Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

542 results about "Martensite transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

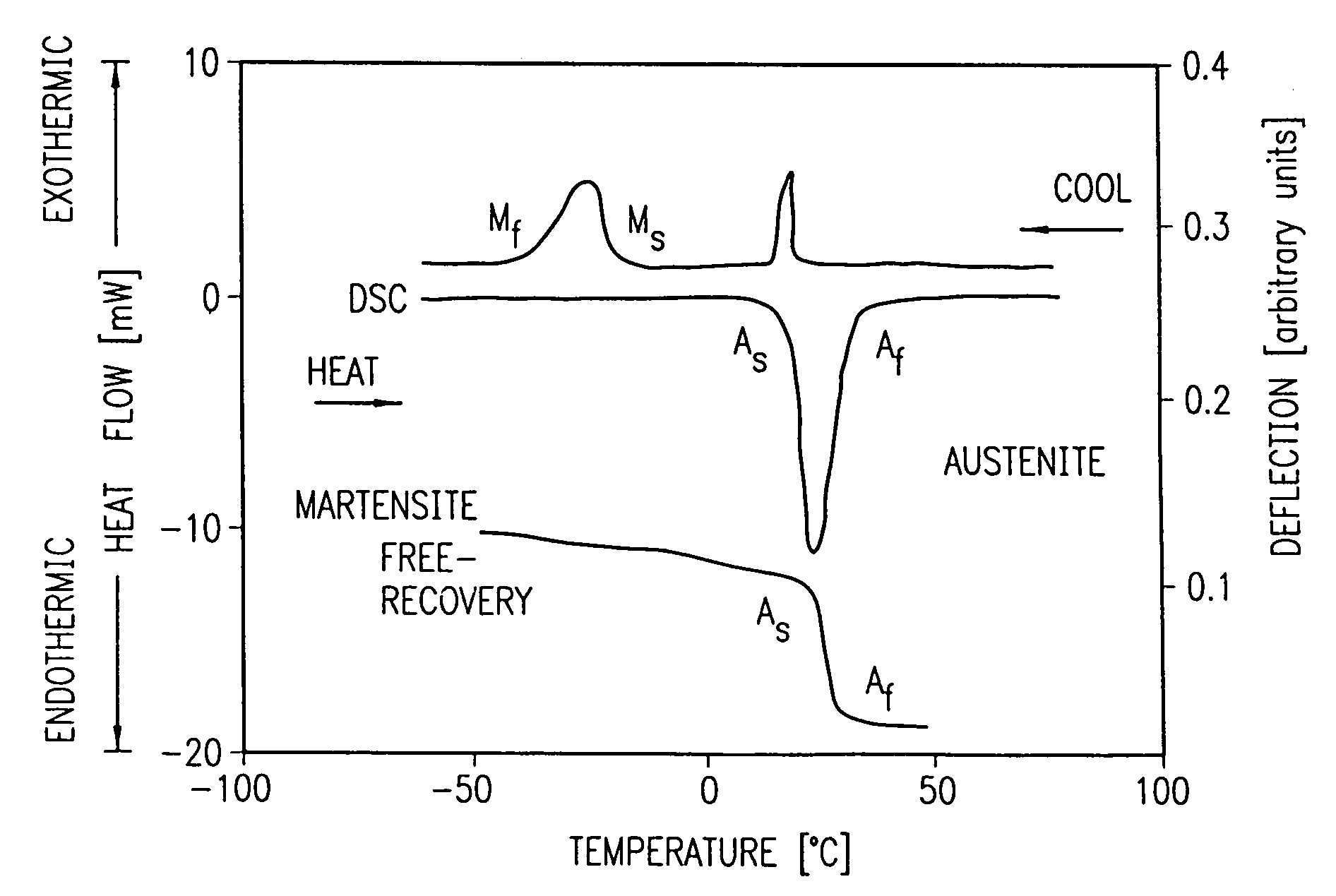

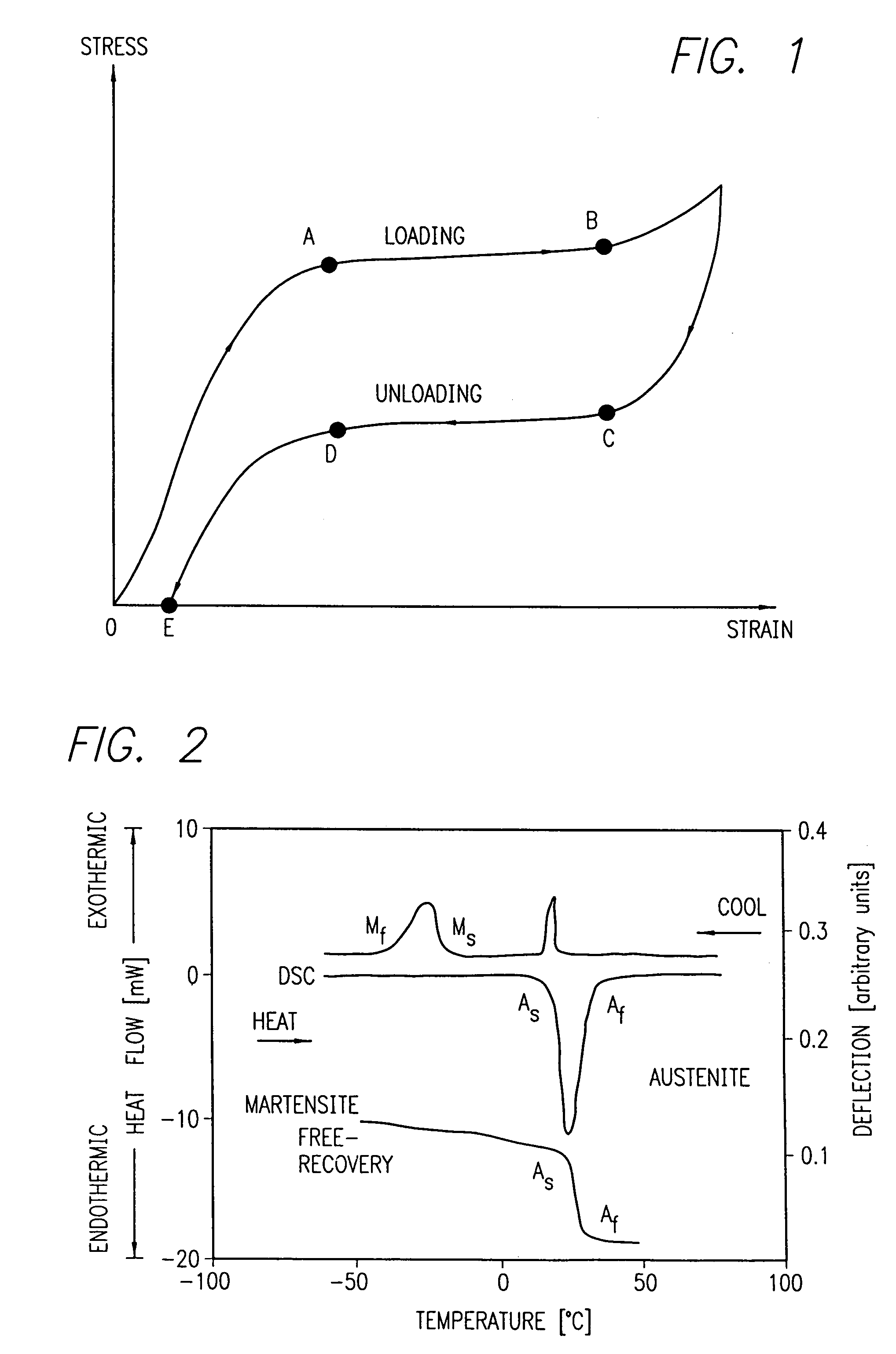

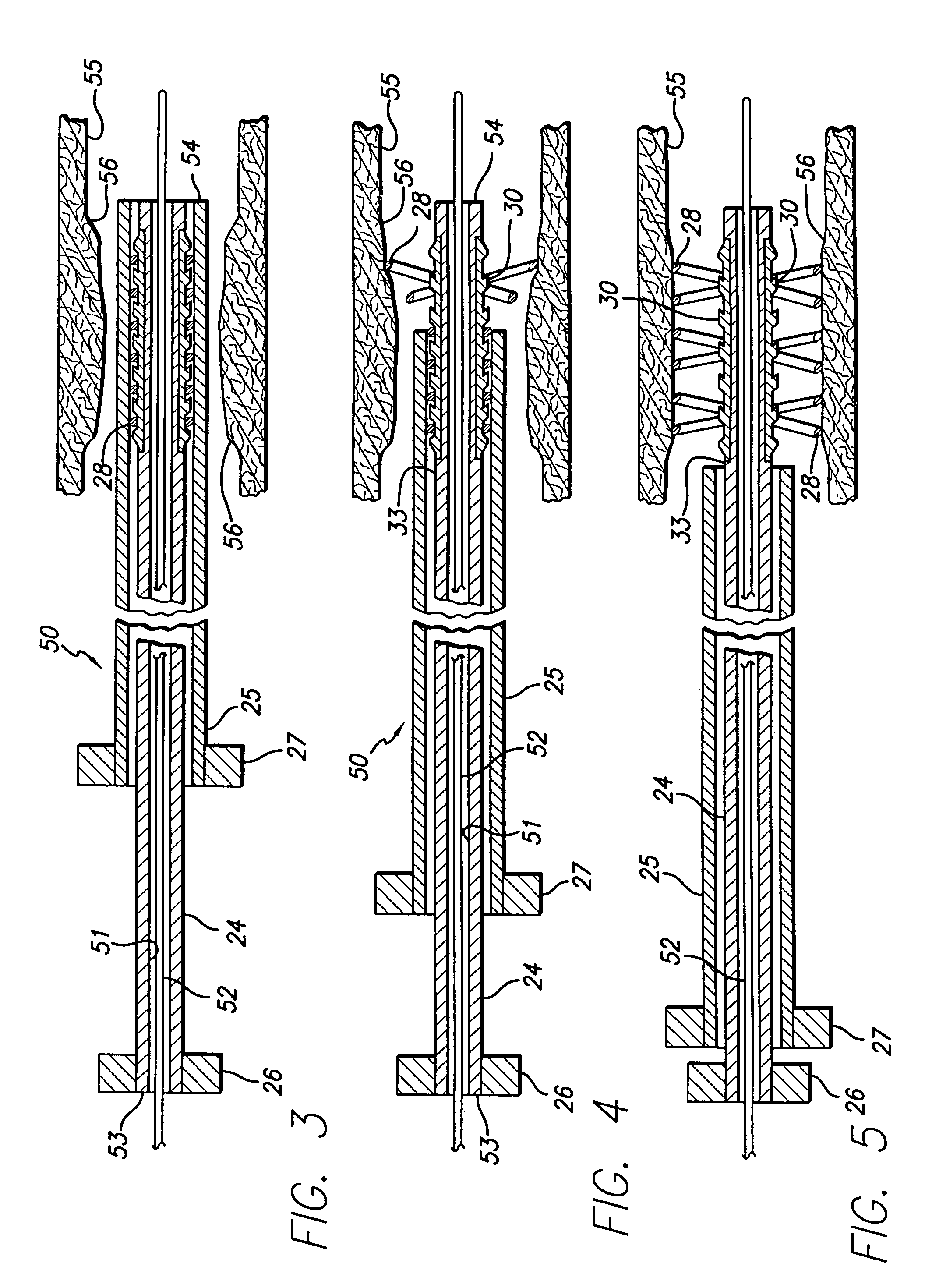

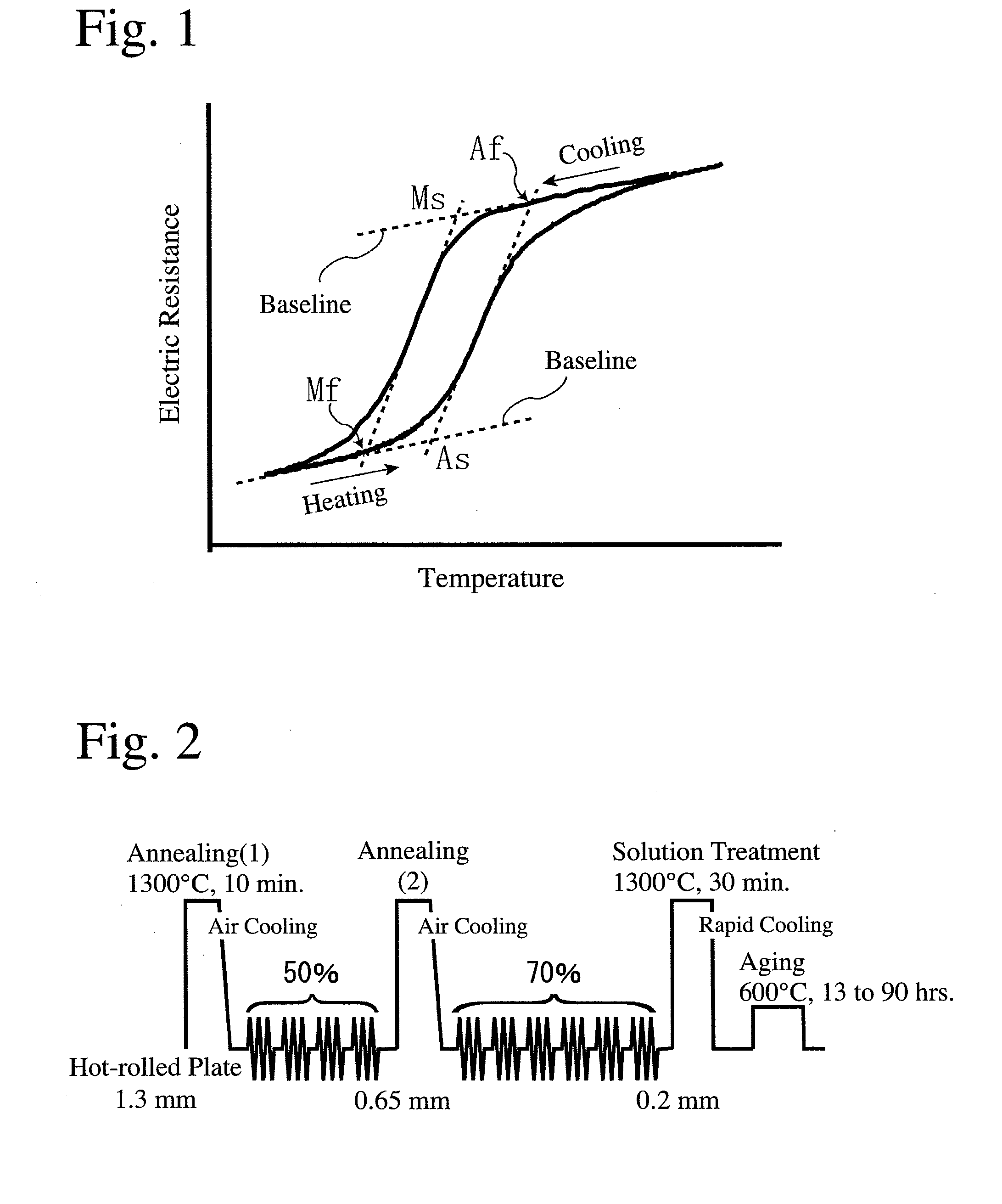

A martensitic transformation is a specific type of crystal structure change that occurs when cooling certain specific metals, including Nitinol. The crystal structure found at high temperatures is the parent phase, often referred to austenite, and the phase that results from a martensitic transformation is called martensite.

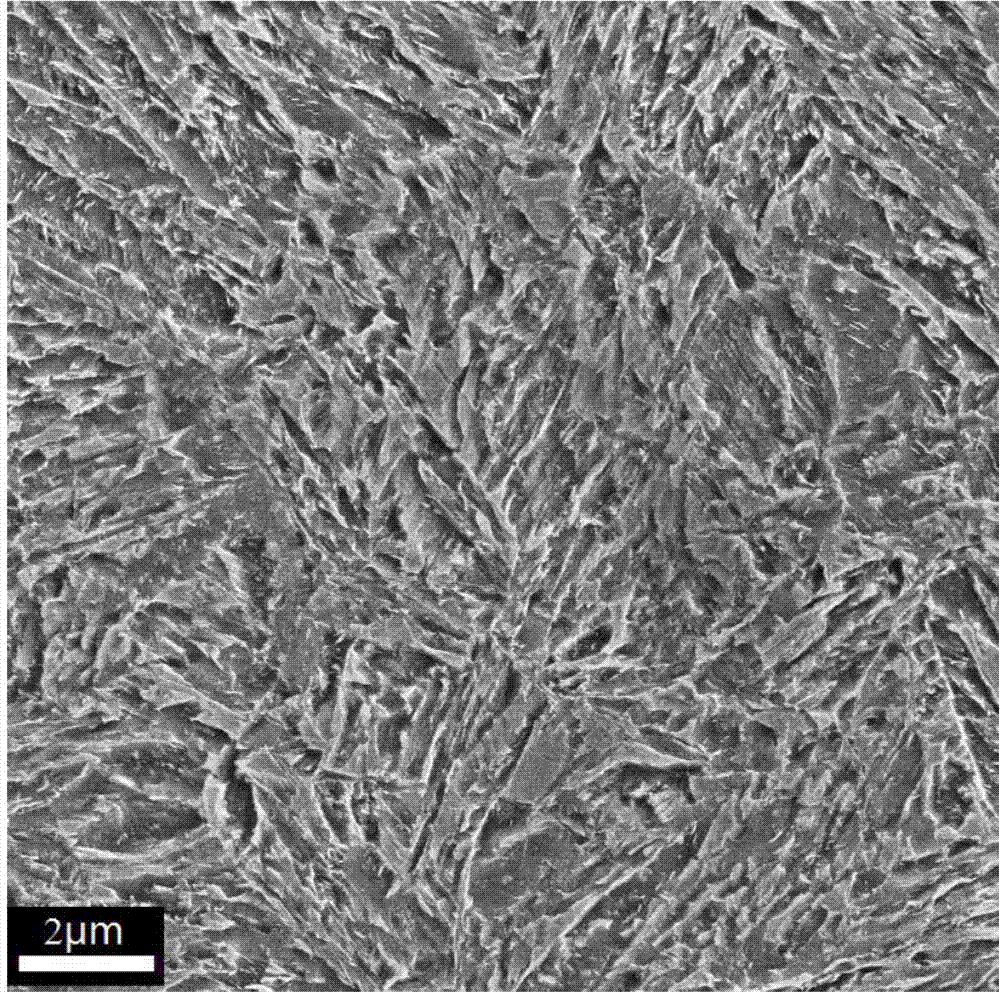

Automobile steel with low cost and high strength ductility balance and preparation method thereof

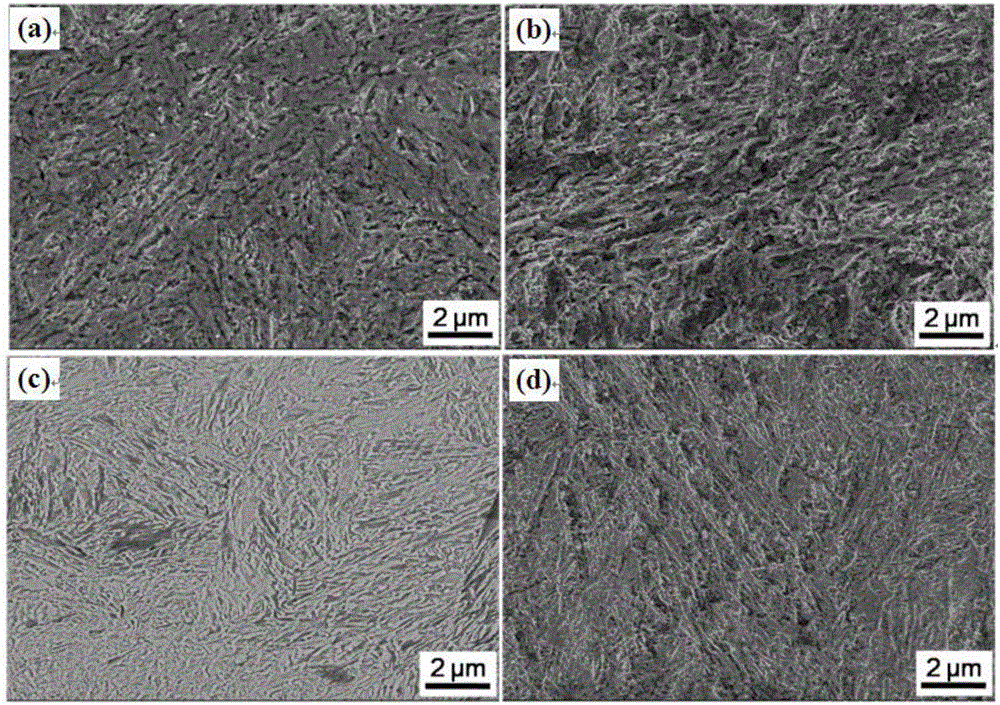

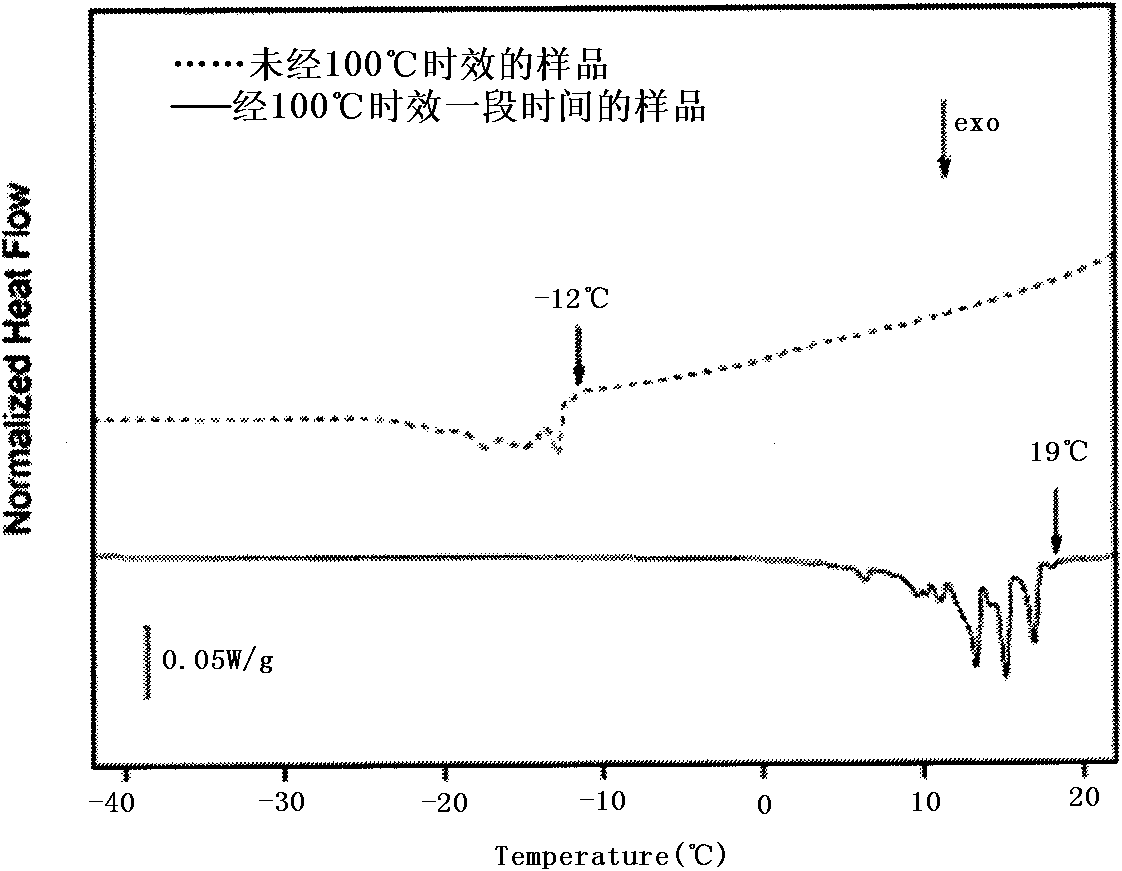

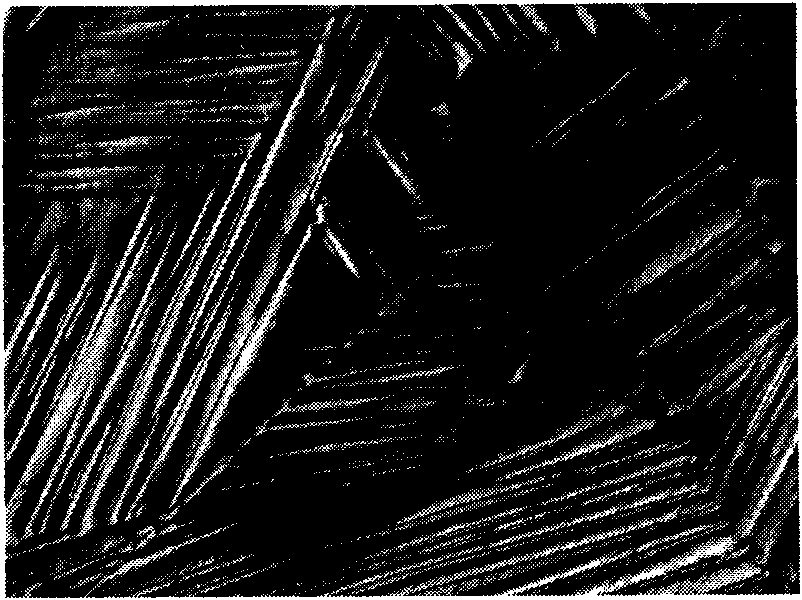

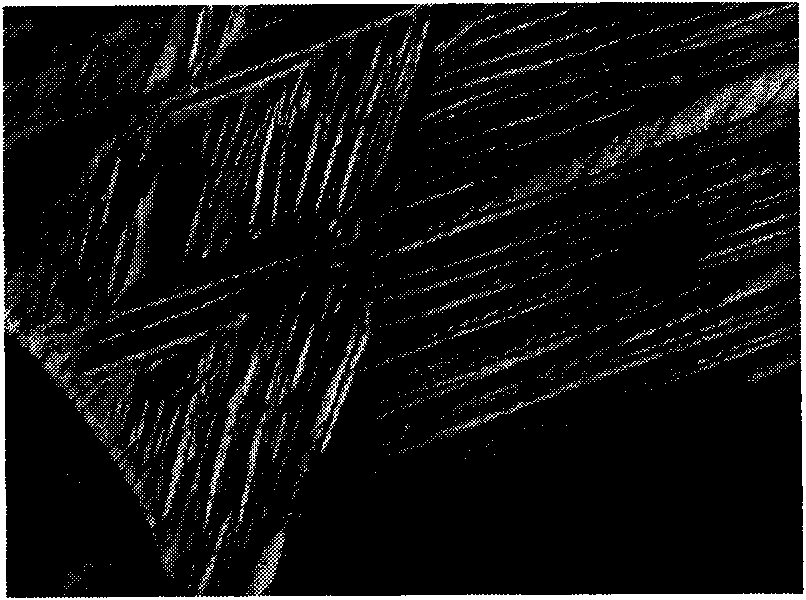

The invention provides automobile steel with low cost and high strength ductility balance and a preparation method thereof, belonging to the technical field of automobile steel. A multiphase, metastable and multiscale M<3> type organization structure is obtained based on reasonable design of chemical composition and partition of alloy elements and crucially based on the control of martensite phasetransformation, the repartition of solute such as C / Mn and the like and the austenite inverse phase transformation. The invention is characterized in that the martensite structure is obtained by using 0.02-0.50 wt%C and 3.50-9.00 wt%Mn in the cooling process of the inductrial production of steel plates and steel coils and the like; and superfine adverse transformation austenite and alpha phase substrate can be obtained through the partition of Mn and C in the heat preserving process between 100 DEG C below Acl and Acl, thus realizing the industrial production of hot rolled sheets and cold rolled sheets with high strength ductility balance used in automobiles. The invention has the advantages that the intensity is 0.7-1.3 GPa, the extension rate is 55-30% and the strength ductility balanceis 35-55 GPa%.

