Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Pure shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

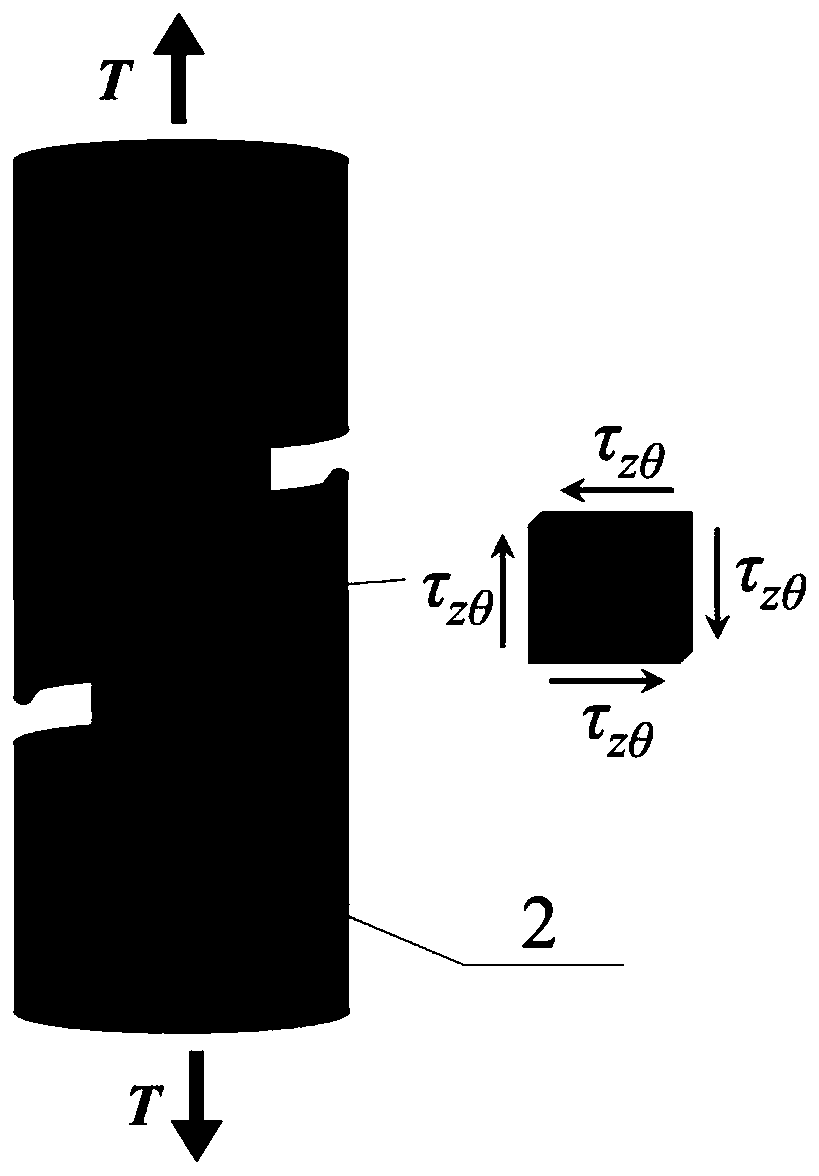

In mechanics and geology, pure shear is a three-dimensional homogeneous flattening of a body. It is an example of irrotational strain in which body is elongated in one direction while being shortened perpendicularly. For soft materials, such as rubber, a strain state of pure shear is often used for characterizing hyperelastic and fracture mechanical behaviour. Pure shear is differentiated from simple shear in that pure shear involves no rigid body rotation.

