Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

387results about How to "Reduce span" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

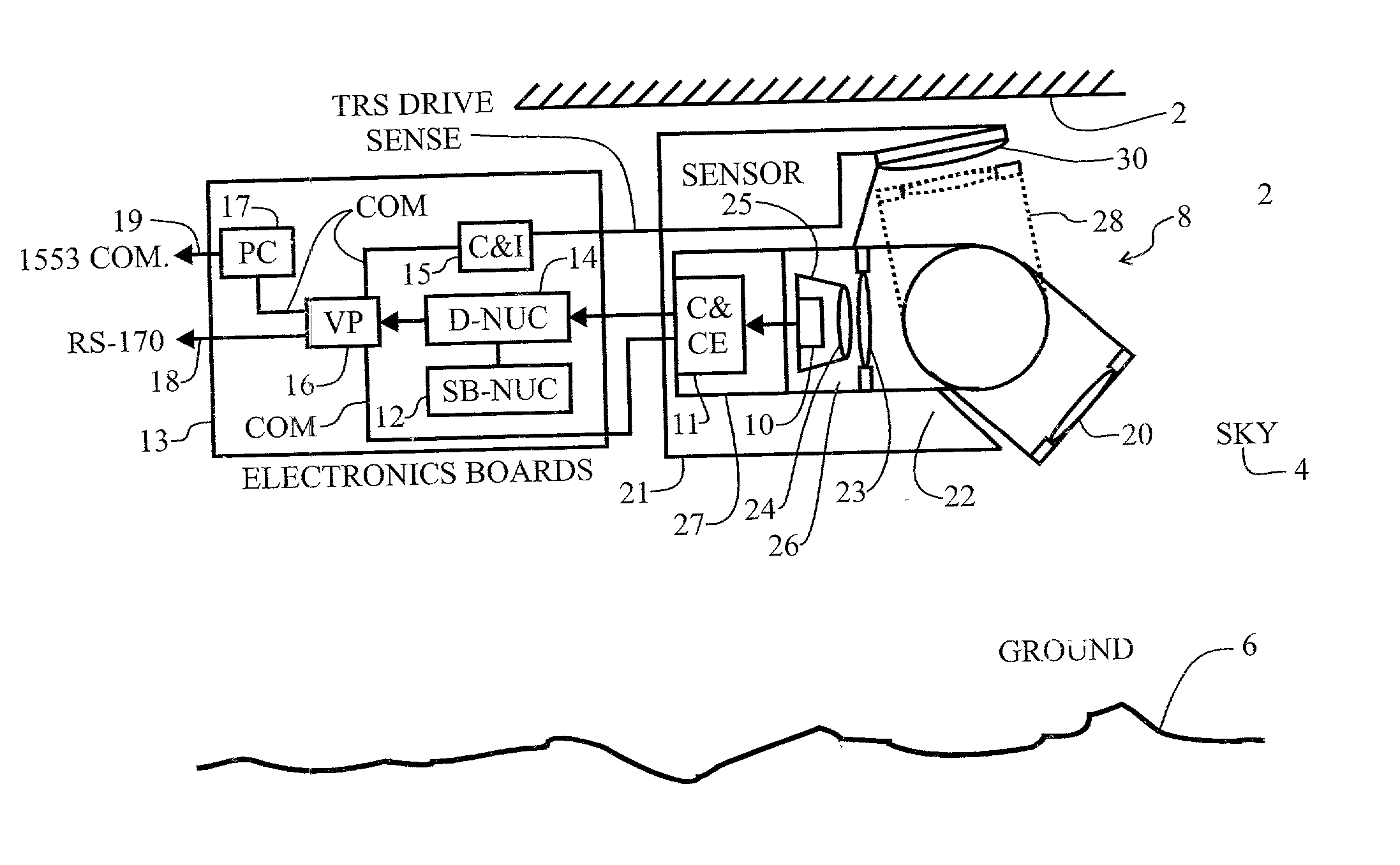

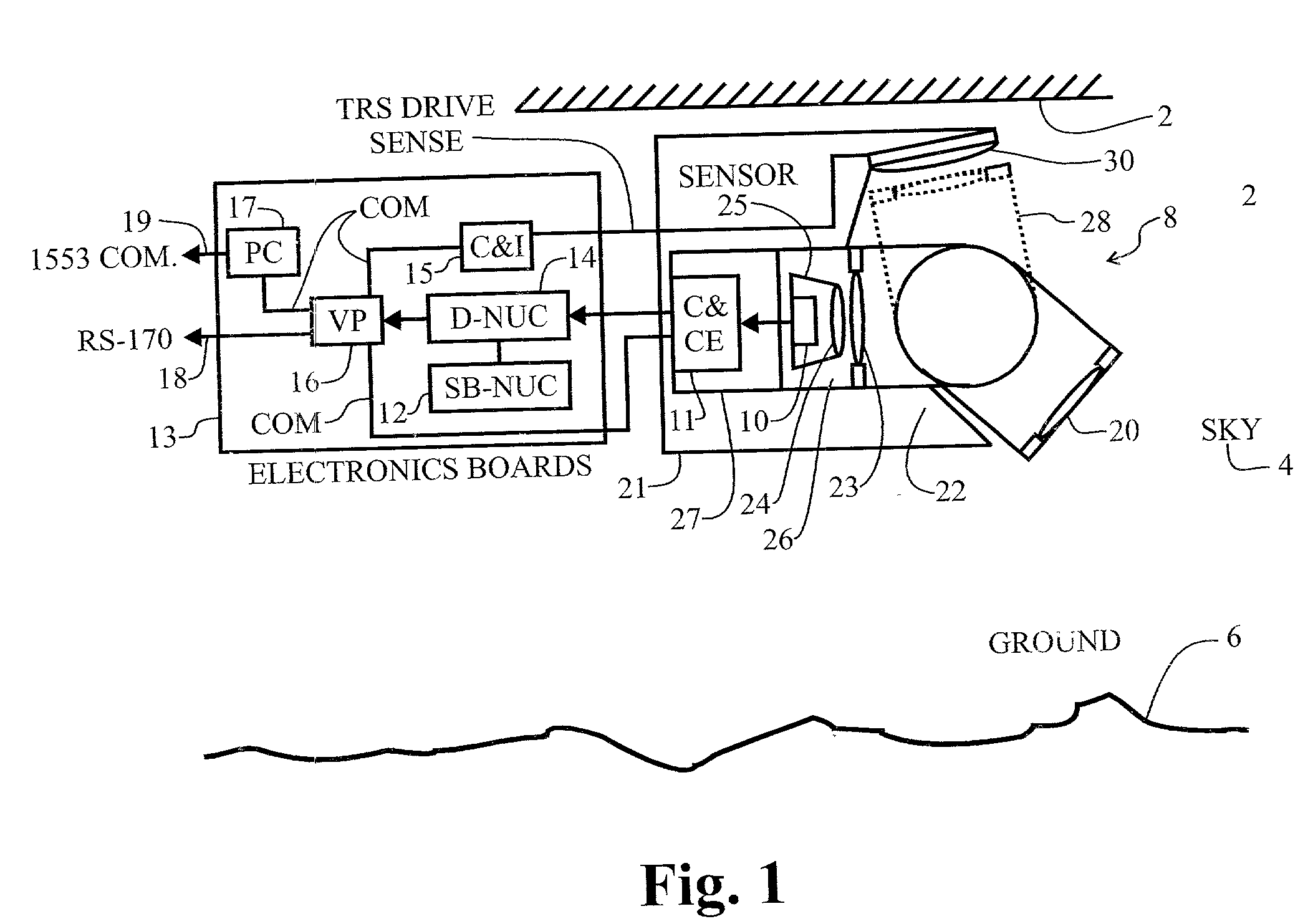

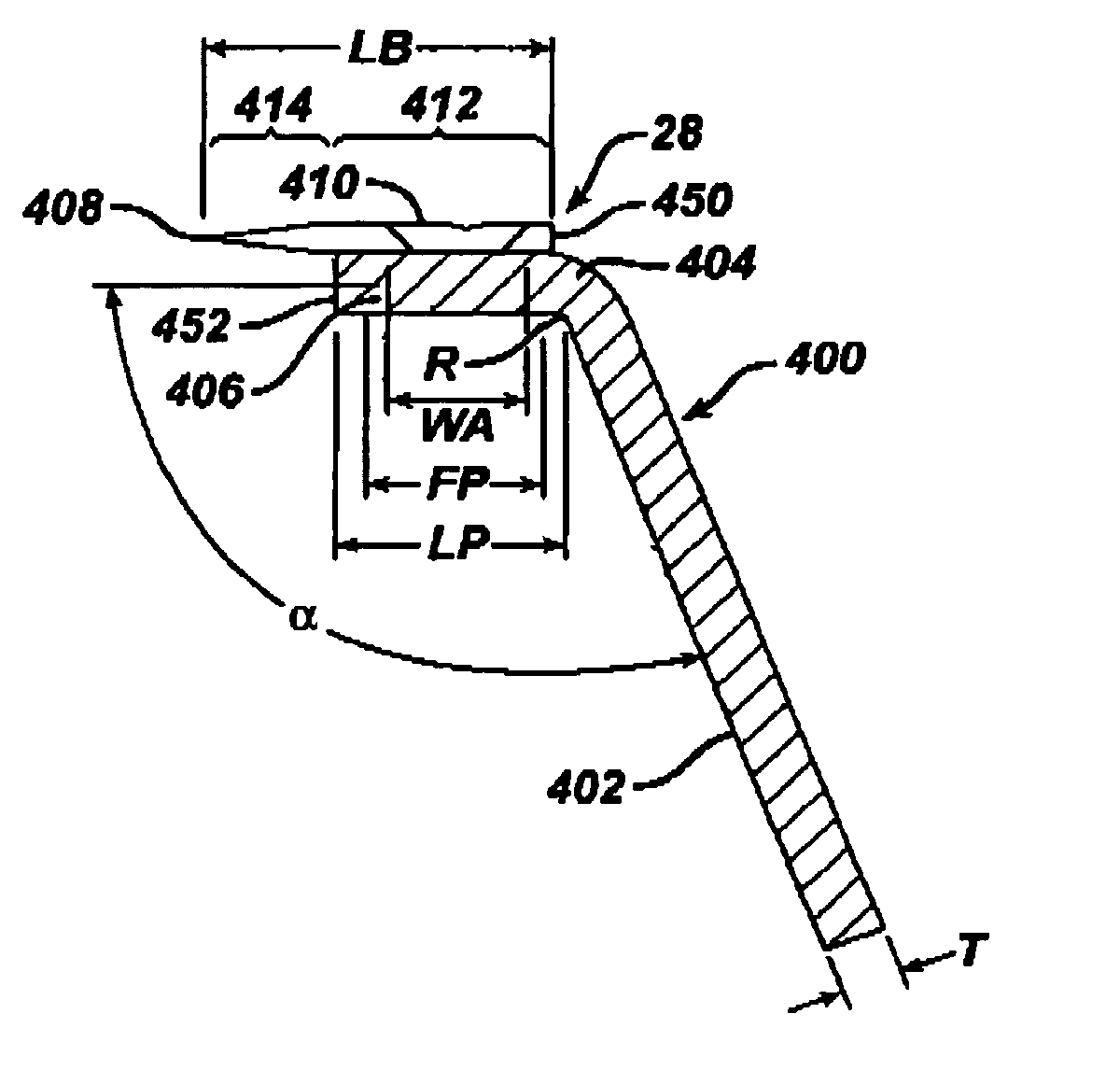

Display uniformity calibration system and method for a staring forward looking infrared sensor

InactiveUS20030183756A1Eliminate needHysteresis effectTelevision system detailsSolid-state devicesHysteresisEngineering

A method and system for maintaining uniformity in a FLIR display. During a one-time initialization procedure, a plurality of dynamic ranges are defined by covering a specific range of bucket fill levels when in a certain gain. To cover all dynamic ranges possible, a plurality of pairs of responsivity equalization (RE) calibrations (each pair producing a RE set of pixel gain corrections) are also accomplished in the same one time initialization period. A plurality of corresponding level equalization (LE) calibrations (each using the appropriate calibrated RE set and producing a LE set of pixel level corrections) for each anticipated dynamic range are made at every power-up initialization. Each of the calibrations is done with respect to a thermal reference source to produce a uniform scene at the desired bucket fill level. An algorithm is employed which forces the two bucket fill points defined during the responsivity calibration to span as far as possible the dynamic range and forces the level equalization bucket fill point to fall within the two bucket fill points of the responsivity calibration. Then, during an operational time period, the scene and optics temperatures are monitored, and if the average bucket fill value exceeds the bucket fill range of the present dynamic range, the presently selected dynamic range is changed to a second dynamic range (gain is changed along with the RE set and LE set). The dynamic ranges are designed to overlap so that a hysteresis effect is achieved. The pre-calibrations and automatic dynamic range switching prevent saturation and create the best uniformity (lowest fix pattern noise) possible while allowing for continuous operation of the FLIR system, thus eliminating the interruption caused by the prior art touch-up calibration procedure.

Owner:RAYTHEON CO

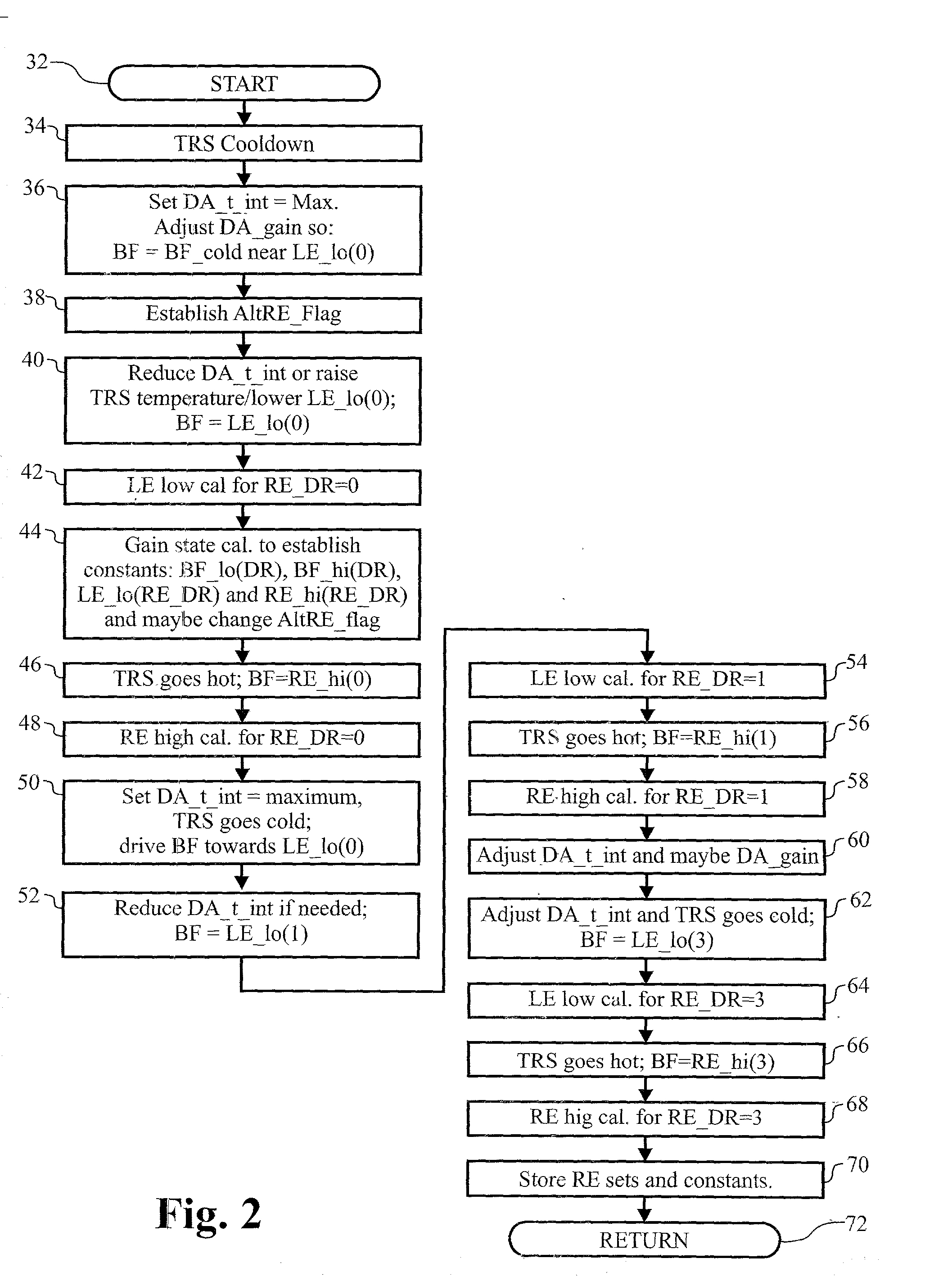

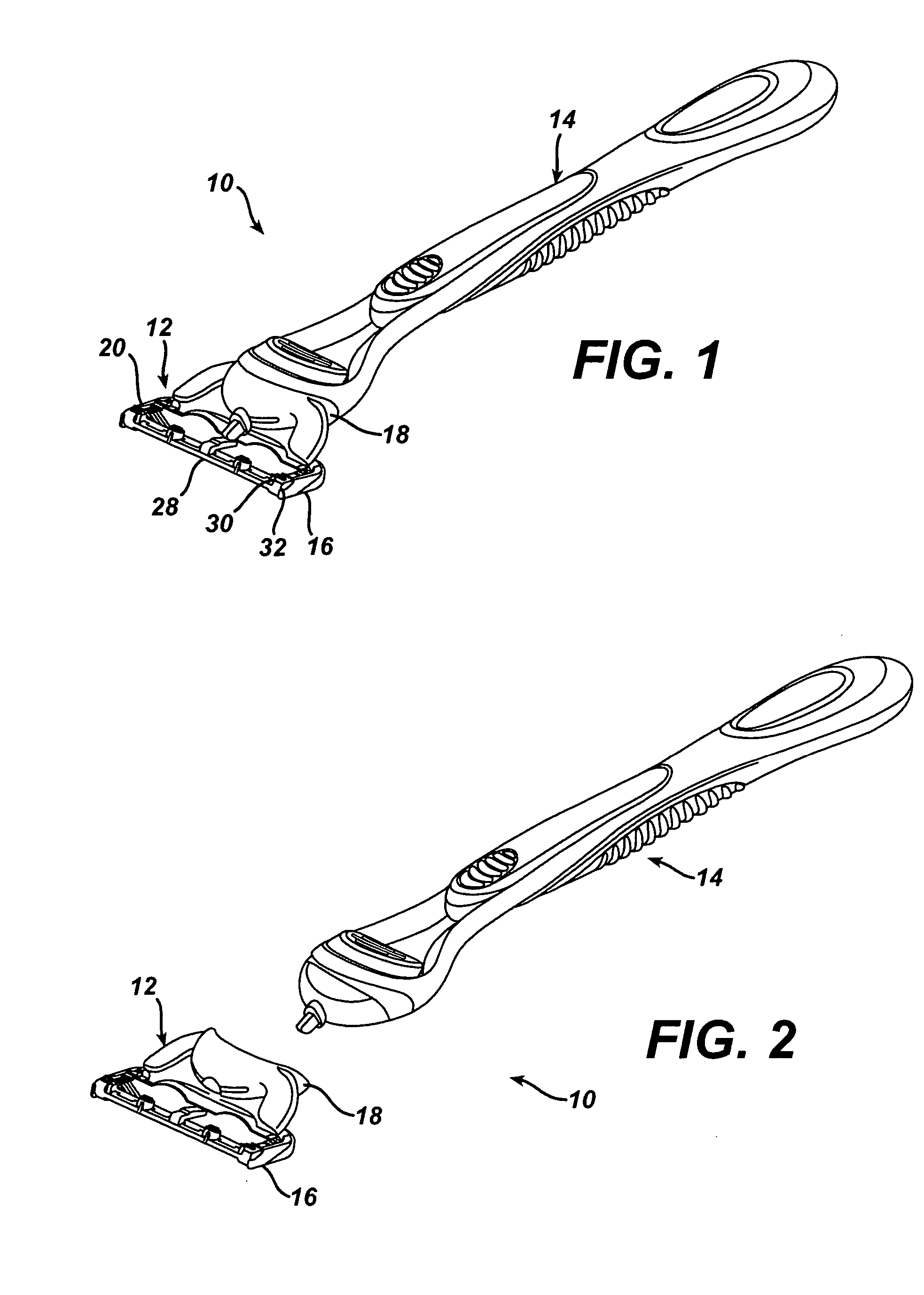

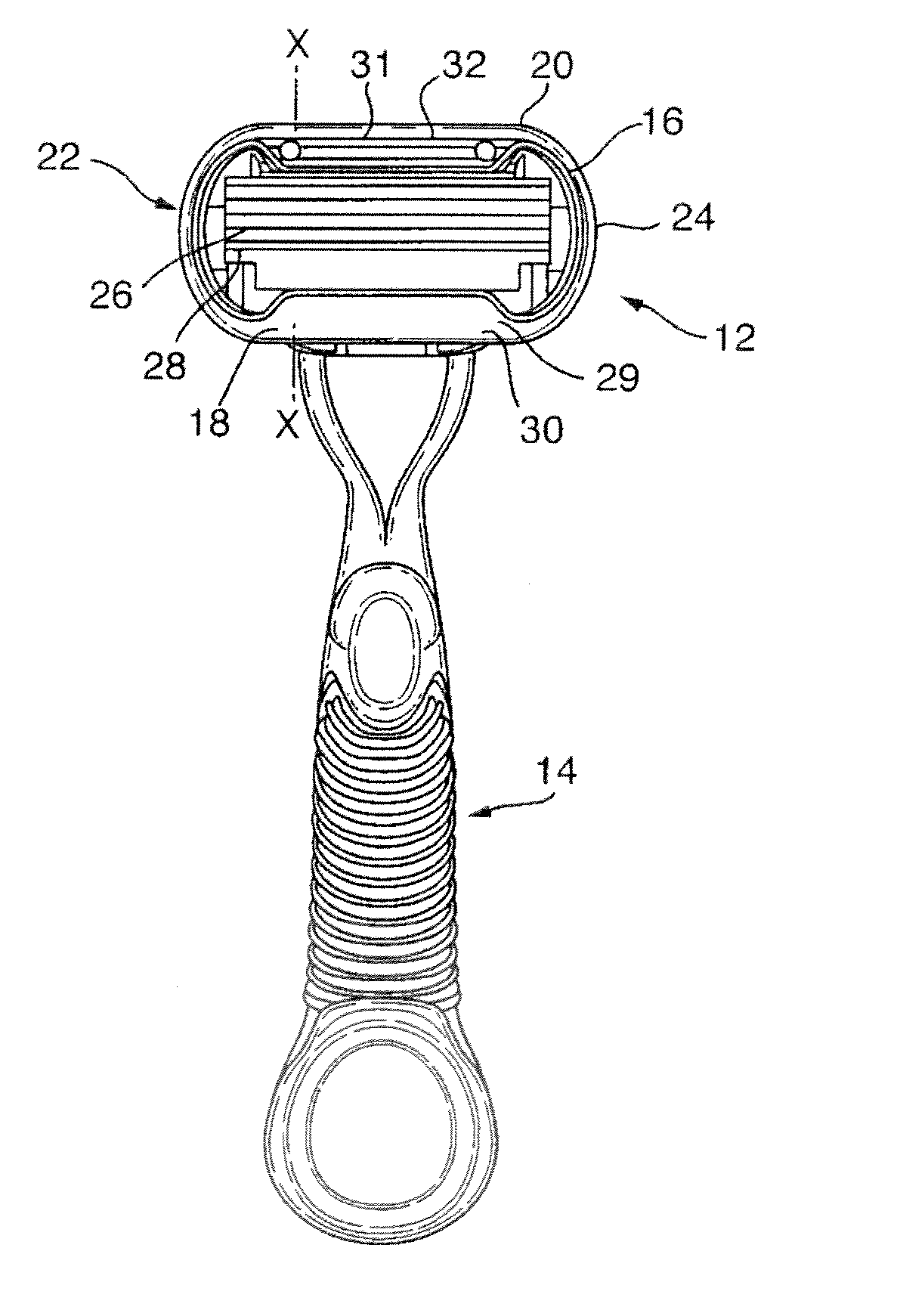

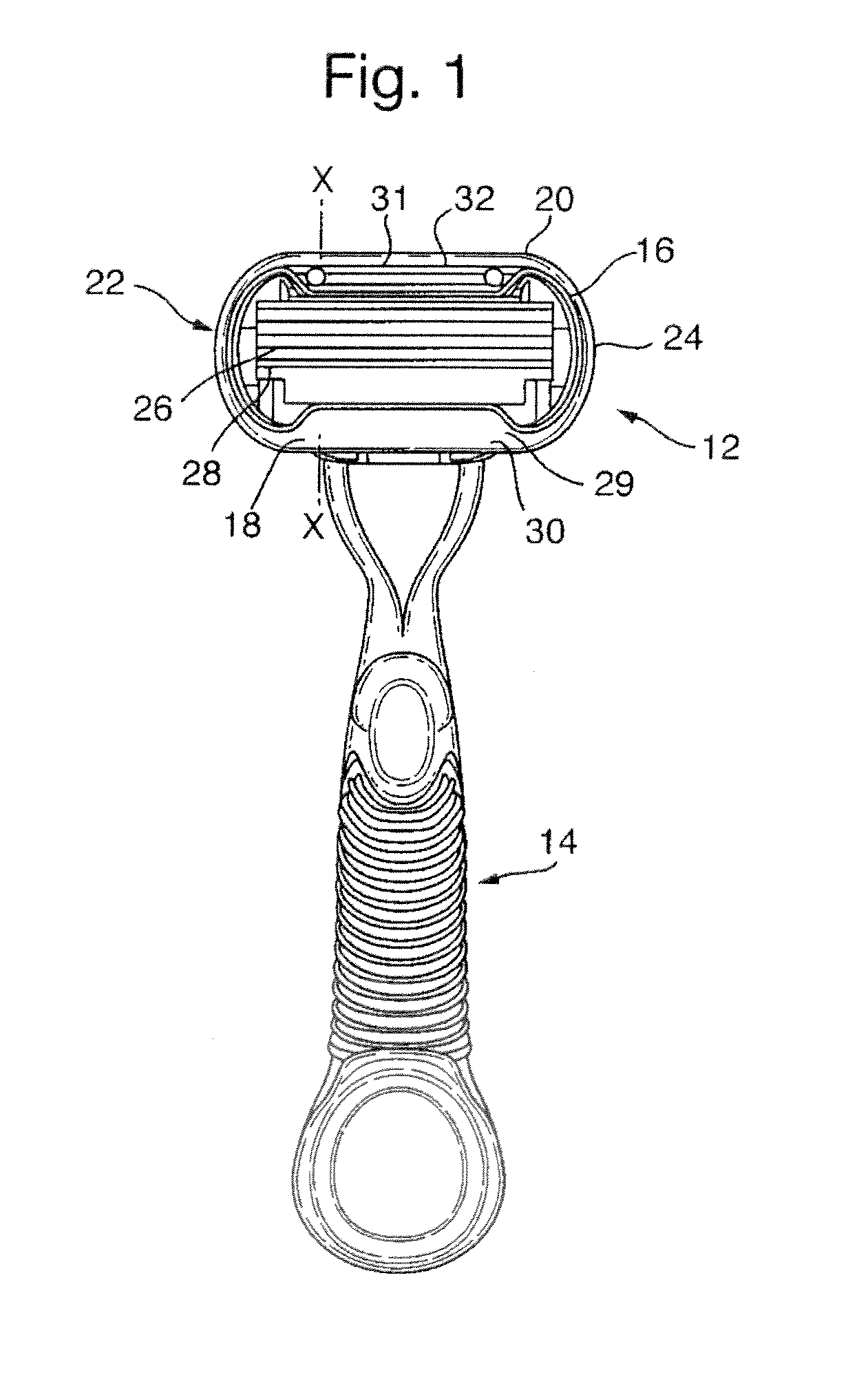

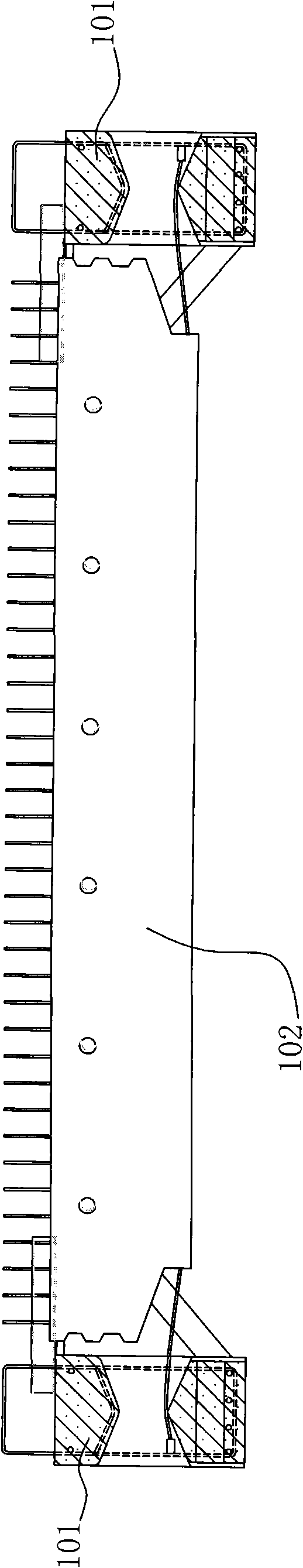

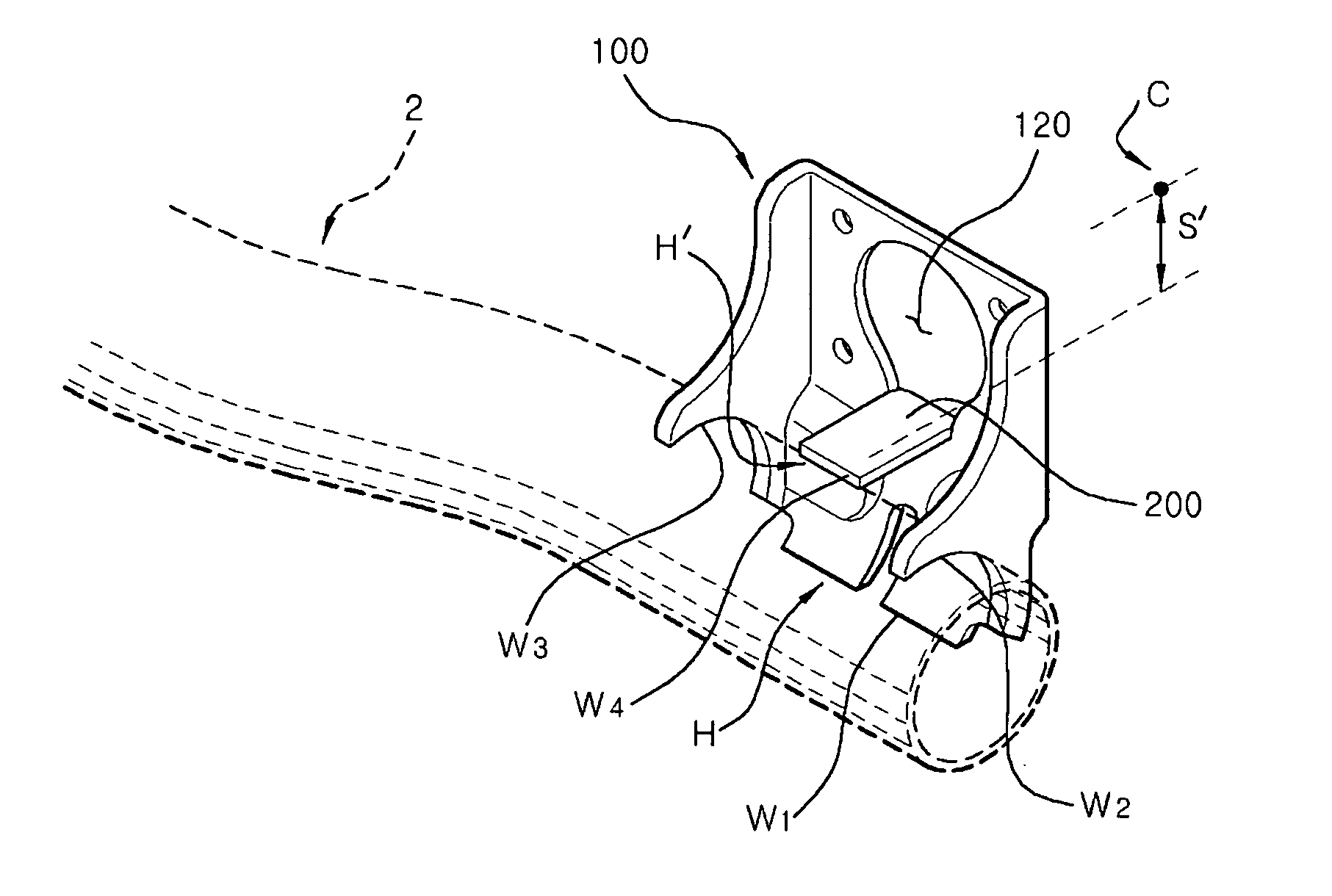

Cutting members for shaving razors with multiple blades

ActiveUS7131202B2Reliable manufacturingSufficiently compactMetal working apparatusRazor stropEngineering

