Machining equipment of steel fiber material

A processing equipment and steel fiber technology, applied in the field of processing equipment for steel fiber materials, can solve the problems of water insolubility, single variety, low production capacity, etc., and achieve the effects of easy stirring, simple and convenient addition, and elimination of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0009] Specific embodiments: The present invention will be further described below in conjunction with the drawings;

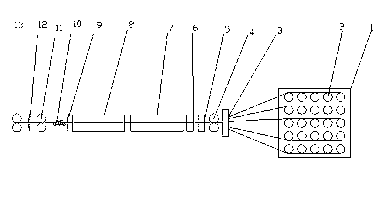

[0010] The processing equipment of steel fiber material includes a gathering device 3, a straightening device 4, and an integration device 5. It is characterized in that a number of steel fiber discs 2 are evenly distributed on the disc rack 1, and each steel fiber disc 2 is The steel fiber thread passes through the gathering device 3, the straightening device 4, the integration device 5, the glue squeegee device 6, the drying device 7, the cooling device 8, the left and right deviation detection device 9, the left and right deviation check device 10, and the power The traction device 11, the front and rear speed difference detection device 12, and the forming and cutting device 13 are processed into grade Ⅲ steel fiber ≥1000MPa; the tray 1 is provided with an alarm; the straightening device 4 is provided with broken wires Alarm; the glue squeegee device 6 is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com