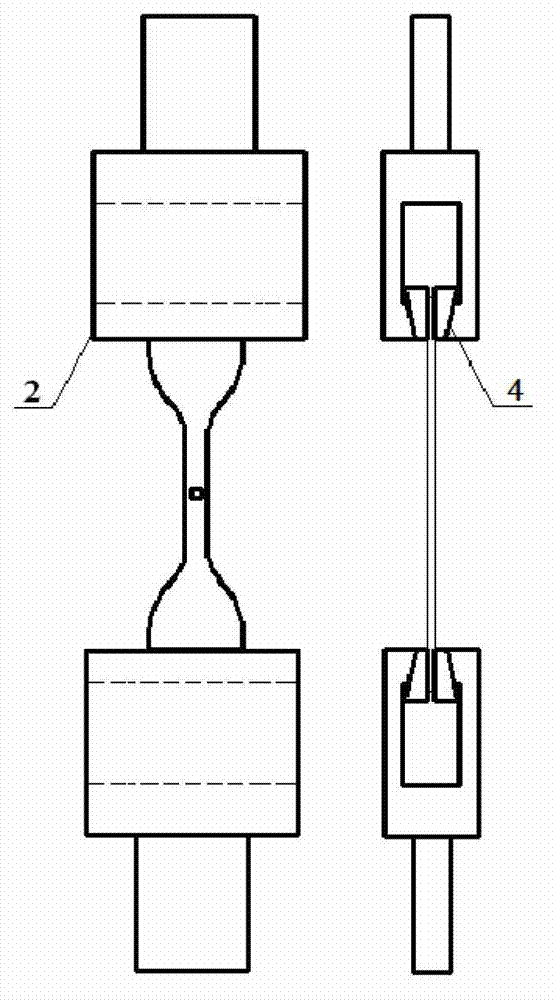

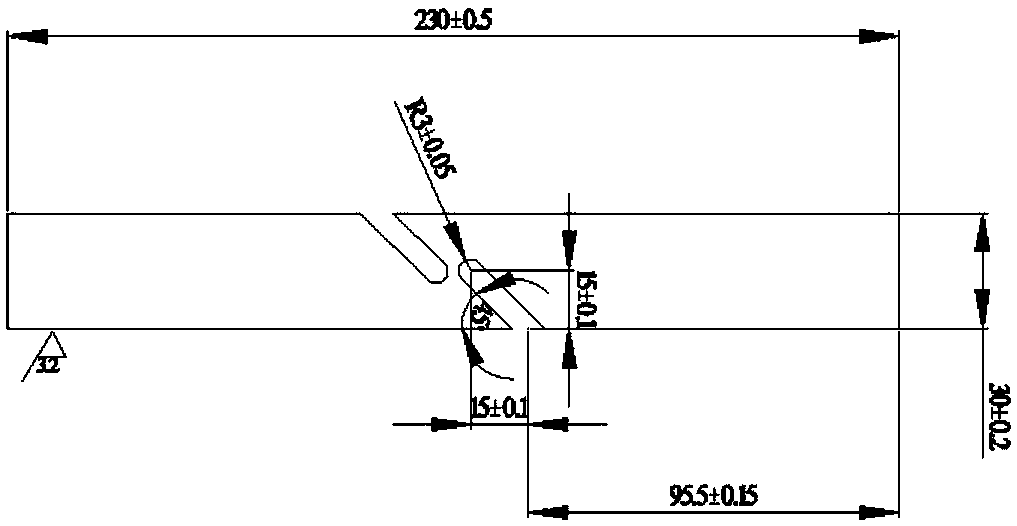

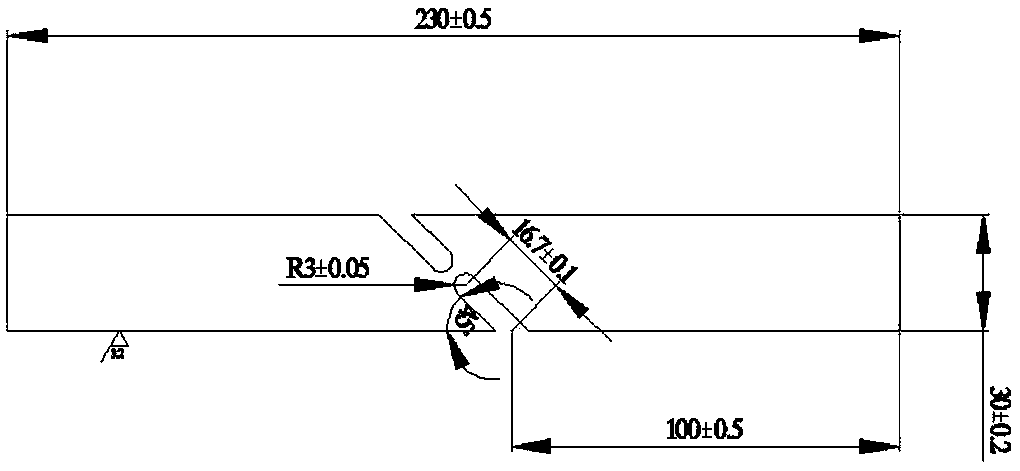

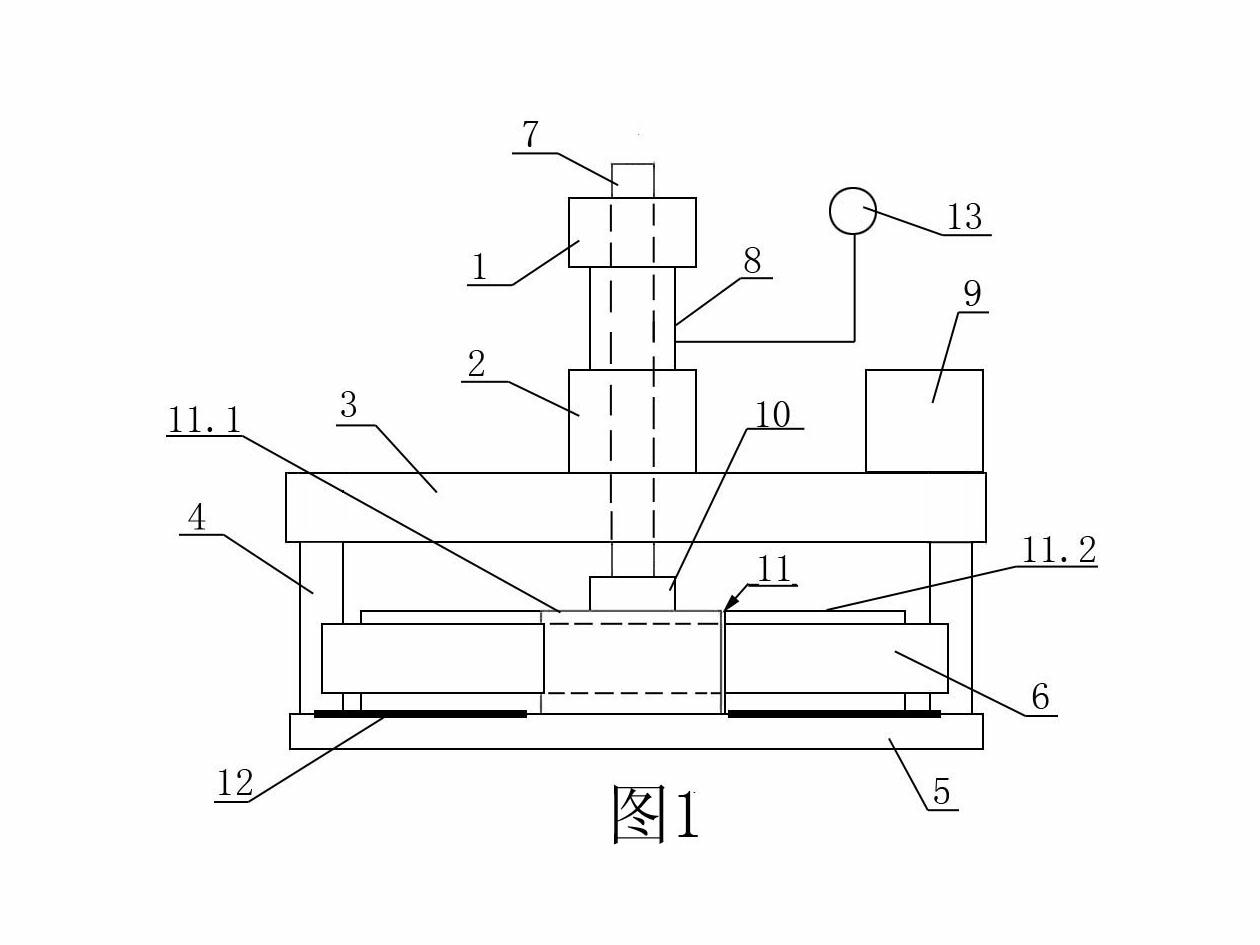

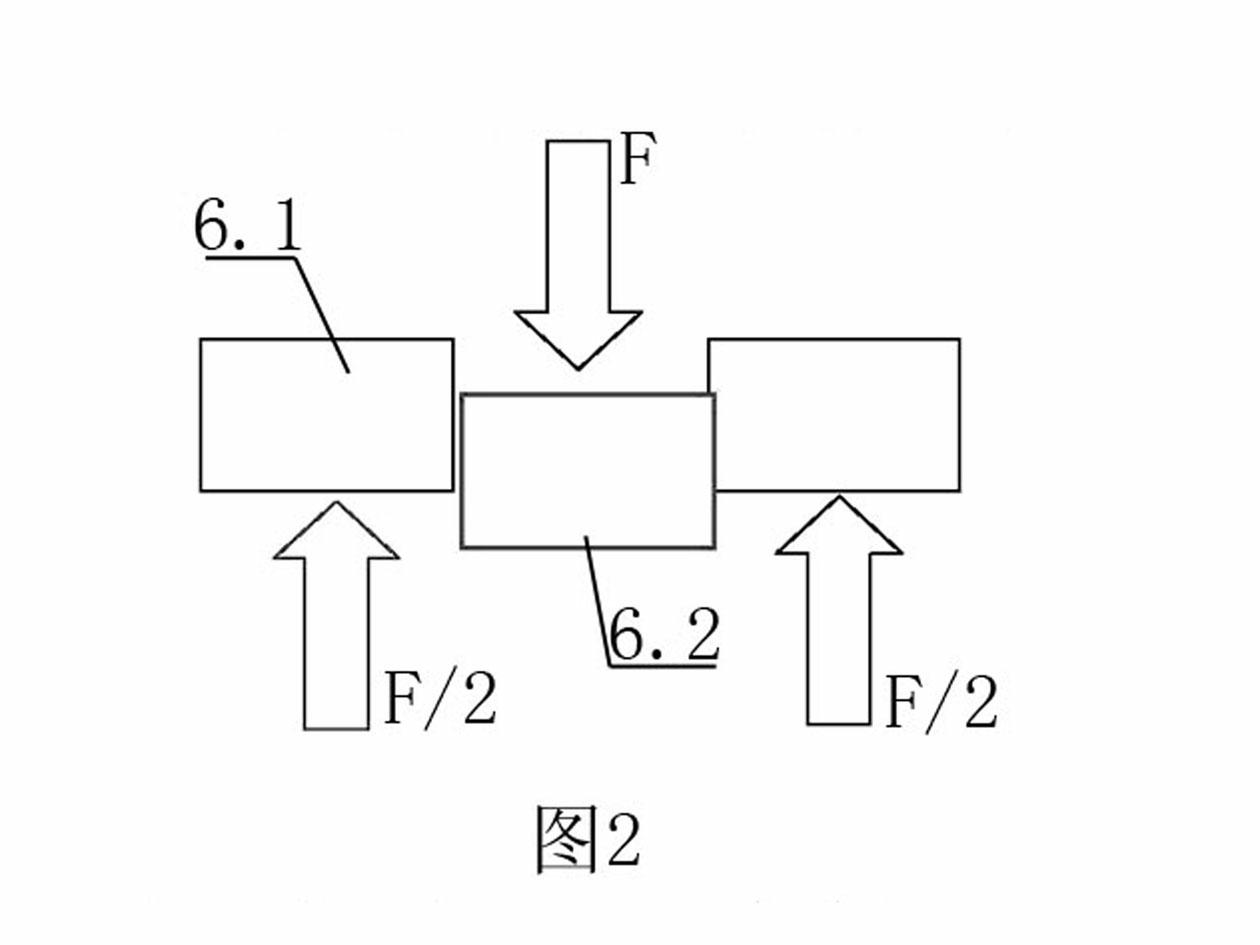

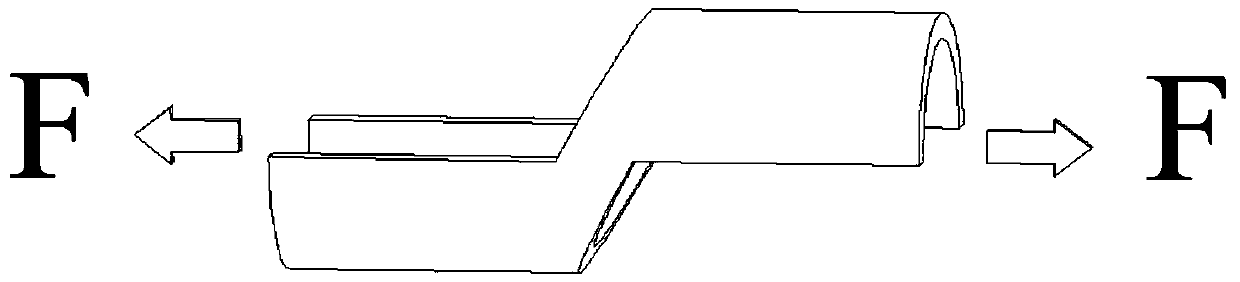

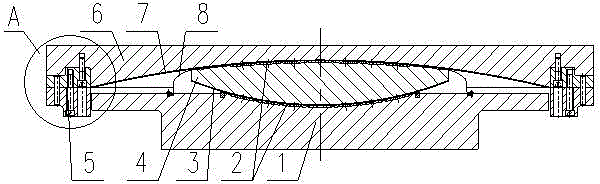

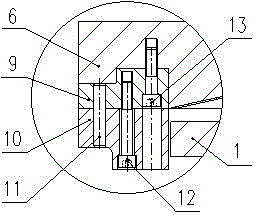

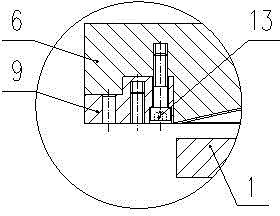

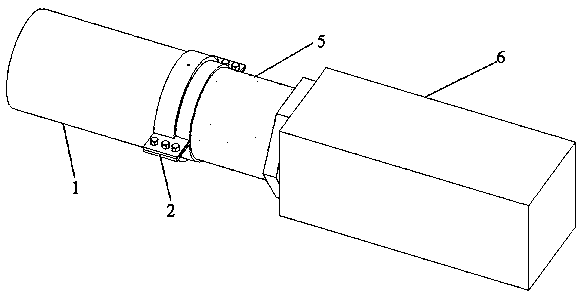

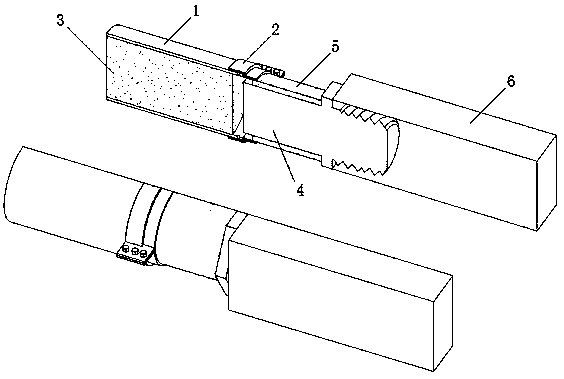

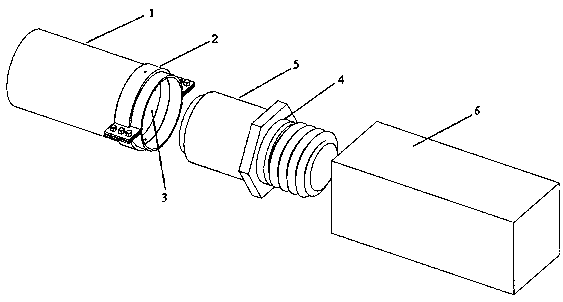

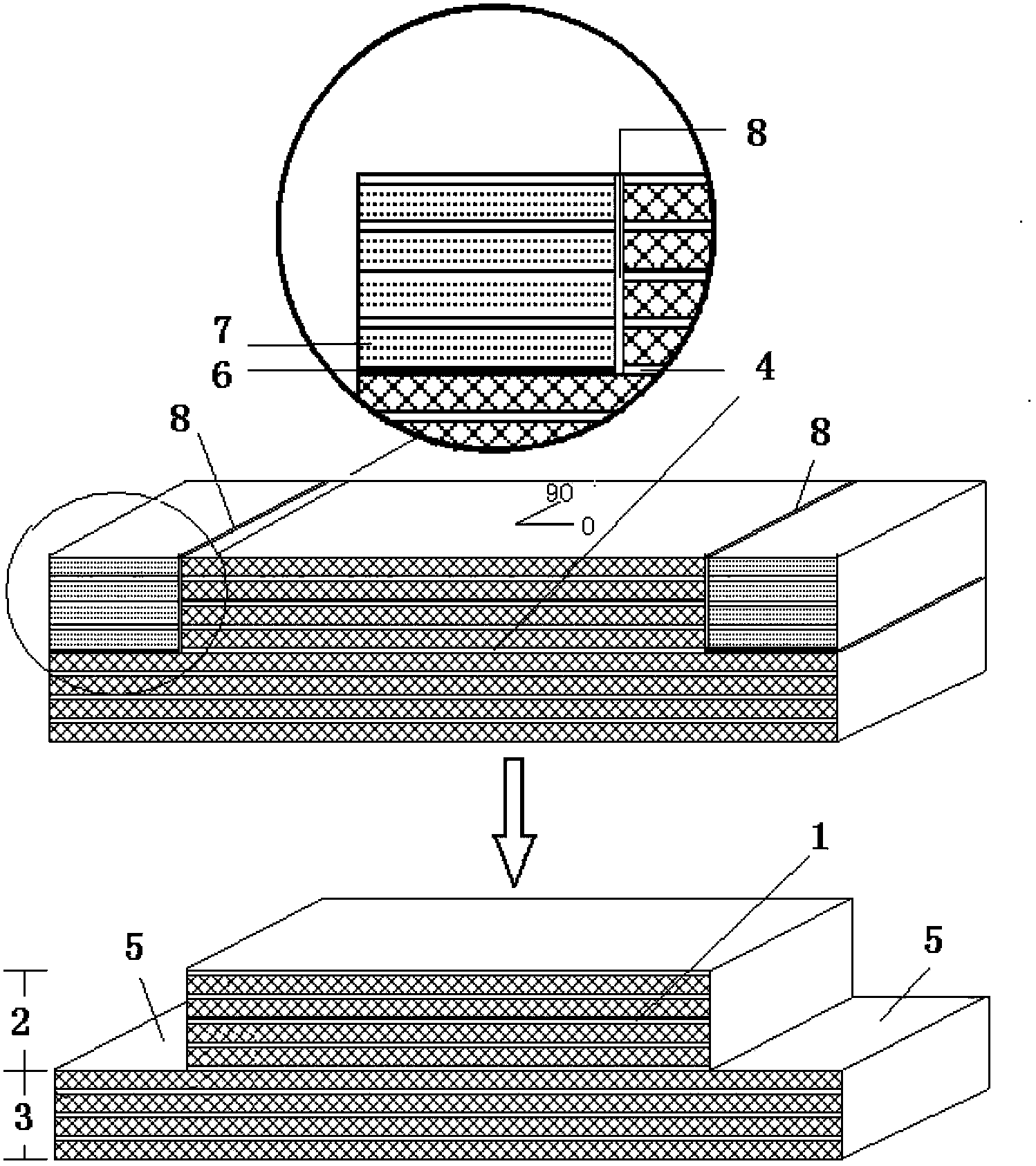

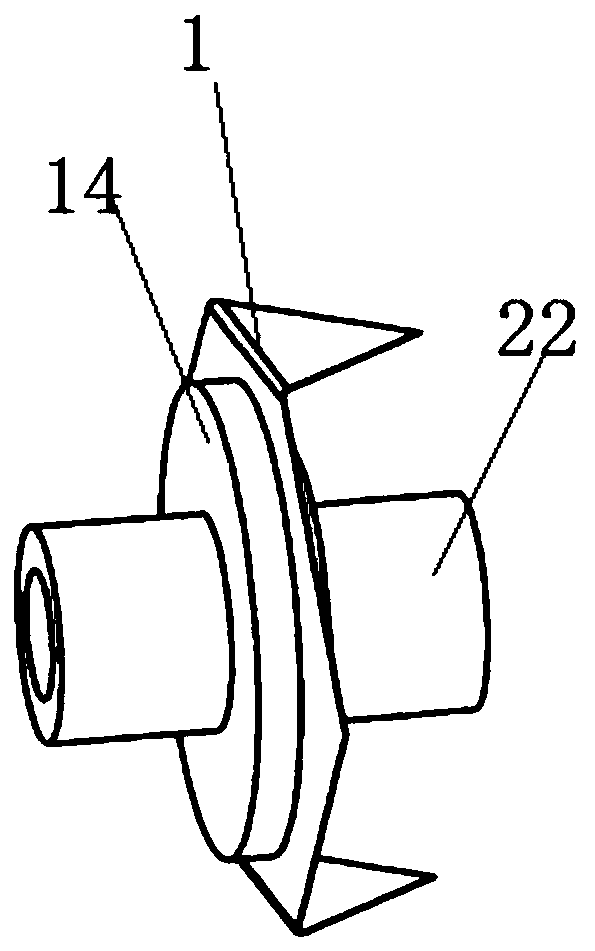

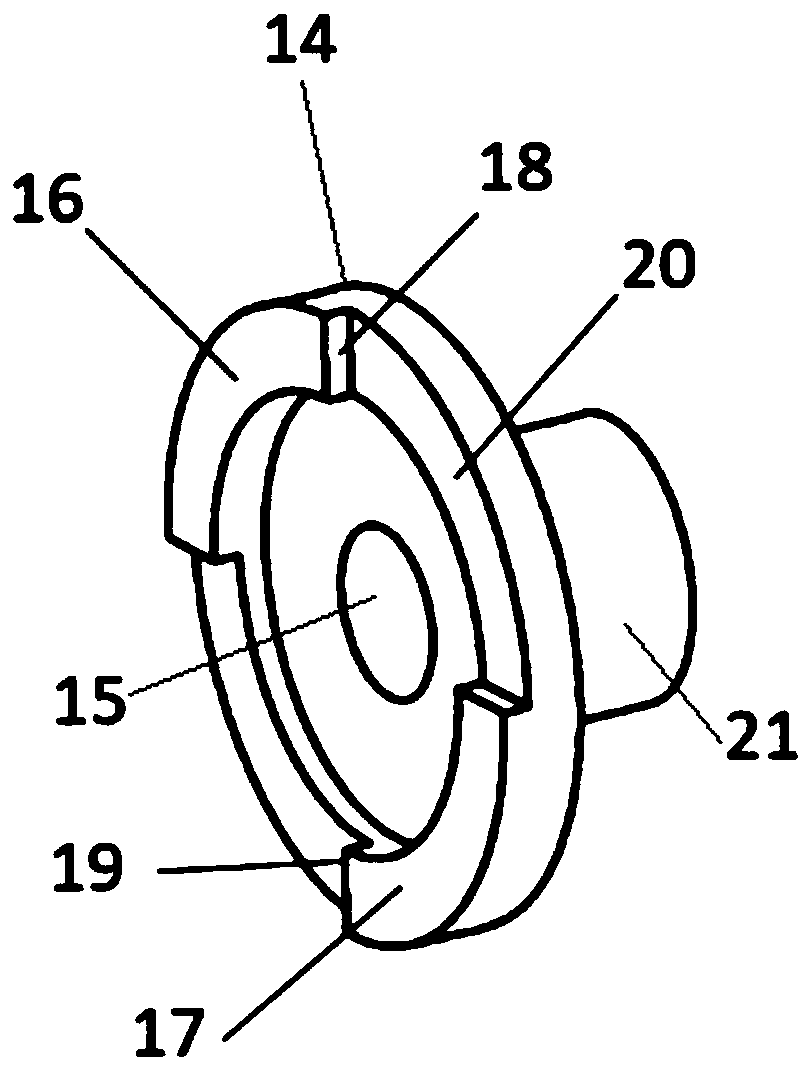

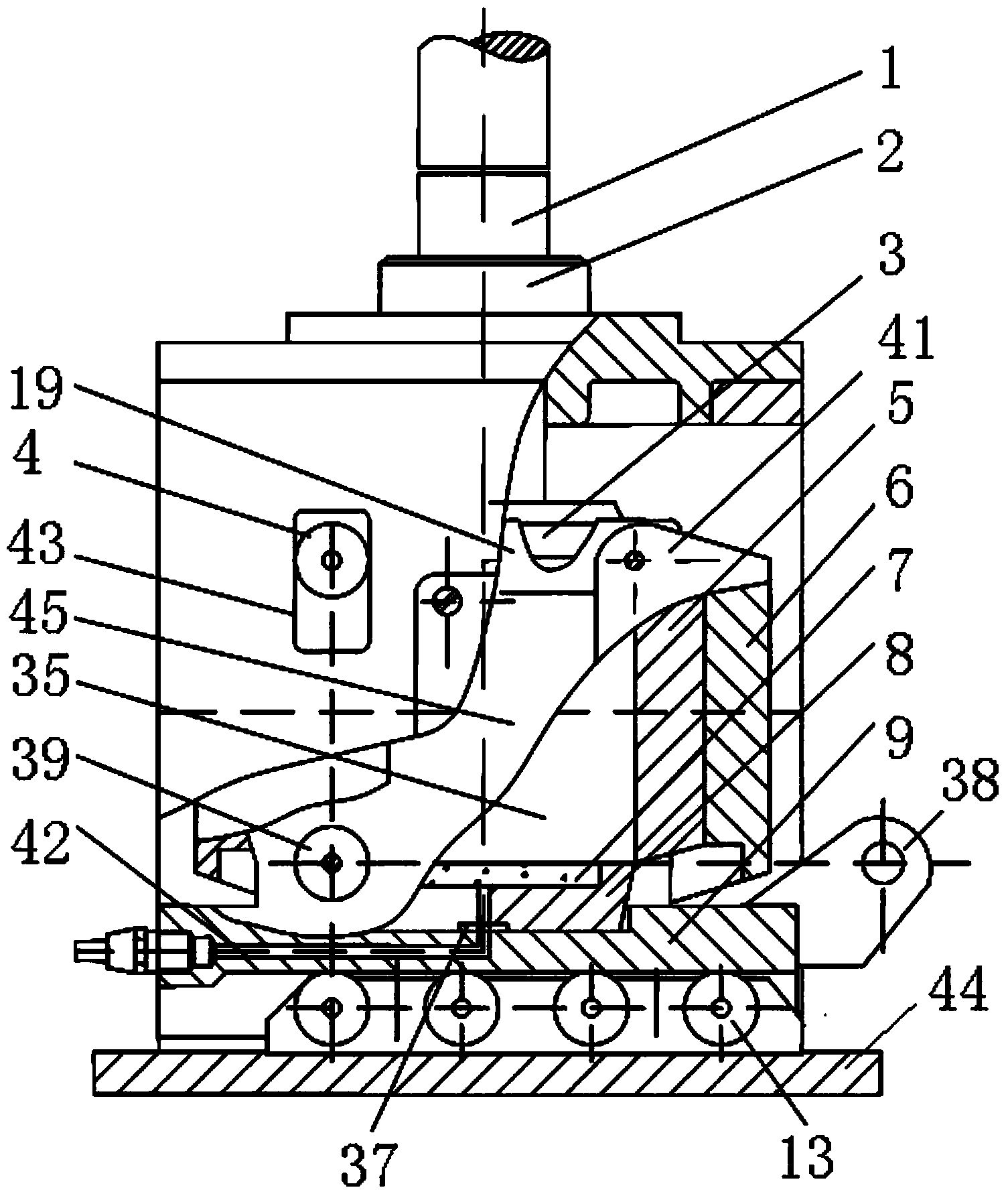

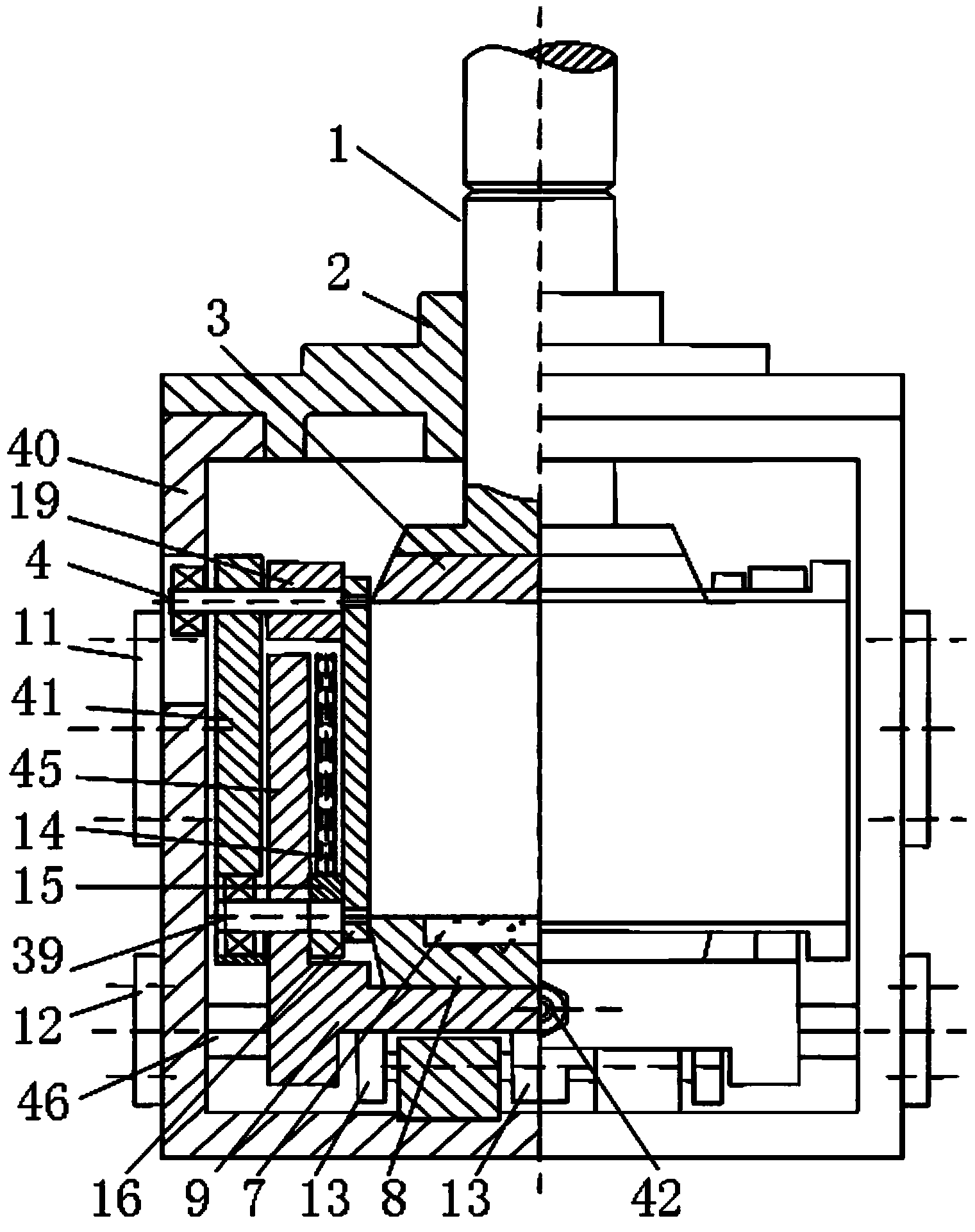

Clamp, device with clamp for testing mechanical property of hyper-elastic material and method

InactiveCN102768149AUniform deformationQuick disassemblyMaterial strength using tensile/compressive forcesData acquisitionHyper elastic

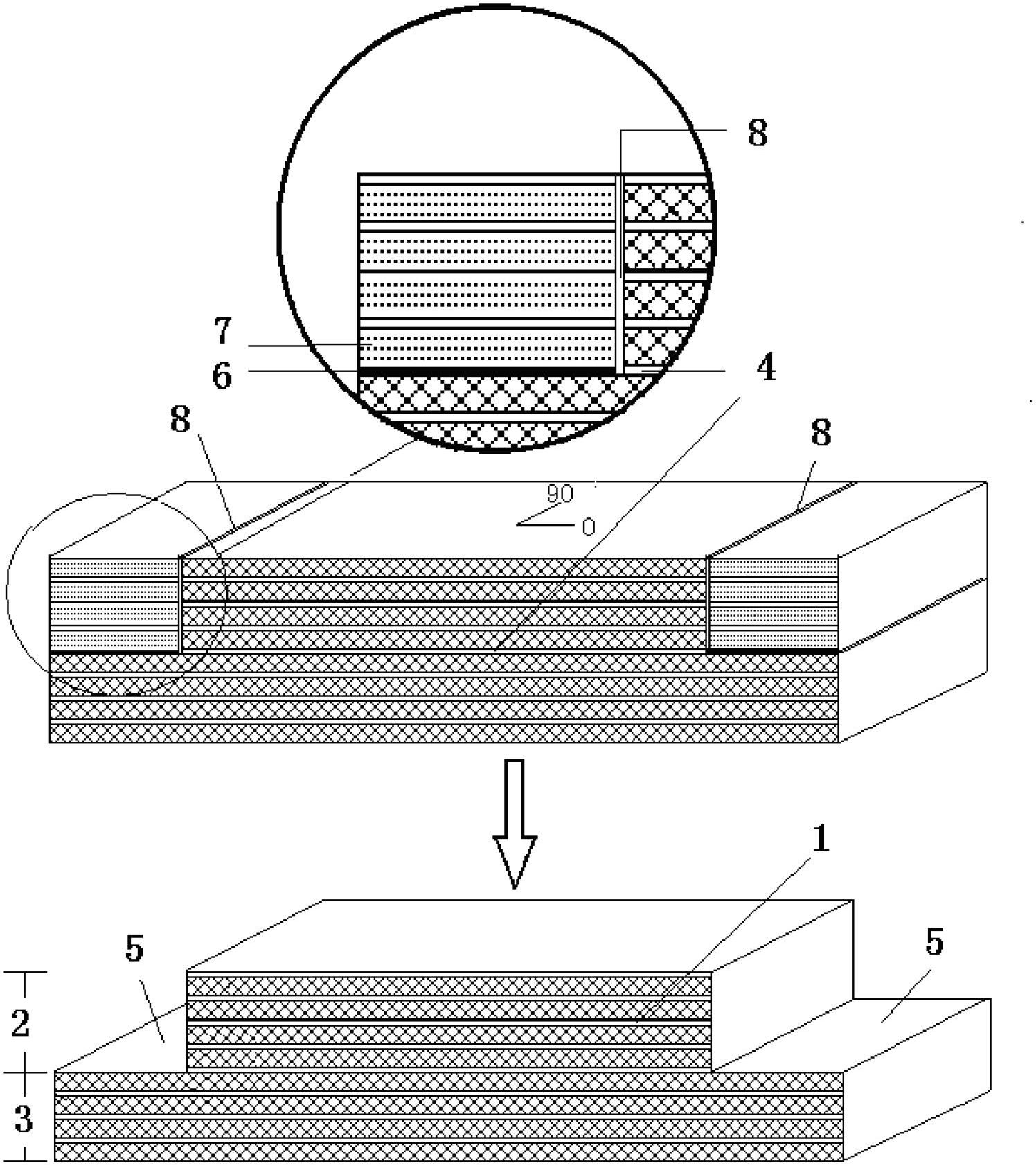

The invention relates to a device and a method for testing mechanical property of a hyper-elastic material. The device mainly comprises a reinforcing piece (4) at the end of a test piece and a test piece clamp, wherein the reinforcing piece (4) has a trapezoidal cross section; a clamping port of the clamp is an inclined surface; the reinforcing piece (4) is adhered to the end of the test piece and is arranged in the clamp, the inclined surface of the clamp tightly clamps the inclined surface of the reinforcing piece (4), and the clamp is self-locked in the tensioning process and is prevented from locally deforming. The device is applied to multiple stress-strain tests of the hyper-elastic material such as uniaxial tension, equally biaxial tension and planar tension (pure shear). Stress data is acquired by a data acquisition system of an electronic universal testing machine, and the strain data is acquired by a charge coupled device (CCD) image acquisition device. Due to the technical scheme, the clamping force is high when the tension is high in the process of tensioning the test piece, so that the test piece is uniformly stressed, more accurate testing data can be obtained, and the mechanical property parameters of the hyper-elastic material obtained accordingly are more reliable.

Owner:TSINGHUA UNIV

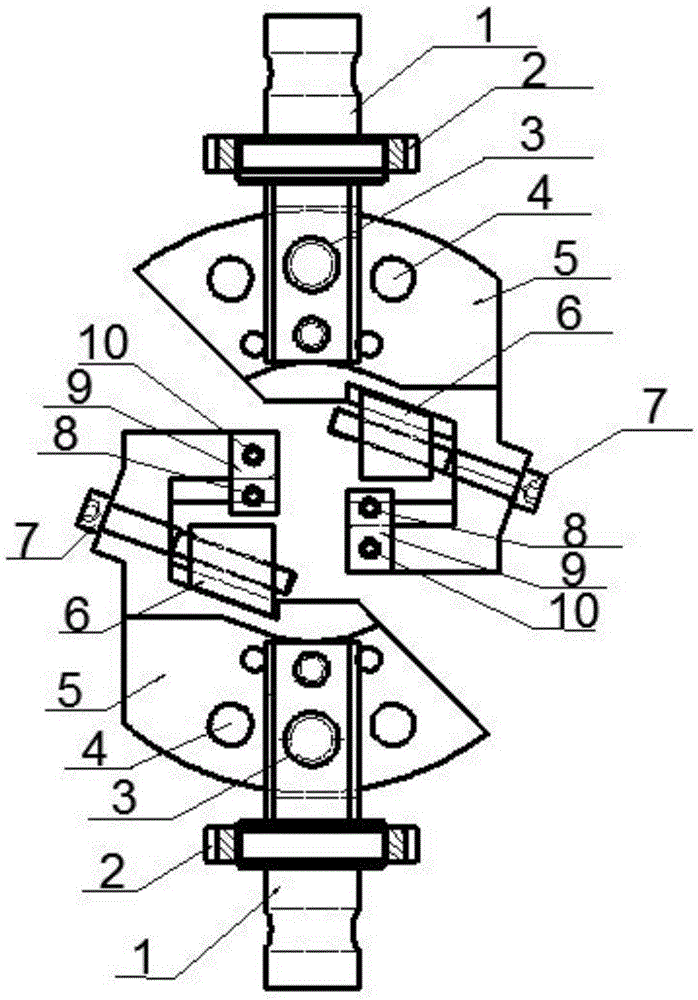

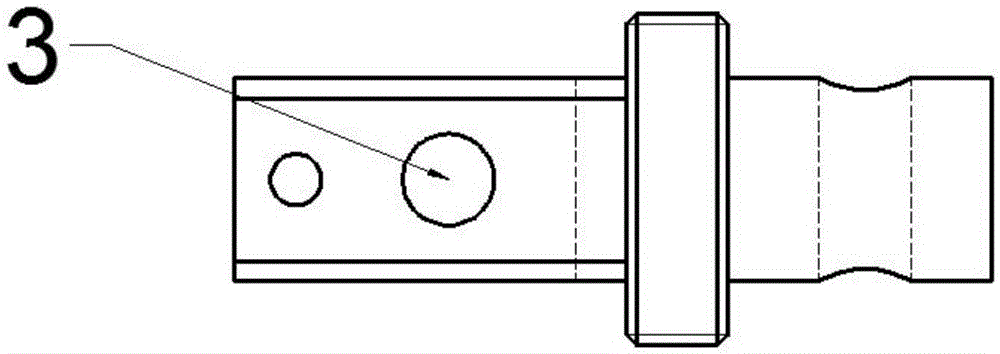

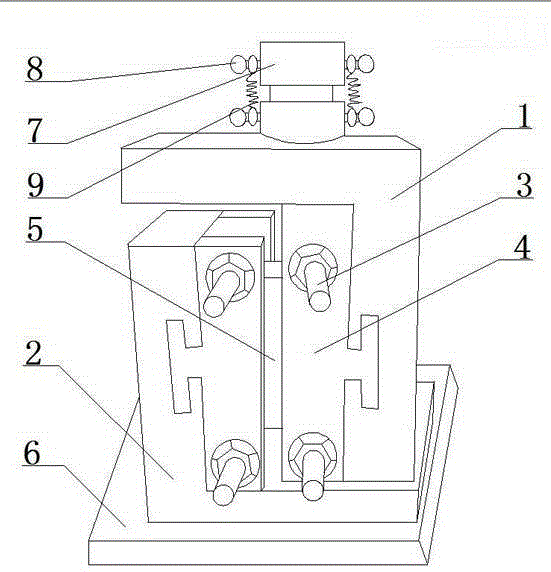

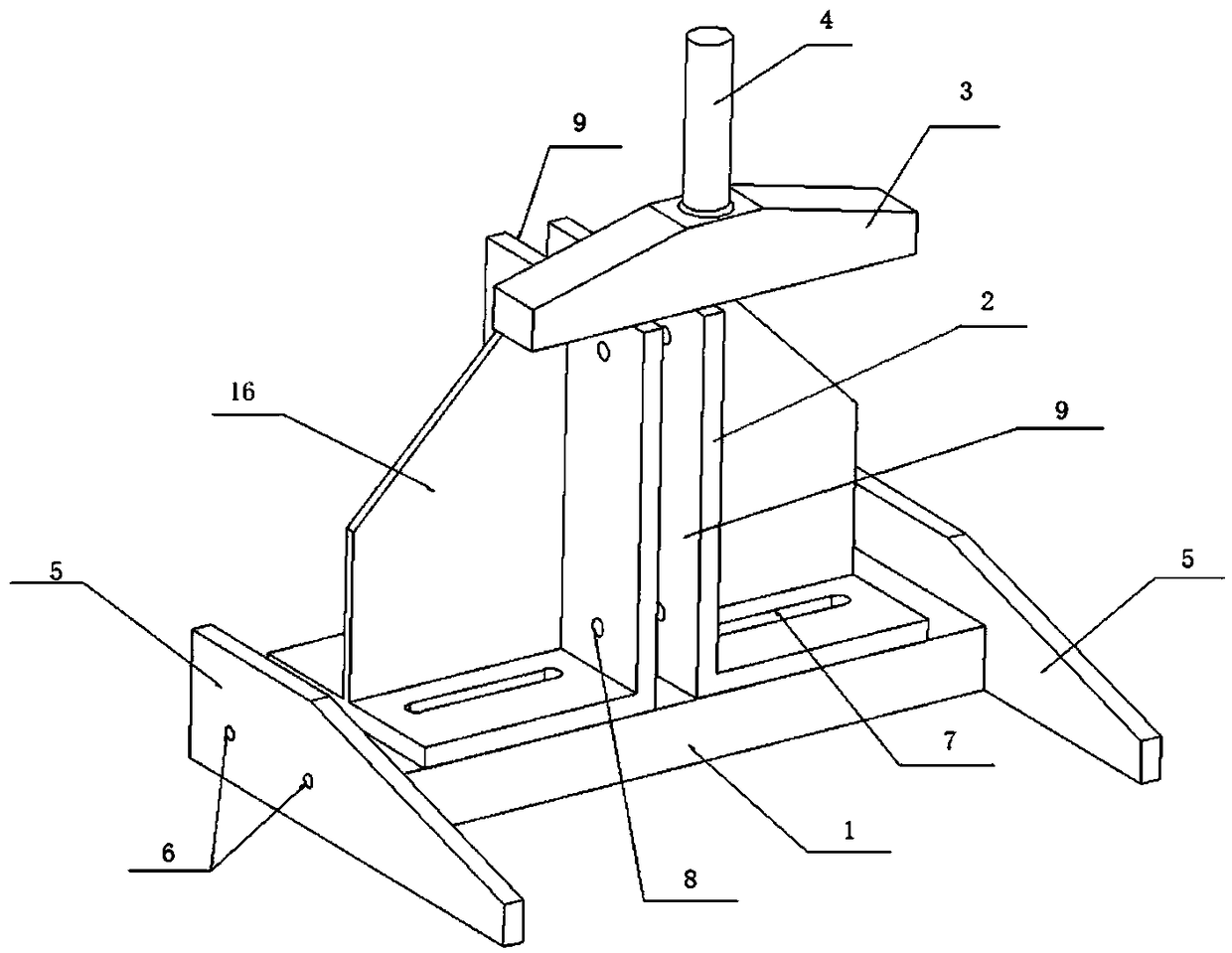

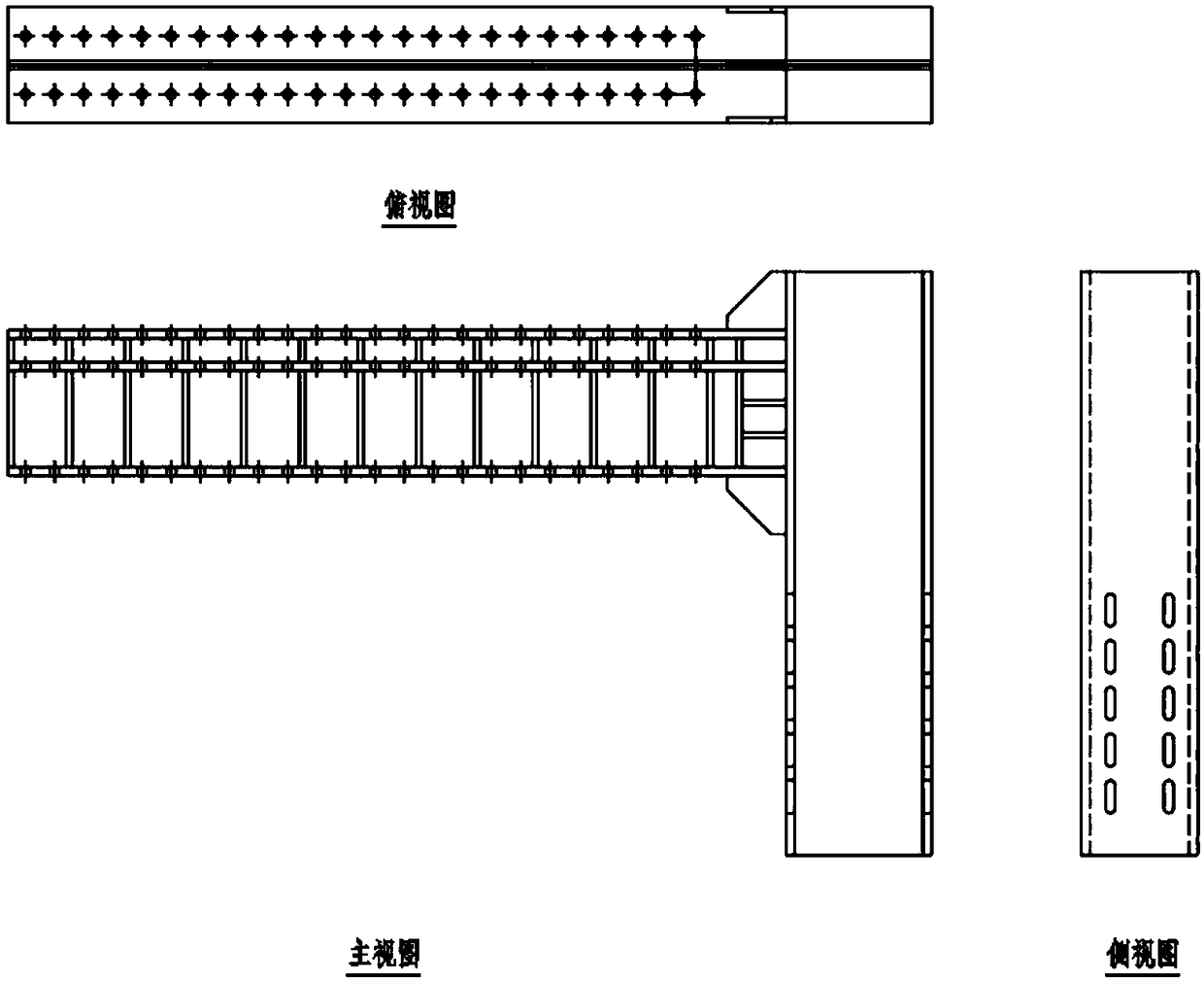

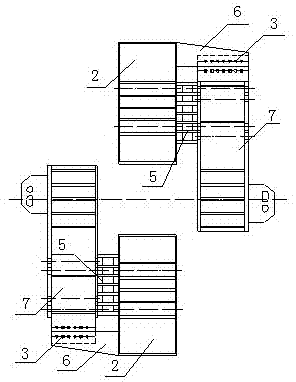

Multifunctional shearing test fixture used for composite material parameter identification

InactiveCN105628496ACompact structureEasy to disassembleMaterial strength using steady shearing forcesEngineeringTest fixture

The invention discloses a multifunctional shearing test fixture used for composite material parameter identification. The multifunctional shearing test fixture comprises an upper fixture body and a lower fixture body, wherein the upper fixture body is connected with a loading part of a testing machine; the lower fixture body is connected with a supporting platform of the testing machine; the upper fixture body is the same as the lower fixture body in structure and in central symmetry with the lower fixture body; each of the upper fixture body and the lower fixture body comprises a connecting piece (1), a clamping piece (5) and a clamping mechanism; the connecting pieces (1) are connected with the testing machine and the clamping pieces (5); each clamping piece (5) is divided into an upper part and a lower part; the upper parts are connected with the connecting pieces (1) and an angle limiting mechanism is arranged at the upper part; the lower parts and the clamping mechanisms are jointly used for clamping a test piece; the clamping mechanisms comprise regulating parts and compressing pieces (6); the compressing pieces (6) are connected with the clamping pieces (5) through an adjusting mechanism; a limiting mechanism is arranged on the clamping piece (5) and used for limiting positions of the compressing pieces to enable the compressing pieces to perform movement along set tracks. The multifunctional shearing test fixture has the advantages of being light in weight, simple in operation and easy to dissemble and capable of realizing pure shear, tension-shear and tension-shear combined loading.