Owner:CENT IRON & STEEL RES INST

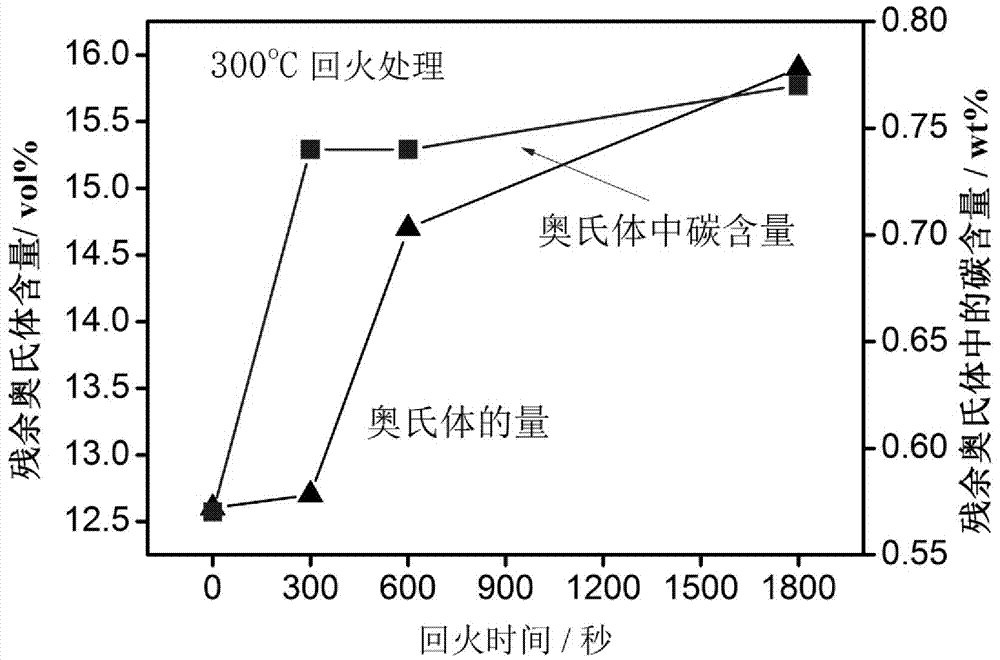

Avoiding stress-induced martensitic transformation in nickel titanium alloys used in medical devices

A process for assembling a medical device made from a nickel-titanium alloy for use in a mammalian body while avoiding the formation of stress-induced martensite and a medical device used in combination with a delivery system for deployment into the mammalian body are disclosed. By heating the nickel-titanium alloy of the medical device to a temperature above Md, and deforming and installing the device into a delivery system or holding capsule, it is possible to avoid the formation of stress-induced martensite in the stent, which stays in the austenitic phase throughout.

Owner:ABBOTT LAB INC

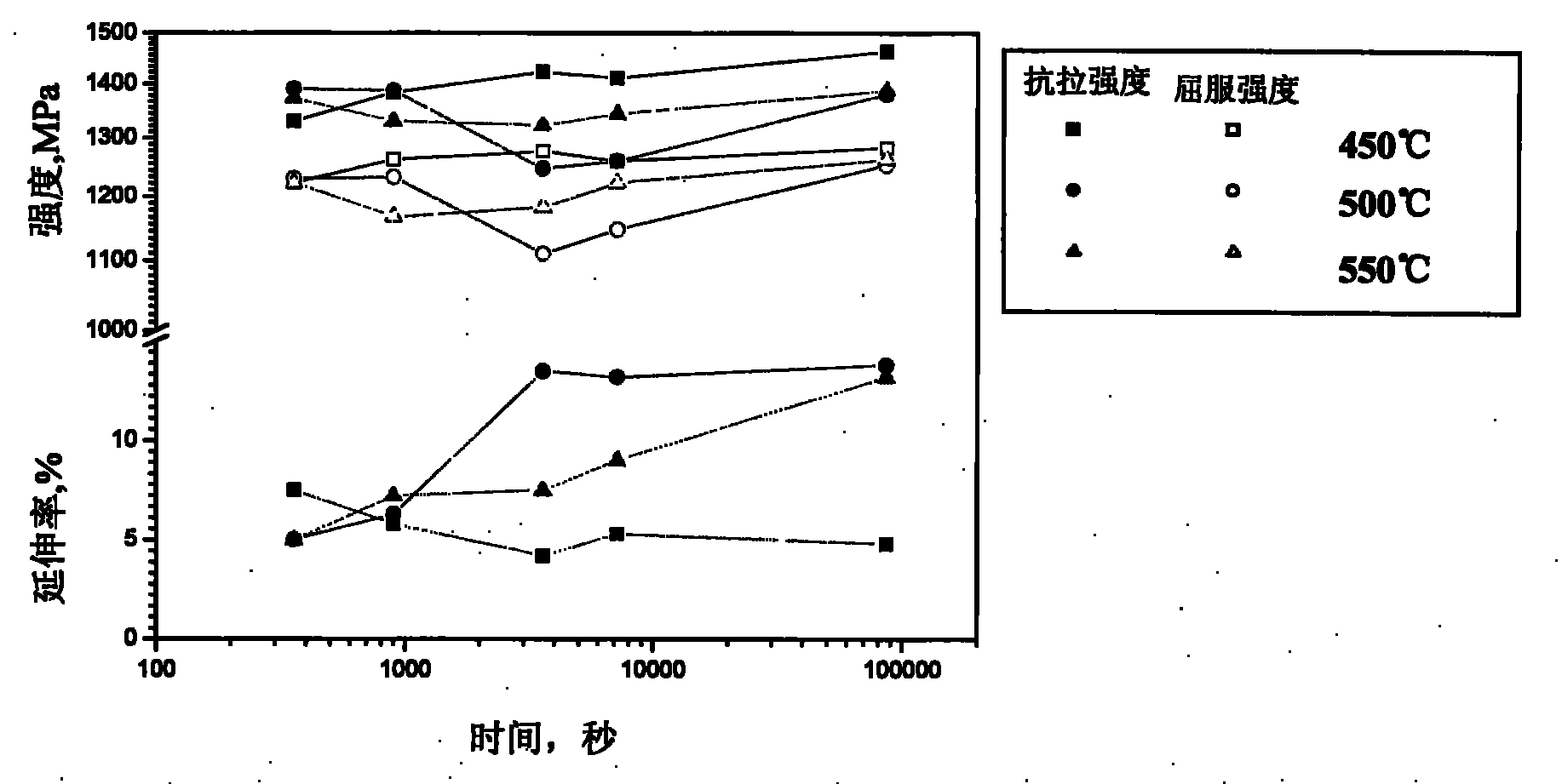

Steel plate for hot stamping, hot stamping process and hot-stamped member

ActiveCN104846274ALow austenitizing temperatureQuenching temperature is lowShaping toolsFurnace typesHot stampingMartensite transformation

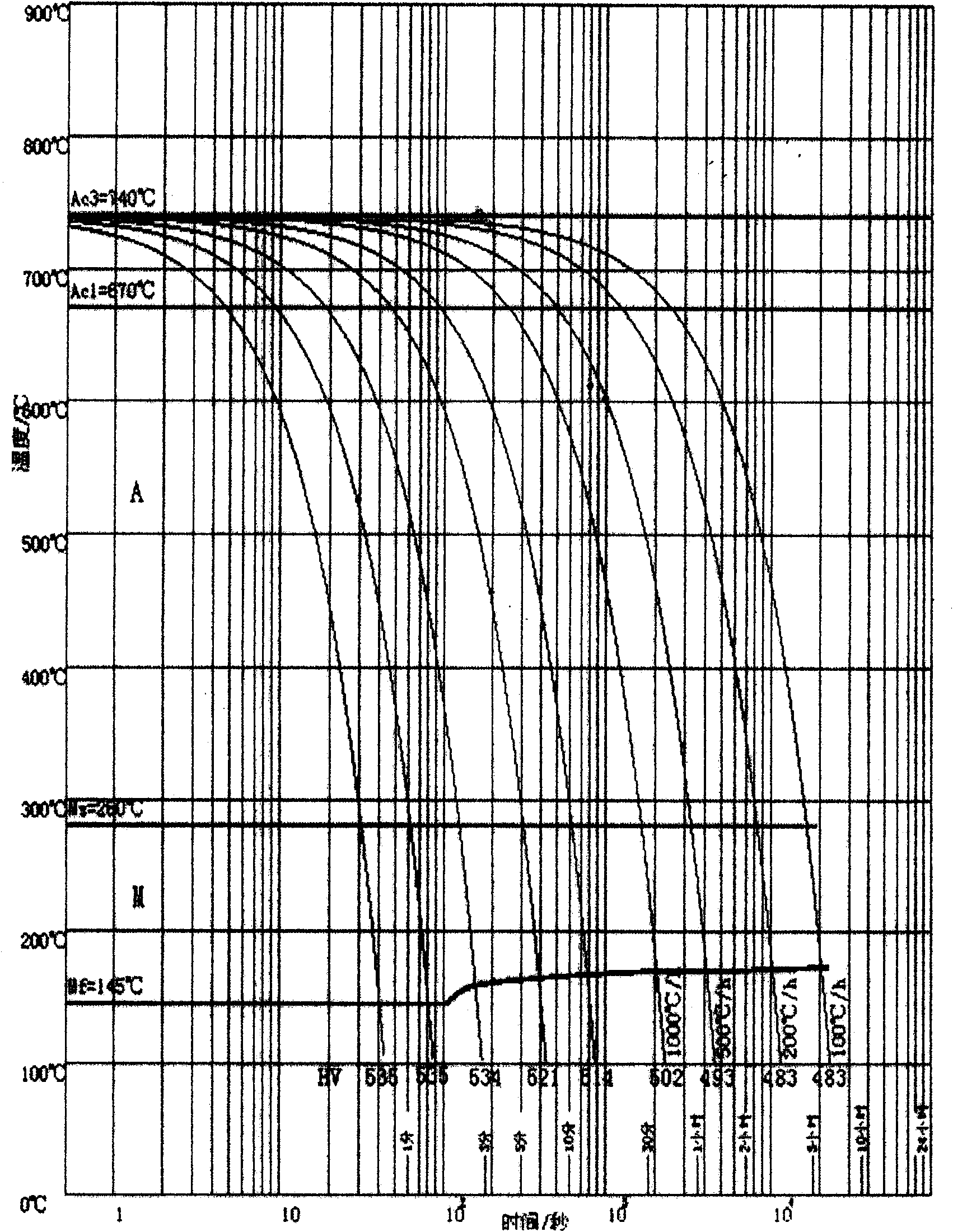

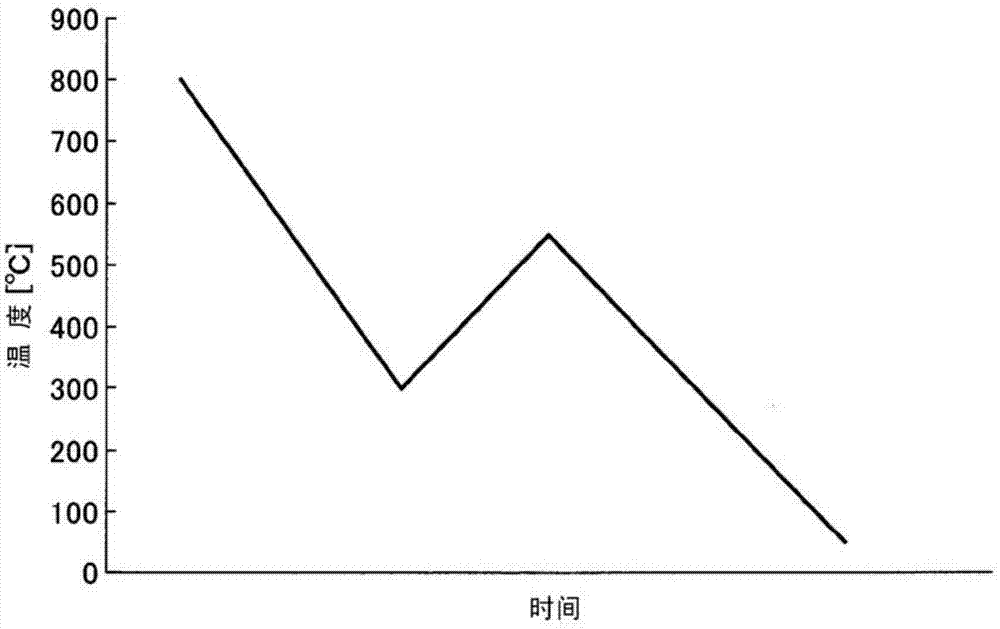

The invention relates to a steel plate for hot stamping, a hot stamping process and a hot-stamped member. The steel plate for hot stamping is characterized by comprising, by weight, 0.18 to 0.42% of C, 4 to 8.5% of Mn and 0.8 to 3.0% of Si and Al, with the balance being Fe and avoidable impurities, wherein the alloy component of the steel plate satisfy the condition that the actual measured value of martensite phase transformation beginning temperature is no more than 280 DEG C. A manufacturing method for the hot-stamped member comprises the following steps: heating a material to 700 to 850 DEG C and carrying out stamping; then carrying out cooling in a die or air cooling or cooling in other manners to 150 to 260 DEG C below the martensite phase transformation beginning temperature; and heating the stamped member to 160 to 450 DEG C, maintaining the temperature for 1 to 100,000 s, carrying out tempering heat treatment and cooling the stamped member to room temperature. The hot-stamped member prepared in the invention has yield strength of no less than 1200 MPa, tensile strength of no less than 1600 MPa and total elongation percentage of no less than 10%.

Owner:EASYFORMING STEEL TECH CO LTD

Alloy powder used for laser remanufacturing of martensitic stainless steel parts and preparation method

ActiveCN105039869ASolve and improve formabilitySolve and improve crack resistanceMetallic material coating processesSlagMartensitic stainless steel

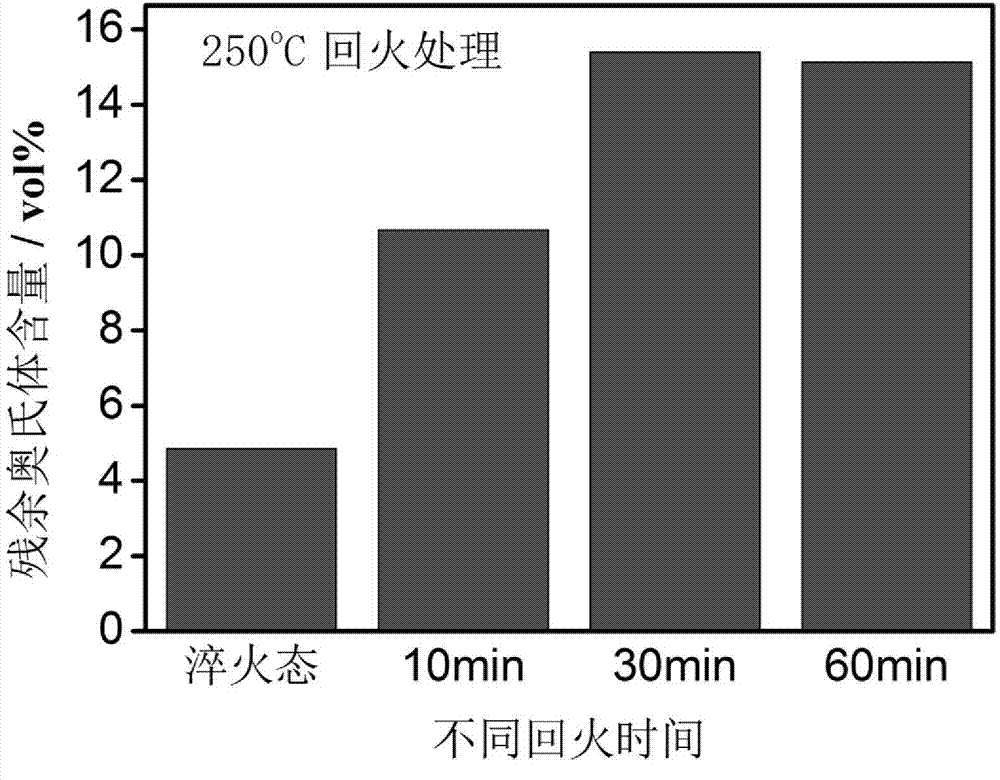

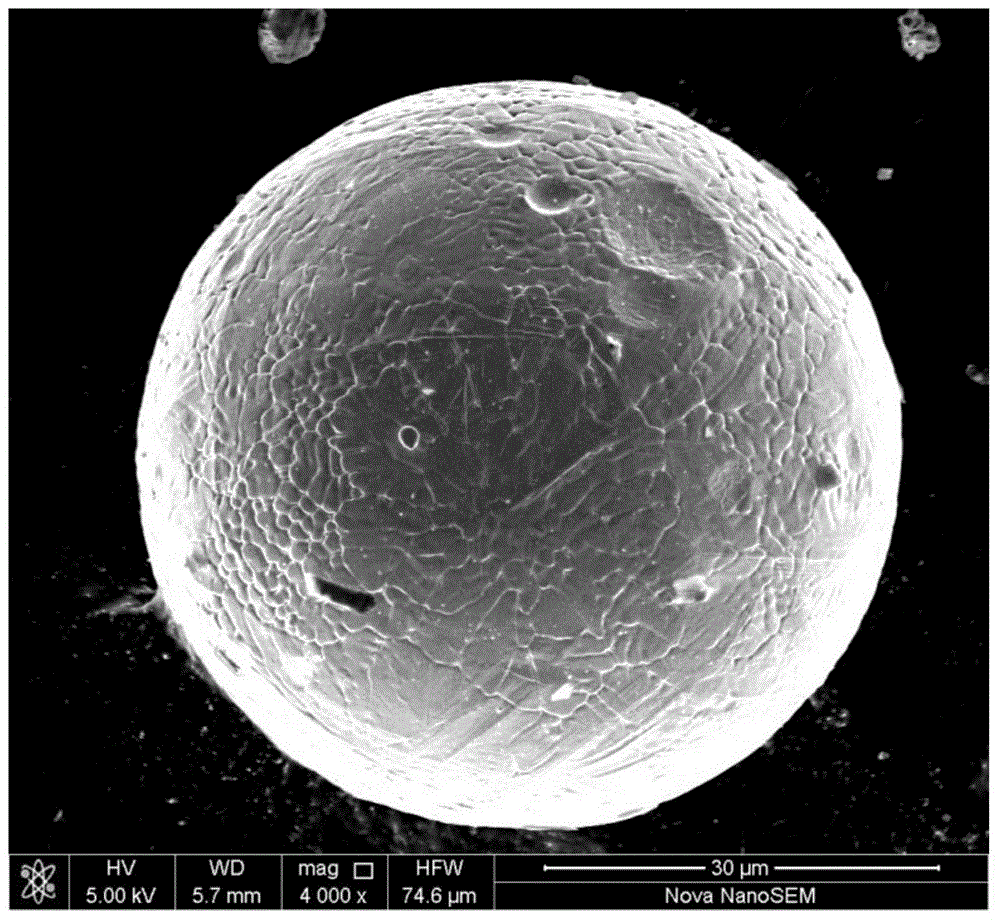

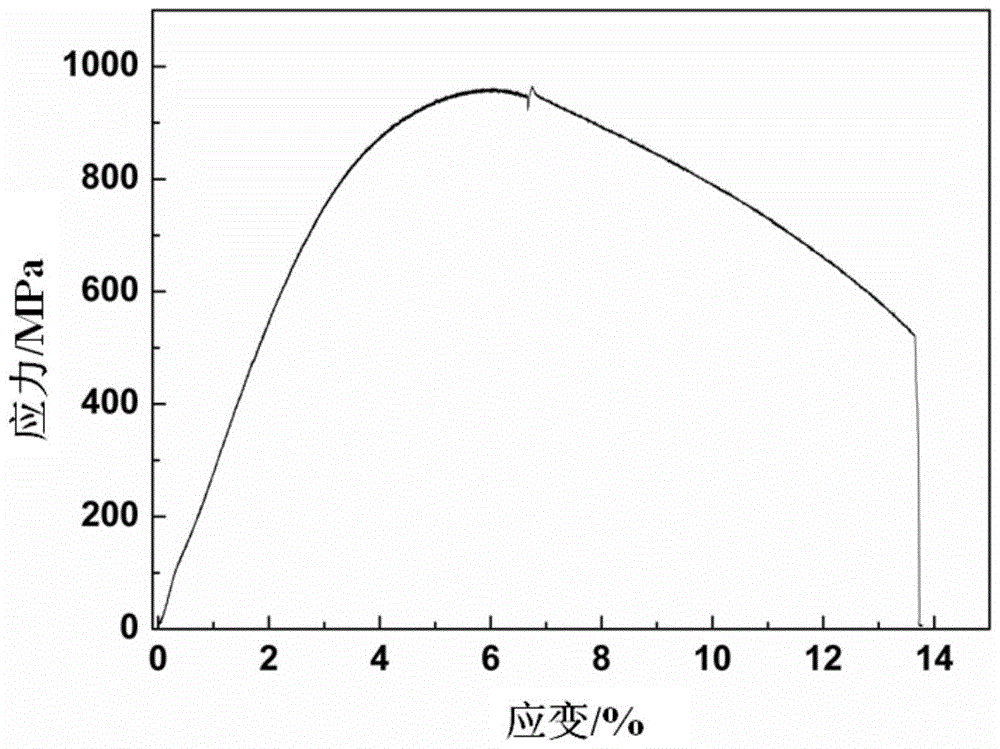

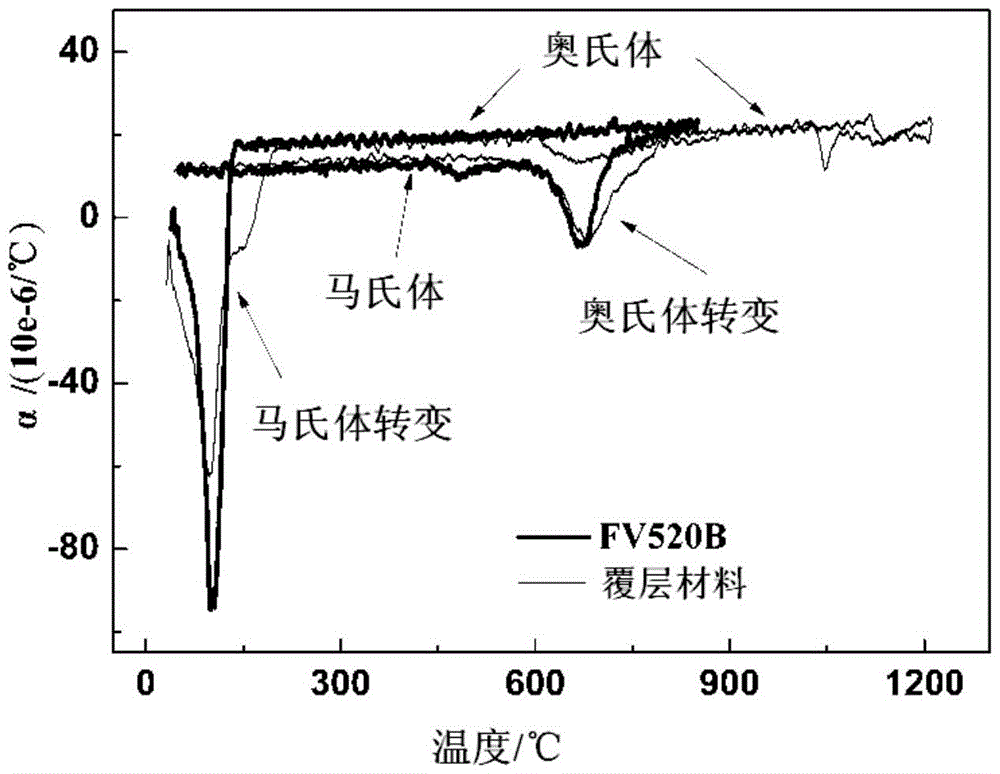

The invention provides alloy powder used for laser remanufacturing of FV520B martensitic stainless steel parts and a preparation method. The chemical components of the alloy powder include, by weight percentage, 0.01-0.3% of C, 12-17% of Cr, 3-7% of Ni, 0.4-2% of Mo, 0.1-2% of Mn, 0.15-0.55% of Nb, 0-3% of Cu, 0.05-2% of Si, 0-1.6% of B and the balance Fe. The preparation method of the alloy powder is a vacuum melting-high pressure gas atomization method. The alloy powder can have the density and the thermal expansion coefficient which are similar to those of FV520B materials when precipitation hardening elements, deoxygenation slag forming elements and elements used for lowering the martensite phase transformation point are added and the weight percent content of all the elements are regulated; the residual stress level is lowered through the martensite phase transformation accompanying effect; and therefore the problems of cracks, deformation and the like are greatly relieved, and the forming property, the anti-cracking property and the process stability are achieved and improved when the FV520B parts are subjected to laser remanufacturing through the alloy powder.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

