Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

959results about How to "Reduced corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

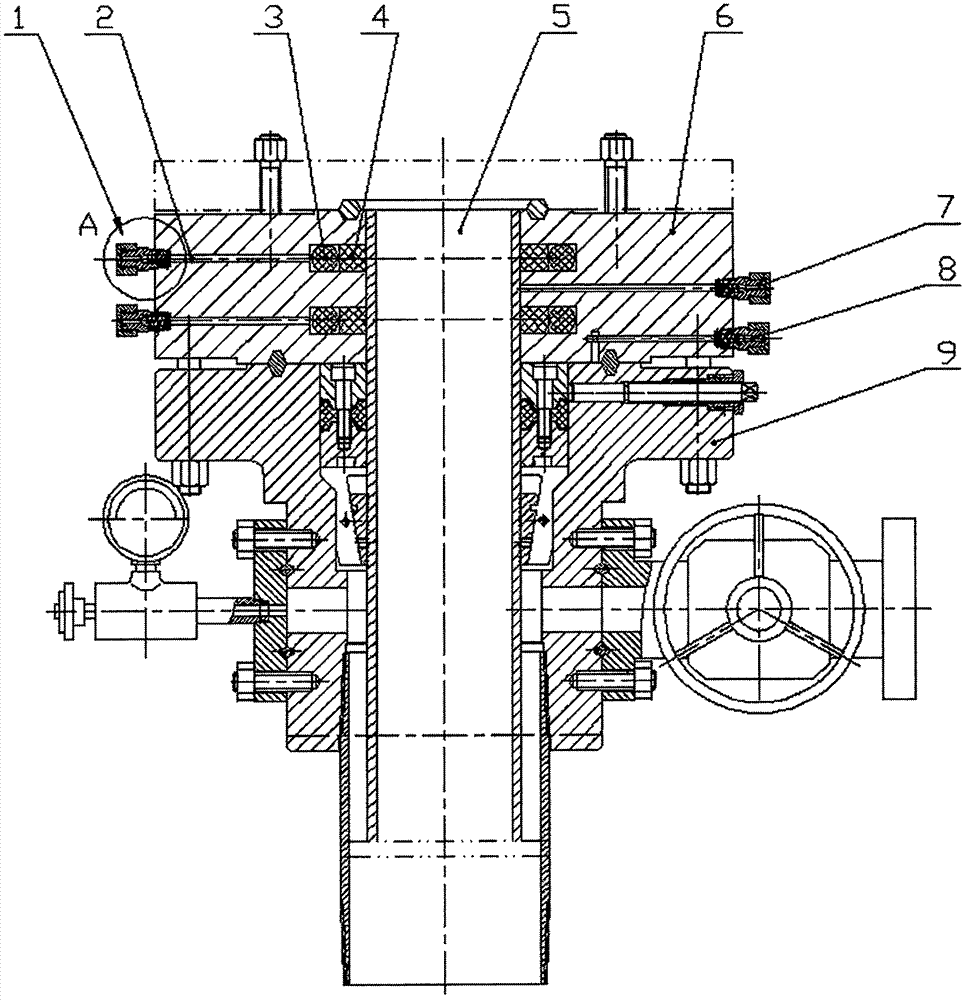

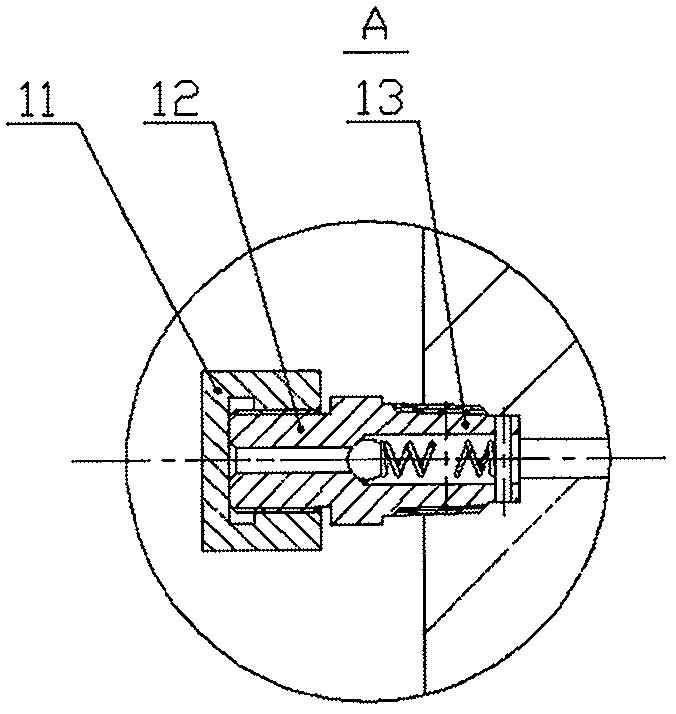

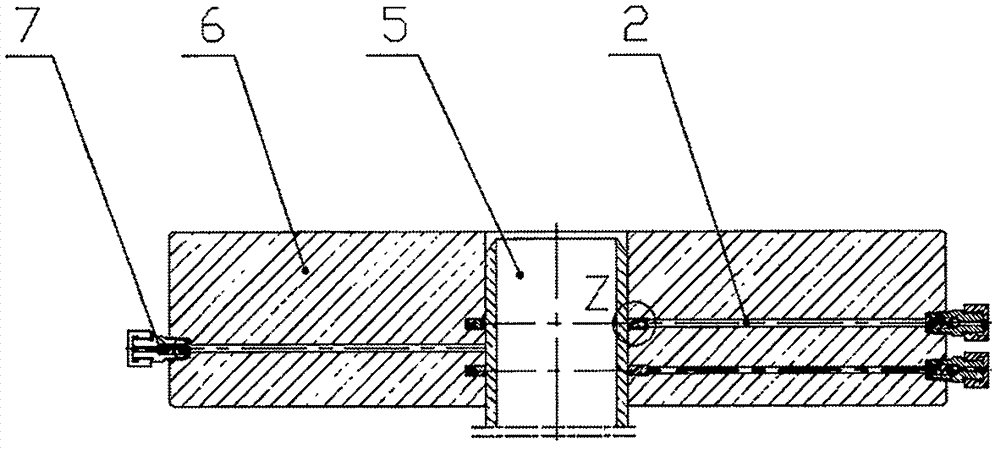

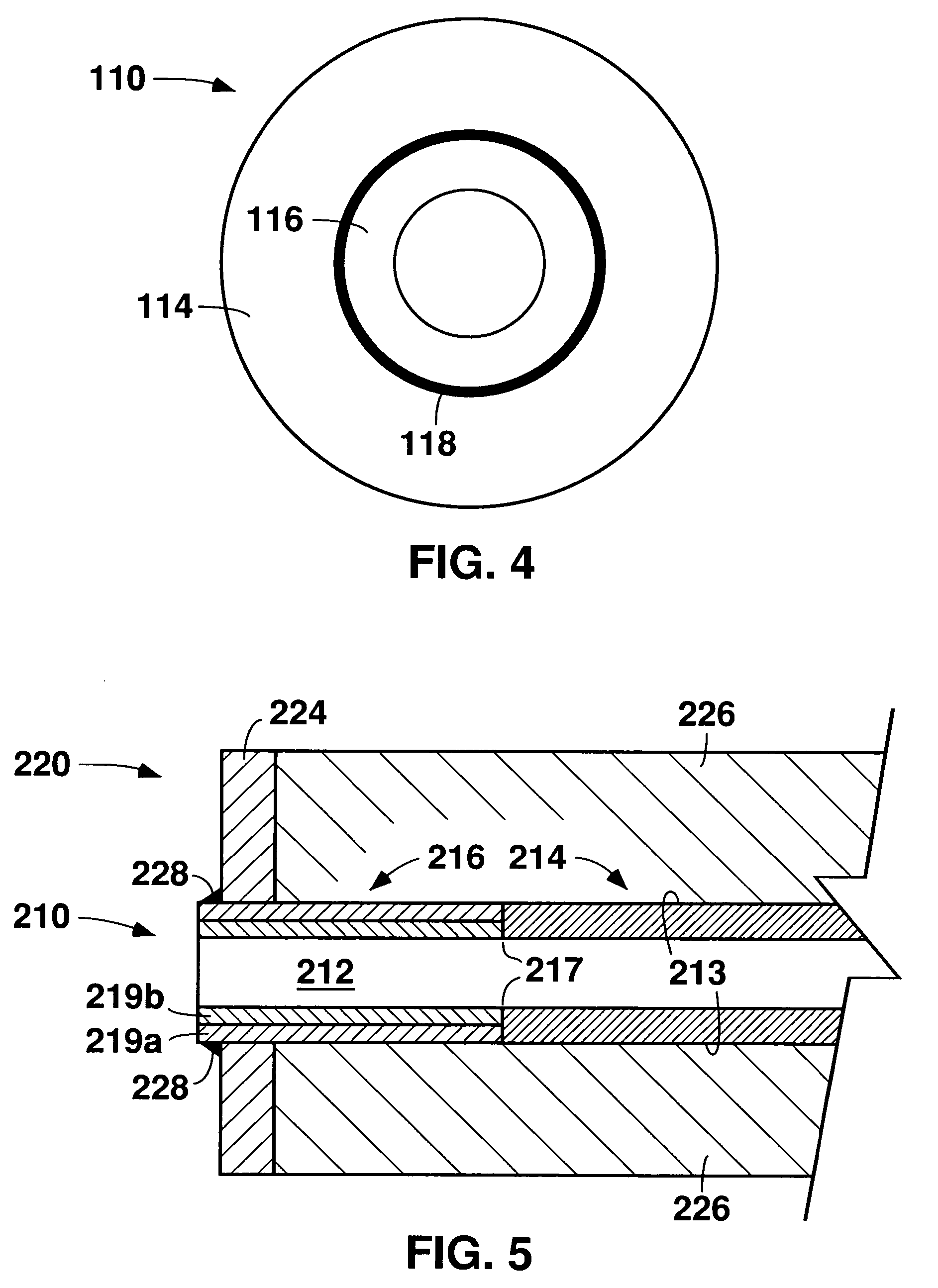

Petroleum wellhead annular space sealing device

PendingCN107143298AGood corrosion resistanceDirectionalSealing/packingWellheadMechanical engineering

The invention discloses a petroleum wellhead annular space sealing device. The petroleum wellhead annular sealing device is used for sealing an annular space between a wellhead sealing body and a petroleum pipe, at least one annular groove is formed in the inner wall surface of the sealing body, and the sealing body is provided with an injection hole which is communicated to a centrifugal end of the annular groove; the petroleum wellhead annular space sealing device further comprises a sealing ring, a power ring, and an injection component, wherein the sealing ring is embedded into the annular groove, the sealing ring is used for sealing the groove in the radial direction by being jointed to the wall surface of the annular groove, and is used for sealing the annular space by being jointed to the outer wall of the petroleum pipe, the power ring is installed in the annular groove and is located between the groove bottom of the annular groove and the sealing ring, and the injection component is installed in an inlet of the injection hole, and is used for injecting fluid with given pressure so as to make the power ring push the sealing ring to tightly press the petroleum pipe. In the petroleum wellhead annular space sealing device, the requirement for deformation capability of a sealing part is low, and meanwhile the sealing capability can be effectively improved.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Photoresist residue removing liquid composition

InactiveUS6864044B2Changing dielectric constantEfficient removalSemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsPhotoresistLiquid composition

The object of the present invention is to provide, in the production of semiconductor circuit elements, a photoresist residue removing liquid composition which is excellent for removing photoresist residues after dry etching without attacking the wiring material or the interlayer insulating film etc.This is made possible by a photoresist residue removing liquid composition containing one or more members selected from the group consisting of reducing compounds and their salts and one or more members selected from the group consisting of aliphatic polycarboxylic acids and their salts.

Owner:KANTO CHEM CO INC

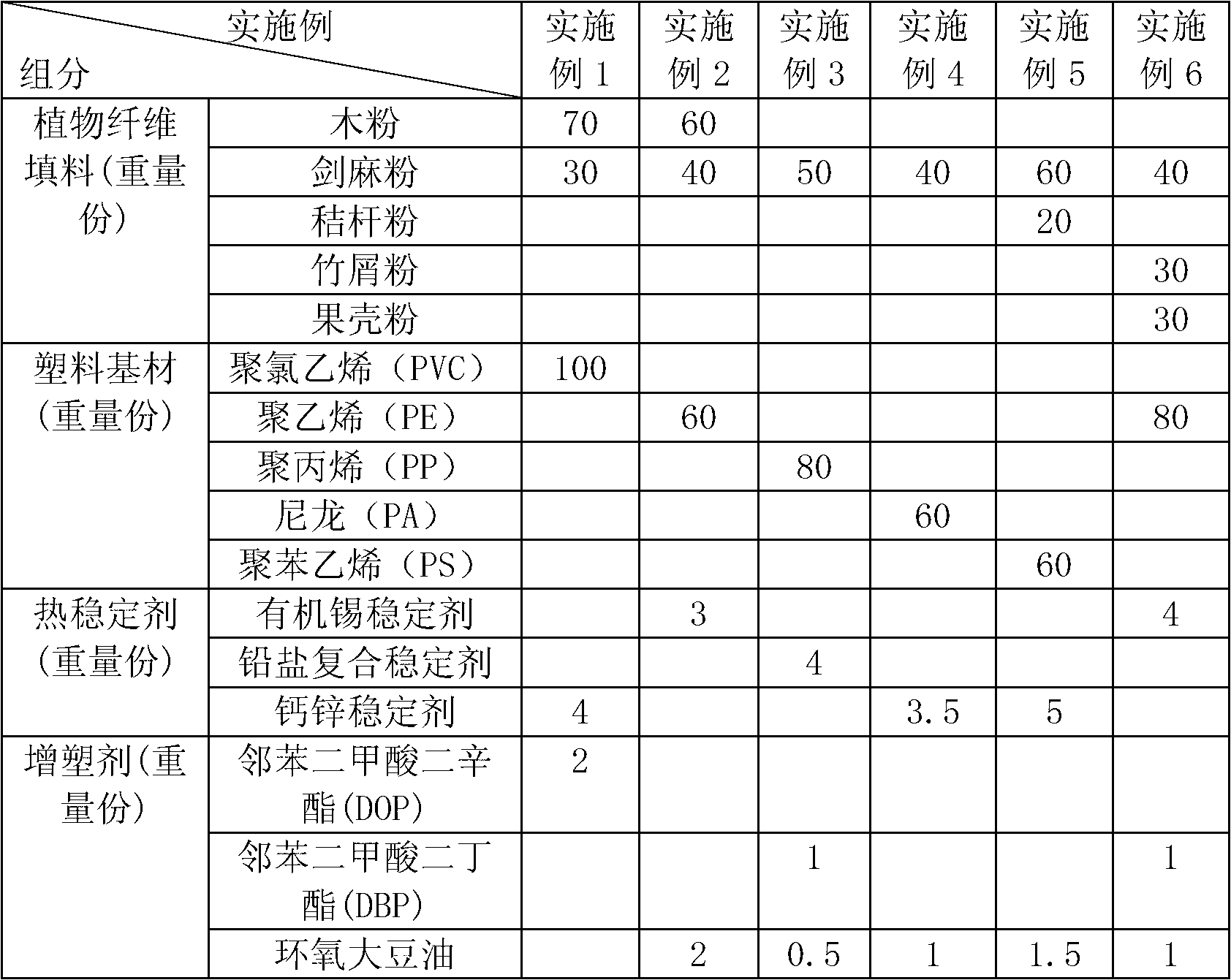

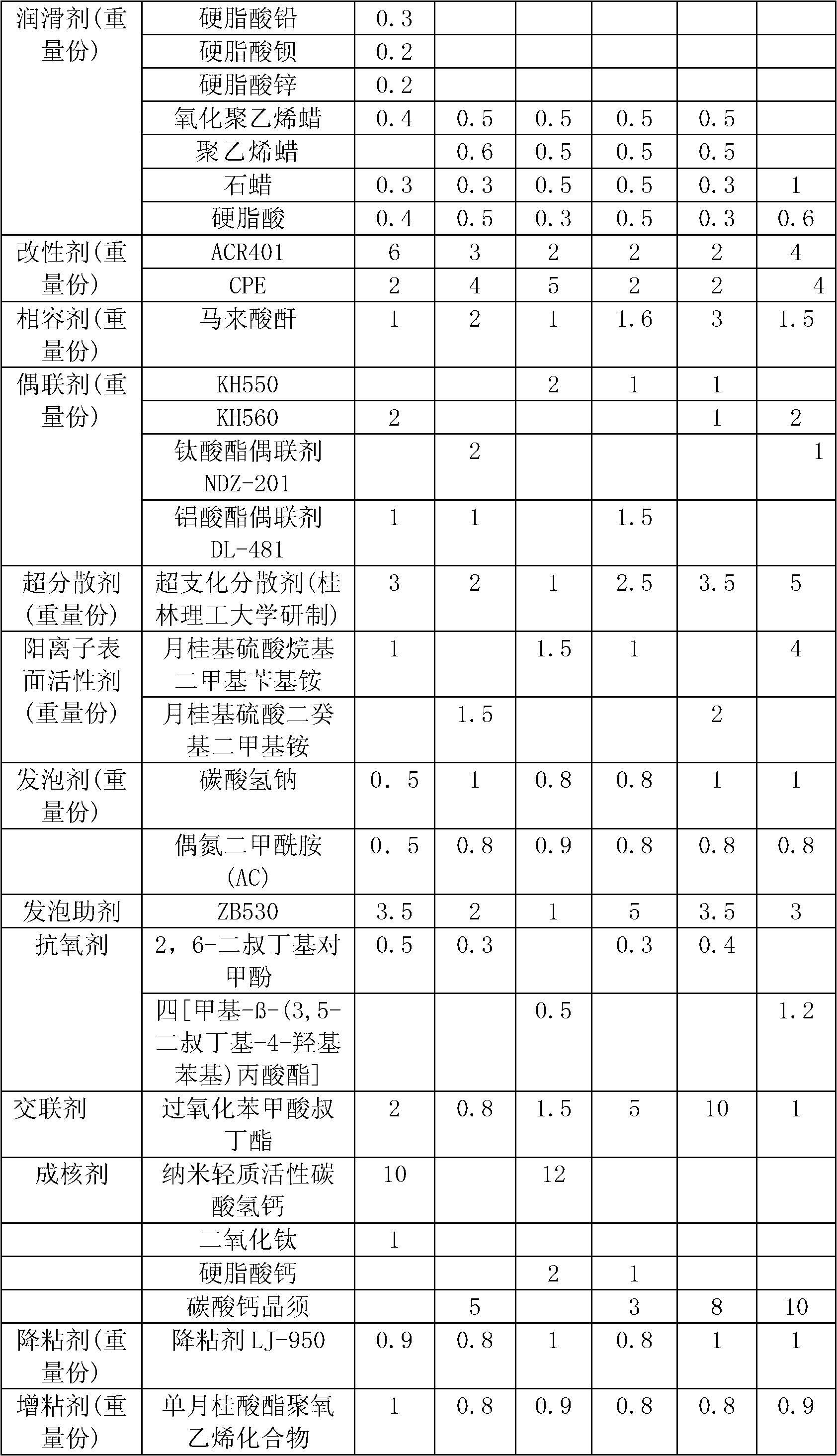

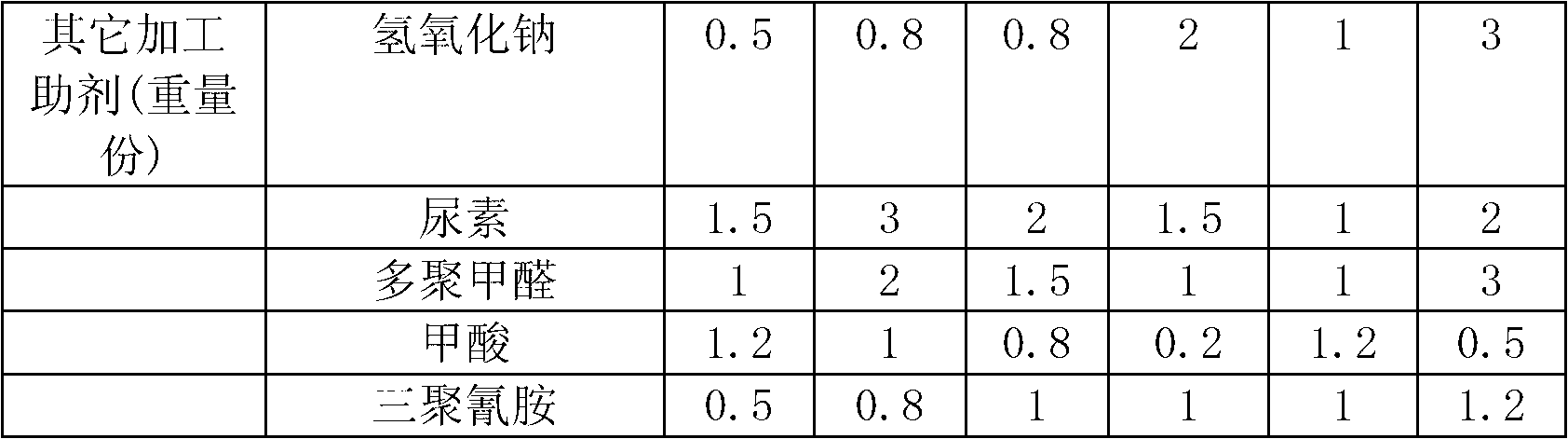

New macromolecule fiber composite material

The invention discloses a new macromolecule fiber composite material which is prepared by the following components in parts by weight, 40-100 parts of plant fiberfill, 60-100 parts of plastic base material, 3.5-5 parts of heat stabilizer, 1-2 parts of plasticizer, 1.6-2 parts of lubricating agent, 4-8 parts of modifying agent, 1-3 parts of compatilizer, 2-3 parts of coupling reagent, 1-5 parts of super dispersing agent, 1-4 parts of positive ion surface active agent, 1-1.8 parts of foaming agent, 1-5 parts of blowing promoter, 0.3-1.2 parts of antioxygen, 1-10 parts of cross-linking agent, 1-20 parts of nucleating agent, 0.8-1 part of viscosity reducer, 0.8-1 part of tackifier and 3.2-13.4 parts of other auxiliaries. The new composite material can not easily cause wet swelling and air shrinkage, and is low in expansibility and water absorbability, so that the prepared product has good stability.

