Test device for testing shearing performance

A test device and performance technology, which is applied in the measurement device, uses a stable shear force to test the strength and strength characteristics of materials, etc., can solve the problems of reducing the test accuracy and reliability, increasing the maximum shear load, etc., and achieves load transfer. The effect of clear, high-precision test loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

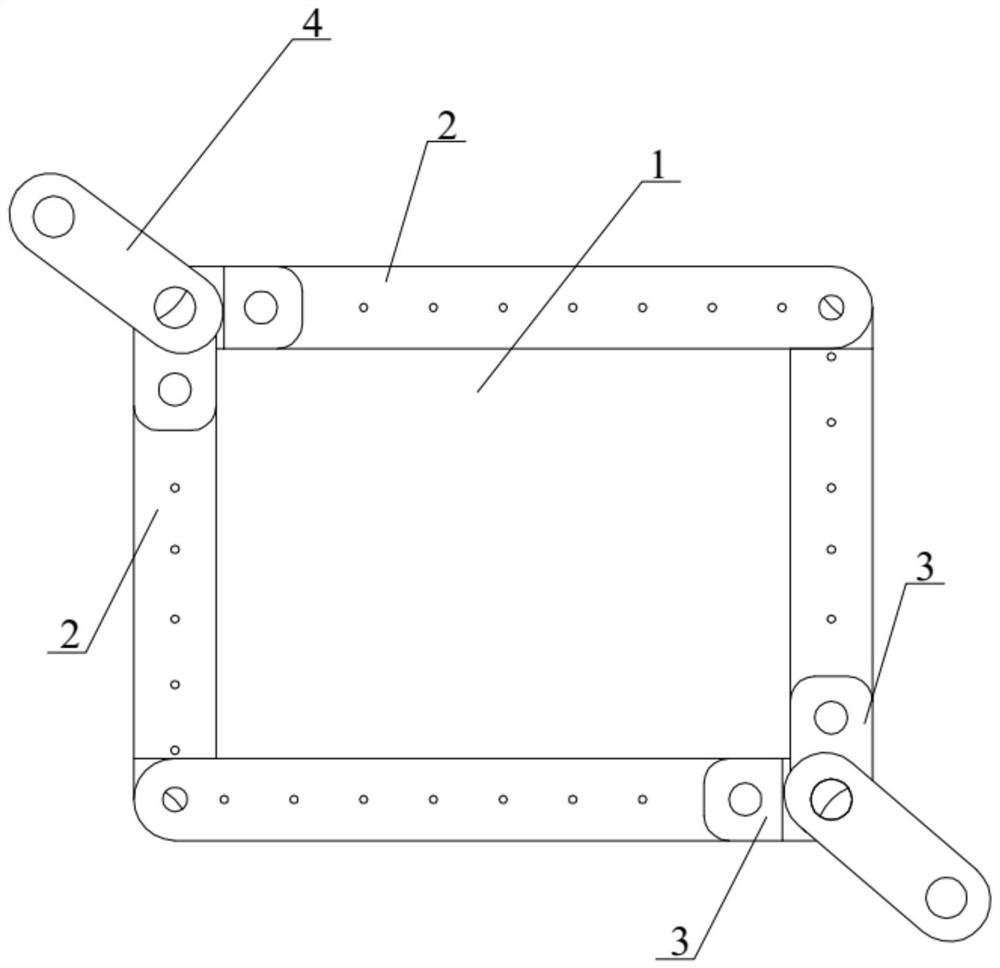

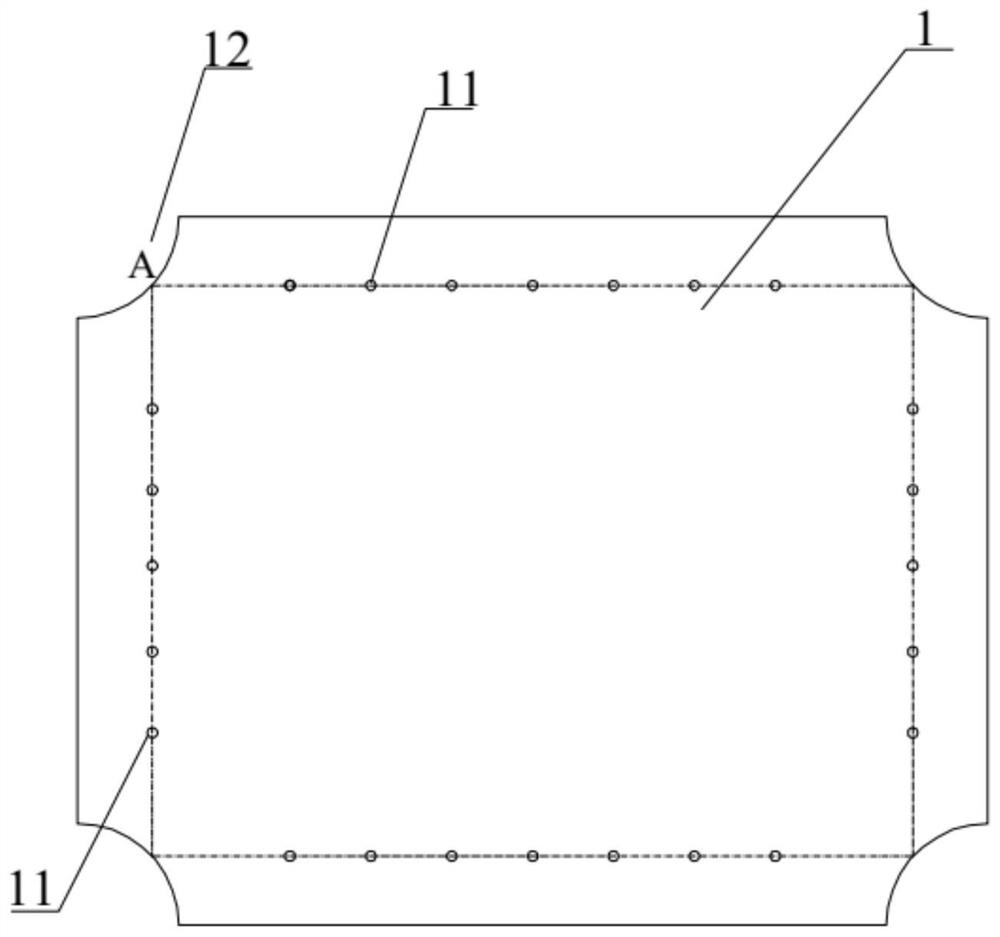

[0053] Such as Figure 1-Figure 5 As shown, the present embodiment provides a test device for testing shear performance, which includes a clamp, a connecting joint 3 and a loading joint 4, the clamp is detachably connected to the edge of the test piece 1, and the first edge of the test piece 1 is passed through the clamp. The load is applied diagonally; the two corners corresponding to the first diagonal are provided with a connecting joint 3 and a loading joint 4, one end of the connecting joint 3 is hinged to the fixture, and the other end is hinged to the loading joint 4, and the loading joint is connected to the testing machine. hinged.

[0054] The test device for testing the shear performance provided in this embodiment, the clamp is detachably connected to the edge of the test piece 1, and the load is applied along the first diagonal line of the test piece 1 through the clamp, and the two corners corresponding to the first diagonal line Both are provided with a connect...

Embodiment 2

[0067] The difference between the test device for testing the shear performance provided by the present embodiment and the first embodiment is:

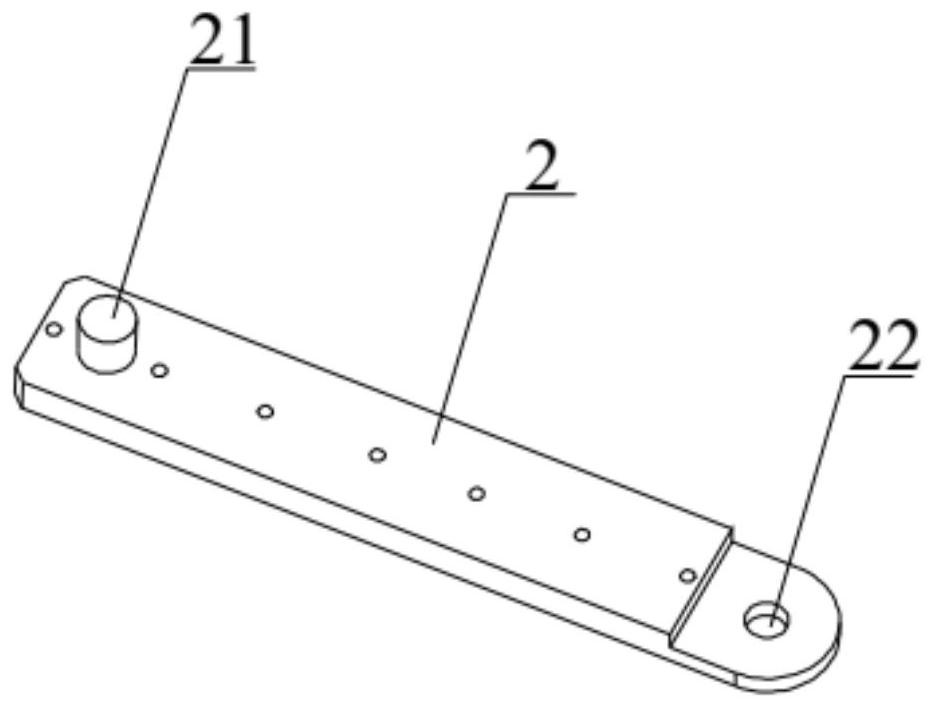

[0068] Such as Figure 12 As shown, a first connecting column 21 on each connecting plate 2 is arranged in the middle of the connecting plate 2. Adaptively, the length of the connecting joint 3 is relatively long, so that the first connecting hole 31 on the connecting joint 3 is connected to the first connecting hole 31. A connecting column 21 is matched and connected.

[0069] The bolt load of test piece 1 and the strain analysis of test piece 1 are carried out by the method of finite element analysis. Figure 13-Figure 17 It can be seen that an effect similar to that of Embodiment 1 is obtained.

Embodiment 3

[0071] The difference between the test device for testing the shear performance provided by the present embodiment and the first embodiment is:

[0072] Such as Figure 18 As shown, two first connecting columns 21 are arranged on each connecting plate 2, and each connecting plate 2 corresponds to two connecting joints 3, and the two connecting joints 3 are hinged. Specifically, among the two connecting joints 3 , one end of one connecting joint 3 is provided with a second connecting post 33 , and is hinged to the other connecting joint 3 through the second connecting post 33 . In this embodiment, the second connecting post 33 of one of the connecting joints 3 is hinged to the second connecting hole 32 of the other connecting joint 3 .

[0073] Using finite element analysis to analyze the loading condition of test piece 1, Figure 19 and Figure 20 The schematic diagrams of the analysis and simulation of the load parallel to the edge of the test piece 1 and the load perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com