Energy-saving servo control system for injection molding machine

A servo control system and servo controller technology, applied in the field of injection molding machine control modules, can solve the problems of general control accuracy and poor energy-saving effect, and achieve the effects of accurate and fast control, elimination of useless power, and easy centralized control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

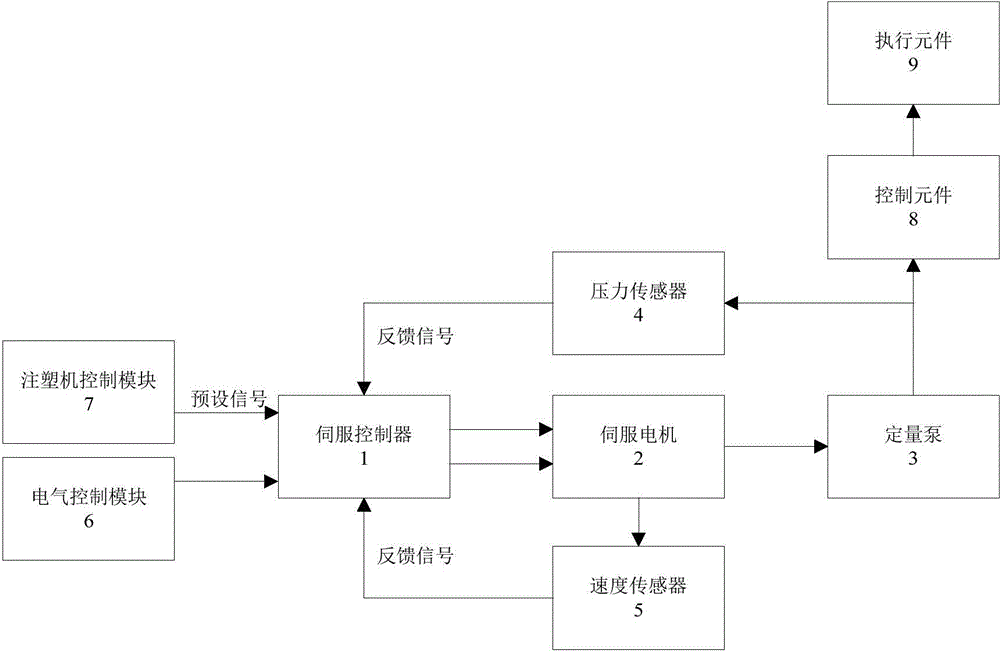

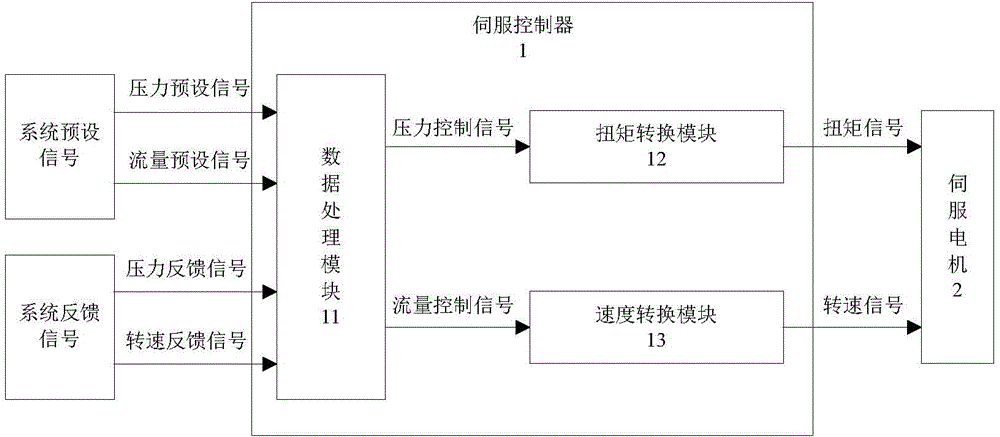

[0028] Such as figure 1 As shown, an energy-saving servo control system for an injection molding machine includes an injection molding machine control module 7, a servo motor 2, a quantitative pump 3, a control element 8 and an actuator 9. The servo motor 2 is connected to the quantitative pump 3, and the quantitative pump 3 is connected to the control element 8. , The control element 8 is connected to the actuator 9, and also includes a servo controller 1, a pressure sensor 4 and a speed sensor 5. The servo controller 1 includes a data processing module 11, a torque conversion module 12 and a speed conversion module 13, and the injection molding machine control module 7 is connected The data processing module 11 and the data processing module 11 are respectively connected to the pressure sensor 4, the speed sensor 5, the torque conversion module 12 and the speed conversion module 13. The torque conversion module 12 and the speed conversion module 13 are respectively connected to...

Embodiment 2

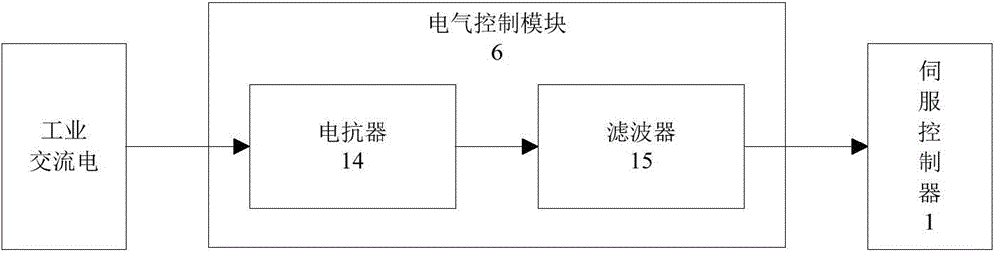

[0038] Compared with the first embodiment, this embodiment further includes an electrical control module 6 which is respectively connected to the industrial AC power supply and the servo controller 1. Such as image 3 As shown, the electrical control module 6 includes a filter 15 and a reactor 14. The filter 15 is connected to the reactor 14 and the servo controller 1 respectively, and the reactor 14 is connected to an industrial AC power supply. The working process is the same as that of the first embodiment, and the electrical control module 6 can suppress the high-order harmonics in the input power supply to eliminate current impact, improve the power factor, and reduce wasteful work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com