Owner:GUILIN SHUKANG BUILDING MATERIAL

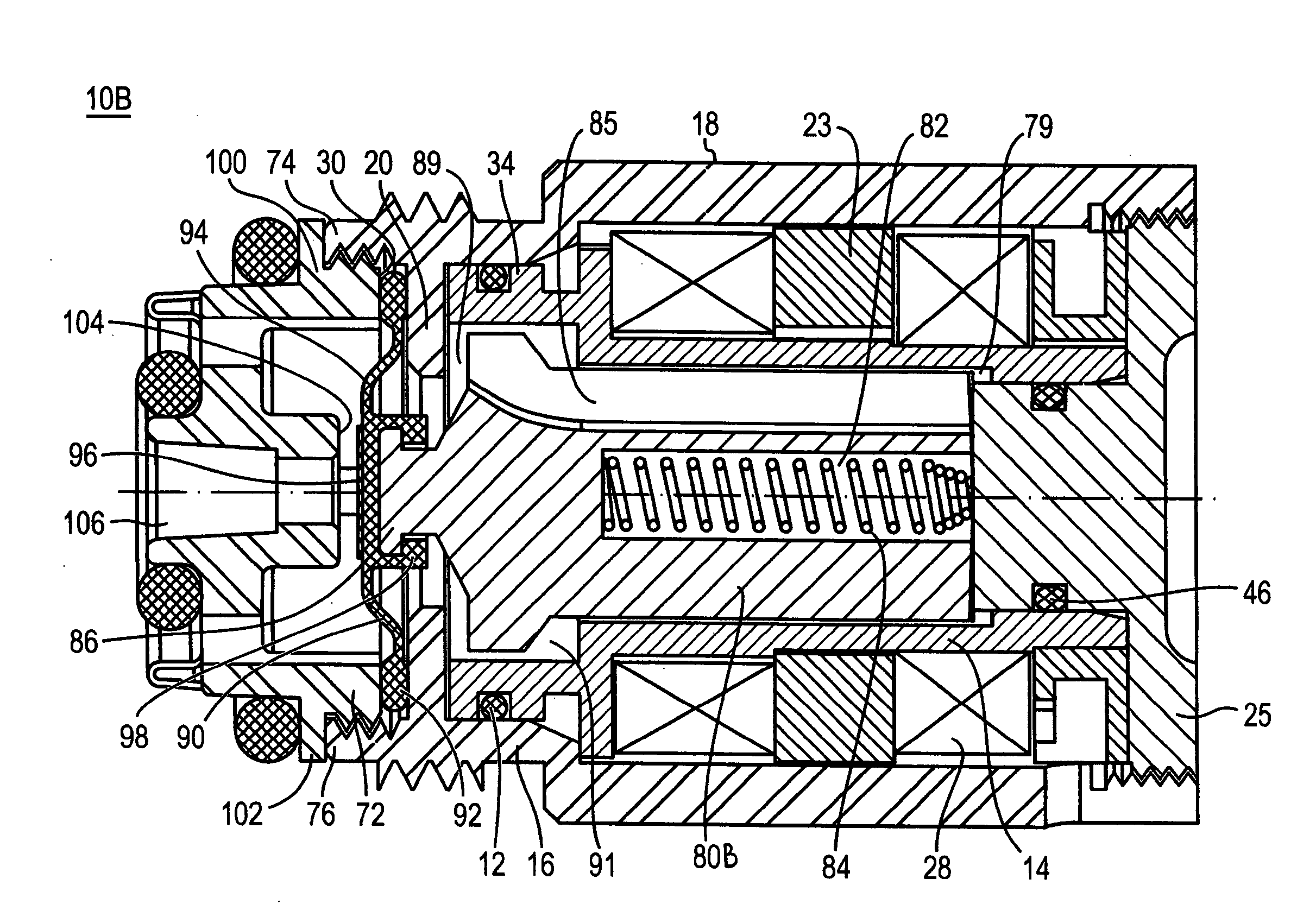

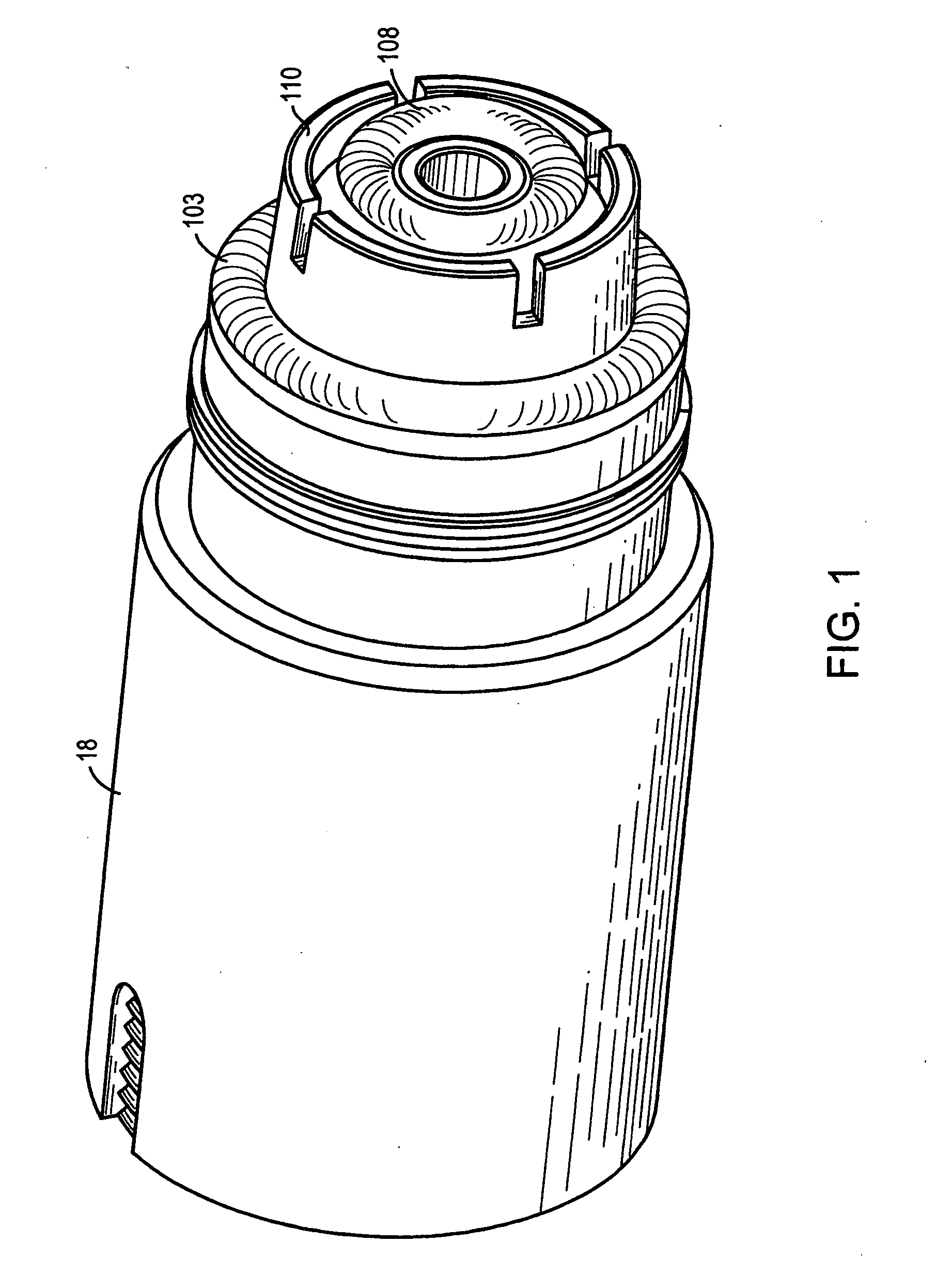

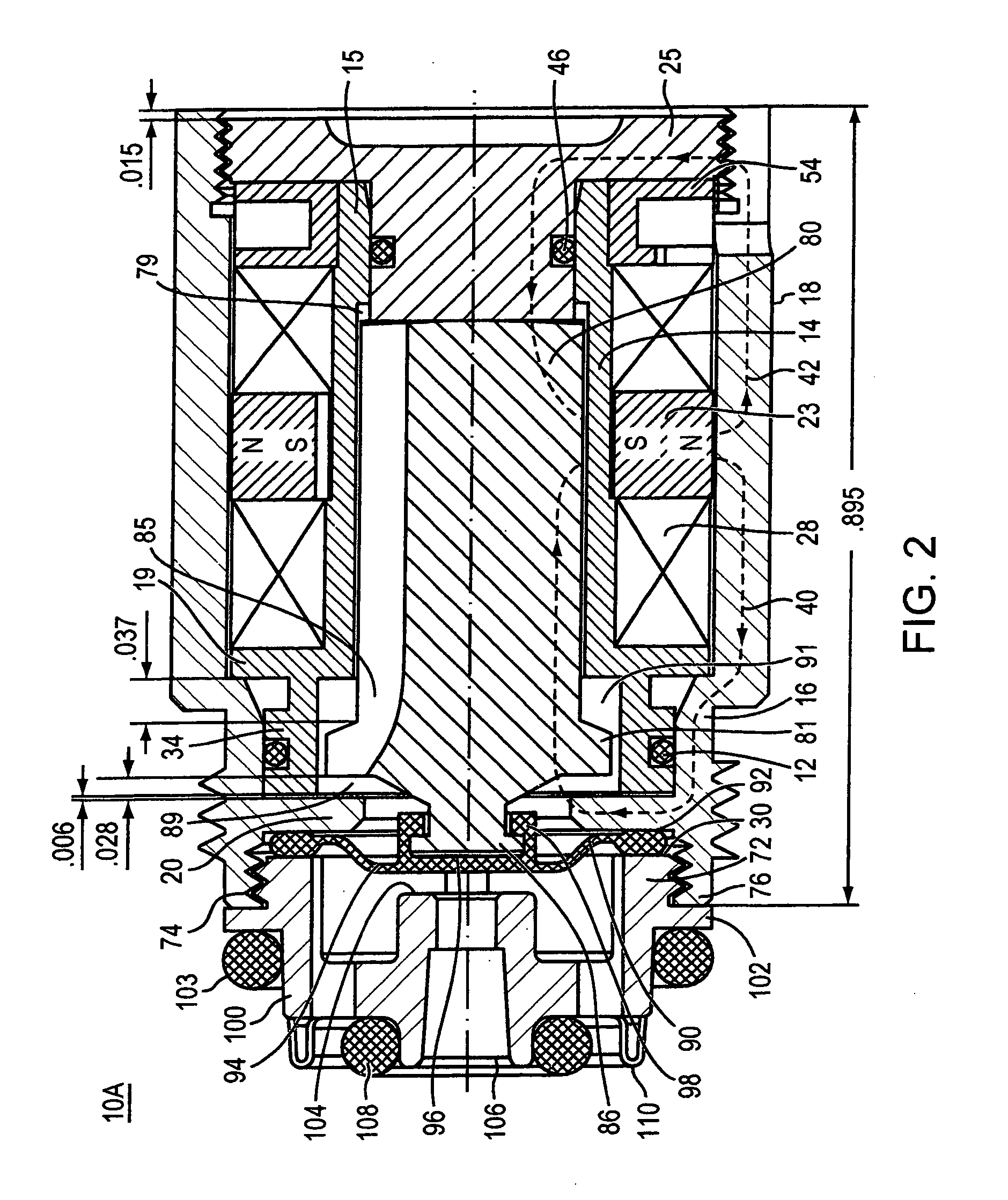

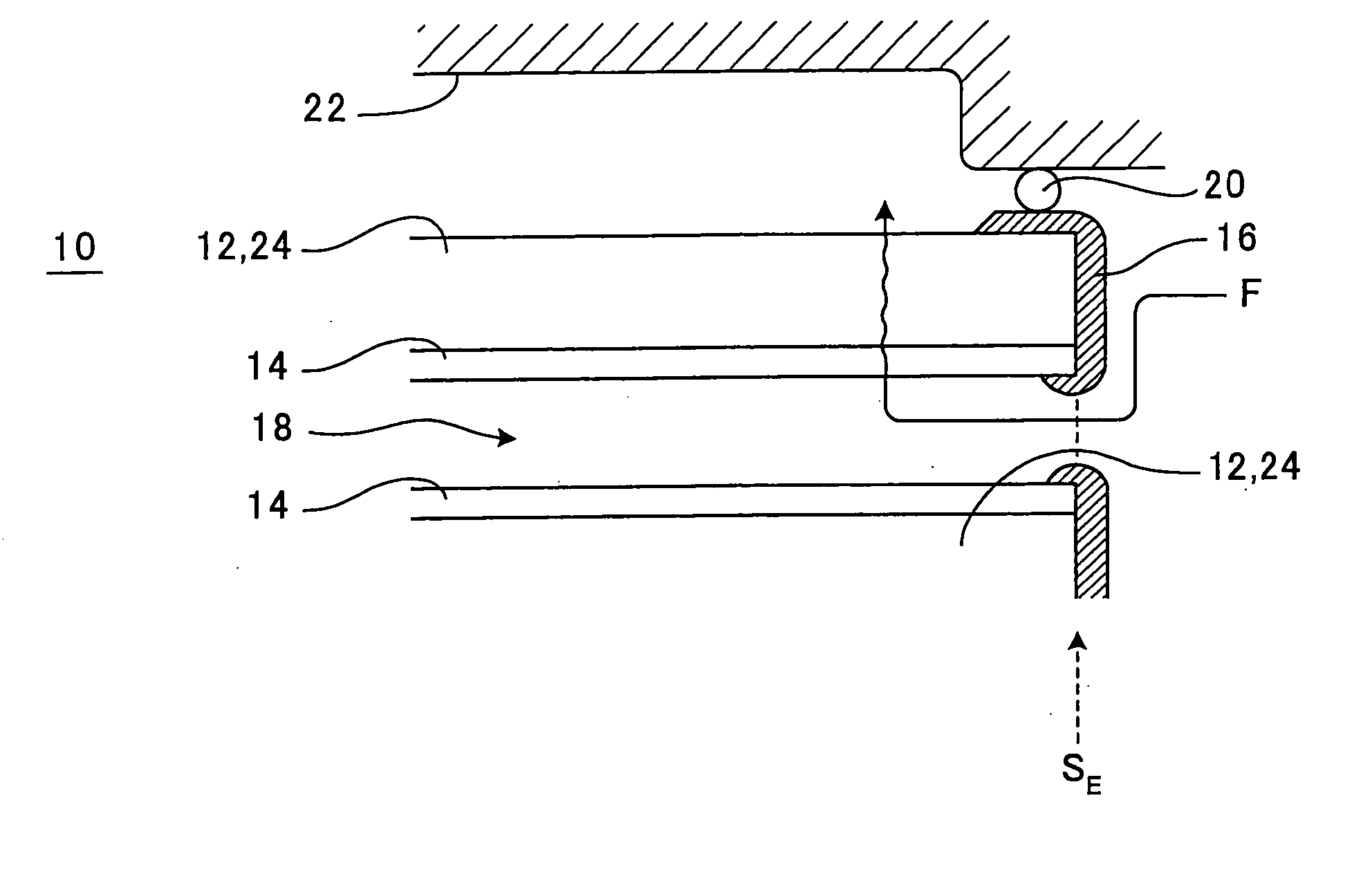

Electromagnetic apparatus and method for controlling fluid flow

InactiveUS20070241298A1Reduce energy wasteReduce energy consumptionSpindle sealingsDiaphragm valvesDriving currentBobbin

An actuator including actuator base, bobbin, and pole piece forming a pocket for a ferromagnetid armature located therein. The actuator including a radial magnet and a solenoid coil constructed and arranged to cause a linear displacement of the armature upon application of a coil drive current from a control circuit. The actuator may include a flexible membrane that partially encloses the armature to form an armature chamber filled with an incompressible fluid. In a valve design, a fluid flow is stopped by driving the membrane against a valve seat. Pressure from the controlled fluid in the conduit is transmitted through the membrane to the fluid within the armature chamber so that the armature does not need to counteract force applied to the membrane by the conduit fluid's pressure. A fluid flow is opened by driving the membrane away from the valve seat.

