Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

593results about How to "React Safe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

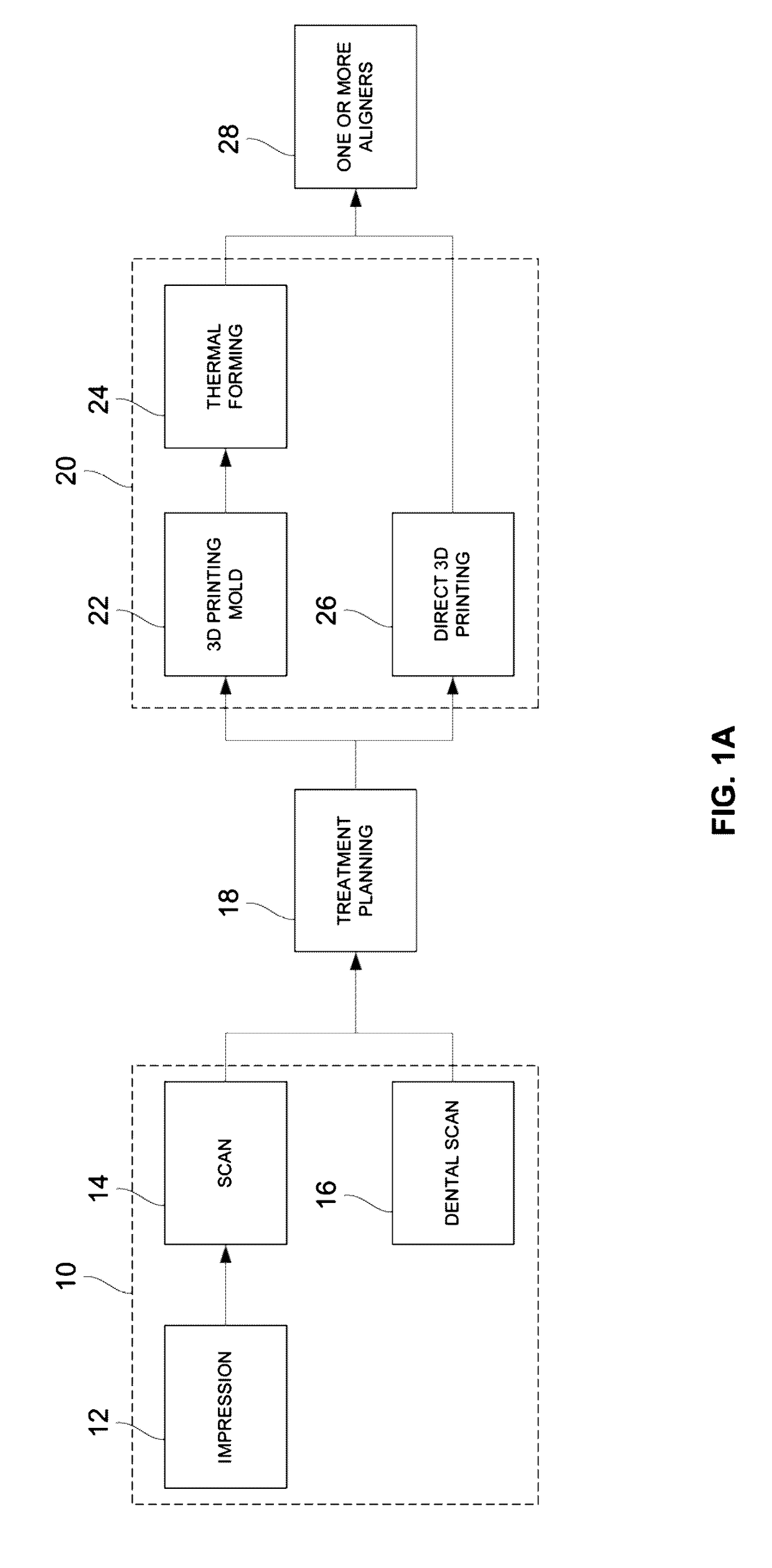

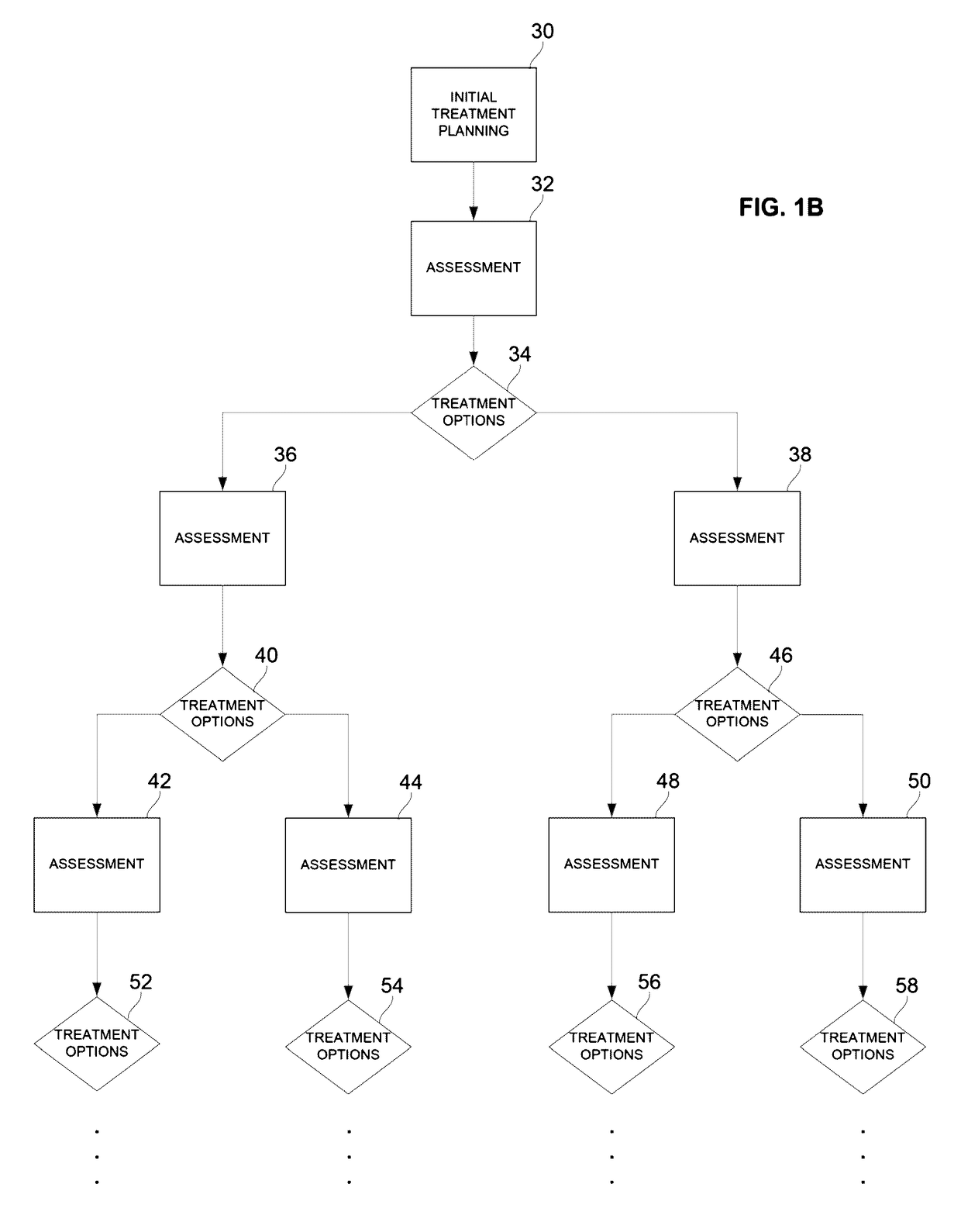

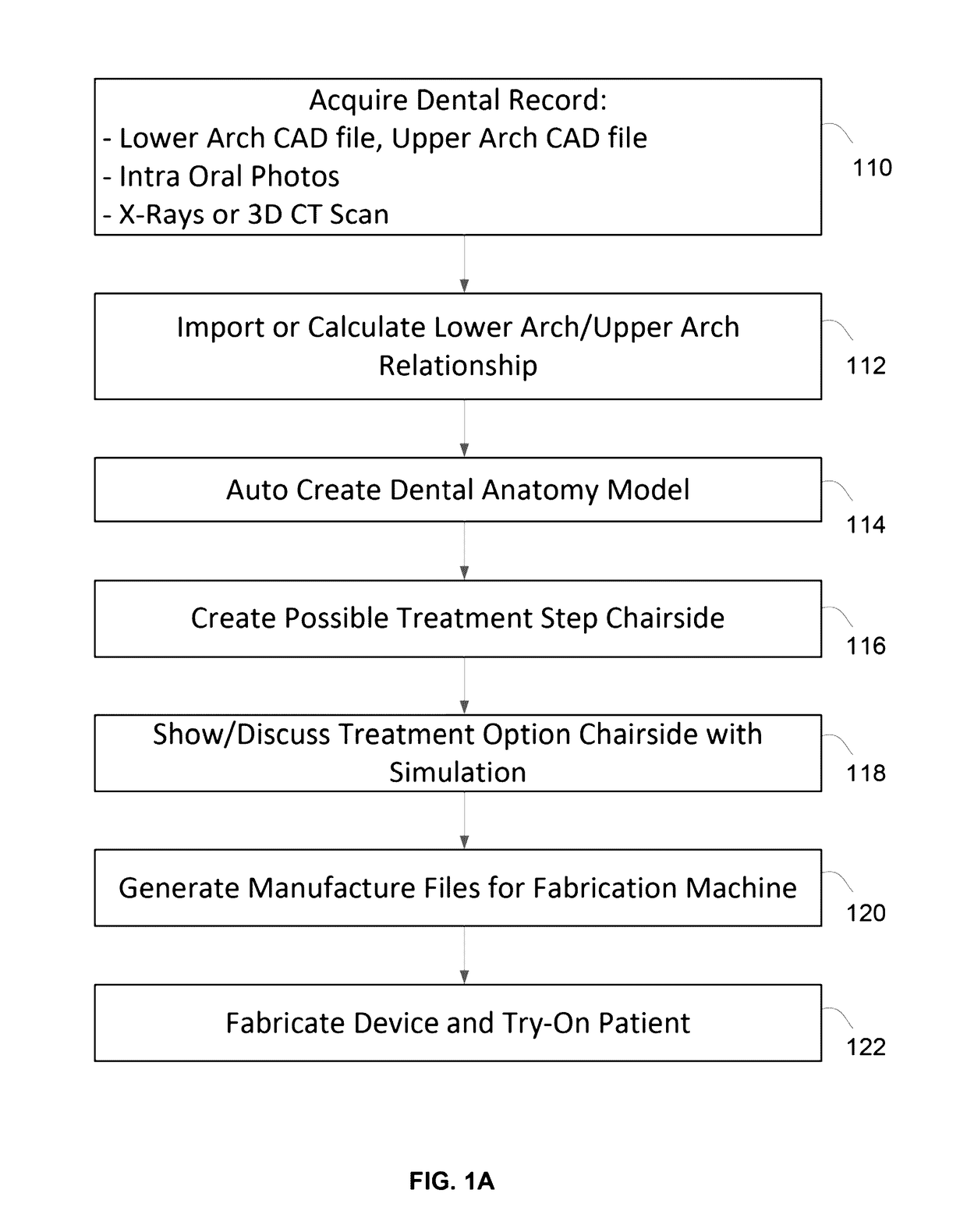

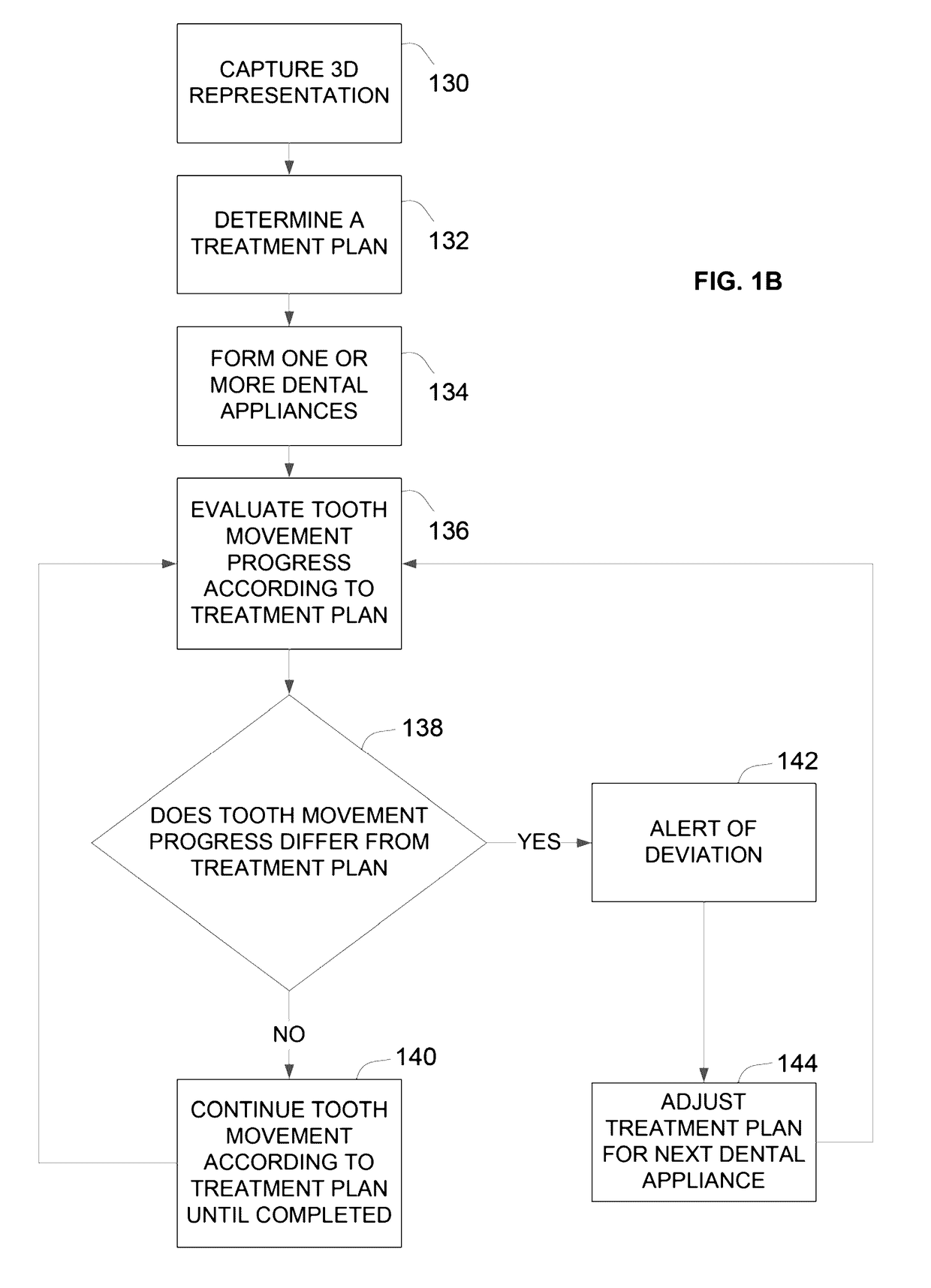

Orthodontic planning systems

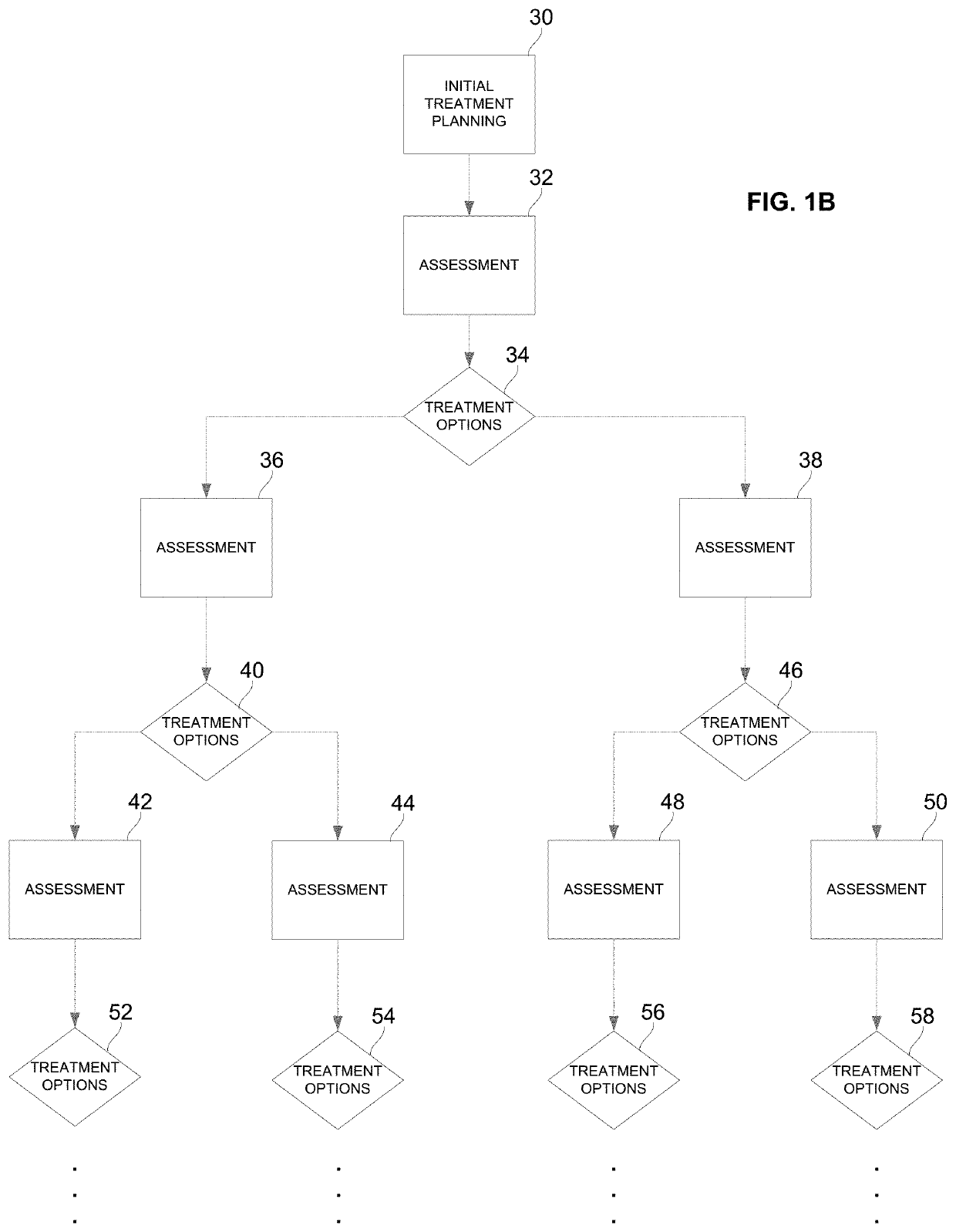

ActiveUS20170100214A1Reduce riskMinimal forceMedical simulationOthrodonticsProgram planningDentition

