Preparation method of phenolic resin aerogel

A technology of phenolic resin and airgel, which is applied in the preparation/purification of carbon, chemical instruments and methods, and other chemical processes. It can solve the problems of complex synthesis, limited application, and high cost of ionic liquids, and achieves wide sources and easy storage. , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The invention discloses a preparation method of phenolic resin gel, comprising:

[0062] a1, disperse chitosan in water or water / dehydrated ethanol mixed solution, add acid again, stir to obtain chitosan sol;

[0063] Or add filler and chitosan to water or water / dehydrated ethanol mixed solution, stir well and then add acid, stir to obtain chitosan sol;

[0064] b1, add phenols in chitosan sol, after stirring evenly, then add aldehydes, stir again to obtain mixed sol;

[0065] c1, put the mixed sol into a hydrothermal kettle, place it in an oven for hydrothermal reaction, and obtain a phenolic resin organogel;

[0066] d1. Soak the phenolic resin organogel in an organic solvent to replace until the organic solvent changes color, replace the organic solvent until the organic solvent after soaking the phenolic resin organogel is colorless, take out the phenolic resin organogel and perform supercritical drying to obtain the phenolic resin Aerogel;

[0067] Or place the ...

Embodiment 1

[0087] The present embodiment phenolic resin airgel is carried out as follows:

[0088] a. In a beaker with a volume of 100mL, disperse 0.45g of chitosan (Shanghai Sinopharm Group) in 30ml of deionized water, add 0.6ml of acetic acid, and stir to obtain a colorless and transparent chitosan sol;

[0089]b. Put phenol in an oven at 60°C until it melts, weigh 9.411g of liquid phenol and add it to the above-mentioned colorless and transparent chitosan sol, stir fully and quickly to make it evenly mixed into a white emulsion, and then quickly add 3ml For formaldehyde solution, keep fast and uninterrupted stirring evenly until its viscosity increases significantly to obtain a mixed sol;

[0090] c. Put the mixed sol into a 50ml hydrothermal kettle, place it in an oven at 160°C, and conduct a hydrothermal reaction for 10 hours to obtain a phenolic resin organogel, which is called organogel 1;

