Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1004results about "Flanged caps application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

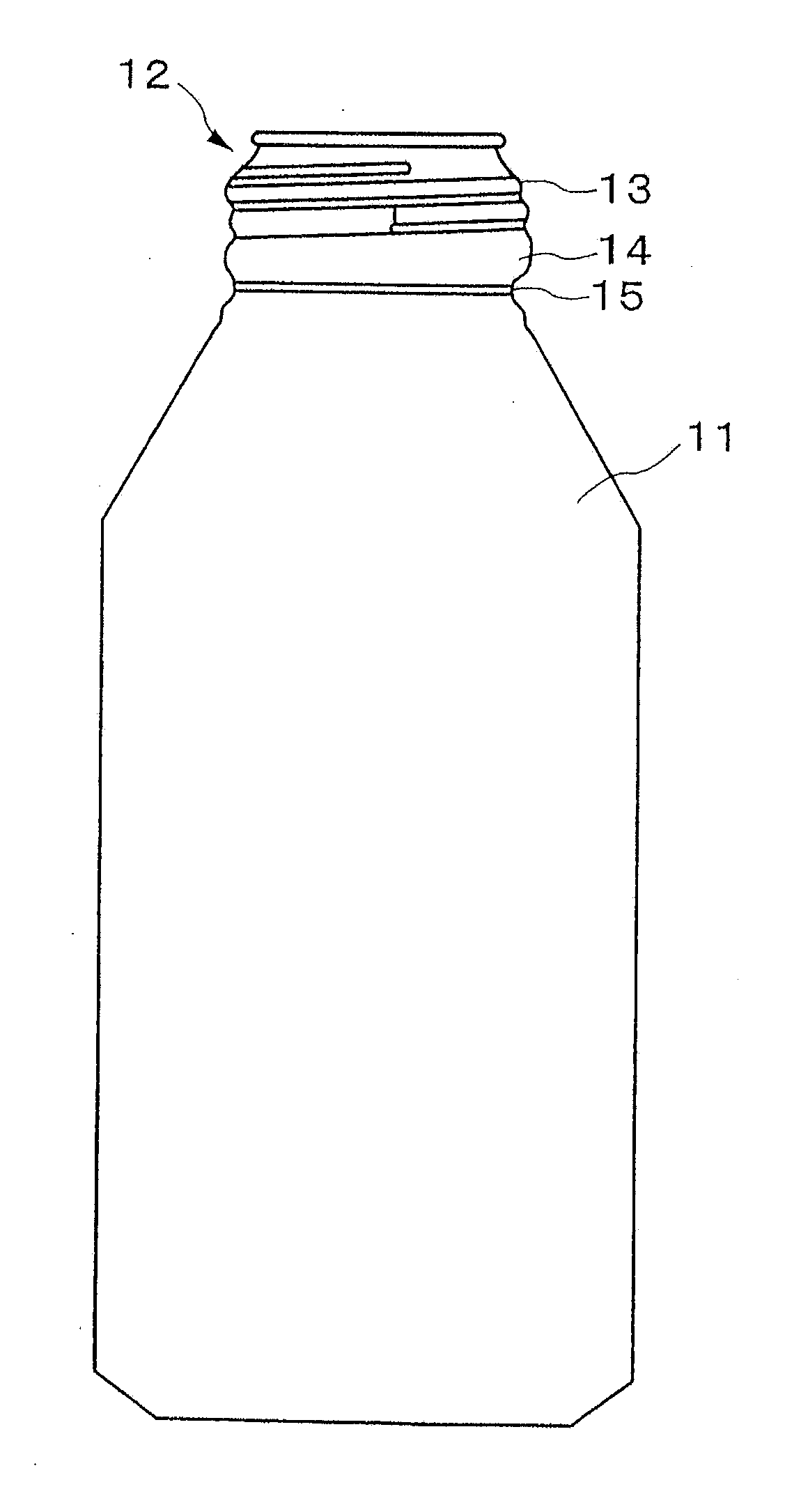

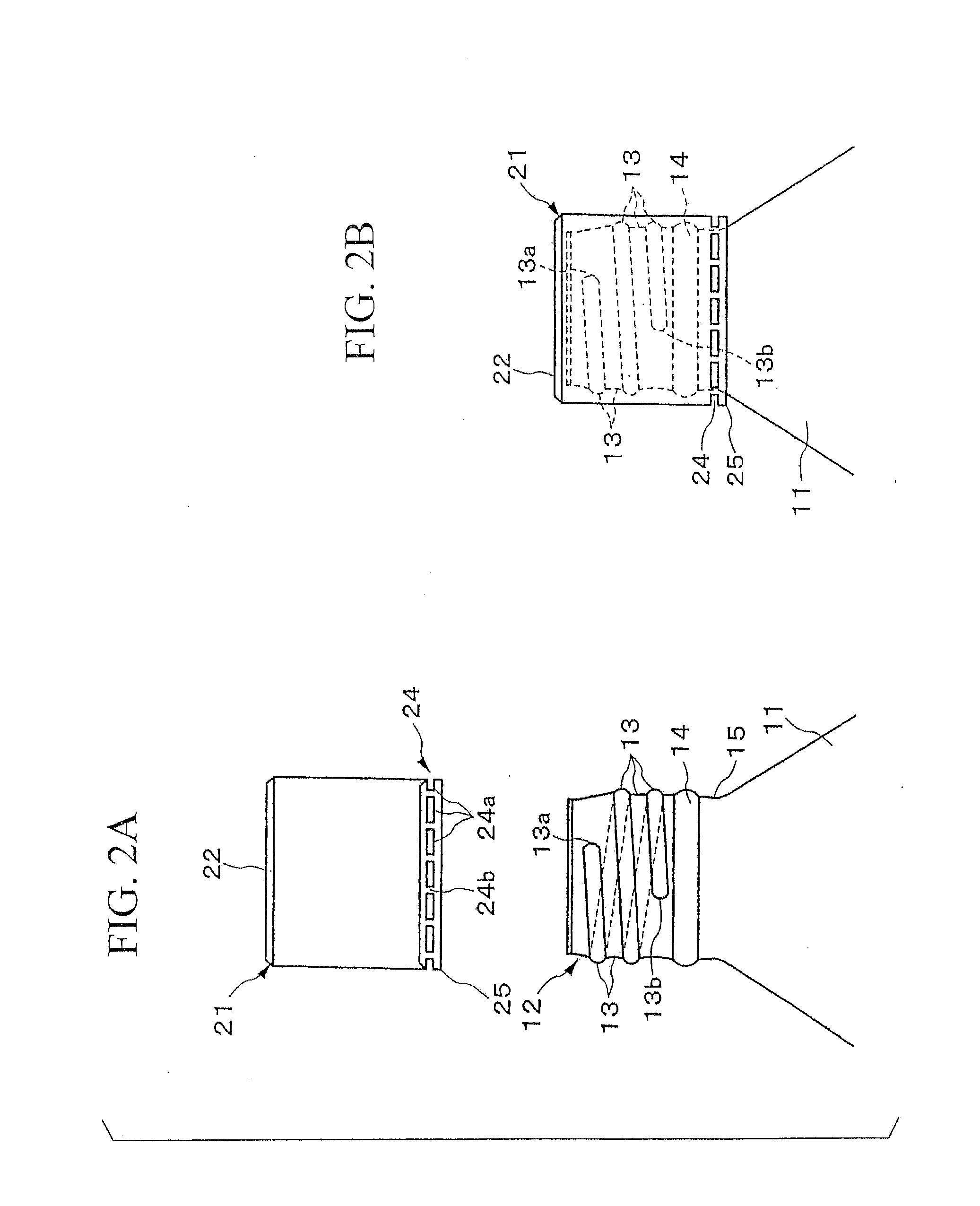

Bottle can member, bottle, and thread forming device

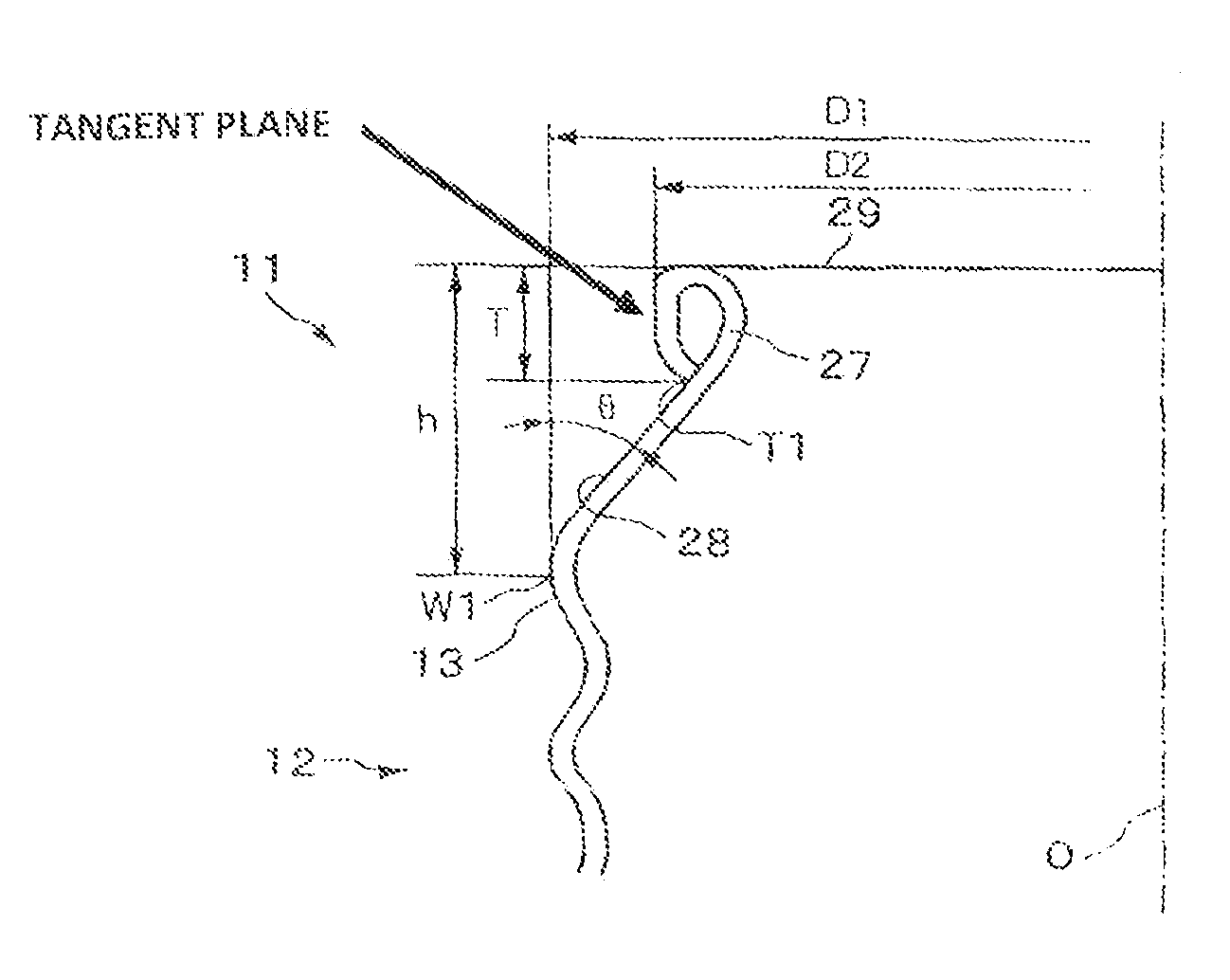

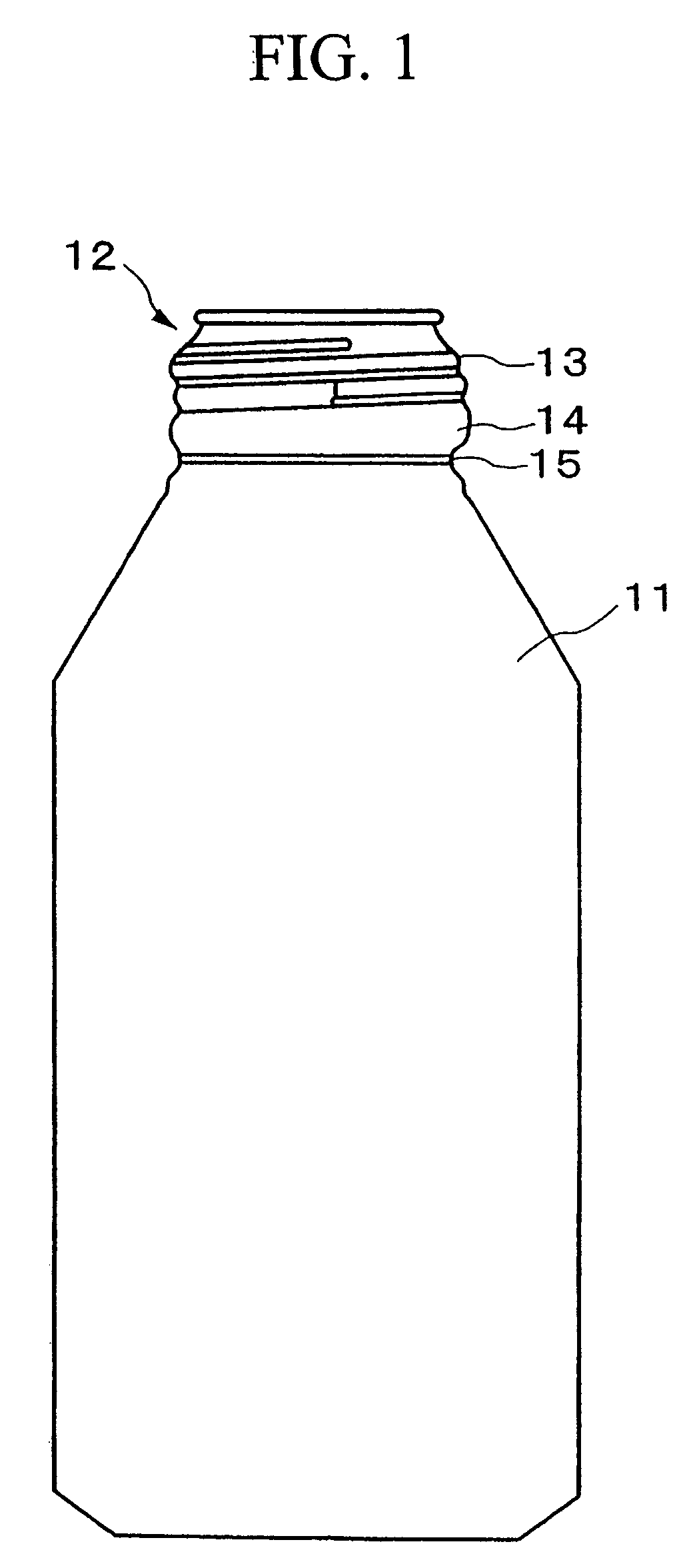

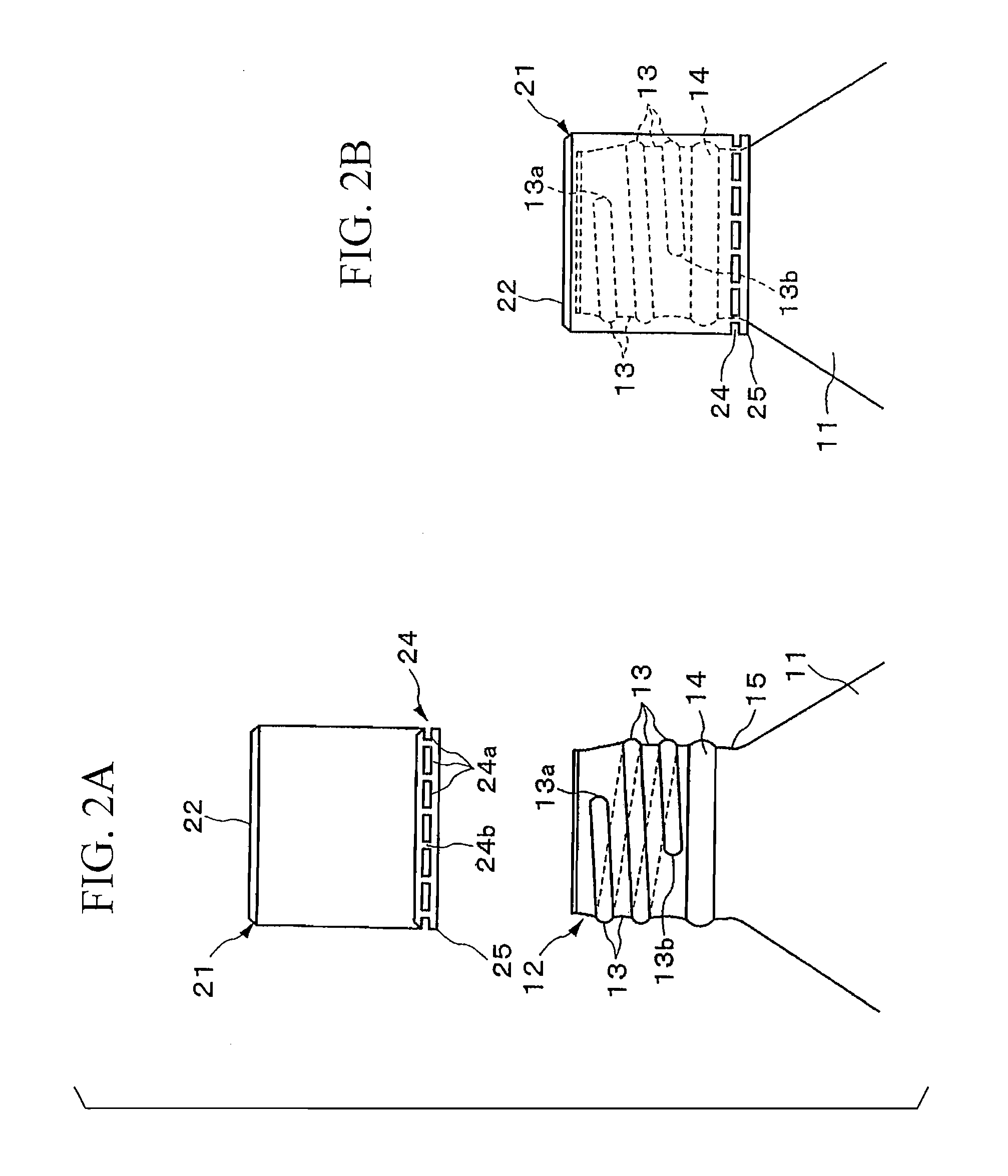

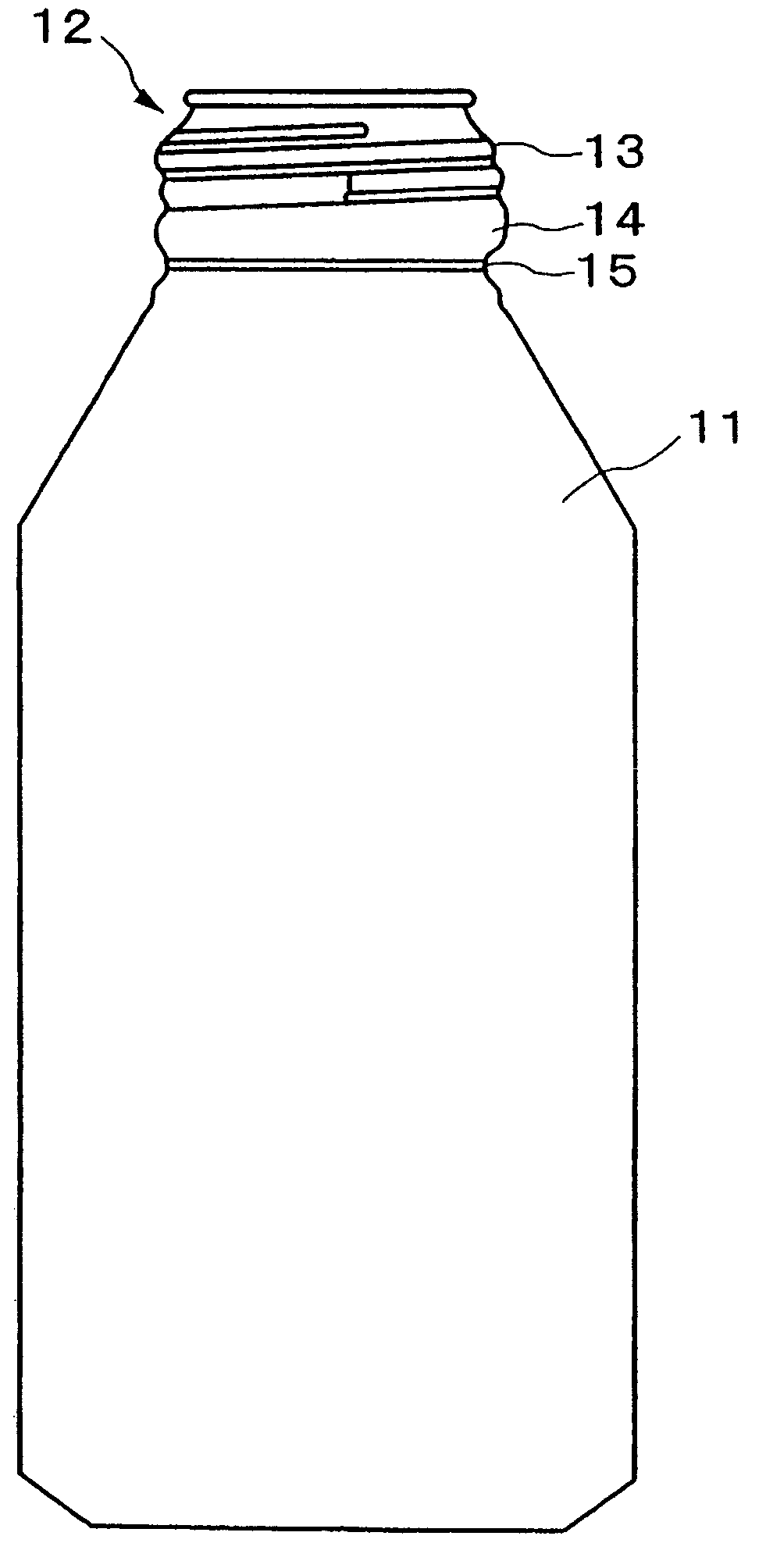

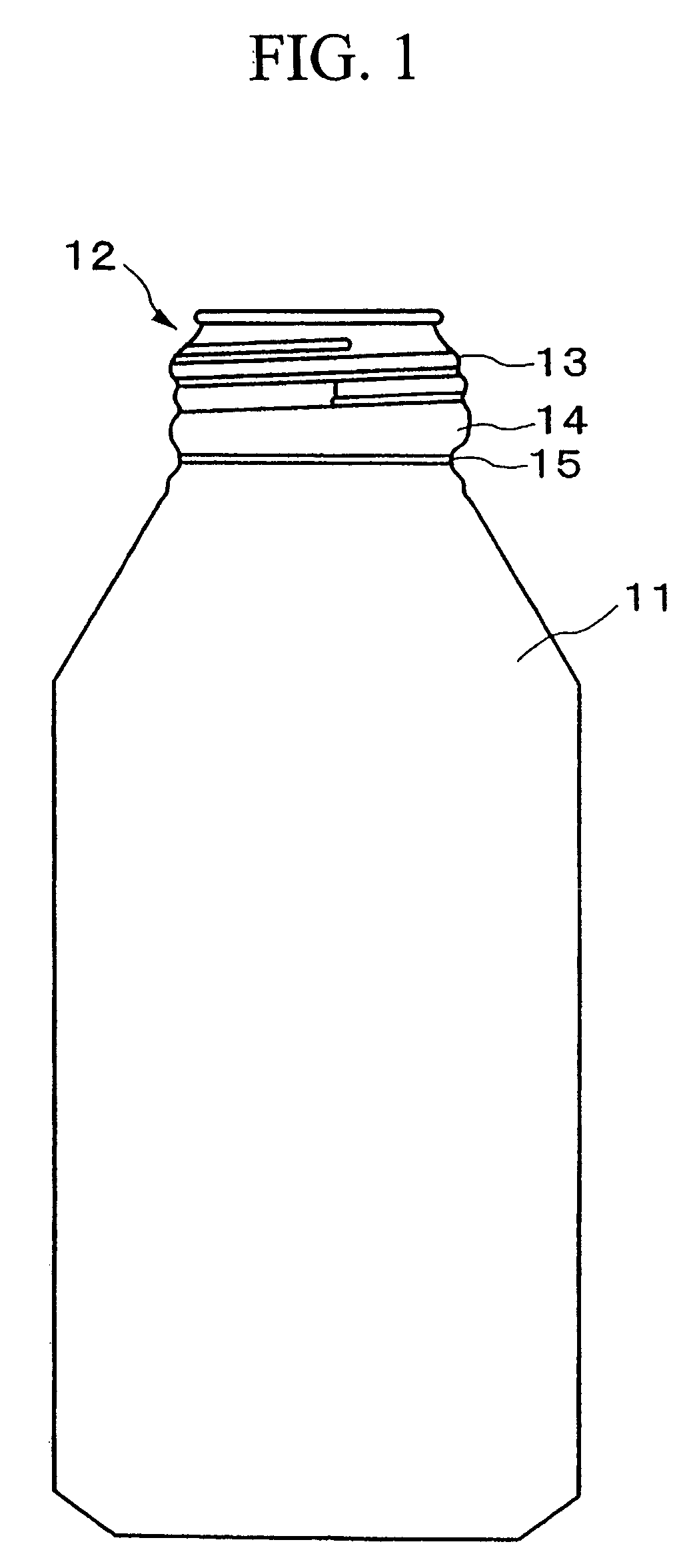

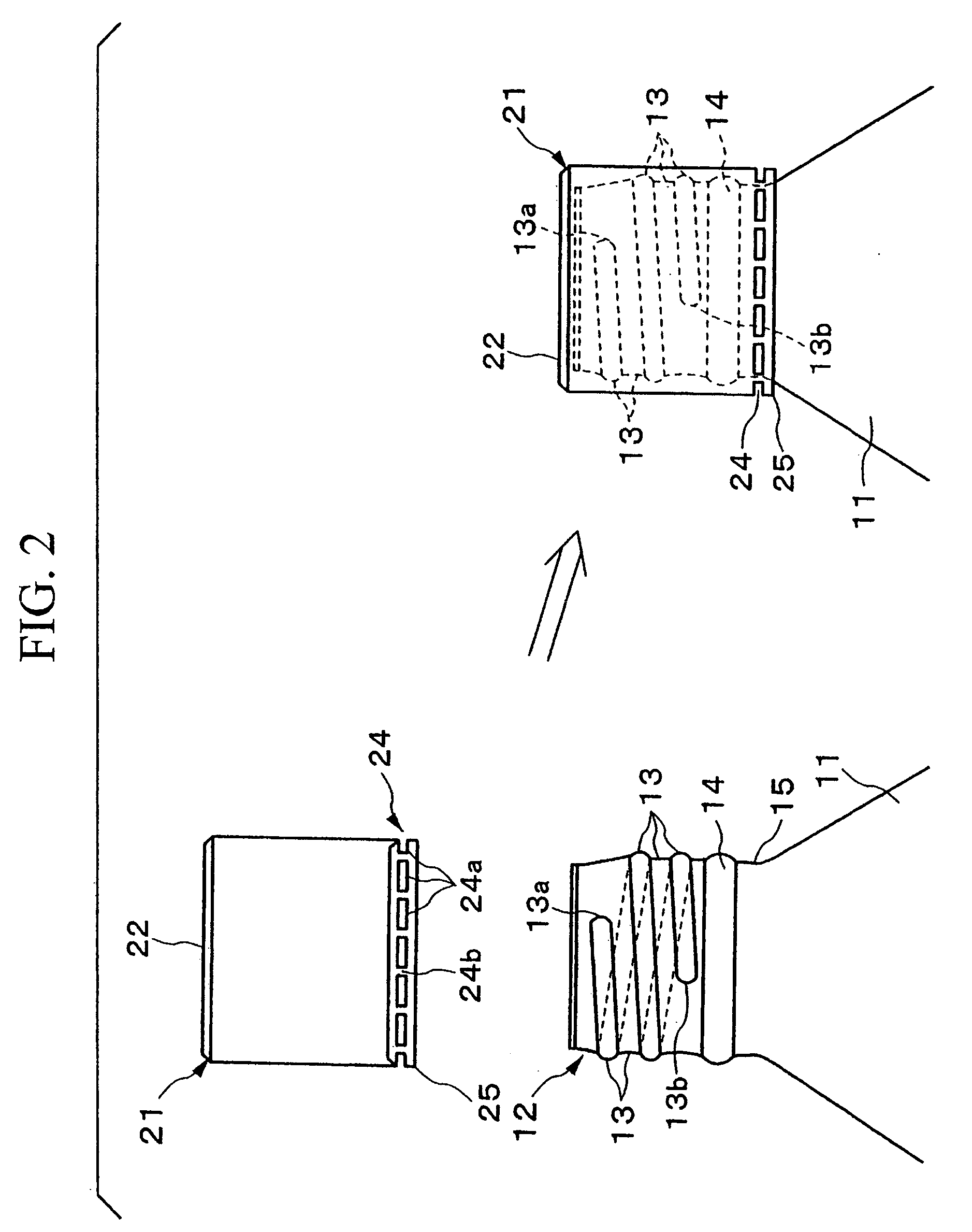

An effective thread number in the thread section which is disposed on the mouth section of the bottle is formed to be 2.2. That is, the thread section is formed such that the thread section 13 should serve effectively in the mouth section such that an interval between a start position and an end position should be 2.0 to 2.5. In the bottle can member 11 which has such a thread section, an outer diameter of the thread section which is formed on the mouth section is 28 to 38 mm. Also, the thickness of the mouth section is 0.25 to 0.4 mm. The thread section which has the effective thread number 2.0 to 2.5 is formed by eight-thread per inch pitch. By doing this, it is possible to put the cap desirably.

