Novel paper pasting machine simple in structure and convenient for adjusting differential speed

A technology with a simple structure and a differential mechanism, which can be used in differential transmission, papermaking, mechanical equipment, etc., and can solve problems such as speed error of subordinate equipment and product quality problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

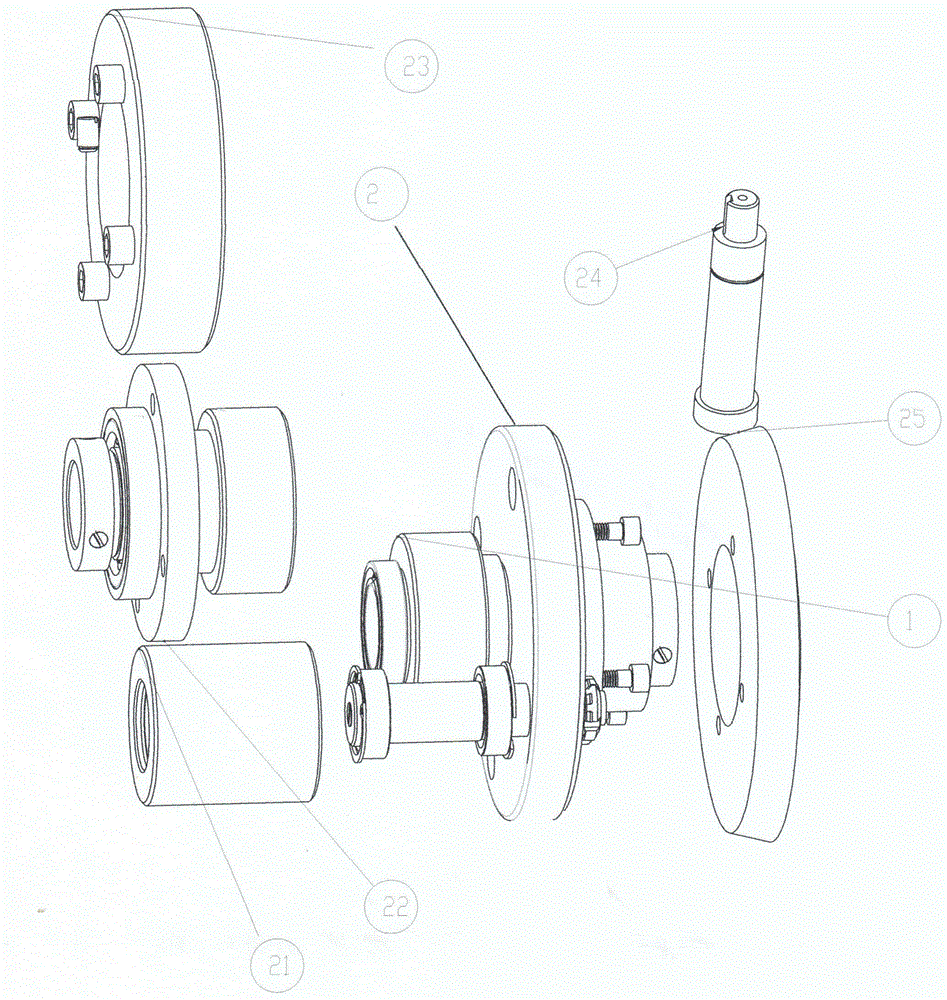

[0008] refer to figure 1 , the present invention provides a new paper gluer with a simple structure and is convenient for adjusting the differential speed. The driving gear 1 is connected to the differential mechanism 2, and the differential mechanism 2 is connected to the slave equipment (not shown in the figure). The differential mechanism 2 includes Driven gear 21, large gear 22, slave gear 23, fine-tuning gear 24 and fine-tuning gear 25, said driving gear 1 meshes with driven gear 21, driven gear 21 and bull gear 22 gears, bull gear 22 and slave equipment The gear 23 meshes, and the fine-tuning gear 24 and the fine-tuning gear 25 mesh.

[0009] When the transmission speed of the slave equipment (not shown in the figure) is inconsistent with other mechanisms and needs to be adjusted, turn the fine-tuning gear 24, and the fine-tuning gear 25 meshing with the fine-tuning gear 24 will move clockwise or counterclockwise accordingly, so that the slave Driven gear 21 produces a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com