Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189results about How to "Minimal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

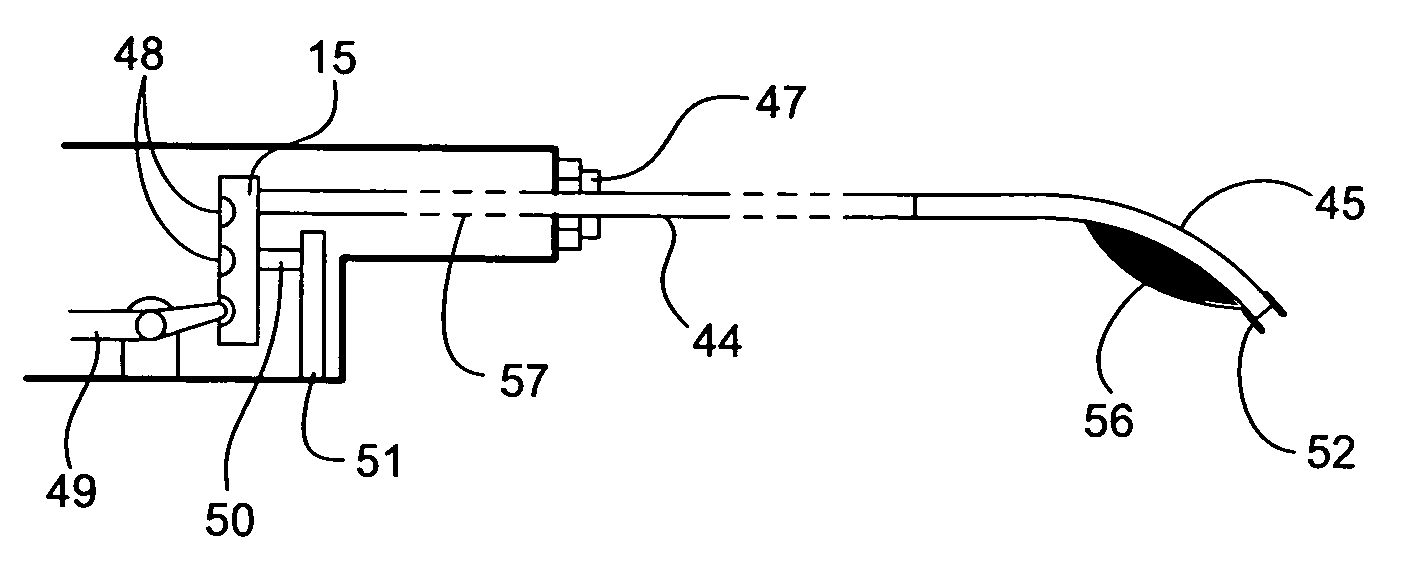

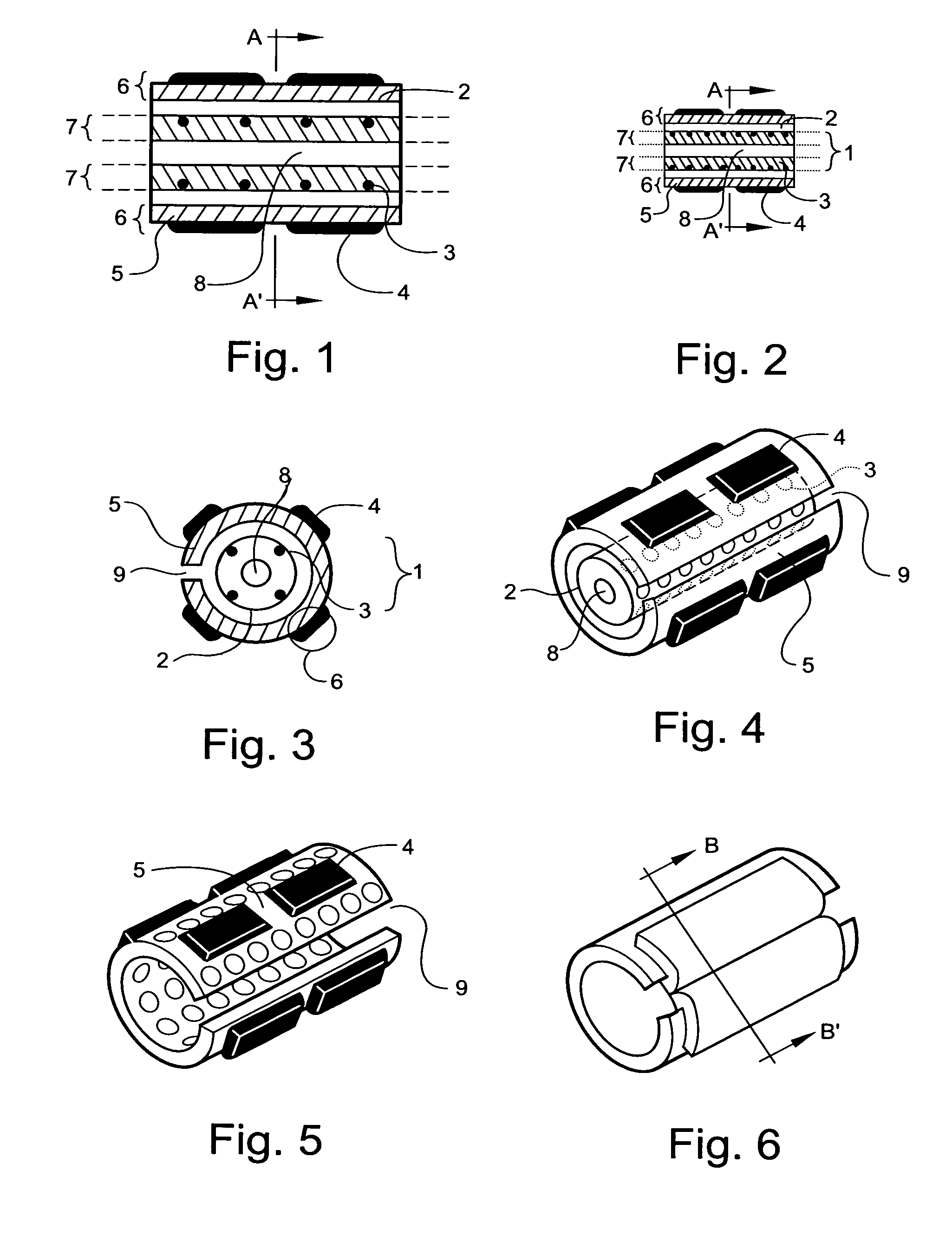

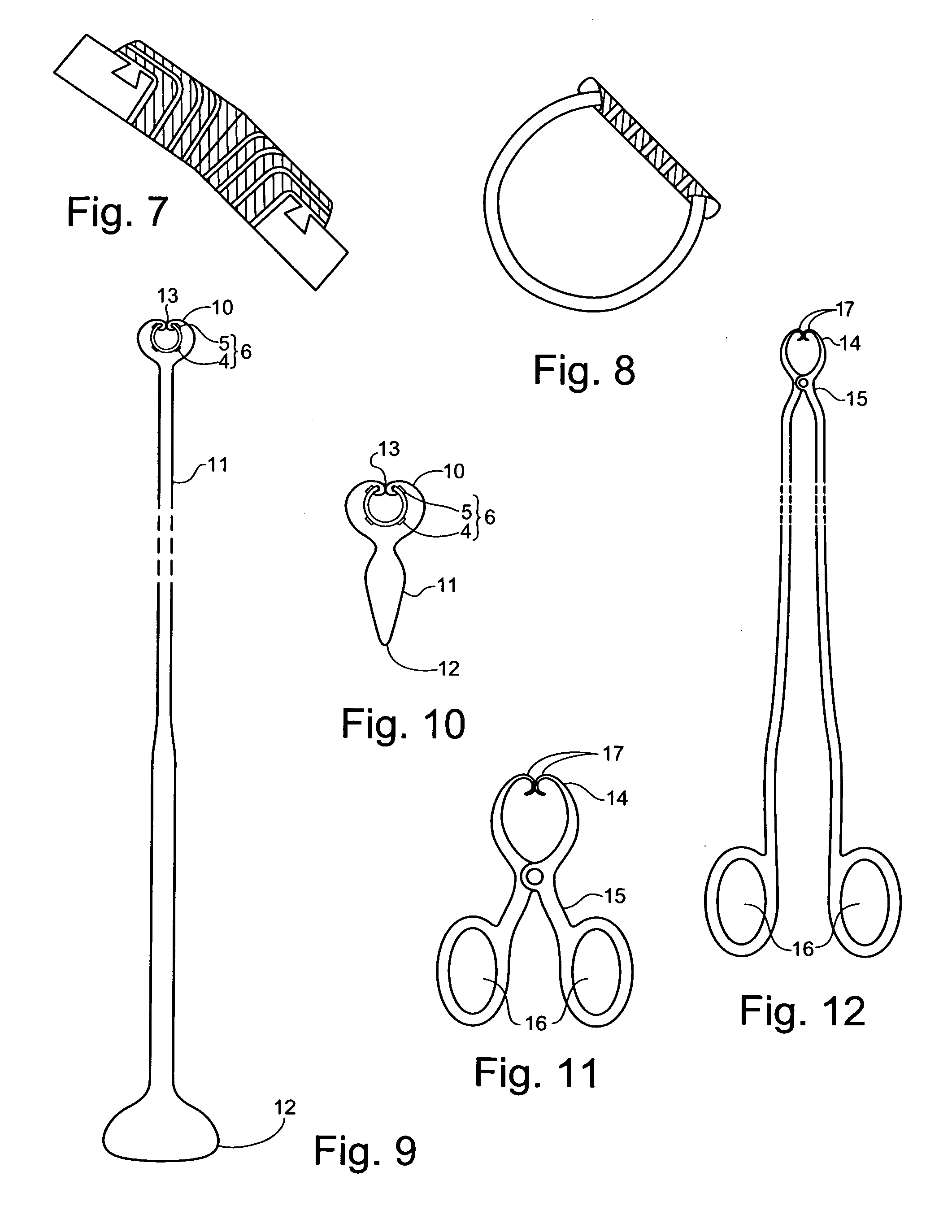

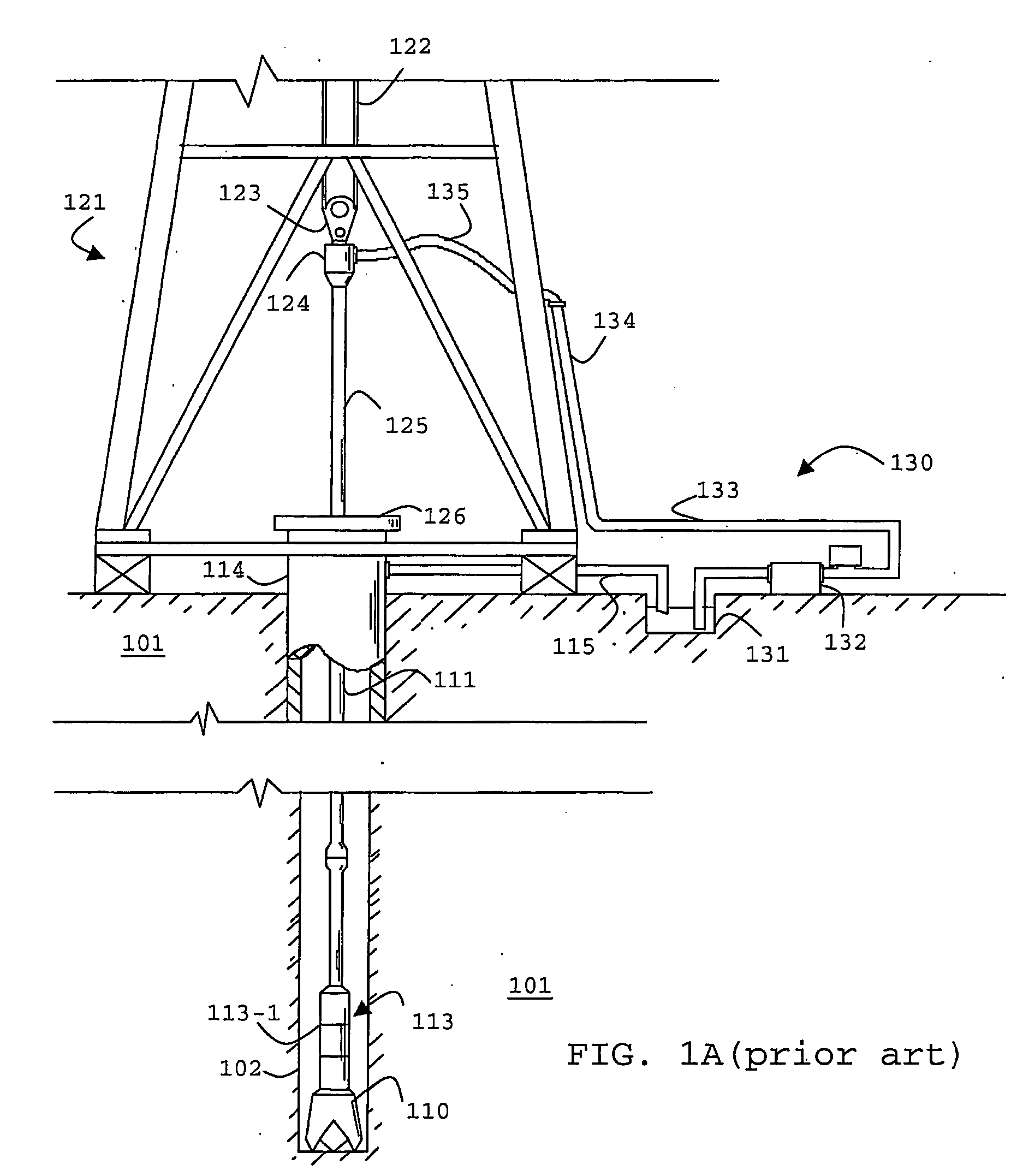

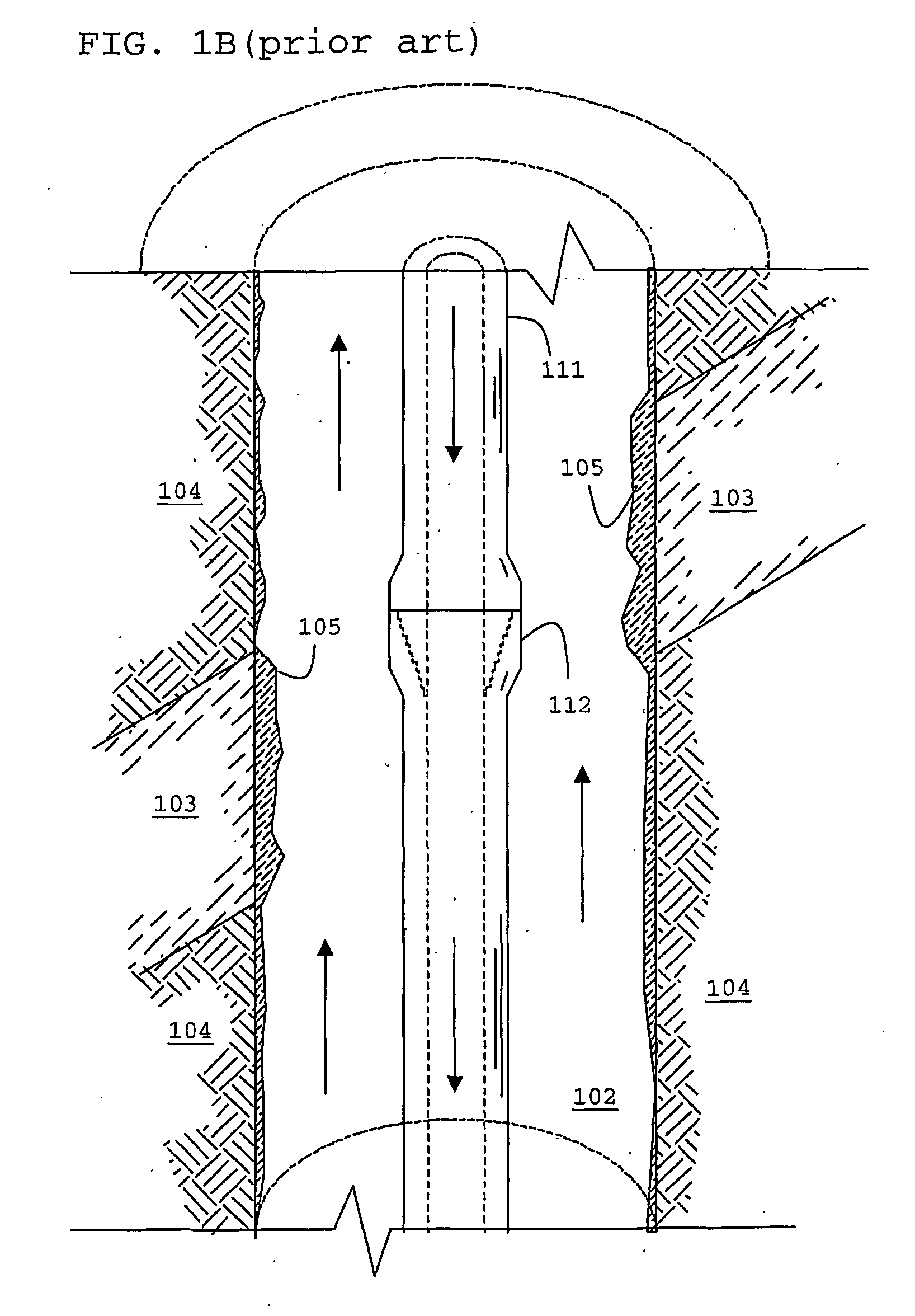

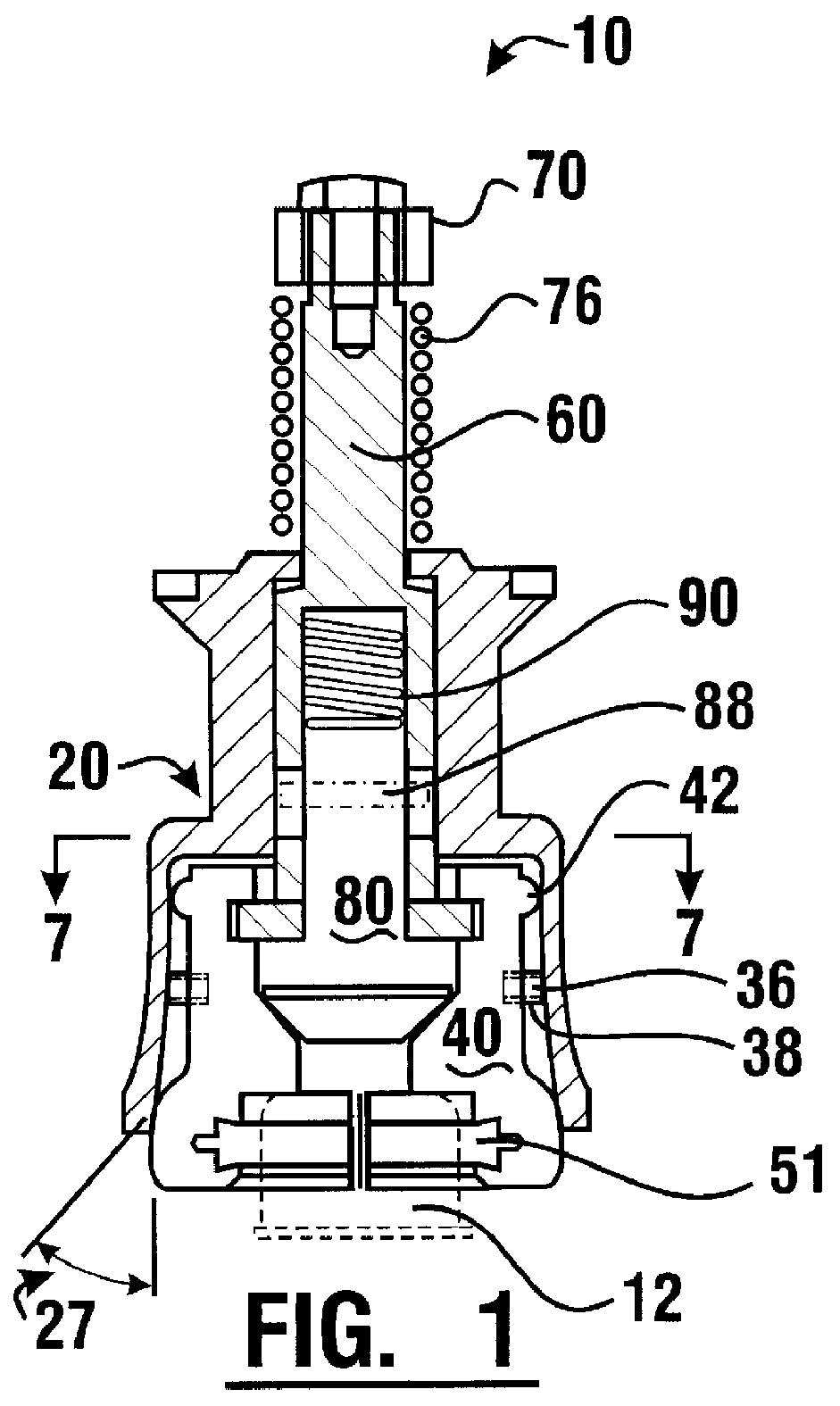

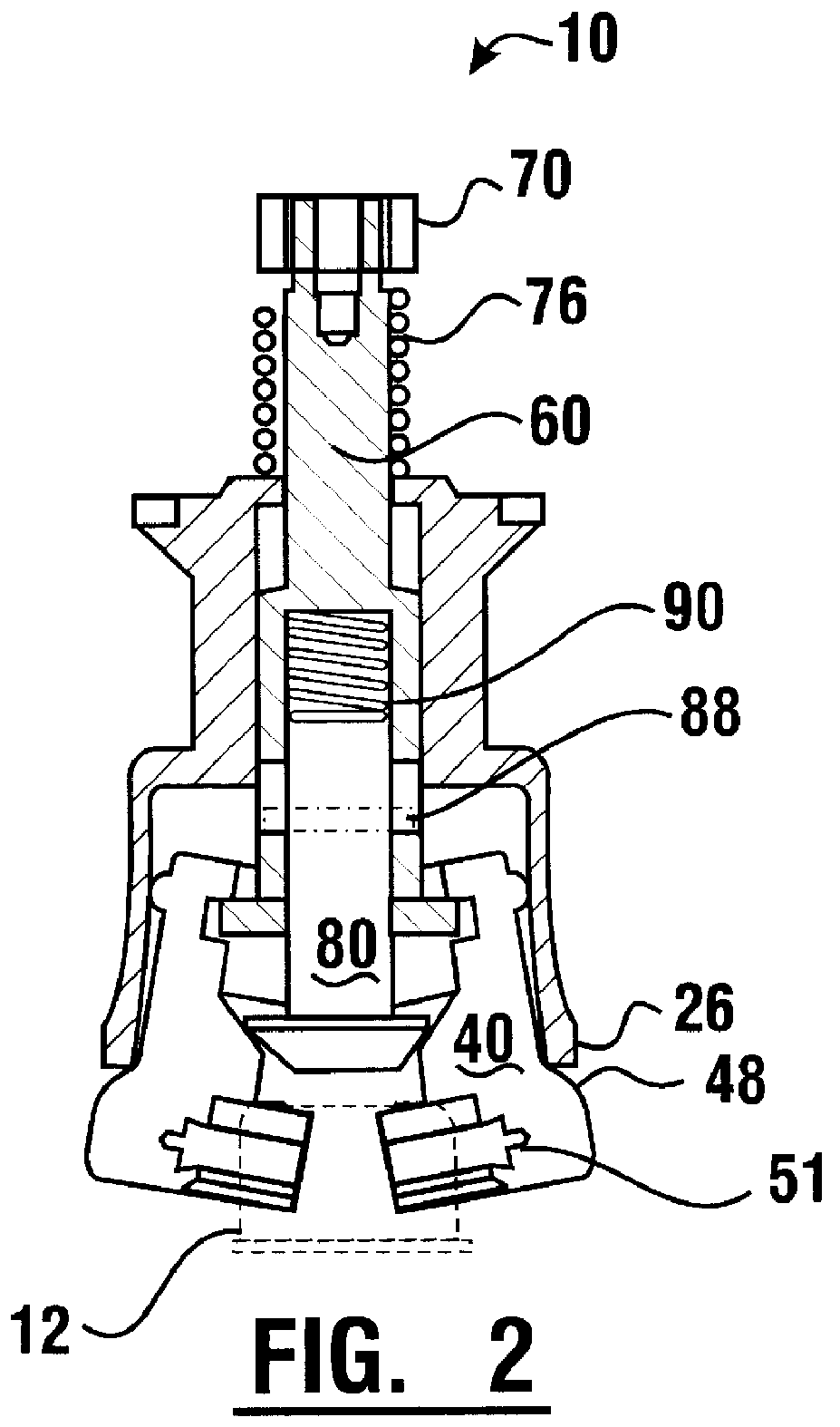

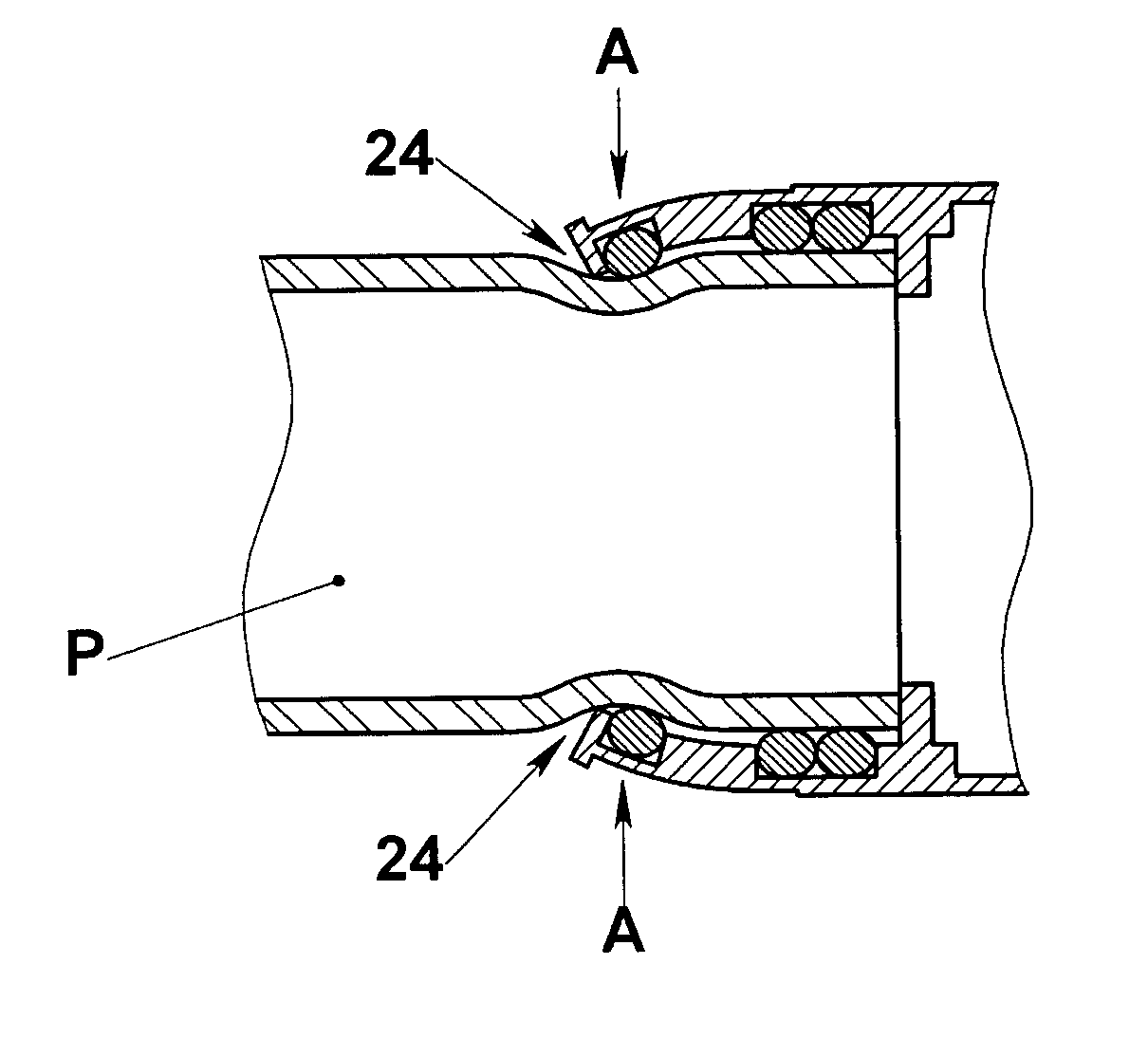

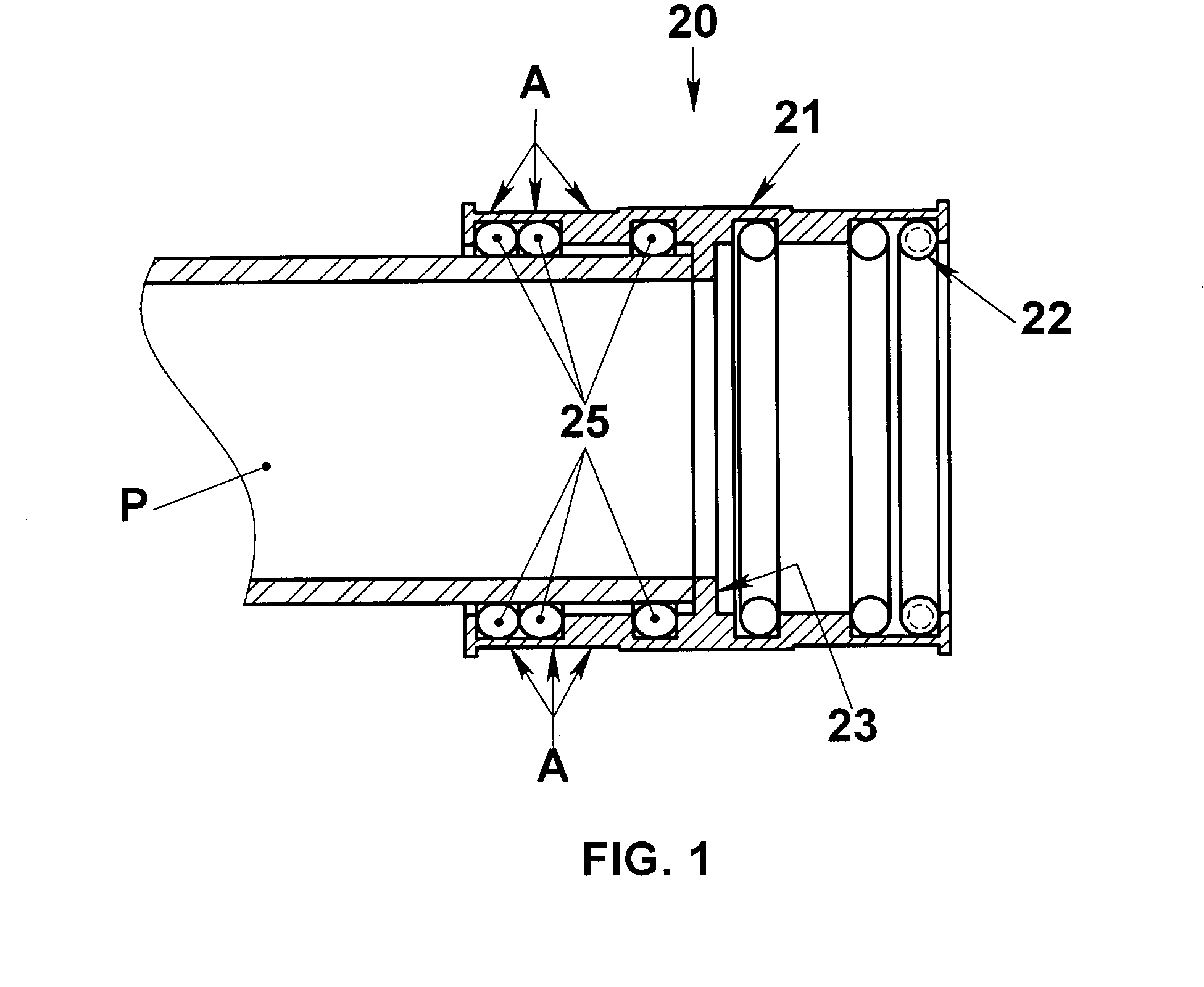

Integrated system for the ballistic and nonballistic infixion and retrieval of implants

InactiveUS20100286791A1Minimal forceMinimize traumaSurgical needlesMedical devicesAdemetionineBiomedical engineering

Provided are methods and apparatus for the use of magnetic traction to maintain the patency of a tubular anatomical structure, whether a vessel, duct, the trachea, bronchus, bile duct, ureter, vas deferens, fallopian tube, or portions of the digestive tract, as to constitute means for extraluminal stenting. An extraluminal stent consists of a perimedial or medial intravascular and an extravascular component. The intravascular component consists of ferromagnetic spherules implanted aeroballistically or stays implanted by means of a special hand tool, while the extravascular component consists of a pliant jacket or mantle that has magnets mounted about its outer surface. A catheter adapted for use as the barrel of a gas-operated implant insertion gun is so devised that it can be used independently to perform an angioplasty and thereafter have its free or extracorporeal end inserted into the airgun to initiate implantation of the intravascular component without the need for withdrawal and reinsertion through the introducer sheath. When the implants must be spaced too closely together to be controlled by hand, a positional control system is used to effect discharge automatically. Spherules that consist entirely of medication or that have a radiation emitting seed as the core can be implanted with the same apparatus. A glossary of terms follows the specification.

