Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Potassium tetratitanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Especially, potassium tetratitanate whisker (PTW) with the chemical formula K 2 Ti 4 O 9 and sodium trititanate whisker (STW) with the chemical formula Na 2 Ti 3 O 7 have special lamellar structure, such as high surface area and strong ability for cation exchange, which were benefit for the sorption.

Potassium titanate whisker and its synthesis

The present invention is one new synthesis process of potassium titanate whisker. TiO2 and K2O in the molar ratio of 2.5-3.5 and boron compound in the amount of 1-5 wt% of TiO2 are mixed and the mixture is heated inside one alkali-resisting container first to 800 deg.c and then to 900-1200 deg.c at the raising rate of 1 deg.c / min, maintained for 1-4 hr and cooled slowly to 800 deg.c to obtain potassium tetratitanate whisker bundle. The potassium tetratitanate whisker bundle is stirred mechanically in hot water at 80-100 deg.c for 1-4 hr and neutralized in 5-15 % concentration dilute sulfuric acid solution to obtain amorphous hydrate of potassium hexatitanate whisker. Through further staying at 800-1200 deg.c for 2-6 hr to complete crystal conversion, washing in hot water (80-100 deg.C) to eliminate soluble potassium compound and drying at 200 deg.c over, potassium hexatitanate whisker product with average length of 10-50 micron and average diameter less than 0.5 micron is produced.

Owner:上海秀普复合材料有限公司

Silver phosphate-titanium dioxide/potassium salt tetratitanate compound and preparation method thereof and application

InactiveCN106732694AImprove efficiencyImprove stabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationSilver phosphateMethyl orange

The invention discloses a silver phosphate-titanium dioxide / potassium salt tetratitanate compound and a preparation method thereof and an application. Ag3PO4 nano particles are loaded on TiO2 / K2Ti4O9 compounds to obtain the silver phosphate-titanium dioxide / potassium salt tetratitanate compound, loading capacity of the Ag3PO4 nano particles is 20%-75%, AgNO3 is gradually dripped into TiO2 / K2Ti4O9 compound dispersion liquid, NaH2PO4 solution is slowly added again, and mixture reacts in a stirring manner to obtain Ag3PO4-TiO2 / K2Ti4O9 compound. The Ag3PO4-TiO2 / K2Ti4O9 compound serves as a catalyst, photocatalytic degradation of dyes can be achieved, the rate degrading rhodamine B reaches 0.0643min<-1> under visible light, the rate degrading methylene blue reaches 0.391min<-1> under visible light, the rate degrading methyl orange reaches 0.0327min<-1> under visible light, the catalytic activity of individual components of the compound is greatly improved, and the compound has excellent photocatalytic degradation effects.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing photocatalytic foamed ceramics

InactiveCN105110787AAvoid phase changeLow viscosityCatalyst carriersCeramicwareAdhesiveSlurry coating

The invention relates to a method for preparing photocatalytic foamed ceramics. The method comprises the following steps: (1) treating potassium tetratitanate raw powder; (2) modifying stearic acid; (3) pre-treating polyurethane foam; (4) preparing primary slurry; (5) carrying out slurry coating for the first time; (6) preparing secondary slurry; (7) carrying out slurry coating for the second time; and (8) carrying out sintering, and cooling to obtain the photocatalytic foamed ceramics. Compared with the prior art, the method has the advantages that the solid content of potassium tetratitanate slurry can be 75 percent by means of ball milling, rinsing, modifying of stearic acid and adding of a dispersing agent; a photocatalyst is immobilized due to the foamed ceramics prepared by direct slurry coating on the polyurethane foam, the contact area between particles and organic matters is enlarged due to the three-dimensional reticular structure of the foamed ceramics, and the photocatlysis performance is improved; slurry coating is directly performed on the foamed ceramics, so that the preparation method is simple, does not need secondary sintering, and is short in cycle and low in cost; and phase change happening at high temperature of potassium tetratitanate is solved by using low-temperature glass as an adhesive.

Owner:WUHAN UNIV OF TECH

Method for preparing layered K2Ti4O9 continuous nanofiber

InactiveCN103060948AContinuous operationShort cycleInorganic material artificial filamentsFilament/thread formingFiberPolymer science

The invention is a method for preparing nanofiber, and in particular comprises: by using butyl titanate, KNO3, citric acid, ethanol and nitric acid as raw materials, wherein by molar ratio, butyl titanate: KNO3: Citric acid: ethanol: dilute nitric acid = 1:2:2: (38 ~ 50): (19 ~ 25), polyvinyl alcohol or polyvinyl pyrrolidone as a polymer template, and aqueous solution of polyvinyl alcohol as a solvent, preparing a sol solution at room temperature; then preparing composite fiber by using an electrostatic spinning method, wherein an electrostatic spinning voltage is controlled to be 10 ~ 30KV, and curing distance of the nozzle to the accept screen is 8 ~ 20cm; and then performing heat treatment to the composite fiber at 500 ~ 950 DEG C for 3 ~ 8h to obtain layered K2Ti4O9 continuous nanofiber. The method of the invention is simple in process, easy in operation, high in efficiency, low in energy consumption, and simple in production equipment; and the prepared fiber has high purity, good crystallinity, a large surface area, a large length-diameter ratio and good dispersion.