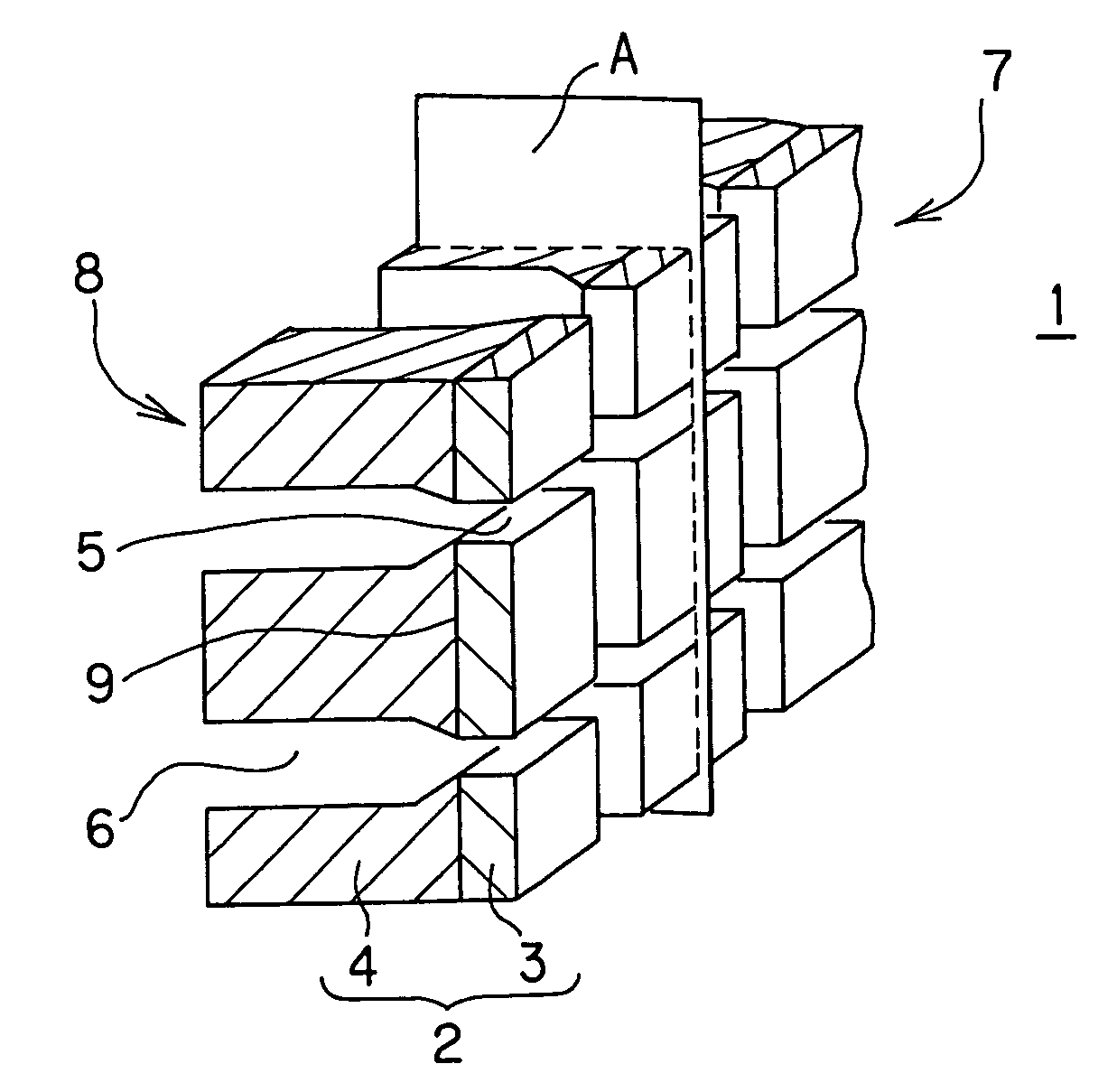

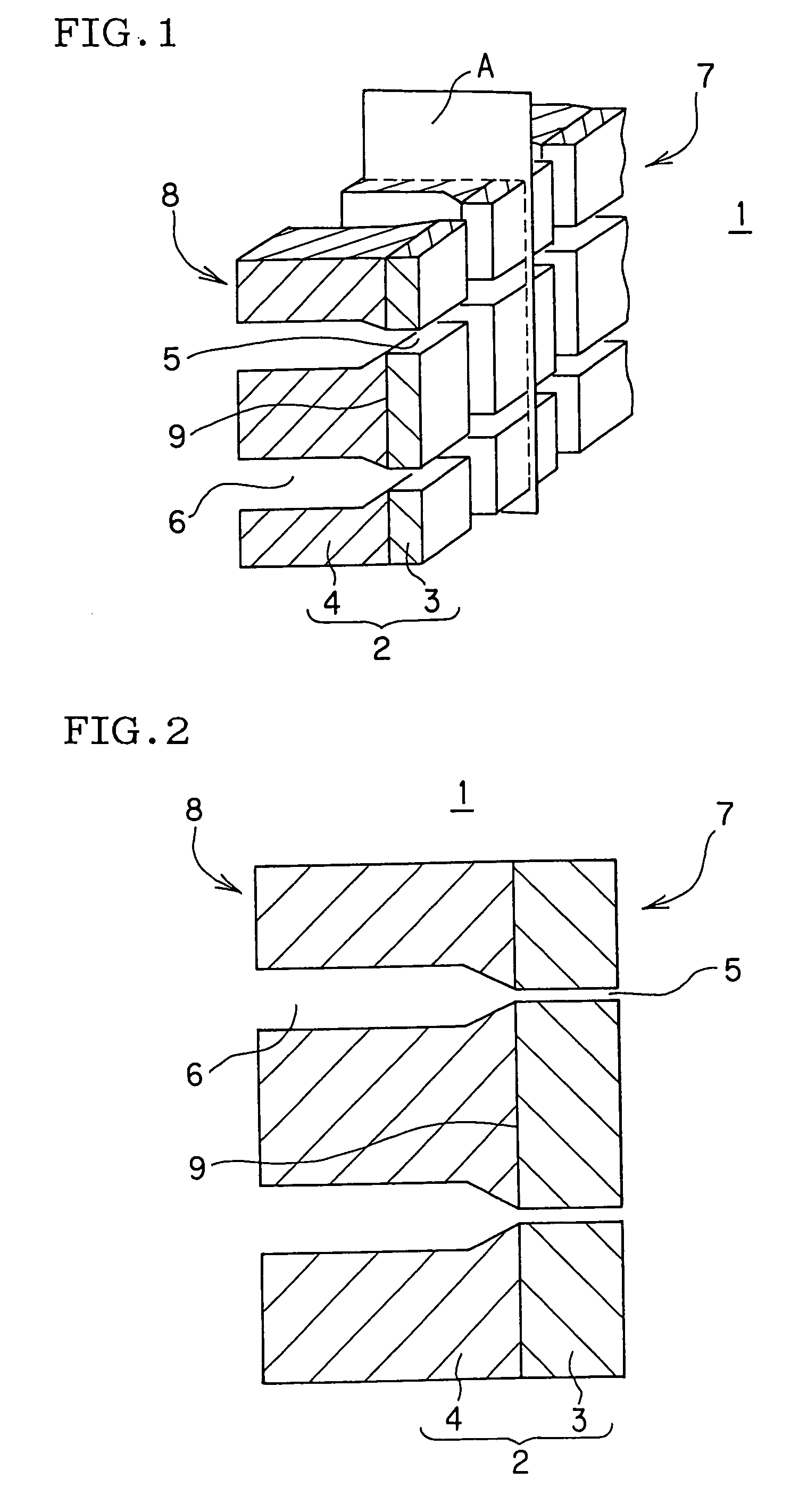

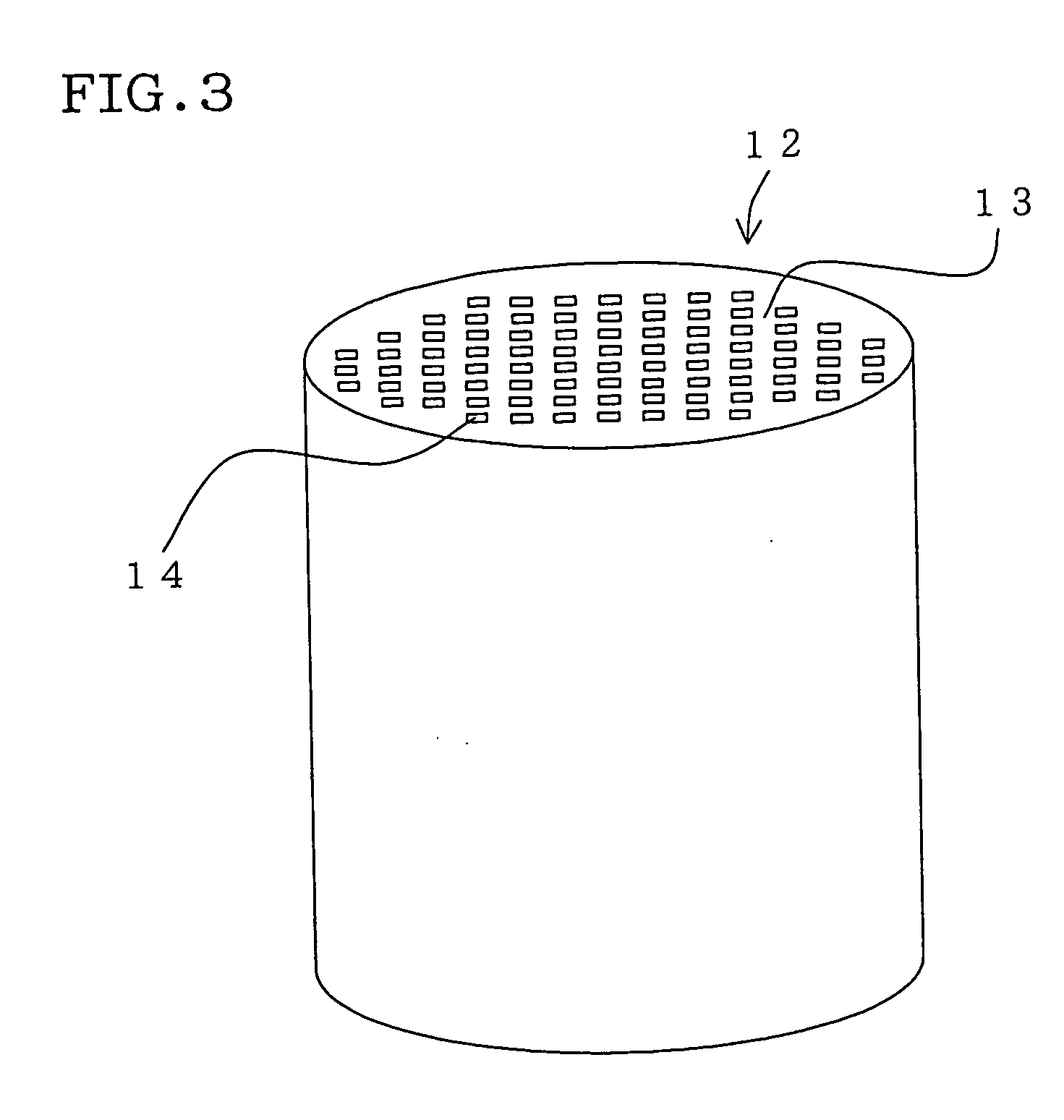

Die for forming honeycomb structure and method of manufacturing the same

ActiveUS20060034972A1Good molding effectImprove wear resistanceConfectioneryCeramic extrusion diesMartensite transformationMetallic materials

There is disclosed a die for forming a honeycomb structure, which realizes a sophisticated formability and which is superior in resistance to wear. A die for forming the honeycomb structure is provided with a die base having two surfaces, one surface is provided with slits of a honeycomb shape, and the other surface is provided with back holes which introduce a forming material therethrough. This die base includes: a die precursor which is obtained by stacking and bonding a first member which is one surface of the die base and is made of a tungsten carbide-based super hard alloy containing at least tungsten carbide, and a second member which is the other surface of the die base and is made of a metal material capable of causing at least one of three phase transformations of martensite transformation, bainite transformation, and pearlite transformation by cooling of an austenite phase together. Tensile and compressive stresses in a mutually bonded surface of the two plate-like members are 1000 MPa or less.

Owner:NGK INSULATORS LTD

Hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability and method of production of same

InactiveUS20070190353A1High strengthImprove adhesionHot-dipping/immersion processesPretreated surfacesMartensite transformationAdditive ingredient

The present invention provides a hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability and a method of production of the same, that is, a hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability containing C: 0.01 to 0.3%, Si: 0.005 to 0.6%, Mn: 0.1 to 3.3%, P: 0.001 to 0.06%, S: 0.001 to 0.01%, Al: 0.01 to 1.8%, and N: 0.0005 to 0.01% and having a metal structure of ferrite and, by area rate, 5% to 60% of tempered martensite and a method of production of the same comprising hot rolling, then cold rolling a slab including the above ingredients, heating the sheet in the hot dip galvanization heating process to Ac1 l to Ac3+100° C., holding it there for 30 seconds to 30 minutes, then cooling it by a 1° C. / s or higher cooling rate to 450 to 600° C., hot dip galvanizing it at that temperature, then cooling it at a 1° C. / s or higher cooling rate to the martensite transformation point or lower in temperature, holding it there at 200° C. to 500° C. for 1 second to 5 minutes, then cooling it at a 5° C. / s or higher cooling rate to 100° C. or less.

Owner:NIPPON STEEL CORP

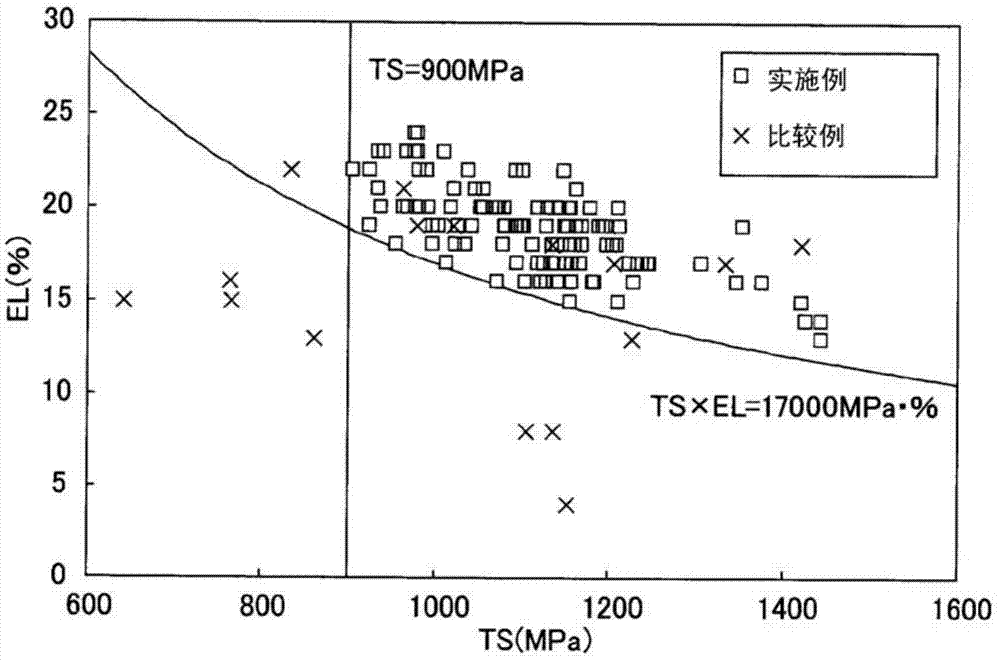

High-strength zinc-plated steel sheet and high-strength steel sheet having superior moldability, and method for producing each

ActiveCN103717774AGood formabilityHot-dipping/immersion processesFurnace typesMartensite transformationUltimate tensile strength

This high-strength zinc-plated steel sheet and high-strength steel sheet having superior moldability and obtaining superior ductility and stretch-flanging properties while securing the high strength of a maximum tensile strength of at least 900 MPa have a predetermined component composition, the steel sheet structure containing 1-20% by volume fraction of a residual austenite phase, the martensite transformation point of the residual austenite phase being no greater than -60 DEG C.

Owner:NIPPON STEEL CORP

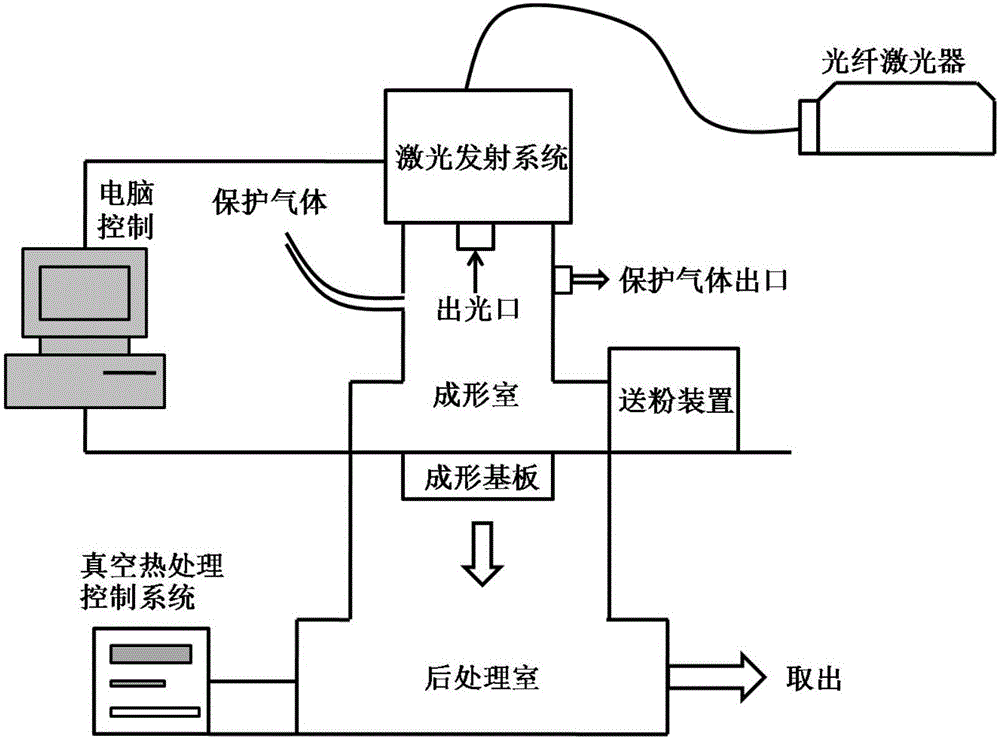

Method for directly obtaining martensite die steel through laser 3D printing technology

ActiveCN105033255AHigh dimensional accuracyHigh surface glossAdditive manufacturing apparatusIncreasing energy efficiencyMartensite transformationIron powder

The invention provides a method for directly obtaining martensite die steel through a laser 3D printing technology. According to the method, a defined amount of Mn, Ni, Cr and other alloy elements are added to iron powder, and within a wide temperature range, martensite transformation is facilitated. The influence rules of laser linear energy density eta (the ratio between laser power and scanning speed) on the density, microscopic structure and mechanical property of an SLM forming part are analyzed, parameters of the laser 3D printing technology are optimized, and a mold of a complex structure in any shape is obtained. Moreover, the forming mold has high hardness, abrasion resistance and good impact toughness, and is better in performance than a mold manufactured in a traditional method. Accordingly, the method is particularly suitable for rapid forming of molds of a complex structure.

Owner:南京瑞德增域三维科技发展有限公司

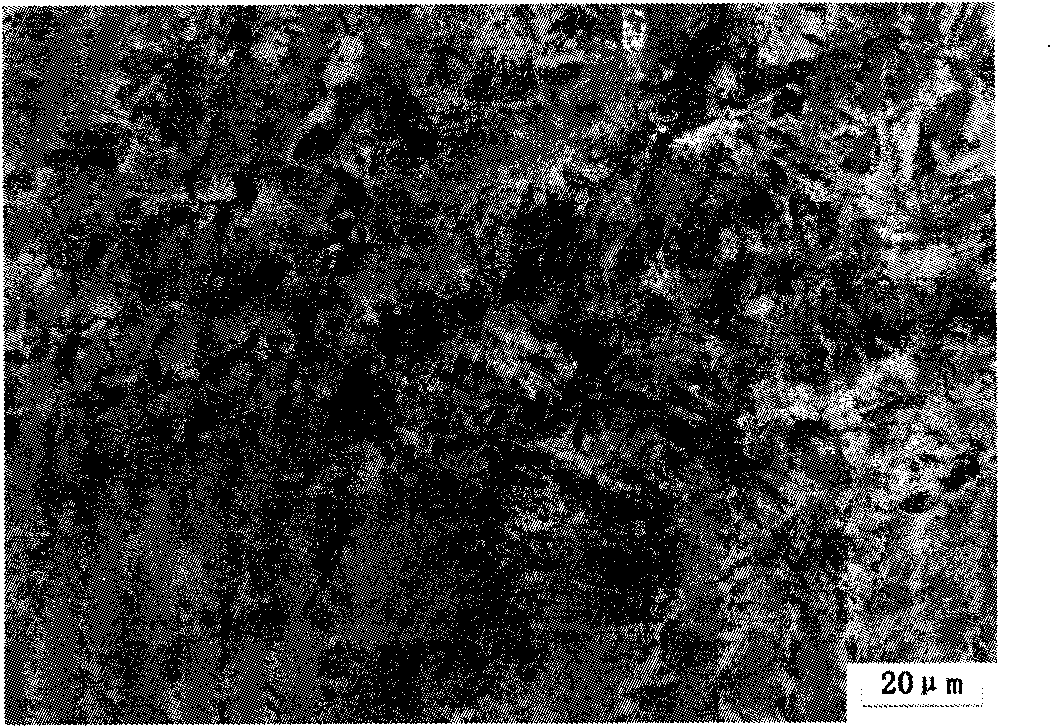

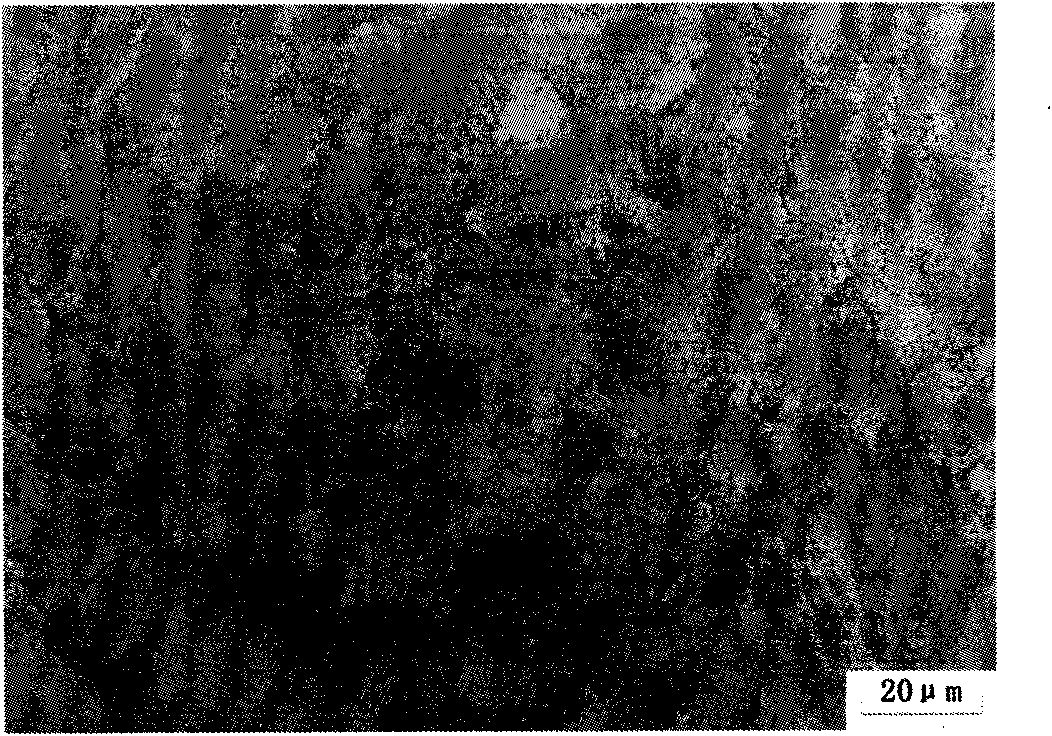

Low-alloy, high-strength and high-toughness composite phase steel and heat treatment method thereof

InactiveCN103045950AGuaranteed uniformityEnsure process stabilityHeat treatment process controlMartensite transformationAlloy

The invention discloses low-alloy, high-strength and high-toughness composite phase steel. The low-alloy, high-strength and high-toughness composite phase steel comprises the following components in mass percentage: 0.40-0.90% of C, 0.5-2.0% of Si, 0.5-3.0% of Mn, 0.5-4.0% of Cr, 2.0-5.0% of Al, less than or equal to 0.01% of S, less than or equal to 0.01% of P and the balance of Fe. The invention further discloses a preparation method of the low-alloy, high-strength and high-toughness composite phase steel, comprising the following steps of: firstly, quickly heating steel to 850-1000 DEG C, and keeping the constant temperature for 2-30min so as to austenitize a workpiece sufficiently; secondly, quickly quenching to -20 to 50 DEG C so as to obtain a partially supersaturated martensite and an austenite without martensitic transformation; thirdly, keeping the constant temperature of the workpiece at 300-600 DEG C for 5-600min for carbon distribution; and finally, quenching to room temperature to obtain the composite phase steel. The preparation method is simple in process; by the preparation method, steel strength is improved, good toughness is ensured, and the low-alloying cost is low; and the preparation method is wide in industrial application prospect.

