Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Shorten final setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

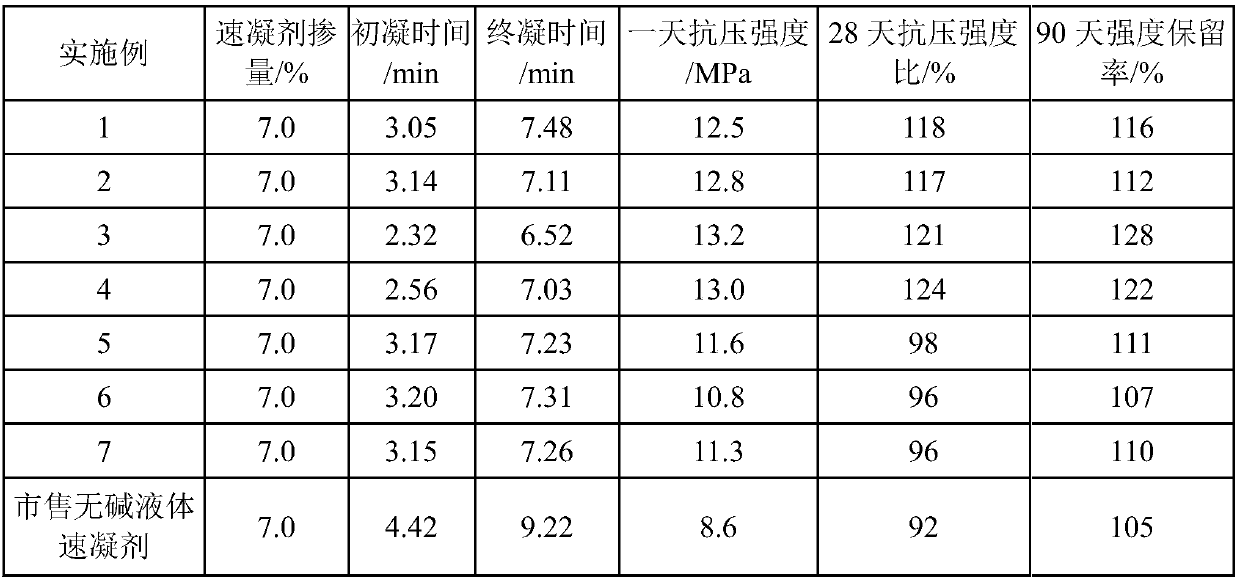

Alkali-free liquid accelerator and preparation method thereof

The invention provides an alkali-free liquid accelerator and a preparation method thereof and belongs to the technical field of concrete admixtures. The alkali-free liquid accelerator is prepared fromthe following raw materials: aluminum sulfate, ferrous sulfate, sodium fluoride, magnesium fluosilicate, precipitated hydrated magnesium silicate, diethanol amine and water. The alkali-free liquid accelerator has a good rapid hardening effect, can effectively shorten the coagulating and final setting time of concrete, and effectively improves the early strength and the later strength of concrete.The preparation method of the alkali-free liquid accelerator comprises the following steps: stirring water and precipitated hydrated magnesium silicate for 15-20 min at 40 DEG C; then adding ferroussulfate and sodium fluoride, and performing mixing and stirring for 8-15 min; after that, adding aluminum sulfate; performing heating up to 75-85 DEG C; after a reaction for 1 h, adding magnesium fluosilicate, and performing stirring for 20-40 min; and at last, adding diethanol amine, performing stirring for 18-25 min to prepare the alkali-free liquid accelerator. The preparation method is simple,the reaction is safe, and the prepared accelerator has good dispersibility.

Owner:PANZHIHUA CITY JIYUAN TECH

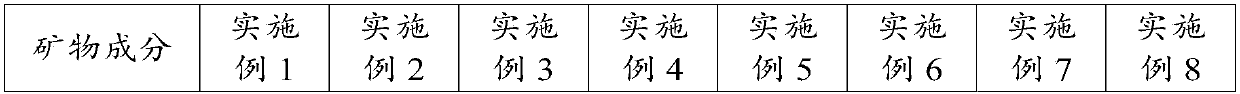

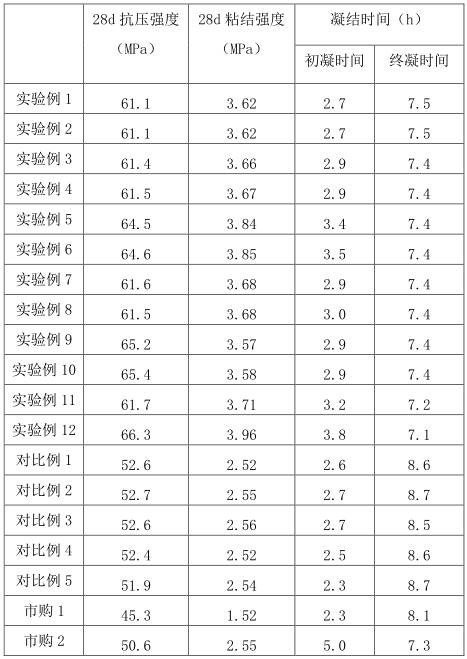

High-bending-strength supersulfate cement and preparation method thereof

ActiveCN107827379AHigh activityAccelerate the rate of hydration hardeningSolid waste managementCement productionGypsumSlag

The invention provides high-bending-strength supersulfate cement and a preparation method thereof and relates to the field of building materials. The high-bending-strength supersulfate cement comprises granulated blast-furnace slag, gypsum and high-belite sulfate aluminum cement clinker. By utilizing the high-bending-strength supersulfate cement, the problem that existing supersulfate cement is low in hydration and hardening speed and early strength and prone to sand shedding caused by the fact that excitants cannot fully excite granulation blast-furnace slag activity in the prior art is solved, and bending strength of the cement is improved greatly; the high-bending-strength supersulfate cement has the advantages of high early-later strength and is ultrahigh in bending strength especially.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Preparation method of concrete surface skeleton exposing agent for prefabricated part

PendingCN110510913AEfficient retardingExpansion of comprehensive utilization channelsPreservativeWater soluble

The invention discloses a preparation method of a concrete surface skeleton exposing agent for a prefabricated part, and the preparation method comprises the following steps: (1) preparation of a polymer / phyllosilicate composite colloidal solution, namely under high-speed dispersion, uniformly dispersing phyllosilicate clay X1 and a water-soluble high-molecular polymer in water; (2) preparation ofan organic-inorganic composite retarding liquid, namely under high-speed dispersion, adding an organic-inorganic composite retarder composition into the polymer / layered silicate composite colloidal solution, and dispersing until no precipitate exists in a homogeneous phase; and (3) skeleton exposing agent forming, namely under the action of high-speed dispersion, sequentially adding a functionalauxiliary agent, a pigment, a filler and a slow-release long-acting preservative into the organic-inorganic composite retarding liquid, and uniformly mixing and dispersing. The concrete surface skeleton exposing agent for the prefabricated part has the multiple advantages of ecological environmental protection, efficient retarding, durability, stability, easiness in facade construction and the like, industrial byproduct gypsum is used as a main retarding component, and secondary utilization of byproducts is realized.