Owner:UNIVERSAL CAN CORP

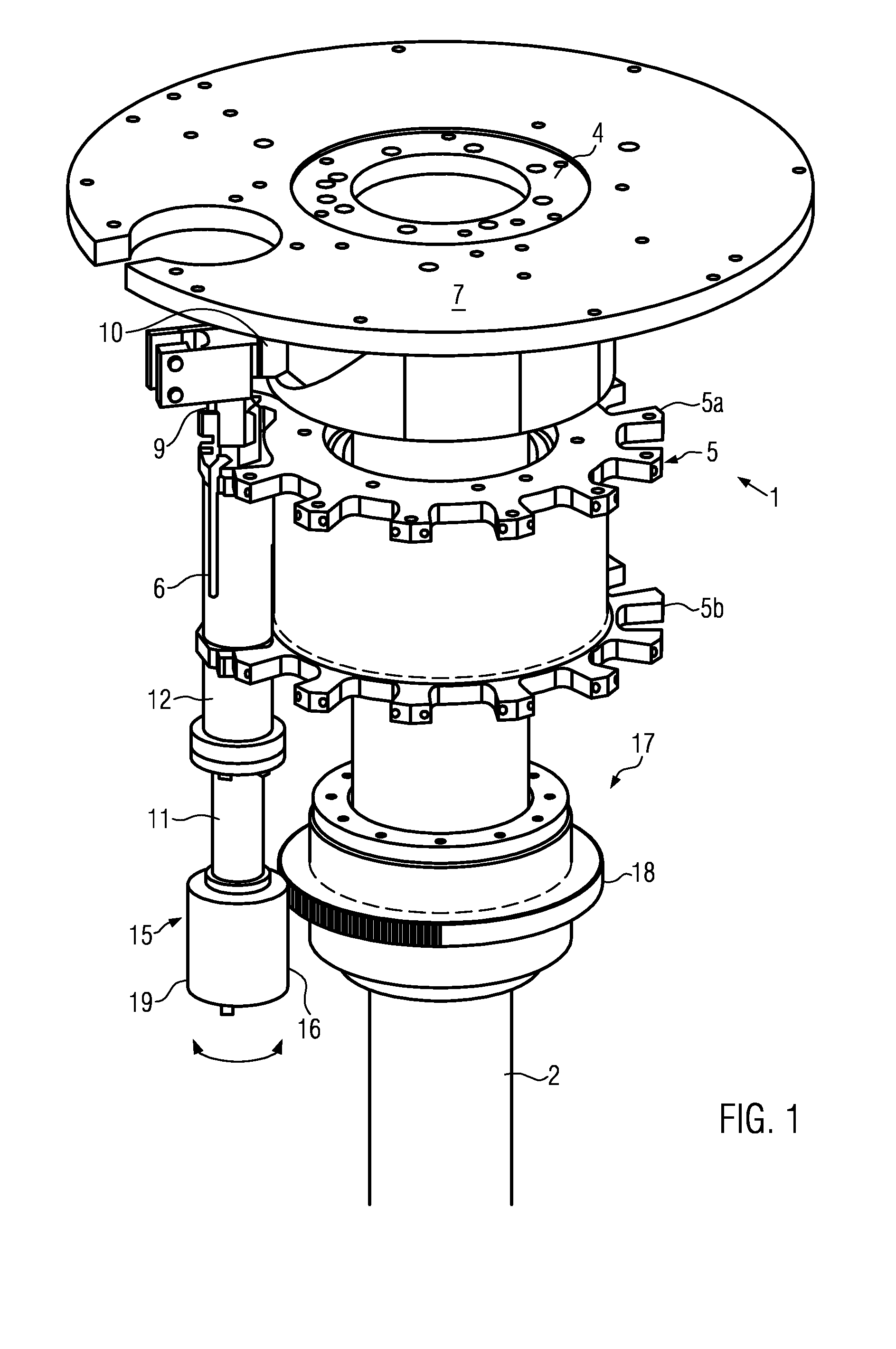

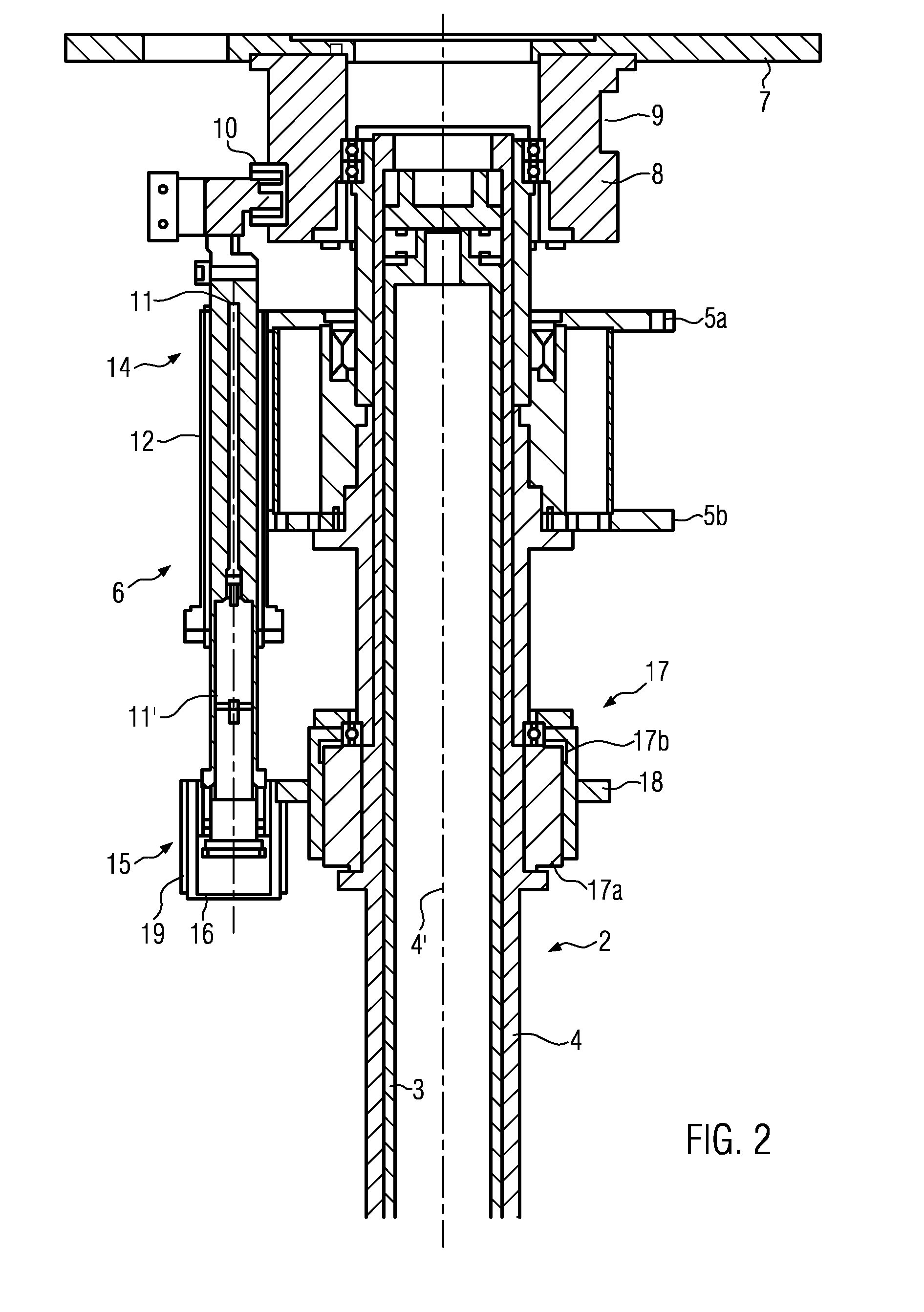

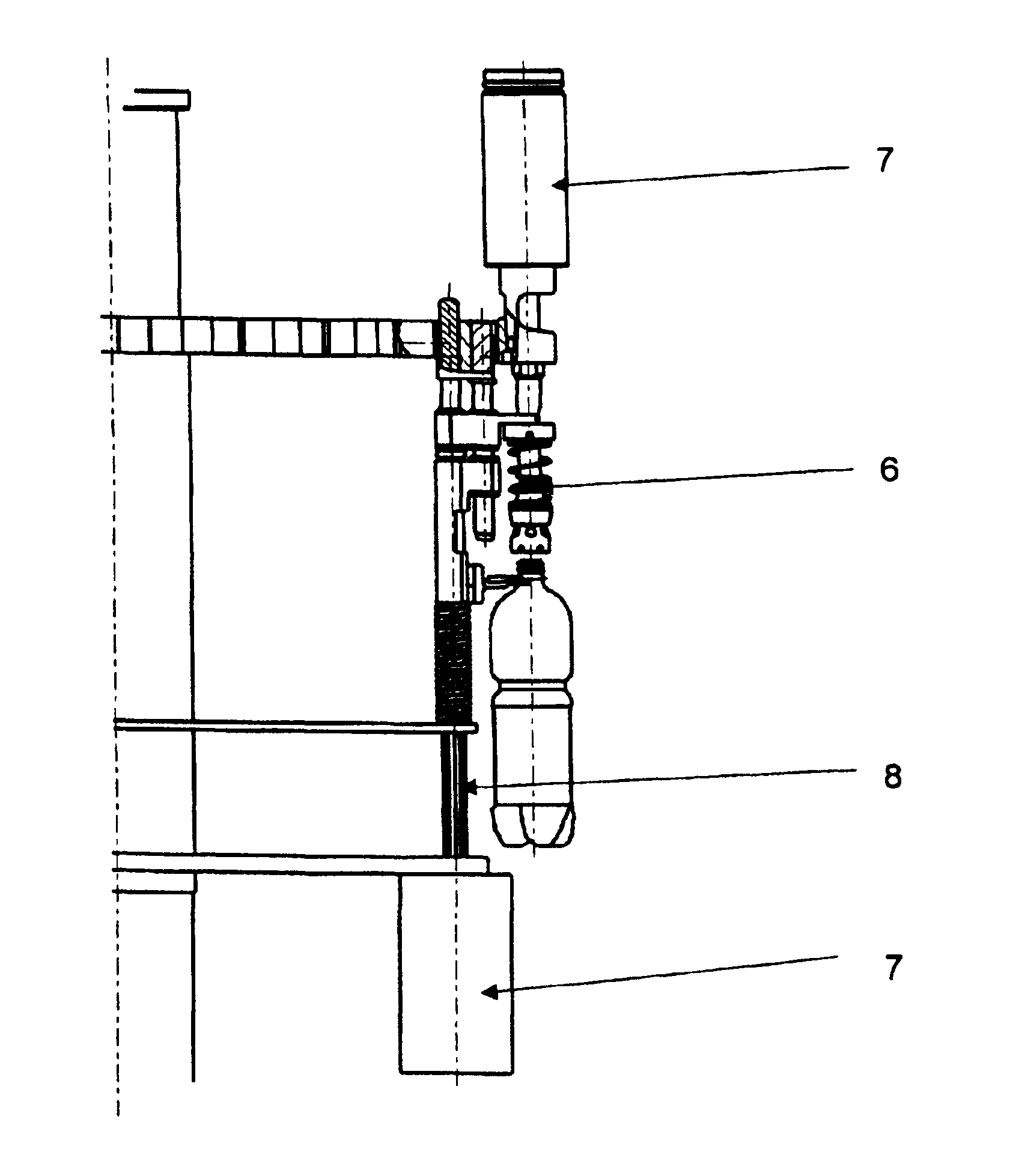

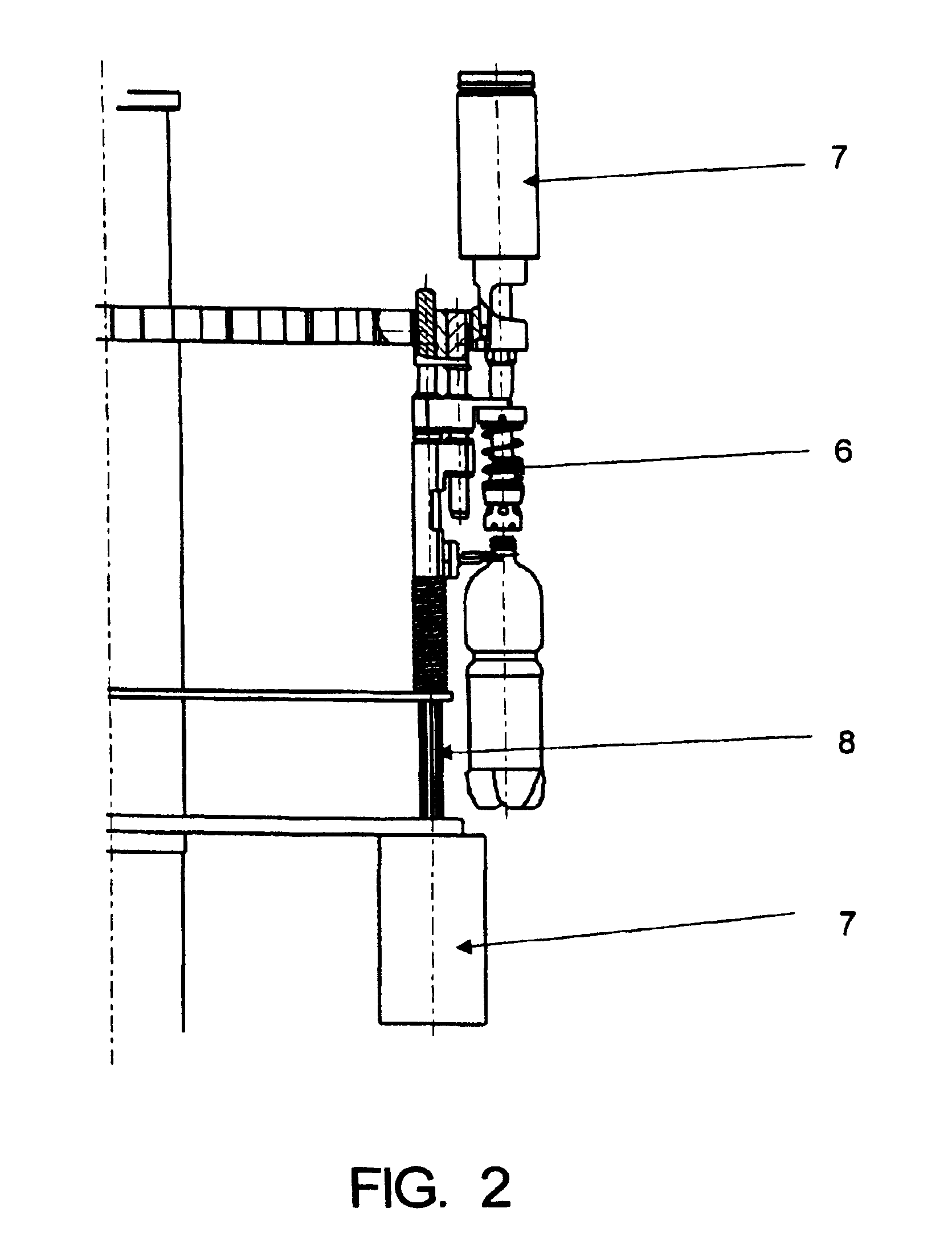

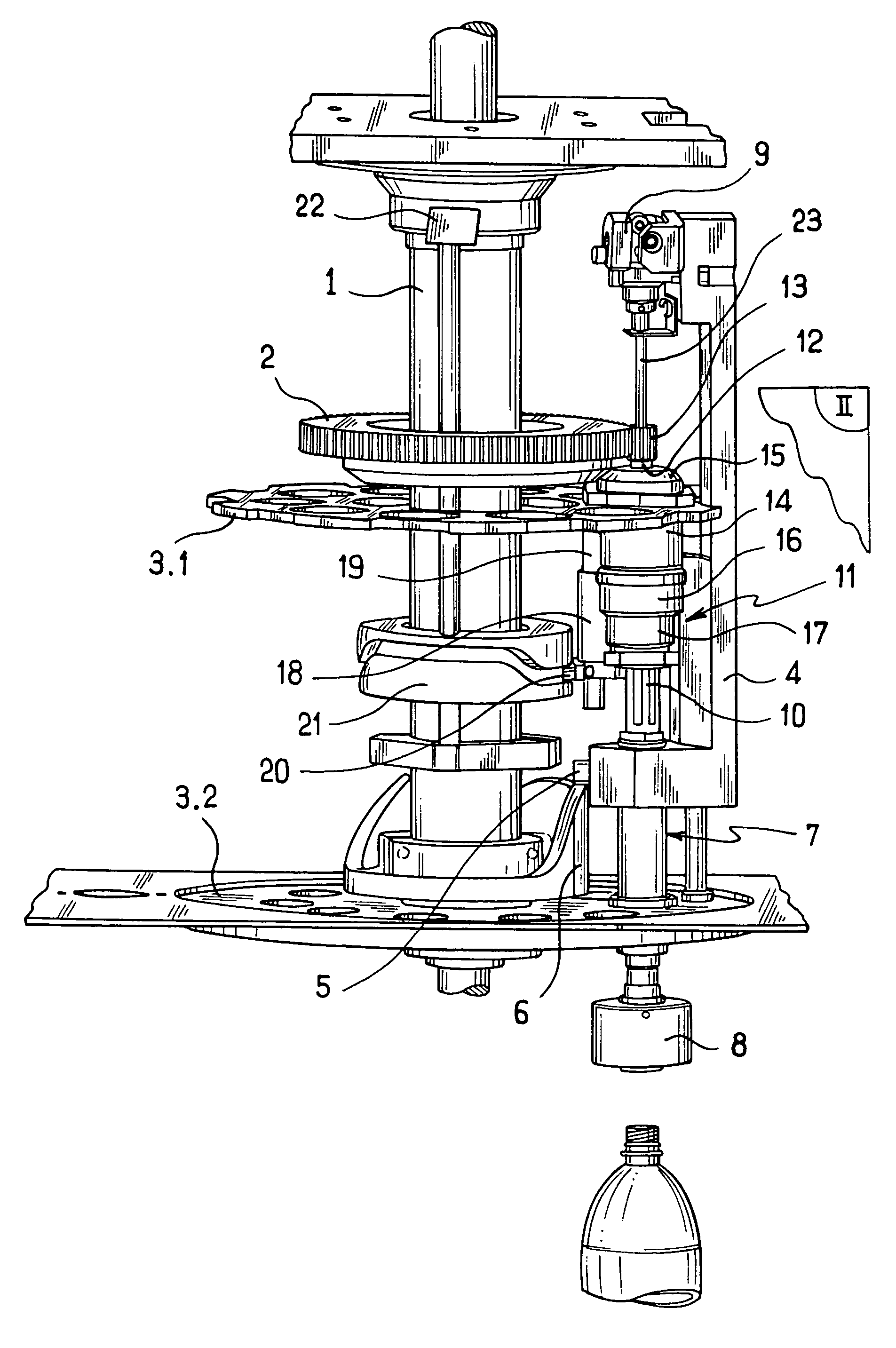

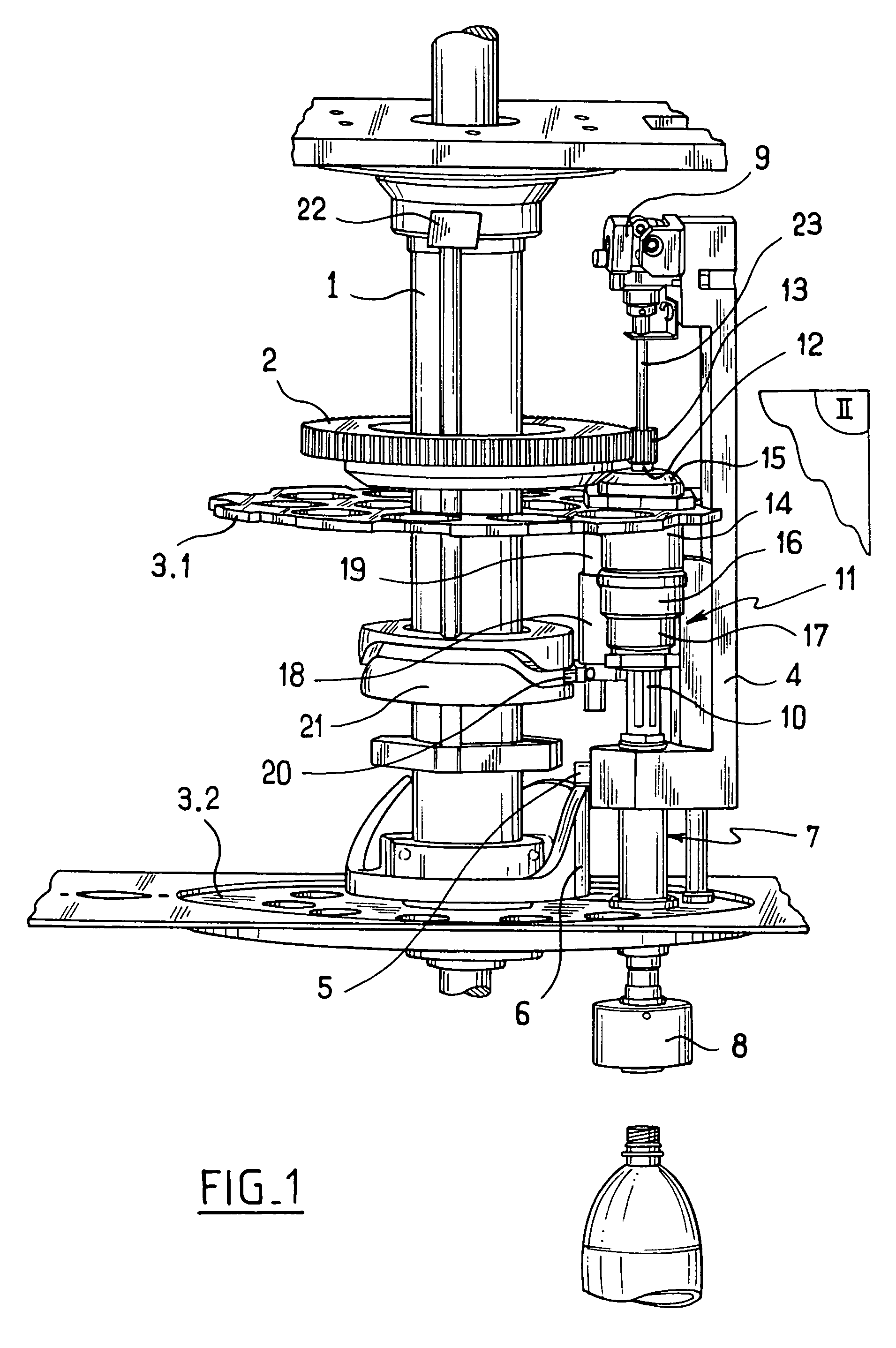

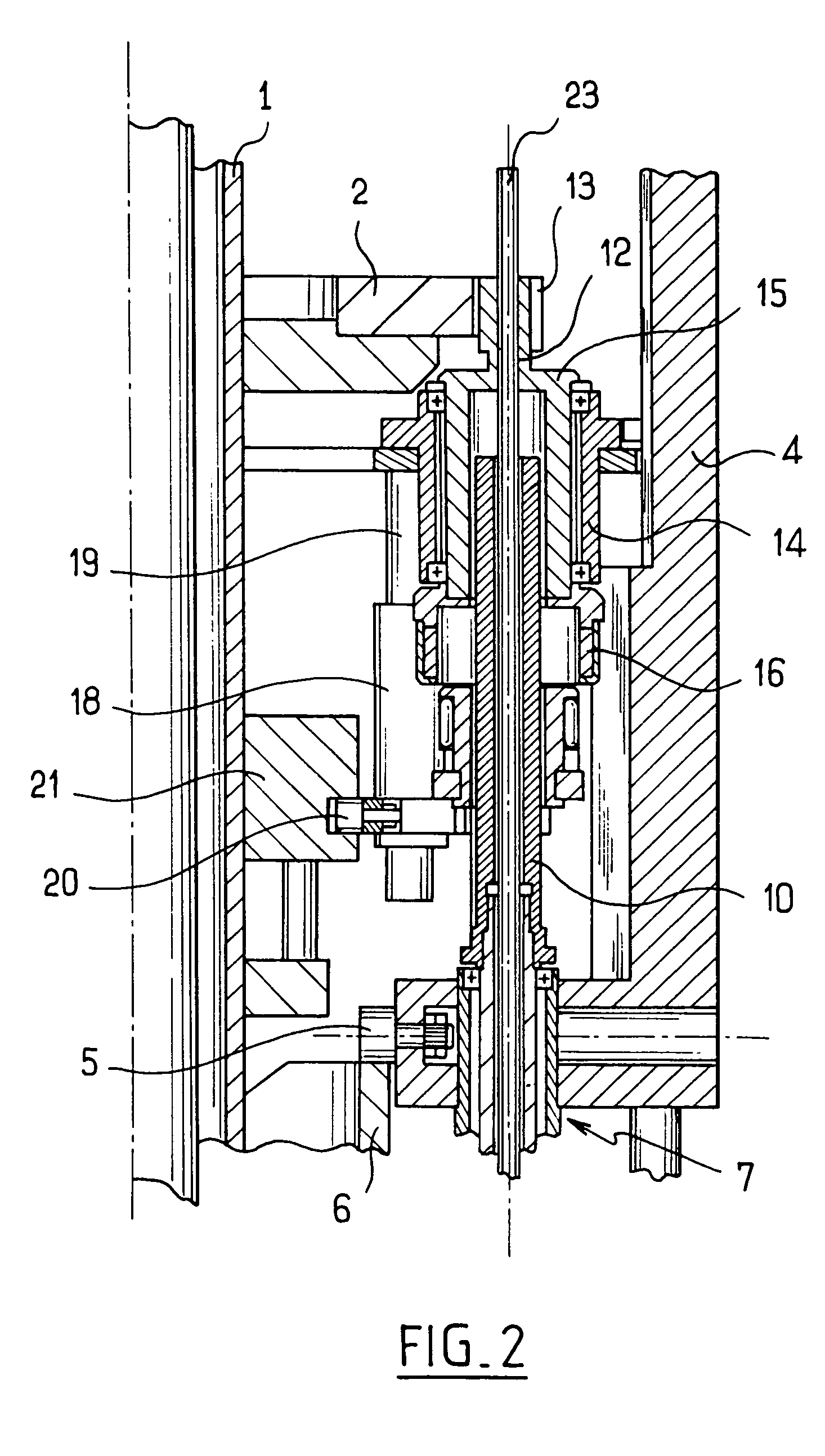

Closing means

InactiveUS20120186194A1Increase flexibilityImprove controllabilityCapsThreaded caps applicationLinear motionGear wheel

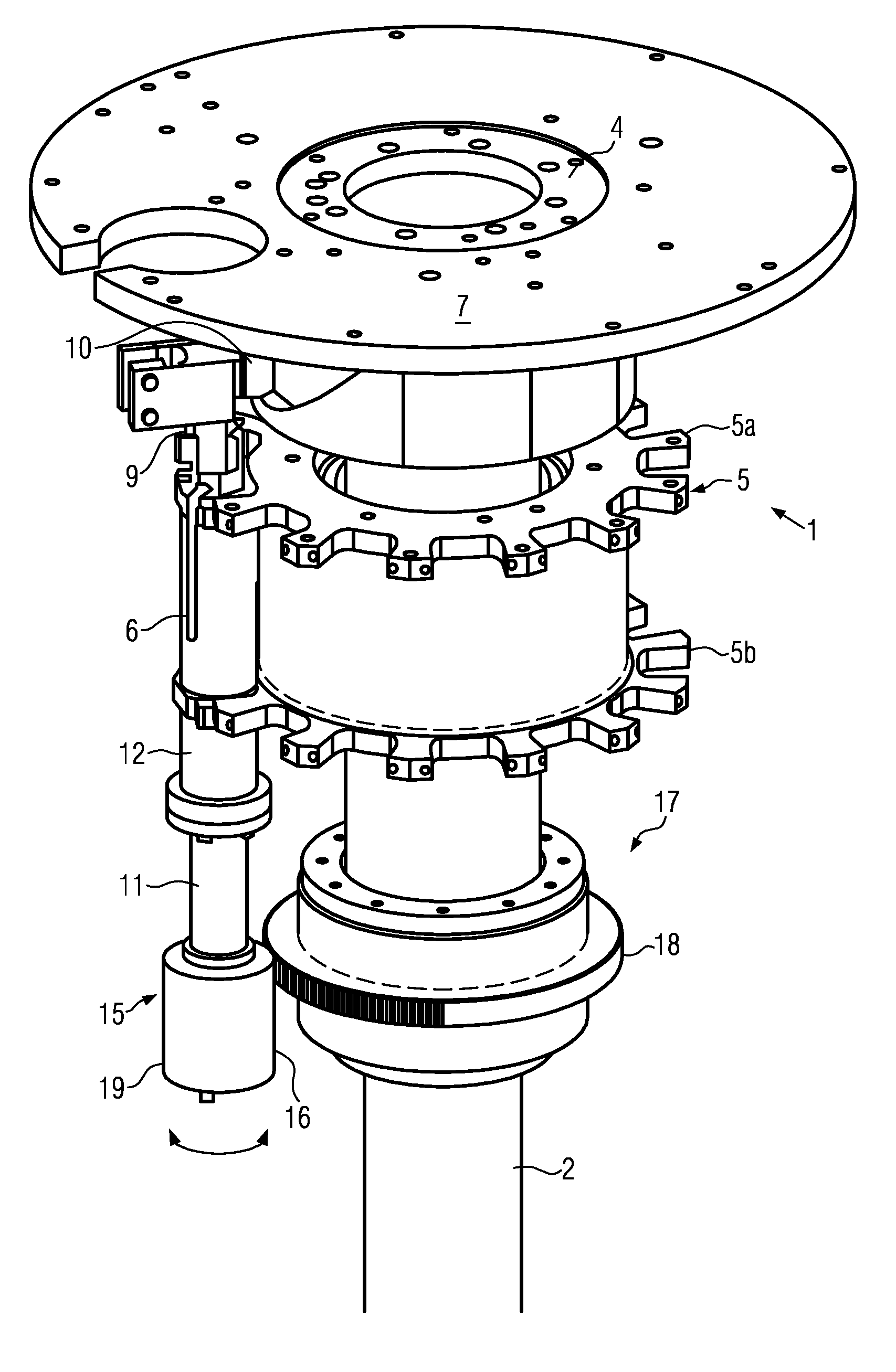

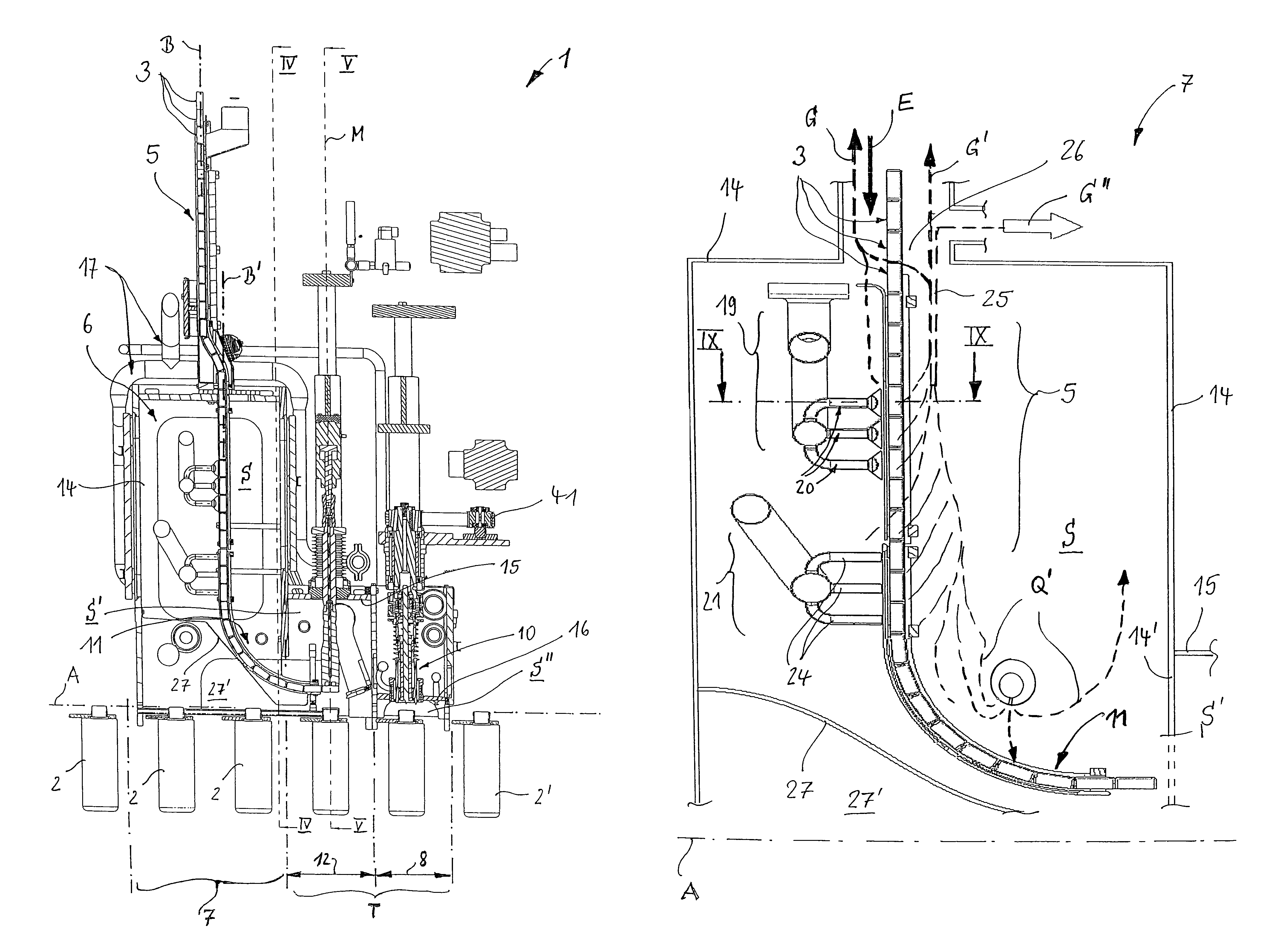

A closing means for containers including a transport means for the containers having a drive and at least one closing unit for applying a closure by a linear motion along a central line and a rotary motion about the central line, wherein the rotary motion is applied by rolling off two gear members. To achieve a structurally simple and flexible embodiment the first one of the gear members is connected with a separate drive independent of the drive of the transport means.

Owner:KRONES AG

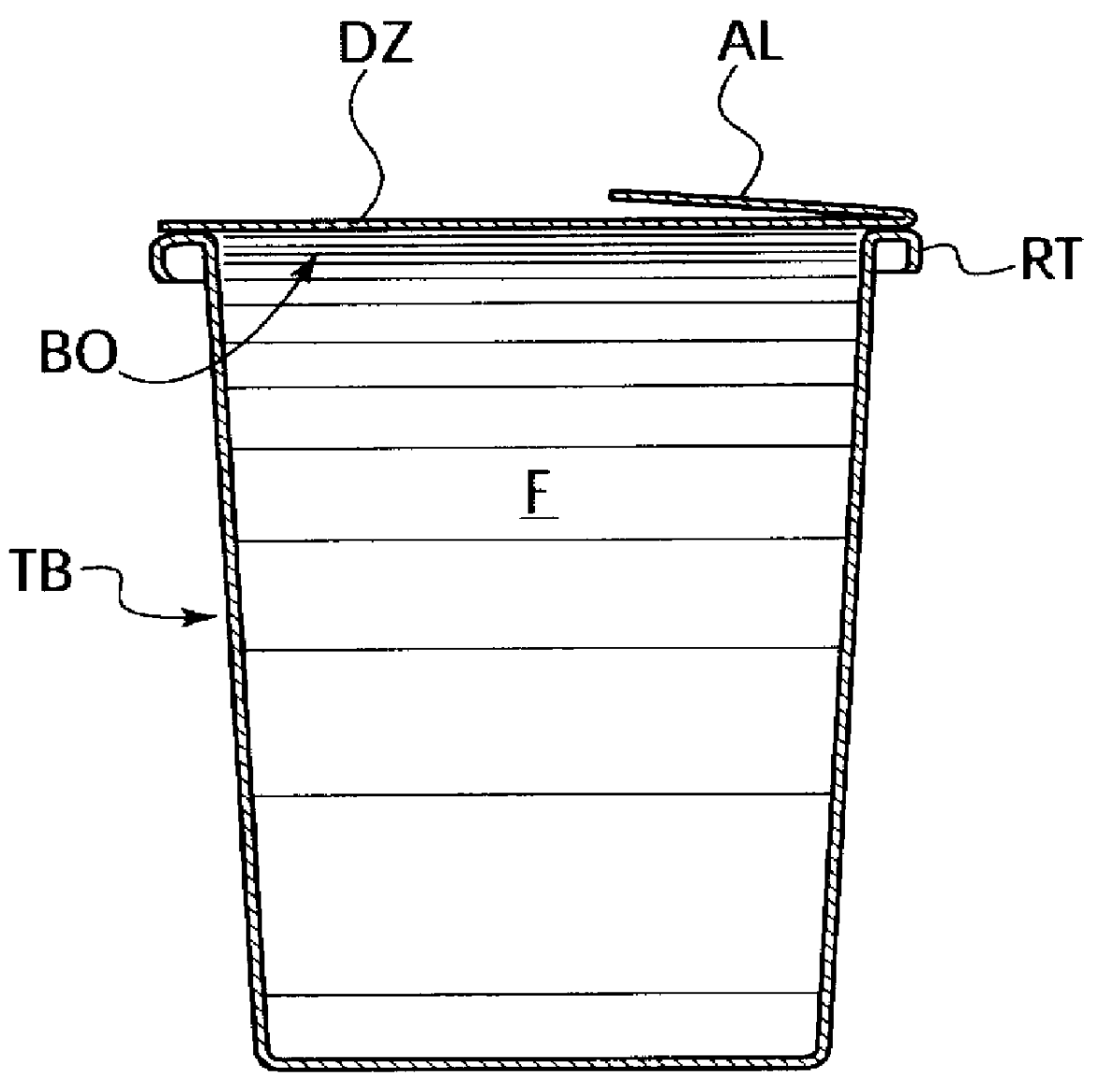

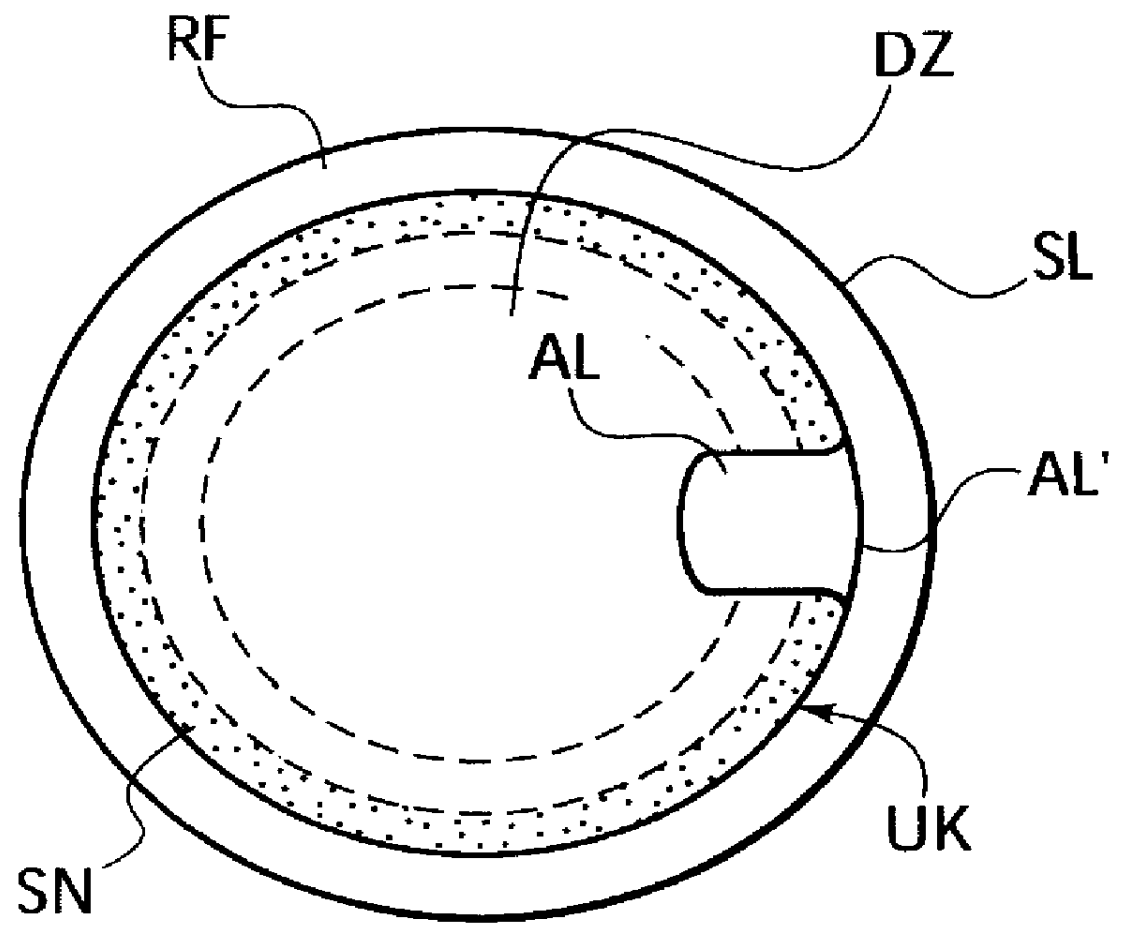

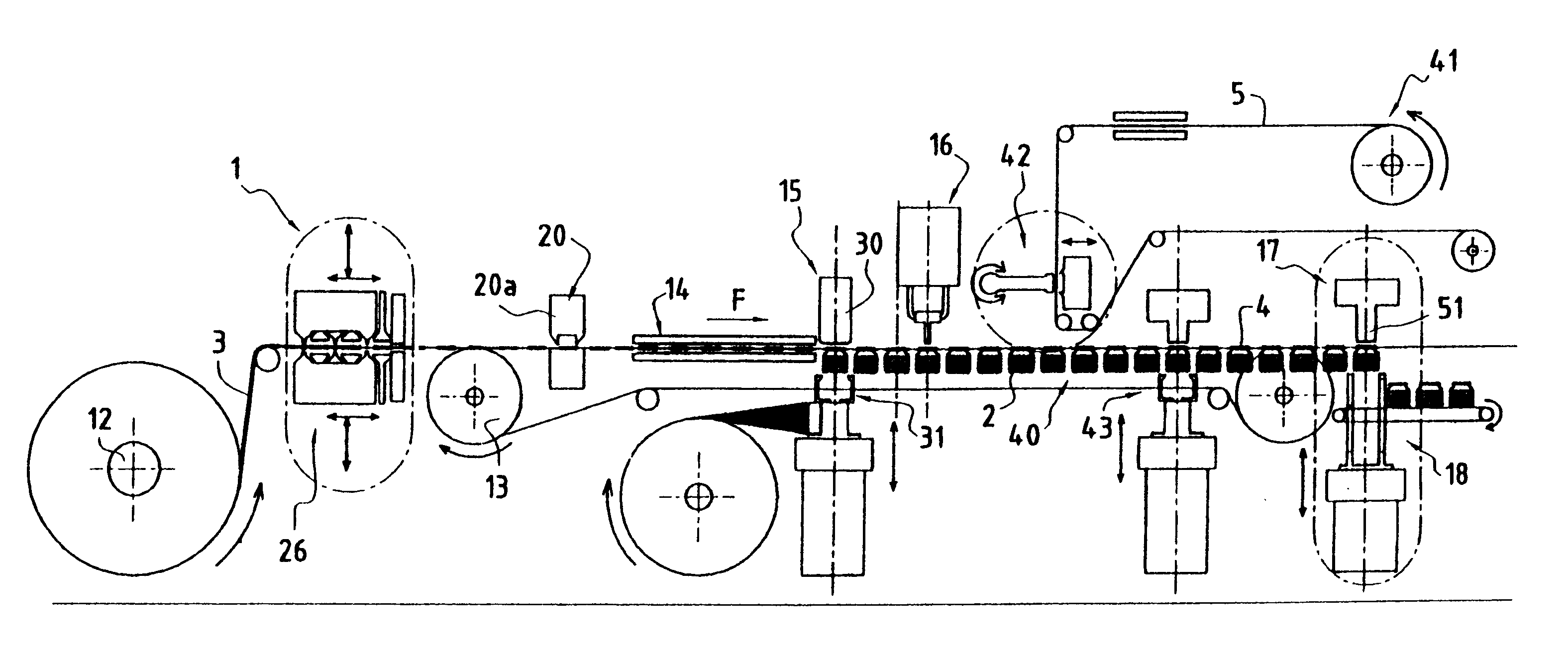

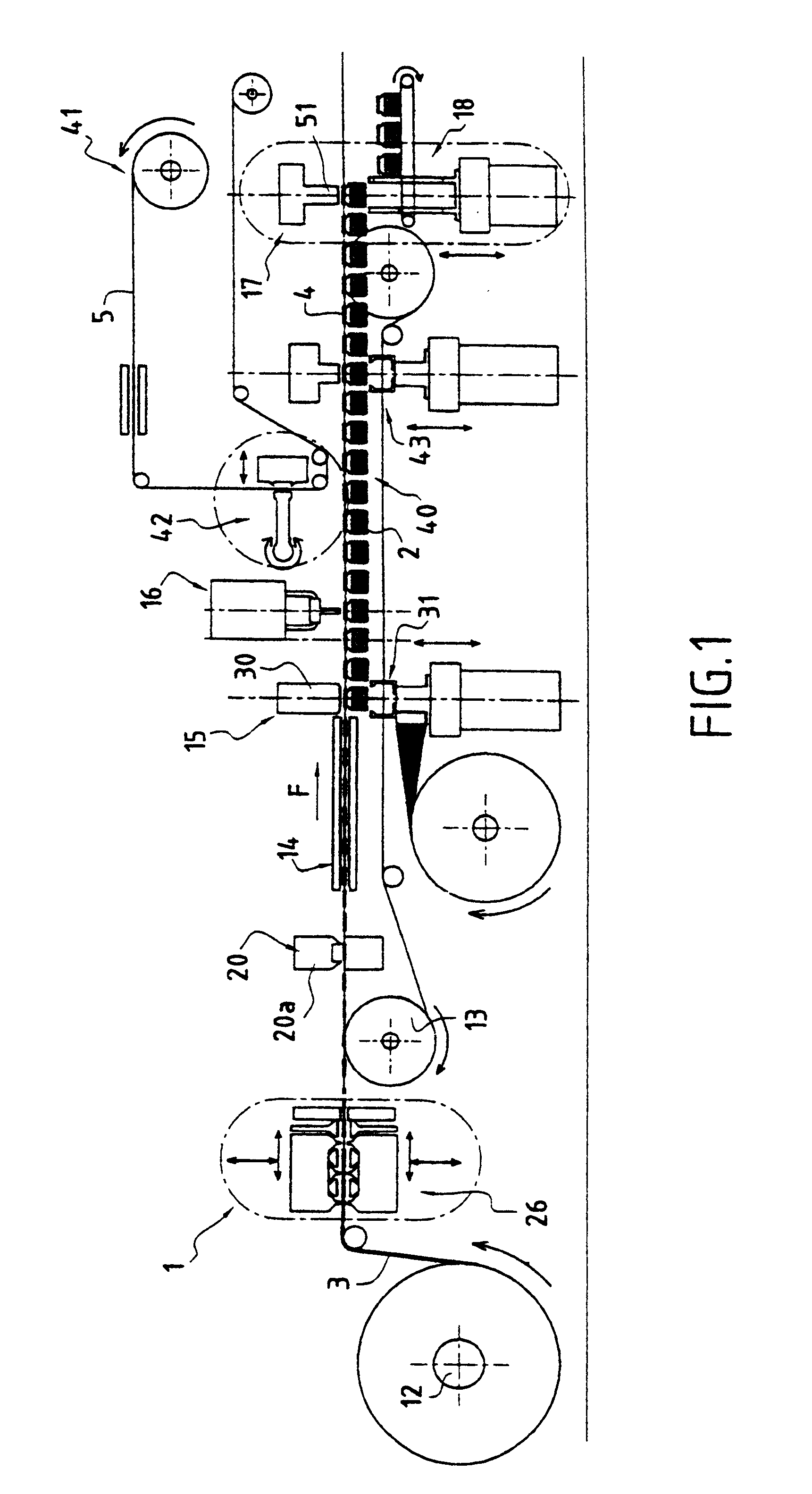

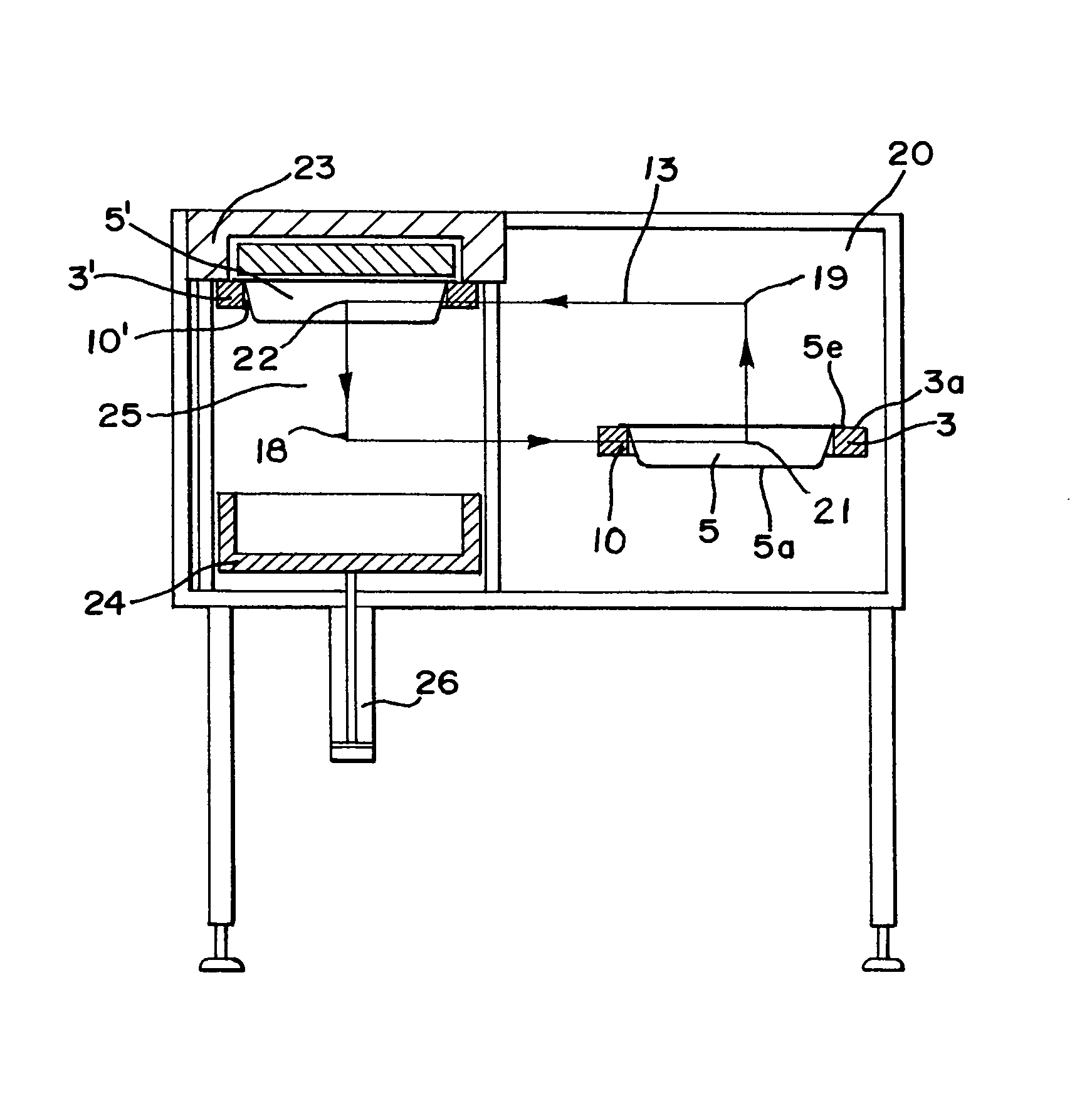

Process and packing machine for manufacturing filled drinking cups

InactiveUS6161367AReduce mechanical forceMinimized cover foil wasteCapsFlanged caps applicationPack materialEngineering

The invention is concerned with a process of manufacturing filled drinking cups closed by cover foil blanks heat-sealed thereto and formed by deep-drawing from a thermoplastic packing material strip, comprising a beaded peripheral flange, with the cover foil blanks being provided with a pull flap. According to the invention the method includes the following steps: cyclically feeding the packing material strip loaded with the deep-drawn and filled cups underneath a cover foil blank transfer means; taking up the cover foil blanks from the transfer means, with the pull flaps, during transfer of the cover foil blanks to the packing material strip, being positioned in a direction substantially vertical to the extension plane of the blanks, and the blanks with the upright pull flaps above the cup openings being applied to the packing material strip; sealing the margins of the cover foil blanks to the unmolded areas of the packing material strip about the cup openings; bending the upright flaps during the advance movement of the packing material strip; punching the cups from the packing material strip along a punching contour line extending in parallel to and at a space from the circumferential contour of the cover foil blanks; and transferring the punched cups into a beading means wherein the peripheral flange portion projecting relative to the cover foil blanks is downwardly beaded.