Owner:BEIHANG UNIV

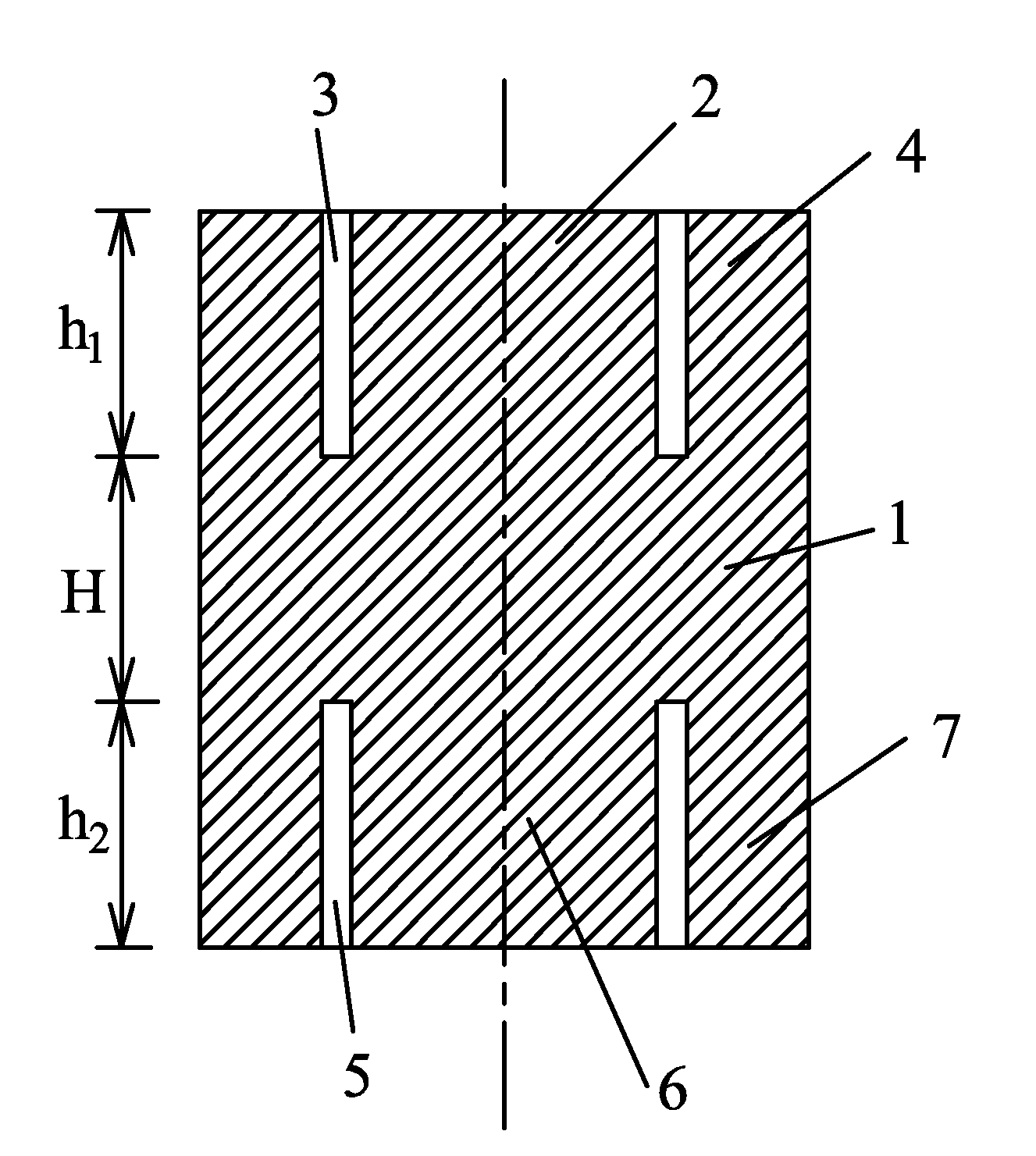

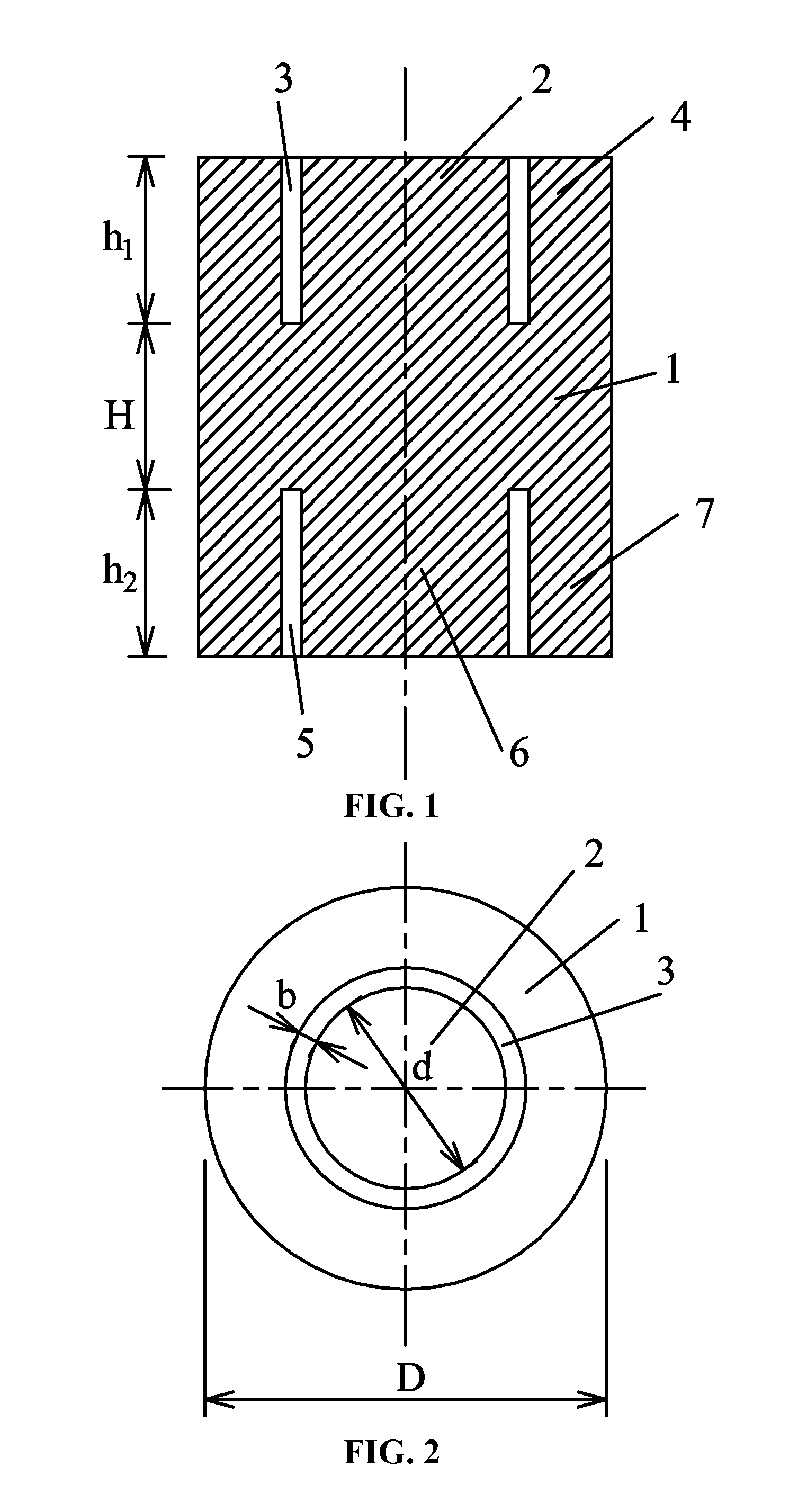

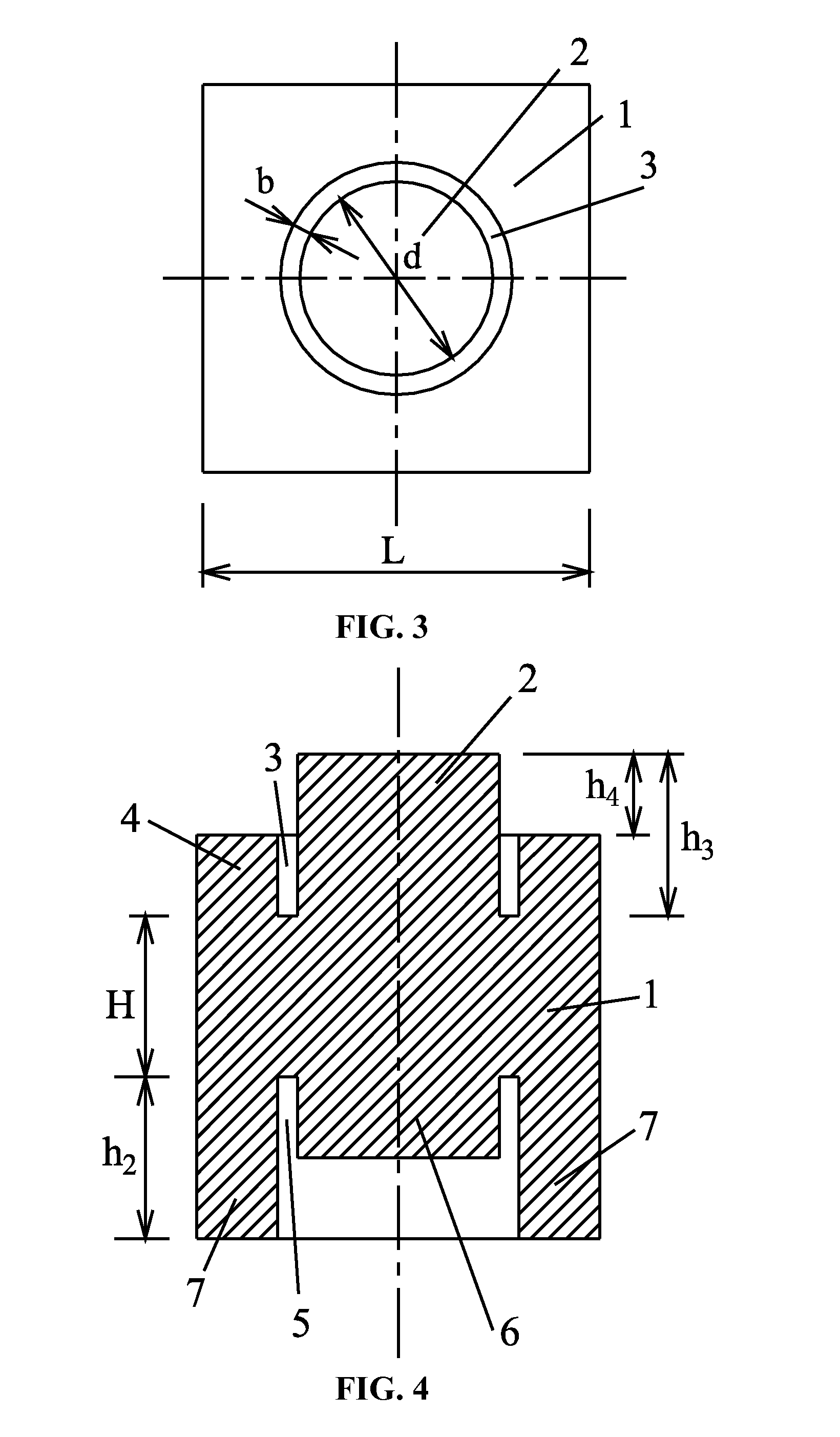

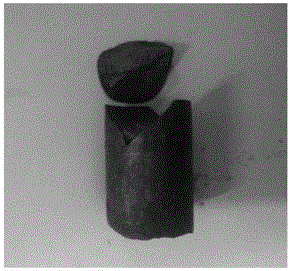

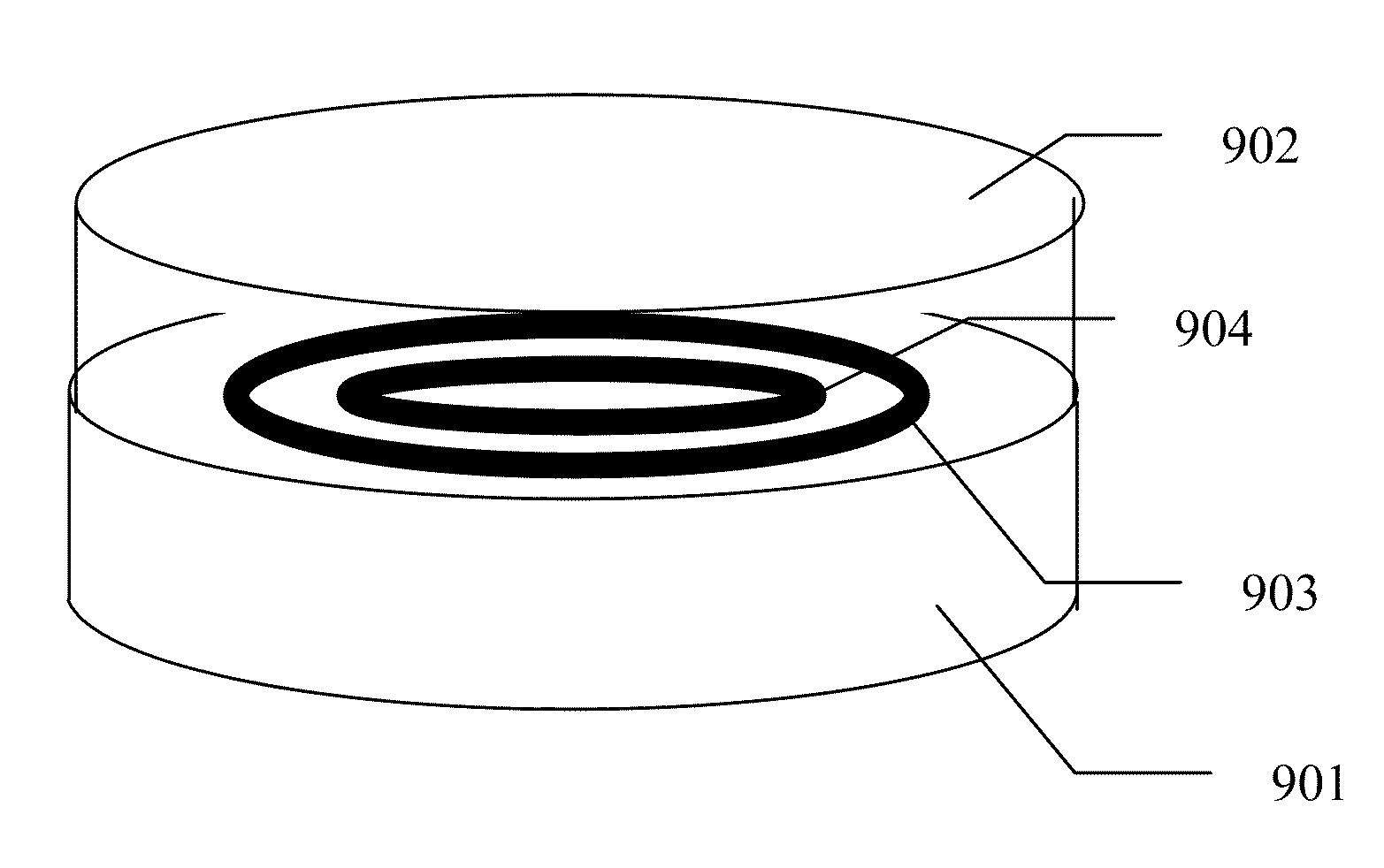

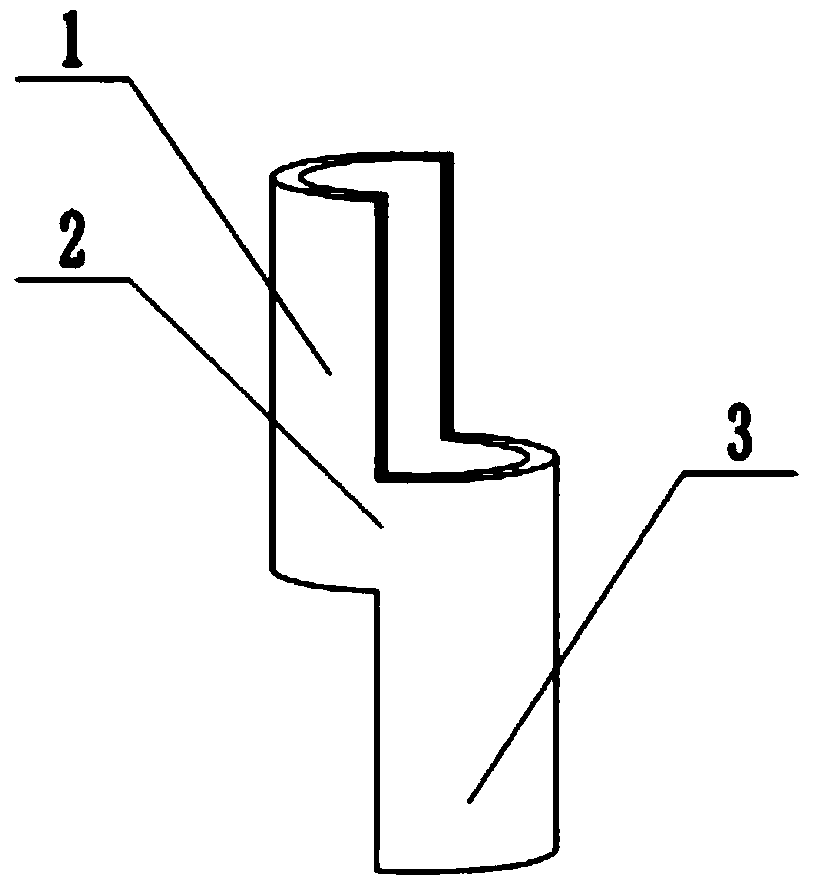

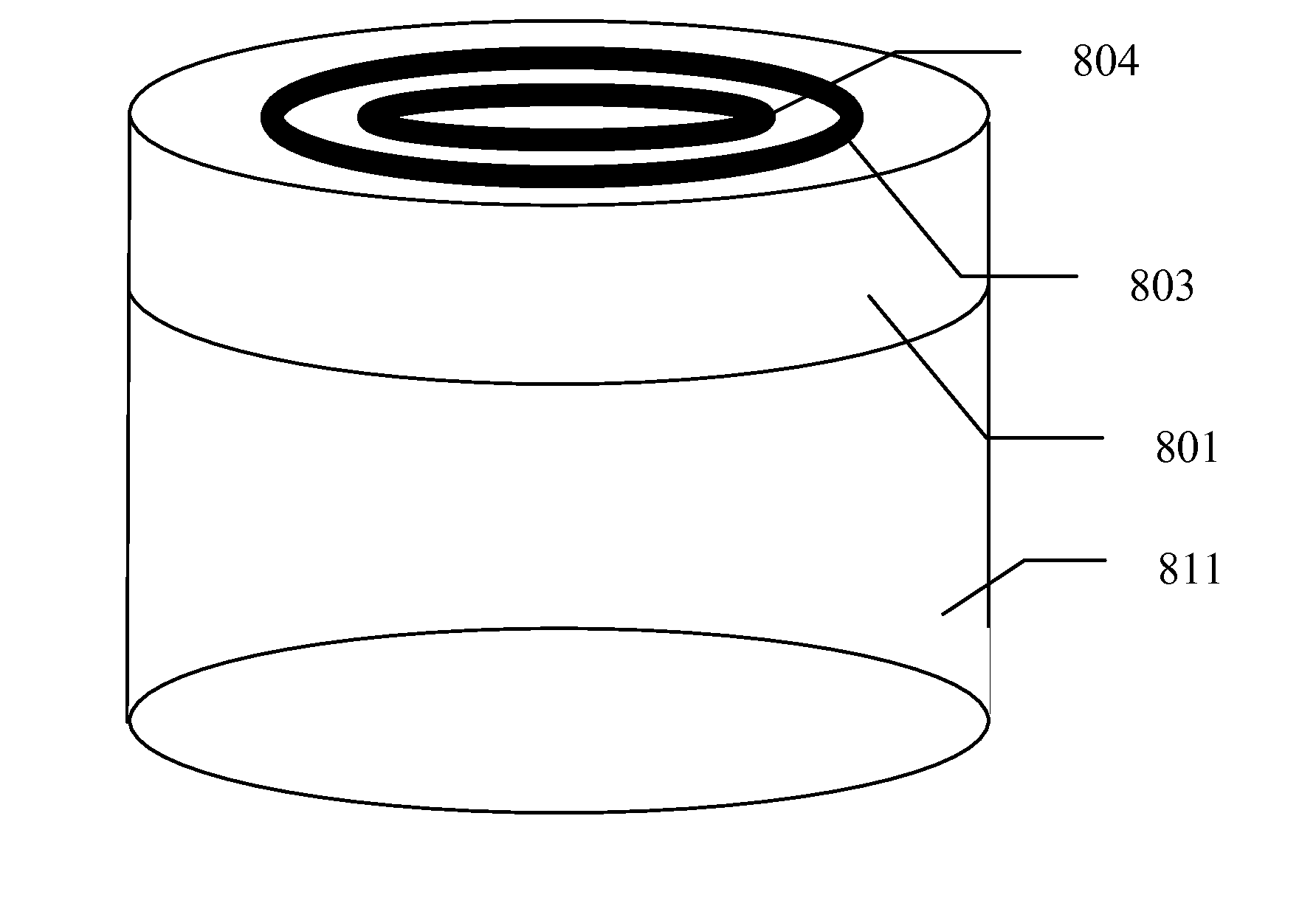

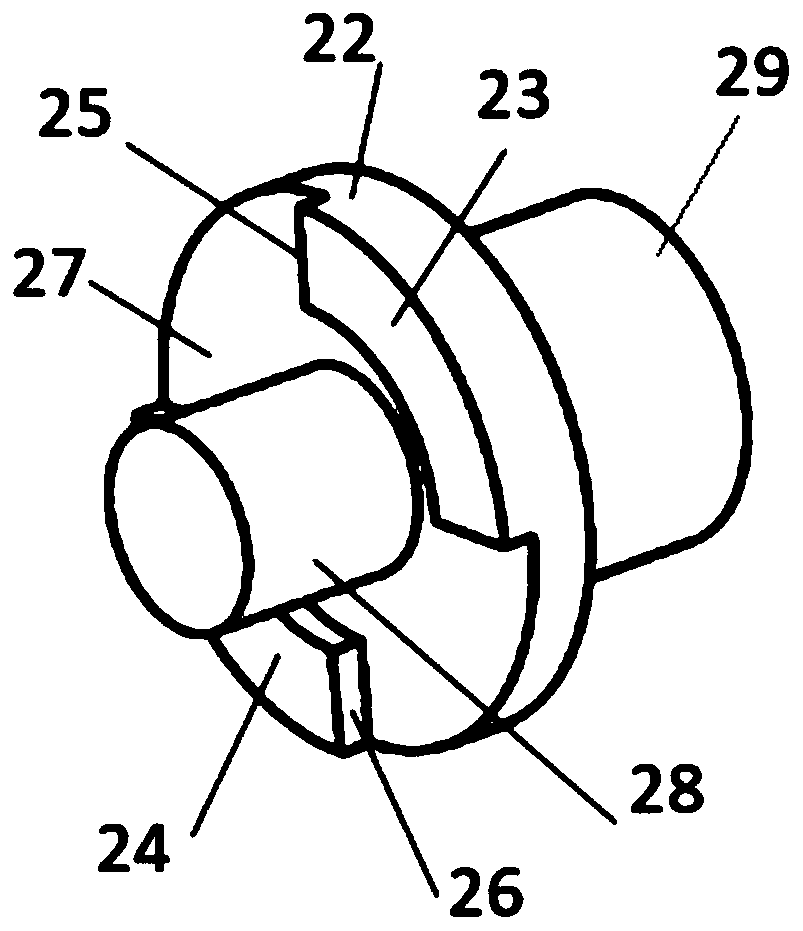

Rock specimen and method for testing pure shear of the same

ActiveUS20160103049A1Easy to measureSolve the real problemEarth material testingMaterial strength using steady shearing forcesPure shearTest bench

A rock specimen, including a rock body. The rock body includes: an upper part, an upper end face, a first circular groove, a first cylinder, a first circular body, a lower part, a lower end face, a second circular groove, a second cylinder, and a second circular body. The first circular groove is disposed on the upper end face of the rock body and has a circle center coinciding with a center of the upper end face. A method for testing pure shear of the rock specimen, includes: 1) disposing the rock specimen on a test bench of a rock mechanics testing system, allowing the end face of the second circular body to contact the test bench; and 2) operating the rock mechanics testing system, loading a pressure on the rock specimen via the end face of the first cylinder and the end face of the second circular body.

Owner:SICHUAN UNIV

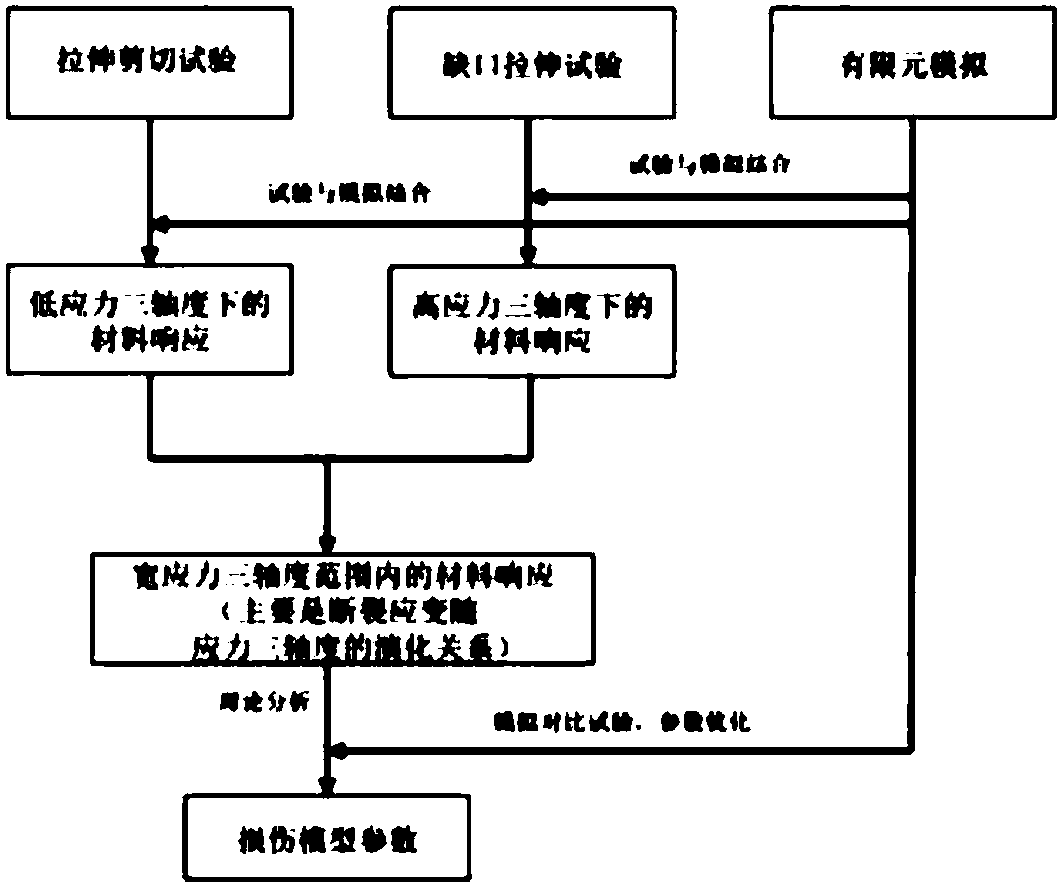

Damage model parameter calibration method based on tensile shear and notch tension tests

InactiveCN107655768AImprove calibration accuracyPrevent buildupDesign optimisation/simulationMaterial strength using steady shearing forcesShear stressStress–strain curve

The invention relates to the field of damage model parameter calibration and discloses a damage model parameter calibration method based on tensile shear and notch tension tests. The method includes:using a special-shaped tensile shear sample to convert uniaxial tensile load into pure shear load, and acquiring the shear stress-strain curve of a material under low stress triaxiality; using the notch tension test to convert uniaxial tension into triaxial tension, and acquiring the triaxial tension stress-strain curve of the material under high stress triaxiality; using full-size finite elementsimulation to acquire the precise stress-strain curve of the material in a wide stress triaxiality range and the evolutionary relationship of the fracture strain along with the stress triaxiality to provide a test foundation for damage model parameter calibration. By the method, workload can be reduced, and parameter calibration precision can be increased greatly.

Owner:CRRC QINGDAO SIFANG CO LTD

Method and device for detecting compression strength of concrete by anti-shearing method

InactiveCN102426143AAvoid damageFew influencing factorsMaterial strength using steady shearing forcesArchitectural engineeringWater transport

The invention relates to a method and a device for detecting the compression strength of concrete by an anti-shearing method. The method comprises the following steps of: calculating anti-shearing strength by recording the anti-shearing load and the area of a broken fracture surface when the concrete is broken; and building a correlated relationship according to the anti-shearing strength and the strength of a corresponding cubic test piece with the edge length of 150mm, so that the compression strength of the concrete is presumed. The influence factor during testing can be reduced by applying pure shear force to a test component, the test precision can be improved, and the test process is simple and easy. The method and the device can be widely used for detecting the solid strength of concrete structures in the industries such as building, railway, traffic, water transport, harborwork and the like.

Owner:CHINA ACAD OF BUILDING RES

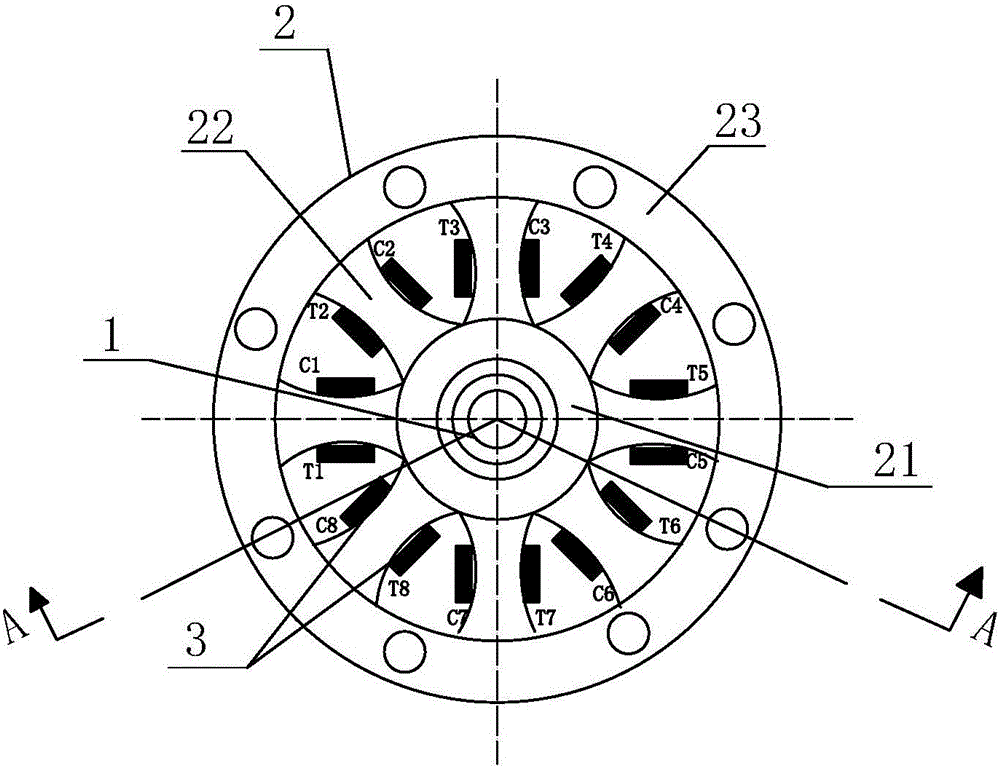

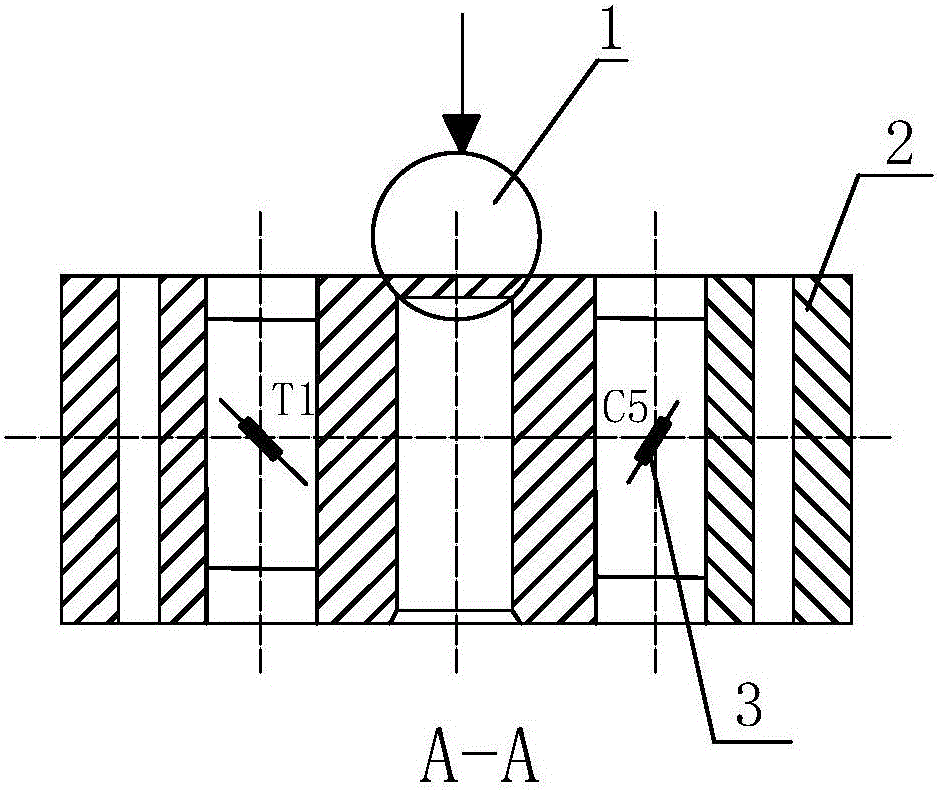

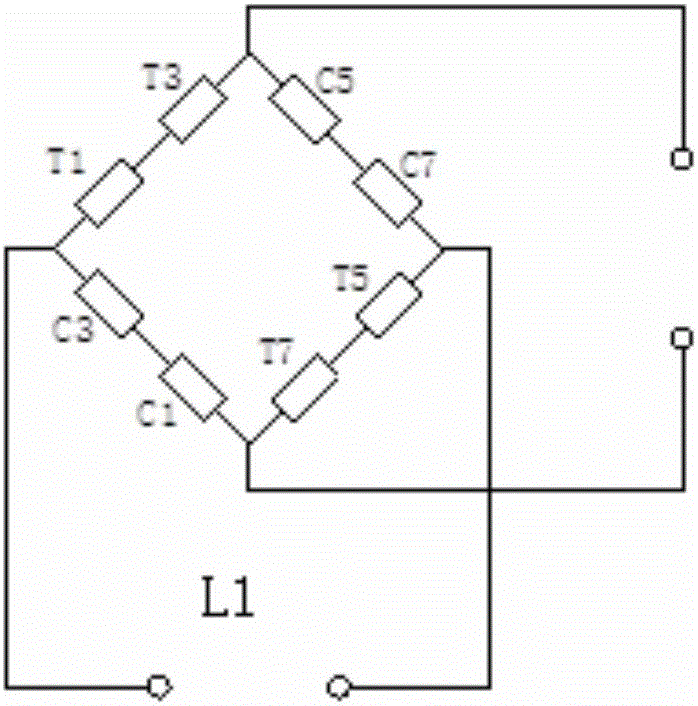

Redundancy weighing sensor

InactiveCN105675097AImprove reliabilityWeighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationElastomerSpherical bearing

The invention discloses a redundant weighing sensor, which comprises a spherical bearing pressure head, an elastic body and a resistance strain gauge, the spherical bearing pressure head is closely attached to the elastic body, and the resistance strain gauge is installed on the elastic body. In the body, they are respectively pasted on the two sides of the elastic body in the direction of tension and the direction of compression, and the resistance strain gauges in the two directions form two or more independent force-measuring detection circuits. The elastic body is a spoke-beam structure consisting of a hub, spokes and tires. The hub is located at the center of the inner ring, the tire is located at the outer ring, and the spokes are evenly distributed and connected between the hub and the spokes. The external force acts on the top of the hub and the bottom of the tire through the spherical load-bearing head, and the spokes between the tire and the hub are subjected to pure shear force, and the load is indirectly measured by measuring the force. The invention has redundant force-measuring detection circuits, and when one of them fails, it can still output correct force-measuring results.