Owner:WUHAN UNIV OF TECH

Long-acting waterborne metal heat-insulating and anti-corrosive paint

InactiveCN110003727AIncrease densityReduce electrostatic repulsionAnti-corrosive paintsEmulsionMicrosphere

The invention discloses long-acting waterborne metal heat-insulating and anti-corrosive paint, and belongs to the technical field of high polymer materials. 40-60 parts by weight of styrene-acrylic emulsion, 10-12 parts by weight of titanium dioxide, 3-4 parts by weight of a dispersing agent, 1-2 parts by weight of a defoaming agent, 5-8 parts by weight of potassium tetratitanate, 10-15 parts by weight of vitrified microspheres, 1-2 parts by weight of a coupling agent, 10-20 parts by weight of an ethanol solution and 20-25 parts by weight of a modifying additive are weighed in sequence; the styrene-acrylic emulsion and the ethanol solution are mixed, titanium dioxide, potassium tetratitanate, the vitrified microspheres, the modifying additive, the coupling agent, the dispersing agent and the defoaming agent are added sequentially, the components are stirred and mixed for 10-30 min at the temperature of 30-50 DEG C and at the revolving speed of 300-400 r / min, then a mixture is left to stand for 1-3 h at the room temperature, and the long-acting waterborne metal heat-insulating and anti-corrosive paint is obtained. The long-acting waterborne metal heat-insulating and anti-corrosive paint prepared according to the technical scheme has the characteristics of excellent anti-corrosive performance and metal surface adsorption performance, and has broad prospects in development of thetechnological industry of the high polymer materials.

Owner:袁杰

Method for preparing potassium hexatitanate lamellar crystal by using solid phase method

InactiveCN106801256AAvoid it happening againEasy to producePolycrystalline material growthFrom solid stateLamellar crystalsPotassium

