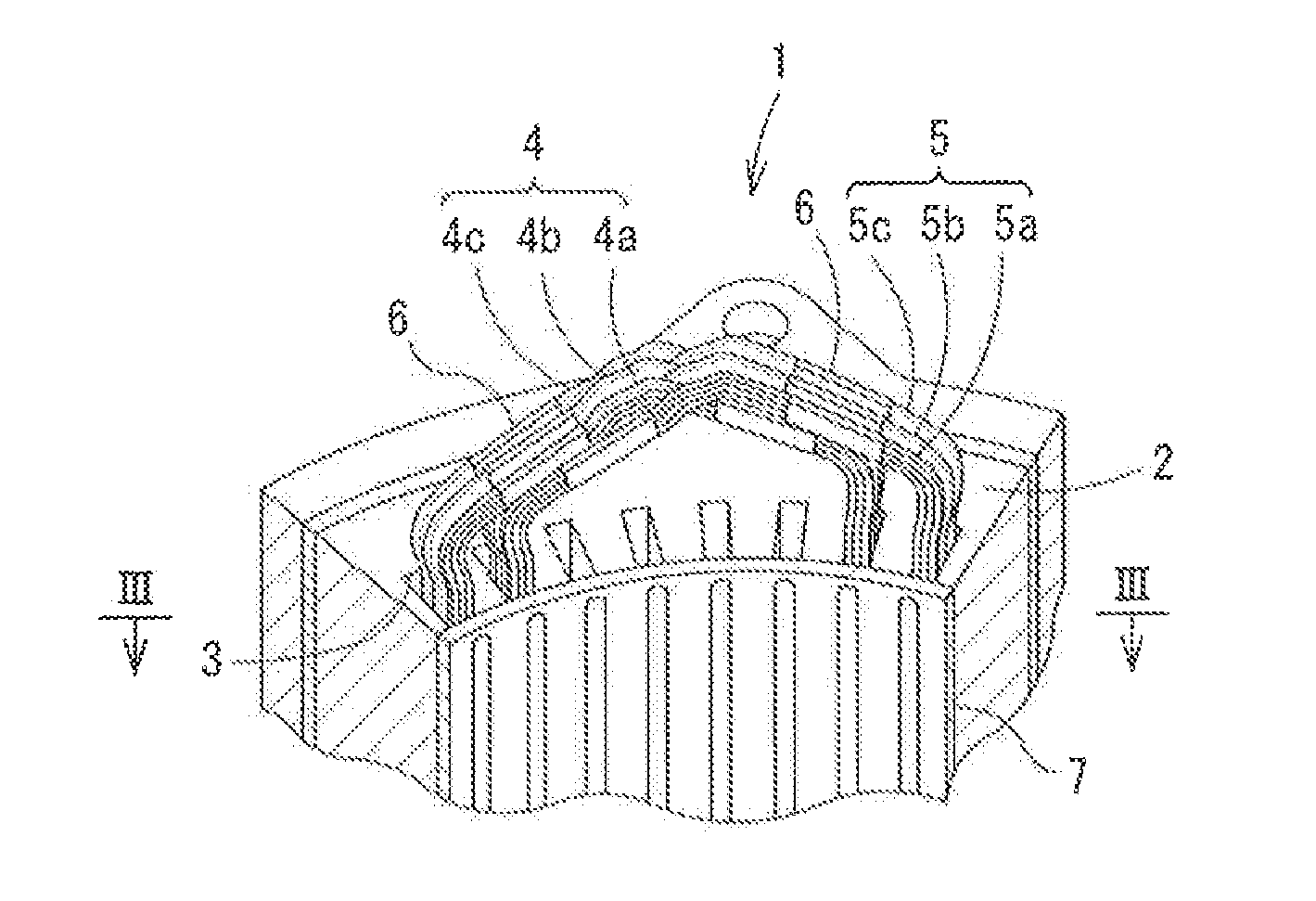

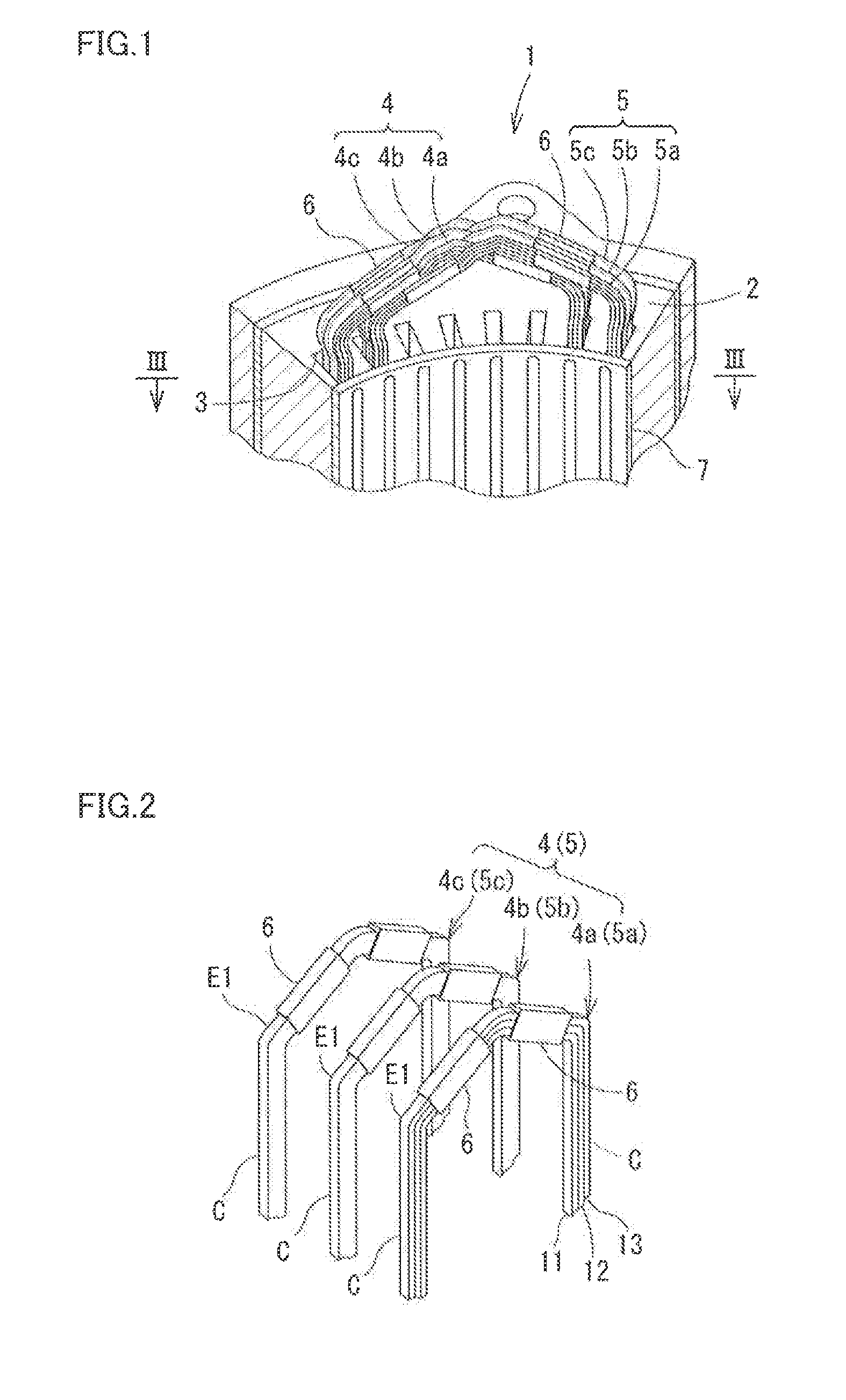

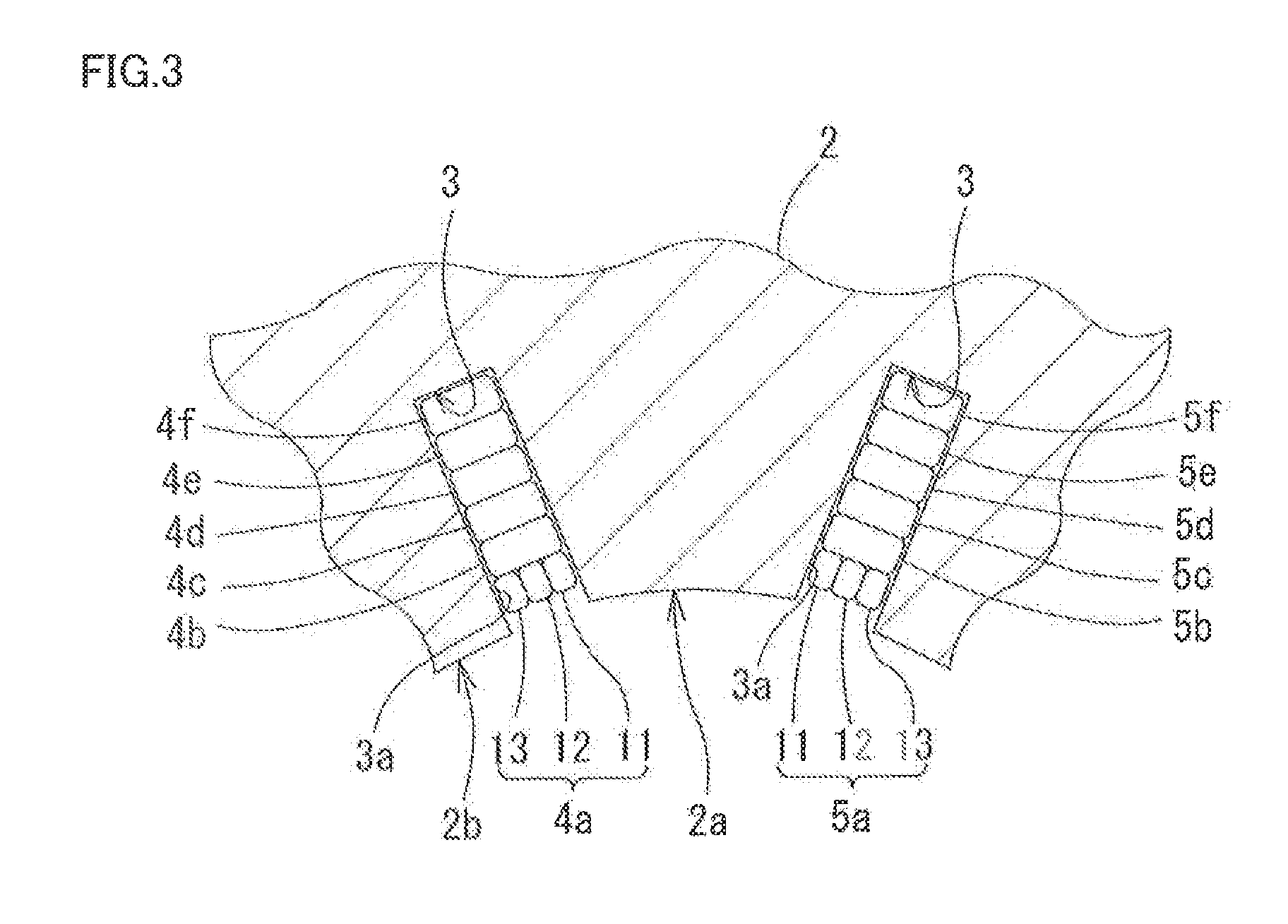

Segment coil, method of manufacturing segment coil, wire rod for segment coil, and stator

InactiveUS20140300239A1Effective preventionEffective prevention of eddy current and magnetic flux leakageWindings insulation shape/form/constructionSynchronous machinesWire rodElectric machine

A segment coil capable of achieving effective prevention of magnetic flux leakage or eddy current and enhancing efficiency of a motor is provided. Segment coils in stator of a rotating electric machine including an annular core and rectangular wire coils in a plurality of layers, which are attached on an innermost circumferential side in a direction of radius of a slot formed in an inner circumferential portion of the annular core and are opposed to a rotor, are each constituted of a plurality of divided wires as divided in a circumferential direction of the annular core. The plurality of divided wires are integrally joined in coil end portions extending from the slot.

