Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2109results about "Magnetic circuit characterised by magnetic materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

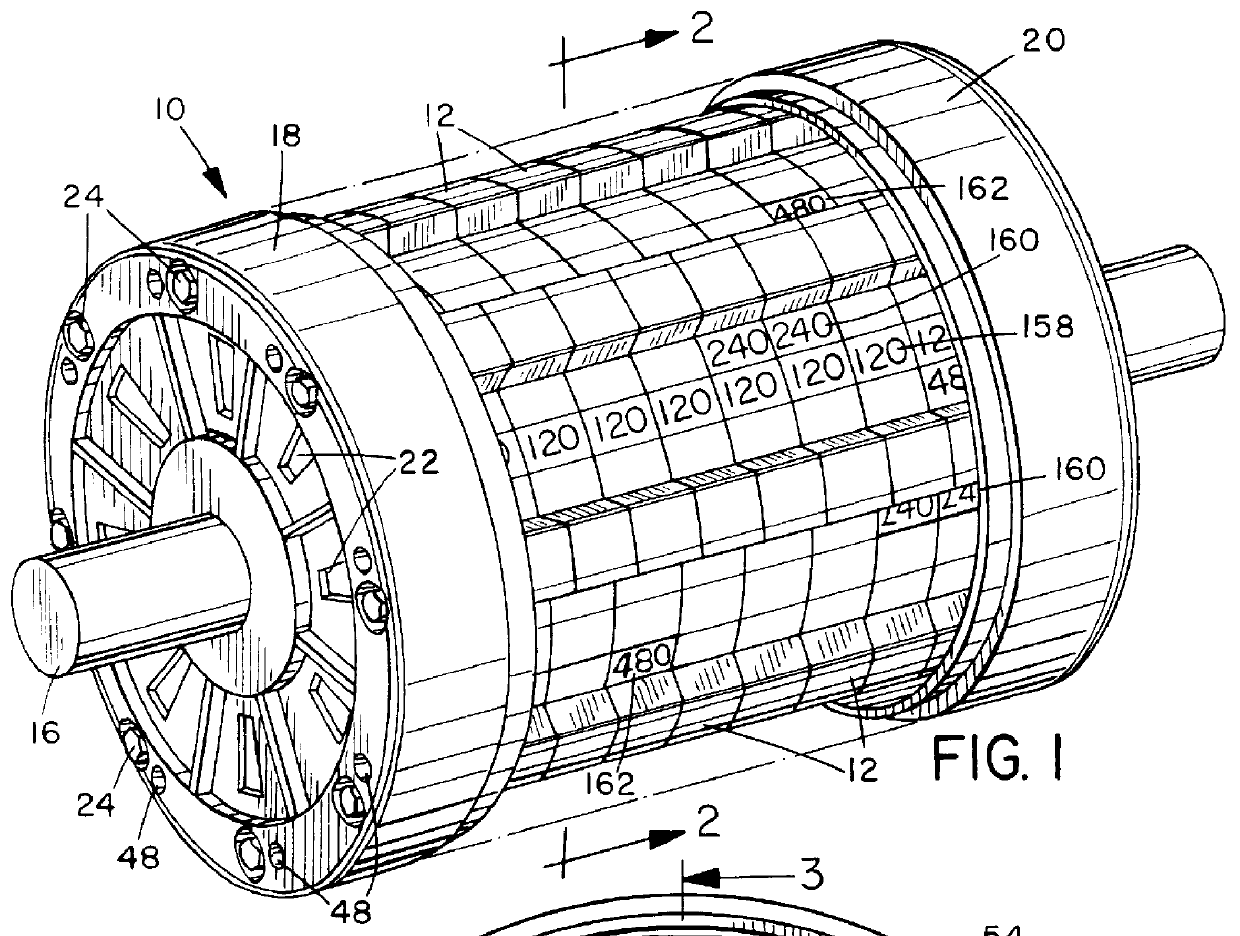

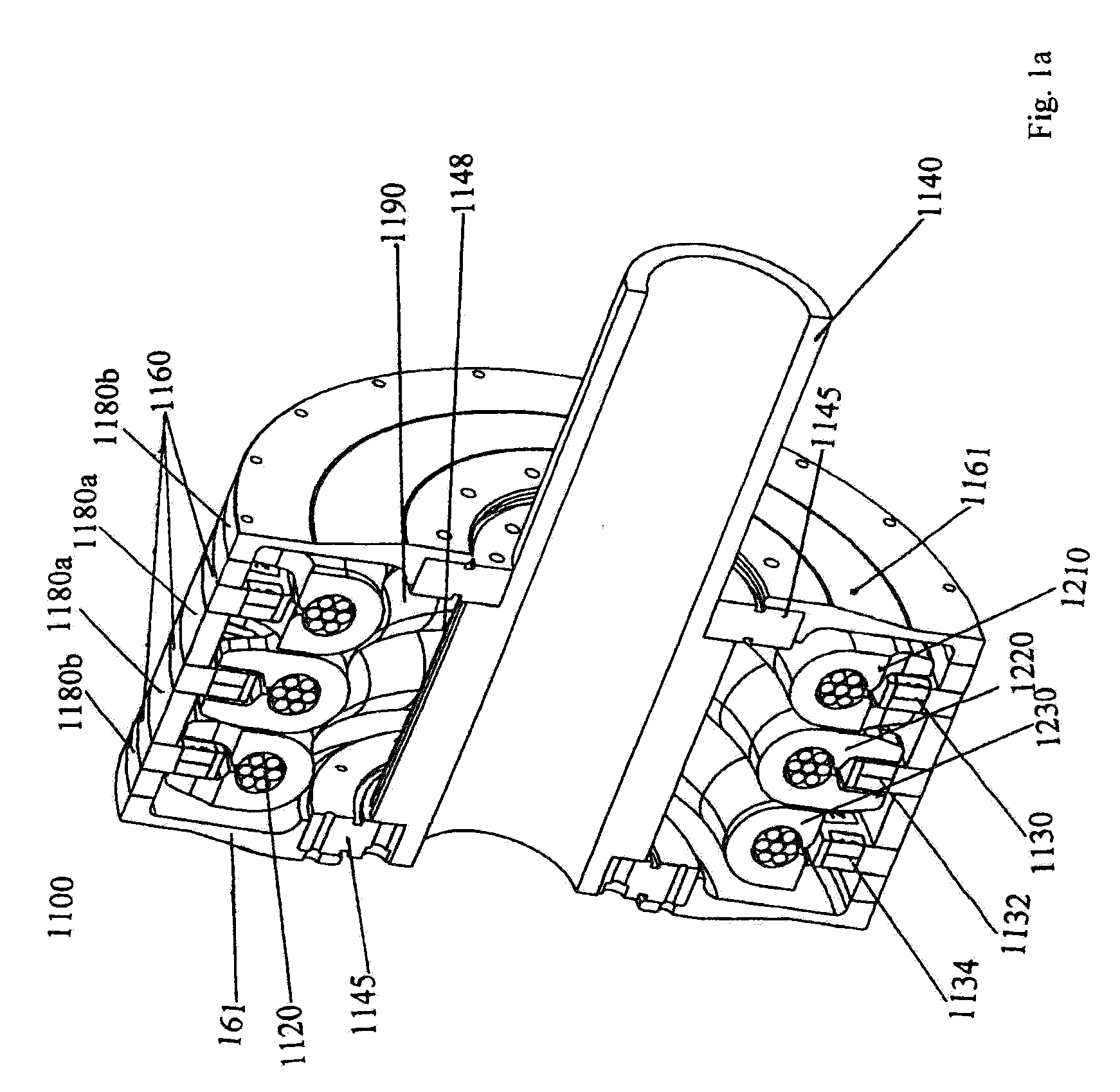

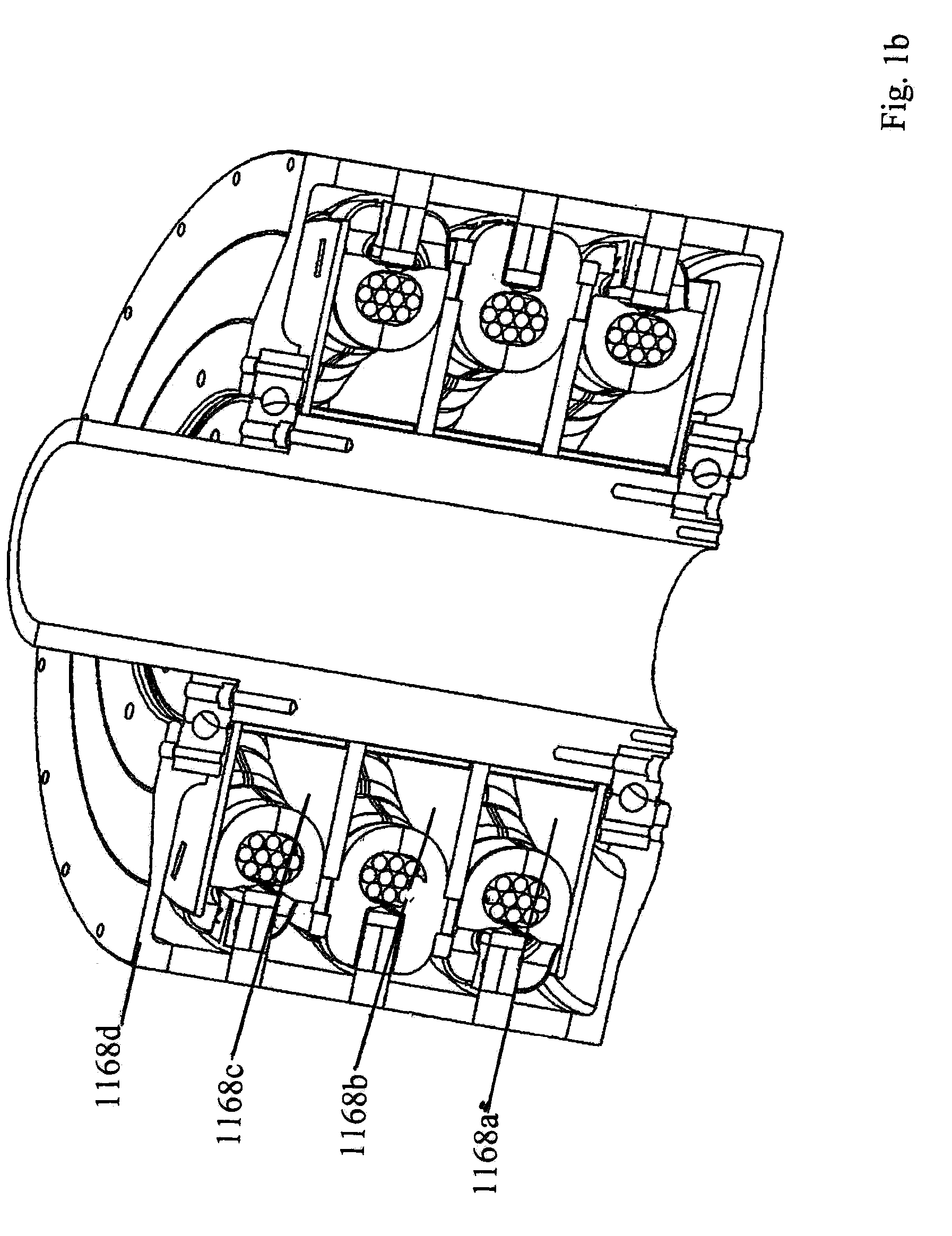

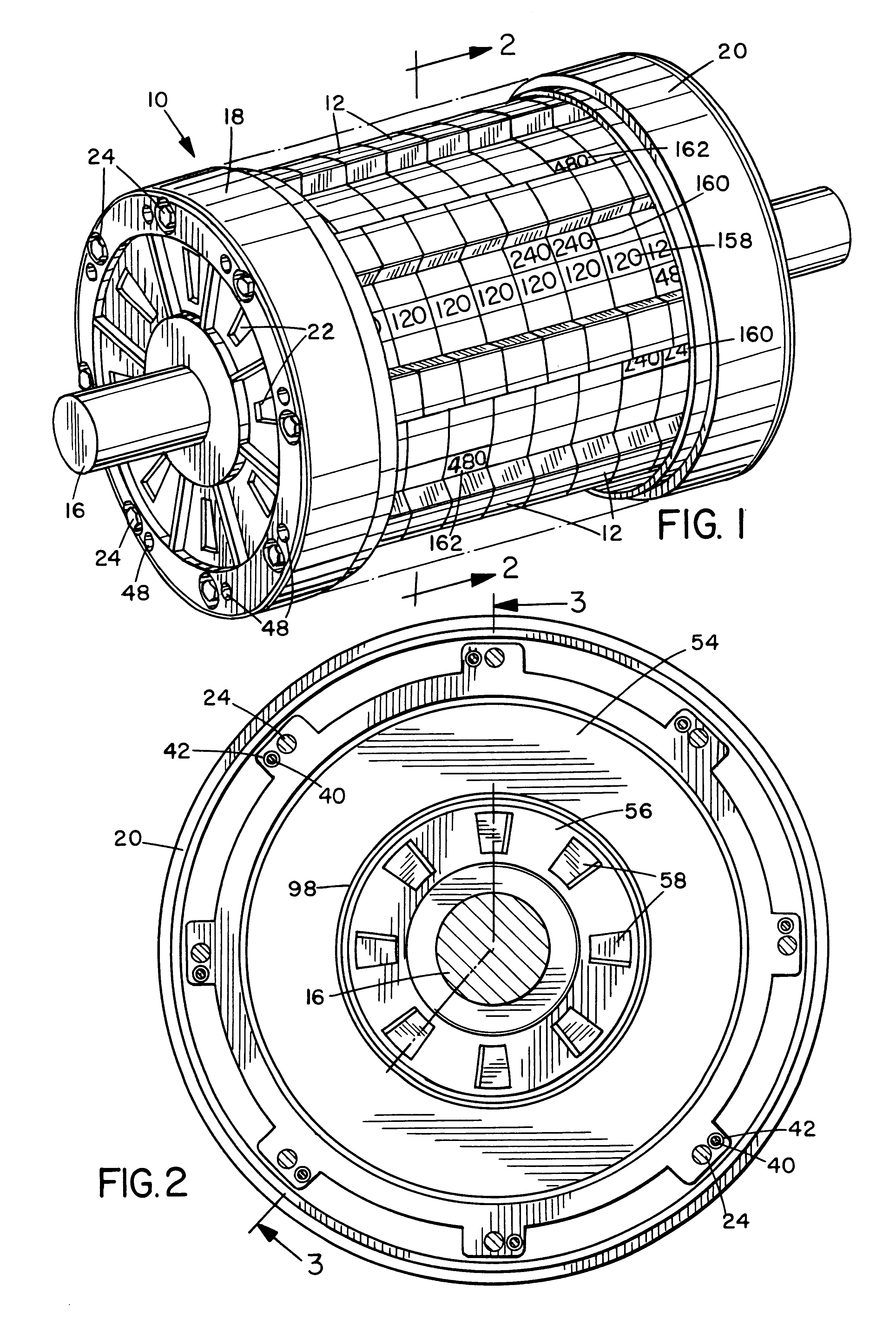

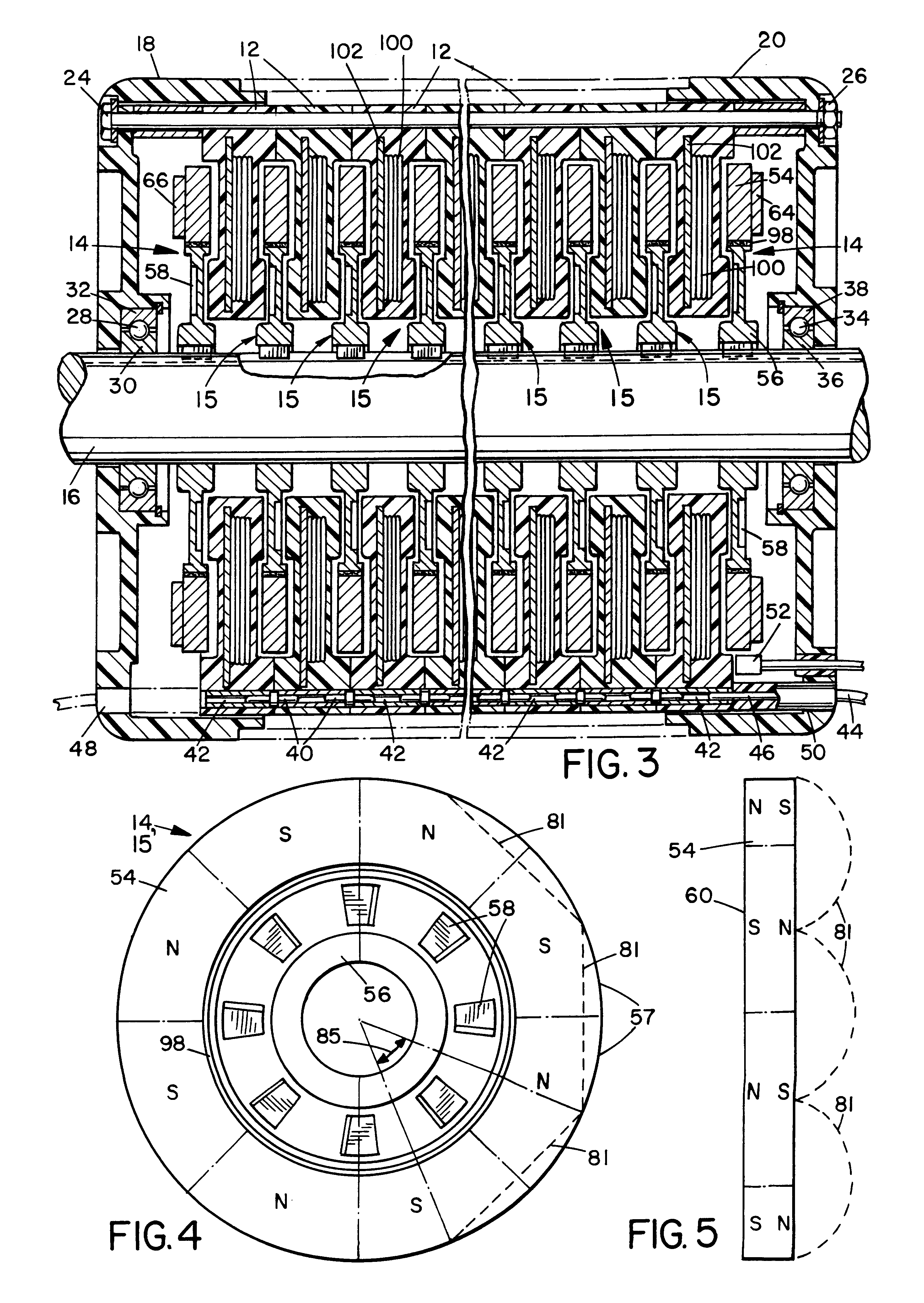

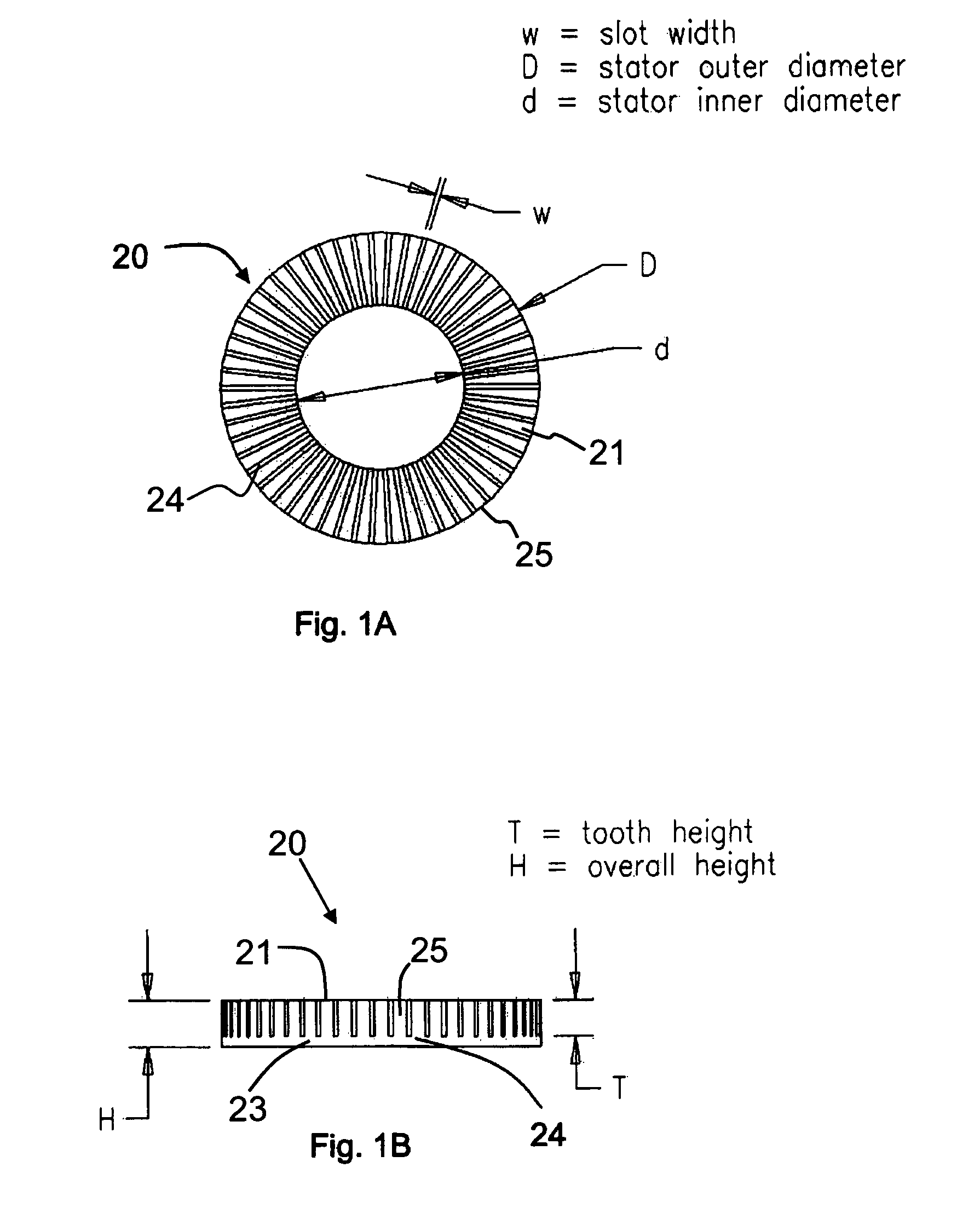

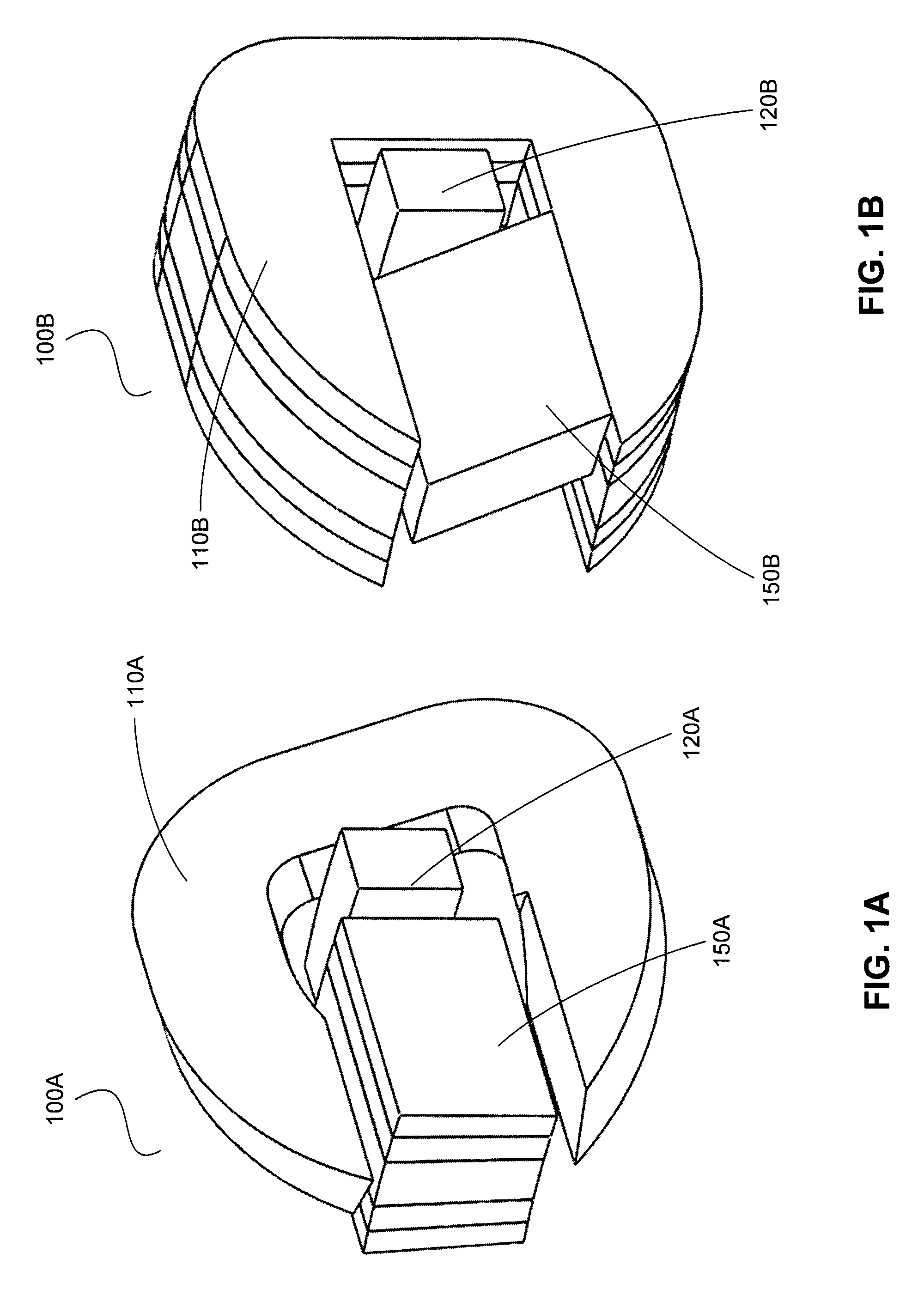

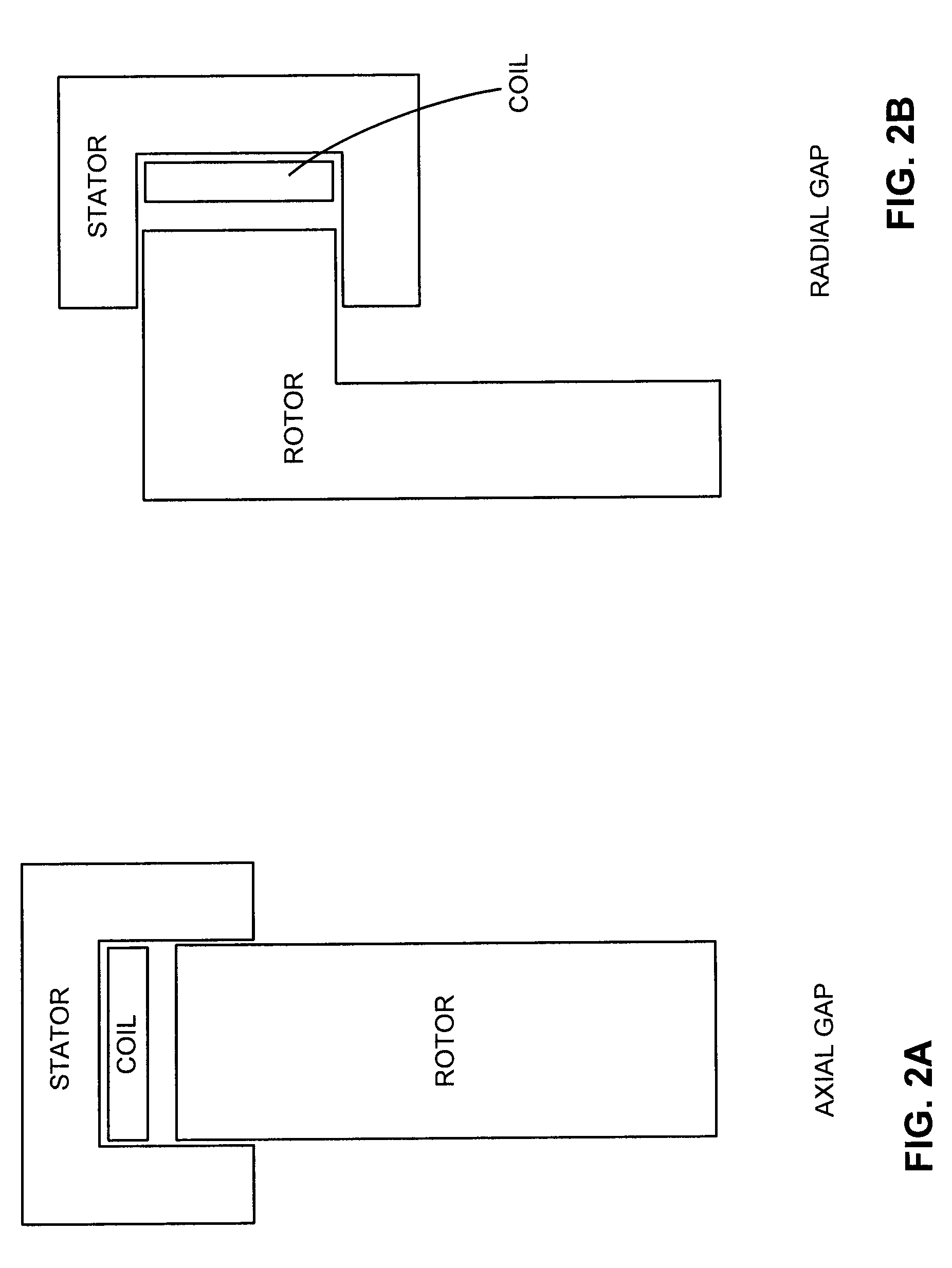

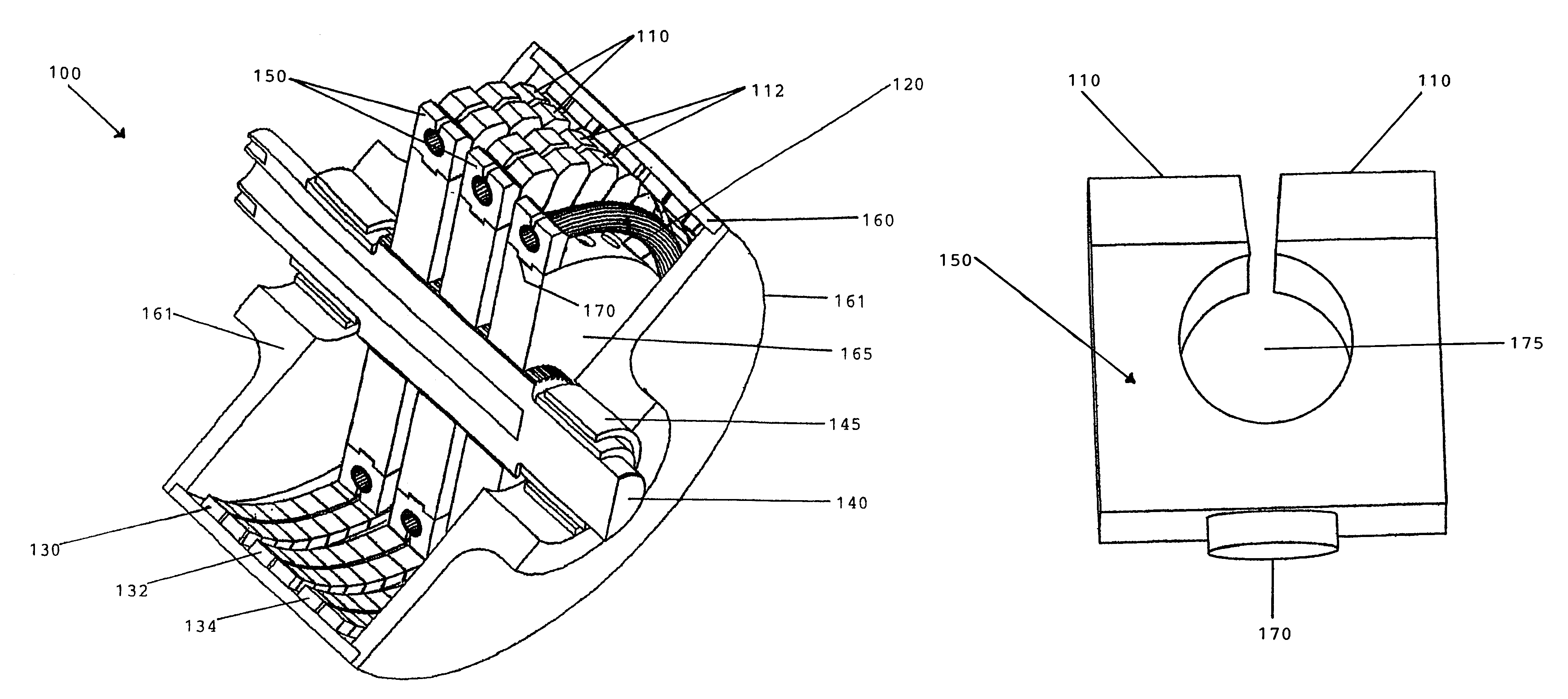

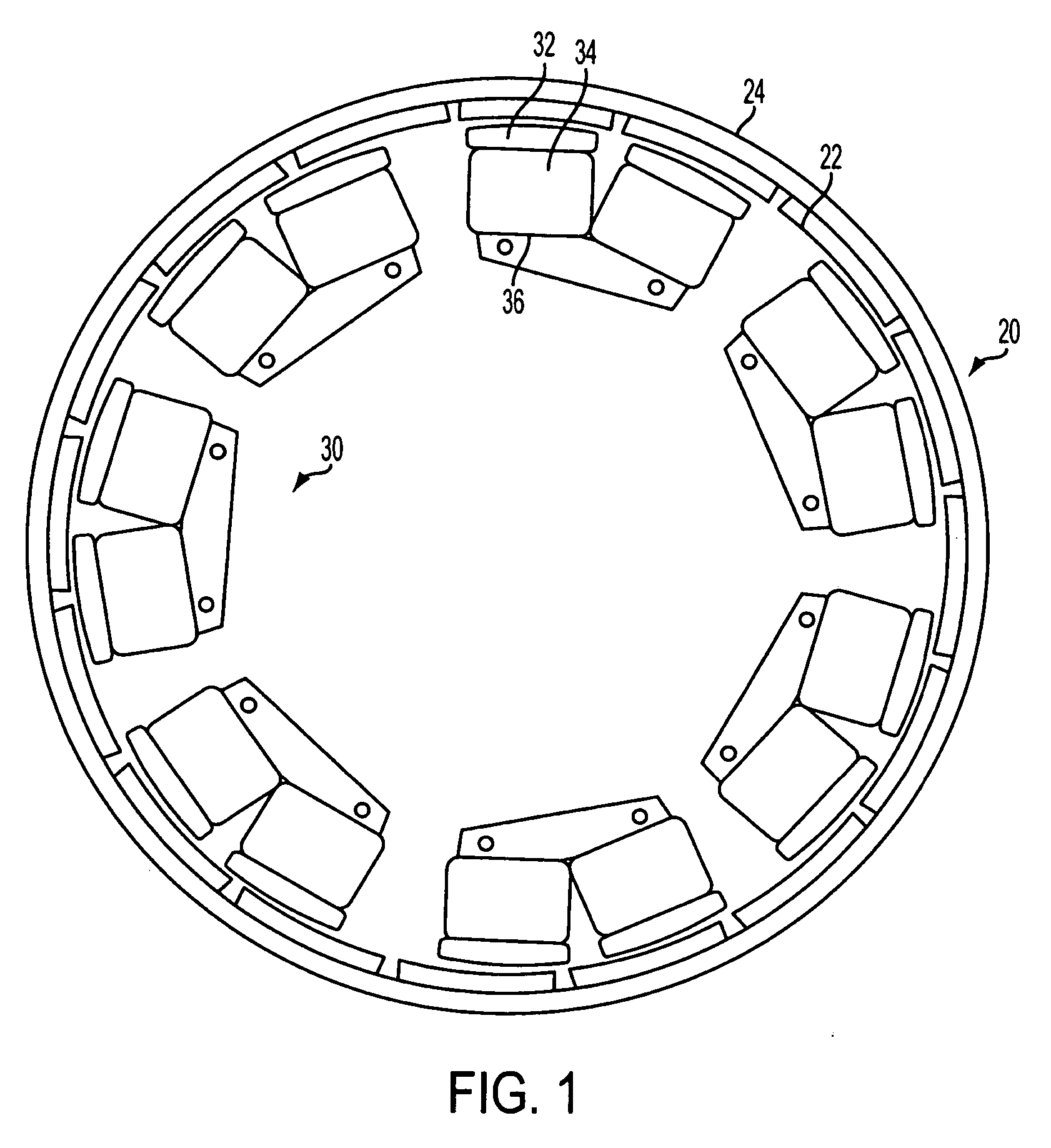

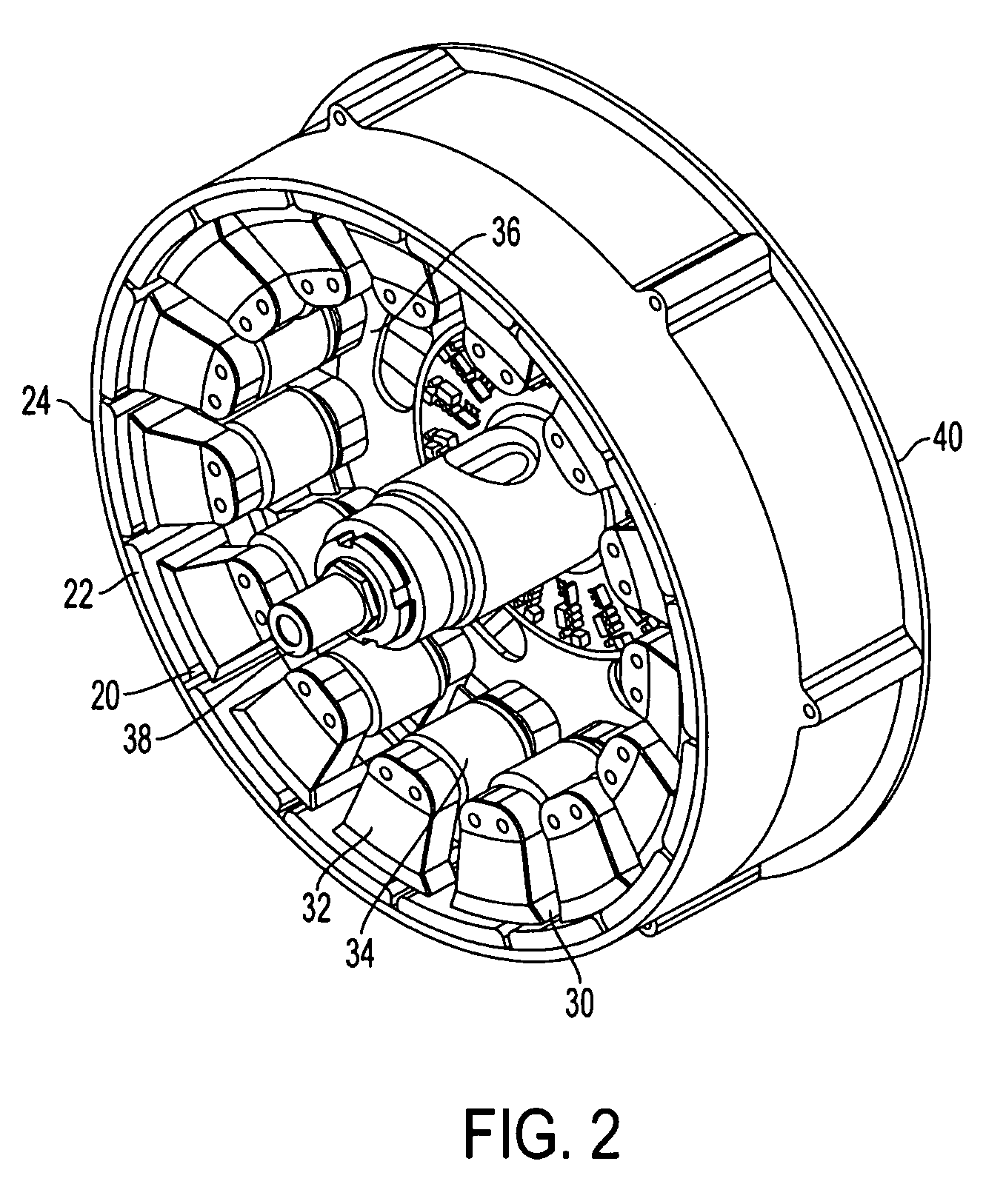

Efficient high-speed electric device using low-loss materials

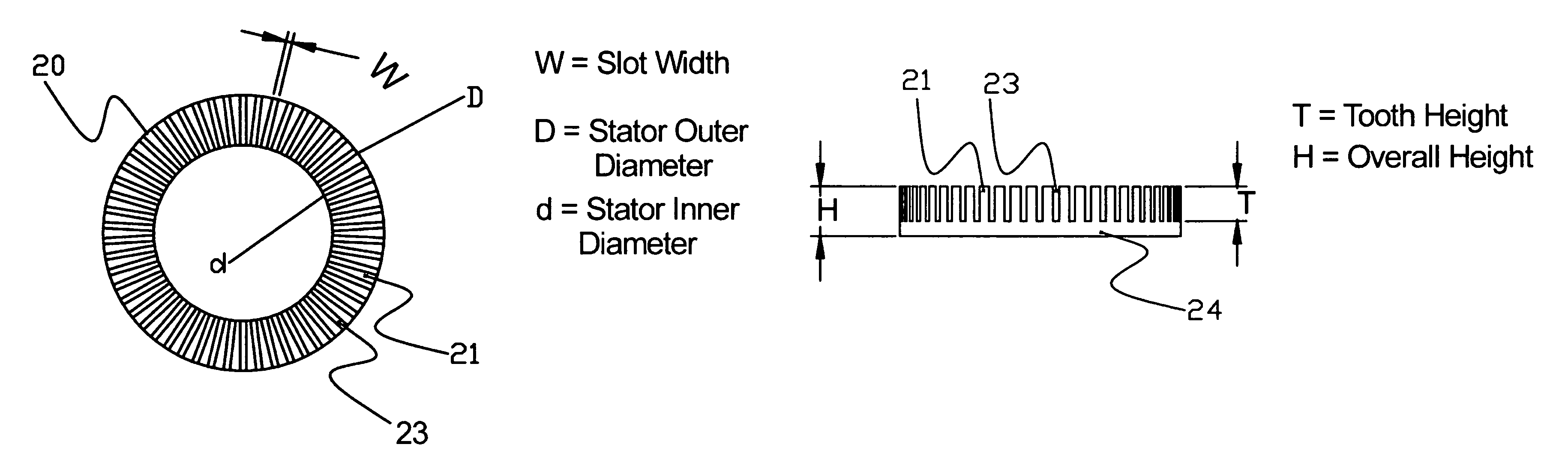

InactiveUS7230361B2Reduce lossHigh frequencyMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringHigh torque

