Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1638results about "Driving chains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

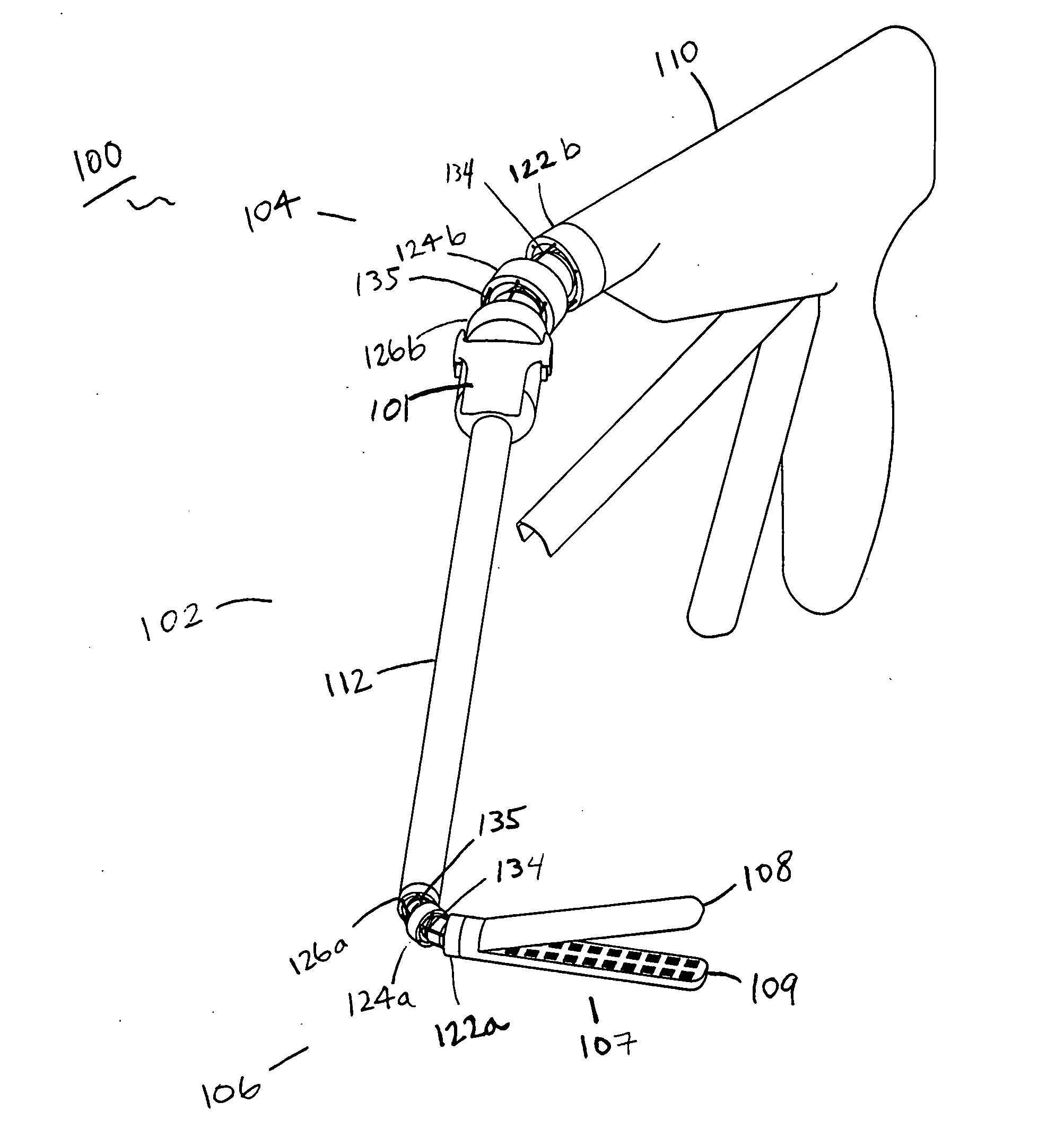

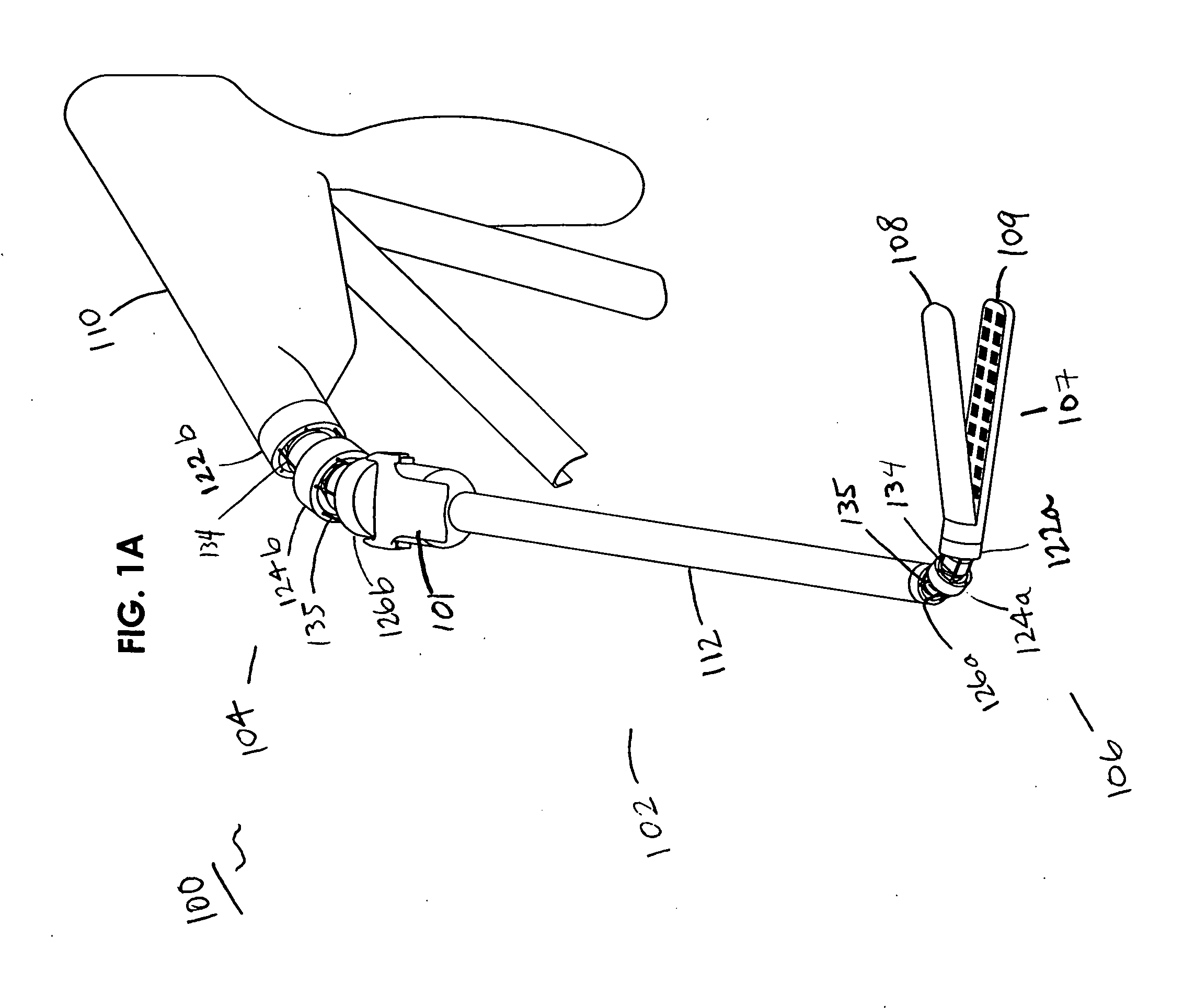

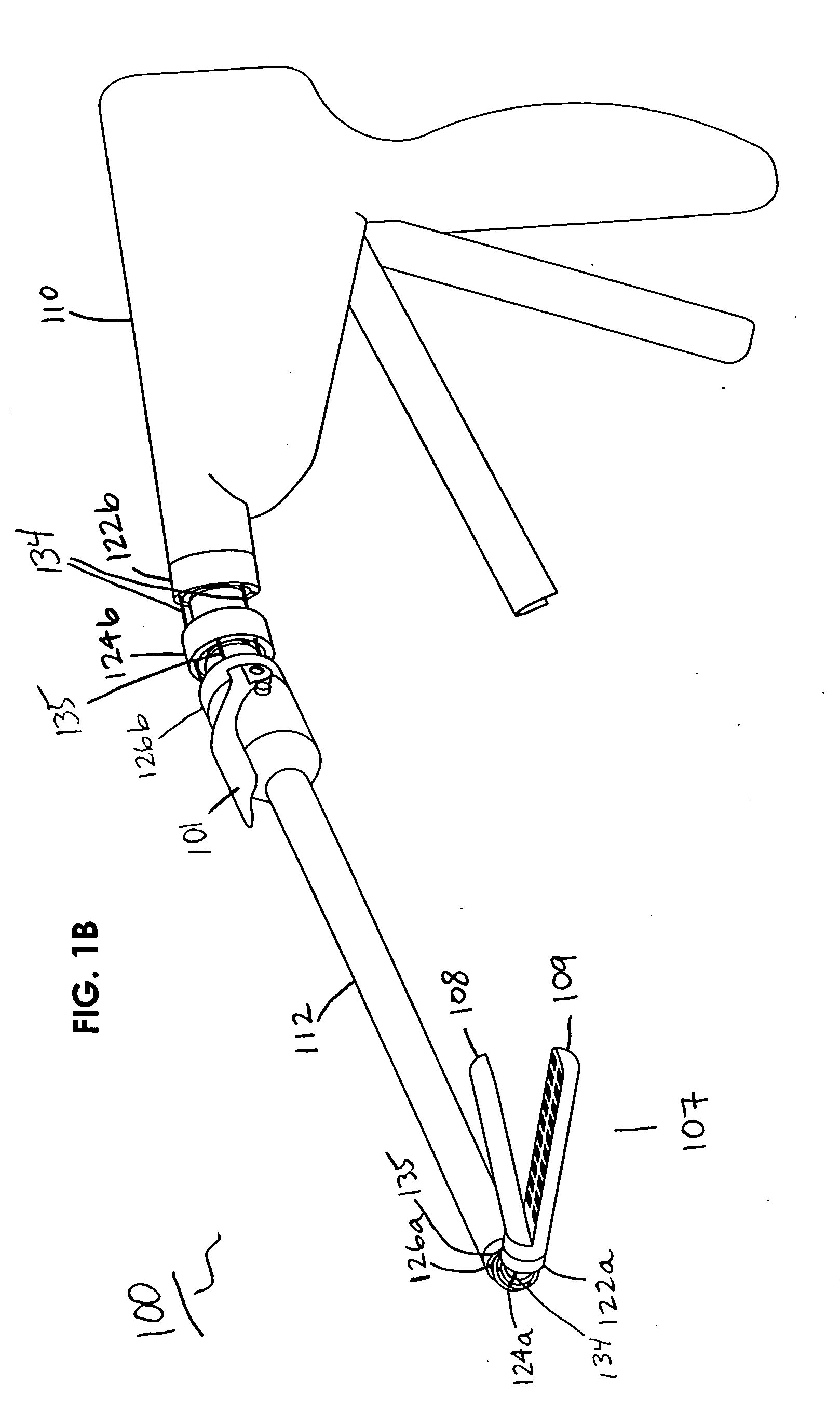

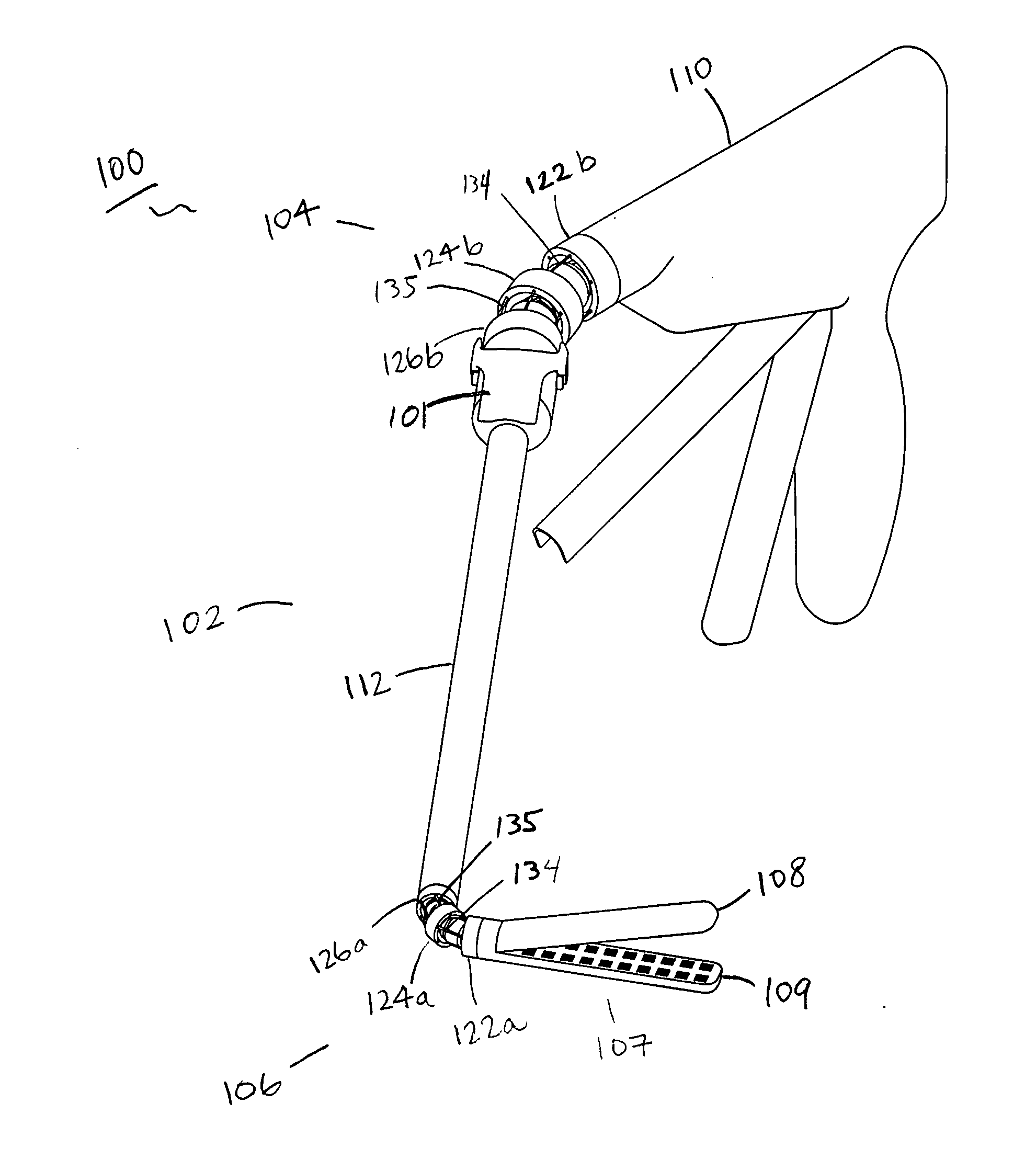

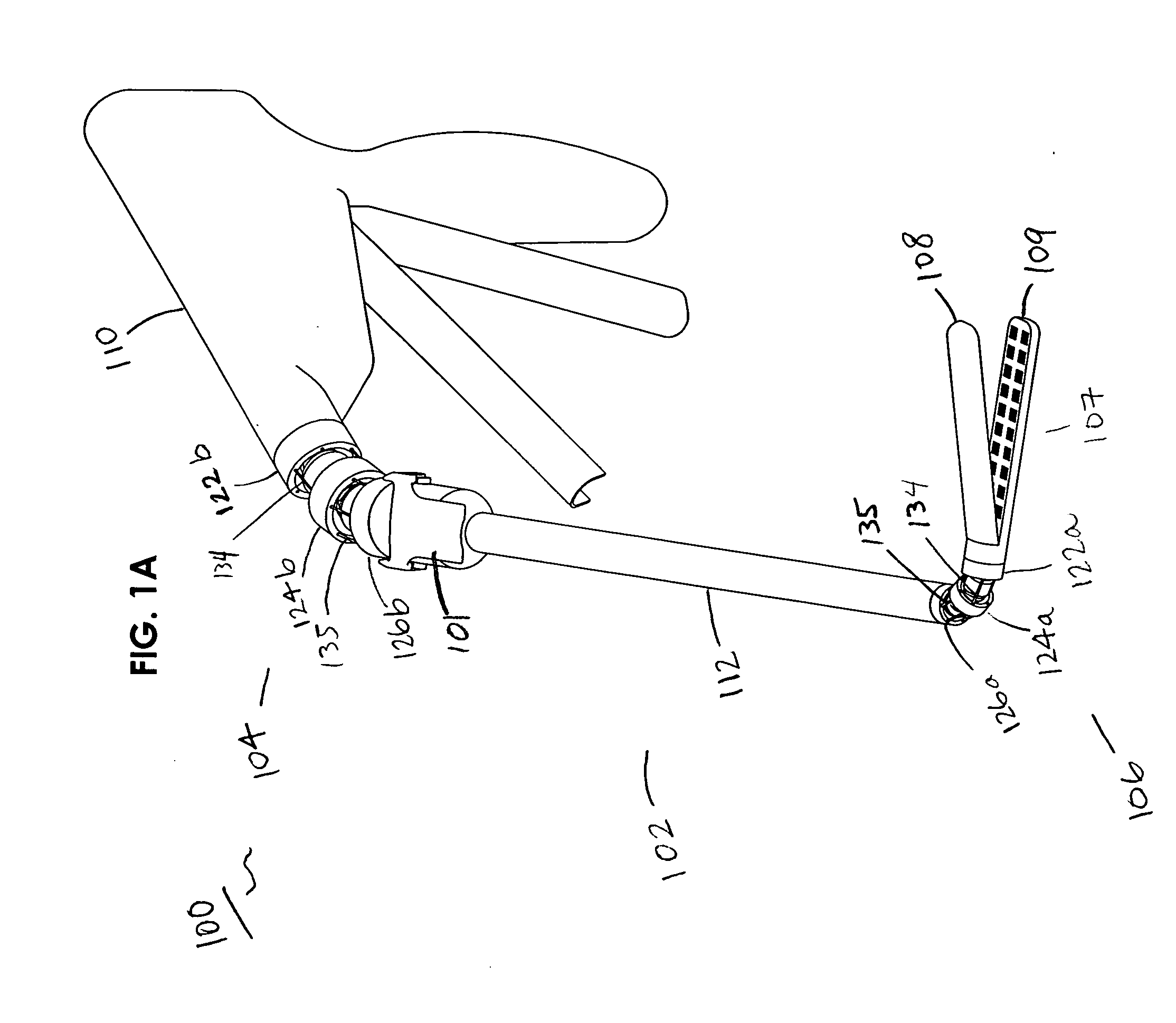

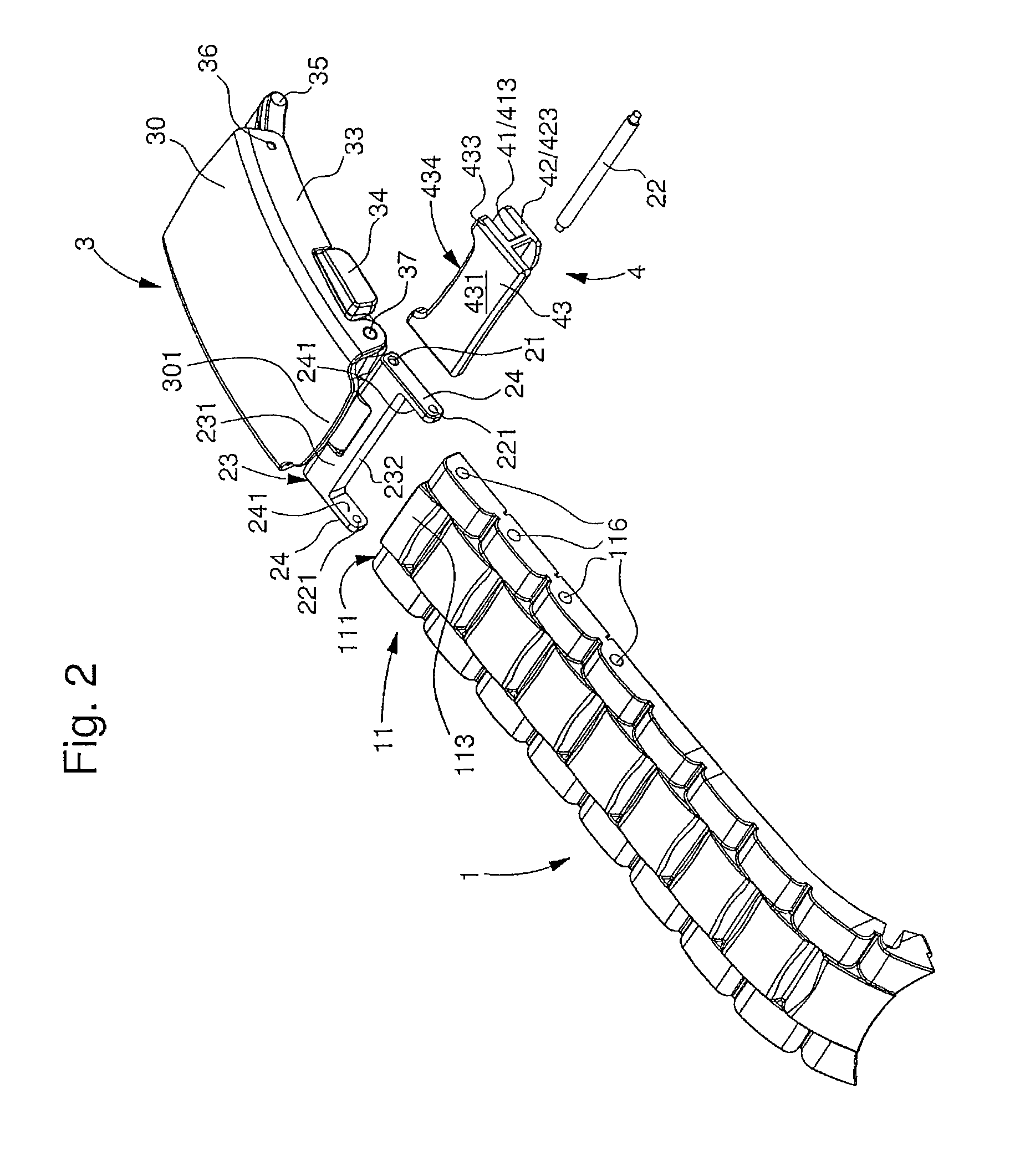

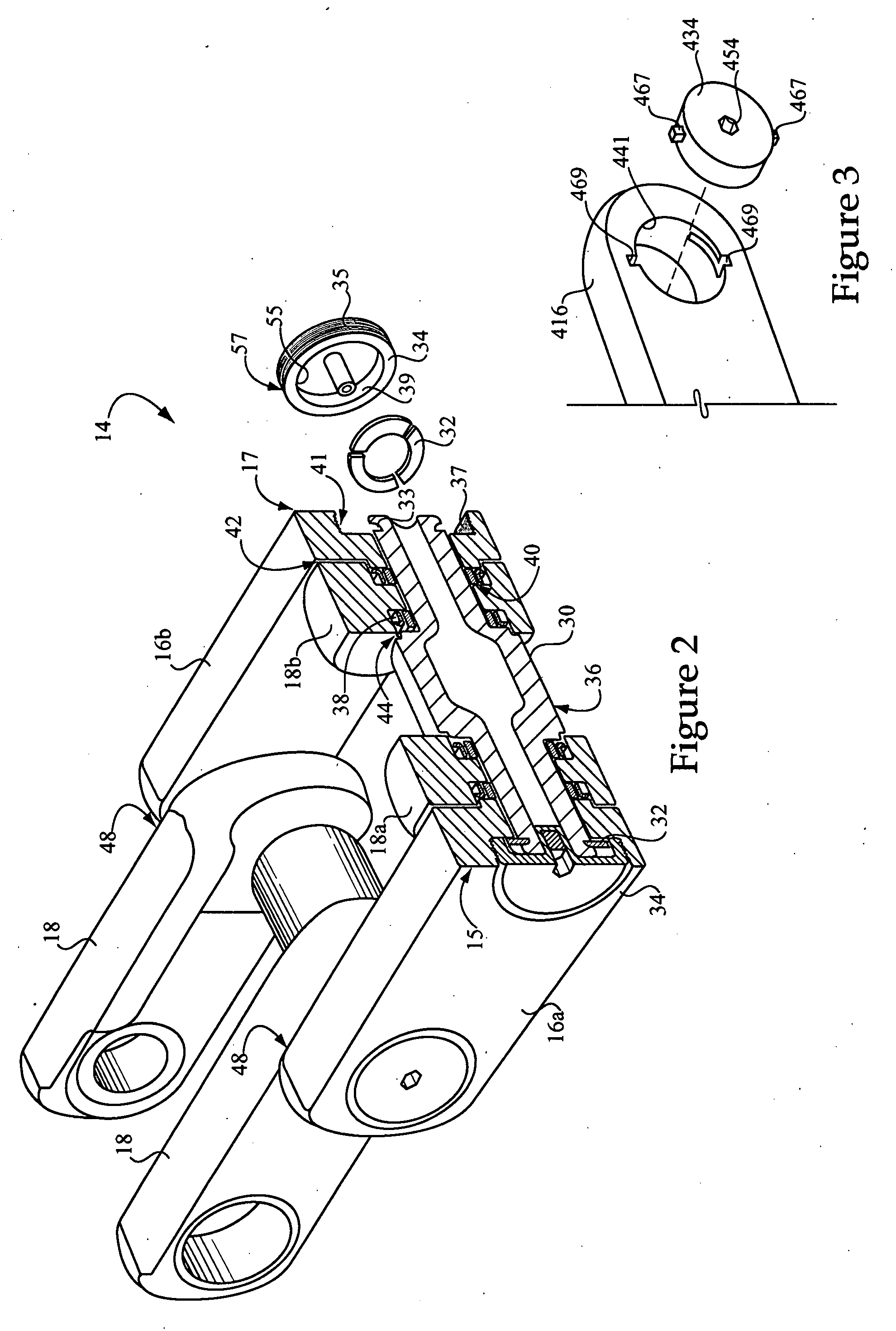

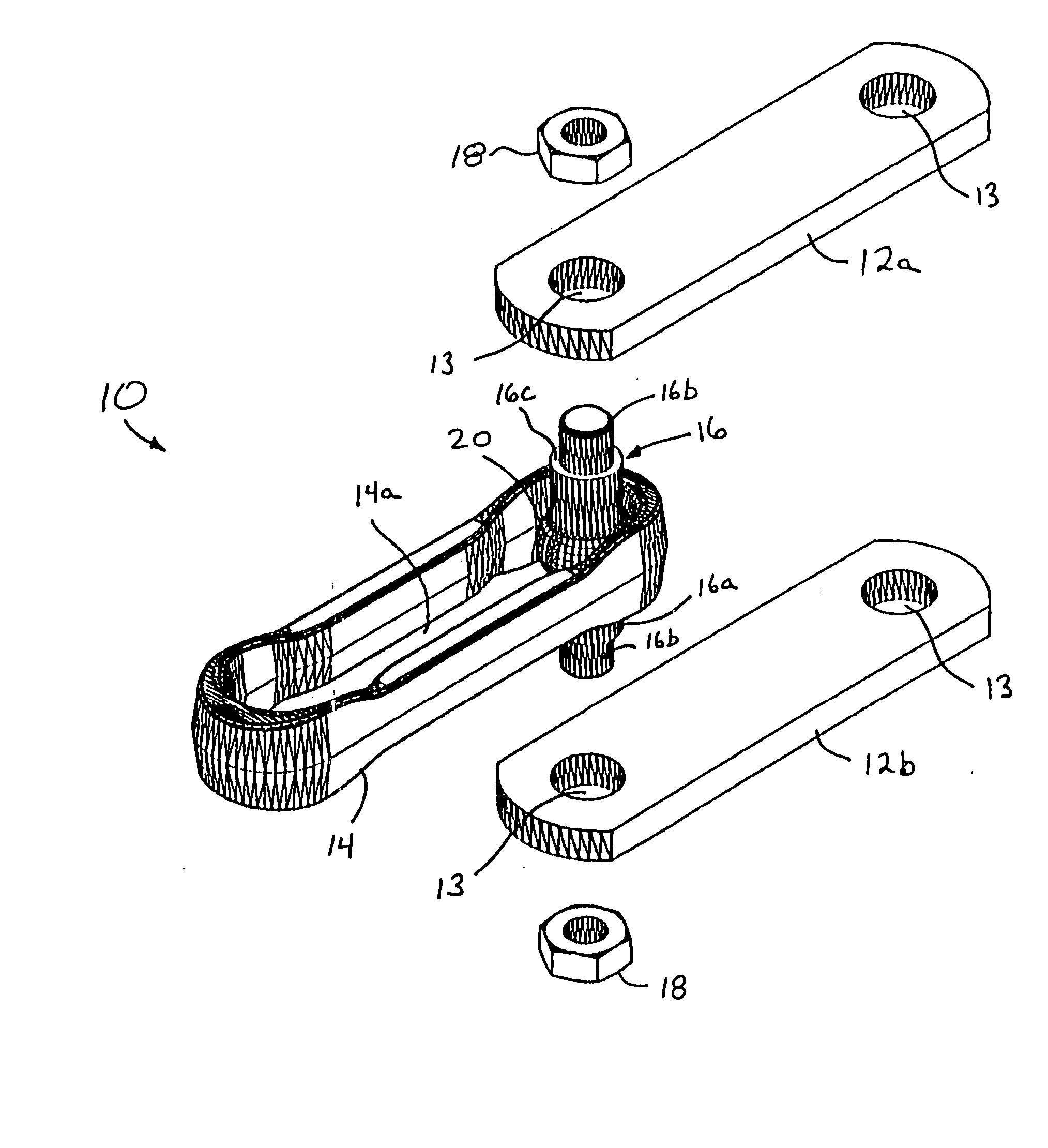

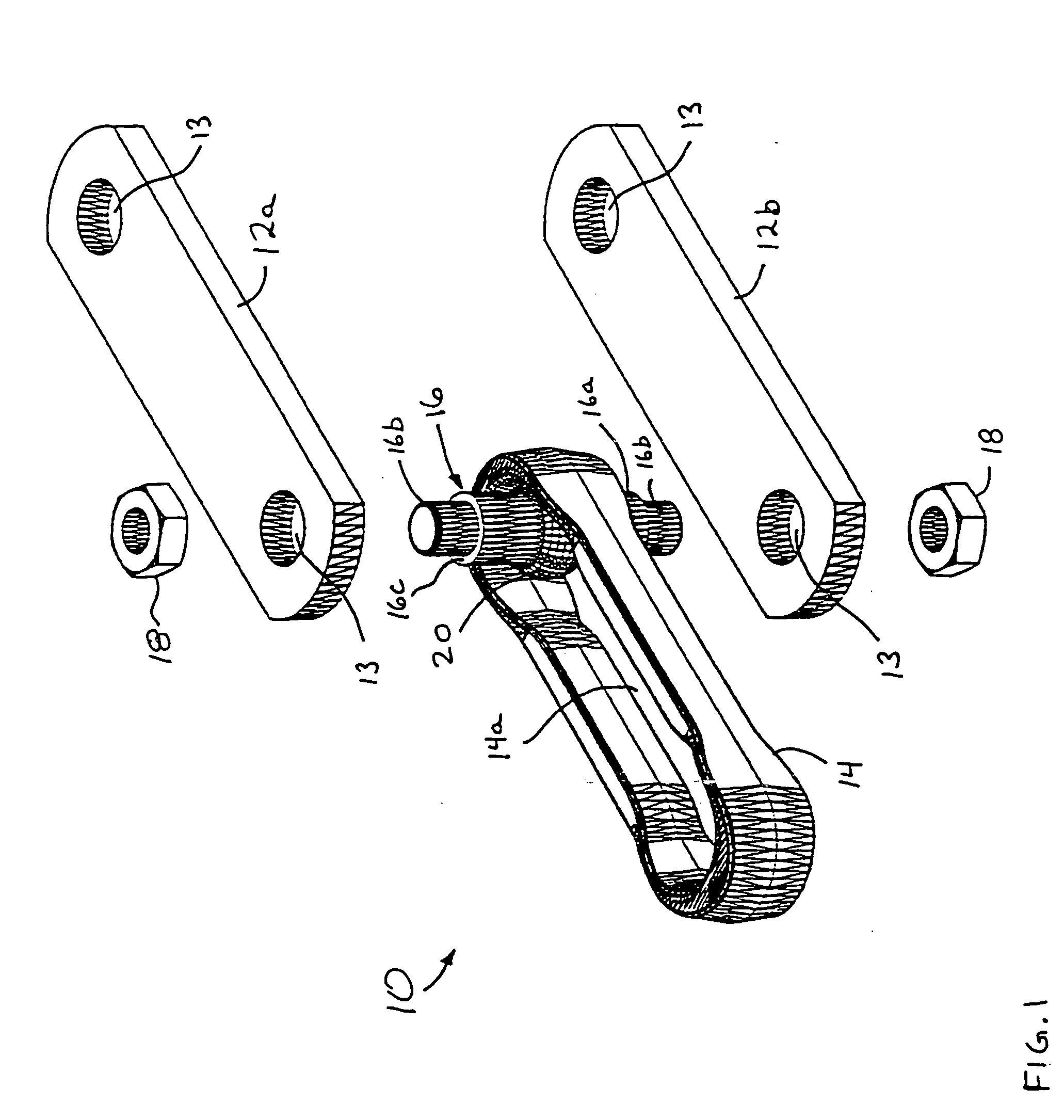

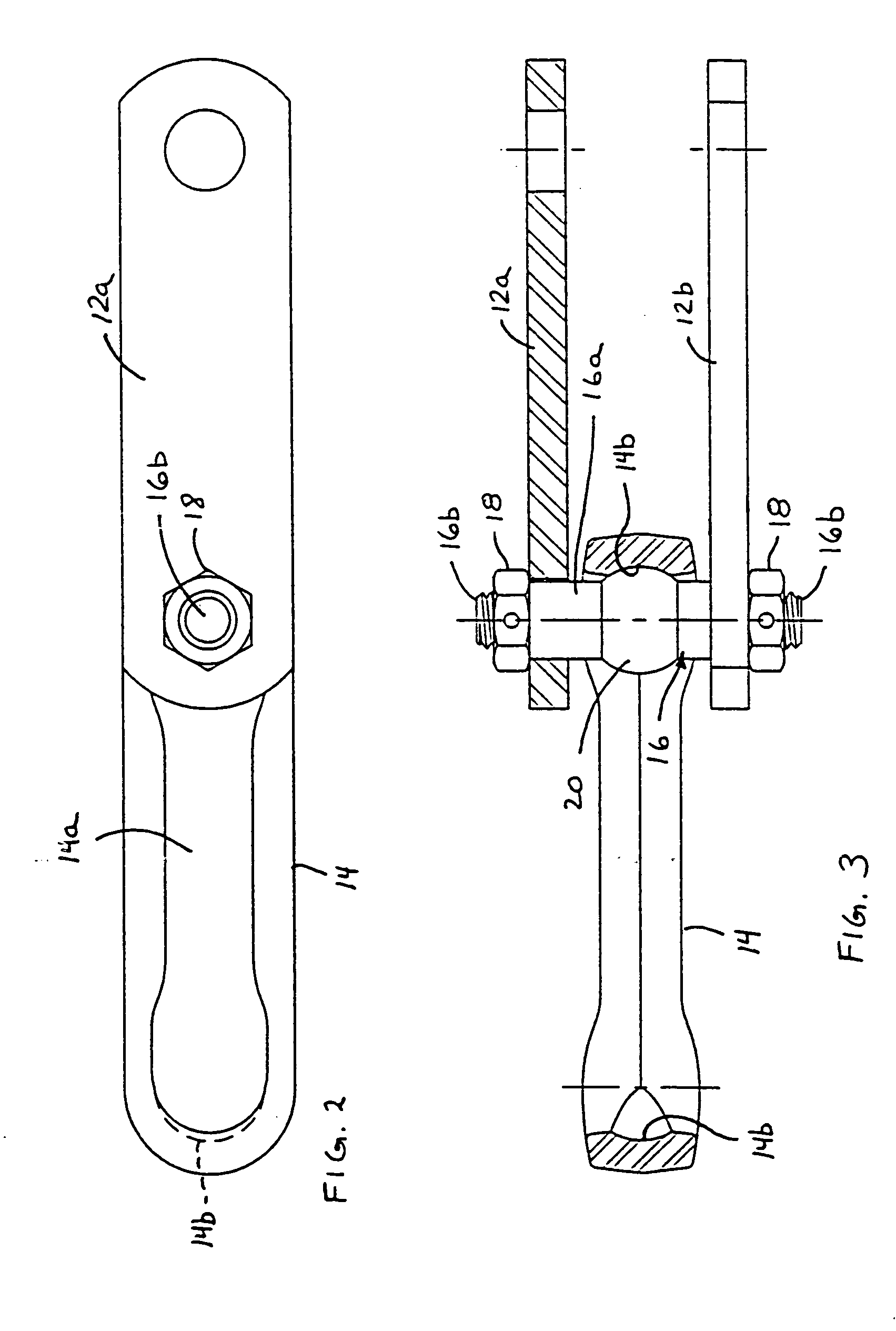

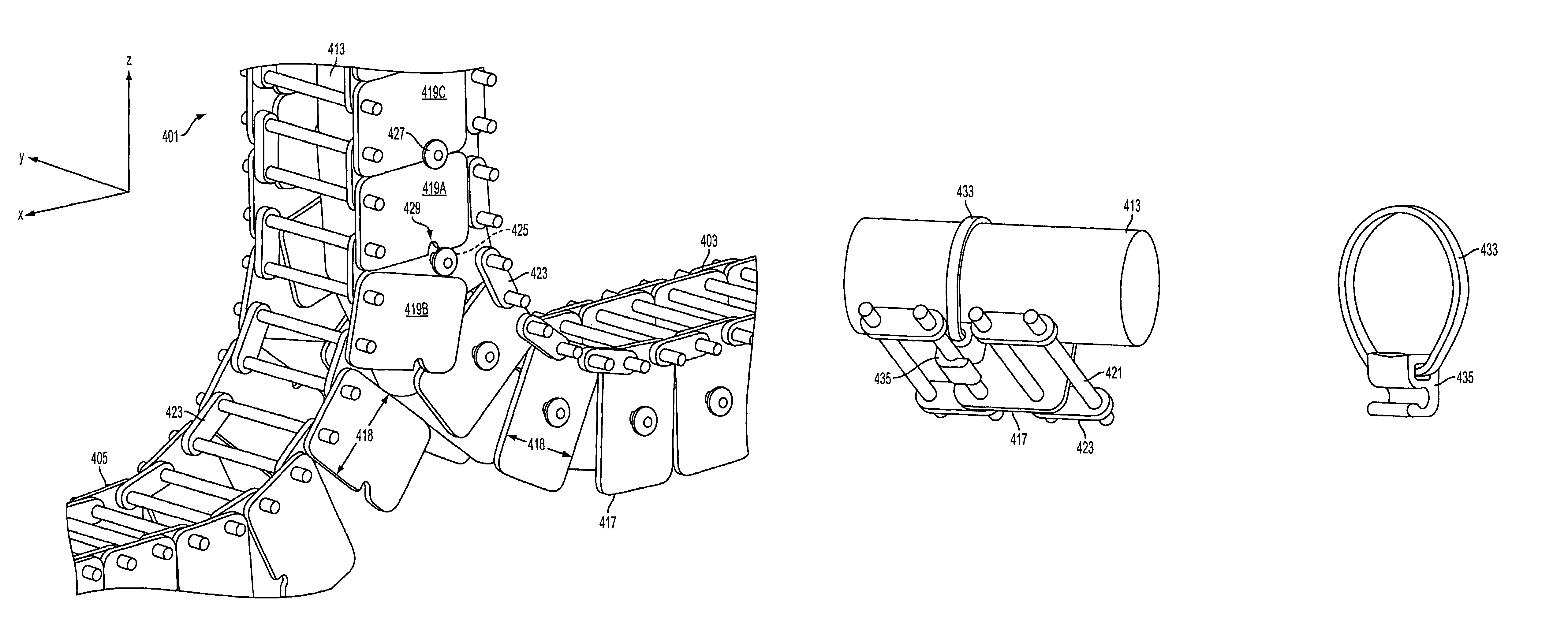

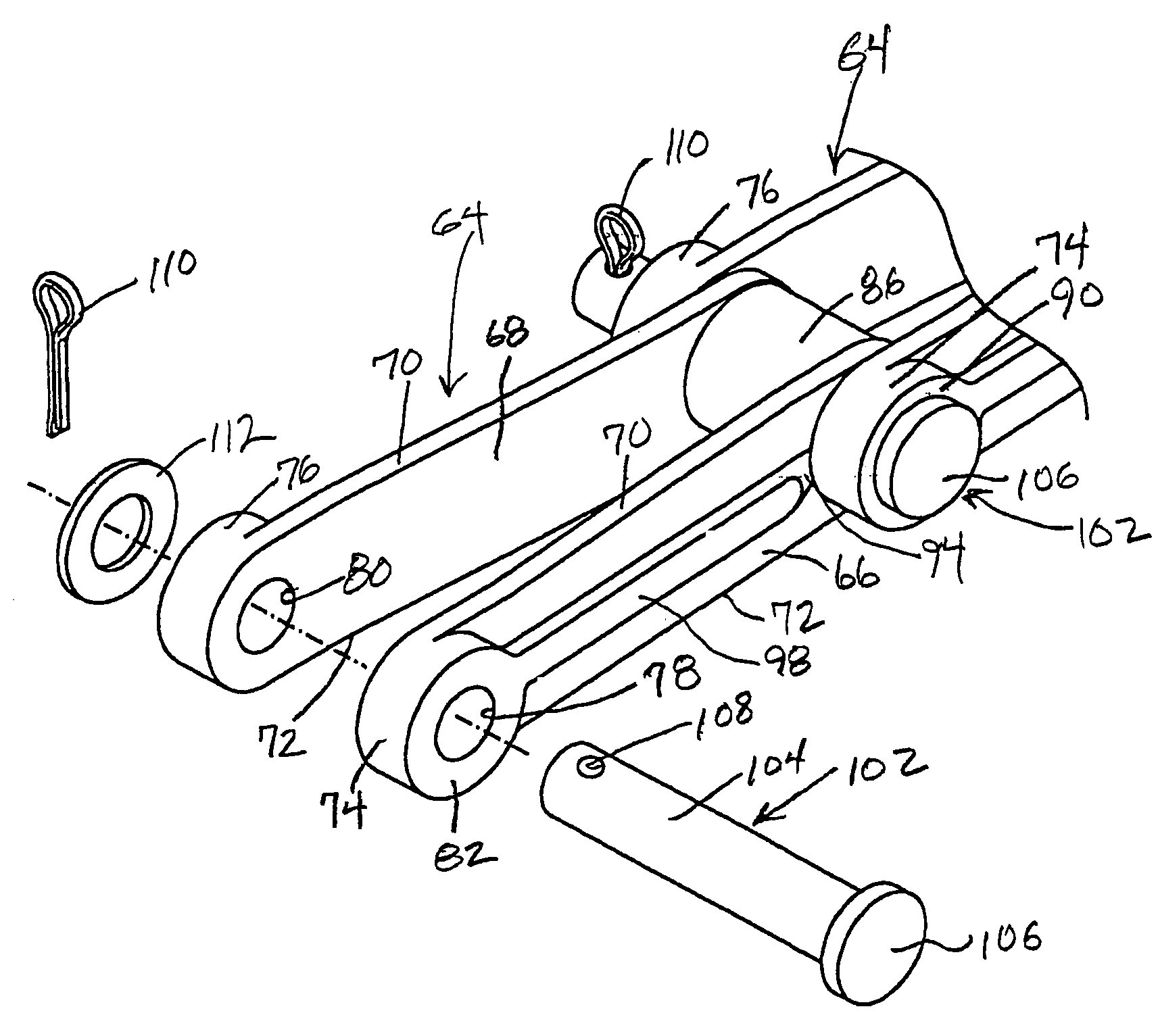

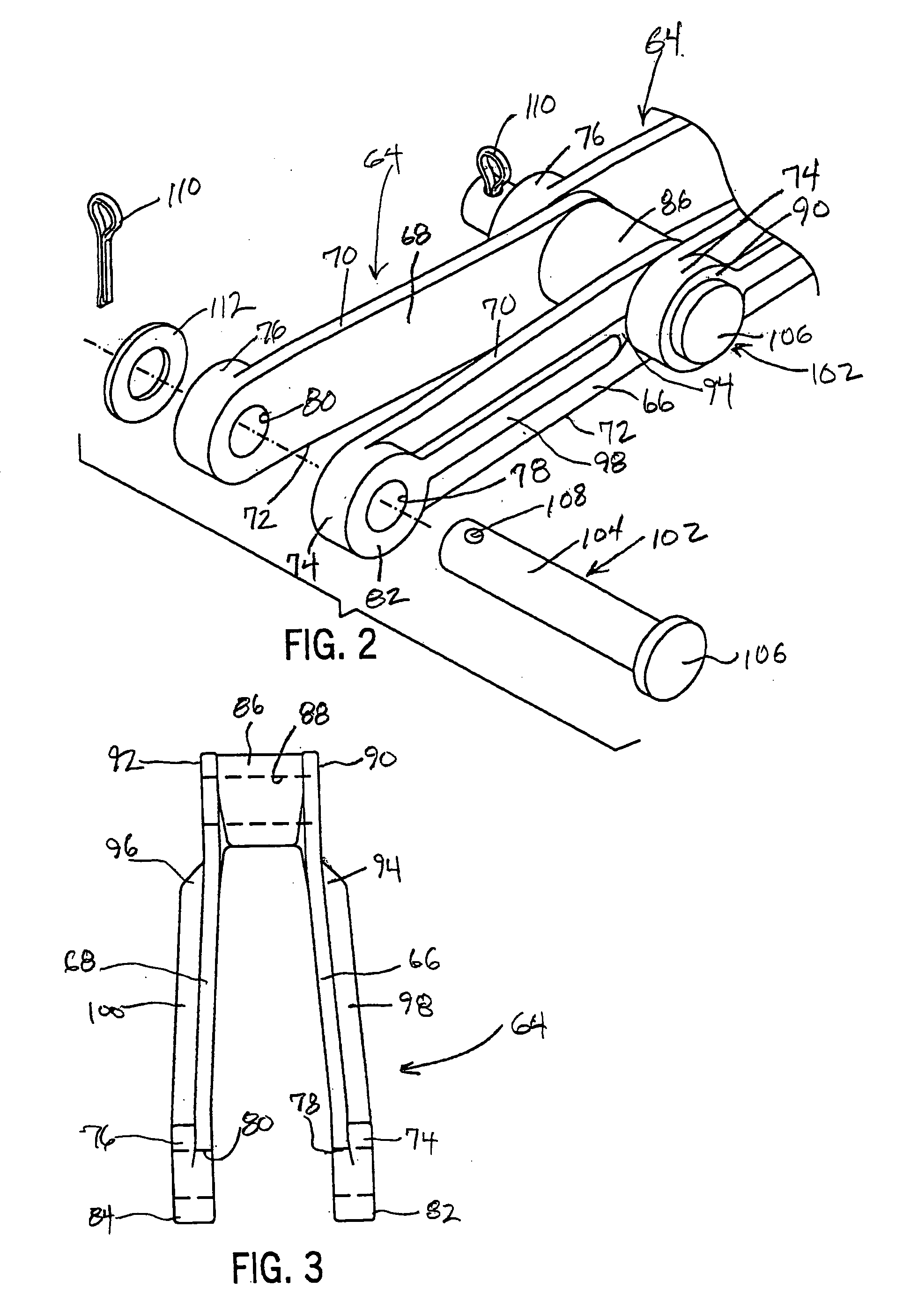

Articulating mechanisms and link systems with torque transmission in remote manipulation of instruments and tools

Articulating mechanisms, link systems, and components thereof, useful for a variety of purposes including, but not limited to, the remote manipulation of instruments such as surgical or diagnostic instruments or tools, are provided. The link systems include links wherein torque can be transferred between at least two adjacent links while allowing for pivoting motion between the links. Mechanisms for preventing undesired lateral movement of links relative to one another are also provided.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Articulating mechanisms and link systems with torque transmission in remote manipulation of instruments and tools

Articulating mechanisms, link systems, and components thereof, useful for a variety of purposes including, but not limited to, the remote manipulation of instruments such as surgical or diagnostic instruments or tools, are provided. The link systems include links wherein torque can be transferred between at least two adjacent links while allowing for pivoting motion between the links. Mechanisms for preventing undesired lateral movement of links relative to one another are also provided.

Owner:INTUITIVE SURGICAL OPERATIONS INC

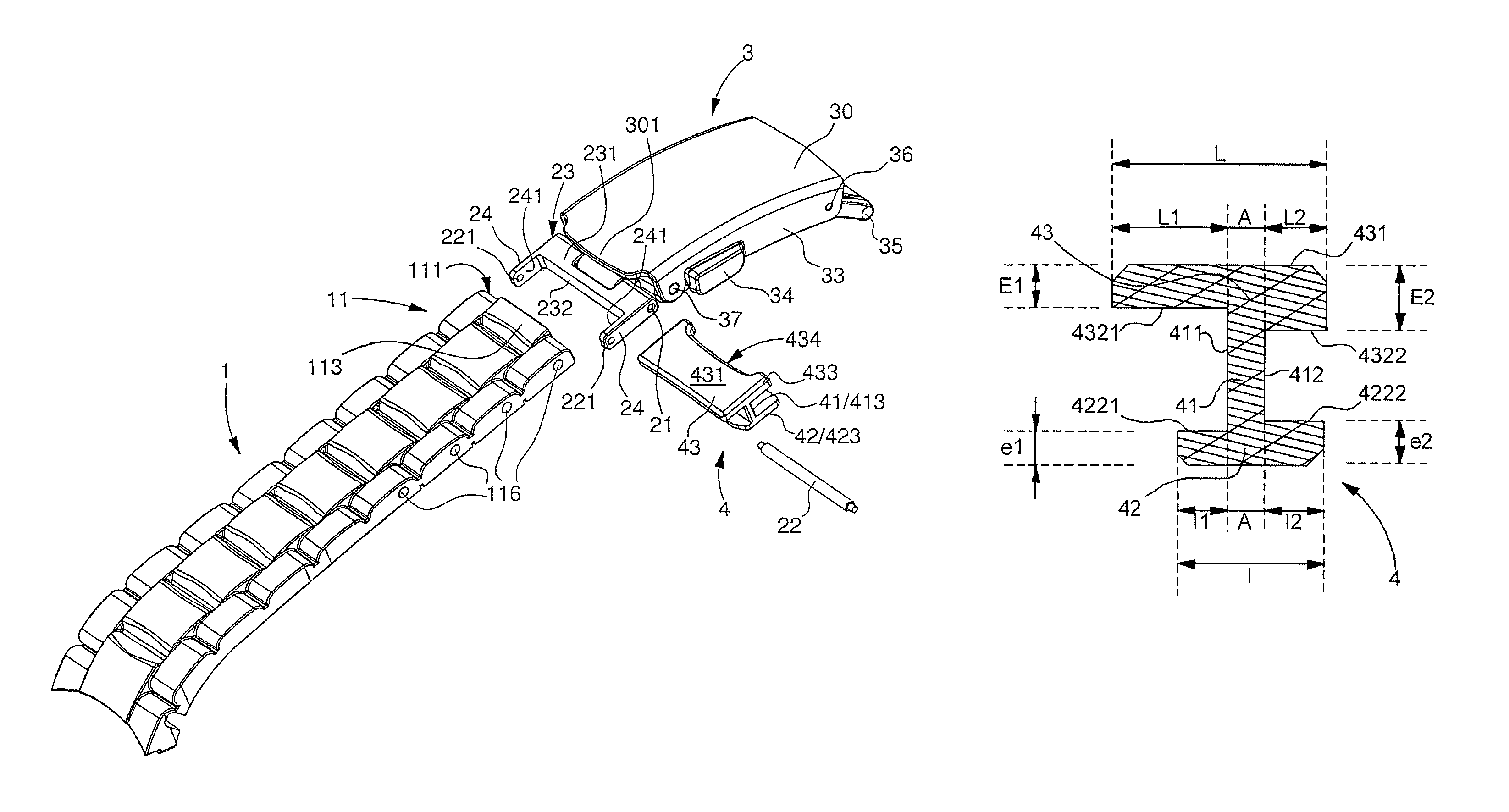

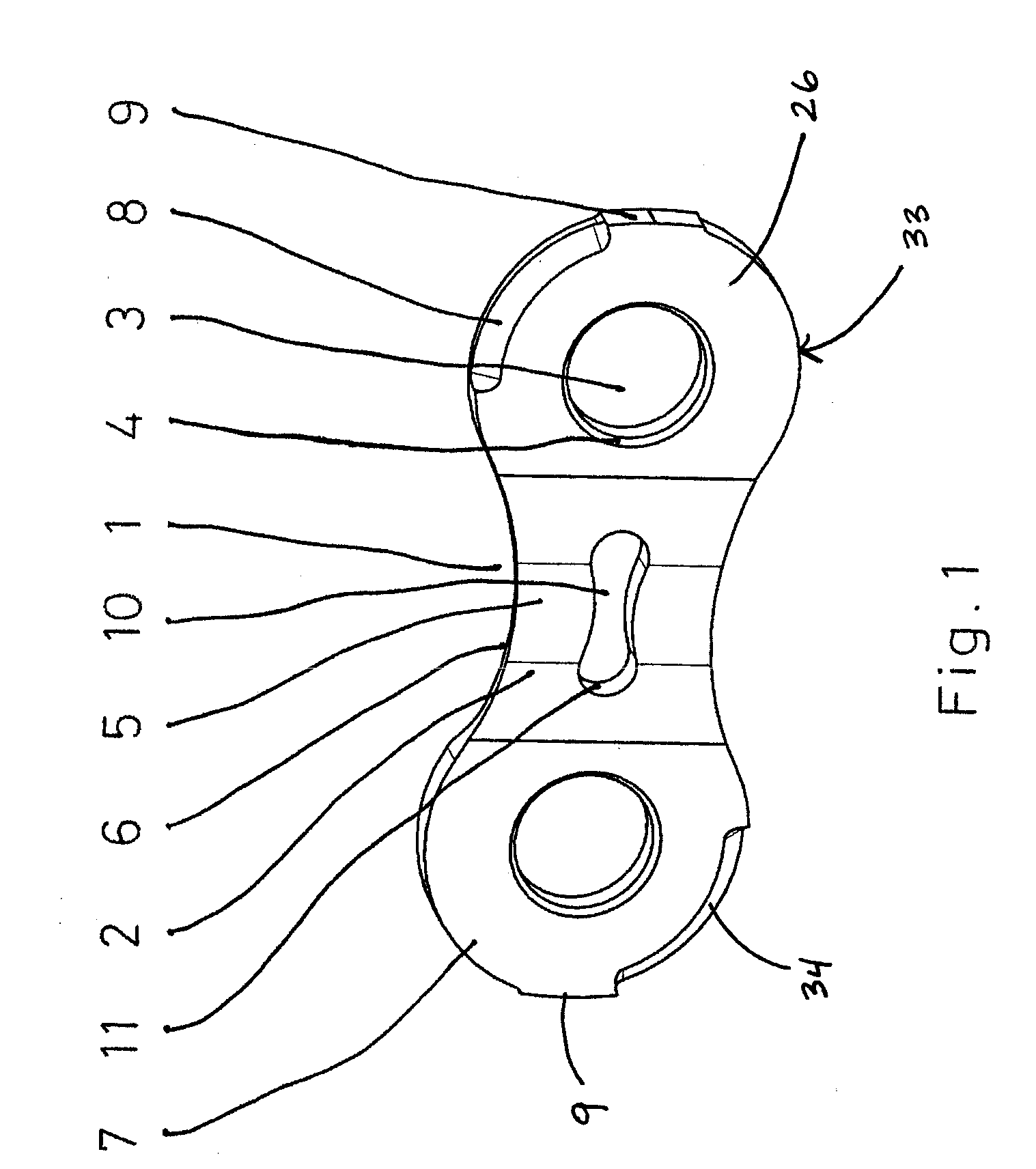

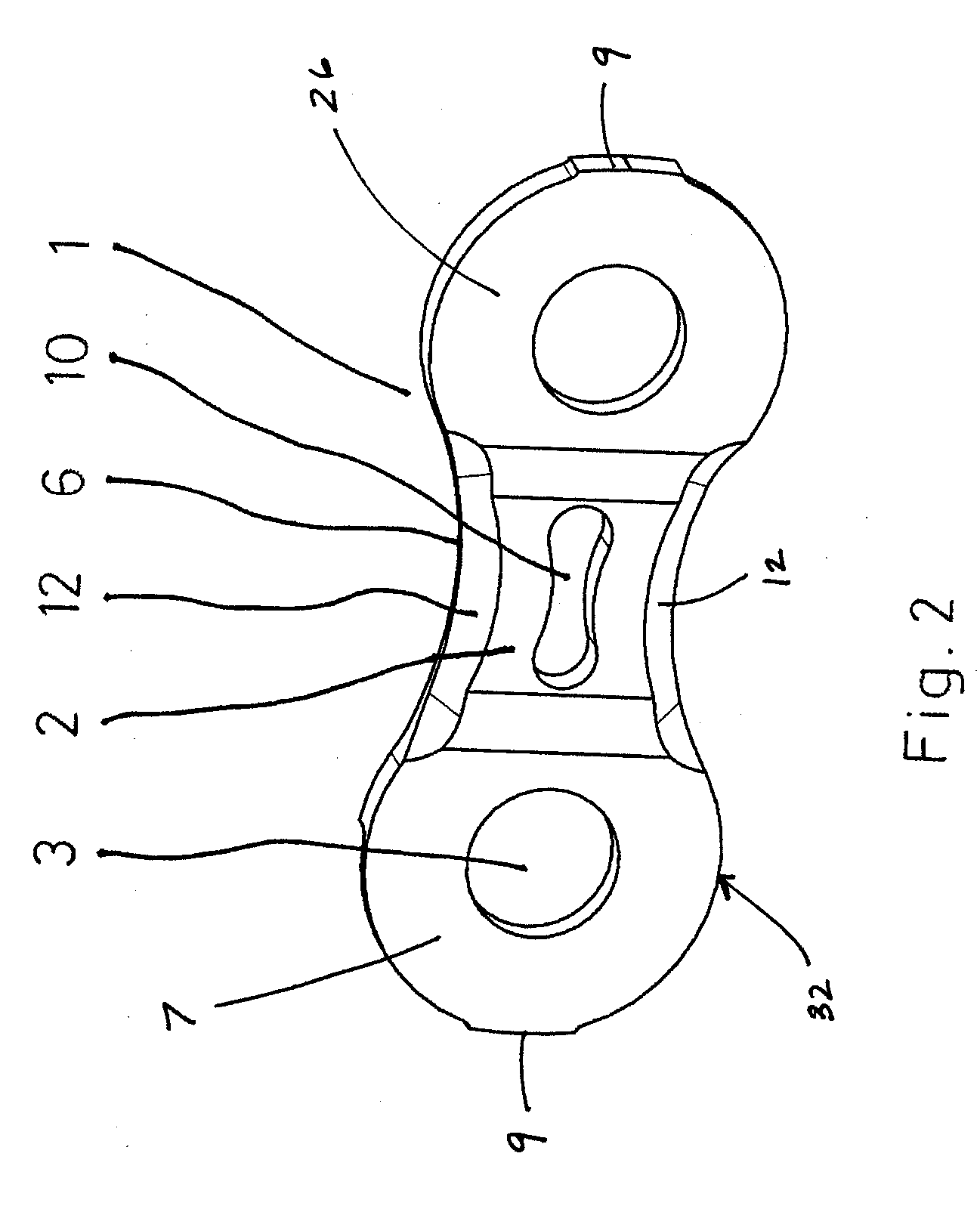

Anti-rotation link

