Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223results about How to "Easy to mix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

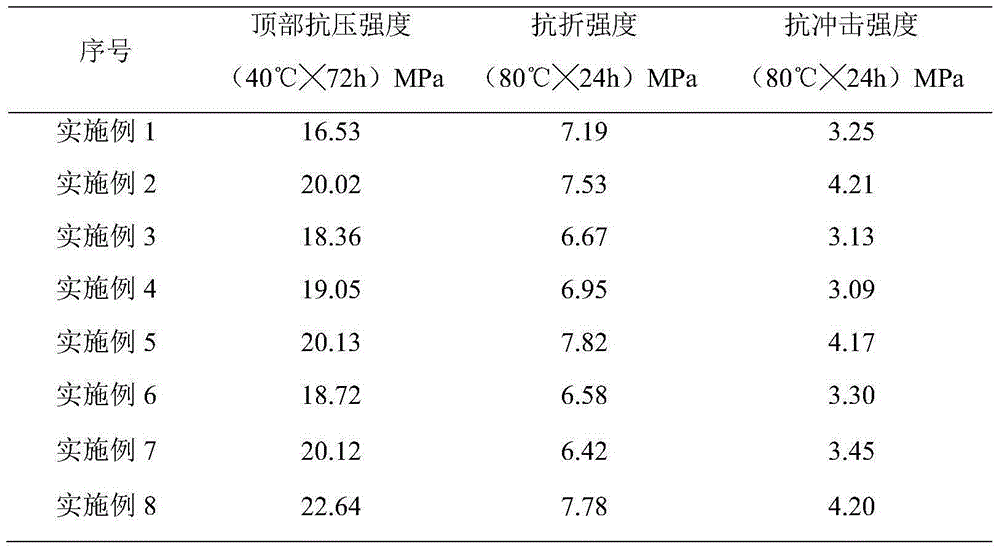

Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

InactiveCN105694625AMeet various style requirements of high-end and high-end exterior finishesShort construction periodFireproof paintsAnti-corrosive paintsPolymer scienceSludge

The invention relates to an exterior wall waterproofing heat-insulating decorating integrated material and a preparation method thereof.The preparation method includes: using conventional resin like polyurea and polyurethane as raw materials, adding compound micropowder prepared from solid waste and sludge, and adding a mixed modifier and a thixotropic agent to prepare A-compound slurry; adding a promoter and a hardener, and performing spray coating, brush coating, roll coating and pouring methods to obtain the exterior wall waterproofing heat-insulating decorating integrated material.The material has the comprehensive advantages of good waterproof effect, high heat insulativity, high hardness, high hole closing rate, low density, good anti-seepage performance, high corrosion resistance, low linear expansion coefficient, high softening temperature, oxidization resistance, aging resistance, flame retardancy and firmness in binding with a substrate.When the material is used for building exterior walls, multiple times of leveling, waterproofing, heat insulating and decorating construction are not needed, on-site moisture-free operation and one-time forming can be realized, and the material is short in construction period, extremely low in cost and great in market prospect.

Owner:NANJING KAIBA ADVANCED MATERIALS CO LTD +1

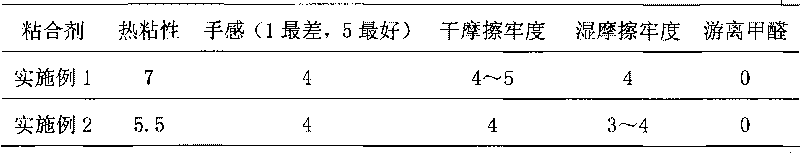

Anti-sticking soft dope printing adhesive and preparation method

The invention discloses anti-sticking soft dope printing adhesive and a preparation method. The adhesive comprises the following raw materials in percentage by mass: 25 to 50 percent of soft monomer, 6 to 20 percent of hard monomer, 0.8 to 5 percent of emulsifying agent, 0.1 to 0.25 percent of initiator, 0.05 to 0.5 percent of buffer, 0.04 to 0.2 percent of thiol and 40 to 65 percent of deionized water. The preparation method comprises the following steps: adding 1 / 8 to 1 / 6 of the soft monomer, the hard monomer and a functional monomer of the raw materials, total emulsifying agent and total deionized water into a reactor, stirring and emulsifying the mixture for 30 to 40 minutes at the room temperature, heating the mixture to between 50 and 65 DEG C, and adding the thiol and the initiator into the reactor; and beginning dripping the mixed monomer, preserving the heat for 2 hours at the temperature of between 50 and 65 DEG C after the dripping is finished, heating the mixture to 70 DEG C, preserving the heat for half an hour, and cooling a product to the room temperature, and discharging the product. The anti-sticking soft dope printing adhesive has the advantages that: the adhesive has excellent washing fastness, super-soft handfeel, environmental protection and no brittleness or after tack, overcomes the defects of hot sticking and poor handfeel of acrylic ester, has many available thickening agent categories, and easily mixes size.

Owner:SHANGHAI JAROS NEW MATERIAL +1

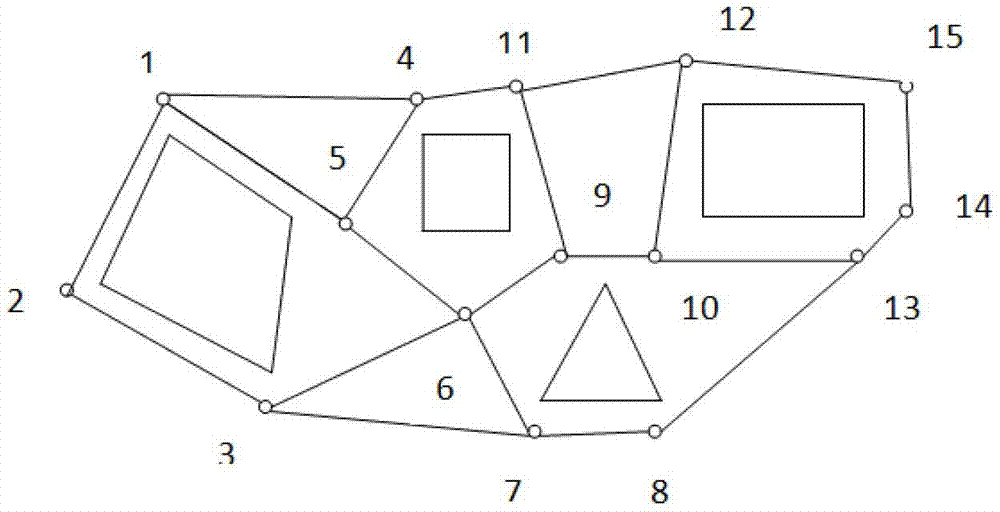

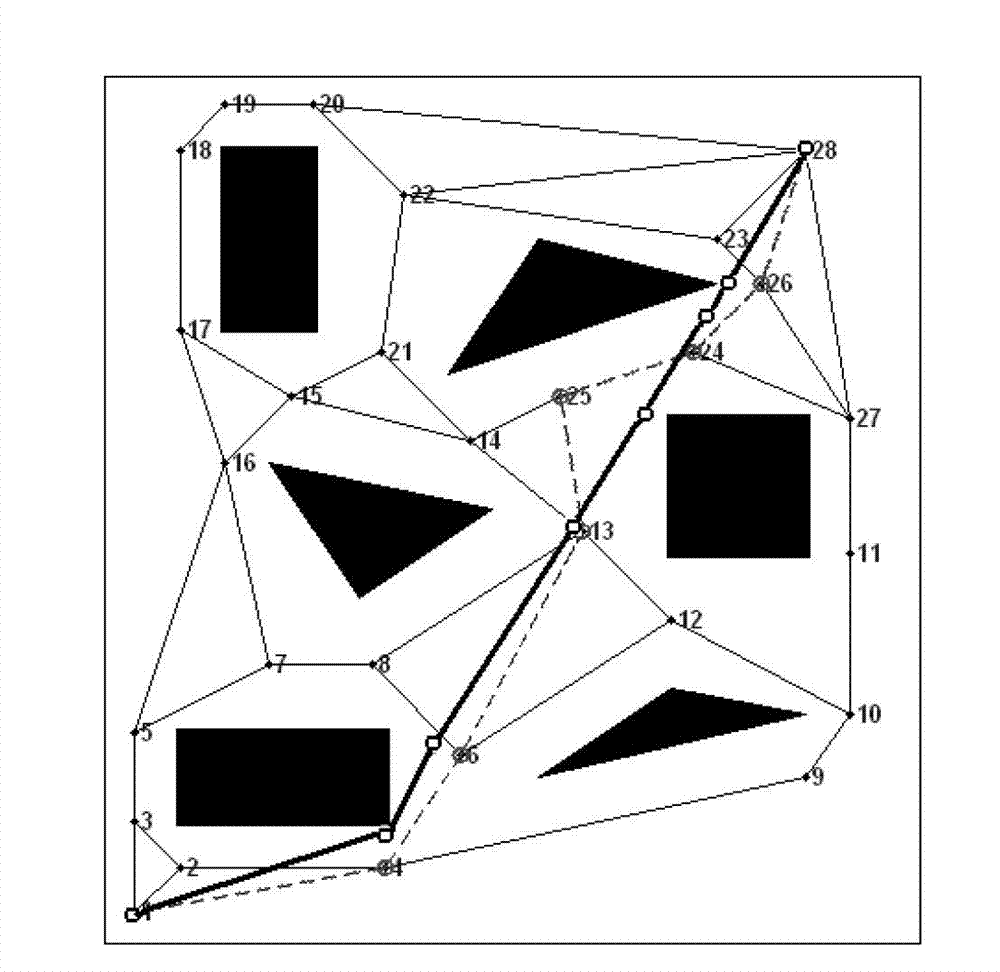

Rapid planning method for surface global path of planet

InactiveCN102929286AImprove versatilityEasy to mixPosition/course control in three dimensionsPath lengthAlgorithm

The invention relates to a rapid planning method for a surface global path of a planet, and belongs to the technical field of deep space exploration. The method comprises the following steps of: firstly obtaining an obstacle distribution information graph in a region to be subjected to path planning, carrying out analysis process on the graph, selecting a plurality of feasible nodes in the feasible region capable of avoiding obstacles and carrying out path connection in the feasible region according to the selected nodes; obtaining the coordinate information of the nodes, creating a network topology which the path planning needs by adopting a Dijkstra algorithm and planning an initial optimal path through taking the length of the path as the constraint condition; and taking the path length function as a fitness function, taking the mathematical function relationship followed in the process of selecting the nodes and the constraint range of the coordinates as a to-be-optimized object and the constraint condition of a genetic algorithm, optimizing the initial optimal path by adopting the genetic algorithm and outputting the optimization result used as the final planning path. The method has the advantages of simplicity in algorithm, high efficiency, good generality and strong expandability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Tunnel fireproof paint

InactiveCN101747675AGood construction performanceConstruction stabilityFireproof paintsCalcium formateToxic material

The invention relates to fireproof paint, in particular to tunnel fireproof paint, which is prepared from the following ingredients: a major bonding agent (ordinary Portland cement), inorganic heat insulation filling materials (expanded perlite, expanded vermiculite, meerschaum, kaoline and wollastonite powder) and addition agents (calcium formate, starch ether, redispersible latex powder, methyl cellulose ether and polypropylene fiber). Through the unique addition agent combination and the prescription mixture ratio, the tunnel fireproof paint has the advantages that the construction performance is obviously improved, at the same time, the integral overall performance of the tunnel fireproof paint is greatly improved, and the tunnel fireproof paint has the characteristics of stable fireproof performance, high adhesion intensity and stable physicochemical performance. Simultaneously, the product per se generates no toxic substance in the construction and burning processes, has the effects of environment protection and high practicability, and can be widely used for the fireproof protection of buildings such as highways, railways, subway tunnels and the like.