Owner:无锡研测技术有限公司

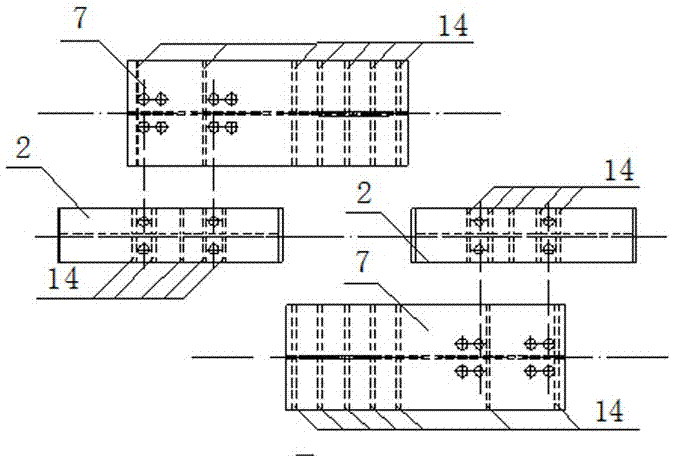

Composite interlaminar shear performance testing method

ActiveCN102680330AReduce finishing linksEasy to operatePreparing sample for investigationMaterial strength using steady shearing forcesInterlaminar shearComposite laminates

The invention belongs to the technical field of composites and relates to a composite interlaminar shear performance testing method. The testing method comprises two steps, namely the preparation of a test piece and the preparation of a testing device. In the step of preparing the test piece in the testing method disclosed by the invention, a common ply splicing and laying technology of a composite laminated plate is utilized, thus the operation is convenient, and the precision is high. When the manufacturing of the composite laminated plate is completed, the manufacturing of the test piece is completed, thus a fine processing link of the test piece is reduced, and the cost can be reduced by above 70%. The interlaminar shear testing method is simple to operate; and by adopting the interlaminar shear testing method, the damages of the test piece between designated tested layers can be ensured, the generation of pure shear damages between the tested layers can be ensured, the composite interlaminar shear performance can be precisely tested, and the testing method is suitable for composite laminated structures in various thicknesses.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Testing device for shear-resistant fatigue property of chemical anchoring stud

InactiveCN103439182AEffective anchoringReasonable designMaterial strength using repeated/pulsating forcesEngineeringStressed state

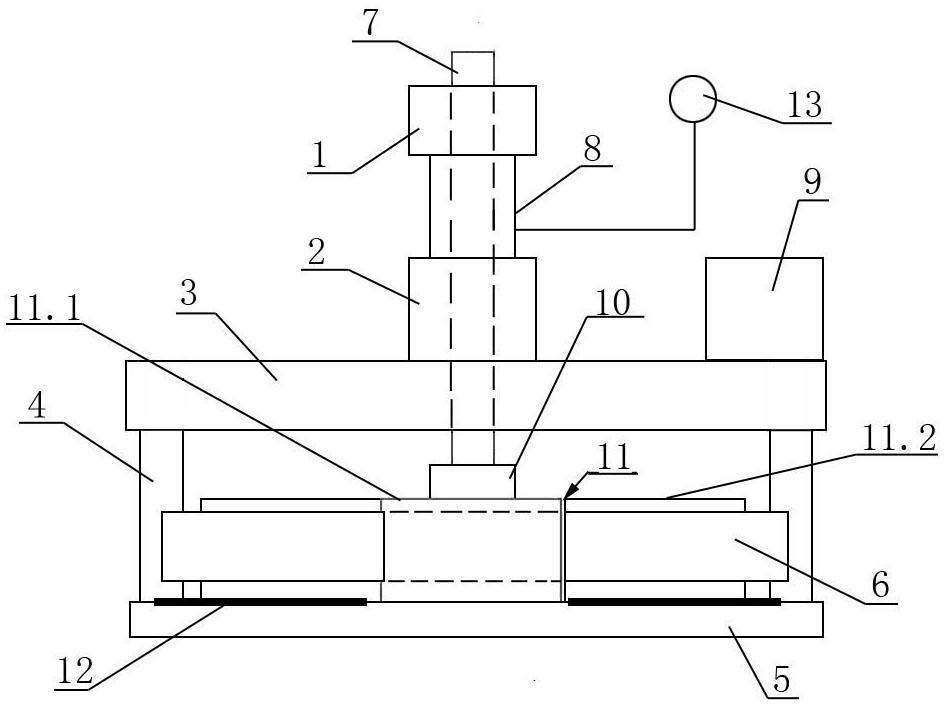

The invention provides a testing device for a shear-resistant fatigue property of a chemical anchoring stud. The testing device comprises a fatigue tester transverse beam (2) and a fatigue tester pedestal (3), wherein the fatigue tester transverse beam (2) is connected with the fatigue tester pedestal (3) by fatigue tester uprights (1), and a fixture assembly guaranteeing a pure shear stress state of the stud during a fatigue test is arranged between the fatigue tester transverse beam (2) and the fatigue tester pedestal (3). The testing device is reasonable in design, simple in structure and easy to operate and use; a T-shaped flange is arranged, and connected by a bolt, so that the testing device can be matched with testers in multiple specifications for use; and an application scope of the testing device is wider.

Owner:CENT SOUTH UNIV +1

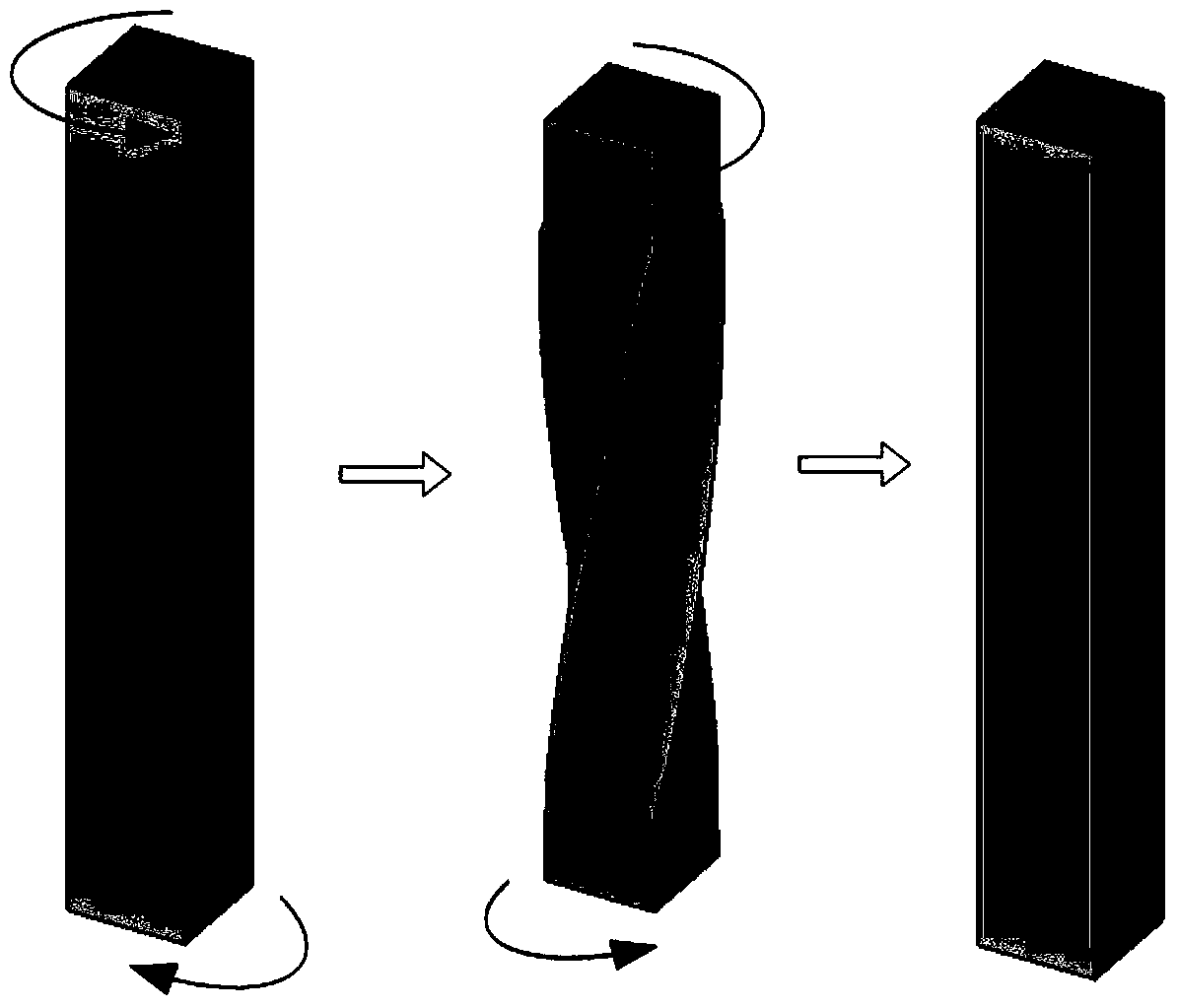

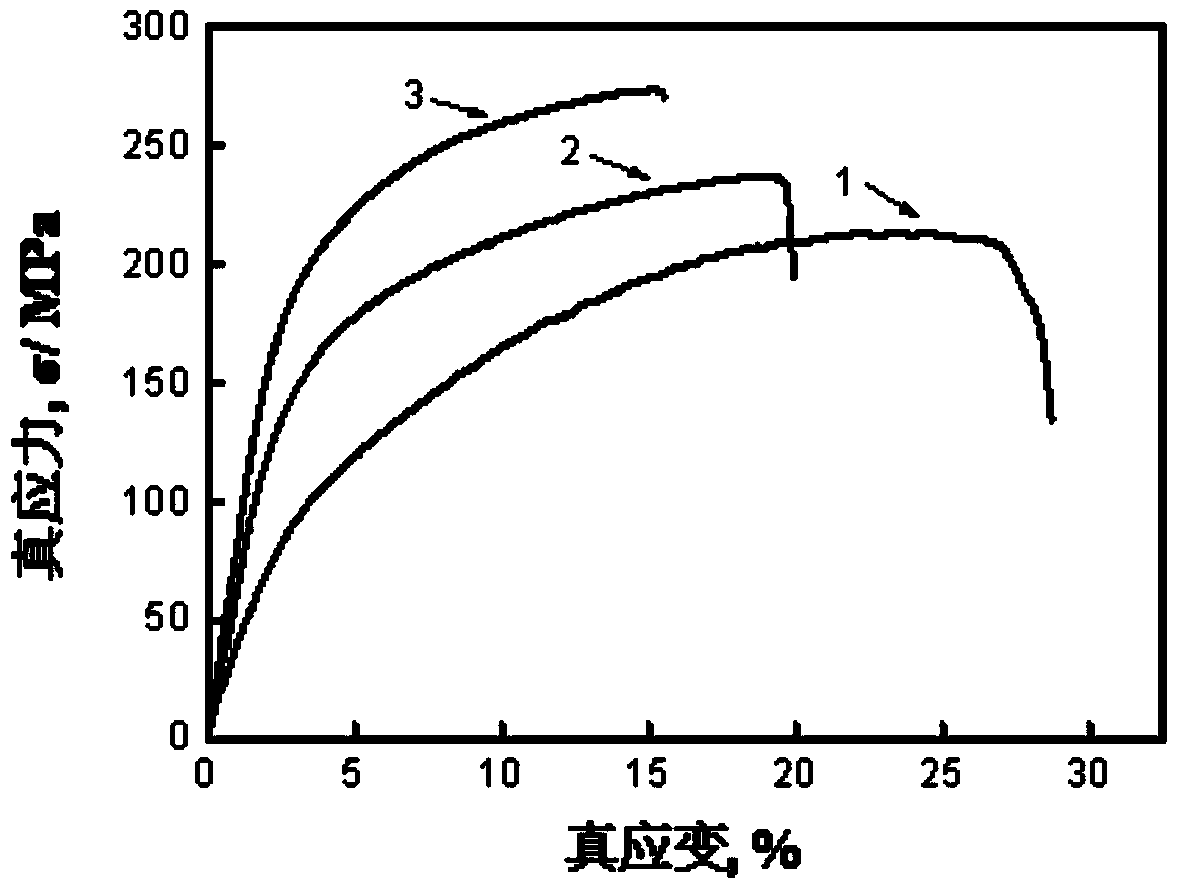

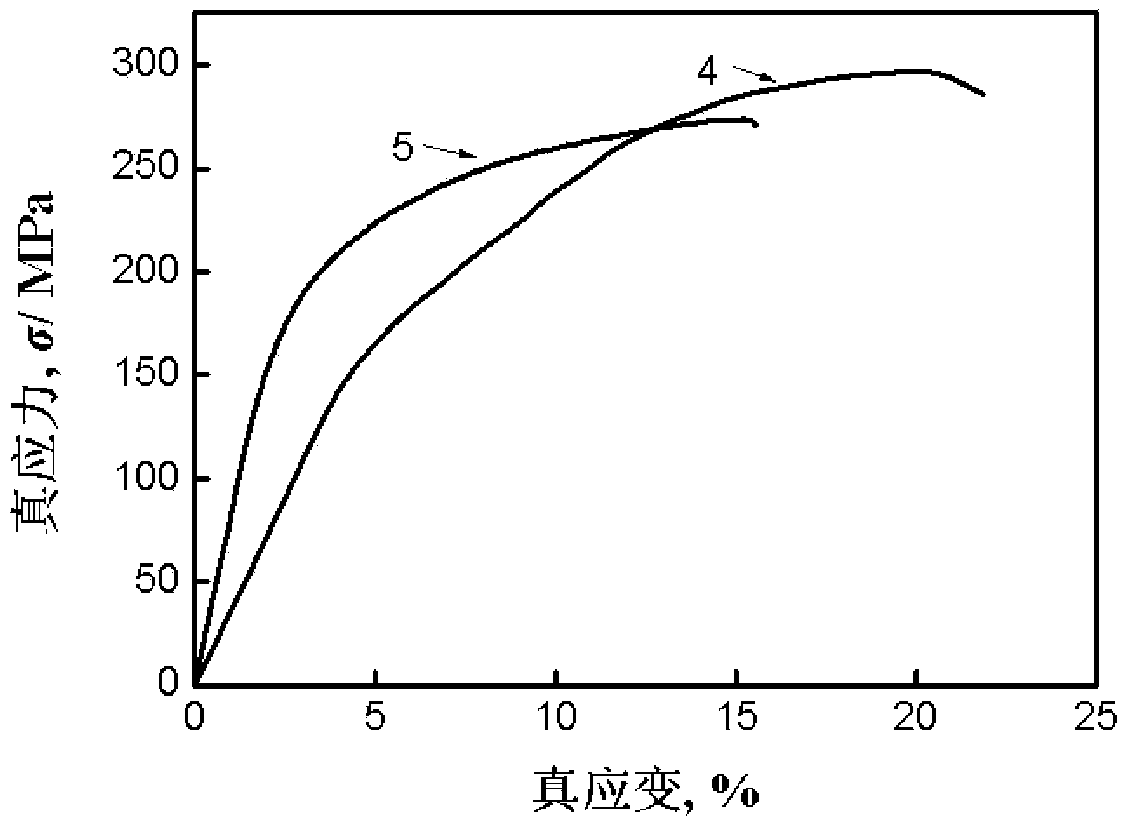

Processing method for improving drawing and pressing asymmetry of magnesium alloy

InactiveCN103540881AImprove tension and compression asymmetryChange distributionCrystal twinningCrystal orientation

The invention relates to a processing method for improving the drawing and pressing asymmetry of magnesium alloy. The method comprises the steps of homogenizing a magnesium alloy rod or pipe; and then, with the axis of the rod or pipe as a rotating center, carrying out clockwise and / or anticlockwise torsional deformation. Crystals are rotated and twinborn because the magnesium alloy rod or pipe is under the action of a pure shear stress through repeated torsional deformation, the volume fractions of produced twin crystals are also in gradient distribution from edges to a central part due to different deformation degrees of a sample from the central parts to the edges on a cross section, and the crystal orientation distribution of the sample can be greatly changed due to the twin crystals, so that the texture of a basal plane can be effectively regulated, and the drawing and pressing asymmetry of magnesium alloy is mainly weakened on the aspect of the texture of the basal plane. The method is reasonable in technological design, simple in equipment requirements, convenient to operate, low in cost, low in energy consumption and high in efficiency, the strength of magnesium alloy is increased, and the drawing and pressing asymmetry problem of magnesium alloy is also greatly improved, and the method has a good industrial application prospect.

Owner:CENT SOUTH UNIV

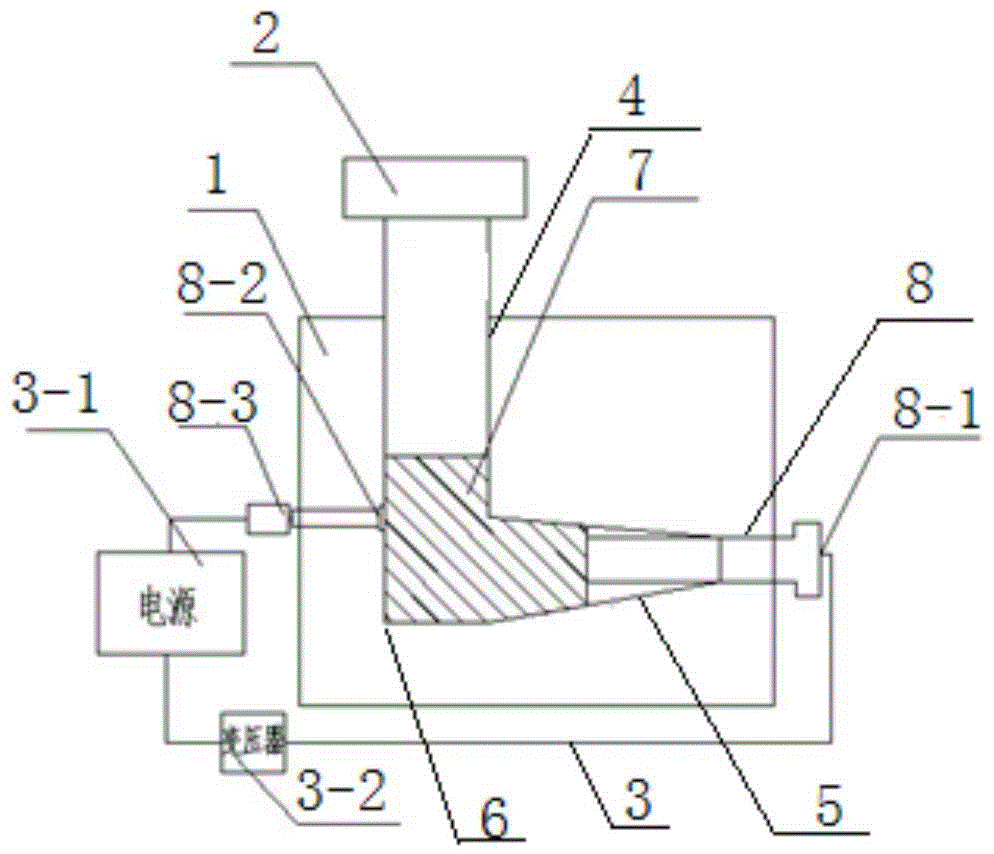

Device and method for preparing fine grains through electroplastic variable-section corner extrusion

The invention discloses a device and method for preparing fine grains through electroplastic variable-section corner extrusion. The device comprises a die and an extrusion rod, and further comprises a power-up device, and a cylinder die cavity and a circular truncated cone die cavity are arranged in the die; and the cylinder die cavity is communicated with the circular truncated cone die cavity, and a corner is formed by connecting positions of the cylinder die cavity and the circular truncated cone die cavity. According to the device, the cylinder die cavity and the circular truncated cone die cavity are combined, pure shear deformation of an extruded workpiece and heading deformation of the extruded workpiece are combined, so that the grain refinement efficiency and homogeneity of the extruded workpiece are improved; and in addition, pure shear deformation and heading deformation defects such as easily-occurring cracks, easily-occurring heave types and surface defects disappear in the deformation process. Meanwhile, currents are applied to the extruded workpiece and will generate joule heat when flowing through the die and the extruded workpiece, the metal plasticity will also be improved through the heat, and the time of heating needed for thermal deformation of the workpiece can be shortened.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

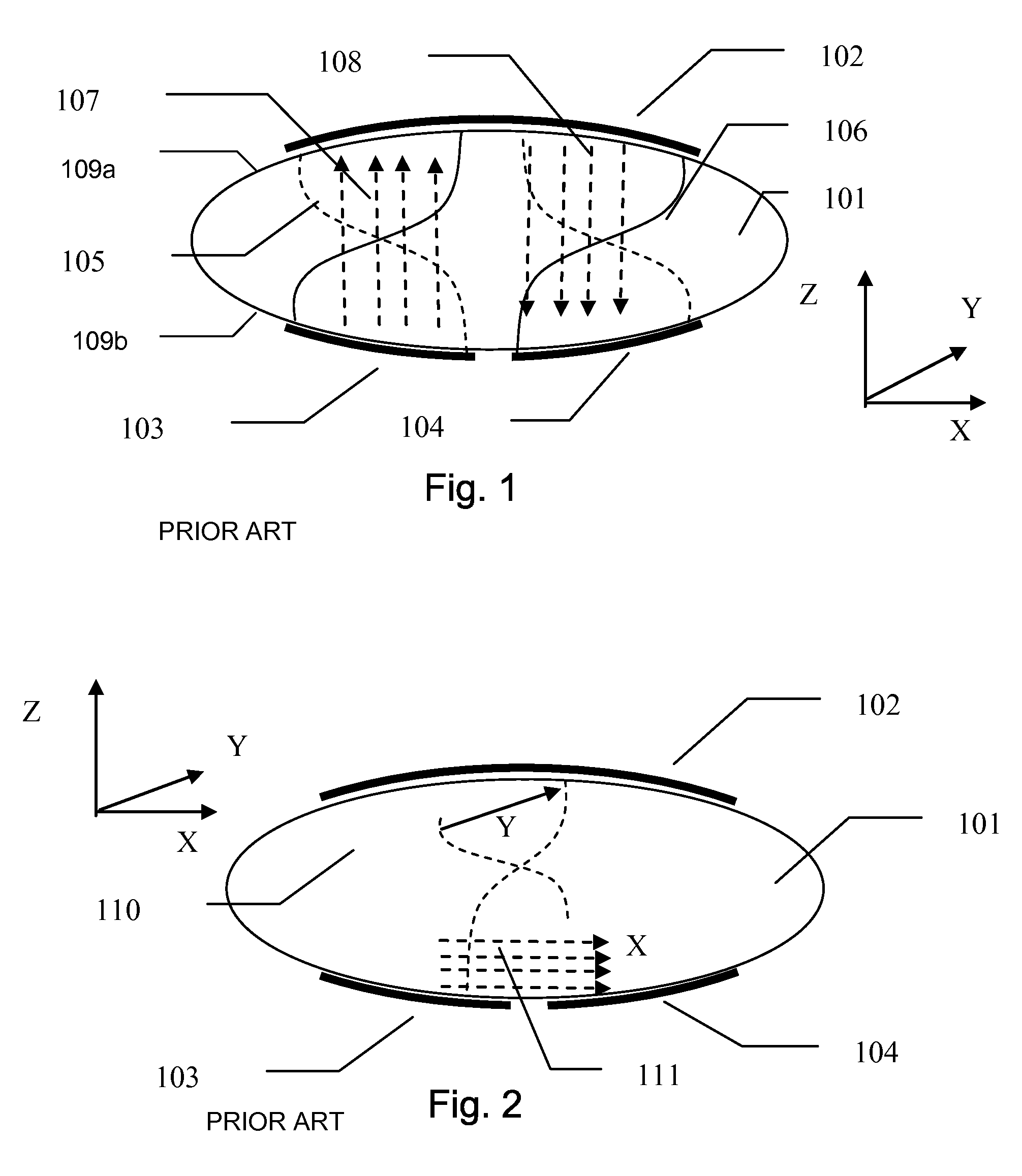

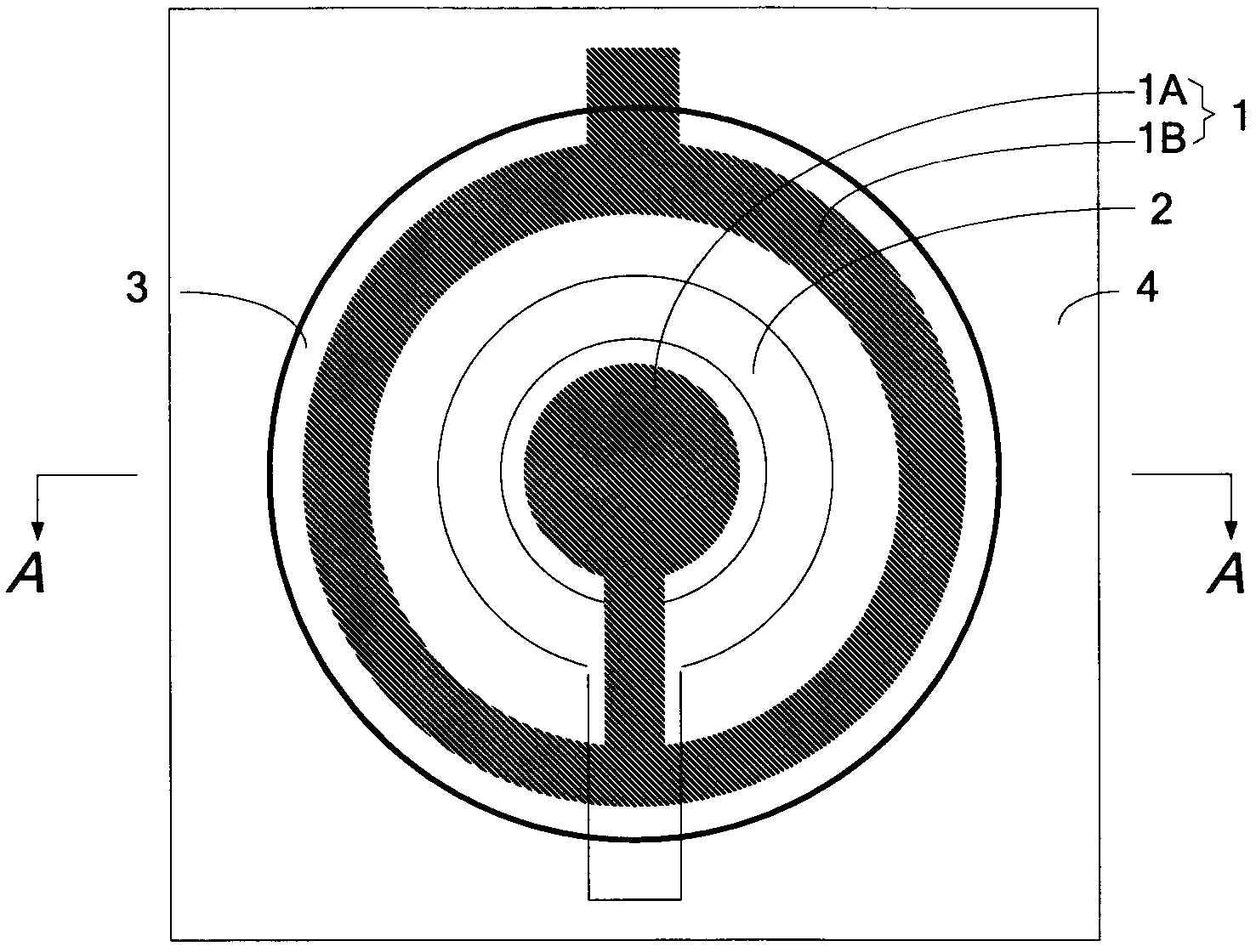

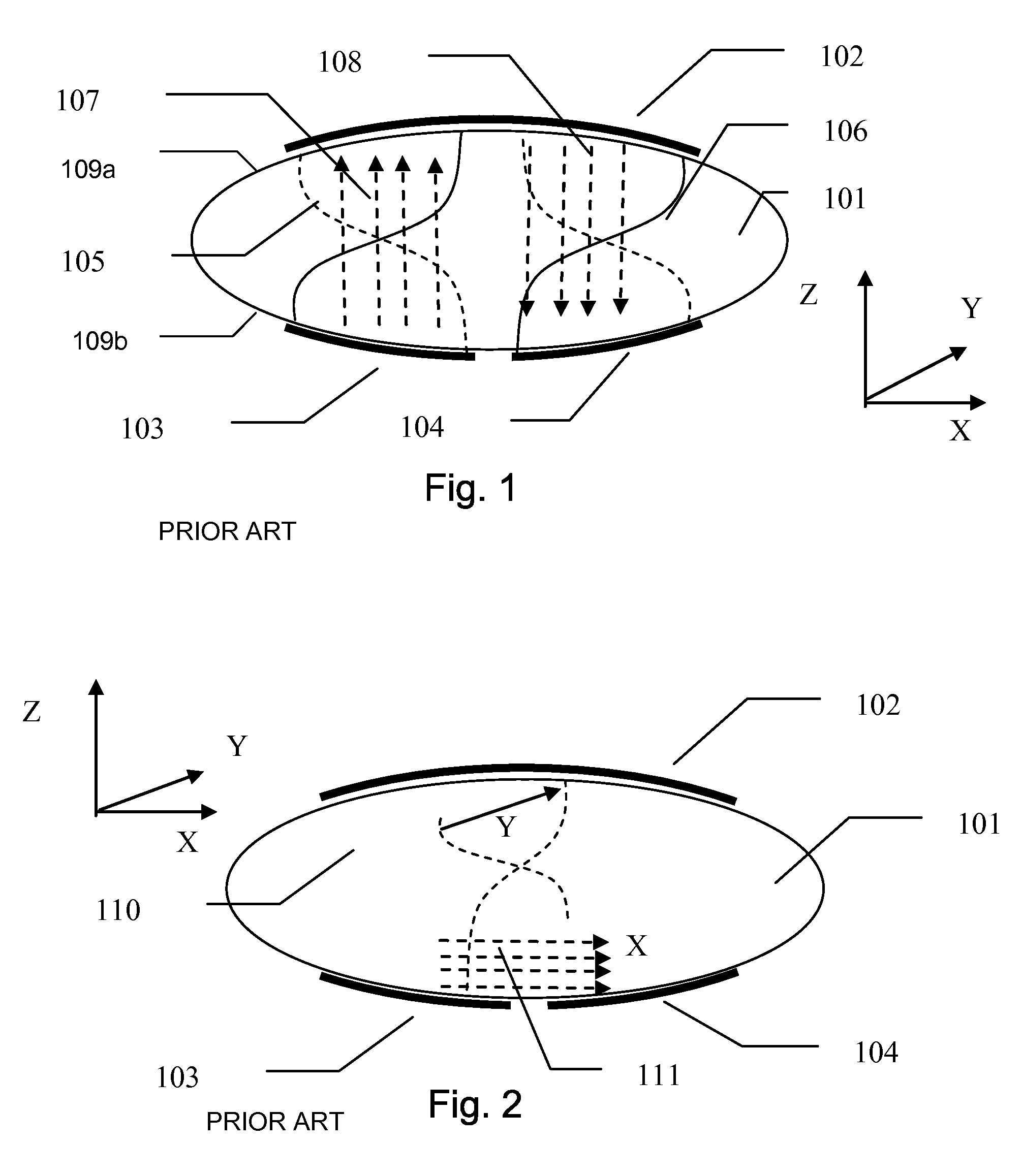

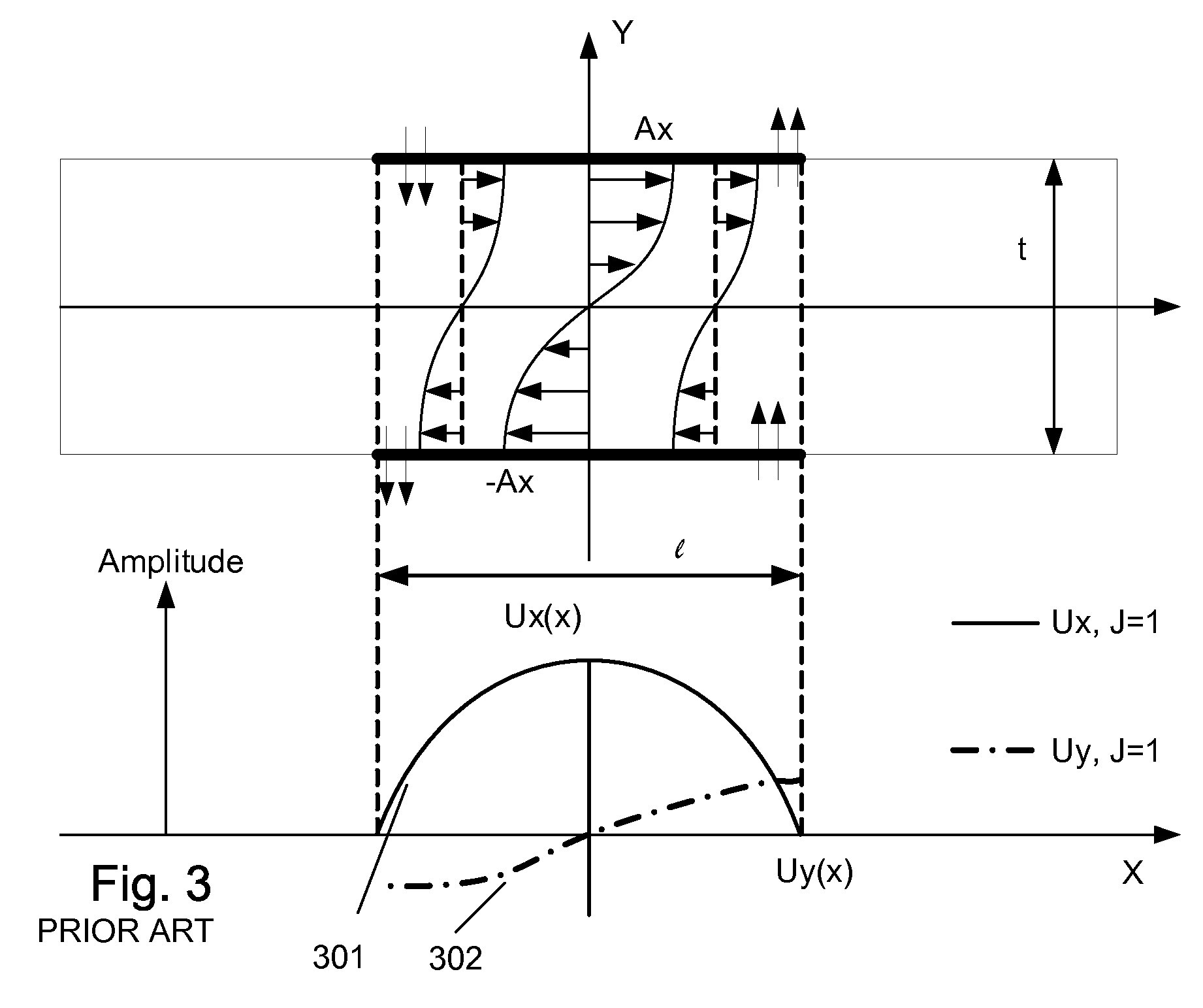

Lateral excitation of pure shear modes

InactiveUS7936110B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesPure shearAtomic physics

Circularly polarized resonant structures are obtained utilizing piezoelectric resonators made of materials and orientations selected in accordance with the teaching provided herewith. Further provided are radially polarized structures. Furthermore, the utilization of such resonators and structures as sensors, for frequency control application, for signal filtering, and the like, is also disclosed.