Owner:GOLDSMITH DAVID S

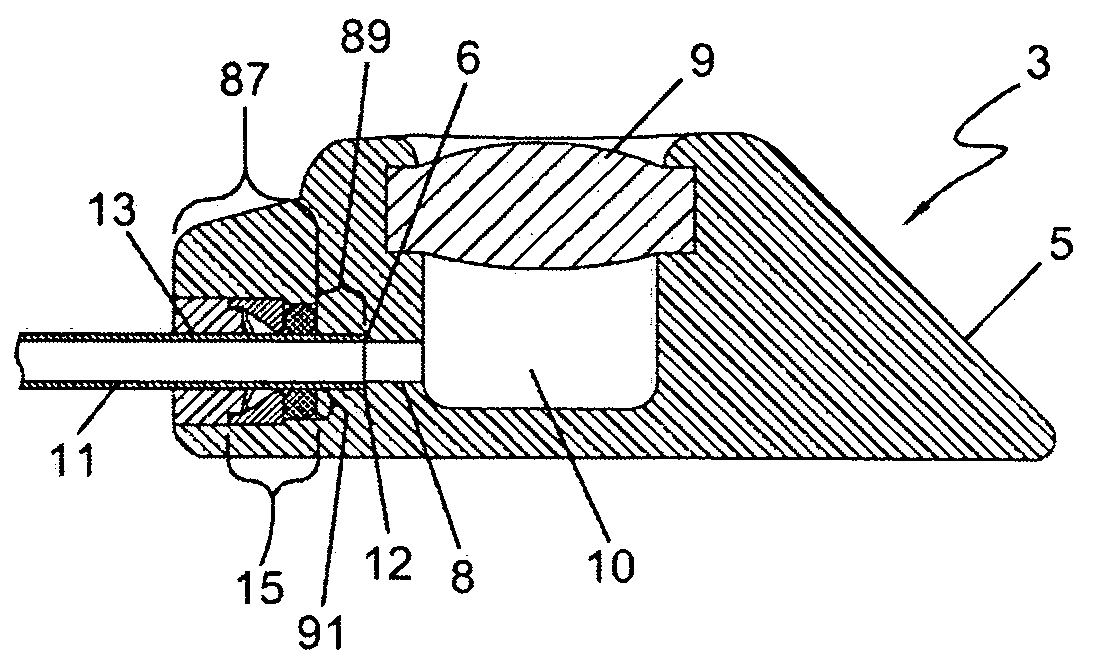

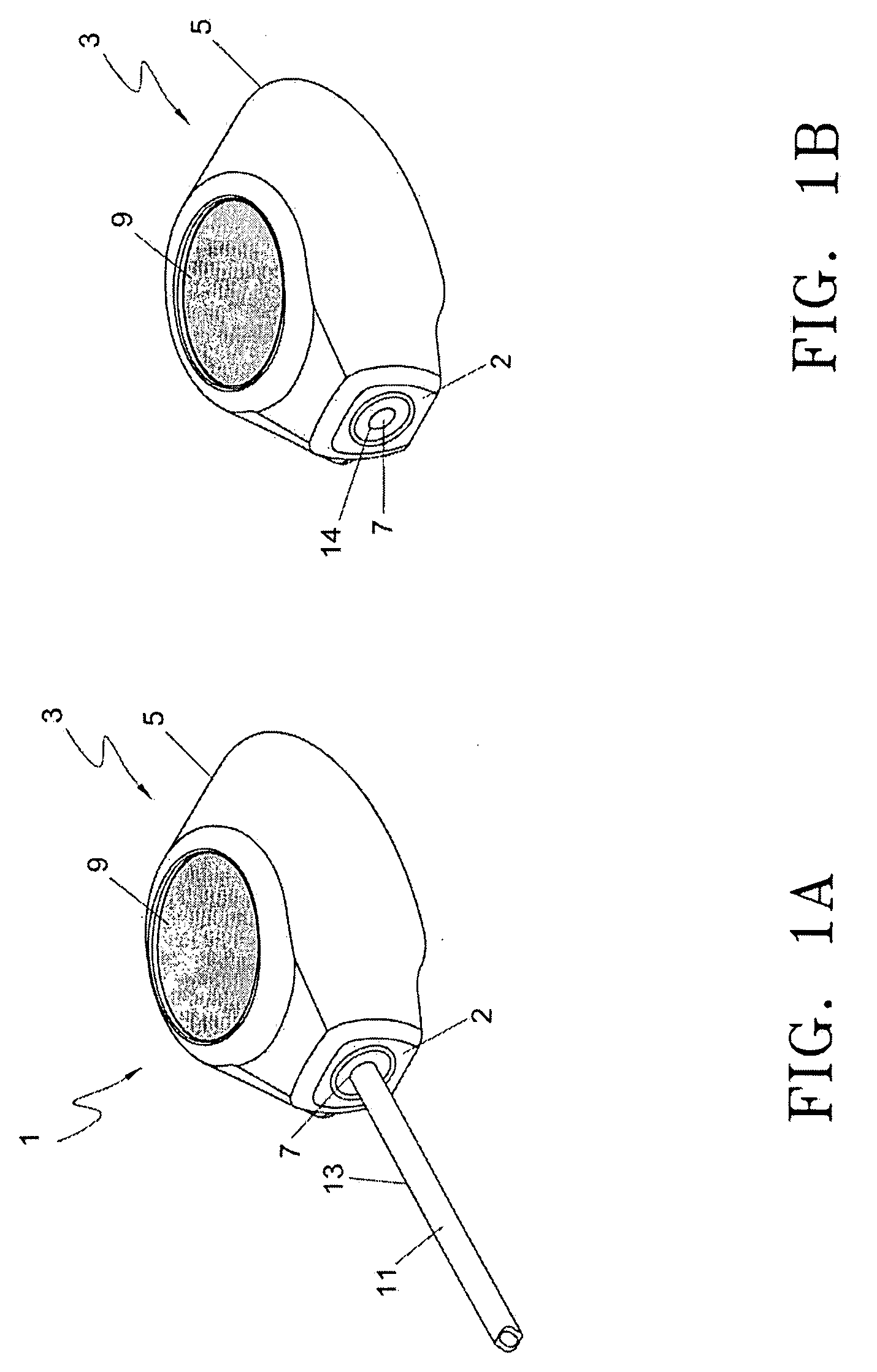

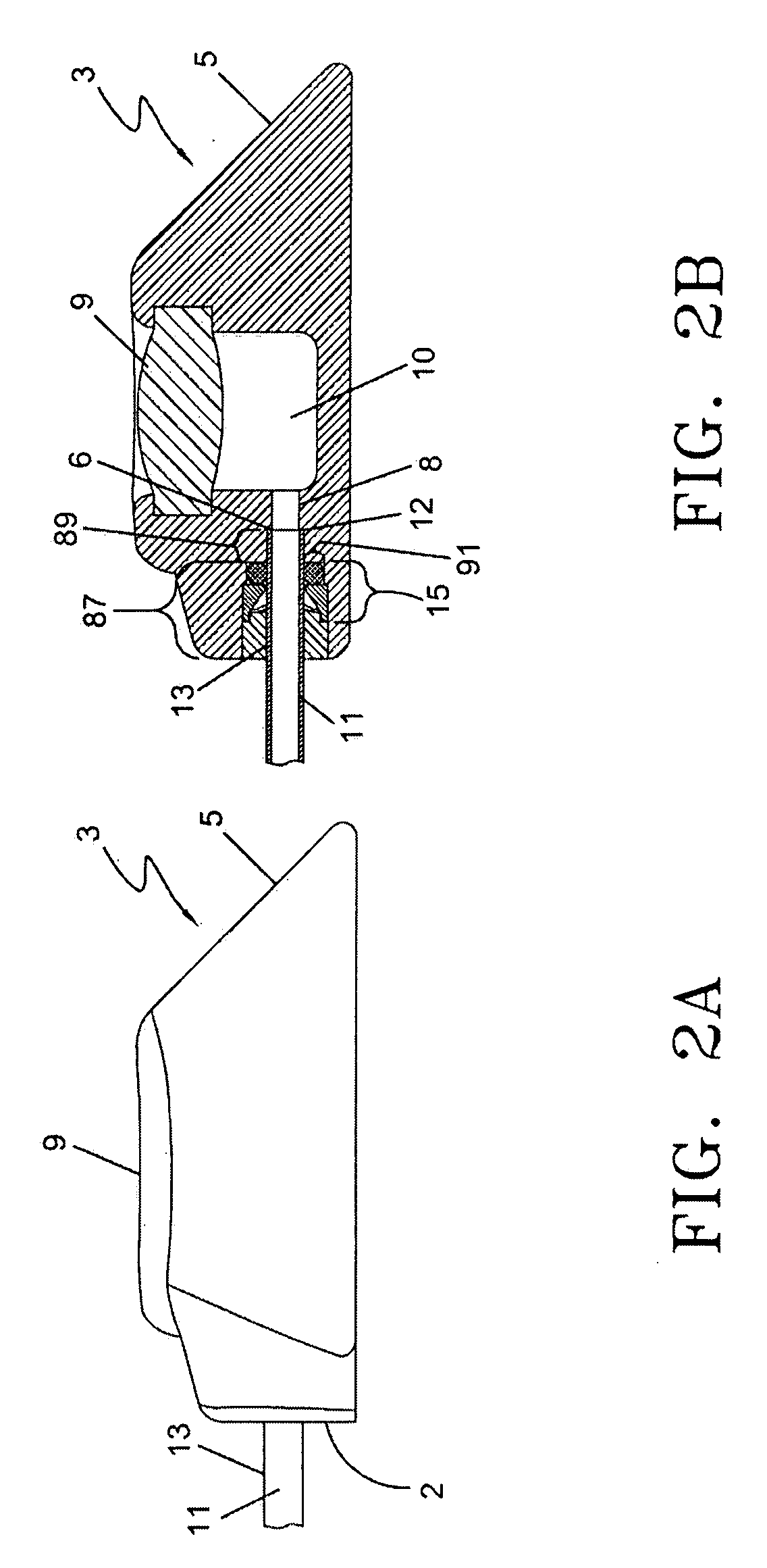

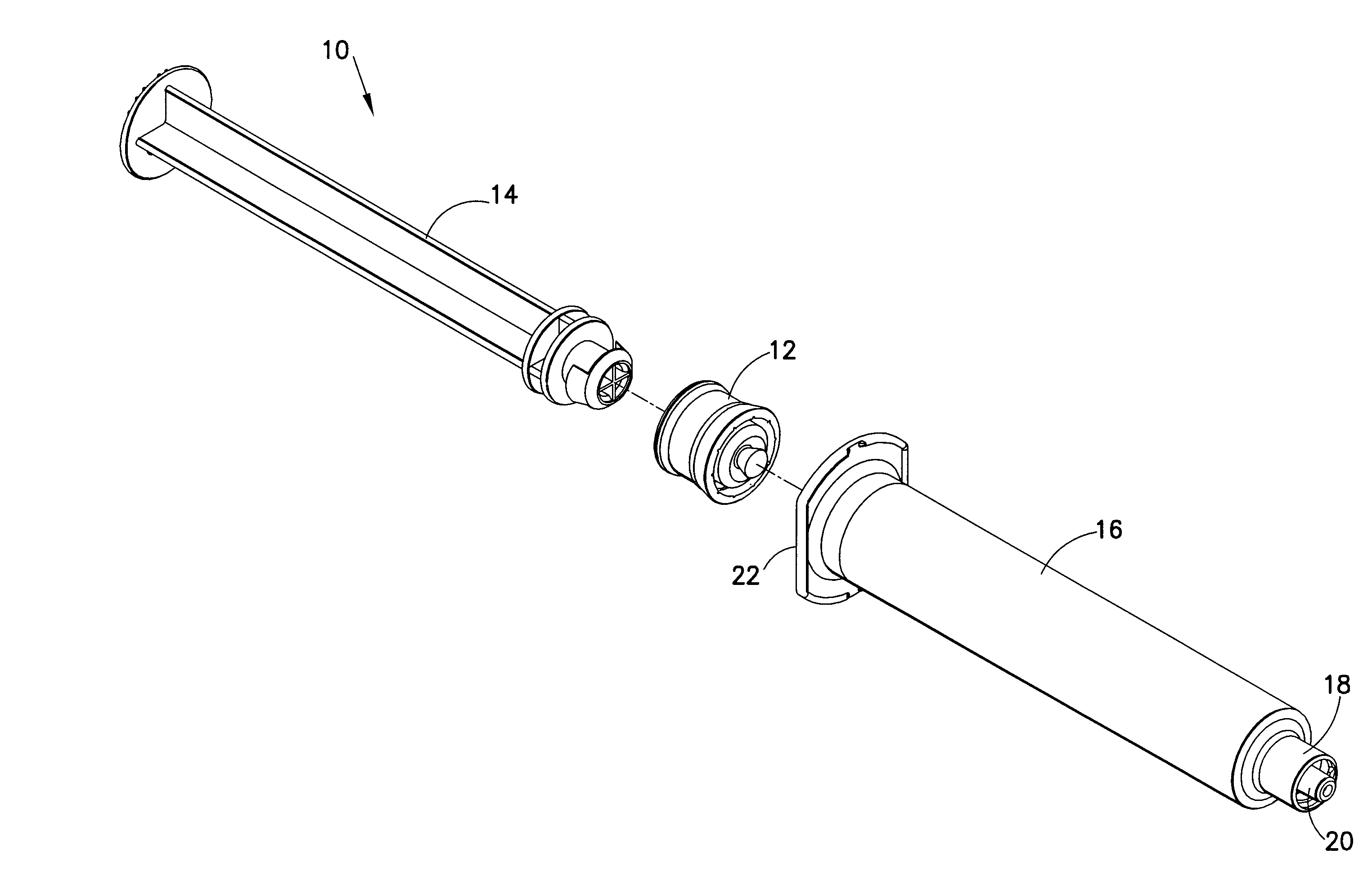

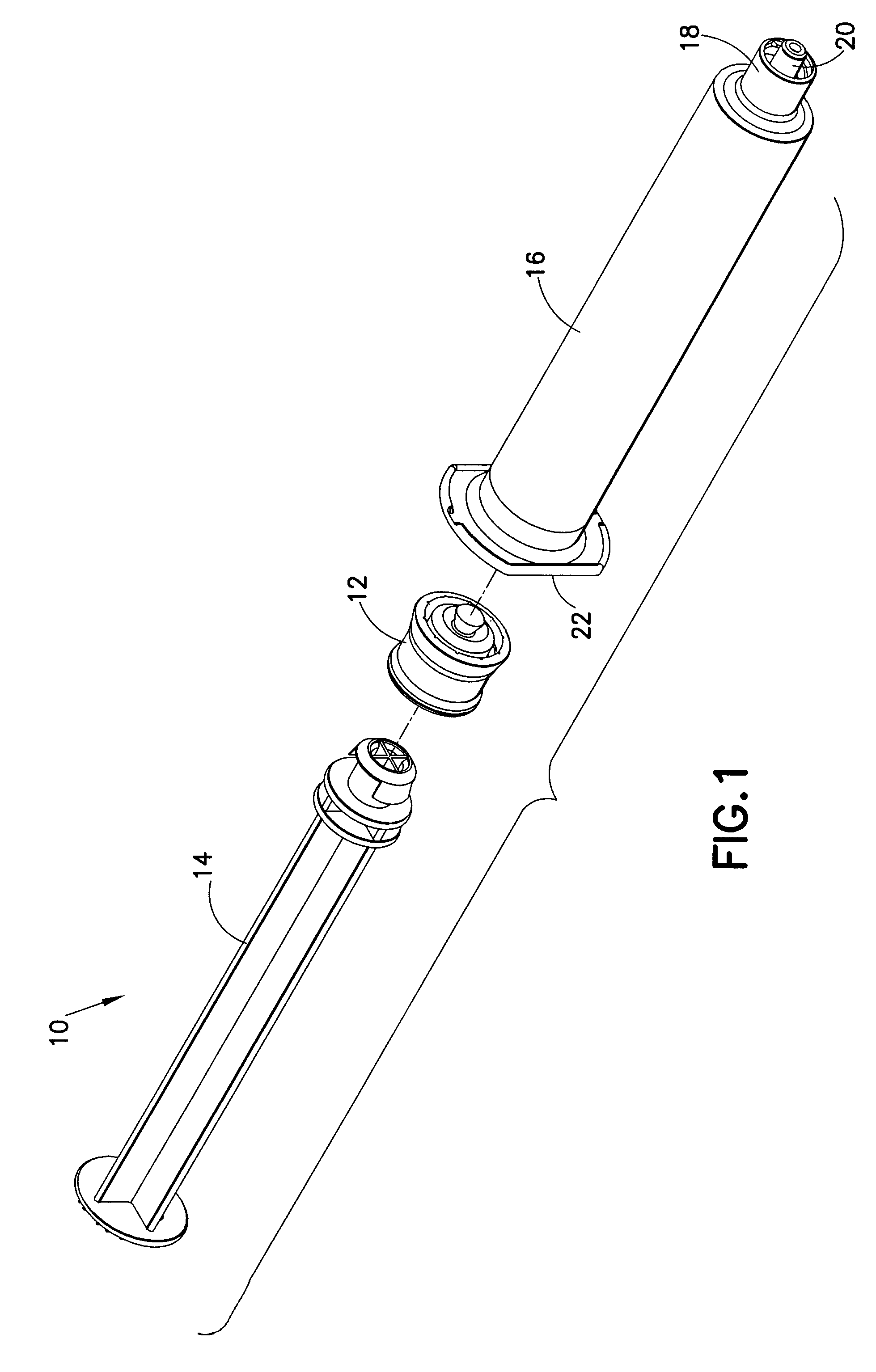

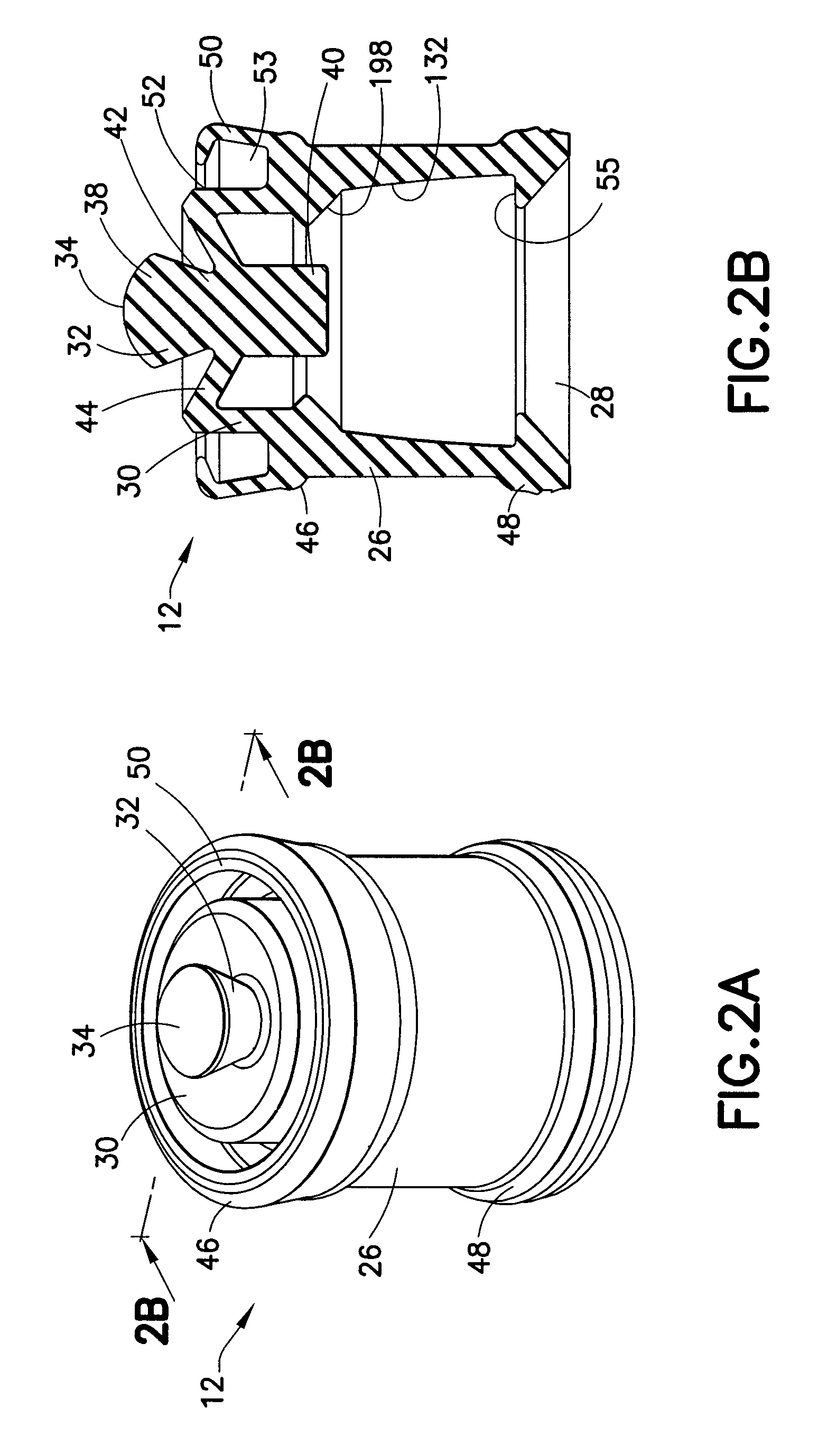

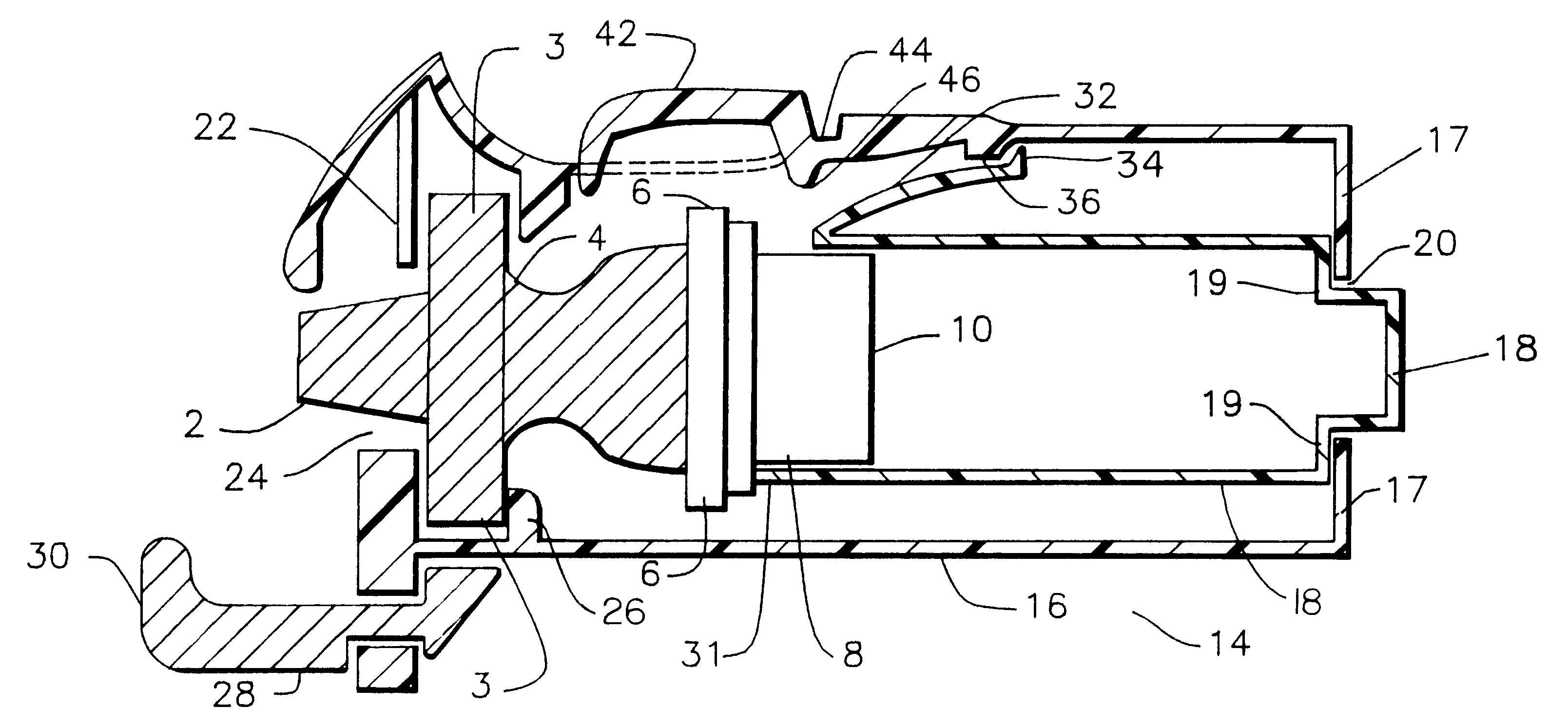

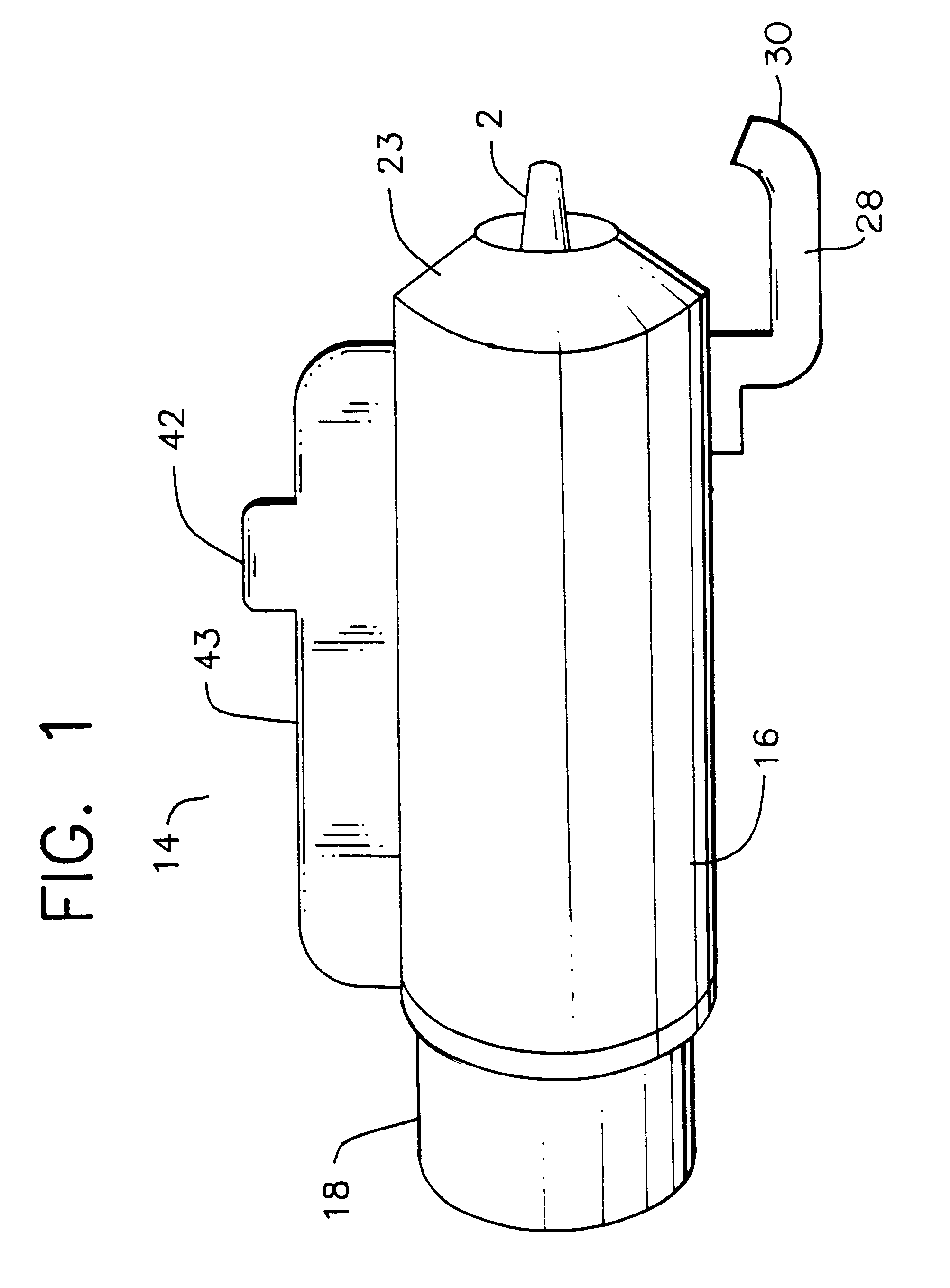

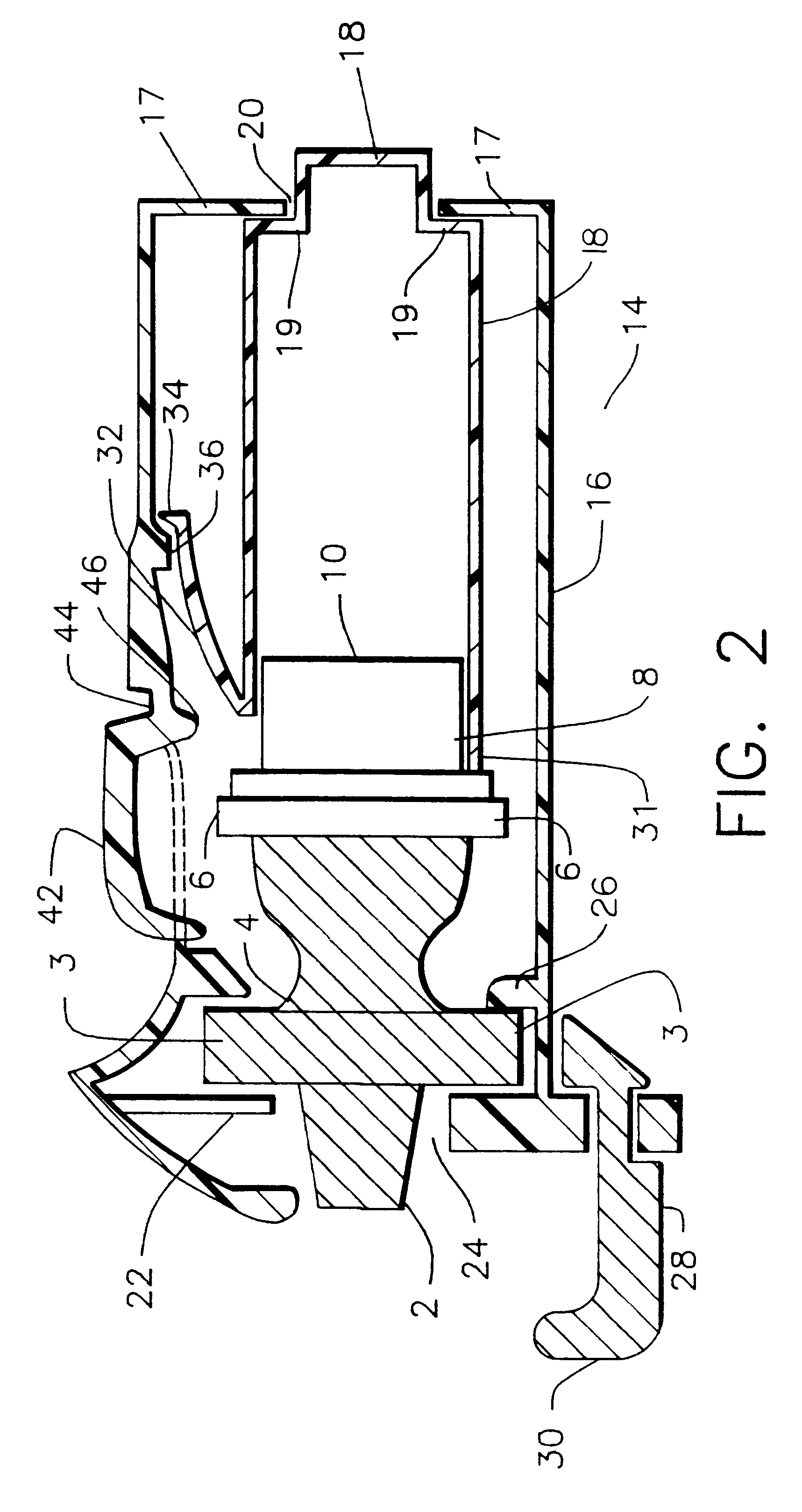

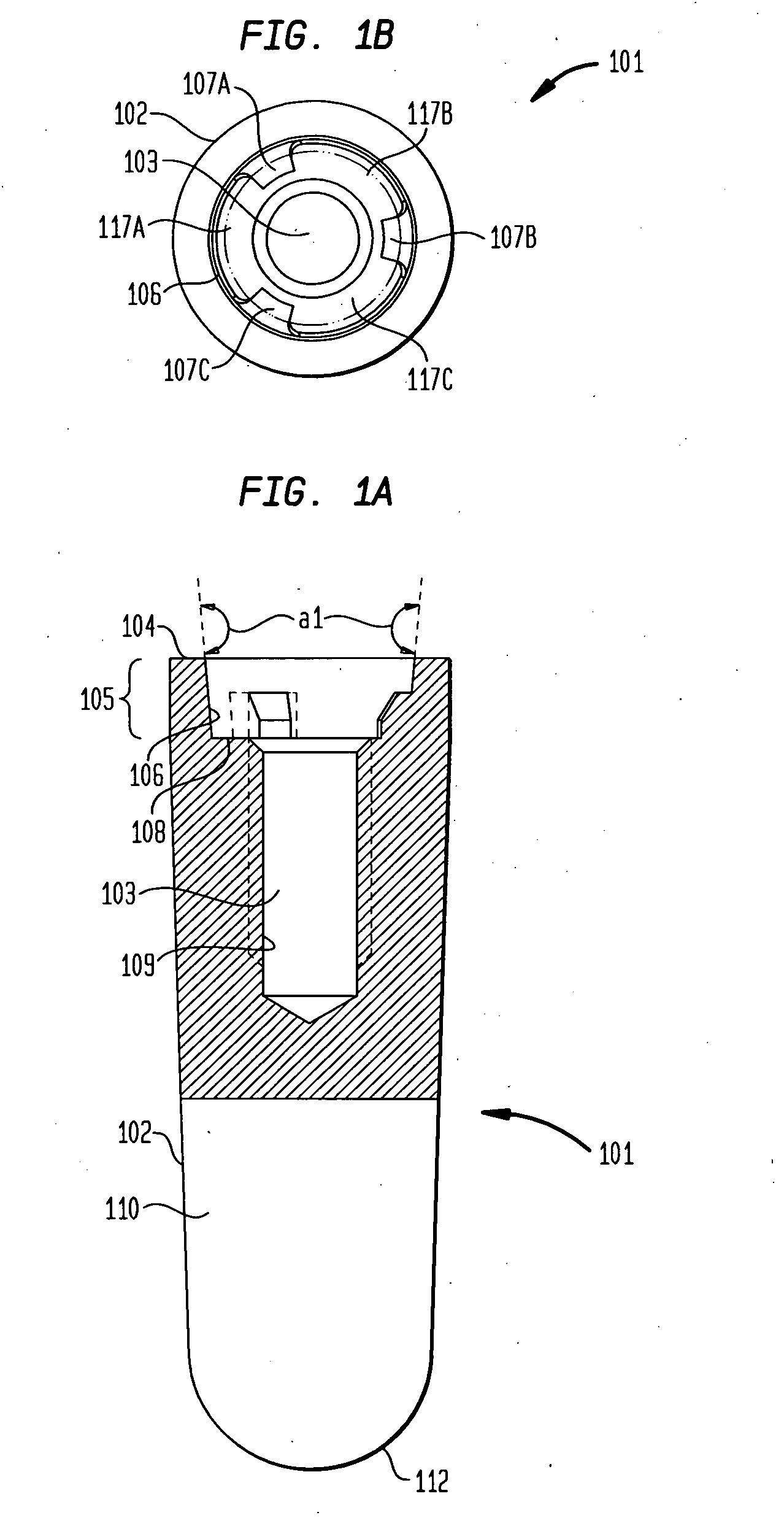

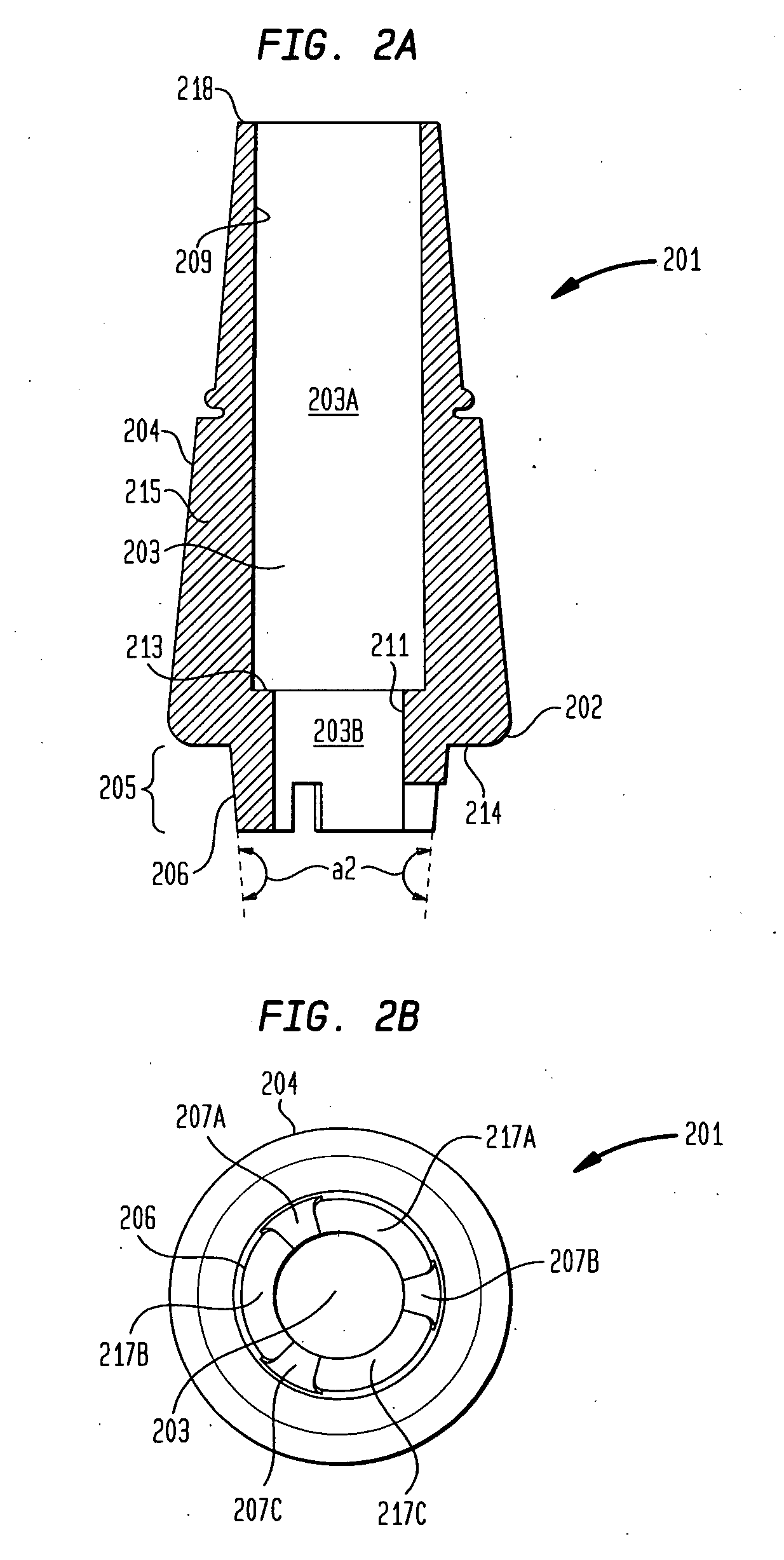

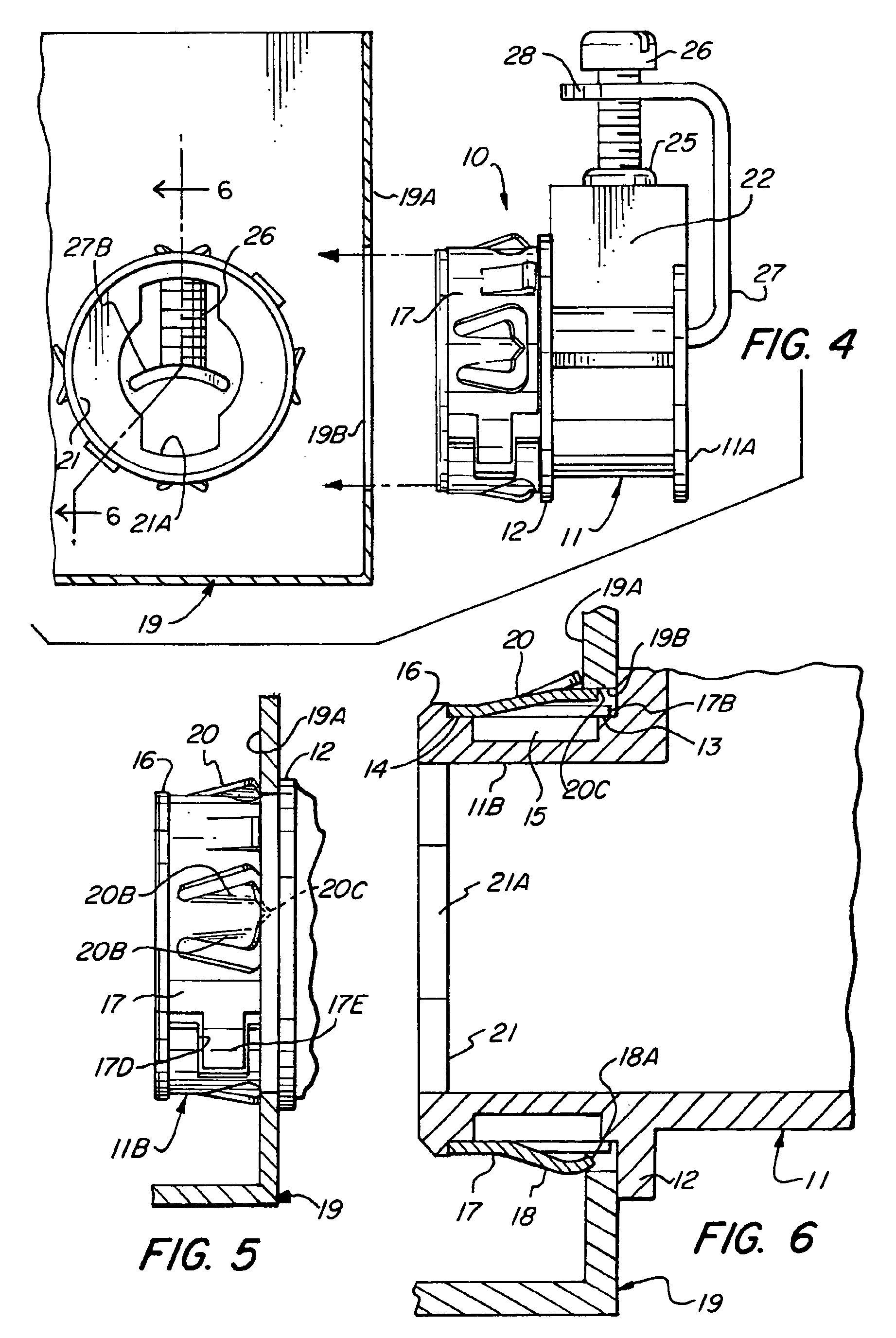

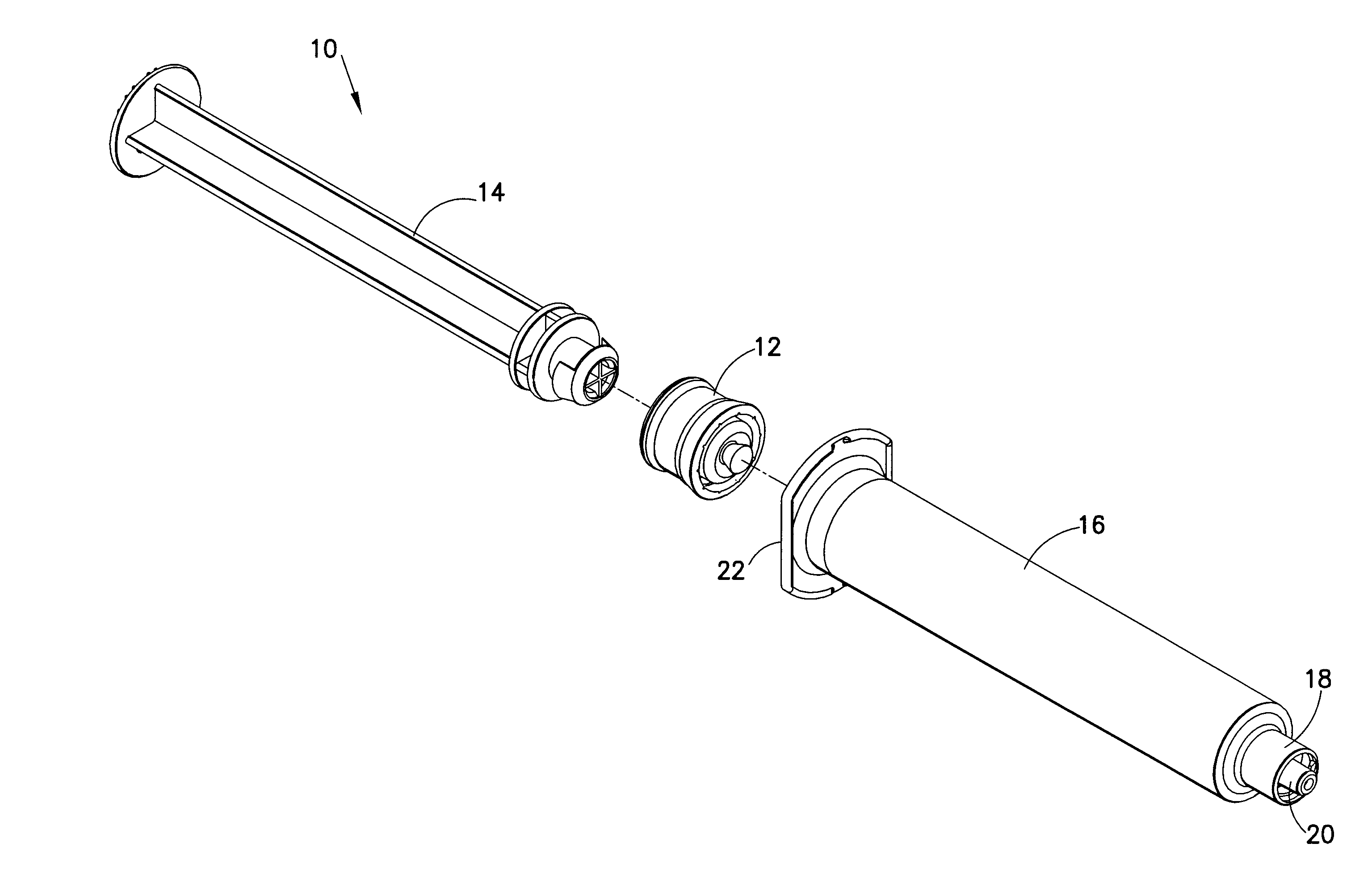

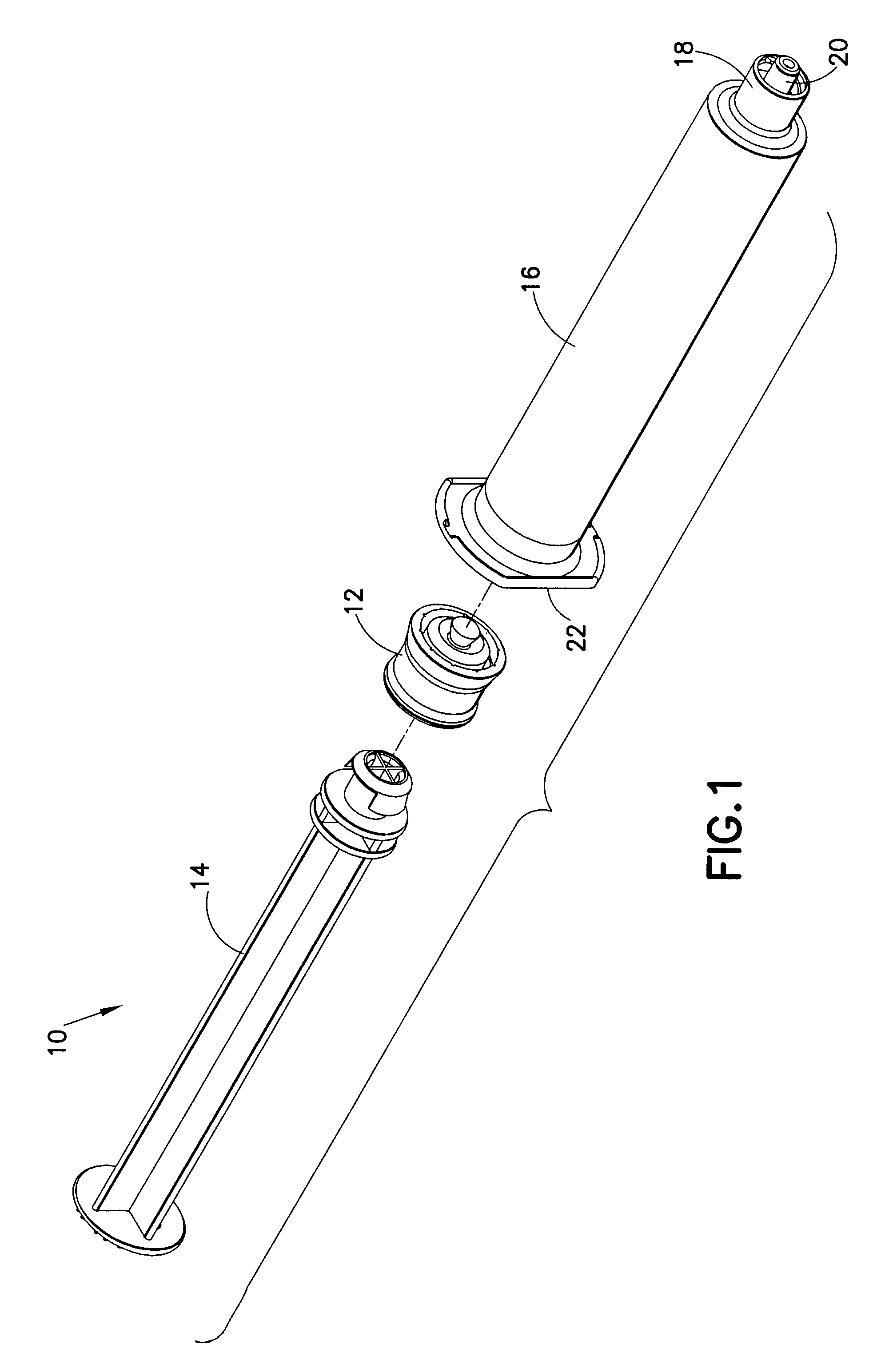

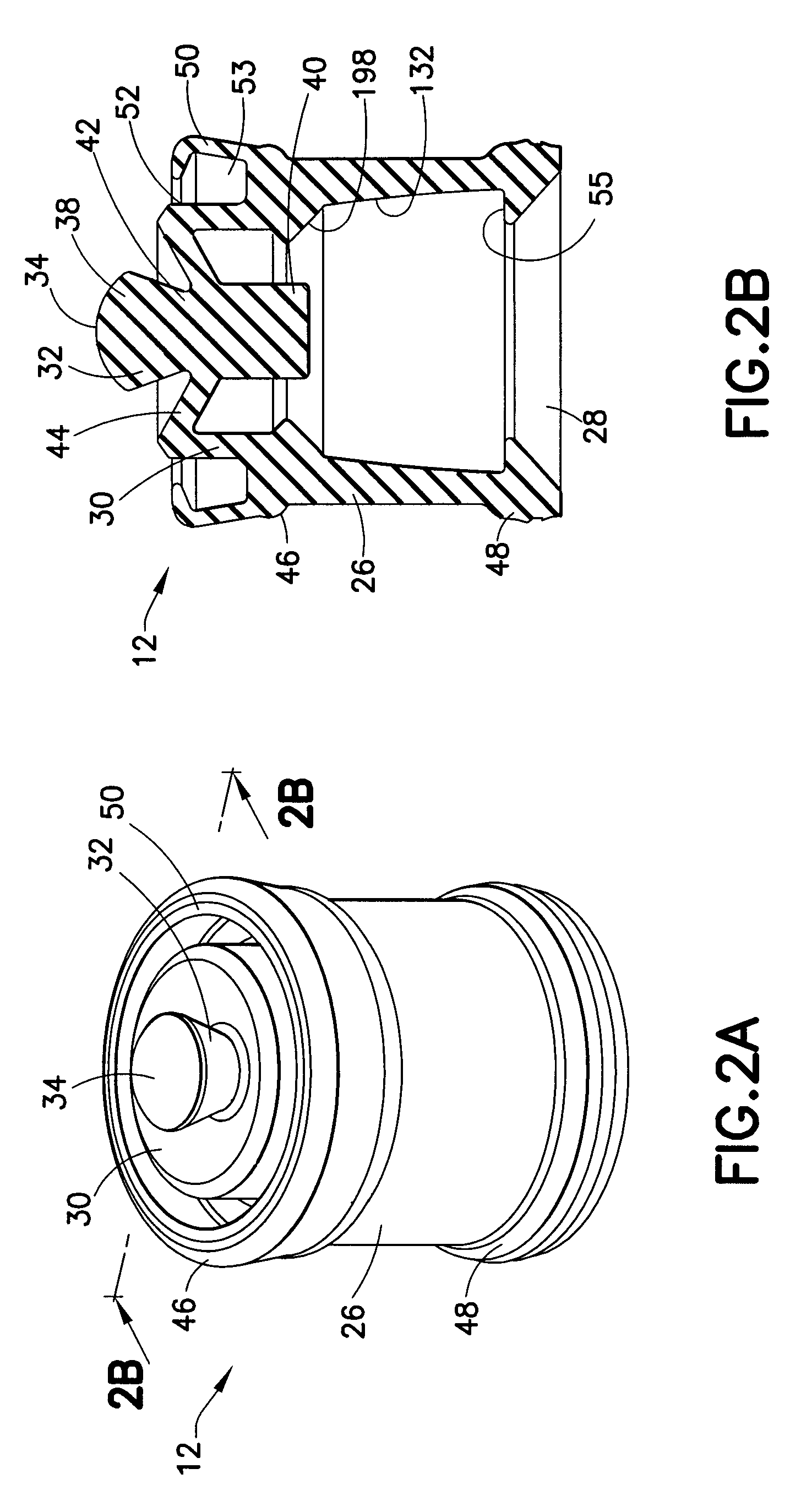

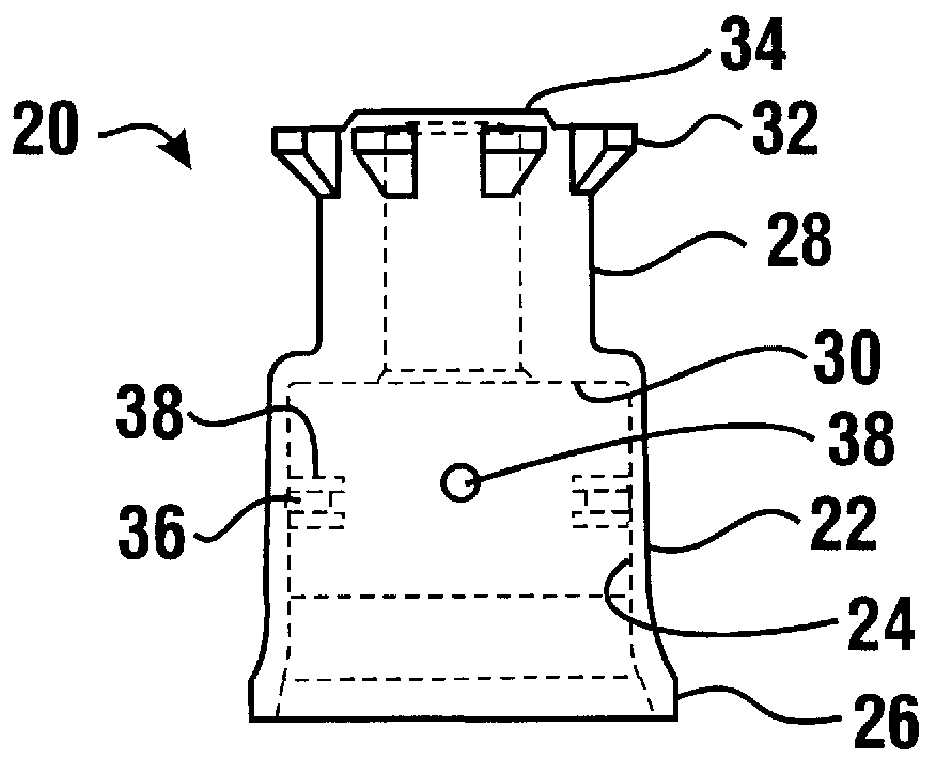

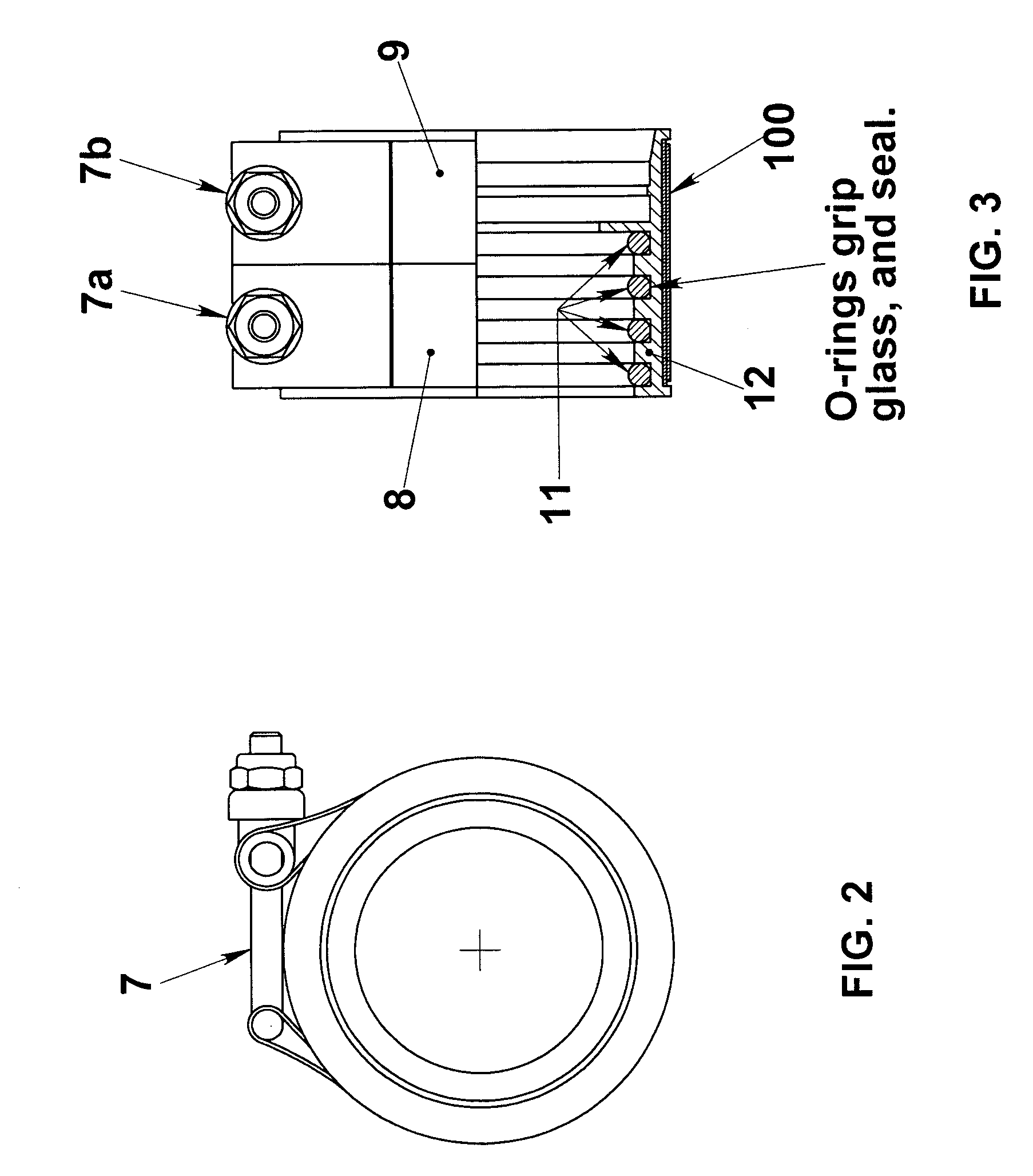

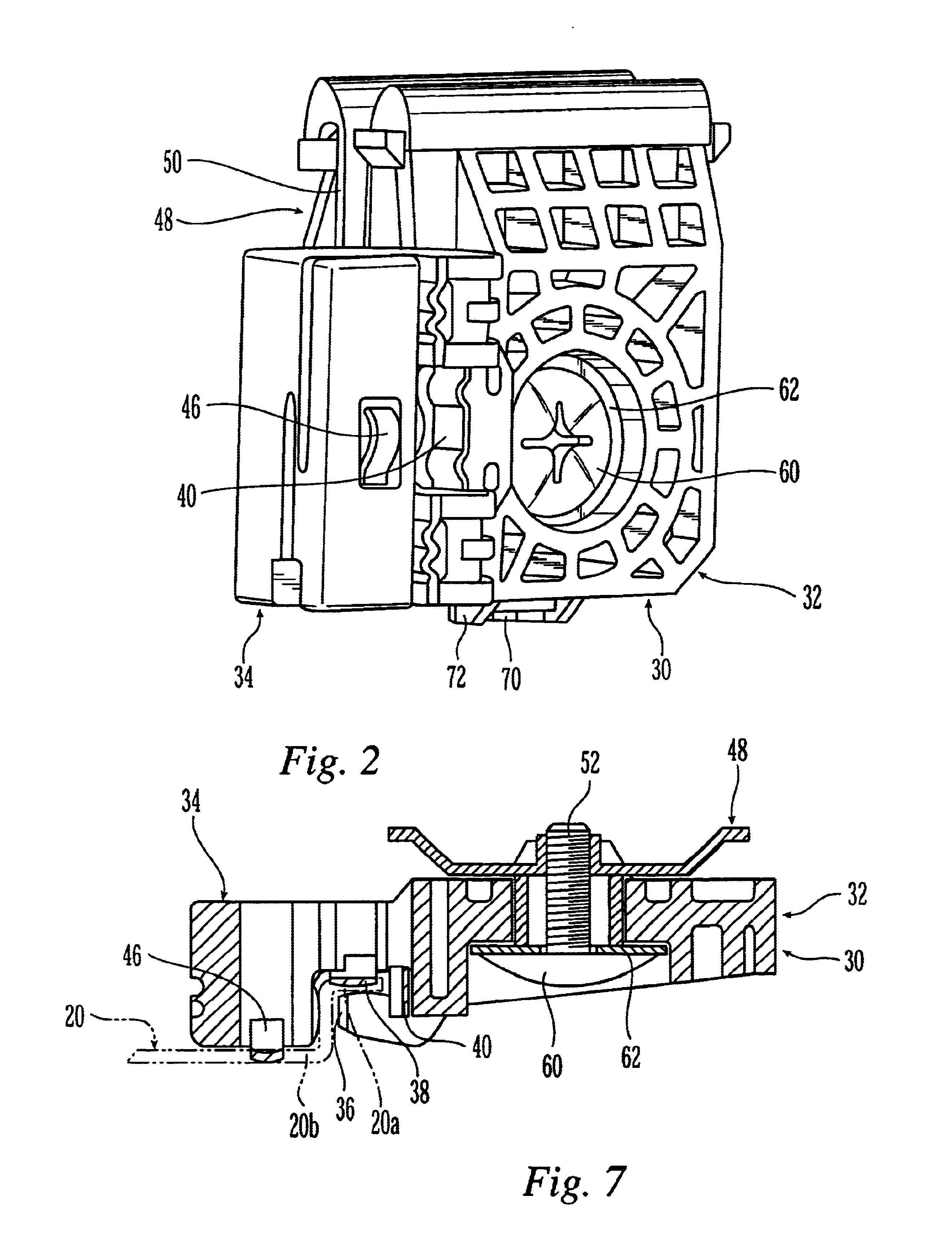

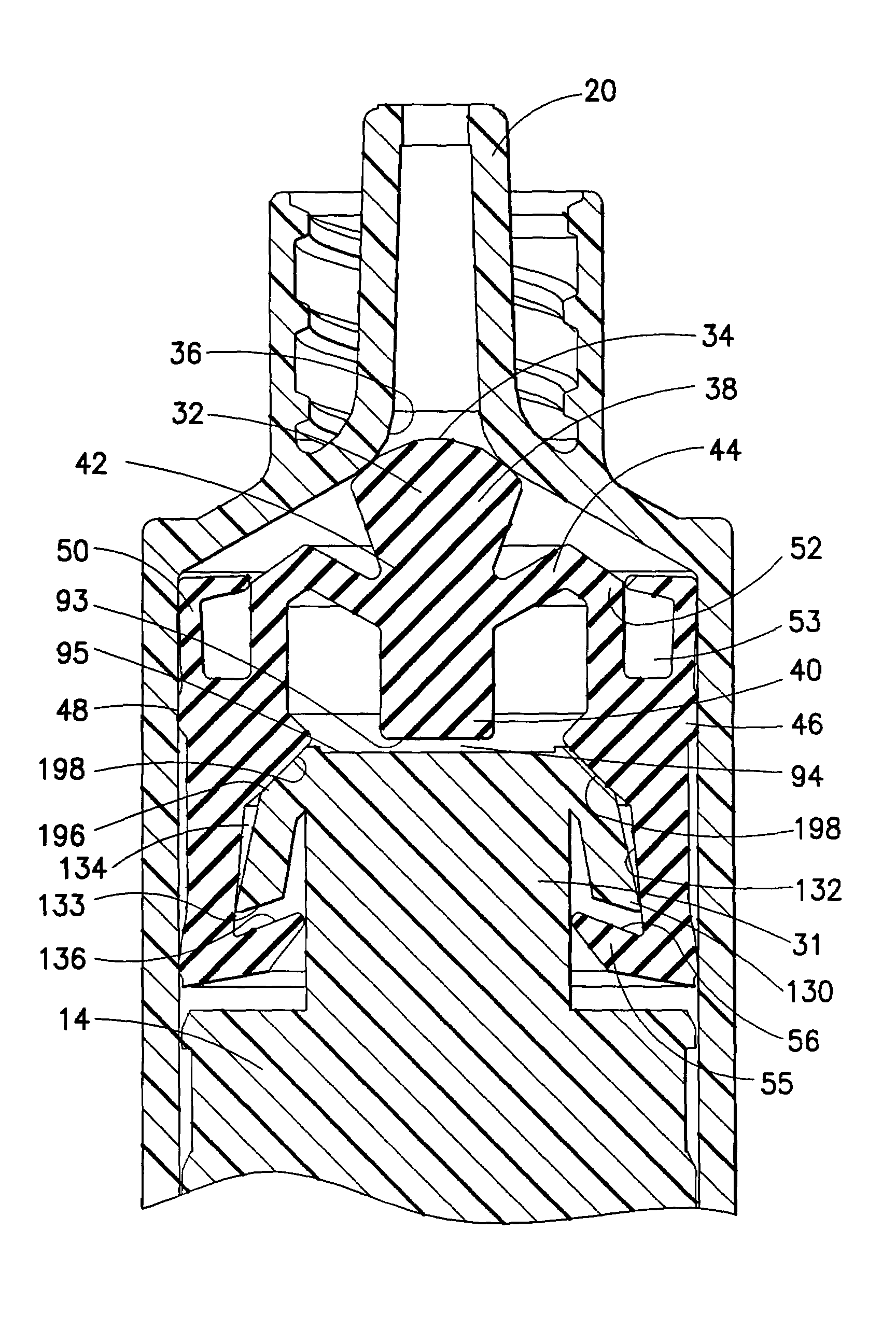

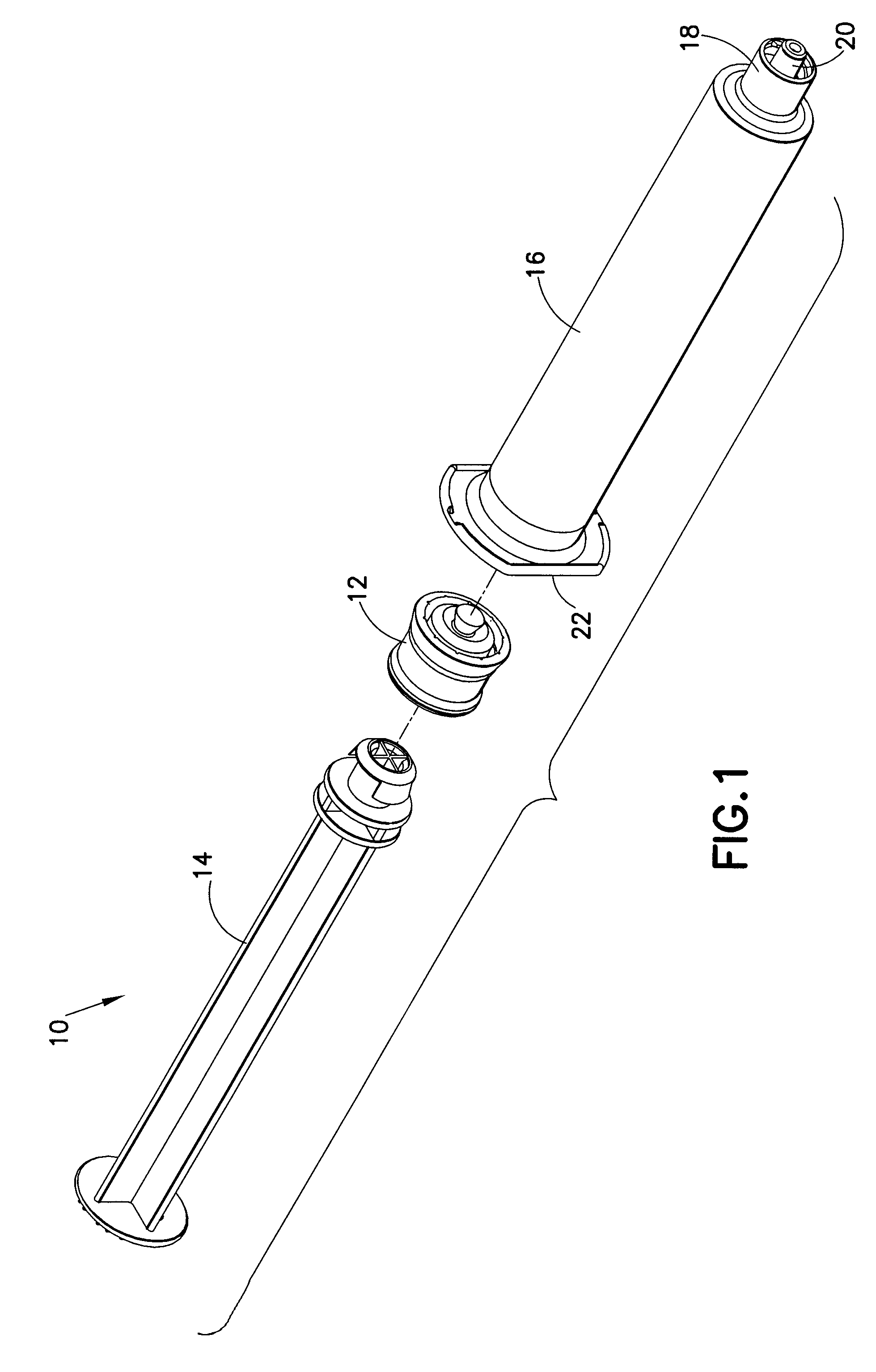

Vascular Access Port with Catheter Connector

An implantable vascular access port assembly that has a septum, a reservoir, and a catheter connector assembly for use in connecting a catheter with the vascular access port. The catheter connector assembly has an O-ring, an O-ring seal, a locking ring, and a catheter connection plug, which components are located in secured adjacent relationship to one another, respectively, in the vascular access port. The catheter connector assembly securely locks the catheter inside of the vascular access port without compromising the lumen cross-sectional area and can withstand high pressures.