Owner:江西三星气龙新材料有限公司

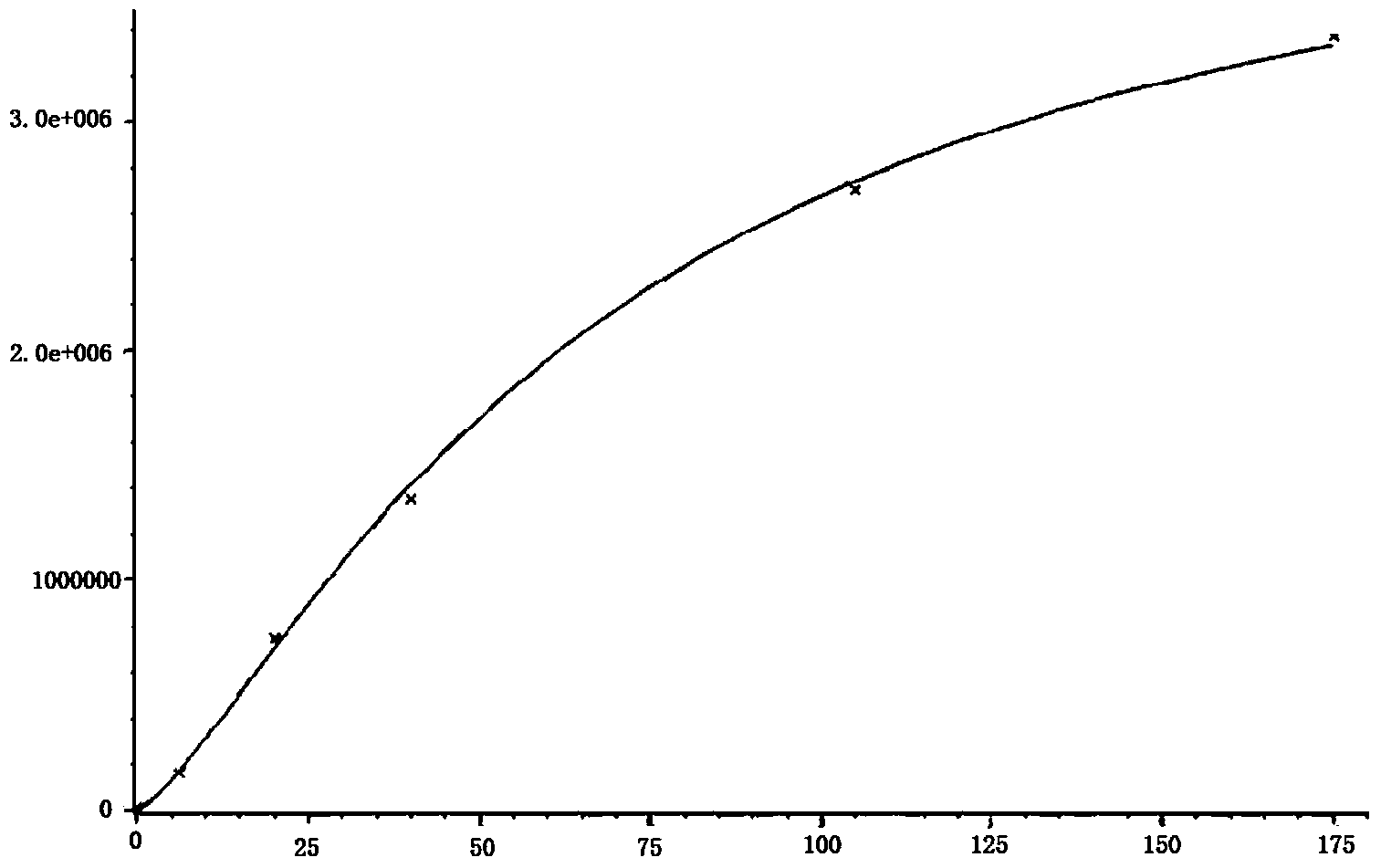

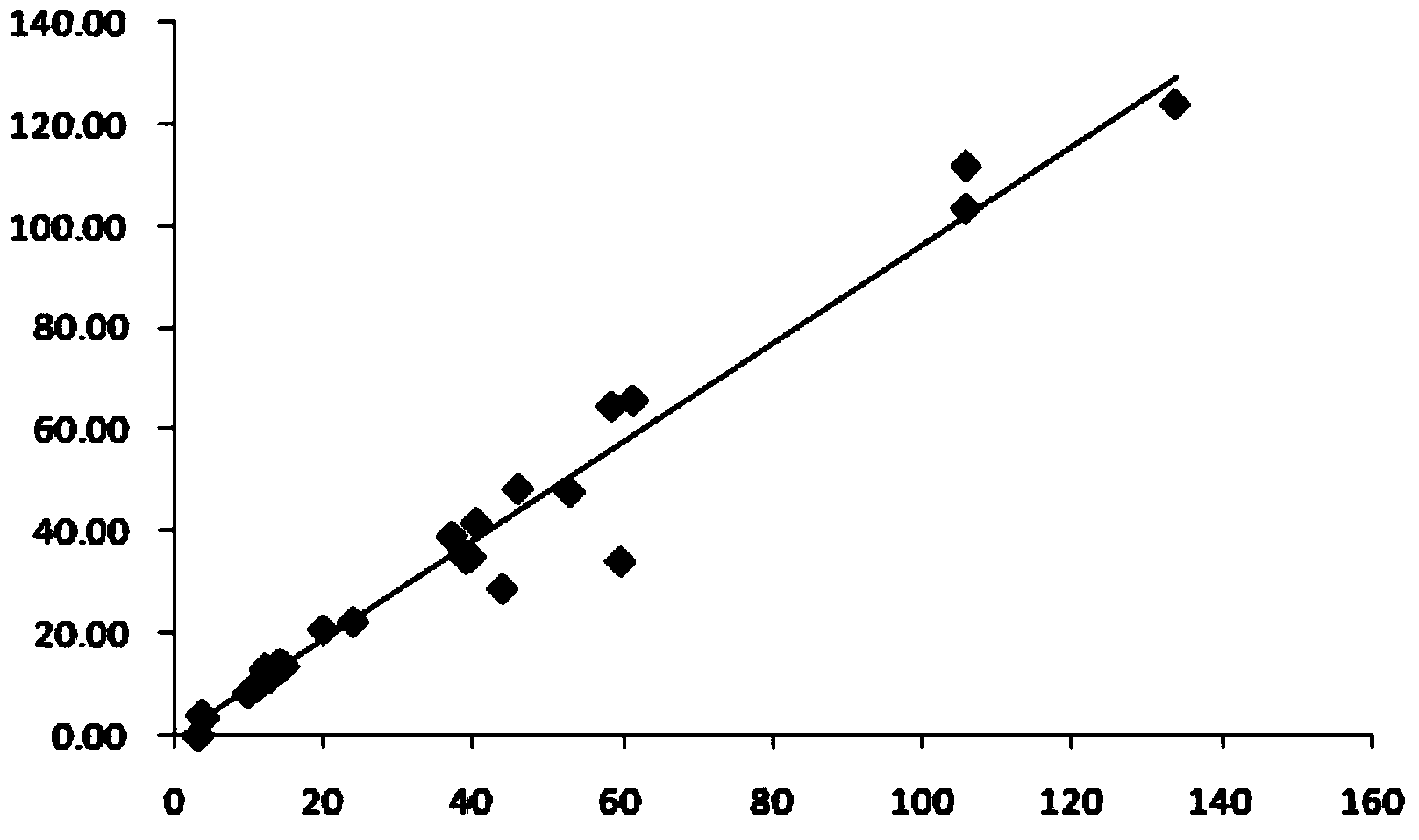

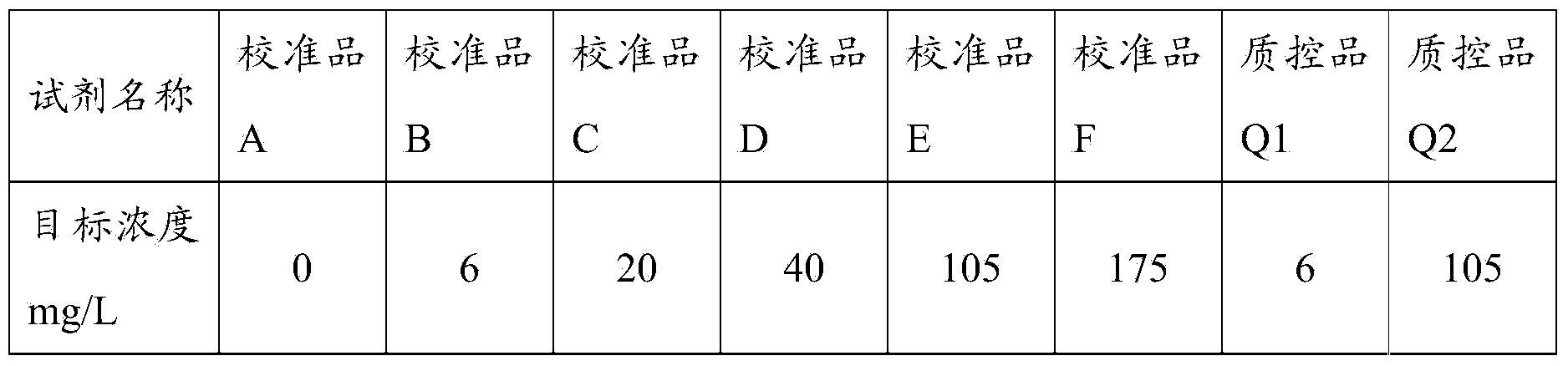

C-reactive protein quantitative determination kit and preparation method thereof

The invention discloses a C-reactive protein quantitative determination kit, belonging to the field of biological immune in-vitro diagnosis of medical devices. The kit comprises a calibrator, a quality control product, an antibody reagent, a magnetic particle reagent and a luminescent substrate. The invention also discloses a preparation method of the kit and a method for detecting C-reactive protein by using the kit. According to the preparation method disclosed by the invention, the antibody reagent is prepared from a C-reactive protein-coated antibody labeled by fluorescein isothiocyanate and a C-reactive protein-labeled antibody labeled by alkaline phosphatase, and the magnetic particle reagent is prepared by coupling an anti-fluorescein-isothiocyanate antibody with carboxyl magnetic beads so as to ensure that uniform mixing and separation are easily carried out in immunoreaction, and the reaction speed can be greatly increased; and a novel chemical luminescent substrate ALPS is used as the substrate, so that the sensitivity and specific performances of the kit can be improved. The detection kit disclosed by the invention is reliable in performance, high in sensitivity and wide in linear range, and can be matched with semi-automatic and full-automatic instruments for use.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV +1

High-density cement slurry suitable for shale gas cementing and preparation method of high-density cement slurry

The invention discloses high-density cement slurry suitable for shale gas cementing. The high-density cement slurry is prepared from the following raw materials in parts by weight: 100 parts of cement, 44-57 parts of fresh water, 15-120 parts of a weighting agent, 0-30 parts of a weighting stabilizer, 30-40 parts of a high-temperature strength stabilizer, 3-5 parts of an elasto-plastic agent, 4-7 parts of a fluid loss agent, 1-2.5 parts of a retarder and 0.5-2.5 parts of a dispersant. The preparation method comprises the following steps of weighing the cement, the fresh water, the weighting agent, the weighting stabilizer, the high-temperature strength stabilizer, filler, the elasto-plastic agent, the fluid loss agent, the retarder, the dispersant and a defoaming agent according to the ratio; mixing the components, and stirring to obtain the high-density cement slurry suitable for shale gas cementing. The high-density cement slurry is easily pulped at normal temperature and is good in high-temperature sedimentation stability, capable of improving the breaking strength, shock resistance and toughness of hardened cement slurry, relatively wide in density adjustable range and capable of meeting various shale gas cementing requirements.

Owner:成都欧美克石油科技股份有限公司

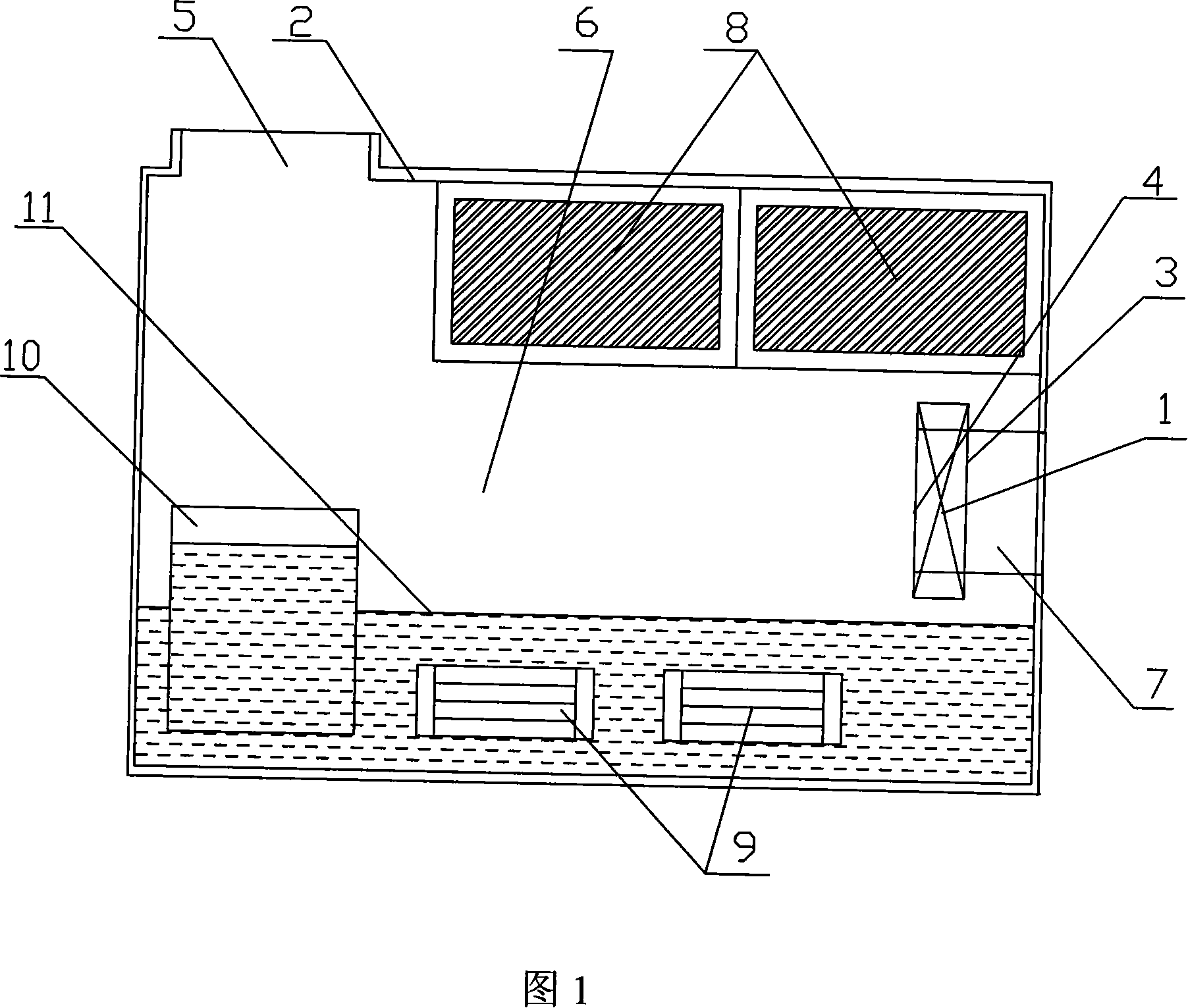

Apparatus for effectively compensating three-phase unbalance load and reactive power

InactiveCN1812219ASolve reactive power compensationSolve balance problemsPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationPower controllerElectric power system

This invention discloses a kind of high-efficiency compensating three-phase imbalanced load and reactive power apparatus. It concludes: three-phase current of three-phase electric system, three-phase voltage sampling circuit, power controller and different three-phase compensating elements controlled by the power controller. According to the sampling results, the power controller controls each unidirectional switch of three-phase compensating elements of different topological structure respectively. It makes them can either compensate together or compensate solely; it can either compensate reaction or balance action; it can either use for static compensating or use for dynamic compensating; it can either adjust three-phase current of adjust three-phase imbalanced voltage. It can be used for improving and replacing the reactive compensation apparatus of the three-phase-four-line mode imbalanced load electric system.