Owner:HASSIA VERPACKUNGSMASCHEN

Method and Machine for Closing Bottles with Sterile Caps

ActiveUS20070006550A1Improve throughputImprove protectionCapsThreaded caps applicationSterile environmentLinear machine

For closing bottles with sterile caps, the caps are placed in a non-sterile environment in a vertical arrangement and are supplied vertically to a first sterile area. The interior of the caps is arranged to be accessible horizontally. The caps are sterilized in the first sterile area and transferred to a second sterile area where the caps are placed onto bottles. Subsequently, the bottle is closed with the cap. The machine for sterile closing of bottles with caps has a sterilization device with an individualization device for picking up caps and a vertical transport path feeding the caps to the sterilization chamber. A placing device receives the caps from the sterilization device and places the caps onto bottles. A closing device closes the bottles with the cap placed thereon. The sterilization device, the placing device, and the closing device operate as synchronized modules of a linear machine.

Owner:KHS CORPOPLAST GMBH & CO KG

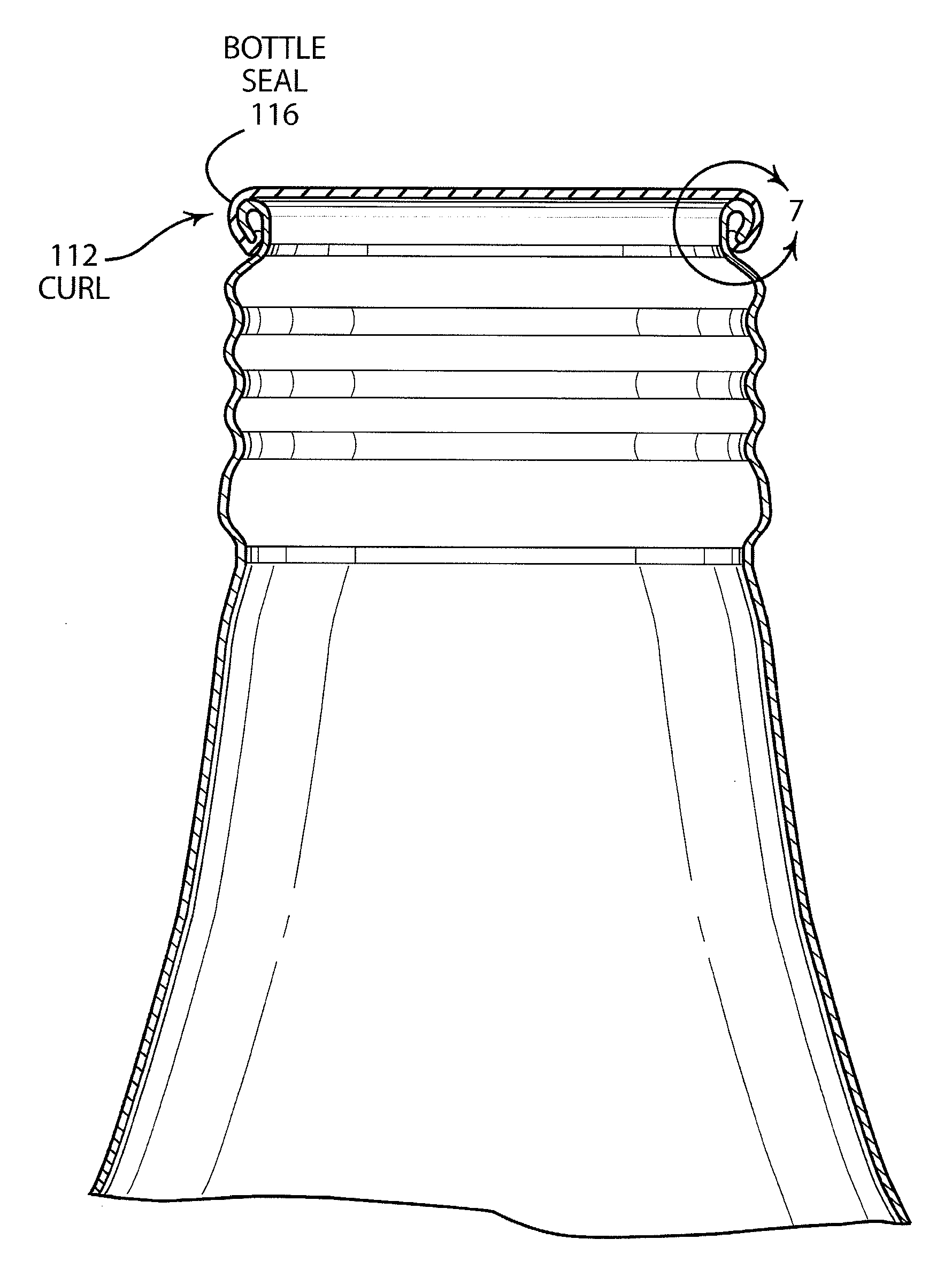

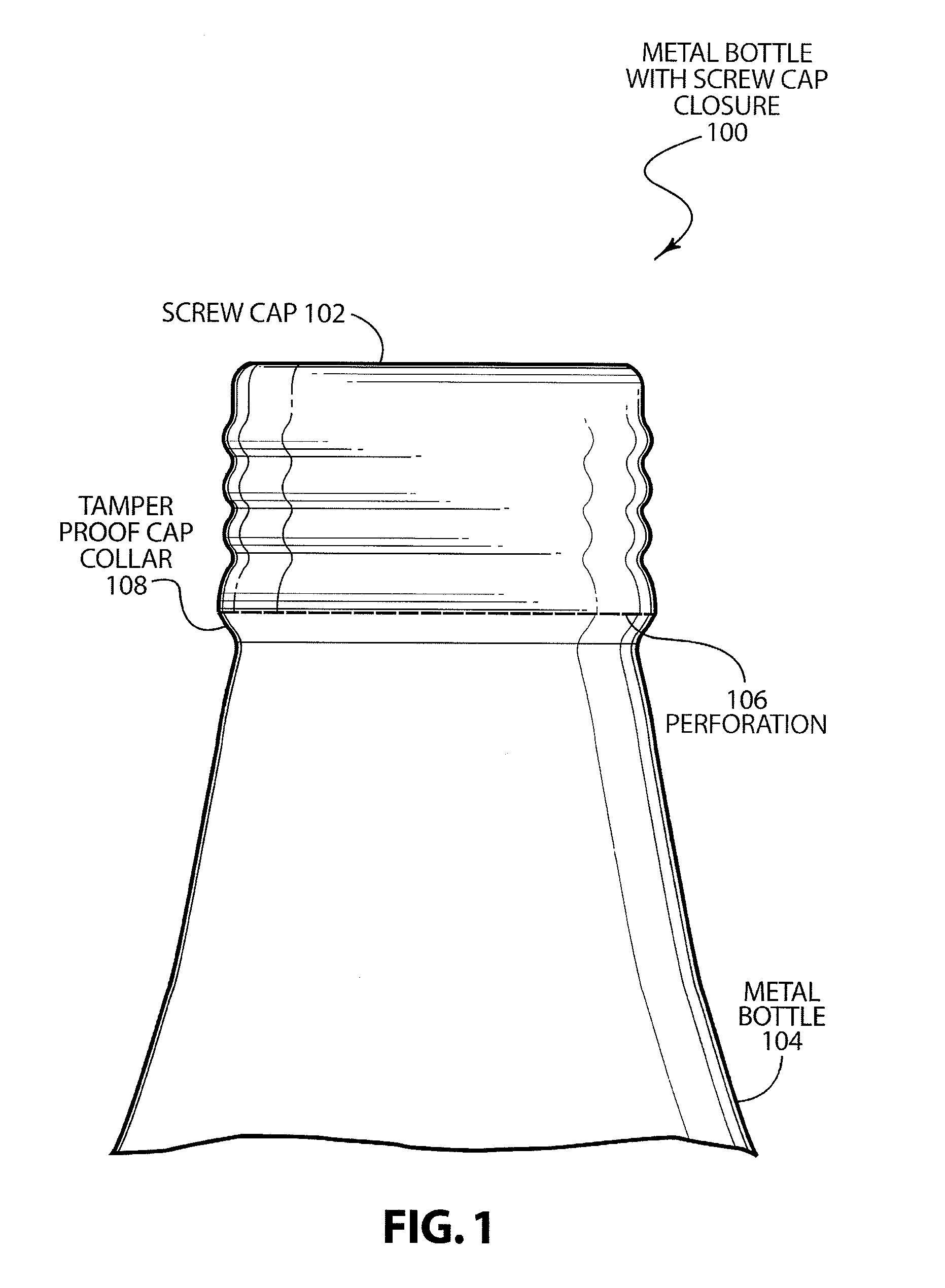

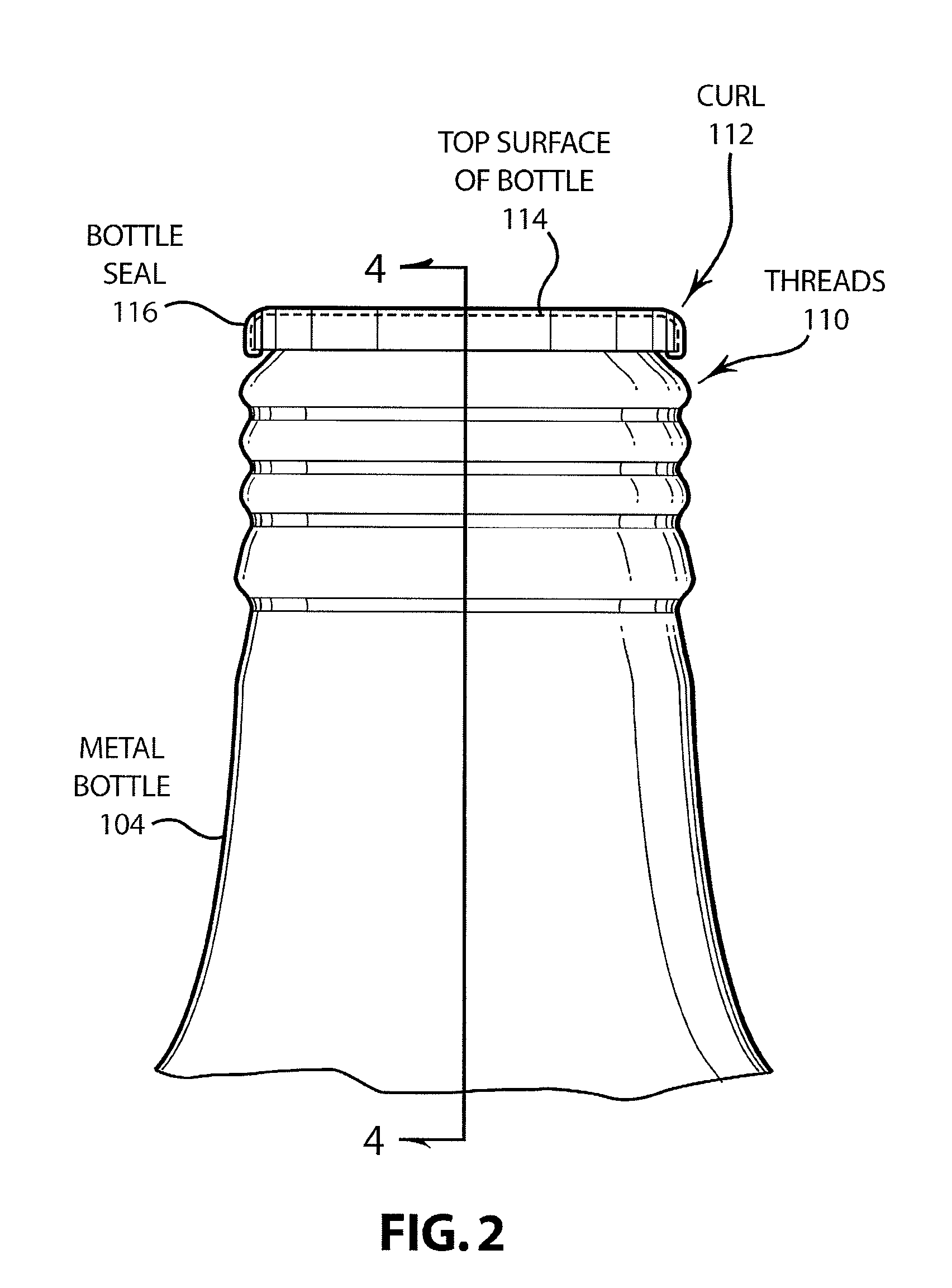

Metal bottle seal

Disclosed is a metal bottle seal that is disposed on the curl of the metal bottle. The bottle seal may be held in place by crimping of the curl. In addition, adhesive may be used to hold the bottle seal on the curl. Adhesives can be used that fill discontinuities that may exist in the curl as a result of substantial drawing and ironing of the metal. Further, the metal bottle seal can be made of a material or laminated with a material that is soft enough to fill the discontinuities. The seal can be preformed as a continuous annulus for easy application to the top of the metal bottle. The metal bottle seal can also be used in conjunction with a cap seal to ensure an adequate and reliable seal.