Owner:ANGIODYNAMICS INC

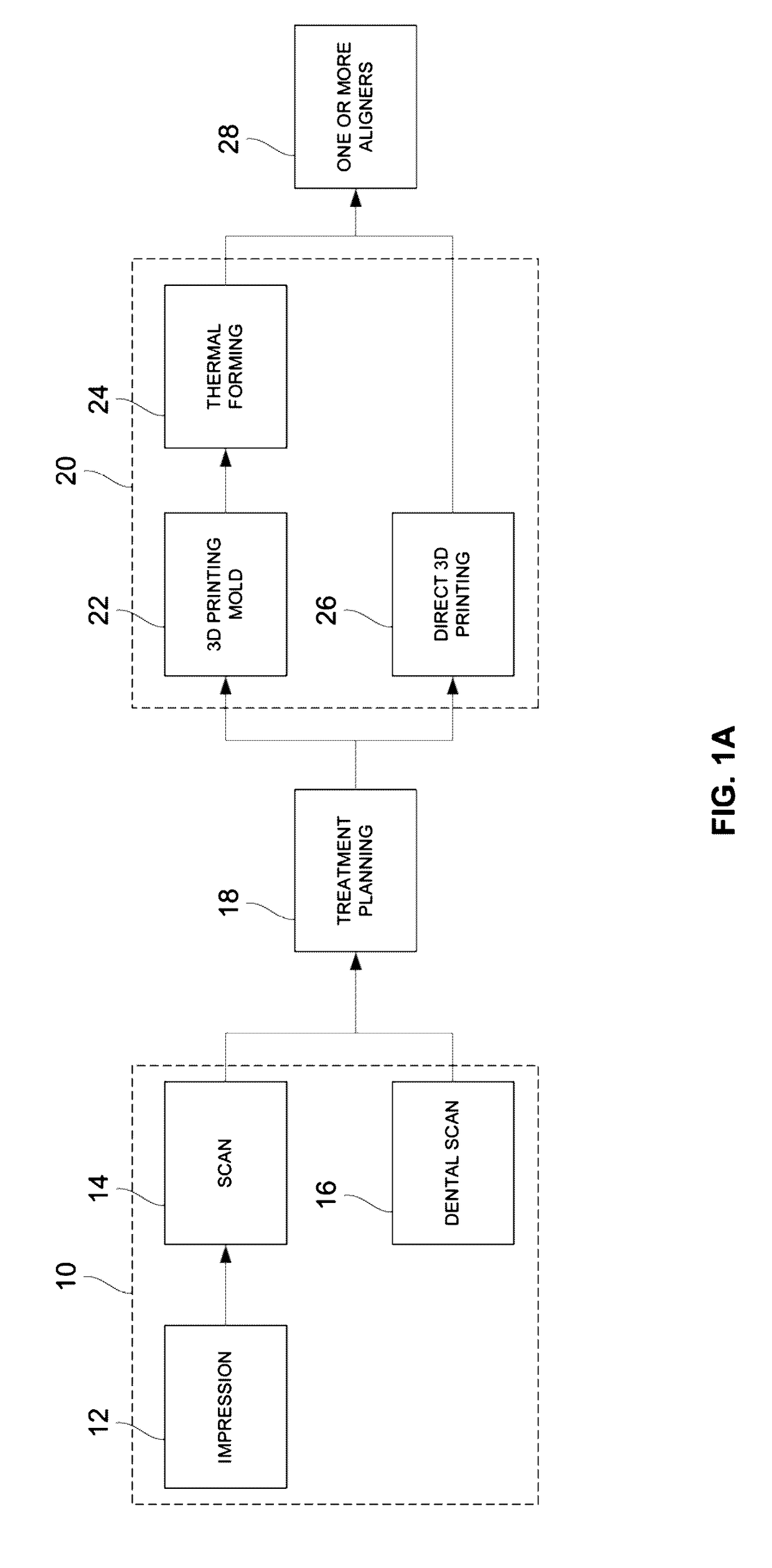

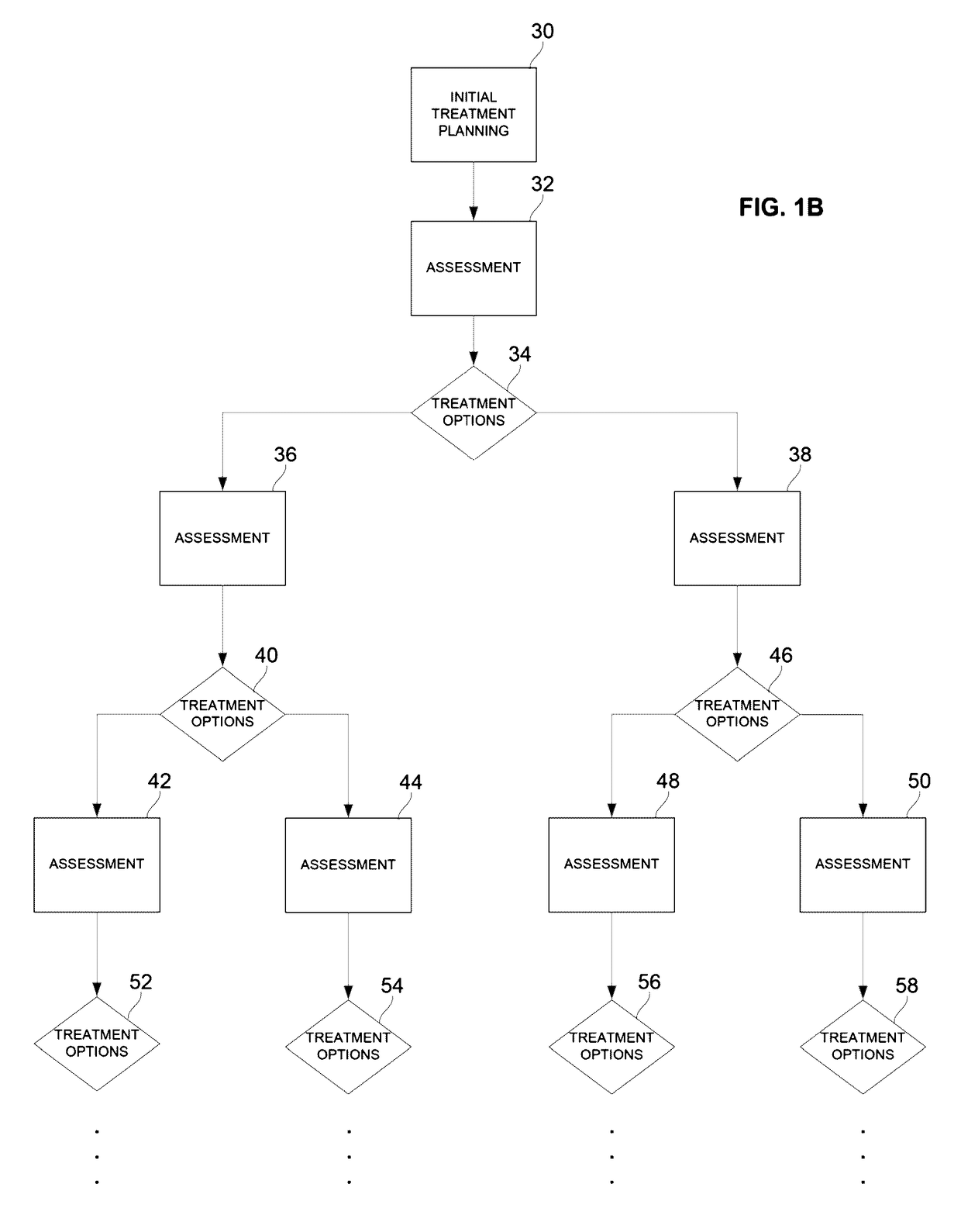

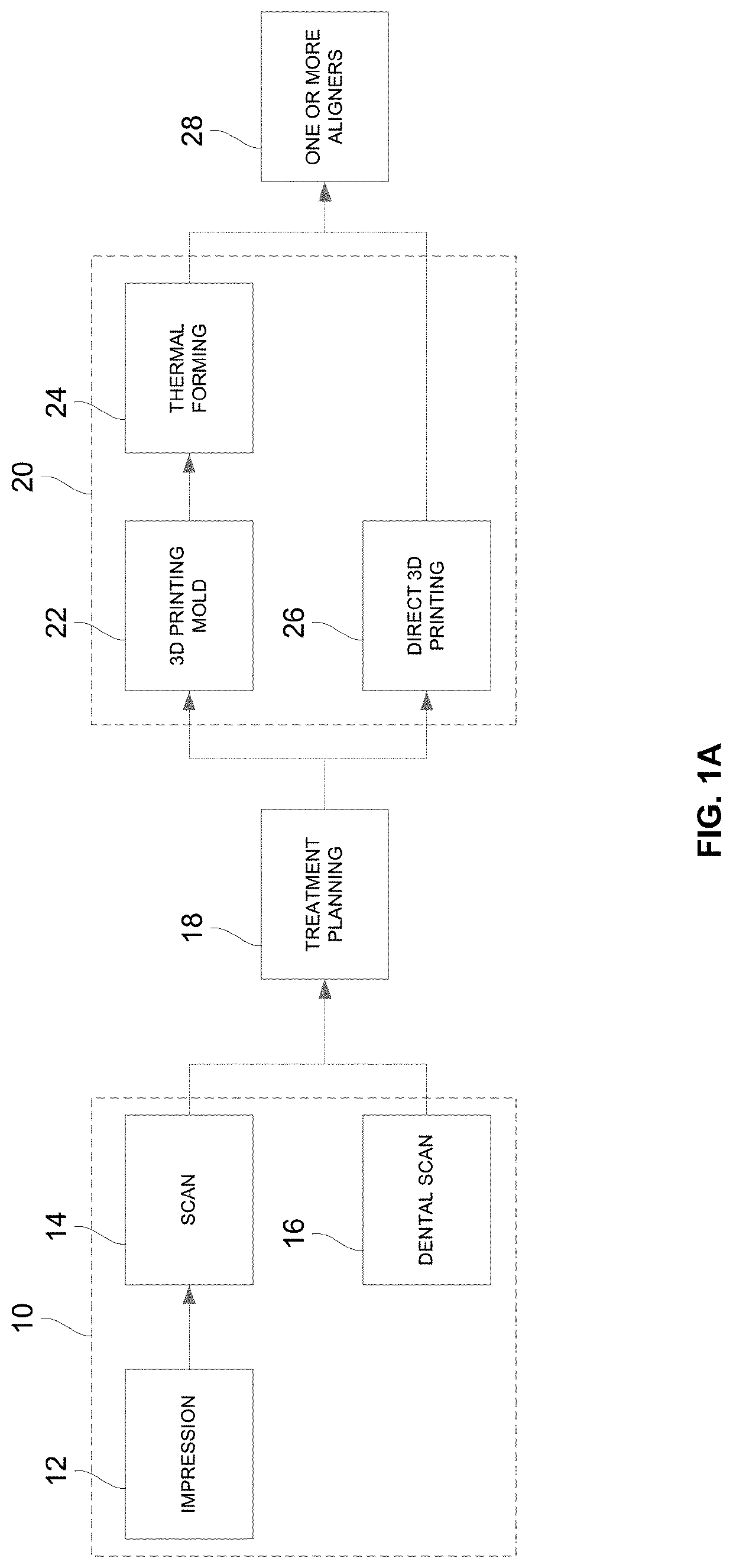

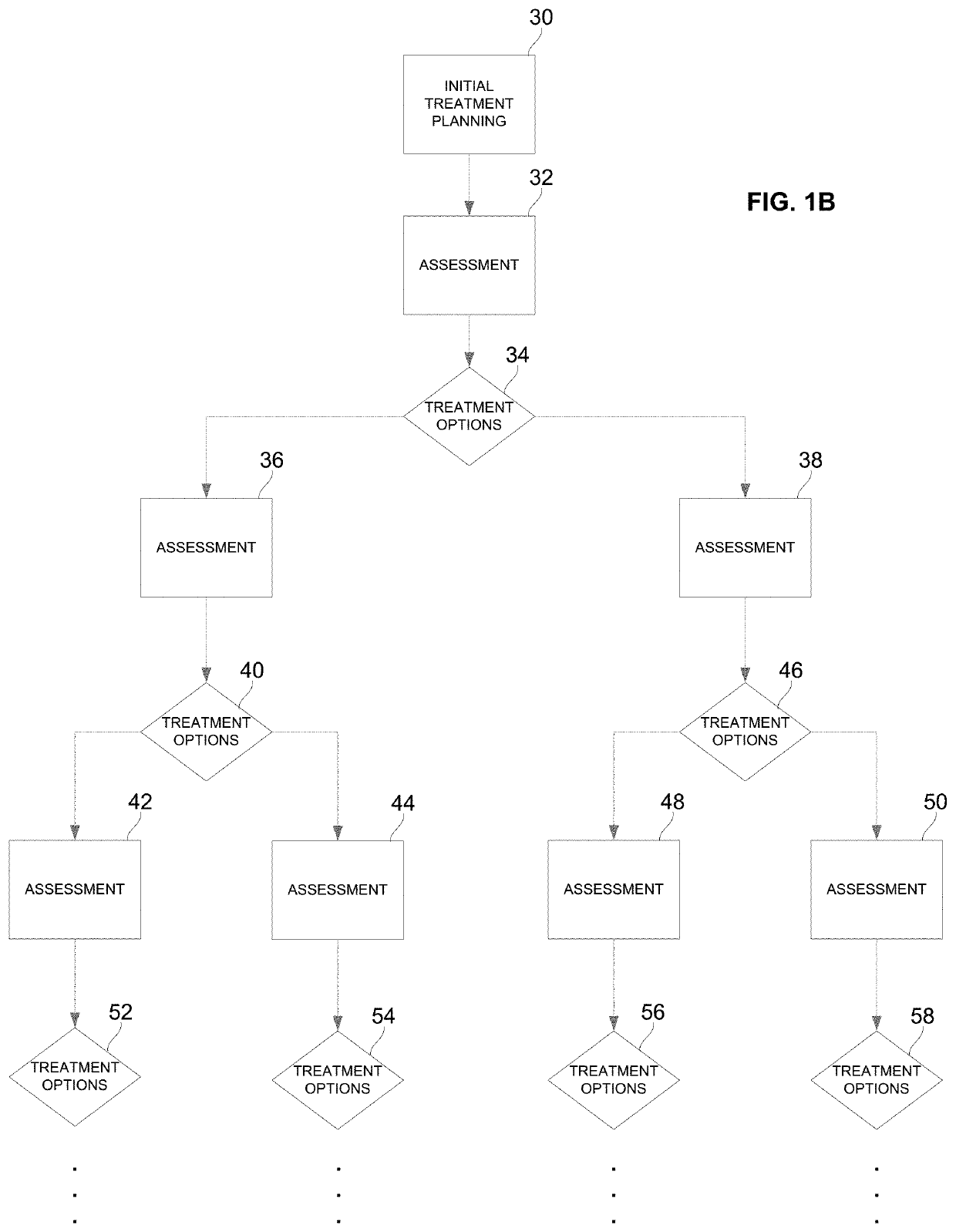

Orthodontic planning systems

ActiveUS20170100214A1Reduce riskMinimal forceMedical simulationOthrodonticsProgram planningDentition

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished in one variation by receiving a scanned dental model of a subject's dentition, determining a treatment plan having a plurality of incremental movements for repositioning one or more teeth of the subject's dentition, and fabricating one or more aligners correlating to a first subset of the plurality of incremental movements.

Owner:ULAB SYST INC

Positive displacement stopper for a pre-filled syringe

ActiveUS20080300550A1Prevent leakageEffectively and consistently reducing and eliminating refluxInfusion syringesIntravenous devicesPrefilled SyringeNose

A stopper adapted for attachment with a plunger rod for use within a syringe barrel is disclosed. The stopper includes a main body defining an open rearward end and a closed front end. The open rearward end is adapted to receive a front forward end attachment portion of the plunger rod. The stopper also includes a core member integrally formed with said main body adjacent the closed front end. The core member includes a nose portion having a profile adapted to create a positive seal with an outlet opening of such syringe barrel.

