Intelligent high-precision fiber winding machine

A high-precision, fiber-winding machine technology, used in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem of insufficient stability, changing tension on the fiber, and easy to cause breaking or loosening. and other problems, to achieve the effect of alleviating inaccuracy, reducing labor costs, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the specific technical solutions of the present invention will be further elaborated.

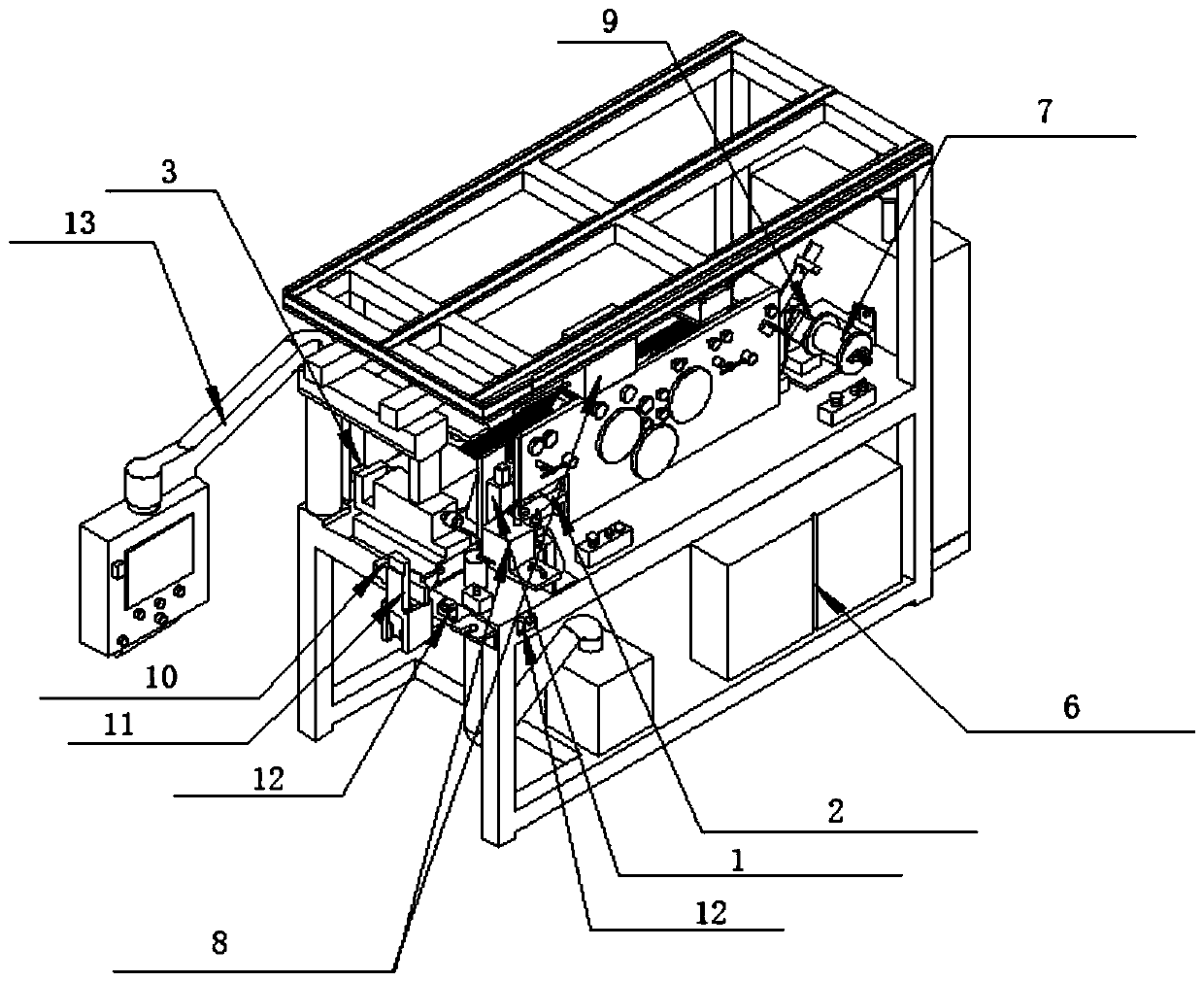

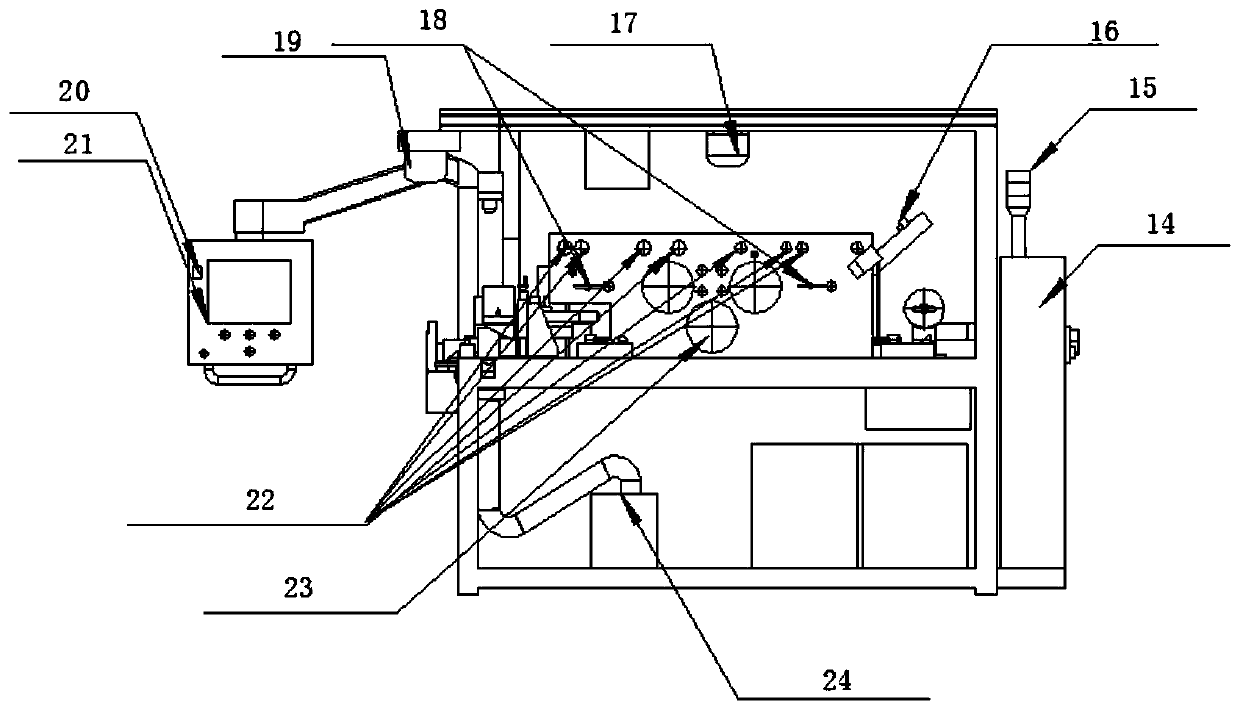

[0029] The invention is a precise and multifunctional intelligent control fiber winding equipment. Such as figure 1 As shown, it mainly includes a touch screen, a control module