Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Speed coordination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

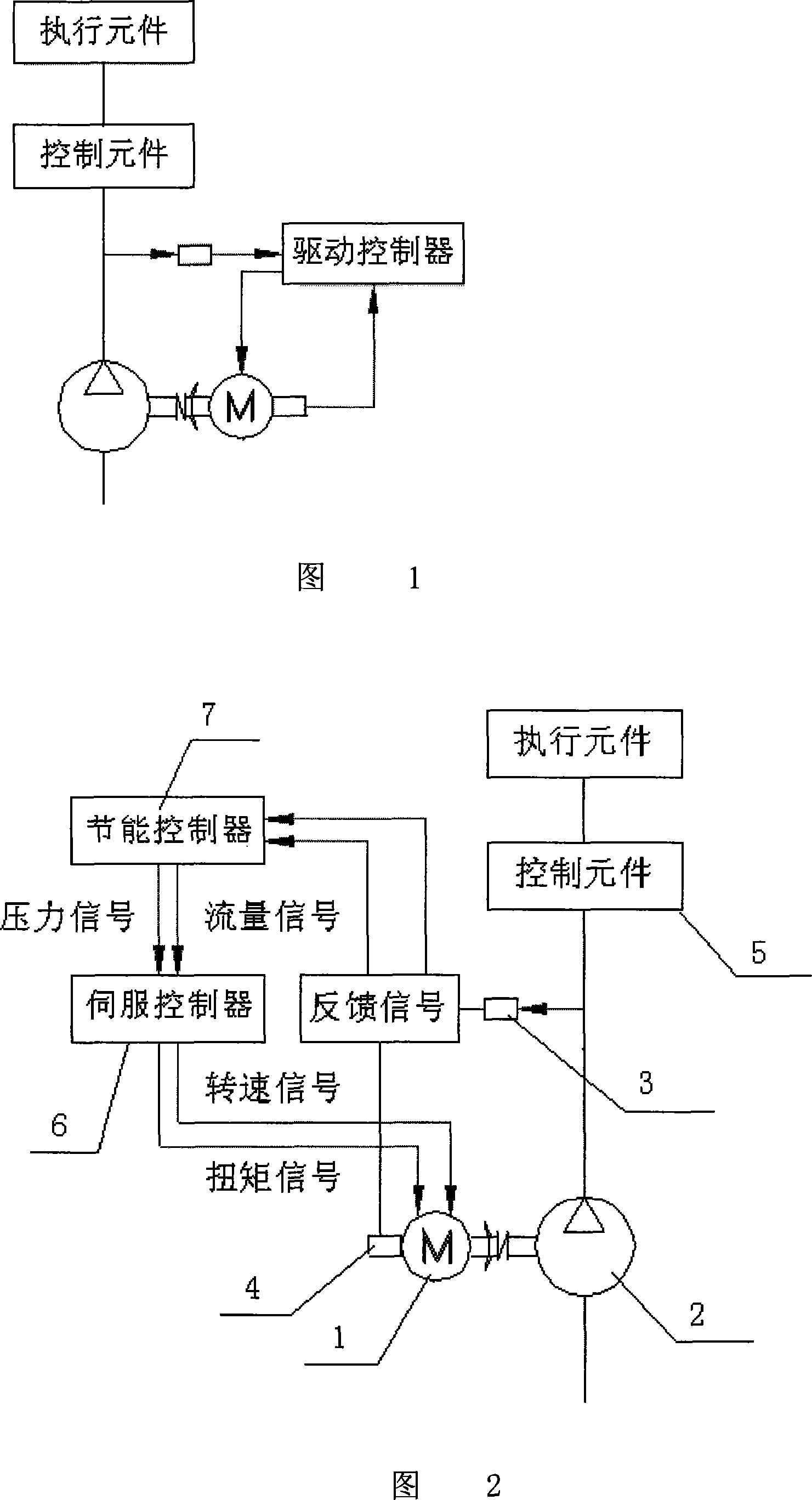

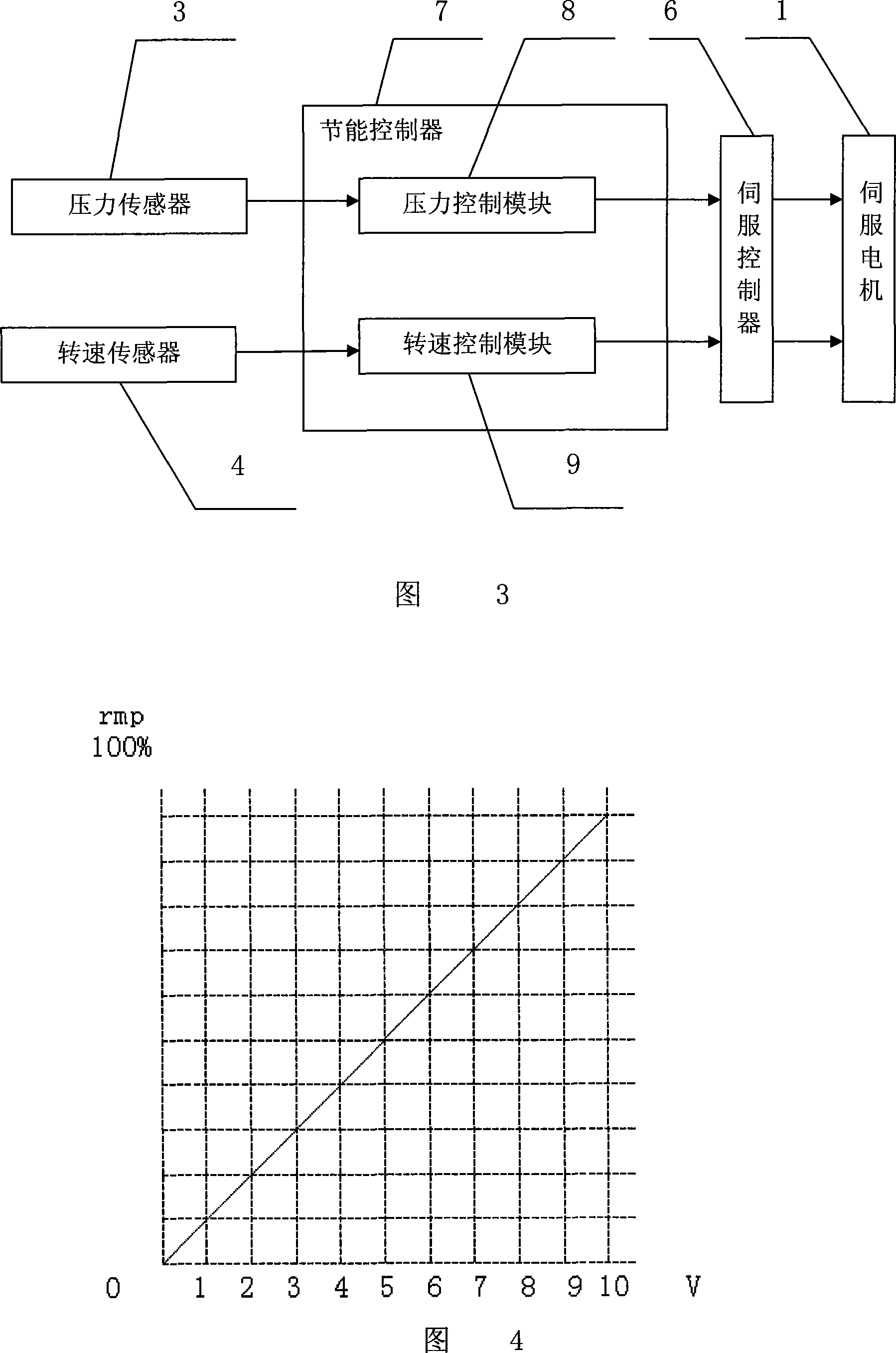

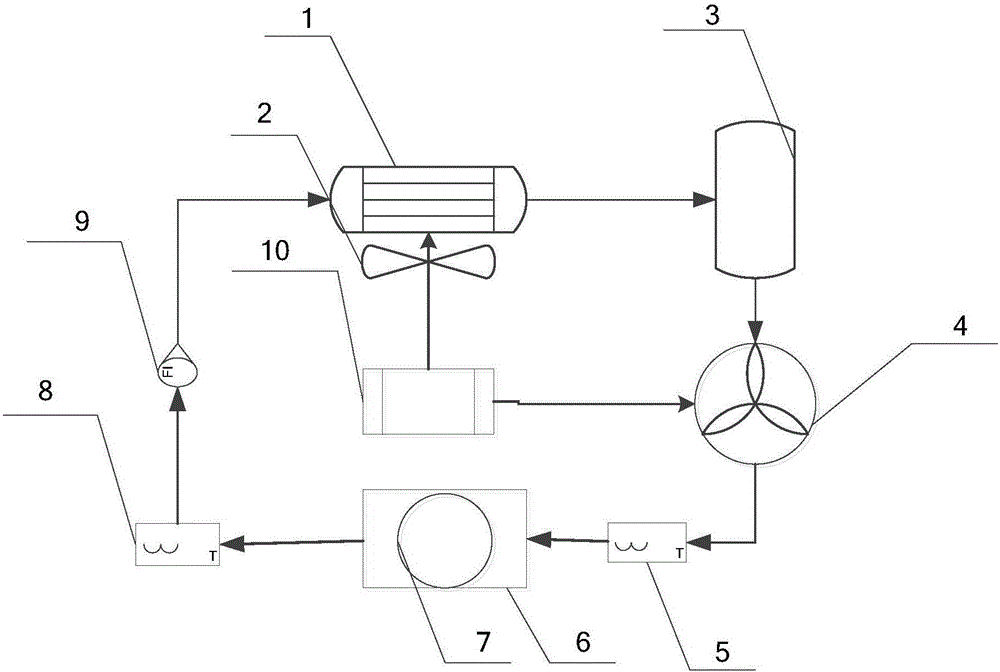

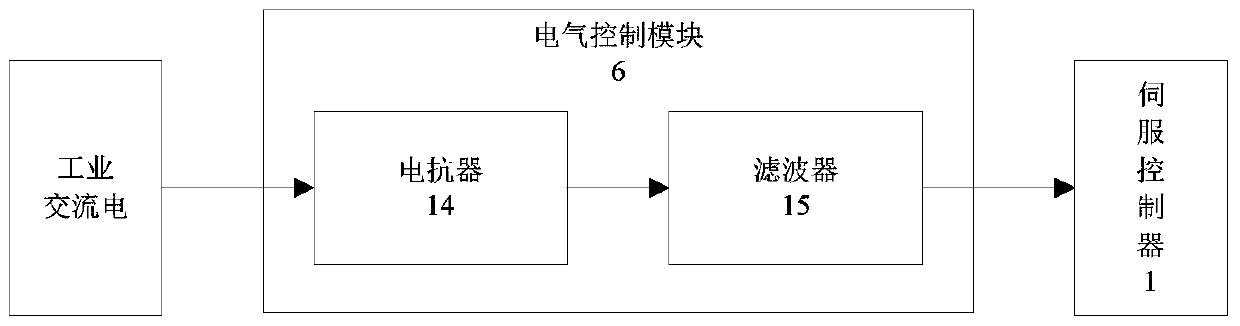

Injection moulding machine servo energy-saving control system

The energy-saving servo control system for injection molding machine includes one servo motor, one constant displacement oil pump providing pressure to the hydraulic system, one pressure sensor, one rotation speed sensor, and one control element, as well as one energy-saving controller connected to the outputs of the pressure sensor and the rotation speed sensor for automatic closed-loop regulation of pressure and flow rate. The servo motor includes one torque regulating input and one rotation speed regulating input; the energy-saving controller includes one pressure control module and one flow rate control module with outputs connected to the servo controller; the servo controller includes one torque driving unit and one rotation speed driving unit connected separately to the torque regulating input and the rotation speed regulating input of the servo motor. The energy-saving servo control system has high adaptability, high sensitivity, high accuracy and high energy-saving effect.