Owner:ANHUI GAODI BUILDING MATERIAL CO LTD

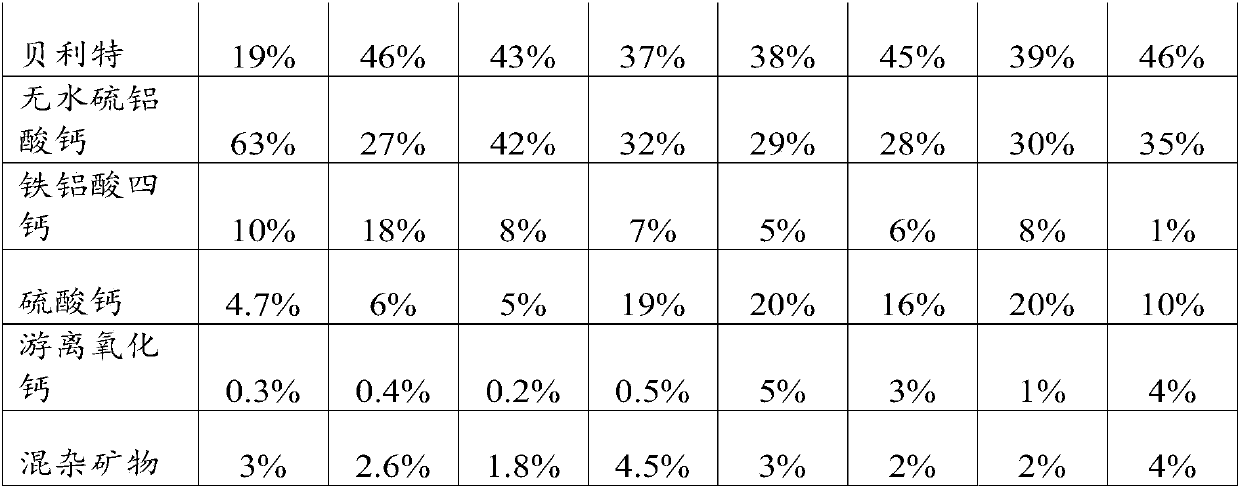

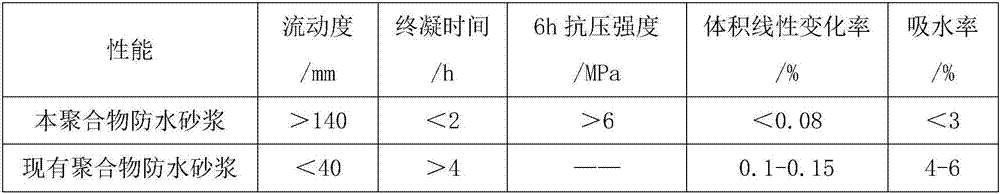

Self-leveling type II polymer cement waterproof mortar

The invention provides self-leveling type II polymer cement waterproof mortar. The mortar comprises Portland cement, a composite hardening accelerator, aggregates, water, polymer and other additives, wherein the composite hardening accelerator comprises the following raw materials in parts by weight: 3 to 6 parts of calcium lime, 2 to 5 parts of sodium sulphate, and 5 to 10 parts of aluminate cement. The mortar solves the durability problem of poor long-term waterproof anti-penetrability performance of common self-leveling motor due to high aluminum cement component content, realizes the self-leveling construction of polymer cement waterproof mortar, and can be applied to various waterproof construction projects, such as toilets, kitchens, roofs, swimming pools and subsurface structures.

Owner:SHANDONG YINGCAI UNIV

Carbide slag modification and method of making cement using modified carbide slag instead of natural gypsum

The present invention relates to a method for modifying carbide slag. The raw material composition for preparing modified carbide slag includes 100 kg of dried carbide slag, 66-118 kg of waste sulfuric acid whose percentage concentration is 60%-86% and 0-44 kg of running water. Its technological process includes the following steps: drying carbide slag, breaking, metering, acidifying, ageing and drying so as to obtain the invented modified carbide slag which can be used for making cement instead of natural gypsum.

Owner:GUANGXI UNIV

Inorganic waterproof material with high impervious performance

The invention discloses an inorganic waterproof material with a high impervious performance. The raw materials comprise silicate cement, fine river sands, grade I coal ash, silicon powder, an expanding agent and a water reducer. The raw materials further comprise ferric chloride. The inorganic waterproof material comprises the following raw materials in parts by weight: 71-75 parts of silicate cement, 144-152 parts of fine river sands, 11-13 parts of grade I coal ash, 2-4 parts of silicon powder, 11-13 parts of an expanding agent, 3 parts of ferric chloride and 1 part of a water reducer. The material disclosed by the invention has the advantages that the chemical substance ferric chloride is added into the raw materials and the part by weight of the raw materials is adjusted, so that the impervious performance of the waterproof material is improved by 8.16%. In the waterproof material disclosed by the invention, the chemical substance ferric chloride has extremely strong activity and can be quickly reacted with a hydration product of cement to generate insoluble matters so as to effectively block fine holes in mortar, thereby greatly improving the impervious performance of the mortar.

Owner:YELLOW RIVER ENG CONSULTING

Compact acid resistant adhesive mortar

The invention discloses a compact acid resistant adhesive mortar, which is prepared by evenly mixing the components of 20-40 wt% of sodium silicate, 3-7wt% of sodium fluosilicate, 50-70wt% of glass-ceramic powder and industrial porcelain powder or glass-ceramic powder, quartz powder and industrial porcelain powder, and 1-3wt% of furfuryl alcohol in proportion at the normal temperature, adding a proper amount of water, stirring and milling to form the acid resistant adhesive mortar in a smearing state, and is used by filling in curing time. The invention has strong acid and alkaline corrosion resistance, high compression strength and bonding strength, short final setting time, simple preparation process and convenient use and operation, and can be widely applied in bonding and filling corrosion resistance and heat preservation lining bodies in the industries such as chemical engineering, smelting, petrifaction, sulfuric acid, papermaking, environment protection and the like.