ActiveUS8601784B2Easy to adjust the lengthImprove aestheticsBraceletsWrist-watch strapsLower wingUpper wing

Link for a wristwatch, characterized in that it comprises a central core connecting a lower wing and an upper wing.

Owner:THE SWATCH GROUP MANAGEMENT SERVICES

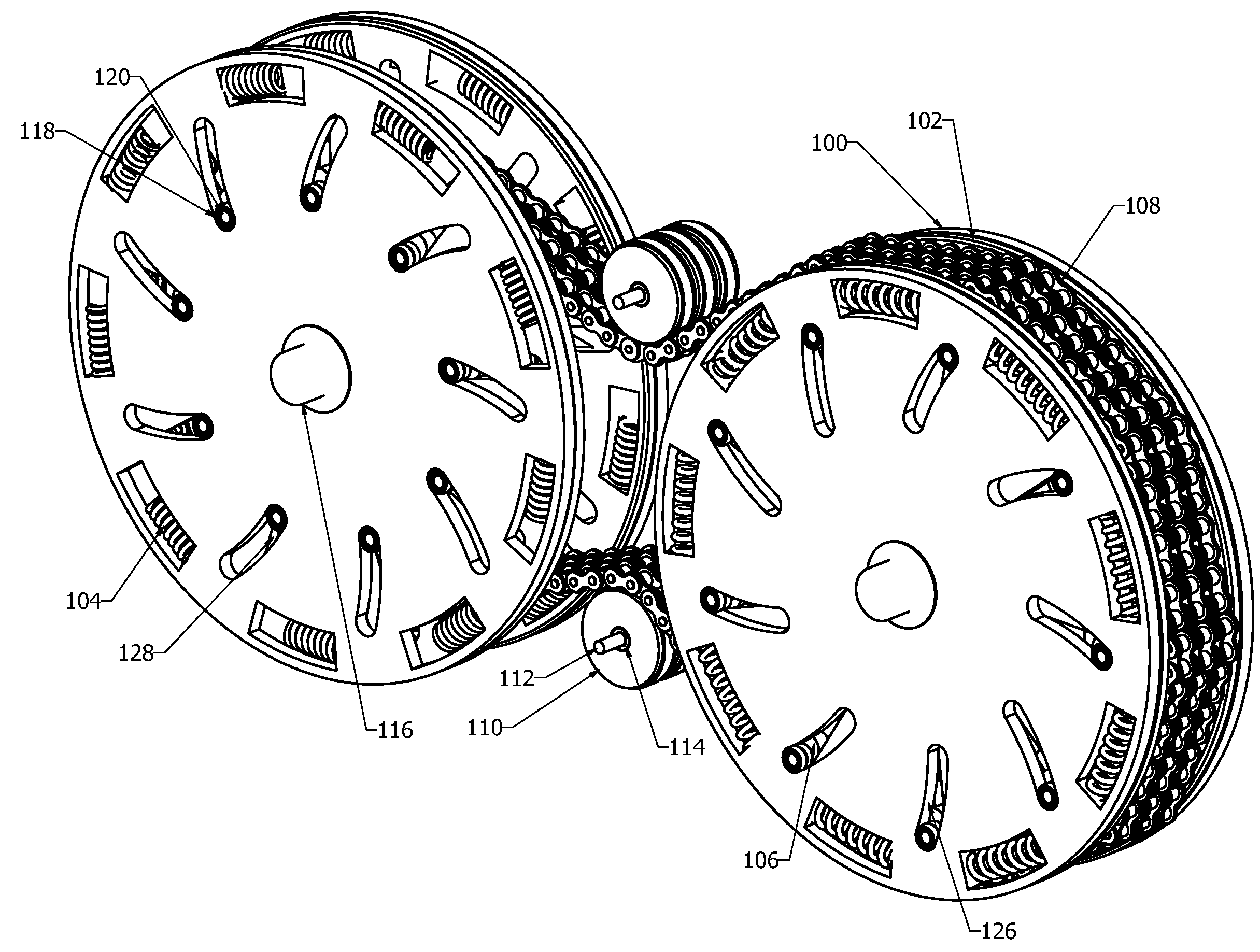

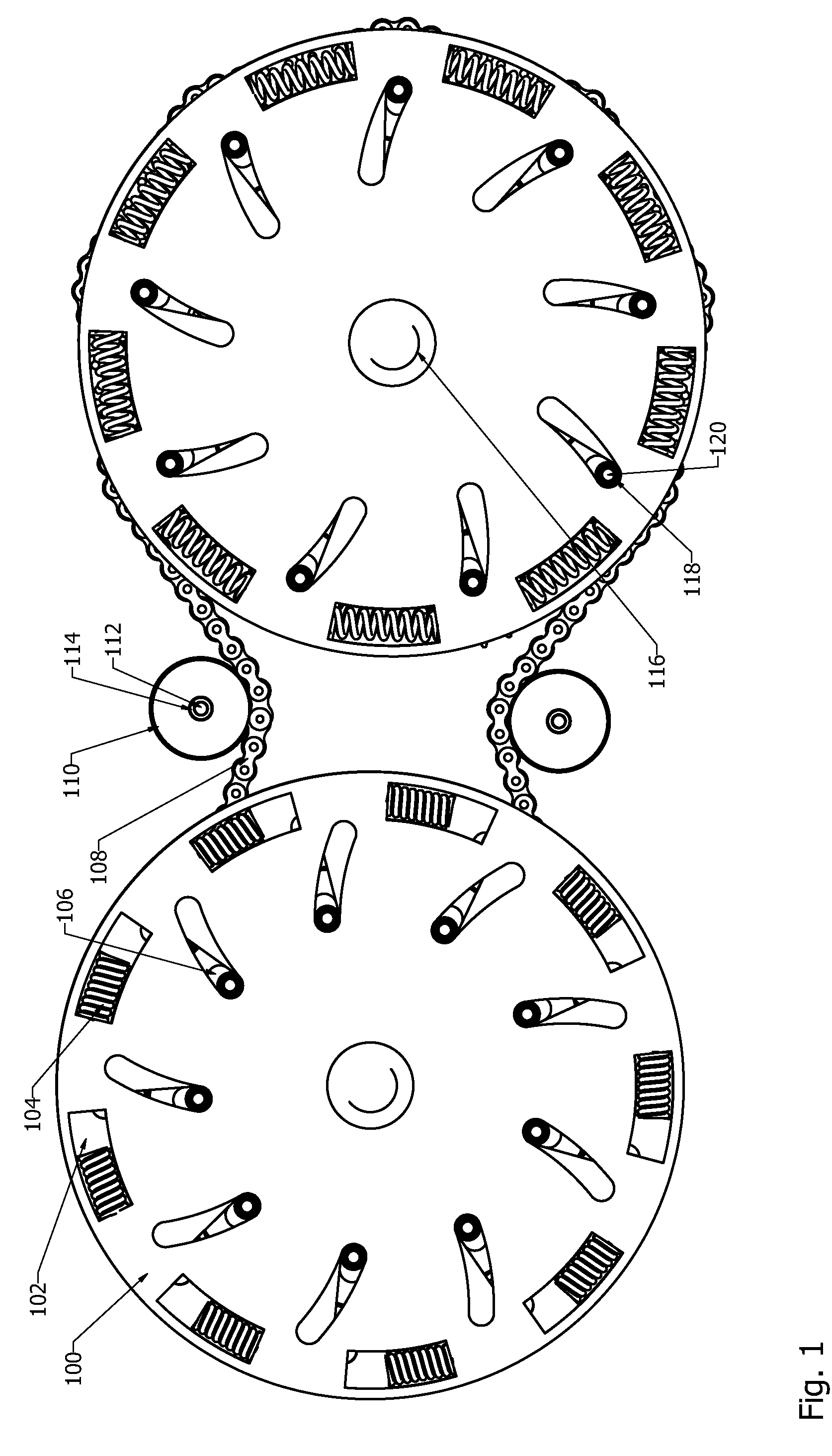

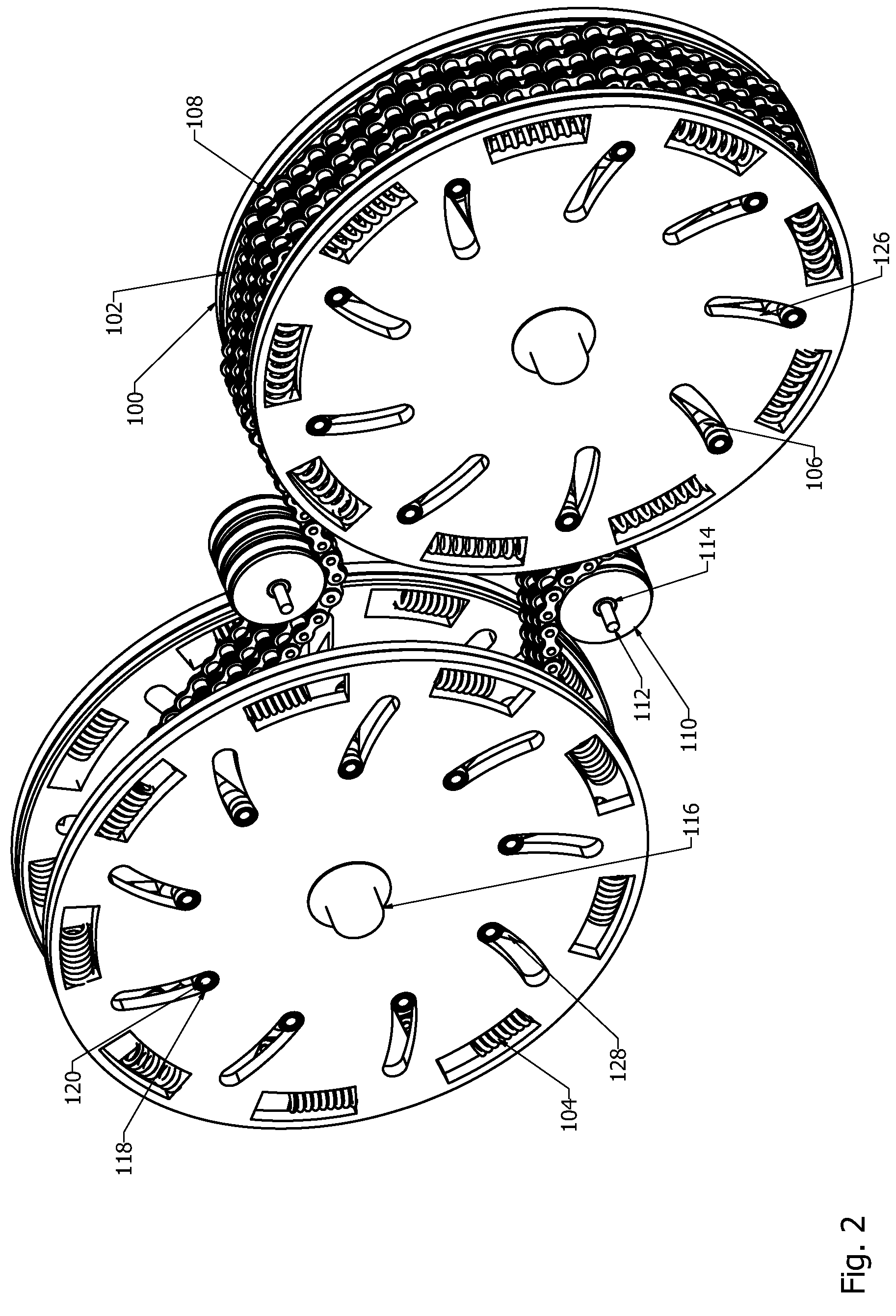

Fixed pitch continuously variable transmission (FPCVT)

A Continuously Variable Transmission (CVT) for use in applications where a transmission is desired to change the speed of the motor relative to the speed of the final drive. The CVT has a set of chains or belts that are mounted around a set of pins set in radially cut slots of a set of spindles so that the pattern of pins are able to expand and contract radially around the CVT axis via these slots. Sprockets that freely spin in either direction unless a chain or belt has fully seated on at least one tooth are arranged on the pins so that only one sprocket engages one chain or belt allowing for smooth ratio changes while the load in engaged. The spindles share a set of springs that act to return the transmission to a higher ratio at moments the load is overcome.

Owner:HAWTHORN KENNETH B

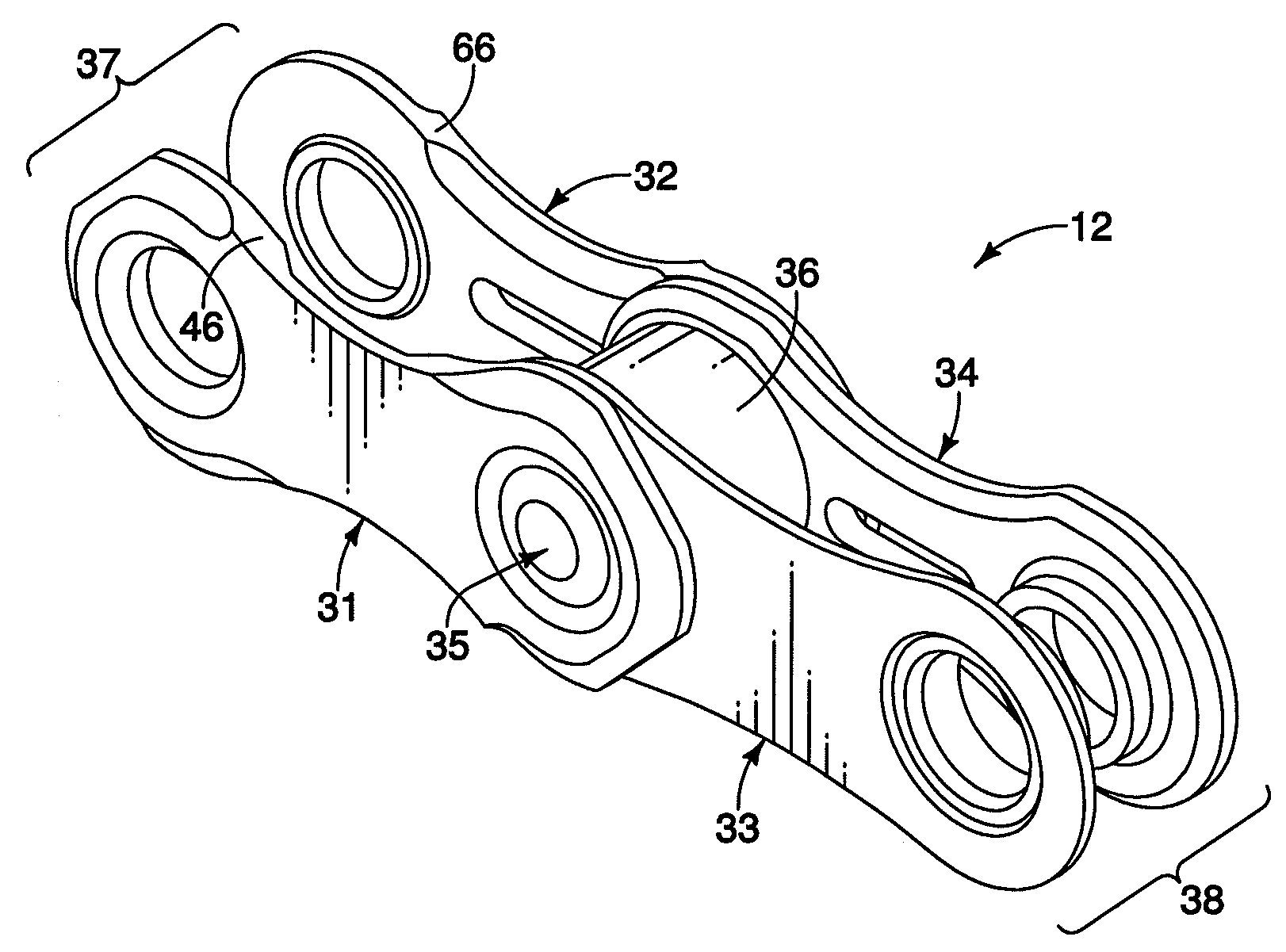

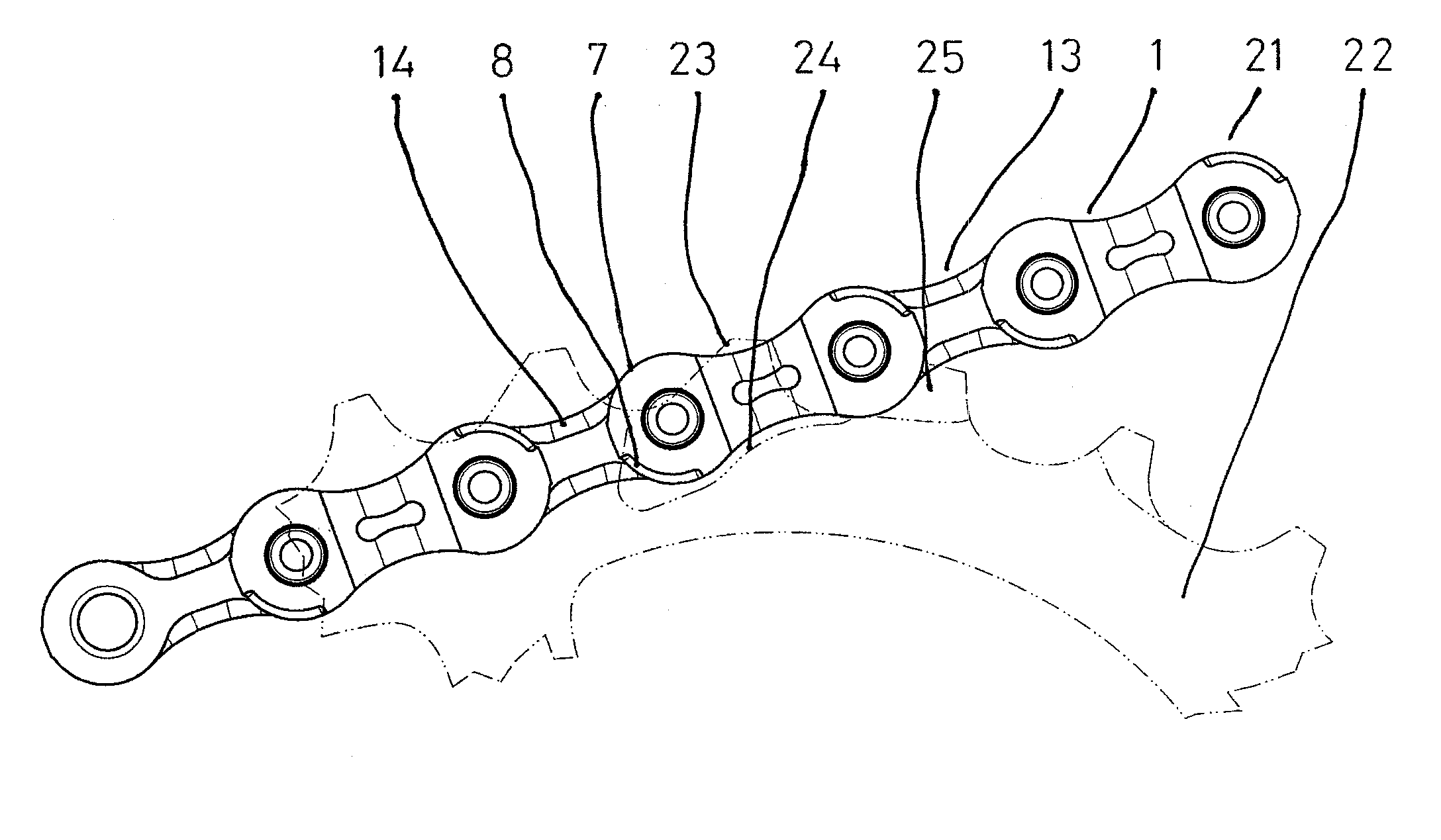

Bicycle chain

A bicycle chain has an outer link with two outer link plates, an inner link formed with two inner link plates and a link pin connecting adjacent ones of the together. The link plates are configured to aid in smoothly shifting a chain moves between sprockets. The outer link plates have the outer link peripheral edges that are shaped differently. One of the outer link plates has an exteriorly facing surface with a first chamfered outer edge portion extending along a section of its outer link peripheral edge at a first end portion and a first reduced area part having a reduced radial dimension with respect to a radial dimension of the first end portion lying along a longitudinal axis. The inner link plates have center connecting portions with different minimum widths.