Owner:CHANGSHENGDA MASCH ZHEJIANG CO LTD

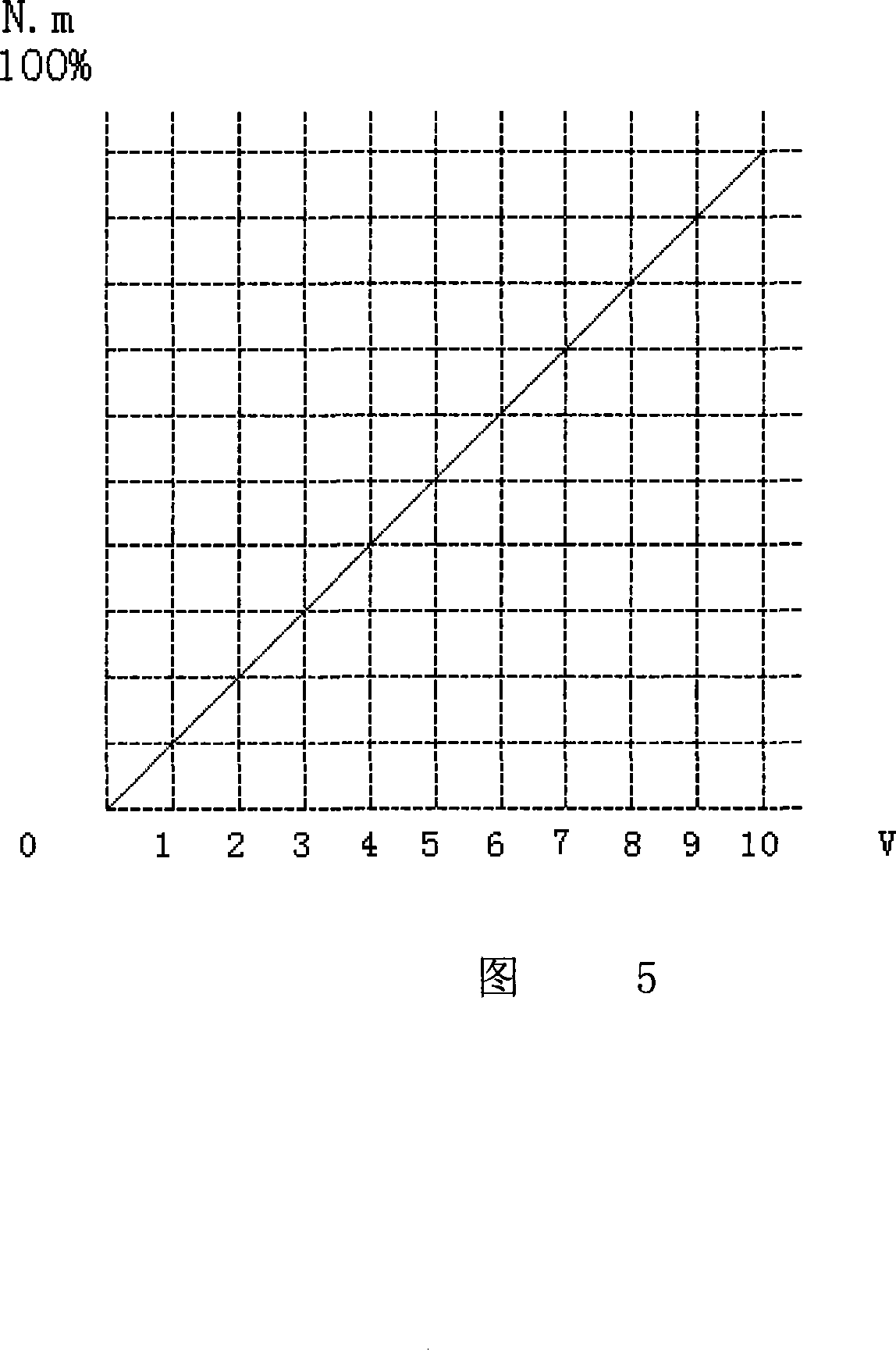

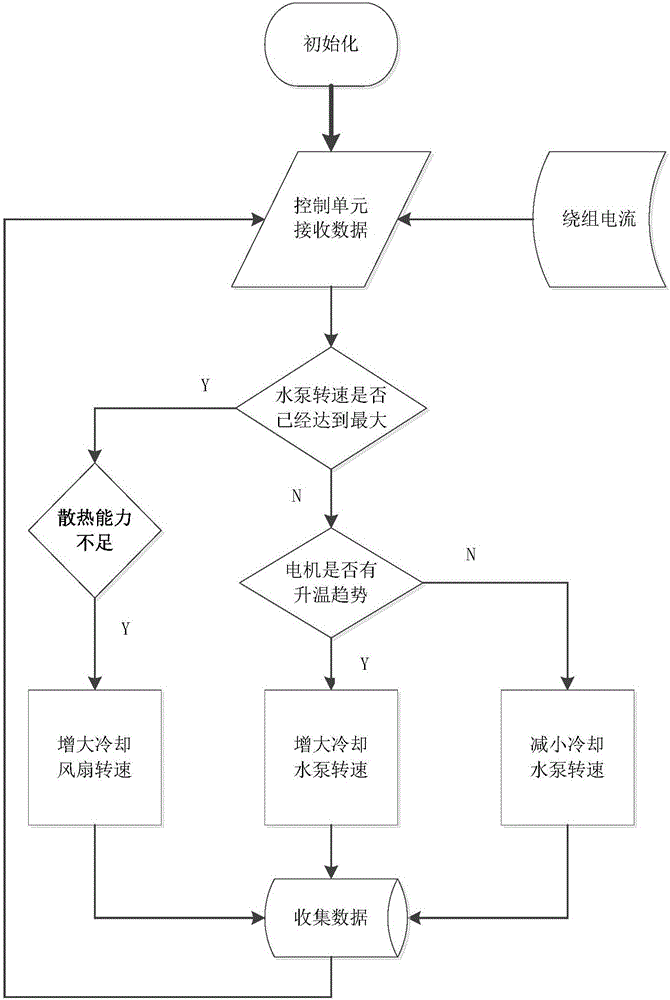

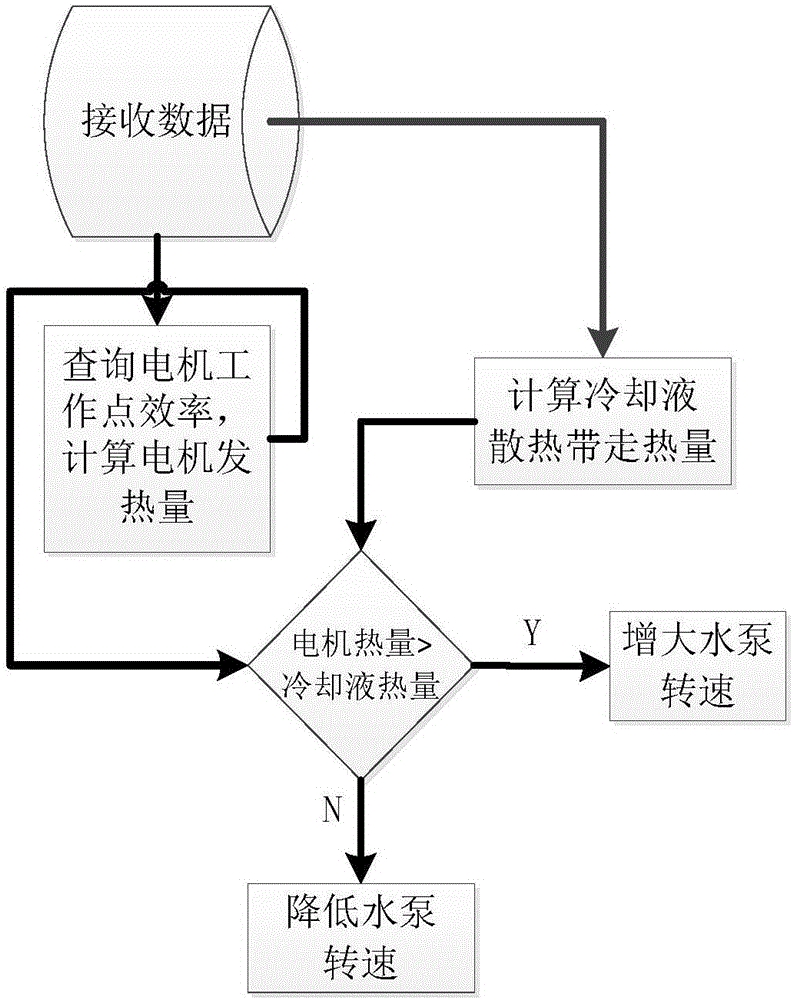

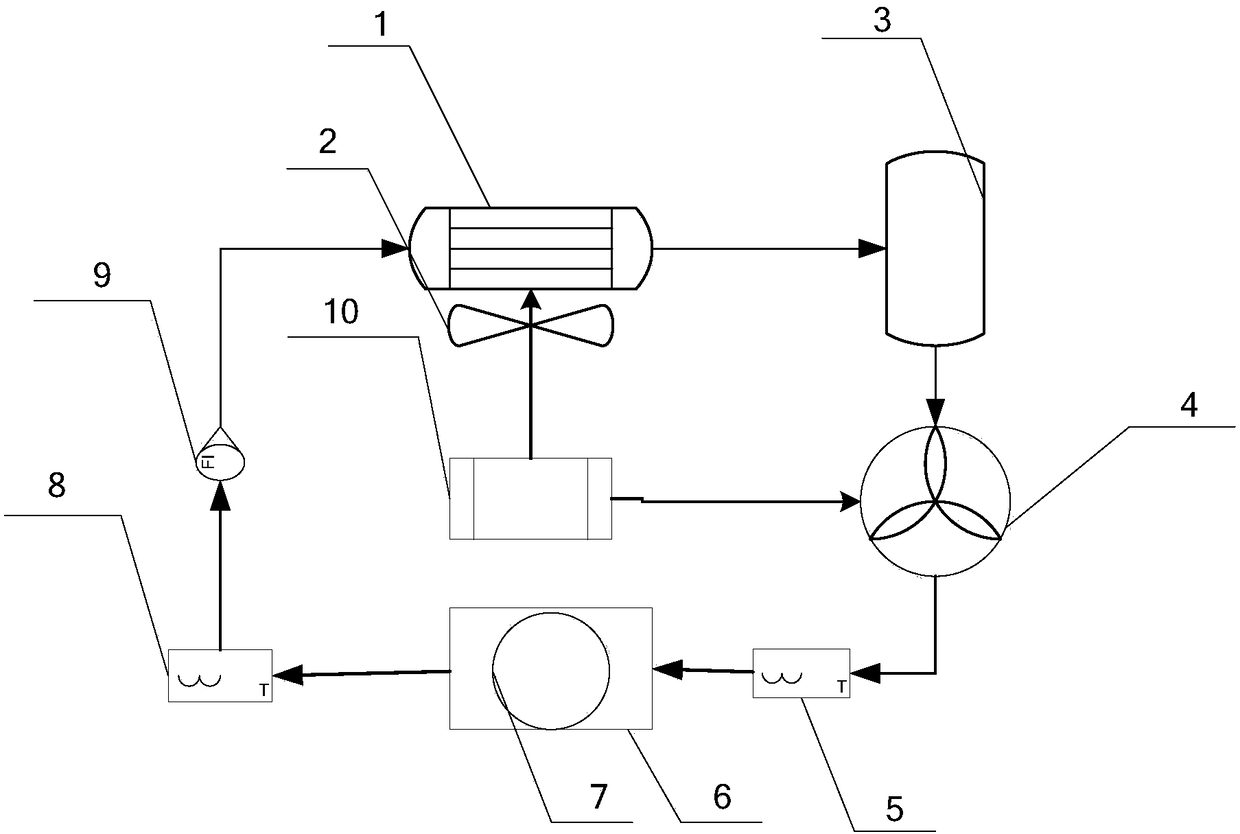

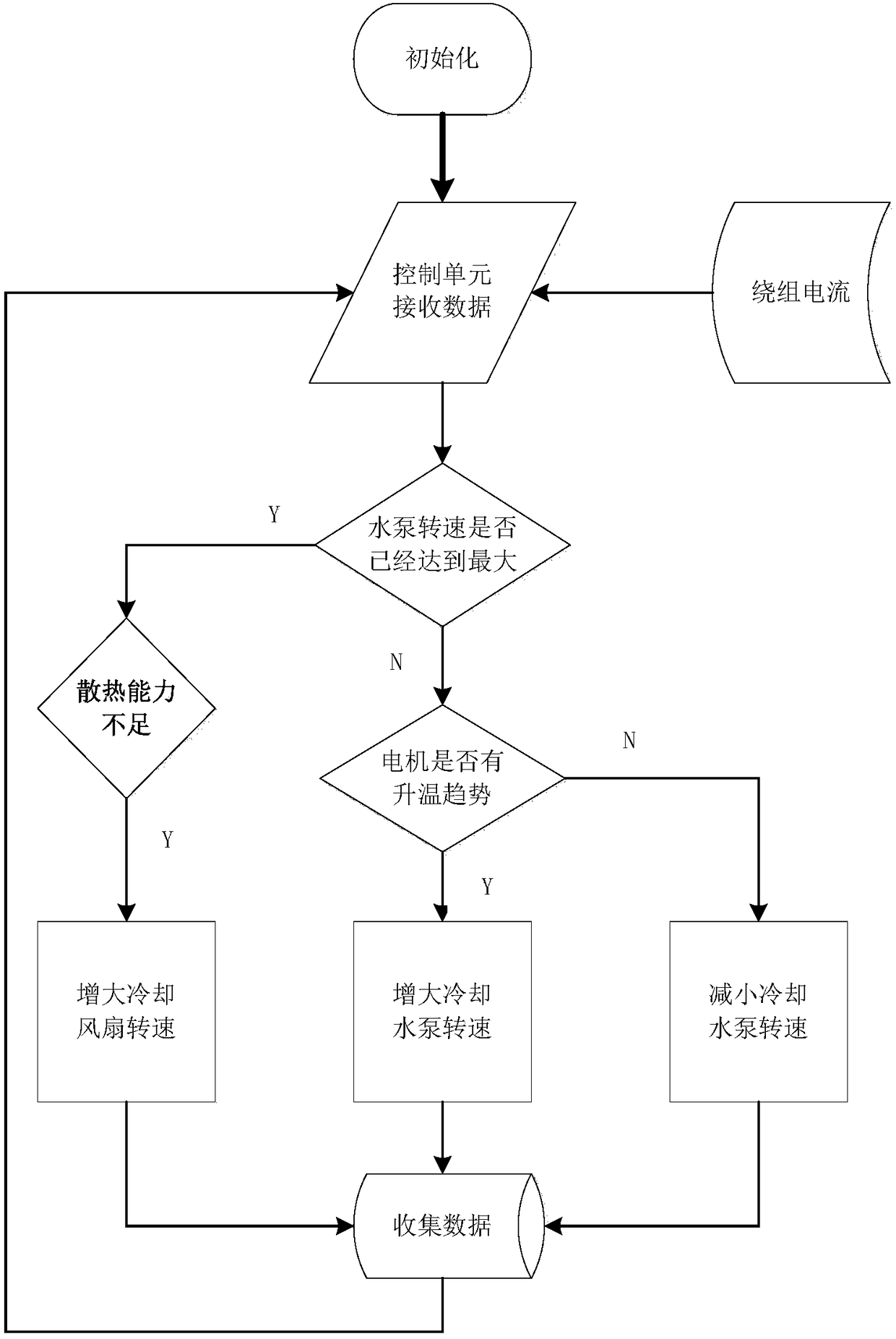

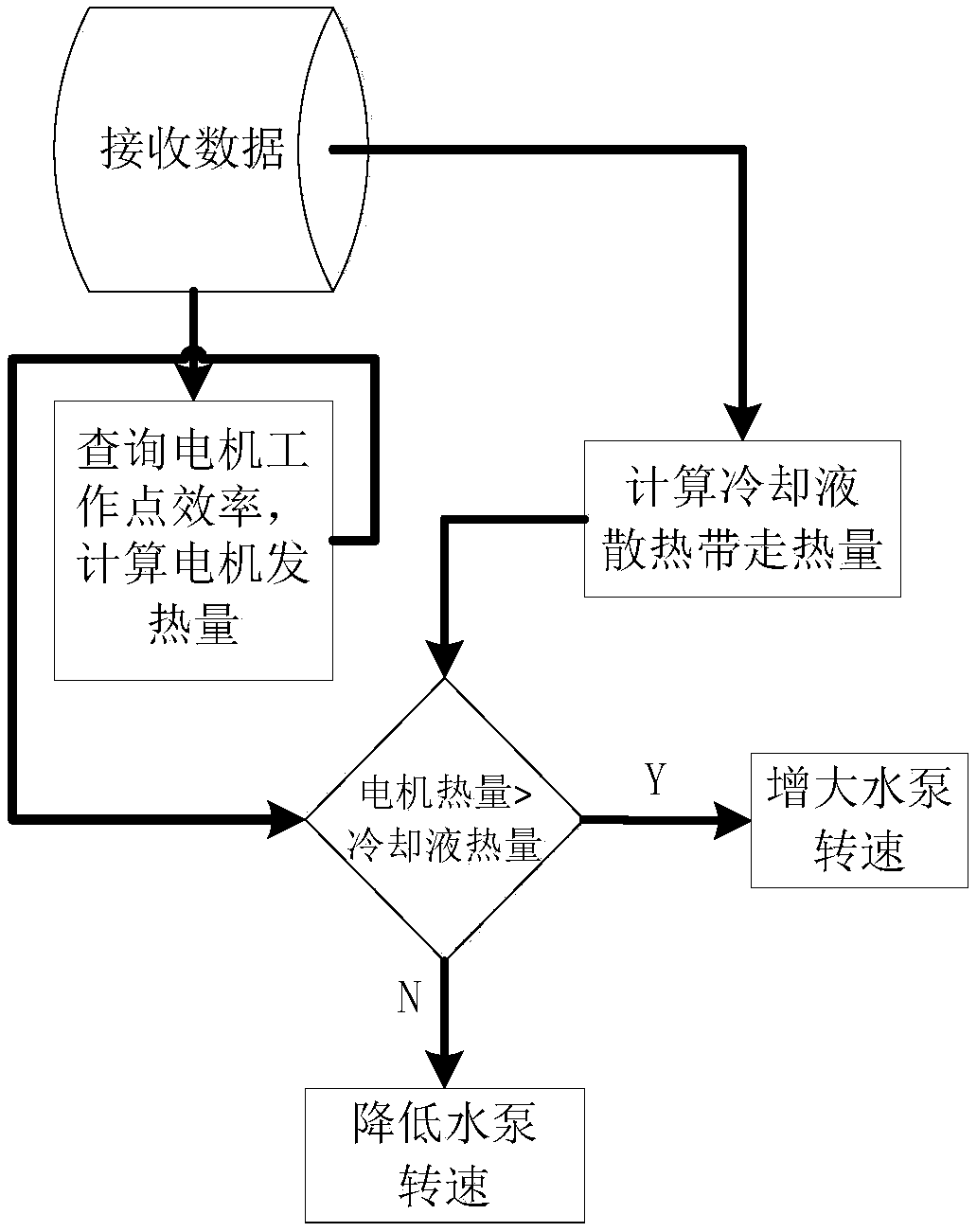

Permanent magnet synchronous motor cooling system for electric automobile and control method thereof

ActiveCN106240341ASpeed coordinationIntelligent controlElectric machinesCooling/ventillation arrangementPermanent magnet synchronous motorWater jacket

The invention discloses a permanent magnet synchronous motor cooling system for an electric automobile and a control method thereof. The cooling system comprises a control unit, a motor winding ammeter, a cooling water pump, a cooling water jacket, a cooling water temperature sensor, a cooling liquid flow meter, a heat radiator and a cooling fan. The control method comprises the following steps: judging whether a permanent magnet synchronous motor has a temperature rising trend or a temperature lowering trend under the working condition through detecting current of a motor stator winding, and adjusting a cooling capability of the cooling system so as to realize active adjustment of the cooling system; meanwhile, introducing auxiliary feedback adjustment and inquiring a working point of a motor through a motor efficiency MAP graph, so as to obtain the efficiency of the motor under the corresponding working condition; calculating the heat productivity of the motor; then feeding a difference value of the heat productivity of the motor and a heat radiation amount of the heat radiator back to the control unit, so as to correct the adjustment of the cooling system. The cooling system is subjected to active cooling control before the temperature of the motor is changed; energy sources are saved while a sufficient heat dissipation capability of the motor is guaranteed.

Owner:WUHAN UNIV OF TECH

Electromagnetic transient and electromechanical transient hybrid simulation method based on real time digital simulator

InactiveCN101826128ALearn about dynamic featuresUnderstanding Electromagnetic Transient ProcessesSpecial data processing applicationsTransient stateReal-time simulation

The invention relates to an electromagnetic transient and electromechanical transient hybrid simulation method based on a real time digital simulator (RTDS), belonging to the technical field of power system transient simulation. The method comprises the following steps: an electromechanical transient simulation system carries out electromechanical transient real-time simulation computation on a first power system; the RTDS carries out electromagnetic transient real-time simulation computation on a second power system; the electromechanical transient simulation system transfers the voltage and amperage of the first power system to the RTDS via an interface process control system and the RTDS carries out electromagnetic transient computation on the second power system by utilizing the voltage and amperage; and the RTDS transfers the voltage and electric power, which are obtained through simulation computation, of the second power system to the electromechanical transient simulation system via the interface process control system and the electromechanical transient simulation system carries out electromechanical transient computation on the first power system by utilizing the voltage and electric power. The method is conductive to understanding the dynamic characteristics of the electromechanical transient process of large-scale power systems and the electromagnetic transient process of a certain specific part and can coordinate the scale, precision and velocity of simulation.

Owner:南方电网技术研究中心 +1

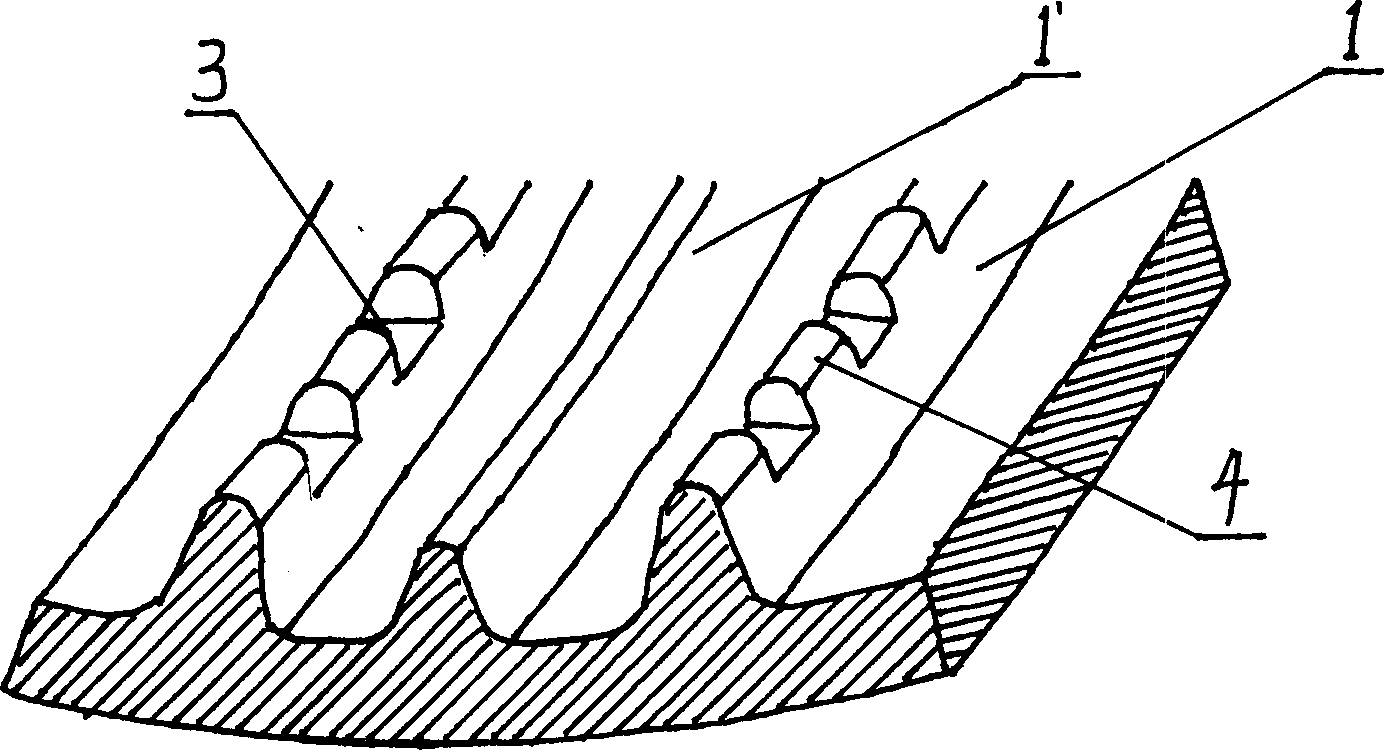

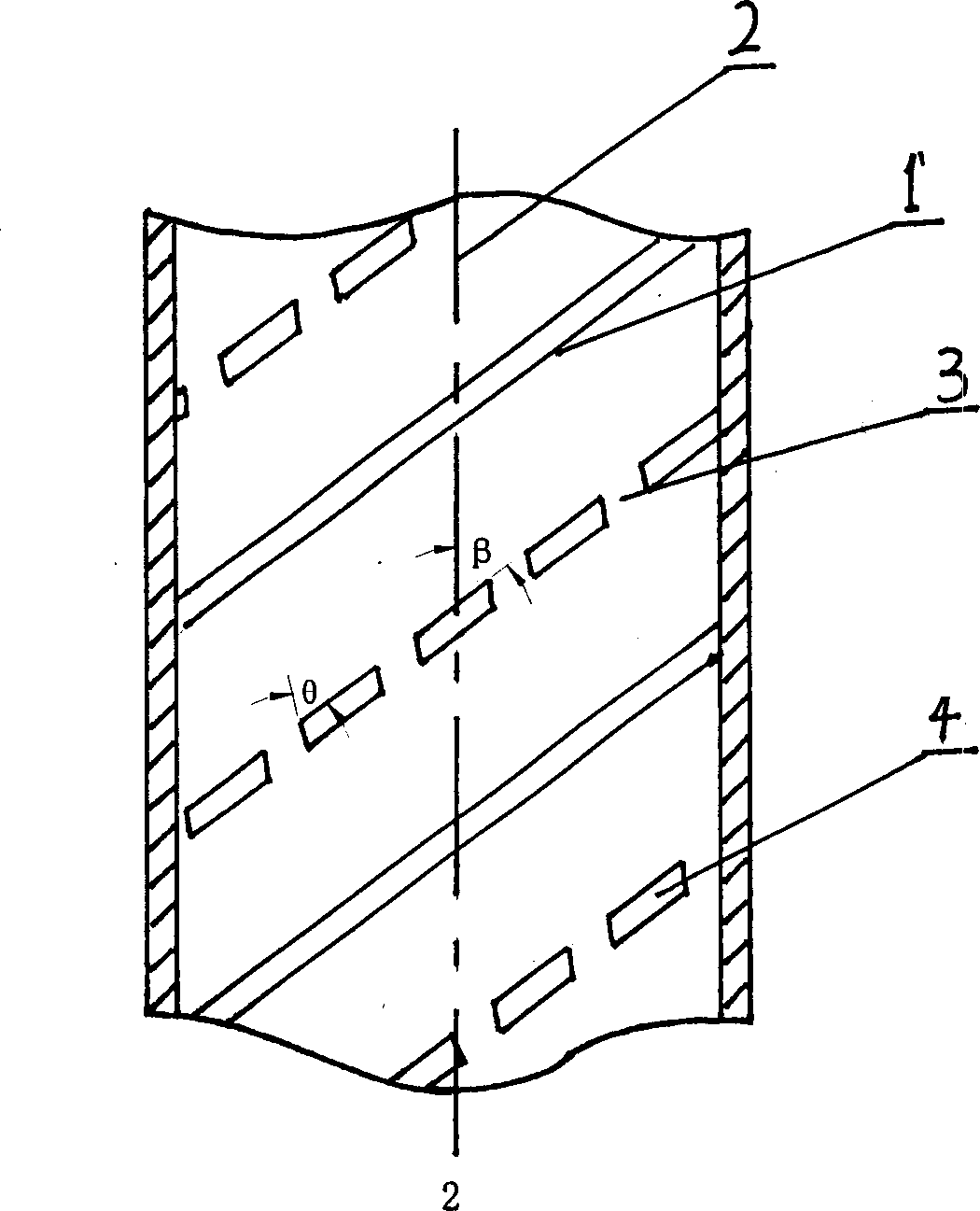

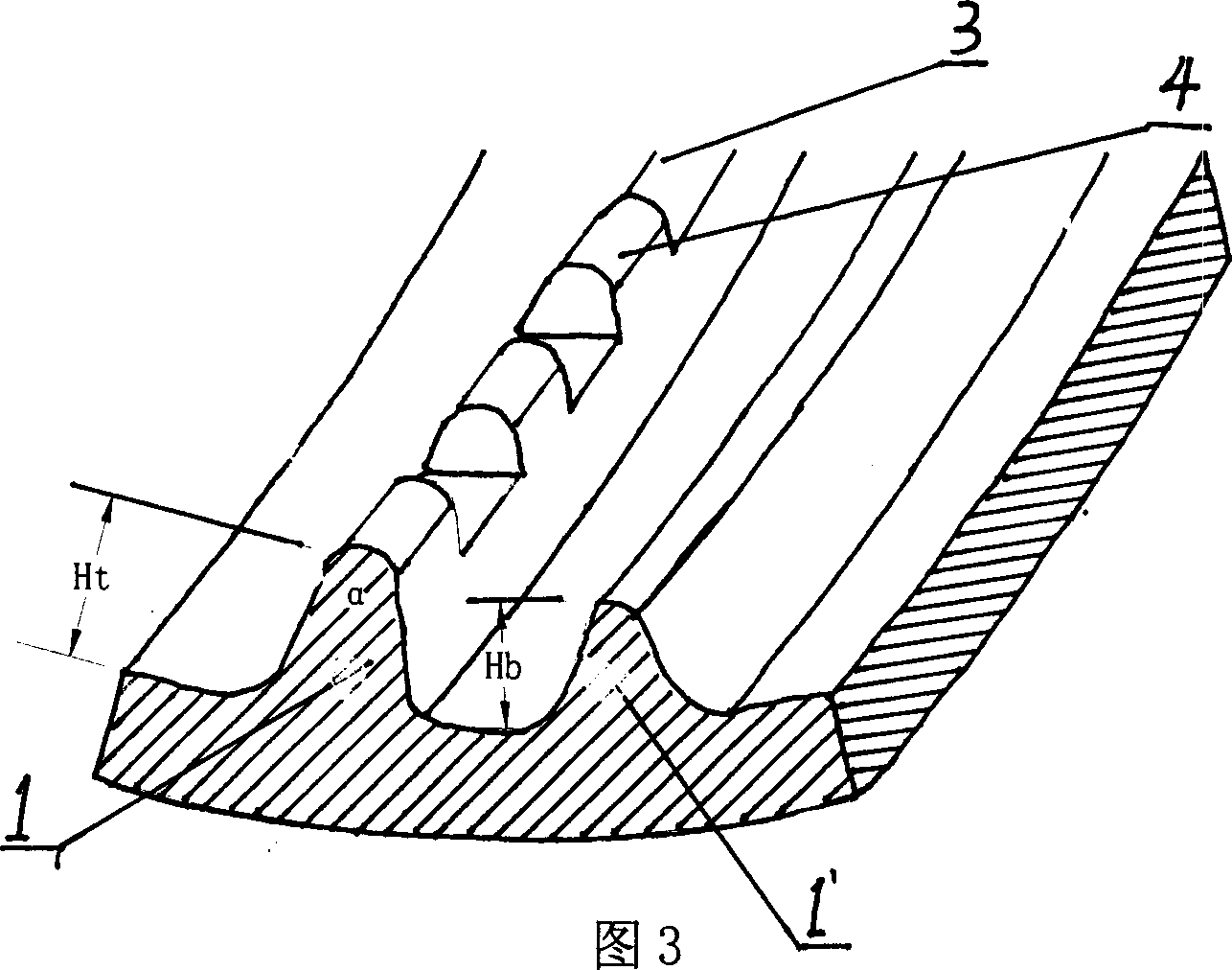

Internal thread heat-transferring pipe

The present invention provides one kind of internal thread heat-transferring pipe for use in the condenser and evaporator of refrigerating equipment and air conditioning equipment with single or mixed refrigerant. In the inner surface of the heat-transferring pipe, there are homogeneously arranged main screw teeth in different height and the relatively higher main screw teeth have miniature protuberance formed in the top. The alternate arrangement of the main screw teeth in different height can reinforce the disturbance to boiling and condensing heat exchange, reduce the heat boundary layer, reduce the angle between the speed vector and the temperature gradient vector, coordinate the speed field and temperature field, strengthen the boiling and condensing heat exchange and raise heat transferring efficiency.