Owner:齐志江

Bitumen modifier

InactiveCN101041744AHigh softening pointImprove anti-aging propertiesBuilding insulationsEpoxyStearic acid

The invention discloses a modifier of pitch for road and water-proofing material, which comprises the following steps: allocating with mass percent as 20-30% polypropylene, 3-10% epoxide resin, 8-10% polyethylene, 8-10% geoceric acid and 40-60% ethylene distearamide; mixing; stirring for 10-15 min; getting the product. This product possesses good stability and predominant water resistance, which can be fit for all of asphalt.

Owner:上海诚鸿道路新材料有限公司

Pig liquid feeding device

InactiveCN102047847AEasy to mixSpeed up preparationOperating means/releasing devices for valvesAnimal feeding devicesEngineeringLogic state

The invention relates to a pig liquid feeding device. The traditional pig feeding usually relies on manual work. In the pig liquid feeding device, solid feed is delivered to a feed sending mechanism by a first feed loading mechanism and a second feed loading mechanism respectively; the feed sending mechanism is provided with two feed outlets, and can selectively deliver the solid feed on the feed sending mechanism to a first feed preparing tank or a second feed preparing tank; water and the solid feed in the first feed preparing tank and the second feed preparing tank are stirred by a first stirring mechanism and a second stirring mechanism, so as to form the liquid feed; a water pump is used for supplying water to the two feed preparing tank for preparing the feed during the stirring; prepared pig disease control medicine in a medicine tank is delivered into the feed preparing tanks by a medicine sending pump, and is mixed with the liquid feed; and the first feed outlet or the second feed outlet can be selected by use of make and break logic states of four electromagnetic valves in an annular distributor. The degree of automation is high, and the pig disease diagnosis and treatment as well as control can be accomplished during the feeding.

Owner:HANGZHOU DIANZI UNIV

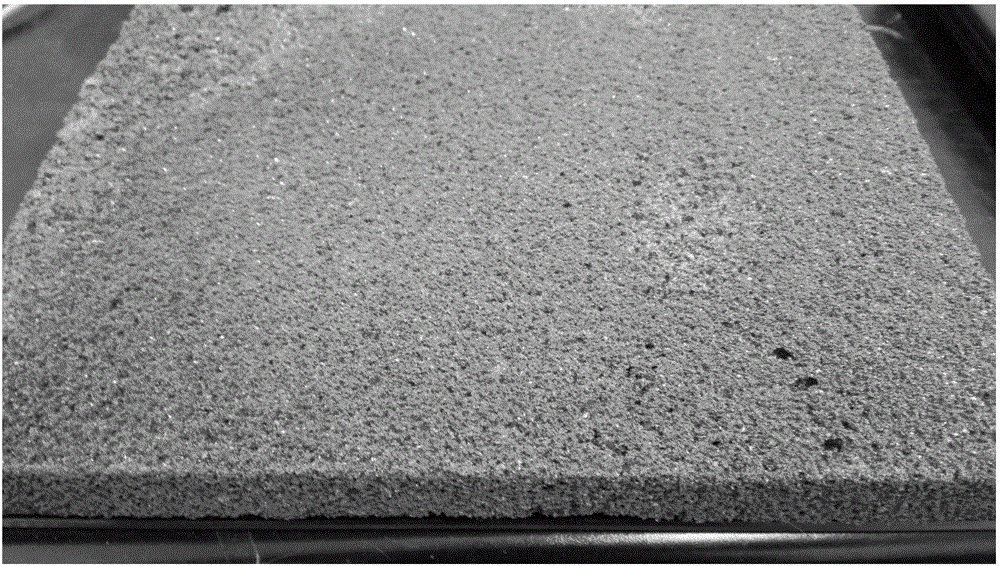

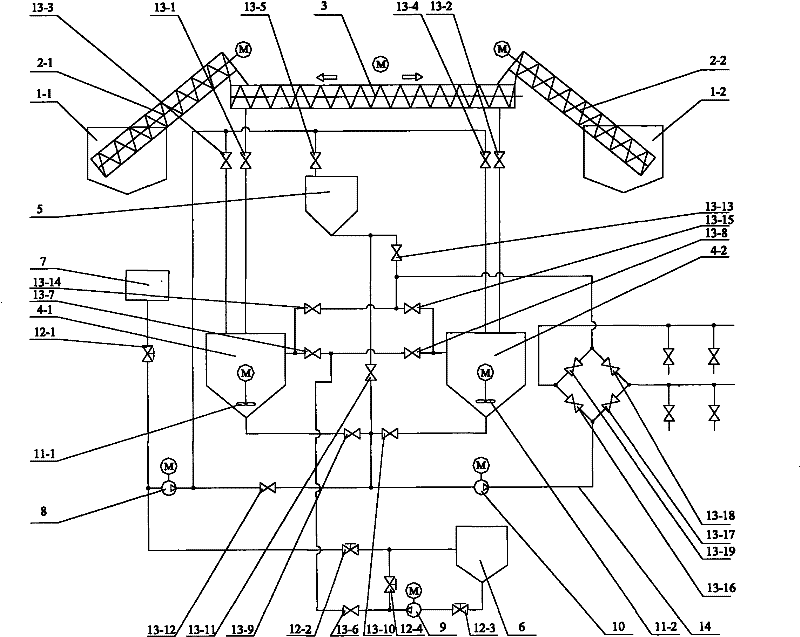

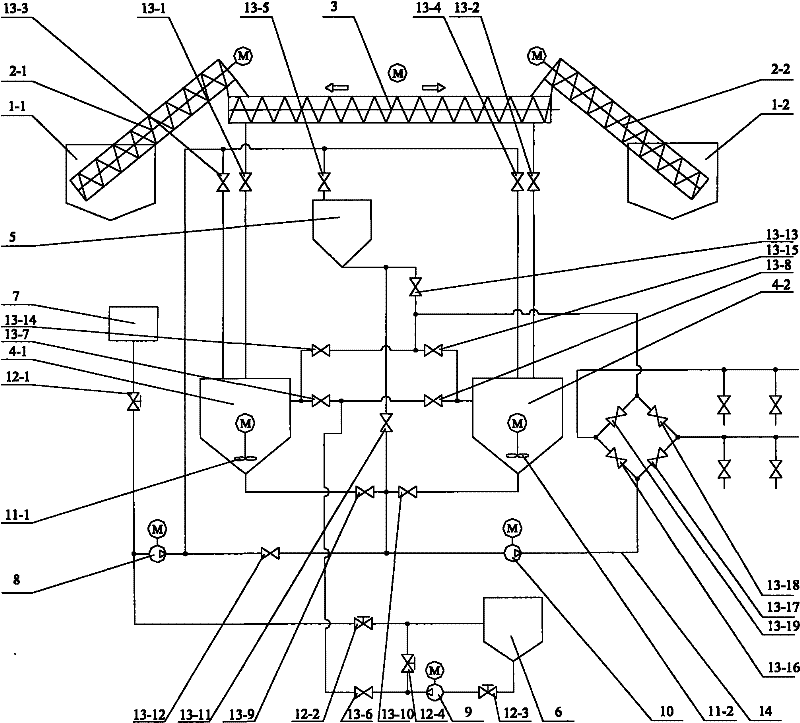

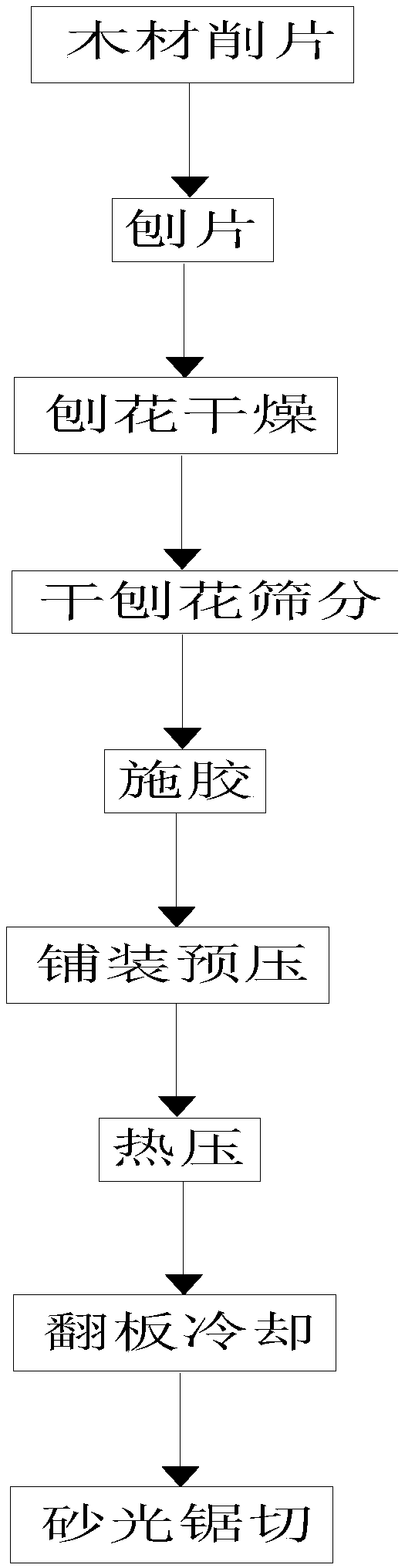

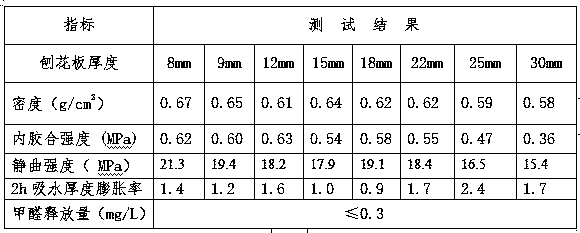

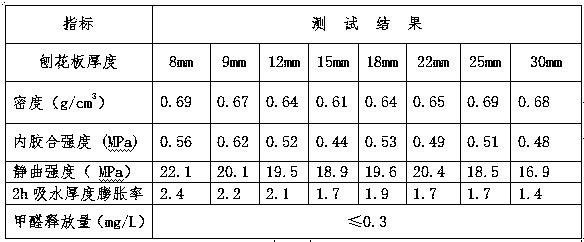

Ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings

InactiveCN109624016ALess squeezeAvoid secondary damageFlat articlesDomestic articlesWood shavingsManufacturing technology

The invention relates to the technical field of artificial plate manufacturing, in particular to an ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings. The ultra-strength shaving board manufacturing technology comprises the processes of wood chipping, flaking, drying, sieving, glue applying, paving and pre-pressing, hot-pressing, board reversingand cooling, sanding and saw cutting, testing and classifying, warehousing and packaging and the like. The quality performance of an ultra-strength shaving board produced and manufactured by the ultra-strength shaving board manufacturing technology is far better than the standards of an European oriented strand board in 'EN300: 2006-OSB' and 'T / CTWPDA03-2017 veneer shaving board', and the strength of the ultra-strength shaving board even reaches the strength level of a hipboard or plywood; the ultra-strength shaving board has the outstanding features of highest mechanical strength compared with a plate with the same density, lowest density compared with a plate with the same strength, and material saving, and the mechanical strength performance of the ultra-strength shaving board is improved greatly due to the fact that the product structure is uniform and compact; and the advantages of a stable size, non-deformation, small thickness tolerance and the like are realized, and the transformation and upgrading of the artificial board industry, especially shaving board industry are facilitated greatly.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