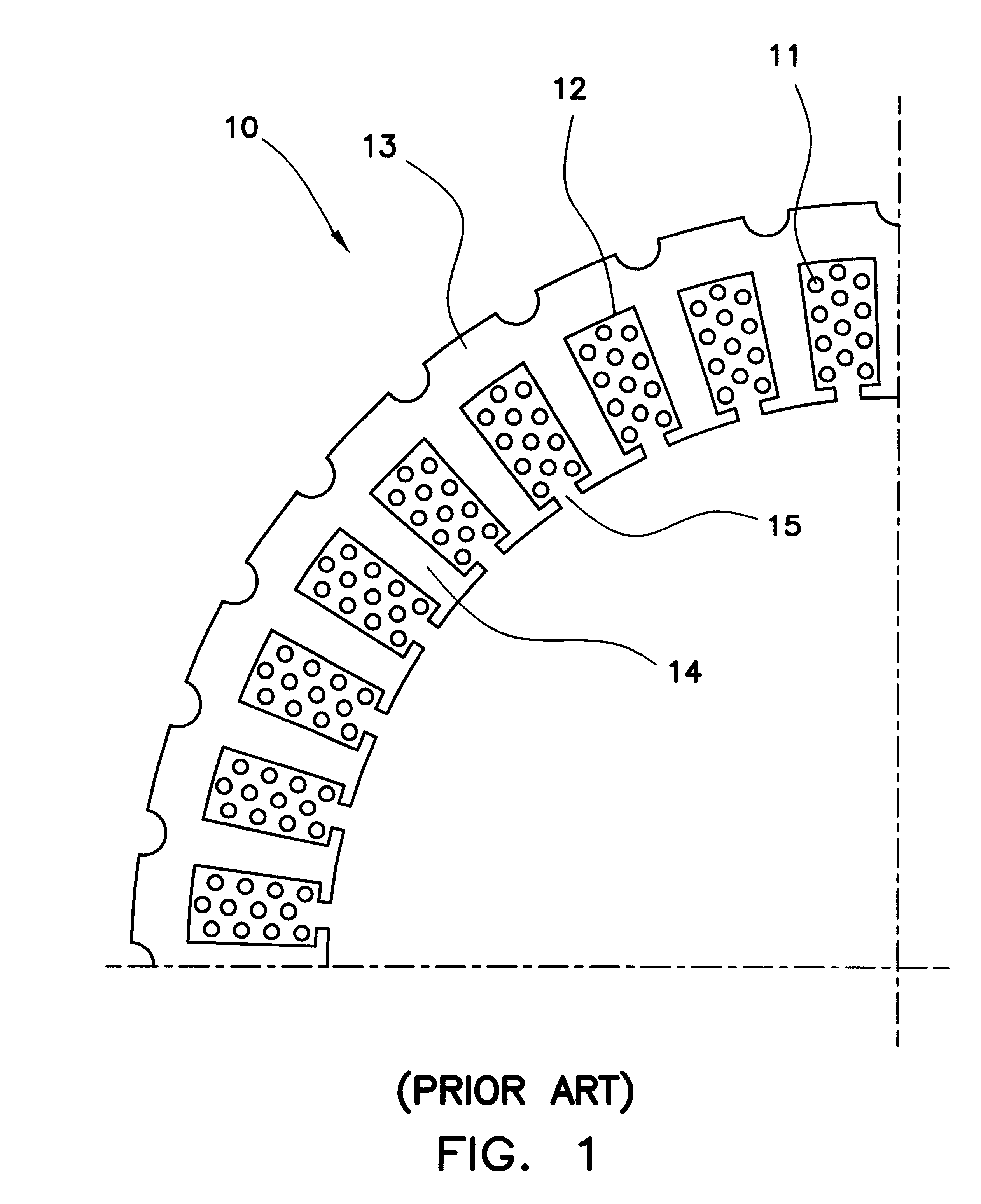

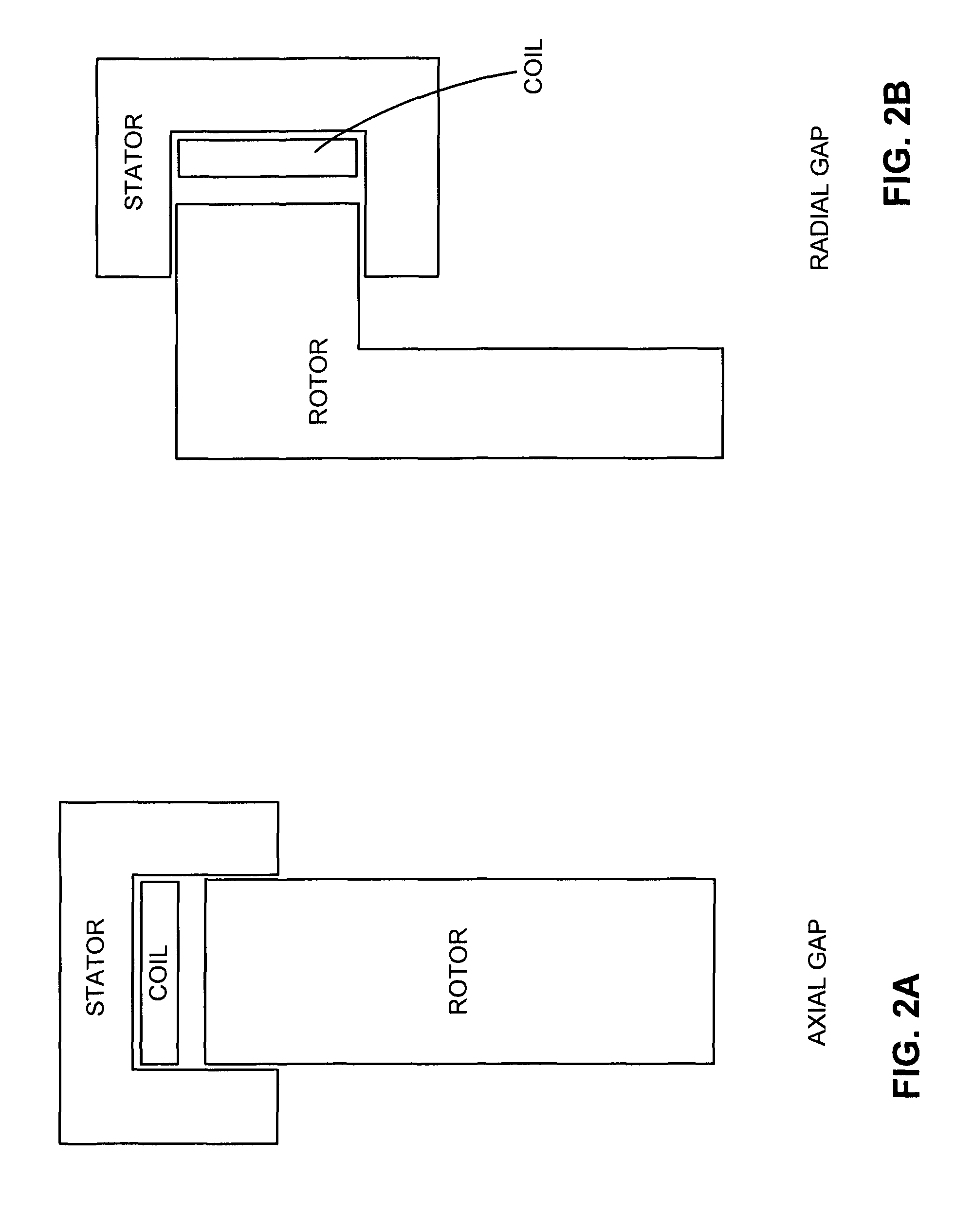

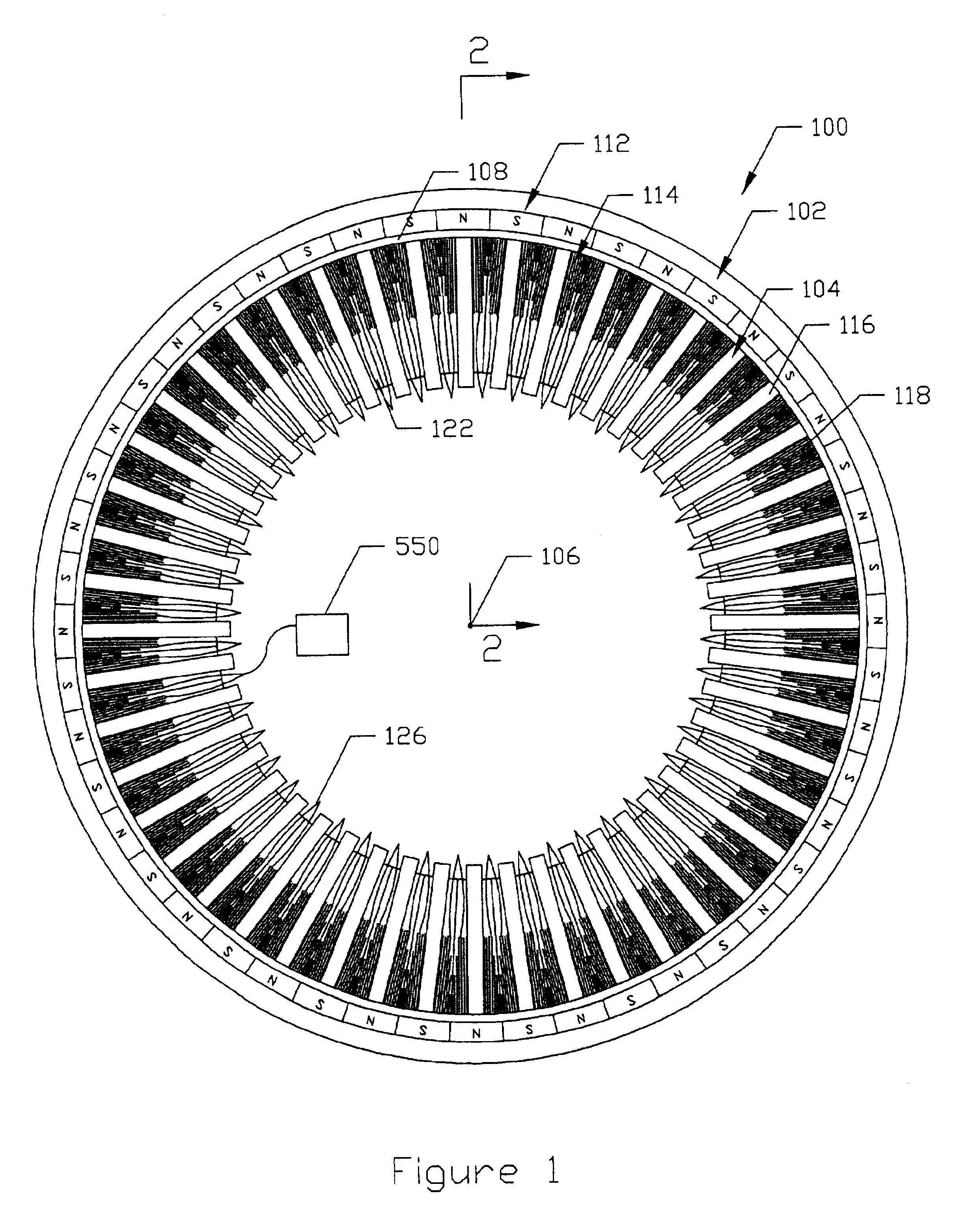

The invention relates generally to an electric device, such as an electric motor, a generator, or a regenerative motor, having a wound stator core made from advanced low-loss material. In preferred embodiments, the electric device is an axial airgap-type configuration. The invention provides an electric device having a high pole count that operates at high commutating frequencies, with high efficiency and high torque and power densities. Advanced low-loss materials exploited by the present invention include amorphous metals, nanocrystalline metals, and optimized Fe-based alloys.

Owner:BERG & BERG ENTERPRISES

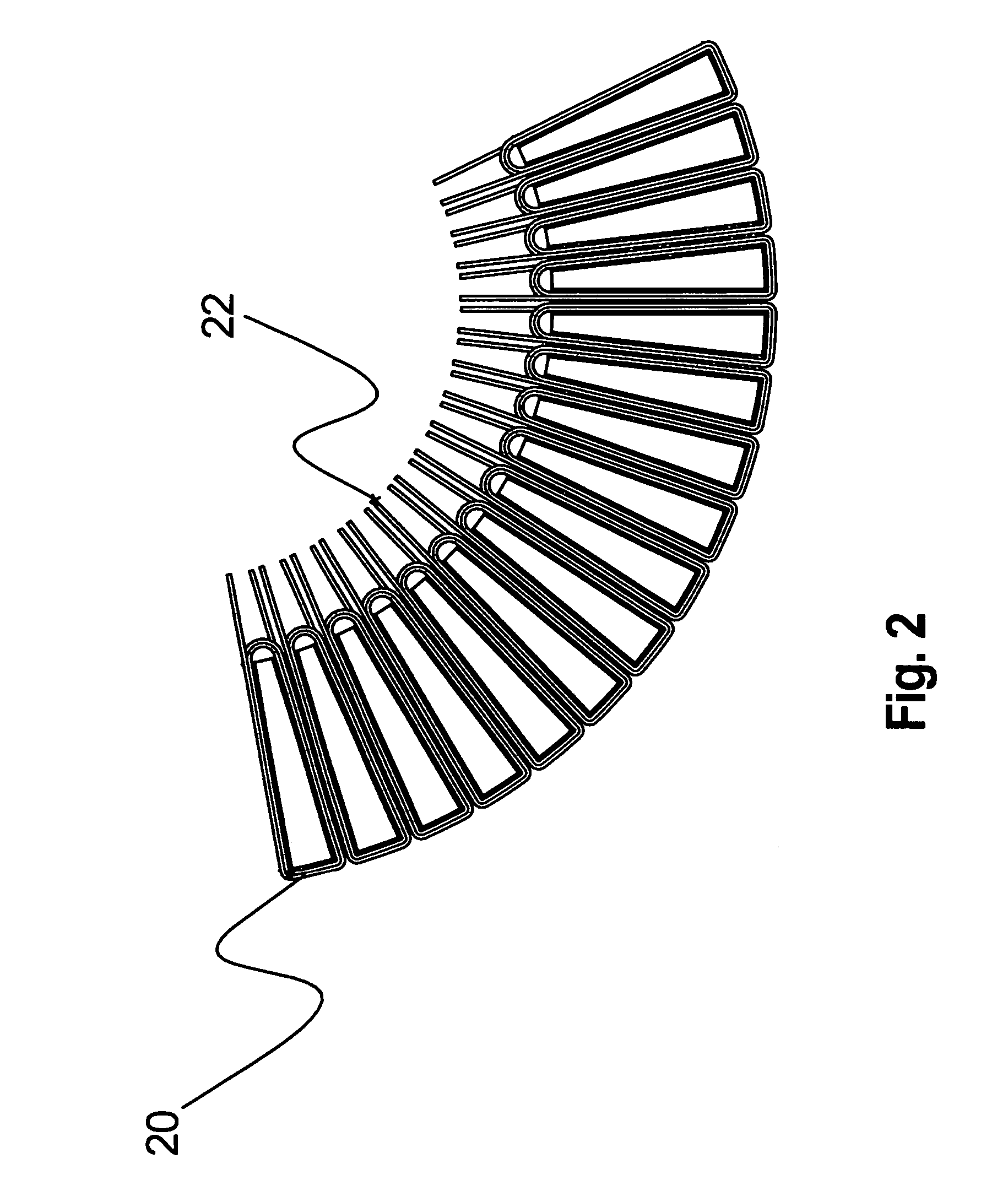

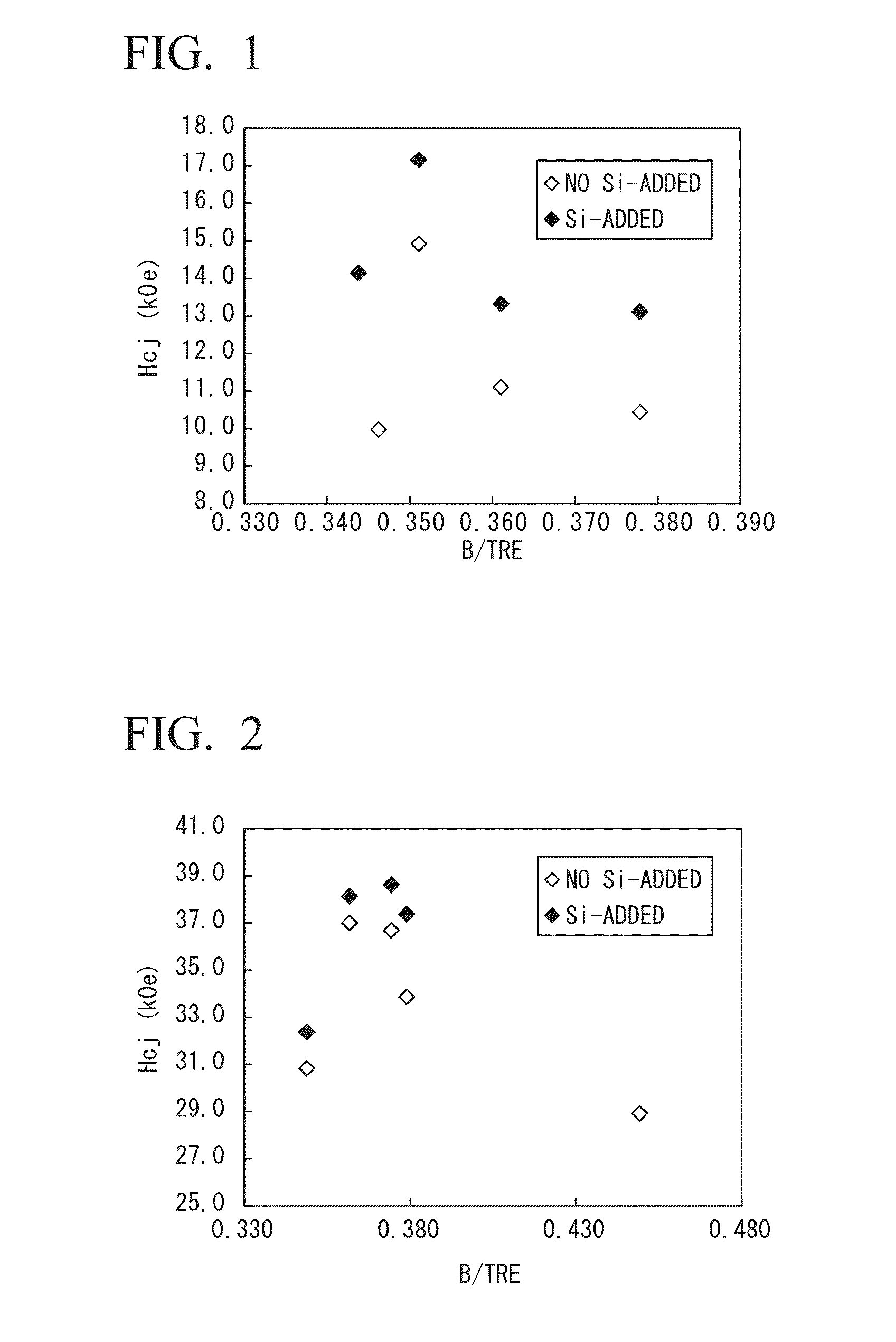

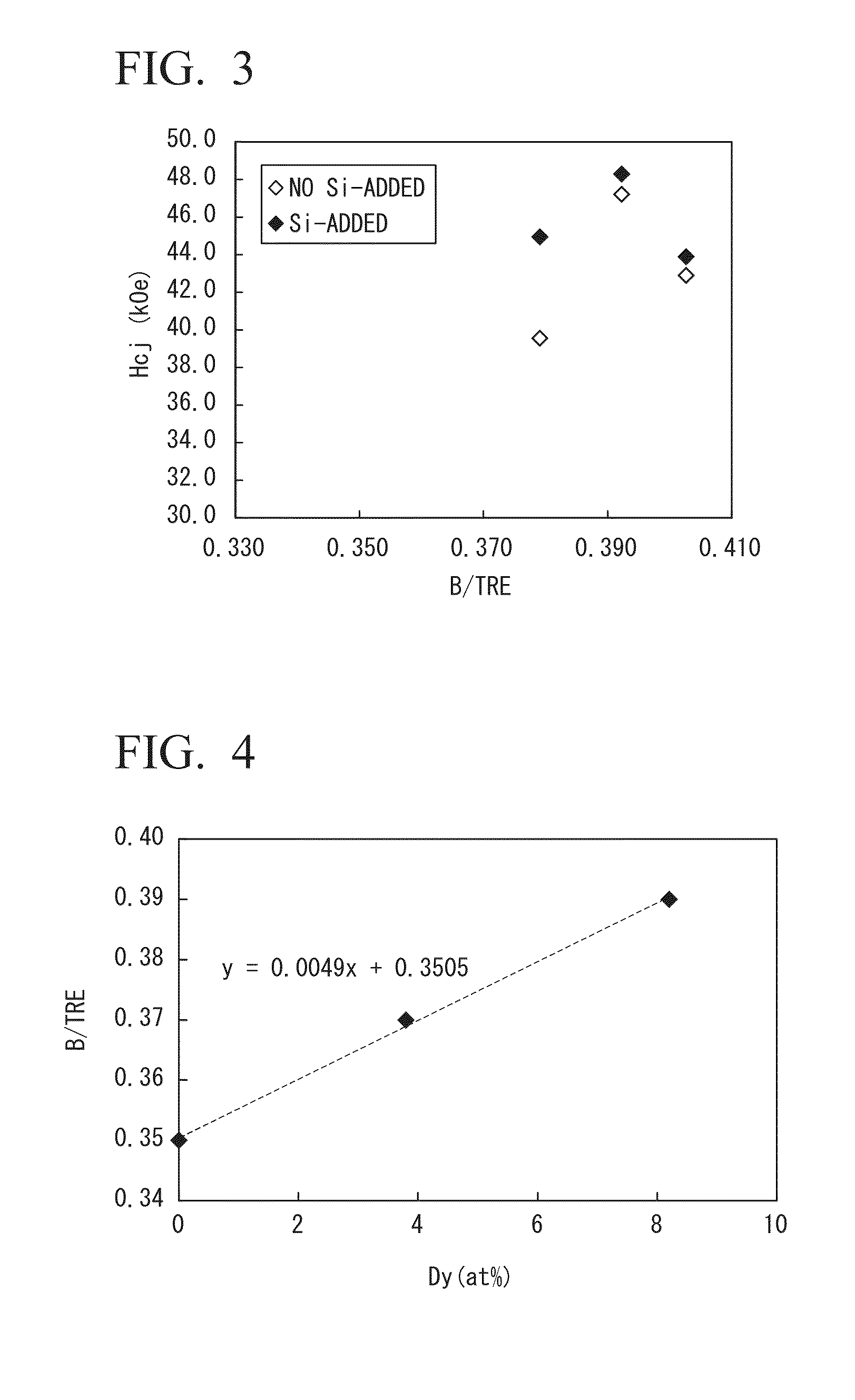

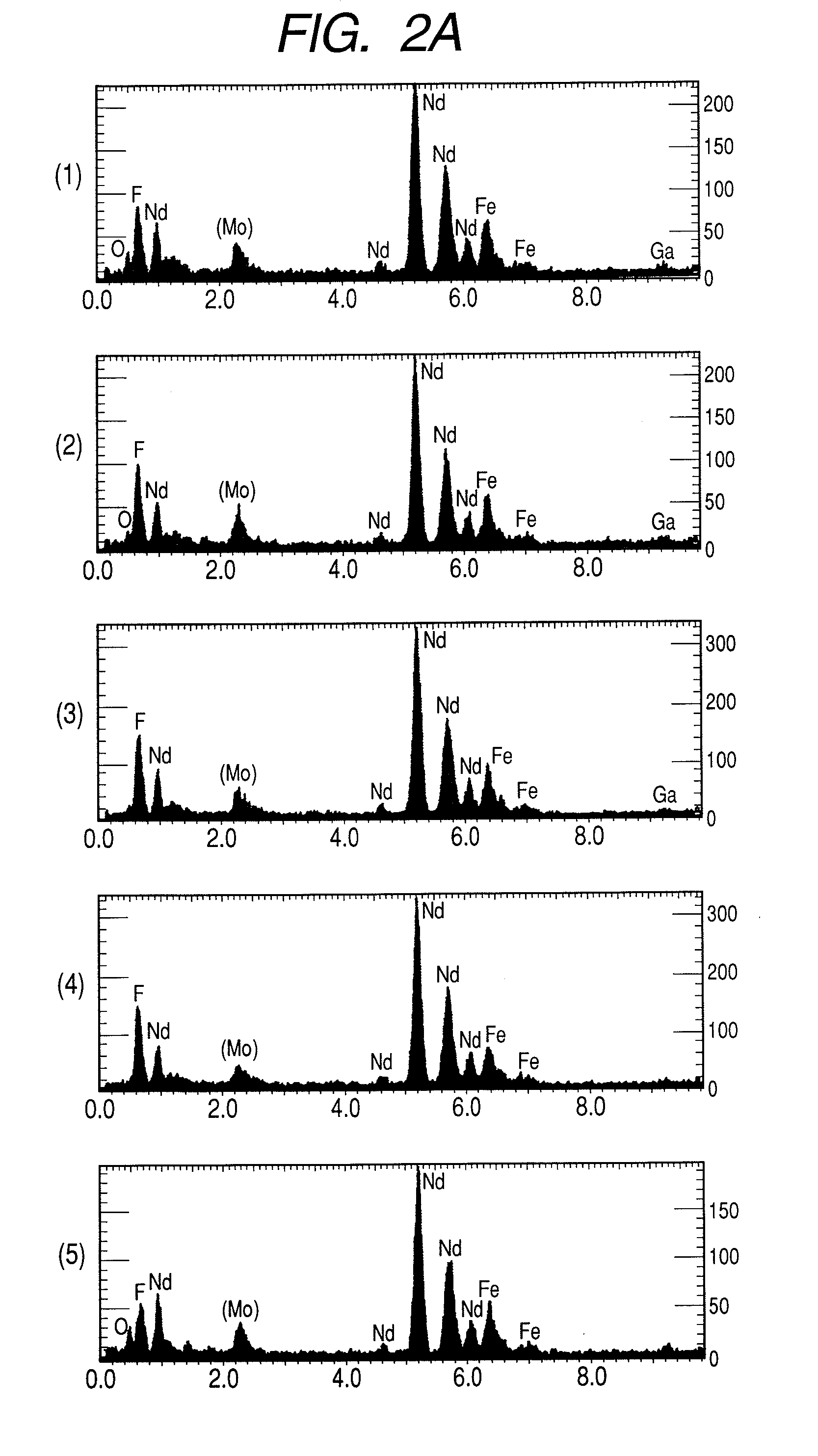

Alloy for r-t-b-based rare earth sintered magnet, process of producing alloy for r-t-b-based rare earth sintered magnet, alloy material for r-t-b-based rare earth sintered magnet, r-t-b-based rare earth sintered magnet, process of producing r-t-b-based rare earth sintered magnet, and motor

InactiveUS20140132377A1Improve coercive forceSuppression amountPermanent magnetsInorganic material magnetismRare-earth elementSintered magnets

An alloy for R-T-B-based rare earth sintered magnets which contains R which is a rare earth element; T which is a transition metal essentially containing Fe; a metallic element M containing one or more metals selected from Al, Ga and Cu; B and inevitable impurities, in which R accounts for 13 at % to 15 at %, B accounts for 4.5 at % to 6.2 at %, M accounts for 0.1 at % to 2.4 at %, T accounts for balance, a proportion of Dy in all rare earth elements is in a range of 0 at % to 65 at %, and the following Formula 1 is satisfied,0.0049Dy+0.34≦B / TRE≦0.0049Dy+0.36 Formula 1wherein Dy represents a concentration (at %) of a Dy element, B represents a concentration (at %) of a boron element, and TRE represents a concentration (at %) of all the rare earth elements.

Owner:SHOWA DENKO KK

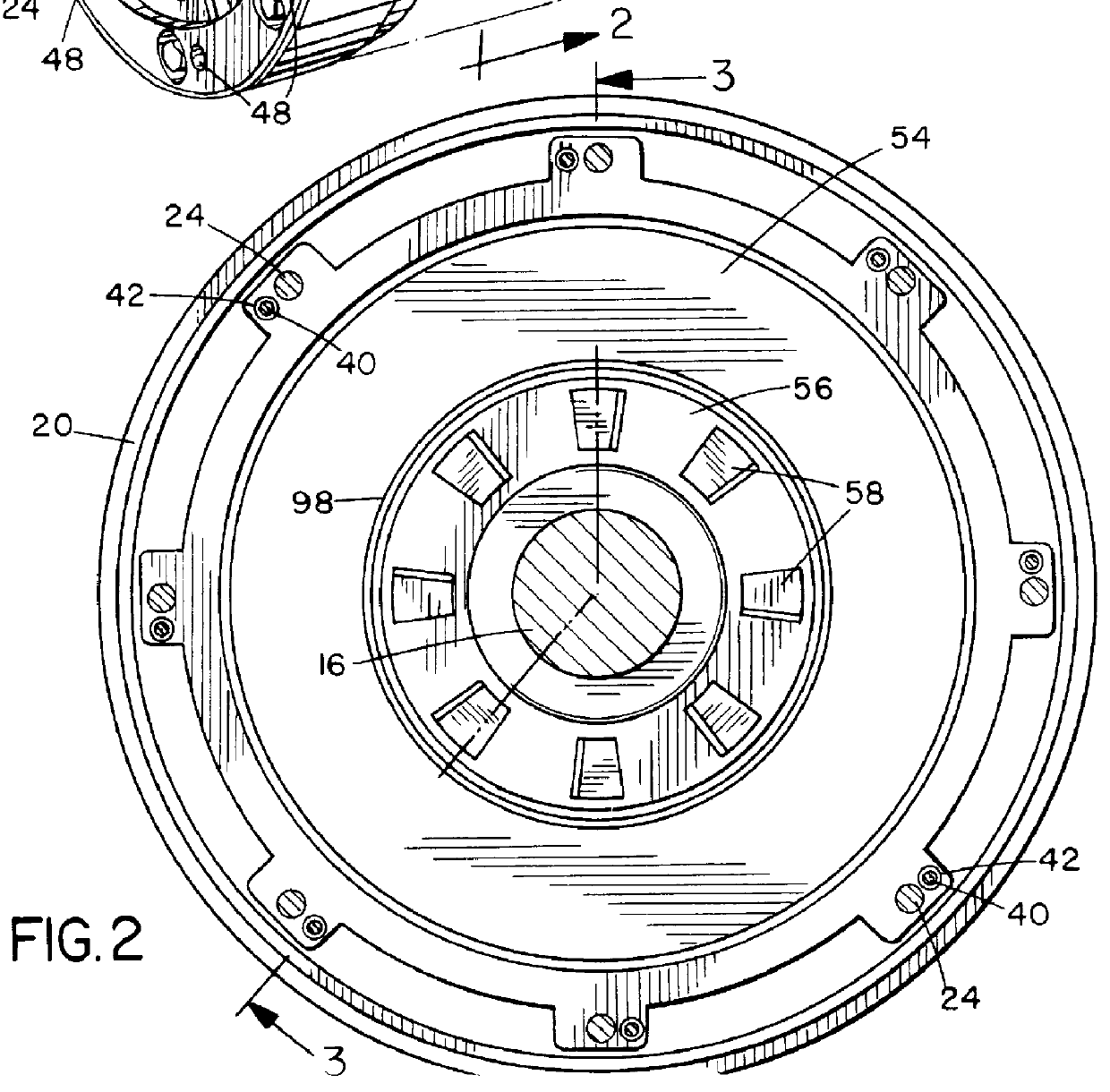

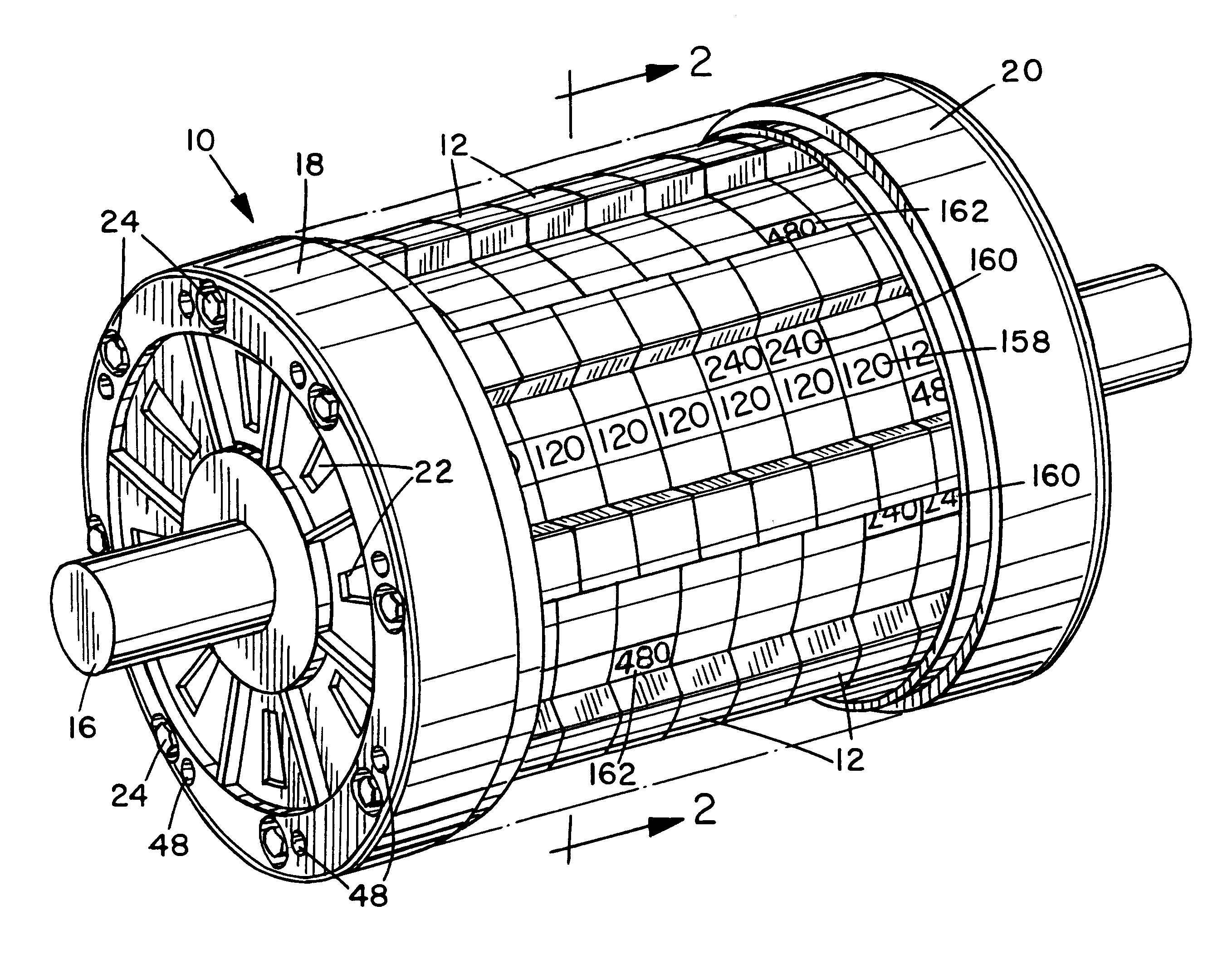

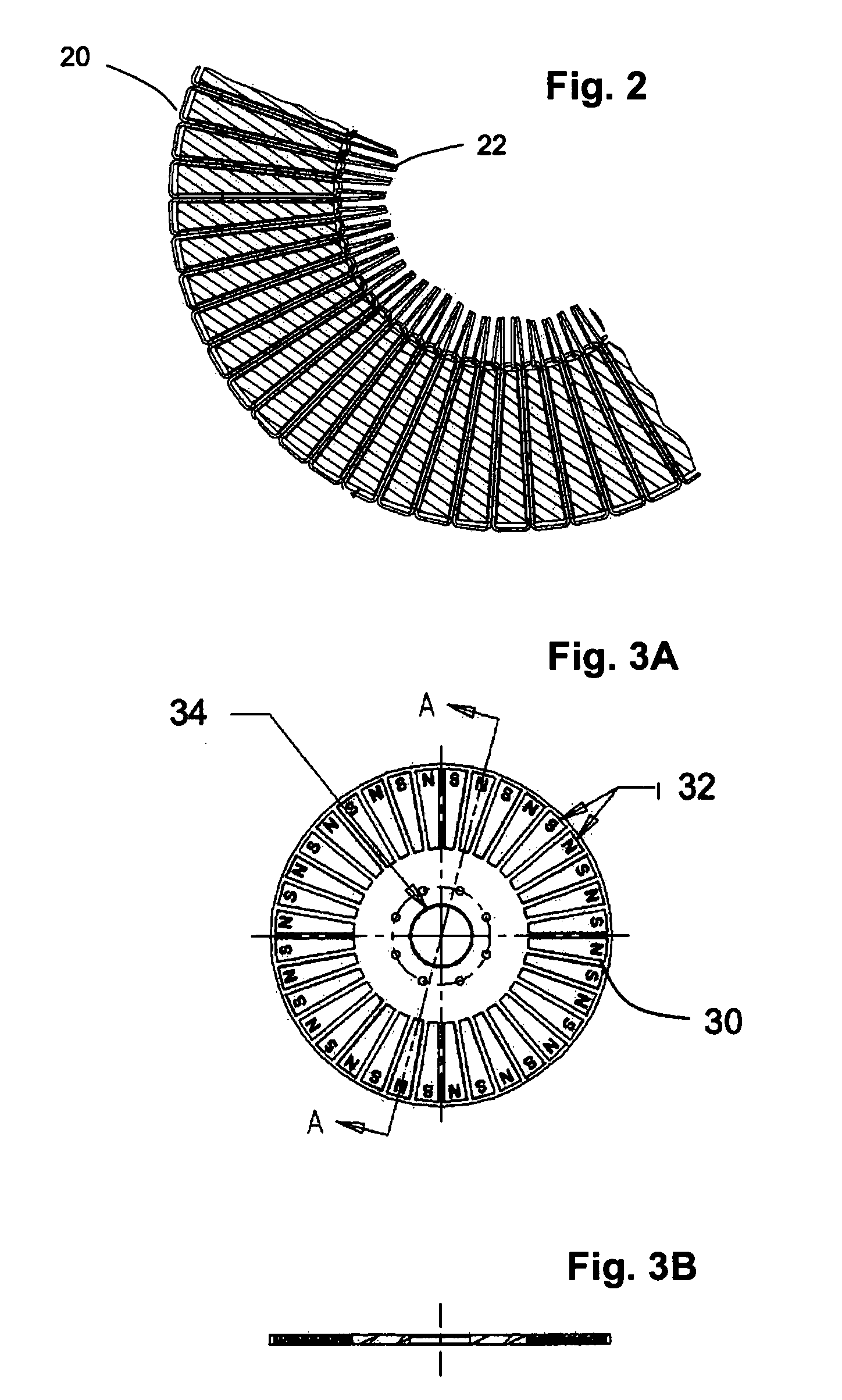

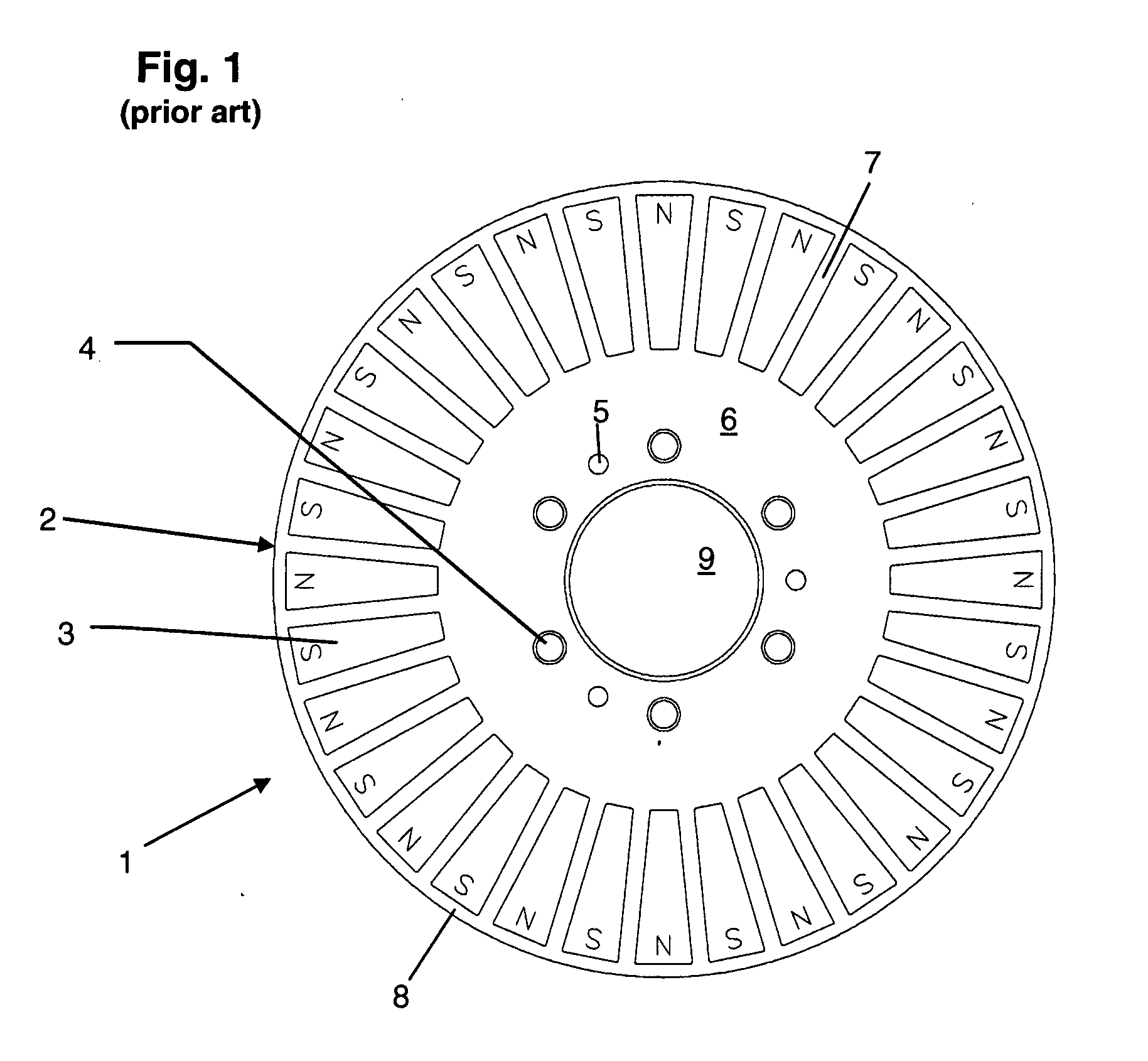

Motor generator including interconnected stators and stator laminations

InactiveUS6163097AMaximization of overall densityShort gapWindings insulation shape/form/constructionAsynchronous induction motorsCross-linkElectrical conductor