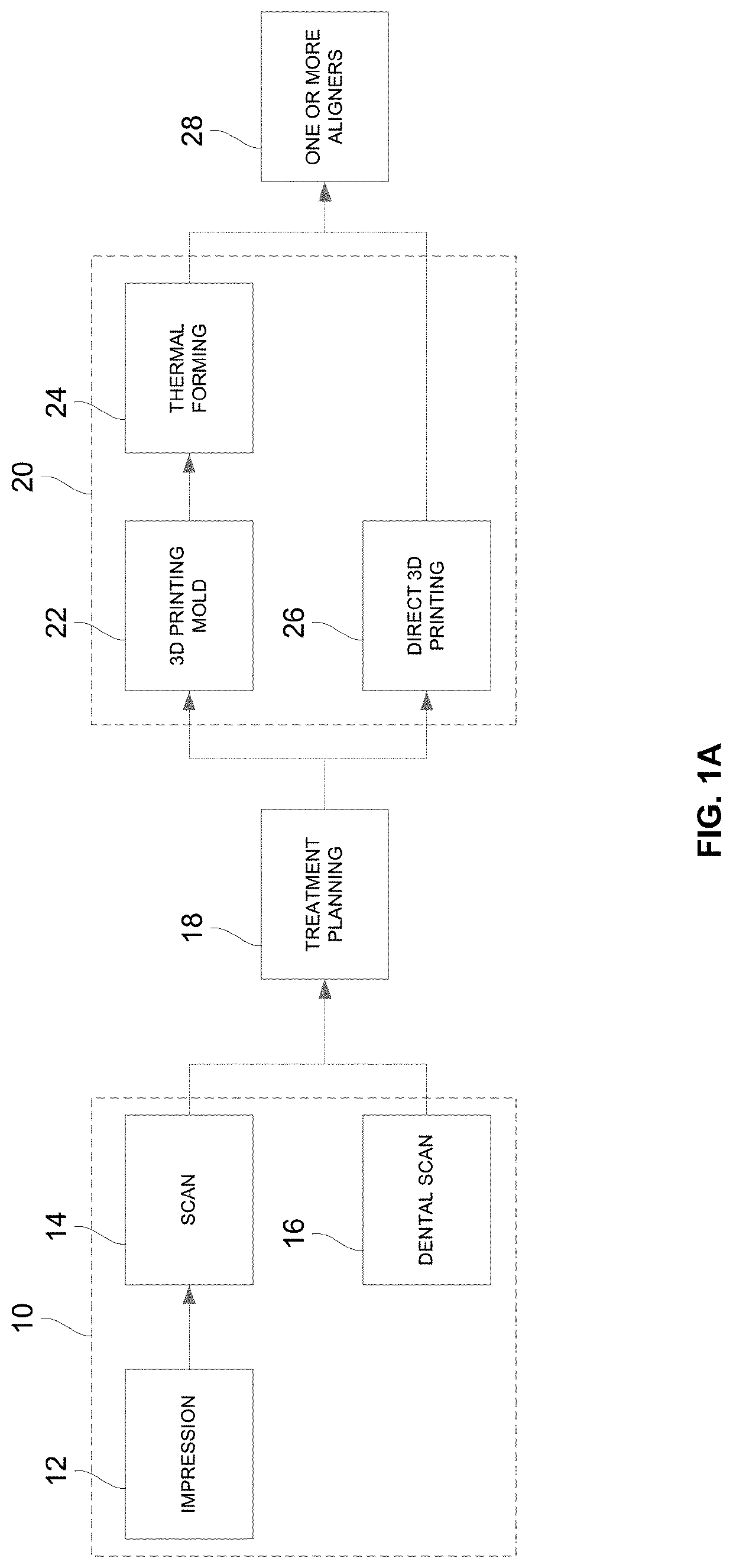

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished in one variation by receiving a scanned dental model of a subject's dentition, determining a treatment plan having a plurality of incremental movements for repositioning one or more teeth of the subject's dentition, and fabricating one or more aligners correlating to a first subset of the plurality of incremental movements.

Owner:ULAB SYST INC

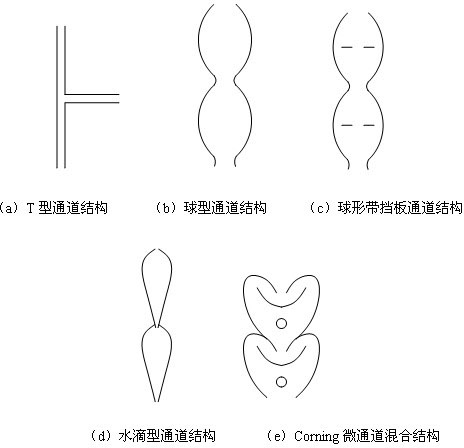

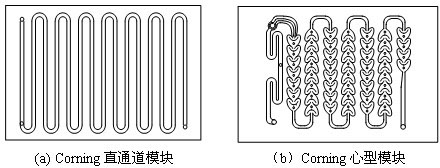

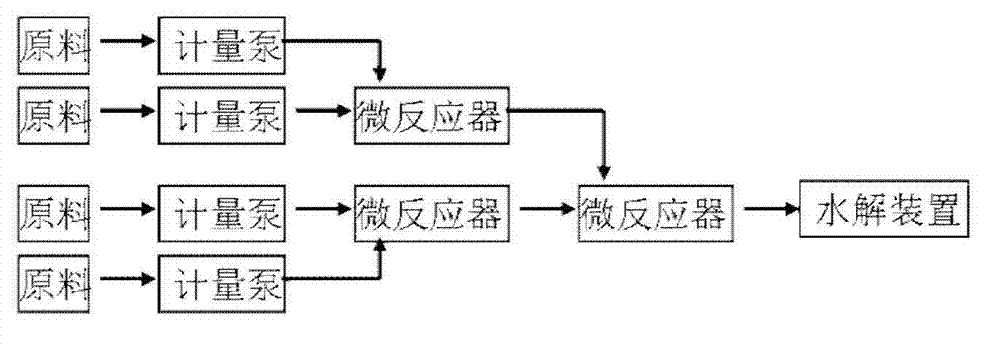

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471APrevent leakageAvoid dangerNitro compound preparationTemperature controlChlorobenzene

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

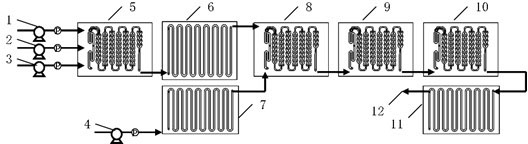

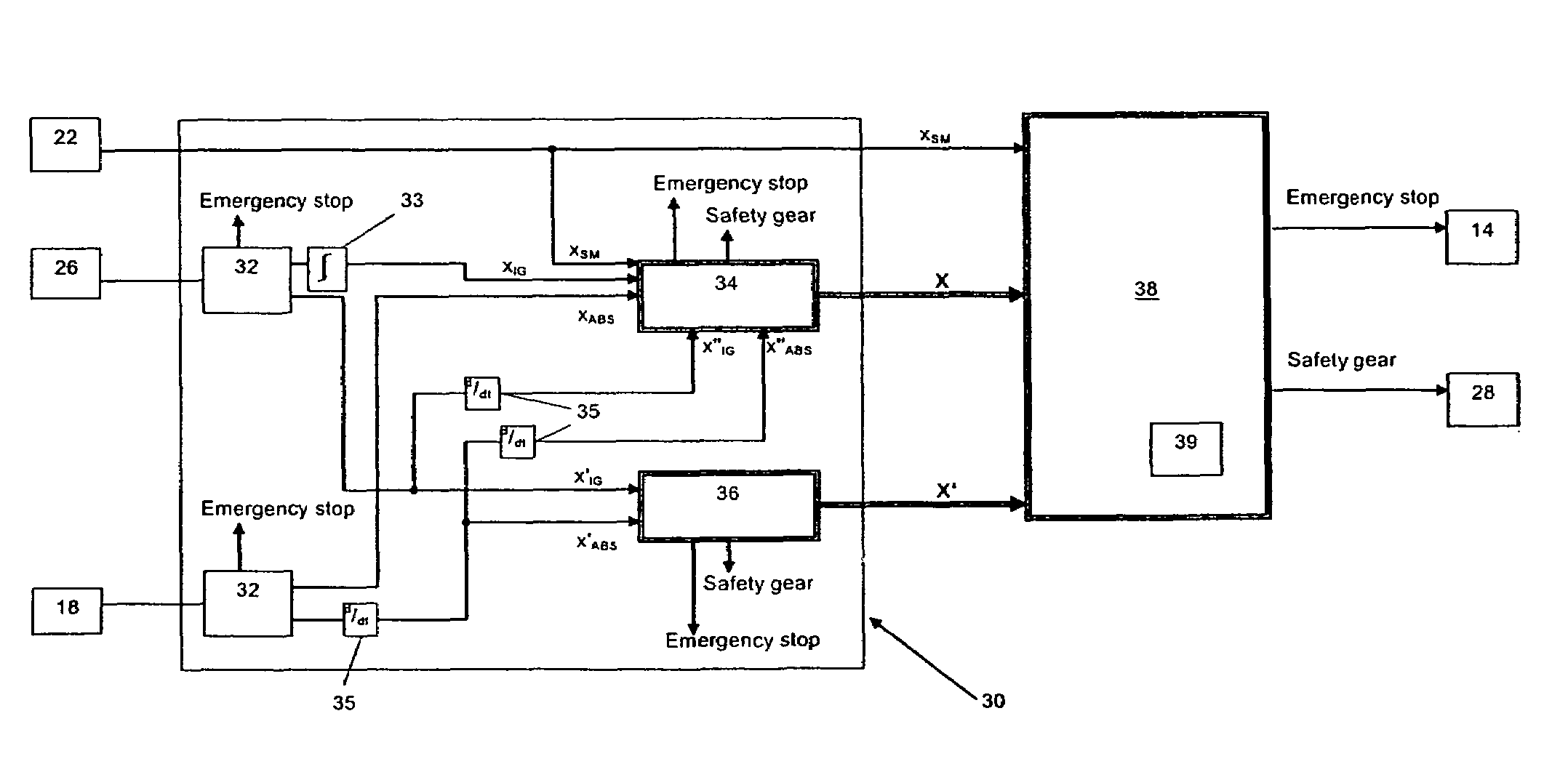

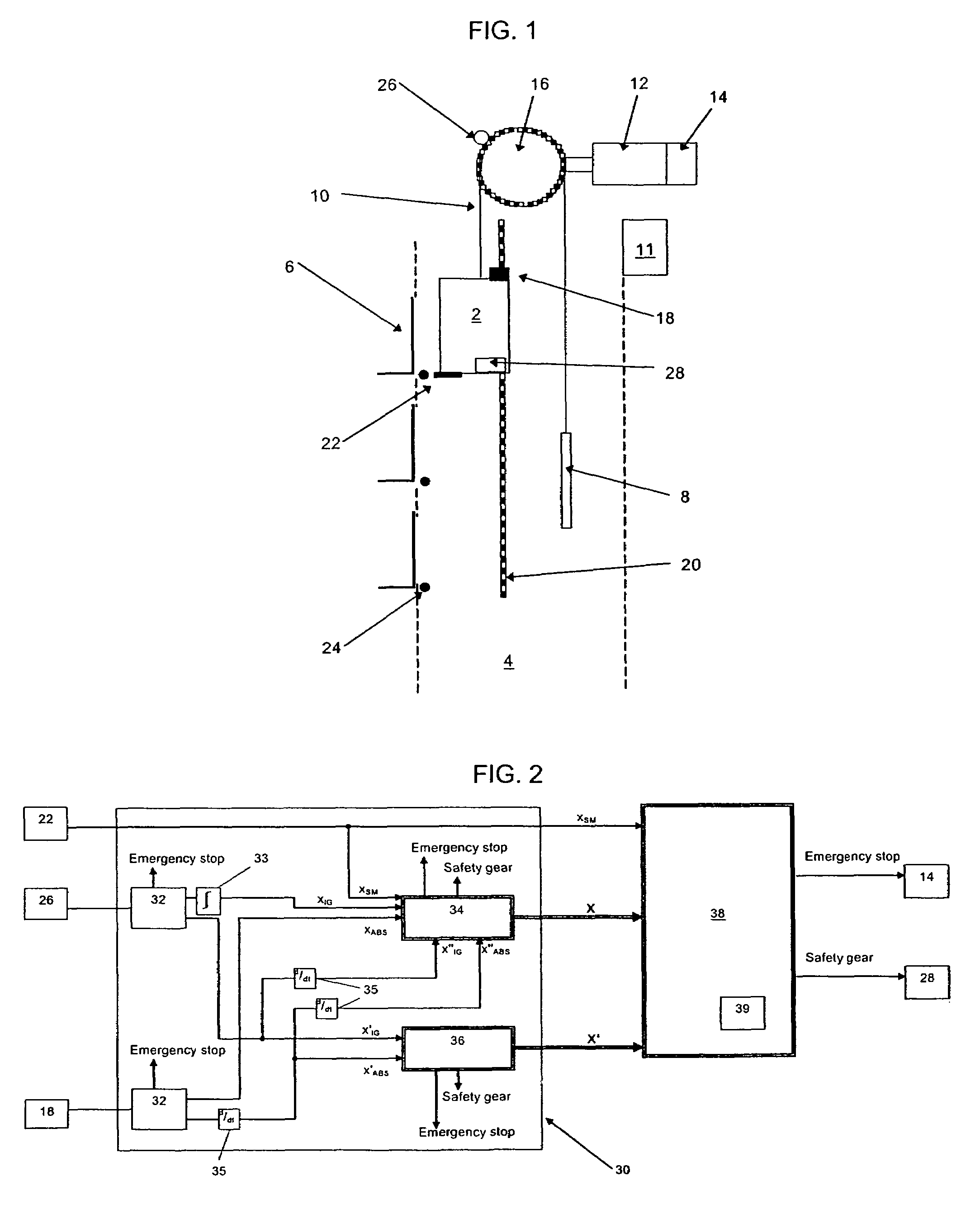

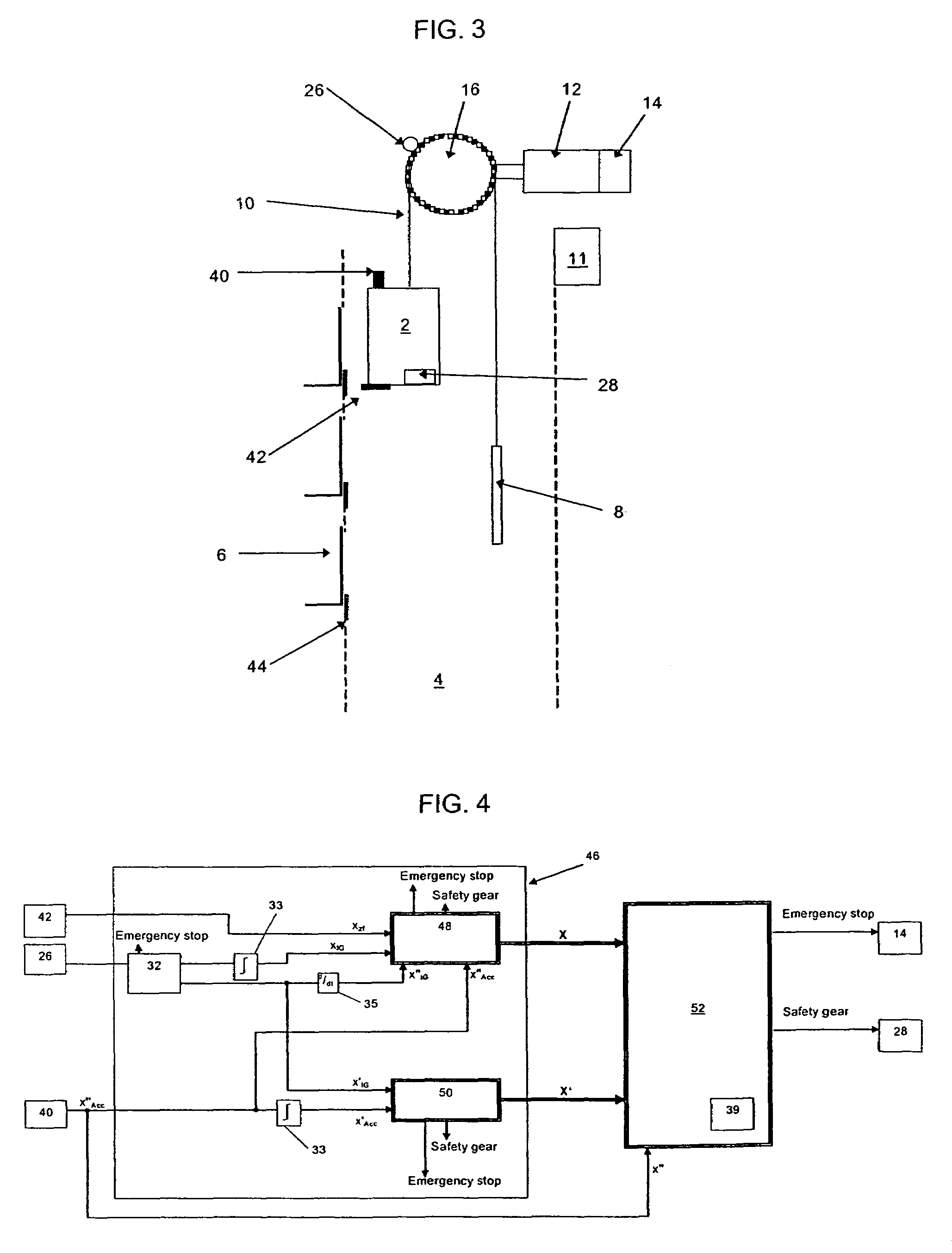

Elevator supervision

ActiveUS7353916B2Improve business performanceEasy to useElevatorsBuilding liftsCar drivingTwo parameter

A method and system for supervising the safety of an elevator having a car driven by a drive within a hoistway wherein a travel parameter (XABS,X″Acc,X′IGB) of the car is sensed and continually compared with a similarly sensed travel parameter (X′IG) of the drive. If the comparison shows a large deviation between the two parameters, an emergency stop is initiated. Otherwise one of the travel parameters (XABS,X″Acc X′IGB; X′IG) is output as a verified signal (X;X′). The verified signal is then compared with predetermined permitted values. If it lies outside the permitted range then an emergency stop is initiated.