Owner:TOYOTA JIDOSHA KK

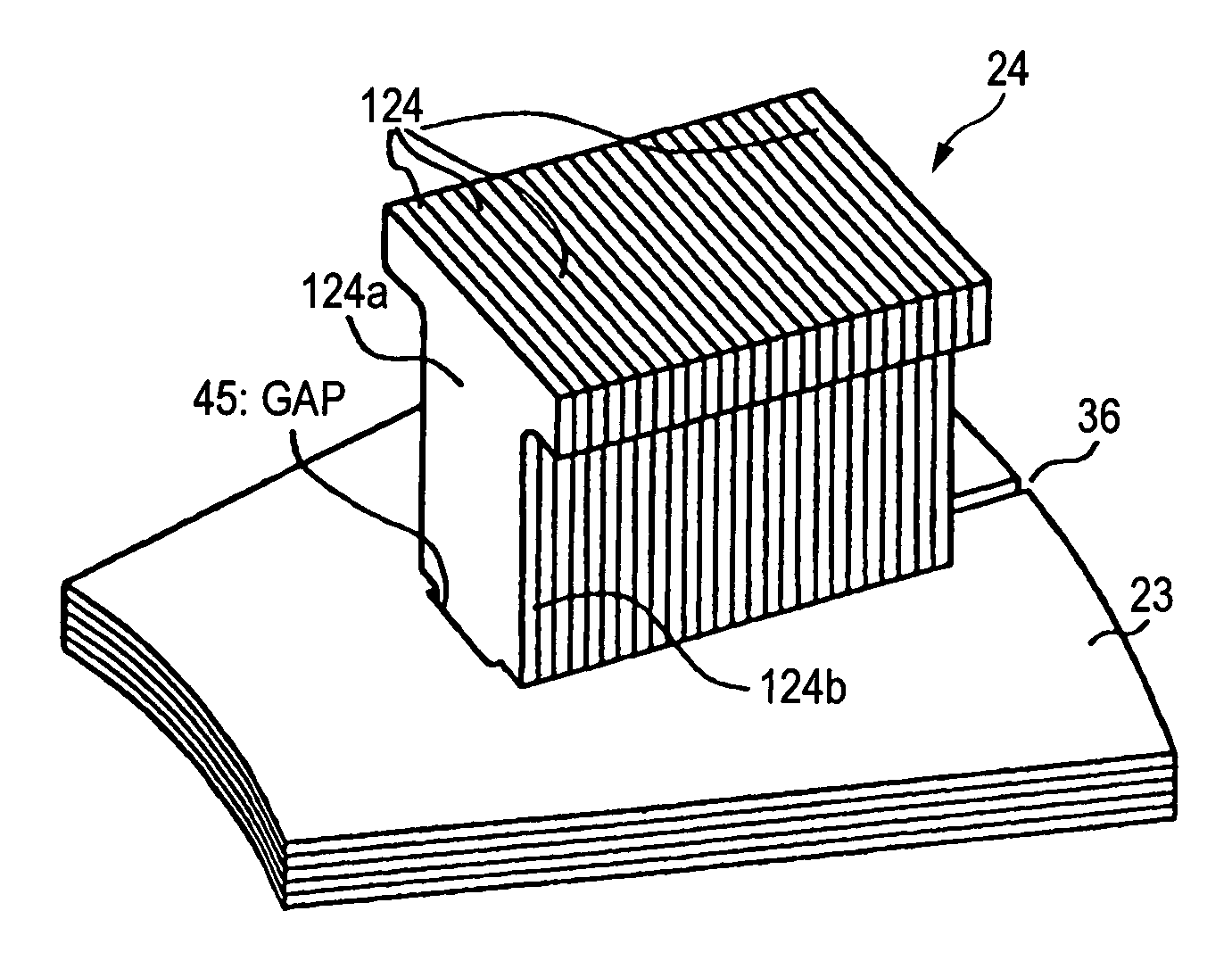

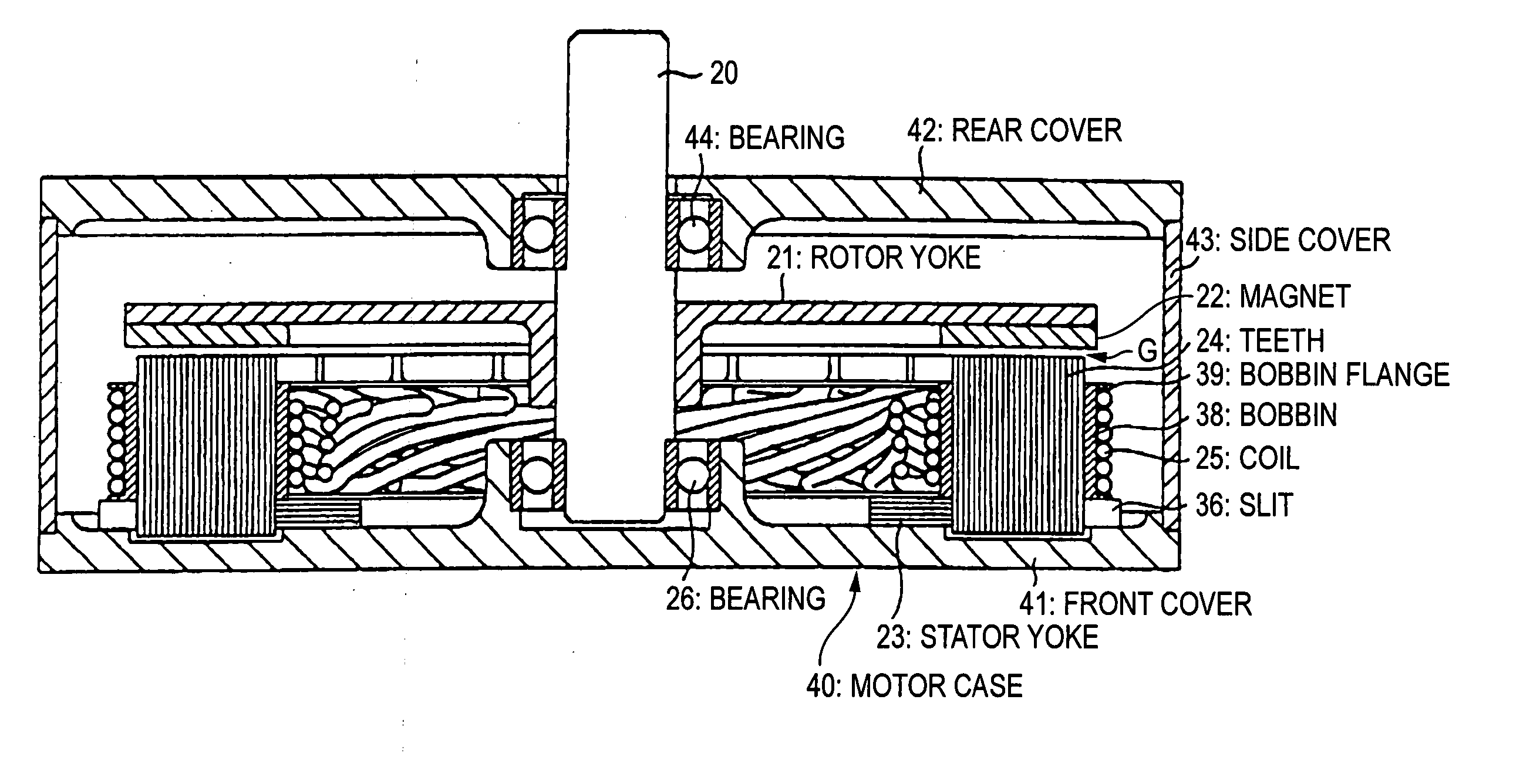

Axial gap type dynamo-electric machine

InactiveUS7173357B2Loss is smallTotal current dropSuspensionsMagnetic circuit rotating partsElectric machineHigh torque

There is provided an axial gap type rotating electric machine which is small-sized and achieves a high motor efficiency as a drive source having a high torque using, for example, a strong magnet by reducing an energy loss by an induced current.An axial gap type rotating electric machine having a yoke on a side of a rotor in a circular plate shape fixed to a rotating shaft, a yoke 23 on a side of a stator in a circular plate shape opposed to the yoke on the side of the rotor, a magnet fixed to a side of an opposed face of either one of the yokes on the side of the rotor or the side of the stator, a plurality of teeth 24 arranged on a side of an opposed face of other yoke on the side of the rotor or the side of the stator radially and opposedly to the magnet and fixed to the yoke 23, and a coil wound around each of the plurality of teeth, in which the teeth 24 has a laminated member of plate members 124 for the teeth and faces 124a to be superposed of the plate members 124 for the teeth are arranged in a circumferential direction.

Owner:YAMAHA MOTOR CO LTD

Axial gap type rotating electric machine

ActiveUS20050017596A1Large outputIncrease torqueSuspensionsMagnetic circuit rotating partsElectric machineEngineering

There is provided an axial gap type rotating electric machine which is small-sized and achieves a high motor efficiency as a drive source having a high torque using a strong magnet by reducing energy loss by an induced current. An axial gap type rotating electric machine having a yoke on a side of a rotor in a circular plate shape fixed to a rotating shaft, a yoke 23 on a side of a stator in a circular plate shape opposed to the yoke on the side of the rotor, a magnet fixed to a side of an opposed face of either one of the yokes on the side of the rotor or the side of the stator, a plurality of teeth 24 arranged on a side of an opposed face of other yoke on the side of the rotor or the side of the stator radially and opposedly to the magnet, and a coil 25 wound around each of the plurality of teeth, in which the yoke 23 has a fixing portion including a hole or a recess for inserting a portion of the teeth to fix, and in which a resistance portion against an induced current (slit 36) is provided at a surrounding of the fixing portion.

Owner:YAMAHA MOTOR CO LTD

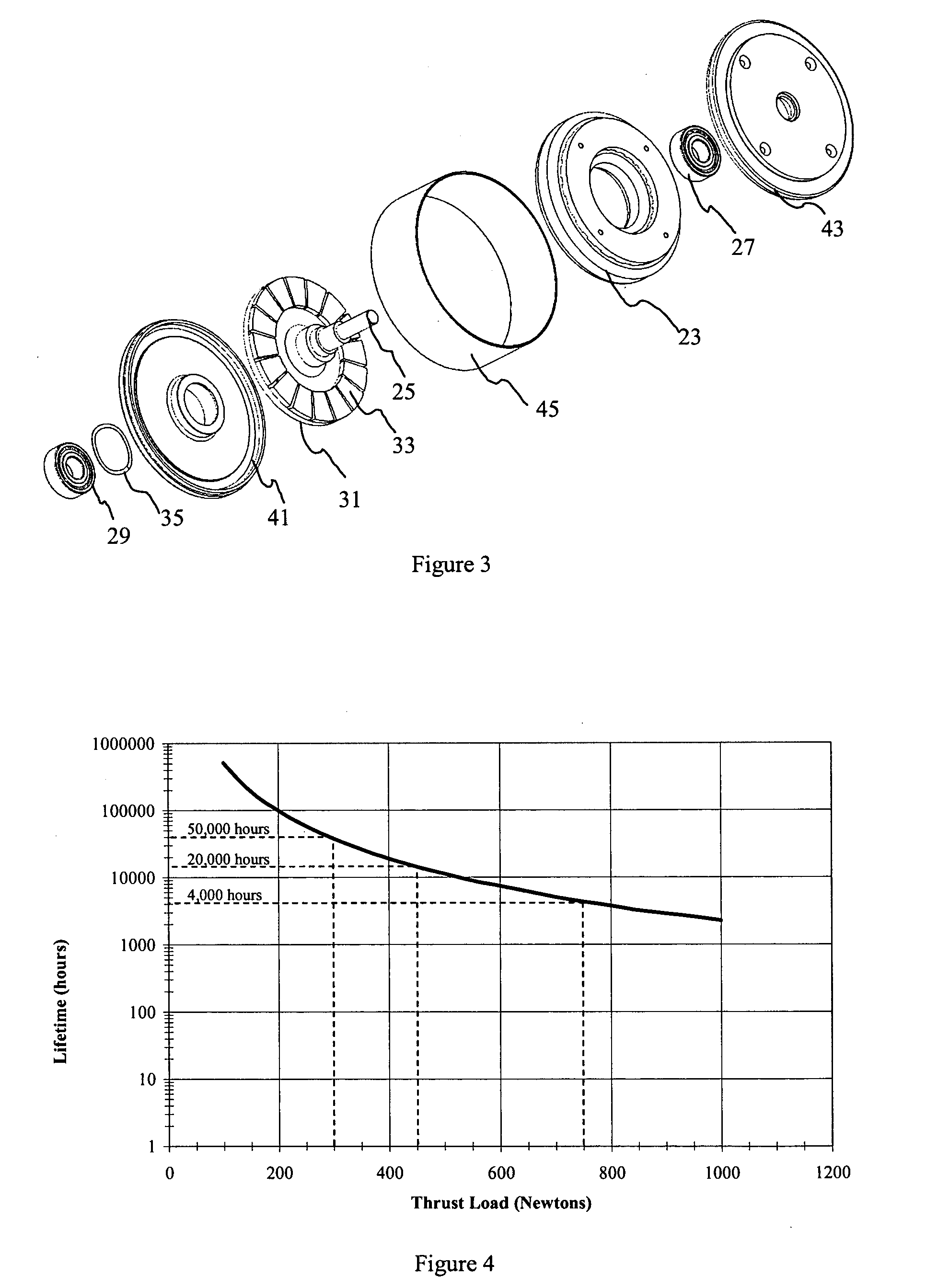

Axial flux electrical machine

ActiveUS20100164313A1Reduce loadExtended service lifeRolling contact bearingsShaftsAxial thrustAxial flux

An axial flux electrical machine including a housing, a stator located within the housing, a rotatable shaft carried by the housing by means of at least a main bearing, and a rotor fixed to the shaft within the housing. Magnetic attractive forces between the rotor and the stator produce an axial thrust on the main bearing and a biasing means (preferably in the form of a spring) is arranged to urge the shaft in a direction opposite to the axial thrust so as to reduce the net load on the main bearing. This reduction in net load on the main bearing increases bearing life and improves motor efficiency.

