Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150 results about "Hyperelastic material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hyperelastic or green elastic material is a type of constitutive model for ideally elastic material for which the stress–strain relationship derives from a strain energy density function. The hyperelastic material is a special case of a Cauchy elastic material.

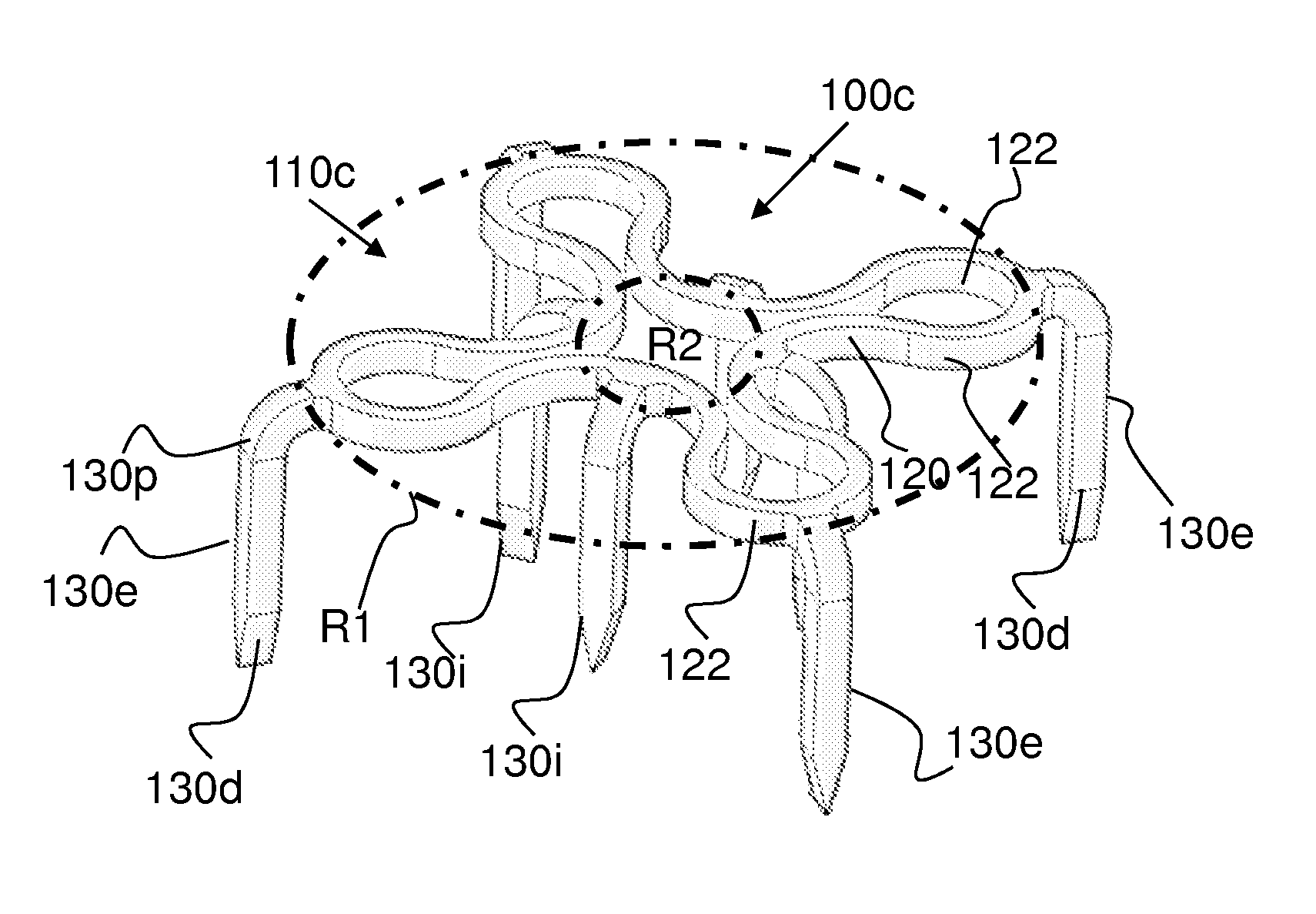

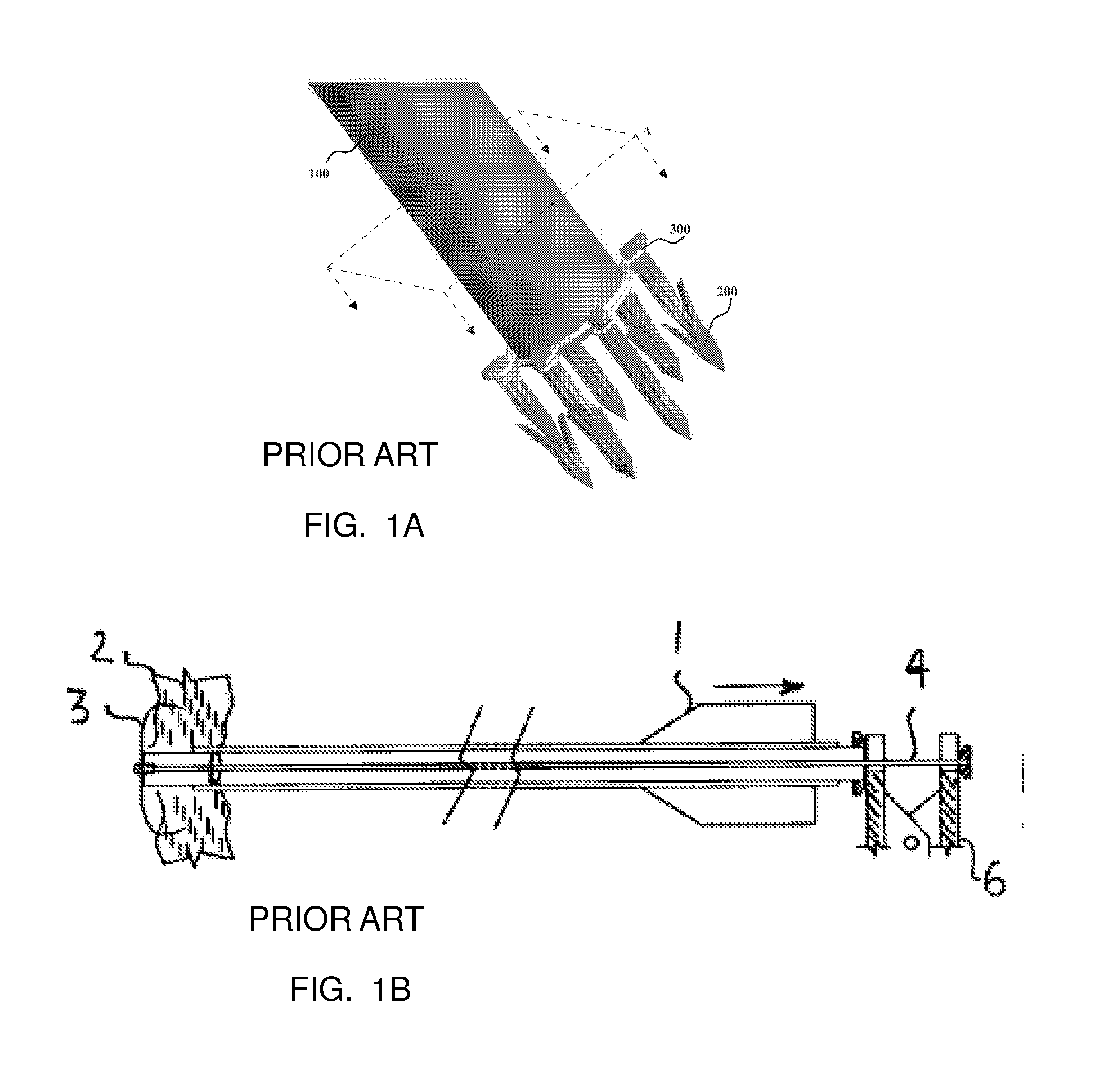

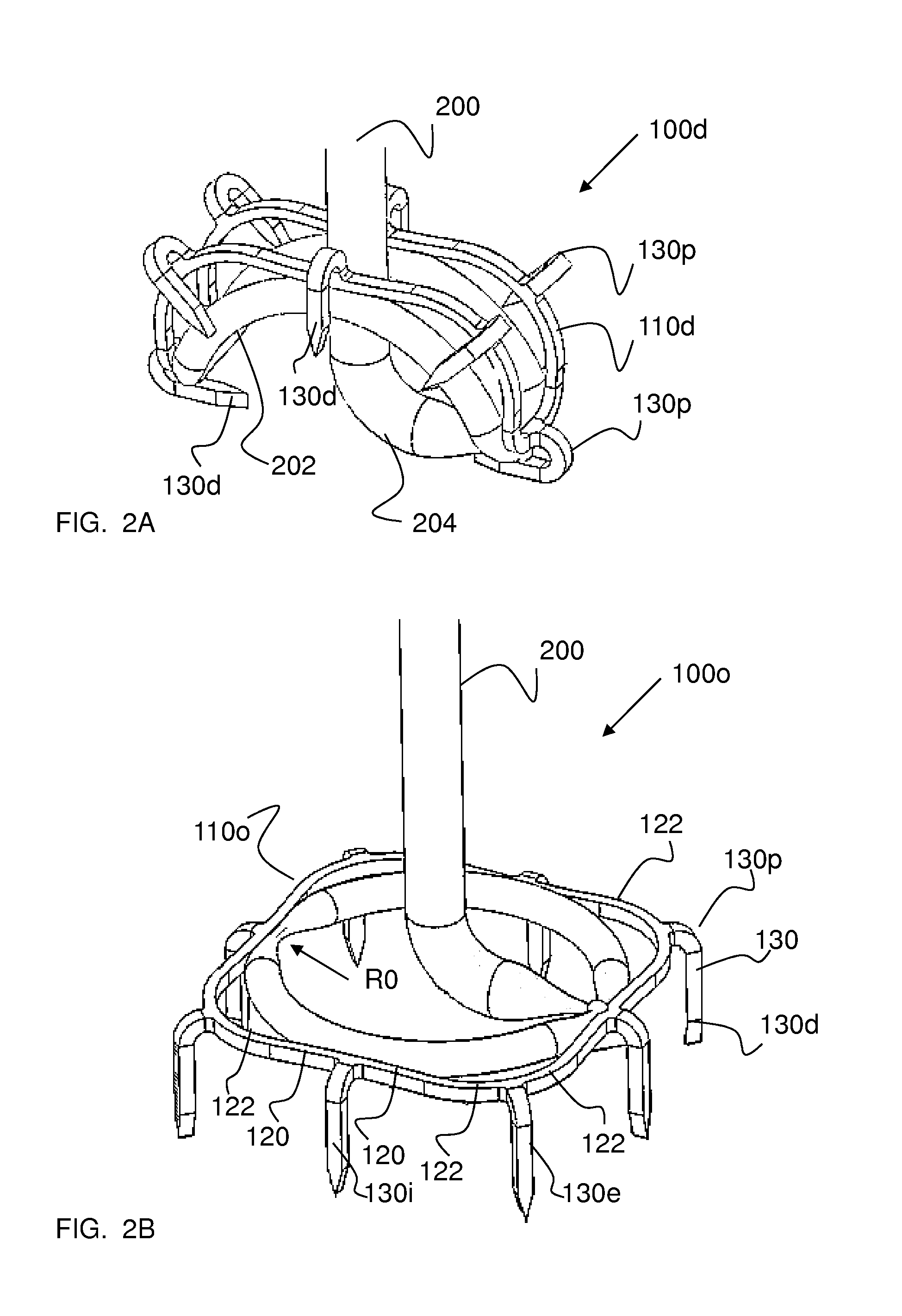

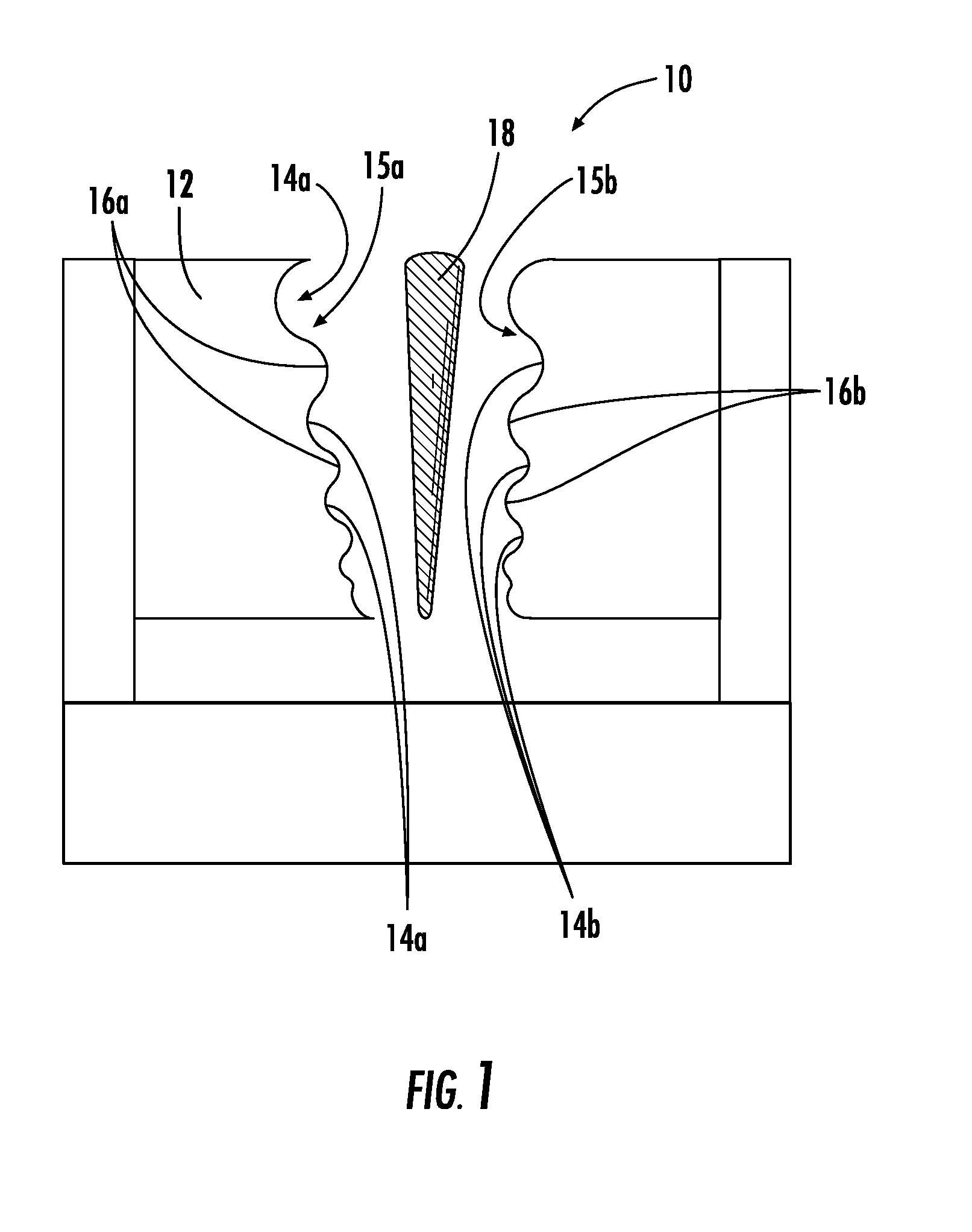

Tissue closure device and method of deliver and uses thereof

The present invention relates generally to a tissue closure device and in particular to a tissue closure device having a plurality of configurations providing for delivery and use in minimally invasive procedures. A tissue closure device (100) is provided from shape memory or super-elastic materials for closing a tissue site opening (50), the device comprising a plurality of tissue anchors (130) extending from a closed loop surface (110) wherein the plane of said tissue anchors is provided at an angle essentially perpendicular with respect to the plane of said closed loop surface; a. wherein said plurality of tissue anchors (130) comprise a proximal end (130p) and a distal end (130d); said distal end provided for anchoring said device onto tissue (50); and wherein said proximal end (130p) is fluid with and extends from said closed loop surface (110); and b. said closed loop surface (110) having a plurality of configurations including: a delivery configuration (1OOd), an open configuration (1000) and a closed configuration (100c) wherein said closed loop surface (110) may undergo a transformation between one of said plurality of configurations to another; said delivery configuration (1OOd) defining a low profile of said device (100) and adapted for delivery to a tissue site (50) through a small profile access point having a first diameter and wherein said closure device is utilized to close a tissue site having a second diameter such that said second diameter is larger than said first diameter.

Owner:NOVOGATE MEDICAL

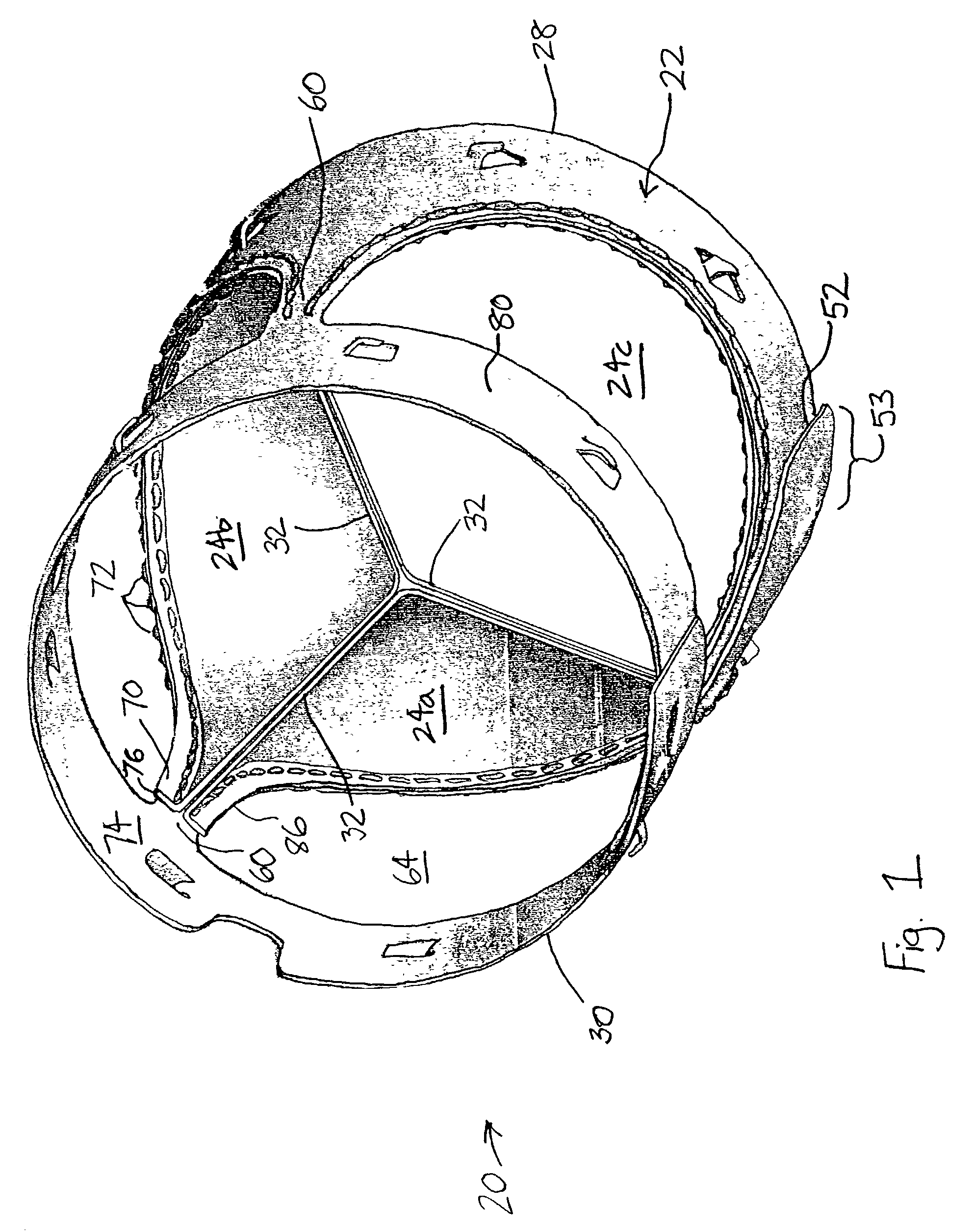

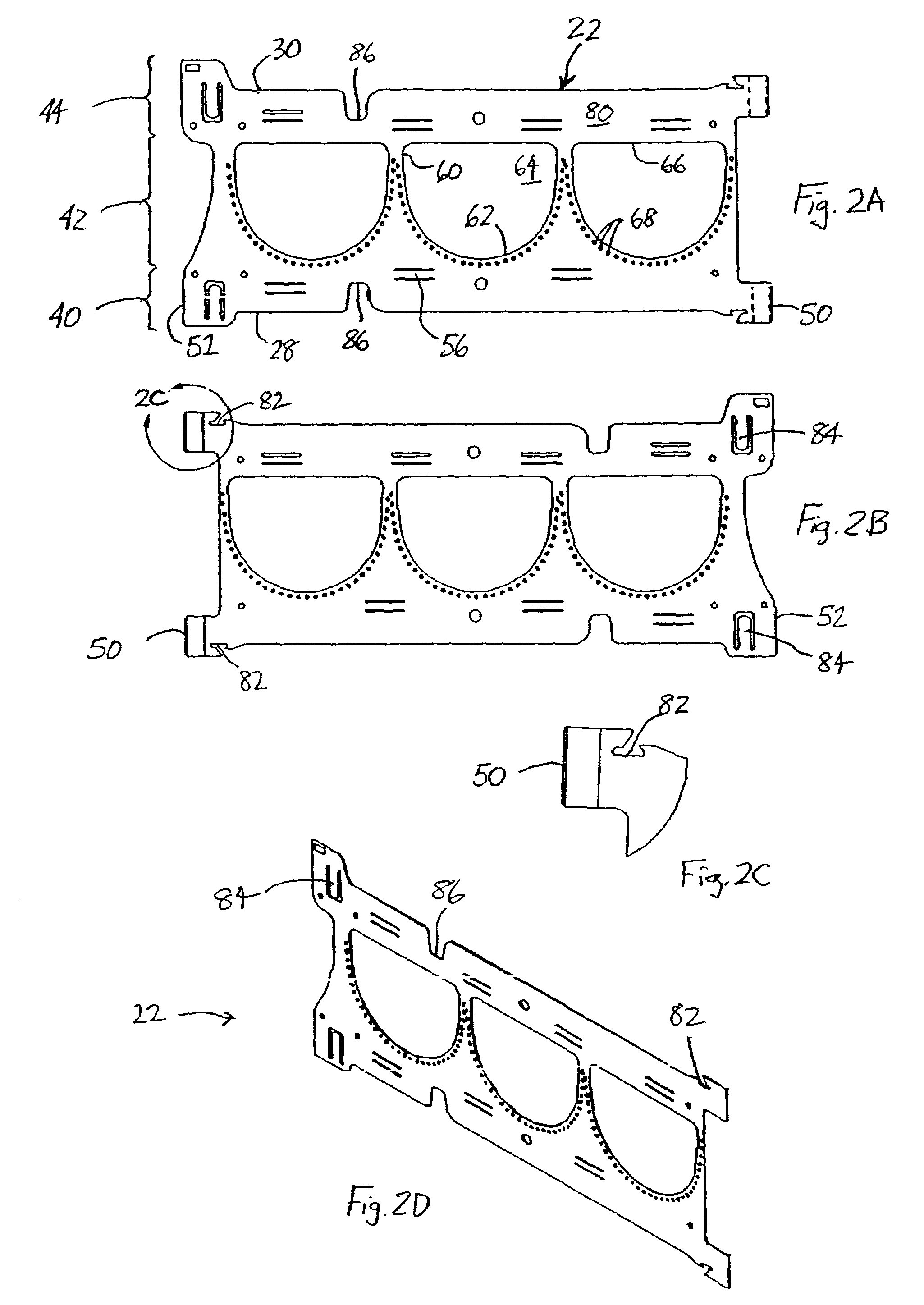

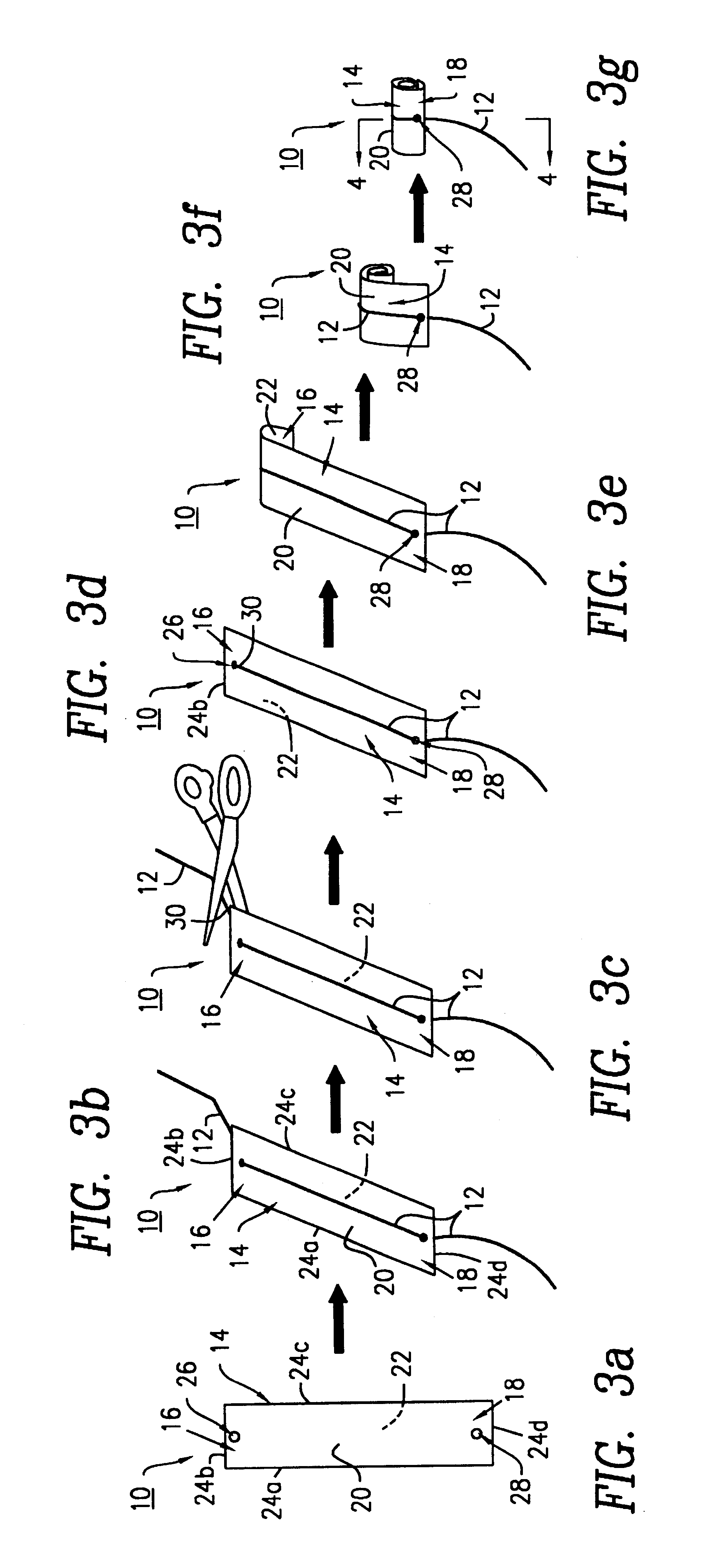

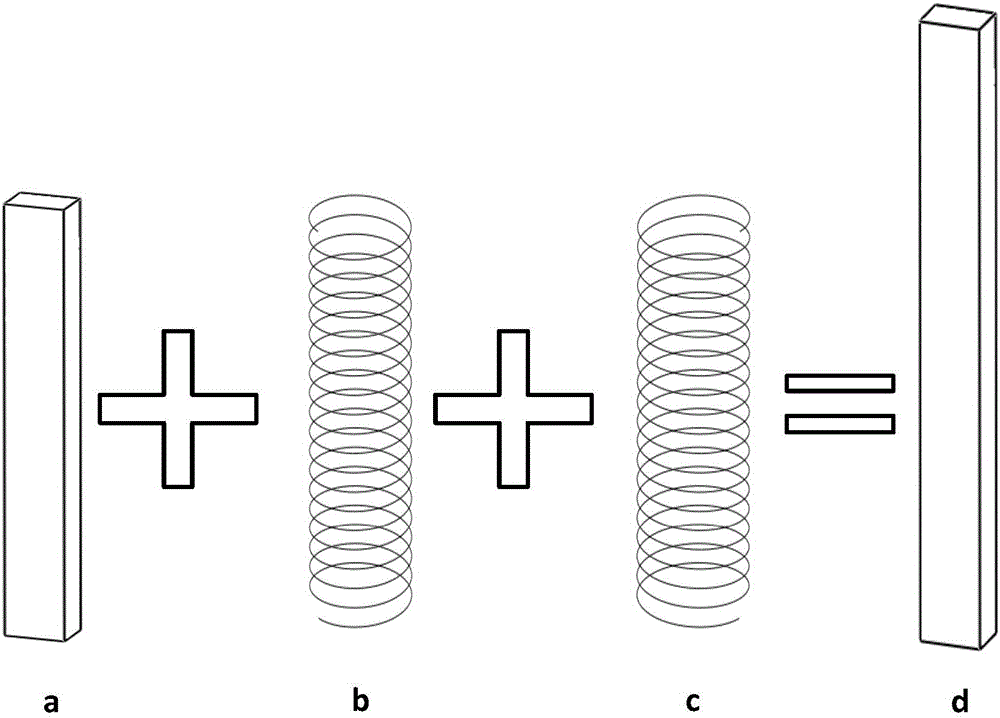

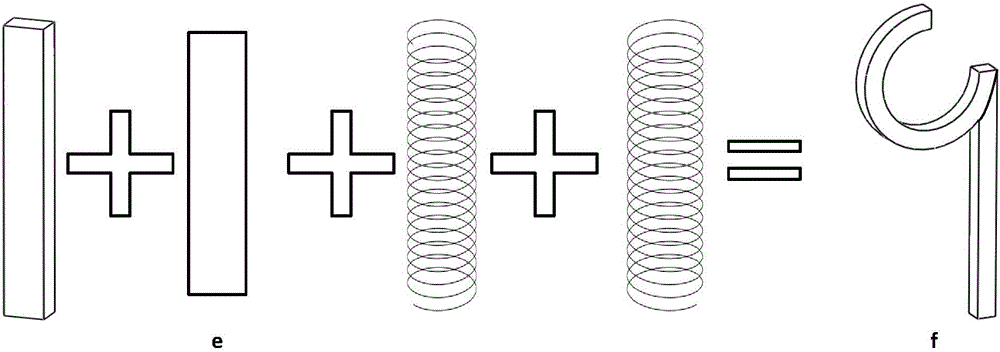

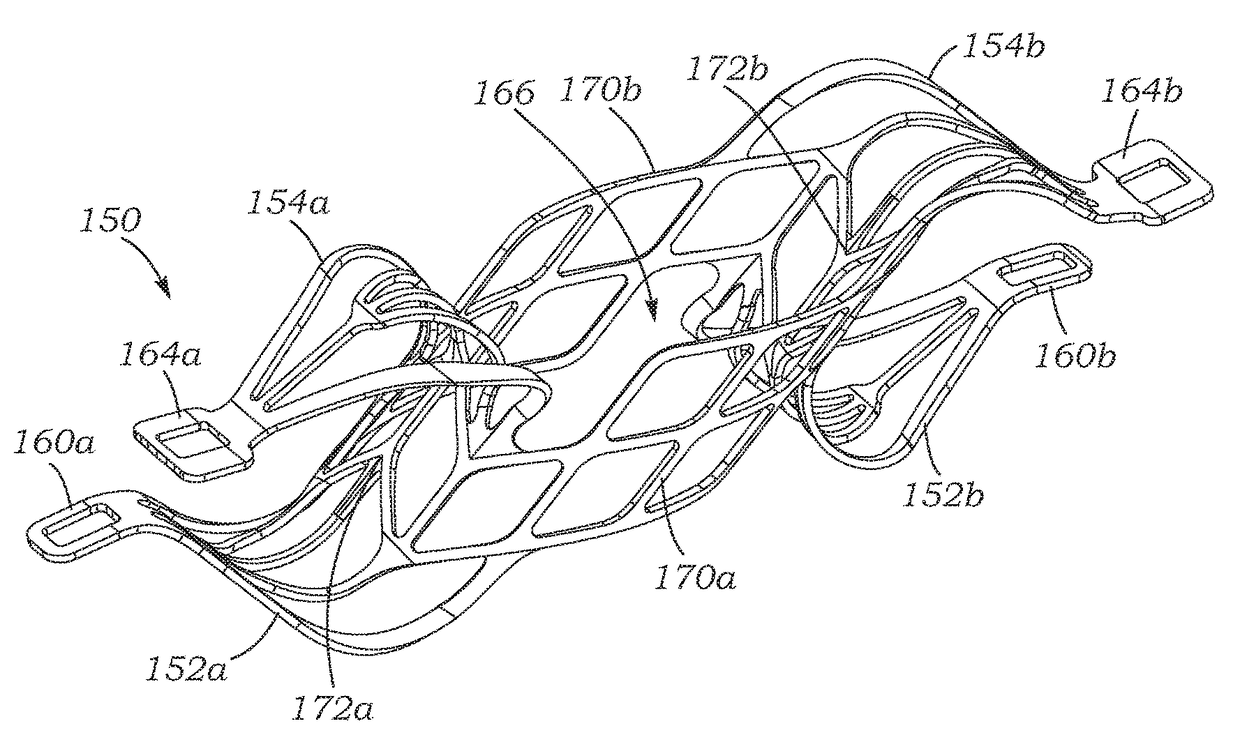

Rolled minimally-invasive heart valves and methods of manufacture

Expandable heart valves for minimally invasive valve replacement surgeries are disclosed. The valves are rolled into a first, contracted configuration for minimally invasive delivery using a catheter, and then unrolled or unfurled at the implantation site. One- and two-piece stents may be used in conjunction with a plurality of flexible leaflet-forming membranes. The stents may include an annulus section, a sinus section with the membranes attached over sinus apertures, and an outflow section. Lockout tabs and making slots secure the stents in their expanded shapes. Alignment structure ensures concentric unfurling of the stent. Anchoring elements at the stent edges or in the stent body secure the valve within the annulus. A method of manufacture includes shape setting the sheet-like stent to ensure an outward bias during deployment. The stent may also include dear tracks for engagement with a gear mechanism for deployment. The stent is desirably made of a superelastic material such as Nitinol and may have areas removed or thinned to reduce the bending stresses when rolled into its small spiral for catheter delivery.

