Redundancy weighing sensor

A weighing sensor and redundant technology, applied in the direction of weighing equipment testing/calibration, instruments, weighing, etc., can solve the problems of single sensor, no redundant function, etc., and achieve the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

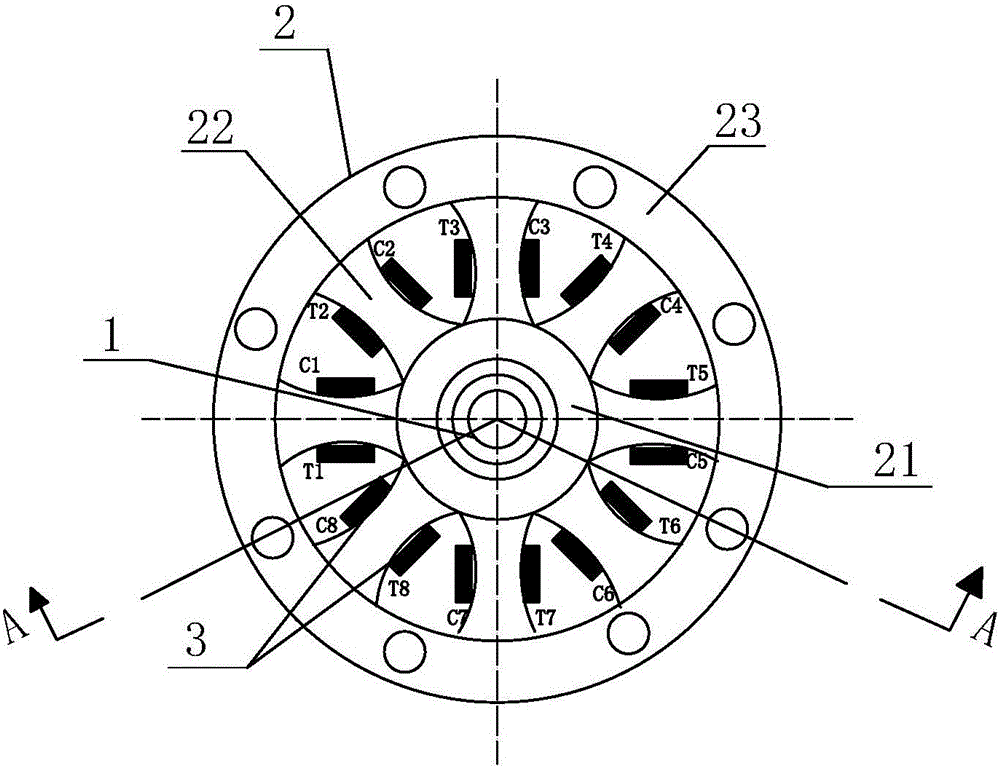

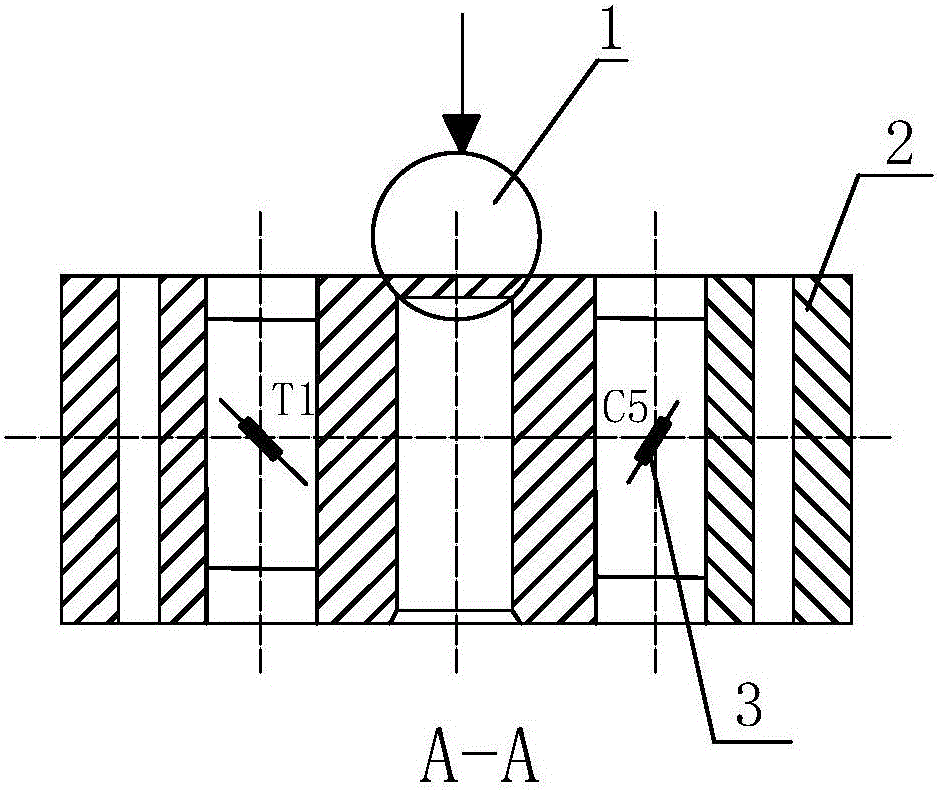

[0024] refer to figure 1 and figure 2 , a kind of redundant weighing sensor, comprises spherical bearing pressure head 1, spoke beam type elastic body 2 and resistance strain gage 3, and spoke beam type elastic body 2 is made up of wheel hub 21, wheel spoke 22 and wheel tire 23, and described wheel hub 21 Located at the center of the inner