Owner:SLOAN VALVE COMPANY

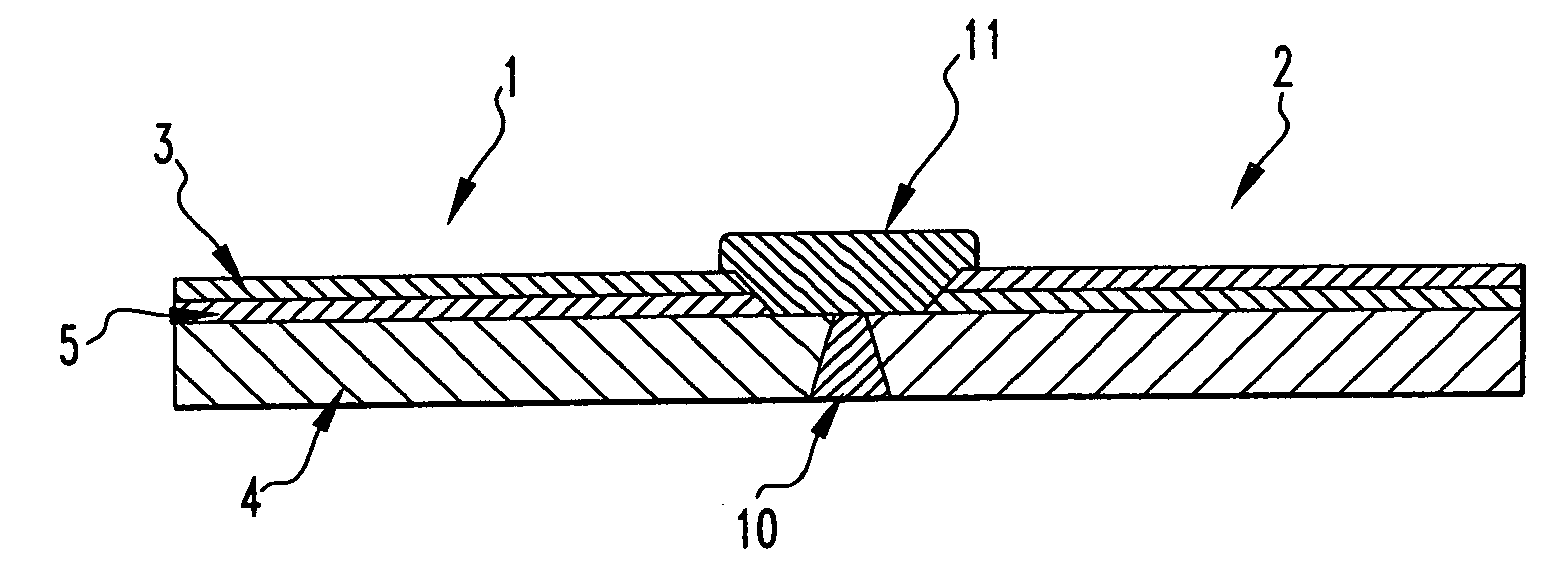

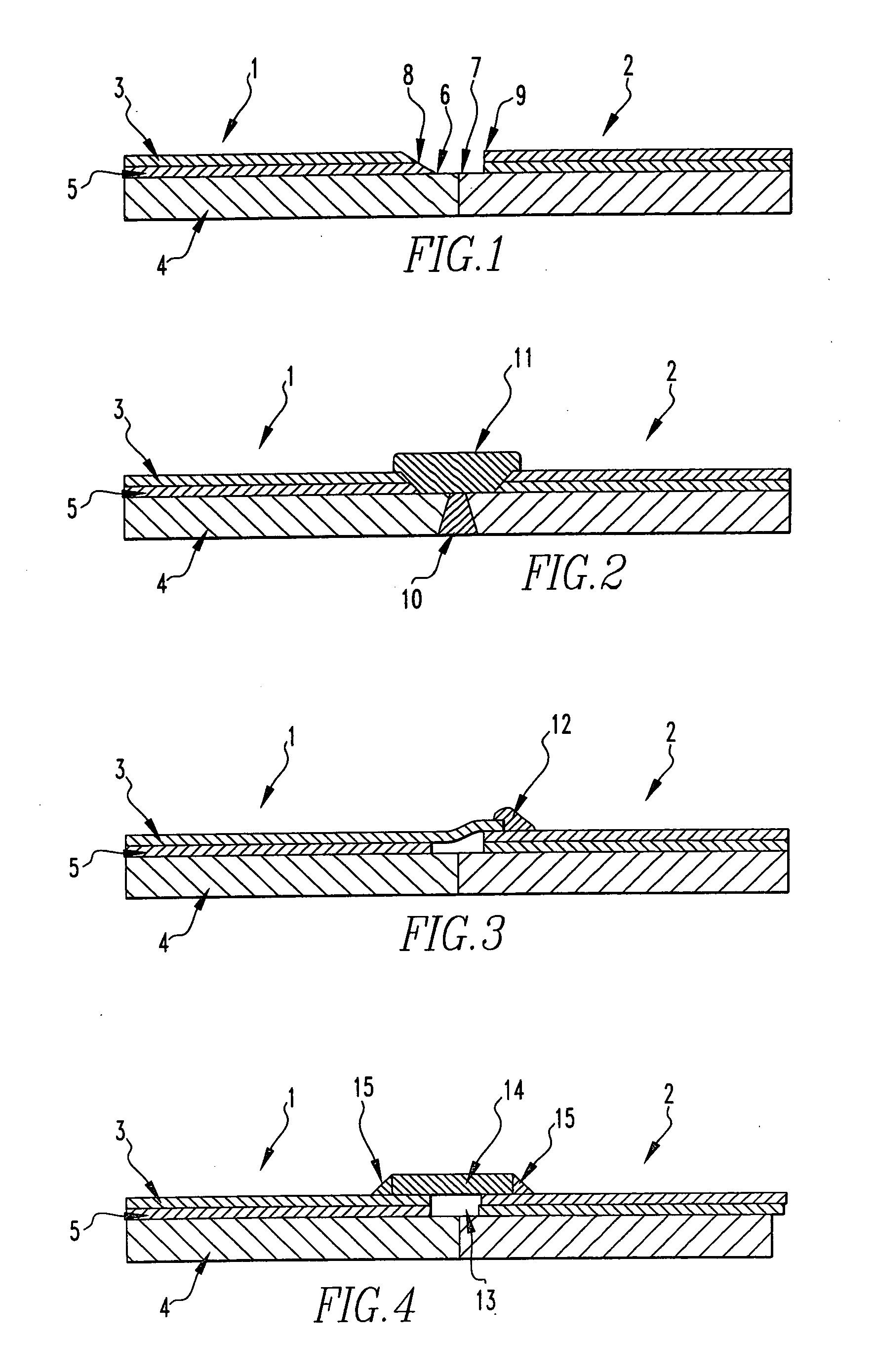

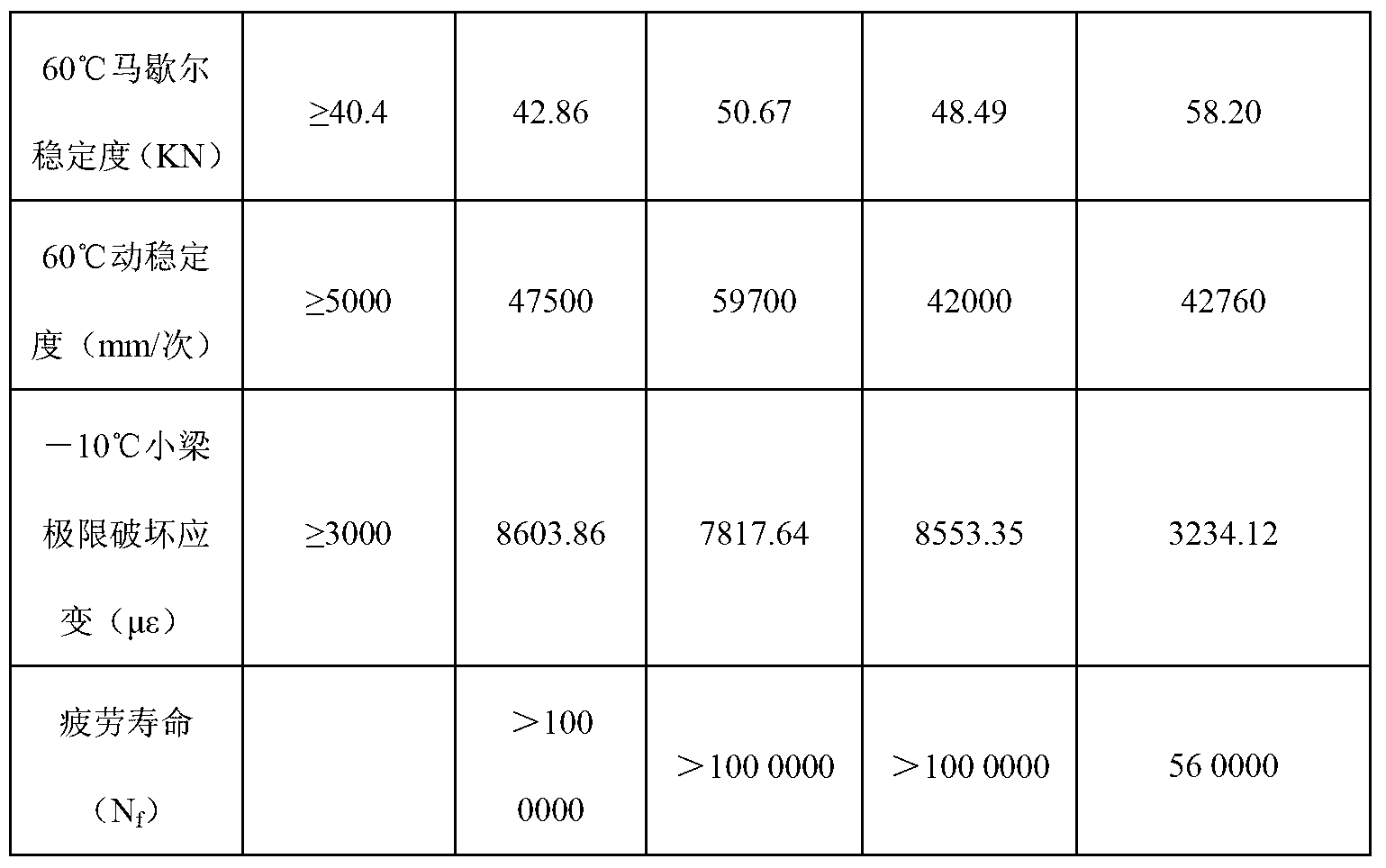

Method of joining tantalum clade steel structures

InactiveUS20080145688A1Reduce oxidationHigh densityLamination ancillary operationsLaminationTantalumEdge region

The present invention is directed to a process for joining tantalum clad steel structures. The process broadly comprises:a) providing a first tantalum clad section, said first tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,b) providing a second tantalum clad section, said second tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,c) locating said steel edge regions adjacent each other,d) welding the steel edge regions together,e) cold spraying a tantalum powder onto the welded edge regions and over the tantalum layers adjacent said edge regions thereby joining the tantalum clad steel sections.The invention is also directed to tantalum welds or joints formed by cold spraying tantalum powder.

Owner:GLAS TRUST +1

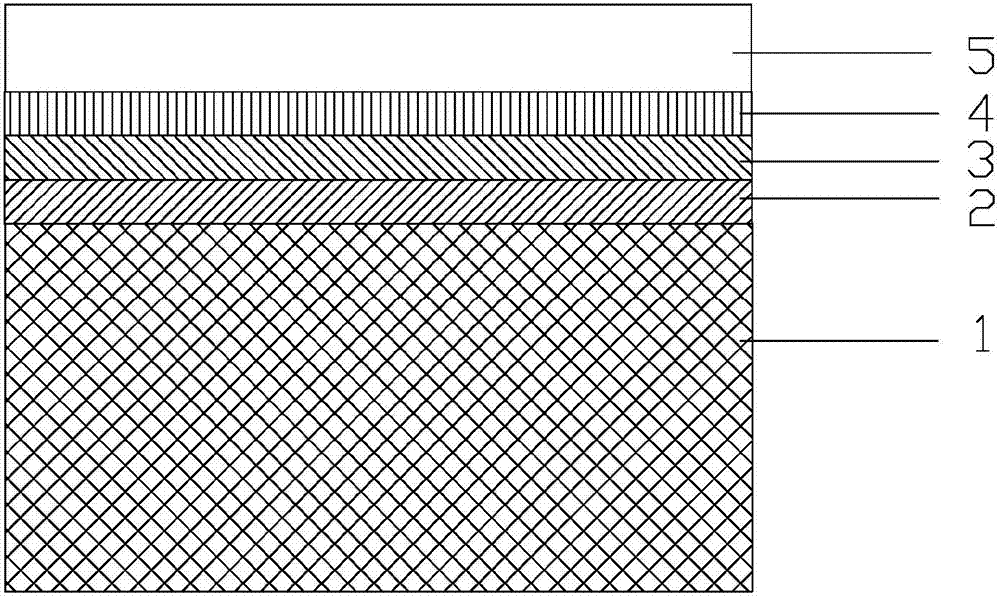

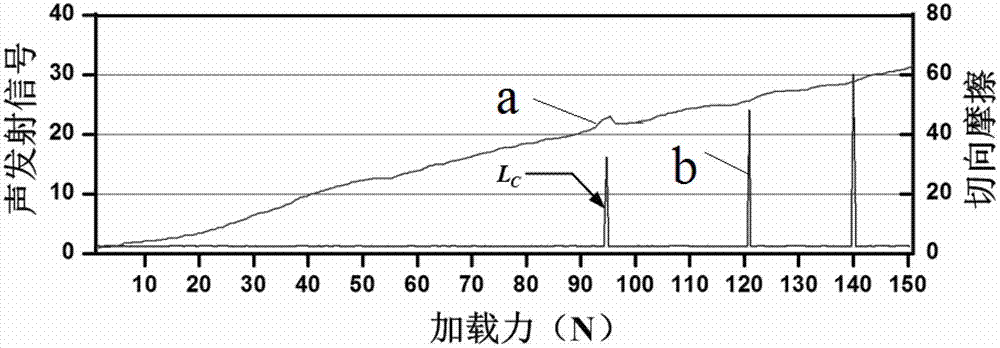

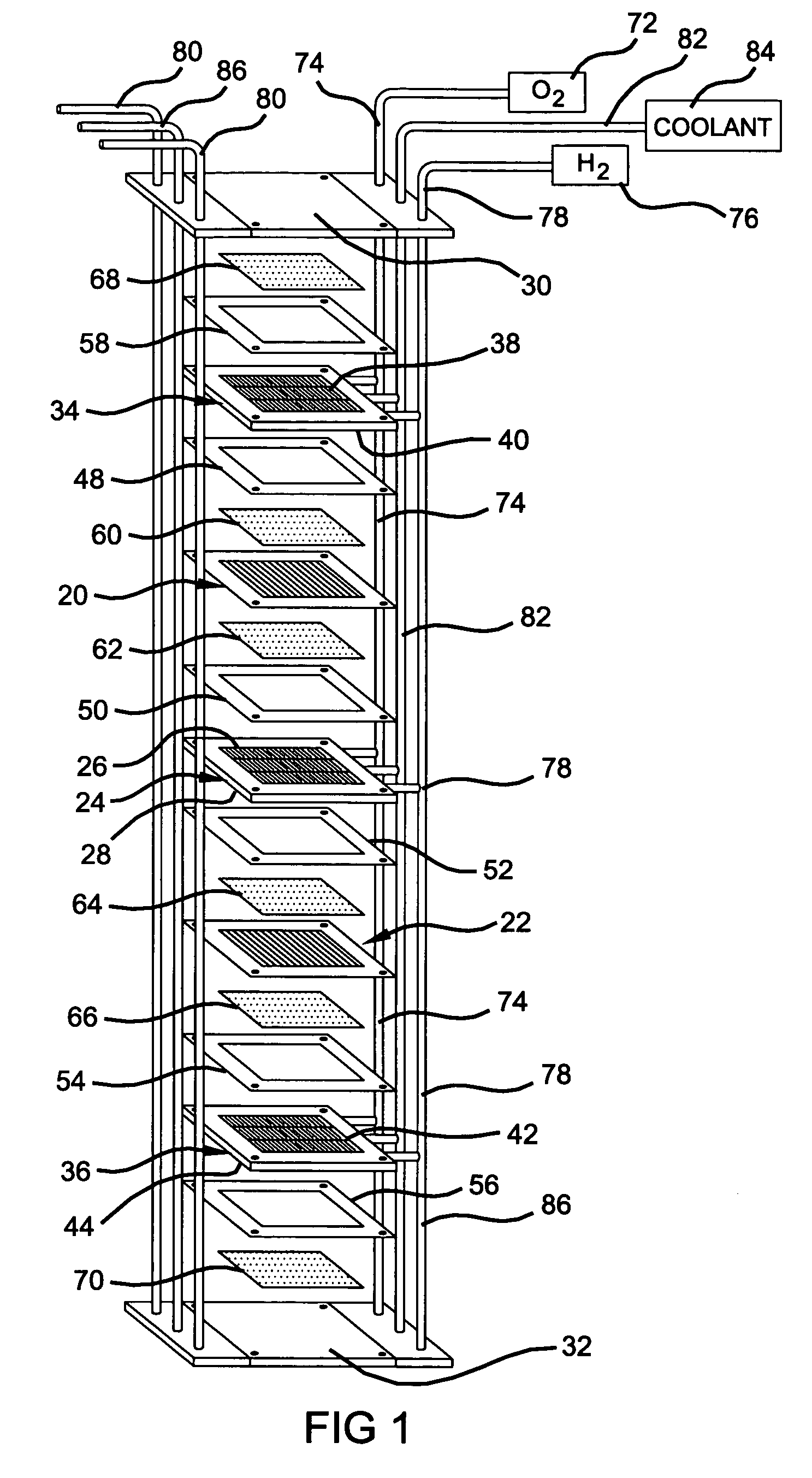

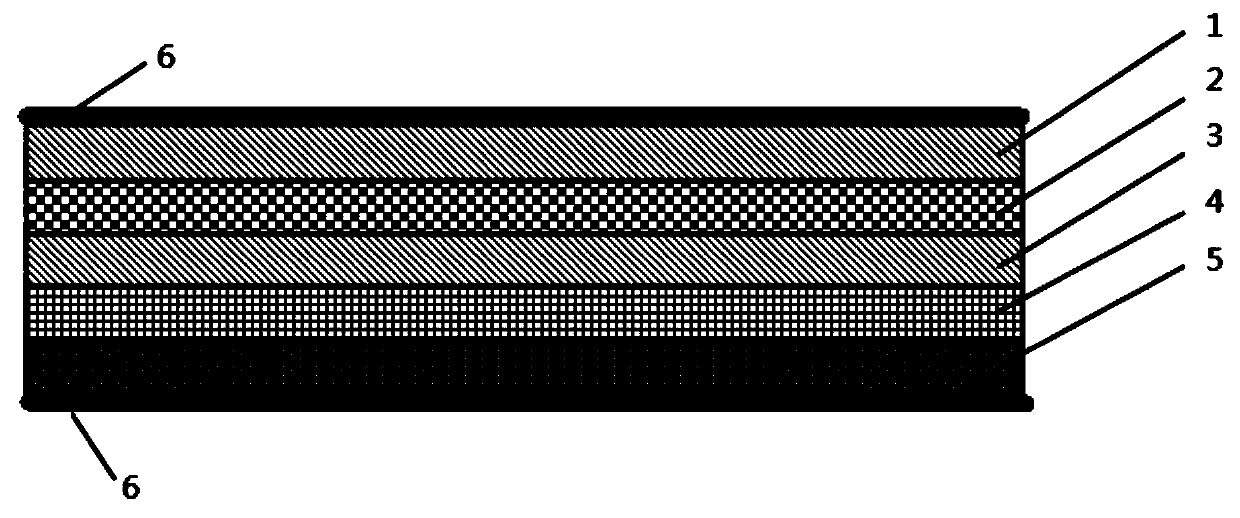

Fuel cell metal bipolar plate with conductive and anti-corrosion plating and preparation method thereof

ActiveCN102931421AImprove the binding force of membrane baseReduced corrosion resistanceFinal product manufactureVacuum evaporation coatingChromium carbideBinding force

The invention relates to a fuel cell metal bipolar plate with the conductive and anti-corrosion plating and a preparation method thereof. Chromium-nitrogen-carbon ternary composite step plating is formed on the surface of the metal bipolar plate by using a closed field unbalanced magnetron sputtering technology, and a pure chromium base layer, a chromium nitride transition layer, a chromium-carbon-nitrogen coexistence layer and an amorphous carbon layer are arranged upwards successively on the surface of the metal bipolar plate. Compared with the prior art, the fuel cell metal bipolar plate with the conductive and anti-corrosion plating and the preparation method thereof combine toughness of the chromium nitride, the corrosion resistance of the chromium carbide and the conductivity of amorphous carbon film fully, and the chromium nitride, the chromium carbide and the amorphous carbon film are composited through a step transition method. The modified metal bipolar plate film base binding force is improved apparently, the corrosion resistance and the conductivity are enhanced apparently, and high-performance and long-time use requirements of the fuel cell metal bipolar plate can be met.

Owner:苏州治臻新能源装备有限公司

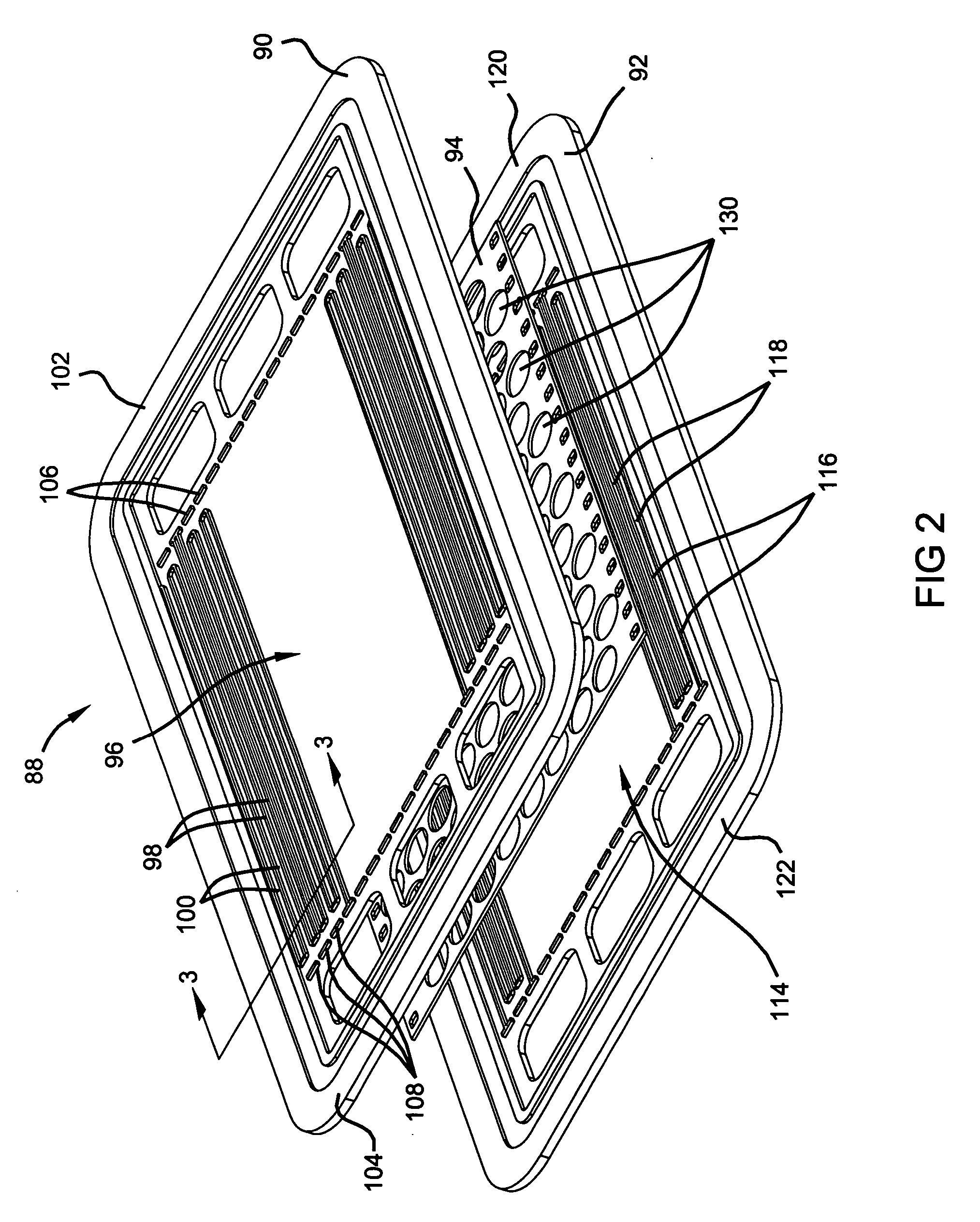

Laser welding of conductive coated metallic bipolar plates

ActiveUS20050252892A1Less corrosion resistantReduced corrosion resistanceFuel cells groupingFinal product manufactureFuel cellsEngineering

The present invention discloses a method of efficiently manufacturing fuel cells having coated bipolar plates. The present invention contemplates the laser welding together of individual plates already having a coating thereon to form the bipolar plates that are used in a fuel cell. The laser welding of the coated plates together does not result in sensitization of the plates to a magnitude sufficient to cause an undesirable level of corrosion resistance. This result is achieved regardless of the presence of the organic coating in the region of the plates being welded and regardless of the ablating of the organic coating by the laser beam.