Owner:XI AN JIAOTONG UNIV

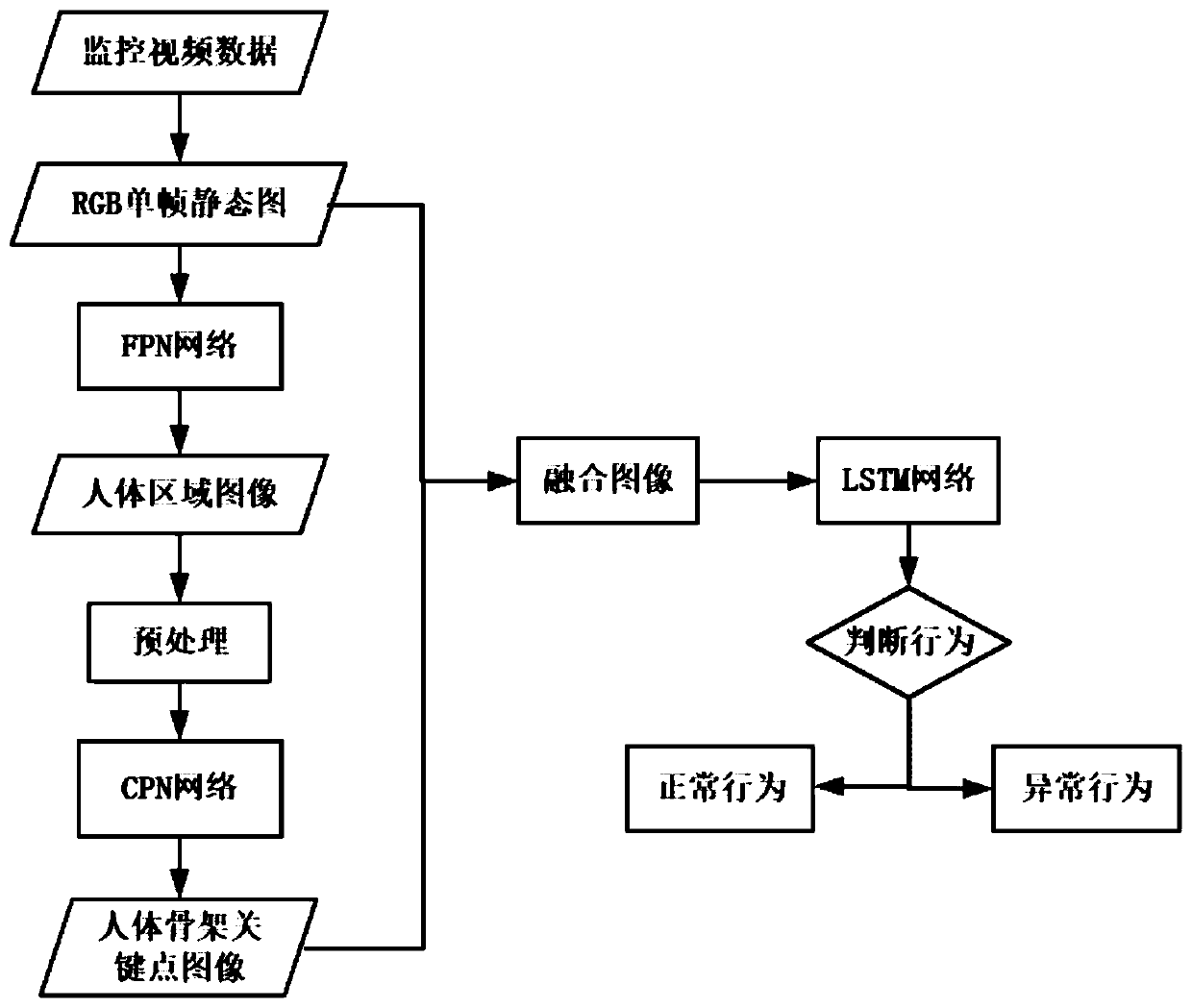

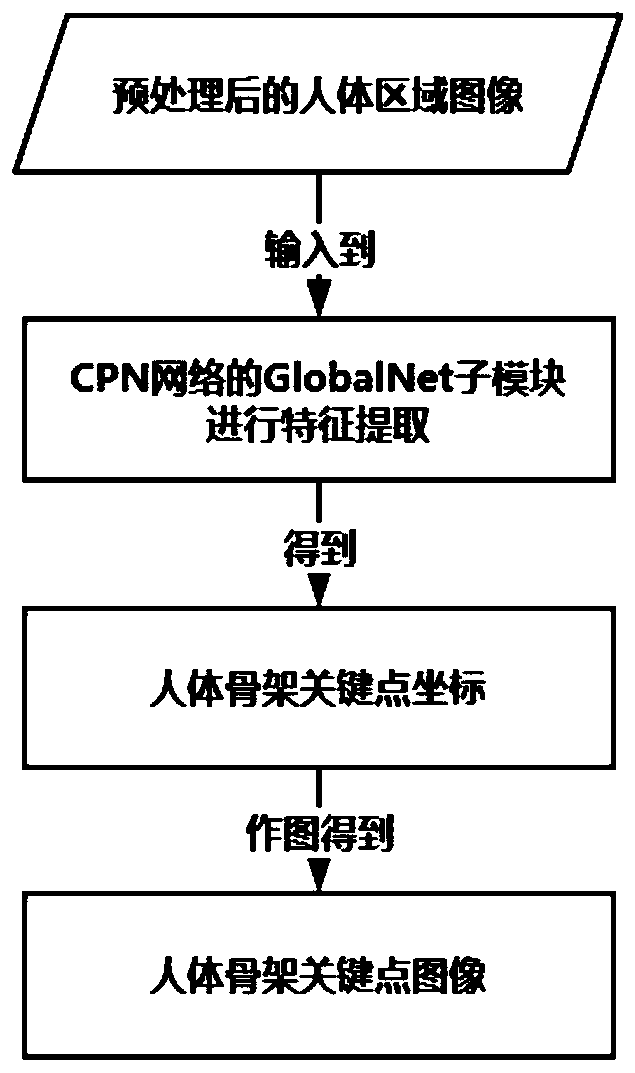

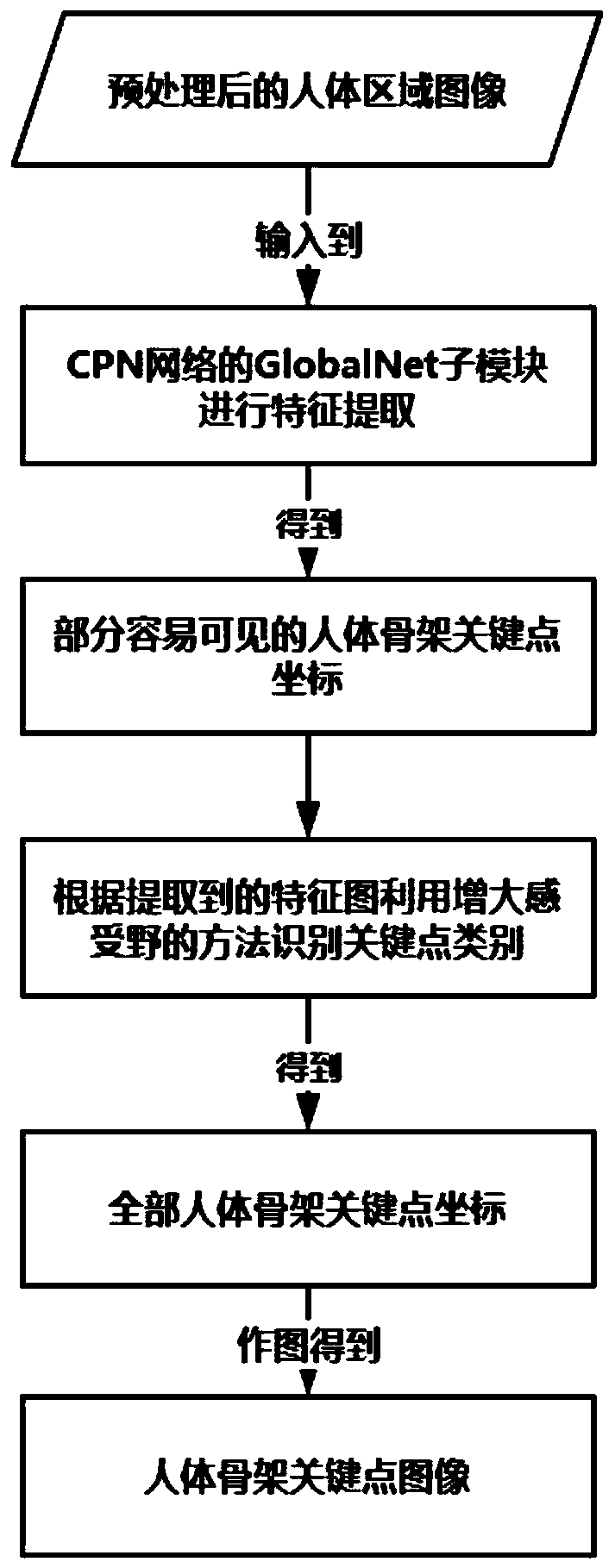

Method for identifying and detecting abnormal behaviors in transformer substation based on artificial intelligence in complex scene

PendingCN111339883AMeet practical application needsEasy to identifyCharacter and pattern recognitionNeural architecturesPattern recognitionHuman body

The invention discloses a method for identifying and detecting abnormal behaviors in a transformer substation based on artificial intelligence in a complex scene. The method comprises the following steps: processing a monitoring video to obtain a static graph; detecting a human body region by using a target detection algorithm FPN network based on deep learning; preprocessing the to-be-identifiedimage to generate a binary image; taking the binarized image as the input of a CPN network to detect the key points of the human skeleton; fusing the human skeleton key point image with the RGB single-frame static image, inputting the fused image into an LSTM network for classification and identification, and judging whether the behavior is an abnormal behavior or not. According to the invention,automatic detection and identification tasks of abnormal behaviors of the working area of the transformer substation in a complex scene are realized, and the method has good accuracy, stability and real-time performance, and can meet the actual application requirements of the transformer substation.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

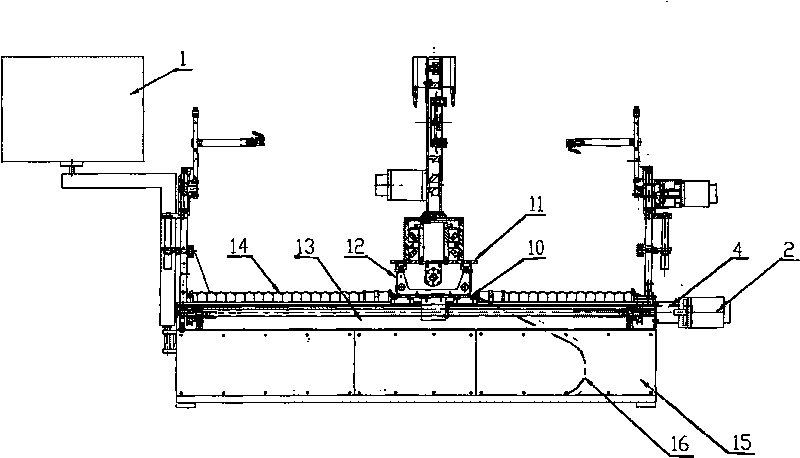

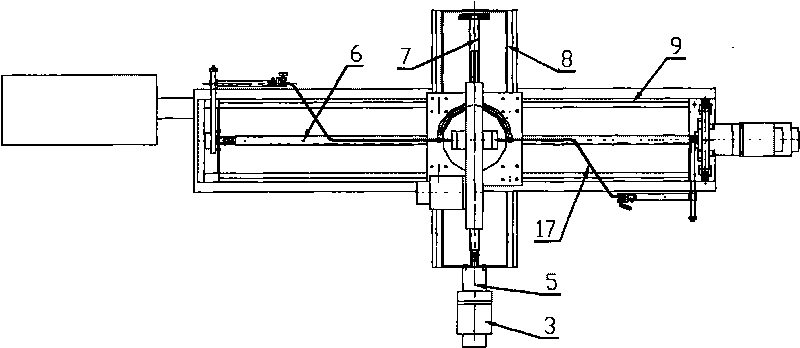

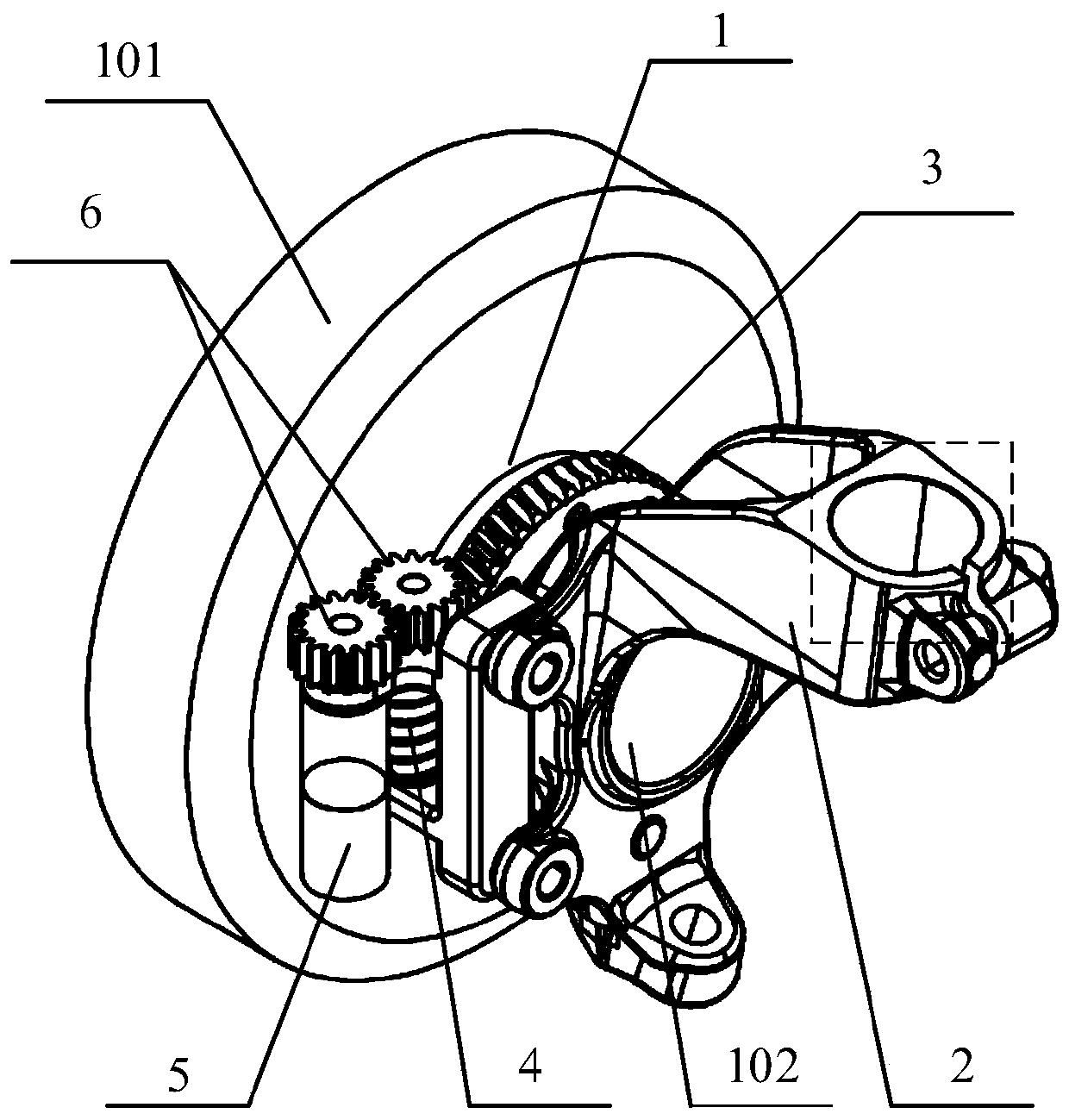

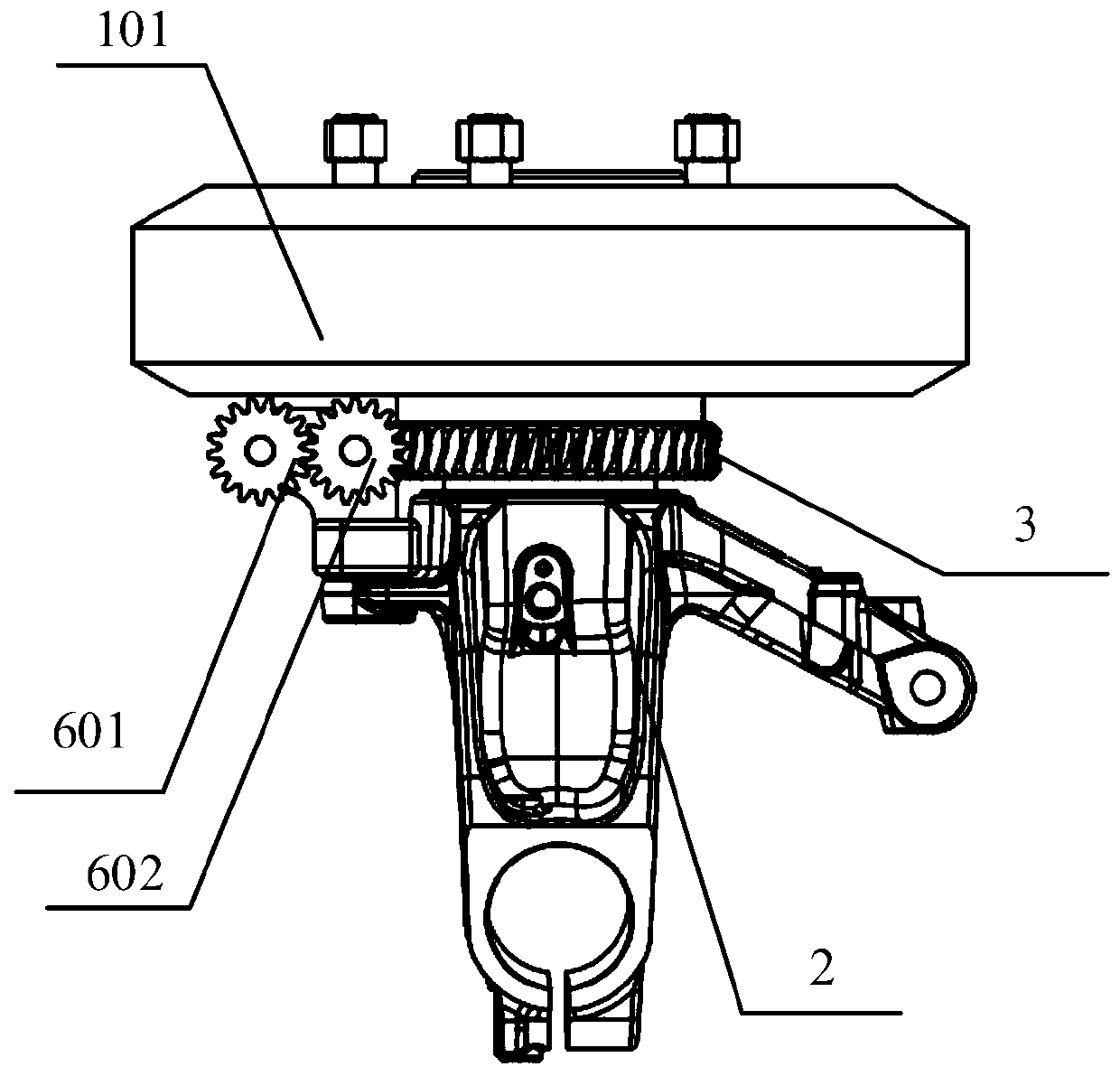

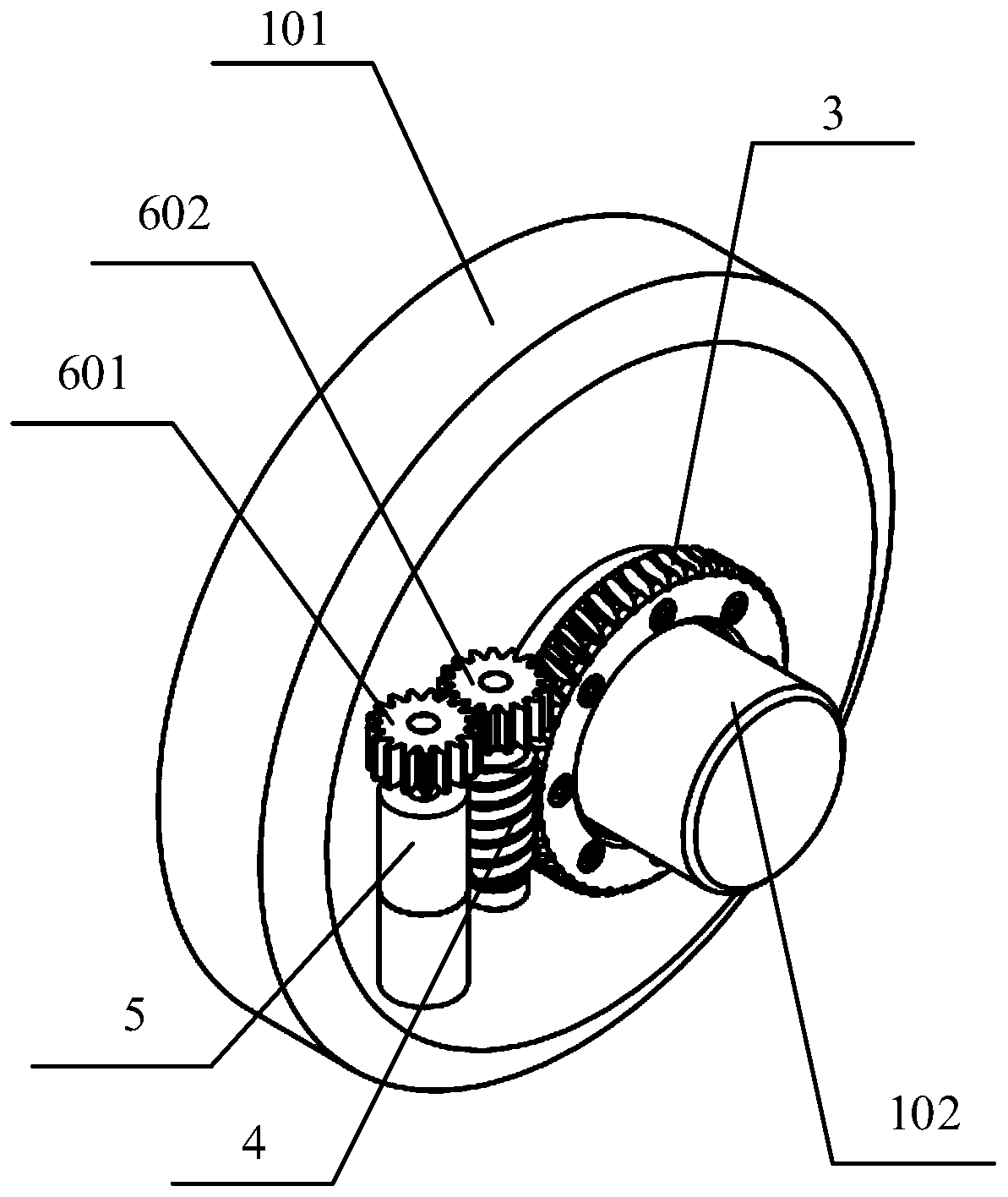

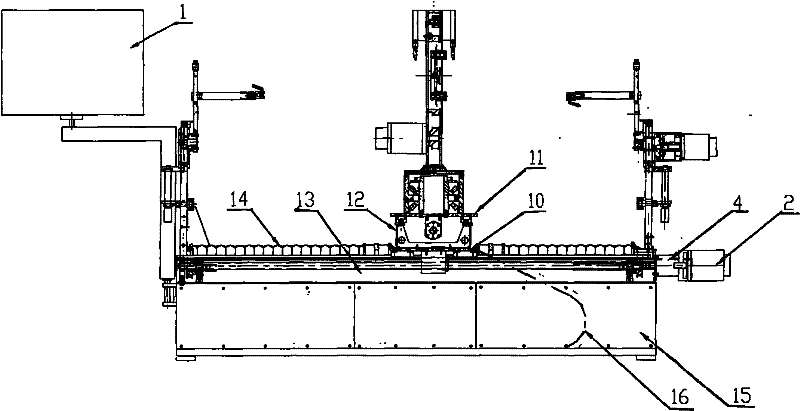

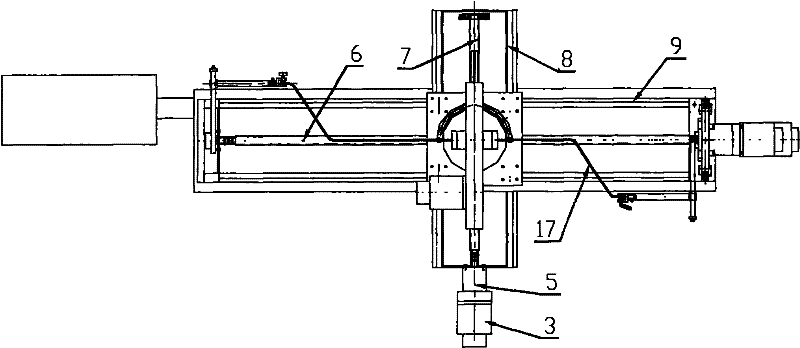

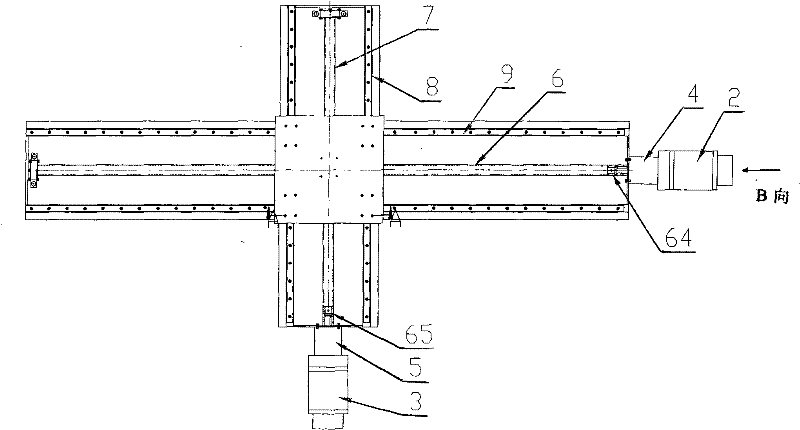

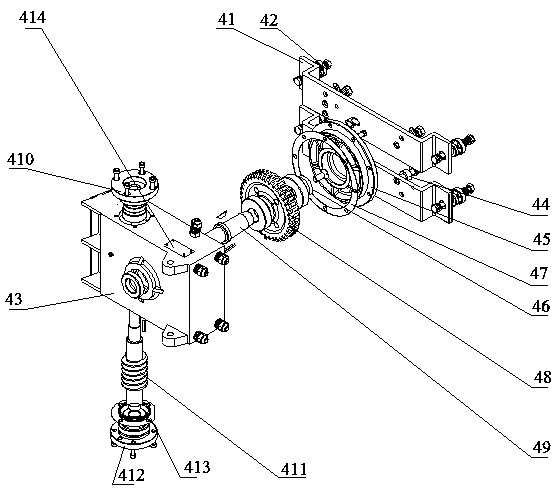

Rotor coil binding machine of wind power generator

InactiveCN101707421AFit tightlySufficient clamping rangeManufacturing dynamo-electric machinesWind energy generationCoil bindCoupling

The invention relates to the technology of rotor coil binding of generators, in particular to a rotor coil binding machine of a wind power generator. The invention solves the problems of large labor intensity, low efficiency and difficult control of quality caused by manual binding because of the insulation of the rotor coil of the traditional wind power generator. The rotor coil binding machine of the wind power generator comprises a numerical control system, a stand, a feeding system, a rotor coil clamping synchronous device and a lapping head, and mainly comprises a servo motor, a decelerator, a ball screw, as well as a trailing plate and a linear guide rail connected by a shaft coupler, a synchronous driving pulley, a synchronous driven pulley and a synchronous belt, wherein the synchronous belt with a tension wheel is arranged on the synchronous driven pulley, the shaft coupler is arranged between synchronous transmission pulleys at the bottom end, and the synchronous driving pulley and the synchronous driven pulley at the upper end are respectively provided with a rocking arm, a left clamp rod, a right clamp rod and a clamp. Compared with the binding machine in the prior art, the rotor coil binding machine of the wind power generator has reasonable structure, favorable effect and optimal cost performance.