A cutting member for a shaving razor includes an elongated metal blade having a cutting edge, a blade end, a tapered portion near the blade end and a uniform thickness portion extending from the blade end to the tapered portion, and an elongated bent metal support that has a platform portion, a bent portion and a base portion extending downward from the bent potion. The platform portion extends forward from the bent portion to a front end. The platform portion includes an attachment area that is spaced from the front end and the bent portion, and a flat portion that includes and extends beyond the attachment area. The uniform thickness portion of the blade is supported on the platform portion and secured thereto at the attachment area, the tapered portion extending forward beyond the front end of the platform portion.

Owner:THE GILLETTE CO

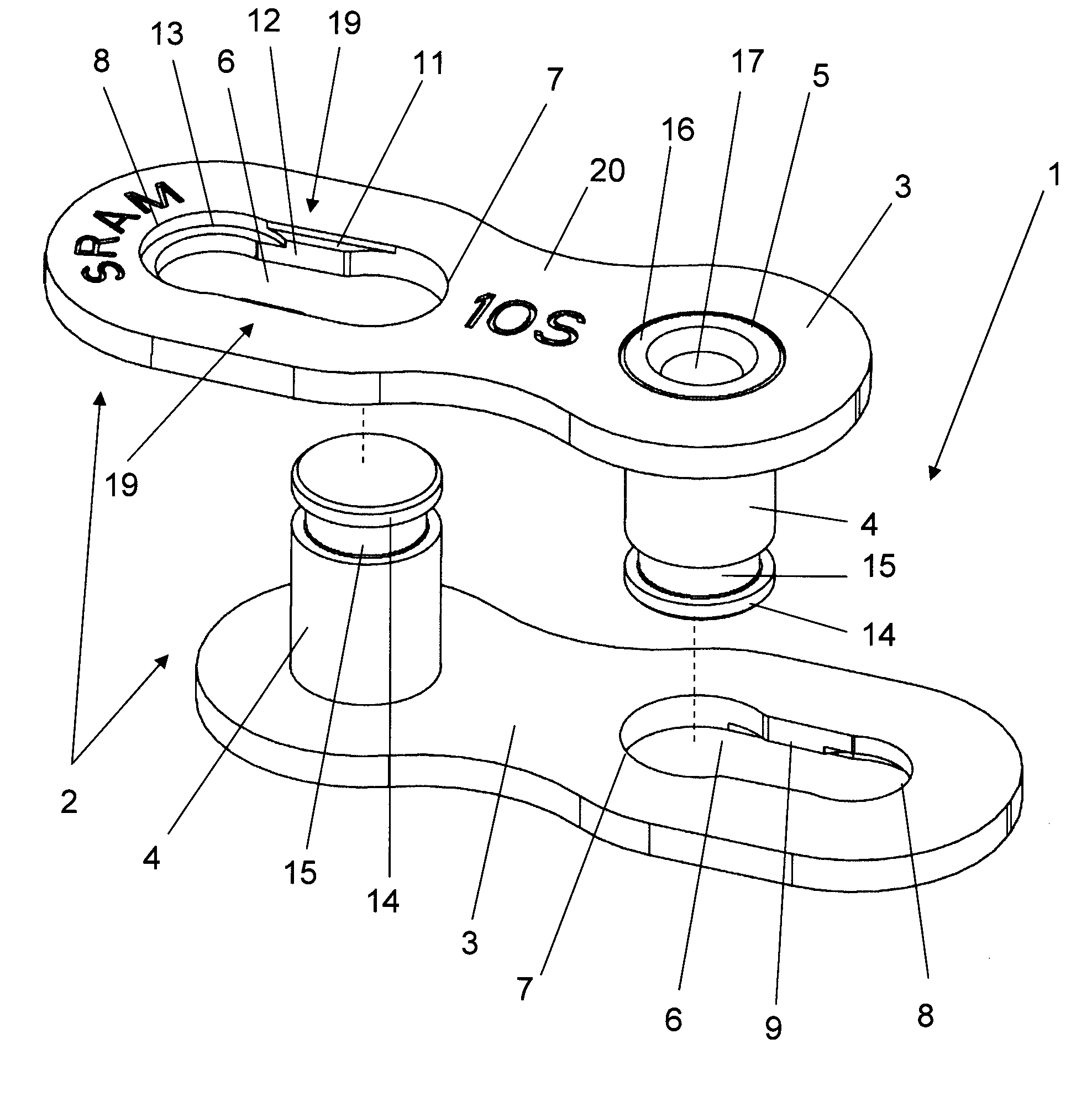

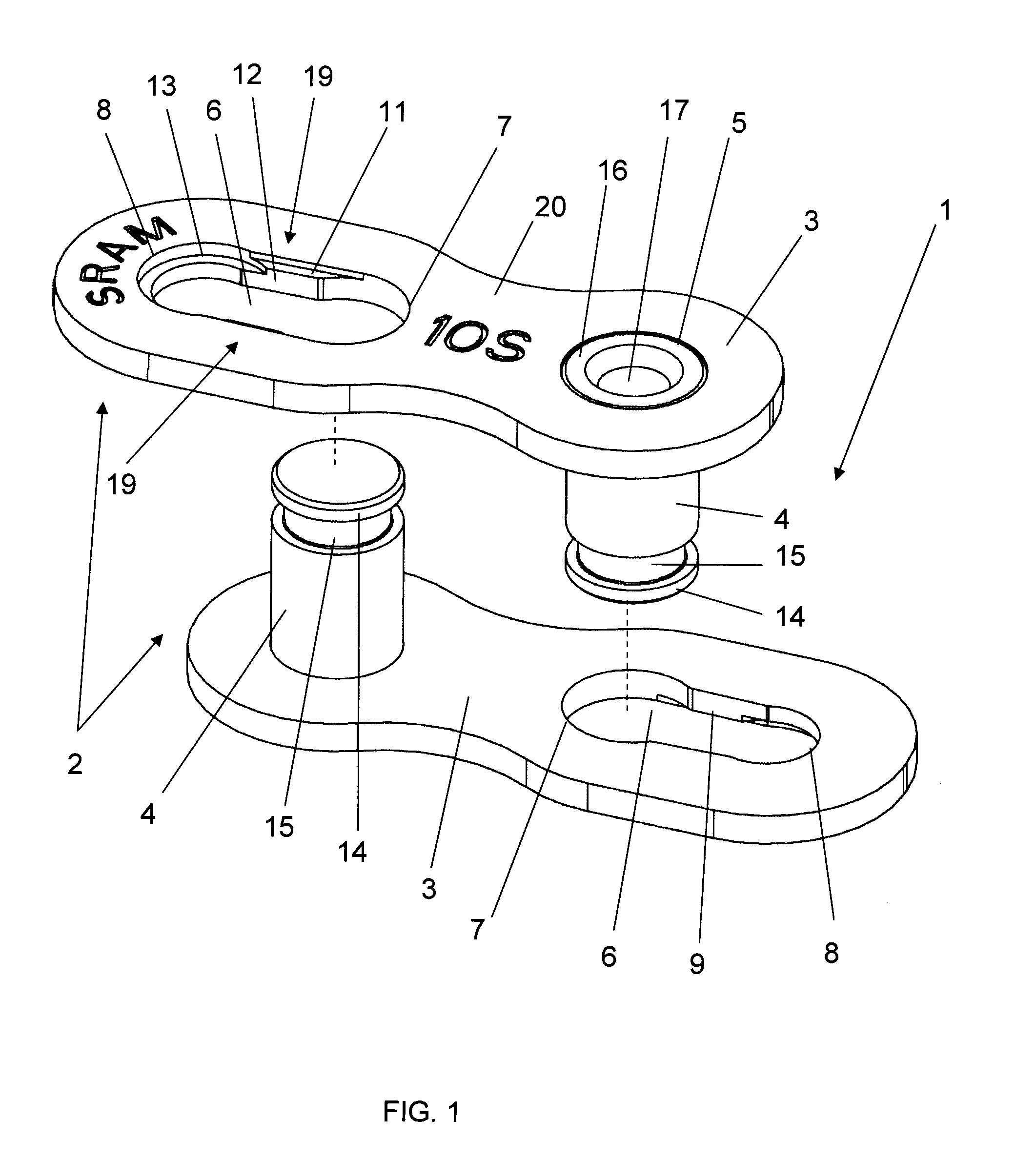

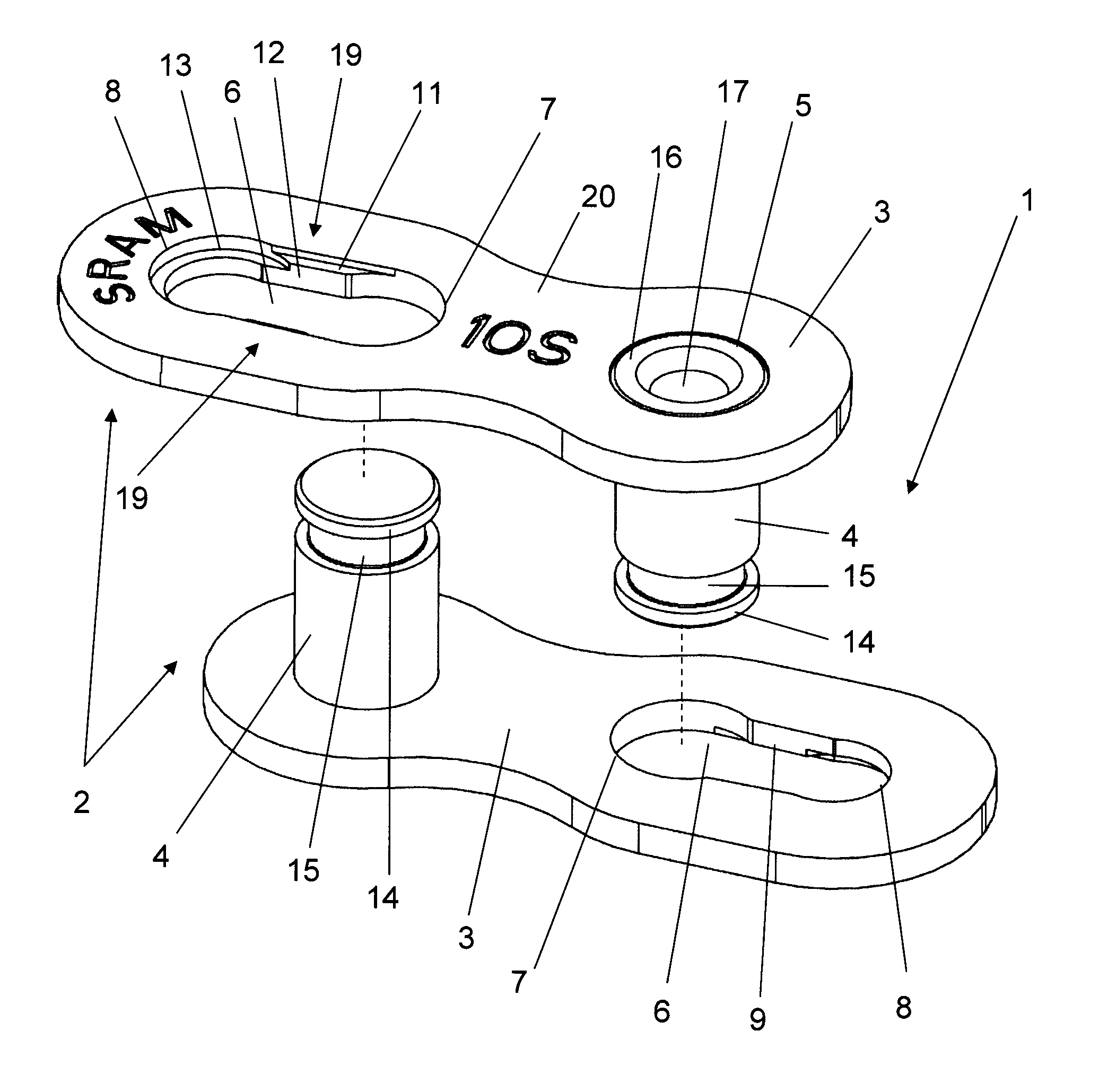

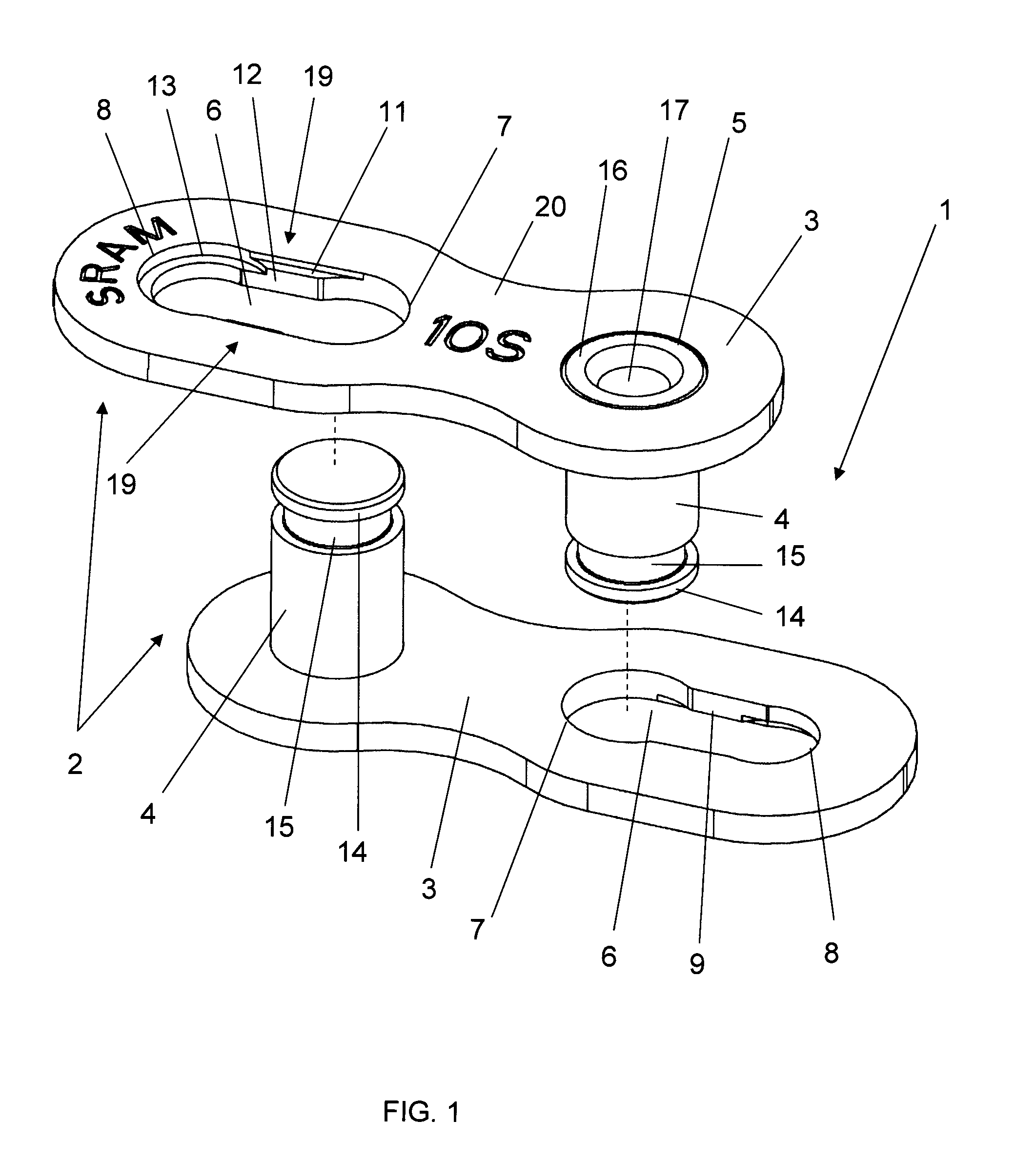

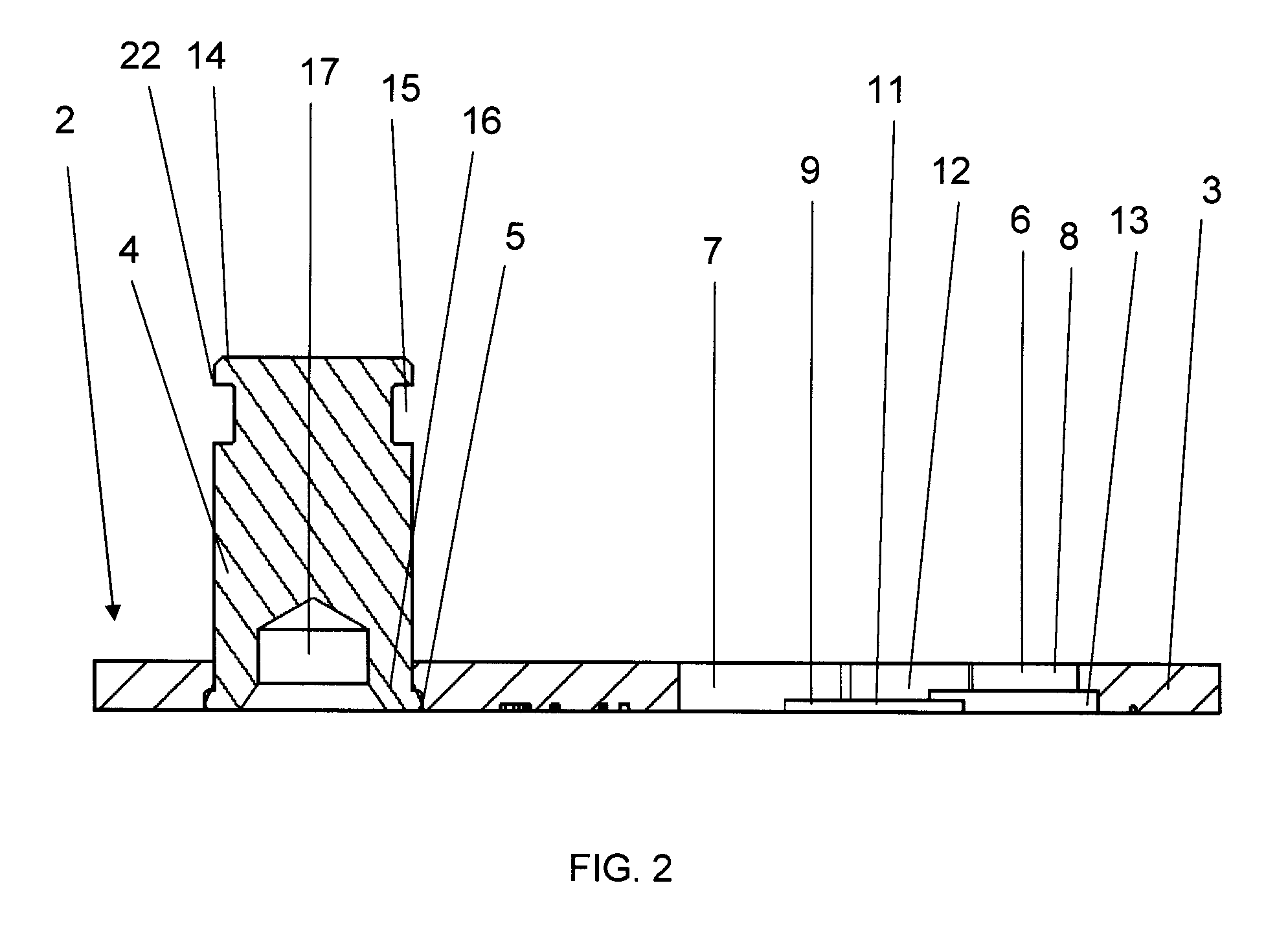

Closing Link For A Bicycle Chain

A closing link for a bicycle chain that includes a first outer link plate having a first elongated hole and a first chain pin extending therefrom and a second outer link plate having a second elongated hole and a second chain pin extending therefrom. The first chain pin is received in the second elongated hole and the second chain pin is received in the first elongated hole Each chain pin has a head at one end, a foot at the other end and a groove therebetween. Each elongated hole has a larger diameter end, a smaller diameter end and a displacement region therebetween. The larger diameter end has a diameter larger than a diameter of the pin head. The smaller diameter end receives the groove of the chain pin and includes a countersink to receive the pin head. The displacement region includes sides having recessed and unrecessed portions. The recessed portions have a smaller depth than a depth of the countersink at least in the region of the countersink.