Owner:EDWARDS LIFESCIENCES CORP

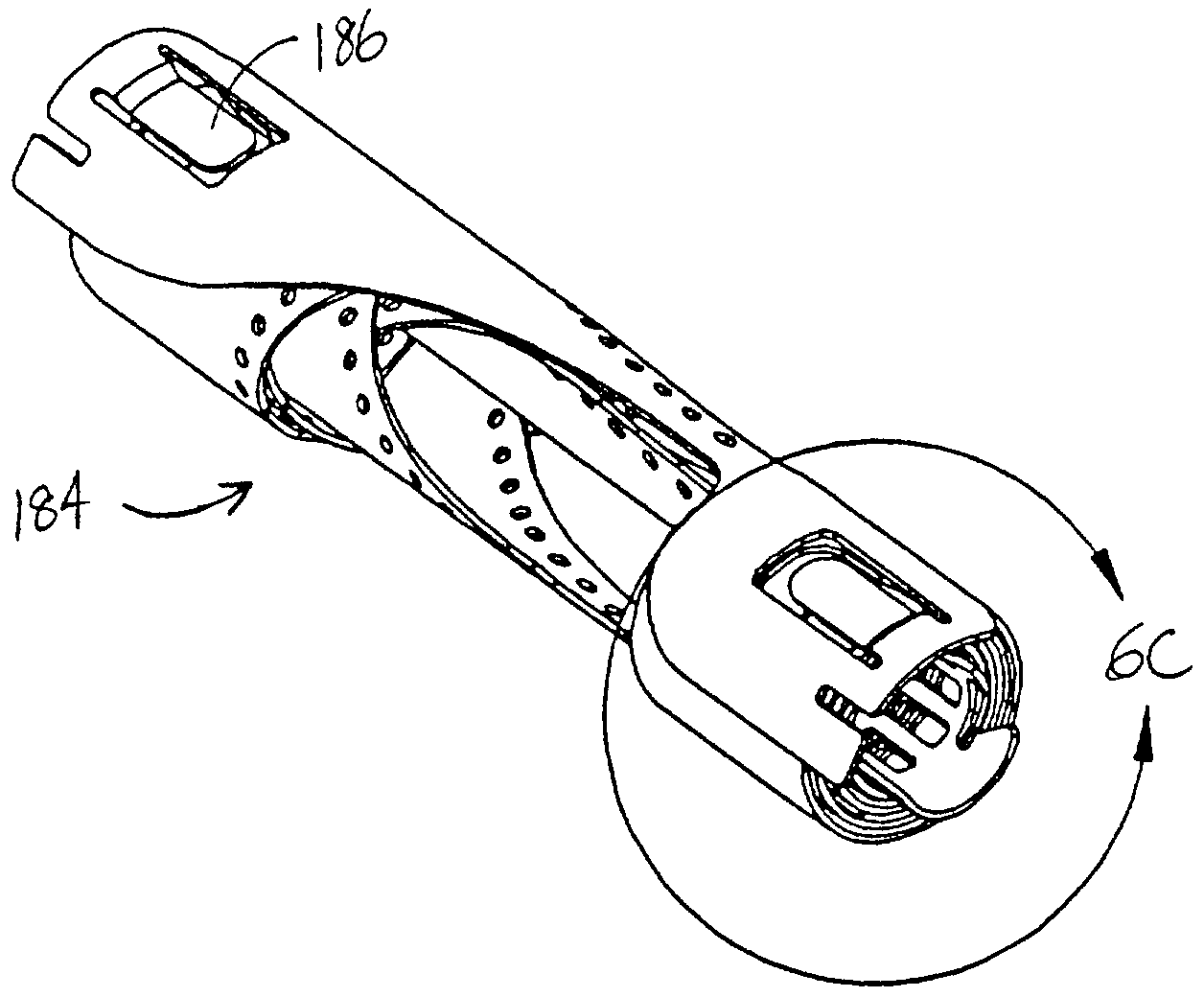

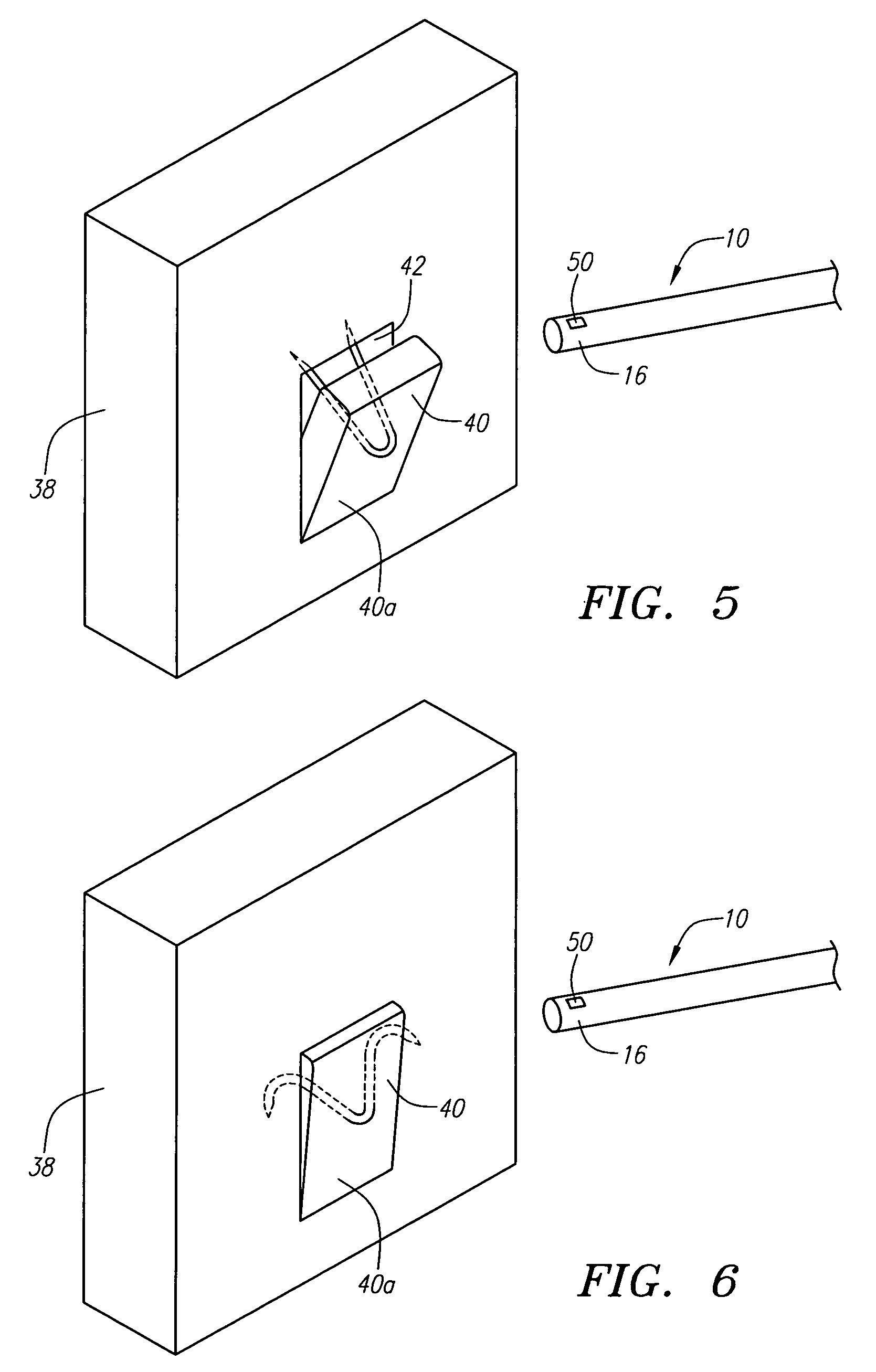

Suture anchoring and tensioning device

InactiveUS6652562B2Eliminate knotsEasy to useSuture equipmentsSurgical needlesSuture anchorsHyperelastic material

Owner:ETHICON INC

Endoscopic compression clip and system and method for use thereof

A compression clip assembly for compressing tissue and operable by means of a user-operated applier. The assembly comprises a compression clip and a lock element. The clip includes a pair of normally spaced apart elongate members each having an outward-facing surface, and having respective inward-facing opposing surfaces for compressing tissue; a hinge formed at least partly of a superelastic material and in operative mechanical connection with the elongate members; and a lock region formed on the outer surface of each of the elongate members adjacent to the hinge, each lock region being delimited by a first stop element proximal to the hinge and a second stop element distal from the hinge. The lock element is constructed for lockably engaging the lock regions so as to lock the clip in its closed position. The invention also encompasses a system and method for using the compression clip assembly.

Owner:NOVOGI

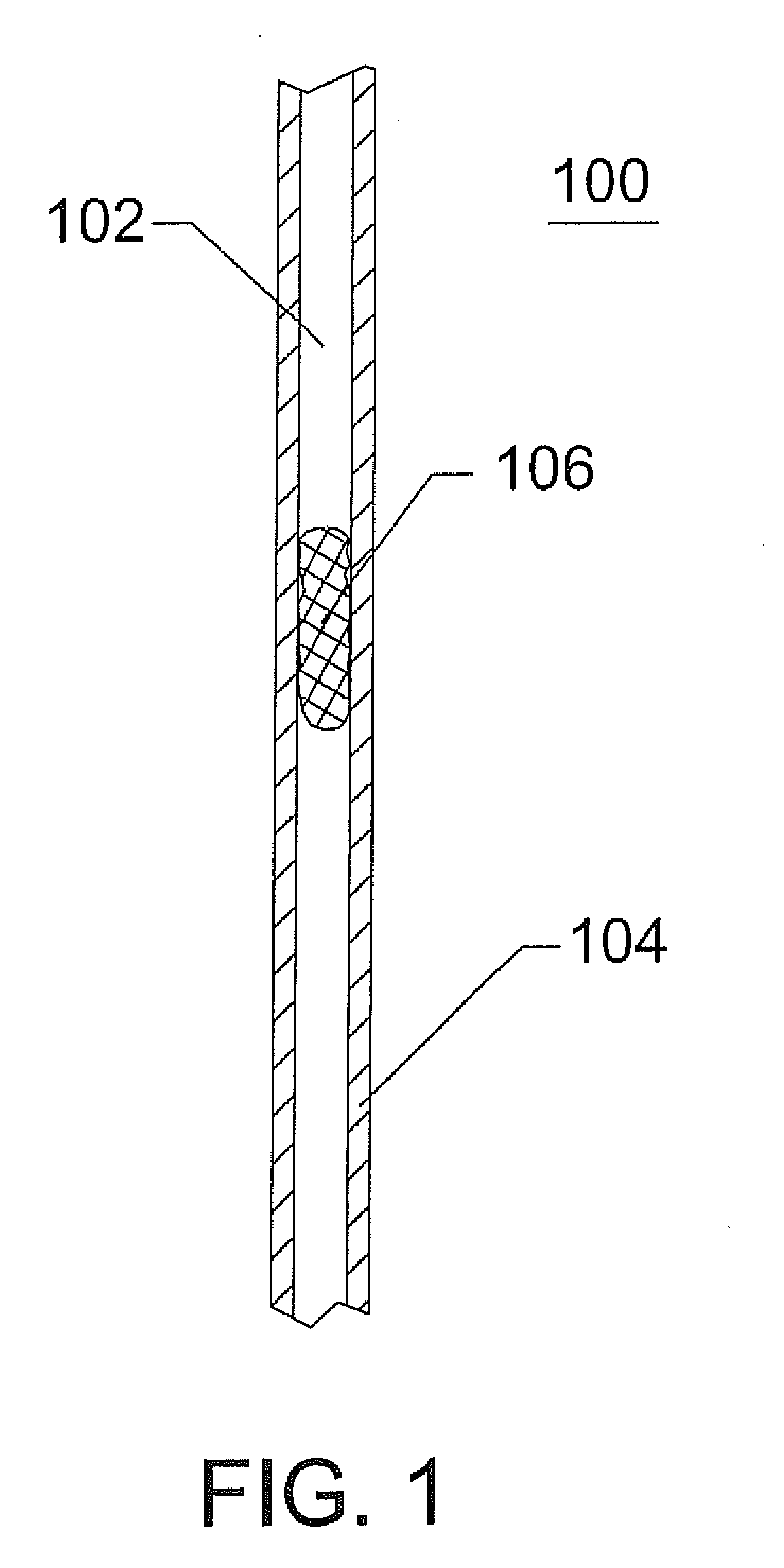

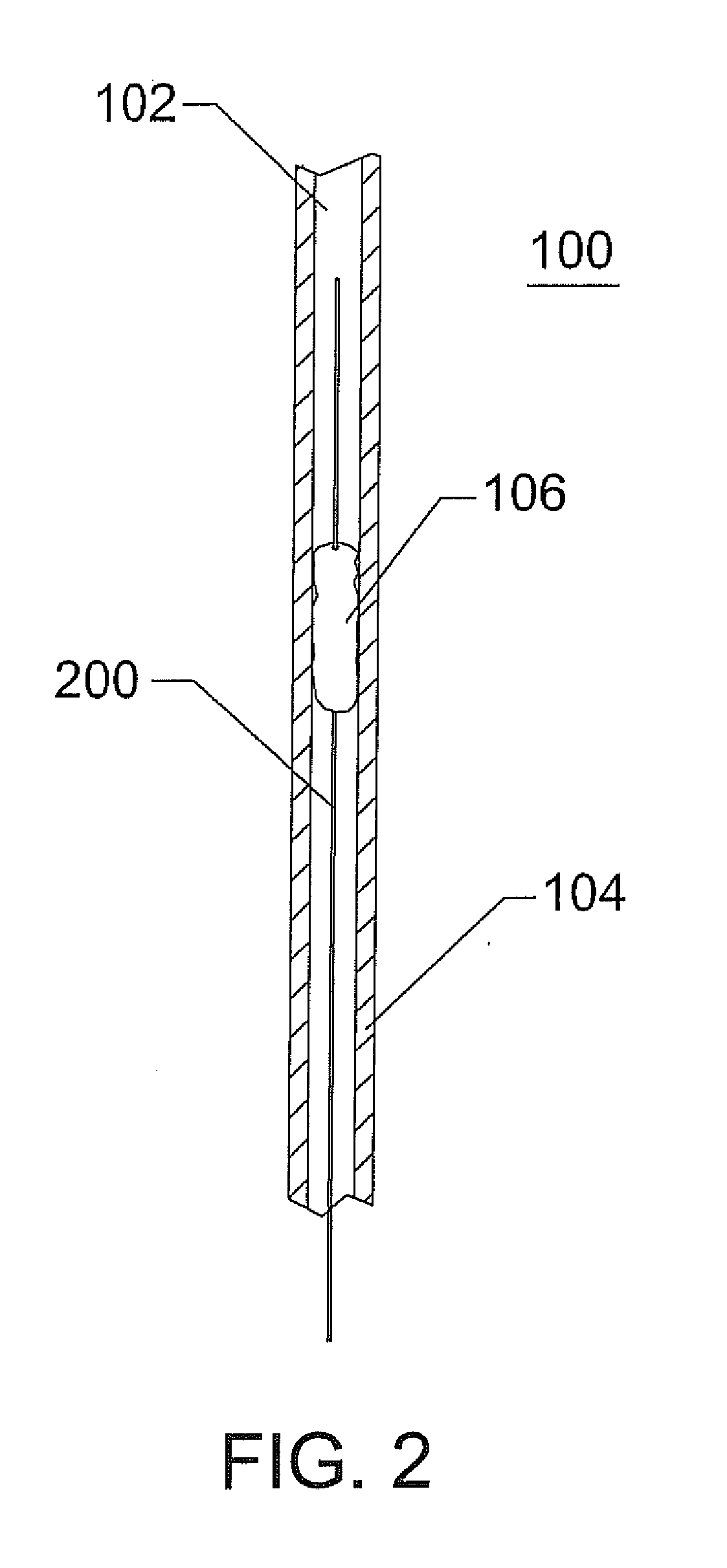

Radiopaque markers for medical devices

InactiveUS20050060025A1High level of radiopacitySufficient radiopacityStentsBlood vesselsIridiumRhenium

An implantable medical device includes a structural body made from a superelastic material and includes one or more marker holders integrally formed on the structural body. Each marker holder is designed to hold a radiopaque marker which has a level of radiopacity greater than the superelastic material. The radiopaque marker can be made from a nickel-titanium alloy which includes a ternary element. The ternary element can be selected from the group of elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, and hafnium. In one form, the marker holder includes a pair of projecting fingers connected together at a notched region to cooperatively create a particular-shaped opening. This opening, in turn, is adapted to receive a similarly shaped portion formed on the radiopaque marker. In one form, the radiopaque marker includes an inner core which is partially, or completely, encased by an outer layer. This inner core can be made from a highly radiopaque material while the outer layer is formed from a material that is easier to weld to the marker.

Owner:ABBOTT VASCULAR SOLUTIONS

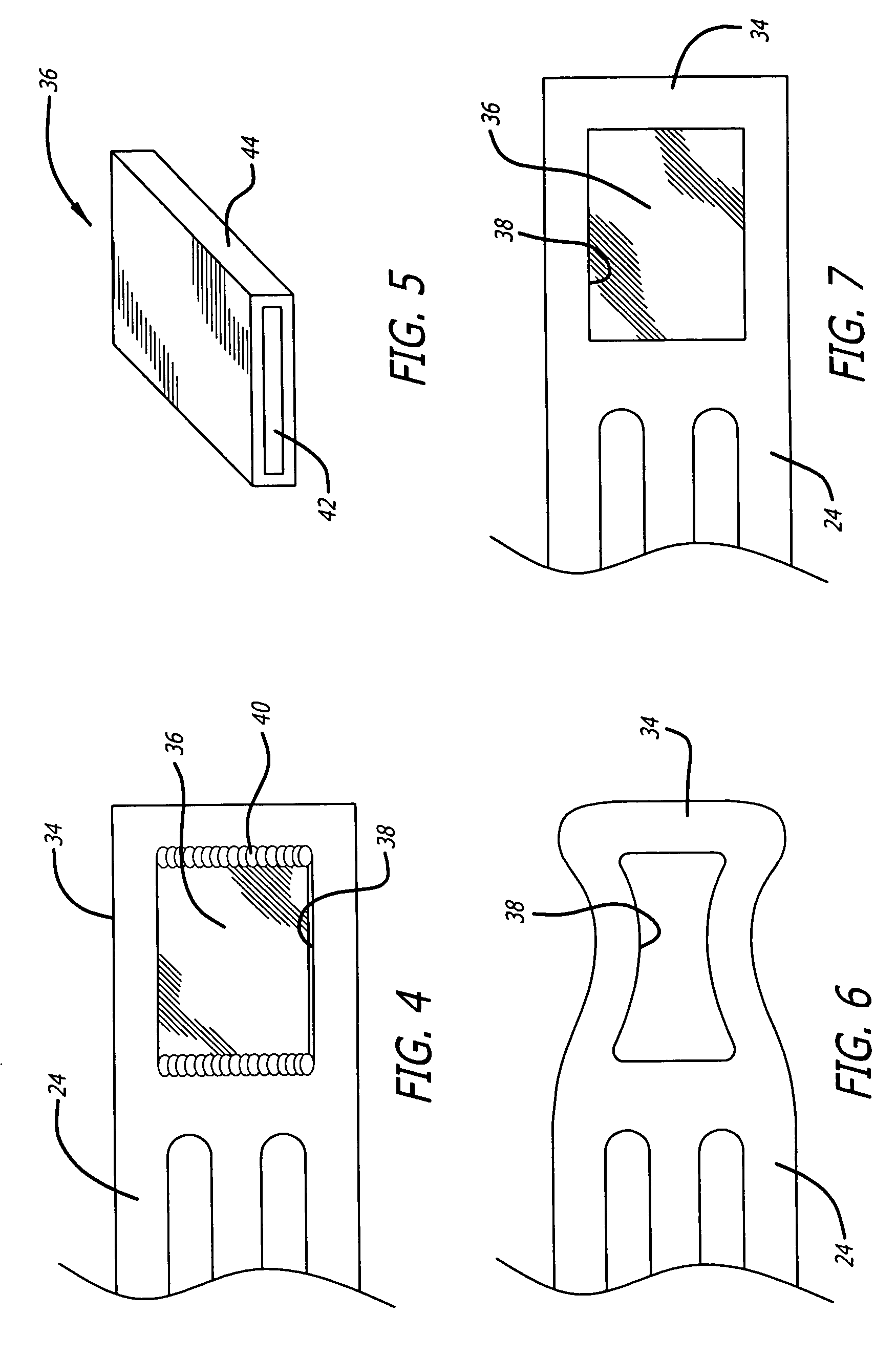

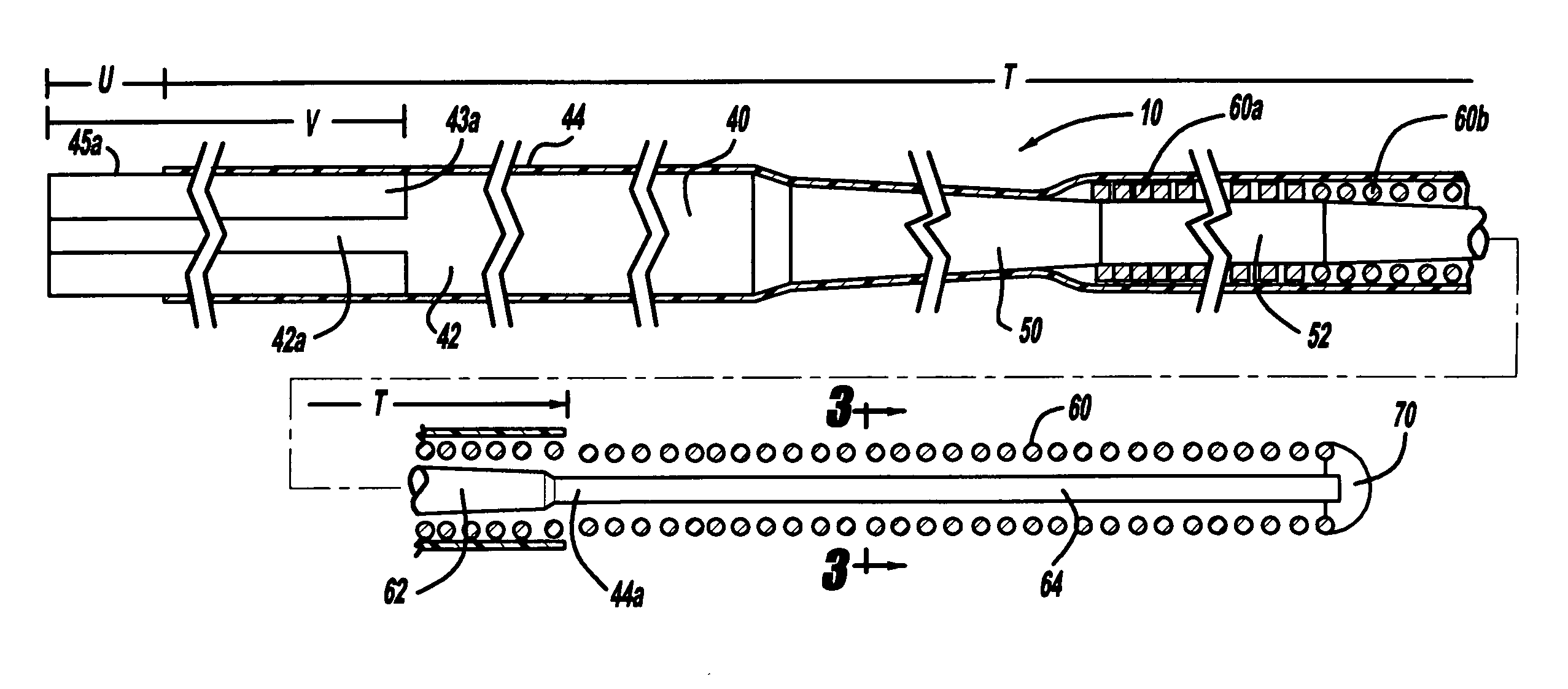

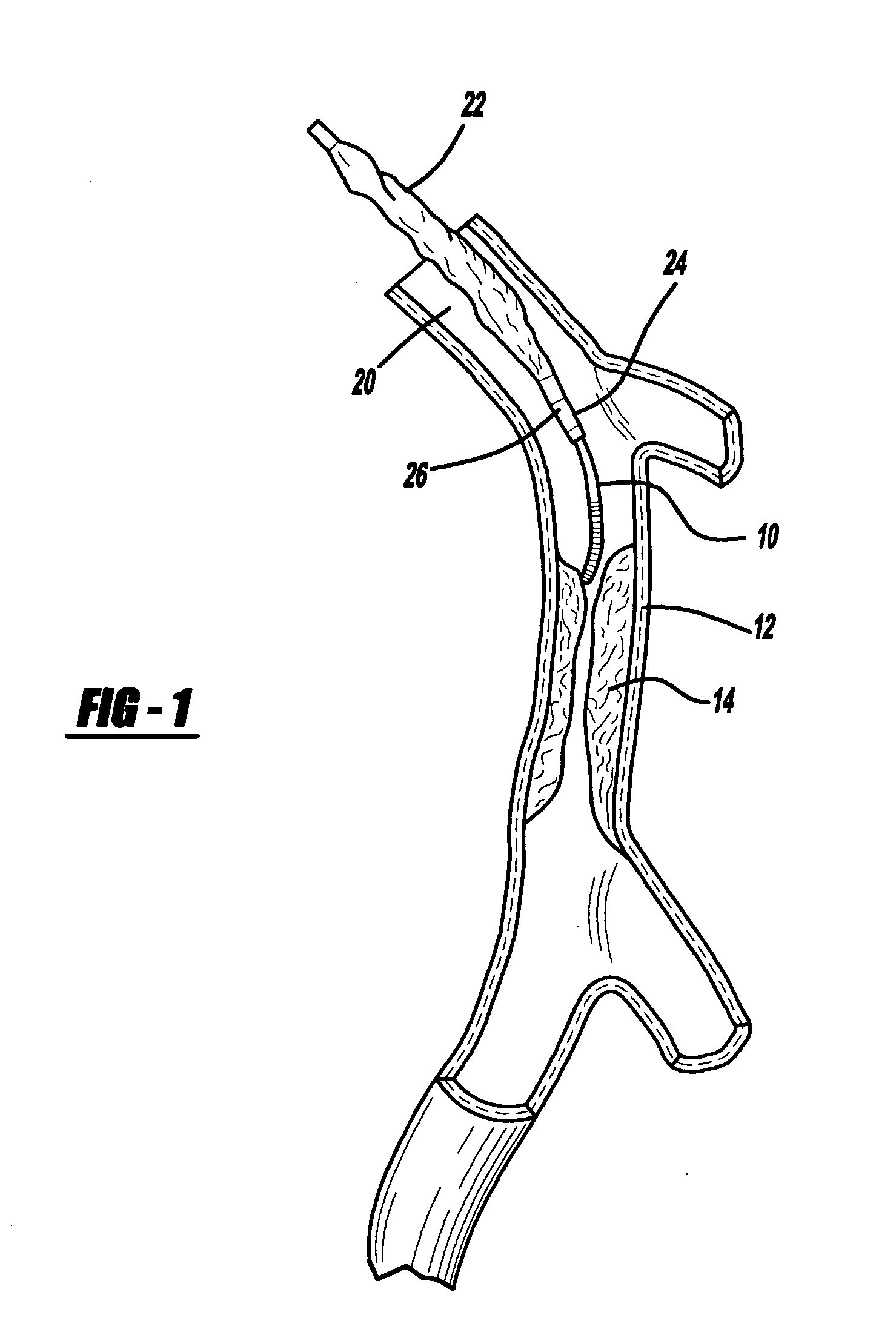

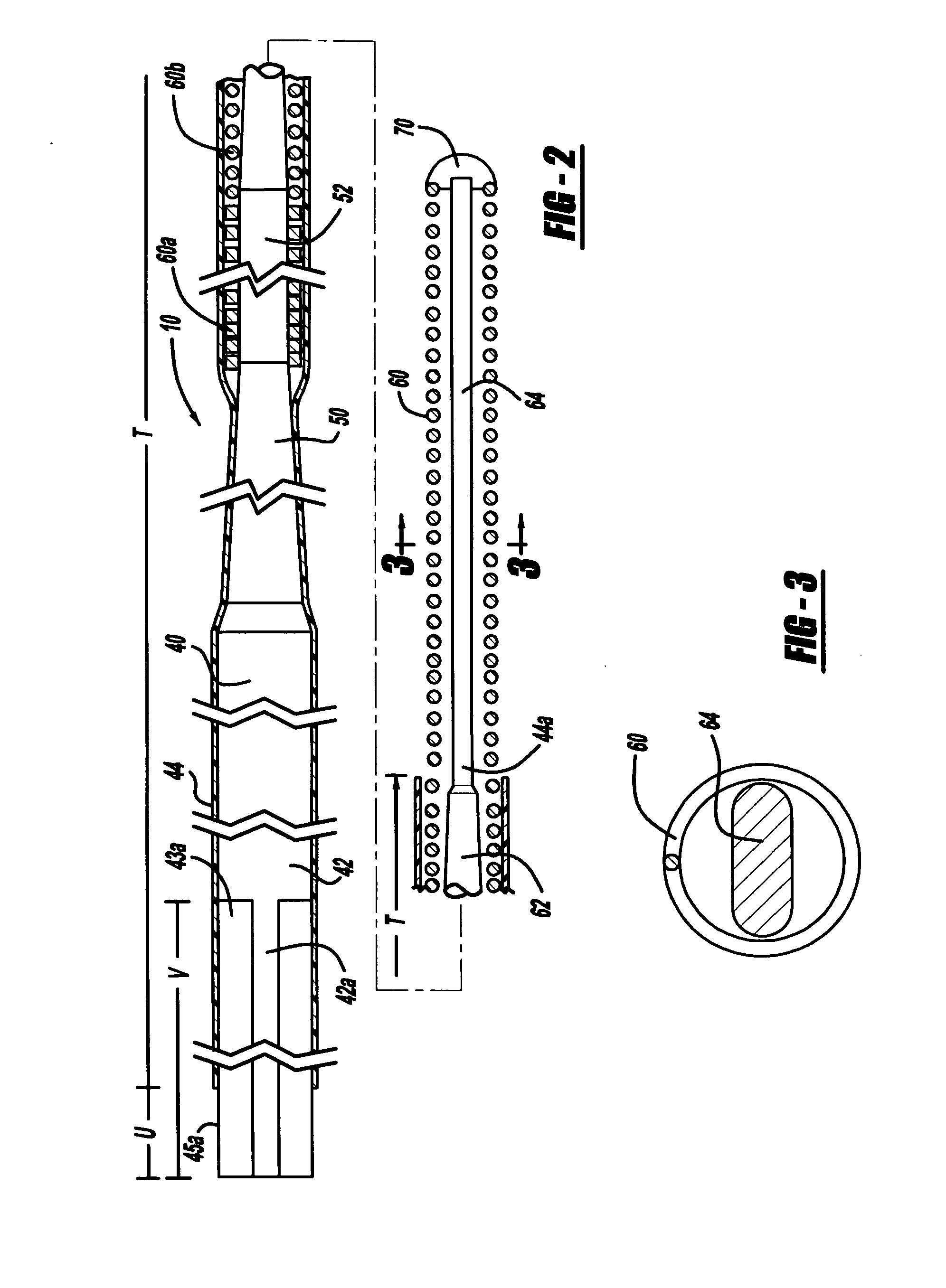

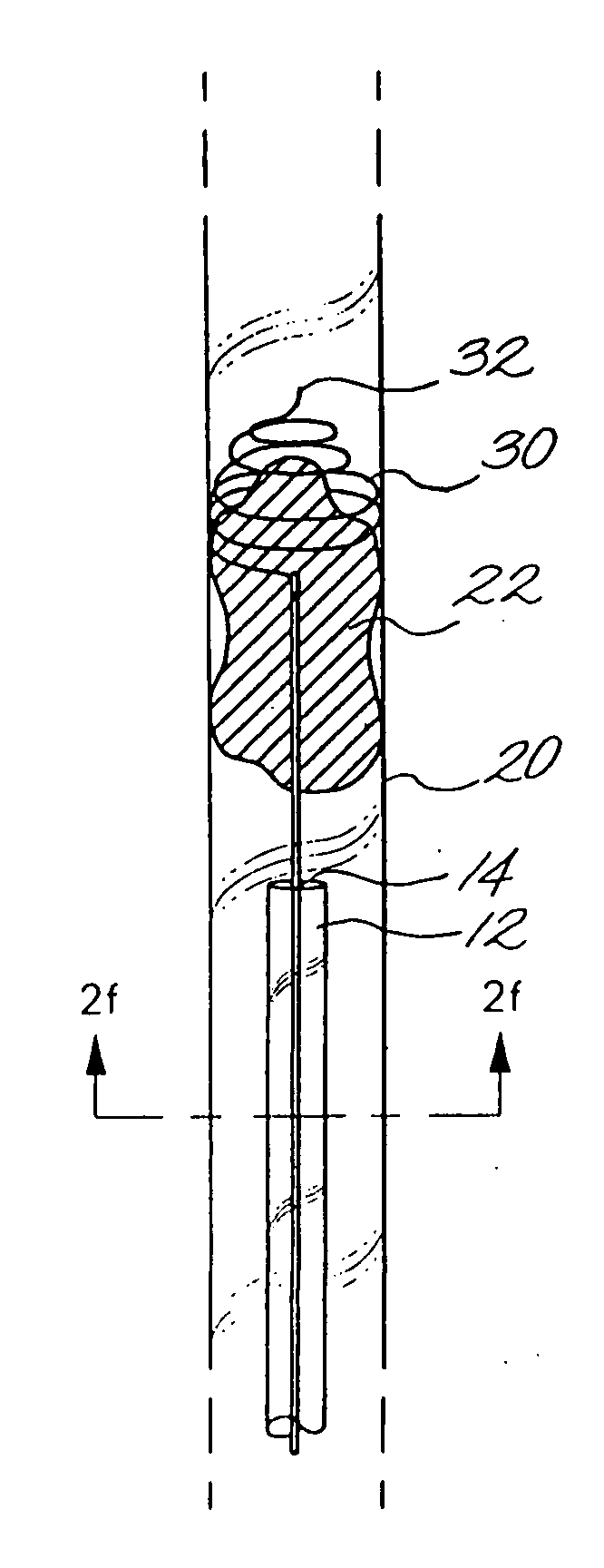

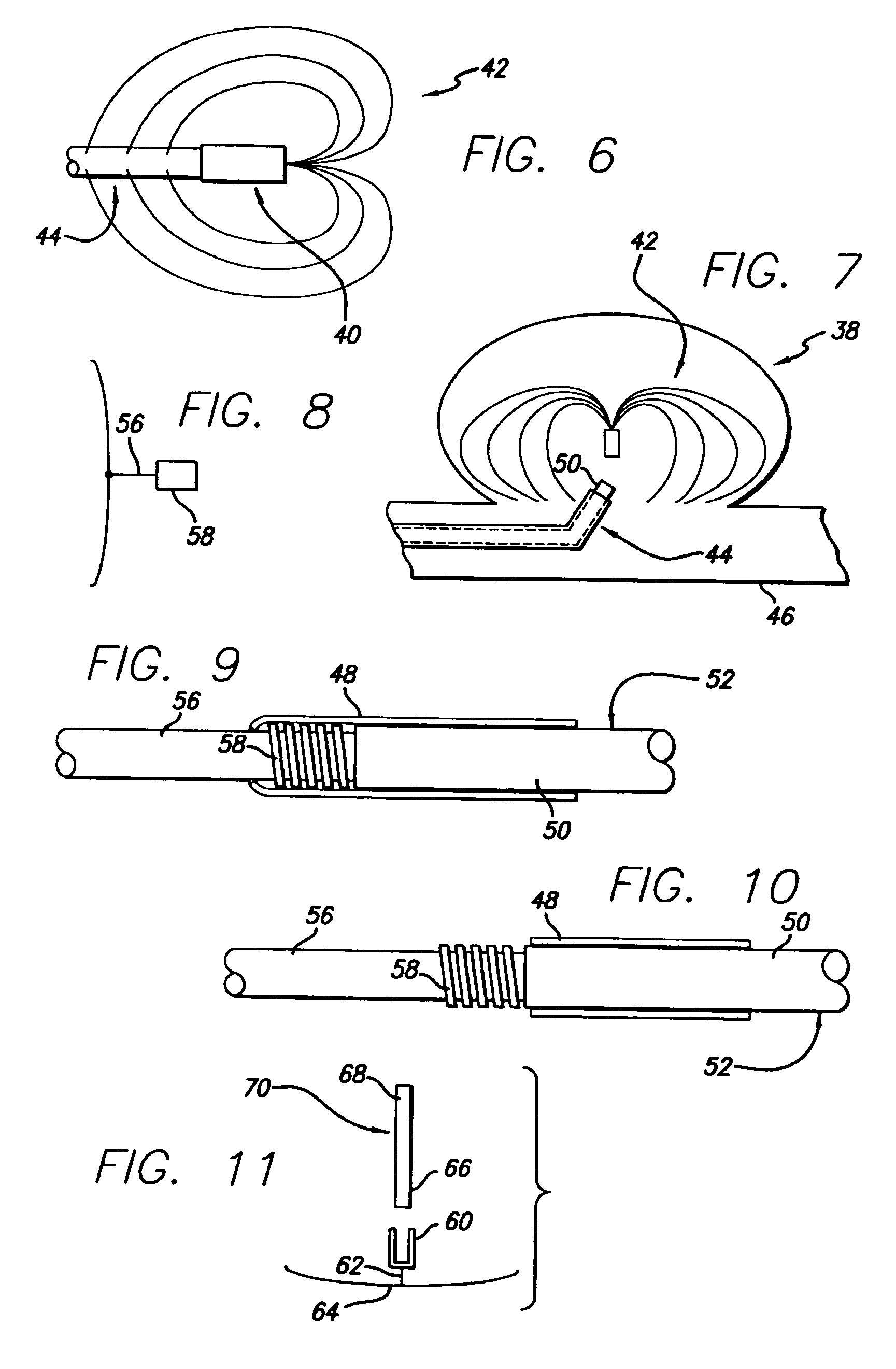

Thrombectomy System and Method

Disclosed is a clot and foreign body removal system, including a catheter with at least one lumen. Located within the catheter is a clot capture wire that is connected to a hub at the proximal end. In one embodiment, the clot capture wire includes a coil made out of an elastic or superelastic material, preferably nitinol. The elasticity or superelasticity of the coil allows it to be deformed within the catheter and to then reform its original coil configuration when the coil is moved outside of the catheter lumen. In another embodiment the coil is a biphasic, shape memory coil, which changes shape upon heating, energy application, or passing an electric current. Once the coil configuration has been established, the coil can be used to ensnare and corkscrew a clot or blockage in a vessel. A clot is extracted from the vessel by moving the clot capture coil and catheter proximally until the clot can be removed completely or released into a different vessel that does not perfuse a critical organ. Foreign bodies are similarly captured by deploying the coil distal to the foreign body and moving the clot capture coil proximally until the foreign body is trapped within the coil. By removing the device from the body, the foreign material is also removed.

Owner:TYCO HEALTHCARE GRP LP

Tubular compliant mechanisms for ultrasonic imaging systems and intravascular interventional devices

InactiveUS20070167804A1Successfully penetrateSuccessfully recanalizeUltrasonic/sonic/infrasonic diagnosticsCatheterCompliant mechanismUltrasonic imaging

A micromanipulator comprising a tubular structure and a structural compliance mechanism that are formed from a tube made of an elastic and / or superelastic material. The micromanipulator is useful for intravascular interventional applications and particularly ultrasonic imaging when coupled with an ultrasound transducer. Also disclosed are medical devices for crossing vascular occlusions using radio-frequency energy or rotary cutting, preferably under the guidance of real-time imaging of the occlusion, as well as accompanying methods.