Owner:ZHONGBEI UNIV

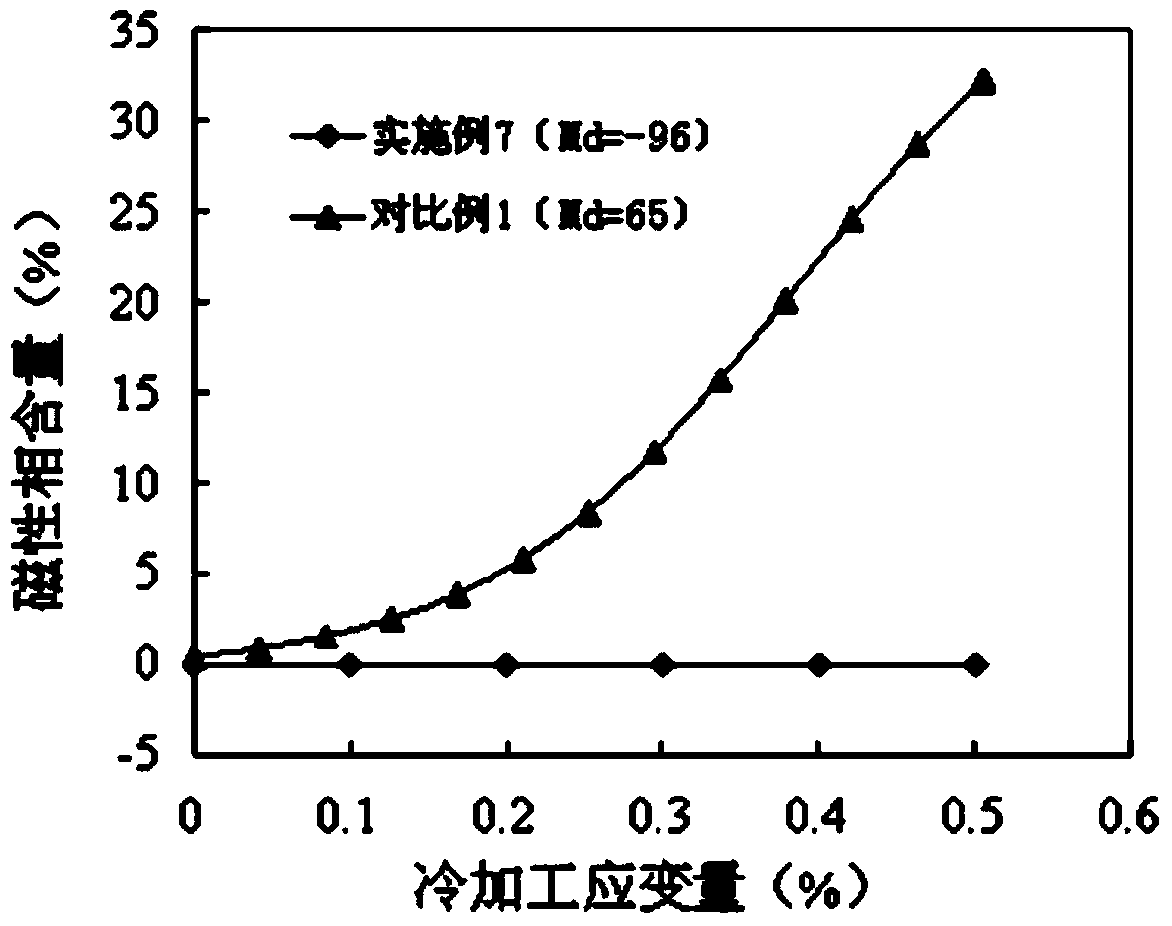

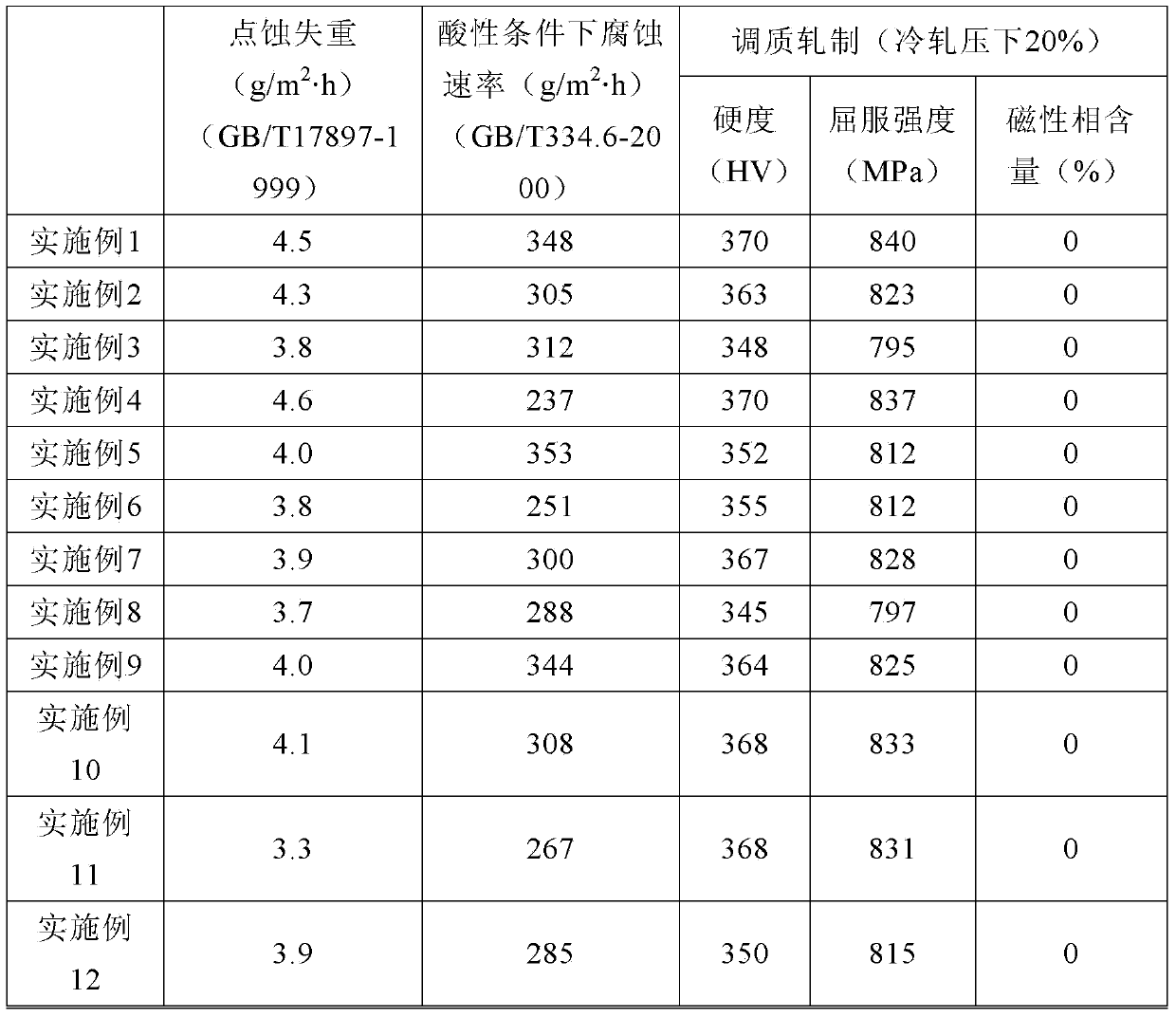

Non-magnetic hard austenitic stainless steel for precision electron and manufacturing method thereof

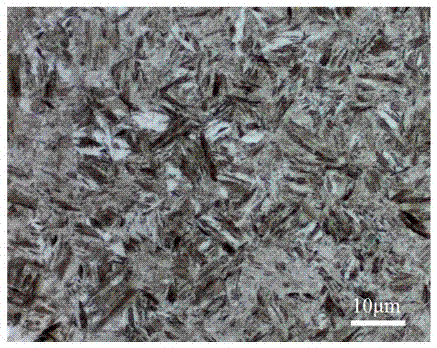

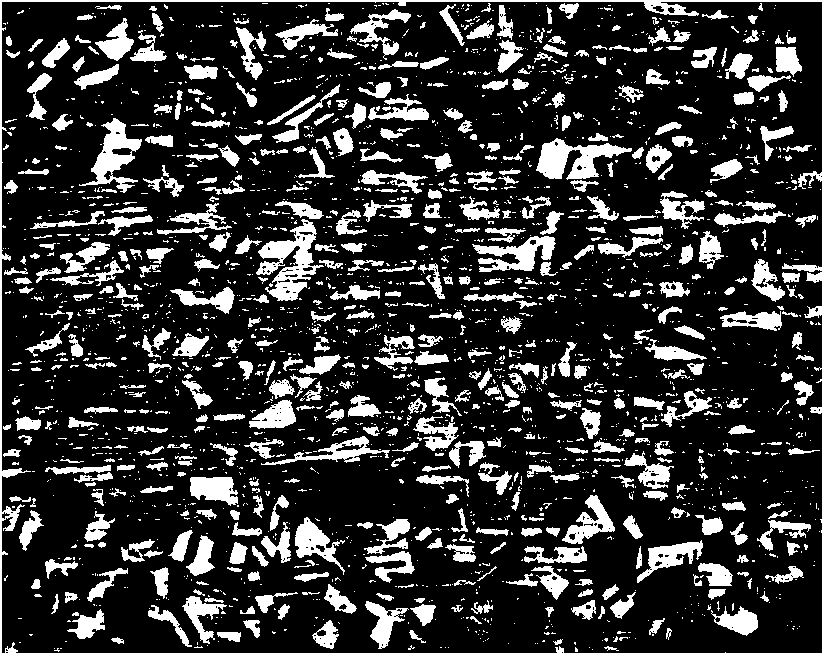

The invention relates to a non-magnetic hard austenitic stainless steel for precision electron and a manufacturing method thereof. The stainless steel comprises the following chemical components by weight percent: 0.06% to 0.10% of C, 0.51% to 0.8% of Si, 11.5% to 12.5% of Mn, 17.0% to 18.0% of Cr, 2.51% to 3.50% of Ni, 0.15% to 0.20% of N, 0.15% to 0.50% of Sn, 0.30% to 0.50% of Mo, 0.30% to 0.75% of Mo and W / 2, 2.0% to 2.5% of Cu and the balance of Fe and inevitable impurities, wherein at least one of the components as follows is selected: less than or equal to 0.1% of V and less than or equal to 0.1% of Nb; and 30Sn%+5Mo%+2.5W%+Ni%+Cu%+0.5Si%-0.25Mn% is greater than or equal to 9.0. Based on the Cu-Mo-Sn-Si alloying, the adverse effect to the corrosion resistance of the stainless steel in which the Ni is reduced and the Mn is added is eliminated, so that the stainless steel has the pitting corrosion resistance superior to 304 and can be prevented from being corroded by a reducing acid. Meanwhile, the temperature of Md30 / 50 is controlled to be lower than -75 DEG C and the austenitic stability is controlled to be superior to 304 and 305, so that the magnetic martensite phase transformation is avoided when the deformation of the stainless steel in cold machining is less than or equal to 50%. Thus, the non-magnetic performance of the hard austenitic stainless steel is also maintained.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