Owner:GM GLOBAL TECH OPERATIONS LLC

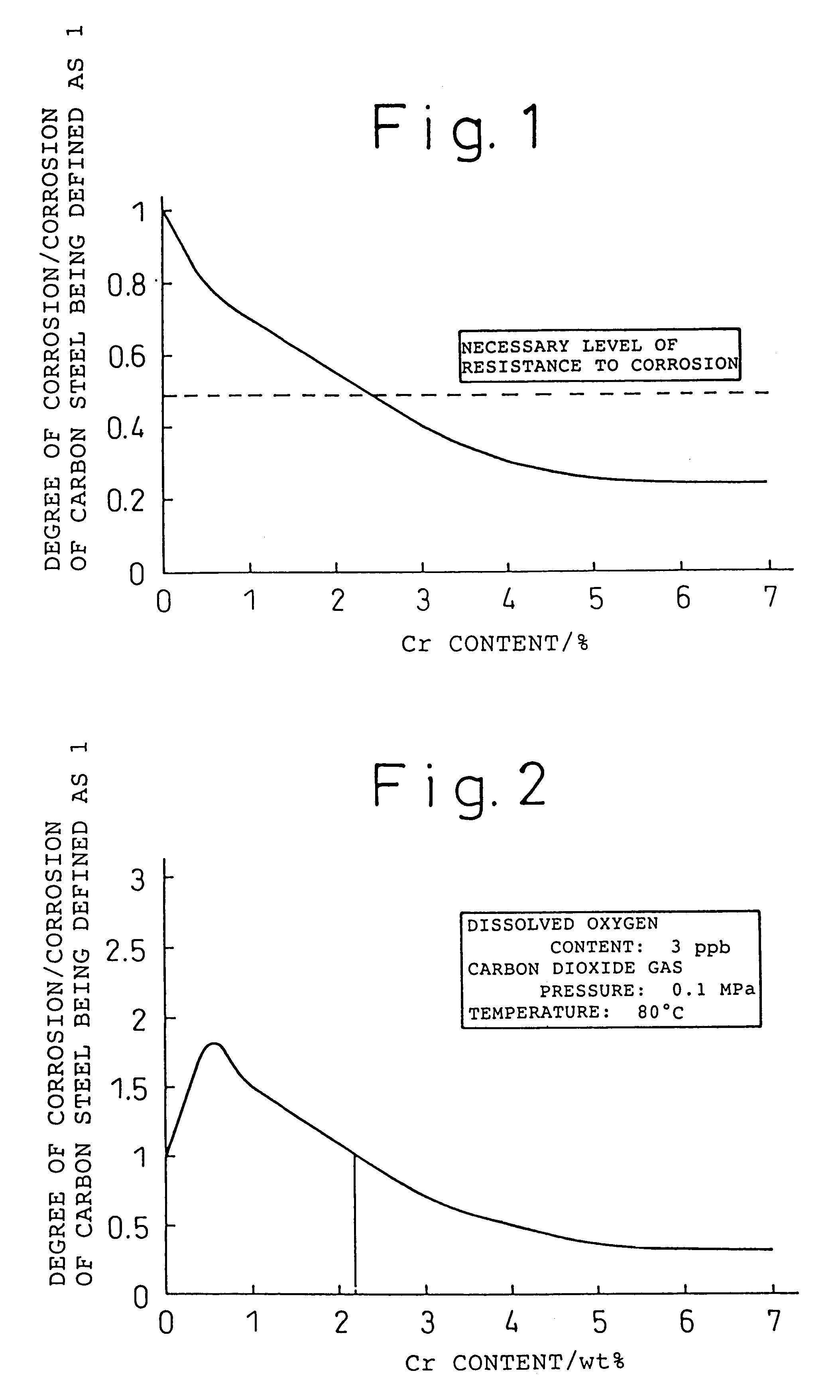

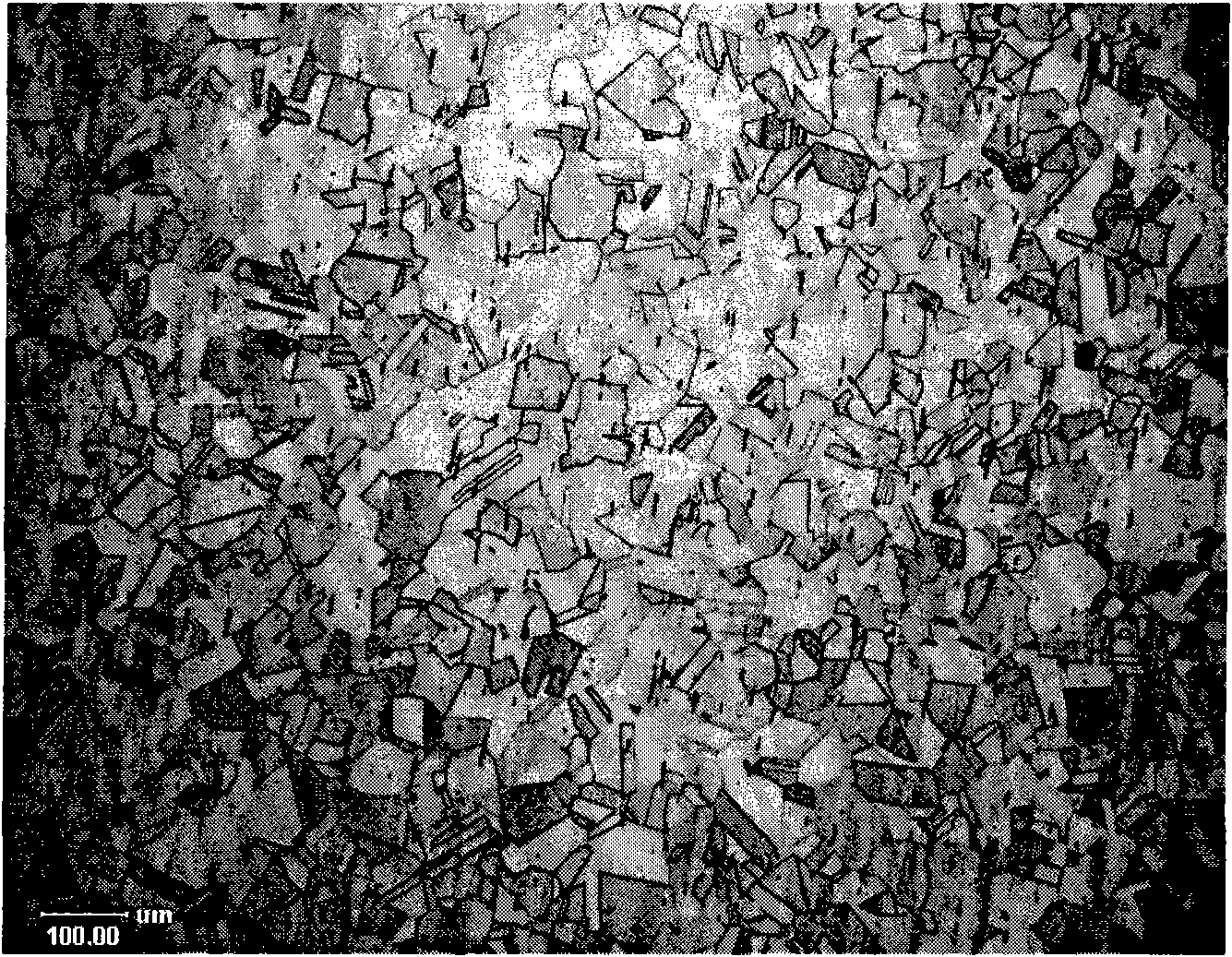

Corrosion resisting steel and corrosion resisting oil well pipe having high corrosion resistance to carbon dioxide gas

InactiveUS6248187B1Excellent in resistance to corrosionHigh strengthMartensiteUltimate tensile strength

An object of the present invention is to provide a corrosion resistant steel excellent in strength and low temperature toughness as well as resistance to corrosion by carbon dioxide and seawater, and most suitable for oil well steel pipes and line pipes for production and transportation of gas, petroleum, etc. used in the field of energy, or a steel for plants, and corrosion resistant oil well steel pipes. The corrosion resistant steel and the corrosion resistant oil well steel pipes comprise, based on weight, up to 0.30% of C, up to 1.0% of Si, 0.2 to 2.0% of Mn, 2.1 to less than 5.0% of Cr, up to 0.03% of P, up to 0.02% of S, up to 0.10% of Al, up to 0.015% of N, optionally containing Cu, Ni, Mo, Ti, Nb and B, and the balance of Fe and unavoidable impurities, and have a martensitic structure as their metallic structure.

Owner:NIPPON STEEL CORP

High temperature water heat processing method for timber

ActiveCN1876343AImprove water absorptionSmall water absorptionWood treatment detailsWood dampingMetallurgyIncrease size

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

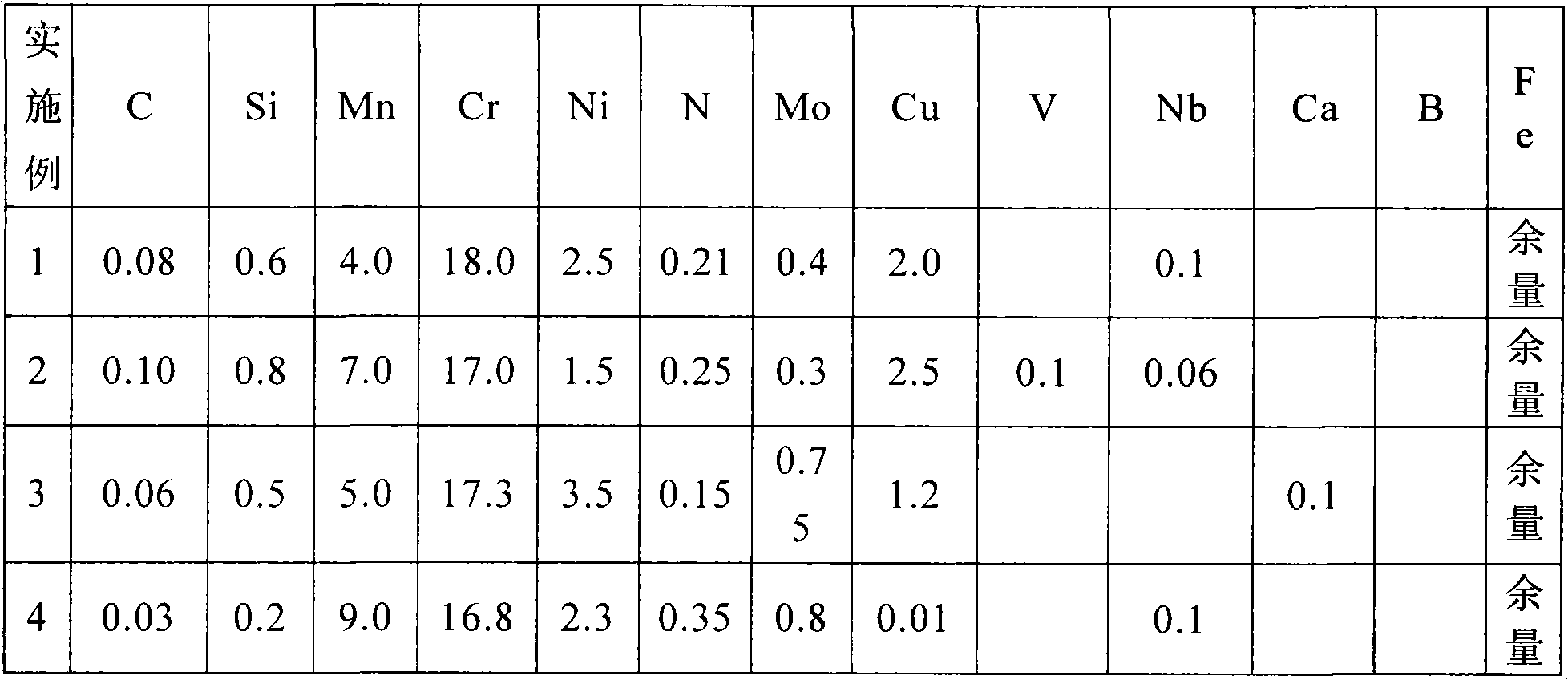

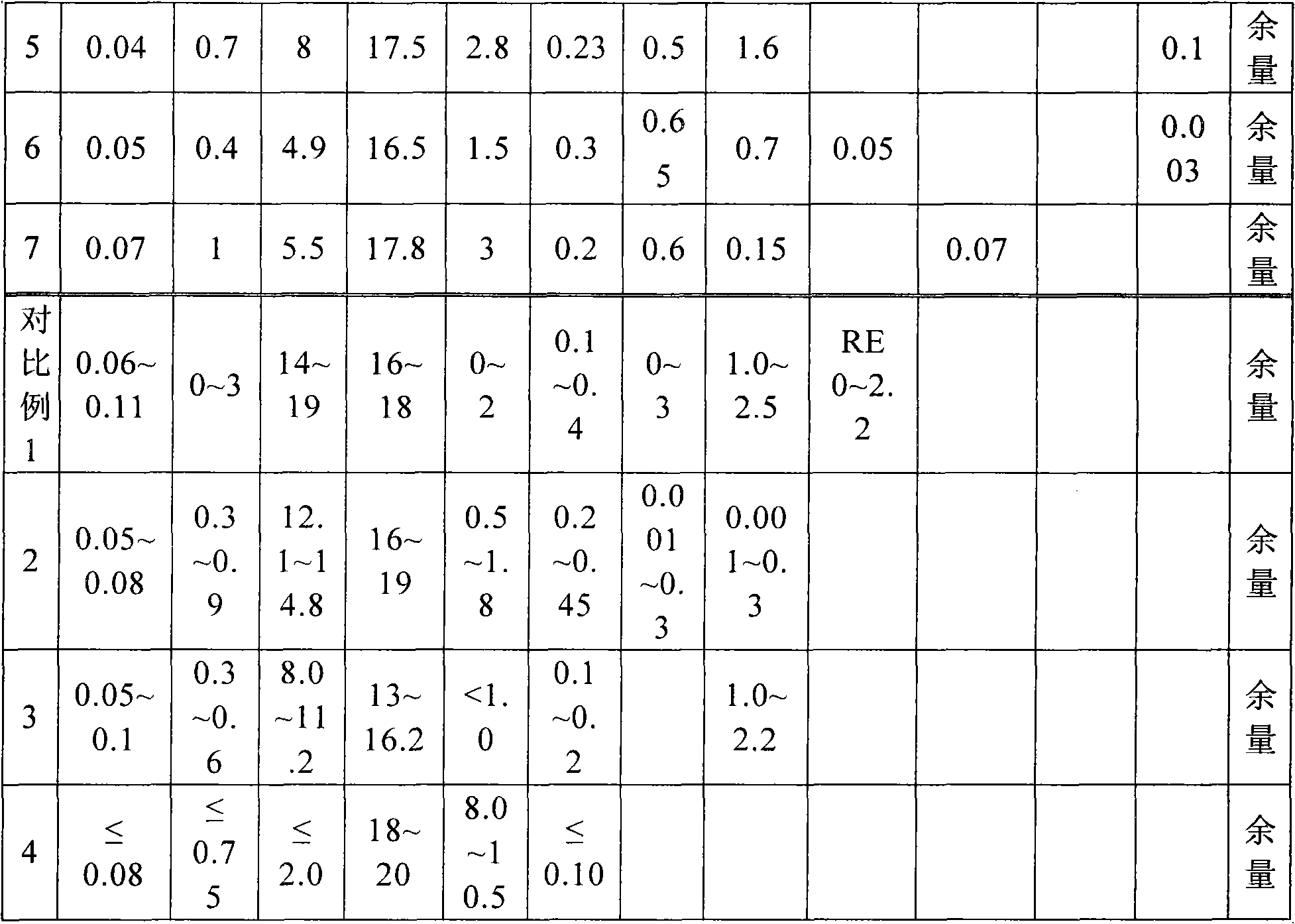

Molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance and manufacturing method thereof

ActiveCN102337481ALow costReduced corrosion resistancePitting resistance equivalent numberAustenitic stainless steel

Owner:BAOSTEEL DESHENG STAINLESS STEEL

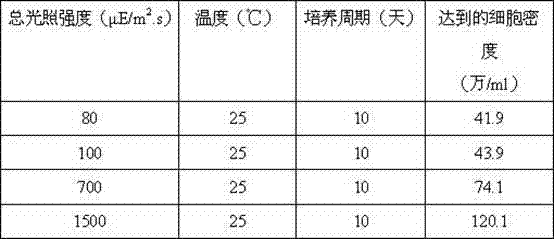

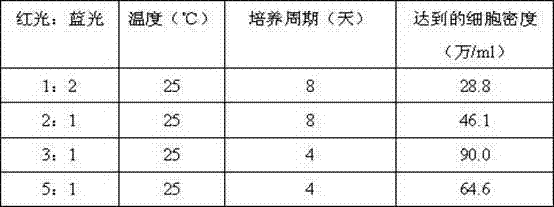

Cultivating and producing method for haematococcus pluvialis

InactiveCN102766578AReduce pollutionReduced corrosion resistanceUnicellular algaeMicroorganism based processesBiotechnologyWavelength range

The invention discloses a cultivating and producing method for haematococcus pluvialis. A haematococcus pluvialis green swarm cell is inoculated to a culture medium in a sealed tank body, a manual light-emitting diode (LED) light source is utilized for irradiation cultivating, the wavelength range of a monochromatic light emitted by the LED light source is 450nm to 640nm with the bandwidth of 30nm, two types of light sources with different wavelengths are simultaneously used according to the proportion of light intensity of red lights and blue lights, which is in a range from 2:1 to 5:1, the total light intensity is in a range from 80mu E / m2.s to 1500mu E / m2.s, the temperature during the cultivating process is maintained in a range from 15 DEG C to 28 DEG C, and the potential of hydrogen (pH) of the cultivating environment is controlled in a range from 8.0+ / -1.0 by adding carbon dioxide. The energy consumption of temperature controlling is remarkably saved, the cultivating period is shortened by above 50% compared with that of traditional methods, and the concentration of the obtained haematococcus pluvialis cell in a green algae liquid is 2 to 5 times of that of the haematococcus pluvialis cell in a green algae liquid by traditional methods.

Owner:陈勇

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

Method of producing an aluminium alloy brazing sheet and light brazed heat exchanger assemblies

