Petroleum wellhead annular space sealing device

A sealing device and annulus technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of high temperature resistance and strength decline of seals, easy failure, and poor high temperature resistance of rubber, etc. , to achieve the effects of small deformation uncertainty, good corrosion resistance and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

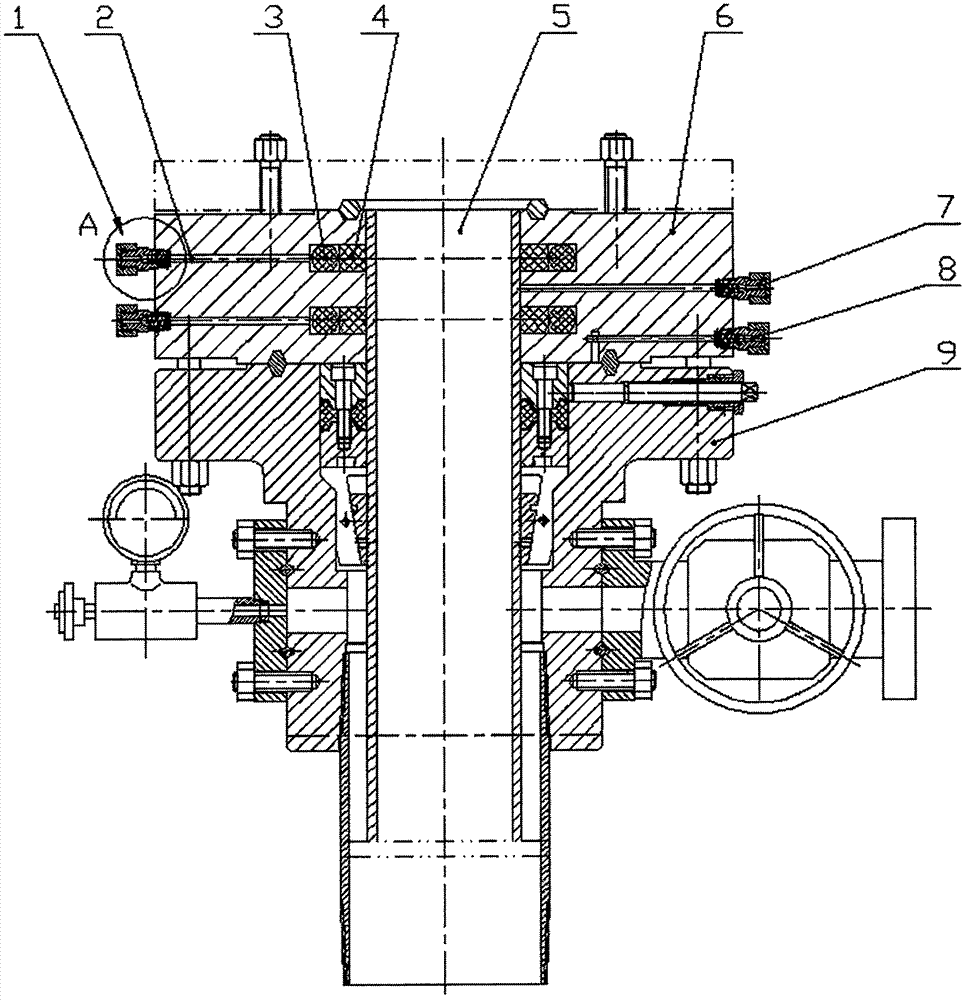

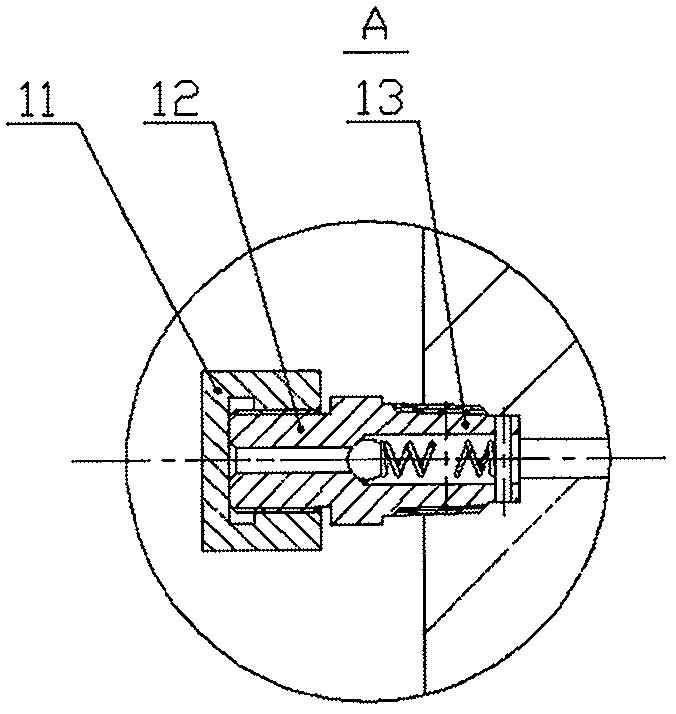

[0037] Refer to the attached figure 1 , is a set of oil wellhead casing heads, and is the assembly structure of the wellhead annulus sealing device on the wellhead equipment in some embodiments. The casing head and the device for sealing the casing annulus, the casing head is the sealing body 6 shown in the figure, which is a part of the oil wellhead (the oil wellhead includes three parts: the casing head, the tubing head and the Christmas tree) .

[0038] As mentioned in the background technology section, there is a relatively large annular space between the sealing body 6 and the oil pipe 5 because the tolerance zone of the oil pipe 5 is relatively wide.

[0039] It will be appreciated that the radial, axial and circumferential directions are generally referenced to the surrounding pipe, based on the pipe and other components fitted around the pipe.

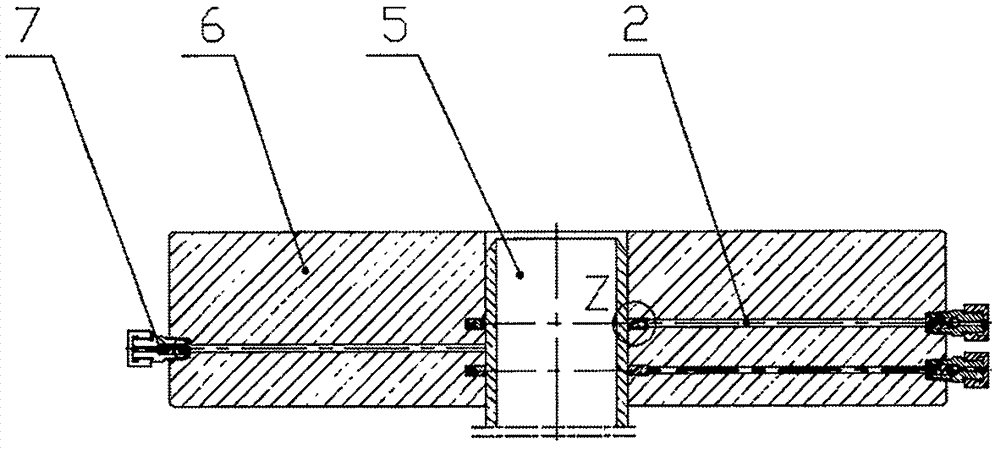

[0040] then if image 3 The oil wellhead annular sealing device shown is used to seal the annular space between the wellhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com