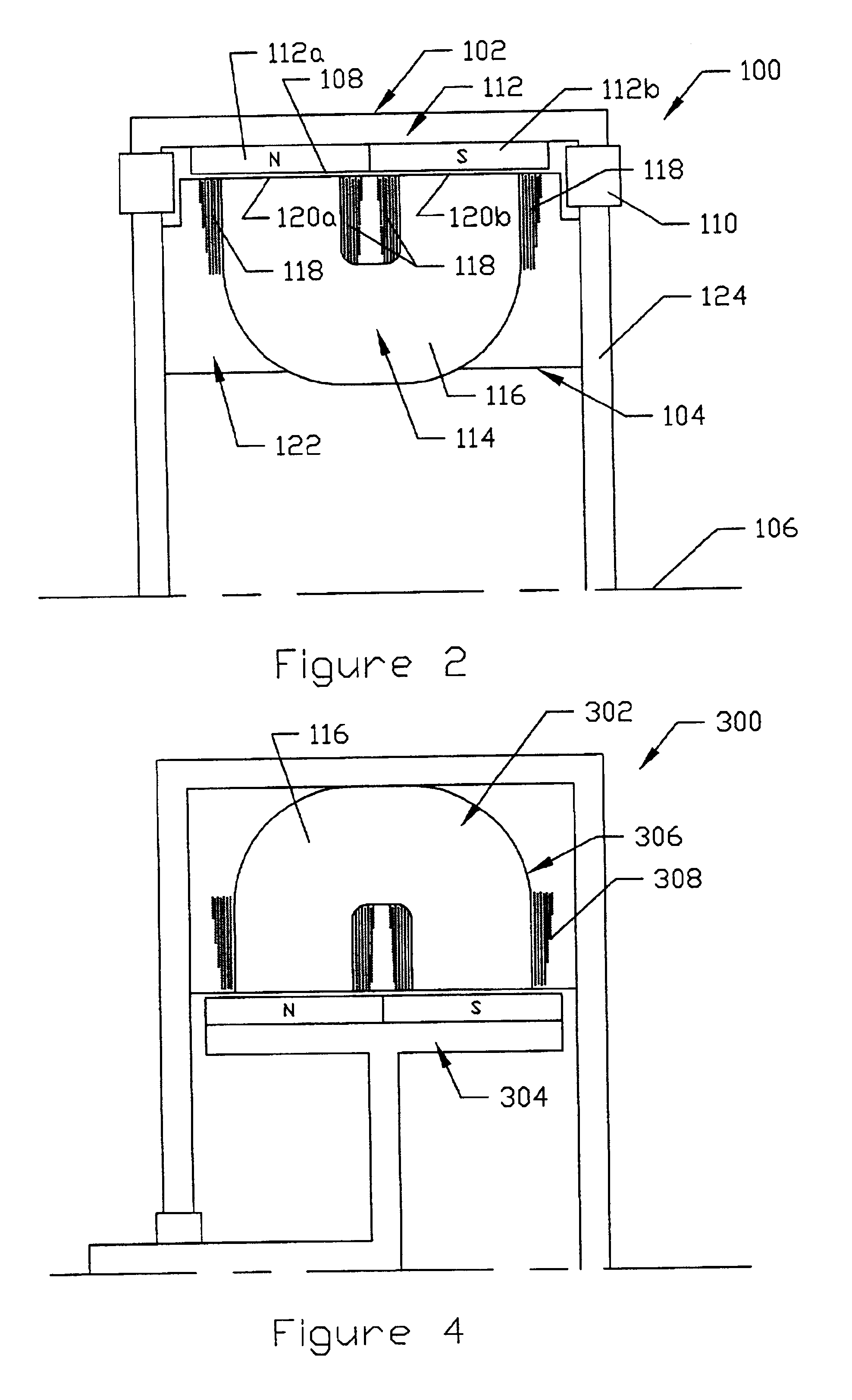

An axial field motor / generator having a rotor that includes at least three annular discs magnetized to provide multiple sector-shaped poles. Each sector has a polarity opposite that of an adjacent sector, and each sector is polarized through the thickness of the disc. The poles of each magnet are aligned with opposite poles of each adjacent magnet. Metal members adjacent the outermost two magnets contain the flux. The motor / generator also has a stator that includes a stator assembly between each two adjacent magnets. Each stator assembly includes one or more conductors or windings. Although the conductors may be formed of wire having a round, uniform cross-section, they may alternatively be formed of conductors having a tapered cross-section that corresponds to the taper of the sectors in order to maximize the density of the conductor in the gap between axially adjacent poles. The conductors may also alternatively be formed of traces in a printed circuit, which may have one or more layers. Each stator assembly may be removably connectable to another stator assembly to provide modularity in manufacturing and to facilitate selection of the voltage at which the motor / generator is to operate. Electrical contacts, such as pins extending from the casing, may removably connect the conductors of adjacent stator assemblies. A magnet may be dynamically balanced on the shaft by hardening a thin ring of cross-linked resin between the magnet and the shaft while the shaft is spun, using ultraviolet light to polymerize the resin.

Owner:SMITH TECH DEV LLC +1

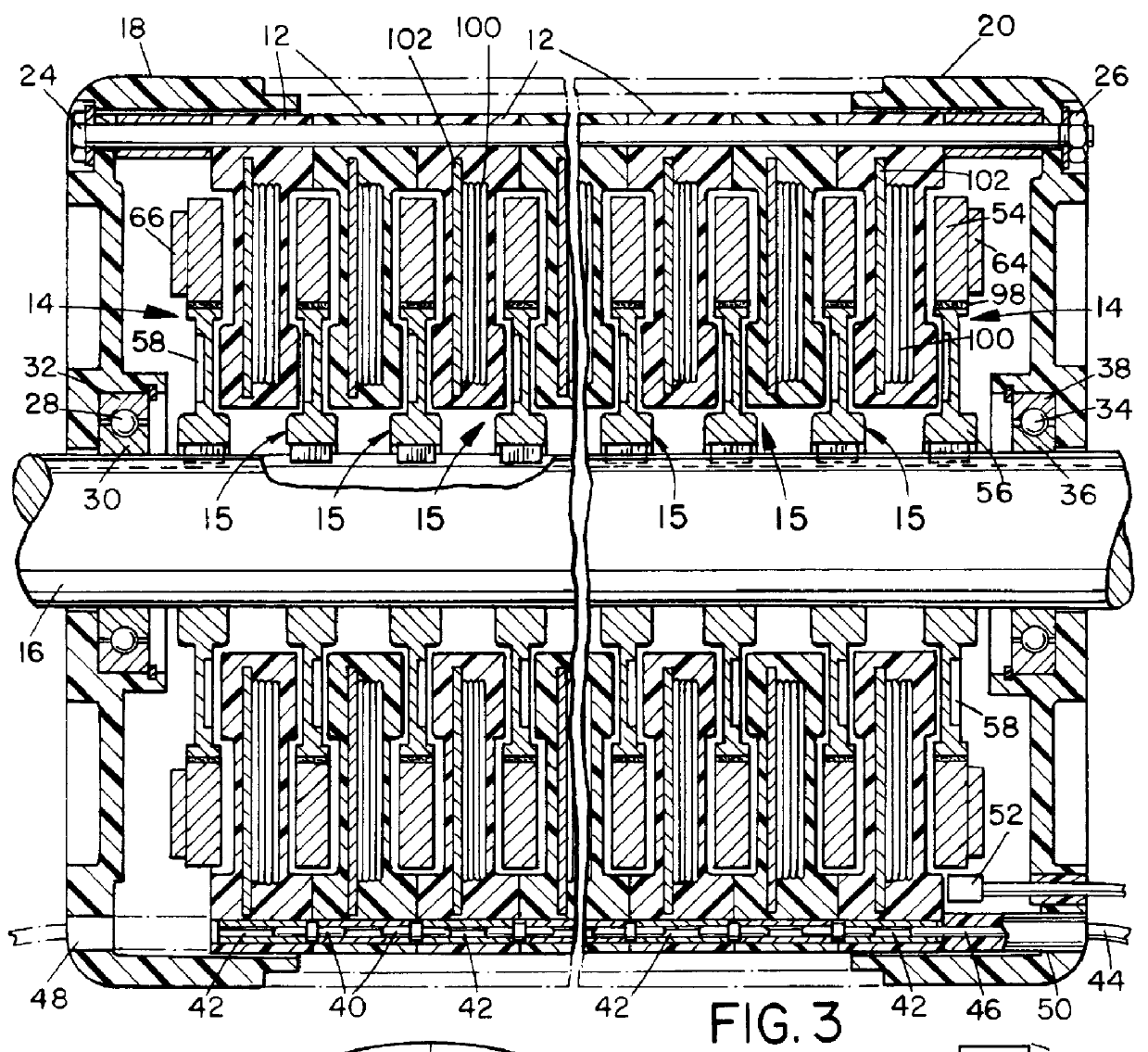

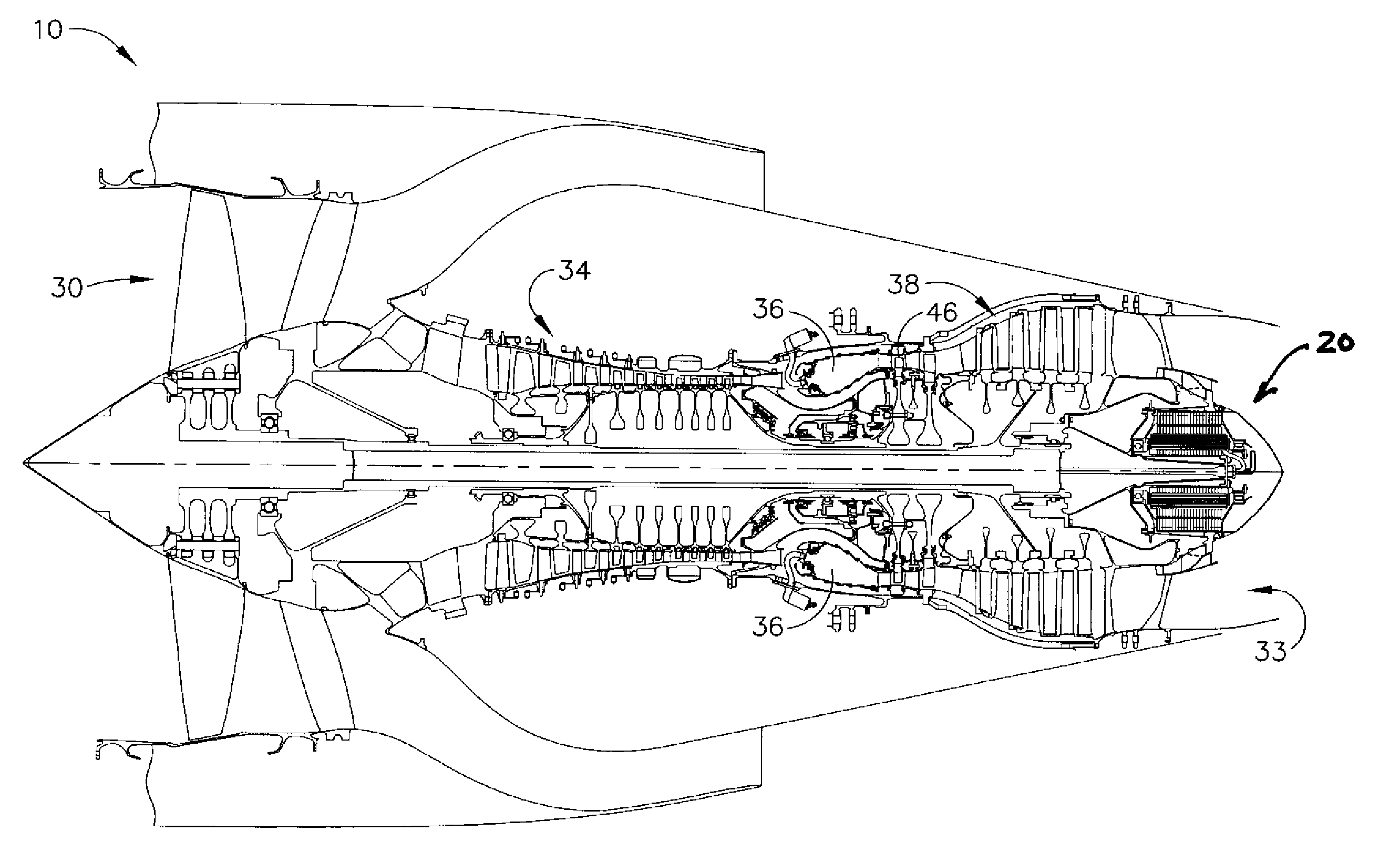

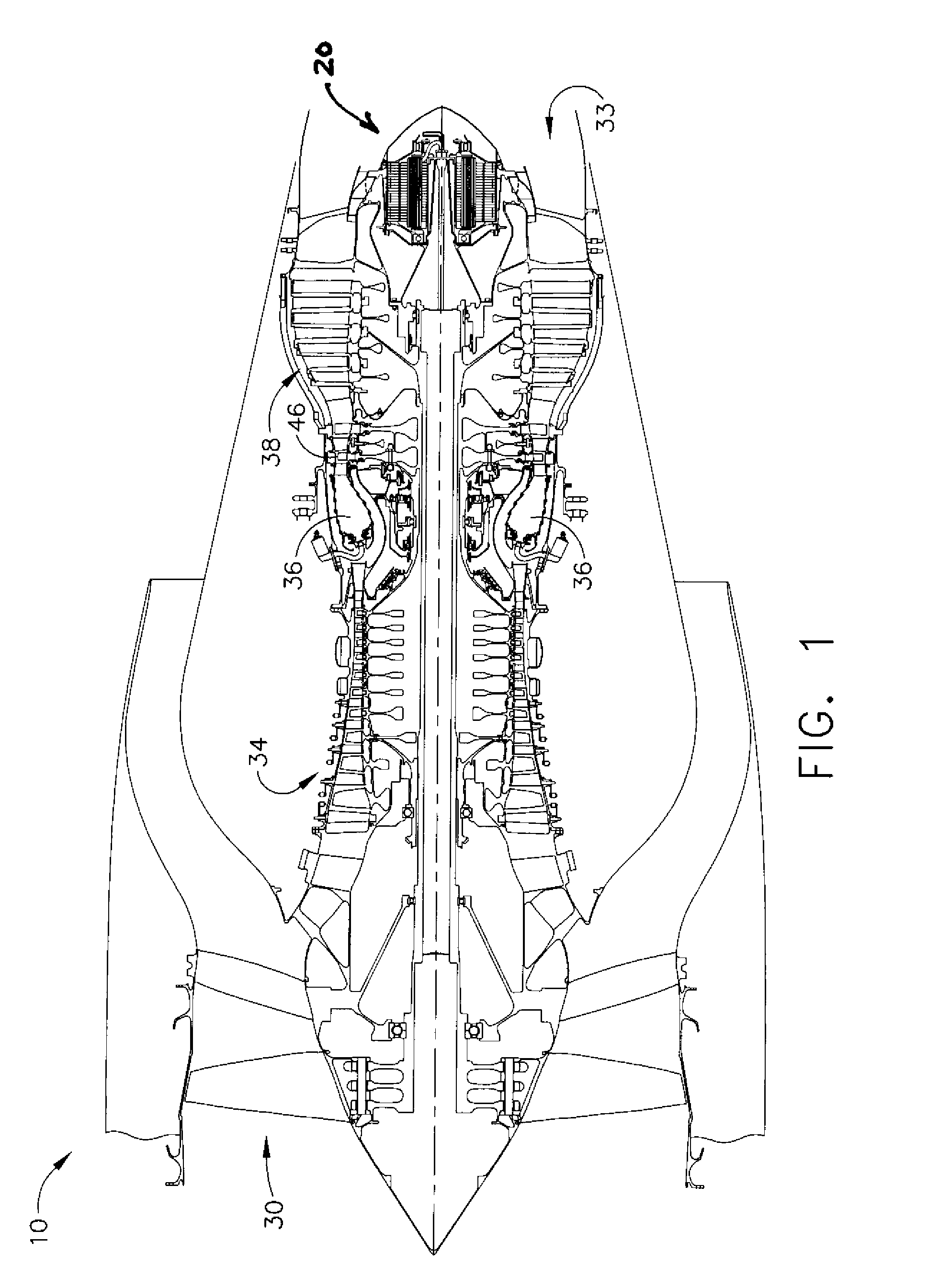

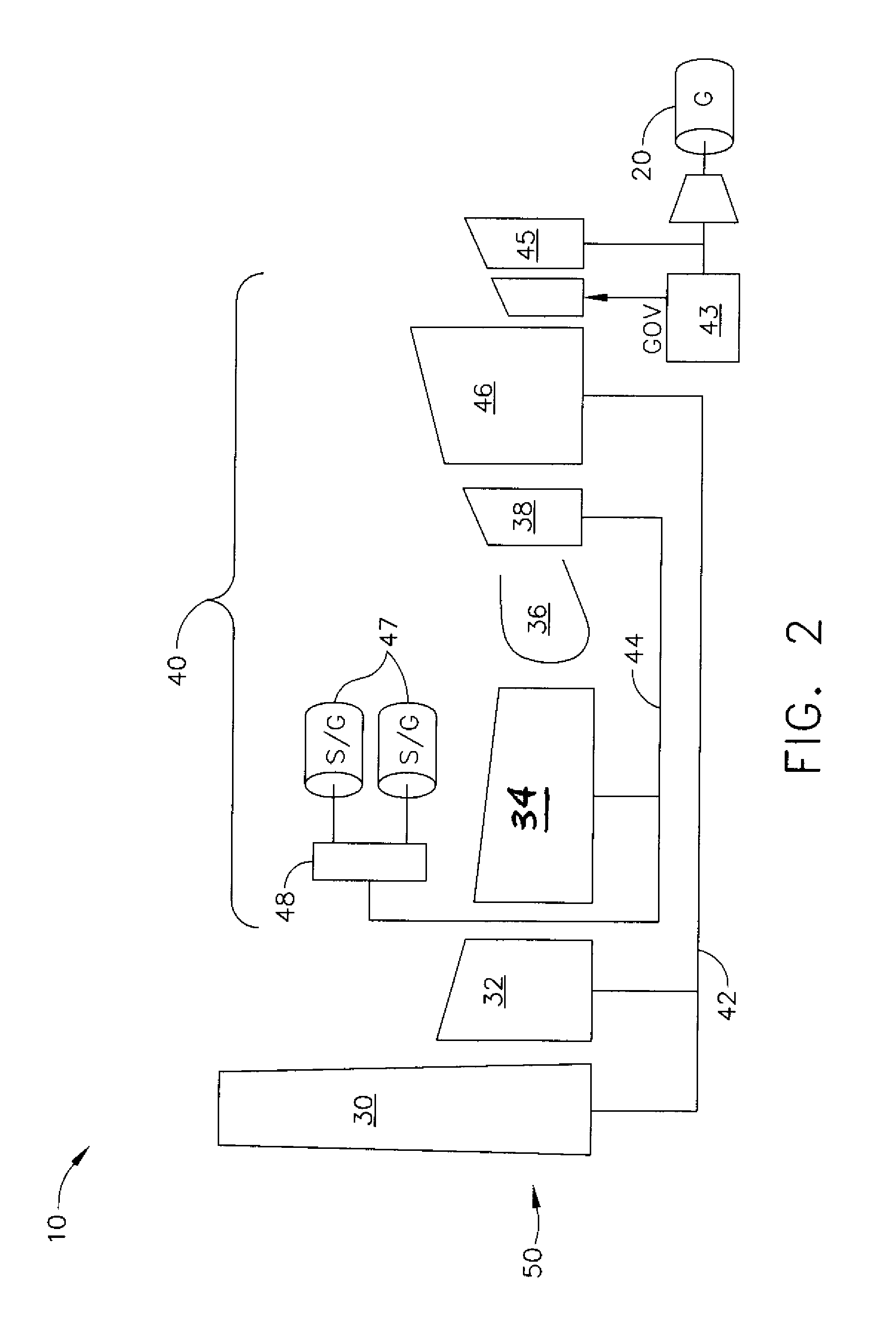

Electric power generation using power turbine aft of LPT

InactiveUS7514810B2Increase speedSmall sizeSynchronous generatorsEfficient propulsion technologiesElectric powerElectric generator

An inside out generator disposed aft of the low-pressure turbine spool to generate power for the electrical demands of an aircraft system. The low-pressure turbine discharge flow is used to drive the power turbine, which is coupled to the generator. The generator is able to extract power at idle conditions of the aircraft engine from ducting the discharge through the inside out generator. The system eliminates the placement of a generator in the hot gas path of the discharge, and enables the injection of power directly to the accessory gear box of the engine.

Owner:GENERAL ELECTRIC CO

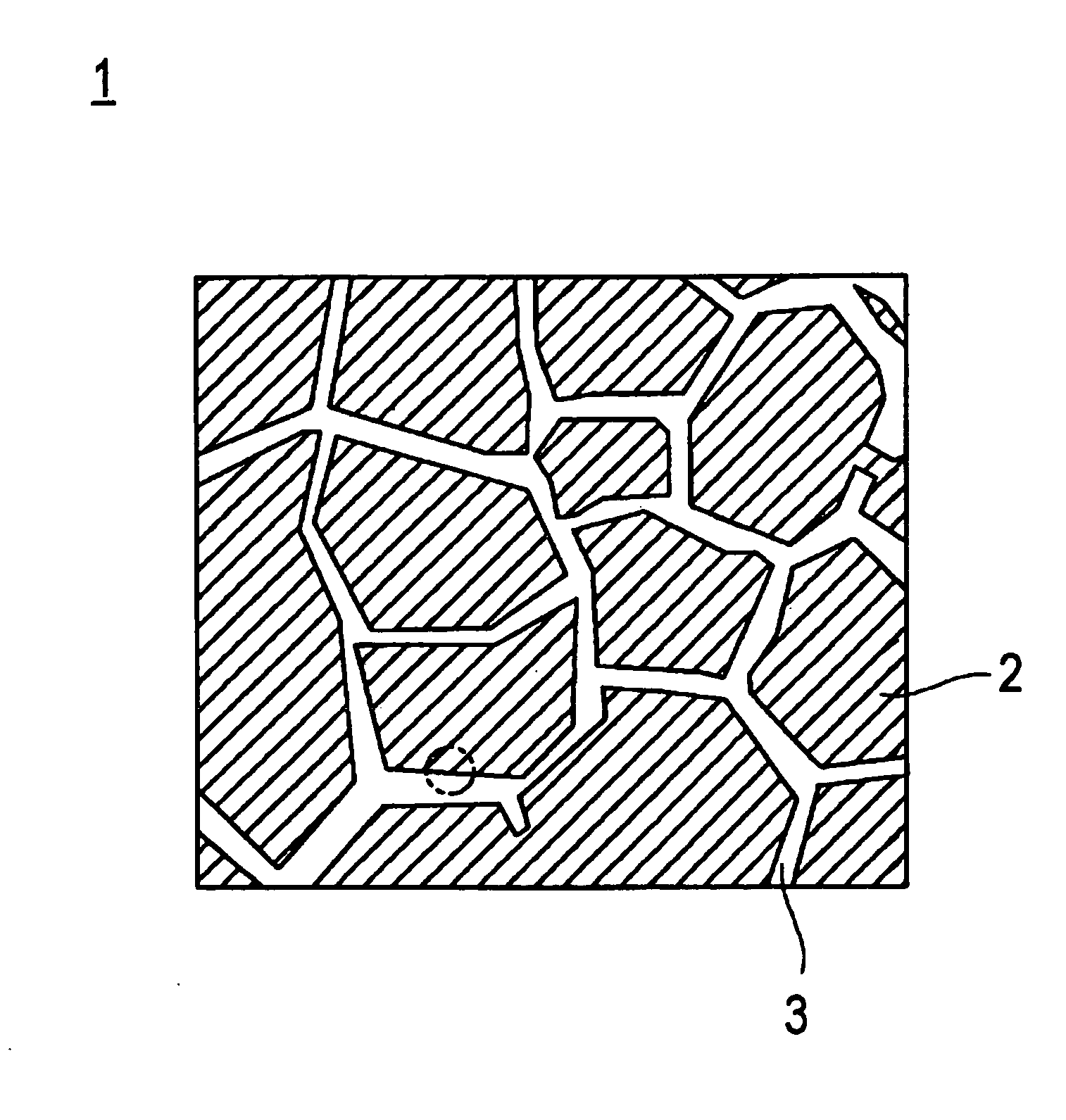

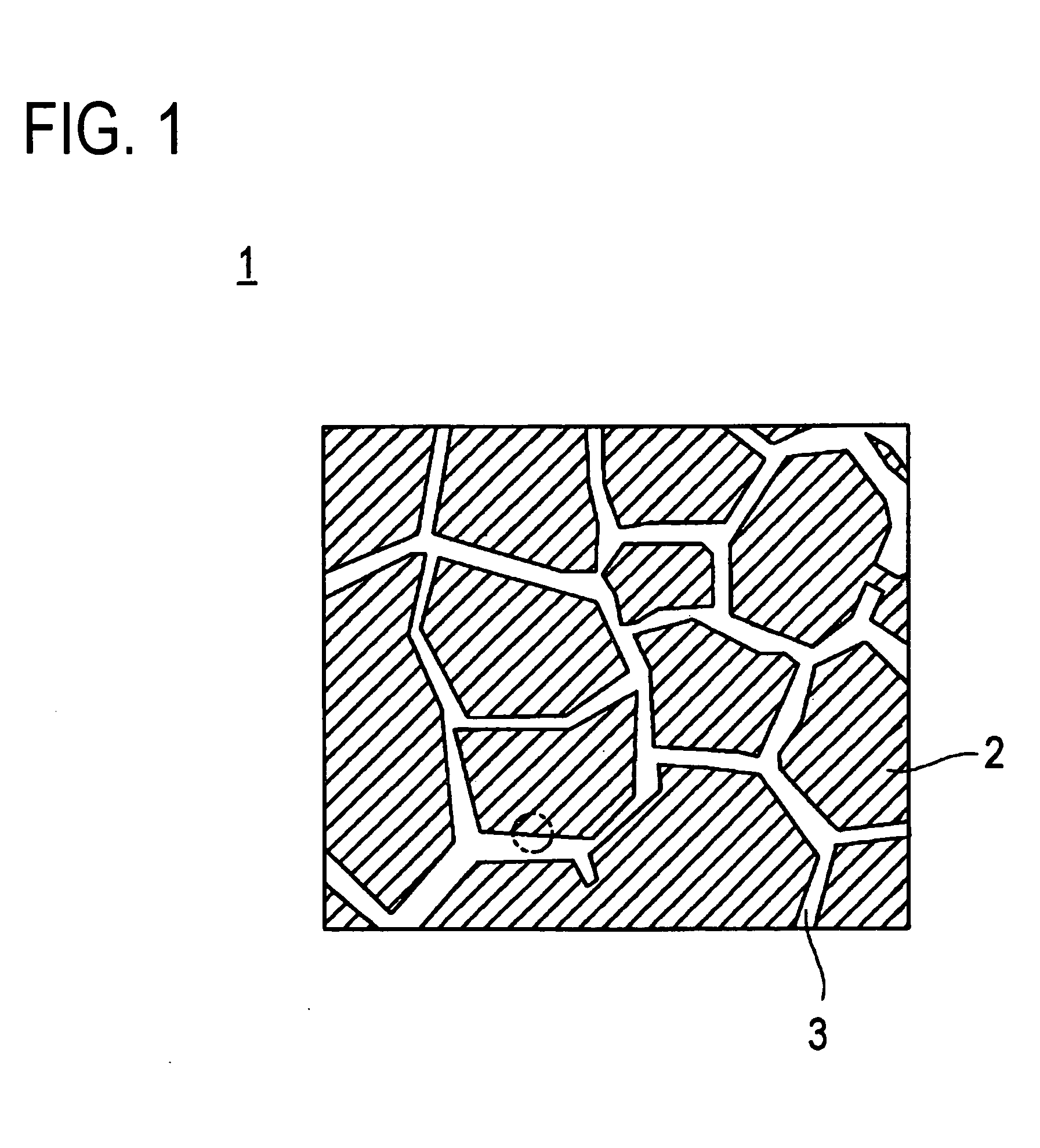

Rare earth magnet and method therefor

InactiveUS20050133117A1Increase resistanceReduced characteristicsMagnetic circuit rotating partsInorganic material magnetismEddy currentRare-earth magnet

A rare earth magnet includes rare earth magnet particles; and amorphous and / or crystalline terbium oxide present at the boundary of the rare earth magnet particles and represented by the formula: TbOn, wherein 1.5<n≦2. The rare earth magnet prevents decrease eddy current effectively.

Owner:NISSAN MOTOR CO LTD

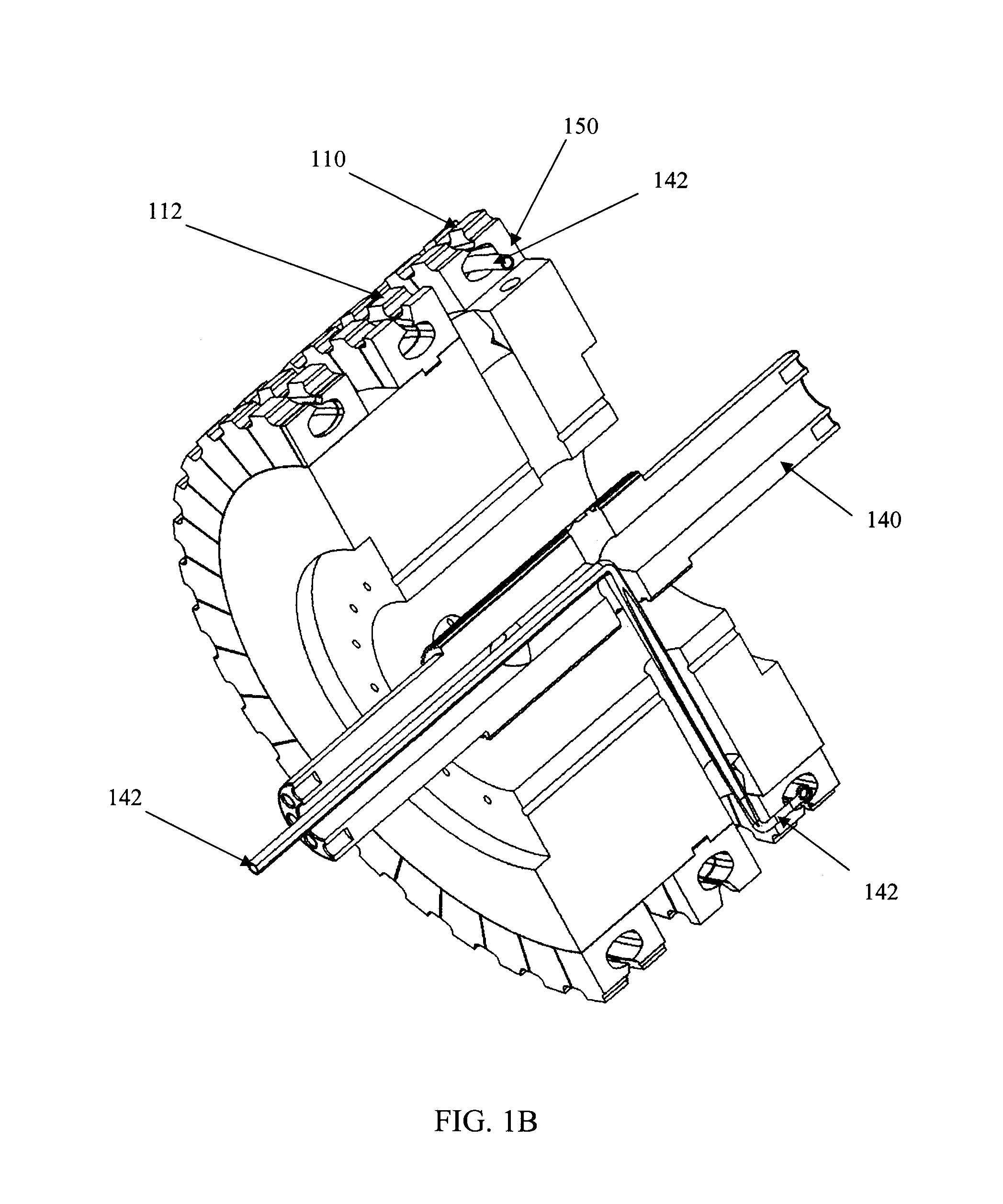

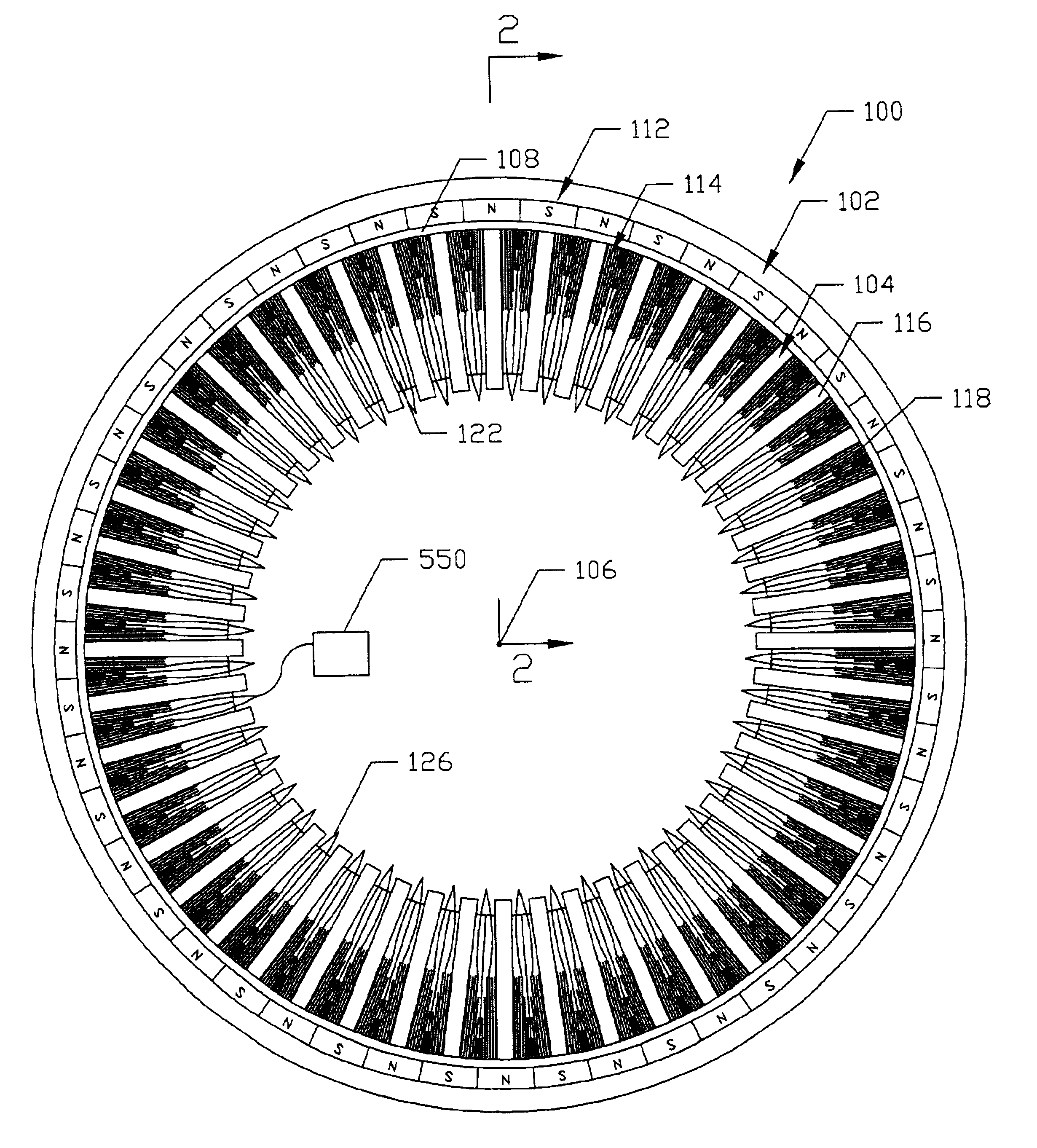

High-Efficiency Wheel-Motor Utilizing Molded Magnetic Flux Channels with Transverse-Flux Stator

InactiveUS20090322165A1Reducing hysteresis lossIncrease torqueMotor/generator/converter stoppersMotor control for very low speedsTransverse fluxEngineering

A motor including an outside rotor having a rotor disc with plural magnets alternating polarities flush mounted in the disc, an inside stator assembly with a ring of pole pieces forming a channel to house a transversely wound stator windings, and a controller coupled with feedback electronics for monitoring a timing, speed and direction and coupling a signal to a processing unit for adjusting the drive electronics driving the phase windings. A u-shaped gap above the channel to receive the rotor disc and focus the captured magnetic flux in the pole pieces toward the magnets. In an embodiment the molded magnetic flux channel pole pieces of the inside stator are sets of molded magnetic flux channel pole pieces, each set forming a channel and corresponding to one phase of the motor; and a section of each one of the transverse windings passing through one channel, the remaining section folding back outside the set in close proximity to the outer base of the set of molded magnetic flux channel pole pieces.