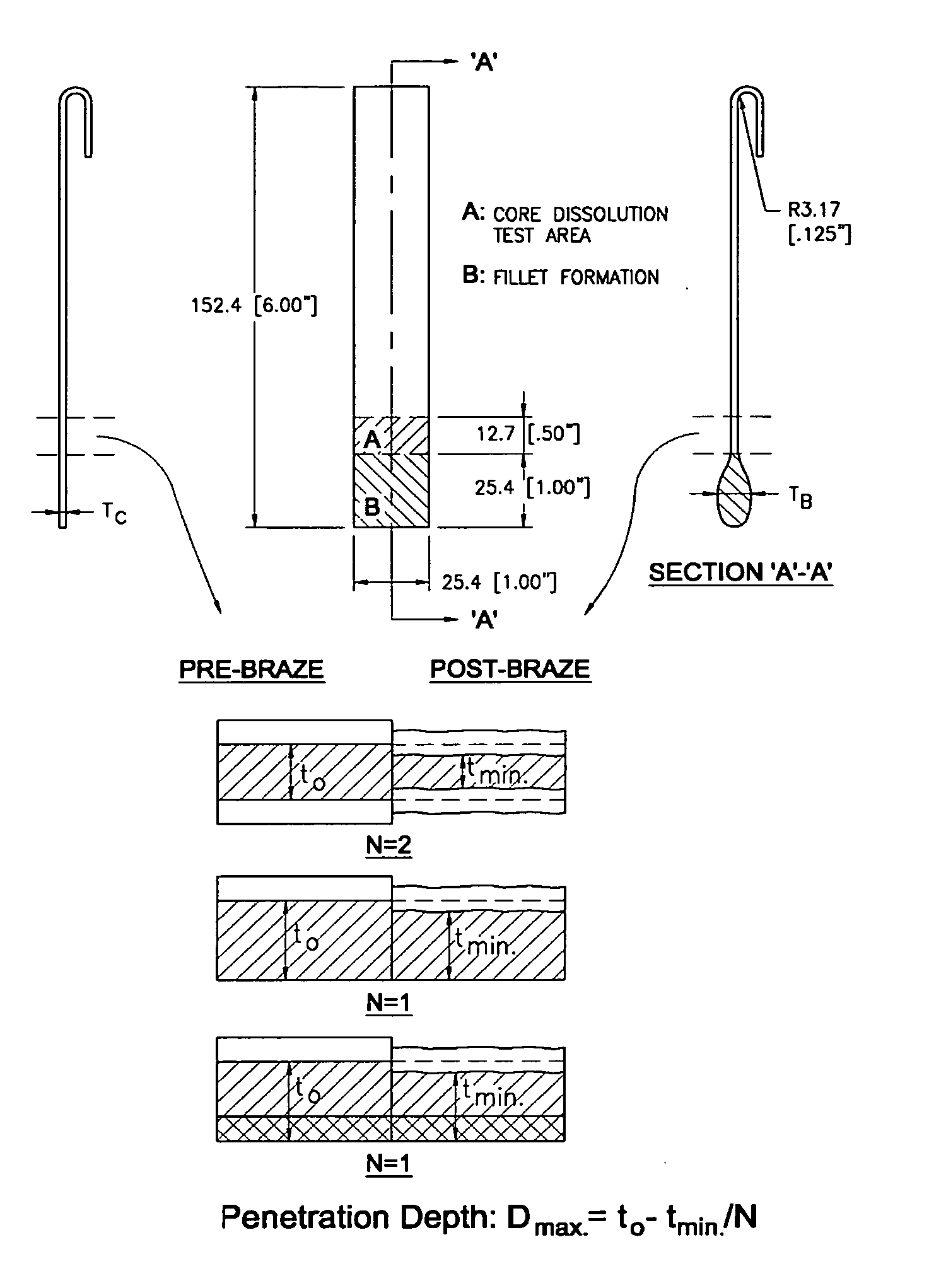

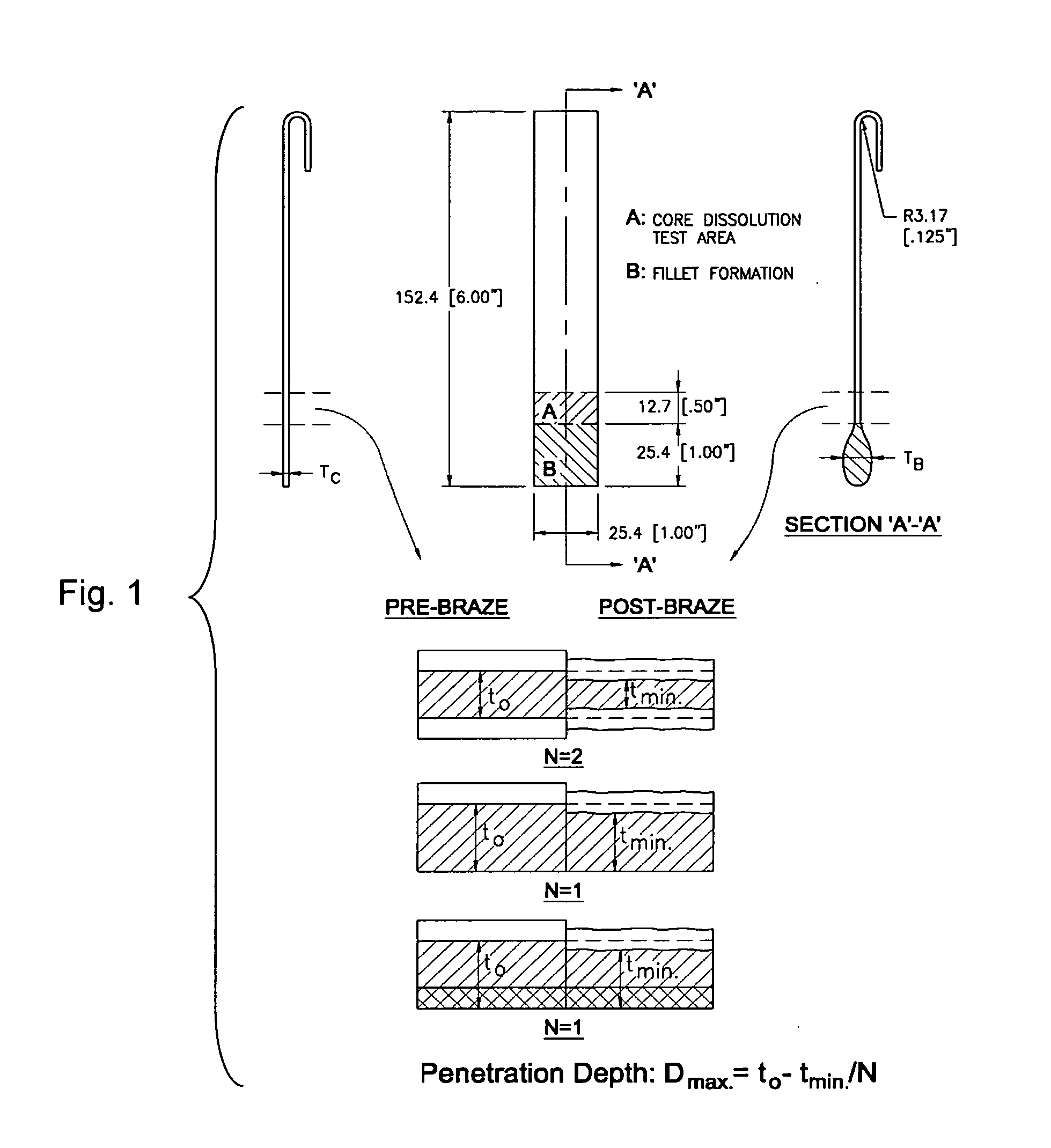

ActiveUS20060105193A1Good molding effectReduce sensitivityFurnace typesWelding/cutting media/materialsHeat exchangerFormability

A method of producing an aluminium alloy brazing sheet for the manufacturing of light brazed assemblies, wherein said brazing sheet has good formability, combined with a low susceptibility to core penetration in the end annealed as-produced condition after stretching, forming and / or shaping and brazing are disclosed. Assemblies made according to the method are also disclosed.

Owner:NOVELIS KOBLENZ GMBH

Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

InactiveCN105694625AMeet various style requirements of high-end and high-end exterior finishesShort construction periodFireproof paintsAnti-corrosive paintsPolymer scienceSludge

The invention relates to an exterior wall waterproofing heat-insulating decorating integrated material and a preparation method thereof.The preparation method includes: using conventional resin like polyurea and polyurethane as raw materials, adding compound micropowder prepared from solid waste and sludge, and adding a mixed modifier and a thixotropic agent to prepare A-compound slurry; adding a promoter and a hardener, and performing spray coating, brush coating, roll coating and pouring methods to obtain the exterior wall waterproofing heat-insulating decorating integrated material.The material has the comprehensive advantages of good waterproof effect, high heat insulativity, high hardness, high hole closing rate, low density, good anti-seepage performance, high corrosion resistance, low linear expansion coefficient, high softening temperature, oxidization resistance, aging resistance, flame retardancy and firmness in binding with a substrate.When the material is used for building exterior walls, multiple times of leveling, waterproofing, heat insulating and decorating construction are not needed, on-site moisture-free operation and one-time forming can be realized, and the material is short in construction period, extremely low in cost and great in market prospect.

Owner:NANJING KAIBA ADVANCED MATERIALS CO LTD +1

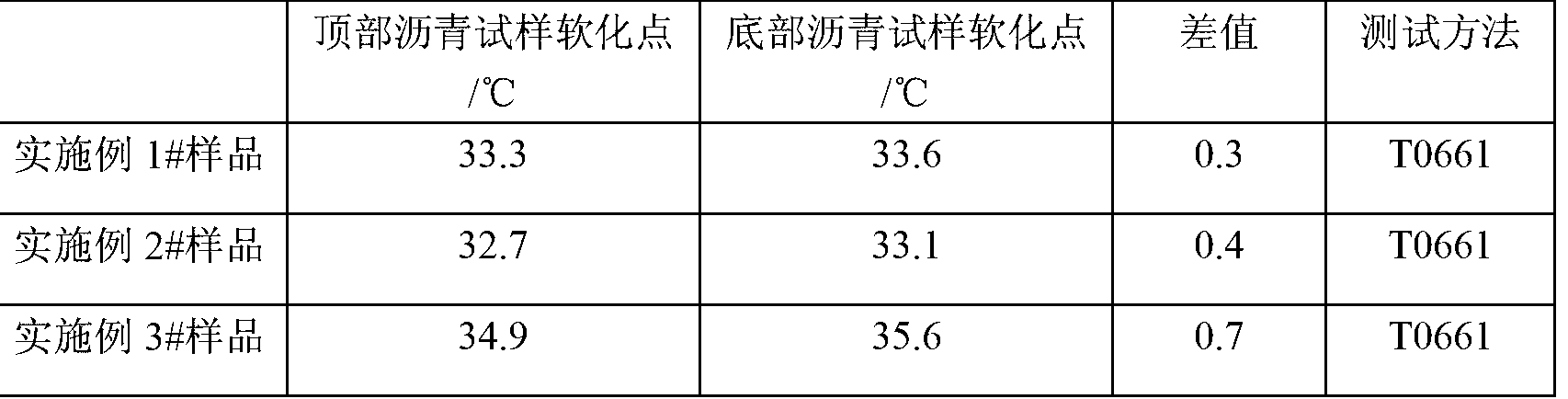

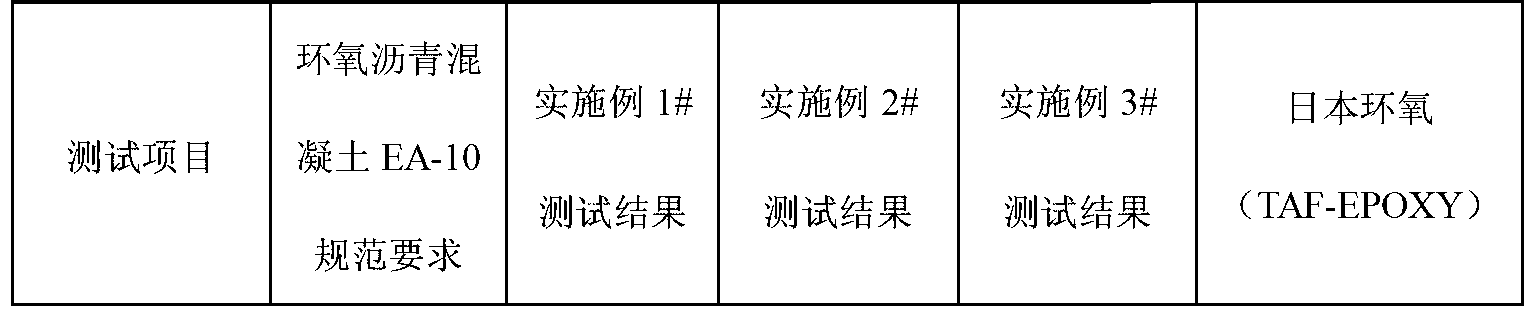

Composite modified asphalt and preparation method thereof

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

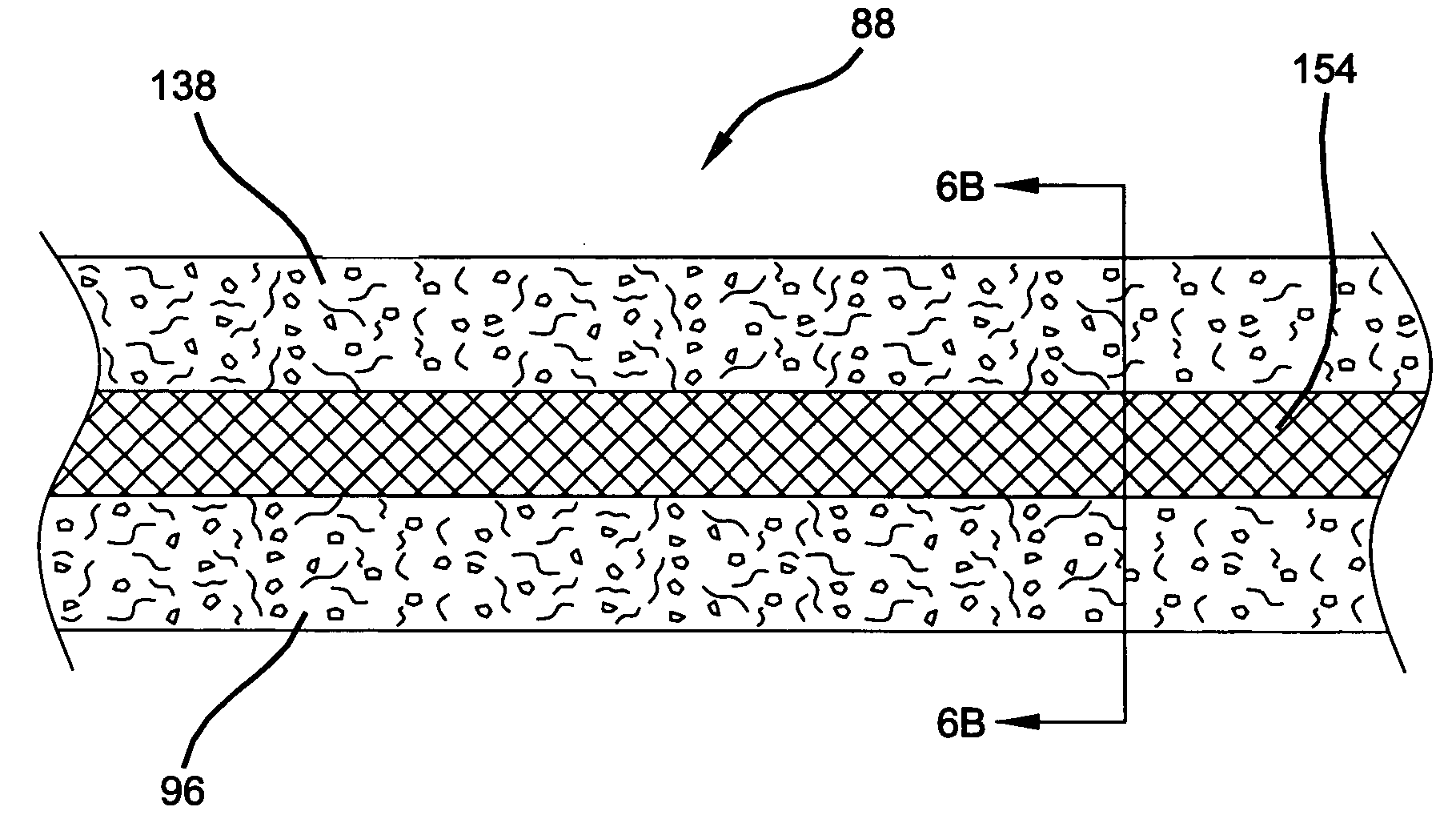

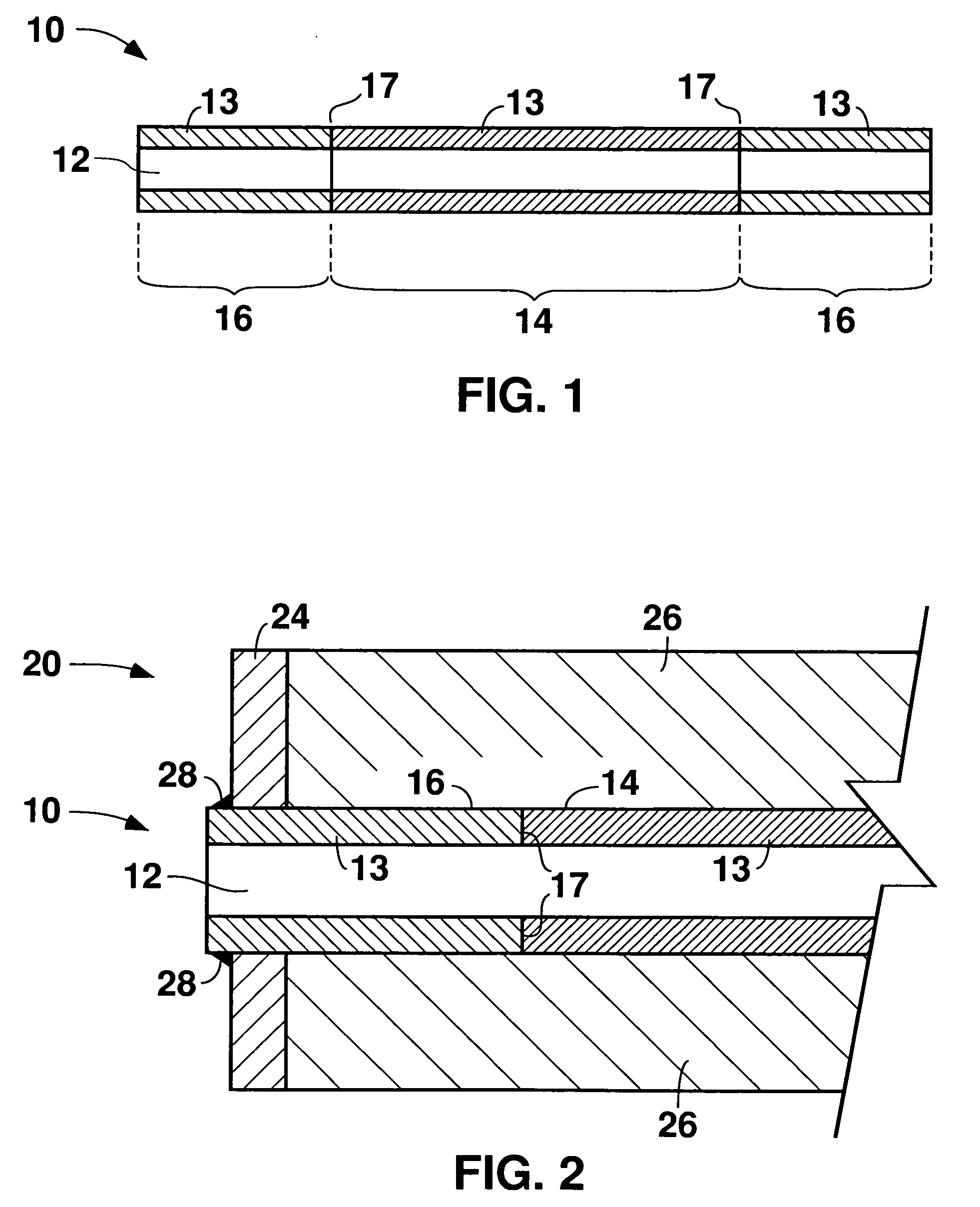

Corrosion resistant fluid conducting parts, methods of making corrosion resistant fluid conducting parts and equipment and parts replacement methods utilizing corrosion resistant fluid conducting parts

ActiveUS20060027628A1Readily cold workedReduced corrosion resistanceWelding/cutting auxillary devicesHeat exhanger sealing arrangementFusion weldingReplacement method

According to one aspect of the present disclosure, a part for an article of equipment includes a fluid conducting first region including a corrosion resistant first material, and a fluid conducting second region including a second material. The first region and the second region are either directly or indirectly joined by solid state welding to form a unitary fluid conducting part. According to another aspect of the present disclosure, a method for replacing at least one fluid conducting part of an article of equipment is disclosed wherein a replacement part is provided that includes a fluid conducting first region including a corrosion resistant first material, and a fluid conducting second region including a second material. The second material is substantially identical to the material of a region of the equipment on which the replacement part is mounted. The first and second regions are either directly or indirectly joined by solid state welding to form a unitary fluid conducting replacement part. The replacement part is secured to the article of equipment by a process comprising fusion welding the second material of the second region of the replacement part to the substantially identical material of the mounting region of the article of equipment.

Owner:ATI PROPERTIES LLC

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

Multifunctional composite material armor plate and preparation method thereof

ActiveCN104215130ABoth infrared stealth featuresHigh strengthSynthetic resin layered productsLaminationCarbon fibersHeat resistance

The invention relates to a multifunctional composite material armor plate and a preparation method thereof. The armor plate comprises multiple structures of a rigid reinforcing layer, a middle bulletproof layer, a back bulge prevention layer and a buffer layer and the multiple structures are formed by die pressing, wherein the rigid reinforcing layer is formed from a fiber fabric, which is made of one or a plurality of aramid fibers and high-performance carbon fibers, and modified thermosetting resin by impregnation; the middle bulletproof layer is formed from a mixed fiber fabric, which is made of ultrahigh molecular weight polyethylene fibers and high-performance carbon fibers, and modified thermoplastic resin by impregnation; the back bulge prevention layer is formed by a fiber fabric, which is made of high-performance carbon fibers, and modified thermosetting resin by impregnation; the buffer layer is made of organic silicon or polyurethane foam. The invention provides the armor plate which is prepared by adopting multilayer laying and vacuum die-pressing integrated forming and has the characteristic of infrared stealth and has high intensity, high rigidity, low back bulge property, corrosion resistance and heat resistance.