Owner:KNOWLES CAPITAL FORMATION

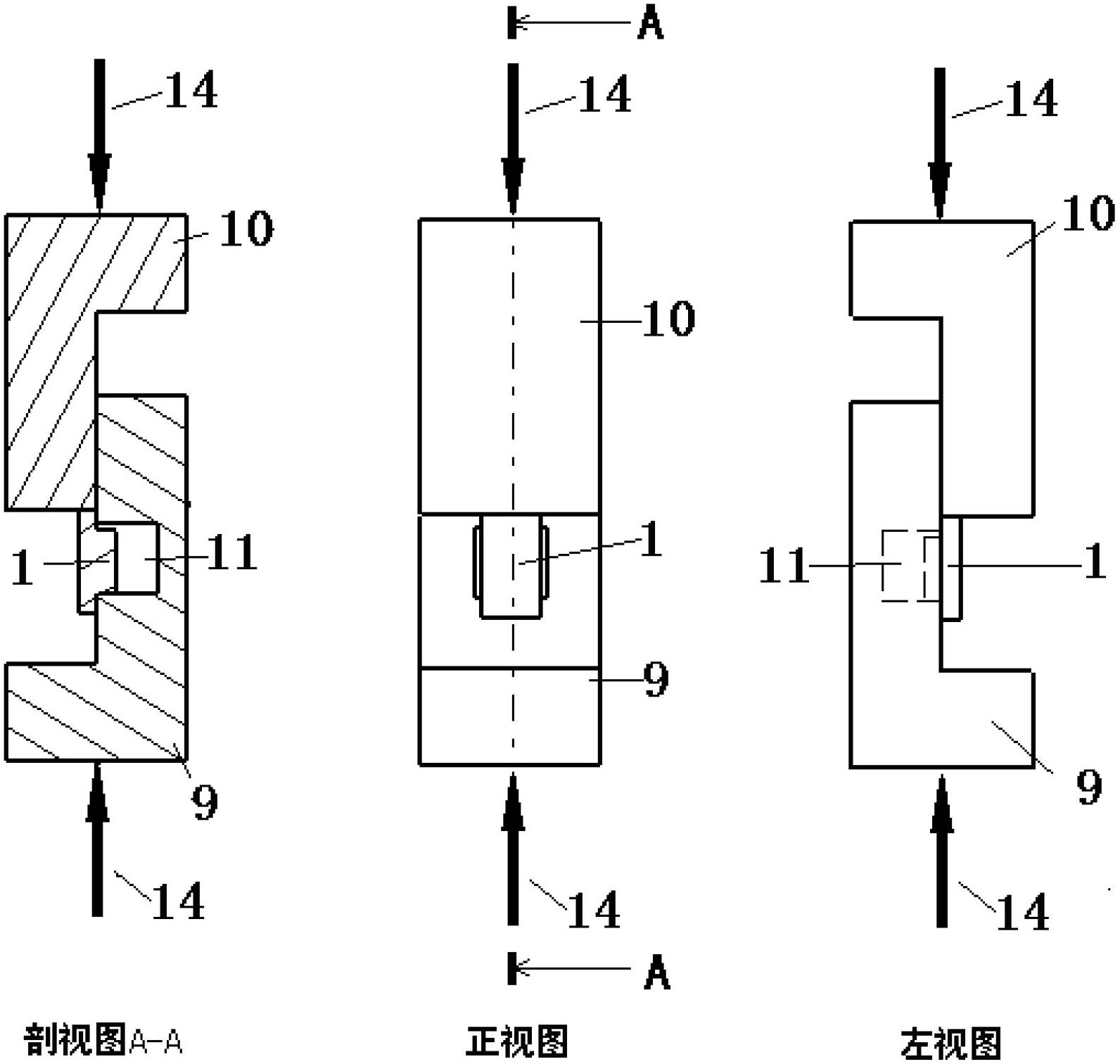

Device for testing shear strength of joint of external prestressing prefabrication and assembly concrete member

InactiveCN103018115AAvoid bending momentEnables pure shear loadingMaterial strength using steady shearing forcesPre stressUltimate tensile strength

The invention discloses a device for testing shear strength of a joint of an external prestressing prefabrication and assembly concrete member. The device disclosed by the invention is characterized in that a first segment of the concrete member is arranged on a support, a hydraulic jack is loaded on the upper end face of a second segment of the concrete member; the cross section of the first segment of the concrete member is of an L shape, the cross section of the second segment of the concrete member is of an inverted L shape, the first segment of the concrete member and the second segment of the concrete member are assembled into a vertical joint, an upper horizontal plane joint and a lower horizontal plant joint by virtue of a post-tensioning prestressing tension device, the upper horizontal plane joint and the lower horizontal plane joint are respectively connected with at least one vertically arranged displacement sensor in a bridging manner, and the vertical joint is connected with one group of displacement sensors horizontally arranged in a bridging manner; and the center connecting line of the support and the hydraulic jack is coincided with that of the vertical joint. The device disclosed by the invention has the advantages that the bending moment of a loaded concrete member can be avoided, pure shear loading is realized, the displacement sensors are arranged at the joint, double control on loading is carried out by virtue of a force and displacements, and the loading failure time can be timely known, so that the device disclosed by the invention has certain safety.

Owner:NINGBO UNIV

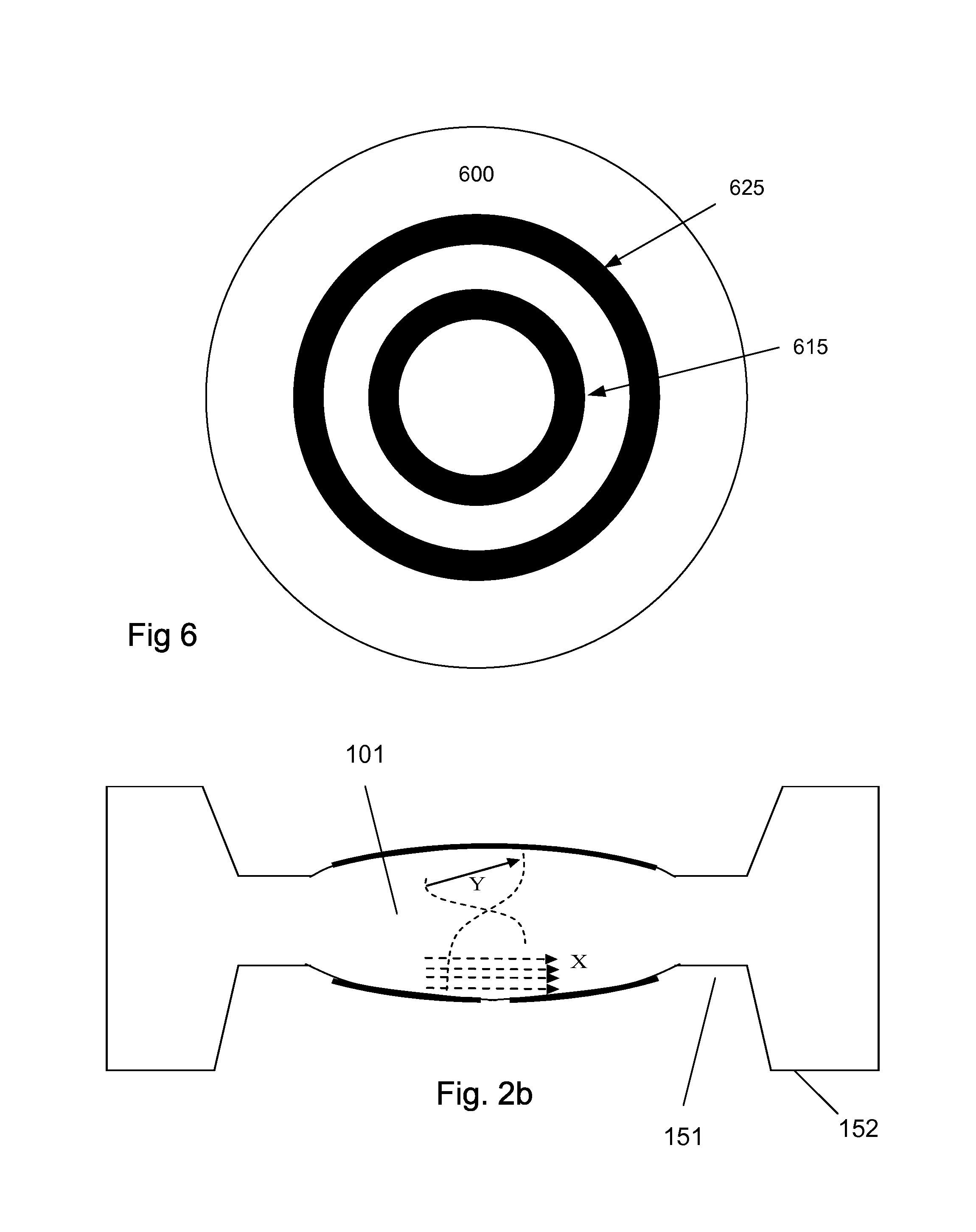

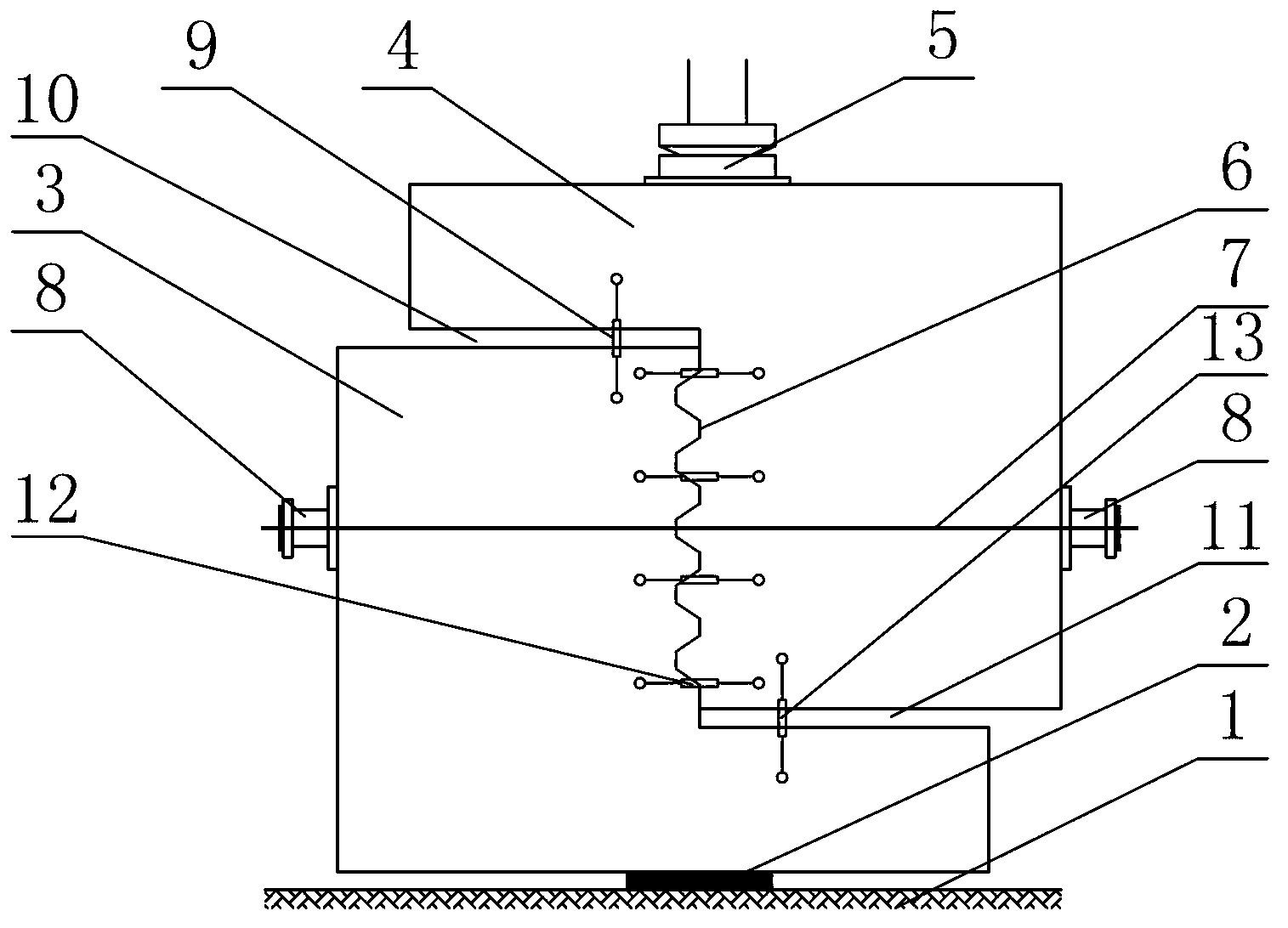

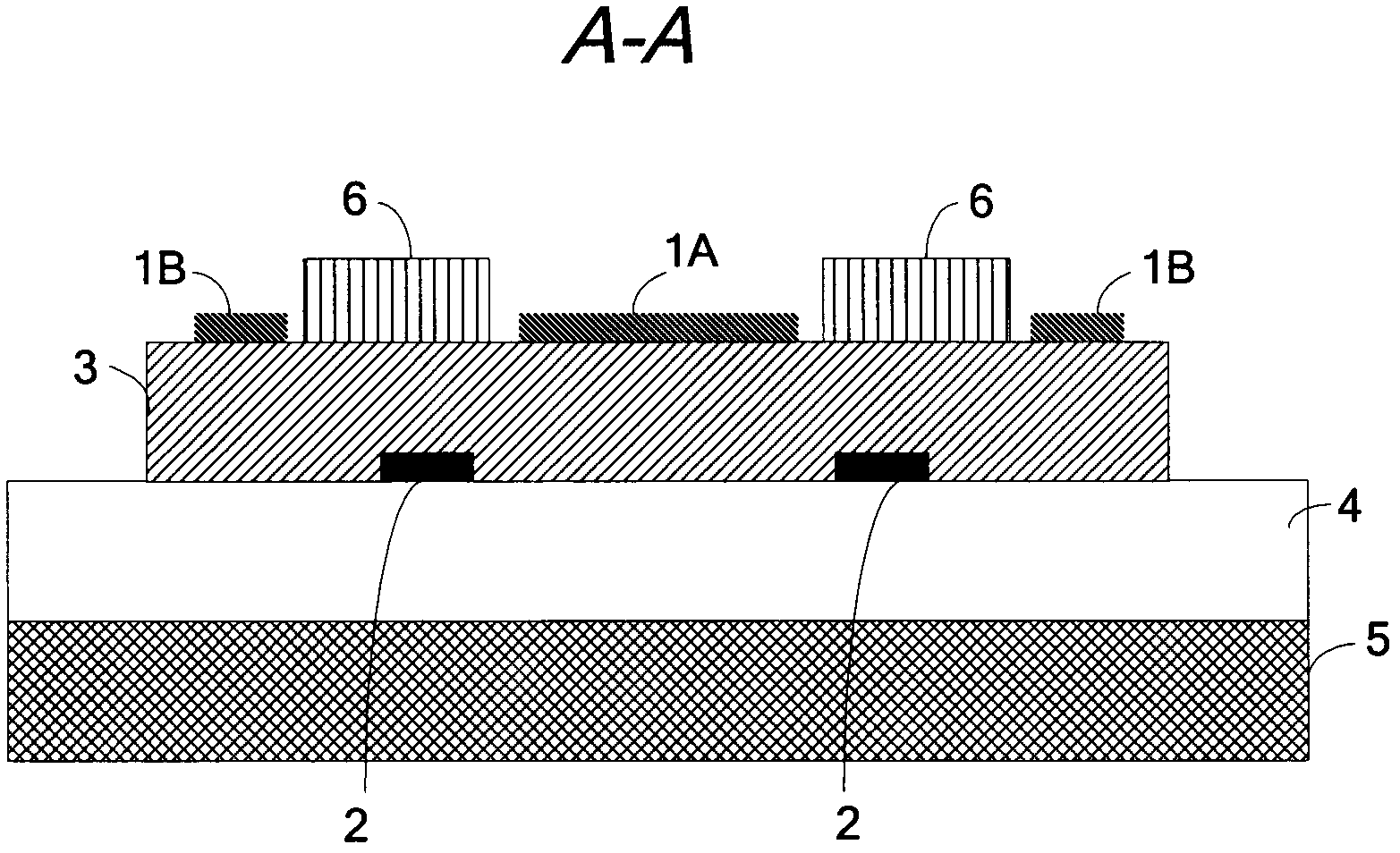

Thin film bulk acoustic resonance biochemical sensor with annular electrodes

InactiveCN102621025AReduce the electric field componentIncreased sensitivityWeighing by absorbing componentAcoustic wavePure shear

The invention discloses a thin film bulk acoustic resonance biochemical sensor with annular electrodes. The sensor comprises an upper electrode, a lower electrode, a piezoelectric thin film and a sound isolating layer, wherein the upper electrode has a ring shape comprising an inner layer and an outer layer which are concentric and consists of an inner layer solid circle and an outer layer hollow ring; the lower electrode has a hollow ring shape which is concentric with that of the upper electrode; and the upper electrode and the lower electrode are not superposed in the vertical direction of the rings. The thin film bulk acoustic resonance biochemical sensor approximate to a pure shear wave mode is acquired by the technical scheme, and the sensibility in liquid is greatly improved.

Owner:SHANDONG UNIV OF SCI & TECH

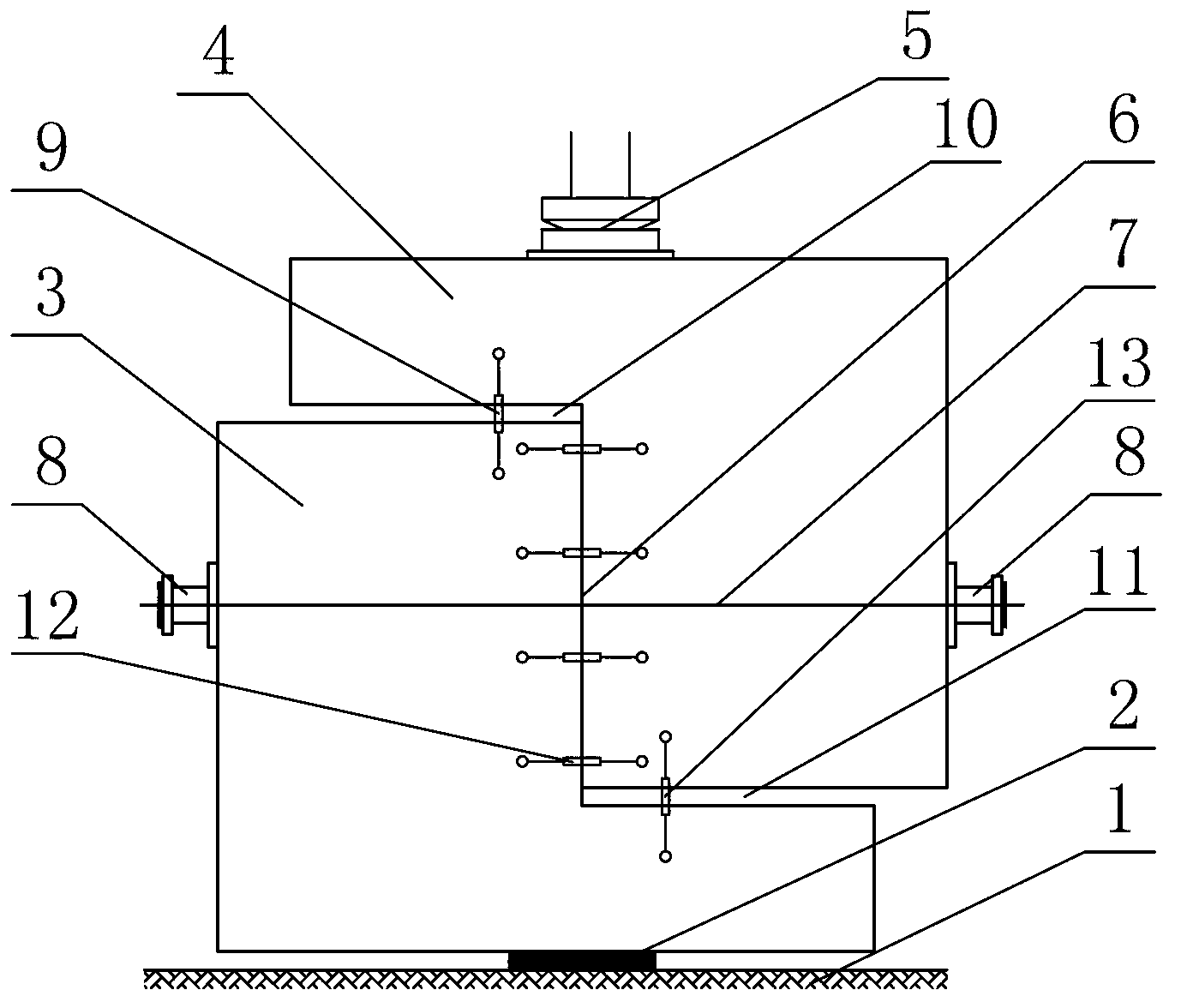

Pure-shearing experimental device for new and old concrete bonding interfaces

ActiveCN105259111AReduce volumeEasy to makeUsing mechanical meansMaterial analysisMachineMechanical property

The invention relates to a novel experimental device in the field of hydraulic and civil engineering and particularly relates to a pure-shearing experimental device for new and old concrete bonding interfaces. The pure-shearing experimental device comprises an upper L-shaped clamp, a lower L-shaped clamp, bolts, a side-surface chuck, a concrete test piece, an experimental machine base, an experimental machine pressing head, screws and a spring. The novel experimental device has the advantages that the size is small, the preparation is simple, the use is convenient, the assembly and the disassembly are convenient, the pure-shearing experiment can be carried out on the new and old concrete bonding interfaces under the pure-shearing condition, the shearing strength of the new and old concrete bonding interfaces under the pure-shearing action can be tested, the shearing stress performance of a new reinforced concrete structure can be analyzed, the shearing strength parameter of the bonding interfaces is provided and can be used as the mechanical property index for the reinforcement and restoration design of the concrete structure, and simultaneously technical guidance is provided for treating the new and old concrete bonding interfaces in concrete reinforcement construction.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

Device for testing shear strength of joint of external prestressing prefabrication and assembly concrete member

ActiveCN103018114AAvoid bending momentEnables pure shear loadingMaterial strength using steady shearing forcesPre stressUltimate tensile strength

The invention discloses a device for testing the shear strength of a joint of an external prestressing prefabrication and assembly concrete member. The device disclosed by the invention is characterized in that a first segment of the concrete member is arranged on a support, a hydraulic jack is loaded on the upper end face of a second segment of the concrete member; the cross section of the first segment of the concrete member is of an L shape, the cross section of the second segment of the concrete member is of an inverted L shape, the first segment of the concrete member and the second segment of the concrete member are assembled into a vertical joint, an upper horizontal plane joint and a lower horizontal plant joint by virtue of an external prestressing tension device, the upper horizontal plane joint and the lower horizontal plane joint are respectively connected with at least one vertically arranged displacement sensor in a bridging manner, and the vertical joint is connected with one group of displacement sensors horizontally arranged in a bridging manner; and the center connecting line of the support and the hydraulic jack is coincided with that of the vertical joint. The device disclosed by the invention has the advantages that the bending moment of a loaded concrete member can be avoided, pure shear loading is realized, the displacement sensors are arranged at the joint, double control on loading is carried out by virtue of a force and displacements, and the loading failure time can be timely known, so that the device disclosed by the invention has certain safety.