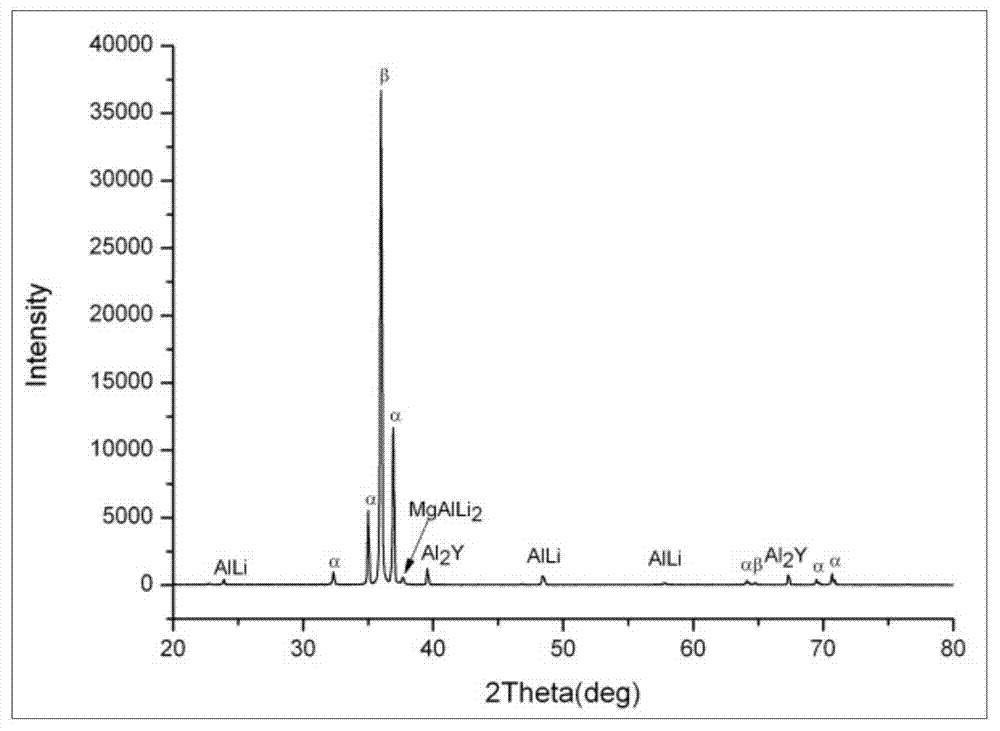

High-strength two-phase ultralight magnesium lithium alloy and preparation method thereof

The invention relates to high-strength two-phase ultralight magnesium lithium alloy and a preparation method thereof and belongs to the technical field of light metal material preparation. The high-strength two-phase ultralight magnesium lithium alloy disclosed by the invention comprises the following components in mass percent: 6.0-9.0 percent of Li, 1.0-6.0 percent of Al, 0.01-1.0 percent of Y and 0.21-0.5 percent of Ca. According to the preparation method disclosed by the invention, magnesium lithium alloy is smelted in a general resistance furnace by adopting a flux-covering and gas protection method, so that the high-strength two-phase ultralight magnesium lithium alloy with the room temperature tensile strength of 162-190Mpa, the yield strength of 150-170Mpa, the percentage elongation of 15-30 percent and the density of 1.43-1.48g / cm<3> is obtained. The preparation process is simple; the obtained products are excellent in performance and industrial production is facilitated.

Owner:CENT SOUTH UNIV

Composite vitamin emulsion and preparation thereof

InactiveCN101297680AEasy to mixRich varietyAnimal feeding stuffAccessory food factorsPantothenic acidChemistry

The invention discloses a compound vitamin emulsion and a preparation method thereof, aiming at providing a compound vitamin emulsion which can dissolve in water and is convenient for use and the preparation method thereof. The method includes the following steps: cooking oil is taken to dissolve fat-soluble vitamin A, vitamin D [3], and vitamin E in water bath which is at 70 DEG C, and then agitated and ground with Twain-80, span-85, and water into emulsion stroma; in addition, water is taken to dissolve vitamin C, vitamin K [3], vitamin B [1], vitamin B [2], folic acid, and pantothenic acid sodium; liquid prepared in the two steps is merged and agitated evenly, and then the compound vitamin emulsion of the invention is obtained. The compound vitamin emulsion prepared by the method of the invention can be mixed with water according to arbitrary proportion without lamination or precipitate, has simple operation and can be used industrially and automatically in batch in using process by users.

Owner:TIANJIN SHENGJI GRP CO LTD

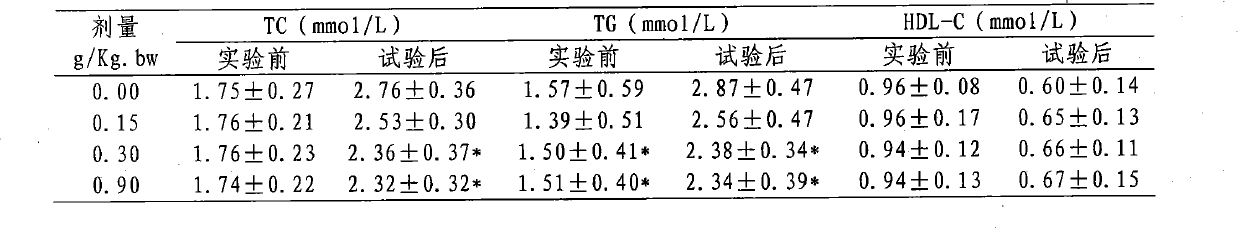

Beta-glucan-containing powdered oil, preparation method and application thereof

InactiveCN101999475AImprove stabilityGuaranteed to be free from interferenceEdible oils/fatsControlled releaseBeta-glucan

The invention relates to the technical field of biological engineering and the fields of food and medicine, and specifically provides glucan-containing powdered oil, in particular beta-glucan-containing powdered oil and a capsule thereof. The powdered oil is prepared by using glucan, in particular beta-glucan taken as wall material and using functional oil as core material through the step of encapsulating the functional oil into the glucan wall material so as to obtain microencapsulated powdered oil with controlled-release function characteristics, so that the beta-glucan-containing powderedoil is convenient to use and endowed with special physiological functions such as immune adjustment and blood fat adjustment and the like. The microencapsulated powdered oil is filled into an empty capsule so as to obtain a hard capsule, and the hard capsules can be used as medicines and health products or food.