Owner:STOLLE MACHINERY +1

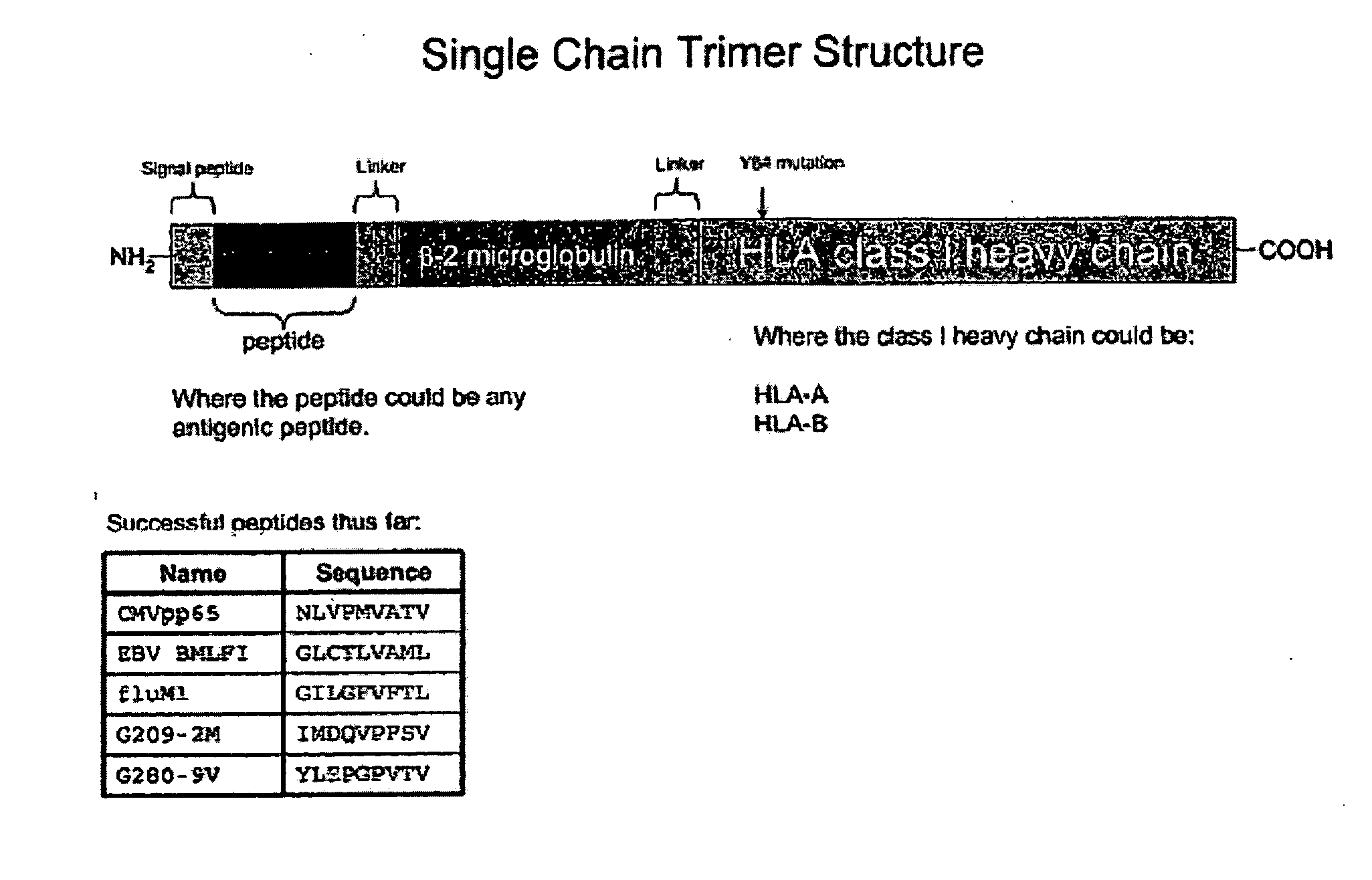

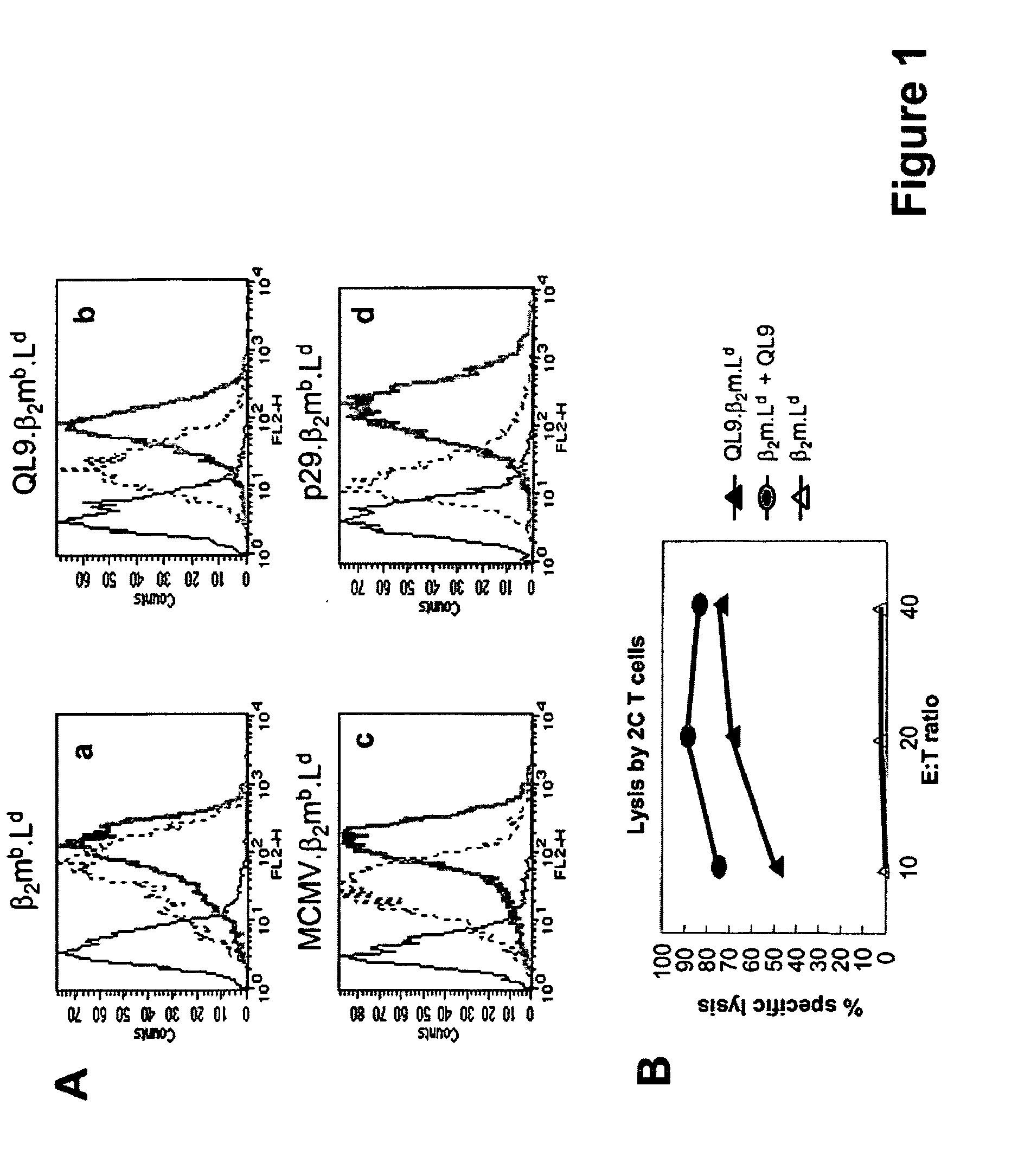

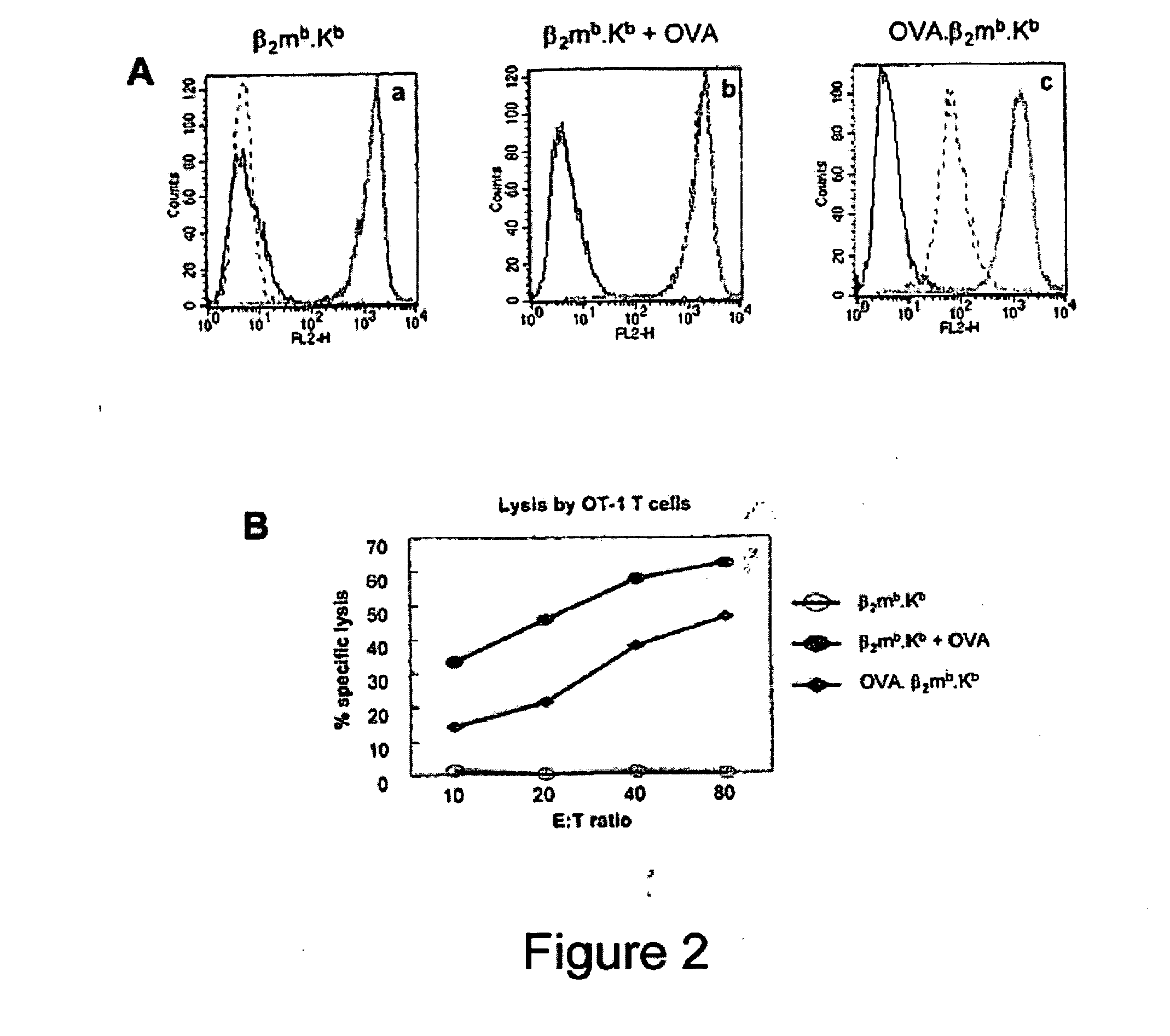

Single chain trimers and uses therefor

Owner:WASHINGTON UNIV IN SAINT LOUIS

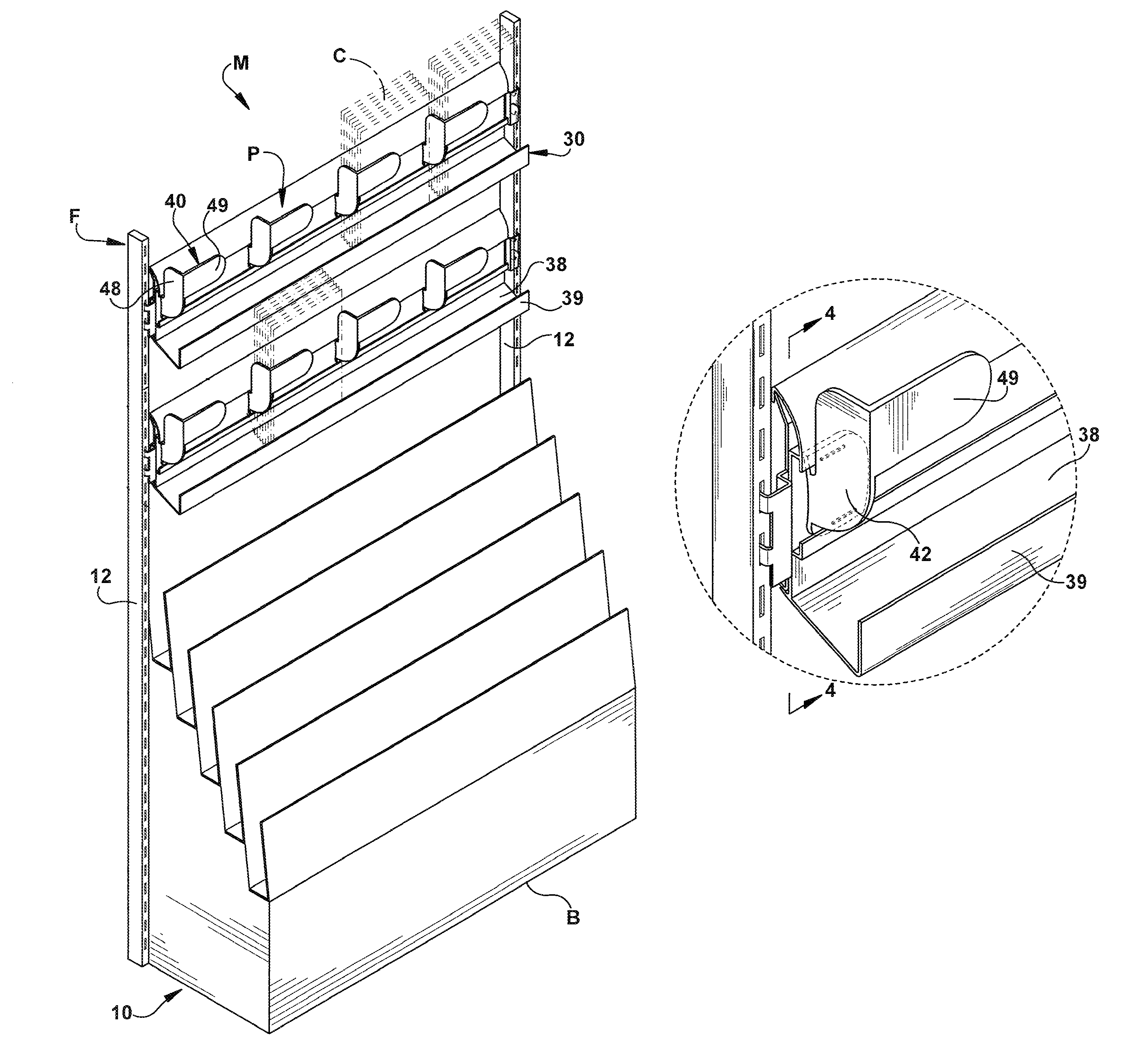

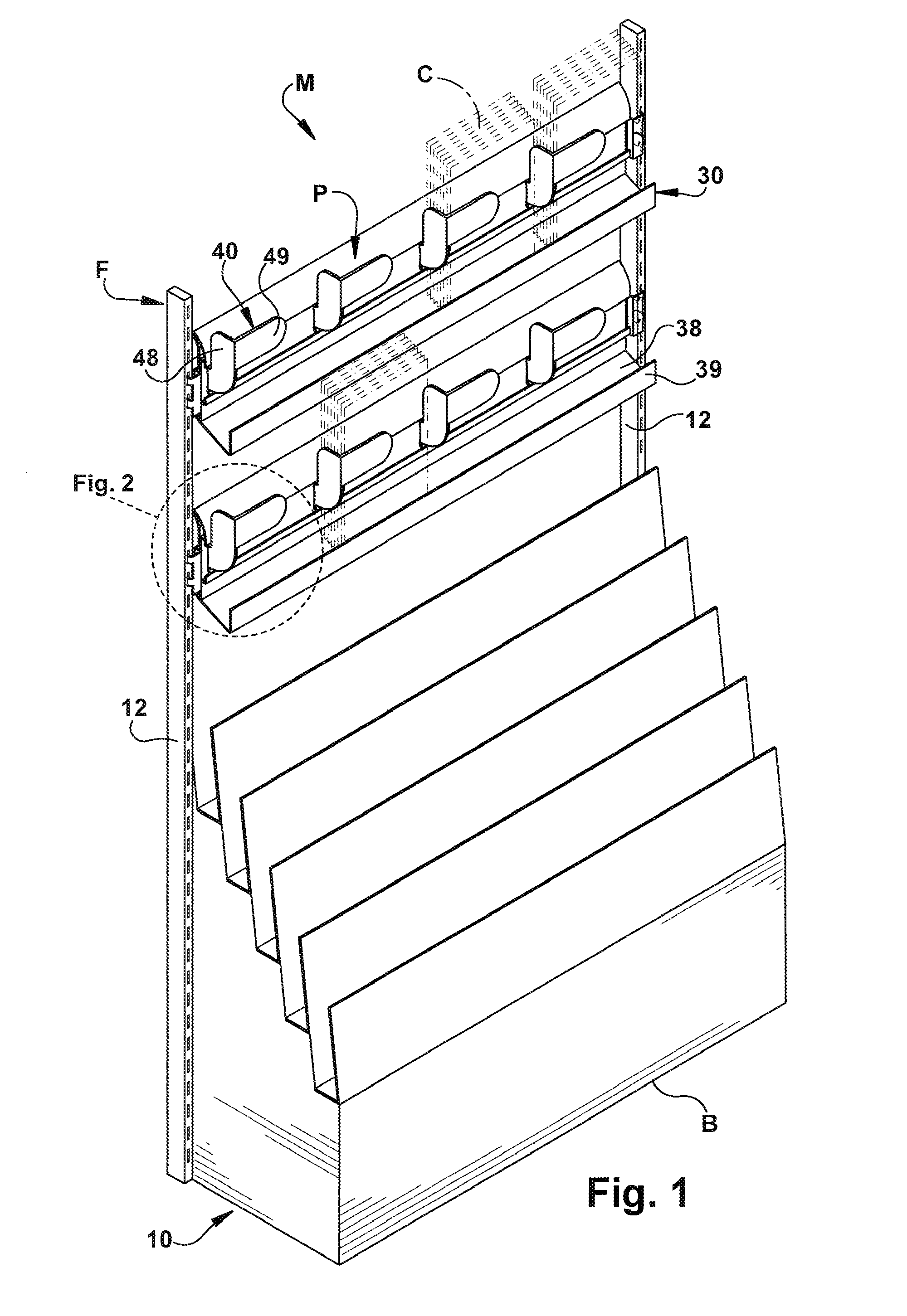

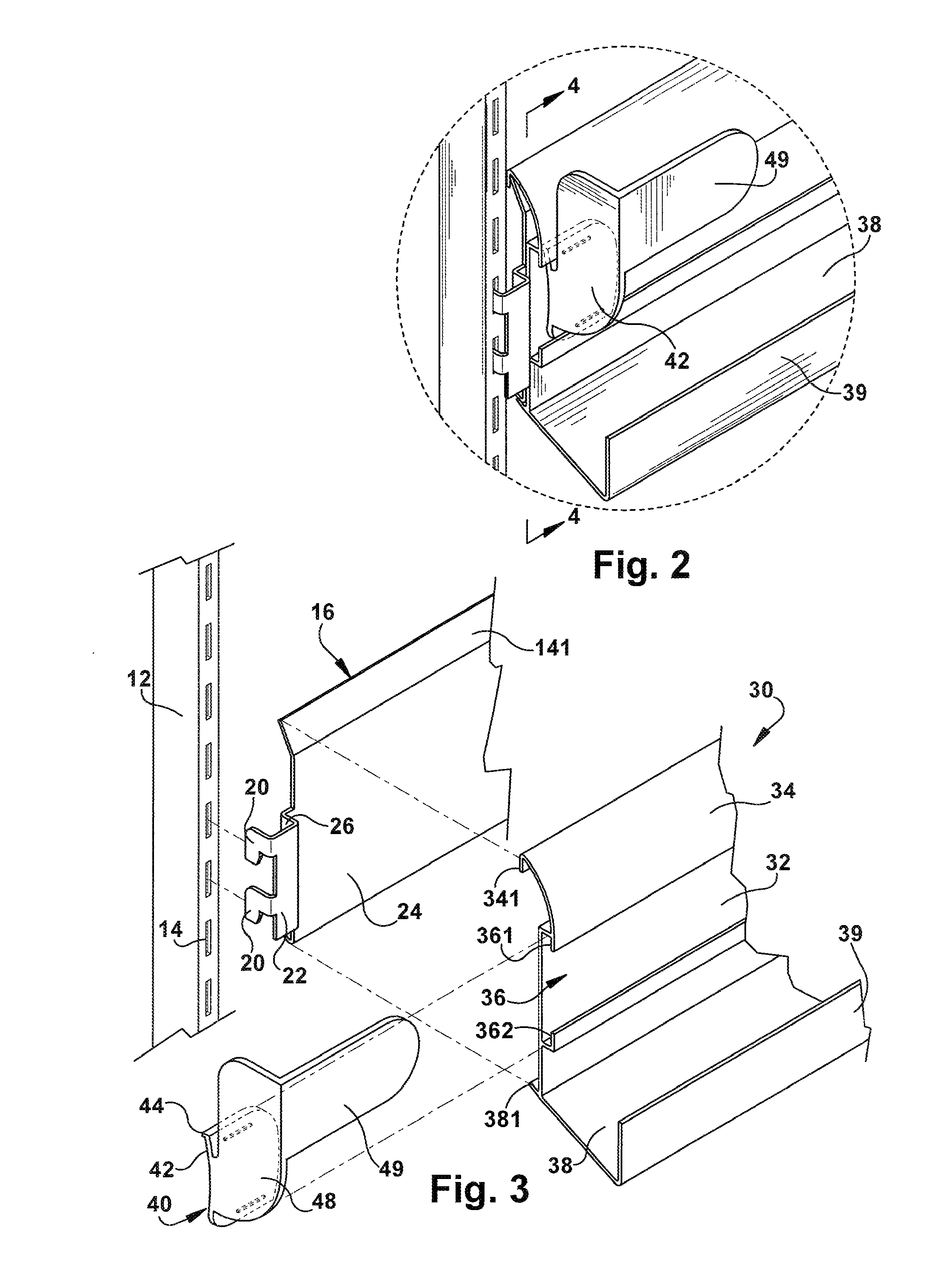

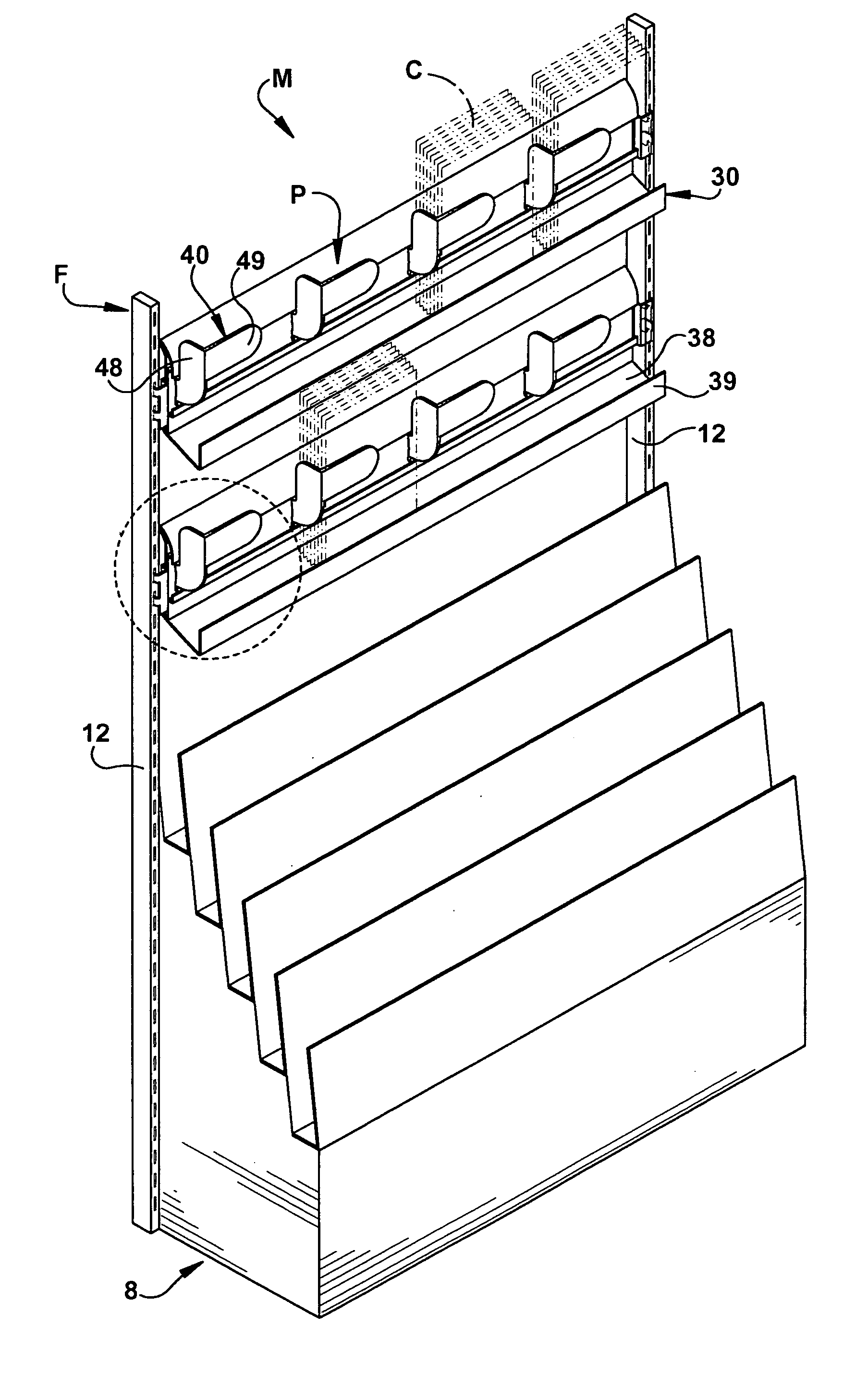

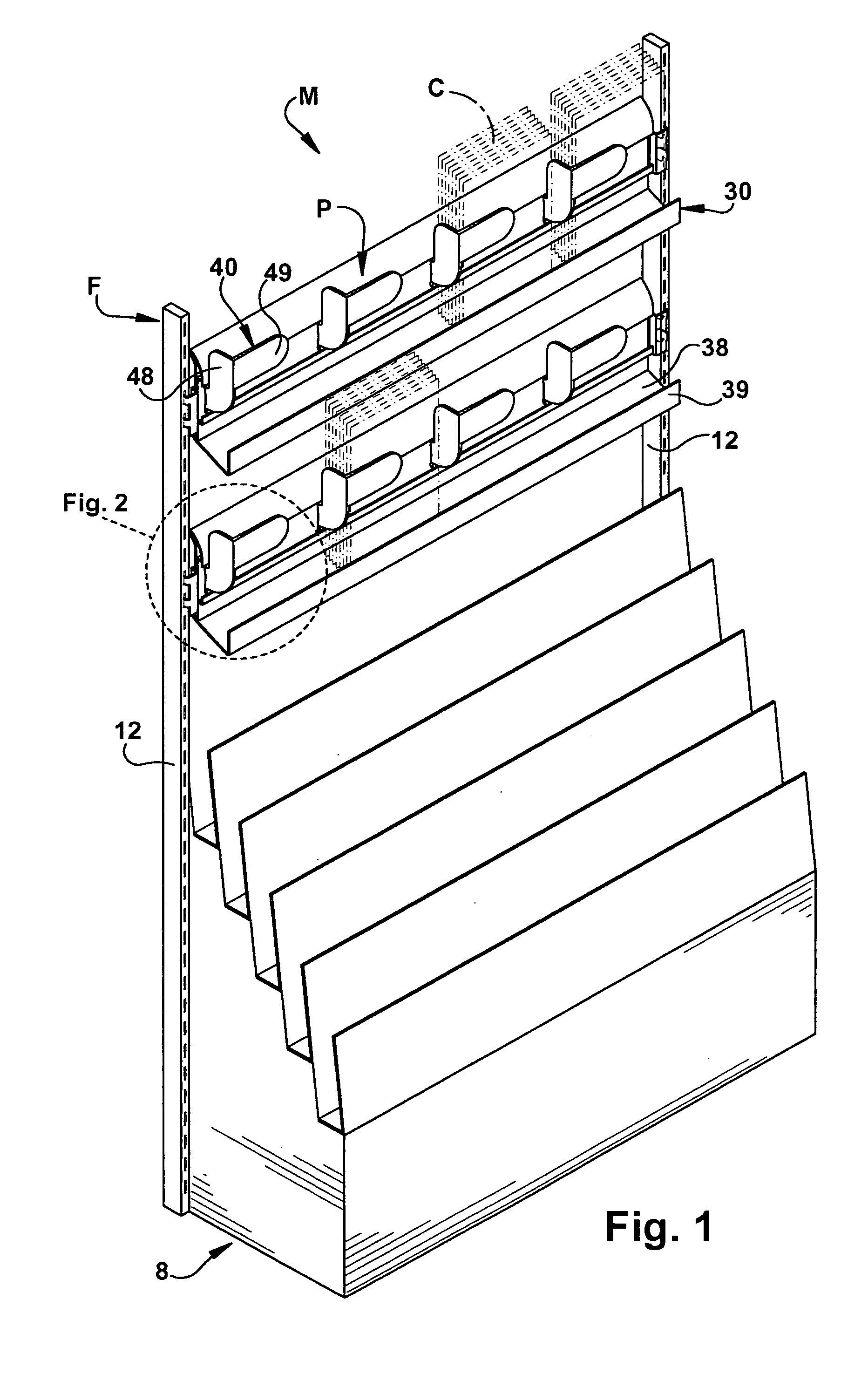

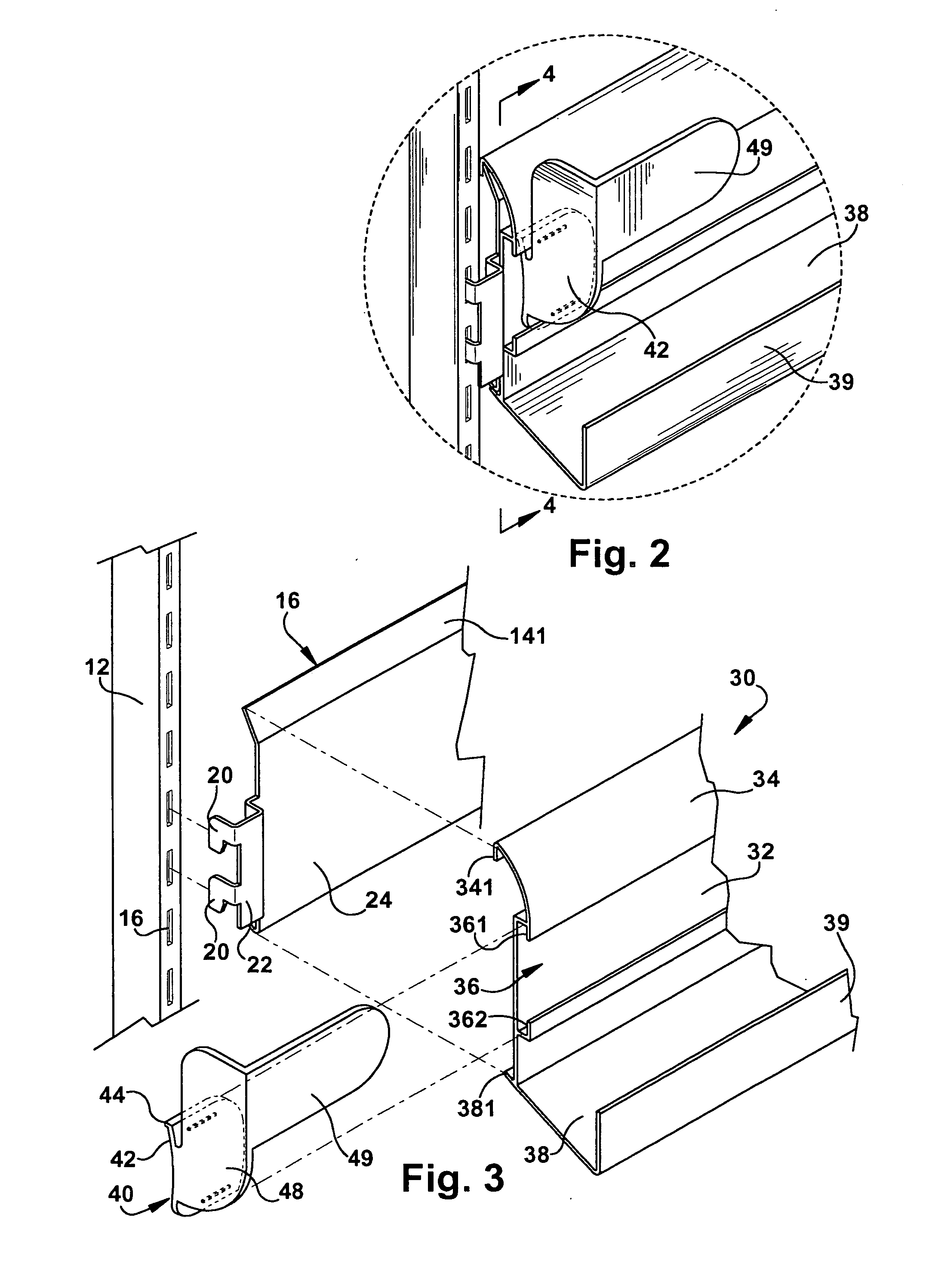

Retail display for greeting cards

Owner:AMERICAN GREETINGS

Retail display for greeting cards

Owner:AMERICAN GREETINGS

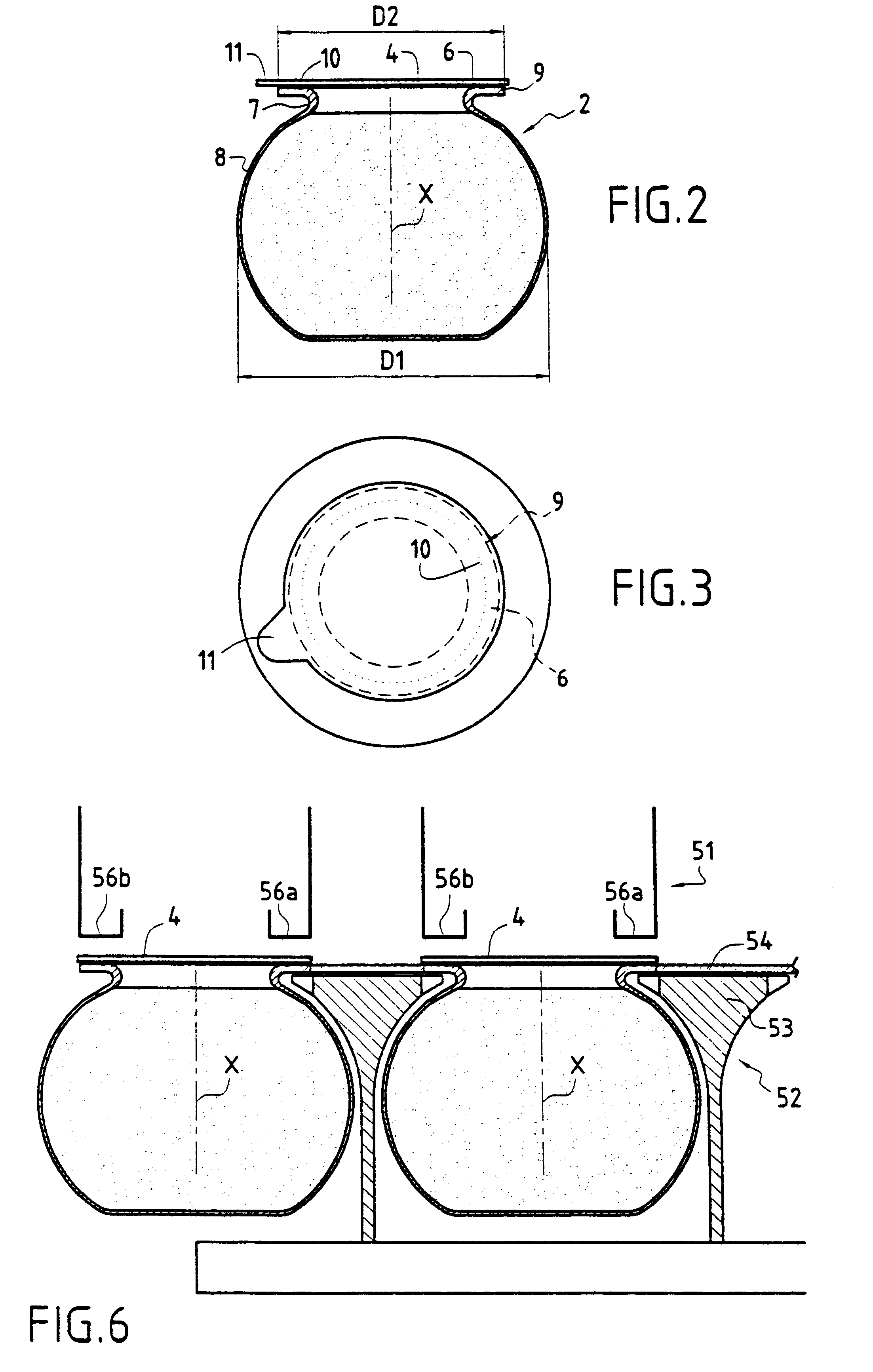

Method and an installation for thermoforming, filling, and closing re-entrant receptacles

The method and the installation of the invention enable re-entrant receptacles to be thermoformed, filled, and closed, the rim of each receptacle having a diameter that is smaller than the diameter of its body. Prior to thermoforming a row of receptacles, preliminary cuts separated by attachment points are made in a transverse stripe of the strip of the thermoplastic strip that is to be used for thermoforming in a subsequent cycle, and for each receptacle that is to be thermoformed, the cuts define practically the entire final periphery of the rim of said receptacle, the attachment points being broken when the receptacles are separated in a subsequent cycle after the filled receptacles have been closed.

Owner:ERCA FORMSEAL

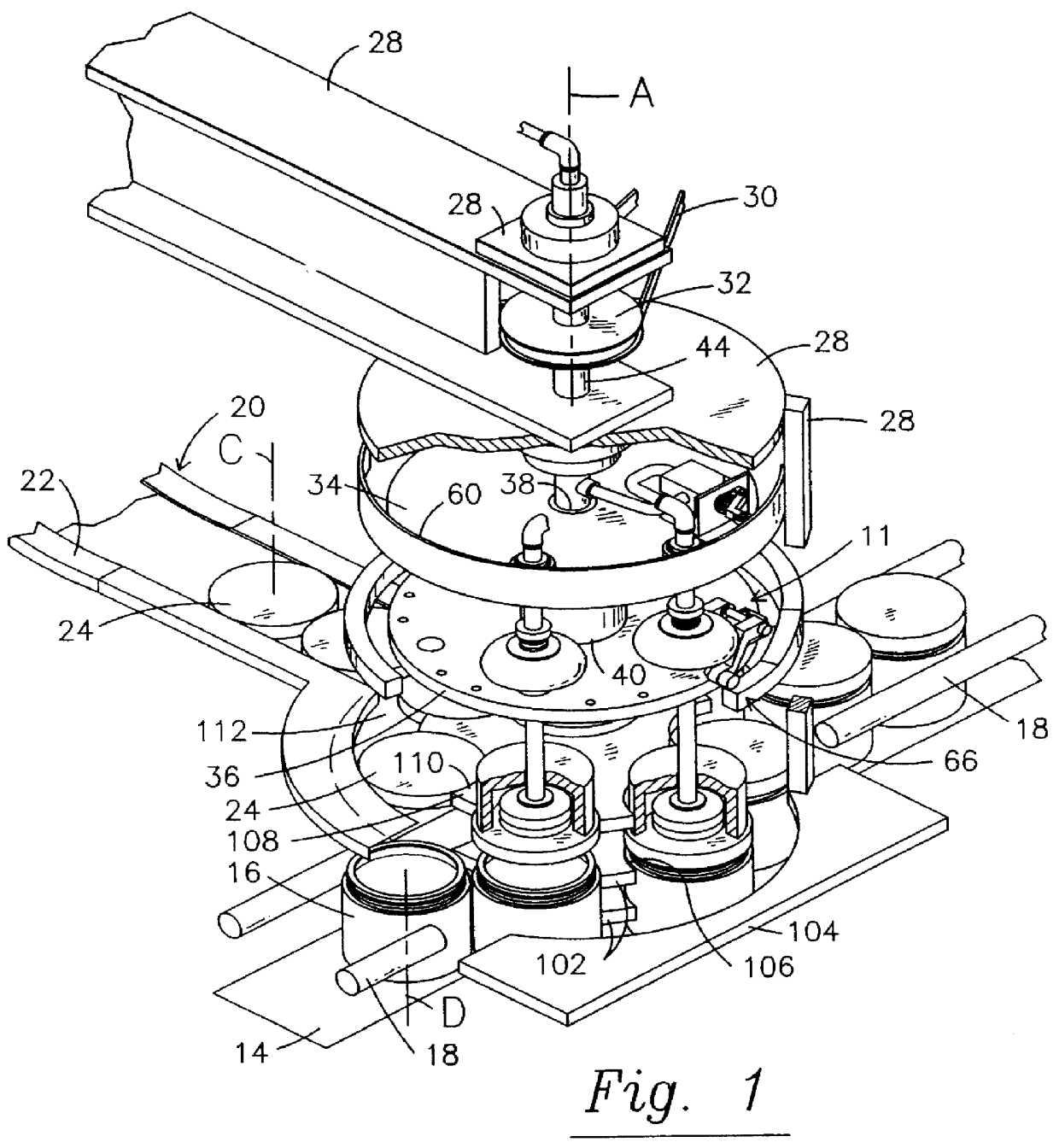

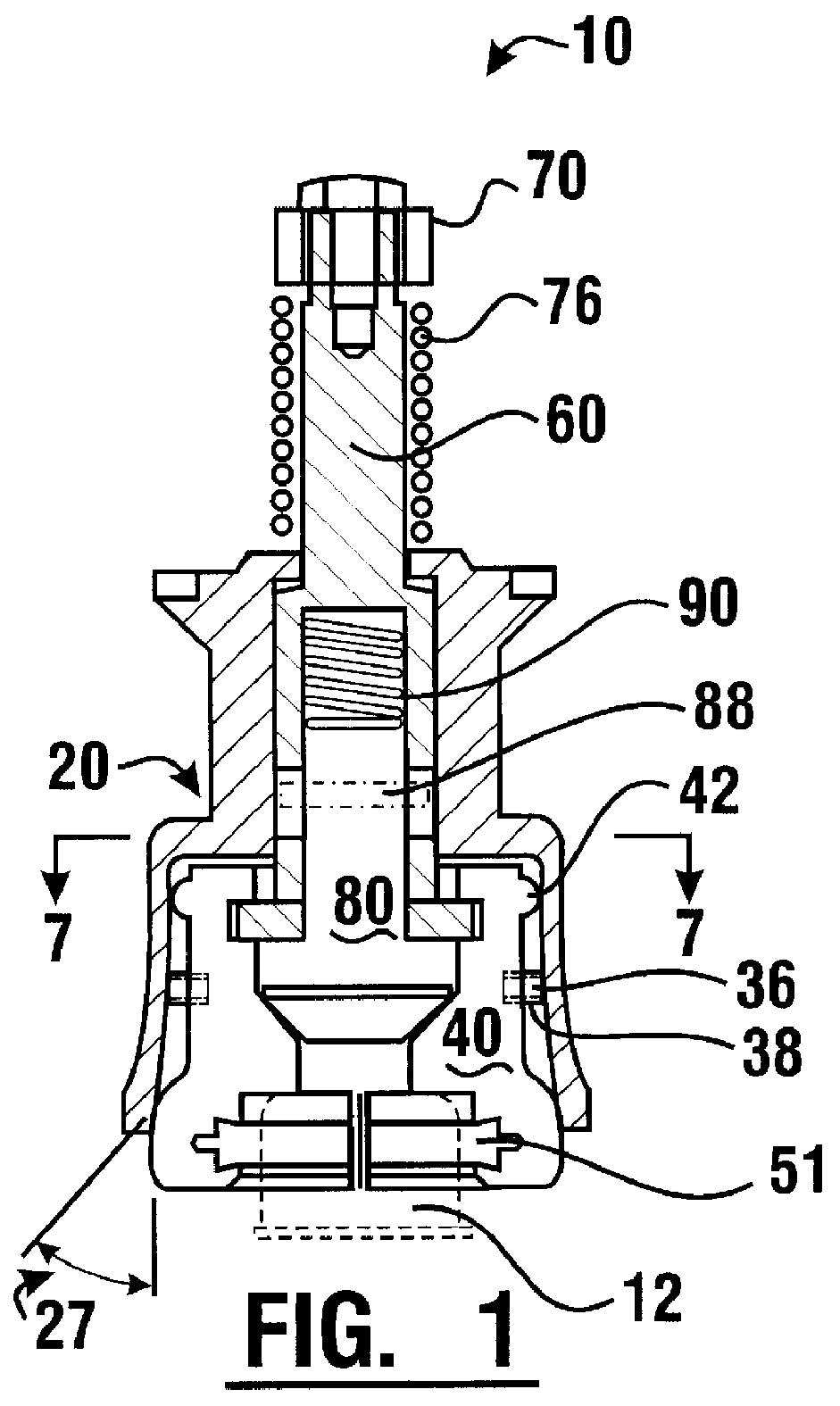

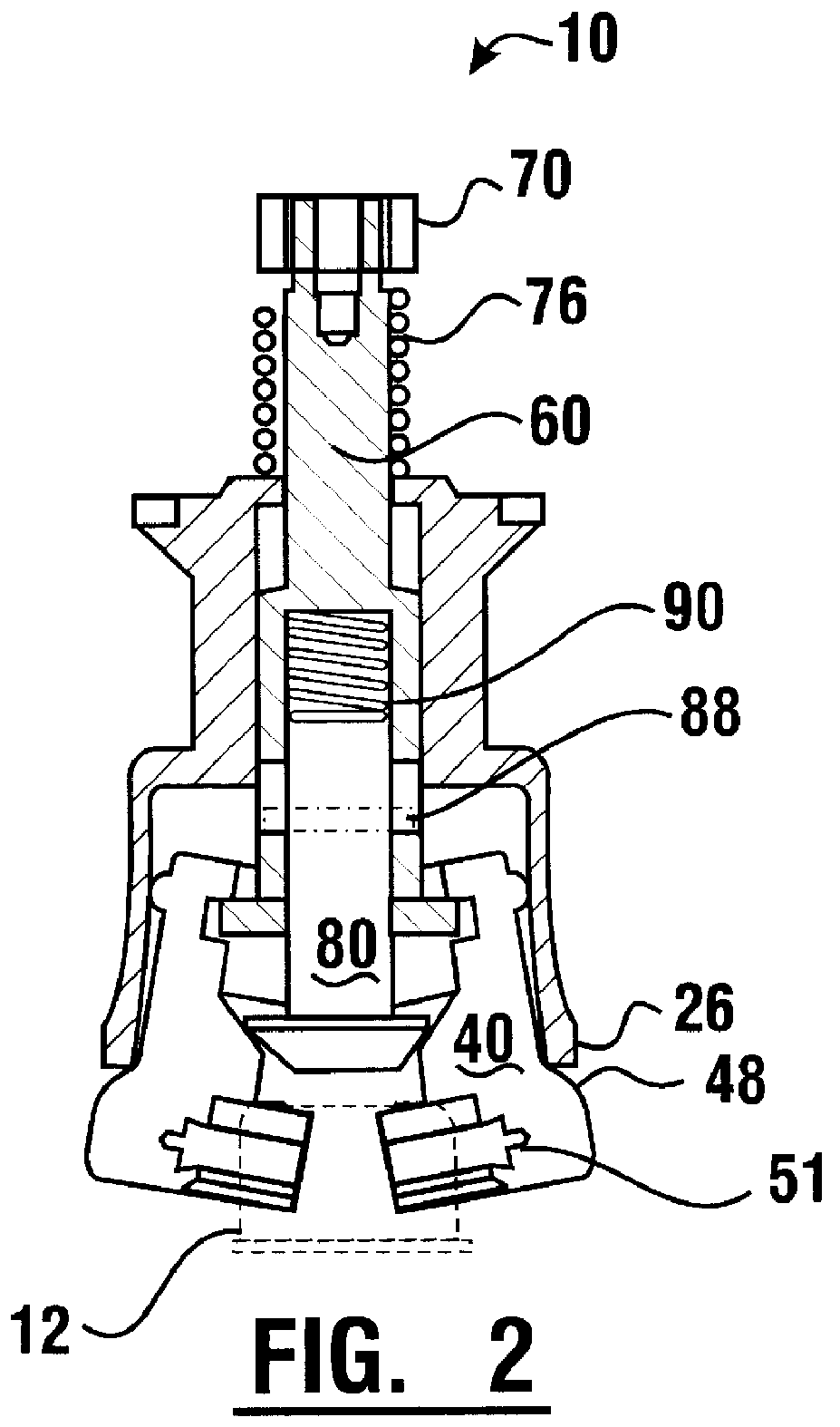

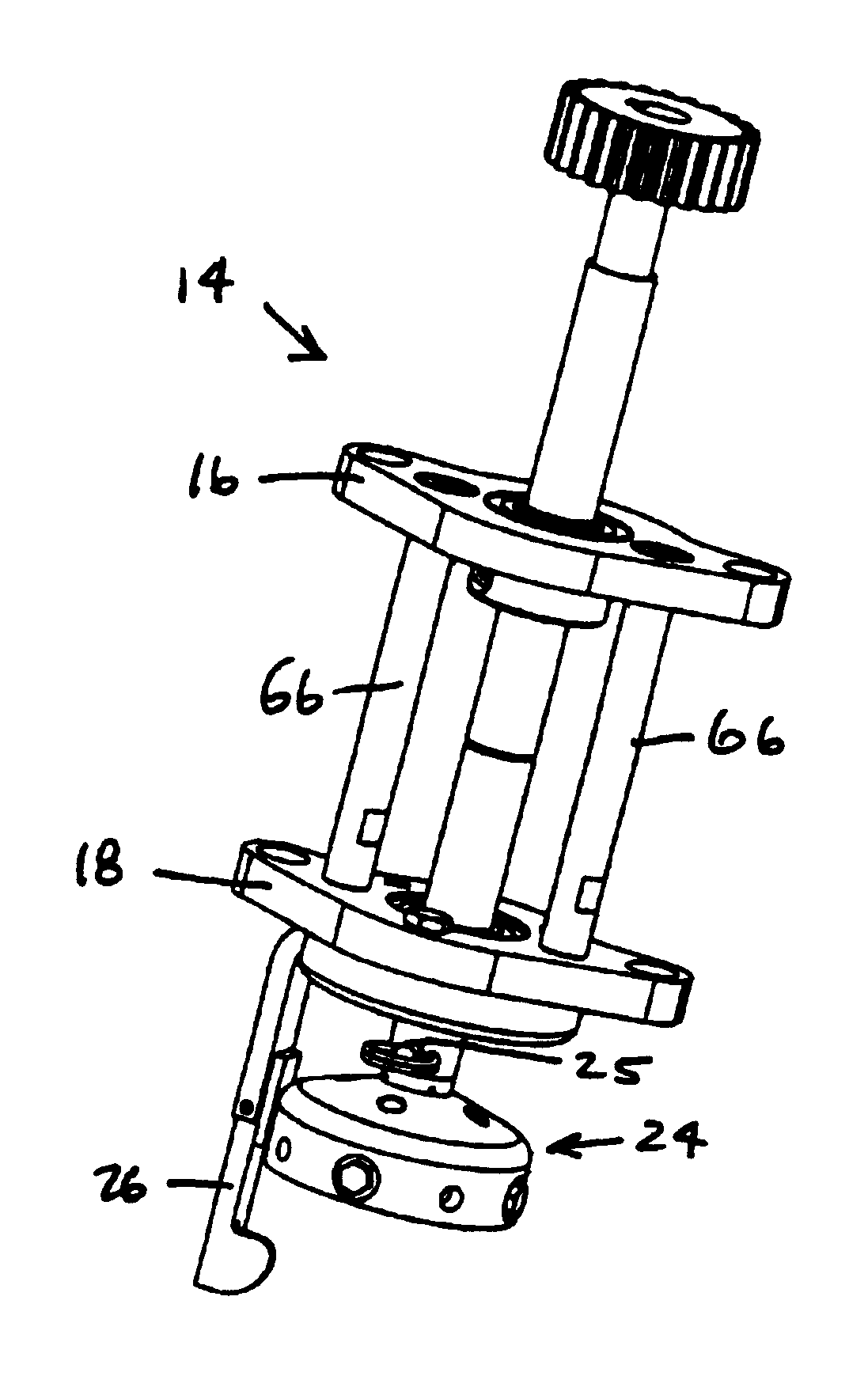

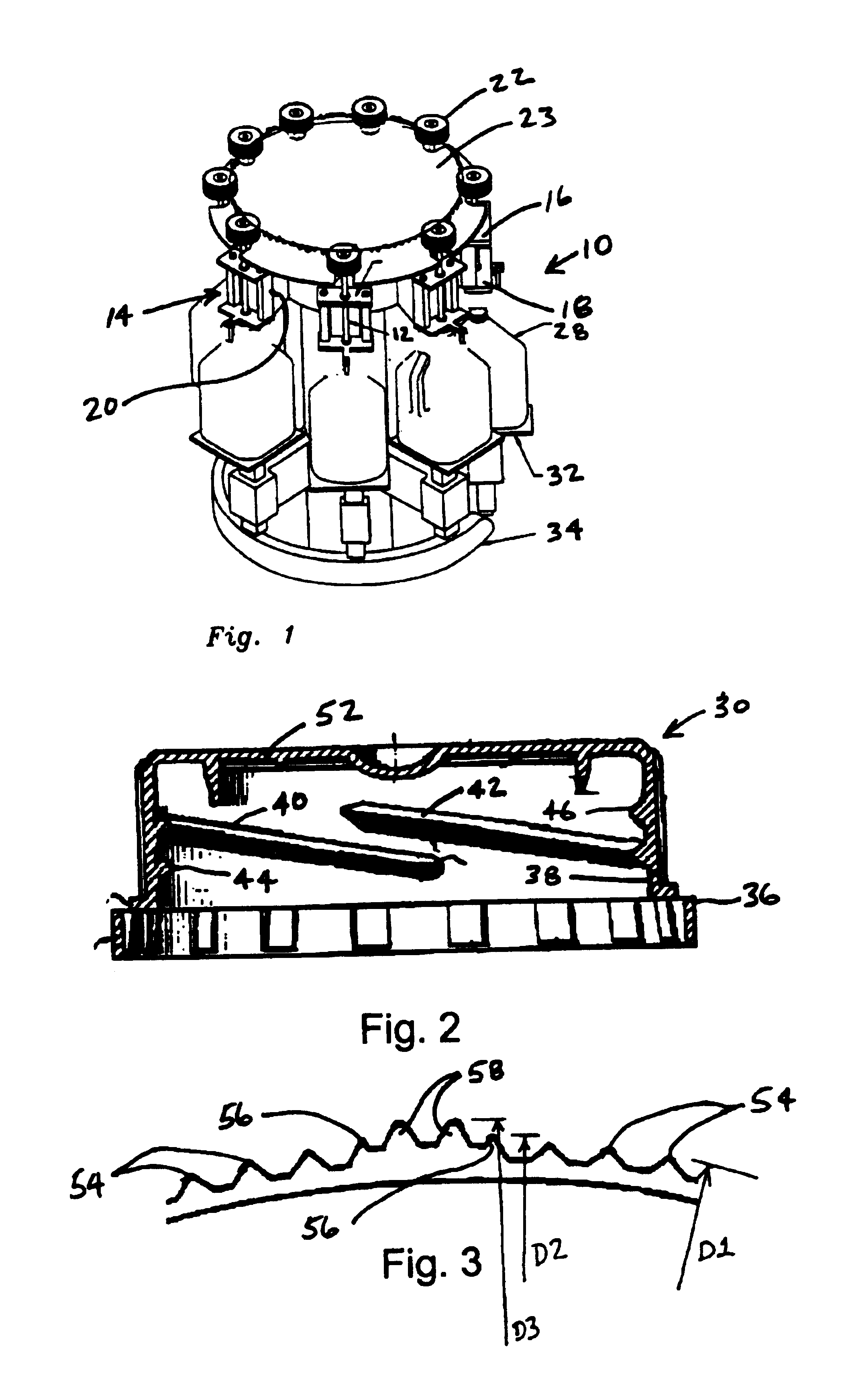

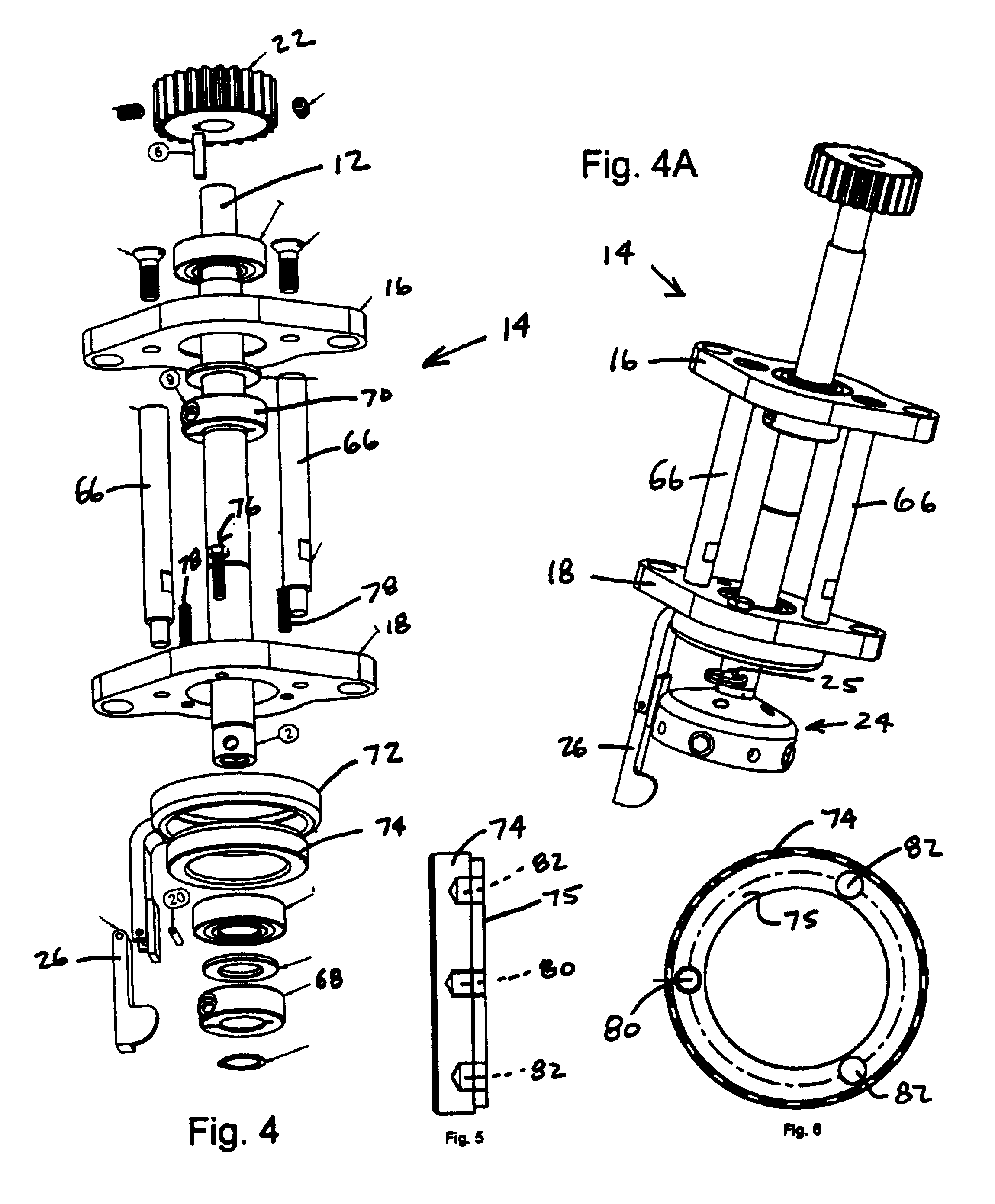

Apparatus and method for pre-capping containers

An improved pre-capping machine and method for pre-capping containers that are advanced along a predetermined path by standard conveyor systems. The present invention pretightens caps, plugs, overcaps and other fitments to ensure that they are squarely placed on the containers, without damage to the containers, in preparation for their final closure. The apparatus comprises a spindle assembly, having a longitudinal spindle axis, that is connected to a frame for movement of the spindle assembly along the spindle axis. The spindle assembly comprises a cap gripper that is configured to hold a cap centered over the open end of a container so that axes through the cap, the open end of the container and the spindle assembly generally coincide. To place a cap on the container, the spindle is released for free movement along the spindle axis.

Owner:NEW ENGLAND MACHINERY

Chuck for capping machine

Owner:PNEUMATIC SCALE CORP

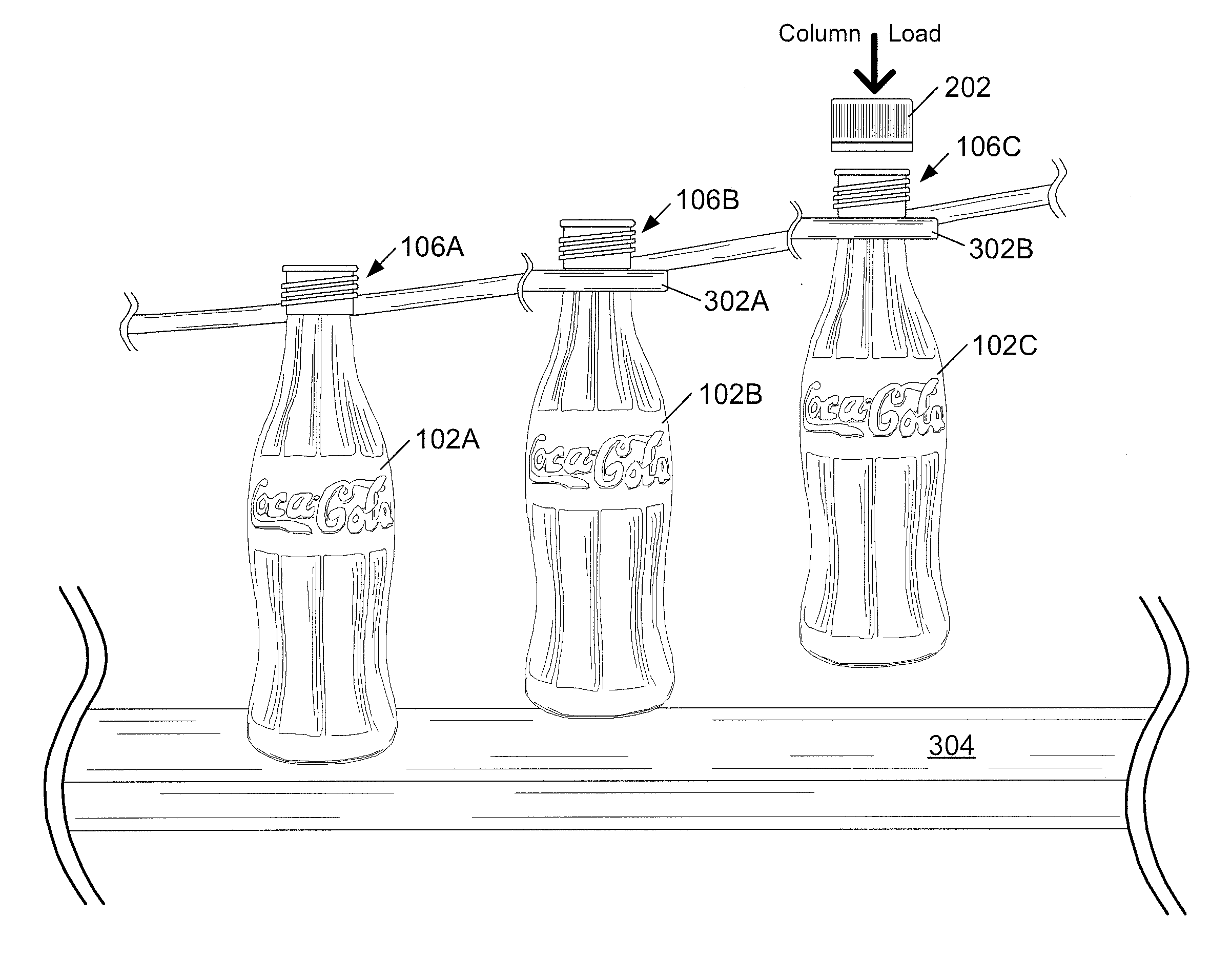

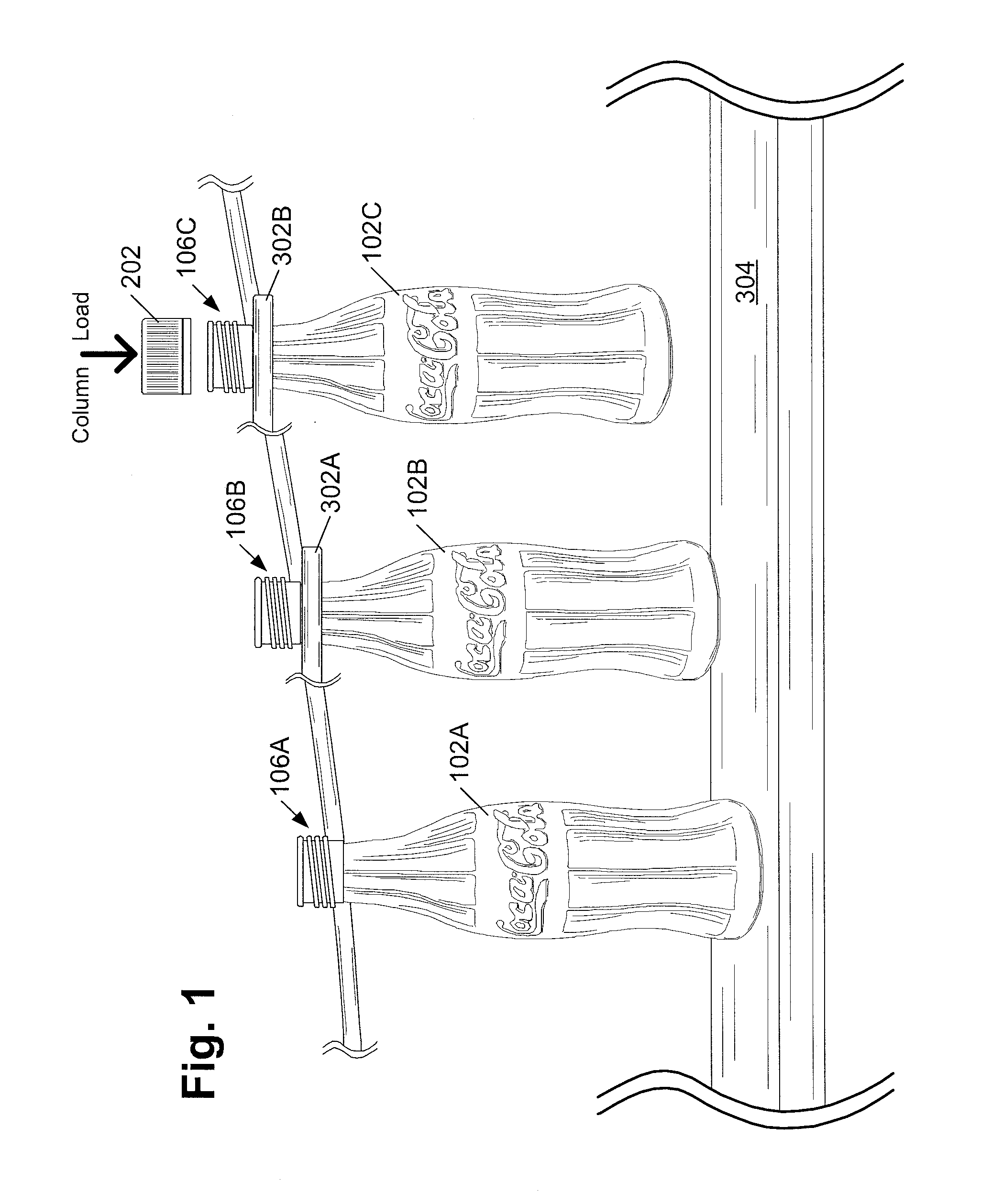

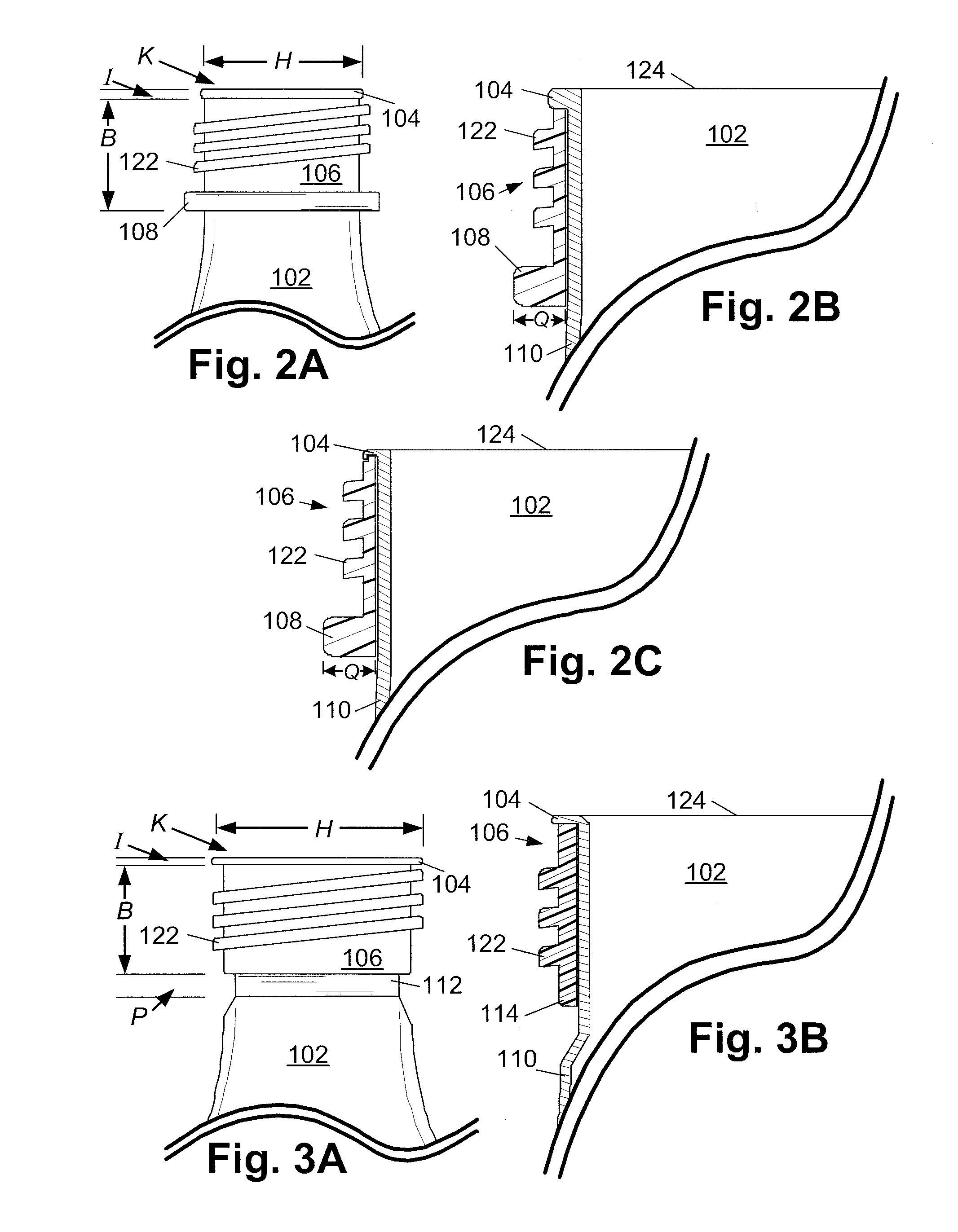

Method of isolating column loading and mitigating deformation of shaped metal vessels

InactiveUS20110113732A1Overcomes shortcomingReduce distortionThreaded caps applicationBottlesEngineeringMetal

The present invention relates to a method of isolating column loading and mitigating deformation of shaped metal vessels, the method comprising forming a cylindrical metal tube into a shaped metal vessel, the shaped metal vessel comprising a sealed end, an open end, and an integral carry ring proximate the open end. Column load is isolated between the open end and the carry ring by supporting the shaped metal vessel by the carry ring. The shaped metal vessel is sealed with a closure, wherein deformation of the shaped metal vessel between the sealed end and the carry ring due to column load is minimized during application of the closure.