Owner:INVENTIO AG

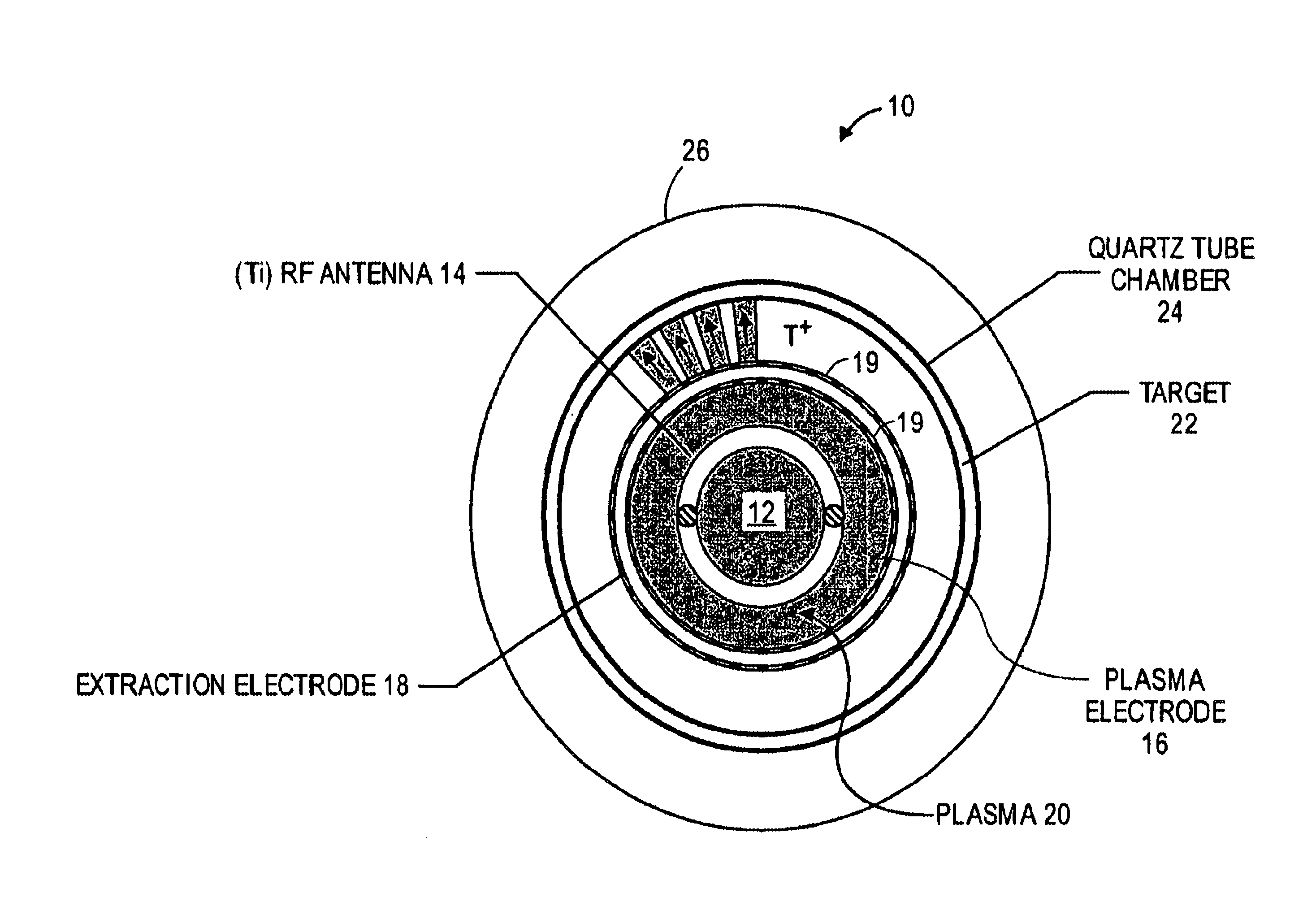

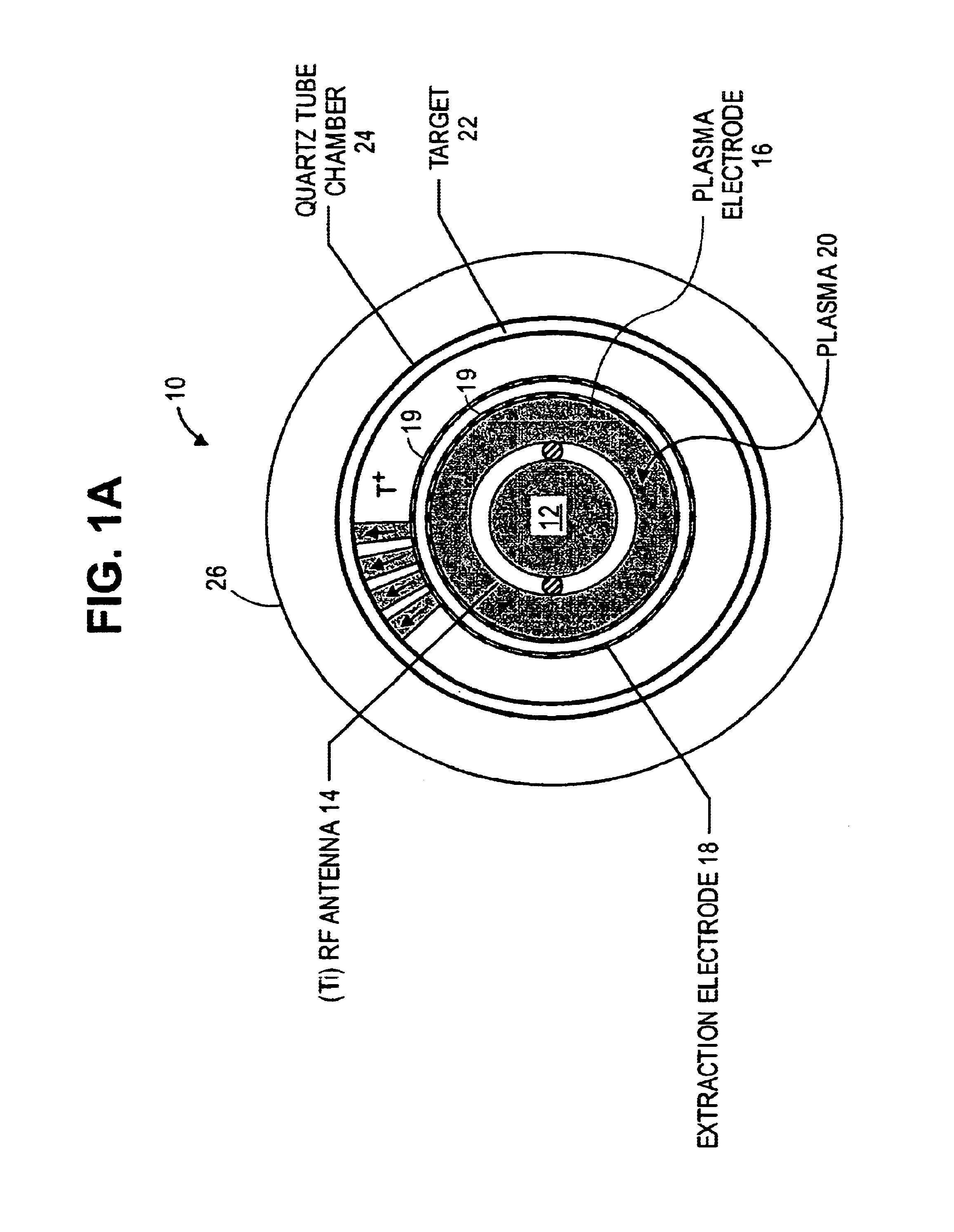

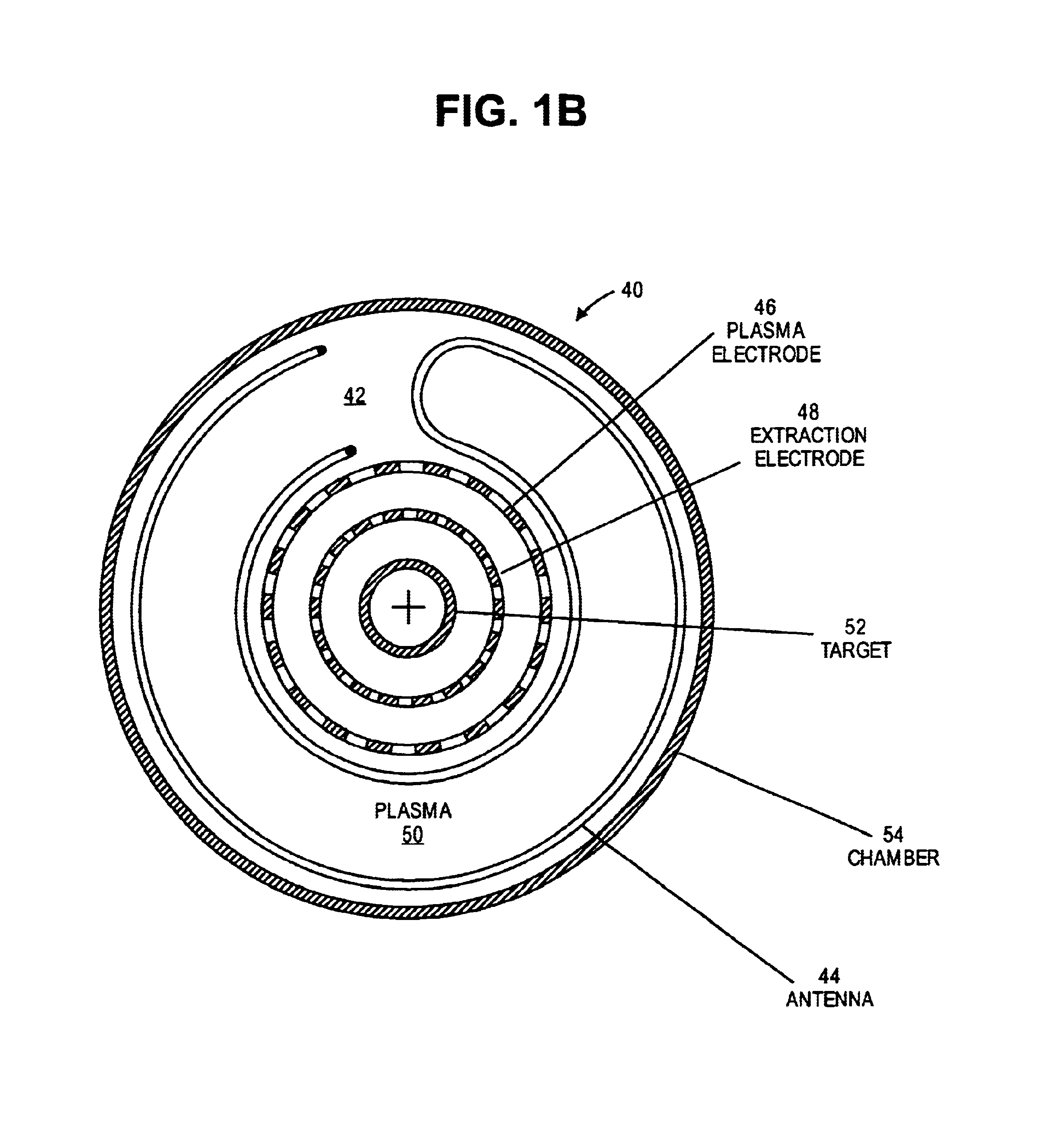

Cylindrical neutron generator

InactiveUS6907097B2Increase neutron fluxHigh densityConversion outside reactor/acceleratorsNuclear energy generationPlasma generatorNeutron flux

A cylindrical neutron generator is formed with a coaxial RF-driven plasma ion source and target. A deuterium (or deuterium and tritium) plasma is produced by RF excitation in a cylindrical plasma ion generator using an RF antenna. A cylindrical neutron generating target is coaxial with the ion generator, separated by plasma and extraction electrodes which contain many slots. The plasma generator emanates ions radially over 360° and the cylindrical target is thus irradiated by ions over its entire circumference. The plasma generator and target may be as long as desired. The plasma generator may be in the center and the neutron target on the outside, or the plasma generator may be on the outside and the target on the inside. In a nested configuration, several concentric targets and plasma generating regions are nested to increase the neutron flux.