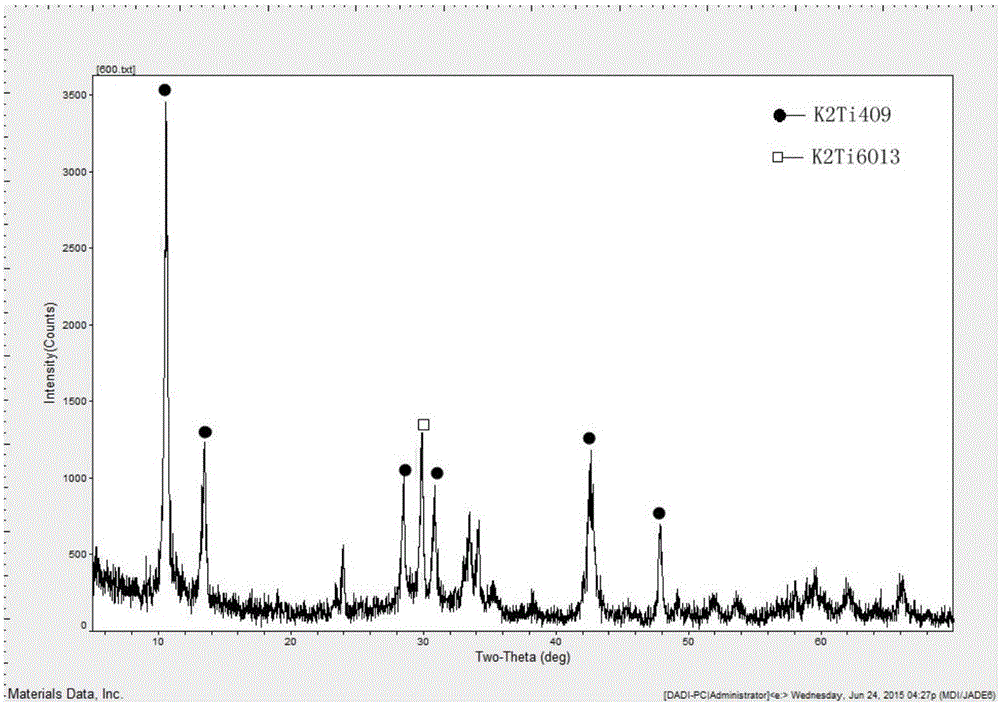

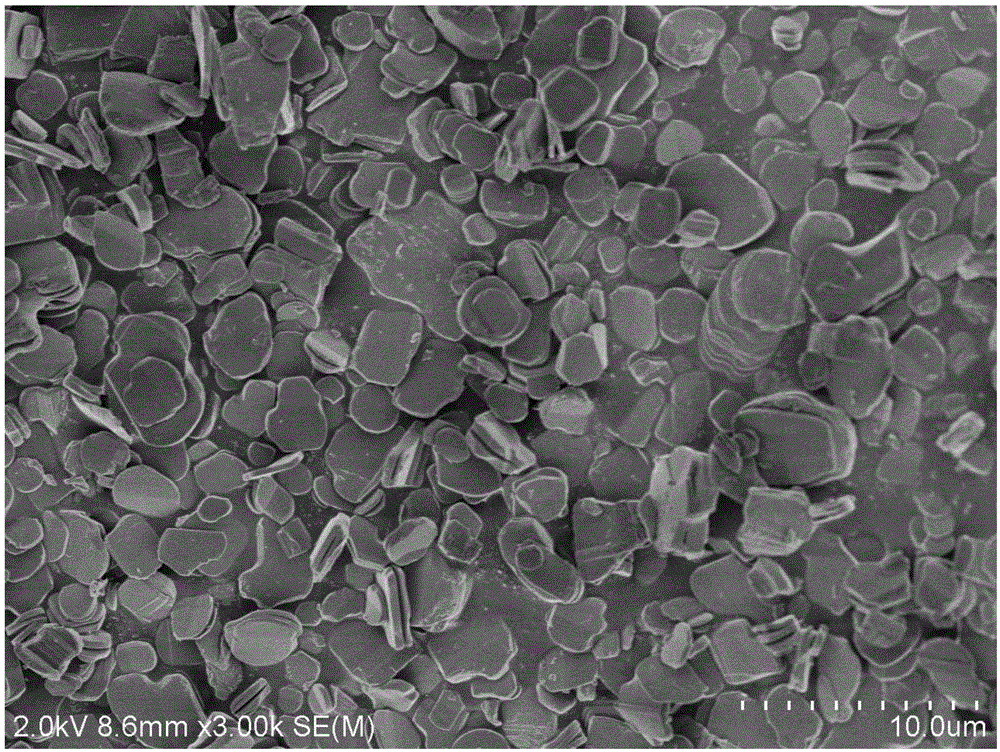

The invention discloses a method for preparing potassium hexatitanate lamellar crystal by using a solid phase method, belonging to the technical field of preparing an inorganic material. The method is mainly characterized by comprising the following steps: by taking potassium source and tiantium source as raw materials, adding less crystal form inducer, evenly mixing, then calcinating the mixture at high temperature to obtain potassium tetratitanate lamellar crystal, and performing secondary calination through taking the potassium tetratitanate lamellar crystal as a precursor, thus preparing the potassium hexatitanate lamellar crystal with the average diameter of being 1.0-5.7mum and the average thickness of being 0.1-0.5mum. The potassium hexatitanate lamellar crystal is prepared by using the solid phase method rather than the traditional wet technology, not only can the production proceudres be simplified and the energy consumption of enterprises be reduced and potassium tetratitanate lamellar crystal can be prepared at one step by utilizing the crystal form inducer, but also the treatment problem of waste water generated by using the wet preparation technology can be avoided, therefore, the method is suitable for industrial production.

Owner:JIANGNAN UNIV

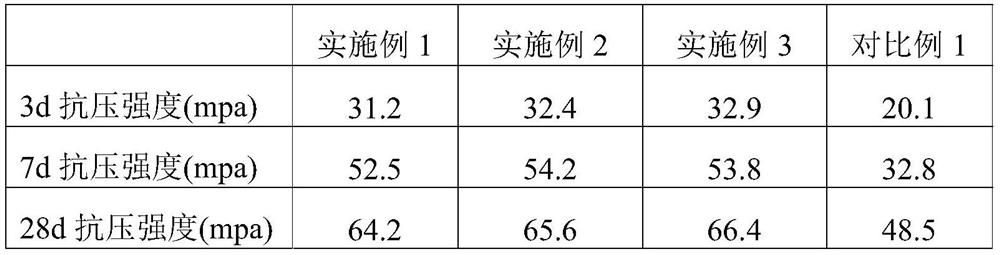

Cement containing large-proportion slag and preparation method of cement

ActiveCN112573886AHigh compressive strengthImprove flexural strengthSolid waste managementPotassium octatitanatePortland cement

The invention relates to cement containing large-proportion slag and a preparation method of the cement. The cement is prepared from the following raw materials in parts by weight: 90 to 100 parts ofPortland cement, 10 to 15 parts of gypsum, 10 to 20 parts of fly ash, 70 to 90 parts of slag, 15 to 20 parts of magnesium sulfate whisker, 22 to 36 parts of potassium titanate whisker, 10 to 16 partsof aluminum sulfate and 7.2 to 12.2 parts of grinding aid. By adding the potassium titanate whiskers into the cement, the compressive strength and breaking strength of the Portland cement are effectively improved, and the cement is superior to ordinary Portland cement on the market. By adding the mixture of the potassium tetratitanate whiskers and the potassium octatitanate whiskers, the whiskersare better adsorbed on the surface of the slag, so that the corrosion of an alkaline environment to slag powder is reduced, meanwhile, the overall sulfuric acid corrosion resistance and salt freezingdenudation resistance of the cement can be further improved, the final setting time is shortened, and the solidification and hardening of the cement are facilitated.

Owner:湖北环沙再生资源有限公司

Method for preparing sodium metatitantate-potassium tetratitanate composite catalytic material by molten salt method

InactiveCN108620053ASimple equipmentSimple processHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsSolventPhotocatalytic degradation

The invention relates to a method for preparing sodium metatitantate-potassium tetratitanate composite catalytic material by a molten salt method through using mixed nitrate as a cosolvent, and belongs to the technical field of material preparation. Tetrabutyl titanate is used as raw materials; a TiO2 material precursor is prepared by a hydrothermal method; then, the mixed nitrate is used as the cosolvent; the sodium metatitantate-potassium tetratitanate composite catalytic material is prepared by a nitrate molten salt method. The method has the advantages that the preparation conditions are simple, convenient and controllable; the equipment and the process are simple; the yield is great; the cost is low, and the like. The obtained product is a nanobelt with the length being 6 to 13 microns and the width being about 200 nm; wide application prospects are realized in the aspects of photocatalysis degradation of contaminant, photocatalysis hydrogen production and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Anti-corrosion weather-proof powder coating and preparation method thereof