Owner:THE COCA-COLA CO

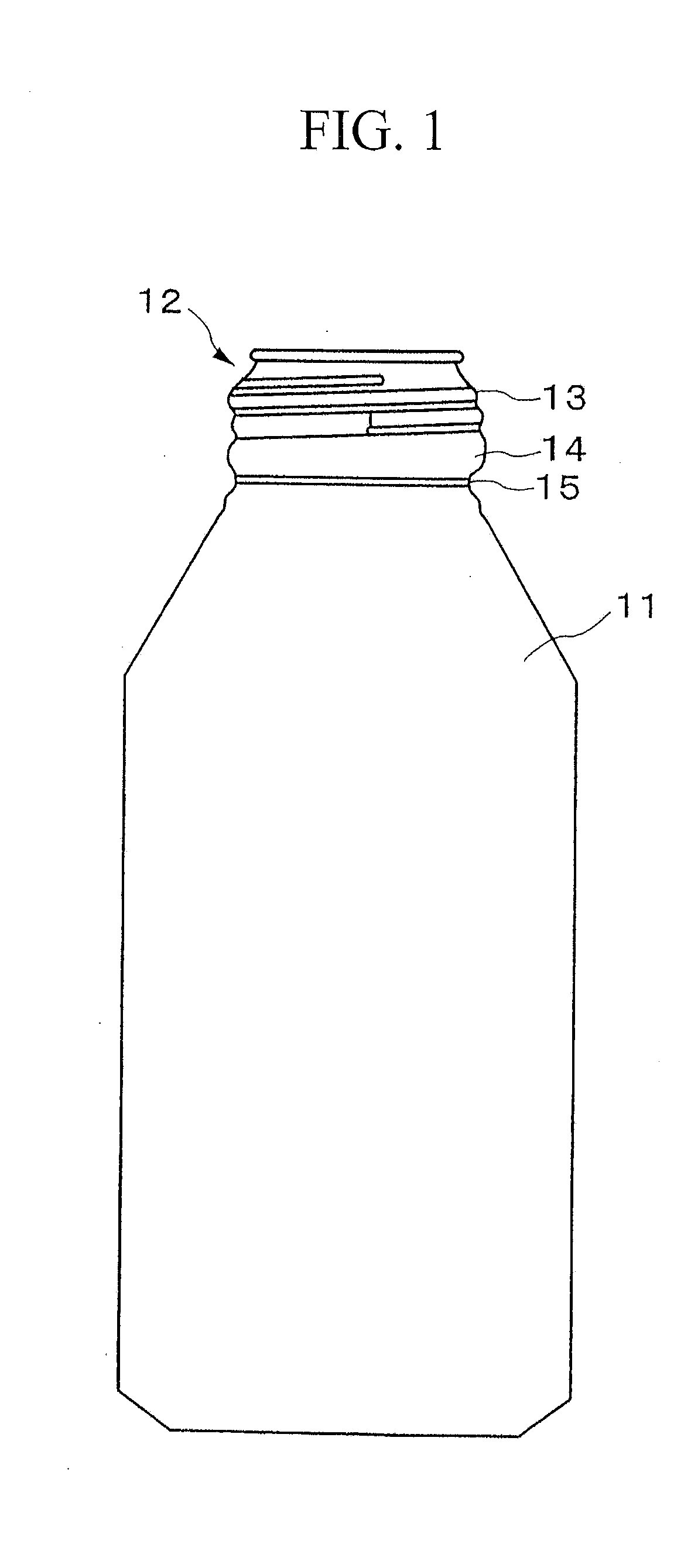

Bottle container, bottle, and screw forming device

ActiveUS20050067365A1Improve sealingDetach the cap smoothlyCapsClosure capsBottleBiomedical engineering

An effective thread number in the thread section which is disposed on the mouth section of the bottle is formed to be 2.2. That is, the thread section is formed such that the thread section 13 should serve effectively in the mouth section such that an interval between a start position and an end position should be 2.0 to 2.5. In the bottle can member 11 which has such a thread section, an outer diameter of the thread section which is formed on the mouth section is 28 to 38 mm. Also, the thickness of the mouth section is 0.25 to 0.4 mm. The thread section which has the effective thread number 2.0 to 2.5 is formed by eight-thread per inch pitch. By doing this, it is possible to put the cap desirably.

Owner:UNIVERSAL CAN CORP

Method and machine for closing bottle with sterile caps

ActiveUS7536839B2Easy to operateImprove throughputCapsDecorative coversSterile environmentLinear machine

Owner:KHS CORPOPLAST GMBH & CO KG

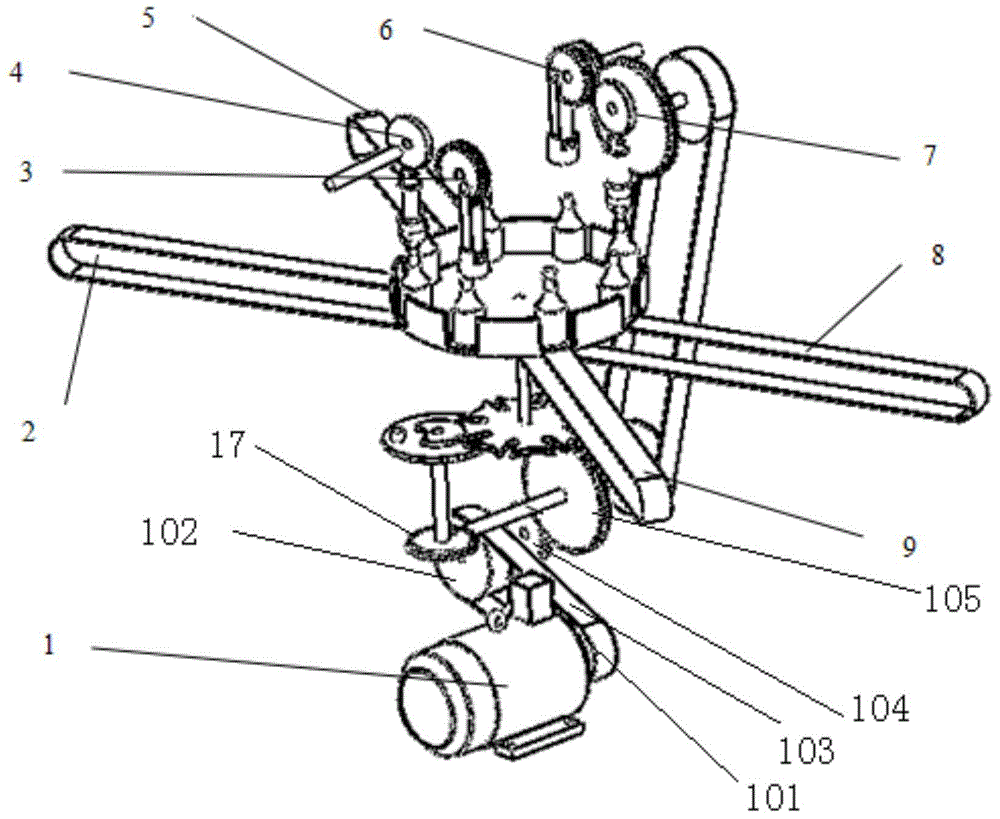

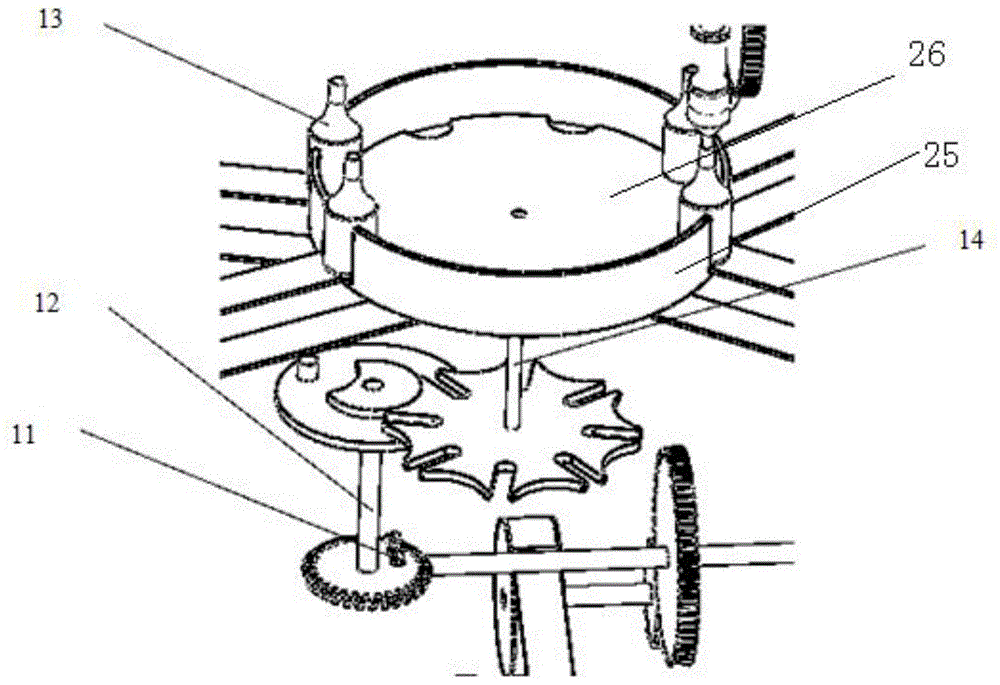

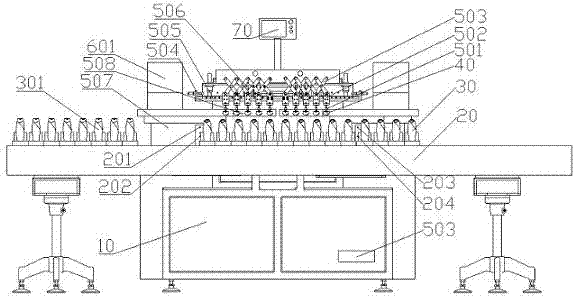

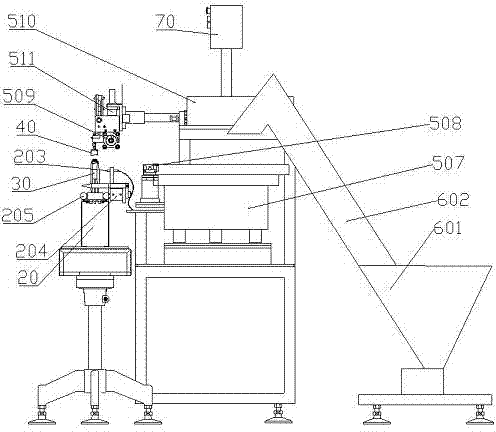

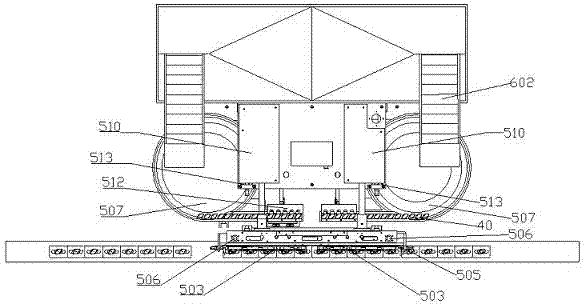

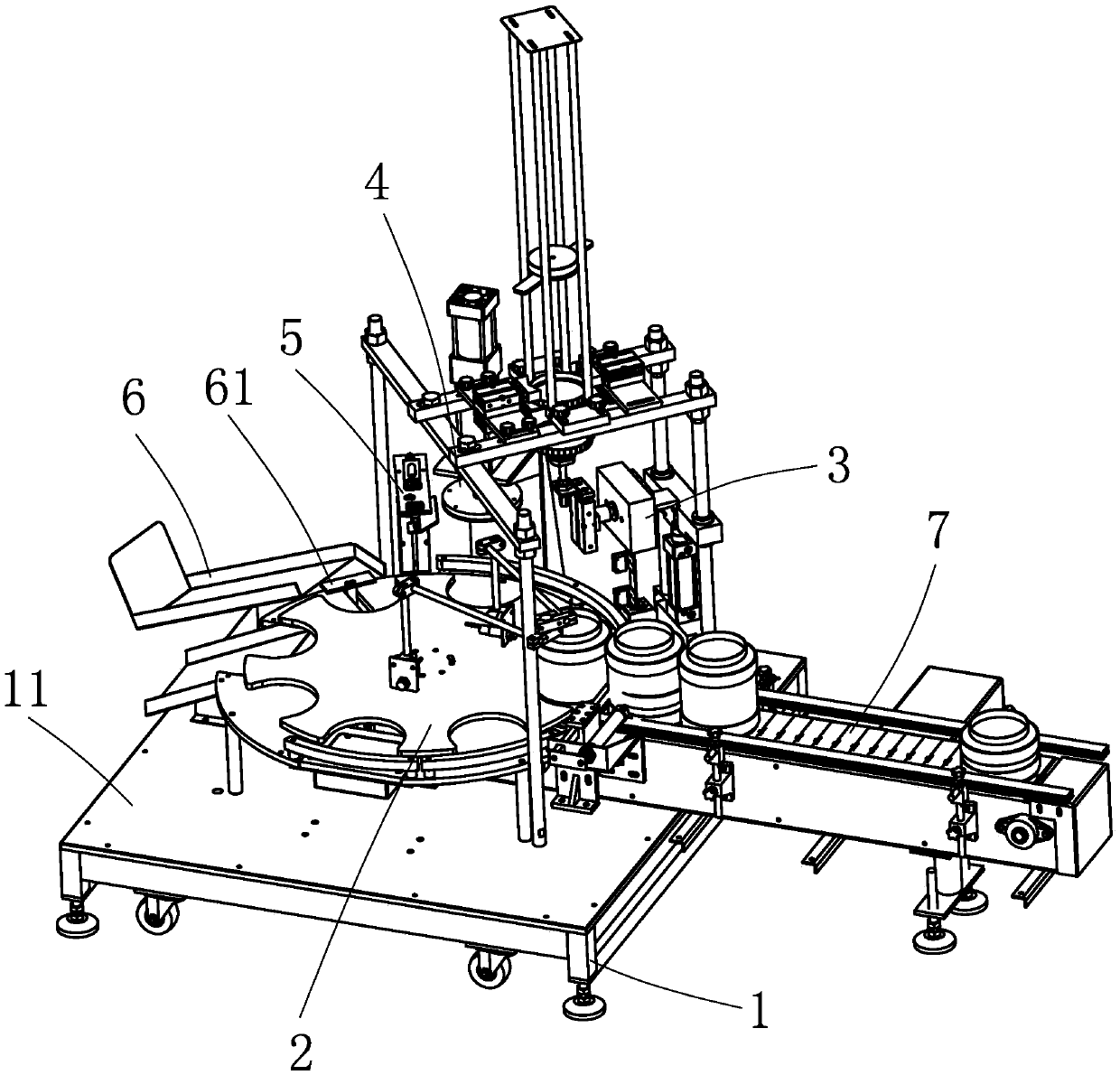

Rotary filling machine

ActiveCN104591064ASimple structureImprove structural performanceSynchronising machinesFlanged caps applicationIntermittent motionEngineering

The invention discloses a rotary filling machine, which comprises: a fixed workbench, which is provided with a plurality of constraint positions; a rotary workbench, which is equipped with a plurality of bottle clamping positions, during rotation of the rotary workbench, with the constraint positions and the corresponding clamping positions composing a plurality of stations, at least one of which is a gland station and at least one of which is a filling station; a workbench drive device, which is in transmission connection with the rotary workbench so as to drive the rotary workbench to do intermittent motion relative to the fixed workbench; a gland device, which comprises a gland component and a gland drive mechanism driving the action of the gland component, with the gland component being disposed over the gland station; and a filling device, which consists of a filling component and a filling drive mechanism driving the action of the filling component, with the filling component being disposed over the filling station. The rotary filling machine provided by the invention can perform filling on materials according to a fixed cycle to realize filling automation, thus improving the filling efficiency, reducing the cost and enhancing product quality.

Owner:无锡精派机械有限公司

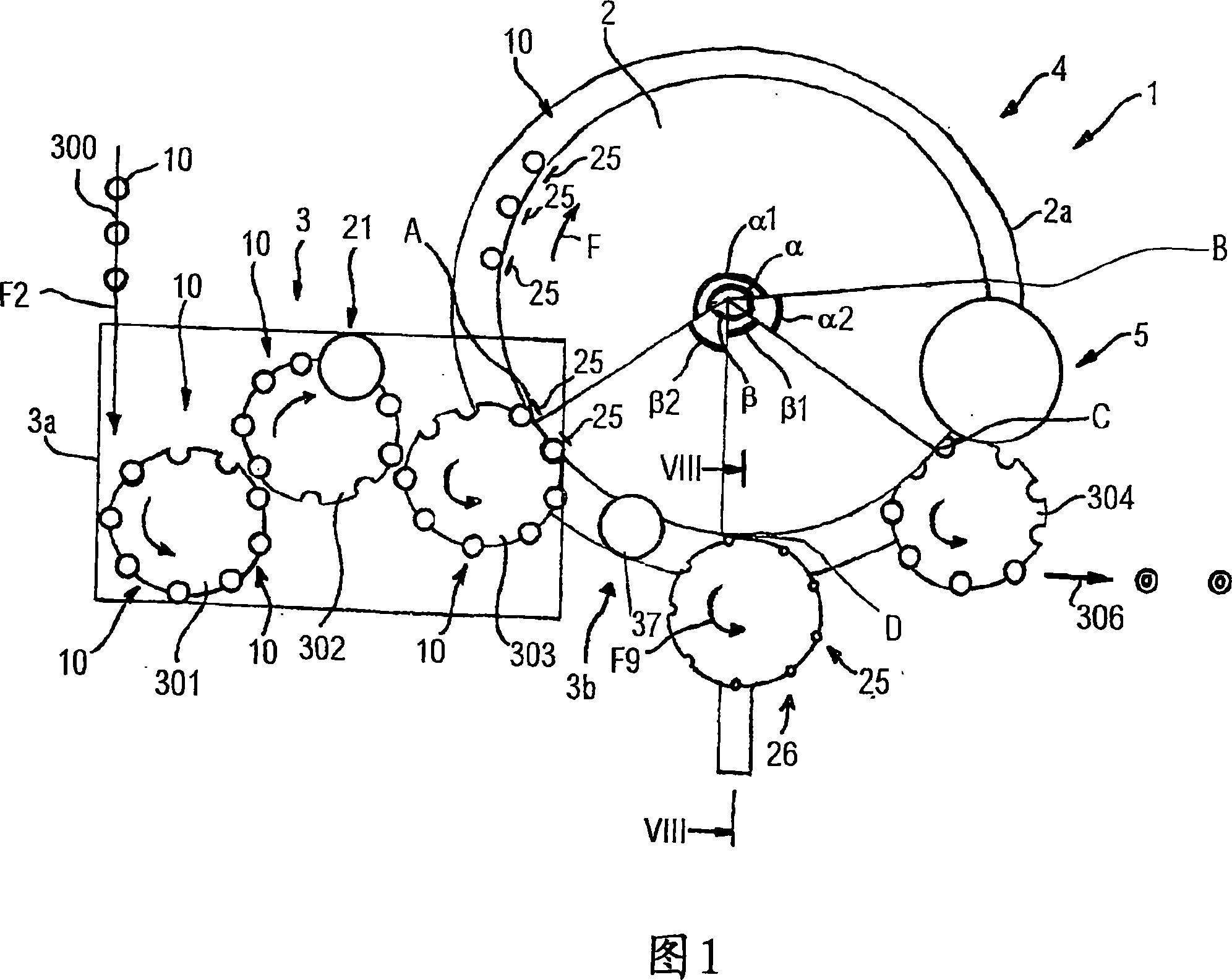

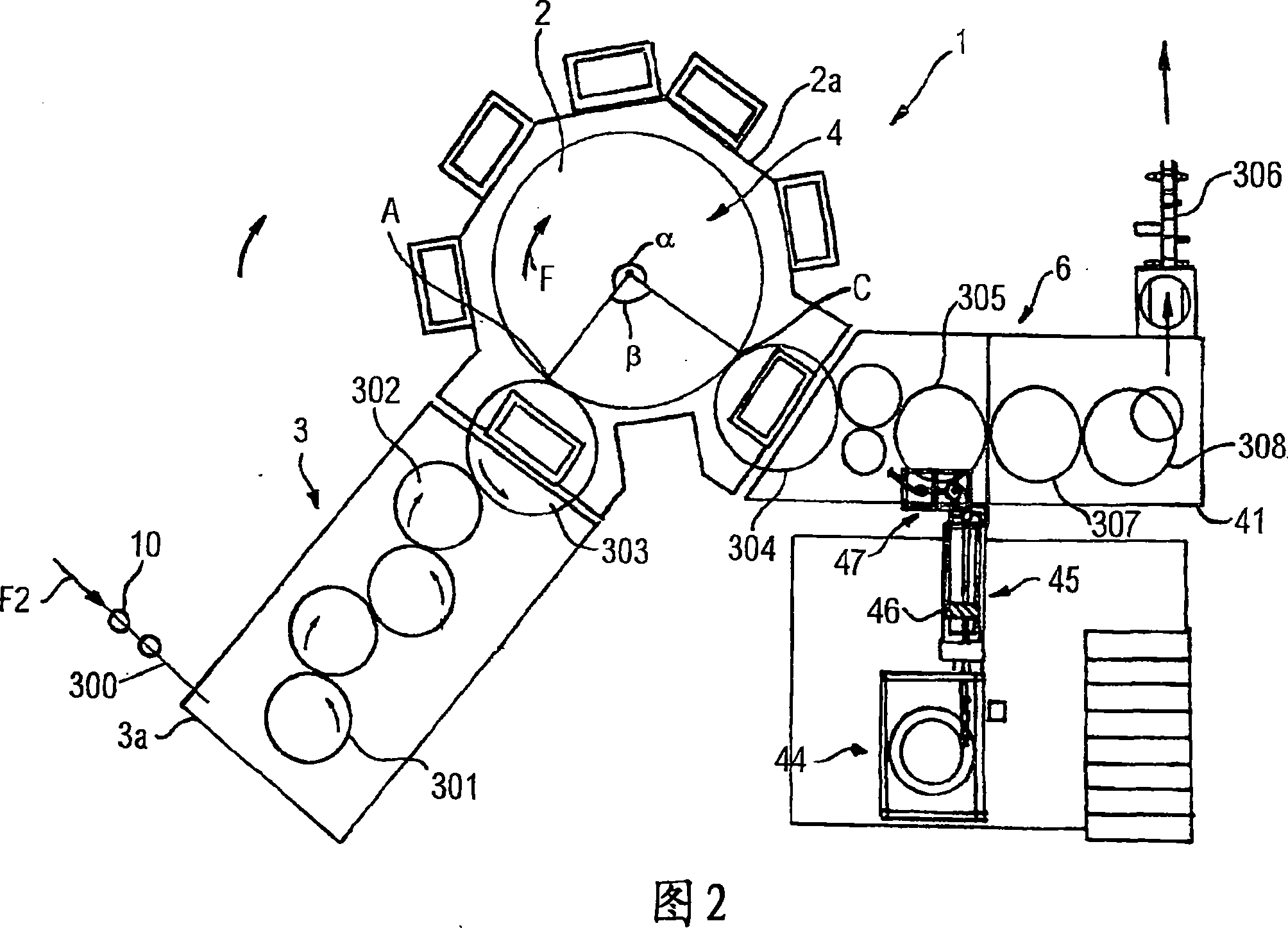

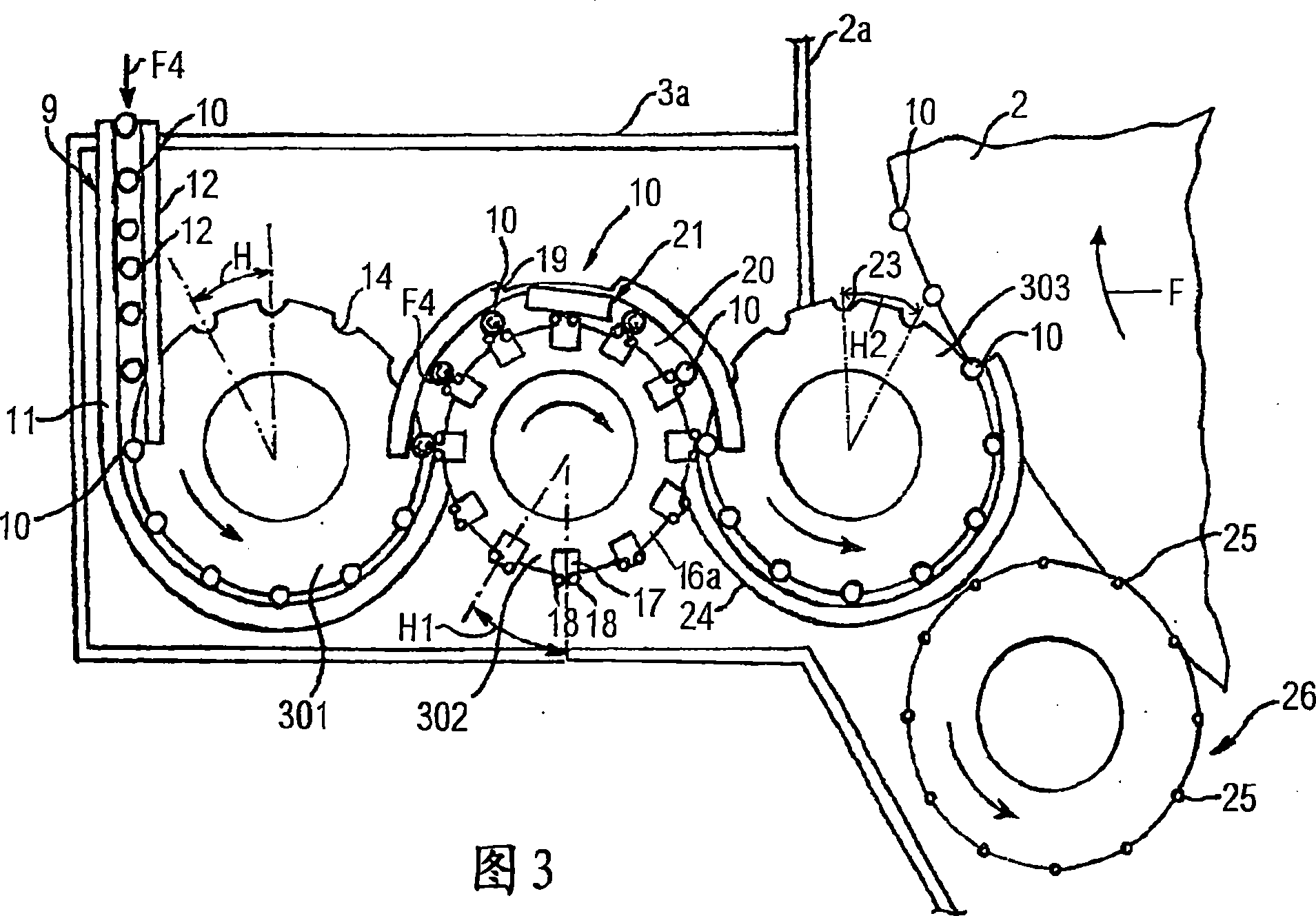

Apparatuses and methods for sterilising and filling components of packaging units, particularly bottles and/or caps

InactiveCN1968888AImprove sterilization efficiencyEffective sterilizationClosing machinesCapsEngineeringBottle

An apparatus comprises rotating conveying means (301, 302, 303, 2; 301, 160, 303, 2) for conveying along a curved path components (10, 25) of packaging units comprising containers (10) and container closures (25), filling means (30) for filling with a product said containers (10) on said rotating conveying means (301, 302, 303, 2; 301, 160, 303, 2), sterilising means (21, 37) for sterilising at least part of said components (10, 25) mounted along said path and comprising irradiating means arranged to emit radiation.

Owner:SIDEL S. P. A.

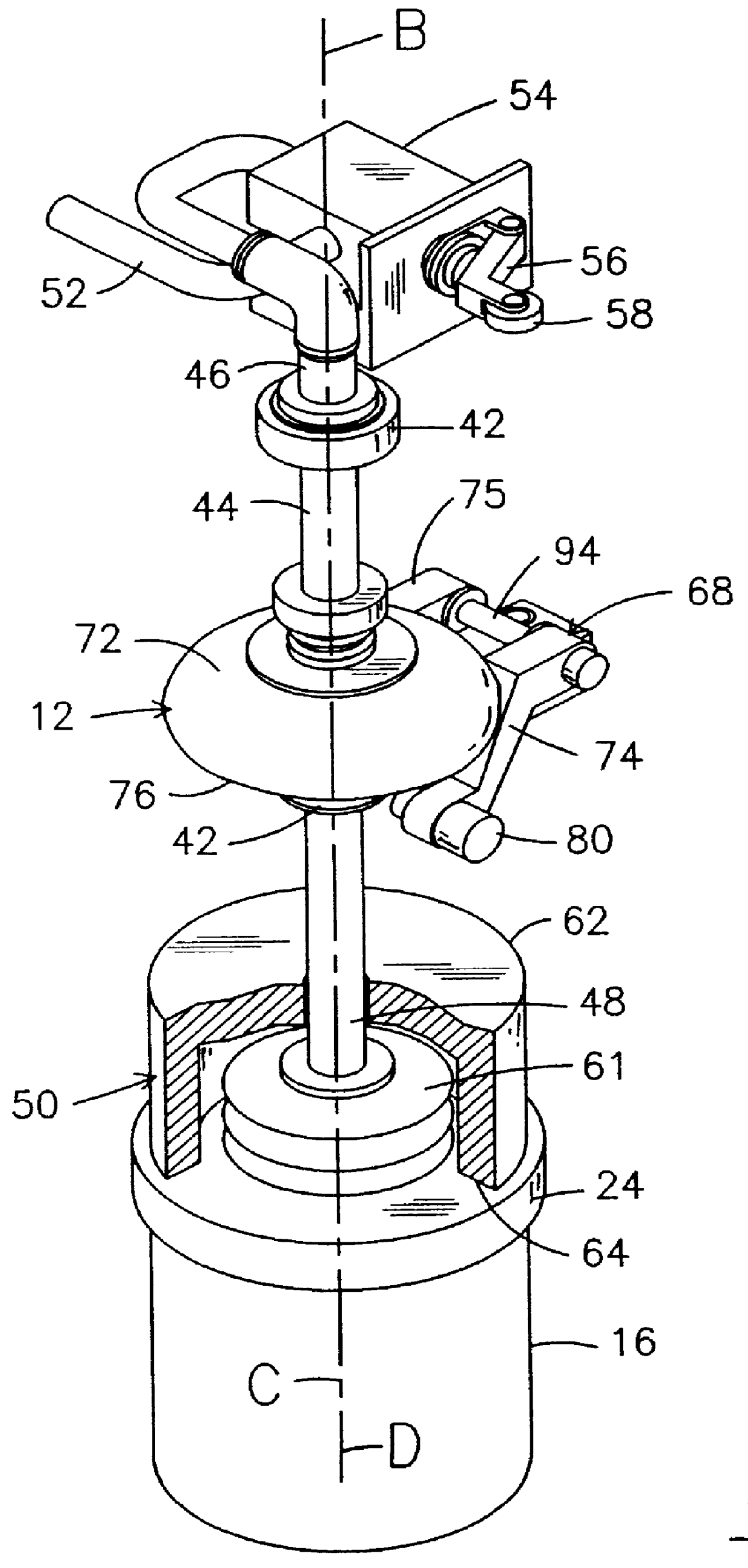

Container closure system

InactiveUS6945011B2Prevent peelingSimplify and facilitate applicationCapsThreaded caps applicationFast releaseEngineering

A system for sealing threaded containers. The system includes a clutch-free spindle assembly which is easily disassembled and cleaned. The special interface between the exterior surface of the cap an the gripping jaws of the chuck allow the system to operate without the moving parts and complications that attend the use of clutch. The spindle assembly features an easily adjustable stop arm and a quick release pin for removing and cleaning the chuck. The chuck has several passageways for the rapid infusion of cleaning fluid.

