New macromolecule fiber composite material

A technology of polymer fibers and new materials, applied in the field of polymer fiber composite new materials, can solve problems such as poor mechanical properties, and achieve the effects of smooth surface, not easy to swell and shrink, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

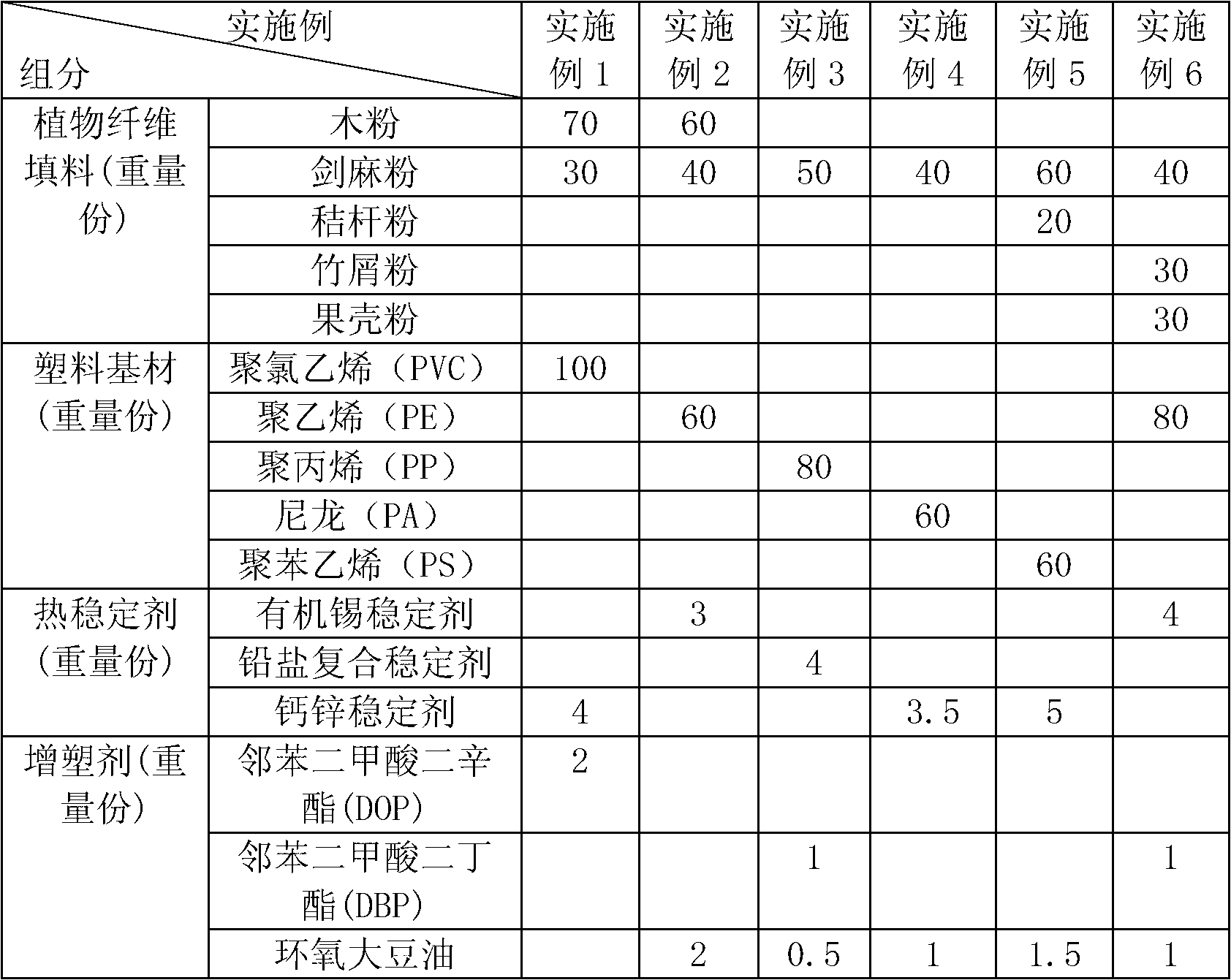

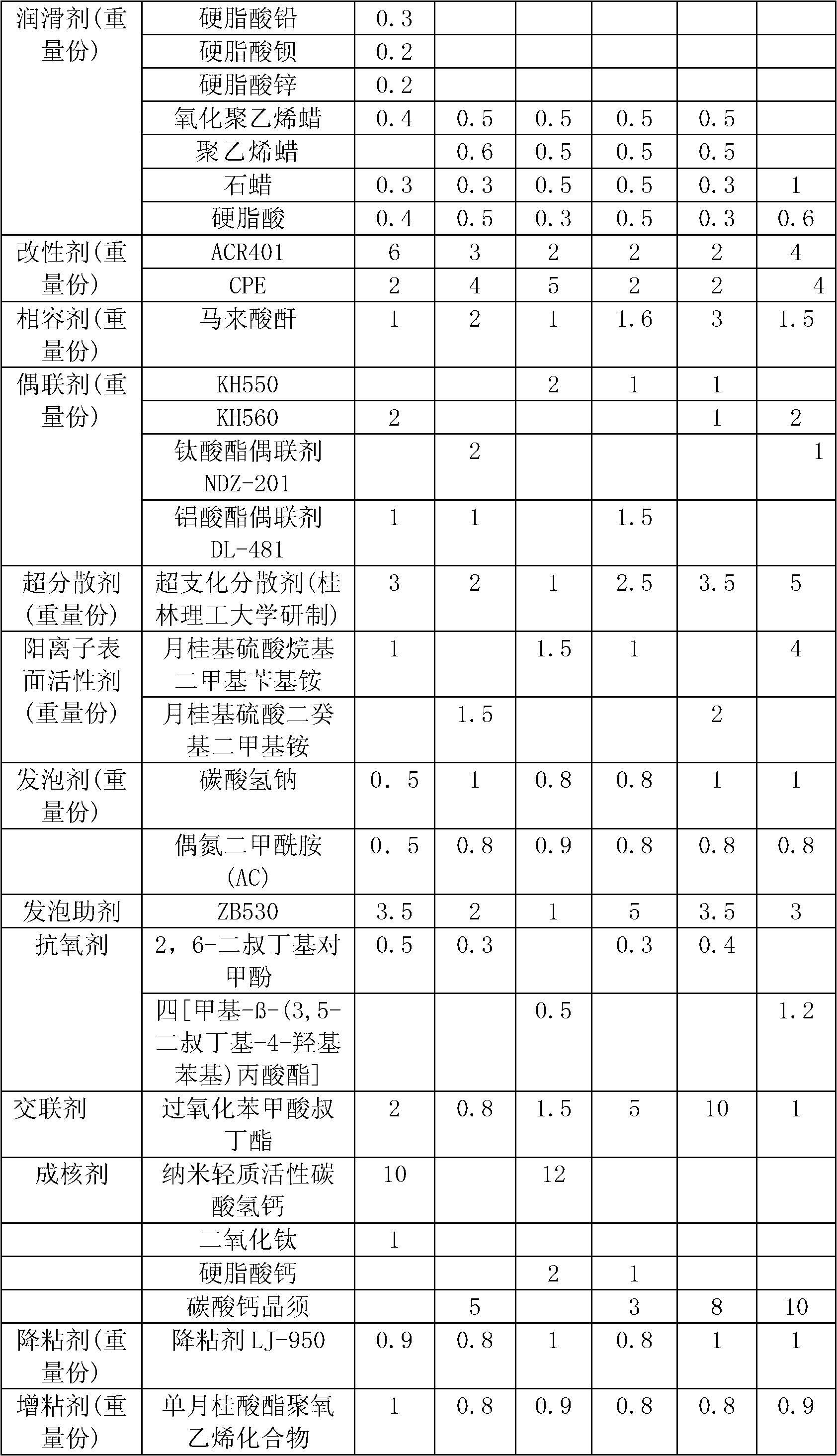

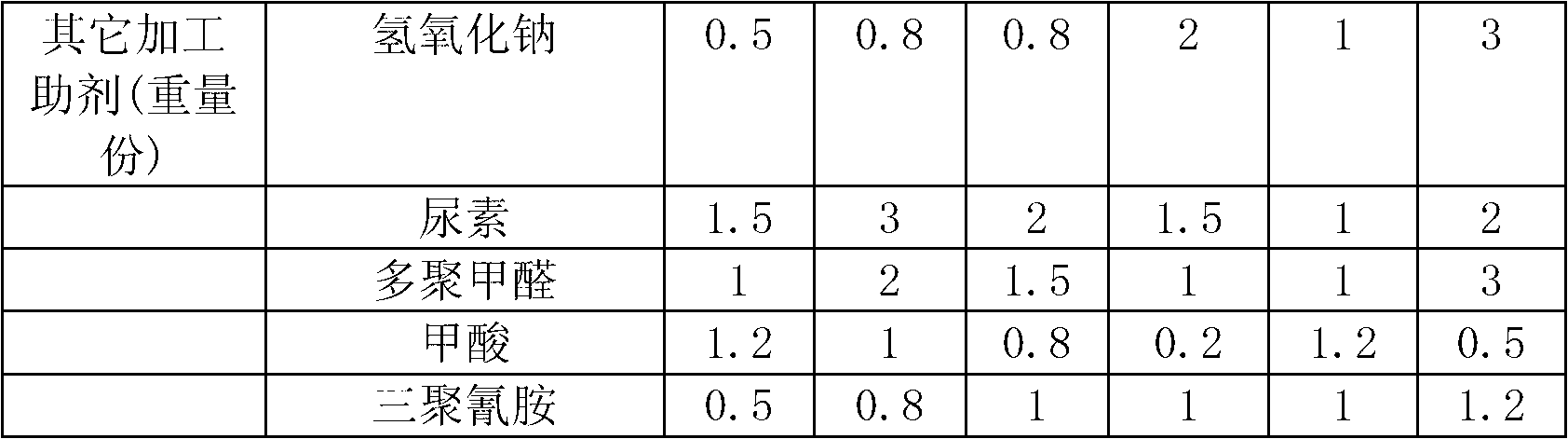

Embodiment 1

[0055] Each component was weighed according to the formula of Example 1 in the following Table 1, and the plate was made according to the above method.

Embodiment 2

[0057] Each component was weighed according to the formula of Example 2 in the following Table 1, and the plate was made according to the above method.

Embodiment 3

[0059] Each component was weighed according to the formula of Example 3 in the following Table 1, and the plate was made according to the above method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com