ring, the tire 23 is located at the outer ring, and the spokes 22 are provided with eight, evenly distributed and connected between the hub 21 and the spokes 23, the whole is like a wheel.

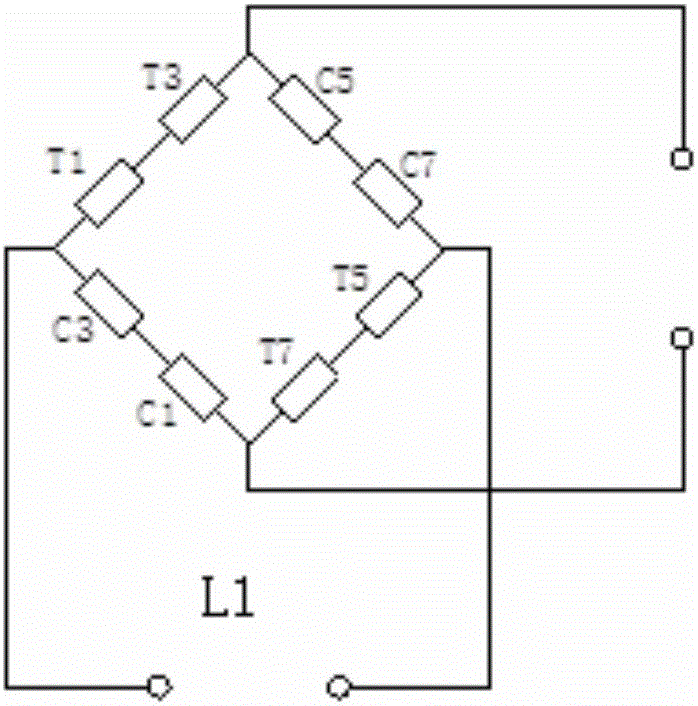

[0025] The spherical bearing pressure head 1 is closely attached to the spoke beam type elastic body 2, which mainly plays the roles of anti-eccentric load, anti-torsion and anti-side. The resistance strain gauges 3 are installed in the spoke beam elastic body 2, and are respectively pasted on the two sides of the spokes 22 in the direction of tension and in the direction of compression. The resistance strain gauges 3 in the two directions respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com