Owner:RITTENHOUSE NORMAN P

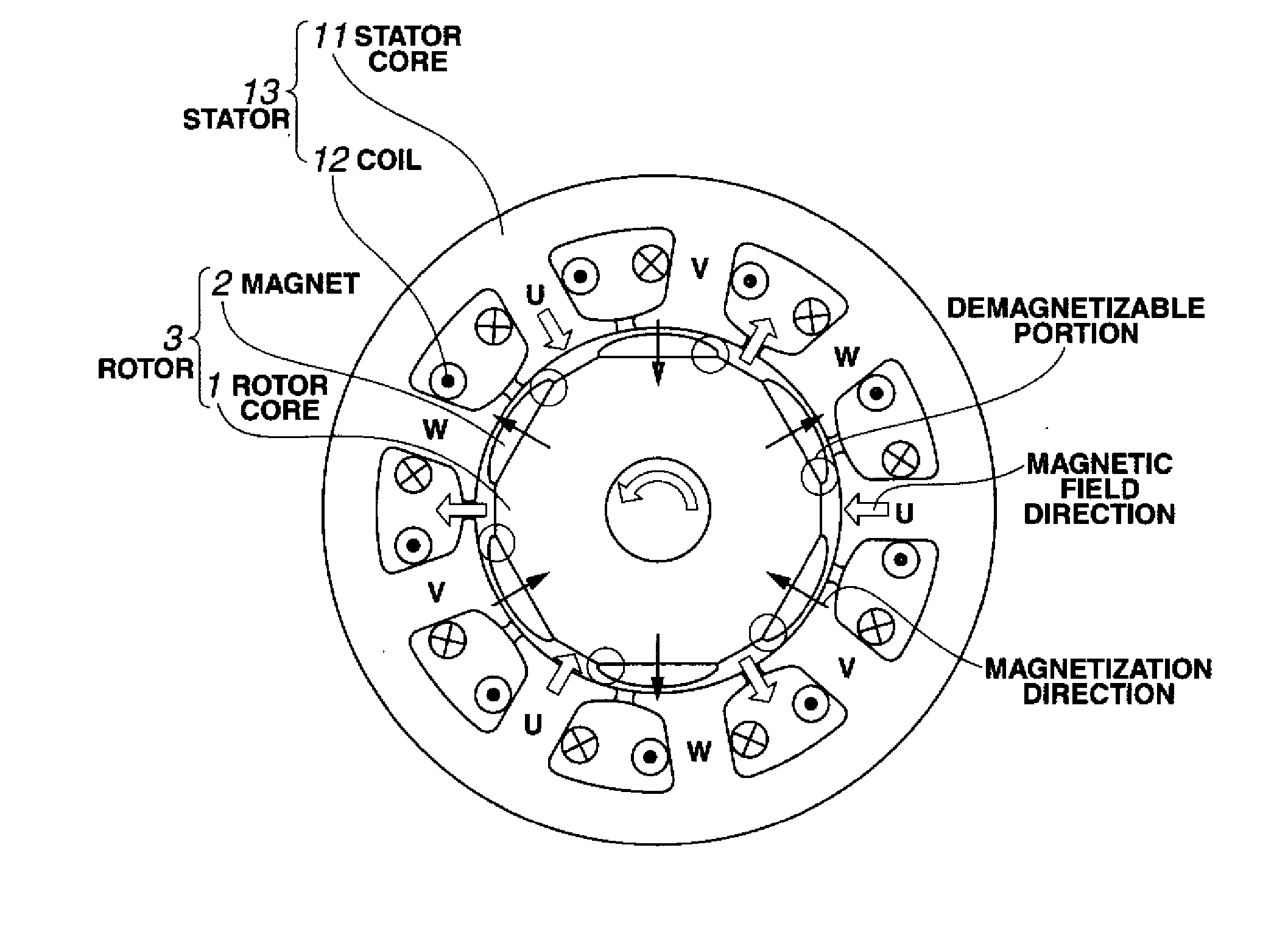

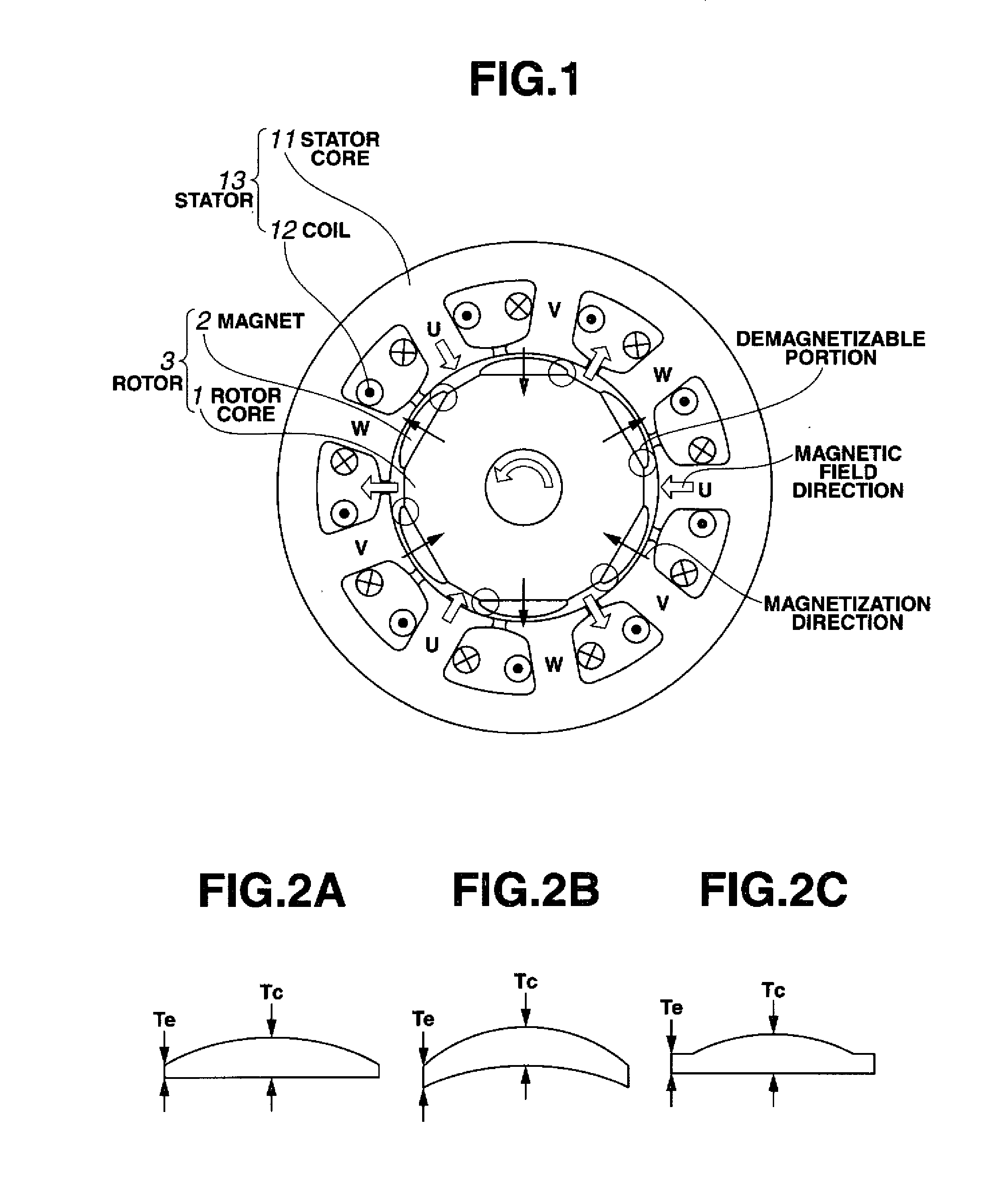

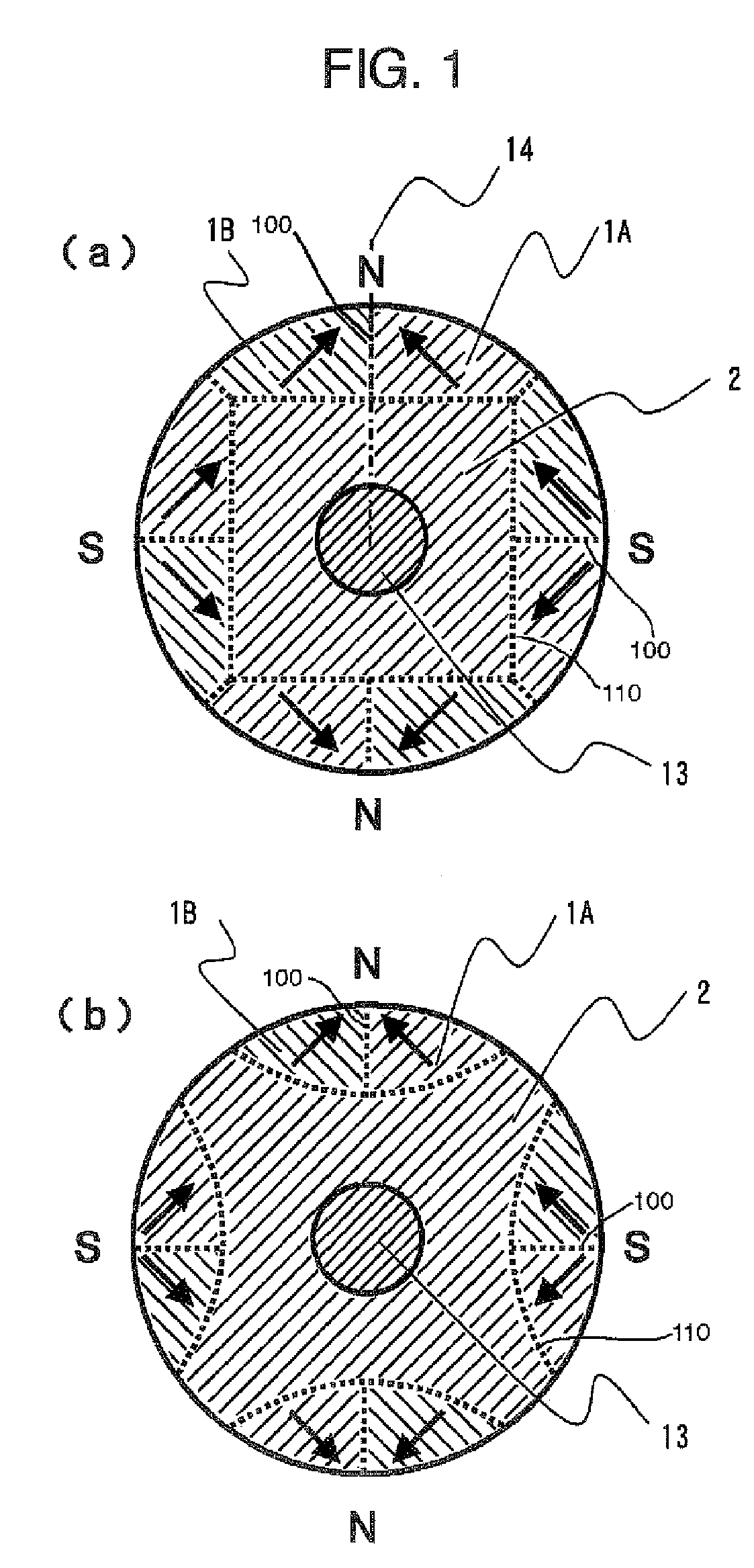

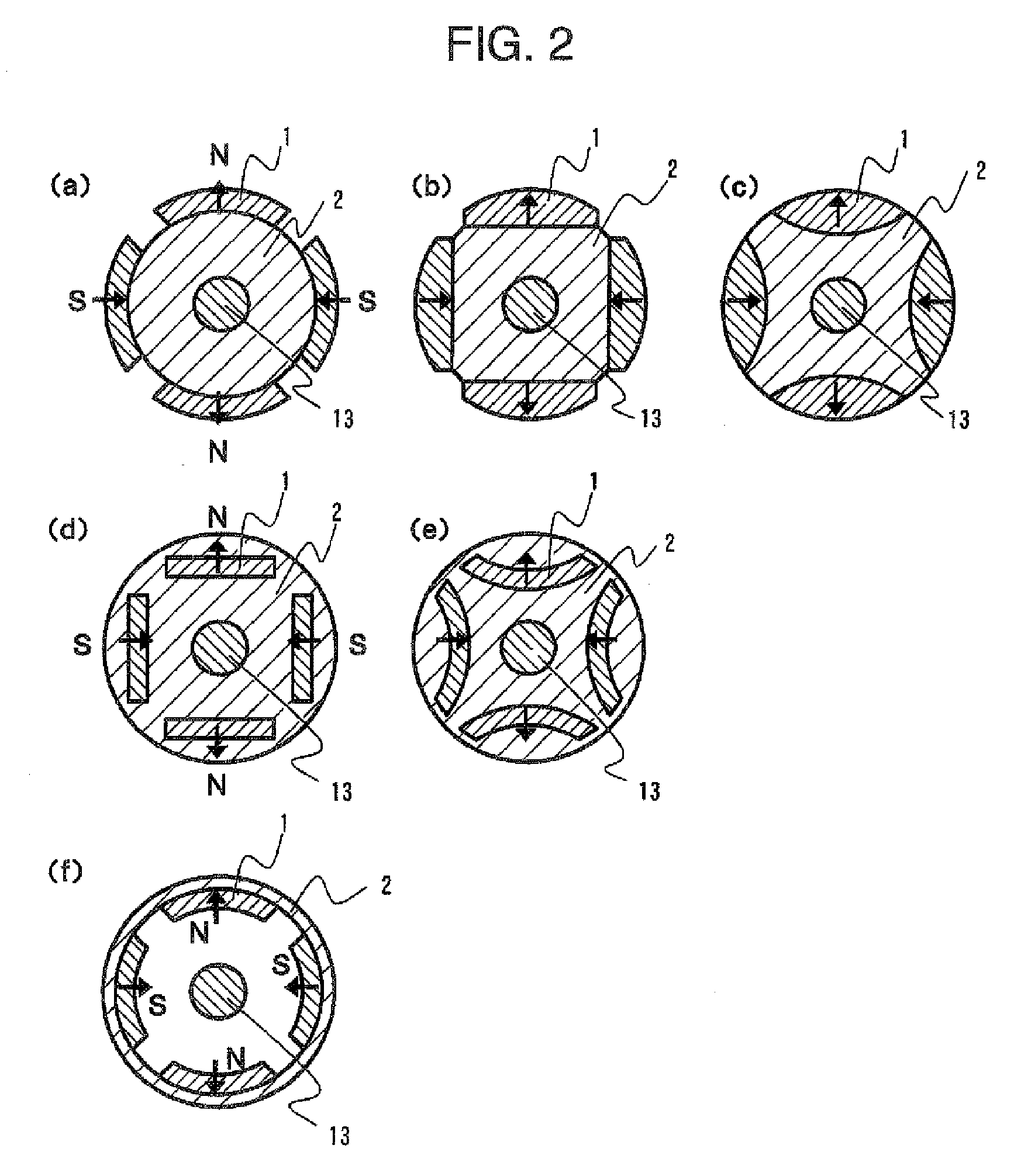

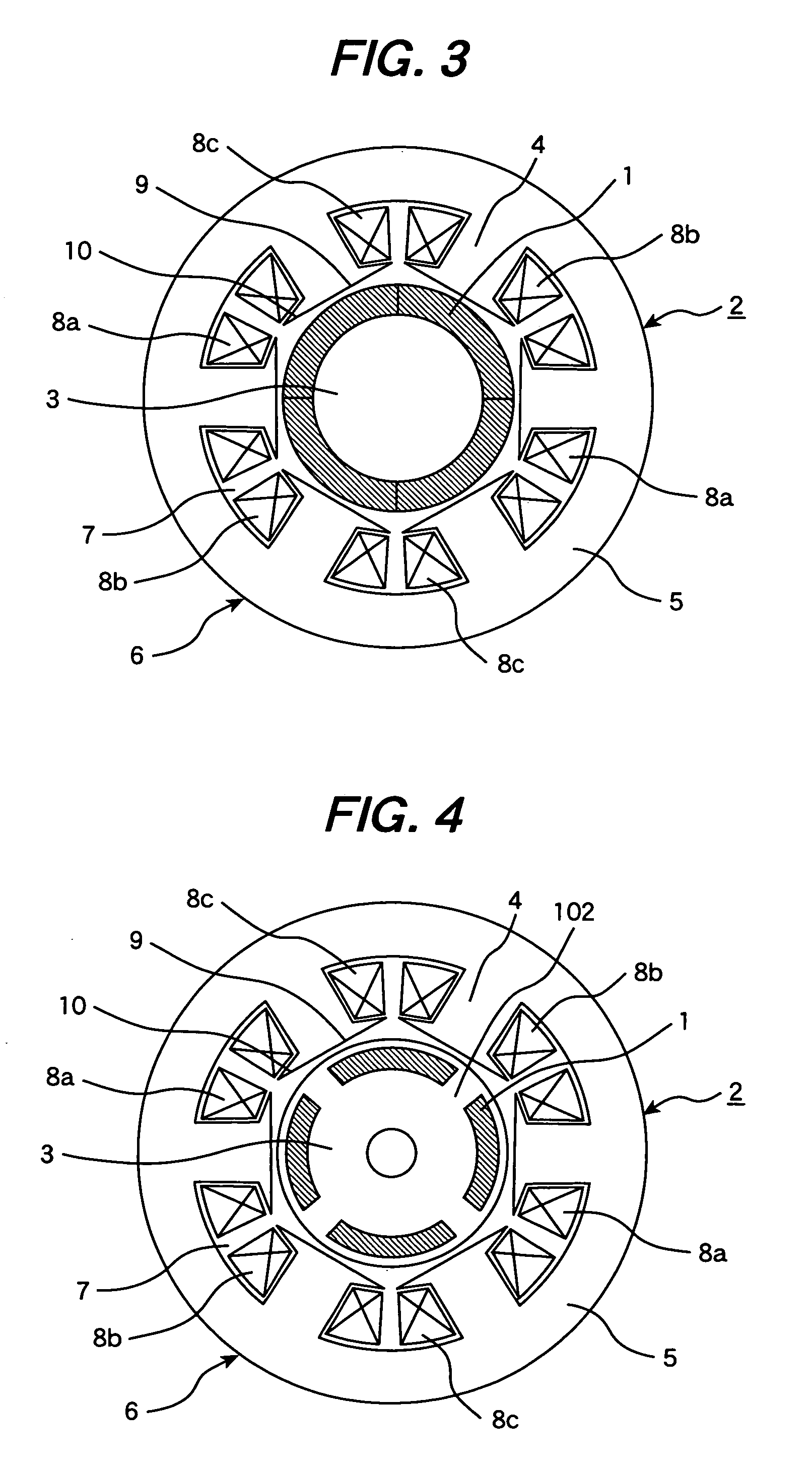

Permenent magnet rotating machine

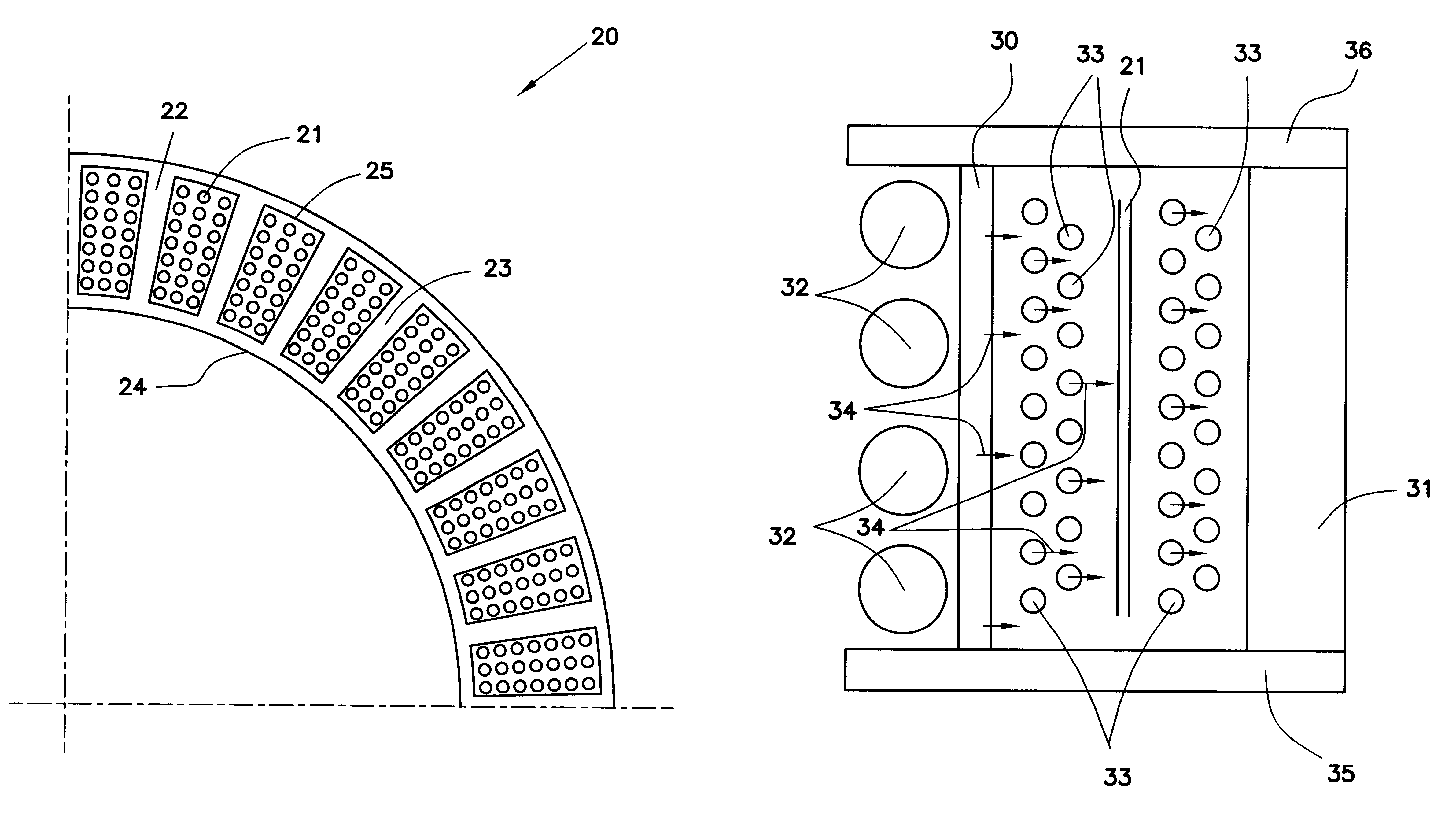

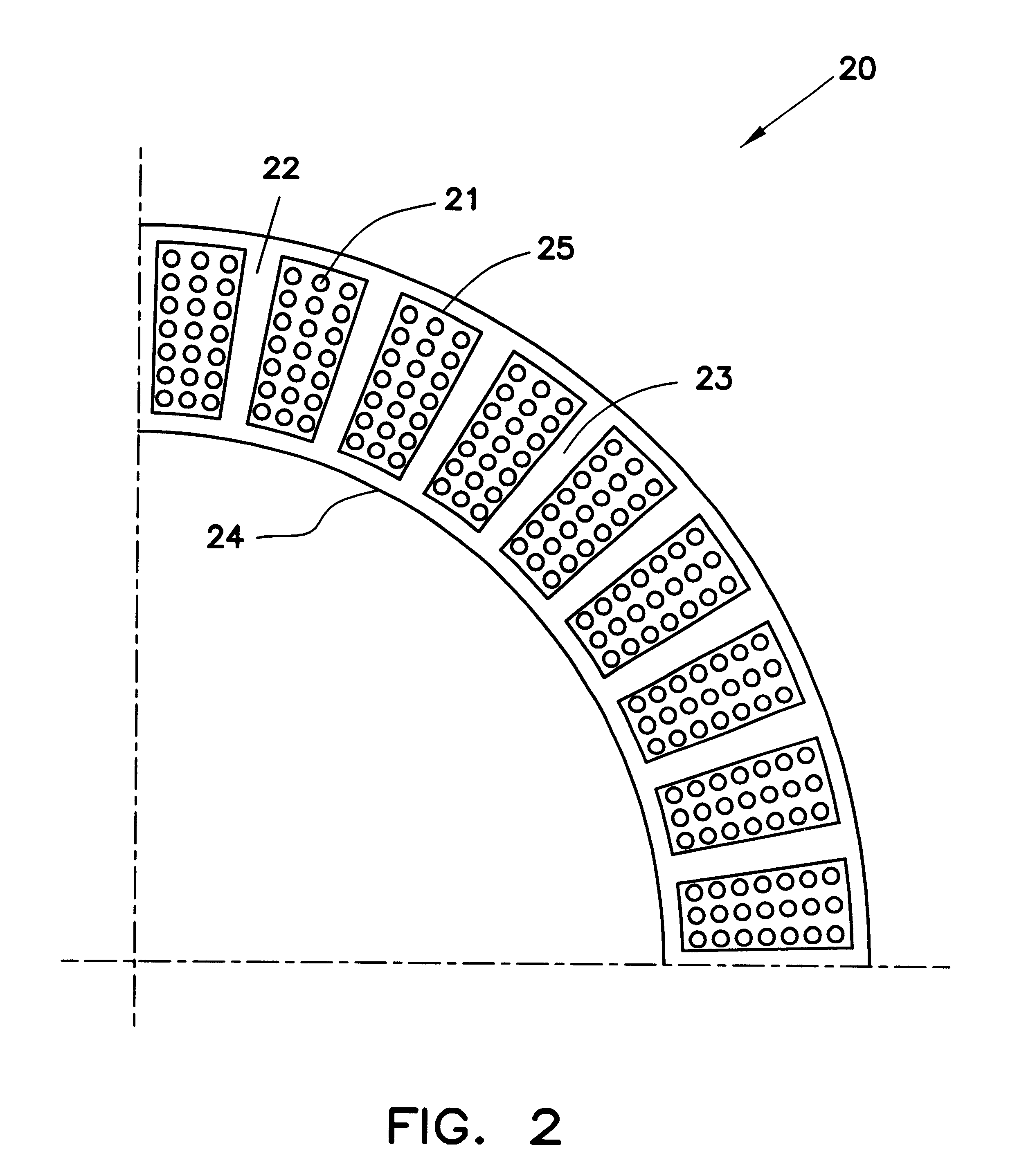

ActiveUS20080054736A1Improve remanenceImprove coercive forceMagnetic circuit rotating partsManufacturing dynamo-electric machinesRare-earth elementSintered magnets

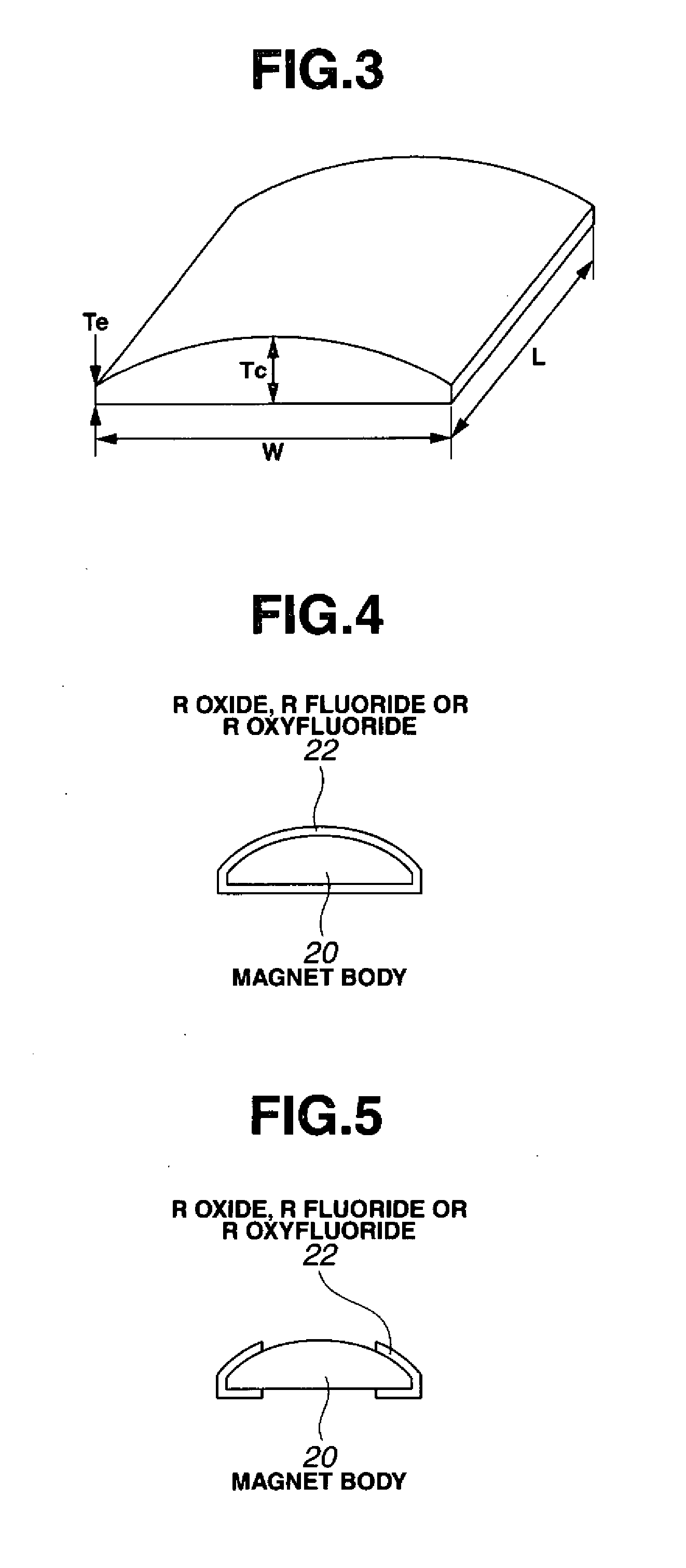

In a rotating machine comprising a rotor including a rotor core and a plurality of permanent magnet segments, and a stator including a stator core and windings, the permanent magnet segment is obtained by disposing a powder comprising an R2 oxide, R3 fluoride or R4 oxyfluoride on a sintered magnet body of R1—Fe—B composition, wherein R1 to R4 are rare earth elements, and heat treating the powder-covered magnet body. The permanent magnet segment of a cross-sectional shape which is tapered from the center toward opposed ends has a higher coercive force at the ends than at the center.

Owner:SHIN ETSU CHEM IND CO LTD

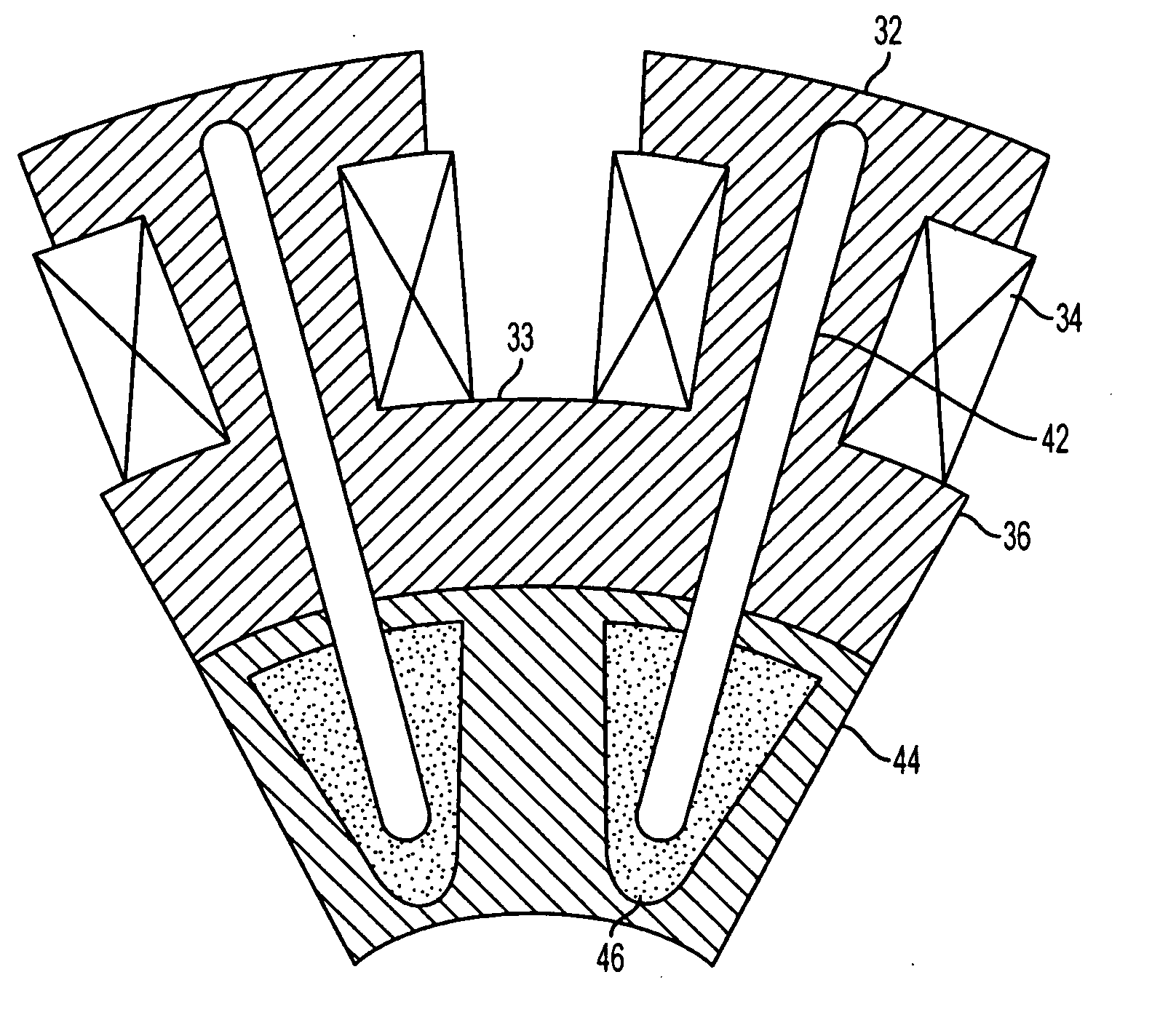

Electromagnetic device with embedded windings and method for its manufacture

InactiveUS6232681B1Maximize electromagnetic couplingGap minimizationSynchronous machinesMagnetic circuit stationary partsReduced sizeConductor Coil

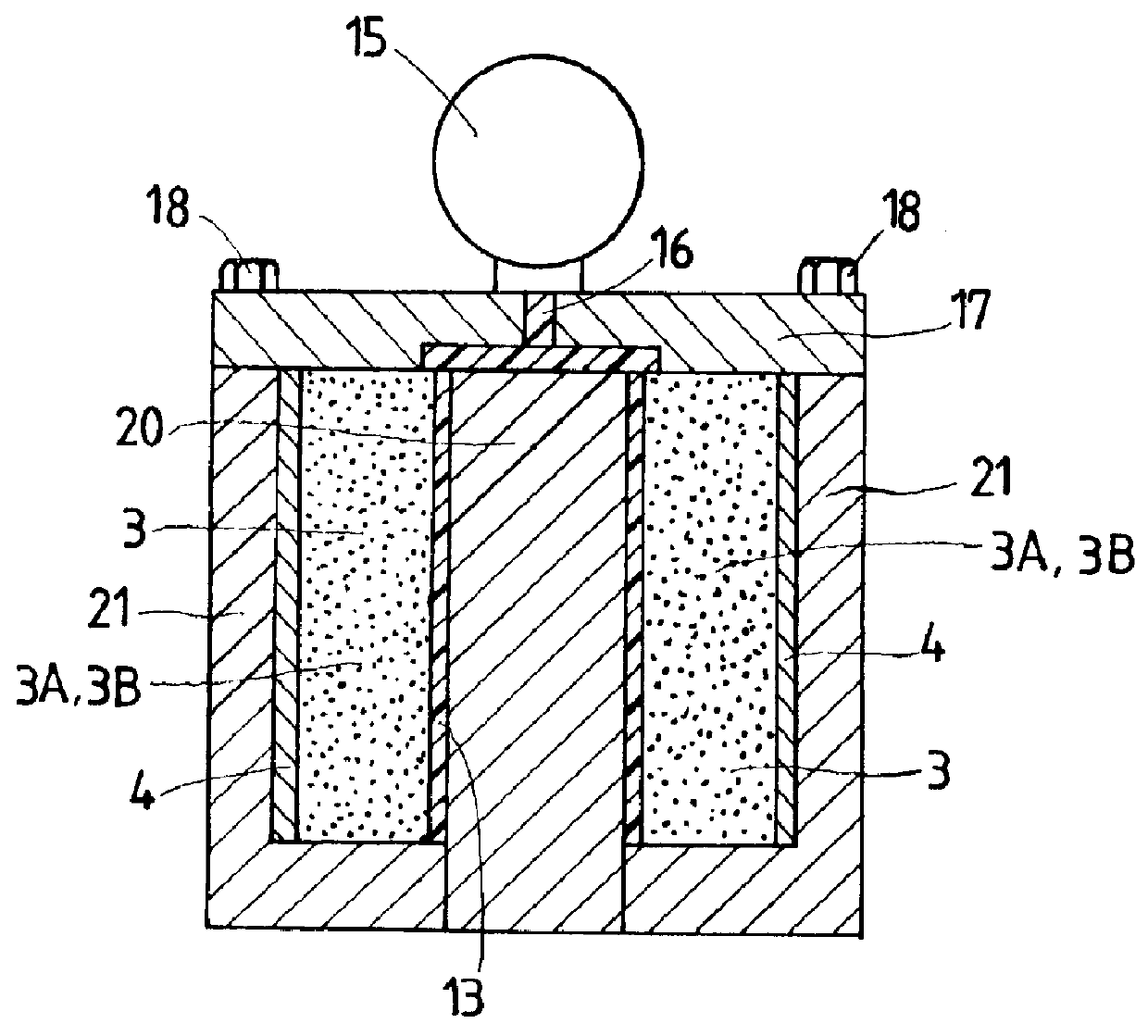

A powdered magnetic material stator core with embedded stator windings and a method for its manufacture. Embedding the windings within a radially compacted powdered magnetic material stator core enables equivalent or better electromagnetic performance in a significantly reduced size. Radial compaction of the powdered magnetic material minimizes the distortion of the stator windings during compaction.