Owner:BINZHOU UNIV +1

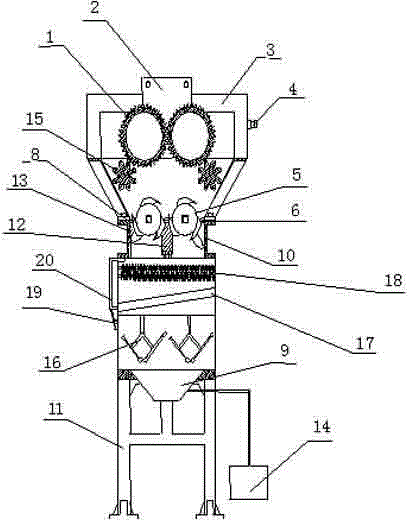

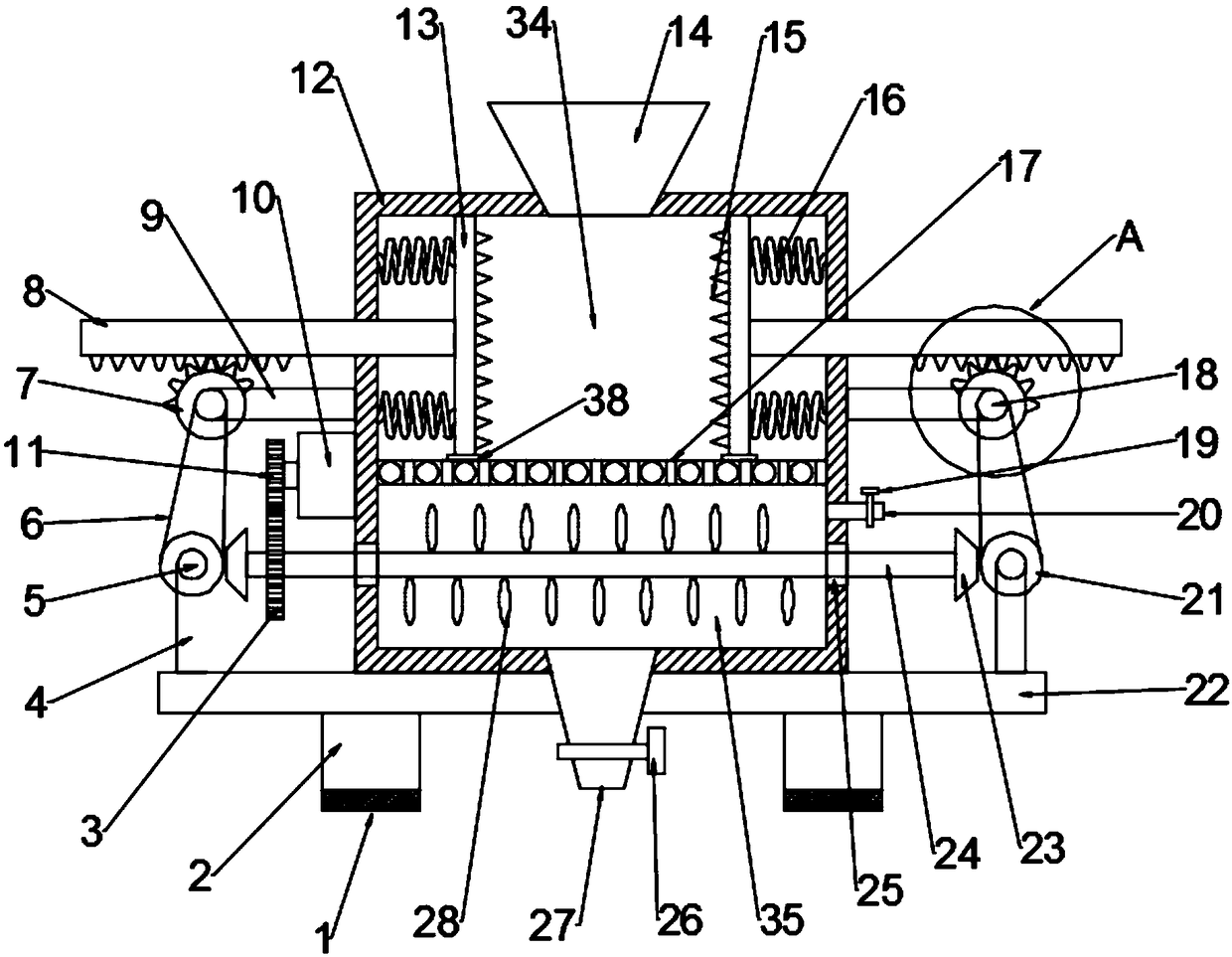

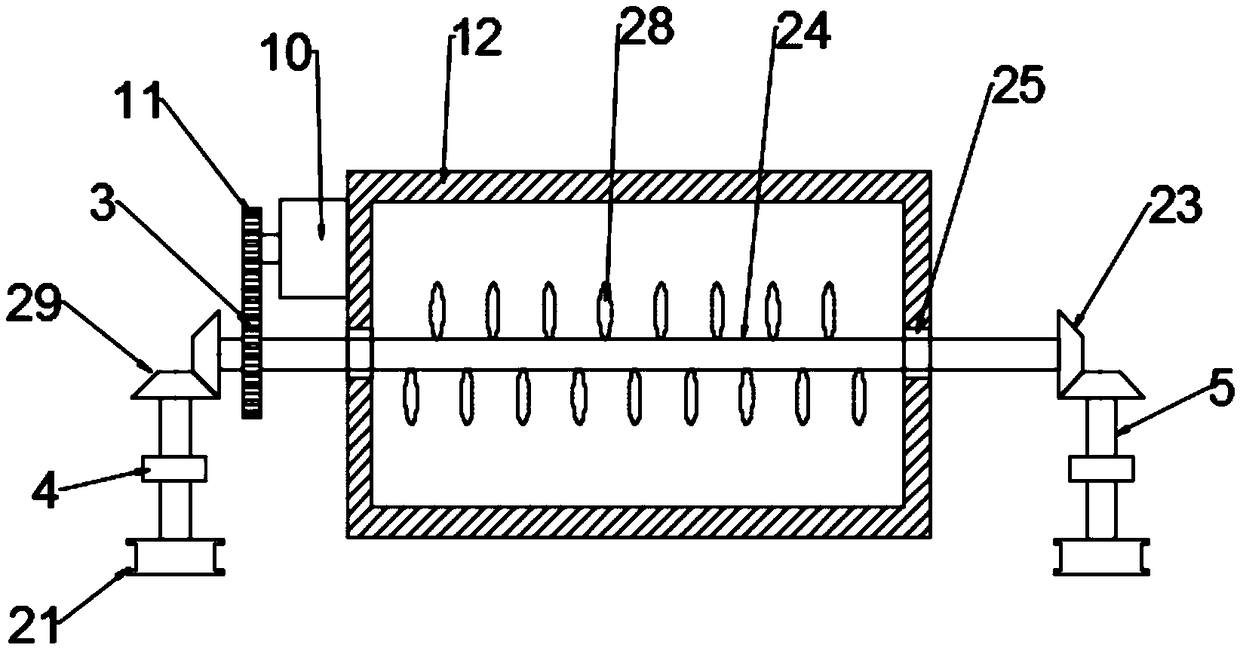

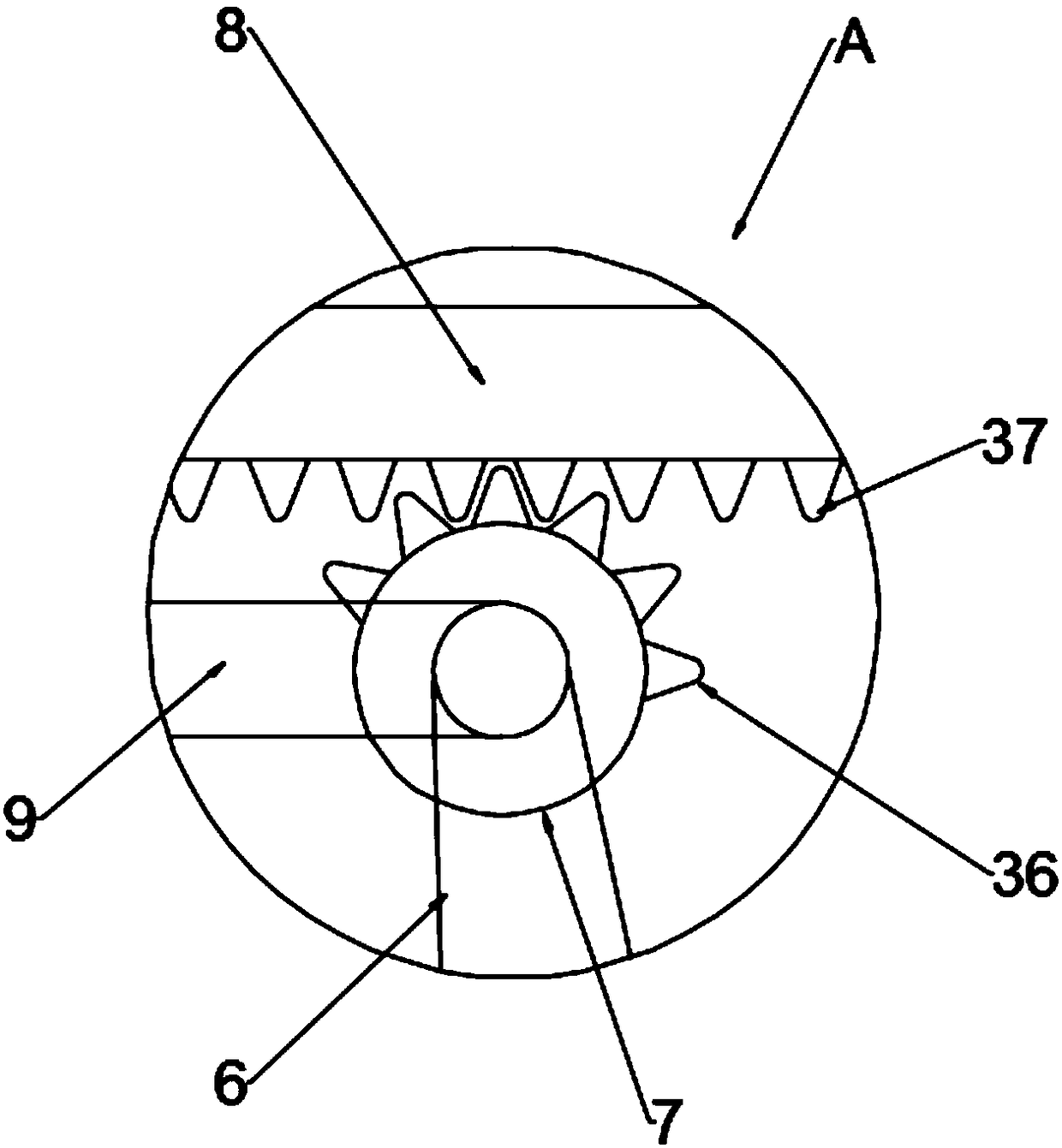

Dual-stirring rubber crusher

InactiveCN105252675AReduce energy consumptionNot subject to shock loadsPlastic recyclingGrain treatmentsElectric machineryRotational axis

The invention discloses a dual-stirring rubber crusher. A roller device, a rubber cutter group and a power mechanism are arranged inside a rubber crushing chamber; the roller device is arranged at the top of the rubber crushing chamber and comprises two mutually matched rollers, and rubber scrapers which are close to the inner walls of a stirring chamber are arranged on the two sides of the rollers; the rubber cutter group comprises a moving cutter and a fixed cutter which are mutually matched; the power mechanism comprises a motor which drives the rollers and the rubber cutter group to rotate; a rotary stirrer is arranged on the upper portion of the inside of a dual-stirring chamber, and a horizontal rotating shaft of the rotary stirrer is provided with spiral teeth; an inclined screen is arranged in the middle of the inside of the dual-stirring chamber, the lower end of the inclined screen is connected with a recycling pump through a recycling pipe, and V-shaped stirrers are arranged on the lower portion of the inside of the dual-stirring chamber. Rubber is pressed into a sheet which is then cut up, and energy consumption of rubber crushing is reduced. Dual-stirring is performed by means of the rotary stirrer and the V-shaped stirrers, so that the rubber crushing effect is good, the plasticity of the rubber is improved, and subsequent rubber refining is easier.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

Warm mix asphalt and preparation method thereof

The invention discloses warm mix asphalt and a preparation method thereof. The warm mix asphalt comprises asphalt, aggregate, mineral powder and warm mixing agent, wherein the warm mixing agent is inorganic silico-aluminate of which the water content is 18 to 23 percent; based on 1 weight part of asphalt, the warm mix asphalt contains 15 to 30 parts of aggregate, 0.5 to 1.5 parts of mineral powder and 0.05 to 0.01 part of warm mixing agent; and the invention discloses the preparation method for the warm mix asphalt, and adding sequence, control temperature and mixing time of the materials are detailed in the method. According to the warm mix asphalt, the mixing temperature of the asphalt is effectively reduced, consumption of fuel and emission of harmful gases are reduced, damage to the environment and harm to health of constructors are reduced, and storage type production is facilitated; and by the preparation method for the warm mix asphalt, the production procedures of the mixture are simplified, the warm mix asphalt can be produced in the conventional equipment, and equipment input and maintenance cost are reduced.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Ultrasonic atomizing fire extinguisher

The invention relates to an ultrasonic atomization fire extinguisher, which comprises a power supply unit, a water level adjusting unit and an ultrasonic atomization unit, which is characterized in that a circulating fan that is arranged in an atomization cavity and forms internal circulating airflow of the atomization cavity and an overflow port of gas phase and water phase is a water mist outlet of the atomization cavity. A ventilation unit of the invention realizes the circulation flow of air in an atomizer, thus preventing outside air from diluting the water mist, greatly prompting the dripping mass fraction of the water mist and causing ultrasonic atomization to be applied in fire fighting.

Owner:UNIV OF SCI & TECH OF CHINA

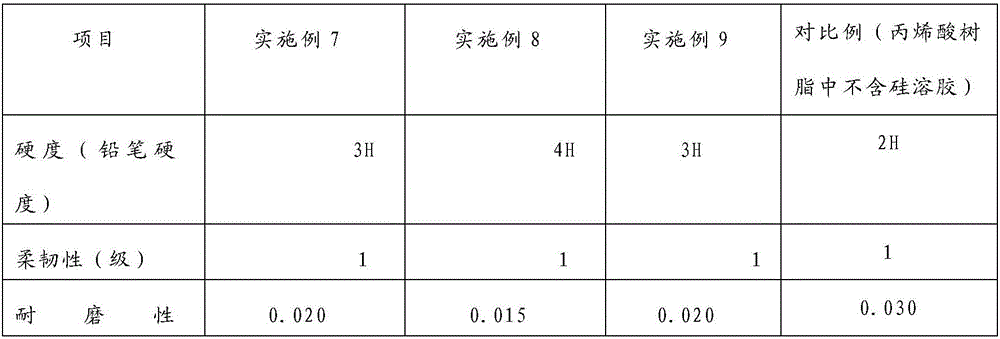

Silica sol, preparation method of silica sol, acrylic resin and acrylic dual-component polyurethane coating

ActiveCN106749856AImprove coating performanceEasy to mixPolyurea/polyurethane coatingsSilicon compoundsChemistrySilane coupling

The invention provides silica sol, a preparation method of the silica sol, acrylic resin and acrylic dual-component polyurethane coating and is used for solving the problem that existing acrylic dual-component polyurethane coating has poor performance of hardness, wear resistance, impact resistance, adhesion and the like. The preparation method of the silica sol provided by the invention comprises the following steps: the step 1) reacting tetraethoxysilane with absolute ethyl alcohol under acid condition to form intermediate reaction solution; the step 2) adding the absolution ethyl alcohol and a silane coupling agent (gamma-(methylacryloyl oxy) propyl trimethoxy silane) into the intermediate reaction solution to react and aging to obtain the silica sol. Furthermore, the silica sol can be applied to modify the acrylic resin, the modified acrylic resin can be applied to the acrylic dual-component polyurethane coating to obtain the acrylic dual-component polyurethane coating containing silica sol modified acrylic resin, and the obtained acrylic dual-component polyurethane coating has excellent performance of hardness, wear resistance, impact resistance and adhesion.

Owner:SHANGHAI ZHENGOU IND

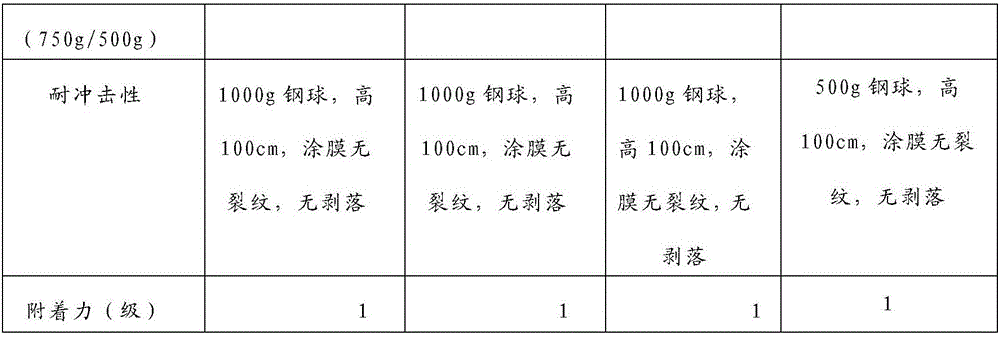

Remediation method of alkaline soil

InactiveCN109220039AReduce alkalinityGood characterSuperphosphatesCalcareous fertilisersAlkalinitySoil characteristics

The invention provides a remediation method of alkaline soil, and relates to the technical field of soil improvement. The method comprises the steps of (1), soil preparation; (2), soil loosening agentapplication; (3), soil improving fertilizer application. According to the method, the alkaline soil is restored through the steps of soil preparation, soil loosening agent application, soil improvement fertilizer application and the like to reduce soil alkalinity, improve soil characteristics, loosen soil, increase soil fertility to gradually improve soil alkalinization, soil sterilization and fertilizer addition are conducted while the soil alkalinity is reduced, and the method is a remediation method which has the effects of alkaline soil conditioning agent and value improving and synergism.