Owner:VOLCANO CORP

Guidewire with superelastic core

InactiveUS20060173382A1Precise positioningGuide wiresDiagnostic recording/measuringEngineeringHyperelastic material

Owner:CORDIS CORP

Tubular compliant mechanisms for ultrasonic imaging systems and intravascular interventional devices

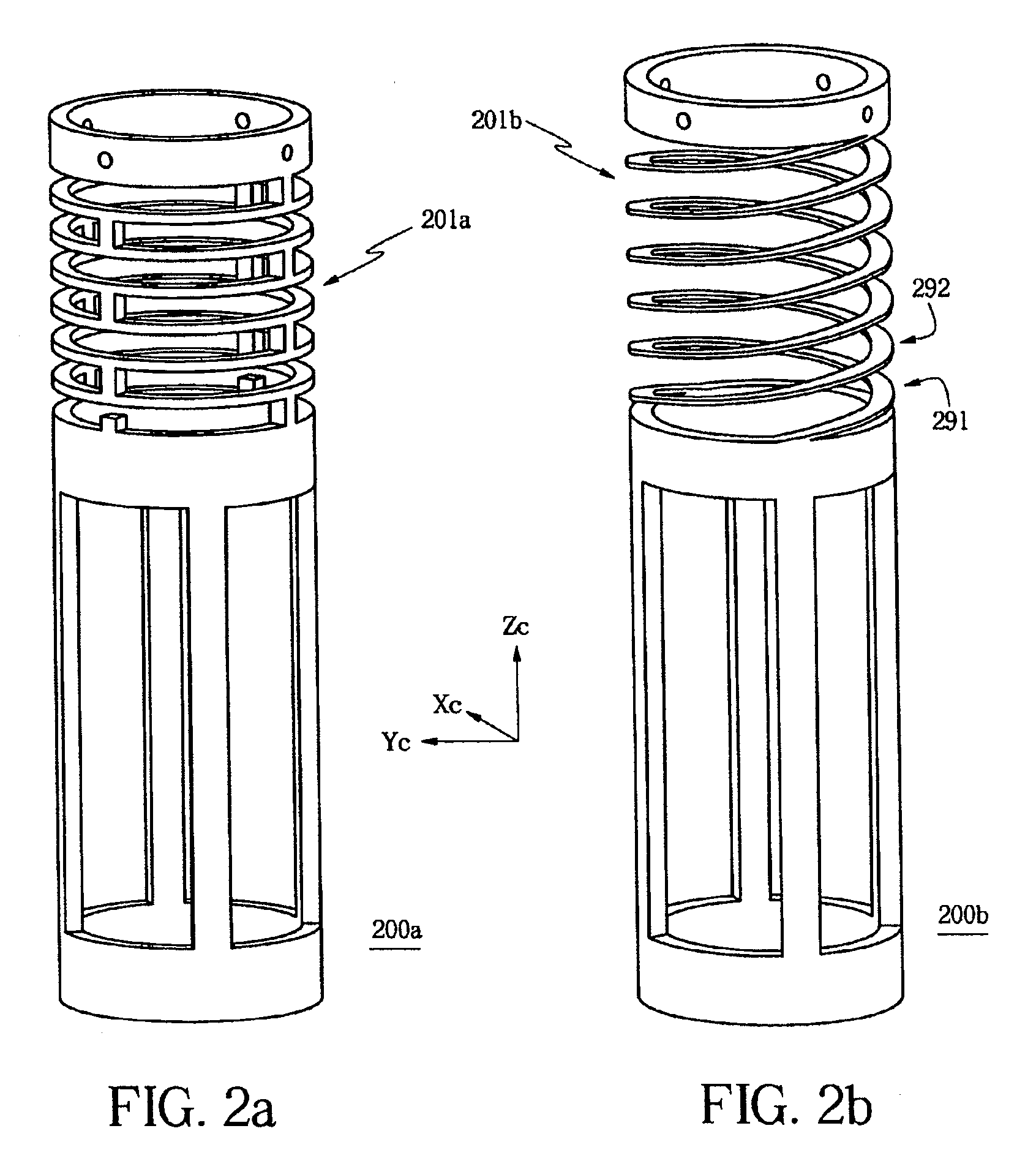

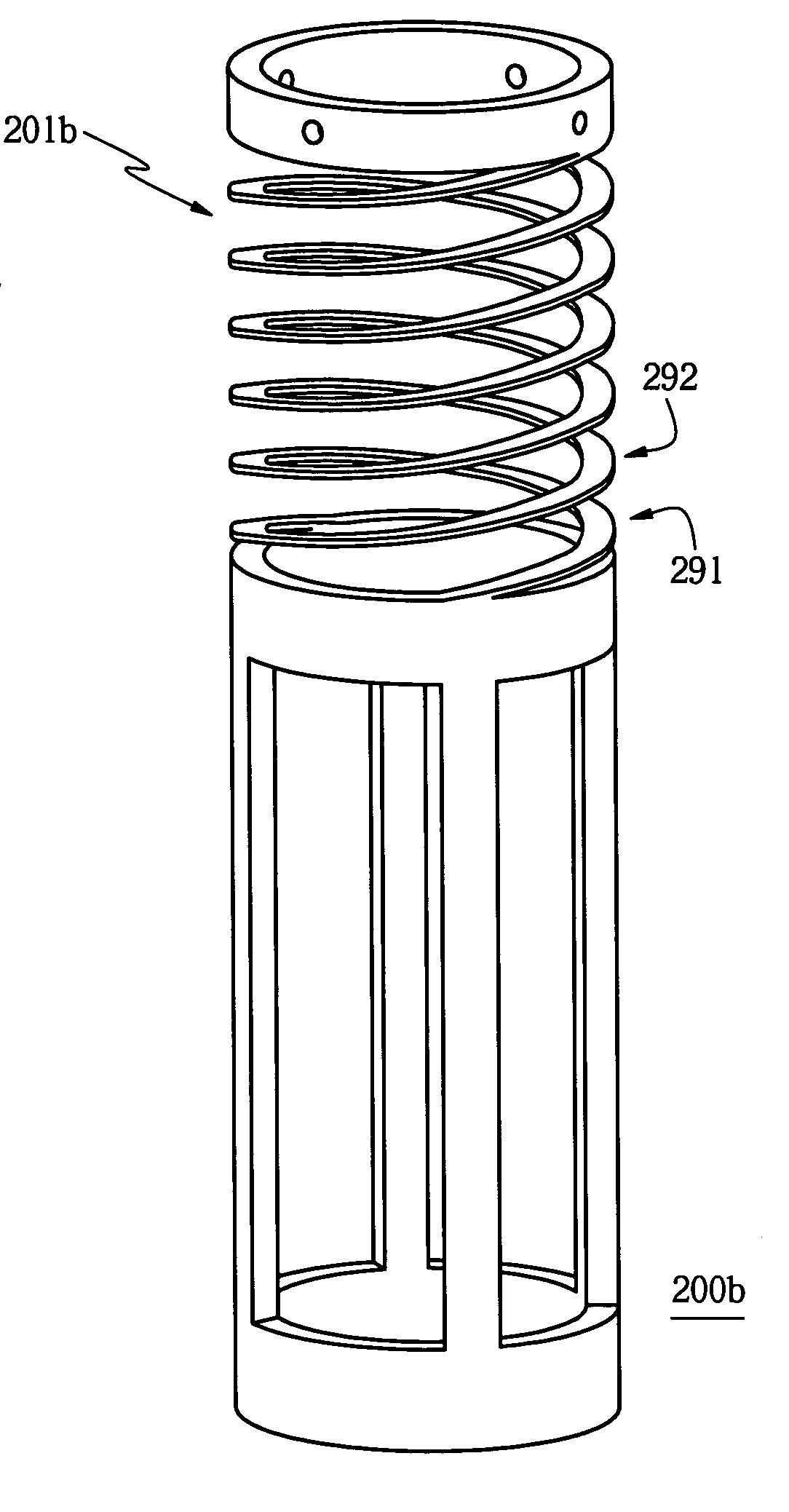

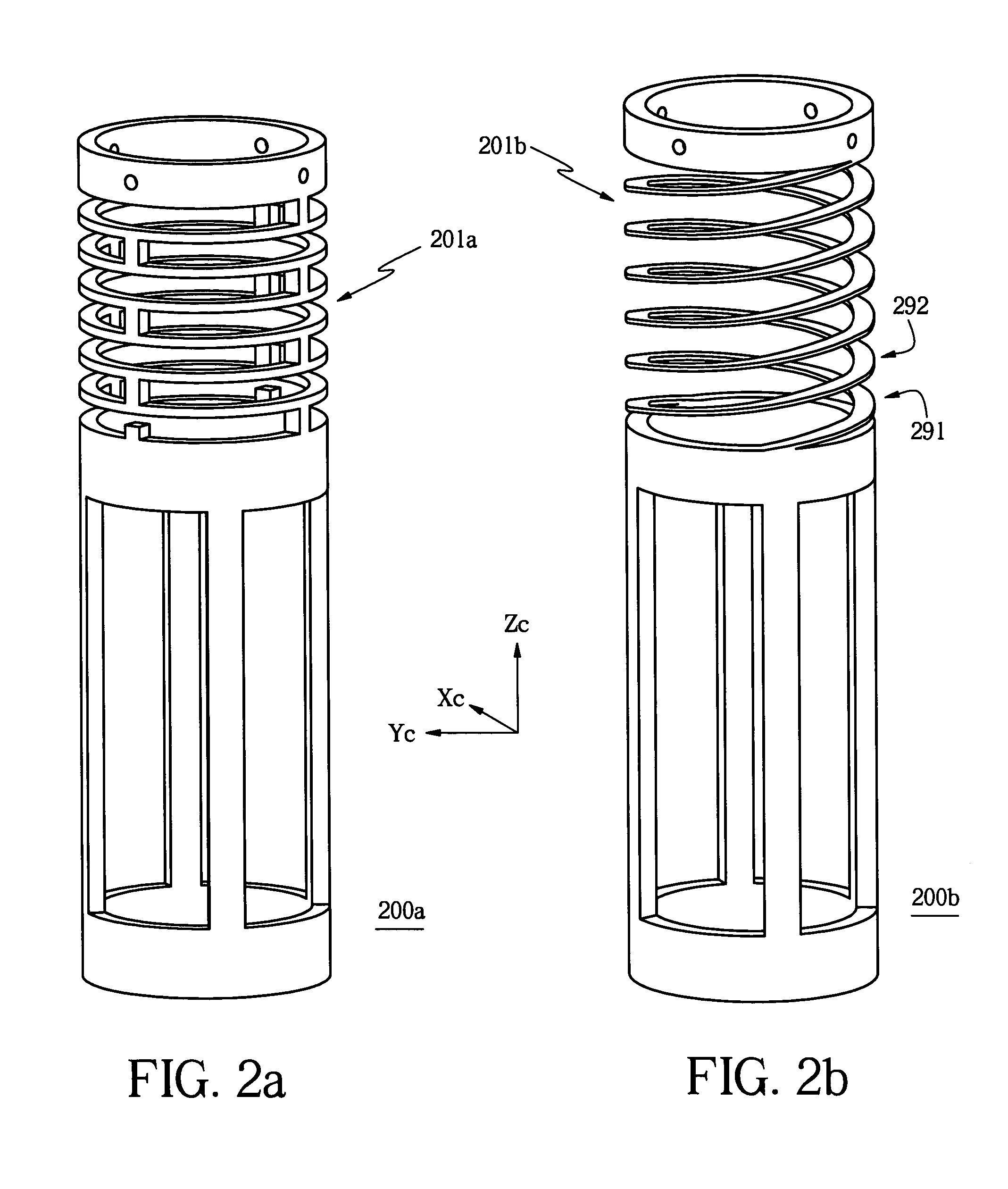

InactiveUS7115092B2Small sizeHigh resolutionElectrothermal relaysSurgeryCompliant mechanismShape-memory alloy

A micromanipulator comprising a tubular structure and a structural compliance mechanism that are formed from a tube made of an elastic and / or superelastic material. Fabricated with laser machining and has no mechanical joints, the micromanipulator can be manipulated in various motions and degree-of-freedoms without permanent deformation. Shape Memory Alloys (SMAs) in one embodiment are implemented as main actuators of the micromanipulator. The micromanipulator can be implemented with multiple SMAs to manipulate the mechanism with multiple degree-of-freedom. In another implementation, multiple segments of the mechanisms are formed and arranged in various configurations, including a “double-helix”-like configuration, for enabling intricate motions of the micromanipulator. The micromanipulator is useful for intravascular interventional applications and particularly ultrasonic imaging when coupled with an ultrasound transducer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

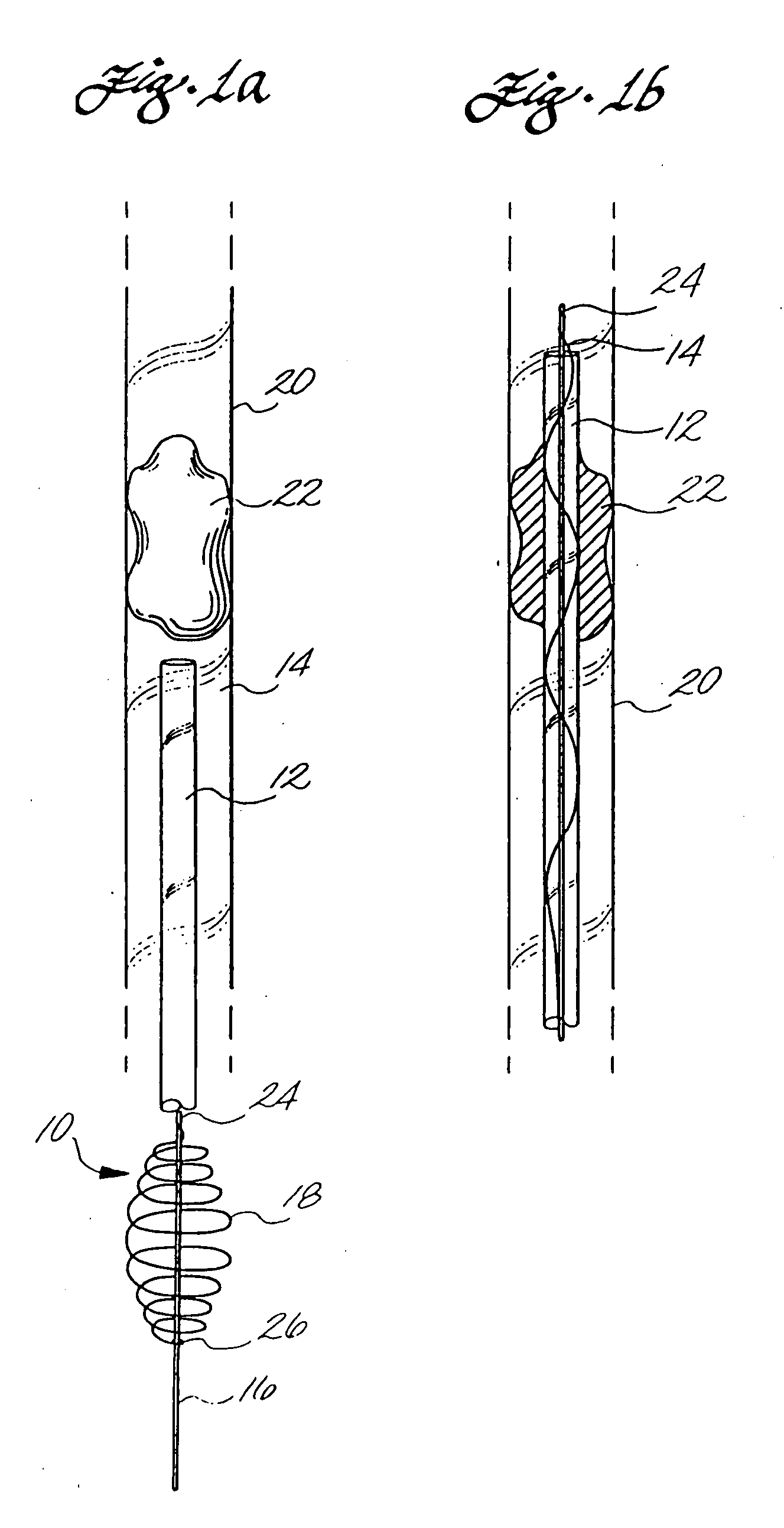

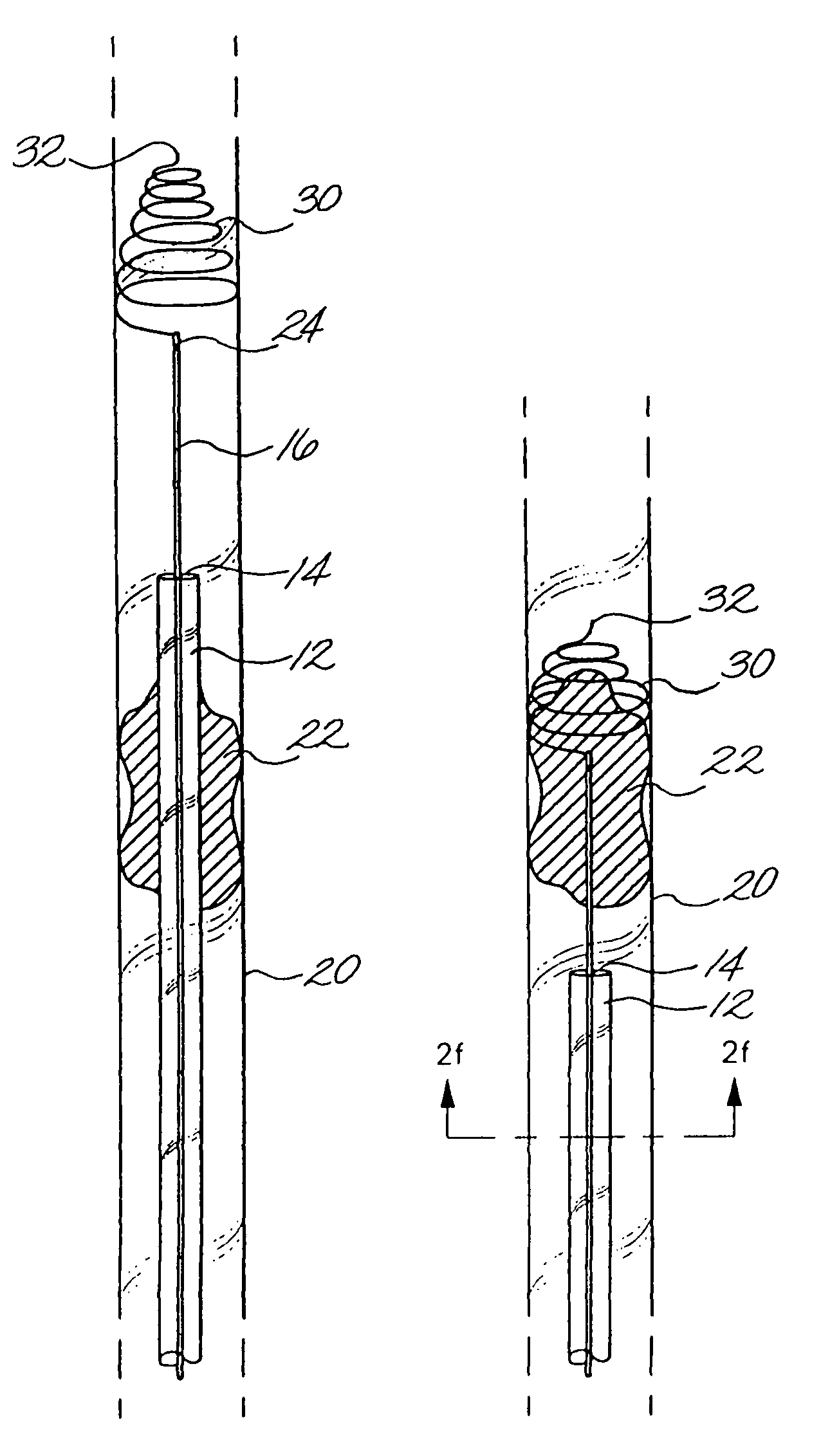

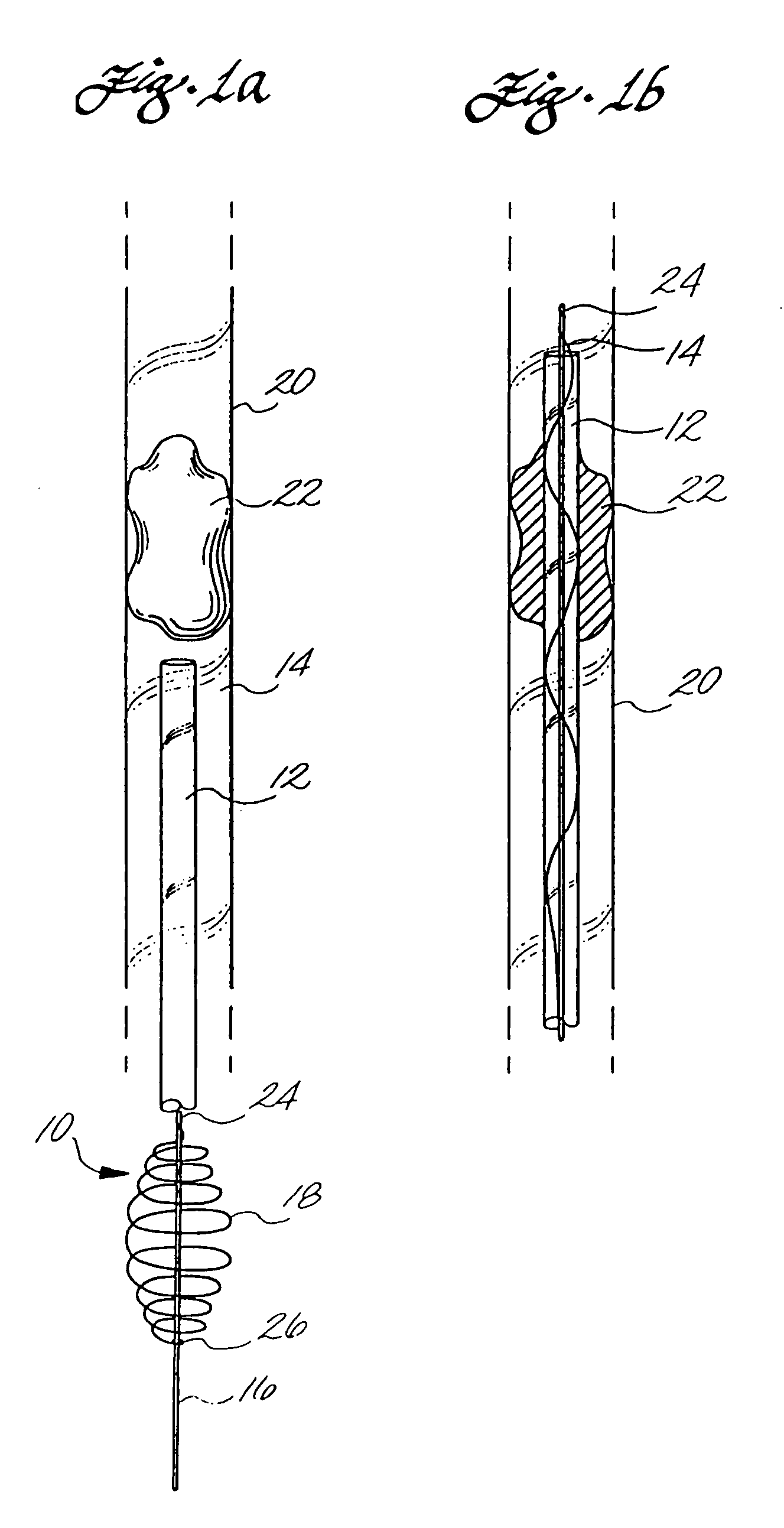

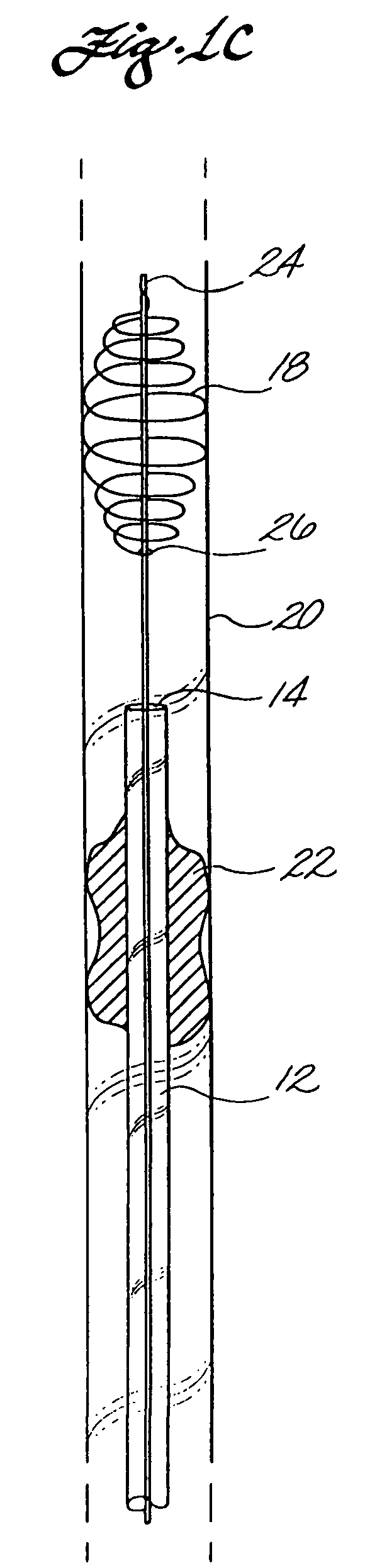

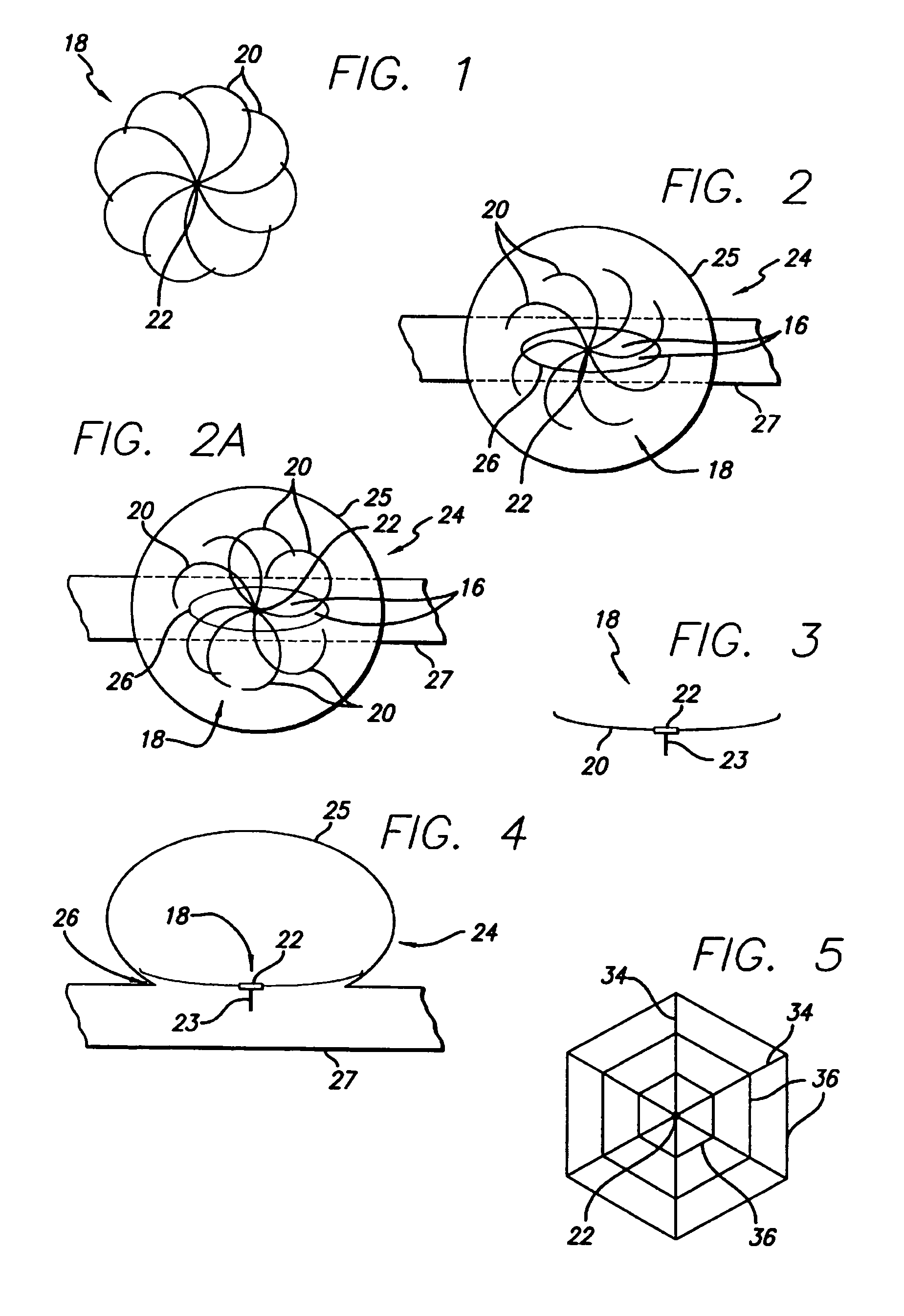

Clot capture coil

A clot and foreign body removal device is described which comprises a catheter with at least one lumen. Located within the catheter is a clot capture coil that is connected to an insertion mandrel. In one embodiment, the clot capture coil is made out of a solid elastic or superelastic material which has shape memory, preferably nitinol. The elasticity or superelasticity of the coil allows it to be deformed within the catheter and to then reform its original coil configuration when the coil is moved outside of the catheter lumen. In another embodiment the coil is a biphasic coil which changes shape upon heating or passing an electric current. Once the coil configuration has been established, the coil can be used to ensnare and corkscrew a clot in a vessel. A clot is extracted from the vessel by moving the clot capture coil and catheter proximally until the clot can be removed or released into a different vessel that does not perfuse a critical organ. Foreign bodies are similarly captured by deploying the coil distal to the foreign body and moving the clot capture coil proximally until the foreign body is trapped within the coil. By removing the device from the body, the foreign material is also removed.