Owner:RGT UNIV OF CALIFORNIA

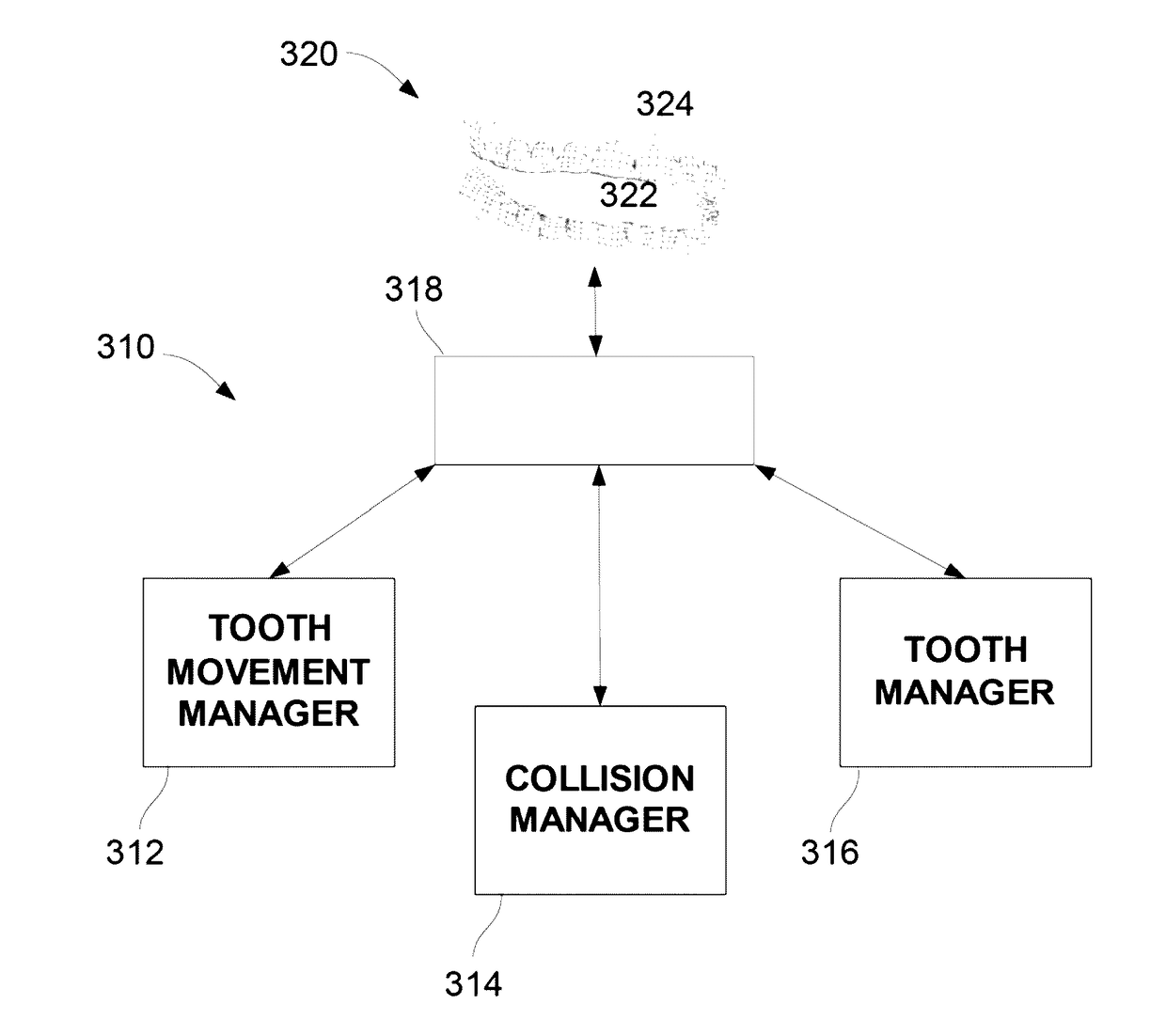

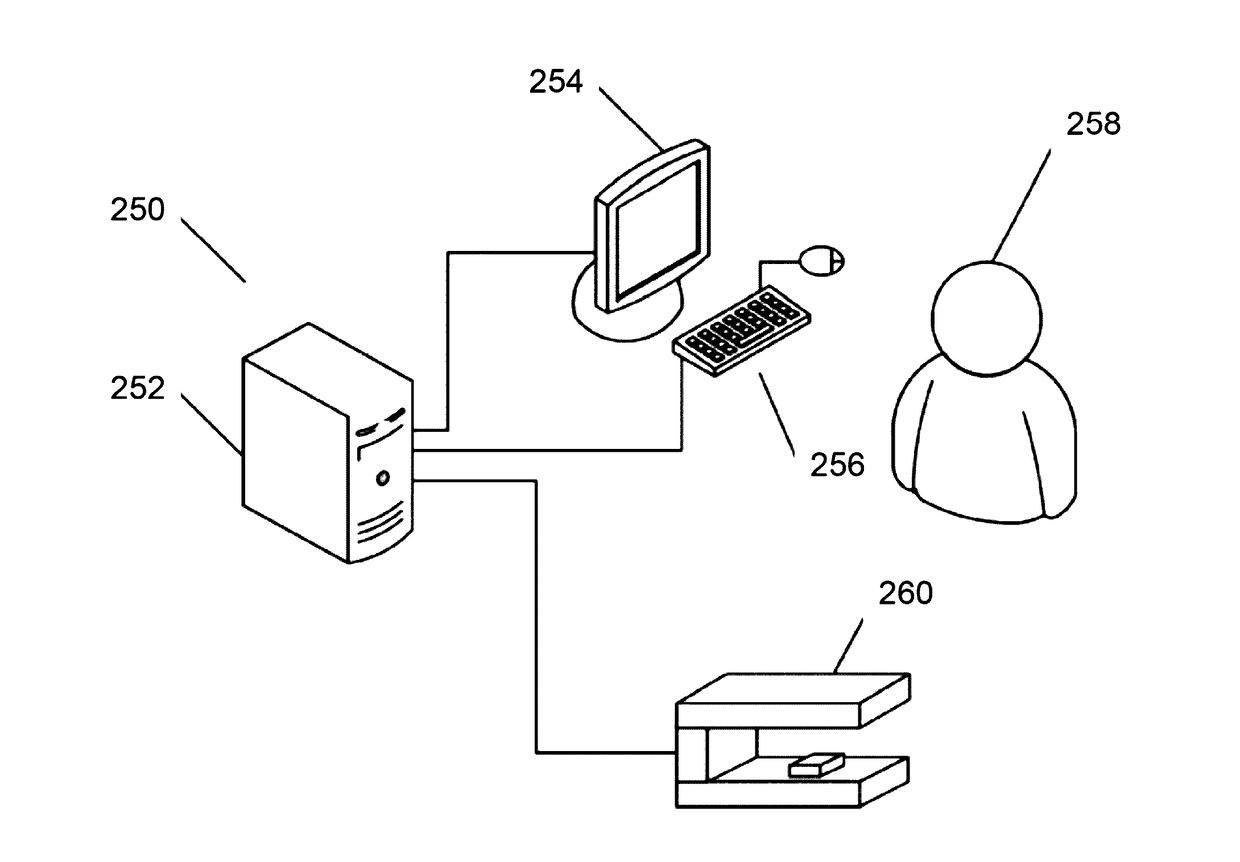

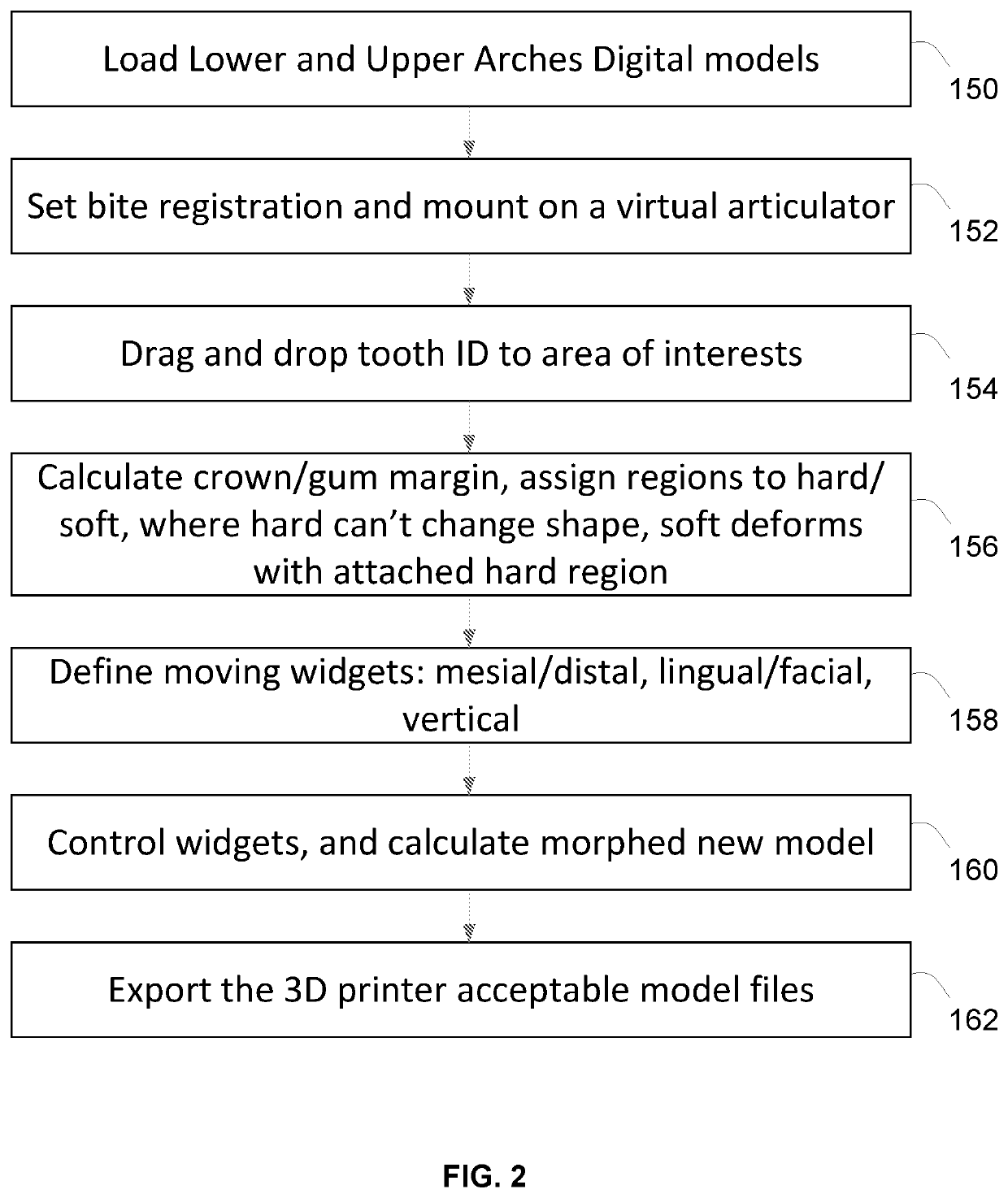

Tooth modeling system

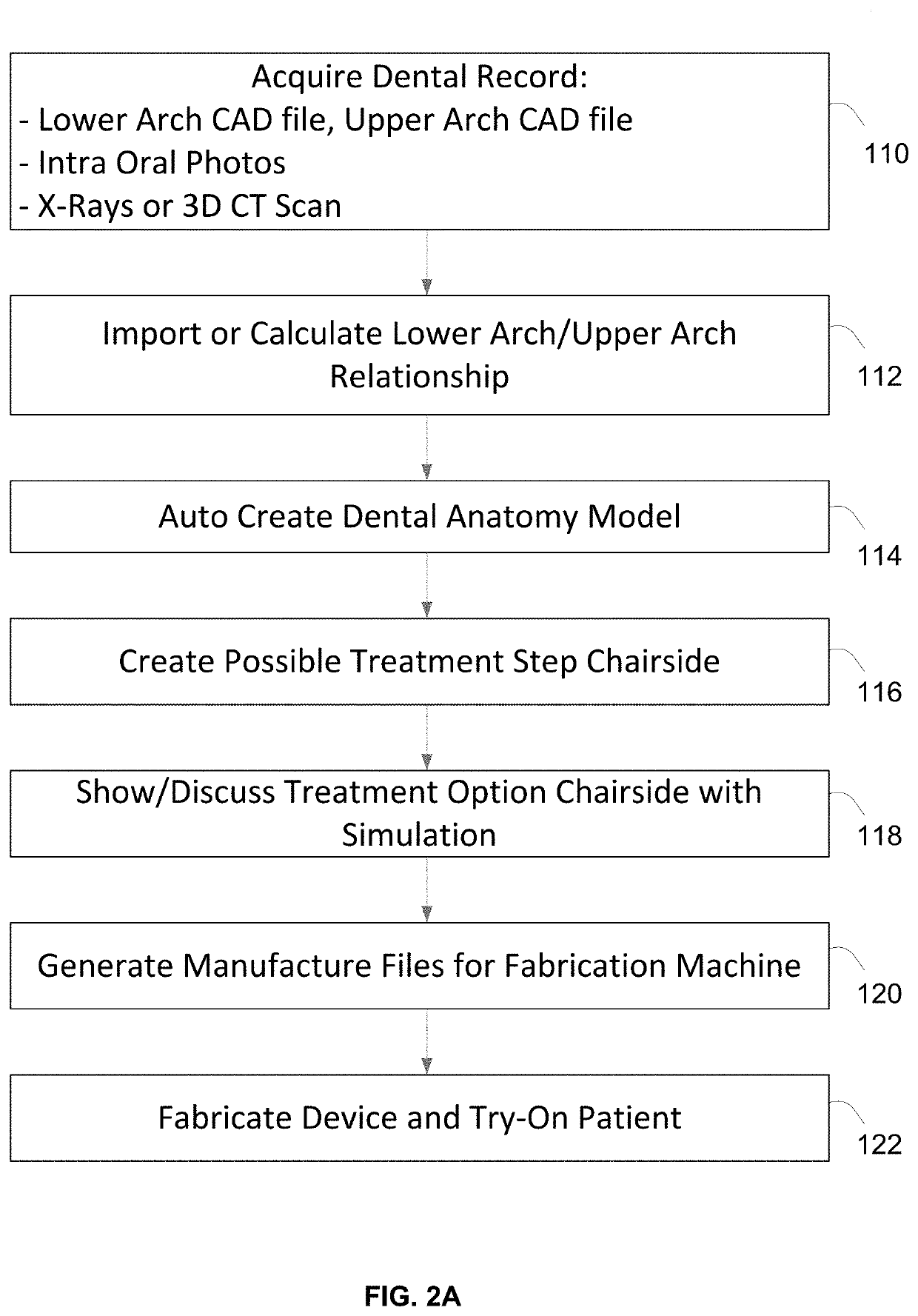

ActiveUS20170100207A1Avoid collisionReact SafeImage enhancementImpression caps3d printedDental Models

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished by applying a series of labels to a digital dental model and applying a rolling ball process to identify tooth boundaries separating one tooth from a neighboring tooth and to also determine the crown / gum margin. The user may further assign regions to the dental model to indicate hard regions and soft regions. With the dental model labeled and defined, the user may then generate a treatment plan for moving the labeled and defined tooth or teeth relative to one another to correct for any malocclusions. Upon approval of the treatment plan, a series of 3D printed dental appliances or aligners to be worn in series by the patient may be fabricated to ultimately move the tooth or teeth to a desired position.

Owner:ULAB SYST INC

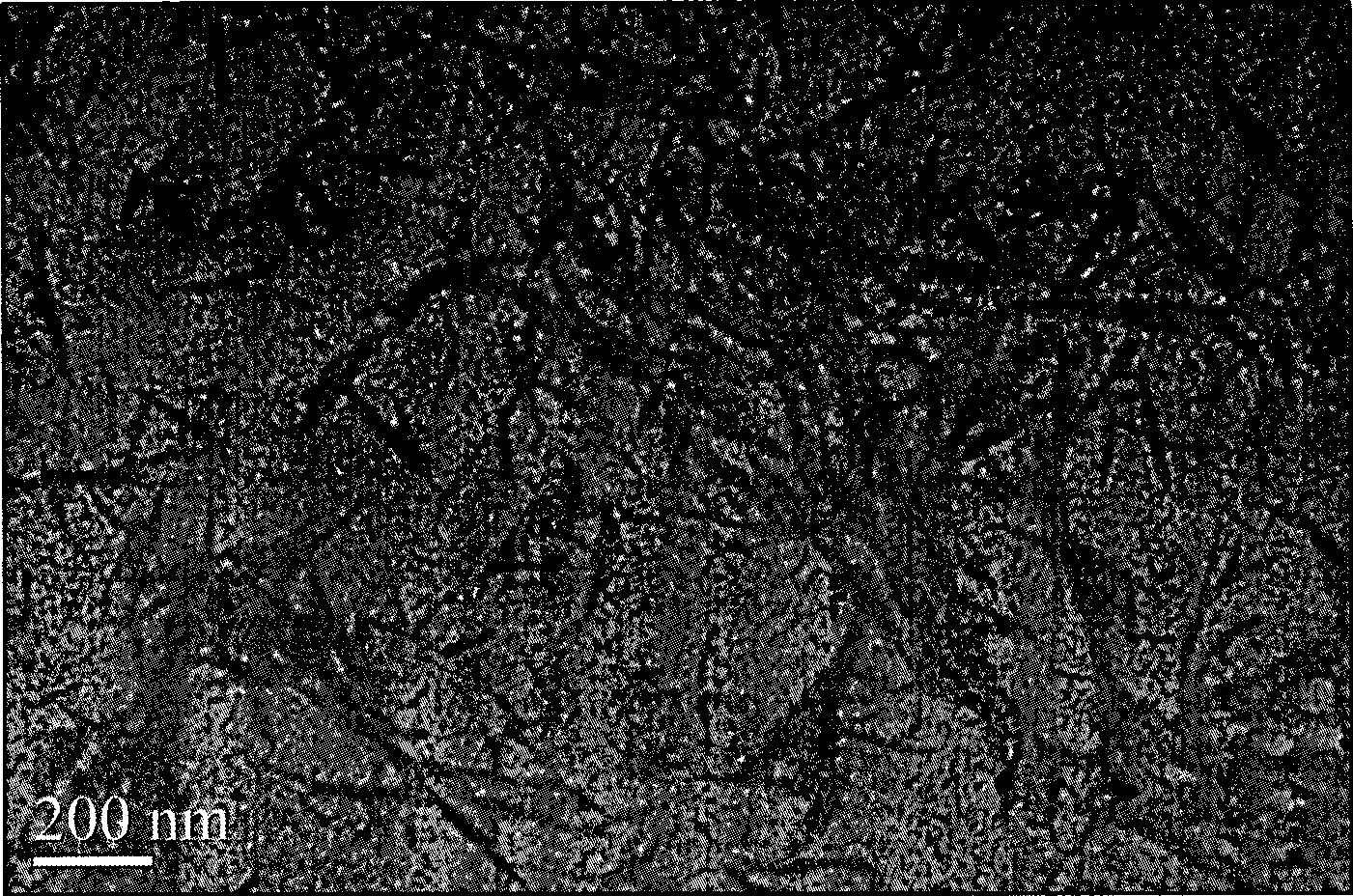

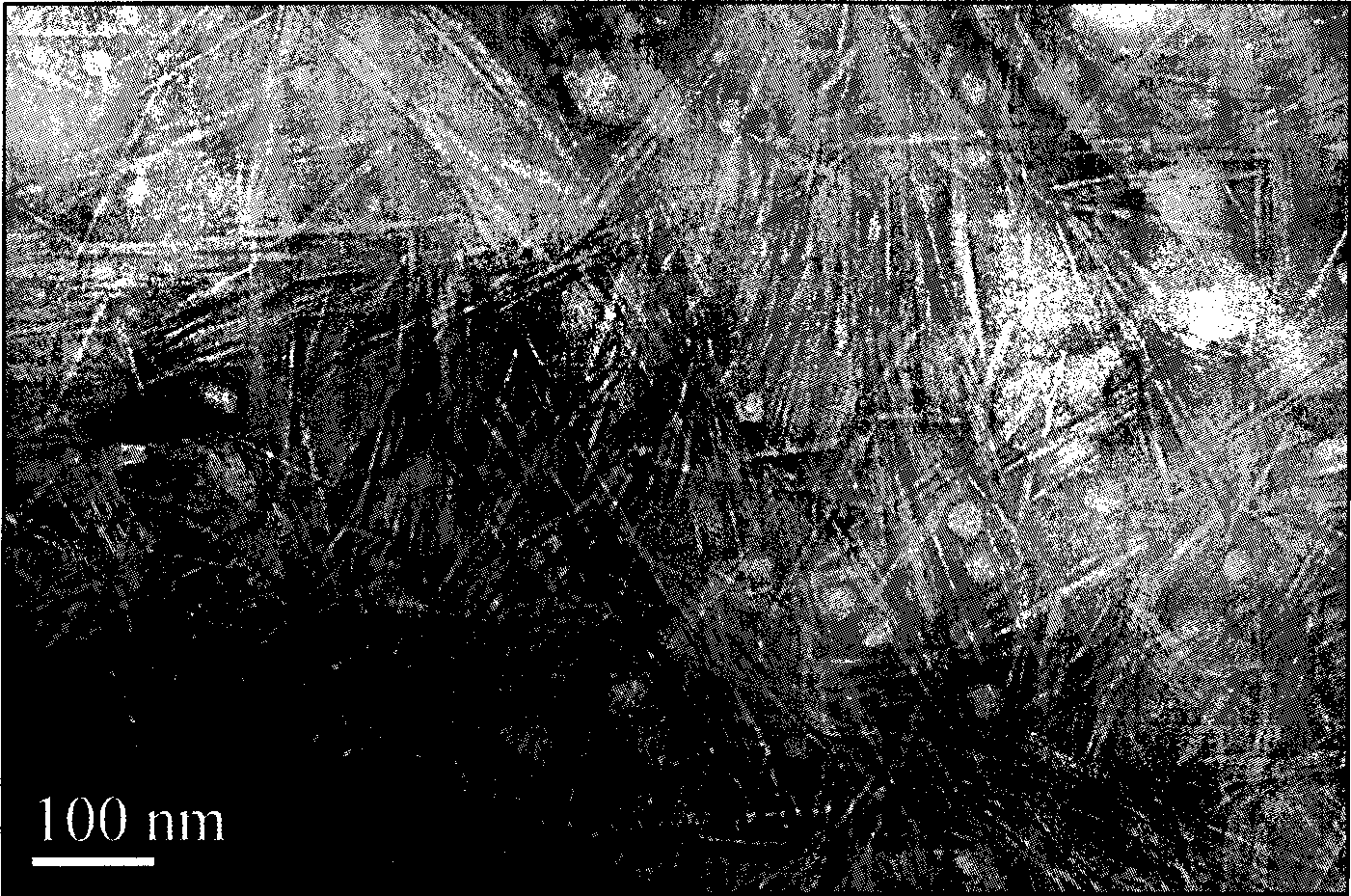

Method of preparing clubbed nano-cellulose

The invention discloses a method for preparing nano-rod cellulose, which comprises the following steps: dispersing fiber raw material into sulphuric acid water solution of which mass concentration is 50 to 65 percent, hydrolyzing the fiber raw material by single-mode microwave radiation for 5 to 60 minutes at a temperature of between 20 and 50 DEG C and at the microwave radiation power of 10 to 100 watts, then adding distilled water into hydrolysis solution and diluting the hydrolysis solution to have 10 times of volume, and obtaining stable nano-rod cellulose suspension through post treatment processes such as centrifugal separation, dialysis, filter, ultrasonic dispersion and the like of the diluent, so as to obtain the nano-rod cellulose of which width is about 10 nanometers and length is about 200 to 300 nanometers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