Owner:SHANDONG UNIV +1

Rare earth element sintered magnet and method for producing rare earth element sintered magnet

ActiveUS20050028890A1Incur damageResistance can be maintainedInorganic material magnetismSolid state diffusion coatingRare-earth elementSintered magnets

Owner:SHIN ETSU CHEM IND CO LTD

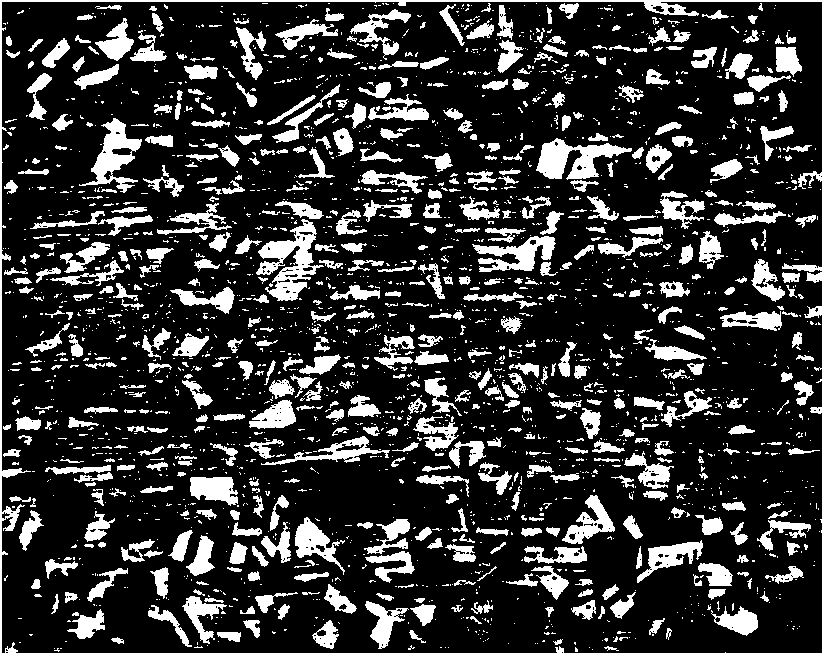

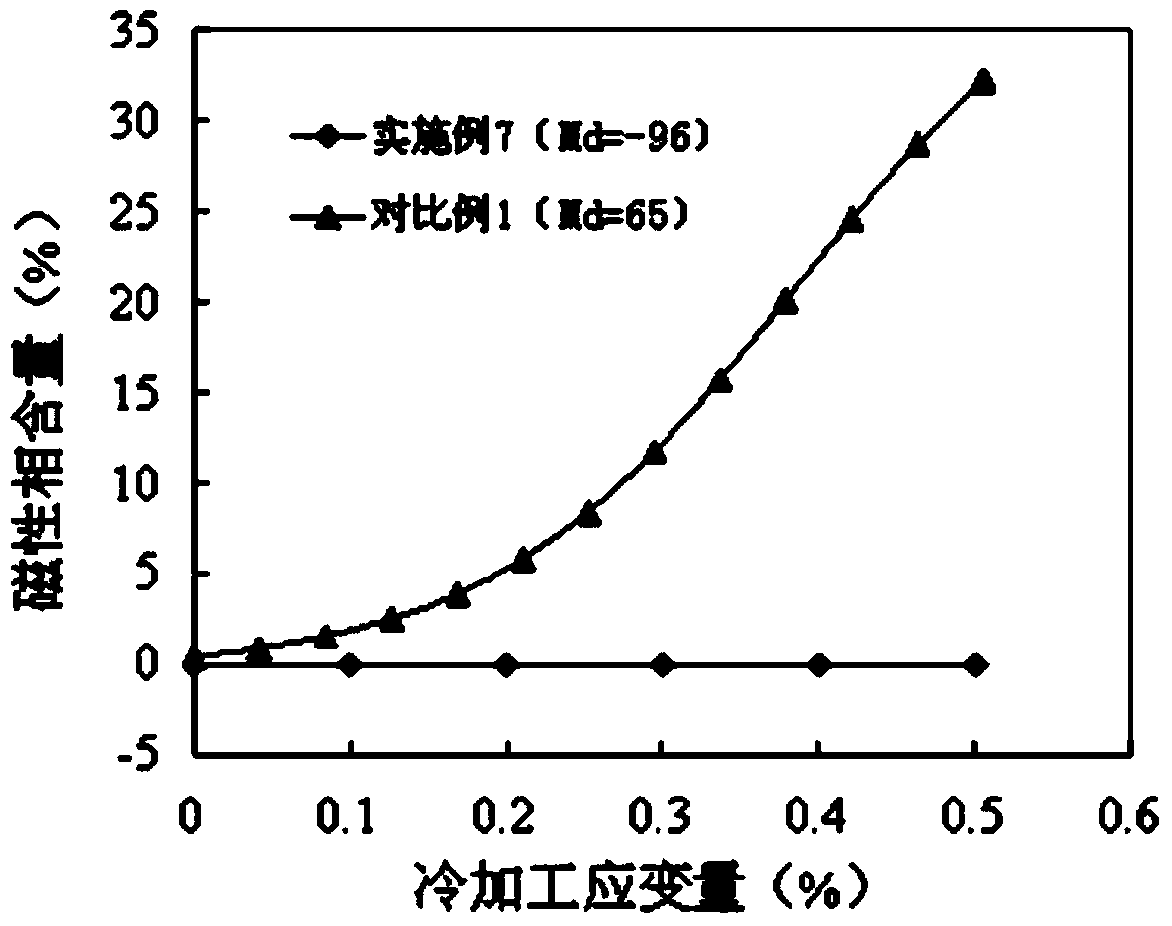

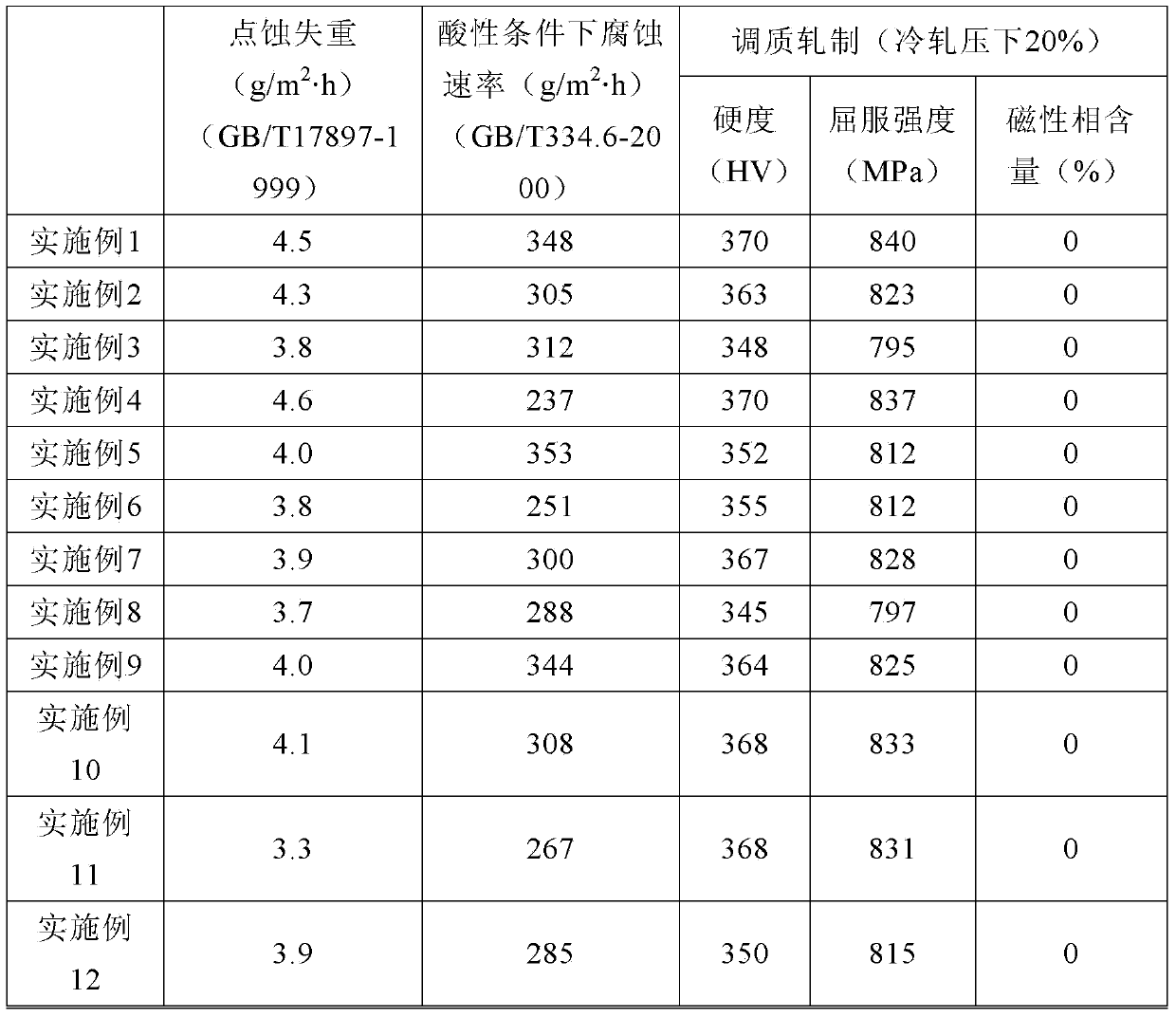

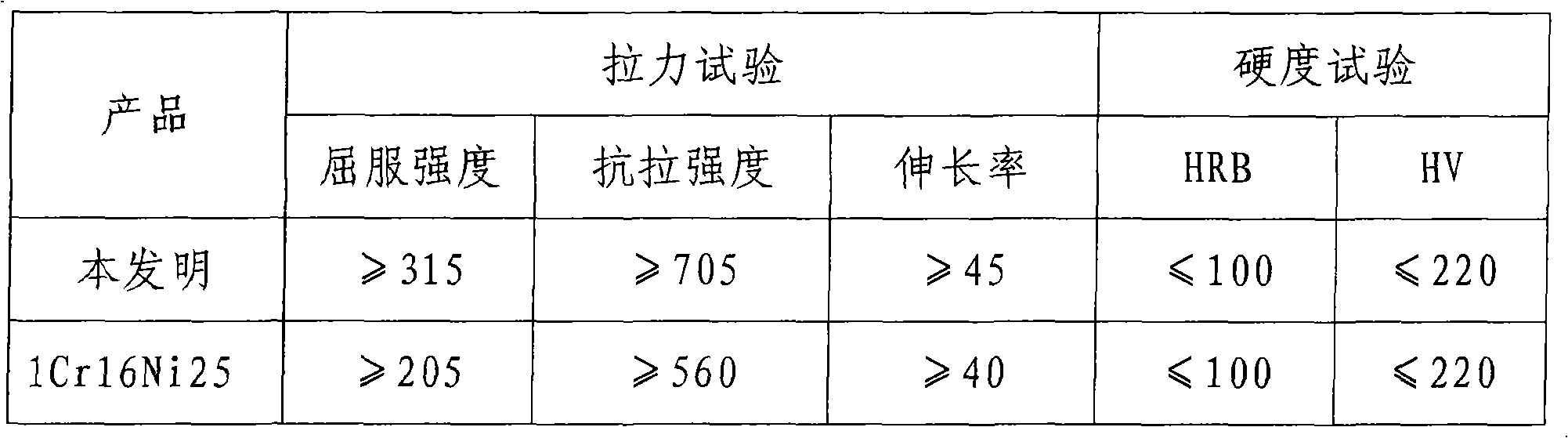

Non-magnetic hard austenitic stainless steel for precision electron and manufacturing method thereof

The invention relates to a non-magnetic hard austenitic stainless steel for precision electron and a manufacturing method thereof. The stainless steel comprises the following chemical components by weight percent: 0.06% to 0.10% of C, 0.51% to 0.8% of Si, 11.5% to 12.5% of Mn, 17.0% to 18.0% of Cr, 2.51% to 3.50% of Ni, 0.15% to 0.20% of N, 0.15% to 0.50% of Sn, 0.30% to 0.50% of Mo, 0.30% to 0.75% of Mo and W / 2, 2.0% to 2.5% of Cu and the balance of Fe and inevitable impurities, wherein at least one of the components as follows is selected: less than or equal to 0.1% of V and less than or equal to 0.1% of Nb; and 30Sn%+5Mo%+2.5W%+Ni%+Cu%+0.5Si%-0.25Mn% is greater than or equal to 9.0. Based on the Cu-Mo-Sn-Si alloying, the adverse effect to the corrosion resistance of the stainless steel in which the Ni is reduced and the Mn is added is eliminated, so that the stainless steel has the pitting corrosion resistance superior to 304 and can be prevented from being corroded by a reducing acid. Meanwhile, the temperature of Md30 / 50 is controlled to be lower than -75 DEG C and the austenitic stability is controlled to be superior to 304 and 305, so that the magnetic martensite phase transformation is avoided when the deformation of the stainless steel in cold machining is less than or equal to 50%. Thus, the non-magnetic performance of the hard austenitic stainless steel is also maintained.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Ultra high-temperature resistant nickel-chrome alloy and manufacturing method thereof

InactiveCN101684530AImprove high temperature resistanceImprove oxidation resistanceNickelHeat processing

The invention provides an ultra high-temperature resistant nickel-chrome alloy and a manufacturing method thereof, wherein the ultra high-temperature resistant nickel-chrome alloy has a higher meltingpoint, can resist the high temperature higher than 1300 DEG C for a long time and has better tensile strength and yield strength simultaneously. The ultra high-temperature resistant nickel-chrome alloy basically comprises the following components in percentage by weight: 21-25 of Cr, 58-63 of Ni, Al which is not less than 1 and not more than 1.7, Cu which is not less than 0.5 and not more than 1.0, C which is not less than 1 and more than 0.1, Si which is not less than 0.5 and more than 0, Mn which is larger than 0 and not more than 1.0, S which is larger than 0 and less 0.015, and the balance of Fe. The manufacturing method comprises the following steps: mixing the materials according to the alloy components and then smelting; carrying out secondary refining; first heating the mixture to900-1200 DEG C, keeping the temperature for 10-40 minutes, and then forging; cold processing; and water cooling. The invention improves the high-temperature resistant performance, the tensile strength and the yield strength of the alloy, and has better comprehensive benefit. The manufacturing method solves the problems of alloy smelting and heat processing, and improves the product purity.

Owner:杭正奎

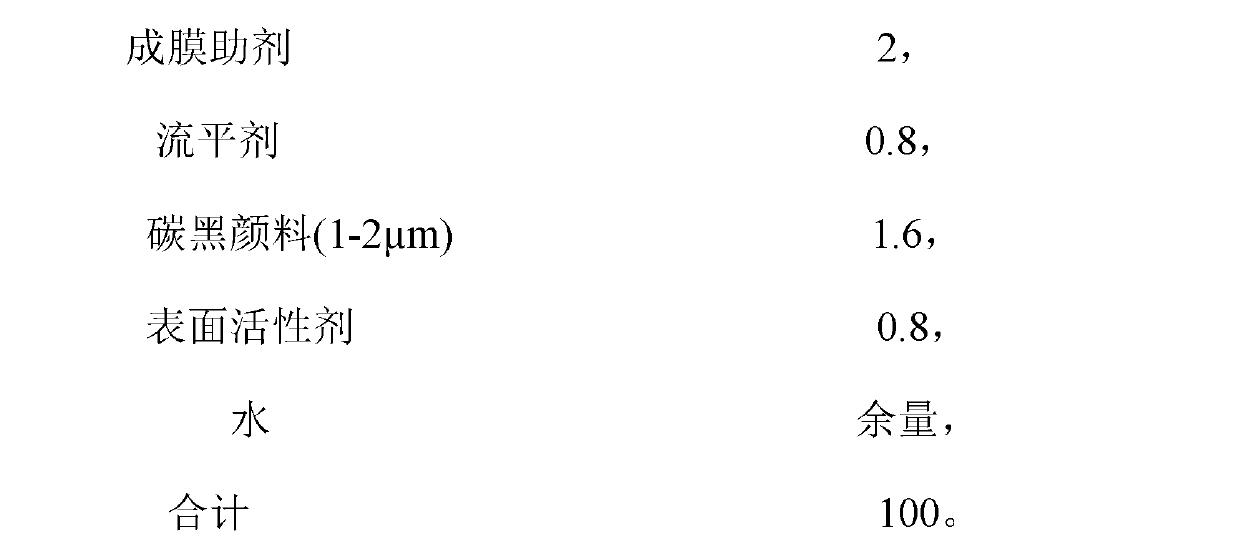

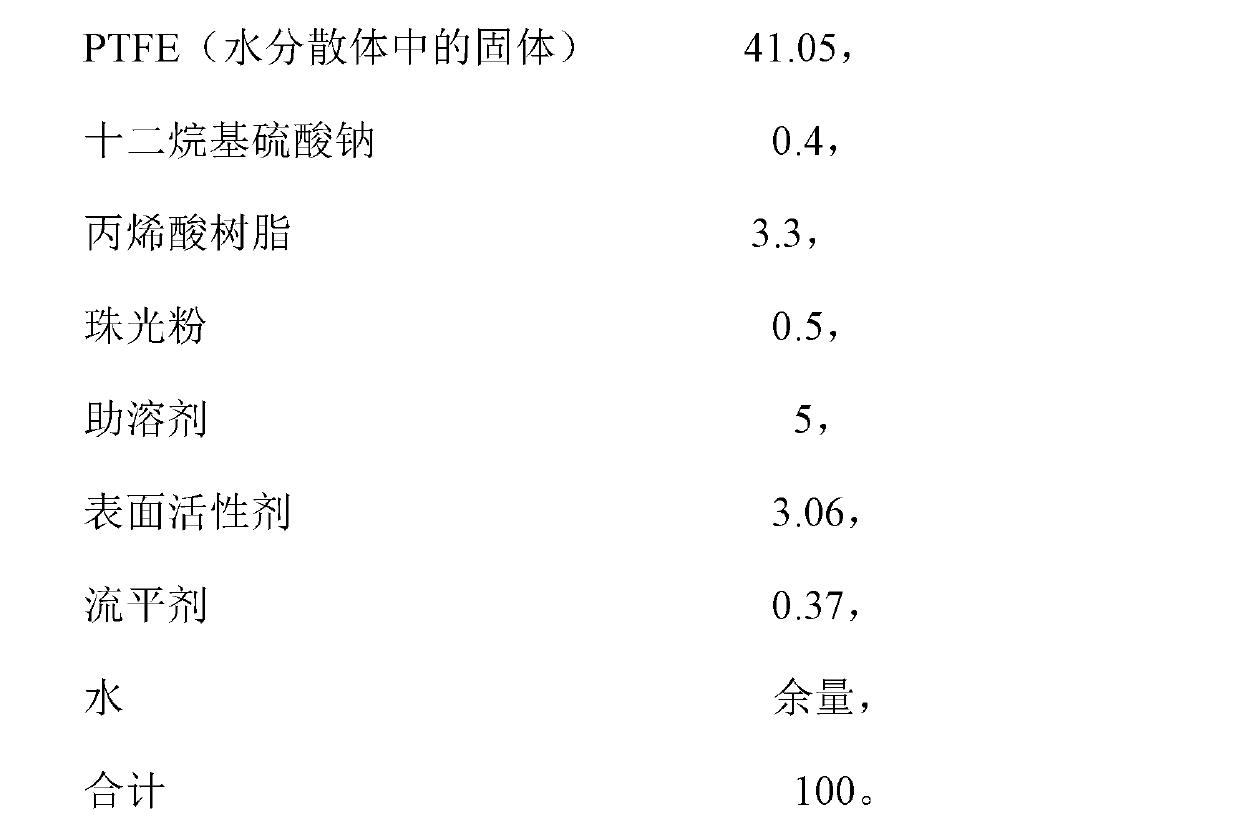

Non-stick coating layer with characteristics of high hardness, scratch resistance and corrosion resistance, and coating method thereof

ActiveCN103213357AHigh hardnessReduced corrosion resistanceSynthetic resin layered productsPretreated surfacesFluorocarbonCorrosion

The present invention relates to a non-stick coating layer with characteristics of high hardness, scratch resistance and corrosion resistance. The coating layer comprises a prime coat containing PES and PEEK, and a surface coat containing a fluorocarbon resin and PEEK, wherein the prime coat contains 20-30% of the PES and 20-30% of the PEEK, and the surface coat contains 20-30% of the PEEK and 3-10% of the fluorocarbon resin. The present invention further provides a coating method for the non-stick coating layer. Compared with the conventional aqueous fluorine-containing resin non-stick coating layer, the coating layer of the present invention provides significantly improved hardness, scratch resistance, corrosion resistance and other performances.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