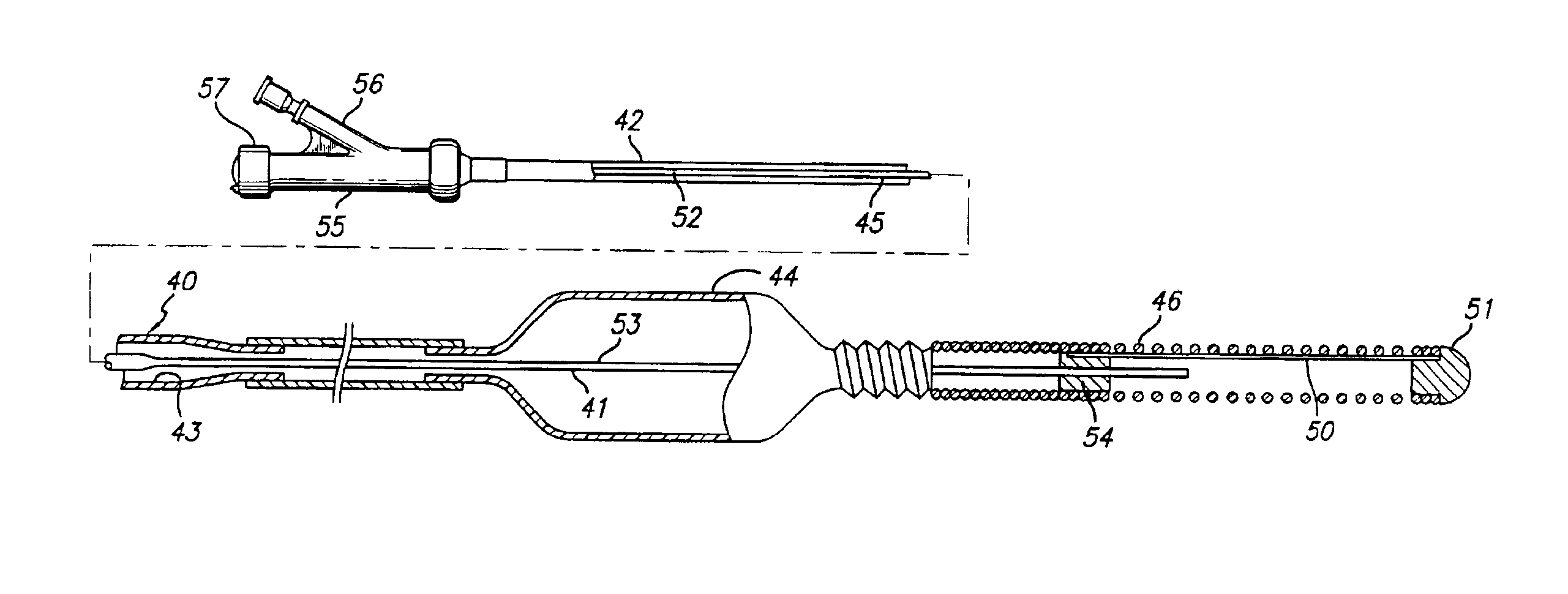

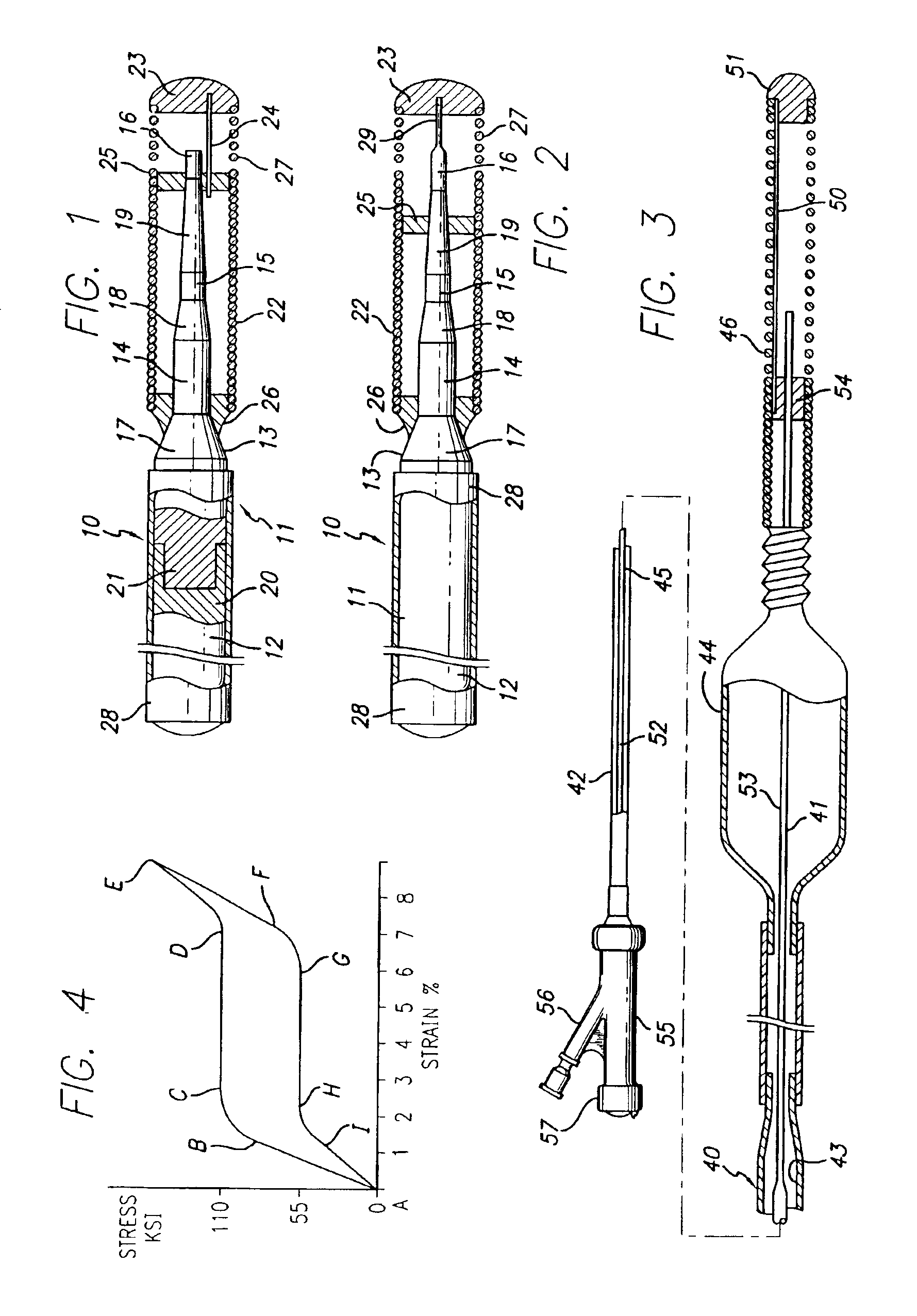

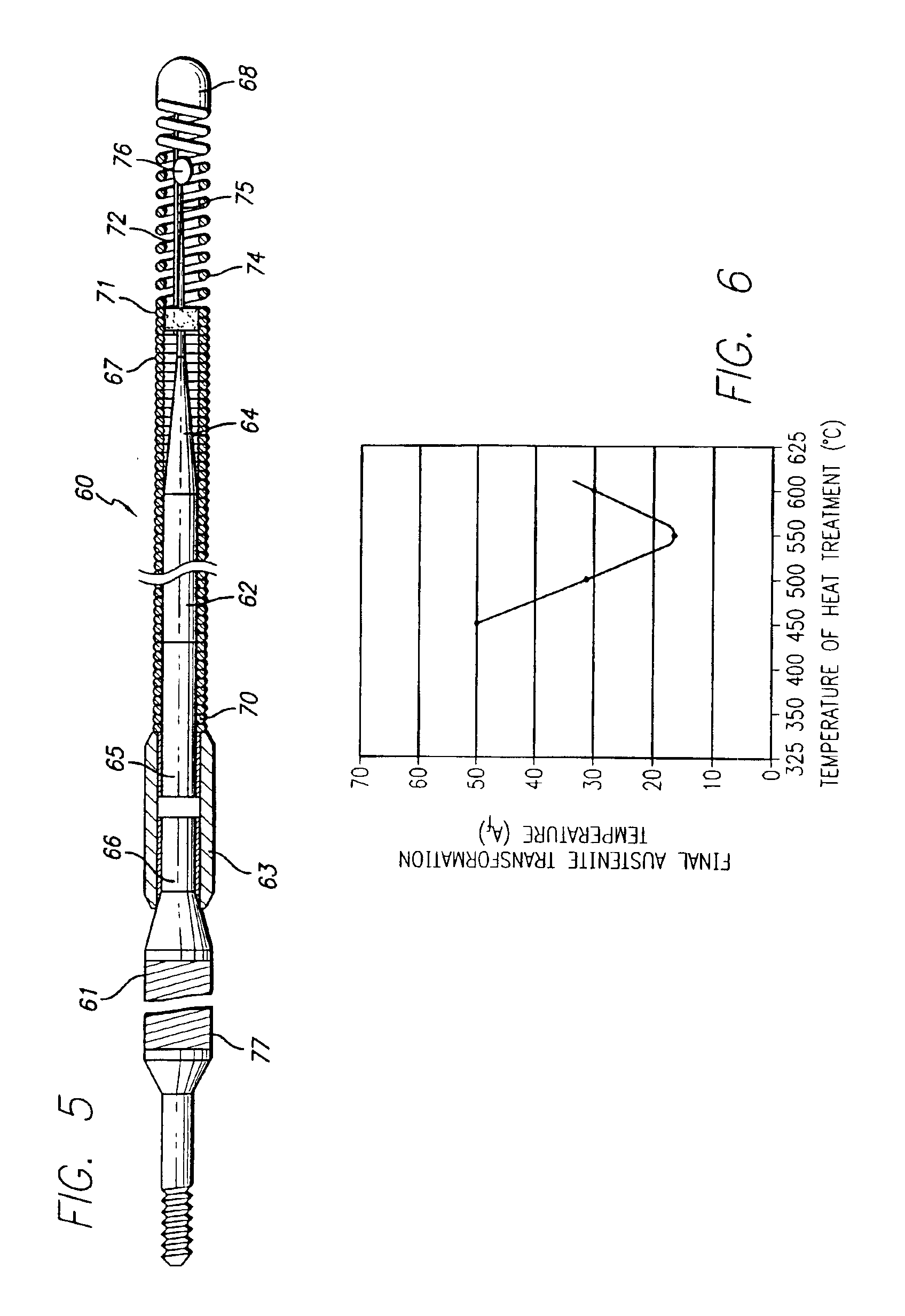

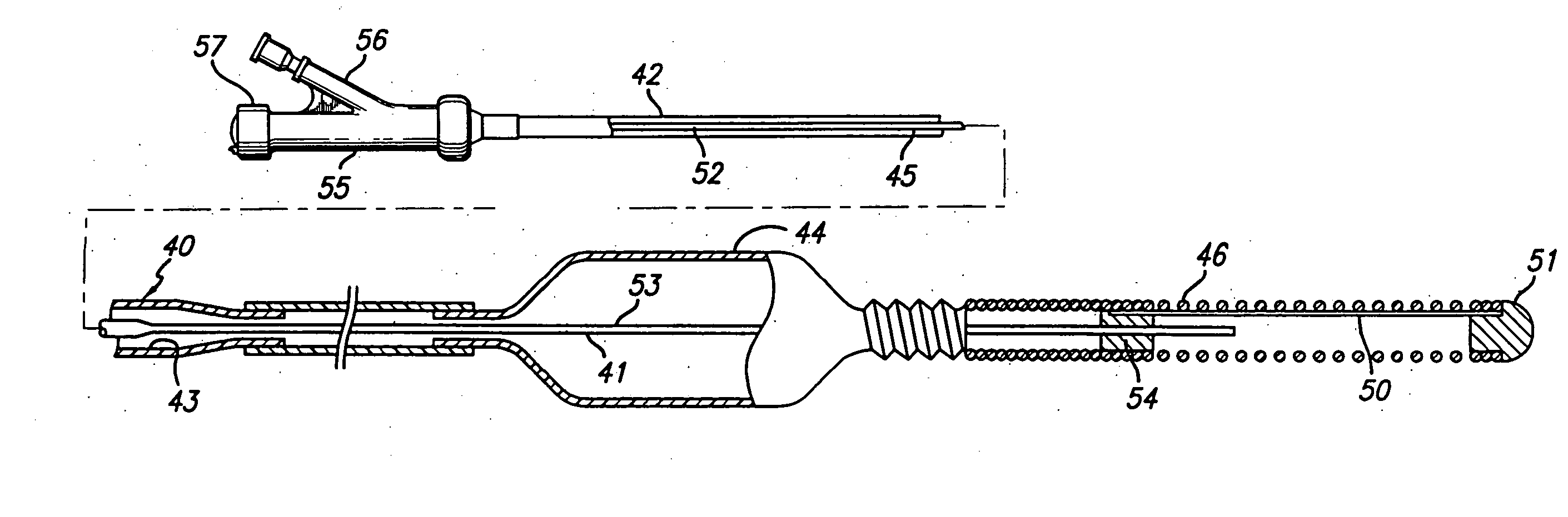

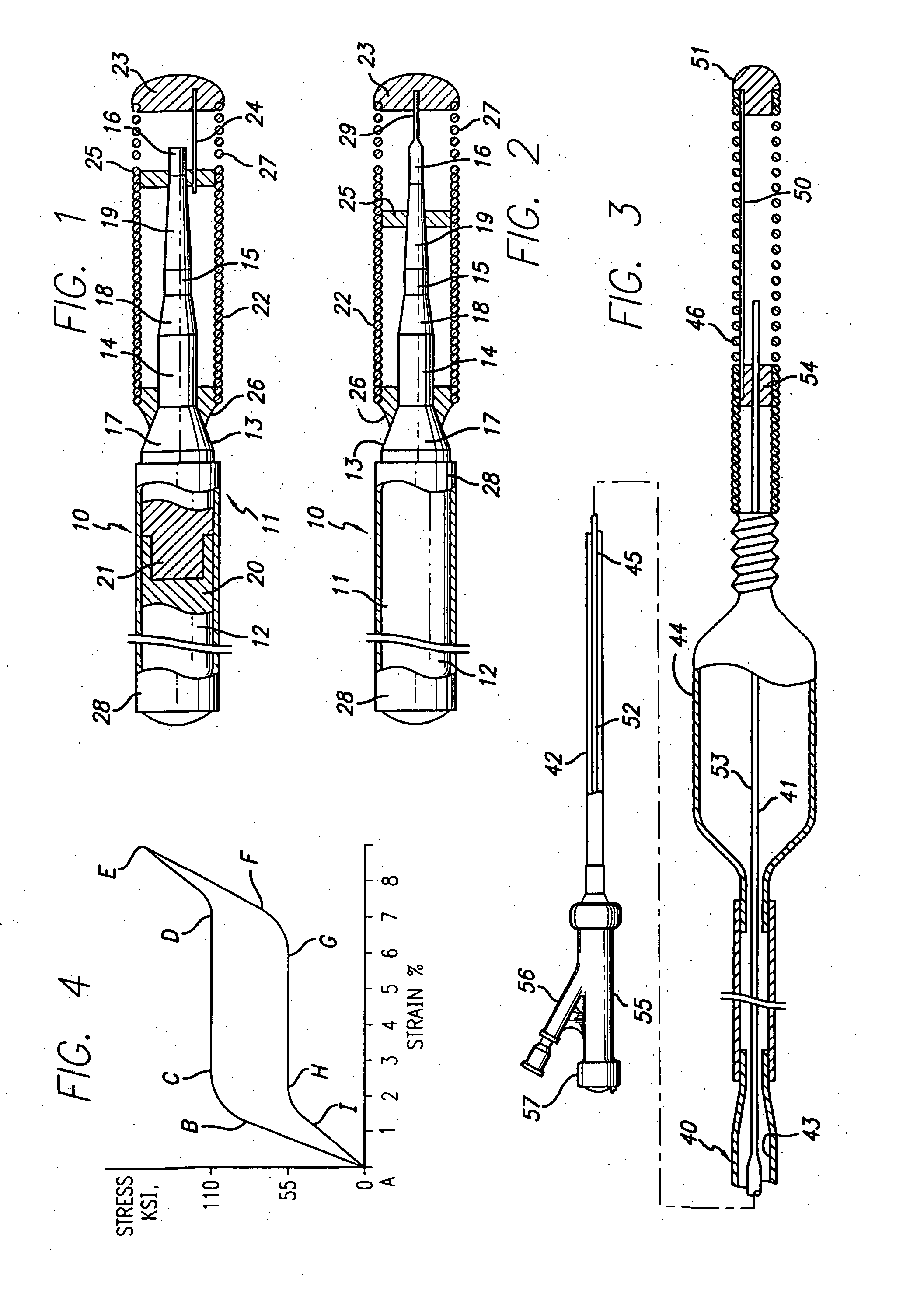

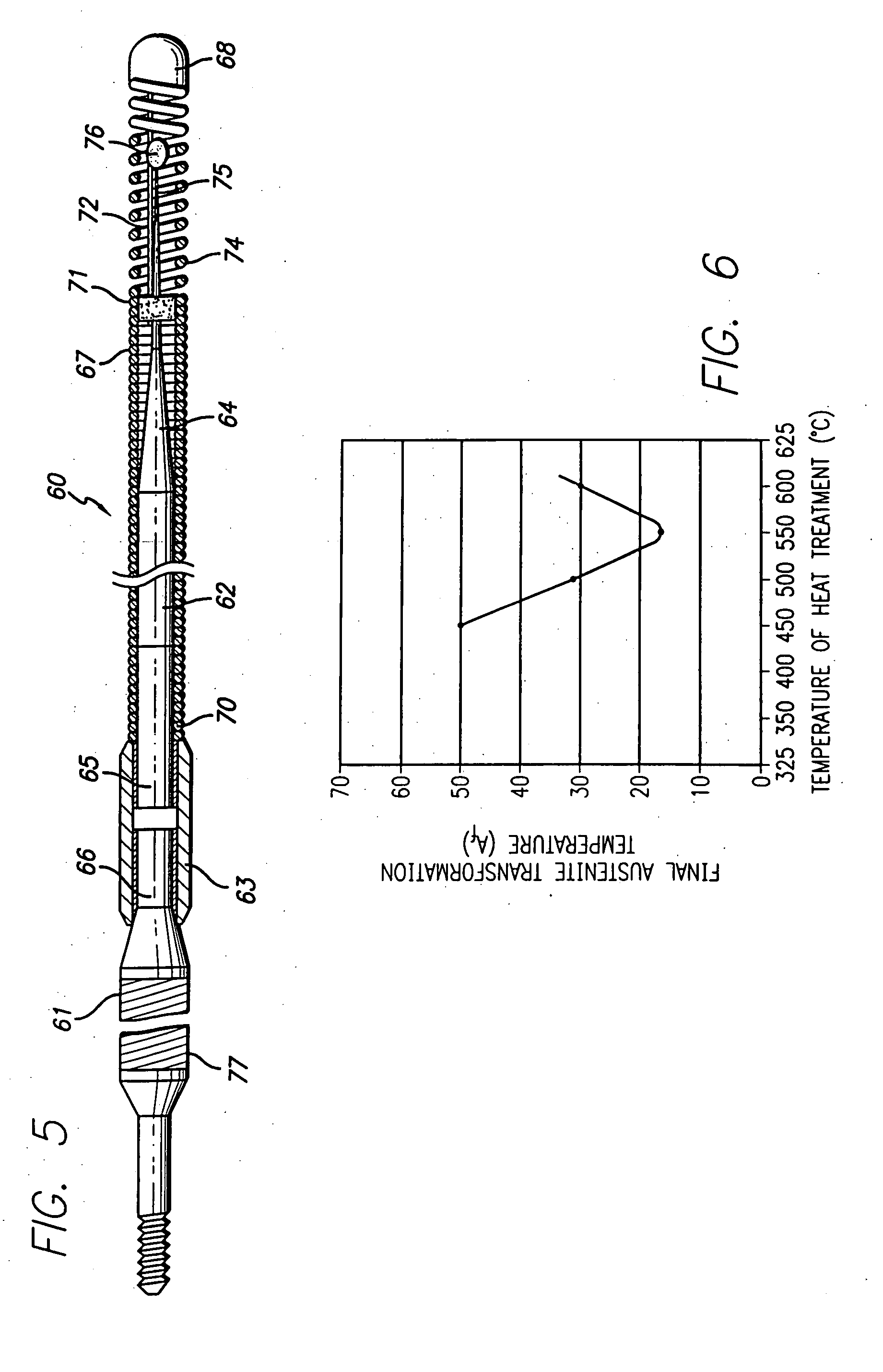

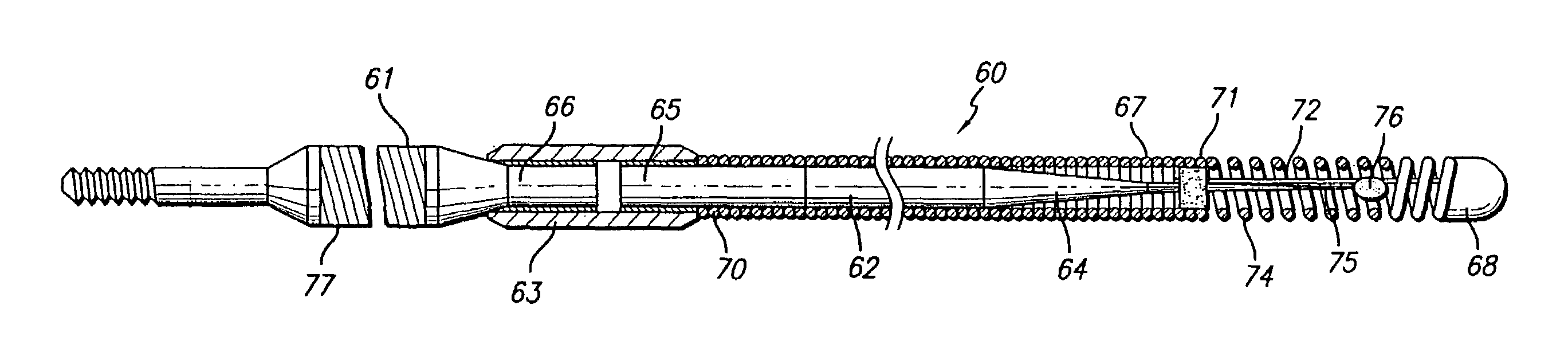

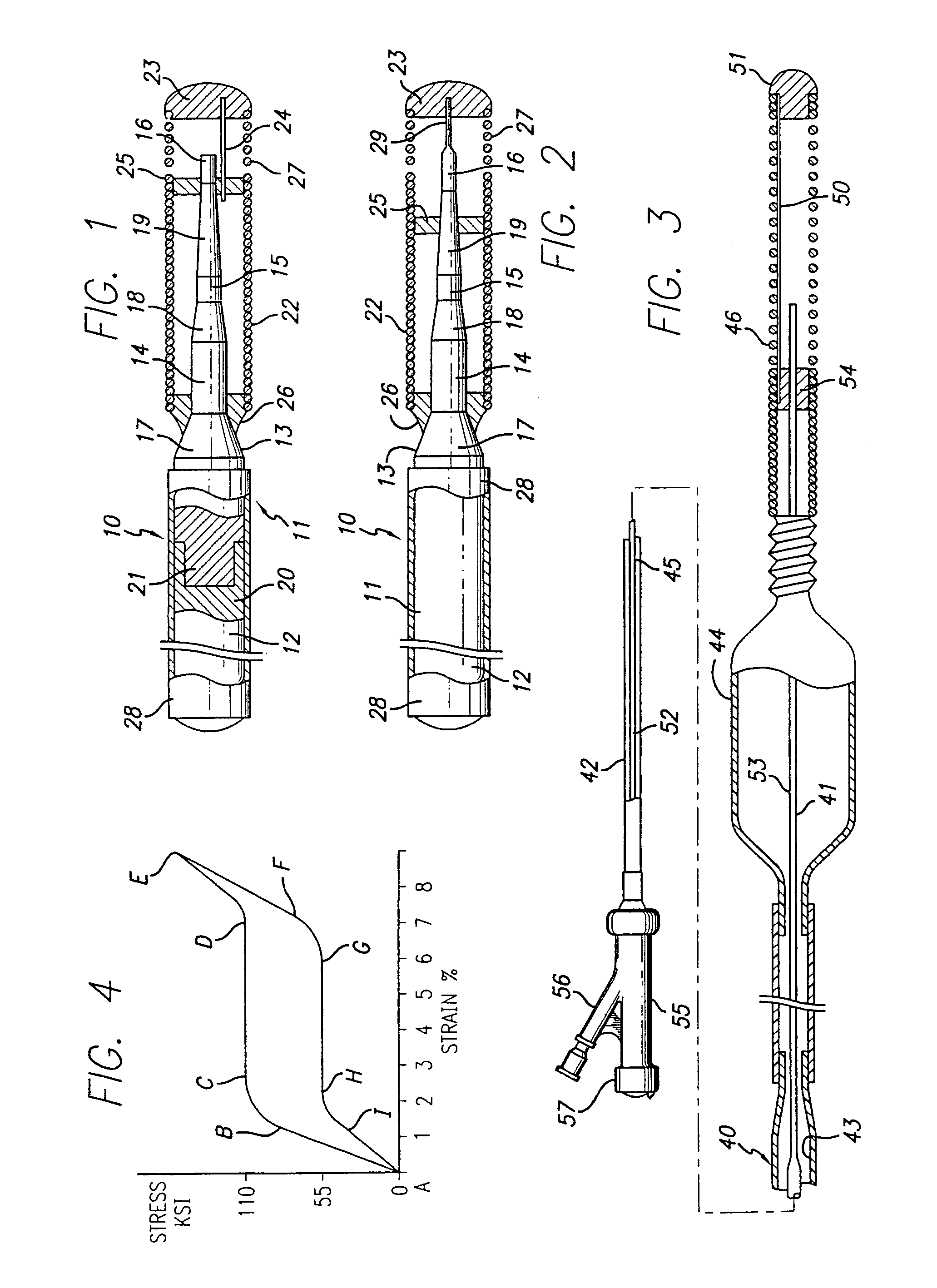

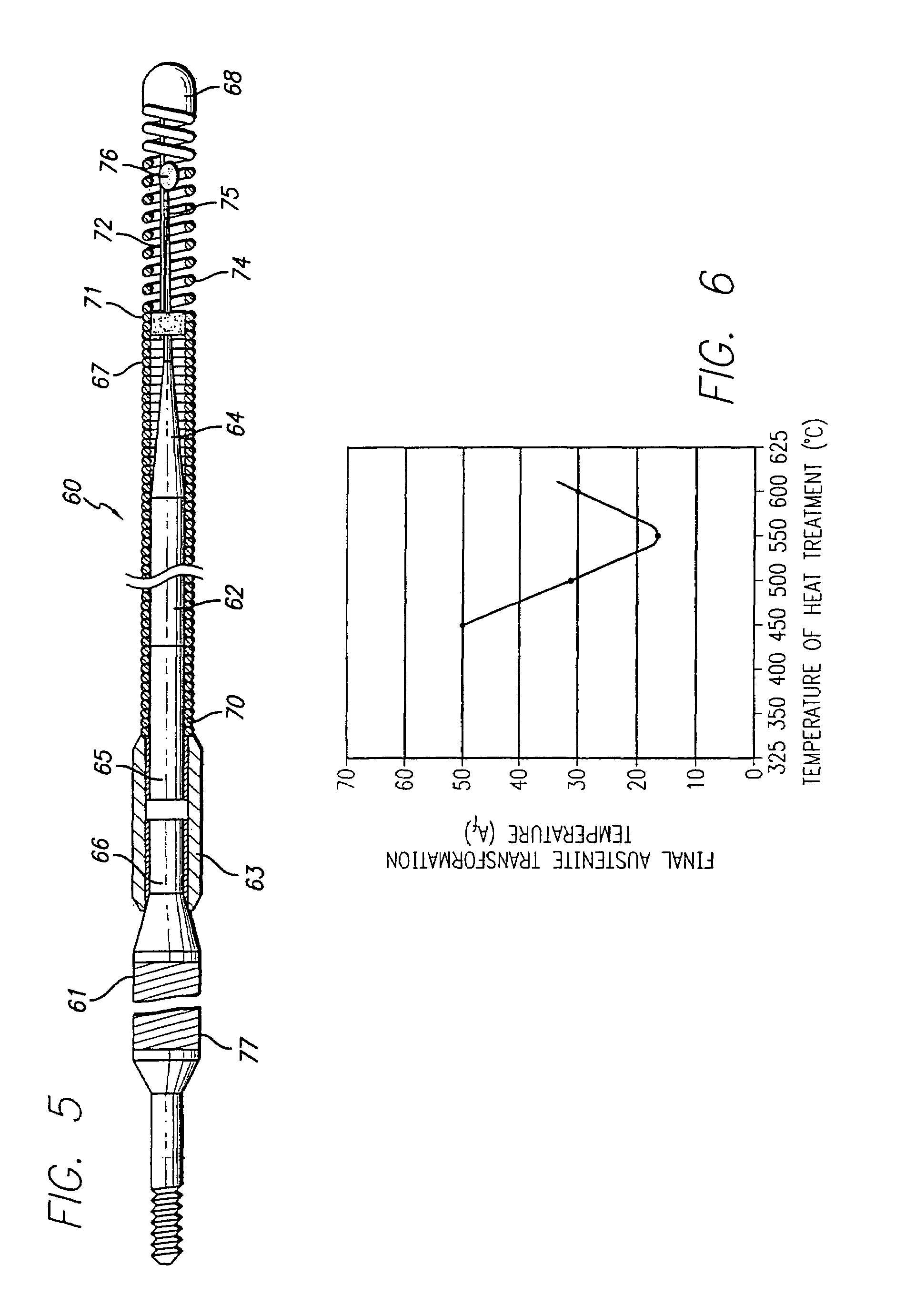

Superelastic guiding member

InactiveUS7244319B2Uniform residual stressImproved torque responseStentsGuide wiresStress inducedNiobium

An improved guiding member for use within a body lumen having a unique combination of superelastic characteristics. The superelastic alloy material has a composition consisting of about 30% to about 52% (atomic) titanium, and about 38% to 52% nickel and may have one or more elements selected from the group consisting of iron, cobalt, platinum, palladium, vanadium, copper, zirconium, hafnium and niobium. The alloy material is subjected to thermomechanical processing which includes a final cold working of about 10 to about 75% and then a heat treatment at a temperature between about 450° and about 600° C. and preferably about 475° to about 550° C. Before the heat treatment the cold worked alloy material is preferably subjected to mechanical straightening. The alloy material is preferably subjected to stresses equal to about 5 to about 50% of the room temperature ultimate yield stress of the material during the thermal treatment. The guiding member using such improved material exhibits a stress-induced austenite-to-martensite phase transformation at an exceptionally high constant yield strength of over 90 ksi for solid members and over 70 ksi for tubular members with a broad recoverable strain of at least about 4% during the phase transformation. An essentially whip free product is obtained.

Owner:ABBOTT CARDIOVASCULAR

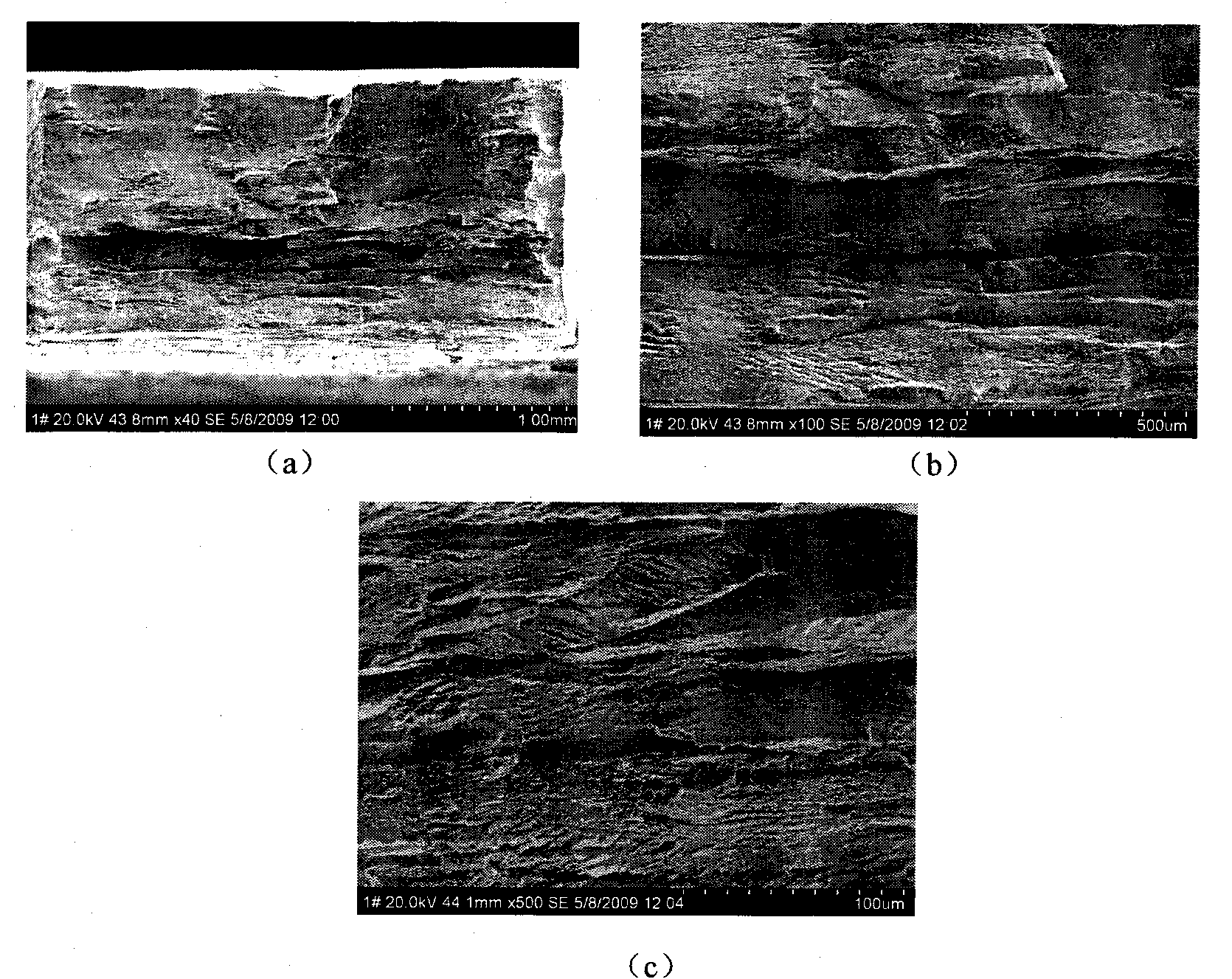

Deformation induced maraging stainless steel and machining process thereof

The invention belongs to the field of iron nickel-based martensite precipitation hardening-type alloys, and in particular relates to deformation induced maraging stainless steel with high strength, high toughness and high corrosion resistance and a machining process thereof. The stainless steel is a novel material mainly applied to the important fields of aviation, spaceflight, machinofacture, atomic energy and the like. The steel comprises the following components in percentage by weight: 11.0-13.0 percent of Cr, 11.0-14.0 percent of Ni, 1.5-2.1 percent of Ti, 0.1-1.0 percent of Mo, 0.5-2.0 percent of Cu, 1.5-2.2 percent of Co, 0.5-1.5 percent of Mn, 0.1-1.0 percent of Si, 1.0-2.0 percent of Al, less than 0.01 percent of Nb, less than 0.01 percent of C, less than 0.01 percent of N, less than 0.01 percent of V and the balance of Fe. The machining process comprises the following steps of: (1) heating and forging in an austenite single phase zone, and air-cooling to the room temperature after the forging is ended, wherein the forge and press ratio is 6-9; (2) hot-rolling after the forging is ended and air-cooling to the room temperature after the rolling is ended, wherein the blooming temperature is 1100-1200 DEG C, and the finished rolling temperature is 800-900 DEG C. The invention obtains a martensite matrix with high-order dislocation density through deformation induced martensite phase change and simultaneously obtains high strength, high toughness and high corrosion resistance through adding the proper matching of precipitation strength elements, such as Ni, Ti, Mo, Cu and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Superelastic guiding member

InactiveUS20070249965A1Guaranteed normal transmissionConstant stress levelGuide wiresSurgeryStress inducedNiobium

An improved guiding member for use within a body lumen having a unique combination of superelastic characteristics. The superelastic alloy material has a composition consisting of about 30% to about 52% (atomic) titanium, and about 38% to 52% nickel and may have one or more elements selected from the group consisting of iron, cobalt, platinum, palladium, vanadium, copper, zirconium, hafnium and niobium. The alloy material is subjected to thermomechanical processing which includes a final cold working of about 10 to about 75% and then a heat treatment at a temperature between about 450° and about 600° C. and preferably about 475° to about 550° C. Before the heat treatment the cold worked alloy material is preferably subjected to mechanical straightening. The alloy material is preferably subjected to stresses equal to about 5 to about 50% of the room temperature ultimate yield stress of the material during the thermal treatment. The guiding member using such improved material exhibits a stress-induced austenite-to-martensite phase transformation at an exceptionally high constant yield strength of over 90 ksi for solid members and over 70 ksi for tubular members with a broad recoverable strain of at least about 4% during the phase transformation. An essentially whip free product is obtained.

Owner:ABBOTT CARDIOVASCULAR

Zinc hot dip galvanized composite high strength steel plate excellent in formability and bore-expanding characteristics and method for production thereof

ActiveCN1930316AGood formabilityExcellent hole expandabilityHot-dipping/immersion processesFurnace typesMartensite transformationSheet steel

The present invention provides a hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability and a method of production of the same, that is, a hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability containing C: 0.01 to 0.3%, Si: 0.005 to 0.6%, Mn: 0.1 to 3.3%, P: 0.001 to 0.06%, S: 0.001 to 0.01%, Al: 0.01 to 1.8%, and N: 0.0005 to 0.01% and having a metal structure of ferrite and, by area rate, 5% to 60% of tempered martensite and a method of production of the same comprising hot rolling, then cold rolling a slab including the above ingredients, heating the sheet in the hot dip galvanization heating process to Ac 1 to Ac 3 +100°C, holding it there for 30 seconds to 30 minutes, then cooling it by a 1°C / s or higher cooling rate to 450 to 600°C, hot dip galvanizing it at that temperature, then cooling it at a 1°C / s or higher cooling rate to the martensite transformation point or lower in temperature, holding it there at 200°C to 500°C for 1 second to 5 minutes, then cooling it at a 5°C / s or higher cooling rate to 100°C or less.