Owner:REGAL BELOIT AUSTRALIA PTY LTD

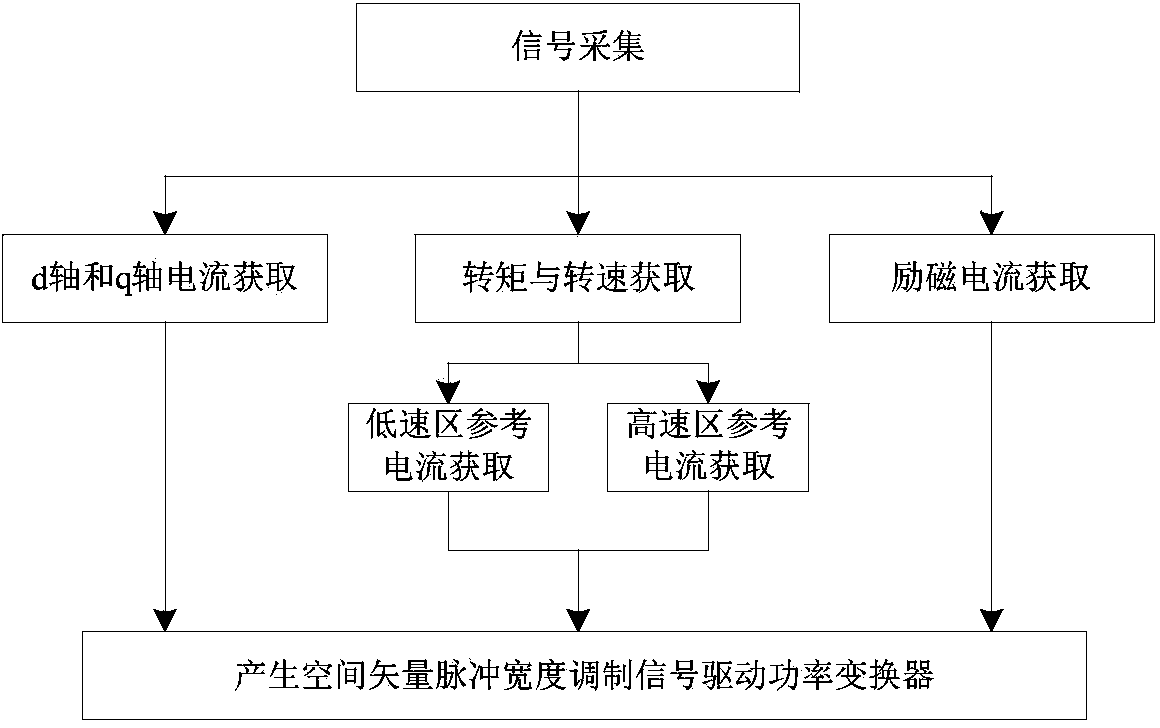

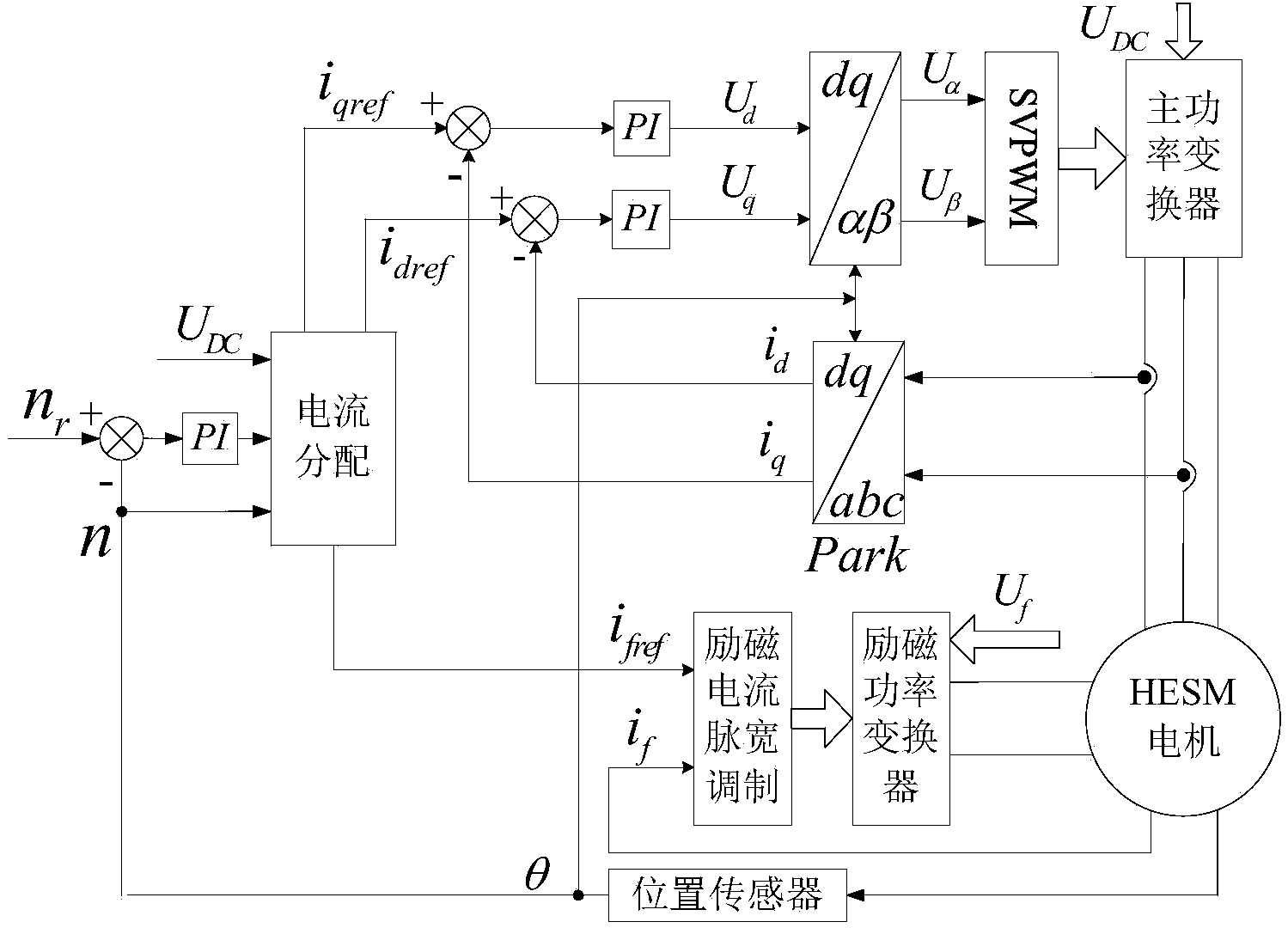

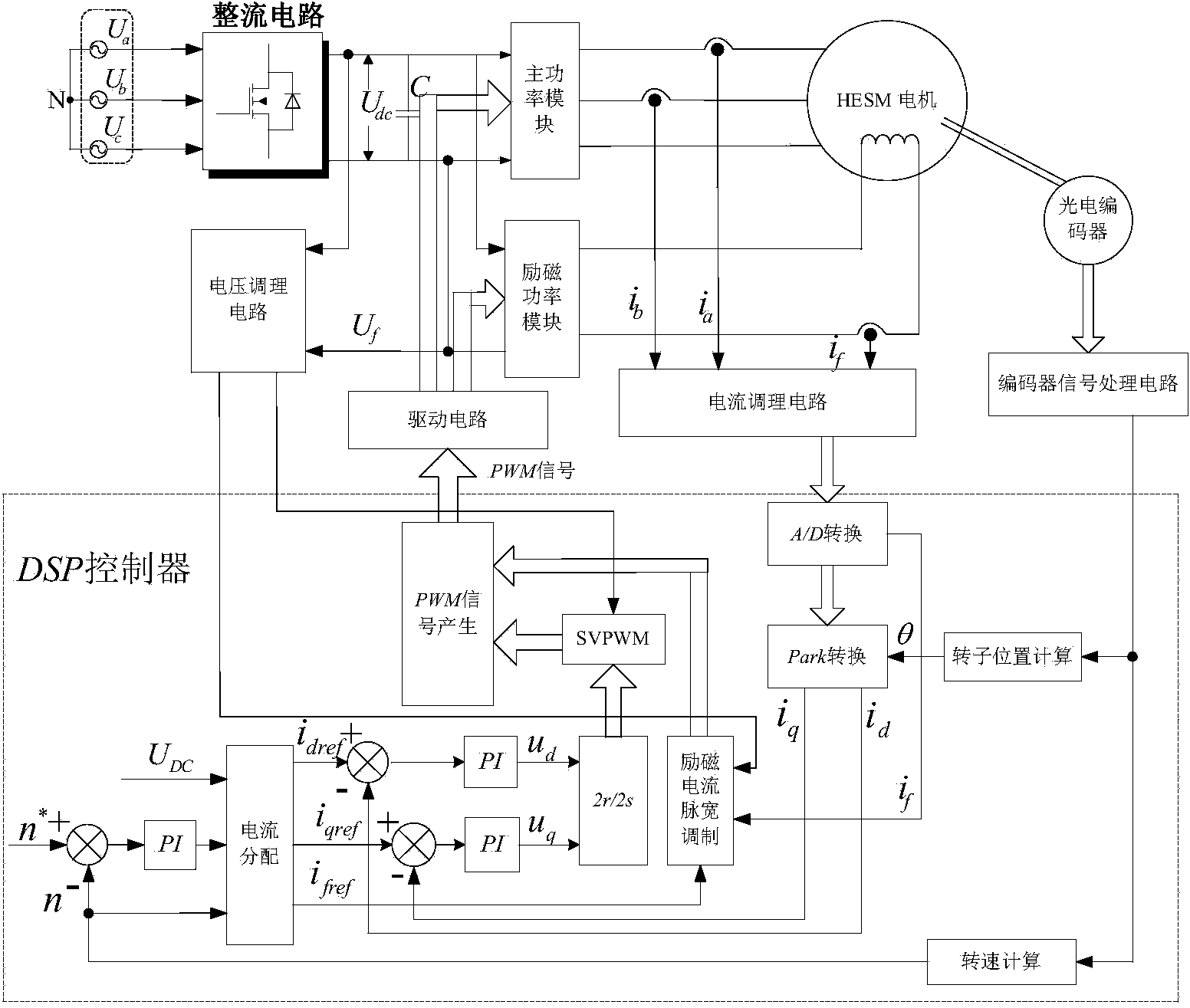

Hybrid excitation synchronous motor efficiency optimized control method

InactiveCN103647489AImprove efficiencyIncrease usageElectronic commutation motor controlAC motor controlLow speedSynchronous motor

The invention discloses a hybrid excitation synchronous motor efficiency optimized control method. In the condition that motor output torque and rotation speed are satisfied, d shaft, q shaft and excitation winding current are controlled, thus iron consumption and copper consumption of a hybrid excitation synchronous motor are minimal, the optimized efficiency of the hybrid excitation synchronous motor is achieved, and the motor efficiency is raised. When the motor runs in a low speed area, according to the size of a load, and through the d shaft, q shaft and excitation winding current coordinated control, the sum of iron consumption and copper consumption is minimal. When the motor runs in a high speed area, by using d shaft current and excitation winding current common flux weakening, through the d shaft, q shaft and excitation winding current coordinated control, the iron consumption and copper consumption of the motor are minimal, and the optimal efficiency of a hybrid excitation synchronous motor is achieved. According to the hybrid excitation synchronous motor efficiency optimized control method, the motor loss is reduced, the efficiency of energy use is raised, and the energy saving effect is achieved.