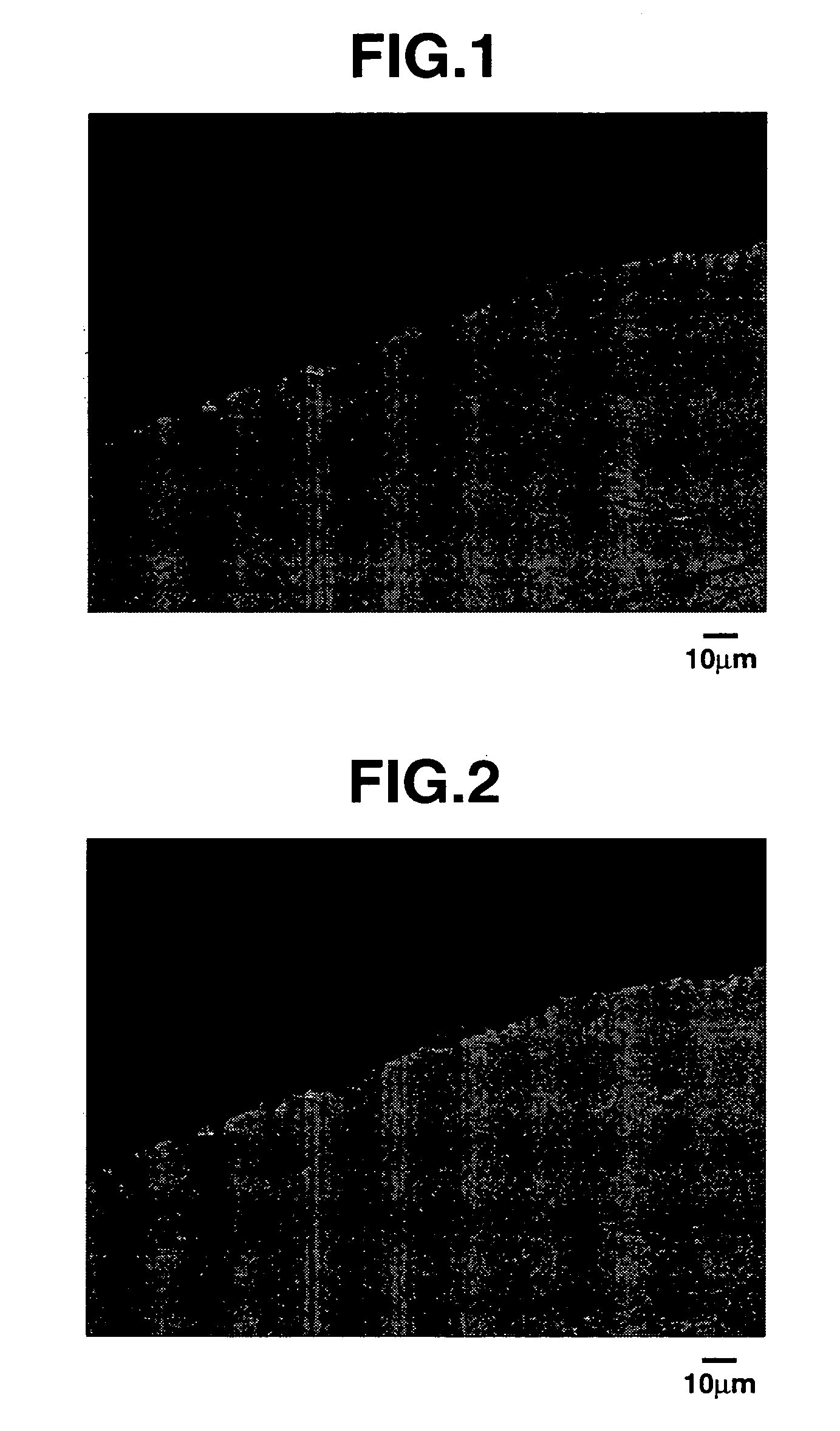

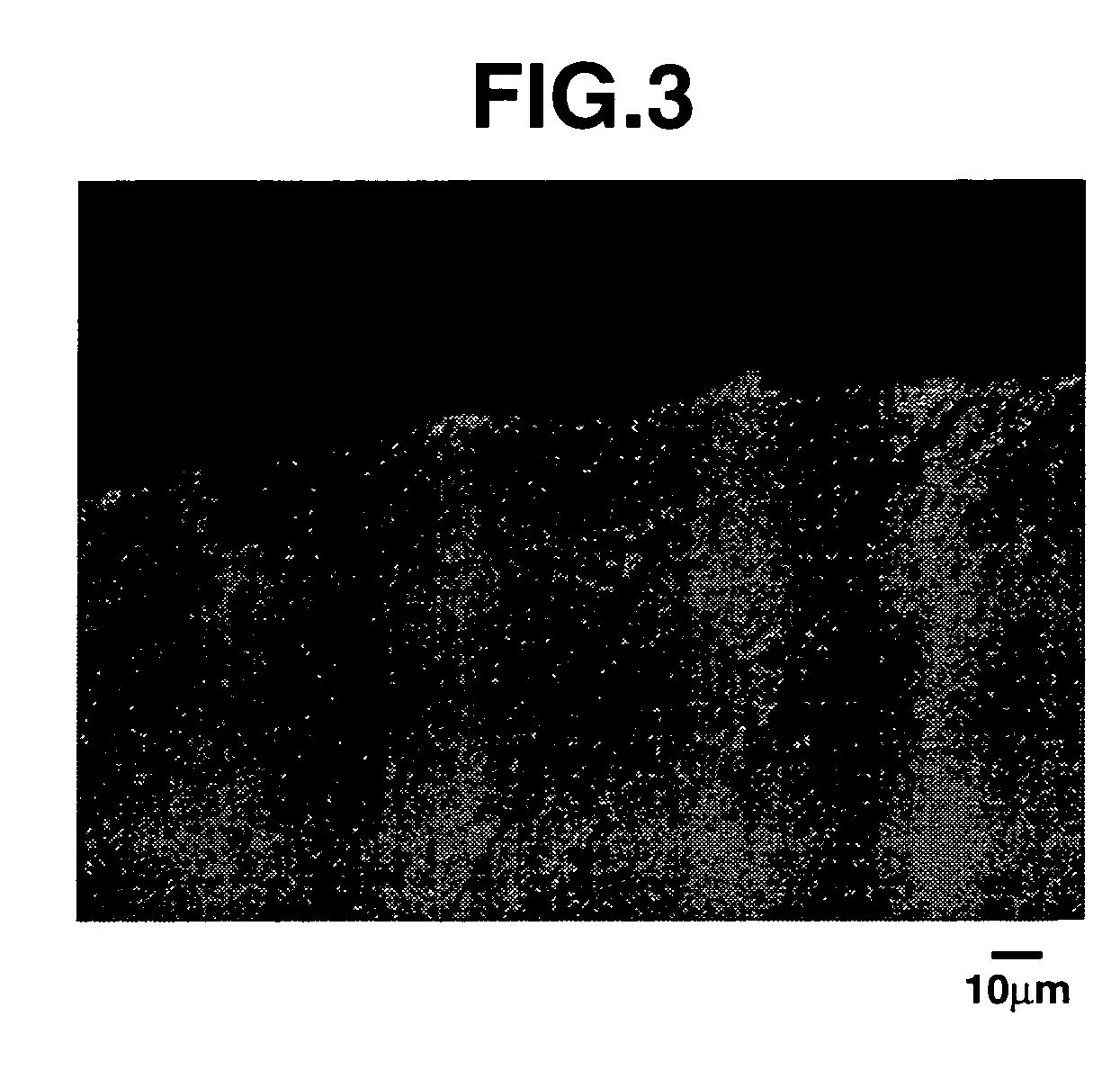

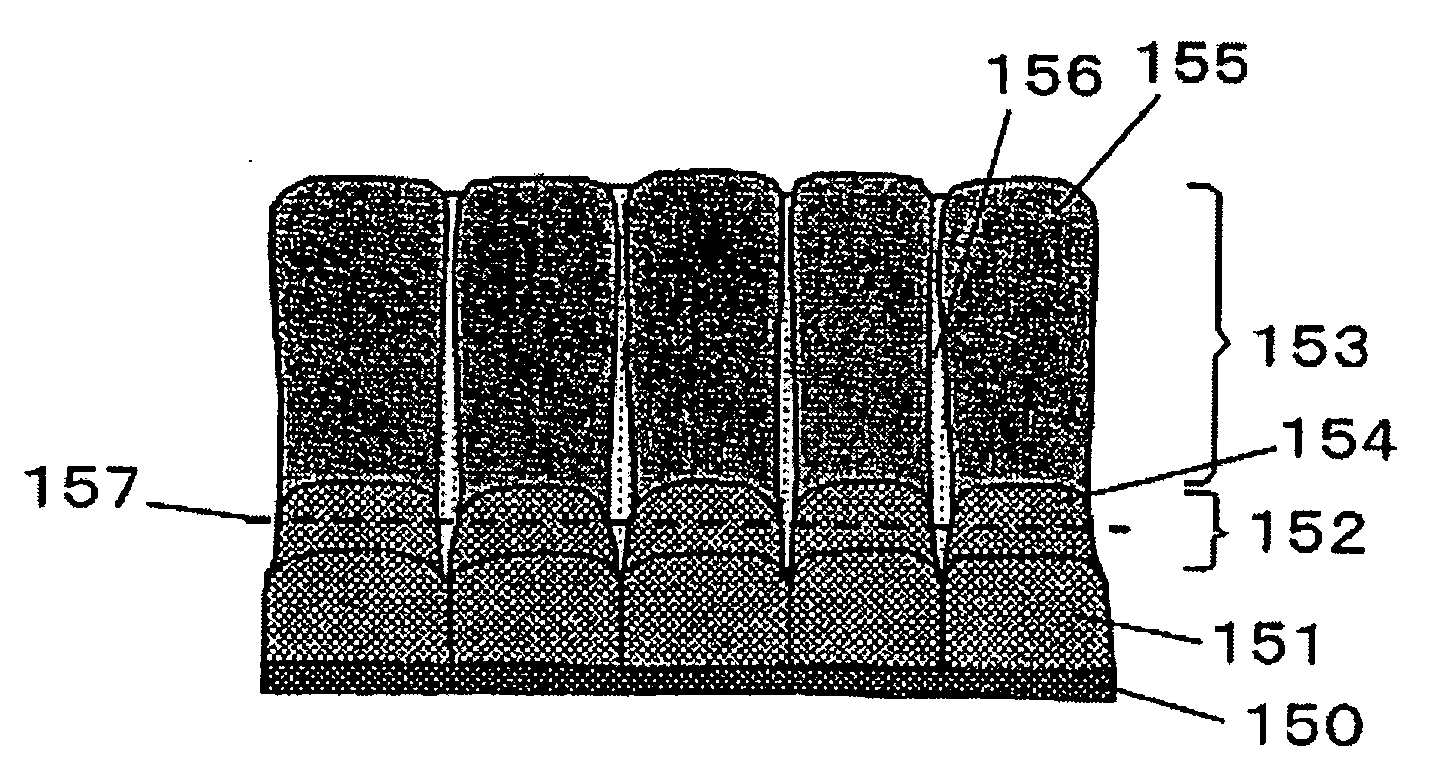

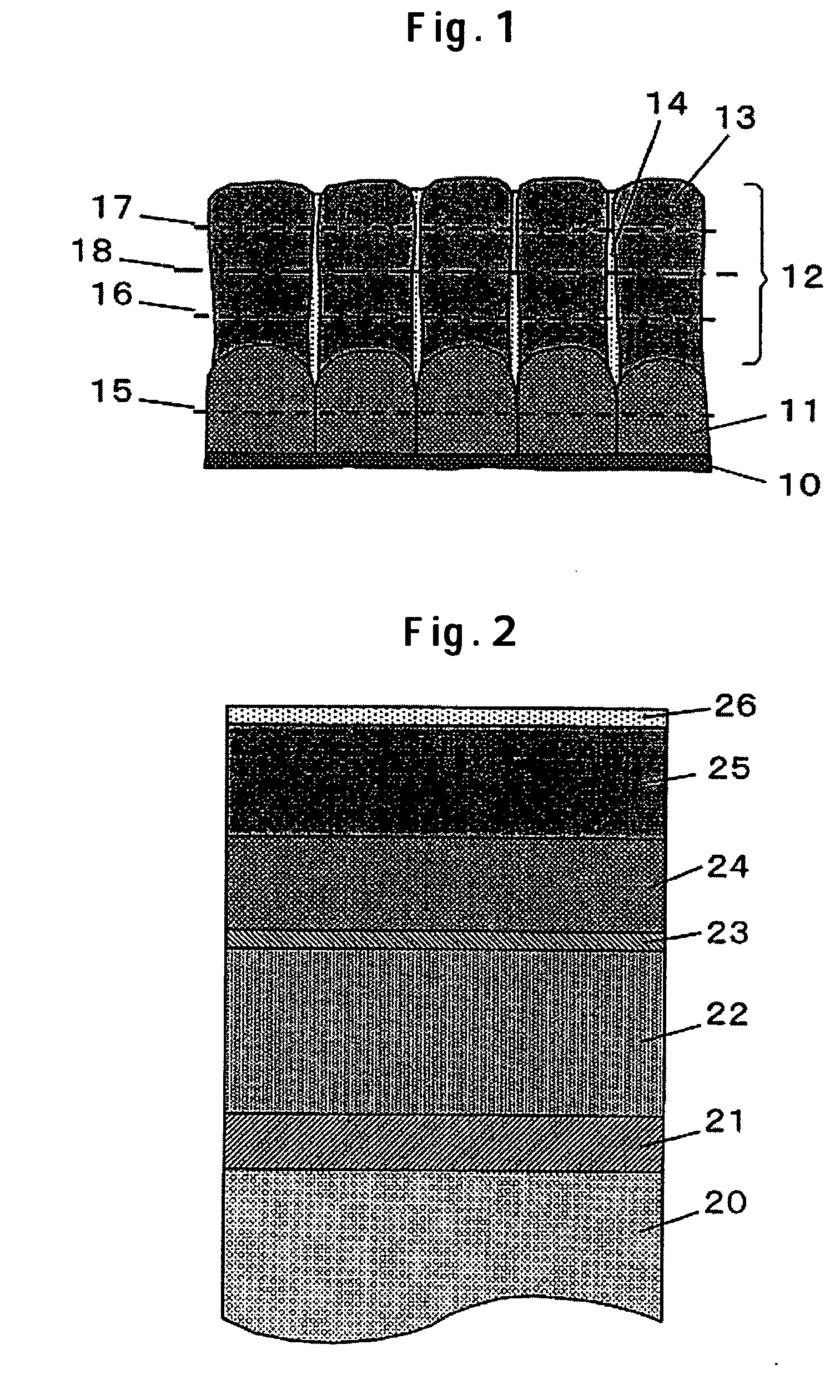

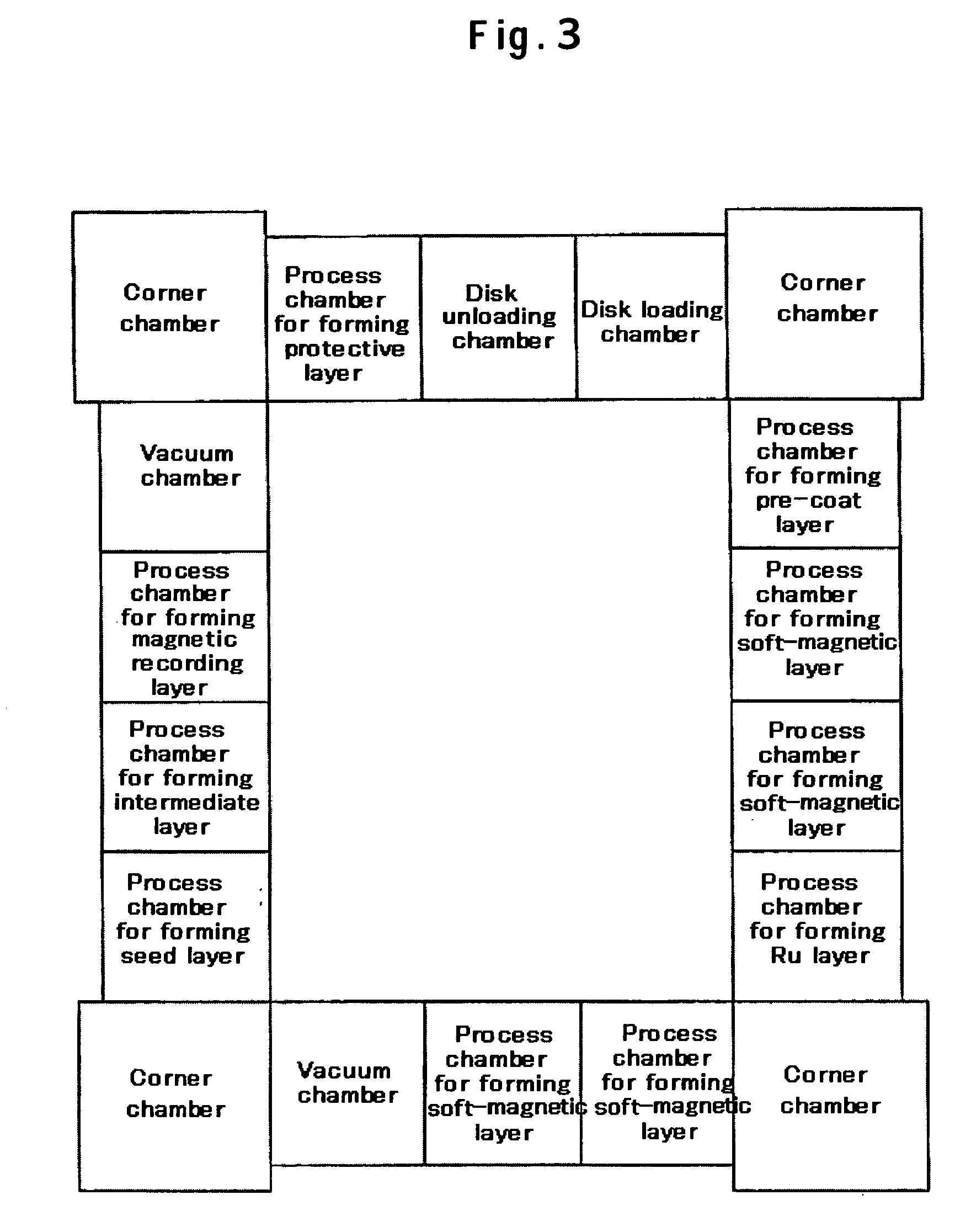

Perpendicular magnetic recording medium with granular structured magnetic recording layer, method for producing the same, and magnetic recording apparatus

InactiveUS20060088737A1Secure durabilitySecure flyabilityVacuum evaporation coatingSputtering coatingRecording layerProtection layer

Embodiments of the invention provide a perpendicular magnetic recording medium having a granular structured magnetic recording layer including many columnar grains, and grain boundary layers containing oxide, wherein a high medium S / N ratio is obtained while securing head flyability and durability. In an embodiment, the perpendicular magnetic recording medium includes a granular structured magnetic recording layer having many columnar grains, as well as grain boundary layers including oxide respectively. Assuming that the columnar grains are divided equally in the film thickness direction into a protective layer side portion and an intermediate layer side portion, and the diameter of the protective layer side portion is larger than that of the intermediate layer side portion.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Hot-dip zinc aluminum magnesium silicon rare earth coated steel strips taking air as air source of air knife during production

InactiveCN101812653AEvenly distributedUniform tissue structureHot-dipping/immersion processesCeriumAir knife

The invention relates to hot-dip zinc aluminum magnesium silicon rare earth coated steel strips taking air as an air source of an air knife during production. The coating material on the surface of the steel strips comprises the following components in percentage by weight: 9.9 to 12.1 percent of Al, 1.0 to 1.8 percent of Mg, 0.18 to 0.22 percent of Si, 0.01 to 0.3 percent of rare earth (RE), and the balance of Zn. Based on a quaternary component Zn-Al-Mg-Si in Nippon Steel, the rare earth (RE) comprising lanthanum and cerium is added into the coating material so as to become a quintuple component Zn-Al-Mg-Si-RE, and the content of the magnesium is reduced. Because of the addition of the trace RE, the component distribution of the coating can become more uniform, the organizational structure is more uniform, and the corrosion resistance is further improved based on the original corrosion resistance; and because the content of the magnesium is reduced properly, the coating can bear the blowing of the air knife and cannot be oxidized and discolored on the premise of ensuring high corrosion resistance, and meets the requirements of the corrosion resistance and apparent mass.

Owner:梁士臣

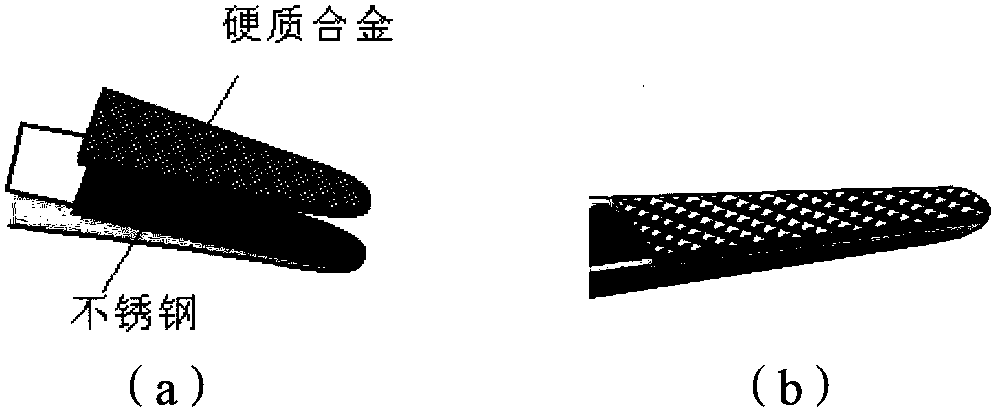

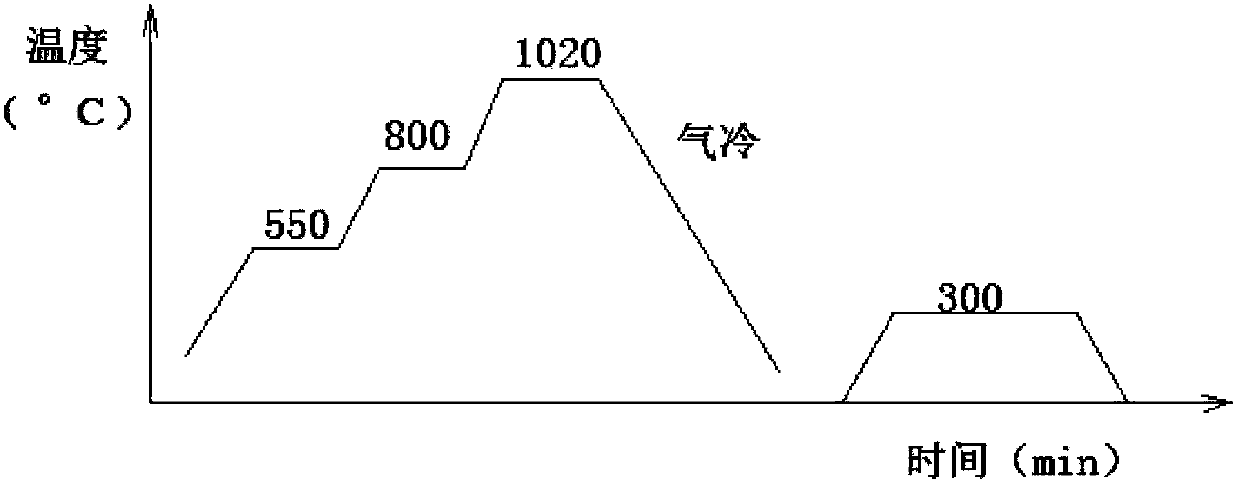

Vacuum brazing and thermal treatment composite process for stainless steel surgical instrument and application of process

InactiveCN103386525AImprove anti-corrosion performanceNot easy to rustSoldering apparatusCemented carbideProduction rate

The invention relates to a vacuum brazing and thermal treatment composite process for a stainless steel surgical instrument and the application of the process. An embedding method is adopted for embedding cemented carbide in the working end of the stainless steel surgical instrument, vacuum brazing and vacuum thermal treatment are adopted for synchronous treatment, the two processes are combined into one process, and on the basis of controlling the vacuum degree, the heating speed, the heating temperature, the brazing temperature, the brazing opportunity and the cooling method, the stainless steel surgical instrument with the working end embedded with the brazed cemented carbide is obtained. The stainless steel surgical instrument has excellent abrasive resistance, anti-slip performance, anti-corrosive performance and the like, the product quality is high, the energy consumption is low, the production rate is high and the operation environment is improved, and quality defects of the original process are overcome. The composite process has great significance in the process of treating stainless steel surgical instruments.