Owner:SHIMANO INC

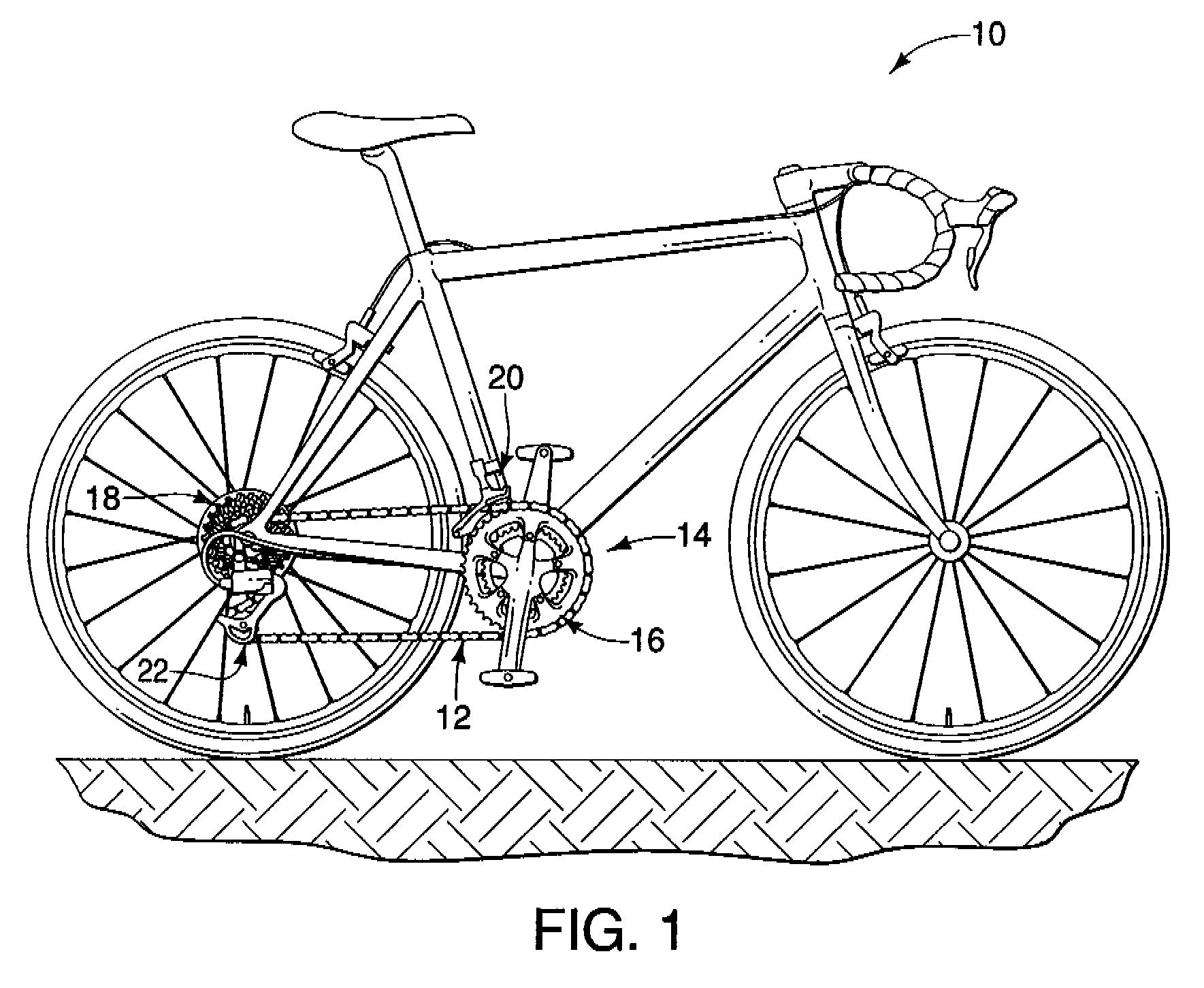

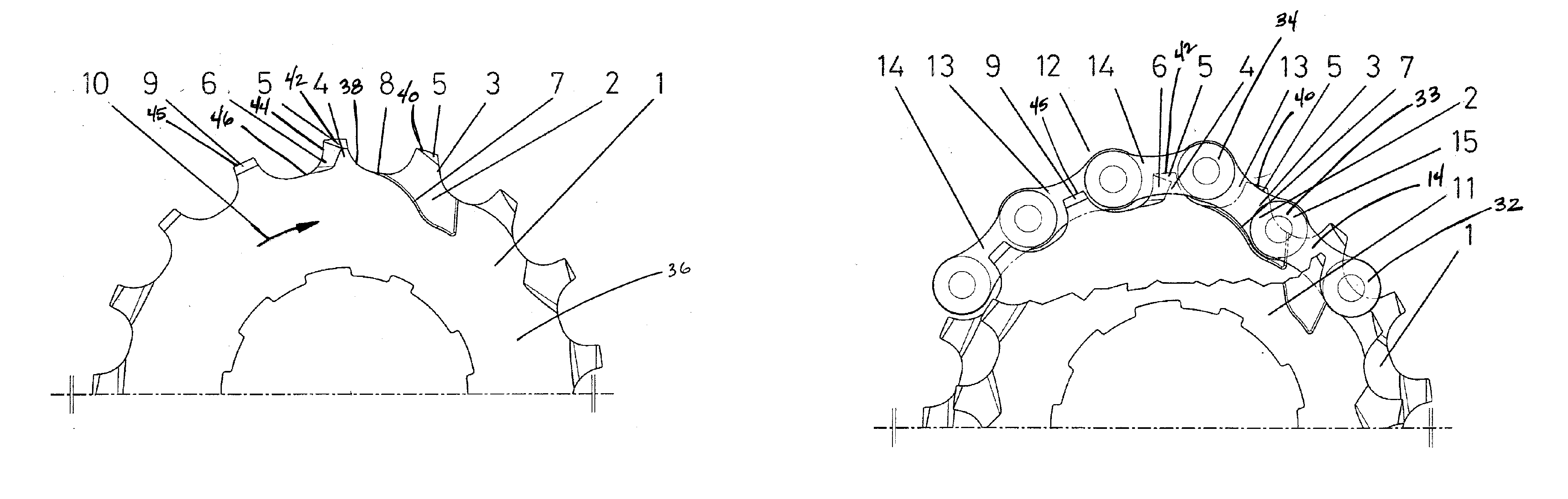

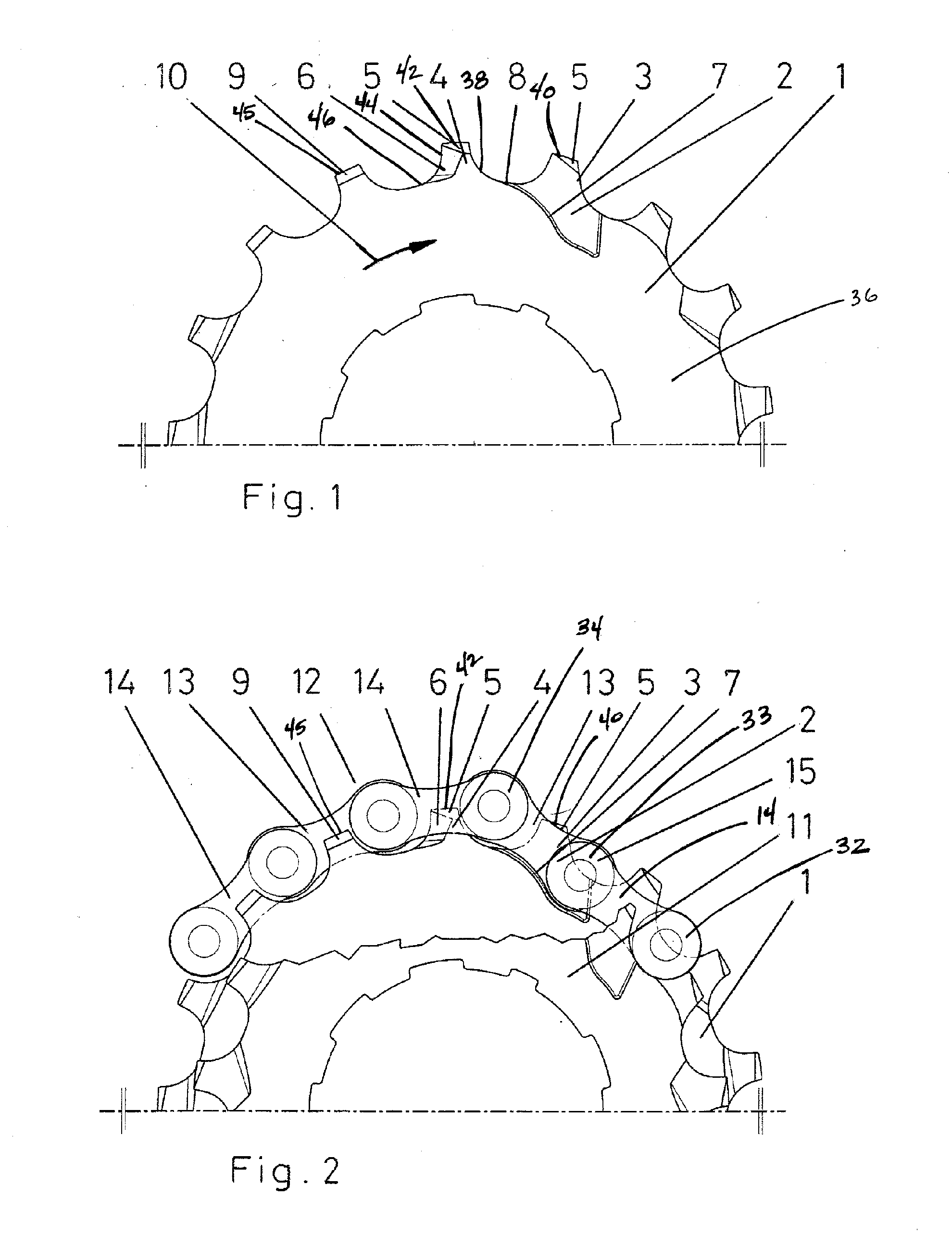

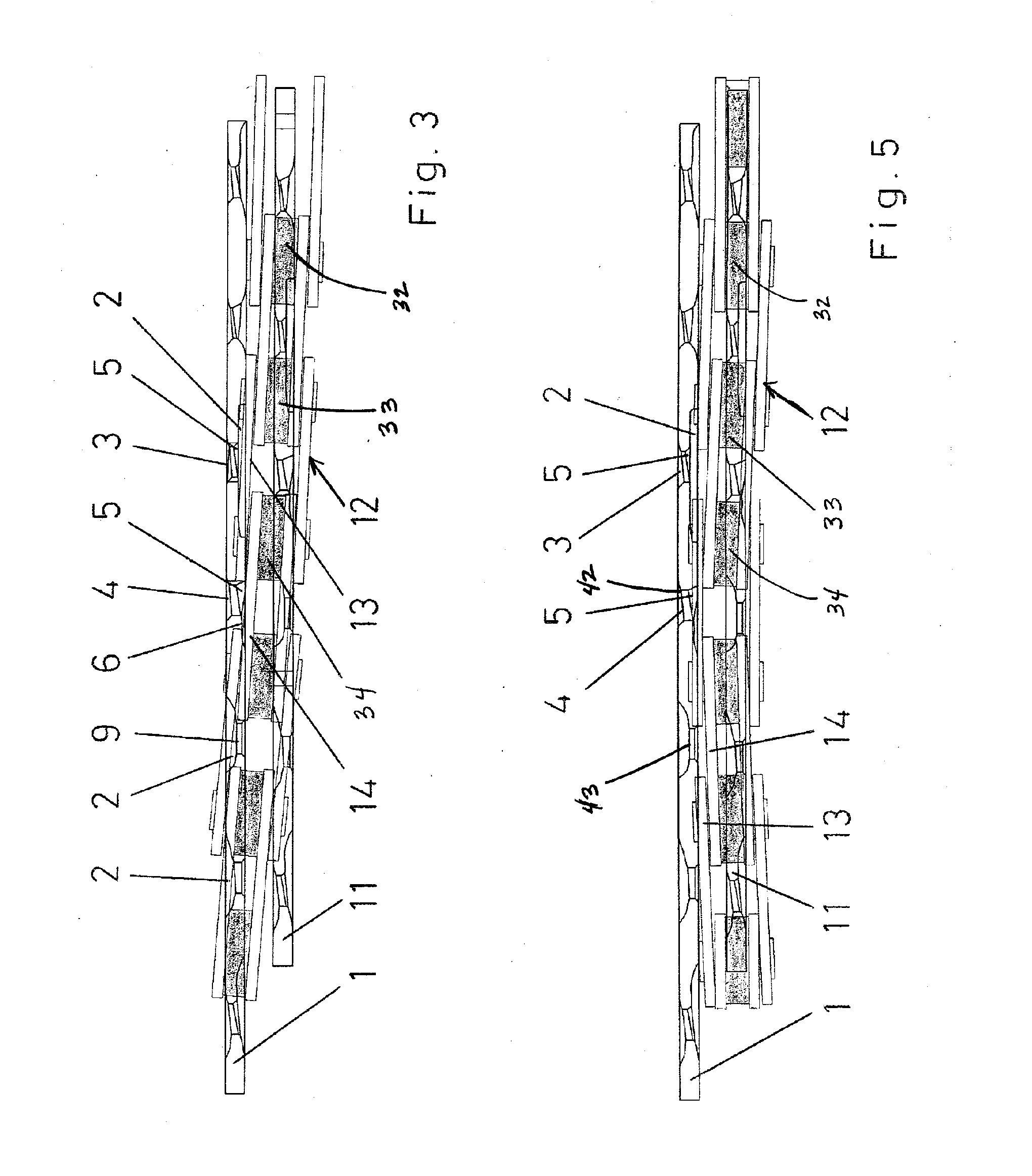

Low-noise chainwheel

ActiveUS20050079940A1Eliminates orReduce noiseChain/belt transmissionPortable liftingLow noiseSprocket

A bicycle chainwheel assembly that includes at least one smaller chainwheel and at least one larger chainwheel, the chainwheels engageable by a chain. The larger chainwheel includes a first tooth and a second tooth disposed adjacent the first tooth opposite a drive rotation direction. The first tooth and the second tooth have a configuration that improves the shifting of a chain from a smaller chainwheel to the larger chainwheel. The first tooth has a lateral recess and the second tooth has a deflection chamfer. The second tooth may also have a recess. The first and second teeth have a configuration that prevents the first and second teeth from capturing the chain. An inner link plate of the chain includes a chamfer disposed on an outer side surface in a central region of the plate.

Owner:SRAM +1

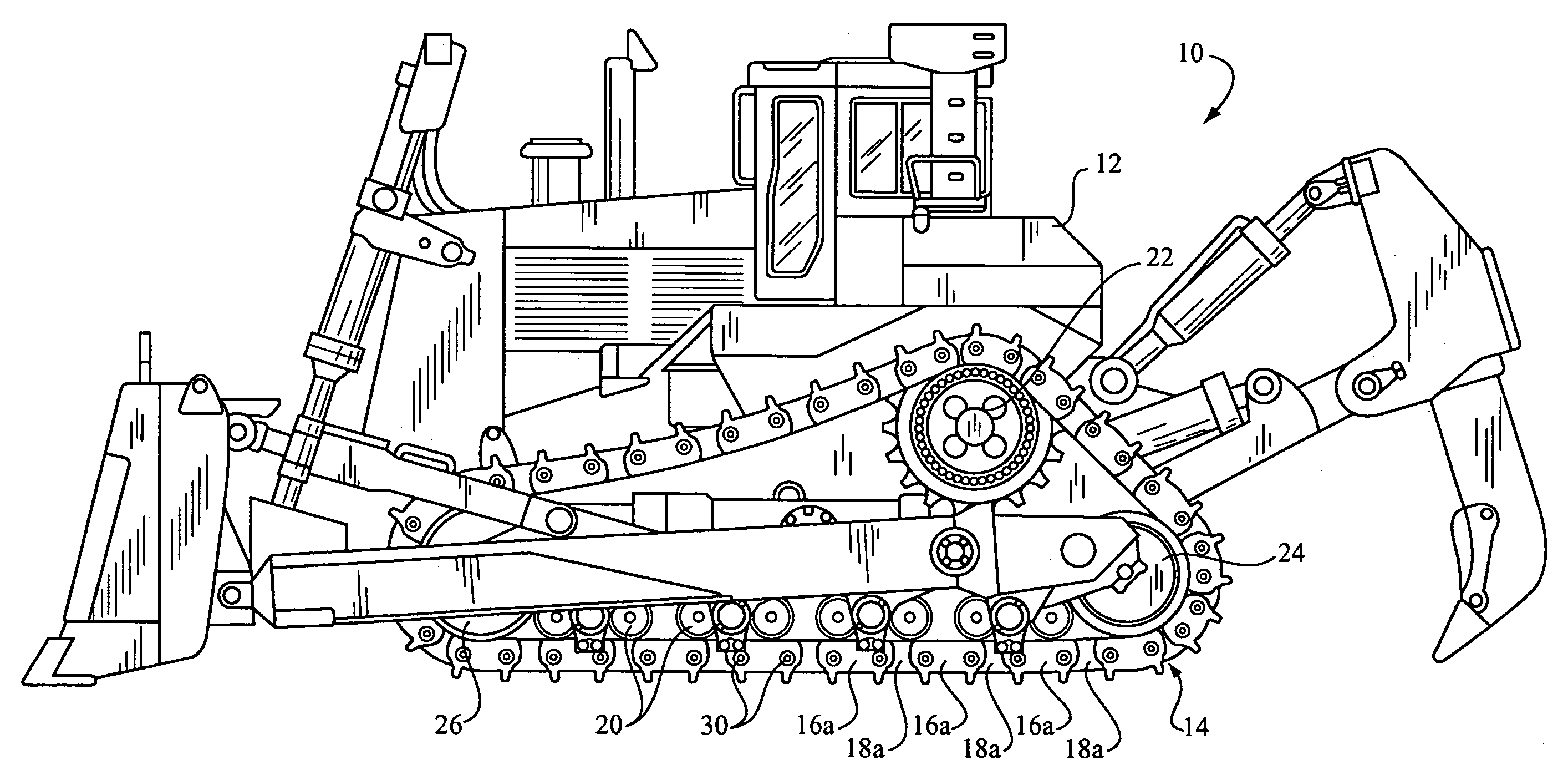

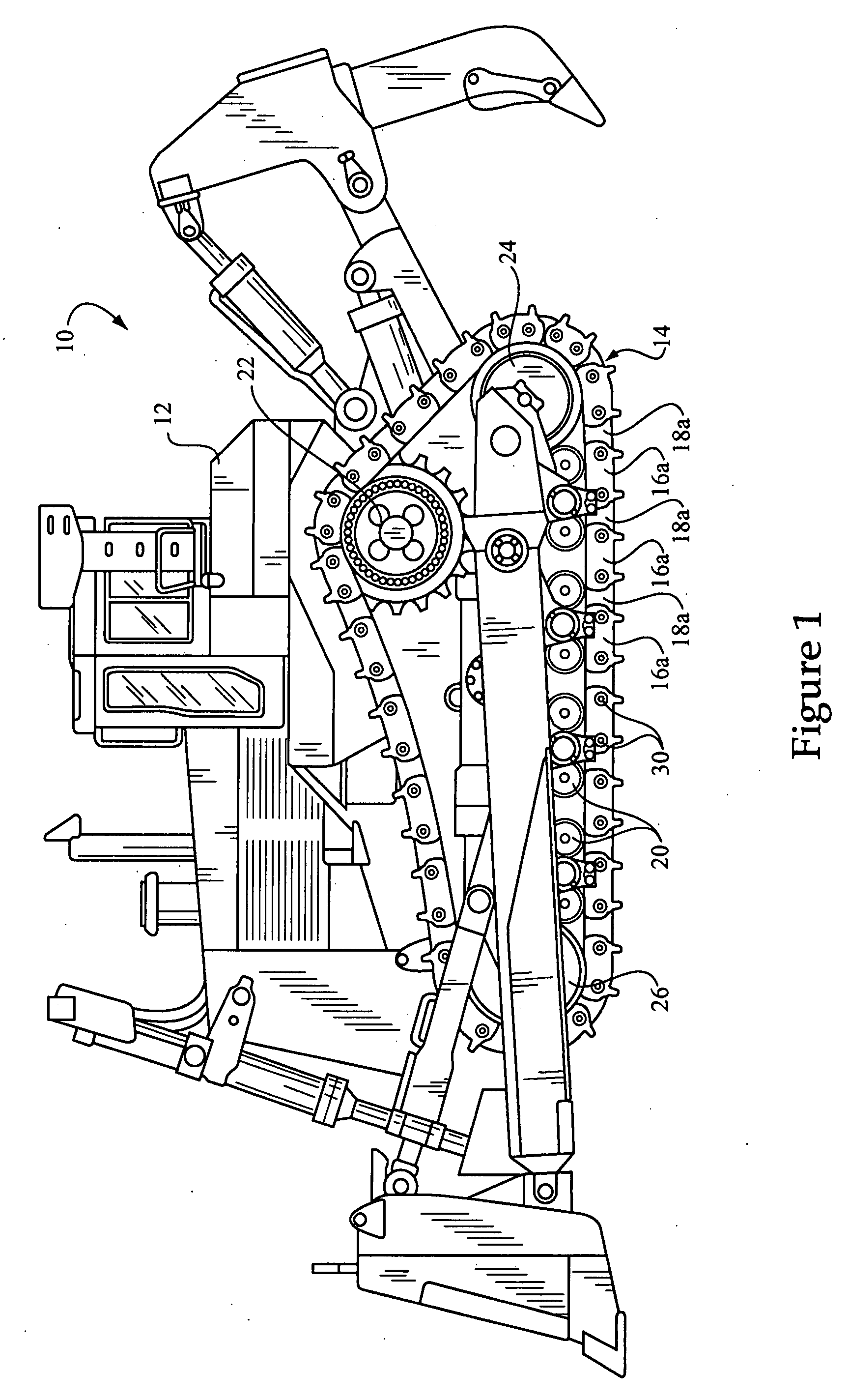

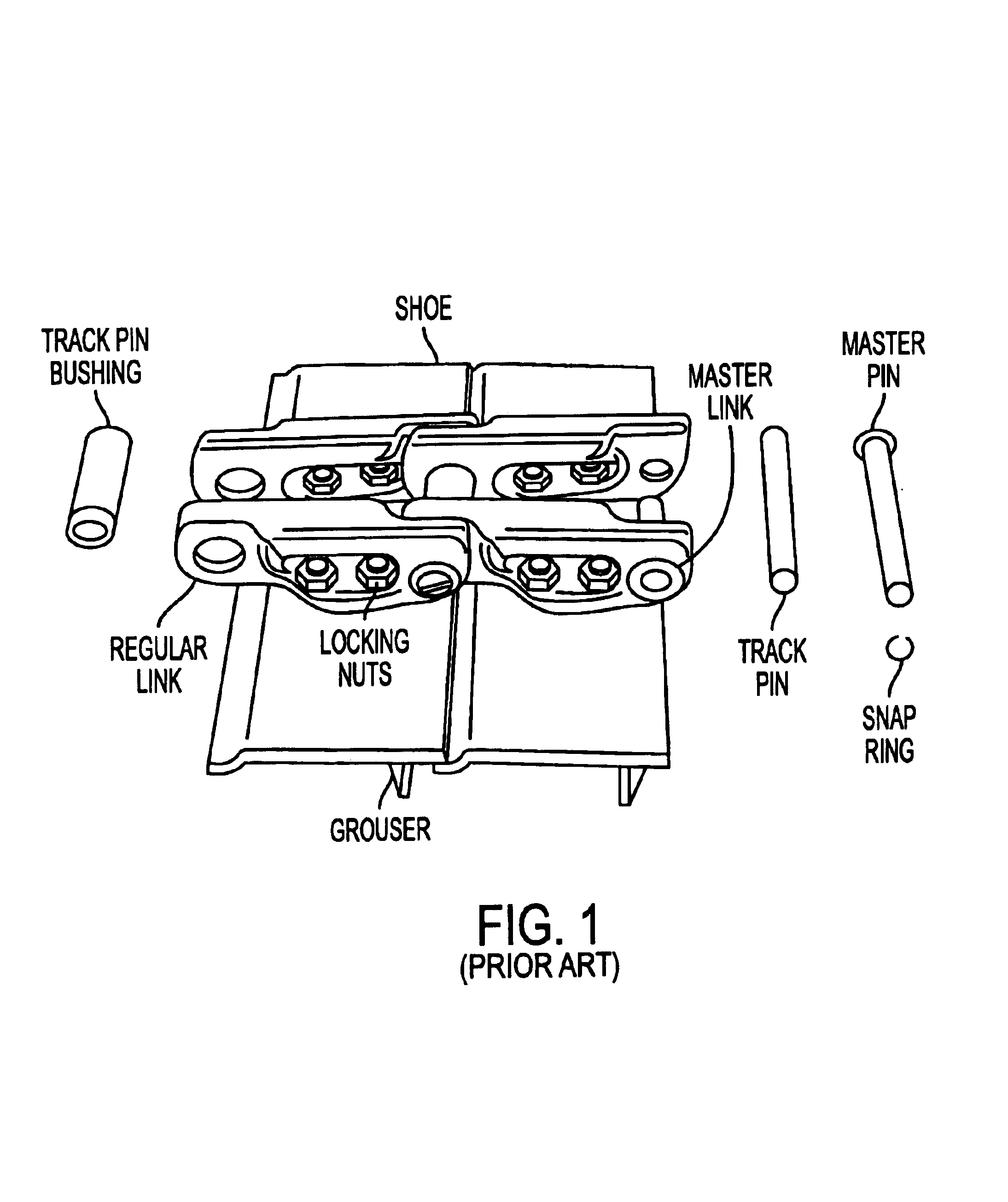

Bolt together machine track and method

A machine includes a bolt together track having sets of straight track links positioned in parallel and coupled via at least one pin. Retainer assemblies for the first and second sets of track links include at least one keeper engageable with the at least one pin and a keeper retainer configured to rotationally interlock with the track segment via threads, to inhibit disassembly of the keepers from the at least one pin. An assembly method for a machine track segment includes positioning first and second sets of track links on at least one pin, installing keepers on the at least one pin and inhibiting disassembly of the links by interlocking keeper retainers with the machine track segment, for instance rotationally interlocking the keeper retainers via external threads with threaded bores in the track links.

