Coupling method for improving blade cooling efficiency and combustion efficiency of interstage/afterburner/channel combustion chambers

A blade cooling and combustion efficiency technology, applied in the combustion method, combustion chamber, continuous combustion chamber, etc., can solve the problems of large exhaust noise and pollution emissions, increased engine fuel consumption, increased exhaust speed, etc. Emission of pollution, improved cooling efficiency, and improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

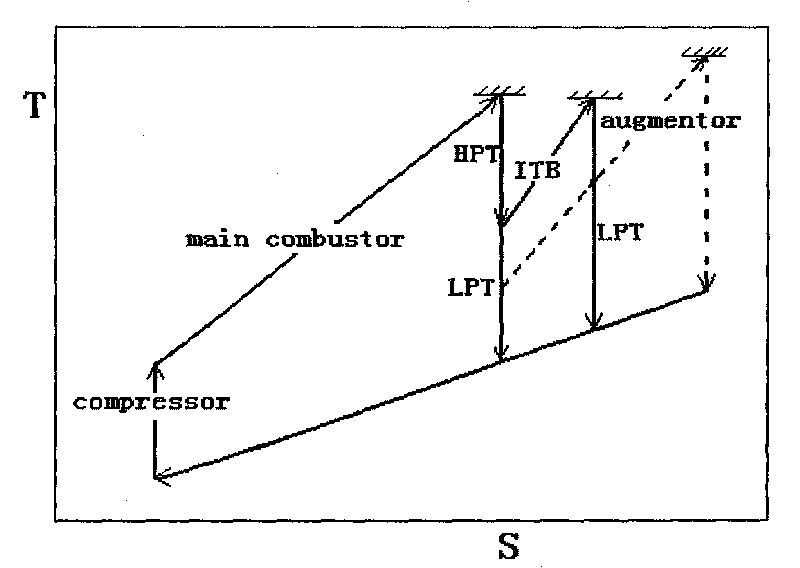

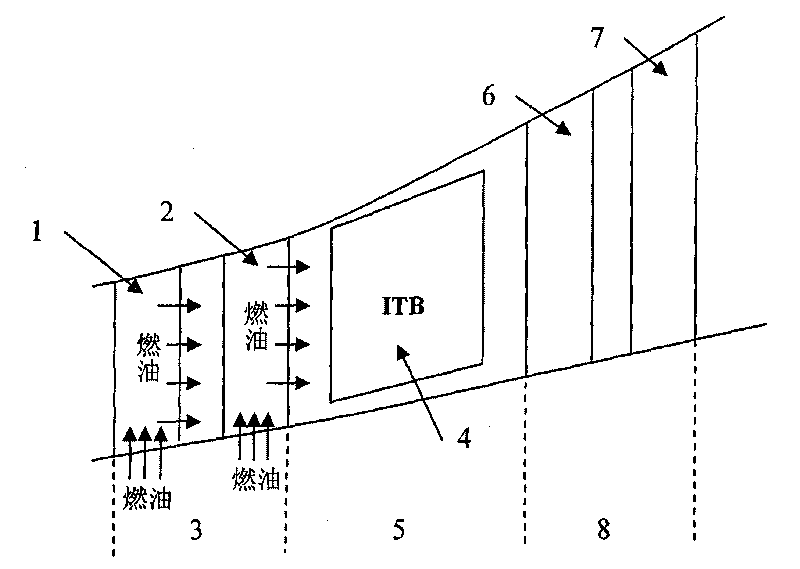

[0029] Embodiment 1: The implementation process for improving the cooling efficiency of the blades of the high-pressure turbine 3 and the combustion efficiency of the turbine interstage combustion chamber (ITB) 4 .

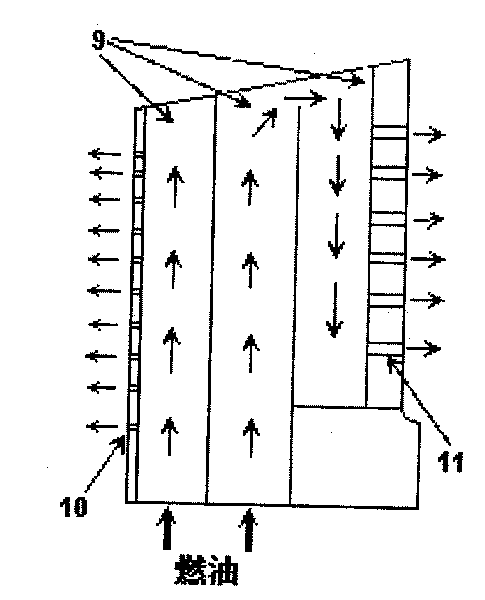

[0030] Such as figure 2 As shown, the high-pressure turbine 3 includes a high-pressure turbine vane 1 and a high-pressure turbine bucket 2 , and the low-pressure turbine 8 includes a low-pressure turbine vane 6 and a low-pressure turbine bucket 7 . Between the high-pressure turbine 3 and the low-pressure turbine 8 is a transition section 5 , in which the turbine interstage secondary combustion chamber (ITB) 4 is located. Figure 3a and Figure 3b It is a schematic diagram of the cooling structure in the blade, since it is a schematic diagram, so Figure 3a and Figure 3b The blades shown may be turbine blades (high-pressure turbine vane 1 or high-pressure turbine blade 2 ), or other blades such as strut blades 12 . The implementation process of the present in...

Embodiment 2

[0038] Embodiment 2: The implementation process for improving the cooling efficiency of the afterburner front strut blade 12 and the combustion efficiency of the afterburner 13 .

[0039] Such as Figure 4 The strut vanes 12 are located in front of the afterburner 13 as shown. Since the cooling structure of the strut blade 12 is similar to that of the turbine blade in Embodiment 1, it is also used here Figure 3a and Figure 3b A schematic diagram of the cooling structure of the strut blade. The implementation process of the present invention is: introduce a certain amount of pressurized fuel oil from the engine fuel system, and then pass the fuel oil into the blade 12 of the support plate. Such as Figure 3a As shown, the fuel oil flows into the cooling channel 9 after being introduced into the blade. When the fuel oil flows through the cooling channel 9, it conducts convective heat exchange with the blades, and cools the blades along the way. As the fuel absorbs the he...

Embodiment 3

[0047] Embodiment 3: The implementation process for improving the cooling efficiency of the high-pressure turbine guide vane 1 and the combustion efficiency of the channel combustor 14 .

[0048] Such as Figure 5 As shown, the channel combustor 14 is located in the channel of the high-pressure turbine vane 1 . The implementation process of the present invention is: introduce a certain amount of pressurized fuel oil from the engine fuel system, and then pass the fuel oil into the high-pressure turbine guide vane 1 blade. Such as Figure 3a As shown, the fuel oil flows into the cooling channel 9 after being introduced into the blade. When the fuel oil flows through the cooling channel 9, it conducts convective heat exchange with the blades, and cools the blades along the way. As the fuel absorbs the heat conducted by the blades, the temperature will rise. The fuel oil can be phase-changed into oil vapor in the internal cooling channel 9 of the blade, and flow out from the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com