Owner:BECTON DICKINSON & CO

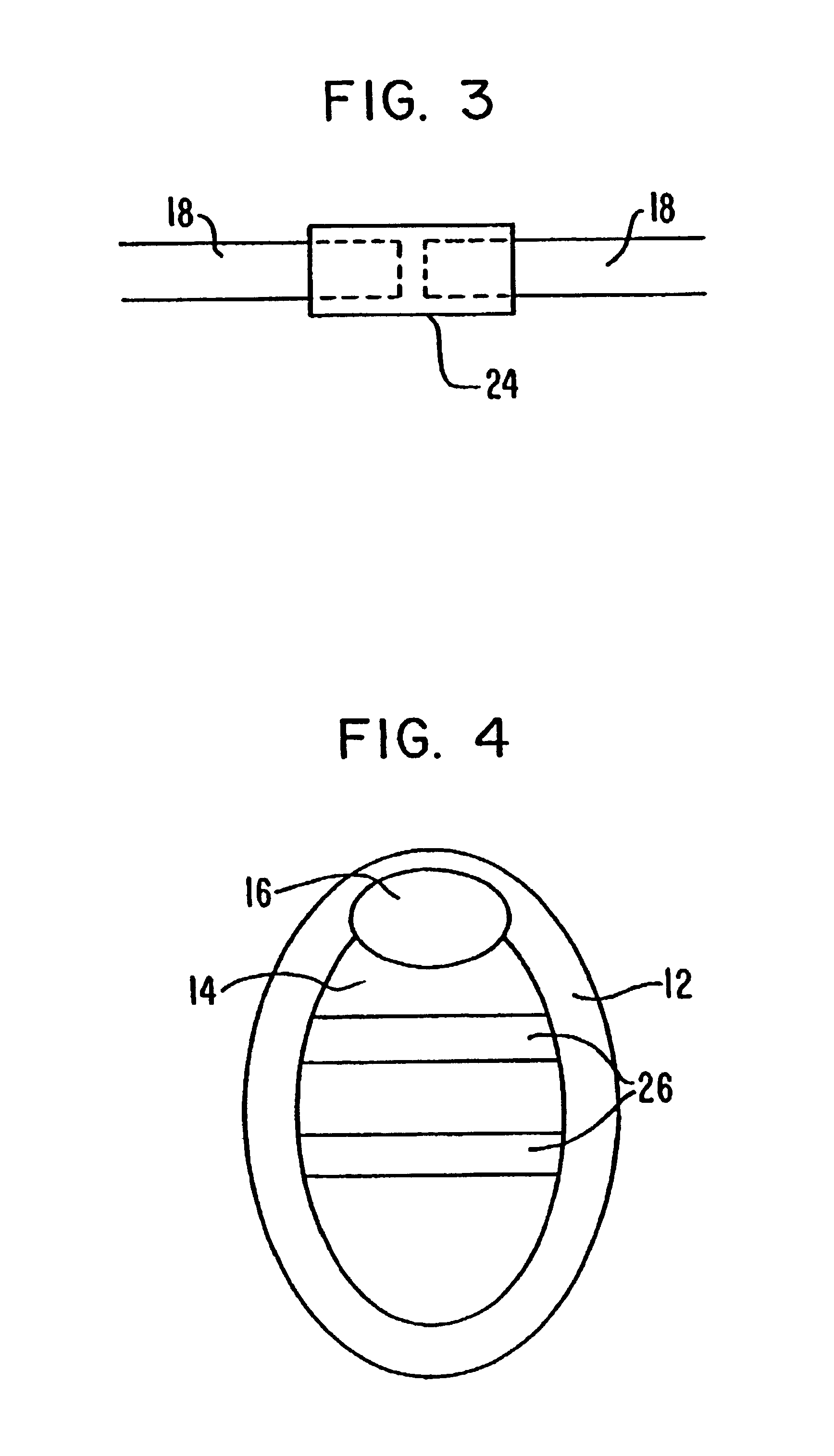

Cartridge for applying medicament to an eye from a dispenser

InactiveUSRE37047E1Accurate deliveryPrecise deliveryPharmaceutical containersLarge containersEyelidVial

A cartridge for actuating a piston-like or accordion-like dispenser-vial for applying medicament to an eye. The cartridge includes a housing for holding the dispenser-vial and a telescoping cylinder for compressing the dispenser-vial in the longitudinal direction to actuate the vial. The cartridge includes a locking mechanism for locking the telescoping cylinder to restrict its movement and a trigger mechanism for releasing the cylinder from the locked position so that a drop is released from the dispenser. The housing includes a finger for engaging the lower eyelid and exposing the conjunctival cul de sac.

Owner:MEDINSTILL DEV

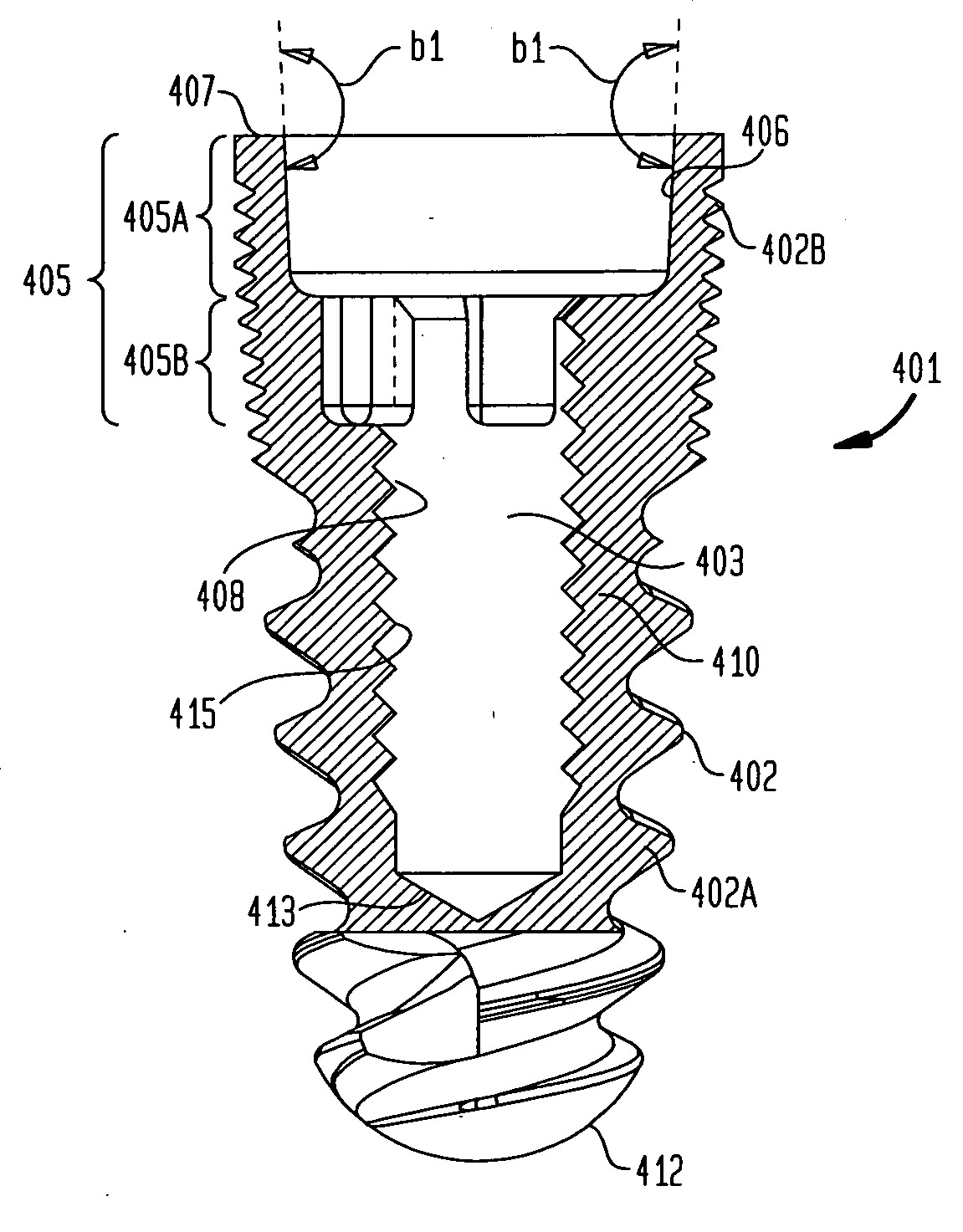

Dental implant and abutment mating system

Various embodiments of the present invention relate to devices for dental surgery and more specifically to dental implant and abutment mating system comprising a dental implant secured in the mouth of a patient and an abutment secured to the dental implant, wherein the dental implant and abutment comprise anti-rotational and taper locking elements.

Owner:SIMPACT

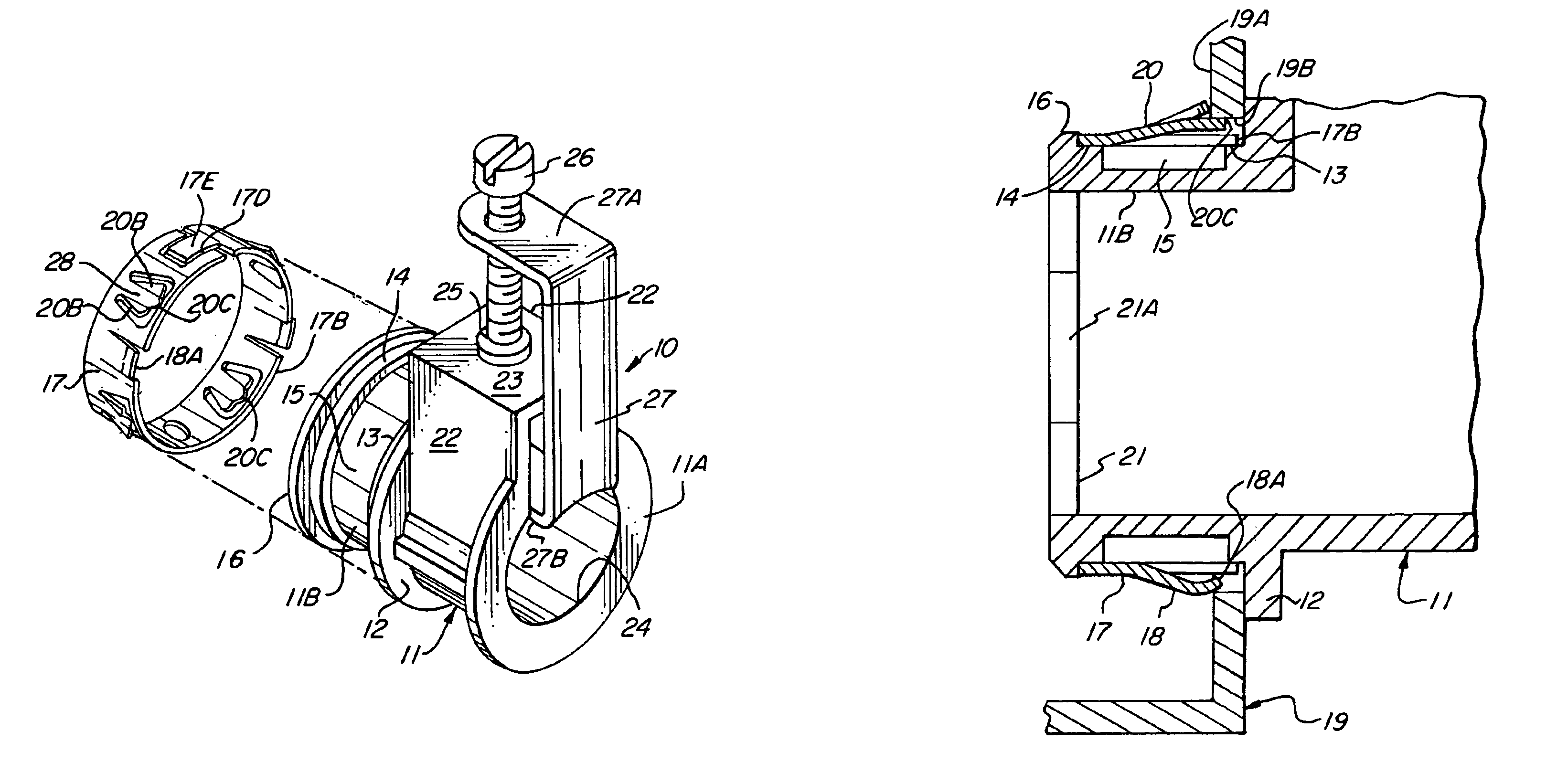

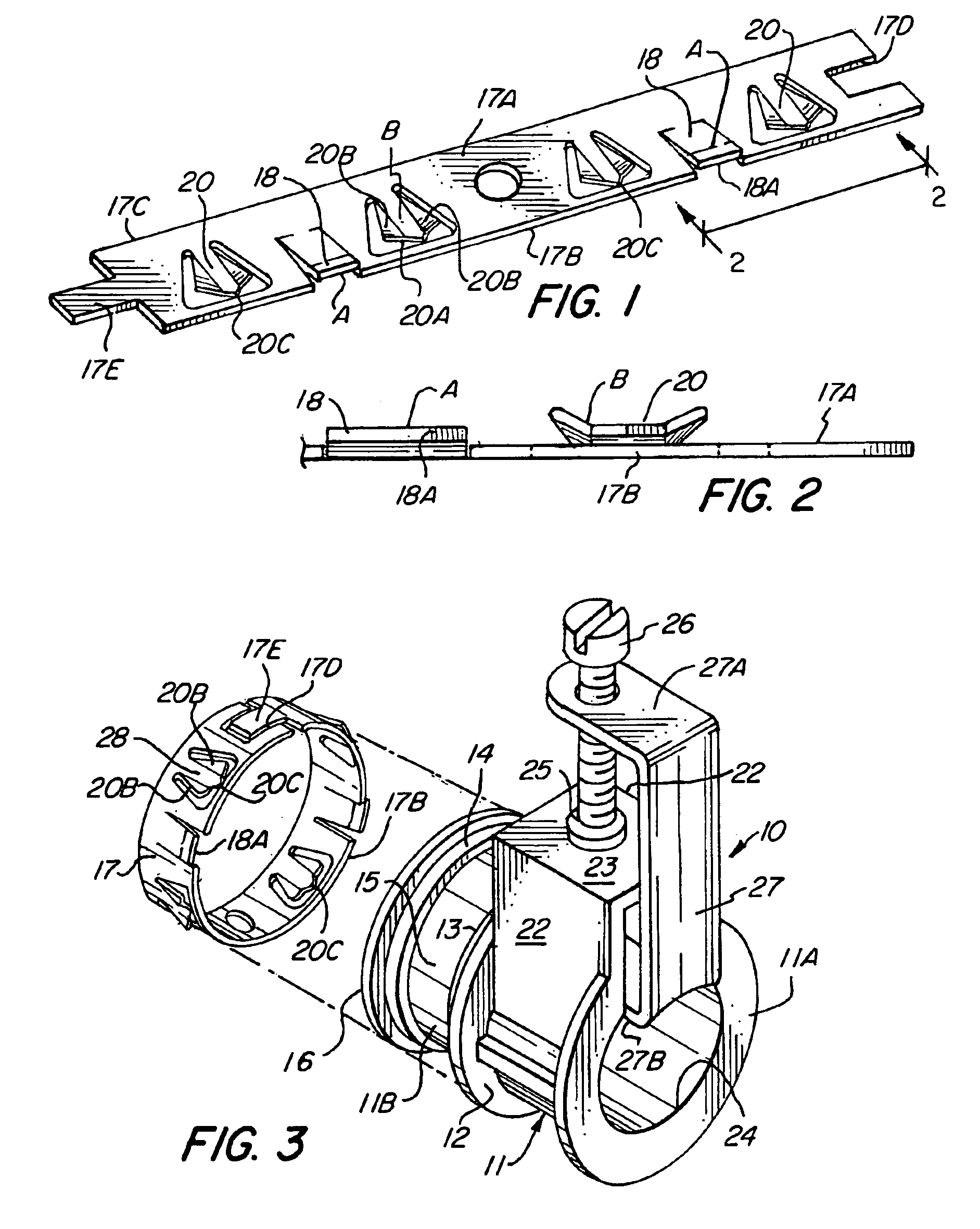

Snap fitting electrical connector

InactiveUS6860758B1Minimal forceMaximum easeContact member manufacturingSubstation/switching arrangement detailsEngineeringElectrical connector

An electrical connector having an inlet end and an outlet end wherein the leading or outlet end is provided with a pair of spaced apart shoulders defining therebetween an annular recess and a snap fit retainer ring fitted onto the outlet end, the retainer ring having at least two series of spring tangs blanked out of the plane thereof, and which tangs are formed to effect a positive grounding connection with an associated electric box in the event any slight deviations are encountered within the parameters of the adopted standards, and whereby the annular recess functions to provide a relief for the spring tangs to facilitate and minimize the required insertion force and to insure a positive ground connection between the connector and the electrical box in the assembled position.