InactiveCN112409887AGood acid and alkali resistanceGood resistance to salt sprayAnti-corrosive paintsPowdery paintsWeather resistanceFirming agent

The invention relates to the technical field of powder coatings, in particular to an anti-corrosion weather-proof powder coating and a preparation method thereof. The anticorrosive weather-resistant powder coating is prepared from bisphenol A epoxy resin, modified potassium tetratitanate whiskers, sericite powder, graphene, ultrafine barium, titanium dioxide, a leveling agent, a dispersing agent,an antifoaming agent and a curing agent. The anticorrosive weather-resistant powder coating prepared by the invention has the characteristics of excellent acid and alkali resistance, salt spray resistance, weather resistance, water resistance and the like, has very strong adhesive force to a base material, has an adhesive force up to first grade level, has very good adhesive force to steel structures and the like, and can be widely applied to severe outdoor environments such as outdoor containers, engineering machinery, ships and the like.

Owner:安徽博泰装饰材料有限公司

Preparation method of high-frequency noise-reduction asphalt

InactiveCN109735127AImprove hydrophobicityGuaranteed porosityBuilding insulationsPolymer scienceMass ratio

The invention discloses a preparation method of high-frequency noise-reduction asphalt, and belongs to the technical field of building materials. The preparation method of the high-frequency noise-reduction asphalt comprises the following steps: sequentially weighing the following components in parts by weight: 80-100 parts of SBS modified asphalt, 20-30 parts of modified potassium tetratitanate,5-8 parts of barium sulfate and 10-15 parts of waste rubber powder; mixing the SBS modified asphalt with polytetrafluoroethylene according to the mass ratio of 1: 3-1: 4; heating and melting at the temperature of 120-180 DEG C, adding the modified potassium tetratitanate, the barium sulfate and the waste rubber powder into the mixture of the SBS modified asphalt and the polytetrafluoroethylene, stirring and mixing at the temperature of 100-160 DEG C and the rotation speed of 180-300 r / min for 2-3 hours, and pressing and forming at the temperature of 180 DEG C to obtain the noise-reduction asphalt. The noise-reduction asphalt prepared by the technical scheme has the characteristics of excellent noise-reduction performance and long noise-reduction aging time, and has wide prospects in the development of the building material technology industry.

Owner:翟治国

Method for preparing high-solid-content low-viscosity ceramic slurry

The invention relates to high-solid content low-viscosity ceramic slurry and a preparation method thereof. The preparation method comprises the following steps of ball milling, wherein potassium tetratitanate original whiskers are placed in a ball milling tank to be subjected to ball milling on a ball mill, and the potassium tetratitanate original whiskers are taken out for use; 2, washing, wherein the potassium tetratitanate whiskers subjected to ball milling are dispersed in deionized water and placed on a magnetic stirrer to be stirred, and vacuum filtration and drying are carried out; 3, primary modification of stearic acid; 4, secondary modification of stearic acid; 5, pH adjustment, wherein the modified potassium tetratitanate whisker obtained in the step 4 is placed in deionized water, and pH is adjusted; 6, dispersing agent adding, wherein a dispersing agent is added to slurry obtained in the step 5 to be stirred, and the high-solid-content low-viscosity ceramic slurry is obtained. The high-solid-content low-viscosity ceramic slurry and the preparation method thereof have the main advantages that the operation of adjusting pH and adding the dispersing agent is simple, the slurry with the higher solid content can be obtained on the premise of guaranteeing the liquidity of the slurry, and the highest solid content of the potassium tetratitanate slurry can reach 75%.

Owner:WUHAN UNIV OF TECH

Shock absorber connecting rod and machining method thereof

InactiveCN107881419AImprove current efficiencyIncrease coverageSpringsFurnace typesWear resistanceImpurity

The invention relates to a shock absorber connecting rod and a machining method thereof and belongs to the technical field of machining of shock absorber components. The connecting rod is made of alloy steel comprising, 0.05-0.25% of C, 0.8-1.2% of Si, 2.8-3.8% of Cr, 0.15-0.25% of Mn, 0.08-0.16% of Ga, 0.12-0.20% of N, 0.12-0.3% of nano WC, 0.3-0.5% of nano CBN, 0.08-0.25% of potassium tetratitanate and the balance Fe and inevitable impurities. The alloy steel of the shock absorber connecting rod is reasonable in compatibility, meanwhile, the raw materials are added in batches, vibration is applied during pouring, finally, electroplating is performed, and the abrasion resistance and corrosion resistance of the connecting rod are further improved.

Owner:宁波吉铭商贸有限公司

Plastic for hydrogen storage pressure vessel and preparation method thereof

InactiveCN113881163AImprove sealingReduce leakageVessel manufacturingVessel wallsPolymer scienceEthylene

The invention relates to the technical field of high polymer materials, in particular to plastic for a hydrogen storage pressure vessel and a preparation method thereof. The plastic is prepared from PVC resin, HDPE resin, ethylene copolymer and modified potassium tetratitanate whiskers. The plastic can be used as an isolation layer in the liner of the hydrogen storage pressure vessel, and the ethylene-vinyl acetate copolymer and the modified potassium tetratitanate whisker are added, so that the physical properties such as tensile strength and elongation at break can be further improved, the sealing property of the whole liner of the vessel can be enhanced, the leakage amount of hydrogen is further reduced, and thus the hydrogen storage requirement is met.