Owner:CATERPILLAR INC

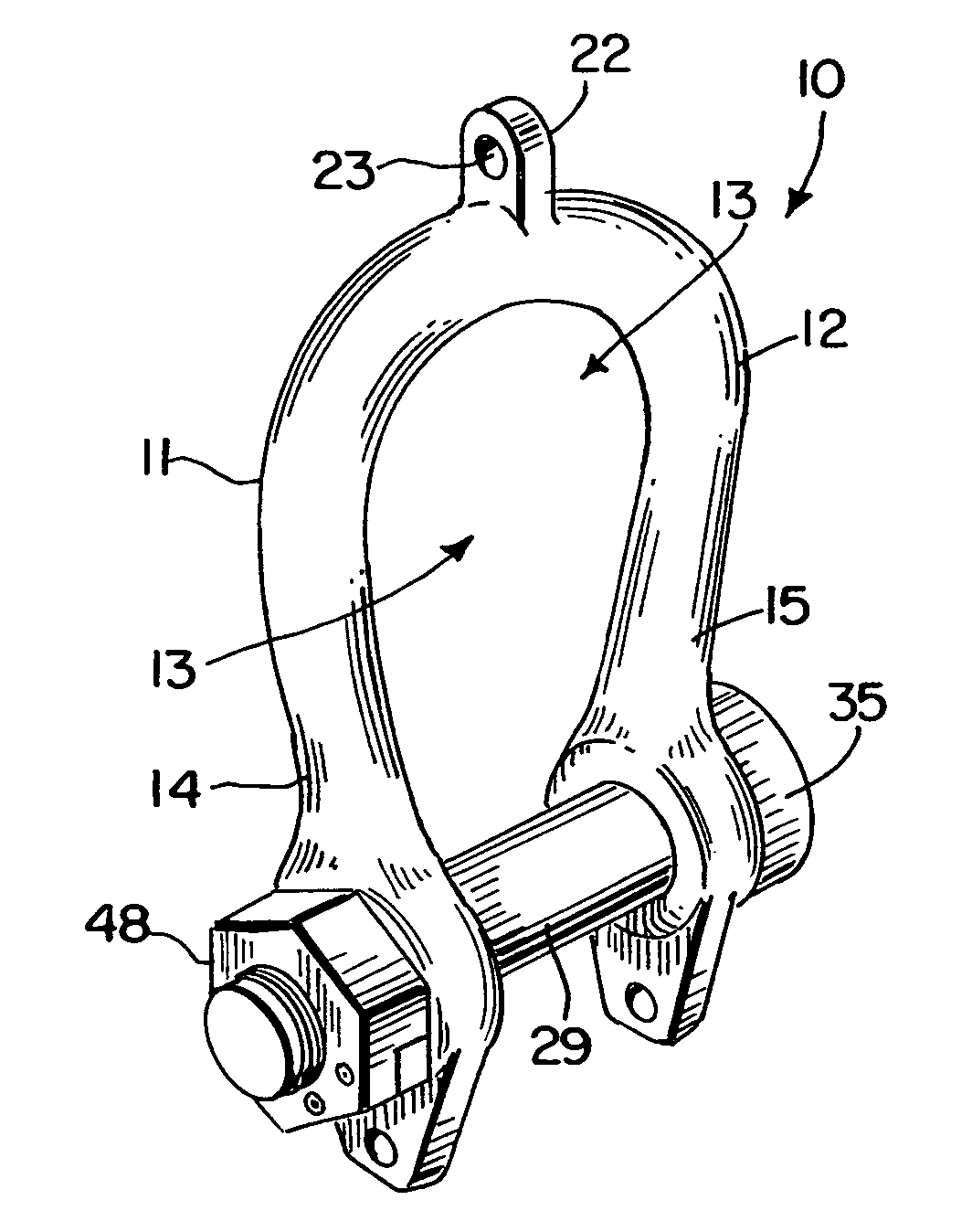

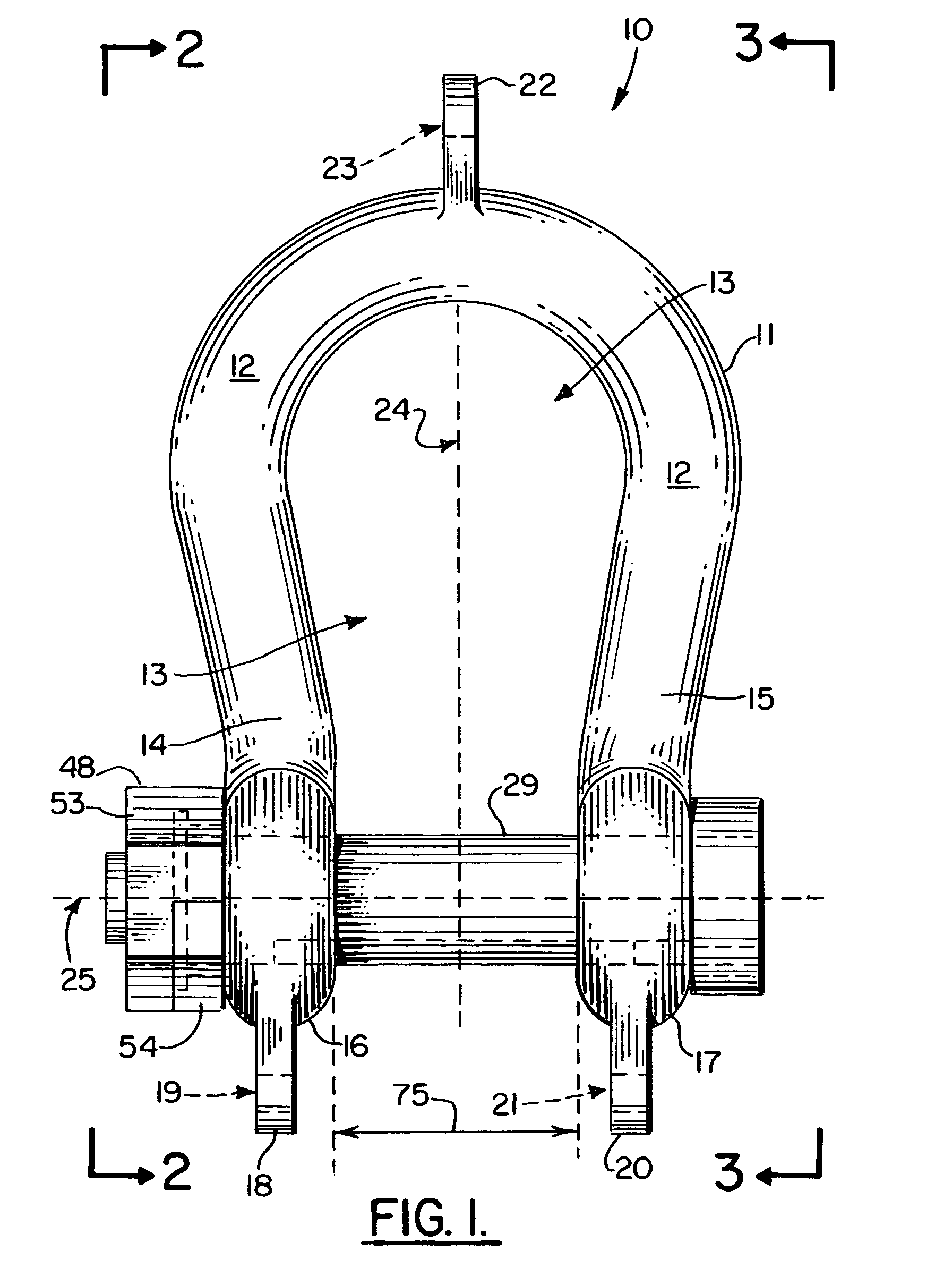

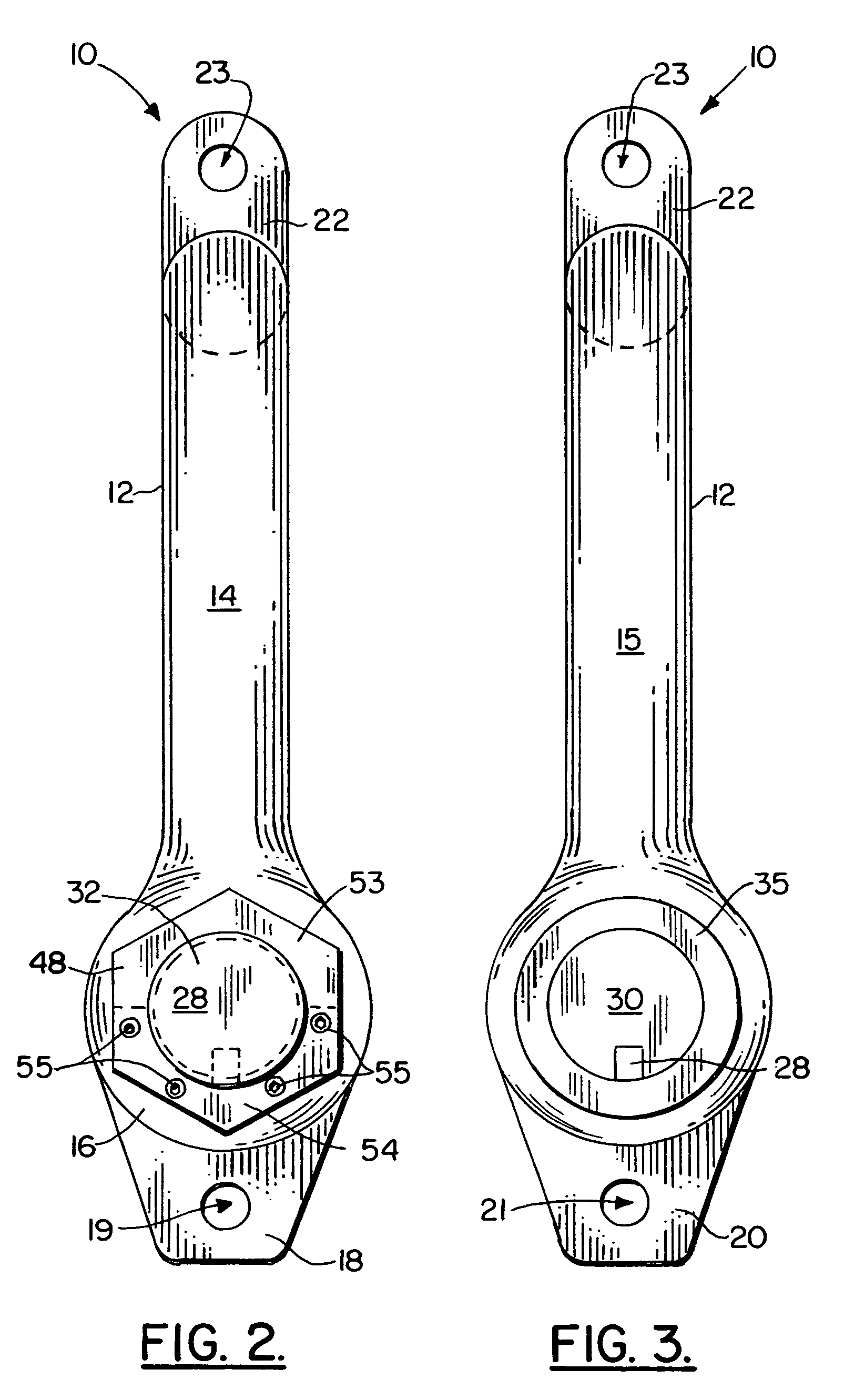

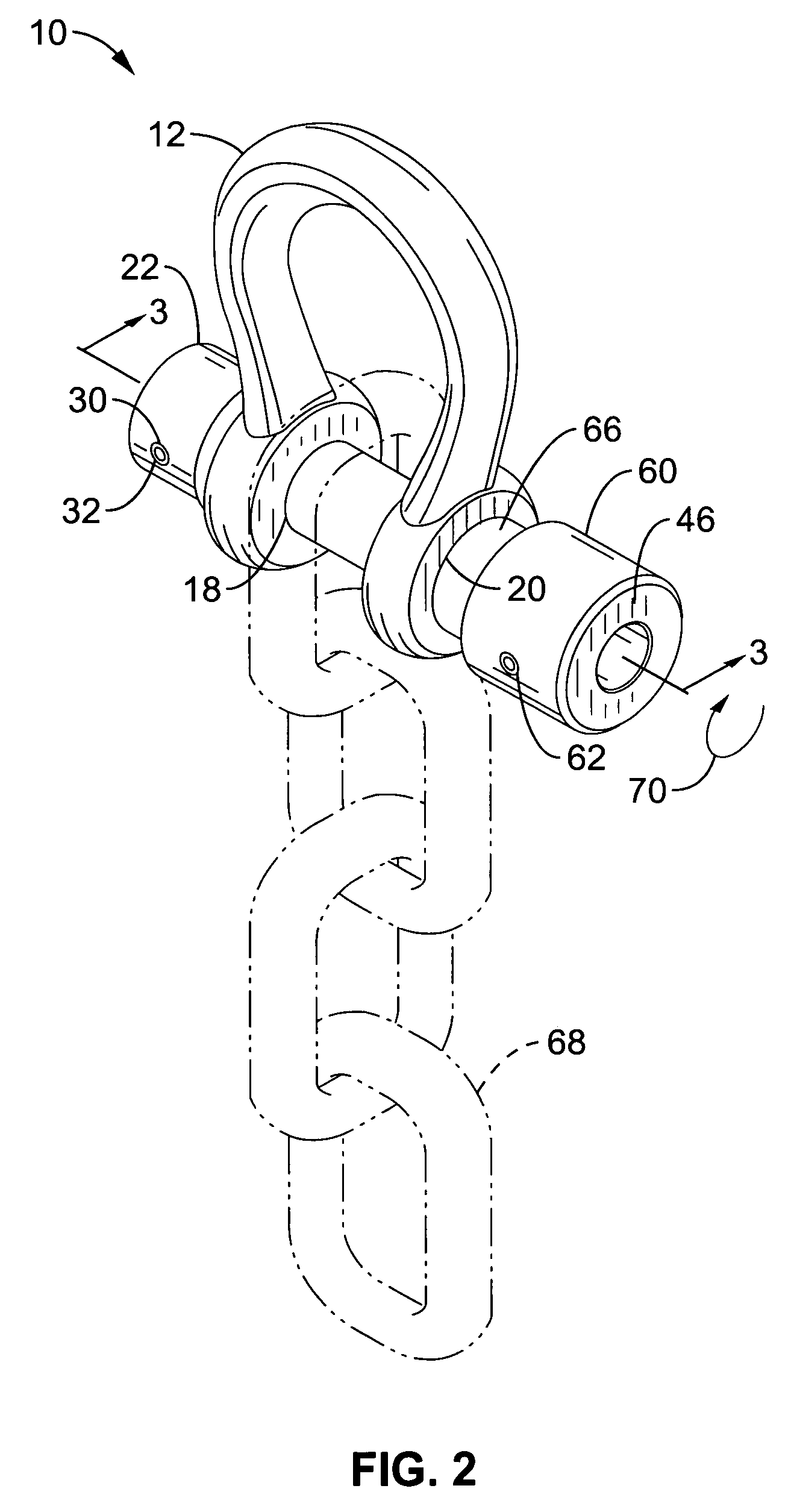

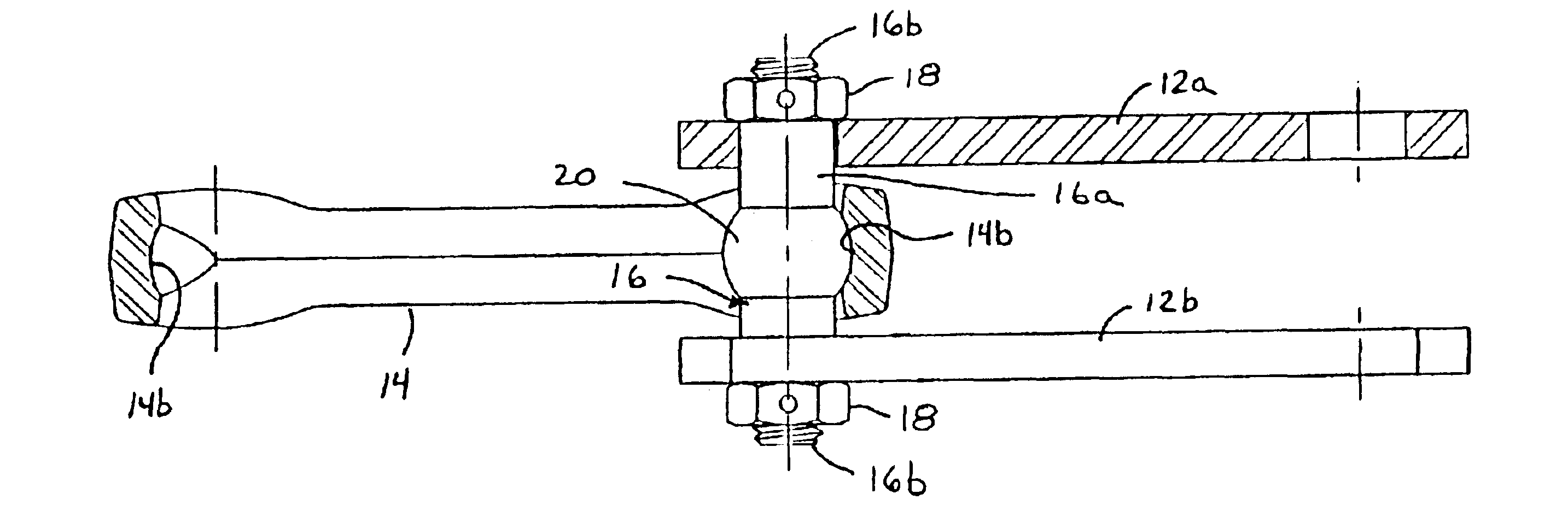

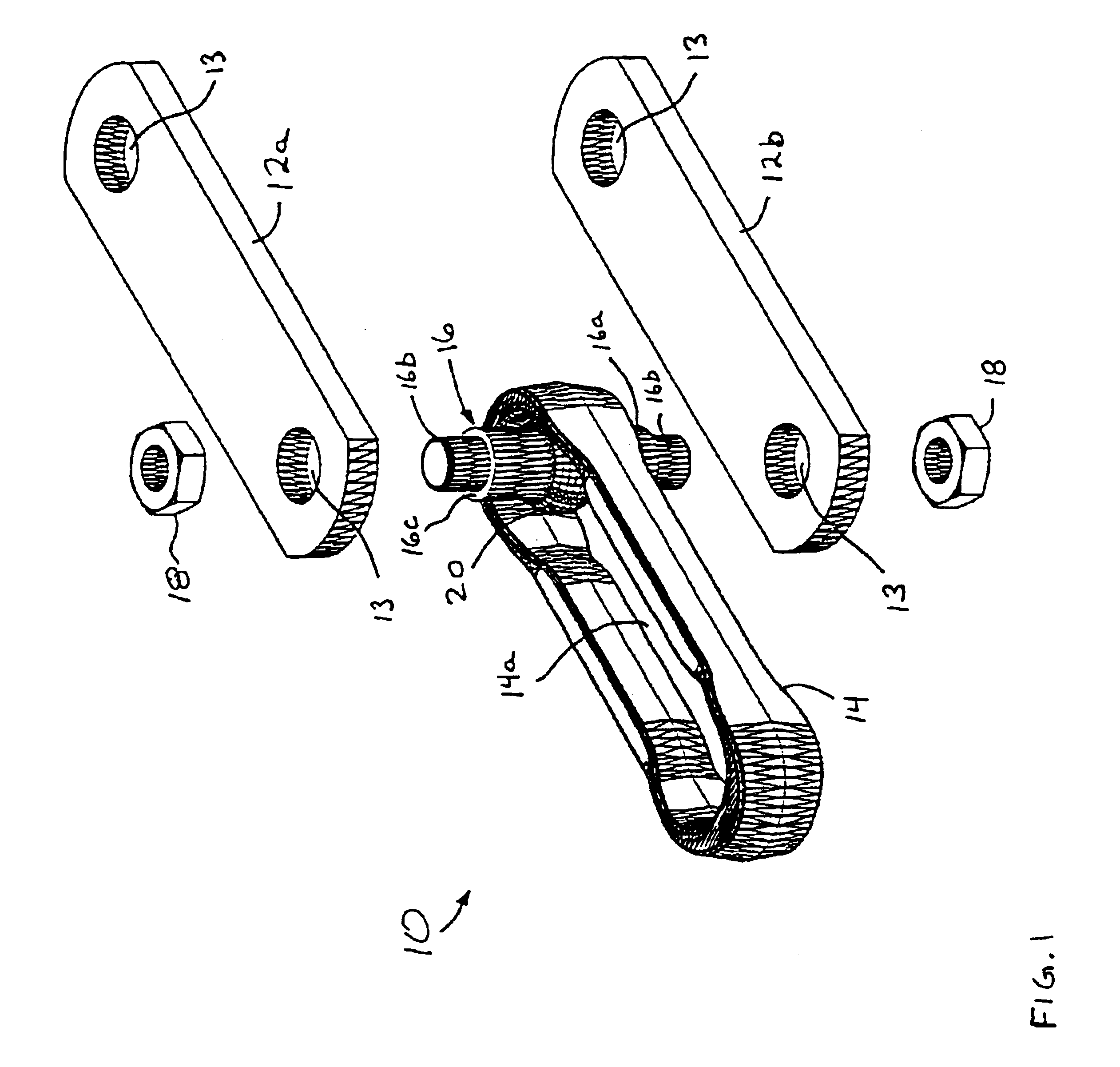

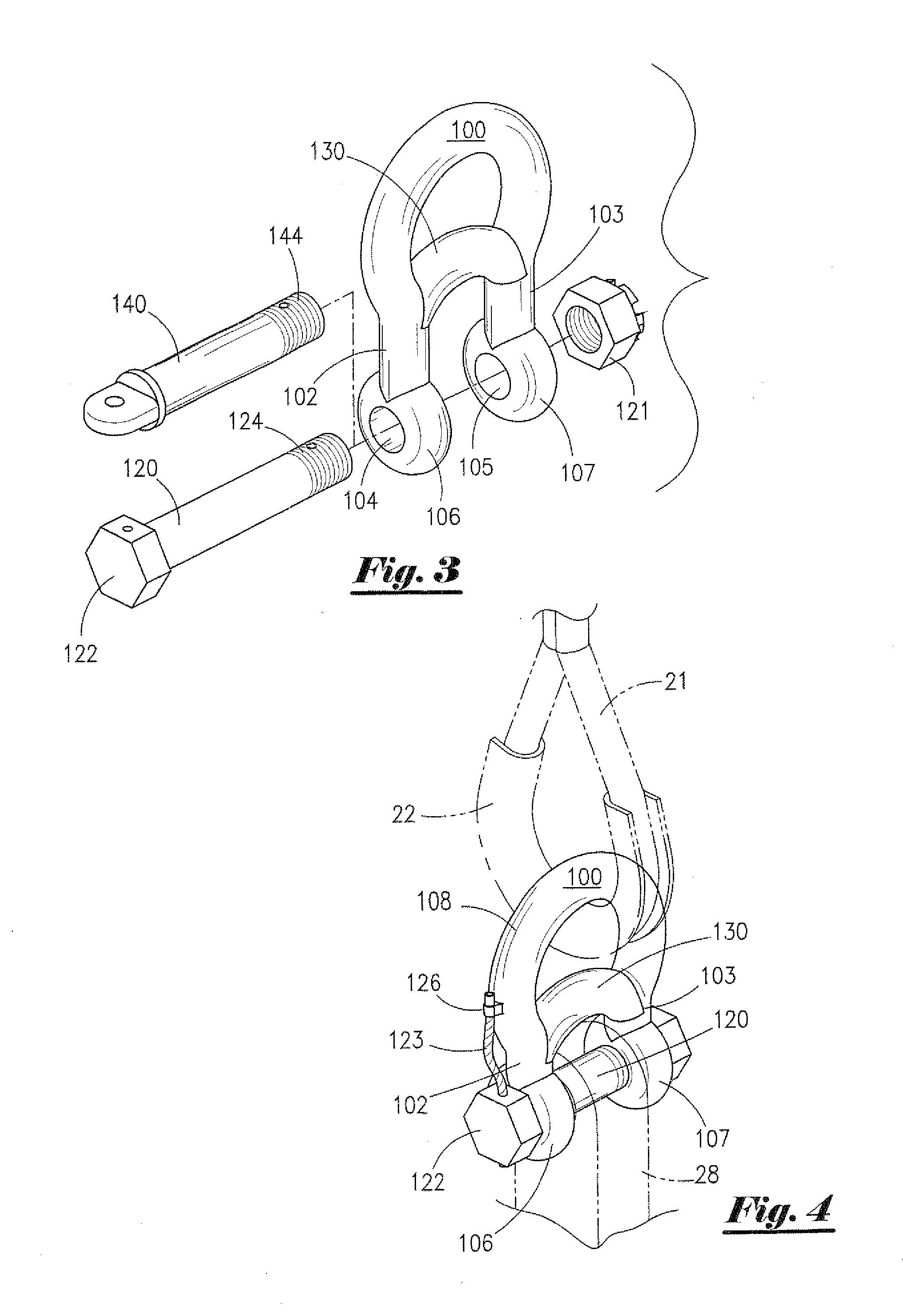

Shackle

The present invention provides an improved shackle having particular utility in underwater salvage operations. The present invention discloses a shackle that has a generally U shaped body that is comprised of a bow portion and first and second spaced apart arms. Each arm has an end portion with an opening for receiving a shackle pin. The shackle pin is sized and shaped to simultaneously fit through the shackle pin openings, and end portion of the pin having external pin threads. A nut provides an internally threaded opening for engaging external threads of a shackle pin. The nut is rotatably mounted to a second end portion of the shackle body. The external pin threads of the shackle pin and the internal threads of the nut are engaged when the pin is connected to the nut by rotating the nut. The pin does not rotate relative to the shackle body, due to an elongated groove in the pin that travels on a key portion of the shackle body that is in one of the openings.

Owner:BISSO IV WILLIAM A

Sliding structure for automotive engine

InactiveUS6886521B2Preventing cracking and separationReduce coefficient of frictionPiston ringsMolten spray coatingCarbon filmPiston ring

A sliding structure for an automotive engine includes a sliding member with a sliding portion and a lubricant applied to the sliding portion so that the sliding portion can make sliding contact with a counterpart member via the lubricant. The sliding member is either of a piston ring, a piston pin, a cam lobe, a cam journal, a plain bearing, a rotary vane and a timing chain. The sliding portion has a base made of a steel or aluminum material and a hard carbon film formed on the base to coat the sliding portion. The hard carbon film has a thickness of 0.3 to 2.0 mum, a Knoop hardness of 1500 to 4500 kg / mm2, a surface roughness Ry (mum) satisfying the following equation: Ry<{(0.75-Hk / 8000)xh+0.07 / 0.8}, where h is the thickness (mum) of the film; and Hk is the Knoop hardness (kg / mm2) of the film.

Owner:NISSAN MOTOR CO LTD

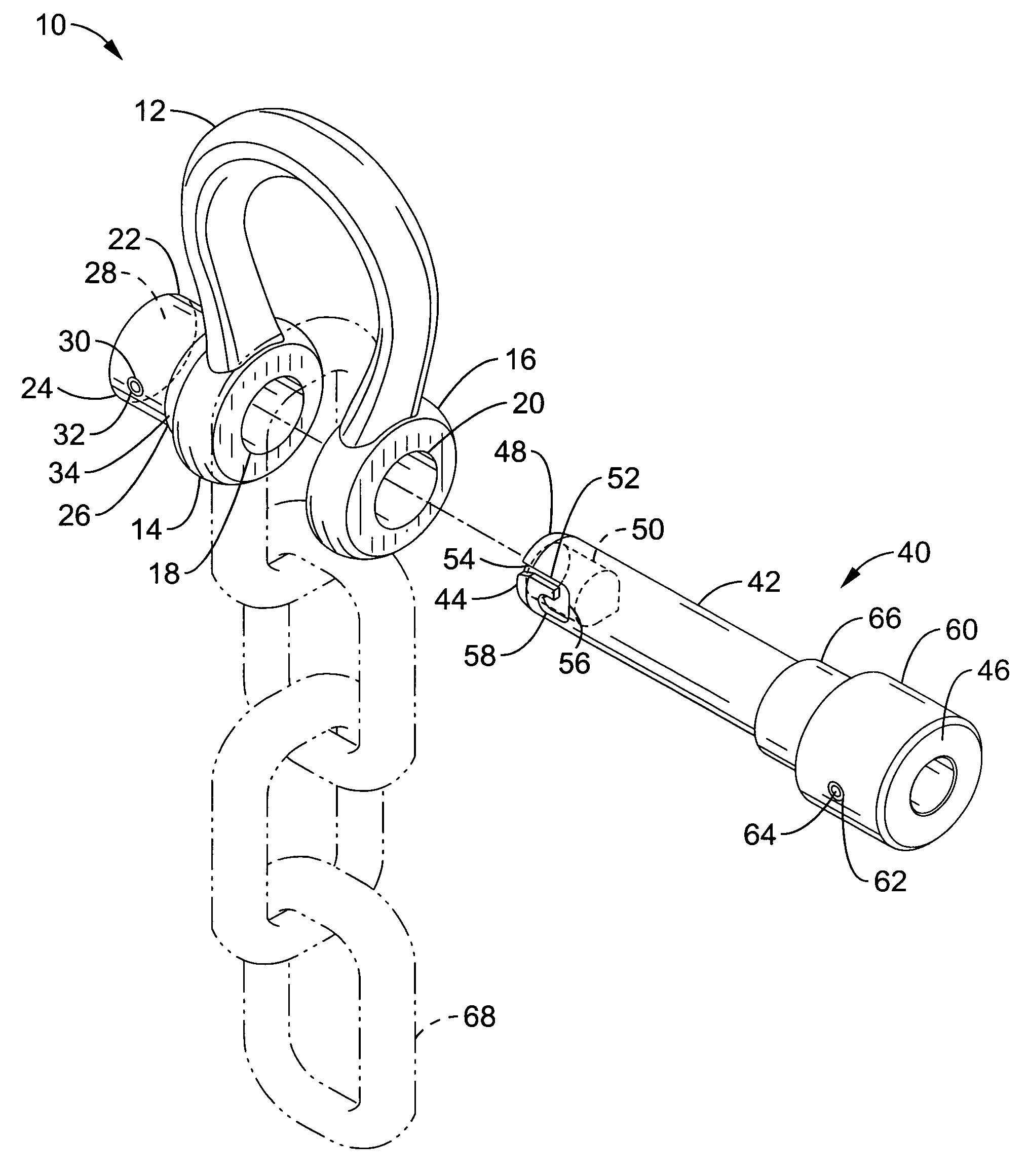

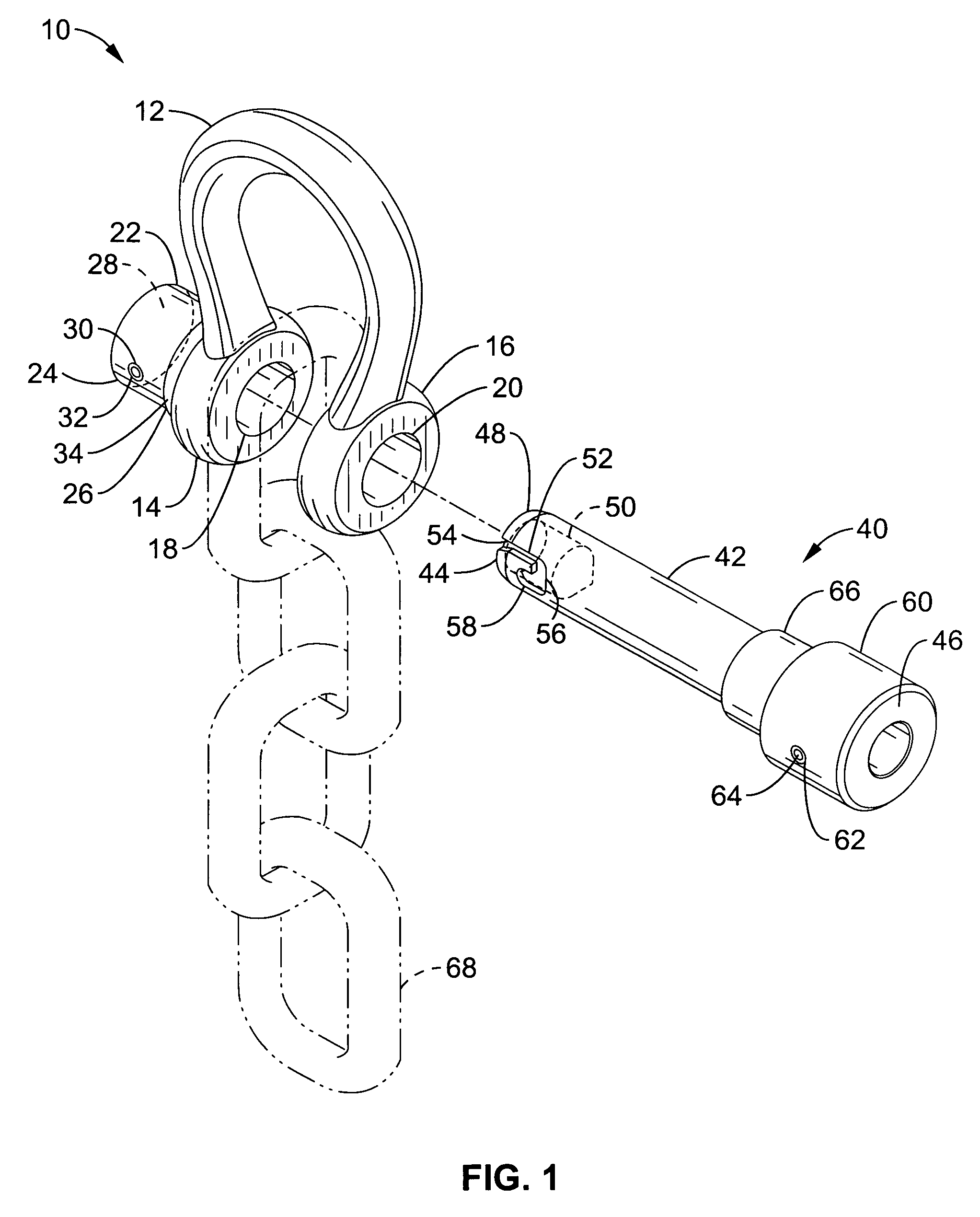

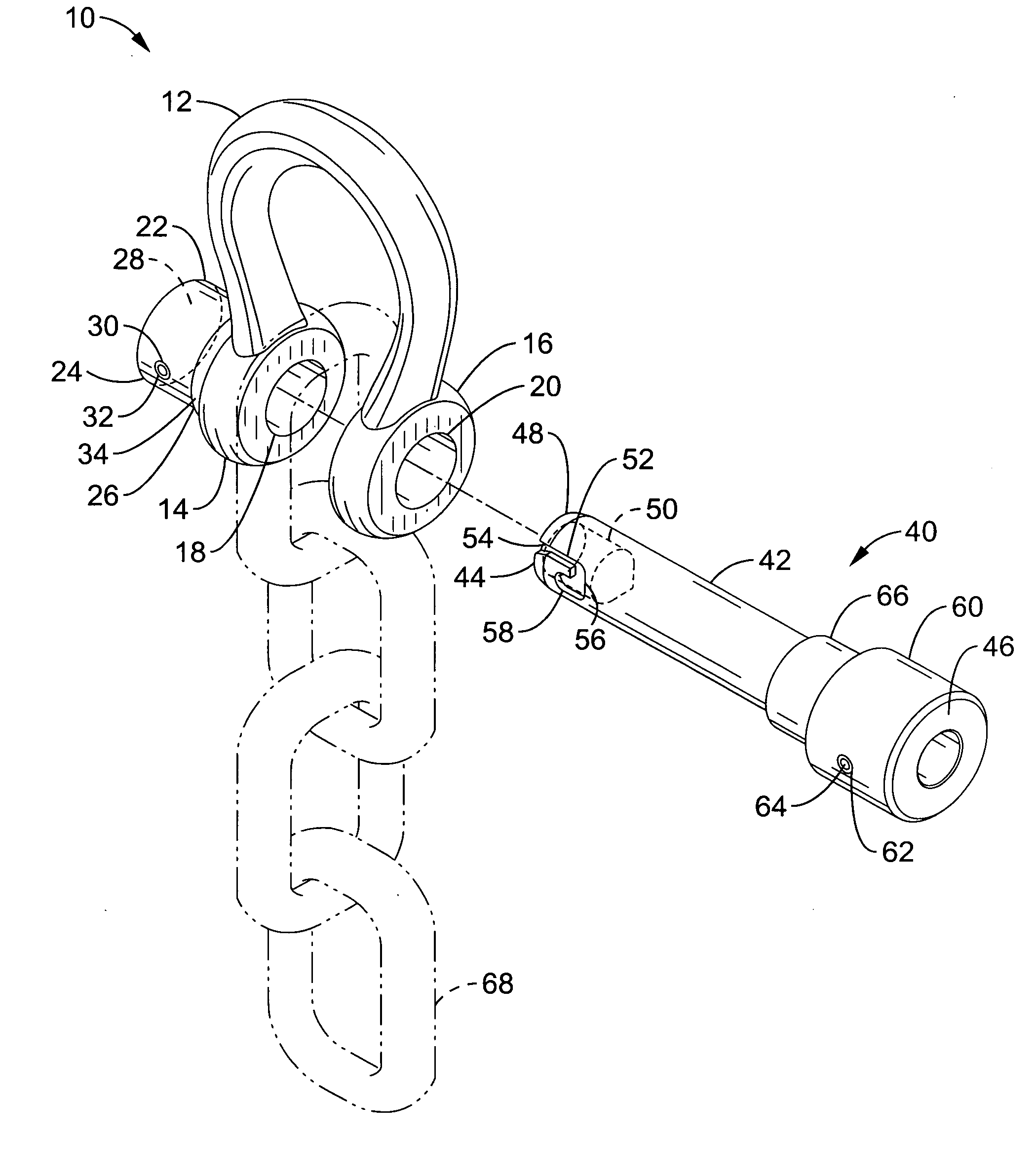

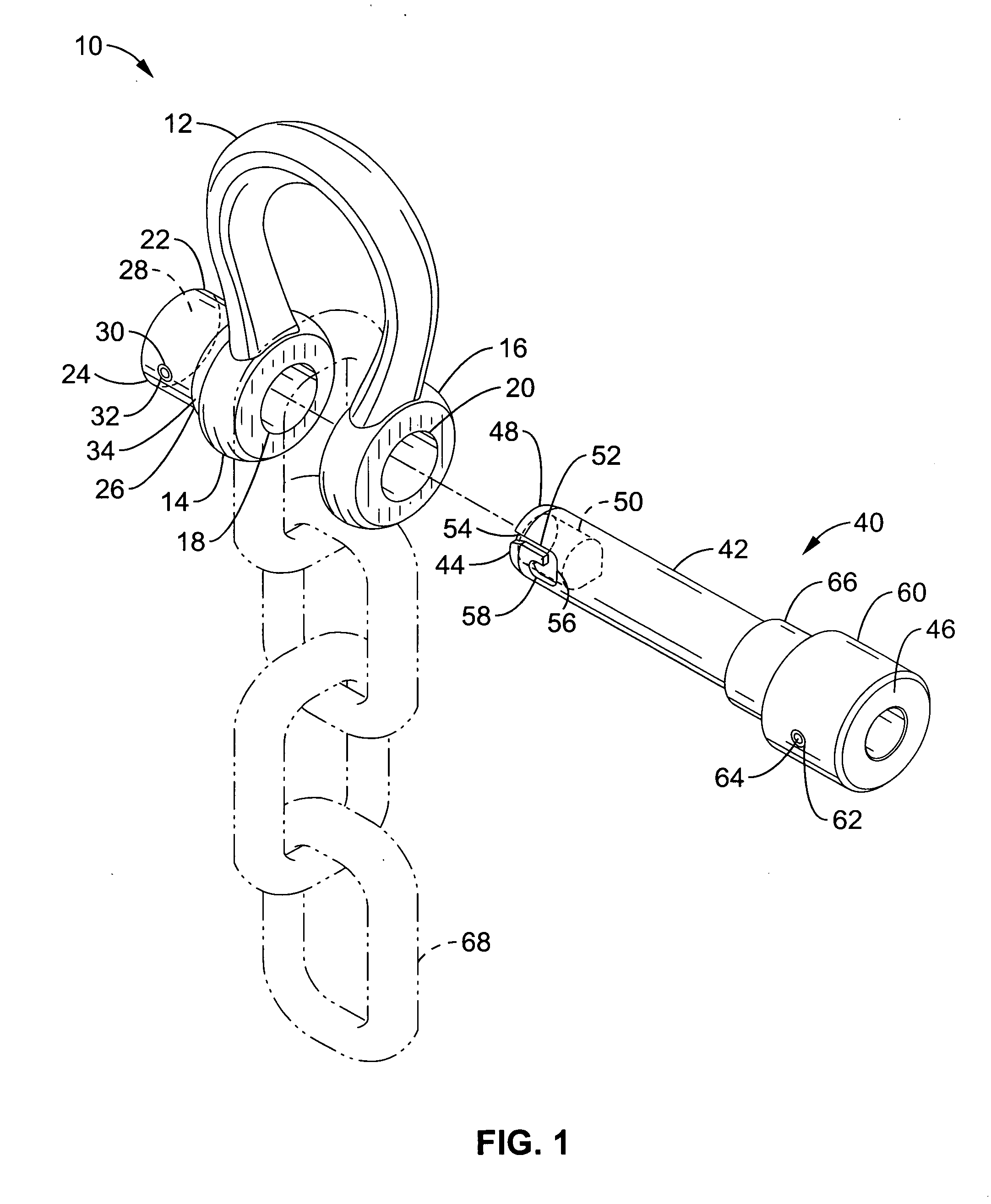

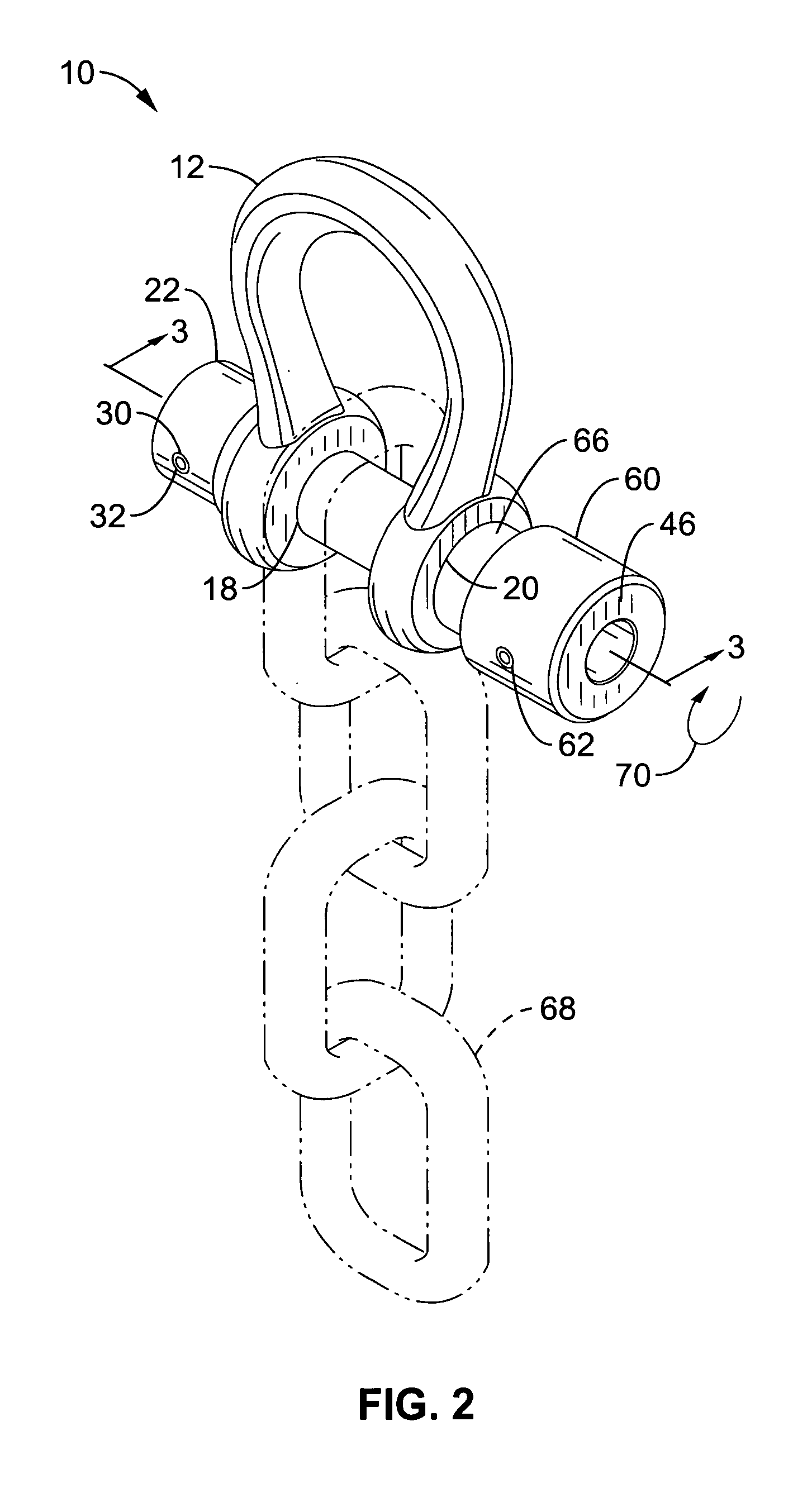

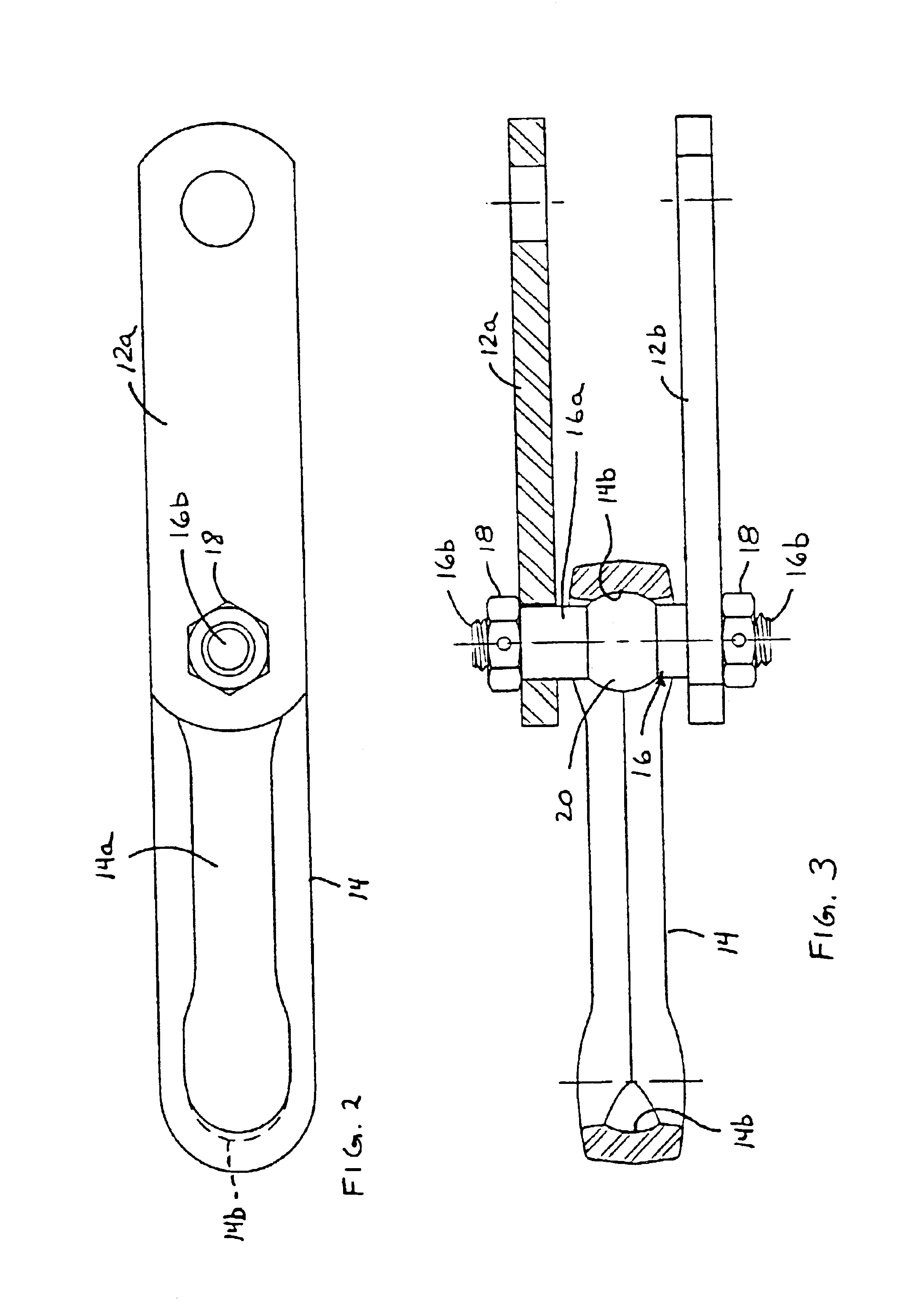

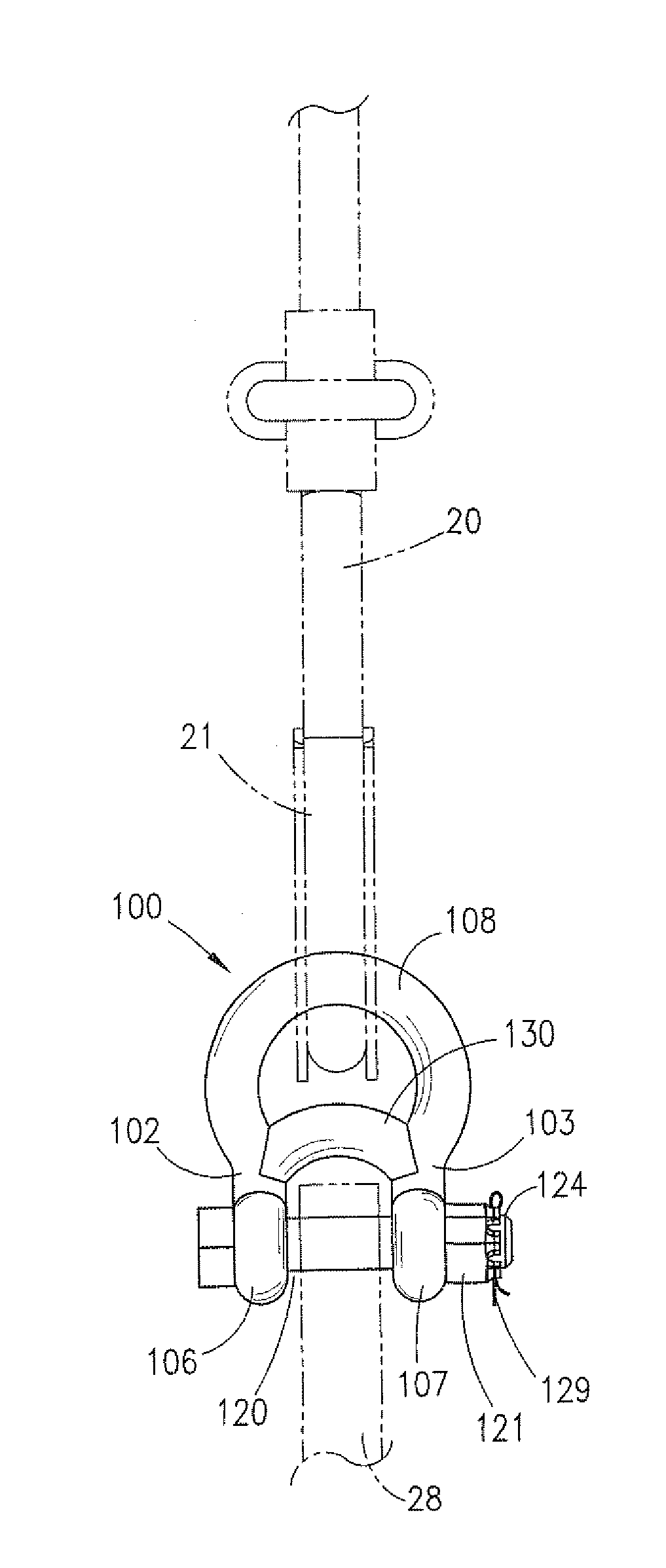

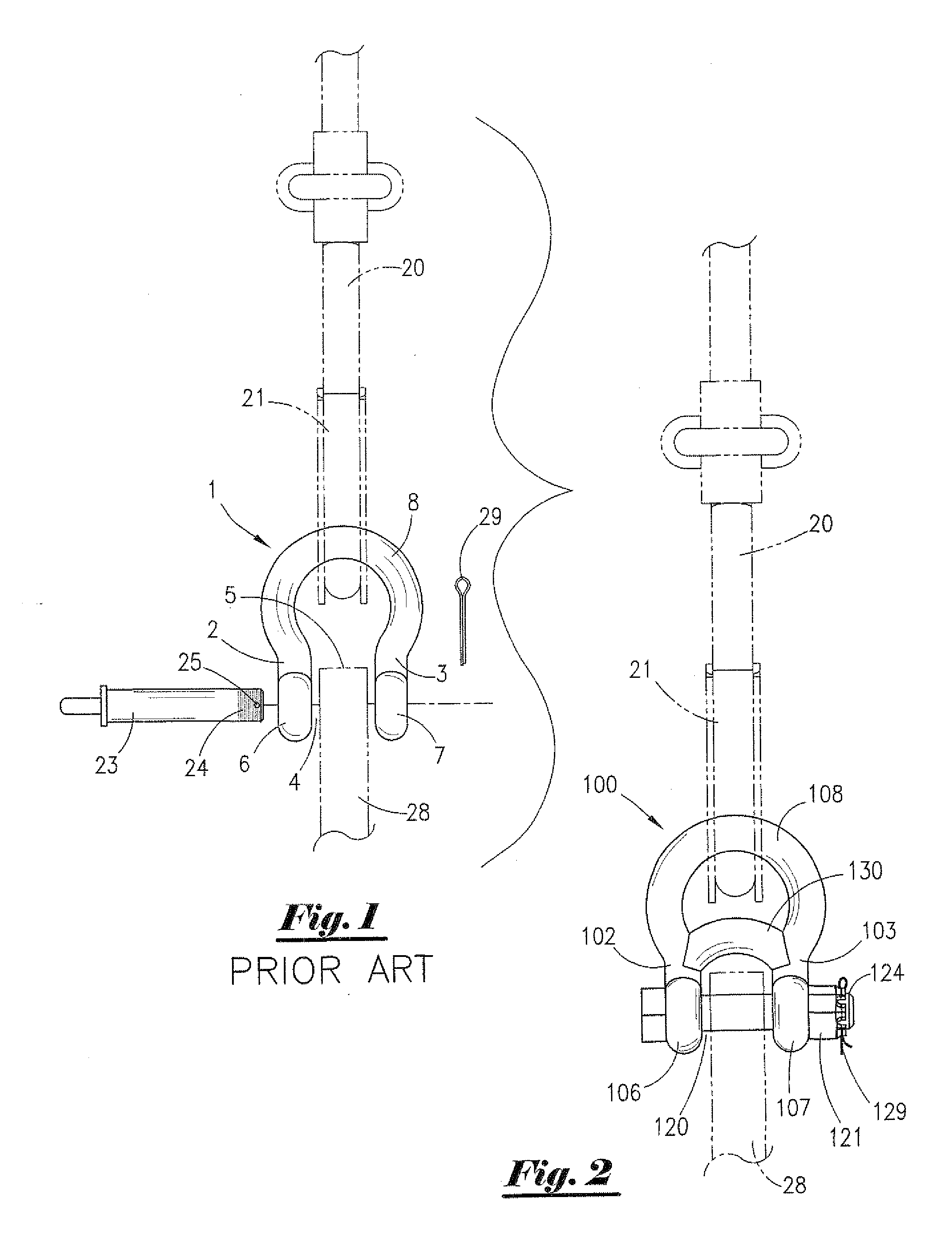

Quick release shackle pin system

A spring loaded quick release pin and tubular receiver with a retainer pin configured to secure the quick release pin in a shackle, clevis, yoke or forked rod end. The receiver is welded to a shackle or cast with the shackle as a single body. One end of the quick release pin has aligned J slots that engage the retainer pin positioned in the receiver with a clockwise twist. The other end of the quick release pin has a cap and a spring loaded sleeve that biases the cross pin against outside of the second leg of the shackle. The spring bias keeps the short leg of the J slot engaged with the retaining pin. The quick release pin is removed with a push and counter clockwise twist. The invention includes a kit with a receiver, a bushing and a quick release pin for installing or retrofitting existing shackles.