Owner:BRIDGEPORT FITTINGS LLC

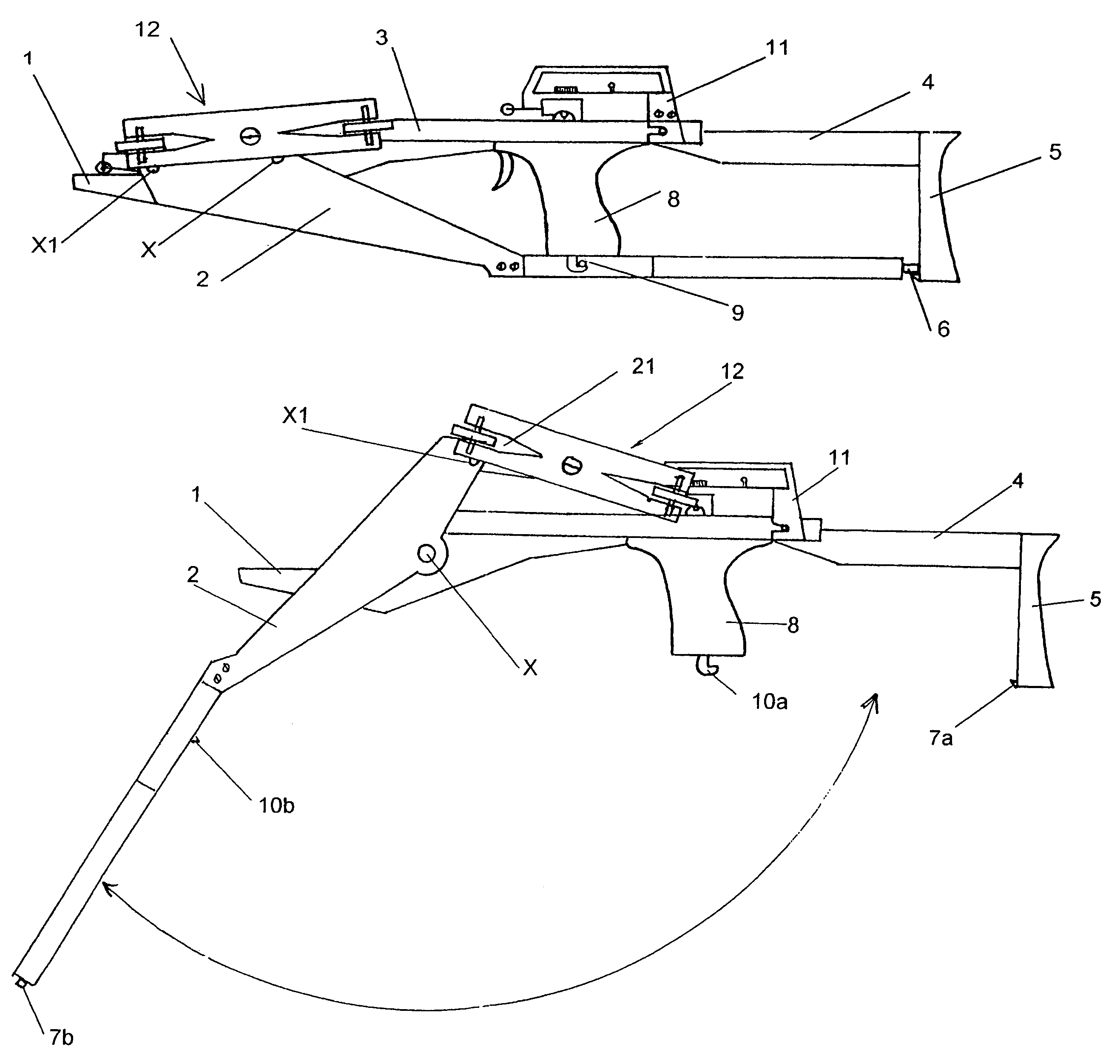

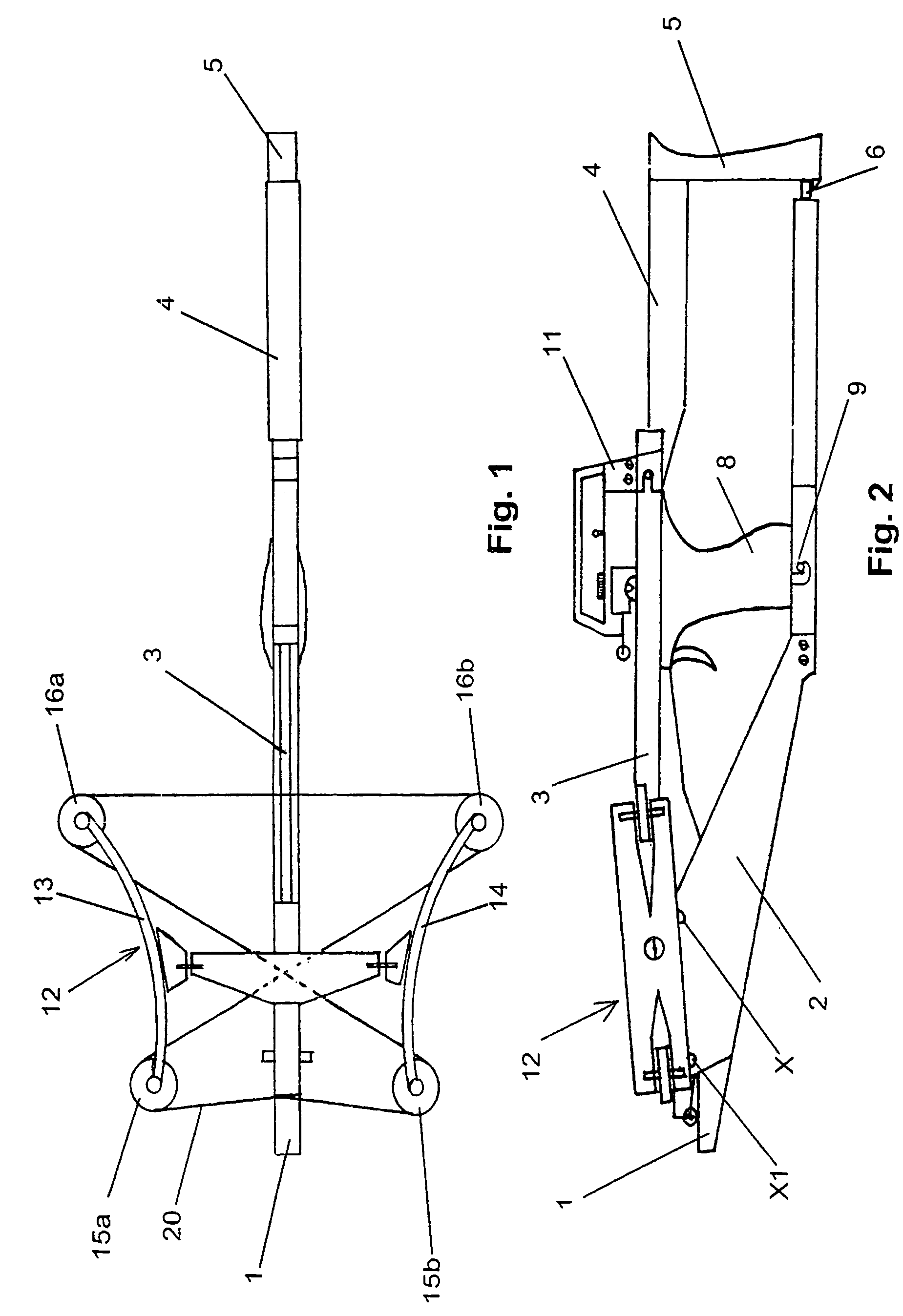

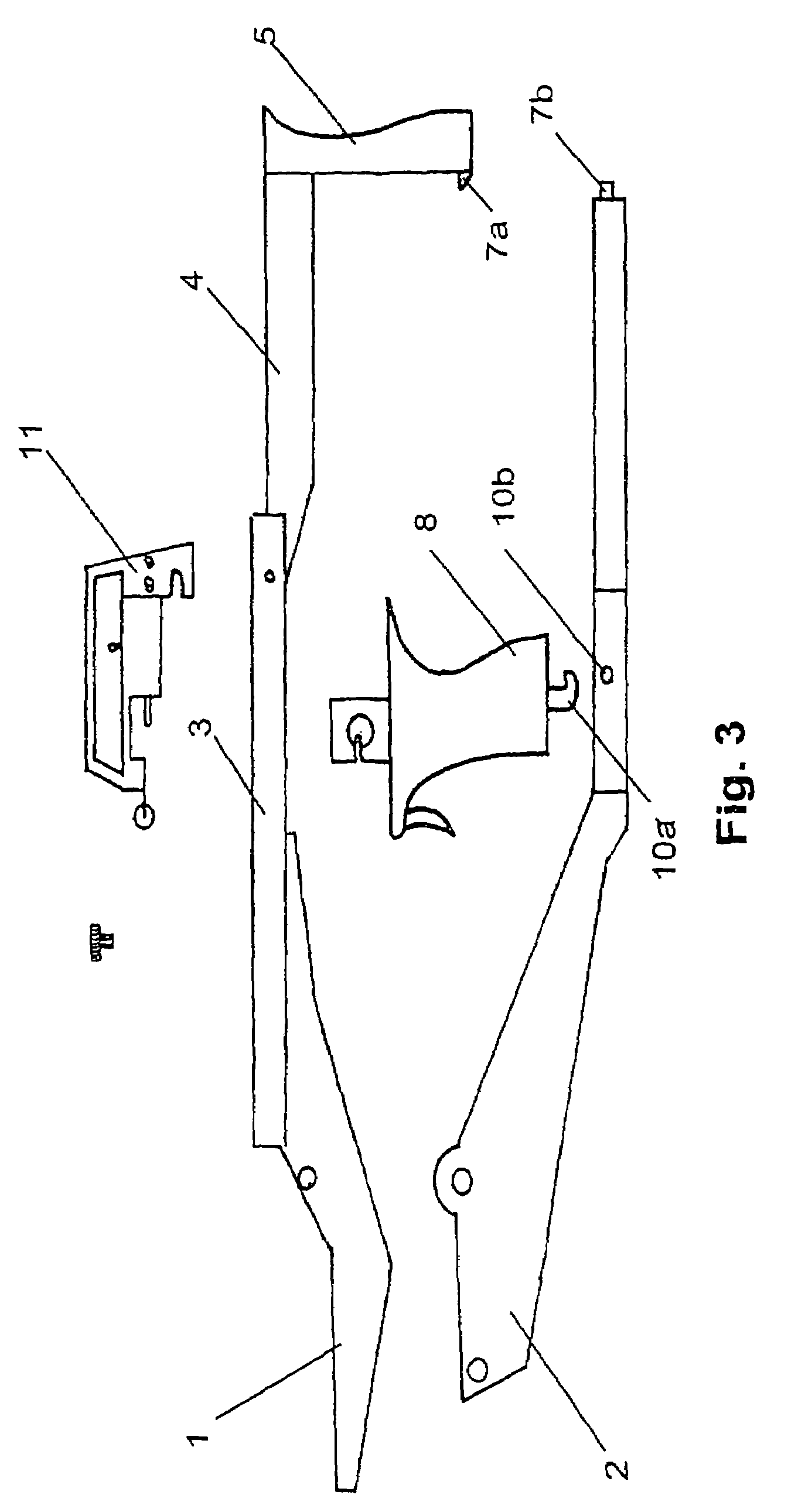

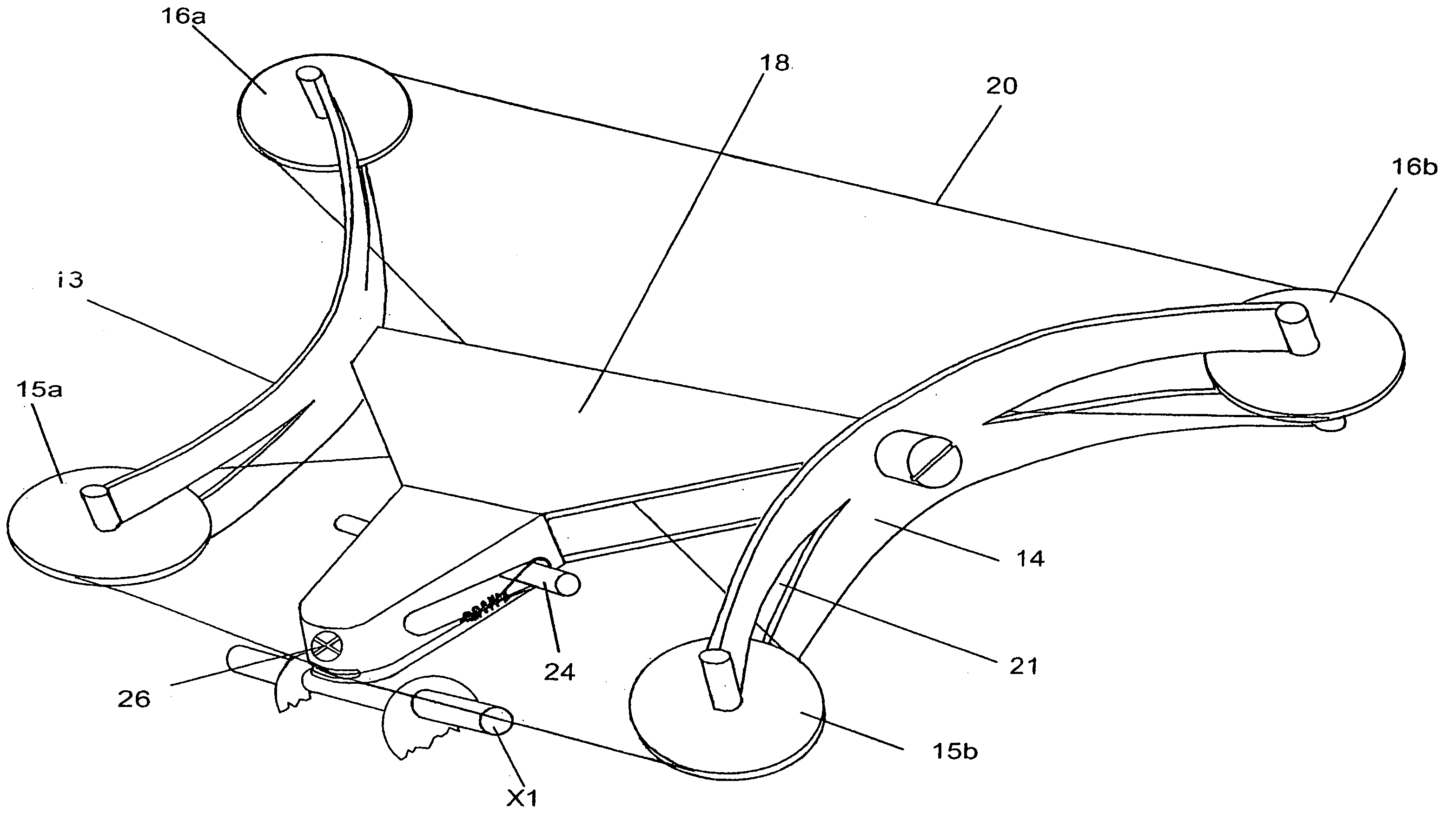

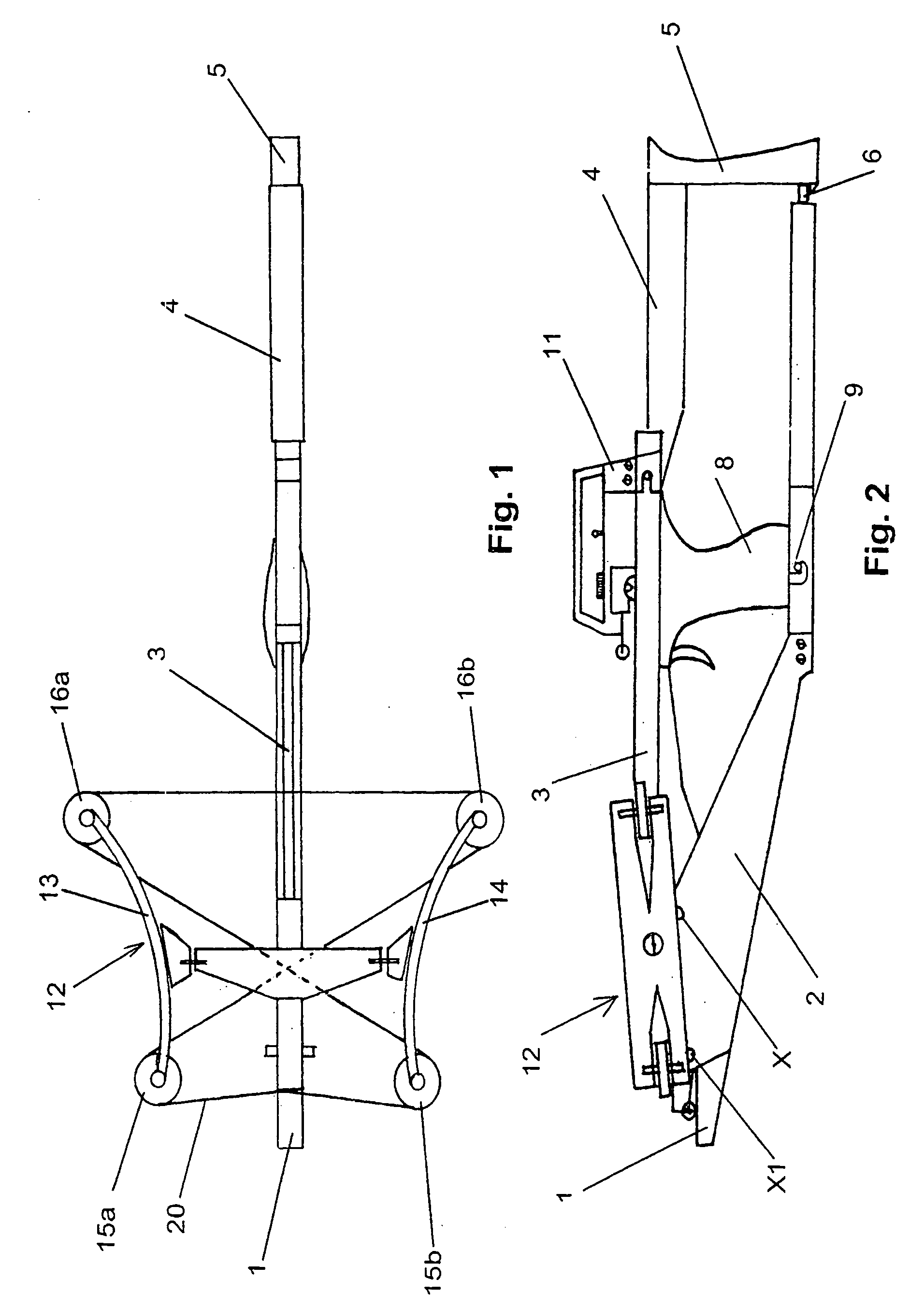

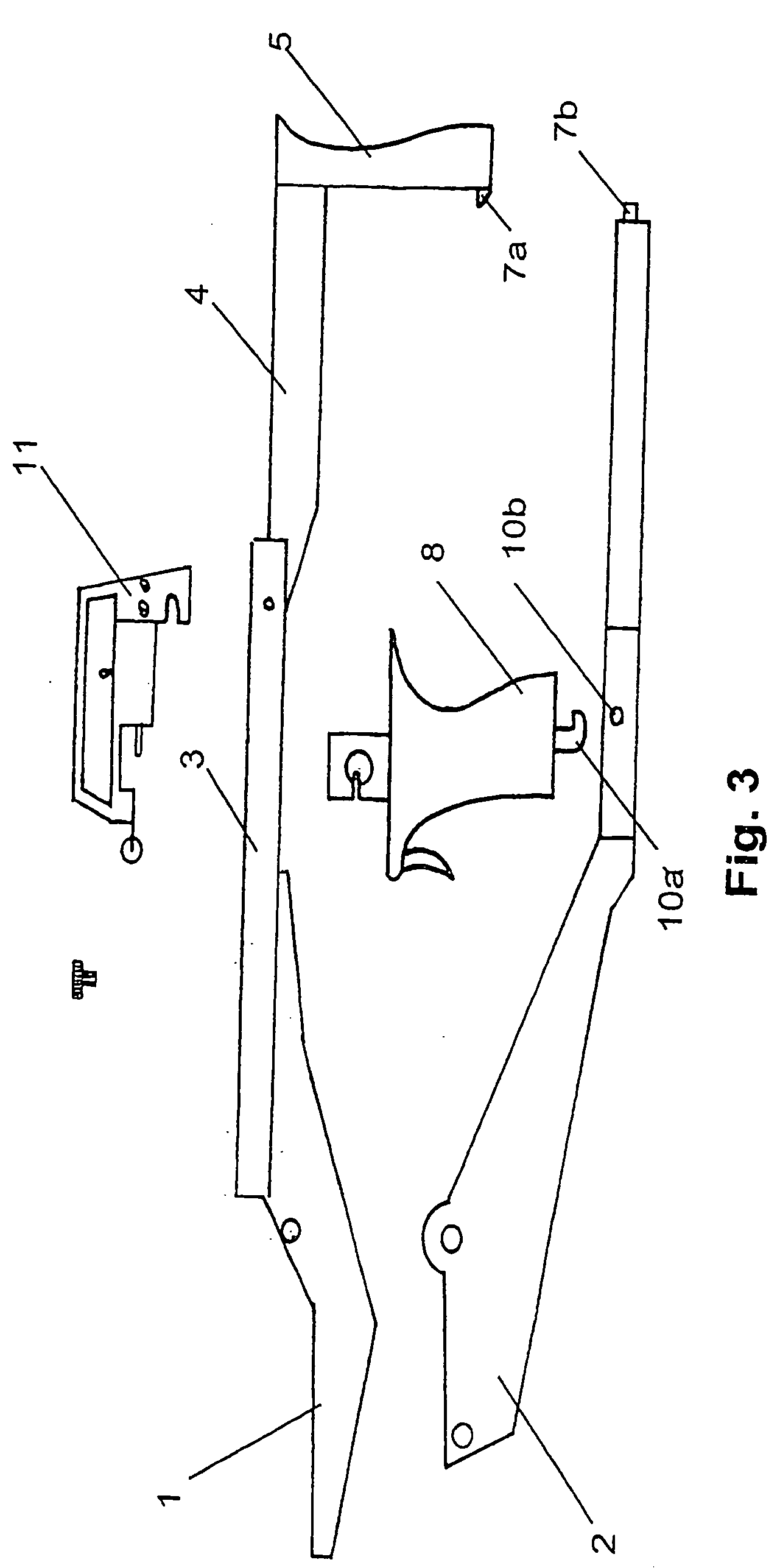

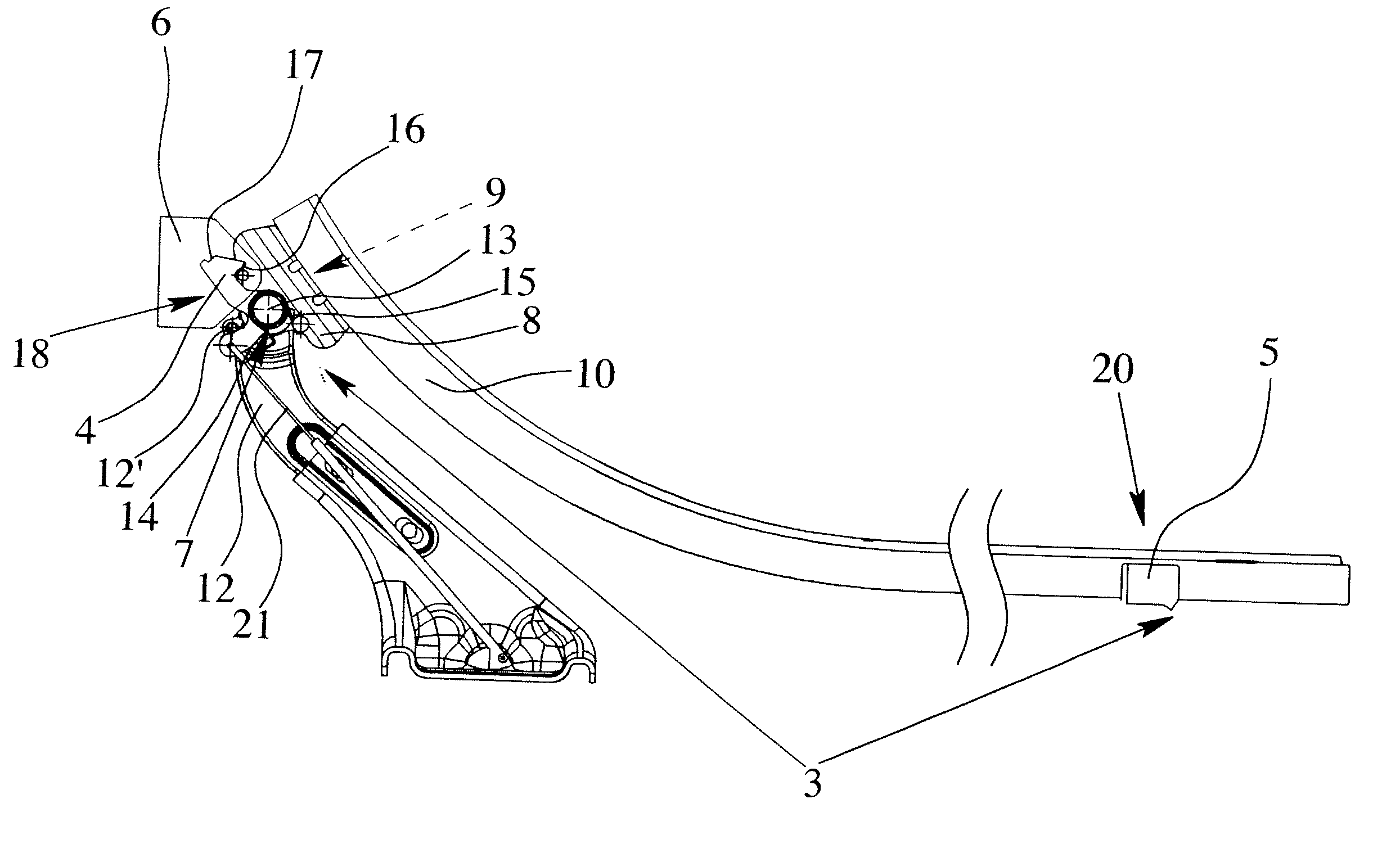

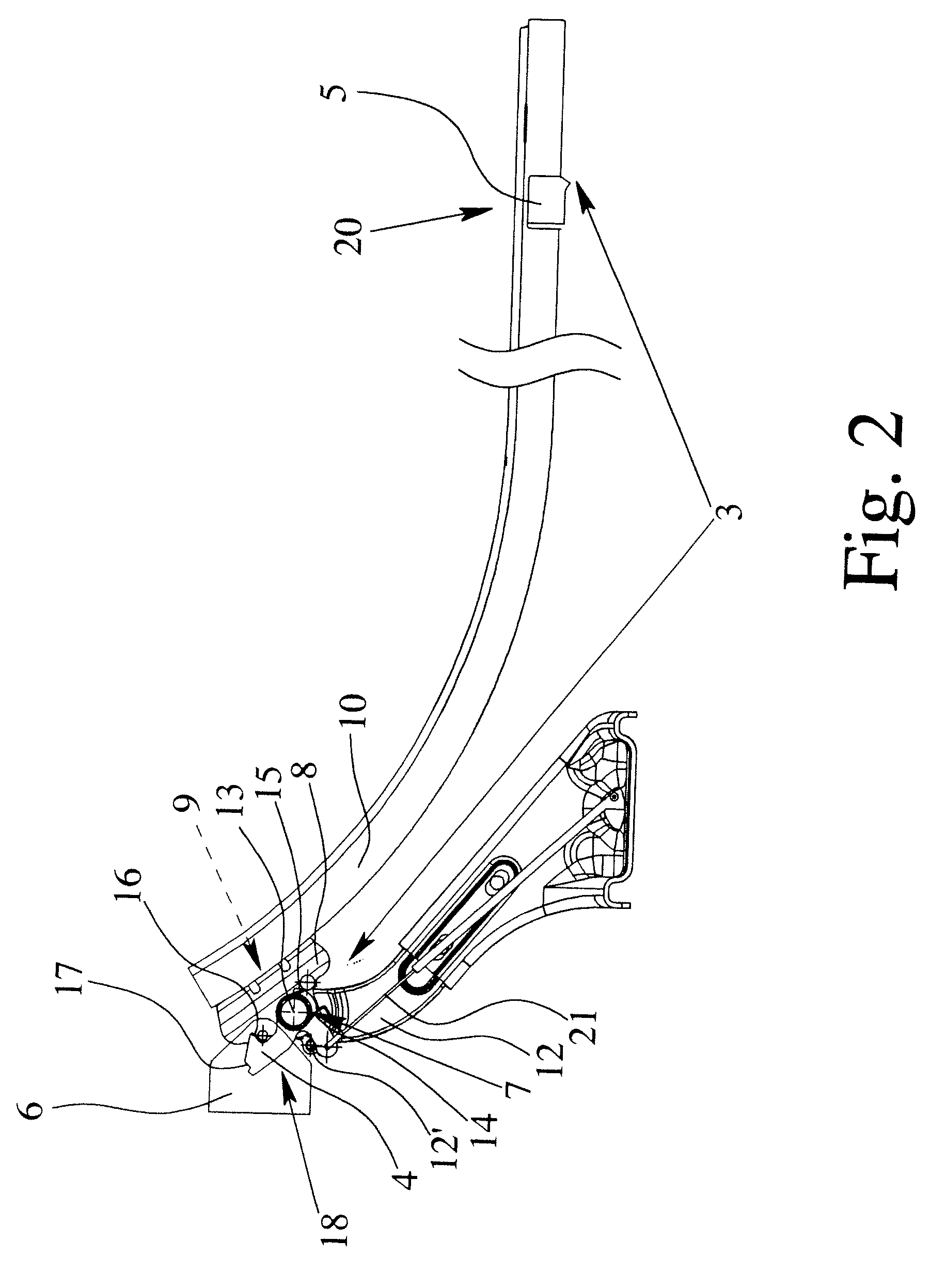

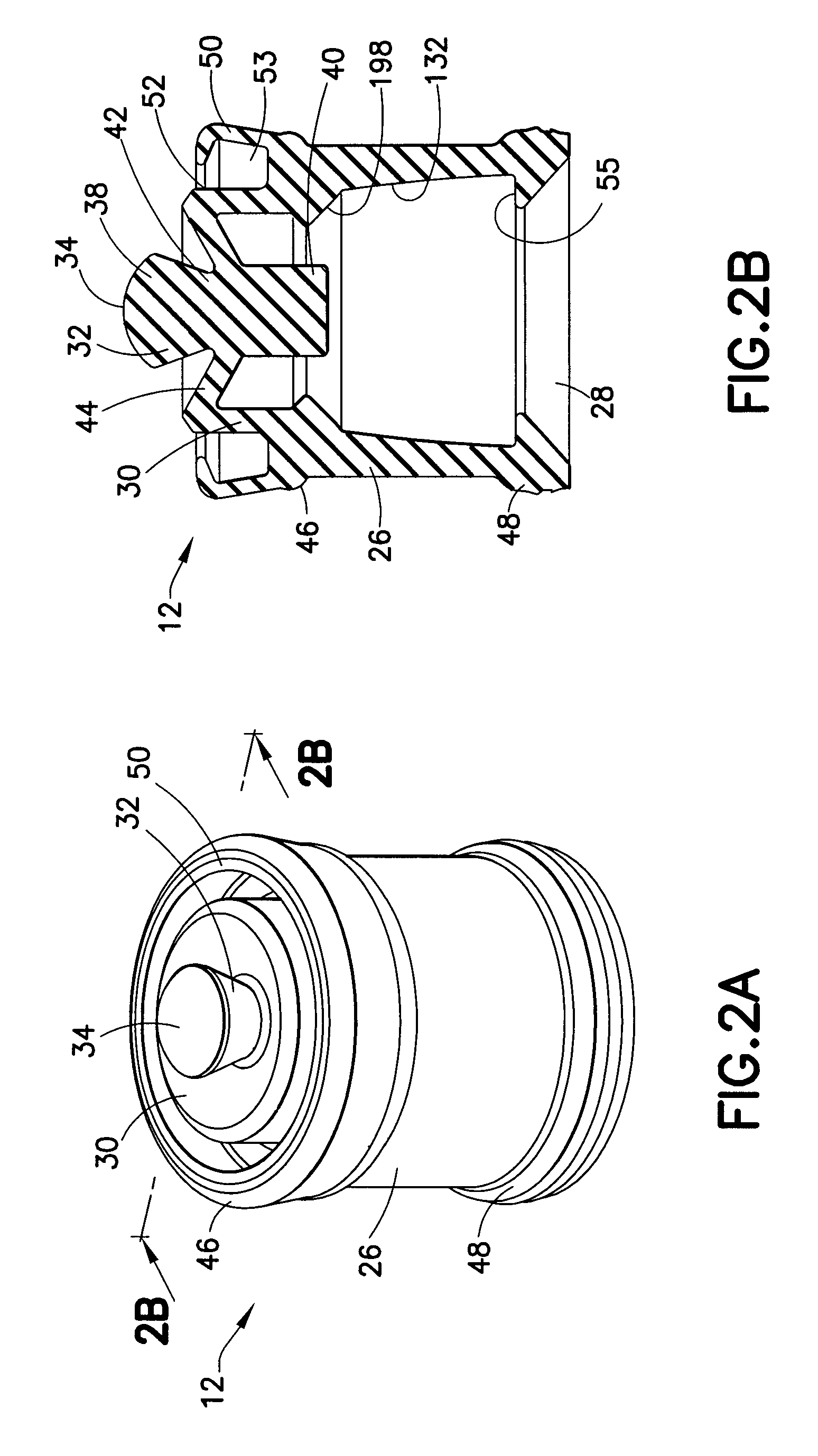

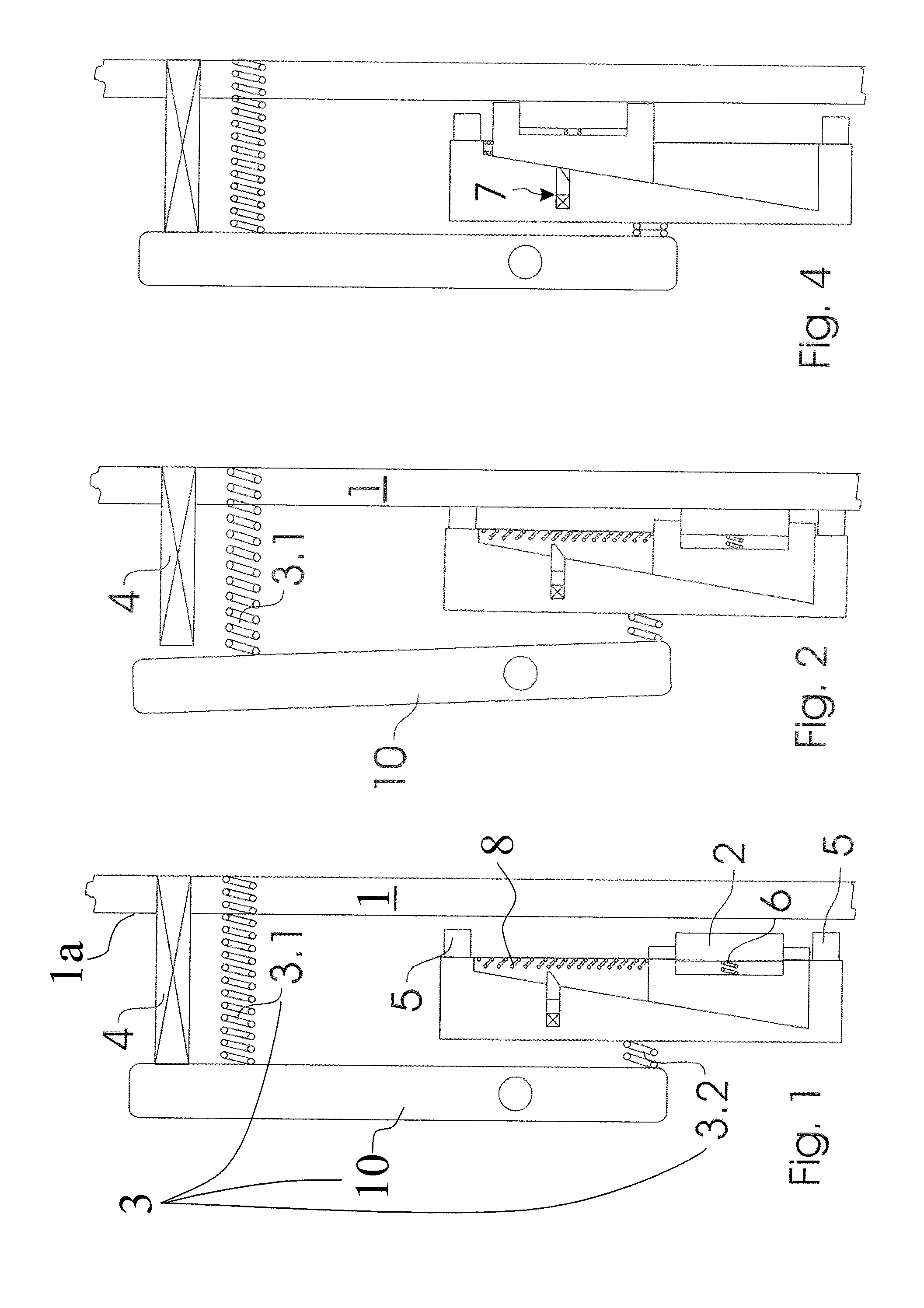

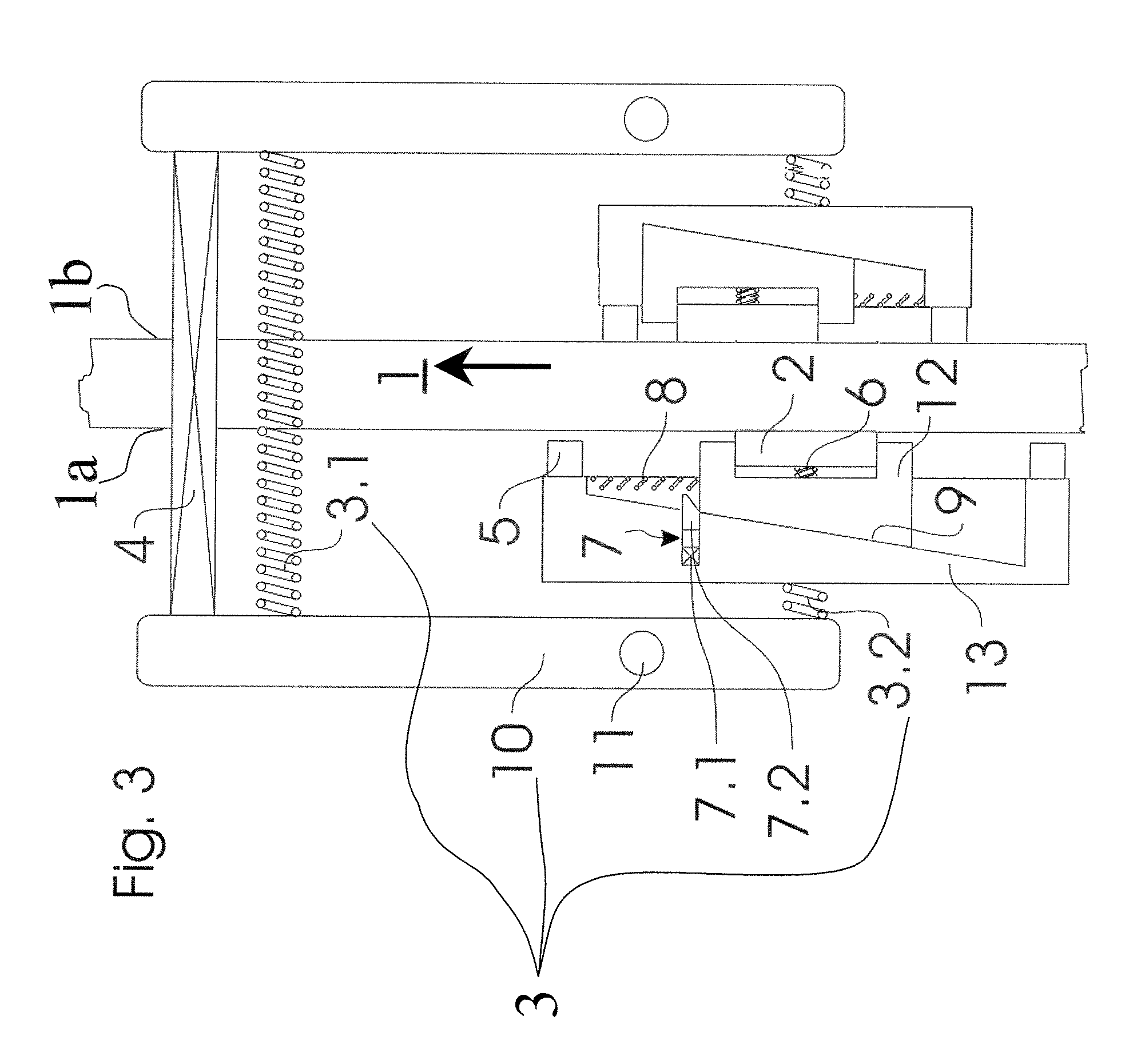

Tiller, bow and trigger mechanism for a crossbow, and a crossbow

The invention relates to a tiller for a crossbow which has a cocking lever in the form of an upper arm (1) and a lower arm (2) pivotally connected with each other about an axis (X) in the front part of the tiller, whereas in the rear part of the tiller said upper arm (1) is connected with the upper end of a butt (5), and said lower arm (2) is connected with the lower end of the butt (5) in the folded state of the tiller by means of a snap fastener (6). Said tiller for a crossbow can be assembled with any appropriate bows and trigger mechanisms, but preferably it is used with a novel bow for a crossbow which is also disclosed.

Owner:RAVIN CROSSBOWS

Stopper and plunger rod for a pre-filled syringe

ActiveUS20080300551A1High contact pressurePrevent leakageInfusion syringesIntravenous devicesPrefilled SyringeBiomedical engineering

A plunger rod adapted for attachment with a stopper for use with a syringe barrel is disclosed. The plunger rod includes an elongated member having a front end and a back end, the plunger rod extending along a longitudinal axis. The plunger rod includes at least one deflecting arm associated with the front end of the elongated member. The deflecting arm is capable of deflecting radially inward during insertion of the plunger rod into a stopper, and deflecting outward into contact with an inner surface of the stopper after insertion to lock the plunger rod within the stopper.

Owner:BECTON DICKINSON & CO

Tiller. bow and trigger mechanism for a crossbow, and a crossbow

The invention relates to a tiller for a crossbow which has a cocking lever in the form of an upper arm (1) and a lower arm (2) pivotally connected with each other about an axis (X) in the front part of the tiller, whereas in the rear part of the tiller said upper arm (1) is connected with the upper end of a butt (5), and said lower arm (2) is connected with the lower end of the butt (5) in the folded state of the tiller by means of a snap fastener (6). Said tiller for a crossbow can be assembled with any appropriate bows and trigger mechanisms, but preferably it is used with a novel bow for a crossbow which is also disclosed.

Owner:RAVIN CROSSBOWS

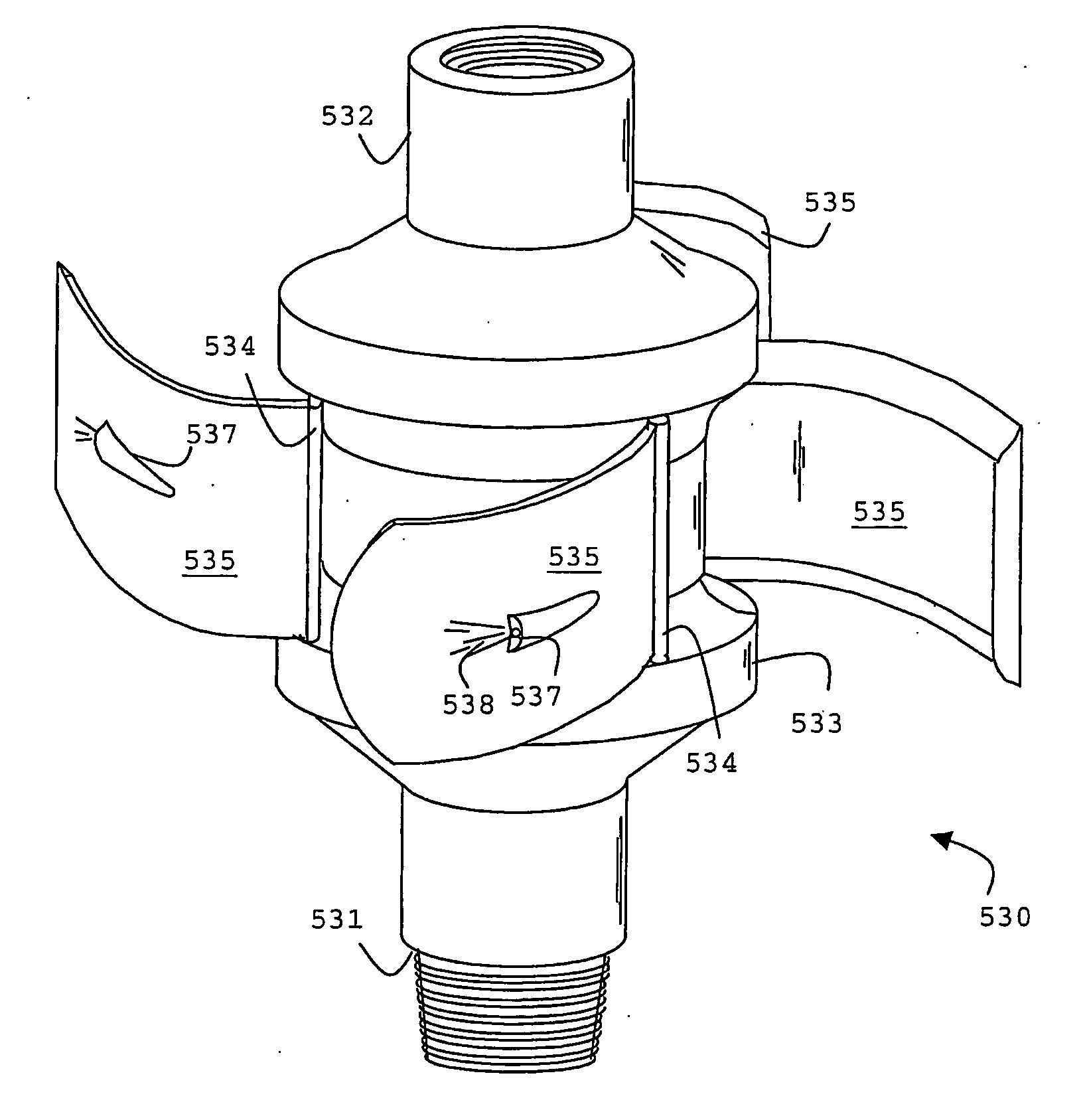

Wellbore consolidating tool for rotary drilling applications

InactiveUS20060144620A1Increase resistance against wearIncrease tear downholeDrilling rodsCleaning apparatusWell drillingAngle of attack

A subpart (430) of a drill string (211) is described having an outer circumferential surface which is contoured and adapted to engage the wall of the borehole with a small angle of attack while exerting during rotary drilling operations an compacting pressure on mud cake and / or cuttings present in the annulus between the drill string and the borehole.

Owner:SCHLUMBERGER TECH CORP

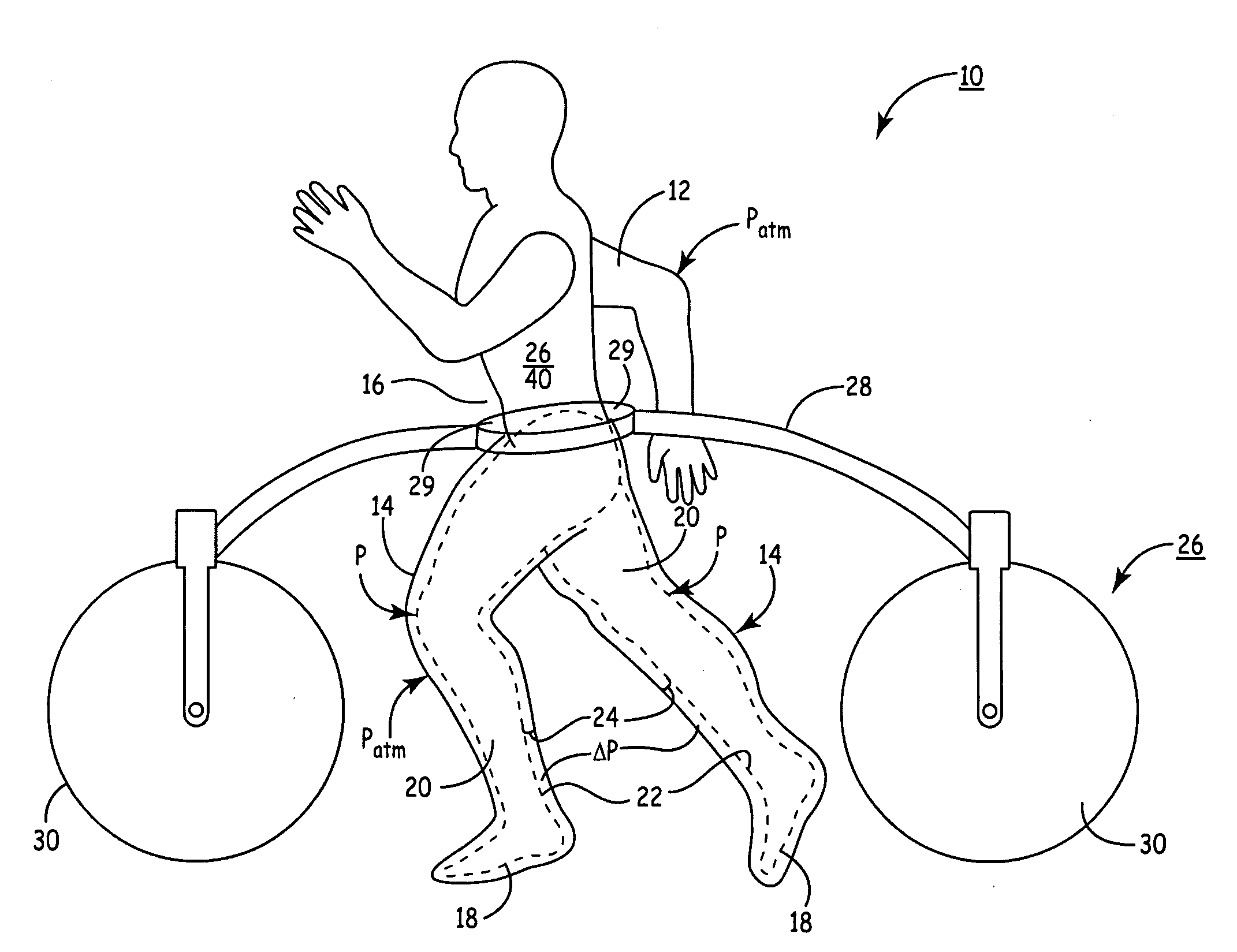

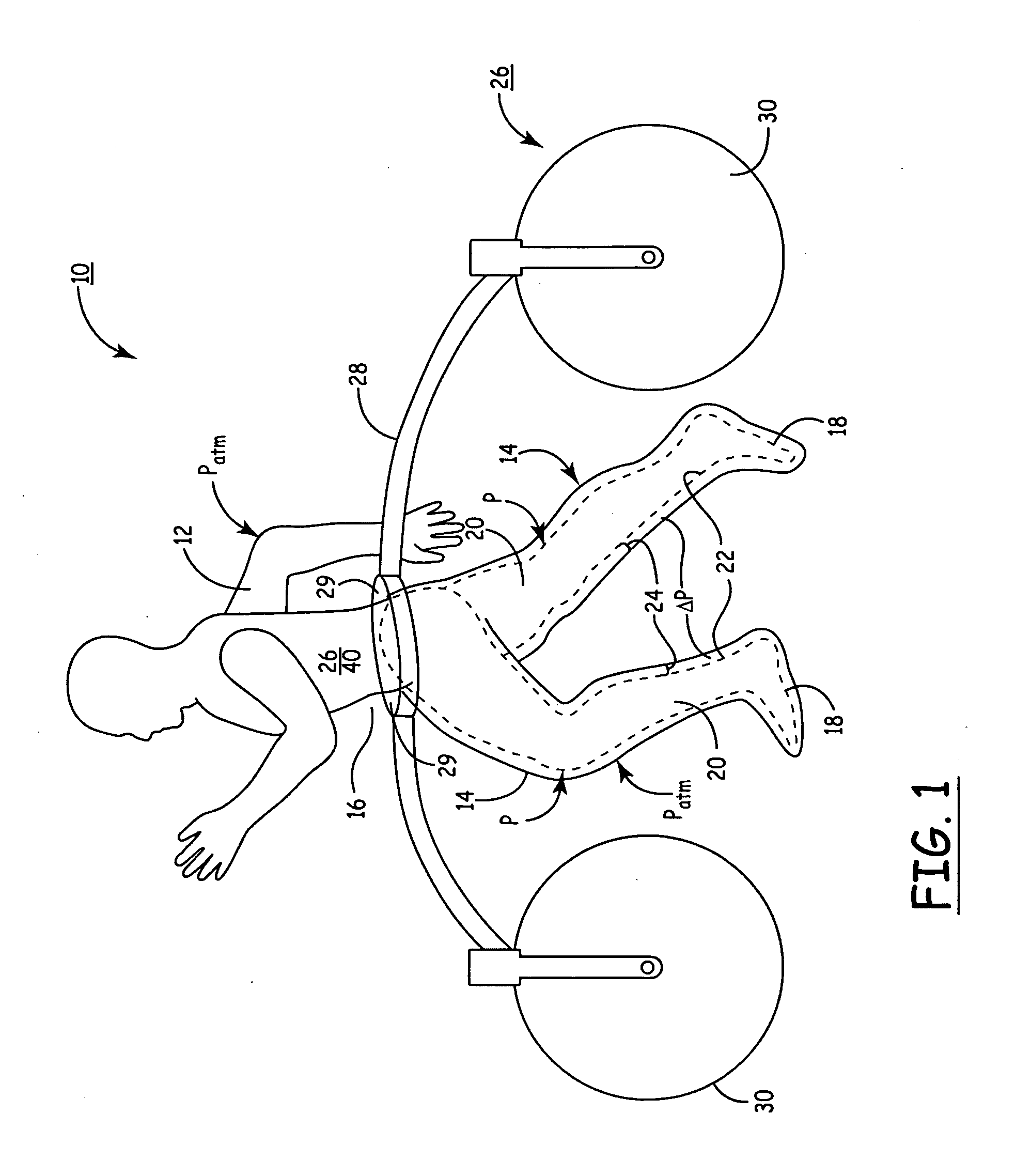

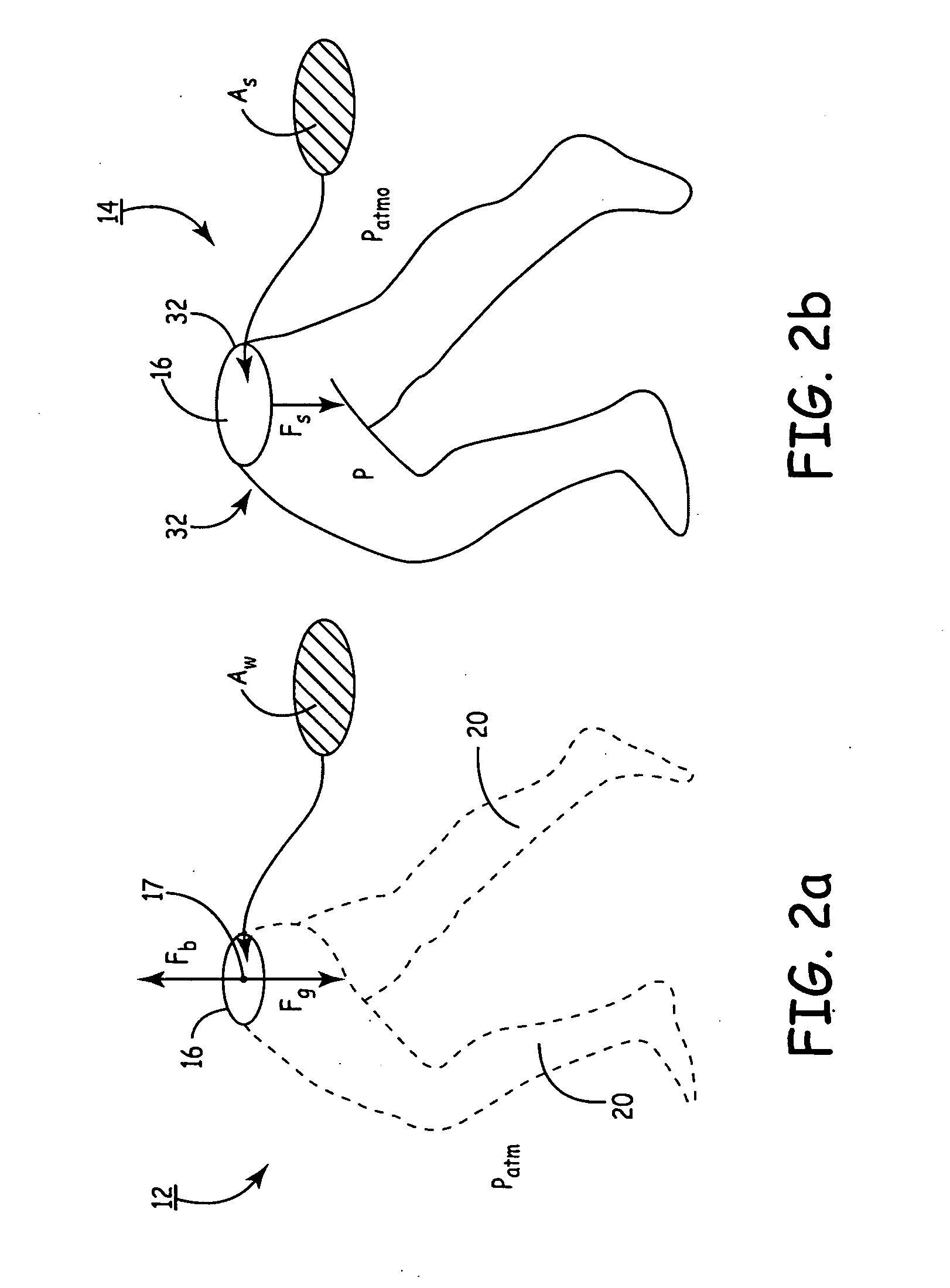

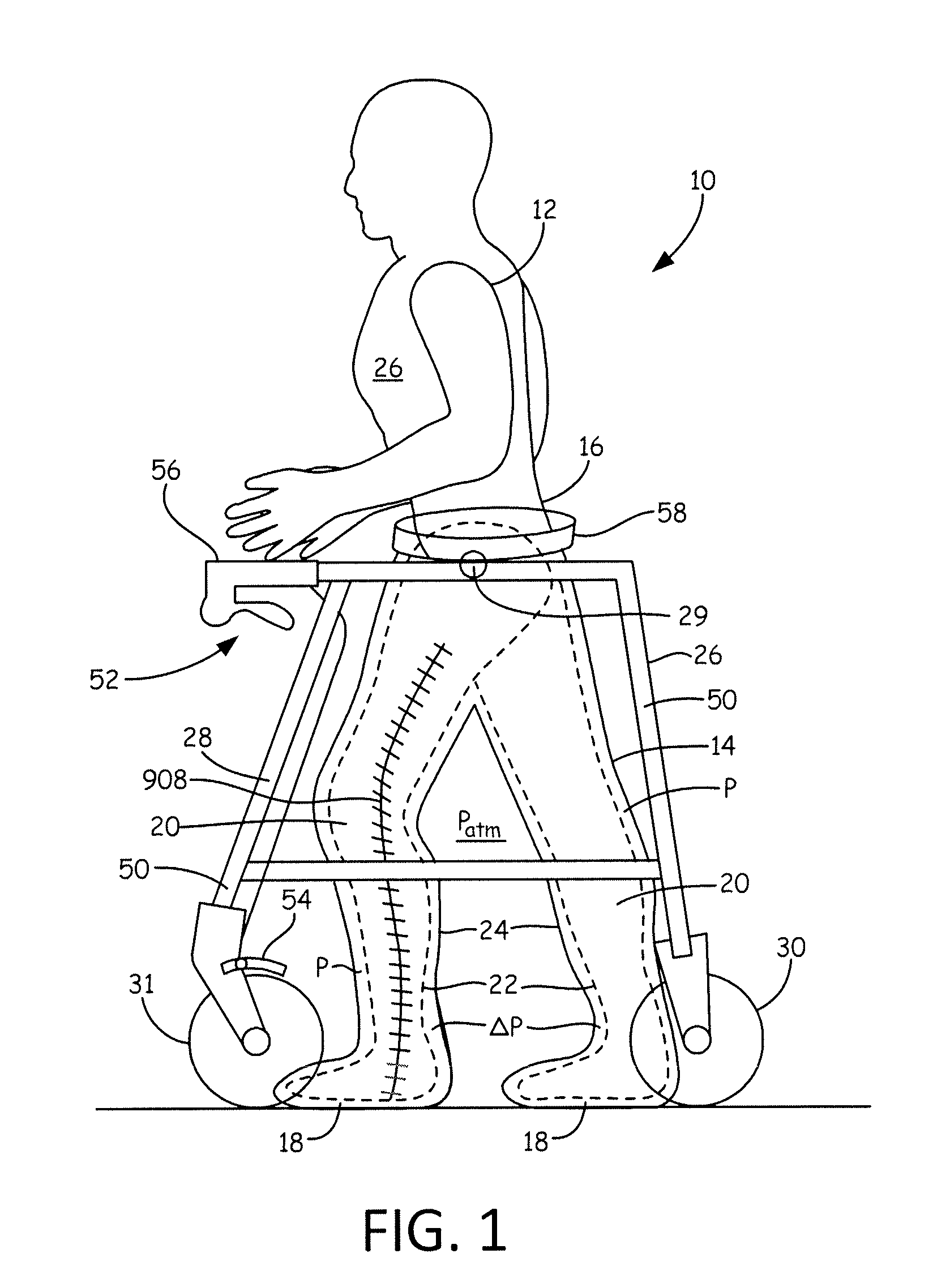

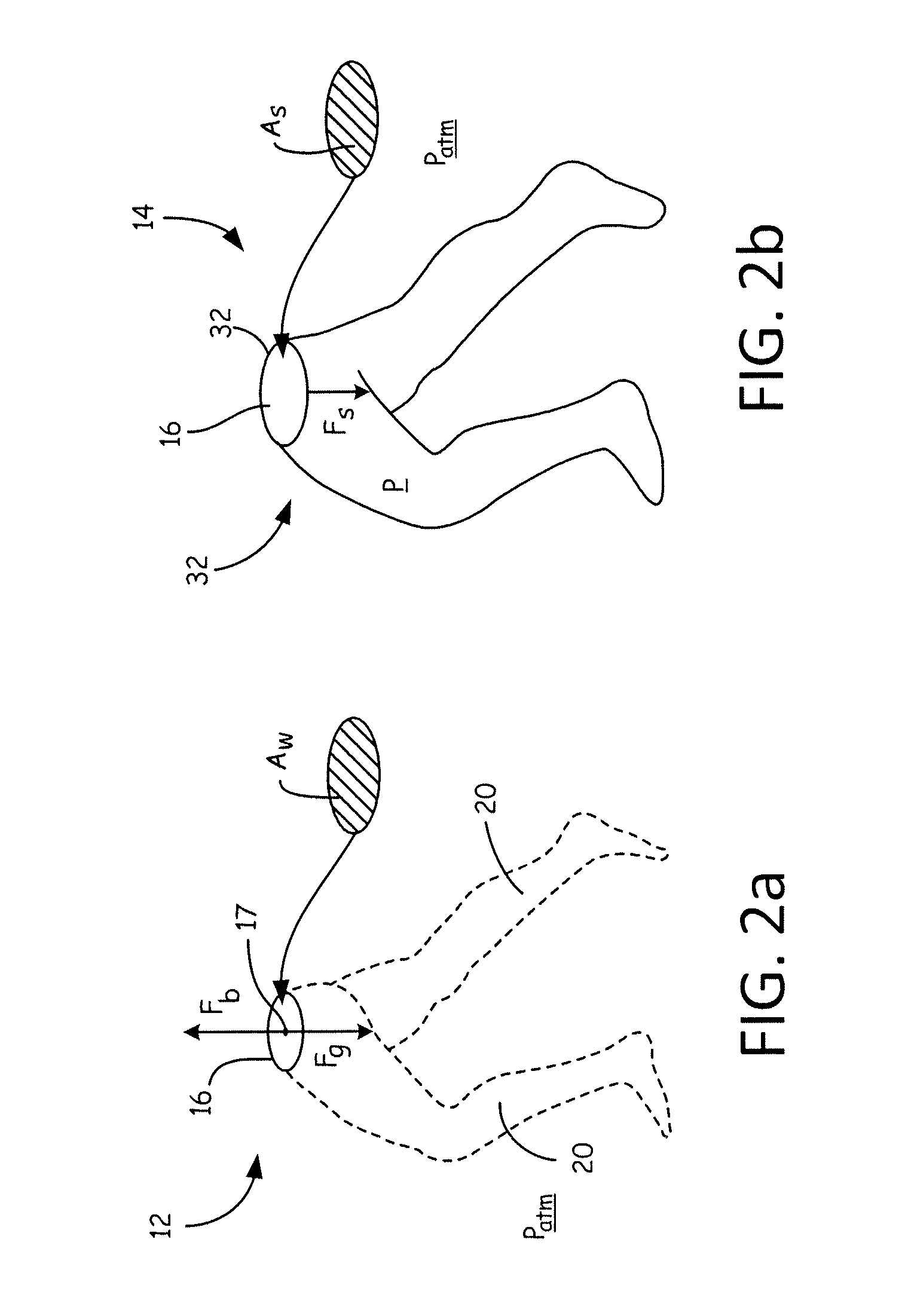

Portable system for assisting body movement

ActiveUS20100000547A1Lose weightPortable and convenientBlood stagnation preventionOperating chairsDifferential pressureExercise performance

The present invention provides a differential pressure body suit with external support against body suit migration. In its preferred embodiment, such body suit may comprise a close-fitting, multi-layered suit sealed against a mammal's skin to contain the differential pressure, or a looser-fitting suit that bends at the mammal's joints with minimal force. External support means include either fixed or movable mechanical supports attached to the body suit, extraordinary air pressure levels for making the body suit rigid, or exoskeletons attached to the body suit. A cyclic control system can turn the differential pressure condition within the body suit on and off on a selective basis to accommodate the movement of the legs of the mammal. This differential pressure body suit provides a portable and convenient system for, e.g., rehabilitating a skeletal joint injury or training the mammal for injury prevention or athletic performance or fat burning. The pressurization reduces the weight of the body to greater or lesser extents, and offloads the weight to the ground through the external support means.