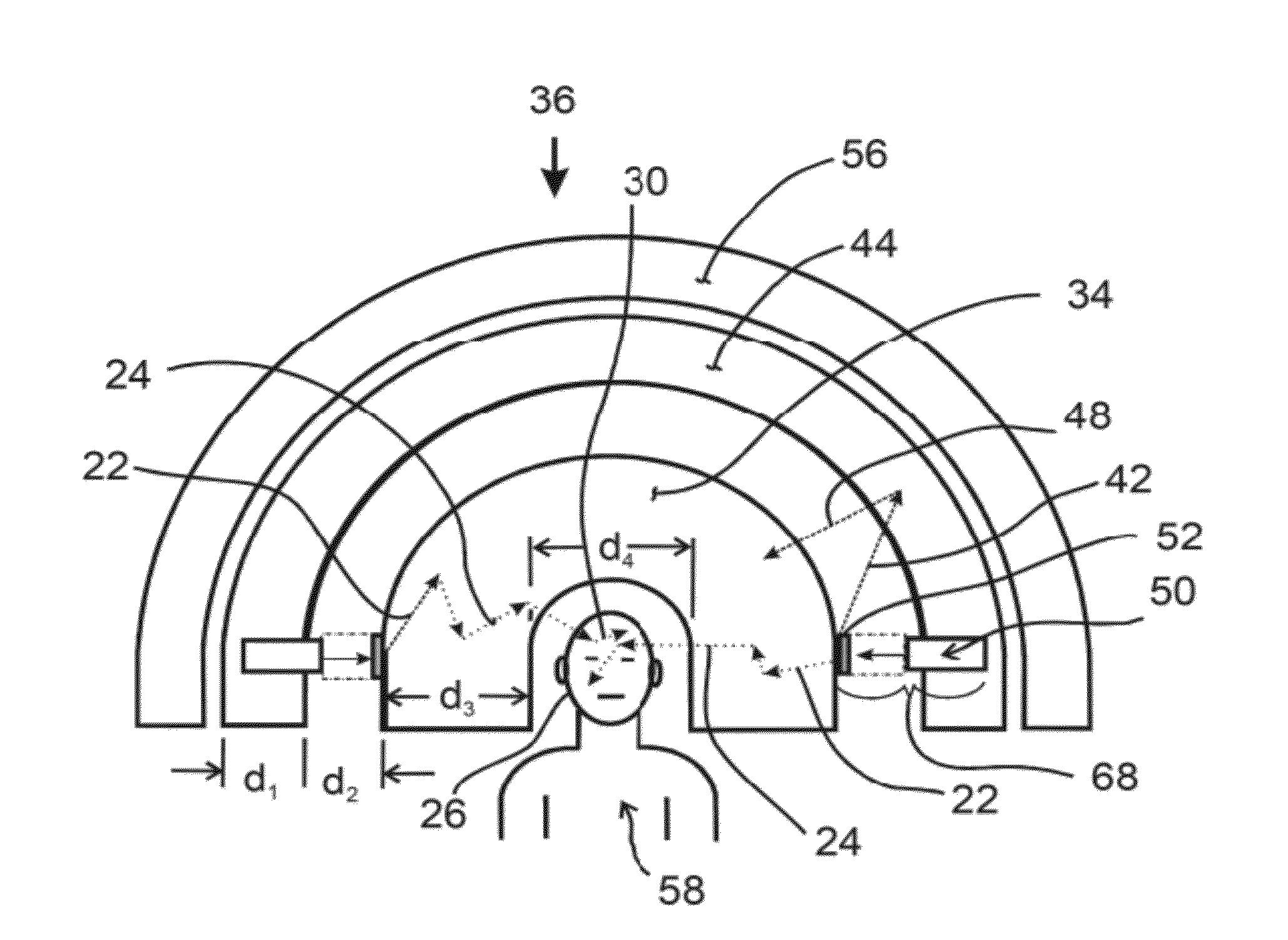

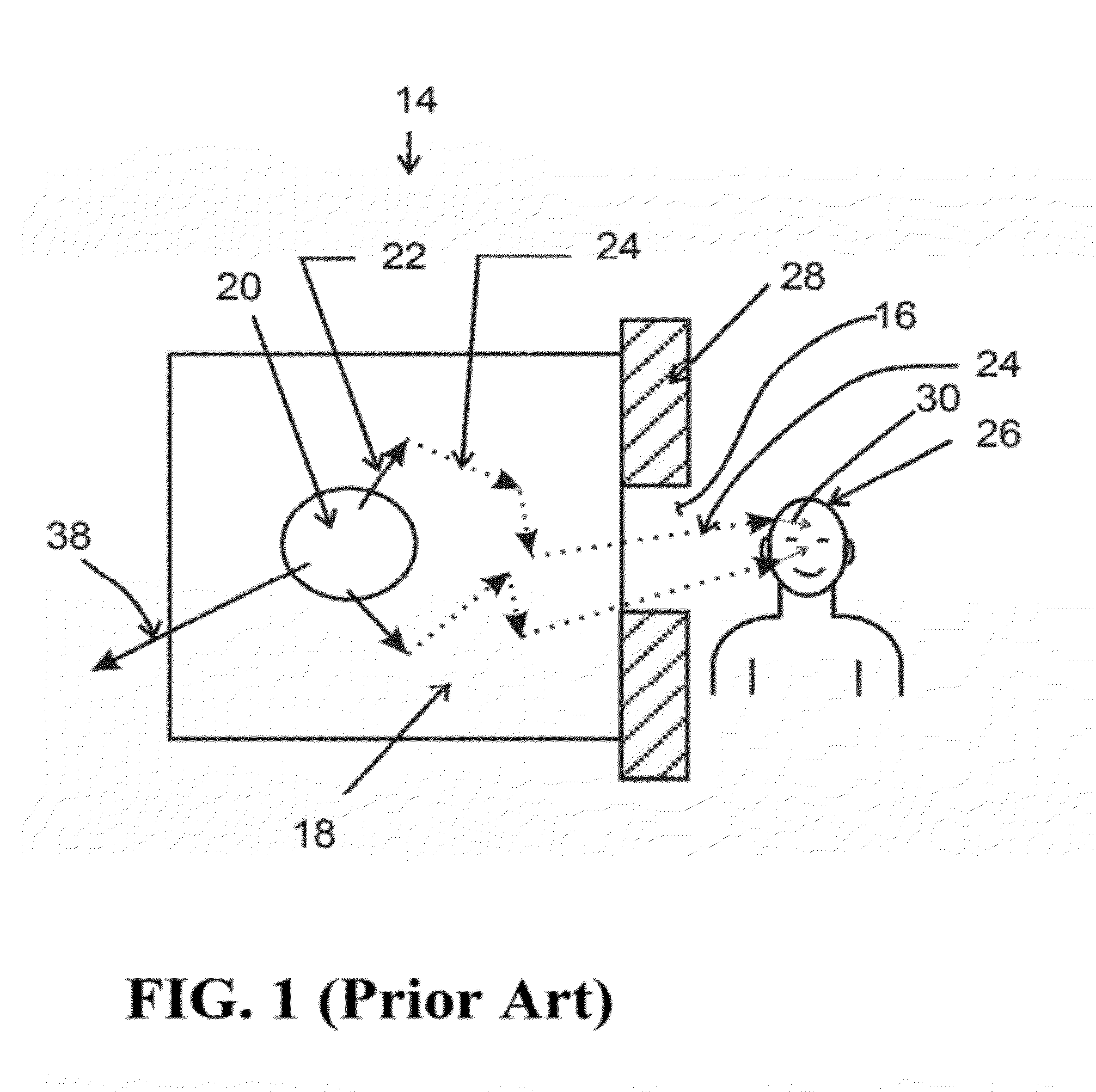

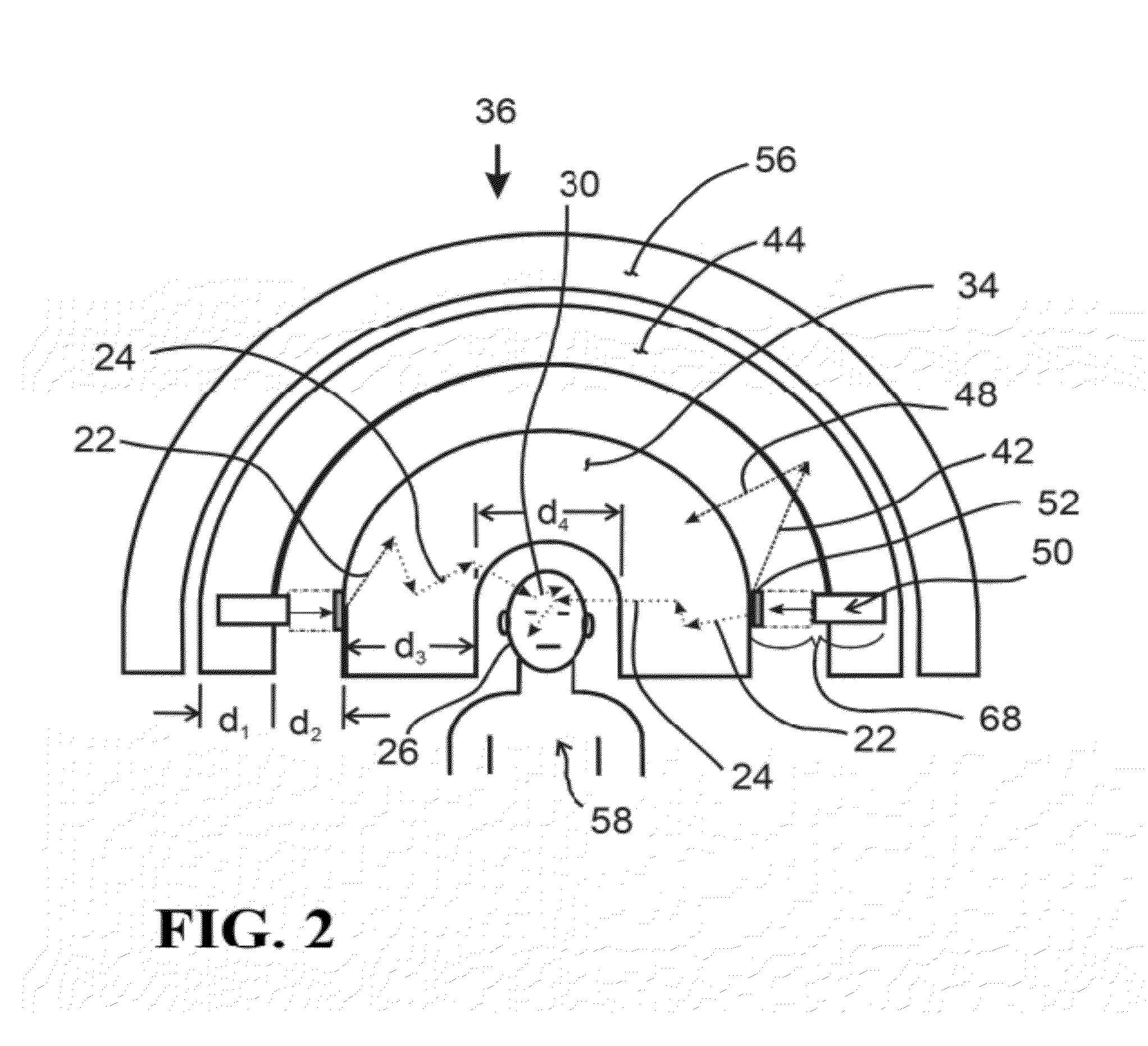

Neutron Source for Neutron Capture Therapy

InactiveUS20120330084A1Reduce electric powerReact SafeNeutron sourcesX-ray/gamma-ray/particle-irradiation therapyNeutron captureGamma ray

A therapy apparatus for producing thermal neutrons at a tumor site in a patient has a plurality of fast neutron sources surrounding a moderator, a fast neutron reflecting media around the fast neutron sources, a gamma-ray and neutron shielding media surrounding the fast neutron reflecting media, and a patient chamber positioned inside the moderator. The fast neutron sources are positioned around the moderator to maximize and direct the neutron flux to said tumor site.

Owner:ADELPHI TECH INC

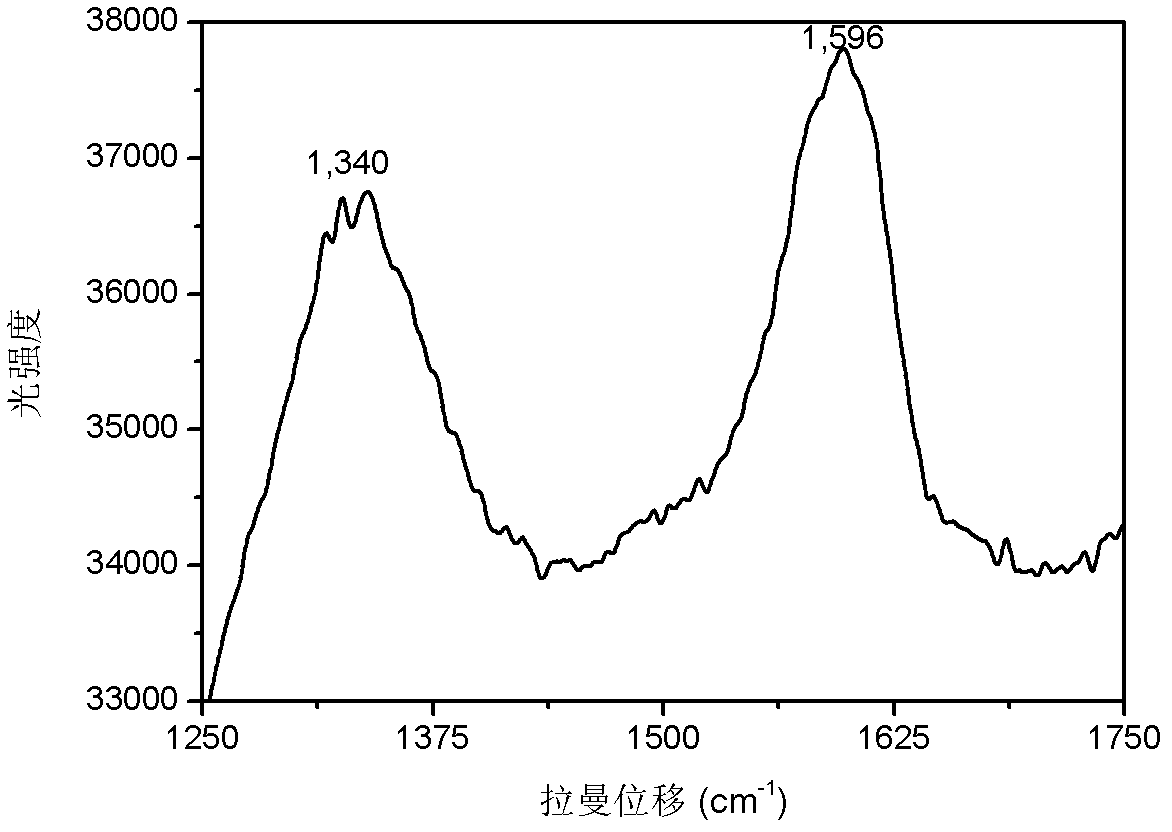

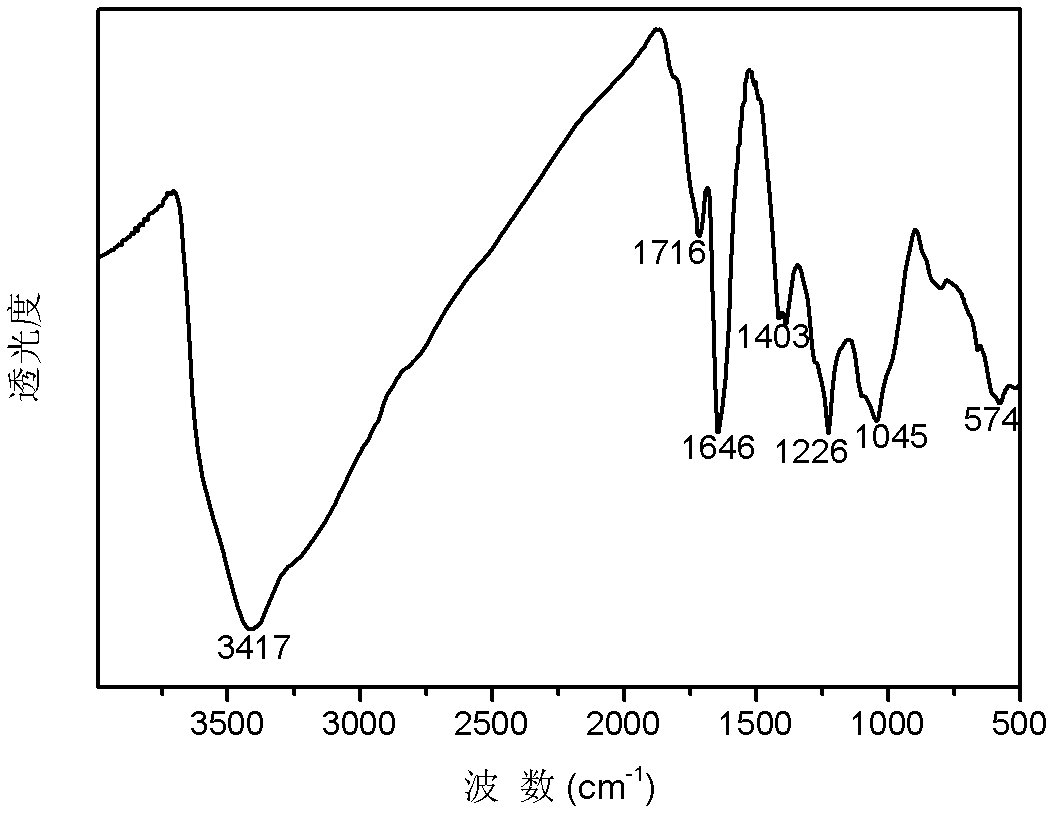

Preparation method for polymer grafted graphene oxide

The invention discloses a preparation method for polymer grafted graphene oxide. The method comprises the following steps: (1) carrying out pre-oxidation on graphite by using phosphorus pentoxide to obtain pre-oxidized graphite; (2) adopting potassium permanganate and concentrated sulfuric acid to oxidize the pre-oxidized graphite, and washing to obtain graphene oxide with hydroxyl on the surface; (3) mixing the graphene oxide with the hydroxyl on the surface and an alkene monomer, heating and introducing nitrogen, adding a tetravalent cerium ion-containing solution in a dropwise manner, carrying out a reaction for 1-6 hours while stirring under the case of nitrogen introducing, and carrying out treatments of filtering, washing and drying to obtain the polymer grafted graphene oxide. According to the present invention, a new method for preparing the polymer grafted graphene oxide is developed; the polymer grafted with the graphene oxide on the surface is obtained with one step through the redox polymerization method based on the graphene oxide, such that the steps are convenient, the reaction is safe, the environmental protection is achieved, and the efficiency is high.

