Alkali-free liquid accelerator and preparation method thereof

A technology of quick-setting agent and liquid, applied in the field of alkali-free liquid quick-setting agent and its preparation, can solve problems such as damage to human health, corrosion of construction equipment, etc., so as to reduce pollution, avoid corrosion, and shorten the time of initial setting and final setting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

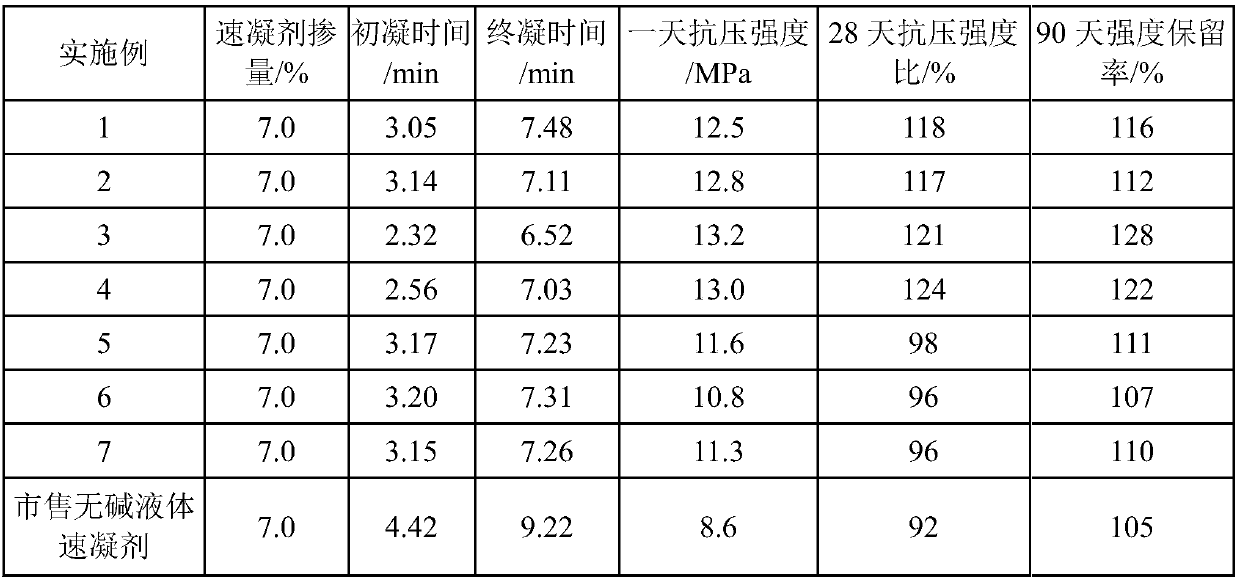

Examples

preparation example Construction

[0019] The present invention proposes a kind of preparation method of non-alkali liquid quick-setting agent, comprises the following steps:

[0020] Mix 35-45 parts by weight of water with 0.5-0.8 parts by weight of precipitated hydrated magnesium silicate, stir at 40°C for 15-20 minutes, then add 5-10 parts by weight of ferrous sulfate and 2.5-3 parts by weight Mix and stir the sodium fluoride for 8-15 minutes, then add 40-50 parts by weight of aluminum sulfate, heat to 75°C-85°C, react for 1 hour, add 1-1.8 parts by weight of magnesium fluorosilicate, stir for 20-40 minutes, and finally Add 2.5-3.5 parts by weight of diethanolamine and stir for 18-25 minutes to prepare the alkali-free liquid quick-setting agent.

[0021] First add precipitated hydrated magnesium silicate in the water, the purpose is to make the precipitated hydrated magnesium silicate can be well dispersed in water, if the precipitated hydrated magnesium silicate is added later, the dispersion will not be go...

Embodiment 1

[0025] A preparation method of an alkali-free liquid quick-setting agent, comprising the following steps:

[0026] Mix 35g of water with 0.5g of precipitated hydrated magnesium silicate, stir at 40°C for 15min, then add 5g of ferrous sulfate and 2.5g of sodium fluoride, mix and stir for 8min, then add 40g of octadecanohydrate sulfuric acid aluminum, heated to 75°C, reacted for 1 hour, then added 1 g of magnesium fluorosilicate, stirred for 20 minutes, and finally added 2.5 g of diethanolamine and stirred for 18 minutes to obtain an alkali-free liquid quick-setting agent.

Embodiment 2

[0028] A preparation method of an alkali-free liquid quick-setting agent, comprising the following steps:

[0029] Mix 45g of water with 0.8g of precipitated hydrated magnesium silicate, stir at 40°C for 20min, then add 10g of ferrous sulfate and 3g of sodium fluoride, mix and stir for 15min, then add 50g of octadecahydrate aluminum sulfate , heated to 85°C, reacted for 1 hour, added 1.8g of magnesium fluorosilicate, stirred for 40 minutes, and finally added 3.5g of diethanolamine and stirred for 25 minutes to obtain an alkali-free liquid quick-setting agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com