Owner:CRRC YONGJI ELECTRIC CO LTD

Casting device and casting method

InactiveCN104001860AFlow velocity increases or decreasesDoes not require complex controlsFoundry mouldsFoundry coresElectromagnetic castingElectromagnetic field

The invention relates to a direct electromagnetic casting driving apparatus (1) and a method of manufacturing a cast component through a plurality of casting channels (10, 11, 12). Different solution channels (20, 21, 22) in the casting channels (10, 11, 12) are heated, braked or accelerated in different degrees by means of the electromagnetic fields of electrified coils (30, 31, 32, 33). A non-contact feed is also provided. Required casting driving force is reduced. The invention ensures controllable starting of a second casting step and reverse action on edge layer solification. Meanwhile, the running material is reduced and the injection weight is minimized.

Owner:舒乐绞扭机有限责任公司

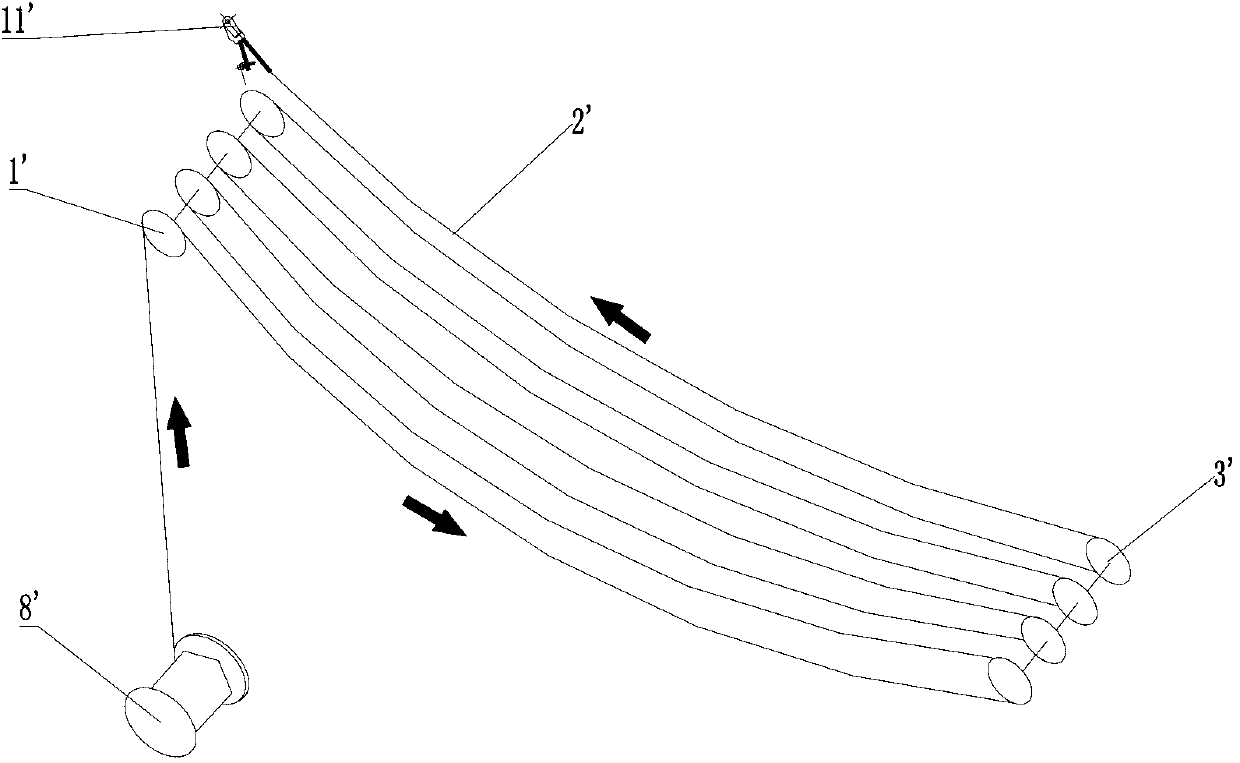

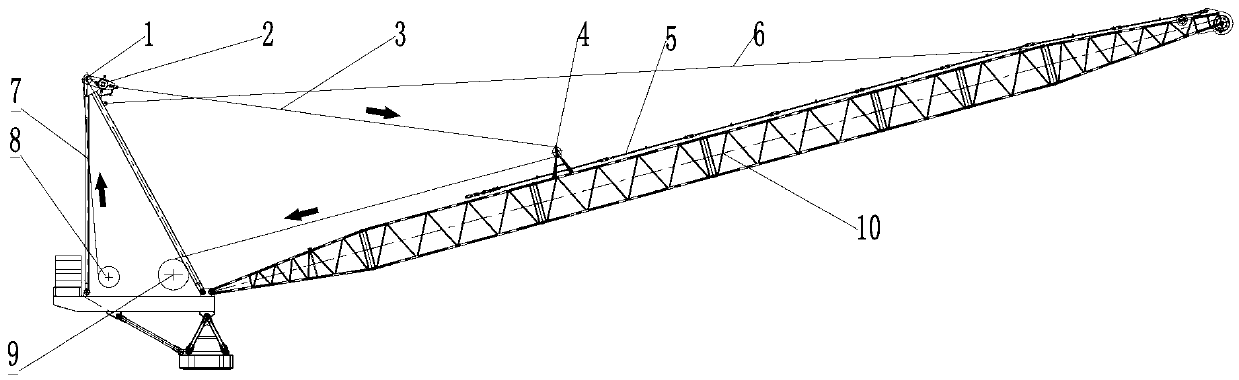

Tower crane with luffing boom and mounting method for variable-amplitude pull rod of tower crane

The invention provides a tower crane with a luffing boom and a mounting method for a variable-amplitude pull rod of the tower crane. The tower crane with a luffing boom comprises an A-shaped frame, a boom frame, an A-shaped frame fixed pulley block, a variable-amplitude pull rod movable pulley block, a variable-amplitude drum and a variable-amplitude rope, wherein one end of the boom frame is articulated with the A-shaped frame, the A-shaped frame fixed pulley block is arranged at the top end of the A-shaped frame; the variable-amplitude rope is threaded and wound on the variable-amplitude pull rod movable pulley block and the A-shaped frame fixed pulley block, one end of the variable-amplitude rope is wound to the variable-amplitude drum and the other end of the variable-amplitude rope is fixed at the end fixing point of the variable-amplitude rope on the A-shaped frame; and the tower crane with the luffing boom further comprises at least two traction ropes, and each of the traction ropes is connected at intervals on a pulley frame of the variable-amplitude pull rod movable pulley block and connected with a traction mechanism. Based on the technical scheme provided by the invention, the balance of the movable pulley block during traction is guaranteed by at least two traction ropes to prevent the twisting of the mounted variable-amplitude rope caused by the inclination of the movable pulley block, so that the traction process is smooth and safe.