Owner:SOUTHEAST UNIV

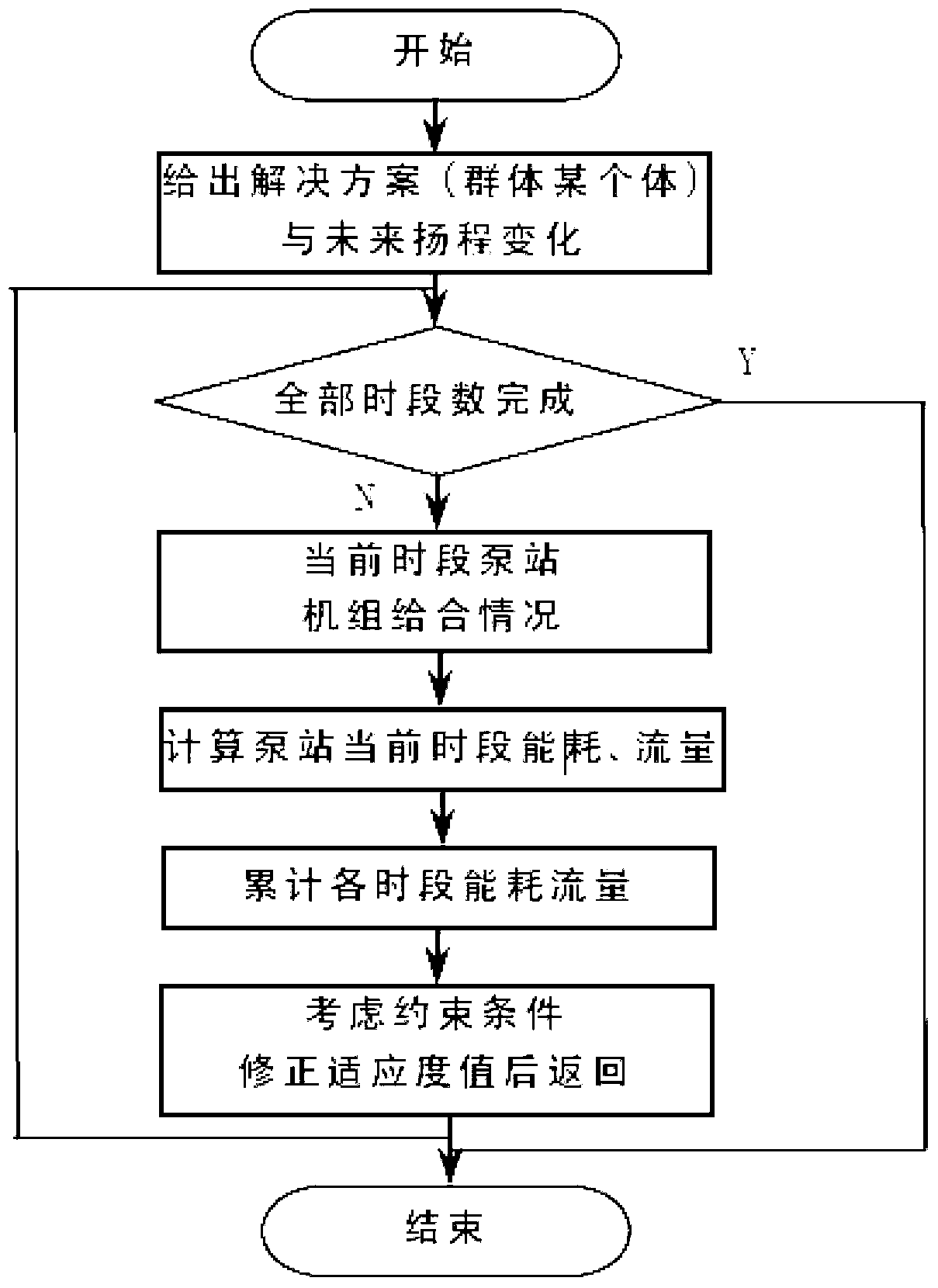

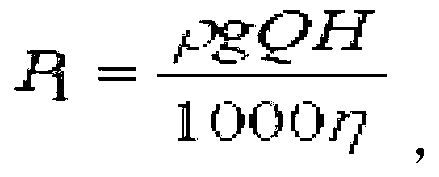

Optimal scheduling method for single-stage pump station

InactiveCN103277291AReduce energy consumptionOptimize operating parametersPump controlPositive-displacement liquid enginesMotor speedMathematical model

The invention relates to an optimal scheduling method for a single-stage pump station. The optimal scheduling method comprises the following steps: establishing mathematical models according to water pump energy consumption and water pump performance and optimizing pump station running parameters; establishing a mathematical model according to water pump energy consumption influencing factors including water pump flow and lift, and obtaining functional relations between the water pump energy consumption and every influencing factor; establishing a mathematical model according to water pump performance influencing factors including water pump flow, lift, efficiency, motor speed, upstream and downstream water level difference of the pump station and resistance factors of a system pipeline, and obtaining functional relations between the water pump performance and every factor; and adjusting the pump station by combination with the mathematical models established according to the water pump energy consumption and the water pump performance and specific changes of the real-time parameters. According to scientific management optimization technology and scheduling decisions, the water pump performance and motor efficiency factors are considered comprehensively, minimum of energy consumption of the pump is achieved for a goal of minimum of total power consumption of a pump station unit on the premise that the required flow of every time period and the lift are met.

Owner:SHANGHAI EAST PUMP AUTOMATION CO LTD

Motor hold shaft installation type permanent-magnetic direct-drive bogie

InactiveCN105197021AImprove efficiencyReduce volumeElectric motor propulsion transmissionAxle-boxes mountingBogieElectric machine

A motor hold shaft installation type permanent-magnetic direct-drive bogie comprises two frame devices, two permanent-magnetic synchronous traction motors, two triangular elastic supporting devices and four wheel pair box devices, wherein two adjacent front and rear wheel pair box devices are connected through the frame devices, two wheels on the left and right symmetric sides are connected through an axel, the permanent-magnetic synchronous traction motors and the axle are integrated through rotors, and driving is realized by rotating the axel; the two frame devices are symmetrically located on the left side and the right side of the advancing direction of a railway vehicle and are connected by double traction rod devices, and the triangular elastic supporting devices are connected with the permanent-magnetic synchronous traction motors and the double traction rod devices. According to the motor hold shaft installation type permanent-magnetic direct-drive bogie, the permanent-magnetic synchronous traction motors are adopted, rotor excitation power is saved, the motor efficiency is improved, the transmission efficiency is improved further after a gear box device is saved, the wheel base of the bogie is shortened, and the motor hold shaft installation type permanent-magnetic direct-drive bogie has the advantages that energy is saved, environment is protected and the small curve through capacity is high, and can be widely applied to various urban railway traffic vehicles.