Owner:NINGBO UNIV

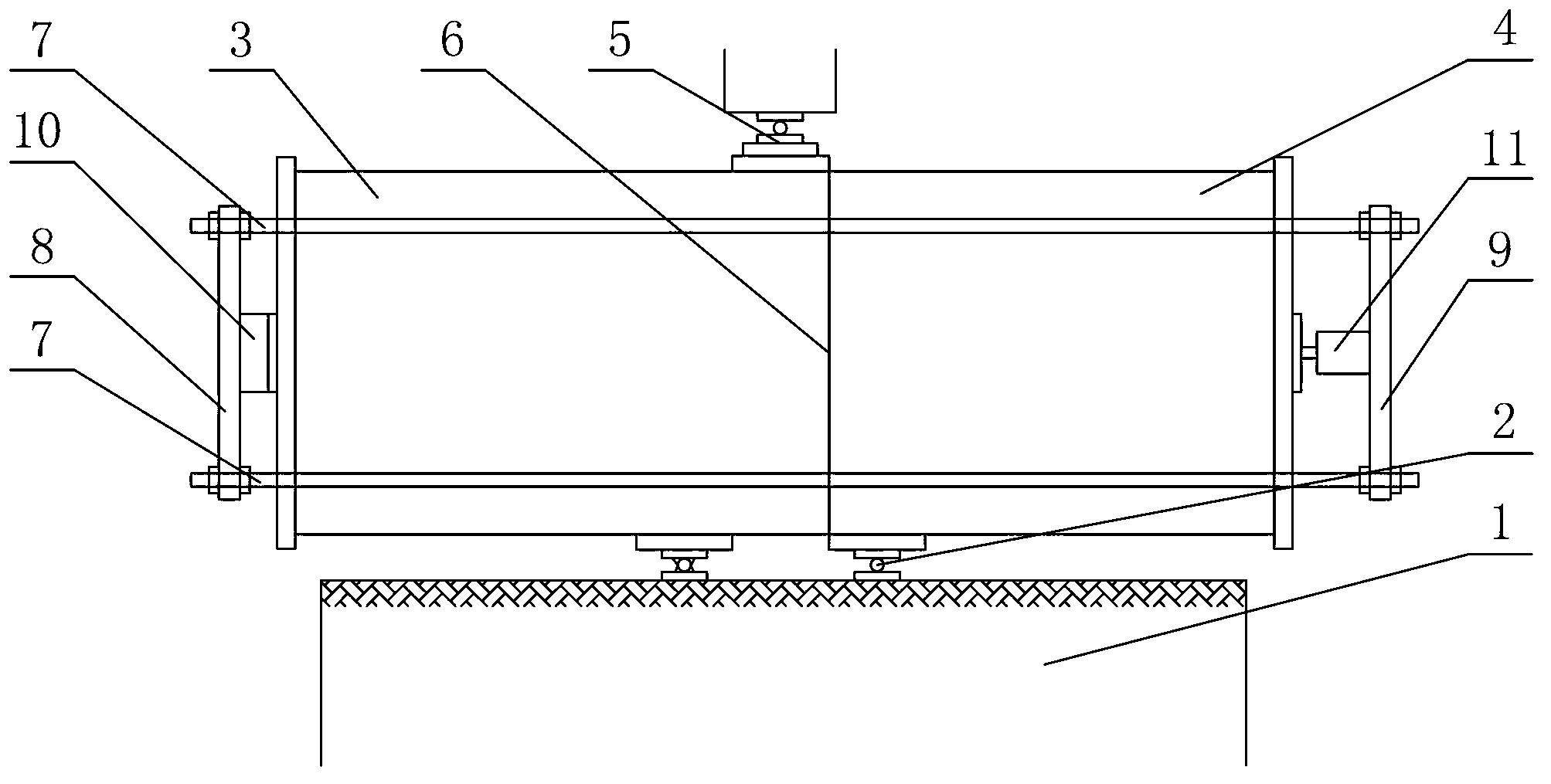

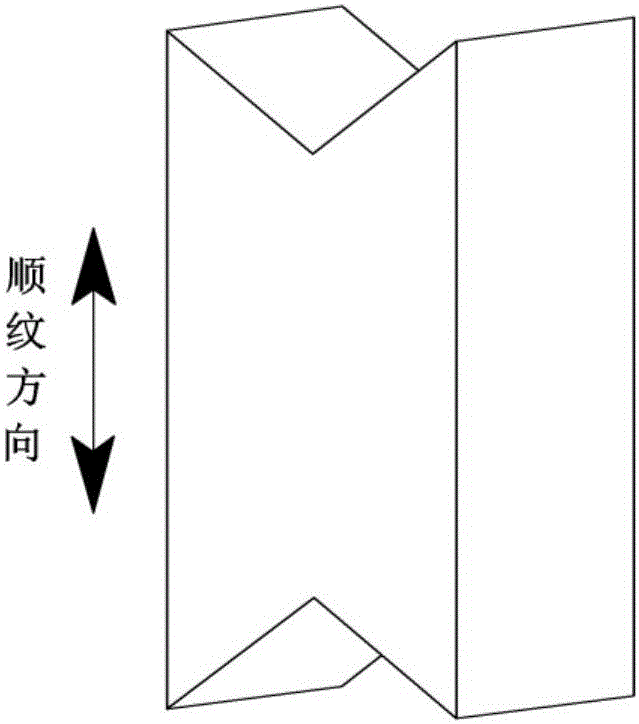

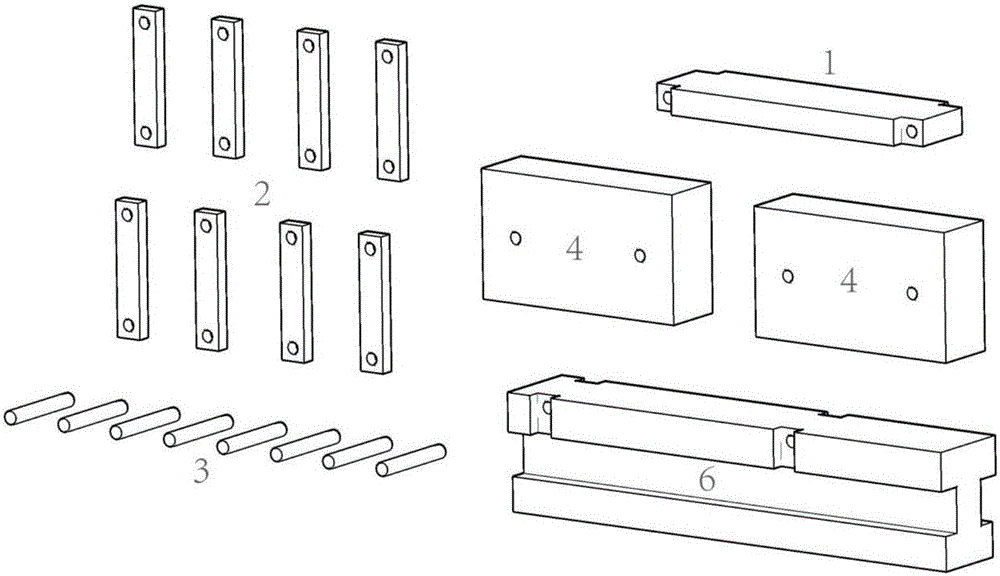

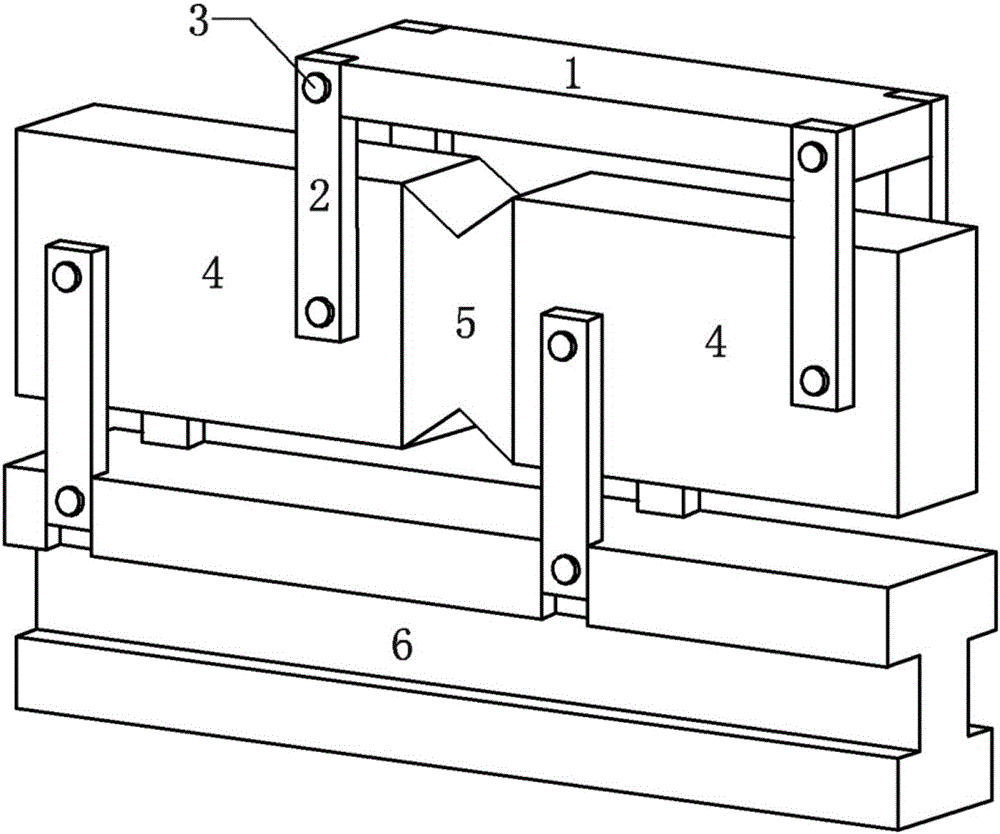

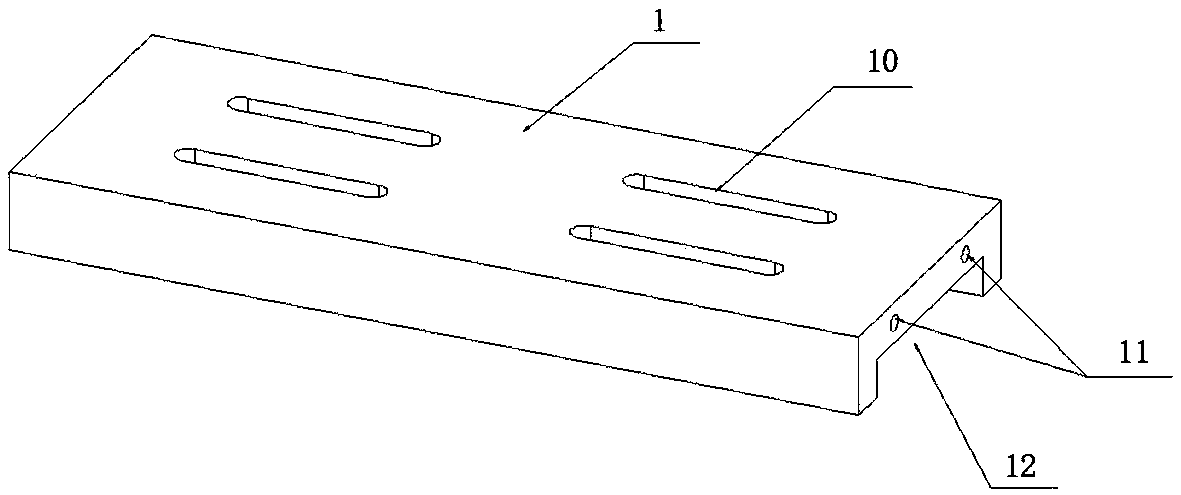

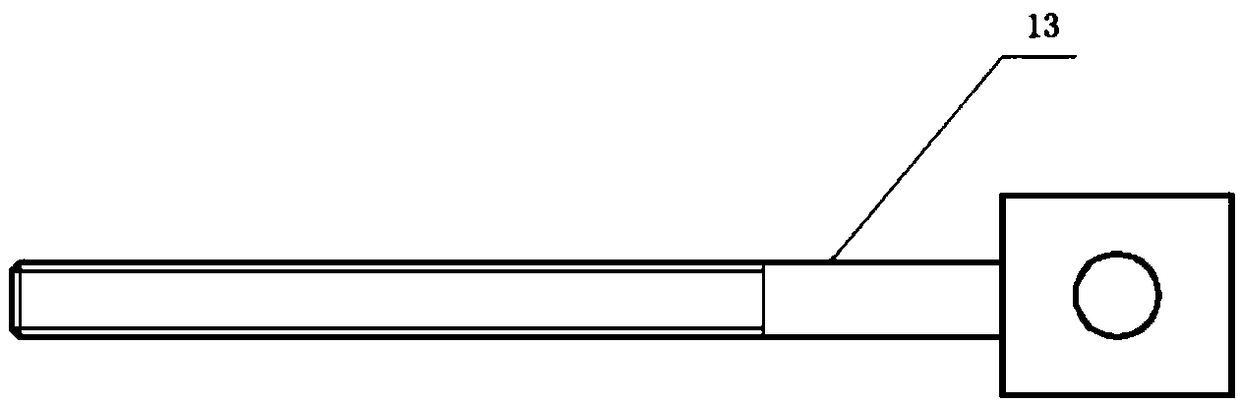

Measurement device of wood along-grain direction pure shear strength

InactiveCN105842084AShear Strength AccurateMaterial strength using steady shearing forcesStress distributionStress concentration

The invention provides a measurement device of wood along-grain direction pure shear strength. The measurement device mainly includes: a wood material having a V-shaped groove, which is arranged between two aluminum pieces at the left and the right and are bond to the two aluminum pieces to form an aluminum-wood composed beam, which is respectively connected to an upper transmission beam at the upper part and a lower pedestal at the lower part through connectors, thereby forming an integrated structure with the upper transmission beam and the lower pedestal. The apparatus can obtain an accurate result of shear strength of the wood and overcomes the defects of non-uniform shear force distribution on a shear rupture plane, stress concentration in concave angles, and bending stress on a rupture plane in shear test in wood specification, and overcomes the defects that the rupture in a test of measuring shear strength of the wood material with an Iosipescu shear apparatus directly does not occur in a theoretical rupture plane, the stress distribution at the left and right on a sample is asymmetric, deformation of the sample is intensive and the sample may slide.

Owner:BEIJING JIAOTONG UNIV

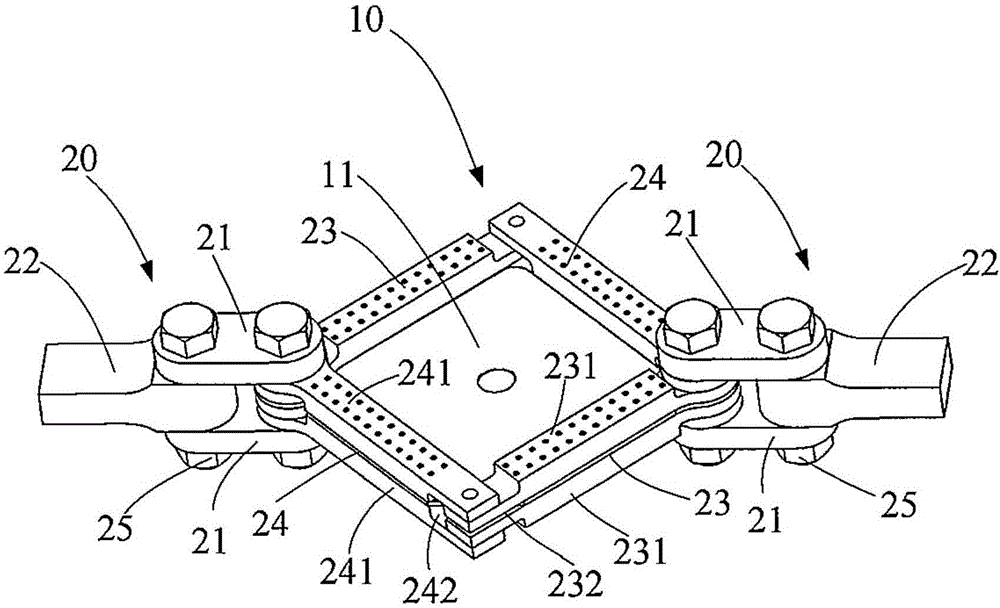

Test device for testing shearing performance

PendingCN112161880APass clearHigh precisionMaterial strength using steady shearing forcesStructural engineeringMachine

The invention discloses a test device for testing the shearing performance, and relates to the technical field of shearing performance testing. The test device for testing the shearing performance comprises a clamp, a connecting joint and a loading joint, the clamp is detachably connected with the edge of a test piece, a load is applied along a first diagonal line of the test piece through the clamp, the connecting joint and the loading joint are arranged on two corners corresponding to the first diagonal line, one end of the connecting joint is hinged with the clamp, the other end of the connecting rod is hinged with the loading joint, and the loading joint is hinged with a testing machine. According to the test device for testing the shearing performance, the connecting joint is hinged with the clamp and the loading joint, so that the load transmission is clear, the test load of near-pure shearing can be provided for the test piece, and the high-precision test loading is realized.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

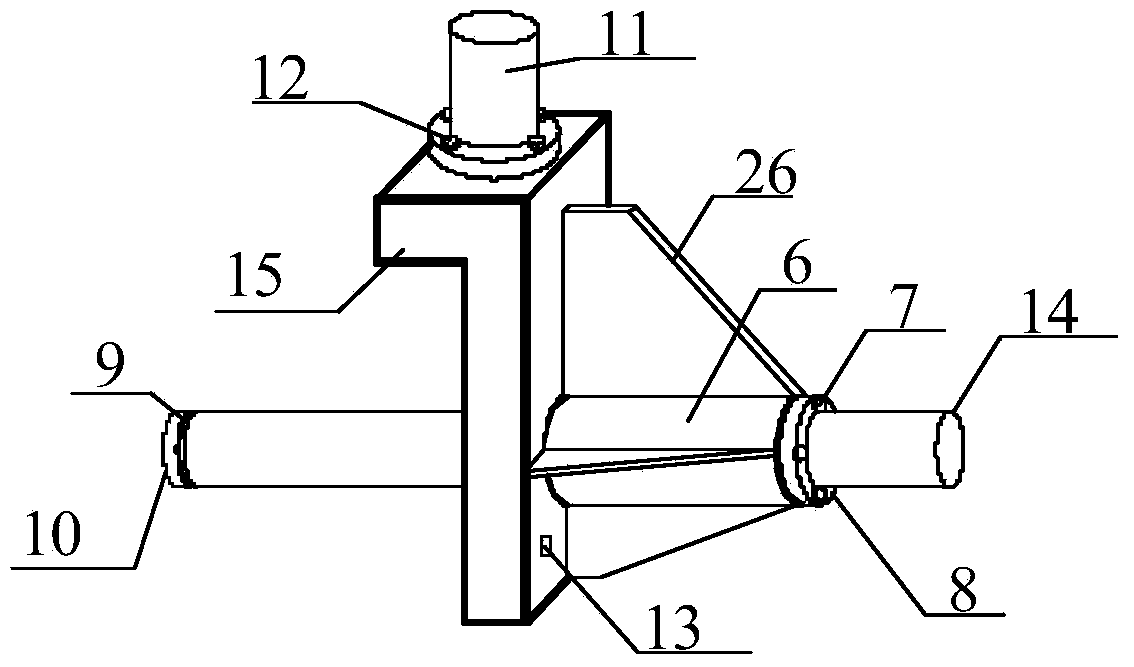

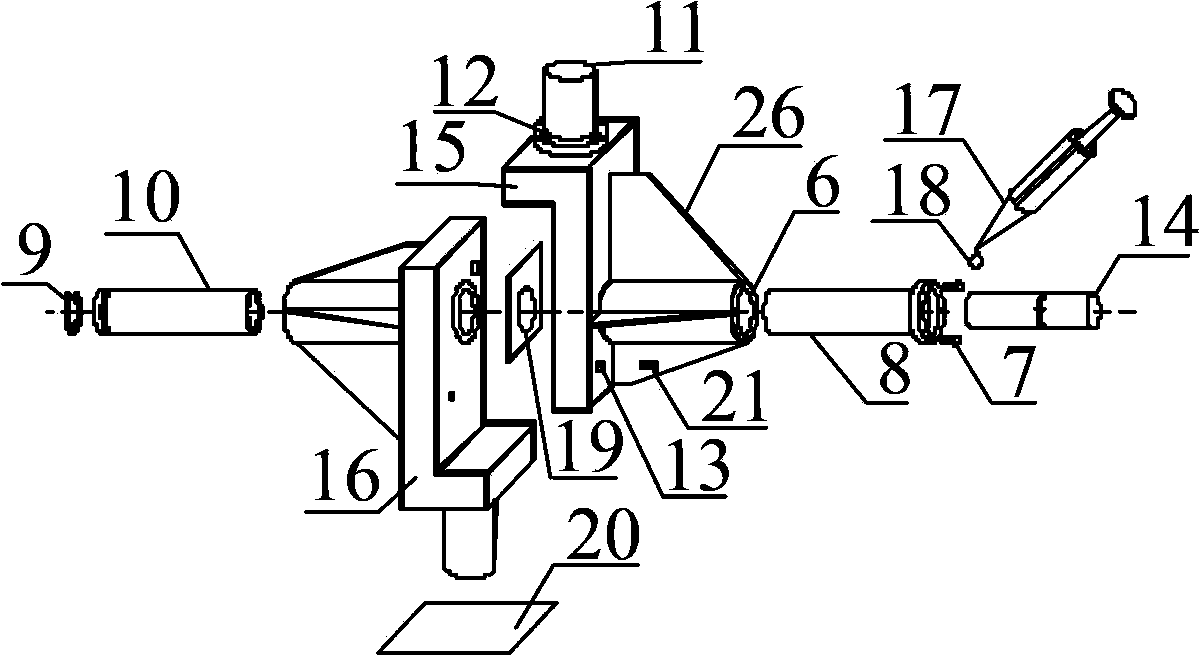

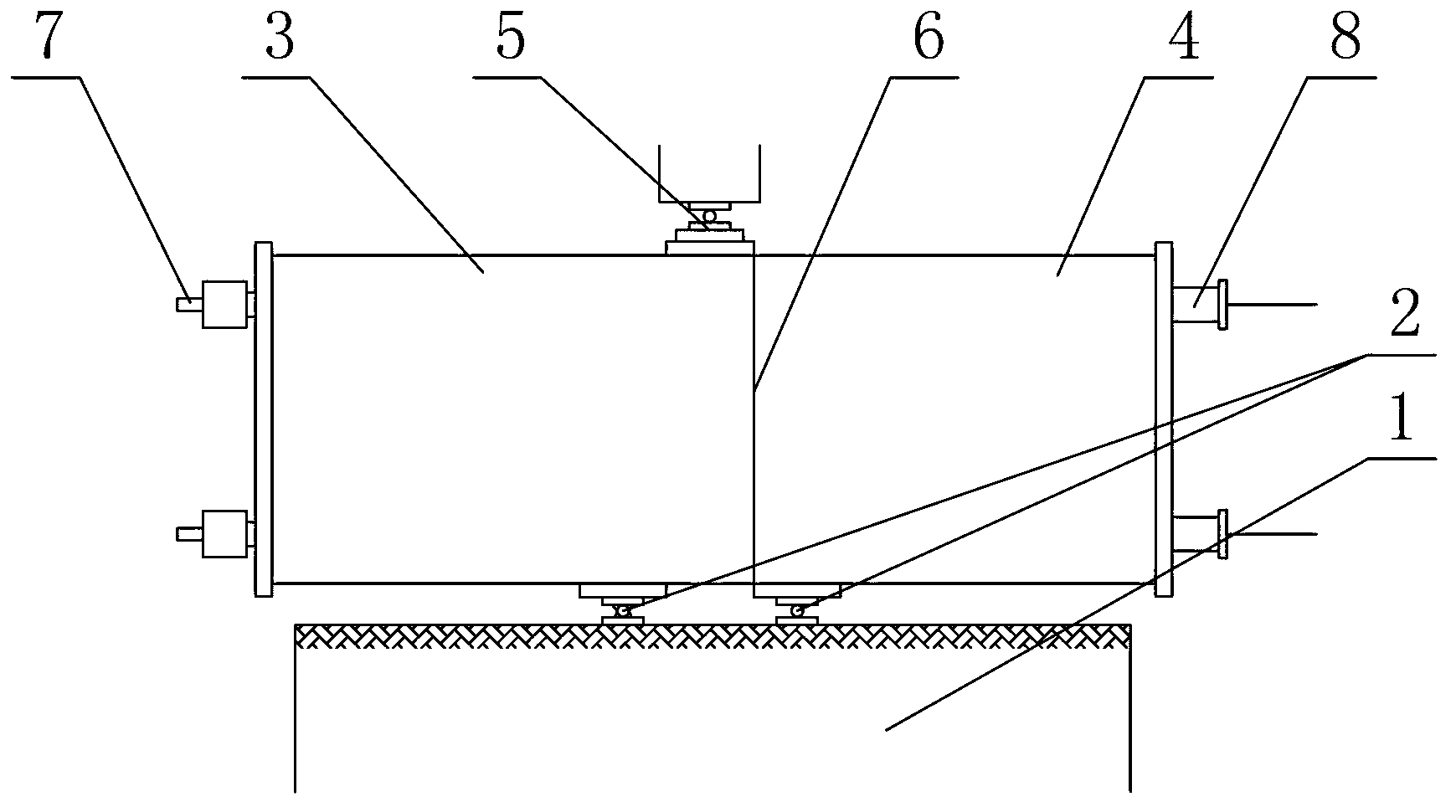

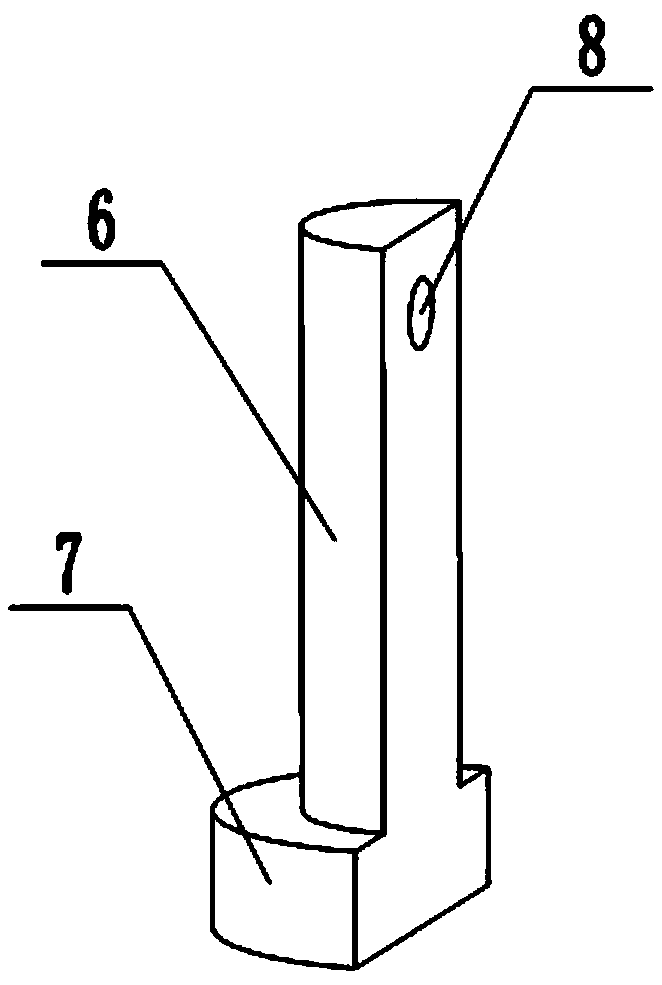

Pure-shear loading device and method for tubular product

ActiveCN109520862AFunction to limit rotationGet shear propertiesMaterial strength using steady shearing forcesSpecial designShearing deformation

The invention discloses a pure-shear loading device and method for a tubular product. A first core shaft penetrates into a first half pipe; a second core shaft penetrates into a second half pipe; thesize of the first core shaft is matched with the size of the first half pipe; the size of the second core shaft is matched with the size of the second half pipe; a first connection part of the first core shaft and a second connection part of the second core shaft are loaded; a first protruding part and a second protruding part are used for transmitting a force to a tubular product to be detected,so that a material, which is located on the same plane of a right plane or a left plane of the first half pipe and the left plane or the right plane of the second half pipe, on a whole pipe is at a pure-shear stress state. The pure-shear loading device disclosed by the invention is simple in structure; the first core shaft and the second core shaft, which have special designs, are used for inhibiting the rotation of the tubular product to be detected, which is difficult to control, in a shear deformation process; and the material, which is located on the same plane of the right plane or the left plane of the first half pipe and the left plane or the right plane of the second half pipe, on the whole pipe can be at the stable pure-shear stress state in a whole deformation process.

Owner:HARBIN INST OF TECH +1

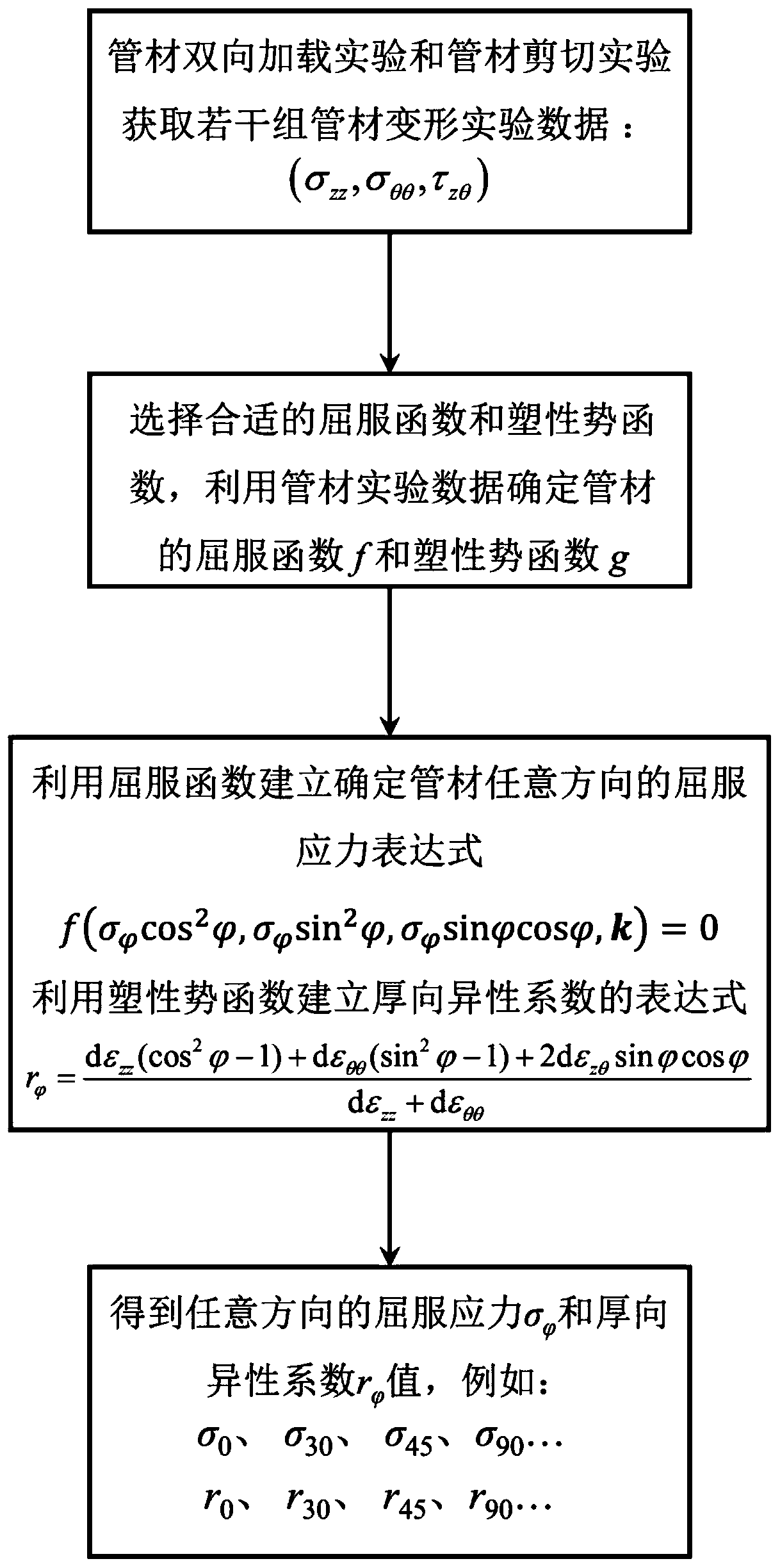

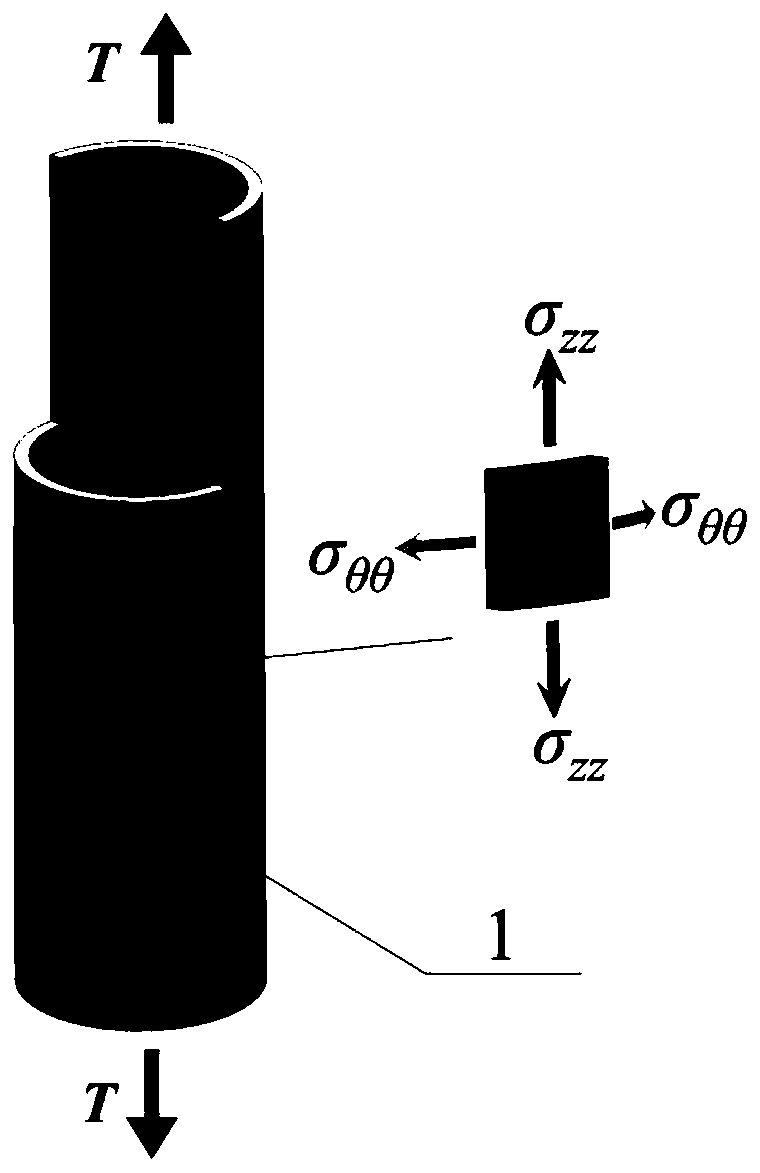

Method for measuring coefficient of normal anisortopy and yield stress of pipe in any direction

ActiveCN110763567ASolving for Thickness Anisotropy CoefficientSolving Yield StressMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesShear stressPipe

The invention provides a method for measuring a coefficient of normal anisortopy and a yield stress of a pipe in any direction, and belongs to the field of pipe performance test. The method comprisesthe following steps of step 1, carrying out a bidirectional pipe loading experiment to obtain stress and strain experimental data of the pipe under a plurality of bidirectional stress states; step 2,preparing a pipe shear sample, and acquiring shear stress and strain experimental data under a pipe pure shear stress state; step 3, calculating a stress value and / or a plastic strain increment ratioof the pipe under different stress states of a bidirectional loading and pure shear experiment when the same plastic work is reached, and determining all coefficients in a yield function and a plasticpotential function of the pipe; step 4, establishing an expression for measuring the yield stress of the pipe direction and the coefficient of normal anisotropy; step 5, giving an angle, and obtaining values of the yield stress and the coefficient of normal anisotropy of the pipe direction; and step 6, changing the angle to obtain the values of the yield stress and the coefficient of normal anisotropy of the pipe in any direction. The method provided by the invention is used for measuring the coefficient of normal anisotropy and the yield stress of the pipe in any direction.