Owner:ZOOMLION HEAVY IND CO LTD

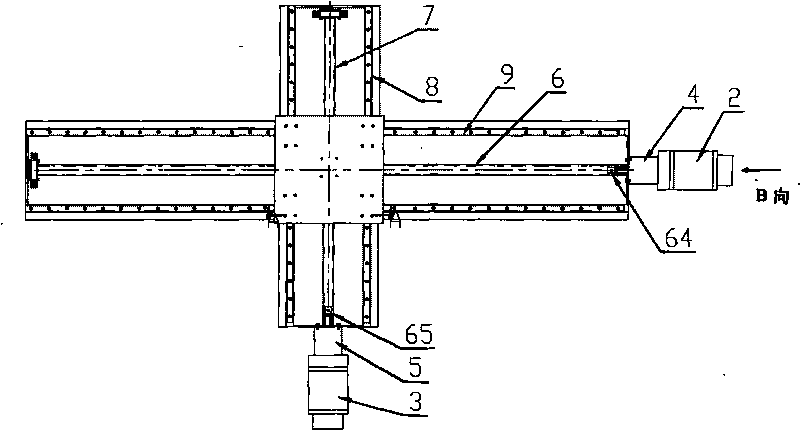

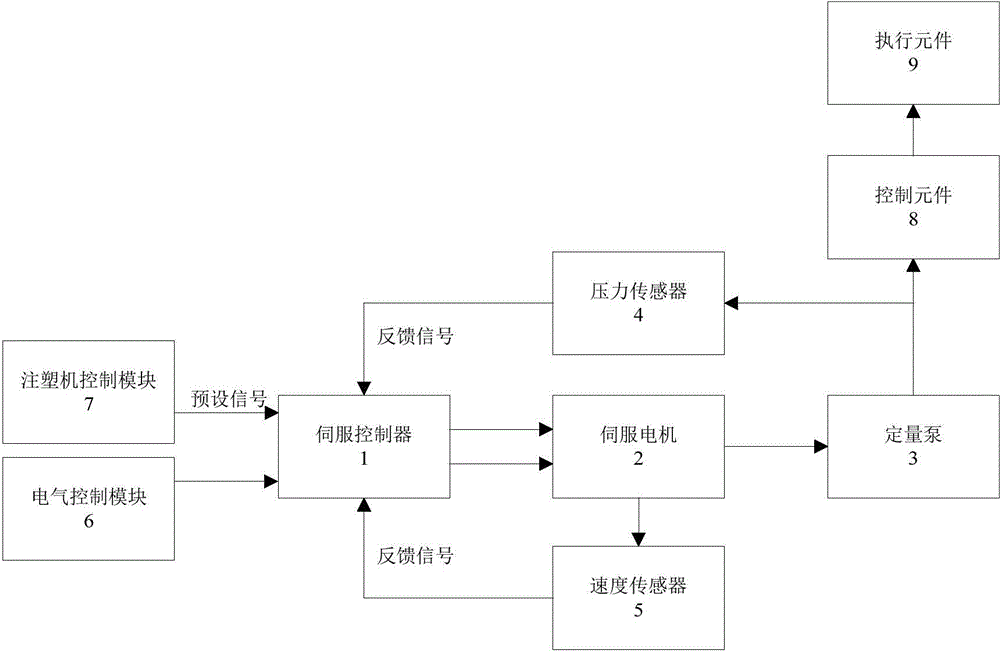

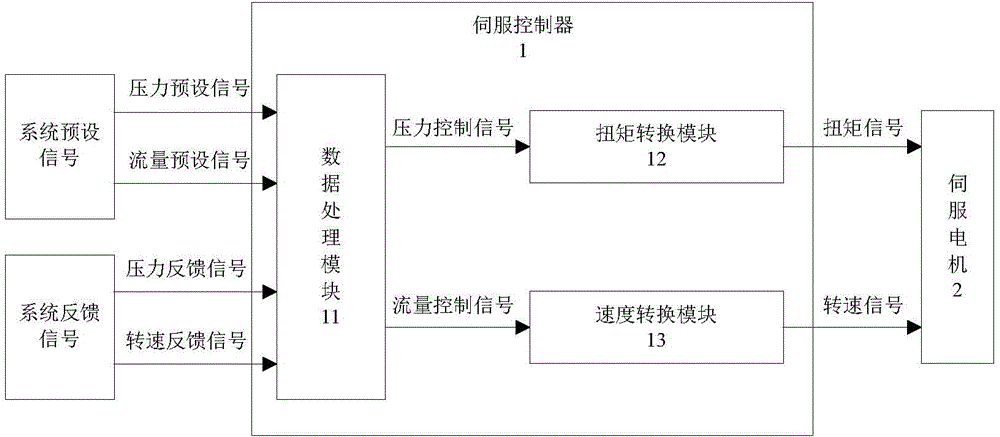

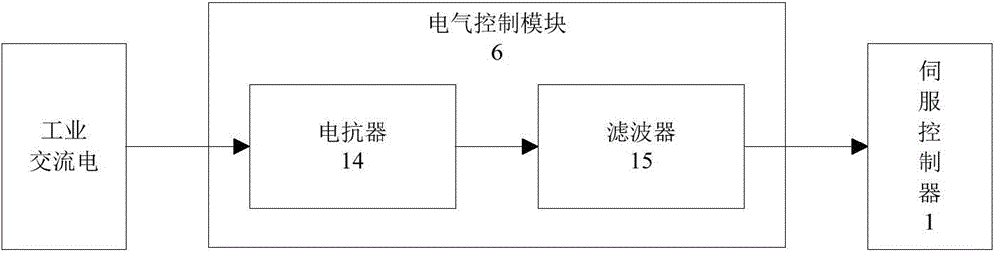

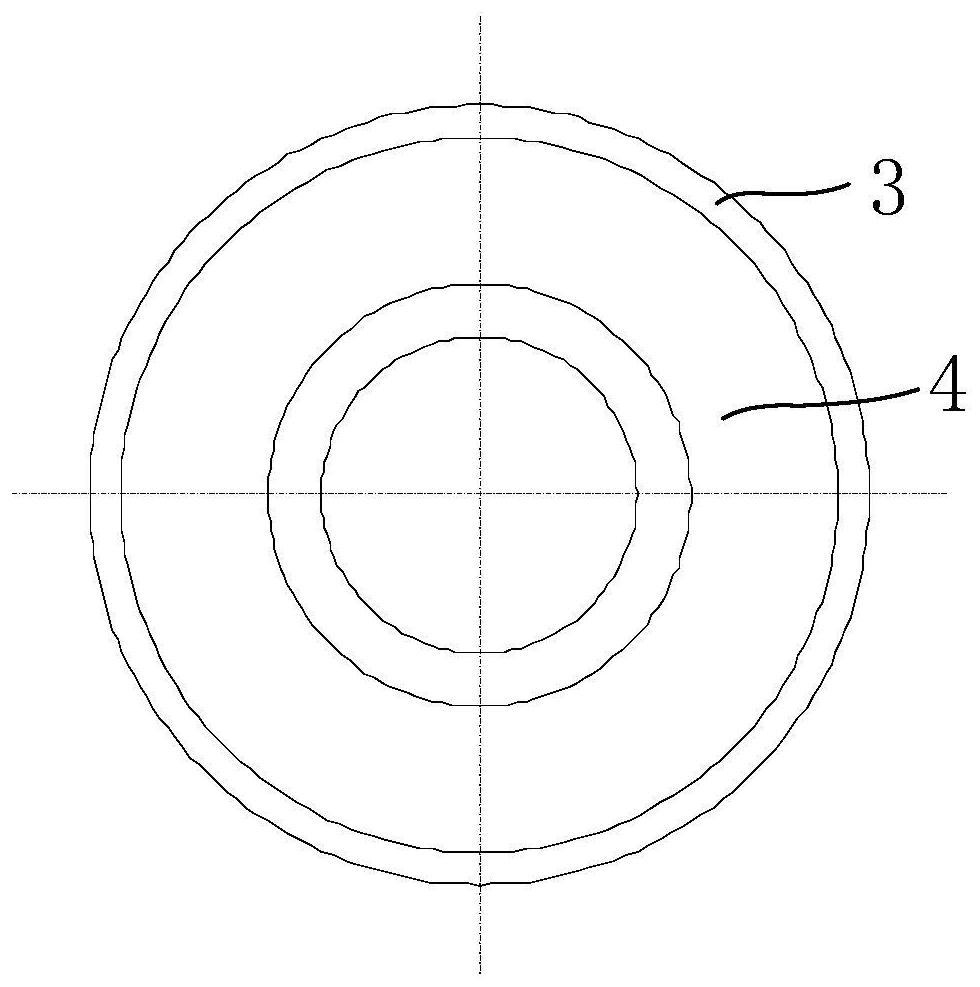

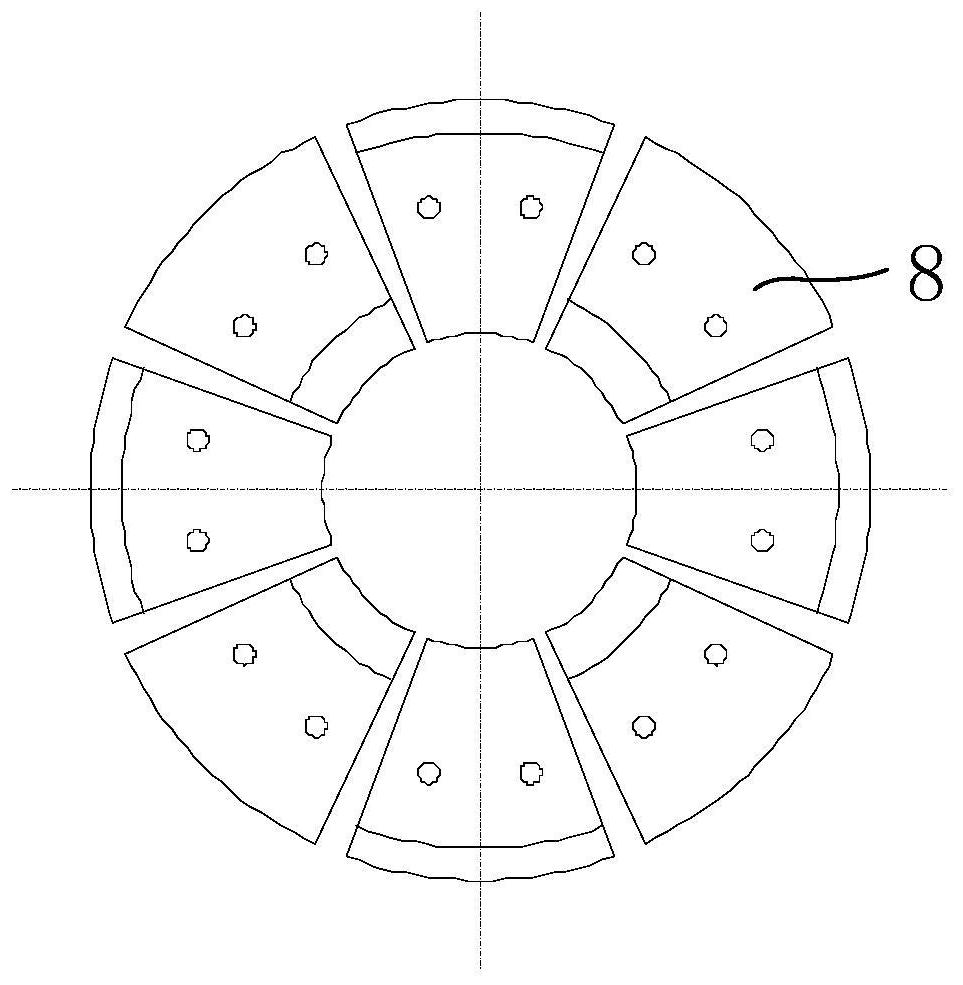

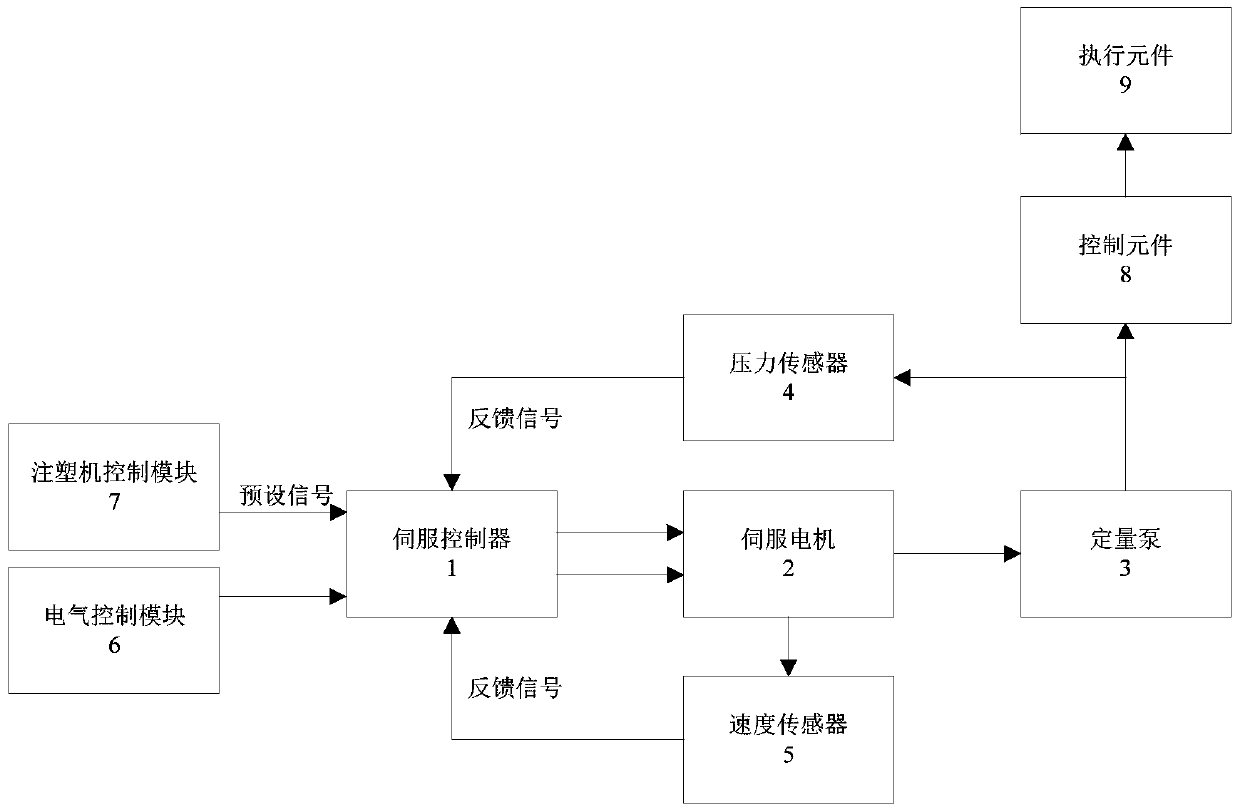

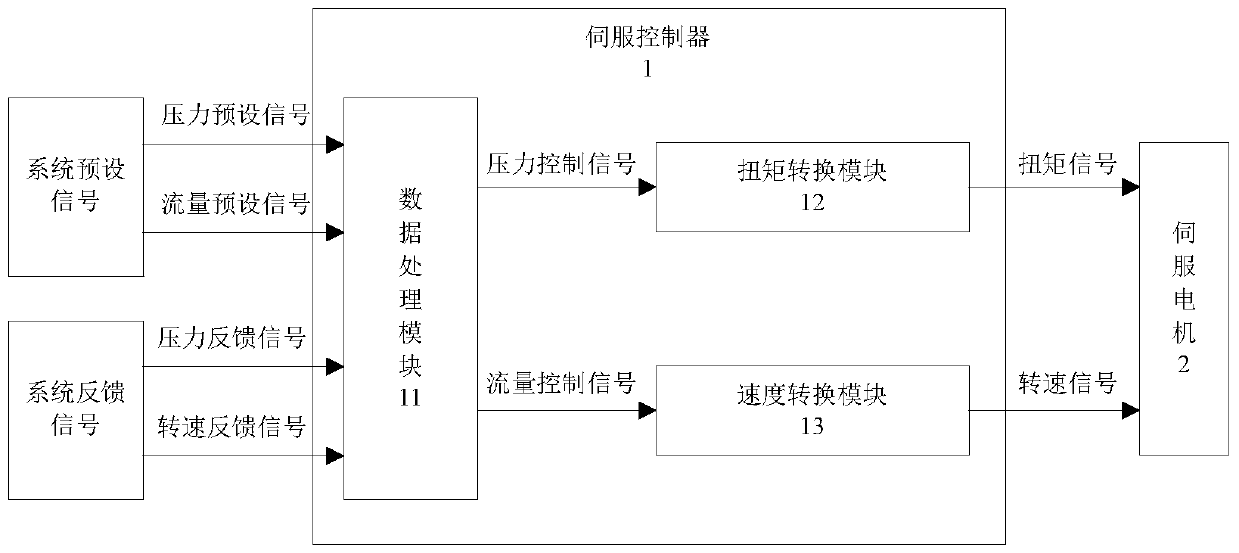

Energy-saving servo control system for injection molding machine

The invention relates to an energy-saving servo control system for an injection molding machine. The energy-saving servo control system comprises a control module of the injection molding machine, a servo motor, a constant displacement pump, a control element and a performing element, and further comprises a servo controller, a pressure sensor and a speed sensor, wherein the servo controller comprises a data processing module, a torque conversion module and a speed conversion module; the control module of the injection molding machine comprises a data processing module which is respectively connected to the pressure sensor, the speed sensor, the torque conversion module and the speed conversion module; the torque conversion module and the speed conversion module are respectively connected to the servo motor; the pressure sensor is arranged on an oil outlet pipeline of the constant displacement pump; the speed sensor is arranged on the output shaft of the servo motor; and the servo motor is used for receiving a torque signal and a rotation speed signal which are independent from one another. Compared with the prior art, a purpose of regulating the control system by double closed-loop feedback of a pressure flow rate and rotation speed is realized, so that the working performance of the operation of the injection molding machine is relatively stable, and the energy utilization efficiency of the injection molding machine is improved.

Owner:SHANGHAI UNIV OF ENG SCI

Machining equipment of steel fiber material

The invention discloses machining equipment of steel fiber materials. The machining equipment comprises a gathering device, a straightening device and an integrating device, wherein a plurality of steel fiber discs are uniformly arranged on a disc shelf; steel fiber wires on each steel fiber discs sequentially pass through the gathering device, the straightening device, the integrating device, an adhesive coating and scrapping device, a drying device, a cooling device, a left and right error detecting device, a left and right error checking device, a power traction device, a front and back speed difference detecting device and a molding cutting device so as to be machined into III-class steel fibers which are is greater than or equal to 1000MPa. The machining equipment is simple to operate; the problems that the existing steel fiber equipment is low in capacity and single in variety, the strength of the performance of a product cannot be sufficiently revealed in concrete, and the steel fiber is insoluble in water are solved; the mixing amount of the steel fiber produced by the machining equipment under the same condition is reduced by 40-50% per square meter of concrete compared with a common steel fiber product; a variety of products, such as low-carbon wires, galvanized wires and stainless steel wires, are provided, the tensile strengths are all greater than or equal to 1100MPa, so that the requirements of different clients are met.

Owner:符竹娟

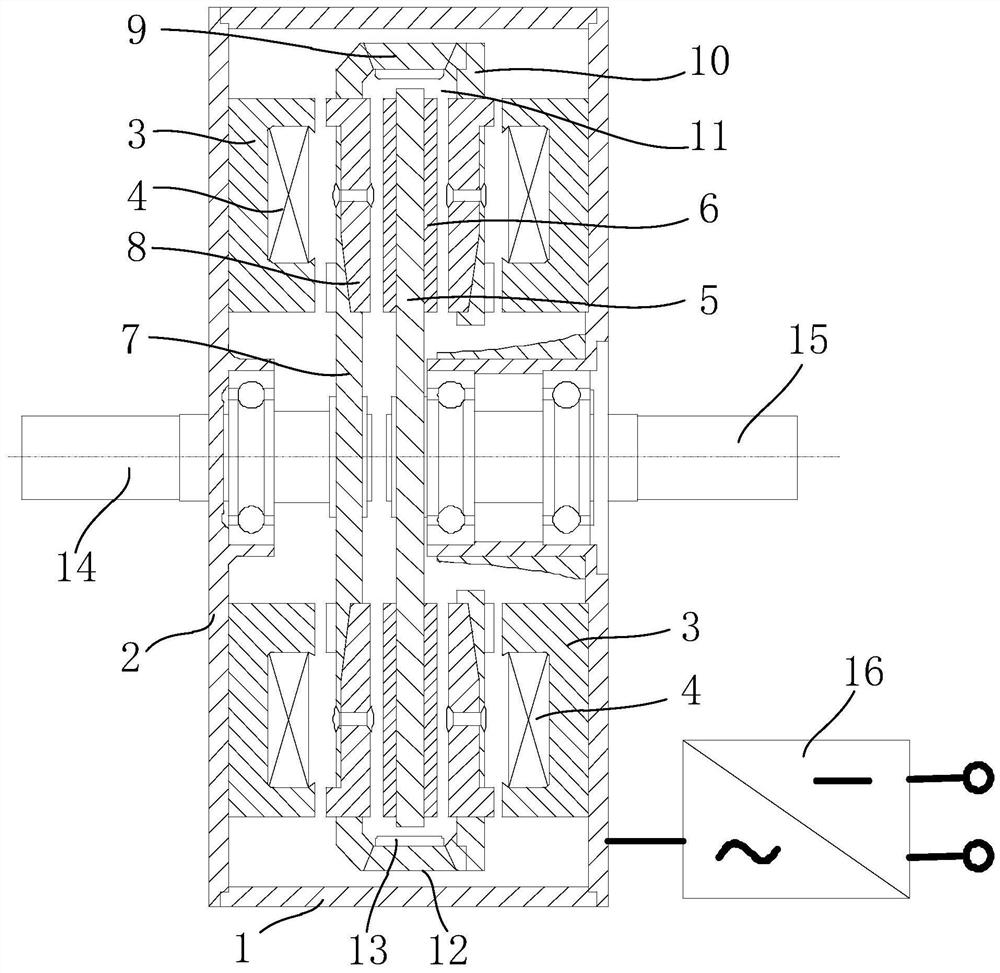

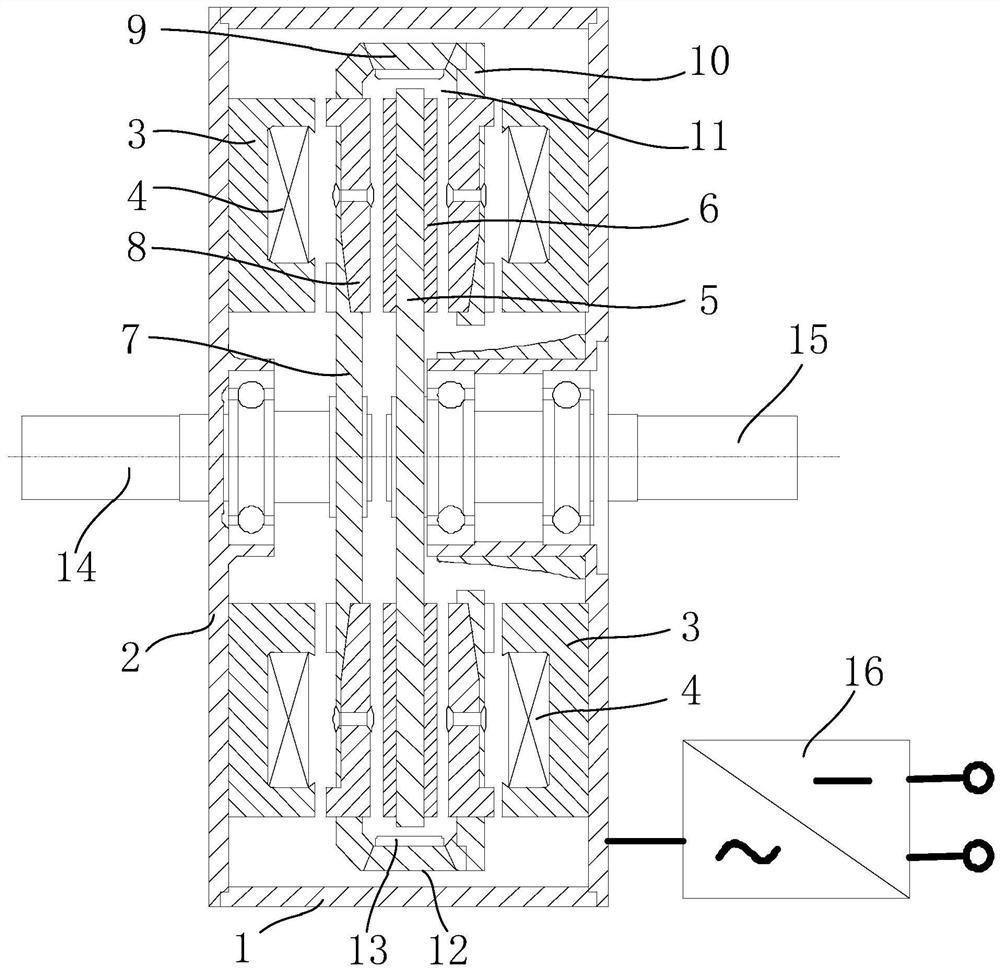

Brushless disc type double-rotor motor

ActiveCN111628621ASpeed/torque differential adjustmentReduce volumeMagnetic circuit rotating partsElectric machinesElectric machineClassical mechanics

The invention discloses a brushless disc type double-rotor motor. The motor comprises a motor shell, stators fixedly arranged at the inner sides of two axial ends of the motor shell, an outer rotor arranged in the motor shell and matched with the stators, an outer rotor output shaft rotatably connected with one end of the motor shell and fixedly connected with the outer rotor, an inner rotor arranged in the motor shell and matched with the stators and the outer rotor, an inner rotor output shaft rotatably connected with the other end of the motor shell and fixedly connected with the inner rotor, and an inverter electrically connected with the stator. The motor has the characteristics of a disc-type permanent magnet motor; the stators are fixed at the inner sides of the end covers at two ends; the permanent magnet inner rotor is fixed on the inner rotor output shaft to rotate together; the claw-pole rotor is located between the two stators and the inner rotor, an electrical angle of 90degrees is formed, the claw-pole rotor and the inner rotor are jointly fixed to the output shaft of the outer rotor to rotate together, coordinated work can be achieved only through one two-phase inverter, and brushless feeding and adjustment of the rotating speed / torque difference value between the two rotating shafts are achieved.

Owner:陕西榆林能源集团横山煤电有限公司

An energy-saving servo control system for an injection molding machine

The invention relates to an energy-saving servo control system for an injection molding machine. The energy-saving servo control system comprises a control module of the injection molding machine, a servo motor, a constant displacement pump, a control element and a performing element, and further comprises a servo controller, a pressure sensor and a speed sensor, wherein the servo controller comprises a data processing module, a torque conversion module and a speed conversion module; the control module of the injection molding machine comprises a data processing module which is respectively connected to the pressure sensor, the speed sensor, the torque conversion module and the speed conversion module; the torque conversion module and the speed conversion module are respectively connected to the servo motor; the pressure sensor is arranged on an oil outlet pipeline of the constant displacement pump; the speed sensor is arranged on the output shaft of the servo motor; and the servo motor is used for receiving a torque signal and a rotation speed signal which are independent from one another. Compared with the prior art, a purpose of regulating the control system by double closed-loop feedback of a pressure flow rate and rotation speed is realized, so that the working performance of the operation of the injection molding machine is relatively stable, and the energy utilization efficiency of the injection molding machine is improved.

