Hybrid excitation permanent magnet motor for wireless transmission and tooth harmonic excitation

A wireless transmission and hybrid excitation technology, applied in the field of electric motors, can solve the problems of reducing the reliability of motor operation, difficulty in adjusting the air gap magnetic field, and increasing the maintenance of the motor, so as to achieve the advantages of optimizing the design, improving the reliability and response speed, and improving the structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

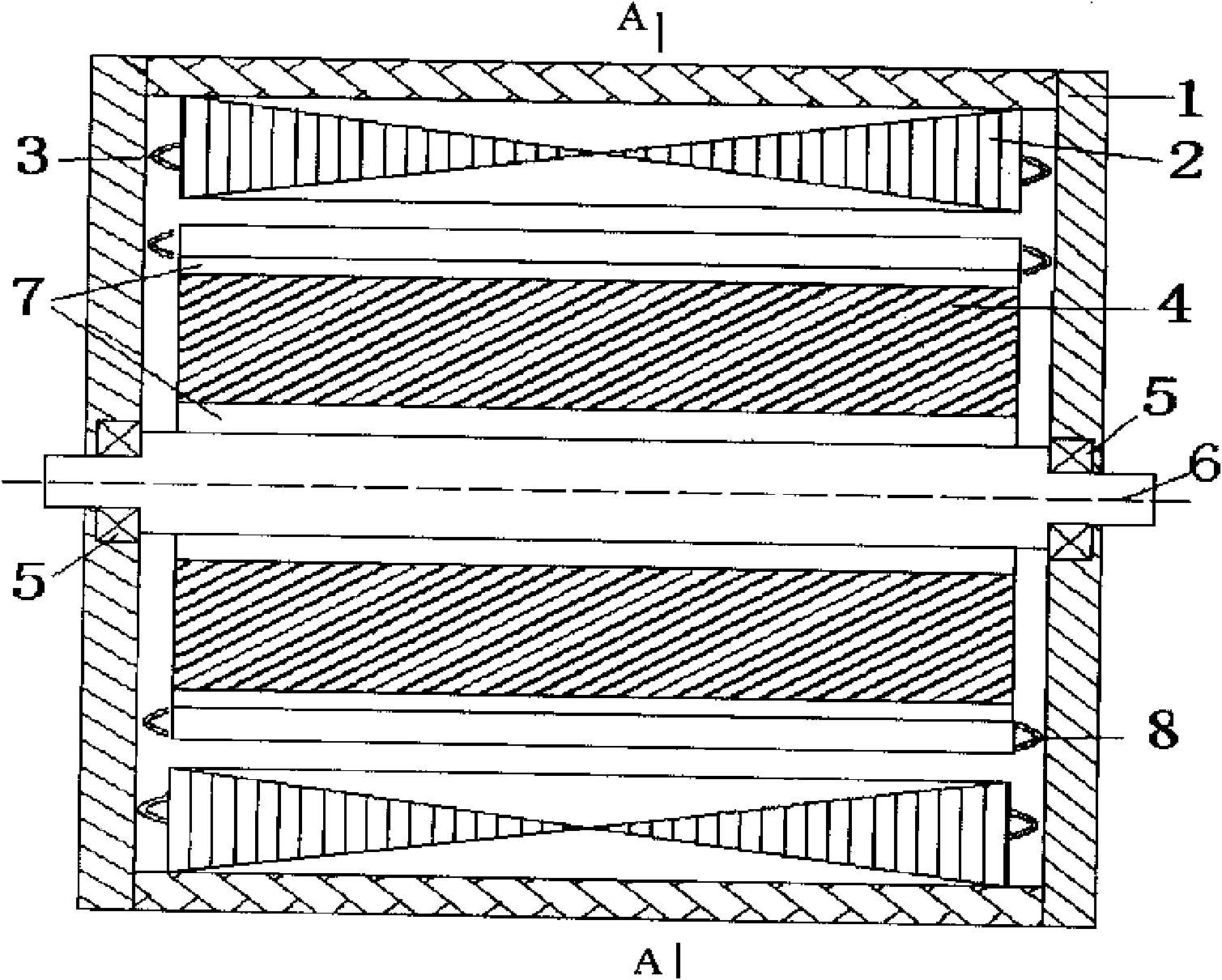