Owner:SUZHOU UNIV

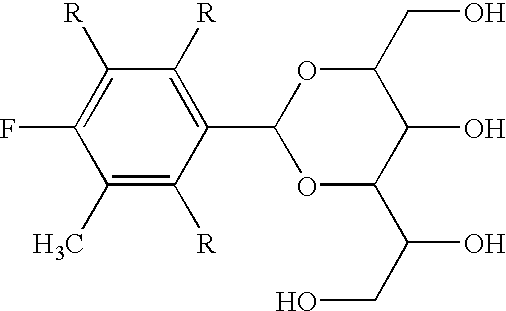

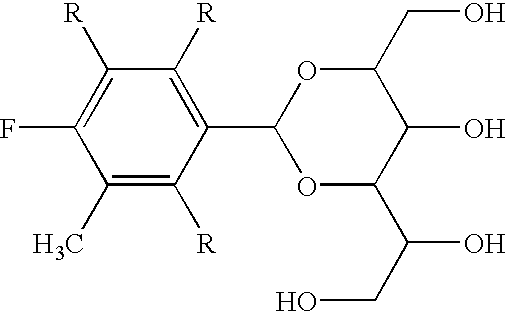

Method of producing high yield alditol acetals with mineral acids and surfactants

This invention relates to a process for preparing alditol acetals, such as dibenzylidene sorbitols, monobenzylidene sorbitols, and the like, through the reaction of unsubstituted or substituted benzaldehydes with alditols (such as sorbitol, xylitol, and ribitol) in the presence of a mineral acid and at least one surfactant having at least one pendant group of 6 carbon chains in length. Such a reaction provides a cost-effective, relatively safe procedure that provides excellent high yields of alditol acetal product. Furthermore, such a specific reaction is also the best known procedure for the production of certain compounds which can be easily separated from other formed isomers. Additionally, such a procedure facilitates the production of certain asymmetric alditol acetal compounds and compositions in acceptable yields as well. Such alditol acetals are useful as nucleating and clarifying agents for polyolefin formulations and articles, as one example.

Owner:MILLIKEN & CO

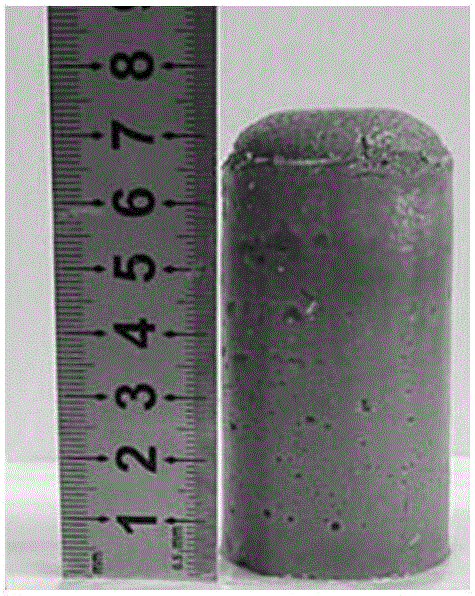

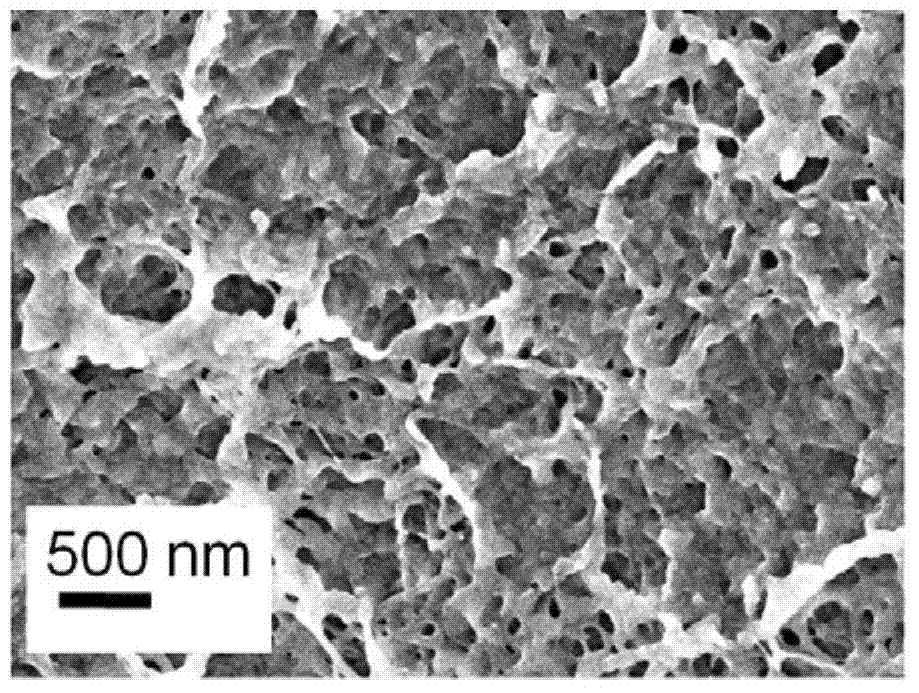

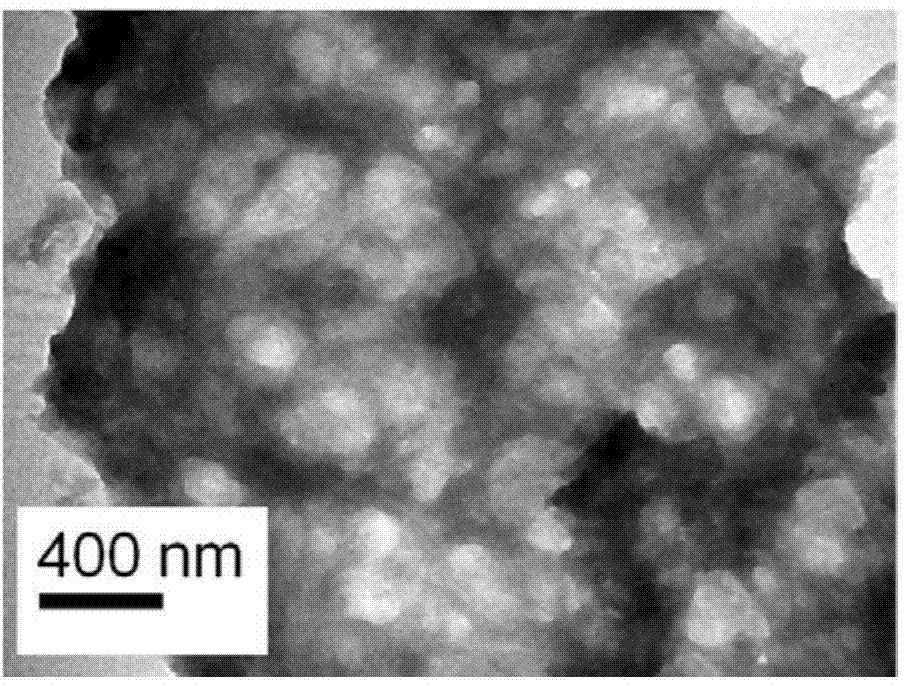

Phenolic resin/silicon dioxide composite aerogel materialand preparation method thereof

ActiveCN106189066ANo sheddingNo separabilityBulk chemical productionThermal insulationNanoscopic scale

The invention provides a phenolic resin / silicon dioxide compositeaerogel material and a preparation method thereof. The phenolic resin / silicon dioxide composite aerogel material has a nano-grid structure in which a silicon dioxide phase and a resin phase are mutually tangled. The phenolic resin / silicon dioxide composite aerogel material is prepared from a material containing an organic silicon precursor, a phenolic compound, an aldehyde compound and chitosan by virtue of a sol-gel method and supercritical carbon dioxide. According to the composite aerogel material, an organic phase and an inorganic phase are respectively continuous nano-scale tangle structures and are integrated with the mechanical property of organic aerogel and the thermal insulation property and fire resistance of silicon dioxide aerogel; and after the composite gel material with a thickness of 1cm is impacted by the 1300-DEG C flame of a blast burner for over 30 minutes, the falling and the separation of the inorganic phase are not caused, and meanwhile, the temperature of a protected side does not exceed 300 DEG C. The preparation method has the beneficial effects that the operation is simple, the reaction is safe and reliable, and the thermal insulation property and the fire resistance of the material can be regulated and controlled by simply changing the material proportion.

Owner:UNIV OF SCI & TECH OF CHINA

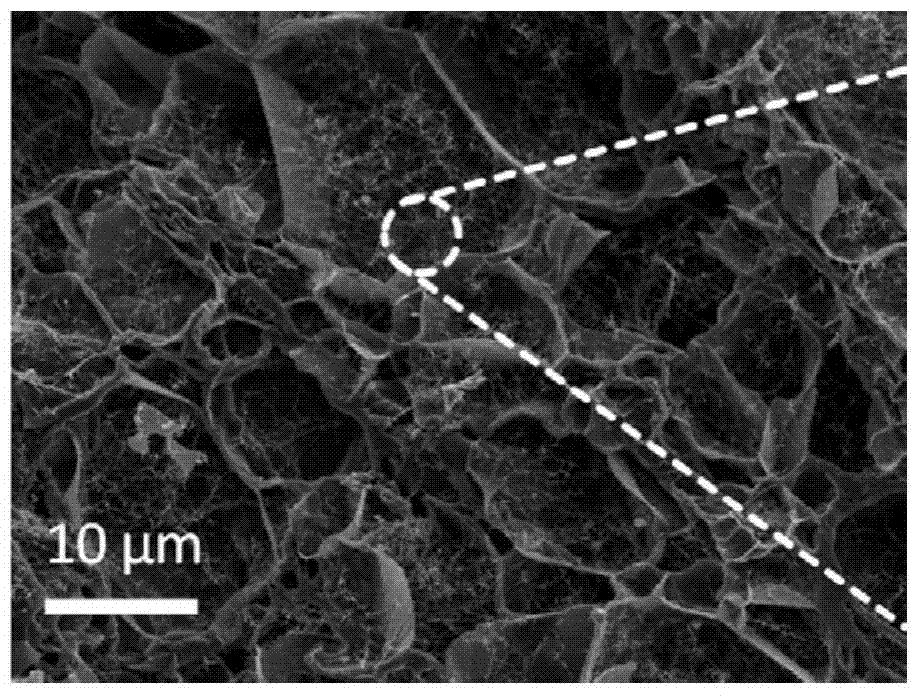

Preparation method of phenolic resin aerogel

ActiveCN103709346AStructural regulationControl mechanical propertiesOther chemical processesCarbon preparation/purificationAnhydrous ethanolOrganic solvent

The invention discloses a preparation method of phenolic resin aerogel. The preparation method is characterized in that chitosan, one or more acid, one or more filling materials, one or more phenols, one or more aldehydes, and water or a water-anhydrous ethanol mixture are mixed; the mixture undergoes a hydrothermal reaction to produce phenolic resin organogel; the phenolic resin organogel is immersed in an organic solvent for replacement; and the replacement product is subjected to supercritical CO2 drying so that the phenolic resin aerogel is obtained. The preparation method has simple processes and safe and reliable reactions and realizes adjustment of a structure and mechanical properties of the phenolic resin organogel. The structure and density of the phenolic resin aerogel obtained by drying and porosity and a specific surface area of the derivative porous carbon material obtained by carbonization of the phenolic resin aerogel are adjusted and controlled well.

Owner:UNIV OF SCI & TECH OF CHINA

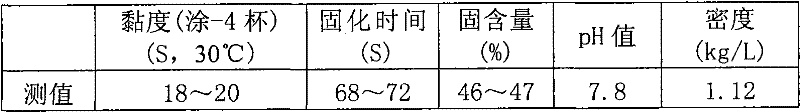

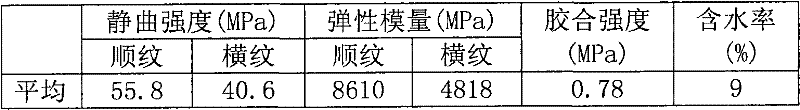

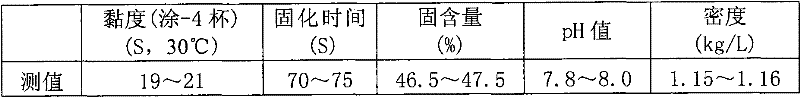

Modified urea-formaldehyde resin adhesive for concrete formwork and production method of adhesive

ActiveCN102391805AImprove performanceEasy to operateAldehyde/ketone condensation polymer adhesivesWood veneer joiningStrong acidsMelamine

The invention discloses a modified urea-formaldehyde resin adhesive for a concrete formwork, which is mainly prepared from the following raw materials in parts by weight: 50 to 60 parts of formaldehyde with the mass concentration of 37 percent, 20 to 30 parts of urea with purity of 98 percent, 6 to 8 parts of melamine, 0.1 to 0.2 part of tackifier and 0.2 to 0.3 part of accelerant. The adhesive has an Uron-ring improved structure, so that the waterproofness of the formwork can be improved. The invention also discloses a production method of the adhesive, which comprises three steps of strong acid, weak acid and weak base. The reaction between the formaldehyde and the urea under a strong acid reaction condition can be effectively controlled by controlling temperature, pH value, charging speed, charging time and molar ratio. Meanwhile, two endpoint control indexes which are simple and convenient and are easy to operate are provided, and therefore processing implementing can be controlled conveniently and accurately.

Owner:GUANGXI UNIV

Core-shell type cationic/anionic polyacrylamide profile control oil displacing microsphere and preparation method thereof

The invention discloses a core-shell type cationic / anionic polyacrylamide profile control oil displacing microsphere and a preparation method thereof. The core-shell type cationic / anionic polyacrylamide profile control oil displacing microsphere with a micrometer particle size range is prepared in one pot by adopting a dispersion polymerization method, and the whole preparation process is continuously completed by two steps: firstly synthesizing a core part of a microsphere, and then synthesizing a shell part of the microsphere. The core part of the microsphere consists of water-soluble monomer acrylamide, an ionic monomer I and a crosslinking agent; the shell part of the microsphere consists of water-soluble monomer acrylamide, an ionic monomer II and a crosslinking agent; and the ionic monomer I and the ionic monomer II have opposite charges. The particle size of the core-shell type cationic / anionic polyacrylamide profile control oil displacing microsphere is 1-200mu m. The preparation method is simple in preparation process, the whole preparation process is environmentally friendly and low in cost; and a solvent can be recycled, and the recycling rate is above 80 percent. The core-shell type cationic / anionic polyacrylamide profile control oil displacing microsphere is used as a profile control oil displacing material, and has excellent injectivity and mobility.

Owner:TIANJIN UNIV

Method for continuously synthesizing arylboronic acid ester by utilizing microreactor

InactiveCN103275112ADegree of reductionShort reaction timeGroup 3/13 element organic compoundsOrganic synthesisN-butyl nitrite

The invention relates to a method for continuously synthesizing arylboronic acid ester by utilizing a microreactor, which belongs to the technical field of green organic synthesis application. The method comprises the following steps of: preheating substituted arylamine, tert-butyl nitrite, bisdiborane in a continuous-flow micro-channel reactor system by using substituted arylamine, acetonitrile, tert-butyl nitrite and bisdiborane as starting materials; and mixing the substituted arylamine with the bisdiborane and then reacting the obtained mixture with the tert-butyl nitrite, wherein in the reaction, the molar ratio of the substituted arylamine to the bisdiborane is (1:0.5)-(1:1.25), the molar ratio of the substituted arylamine to isoamyl nitrite is (1:1.1)-(1:1.5), the reaction temperature is 60 DEG C-120 DEG C, the reaction time is 50 seconds-3600 seconds, and the effective conversion ratio of the substituted arylamine is 50%-90%. The continuous-flow microreactor, which is capable of strengthening the mixing effect, the mass transfer effect and the heat transfer effect, is especially suitable for carrying out homogeneous reaction of the method. Moreover, the method has the characteristics of stable temperature control, safe process and less waste material.

Owner:JINAN SHAOYUAN MEDICAL TECH

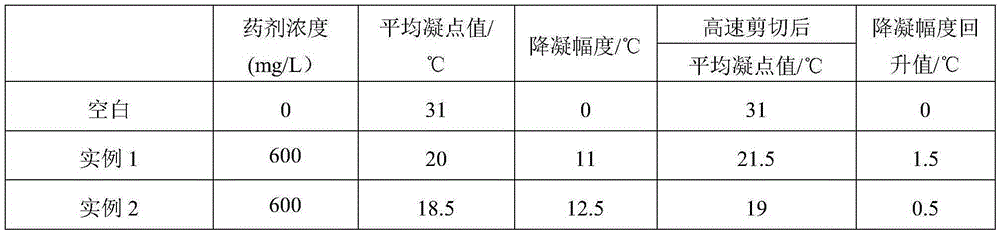

Orthodontic planning systems

ActiveUS10548690B2Reduce complexityAvoid collisionMedical simulationOthrodonticsDental malocclusionDentition

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished in one variation by receiving a scanned dental model of a subject's dentition, determining a treatment plan having a plurality of incremental movements for repositioning one or more teeth of the subject's dentition, and fabricating one or more aligners correlating to a first subset of the plurality of incremental movements.

Owner:ULAB SYST INC

Method of producing high yield alditol acetals with mineral acids and surfactants

This invention relates to a process for preparing alditol acetals, such as dibenzylidene sorbitols, monobenzylidene sorbitols, and the like, through the reaction of unsubstituted or substituted benzaldehydes with alditols (such as sorbitol, xylitol, and ribitol) in the presence of a mineral acid and at least one surfactant having at least one pendant group of 6 carbon chains in length. Such a reaction provides a cost-effective, relatively safe procedure that provides excellent high yields of alditol acetal product. Furthermore, such a specific reaction is also the best known procedure for the production of certain compounds which can be easily separated from other formed isomers. Additionally, such a procedure facilitates the production of certain asymmetric alditol acetal compounds and compositions in acceptable yields as well. Such alditol acetals are useful as nucleating and clarifying agents for polyolefin formulations and articles, as one example.