Owner:BLACKHAWK MOLDING

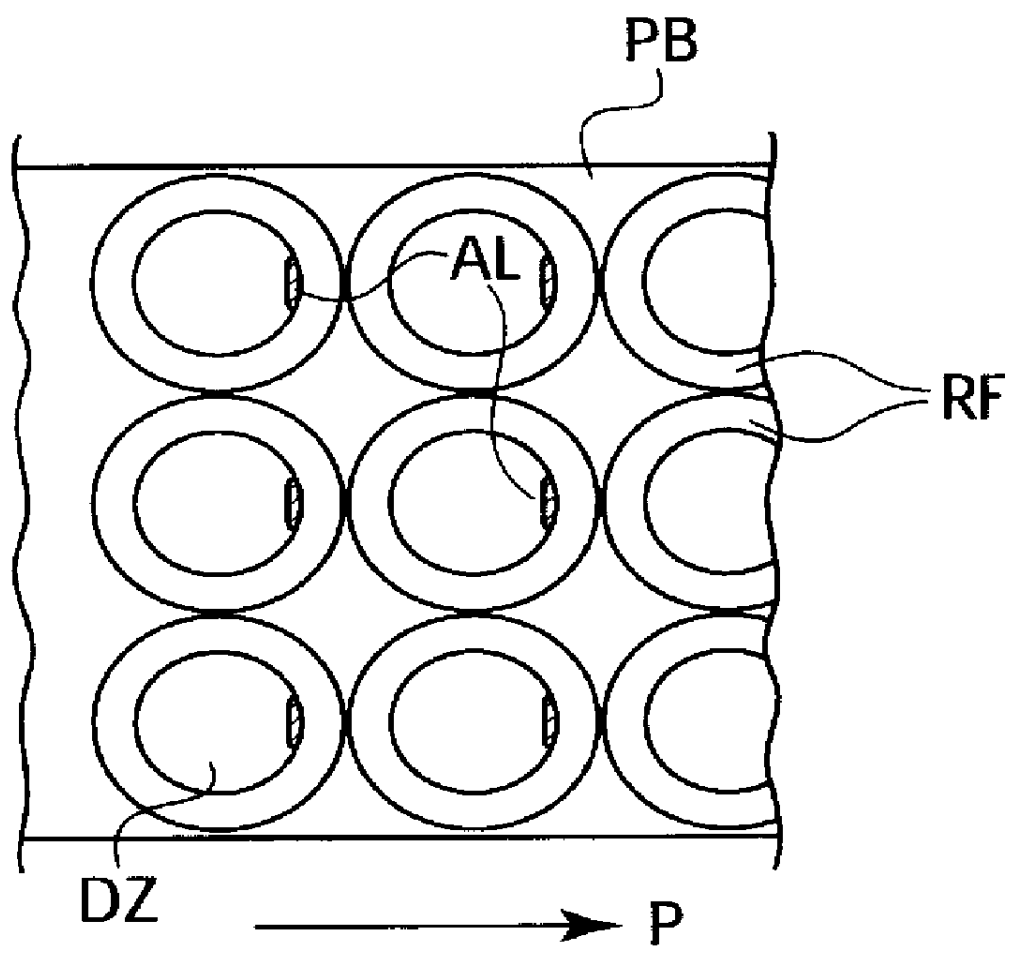

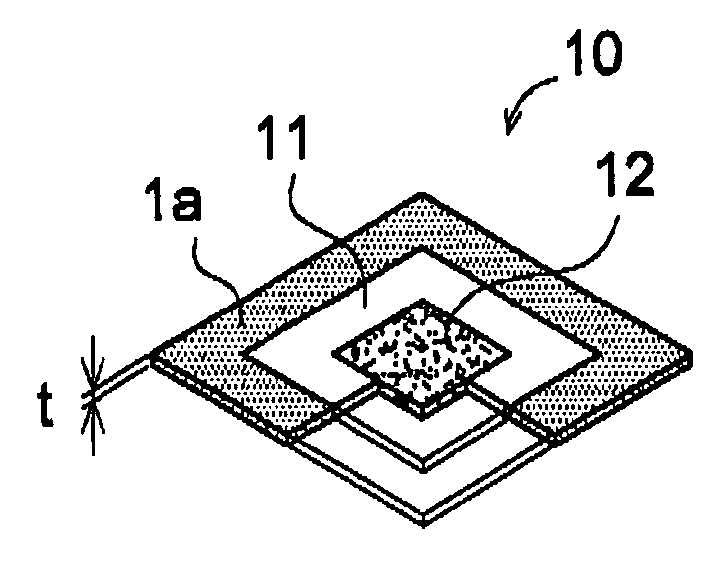

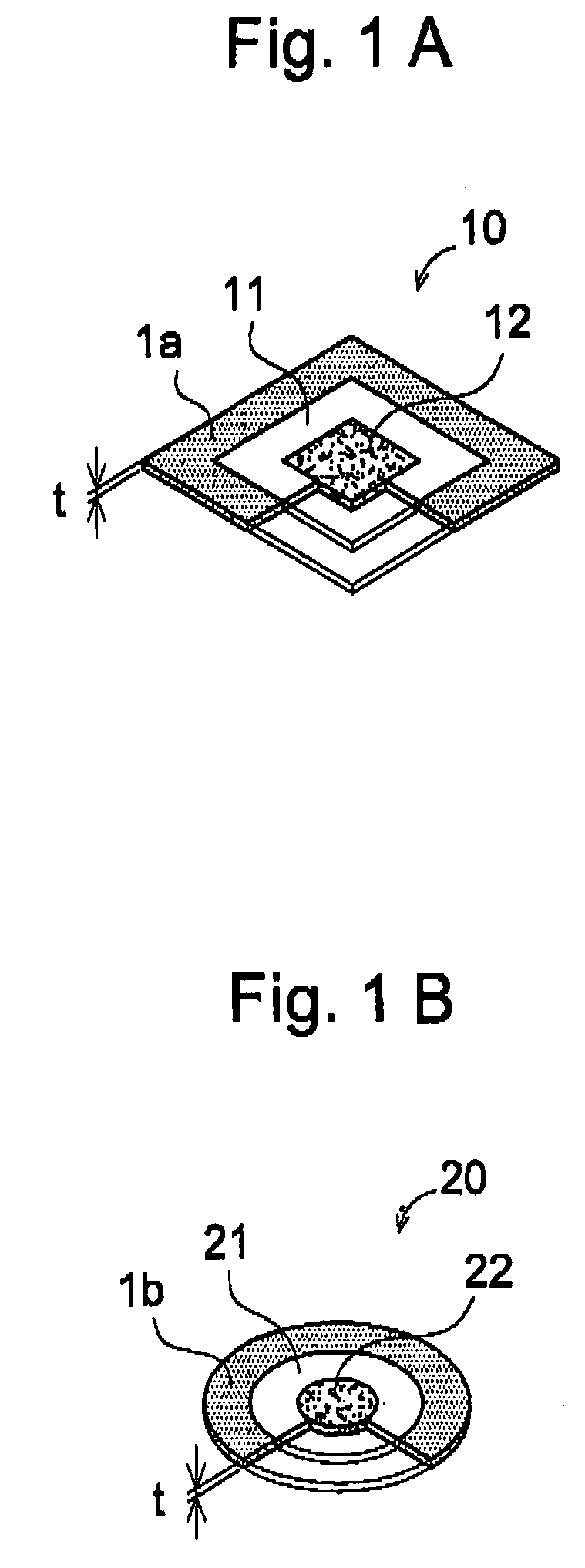

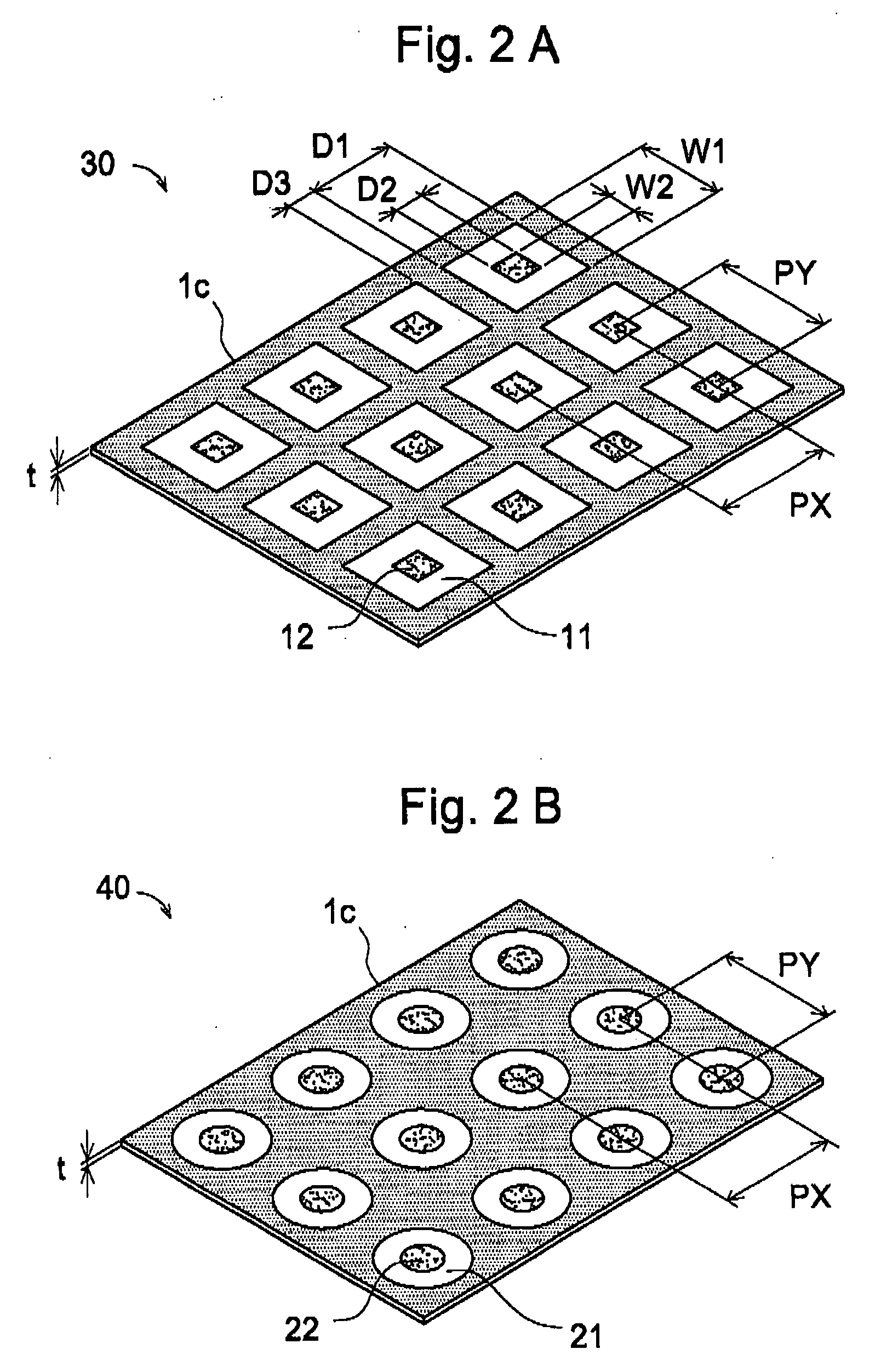

Anisotropic conductive sheet

InactiveUS20060162287A1Noise from junctionAvoid noiseCapsCoupling contact membersElastomerEngineering

An anisotropic conductive sheet for high frequencies is provided as elastomer for connecting high-integrated circuit boards and fine pitch electronic components of recent years. Anisotropic conductive sheet (30) has a sheet-shaped elastomer (1c), and a non-conductive rectangular first penetrating region (11) is formed vertically and horizontally in a state surrounded by the sheet-shaped elastomer (1c). In addition, an electrically-conductive second penetrating region (12) is formed in a rectangular manner in a state surrounded by the first penetrating region (11). The first penetrating region 11 can be a high-dielectric rectangular third penetrating region. The anisotropic conductive sheet (30) has an effect in that electrostatic shield is provided between connected electronic components.

Owner:JST MFG CO LTD

Bottle can member, bottle, and thread forming device

An effective thread number in the thread section which is disposed on the mouth section of the bottle is formed to be 2.2. That is, the thread section is formed such that the thread section 13 should serve effectively in the mouth section such that an interval between a start position and an end position should be 2.0 to 2.5. In the bottle can member 11 which has such a thread section, an outer diameter of the thread section which is formed on the mouth section is 28 to 38 mm. Also, the thickness of the mouth section is 025 to 0.4 mm. The thread section which has the effective thread number 2.0 to 2.5 is formed by eight-thread per inch pitch. By doing this, it is possible to put the cap desirably.

Owner:UNIVERSAL CAN CORP

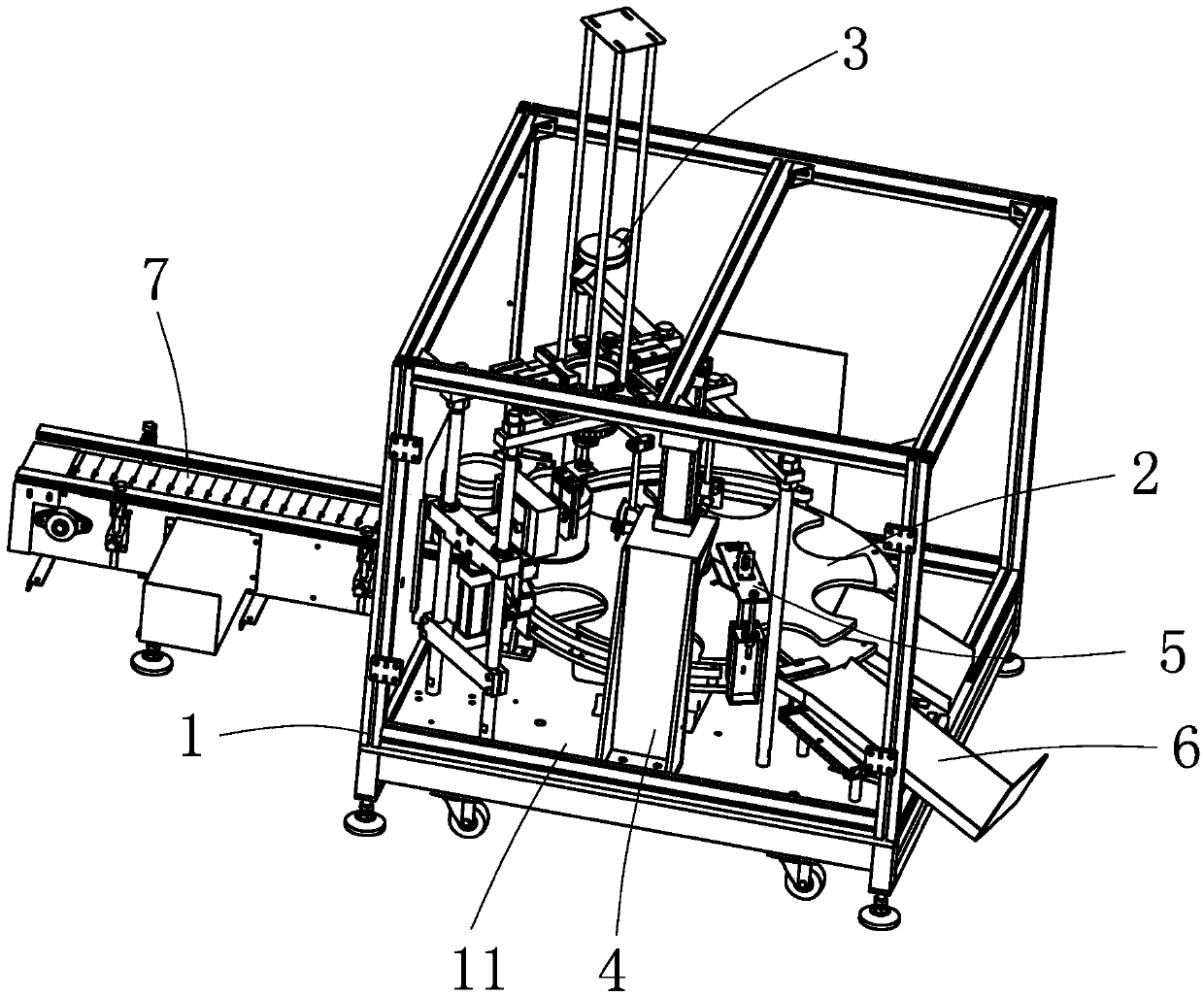

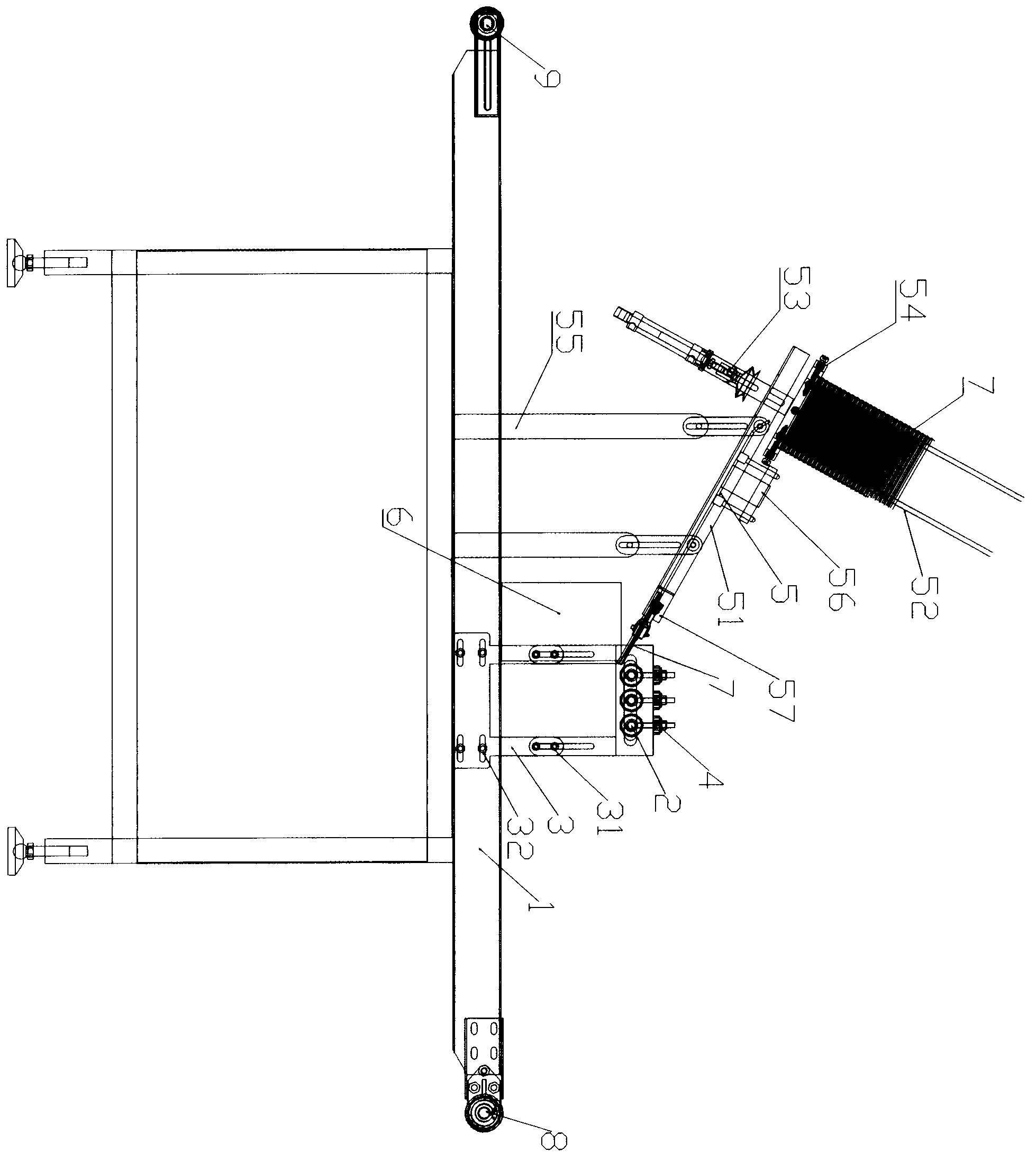

Automatic capping machine

InactiveCN103318820ANo human intervention requiredImprove capping efficiencyFlanged caps applicationConveyor partsControl systemMan machine

The invention provides an automatic capping machine. The automatic capping machine is used for capping a cap, especially an irregular-shaped cap, onto a bottle and substantially comprises a capping device, a feeding device and a control system. The capping device comprises a cap gripping mechanism which is used for absorbing caps and capping products to be capped on a product conveyer belt, a lifting mechanism which controls the lifting of the cap gripping mechanism, and a transversely-moving mechanism which control the cap gripping mechanism and the lifting mechanism to move forward and backward. The lifting mechanism is arranged at the front end of the transversely-moving mechanism, the front end of the transversely-moving mechanism is provided with guide rails, the cap gripping mechanism is mounted on the guide rails and comprises sucker mounting blocks and suckers, and the sucker mounting blocks are mounted on the guide rails and can move along the guide rails. The feeding device comprises a feed supplement mechanism which is used for supplementing the caps and a feed tidying mechanism which is used for tidying the caps provided by the feed supplement mechanism. The control system is a man-machine control system controlling the action of every mechanism. The automatic capping machine can automatically cap caps onto bottles and solve the problem of low efficiency and large labor intensity of manual operation.

Owner:GUANGZHOU BEAUTY STAR CO LTD

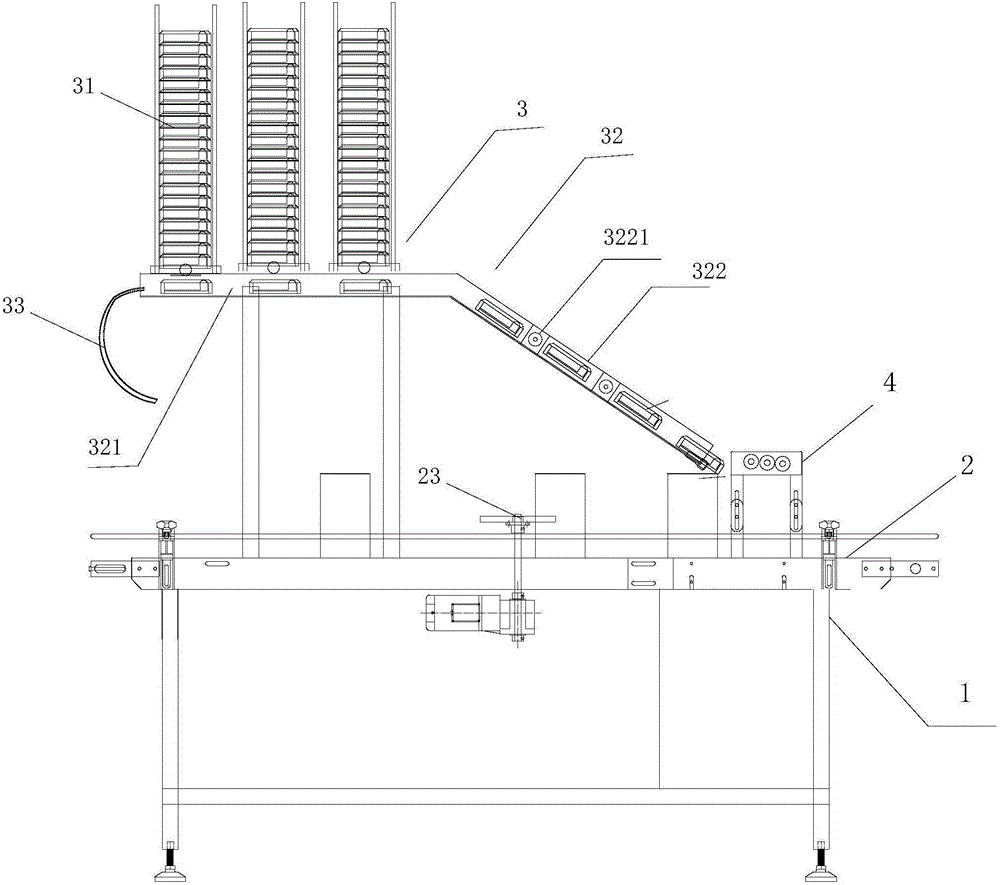

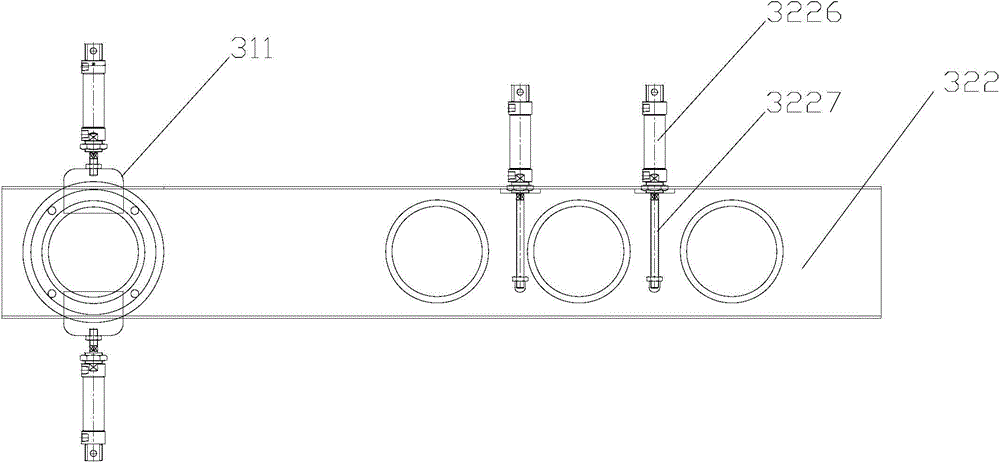

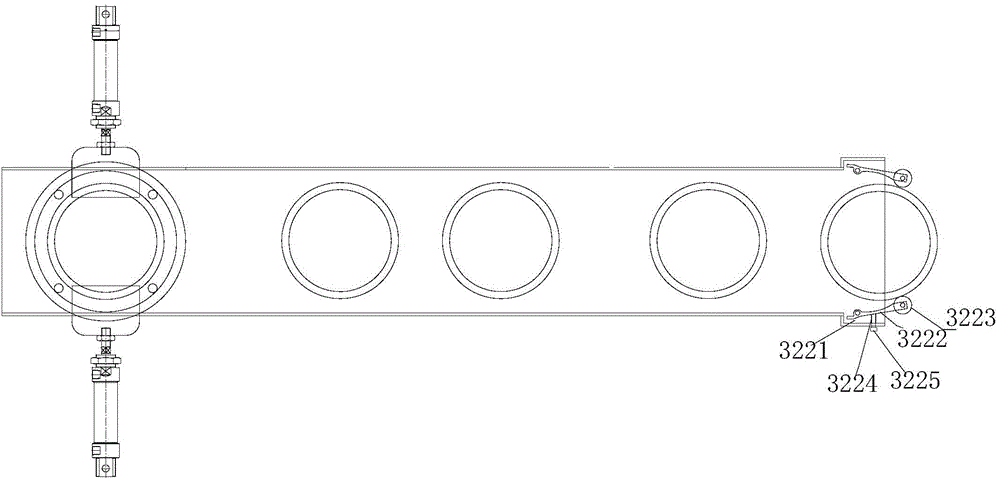

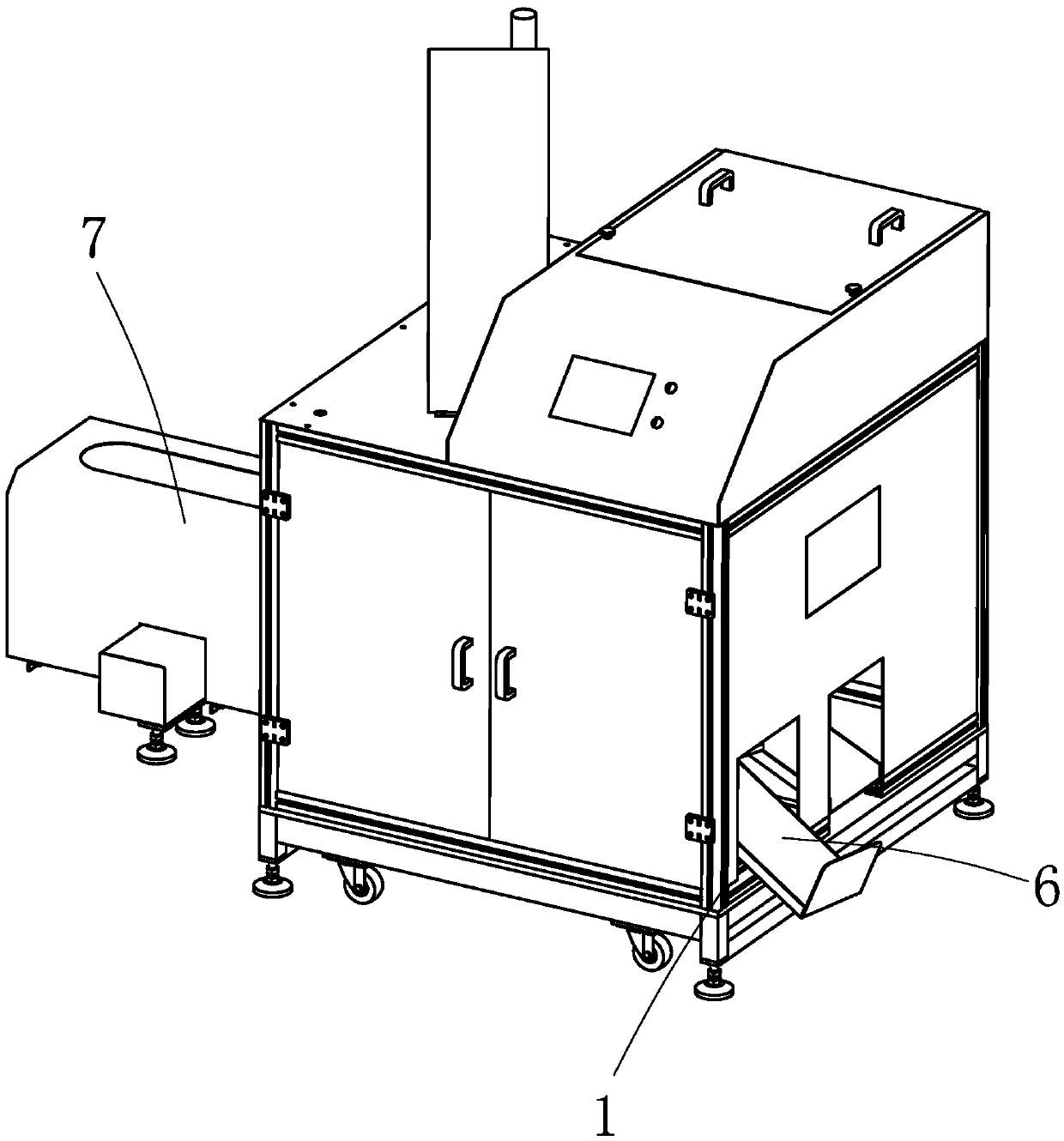

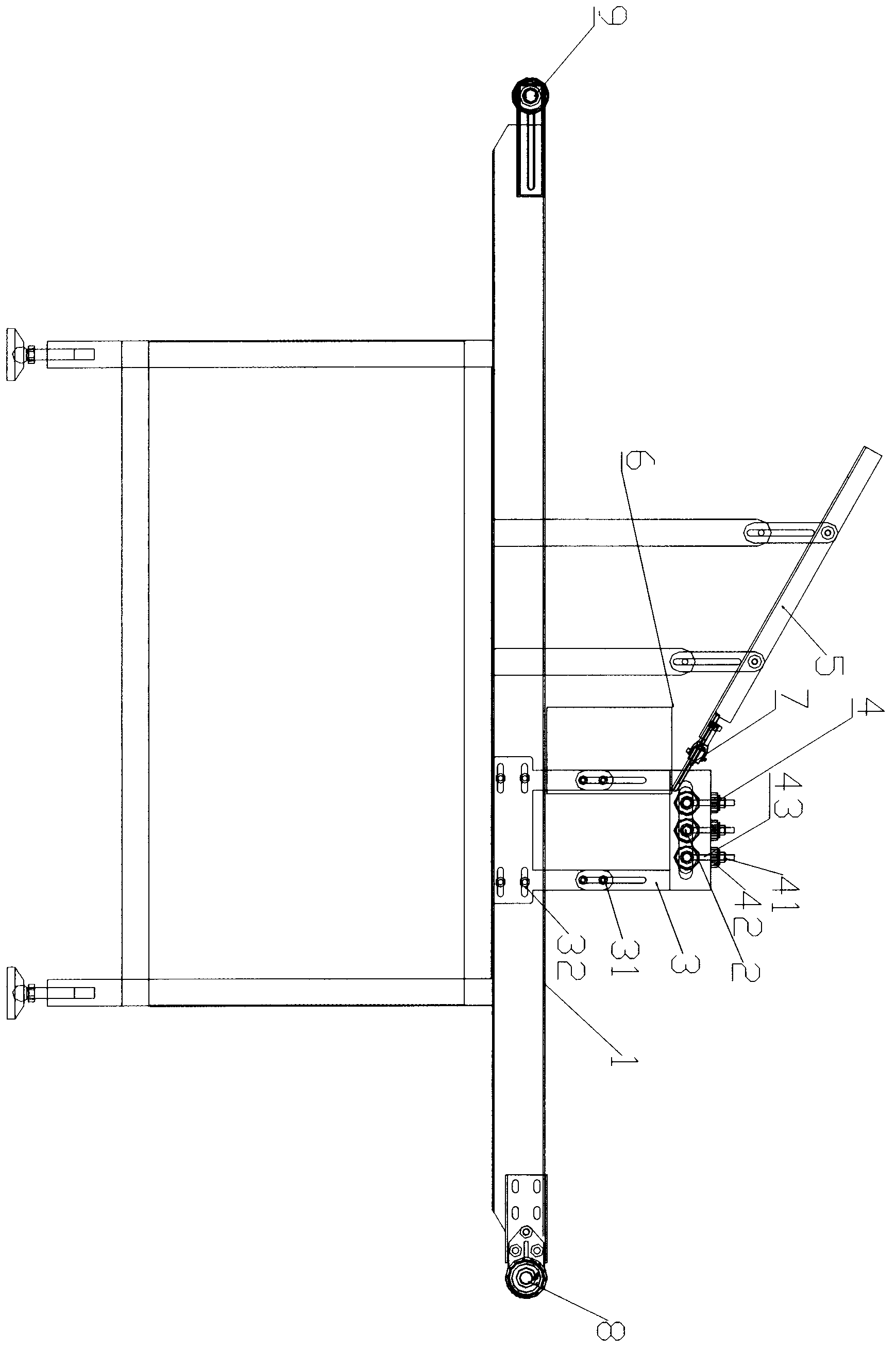

Automatic capping machine for plastic cans

InactiveCN104671166ASmooth transmissionStable and durable transmissionCapsFlanged caps applicationEngineeringPlastic bag

The invention discloses an automatic capping machine for plastic cans. The automatic capping machine for the plastic cans is characterized by comprising a stand (1), wherein the stand (1) is provided with a conveying belt mechanism (2); the conveying belt mechanism (2) is used for conveying the plastic cans to be capped; a plastic cap feeding mechanism (3) is arranged above the conveying belt mechanism (2) and is used for conveying the plastic caps; and a roller capping mechanism (4) which is used for tightly pressing the plastic caps on the plastic cans is arranged on a junction of the conveying belt mechanism (2) and the plastic cap feeding mechanism (3). By the automatic capping machine for the plastic cans, the capping efficiency and the capping stability can be improved, the occupied area of the whole automatic capping machine can be greatly reduced, and the cost is low.

Owner:SUZHOU JIAHONG MACHINERY

Automatic cover pressing/screwing machine capable of conducting self-adaption on high bottles and low bottles

The invention discloses an automatic cover pressing / screwing machine capable of conducting self-adaption on high bottles and low bottles. The automatic cover pressing / screwing machine comprises a rack, the rack is provided with a scale division bottle feeding mechanism, the periphery of the scale division bottle feeding mechanism is provided with a sample bottle feeding station, a high-low bottle recognition and cover placement station, a cover pressing / screwing station, a detection station, a removing station and an output station. According to the automatic cover pressing / screwing machine, after being subjected to automatic high-low bottle detection and recognition, automatic cover feeding, automatic cover pressing / screwing and cover pressure in-place detection, pressed / screwed covers are sent to a fully-automatic sample storage work station and sent to a sample storage and examination chamber or a test cabinet, and the automatic cover pressing / screwing machine has the advantages of being reasonable in structure, high in sample bottle packaging efficiency and the like.