Owner:RGT UNIV OF CALIFORNIA

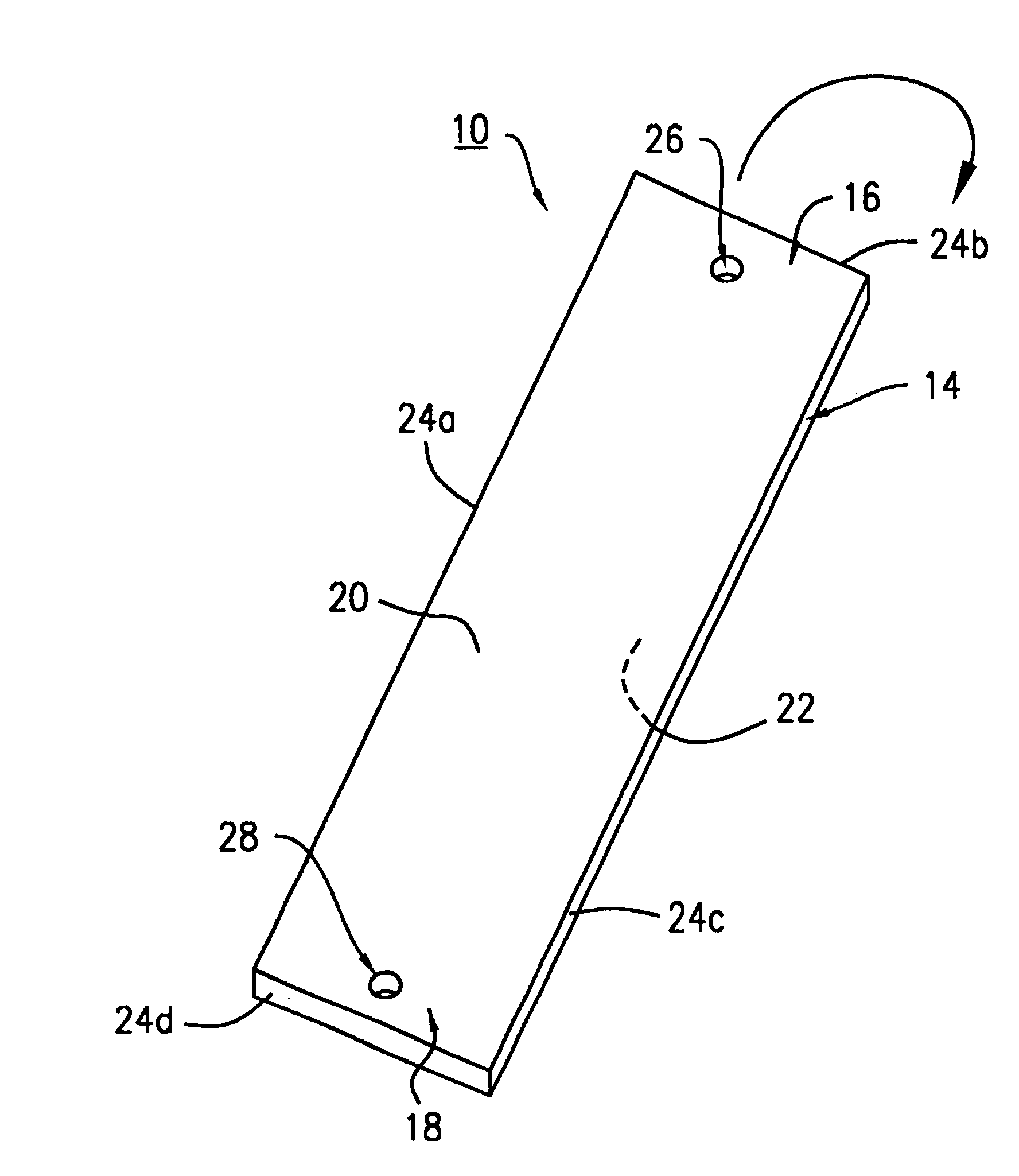

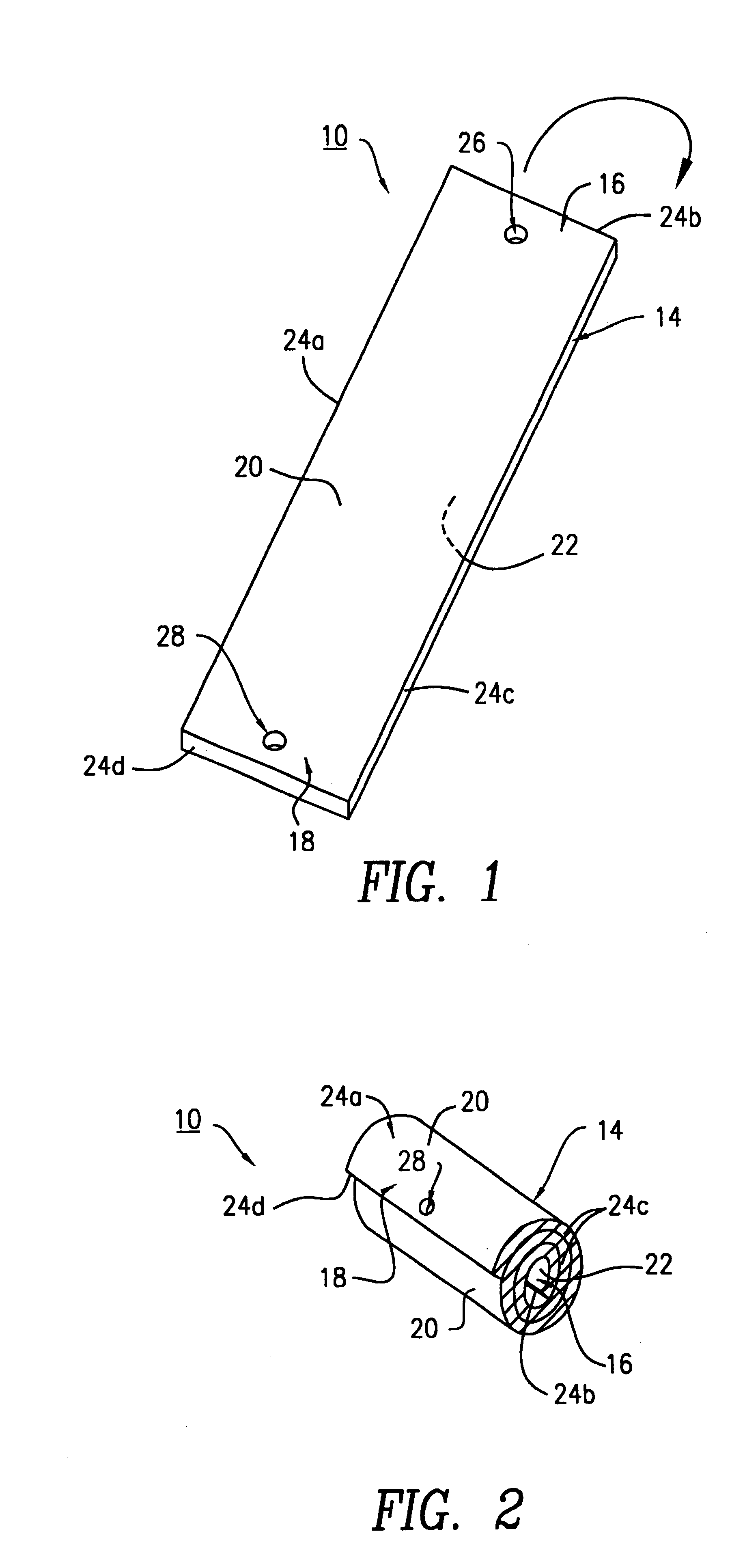

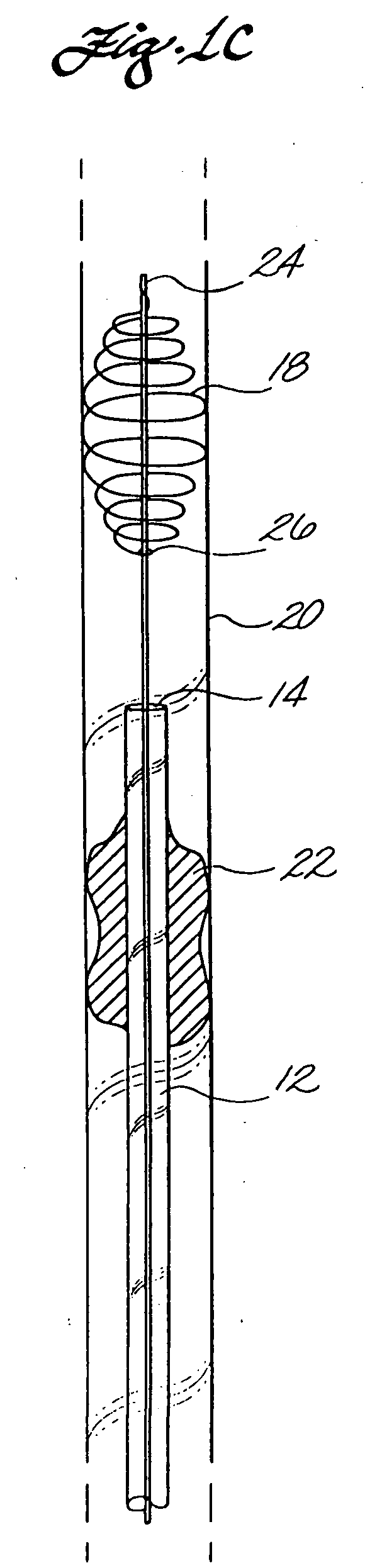

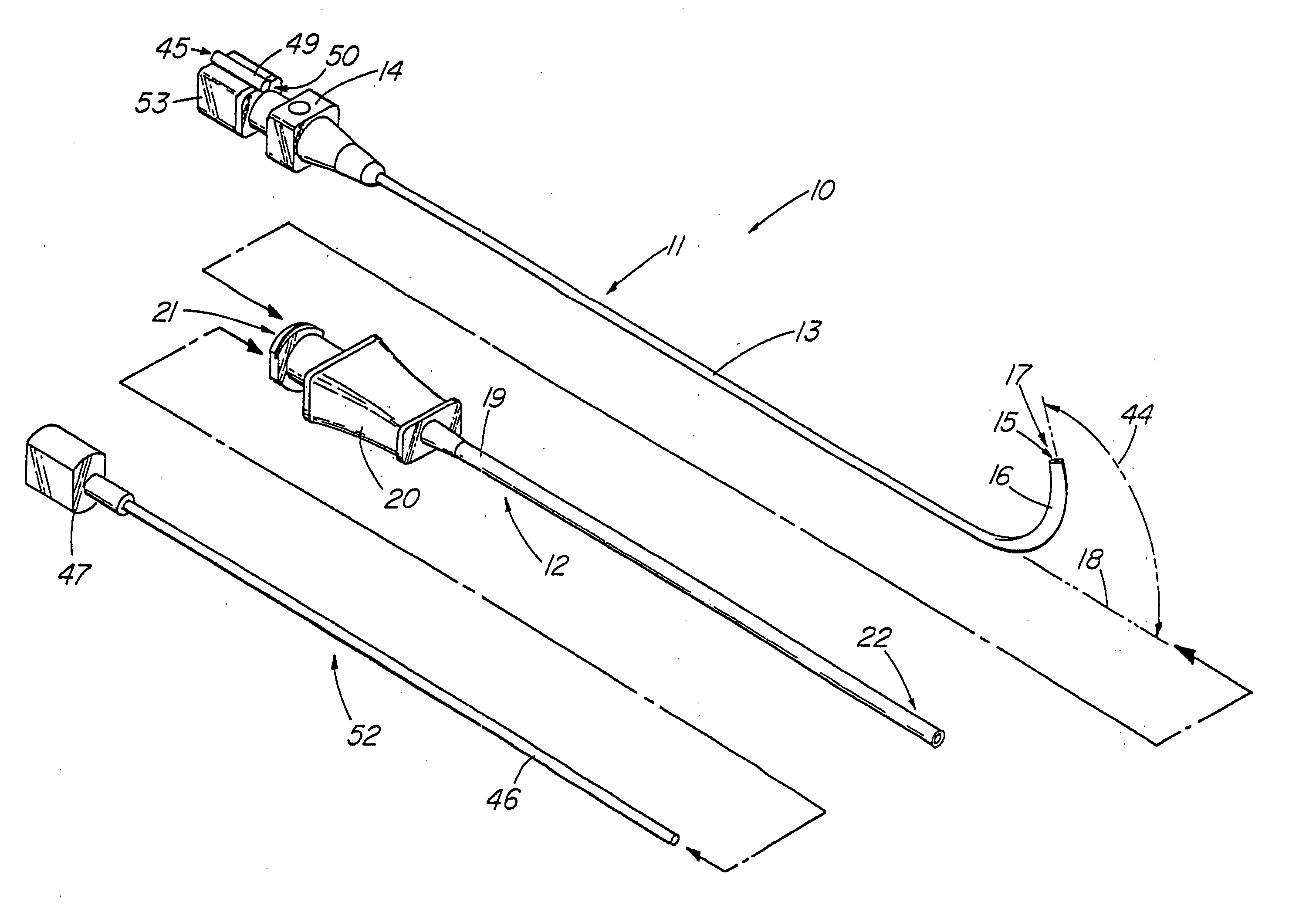

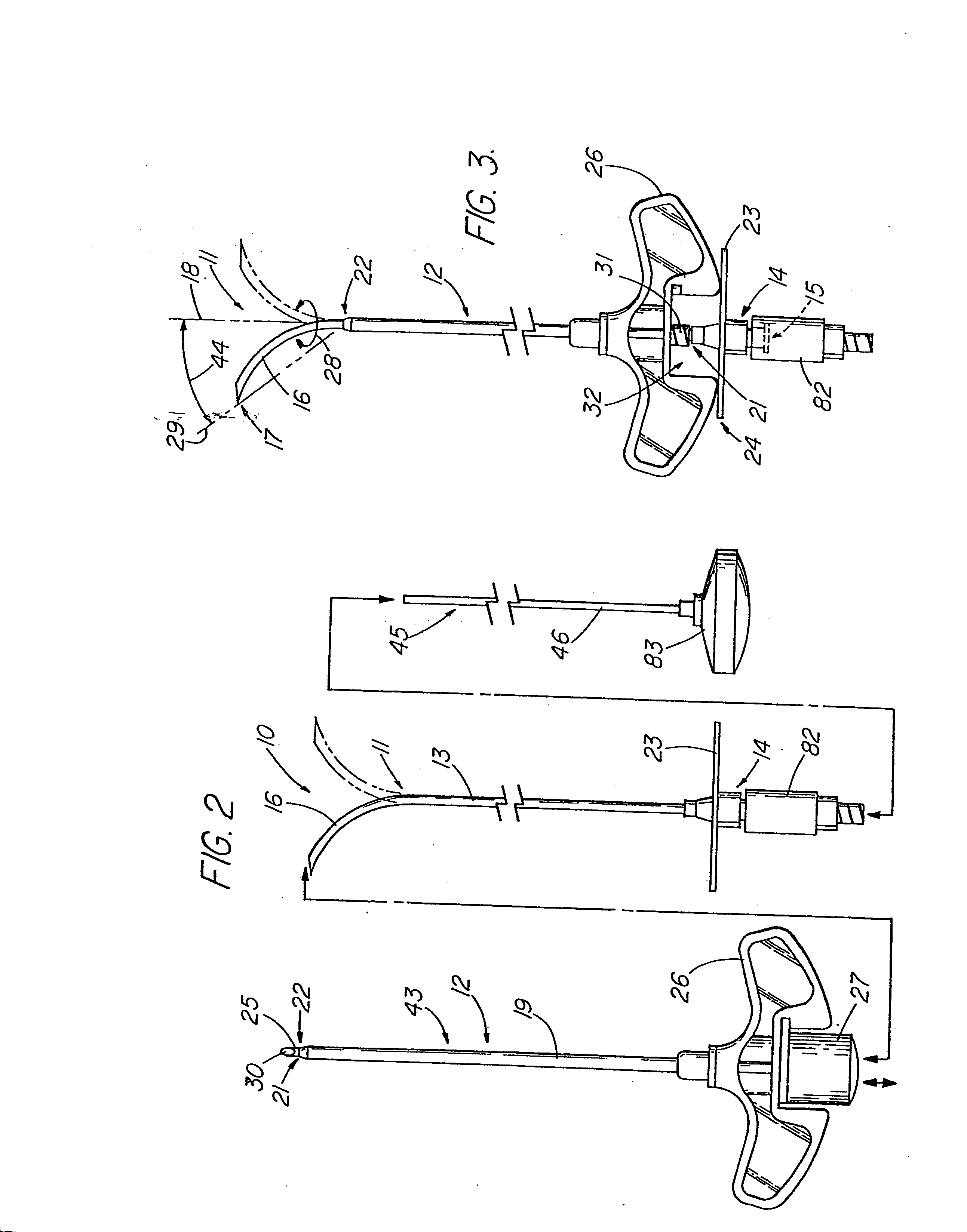

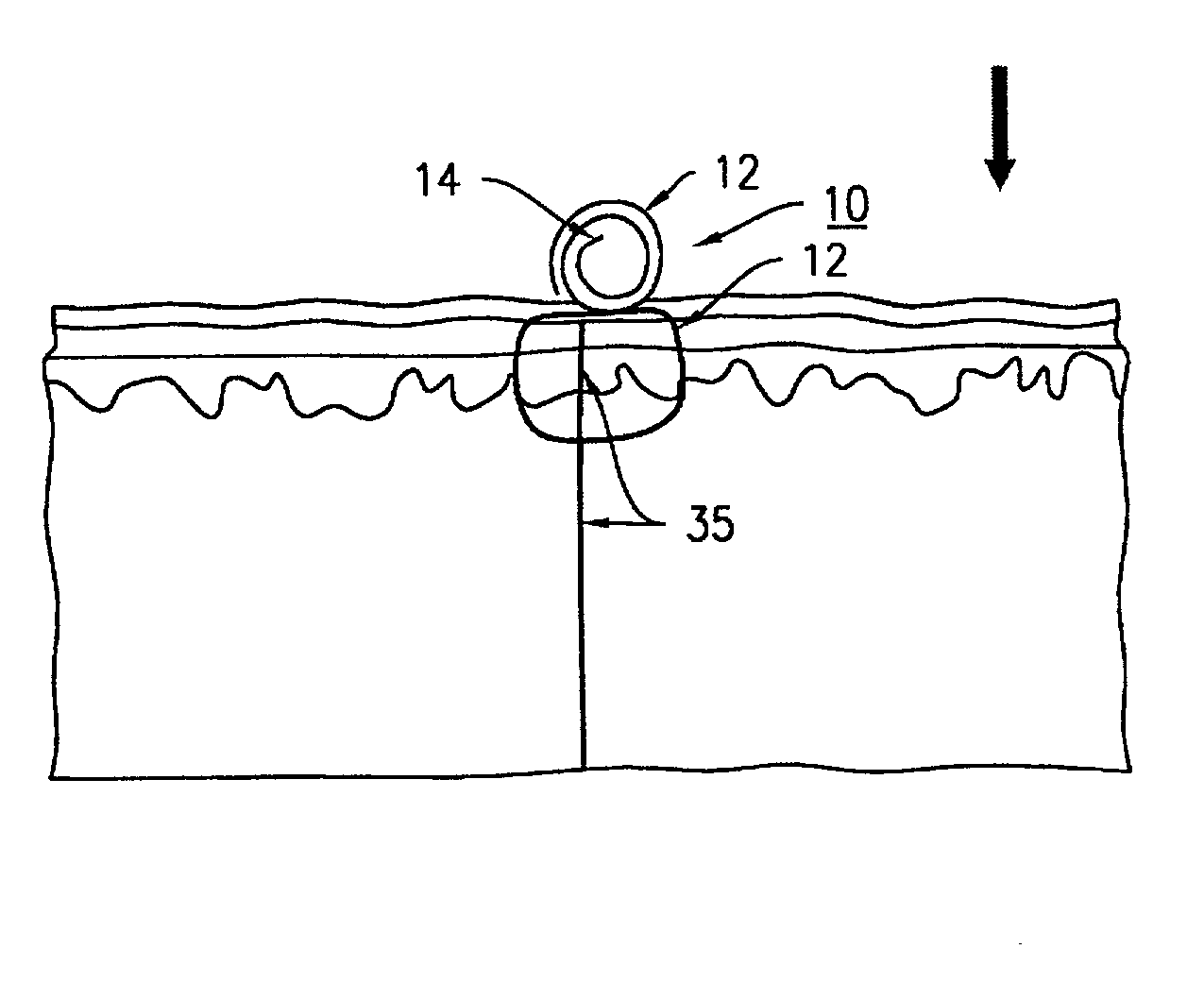

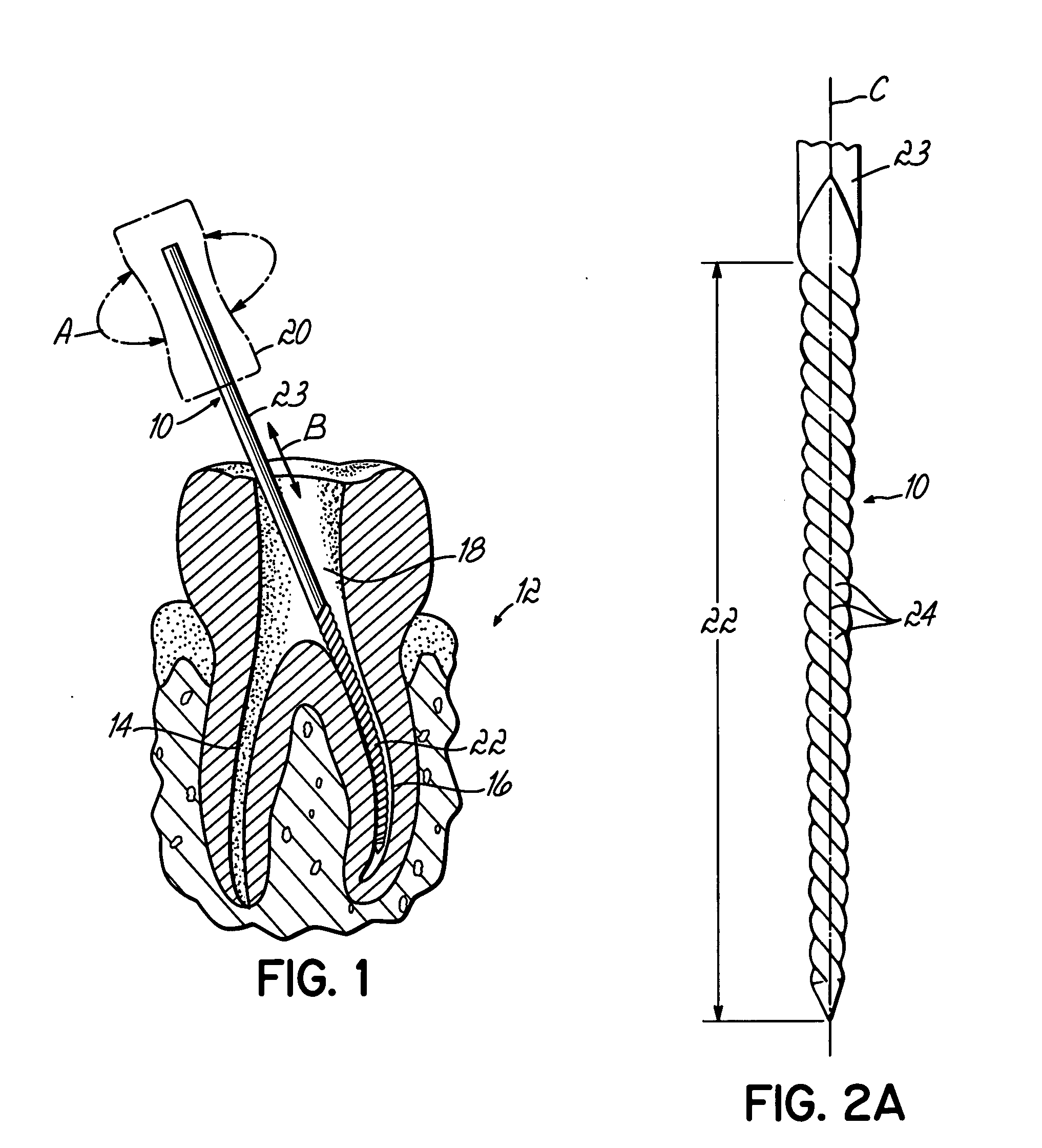

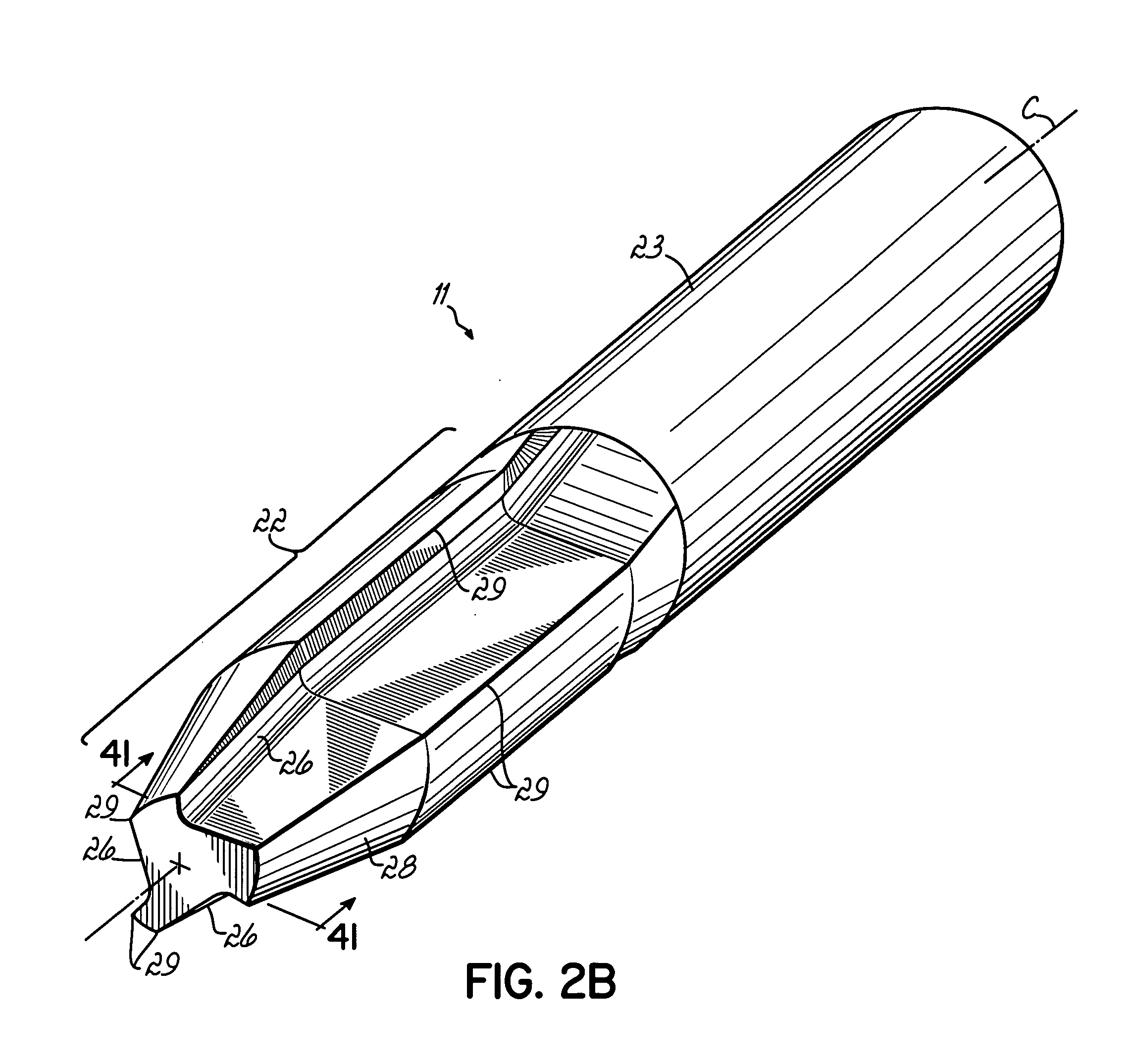

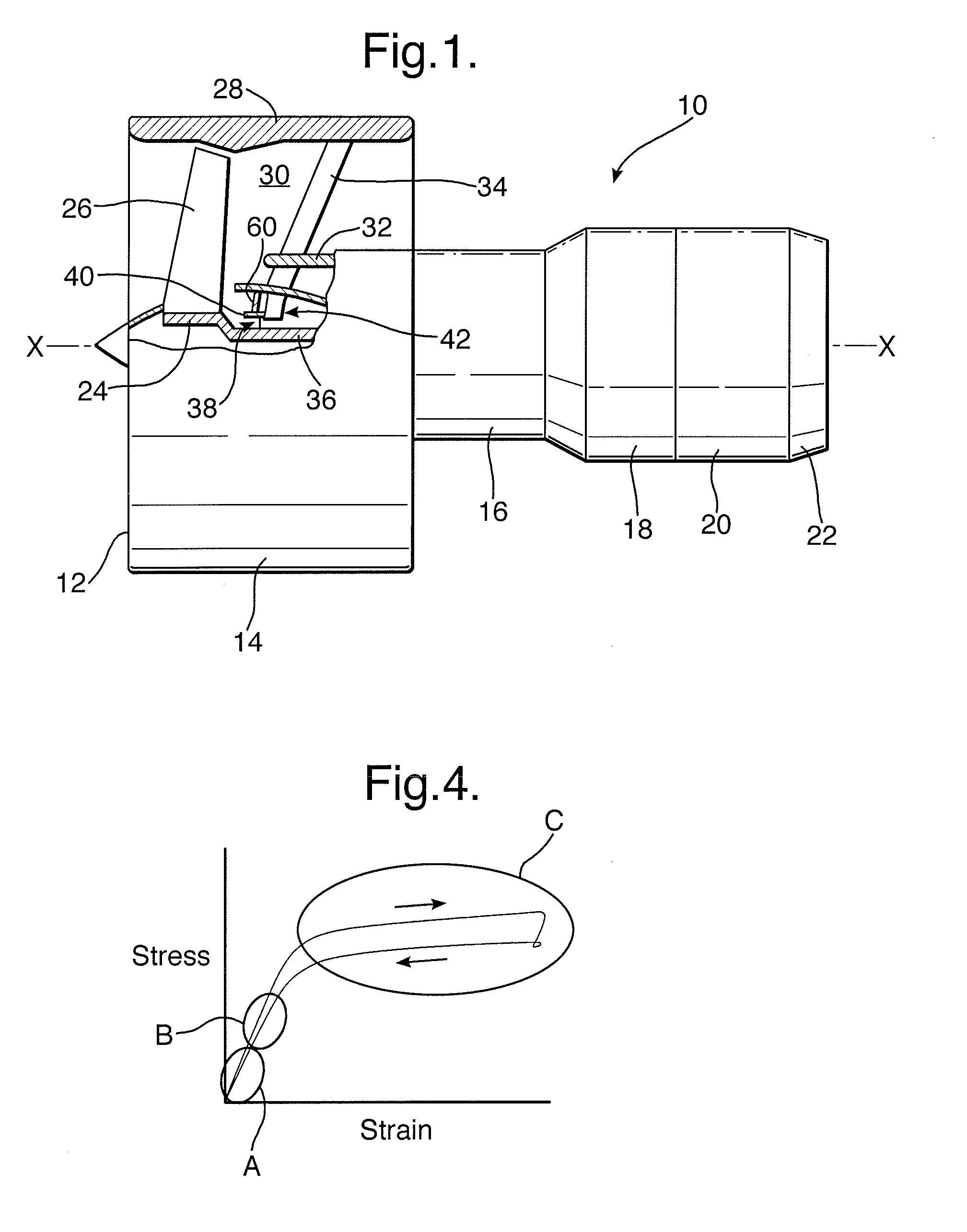

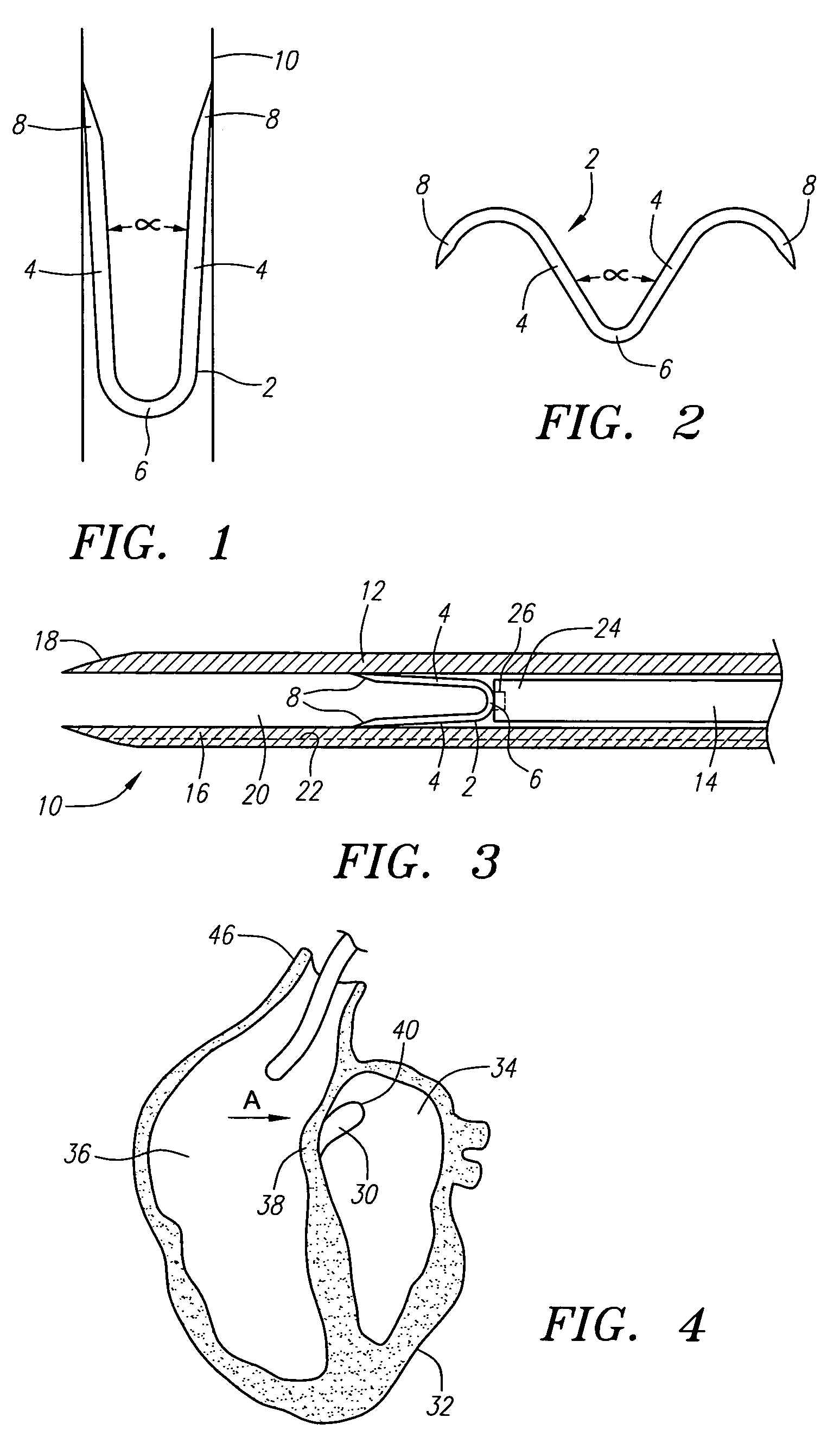

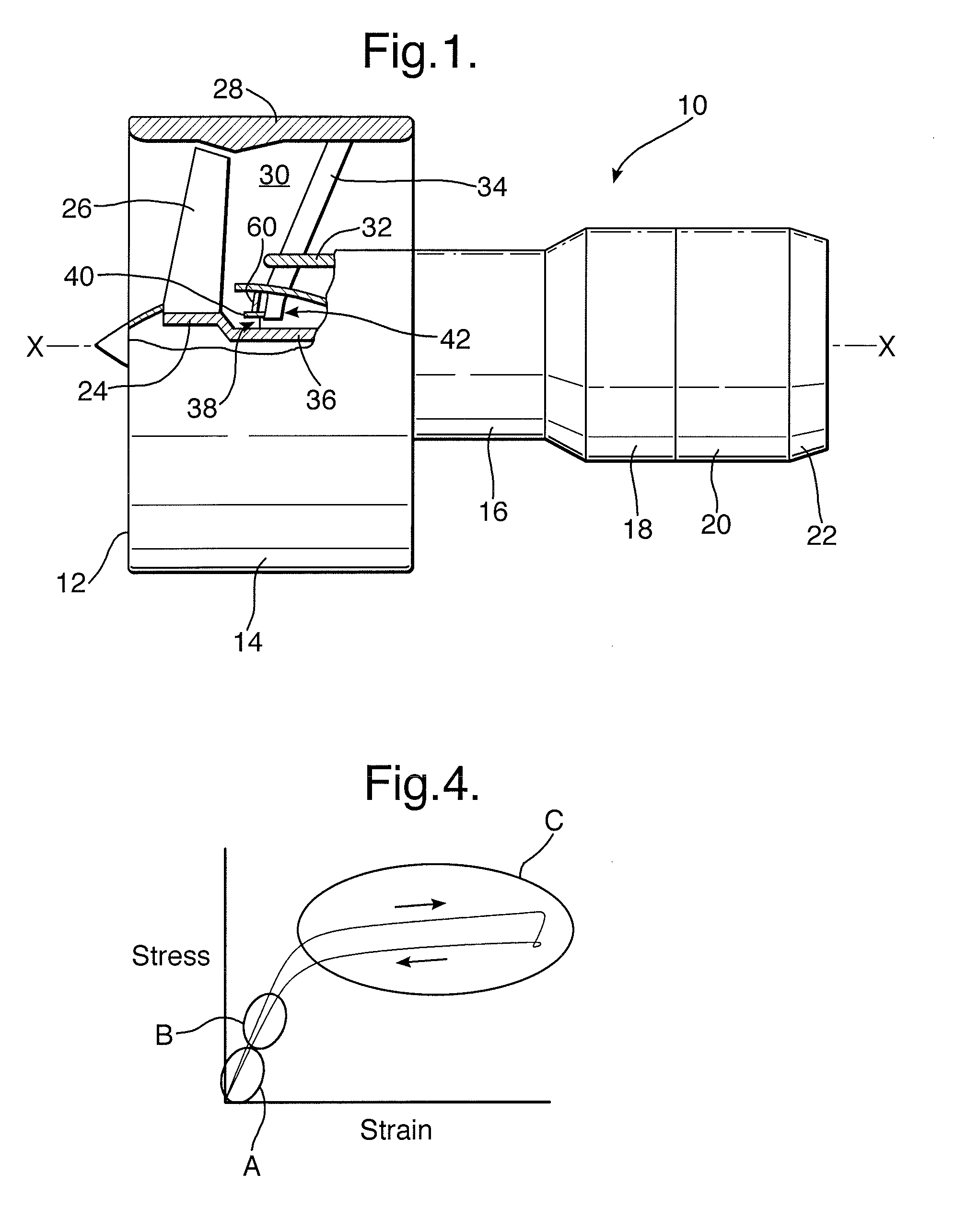

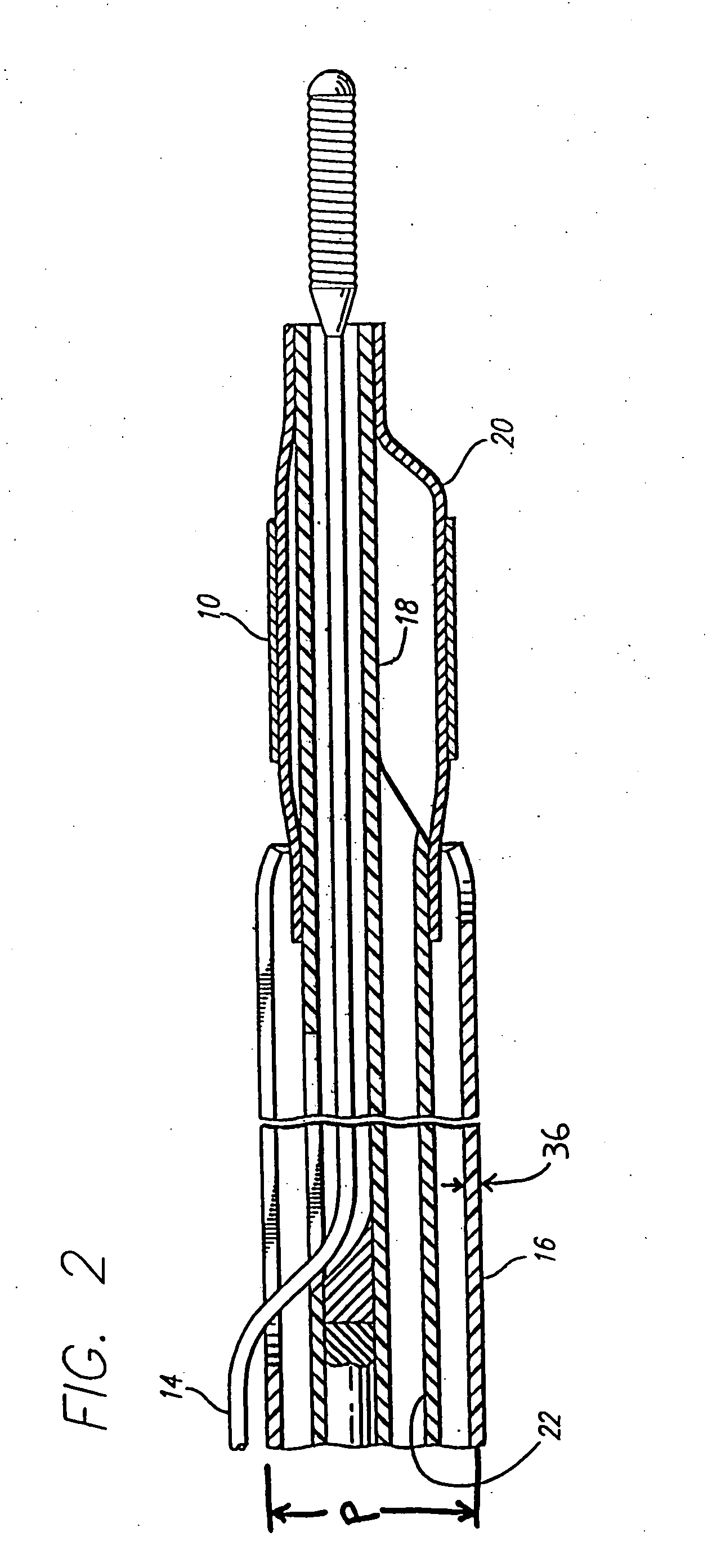

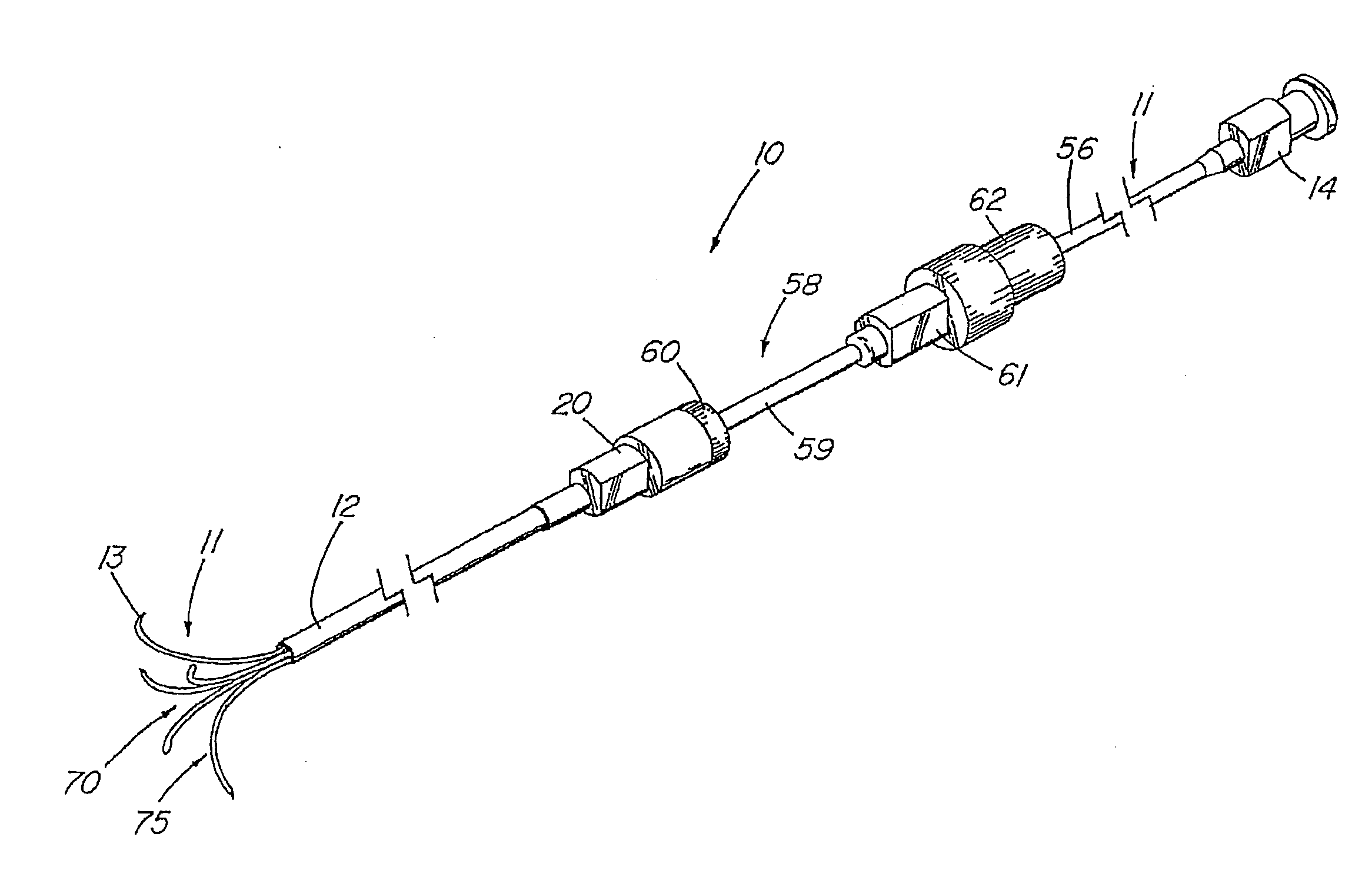

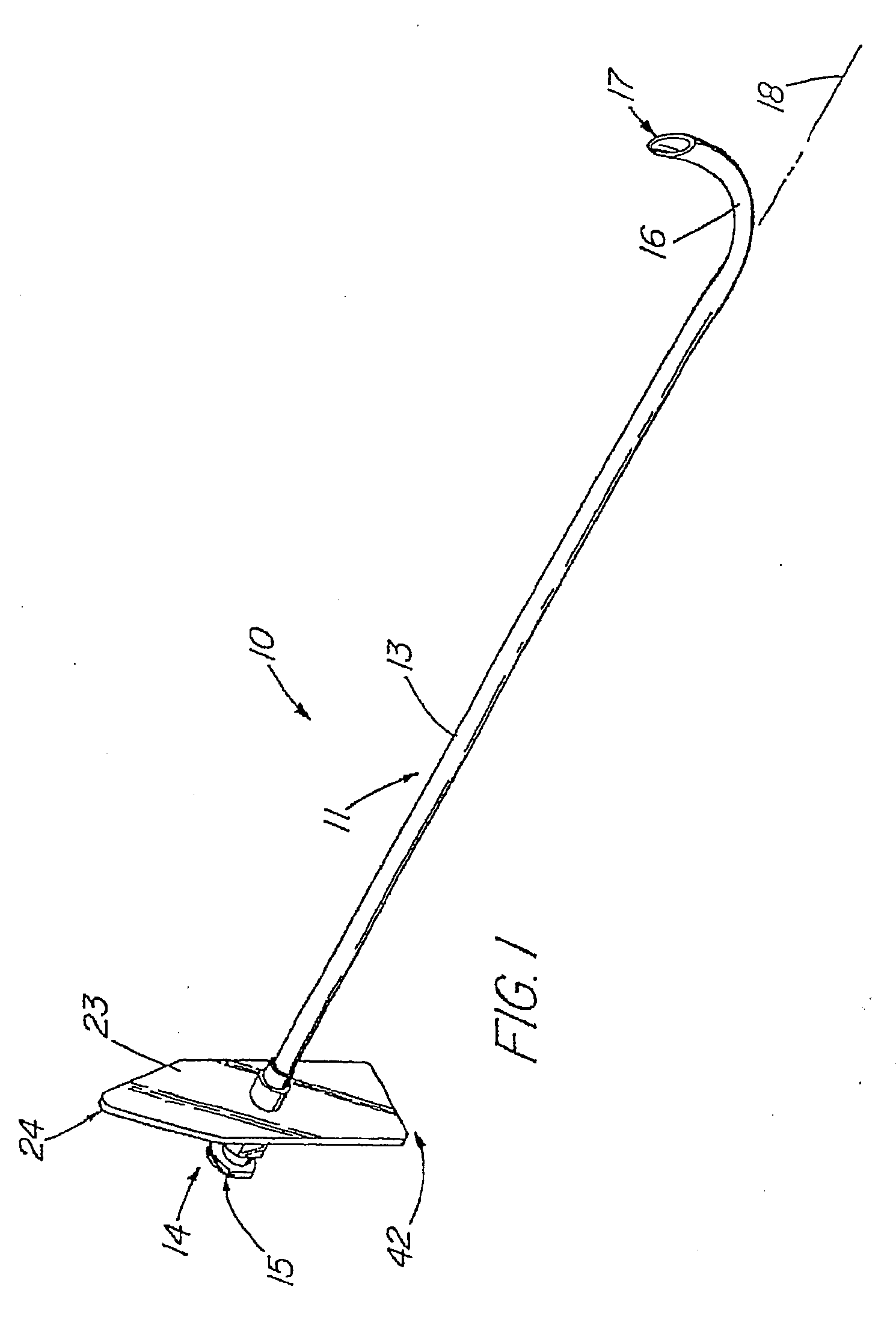

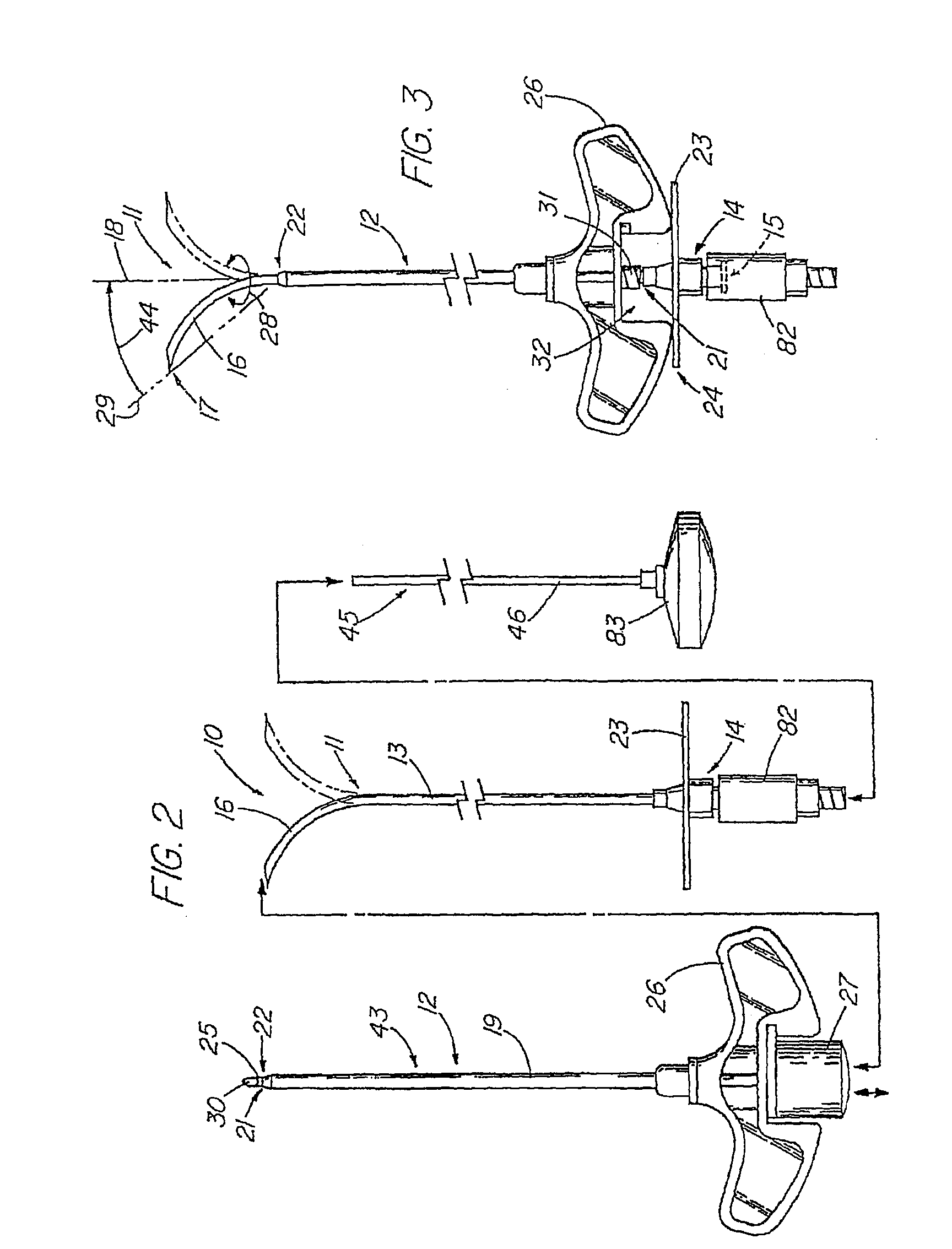

Hollow curved superelastic medical needle and method

InactiveUS20060129101A1Reduce eliminateGuide needlesInfusion syringesOuter CannulaBiomedical engineering

A needle assembly 10 compromising an infusion needle 11 that includes a needle cannula 13 made of a superelastic material such as Nitinol. The needle cannula is cold-worked or heat annealed to produce a preformed bend 16 that can be straightened within passageway 21 of a coaxial outer cannula 12 for introduction into the body of a patient. Upon deployment from the outer cannula, the needle cannula substantially returns to the preformed configuration for the introduction or extraction of materials at areas lateral to the entry path of the needle assembly. The needle assembly can compromise a plurality of needle cannulae than can be variably arranged or configured for attaining a desired infusion pattern.

Owner:REX MEDICAL LP

Clot capture coil

A clot and foreign body removal device is described which comprises a catheter with at least one lumen. Located within the catheter is a clot capture coil that is connected to an insertion mandrel. In one embodiment, the clot capture coil is made out of a solid elastic or superelastic material which has shape memory, preferably nitinol. The elasticity or superelasticity of the coil allows it to be deformed within the catheter and to then reform its original coil configuration when the coil is moved outside of the catheter lumen. In another embodiment the coil is a biphasic coil which changes shape upon heating or passing an electric current. Once the coil configuration has been established, the coil can be used to ensnare and corkscrew a clot in a vessel. A clot is extracted from the vessel by moving the clot capture coil and catheter proximally until the clot can be removed or released into a different vessel that does not perfuse a critical organ. Foreign bodies are similarly captured by deploying the coil distal to the foreign body and moving the clot capture coil proximally until the foreign body is trapped within the coil. By removing the device from the body, the foreign material is also removed.

Owner:RGT UNIV OF CALIFORNIA

Expandable curvilinear strut arrangement for deployment with a catheter to repair an aneurysm

The vasoocclusive apparatus can be used in a method of interventional therapy and vascular surgery by inserting the apparatus into a portion of a vasculature, for treatment of a body vessel such as an aneurysm in conjunction with a secondary vasoocclusive device to be placed within the vessel. The vasoocclusiveVasooclusive apparatus includes a plurality of strut members connected together at a central hub that extend from a collapsed position to an expanded configuration to cross the neck of the aneurysm, dividing the neck into smaller openings, allowing the deployment of the secondary vasoocclusive device within the aneurysm but preventing migration of the secondary vasoocclusive device from the aneurysm. The strut members can be made from a twisted cable of strands of a superelastic material, such as a shape memory nickel titanium alloy, with at least one radiopaque strand. A shape memory collar is provided for detachably mounting the vasoocclusive apparatus to a pusher member and for detaching the vasoocclusive apparatus for deployment when a desired placement within an aneurysm to be treated and out of a parent vessel is achieved.

Owner:MICRUS CORP

Suture anchoring and tensioning device

InactiveUS20030125767A1Eliminate knotsEasy to useSuture equipmentsSurgical needlesSuture anchorsHyperelastic material

Owner:ETHICON INC

EMG controlled air-operated soft body rehabilitative mechanical hand

ActiveCN106309083AImprove securityReduce weightProgramme-controlled manipulatorDiagnosticsLow noiseFiber