Owner:DALIAN UNIV OF TECH

T-joint shear testing device

PendingCN109443952ASolve the additional bending moment problemImprove accuracyMaterial strength using steady shearing forcesUltimate tensile strengthMechanical engineering

The invention discloses a T-joint shear testing device, and belongs to the technical field of testing of the shearing strength of a material. Support plates are arranged on the two sides of a base, supporting clamping plates are symmetrically arranged above the base, a sample is arranged between the supporting clamping plates, a pressing head is transversely arranged above the supporting clampingplates, a base sliding chute is formed in the base, a supporting clamping plate sliding chute is arranged on the lower side of the supporting clamping plate, the base sliding chute and the supportingclamping plate sliding chute correspond in position, a tightening handle penetrates through the supporting clamping plate sliding chute and the base sliding chute to connect the base and the supporting clamping plate; a locating cushion block is further arranged at the upper part of the base; web samples with different thicknesses in a T-joint are met through the distance adjustment of the supporting clamping plate, so that the universality of the testing device is improved; in addition, the clamping mode of the clamping plate guarantees that the loading pressing head applies a pure shear loadonto the sample in the vertical direction, no additional bending moment is produced on the sample in the test process, and the reliability of the shear test is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

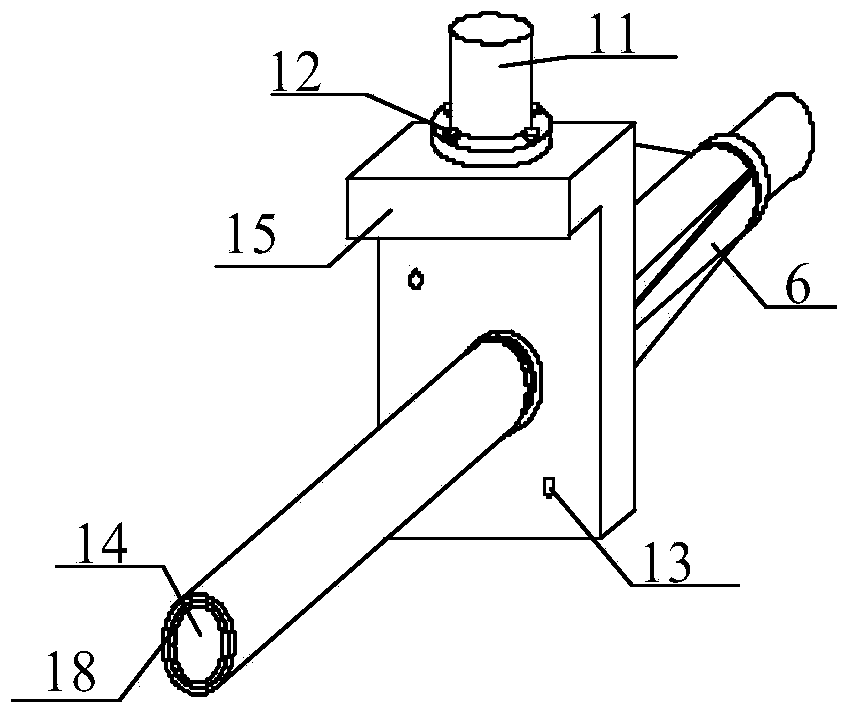

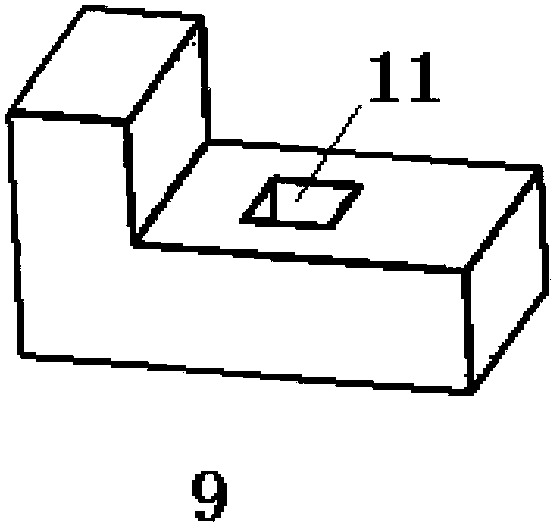

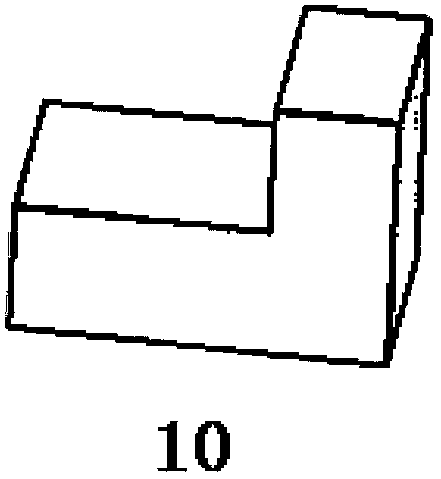

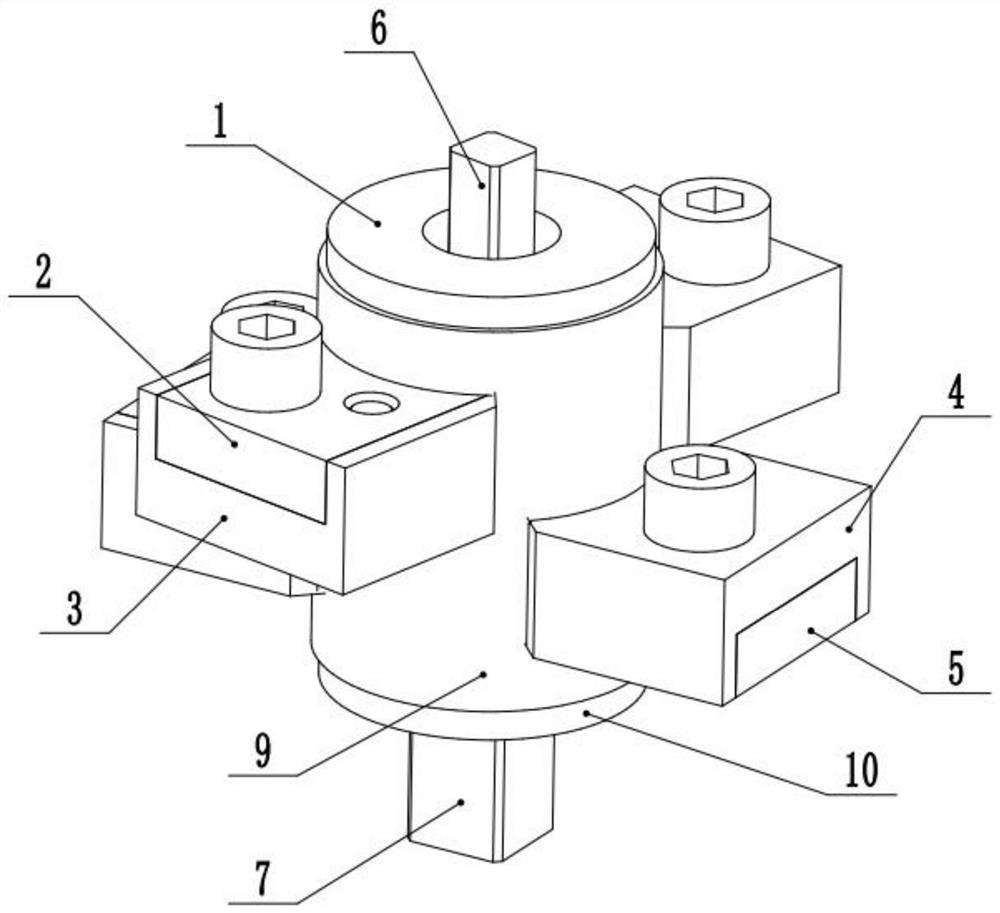

Double-curved-surface spherical seismic mitigation and absorption supporting base with limiting device easy to replace

InactiveCN104452579AAccurate control of design forceEasy to operateBridge structural detailsShock proofingHorizontal forceStructure of the Earth

The invention belongs to the technical field of bridges and building structures, and provides a double-curved-surface spherical seismic mitigation and absorption supporting base with a limiting device easy to replace. The double-curved-surface spherical seismic mitigation and absorption supporting base with the limiting device easy to replace comprises an upper base plate (6), a middle base plate (4) and a lower base plate (1). The end of the upper base plate (6) is provided with the limiting device corresponding to the lower base plate. The limiting device is composed of a pressing plate (9) and a limiting plate (10). The pressing plate (9) and the upper base plate (6) are combined in an embedded mode and are connected into a whole through an anti-draw screw II (13). The limiting plate is connected with the pressing plate (9) through an anti-draw screw I (12) and an anti-shear pin (11). The anti-draw screw I (12) is close to the lower base plate (1). The anti-shear pin (11) is far away from the lower base plate (1). The double-curved-surface spherical seismic mitigation and absorption supporting base ensures that the anti-shear pin bears the pure shear effect rather than bending moment effect on the horizontal force effect, and has the advantages of being easy to operate and facilitating replacement.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

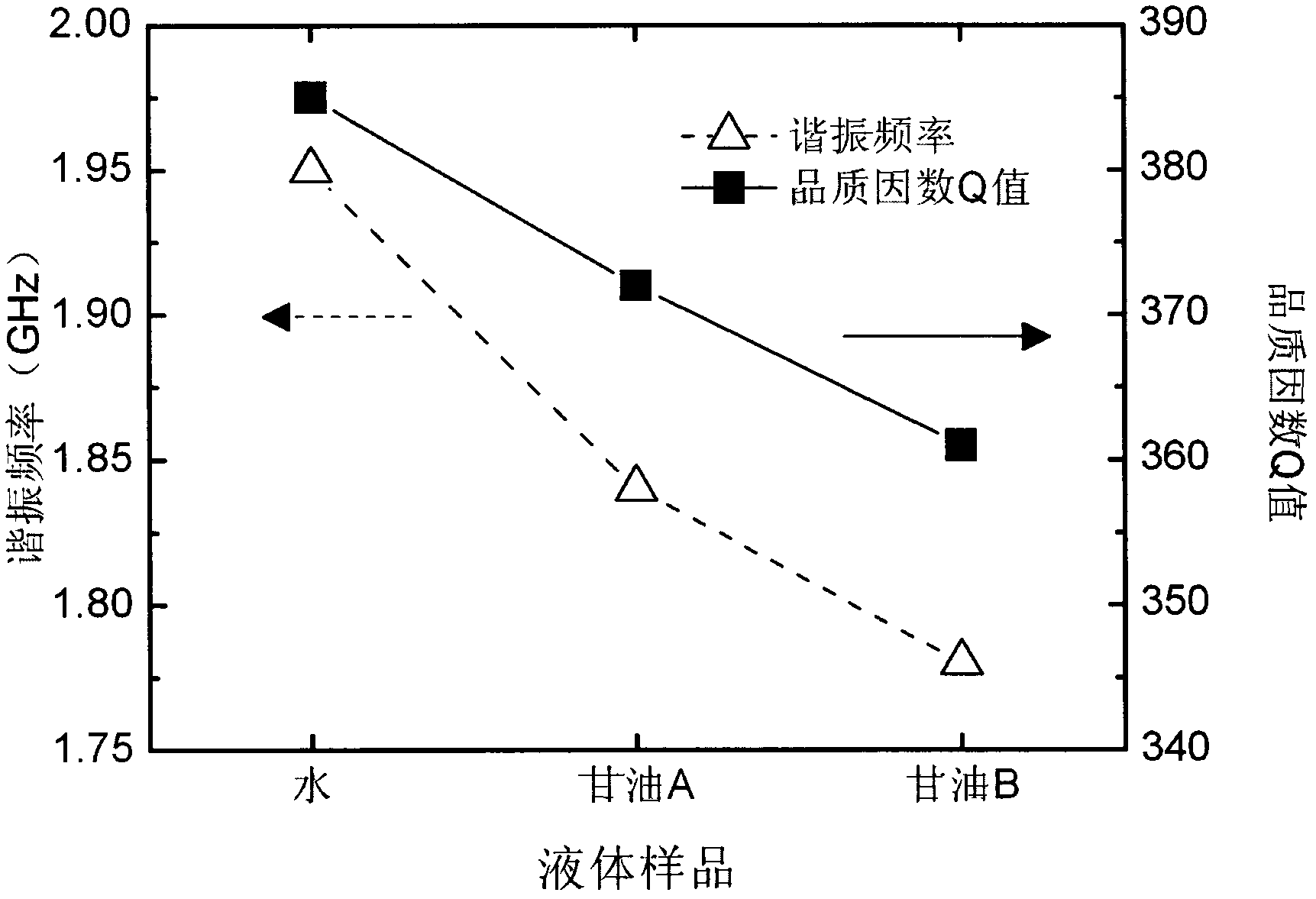

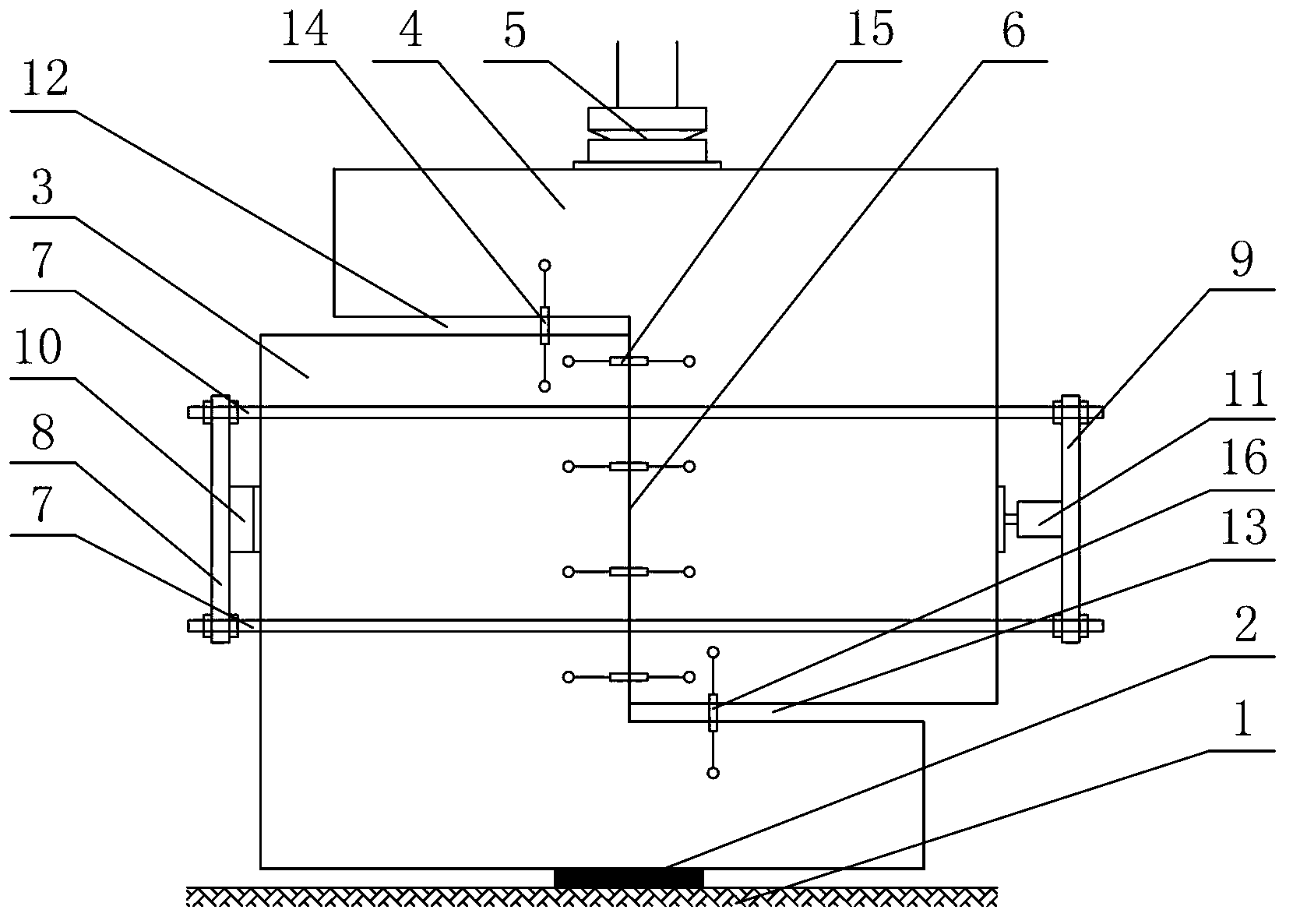

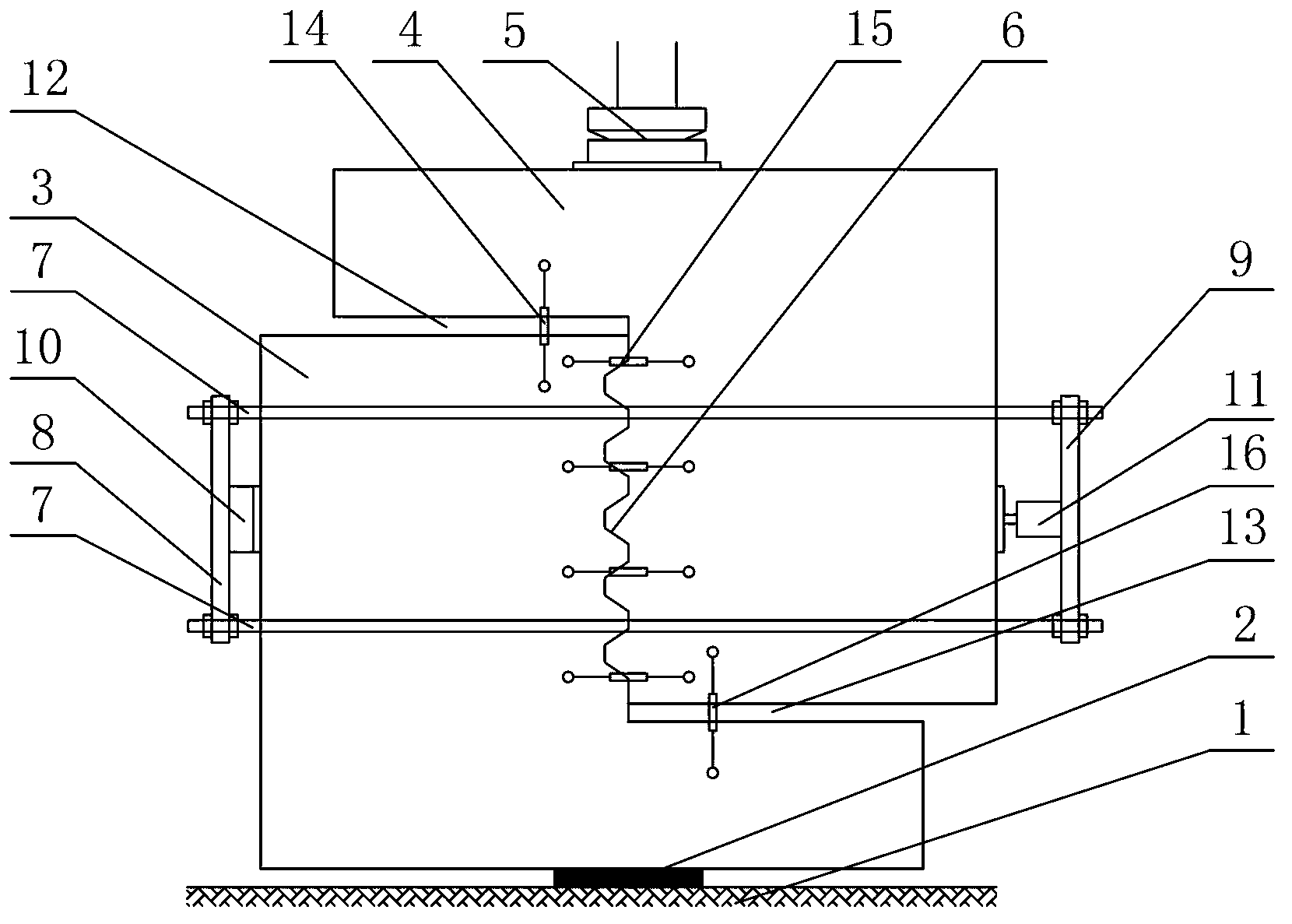

Testing device for small-span high-ratio connecting beam pure shear loading

PendingCN109406300AEasy to installAdjustment and flexible implementationMaterial strength using steady shearing forcesSteel frameActuator

The invention discloses a testing device for small-span high-ratio connecting beam pure shear loading, and belongs to the technical field of testing loading devices. The testing device comprises a loading frame part, an active loading part, a rotary limiting part, a connecting beam test piece part and an auxiliary loading part. The loading frame part is composed of an L-shaped steel frame and a side square roller. One end of the side square roller is fixed to a portal type counterforce frame, and the other end of the side square roller ejects the L-shaped steel frame through a roller. The active loading part is composed of an actuator, a loading head, a converting steel plate and high-strength screws. The actuator and the loading head are connected with the L-shaped steel frame through thehigh-strength screws. The rotary limiting part is composed of eight connecting rods, two transverse beams, a support cushion plate and a support. The connecting rods are connected with the L-shaped steel frame, a bottom beam and the transverse beams through the support cushion plate, the support, pins and high-strength bolts. The connecting beam test piece part is composed of a connecting beam and two concrete end blocks and is arranged between the L-shaped steel frame and the bottom beam. The auxiliary loading part is composed of the bottom beam, a jack and a pressing beam. A test piece is connected with the bottom beam and the L-shaped steel frame through high-strength screws. The testing device is simple in structure and convenient to use and detach, and pure shear displacement can beexerted on the small-span high-ratio connecting beam.

Owner:DALIAN UNIV OF TECH

Lateral Excitation of Pure Shear Modes

InactiveUS20100231092A1Minimize divergenceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesPure shearAtomic physics

Circularly polarized resonant structures are obtained utilizing piezoelectric resonators made of materials and orientations selected in accordance with the teaching provided herewith. Further provided are radially polarized structures. Furthermore, the utilization of such resonators and structures as sensors, for frequency control application, for signal filtering, and the like, is also disclosed.

Owner:KNOWLES CAPITAL FORMATION

Device and method for testing shear strength and rigidity of concrete and FRP bonding interface

ActiveCN111122349AOvercome the defect of interfacial shear strength influenceAvoid the effects of shear strengthMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesBond interfaceUltimate tensile strength

The invention provides a device and a method for testing shear strength and rigidity of a concrete and FRP bonding interface. The device and the method belong to the technical field of bonding shear strength tests. The device comprises an outer sleeve, a connecting rod and a fastening sealing ring, wherein the inner diameter of the outer sleeve is consistent with the outer diameter of the FRP sleeve; the connecting rod comprises a round rod part and a threaded part; the end part of the round rod part is positioned outside the FRP sleeve; the fastening sealing ring comprises two semi-fasteningrings and a bolt for connecting the two semi-fastening rings; each semi-fastening ring comprises a first semi-ring body, a second semi-ring body and bolt connecting lugs arranged on the first semi-ring body and the second semi-ring body; the inner diameter of the first semi-ring body is consistent with the outer diameter of the outer sleeve, and an adhesive injection hole is formed in the first semi-ring body; and the inner diameter of the second semi-ring body is consistent with the outer diameter of the FRP sleeve. According to the device and the method, the shear strength of the concrete and FRP bonding interface in a pure shear stress state is measured, and the defect that the shear strength of the interface is influenced by tensile stress of a conventional shear test result is overcome.