Owner:XIAMEN SAIMO JISHUO TECH CO LTD

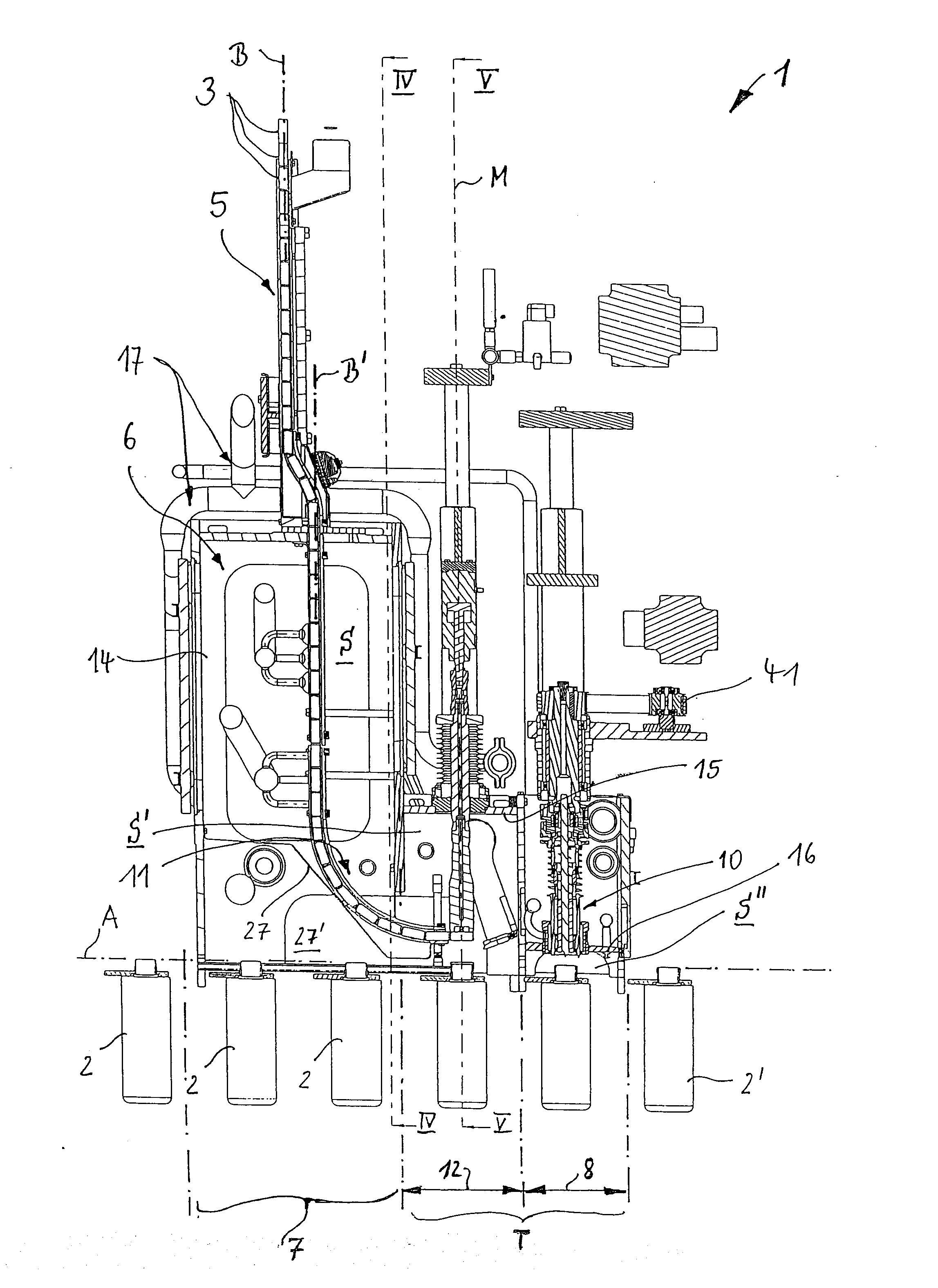

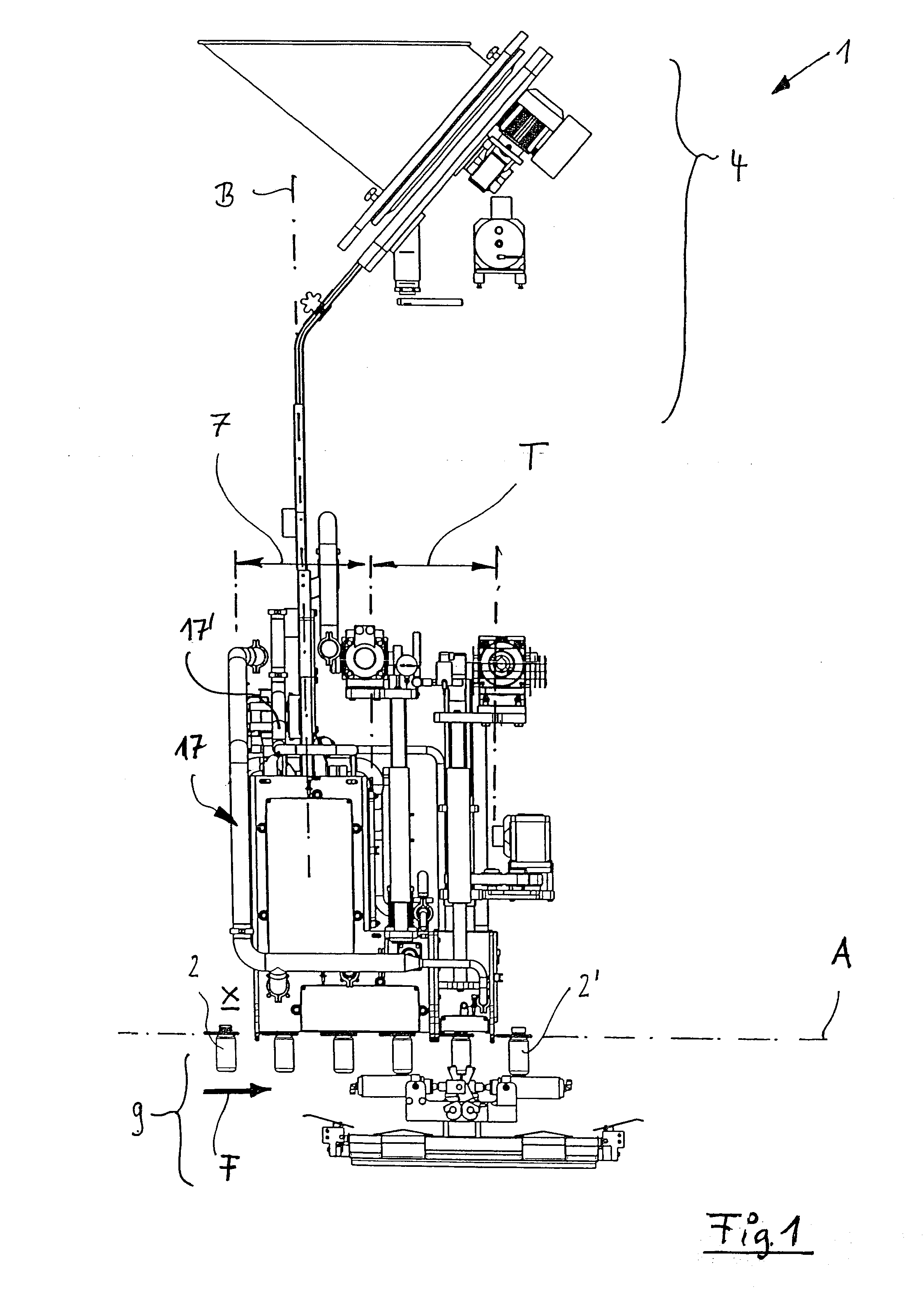

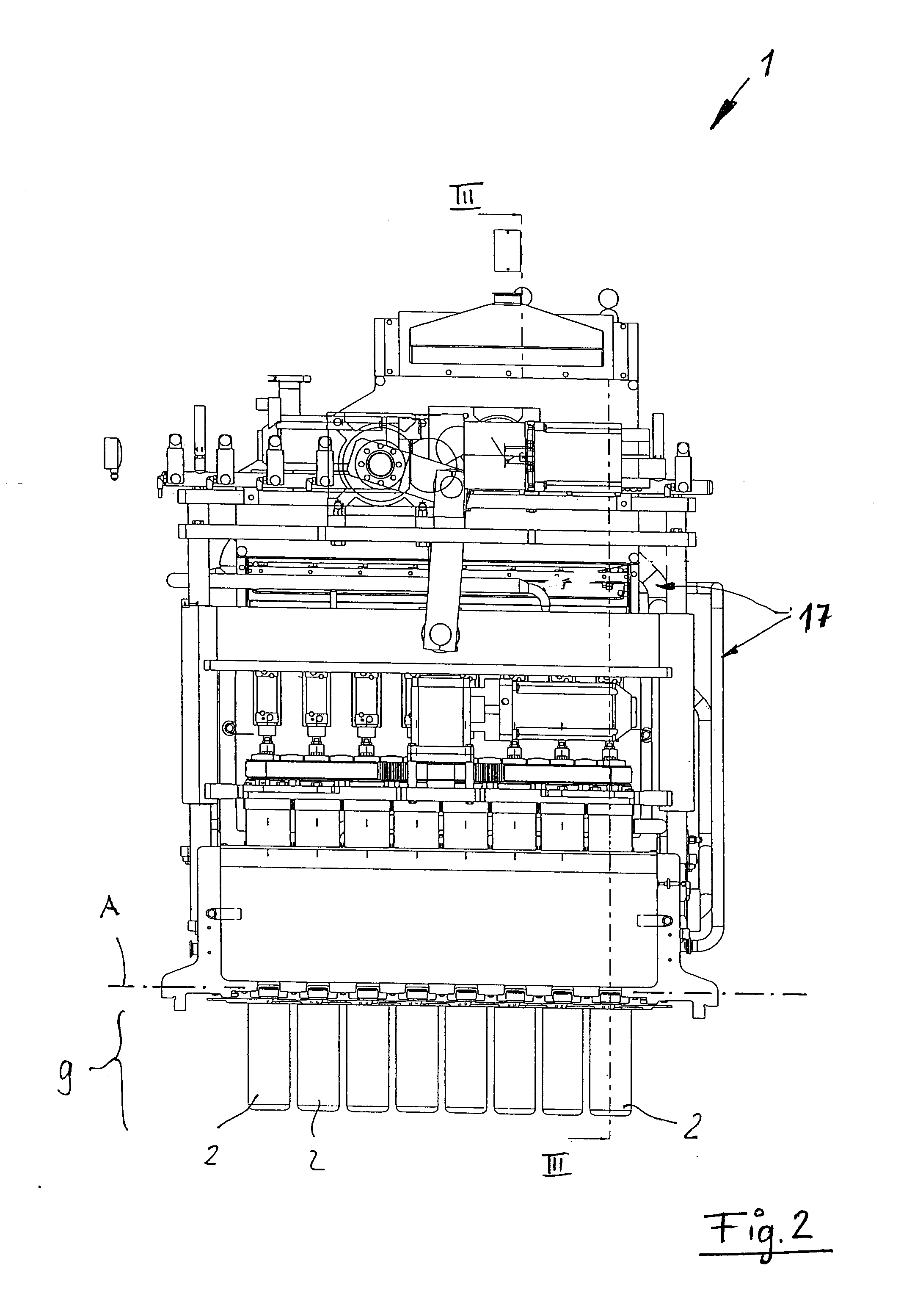

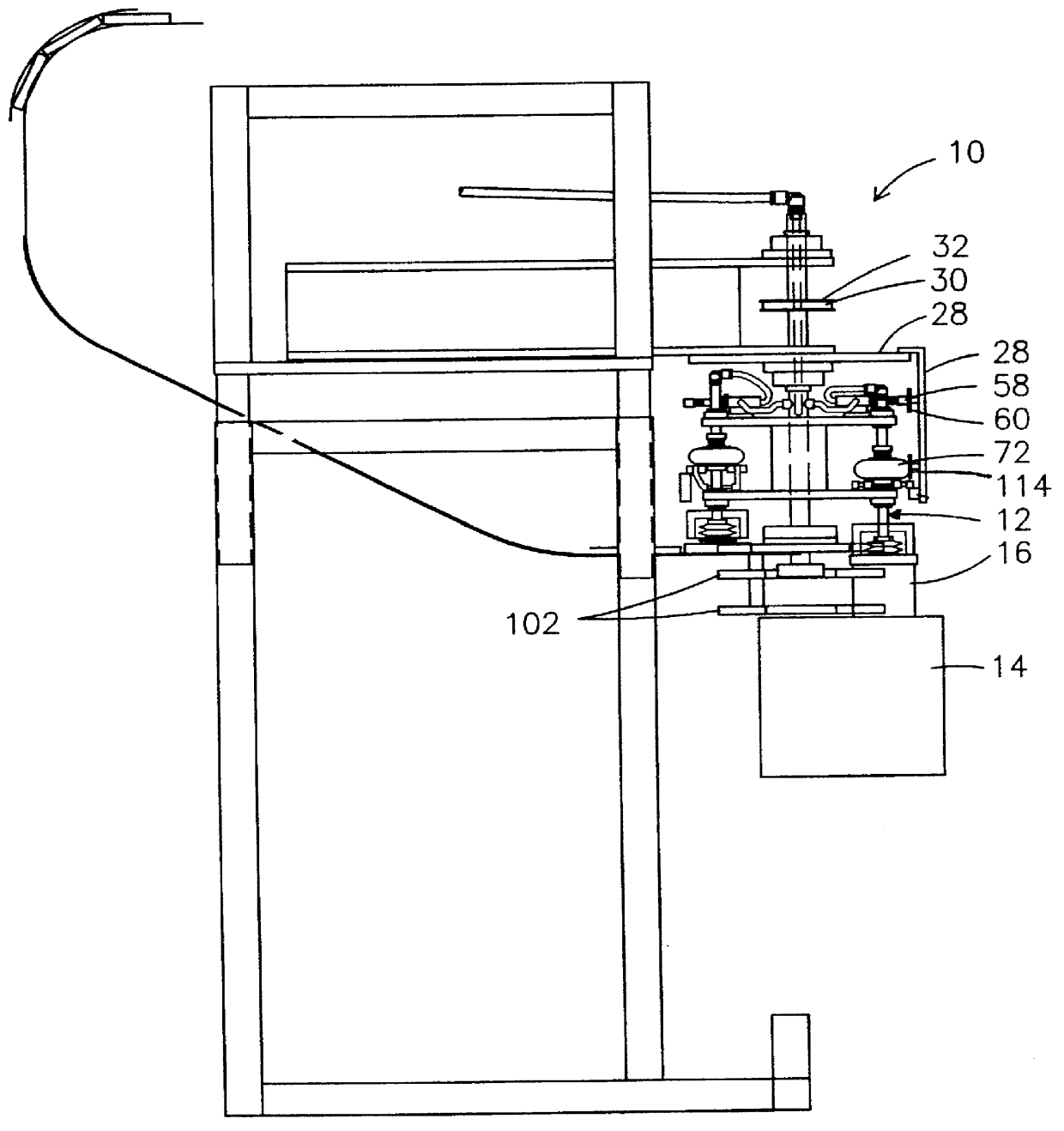

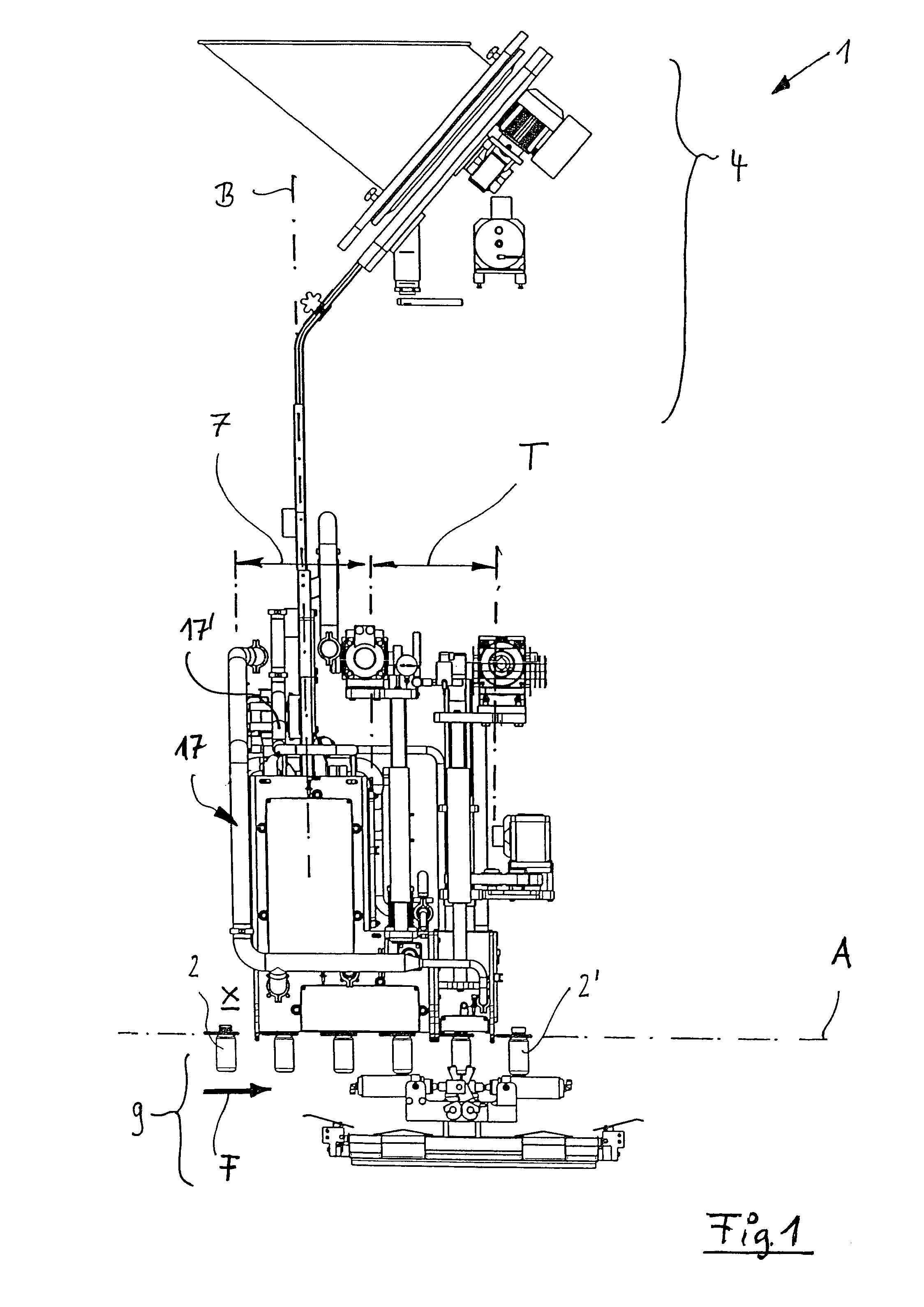

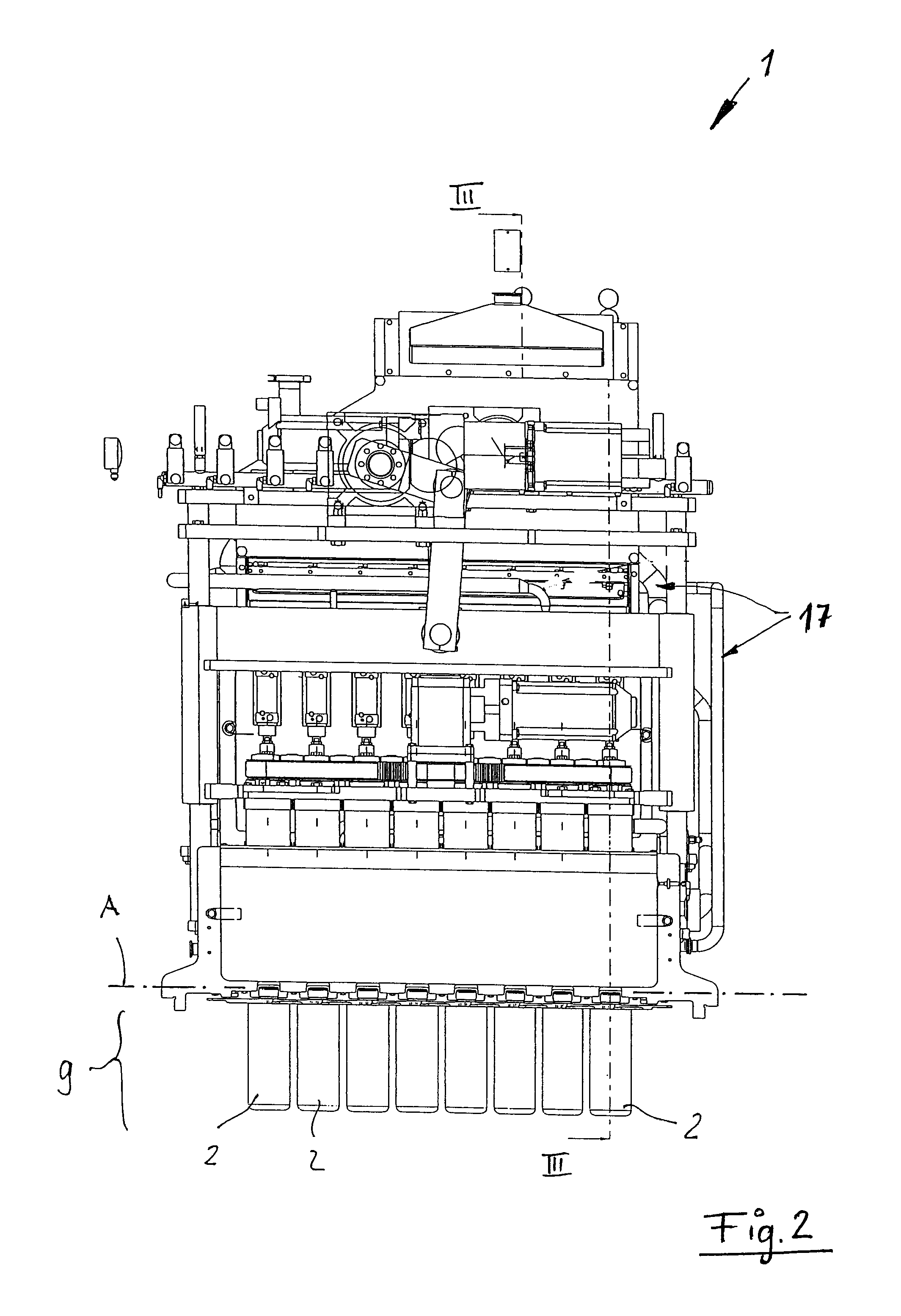

Beverage bottle closing machine being configured and disposed to close tops of filled beverage bottles with screw-type and other caps

A beverage bottle closing machine being configured and disposed to close tops of filled beverage bottles with screw-type and other caps. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

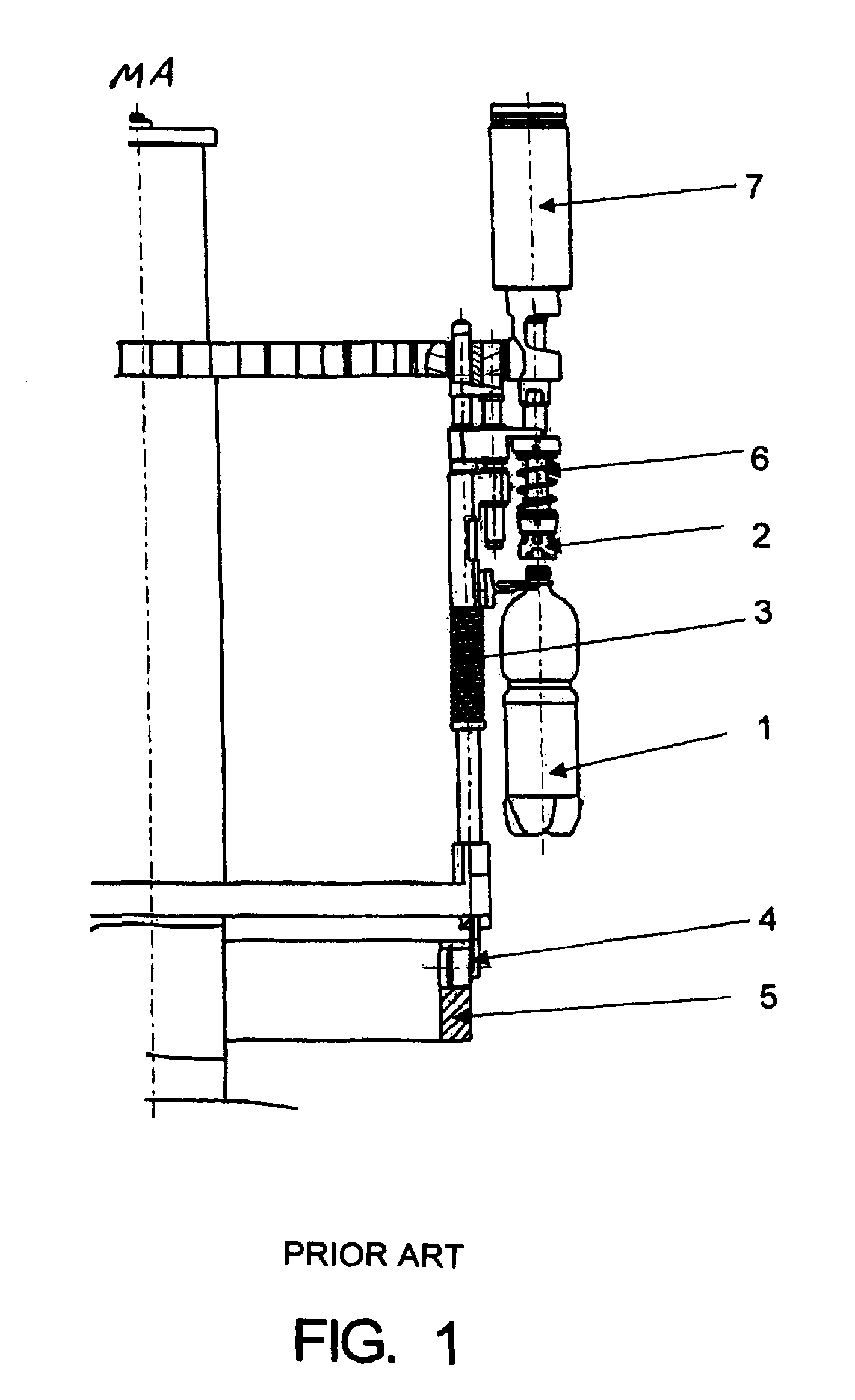

Device for screwing caps onto receptacles

InactiveUS7334380B2Simple and inexpensive for adjusting the clamping torqueStop rotatingCapsThreaded caps applicationDrive shaftScrew cap

A device for screwing caps onto receptacles, the device comprising a rotary spindle having a first end provided with a cap gripper head and a second end connected to a two-portion clutch member, one of which portions is constrained to rotate with the second end of the rotary spindle, and the other of which portions is constrained to rotate with a drive shaft on the same axis as the spindle and associated with a drive member, wherein the portions of the clutch member comprise a magnetic bell and a magnetic core having dimensions suitable for enabling it to be engaged in the bell, the device further comprising a displacement member for displacing the bell and the core relative to each other between a position in which the core is engaged in the bell and a position in which the core is disengaged from the bell.

Owner:SERAC GROUP

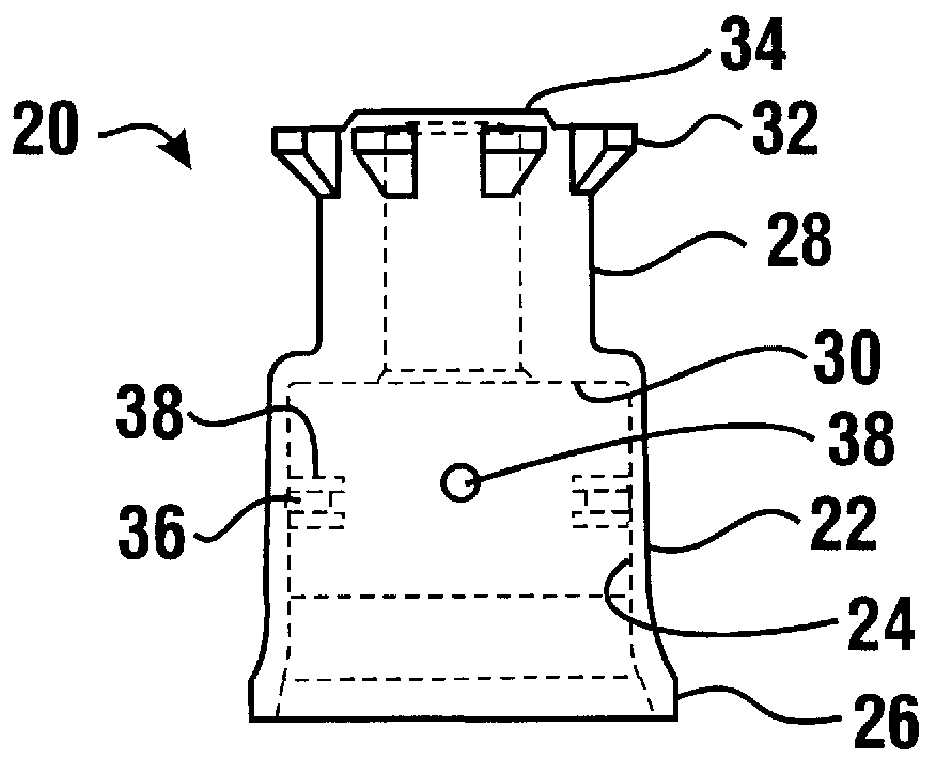

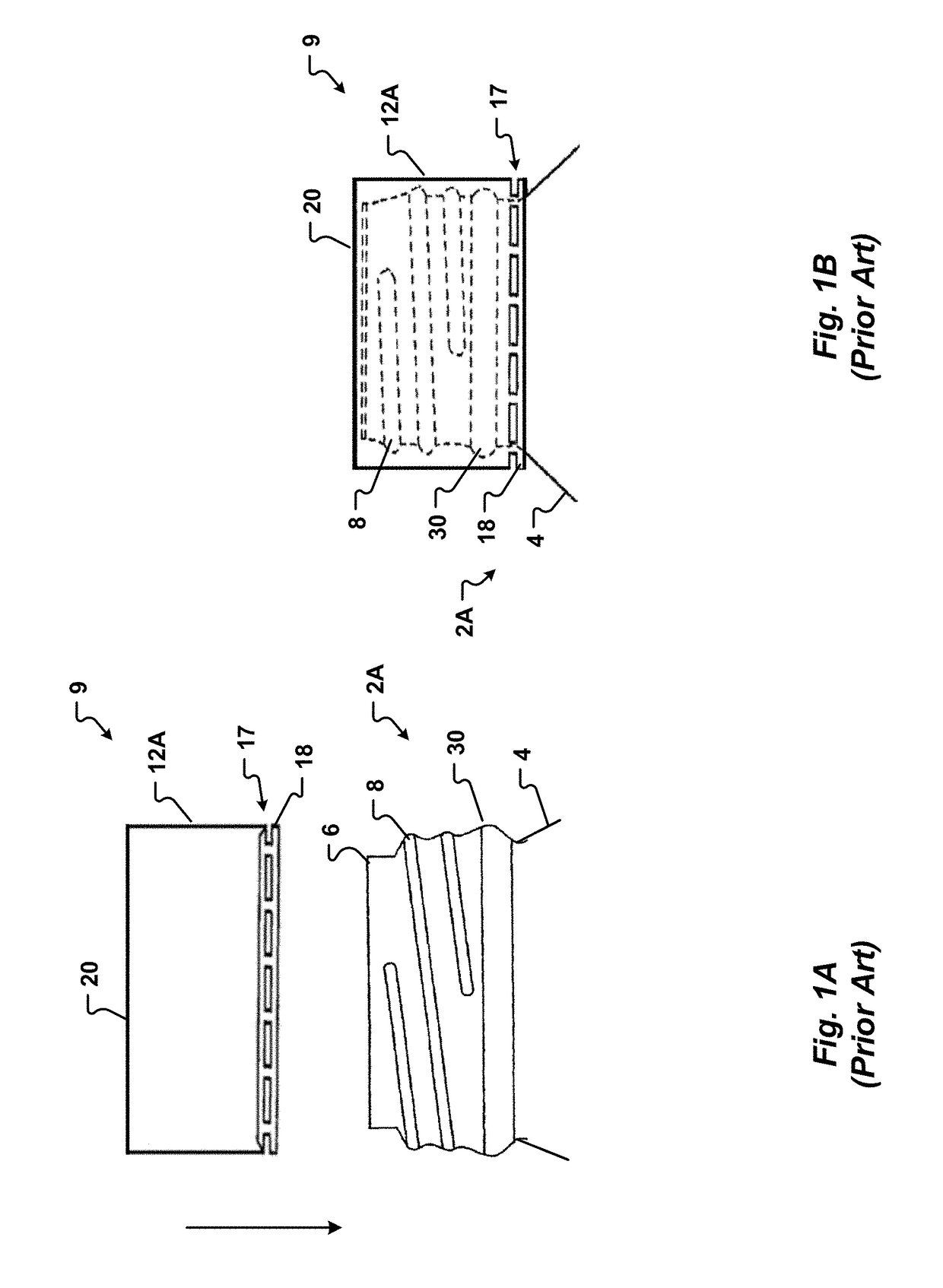

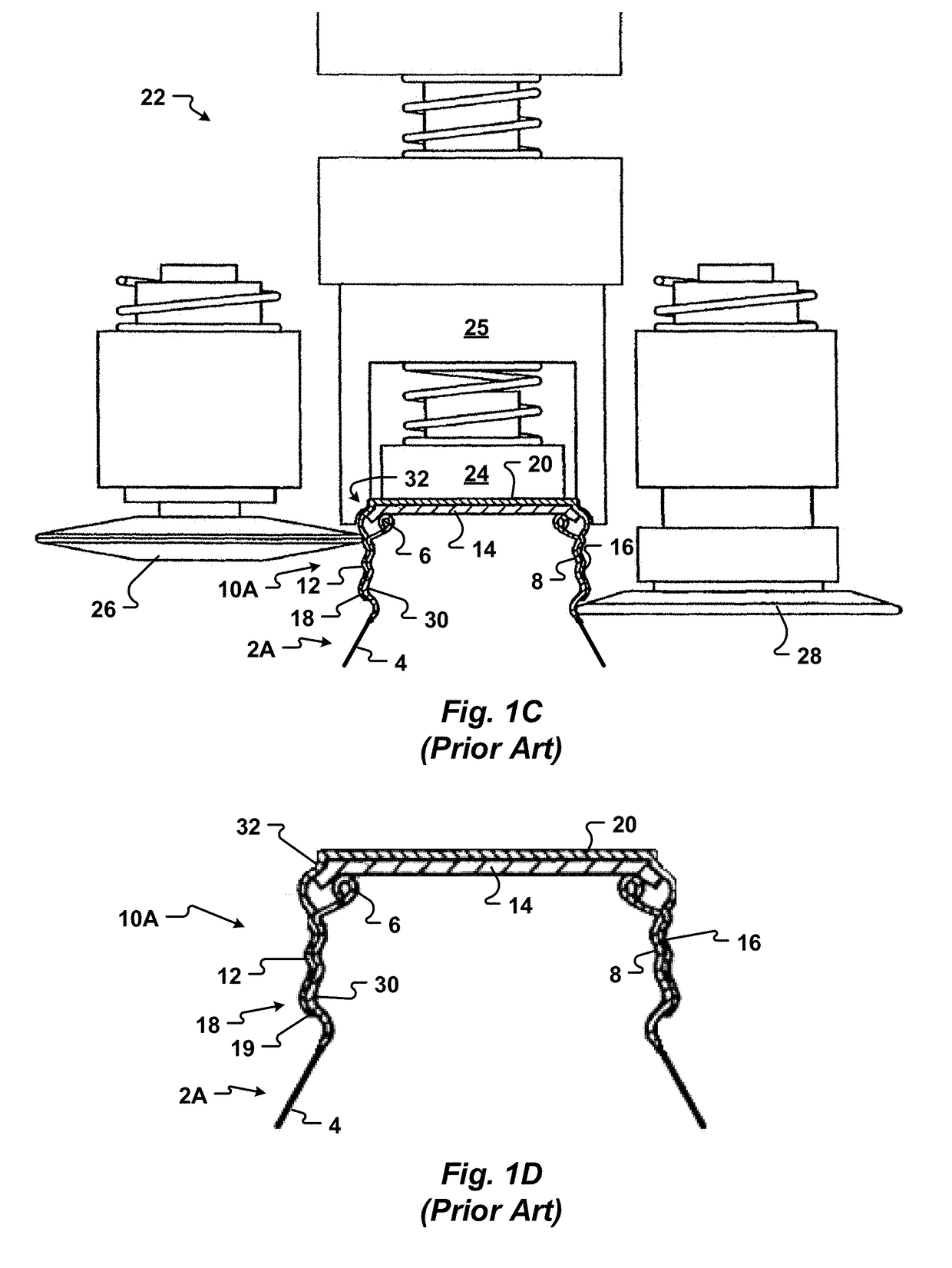

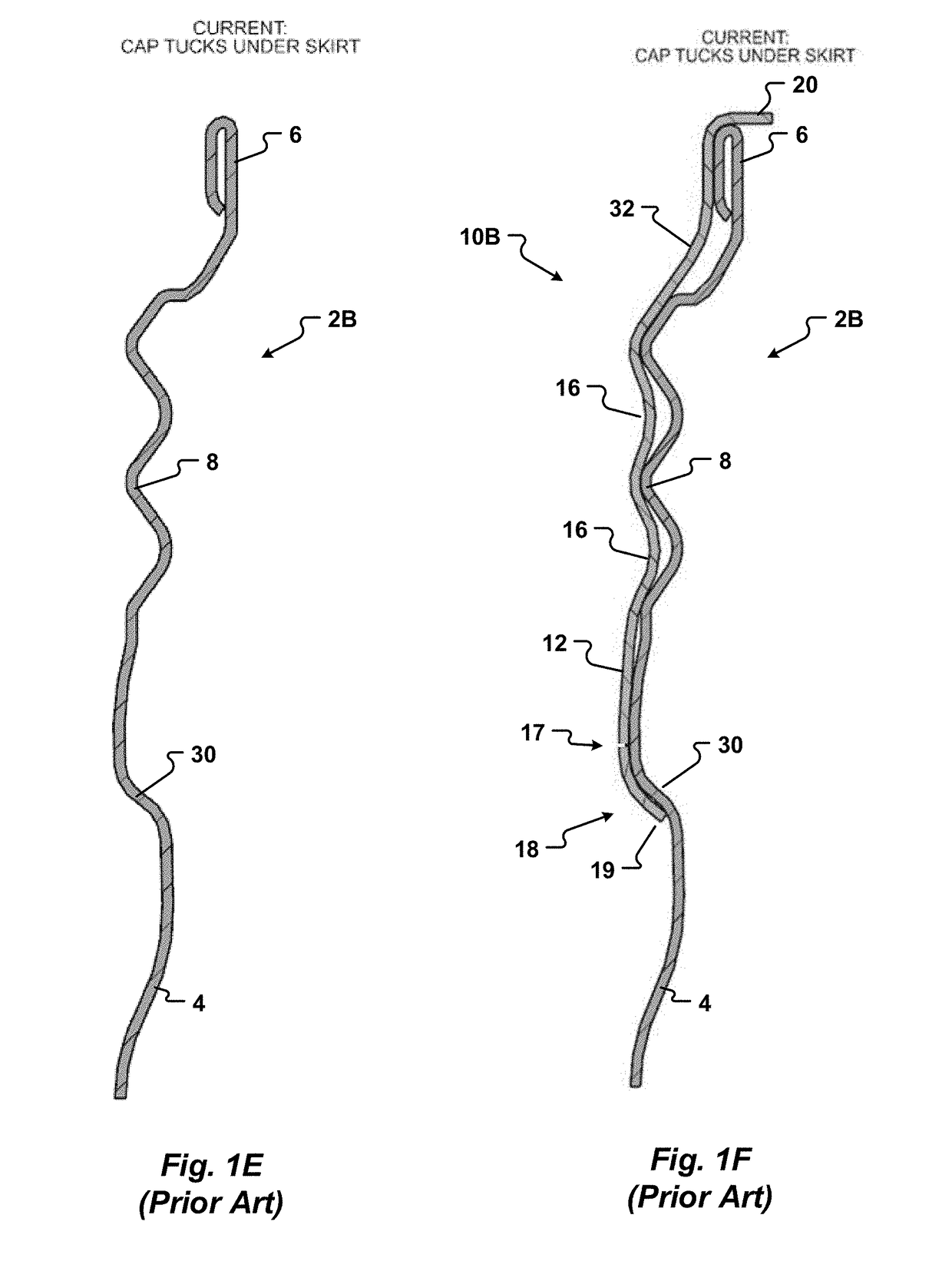

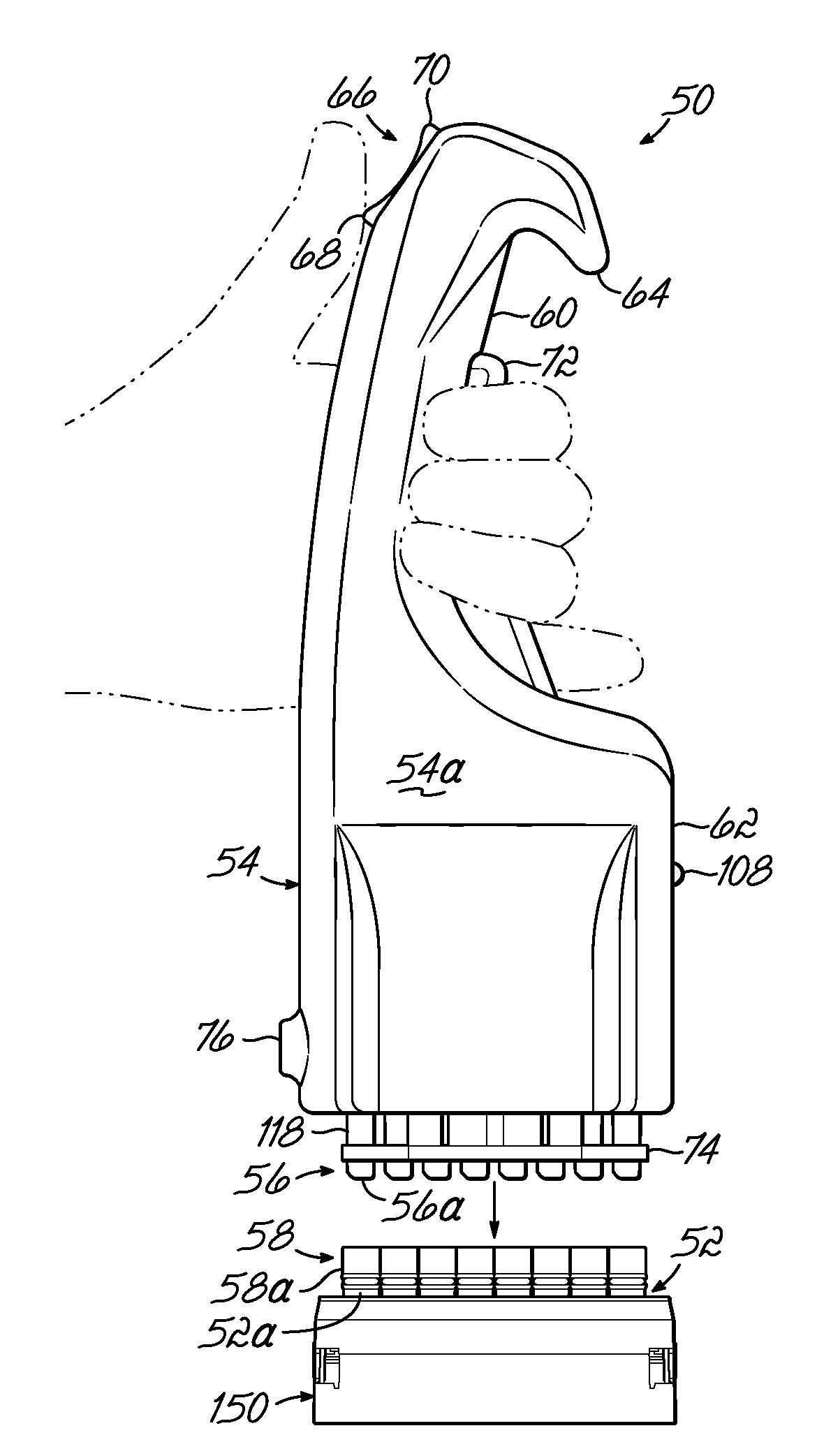

Tamper evidence device for roll-on pilfer proof closures

Methods and apparatus of sealing bottles with Roll-on Pilfer Proof (ROPP) closures and providing tamper evidence are provided. More specifically, the present invention relates to novel ROPP closures that may be used to seal a bottle shaped container which can subsequently receive a tamper evidence device. The bottle can have a neck portion formed without a skirt portion. Optionally, the bottle can include an annular ring. The ROPP closure generally includes a body portion. In one embodiment, the body portion has a curl. A tamper evidence device can be applied to a bottle sealed with a ROPP closure by a capping apparatus. The tamper evidence device may be visually altered when the ROPP closure is rotated in an opening direction. In one embodiment, the ROPP closure cannot be rotated while the tamper evidence device is associated with the bottle. In another embodiment, the tamper evidence device includes at least one protrusion which extends inwardly at least partially into the bottle annular ring.