Owner:广西百乐德农业投资有限公司

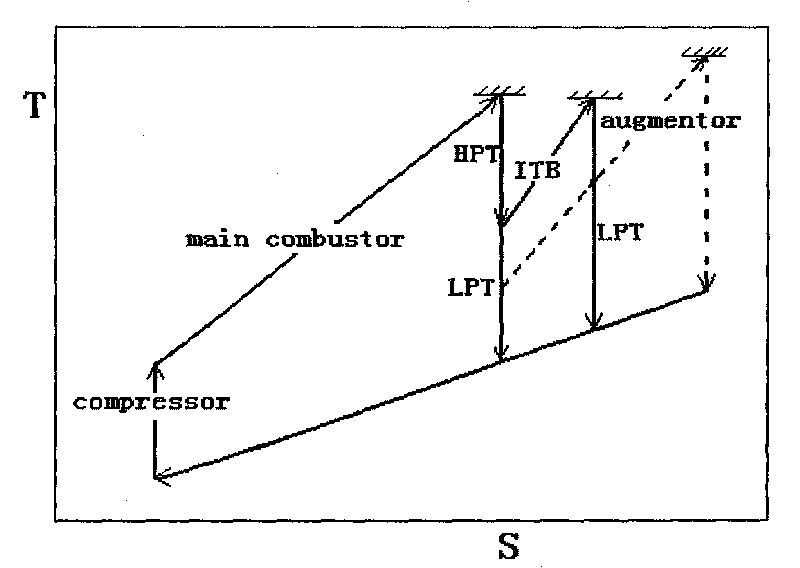

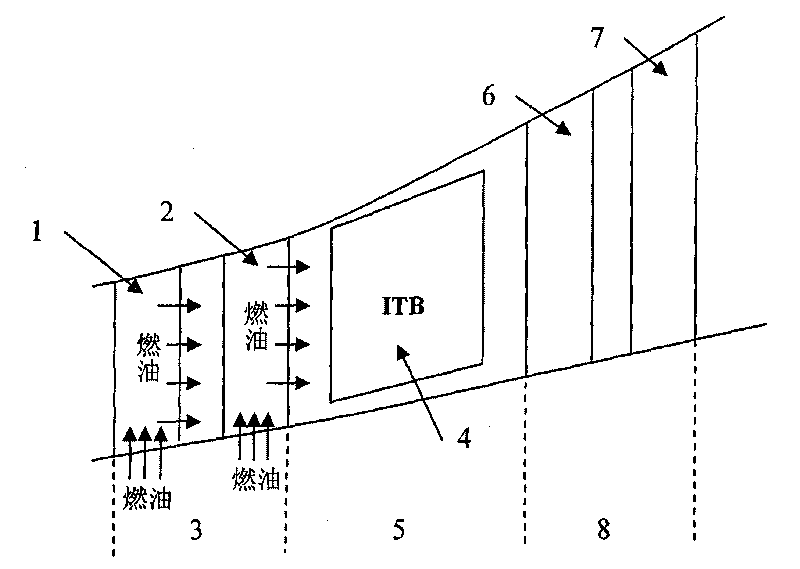

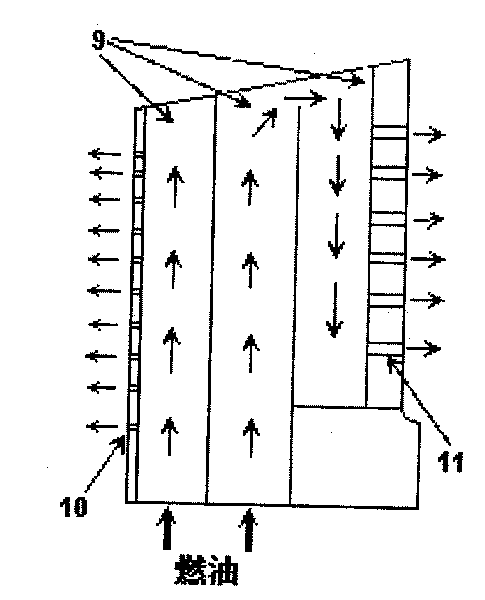

Coupling method for improving blade cooling efficiency and combustion efficiency of interstage/afterburner/channel combustion chambers

InactiveCN101709656AImprove cooling efficiencyShorten the lengthContinuous combustion chamberBlade accessoriesCombustion chamberCoupling

The invention provides a coupling method for improving blade cooling efficiency and combustion efficiency of combustion chambers. Blades are turbine blades or front support plate blades of afterburners, and combustion chambers are turbine interstage combustion sub-chambers, afterburners or channel inside combustion chambers. The blades are cooled through fuel, namely introducing the fuel into theblades; the fuel is subjected to convective heat exchange with the blades when flowing through cooling channels inside the blades; the fuel absorbs heat conducted by the blades; temperature is raised; and the fuel undergoes phase change, turns into a gas state, namely oil vapor, and flows out from gas film holes or splitting seams on the surfaces of the blades; or supercritical fuel is formed, sprayed out from the gas film holes or the splitting seams of the blades and rapidly atomized. The oil vapor or the atomized fuel is mixed with high-temperature gas in the channels after entering the blade channels to form mixture gas, and the mixture gas is introduced into the combustion chamber and ignited for combustion. The method can improve not only the cooling efficiency of the blades but also the combustion efficiency of the combustion chambers.

Owner:BEIHANG UNIV

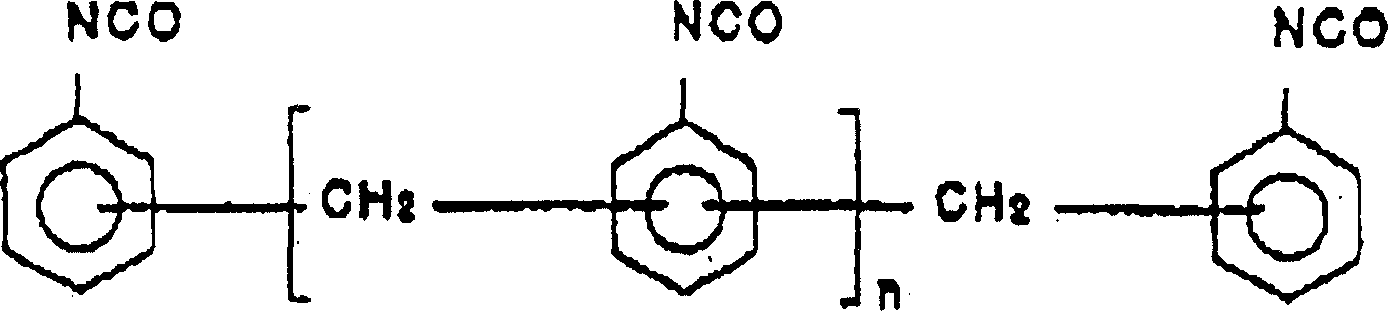

Granular drug pulverizing and mixing device for pharmacy

InactiveCN109261250AImprove crushing efficiencyEasy to mixRotary stirring mixersTransportation and packagingDrugDrive motor

The invention discloses a granular drug pulverizing and mixing device for pharmacy. The granular drug pulverizing and mixing device comprises a cabinet, a driving mechanism and a pulverizing mechanism; the pulverizing mechanism comprises a pulverizing plate, a straight rack, a semicircular-tooth gear, a screen plate and a return spring; second teeth are arranged on the lower end face of the straight rack, and first teeth meshed with the second teeth are arranged on the semicircular-tooth gear; the pulverizing plate is fixedly connected to one end, located in the cabinet, of the straight rack,and is provided with pulverizing teeth; a sliding plate connected to the bottom end of the pulverizing plate is abutted against the side wall of a steel grinding ball; two ends of the return spring are respectively connected with the pulverizing plate and the inner wall of the cabinet; the driving mechanism comprises a driving motor, a driving gear and a driven gear, an output shaft of the drivingmotor is connected with the driven gear, and the driving gear is meshed with the driven gear. The granular drug pulverizing and mixing device for the pharmacy has the advantages of simple structure,high pulverization and mixing efficiency, simplicity and convenience in operation, strong linkage, less proneness to blockage of sieve holes, sufficiency and uniformity in mixing, and high practicability.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

Aqueous polyurethane cement composition

The present invention relates to a water-based polyurethane mortar composition, which can prevent warpage and cracks caused by the shrinkage of the coating film without greatly reducing curing shrinkage, maintain heat resistance or physical properties, and do not damage the coating In terms of workability and surface appearance, even a film layer with a coating film thickness of 1 to 4 mm can obtain a water-based polyurethane mortar composition that does not warp or surface cracks despite curing shrinkage. The present inventors found that in the water-based polyurethane mortar composition formed by blending polyester polyol, isocyanate and the aggregate containing hydraulic mortar, when the compressive strength is 30N / mm2 or more than 30N / mm2, and the shrinkage stress is 3.0~ When it is 10.0N / mm2, the material strength or surface strength is improved, and the surface of the coating film is not easily damaged. In addition, there is no warping phenomenon or induction of cracks on the surface.

Owner:AICA KOGYO CO LTD

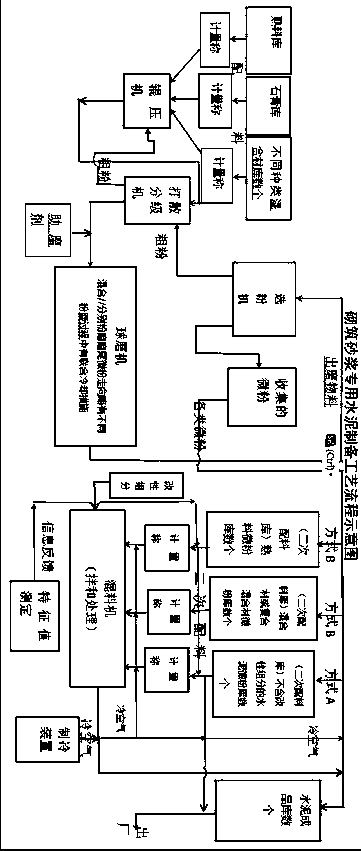

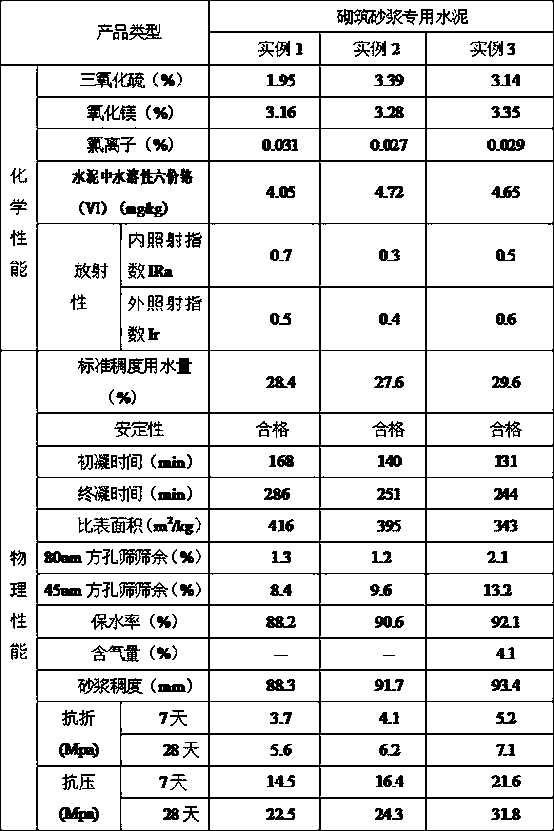

Special cement for masonry mortar and preparation method thereof

ActiveCN109851259APromoting energy saving, consumption reduction, emission reduction and waste utilizationSimple preparation processCement productionSlagCement mortar

A special cement for masonry mortar comprises the following raw materials in proportion: clinker, gypsum, limestone, grinding aid and modifying component, and also comprises one or more of active or inactive mixtures including granulated blast furnace slag, granulated blast furnace slag powder, pozzolanic mixture and fly ash and other waste slag is allowed to replace the active mixture. The invention also discloses a preparation method of a special cement for masonry mortar, and a secondary batching mixing and homogenizing system is adopted in the design. The method has a wide source of raw materials and relates to the field of cement mortar. The homogeneity of cementitious material system in mortar is improved and the properties and construction efficiency of mortar are improved without adding admixtures and additives when the special cement for masonry mortar is used to prepare masonry mortar.