Owner:SHANGHAI UNIV OF ENG SCI

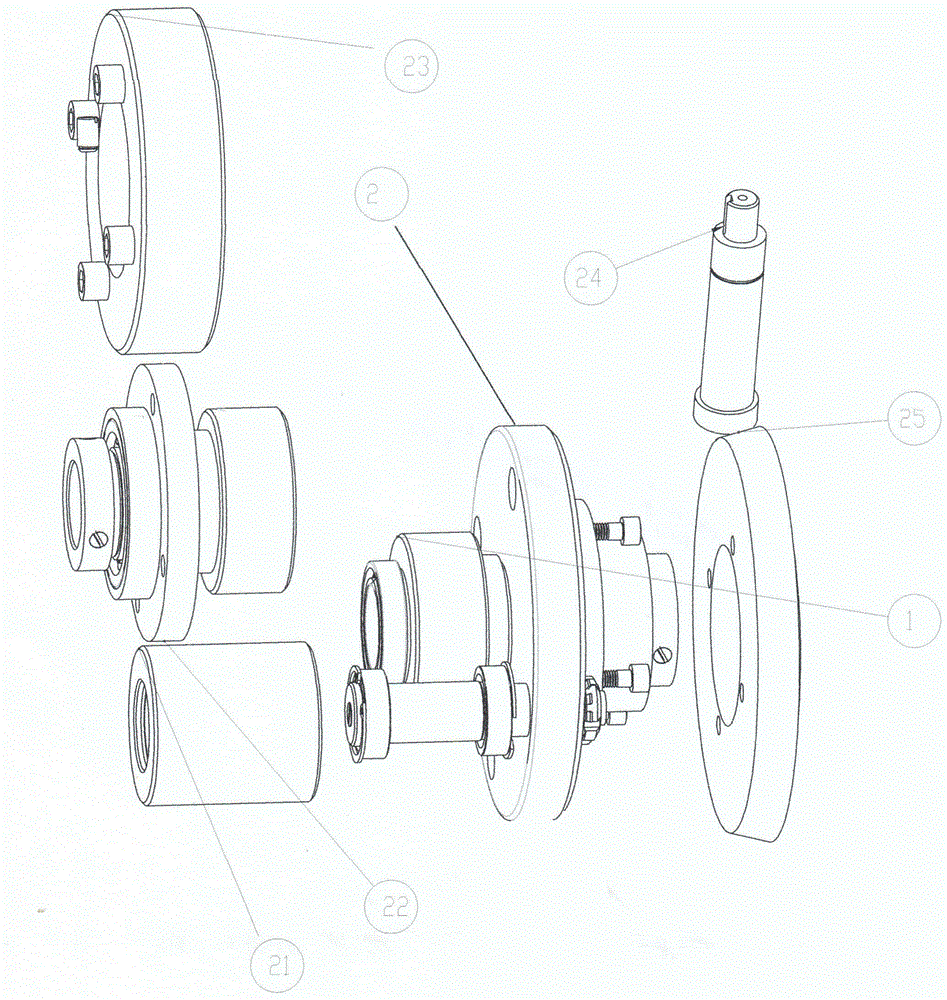

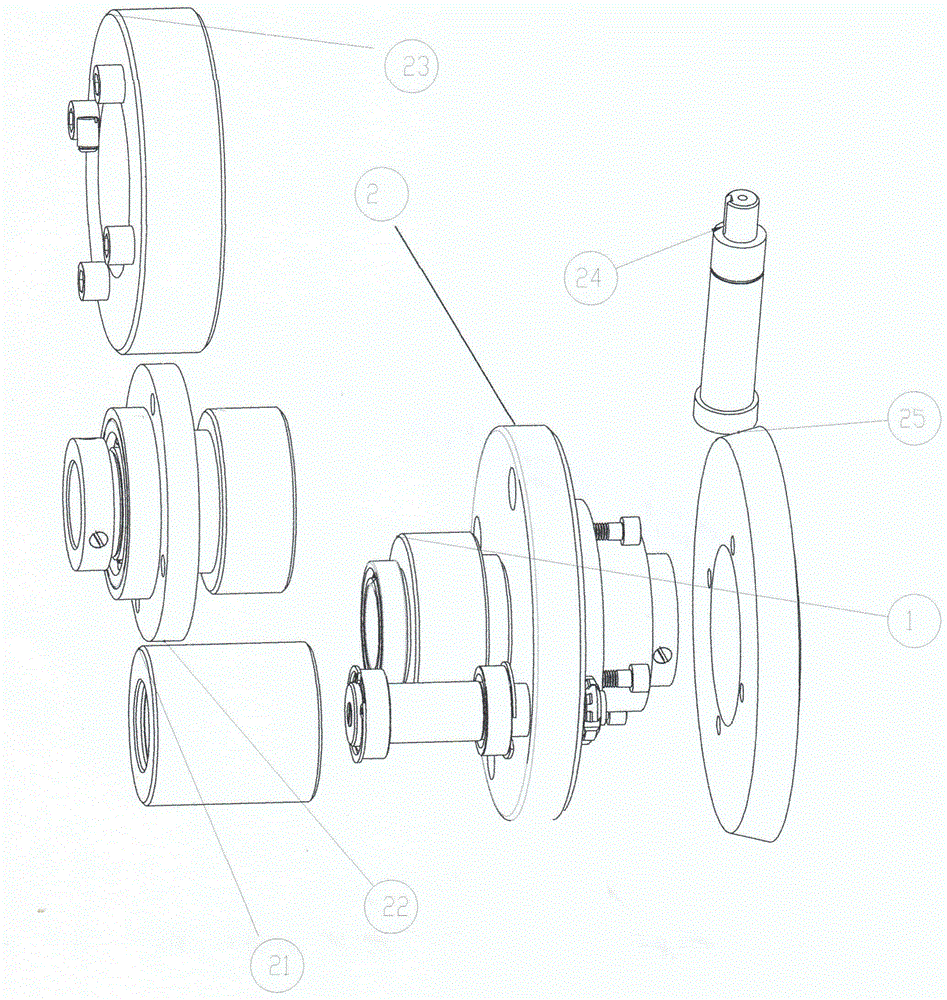

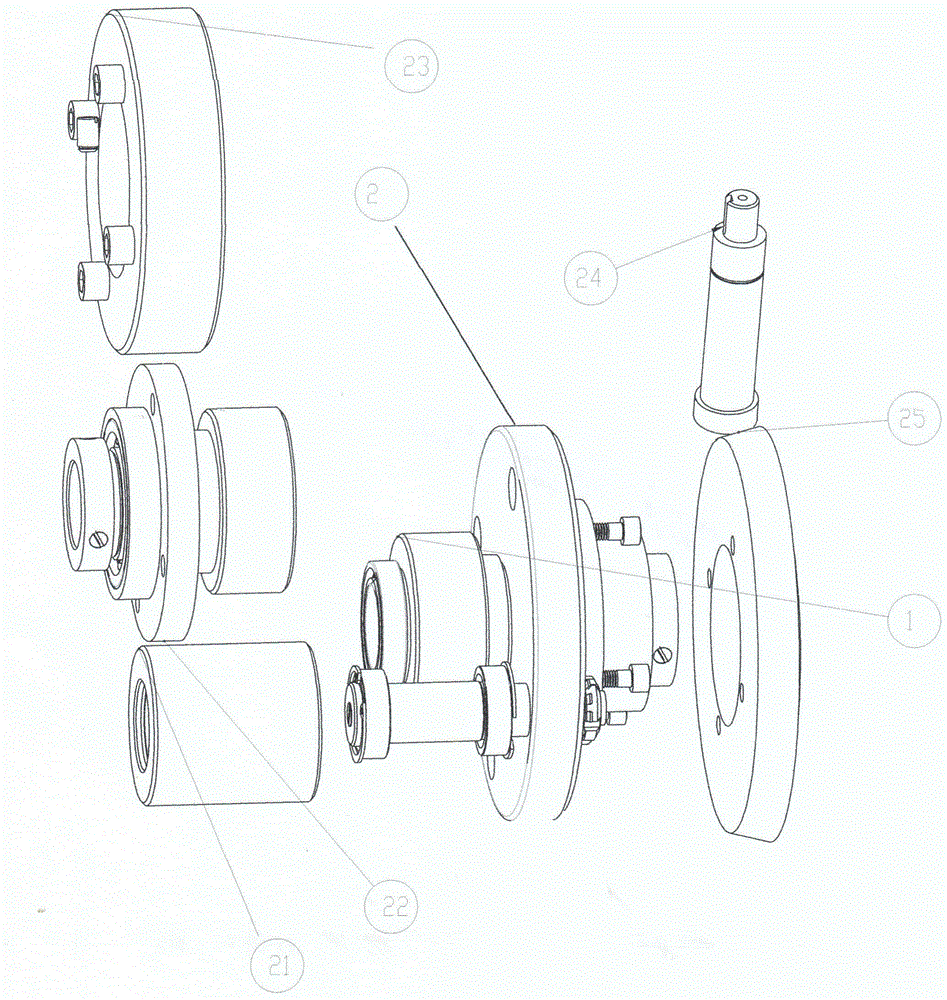

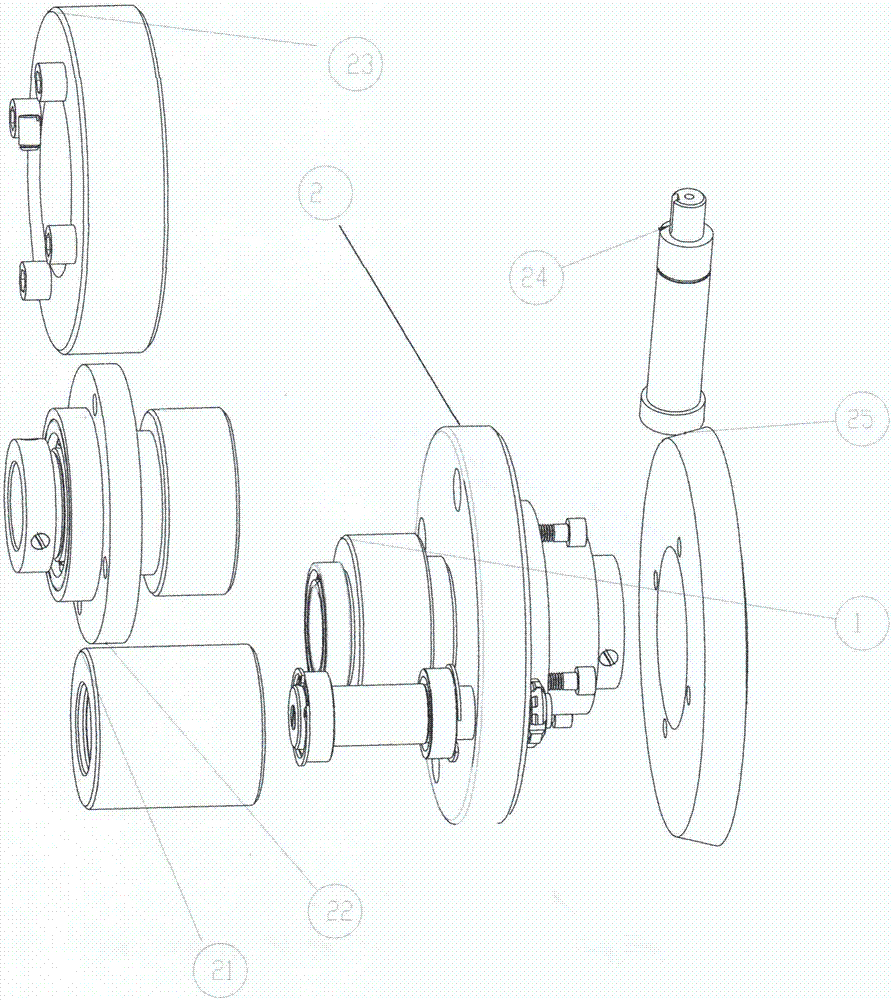

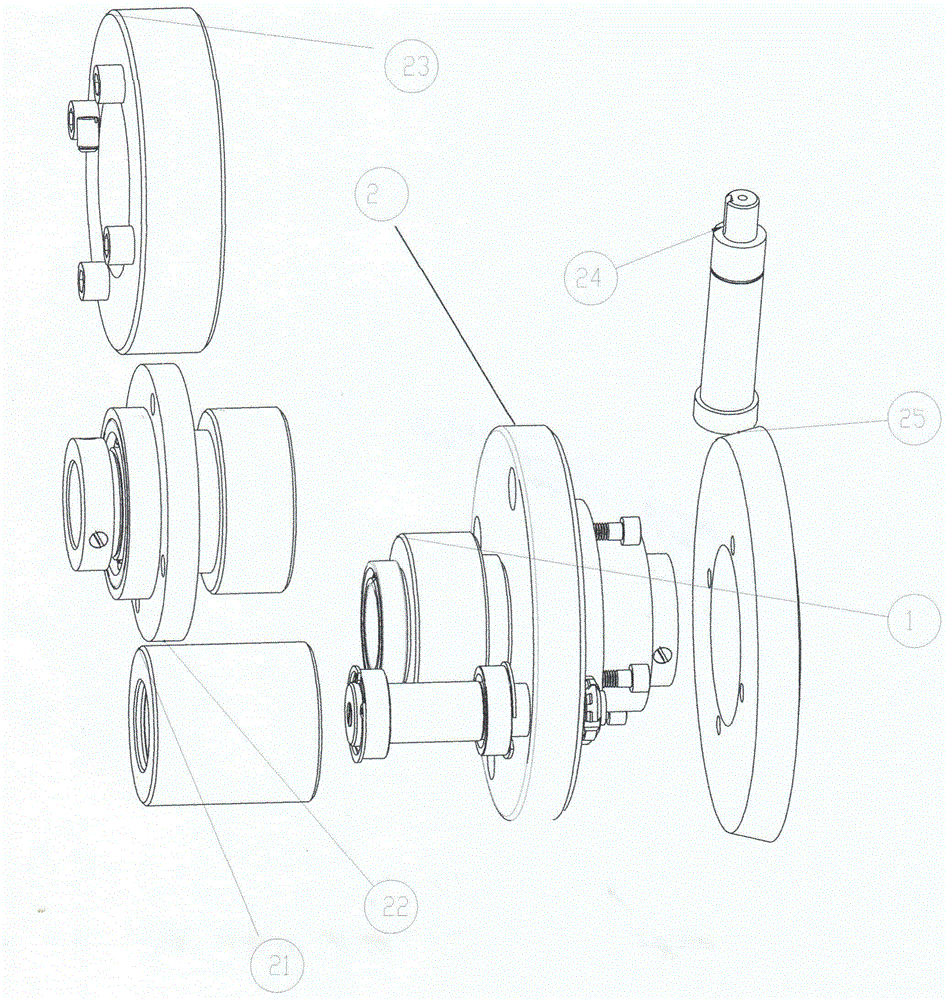

Novel paper pasting machine simple in structure and convenient for adjusting differential speed

The invention provides a novel paper pasting machine simple in structure and convenient for adjusting differential speed, wherein a driving gear 1 is connected with a differential mechanism 2; the differential mechanism 2 is connected with a slave unit and comprises a driven gear 21, a gear wheel 22, a slave unit gear 23, a fine tuning gear 24 and a fine tuning gear 25; the driving gear 1 is meshed with the driven gear 21; the driven gear 21 is meshed with the gear wheel 22; the gear wheel 22 is meshed with the slave unit gear 23; the fine tuning gear 24 is meshed with the fine tuning gear 25; and when the slave unit of the paper pasting machine is not coordinated with other mechanisms in speed, the speed of the slave unit can be adjusted just by adjusting the fine tuning gears of the differential mechanism, so that the slave unit of the paper pasting machine is coordinated with the other mechanisms in speed.

Owner:唐克平

Paper bag bottom pasting machine and gluing pneumatic clutch differential mechanism of paper bag bottom pasting machine

The invention provides a paper bag bottom pasting machine and a gluing pneumatic clutch differential mechanism of the paper bag bottom pasting machine. The paper bag bottom pasting machine comprises a driving gear 1 connected with a differential mechanism 2; the differential mechanism 2 is connected with slave equipment; the differential mechanism 2 includes a driven gear 21, a large gear 22, a slave equipment gear 23, a fine adjustment gear 24 and a fine adjustment gear 25; the driving gear 1 is engaged with the driven gear 21; the driven gear 21 is engaged with the large gear 22; the large gear 22 is engaged with the slave equipment gear 23; the fine adjustment gear 25 is engaged with the fine adjustment gear 25; and when the slave equipment of a paper pasting machine is not coordinated with other mechanisms in speed, the speed of the slave equipment of the paper pasting machine can be adjusted only by adjusting the fine adjustment gear of the differential mechanism, so that the slave equipment of the paper pasting machine is coordinated with other mechanisms in speed.

Owner:周保国

Chassis and vehicle

ActiveCN110696787AReduce speedSpeed coordinationBraking element arrangementsElectric machineryControl theory

The invention relates to a chassis and a vehicle, and belongs to the technical field of vehicles. The chassis comprises an advancing assembly with a braking function, and the advancing assembly comprises a hub motor, a steering knuckle, a braking worm gear, a braking worm and a braking motor, wherein the hub motor comprises a rotor and a stator, the braking worm gear is fixed on the rotor, and thestator is fixed on the steering knuckle; the brake worm is rotatably connected with the steering knuckle, the brake worm wheel is meshed with the brake worm, the brake worm wheel and the brake worm meet a self-locking condition, and the brake motor is used for controlling the rotation of the brake worm. By the application, the technical problem that the brake device is more complex in structure,so that the manufacturing cost of the brake device is higher, can be effectively solved.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

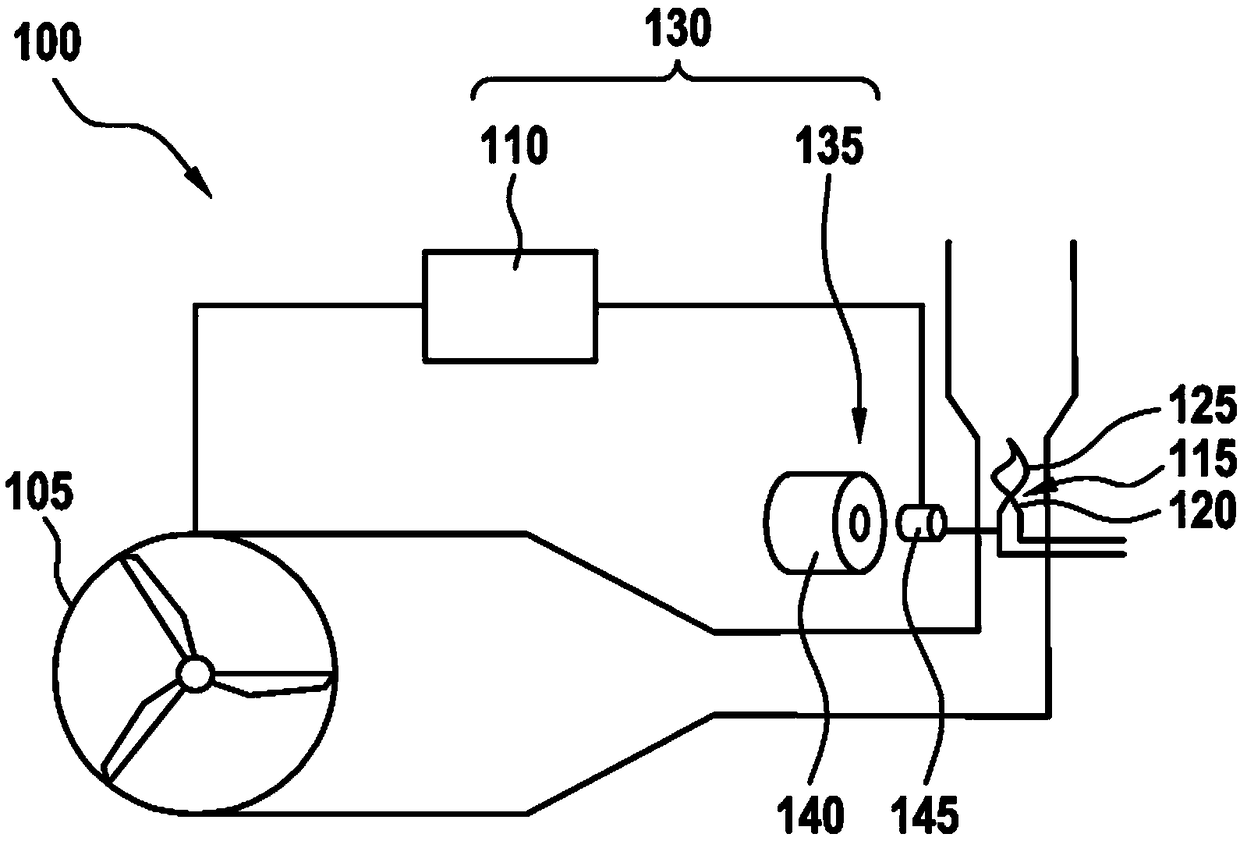

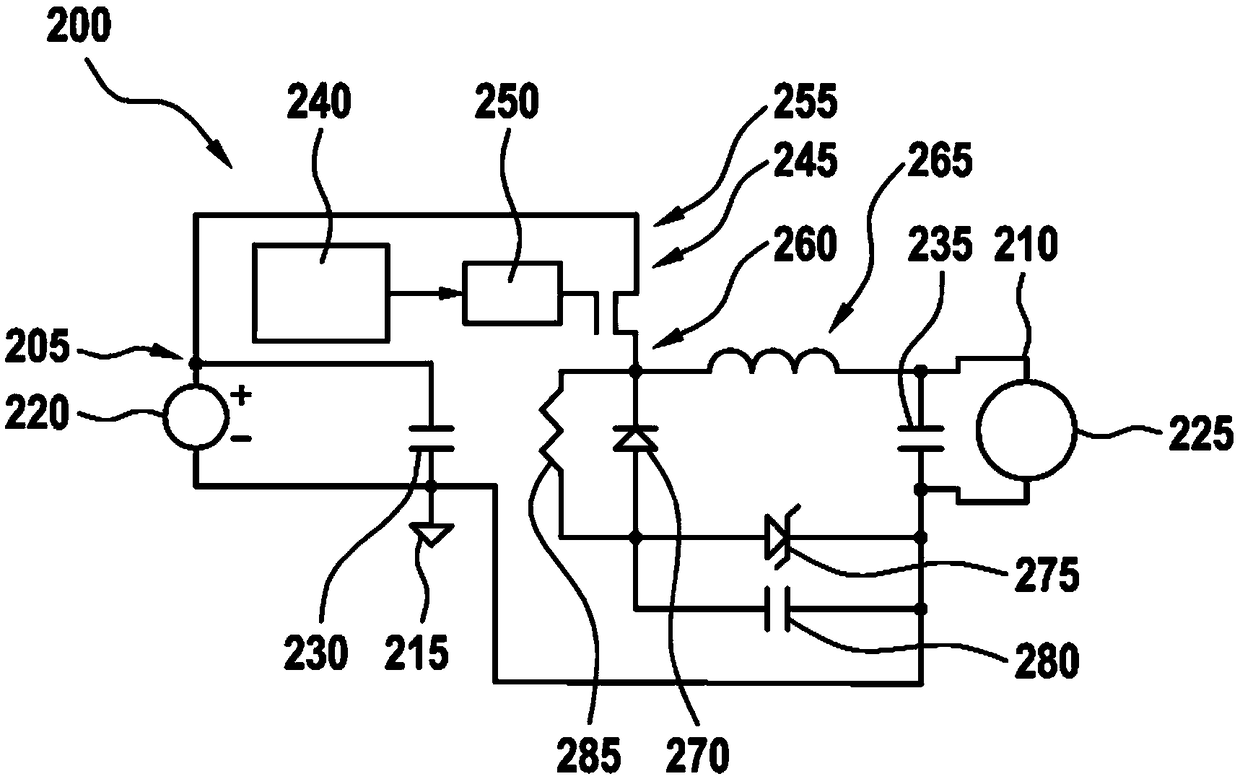

Voltage converter, actuator and gas burner

InactiveCN108702092AImprove efficiencyAccurately regulate the currentFluid heatersFuel supply regulationConvertersZener diode

An electrical buck converter comprises a circuit input and a circuit output, wherein the circuit input and the circuit output have a common reference potential; a current valve having an input end andan output end, wherein the input end is connected to the circuit input end; a coil, which is connected between the output of the current valve and the circuit output; a diode, which is used in the forward direction from the reference potential to the output of the current valve; an output capacitor between the circuit output and the reference potential; a control device for periodically opening and closing the current valve. A Zener diode with a forward direction to the reference potential is inserted between the anode of the diode and the reference potential, and a resistor is provided parallel to the diode.

Owner:BOSCH TERMOTECHA

Novel differential system convenient and fast to adjust

The invention provides a novel differential system convenient and fast to adjust. The novel differential system convenient and fast to adjust comprises a drive gear 1 connected with a differential mechanism 2. The differential mechanism 2 is connected with a slave device. The differential mechanism 2 comprises a driven gear 21, a large gear 22, a slave device gear 23, a fine adjustment gear 24 and a fine adjustment gear 25. The drive gear 1 is engaged with the driven gear 21. The driven gear 21 is engaged with the large gear 22. The large gear 22 is engaged with the slave device gear 23. The fine adjustment gear 24 is engaged with the fine adjustment gear 25. When the slave device of a paper pasting machine is uncoordinated with other mechanisms in speed, the speed of the slave device of the paper pasting machine can be adjusted simply by adjusting the fine adjustment gears of the differential mechanism, and therefore the slave device of the paper pasting machine can be coordinated with other mechanisms in speed.

Owner:肖斌

Power assembly system with internal combustion engine and continuously variable transmission

InactiveCN104088988ANo lossEliminate Flow LossGearboxesControl devicesExternal combustion engineEngineering

The invention relates to a power assembly system which comprises an internal combustion engine (2) and a continuously variable transmission (3). To achieve relatively small loss with small consumption, particularly within a relatively high rotation speed range under the condition of compact structure manner, according to the power assembly system, a first speed change mechanism machine unit (8a) and a second speed change mechanism machine unit (8b) which is in action connection with the first speed change mechanism machine unit (8a) can be mechanically connected with each other through a switchable clutch (14).

Owner:LINDE HYDRAULICS

Rotor coil binding machine of wind power generator

InactiveCN101707421BFit tightlySufficient clamping rangeManufacturing dynamo-electric machinesWind energy generationCoil bindCoupling

The invention relates to the technology of rotor coil binding of generators, in particular to a rotor coil binding machine of a wind power generator. The invention solves the problems of large labor intensity, low efficiency and difficult control of quality caused by manual binding because of the insulation of the rotor coil of the traditional wind power generator. The rotor coil binding machine of the wind power generator comprises a numerical control system, a stand, a feeding system, a rotor coil clamping synchronous device and a lapping head, and mainly comprises a servo motor, a decelerator, a ball screw, as well as a trailing plate and a linear guide rail connected by a shaft coupler, a synchronous driving pulley, a synchronous driven pulley and a synchronous belt, wherein the synchronous belt with a tension wheel is arranged on the synchronous driven pulley, the shaft coupler is arranged between synchronous transmission pulleys at the bottom end, and the synchronous driving pulley and the synchronous driven pulley at the upper end are respectively provided with a rocking arm, a left clamp rod, a right clamp rod and a clamp. Compared with the binding machine in the prior art, the rotor coil binding machine of the wind power generator has reasonable structure, favorable effect and optimal cost performance.