Owner:SHANXI UNIV

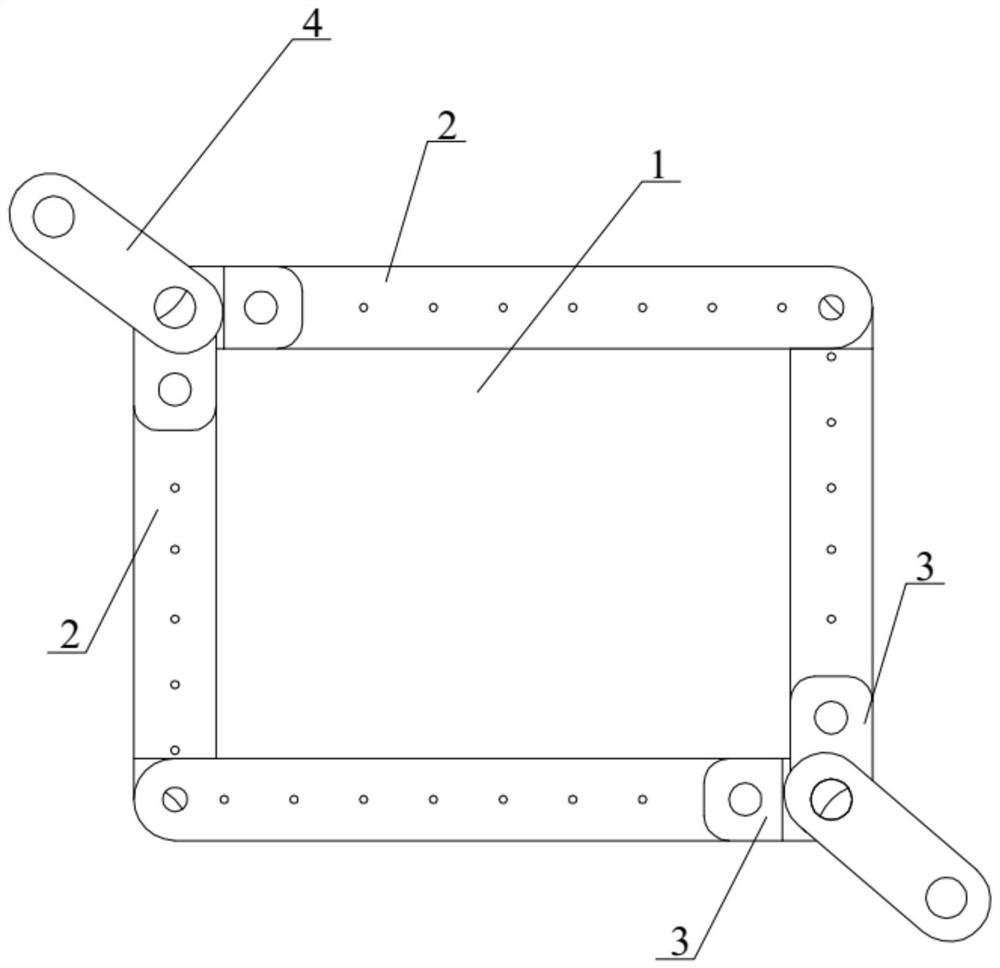

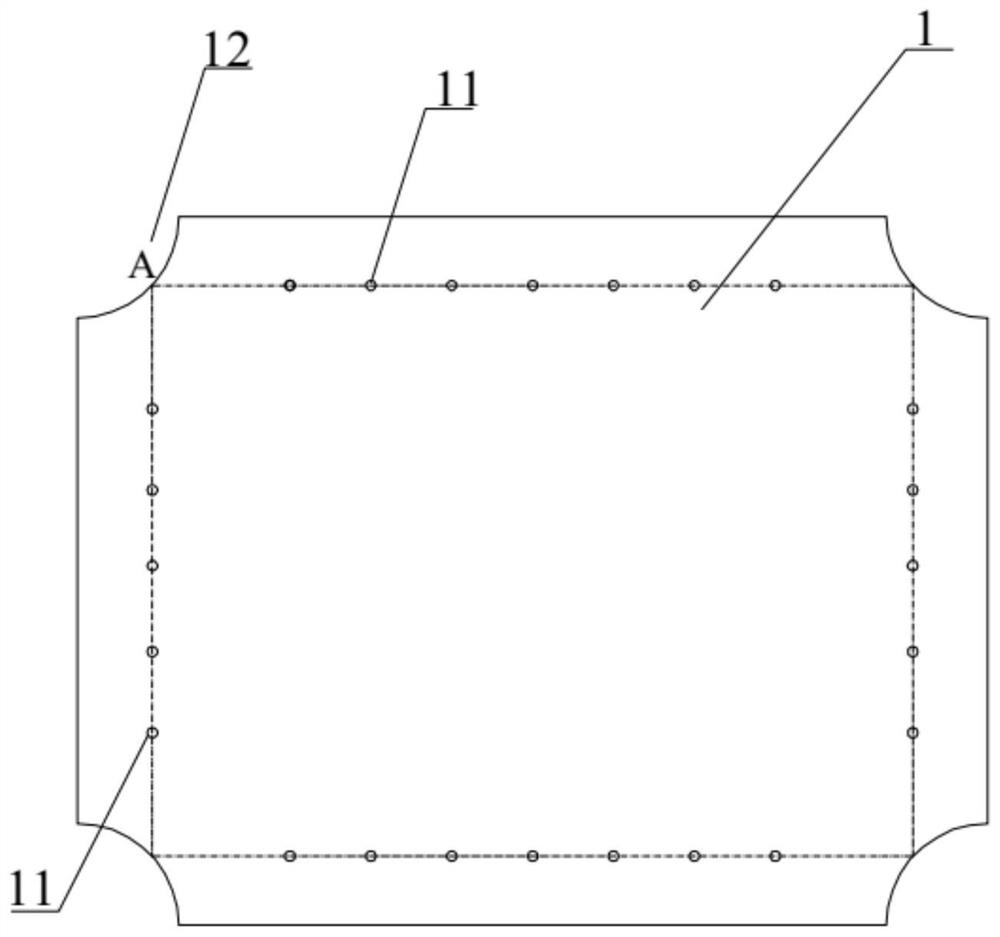

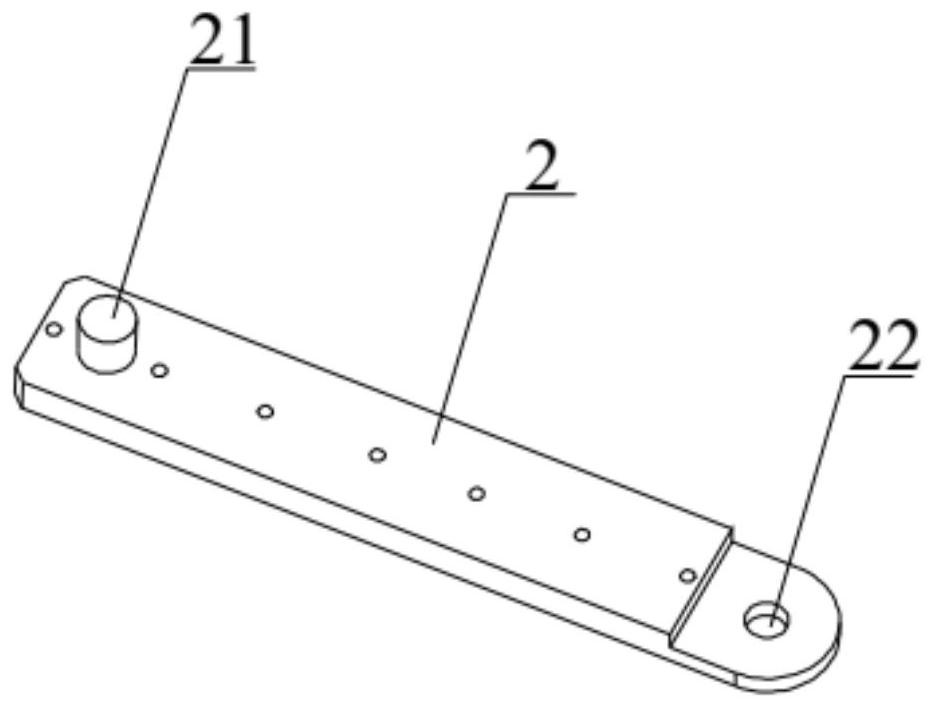

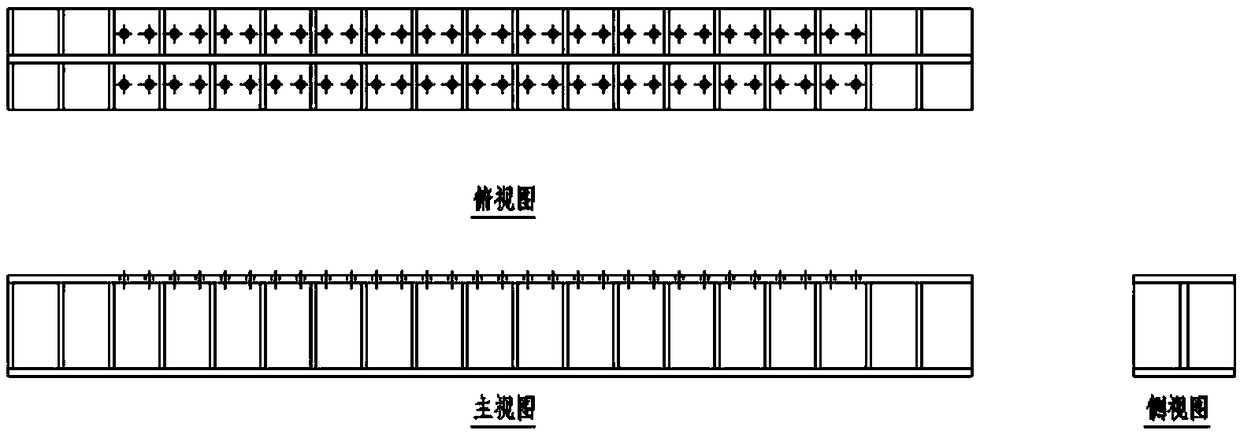

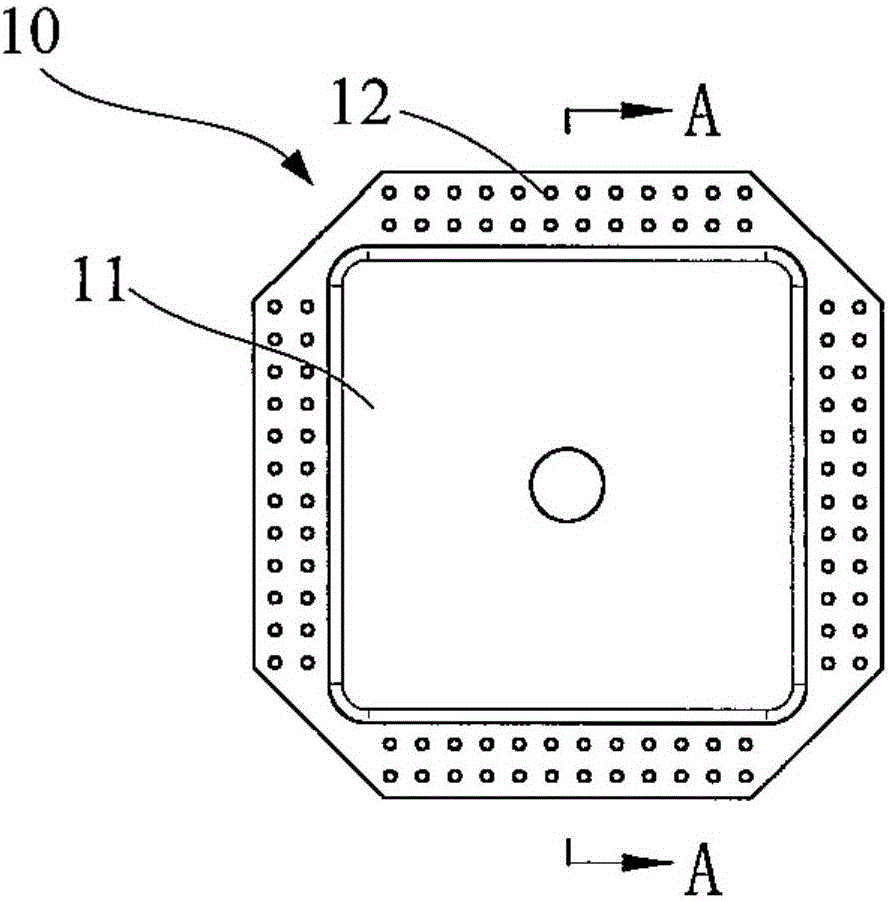

Pure shear fatigue test device for metal web plate

ActiveCN106442167AReduce stress concentration effectsAvoid destructionMaterial strength using steady shearing forcesEngineeringPure shear

The invention provides a pure shear fatigue test device for a metal web plate, comprising a square metal web plate provided with four chamfer parts and a clamp assebly, wherein the metal web plate comprises a central region and a peripheral region, and the thickness of the peripheral region is greater than the thickness of the central region; and the clamp assembly comprises two clamps for clamping the metal web plate, and each clamp comprises two draw plates arranged mutually in parallel along the horizontal direction, a loading single ear arranged between the two draw plates and fixed to one side of the two draw plates, and a first clamp plate and a second clamp plate arranged between the two draw plates and fixed to the other side of the two draw plates. The device can reduce the damaged probability of a non-fatigue examined detailed part, and completely meets the design requirements of a test for allowable values of a fatigue sheared plate.

Owner:COMAC +1

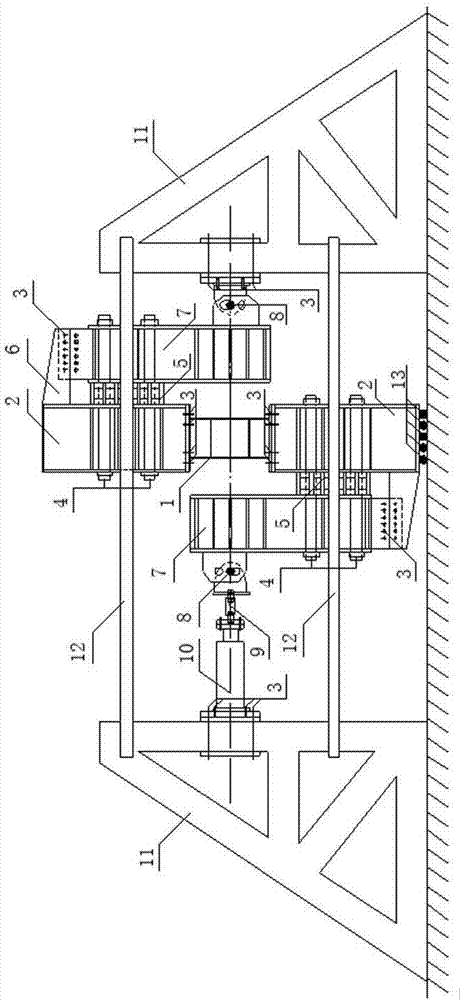

Testing and loading device for pure shear on shear type link beam

ActiveCN107478502ATo achieve separate loadingEasy to installMaterial strength using steady shearing forcesEngineeringPure shear

The invention relates to a testing and loading device for pure shear on a shear type link beam. The whole testing device comprises a loading frame part, an active loading part, a passive loading part and a shear type link beam part, wherein a loading frame is formed by connecting loading beams and framework beams; the framework beams and the loading beams are connected by high-strength bolts, high-strength pull rods, box type cushion blocks and connecting plates; the active loading part consists of a high-strength bolt left hinge support base, a sensor, a pull and press jack and a left triangular counterforce frame, the left hinge support base is connected with the sensor through a screw rod, the sensor is connected with the pull and press jack through a screw rod, and the pull and press jack is fixedly arranged on the left triangular counterforce bracket through cushion plates and high-strength bolts; the passive loading part consists of a right hinge support base and a right triangular counterforce bracket, and the right hinge support base is fixedly arranged on the right triangular counterforce bracket through cushion plates and high-strength bolts; the shear type link beam can be independently loaded, so that the shear type link beam can endure pure shear.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Composite interlaminar shear performance testing method

ActiveCN102680330BReduce finishing linksEasy to operatePreparing sample for investigationMaterial strength using steady shearing forcesInterlaminar shearComposite laminates

The invention belongs to the technical field of composites and relates to a composite interlaminar shear performance testing method. The testing method comprises two steps, namely the preparation of a test piece and the preparation of a testing device. In the step of preparing the test piece in the testing method disclosed by the invention, a common ply splicing and laying technology of a composite laminated plate is utilized, thus the operation is convenient, and the precision is high. When the manufacturing of the composite laminated plate is completed, the manufacturing of the test piece is completed, thus a fine processing link of the test piece is reduced, and the cost can be reduced by above 70%. The interlaminar shear testing method is simple to operate; and by adopting the interlaminar shear testing method, the damages of the test piece between designated tested layers can be ensured, the generation of pure shear damages between the tested layers can be ensured, the composite interlaminar shear performance can be precisely tested, and the testing method is suitable for composite laminated structures in various thicknesses.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Pipe circumferential pure shearing loading method and device

PendingCN112540012AAvoid distortionStabilized hoop pure shear loadingMaterial strength using steady torsional forcesMaterial strength using steady shearing forcesClassical mechanicsEngineering

The invention provides a pipe circumferential pure shearing loading method and device, and relates to the technical field of pipe mechanical property testing. According to the technical scheme, the method includes the steps that a notch is machined in a to-be-detected pipe in advance, a connecting part is reserved, and a core shaft is arranged to prevent the side wall of the pipe from being twisted and deformed inwards in a twisting process; and then opposite torsional force in the circumferential direction of the pipe is applied to the first edge and the second edge through a torsion device,the upper pipe is twisted relative to the lower pipe, a plurality of anti-deformation surfaces are further arranged on the torsion device, and each anti-deformation surface is respectively propped against the other edges, except the first edge and the second edge, of the first notch and the second notch so as to prevent the other edges from deforming when the upper pipe and the lower pipe are twisted. According to the invention, the pipe circumferential pure shearing loading method and device provided by the invention can enable the to-be-detected pipe to be always in a stable circumferentialpure shearing loading state in the torsional deformation process when the to-be-detected pipe is subjected to torsional shearing.

Owner:HARBIN INST OF TECH +1

Pure shear test loading device for boards

ActiveCN110031288AShear deformation stabilityPrevent wrinkling and instabilityMaterial strength using steady shearing forcesShear stressLoad torque

The invention discloses a pure shear test loading device for boards, and belongs to the technical field of board mechanics performance testing. The device comprises a board test-piece, a front loadingdevice and a rear loading device; the board test-piece is arranged between the front loading device and the rear loading device; a front loading device locating hole is formed in a front connection torsion testing machine area; a front upper shear force applying step and a front lower shear force applying step are arranged on the locating plane of the front loading device; a rear upper shear force applying step and a rear lower shear force applying step are arranged on the locating plane of the rear loading device; and a loading device locating pin is arranged at the center position in the front loading device locating hole. According to the device provided by the invention, via the special relative positions set by the front and rear loading devices, the accurate conversion relation between the shear stress and the load torque can be acquired, and thus the accurate board pure shear test stress-strain relation can be acquired. According to the loading mode, the board can be completelysheared under the pure shear condition.

Owner:王渡初

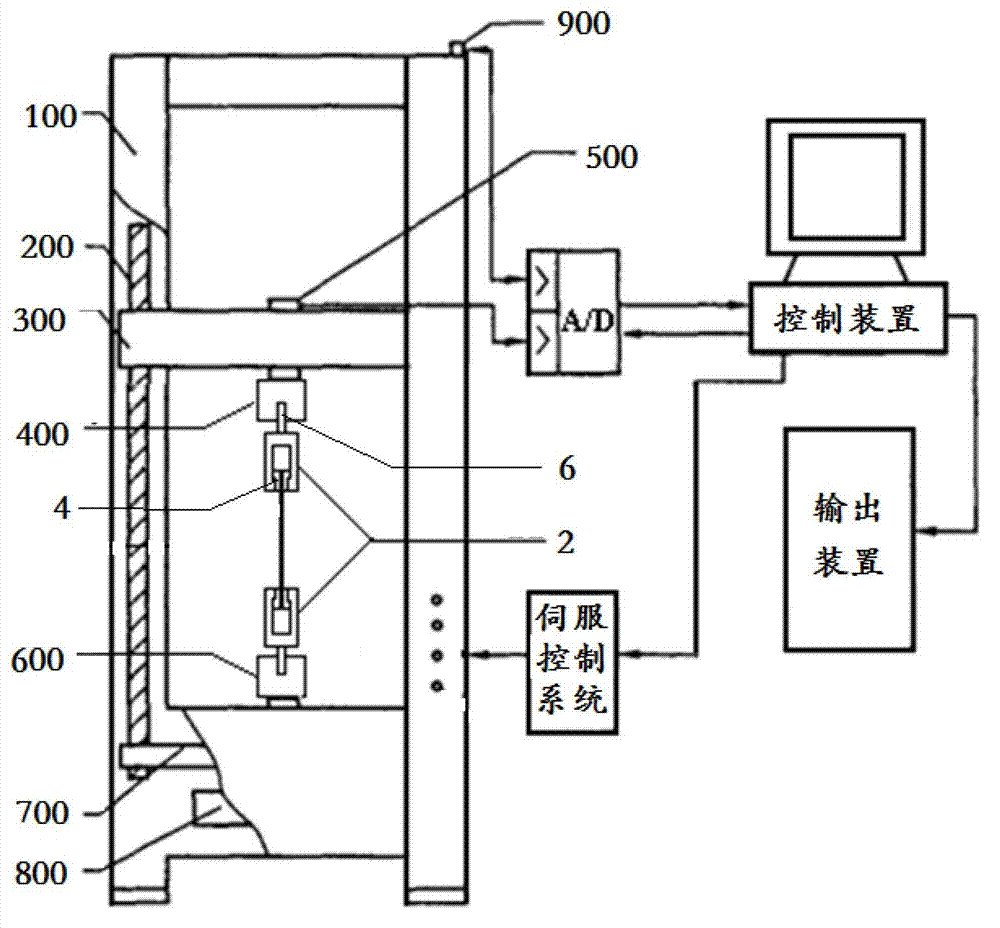

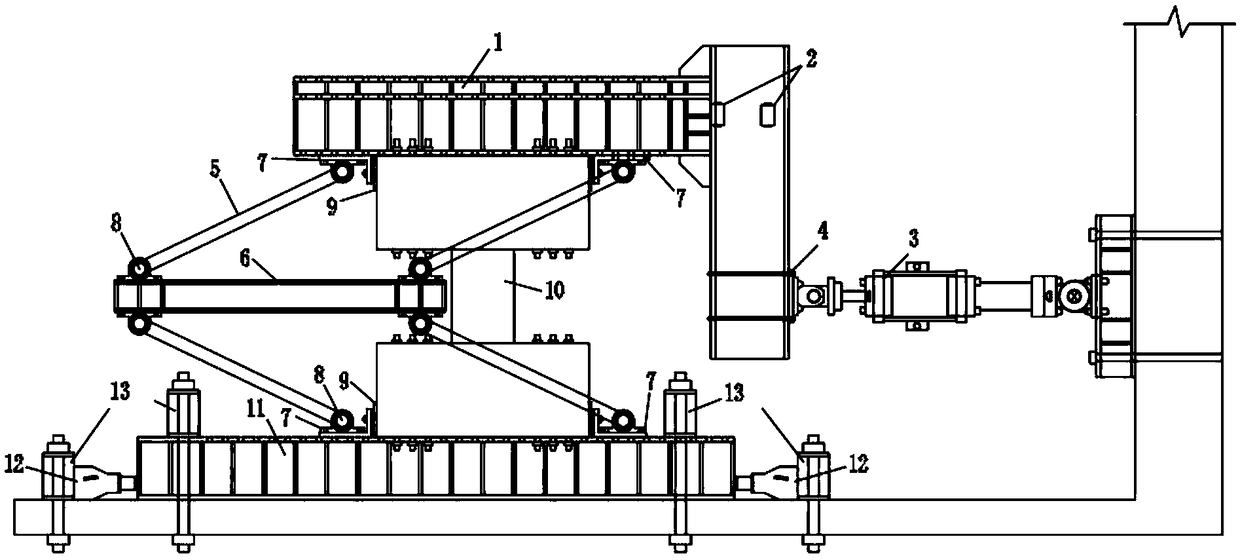

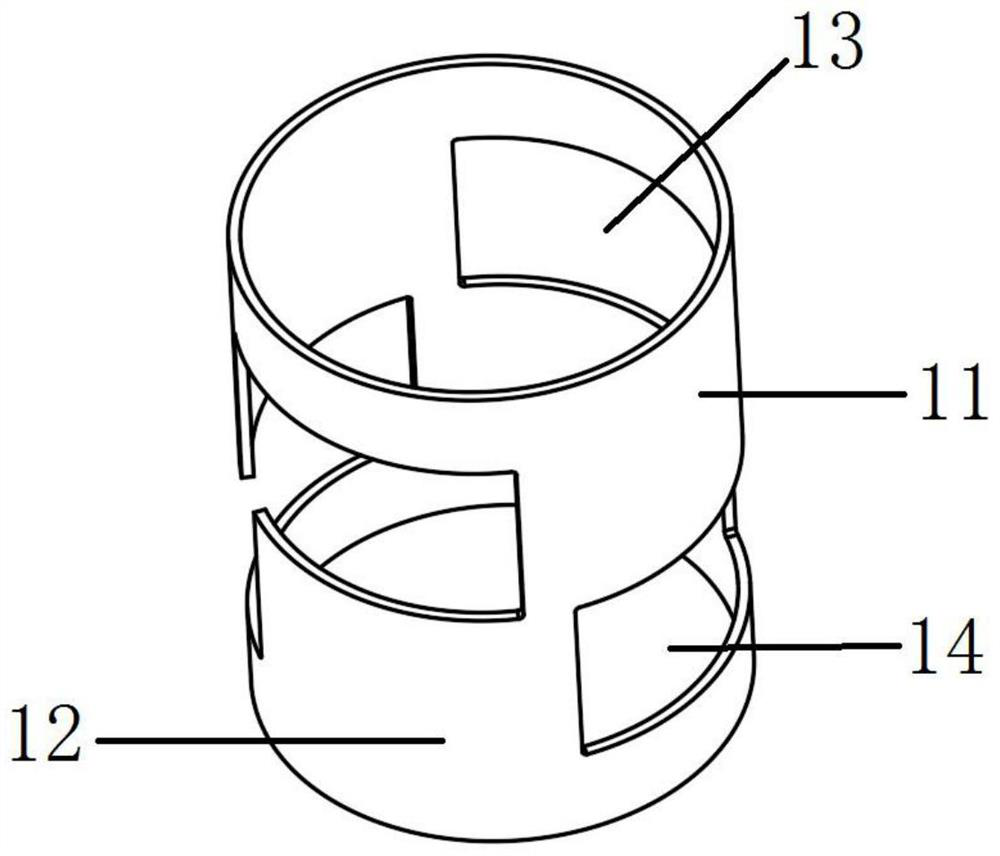

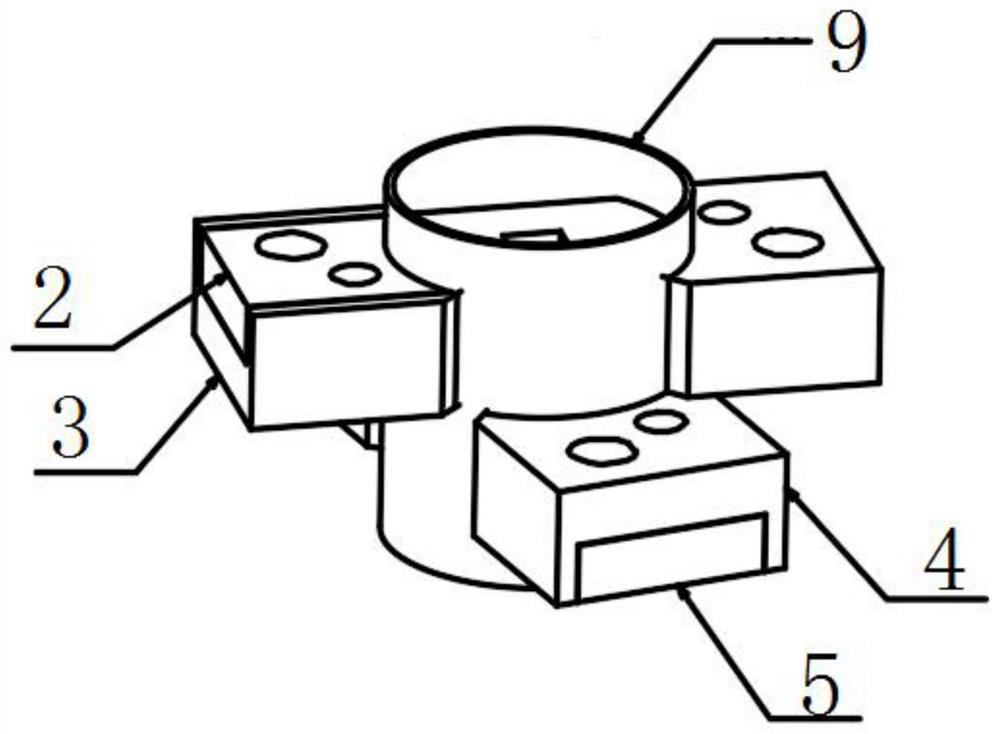

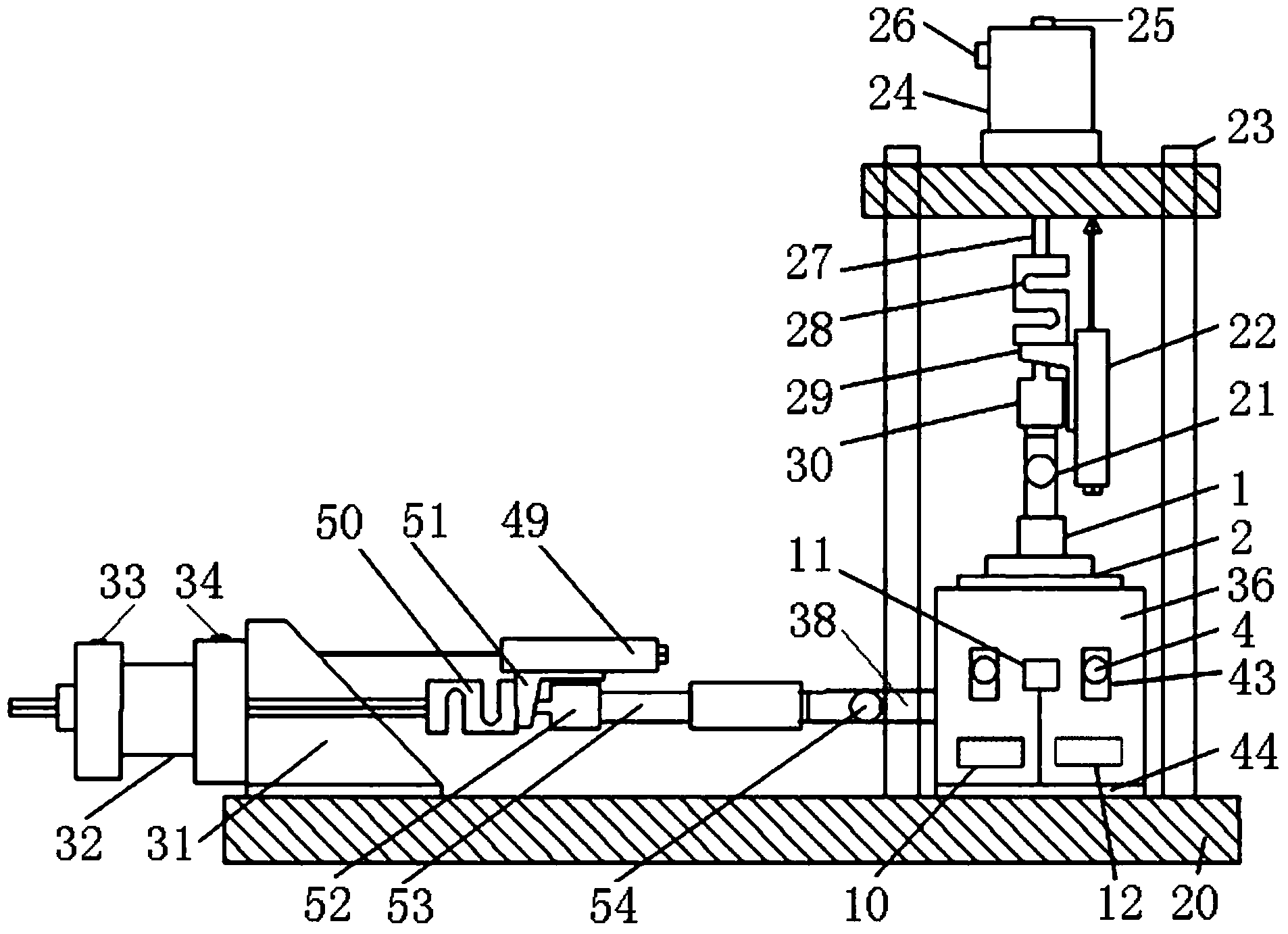

Dynamic simple shear apparatus of servo cylinder-driven cubic articulated mechanism

ActiveCN103454161ASimple structureEasy to operateMaterial strength using steady shearing forcesGeological processMachine parts

The invention discloses a dynamic simple shear apparatus of a servo cylinder-driven cubic articulated mechanism. The dynamic simple shear apparatus comprises a main machine part, a loading mechanism, and a measurement signal collecting and processing mechanism, wherein the main machine part is a core for applying a load to a sample; the loading mechanism comprises a vertical loading mechanism and a horizontal loading mechanism; the measurement signal collecting and processing mechanism is used for automatically controlling deformation, load signal input and sensor signal output. The device disclosed by the invention improves the structure of the existing dynamic simple shear apparatuses, and is simple and convenient to use and operate; a plurality of actual loading conditions of the scene can be simply and accurately simulated under the condition of pure shear deformation, so that the dynamic simple shear apparatus is suitable for researching a plurality of dynamics problems of rock-soil, such as geological process, and can directly research the relations between dynamic shear stress and dynamic shear strain under drainage and non-drainage conditions. In addition, the power cycle function also can be used for researching the damping ratio and the liquefaction characteristics.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com