Owner:MILLIKEN & CO

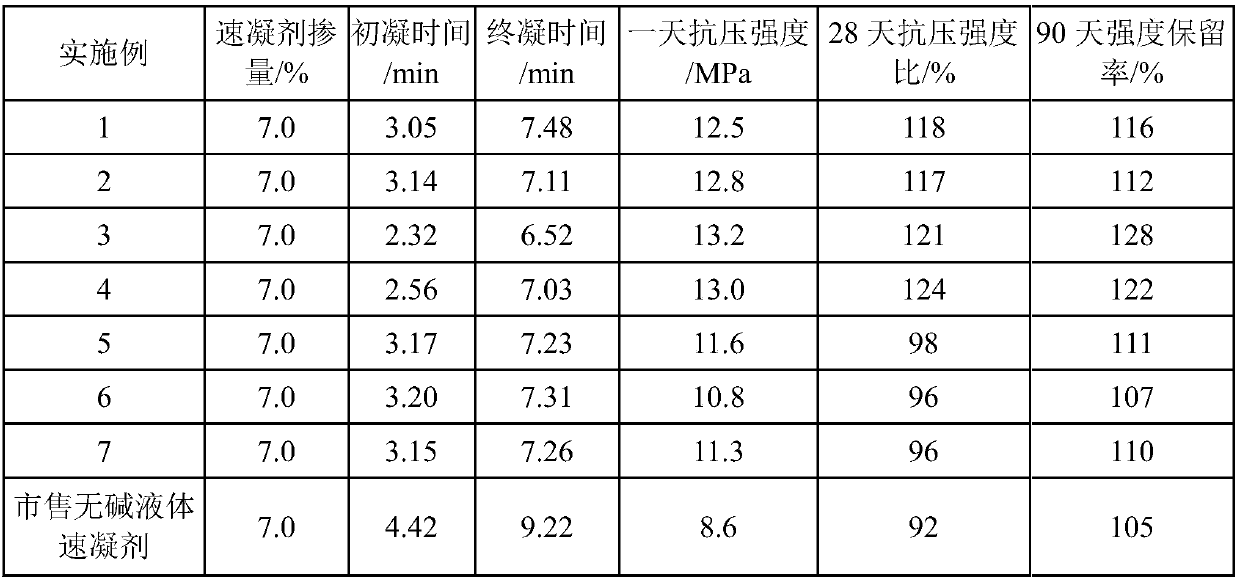

Alkali-free liquid accelerator and preparation method thereof

The invention provides an alkali-free liquid accelerator and a preparation method thereof and belongs to the technical field of concrete admixtures. The alkali-free liquid accelerator is prepared fromthe following raw materials: aluminum sulfate, ferrous sulfate, sodium fluoride, magnesium fluosilicate, precipitated hydrated magnesium silicate, diethanol amine and water. The alkali-free liquid accelerator has a good rapid hardening effect, can effectively shorten the coagulating and final setting time of concrete, and effectively improves the early strength and the later strength of concrete.The preparation method of the alkali-free liquid accelerator comprises the following steps: stirring water and precipitated hydrated magnesium silicate for 15-20 min at 40 DEG C; then adding ferroussulfate and sodium fluoride, and performing mixing and stirring for 8-15 min; after that, adding aluminum sulfate; performing heating up to 75-85 DEG C; after a reaction for 1 h, adding magnesium fluosilicate, and performing stirring for 20-40 min; and at last, adding diethanol amine, performing stirring for 18-25 min to prepare the alkali-free liquid accelerator. The preparation method is simple,the reaction is safe, and the prepared accelerator has good dispersibility.

Owner:PANZHIHUA CITY JIYUAN TECH

Catalytic system for catalyzing and oxidizing alcohol to prepare aldehyde and ketone and method of preparing aldehyde and ketone

InactiveCN1651381AImprove efficiencyHigh selectivity andOxygen-containing compound preparationOrganic compound preparationHalogenPressure reactor

A catalyst system for preparing aldehyde and ketone by catalytic oxidization of alcohol is composed of the catalyst consisting of 2,2,6,6-tetramethylpiperidine-free oxygen radical, halogen and nitrite, and the oxidant. The process for preparing said aldehyde and ketone features the high-sensitivity oxidizing reaction between catalyst, alcohol and air or oxygen in pressure reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

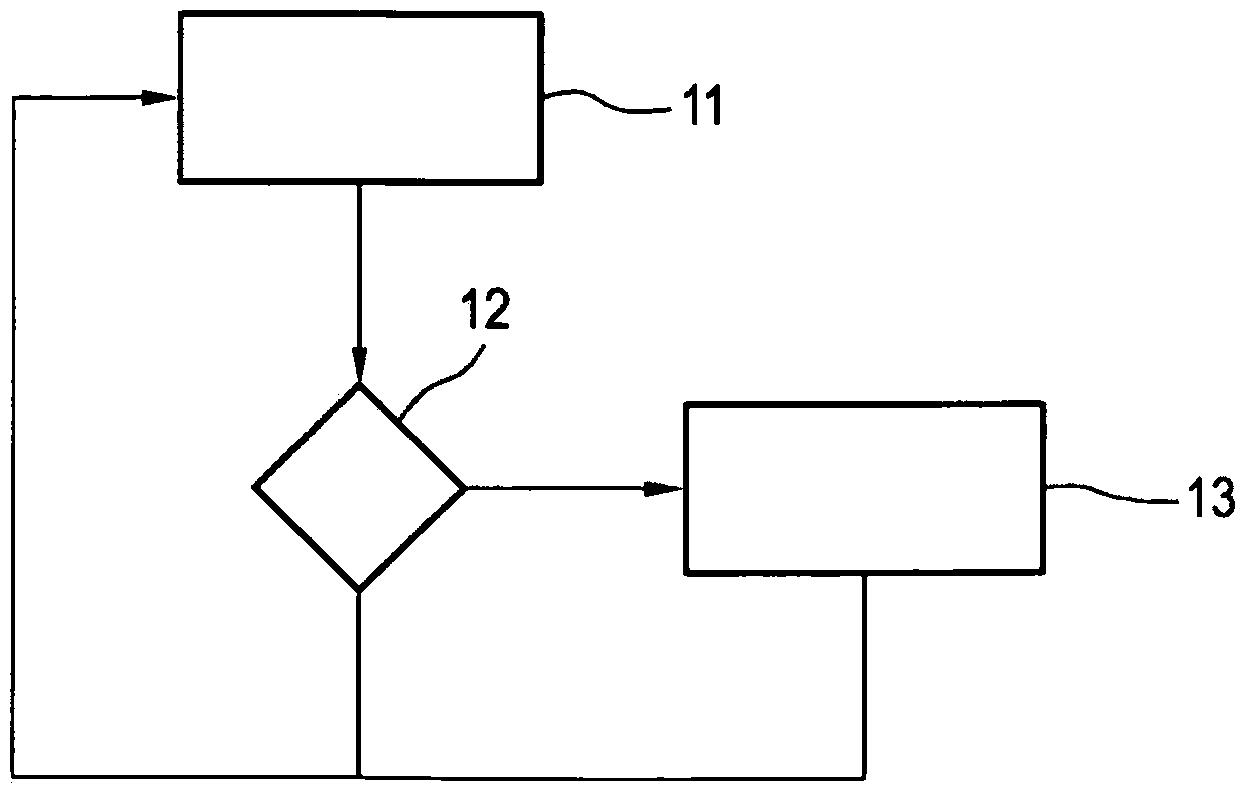

Method for operating a longitudinal driver assistance system of a motor vehicle and motor vehicle

ActiveCN103534741AImprove securityImprove responseAnti-collision systemsExternal condition input parametersTravel modeSystems design

Method for operating a longitudinal driver assistance system of a motor vehicle (1), especially of an ACC system (2), which is designed to control the speed of a motor vehicle (1) to a desired speed in a free travel mode and / or keeps a controlled distance to a vehicle in front as the control object in a follow mode, at least one control parameter influencing control being adapted depending on at least one item of traffic information that describes traffic conditions on the currently traveled route, especially in the further course of the route, said information being received from an external transmitter (7,9).

Owner:AUDI AG

Ammonium stearate emulsion and producing method thereof

The invention relates to ammonium stearate emulsion and a producing method thereof, belonging to the technical field of auxiliary chemicals. The ammonium stearate emulsion comprises the following components with the weight percentage: 15-35% of stearic acid, 6-14% of 20% ammonia water, 1-3% of lauryl sodium sulfate and the rest of water. The production technique is that a reaction vessel is sequentially added with the stearic acid, the lauryl sodium sulfate and the water according to the formulation amount, the temperature is regulated to be 10-25 DEG C; after being evenly stirred, the mixture in the reaction vessel is added with the ammonia water, and the mixing speed is adjusted; the prepared ammonium stearate liquid is absorbed into an emulsifying tank for emulsification, stands still for 1-2h, and then is filtered, so that the ammonium stearate emulsion is obtained. The invention is suitable for large scale continuous production, ensures the reaction to be very safe under normal temperature and pressure, and has the advantages of simple input equipment, saved cost, no pollution and emission in the whole production process, silvery white and lustrous finished products, excellent fluidness and stability, low product viscosity (being lower than or equal to 350cps), high purity, good dispersion effect and convenient use. The ammonium stearate emulsion can be fully dispersed in waterborne liquid, has about six-month shelf life and is hard to become thick after being placed for a long time.

Owner:海宁市树桥纺织科技有限公司

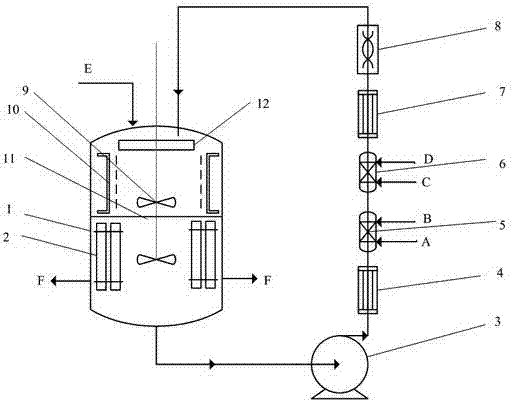

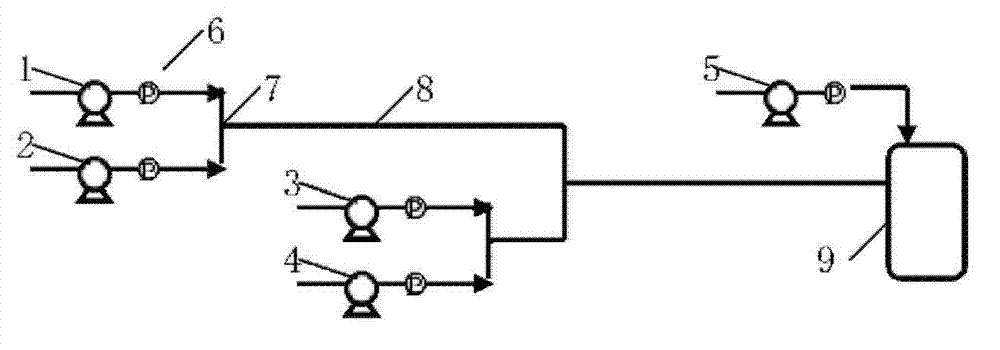

Ammoximation reaction and separation coupling process and device

The invention discloses an ammoximation reaction and separation coupling process which comprises the following steps: continuously adding reaction raw materials and a solvent in different groups outside a reaction kettle into a pipeline reactor for reaction, mixing the components in a mixer, and subsequently feeding the mixture into the reaction kettle for sufficient reaction, wherein the upper part of the reaction kettle is a reaction zone, and the lower part of the reaction kettle is a filtration separation zone; separating a reaction product, namely, cyclohexanone-oxime from a catalyst in the filtration separation zone, feeding the separated cyclohexanone-oxime into a later process, and circulating the catalyst back to the reaction kettle for continuous reaction through equipment such as the pipeline reactor outside the reaction kettle. Backwashing is performed once every 10-300 seconds, so that the continuity of reaction separation is ensured. As the raw materials sufficiently contact the catalyst, the reaction is complete, and the conversion rate of cyclohexanone can be 99.9-100%. The whole set of reaction separation devices is reasonable in arrangement and stable in reaction.

Owner:河北美邦工程科技股份有限公司

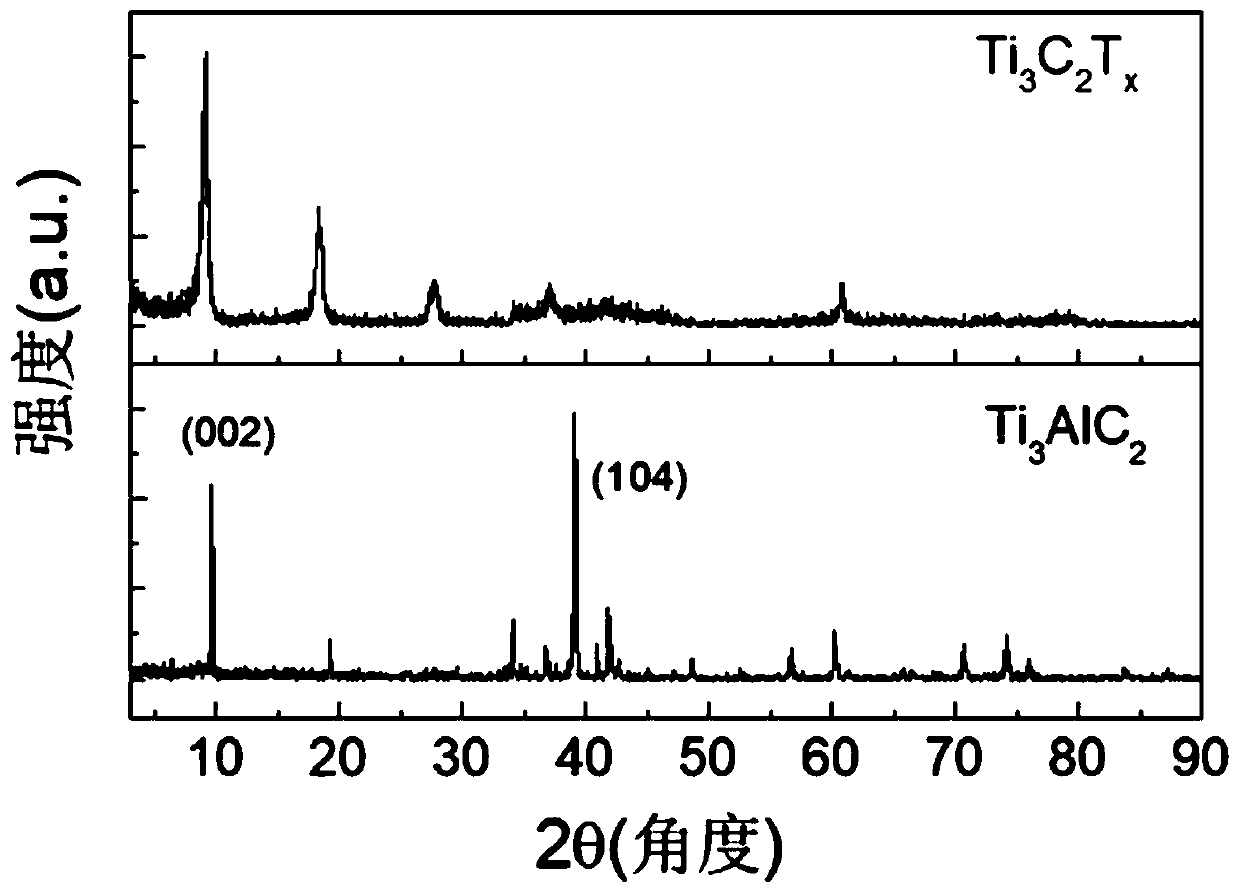

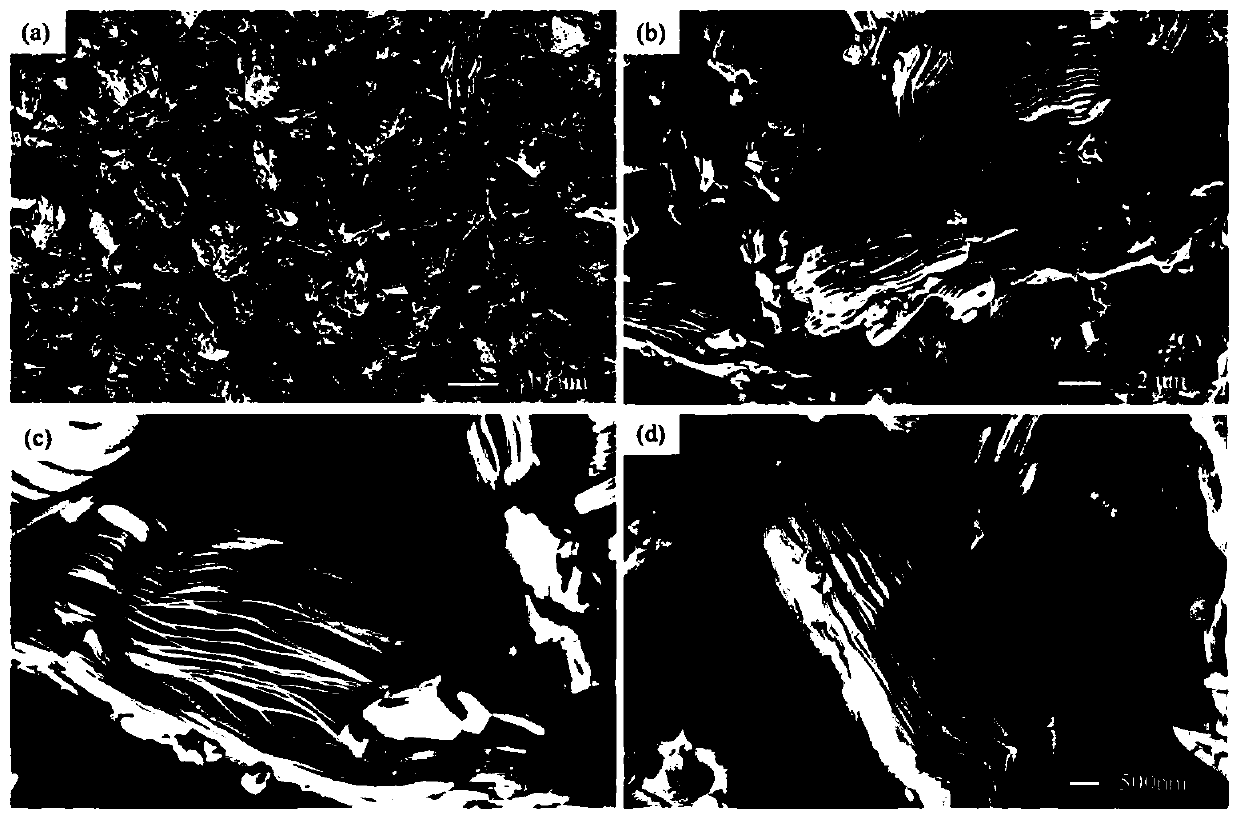

Rapid preparation method and application of few layer MXenes

ActiveCN110534741AMild responseLow costMaterial nanotechnologyFinal product manufactureChemistryLithium electrode

The invention discloses a rapid preparation method and application of few layer MXenes. According to the preparation method of the few layer MXenes material, a few layer MXenes solution with good dispersibility is obtained by stripping a multi-layer MXenes liquid phase; the electrostatic balance of the few layer MXenes solution with is destroyed by introducing an electrolyte solution, and the obtained sol, precipitate or filter cake is the few layer MXenes material by means of cation-assisted electrostatic precipitation process (such as NH4 +) through standing or low-speed centrifugation or pumping filtration; and then macro-scale preparation of the few layer MXenes powder can be realized through freeze drying and subsequent annealing treatment. The preparation method has advantages of simple process and thin layers, large sheet diameter, good dispersibility, no agglomeration and agglomeration phenomenon and good electrochemical performance of the prepared few layer MXenes and is suitable for large-scale development and application of lithium ion batteries or sodium ion batteries.

