Device for testing shear strength of joint of external prestressing prefabrication and assembly concrete member

A prefabricated assembly, shear strength technology, applied in the direction of using a stable shear force to test the strength of materials, can solve the problems of not easy to control the shear force, not shear loading, and low shear loading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

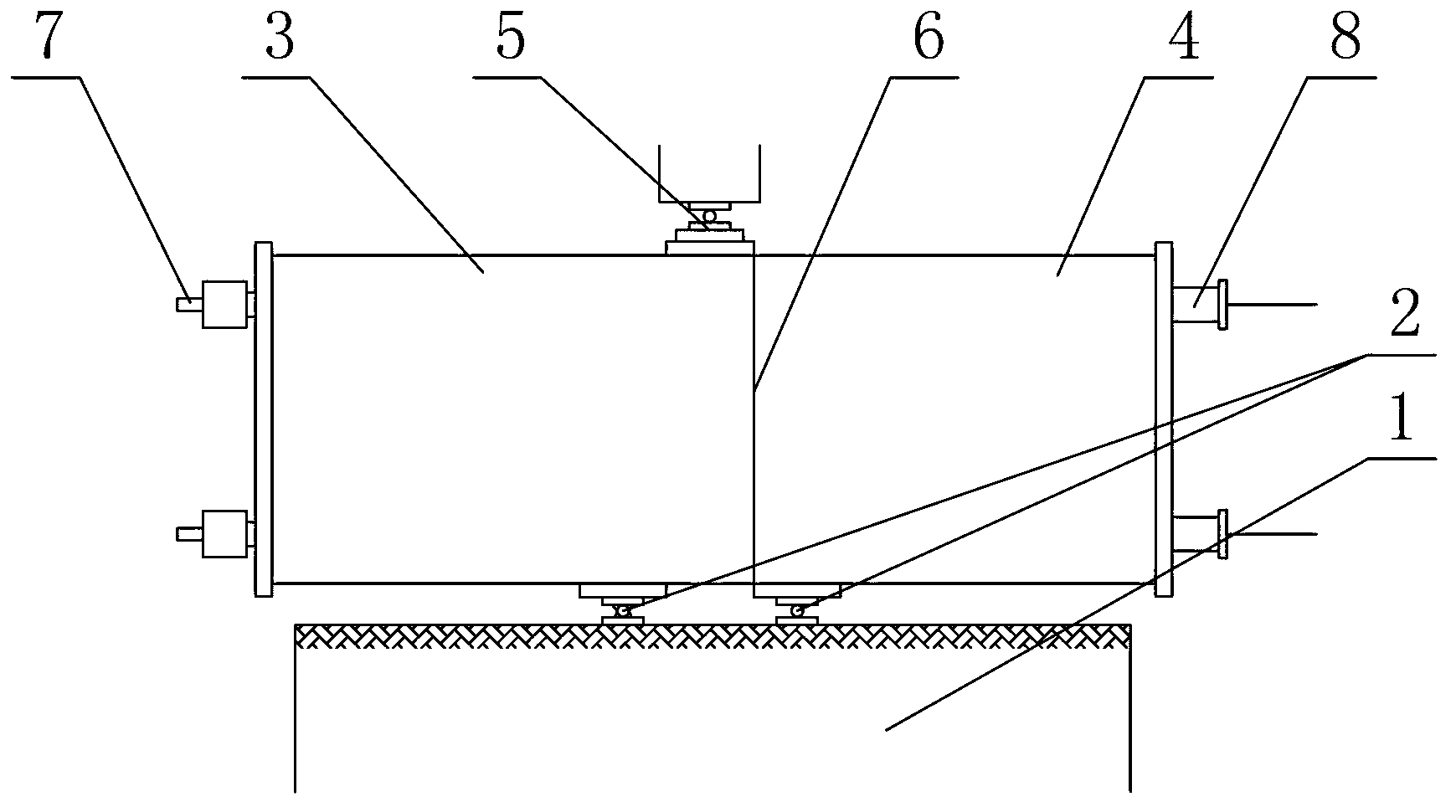

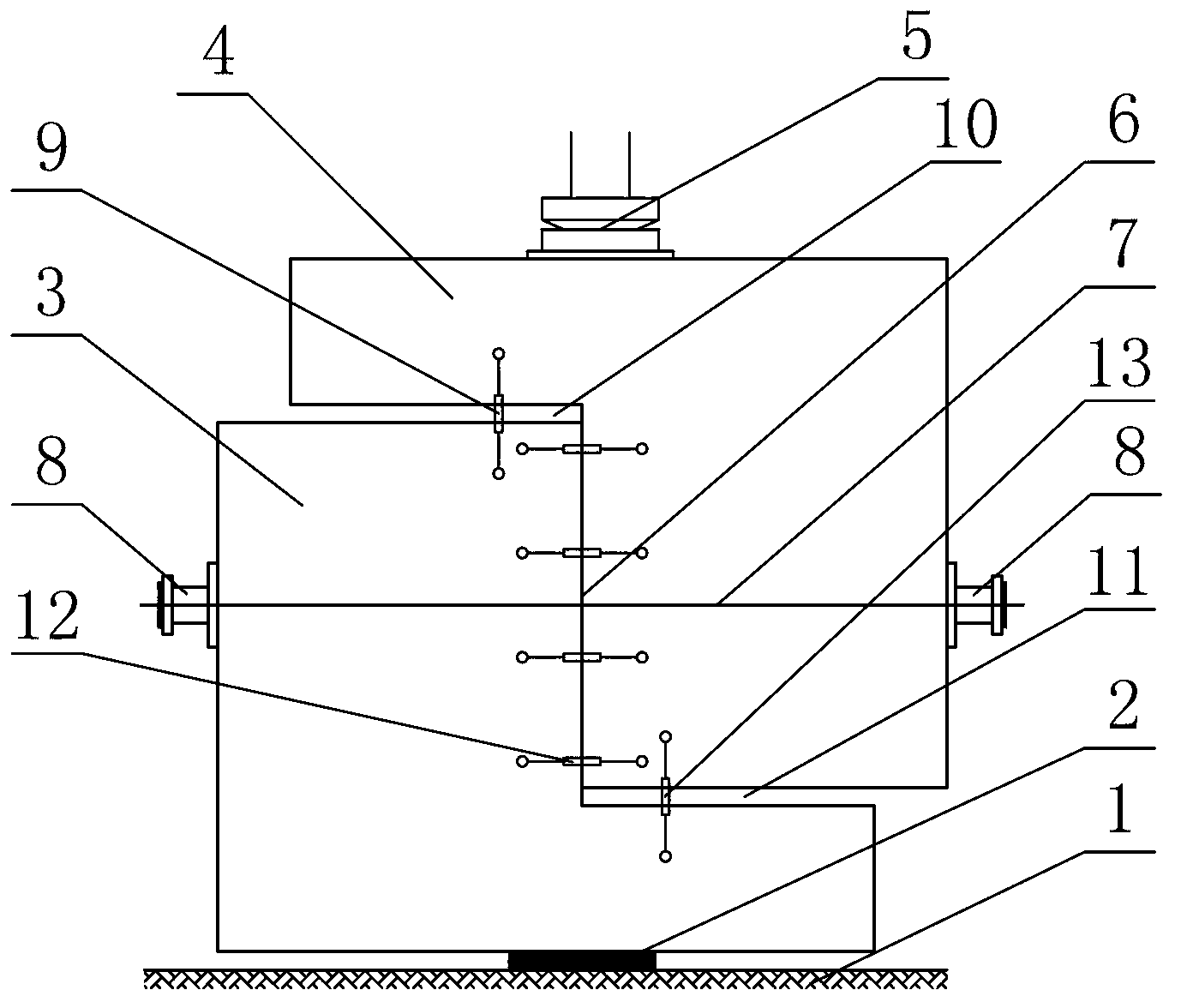

[0026] Embodiment one: if figure 2 As shown, a prefabricated assembled concrete component joint shear strength test device includes a loading base 1, a support 2 arranged on the loading base 1, a prefabricated assembled component and a hydraulic jack 5 arranged on the prefabricated assembled component. The assembled component is arranged on the support 2, and the prefabricated assembled component includes a first segment member 3 and a second segment member 4, wherein the first segment member 3 is arranged on the support 2, and the hydraulic jack 5 is arranged on the second segment On the upper end face of the segmental member 4, a vertical shearing force is applied to the prefabricated assembled member through the hydraulic jack 5; the cross section of the first segmental member 3 is L-shaped, and the cross-section of the second segmental member 4 is inverted L-shaped , the first segment member 3 and the second segment member 4 are assembled by a prestressed tensioning devic...