Owner:REMY TECHNOLOGIES LLC

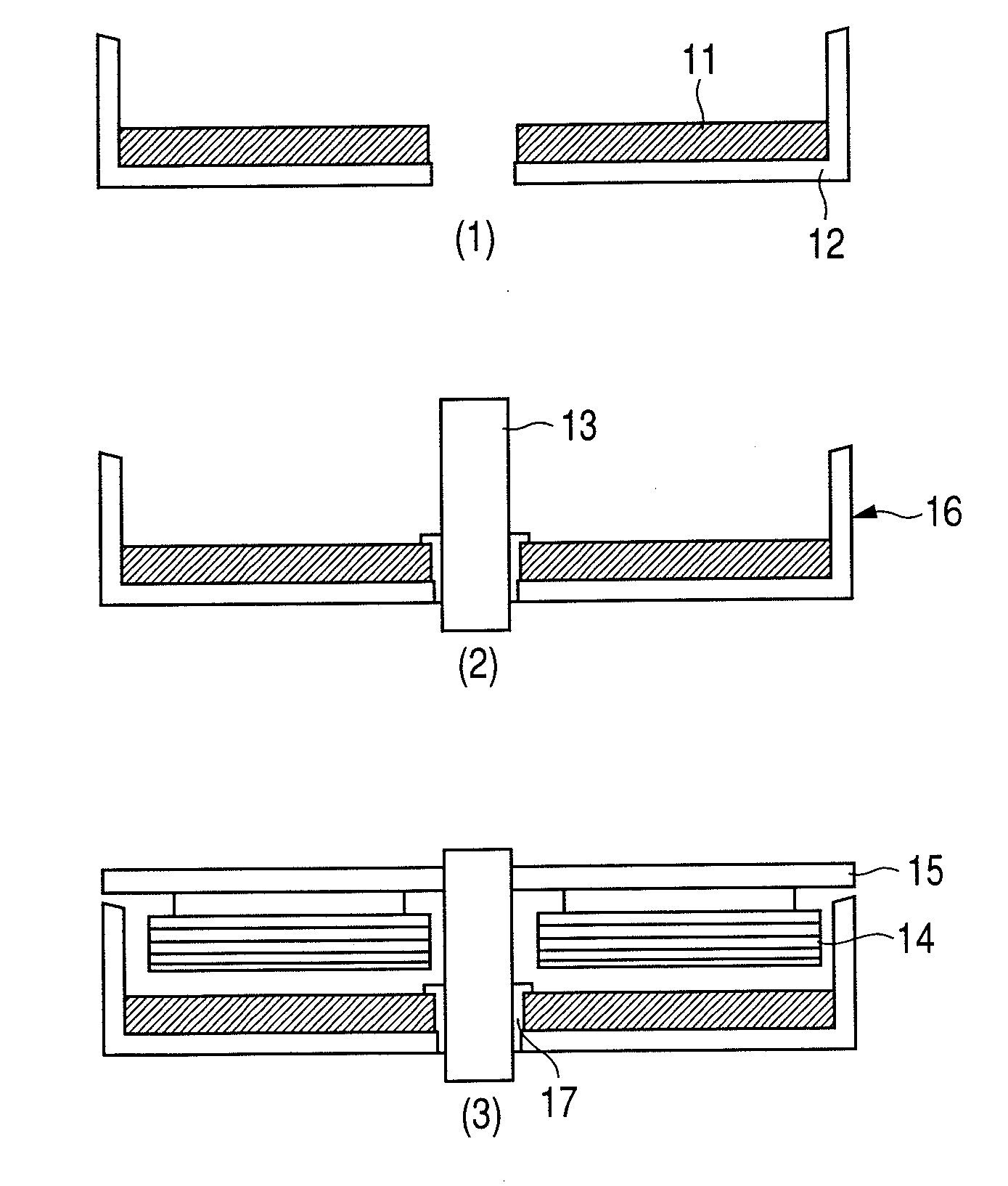

Structure of rotor for generators and method of manufacturing the same rotor

InactiveUS6144130AReduce manufacturing costImprove permeabilityMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsFiberEngineering

Owner:ISUZU MOTORS LTD

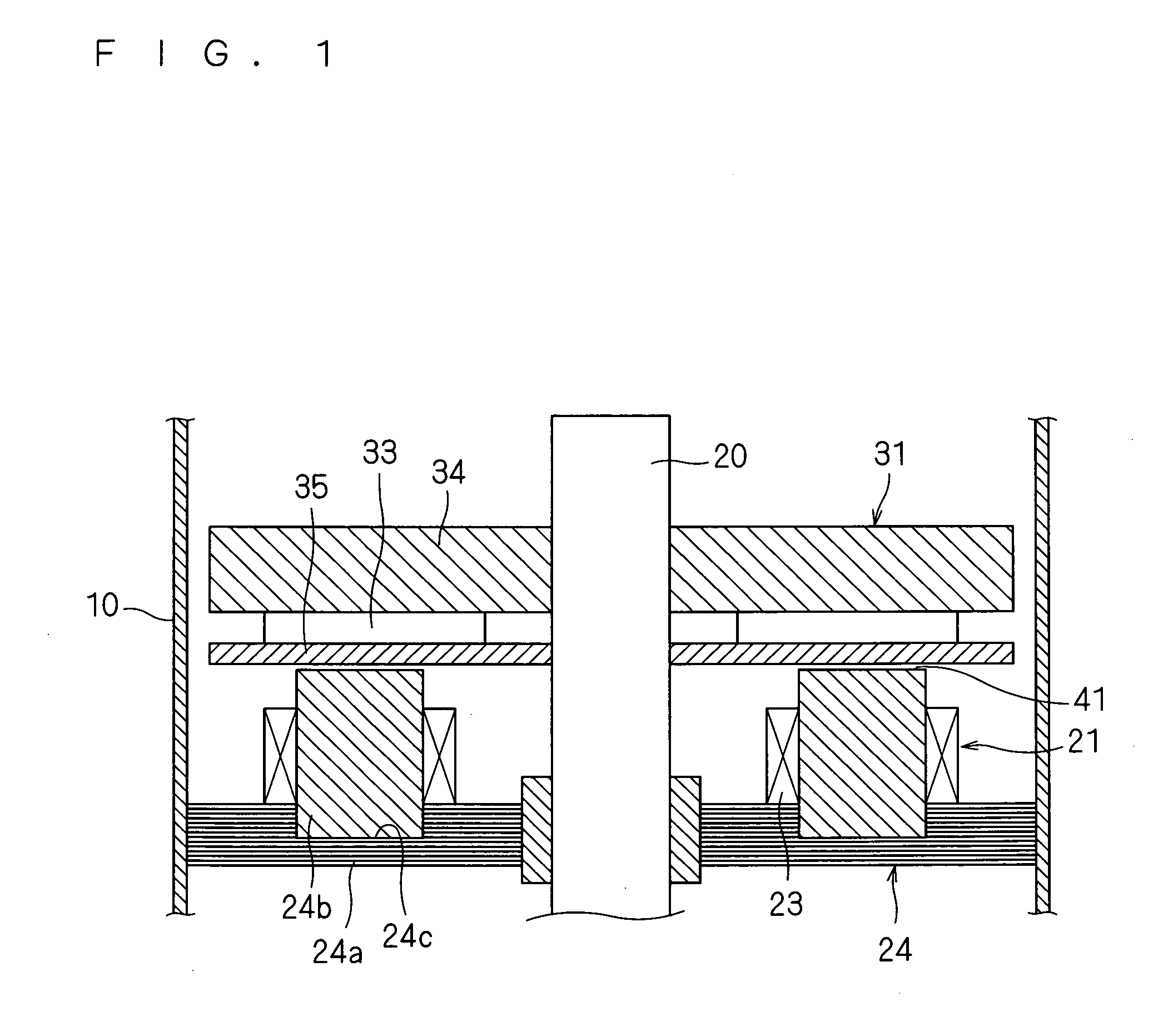

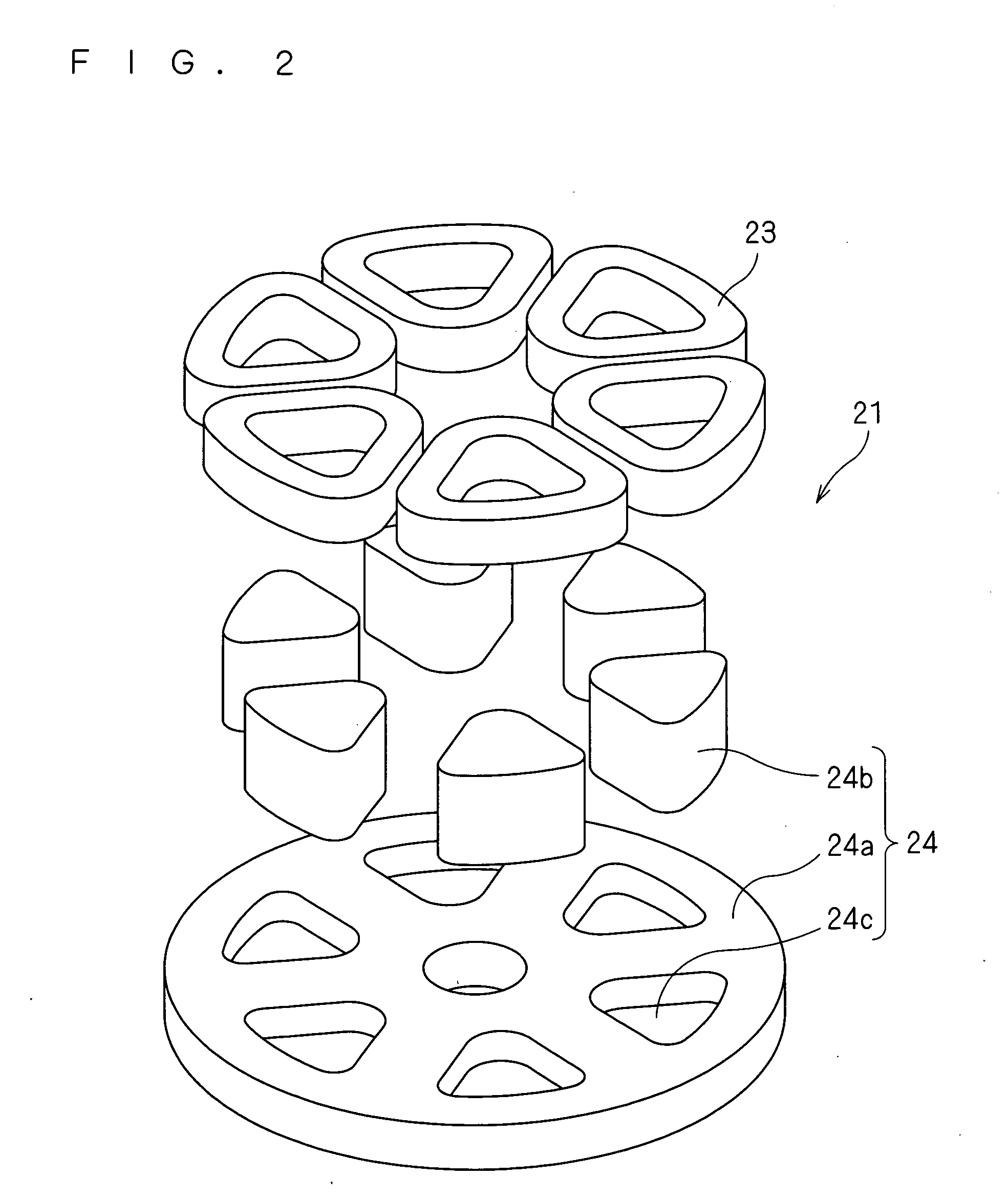

Armature Core, Motor Using It, and Its Manufacturing Method

InactiveUS20100225195A1High magnetic flux densityPrevents impairment of motor characteristicMagnetic circuit rotating partsPositive displacement pump componentsMagnetic fieldElectric motor

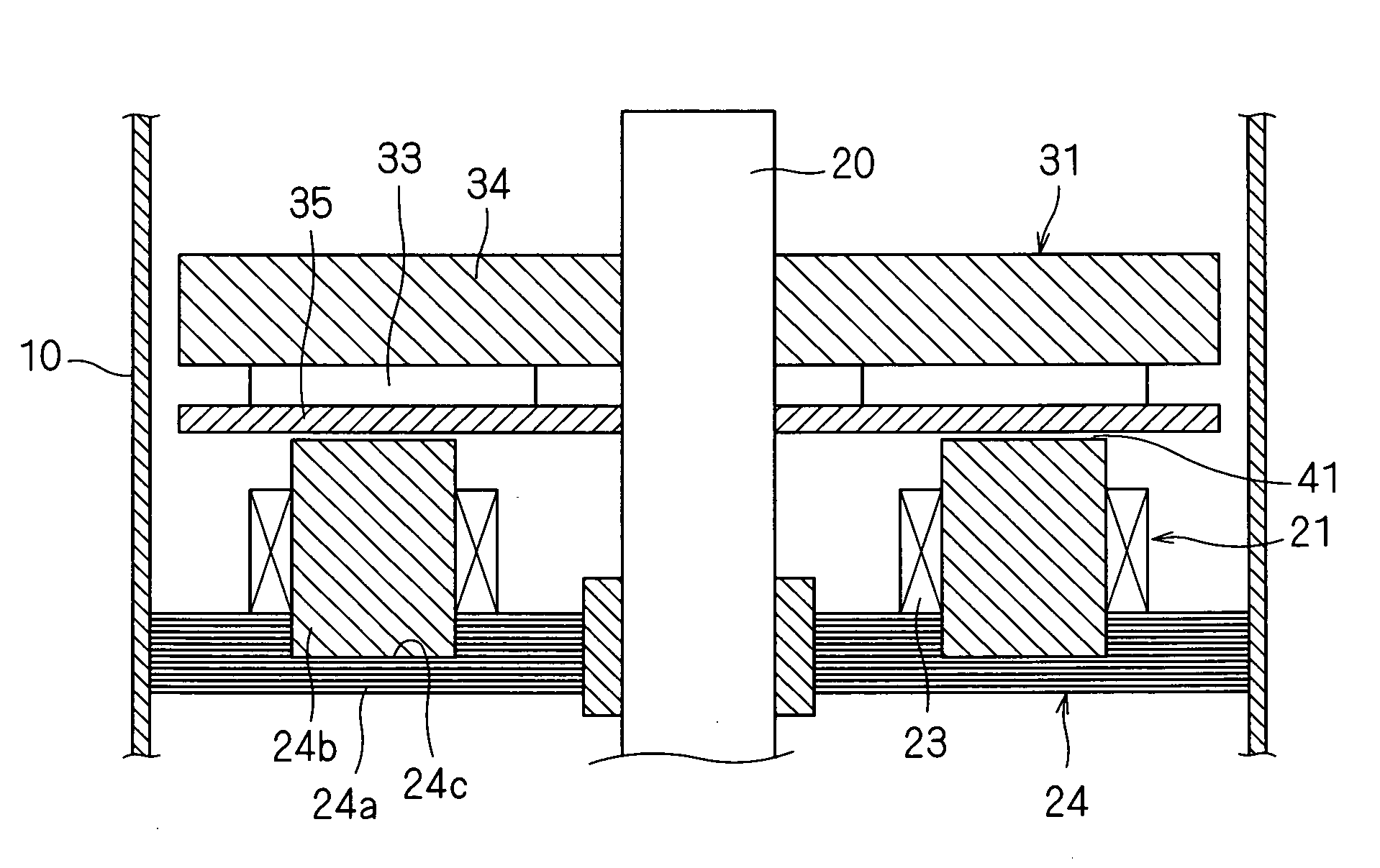

An object is to enable simple manufacture of a motor, especially, a stator core or a field without impairment of motor characteristics. The motor includes a shaft, a rotor fixed to the shaft, and a stator including a stator core that faces the rotor with a certain space therebetween and coils that are attached to the stator core. The stator includes a back yoke, and the stator core having a plurality of teeth that are circumferentially placed in an axial end face of the back yoke so as to stand upright axially of the back yoke, and that are formed of a dust core made of pressed magnetic powder. The above-mentioned teeth are buried axially to a certain depth in the back yoke.

Owner:DAIKIN IND LTD

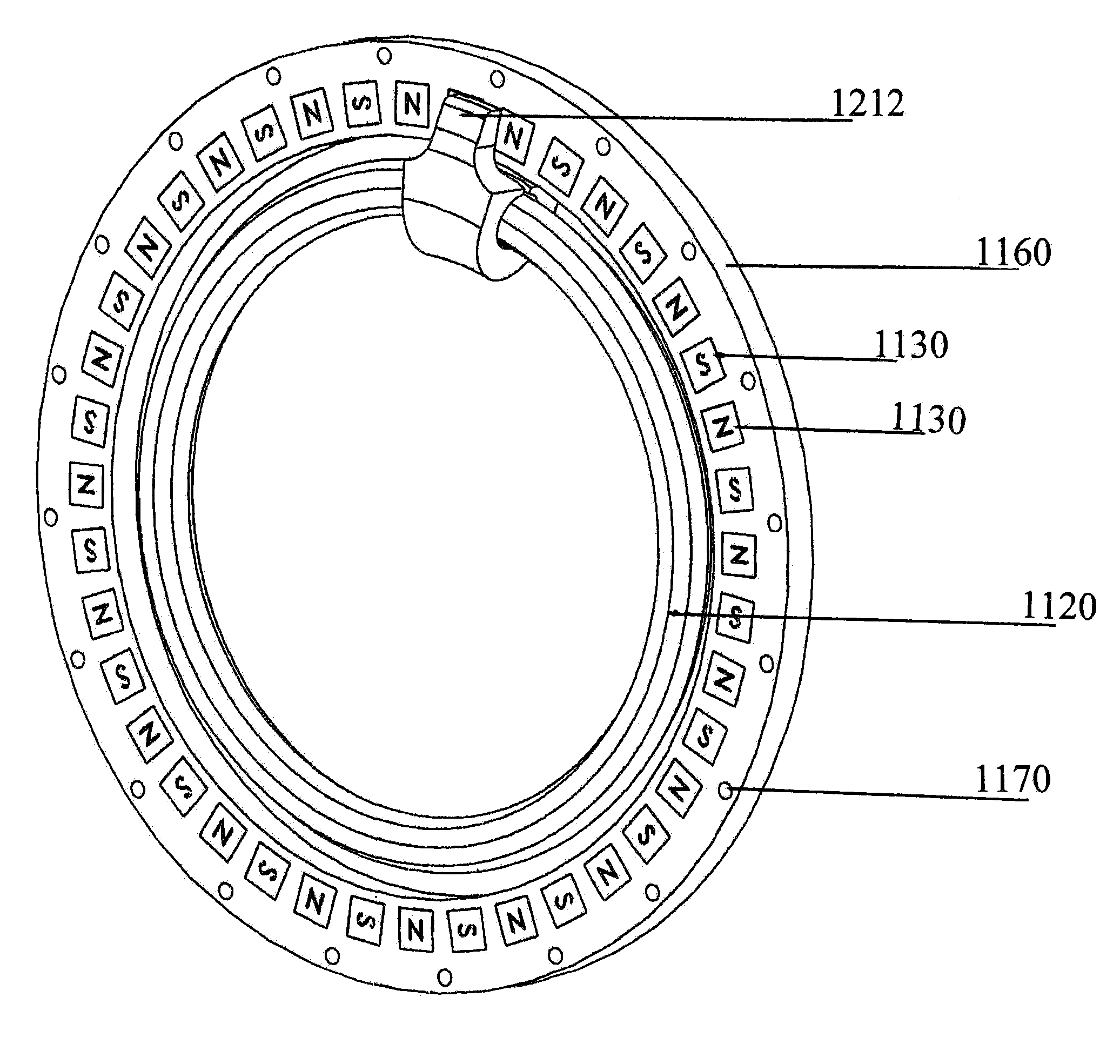

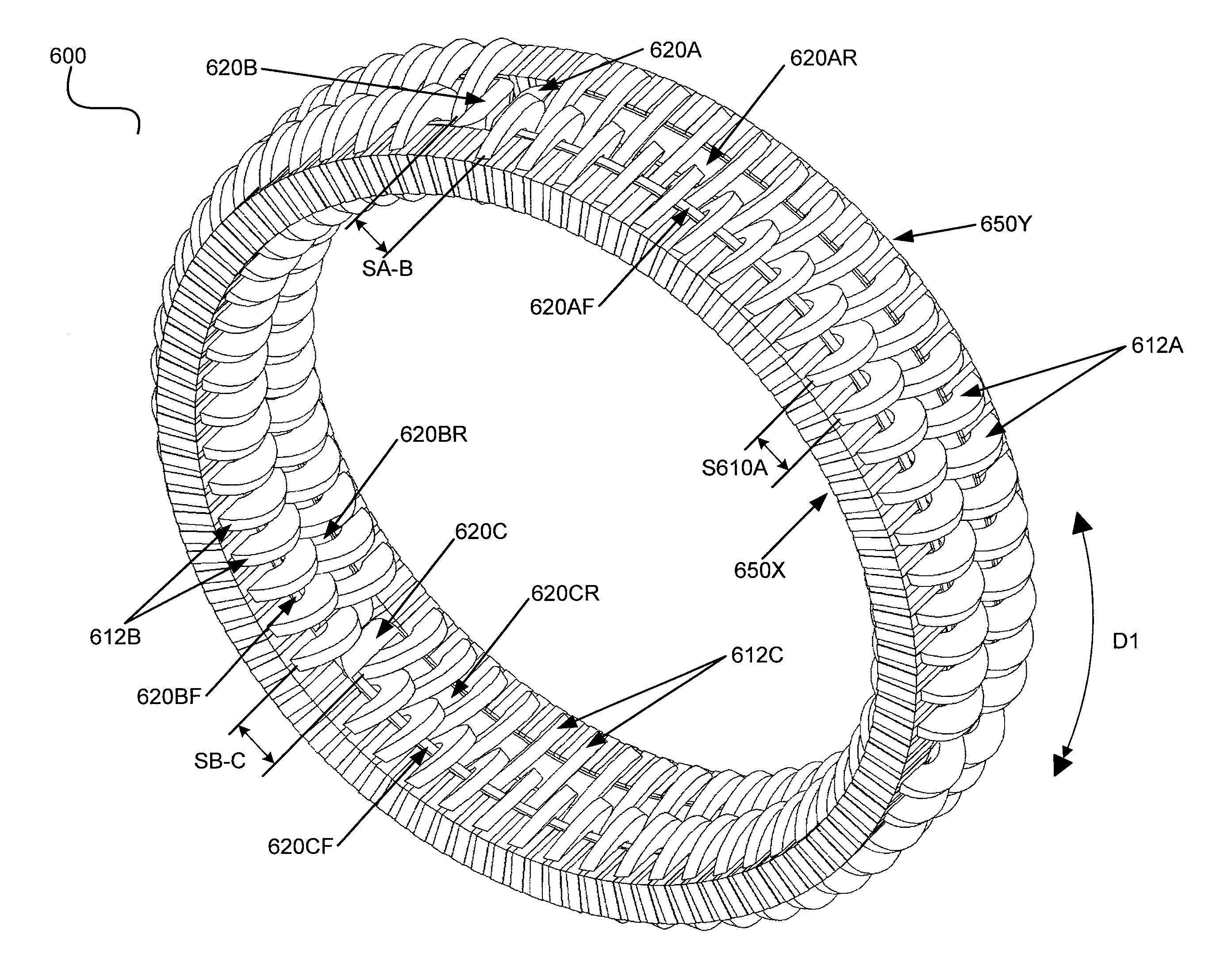

Transverse and/or commutated flux system stator concepts

Disclosed are transverse and / or commutated flux machines and components thereof, and methods of making and using the same. Certain exemplary stators for use in transverse and commutated flux machines may be configured with gaps therebetween, for example in order to counteract tolerance stackup. Other exemplary stators may be configured as partial stators having a limited number of magnets and / or flux concentrators thereon. Partial stators may facilitate ease of assembly and / or use with various rotors. Additionally, exemplary floating stators can allow a transverse and / or commutated flux machine to utilize an air gap independent of the diameter of a rotor. Via use of such exemplary stators, transverse and / or commutated flux machines can achieve improved performance, efficiency, and / or be sized or otherwise configured for various applications.

Owner:ELECTRIC TORQUE MASCH INC

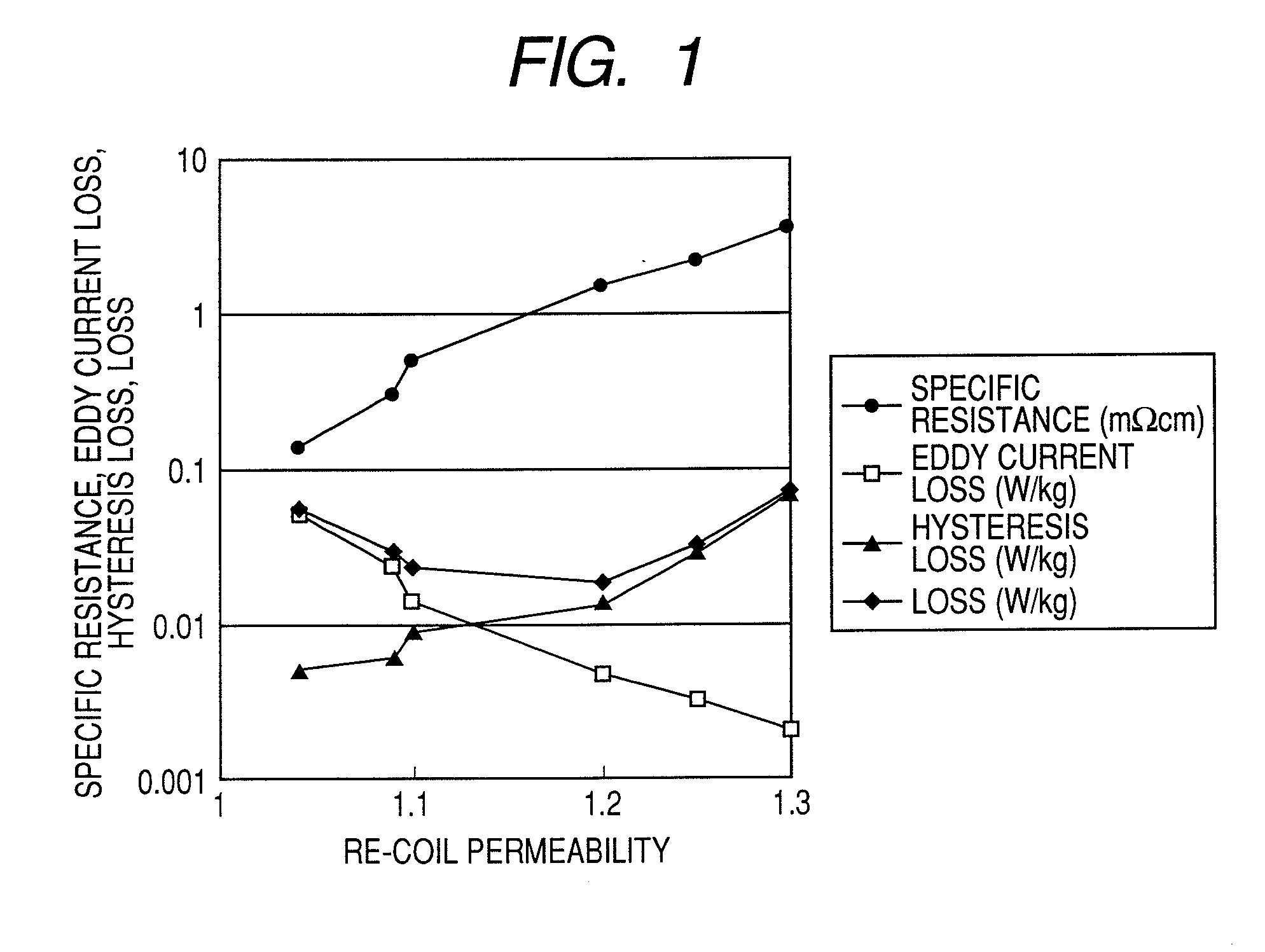

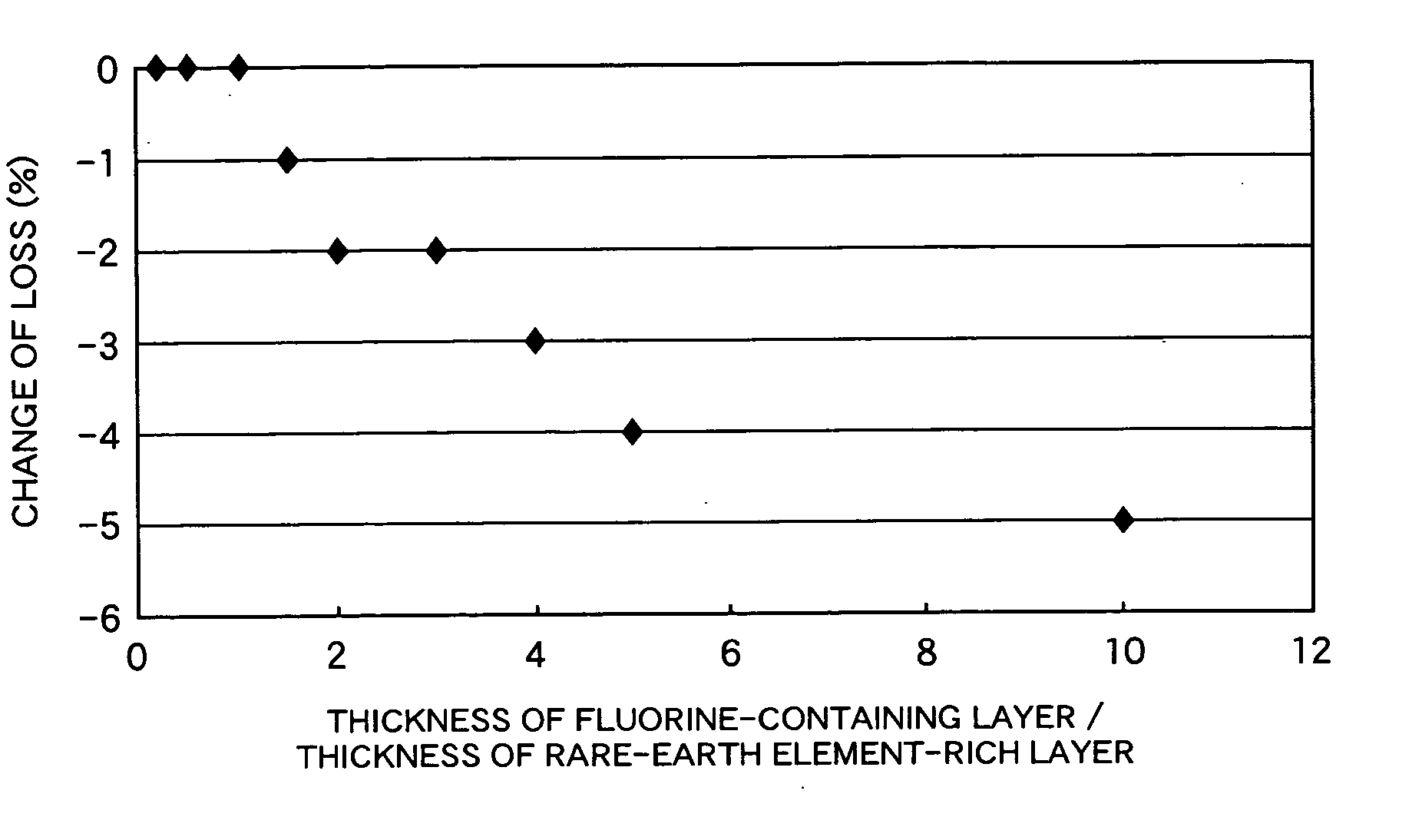

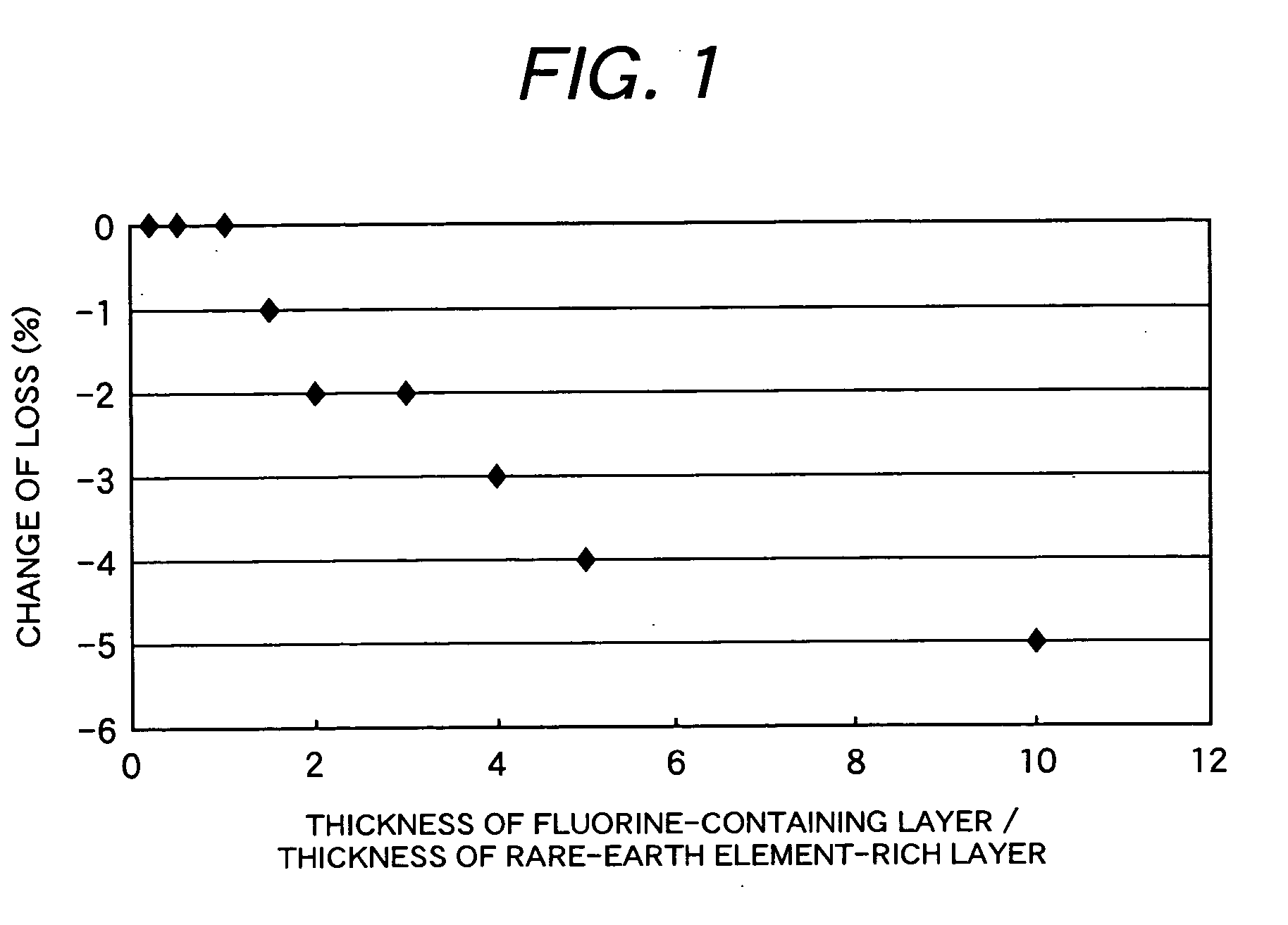

High resistance magnet and motor using the same

InactiveUS20080054738A1Improve magnetic propertiesImprove propertiesLayered productsNanoinformaticsRare-earth elementHigh resistance

A magnet comprising grains of a ferromagnetic material whose main component is iron and a fluorine compound layer or an oxy-fluorine compound layer of fluoride compound particles of alkali metals, alkaline earth metals and rare earth elements, present on the surface of the ferromagnetic material grains, wherein an amount of iron atoms in the fluorine compound particles is 1 to 50 atomic %.

Owner:HITACHI LTD

AC motor having stator windings formed as loop coils, and control apparatus for the motor

ActiveUS20050099082A1Easy to assembleEasy constructionTorque ripple controlWindingsToroidal coilConductor Coil

A synchronous AC motor has a stator with stator poles arranged as a plurality of circumferentially extending stator pole groups, with each stator pole group having a pair of corresponding circumferentially extending loop-configuration stator windings disposed adjacent on either side or a single such winding disposed adjacent at one side, adjacent stator pole groups being mutually circumferentially displaced by a fixed amount corresponding to a specific electrical phase angle. A rotating magnetic field is produced by applying respective polyphase AC voltages to the windings, such that currents of mutually opposite direction flow in each pair.

Owner:DENSO CORP

Method for selectively coupling layers of a stator in a motor/generator

InactiveUS6181048B1Maximization of overall densityShort gapWindings insulation shape/form/constructionManufacturing stator/rotor bodiesCross-linkElectrical conductor

An axial field motor / generator having a rotor that includes at least three annular discs magnetized to provide multiple sector-shaped poles. Each sector has a polarity opposite that of an adjacent sector, and each sector is polarized through the thickness of the disc. The poles of each magnet are aligned with opposite poles of each adjacent magnet. Metal members adjacent the outermost two magnets contain the flux. The motor / generator also has a stator that includes a stator assembly between each two adjacent magnets. Each stator assembly includes one or more conductors or windings. Although the conductors may be formed of wire having a round, uniform cross-section, they may alternatively be formed of conductors having a tapered cross-section that corresponds to the taper of the sectors in order to maximize the density of the conductor in the gap between axially adjacent poles. The conductors may also alternatively be formed of traces in a printed circuit, which may have one or more layers. Each stator assembly may be removably connectable to another stator assembly to provide modularity in manufacturing and to facilitate selection of the voltage at which the motor / generator is to operate. Electrical contacts, such as pins extending from the casing, may removably connect the conductors of adjacent stator assemblies. A magnet may be dynamically balanced on the shaft by hardening a thin ring-of cross-linked resin between the magnet and the shaft while the shaft is spun, using ultraviolet light to polymerize the resin.

Owner:SMITH TECH DEV LLC +1

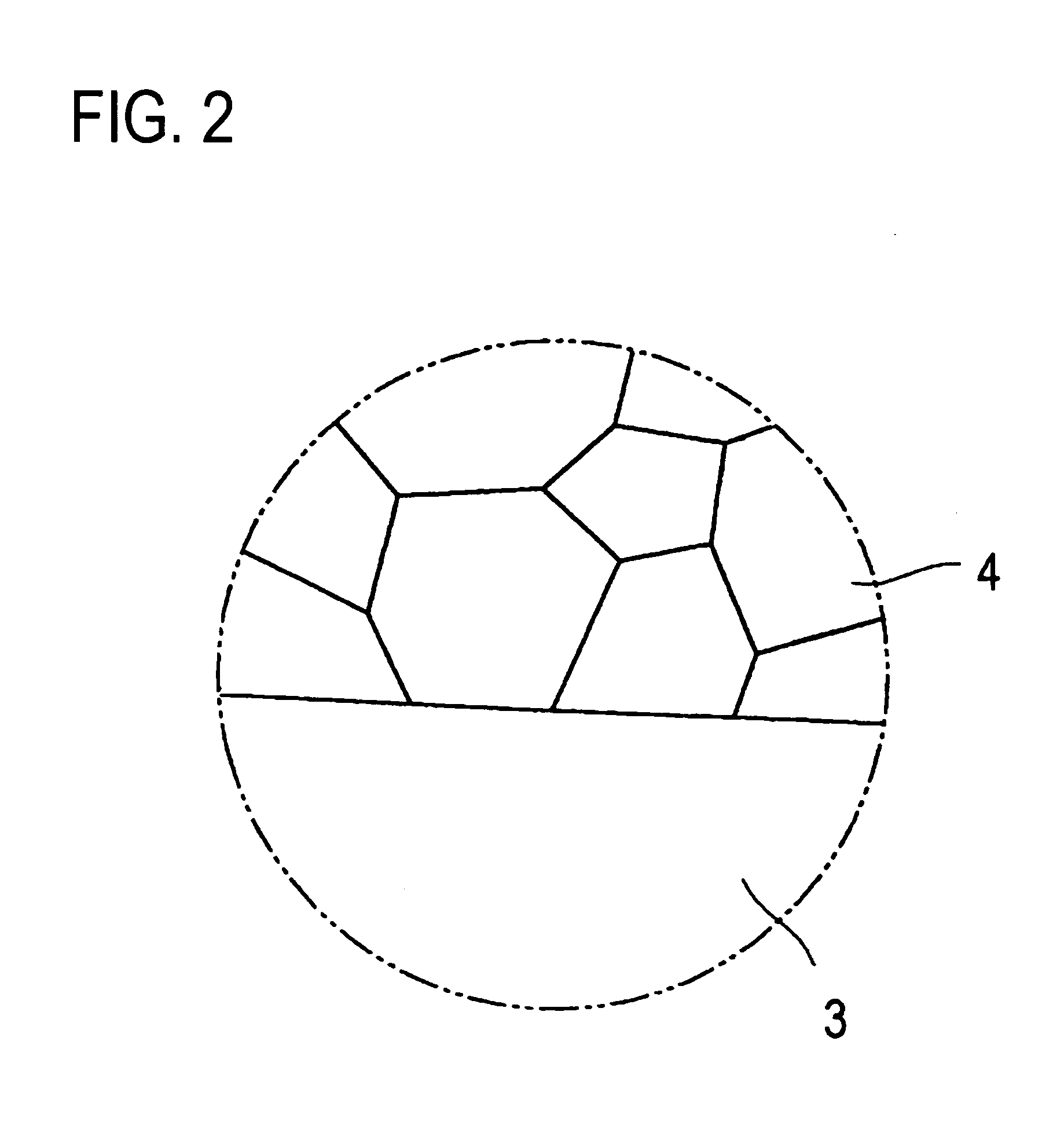

Ellipsoid generator

A dynamoelectric device that is highly adaptable to a broad range of applications while providing robust output and energy conversion. The magnetic pole faces of the rotor lie in an ellipsoid. With or without a rotor shaft, the device allows options of either physical connection or contact-less, magnetic coupling. Surrounding the rotor is a brush-less stator having a bobbin-type, axial-centered coil conductor that provides a total capture of magnetic flux emanating from a rotor having an entire surface area of uniform flux density. Devices without a rotor shaft, and those having an air gap filled with ferrofluid, provide a two part generator with remarkable efficiency that is easily waterproofed and mechanically stable.