Owner:BALL CORP

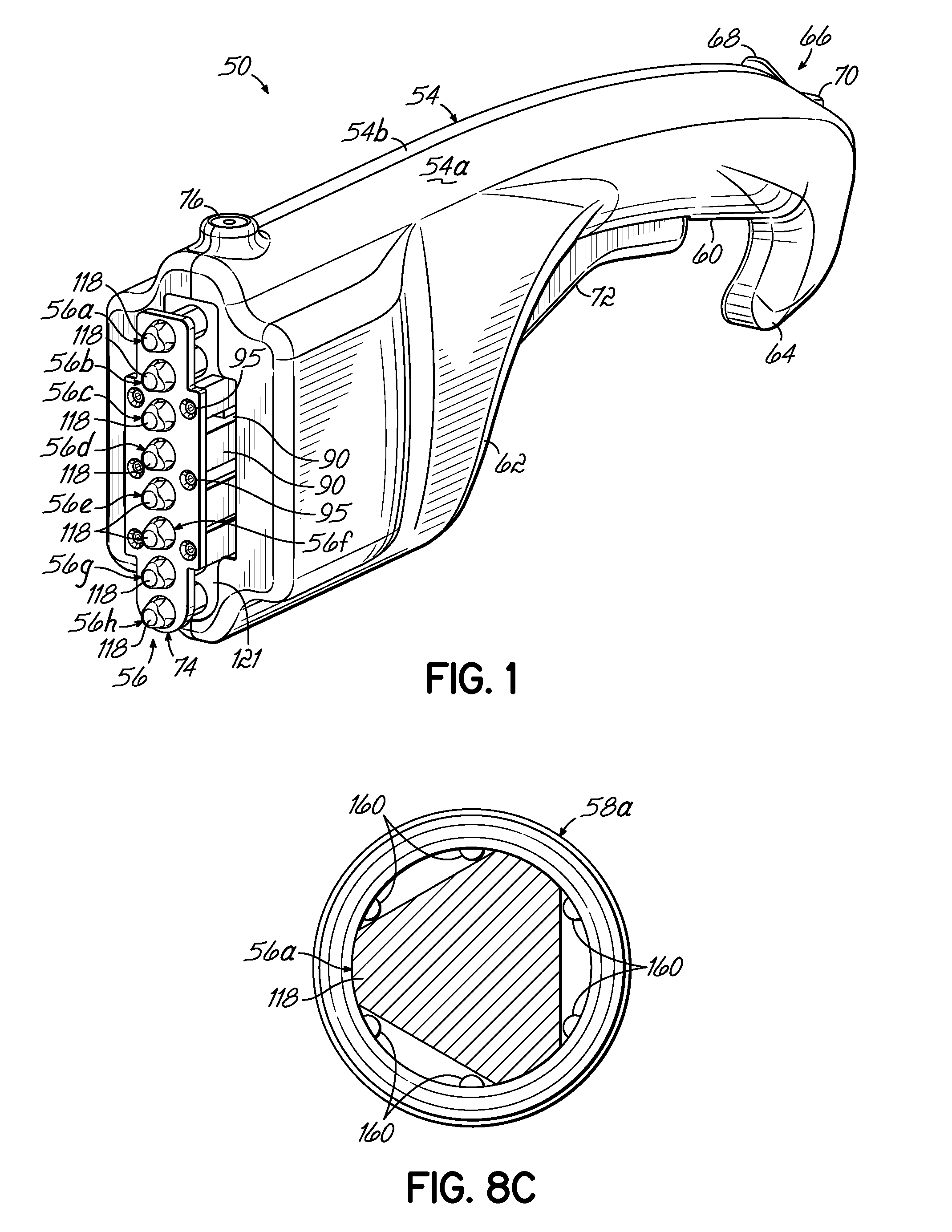

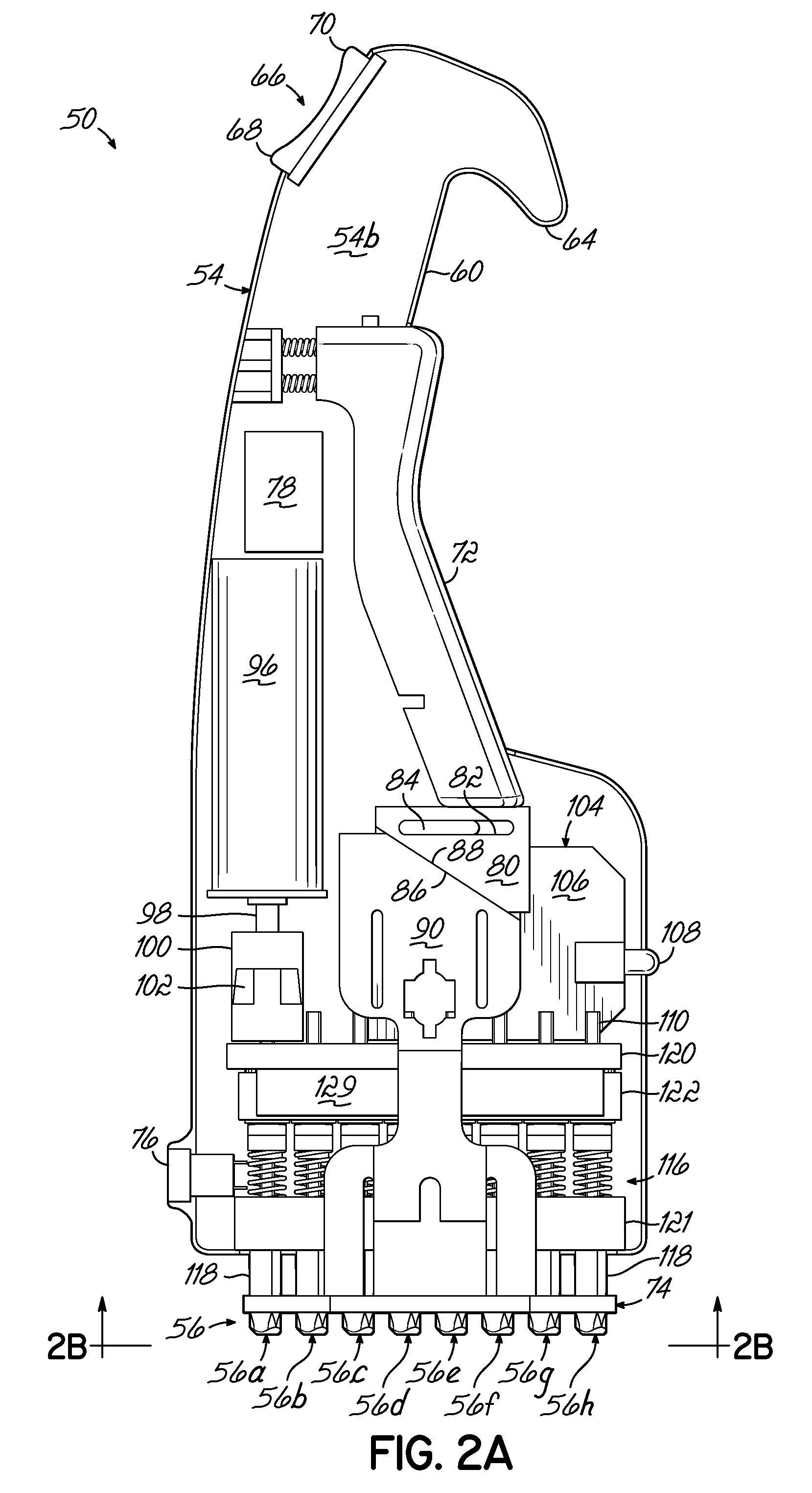

Handheld Tube Capper/Decapper

A tube capper and decapper and method of using the same. The tube capper includes a handheld housing that supports a one-dimensional array of spindles. Each spindle is shaped to receive a cap. A drive mechanism rotates each spindle of the one-dimensional array in unison for capping or decapping a corresponding one-dimensional array of tubes.

Owner:MATRIX TECH

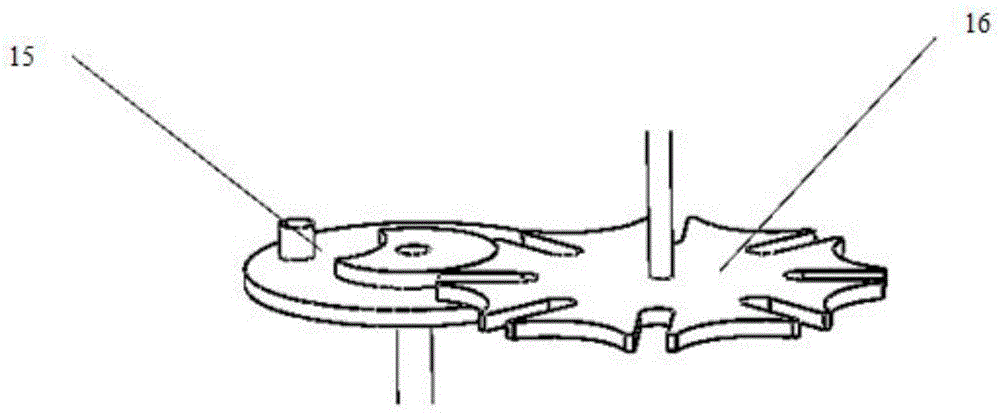

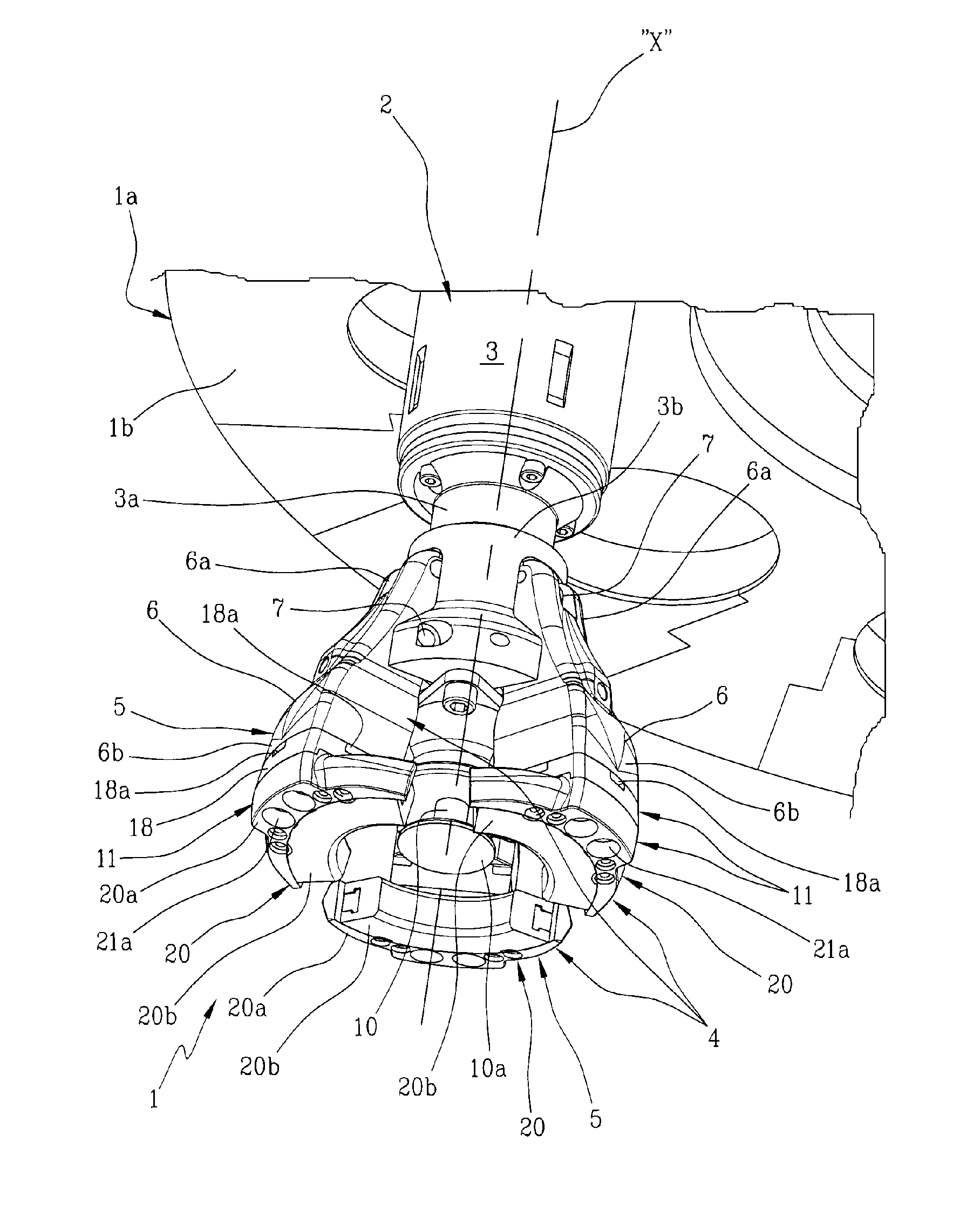

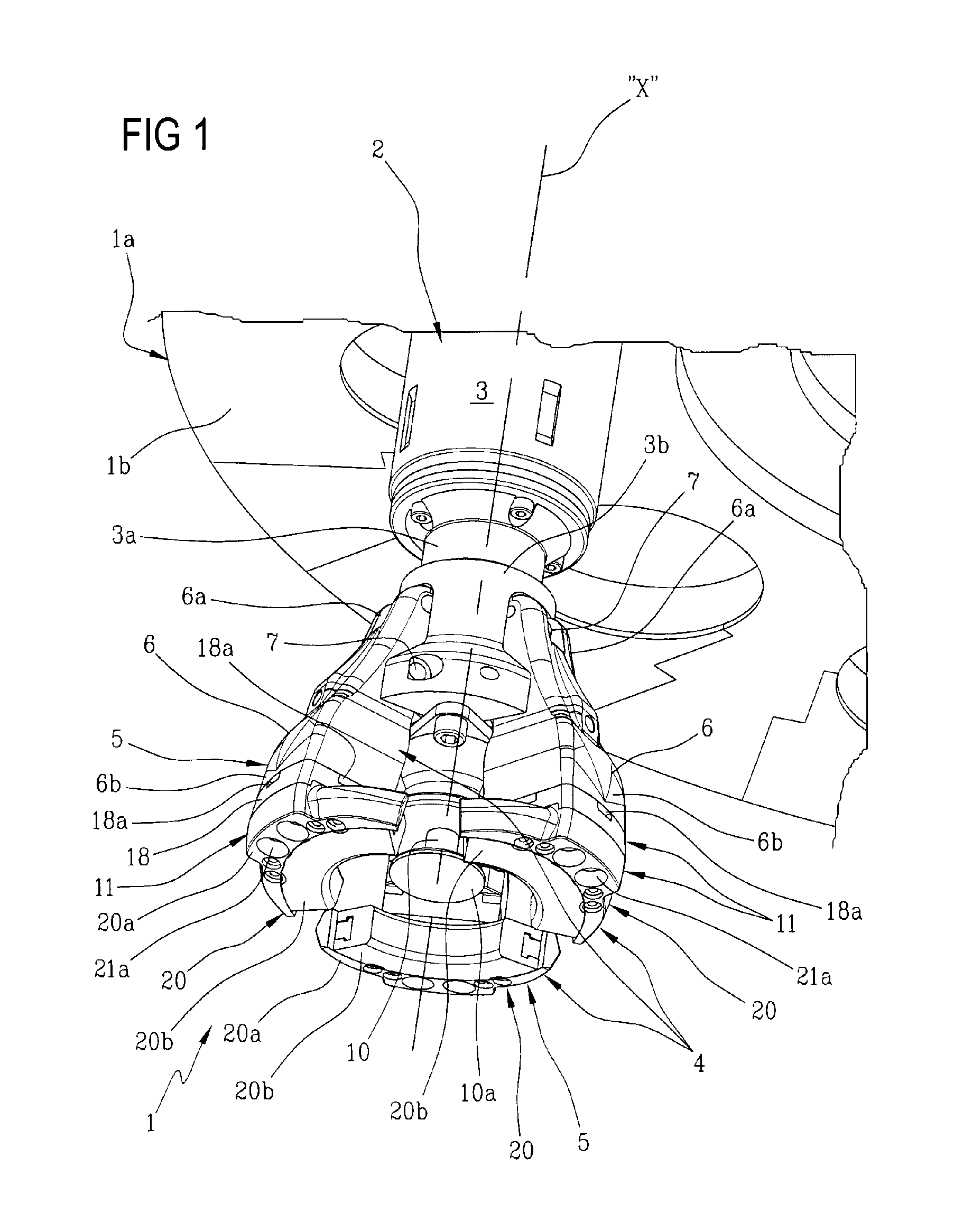

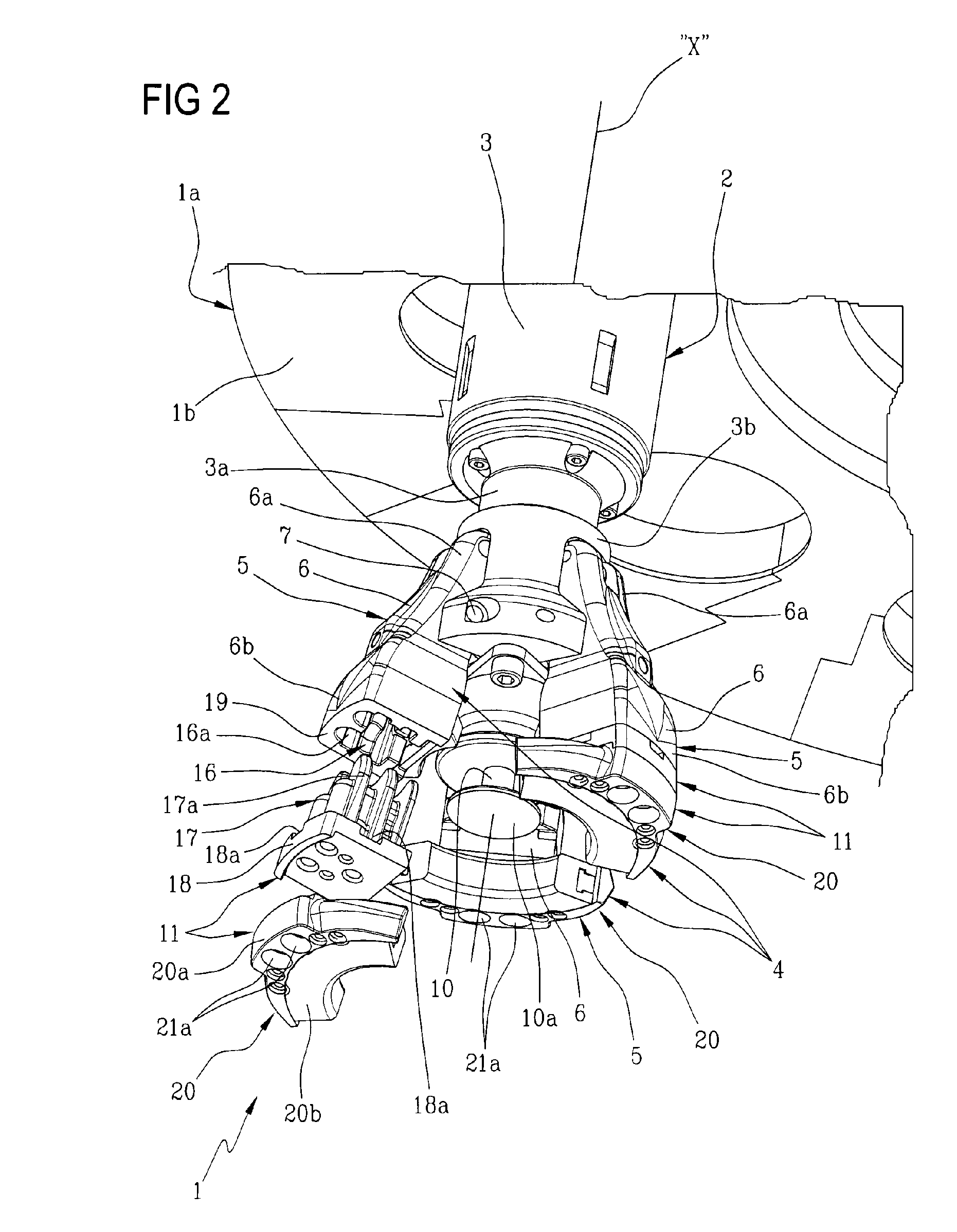

Gripping apparatus for capping assemblies in container packaging machines

Capping assemblies (2) of the type fitted to capping units (1a) in a machine for packaging containers filled with fluid or powdered products are equipped with a gripping apparatus (1) comprising a gripper (4) with three arms (5), each carrying an adapter (20) furnished with a pad (20b) offered in direct contact to the cap, through which the gripping action is applied. Each adapter (20) is secured to a fitting (17, 18) insertable into a socket (16) afforded by the bottom of a structural member (6) that forms the main part of each arm (5) and is hinged to the movable head of a relative capping assembly (2); when inserted into the structural member (6), the fitting (17, 18) is retained automatically by a snap lock mechanism (12) incorporated into the arm (5), which can be released subsequently by introducing the tip of a screwdriver into a slot (18a) created in the side of the fitting (17, 18) and levering the components apart.

Owner:AZIONARIA CONSTR MASCH AUTOMATICHE A C M A SPA

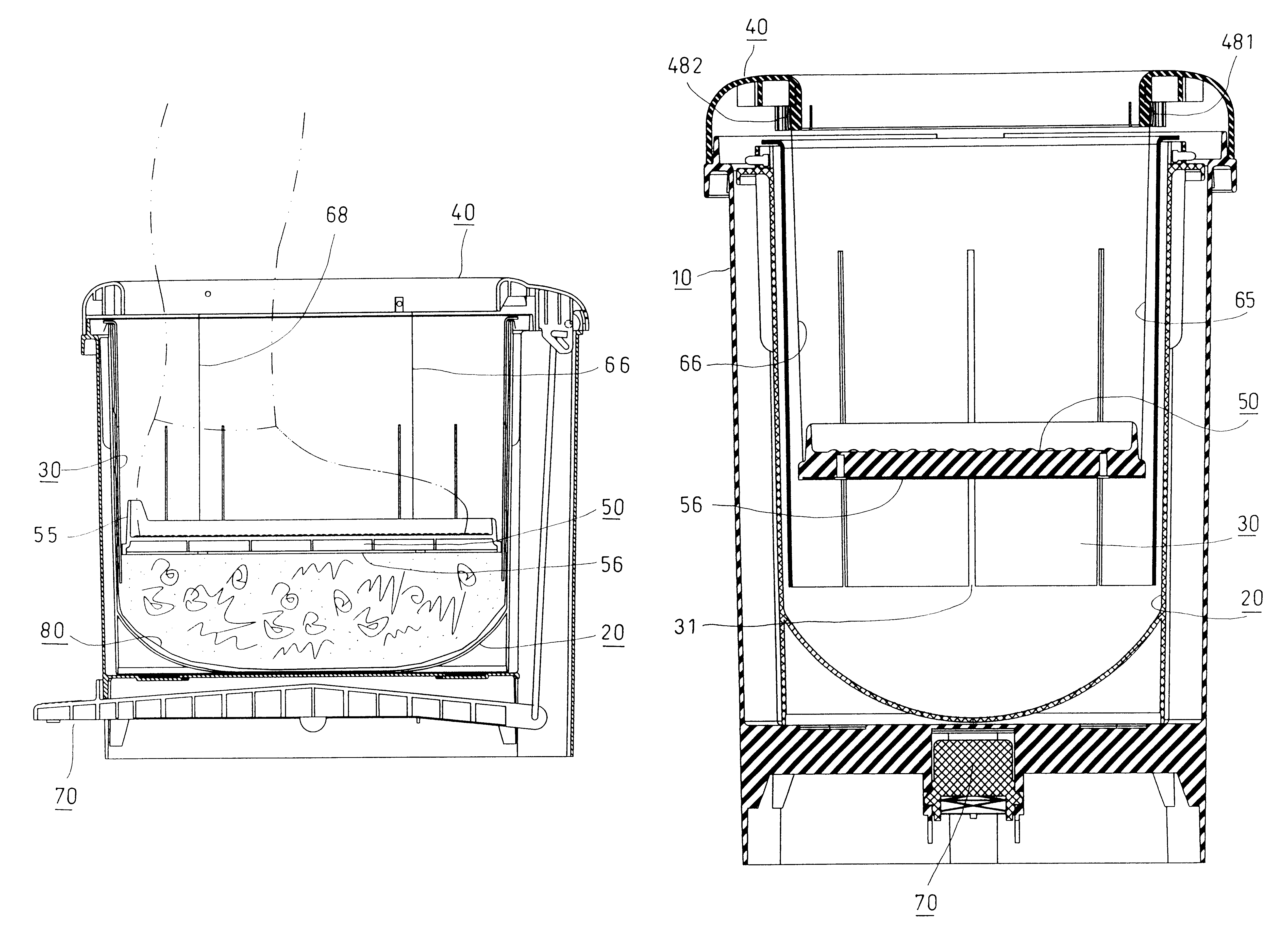

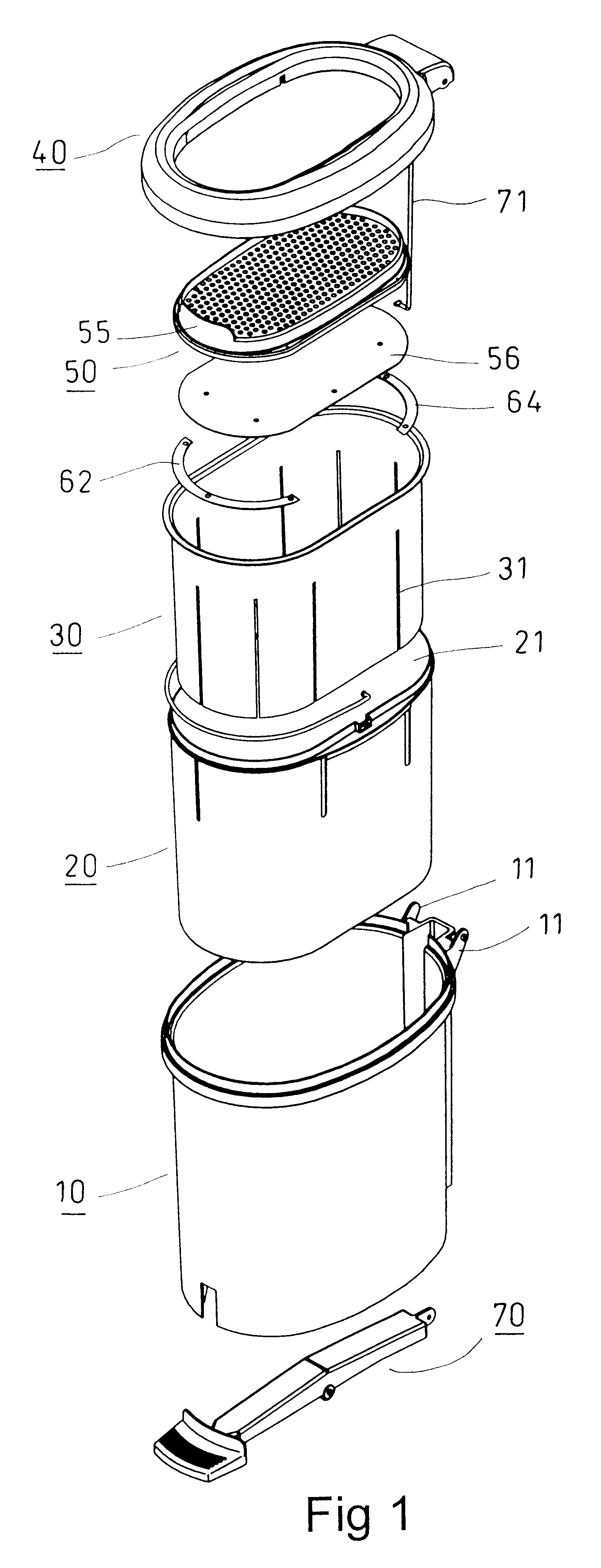

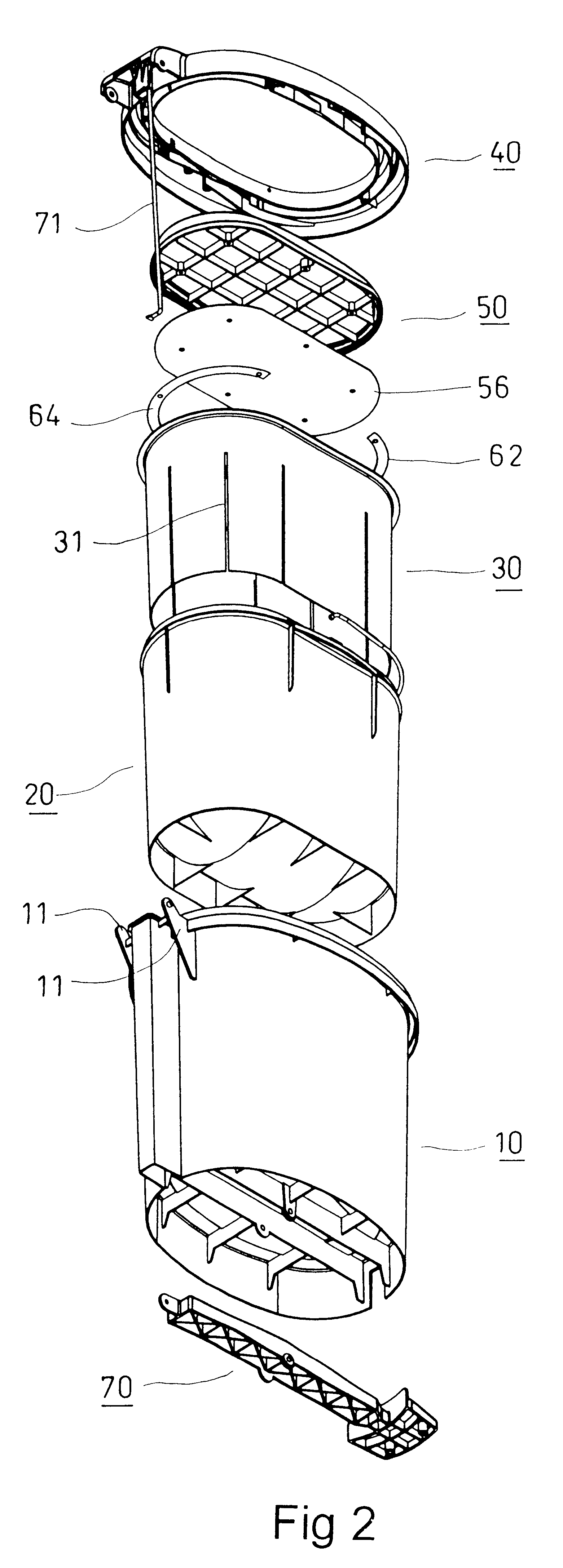

Garbage can capable of compresing garbage volume

InactiveUS6983685B2Less spaceReduce consumptionCapsFlanged caps applicationEngineeringMechanical engineering

Owner:KO WEN HSIUNG

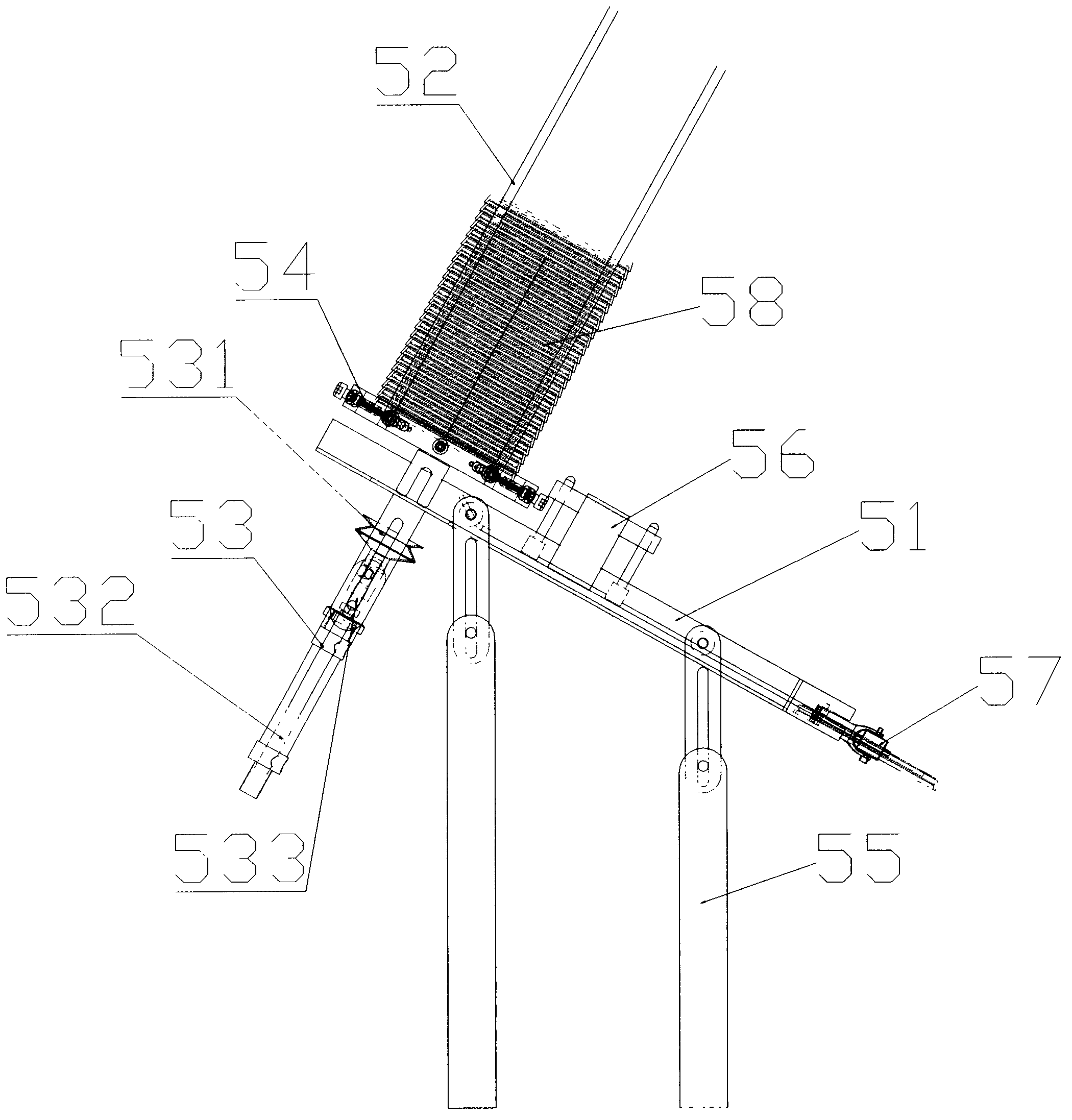

Automatic cover pressing machine of plastic covers

InactiveCN103288019AGood compression sealReduce flatness requirementsFlanged caps applicationDistortionSelf adjusting

The invention discloses an automatic cover pressing machine of plastic covers. The automatic cover pressing machine of the plastic covers is characterized by comprising a pressing mechanism used for tightly pressing the plastic covers on cans and a conveying mechanism used for conveying the plastic covers to the entry of the pressing mechanism. The pressing mechanism can automatically adjust the degree of tightness of cover pressing through a tightness self-adjusting spring mechanism according to the bending and the deformation of the plastic covers, the phenomenon of pressure leakage is effectively avoided, and continuous production can be carried out on the cans with various heights. The conveying mechanism places the plastic covers in a sliding channel one by one through a vacuum suction cup to carry out automatic gravity conveying, the whole conveying mechanism can work continuously and stably, the requirements for the flatness of the plastic covers is not high, and the situation that conveying is stopped due to slight distortion of the plastic covers is avoided.

Owner:SUZHOU JIAHONG MACHINERY

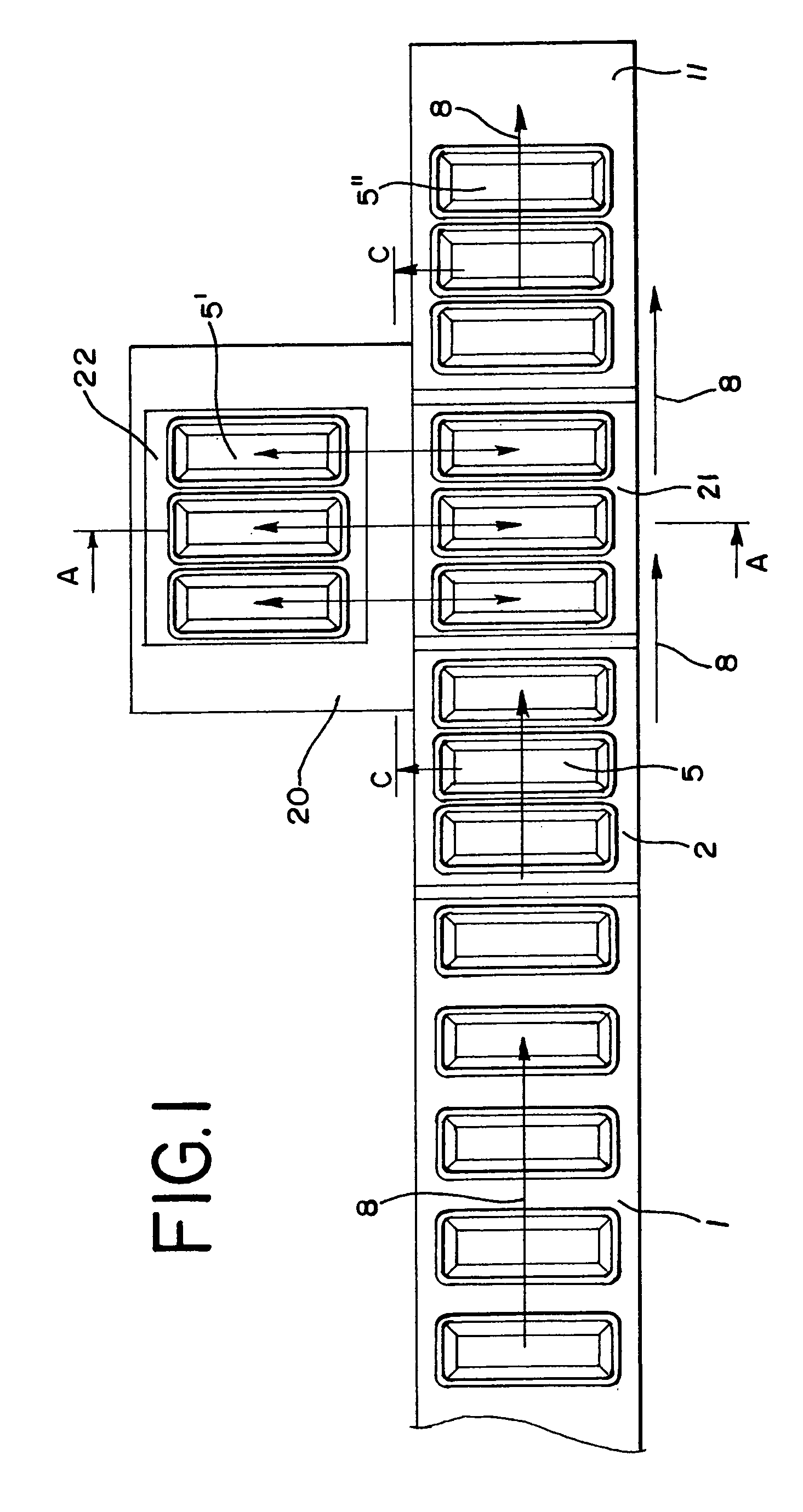

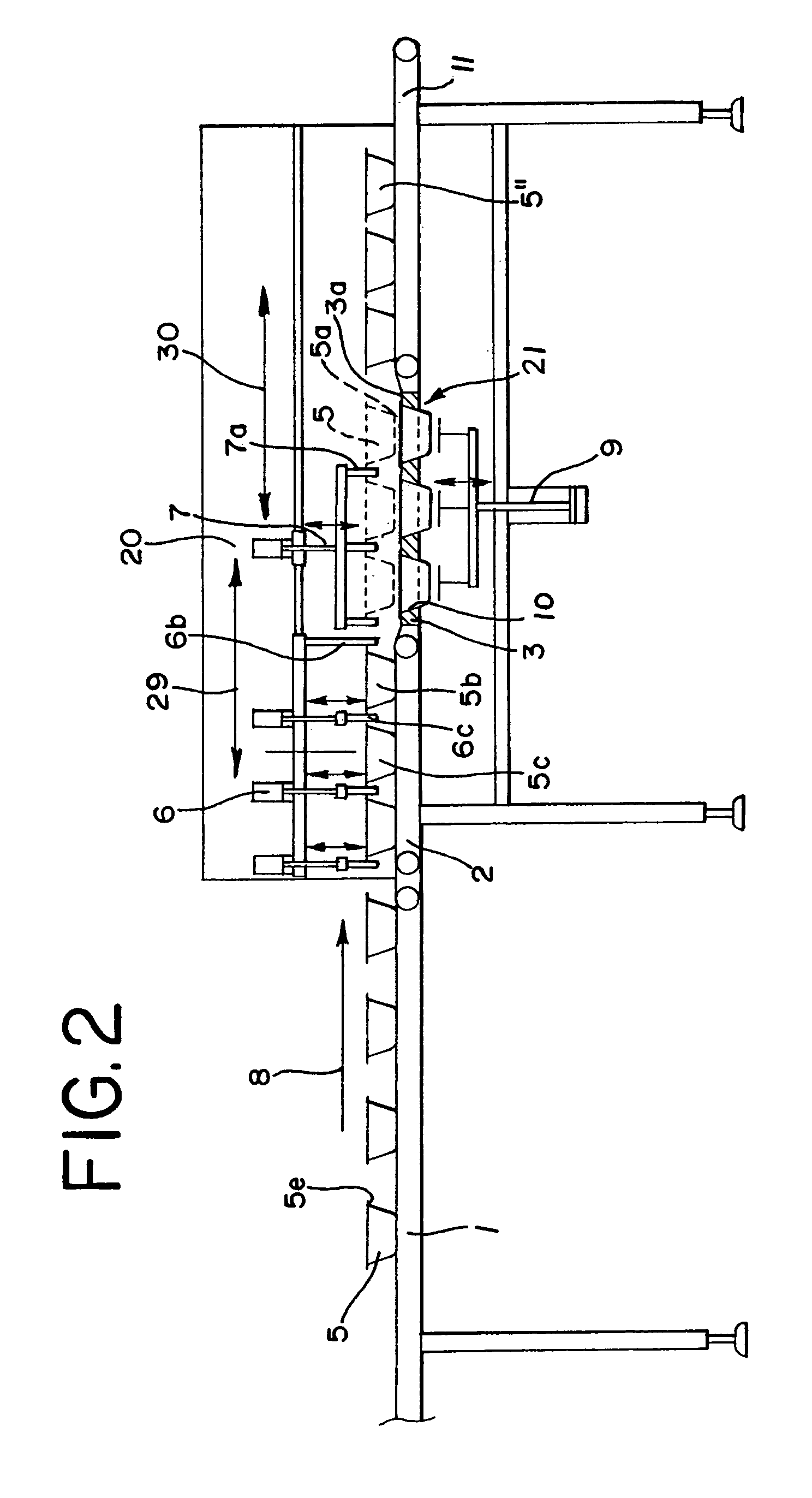

Packaging machine and method for closing containers

InactiveUS7290380B2Easy to changeSignificantly more cost-efficientCapsDecorative coversLinear motionEngineering

A packaging machine for closing containers (5) is provided having a supply device (1, 2) for supplying containers (5) to be closed; a removal device (11) for removing closed containers (5″); and a closing device (25) between the supply device (1, 2) and the removal device (11). The closing device (25) is arranged lateral of a main transport path (8) of the containers (5) from the supply device (2) to the removal device (11) and a device is provided which transports at least one container (5) to be closed into the closing device (25) by means of a linear motion while transporting at least one closed container (5″) out from the closing device (25).

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com