Owner:JIANGSU GOLDEN MATERIAL TECH

Heat-insulating corrosion-resistant powder coating material and preparation method thereof

PendingCN113045959AGood dispersionHigh porosityAnti-corrosive paintsPowdery paintsMicrowave ovenFirming agent

The invention discloses a heat-insulating corrosion-resistant powder coating material, and relates to the technical field of new materials. The preparation method comprises the following steps: firstly, modifying nano zinc powder with dopamine to prepare modified nano zinc powder, then treating potassium tetratitanate with acid liquor to prepare tetratitanate sol, mixing the modified nano zinc powder with the tetratitanate sol, preparing a heat-insulating filler blank under the action of a sodium dihydrogen phosphate solution, reacting the heat-insulating filler blank in a microwave oven for a period of time to obtain a pretreated heat-insulating filler blank, coating the pretreated heat-insulating filler blank with silicon dioxide sol to obtain a heat-insulating filler, mixing epoxy resin, the heat-insulating filler, a curing agent, a leveling agent and a silane coupling agent, tabletting, crushing, and sieving to obtain the heat-insulating and corrosion-resistant powder coating material. The heat-insulating corrosion-resistant powder coating material prepared by the invention has excellent heat-insulating property, corrosion resistance and toughness.

Owner:王海燕

Surface imprinting Fe<3+> potassium tetratitanate crystal whisker adsorption agent and preparation method thereof

ActiveCN109201015AReduce usageEasy to operateOther chemical processesAlkali metal oxides/hydroxidesProtonationSorbent

The invention discloses a surface imprinting Fe<3+> potassium tetratitanate crystal whisker adsorption agent and a preparation method thereof. A synthesis process comprises the steps of (1) loading nanometer TiO2 onto protonation potassium tetratitanate crystal whisker surfaces to obtain crystal whisker composite materials; (2) mixing Fe<3+> and chitosan with the obtained crystal whisker compositematerials; adding crosslinking agents; performing illumination so that a reaction system performs crosslinking polymerization and imprinting separation in a scattered state; (3) removing Fe<3+> templates. By using a surface molecular imprinting technology, the Fe<3+> is imprinted onto the potassium tetratitanate crystal whiskers; the goal of modifying the potassium tetratitanate crystal whiskersis achieved; the adsorption agent with selective adsorption capability on Fe<3+> is obtained; the preparation method achieves the environment-friendly effects; the product dispersion performance is high; the ion selectivity is high.

Owner:QINGDAO UNIV OF SCI & TECH

A kind of high modulus environment-friendly glass fiber and its processing technology

The invention discloses a high-modulus environment-friendly glass fiber and a processing technology thereof, and belongs to the field of inorganic nonmetallic materials. The method comprises the following steps: firstly, treating glass fibers by using a silane coupling agent and bovine serum albumin to prepare high-surface-activity glass fibers, then carrying out modification by using halohydrocarbon modified lignosulphonate, adding n-dodecylamine solution modified aminated potassium tetratitanate to prepare a treating agent adsorbed on the surface of the high-surface-active glass fiber, mixing the treating agent with the high-surface-active glass fiber, then carrying out filtering and drying to obtain a blank, and finally carrying out high-temperature carbonization on the blank at a certain temperature to prepare the high-modulus environment-friendly glass fiber. The high-modulus environment-friendly glass fiber prepared by the invention has relatively high tensile modulus and excellent alkali resistance.

Owner:WUHAI SHIHUAN NEW CERAMIC BUILDING MATERIAL CO LTD

A kind of surface imprinted fe3+potassium tetratitanate whisker adsorbent and preparation method thereof

ActiveCN109201015BReduce usageEasy to operateOther chemical processesAlkali metal oxides/hydroxidesProtonationPotassium

The invention discloses a surface imprinted Fe 3+ Potassium tetratitanate whisker adsorbent and preparation method thereof, the synthesis process steps include: ① loading nano TiO on the surface of protonated potassium tetratitanate whisker 2 Obtain whisker composite material; ② Fe 3+ Mix with chitosan and the obtained whisker composite material, add a crosslinking agent and light to make the reaction system crosslink and polymerize in a dispersed state and imprint and precipitate; ③ remove Fe 3+ template. By using surface molecular imprinting technology, the Fe 3+ Imprinted on the potassium tetratitanate whisker, to achieve the purpose of modifying the surface of the potassium tetratitanate whisker, to obtain a 3+ The adsorbent with selective adsorption capacity, the preparation method is environmentally friendly, the product has strong dispersibility, and the ion selectivity is high.

