Simple differential gear of subsidiary mechanism of bottom pasting machine

A technology of auxiliary mechanism and differential device, which is applied in the direction of differential transmission device, transmission device, mechanical equipment, etc., and can solve problems such as speed error of auxiliary mechanism and product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

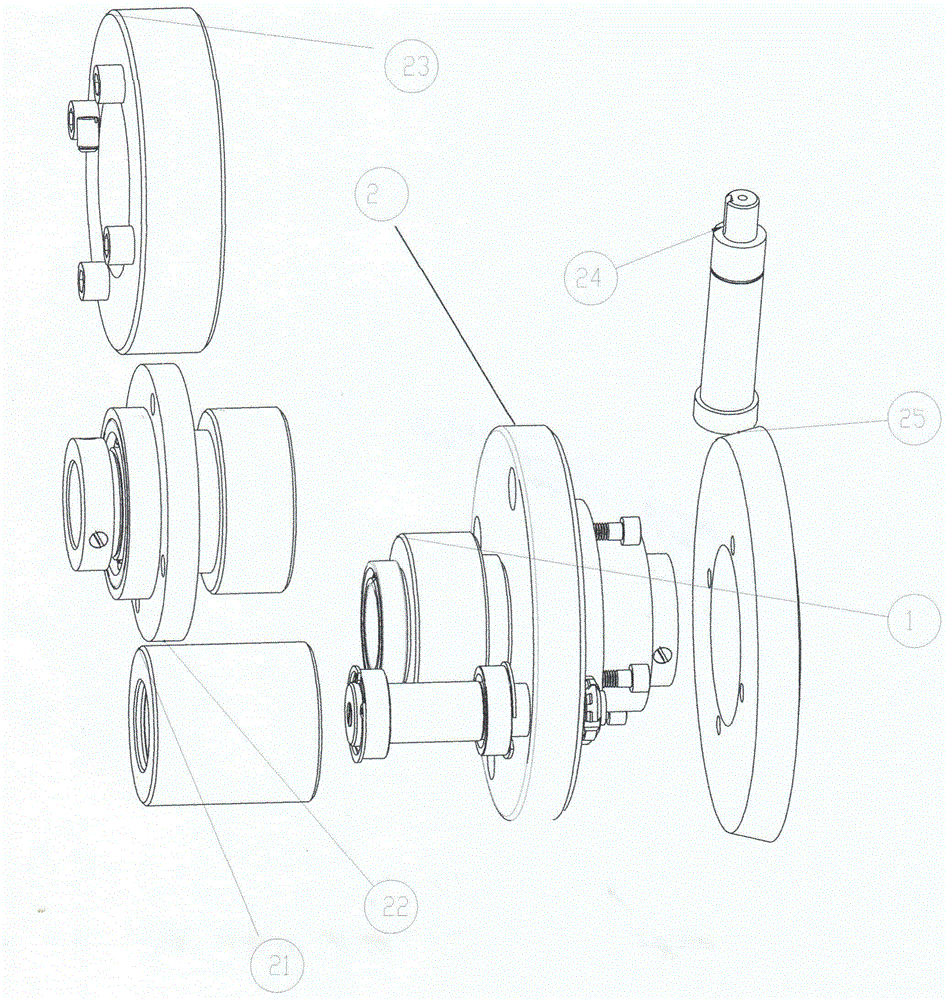

[0008] refer to figure 1 , a differential device for the auxiliary mechanism of the bottom paste machine provided by the present invention, the transmission gear 1 is connected to the differential 2, and the differential 2 is connected to the auxiliary mechanism (not shown in the figure), and the differential 2 includes planetary Gear 21, sun gear 22, auxiliary mechanism gear 23, adjusting bevel gear 24 and adjusting bevel gear 25, the transmission gear 1 meshes with planetary gear 21, planetary gear 21 and sun gear 22 gears, sun gear 22 and auxiliary mechanism gear 23 Mesh, adjust bevel gear 24 and adjust bevel gear 25 mesh.

[0009] When the transmission speed of the subsidiary mechanism (not shown in the figure) is inconsistent with other mechanisms and needs to be adjusted, the bevel gear 24 is rotated, and the bevel gear 25 meshed with the bevel gear 24 moves clockwise or counterclockwise accordingly, so that Manually make the planetary gear 21 generate a relative motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com