The invention discloses an EMG controlled air-operated soft body rehabilitative mechanical hand. The mechanical hand can help a stroke patient or a patient suffering from hand disability conduct hand rehabilitation activity. Different from a traditional rigid body type mechanical hand, every finger of the soft body mechanical hand is a hollow cavity structure composed of soft materials (super-elastic materials like silicone rubber and the like), a fiber and a limit strained layer is arranged on the periphery, soft body fingers are designed by combining structures of bending distortion, extending distortion, distortion, torsional and extending distortion, and motion distortion is achieved through air-operated driving. The EMG controlled air-operated soft body rehabilitative mechanical hand can achieve multi-section type bending similar to human's fingers, drives bending and stretching of stroke fingers, and restores a patient's athletic ability. The air-operated soft body rehabilitative mechanical hand has the advantages of low rigidity, high safety, high comfort, low weight, low noise and the like, has more remarkable superiority compared with current traditional mechanical rigid body type rehabilitative hand, and has very wide application prospect in the field of rehabilitation.

Owner:XI AN JIAOTONG UNIV

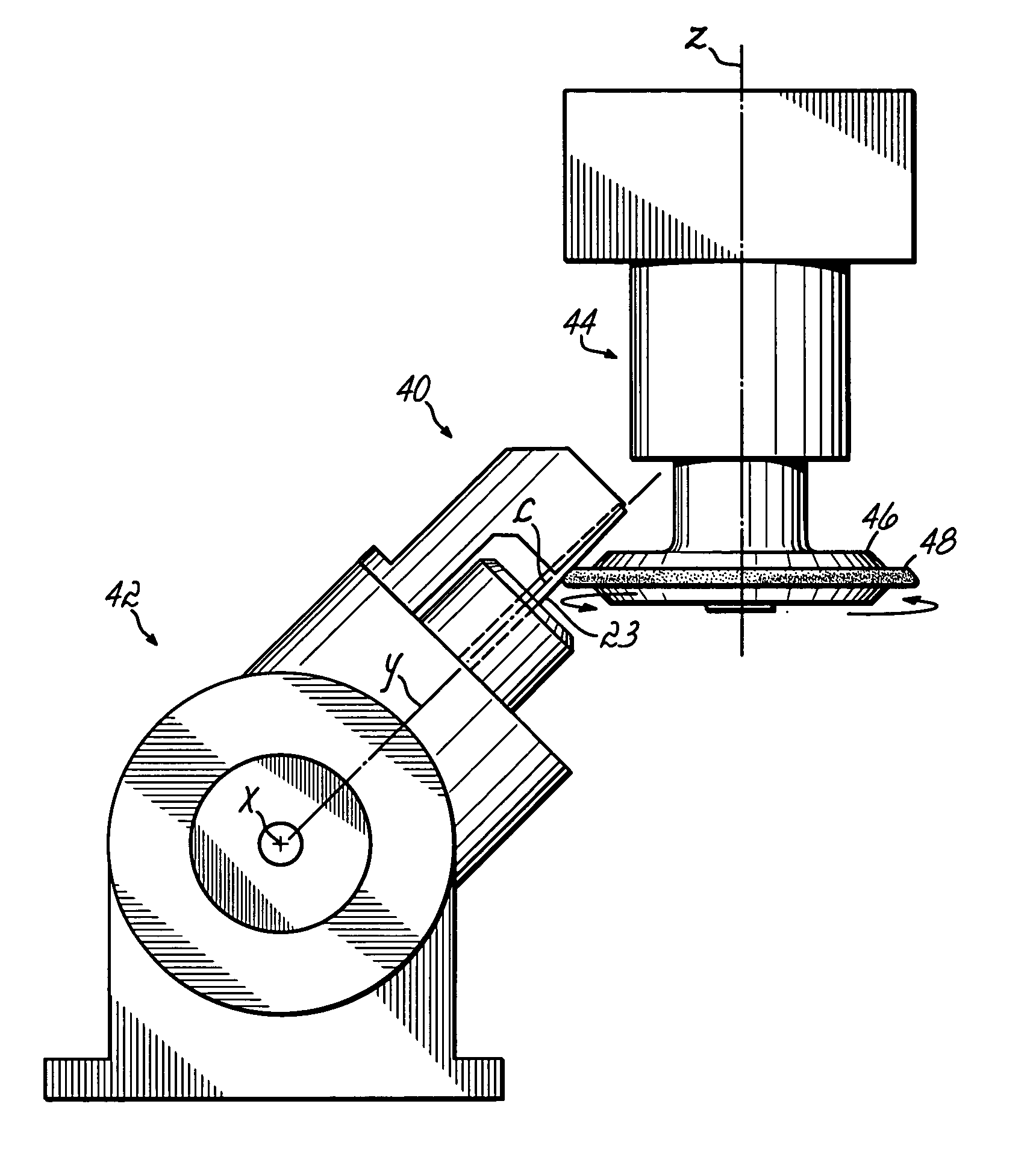

Method of manufacturing a dental instrument

Method for manufacturing a dental instrument having a desired machined configuration, without twisting the instrument. A blank of superelastic material is brought to an annealed state comprising a phase structure including a rhombohedral phase alone or in combination with austenite and / or martensite, or a combination of martensite and austenite. In this annealed state, a portion of the annealed material is removed at low temperature, for example less than about 100° C., and advantageously at ambient temperature, to form a final machined configuration for the instrument. The instrument is then heat treated and rapidly quenched to a superelastic condition.

Owner:ORMCO CORP

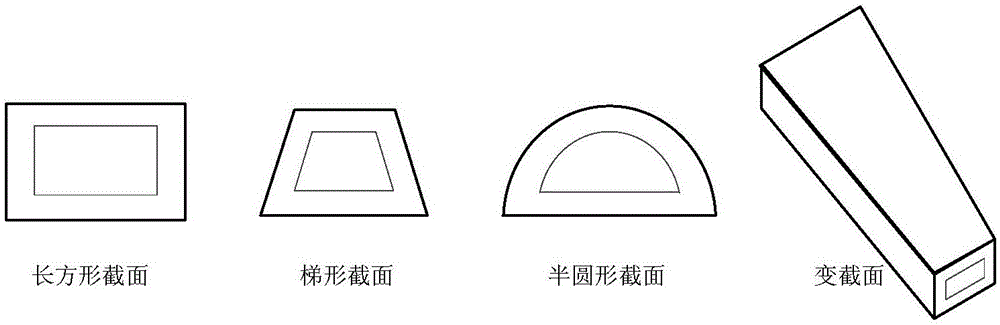

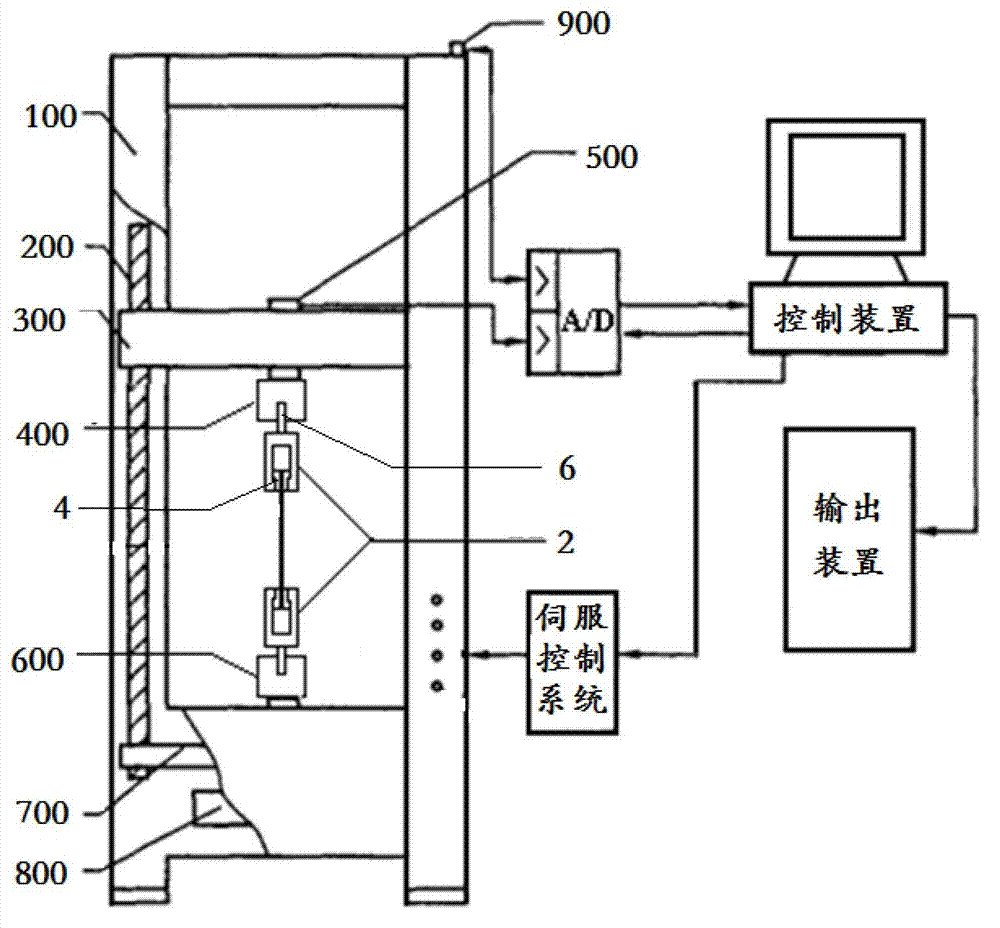

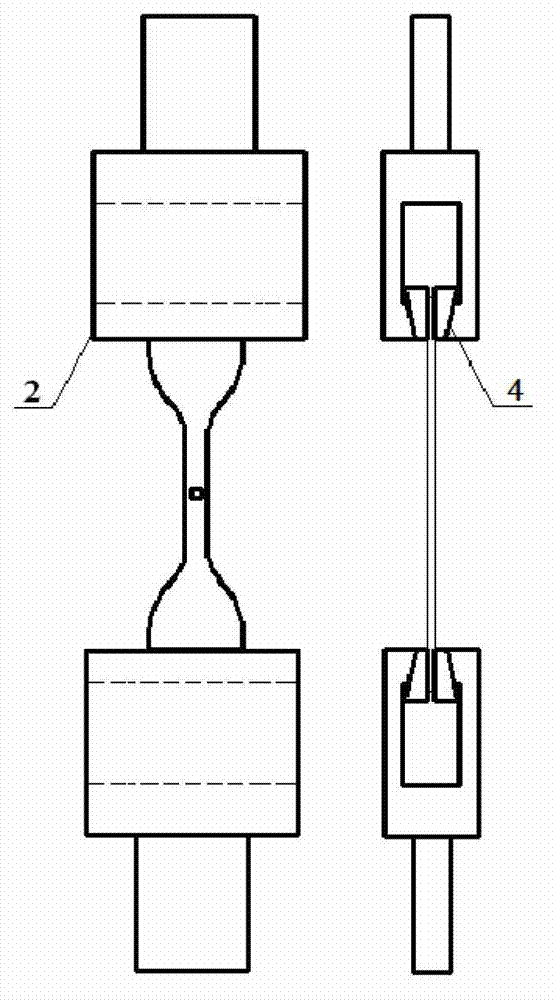

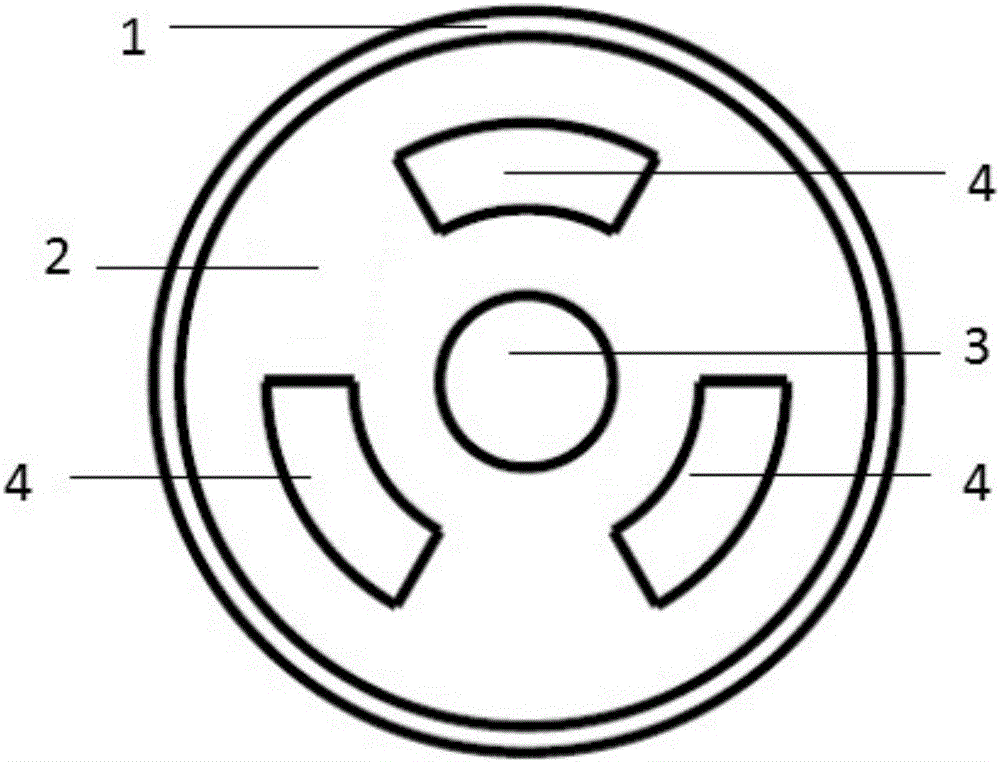

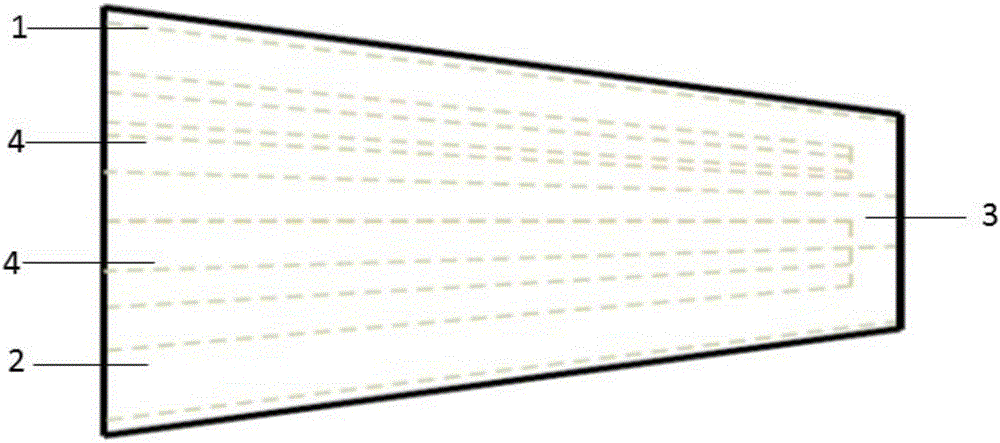

Clamp, device with clamp for testing mechanical property of hyper-elastic material and method

InactiveCN102768149AUniform deformationQuick disassemblyMaterial strength using tensile/compressive forcesData acquisitionHyper elastic

The invention relates to a device and a method for testing mechanical property of a hyper-elastic material. The device mainly comprises a reinforcing piece (4) at the end of a test piece and a test piece clamp, wherein the reinforcing piece (4) has a trapezoidal cross section; a clamping port of the clamp is an inclined surface; the reinforcing piece (4) is adhered to the end of the test piece and is arranged in the clamp, the inclined surface of the clamp tightly clamps the inclined surface of the reinforcing piece (4), and the clamp is self-locked in the tensioning process and is prevented from locally deforming. The device is applied to multiple stress-strain tests of the hyper-elastic material such as uniaxial tension, equally biaxial tension and planar tension (pure shear). Stress data is acquired by a data acquisition system of an electronic universal testing machine, and the strain data is acquired by a charge coupled device (CCD) image acquisition device. Due to the technical scheme, the clamping force is high when the tension is high in the process of tensioning the test piece, so that the test piece is uniformly stressed, more accurate testing data can be obtained, and the mechanical property parameters of the hyper-elastic material obtained accordingly are more reliable.

Owner:TSINGHUA UNIV

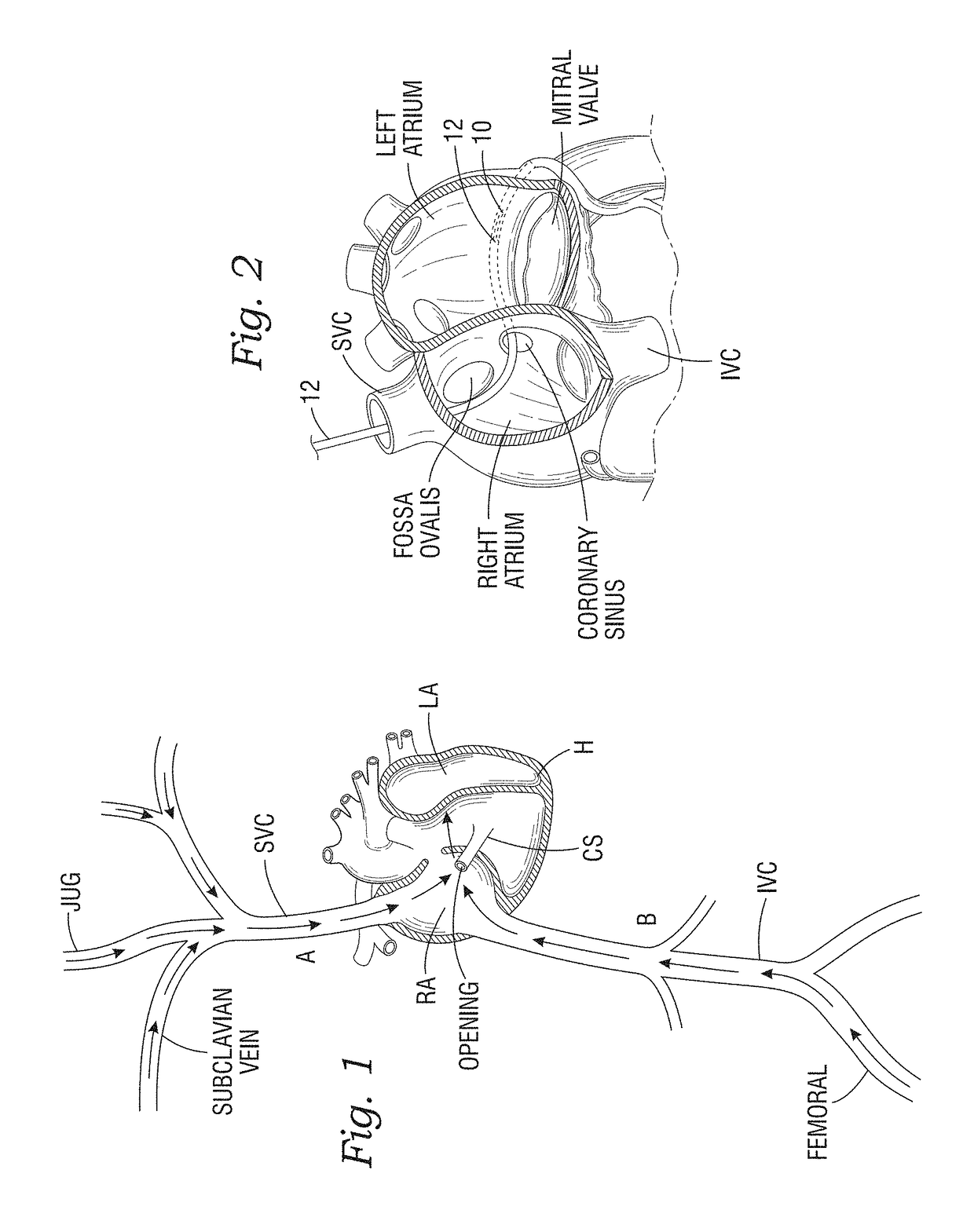

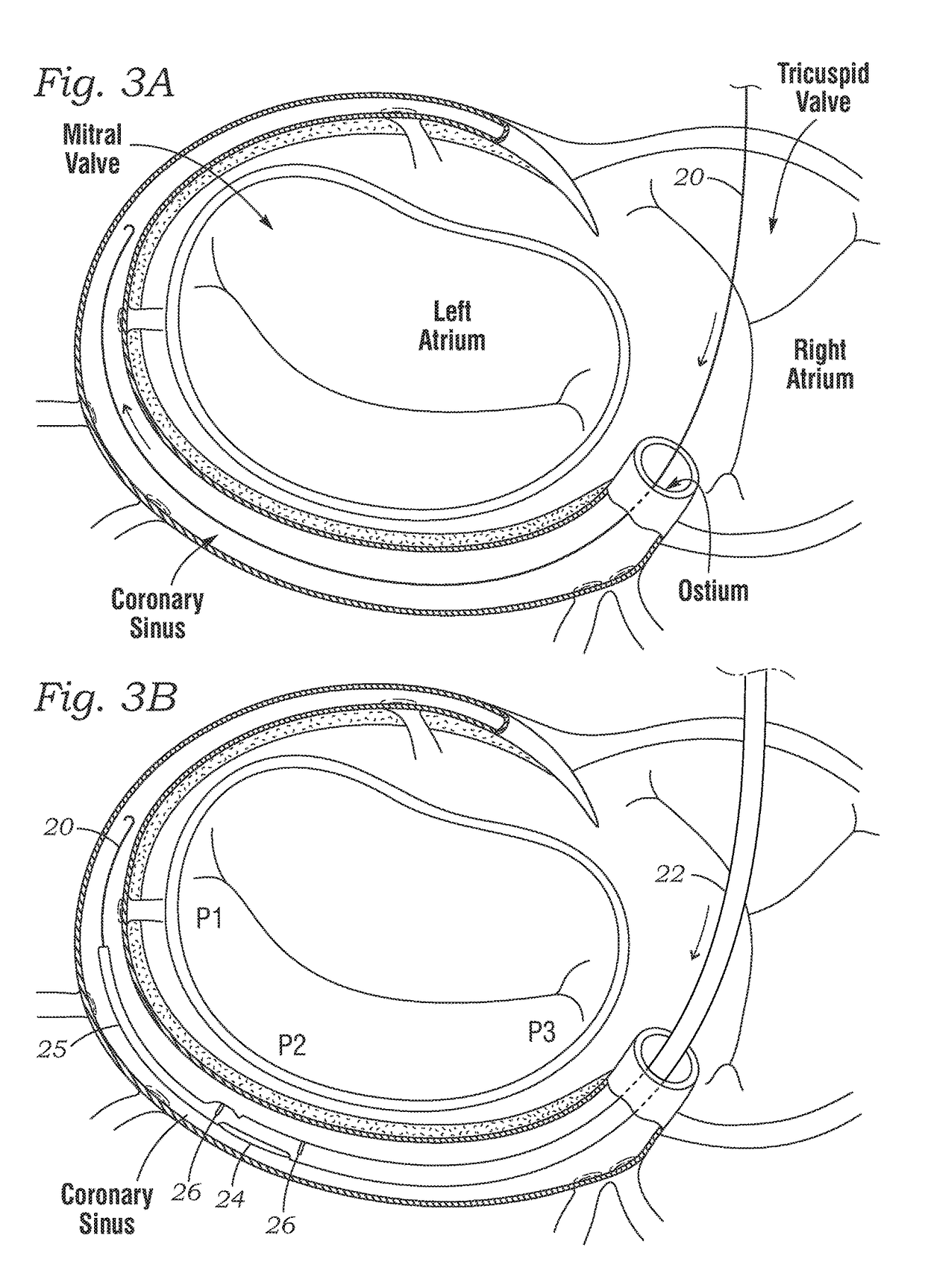

Expandable cardiac shunt

Disclosed are cardiac shunts and method of delivery, and in particular, to a shunt to reduce elevated left atrial pressure (LAP). The methods include forming a puncture hole between the left atrium and the coronary sinus, widening the puncture hole, and placing an expandable shunt within the widened puncture hole. A first catheter having a side-extending needle may be used to form a puncture into the left atrium. A second catheter extends along a guidewire and an expandable shunt with distal and proximal flanges is expelled therefrom into the puncture. The shunt defines a blood flow passage therethrough that permits shunting of blood from the left atrium to the coronary sinus when the LAP is elevated. The shunt is desirable formed of a super-elastic material and manipulated with control rods. The shunt defines a tilted flow tube that facilitates collapse into the catheter.