Owner:HARMONIC DRIVE INC

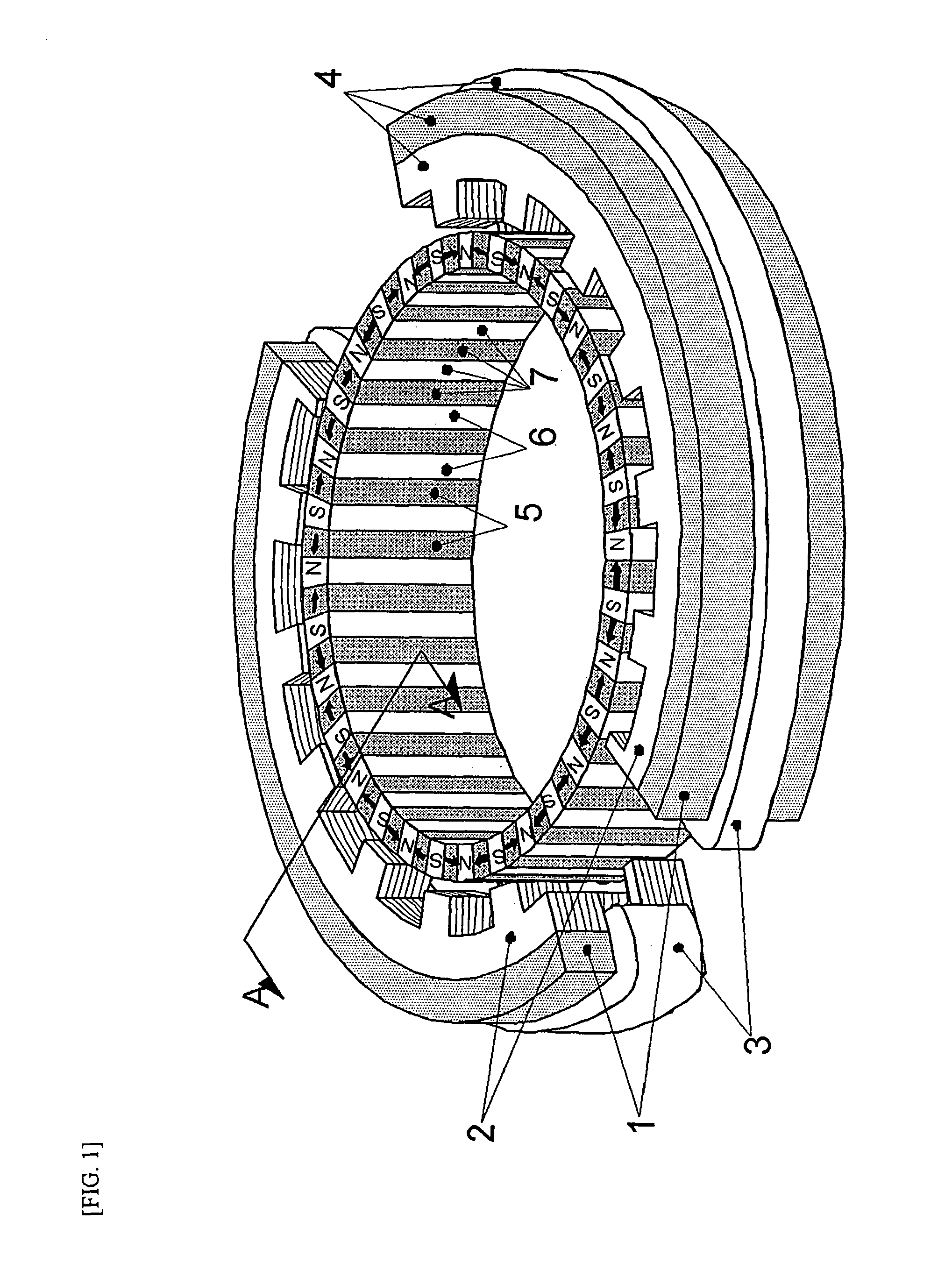

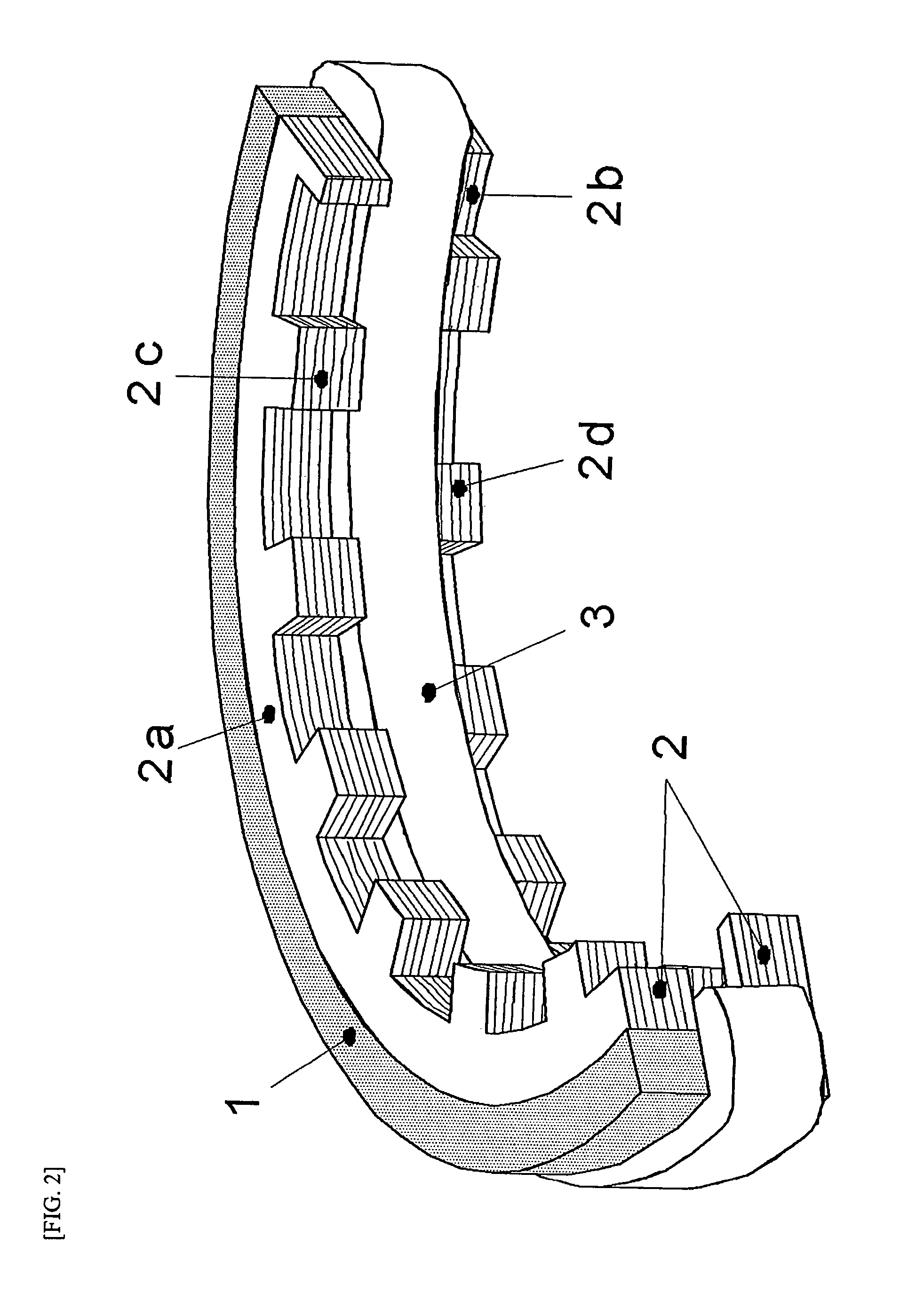

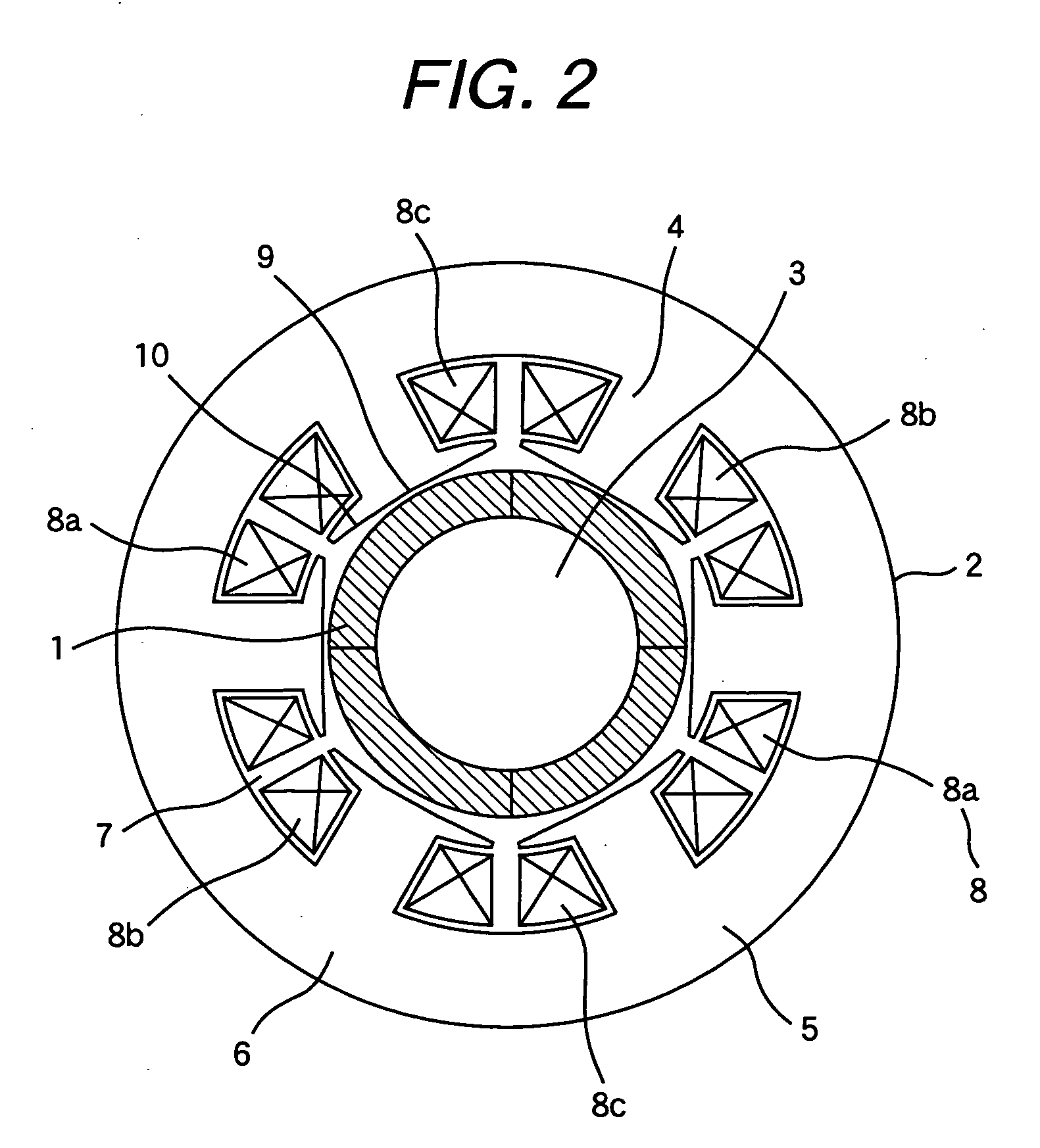

Inner rotor type permanent magnet excited transverse flux motor

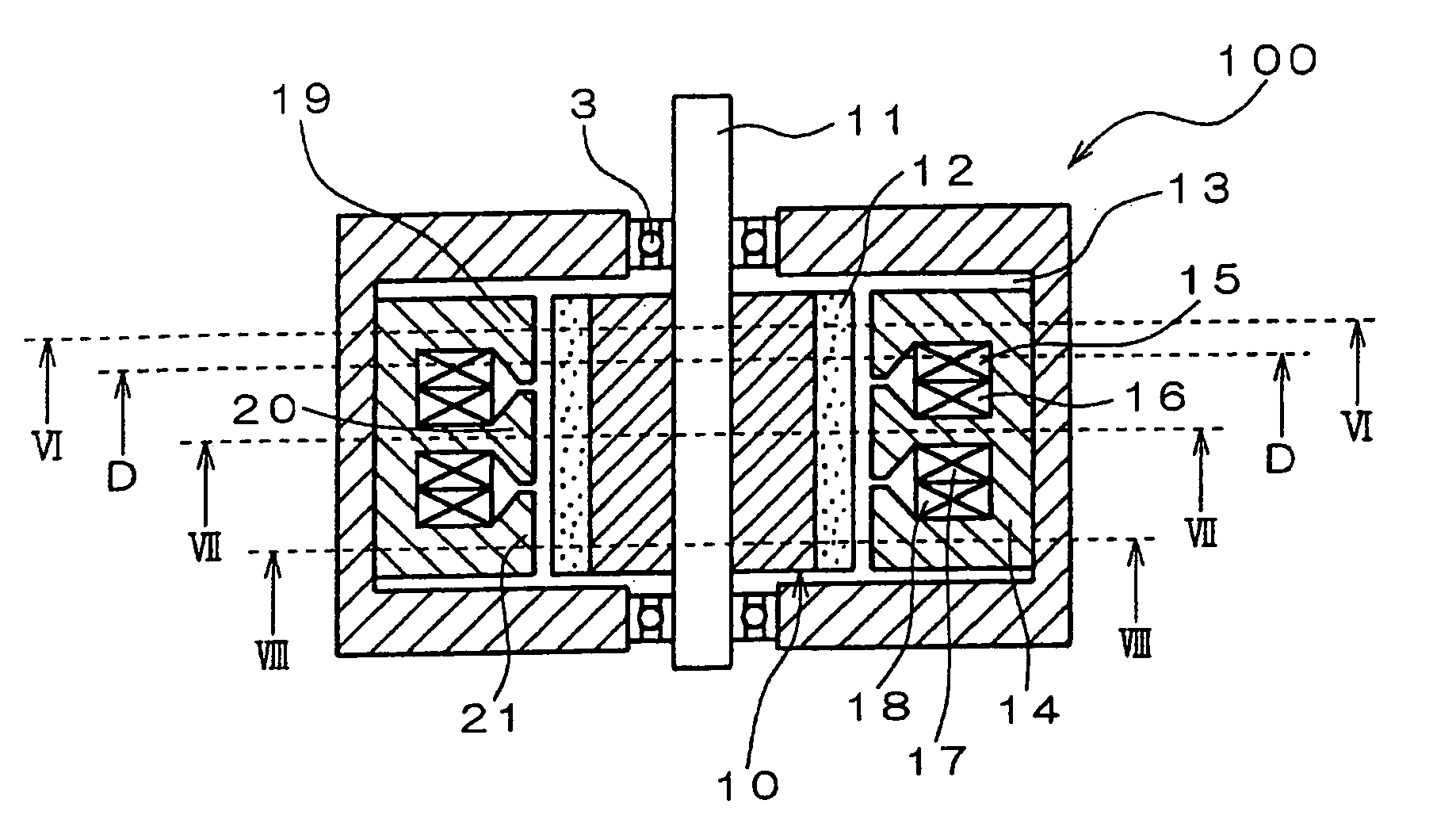

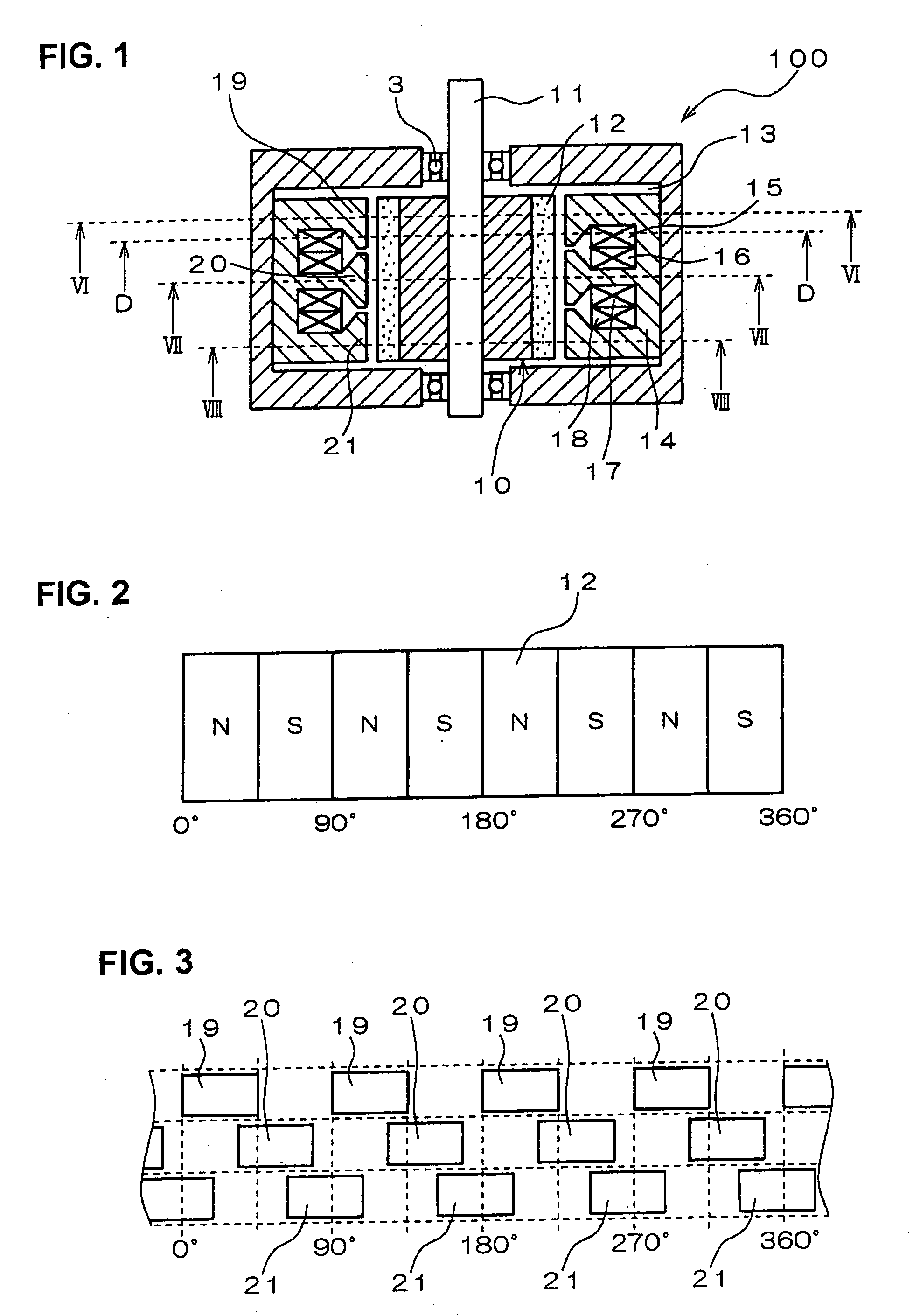

ActiveUS7952252B2Reducing iron lossImprove efficiencyMagnetic circuit stationary partsManufacturing dynamo-electric machinesTransverse fluxPower flow

Disclosed herein is an inner rotor type permanent magnet excited transverse flux motor, in which a laminated structure in an axial direction or in a radial shape is applied to a stator iron core so as to employ a small amount of permanent magnets compared with a conventional outer rotor type permanent magnet excited transverse flux motor, thus providing high output power, increasing the efficiency of power generation, and reducing noise and vibration. For this, the present invention provides an inner rotor type permanent magnetic excited transverse flux motor comprising: a stator including a stator powdered iron core press-molded using a mold, a stator laminated iron core laminated on upper and lower layer portions of the circumference of the stator powdered iron core at regular intervals, and a stator winding which winds the segmented stator powdered iron core in which a current flows is wound between the intervals; and a rotor in which a rotor permanent magnet and a rotor powdered iron core are arranged alternately to face each other.

Owner:KOREA ELECTROTECH RES INST

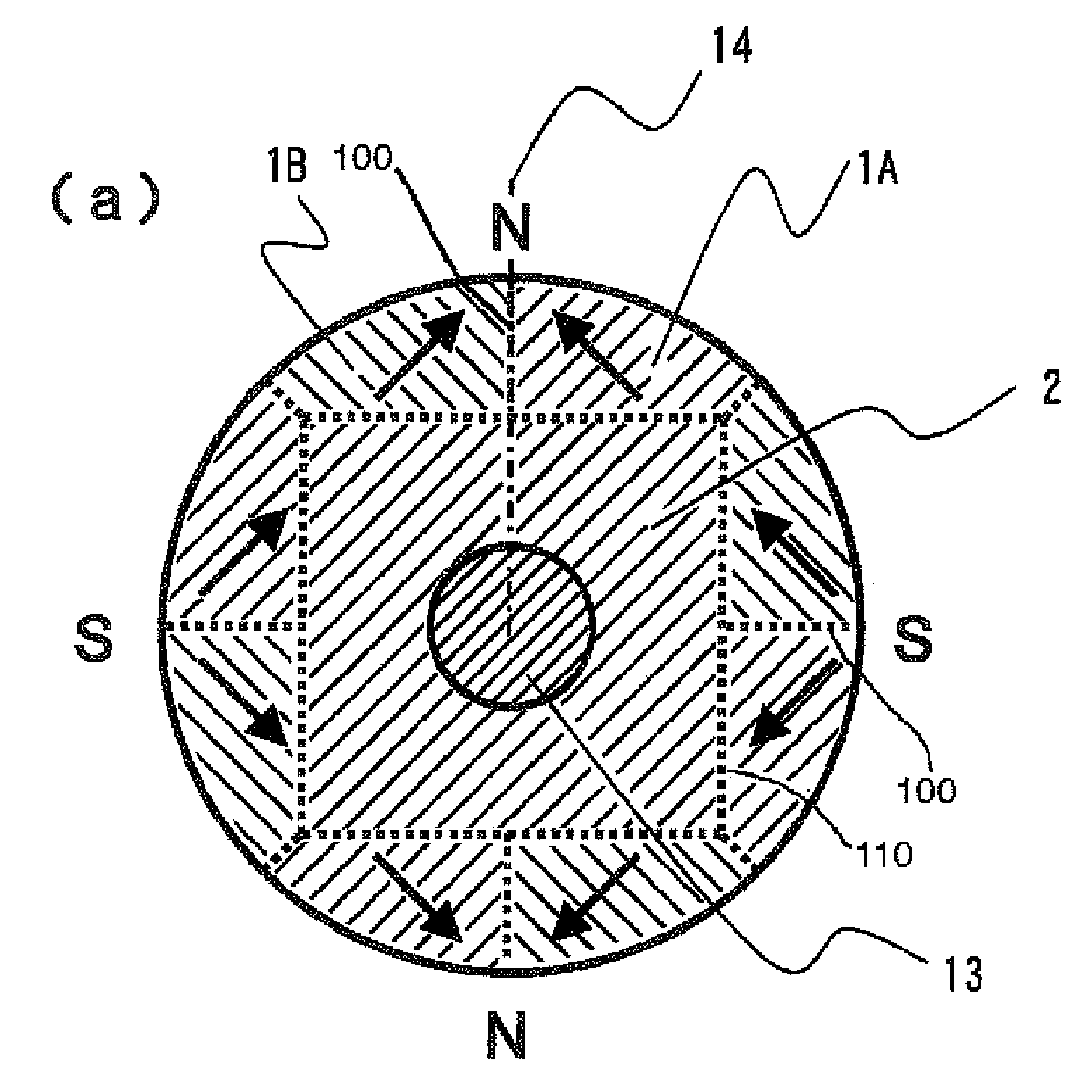

Rotor for Motor and Method for Producing the Same

InactiveUS20080218007A1Stable and small in pole pitchSimple structureMagnetic circuit rotating partsPermanent magnetsStructural reliabilityMagnetization

A surface magnet type rotor and an inner magnet type rotor having good motor characteristics in which bonding strength is high between a magnet section and a soft magnetic yoke section, and structural reliability is high even in high speed use, and its producing method. The rotor comprises an anisotropic bond magnet section and a soft magnetic section wherein the anisotropic bond magnet section is preformed in magnetic field and then formed to be integrated with the soft magnetic section in nonmagnetic field. Subsequently, it is heat hardened to produce a surface magnet type rotor. Magnet units, each having a magnetic pole composed by bonding a pair of permanent magnets such that the directions of magnetization become symmetric with respect to the bonding surface, are linked such that magnetic poles of different polarities appear alternately on the magnetic action surface thus forming an anisotropic magnet body. Good motor characteristics can be attained by setting an angle to 5-40° between the direction of magnetization of the permanent magnet and a diametral direction passing the bonding surface.

Owner:HITACHI METALS LTD

Rare-earth magnet

InactiveUS20060022175A1Improve efficiencyReduce magnetic noiseConductive materialInductances/transformers/magnets manufactureRare-earth elementRare-earth magnet

In a ferromagnetic material containing at least one kind of rare-earth element, a layer containing at least one kind of alkaline earth element or rare-earth element and fluorine is formed at the grain boundary or near the powder surface of the ferromagnetic material. A further layer containing at least one kind of rare-earth element, having a fluorine concentration lower than that of the layer described first and having a rare-earth element concentration higher than that of the host phase of the ferromagnetic material, or an oxide layer containing a rare-earth element is formed in adjacent with a portion of the layer described first.