Owner:NIPPON STEEL CORP

Vanadium micro-alloyed 1300 Mpa-grade high-strength hot-rolled steel plate and production method of cold-rolled dual-phase steel plate

The invention discloses a vanadium micro-alloyed 1300 Mpa-grade high-strength hot-rolled steel plate and a production method of a cold-rolled dual-phase steel plate. The technical problem that the strength of the double-phase steel plate prepared by the existing method is insufficient is solved. According to the technical scheme, the 1300 Mpa-grade high-strength hot-rolled steel plate is formed through control cooling and through steel smelting and solidification, casting blank or hot continuous rolling after ingot casting cogging, after the hot continuous rolling is carried out at a certain temperature in a coiled mode, acid washing and room temperature cold rolling are carried out to 1-3 mm thick, then instant quenching is carried out at a certain temperature short-time heat preservationtime in a 720-780 DEG C two-phase region, and the vanadium micro-alloyed 1300 Mpa-grade high-strength dual-phase cold-rolled steel plate is prepared. According to the preparation process, nano-vanadium carbide particle precipitation strengthening and martensite phase change strengthening are combined, the strength of the existing dual-phase steel is remarkably improved, and meanwhile, the production efficiency is also guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

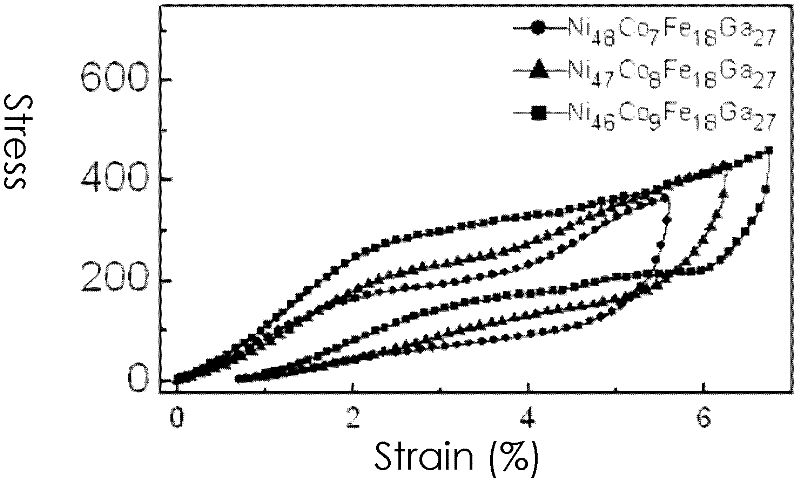

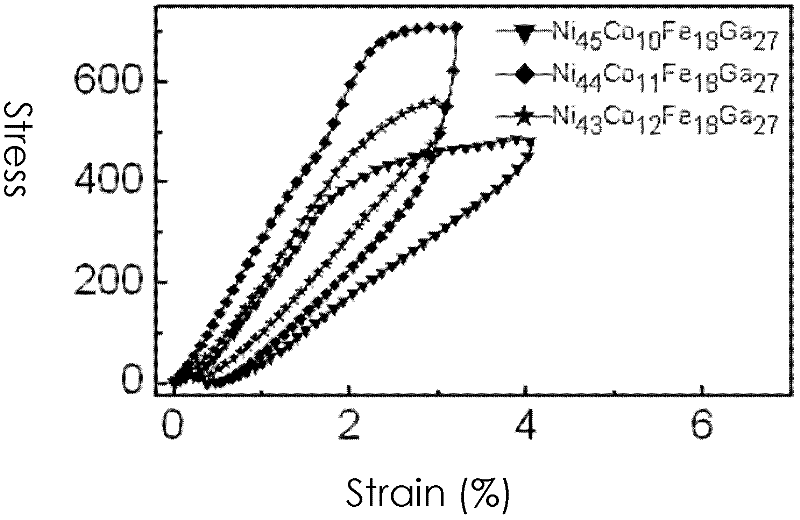

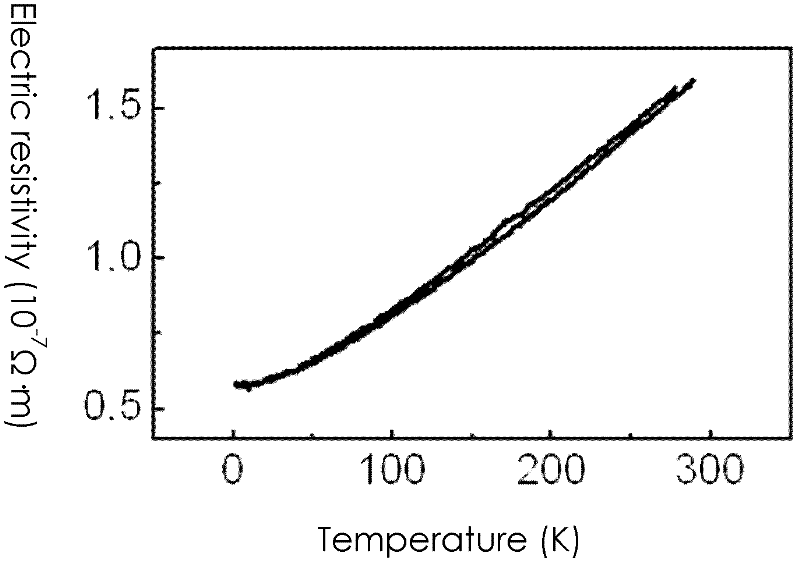

Nickel-cobalt-iron-gallium hyperelastic alloy material and preparation method thereof

The invention relates to a nickel-cobalt-iron-gallium hyperelastic alloy material and a preparation method thereof, belonging to the technical field of alloy. The alloy material is a Ni55-xCoxFe18Ga27 hyperelastic material, wherein when x ranges from 7 to 12, the alloy material comprises hyperelastic actions at room temperature; when x ranges from 10 to 12, the alloy material comprises narrow-hysteresis hyperelastic actions at room temperature; and the alloy material comprises no martensitic phase transformation actions at the temperature ranging from 0K to 298K. The alloy material is obtained through smelting, suction casting and annealing treatment in sequence. The alloy material disclosed by the invention has lower cost in comparison with NiTi series of hyperelastic alloy, so that low price and popularization of hyperelastic alloy for daily use are hopefully achieved; the alloy material has the advantages of narrow-hysteresis hyperelastic actions, low internal friction and capability of being widely applied to industrial production; and moreover, the alloy material is simple in preparation method and low in cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for forming Pt-modified NiAl+Ni3Al thermal barrier adhering layer on surface of nickel-based super alloy

InactiveCN102181860APrevent oxidationGuaranteed bonding performanceSolid state diffusion coatingSuperimposed coating processMartensite transformationCoated surface

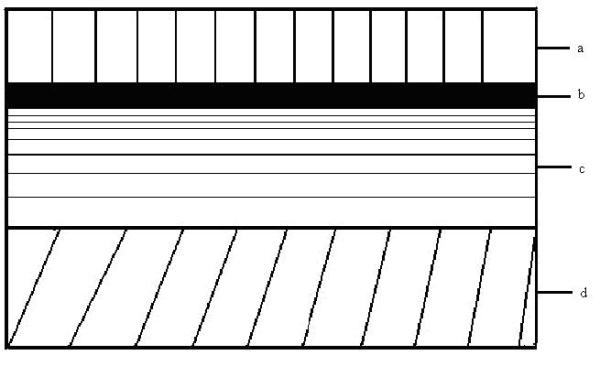

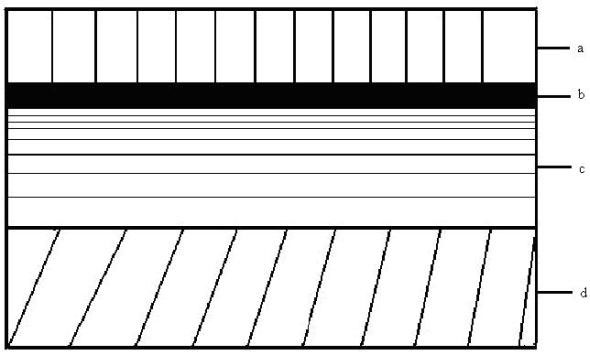

The invention relates to a method for forming a Pt-modified Beta-NiAl+Gamma'-Ni3Al thermal barrier coating adhering layer on the surface of nickel-based super alloy (c). Specially speaking, the surface (a) of a coating is a Pt+Beta-NiAl phase, and the inner part (b) of the coating is a Pt-Gamma-Ni+Gamma'-Ni3Al phase Due to the double-phase structure, the problem of martensite phase transformation in the traditional thermal barrier coating adhering layer is solved as the difference between the coating and the base aluminum is larger, and the aluminum diffuses rapidly, the oxidation resistance of the coating is guaranteed and simultaneously, the adhering property of the coating and the base is combined, and compared with the traditional adhering-layer material, the adhering layer has superior advantages. In the invention, the Pt+Beta-NiAl+Gamma'-Ni3Al coating is formed in a powder embedding and aluminizing way. The specific implementation process is as follows: plating a layer of Pt on the super alloy base, then heating and diffusing the super alloy base, and finally conducting powder embedding and aluminizing on the Pt-plated base diffused uniformly, thus obtaining the coating with the structure and the phase by aluminizing control process.

Owner:SHANGHAI UNIV

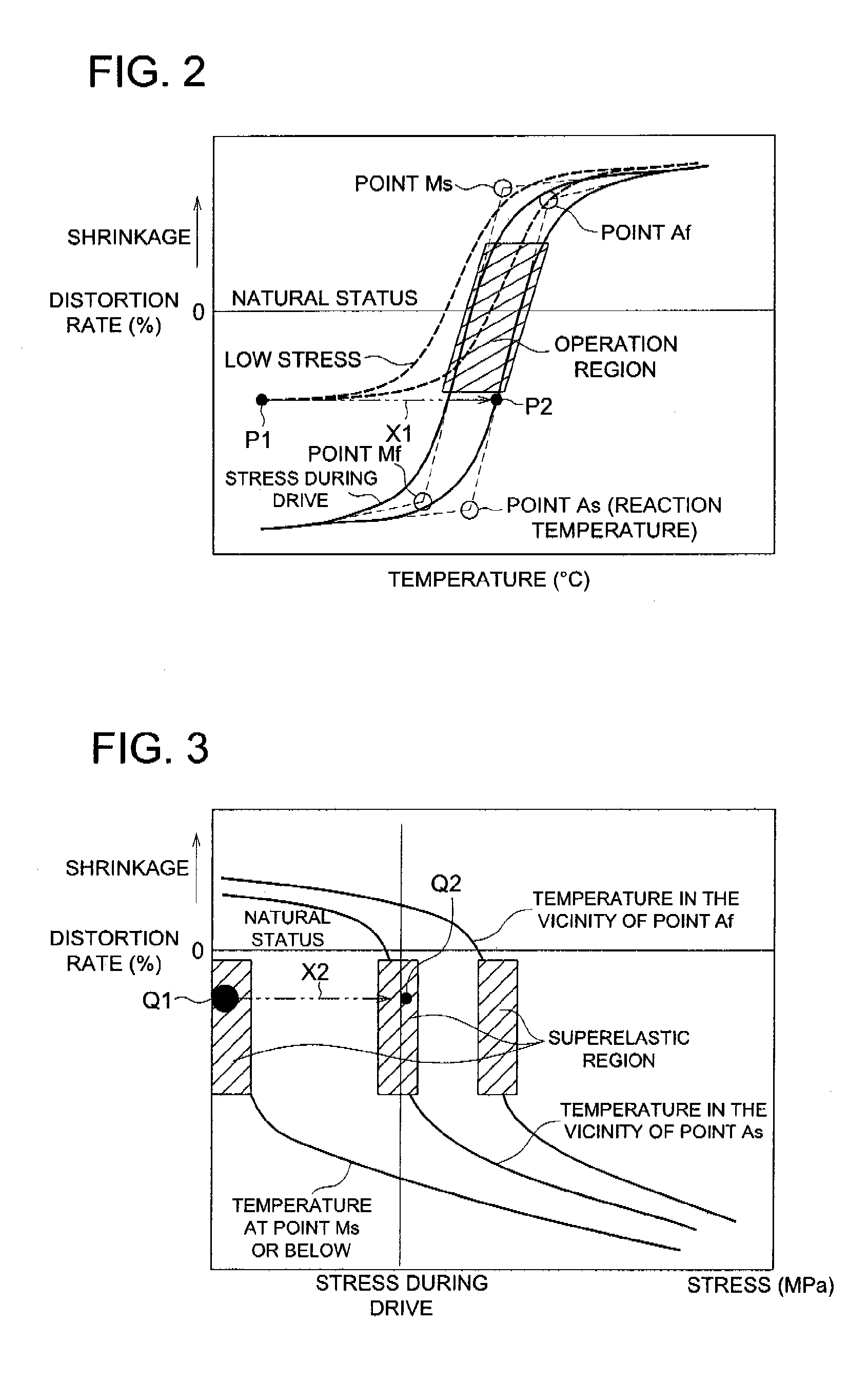

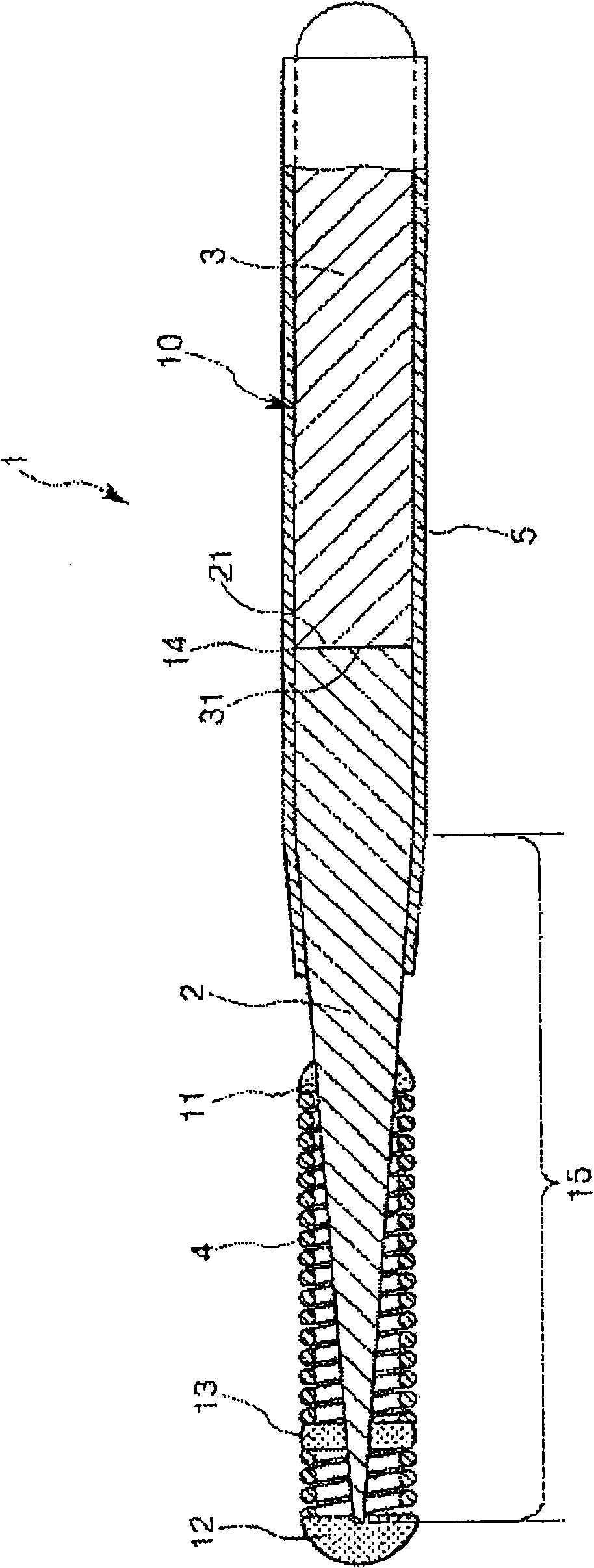

Drive apparatus and lens drive apparatus

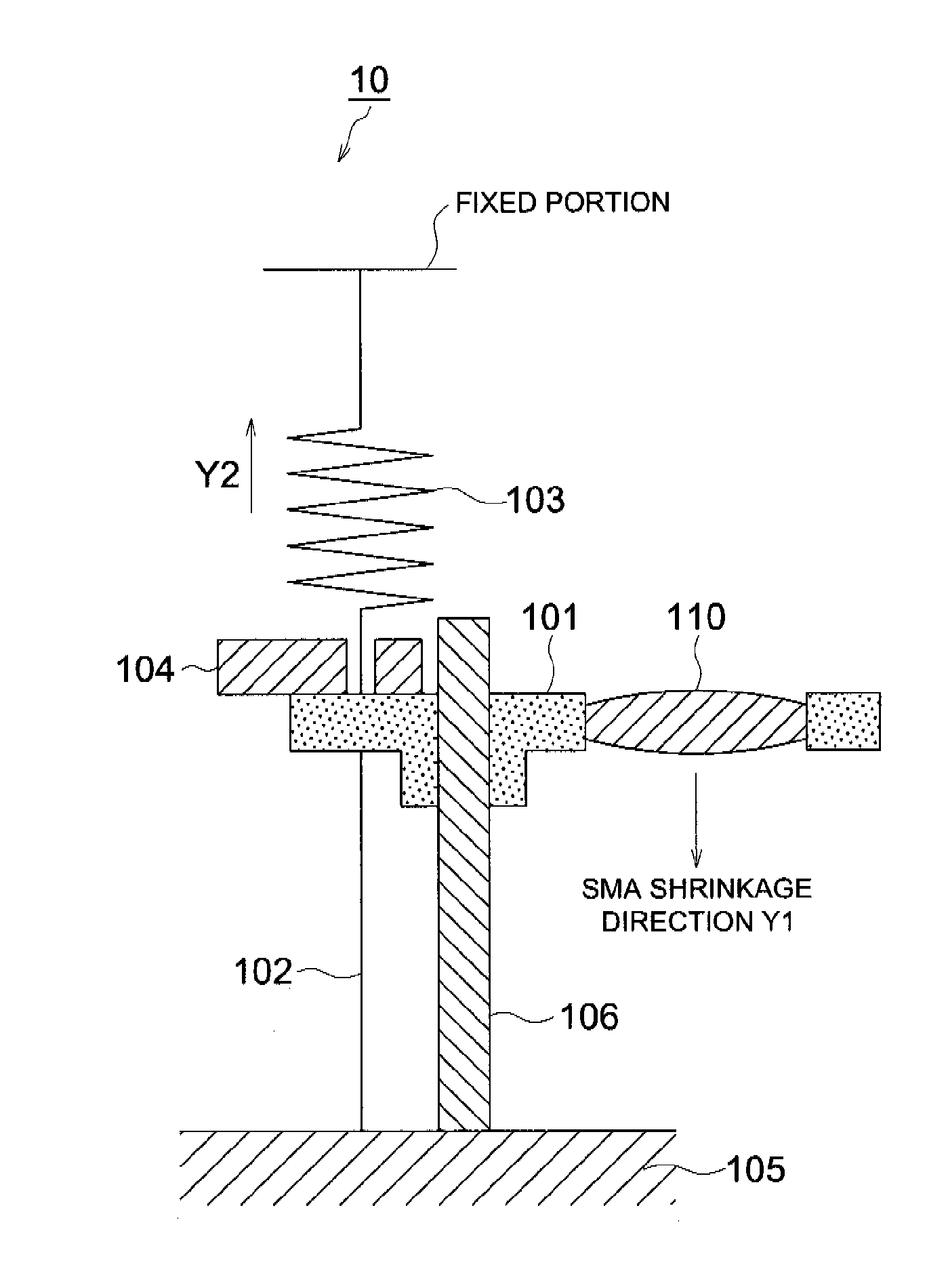

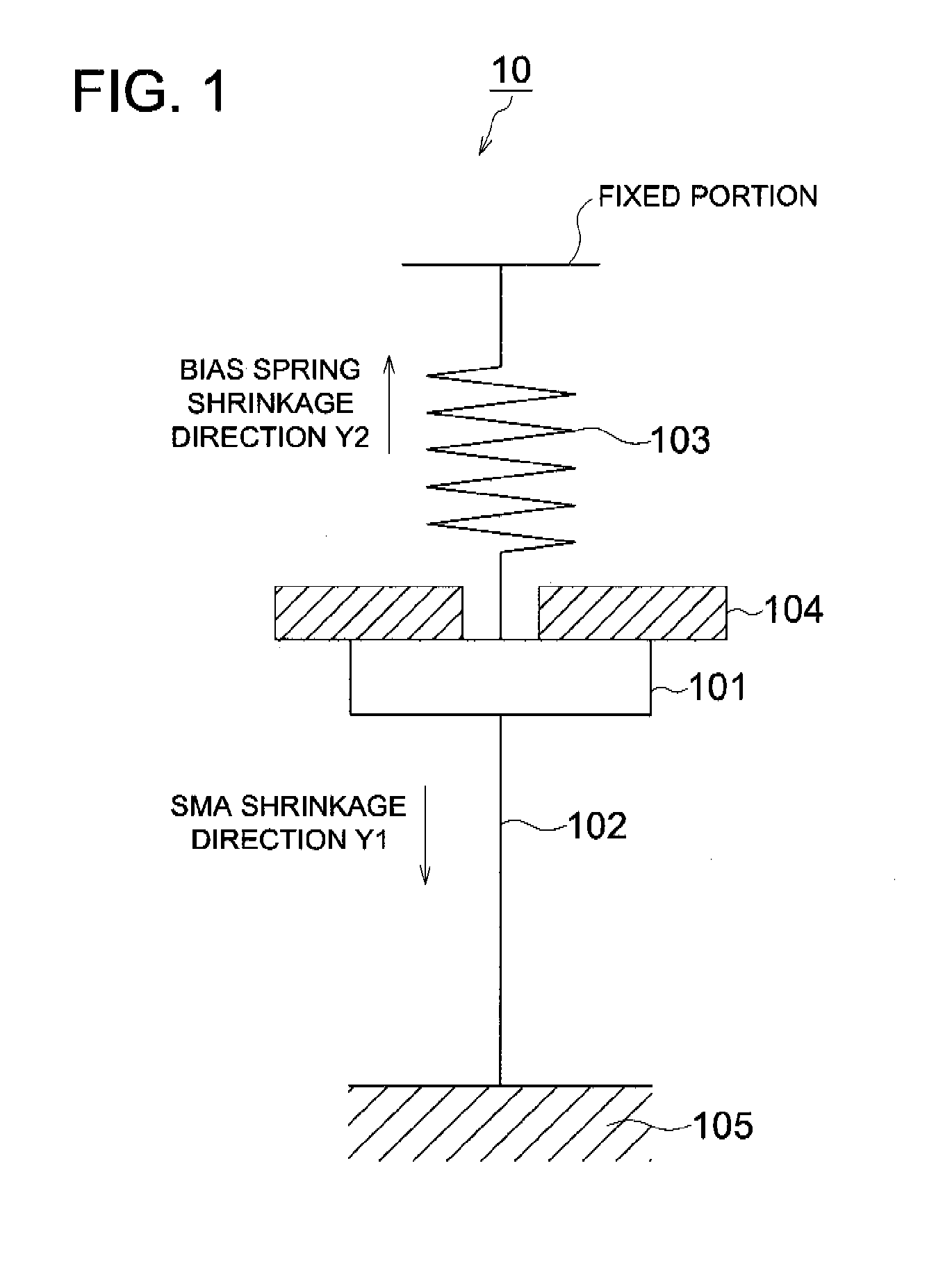

InactiveUS20080282696A1Increase pressureRelieve pressureProjector focusing arrangementCamera focusing arrangementMartensite transformationShape-memory alloy

A drive apparatus having: a shape memory alloy having a property such that a temperature transformation sensitivity in a temperature range from a starting point of austenite transformation (As) at a predetermined stress to an end point of austenite (Af) is higher than a temperature transformation sensitivity in other temperature range, and a temperature transformation sensitivity in a temperature range from a starting point of martensite transformation (Ms) at a predetermined stress to an end point of martensite transformation (Mf) is higher than a temperature transformation sensitivity in other temperature range; and a driven member which is moved by a transformation of the shape memory alloy; wherein the driven member is moved in a temperature range of higher temperature transformation sensitivity.

Owner:KONICA MINOLTA OPTO

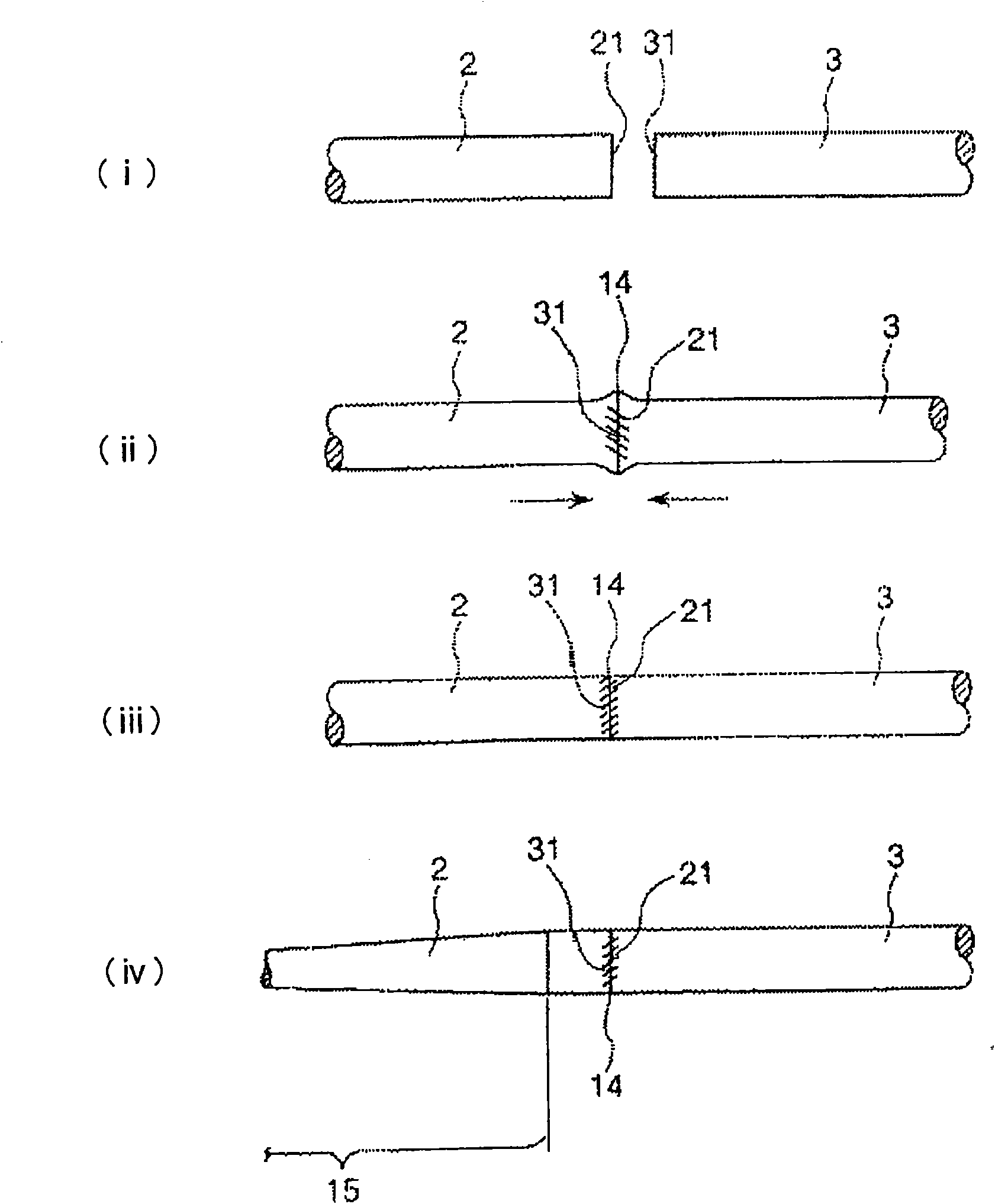

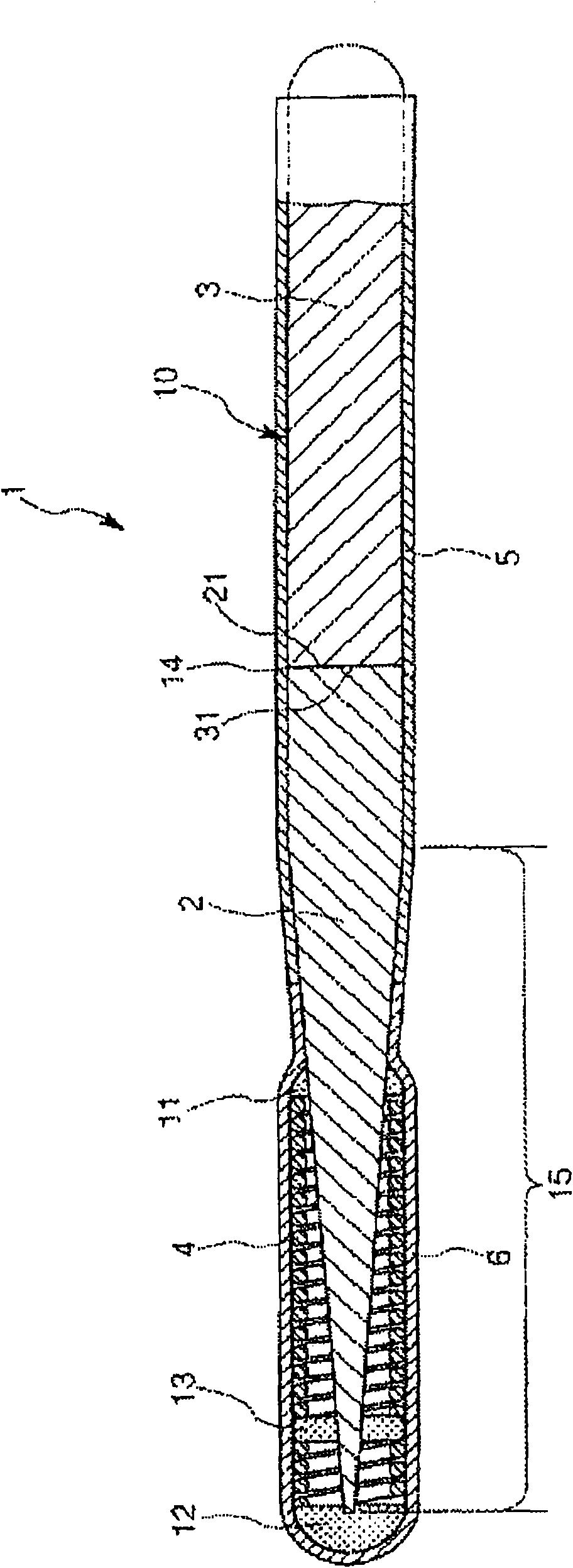

Guide wire and stent

ActiveCN101674861AEasy to slideExcellent X-ray contrastStentsGuide wiresPlastic materialsYoung's modulus

A guide wire that due to its wide elastic region and high Young's modulus, simultaneously has pliability and pushability, and that even when its surface is coated with a plastic material of high melting point, is highly impervious to influences of heat treatment, and that has excellent slidability and excels in weldability between a distal-end-side base material and a proximal-end-side core material. The guide wire has a core material comprising a distal-end-side core material and a proximal-end-side core material. The distal-end-side core material is made of an iron alloy having shape memorycapability and superelasticity, consisting essentially of two phases of gamma-phase and gamma'-phase and exhibiting, in a thermal hysteresis of martensite transformation and reverse transformation, adifference between reverse transformation completion temperature (Af-point) and martensite transformation starting temperature (Ms-point) of 100 DEG C or below. The proximal-end-side core material ismade of an alloy containing iron and has an elastic modulus higher than that of the distal-end-side core material. The distal-end-side core material and the proximal-end-side core material are weldedtogether.