Owner:EDWARDS LIFESCIENCES CORP

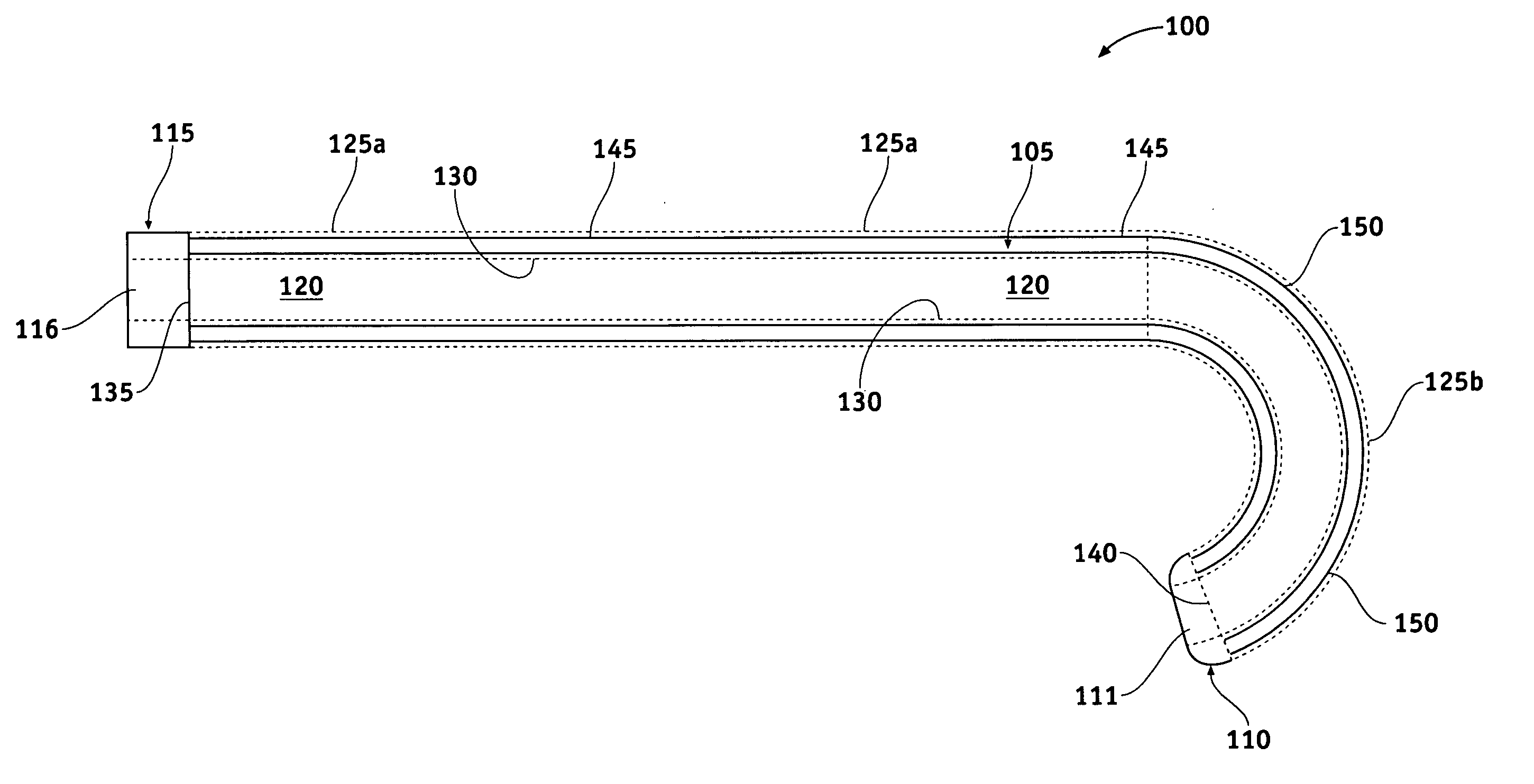

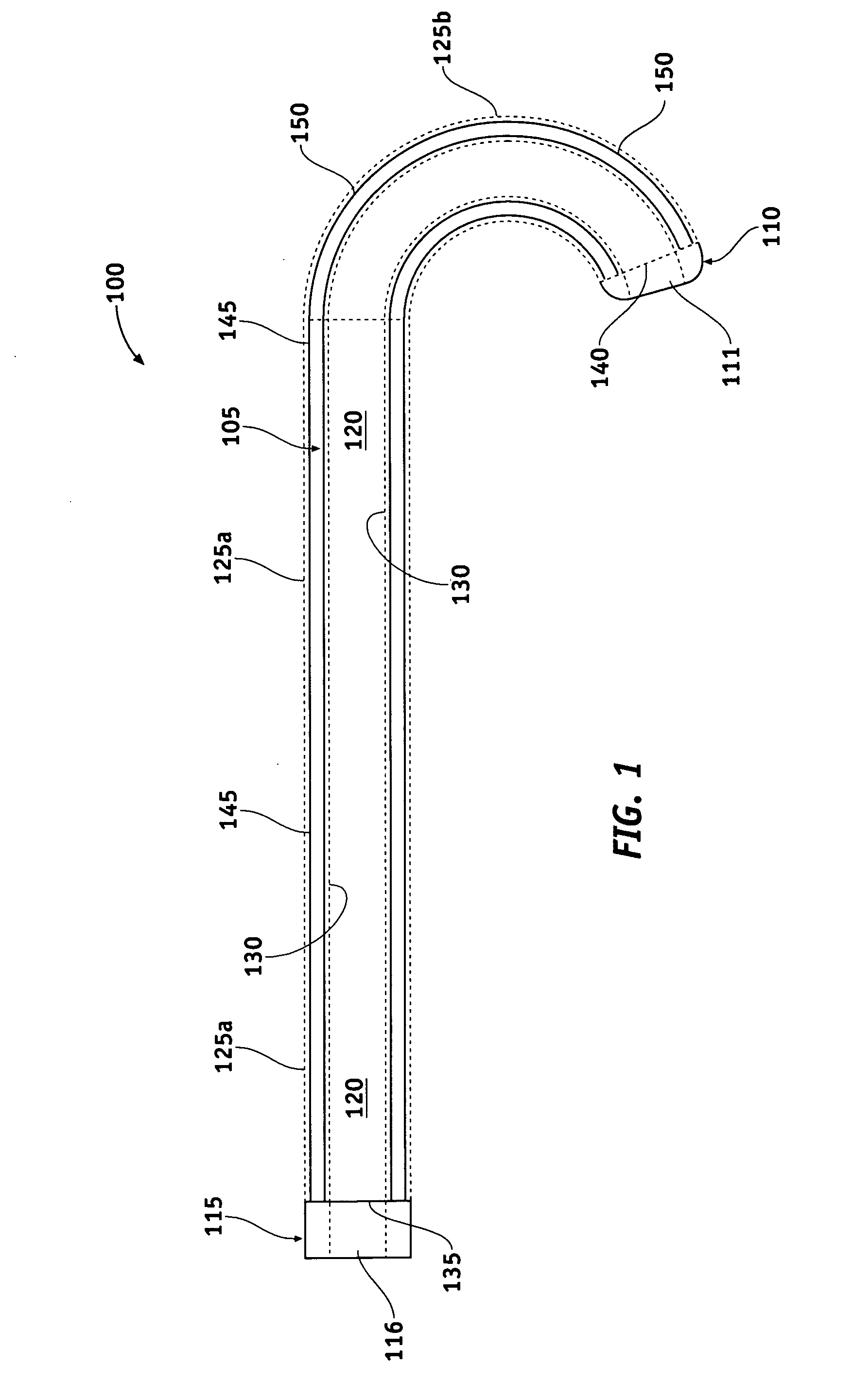

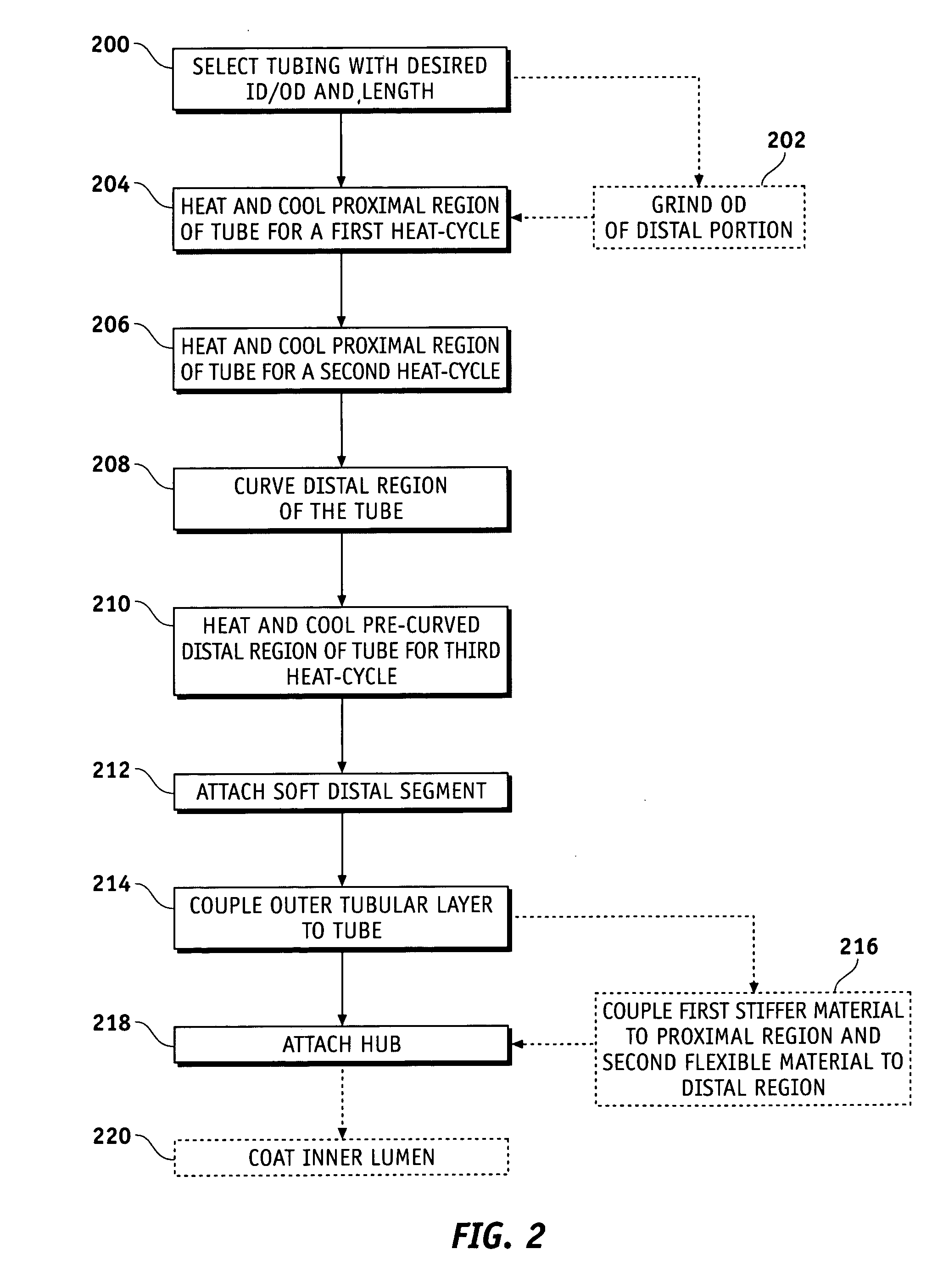

Curved catheter comprising a solid-walled metal tube with varying stiffness

InactiveUS20060074403A1Improve performanceImprove simplicityMedical devicesCatheterCurve shapePhysical property

A curved catheter comprising a solid-walled metal tube with varying stiffness along it length. The catheter includes a tube comprising material capable of being variably heat-treated to set different physical properties along the length of the tube. The tube has a distal region with a pre-curved shape, a proximal region, distal and proximate ends, and a lumen there through. The proximal region is configured to be flexible at a first temperature and to become stiffer at a second temperature, the second temperature being higher than the first temperature. The material for the tube may be a superelastic material, such as nitinol. The superelastic material may also be capable of deformation of the pre-curved shape at the first temperature and recovery of the pre-curved shape at the second temperature. Methods of making the catheter are also disclosed.

Owner:MEDTRONIC VASCULAR INC

Endodontic instrument and method of manufacturing

InactiveUS20100233648A1Good curative effectReduce in quantitySurgeryWheelchairs/patient conveyanceENDODONTIC PROCEDURESEngineering

An endodontic instrument and method for making same is provided. A rod of superelastic material is set into a shaped configuration to form an instrument, such that the instrument may be inserted into a root canal in a configuration different than the shaped configuration and revert towards its shaped configuration during the endodontic procedure.

Owner:FERBER MARK S

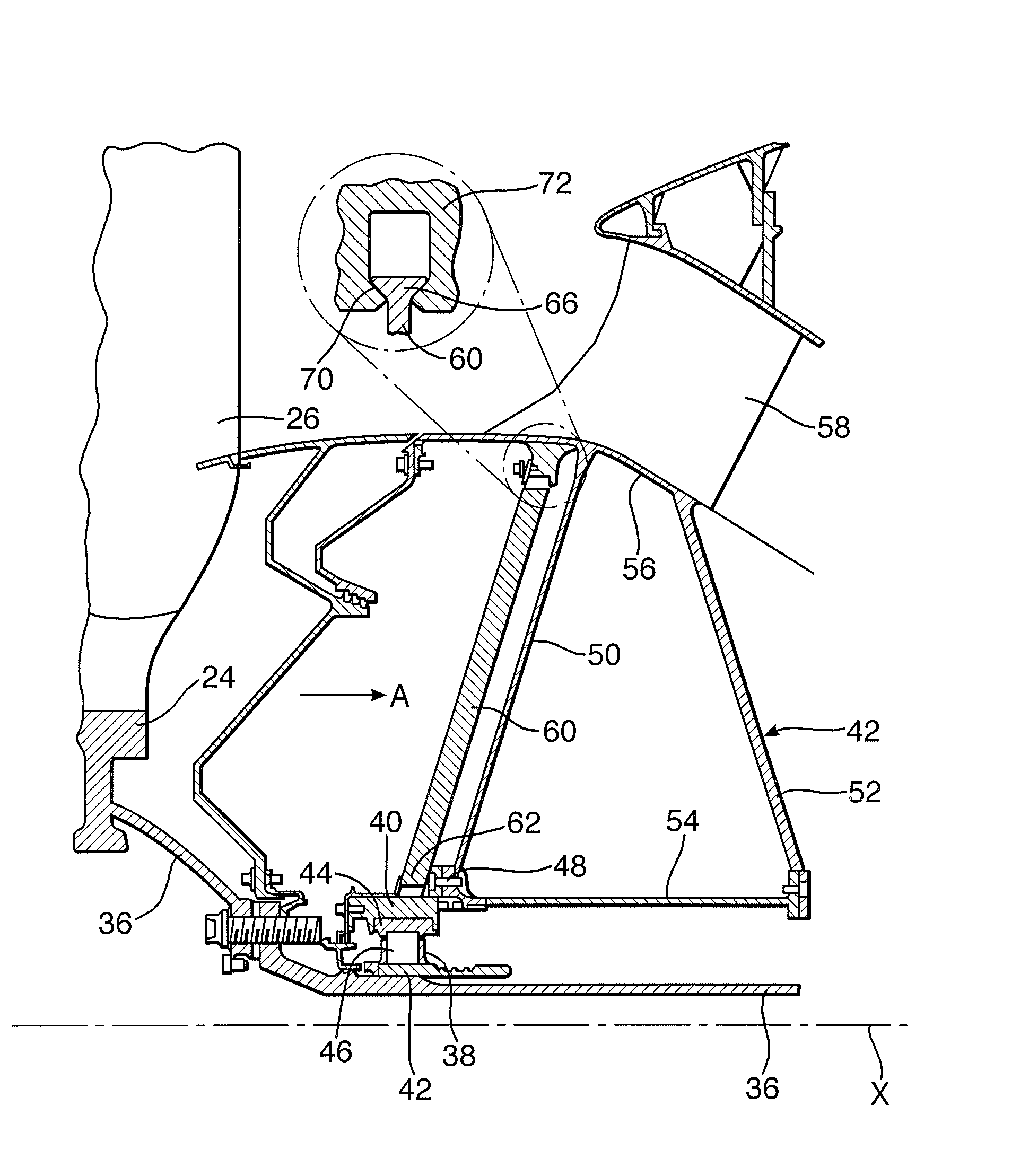

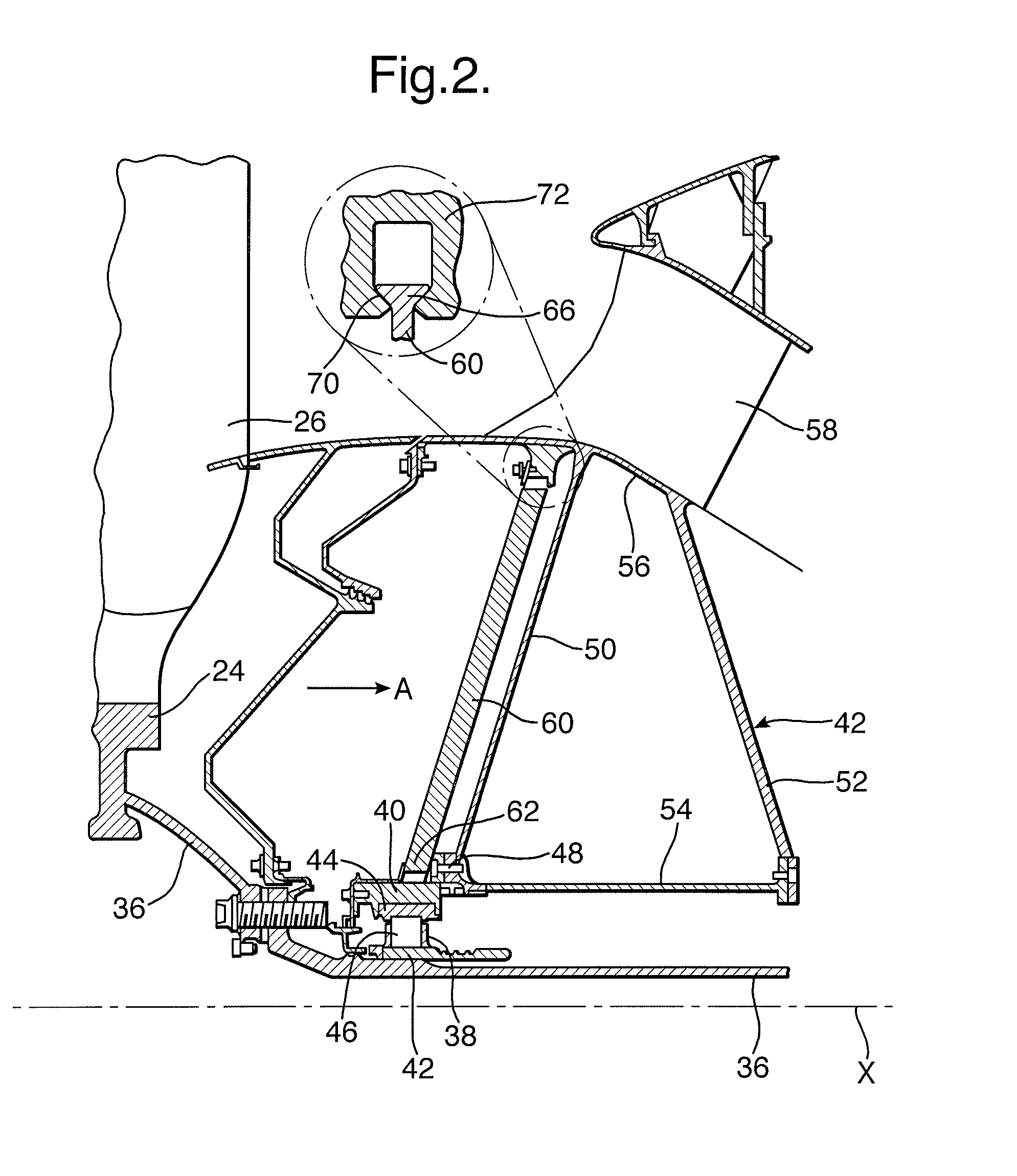

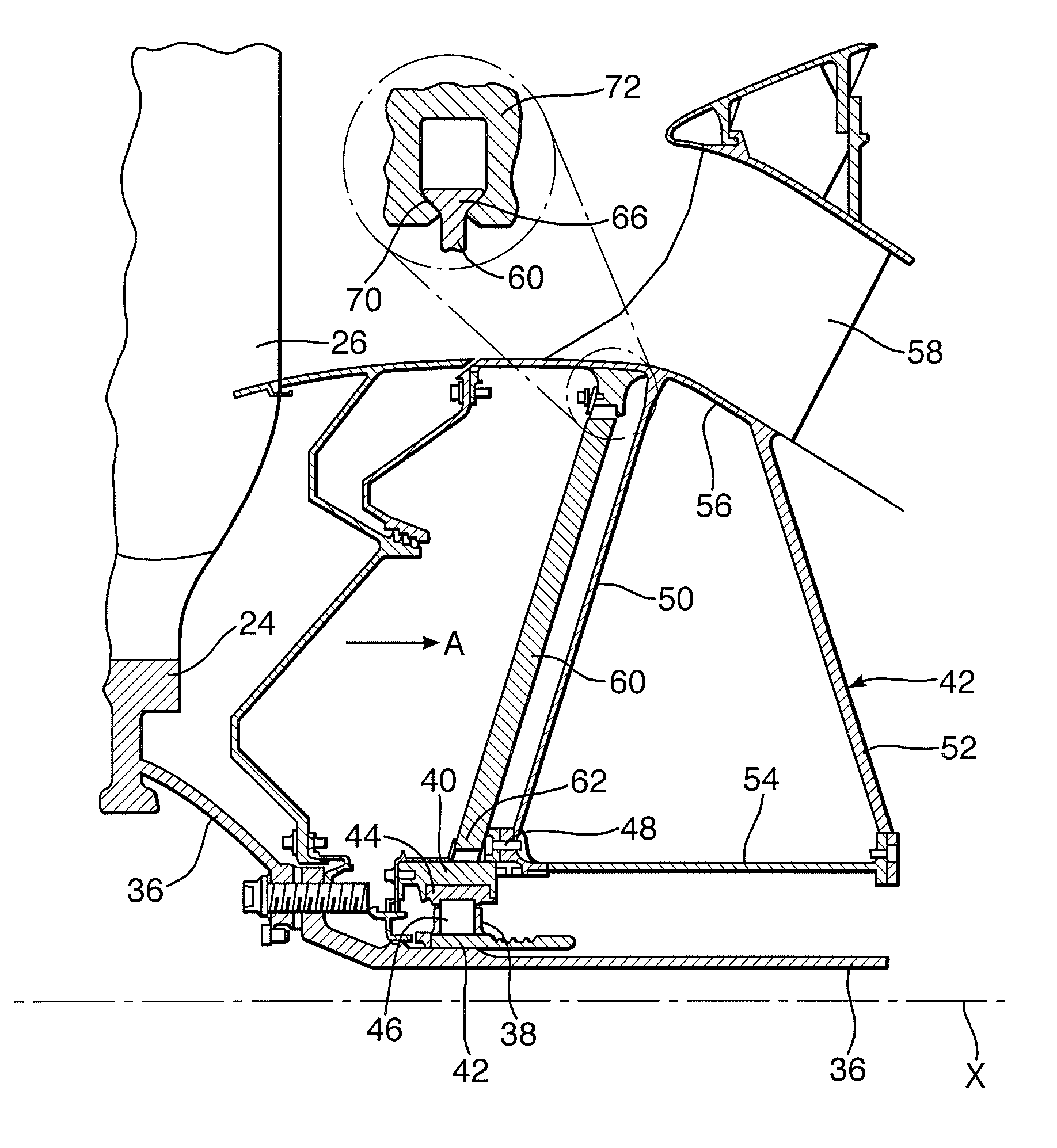

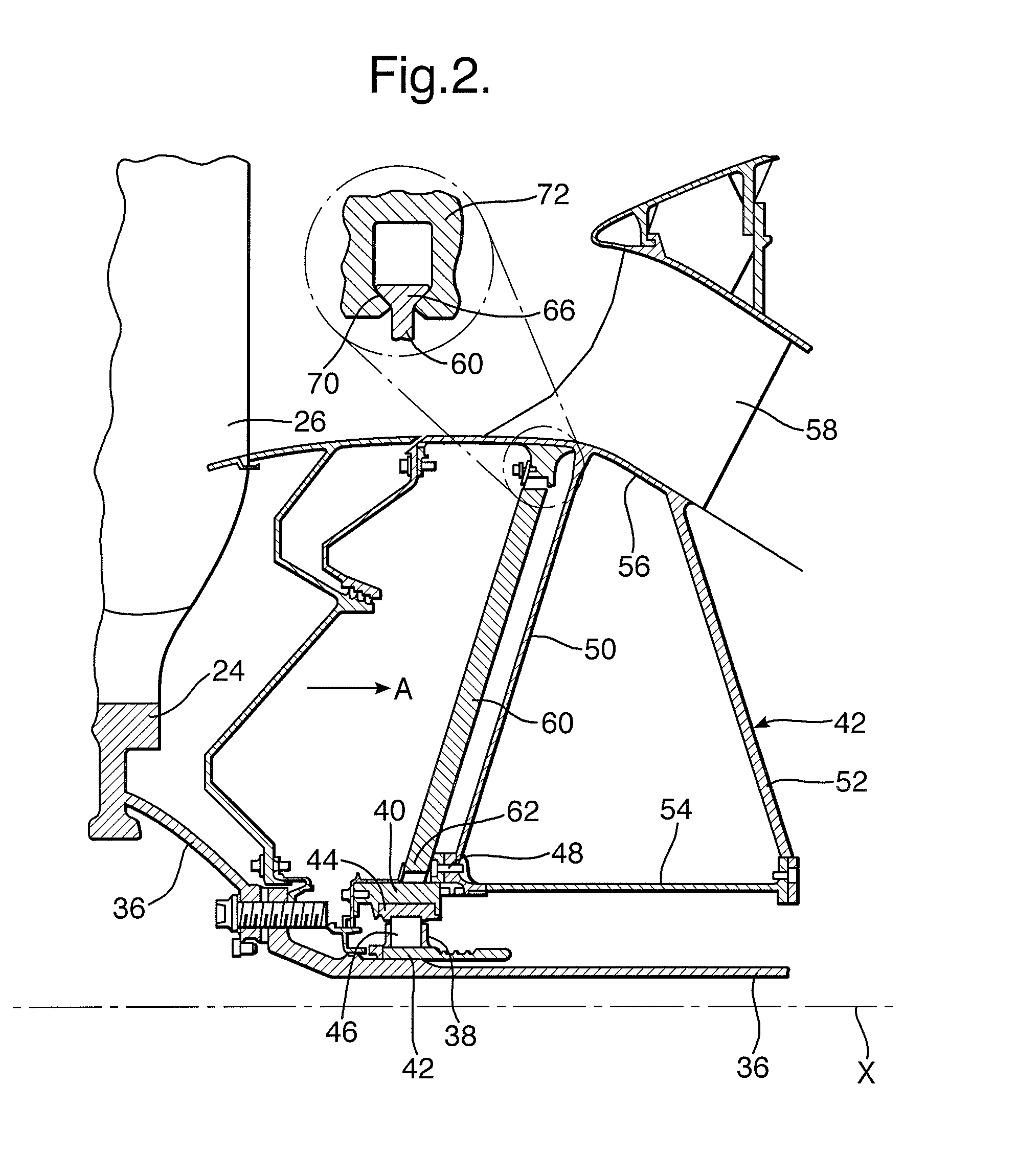

Turbofan gas turbine engine

ActiveUS20080181763A1Weight increaseStiff structureRoller bearingsEngine manufactureRotational axisEngineering

In a turbofan gas turbine engine, a fan shaft is rotatably mounted and radially supported by a bearing in a bearing support structure supported from a fixed engine structure by radially frangible bolts and radially extending spokes. The radially inner ends of the radially extending spokes are mounted on a common member that engages the bearing support structure. The radially outer ends of the radially extending spokes are mounted on a fixed engine structure located radially outwardly of the bearing support structure. The radially extending spokes are held in tension and include a super elastic material to exert a radially inward restoring force on the bearing support structure, subsequent to any radial excursion of at least part of the fan shaft relative to an engine rotational axis (X) following any fracture of the frangible bolts.

Owner:ROLLS ROYCE PLC

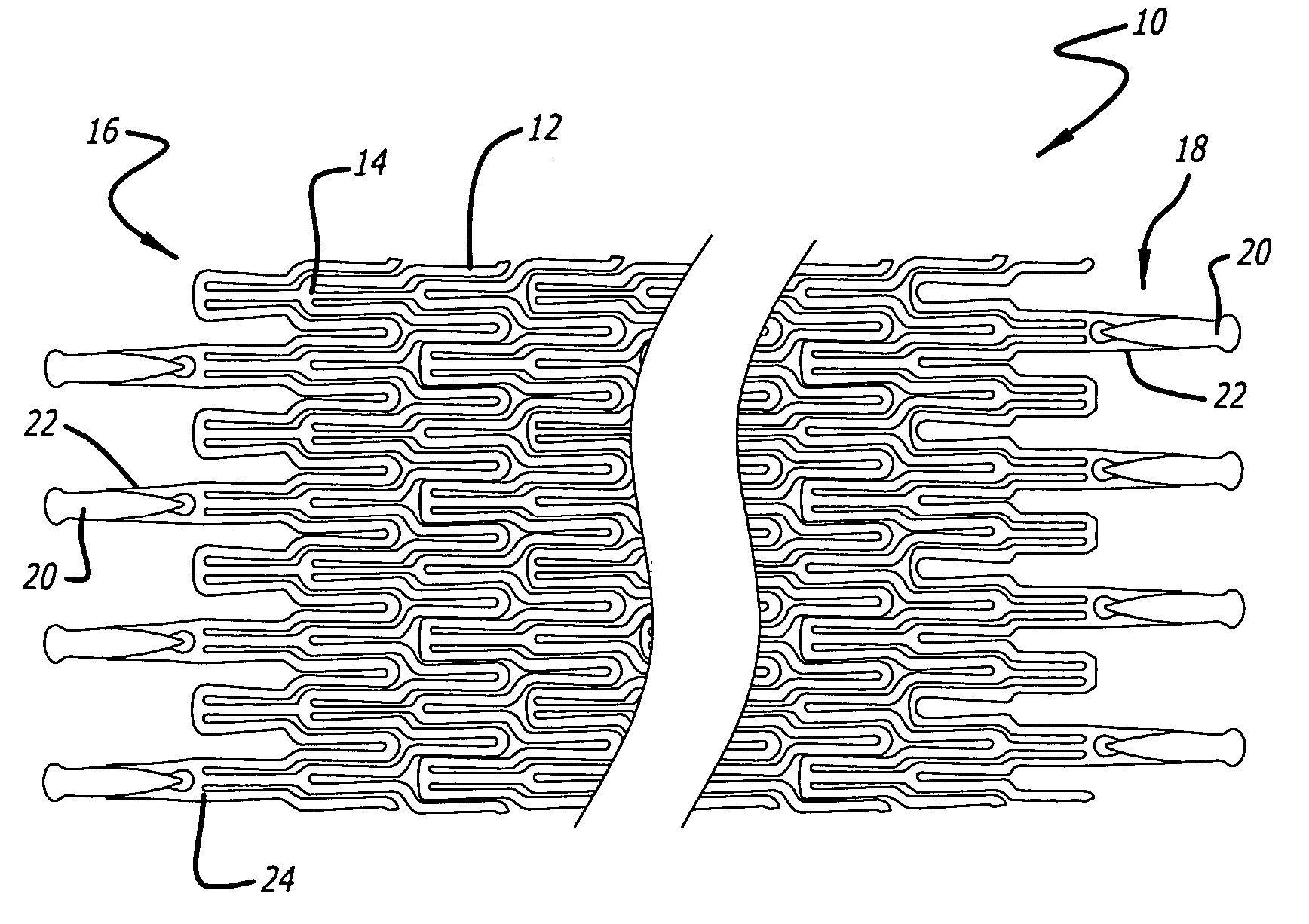

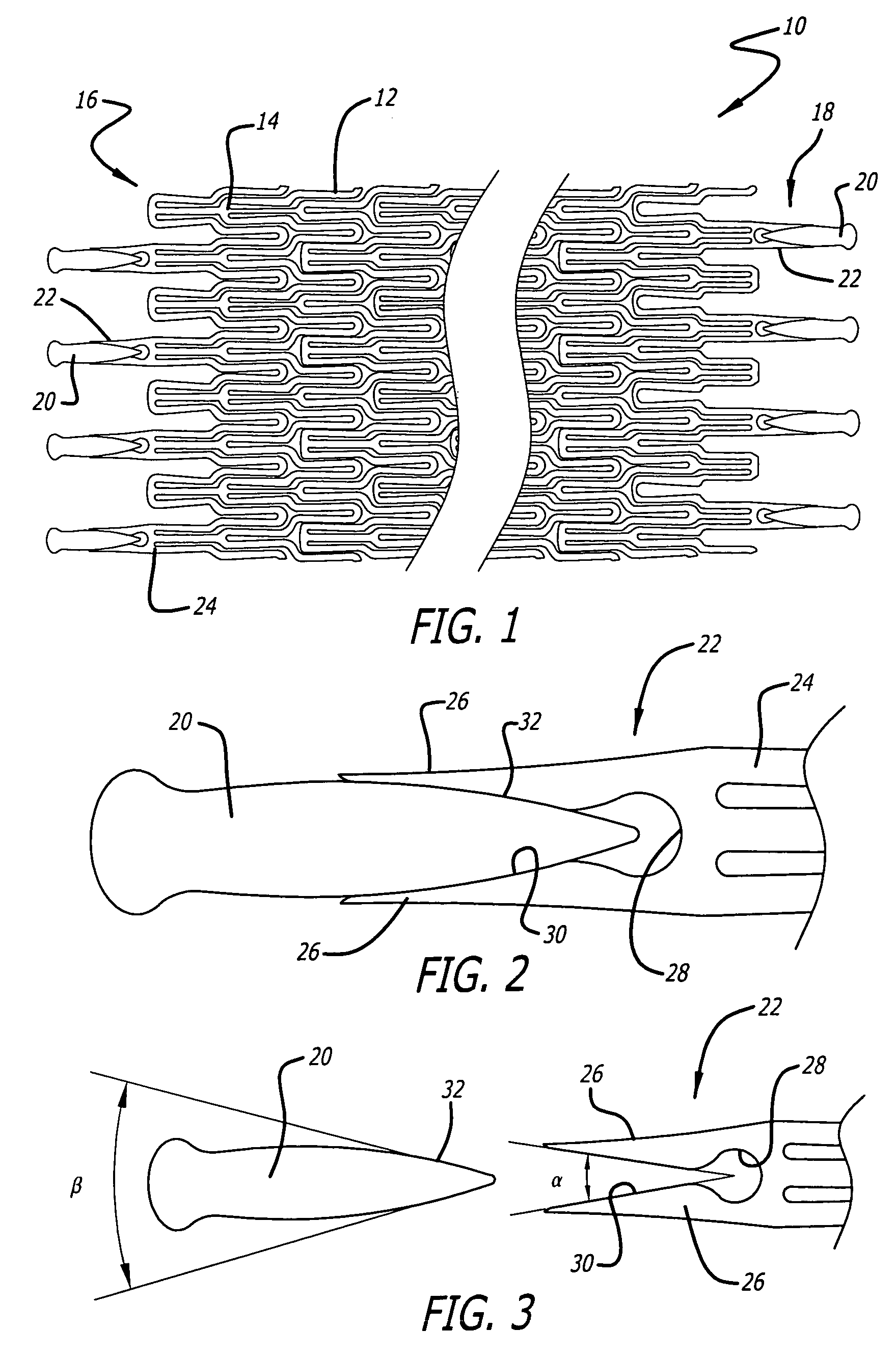

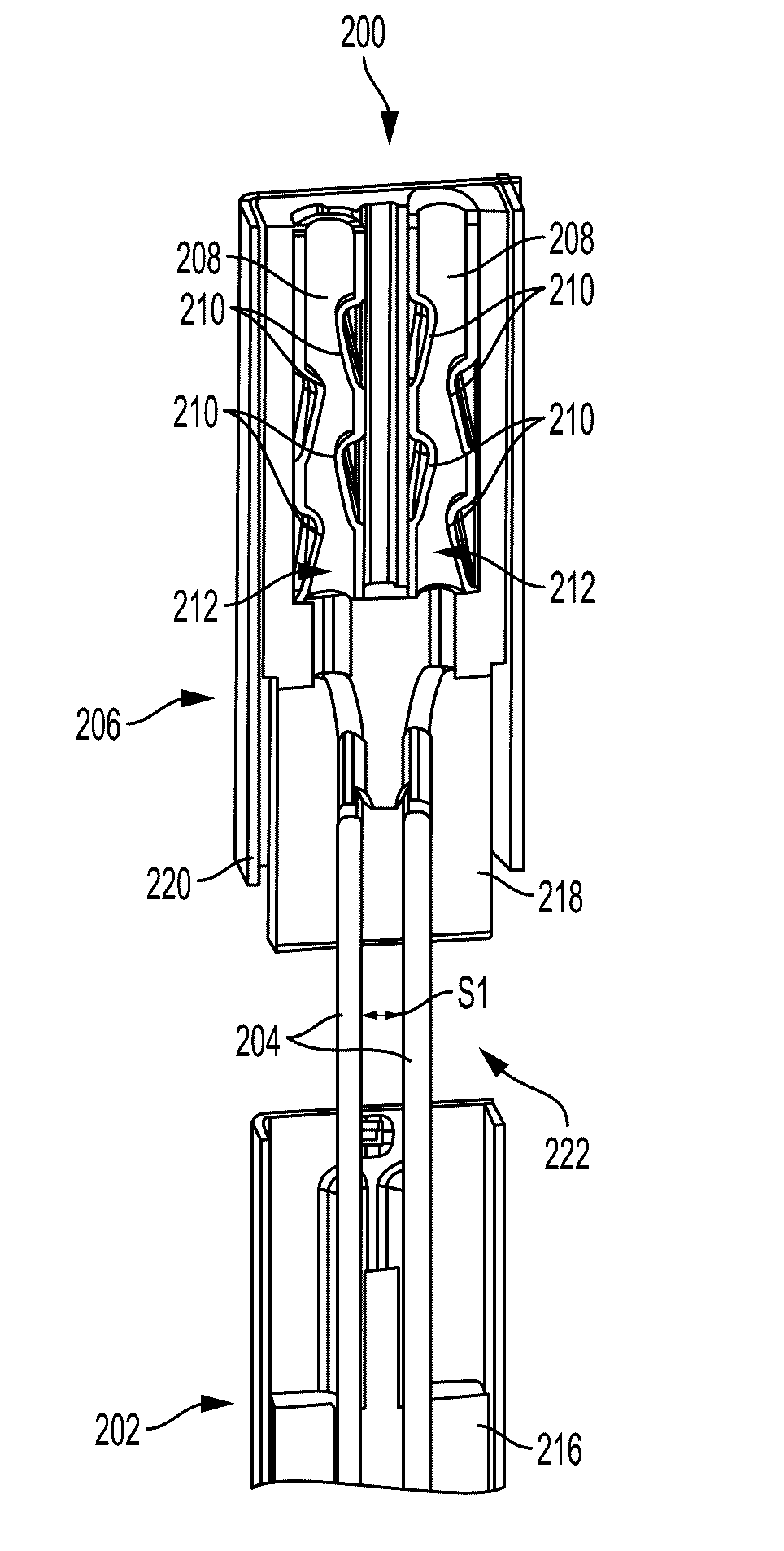

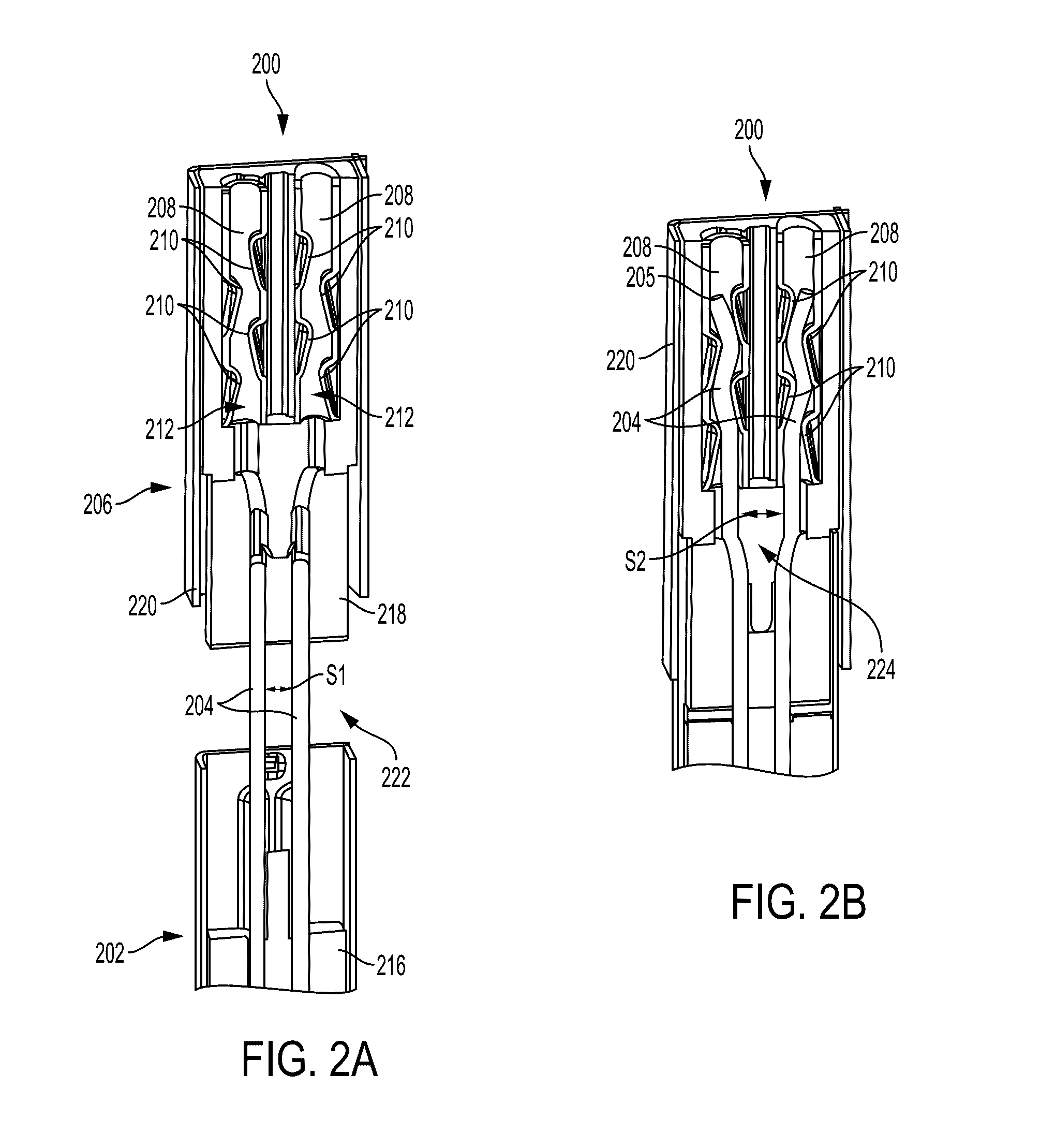

Electrical connectors

ActiveUS20160308296A1Improve performanceEnhanced signalSecuring/insulating coupling contact membersCoupling contact membersHigh densityEngineering

Embodiments related to electrical connectors including superelastic components are described. The high elastic limit of superelastic materials compared to conventional connector materials may allow for designs which provide reliable connections and high frequency operation. Superelastic components also may enable connector designs with higher densities of connections. In some embodiments, a connector includes one or more superelastic elongated members forming the mating contacts of the connector. The superelastic elongated members deform within one or more conductive receptacles to generate a suitable contact force. The conductive receptacles may include a plurality of protrusions arranged to deflect the superelastic elongated members during mating. A superelastic component may also be provided in a receiving portion of a connector, and may form a portion of a conductive receptacle.