Owner:SRAM

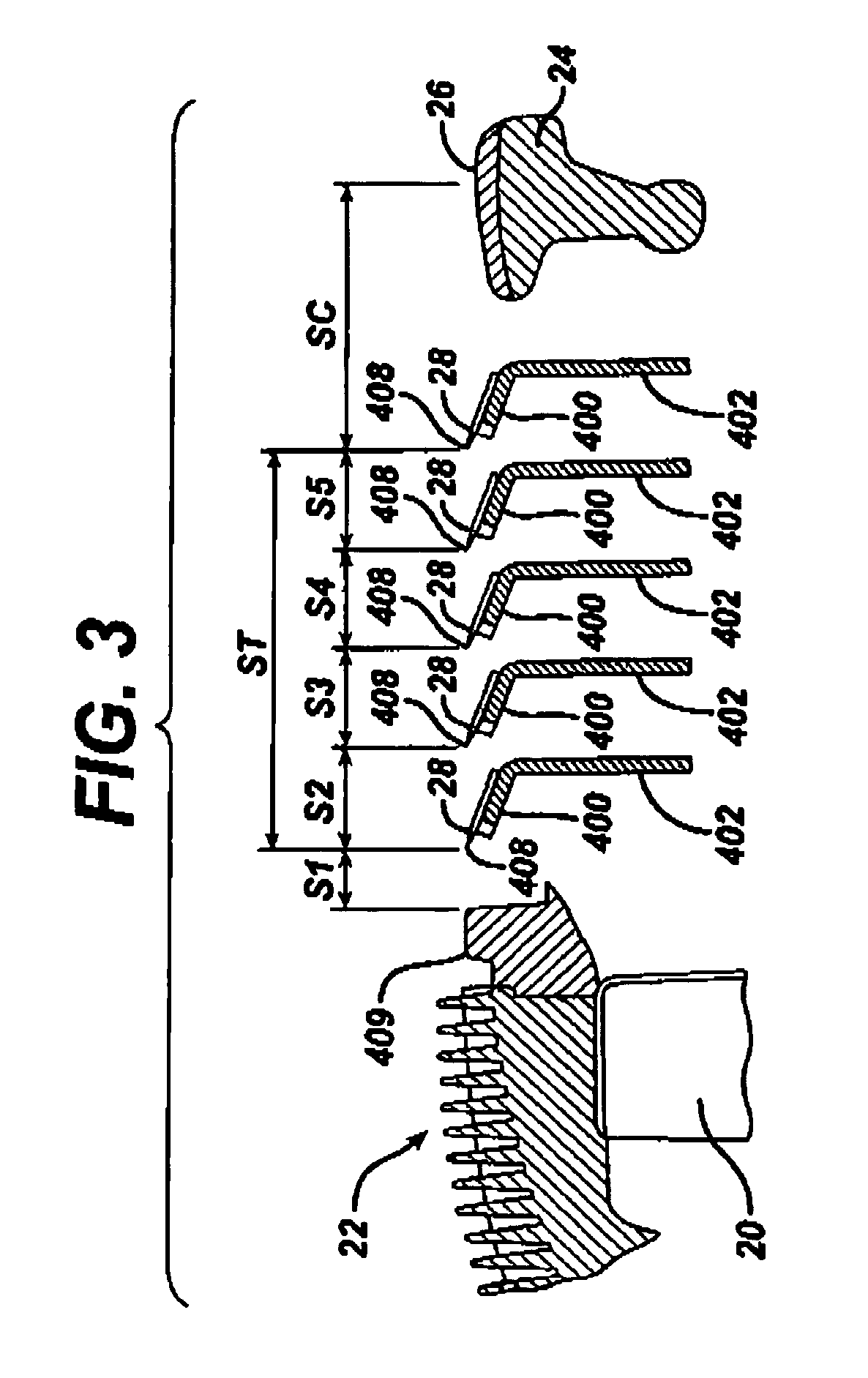

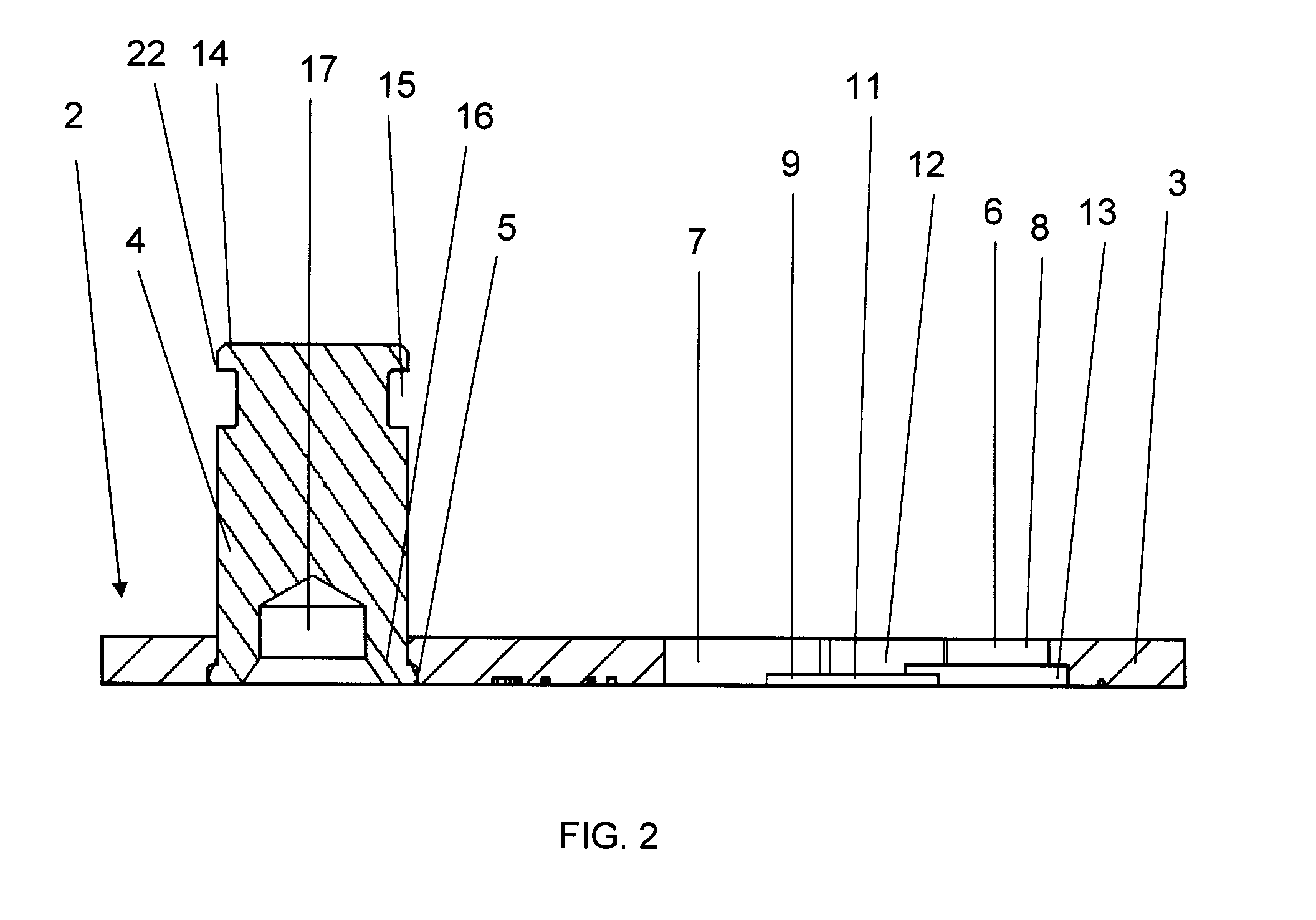

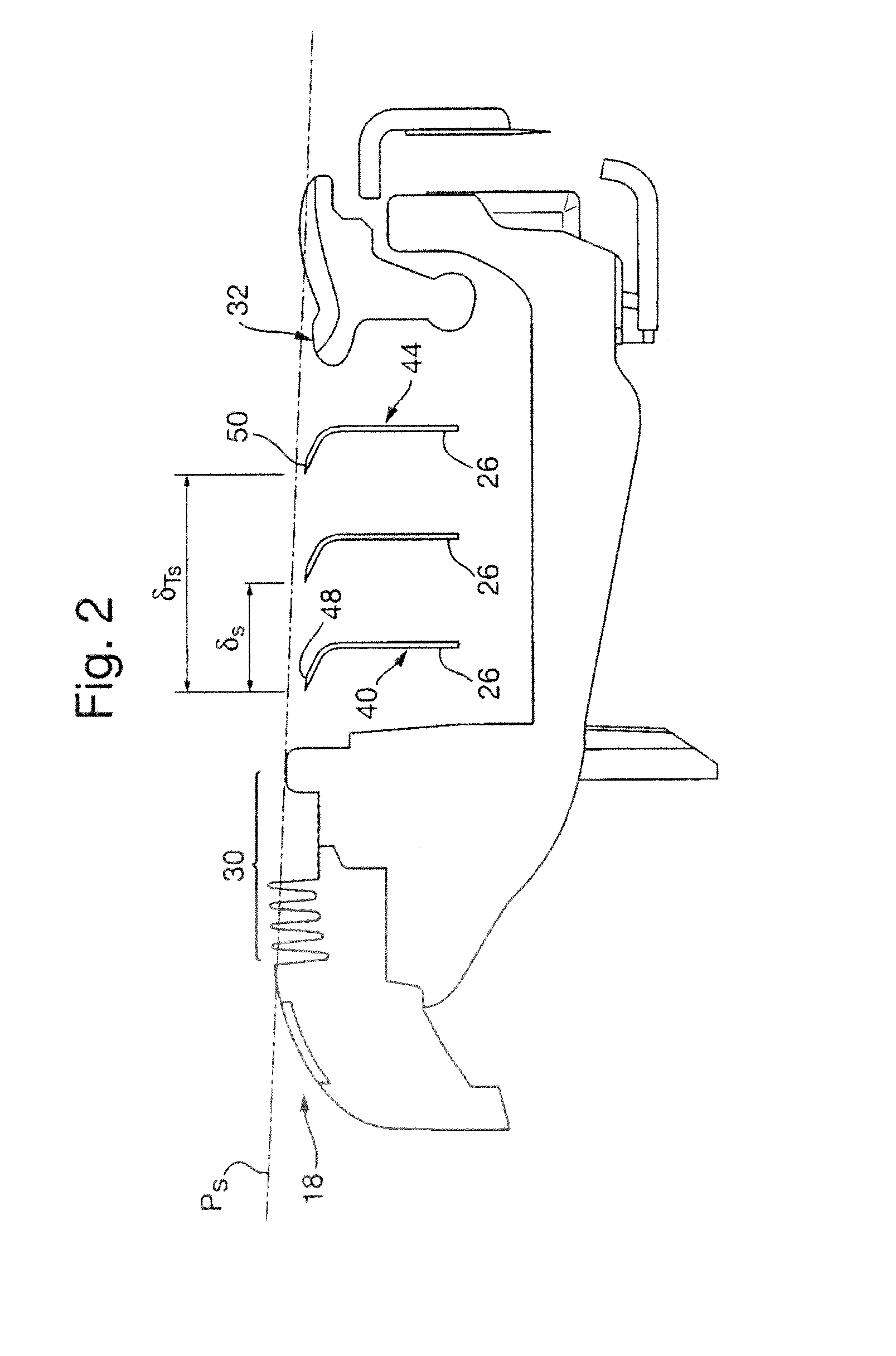

Razor cartridges

A razor cartridge has a housing having a front and a rear. At least two adjacent blades are provided, each pair having a leading blade and a trailing blade. Each of the leading and trailing blades having a cutting edge directed towards a front of the housing, the cutting edge of the leading blade being positioned between the cutting edge of the trailing blade and the front of the housing. A span δs of less than 1.0 mm is provided between the cutting edges of at least one adjacent pair of trailing and leading blades and an inter-blade gap δg is provided between said pair of adjacent leading and trailing blades, measured at the shortest distance between the adjacent leading and trailing blades, wherein the gap δg is less than or equal to the span and greater than 0.15 mm.

Owner:THE GILLETTE CO

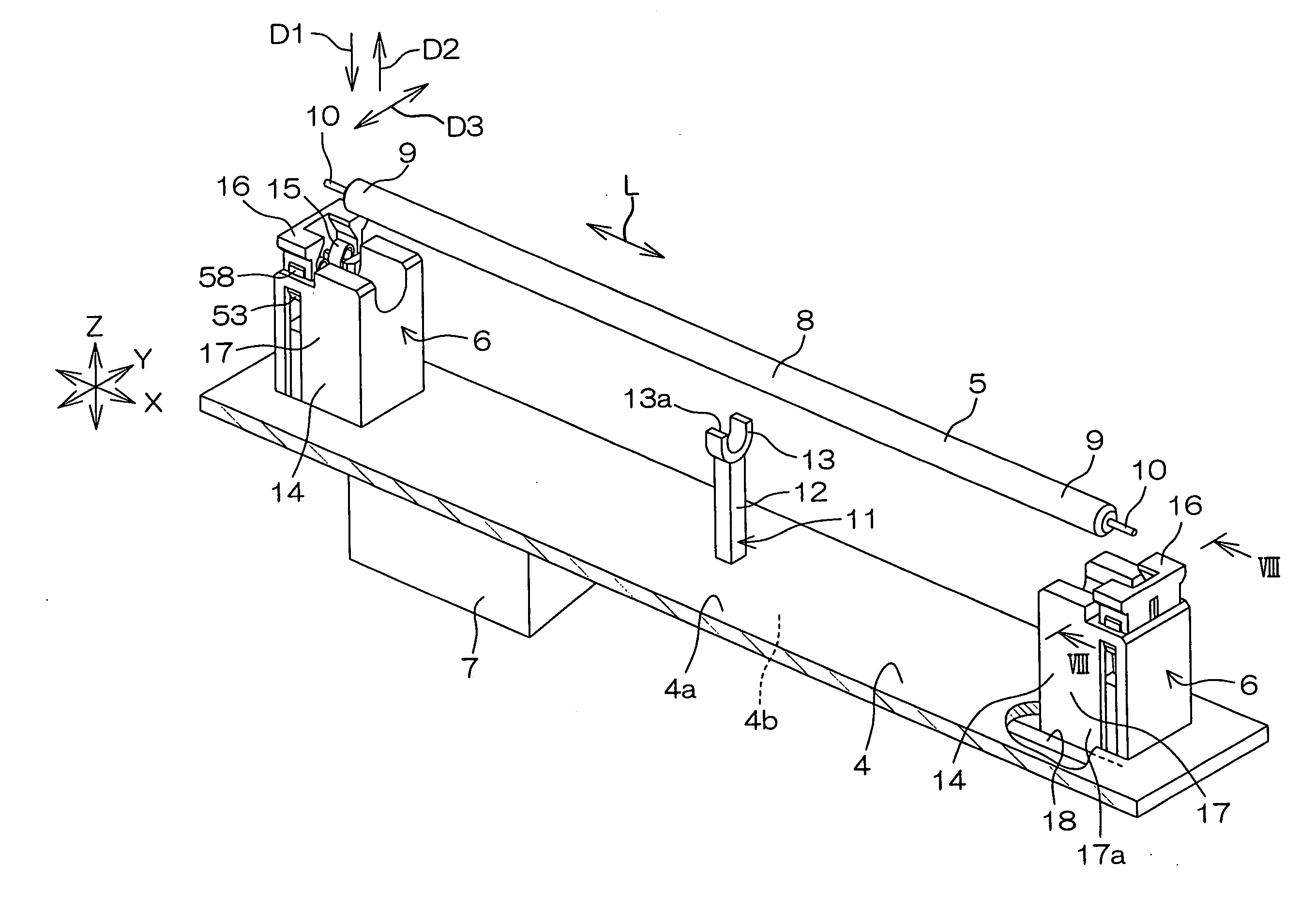

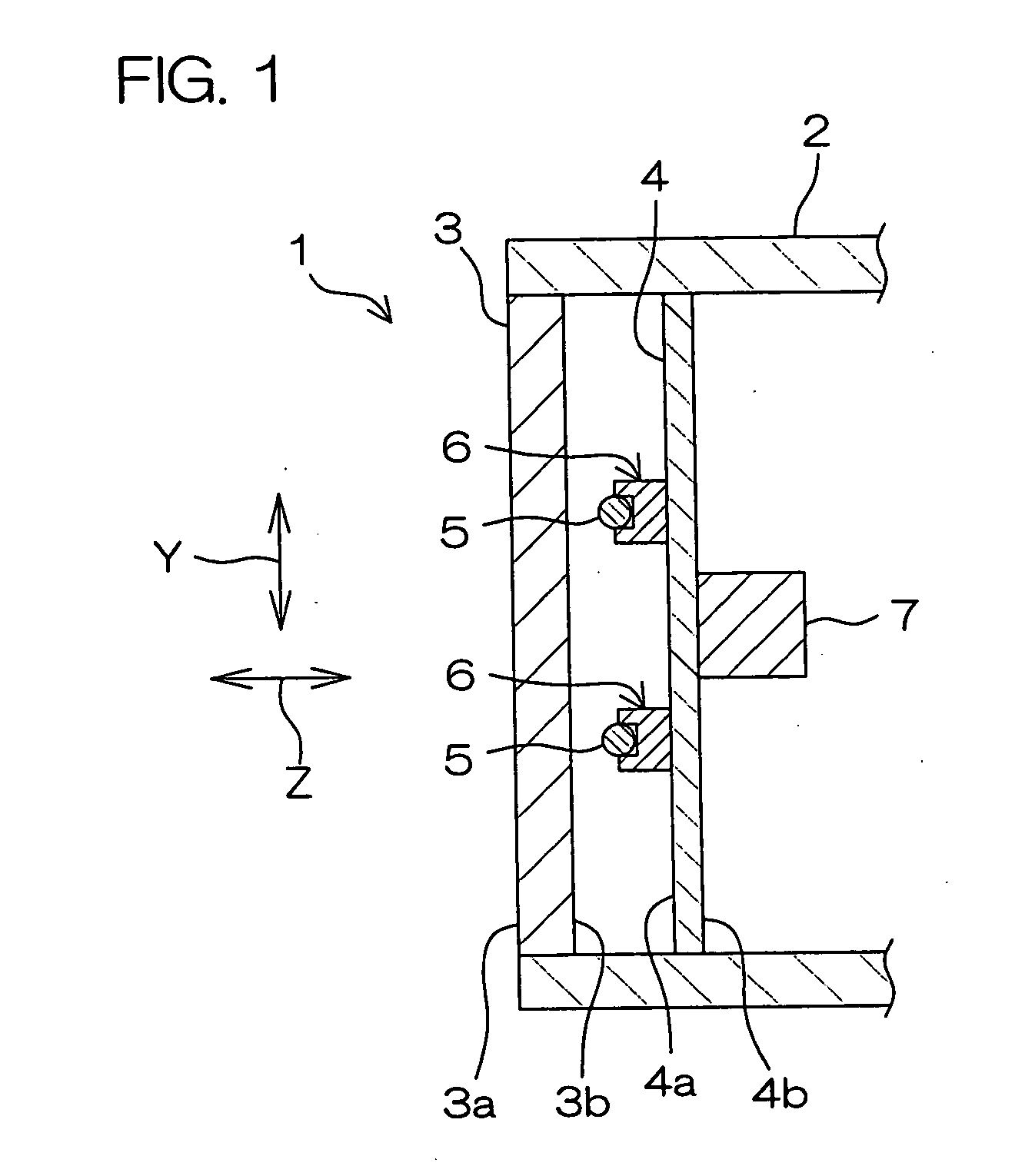

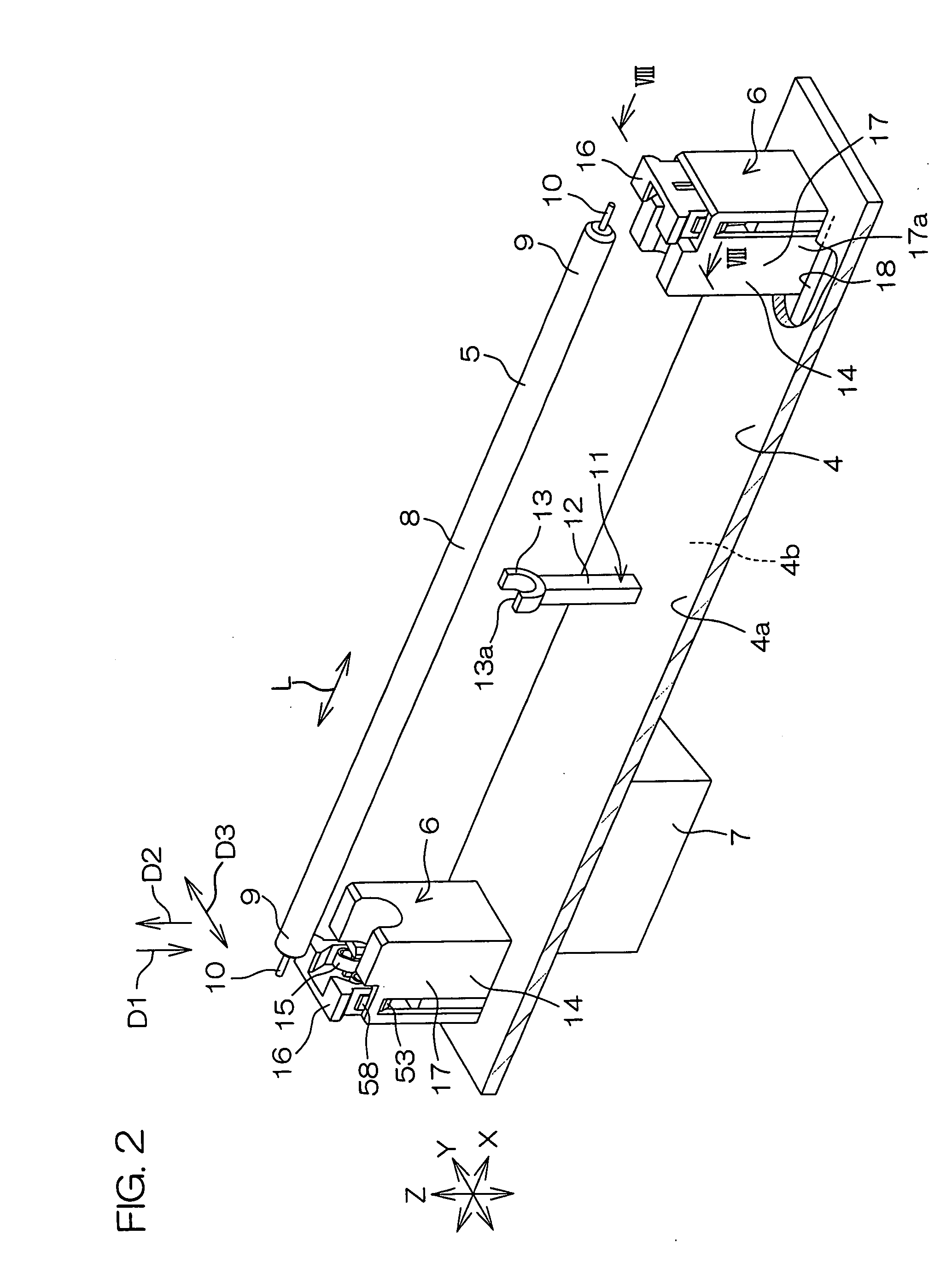

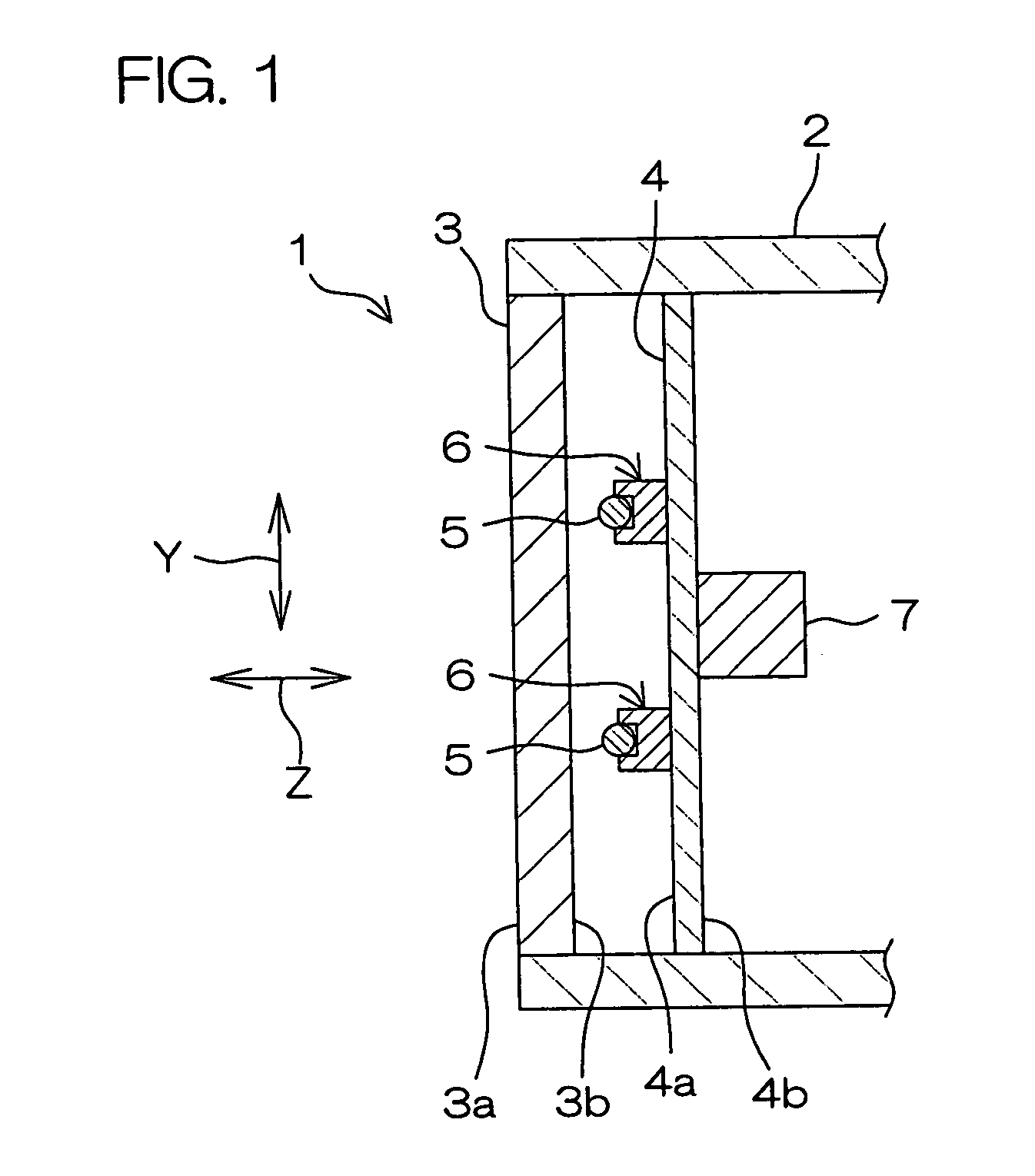

Fluorescent tube attaching structure

InactiveUS20070037427A1Positional deviationAdjustable positionEngagement/disengagement of coupling partsLighting support devicesMechanical engineering

Owner:JST MFG CO LTD

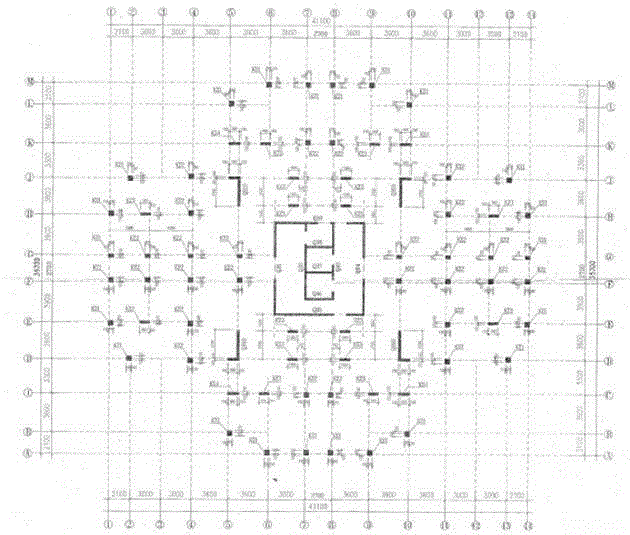

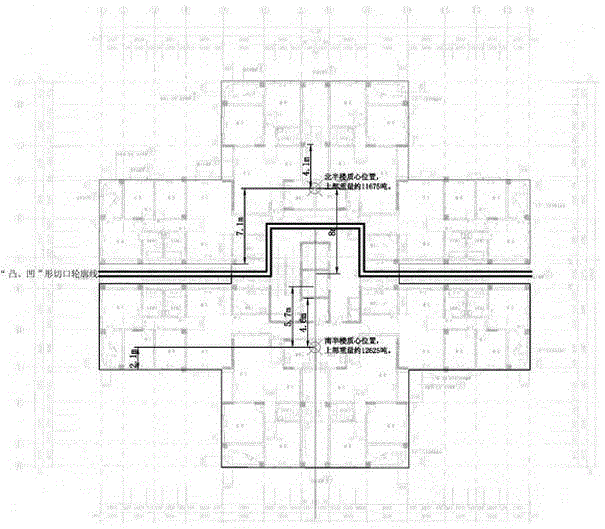

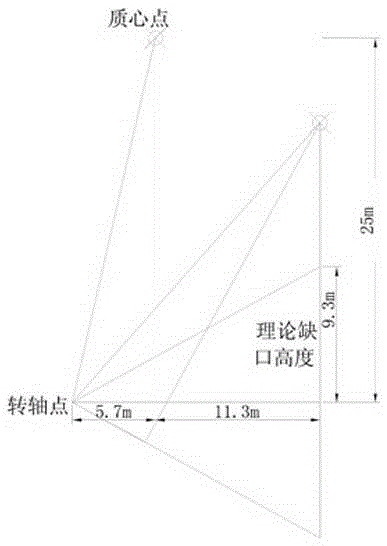

Blasting demolition construction key technology and construction method of intersecting-parallels-shaped high-rise building

ActiveCN105401742AEasy to pourReduce spanBuilding repairsShock proofingArchitectural engineeringStructural engineering

The invention discloses a blasting demolition construction key technology and construction method of an intersecting-parallels-shaped high-rise building, and aims at providing an economical and quick blasting demolition construction method of an intersecting-parallels-shaped high-rise building. The construction method is small in engineering amount, low in construction cost and good in blasting effect. The construction method comprises the following steps that a, division pretreatment is carried out on the building, wherein U-shaped and T-shaped cutting seams are arranged in the center direction by bypassing a core barrel, the building is divided into a part A and a part B, and the whole core barrel is cut and merged into the part B; b, blasting cutting openings are formed in the bottoms of the divided building, wherein the blasting cutting openings are formed in the part A, the part B and the core barrel based on the high-rising building blasting demolition principle respectively; c, frame structure predemolition is carried out on a few key positions of the divided building needing blasting demolition; d, holes are drilled and checked; e, charging and protection construction are carried out; and f, networking, alerting and detonation are carried out. The blasting demolition construction key technology and construction method is applied to the technical field of building blasting demolition.