Owner:JIANGXI PINGXIANG LONGFA ENTERPRISE

Method for carrying out cement solidification on radioactive raffinate by using NaAlO2 and Ca(OH)2 coagulant

InactiveCN102254579AHigh compressive strengthShorten final setting timeRadioactive decontaminationSetting timeRaffinate

The invention discloses a method for carrying out cement solidification on radioactive raffinate by using NaAlO2 and Ca(OH)2 coagulant, belonging to the technical field of cement solidification on radioactive raffinate. The method comprises the following steps of: evenly mixing sulphoaluminate cement, a composite mineral additive, NaAlO2 and Ca(OH)2 to obtain a mixture, stirring the mixture and the radioactive raffinate in a stirring pot, moving to a die and curing. When the radioactive raffinate is solidified by using the method disclosed by the invention, the boron concentration of the solidified radioactive raffinate can reach 45g / L, the capacity of the raffinate in the solidified body can reach 60 percent, the final setting time is shortened to be within 24h, the appropriate initial setting time can be ensured for solidification operation, and the solidified body can have higher compressive strength.

Owner:TSINGHUA UNIV

Method for treating water disaster in separation layer of mine

ActiveCN108843390ASolve the problem of water damageReduce dosageMining devicesUnderground chambersPotential spaceSlurry

The invention relates to the technical field of treatment and prevention of the water disaster in a separation layer of a coal mine and provides a method for treating the water disaster in the separation layer of the mine. The method comprises the following steps: forming a sampling hole in the ground surface; sampling various rock layers through the sampling hole to acquire layer information of various key layers; forming a plurality of grouting holes respectively extending to a grouting layer in the advancing direction of a working face in the ground surface, wherein the grouting layer is the key layer below a water-bearing layer and the layer of a target key layer and a weak layer below the target key layer; injecting water into various grouting holes through a high pressure pump; mining the coal in the advancing direction of the working face, judging whether the hydraulic pressure of each grouting hole is reduced at the same time, if so, then injecting premixed pulverized fuel ashinto the corresponding grouting hole through the high pressure pump. The grouting time is judged according to the change of the hydraulic pressure in the preformed grouting hole, the formation of theseparation layer is intervened in advance, and the potential space of the grouting layer originally used for storing underground water is fully filled with pulverized fuel ash slurry.