Owner:AMPHENOL CORP

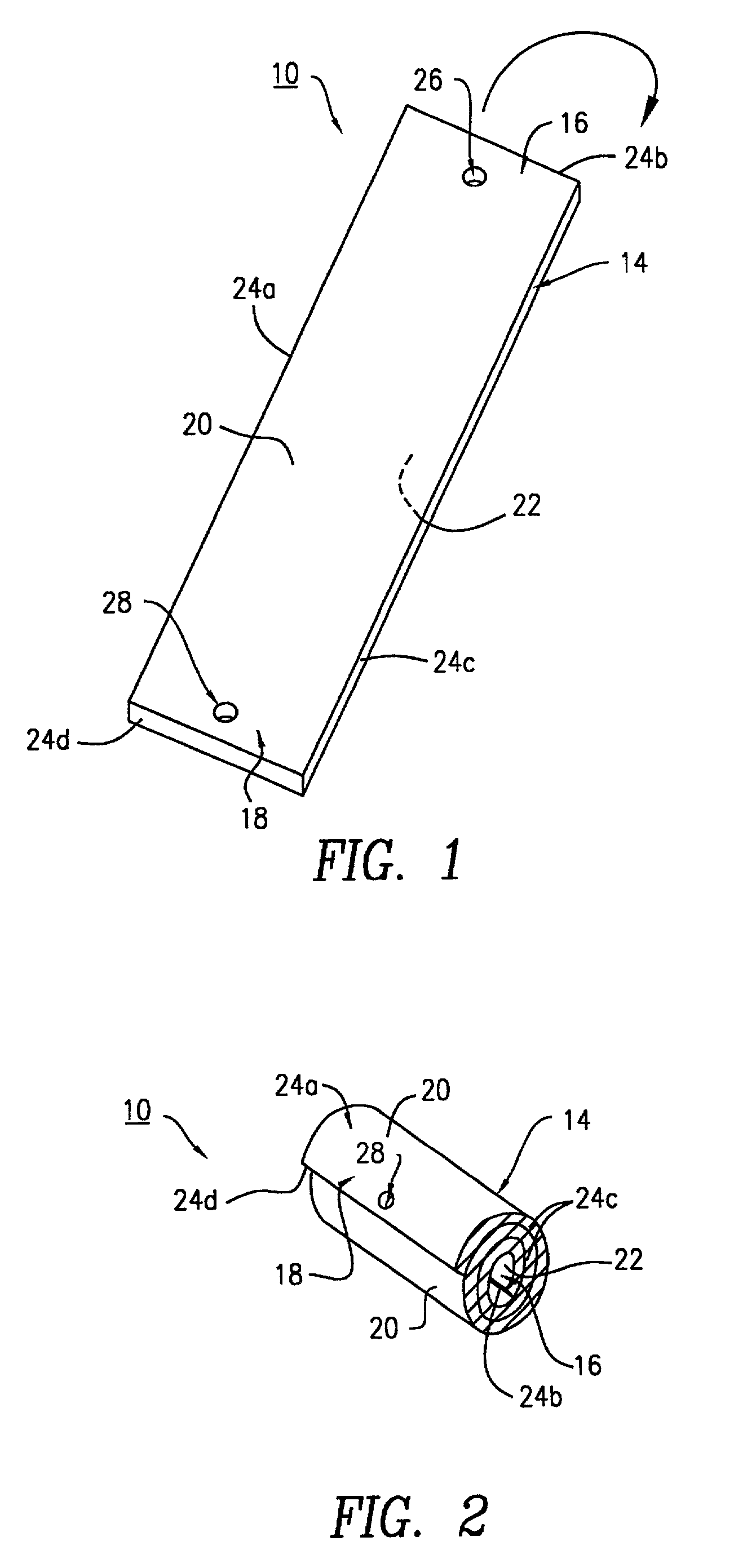

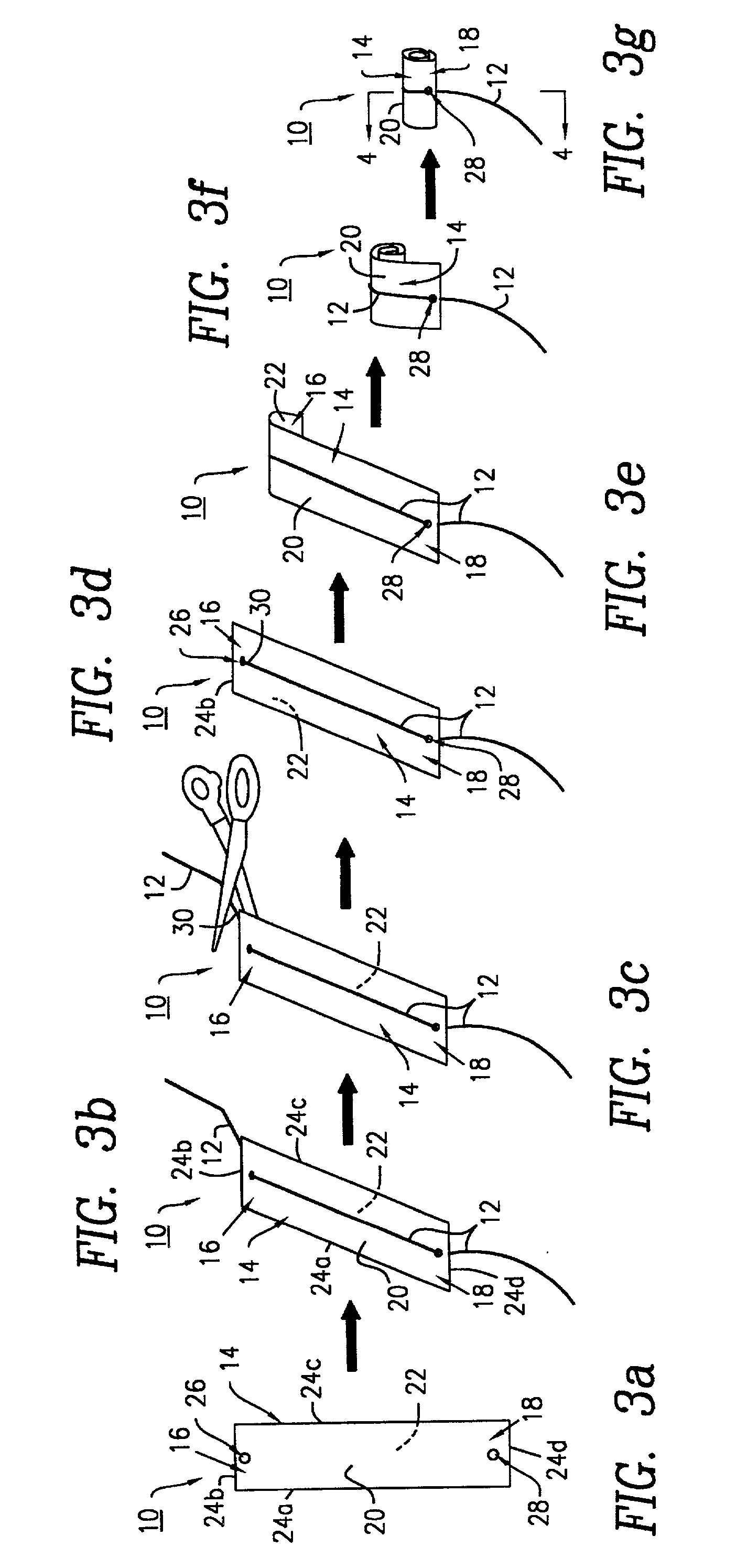

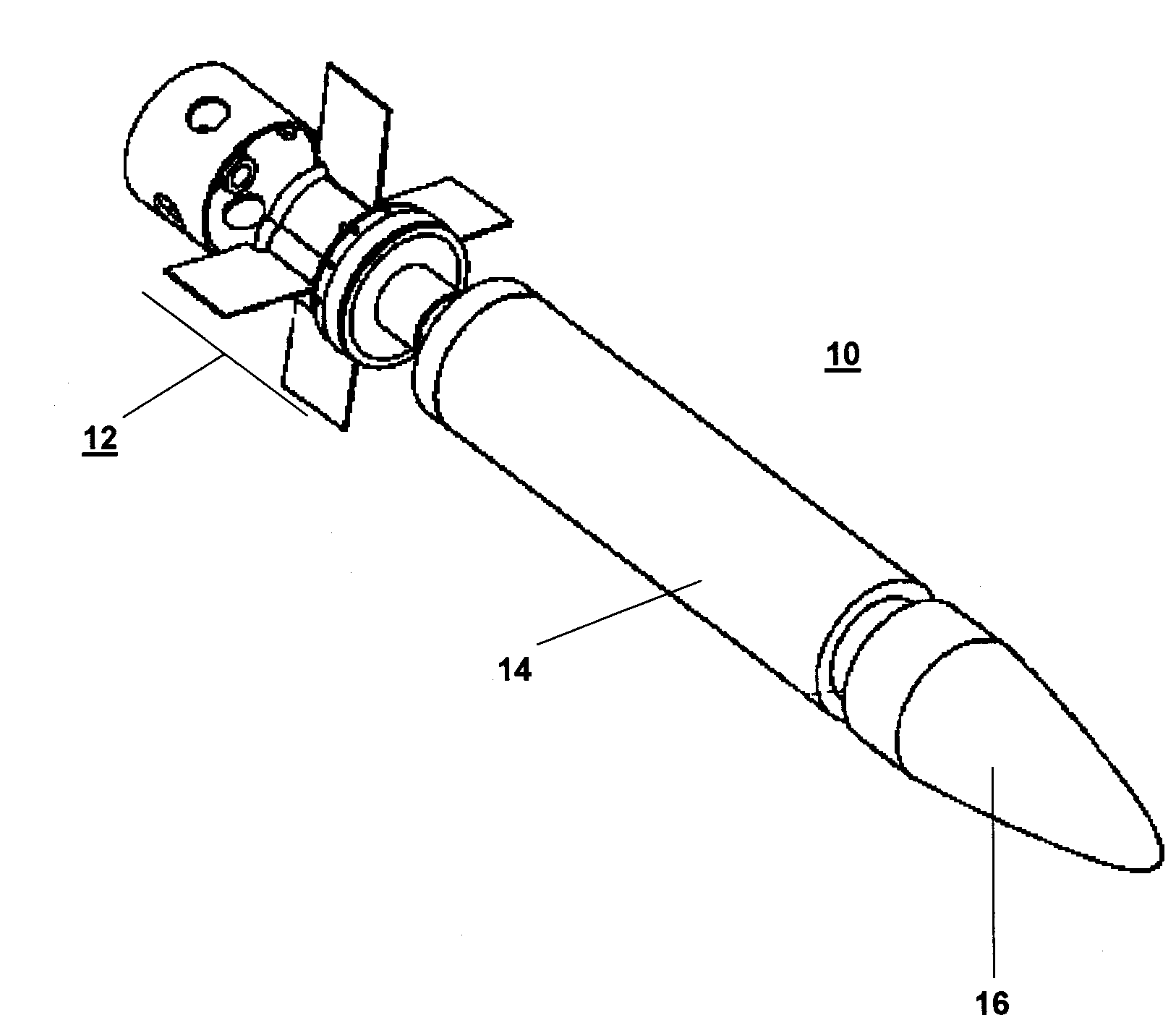

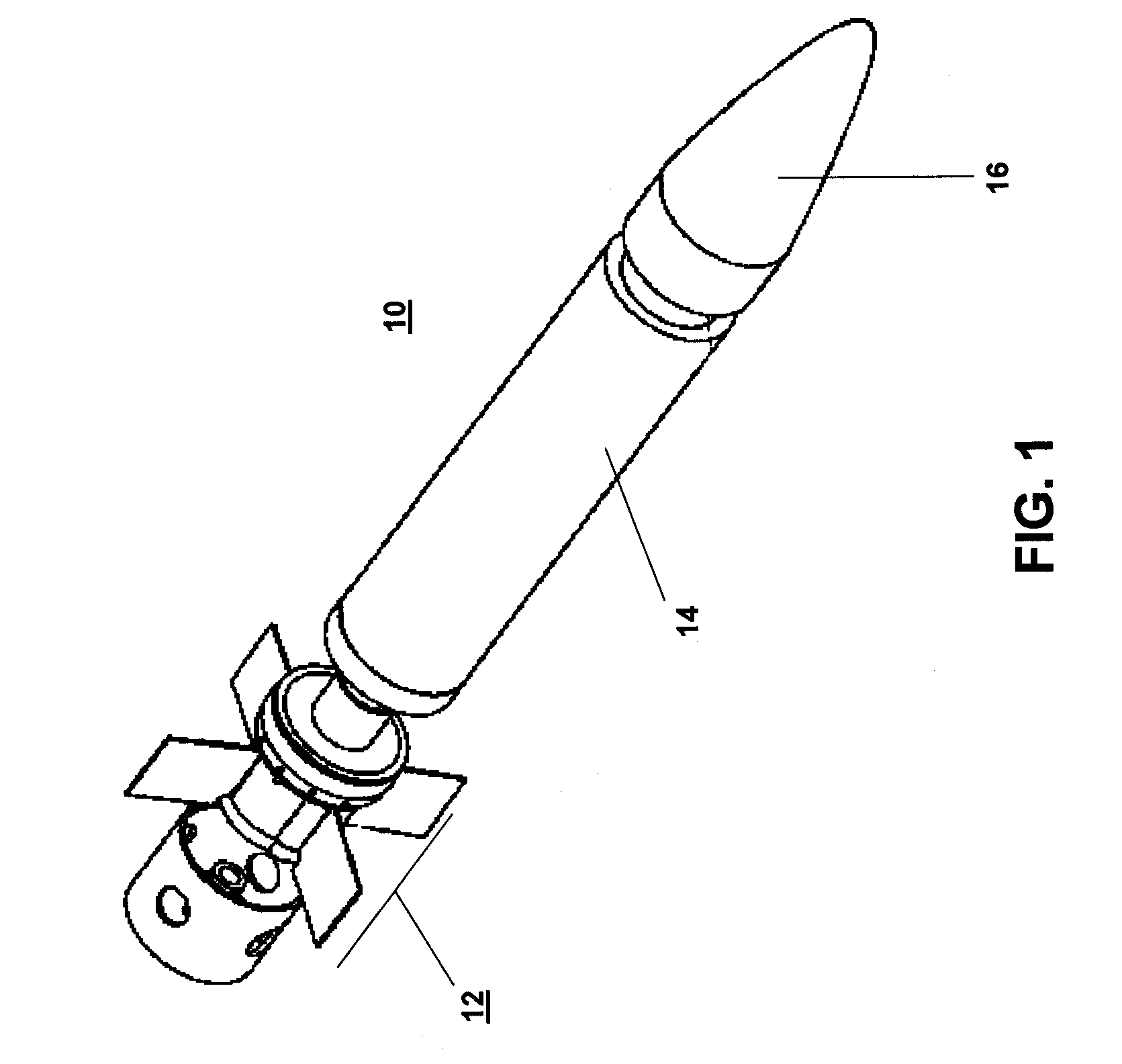

Space saving fin deployment system for munitions and missiles

InactiveUS6978967B1Substantial space savingIncreasing onboard towing capacityFall bombsSelf-propelled projectilesMarine engineeringLethality

A fin deployment system for missiles and munitions that deploys and activates straight flat fins for roll control authority. The fin deployment system employs numerous design features, among which are the following: A wrap-around fin concept generates space-savings within a projectile body whereby the fins are arranged in a wrapped configuration around a boomtail structure. The fins may be constructed of a super-elastic material; the system eliminates mechanical means of deploying the wrapped fins, eliminating the need for springs to deploy the fins. The fin deployment achieves substantial space savings for increasing the onboard towing capacity of electronic packaging or lethality in the missiles and munitions systems, while at the same time providing a good roll control authority during flight by enabling a straight fin deployment resulting from the use of super-elastic materials.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

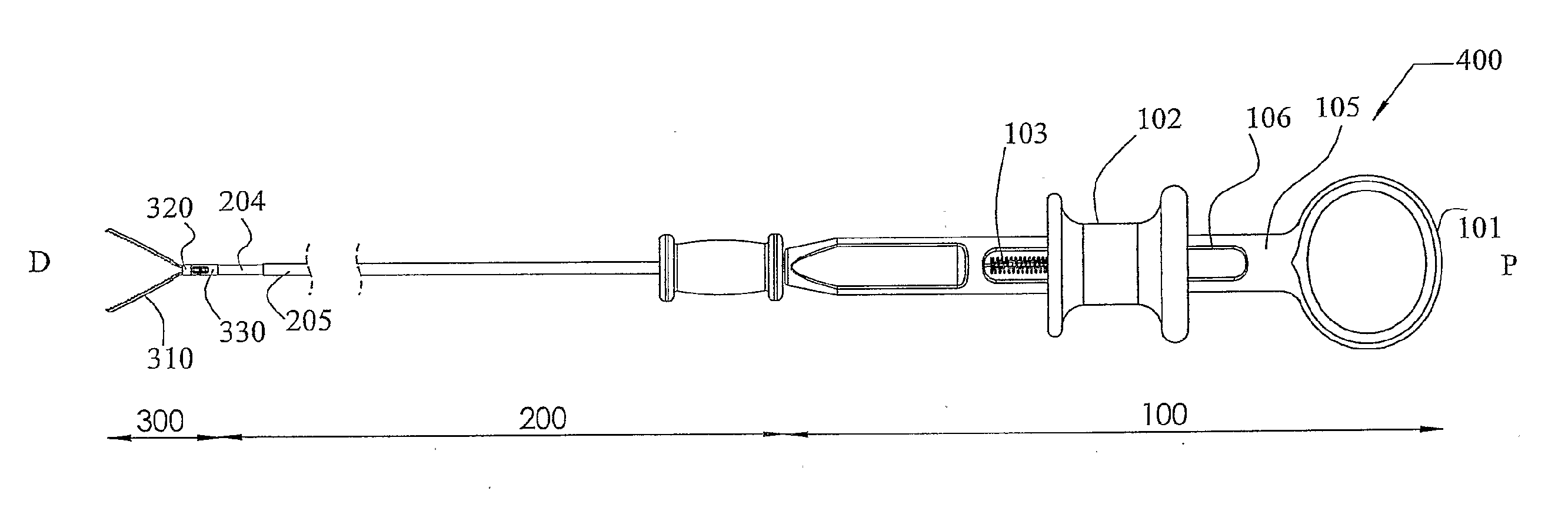

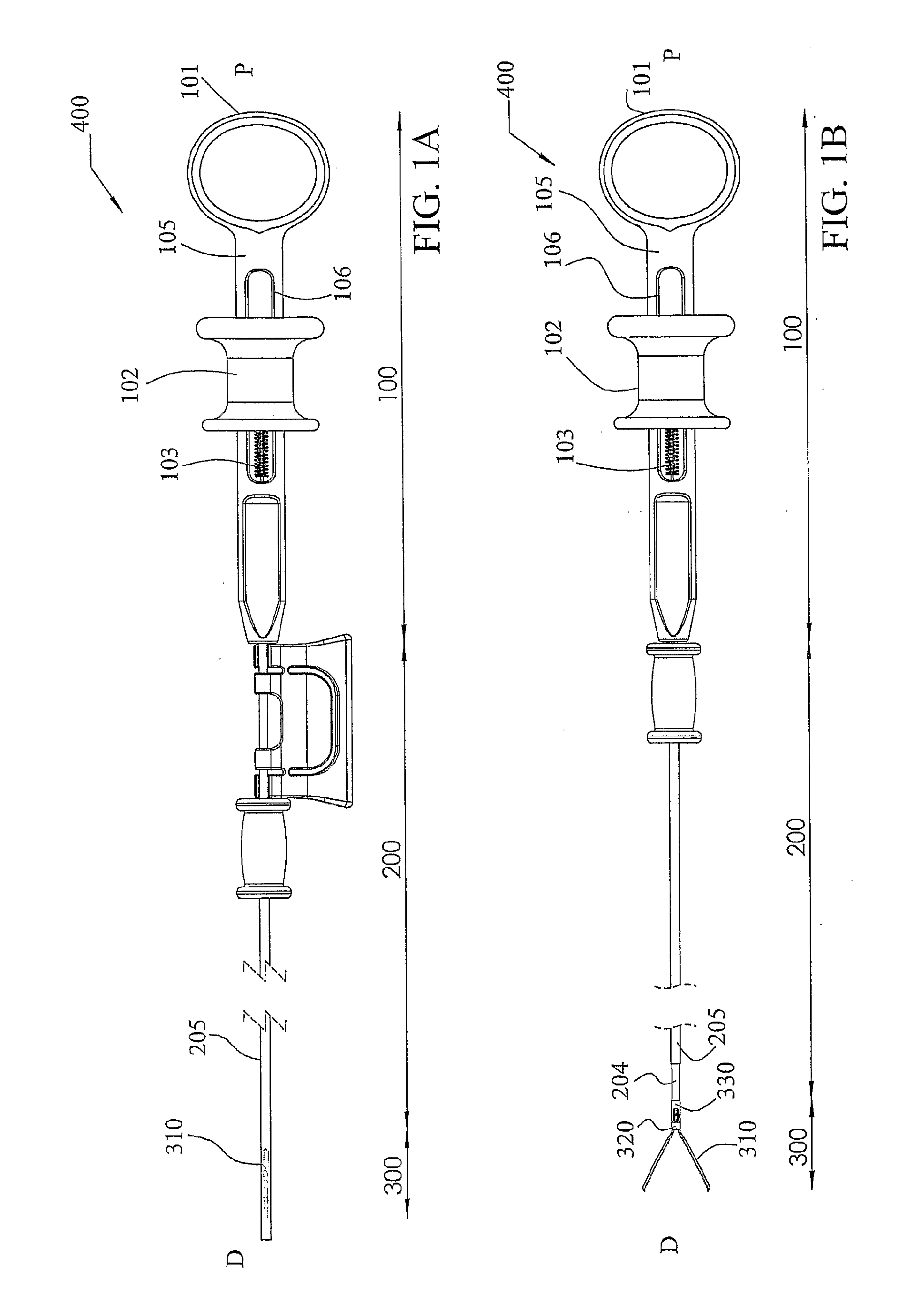

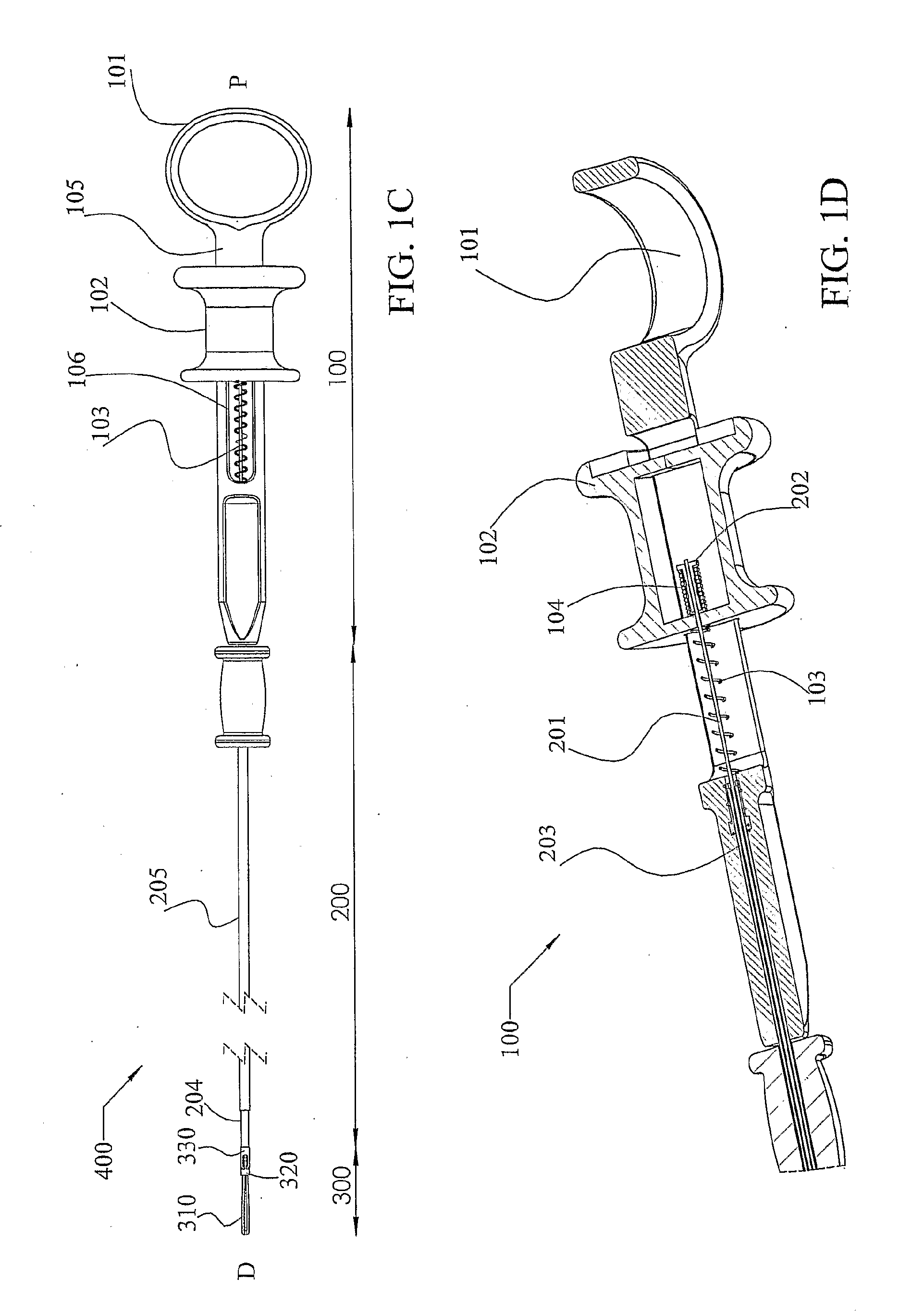

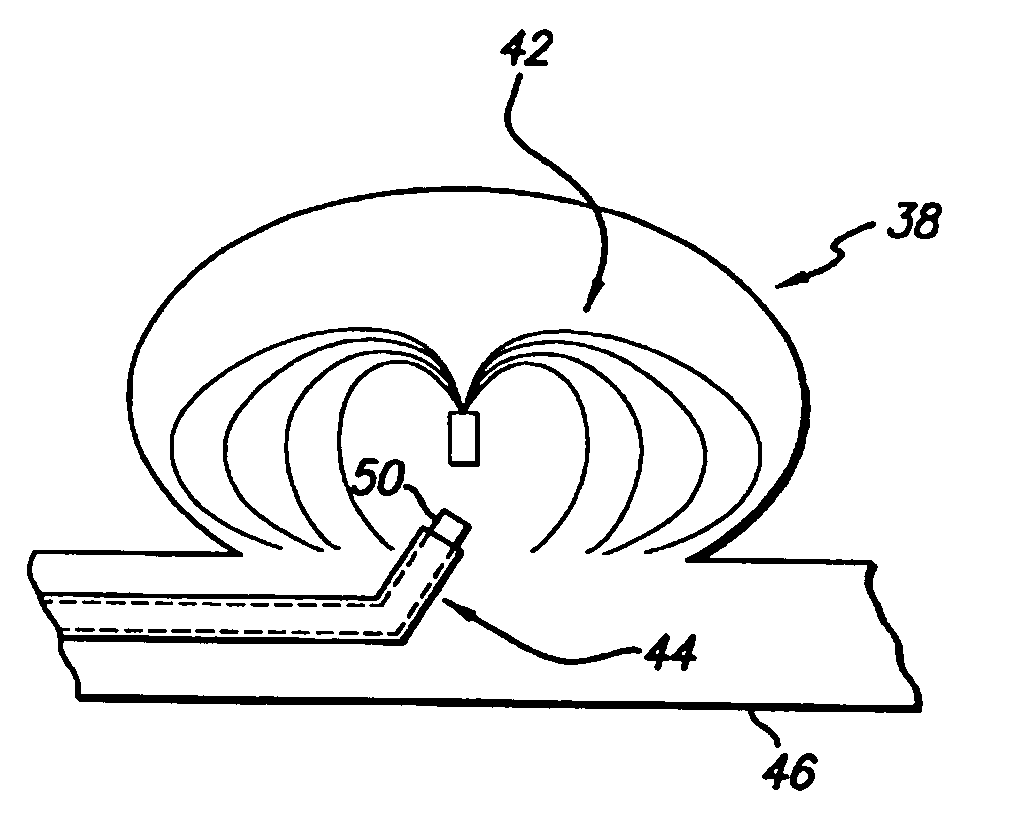

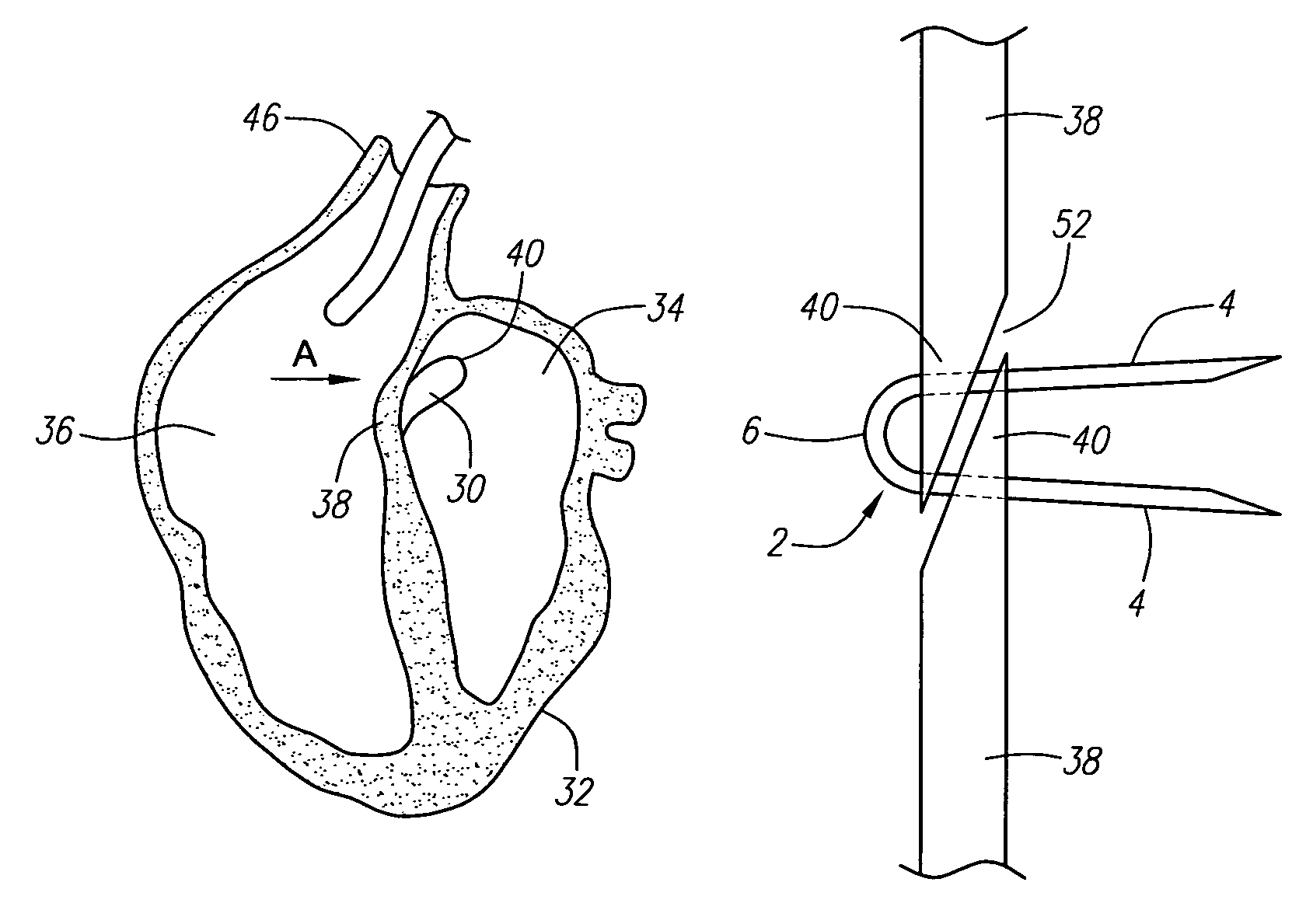

Clip apparatus for closing septal defects and methods of use

InactiveUS7740640B2Limited advancementSuture equipmentsSurgical needlesBiomedical engineeringPatent foramen ovale

A device for closing a septal defect, such as a patent foramen ovale, includes a clip formed from a superelastic material that is inserted into a septum wall of a heart. The clip is advanced through a patient's vasculature, e.g., within a delivery apparatus, until the clip is disposed within a first chamber adjacent the septal defect. Tines of the clip are directed through a flap of tissue of the septal defect until the tines of the clip are disposed within a second opposing chamber. The clip then transforms into its relaxed state, wherein the tines of the clip engage with a surface of the second chamber, thereby substantially closing the septal opening.

Owner:PROMED

Turbofan gas turbine engine

In a turbofan gas turbine engine, a fan shaft is rotatably mounted and radially supported by a bearing in a bearing support structure supported from a fixed engine structure by radially frangible bolts and radially extending spokes. The radially inner ends of the radially extending spokes are mounted on a common member that engages the bearing support structure. The radially outer ends of the radially extending spokes are mounted on a fixed engine structure located radially outwardly of the bearing support structure. The radially extending spokes are held in tension and include a super elastic material to exert a radially inward restoring force on the bearing support structure, subsequent to any radial excursion of at least part of the fan shaft relative to an engine rotational axis (X) following any fracture of the frangible bolts.

