Ultrasonic atomizing fire extinguisher

An ultrasonic atomization and fire extinguisher technology, applied in fire rescue and other directions, can solve the problems of small fog flux, inability to use fire extinguishing, low droplet mass fraction, etc., and achieve the effect of avoiding dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

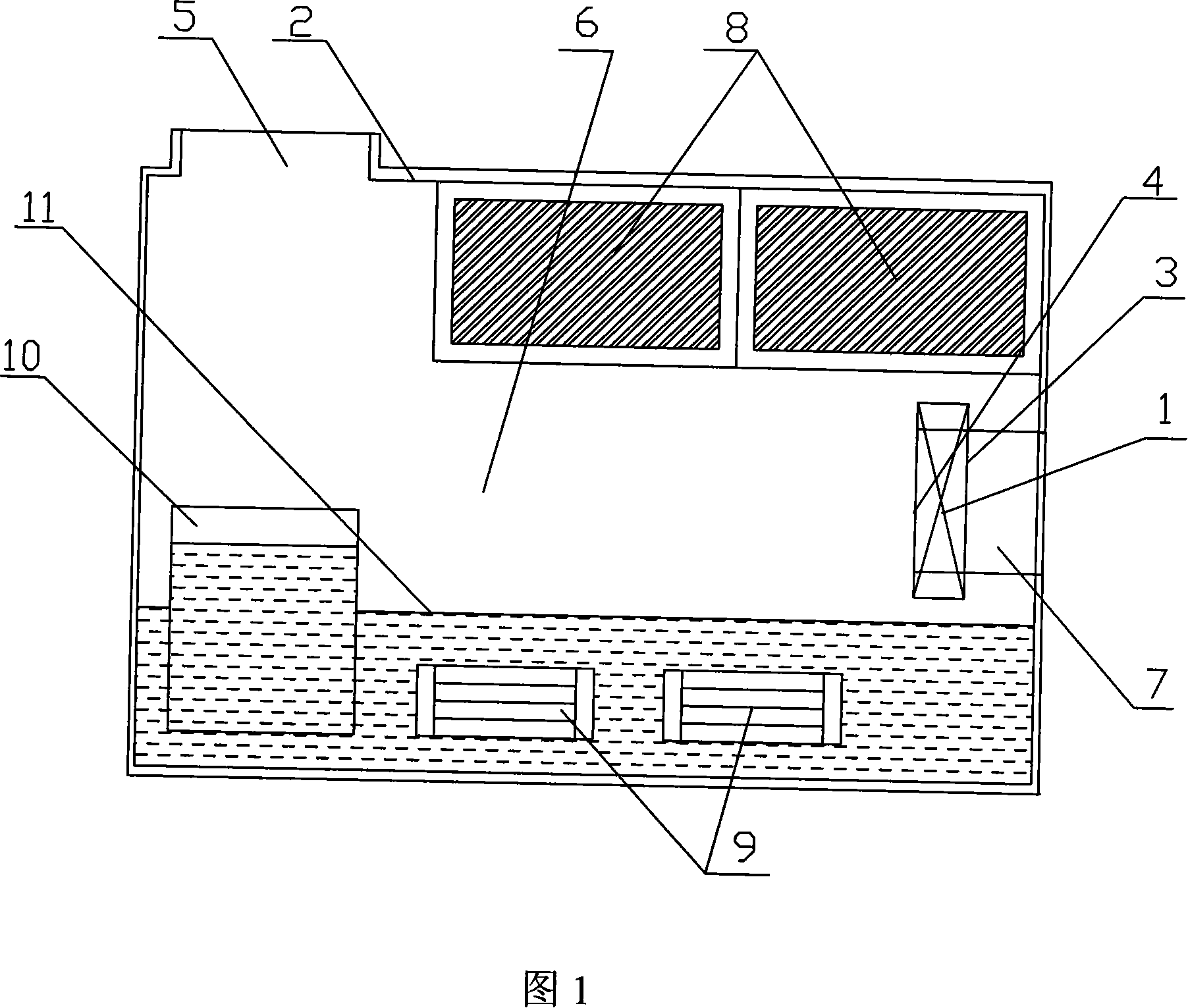

[0017] Referring to FIG. 1 , according to the conventional structure of the ultrasonic atomization device, the arrangement in the atomizer housing 2 includes a power supply unit 8 , a water level adjustment unit 10 and an ultrasonic atomization unit 9 .

[0018] In this embodiment, in order to increase the mist flux and increase the mass fraction of mist droplets per unit volume, a circulation fan 1 is arranged in the atomization chamber 6 to form a circulating air flow inside the atomization chamber, and the outlet of the gas-water two-phase flow is used as the atomizer The water mist outlet 5 of chamber 6.

[0019] In specific implementation, the circulation fan 1 together with the circulation fan air inlet 3 and the circulation fan outlet 4 are all located in the atomization chamber 6 , and the water mist outlet 5 deviates from the circulation fan air inlet 3 and the circulation fan outlet 4 .

[0020] A gas fire extinguishing agent inlet passage 7 can be provided, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com