Owner:中国煤炭地质总局勘查研究总院

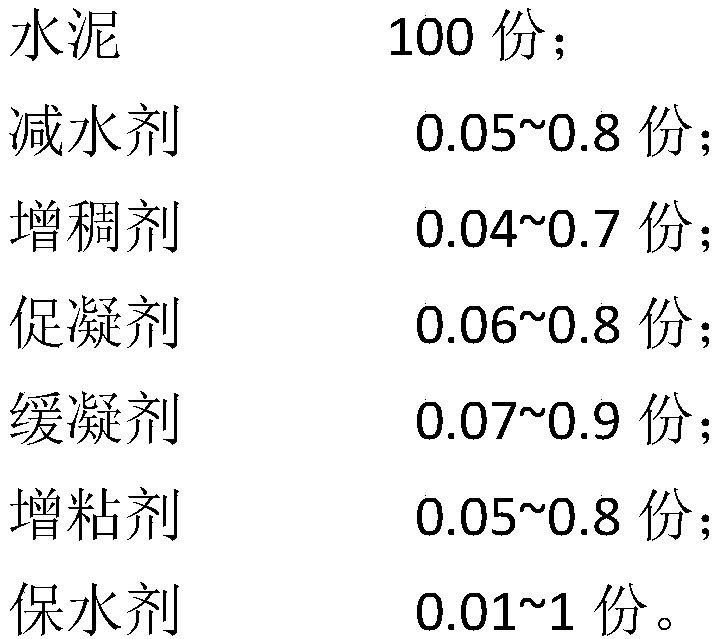

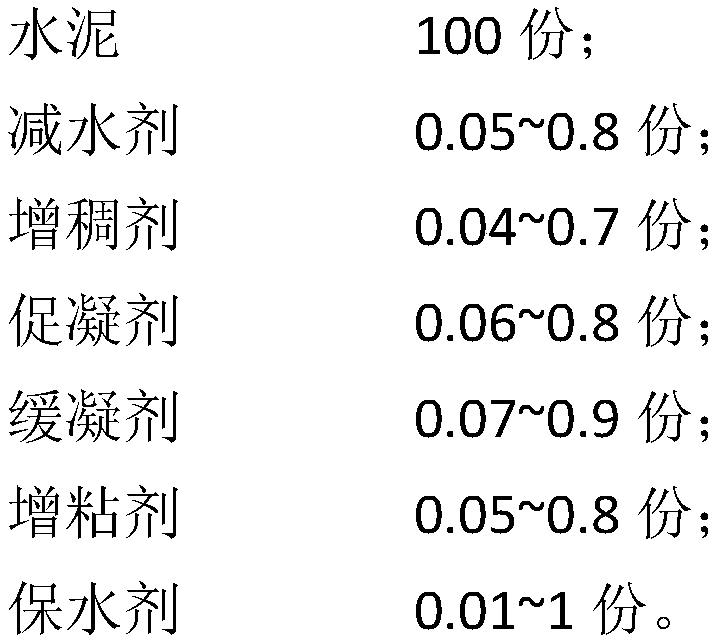

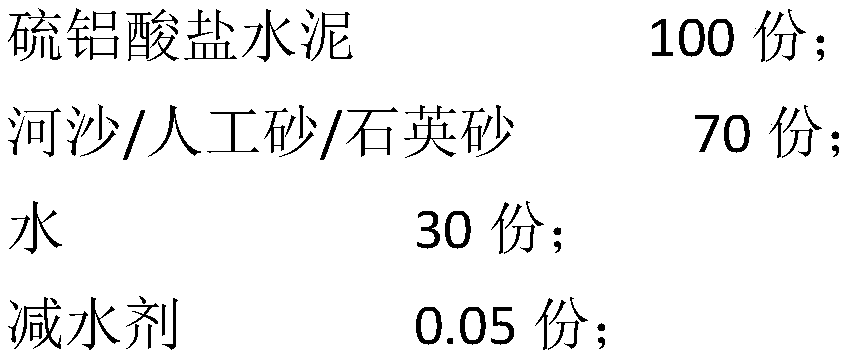

Quick-setting type adjustable gel grouting material and application thereof

InactiveCN109608144AShorten final setting timeSpeed up the construction progressHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses a quick-setting type adjustable gel grouting material and application thereof. The quick-setting type adjustable gel grouting material comprises the following components in parts by weight: 100 parts of cement, 0.05-0.8 part of a water reducer, 0.05-0.8 part of a thickening agent, 0.06-0.8 part of a coagulant, 0.07-0.9 part of a retarder, 0.05-0.8 part of a tackifier and 0.01-1 part of a water-retaining agent, wherein the cement is a sulfur-lithium-acid salt cement; the water reducing agent is a polycarboxylate water reducer, a melamine water reducer or a naphthalene water reducer; wherein the thickening agent is hydroxypropyl methyl cellulose or hydroxymethyl propyl cellulose; the coagulant is aluminum carbonate or calcium formate; the retarder is boric acid or citric acid or tartaric acid; and the tackifier is glue essence ( with the component of PVA or PVE). According to the anchor rod grouting material disclosed by the invention, the initial setting can be realized within 20 minutes, and middle setting can be realized within 25-40 minutes, so that blasting operation and engineering construction in a tunnel are synchronously carried out, the constructionprogress is improved, and good economic benefits are achieved.

Owner:SHENZHEN WEITENAI NEW MATERIAL CO LTD

Mosaic tile sticking and jointing integrated binder mosaic tile glue and preparing method thereof

ActiveCN105384396ASimple construction methodShorten construction timePolymer scienceHigh wear resistance

The invention discloses mosaic tile sticking and jointing integrated binder mosaic tile glue and a preparing method thereof and belongs to the technical field of building materials. The mosaic tile sticking and jointing integrated binder mosaic tile glue not only can meet the requirement for high bonding strength, but also can meet the requirements for high wear resistance and low water absorption of a joint mixture. According to the technical scheme, the mosaic tile sticking and jointing integrated binder mosaic tile glue is prepared from 20-50% of cement, 10-60% of fine sand, 5-30% of dolomite dust, 0.1-0.5% of HPMC, 0.1-1% of thixotropy lubricant, 1-5% of polymer dispersion powder, 0.1-1% of water repellent and 0.1-1% of early strength agent, and the total percentage is 100%.

Owner:广州协堡建材有限公司

Concrete exposed aggregate agent and preparation method thereof

The invention discloses a concrete exposed aggregate agent and a preparation method thereof and belongs to the field of buildings. The concrete exposed aggregate agent comprises the following components in parts by mass: 15-25 parts of white sugar, 5-8 parts of sodium citrate, 1-3 parts of a penetrating agent, 0.5-1 part of an anti-rust agent, 0.5-2 parts of a bactericide and 50-70 parts of deionized water. The concrete exposed aggregate agent disclosed by the invention is mainly applied to concrete aggregate exposed treatment, methods for milling, planing, chiseling, filing and the like are not need during treatment of buildings, concrete constructed joints, tail ends or continuous construction, the formed aggregate exposed rough and solid concrete surface can be connected with fresh concrete into a whole, and the joint interface is kept firm and crack-less.

Owner:石家庄筑佳节能产品科技有限责任公司

High-rate quick-setting mining hole sealing material and use method thereof

The invention discloses a high-rate quick-setting mining hole sealing material and a using method thereof, and belongs to mining hole sealing materials. The hole sealing material is prepared from thefollowing raw materials in percentage by mass: 10%-30% of quick-setting powder, 60%-80% of Portland cement, 1%-6% of bentonite, 0.3%-0.5% of sodium chloride, 0.1%-0.3% of sodium aluminate, 3%-8% of quick lime, 0.05%-0.2% of a water reducing agent and 0.05%-0.2% of an active agent through even stirring according to the mass ratio of 1: 1.6-2. The hole sealing material is high in multiplying power and short in setting time, the expansion multiplying power ranges from 10% to 100%, the final setting time is shorter than 120 min, the compressive strength and the setting time are not affected whilethe multiplying power is improved, the strength and the setting time of gas extraction are met, and the long-term effect of hole sealing is guaranteed. Due to the high-expansion property of the hole sealing material, the pipe wall is filled with the hole sealing material, gas leakage caused by pores is avoided, the safety performance is improved, materials are saved for extraction pipes with the same length, and the gas extraction cost is reduced. The hole sealing material has the advantages of low price, no toxicity, no pollution, high hole sealing efficiency, favorable flowability and favorable plasticity.

Owner:安徽春雨安全科技有限公司

Chloride-free alkali-free liquid setting accelerator and preparation method thereof

InactiveCN110436811ALittle loss of strengthDoes not affect the coagulation effectAlkali freeRoom temperature

The invention discloses a chloride-free alkali-free liquid setting accelerator and a preparation method thereof. The preparation method of the chloride-free alkali-free liquid setting accelerator comprises the following steps: preparing aluminum fluosilicate for later use; mixing the aluminum fluosilicate with water, and performing a stirring reaction so as to obtain an aluminum fluosilicate solution; adding aluminum sulfate octadecahydrate into the aluminum fluosilicate solution, and performing continuous stirring so as to obtain a stirring liquid; sequentially adding a stabilizer, a surfactant and the rest of water into the stirring liquid, performing a stirring reaction, and performing cooling to the room temperature, so as to obtain the liquid setting accelerator. The liquid setting accelerator disclosed by the invention is free of chloride or alkali, so that the problems that concrete has large later strength loss, has serious corrosiveness and causes environment pollution becauseof strong basicity of a conventional setting accelerator can be solved; in addition, the liquid setting accelerator is easy in raw material obtaining, low in price, simple in preparation method, lowin production cost and mild in condition, the glue-sand performance of the obtained chloride-free alkali-free liquid setting accelerator in a doping amount of 6% is far greater than standard requirements, the one-day mortar strength is up to 7Mpa or greater, the later strength is barely lost, and the rebound rate is as low as 10% or lower.