Owner:CRRC YONGJI ELECTRIC CO LTD

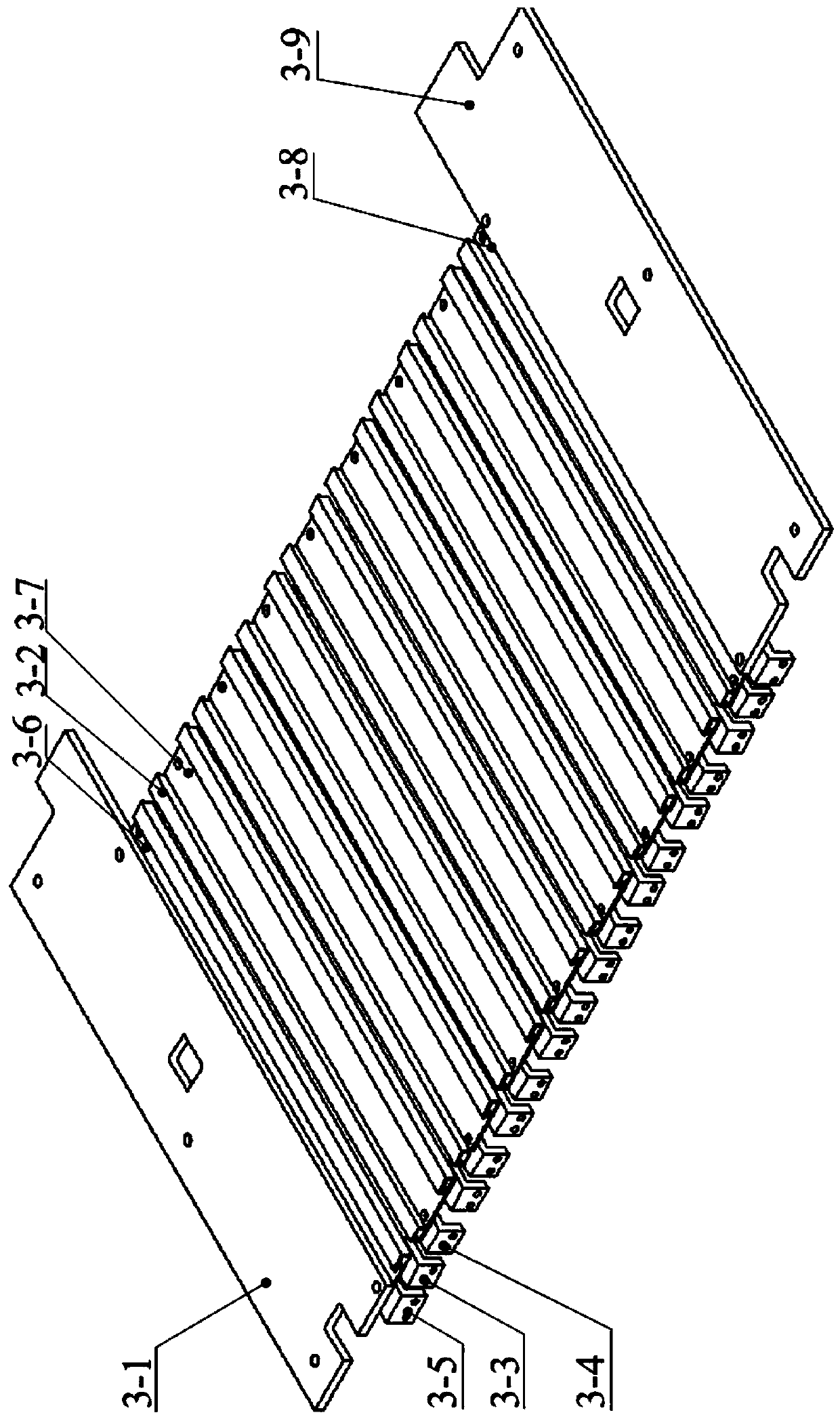

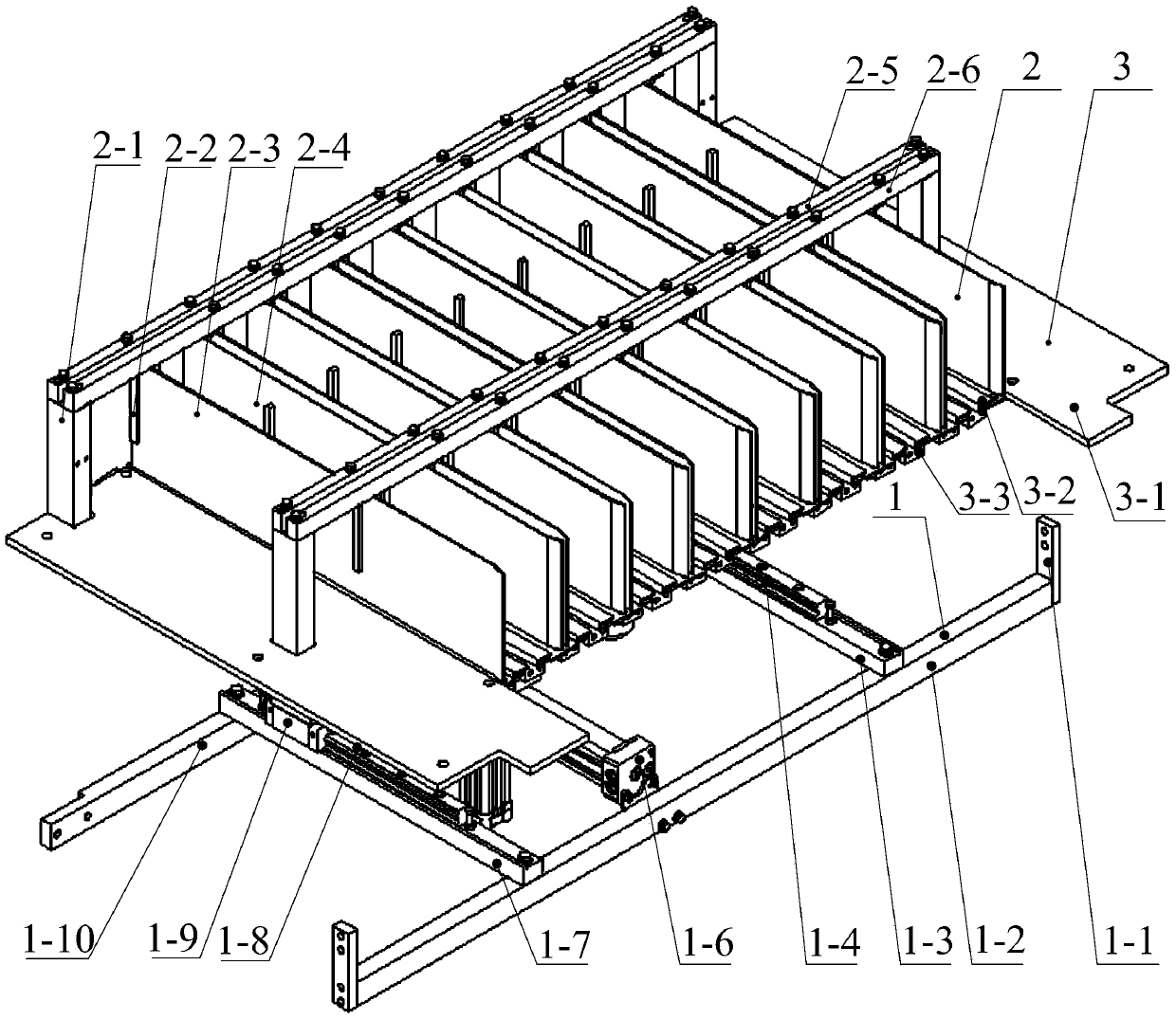

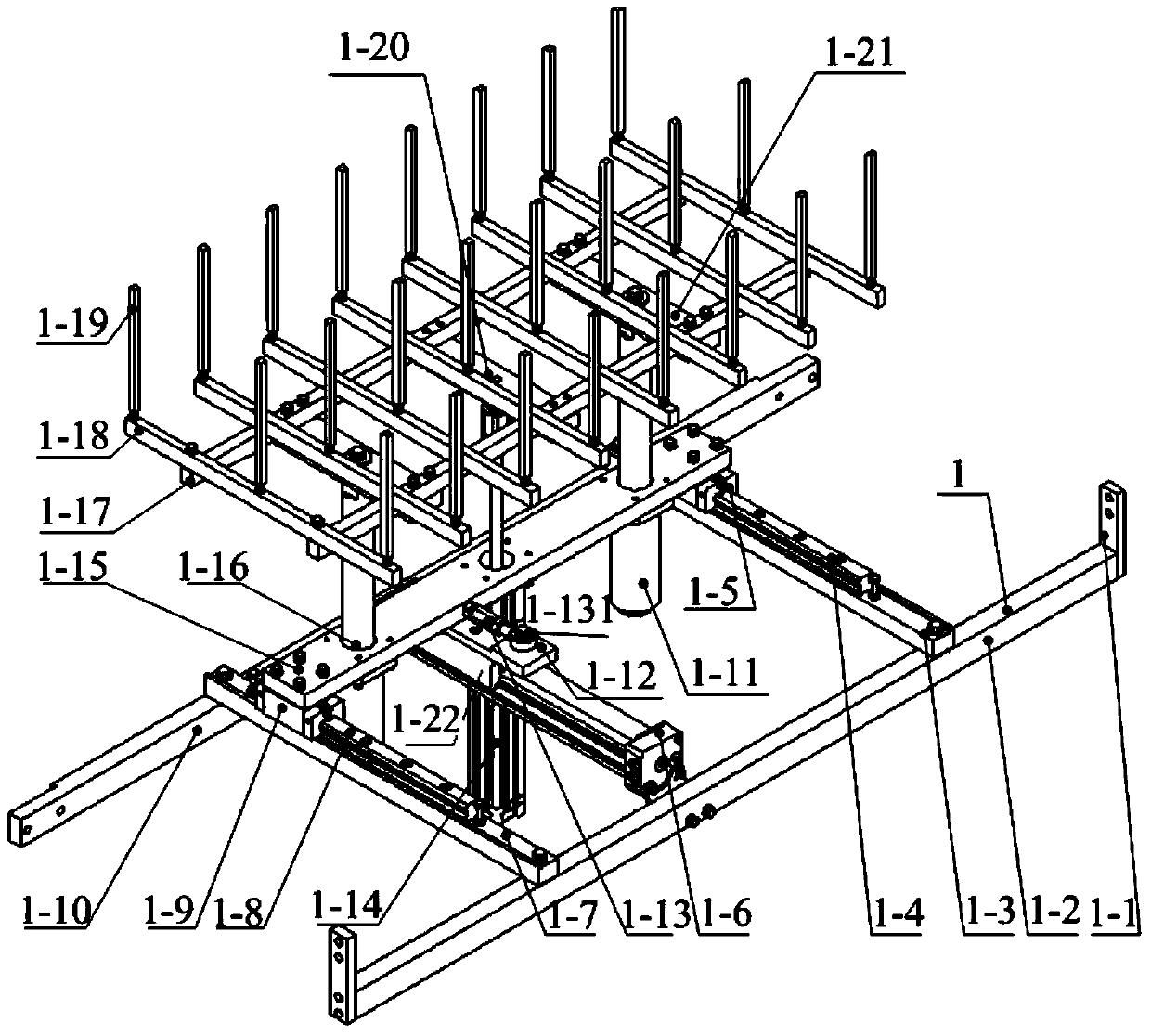

Automatic caching mechanism

The invention belongs to the technical field of paper financial product packaging production, and in particular relates to an automatic caching mechanism. The automatic caching mechanism comprises a longitudinal push lifting mechanism (1), a longitudinal guide rail (2) and a panel component (3). The longitudinal push lifting mechanism (1) comprises two cross beams, two longitudinal push guide rails, a longitudinal push cylinder (1-6), lifting linear bearings (1-11), a lifting cylinder (1-14), a connecting beam and push rods (1-19). The longitudinal guide rail (2) comprises fixed stand columns (2-1), front side plate connecting pieces (2-2), front side plates (2-3), back side plates (2-4), a side plate right connecting beam (2-5), a side plate left connecting beam (2-6) and back side plate connecting pieces (2-7). The panel component (3) comprises rectangular hollow steel pipes (3-2), left rectangular hollow steel pipe connecting blocks (3-3) and right rectangular hollow steel pipe connecting blocks (3-4). The beneficial effects are that the automatic caching mechanism can temporarily cache thousands of 182*196mm products in three rows so as to coordinate the speed of a thousand collecting unit and a clearing machine in a cutting and cleaning automatic production line.

Owner:BEIJING AREOSTANARD NEW TECH +2

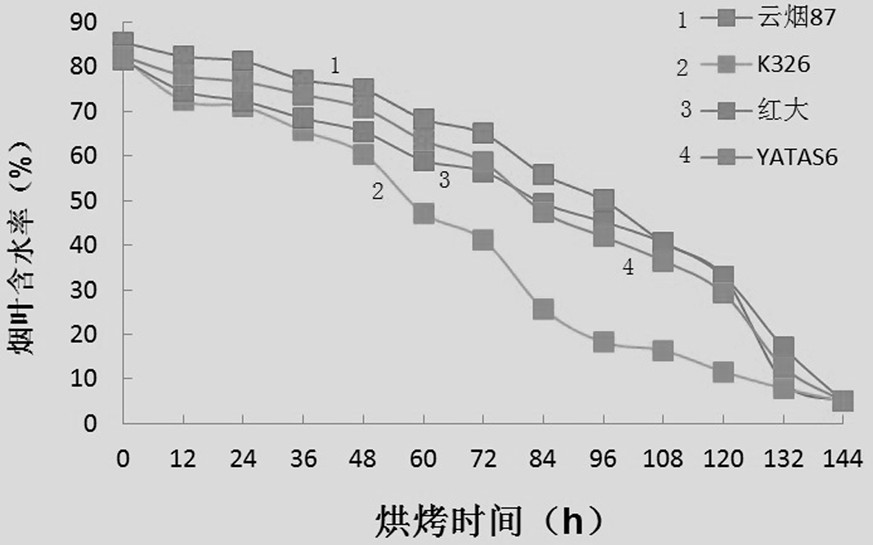

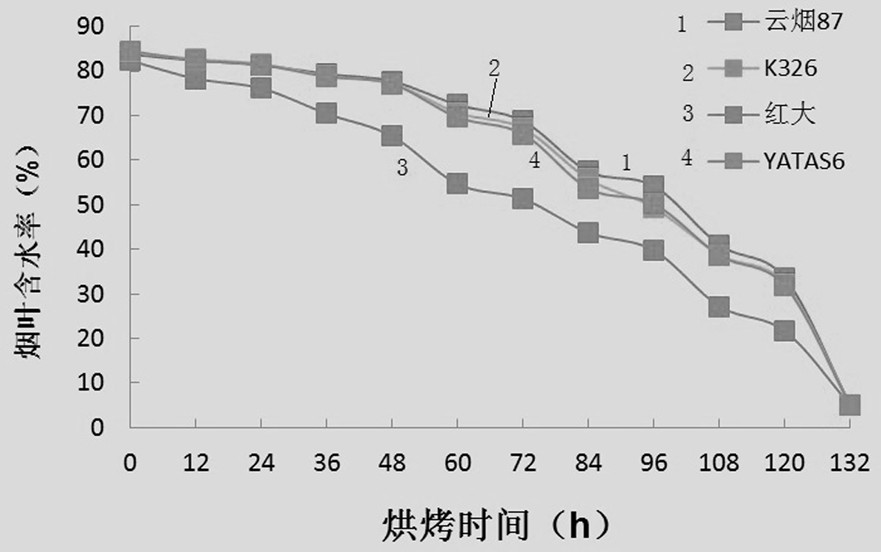

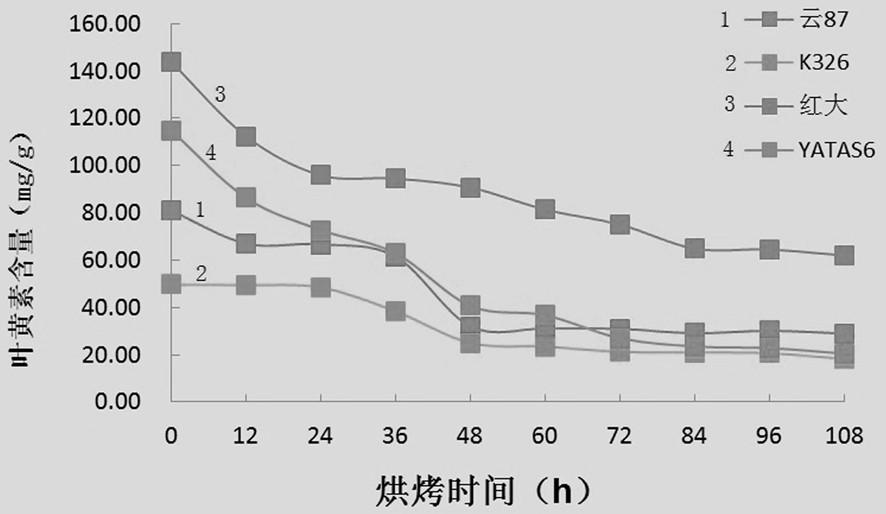

A curing process suitable for flue-cured tobacco variety nc-yatas6 tobacco leaves

ActiveCN109892683BHigh average priceImprove bake qualityTobacco preparationEconomic benefitsEngineering

The invention discloses a curing process suitable for flue-cured tobacco variety NC-YATAS6 tobacco leaves. The curing process harvests mature fresh tobacco leaves of the NC-YATAS6 variety for baking, and the curing includes the yellowing period, withering period, and color fixing The early stage, the late stage of color fixation and the dry gluten stage. The fresh tobacco leaves of the NC-YATAS6 variety are roasted by the process of the present invention. Compared with the conventional roasting process, the chroma is fuller, and the average price of the tobacco leaves is much higher than that of the conventional process technology. At the same time, the tobacco leaves obtained by adopting the curing process of the present invention not only have excellent curing quality and better smoking quality, but also improve the industrial usability of the cured tobacco leaves, significantly increase the economic benefits, and are easy to popularize and apply.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Comprehensive coordination system for conveniently adjusting rotating speed difference of paper pasting machine at any time

The present invention provides a comprehensive coordinating system for conveniently adjusting the rotational speed difference of the paper gluer at any time, which includes a driving gear 1 connected to a differential mechanism 2, and the differential mechanism 2 is connected to a slave device, and the differential mechanism 2 includes a driven gear 21 , bull gear 22, slave equipment gear 23, fine-tuning gear 24 and fine-tuning gear 25, described driving gear 1 meshes with driven gear 21, driven gear 21 and bull gear 22 gears, bull gear 22 meshes with slave equipment gear 23, The fine-tuning gear 24 meshes with the fine-tuning gear 25; when the speed of the subordinate equipment of the paper paste machine is inconsistent with other mechanisms, the speed of the subordinate equipment of the adjustment machine can be reached by adjusting the fine-tuning gear of the differential mechanism, so that the subordinate equipment of the paper paste machine Coordinate with the speed of other institutions.

Owner:张丹丹

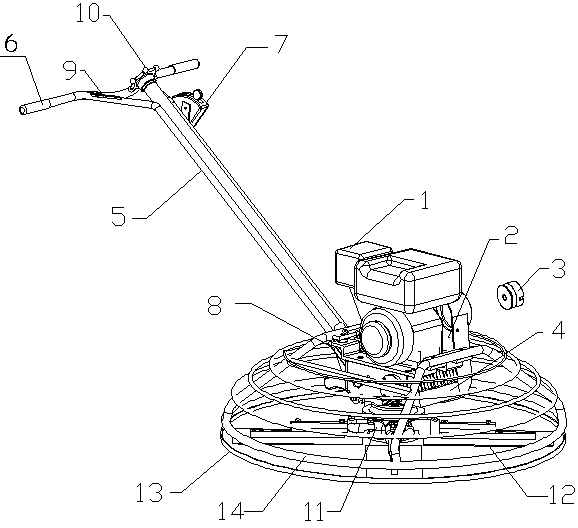

Decelerator assembly for troweling machine

PendingCN108316103ACompact designEasy to operateBuilding constructionsRoads maintainenceEngineeringMechanical engineering

The invention discloses a decelerator assembly for a troweling machine. The decelerator assembly consists of a transition plate, a steel bowl, a box body, a washer, a box cover, a pressure ring, a first gasket, a worm wheel, a worm wheel shaft, a left bearing seat, a worm, a right bearing seat, a second gasket and a nameplate. One end of the worm wheel is connected to the box body through the wormwheel shaft, and the other end of the worm wheel connected to the box cover is directly provided with het pressure ring and the first gasket, and the outside of the box cover is connected to the transition plate through the washer and the steel bowl. The decelerator assembly for a troweling machine provided by the invention has the characteristics of compact structural design, convenient operation and high transmission efficiency. The decelerator assembly can well realize speed coordination of an engine and a cross seat and improve the construction efficiency.

Owner:江苏杰工机电设备有限公司

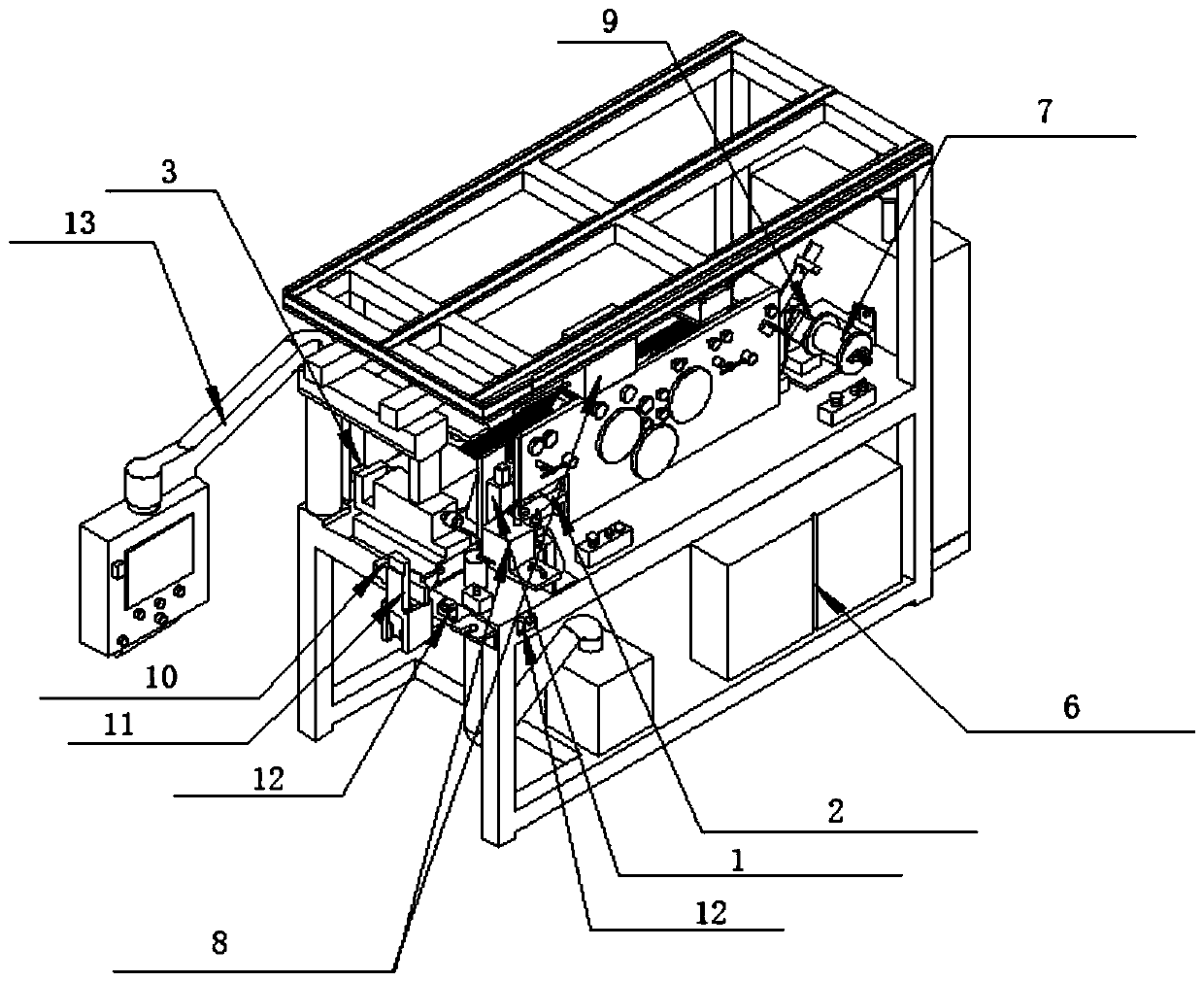

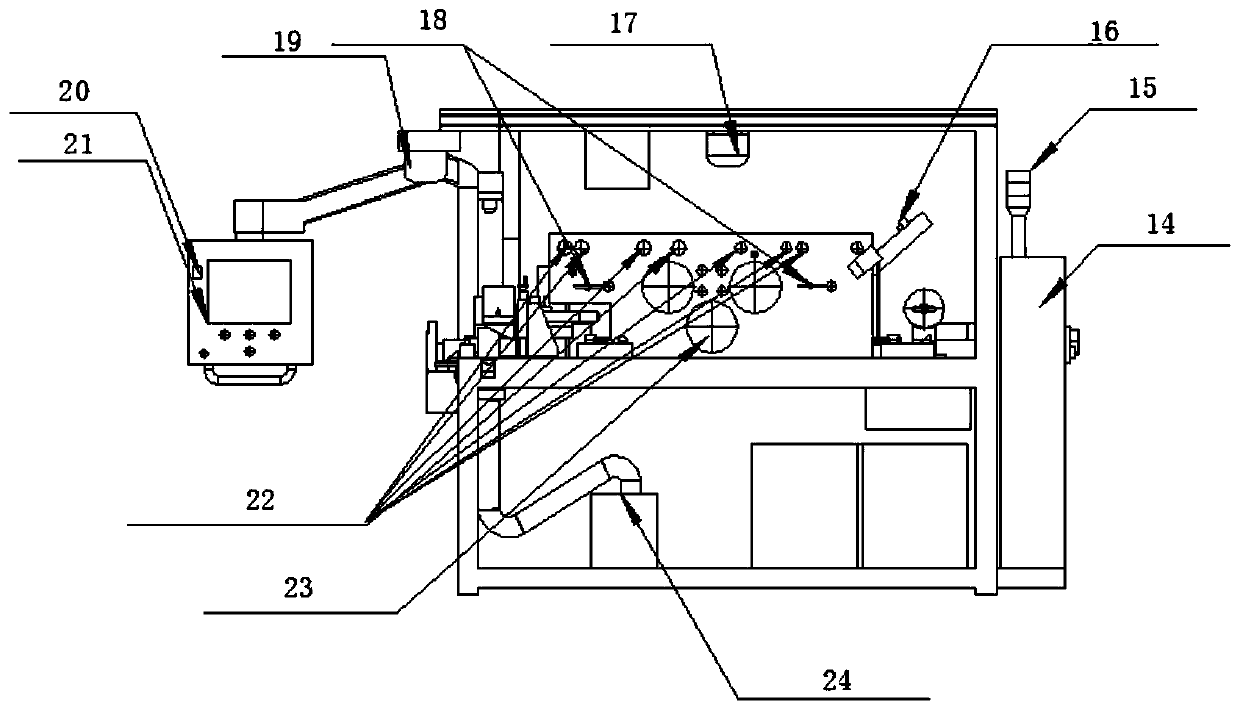

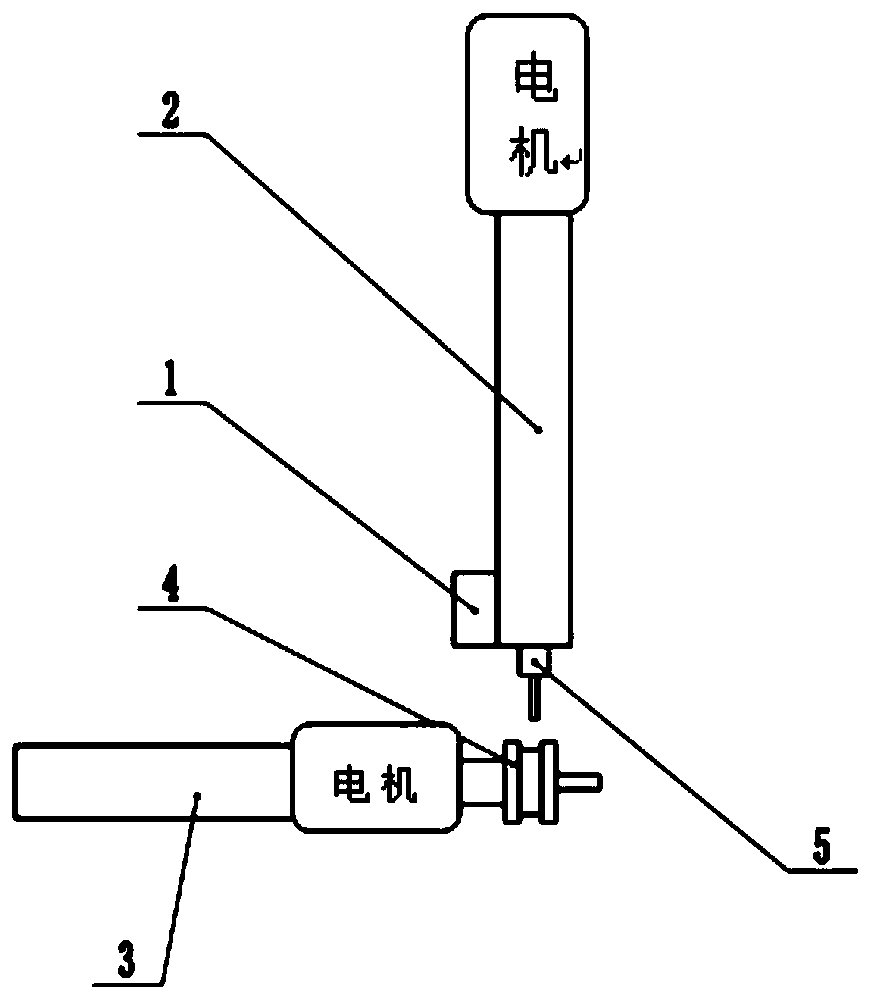

Intelligent high-precision fiber winding machine

The invention discloses an intelligent high-precision fiber winding machine. The intelligent high-precision fiber winding machine comprises a control module and a fiber winding module; the control module comprises a touch screen and a PLC intelligent control module; the PLC intelligent control module is used for collecting, storing and calibrating parameters fed back by the fiber winding module ina real-time fiber winding process, and the touch screen is used for inputting parameters and switching instructions; the fiber winding module comprises a fiber winding device and a fiber dischargingdevice corresponding to the fiber winding device; the fiber winding machine is used for accurately controlling the fiber discharging position and the fiber winding position of an optical fiber in three dimensions, and three axes are respectively used for controlling the vertical movement, horizontal movement and front-back movement; a mandrel can be controlled to move, the left and right positionswhere the optical fiber is discharged are unchanged, the control is realized through the movement of the mandrel, the movement proportion of different optical fibers is adjustable, and the precisionis better; and the labor cost is reduced, and the degree of automation is high.