Owner:珠海爆破新技术开发有限公司

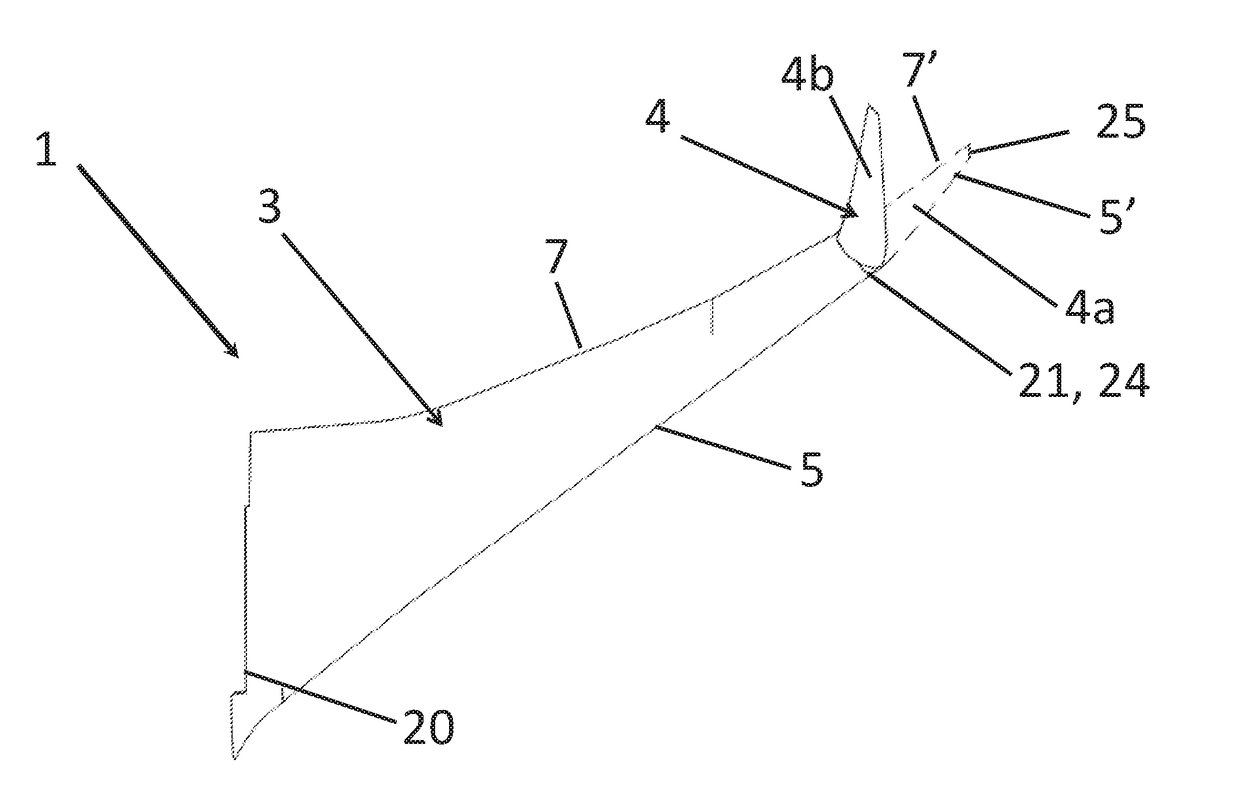

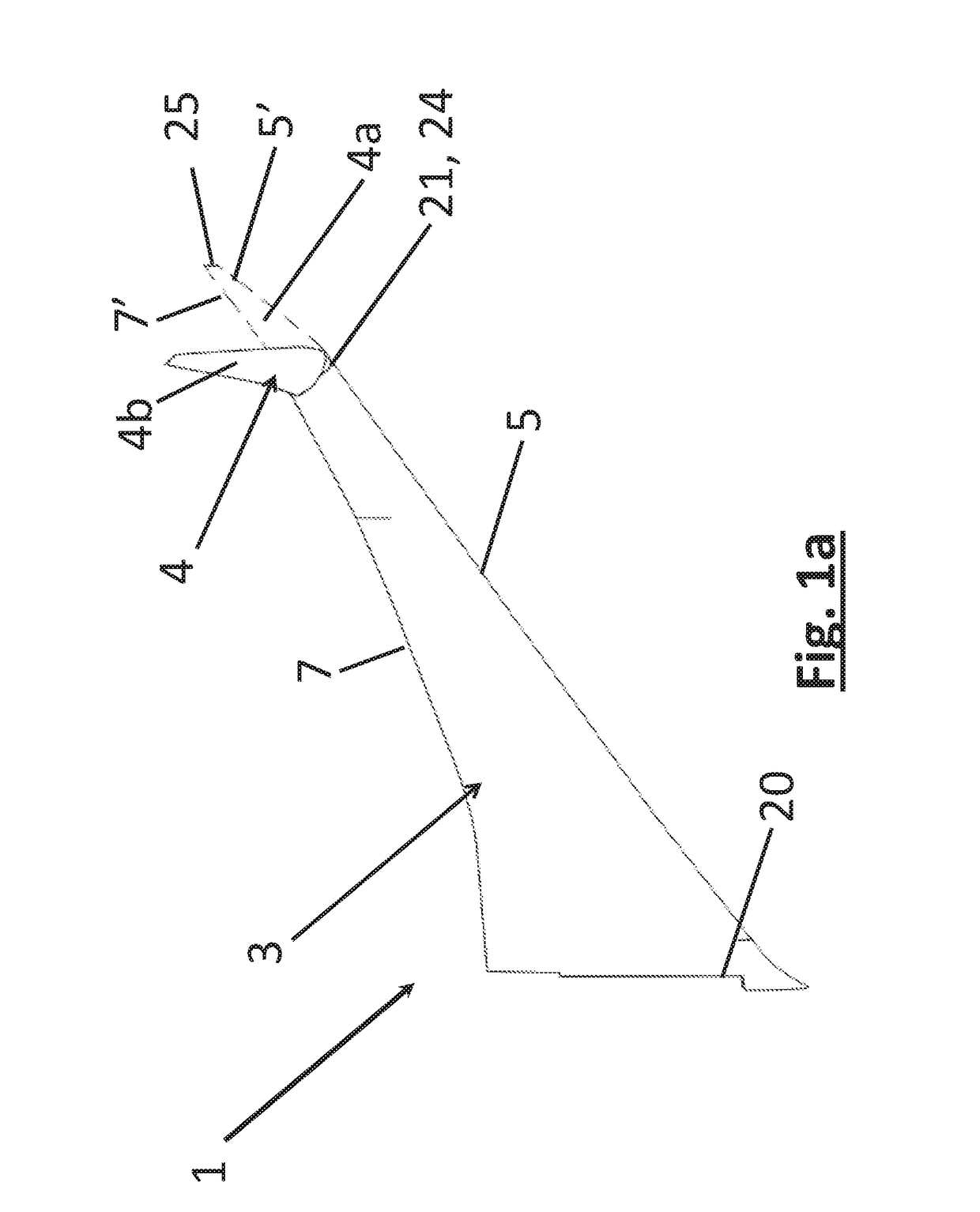

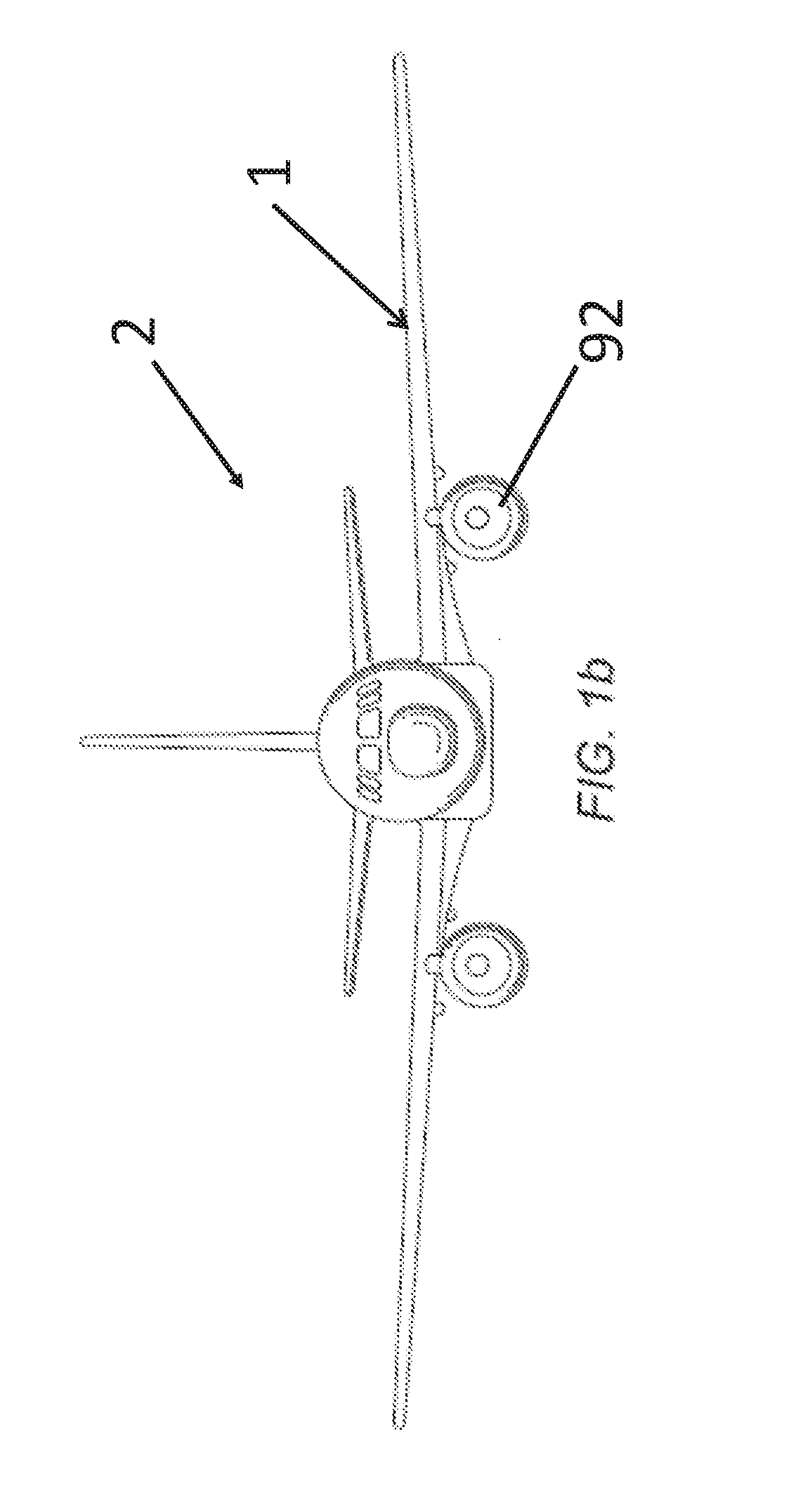

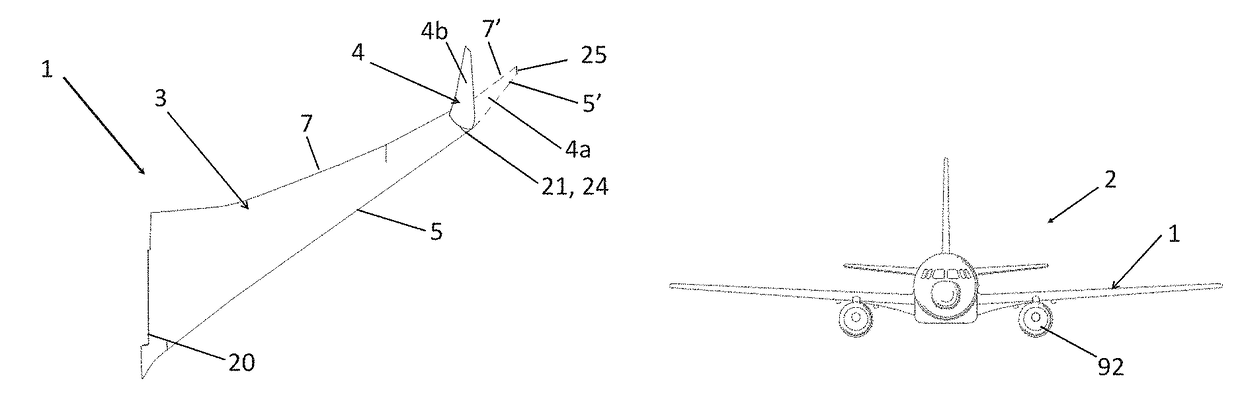

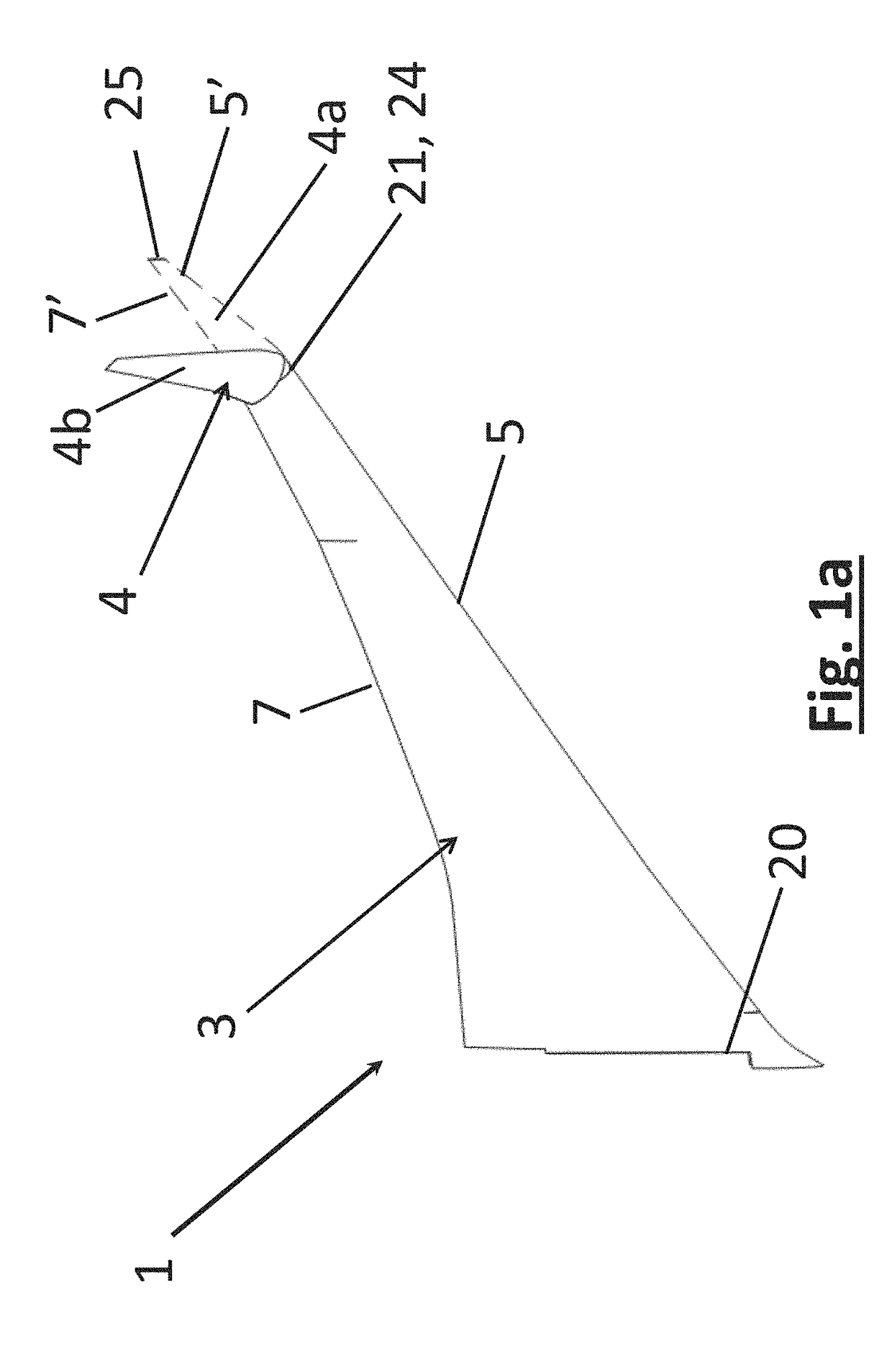

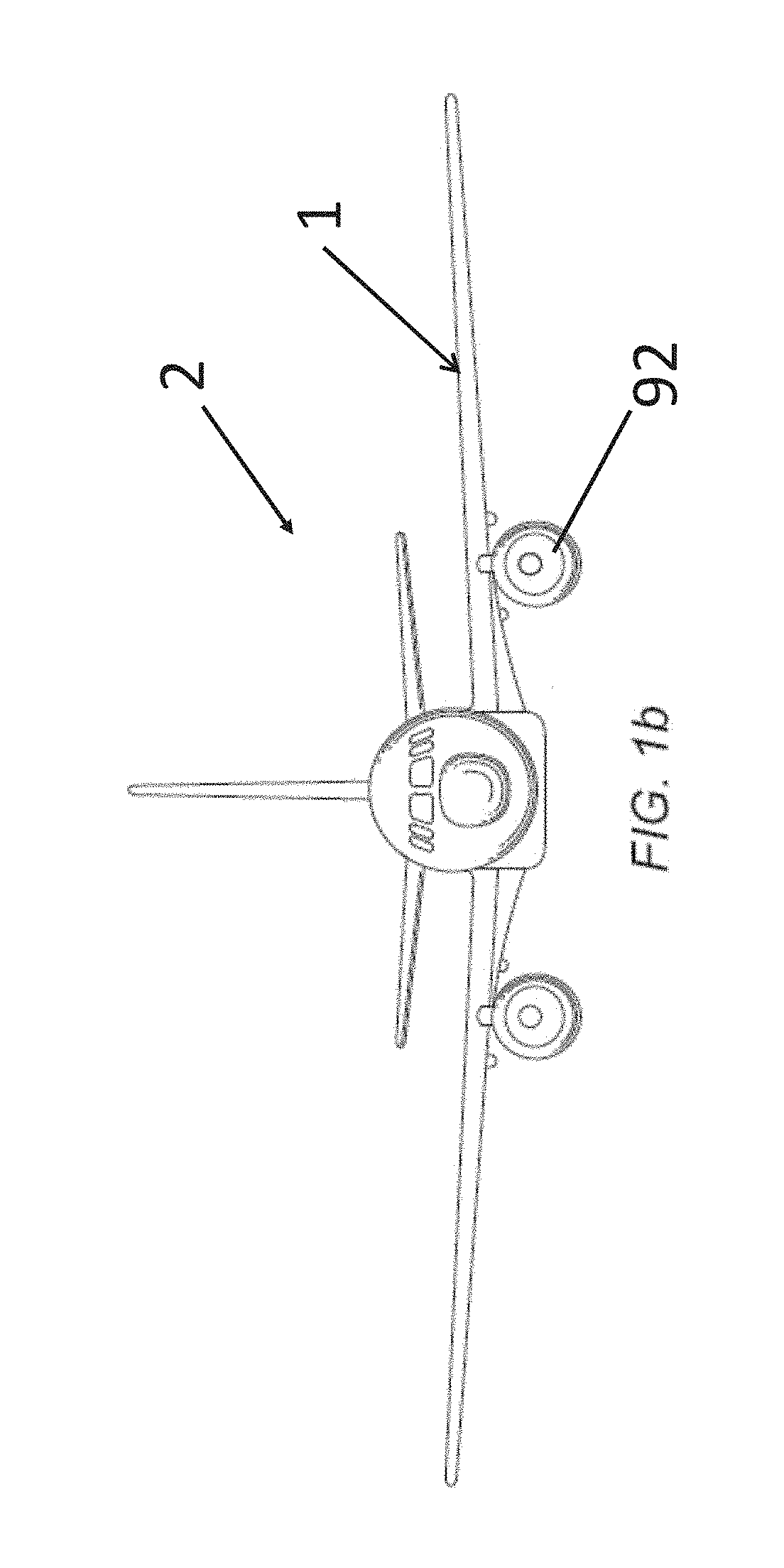

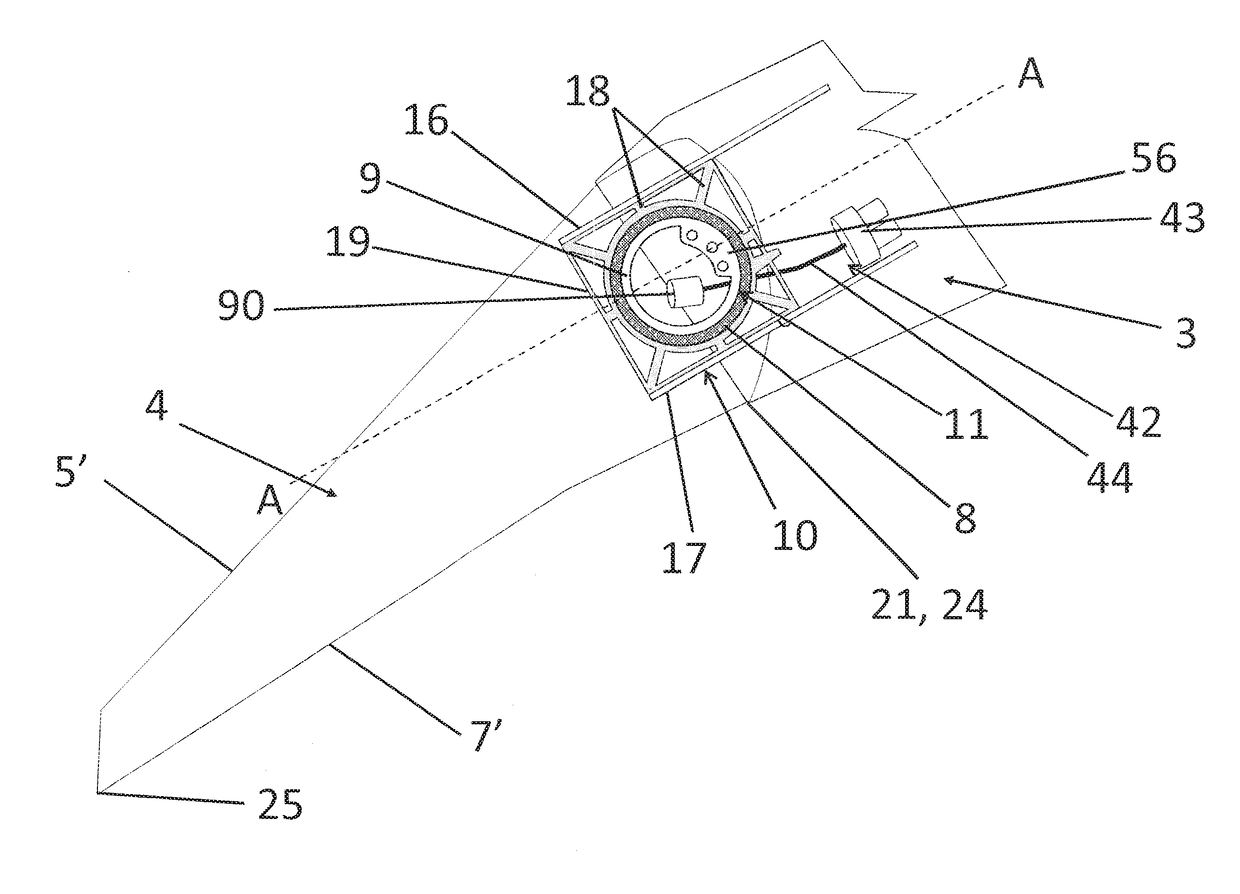

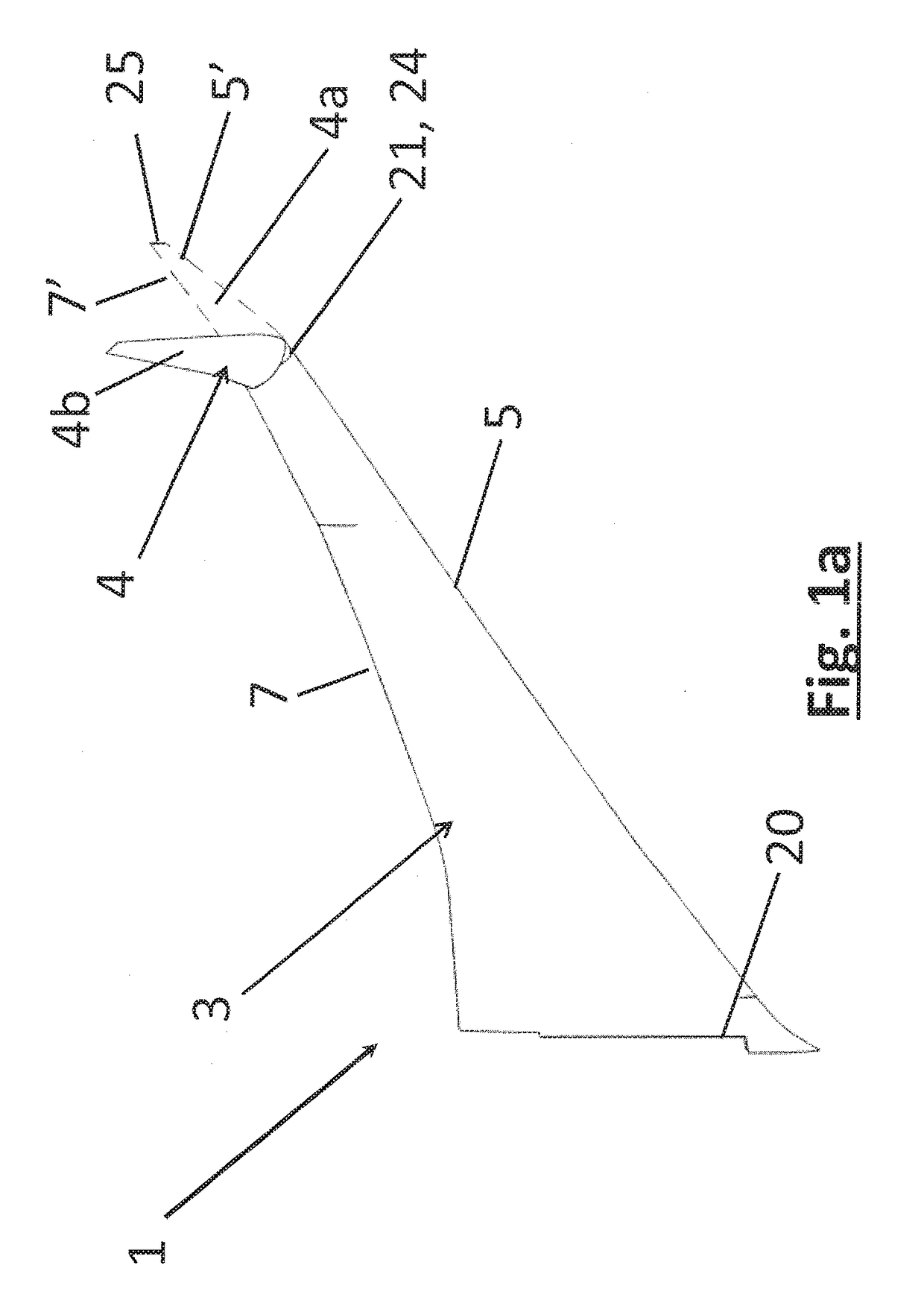

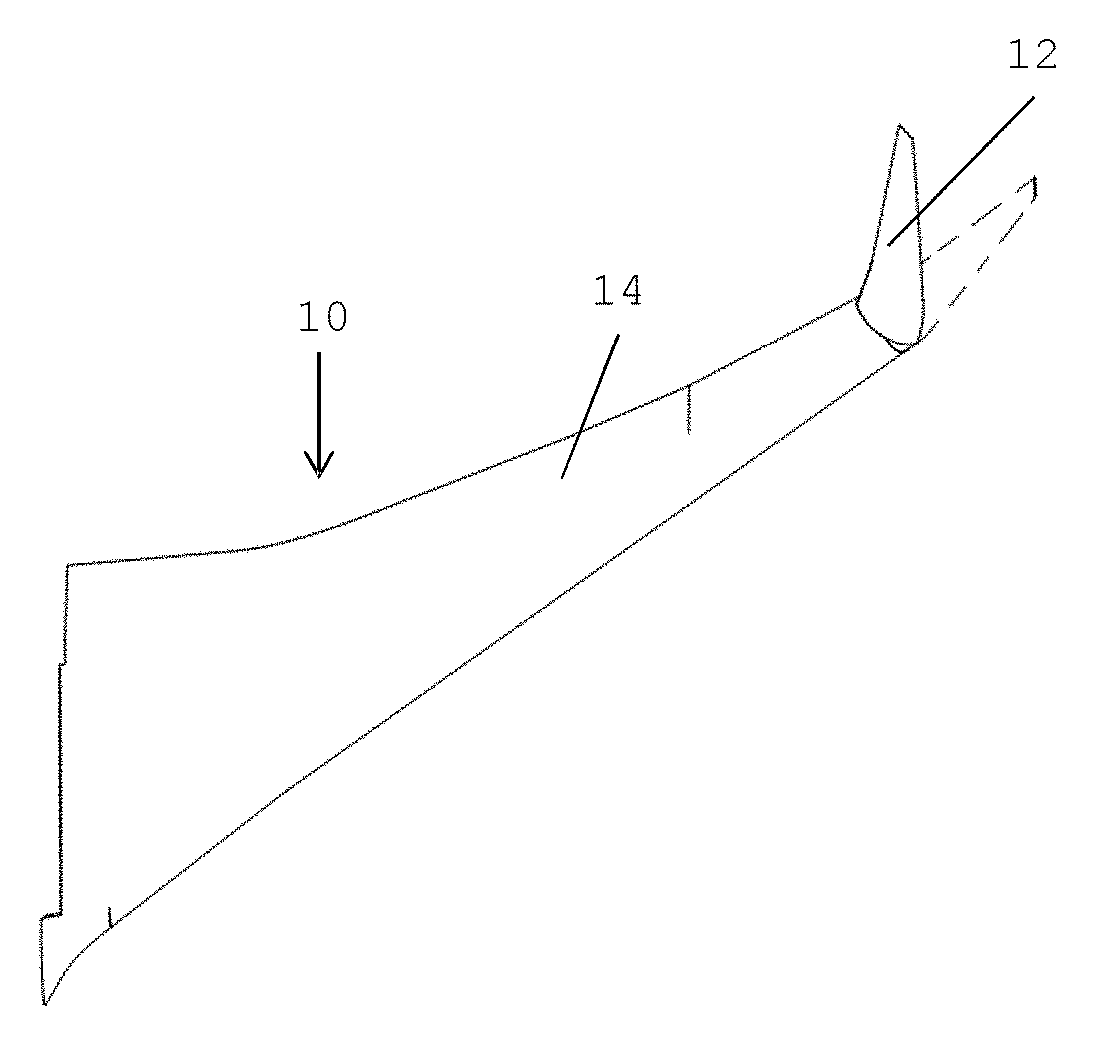

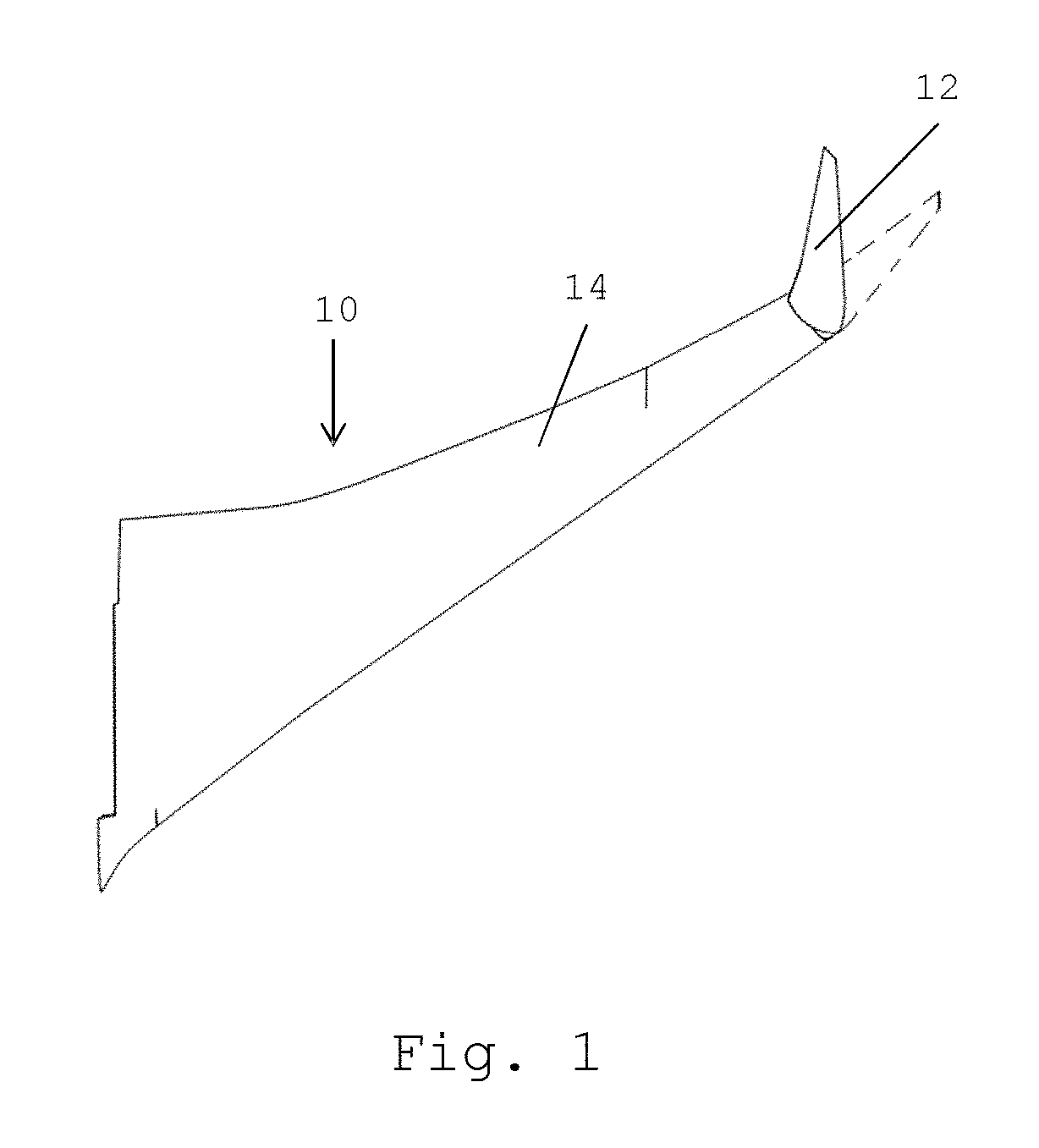

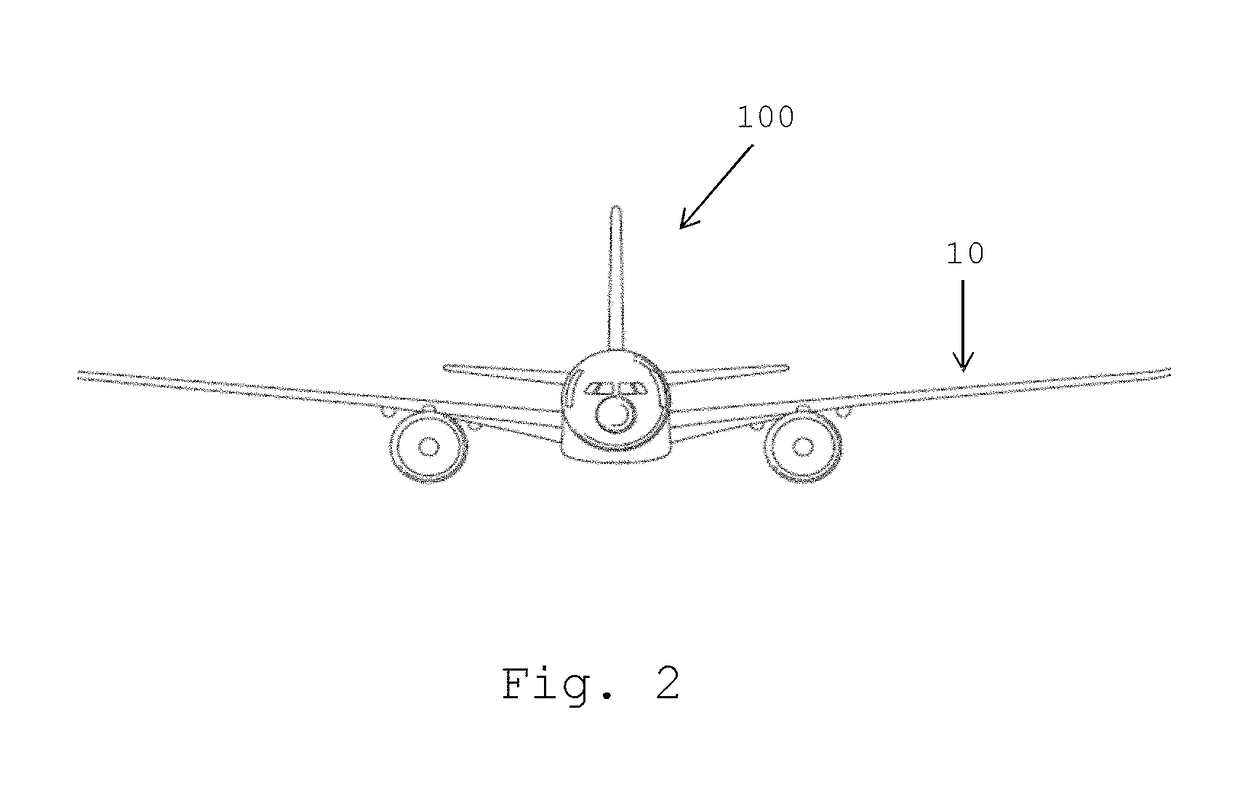

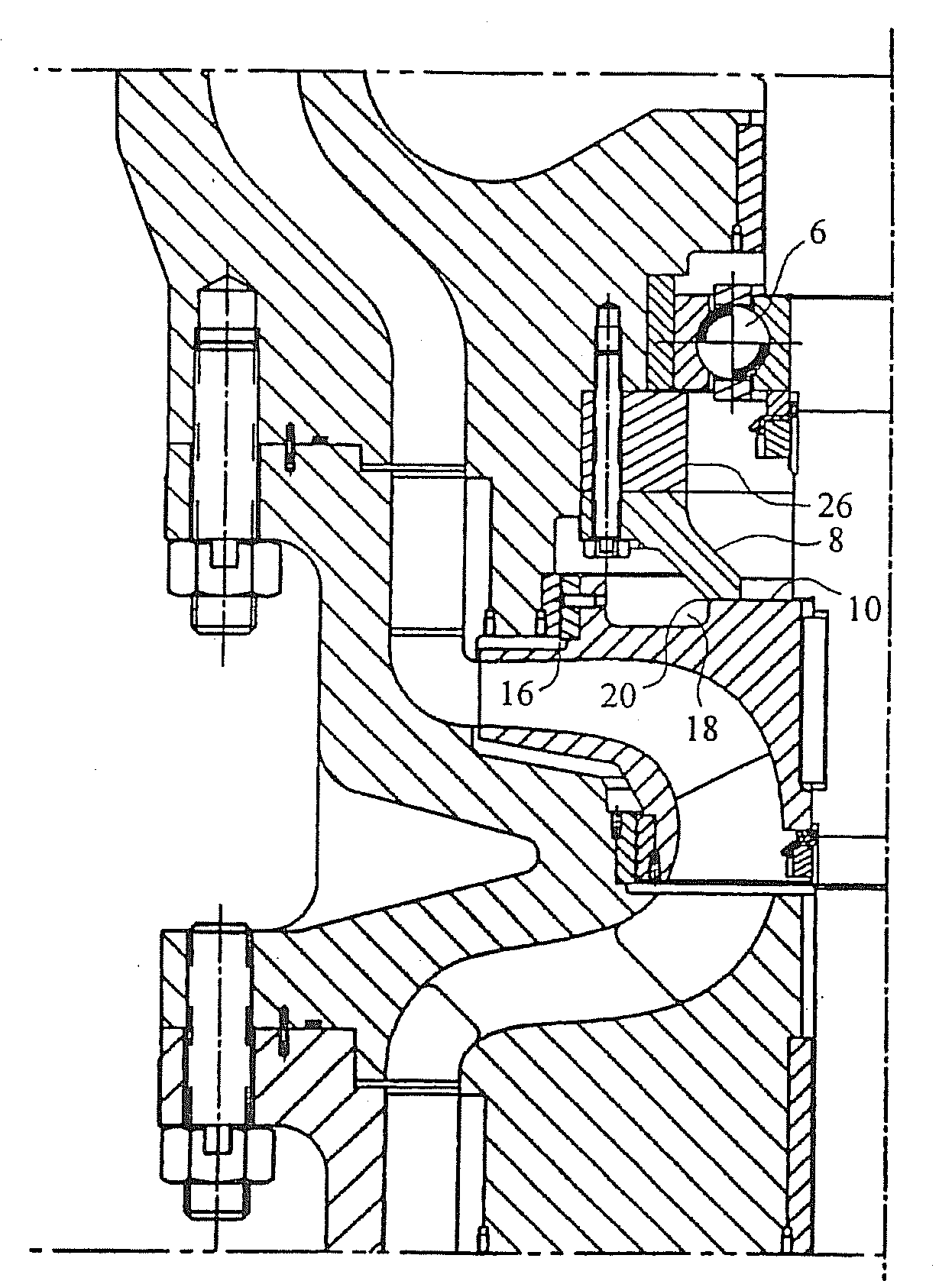

Rotational joint for an aircraft folding wing

ActiveUS20170355438A1Reducing and eliminating undesirable forceReduce spanWing adjustmentsDrag reductionRotational axisCoupling

An aircraft (2) including a wing (1), the wing (1) comprising a fixed wing (3) and a wing tip device (4) that is rotatable between a flight configuration and a ground configuration, the wing having a rotational joint (101) that rotatably couples the wing tip device (4) to the fixed wing (3), the rotational joint having an outer race (8) and an inner race (9), one of which is rotationally fixed relative to the wing tip device (4), to rotate about a rotational axis (B), and the other of which is rotationally fixed relative to the fixed wing (3), a rotational drive member (70) and the race that is rotationally fixed relative to the wing tip device (4) each being provided with a coupling section (110, 111, 114), the coupling sections being coupled to each other by a coupling member (119), that is received in a bore (112, 113) in one of the coupling sections, such that rotation of the drive member (70) rotates the race that is rotationally fixed relative to the wing tip device, to rotate the wing tip device (4) from one configuration to the other, wherein the coupling member (119) is mounted in the bore such that it is movable radially within the bore.