Owner:CRRC NANJING PUZHEN CO LTD

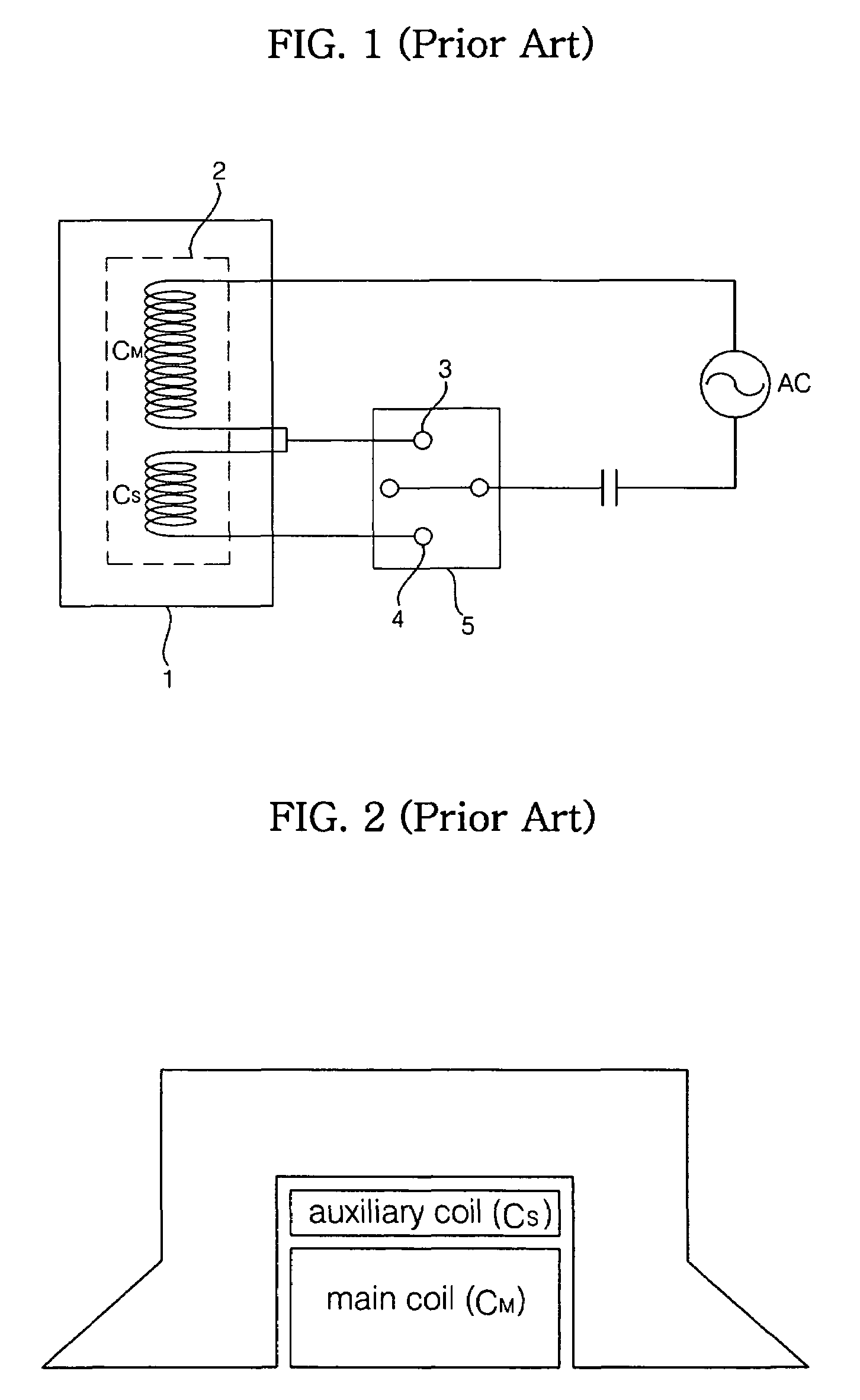

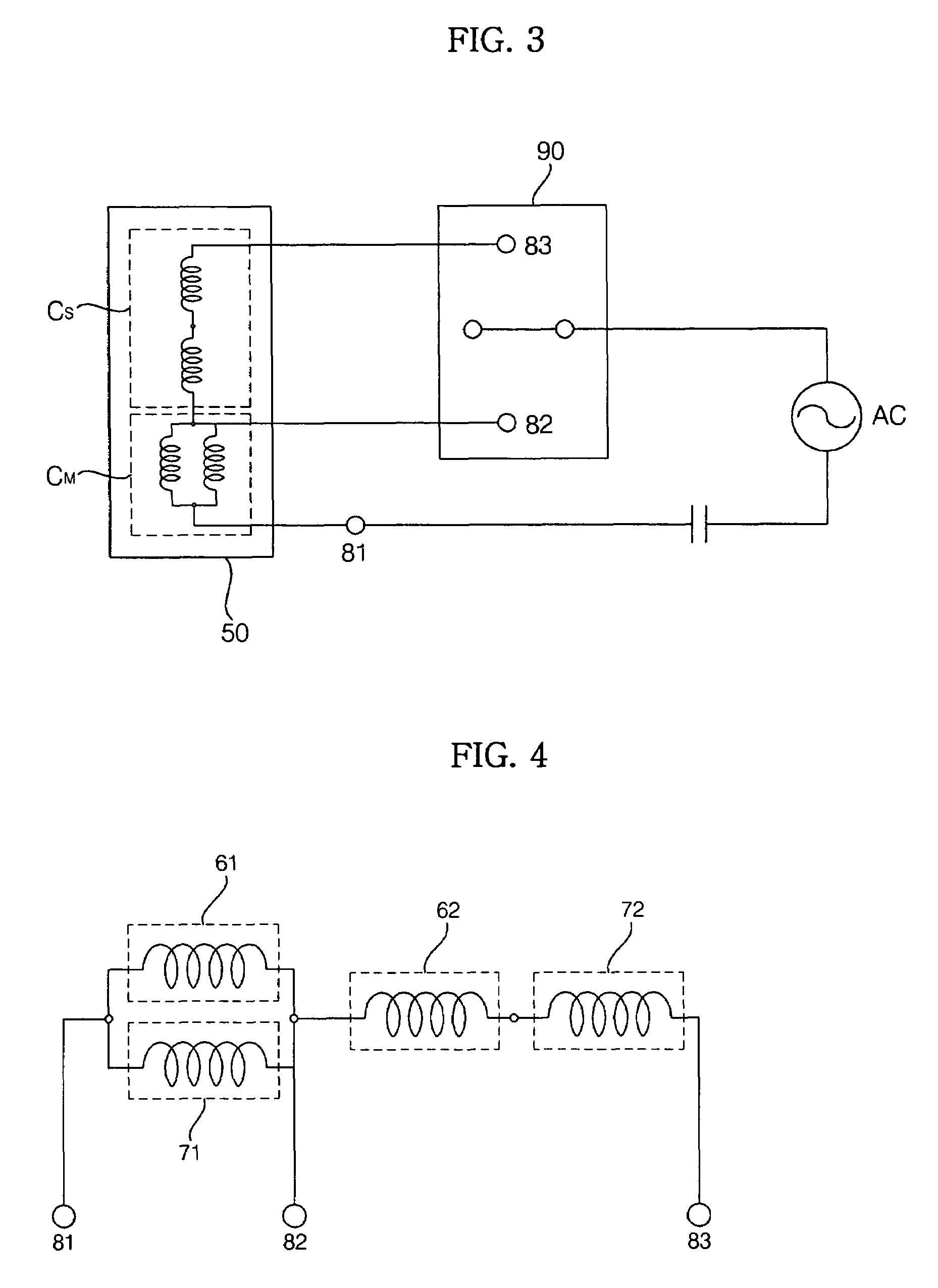

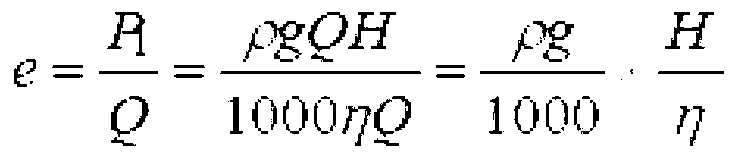

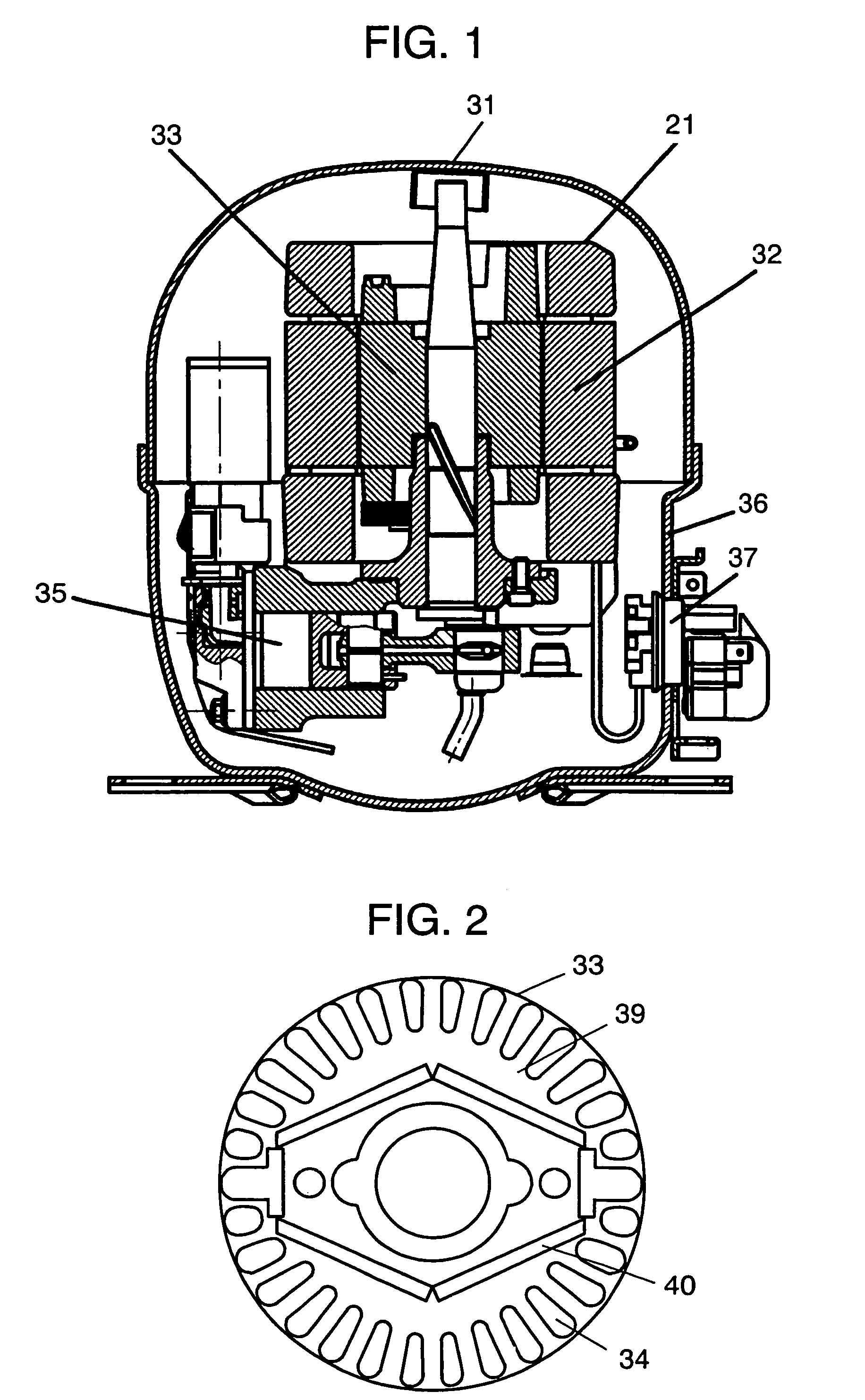

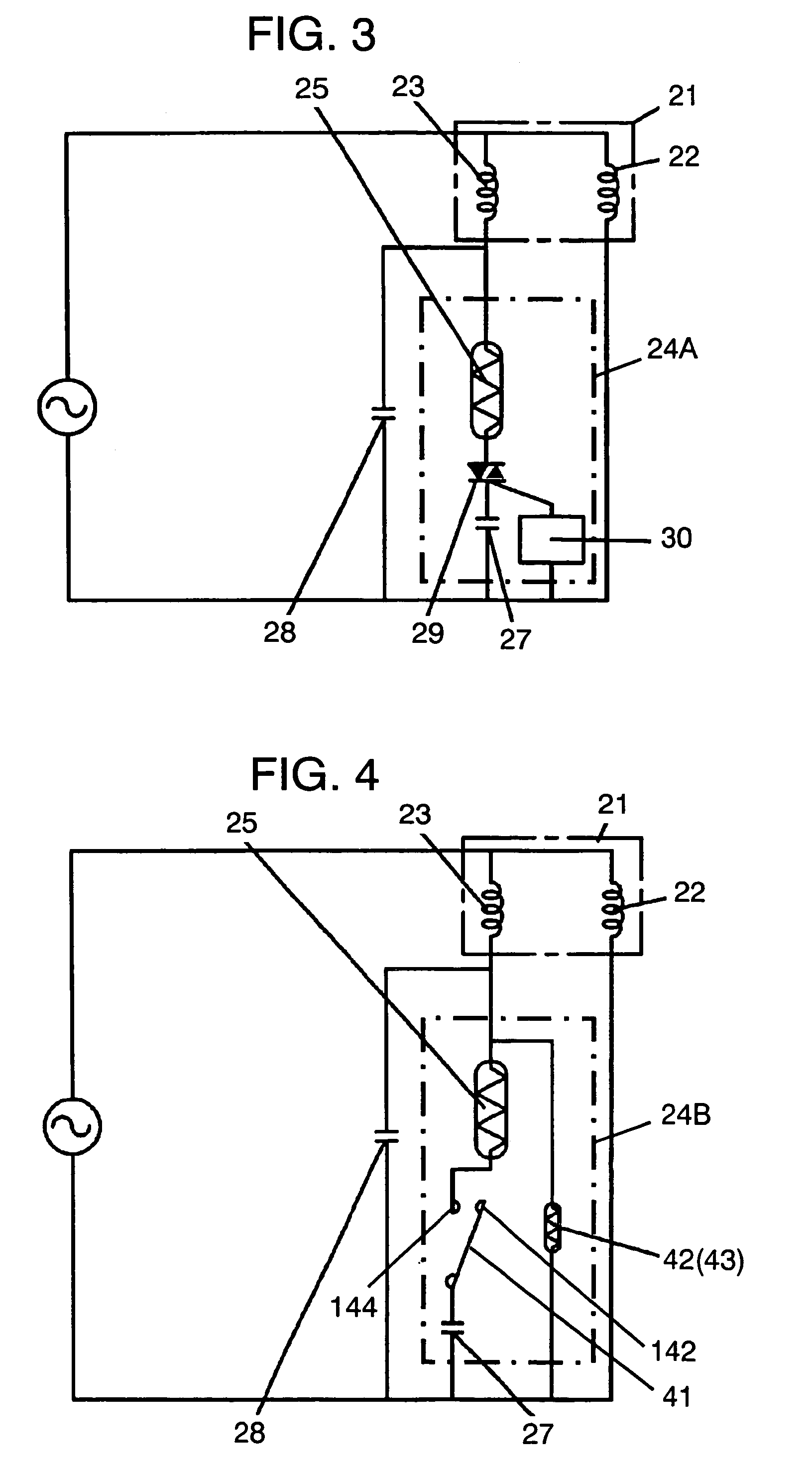

Synchronous induction motor and electric hermetic compressor using the same

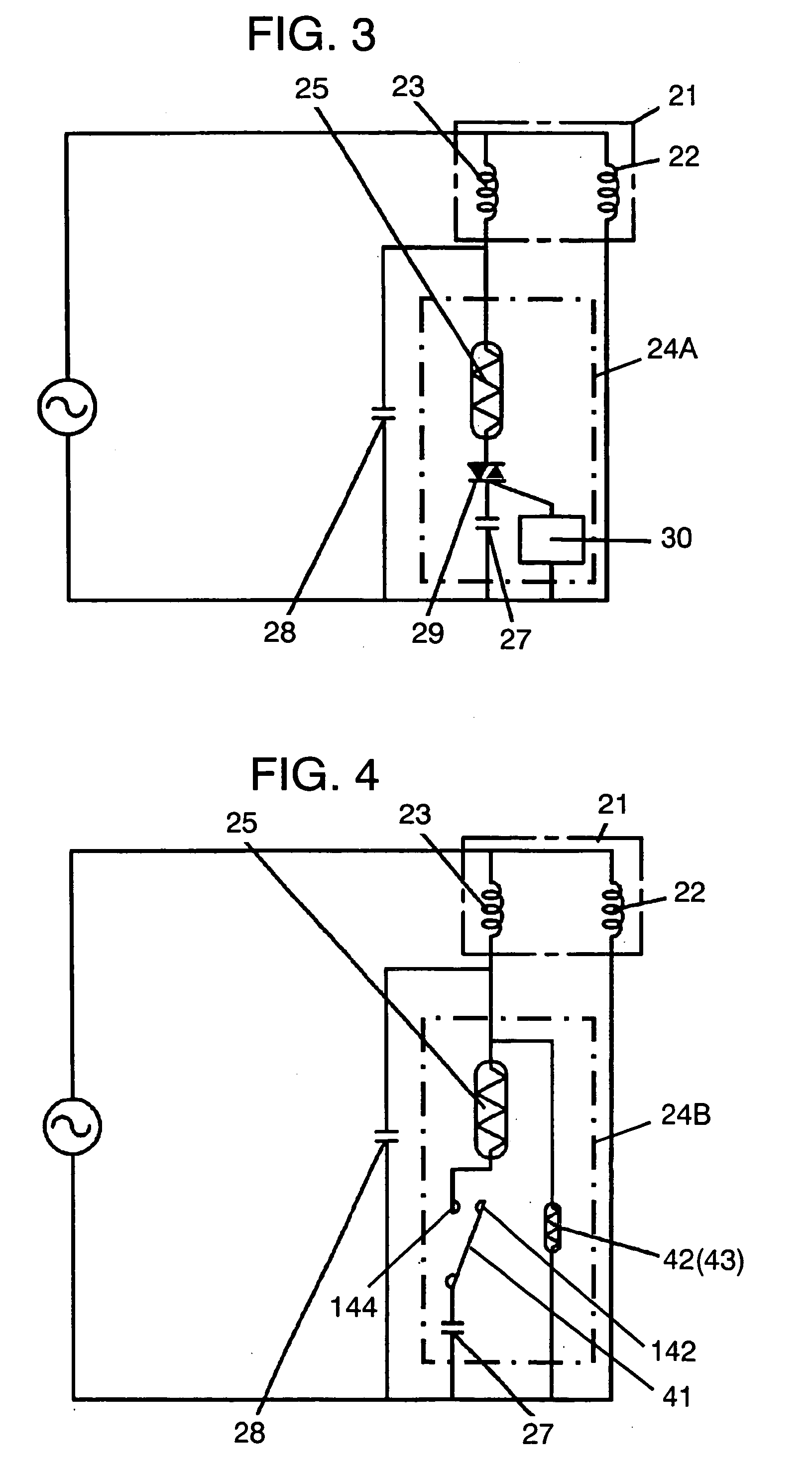

ActiveUS7071650B2Single-phase induction motor startersAC motor controlElectrical conductorSynchronous reluctance motor

A synchronous induction motor has a stator having a main winding and an auxiliary winding; a rotor having a yoke, a permanent magnet embedded in the yoke and a secondary conductor provided in the vicinity of periphery of the yoke; and a starter. The starter has a starting capacitor connected in series with the auxiliary winding of the synchronous induction motor, and a switching unit to open / close a circuit from the starting capacitor to the auxiliary winding. The switching unit closes the circuit from the starting capacitor to the auxiliary winding when the synchronous induction motor is at rest, and opens the circuit after the synchronous induction motor is started. The synchronous induction motor is highly efficient and easy to re-start with low power consumption. The electric hermetic compressor equipped with the synchronous induction motor can perform with the similar effects.