Owner:上海医疗器械(集团)有限公司

Ceramic filter

ActiveUS20060213165A1Avoid erosionImprove corrosion resistanceSemi-permeable membranesDispersed particle filtrationAlkali freePore diameter

A ceramic filter has (A) a base body having partition walls made of a ceramic porous body, wherein cells 18 are defined by the partition walls, (B) filer membranes provided on the partition walls, made of a ceramic porous body having an average pore diameter smaller than that of the surface of each partition wall, and (C) a glass seal provided so as to cover at least the end face of the base body, wherein the glass seal is constituted by an alkali-free glass containing silica (SiO2) in an amount of 55 to 65 mol %, zirconia (ZrO2) in an amount of 1 to 10 mol % and at least one kind of alkaline earth metal oxide selected from calcia, baria and strontia but substantially not containing zinc oxide.

Owner:NGK INSULATORS LTD

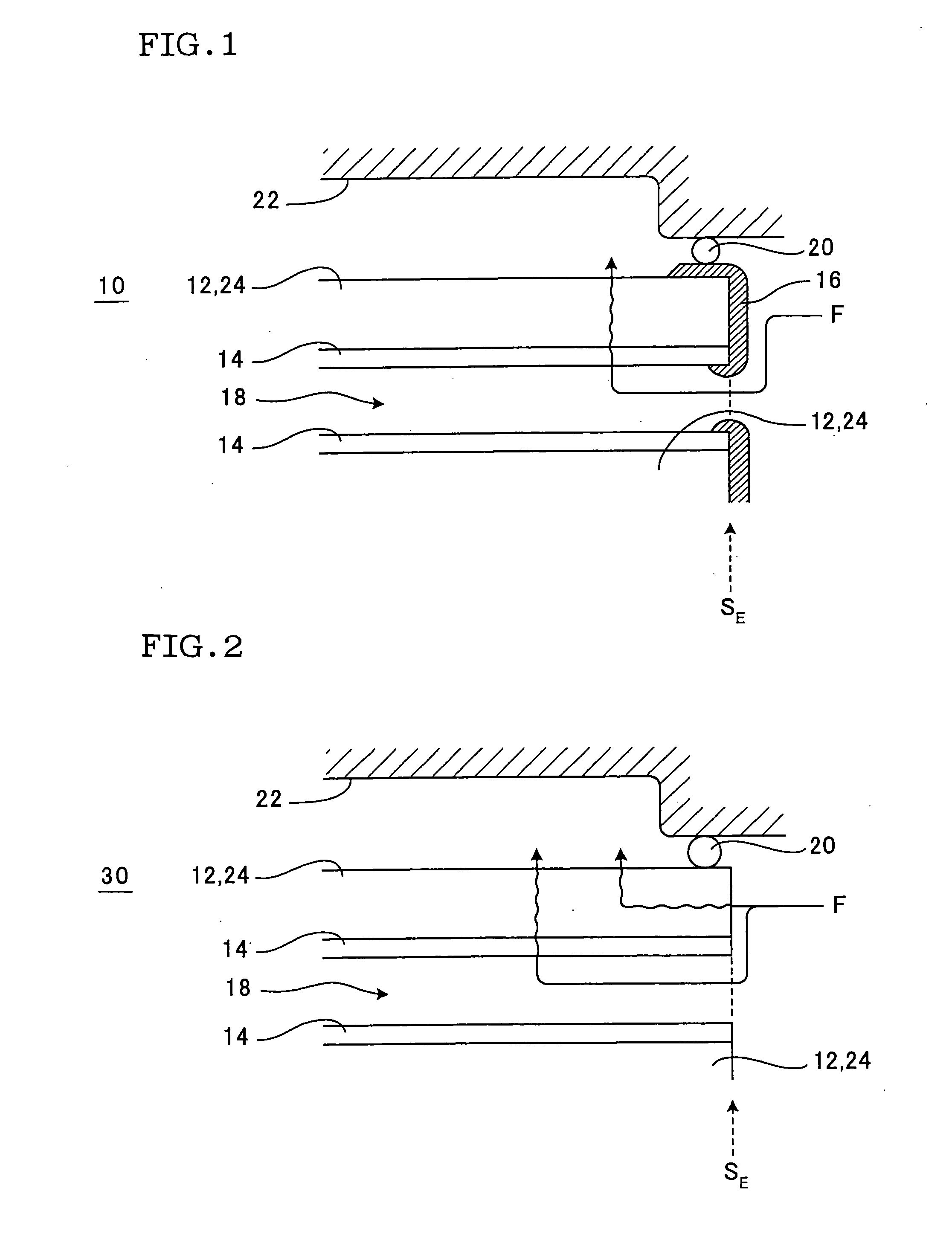

Before-coating metal surface treatment method

ActiveCN105369271AImprove permeabilityFast film formationMetallic material coating processesNonferrous metalAcid washing

The invention discloses a before-coating metal surface treatment method. The before-coating metal surface treatment method comprises such steps as oil removal, alkali washing, acid washing, two times of water washing and phosphorization. Adopted environment-friendly alkaline cleaning liquid has the technical effects of energy conservation and environmental protection, and has an excellent cleaning effect on both black metal and nonferrous metal; adopted phosphorization liquid has such advantages as quick film formation, strong paint film bonding force, good corrosion resistance, capability of operating through brushing or spraying, simple operation and low cost; the prepared phosphorization liquid reduces phosphorization liquid sediments, and guarantees the quality of phosphorized film; and the film layers are uniform and exquisite, so that the metal surface treatment method can realize the before-coating metal surface treatment more environment-friendly and more efficiently, and has active effects on the coating process and the coating quality.

Owner:苏州天成涂装系统股份有限公司

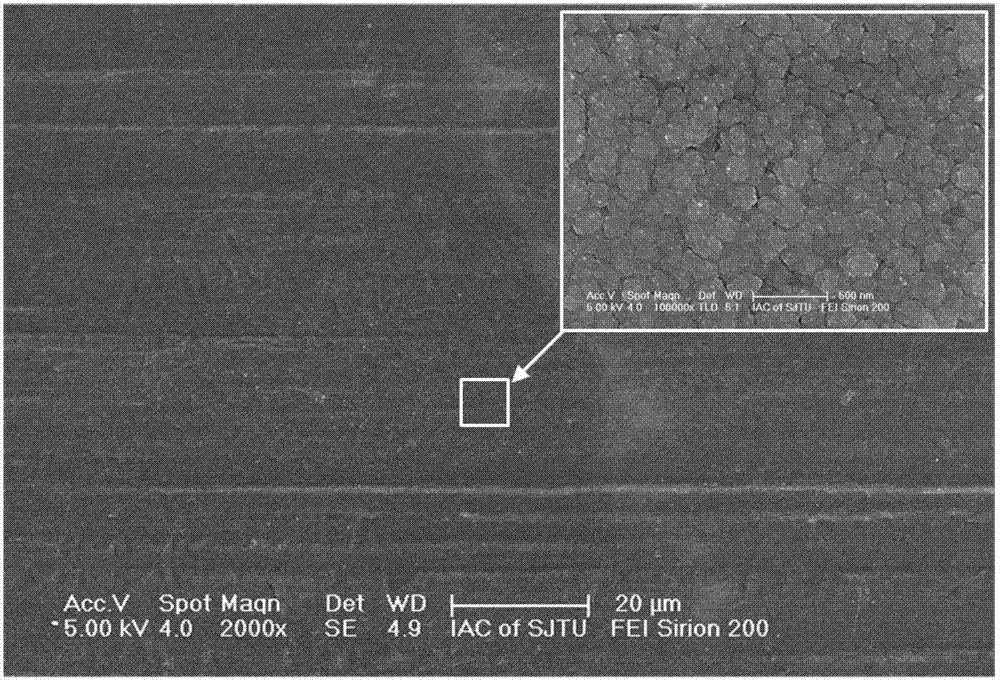

Bipolar plate of fuel cell and method for preparing carbon titanium nanocomposite film on surface thereof

The invention discloses a bipolar plate of a fuel cell and a method for preparing a carbon titanium nanocomposite film on the surface thereof, belongs to the technical field of surface modification of metallic materials and fuel cells, and relates to a bipolar plate of a regenerative fuel cell and a proton exchange membrane fuel cell and a preparation technology of a surface modified film of the bipolar plate. The bipolar plate consists of a metal thin plate substrate and carbon titanium nanocomposite films which are formed on the surfaces at two sides of the substrate, wherein the metal thin plate substrate is a titanium plate and a stainless steel plate; the carbon titanium nanocomposite film is an amorphous and nanocrystalline composite film which is prepared on an amorphous carbon substrate with an arc ion film plating method and on which titanium and titanium carbide nanocrystals are distributed; the thickness of the film is of micron dimension; and the size of the crystal grains of the nanocrystals is of micron dimension. The invention has the effects and advantages that: the bipolar plate is low in manufacturing cost, has prominent composite performance such as corrosion resistance, conductivity, hydrophobicity and the like, can be used for replacing a noble metal bipolar plate and a graphite bipolar plate, and can be used as a cell bipolar plate of the proton exchange membrane fuel cell and an electrolytic cell bipolar plate of the regenerative fuel cell.

Owner:DALIAN UNIV OF TECH

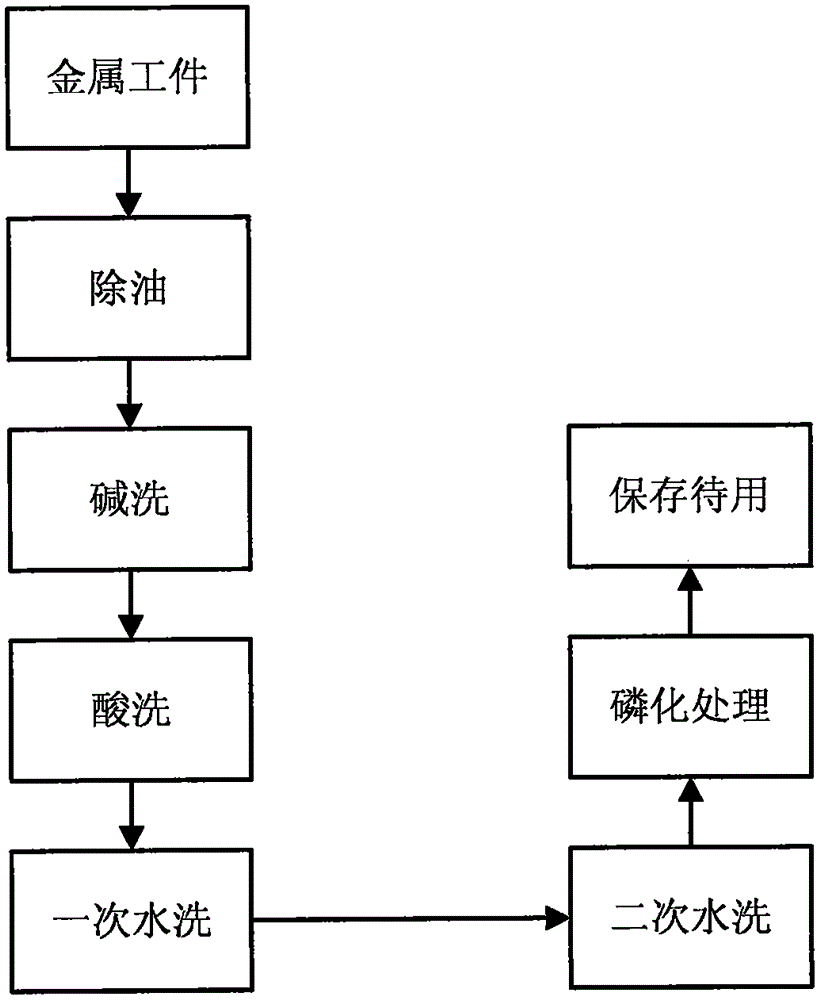

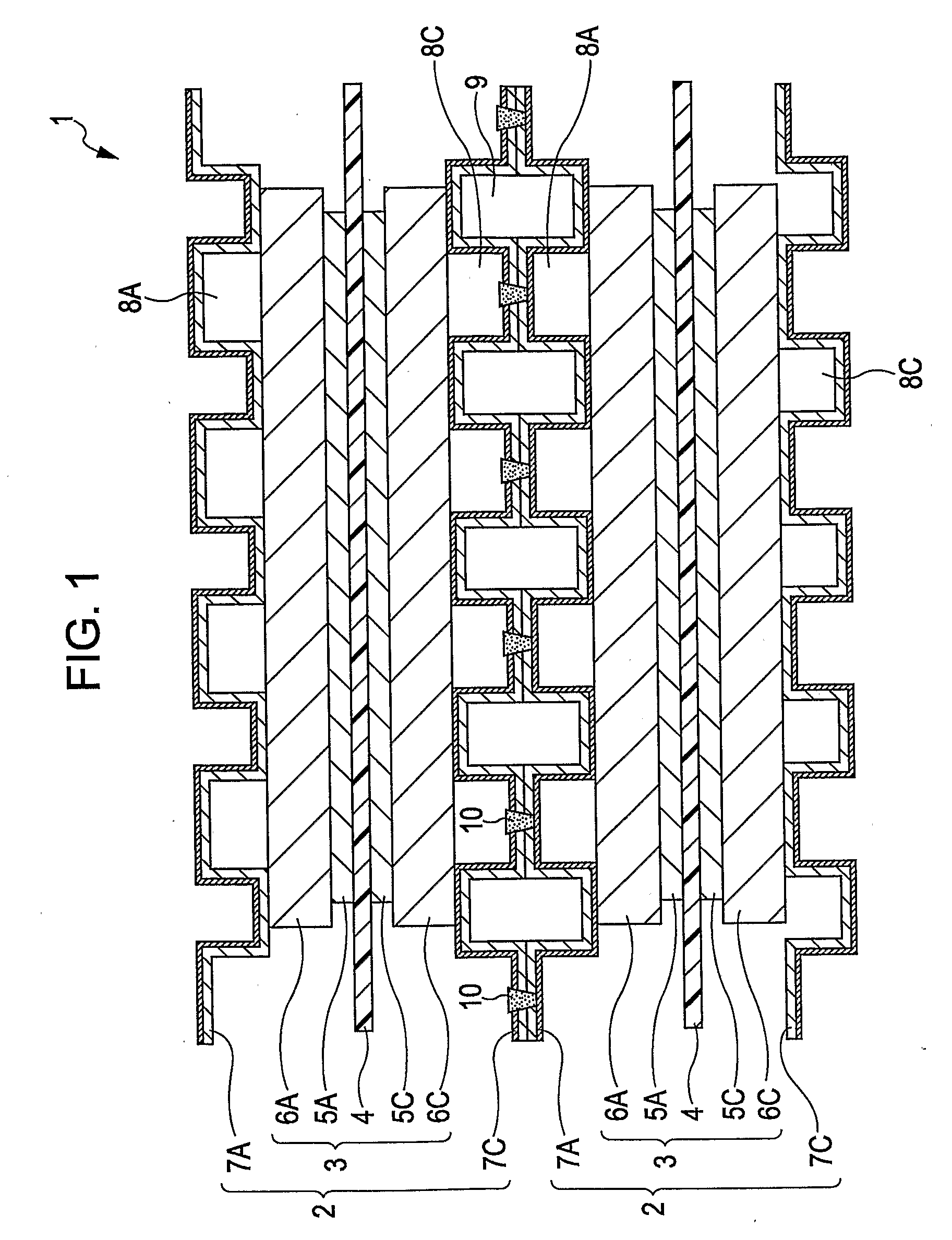

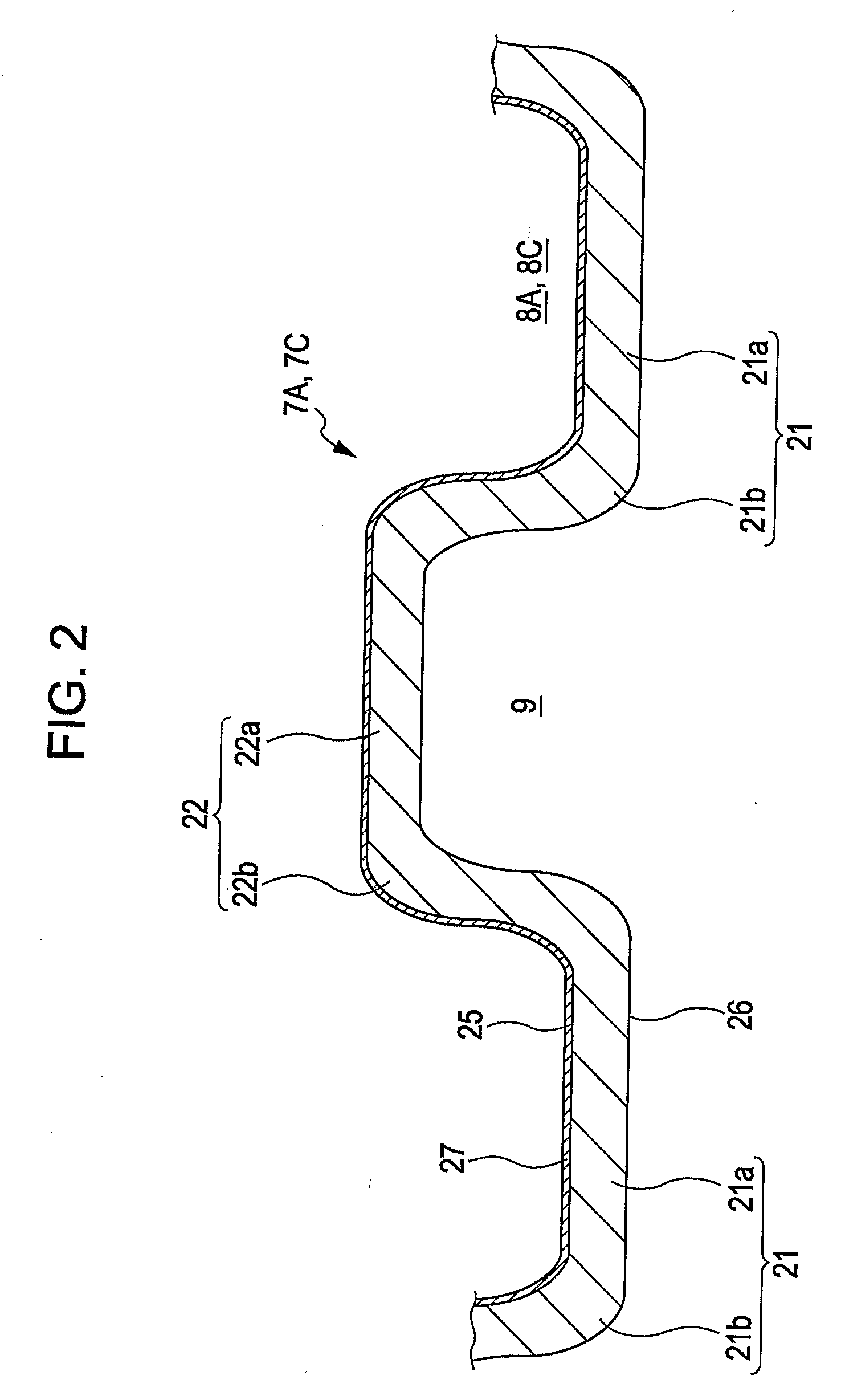

Fuel cell stack and method of producing its separator plates

ActiveUS20090092872A1Reduce contact resistanceCorrosion resistance can be ensuredExhaust apparatusFinal product manufactureTemperature controlFuel cells

A cell of a fuel cell includes a membrane electrode assembly, and metal first and second separators which sandwich the membrane electrode assembly to form gas flow paths disposed on each side of the membrane electrode assembly. A back surface of the first separator and a back surface of the second separator, the first separator and the second separator being included in adjacent cells, are in contact with each other, thereby forming a temperature-control medium flow path between the first separator and the second separator. In the first separator and the second separator, corrosion-resistant coating layers are provided only on reaction-side surfaces of the first separator and the second separator, the reaction-side surfaces facing the membrane electrode assembly, and portions where the back surface of the first separator is in contact with the back surface of the second separator are joined by welded portions.

Owner:NISSAN MOTOR CO LTD

Environment-friendly type insulated dope for cold rolling non-oriented silicon steel and preparation method for coat thereof

The invention relates to an environment-friendly insulating coating for cold-rolled non-oriented silicon steel and a preparation method thereof. The components of the insulating coating include: phosphate, molybdate, water, organic resin, silane coupling agent, and glycerol; the above-mentioned The weight ratio of each component is: phosphate 100, molybdate 3-20, water 800-1500, organic resin 20-50, silane coupling agent 0.5-5, glycerol 8-15. The steps of the coating preparation method are: (1) coating insulating paint on the surface of cold-rolled non-oriented silicon steel; (2) baking and drying, the baking temperature is 150-300 ° C; 600°C, the sintering time is 30-90 seconds; (4) Finished product. The insulating paint of the invention does not contain harmful elements, and the coating has good insulating performance, good adhesion and corrosion resistance, good punching and shearing processability and weldability, and can withstand heat resistance of stress-relieving annealing. The method of the invention is simple to operate, and the coating prepared by the method has good punching and shearing processability and weldability, and can withstand heat resistance of stress-relieving annealing.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com