Modified urea-formaldehyde resin adhesive for concrete formwork and production method of adhesive

A technology of concrete formwork and urea-formaldehyde resin, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., to achieve the effect of convenient control of the process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

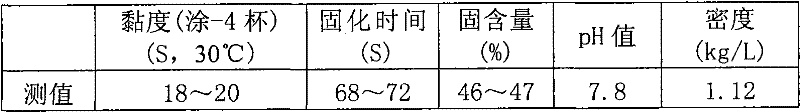

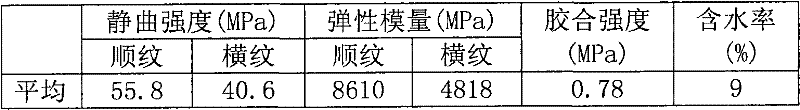

Embodiment 1

[0020] 1. Formula composition

[0021] The molar ratio of formaldehyde to urea is F / U=2.04, 530 parts of formaldehyde (concentration 37%), 197 parts of urea (purity 98%), 65 parts of melamine, 1.4 parts of polyvinyl alcohol, 1 part of hexamethylenetetramine, 2 parts of dicyandiamide.

[0022] 2. Glue making process

[0023] Put 530 parts of formaldehyde solution and 1.4 parts of polyvinyl alcohol into the reaction kettle, start the agitator, start heating and heating, stop heating when the temperature rises to 38-40 °C, and when the temperature inertia rises to 48 °C, use 31-36% hydrochloric acid to adjust the pH value to 1.7-2.0;

[0024] When the temperature rises to 51°C, add 140 parts of the first batch of urea evenly within 7-10 minutes, and the temperature rises to 83-85°C;

[0025] Immediately use 25-30% sodium hydroxide aqueous solution to adjust the pH to 5.8-6.2. When the temperature is 83-85°C, add 35 parts of the second batch of urea evenly, stir for 10 minut...

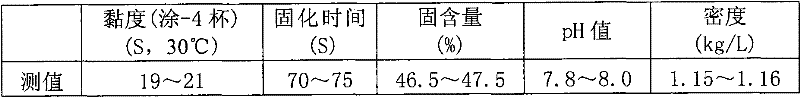

Embodiment 2

[0040] 1. Formula composition

[0041] The molar ratio of formaldehyde to urea is F / U=1.82, 590 parts of formaldehyde (concentration 37%), 245 parts of urea (purity 98%), 75 parts of melamine, 1.5 parts of polyvinyl alcohol, 1 part of hexamethylenetetramine, 2 parts of dicyandiamide;

[0042] 2. Glue making process

[0043] Put 590 parts of formaldehyde solution and 1.5 parts of polyvinyl alcohol into the reaction kettle, start the agitator, start heating and heating, stop heating when the temperature rises to 38-40°C, and when the temperature inertia rises to 48°C, use 31-36% hydrochloric acid to adjust the pH value to 1.7-2.0;

[0044] When the temperature rises to 51°C, evenly add 156 parts of the first batch of urea within 7-10 minutes, and the temperature rises to 81-85°C.

[0045] Immediately use 25-30% sodium hydroxide aqueous solution to adjust the pH to 5.5-6.0, and add 38 parts of the second batch of urea evenly when the temperature is 83-85 °C, and add 30 parts o...

Embodiment 3

[0060] 1. Formula composition

[0061] The molar ratio of formaldehyde to urea is F / U=2.107, 1200 parts of formaldehyde (concentration 37%), 430 parts of urea (purity 98%), 115 parts of melamine, 3 parts of polyvinyl alcohol, 2 parts of hexamethylenetetramine, 4 parts of dicyandiamide;

[0062] 2. Glue making process

[0063] Put 1200 parts of formaldehyde solution and 3 parts of polyvinyl alcohol into the reaction kettle, start the agitator, start heating and heating, stop heating when the temperature rises to 37-38 °C, and when the temperature inertia rises to 47 °C, use 30-36% hydrochloric acid to adjust the pH value to 1.7-2.0;

[0064] When the temperature rises to 51°C, evenly add 312 parts of the first batch of urea within 10-12 minutes, and the temperature rises to 83-85°C.

[0065] Immediately use 25-30% sodium hydroxide aqueous solution to adjust the pH to 5.5-6.0, and add 76 parts of the second batch of urea evenly when the temperature is 83-85 °C, and add 40 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com