Owner:PANASONIC APPLIANCES REFRIGERATION DEVICES SINGAPORE

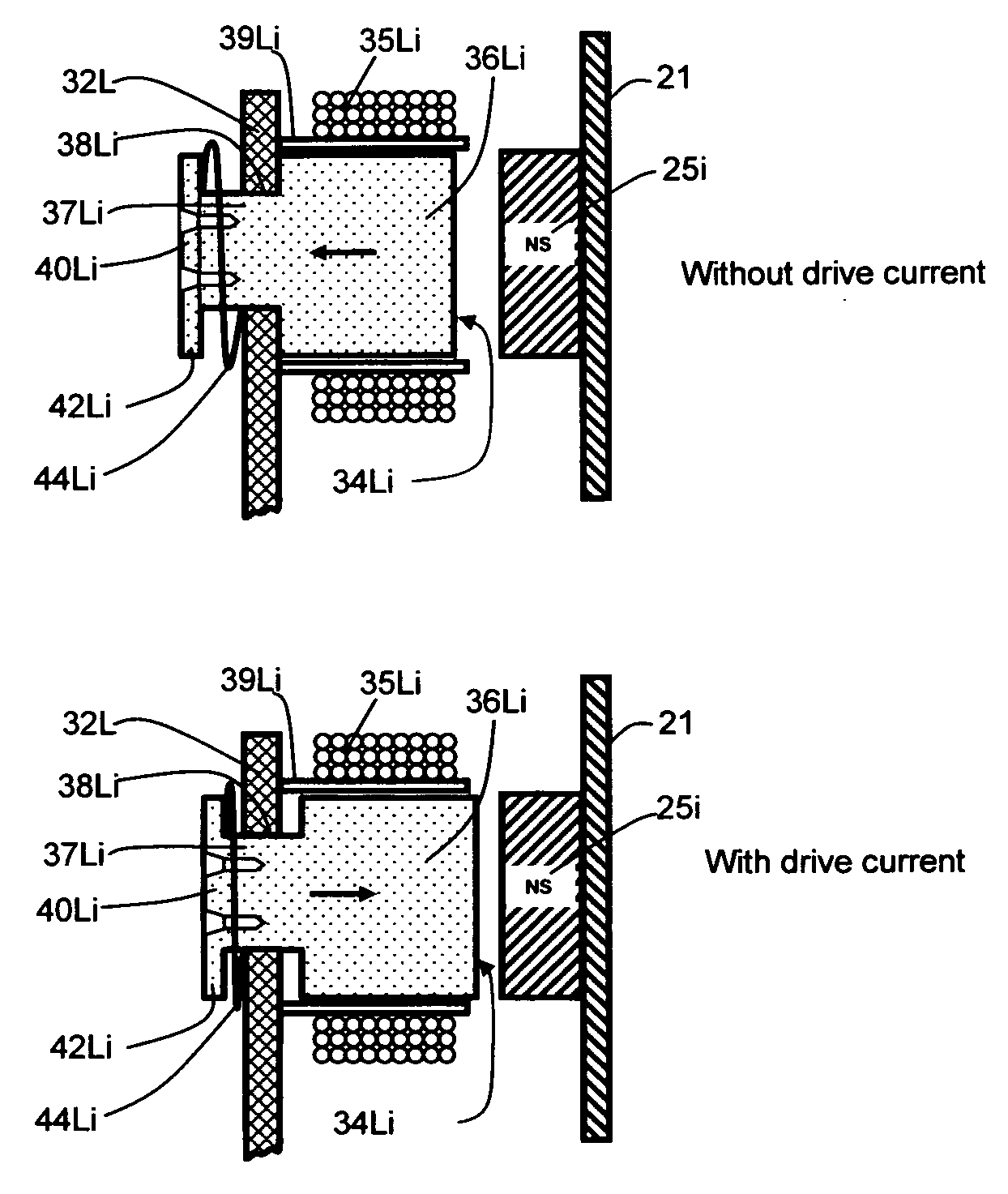

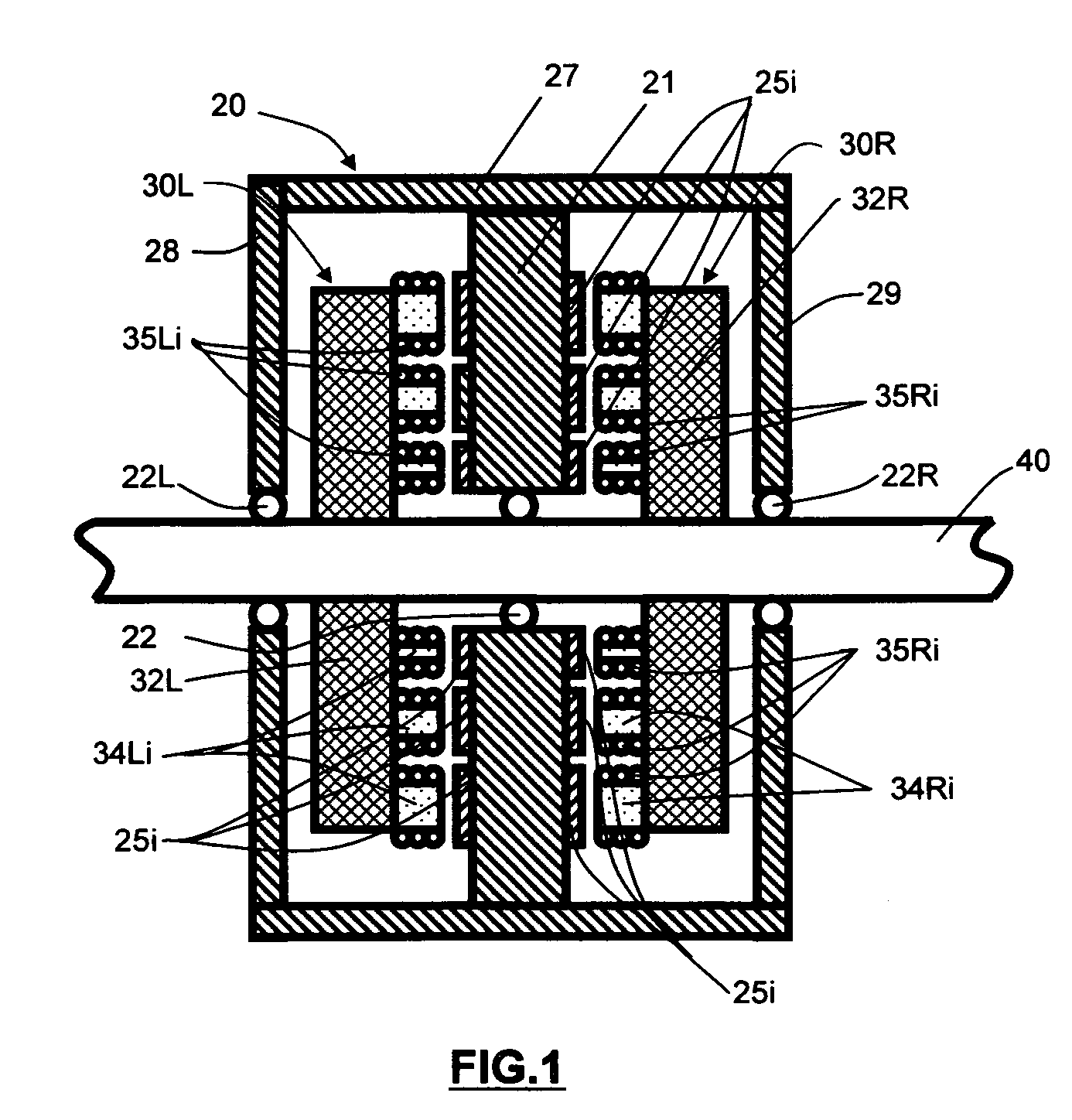

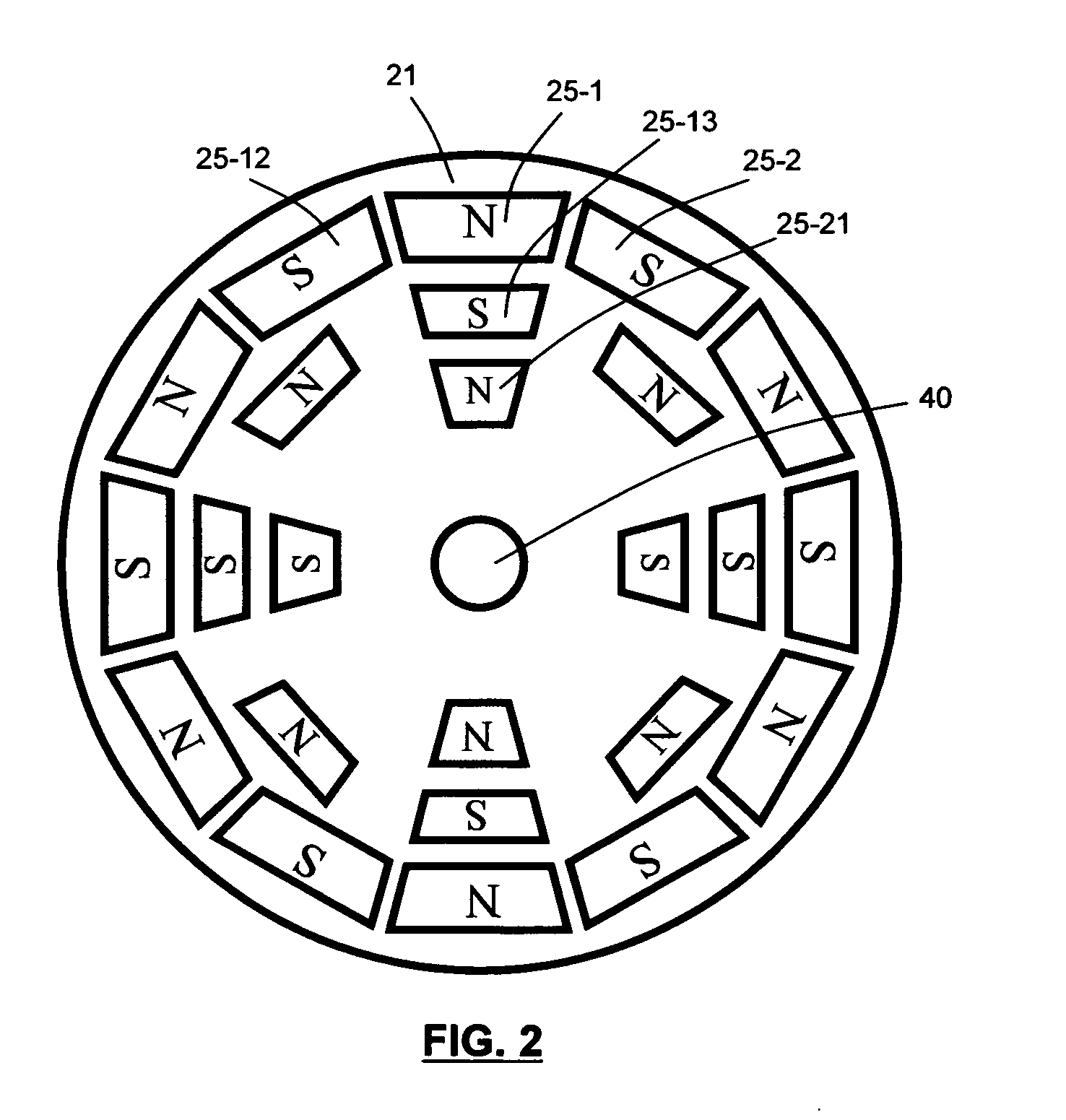

Vehicle disk motor with movable magnet poles

ActiveUS20110121676A1Improve efficiencyEliminate the effects ofWindingsAsynchronous induction motorsEngineeringPole piece

A brushless D.C. disk motor has one or more disk rotor assemblies and pairs of stator assemblies for each rotor assembly. Each disk rotor assembly has a disk and a plurality of permanent magnets distributed along two or more circular paths in the disk inboard of the peripheral edge of the rotor. Each stator assembly has a plurality of pole pieces and coils distributed along a mounting plate in corresponding circular paths. The disk is rotatably mounted to a support member; while the stator sub-assemblies are fixed to the support member. The coils are selectively activated by commutated power control signals generated in response to a vehicle condition parameter, such as vehicle speed or disk motor load, to optimize power drain from the source of electrical power in accordance with the value of the vehicle condition parameter. The stator assembly pole pieces are movably mounted on the stator mounting plate to improve motor efficiency.