Owner:NANJING ZHONGTAN MARINE INTERNET OF THINGS CO LTD

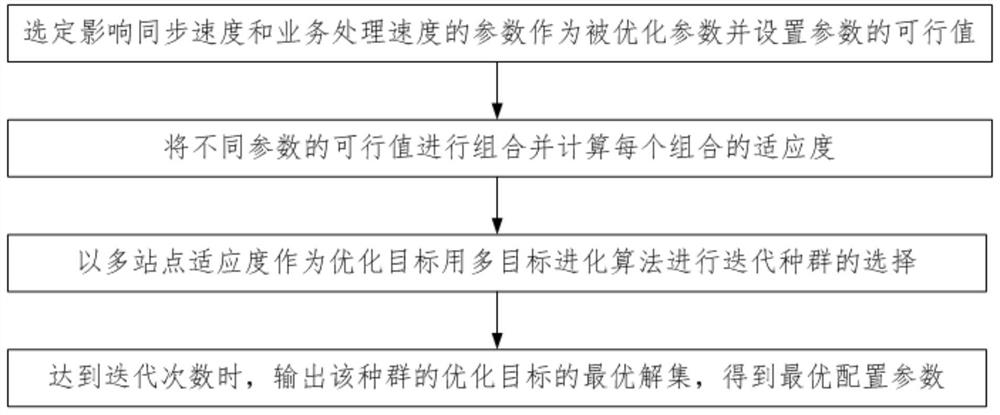

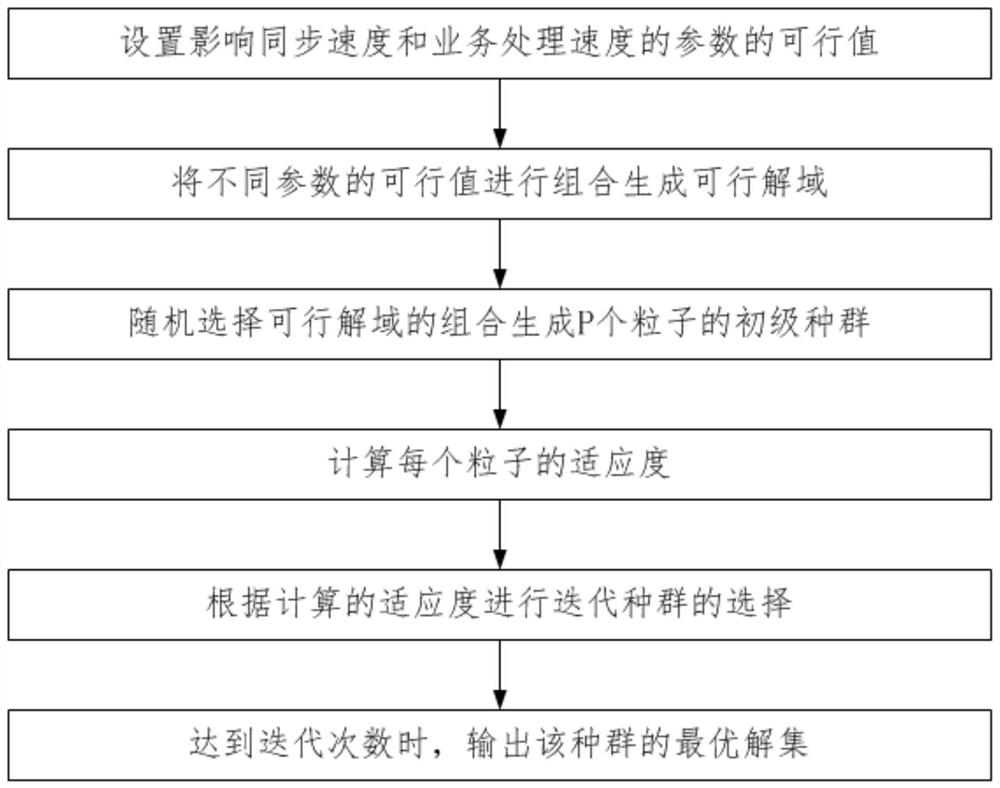

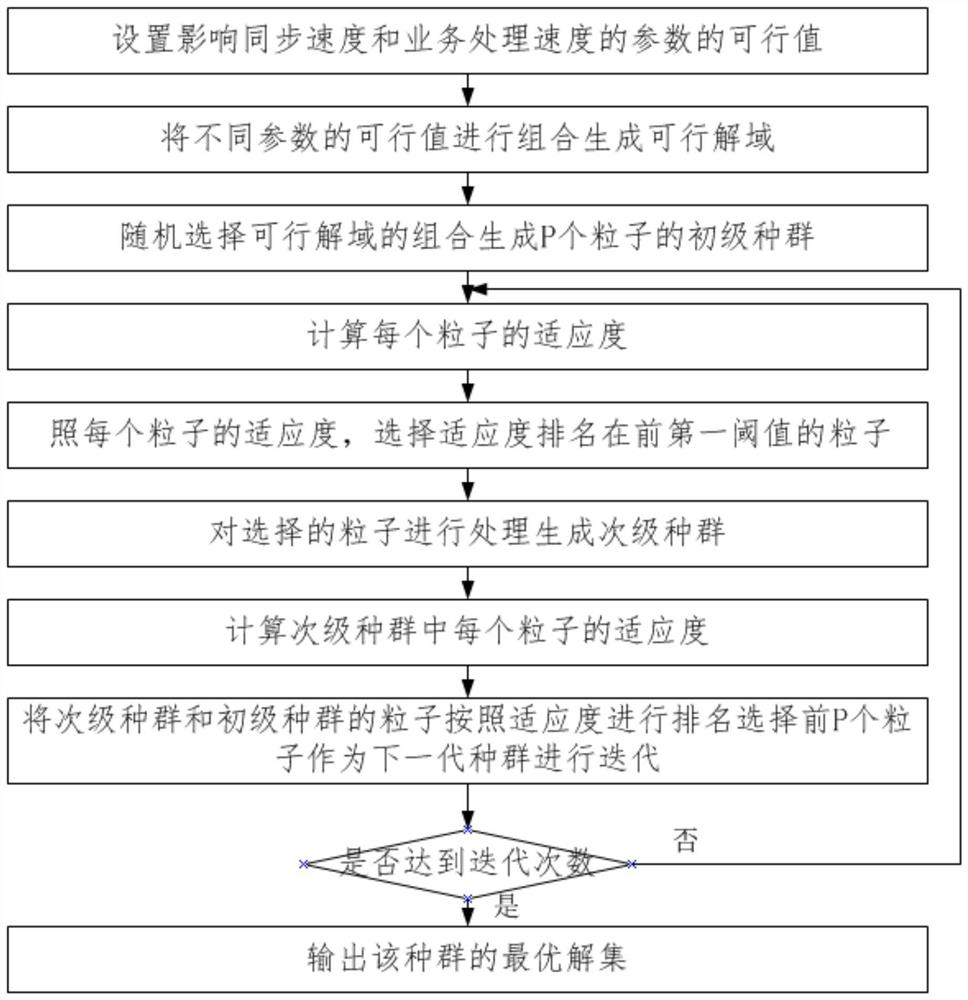

Distributed storage multi-site synchronization optimization method and device, equipment and storage medium

ActiveCN114153397AEfficiently handle optimization problemsSpeed coordinationInput/output to record carriersDistributed computingIndustrial engineering

The invention belongs to the technical field of distributed storage multi-target parameter optimization, and particularly provides a distributed storage multi-site synchronous optimization method and device, equipment and a storage medium, and the method comprises the following steps: selecting optimized parameters, calculating the fitness according to the selected optimized parameters, taking the multi-site fitness as an optimization target, and optimizing the multi-site parameters according to the optimization target; a distributed storage multi-site synchronous optimization problem is converted into a multi-objective problem, and a multi-objective evolutionary algorithm is adopted to solve an optimal configuration parameter. The optimization problem of multi-site synchronization can be effectively solved, the optimal configuration parameters are obtained, and a user can configure the parameters of multi-site synchronization according to the optimal solution sets and actual needs of the user, so that the speed and the service performance of multi-site synchronization are coordinated.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Simple differential gear of subsidiary mechanism of bottom pasting machine

The invention discloses a bottom pasting machine provided with a synchronization control system. A drive gear 1 is connected with a differential mechanism 2 which is connected with a subsidiary mechanism; the differential 2 comprises a planetary gear 21, a sun wheel 22, an auxiliary mechanism gear 23, an adjust bevel gear 24 and an adjust bevel gear 25; the drive gear 1 is engaged with the planetary gear 21 which is engaged with the sun wheel 22; the sun wheel 22 is engaged with the auxiliary mechanism gear 23; and the adjust bevel gear 24 is engaged with the adjust bevel gear 25. When the subsidiary mechanism of the bottom pasting machine is discordant with other mechanisms in speed, the speed of the subsidiary mechanism can be adjusted only by adjusting the adjust bevel gears of the differential mechanism, so that the speed of the subsidiary mechanism of the bottom pasting machine is in accordance with the speeds of other mechanisms.

Owner:张丹丹

Brushless disc double rotor motor

ActiveCN111628621BSpeed/torque differential adjustmentReduce volumeMagnetic circuit rotating partsElectric machinesElectric machineClassical mechanics

The invention discloses a brushless disc type double-rotor motor, which comprises a motor housing, a stator fixedly arranged inside the axial ends of the motor housing, an outer rotor arranged in the motor housing and matched with the stator, and One end of the motor housing is rotatably connected to the outer rotor output shaft fixedly connected to the outer rotor, and the inner rotor arranged in the motor housing and matched with both the stator and the outer rotor is rotatably connected to the other end of the motor housing and connected to the inner rotor. The output shaft of the inner rotor is fixedly connected, and the inverter is electrically connected to the stator. The present invention has the characteristics of a disc-type permanent magnet motor, the stator is fixed on the inner side of the end covers at both ends, the permanent magnet inner rotor is fixed on the inner rotor output shaft to rotate together, the claw pole rotor is located between the two-phase stator and the inner rotor, and They form an electrical angle of 90° to each other, and are fixed on the output shaft of the outer rotor to rotate together. Only a set of two-phase inverters can be used to coordinate the work to realize brushless power feeding and the speed / torque difference between the two shafts. adjust.

Owner:陕西榆林能源集团横山煤电有限公司

Cooling system and control method for permanent magnet synchronous motor for electric vehicle

ActiveCN106240341BSpeed coordinationIntelligent controlElectric machinesCooling/ventillation arrangementPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a permanent magnet synchronous motor cooling system for an electric automobile and a control method thereof. The cooling system comprises a control unit, a motor winding ammeter, a cooling water pump, a cooling water jacket, a cooling water temperature sensor, a cooling liquid flow meter, a heat radiator and a cooling fan. The control method comprises the following steps: judging whether a permanent magnet synchronous motor has a temperature rising trend or a temperature lowering trend under the working condition through detecting current of a motor stator winding, and adjusting a cooling capability of the cooling system so as to realize active adjustment of the cooling system; meanwhile, introducing auxiliary feedback adjustment and inquiring a working point of a motor through a motor efficiency MAP graph, so as to obtain the efficiency of the motor under the corresponding working condition; calculating the heat productivity of the motor; then feeding a difference value of the heat productivity of the motor and a heat radiation amount of the heat radiator back to the control unit, so as to correct the adjustment of the cooling system. The cooling system is subjected to active cooling control before the temperature of the motor is changed; energy sources are saved while a sufficient heat dissipation capability of the motor is guaranteed.

Owner:WUHAN UNIV OF TECH

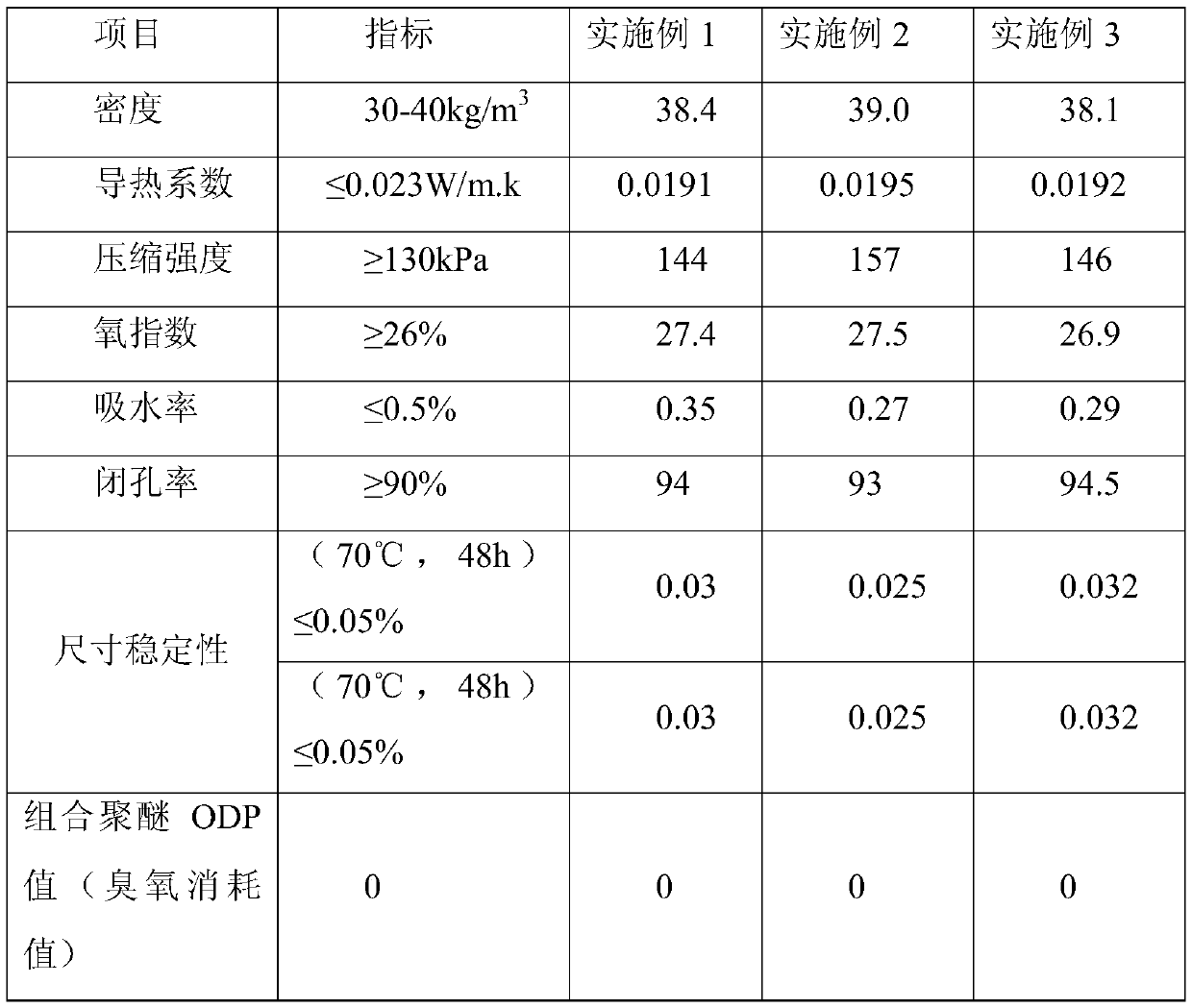

Combined polyether for high flame-retardant water heater water tank and its preparation method and application

The invention belongs to the technical field of polyurethane, and specifically relates to premixed polyols for a high-fire-retardant water tank of a water heater, a preparation method and application thereof. The premixed polyols for the high-fire-retardant water tank of the water heater comprises a component A and a component B, wherein the component A comprises 15-25% by weight of polyether polyol A, 15-25% by weight of polyether polyol B, 10-15% by weight of polyester polyol C, 1-2% by weight of a foam stabilizer, 1-2% by weight of a chemical foaming agent, 1-2.7% by weight of a catalyst, 20-30% by weight of a fire retardant, and 18-25% by weight of a physical foaming agent; the component B is polydiphenyl methane diisocyanate. According to the premixed polyols for the high-fire-retardant water tank of the water heater, the independently-prepared polyether and fire-retardant polyester are matched, and fire retardant is added, so that the obtained polyurethane foam is high strength and high in fire resistance; meanwhile, the product has the characteristics of being high in heat insulation effect, smooth in surface, and free from defects.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

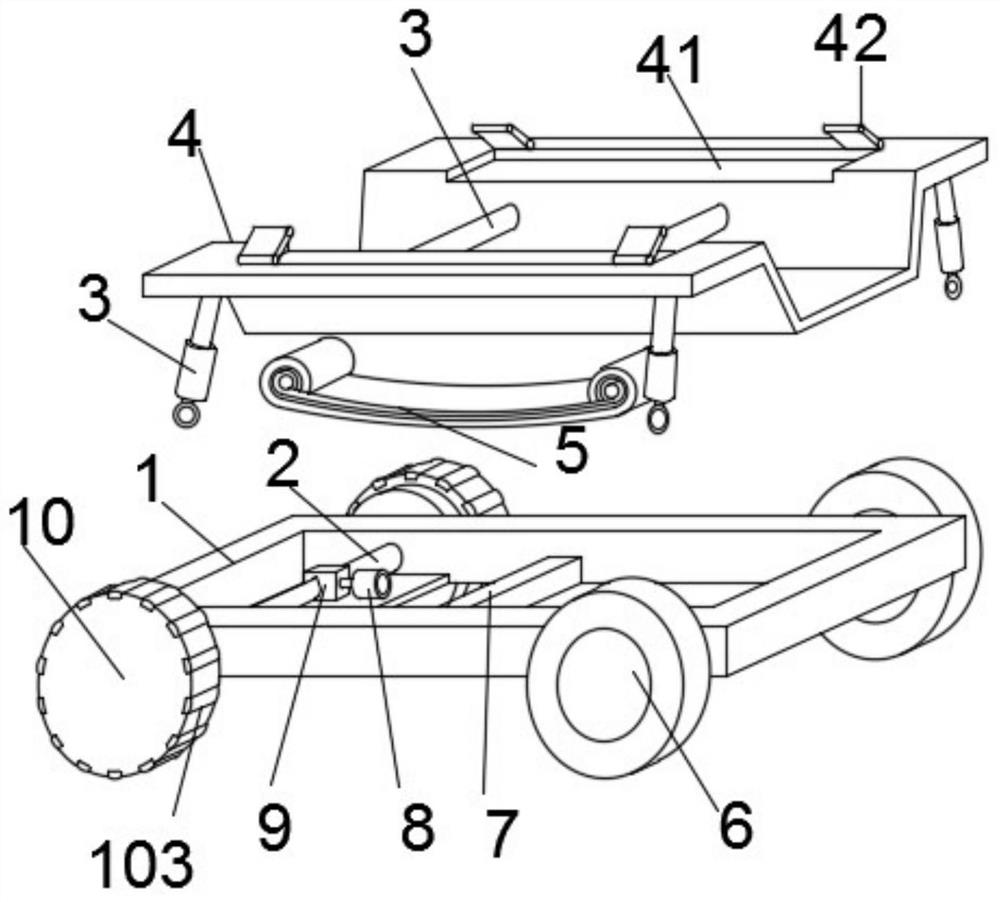

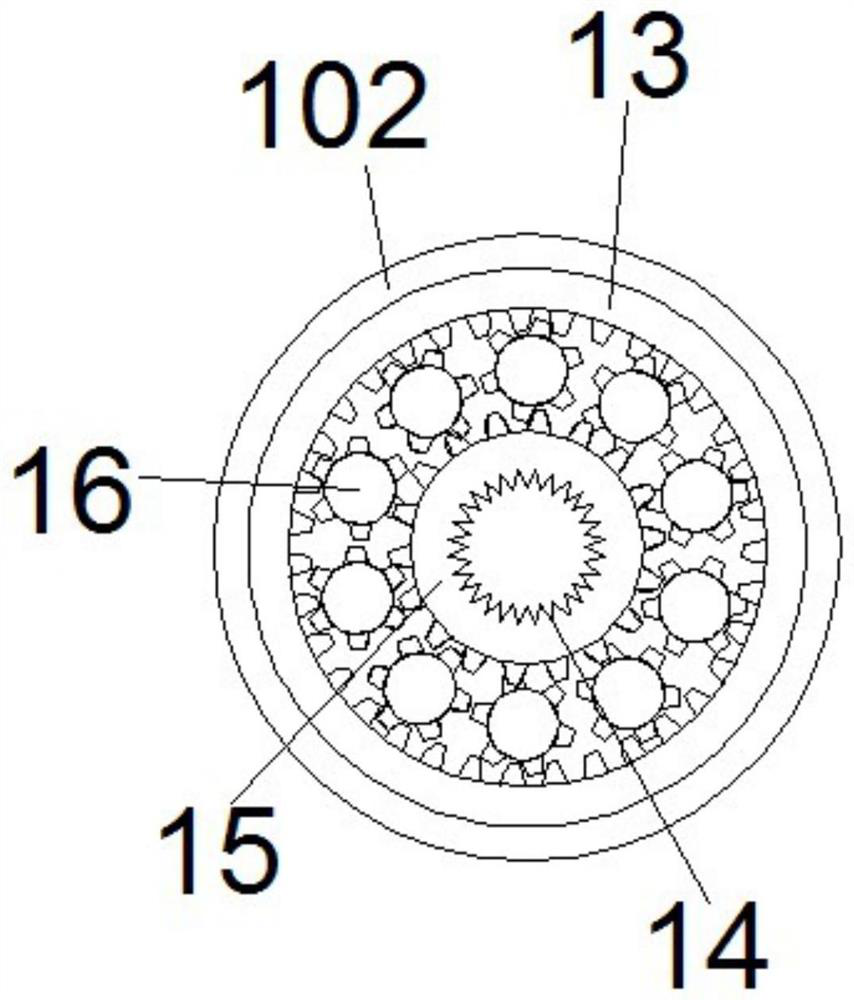

A robot bottom moving mechanism

The invention discloses a bottom moving mechanism of a robot and a method for using the same. It comprises a moving frame and a trapezoidal structure bearing plate with an upper opening. A driving axle is fixedly installed at one end of the inner side of the moving frame. A gear box and a gear box are fixedly installed in the middle of the driving axle. One side of the box is rotated with a motor, and the gearbox is fixedly connected to the driving wheel at one end of the mobile frame through the transmission shaft. Shock absorber A, the other end of the mobile frame rotates through the rotating shaft and is equipped with a driven wheel, the two inner walls of the bearing plate are connected by the shock absorber B, the upper end of the bearing plate is provided with a connecting groove, and by setting the planetary gear, the planetary gear The ring gear acts as the driving shaft, and the planetary gear acts as the follower, its torque is increased, and the speed of the planetary gear is also increased, and the torque and speed are increased at the same time, so that the wheel has both a certain torque and a high speed.

Owner:南京斯杩克机器人技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com