Non-stick coating layer with characteristics of high hardness, scratch resistance and corrosion resistance, and coating method thereof

A technology of non-stick coating and corrosion resistance, which is applied in coatings, chemical instruments and methods, layered products, etc., and can solve problems such as poor mechanical properties, poor coating hardness, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0043] Among embodiments 1-6, the components of the topcoat composition are shown in Table 1, and the components of the primer composition are shown in Table 2. By changing the ratio of PES and PEEK in the primer coat, it is investigated that it affects the coating performance Impact.

Embodiment 7-11

[0045] In embodiment 7-11, the composition of top coat composition is shown in Table 1, and the composition of base coat composition is identical with embodiment 4, examines its opposite coating by changing the proportioning of PTFE and PEEK in the base coat. layer performance.

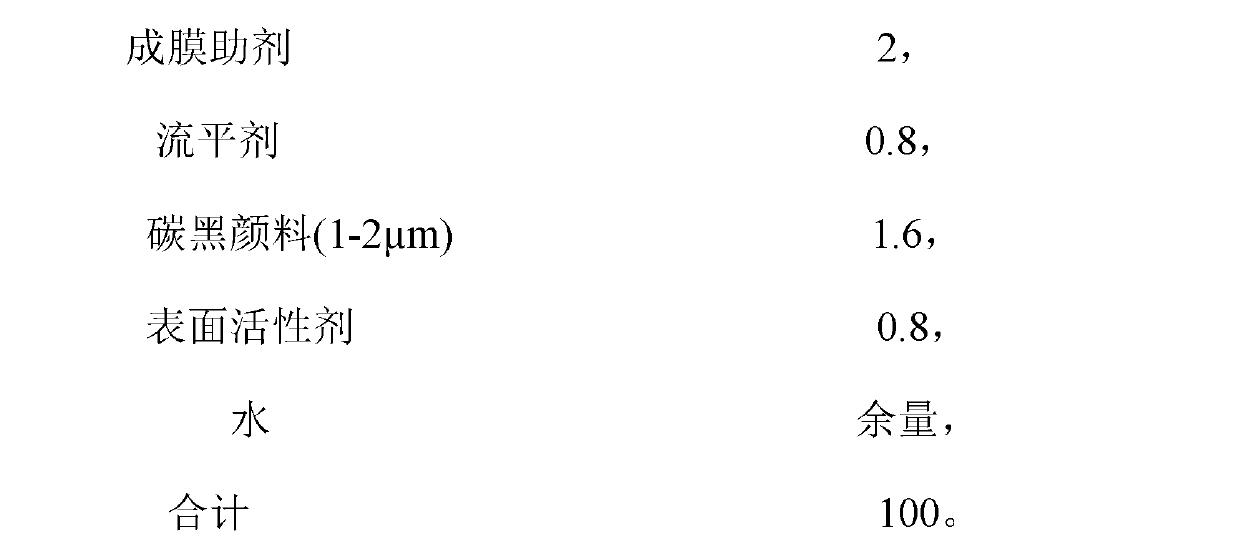

[0046] Table 1 Topcoat composition

[0047]

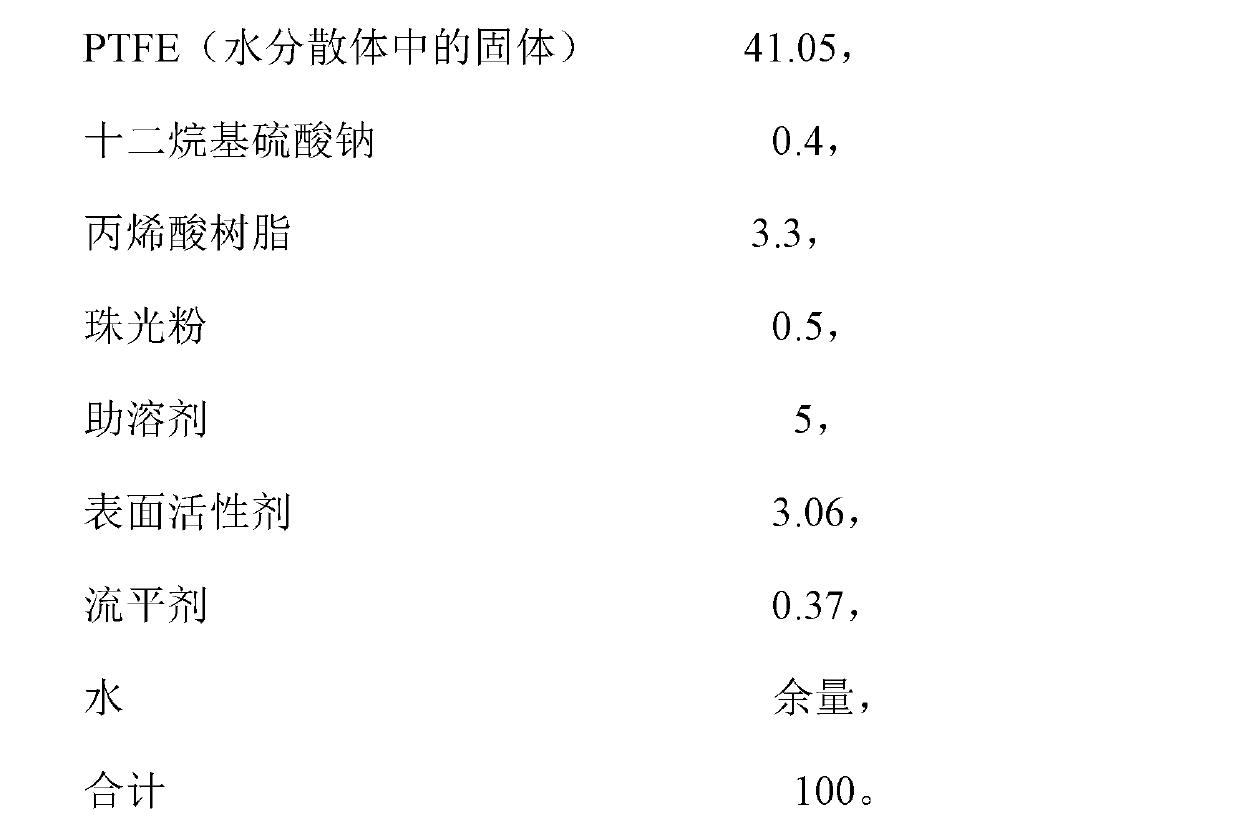

[0048] Table 2 Undercoat composition

[0049]

[0050] The coating method of embodiment 1~11:

[0051] The substrate is a flat-bottomed stretched aluminum pan for spray coating using the topcoat composition and the undercoat composition of Examples 1-11.

[0052] Firstly, the surface of the substrate is cleaned and roughened, and the roughened treatment is specifically sandblasting.

[0053] Then, mix the undercoat composition evenly and apply it on the surface of the substrate, then dry the undercoat at the temperature of the substrate at 400°C±10°C for 10 minutes, cool to room temperature, and then apply the evenly mixed surface coating composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com