Embodiment 2

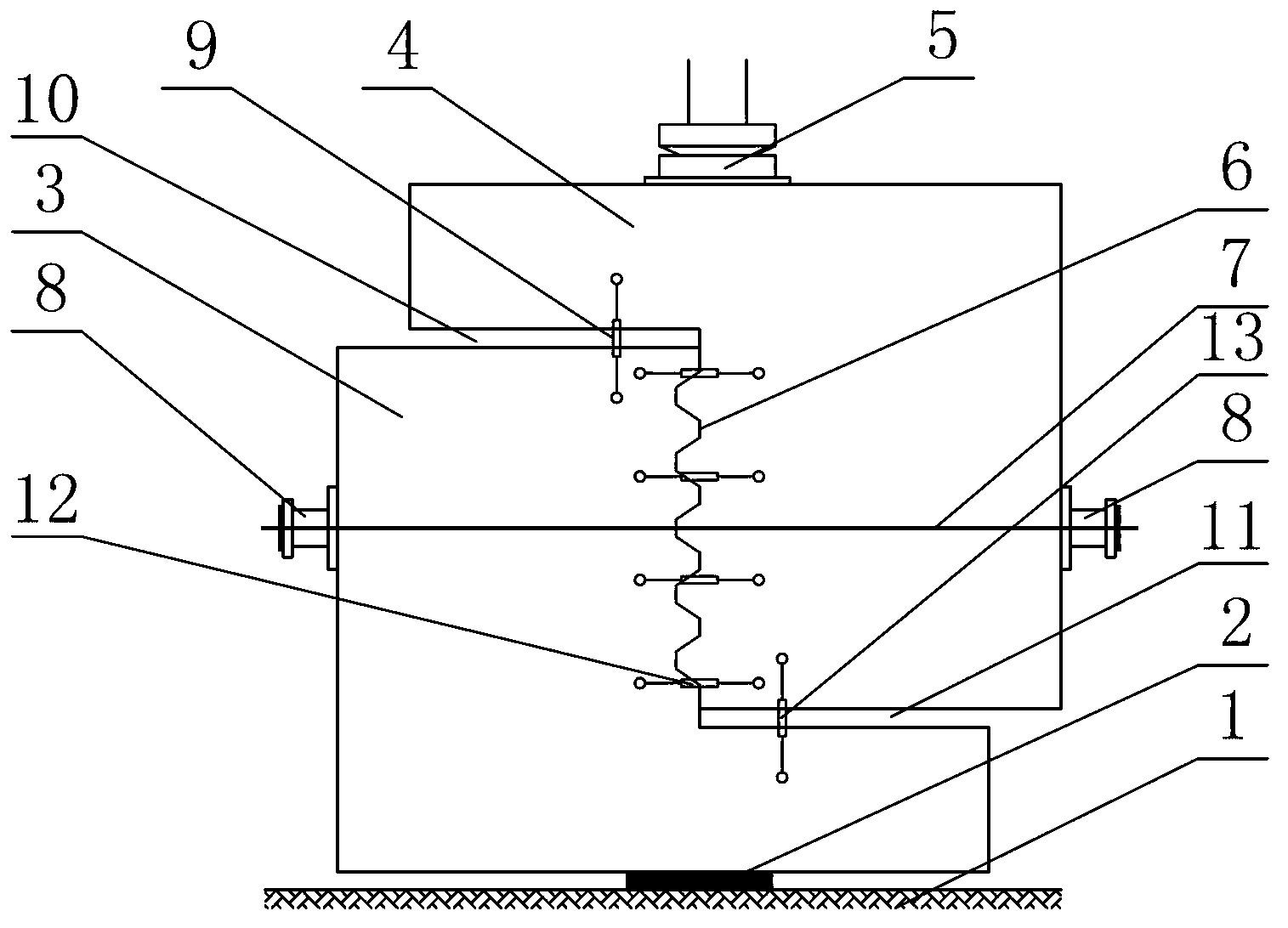

[0032] Embodiment 2: other parts are the same as Embodiment 1, the difference is that the inner surface of the first segment member 3 forming the vertical joint is opposite to the second segment member 4 and is provided with a shear key, such as image 3 shown.

Embodiment 3

[0033] Embodiment three: other parts are the same as embodiment one, the difference is that the vertical seam 6 is a wet seam, such as Figure 4 As shown, where the wet joint is filled with concrete or mortar or epoxy glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com