Owner:LITE RUN

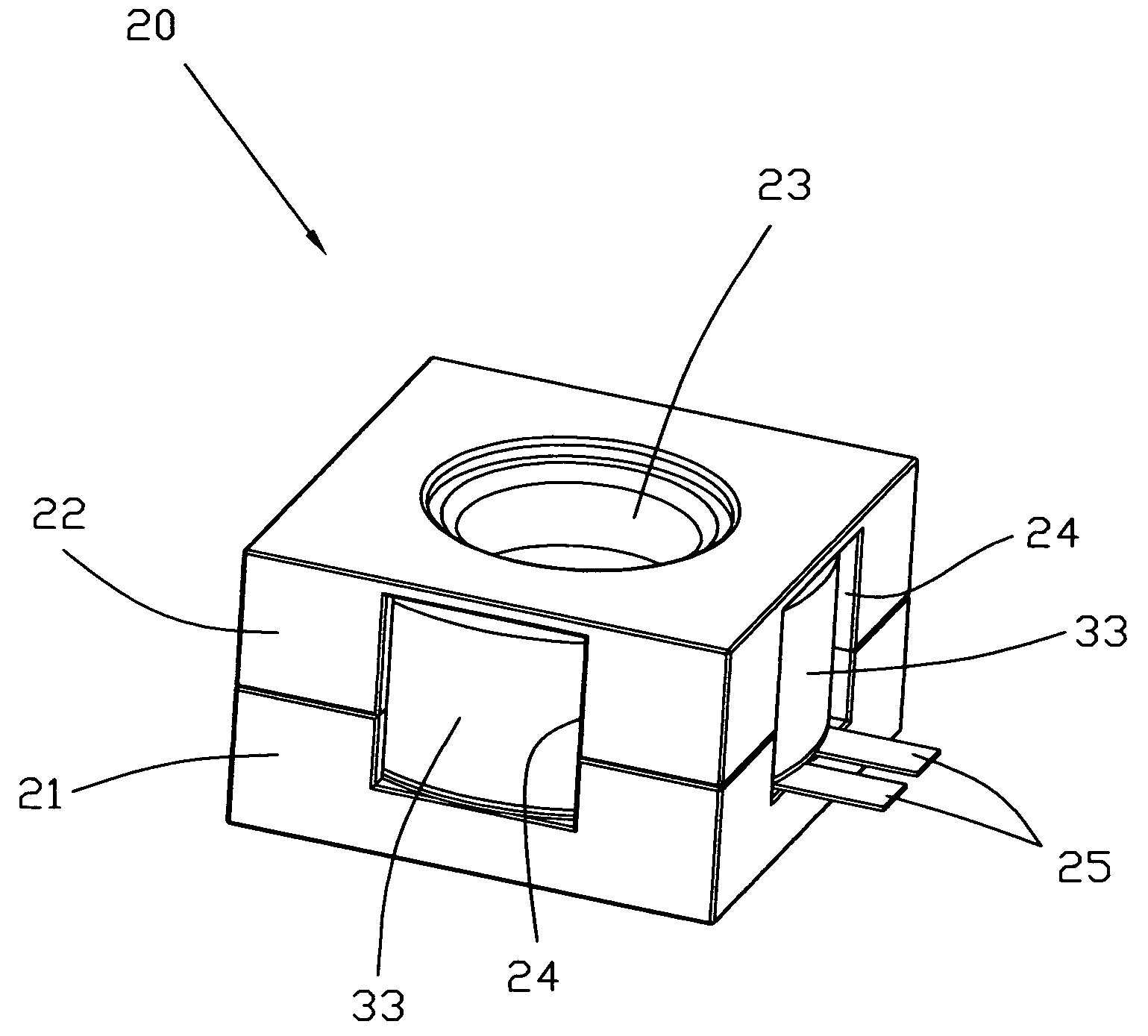

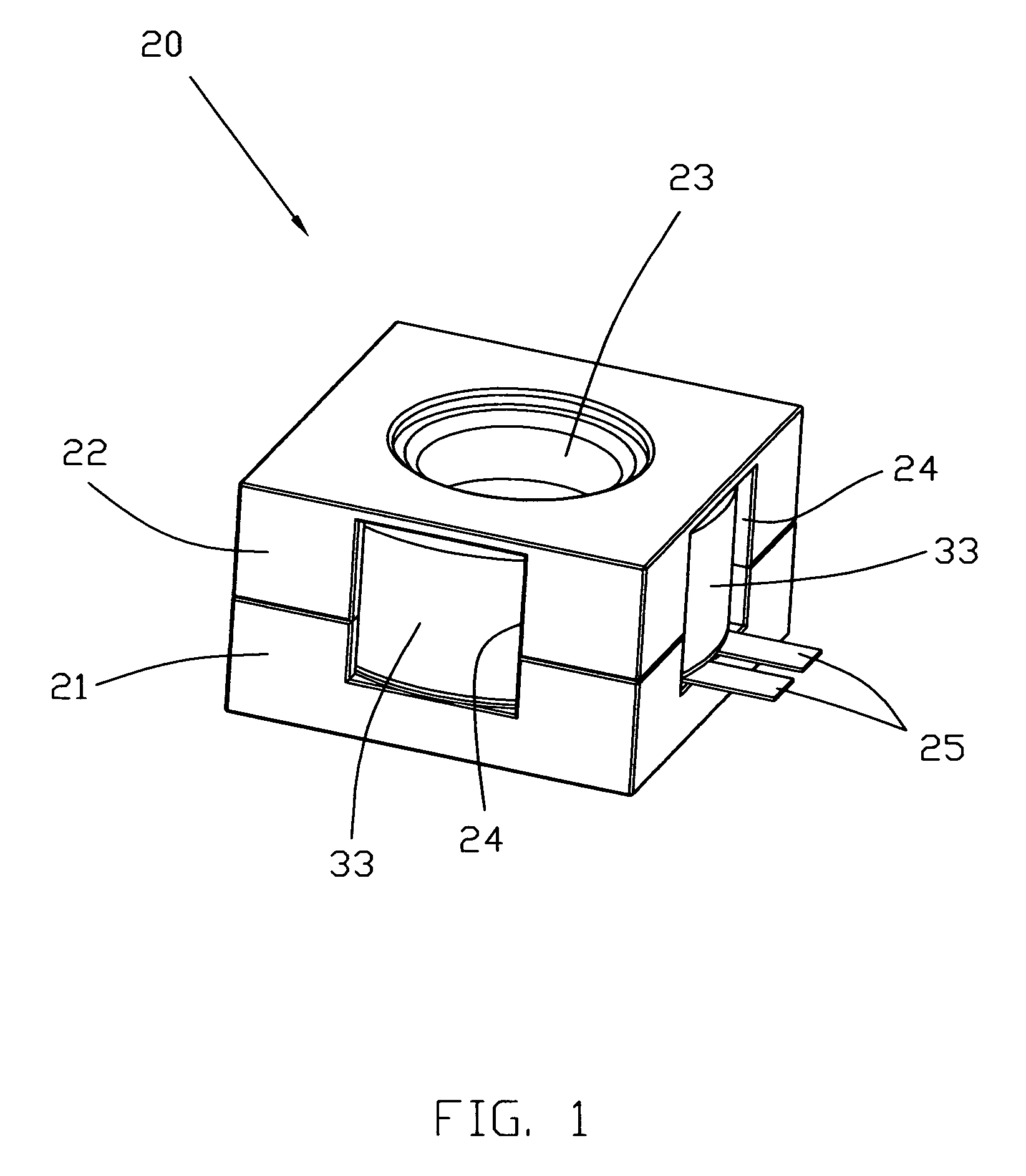

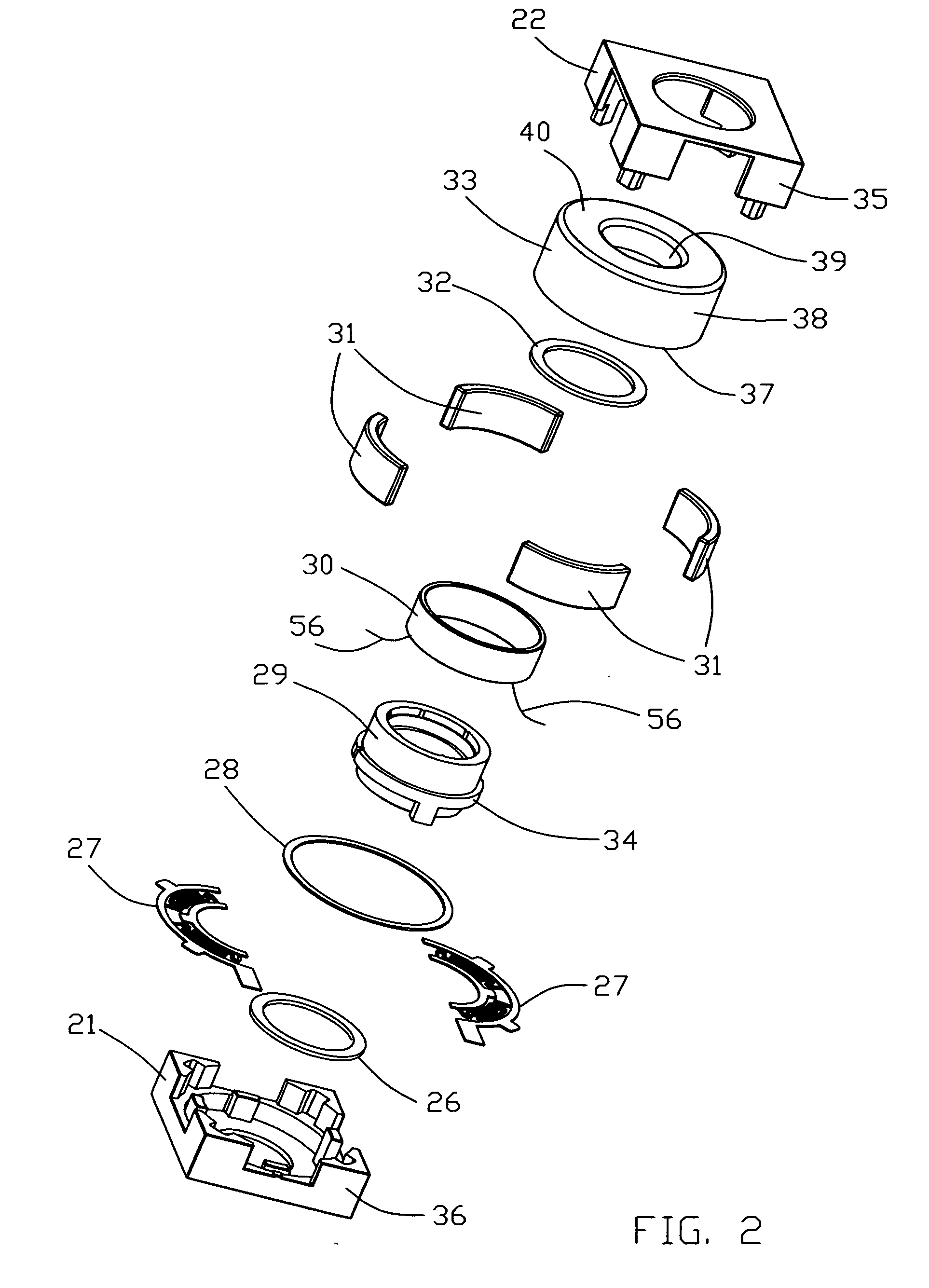

Voice coil motor

InactiveUS20080198254A1Make smallFast in response timeTelevision system detailsProjector focusing arrangementCushionImage sensor

A voice coil motor lens module has a two part casing accommodating a magnet housing of annular form with an outer wall and an inner wall joined by a top wall. One or more magnets producing a magnetic field, are fitted to the inner surface of the outer wall. A lens holder, for supporting a lens, has a coil fitted to an outer surface thereof and is suspended by a pair of springs such that the coil is disposed within the magnetic field. The lens holder has an inner bore and an axially upper end. The inner wall extends into the inner bore of the lens holder and the upper end of the lens holder rests, in a park position, against an upper cushion fixed to an inner surface of the top wall. In use, current passing through the coil moves the lens holder downwardly to focus an image on an image sensor below the lens holder. At a fully extended position, the lower end of the lens holder rests against a lower cushion fixed to the casing.

Owner:JOHNSON ELECTRIC INTERNATIONAL AG

Chuck for capping machine

Owner:PNEUMATIC SCALE CORP

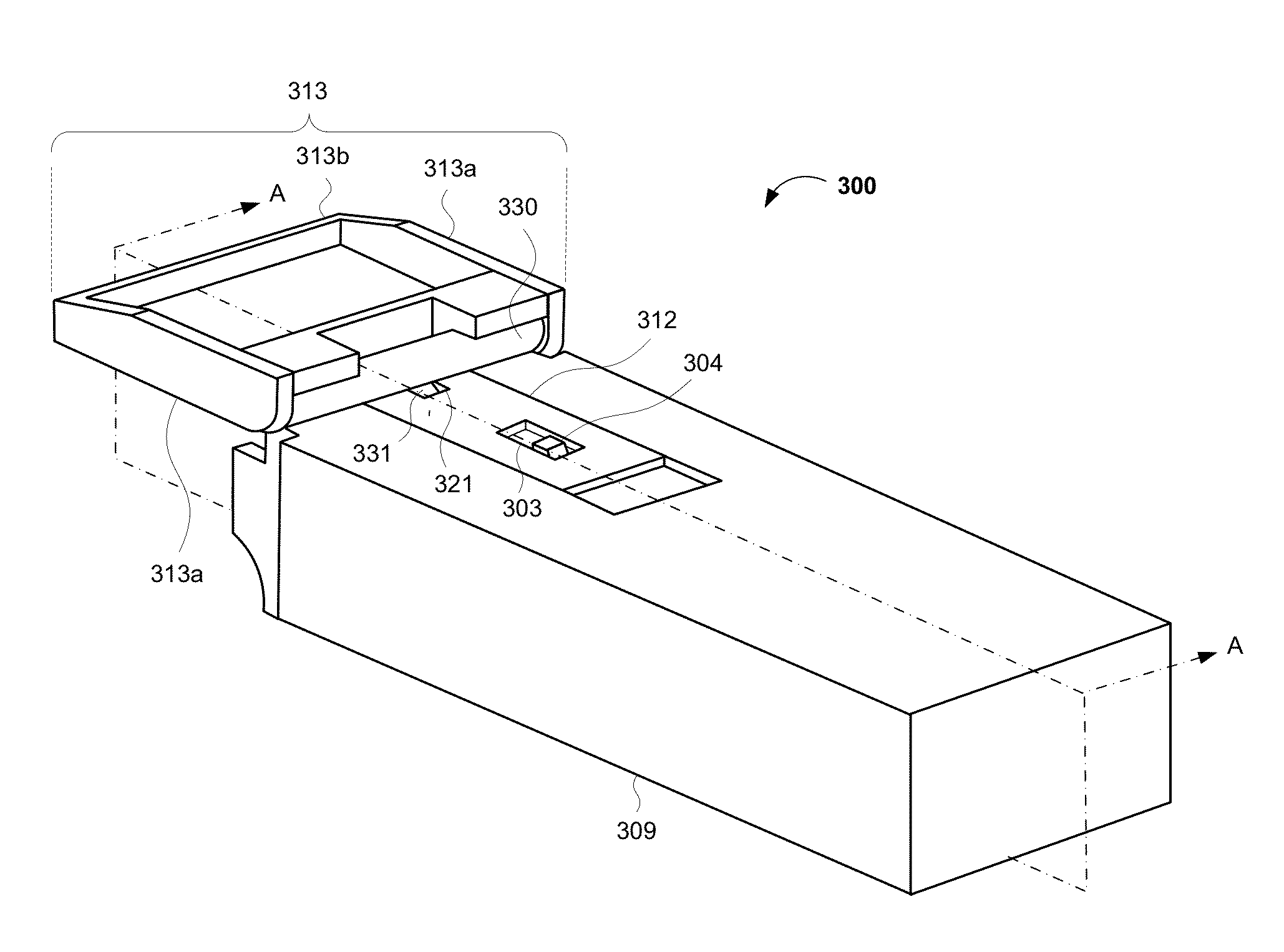

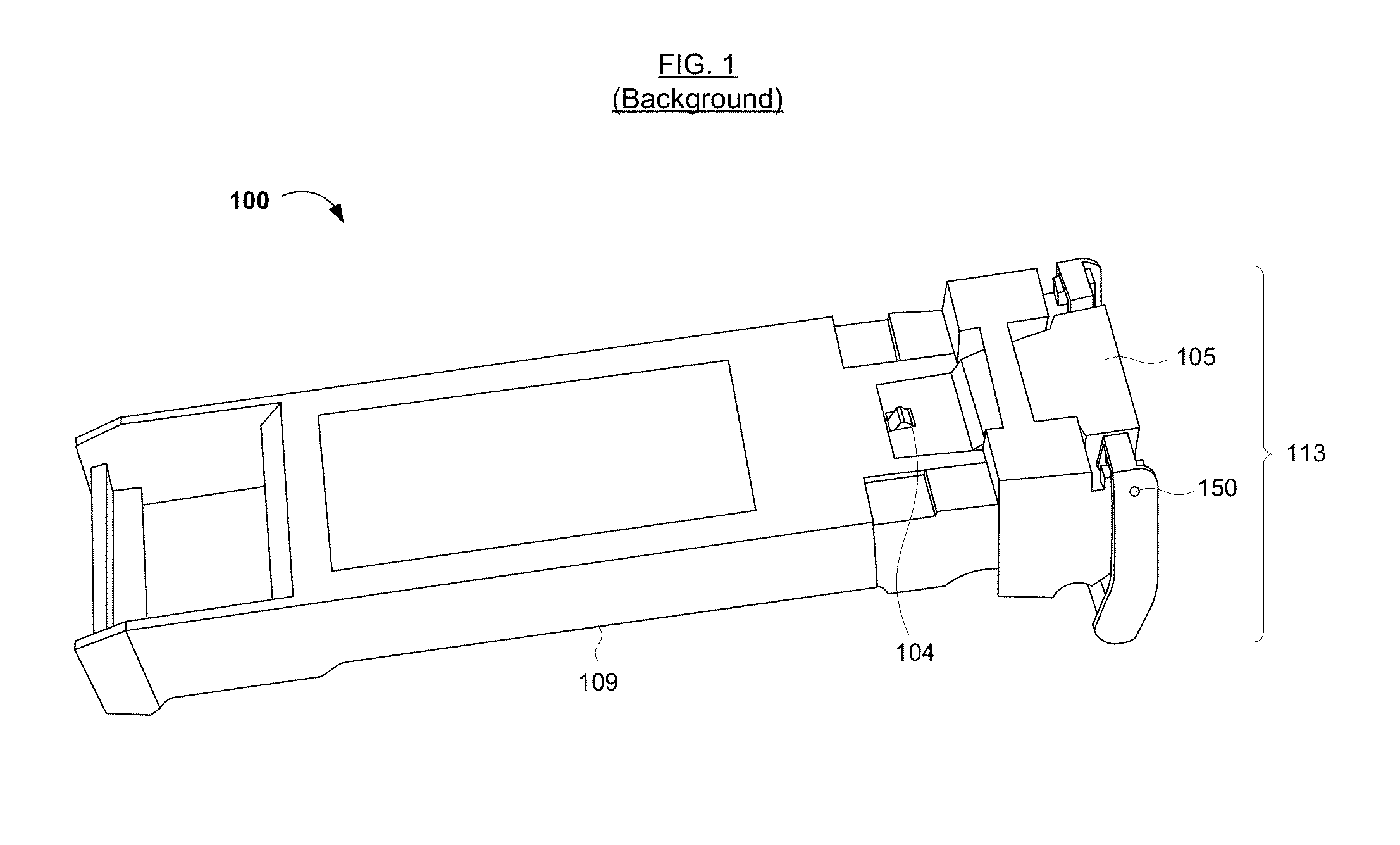

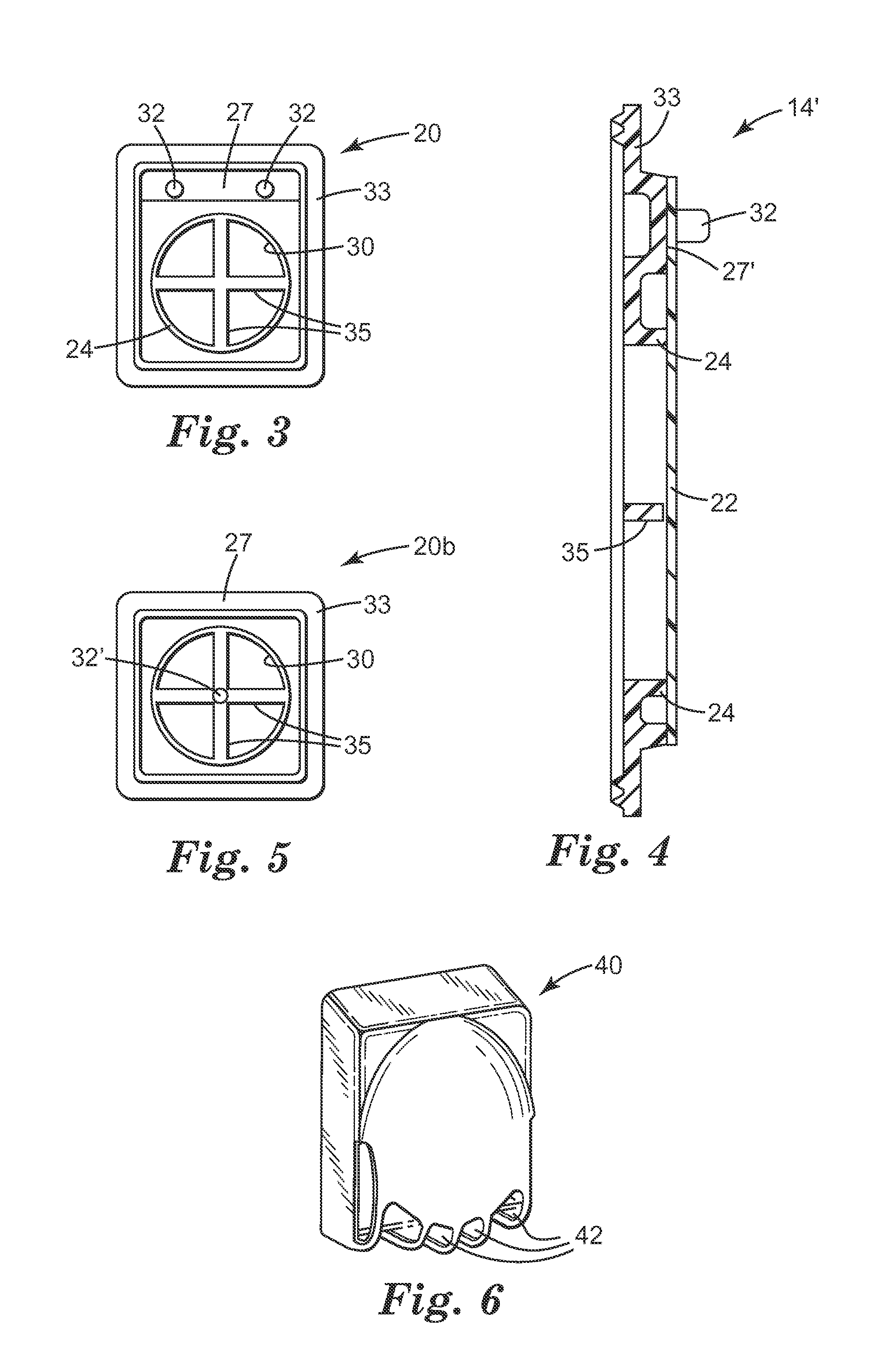

Latchable Module Housings and Methods of Making and Using the Same

ActiveUS20130322832A1Reliably movedEasy seatingCoupling light guidesMetal working apparatusEngineeringOptical Module

An optical module housing that may be easily seated, locked in and removed from a socket, thereby reducing or eliminating potential damage to the module and socket, and methods for making and using the housing are disclosed. The module housing generally includes a chassis, one or more pivots attached to the chassis, a latch configured to secure the housing in a corresponding slot when in a locked position, a slider configured to be in contact with and / or connected to the latch and to move the latch relative to the chassis, the latch and / or the slider being configured to move on and / or around the pivot(s) and a handle configured to be in contact with and / or connected to the slider such that when the handle moves from a first position to a second position, the slider and latch move to the locked and / or an unlocked positions.

Owner:SOURCE PHOTONICS

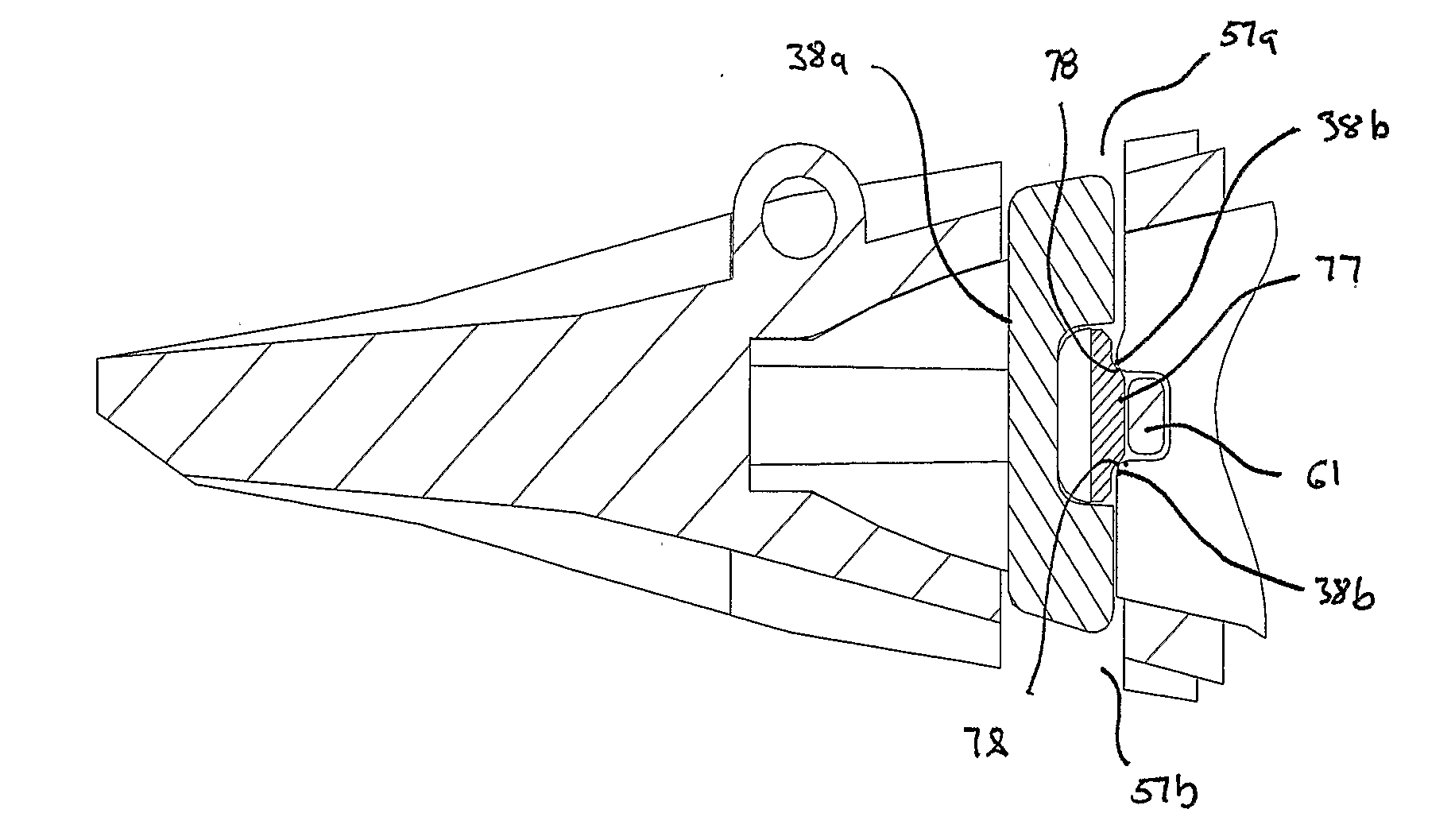

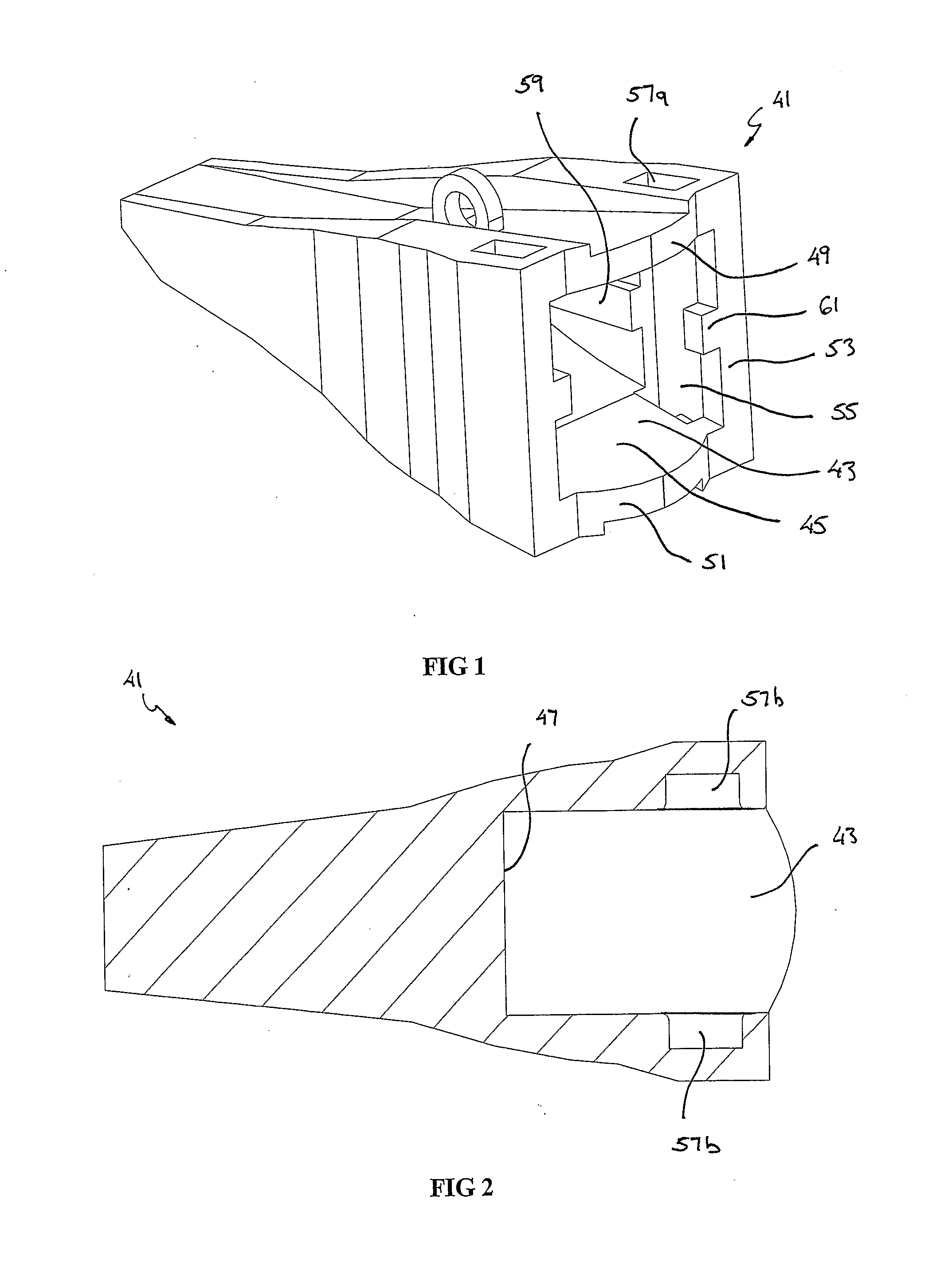

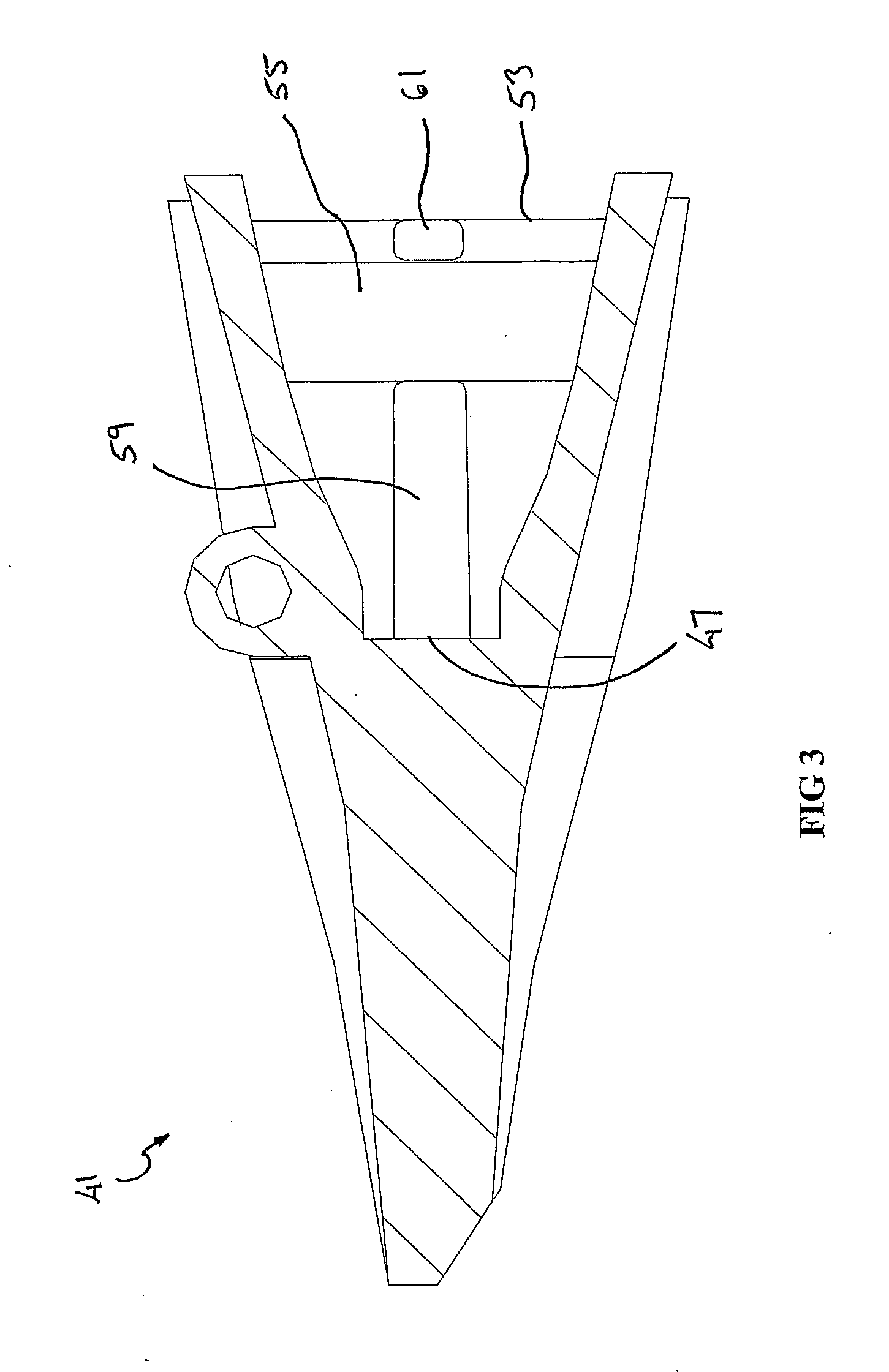

Tooth and Adaptor Assembly

Abstract A tooth and adaptor assembly (11) for use on earthmoving machinery, the assembly comprising an adaptor (21) adapted to be secured to a bucket or like component on the earthmoving machinery. The adaptor (21) comprising a nose (27) having an at least one sidewall (35) incorporating a first channel (37) and a second channel (39) angled relative to each other. The assembly (11) also a tooth (41) adapted to be received on the adaptor (41) and releasably secured thereto. The tooth comprises a socket (43) having sidewalls (53). At least one sidewall (53) incorporates a third channel (55) at an angle complementary to the second channel (39), such that when assembled the two channels (39, 55) co-operate to define an enclosure (91). An upper wall (49 of the socket (43) has at least one aperture (57) therethrough, and which is aligned with the third channel (55). The assembly (11) further comprises at least one locking mechanism (71) for locking the tooth (41) to the adaptor (21). The locking mechanism (71) having at least one projection (77) and adapted to be received through the aperture (57). During assembly the projection (77) moves inwardly with respect to the locking mechanism (71) as it enters the enclosure, the locking mechanism (71) moving towards its normal extended position when the projection (77) aligns with the first channel (37) wherein the assembly (11) is in its locked condition.

Owner:BRADKEN OPERATIONS

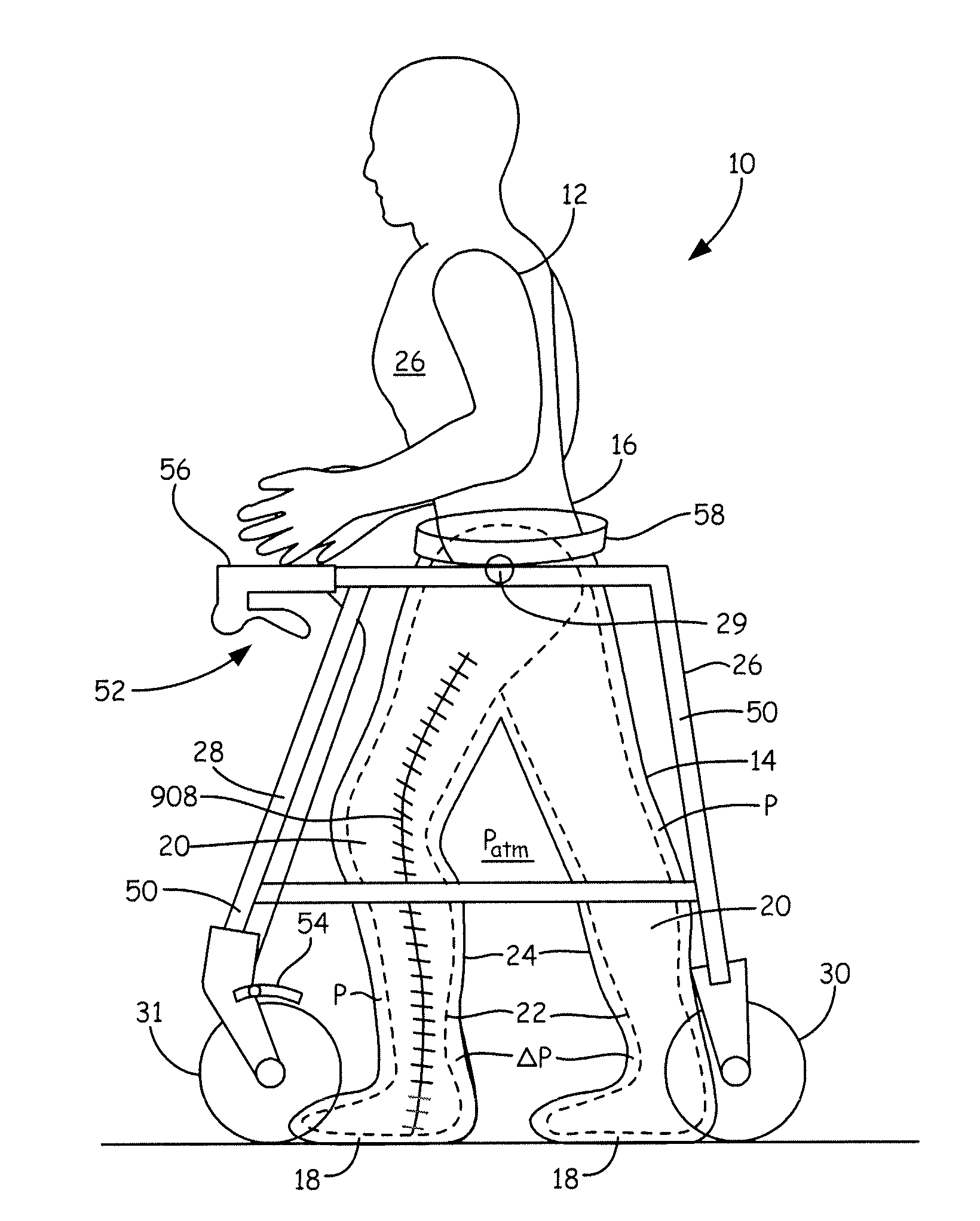

Body lift-assist walker device

ActiveUS20160166454A1Minimal forceGood adhesionBlood stagnation preventionPneumatic massagePositive pressureDifferential pressure

The present invention provides a body lift-assist walker device for gait training is provided by the invention. The patient wears a pressurized body suit over all or a portion of his lower body, and the suit is attached to the walker device. A positive pressure or vacuum condition is applied to the interior of the suit, so that the differential pressure condition across the suit offloads a portion of the patient's body weight to the ground through the supportive walker device to make it easier for him to walk or run. The walker device also includes a lift-assisted body weight support device operated by a constant force mechanism like a pneumatic air cylinder that can lift the patient from a sitting position to a standing position with minimal physical effort. The device provides a portable and convenient system for persons undergoing physical therapy for treatment of gait or balance problems following an injury, stroke, or neurological disorder, or for use by elderly or disabled persons who have encounter difficulties in the sit-to-stand movement or walking.