Owner:AIRBUS OPERATIONS GMBH

Rotational joint for an aircraft folding wing and method of assembly

ActiveUS20170355440A1Repair and replacementSpan of the aircraft wing is reducedWing adjustmentsAircraft assemblyAirplaneFixed wing

A method of rotatably couple a wing tip device (4) to a fixed wing (3) by a rotational joint (101) having an outer race (8) and an inner race (9) that is received in the outer race (8) one of the inner and outer races comprises a male member (76) and the other is a two-part assembly comprising a first part (9a) and a second part (9b) that together form a female member (72), the method brings the first and second parts together to form the female member (72) about the male member (76) such that the male member (76) is received in the female member (72) and fixing the first and second parts (9a, 9b) such that the race that is rotationally fixed relative to the wing tip device (4) is axially and radially retained relative to the race that is rotationally fixed relative to the fixed wing (3).

Owner:AIRBUS OPERATIONS LTD

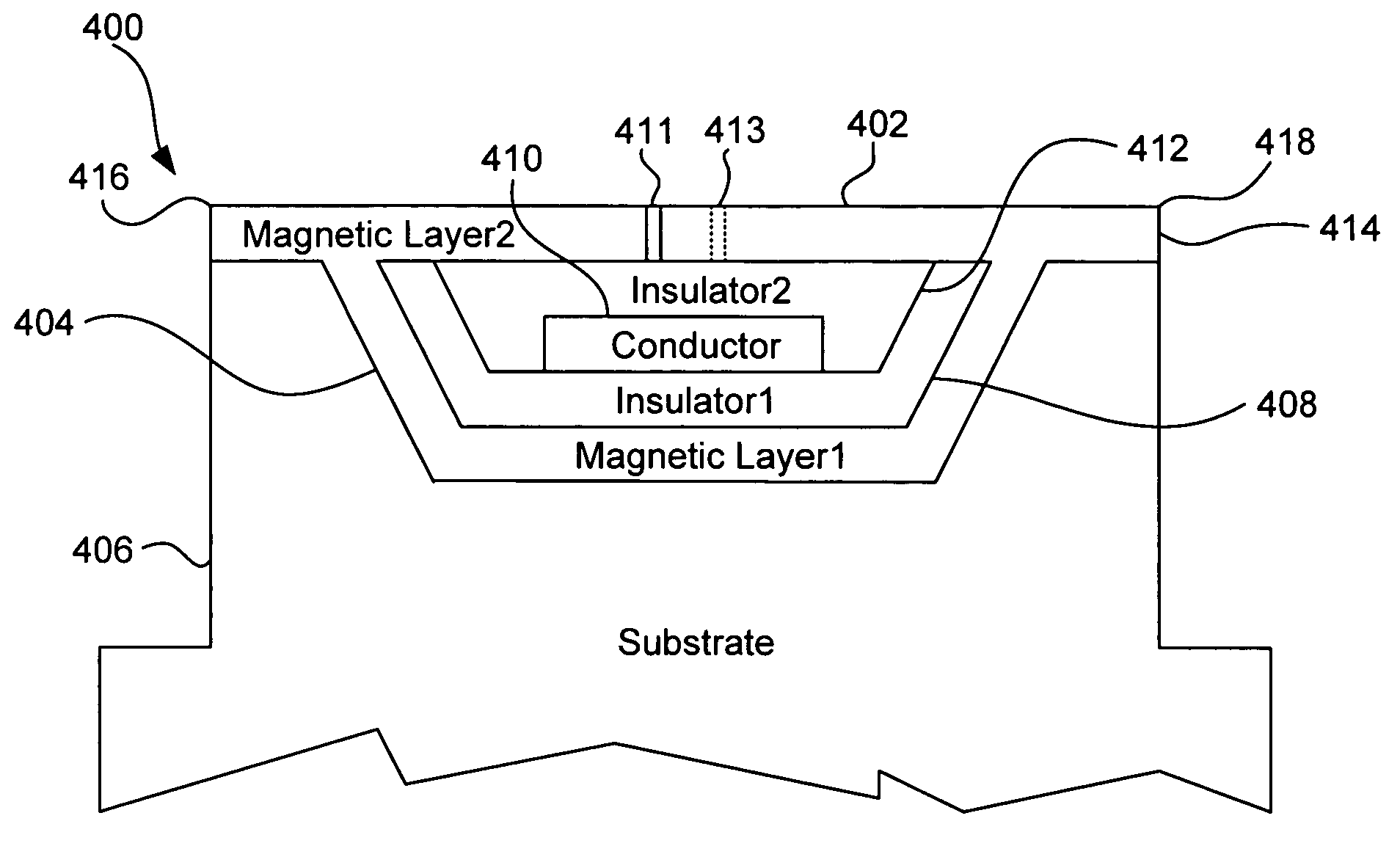

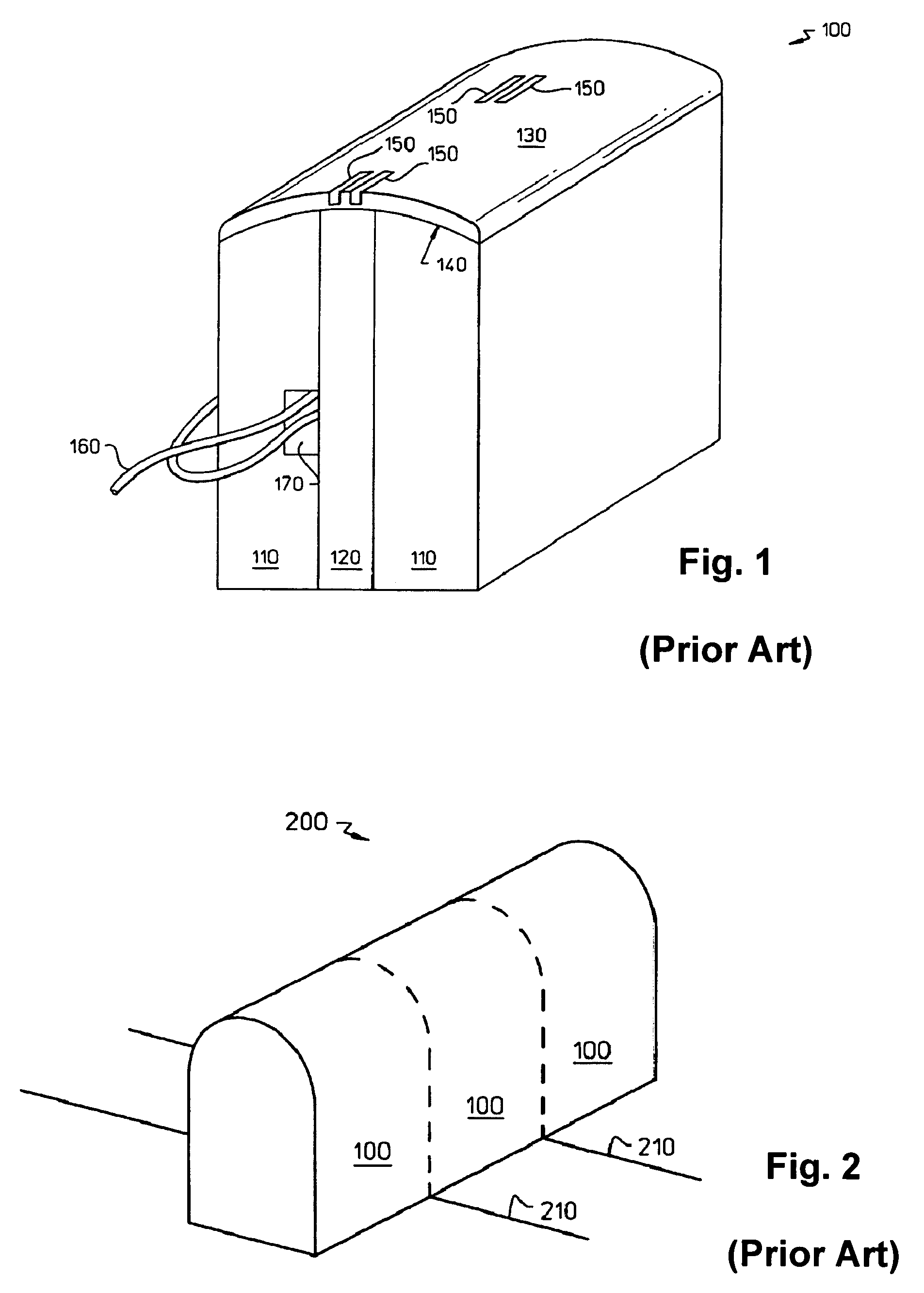

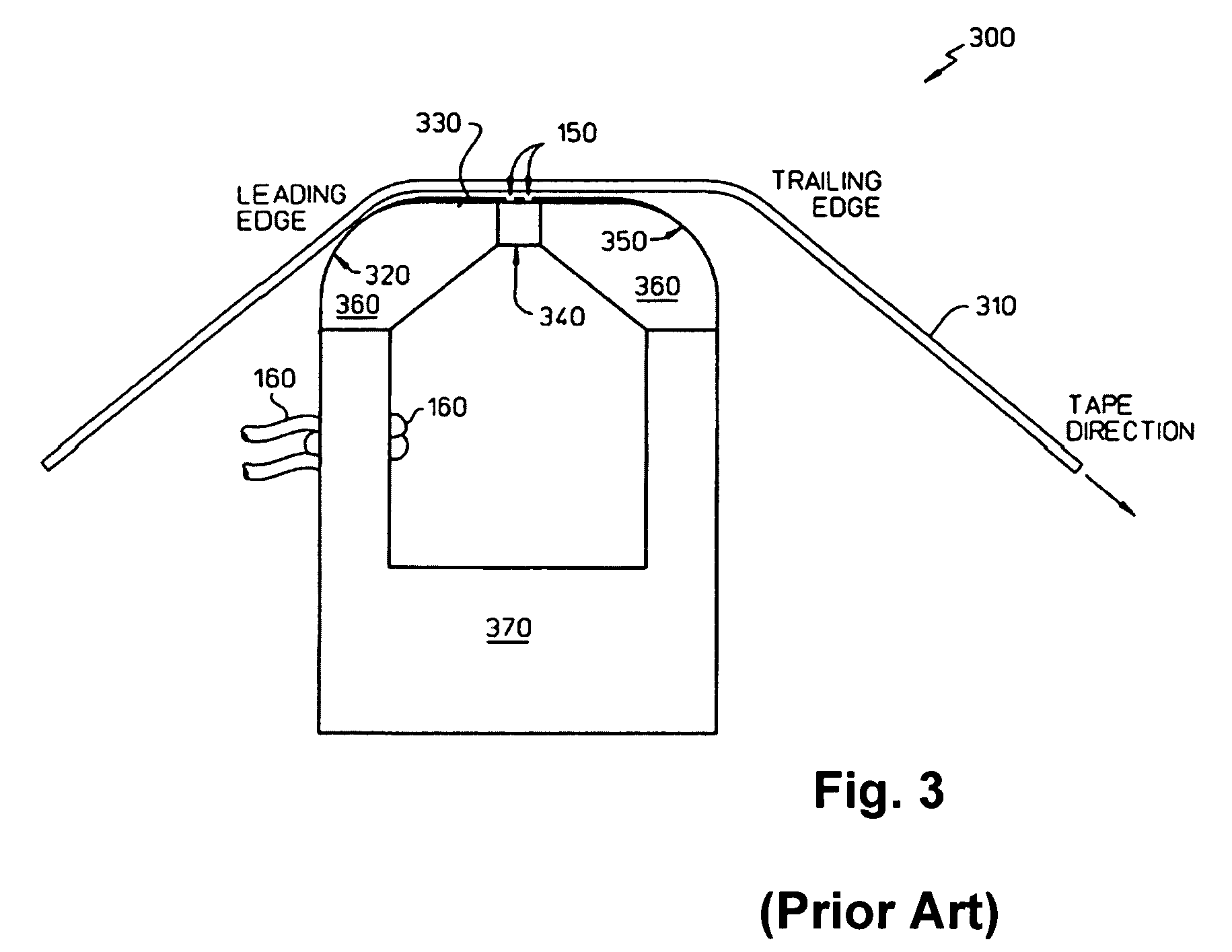

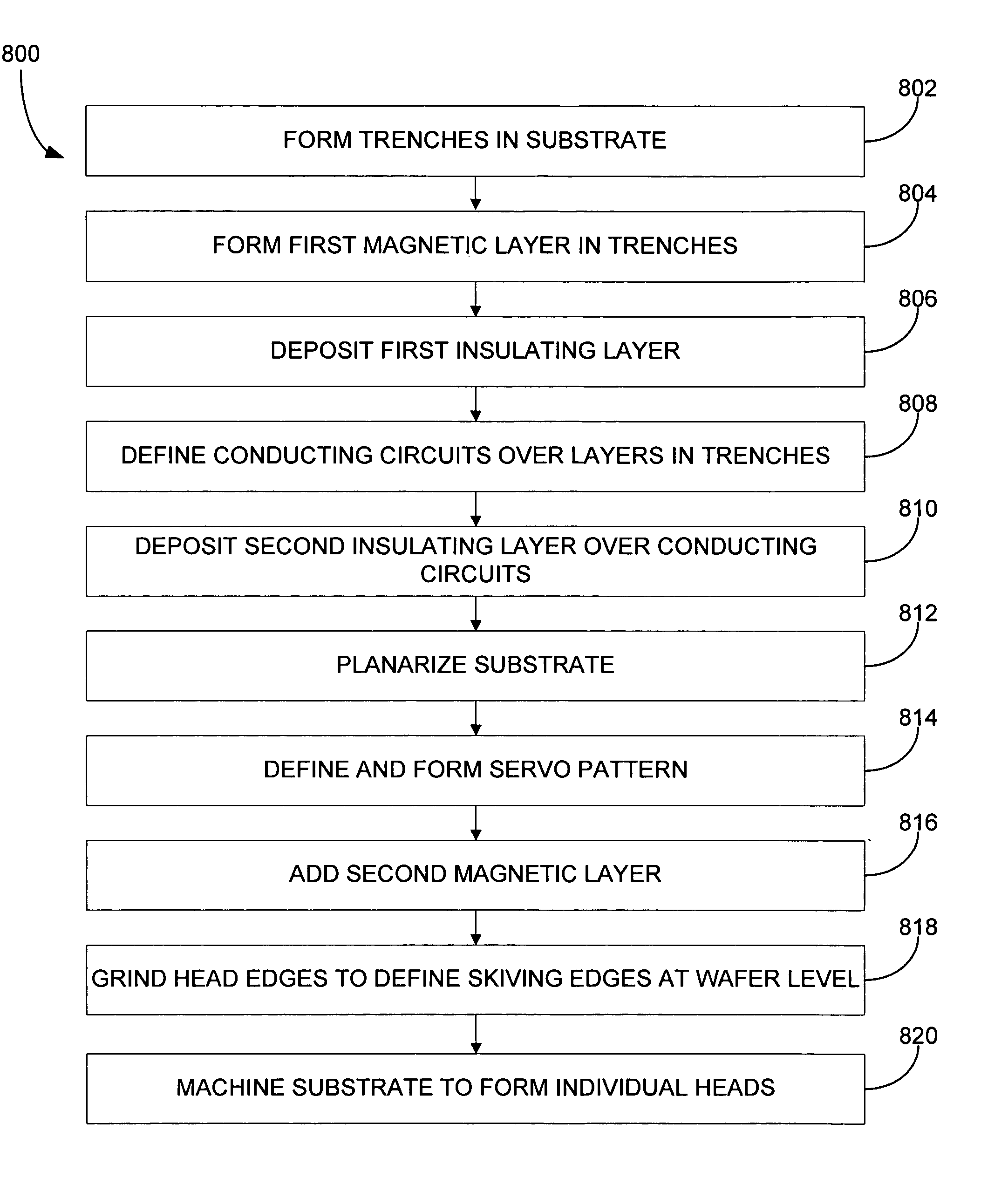

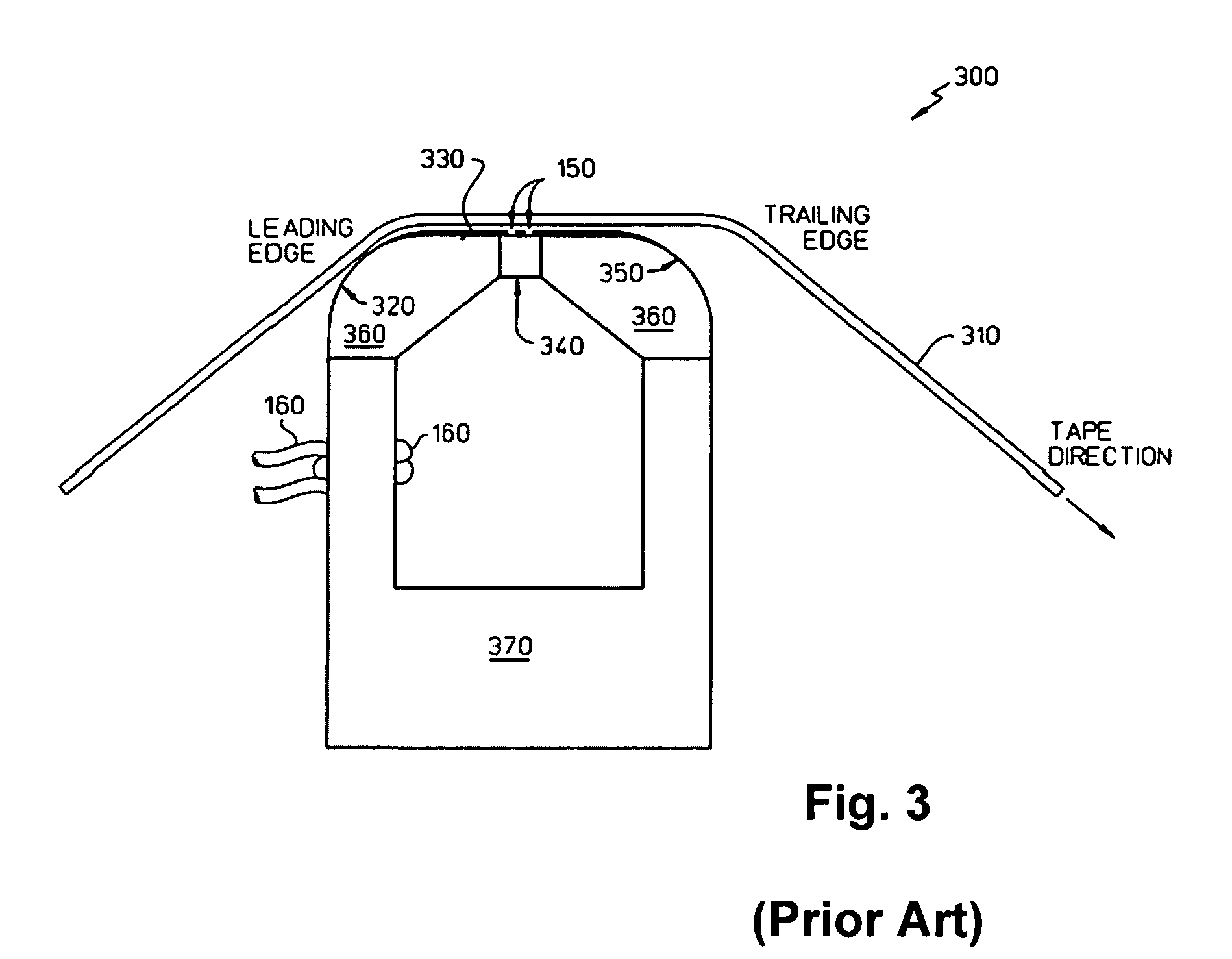

Method for fabricating magnetic write heads

InactiveUS7322096B2Reduce spanImprove abilitiesManufacture head surfaceElectrical transducersMagnetic fluxMagnetic layer