Owner:SILVA FRED

Conveyor chain

InactiveUS20050061636A1Increase flexibilityReducing and controlling wearConveyorsPackagingEngineeringChain link

A section of chain for conveying product along a material handling system includes a pin connecting a center link between two side links. The pin may be dialable or selectably positioned at the side links to control and adjust the wear surface of the pin relative to the chain links. The pin may have a rotationally non-symmetrical shaft portion to provide different wear surfaces that engage a center link of the section of chain. The different wear surfaces may be sized and shaped to accommodate wear at the wear surface of the center link. The shaft portion may include a rotationally non-symmetrical ball member or portion on the shaft portion to enhance flexibility of the section of chain. The pin may be dialed to the next position or wear surface in response to an output of a wear measurement device or system.

Owner:FROST TECH

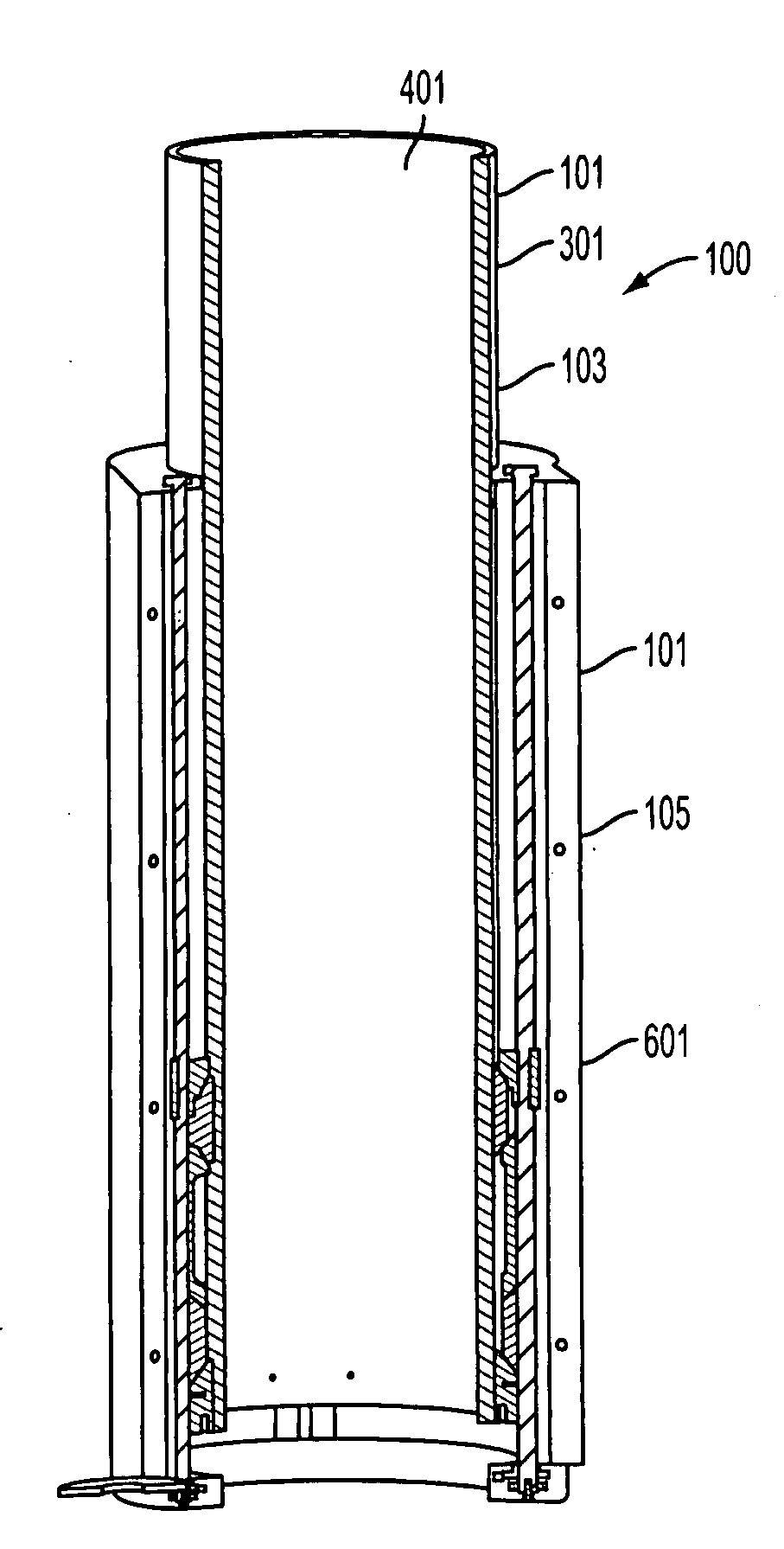

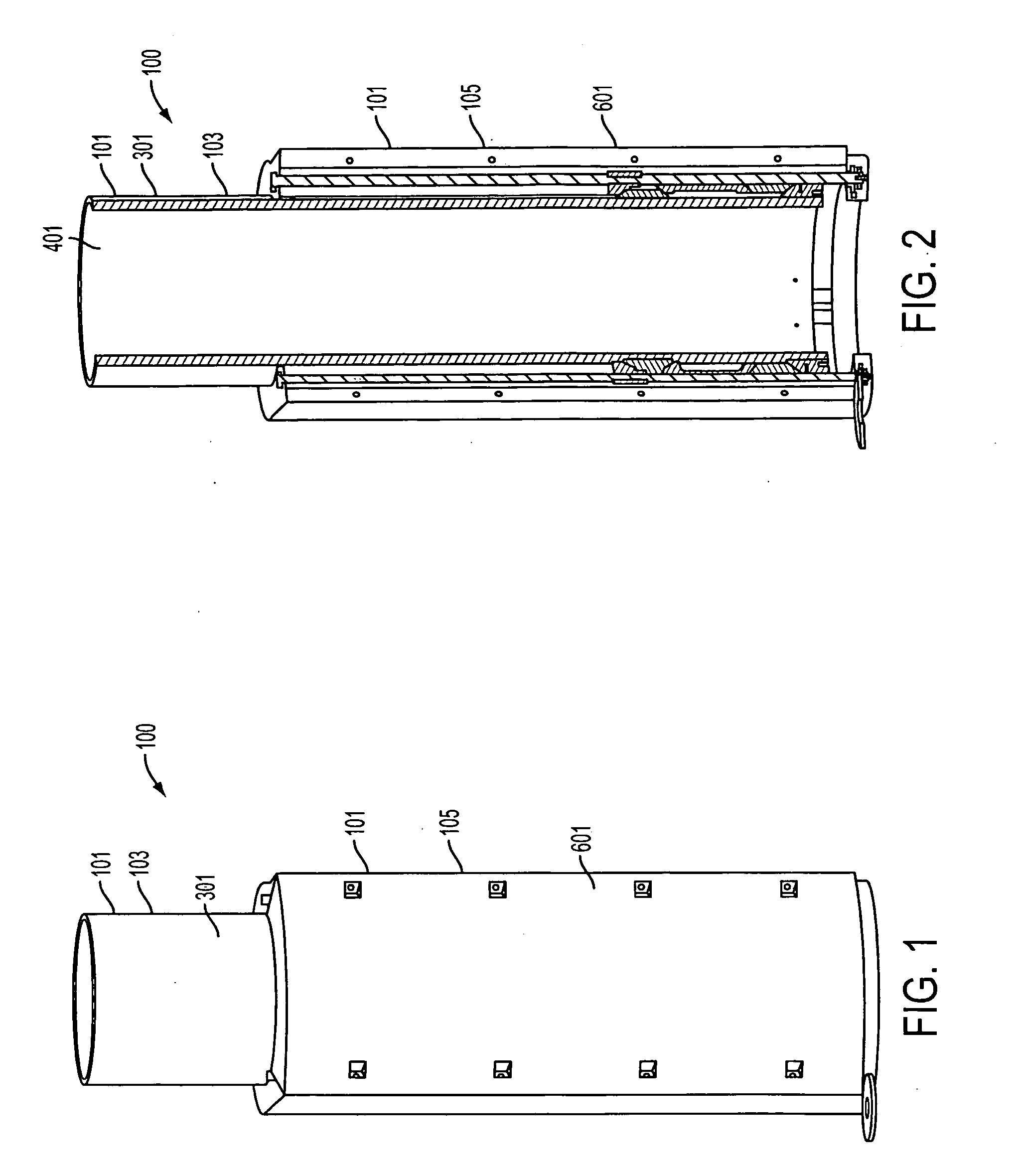

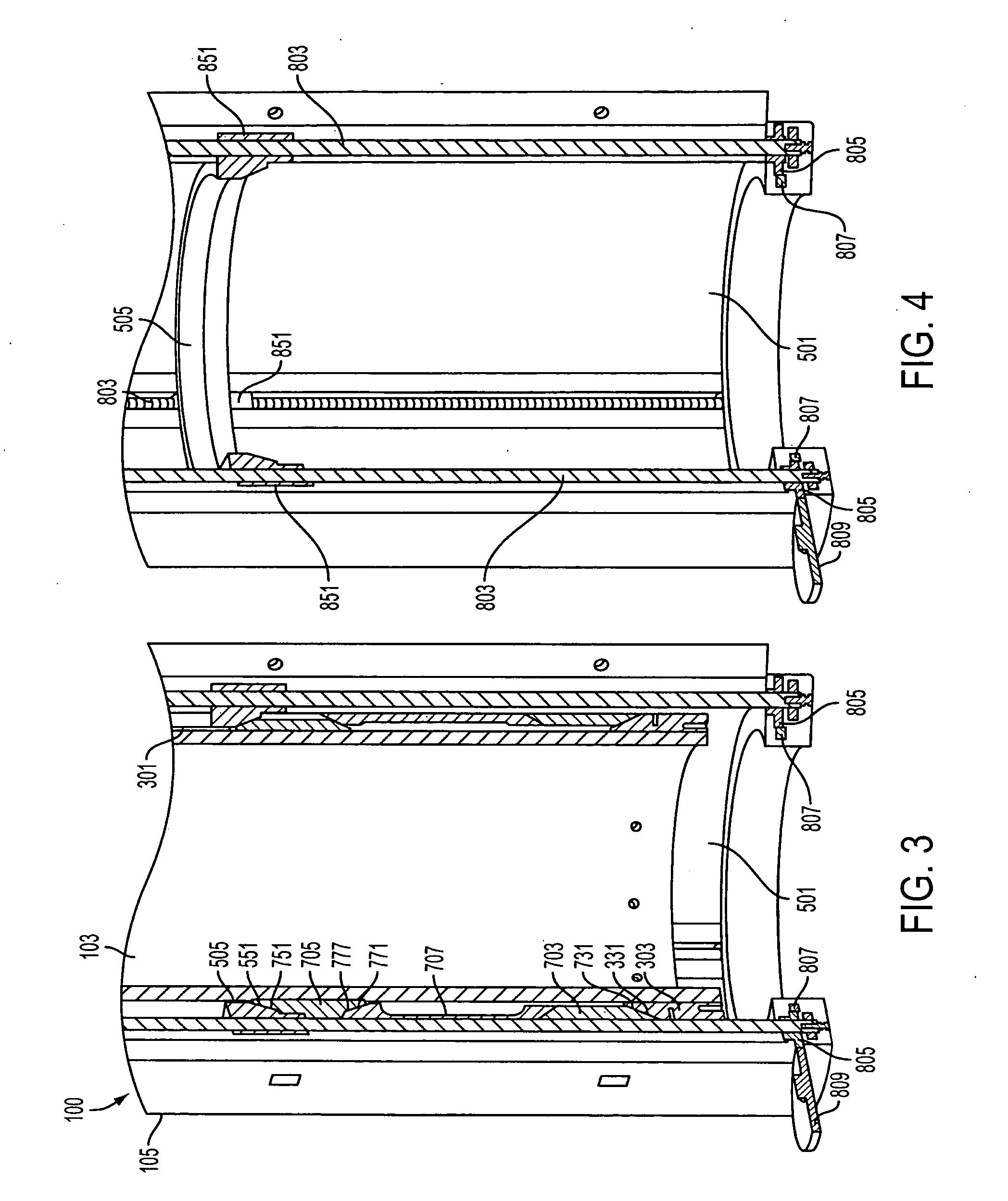

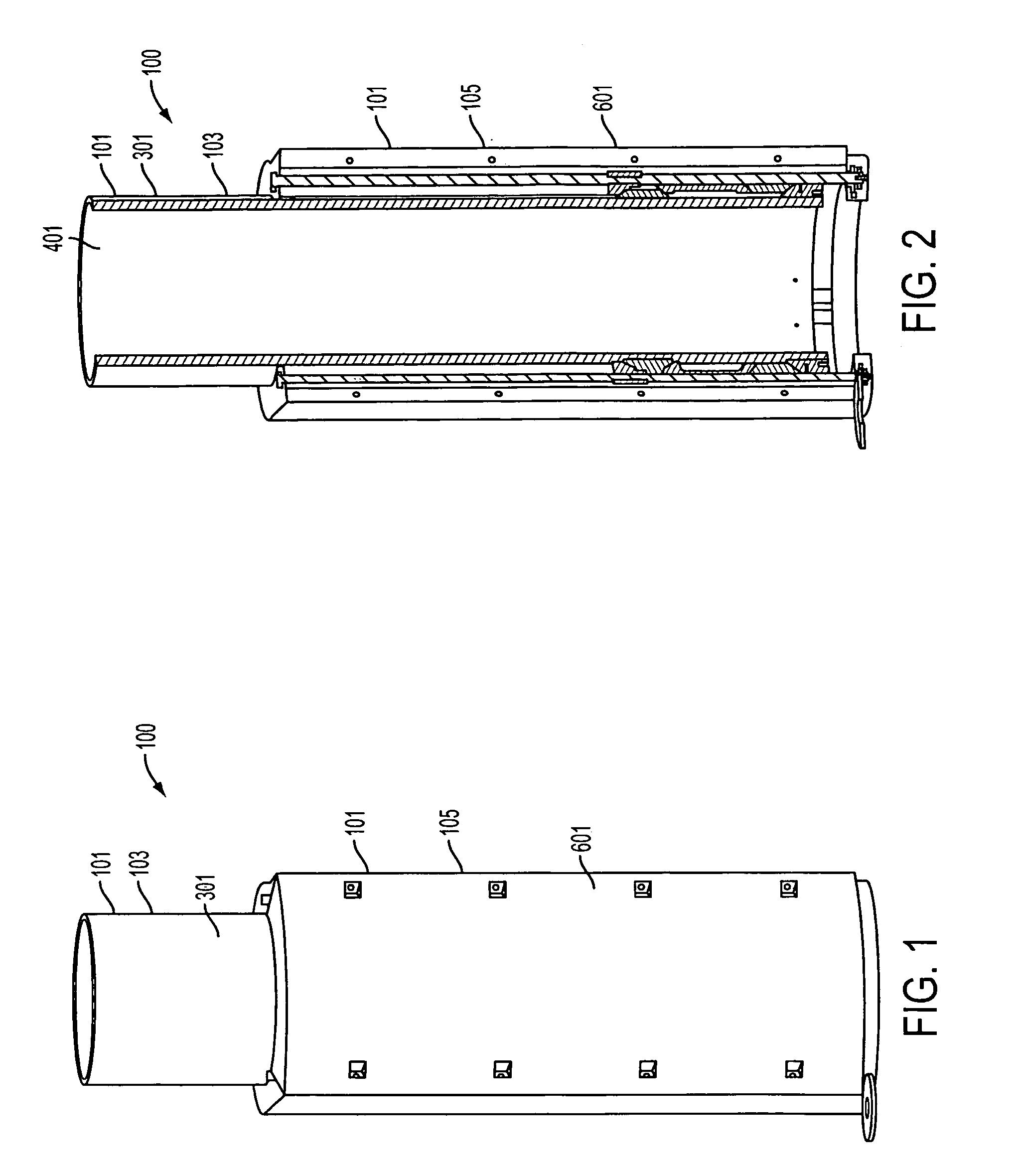

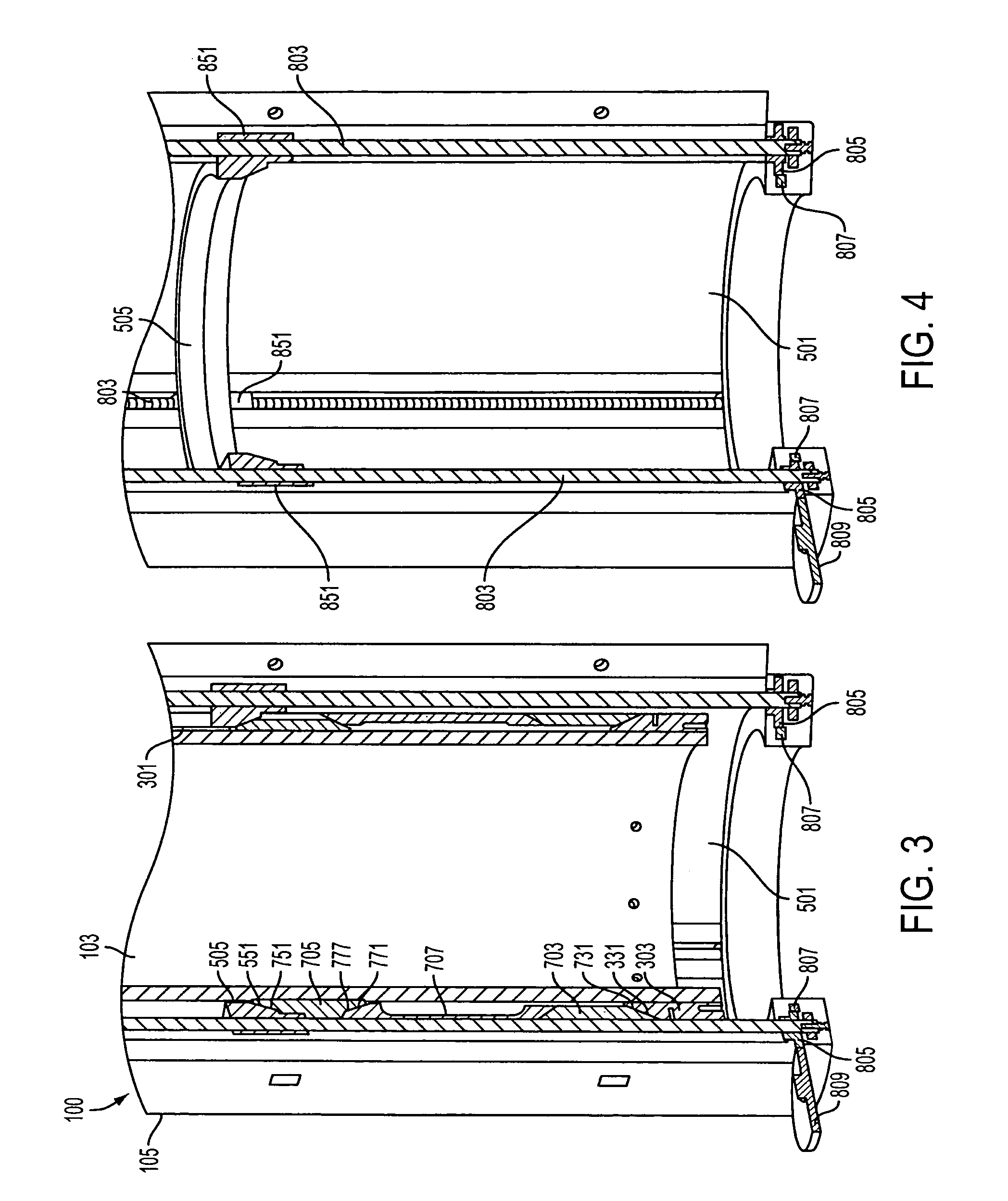

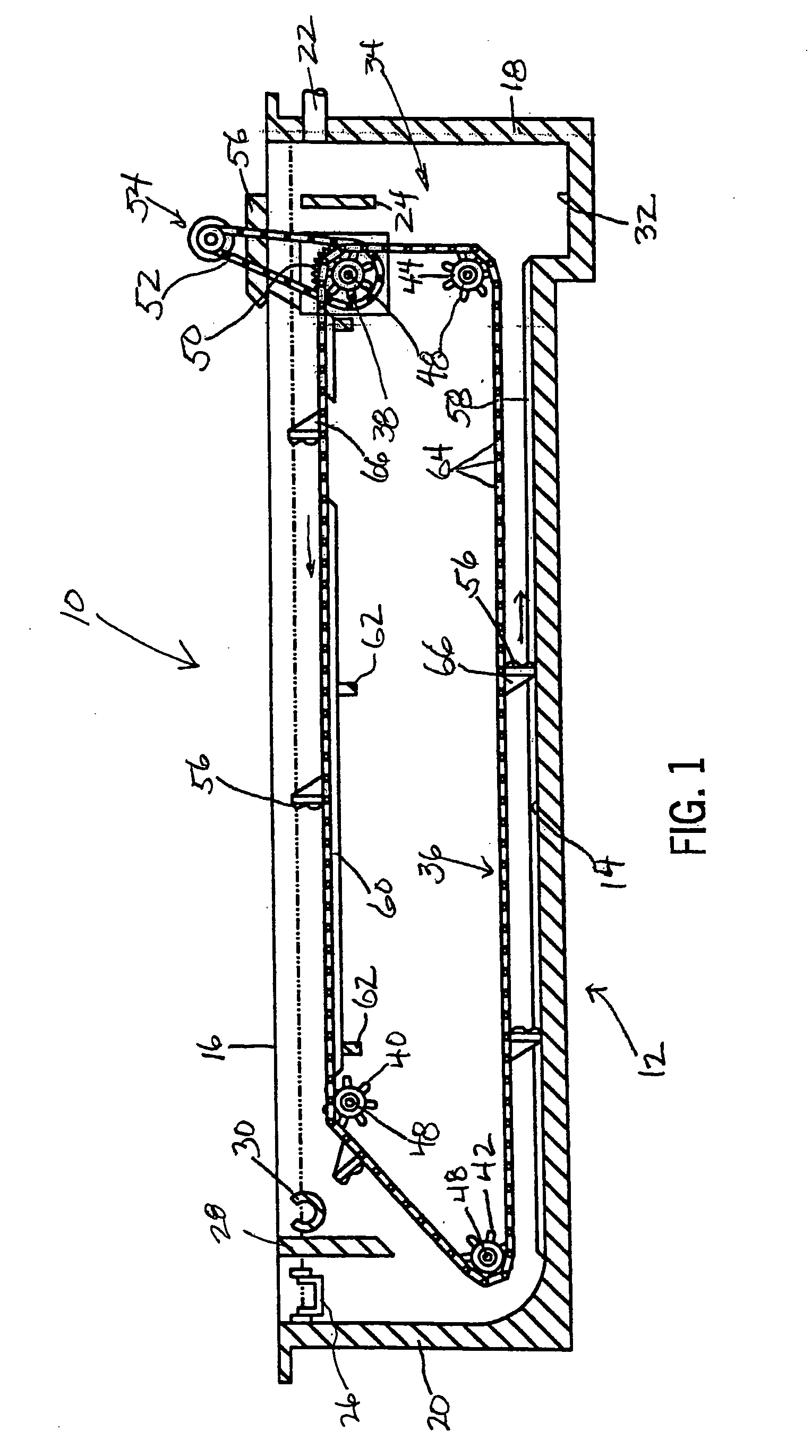

Telescoping mast having variable height locking and a chain erection mechanism with a cable management system

A telescoping mast for supporting and raising a load may be telescopically extended by a zipper-action chain extension system further comprising a system for the management of one or more cables, such as power or communication cables traversing the length of the mast, and is capable of being locked into a rigid formation along a range of telescopic lengths.