Owner:SILICON VALLEY MICRO MCORP

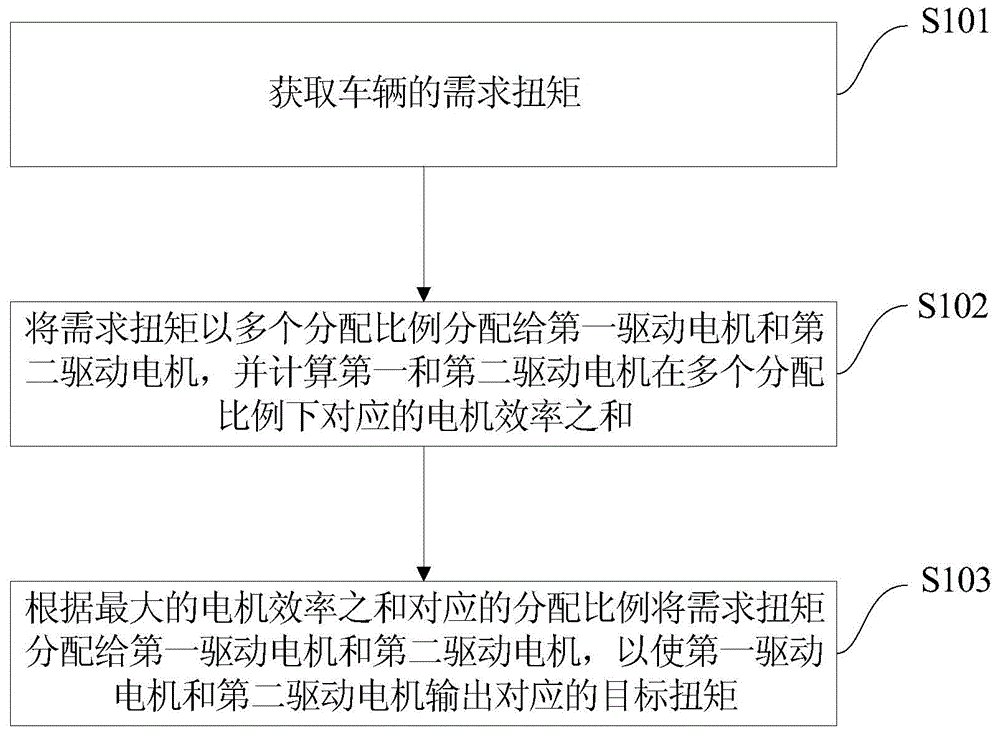

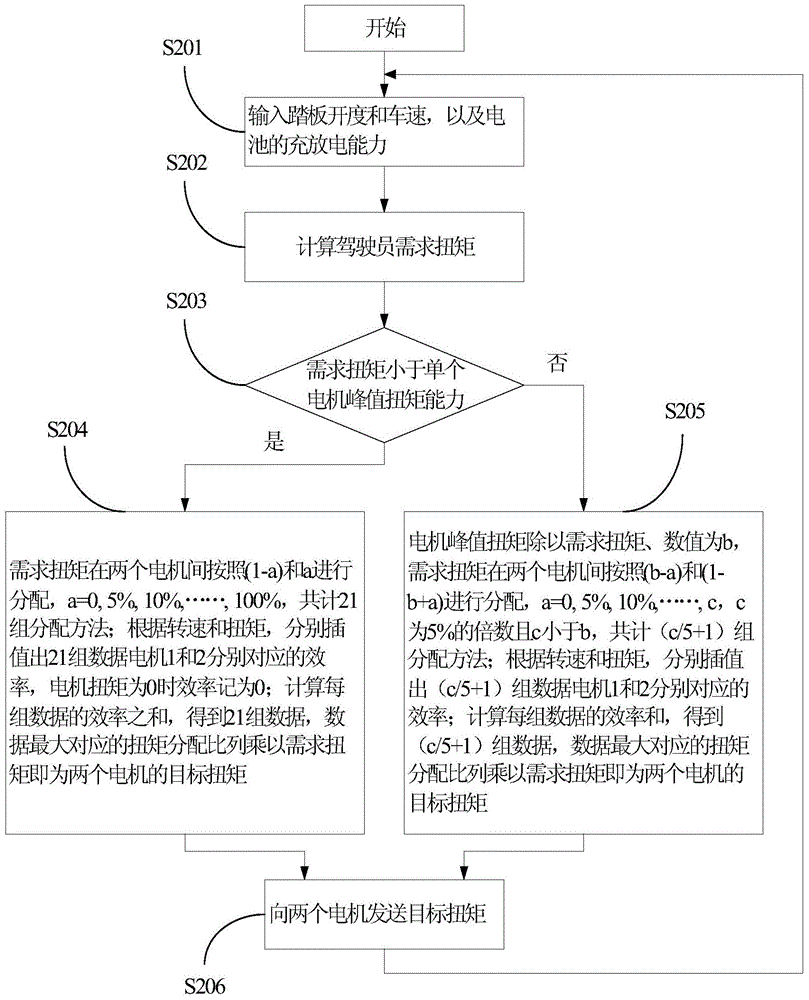

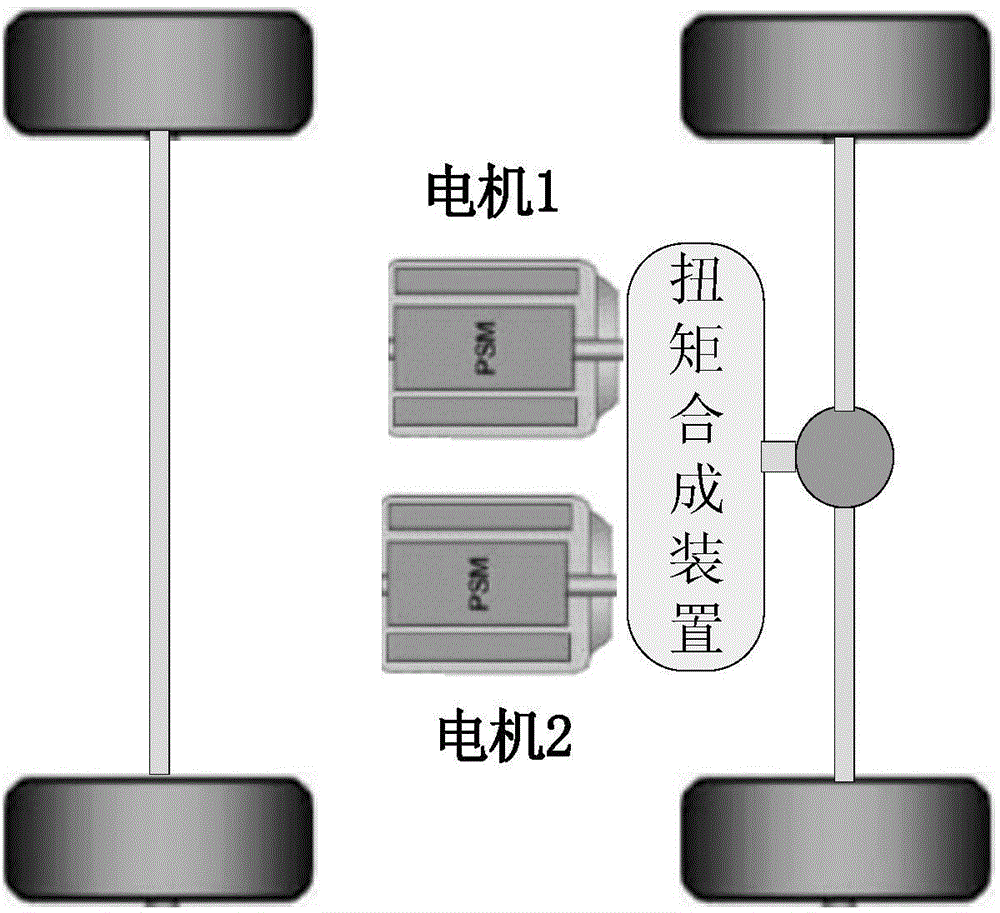

Torque distribution method of dual-motor electric vehicle, system and vehicle

ActiveCN104859486AReduce battery consumptionImprove battery lifeSpeed controllerElectric machinesElectricityDrive motor

The invention puts forward a torque distribution method of a dual-motor electric vehicle, which comprises that torque required by the vehicle is acquired; the required torque is distributed to a first drive motor and a second drive motor according to multiple distribution proportions, and sum of motor efficiencies corresponding to the first drive motor and the second drive motor under the multiple distribution proportions is calculated; and according to the distribution proportion corresponding to the sum of the maximum motor efficiencies, the required torque is distributed to the first drive motor and the second drive motor in order to make the first drive motor and the second drive motor output corresponding target torque. According to the torque distribution method of the dual-motor electric vehicle, electricity consumption of the vehicle can be reduced, and a driving mileage of the vehicle is brought up. The invention also discloses a torque distribution system of the dual-motor electric vehicle and the vehicle.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Synchronous induction motor and electric hermetic compressor using the same

A synchronous induction motor has a stator having a main winding and an auxiliary winding; a rotor having a yoke, a permanent magnet embedded in the yoke and a secondary conductor provided in the vicinity of periphery of the yoke; and a starter. The starter has a starting capacitor connected in series with the auxiliary winding of the synchronous induction motor, and a switching unit to open / close a circuit from the starting capacitor to the auxiliary winding. The switching unit closes the circuit from the starting capacitor to the auxiliary winding when the synchronous induction motor is at rest, and opens the circuit after the synchronous induction motor is started. The synchronous induction motor is highly efficient and easy to re-start with low power consumption. The electric hermetic compressor equipped with the synchronous induction motor can perform with the similar effects.

Owner:PANASONIC APPLIANCES REFRIGERATION DEVICES SINGAPORE

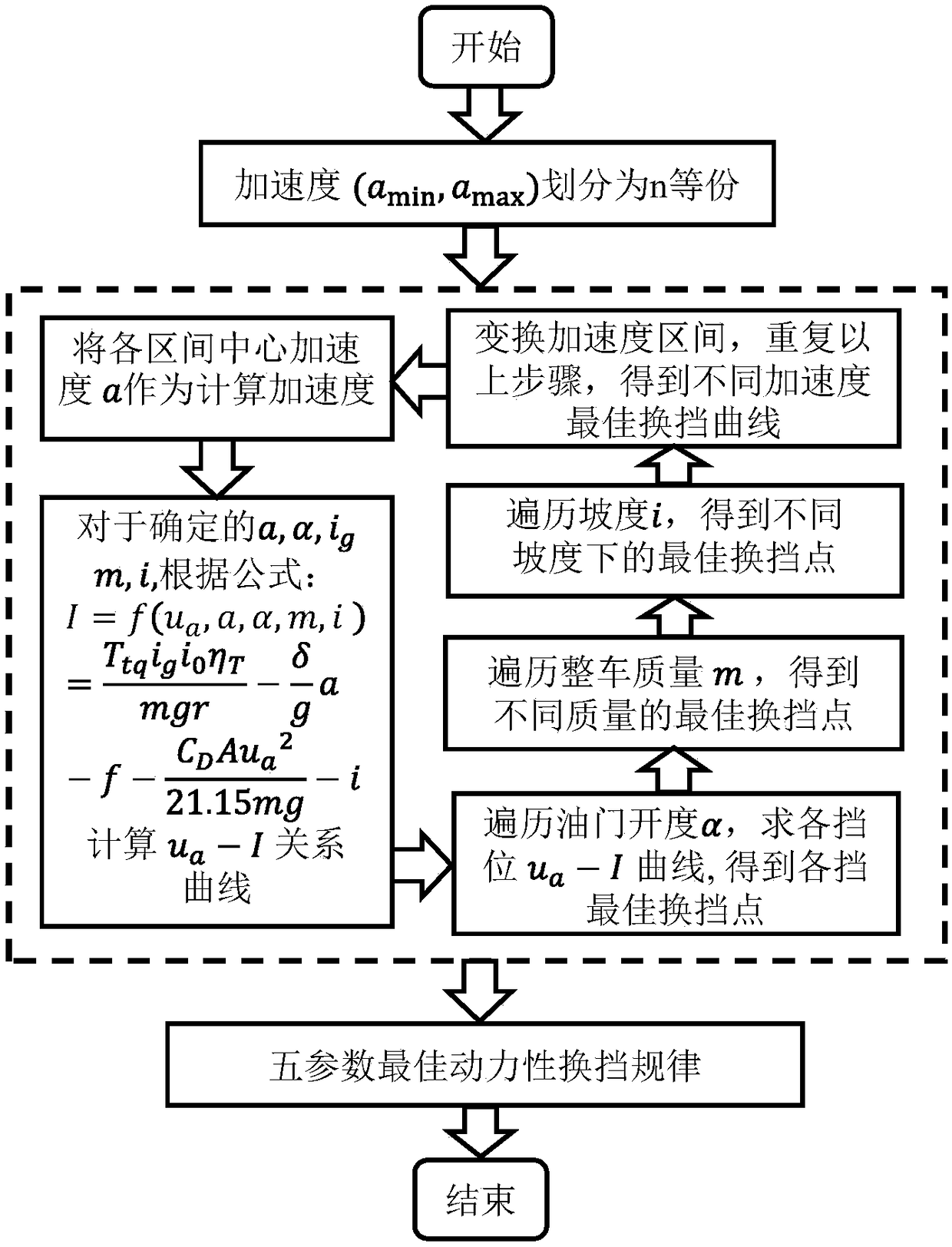

Mechanical type automatic transmission gear shifting method

The invention relates to a mechanical type automatic transmission gear shifting method. The mechanical type automatic transmission gear shifting method includes the following steps that the current vehicle mass and the current slope are acquired; with the maximum acceleration which a vehicle can reach as a power performance index, a best power performance gear position under different vehicle speeds, different accelerations, different accelerator opening degrees, different masses and different slopes is calculated, and serves as a vehicle power performance gear shifting strategy; with the motor efficiency being an economic index, on the basis that the slope climbing requirement of the vehicle is met, a best economy gear position under different vehicle speeds, different accelerations, different accelerator opening degrees, different masses and different slopes is calculated, and serves as a vehicle economy gear shifting strategy; and the current power performance and economy requirements of the vehicle are judged, one of the vehicle power performance gear shifting strategy and the vehicle economy gear shifting strategy is selected to determine a gear shifting point. For different masses of the vehicle and different slopes of a road, an optimal gear shifting strategy is calculated; by means of a multi-target optimization method based on road condition information and a vehicle state, the gear shifting strategies are optimized, so that the intelligent level of gear shifting can be improved, frequent gear shifting is avoided, and power performance and economy of the vehicle become best.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