Owner:LITE RUN

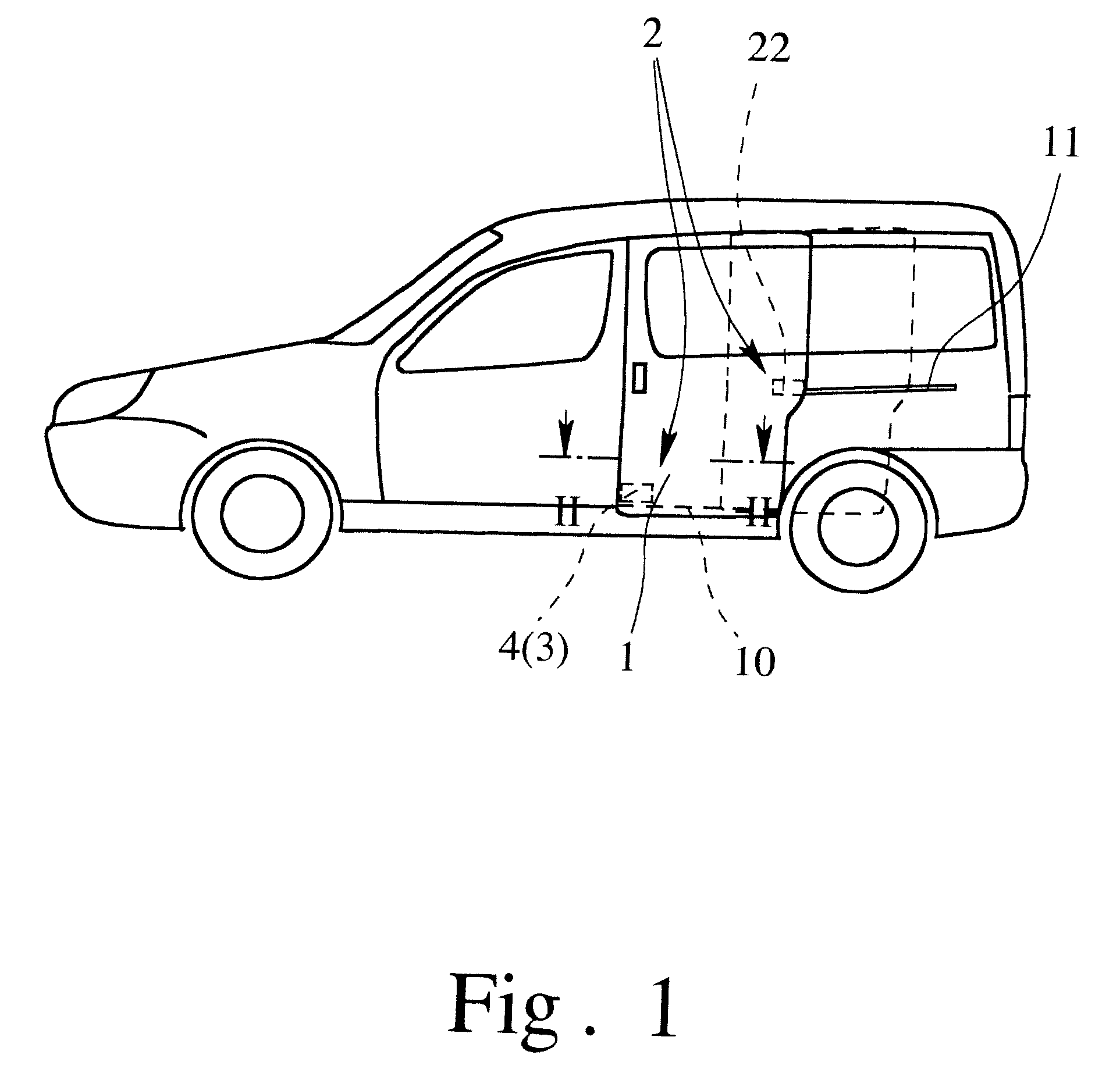

Sliding door arrangement for a motor vehicle

InactiveUS20070096504A1Improve the level ofExcellent ease of useVehicle locksMan-operated mechanismEngineeringMotorized vehicle

Owner:BROSE SCHLIESSSYSTEME GMBH & CO KG

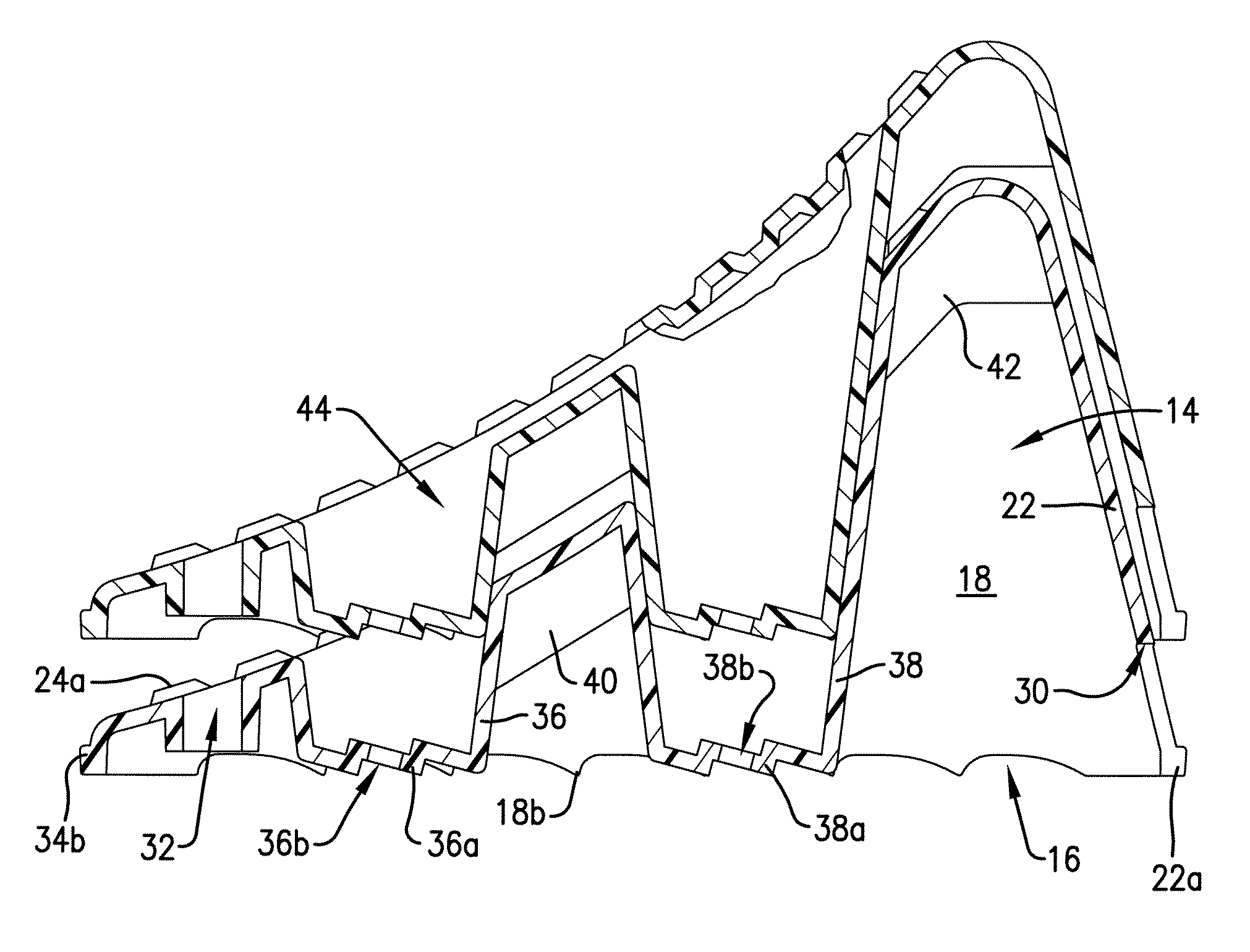

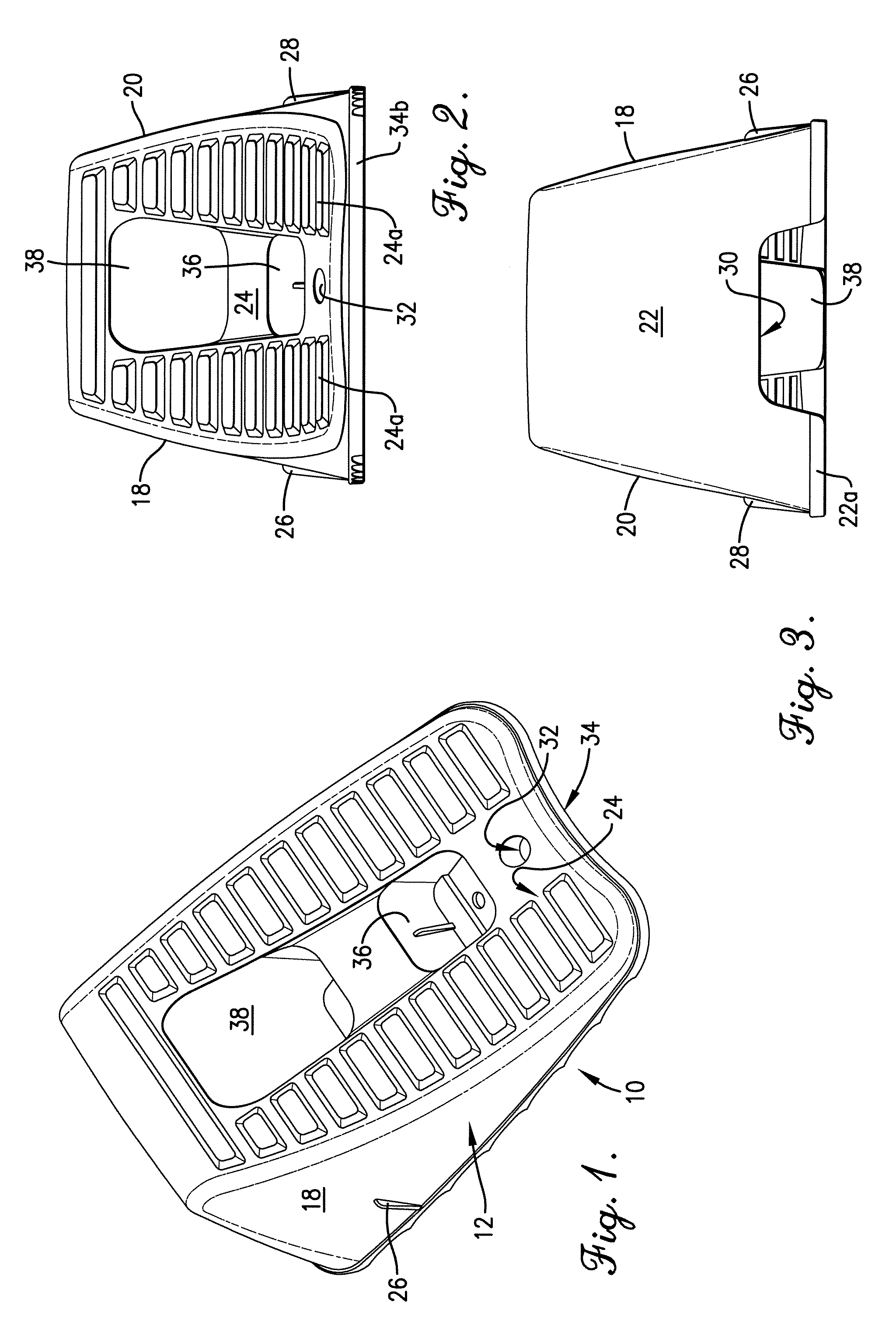

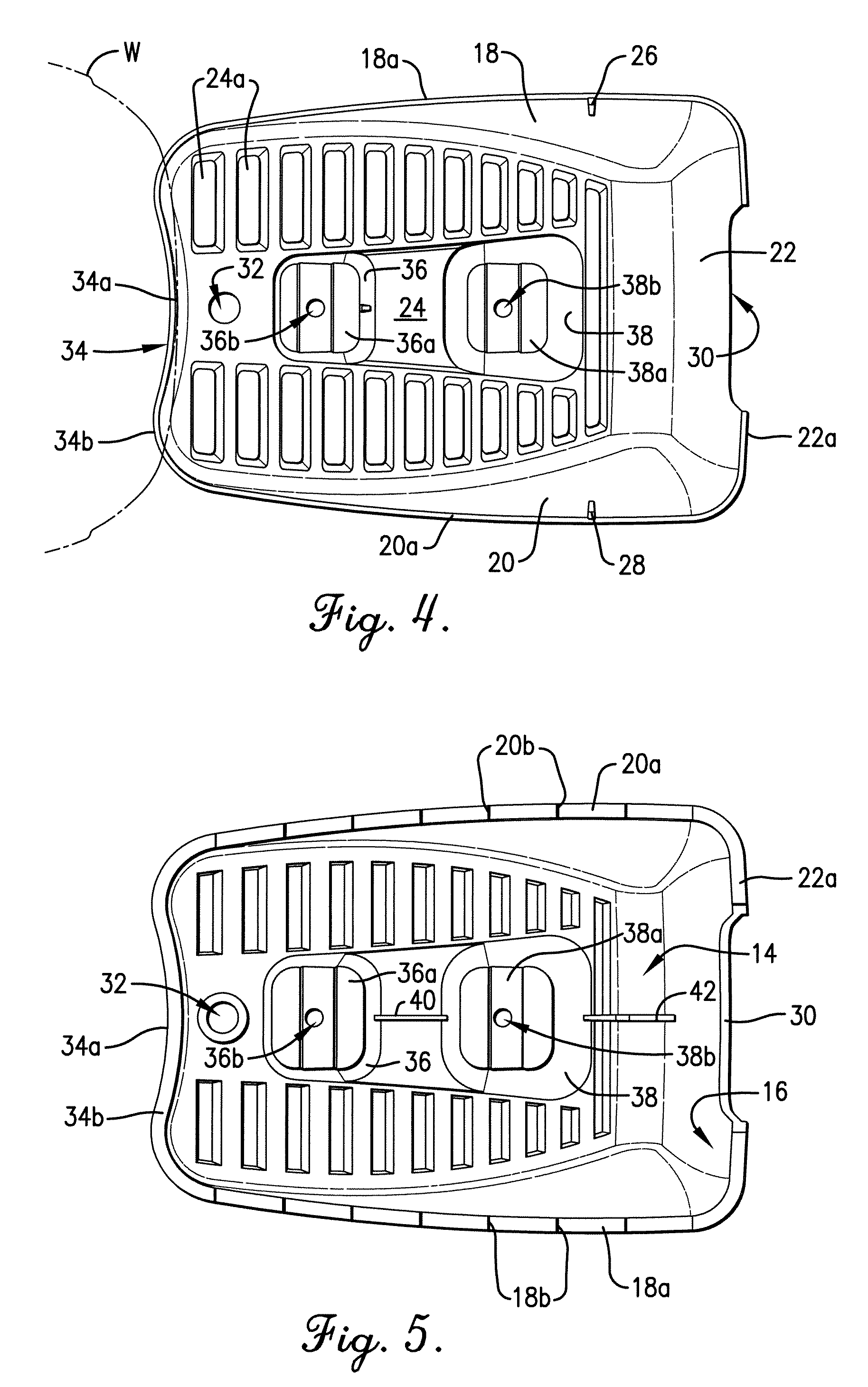

Wheel chock

InactiveUS7040461B2Effective and easy to useEfficient storagePortable braking systemLeading edgeEngineering

A wheel chock (10) configured for placement under a resting rubber tired wheel (W), such as a wheel found on a powered vehicle, to maintain the wheel (W) at rest is disclosed. The wheel chock (10) broadly includes a body (12) that defines an internal chamber (14) in communication with an open face (16) presented by the body (12). The body (12) presents a prism-like configuration having a generally triangular shape and includes a pair of oppositely spaced sidewalls (18, 20), a rear wall (22) extending between and adjoining the sidewalls (18,20), and a wheel-supporting surface (24) extending between and thereby enclosing the walls (18,20,22). The wheel-supporting surface (24) presents a low profile, arcuate leading tire-engaging edge (34). The arcuate leading edge (34) substantially complements the contour of the tire and enables the chock (10) to be easily placed under the wheel (W) in an optimal operating position i.e., in close adjacent alignment with the wheel (W) so that at least a portion of the majority of the circumferentially extending treads of the rubber tire of the wheel (W) engage at least a portion of the chock (10) with a minimal exertion of force and effort by the user. The internal chamber (14) in communication with the open face (16) enables the body (12) of the chock (10) to be stackably nested within another similarly configured wheel chock to provide a compact, space-efficient storage of the chocks that facilitates ready portability for transportation of a pair or more of the chocks in the vehicle.

Owner:HOPKINS MFG

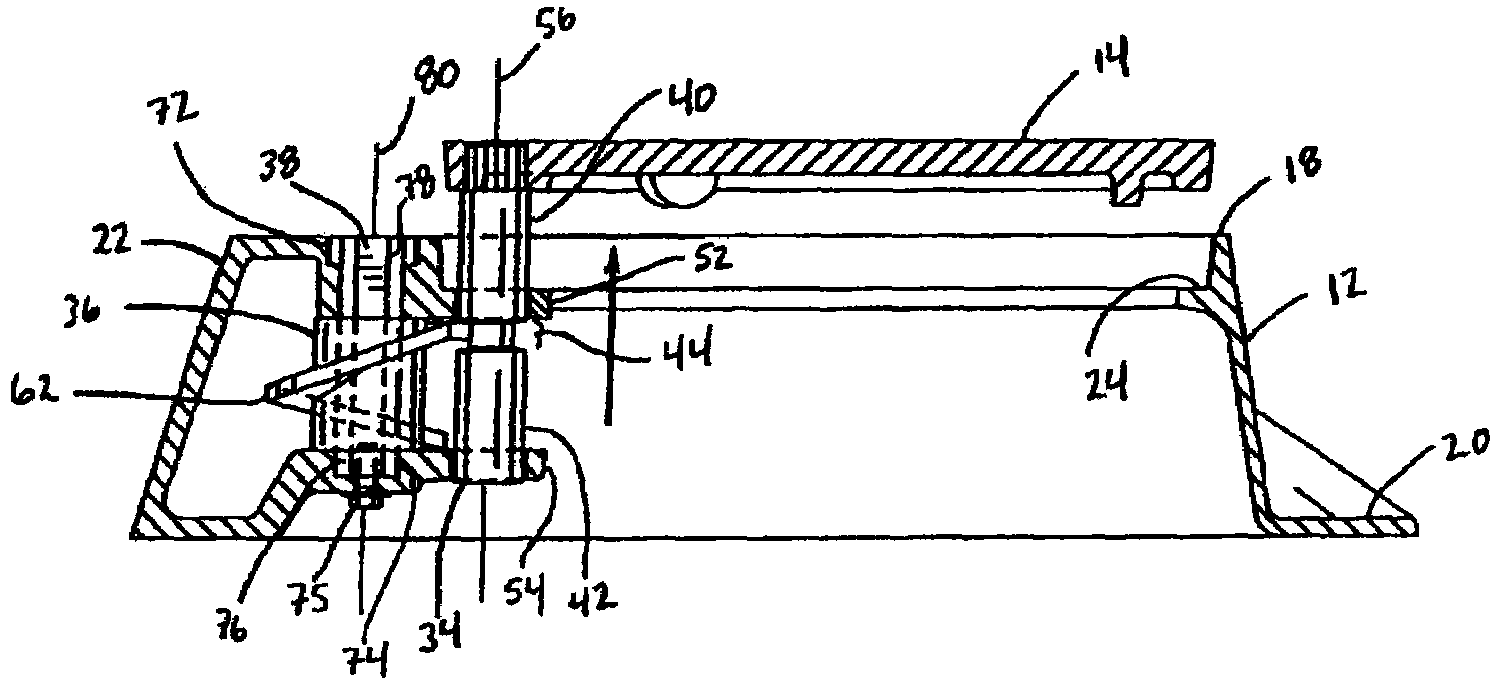

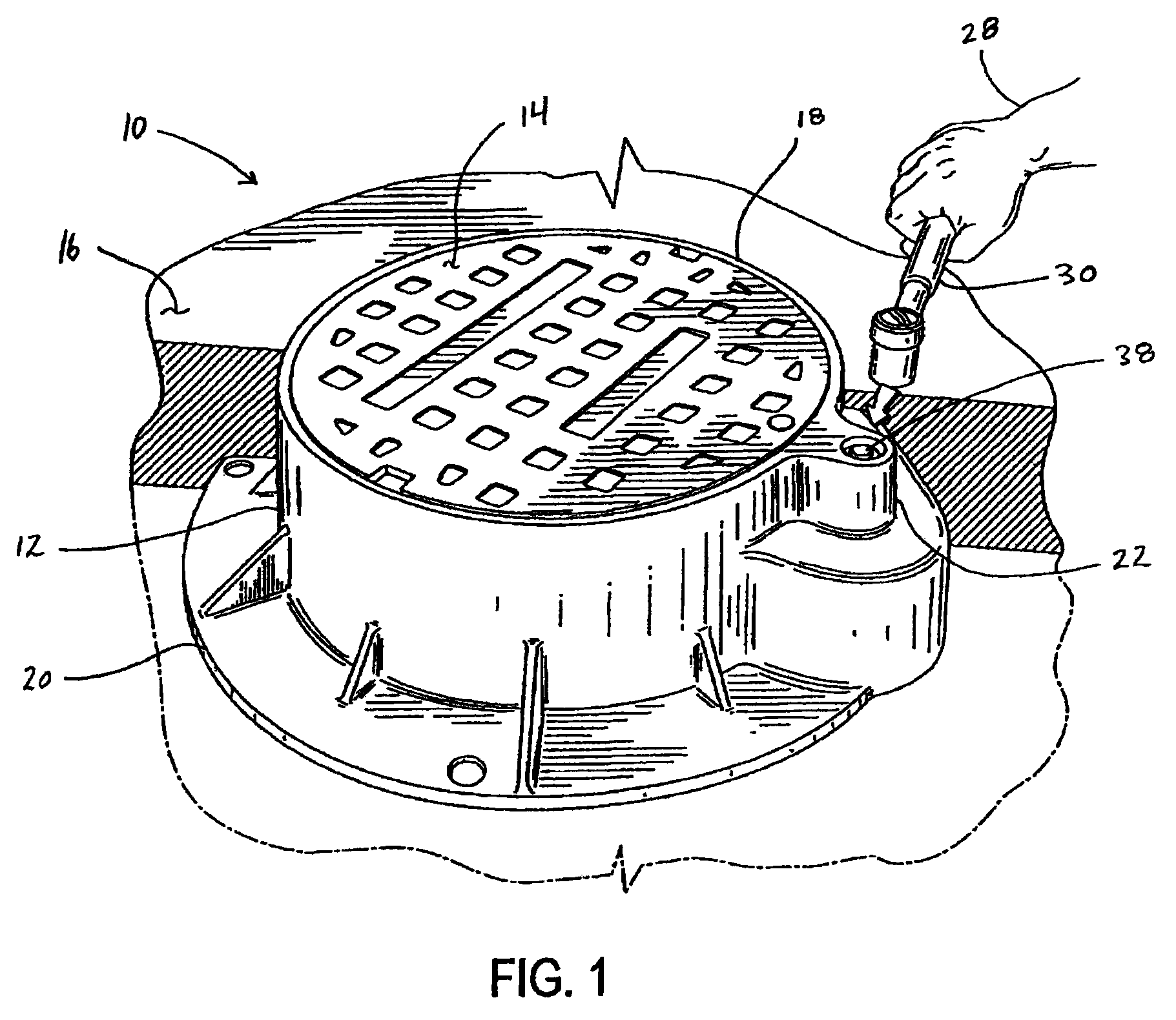

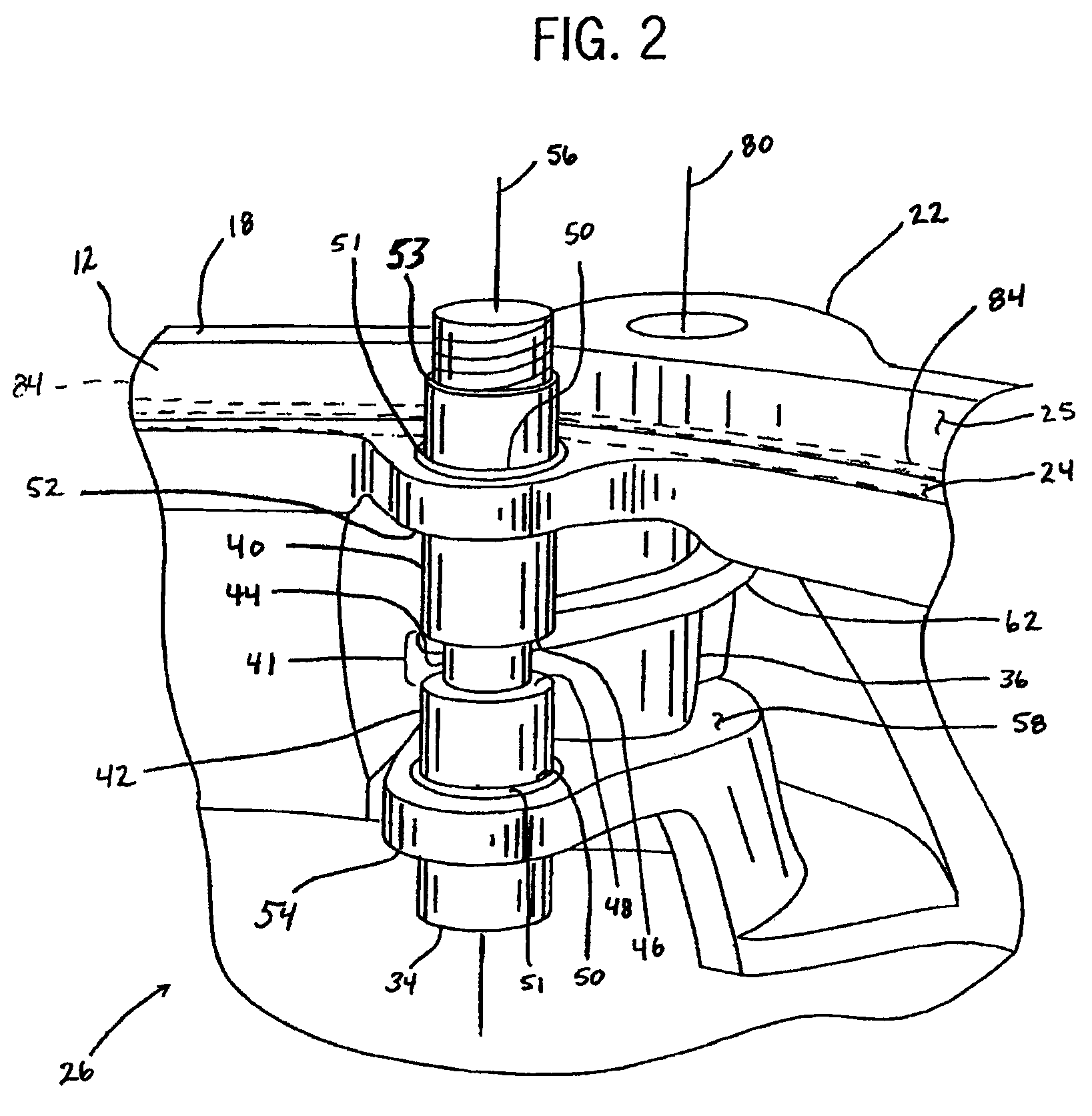

Cam-lift for a manhole cover

A manhole cover assembly including a frame defining an opening and a cover sized to engage the opening. A lift pin is retained by the frame, defining a first axis, and includes a bearing portion, and a top end connected to the cover. The lift pin is free to slide axially along the first axis. A spiral cam is retained to the frame by a torque shaft including an upper and lower end, defining a second axis offset from the first axis. The spiral cam includes a cam surface in selective engagement with the bearing portion of the lift pin so that rotation of the torque shaft about the second axis causes rotation of the spiral cam about the second axis and displacement of the lift pin along the first axis.

Owner:NEENAH FOUNDRY

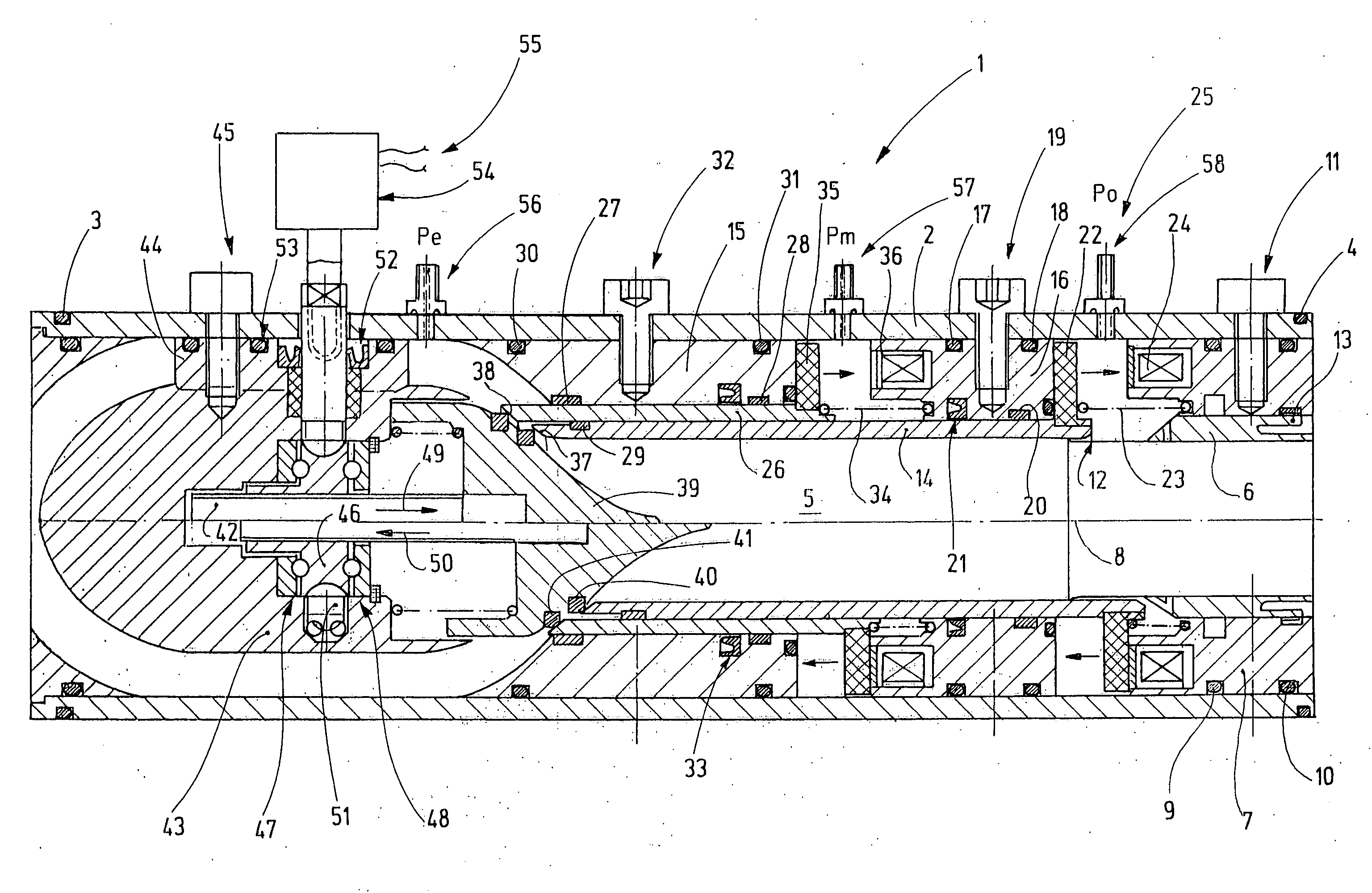

Tubular valve device

InactiveUS20100102259A1Easy to closeEasy to openOperating means/releasing devices for valvesCheck valvesEngineeringValve seat

The presented valve (1) is based on two axially adjustable sleeve-shaped valve seat rings (14, 36) that are associated with locking arrangements in the form of annular armature plates (22, 35) and associate holding coils (24, 36). The valve closure member (39) can be variably adjusted via a position adjustment drive. Said valve closure member has a double function. On the one hand, it acts to move the valve seat rings (14, 26) into locking position and, on the other hand, it acts to control the gas flow.

Owner:KARL DUNGS

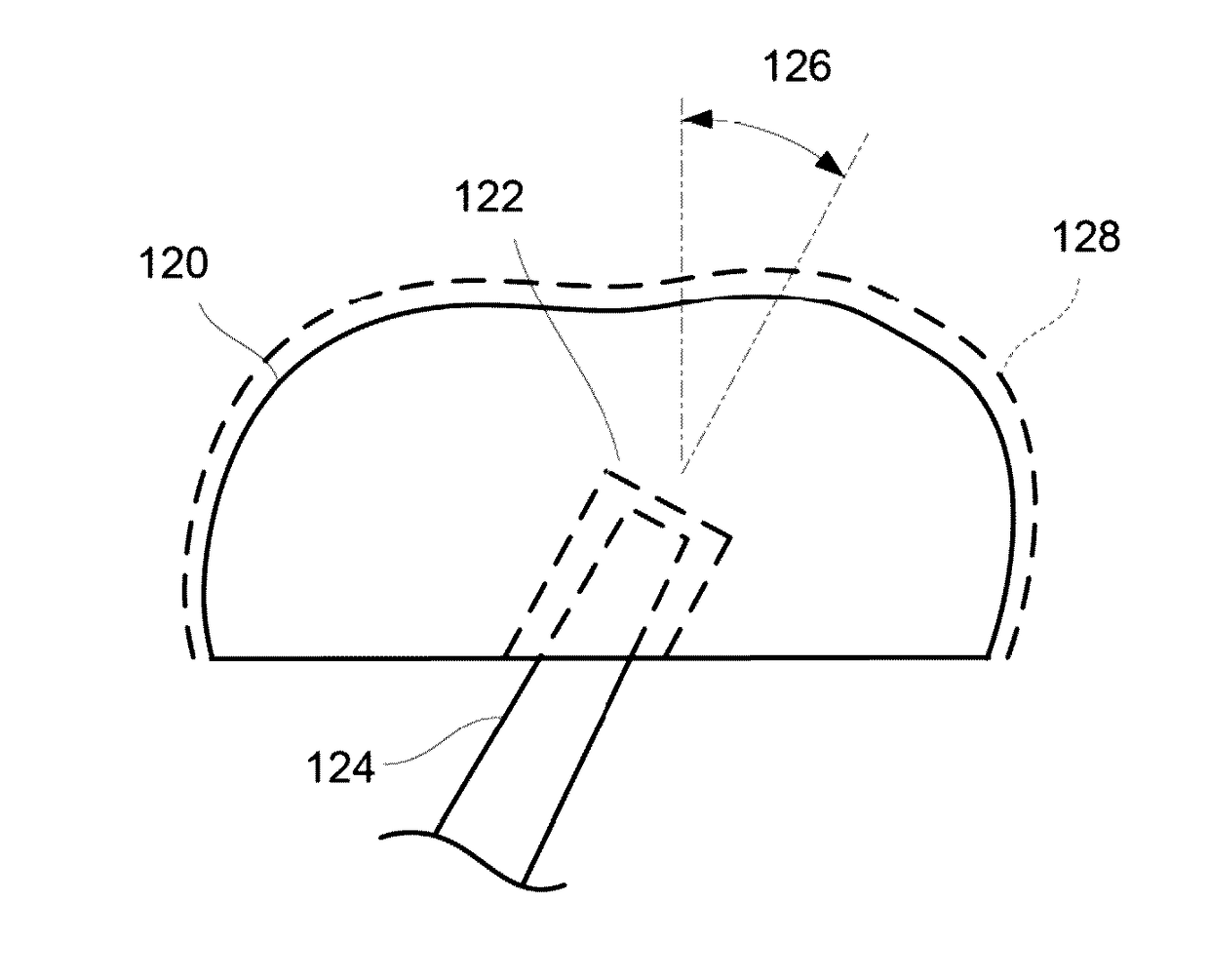

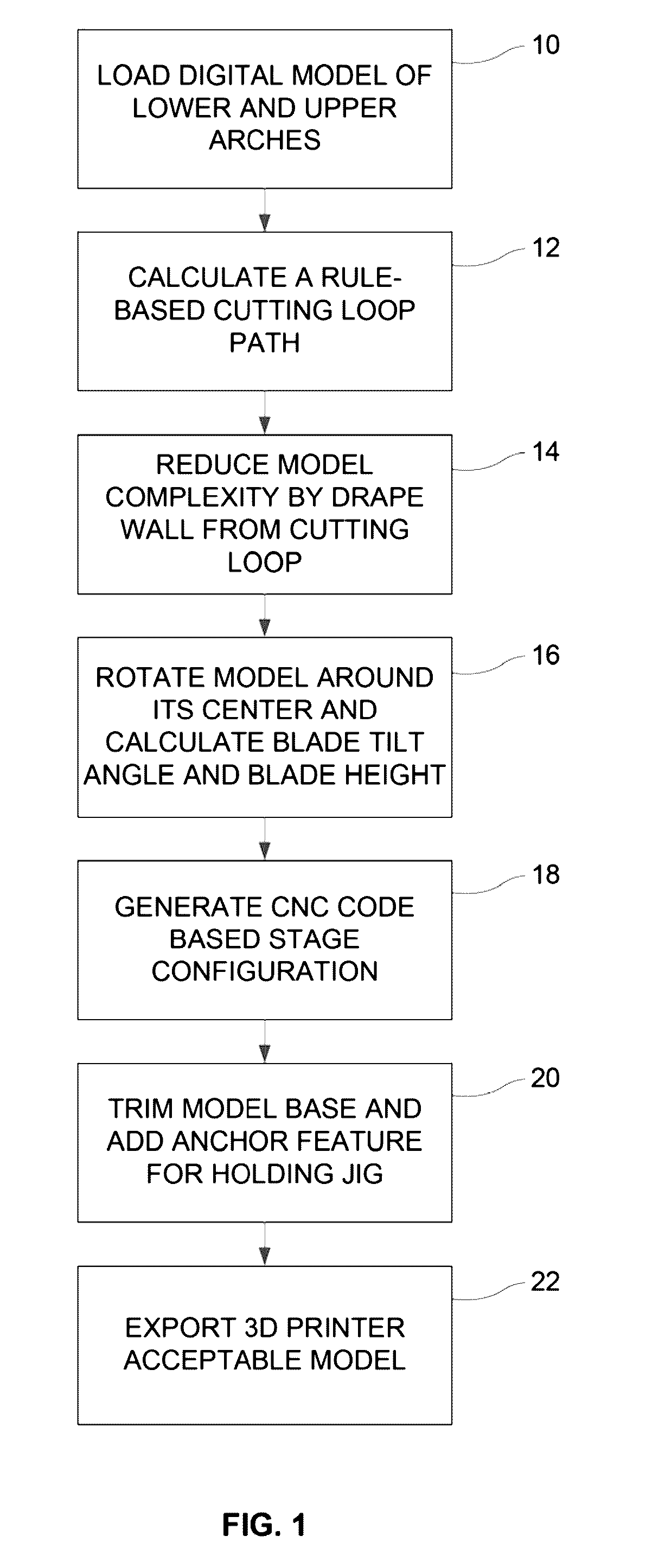

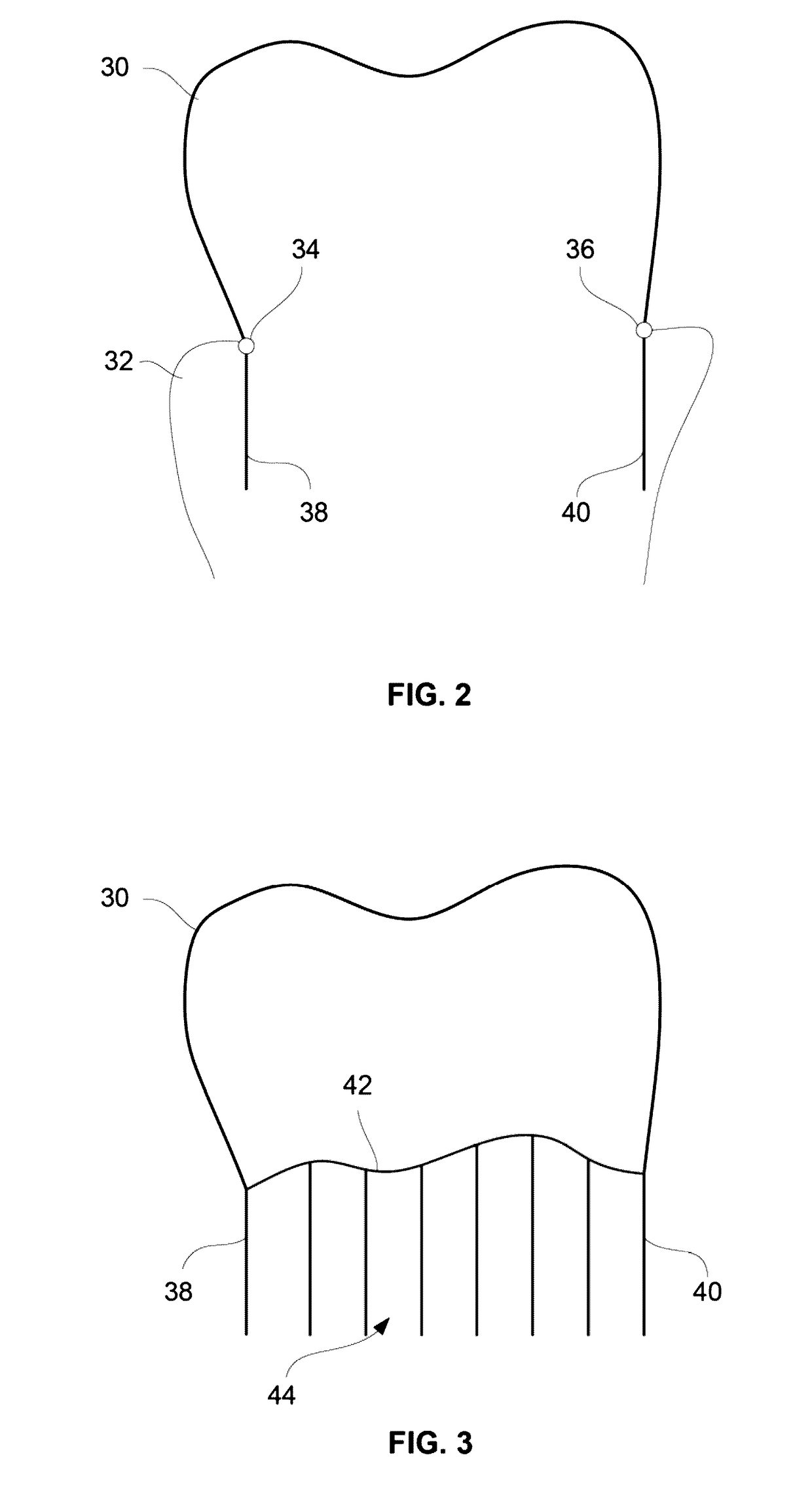

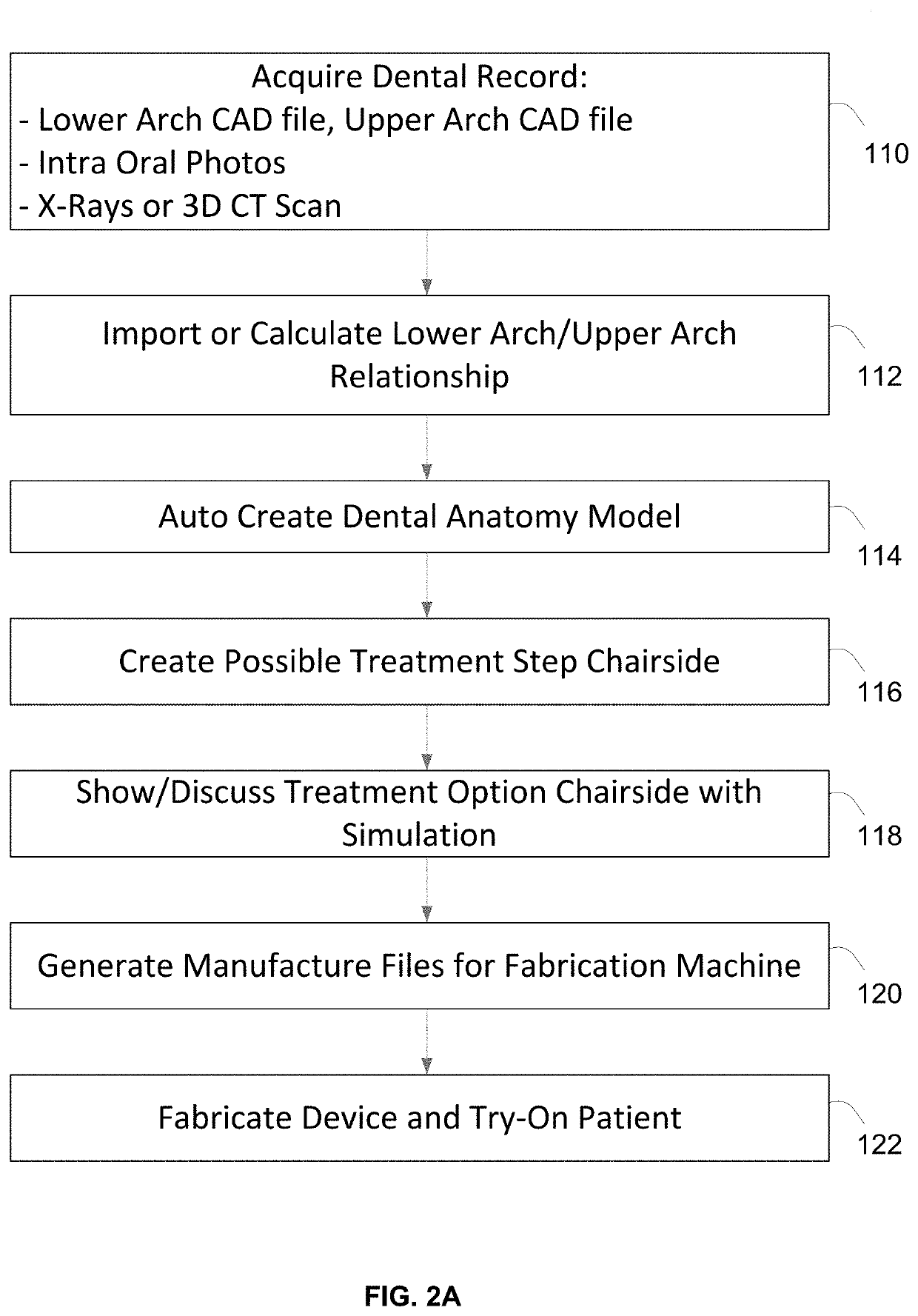

Systems and methods for fabricating dental appliances or shells

Systems and methods are disclosed for cutting and trimming dental molds and oral appliances by receiving a digital model of teeth, determining a cutting loop path and applying a drape wall to the cutting loop to generate a simplified tooth base in a dental mold having an inner arch curve and an outer arch curve. The oral appliance may be formed on the dental mold and a cutter may be applied using a sweeping motion across the inner and outer arch curves.