Owner:HITACHI LTD

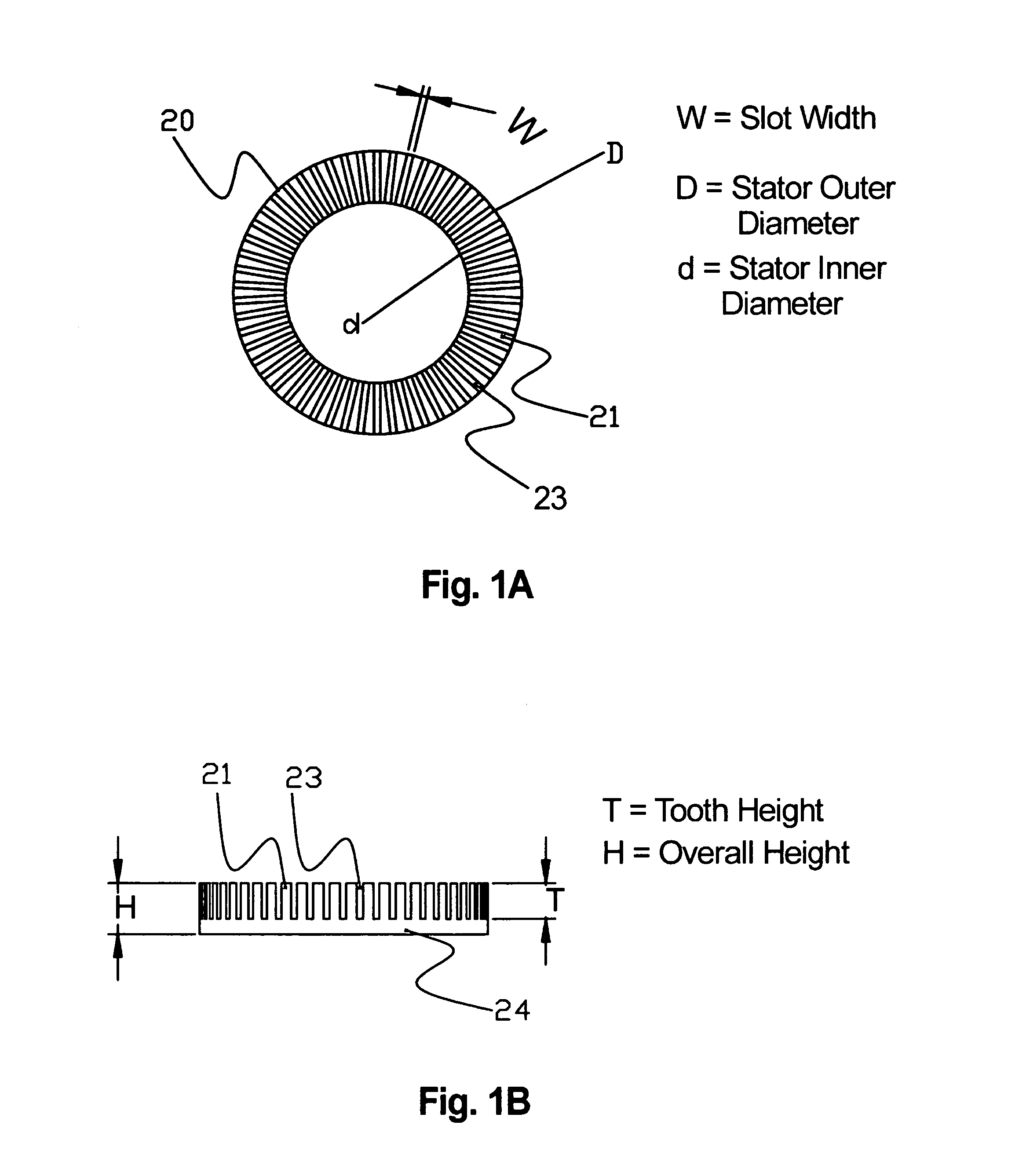

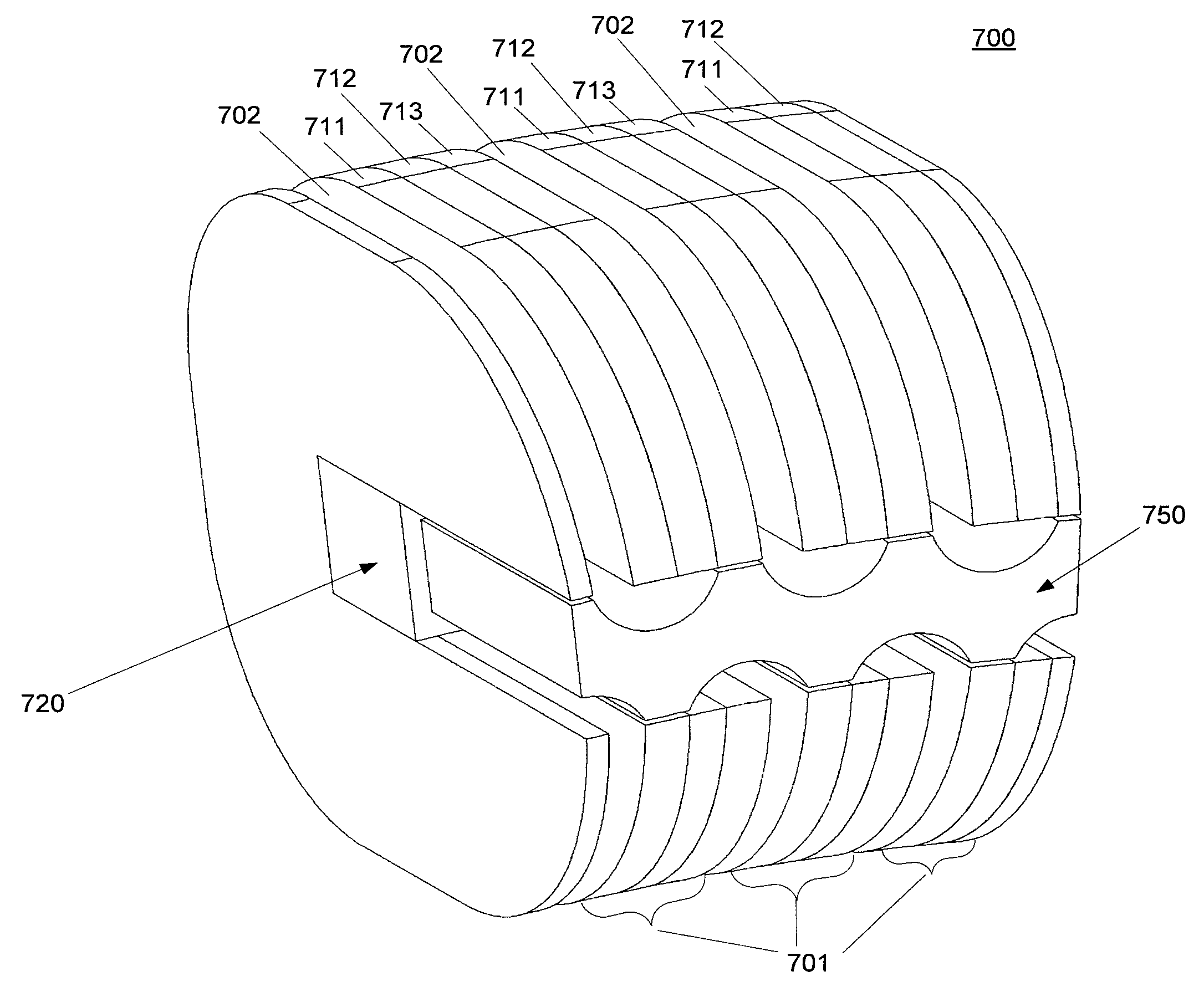

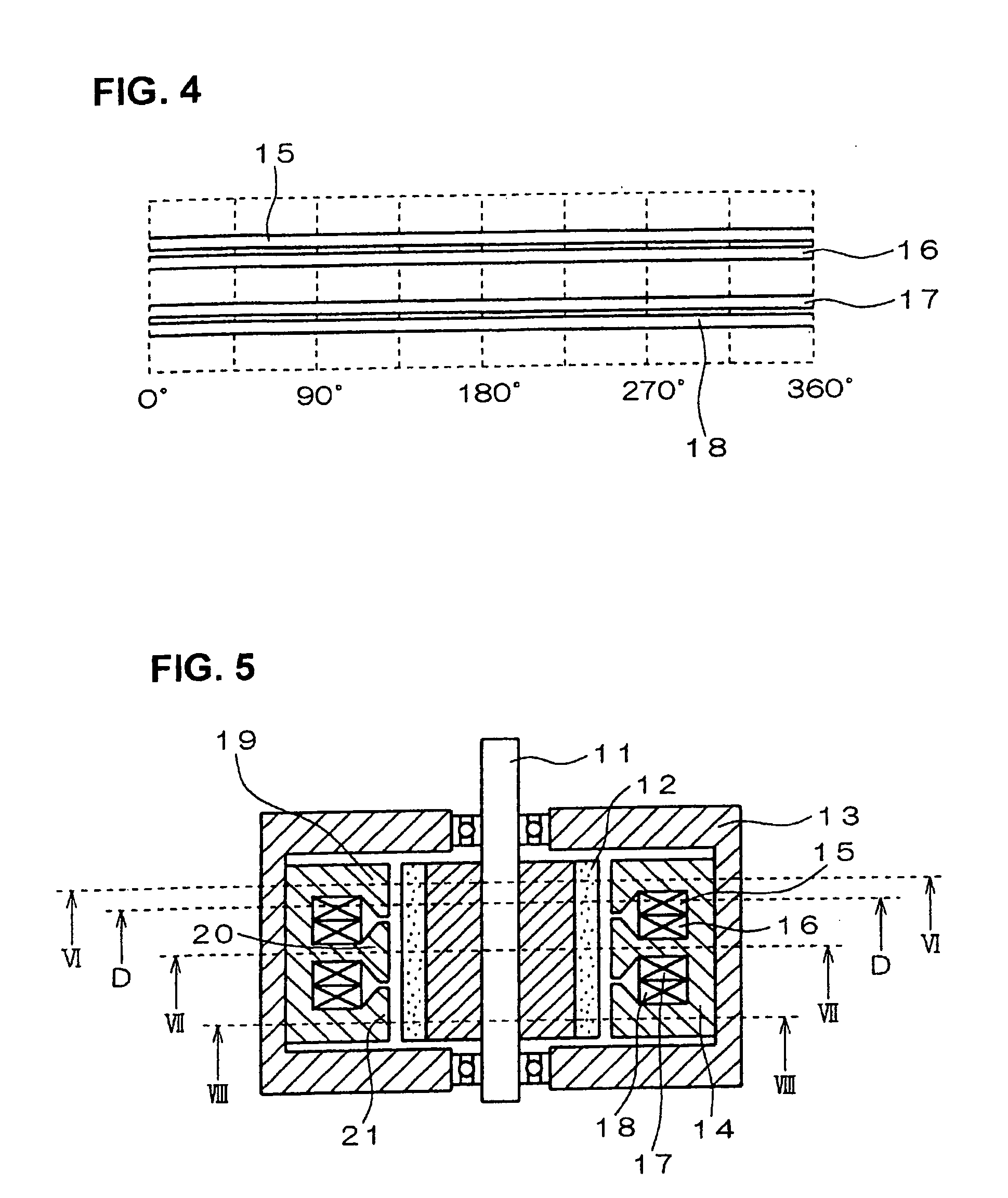

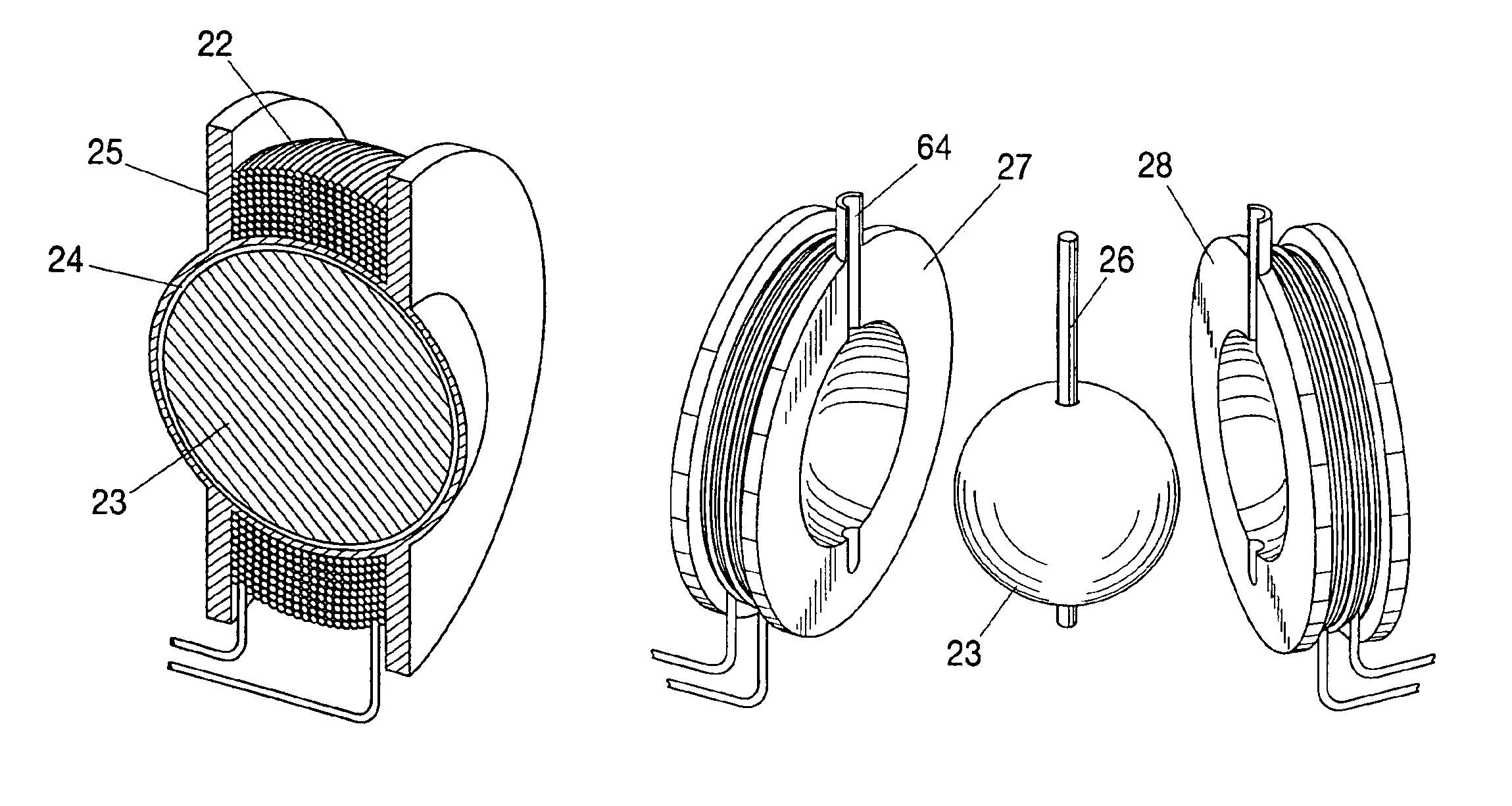

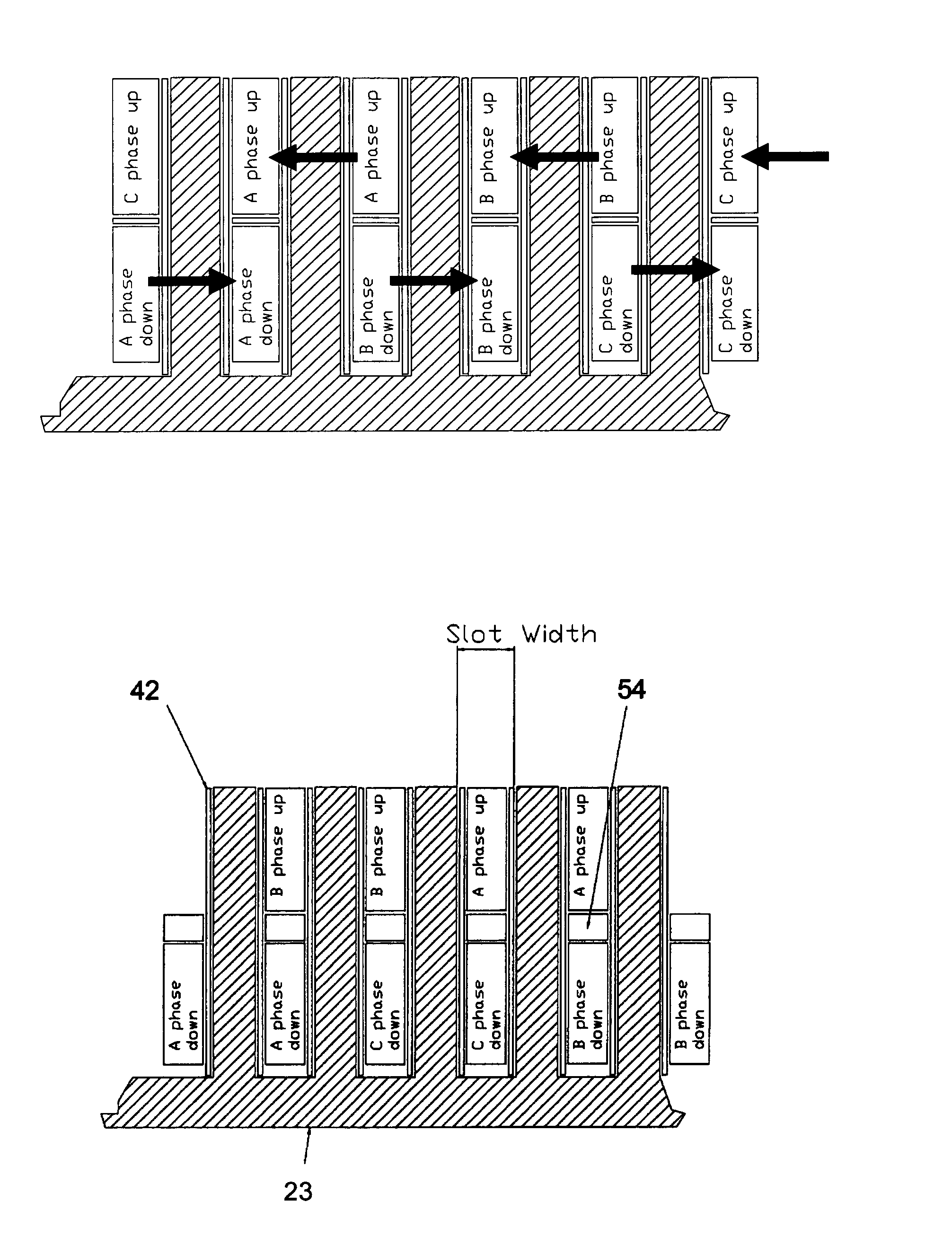

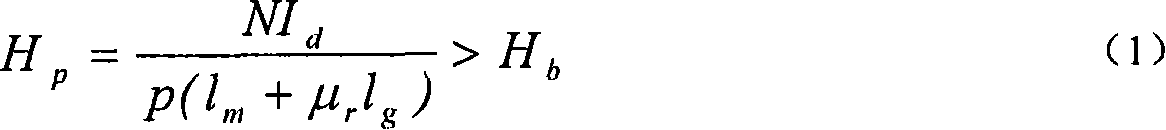

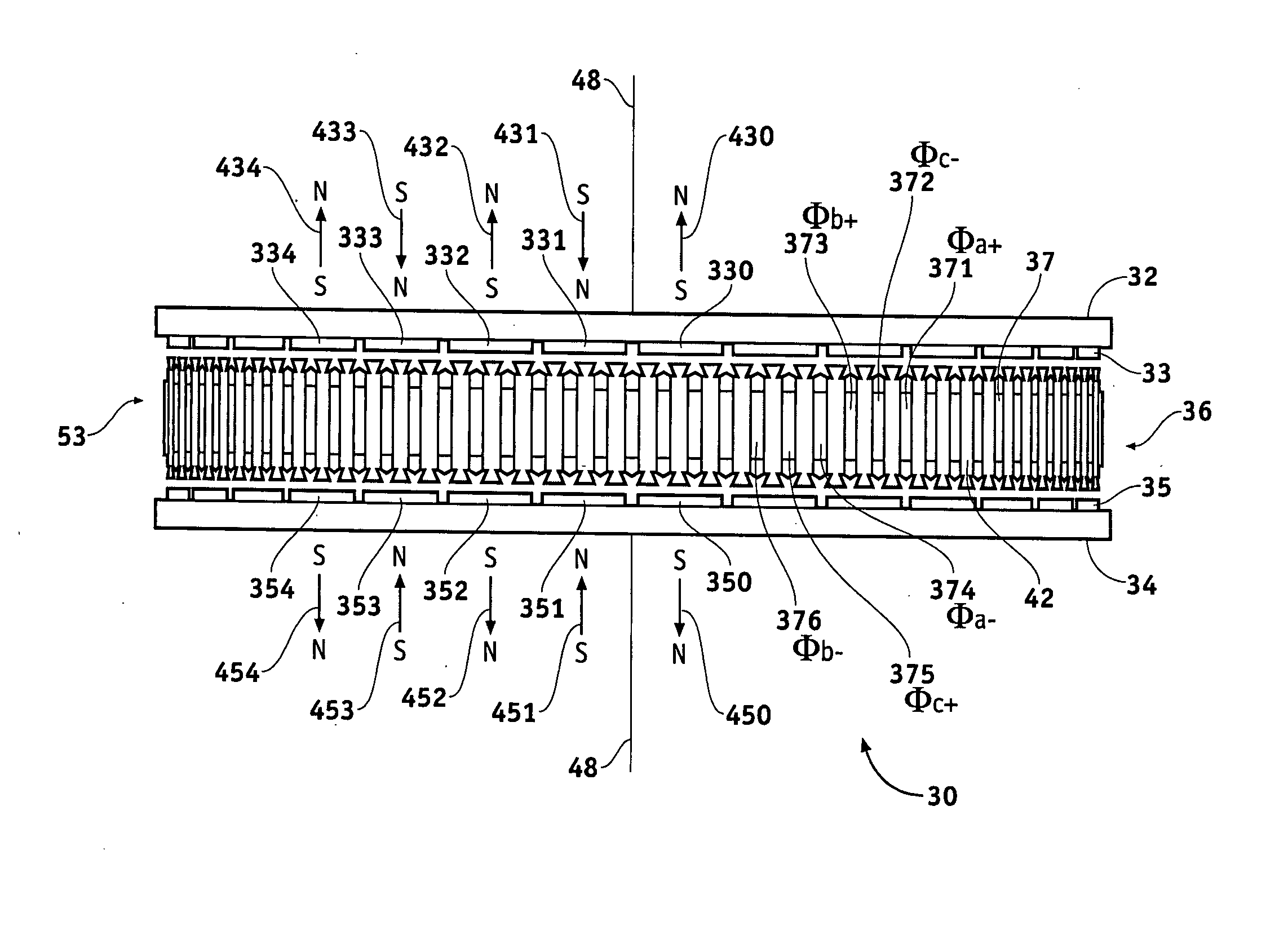

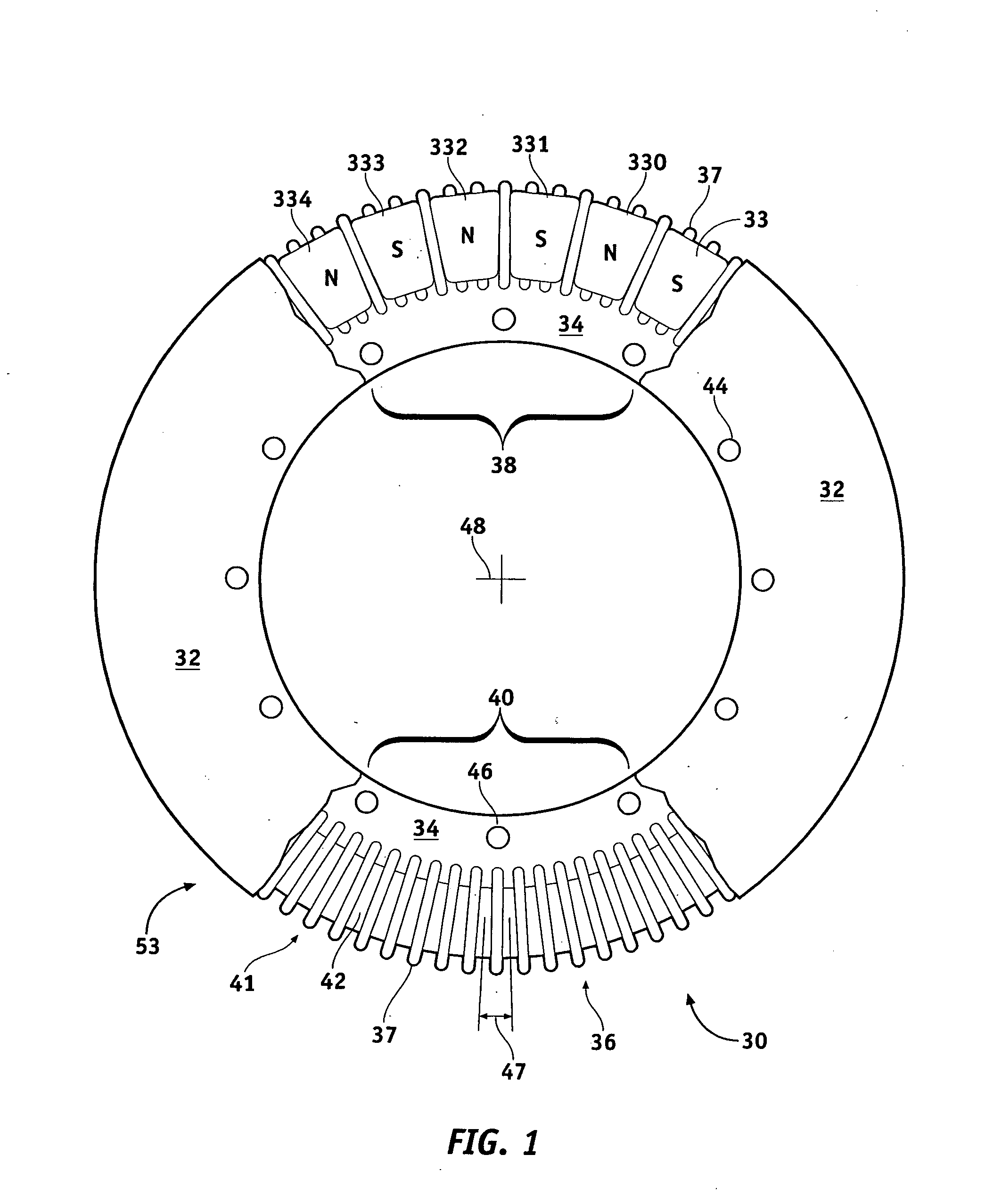

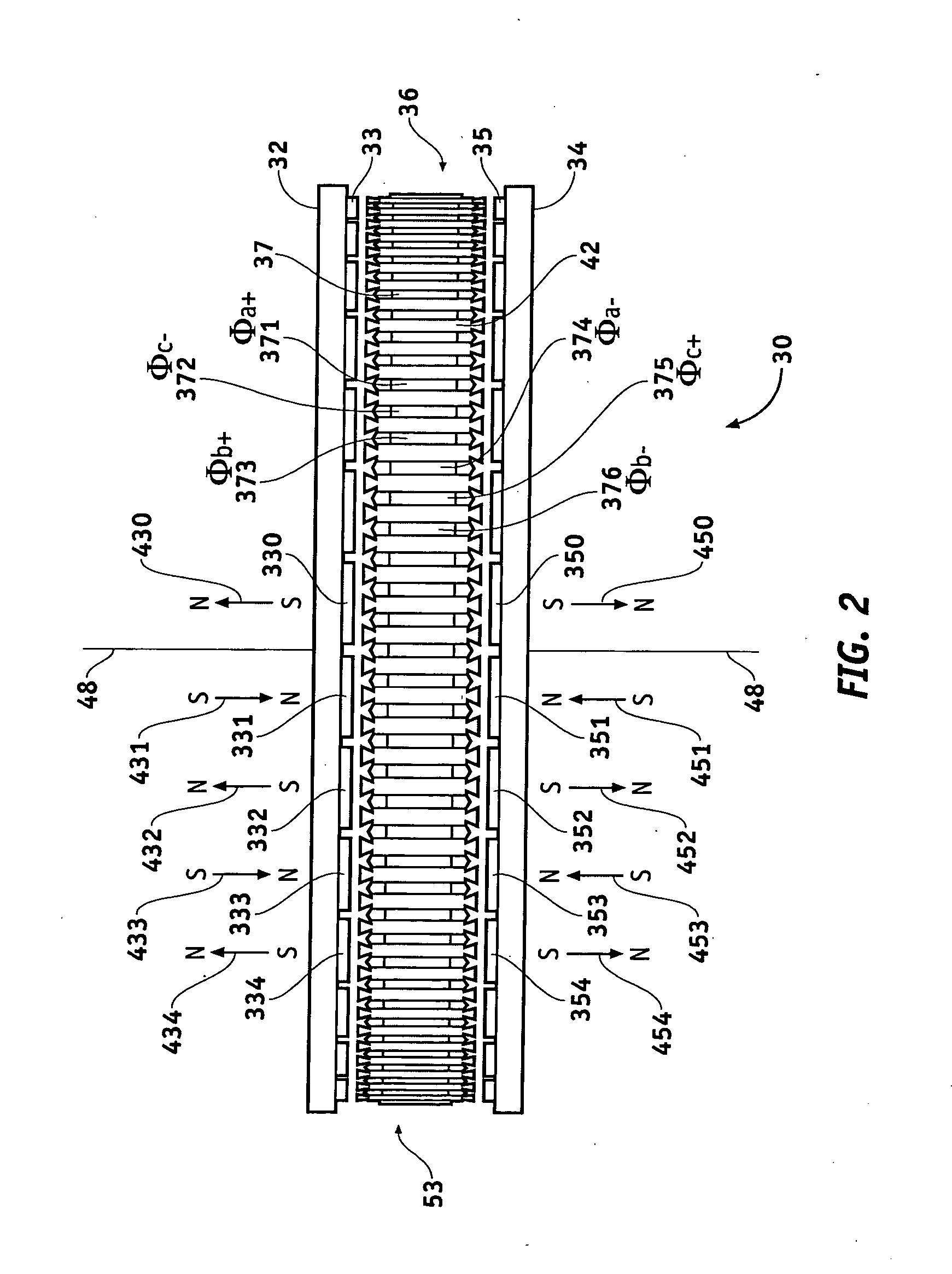

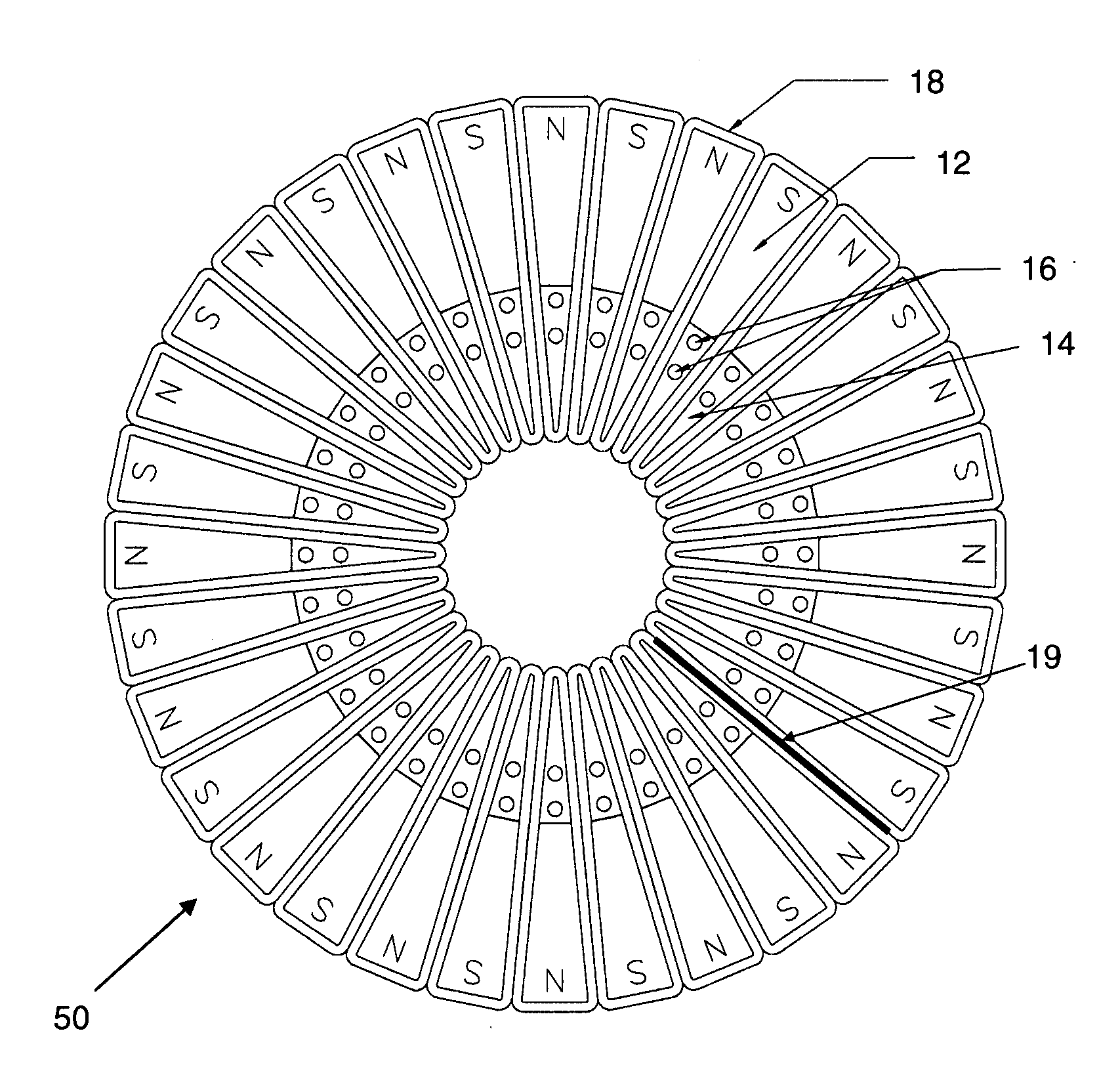

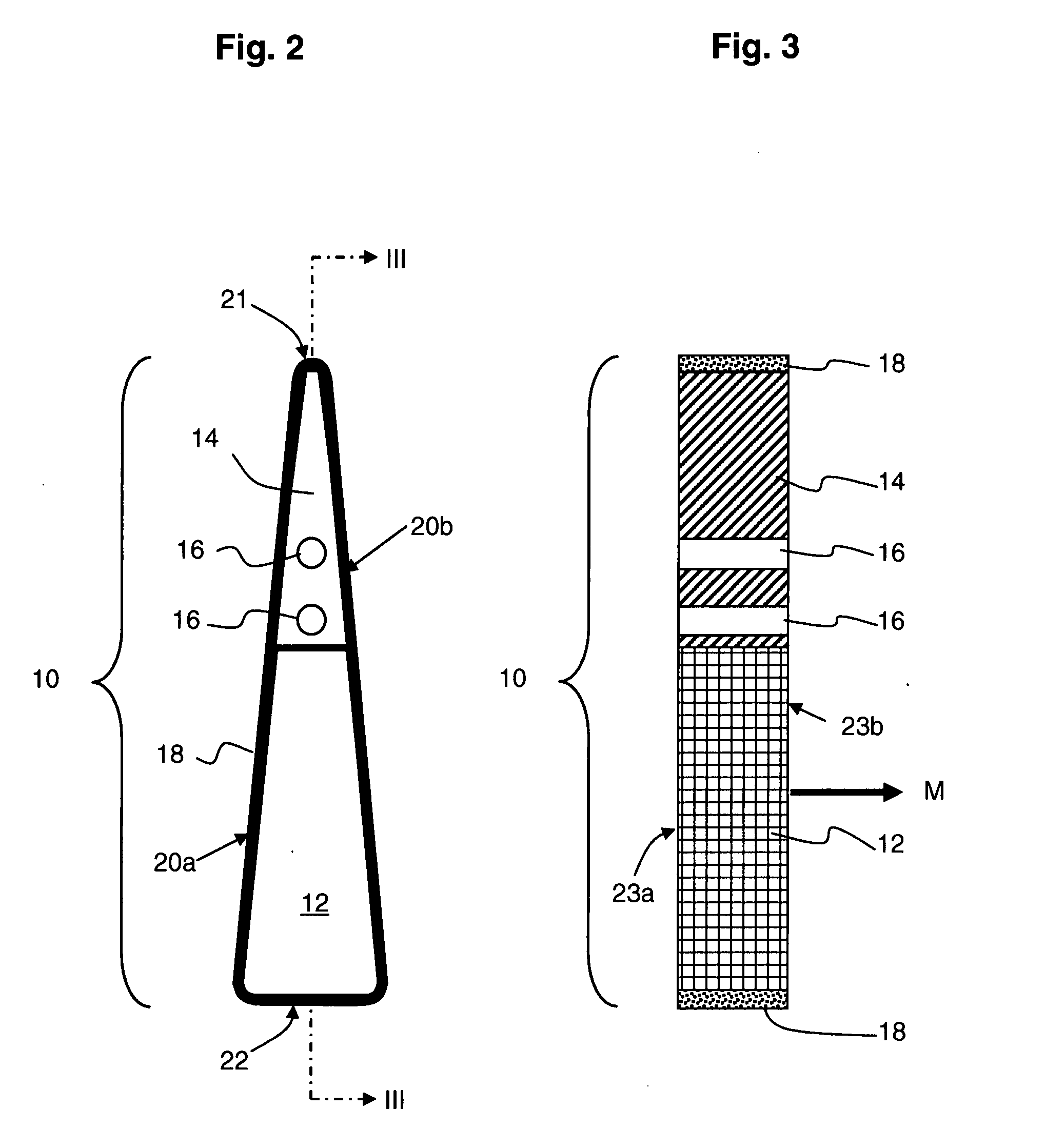

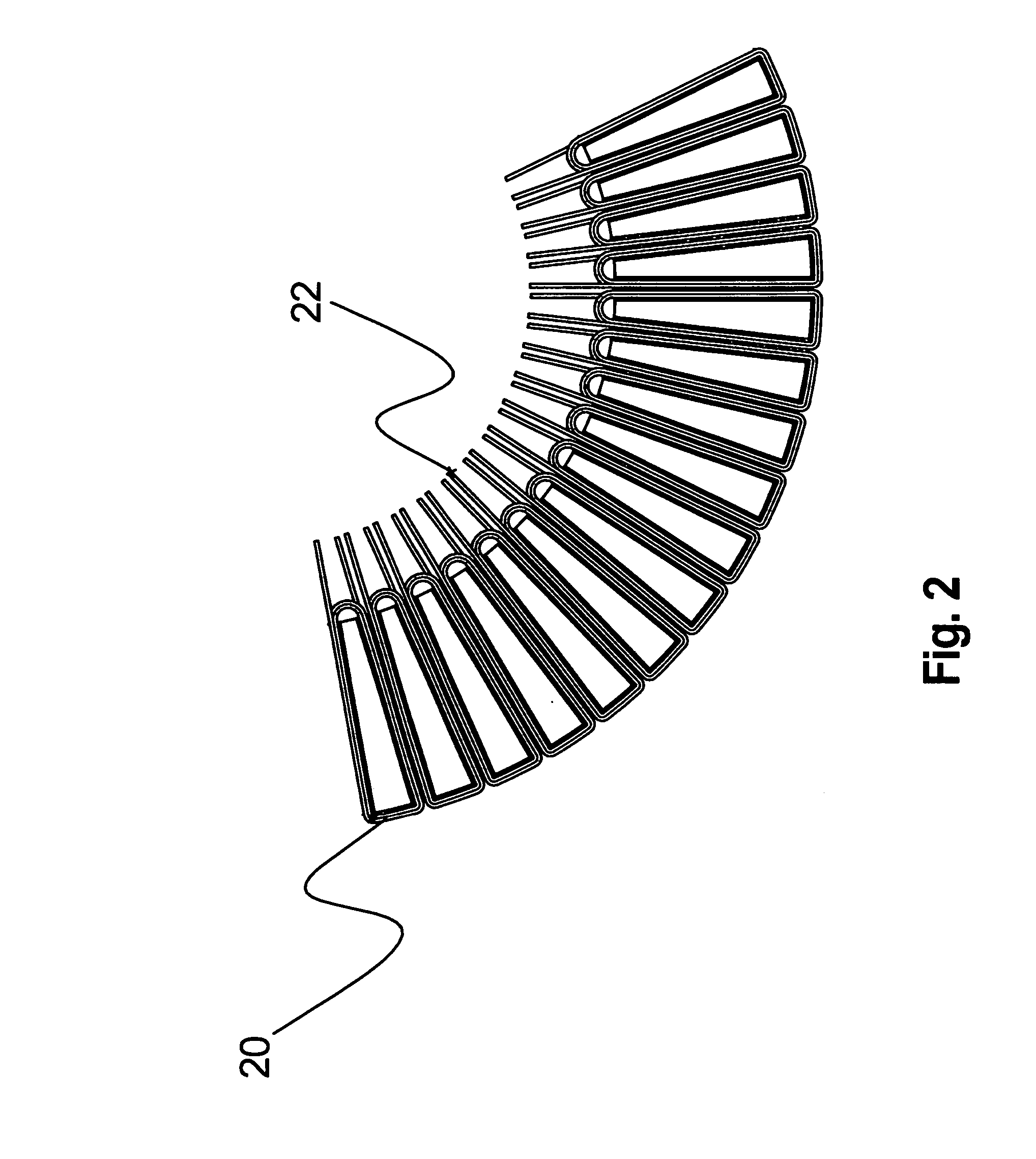

Stator coil arrangement for an axial airgap electric device including low-loss materials

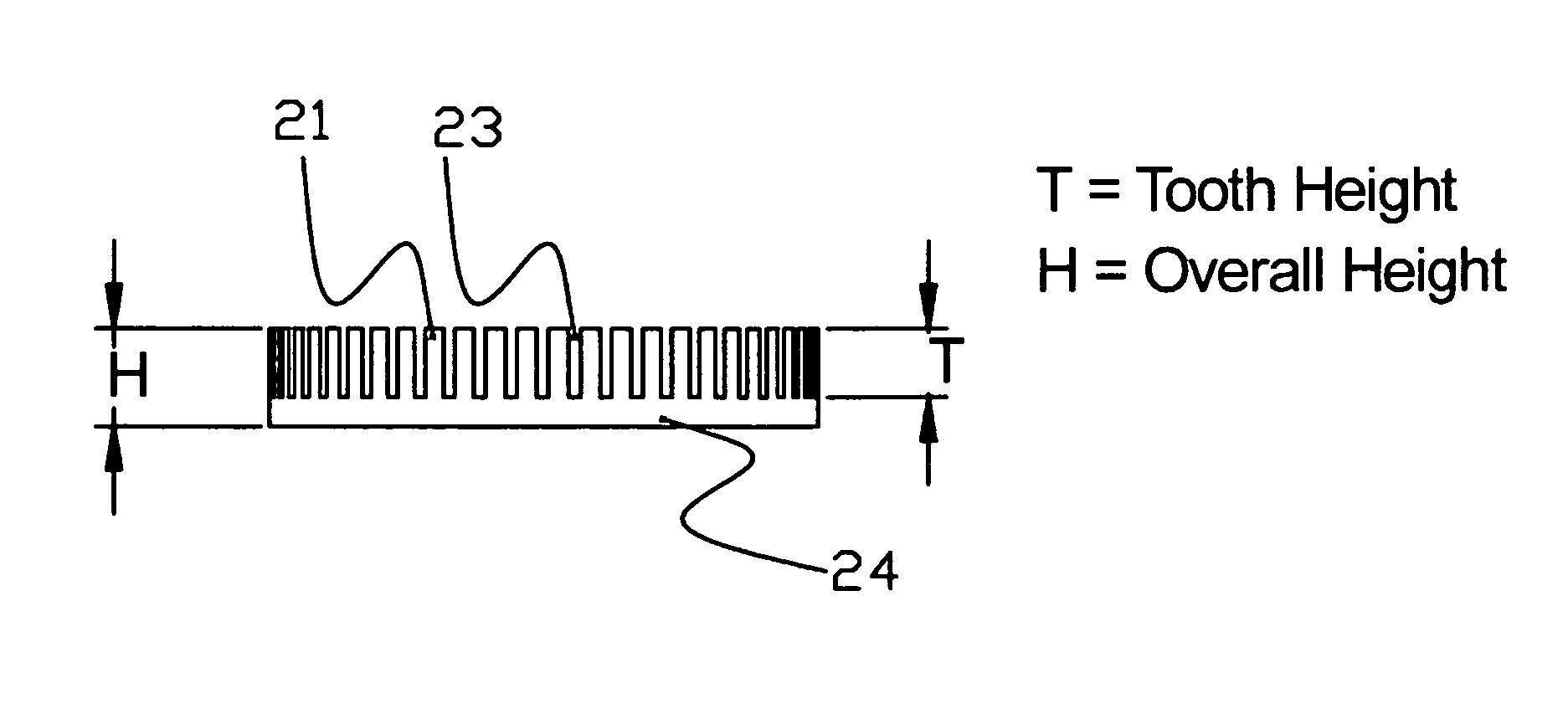

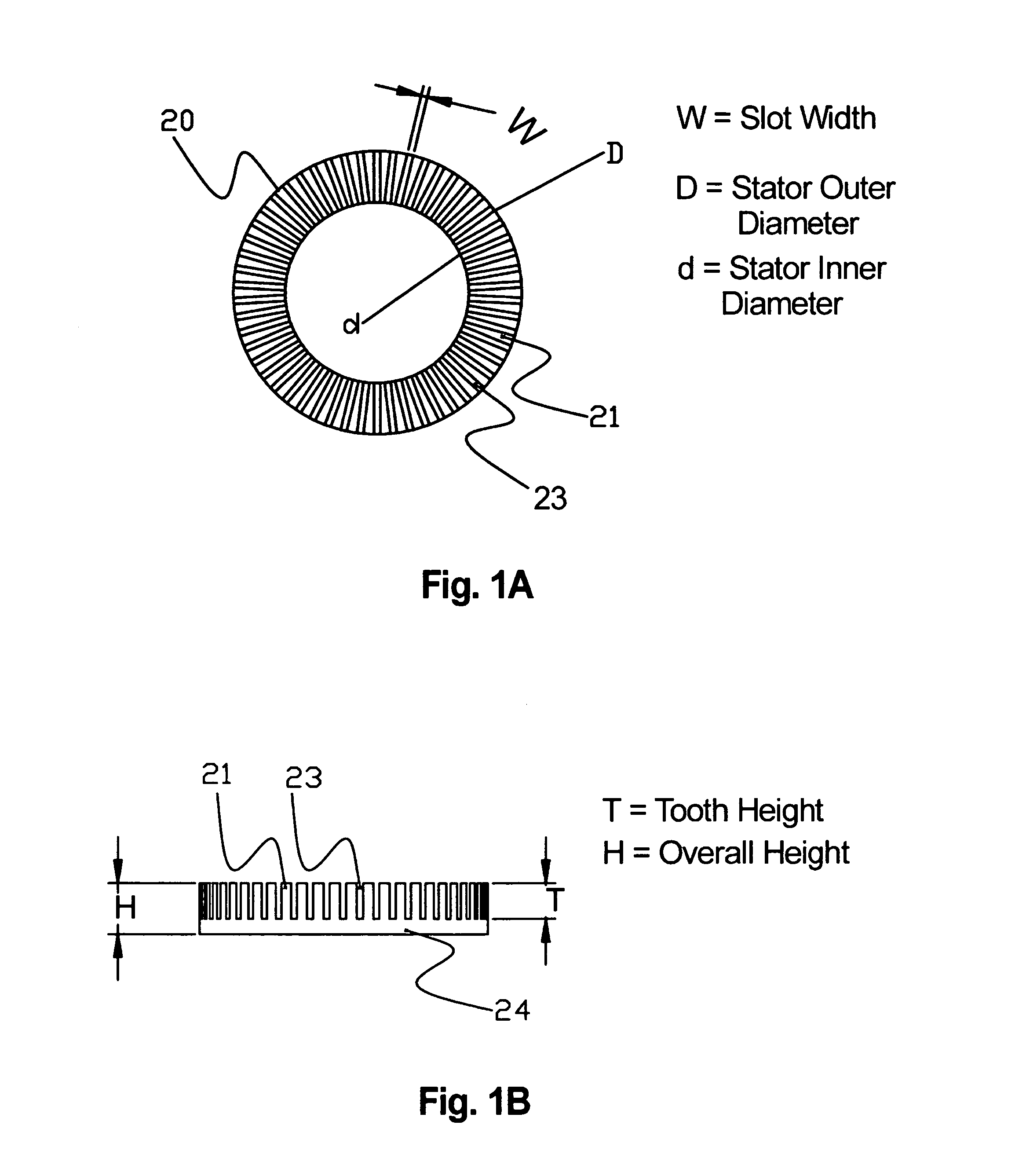

InactiveUS7190101B2Bulky designHigh operating requirementsSynchronous generatorsMagnetic circuit rotating partsElectric machineStator coil

A dynamoelectric, rotating electric machine includes a stator assembly that includes stacked stator coil windings. The machine is preferably a polyphase, axial airgap device. Improved slot filling results from the stacked stator coil configuration. Device performance capability is thereby increased. The stator assembly of the electric device has a magnetic core made from low loss, high frequency material. A high pole count permits the electrical device to operate at high commutating frequencies, with high efficiency, high power density and improved performance characteristics. Low-loss materials incorporated by the device include amorphous metals, nanocrystalline metals, optimized Si—Fe alloys, grain-oriented Fe-based materials or non-grain-oriented Fe-based materials.

Owner:LIGHT ENGINEERING INC

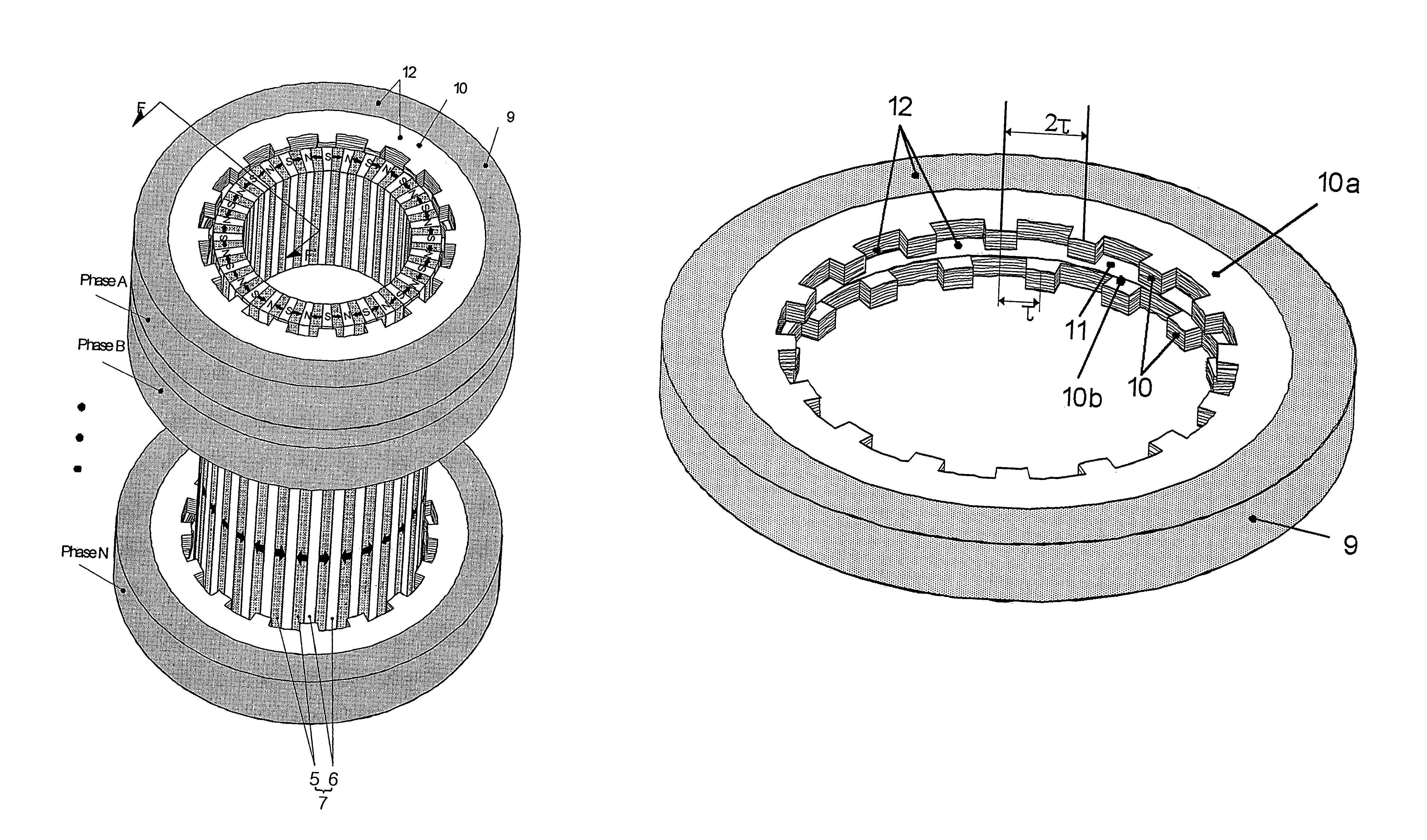

Polyphase transverse and/or commutated flux systems

Disclosed are single- and poly-phase transverse and / or commutated flux machines and components thereof, and methods of making and using the same. Exemplary devices, including polyphase devices, may variously be configured with an interior rotor and / or an interior stator. Other exemplary devices, including polyphase devices, may be configured in a slim, stacked, and / or nested configuration. Via use of such polyphase configurations, transverse and / or commutated flux machines can achieve improved performance, efficiency, and / or be sized or otherwise configured for various applications.

Owner:ELECTRIC TORQUE MASCH INC

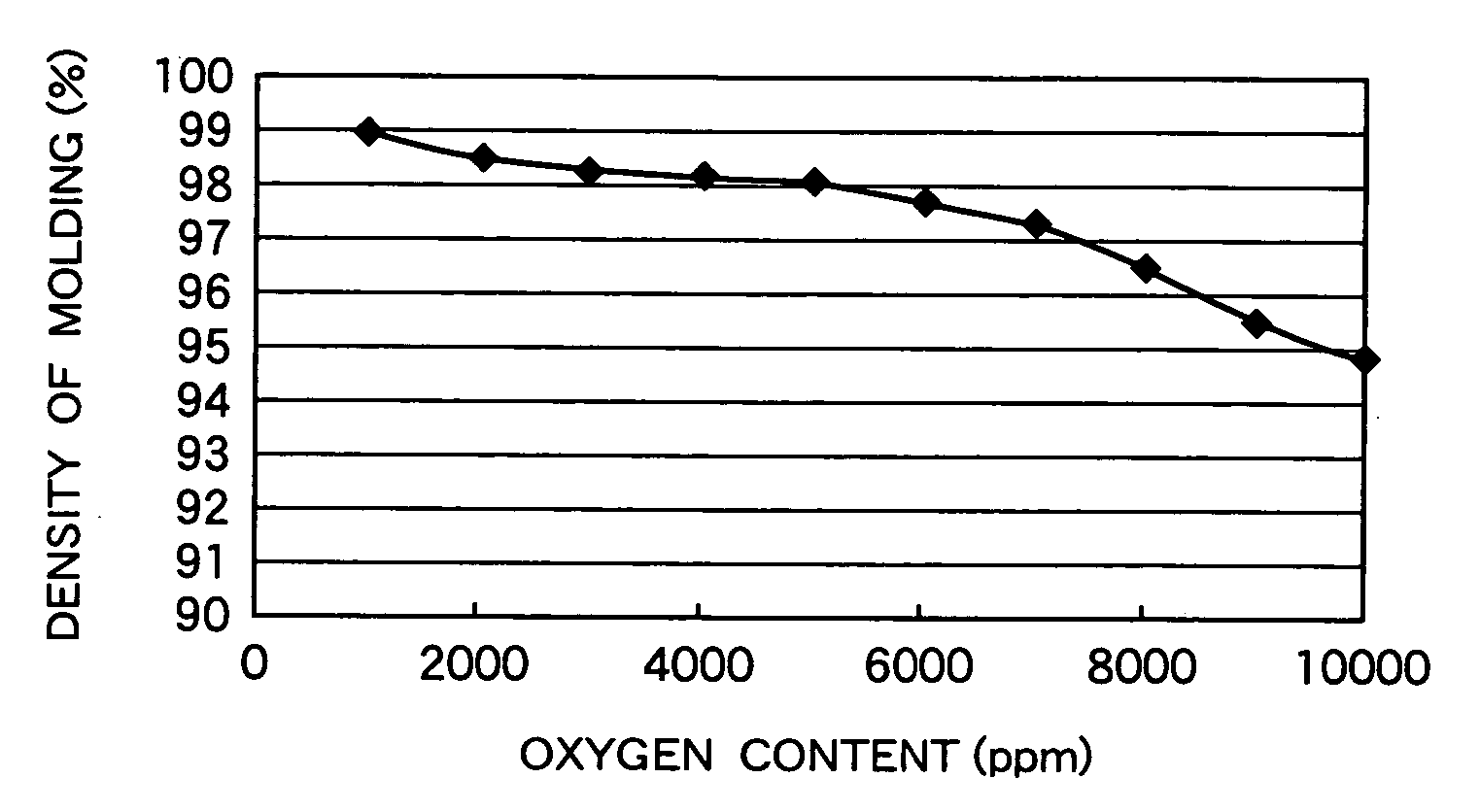

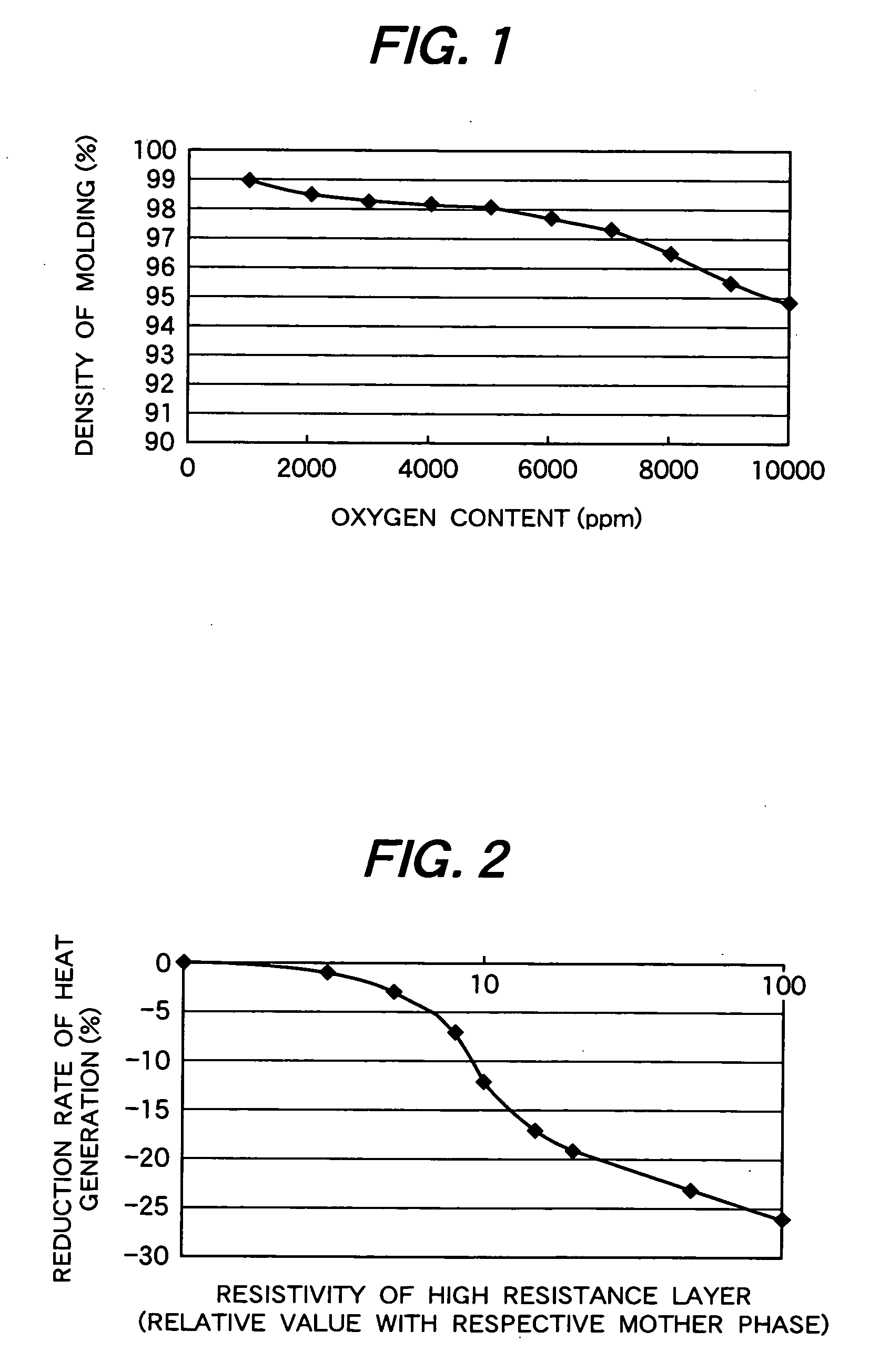

Low loss magnet and magnetic circuit using the same

InactiveUS20070151632A1Simple interfaceIncrease resistanceInorganic material magnetismInductances/transformers/magnets manufactureHigh resistanceVolumetric Mass Density

A lamellar high resistance layer having resistivity ten times or higher than that of a mother phase containing iron or cobalt is formed and an oxygen content is controlled to 10 to 10000 ppm so that the reliability and residual magnetic flux density are increased.

