Automatic cover pressing/screwing machine capable of conducting self-adaption on high bottles and low bottles

A capping machine and self-adaptive technology, applied in screw caps, flanged caps, etc., can solve the problems of low efficiency and many manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

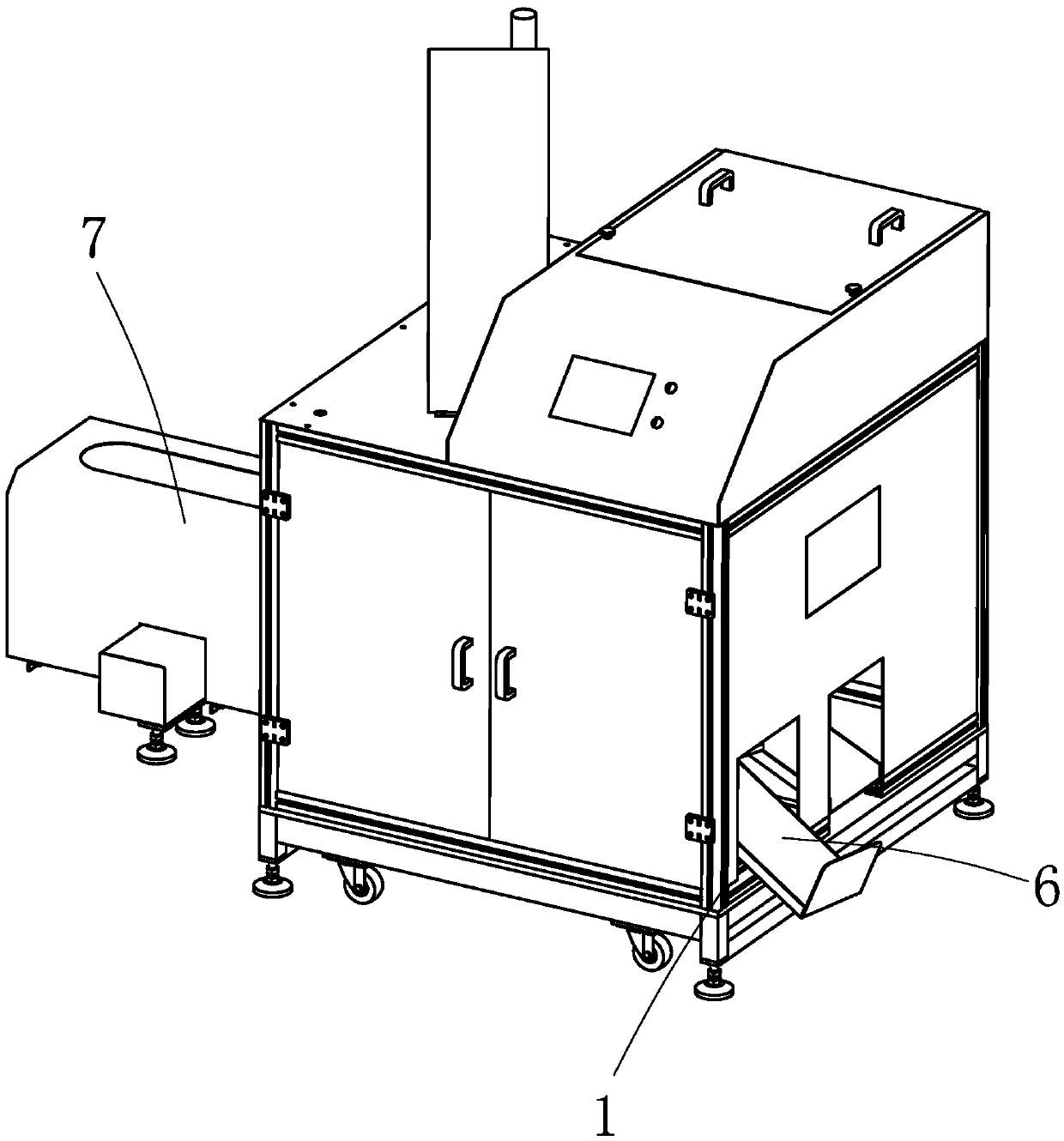

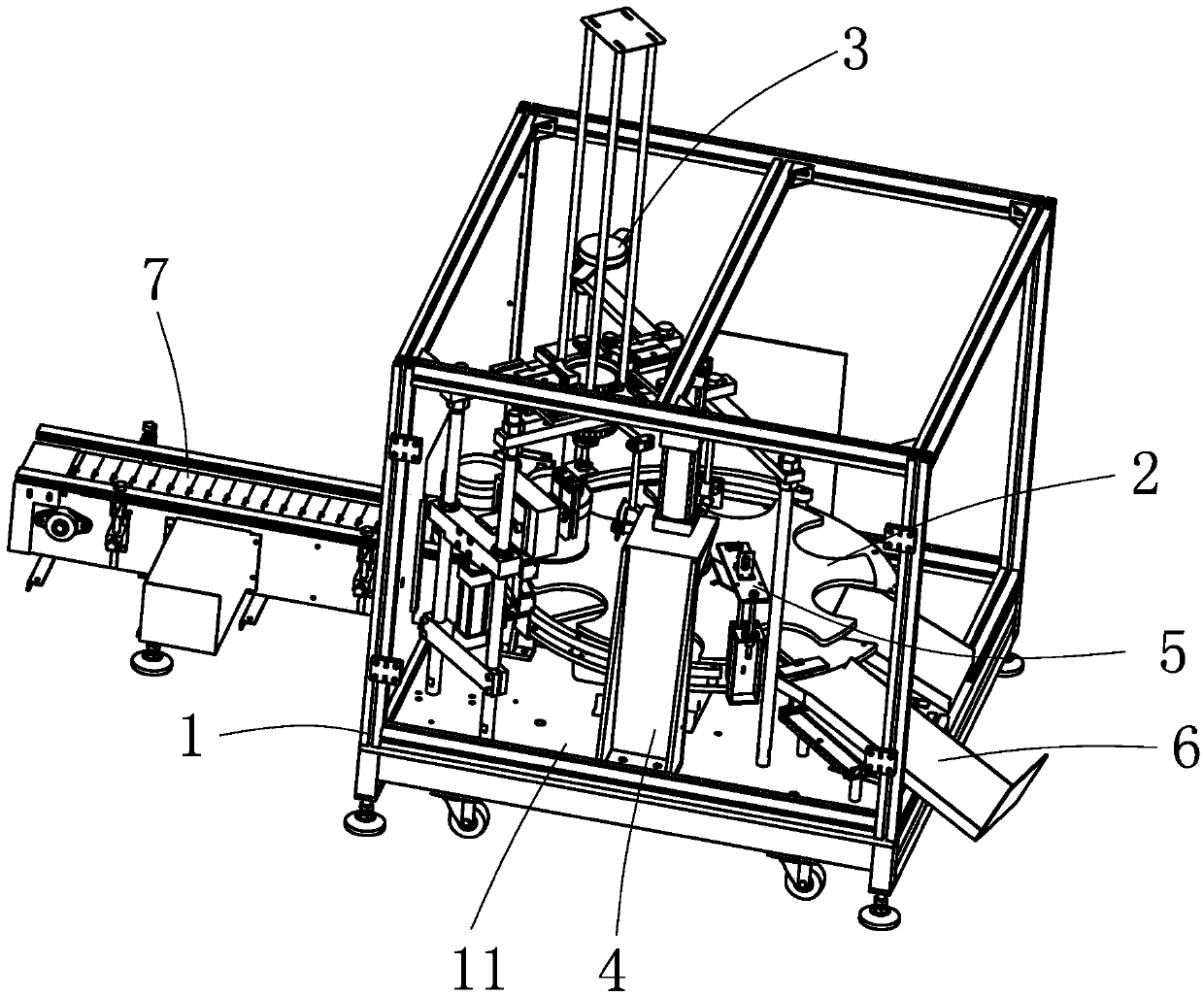

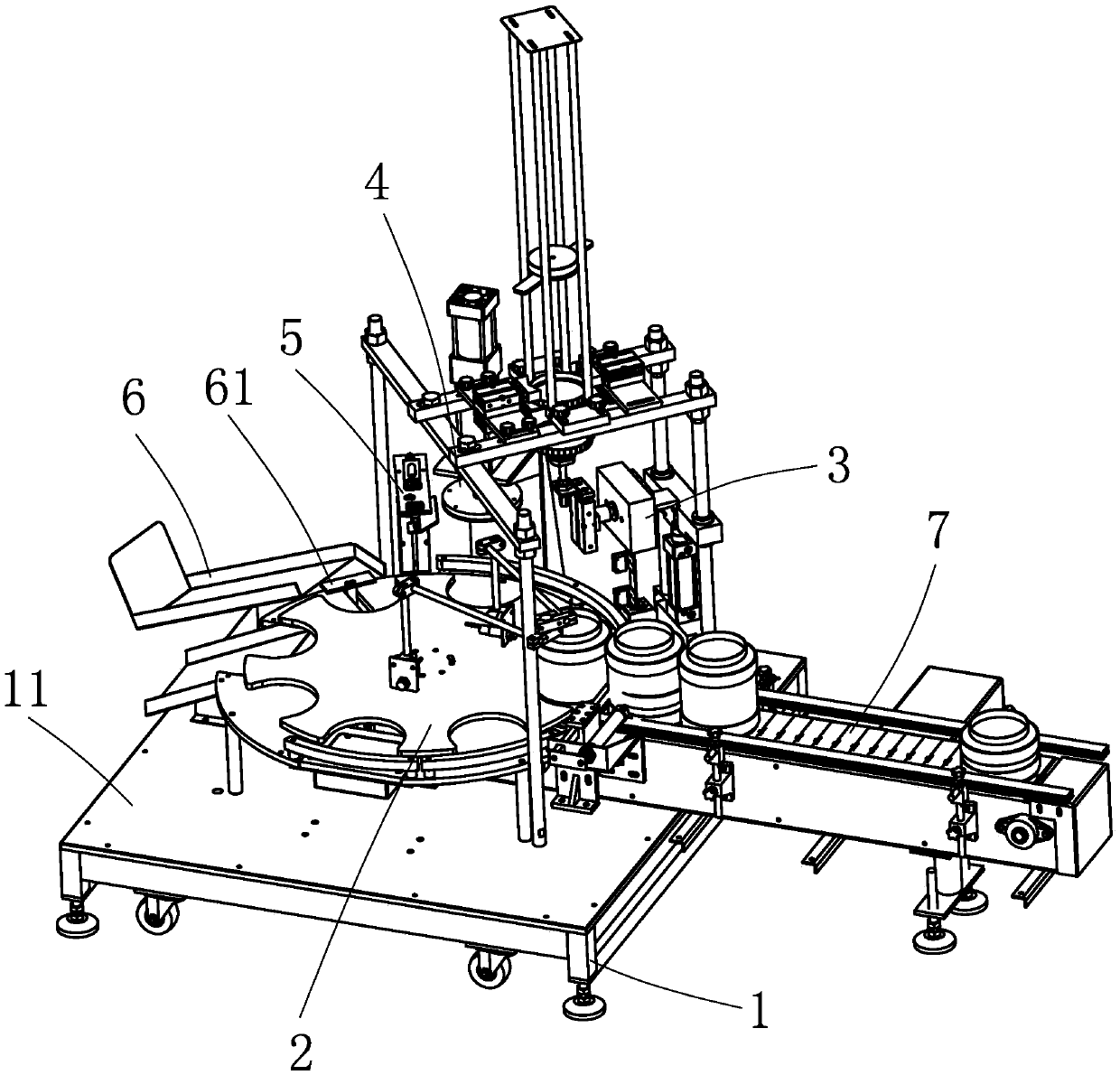

[0036] Example: see Figure 1 to Figure 15 , an automatic pressure / capping machine for self-adaptive high and low bottles, including a frame 1, an indexing bottle feeding mechanism 2 is arranged on the frame 1, and a sample bottle feeding station is arranged around the indexing bottle feeding mechanism 2 , high and low bottle identification and capping station, pressing / capping station, detection station and rejecting station, output station, among which

[0037] The sample bottle is sent to the station, which is connected to the input buffer channel;

[0038] High and low bottle identification and capping station, one side is equipped with high and low bottle identification and upper cover assembly 3,

[0039] Pressing / capping station, one side of which is provided with a pressing / capping assembly 4 for pressing the bottle cap on the sample bottle;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com