Owner:陕西金石混凝土科技发展有限公司

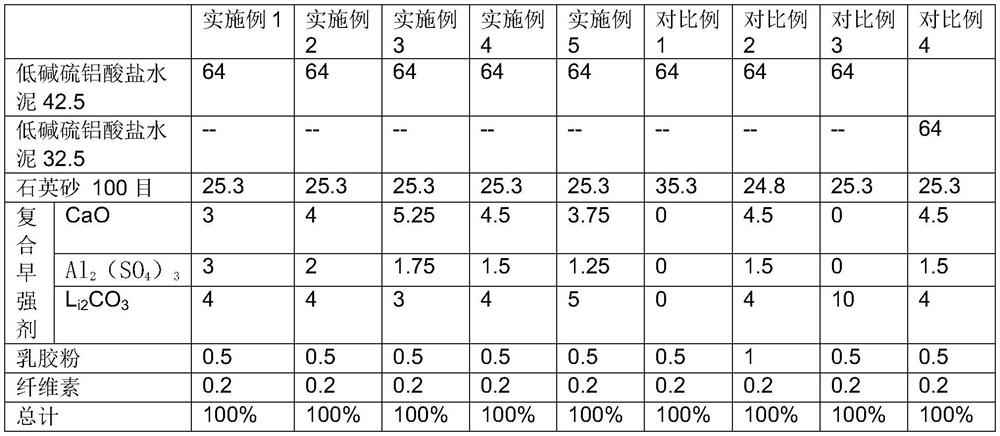

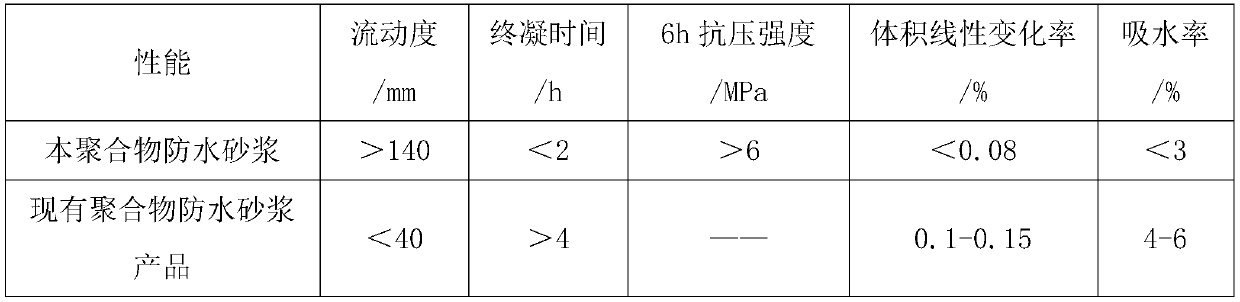

Quick-hardening inorganic waterproof plugging material

The invention discloses a quick-hardening inorganic waterproof plugging material, which is prepared from the following components in percentage by weight: 50-70% of an inorganic cementing material, 30-40% of a filler, 3-12% of a composite early strength agent, 0.3-0.8% of latex powder and 0.1-0.3% of cellulose. By adopting the composite early strength agent, the influence of air temperature on thesetting time can be effectively reduced, open water below 5m can be blocked, the waterproof and leaking stoppage effects are good, hardening can be realized within 30 seconds, the rapid leaking stoppage effect is achieved, high strength can be achieved within one hour, and the emergency construction requirement is met.

Owner:湖北卓宝科技有限公司 +1

Durable anti-cracking concrete for tunnel

The invention discloses durable anti-cracking concrete for a tunnel. The durable anti-cracking concrete comprises the raw materials of silicate cement, silica fume powder, slag powder, sand, latex powder, fine stones, polypropylene fiber, carbon fiber, polyacrylonitrile fiber, ceramic fiber, a polycarboxylic acid water reducing agent, an air entraining agent, an accelerator and water. The durableanti-cracking concrete for the tunnel provided by the invention has the advantages of good workability, good cracking resistance, durability and the like.

Owner:蚌埠市方阵商品混凝土有限公司

Raw wood pulp fiber reinforced calcium silicate sheet

The invention discloses a raw wood pulp fiber reinforced calcium silicate sheet which is mainly prepared from the following components by weight percentage: 6-12% of raw wood pulp fiber, 1-3% of glass fiber, 15-20% of lime, 35-46.04% of quartz, 20-30% of common silicate cement, and 1-2% of expanded perlite. The raw wood pulp fiber reinforced calcium silicate sheet has the advantages as follows: the early strength effect of Na+ salt on the silicate cement is utilized, so that the standing time of the plate-making process is shortened, in addition, the influence of the Na+ salt on the silicate cement is avoided, the problem that the raw wood pulp is directly used for production of a calcium silicate sheet is solved, and wood can be comprehensively utilized; due to the early strength of sodium salt on cement, the final setting time of cement is shortened, the stripping time is shortened (the original stripping time is 4-7 hours, and the current stripping time is 2-5 hours), and the strength is high; the appearance is attractive; the cost is low; the raw material is low in cost, and contains fewer impurities; the raw wood pulp fiber is used to replace rock wool; the 100% wool-free plate is produced; the raw wood pulp fiber reinforced calcium silicate sheet is low in cost, and more environmental-friendly.

Owner:LIUZHOU JIAREN PLATE IND +1

Preparation method of plasterboard and plasterboard

InactiveCN110642581AReduce adhesionHigh hardnessCeramic shaping apparatusFoaming agentProcess engineering

The application provides a preparation method of a plasterboard and the plasterboard. The preparation method comprises the steps: placing gypsum board slurry containing a coagulant on a conveying roller way, and sequentially carrying out a final setting stage, a cutting stage and a drying stage under the drive of the conveying roller way so as to finally set the gypsum board slurry before enteringthe cutting stage. The plasterboard comprises desulfurized gypsum clinker, water, a coagulant, a foaming agent, starch and a functional additive in parts by weight. By using the preparation method ofthe plasterboard, the final setting time of the gypsum slurry is greatly shortened, not only is the slurry disintegrating slag during board cutting reduced, but also the strength of a wet board whenthe wet board enters a drying machine is improved, and influences of disintegrating slag to the surface evenness of the board are reduced.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Material for promoting formation of geopolymer in high-humidity environment and preparation method thereof

PendingCN113666655ALow priceWide variety of sourcesSolid waste managementCement productionPhysical chemistryGeopolymer

The invention discloses a material for promoting formation of a geopolymer in a high-humidity environment and a preparation method of the material. The raw materials comprise solid waste, an exciting agent, an additive and water, the solid wastes are industrial solid wastes and comprise fly ash and phosphorus tailing sand; the exciting agent is an alkaline exciting agent and is one of a sodium hydroxide exciting agent, a sodium hydroxide-silica fume composite exciting agent and a water glass exciting agent; the additive is xanthan gum, and the addition amount of the additive is 1% of the solid waste; and the mass ratio (water-solid ratio) of the water to the solid waste is 0.5-0.75. According to the method, the feasibility of preparing a geopolymer grouting filling material from the solid wastes is improved, the problem that the goaf grouting filling material is difficult to form in the actual grouting process is solved, the forming degree of the geopolymer in the high-humidity environment is improved, the final setting time is shortened, the industrial solid wastes can be consumed, and meanwhile, goaf repair treatment is carried out. The raw materials are industrial solid wastes and are low in price and wide in source.