Owner:DRS SUSTAINMENT SYST

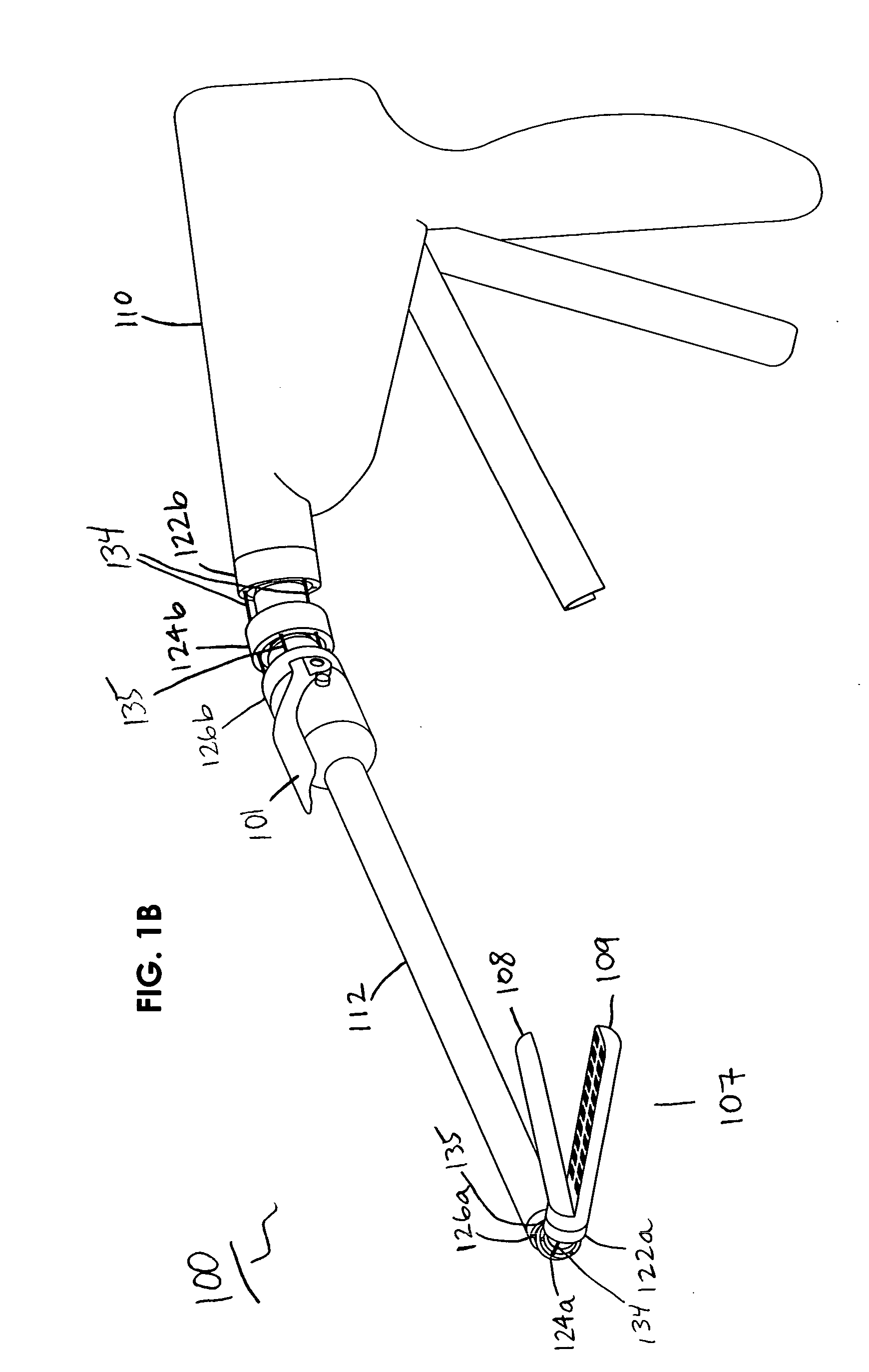

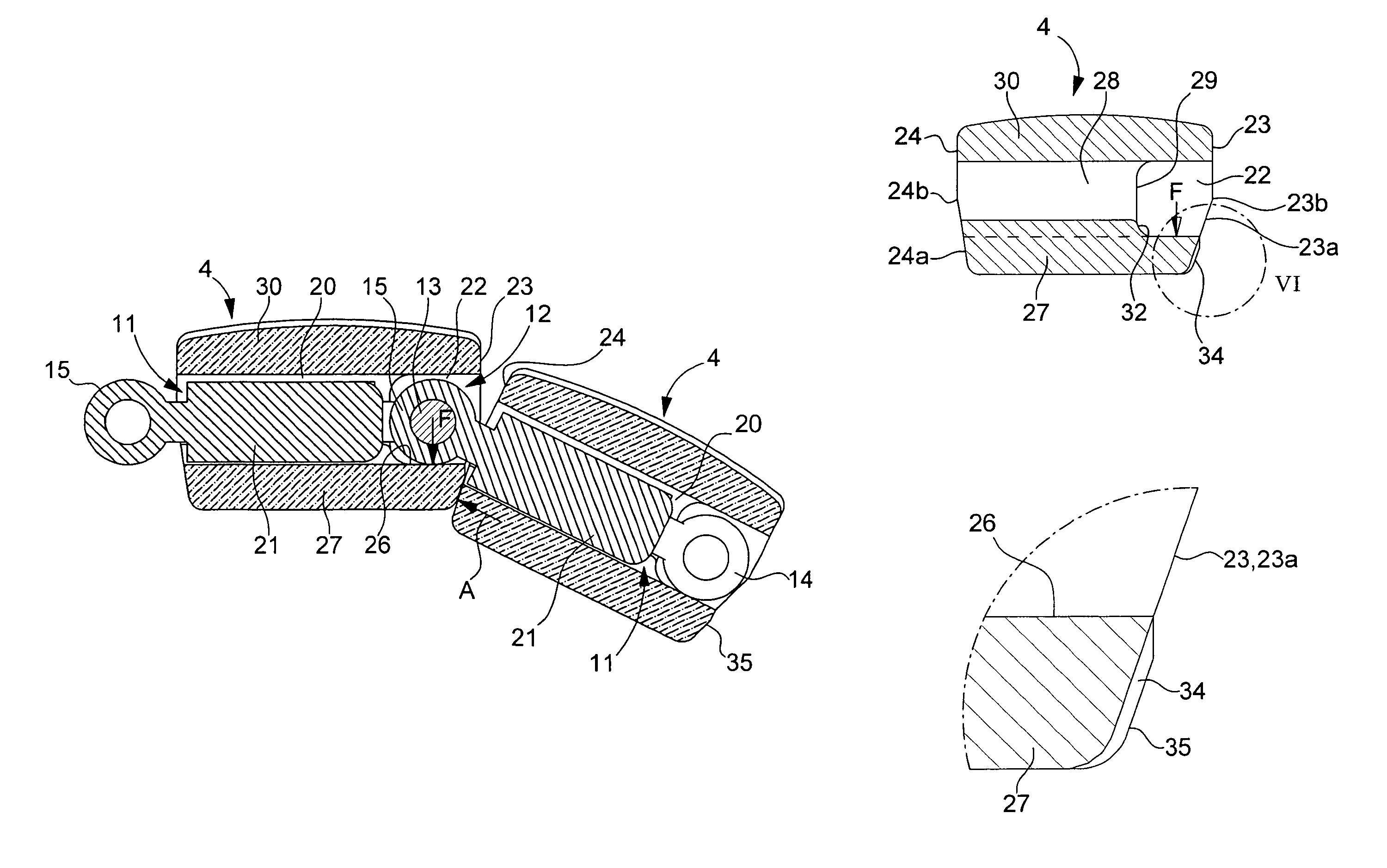

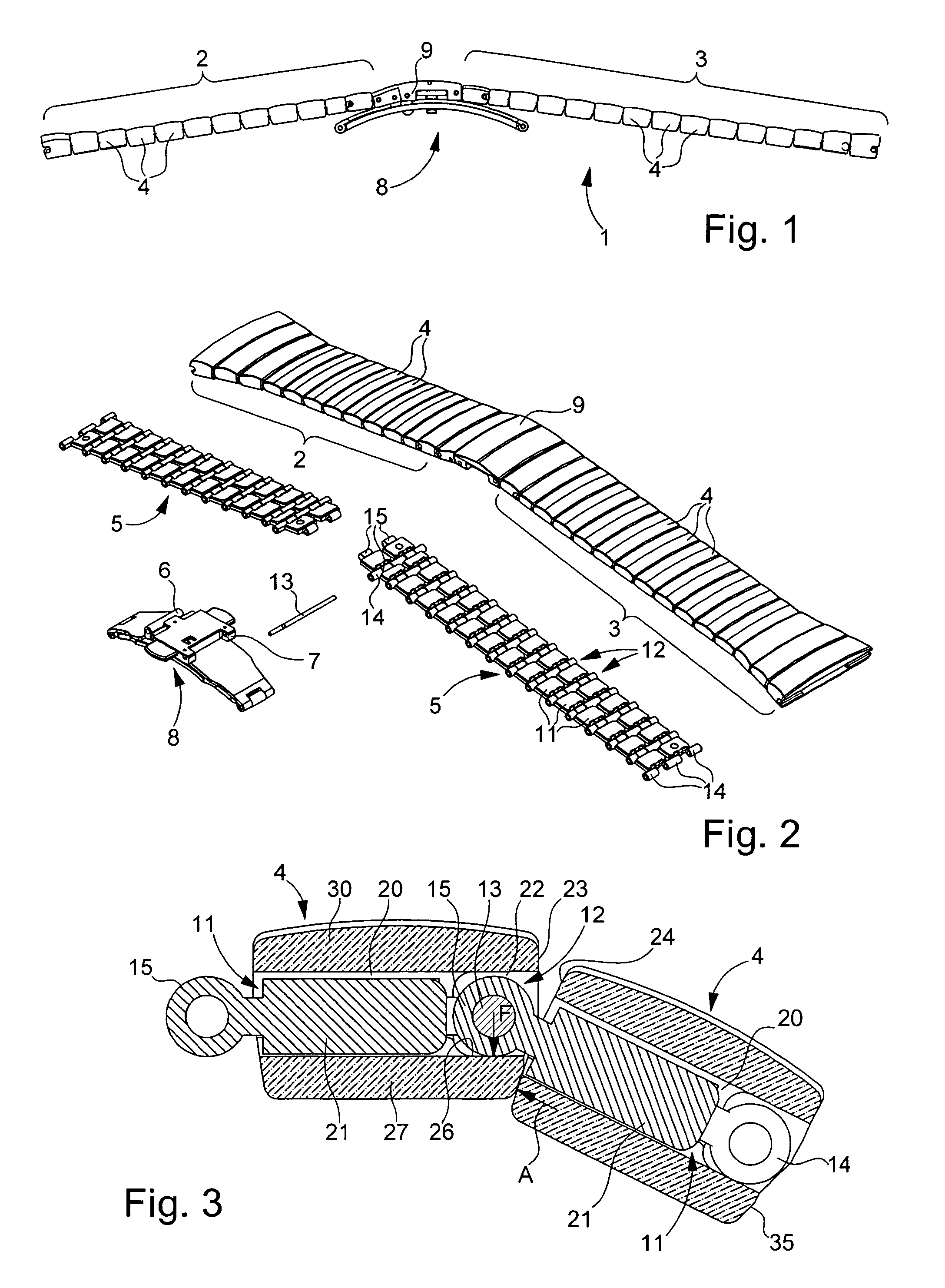

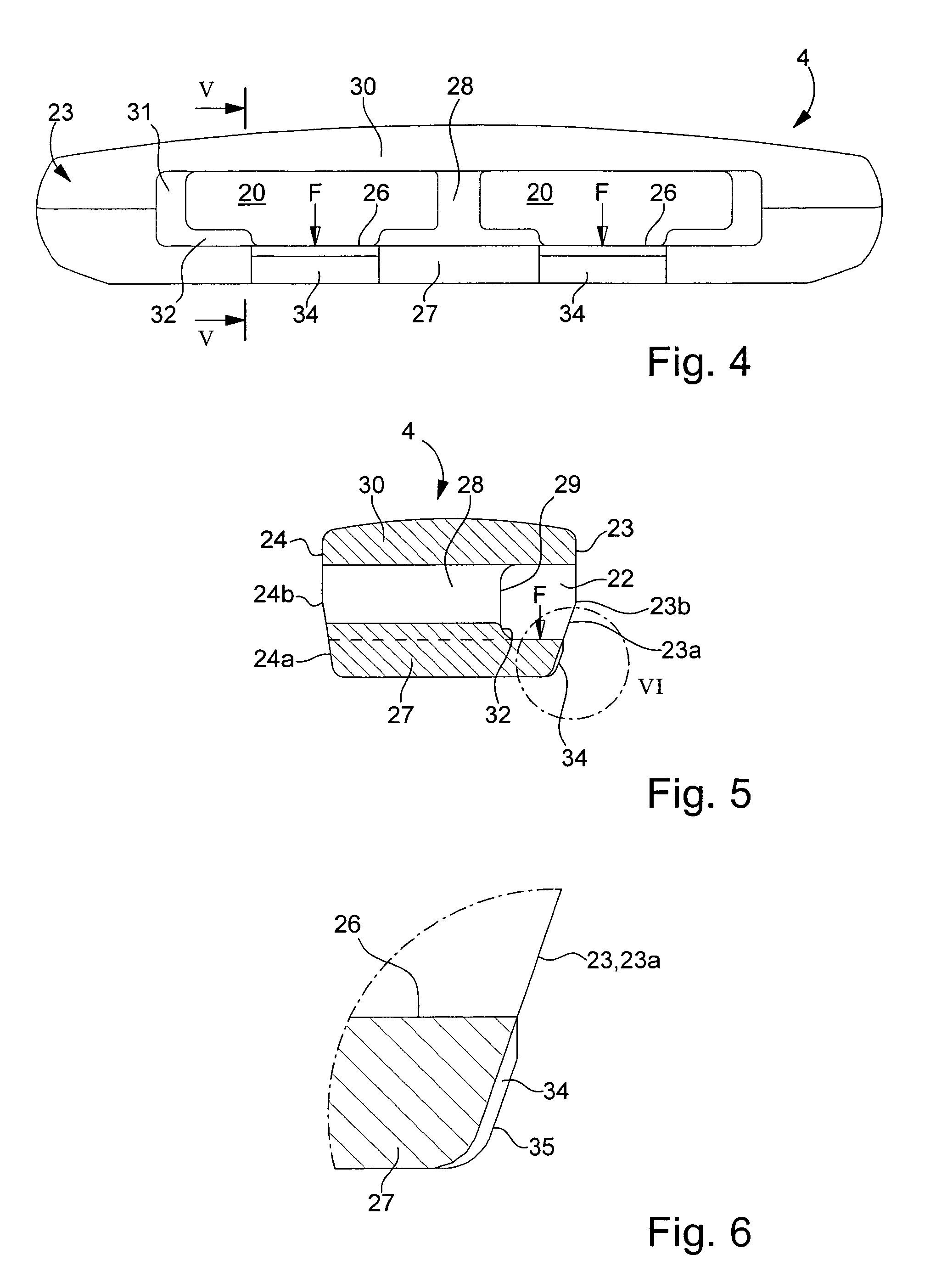

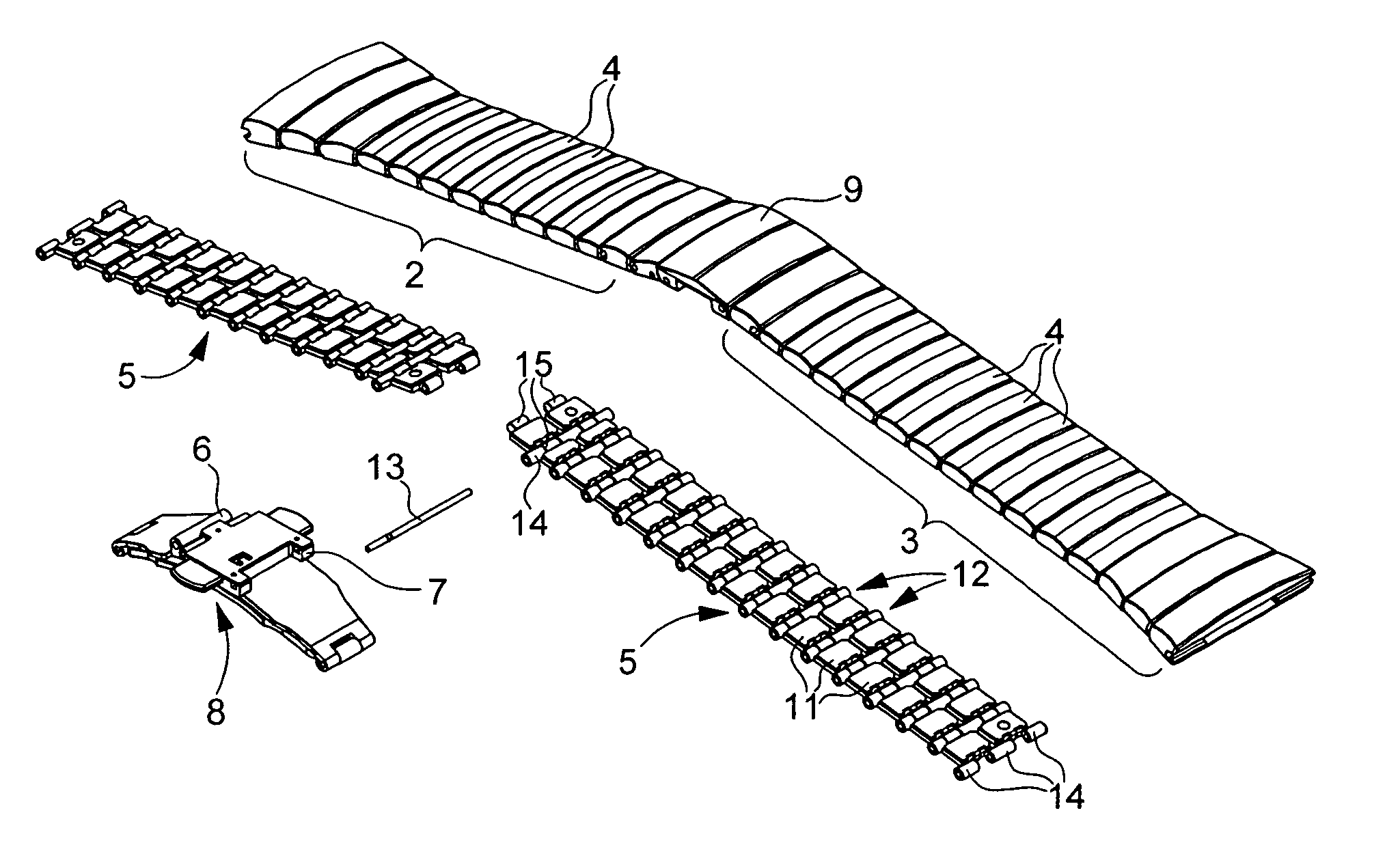

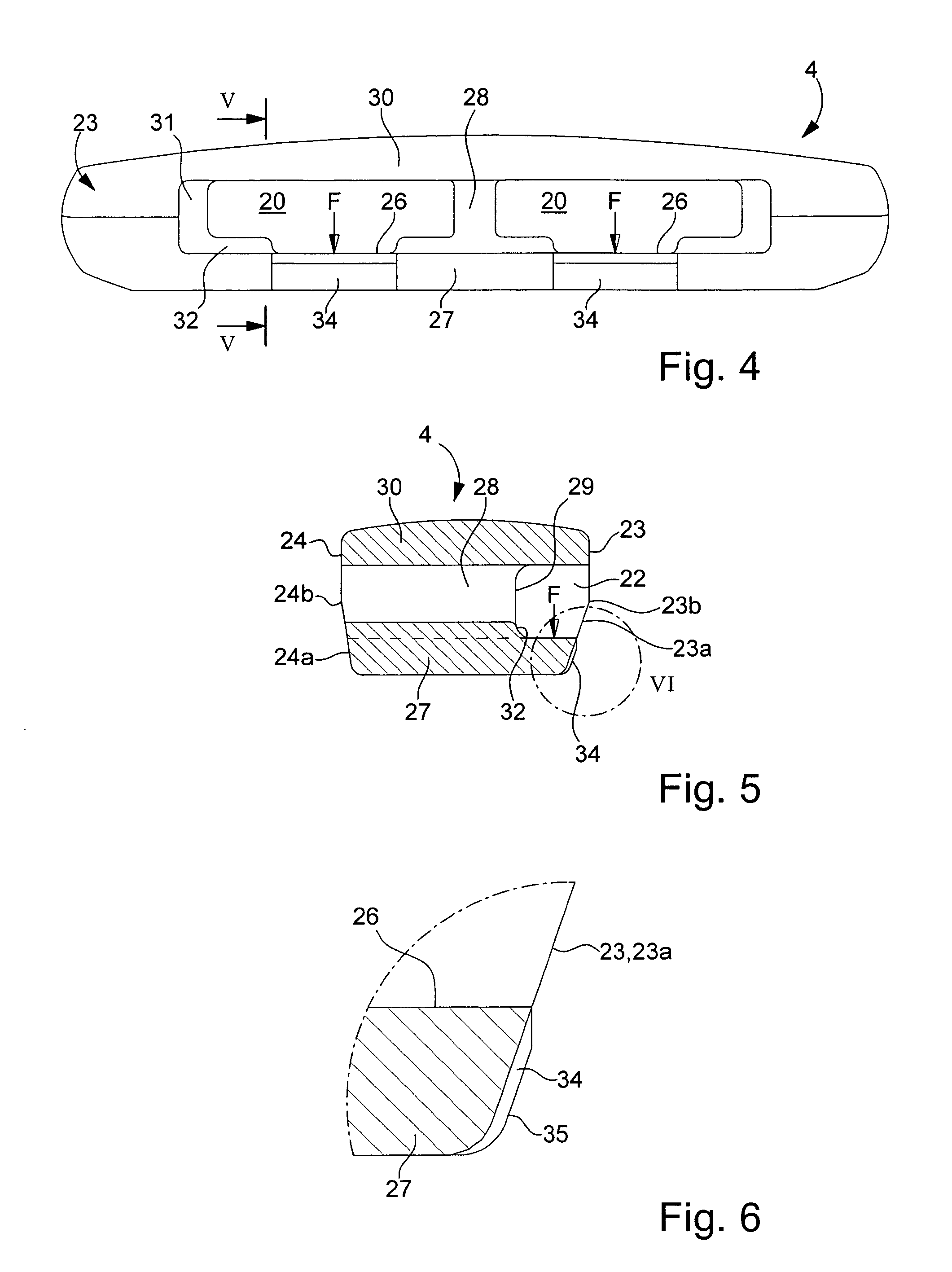

Articulated bracelet including decorative links threaded onto a chain

ActiveUS7013631B2Reduce stressSuppression reductionBraceletsHorseshoeEngineeringMechanical engineering

The linked bracelet, in particular for a watch, comprises a metal hinged chain passing through a series of ornamental tubular links (4) made of ceramic material, each ornamental link (4) having at least one longitudinal passage (20), in which a metal link and a hinge associated with it are housed and can rest against an inside surface (26) of the base (27) of the ornamental link in the region of the hinge, when the hinge is in a folded position. A front face (23) of each ornamental link (4) has at least one raised section (34) located in the same region of the width of the ornamental link as said inside surface (26) where the hinge or the metal link rests, this raised section being arranged to abut against the opposite front face (24) of the adjacent ornamental link when the hinge is in said folded position. This arrangement balances the vertical force (F) exerted by the chain on the base (27) of the ornamental link at the right place and thus prevents any risk of fracture by transverse bending.

Owner:COMADUR

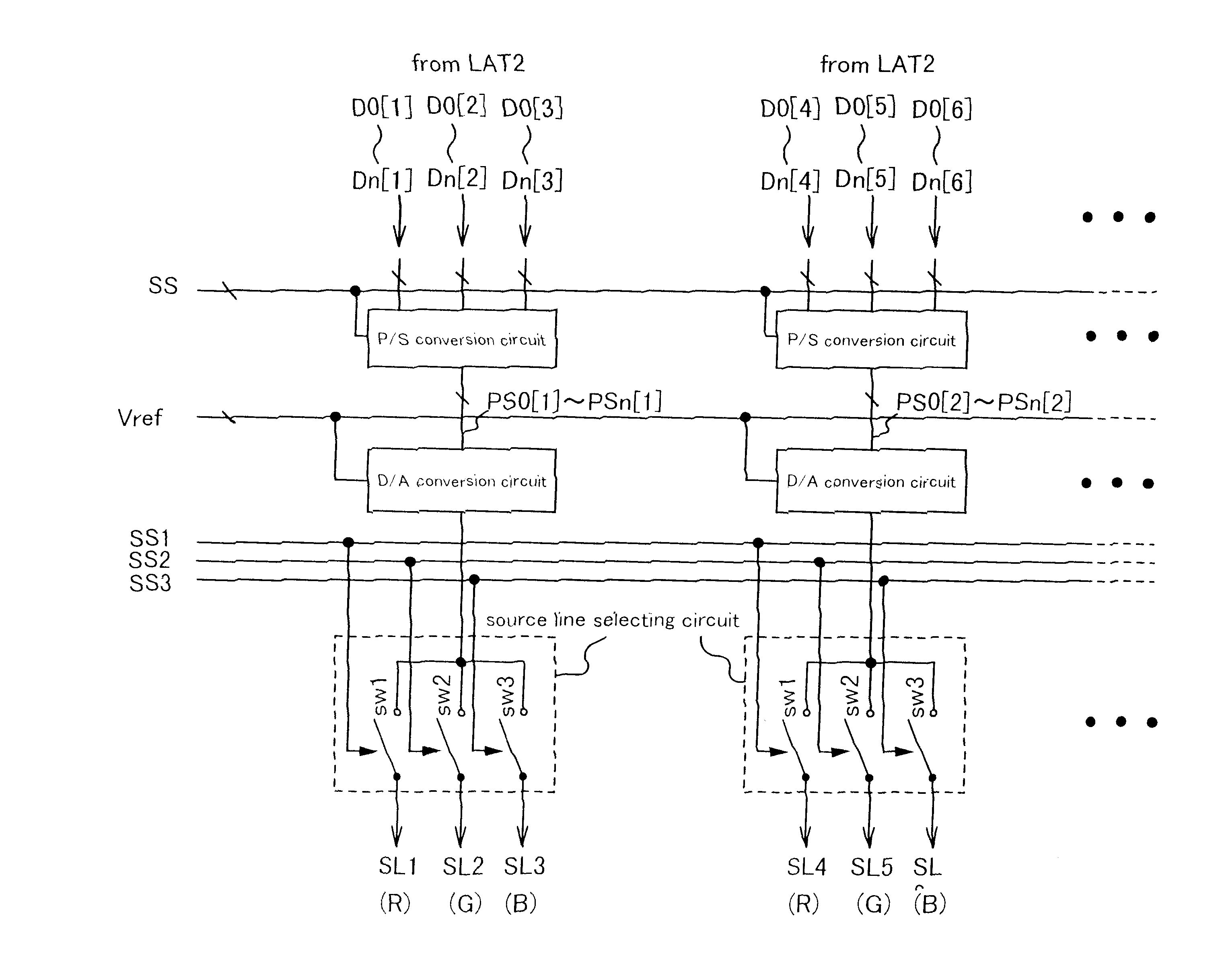

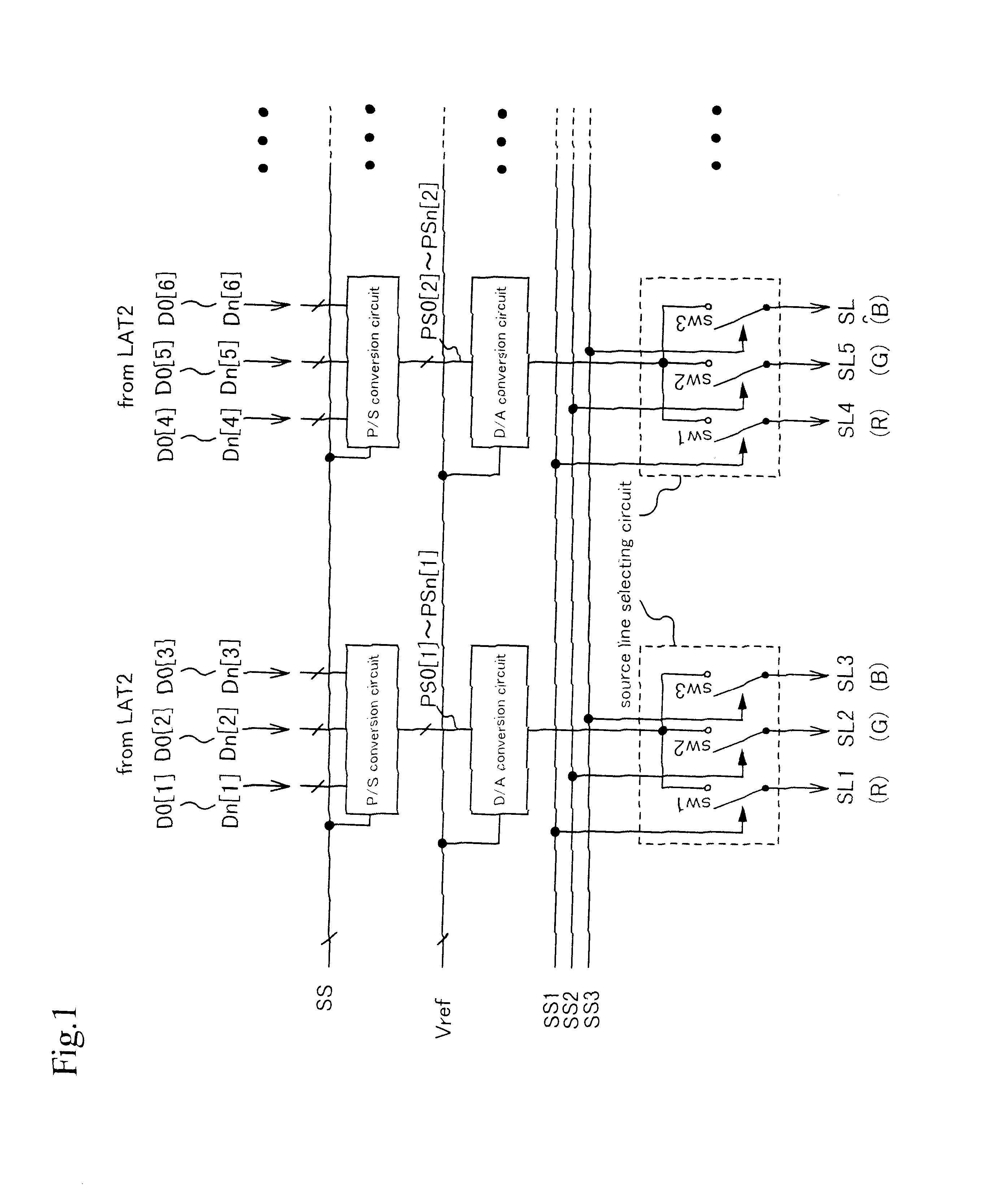

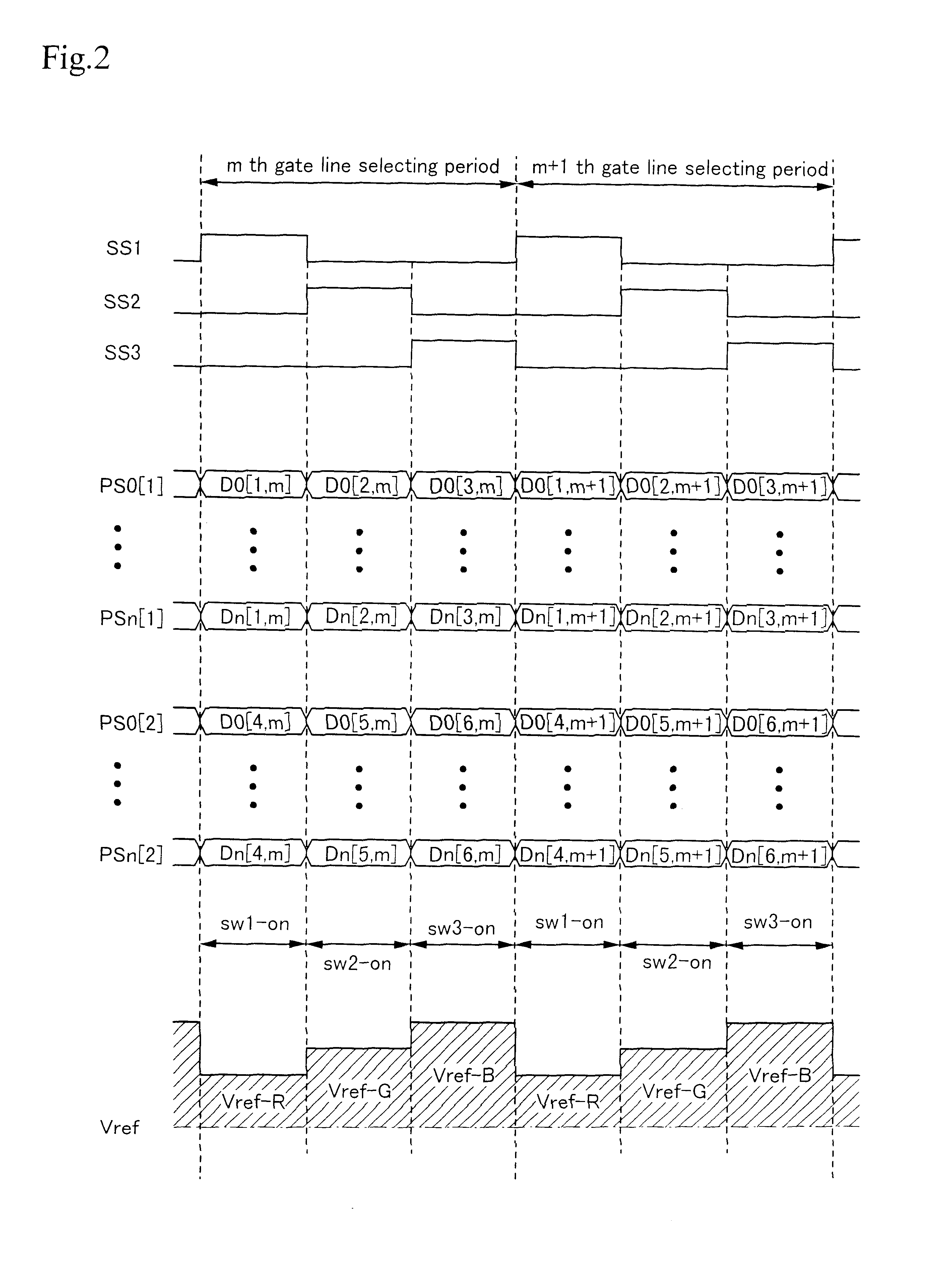

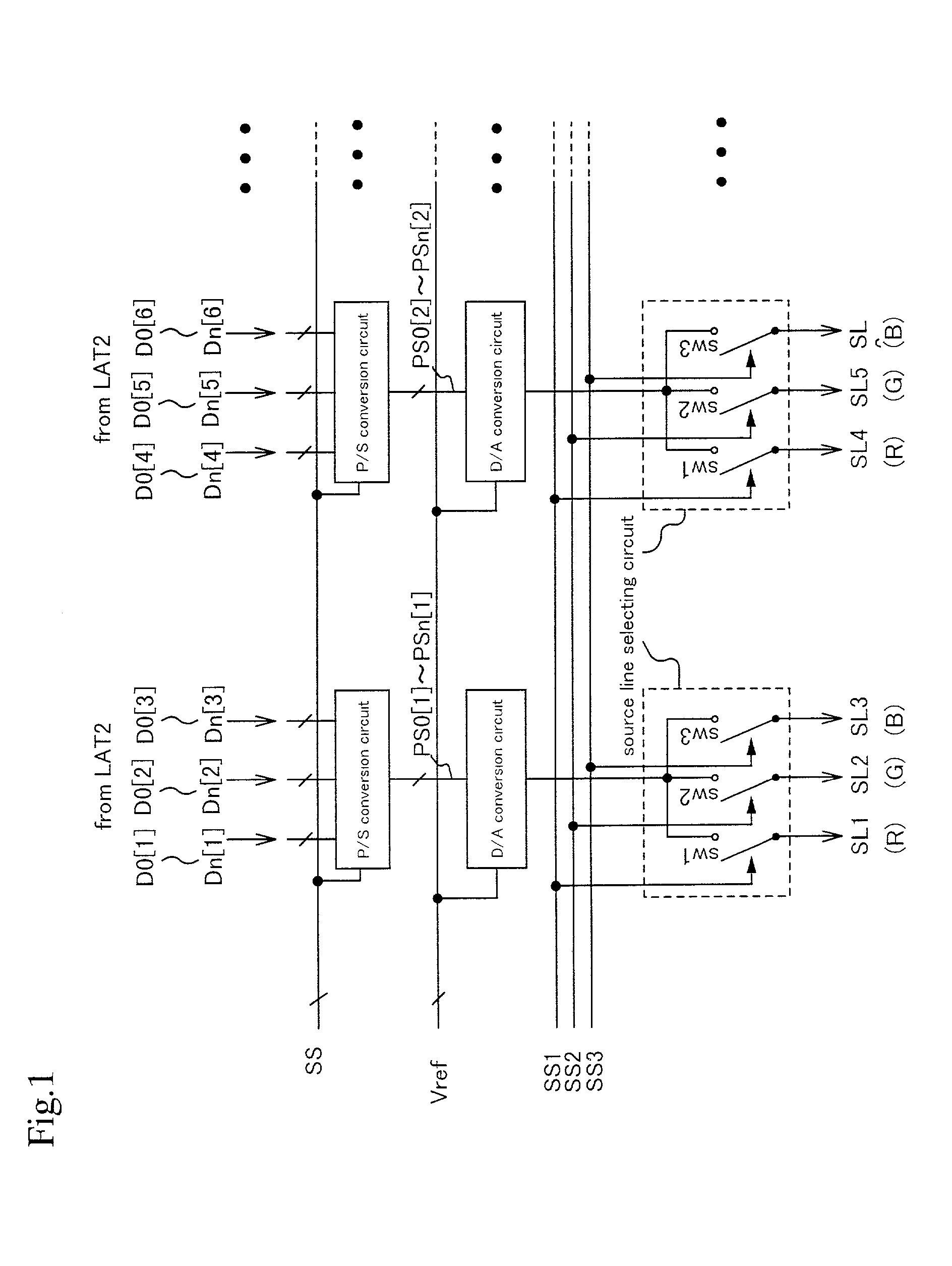

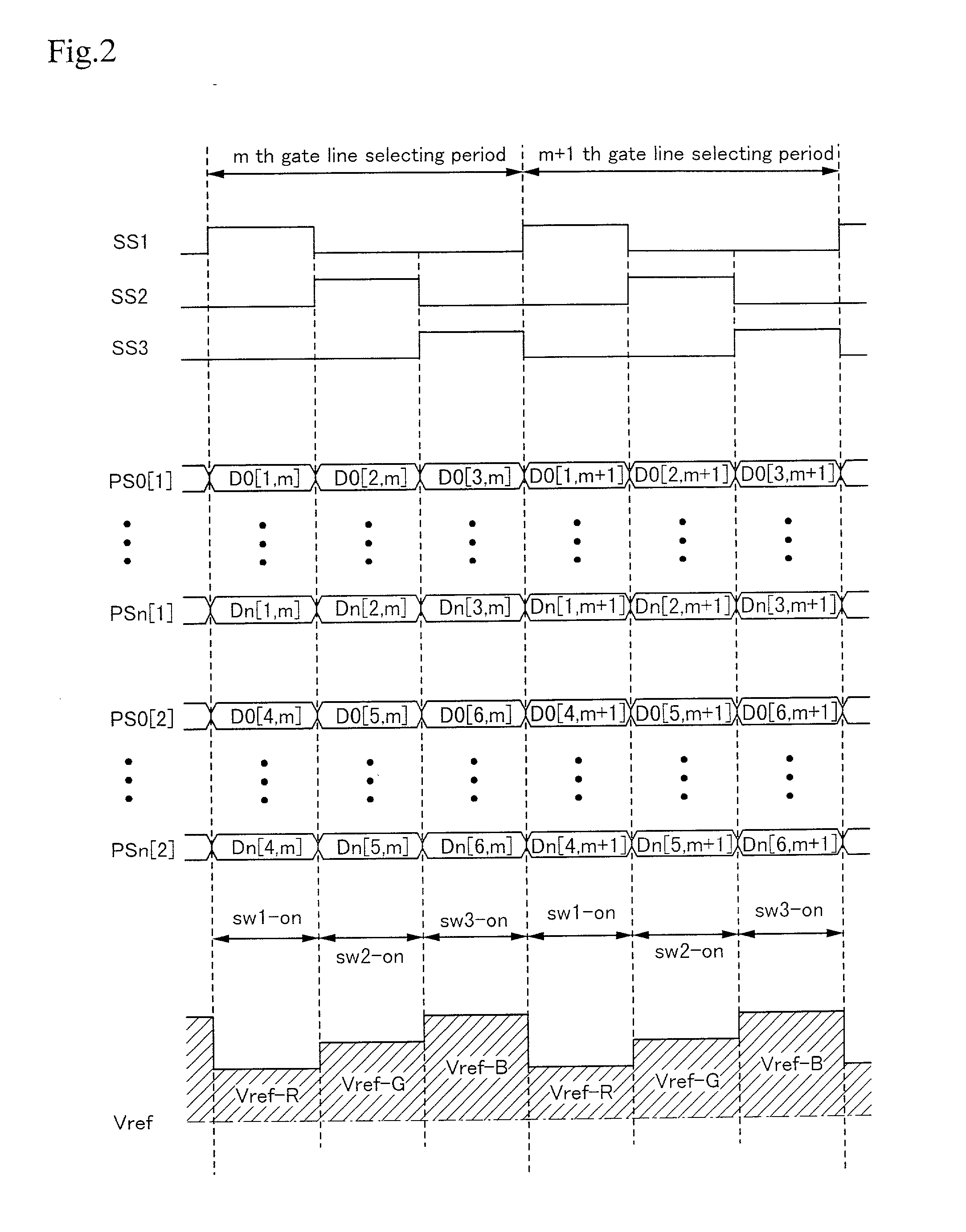

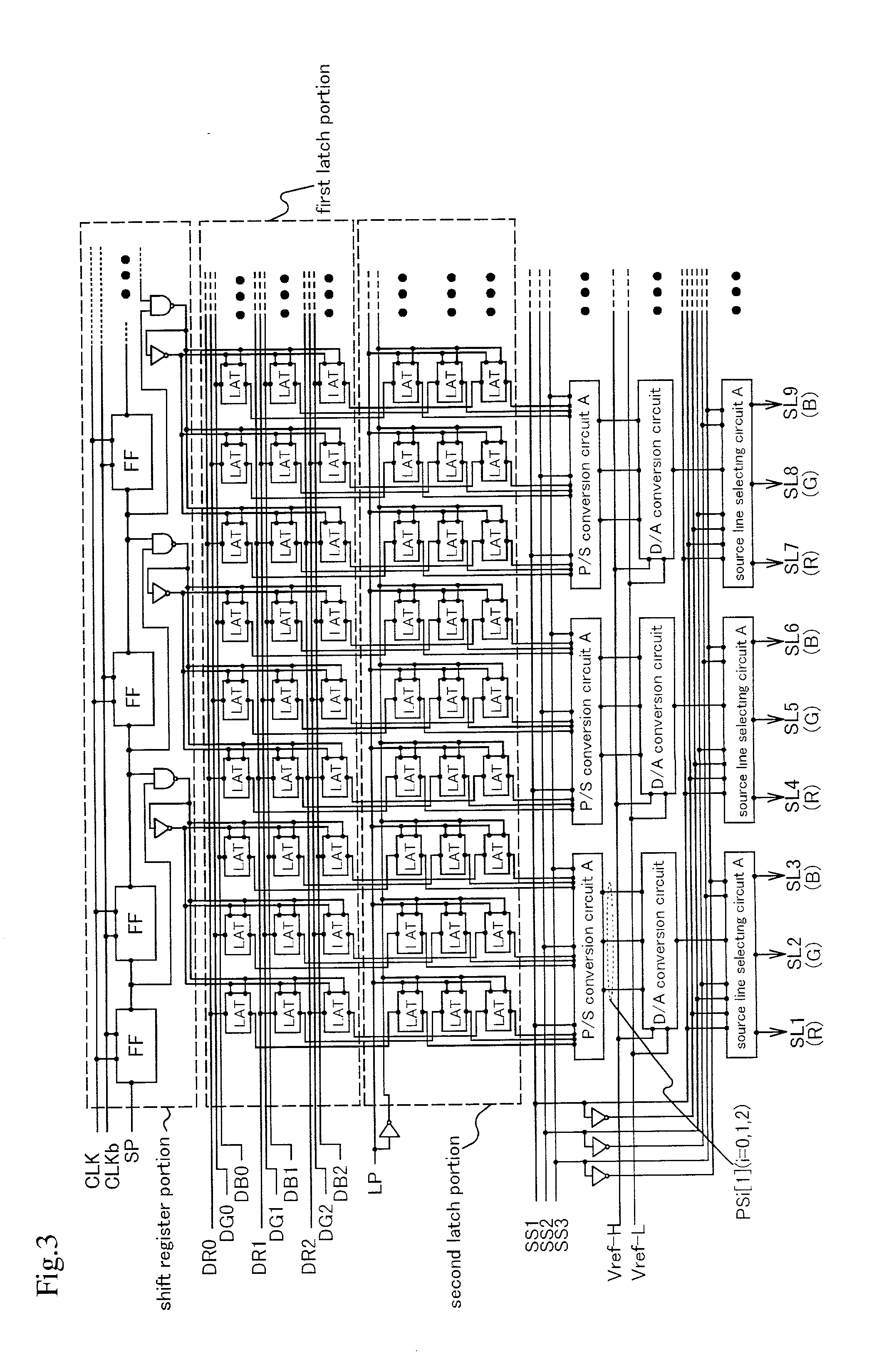

Color image display device, method of driving the same, and electronic equipment

InactiveUS6702407B2Solid-state devicesSemiconductor/solid-state device manufacturingColor imageDisplay device

A gray-scale power supply line supplied to a source signal line driving circuit is made only one system, and each of D / A conversion circuits drives source signal lines in which three source signal lines corresponding to RGB are made a unit and the number of which is a multiple of 3. The periods in which respective source line selecting circuits select source signal lines corresponding to respective colors of the RGB are made synchronous with each other, and the power supply voltage applied to the gray-scale power supply line is changed in one horizontal writing period, so that power supply voltages corresponding to R, G and B are respectively applied to the gray-scale power supply line in periods while the source signal lines of R, G and B are respectively selected.

Owner:SEMICON ENERGY LAB CO LTD

Articulated bracelet including decorative links threaded onto a chain

ActiveUS20050210857A1Reduce stressSuppression reductionBraceletsWrist-watch strapsEngineeringMechanical engineering

The linked bracelet, in particular for a watch, comprises a metal hinged chain passing through a series of ornamental tubular links (4) made of ceramic material, each ornamental link (4) having at least one longitudinal passage (20), in which a metal link and a hinge associated with it are housed and can rest against an inside surface (26) of the base (27) of the ornamental link in the region of the hinge, when the hinge is in a folded position. A front face (23) of each ornamental link (4) has at least one raised section (34) located in the same region of the width of the ornamental link as said inside surface (26) where the hinge or the metal link rests, this raised section being arranged to abut against the opposite front face (24) of the adjacent ornamental link when the hinge is in said folded position. This arrangement balances the vertical force (F) exerted by the chain on the base (27) of the ornamental link at the right place and thus prevents any risk of fracture by transverse bending.

Owner:COMADUR

Telescoping mast having variable height locking and a chain erection mechanism with a cable management system

A telescoping mast for supporting and raising a load may be telescopically extended by a zipper-action chain extension system further comprising a system for the management of one or more cables, such as power or communication cables traversing the length of the mast, and is capable of being locked into a rigid formation along a range of telescopic lengths.

Owner:DRS SUSTAINMENT SYST

Quick release shackle pin system

A spring loaded quick release pin and tubular receiver with a retainer pin configured to secure the quick release pin in a shackle, clevis, yoke or forked rod end. The receiver is welded to a shackle or cast with the shackle as a single body. One end of the quick release pin has aligned J slots that engage the retainer pin positioned in the receiver with a clockwise twist. The other end of the quick release pin has a cap and a spring loaded sleeve that biases the cross pin against outside of the second leg of the shackle. The spring bias keeps the short leg of the J slot engaged with the retaining pin. The quick release pin is removed with a push and counter clockwise twist. The invention includes a kit with a receiver, a bushing and a quick release pin for installing or retrofitting existing shackles.