Owner:TERUMO KK

Gold alloy with 18k span effect and preparation method thereof

The invention discloses a gold alloy with 18k span effect and a preparation method thereof in the technical field of noble metal alloy thermal treatment. The gold alloy comprises the following components according to weight percentage: 75.00 to 82 percent of Au, 13.1 to 19.01 percent of Cu and 4.0 to 6.0 percent of Al. The gold alloy with 18k span effect and the preparation method thereof can obtain martensitic phase transformation without ageing; the obtained 18k span has good stability at room temperature and the temperature of the reversible martensitic phase transformation is above 60 DEG C.

Owner:SHANGHAI JIAO TONG UNIV +1

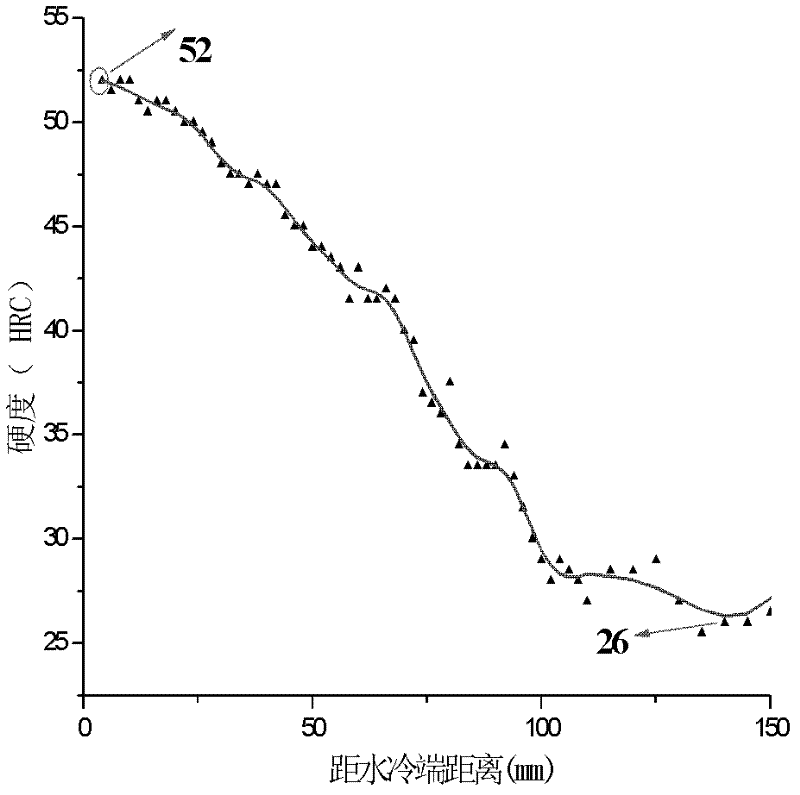

Double quenching technique for 9Cr2Mo leveler roll

InactiveCN101134996AAvoid decompositionGuaranteed hardnessFurnace typesHeat treatment process controlMartensite transformationDecomposition

The double liquid quenching process of 9Cr2Mo straightening roller includes the first quick cooling in water to avoid high temperature decomposition of overcooling austenite to the martensite transformation temperature, and the subsequent cooling in oil for martensite transformation to raise the hardness, reduce quenching deformation and avoid cracking. Before being loaded to furnace, the straightening roller has its end surfaces and central through hole covered with plates to reduce the quench cooling of these parts and ensure hardness of HRC 35-40.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Superelastic guiding member

InactiveUS7258753B2Guaranteed normal transmissionConstant stress levelStentsGuide wiresStress inducedNiobium

An improved guiding member for use within a body lumen having a unique combination of superelastic characteristics. The superelastic alloy material has a composition consisting of about 30% to about 52% (atomic) titanium, and about 38% to 52% nickel and may have one or more elements selected from the group consisting of iron, cobalt, platinum, palladium, vanadium, copper, zirconium, hafnium and niobium. The alloy material is subjected to thermomechanical processing which includes a final cold working of about 10 to about 75% and then a heat treatment at a temperature between about 450° and about 600° C. and preferably about 475° to about 550° C. Before the heat treatment the cold worked alloy material is preferably subjected to mechanical straightening. The alloy material is preferably subjected to stresses equal to about 5 to about 50% of the room temperature ultimate yield stress of the material during the thermal treatment. The guiding member using such improved material exhibits a stress-induced austenite-to-martensite phase transformation at an exceptionally high constant yield strength of over 90 ksi for solid members and over 70 ksi for tubular members with a broad recoverable strain of at least about 4% during the phase transformation. An essentially whip free product is obtained.

Owner:ABBOTT CARDIOVASCULAR

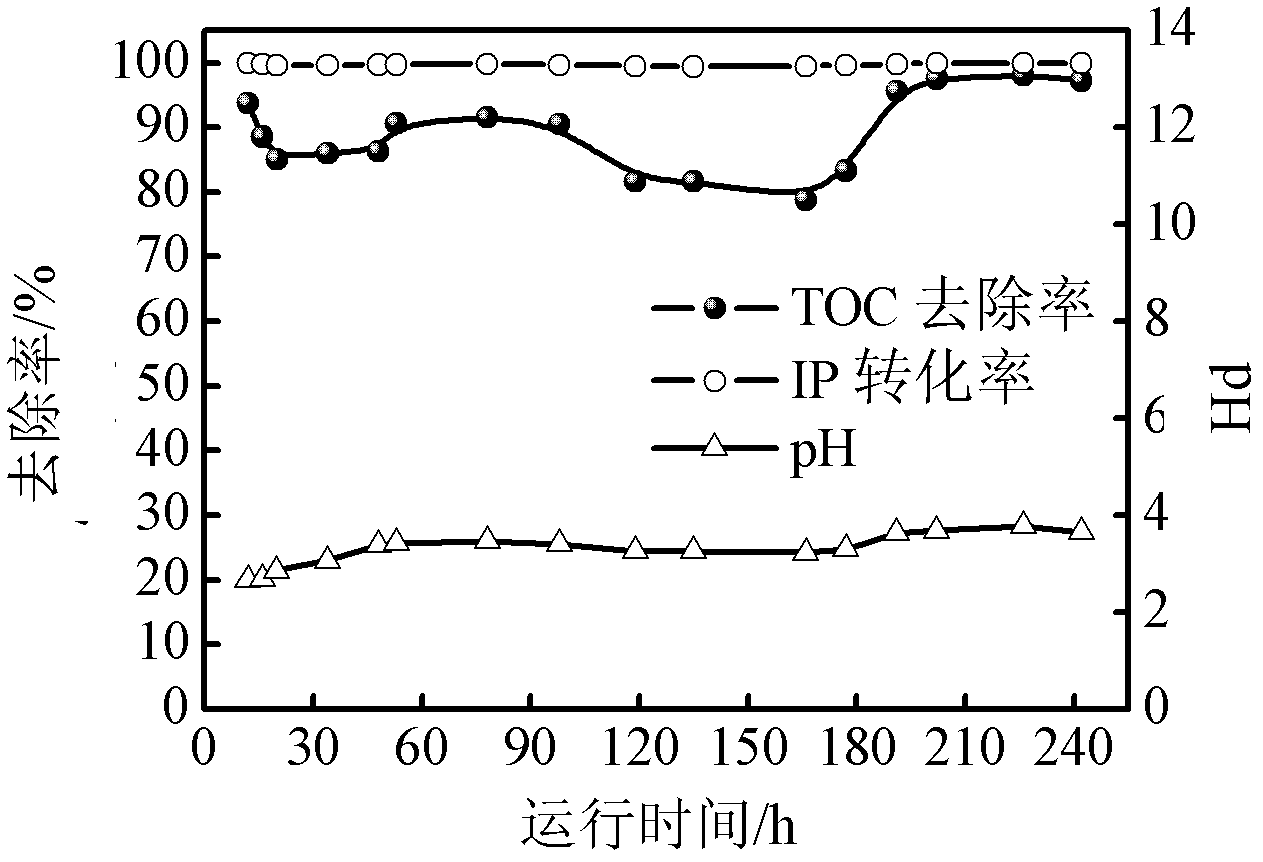

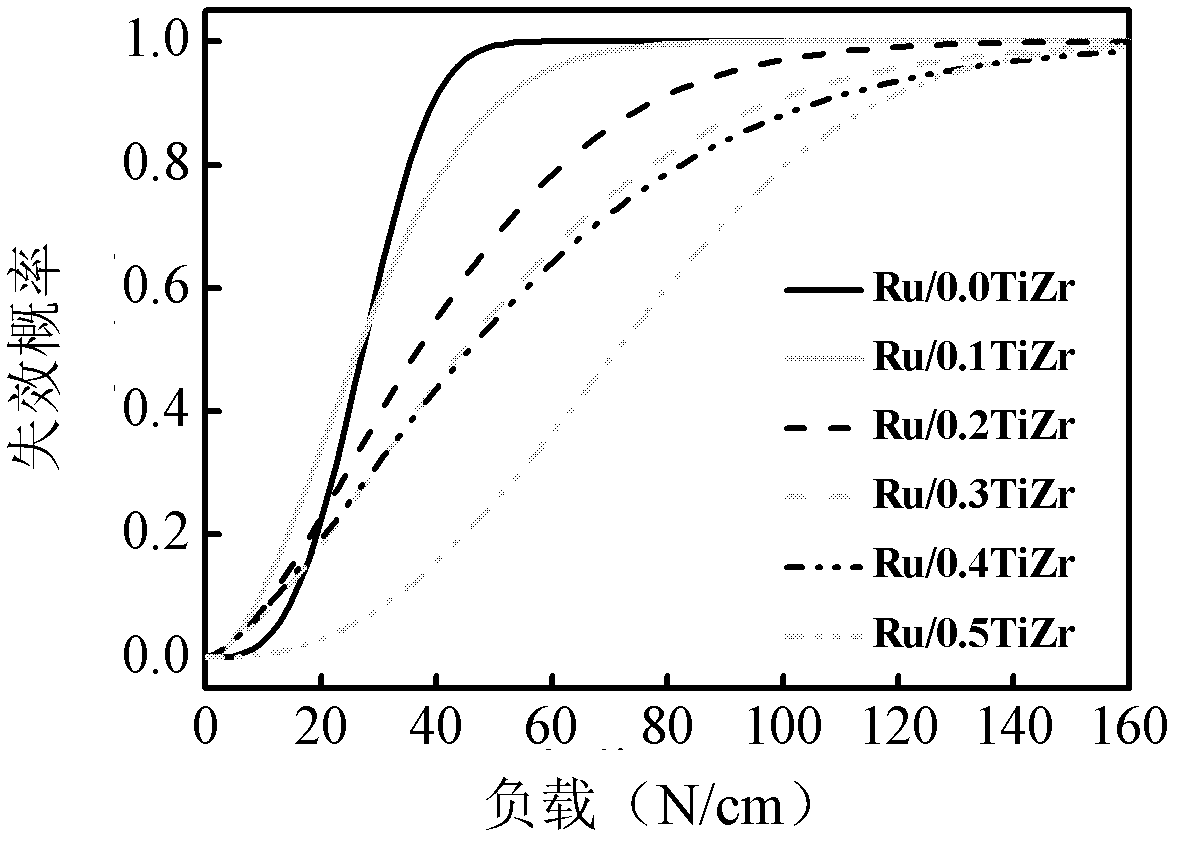

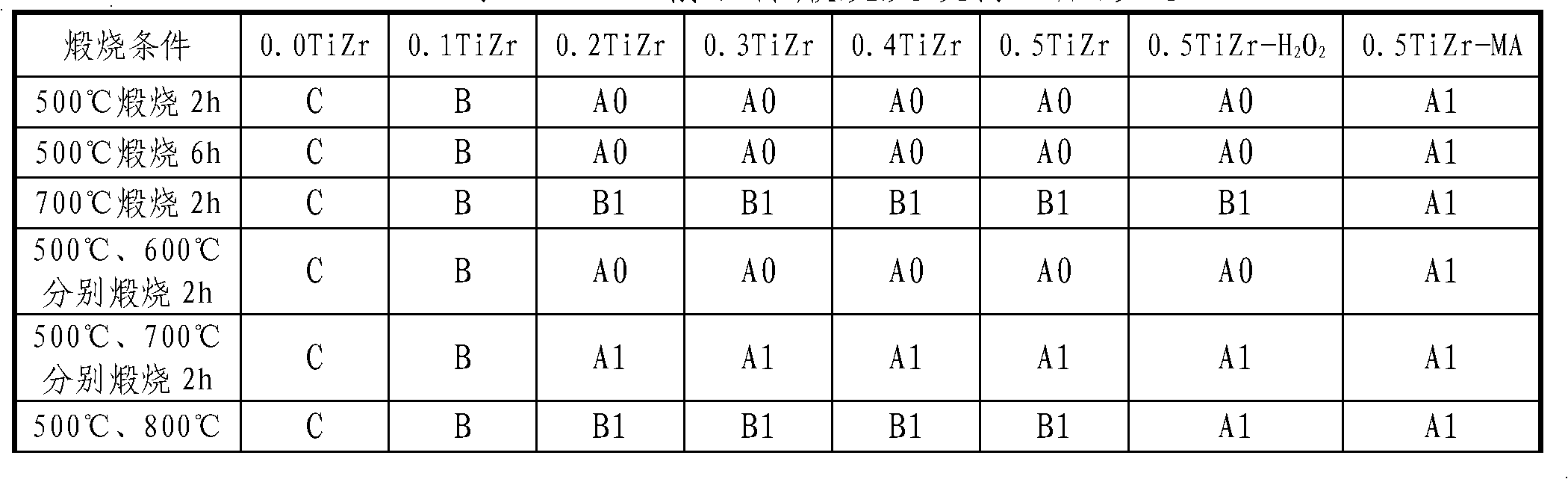

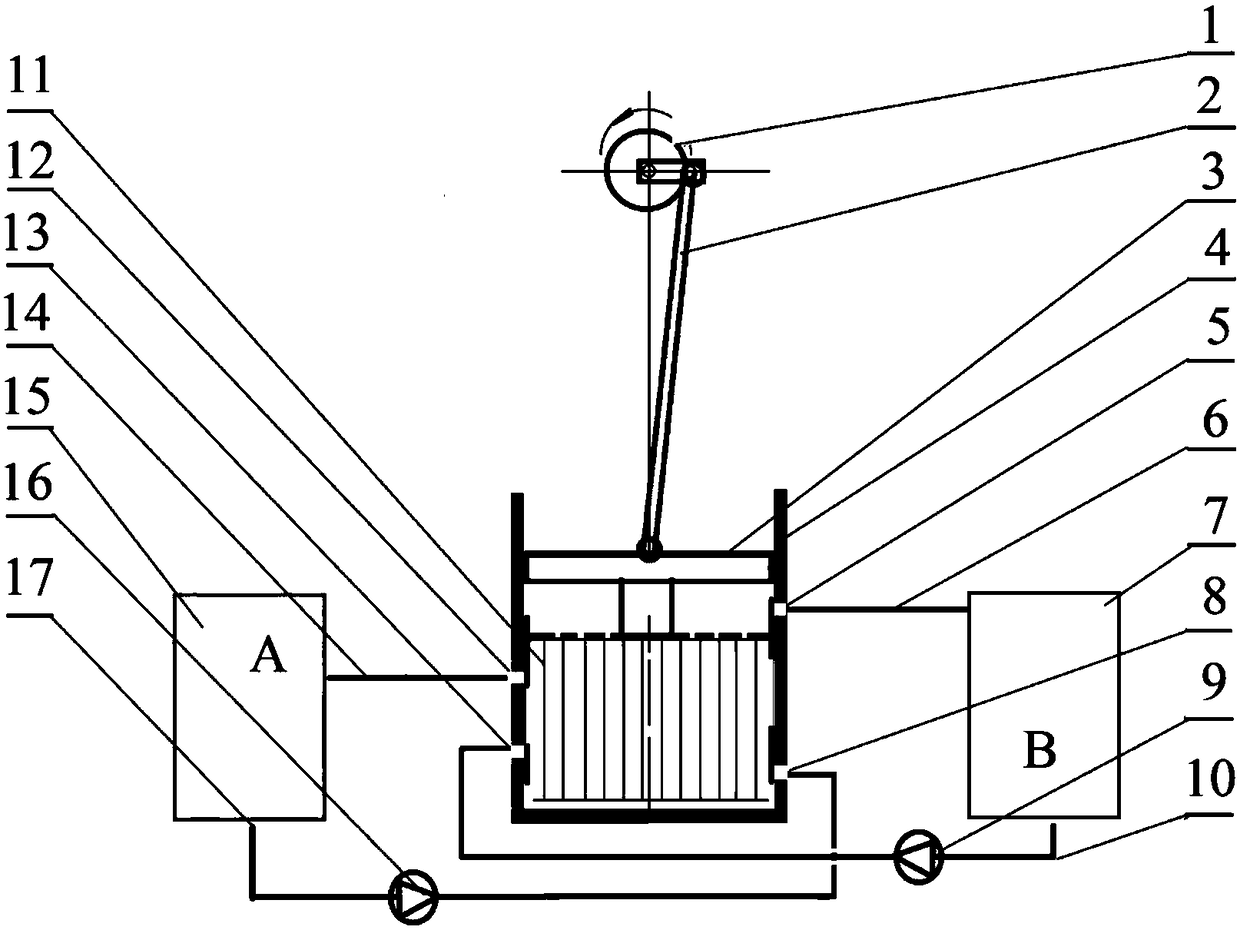

TiZrO2 carrier and precious metal/TIZrO2 catalyst and preparation and application thereof

ActiveCN103157517AHigh activityImprove stabilityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsMartensite transformationHydrogen

The invention provides a TiZrO2 carrier and a precious metal / TIZrO2 catalyst and preparation and application of the TiZrO2 carrier and the precious metal / TIZrO2 catalyst, and belongs to the field of water processing technology and environment function materials. The ZrO2 is stable in chemical property, and not only is not soluble in alkaline solution, but also can exist in acid solution stably. However, the specific surface area of the ZrO2 is small, and generally is only about 20m2 / g to 50m2 / g, and due to the fact that when the ZrO2 is calcined, the ZrO2 can generate martensite transformation, the fact that molded products have no intensity is caused. The precious metal / TIZrO2 catalyst is a catalytic wet air oxidation catalyst which is corrosion resisting, high-temperature resisting, high in strength, and big in specific surface area, and uses zirconium oxide stabilized by titanium oxide as a carrier to support precious metal Ru and Pt with high activity and difficult to run off, and prepares the excellent catalytic wet air oxidation catalyst. The prepared catalyst maintains good form after the prepared catalyst runs for 242 h under a high-temperature high-pressure acid environment with the temperature of 260 DEG C, the pressure of 5.7 MPa and the potential of hydrogen (PH) value of about 3, and the performance is beneficial to the popularization of a zirconium oxide supported catalyst in the industrialized application of catalytic wet air oxidation.

Owner:杭州深瑞环境有限公司

Piston-cylinder refrigerating device based on memory alloy thermoelastic effect

PendingCN108562061AEnhanced Controllable Transfer EfficiencyImprove insulation performancePositive displacement pump componentsFluid circulation arrangementMartensite transformationHydraulic cylinder

A piston-cylinder refrigerating device based on memory alloy thermoelastic effect belongs to the technical field of refrigeration and comprises a motor power system, a memory alloy thermoelastic effect refrigerator, and a dual-circuit controllable liquid-flow heat exchange system. A motor drives a piston to linearly reciprocate in a hydraulic cylinder. Memory alloy is arranged in space between thepiston and the bottom of the hydraulic cylinder; reciprocating of the piston enables the memory alloy to periodically deform by loading and restore by unloading, and alternate martensite phase-changeheat release and inverse-change heat absorption are generated correspondingly. A piston spool and holes in the sidewall of the hydraulic cylinder form two pairs of spool inlets and two pairs of spooloutlets; when the piston moves during upper and lower half cycles, one pair of spool inlets and one pair of spool outlets are opened, one heat exchange flow is controlled to enter the hydraulic cylinder and exchange with heat with the memory alloy; after the piston reciprocates once, heat is transmitted from the flow to another flow through the memory alloy; a single refrigerating cycle is completed. The piston-cylinder refrigerating device based on memory alloy thermoelastic effect is compact in structure, high in refrigerating capacity and applicable to the refrigerating systems, such as anair conditioner and a refrigerator.

Owner:UNIV OF SCI & TECH BEIJING

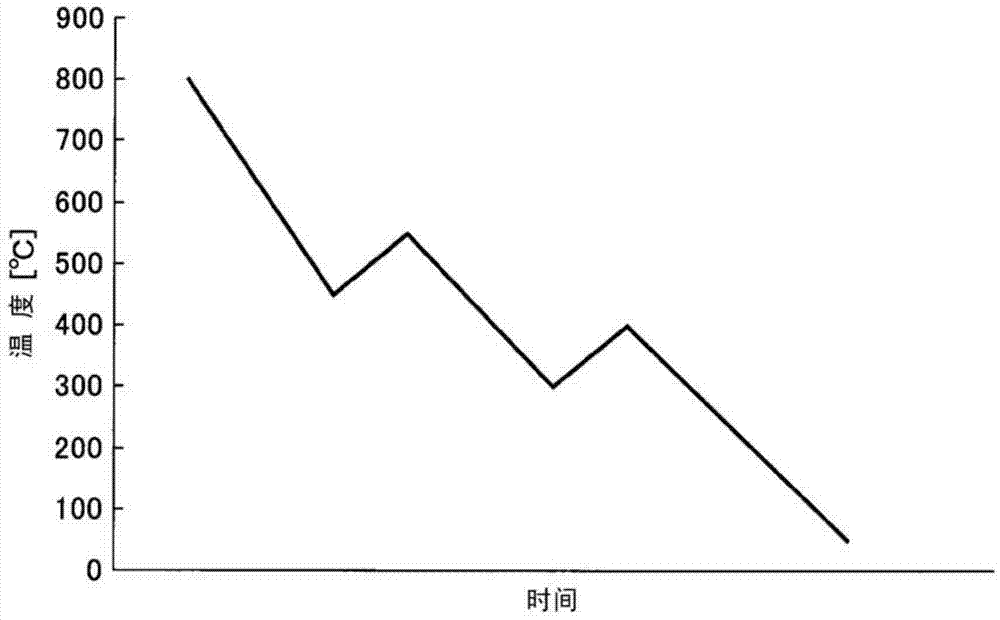

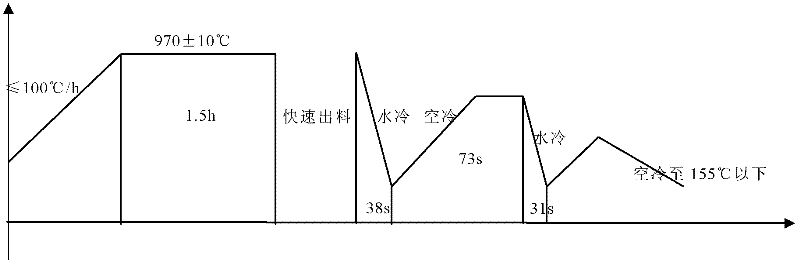

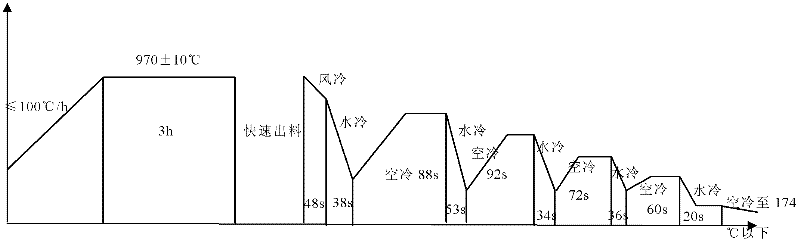

Quenching method for 20Cr13-40Cr13 martensite stainless steel

ActiveCN102392107AEliminate Pollution PotentialEffective control of cooling rateMartensite transformationElectricity

The invention discloses a quenching method for 20Cr13-40Cr13 martensite stainless steel, in which water and air are used for carrying out continuous quenching and realizing industrialized production. The quenching method is realized through the following technical schemes: selecting a 5.0-8.0m overlong workpiece of 20Cr13-40Cr13 martensite stainless steel; rapidly putting the workpiece into a roller hearth type quenching tank after carrying out austenitization in a continuous roller hearth furnace; carrying out discontinuous water quenching and air cooling according to the chemical compositions and the specification of the product; and putting the workpiece into an electric heating continuous roller hearth furnace to carry out tempering after martensite transformation. The quenching method has the following advantages that: discontinuous water quenching is adopted, so that the workpiece cooling speed is improved and effectively controlled, the quenched structures are uniform, the quenching hardness is uniform, the quenching state hardness deviation is controlled within + / -2HRC, the tempering state hardness deviation is controlled within + / -1.5HRC and excellent use performance is provided; and water is used as a quenching agent, so that the hidden dangers such as fires and lampblack pollution in the oil quenching process are eliminated and the environment is protected.