Owner:QINGDAO UNIV OF SCI & TECH

A method for preparing sodium metatitanate-potassium tetratitanate composite catalytic material by molten salt method

InactiveCN108620053BSimple equipmentSimple processHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsNitrate saltsPhysical chemistry

The invention relates to a method for preparing sodium metatitanate-potassium tetratitanate composite catalytic material using a molten salt method using mixed nitrate as a co-solvent, and belongs to the technical field of material preparation. The present invention uses tetrabutyl titanate as raw material and prepares TiO by hydrothermal method. 2 The material precursor is then added with mixed nitrate as a cosolvent, and the sodium metatitanate-potassium tetratitanate composite catalytic material is prepared through the nitrate molten salt method. This method has the advantages of simple and controllable preparation conditions, simple equipment and process, large output, and low cost. The obtained product is a nanoribbon with a length of 6-13 microns and a width of about 200 nanometers. It has broad application prospects in photocatalytic degradation of pollutants and photocatalytic hydrogen production.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for preparing photocatalytic ceramics using potassium tetratitanate whiskers

The invention relates to a method for preparing photocatalyst ceramic by means of potassium tetratitanate whiskers. The method comprises the following steps that 1, the potassium tetratitanate whiskers serve as main raw materials, and after ball milling is performed on the potassium tetratitanate whiskers in a ball mill, surface modification treatment is performed on the potassium tetratitanate whiskers with a silane coupling agent; 2, ceramic slurry is prepared by using the modified potassium tetratitanate whiskers and deionized water, a binder, low temperature glass powder, is added, a pH value is regulated with a NaOH solution, and high-speed stirring is performed in a magnetic stirrer; 3, short-chain amphiphilic molecules are added, and low-speed stirring is performed; 4, high-speed stirring is performed to foam, when big bubbles start to disappear, the high gear is switched to the low gear, and stirring is performed to obtain uniform and fine foam; 5, injection molding forming is performed, moldings are placed in a drying oven to be dried and then taken out after being cooled to the room temperature, and then the moldings are placed in a high-temperature furnace to be fired into porous ceramic according to the set sintering schedule. Due to the fact that catalytic degradation is performed on toxic organic pollutants by means of cheap and clean sunlight, the method for preparing the photocatalyst ceramic by means of the potassium tetratitanate whiskers has the advantages of being efficient, little in secondary pollution, friendly to environment, low in energy cost and the like.

Owner:WUHAN UNIV OF TECH

Low-temperature-resistant and high-temperature-resistant flame-retardant wire cable

PendingCN112280117AImprove mechanical propertiesGood flame retardant insulation performanceRubber insulatorsAluminium hydroxideAntimony trioxide

The invention relates to a low-temperature-resistant and high-temperature-resistant flame-retardant cable. The cable is prepared from natural rubber, ethylene propylene diene monomer, nano aluminum hydroxide, calcium carbonate, antimonous oxide, a zinc-calcium stabilizer, expanded graphite, carbon black, trioctyl trimellitate, dioctyl sebacate and potassium tetratitanate whiskers. The cable provided by the invention has relatively good mechanical properties and also has good flame-retardant and insulating properties. The cable has the characteristics of cold resistance and high temperature resistance, and is suitable for an environment with large temperature change. The use amounts of a flame retardant and a plasticizer are not large, so that the formula cost of the cable is relatively low, and the cable can better adapt to large-scale production.

Owner:安徽福日光电科技有限公司

Method for preparing ultrathin layered K2Ti4O9 crystal whiskers

InactiveCN102839413BSimple processSimple production equipmentPolycrystalline material growthFrom solid statePotassium nitrateEthyl ester

The invention discloses a method for preparing ultrathin layered potassium tetratitanate crystal whiskers with uniform sizes, good crystal forms and attractive appearances by adopting a stearic acid method. The crystal whiskers are 0.8-1.2 mum in diameter; length-diameter ratio exceeds 20; and main raw materials include stearic acid, potassium nitrate and tetraethyl titanate. The method comprises the following steps of: melting reactants into stearic acid by taking stearic acid with low melting point (80 DEG C) and poor dispersibility as a reaction medium; and burning for removing most organic matters; performing a synthetic method for calcining at a high temperature, wherein the stearic acid is taken as a dispersing agent for mixing reactant raw materials on the molecular level in a synthesizing process, and is also taken as a reactant for being subjected to a coordination reaction with K<+> and Ti<4+> in the reactant raw materials. The method has the characteristics of simple operation process, low calcining temperature (800-950 DEG C), short reacting time (2-5 hours), high purity, high crystalizing degree, low product aggregation and the like, and is suitable for large-scale industrial production.

Owner:WUHAN UNIV OF TECH

Potassium titanate whisker and its synthesis

Owner:上海秀普复合材料有限公司

Preparation method of photocatalytic foam ceramics

InactiveCN105110787BAvoid phase changeLow viscosityCatalyst carriersCeramicwareNetwork structureSlurry

The invention relates to a preparation method of photocatalytic foam ceramics, which comprises the following steps: (1) treatment of potassium tetratitanate raw powder; (2) modification of stearic acid; (3) pretreatment of polyurethane foam; (4) ) preparation of primary slurry; (5) primary slurry; (6) preparation of secondary slurry; (7) secondary slurry; (8) sintering and cooling to obtain photocatalytic foamed ceramics. Compared with the prior art, the present invention has the following advantages: through ball milling, water washing, stearic acid modification, and adding dispersant, the solid content of potassium tetratitanate slurry can reach 75%; The prepared foam ceramic realizes the immobilization of the photocatalyst, and its three-dimensional network structure increases the contact area between the particles and the organic matter, and improves the photocatalytic performance; and directly hangs the slurry on the foam ceramic, the preparation method is simple, and no secondary sintering is required. , the cycle is short and the cost is low; at the same time, the low temperature glass is used as the binder to solve the phase transition of potassium tetratitanate at high temperature.

