Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

A technology for exterior walls and pigments, used in anti-corrosion coatings, fire-resistant coatings, epoxy resin coatings, etc., can solve problems such as damage to waterproof and thermal insulation systems, easy cracking, peeling, and low strength of the interface layer, and improve engineering reliability and life. , The effect of eliminating defects on clothing surface and low coefficient of linear expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

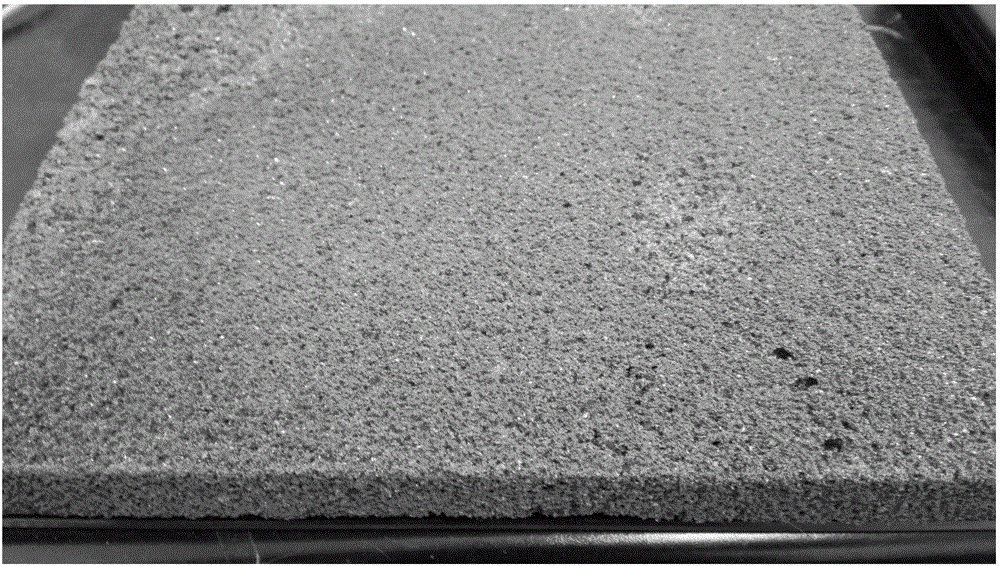

Image

Examples

preparation example Construction

[0056] The preparation method comprises the following steps:

[0057] (1) Micropowder compounding: Weigh the coarse and fine powders and fine powders separately, mix them by equal weight, put them into the mixer, and pour them into the container after fully mixing;

[0058] (2) Mixing modifier preparation: weigh flame retardant, antioxidant, anti-ultraviolet agent, leveling agent, surfactant, coupling agent and phase change heat storage particles in sequence, and put them into the batching pot according to the proportion, at a low speed Stir until completely homogeneous;

[0059] (3) Preparation of component A: Add matrix resin and diluent to the container containing the compounded micropowder, stir thoroughly on the mixer at low speed until completely mixed, then add pigments and mixed modifiers in sequence, and disperse evenly , and then add a thixotropic agent to adjust the viscosity to meet the construction requirements;

[0060] (4) Preparation of component B: weigh the...

Embodiment 1

[0064] Weigh the 100-mesh silicon micropowder and 2000-mesh silicon micropowder separately, mix them by equal weight, put them into the mixer, and pour them into the batching pot after fully mixing. 10 parts of blowing agent, 55 parts of aluminum hydroxide flame retardant, 10 parts of aromatic amine antioxidant, 15 parts of phenyl phthalate anti-ultraviolet agent, 1 part of isophorone leveling agent, 2 parts of polyacrylic acid Sodium surfactant, 2 parts of KH550 coupling agent and 10 parts of paraffin wax particles are weighed according to the proportion, poured into another batching pot, and stirred at a low speed until completely uniform. Add acrylic resin and toluene diluent to the container containing compound micropowder, stir thoroughly on the mixer at low speed until completely mixed, then add pigment titanium dioxide and mixed modifier in turn, and disperse evenly. The amount of each ingredient added is based on the ratio of 10 parts of matrix resin, 10 parts of dilue...

Embodiment 2

[0068] Weigh 500-mesh mica powder and 5000-mesh fly ash separately, mix them according to equal weight, put them into the mixer, and pour them into the batching pot after fully mixing. In turn, 30 parts of foaming agent, 40 parts of flame retardant mixed with equal weight of borax and boric acid, 8 parts of p-phenylenediamine antioxidant, 12 parts of dihydroxybenzophenone anti-ultraviolet agent, 2 parts of diacetone alcohol leveling agent , 1 part of sodium alkylsulfonate surfactant, 5 parts of KH560 coupling agent and 2 parts of paraffin wax particles, weighed according to the proportion, poured into another batching pot, and stirred at a low speed until completely uniform. Add epoxy resin to the container containing the compound micropowder, and stir fully on the mixer at a low speed until it is completely mixed, then add pigment titanium dioxide and mixed modifier in turn, and disperse evenly. The amount of each ingredient added is based on the ratio of 50 parts of matrix r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com