Owner:FUSHUN SPECIAL STEEL SHARES

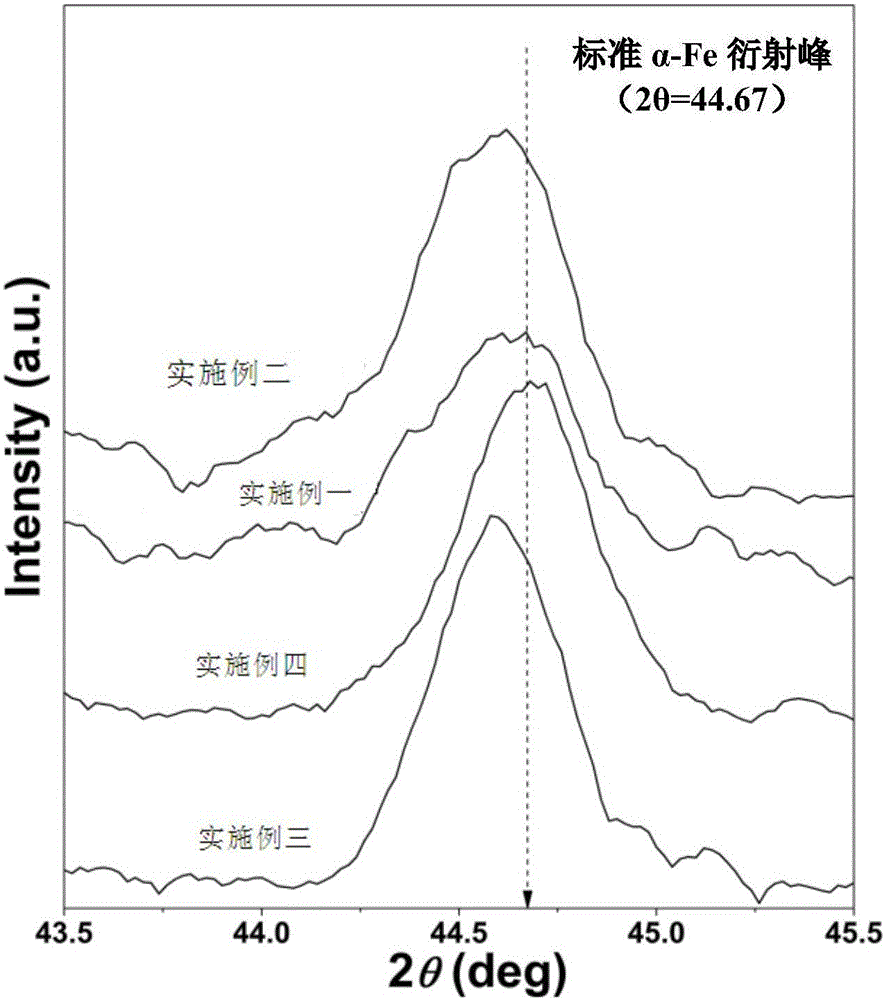

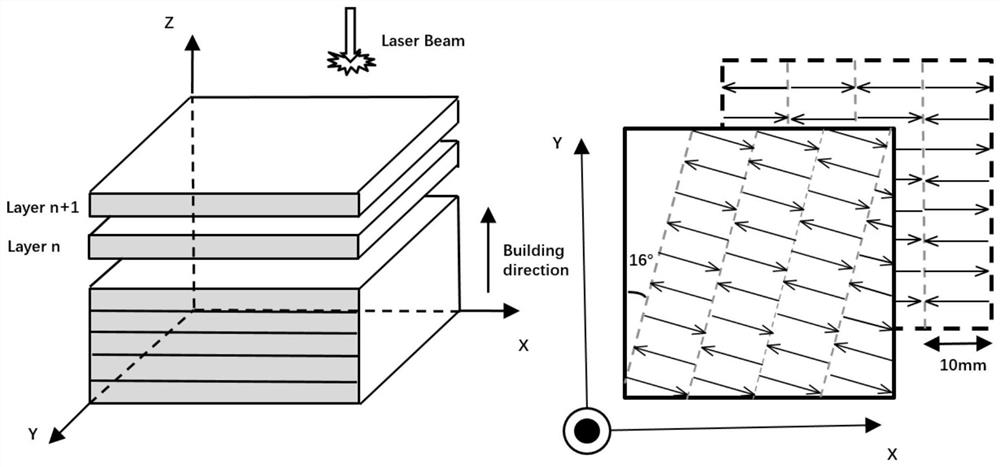

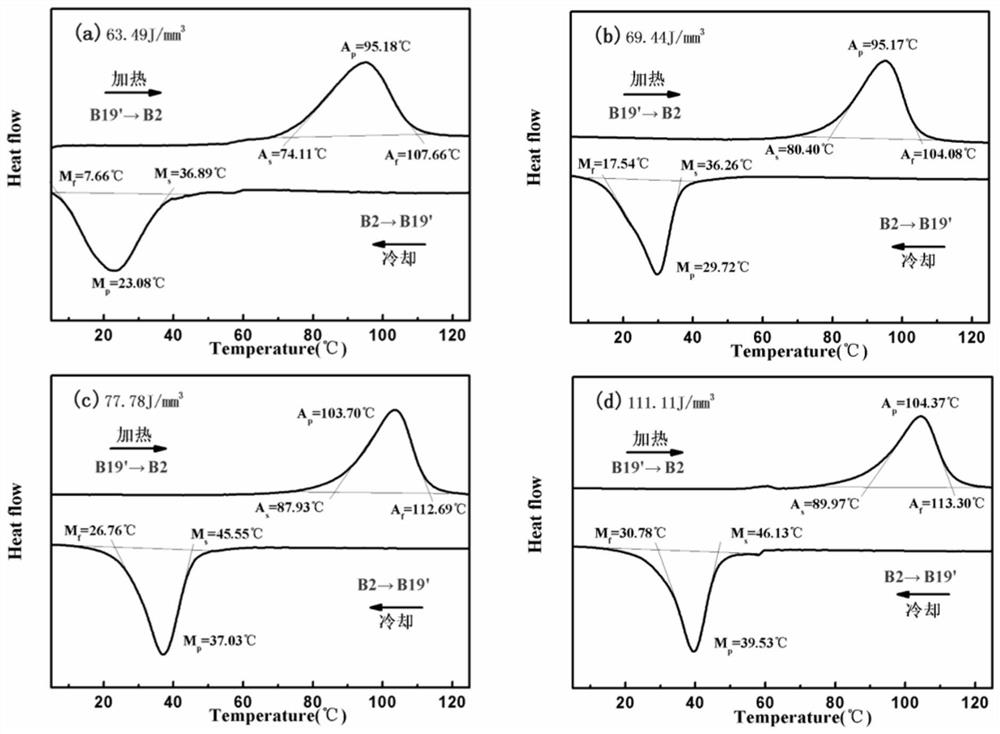

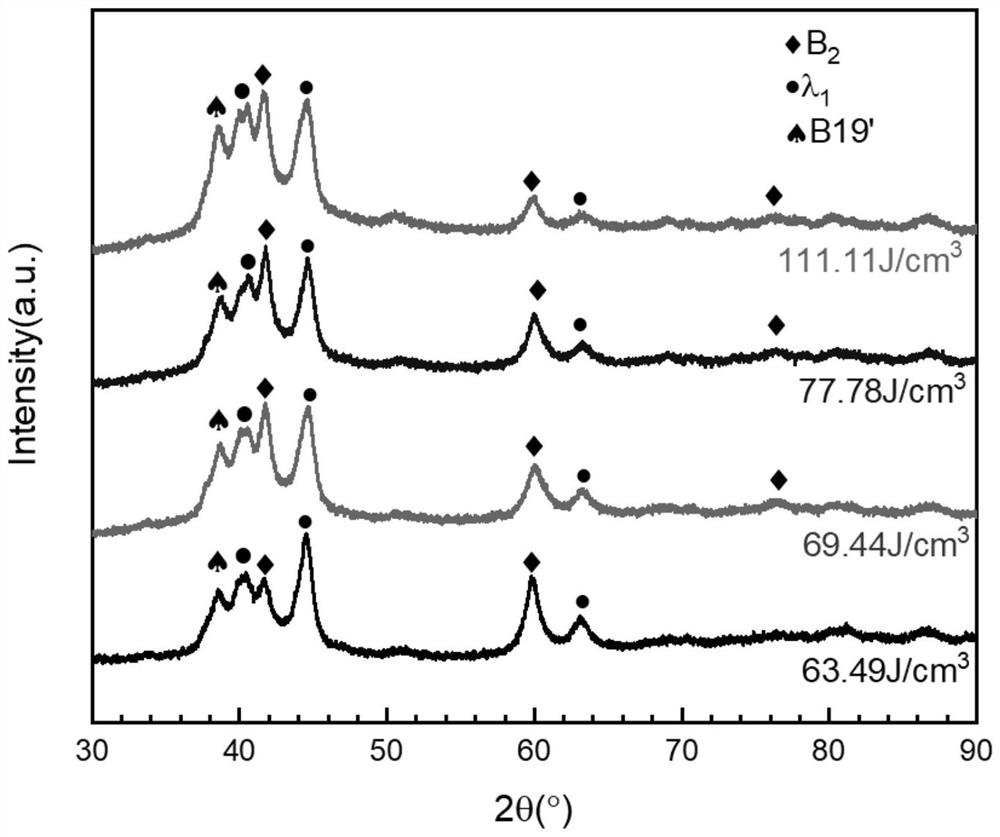

4D printing method of nickel-titanium-based ternary shape memory alloy

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

Hot dip galvanized high strength steel sheet having excellent plating adhesion and hole expansibility, and its production method

InactiveCN1910301AImprove adhesionExcellent hole expandabilityHot-dipping/immersion processesFurnace typesMartensite transformationSheet steel

The present invention provides hot dip galvanized high strength steel sheet excellent in plating adhesion and hole expandability and a method of production of the same, that is, hot dip galvanization steel sheet excellent in plating adhesion and hole expandability containing, by mass%, C: 0.08 to 0.35%, Si: 1.0% or less, Mn: 0.8 to 3.5%, P: 0.03% or less, S: 0.03% or less, Al: 0.25 to 1.8%, Mo: 0.05 to 0.35%, and N: 0.010% or less and having a balance of Fe and unavoidable impurities, said hot dip galvanized high strength steel characterized in that the steel sheet has a metal structure having ferrite, bainite, by area percent, 0.5% to 10% of tempered martensite, and, by volume percent, 5% or more of residual austenite, and a method of production comprising annealing by a continuous annealing process at 680 to 930 DEG C in temperature, then cooling to the martensite transformation point or less, then hot dip galvanizing the steel during which heating the steel to 250 to 600 DEG C, then hot dip galvanizing it.

Owner:NIPPON STEEL CORP

Post-rolling control cooling process for hot-rolled H-shape steel

ActiveCN101758091AHigh strengthImprove toughnessTemperature control deviceWork treatment devicesMartensite transformationRight flank

The invention provides a post-rolling control cooling process for hot-rolled H-shape steel. The hot-rolled H-shape steel enters a cooling device after the rolling is finished, an upper nozzle and a lower nozzle are respectively aligned with upper / lower R parts of the hot-rolled H-shape steel to carry out water spray cooling, and a left nozzle and a right nozzle are respectively aligned with left / right flank centers of the hot-rolled H-shape steel to carry out water spray cooling. The invention is characterized in that the pressure of cooling water is within 0.7 to 1.2MPa, the water quantity is within 1,200 to 2,000m3 / hour, the cooling rate is within 75 to 150 DEG C / s and the cooling time is within 3 to 5 seconds; and the hot-rolled H-shape steel is cooled to 20 to 30 DEG C above the martensitic phase transformation point of the corresponding steel grade after the rolling under the temperature of 850 to 1,000 DEG C is finished. By adopting the cooling process in the invention, the actual grain size of ferrite at the core part of the hot-rolled H-shape steel can be refined from 8-10 grades to 10-12 grades, and a tissue of bainite plus sorbite can be formed on the surface of the hot-rolled H-shape steel, thereby obviously improving the strength and toughness of the hot-rolled H-shape steel and improving the yield strength of the hot-rolled H-shape steel by more than 70MPa.

Owner:MAANSHAN IRON & STEEL CO LTD

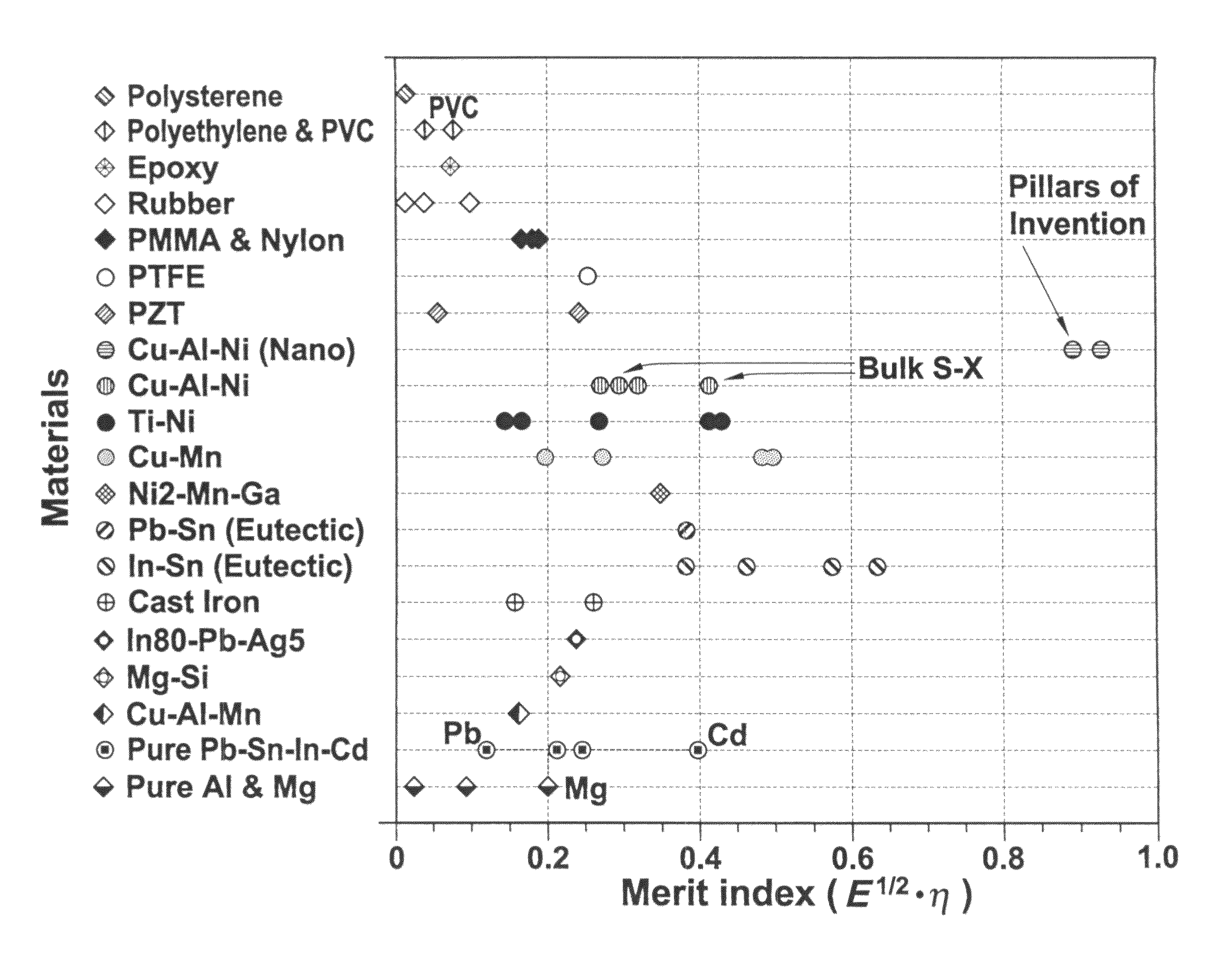

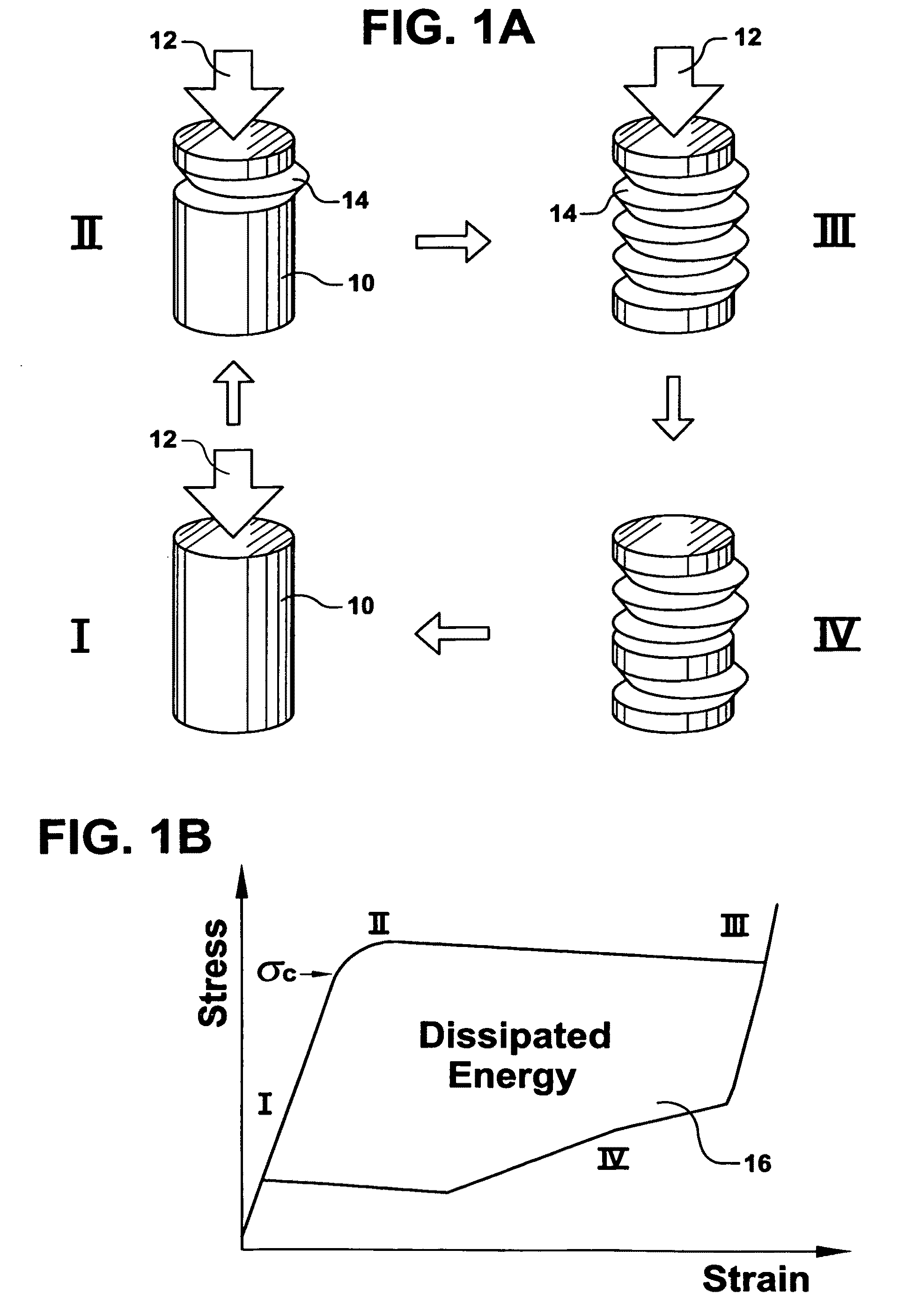

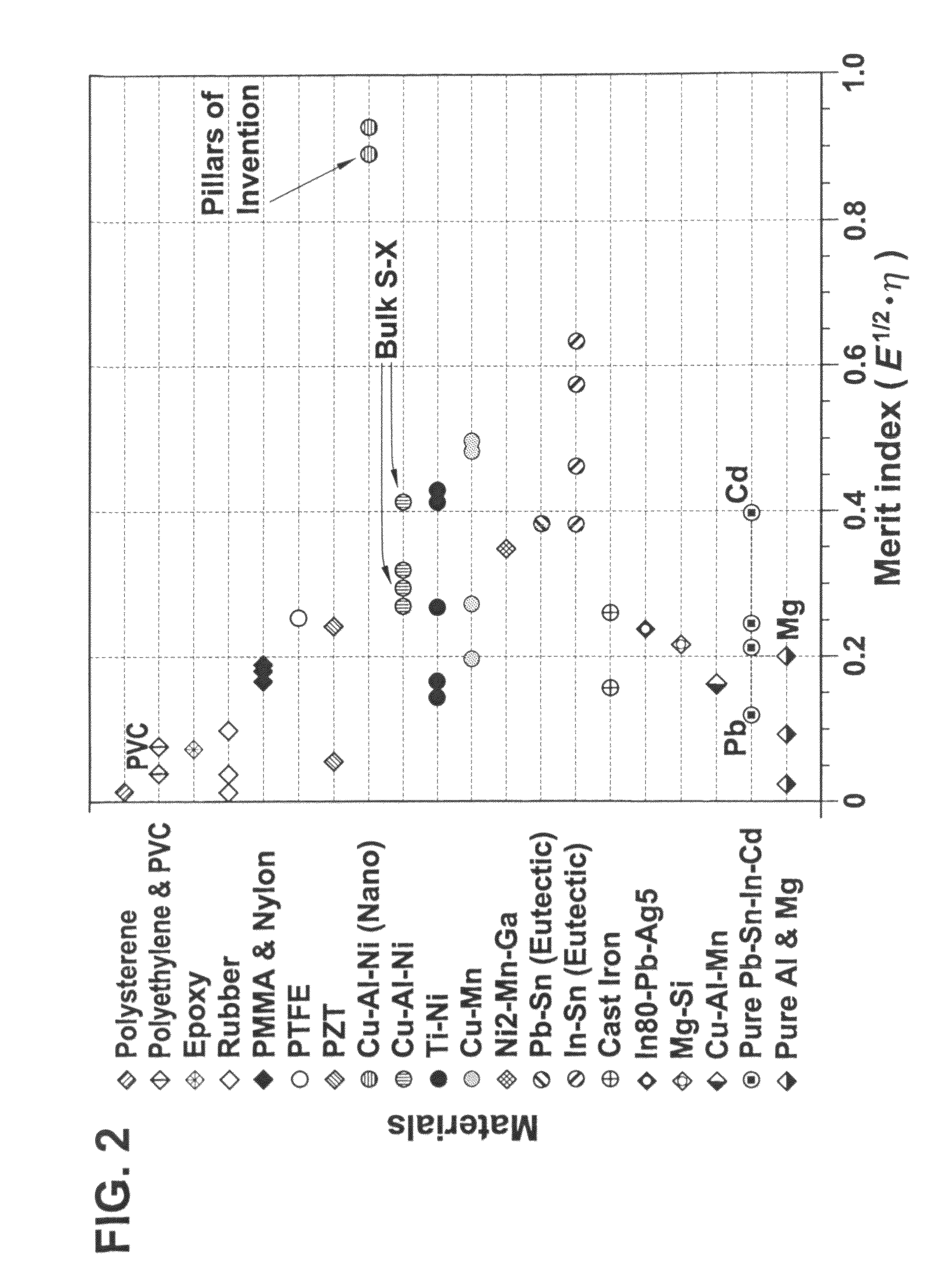

Superelastic alloy structural geometry for ultrahigh mechanical damping

ActiveUS8282746B2Ultra-high-damping performance characteristicsAccurate and reliable processSpringsStands/trestlesMartensite transformationMicrometer

A mechanical structure is provided with a crystalline superelastic alloy that is characterized by an average grain size and that is characterized by a martensitic phase transformation resulting from a mechanical stress input greater than a characteristic first critical stress. A configuration of the superelastic alloy is provided with a geometric structural feature of the alloy that has an extent that is no greater than about 200 micrometers and that is no larger than the average grain size of the alloy. This geometric feature is configured to accept a mechanical stress input.

Owner:MASSACHUSETTS INST OF TECH

Iron-based alloy having shape memory properties and superelasticity and its production method

ActiveUS20090242083A1Good shape memory propertiesGood superelasticityMagnetic materialsHeat treatment process controlMartensite transformationCrystal orientation

An iron-based alloy having shape memory properties and superelasticity, which has a composition comprising 25-35% by mass of Ni, 13-25% by mass of Co, 2-8% by mass of Al, and 1-20% by mass in total of at least one selected from the group consisting of 1-5% by mass of Ti, 2-10% by mass of Nb and 3-20% by mass of Ta, the balance being substantially Fe and inevitable impurities, and a recrystallization texture substantially comprising a γ phase and a γ′ phase, particular crystal orientations of the γ phase being aligned, and the difference between a reverse transformation-finishing temperature and a martensitic transformation-starting temperature being 100° C. or less in the thermal hysteresis of martensitic transformation and reverse transformation.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com