Owner:WUHAN UNIV OF TECH

A kind of cement containing large proportion of slag and preparation method thereof

ActiveCN112573886BHigh compressive strengthImprove flexural strengthSolid waste managementAluminium sulfatePortland cement

The invention relates to a cement containing a large proportion of slag and a preparation method thereof. The cement is composed of the following raw materials in parts by weight: 90-100 parts of Portland cement, 10-15 parts of gypsum, 10-20 parts of fly ash, 70-90 parts of slag, 15-20 parts of magnesium sulfate whiskers, titanium 22-36 parts of potassium acid whiskers, 10-16 parts of aluminum sulfate, and 7.2-12.2 parts of grinding aid. The invention effectively improves the compressive strength and flexural strength of the Portland cement by adding potassium titanate whiskers into the cement, which is superior to the ordinary Portland cement on the market. In the invention, by adding a mixture of potassium tetratitanate whiskers and potassium octatitanate whiskers, the whiskers are better adsorbed on the surface of the slag, thereby reducing the corrosion of the slag powder by the alkaline environment, and at the same time, it can further improve the overall cement. The corrosion resistance of sulfuric acid and the resistance to salt freezing corrosion can shorten the final setting time, which is conducive to the solidification and hardening of cement.

Owner:湖北环沙再生资源有限公司

Acid-resistant and alkali-resistant pure titanium composite pot and processing method thereof

InactiveCN112021944AGood acid and alkali resistanceStrong acid and alkali resistanceMaterial nanotechnologyCooking-vessel materialsCompression moldingTitanium

The invention discloses an acid-resistant and alkali-resistant pure titanium composite pot and a processing method thereof, and relates to the technical field of pot body preparation. The method comprises the following steps: treating a titanium plate with mixed acid, carrying out electrocorrosion to prepare a pretreated titanium plate, reacting the pretreated titanium plate with a mixed sol cylinder to prepare a modified titanium plate, preparing potassium tetratitanate from potassium carbonate and titanium dioxide, carrying out a mixed reaction on the potassium tetratitanate and urea, carrying out a mixed reaction with graphene oxide to prepare modified graphene, mixing the modified graphene and liquid paraffin, and then smearing mixed paste on the surface of the modified titanium plate,and performing compression molding after high-temperature treatment so as to obtain the acid-resistant and alkali-resistant pure titanium composite pot. The acid-resistant and alkali-resistant pure titanium composite pot prepared by the method has excellent acid resistance and alkali resistance.

Owner:淮安帝圣新材料有限公司

Method for preparing photocatalyst ceramic by means of potassium tetratitanate whiskers

The invention relates to a method for preparing photocatalyst ceramic by means of potassium tetratitanate whiskers. The method comprises the following steps that 1, the potassium tetratitanate whiskers serve as main raw materials, and after ball milling is performed on the potassium tetratitanate whiskers in a ball mill, surface modification treatment is performed on the potassium tetratitanate whiskers with a silane coupling agent; 2, ceramic slurry is prepared by using the modified potassium tetratitanate whiskers and deionized water, a binder, low temperature glass powder, is added, a pH value is regulated with a NaOH solution, and high-speed stirring is performed in a magnetic stirrer; 3, short-chain amphiphilic molecules are added, and low-speed stirring is performed; 4, high-speed stirring is performed to foam, when big bubbles start to disappear, the high gear is switched to the low gear, and stirring is performed to obtain uniform and fine foam; 5, injection molding forming is performed, moldings are placed in a drying oven to be dried and then taken out after being cooled to the room temperature, and then the moldings are placed in a high-temperature furnace to be fired into porous ceramic according to the set sintering schedule. Due to the fact that catalytic degradation is performed on toxic organic pollutants by means of cheap and clean sunlight, the method for preparing the photocatalyst ceramic by means of the potassium tetratitanate whiskers has the advantages of being efficient, little in secondary pollution, friendly to environment, low in energy cost and the like.