Owner:中能化江苏地质矿产设计研究院有限公司

A self-leveling type II polymer cement waterproof mortar

The invention provides a self-leveling type II polymer cement waterproof mortar. The mortar includes: Portland cement, composite hardening agent, aggregate, water, polymer, and other additives, wherein the composite hardening agent is composed of the following raw materials in parts by weight: quicklime 3-6 parts, sodium sulfate 2 ‑5 parts, 5‑10 parts of aluminate cement. Solve the durability problem of ordinary self-leveling mortar due to the high content of high-alumina cement components resulting in poor long-term waterproof and impermeable performance, and realize the self-leveling construction of polymer cement waterproof mortar, which can be applied to various building waterproofing projects, such as toilets and kitchens , roofs, swimming pools, underground structures, etc.

Owner:SHANDONG YINGCAI UNIV

Steel slag concrete and preparation method thereof

ActiveCN112552005AShorten final setting timeReduce crackingSolid waste managementSlagCalcium aluminates

The invention relates to a steel slag concrete and a preparation method thereof. The steel slag concrete is prepared from the following raw materials in parts by weight: 100 to 130 parts of Portland cement, 60 to 75 parts of water, 15 to 25 parts of gypsum, 35 to 50 parts of fly ash, 10 to 20 parts of light calcined magnesia, 120 to 180 parts of coarse aggregate, 140 to 200 parts of fine aggregate, 70 to 90 parts of steel slag, 10 to 20 parts of potassium hexatitanate, 2 to 5 parts of boric acid, 6 to 12 parts of anhydrous calcium sulphoaluminate and 3 to 5 parts of polycarboxylic water. The potassium hexatitanate is added into the steel slag concrete, so that the final setting time of the concrete is effectively shortened, and the final setting time of the concrete can better meet the requirements of building construction. The change rule of the compressive strength of the steel slag concrete is equivalent to that of 52.5 R Portland cement, but the average compressive strength of thesteel slag concrete is far higher than that of ordinary Portland cement.

Owner:湖北环沙再生资源有限公司

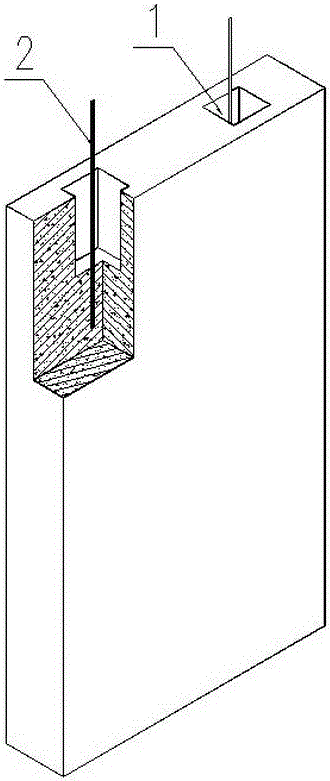

Prefabricated concrete member and manufacturing method thereof

InactiveCN105904587AImprove connection integrityFirmly connectedStrutsConstruction materialFiber-reinforced compositeRebar

The invention relates to a prefabricated concrete member and a manufacturing method of the prefabricated concrete member and belongs to the technical field of prefabricated concrete structures. At least one discontinuous hole is formed in the prefabricated concrete member. Rebars anchored into concrete at the bottoms of the holes are arranged in the holes. The manufacturing method of the prefabricated concrete member includes the steps that the holes are manufactured through inner dies of steel pipes or fiber-reinforced composite pipes, the bottoms of the inner dies are sealed and provided with the holes, and the rebars penetrate the holes. By the adoption of the prefabricated concrete member, the stress performance of the prefabricated concrete structure is improved.

Owner:初明进

Construction method of concrete diaphragm wall in mucky soil body with high water content

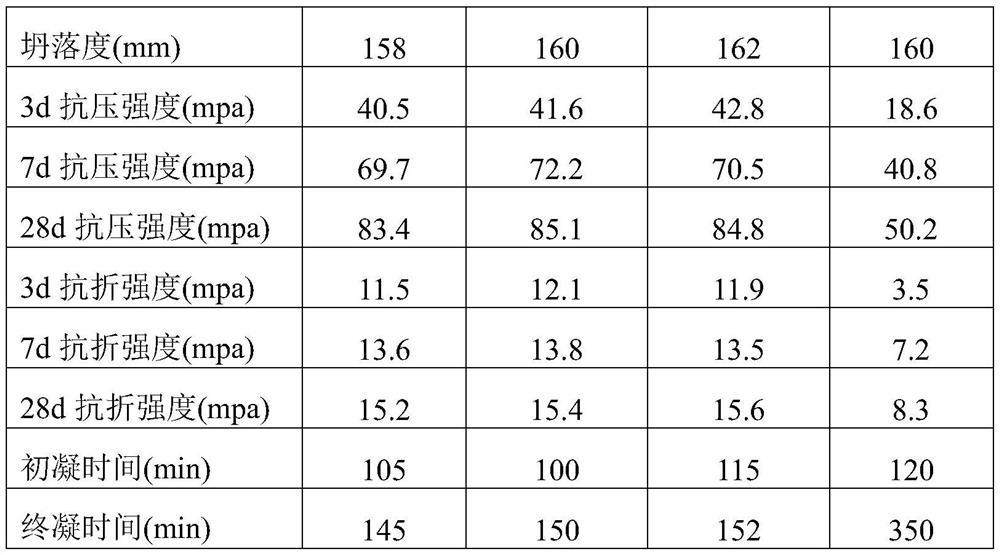

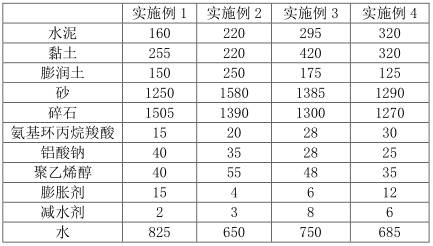

PendingCN114277779AShorten final setting timeHigh compressive strengthMarine site engineeringBulkheads/pilesSoil sciencePolyvinyl alcohol