Owner:SILVA FRED

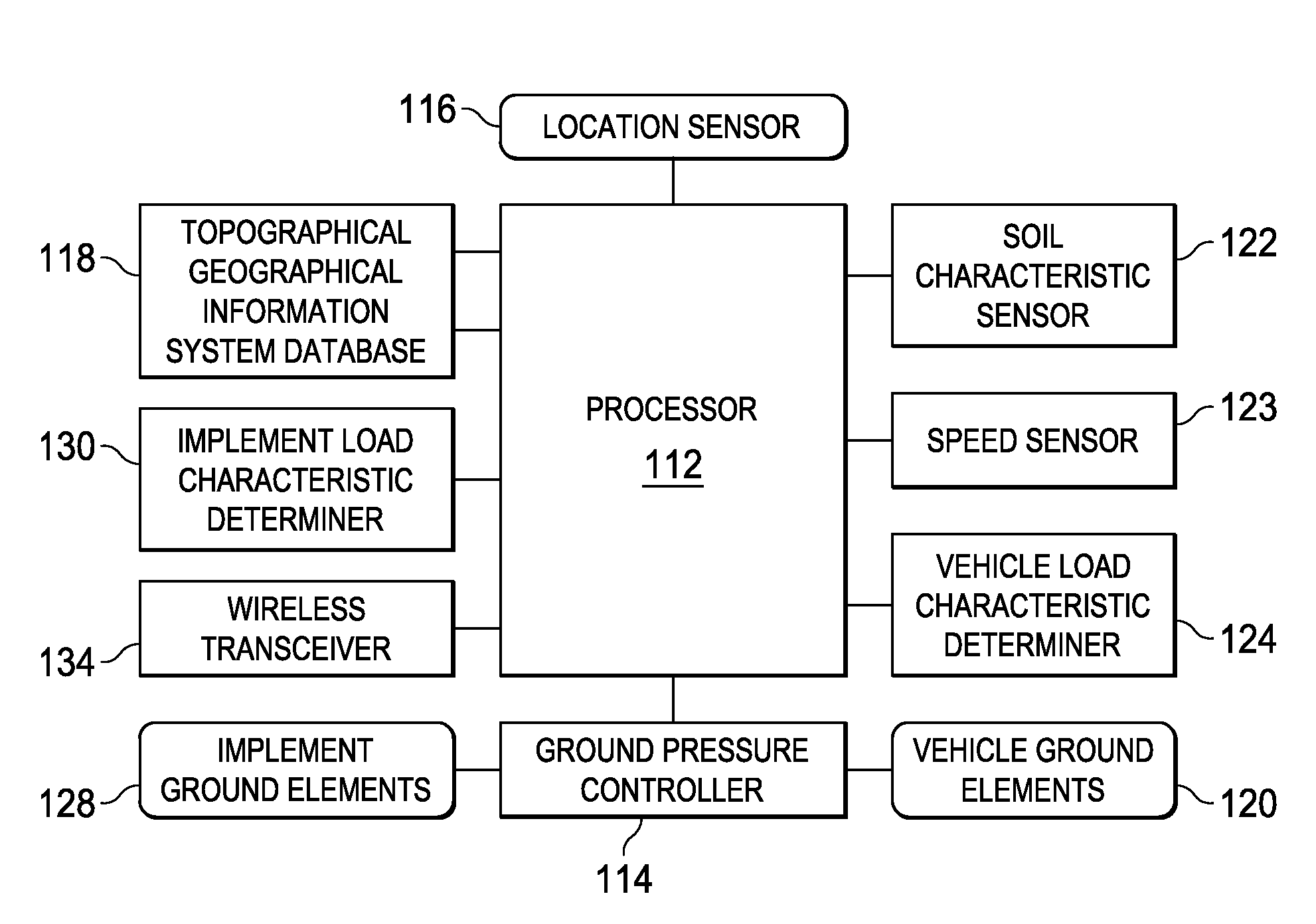

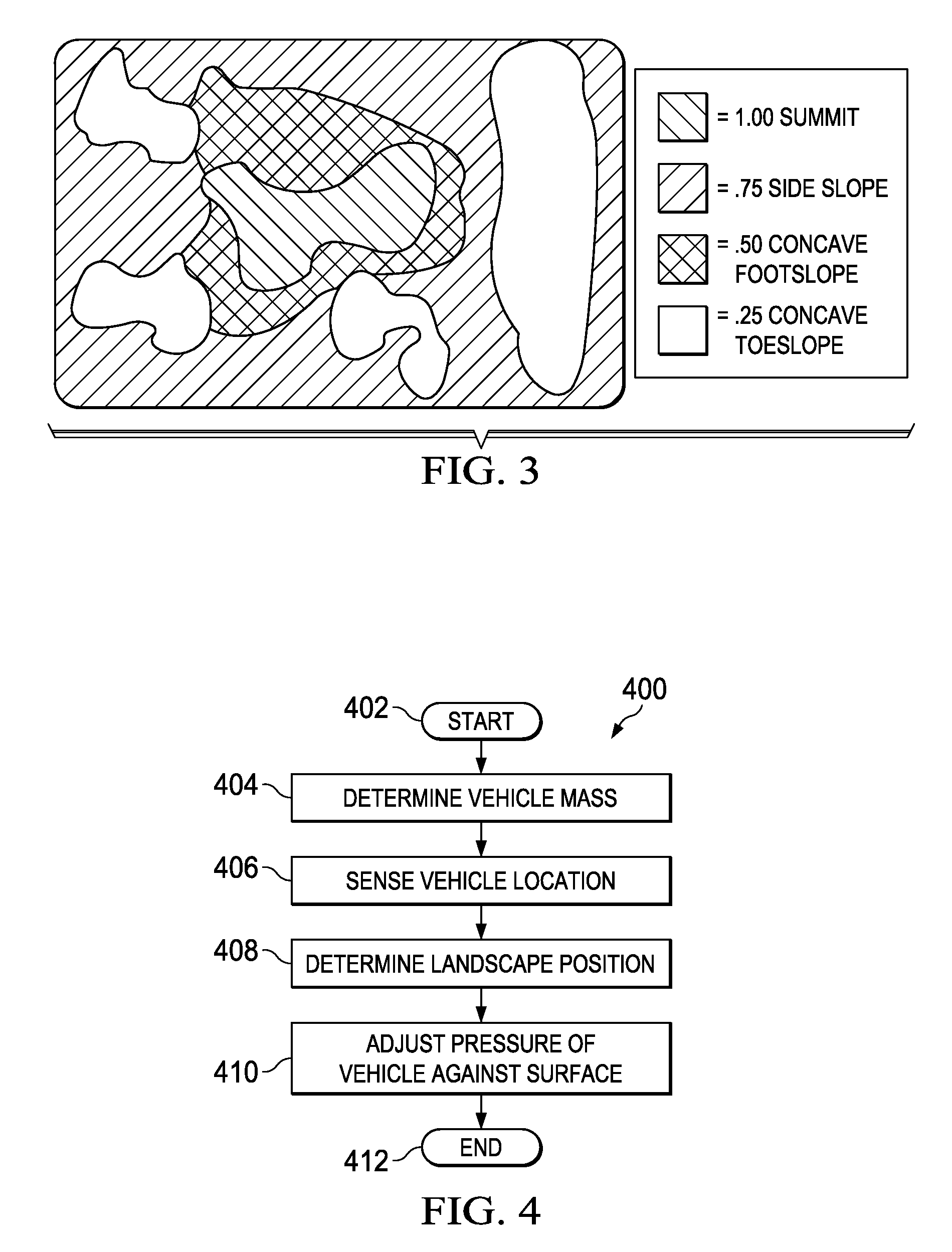

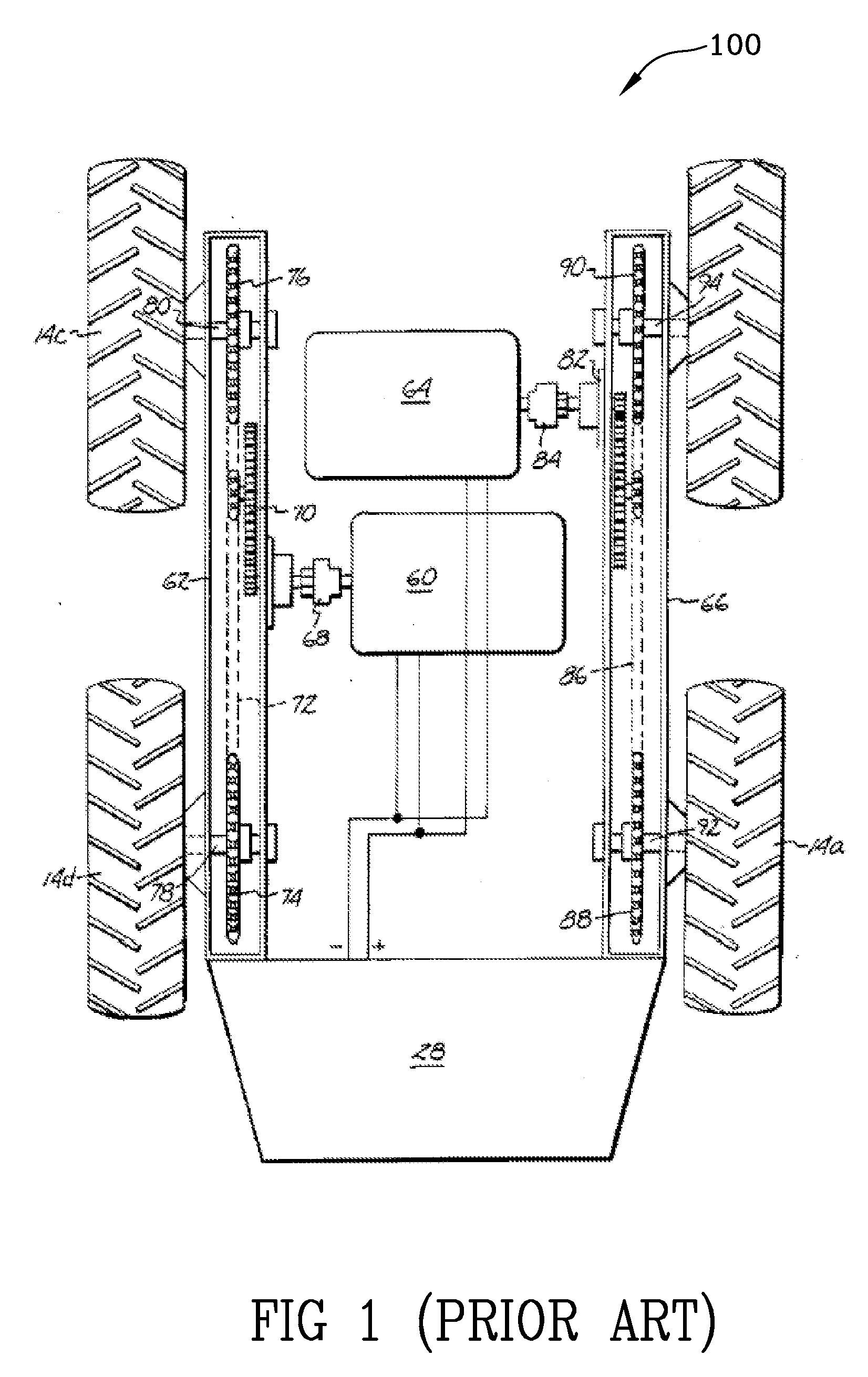

Vehicle soil pressure management based on topography

Systems and techniques are provided for managing an interface between a machine or work vehicle and a surface that the machine / work vehicle travels on in order to provide an optimum work performance level that balances fuel efficiency and surface adversity. Fleet management and reporting capabilities pertaining to such interface management are also provided.

Owner:DEERE & CO

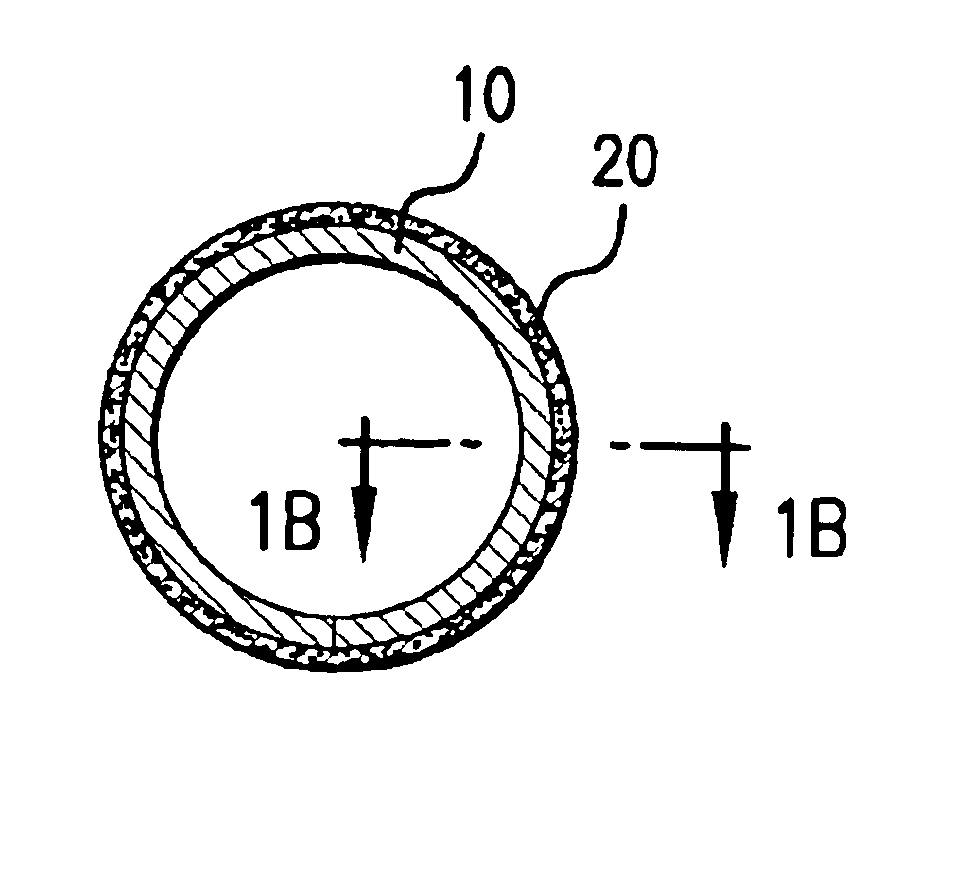

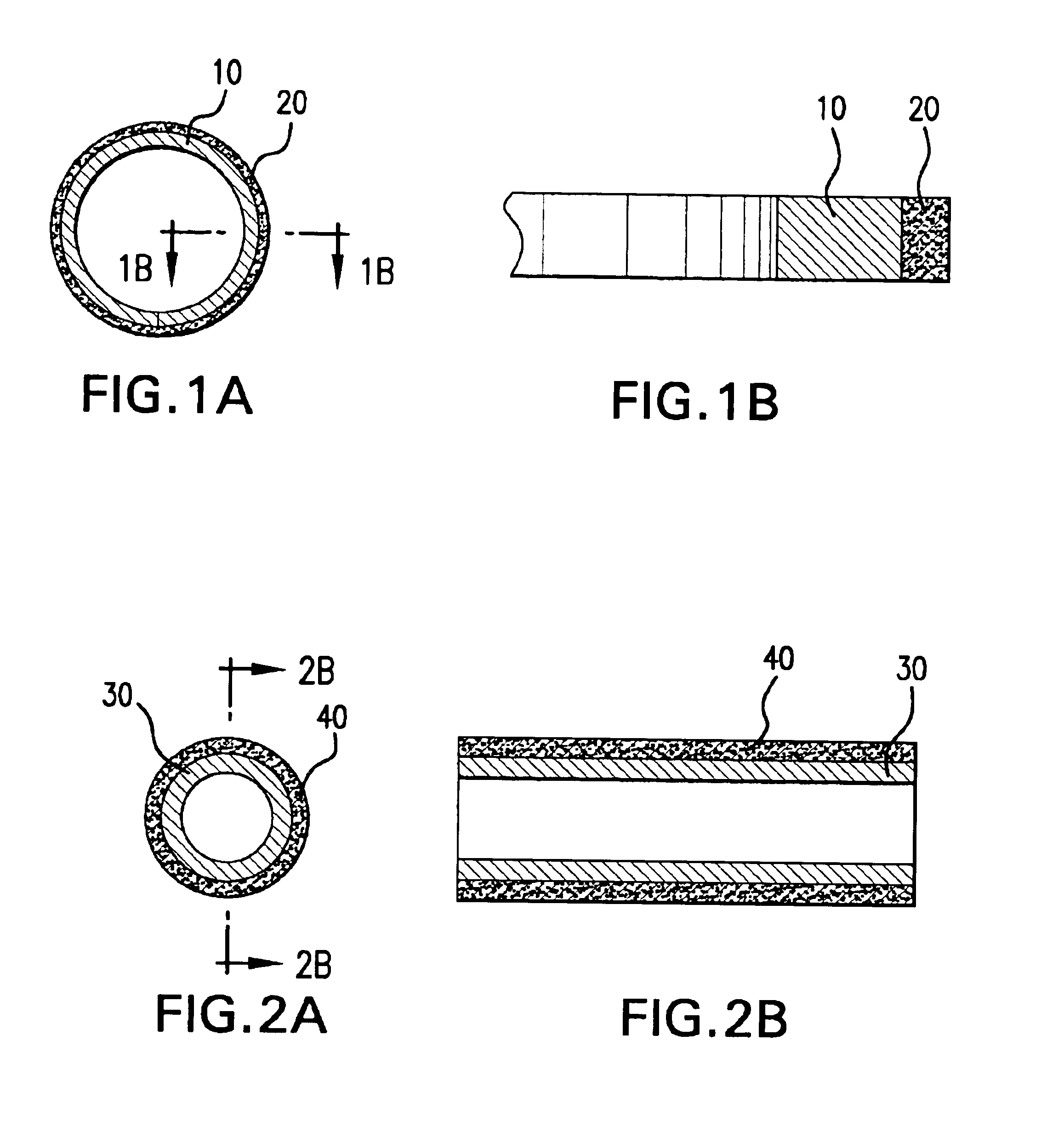

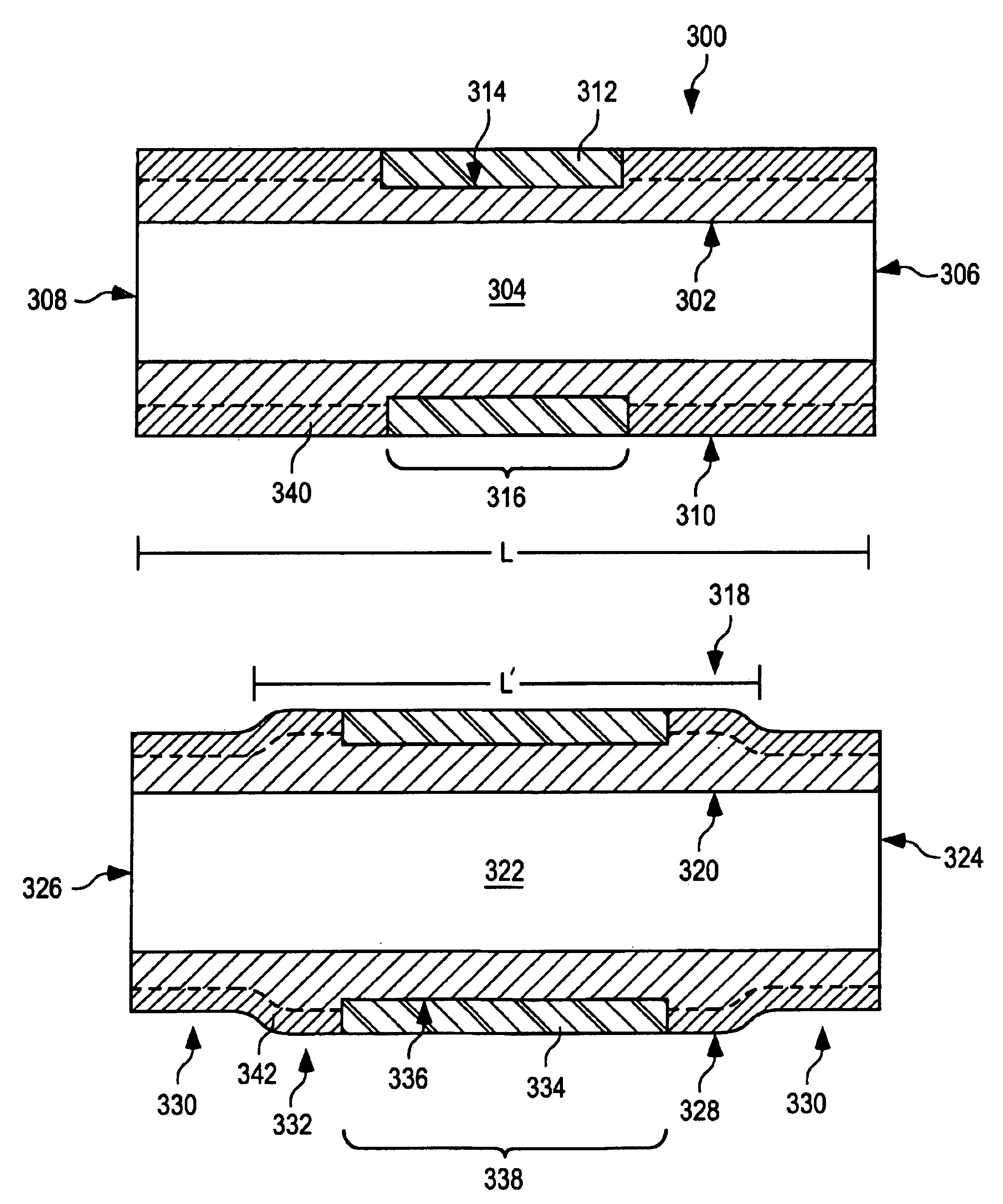

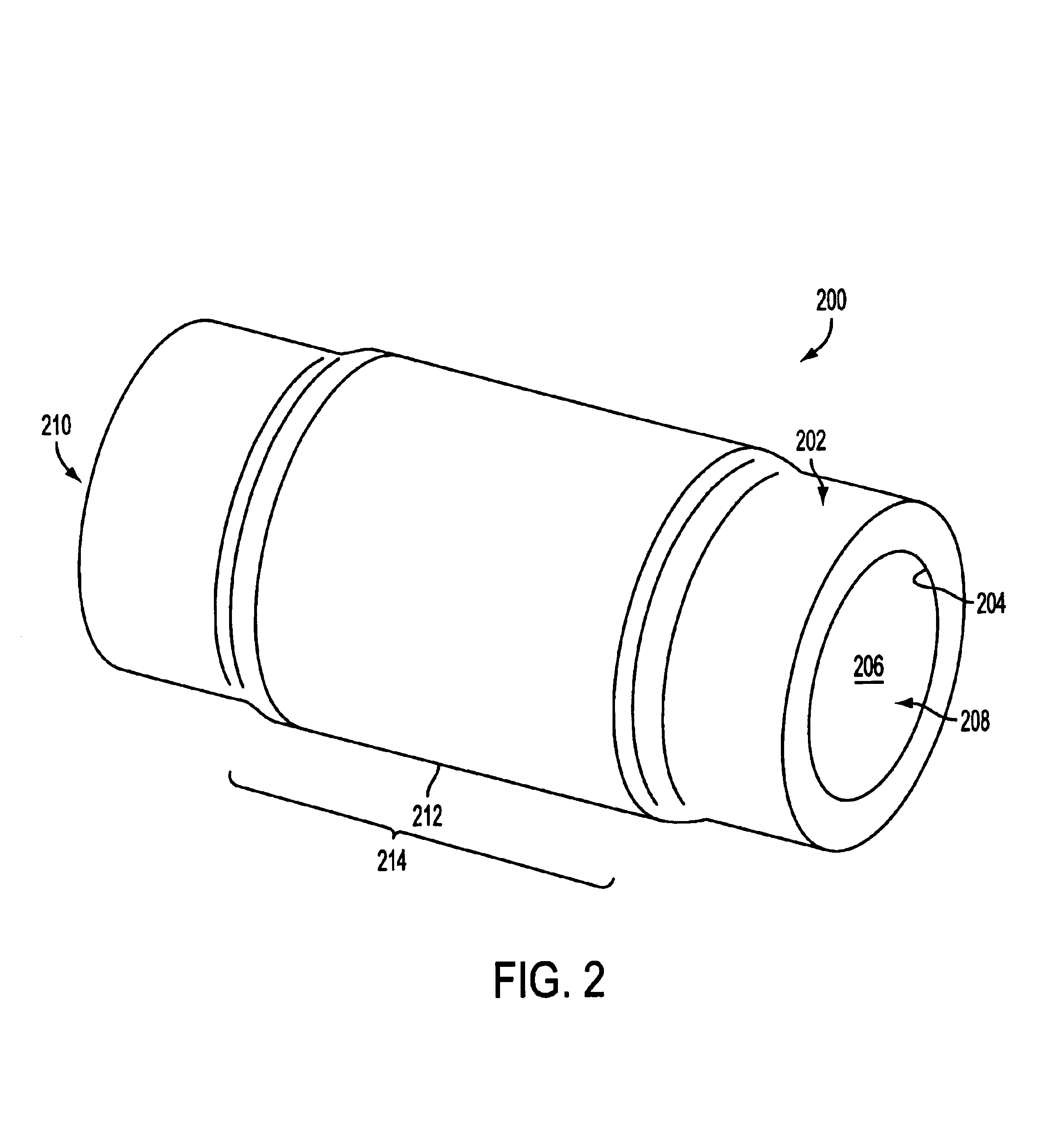

Track pin bushing having a metallurgically bonded coating

A track pin bushing for cooperating with a track pin in an endless track has a tubular body with a metallurgically bonded wear-resistant coating and a method for forming such a coated track pin bushing is taught herein. The tubular body, formed of an iron-based alloy, has an outer surface that is carburized and quenched, i.e., case-hardened, in at least a section thereof. At least a portion of the case hardened section has been removed to a depth sufficient to expose a non-carburized layer of the iron-based alloy. A hard metal alloy slurry is disposed on the non-carburized layer and forms a metallurgical bond between the non-carburized layer and the coated unfused slurry by fusing the hard metal alloy. The thickness of the unfused slurry is adjusted to be from 1.67 to 2.0 times a final thickness of the wear-resistant coating. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof. The portion of the outer surface with the wear-resistant coating corresponds to a contact surface adapted to engage with a drive sprocket in the endless track of the track-type vehicle.

Owner:DEERE & CO

Non-Carburized Components of Track-Type Machines Having A Metallurgically Bonded Coating

Undercarriage assembly components of track-type machines having a metallurgically bonded wear-resistant coating and methods for forming such coated undercarriage assembly components is taught herein. The bodies of the undercarriage assembly components, formed of an iron-based alloy, have a hard metal alloy slurry disposed on a surface or into an undercut or channel and then fused to form a metallurgical bond with the iron-based alloy. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof. The portion of the outer surface of the undercarriage assembly components having the wear-resistant coating corresponds to a wear surface of the component during operation of the endless track of the track-type vehicle.

Owner:DEERE & CO

Conveyor chain

InactiveUS6991094B2Increase flexibilityReducing and controlling wearConveyorsDriving chainsEngineeringSpherical shaped

A section of chain for conveying product along a material handling system includes a pin connecting a center link between two side links. The pin may have a sleeve portion around and at least partially along the shaft portion of the pin. The sleeve portion may engage a center link of the section of chain and may be movable relative to the shaft portion. The sleeve portion may comprise a polymeric material. The sleeve portion may be molded over an I-pin or the like, or may be slid or pressed onto a stud-ended pin or bolt or the like. The pin may include a generally spherical-shaped ball member or portion on the shaft portion to enhance flexibility of the section of chain. The pin may be dialable or selectably positioned at the side links to control and adjust the wear surface of the pin relative to the chain links.

Owner:FROST TECH

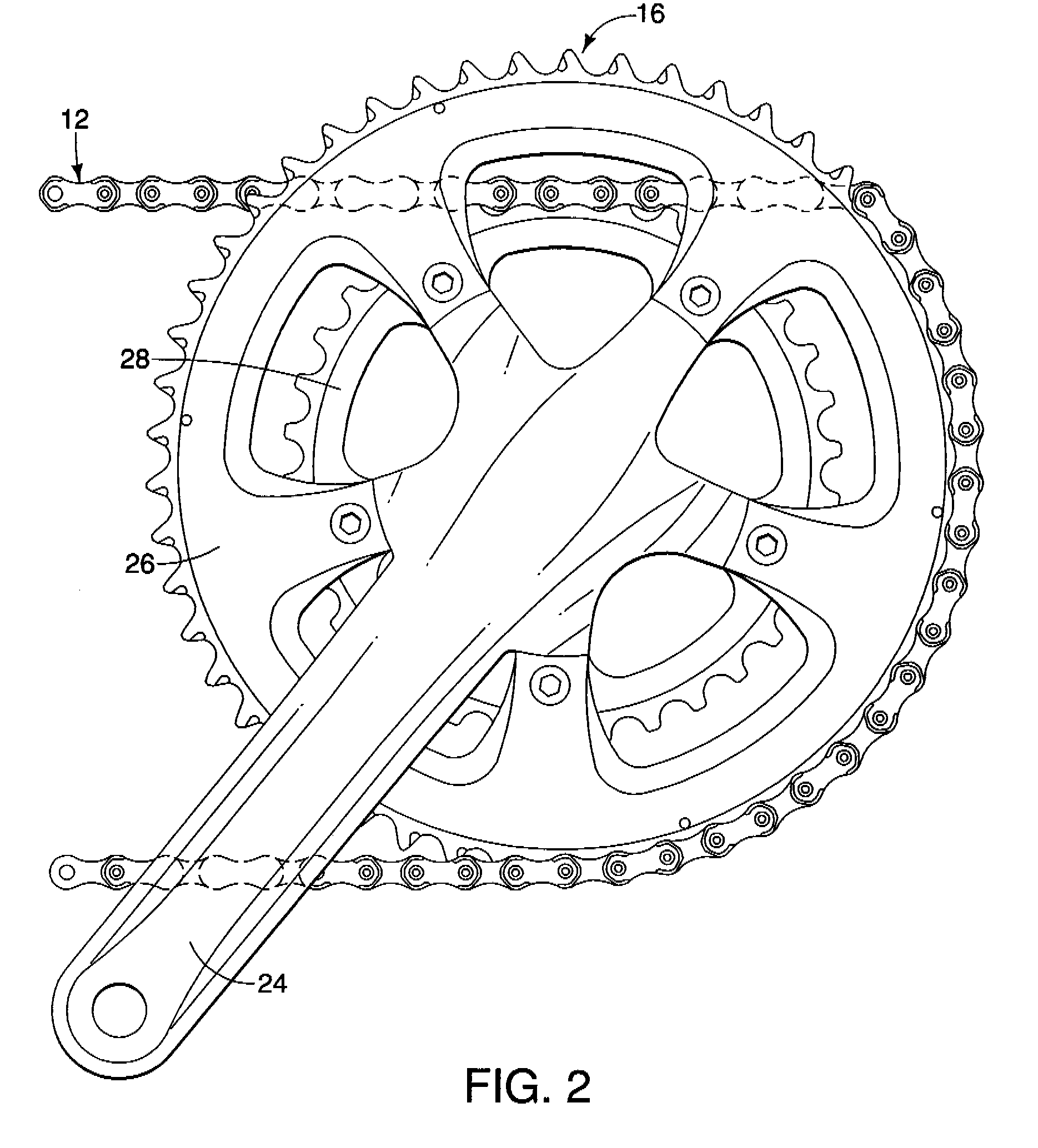

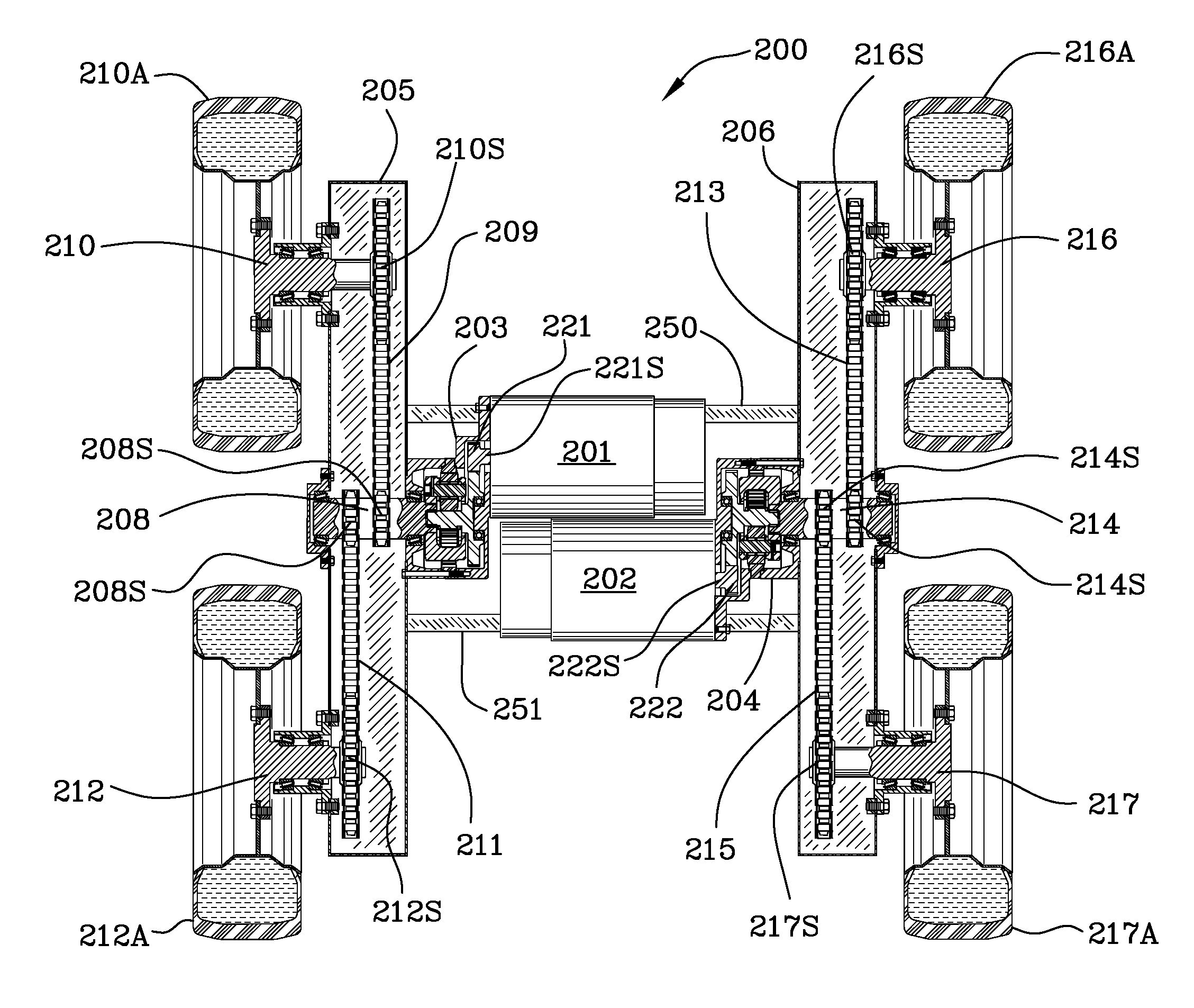

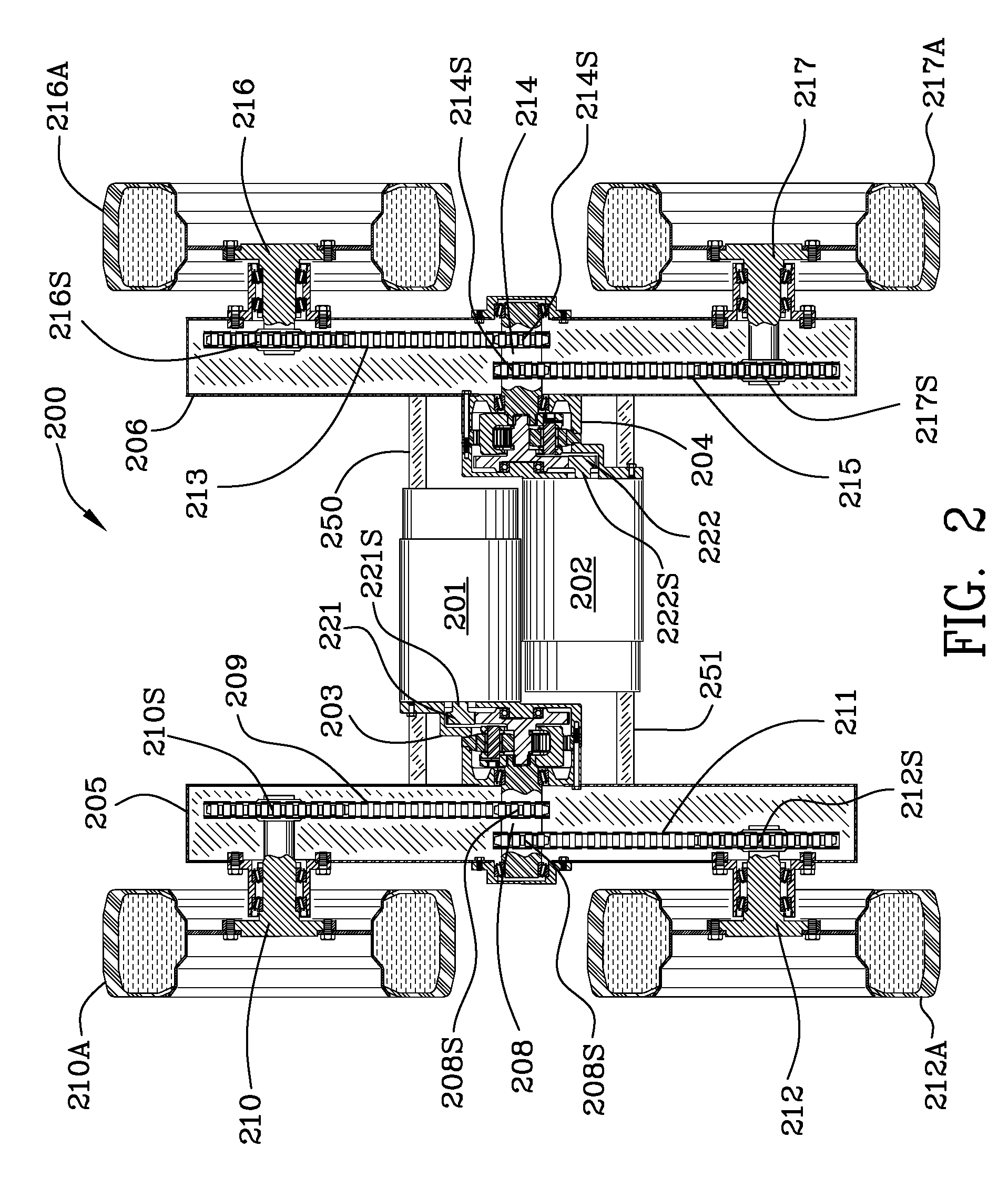

Offset drive system for utility vehicles

ActiveUS20080230284A1Easy to useEfficient production of torqueElectric devicesElectric propulsion mountingGear wheelSprocket

A wheel driven utility vehicle includes a frame and two small volume high speed alternating current electric motors arranged side by side for driving the vehicle. Alternatively high speed direct current, hydraulic or pneumatic direct current motors may be used with suitable controls. Each motor has an output shaft which drives an offset planetary gear reducer. Each offset planetary gear reducer is affixed to the electric motor and includes an output carrier interconnected with an output shaft. Each output shaft includes first and second chain drive sprockets which drive chains interconnected with shafts driving the front and rear wheels respectively. Each offset planetary gear reducer enables use of space saving high speed relatively low-torque alternating current electric motors with attendant large speed reductions. Gear reduction enables the production of sufficient torque at the wheels of the vehicle. Applications in addition to utility vehicles are also specifically contemplated.

Owner:FAIRFIELD MFG CO INC

Fixing structure of link and pin of travelling crawler belt, and fixing method thereof

In a travelling crawler belt in which a pair of left and right links are connected by pins respectively press-fitted into the corresponding links, a fixing end surface of the pin or the links is continuously and locally pressed and deformed in an axial direction of the pin from the fixing end surface, along an inner or outer peripheral portion of an opening of a pin-press-fit hole. Then, a part of the opening peripheral portion of the end of the pin or the link is enlarged or reduced in diameter, so that the diametrically increased or reduced portion is retained and fixed to a mating retaining space. With this fixing method, it is possible to easily and strongly couple the links and the pin, and to obtain a fixing structure of the links and the pin for a crawler belt capable of sufficiently securing a holding force of the pin in the axial direction. When the pin is fixed at the time of the assembling of the pin, an existing press can be used without requiring any exclusive machine, and it is possible to easily and reliably assemble the links and the pin for the crawler belt.