Owner:ZHEJIANG UNIV

Materials and Methods for Delivering Antioxidants into the Skin

InactiveUS20100098752A1React SafeLarge cavity sizeBiocideCosmetic preparationsLipid formationAntioxidant

Compositions and methods for administering one or more antioxidants to a human subject have been developed. The antioxidant-containing lipid vesicles of the invention provide a delivery system for antioxidants which can be applied topically to the skin.

Owner:PINSKY MARK A

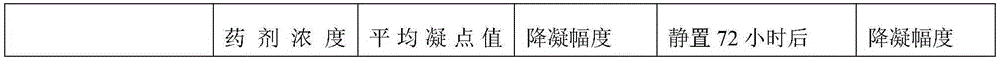

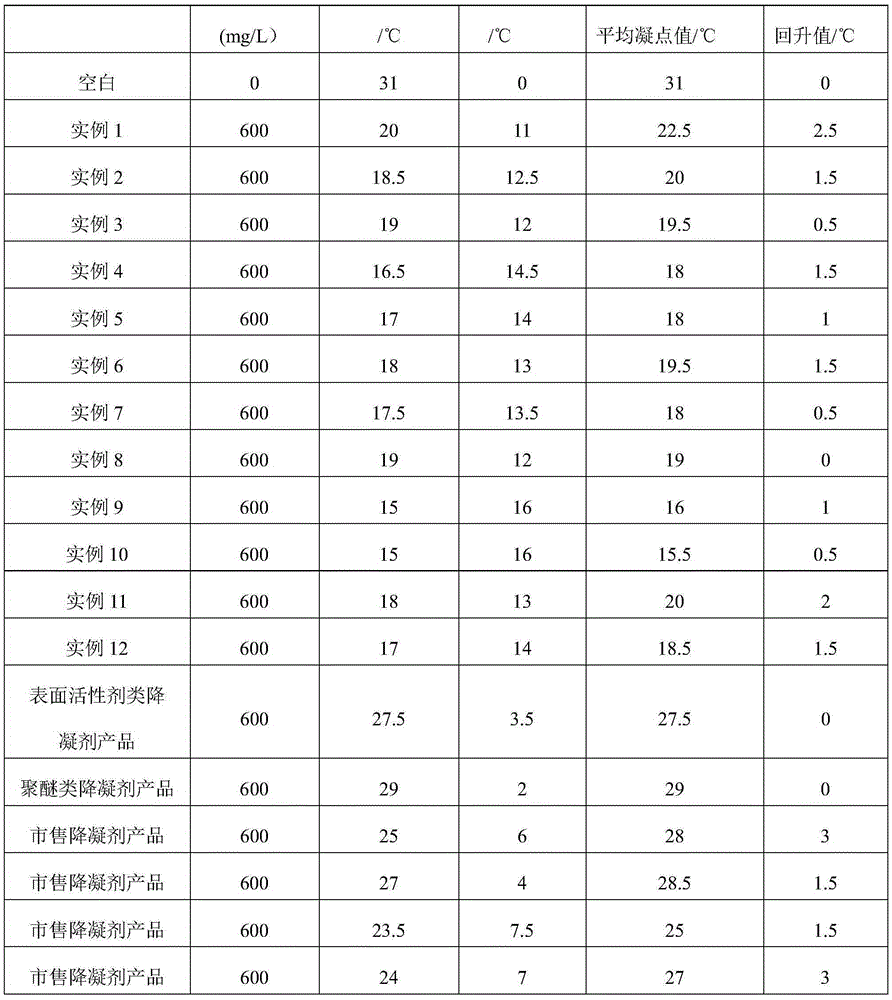

Oil field crude oil pour point depressant and preparing method thereof

The invention belongs to the technical field of oil-gas-water collecting and transporting and discloses an oil field crude oil pour point depressant and a preparing method of the oil field crude oil pour point depressant. The preparing method includes the steps that acrylic ester or metacrylic acid ester is mixed with perfluor carboxylic ester firstly, an organic solvent is added, the temperature rises, and stirring is conducted; then styrene is added, the temperature rises under the nitrogen protection, an organic solvent solution of an initiator is dripped, and a product A is obtained after a reaction; and finally, a-olefin, a polymer B and the product A are mixed and evenly stirred, and the oil field crude oil pour point depressant is obtained. The oil field crude oil pour point depressant has the paraffin prevention pour point depressing function, does not contain chlorine, is very suitable for transporting of crude oil of an offshore oil field and has the characteristics that the dosage is small, and the pour point depressing amplitude is large. The preparing method of the oil field crude oil pour point depressant is simple, a polar group containing fluorine is directly introduced into a molecular chain through a further reaction, the reaction process is easy to control, safe, reliable and environment-friendly, and high general applicability is achieved.

Owner:中海油(天津)油田化工有限公司 +1

Epoxidation vegetable oil preparation method

ActiveCN102864021AIncrease initial reaction speedHigh selectivityFatty acid chemical modificationOrganic acidStrong acids

The invention discloses an epoxidation vegetable oil preparation method. The epoxidation vegetable oil preparation method includes steps of firstly, uniformly mixing mixed acid catalyst containing organic acid and strong acid, uniformly mixing and stirring peroxy acid stabilizer and hydrogen peroxide, dripping the mixed acid catalyst in to mixed solution of the peroxy acid stabilizer and the hydrogen peroxide at the temperature of 25-35 DEG C, and reacting to obtain mixed solution of peroxide intermediates; and secondly, adding the epoxidation stabilizer into vegetable oil, dripping the mixed solution of the peroxide intermediates at the temperature of 65-95 DEG C, reacting for 10-30 minutes with heat preservation; dripping hydrogen peroxide solution, reacting four 1-4 hours with heat preservation, and obtaining epoxidation vegetable oil products after treatment. The vegetable oil is epoxidized by three steps, and suitable catalysts and stabilizers are selected, reaction time is shortened, and thereby reaction selectivity is high, side reaction is reduced, epoxidation time is short, reaction conversion rate is increased, production cost is reduced and production safety is improved.

Owner:SHANDONG JIQING CHEM

Tooth modeling system

ActiveUS10624717B2Avoid collisionReact SafeImage enhancementImpression capsDental malocclusion3d printed

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished by applying a series of labels to a digital dental model and applying a rolling ball process to identify tooth boundaries separating one tooth from a neighboring tooth and to also determine the crown / gum margin. The user may further assign regions to the dental model to indicate hard regions and soft regions. With the dental model labeled and defined, the user may then generate a treatment plan for moving the labeled and defined tooth or teeth relative to one another to correct for any malocclusions. Upon approval of the treatment plan, a series of 3D printed dental appliances or aligners to be worn in series by the patient may be fabricated to ultimately move the tooth or teeth to a desired position.

Owner:ULAB SYST INC

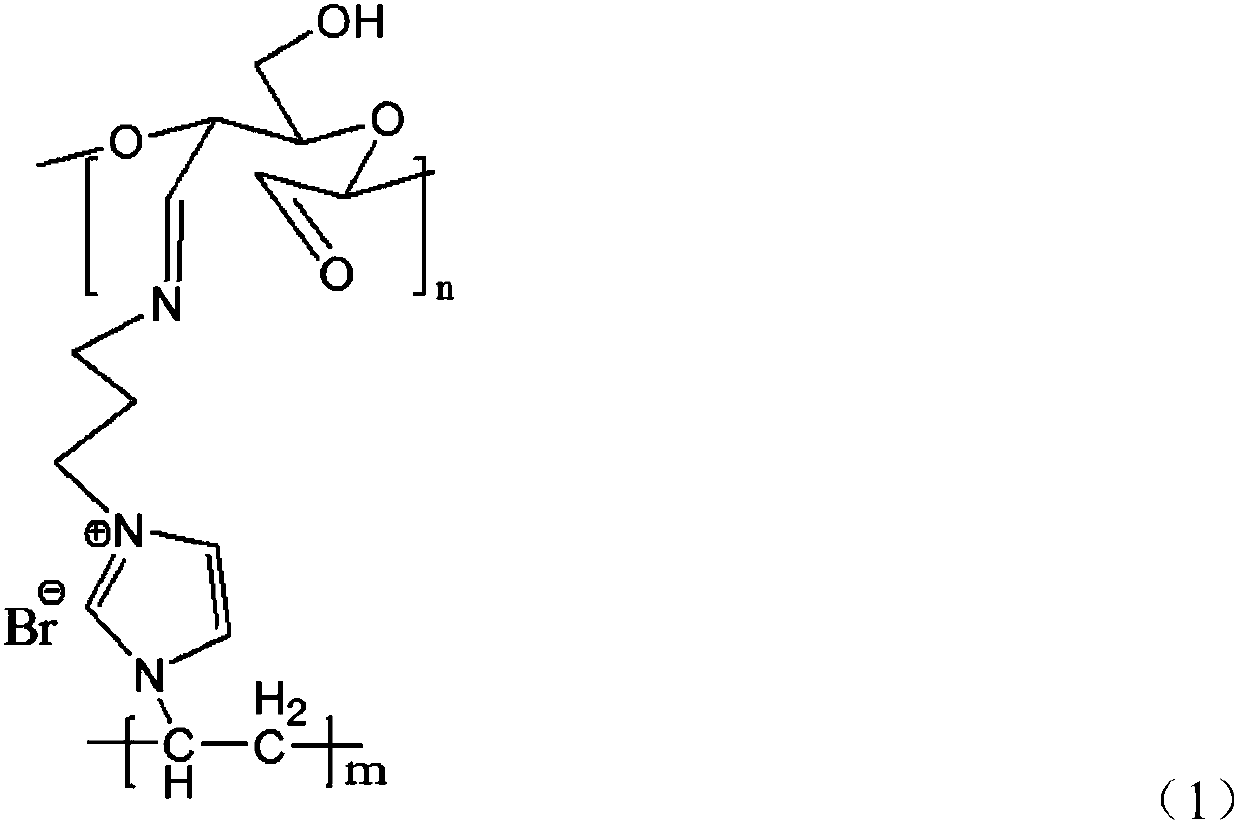

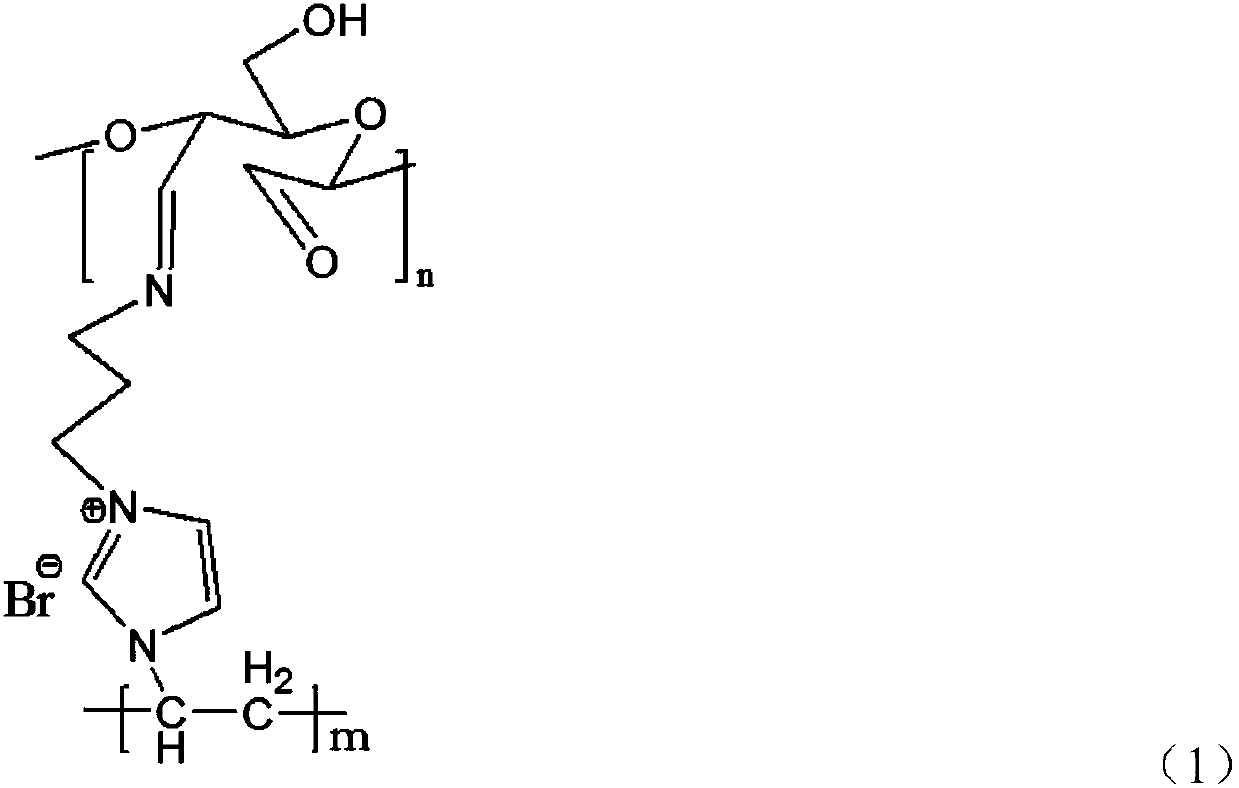

Polyimidazole ionic liquid modified cellulose-based adsorbent as well as preparation method and application of cellulose-based adsorbent

ActiveCN109092265AImprove adsorption capacityPromote degradationOther chemical processesWater contaminantsSorbentDialdehyde cellulose

The invention provides a polyimidazole ionic liquid modified cellulose-based adsorbent as well as a preparation method and an application of the cellulose-based adsorbent. The method comprises the steps as follows: step 1, preparing dialdehyde cellulose and a polyimidazole ion liquid respectively; step 2, immersing dialdehyde cellulose in water, dissolving the polyimidazole ion liquid in an HCl solution, mixing a dialdehyde cellulose water solution and the HCl solution of the polyimidazole ion liquid, controlling the pH in the range of 2.5-3.5, and performing stirring at 20-45 DEG C for 4-8 hto obtain a polyimidazole ion liquid modified cellulose crude product; step 3, washing the polyimidazole ion liquid modified cellulose crude product with ethanol and water, and drying the product to obtain the polyimidazole ionic liquid modified cellulose-based adsorbent. The adsorbent can effectively solve the problems of low adsorption capacity of cellulose in a water phase and single grafted imidazolium ionic liquid functional groups have few adsorption sites and weak adsorption functions in the prior modification art and can be used for treating dye wastewater.

Owner:SHAANXI UNIV OF SCI & TECH

Method for synthesizing nitryl chloroaniline compound by using micro-channel reactor

InactiveCN103113235AShort reaction timeHigh selectivityOrganic compound preparationAmino compound preparationOrganic synthesisNitration

The invention relates to a method for synthesizing nitryl chloroaniline compound by using a micro-channel reactor, and belongs to the technical field of organic synthesis application. In the method, chloroaniline, acylating agent, nitric acid and sulfuric acid are used as original reaction raw materials, the processes of chloroaniline acylation, mixture acid confection, acylated chloroaniline nitration, and the like are carried out in the micro-channel reactor system, and a hydrolysis reaction process is finished out of the micro-channel device by using a normal reactor. In the reaction, acyl chloride, acid anhydride and glacial acetic acid are used as the acylating agent, and nitric acid and sulfuric acid mixture acid is used as the nitrating agent, the chloroaniline acylation transformation rate can reach 100%, and the mass content of the nitryl chloroaniline reaches higher than 92%. The micro-channel reactor used in the invention is especially suitable for carrying out continuously acylation and nitration reaction, and has the characteristics of being stable in temperature control and safe in process.

Owner:CHANGZHOU UNIV

Method for preparing acetylacetone acid molybdenum

InactiveCN101117308AReduce pollutionPrevent self-aggregationGroup 6/16 element organic compoundsPreparation of aldehyde/ketone chelatesCelsius DegreeAntioxidant

The invention discloses a preparation process for molybdenum acetylacetonate. In the prior art, the acetylacetone is easy to be oxidized in the air and polymerized under refluence, so the unreacted molybdenum trioxide and by-products exist in the product, the product is impure and has low yields. In the invention, the molybdenum trioxide is dissolved into the weak-base inorganic alkaline solution, then the antioxidant is added into the solution, the temperature rises to forty to seventy Celsius system, the acetylacetone is dripped into the solution, then the non-oxidizing inorganic acid is added to adjust the solution to the weak acid, then the temperature is preserved until the crystal of molybdenum (II) 2,4-pentanedionate hydrate is precipitated; then the procedure of cooling, filtering, fulling is done to remove the adhesive acetylacetone from the filter cake. The invention is reacted with the molybdenum trioxide under low temperature, thereby the invention avoids the self-polymerization of the acetylacetone, and has less side reactions, high yields as well as high purity.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Preparation method of ethylene sulfate

The invention discloses a preparation method of ethylene sulfate. The method comprises the following steps: firstly, ethylene glycol and thionyl chloride are used as raw materials to synthesize ethylene sulfite, the ethylene sulfite and air or oxygen are subjected to a direct oxidation reaction under the action of a catalyst to form ethylene sulfate, filtration is performed, washing is performed by using water, concentration is performed, crystallization is performed, and therefore the finished-product ethylene sulfate is obtained. The method provided by the invention adopts the novel catalystand uses the air or the oxygen as an oxidant, thereby effectively reducing use costs of the catalyst and the oxidant; and the method has less waste water, thereby being more in line with concepts ofenergy saving, greenness and environmental protection.

Owner:福建博鸿新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com