The invention relates to the field of concrete, and particularly discloses a construction method of a concrete diaphragm wall in a high-water-content mucky soil body, which comprises the following steps: (1) constructing a guide wall; (2) preparing wall-fixing slurry; (3) forming holes and grooves; (4) cleaning the bottom and changing pulp; (5) joint construction; (6) manufacturing and installing a reinforcement cage; (7) pouring concrete, wherein the plastic concrete in the step (7) comprises the following components in parts by weight: 160-320 parts of cement; 220 to 420 parts of clay; 125 to 250 parts of bentonite; 1250 to 1580 parts of sand; 1270 to 1505 parts of broken stone; 15 to 30 parts of aminocyclopropane carboxylic acid; 25 to 40 parts of sodium aluminate; 35 to 55 parts of polyvinyl alcohol; 4-15 parts of an expanding agent; 2-8 parts of a water reducing agent; and 650 to 825 parts of water. The concrete anti-seepage wall has the effect that the bearing capacity of the concrete anti-seepage wall is not prone to being affected.

Owner:乐昌市恒源水电建筑工程有限公司

A kind of concrete exposure stone agent and preparation method thereof

The invention discloses a concrete exposed aggregate agent and a preparation method thereof and belongs to the field of buildings. The concrete exposed aggregate agent comprises the following components in parts by mass: 15-25 parts of white sugar, 5-8 parts of sodium citrate, 1-3 parts of a penetrating agent, 0.5-1 part of an anti-rust agent, 0.5-2 parts of a bactericide and 50-70 parts of deionized water. The concrete exposed aggregate agent disclosed by the invention is mainly applied to concrete aggregate exposed treatment, methods for milling, planing, chiseling, filing and the like are not need during treatment of buildings, concrete constructed joints, tail ends or continuous construction, the formed aggregate exposed rough and solid concrete surface can be connected with fresh concrete into a whole, and the joint interface is kept firm and crack-less.

Owner:石家庄筑佳节能产品科技有限责任公司

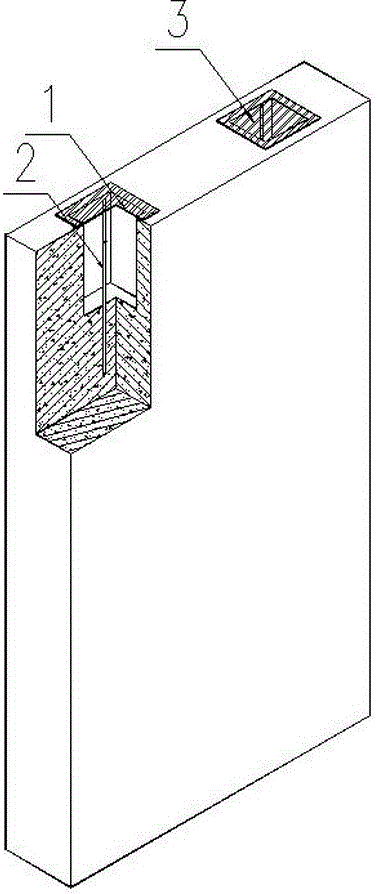

Prefabricated reinforced concrete member and manufacturing method thereof

InactiveCN105926827AImprove connection integrityDirect forceConstruction materialStrutsReinforced concreteMetal foil

The invention relates to a prefabricated reinforced concrete member and a manufacturing method thereof, and belongs to the technical field of prefabricated concrete structures. The prefabricated reinforced concrete member is internally provided with at least one hole. The holes are internally provided with rebars anchored in concrete on the side walls of the holes. The top of each hole is provided with metal foil for sealing the hole. According to the provided manufacturing method of the prefabricated reinforced concrete member, the holes are manufactured by adopting an inner formwork of a steel pipe or a fiber reinforced composite pipe, groove channels are formed in the surface of the inner formwork, and the rebars are placed in the groove channels. By means of the prefabricated reinforced concrete member and the manufacturing method thereof, the mechanical performance of the prefabricated concrete structures is improved.

Owner:初明进

Prefabricated reinforced concrete member and manufacturing method thereof

InactiveCN105926829AImprove connection integrityFirmly connectedConstruction materialStrutsReinforced concreteMetal foil

The invention relates to a prefabricated reinforced concrete member and a manufacturing method thereof, and belongs to the technical field of prefabricated concrete structures. The prefabricated reinforced concrete member is internally provided with at least one non-through hole. The holes are internally provided with rebars anchored in concrete at the bottoms of the holes. The top of each hole is provided with metal foil for sealing the hole. According to the provided manufacturing method of the prefabricated reinforced concrete member, the holes are manufactured by adopting an inner formwork of a steel pipe or a fiber reinforced composite pipe, the bottom of the inner formwork is sealed and provided with a hole, and the rebars penetrate through the hole. By means of the prefabricated reinforced concrete member and the manufacturing method thereof, the mechanical performance of the prefabricated concrete structures is improved.

Owner:初明进

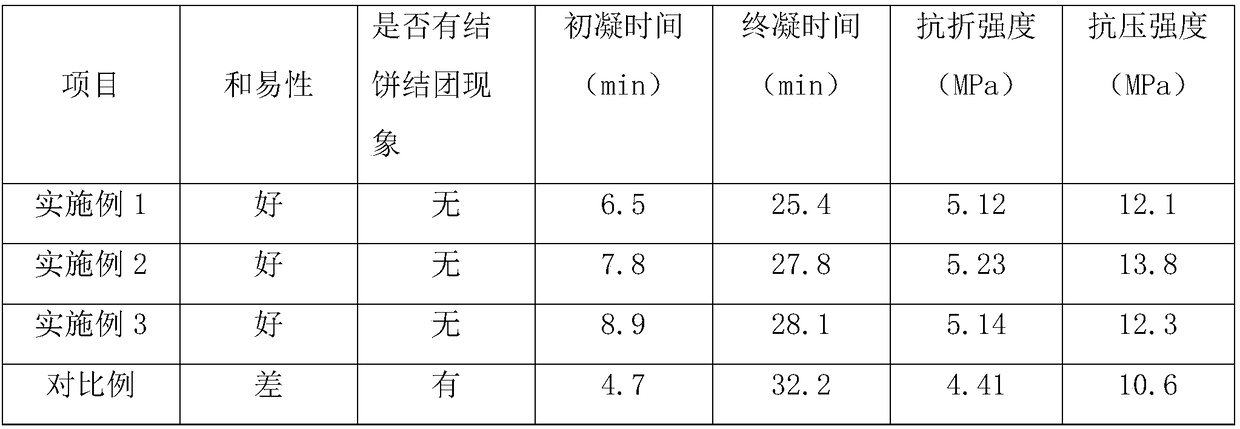

Adhesive special for gypsum blocks and use method thereof

The application discloses an adhesive special for gypsum blocks. The adhesive in mass is prepared from 91-95% of building gypsum powder, 3-7% of cement, 0.3-0.7% of a protein retarder, 0.3-0.7% of a superplasticizer, 0.1-0.3% of a thixotropic agent, 0.2-0.4% of emulsified fat powder, 0.1-0.3% of wood fibers, and 0.2-0.4% of a plant glue. Compared with the existing gypsum adhesive, the adhesive provided by the invention has longer initial setting time, shorter final setting time, higher strength and better peaceability, and is not easy to form cakes when mixing.

