Special micro-flow control chip and single sampling continuous separation electrophoresis method

A microfluidic chip and electrophoresis technology, applied in separation methods, filtration separation, semi-permeable membrane separation, etc., can solve problems such as buffer leakage, poor stability, and large fluctuation range of sample peak height, so as to avoid dilution and enhance repetition performance, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

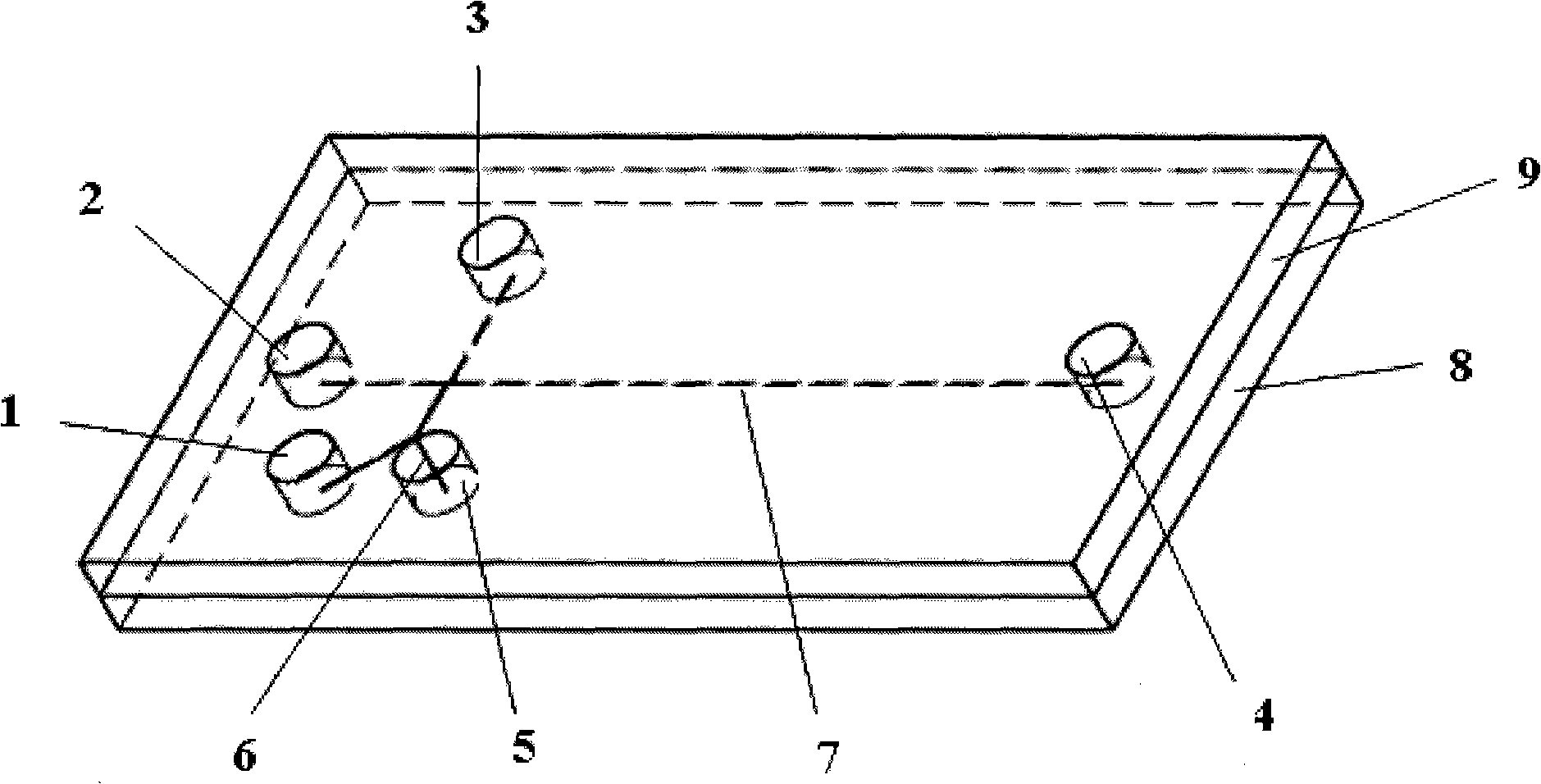

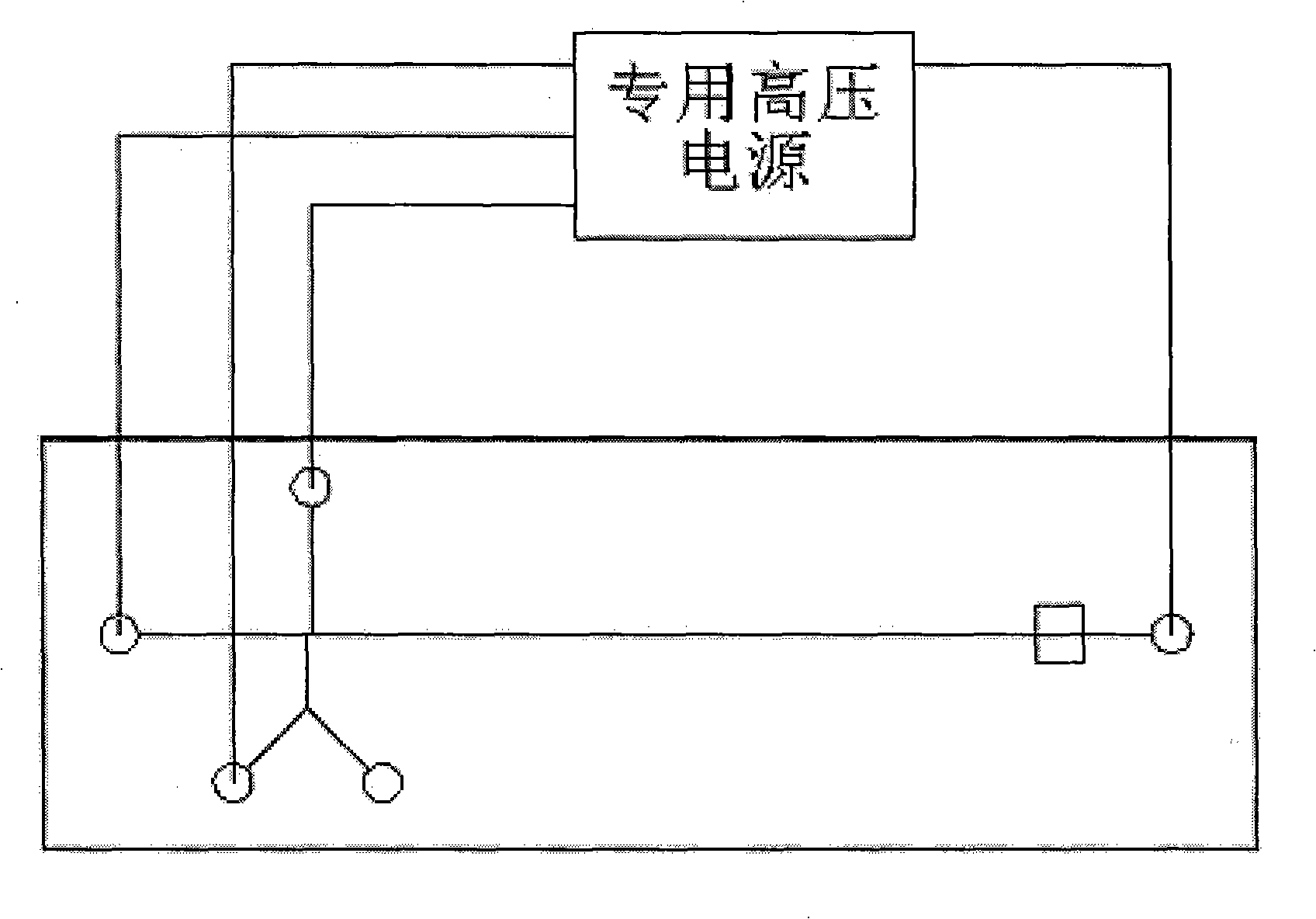

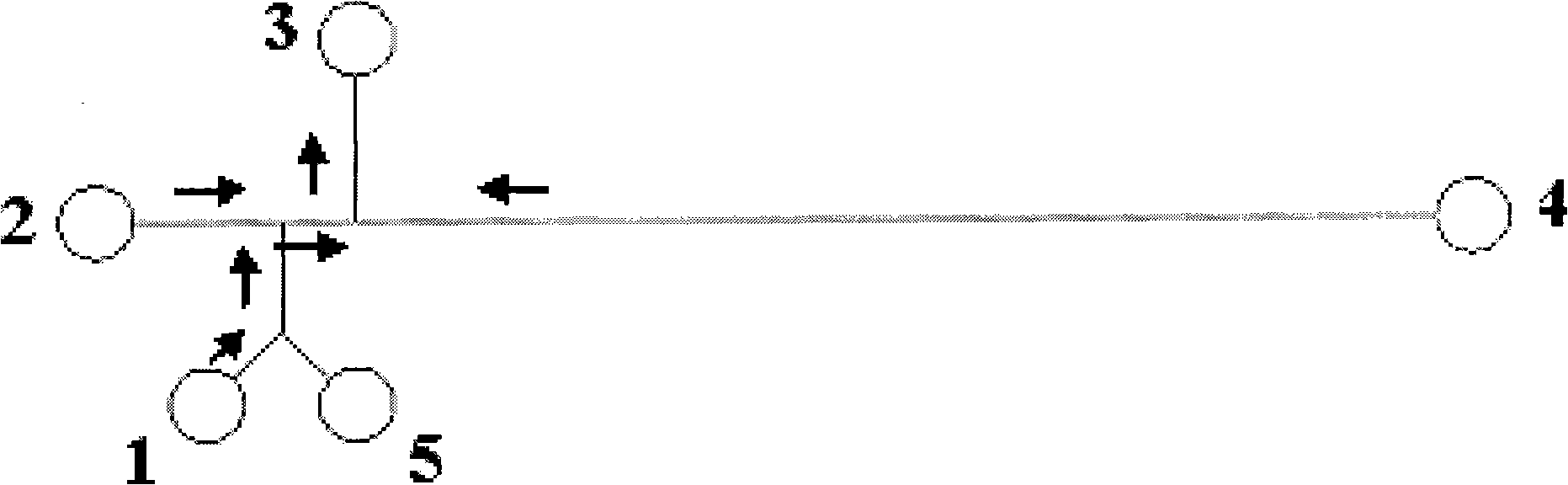

[0015] Such as figure 1 As shown, the special-purpose microfluidic chip is based on the traditional microfabrication method. The chip is composed of an upper cover 9 and a lower substrate 8. The upper cover 9 is distributed with a sample liquid pool 1 and a buffer solution with a diameter of 3 mm. Pond 2, sample waste liquid pool 3, buffer solution waste liquid pool 4, shunt liquid storage pool 5; a plurality of microchannels are distributed on the lower substrate 8, and its intersection area is double T-shaped or cross-shaped, and in the sampling groove A section of split channel 6 is added on the side wall of the channel and intersects with the original sample injection channel to form a bifurcated structure. This bifurcated structure can make the split channel 6 and the original sample injection channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com