that is an intelligent control cabinet, a fiber output device, a fiber winding device, and an indicating device. Working mode such as Figure 4 shown.

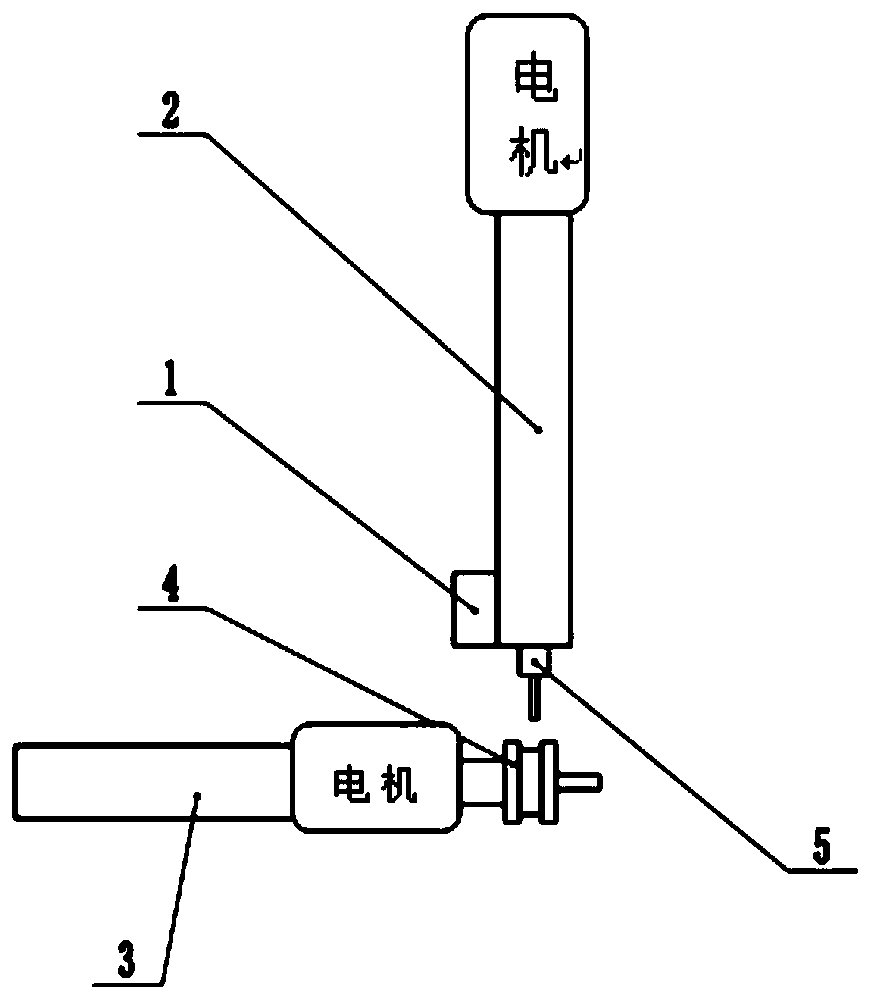

[0030] The fiber winding device includes a fiber winding mandrel 4, and when winding an optical fiber on the mandrel, it usually needs to be wound with a certain width. Compared with ordinary fiber winding machines, the movement of the fiber core shaft during the fiber winding process is not controlled by the movement of the nozzle but by the movement of the core shaft itself. Different fiber movement ratios can be adjusted and the precision is better; image 3 As shown, the fiber winding machine of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com