Owner:王紫娴 +1

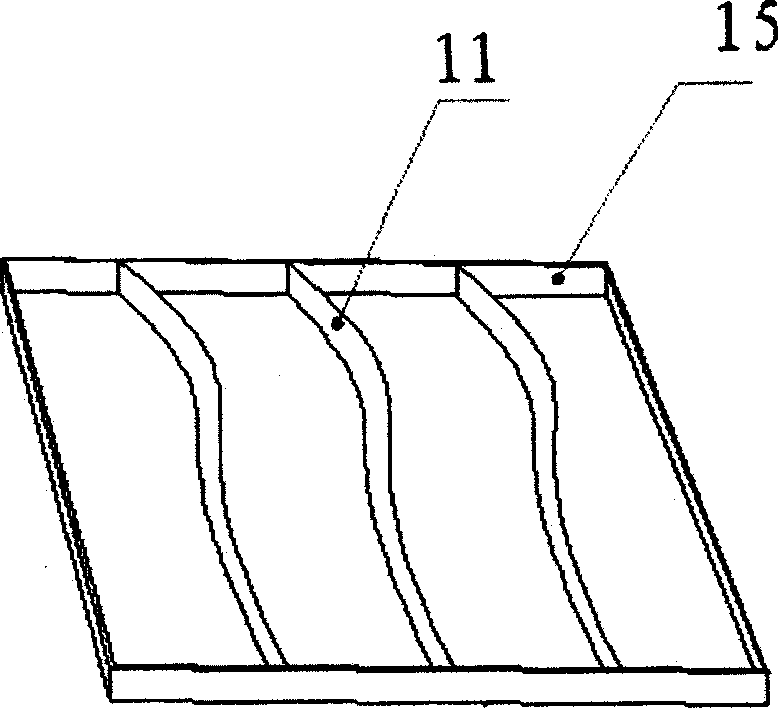

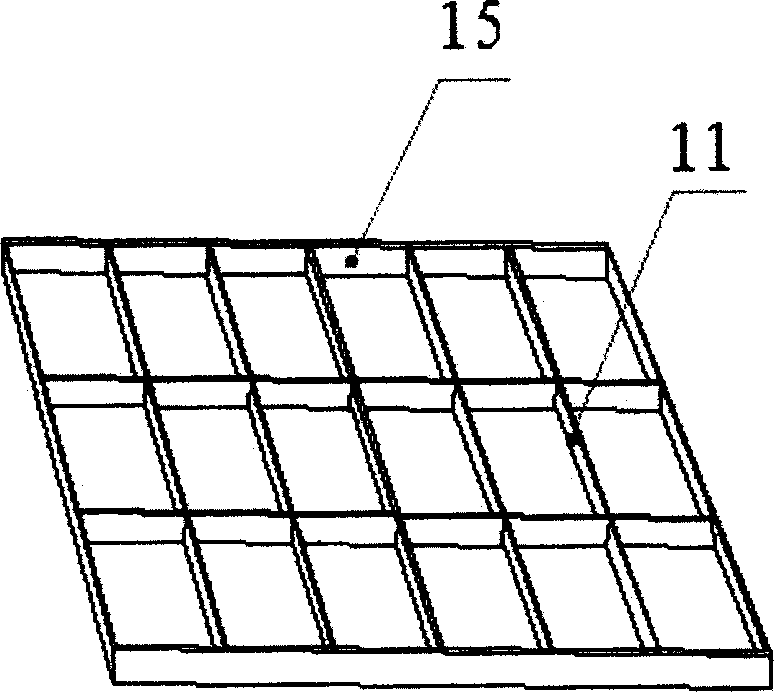

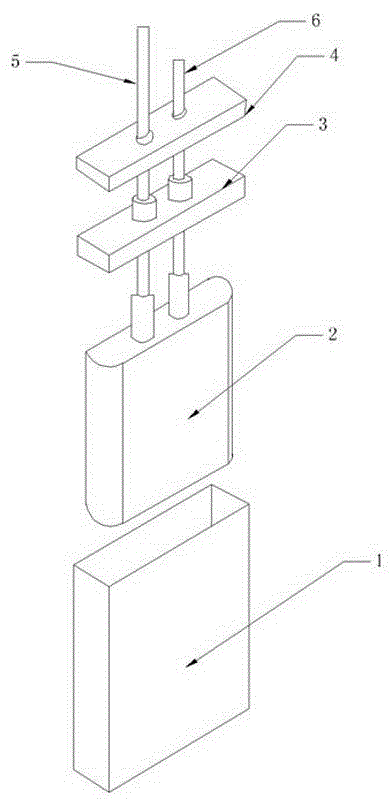

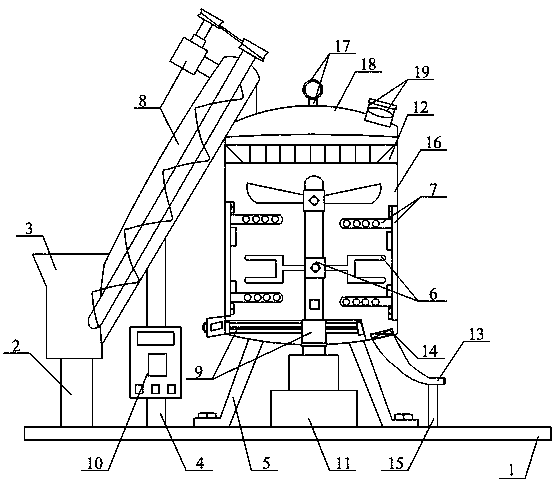

Belljar type grid distribution device for ceramic forming press and its distribution method using the distribution device

InactiveCN1864964AEasy to mixGood decorative effectFeeding arrangmentsShaping conveyorsRelative distributionFixed frame

The invention discloses a bell-jar grid distributor of new ceramic shaping compressor and relative distribution method. Wherein, it uses the bell-jar grid with the cover plate made from flexible material, to be pressed down on the powder surface of transfer band, powder support plate or the flexible band; the wedge fixing frame of grid is inserted into powder to surround the powder; the flexible layer under the grid cover plate deforms to eliminate the space between the grid chamber and the powder, to fix the powder inside the grid; the transfer band, powder support plate, and flexible band are the smooth material with lower friction factor; when the grid moves relative to the powder support plate, transfer band or flexible band, the powder inside the grid will not be mixed and turned over, with better decorate effect. The inventive device has simple structure, high reliability and high versatility.

Owner:钟家欣 +1

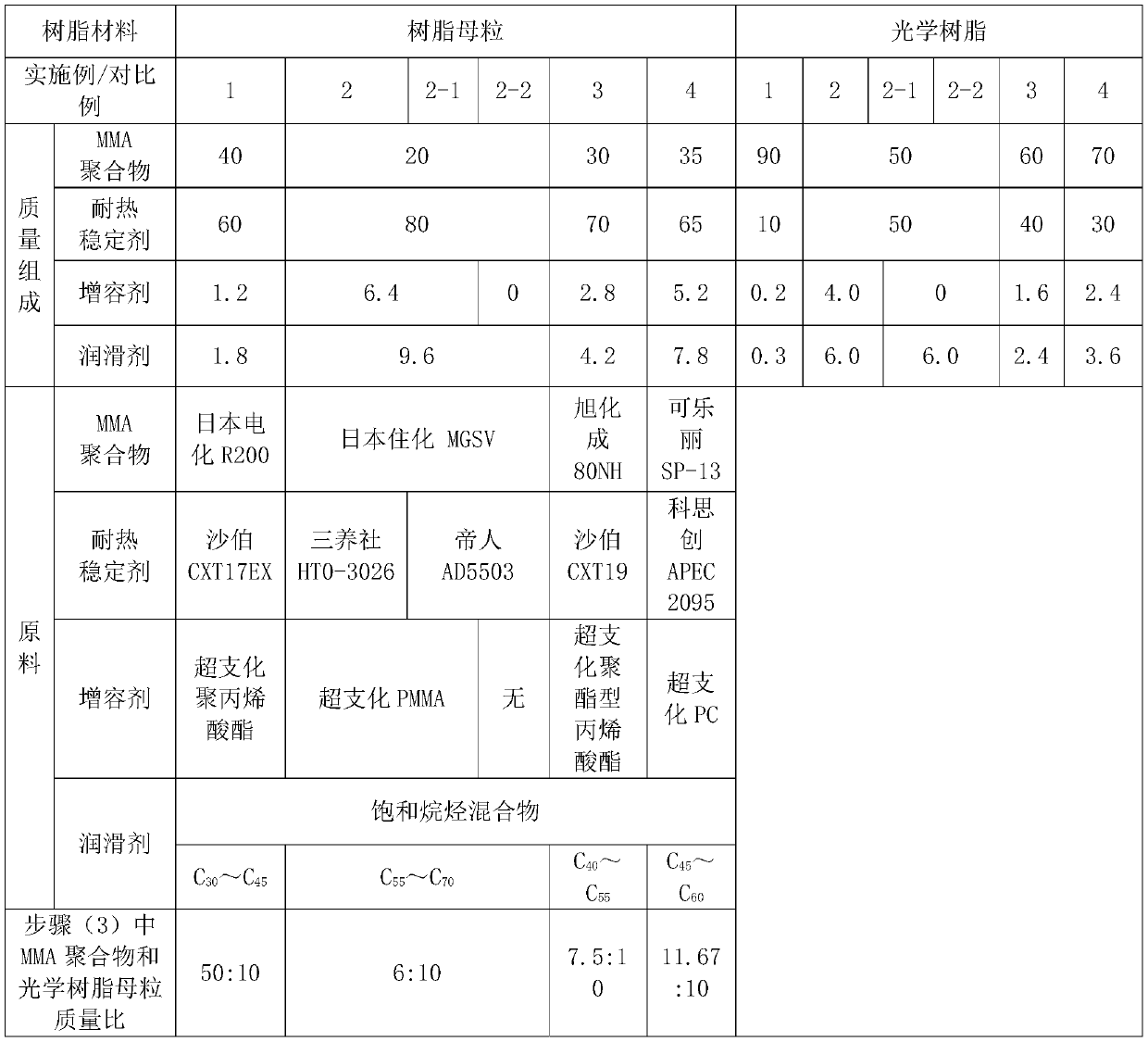

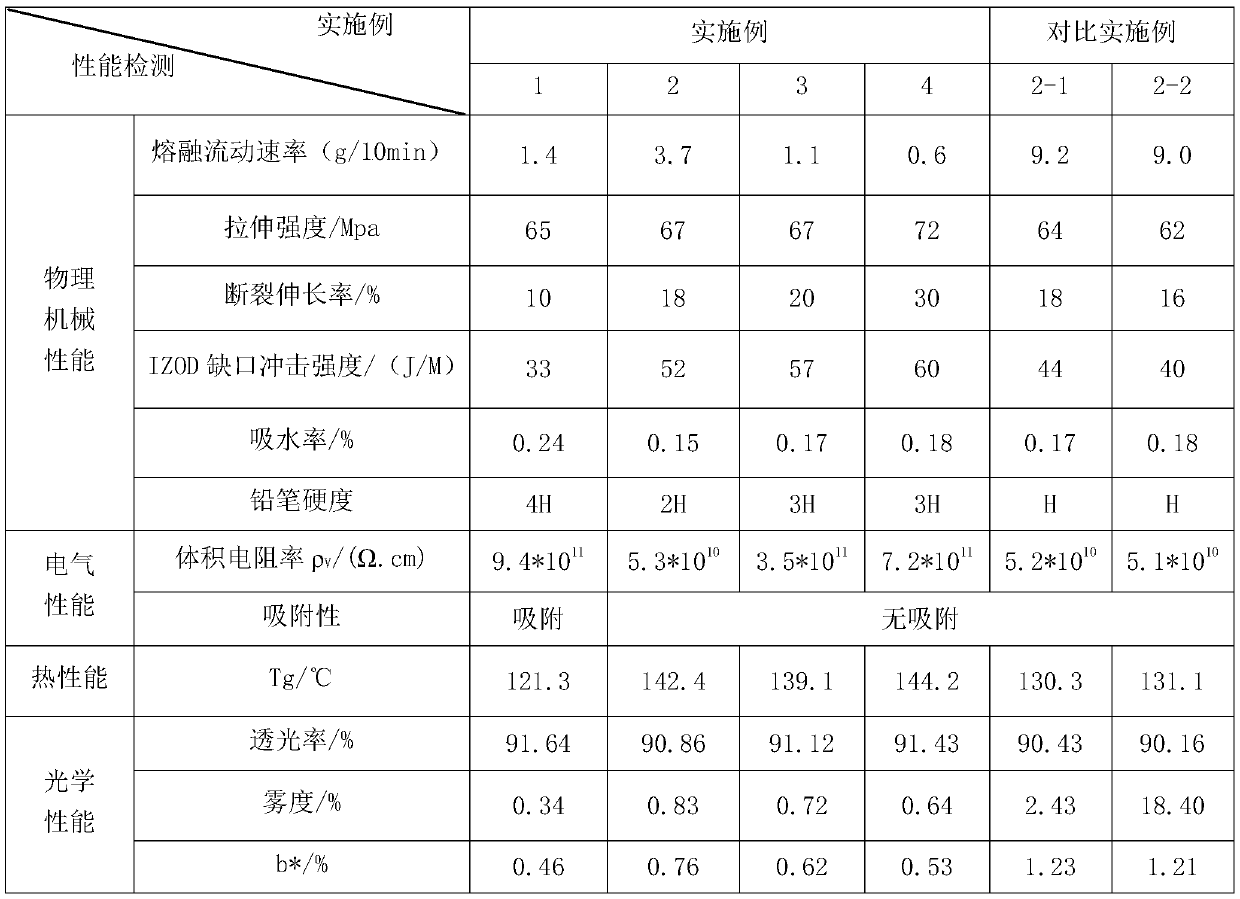

Optical resin for optical protective film and preparation method thereof

ActiveCN111423683AImprove thermal stabilityPlasticized wellOptical elementsPolymer scienceOptical property

The invention relates to an optical resin for an optical protective film and a preparation method thereof. The optical resin for the optical protective film is prepared from the following components in parts by mass: 50-90 parts of a methyl methacrylate polymer, 10-50 parts of a heat-resistant stabilizer, 0.2-4.0 parts of a compatibilizer and 0.3-6.0 parts of a lubricant. The heat-resistant stabilizer is copolycarbonate micro powder. The preparation method of the optical resin for the optical protective film comprises the steps of preparation of the heat-resistant stabilizer, preparation of anoptical resin master batch, preparation of the optical resin and the like. The method is simple in process, low in energy consumption and easy to realize industrialization. Compared with PMMA opticalresin produced in the prior art, the prepared optical resin for the optical protective film has outstanding heat-resistant stability and toughness, relatively low hygroscopicity and volume resistivity and less surface static electricity and is not easy to adsorb dust on the premise of ensuring basic physical and mechanical properties and optical properties.

Owner:聚纶材料科技(深圳)有限公司 +1

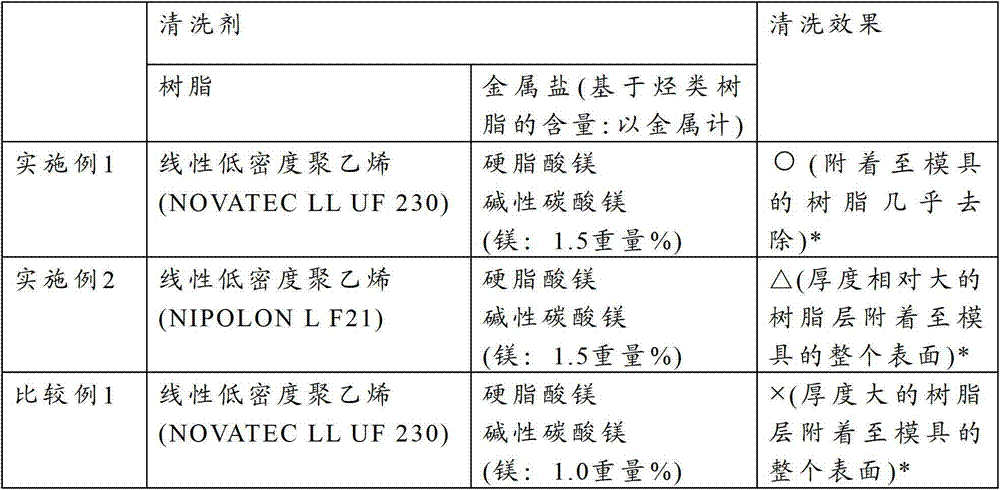

Purging agent and purging method using same

ActiveCN102971130AEasy to mixGood effectInorganic non-surface-active detergent compositionsMolding machineCleansing Agents

Disclosed is a purging agent which is capable of achieving excellent cleaning effect even in a severe environment such as in a die portion of a melt molding machine, where the channel is narrow and the temperature is high. Specifically disclosed is a purging agent which contains a hydrocarbon resin and at least one kind of a salt of a group 1 or group 2 metal of the short form periodic table. The content of the metal salt relative to the hydrocarbon resin is more than 1% by weight in terms of the metal.