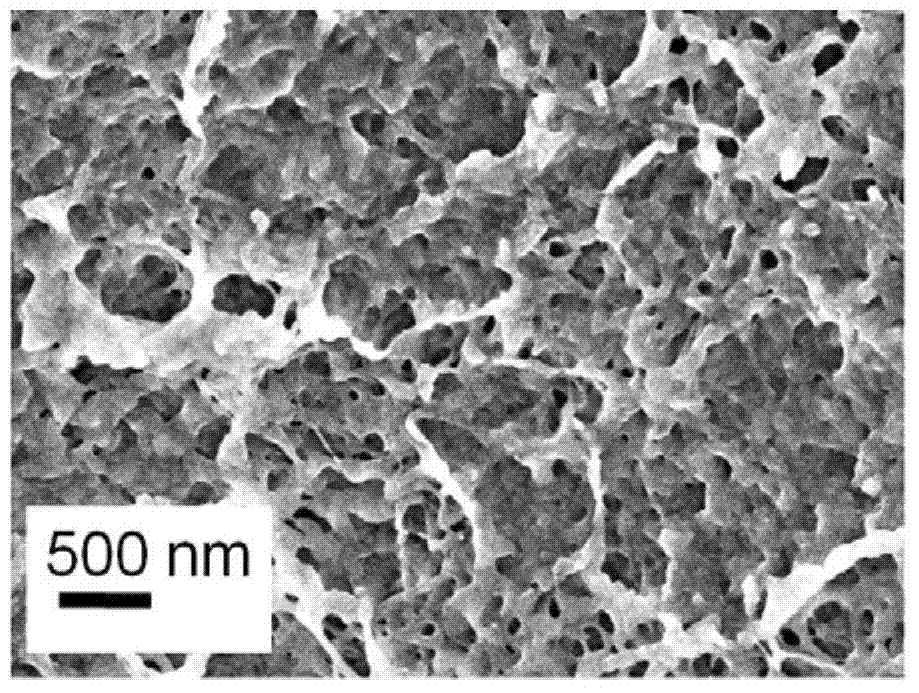

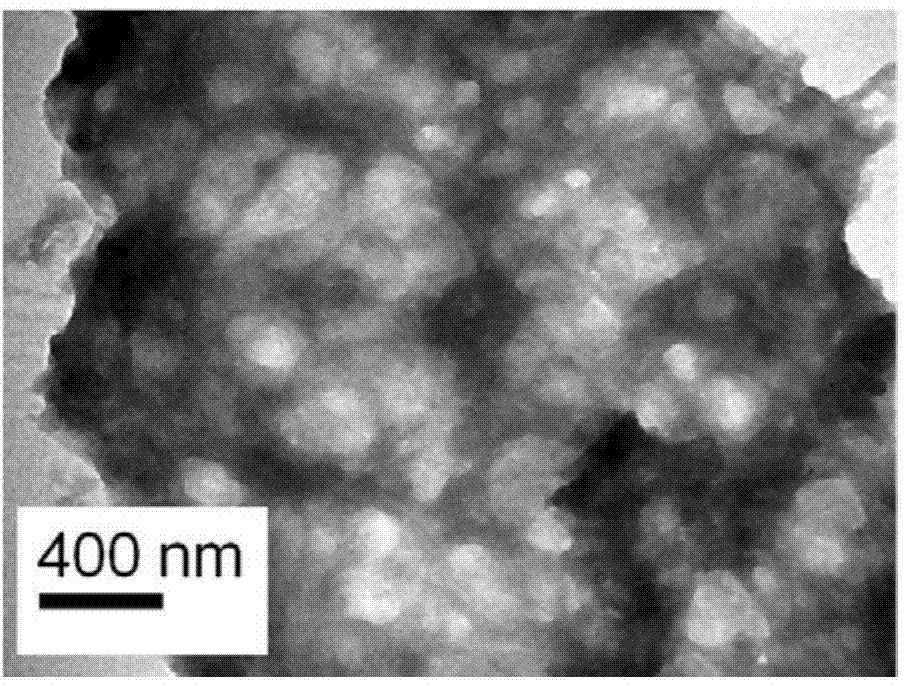

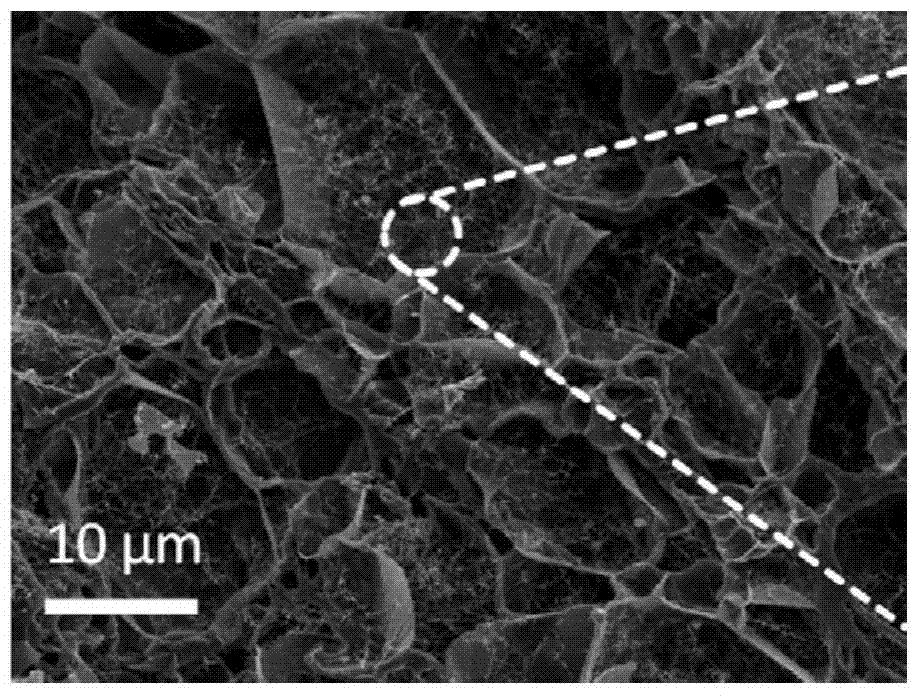

[0091] d, immerse the phenolic resin organogel in acetone for three days, replace new ace...

Embodiment 2

[0094] Utilize the preparation method identical with embodiment 1, adopt 0.45g chitosan, in described step b, the amount of the phenol that adds is 1.882g, 3.764g, 5.647g, 6.588g, 7.529g, 11.29g and 13.175g , the added formaldehyde is 3ml, that is, the ratio of the amount of phenol to formaldehyde (P / F) is 0.5, 1, 1.5, 1.75, 2, 3 and 3.5, respectively, after hydrothermal reaction, different P / F can be obtained Resin organogels, numbered organogel 2 to organogel 8; supercritical CO 2 The airgel obtained after drying and the carbon aerogel obtained after carbonization are respectively numbered as airgel 2 to airgel 8, and carbon aerogel 2 to carbon aerogel 8, respectively.

[0095] Because the amount of chitosan used in the reaction is unchanged, the microscopic skeleton structure is the same. The difference in the ratio of phenol to formaldehyde changes the amount of linear small molecules or oligomers filled in the skeleton, thereby changing the phenolic resin. Mechanical pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com