Owner:遵义汉丰装饰材料有限责任公司

Wall steel strand mesh polymer mortar reinforcing method

ActiveCN114046003AHigh bonding strengthShorten final setting timeCovering/liningsPolymer scienceMeth-

The invention relates to the field of concrete mortar, and particularly discloses a wall steel strand mesh polymer mortar reinforcing method. The method comprises the following steps: (1) weaving a mesh; (2) treating a base layer; (3) mounting a fixed mesh; (4) smearing an adhesion agent; (5) smearing polymer mortar; and (6) maintaining the polymer mortar. The polymer mortar is prepared in advance between the step (4) and the step (5) and comprises the following components in parts by weight: 356-590 parts of sand; 252-361 parts of Portland cement; 85-120 parts of an acrylic acid-2-acrylamide-2-methyl propane sulfonic acid copolymer; 19-30 parts of hydroxy propyl distarch phosphate; 4-12 parts of sodium tripolyphosphate; 1-5 parts of a defoaming agent; 5-9 parts of a water reducing agent; and 100-150 parts of water. The method has the effect of shortening the final setting time of the polymer mortar.

Owner:广东博竣建设工程有限公司

A kind of cement containing large proportion of slag and preparation method thereof

ActiveCN112573886BHigh compressive strengthImprove flexural strengthSolid waste managementAluminium sulfatePortland cement

The invention relates to a cement containing a large proportion of slag and a preparation method thereof. The cement is composed of the following raw materials in parts by weight: 90-100 parts of Portland cement, 10-15 parts of gypsum, 10-20 parts of fly ash, 70-90 parts of slag, 15-20 parts of magnesium sulfate whiskers, titanium 22-36 parts of potassium acid whiskers, 10-16 parts of aluminum sulfate, and 7.2-12.2 parts of grinding aid. The invention effectively improves the compressive strength and flexural strength of the Portland cement by adding potassium titanate whiskers into the cement, which is superior to the ordinary Portland cement on the market. In the invention, by adding a mixture of potassium tetratitanate whiskers and potassium octatitanate whiskers, the whiskers are better adsorbed on the surface of the slag, thereby reducing the corrosion of the slag powder by the alkaline environment, and at the same time, it can further improve the overall cement. The corrosion resistance of sulfuric acid and the resistance to salt freezing corrosion can shorten the final setting time, which is conducive to the solidification and hardening of cement.

Owner:湖北环沙再生资源有限公司

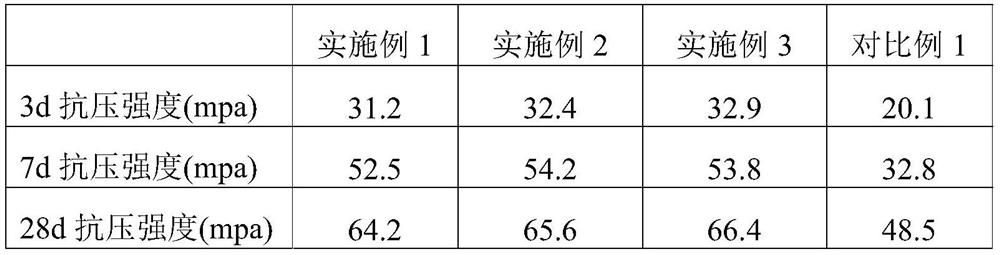

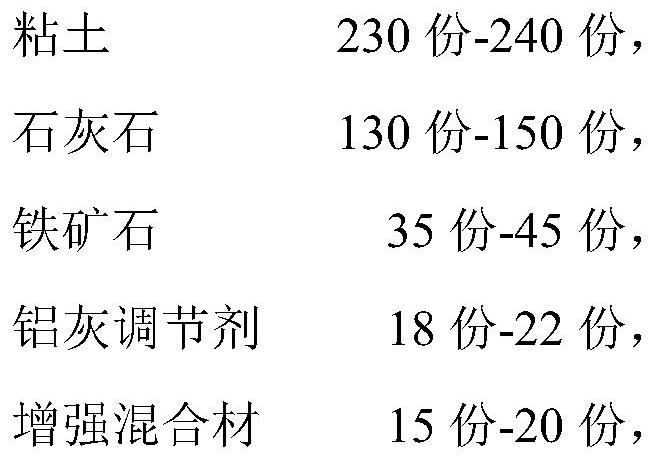

Reinforced cement prepared from aluminum ash regulator

The invention discloses reinforced cement prepared from an aluminum ash regulator, and belongs to the technical field of cement materials. The Portland cement comprises Portland cement clinker and auxiliary materials, and the mass ratio of the Portland cement clinker to the auxiliary materials is 1: 0.3. The Portland cement clinker is prepared from the following raw materials in parts by weight: 200 to 250 parts of clay, 120 to 160 parts of limestone, 30 to 60 parts of iron ore, 15 to 25 parts of an aluminum ash regulator and 10 to 30 parts of a reinforcing mixed material, and the reinforcing mixed material is a mixture of pyrite slag, copper slag and hydroxyethyl methyl cellulose ether. The mass ratio of the pyrite slag to the copper slag to the hydroxyethyl methyl cellulose ether is 4: 5: 17; the auxiliary material is gypsum powder. Grinding into a raw material by using a mill, calcining in a kiln, and cooling to obtain a clinker; then calcining at high temperature to obtain a clinker; and finally, mixing the clinker, the gypsum powder and the reinforced admixture, and grinding for the second time. The reinforced cement disclosed by the invention has relatively good comprehensive performance.

Owner:刘伟荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com