Owner:INT BUSINESS MASCH CORP

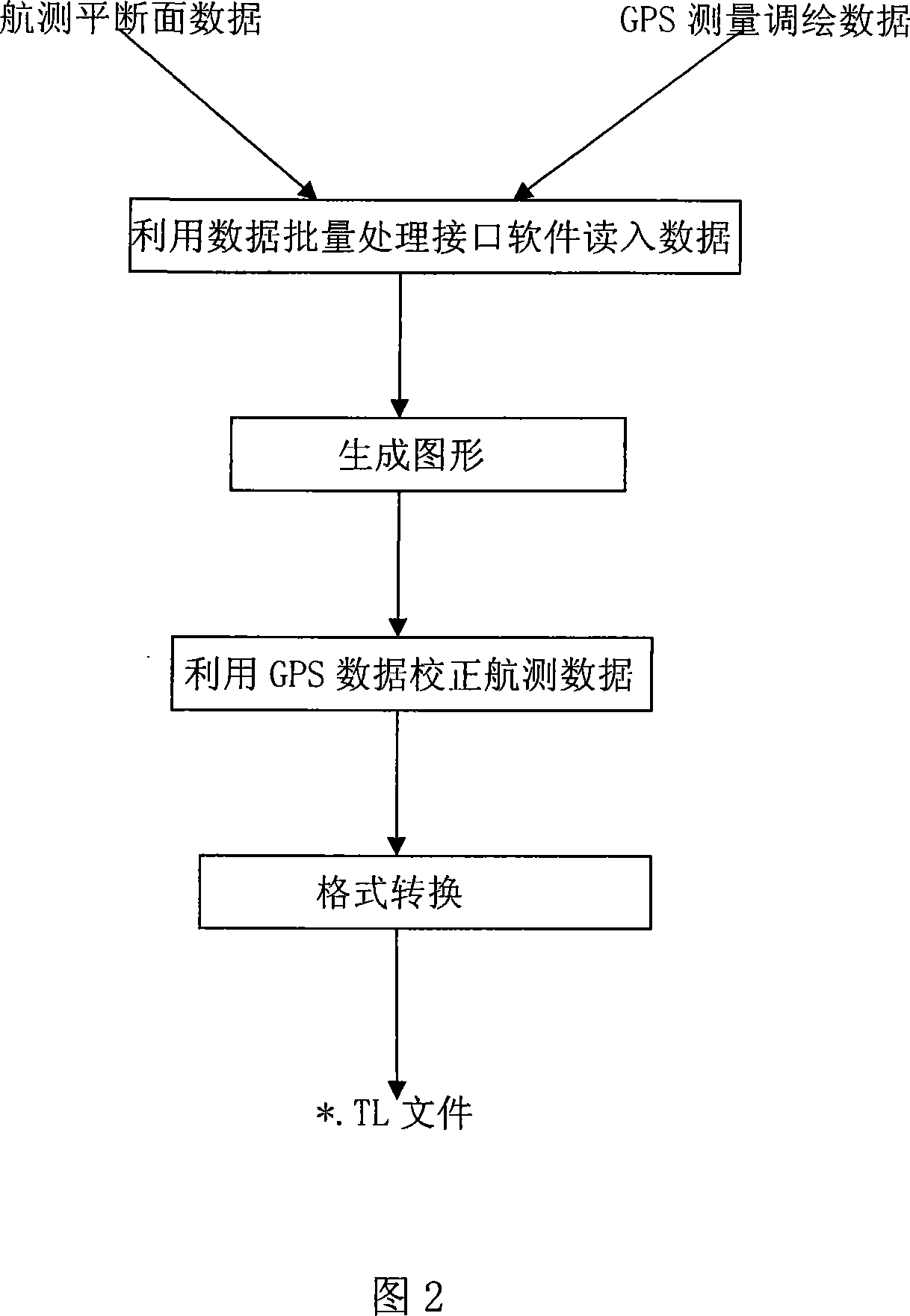

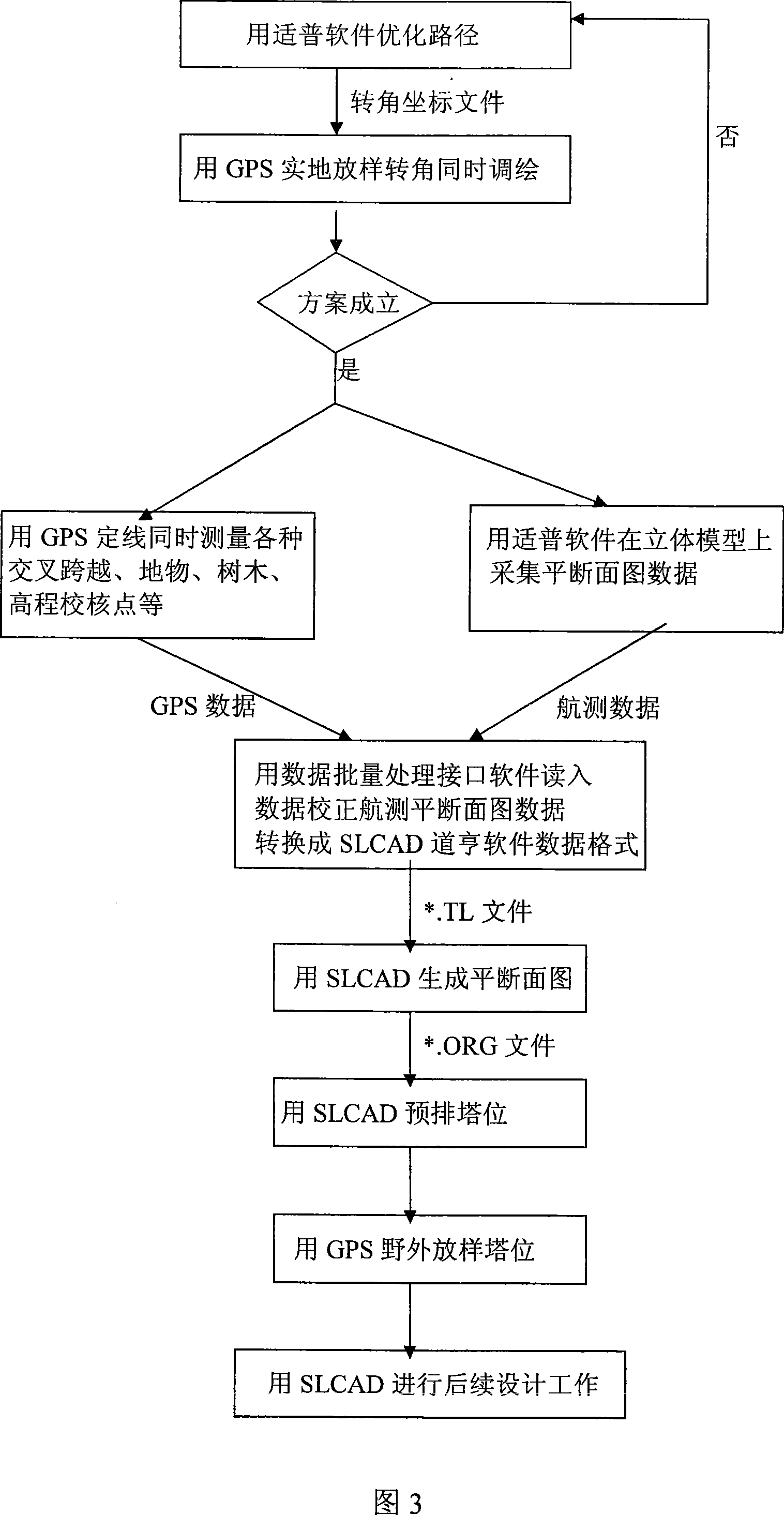

Powerline surveying and designing inside and outside trade integration method using full digitisation photogrammetric technology

ActiveCN101178310ALow costSave steelPhotogrammetry/videogrammetrySpecial data processing applicationsSocial benefitsSurveyor

The present invention relates to a method for integrating the survey and design of power transmission lines with internal and external work using all-digital photogrammetry technology. The present invention is improved on the basis of the prior art. Plane section data, after field measurement and adjustment, use the data batch processing software interface to input the plane section data into the Daoheng software platform. The invention has the beneficial effects of low cost, high work efficiency, reduced labor intensity, less personnel investment, reliable quality, easy popularization and application, and remarkable economic and social benefits.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

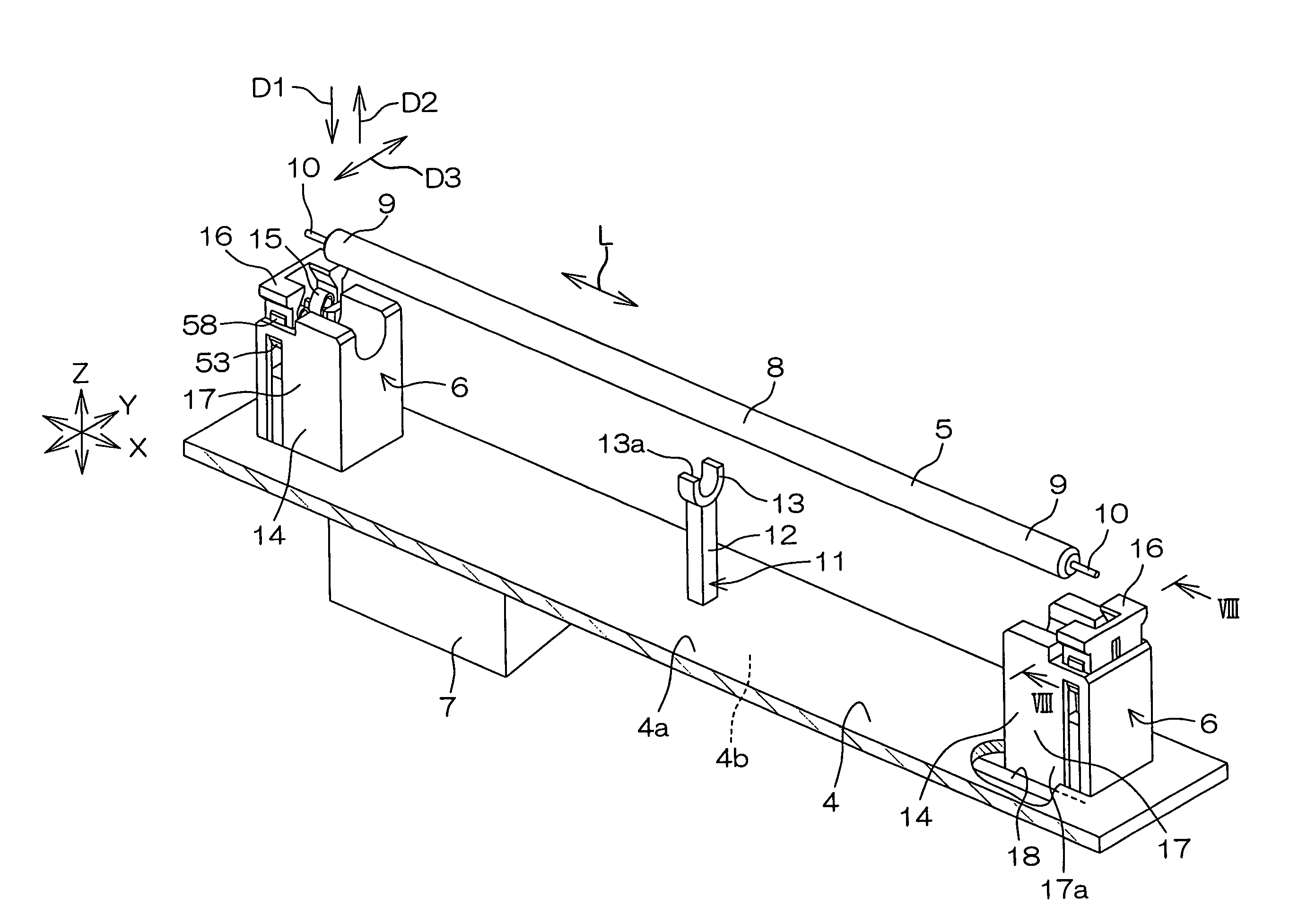

Bulb assembling machine

ActiveCN108436475AReduce spanSave spaceAssembly machinesOther manufacturing equipments/toolsAgricultural engineeringLight head

The invention relates to a bulb assembling machine. The bulb assembling machine comprises bottom shell machining equipment, assembling equipment, a lamp cover feeding conveying line close to the assembling equipment, a bulb discharging conveying line and a bottom shell feeding conveying line close to the bottom shell machining equipment, wherein the bottom shell machining equipment comprises a machine frame, a twelve-station rotating disc, bottom shell mounting seats, a divider rotating disc, a bottom shell feeding mechanism, a wire smoothing mechanism, a lamp holder installing mechanism, a rotating mechanism, a wire shearing mechanism, a wire end pressing mechanism, a drawing pin installing mechanism, a removing mechanism, a drawing pin pressing mechanism, a buckling and riveting mechanism, a turnover discharging mechanism, and a detecting mechanism, and the assembling equipment comprises a rotating disc machine frame, an eight-station rotating disc, a Hengji cam connected with the eight-station rotating disc, a dispensing mechanism, a lamp cover feeding mechanism, a bulb discharging mechanism and a lamp bottom flattening mechanism. The bulb assembling machine has the advantages that the structure design is compact, the size is small, the automation degree of the whole assembling machine is higher, and the working efficiency is higher.

Owner:ANHUI PALLET INTELLIGENT EQUIP CO LTD

Novel reinforced concrete prefabricated integrally-cast building structure system and construction method thereof

ActiveCN102418386AReduce steel consumptionReduce the overall heightFloorsBuilding material handlingReinforced concreteFloor slab

The invention relates to a novel reinforced concrete prefabricated integrally-cast building structure system, which comprises a floor slab, superposed beams and columns and / or shearing walls. Each superposed beam comprises a primary beam and a secondary beam and consists of a prestressed prefabricated beam and a cast-in-situ part. The prestressed prefabricated beam comprises a beam body and prestressed steel stranded wires. Section steel is arranged at the end parts of the beam body. One part of the section steel is buried in the beam body and the other part of the section steel is exposed at the end part of the beam body. The prefabricated beam in the primary beam is connected with the columns and / or the shearing walls through the section steel. The prefabricated beam in the secondary beam is placed on the primary beam through the section steels. A plurality of template supporting holes are longitudinally arranged on the beam body of the prefabricated beam of the secondary beam and the beam body of the prefabricated beam of the primary beam in parallel with the secondary beam. By adopting the prefabricated beams to be integrally cast with the cast-in-situ beams and the cast-in-situ floor slab to form a structure system, the prefabricated beams are fabricated by adopting a pre-tensioning prestressed technique and can be produced on a large scale in plants at one time and the production cost is reduced.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

Rotational joint for an aircraft folding wing

ActiveUS20170355437A1Reduce in quantityReduce overall size and complexity and weightWing adjustmentsDrag reductionLocking mechanismFixed wing

A wing (1) having a fixed wing (3) and a wing tip device (4) rotatable between a flight configuration and a ground configuration, a rotational joint (10) rotatably couples the wing tip device (4) to the fixed wing (3) and a locking mechanism (46) locks the wing tip device (4) in the flight and ground configurations. The locking mechanism (11) includes first and second locking members (51, 52) and first and second receiving members (53, 54), the locking mechanism (11) being configured to lock the wing tip device (4) in one of the flight configuration and ground configuration by receiving the first and second locking members (51, 52) in the first and second receiving members (53, 54) respectively, and to lock the wing tip device (4) in the other of the flight configuration and ground configuration by receiving the first locking member (51) in the second receiving member (54).

Owner:AIRBUS OPERATIONS GMBH

Embedded wire planar write head system and method

InactiveUS20050235483A1Reduce spanImprove abilitiesElectrical transducersManufacture head surfaceHemt circuitsEngineering

A magnetic write head and method for bulk fabrication of the same are provided. A trench is formed in a nonmagnetic substrate. A first magnetically permeable layer is deposited in the trench of the substrate. An optional first insulating layer is deposited in the trench. A conducting circuit is defined in the trench. The conducting circuit creates the magnetic flux. An optional second insulating layer is deposited in the trench. Writer gaps are patterned and then a second magnetic layer is added over the second insulating layer. The substrate is divided to form individual write heads.

Owner:INT BUSINESS MASCH CORP

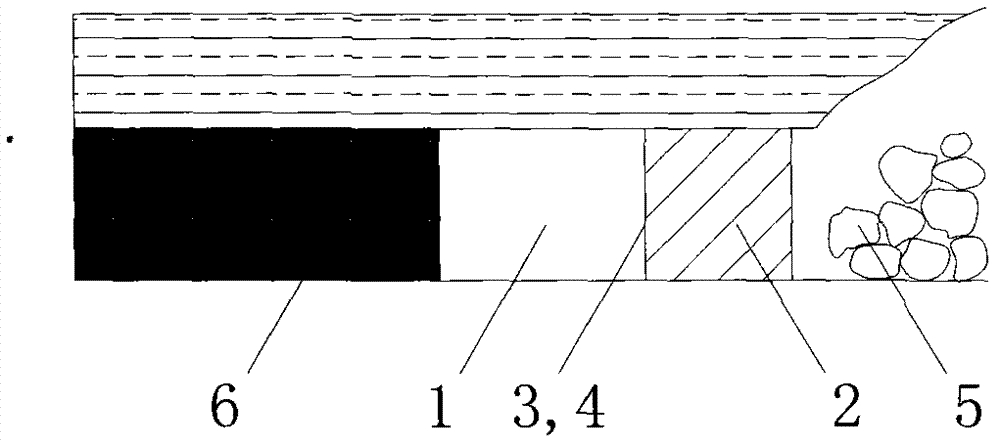

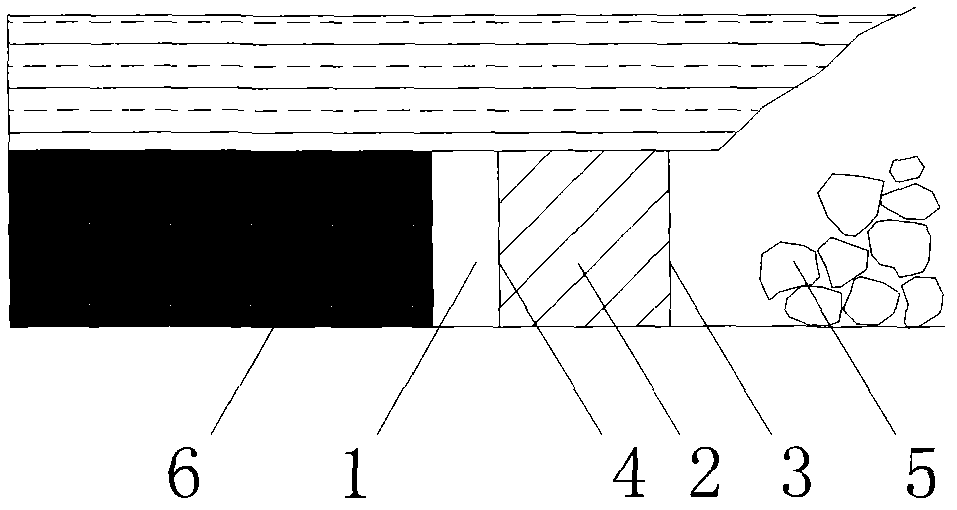

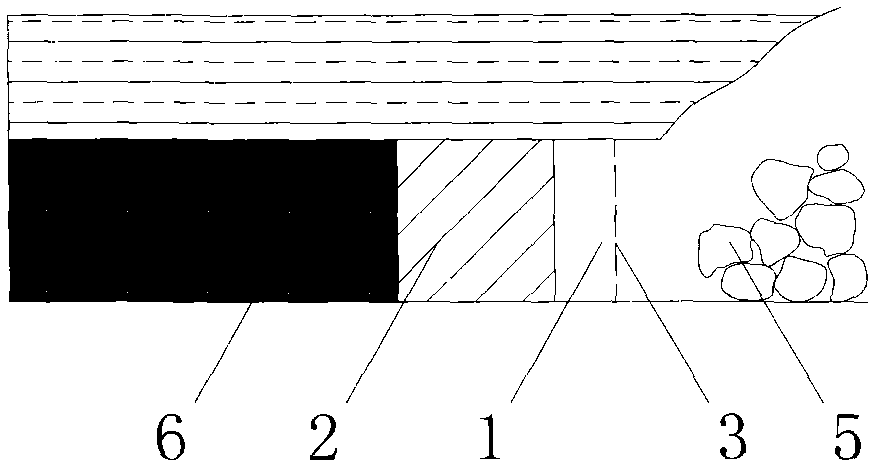

Coal-pillar-free semi-normal-position goaf-side entry retaining method

The invention relates to a goaf-side entry retaining arrangement process of mining of coal mines in a pit, in particular to a coal-pillar-free semi-normal-position goaf-side entry retaining method. The coal-pillar-free semi-normal-position goaf-side entry retaining method is characterized in that a semi-normal-position construction filling wall body is used on a entry retaining working face, one side of the edge of an isolation wall body is located at the position in a lateral wall portion of a recovery side of a roadway before mining for an A distance, and the other side of the edge of an isolation wall body is located in a goaf area. The coal-pillar-free semi-normal-position goaf-side entry retaining method enables one side of the filling wall body to be arranged in an original roadway, is easy in top connection, appropriately reduces entry retaining spans, is apt to reduce strata behavior degree, and is favorable for maintenance of entry retaining section size and integrity of a top plate.

Owner:CHINA UNIV OF MINING & TECH

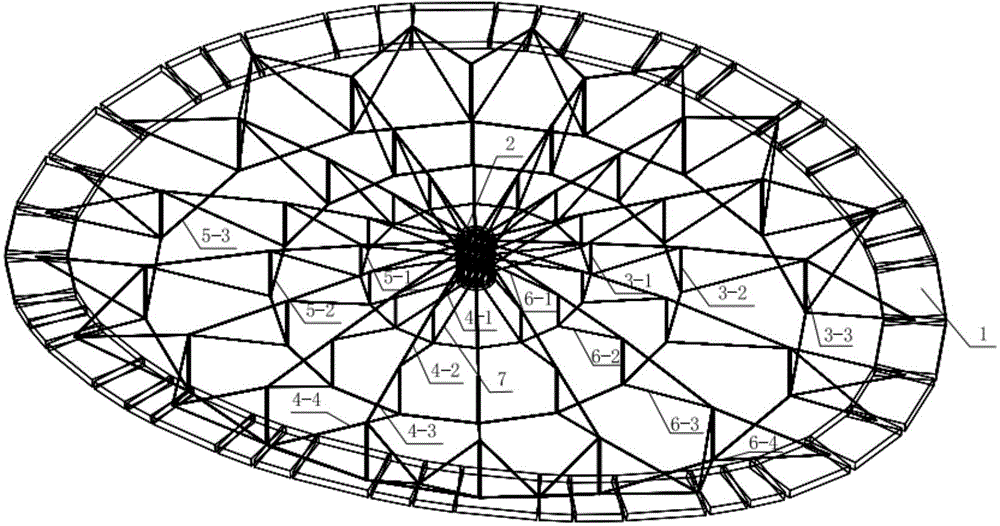

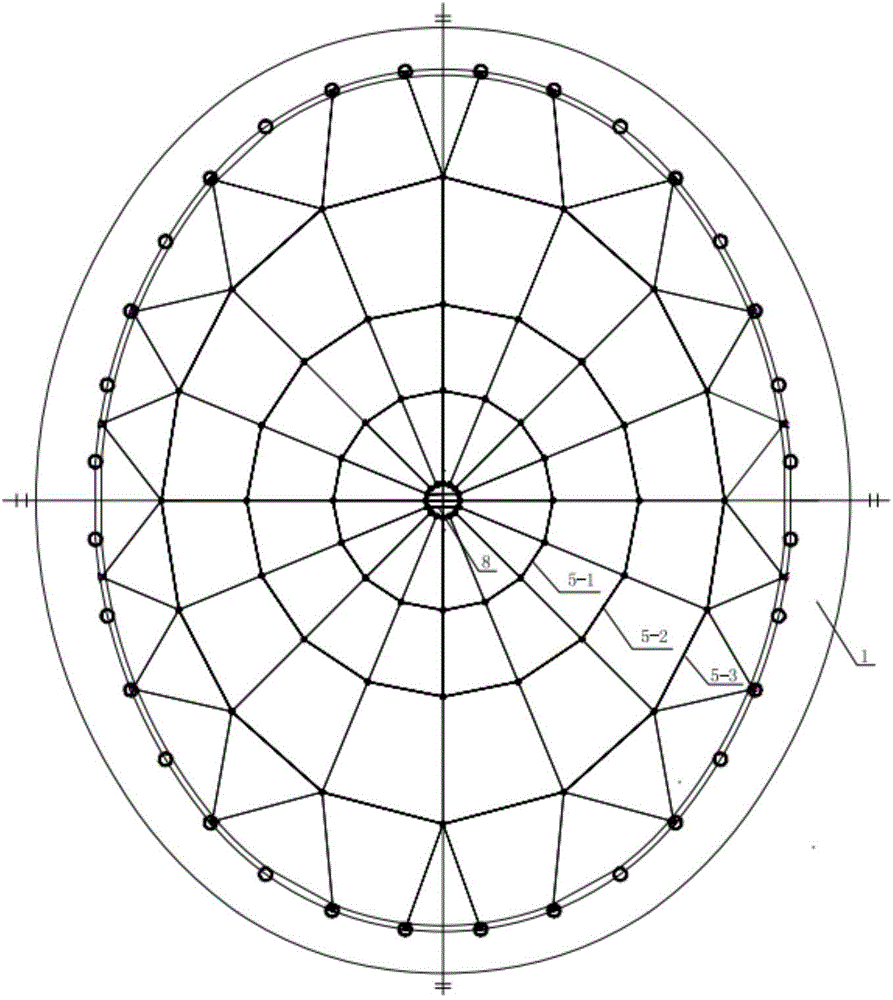

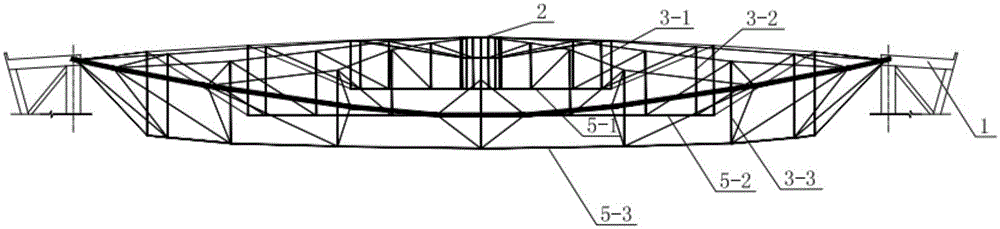

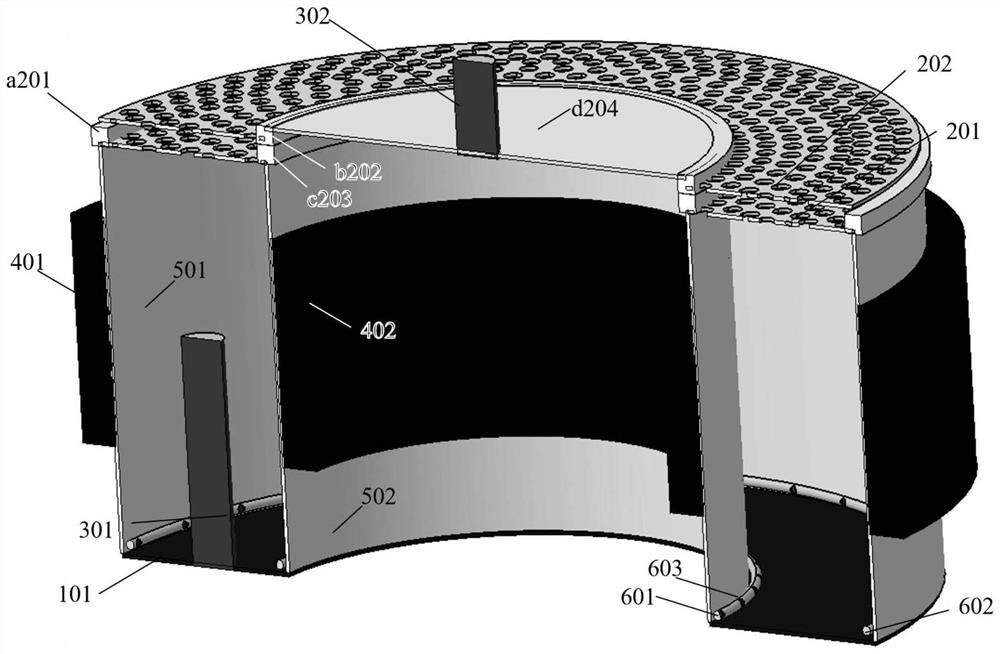

Combined-type cable dome structure for elliptic plane with unequal-height boundary