Owner:ROLLS ROYCE PLC

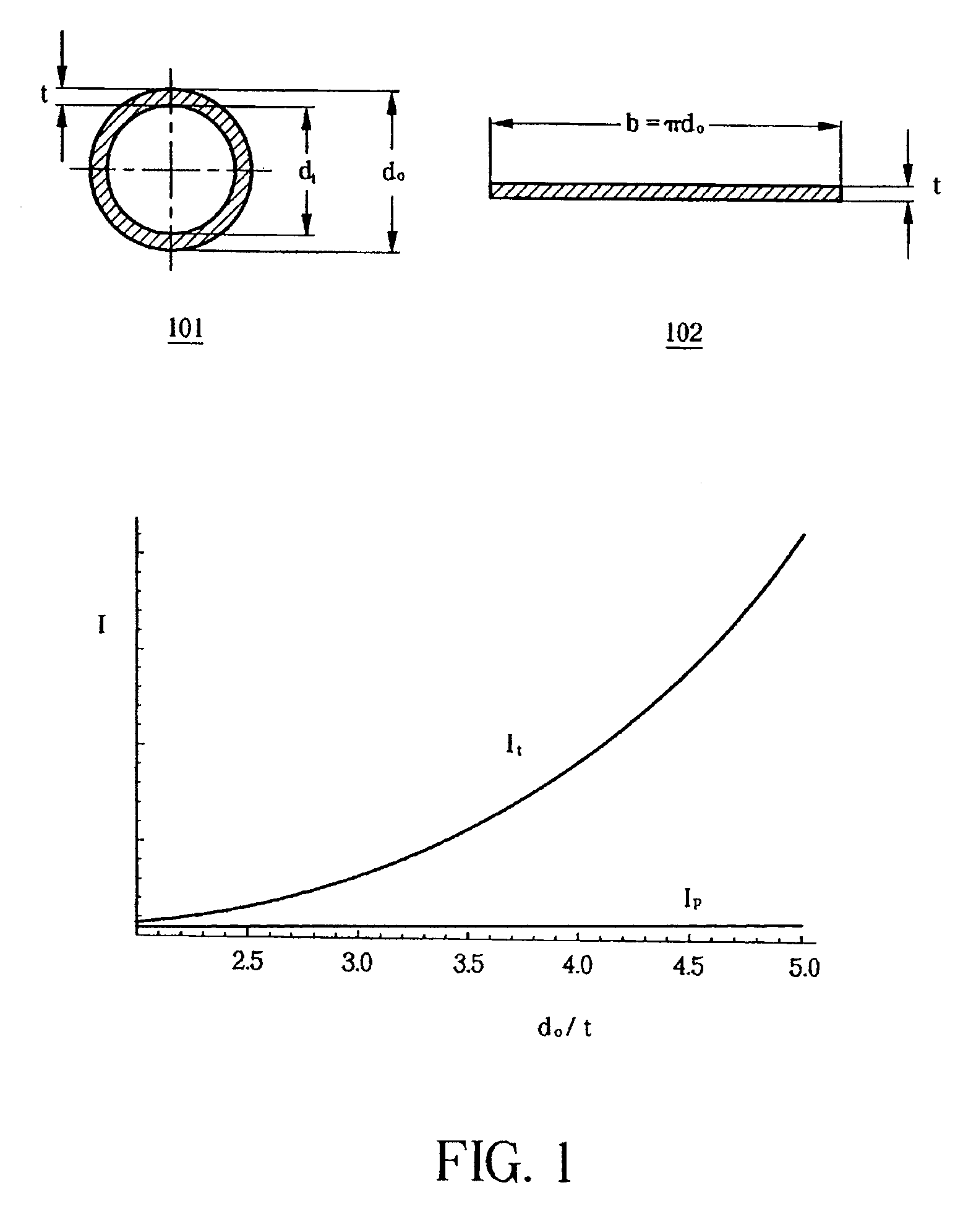

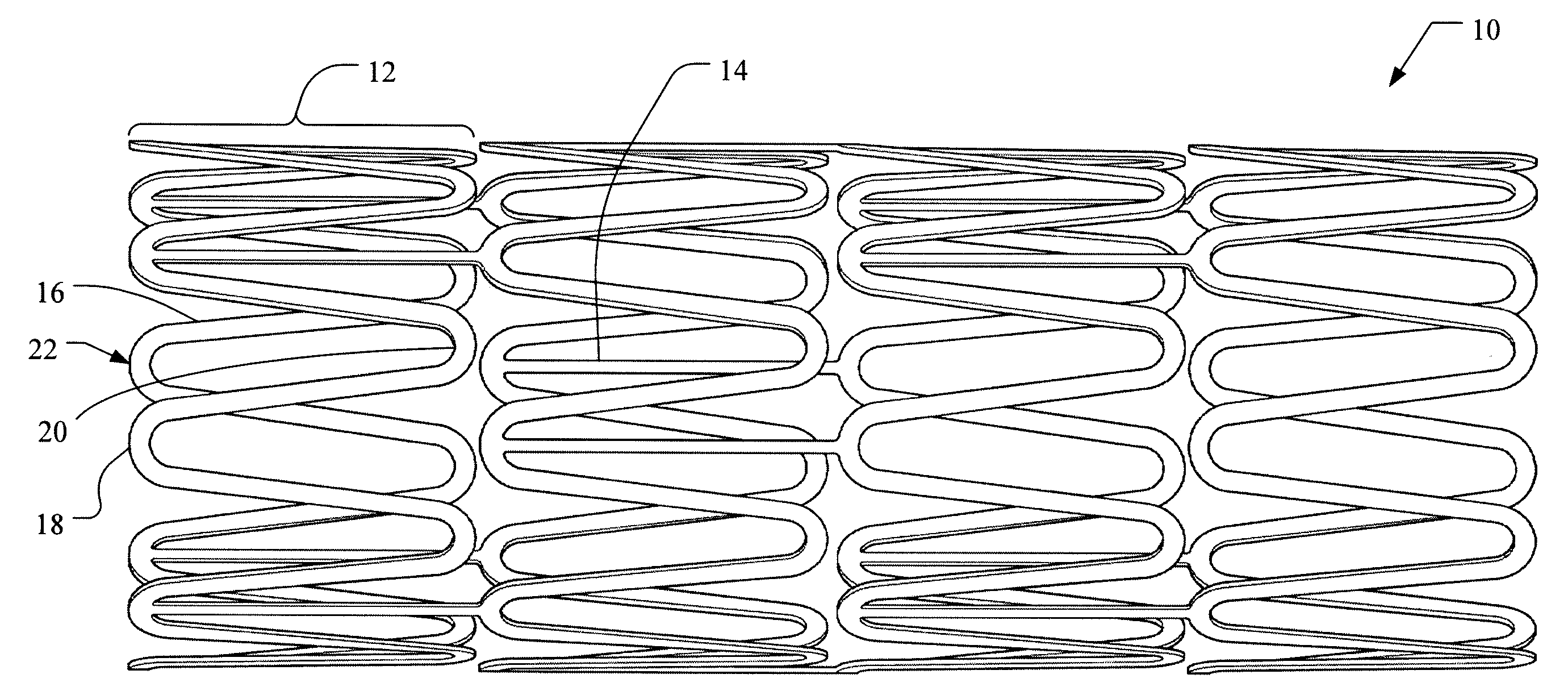

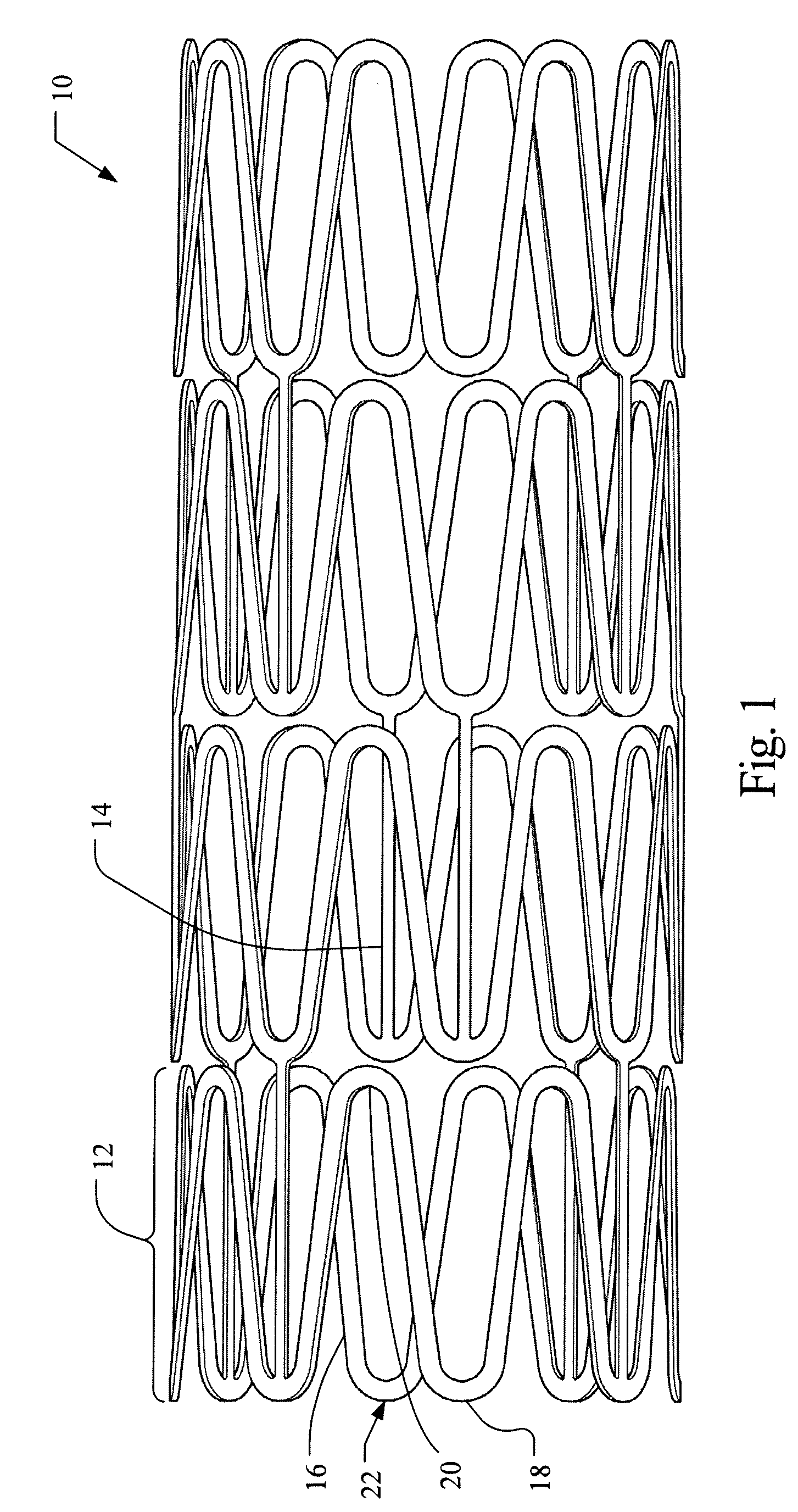

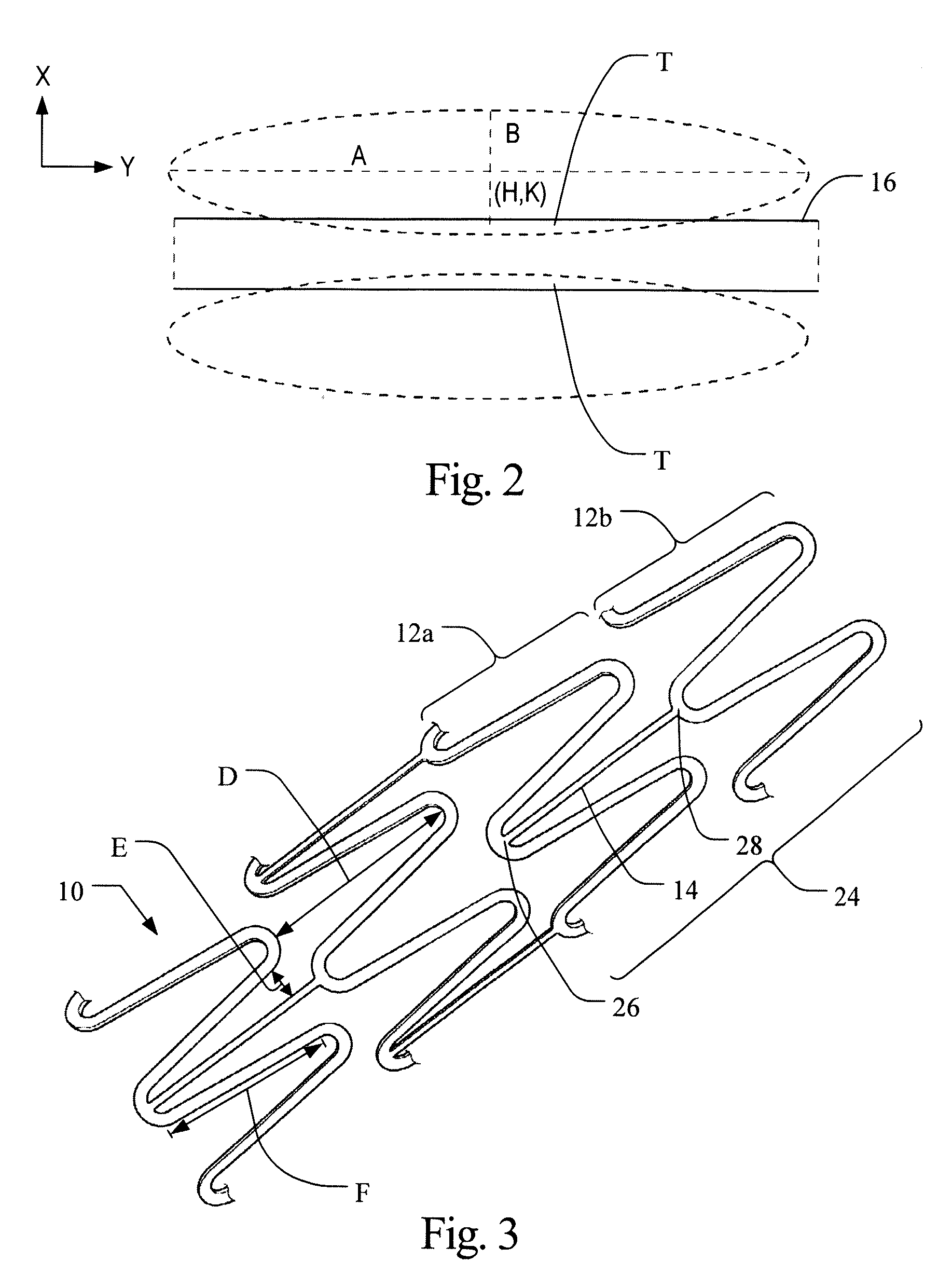

Covered balloon expandable stent design and method of covering

A balloon expandable covered stent consists of a plurality of primary stent units, each having an undulating shape defined by a series of primary strut members converging to form peaks and valleys. The primary stent units are assembled into a single cylindrical structure of the stent by connecting corresponding peaks with secondary strut members. Generally, surfaces of the stent may then coated with a polymeric, hyper-elastic material, preferably Thoralon®, by pre-expanding the stent prior to coating.

Owner:MED INST INC

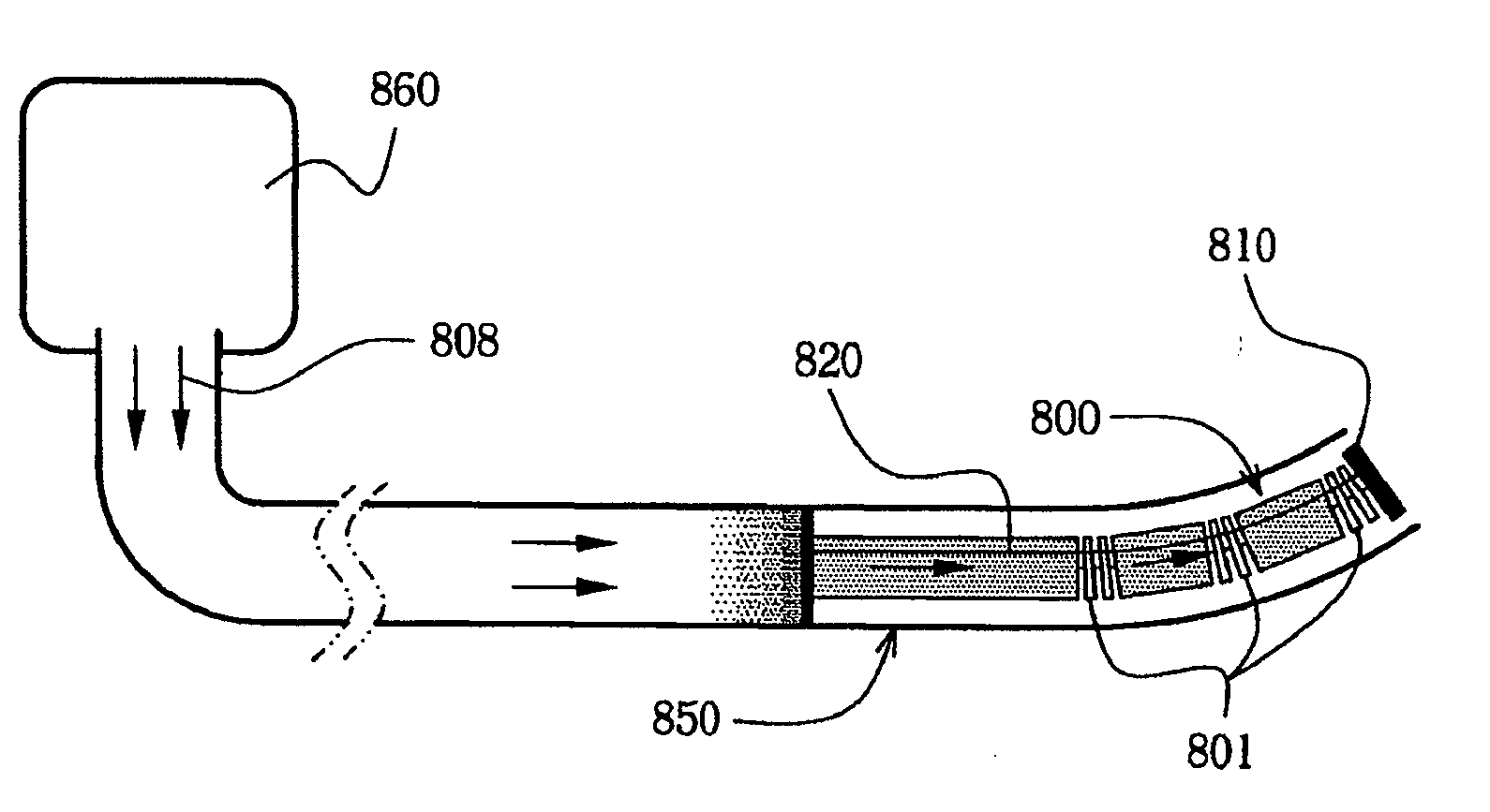

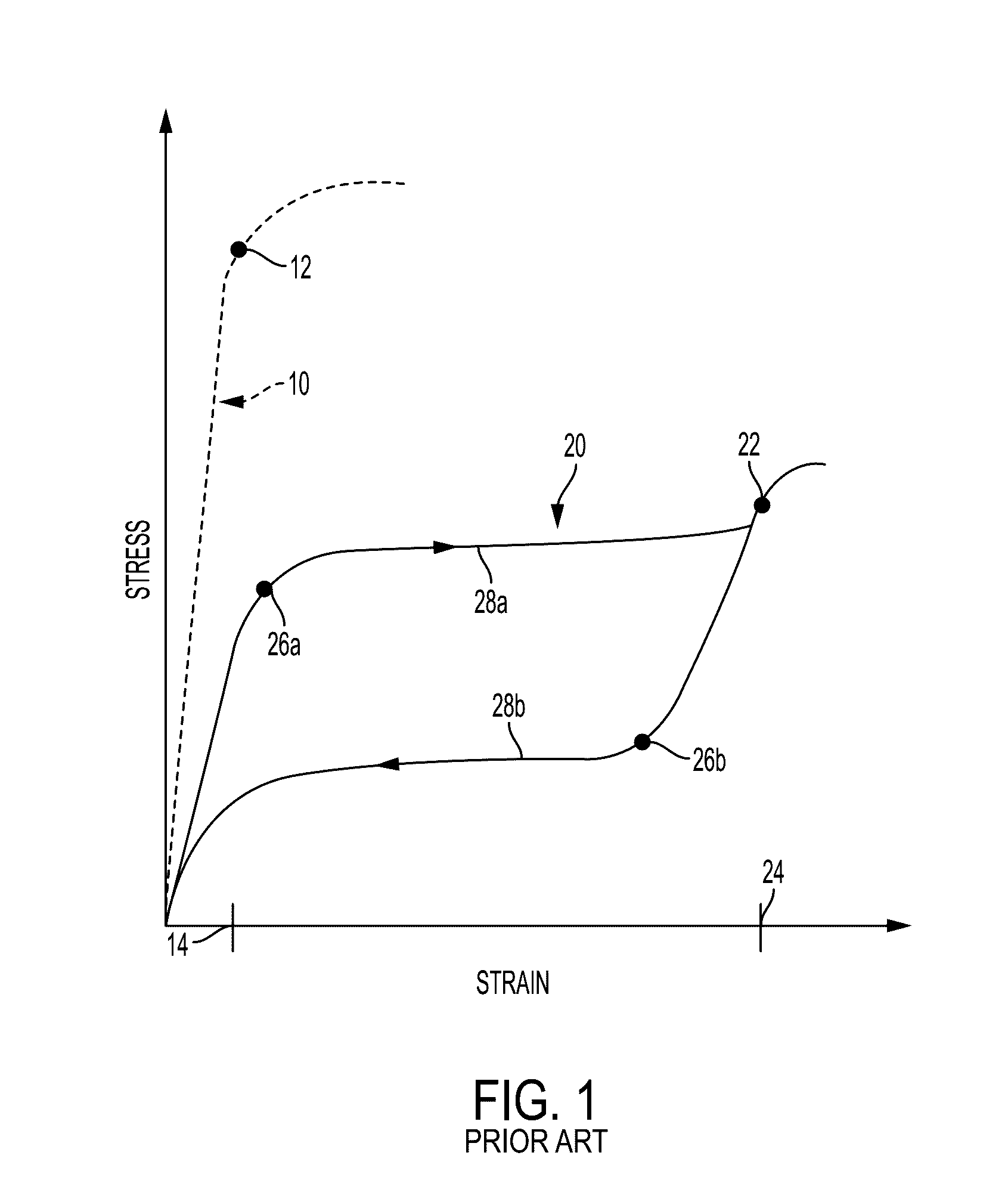

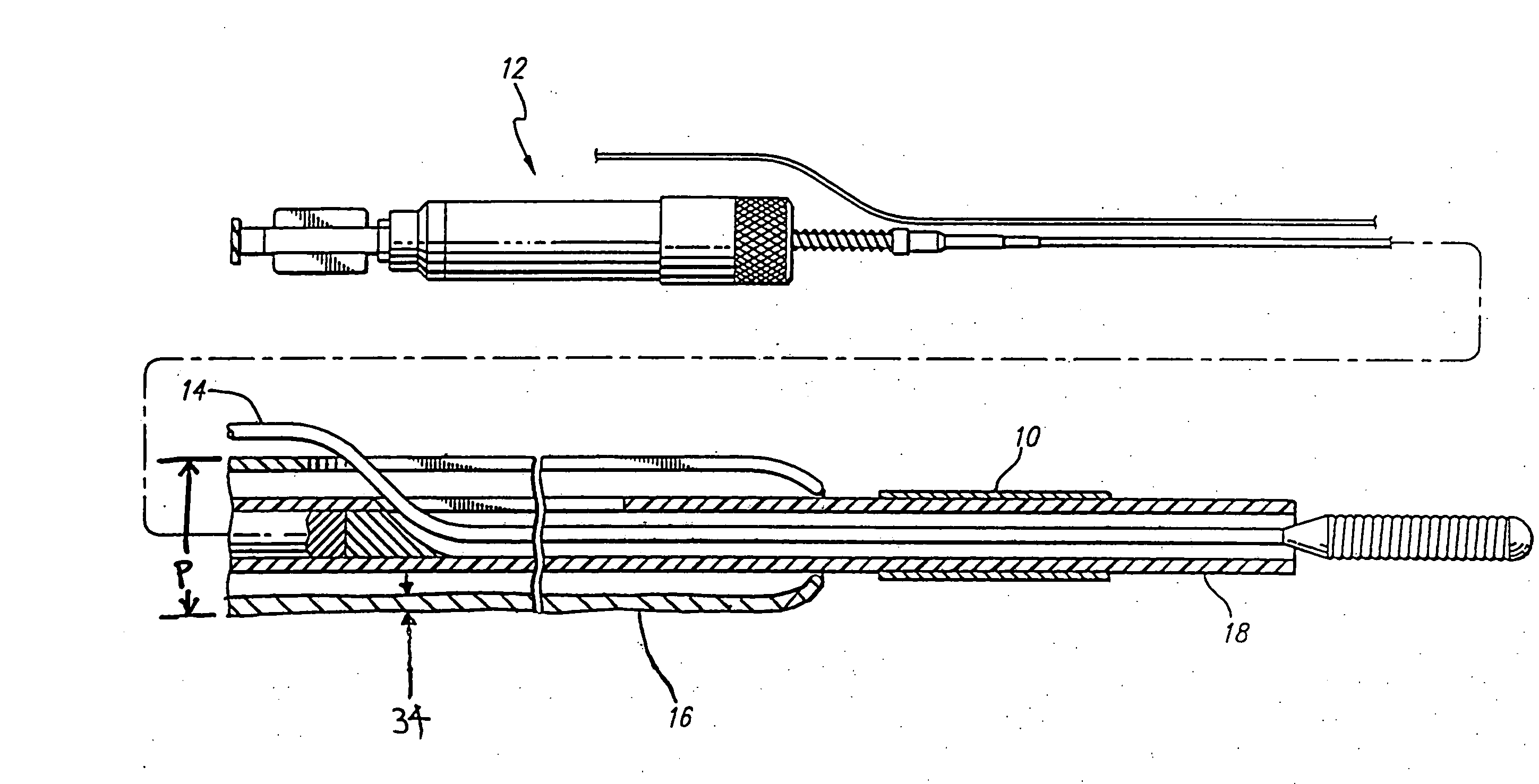

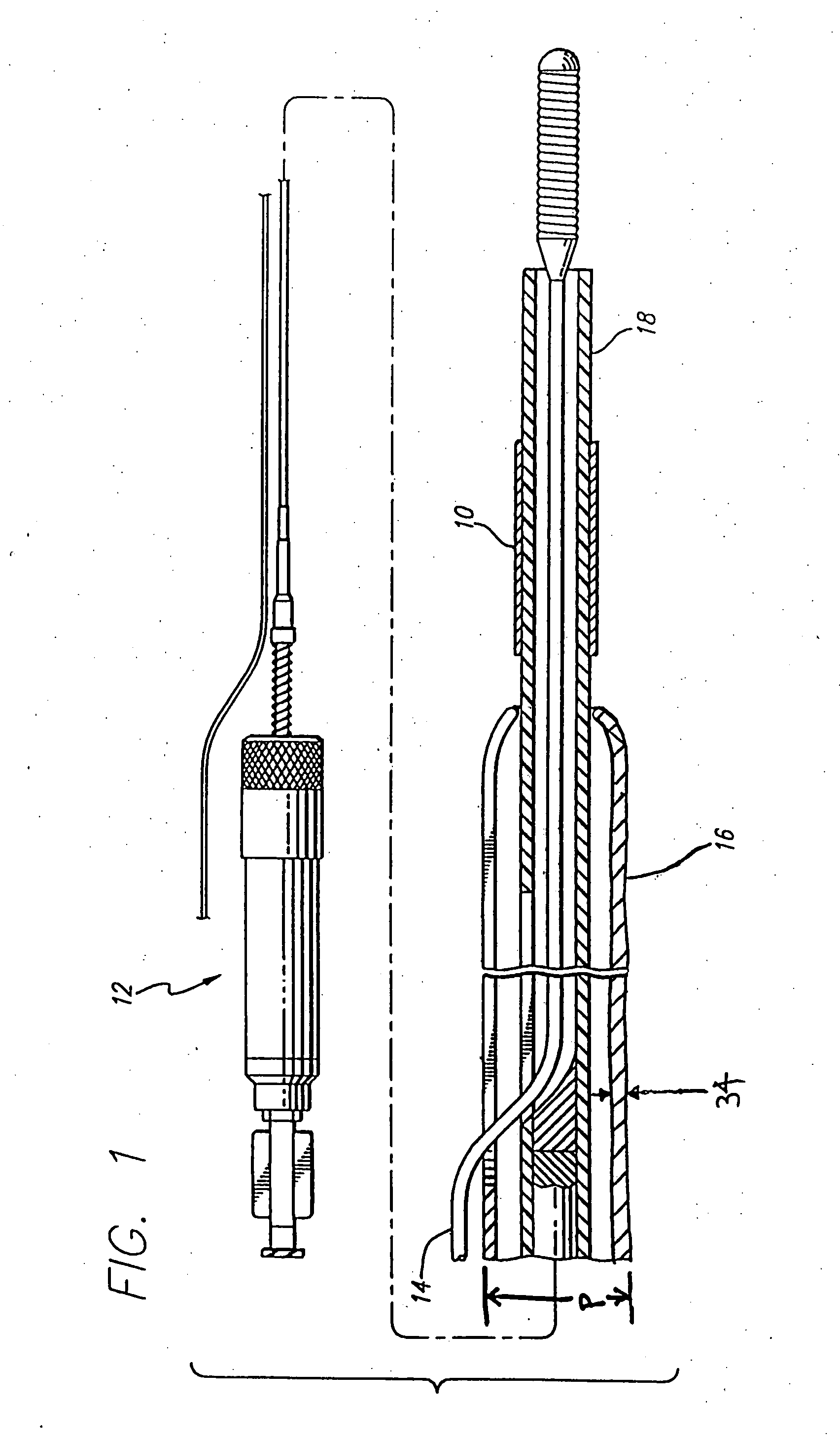

Nitinol alloy design and composition for medical devices

A stent and a delivery system for implanting the stent in a body lumen is disclosed. The stent is made from a superelastic alloy such as nickel-titanium or nitinol, and includes a ternary element in order to minimize the stress hysteresis of the superelastic material. The stress hysteresis is defined by the difference between the loading plateau stress and the unloading plateau stress of the superelastic material. The resulting delivery system has a small profile and includes a sheath covering the stent that has a thin wall. A guide wire core can also be made from the small stress hysteresis superelastic material.

Owner:ABBOTT CARDIOVASCULAR

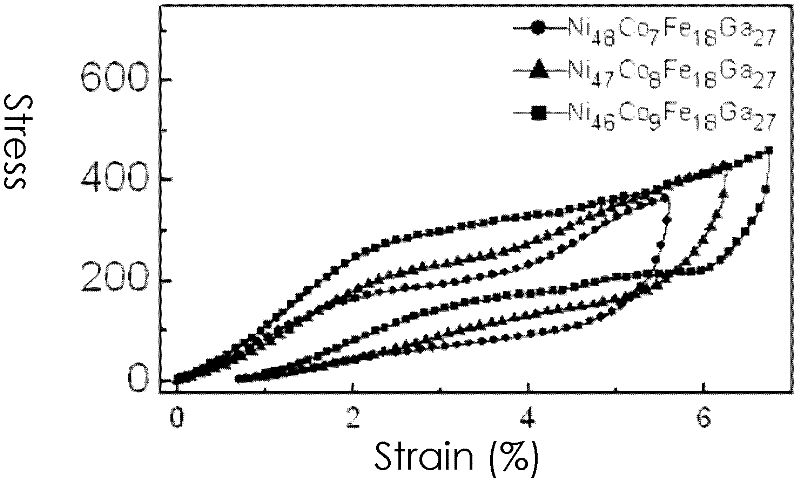

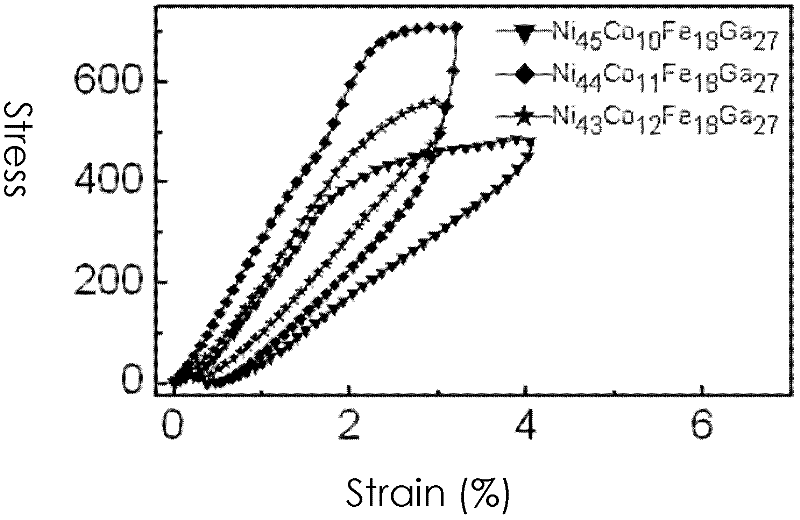

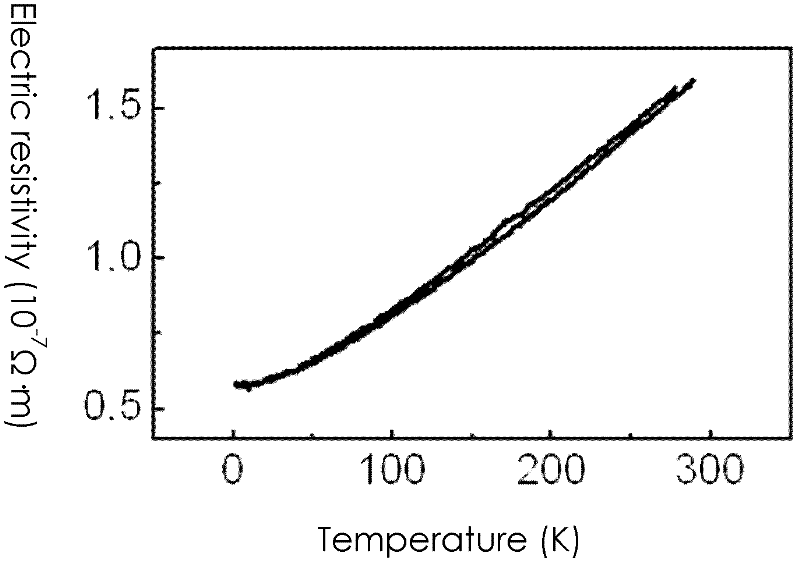

Nickel-cobalt-iron-gallium hyperelastic alloy material and preparation method thereof

The invention relates to a nickel-cobalt-iron-gallium hyperelastic alloy material and a preparation method thereof, belonging to the technical field of alloy. The alloy material is a Ni55-xCoxFe18Ga27 hyperelastic material, wherein when x ranges from 7 to 12, the alloy material comprises hyperelastic actions at room temperature; when x ranges from 10 to 12, the alloy material comprises narrow-hysteresis hyperelastic actions at room temperature; and the alloy material comprises no martensitic phase transformation actions at the temperature ranging from 0K to 298K. The alloy material is obtained through smelting, suction casting and annealing treatment in sequence. The alloy material disclosed by the invention has lower cost in comparison with NiTi series of hyperelastic alloy, so that low price and popularization of hyperelastic alloy for daily use are hopefully achieved; the alloy material has the advantages of narrow-hysteresis hyperelastic actions, low internal friction and capability of being widely applied to industrial production; and moreover, the alloy material is simple in preparation method and low in cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Hollow curved superelastic medical needle and method

InactiveUS20090177161A1Reduce eliminateGuide needlesInfusion syringesOuter CannulaBiomedical engineering

A needle assembly 10 compromising an infusion needle 11 that includes a needle cannula 13 made of a superelastic material such as Nitinol. The needle cannula is cold-worked or heat annealed to produce a preformed bend 16 that can be straightened within passageway 21 of a coaxial outer cannula 12 for introduction into the body of a patient. Upon deployment from the outer cannula, the needle cannula substantially returns to the preformed configuration for the introduction or extraction of materials at areas lateral to the entry path of the needle assembly. The needle assembly can compromise a plurality of needle cannulae than can be variably arranged or configured for attaining a desired infusion pattern.

Owner:COOK INC

Fully compliant pneumatic mechanical arm structure

InactiveCN106584507ASimple structural designSimplify the assembly processToolsArmsHardnessFiber-reinforced composite

The invention discloses a fully compliant pneumatic mechanical arm structure which adopts a lengthwise conical structure. The fully compliant pneumatic mechanical arm structure comprises a fully compliant pneumatic mechanical arm main body, a mechanical arm center body positioned in the conical center hole of the fully compliant pneumatic mechanical arm main body, and air passages evenly surrounding the mechanical arm center body and in axially symmetrical distribution, wherein the air passages extend from a large-diameter end to a small-diameter end and keeps a certain distance with an end surface so as to keep gas inside the air passages, and a layer of fiber reinforced composite material is arranged on the outer surface of a mechanical arm; the air passages in axially symmetrical distribution are of lengthwise conical structures; the fully compliant pneumatic mechanical arm main body is made of a super elastic material, more than 200 percent of deformation is produced under pneumatic pressure, and the hardness of the mechanical arm center body is higher than that of the fully compliant pneumatic mechanical arm main body. Compared with the prior art, the fully compliant pneumatic mechanical arm structure provided by the invention imitates octopus tentacles, and integrates the air passages and the mechanical arm, so that the structural design, the processing and manufacturing, and the assembling of the entire mechanical arm are greatly simplified, 3D printing technology is used for one step processing, and objects in complex shapes can be grabbed, the mass is light, and the transmitting cost is reduced.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com