A kind of cement containing large proportion of slag and preparation method thereof

A technology for cement and slag, applied in the field of cement containing a large proportion of slag and its preparation, can solve problems such as shortage, and achieve the effects of reducing corrosion, improving the overall anti-sulfuric acid corrosion resistance and salt-freezing erosion resistance, and shortening the final setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

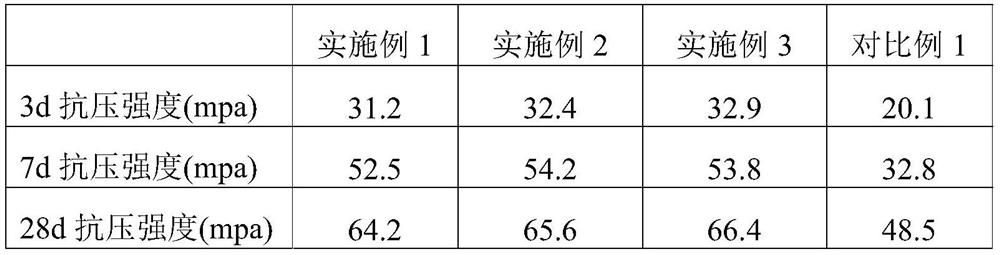

Examples

Embodiment 1

[0034] The specific raw materials are weighed according to Table 1, and the preparation steps are as follows:

[0035] (1) by proportioning triethanolamine is diluted with water, then add sodium phosphate, industrial salt, Yuanming powder and stir to obtain grinding aid;

[0036] (2) mix Portland cement clinker, desulfurized gypsum, fly ash, aluminum sulfate and the grinding aid obtained in step (1) by proportioning, then carry out grinding for 30min to obtain fine powder;

[0037] (3) slag, basic magnesium sulfate crystal whisker, potassium octatitanate crystal whisker, potassium tetratitanate crystal whisker are uniformly mixed by proportioning, and then pulverized for 50min to obtain a blend;

[0038] (4) Mixing the fine powder obtained in step (2) and the blending material obtained in step (3) uniformly, and then baking in a nitrogen-protected environment at 50° C. for 100 min to obtain cement.

Embodiment 2

[0040] (1) by proportioning triethanolamine is diluted with water, then add sodium phosphate, industrial salt, Yuanming powder and stir to obtain grinding aid;

[0041] (2) mix Portland cement clinker, desulfurized gypsum, fly ash, aluminum sulfate and the grinding aid obtained in step (1) by proportioning, and then grind for 40min to obtain fine powder;

[0042] (3) mix slag, basic magnesium sulfate whisker, potassium octatitanate whisker, potassium tetratitanate whisker by proportioning, then carry out grinding for 60min to obtain blend;

[0043] (4) Mixing the fine powder obtained in step (2) and the blending material obtained in step (3) uniformly, and then baking in a nitrogen-protected environment at 60° C. for 90 min to obtain cement.

Embodiment 3

[0045] (1) by proportioning triethanolamine is diluted with water, then add sodium phosphate, industrial salt, Yuanming powder and stir to obtain grinding aid;

[0046] (2) mix Portland cement clinker, desulfurized gypsum, fly ash, aluminum sulfate and the grinding aid obtained in step (1) by proportioning, and then grind for 40min to obtain fine powder;

[0047] (3) mix slag, basic magnesium sulfate whisker, potassium octatitanate whisker, potassium tetratitanate whisker by proportioning, then carry out grinding for 60min to obtain blend;

[0048] (4) Mixing the fine powder obtained in step (2) and the blending material obtained in step (3) uniformly, and then baking in a nitrogen-protected environment at 60° C. for 100 min to obtain cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com