The invention discloses a combined-type cable dome structure for an elliptic plane with an unequal-height boundary. The combined-type cable dome structure comprises an outer-ring beam arranged on unequal-height capitals of a lower structure. The outer-ring beam adopts a space-curve form which changes along with the elevation of capitals of the lower structure. The horizontal projection of the outer-ring beam is ellipse. An inner-ring beam is arranged above the middle portion of the outer-ring beam. Inhaul cables and ridge cables are arranged on the outermost ring of the outer-ring beam and the inner-ring beam through a levy-type structure, and inhaul cables and ridge cables are arranged within the outermost ring through a Geiger-type structure. A connecting beam for a balancing cable is arranged on the inner-ring beam additionally, and the balancing cable is arranged between the inner-ring beam and the outer-ring beam additionally. The combined-type cable dome structure can be applied to a structural engineering of which unequal-height horizontal projection of the boundary is an ellipse plane, the structure is forced uniformly, and the stability is strong; node structure is simple, the manufacturing cost is low, and construction is convenient; laying requirements of rigid roofing material can be met.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

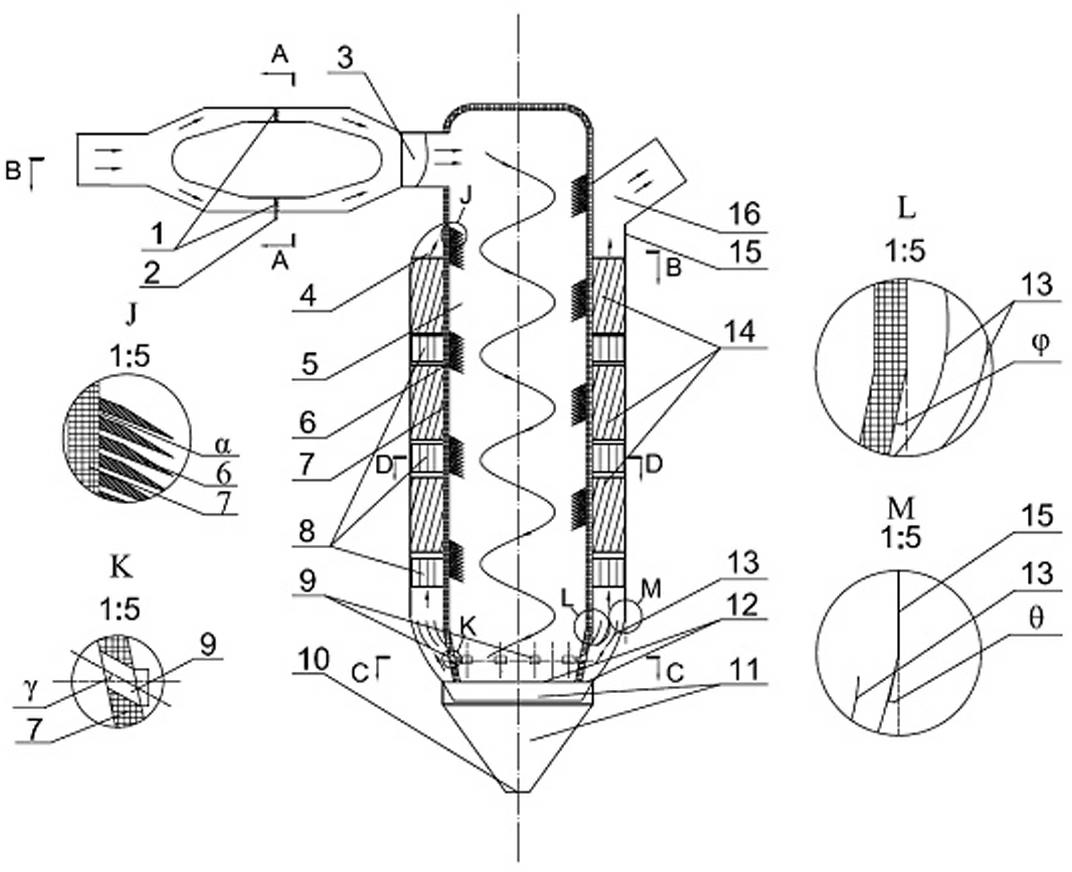

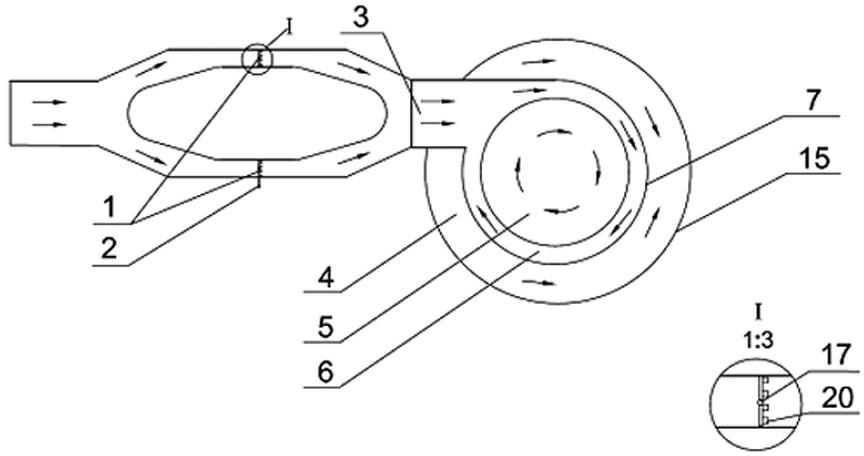

Dedusting-denitrating integrated device

ActiveCN102614779ASimple structureSimple control systemDispersed particle filtrationFlue gasProcess engineering

The invention discloses a dedusting-denitrating integrated device which comprises a flue gas channel, a mixed flue gas inlet and a shell consisting of an outer cylinder and an inner cylinder, and a ash hopper at the bottom of the shell, wherein the inner cylinder is mainly used for dedusting and ammonia mixing, the outer cylinder is mainly used for containing a denitrating catalyst bed, the crosssection of the flue gas channel is ring-shaped, and ammonia spray grilles are distributed in the flue gas channel in a radial manner so that the required NH3-to-NO ratio can be reached more easily. The device provided by the invention can be used for dedusting before carrying out denitrating, a catalyst can be effectively prevented from being worn, poisoned and blocked and the service life of thecatalyst can be prolonged. Under the condition that the length of the device is not increased, the ammonia mixing time is prolonged and ammonia mixing can be performed fully; heat absorbing spiral plates and cooling rectifier plates are arranged in both the inner cylinder and the outer cylinder to share heat of flue gas at the inlet, and therefore the heat loss of flue gas can be reduced, the denitrating efficiency can be improved and the catalyst is prevented from being sintered and inactivated under the action of superheated flue gas.

Owner:HUNAN UNIV

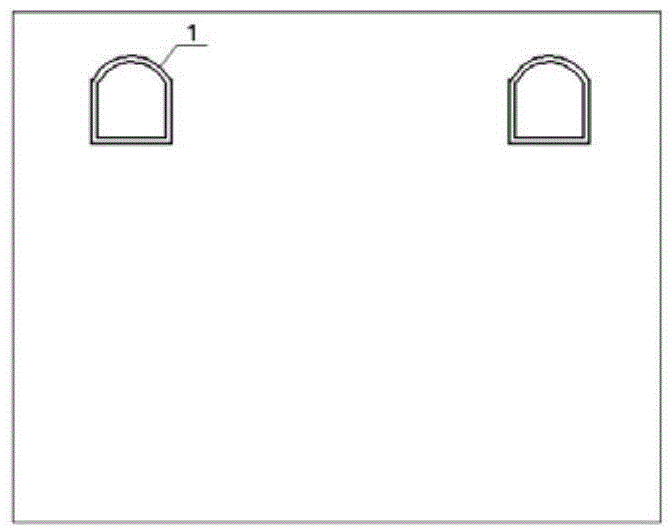

Transverse tunnel cover method for shallow-buried underground excavation large underground space construction

ActiveCN104863597AReduce spanMany working surfacesUnderground chambersTunnel liningSpatial structureGround settlement

The invention discloses a transverse tunnel cover method for shallow-buried underground excavation large underground space construction. Foundation pits or pilot tunnels are formed, in the longitudinal direction of underground space, of the tops of side walls of the underground space to be constructed, temporary transverse stress structures are formed inside the foundation pits or the pilot tunnels at a time and located above a top plate of the underground space to be constructed and are controllable in rigidity, the temporary transverse stress structures are connected with piles inside the foundation pits or the pilot tunnels to form a temporary transverse top cover-pile bearing system, and under protection of the transverse top cover-pile bearing system, a single-span or multi-span and a single-layer or multi-layer underground space structure can be constructed in a sequential construction mode or in an inverse construction mode. In shallow-buried underground excavation large underground space structure construction, ground settlement is effectively controlled, constructed building deformation is reduced, the construction risks are reduced, the construction period is shortened, and the construction cost is lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

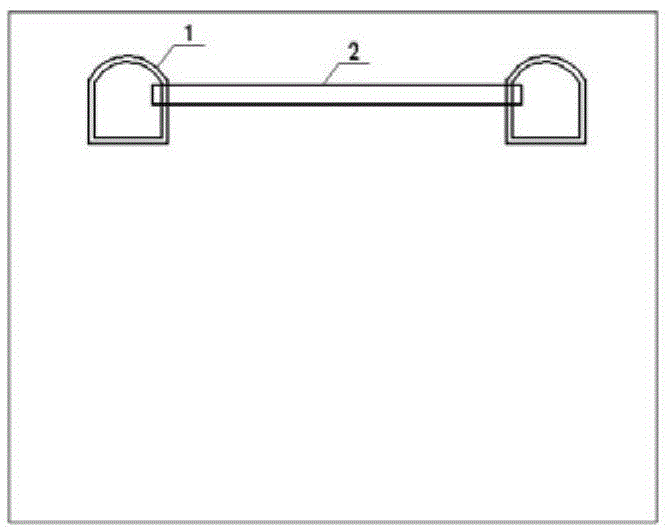

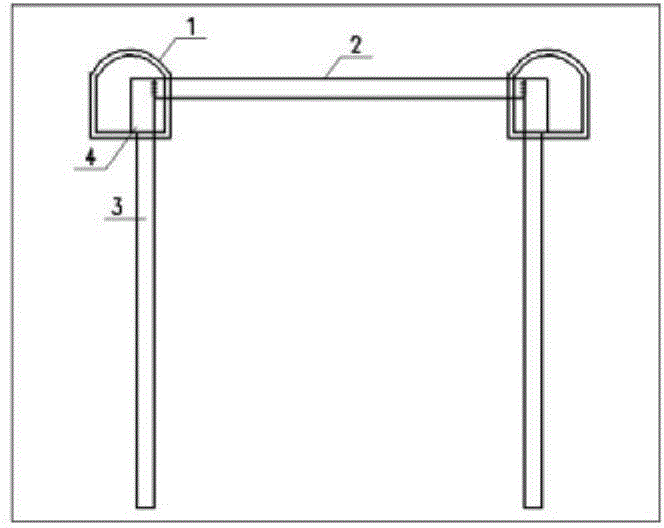

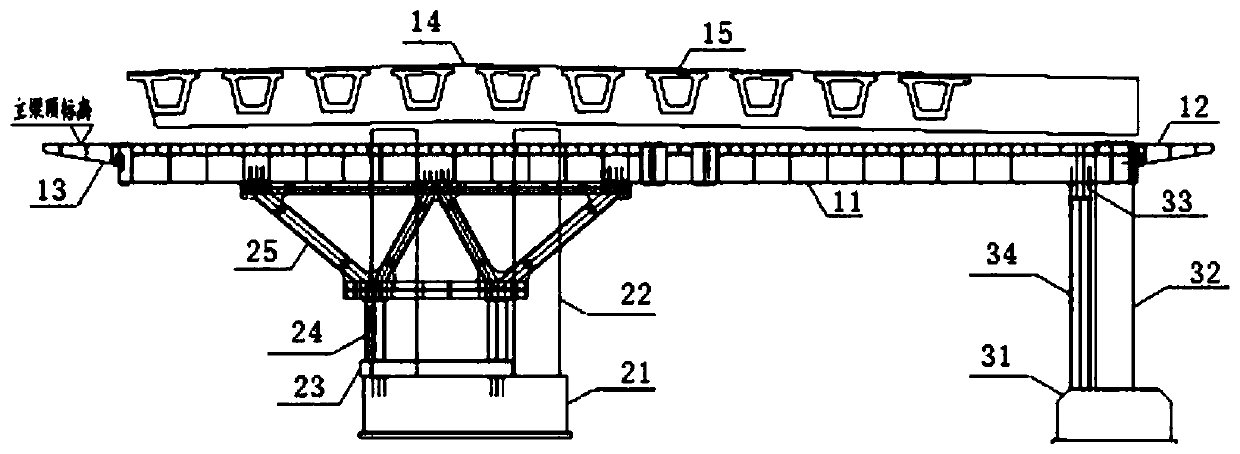

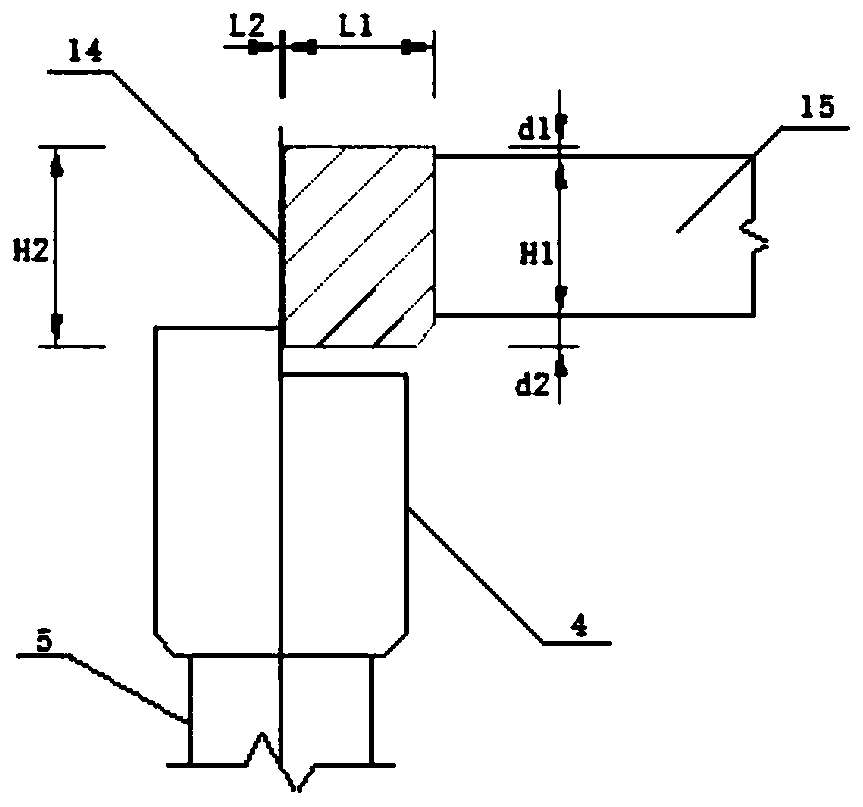

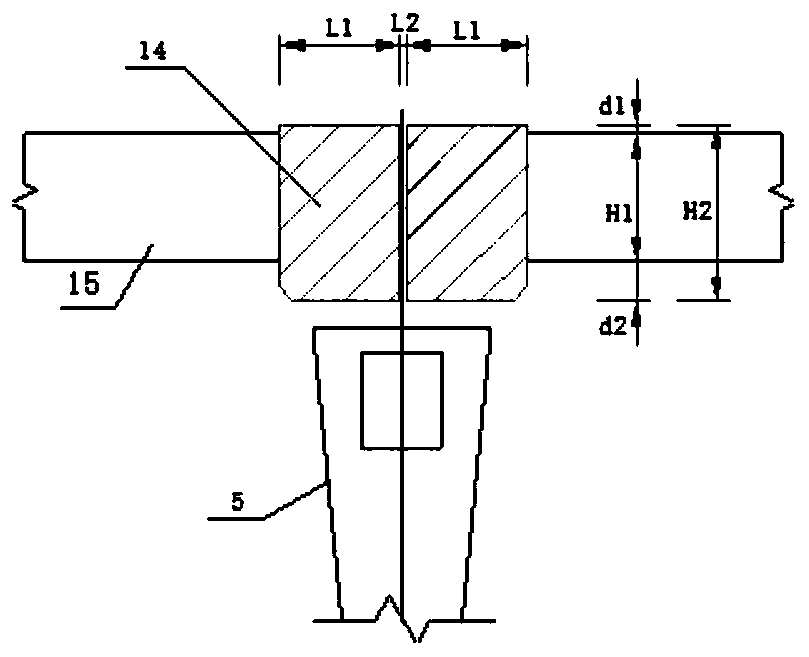

Road bridge prefabricated small box girder type invisible cap beam temporary support system and construction method thereof

ActiveCN110747746AEasy to liftEasy to assemble and disassembleBridge structural detailsBridge erection/assemblySupporting systemArchitectural engineering

The invention discloses a road bridge prefabricated small box girder type invisible cap beam temporary support system and a construction method thereof. The support system comprises a main beam, a main pier supporting system and a side pier supporting system, wherein the main beam is arranged along the transverse side of a road bridge pier; the main pier supporting system is arranged on the transverse side of a main pier area and located below the main beam, the lower end of the main pier supporting system is fixed with a main pier bearing platform, and the upper end of the main pier supporting system is fixed with the main beam; and the side pier supporting system is arranged on the transverse side of a side pier area and located below the main beam, and the lower end of the side pier supporting system is fixed with a side pier bearing platform, and the upper end of the side pier supporting system is fixed with the main beam. Therefore, the support system only has a large cross-diameter support beam (main beam) between the transverse main pier area and the side pier area, and other support systems arranged in the vertical direction are not present, so that a vehicle operation space is provided, and disassembly and assembly of the prefabricated small box girder type invisible cap beam support system are convenient. In addition, the support system has the characteristics of highbearing capacity so as to meet the supporting requirements of the prefabricated small box girder type invisible cap beam.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

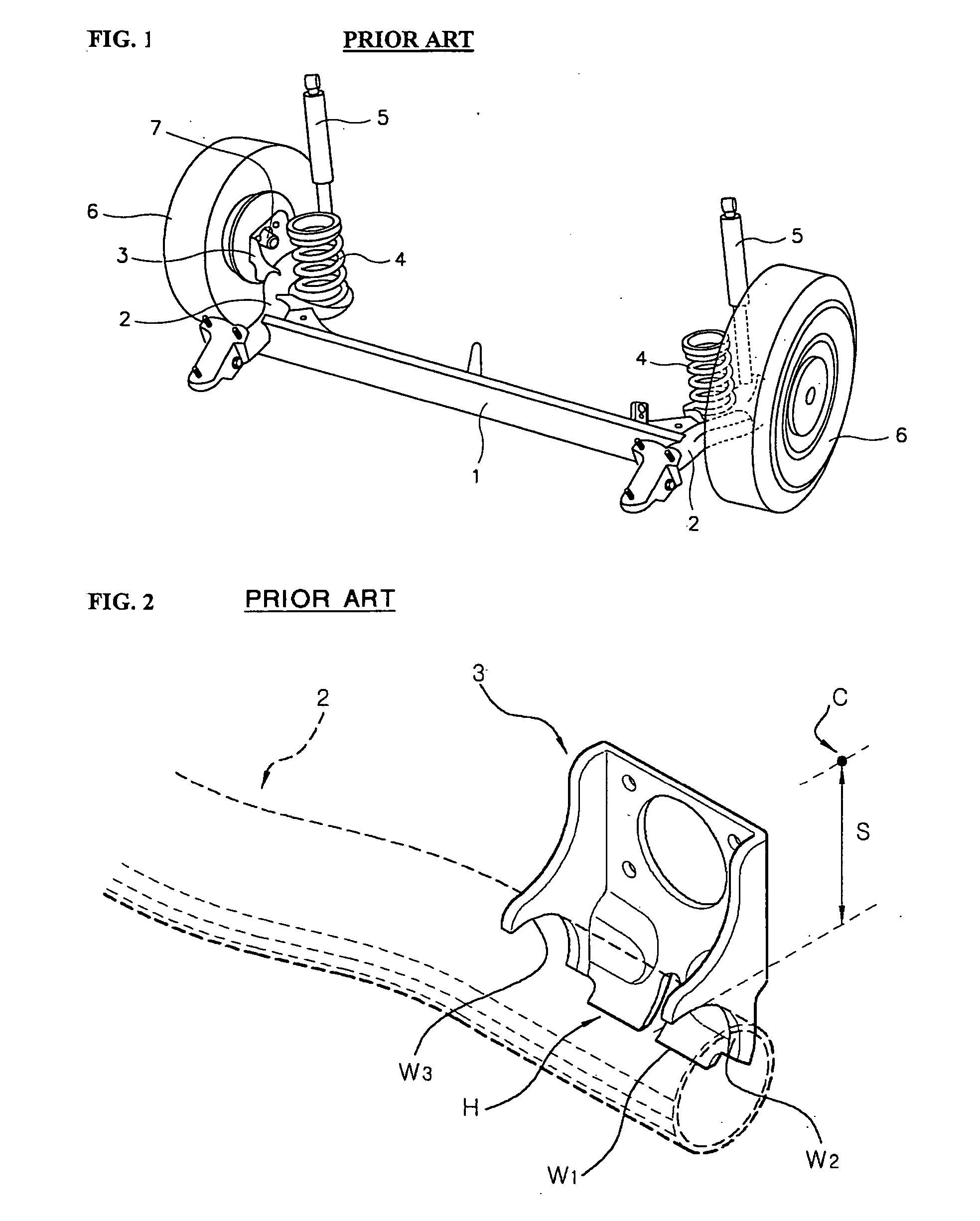

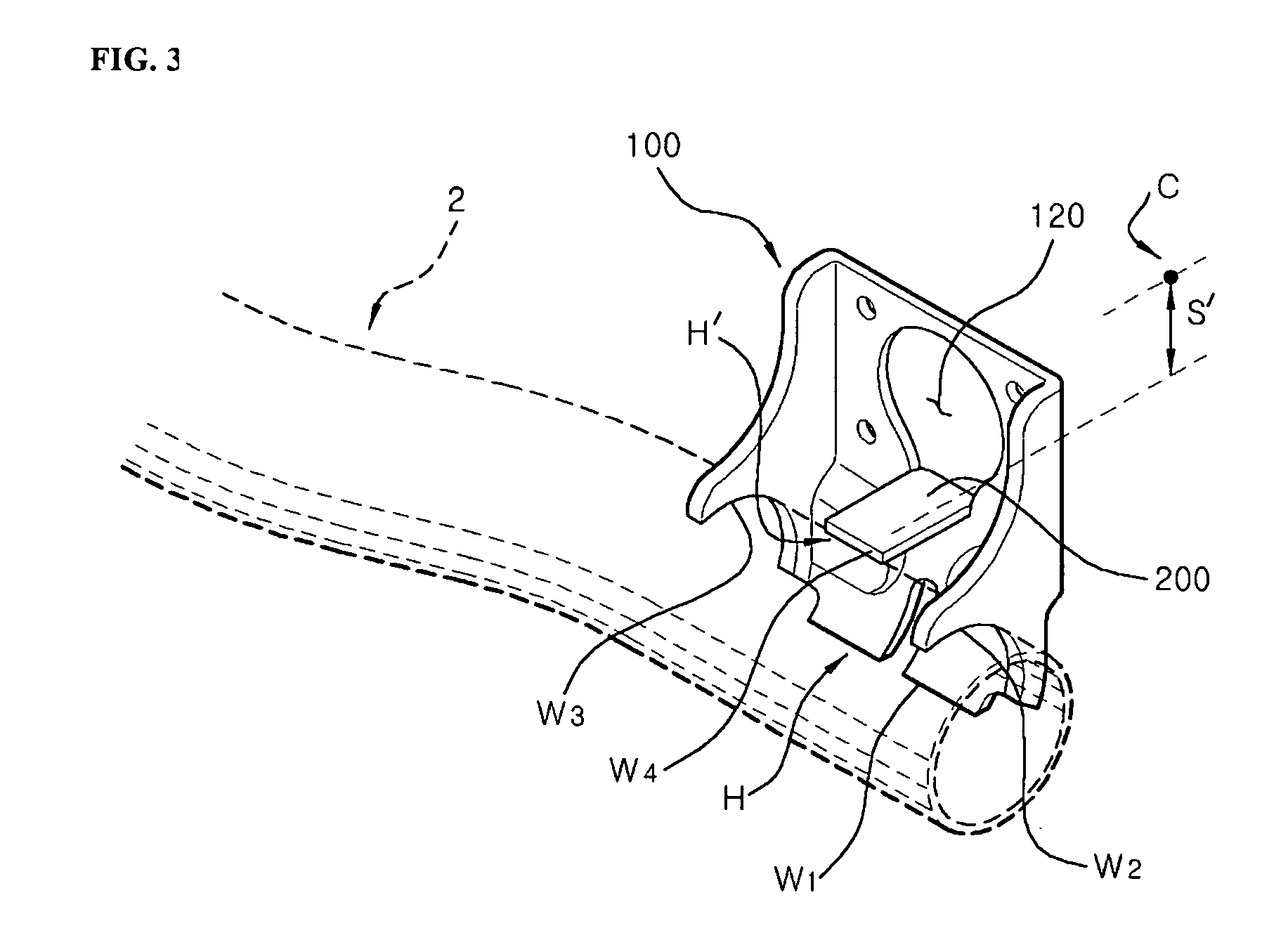

Spindle bracket for rear suspension

InactiveUS20060033303A1Increase the number ofReduce spanSteering linkagesInterconnection systemsTrailing armMechanical engineering

A spindle bracket for rear suspensions includes a bracket body welded to a trailing arm and having a mounting hole into which a spindle is inserted, and a lateral strength reinforcing piece secured between the trailing arm and the bracket body.