Owner:WUHAN UNIV OF TECH

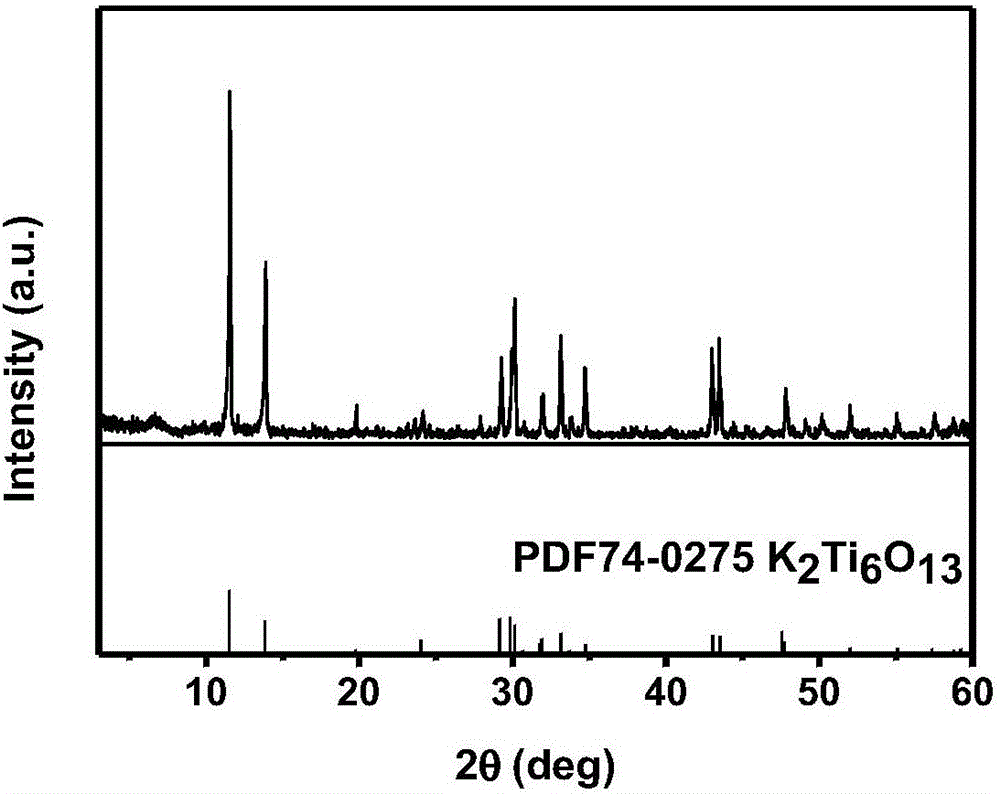

Bronze-type titanium oxide compound containing potassium, method of manufacturing the same, and lithium-ion secondary battery using the same

ActiveUS9174854B2Improve securityLarge capacityAlkali titanatesFinal product manufactureCrystallographyLithium

In a titanium oxide compound according to the present invention, the titanium oxide compound is obtained by eluating potassium of potassium tetratitanate expressed by a general formula K2Ti4O9 and performing thermal processing, and, in an X-ray diffraction spectrum of the potassium tetratitanate obtained by using a Cu—Kα ray source, between a peak intensity Ia of a (200) plane, a peak intensity Ic of a (004) plane and a peak intensity Ib of a (31-3) plane, a relationship of Ia>Ib>Ic is satisfied.

Owner:KUBOTA CORP

Method for preparing layered K2Ti4O9 continuous nanofiber

InactiveCN103060948BSimple processSimple production equipmentInorganic material artificial filamentsFilament/thread formingFiberPolymer science

The invention is a method for preparing nanofiber, and in particular comprises: by using butyl titanate, KNO3, citric acid, ethanol and nitric acid as raw materials, wherein by molar ratio, butyl titanate: KNO3: Citric acid: ethanol: dilute nitric acid = 1:2:2: (38 ~ 50): (19 ~ 25), polyvinyl alcohol or polyvinyl pyrrolidone as a polymer template, and aqueous solution of polyvinyl alcohol as a solvent, preparing a sol solution at room temperature; then preparing composite fiber by using an electrostatic spinning method, wherein an electrostatic spinning voltage is controlled to be 10 ~ 30KV, and curing distance of the nozzle to the accept screen is 8 ~ 20cm; and then performing heat treatment to the composite fiber at 500 ~ 950 DEG C for 3 ~ 8h to obtain layered K2Ti4O9 continuous nanofiber. The method of the invention is simple in process, easy in operation, high in efficiency, low in energy consumption, and simple in production equipment; and the prepared fiber has high purity, good crystallinity, a large surface area, a large length-diameter ratio and good dispersion.

Owner:WUHAN UNIV OF TECH

Preparation method of super-long potassium tetratitanate whisker

ActiveCN113818080AEasy to operateShorten the production cyclePolycrystalline material growthFrom solid statePhysical chemistryPotassium

The invention discloses a preparation method of a super-long potassium tetratitanate whisker. The method comprises the following steps: mixing a titanium-containing raw material and a potassium-containing raw material according to a TiO2 / K2O molar ratio of (2.5-3.5): 1, adding an additive and a solvent, mixing, drying, crushing and sieving to obtain mixed powder; and sintering the mixed powder, dispersing the sintered product with water, and drying to obtain the super-long potassium tetratitanate whisker. The method is simple in whole process flow operation, short in production period, low in cost and suitable for industrial production. The prepared potassium tetratitanate whisker is uniform in morphology, concretely, the diameter D of the whisker is 0.5-2 mu m, the length L is greater than or equal to 100 mu m, and L / D is 100-400. Compared with the potassium tetratitanate whisker without any additive or solvent, the potassium tetratitanate whisker prepared by the method disclosed by the invention is higher in quality, and the length-diameter ratio of the potassium tetratitanate is slender. Meanwhile, the sintered product is loose in structure, and the super-long potassium tetratitanate whisker can be obtained after the sintered product is dispersed with water and dried.

Owner:NANJING UNIV OF TECH +1

Rubber elastomer used in surface of floor tile

Provided is a rubber elastomer used in surface of a floor tile. The rubber elastomer is formed by mixing of ethylene propylene rubber, polyester fiber, nylon, vulcanizer, modified hollow glass beads, silicon dioxide micro powder, modified potassium tetratitanate whisker and fortifier. By presetting a layer of the rubber elastomer on the surface of the floor tile, not only can the rubber elastomer prevent people from bruising when people fall down to the floor, but also a comfort level of walking of people can be increased due to the setting of the rubber elastomer; meanwhile, due to the fact that the rubber elastomer is preset, the layer of the rubber elastomer can be directly formed on the surface of the floor tile after the floor tile is laid, so that laying efficiency is sharply improved and a construction period is shortened.

Owner:河南同伟建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com