Owner:MITSUBISHI CHEM CORP

Square aluminum electrolytic capacitor based on gel electrolyte and preparation method thereof

InactiveCN106409513AEvenly dispersedLow viscosityCapacitor electrolytes/absorbentsCapacitor housing/encapsulationEngineeringAluminum electrolytic capacitor

The invention discloses a square aluminum electrolytic capacitor based on a gel electrolyte. The square aluminum electrolytic capacitor comprises a square aluminum shell, a flat and oval-shaped winding type core bag, a rubber plug and a cover plate, and the core bag is sealed in the square aluminum shell by the rubber plug and the cover plate; aluminum stalks of a positive wire and a negative wire of the core bag are hermetically connected with the rubber plug through UV gum or epoxy thermo-curing gum; the gelatinous electrolyte is formed in the core bag and between the core bag and the square aluminum shell; the gelatinous electrolyte is a gelatinous high-molecular compound obtained by polymerizing a solution system as shown in the description and a solution system as shown in the description under the initiation of an initiating agent. The square aluminum electrolytic capacitor disclosed by the invention is small in thickness (width) and great in length, the height can be the same with that of a cylindrical structure aluminum electrolytic capacitor, and the demand of placing an aluminum electrolytic capacitor in a flat space is satisfied while guaranteeing the volume capacity density requirement of the aluminum electrolytic capacitor.

Owner:HUNAN AIHUA GRP

Method for preparing lithium iron phosphate material by raw material solid phase dry grinding

InactiveCN102856546AUniform particle sizeEasy to mixCell electrodesPhosphorus compoundsSolventSolid phases

The invention relates to a raw material solid phase dry grinding technology, in particular to a method for preparing a lithium iron phosphate material by raw material solid phase dry grinding, and belongs to the field of preparation of a lithium battery material. According to the method, a novel high temperature solid phase dry closed-loop grinding system combining an ultrafine grinding technology with an air classification technology is adopted; raw materials of a lithium iron phosphate cathode material are subjected to nano-scale grinding and mixingl and the raw materials are sintered to obtain the nano-scale lithium iron phosphate cathode material. The invention aims to solve the problems of irregular morphology of a precursor, wide particle size distribution and nonuniform physical and chemical composition of a product, which are caused by large particle size, wide distribution and nonuniform mixing of the raw materials. The invention overcomes the defects of pollution of ammonia and an organic solvent to the environment and energy consumption, which is caused by the wet grinding material drying, in the conventional high temperature solid phase production. Moreover, in the production process, only harmless gases such as CO2, water and the like are discharged; and a lithium iron phosphate green environmental-friendly production process is really implemented.

Owner:JIANGSU FREY NEW ENERGY

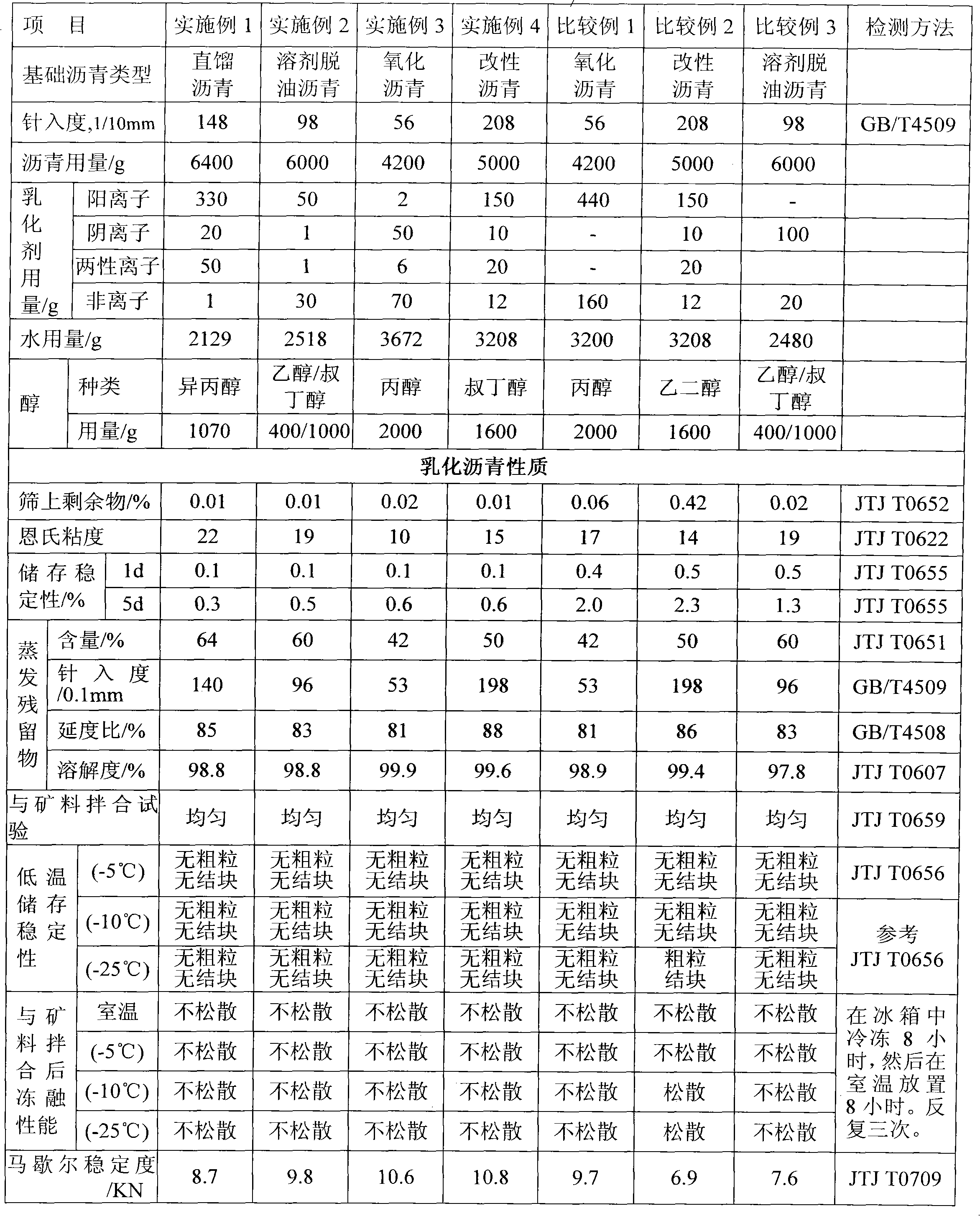

Frost resistant emulsified bitumen prepared from composite emulsifier, and preparation method thereof

ActiveCN102234435AReduce the amount requiredGood emulsifying effectWorking-up pitch/asphalt/bitumenBuilding insulationsFreeze thawingPropanol

The invention discloses frost resistant emulsified bitumen which is prepared from a composite emulsifier, and a preparation method thereof. The emulsified bitumen comprises bitumen, a cationic emulsifier, an anionic emulsifier, an amphoteric emulsifier, a nonionic emulsifier, an alcohol and water. The alcohol comprises one or more selected from ethanol, propanol, isopropanol and tert butyl alcohol. With the present invention, a combination of the composite emulsifier and the low molecular weight fatty alcohol is adopted for the emulsified bitumen while diluents such as diesel oil or kerosene and the like are not added, such that time of water evaporation is shortened, a hardening rate of mixture is increased, frost resistance is improved (the emulsified bitumen cannot be frozen at a temperature of -5 to -25 DEG C), original excellent properties such as bonding performance of the bitumen and the like are maintained, and shrinkage and cracking of the mixture due to a low temperature in winner or surface loosening of the mixture due to freeze thawing is avoided. The frost resistant emulsified frost resistant can be used for road curing and road maintenance.

Owner:CHINA PETROLEUM & CHEM CORP +1

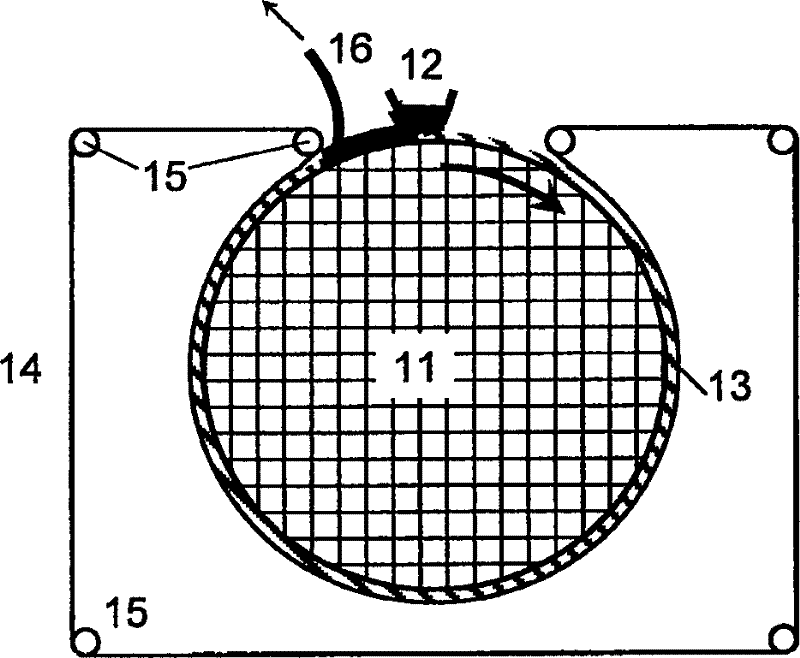

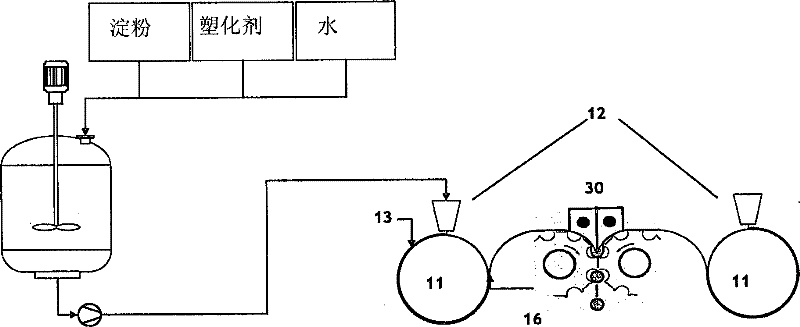

Starch-based soft capsule, and method and apparatus for the production thereof

ActiveCN102365159AImprove mechanical propertiesEasy to mixCapsule deliveryGranular starchThermal treatment

A method for producing soft capsules made of starch includes the following steps: producing a mixture containing starch, softener, and water, more than 50 percent by weight of the starch being provided in the form of granular starch particles; shaping the mixture into a film in a shaping process; solidifying the mixture by increasing the temperature of the mixture by more than 5 DEG C during and / or following the shaping process; and shaping the film into a soft capsule. Soft capsules produced according to said method have interlinked starch particles. An apparatus for carrying out said method comprises a shaping device to allow the starch material to be shaped into a film, and a heating device for performing a thermal treatment in order to destructure the starch during and / or following the shaping process. The apparatus further comprises a rotary die device.

Owner:INNOGEL AG

Intelligent high-speed hybrid equipment for multi-functional new material processing

InactiveCN108355525AConvenient control of the progress of the mixing operationEasy to stir and mixRotary stirring mixersTransportation and packagingIntelligent lightingSolenoid valve

The invention provides intelligent high-speed hybrid equipment for multi-functional new material processing. The intelligent high-speed mixing equipment comprises a fixed base, a supporting column, afeeding hopper, a supporting rod, a supporting frame, a speed measuring hybrid stirring rod structure, a temperature measuring flow guide plate structure, a convenient feeding device, a heating bin structure, an intelligent control cabinet structure, a motor base, a filter screen plate, a discharging pipe, a solenoid valve, a telescopic pole, a hybrid kettle, a hoisting ring, a protective kettle lid and an observation mirror tube. The intelligent high-speed mixing equipment provided by the invention has the benefits that through the arrangement of a speed sensor, the rotating speed of a hybridstirring motor is favorably calculated, so that a basis is provided for the mixing speed of a new material, and the mixed operation process is conveniently controlled; through the arrangement of thestirring rod and stirring blades, the new raw material in the hybrid kettle is favorably mixed and stirred; through the arrangement of a rotating auger, the raw material in the feed hopper is favorably conveyed to the mixed kettle, so that the manual feeding time is saved, the functions of the hybrid equipment are increased, and the labor efficiency is improved.

Owner:无棣县棣棠花服装加工厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com