Owner:HYUNDAI MOBIS CO LTD

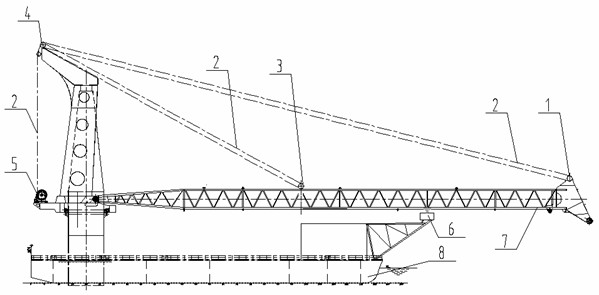

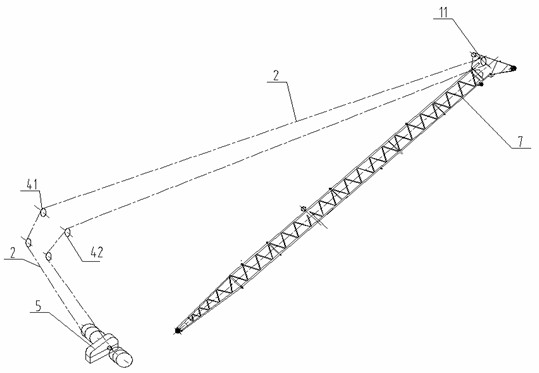

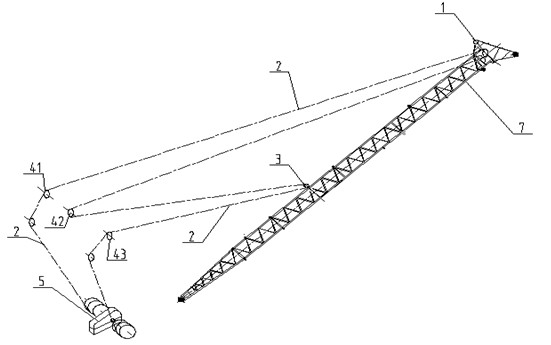

Pretension and lay-off method and device of crane jib for ship

InactiveCN101983894AReduce supportAvoid fatigue damageCargo handling apparatusPassenger handling apparatusEngineeringWinch

The invention relates to a pretension and lay-off method of a crane jib for a ship, belonging to the technical field of a crane. The crane comprises a luffing mechanism composed of a top pulley block, a jib, a winch, a luffing wire rope and a jib head pulley block and a bracket. The method comprises the following steps: A. operating the winch in the forward direction, loosening the jib and layingoff the jib onto the bracket; and B, operating the winch in the reverse direction, pulling the jib upwards to enable the pressure of the jib on the bracket to be less than the pressure on the bracketbefore being subjected to the upward pull, and stopping and shutting off the winch. The invention also relates to a pretension and lay-off device of a crane jib for a ship. The luffing mechanism alsocomprises a middle pulley arranged at the middle of the jib, and the luffing wire rope is connected with the jib head pulley block and the middle pulley through the top pulley block. The pretension and lay-off method and device of a crane jib for a ship can produce a pretension force on the jib by means of the luffing wire rope, thereby reducing the self-weight load of the jib as well as the influence and the destruction on the jib structure as a result of the shock load and the changing load of the bracket on the jib. Besides, the invention has the advantages of simple method and structure, convenient operation and low cost.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

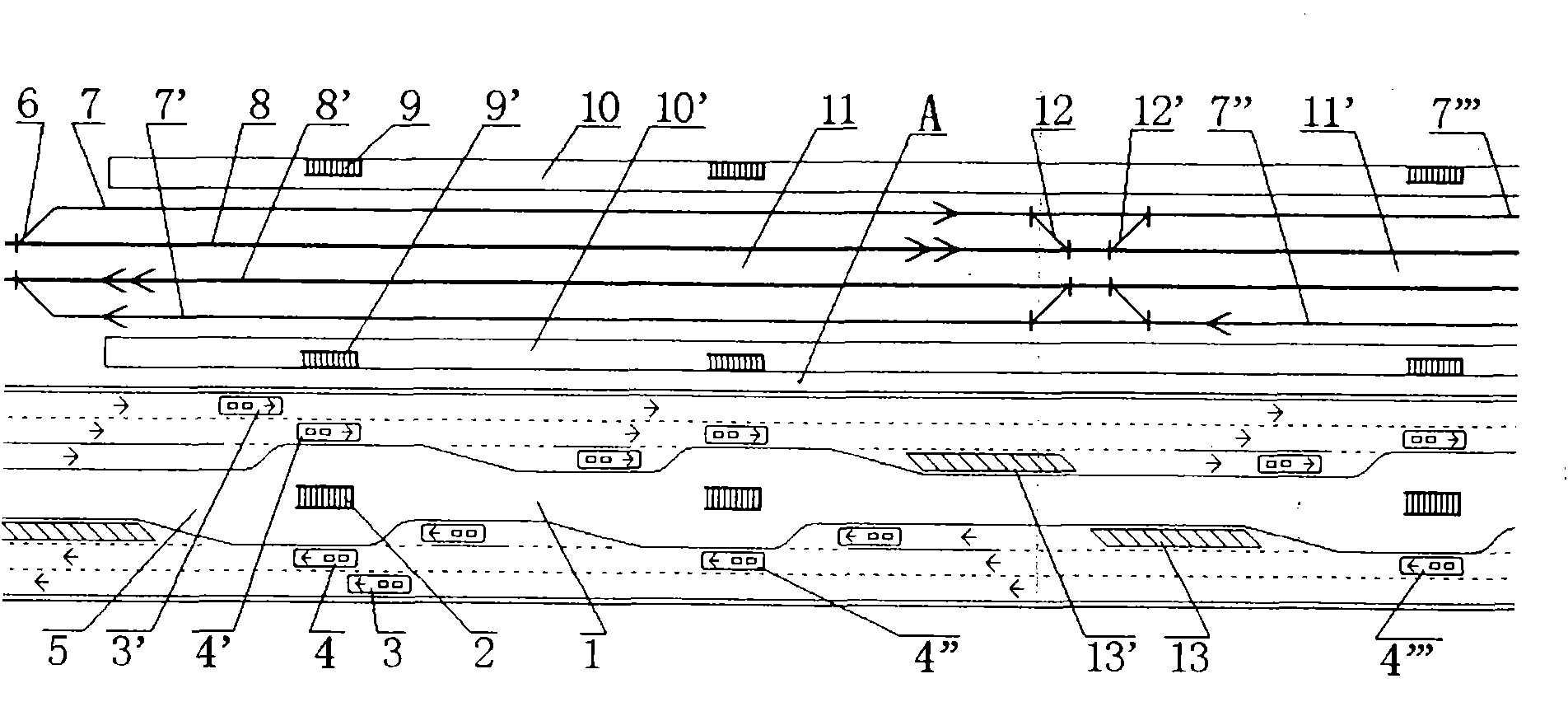

Banded transportation junction formed by paralleling parallel elevated road stations and elevated railway stations

ActiveCN101870294AAvoid overcrowdingReduce trafficRailway componentsElevated railway without suspended vehicleShortest distanceShort distance

The invention relates to a banded transportation junction formed by paralleling parallel elevated road stations and elevated railway stations, belonging to the technical field of railway station construction and aiming at solving the problem of inconvenience brought about for people by the conditions that the stations of various transport means of a large-scale integrated transportation junction are excessively concentrated, a scale is excessively huge, and transport is separated from commerce. The parallel elevated road stations are arranged parallel to one or more than one elevated railway station at short distances to form the banded transport hub; stop stations of island platforms of the parallel elevated road stations correspond to entrances / exits of the elevated railway stations, and passengers can take buses which are convenient for positive-direction and reverse-direction transfer on parallel elevated roads to reach and leave the entrances / exits of elevated railway stations on which the passengers need to take; and when the parallel elevated road stations are parallel to the elevated railway stations in an overlapping way, the parallel elevated road stations are positioned below the elevated railway stations.

Owner:田耕

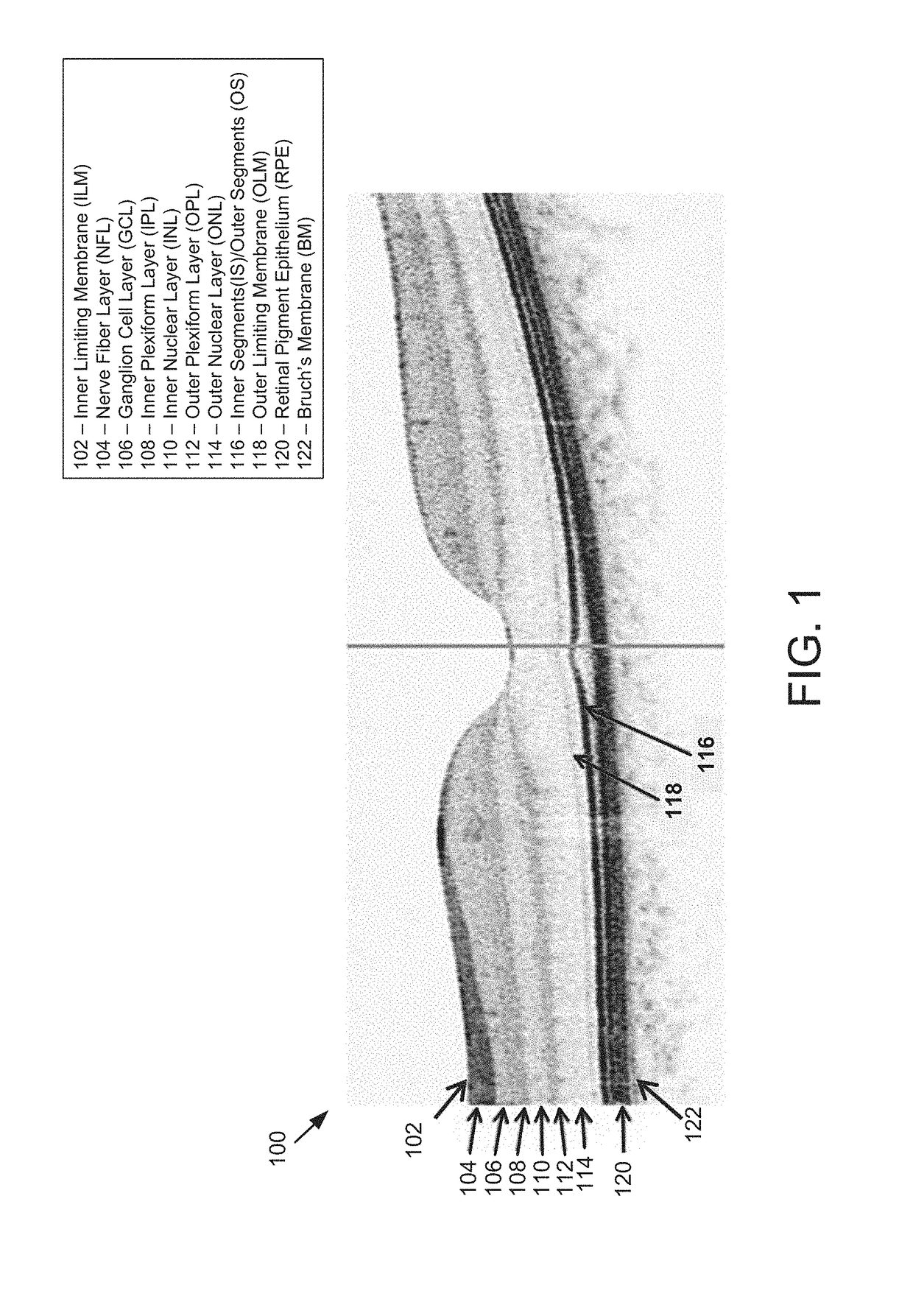

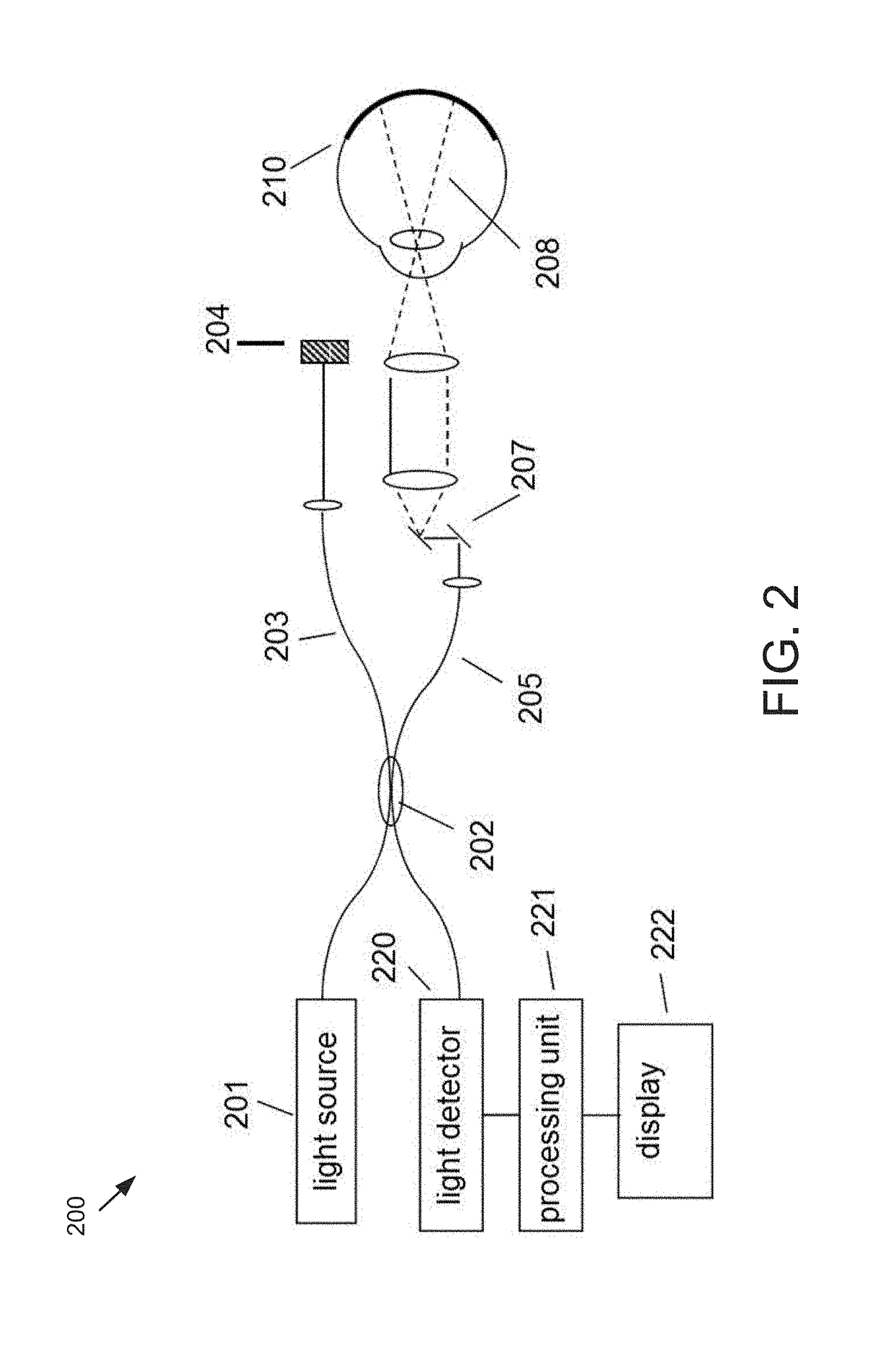

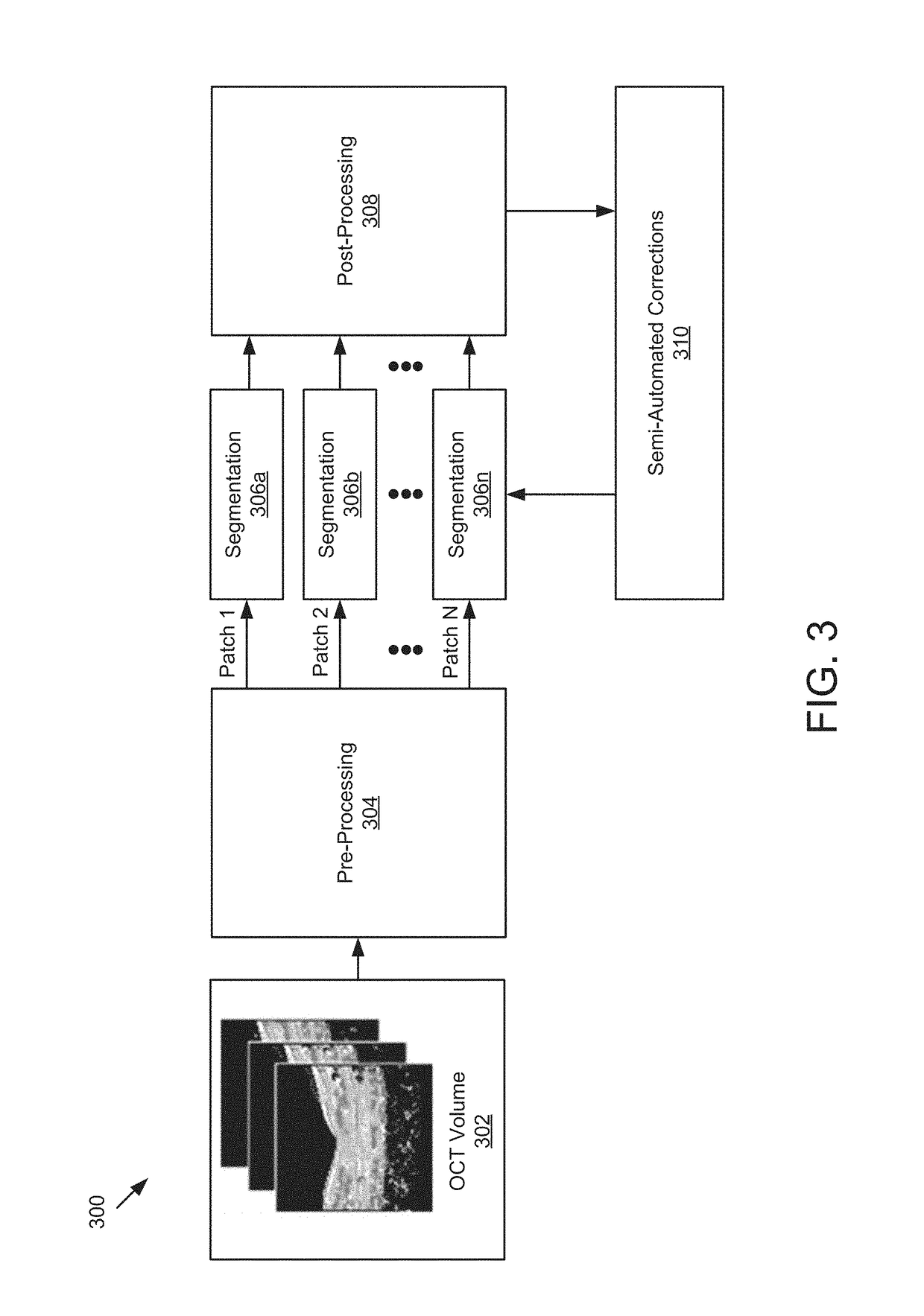

Methods and systems to detect and classify retinal structures in interferometric imaging data

ActiveUS10169864B1Reduce redundant processesReduce segmentation errorImage enhancementImage analysisAnatomical structuresPattern recognition

Methods and systems are presented to analyze a retinal image of an eye and assigns features to known anatomical structures such as retinal layers. One example method includes receiving interferometric image data of an eye. A set of features is identified in the image data. A first subset of identified features is associated with known retinal structures using prior knowledge. A first set of characteristic metrics is determined of the first subset of features. A second set of characteristic metrics is determined of a second subset of features. Using the characteristic metrics of the first and the second sets, the second subset of features is associated with the retinal structures. Another example method includes dividing interferometric image data into patches. The image data in each patch is segmented to identify one or more layer boundaries. The segmentation results from each patch are stitched together into a single segmentation dataset.

Owner:CARL ZEISS MEDITEC INC

Locking device

ActiveUS20180170519A1Prevent movementIncrease frictionBelleville-type springsConstruction fastening devicesLocking mechanismAirplane

An aircraft wing comprises a fixed wing, and a wing tip device at the tip thereof The wing tip device is configurable between (i) a flight configuration for use during flight, and (ii) a ground configuration for use during ground based operations. In the ground configuration with span of the wing is reduced. The wing further comprises a locking mechanism including a locking pin with a longitudinal axis, the locking pin associated with one of the fixed wing and the wing tip device, and a bush associated with the other of the fixed wing and wing tip device, the bush configured to receive the locking pin. The bush is located within a bush housing arranged to allow relative movement of the bush in the direction of the longitudinal axis of the locking pin when the locking pin is received within the bush.

Owner:AIRBUS OPERATIONS LTD

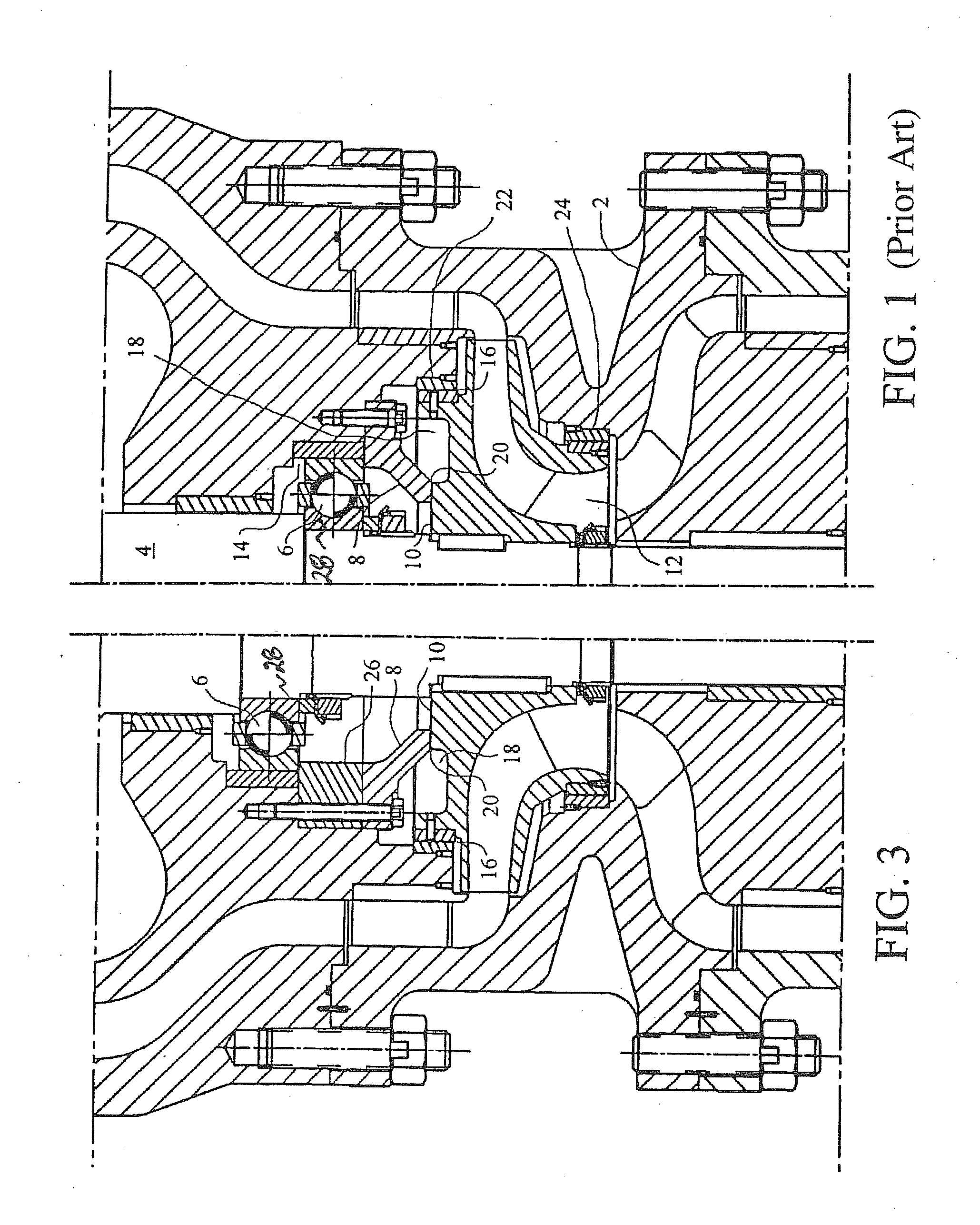

Thrust Balancing Device For Cryogenic Fluid Machinery

ActiveUS20110210556A1Reducing gap therebetweenReduce gapEngine manufacturePump componentsEngineeringTurbine

An improvement for a turbine generator or pump having main bearings separated by a span of shaft and a thrust equalizing mechanism adjacent one of said main bearings, the improvement comprising a stationary length compensator interposed between the thrust equalizing mechanism and its adjacent main bearing to reduce the span between said main bearings. Preferably the length compensator is composed of material that shrinks less than the shaft of the generator, and the height of the length compensator, i.e., the compensating dimension, is selected according to desired thrust equalizing mechanism operating parameters over a temperature range.

Owner:ELLIOTT CO

Fluorescent tube attaching structure

InactiveUS7699496B2Firmly connectedEasy to operateEngagement/disengagement of coupling partsLighting support devicesMechanical engineering

Owner:JST MFG CO LTD

Thrust balancing device for cryogenic fluid machinery

InactiveUS20090074560A1Reducing gap therebetweenReduce gapEngine sealsRolling contact bearingsTurbineFixed length

An improvement for a turbine generator or pump having main bearings separated by a span of shaft and a thrust equalizing mechanism adjacent one of said main bearings, the improvement comprising a stationary length compensator interposed between the thrust equalizing mechanism and its adjacent main bearing to reduce the span between said main bearings. Preferably the length compensator is composed of material that shrinks less than the shaft of the generator, and the height of the length compensator, i.e., the compensating dimension, is selected according to desired thrust equalizing mechanism operating parameters over a temperature range.

Owner:ELLIOTT CO

Closing link for a bicycle chain

ActiveUS7722492B2Reduce lateral movementConnection securityShacklesDriving chainsEngineeringCountersink

Owner:SRAM

Steel-concrete composite tunnel lining supporting structure and manufacturing and construction method thereof

ActiveCN105114105APrevent collapseGood shock resistanceUnderground chambersTunnel liningPressure loadRadian

The invention discloses a steel-concrete composite tunnel lining supporting structure and a manufacturing and construction method thereof. The supporting structure is formed by splicing unit plate pieces with radian in the circumferential direction and axial direction of a tunnel wall. Each unit plate piece is provided with a pair of arc edges and a pair of straight edges. The inner wall of each unit plate piece is provided with protruding ribs at intervals in the straight edge direction. The radian of the protruding ribs is consistent with that of the arc edges, and cavity pillars are formed between the protruding ribs and the unit plate pieces. The surfaces of the protruding ribs are provided with concrete pouring holes, and unit plate pieces corresponding to the protruding ribs are provided with concrete overflowing holes. Meanwhile, the arc edges are inwards bent to form end face flanges, and the straight edges are provided with side edge flanges. The steel-concrete composite tunnel lining supporting structure has the advantages that the supporting structure can bear pressure load of the upper portion of a tunnel and the surrounding rock immediately, and the newly dug tunnel can be supported rapidly and timely and is prevented from collapsing; the supporting structure can be used for the primary lining as well as integrating the primary lining and the secondary lining and an also be used for repairing, reinforcing and the like of crippled tunnels.

Owner:NANJING LIANZHONG CONSTR ENG TECH

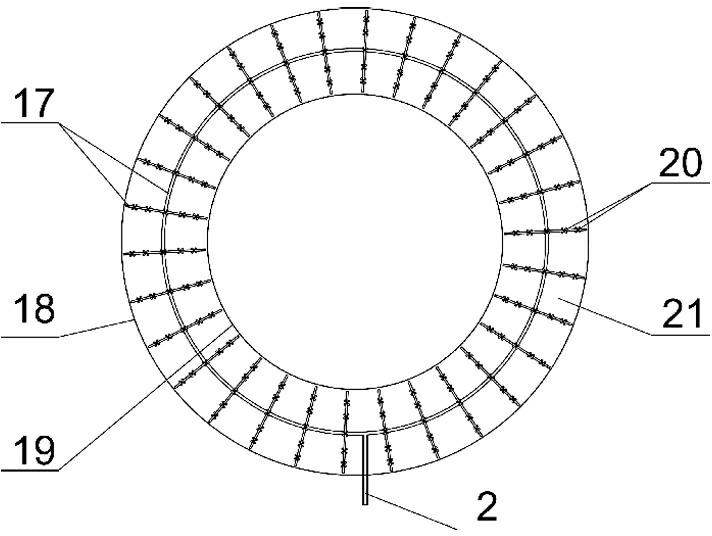

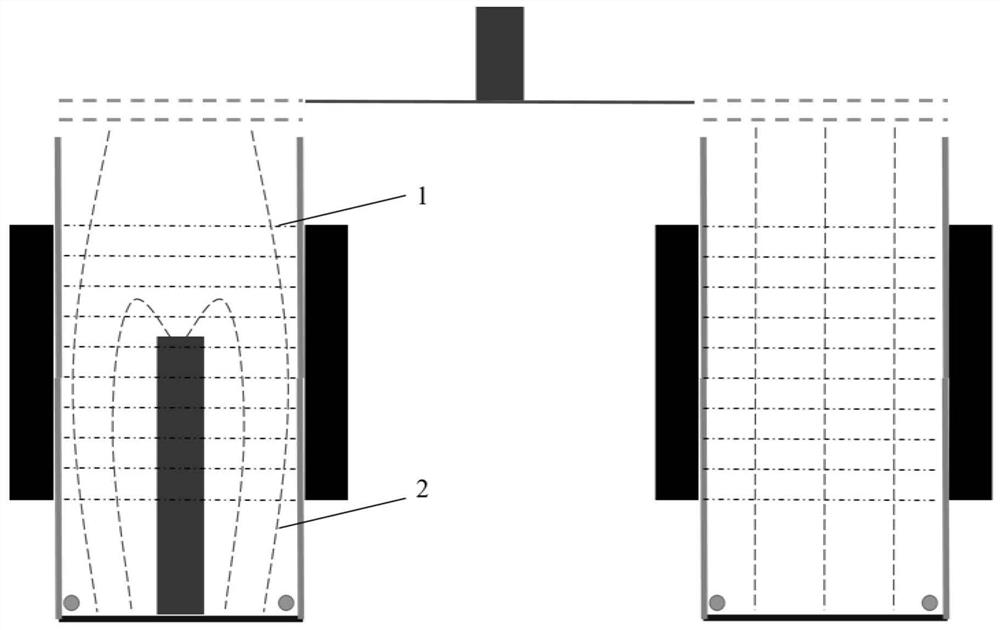

Hall effect ringlike ion thruster

ActiveCN111852802AReduce spanReduce manufacturing difficultyMachines/enginesUsing plasmaPlasmaElectric field

The invention discloses a Hall effect ringlike ion thruster and belongs to the technical field of ion thrusters. The ringlike ion thruster comprises a bottom positive pole, a ringlike grid electrode,ringlike permanent magnets, insulating sleeves, a working medium distributor set, a bias discharging negative pole and a neutralizer. Working medium gas enters a discharging chamber through bottom working medium distributors. Nozzles of the working medium distributors are oriented along the wall face so that the gas can be more uniform in a cavity. An axial electric field is formed among the positive pole, the negative pole and the grid electrode. A radial magnetic field is formed by the inner ringlike permanent magnet and the outer ringlike permanent magnet, and an E*B orthogonal field is formed by the radial magnetic field and the axial electric field. Electrons sprayed out of the negative pole are subjected to Hall drift under the effect of the orthogonal field, and the working medium gas is ionized to generate plasmas. Then, the plasmas are extracted and accelerated by the ringlike grid electrode and neutralized by electrons emitted by the neutralizer to generate thrust. The ionization rate and input power of the thrust generated by the Hall effect ringlike ion thruster are far higher than those of a traditional ion thruster, and performance of the ion thruster can be remarkably improved.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com