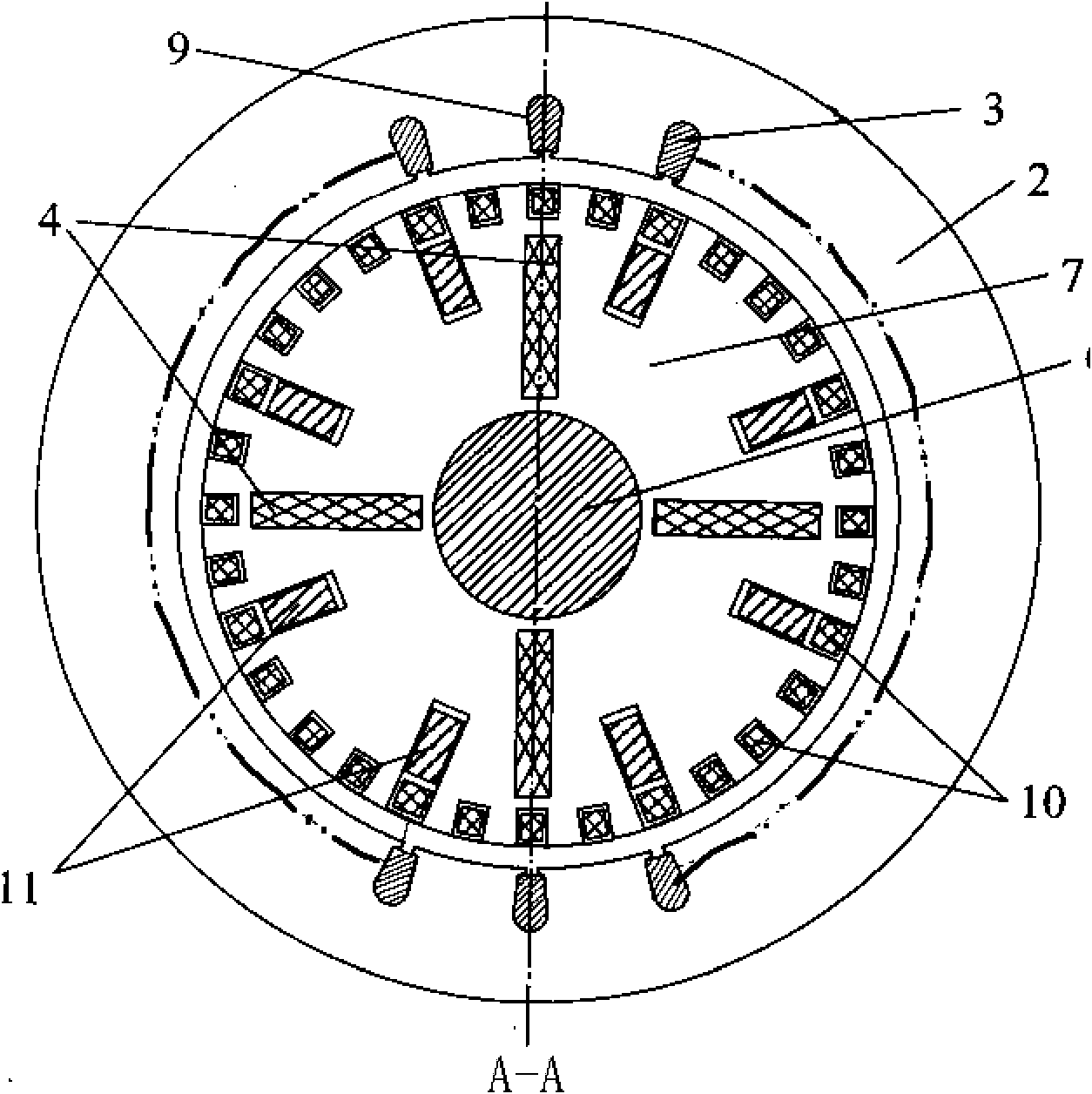

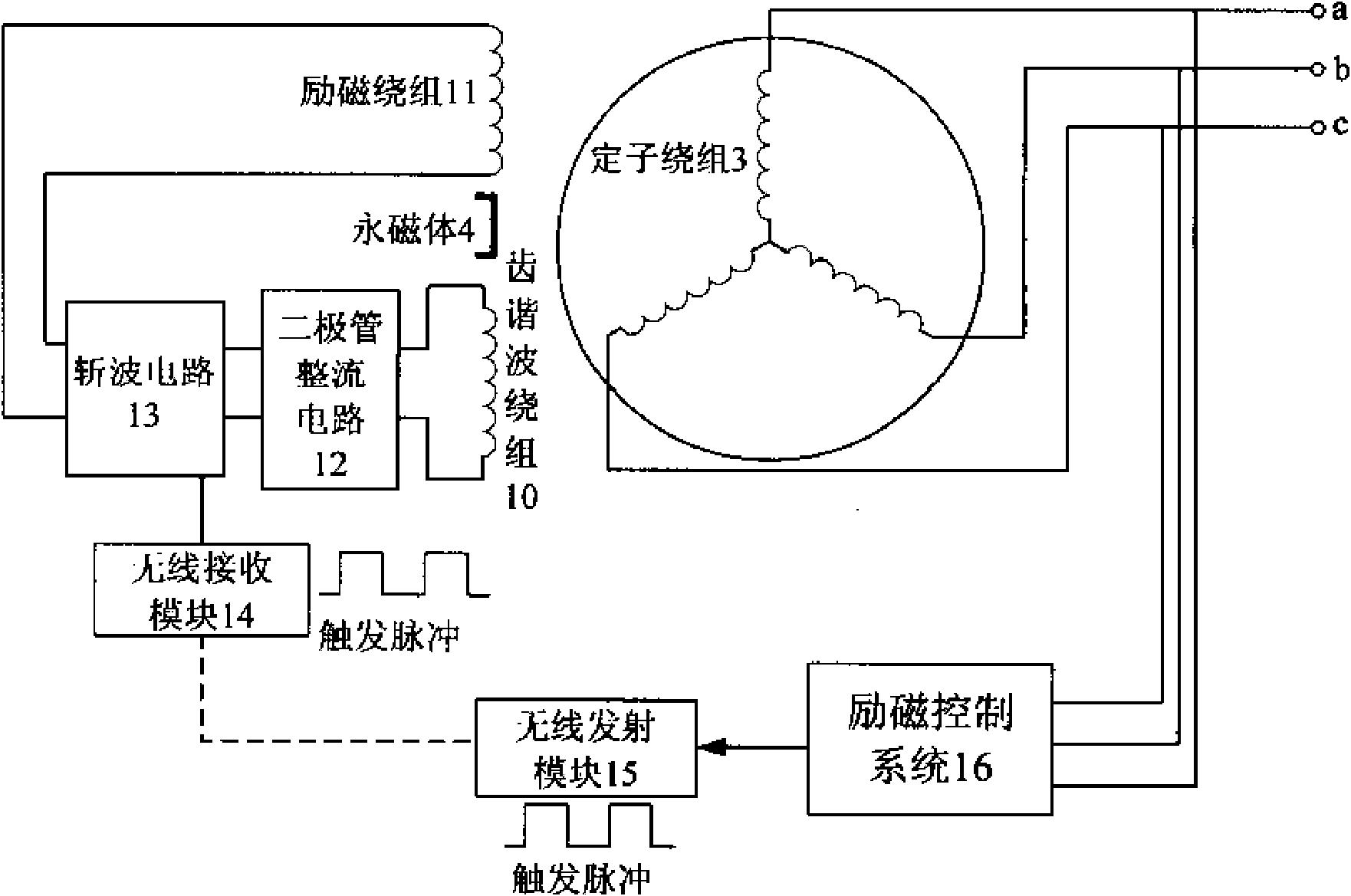

[0027] Depend on figure 1 , 2 , 3 as can be seen, the present invention adopts the hybrid excitation permanent magnet motor of the tooth harmonic excitation of wireless transmission, and stator and rotor are housed in casing 1, and rotating shaft 6 passes through rotor iron core 7 central holes and is fixed with rotor iron core 7; Rotating shaft 6 passes through The bearing 5 is connected with the casing 1; the stator is composed of the stator winding 3 distributed in the groove 9 opened along the circumferential direction on the stator core 2, and the casing 1 and the stator core 2 are fixed. The rotor consists of permanent magnets 4 and rotor windings 8 arranged on the rotor core 7; The rotor tooth harmonic winding 10 and the rotor excitation winding 11 are connected with the chopper circuit 13 through the diode rectifier circuit 12, and the driving signal of the switching device in the chopper circuit 13 is obtained through the wireless receiving module 14; the stator wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com