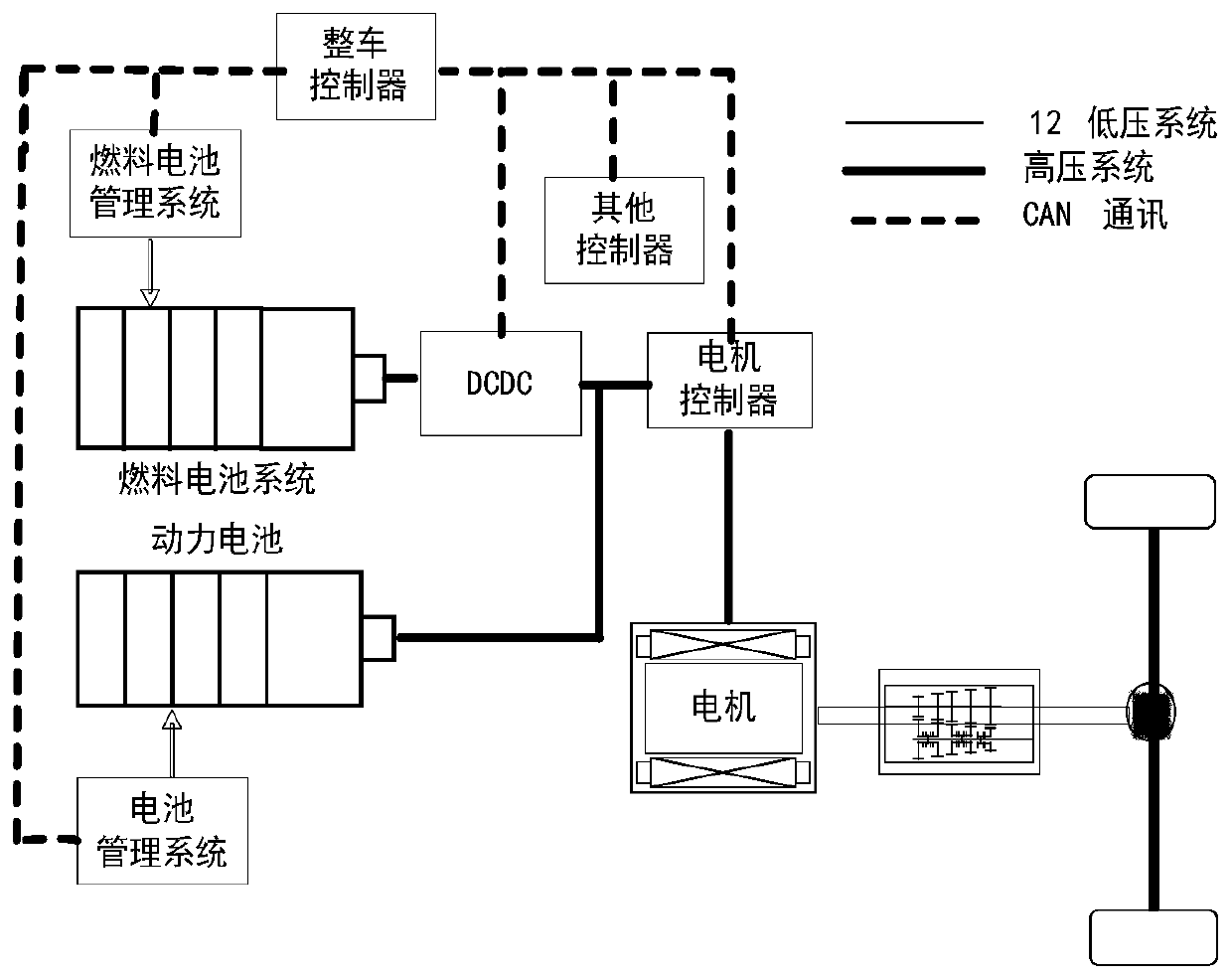

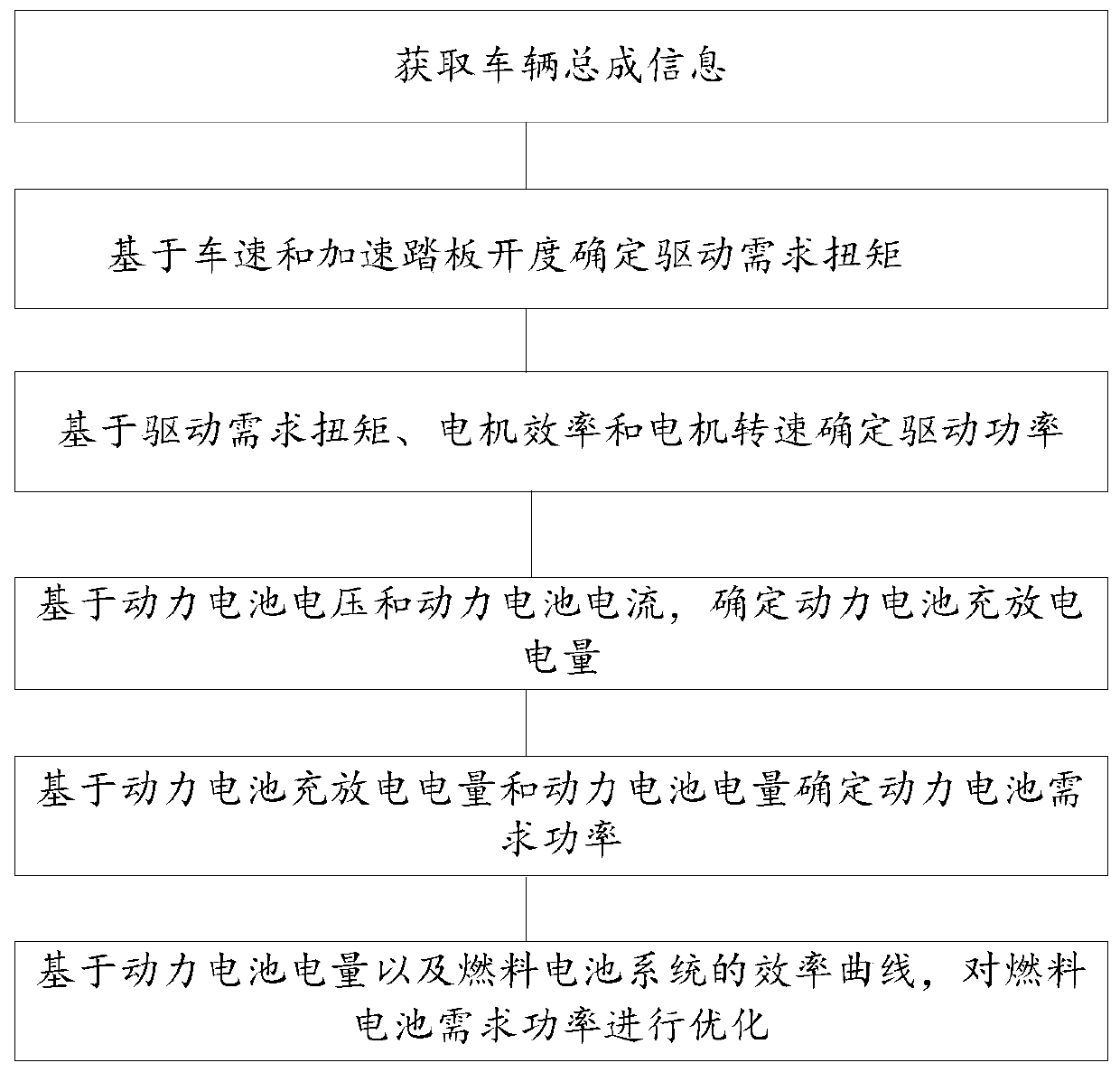

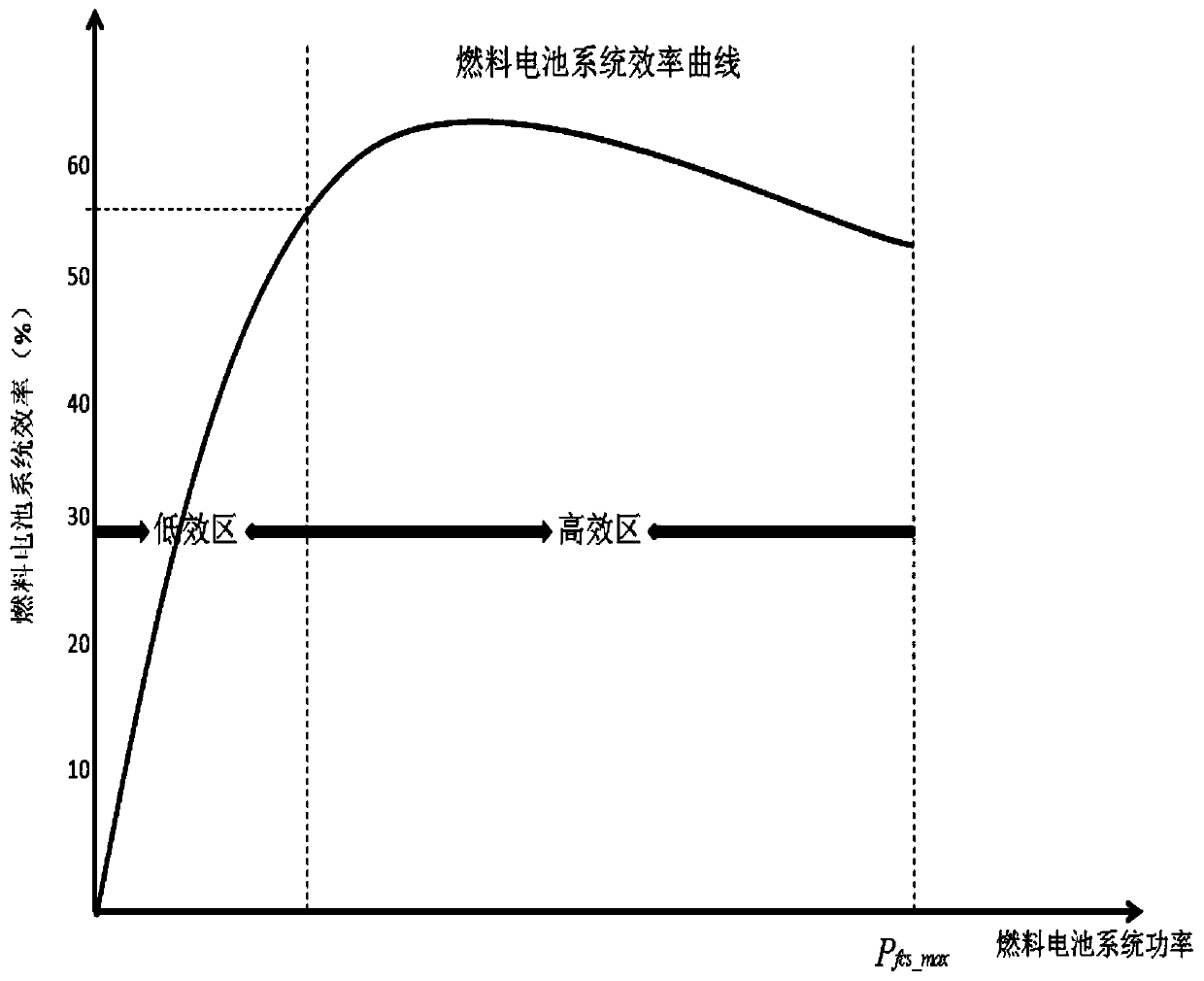

A whole vehicle power distribution control method and system for a fuel cell vehicle

ActiveCN109693578AReduce hydrogen consumption indexImprove efficiencyVehicular energy storageBattery/fuel cell control arrangementPower batteryDistribution control

The invention provides a whole vehicle power distribution control method for a fuel cell vehicle. The whole vehicle power distribution control method comprises the following steps: determining a driving required torque based on a vehicle speed and the accelerator pedal aperture; determining driving power based on the driving required torque, the motor efficiency and a motor rotating speed; based on a power battery voltage and a power battery current, determining the power battery charging and discharging electric quantity; determining a power battery required power based on the power battery charging and discharging electric quantity and the power battery electric quantity; taking a sum value obtained by adding the driving required power and the power battery required power as the fuel battery required power; optimizing the required power of the fuel cell based on the electric quantity of the power battery and the efficiency curve of the fuel cell system. The invention further providesa whole vehicle power distribution control system of the fuel cell vehicle. On the basis of protecting the power battery, the efficiency of the power battery is maximized, and on the basis of protecting the fuel cell system, a hydrogen consumption index of the whole vehicle is reduced to the maximum extent.

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com