Owner:ULAB SYST INC

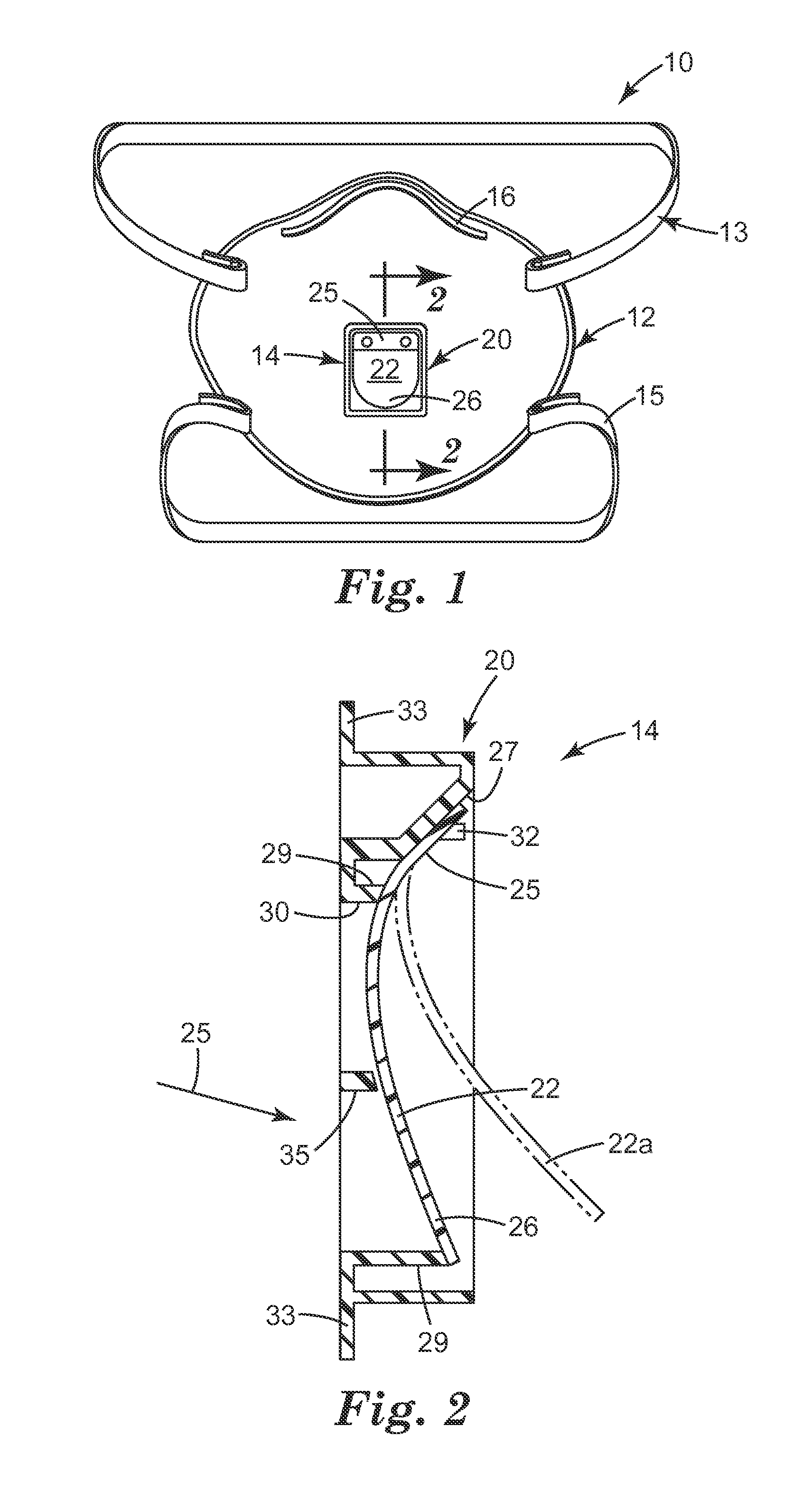

Respirator having valve with an ablated flap

InactiveUS20120167890A1Small pressure dropLess energyRespiratory device testingBreathing filtersRespiratorEngineering

A respirator 10 that has a mask body 12, a harness 13, and an exhalation valve 14. Both the harness 13 and the exhalation valve 14 are secured to the mask body 12. The exhalation valve 14 comprises a valve seat 20 and a flap 22 that has a surface 57 that has been ablated. Through use of an ablated flap, the flap characteristics can be better fashioned to achieve desired valve performance. The valve flap can be fashioned to remain closed under any orientation but also to open with minimal force or pressure from the wearer's exhaled air. A valve having these qualities provides a respirator that is more comfortable for a person to wear, which can be particularly beneficial to workers who wear respirators for extended time periods.

Owner:3M INNOVATIVE PROPERTIES CO

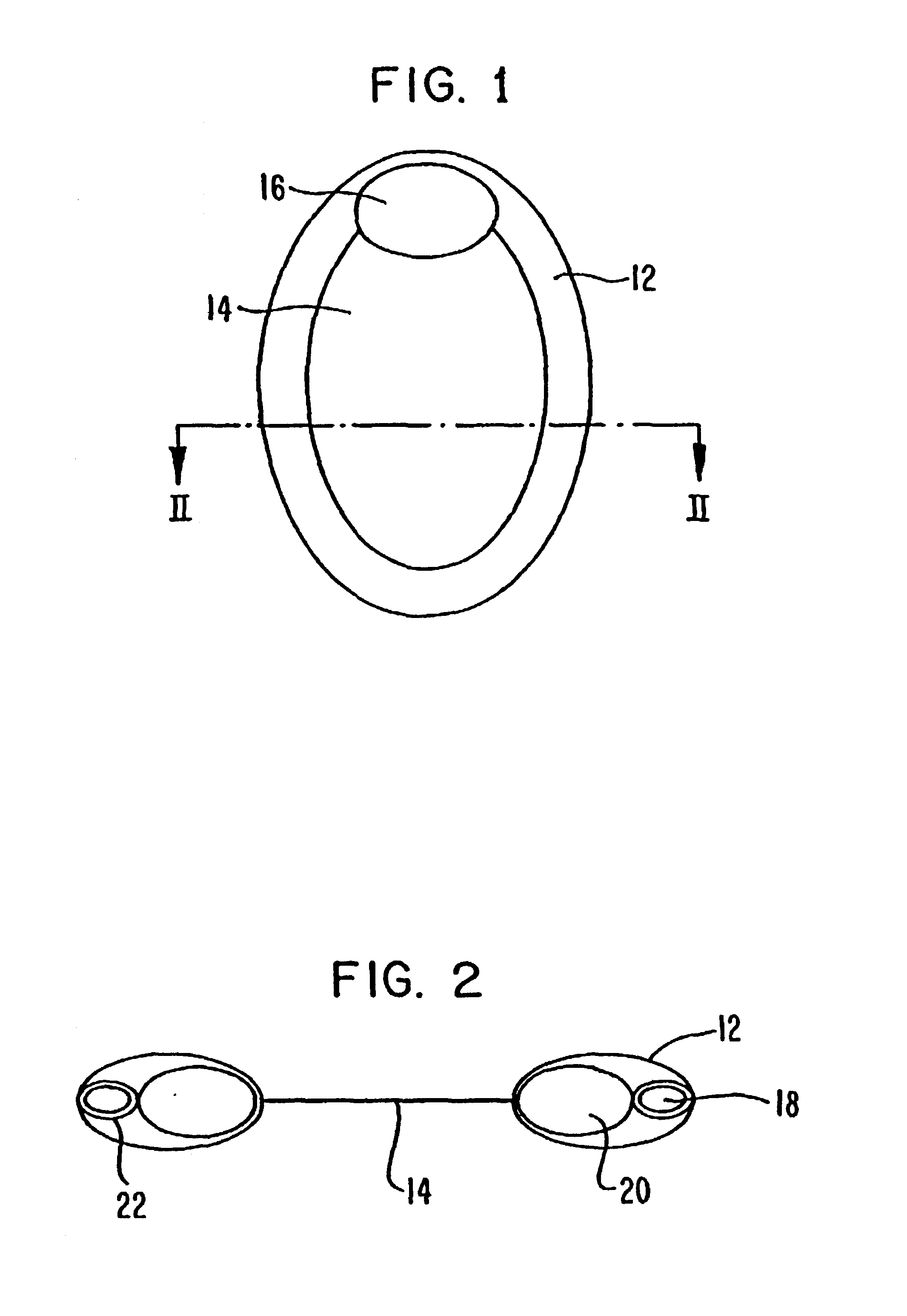

Collapsible flotation device

A device comprises a spring and a sleeve. The spring is configured to form a closed loop. The spring is moveable between a coiled configuration when the spring is collapsed and an uncoiled configuration when the spring is expanded. The spring defines a circumference while in the uncoiled configuration. The spring is disposed within the sleeve. The sleeve includes an inflatable portion disposed about at least a portion of the circumference.

Owner:SPIN MASTER INC

Corrosion-resistant coupling means and methods for using same

InactiveUS6976712B2Avoid contactControl is neededSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

A coupling couples pipes of pipe fixes, especially polytetrafluoroethylene pipes. Methods for using the coupling are also provided.

Owner:MICROMOLD PRODS

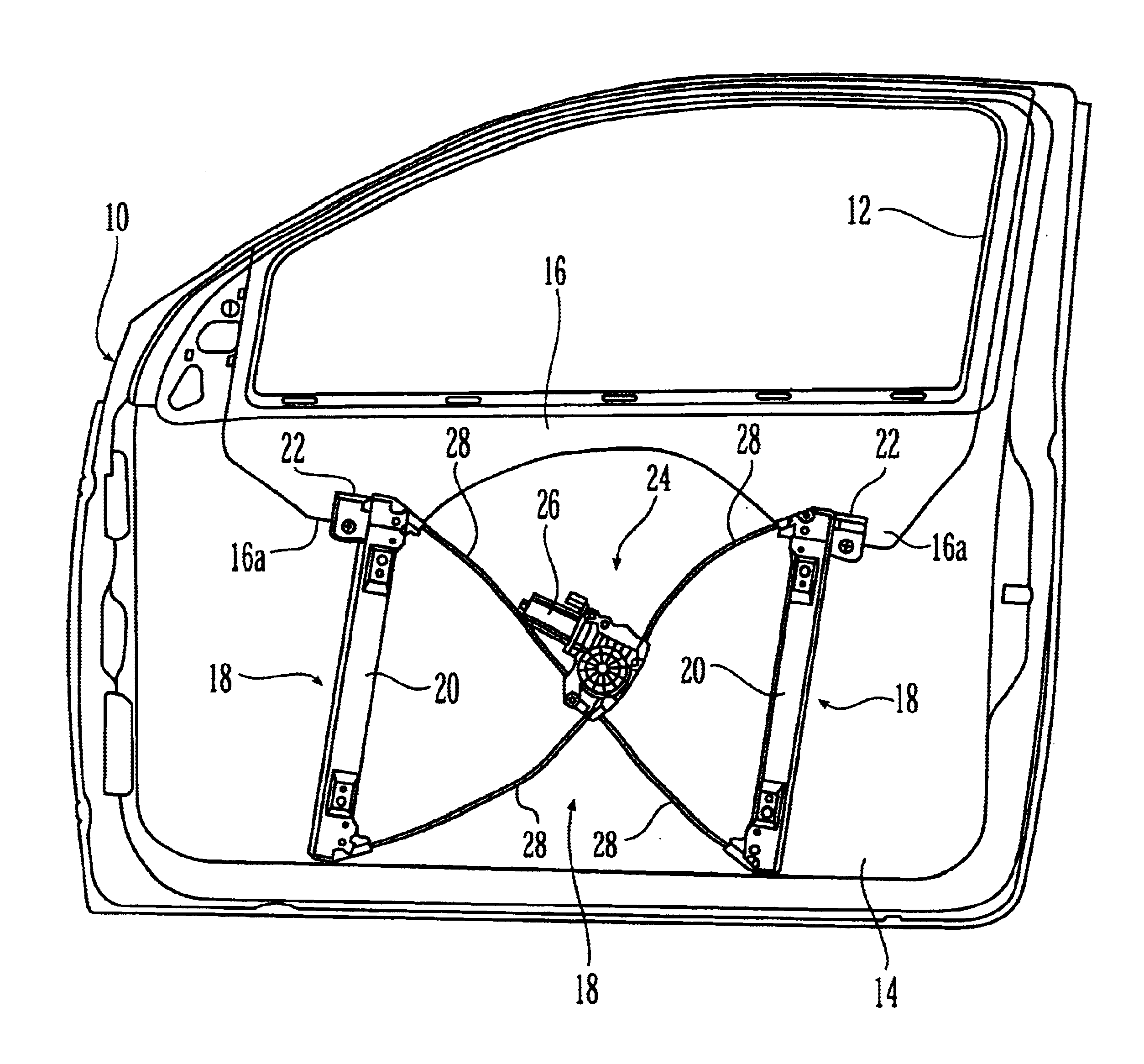

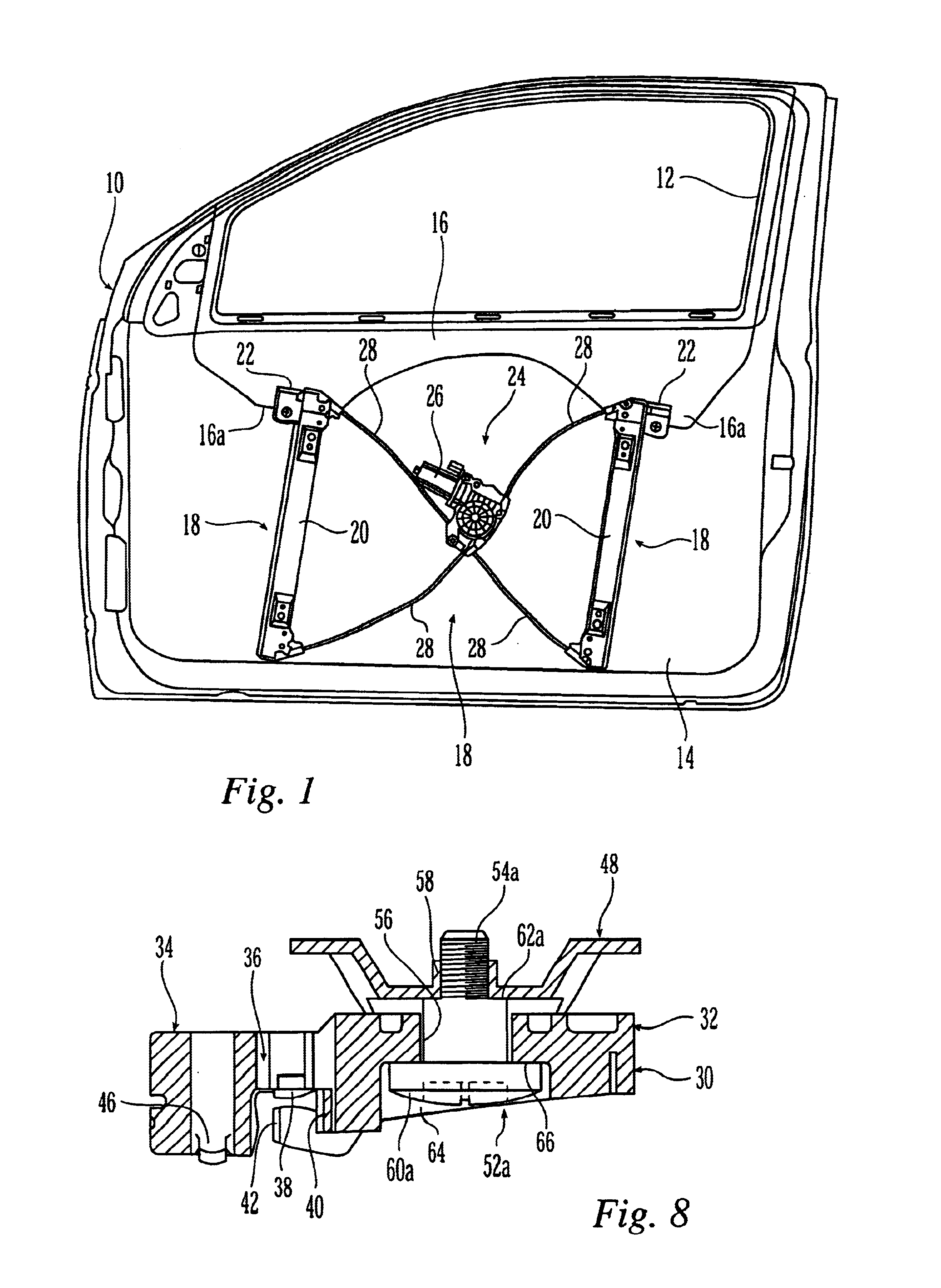

Support slide for window regulators of motor vehicles

A support slide for window regulators of motor vehicles comprises a body formed, in a single piece of molded plastic material, by a plate portion and a lateral appendage. The plate portion constitutes a fixed jaw of a clamp for tightening a lower edge of a sliding window pane, and the lateral appendage has a sliding channel adapted to receive a guide rail. A movable jaw of the clamp cooperates with the fixed jaw to clamp the lower edge of the window pane. The shank of a screw for tightening the clamp is equipped with a spacer which is contained in a through-hole of the fixed jaw and which projects from the hole at least on the face of the plate portion which is turned towards the movable jaw to constitute an annular abutment surface.

Owner:LAMES

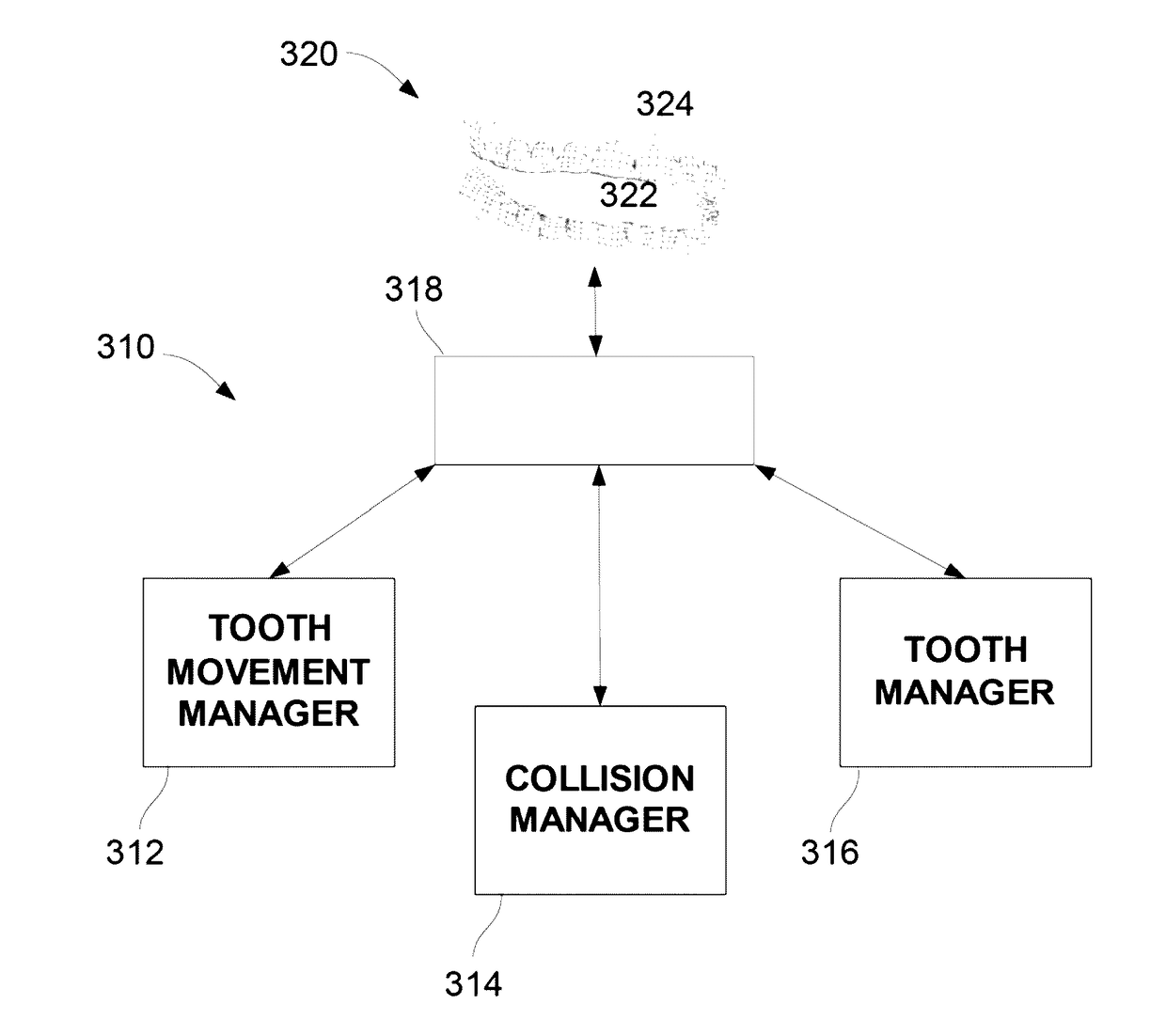

Orthodontic planning systems

ActiveUS10548690B2Reduce complexityAvoid collisionMedical simulationOthrodonticsDental malocclusionDentition

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished in one variation by receiving a scanned dental model of a subject's dentition, determining a treatment plan having a plurality of incremental movements for repositioning one or more teeth of the subject's dentition, and fabricating one or more aligners correlating to a first subset of the plurality of incremental movements.

Owner:ULAB SYST INC

Positive displacement stopper for a pre-filled syringe

ActiveUS8475415B2Prevent leakageEffectively and consistently reducing and eliminating refluxInfusion syringesIntravenous devicesNosePrefilled Syringe

A stopper adapted for attachment with a plunger rod for use within a syringe barrel is disclosed. The stopper includes a main body defining an open rearward end and a closed front end. The open rearward end is adapted to receive a front forward end attachment portion of the plunger rod. The stopper also includes a core member integrally formed with said main body adjacent the closed front end. The core member includes a nose portion having a profile adapted to create a positive seal with an outlet opening of such syringe barrel.

Owner:BECTON DICKINSON & CO

Brake equipment for holding and braking an elevator car in an elevator installation and a method of holding and braking an elevator installation

Brake equipment for holding and braking an elevator car in an elevator installation, which is arranged to be movable along a brake track in two directions of travel, includes a mount with a brake lining which automatically adjusts under friction couple with the brake track on movement of the elevator car relative to the rail and in that case tightens a first tightening means, which can be released by an actuator. The first tightening means tightens the mount together with the brake lining against the brake track by a biasing force. The brake equipment produces, with unmoved brake equipment and an unreleased state of the actuator, a holding force acting in both directions of travel. The holding force is determined substantially by the biasing force acting on the mount.

Owner:INVENTIO AG

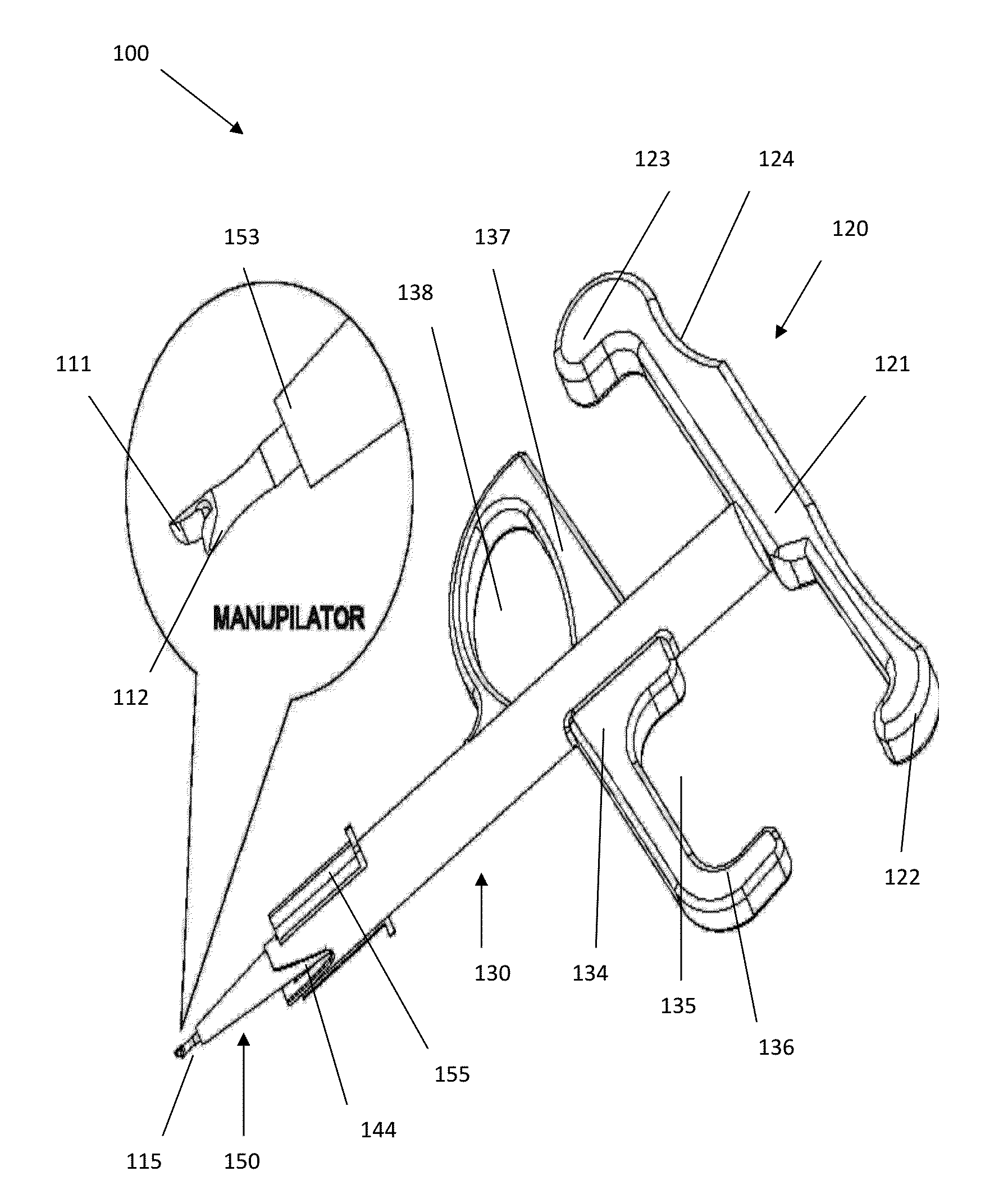

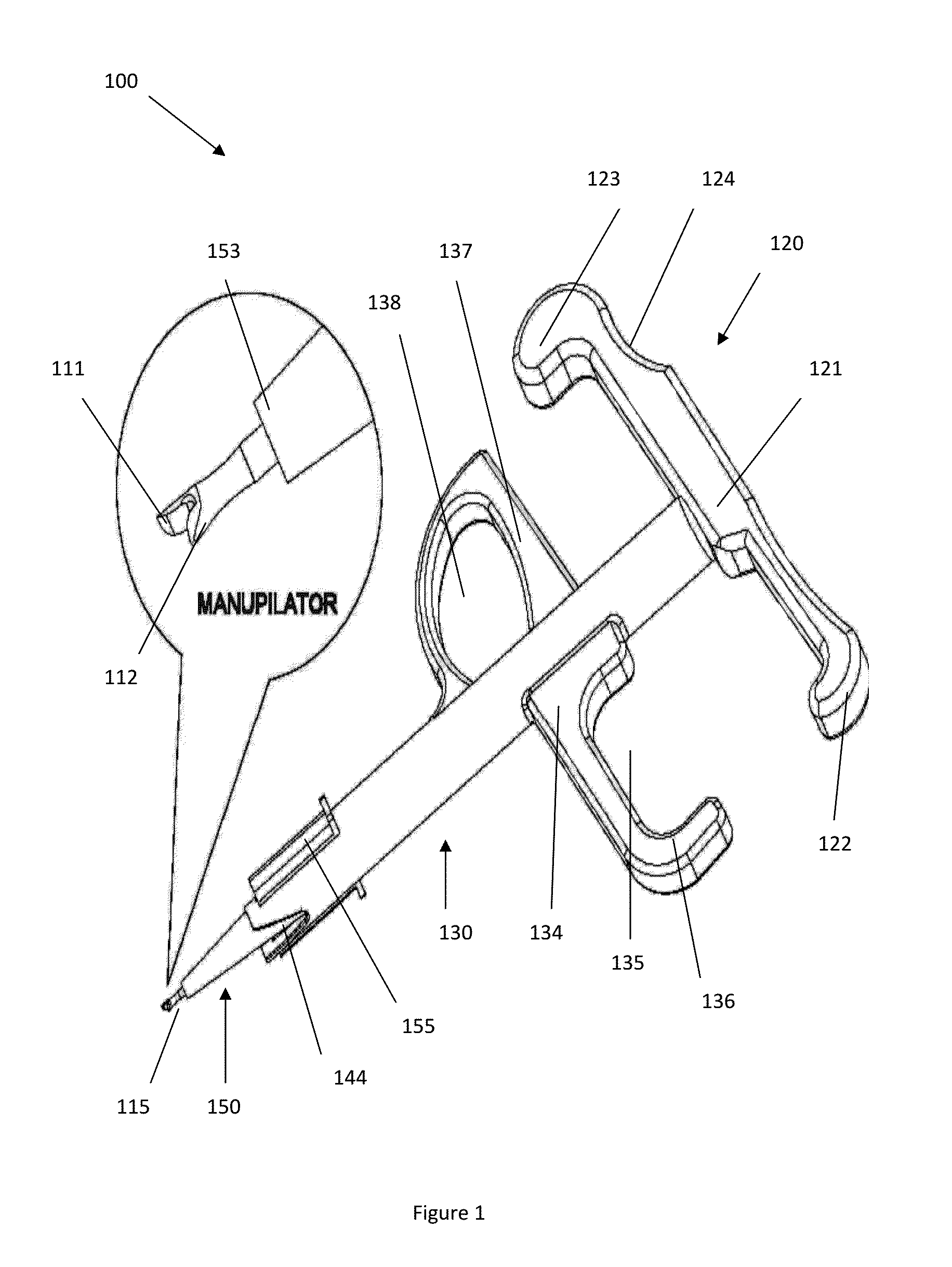

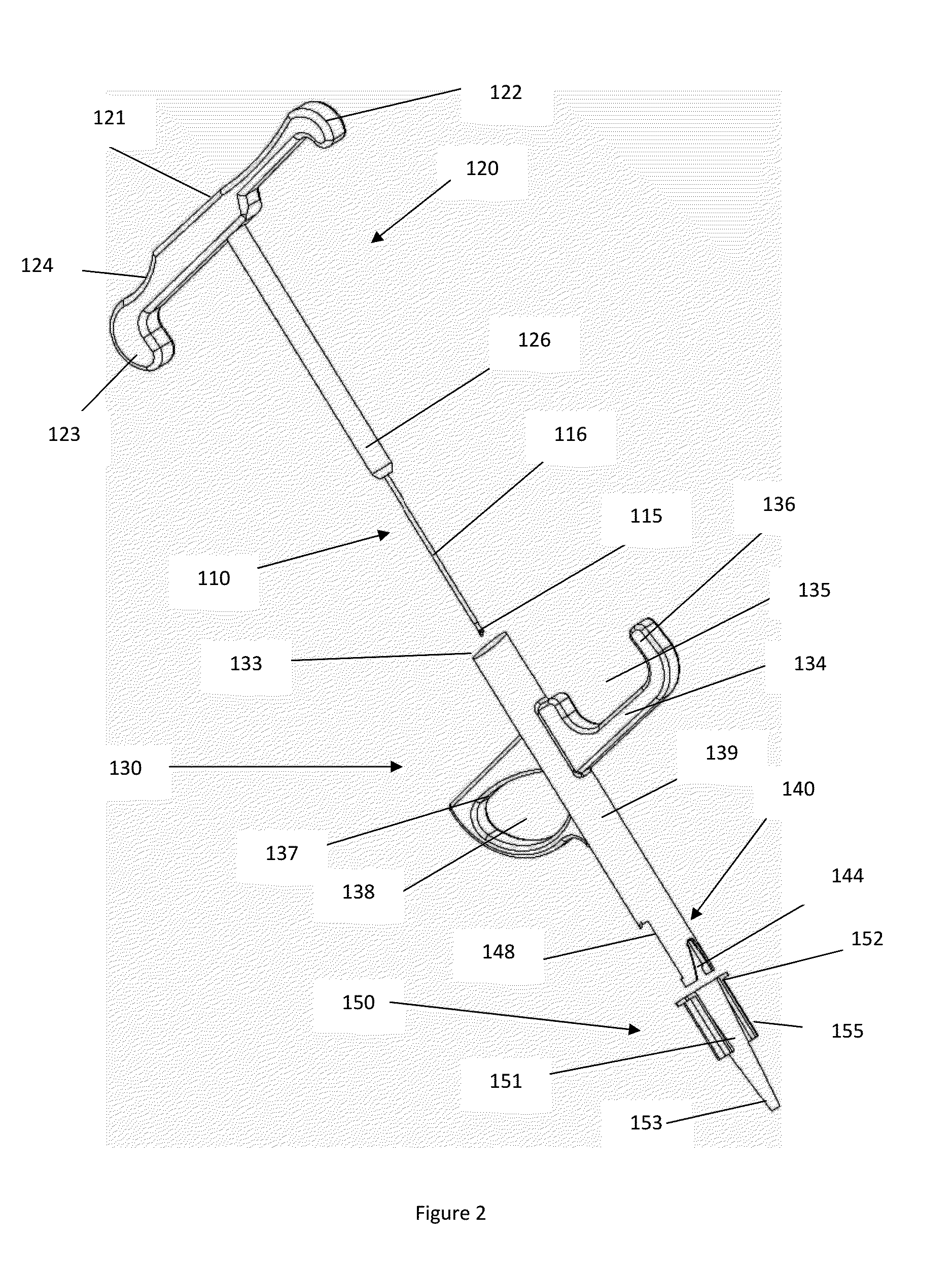

Device for single handled injection of an intraocular lens

ActiveUS20160000556A1Control moreReduce deliveryEye treatmentIntraocular lensIntraocular lensLens plate

A device 100 for delivering intraocular lens into an incision on an eye of a patient comprises a tubular member 130 defined by a hollow elongate passageway 131, a front 132 and a back through opening 133 of the passageway 131; a secured nozzle 150 having an expanded base 152, which is mounted to the front through opening 132 of the tubular member 130, tapering towards a pointed end 153 fashioned to be inserted into the incision, the secured nozzle 150 enclosing a lumen 154 substantially tapered from the base 152 to the pointed end 153 and aligned with the passageway 131 that the lens is disposed within the lumen 154 to be readily delivered; an elongate probe 110, at least partially housed within the passageway 131, having a bifurcated tip 115 which is configured to telescopically slide out from the pointed end 153 of the secured nozzle 150 pushing the disposed lens into the eye; and a plunger assembly 120 having a shaft 126 inserted into and moveable within the passageway 131 to anteriorly engage with the probe 110 to move the probe 110 in relative to the tubular member 130, wherein the bifurcated tip 115 forks into a first 111 and second prongs 112, which are irregular in size, forming a substantially U-shaped or V-shaped construct thereof for manipulating a configuration and / or and orientation of the delivered lens in the eye.

Owner:SINGAPORE HEALTH SERVICES PTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com