Owner:HITACHI LTD

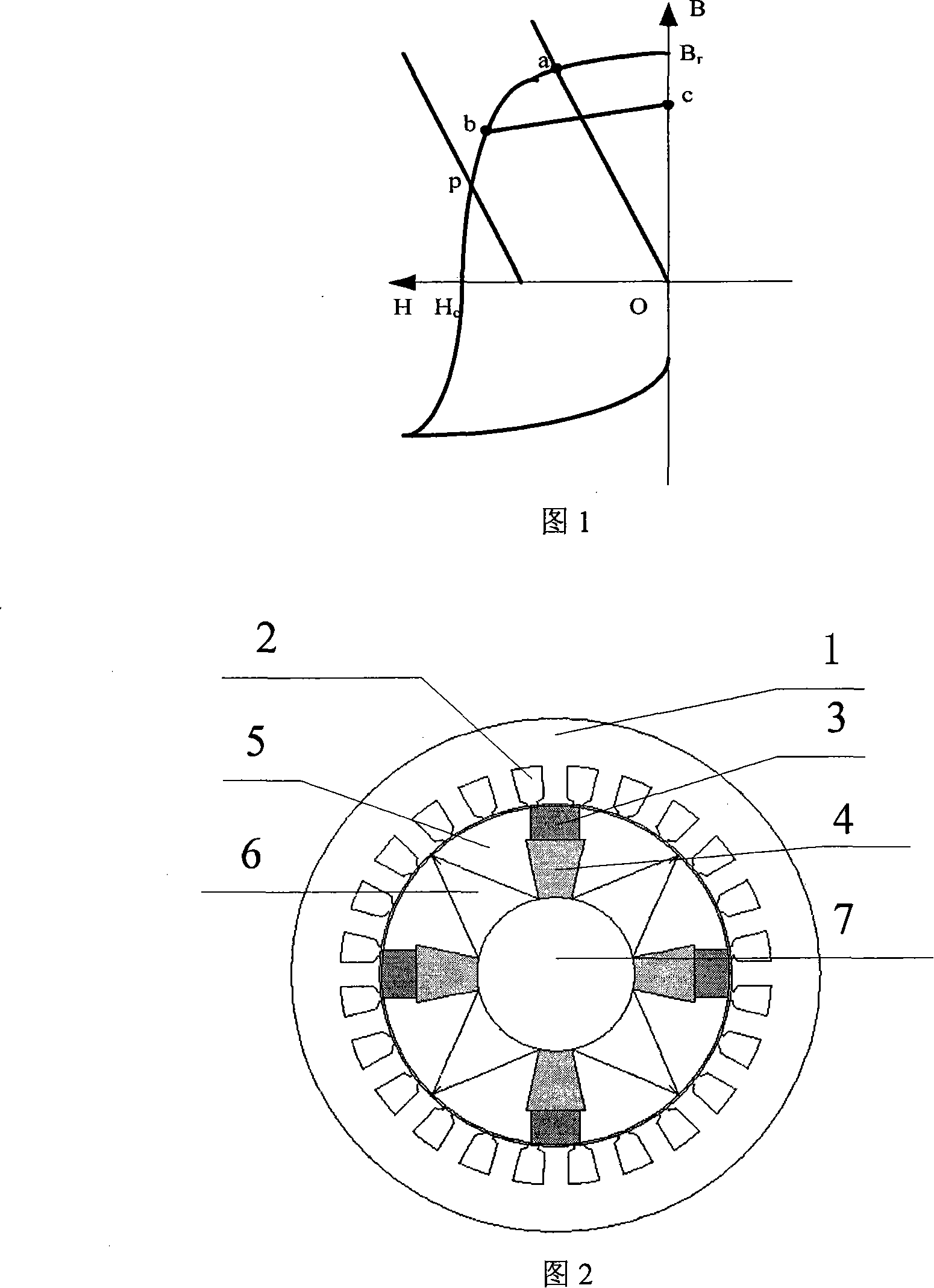

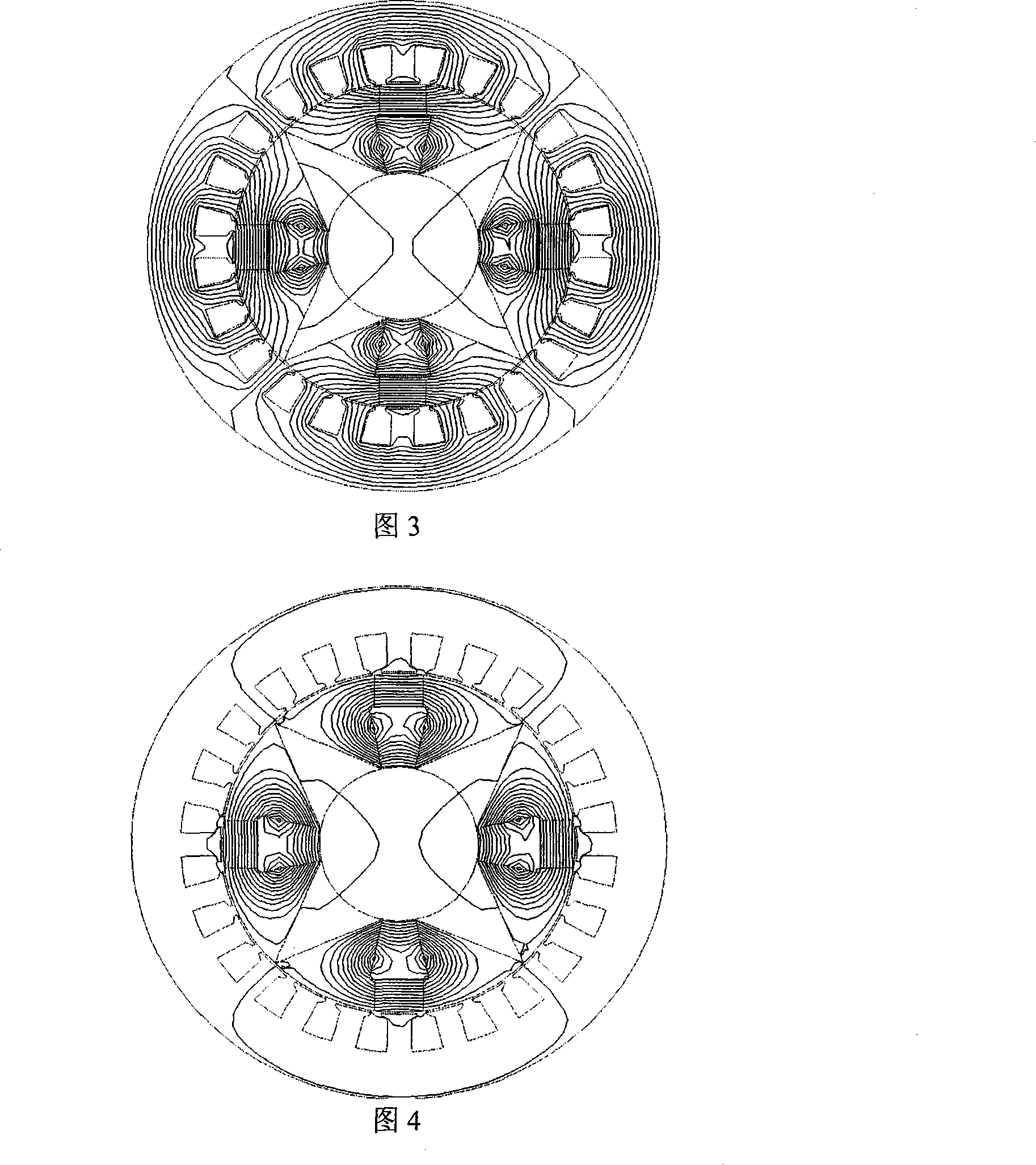

Variable flux permanent magnet synchronous motor

InactiveCN101232205AEasy to adjust magnetismImprove efficiencyMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsElectric machinePermanent magnet synchronous motor

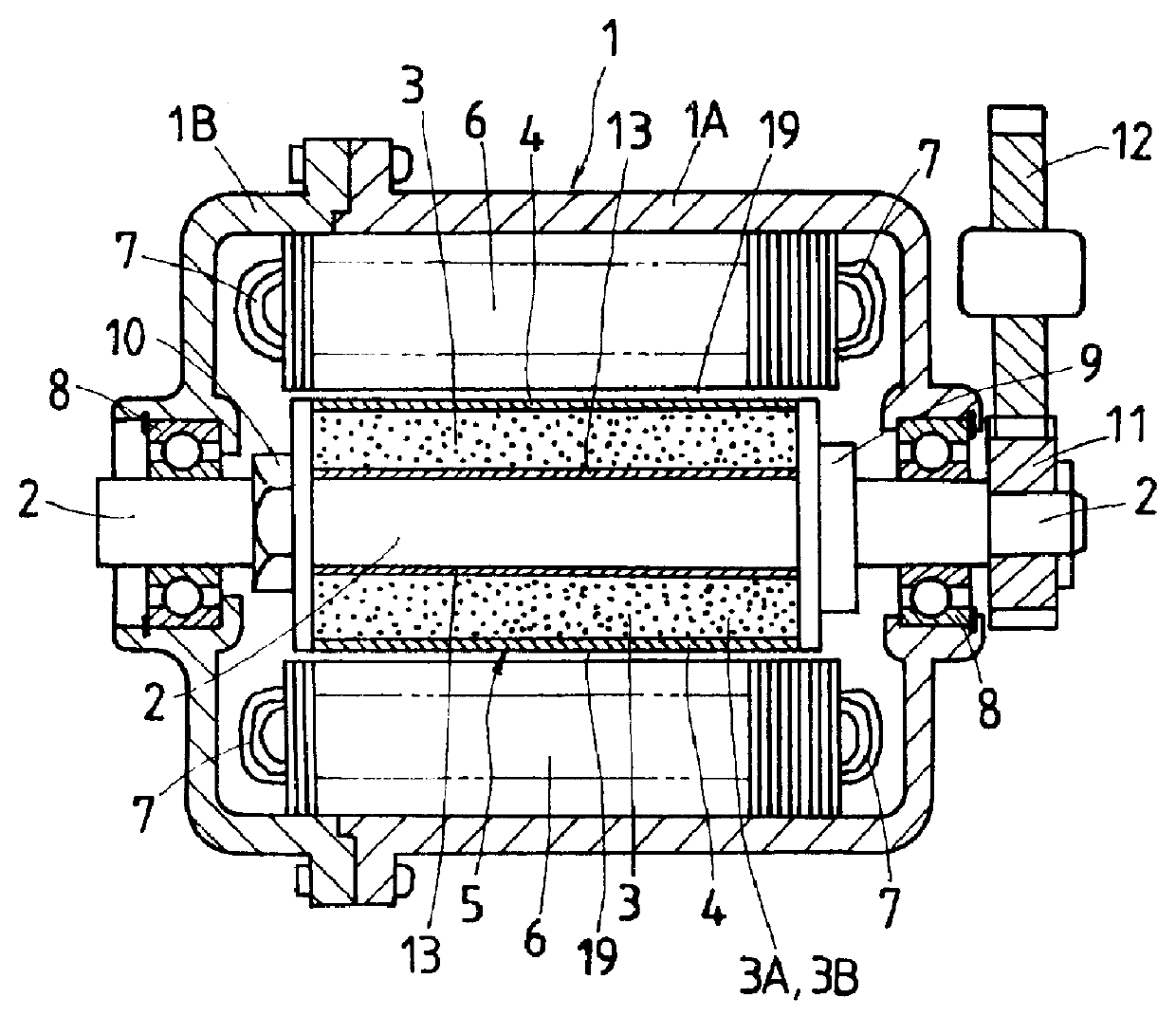

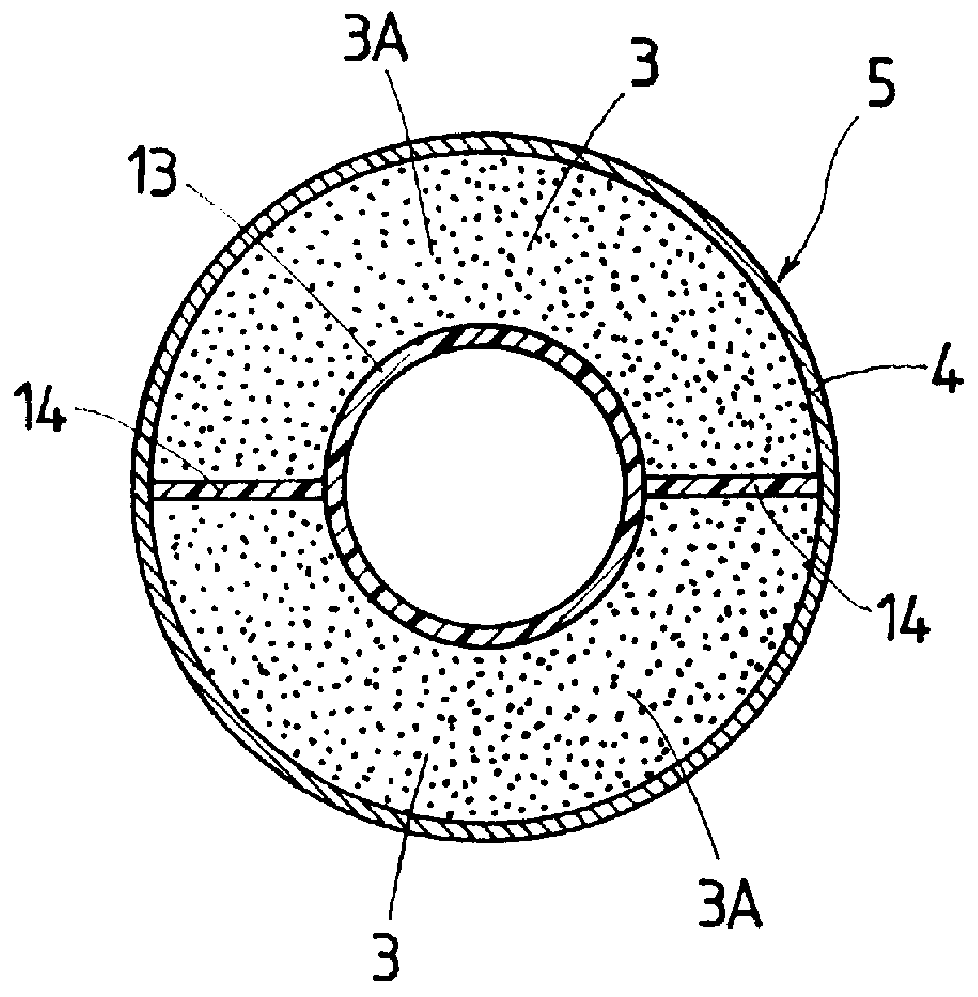

The invention relates to a motor, in particular to a permanent magnet synchronous motor with variable magnetic flux, which has the advantages of easy magnetic field adjusting, high efficiency and wide speed regulation range. The motor comprises a stator consisting of an iron core (1) and an armature winding (2), and a rotor consisting of NdFeB permanent magnet (3), AINiCo permanent magnet (4), soft iron (5), a non-magnetic interlayer (6), a non-magnetic shaft (7), etc. Each permanent magnet in the rotor is composed of two different magnets stacked on each other and tangentially magnetized. The AlNiCo permanent magnet is ladder-shaped and close to the shaft, and the NdFeB permanent magnet is rectangular-shapee and close to an air gap. The non-magnetic interlayer in the rotor is triangular-shaped and connected with the permanent magnet at a section close to the shaft. The entire rotor is packaged by a cylinder with staggered magnetic and non-magnetic regions. The magnetization state of the AlNiCo permanent magnet can be changed by applying a pulse current id to the straight shaft of the stator, thus achieving effectively the adjustment of air-gap magnetic field of the motor.

Owner:SOUTHEAST UNIV

Axial flux motor mass reduction with improved cooling

InactiveUS20050035678A1Low densityReduce weightWindingsVector control systemsEngineeringNon magnetic

Methods and apparatus are provided for an axial electric motor. The apparatus comprises, a stator having coils thereon for producing a magnetic field, a rotor rotated by the magnetic field, and an output shaft coupled to the rotor. The rotor includes a magnetic and non-magnetic component. The non-magnetic component has a lower density than the magnetic component. One or both of the rotor components have apertures therein for ventilation and weight reduction. Permanent magnets are desirably mounted on the magnetic component of the rotor facing the stator and portions of the rotor behind the permanent magnets are hollowed out to be thinner than portions of the rotor between the permanent magnets. This reduces rotor weight without significantly affecting magnetic flux density in the rotor or motor torque.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-efficiency wheel-motor utilizing molded magnetic flux channels with transverse-flux stator

InactiveUS7492074B1Improve efficiencyTotal current dropMagnetic circuit rotating partsSynchronous machinesTransverse fluxPole piece

A motor including a mounting shaft having a hollow channel and a bearing attached to each end, a cylindrical hub having a hollow core for the mounting shaft, and plural rows of plural Molded Magnetic Flux Channels with a hollow core and a channel forming a U-shaped recess and mounted the surface of the hub, each row corresponding to a motor phase. Each magnetic flux channel forms two pole pieces divided by the channel. The motor also includes plural phase windings, one passing through each row of plural Molded Magnetic Flux Channels, a rotating drum having plural rows of permanent magnets on an inner surface, each row pair corresponding to and aligned with one of the plural rows of Molded Magnetic Flux Channels. The rotating drum connected with the bearing, and drive electronics for driving the plural phase windings, wherein the plural Molded Magnetic Flux Channels increases torque and motor efficiency.

Owner:RITTENHOUSE NORMAN

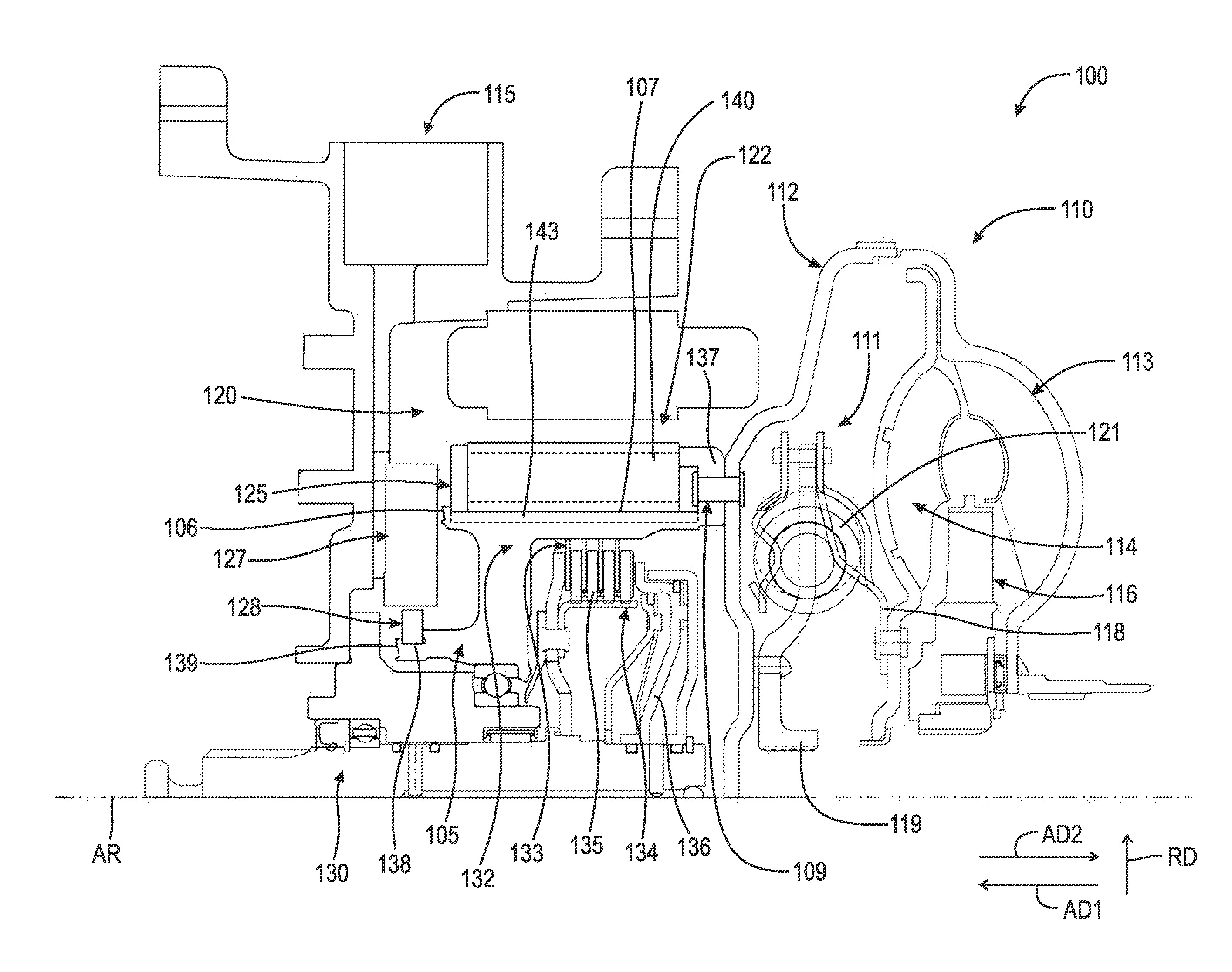

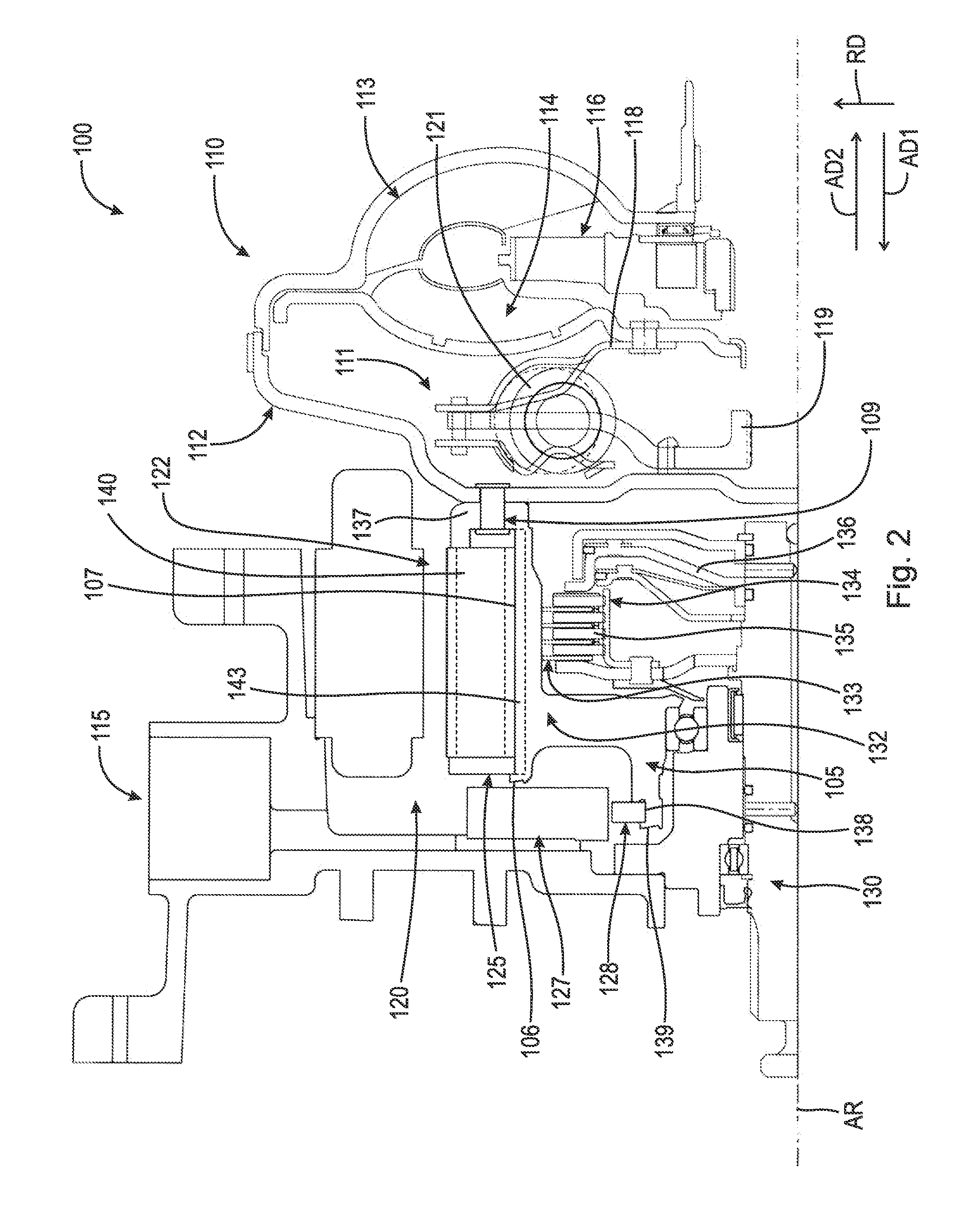

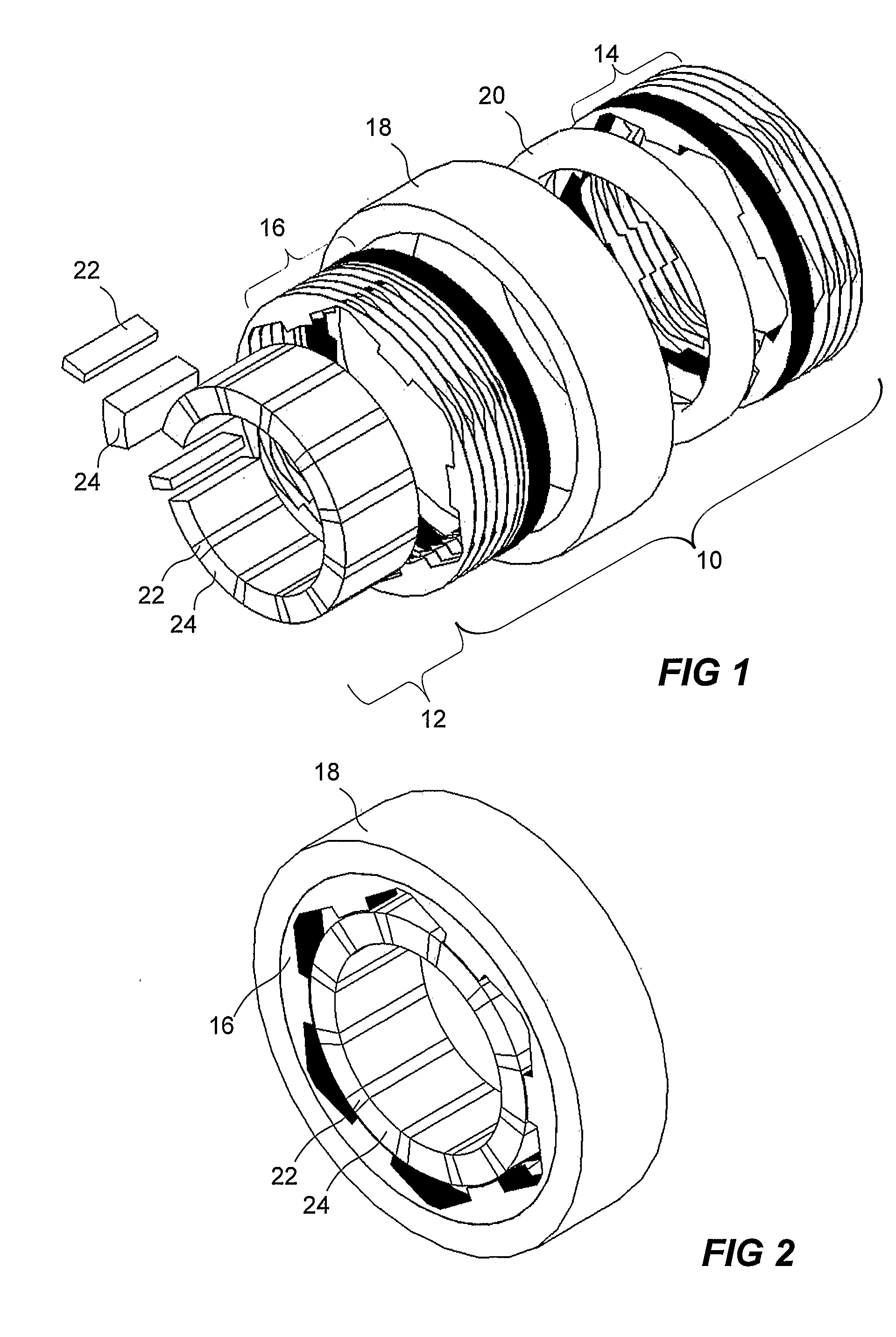

Hybrid drive module having a rotor secured to a hub via staking

A hybrid drive module including: a torque converter with a cover, an impeller and a turbine; a rotor for an electric motor; a hub non-rotatably connected to the rotor and the cover and including a circumferential surface and a plurality of protrusions extending radially outward from the circumferential surface; and an end plate disposed between the plurality of protrusions and the rotor and engaged with the end plate and the rotor. The plurality of protrusions is formed of a material forming the hub and restrains the end plate and the rotor, with respect to the hub, in an axial direction.

Owner:SCHAEFFLER TECH AG & CO KG

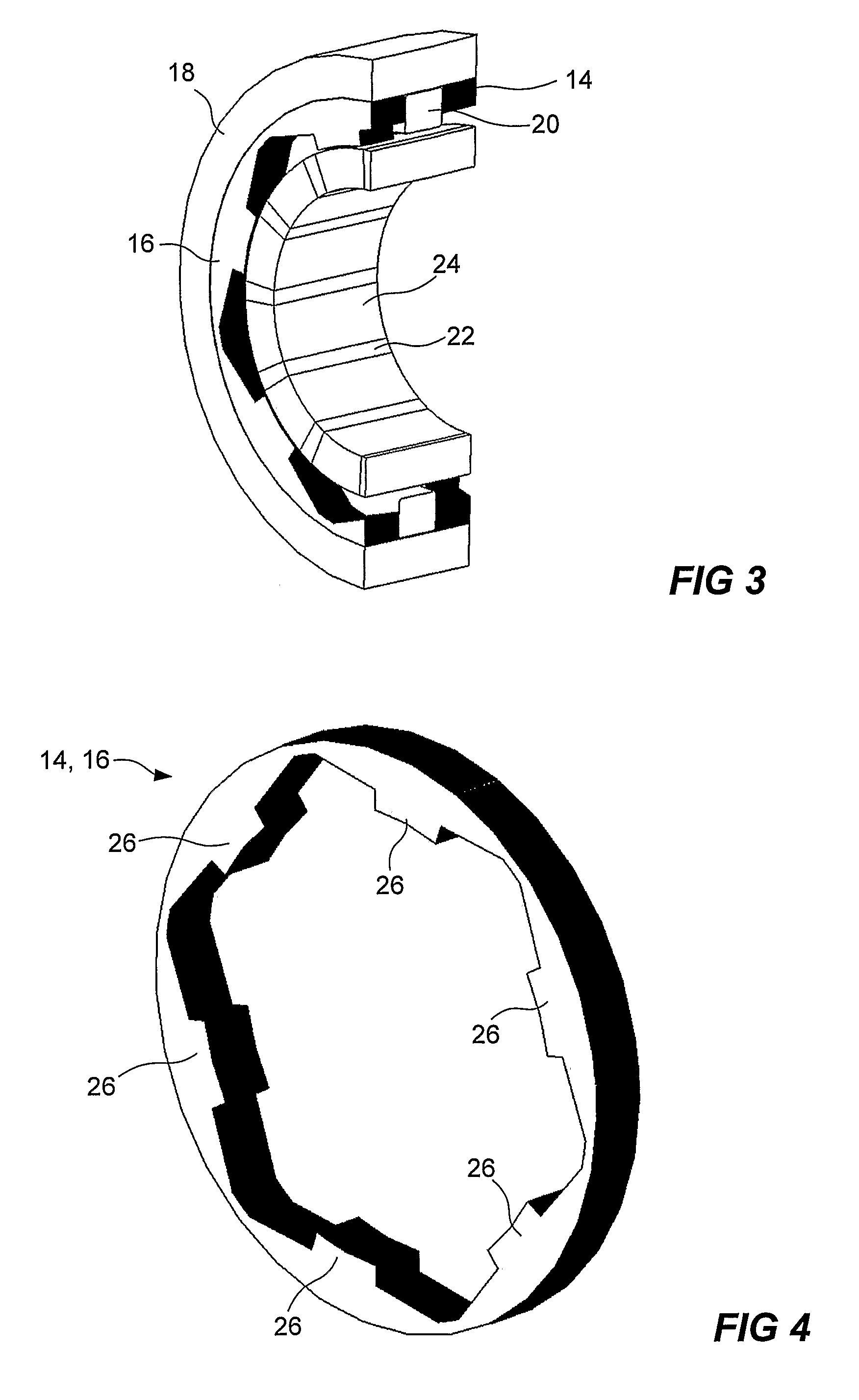

Segmented composite rotor

InactiveUS20090072639A1Improve efficiencyIncreased cost-effectivenessMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsPole numberMagnet

A composite rotor for an axial airgap, permanent magnet dynamoelectric machine comprises a plurality of magnet subassemblies adhesively bonded together to form the rotor. Each magnet subassembly comprises a rotor permanent magnet and an optional spacer. A fibrous belt is wrapped around the periphery of each subassembly to provide high tensile strength at least along the radial sides of the subassembly. The belt is preferably infiltrated with an adhesive agent, such as an epoxy resin, that is used to bond the subassemblies. The rotor is thereby provided with high strength and low mass, making it suitable for use in a high-speed, high pole count electric machine.

Owner:BERG & BERG ENTERPRISES

High frequency electric motor or generator including magnetic cores formed from thin film soft magnetic material

InactiveUS6879080B2Magnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsElectric generatorStator poles

Owner:GREEN RAY TECH

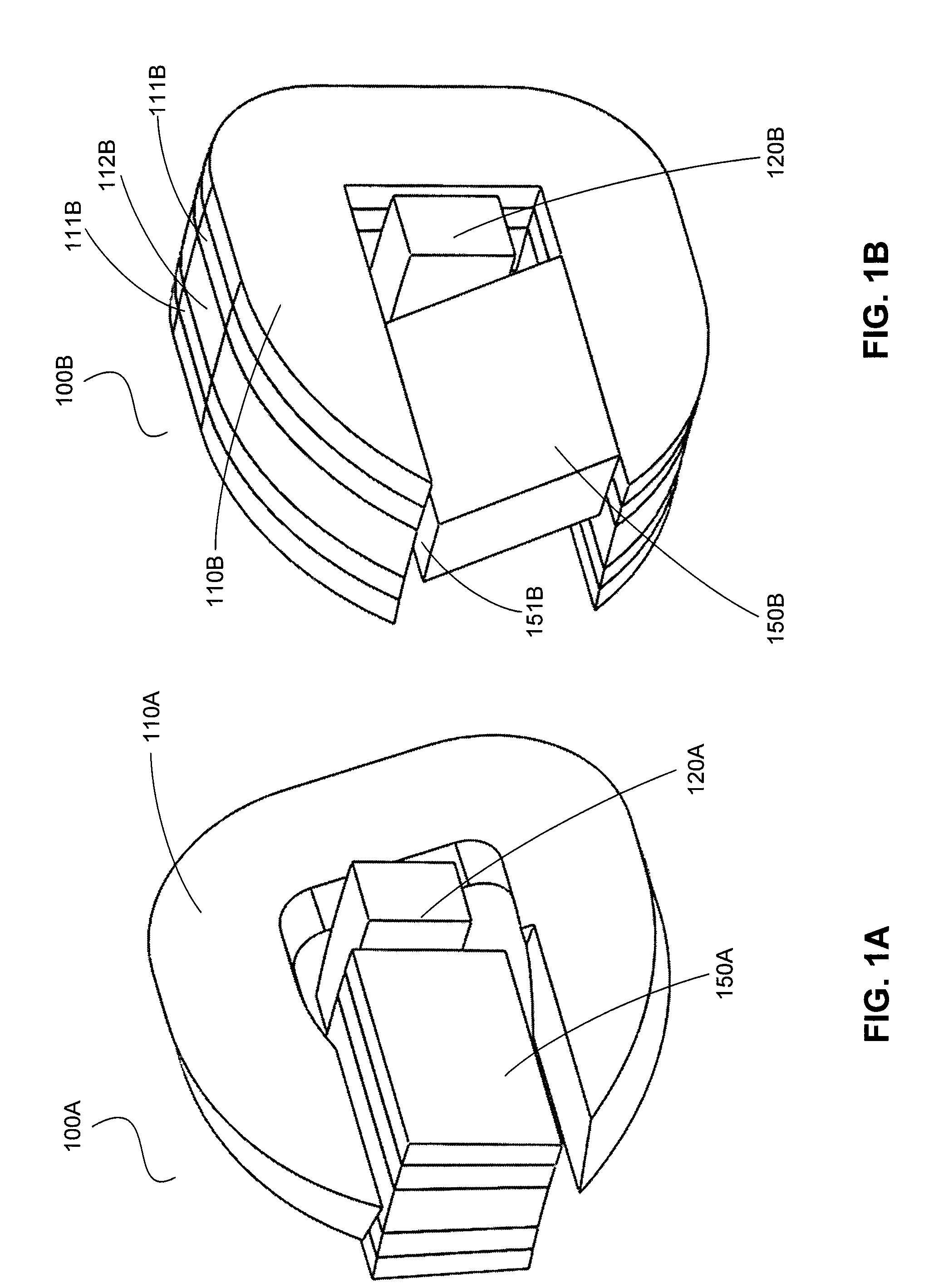

Electric Machine Assembly

InactiveUS20090243406A1Improve performanceEasy to useMagnetic circuit stationary partsManufacturing dynamo-electric machinesElectric machineEngineering

An electrical rotary machine is provided comprising a first stator core section being substantially circular and including a plurality of teeth, a second stator core section being substantially circular and including a plurality of teeth, a coil arranged between the first and second circular stator core sections, and a rotor including a plurality of permanent magnets. The first stator core section, the second stator core section, the coil and the rotor are encircling a common geometric axis, and the plurality of teeth of the first stator core section and the second stator core section are arranged to protrude towards the rotor. Additionally, the teeth of the second stator core section are circumferentially displaced in relation to the teeth of the first stator core section, and the permanent magnets in the rotor are separated in the circumferential direction from each other by axially extending pole sections made from soft magnetic material.

Owner:HOGANAS AB

Efficient high-speed electric device using low-loss materials

InactiveUS20060208606A1Small increase in core lossImprove efficiencyMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsEngineeringVolumetric Mass Density

The invention relates generally to an electric device, such as an electric motor, a generator, or a regenerative motor, having a wound stator core made from advanced low-loss material. In preferred embodiments, the electric device is an axial airgap-type configuration. The invention provides an electric device having a high pole count that operates at high commutating frequencies, with high efficiency and high torque and power densities. Advanced low-loss materials exploited by the present invention include amorphous metals, nanocrystalline metals, and optimized Fe-based alloys.

Owner:BERG & BERG ENTERPRISES

Dynamoelectric machine having heat pipes embedded in stator core

InactiveUS20060038450A1Minimum heat dissipationMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsNuclear engineeringElectric machine

Thermal management of an electric machine is implemented by selecting a stator core configuration in accordance with an intended machine application and determining the minimum heat dissipation necessary to maintain the temperature of the core segment configuration at peak excitation within acceptable limits is determined. A core model is used to ascertain thermal distribution at peak excitation. In accordance therewith, a pattern in the selected core segment configuration is established for placement of at least one heat pipe for removing heat from the core. Preferably, heat pipes are located at high thermal points in the core segment and oriented in alignment with mapped lines of flux. By placing the heat pipe either at the center of the core or at a recessed boundary layer between the core and winding, the heat pipe can capture and conduct excess heat away from the heat generating areas of the core, thus maintaining the core and the excitation windings at desired temperature.

Owner:BLUWAV SYST LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com