Owner:KOMATSU LTD

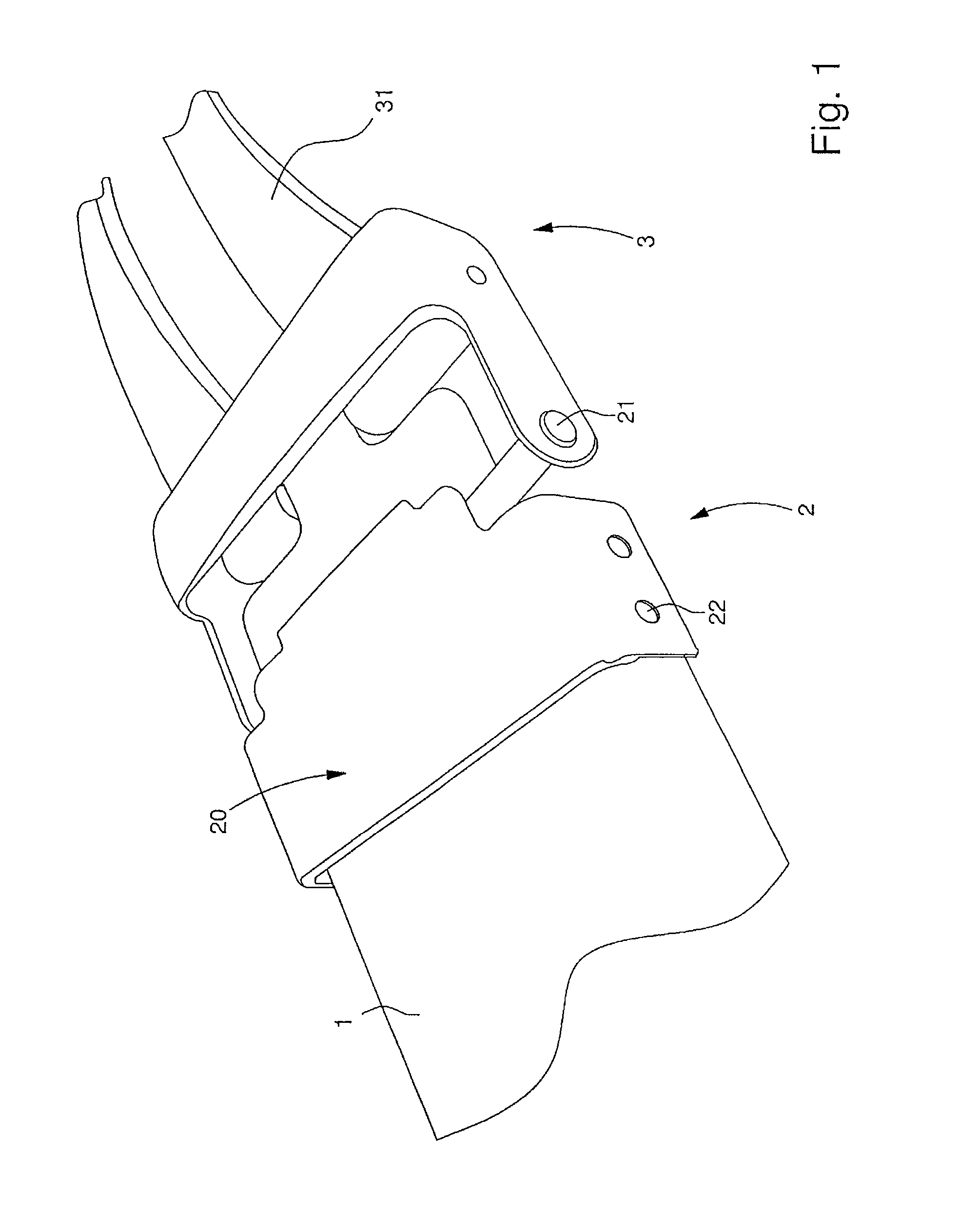

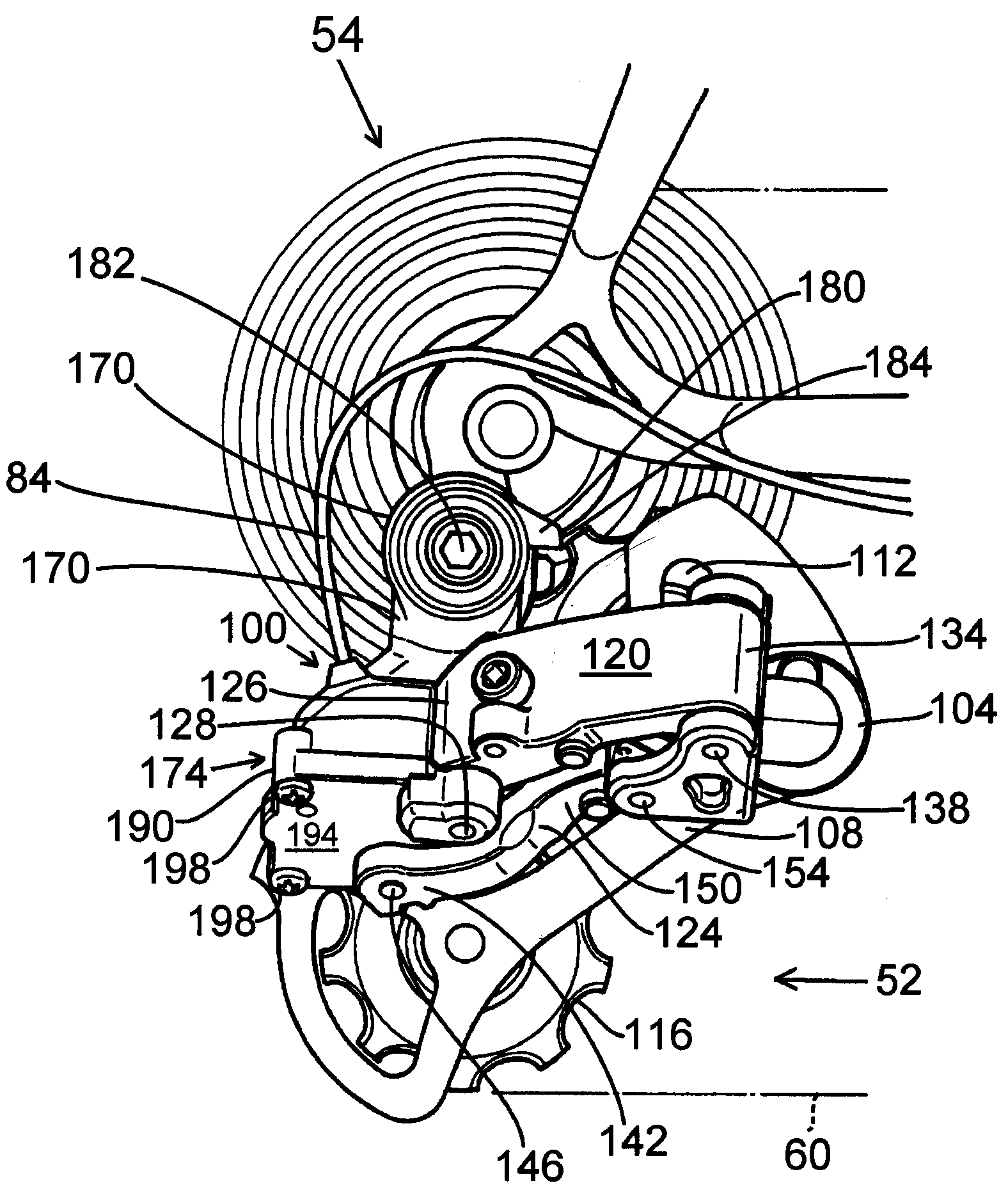

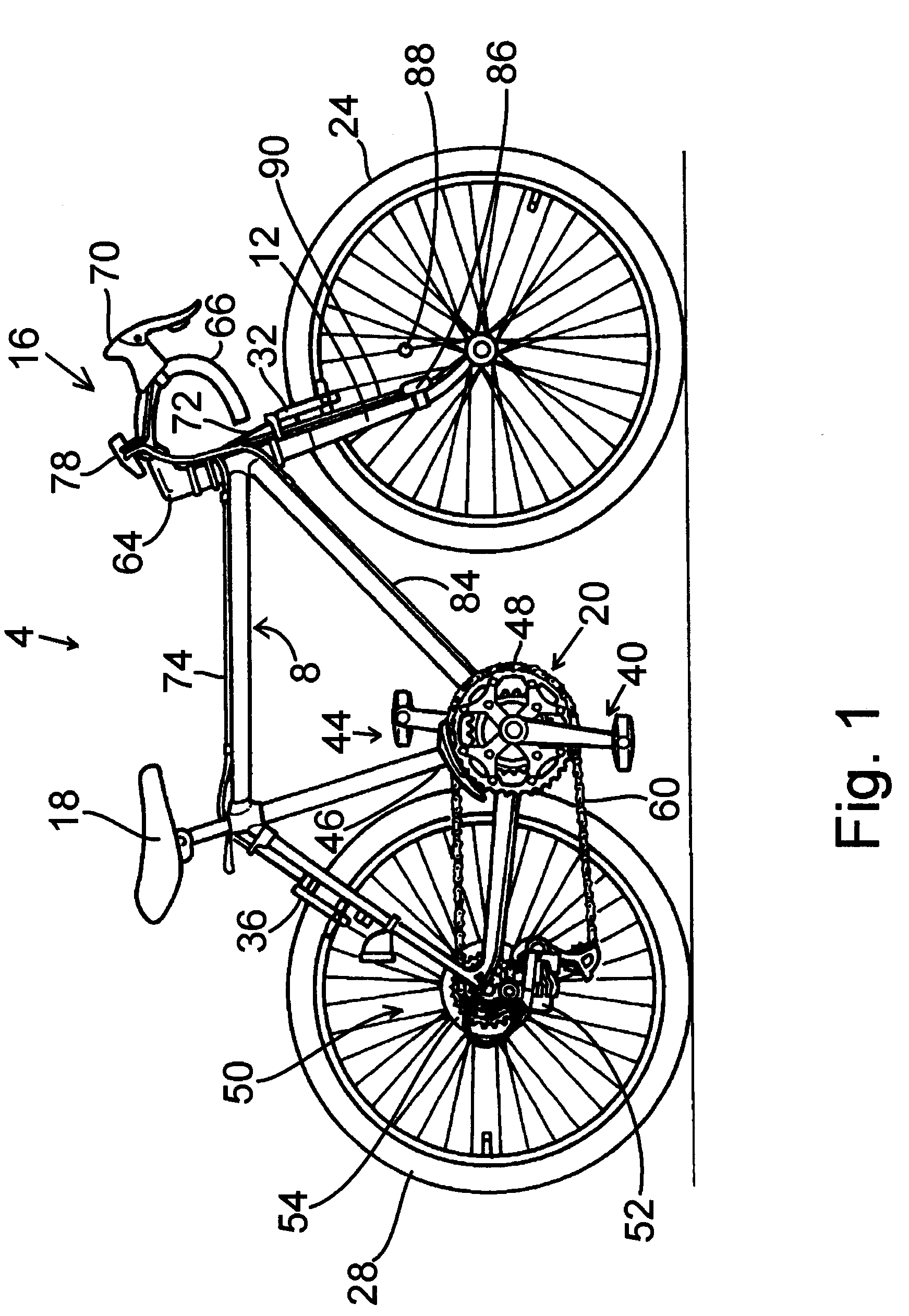

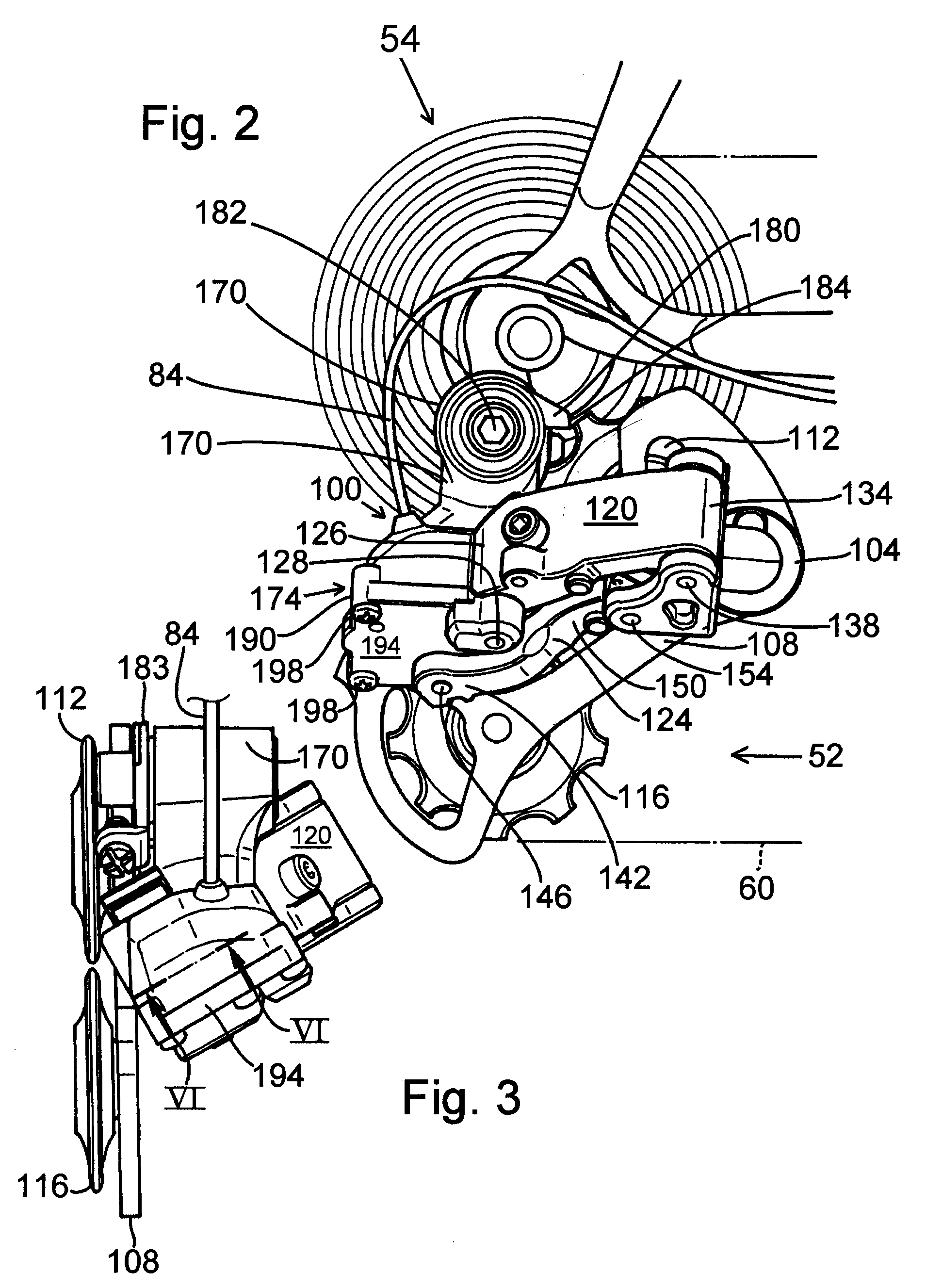

Bicycle derailleur with a motor disposed within a linkage mechanism

A bicycle derailleur comprises a base member, a movable member for supporting a chain guide, a first link member pivotably coupled to the base member and to the movable member through respective first and second link pins, a second link member pivotably coupled to the base member and to the movable member through respective third and fourth link pins, and a motor having a drive shaft that defines a drive shaft vector. The first through fourth link pins define edges of a phantom space, wherein straight continuous phantom lines connecting ends of the first through fourth link pins in a non-crossing manner define remaining edges of the phantom space. At least a part of the primary motor housing is disposed in the phantom space, and the drive shaft vector points away from a plane containing the second and fourth link pins.

Owner:SHIMANO INC

Color image display device, method of driving the same, and electronic equipment

A gray-scale power supply line supplied to a source signal line driving circuit is made only one system, and each of D / A conversion circuits drives source signal lines in which three source signal lines corresponding to RGB are made a unit and the number of which is a multiple of 3. The periods in which respective source line selecting circuits select source signal lines corresponding to respective colors of the RGB are made synchronous with each other, and the power supply voltage applied to the gray-scale power supply line is changed in one horizontal writing period, so that power supply voltages corresponding to R, G and B are respectively applied to the gray-scale power supply line in periods while the source signal lines of R, G and B are respectively selected.

Owner:SEMICON ENERGY LAB CO LTD

Shackle apparatus

A shackle apparatus including a generally U-shaped shackle body having an arcuate end, a pair of parallel arms, and a retaining member spanning a gap defined between the shackle arms. The retaining member cooperates with the shackle body to define a closed loop which can be permanently attached to a sling or lifting cable. The retaining member prevents the shackle apparatus from being removed and installed on another sling or lifting cable without substantially destroying the shackle apparatus of the present invention.

Owner:USEFUL PRODS

Investment cast, stainless steel chain link and casting process therefor

ActiveUS20070107412A1Reduce tensionEliminate wear and tearFoundry mouldsSedimentation separationFree rotationInvestment casting

An investment cast, stainless steel chain link is provided for chains used in water and wastewater treatment. The chain link comprises a pair of spaced apart, elongated sidebars having forward ends and rearward ends. The forward ends are spread apart and are provided with outwardly and laterally extending bosses having transverse boss pin bores coaxially aligned with each other. The rearward ends are interconnected by a cylindrical barrel having a barrel pin bore extending through each of the sidebars. The sidebars are formed with outwardly and laterally projecting reinforcing ribs extending between the bosses and the barrel pin bore along a substantial length of the sidebars. A freely rotatable chain pin is inserted through aligned boss and barrel pin bores from either end thereof for interconnecting first and second pairs of sidebars. An arrangement is provided for preventing the lateral dislodgement of the chain pin from the sidebars.

Owner:HUMCKE MICHAEL W +1

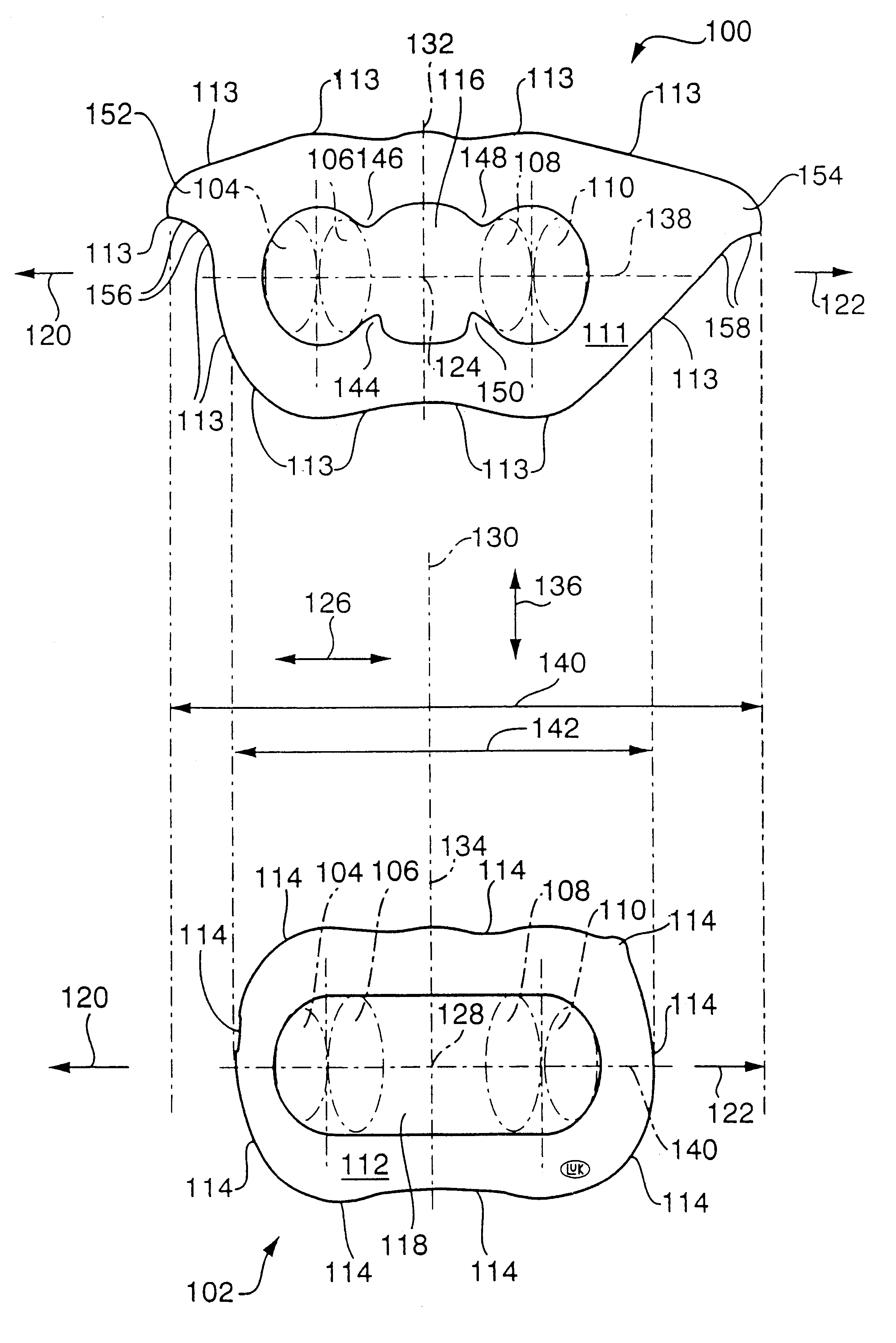

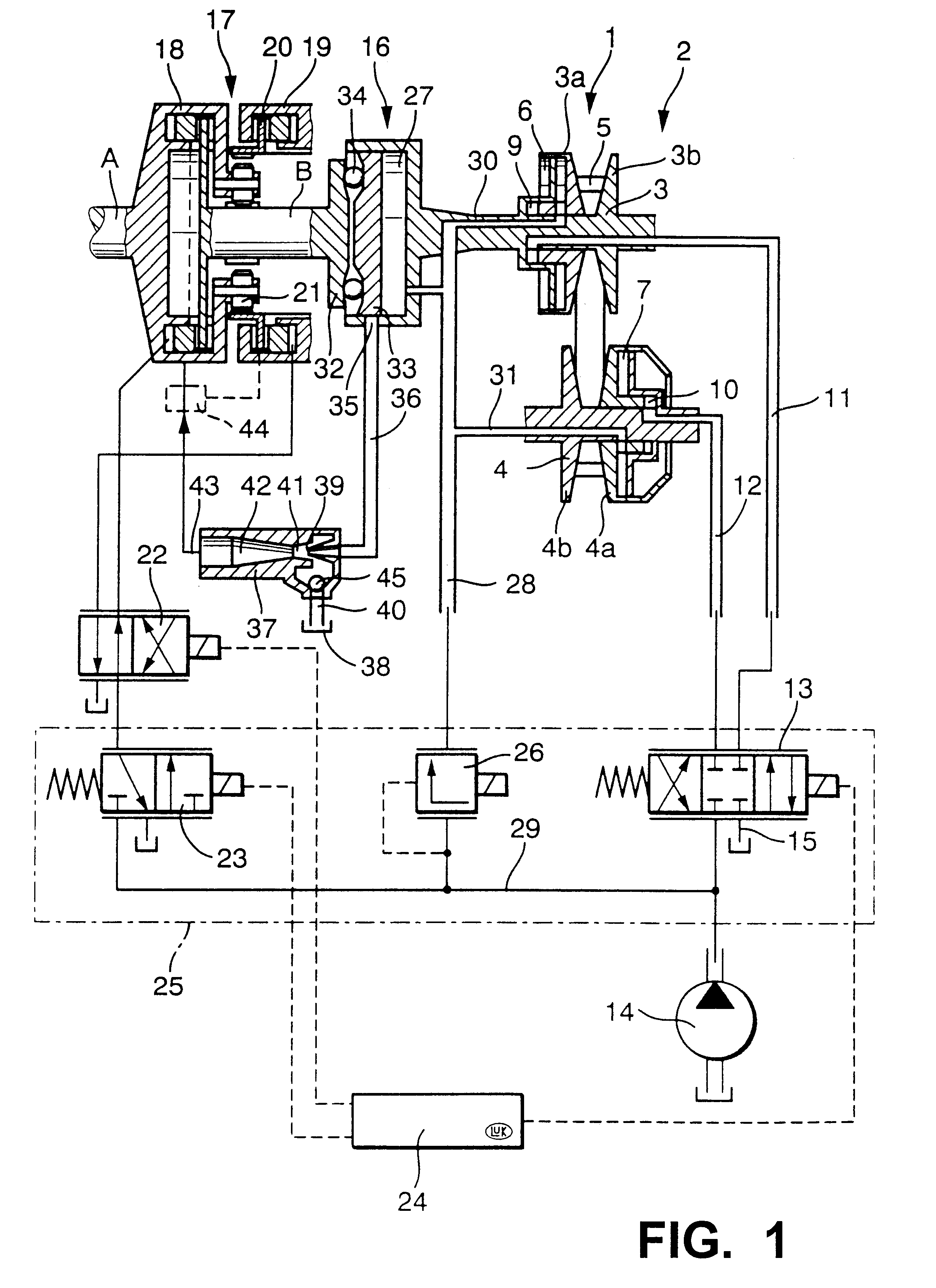

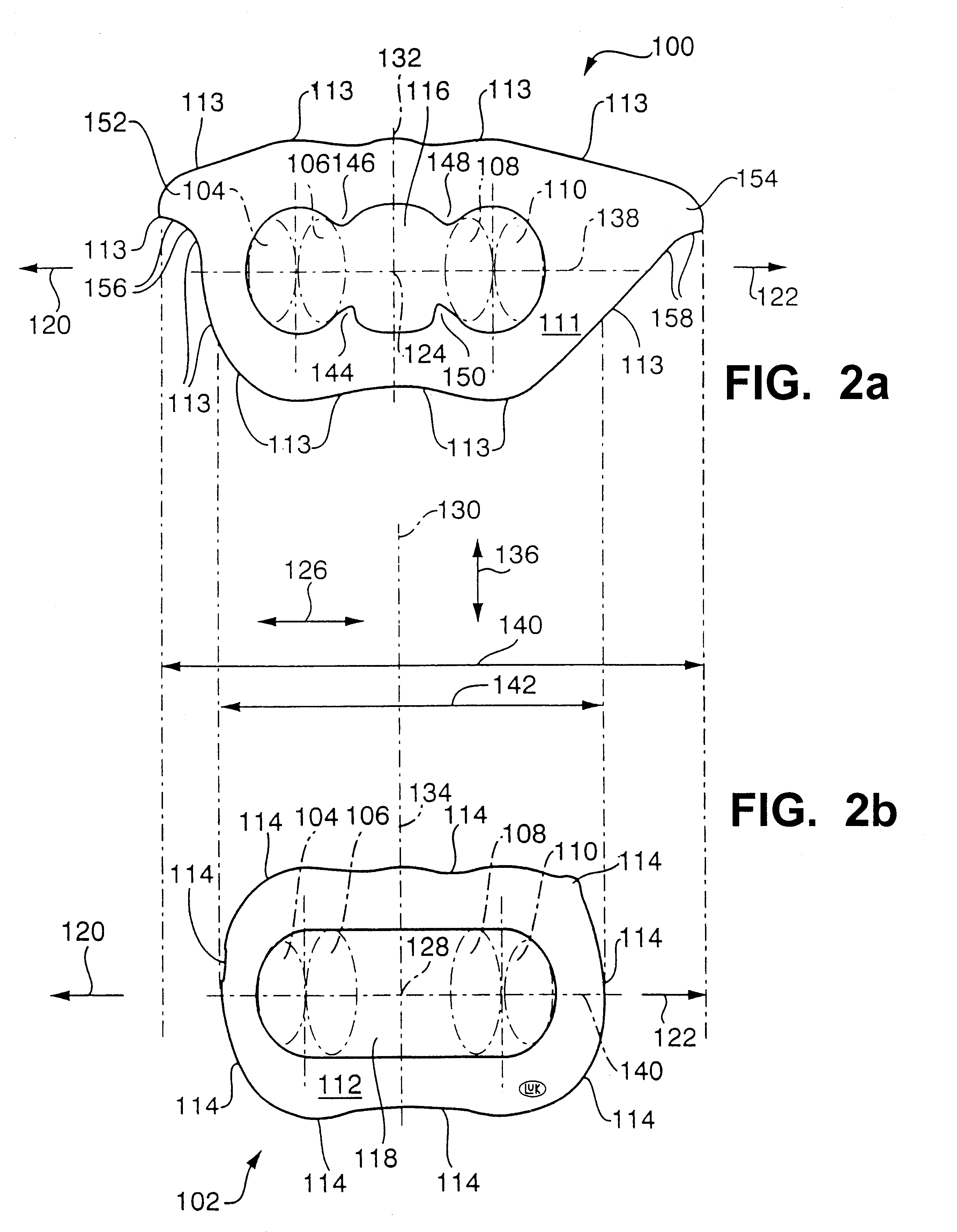

Link chain

InactiveUS6478704B1Simple and inexpensiveExcellent substituteV-beltsGearingParallel plateEngineering

An endless link chain, particularly for use in a continuously variable transmission in the power train of a motor vehicle, has composite links and pintles which articulately connect neighboring links to each other. At least one of the links is assembled of at least two types of parallel plate-like components which differ from each other in size, shape, material and / or strength. The purpose of such selection of the plate-like components is to enhance one or more characteristics of the chain, for example, to reduce or eliminate vibration, to reduce the bulk and / or to properly position the pintles. The distribution of components in one or more links can be selected with a view to influence the above-enumerated and / or other characteristics, such as the resistance to deformation, of the chain.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Bicycle chain

InactiveUS20050202914A1Easy to operateImprove the level ofPortable liftingDriving chainsEngineeringSprocket

Owner:SRAM

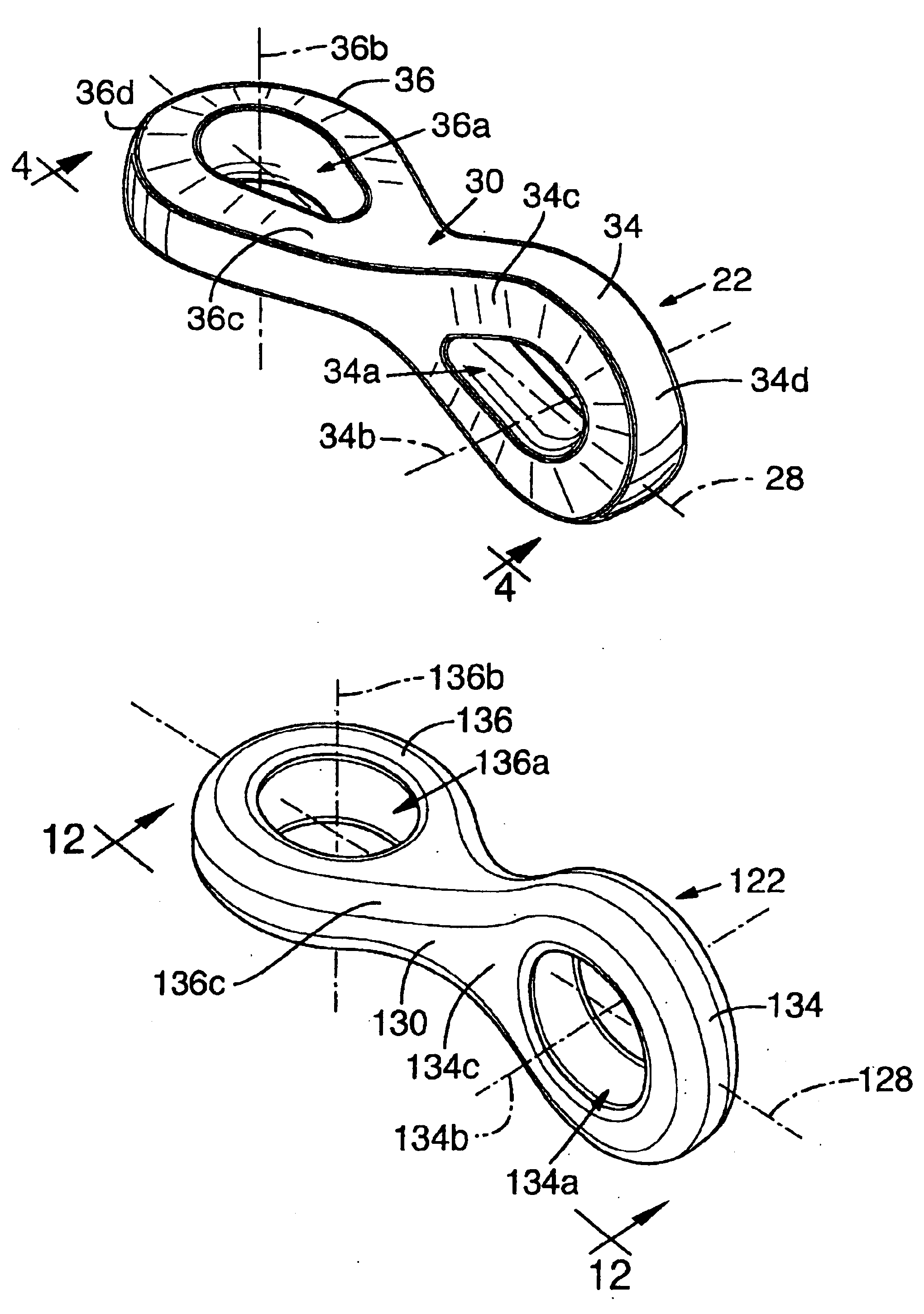

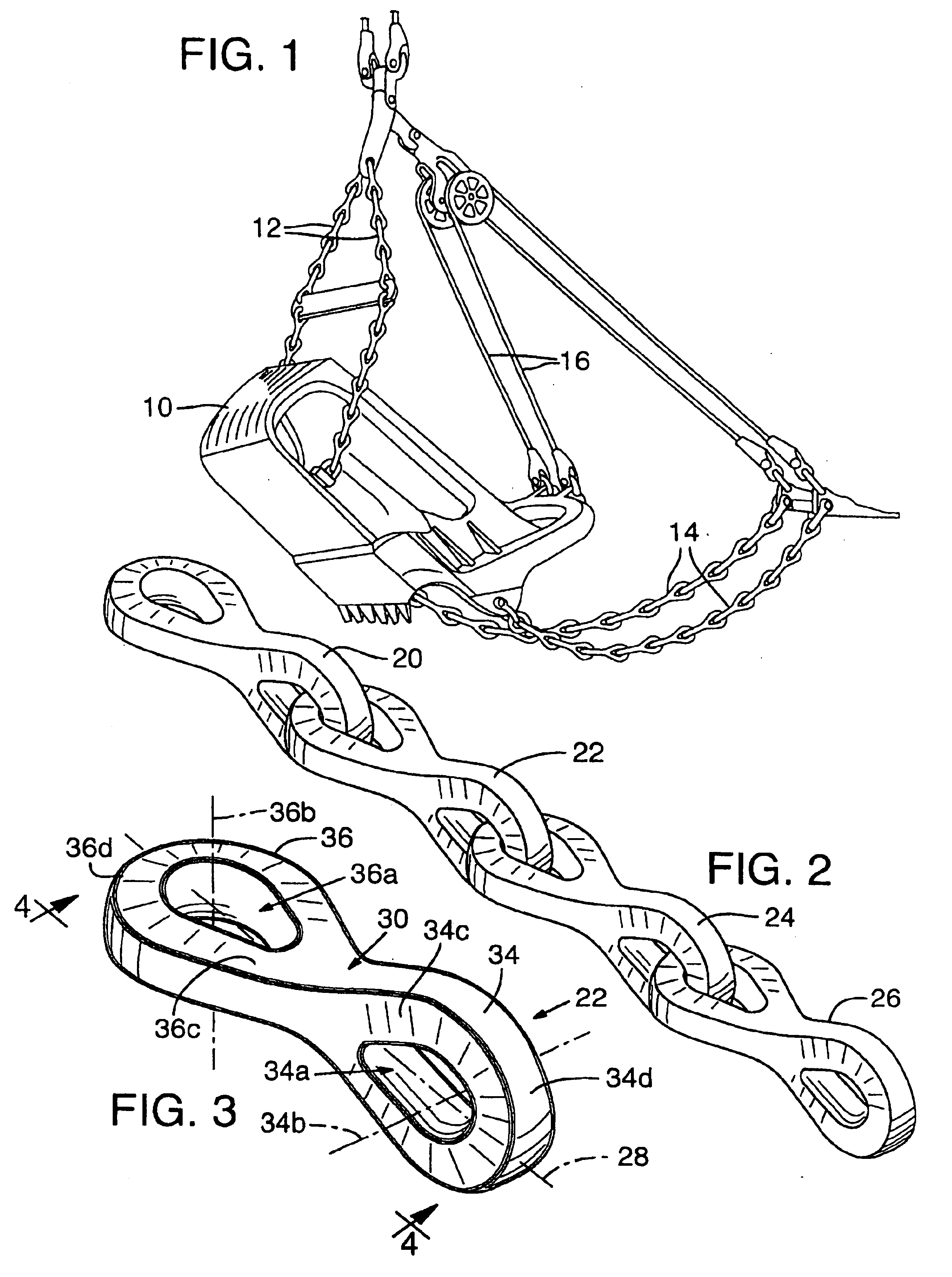

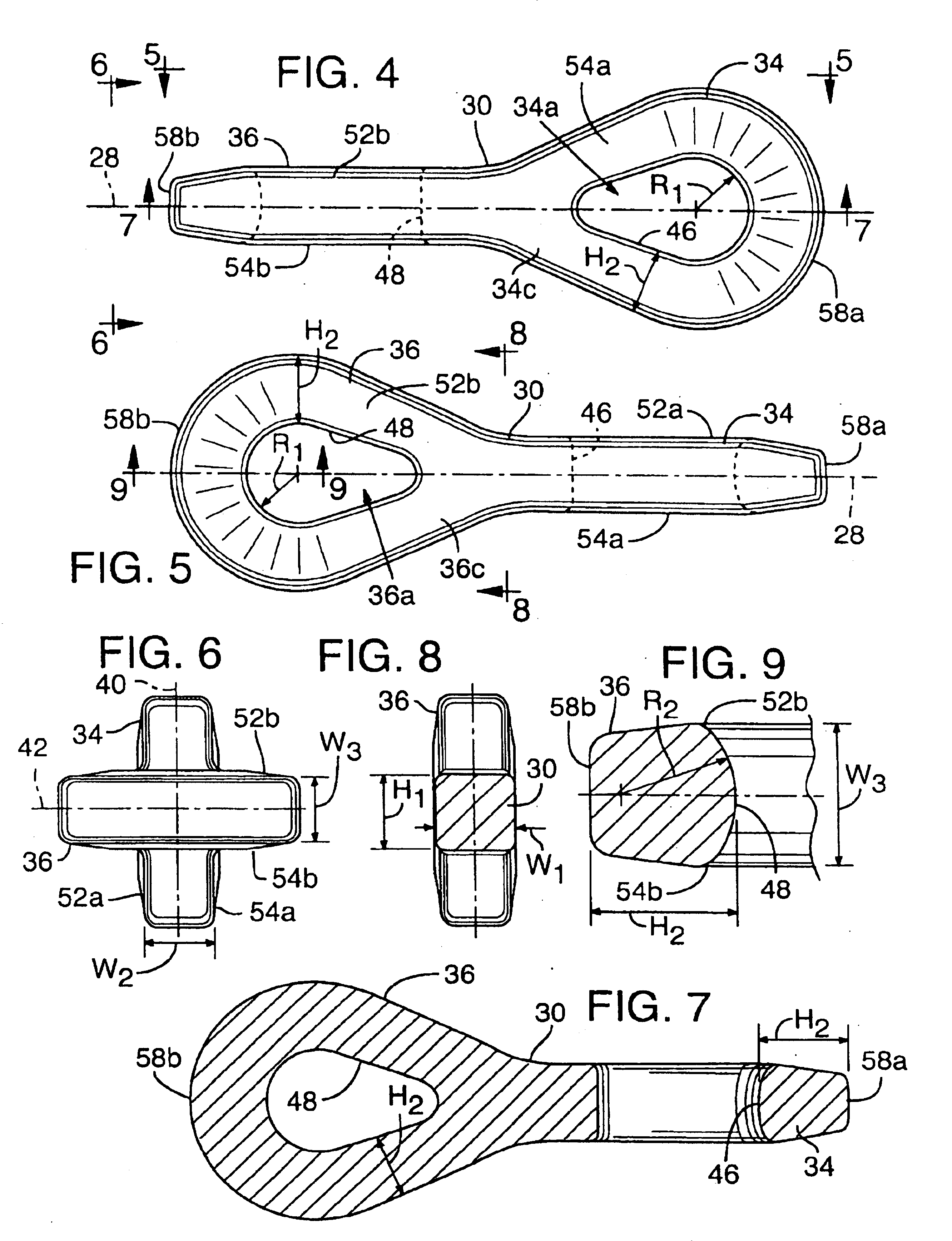

Chain link with angularly disposed end portions

A chain link has a substantially centrally located juncture section with a first eye portion integrally connected to one end of the juncture section and a second eye portion integrally connected to the opposite end of the juncture section. The eye portions extend longitudinally outwardly from opposite ends of the juncture section and are disposed at a substantial angle relative to each other at opposite ends of the link. Such link may be connected to contiguous links to form a segment of a chain, with all of the links in a segment of chain thus produced having substantially the same orientation when the chain is held straight.

Owner:COLUMBIA STEEL CAST PROD LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com