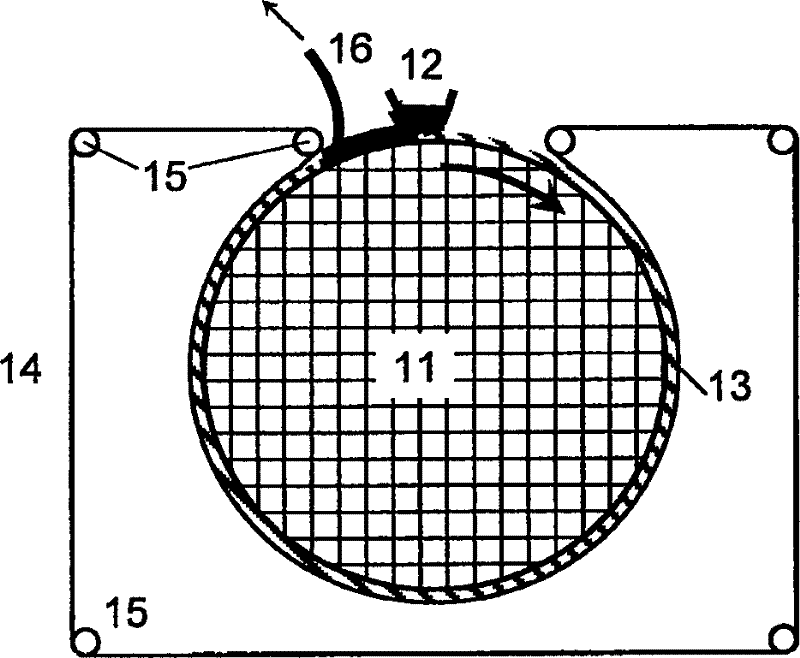

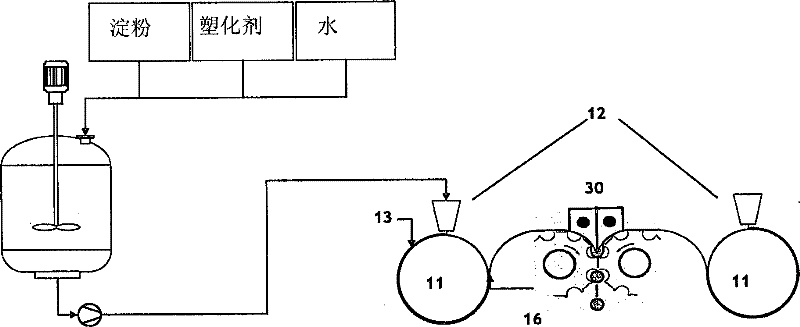

Starch-based soft capsule, and method and apparatus for the production thereof

A soft capsule and starch technology, which is applied in capsule delivery, pharmaceutical formulation, drug delivery, etc. It can solve the problems of complex soft capsule manufacturing, poor capsule performance, and difficulty in welding starch films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0186] According to recipe 1, water and plasticizer are first added at room temperature to a heatable and easily evacuable container equipped with a stirrer, and the two components are then mixed at 100 rpm. Next, starch S1E was added which was extruded at a water content of 35% under very mild conditions and dissolved in a mixture of water and plasticizer at 100 rpm for 5 min. Extruded starch S1E is prepared from dry extrudates (based on starch S1) by means of an impact mill, and the particle size distribution of the extruded starch S1E is in the range of 30-150 μmm, and the extruded The short-chain amylose content of starch S1E is 10% (this short-chain amylose is obtained by complete debranching of tapioca starch by means of pullulanase, and the number-average degree of polymerization of this short-chain amylose DPn is 25).

[0187] To this mixture is then added granular starch S1 with a weight average molecular weight M w 30,100,000 g / mol, and the granular starch S1 was d...

example 2

[0199] Similar to Example 1, but the water content of the molding compound was 35% instead of 38% water. The temperature of the drum was set at 108°C. The mass temperature of the film on the drum was 93°C after 3 / 4 rotation.

example 3

[0201] Similar to Example 1, but the water content of the molding compound was 41.1% instead of 38% water. The temperature of the drum was set at 103°C. The mass temperature of the film on the drum was 89°C after 3 / 4 rotation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Modulus of elasticity | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com