Method for measuring coefficient of normal anisortopy and yield stress of pipe in any direction

A technology of yield stress and thickness anisotropy, which is applied in the field of pipe performance testing, can solve the problems that the characteristic parameters of pipe anisotropy can not be measured accurately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

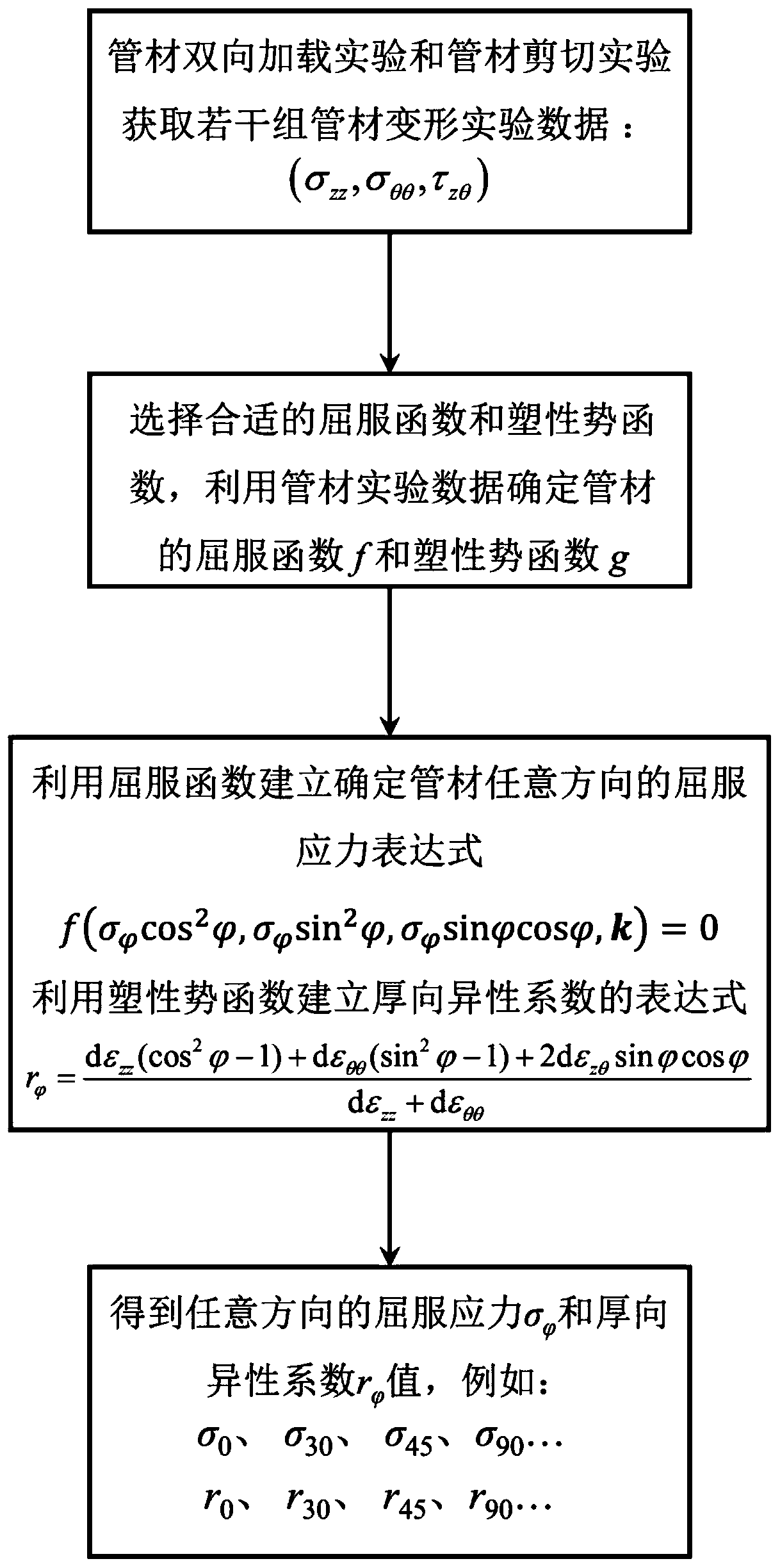

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0052] Take the 6061O tempered aluminum alloy extruded pipe with an outer diameter of 60mm and a wall thickness of 1.8mm as an example. Figure 1-9 The implementation process of the present invention is described:

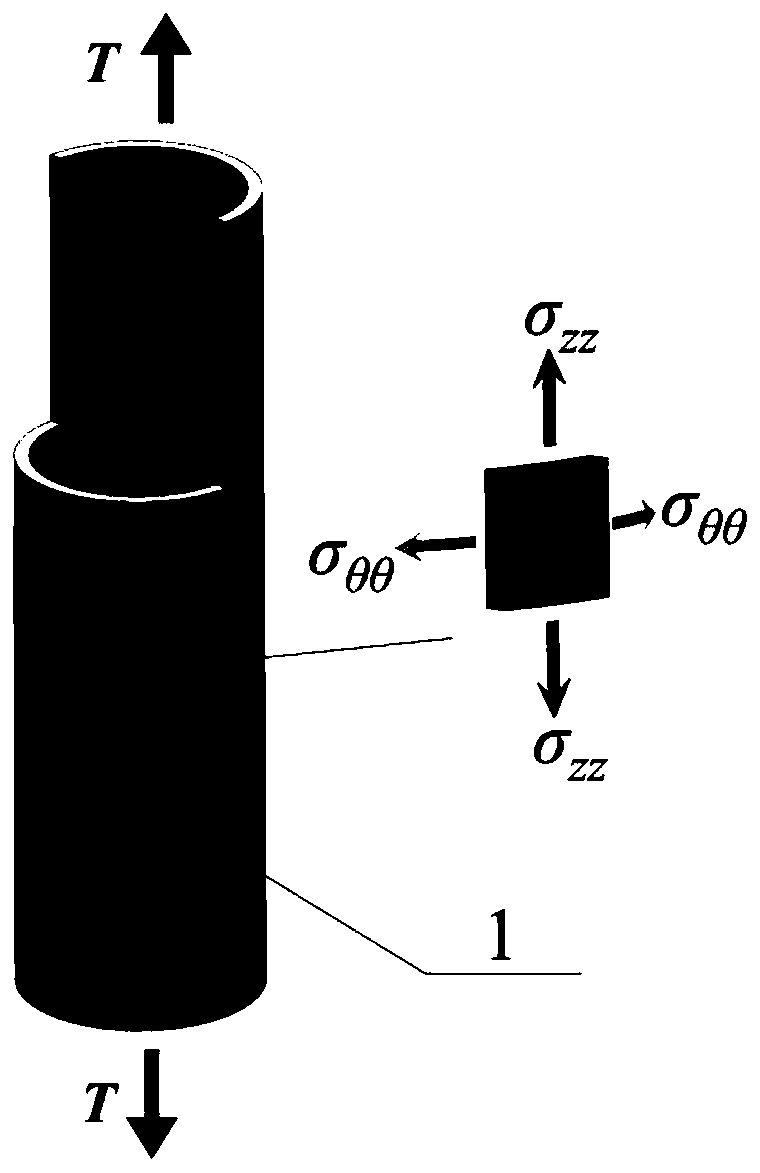

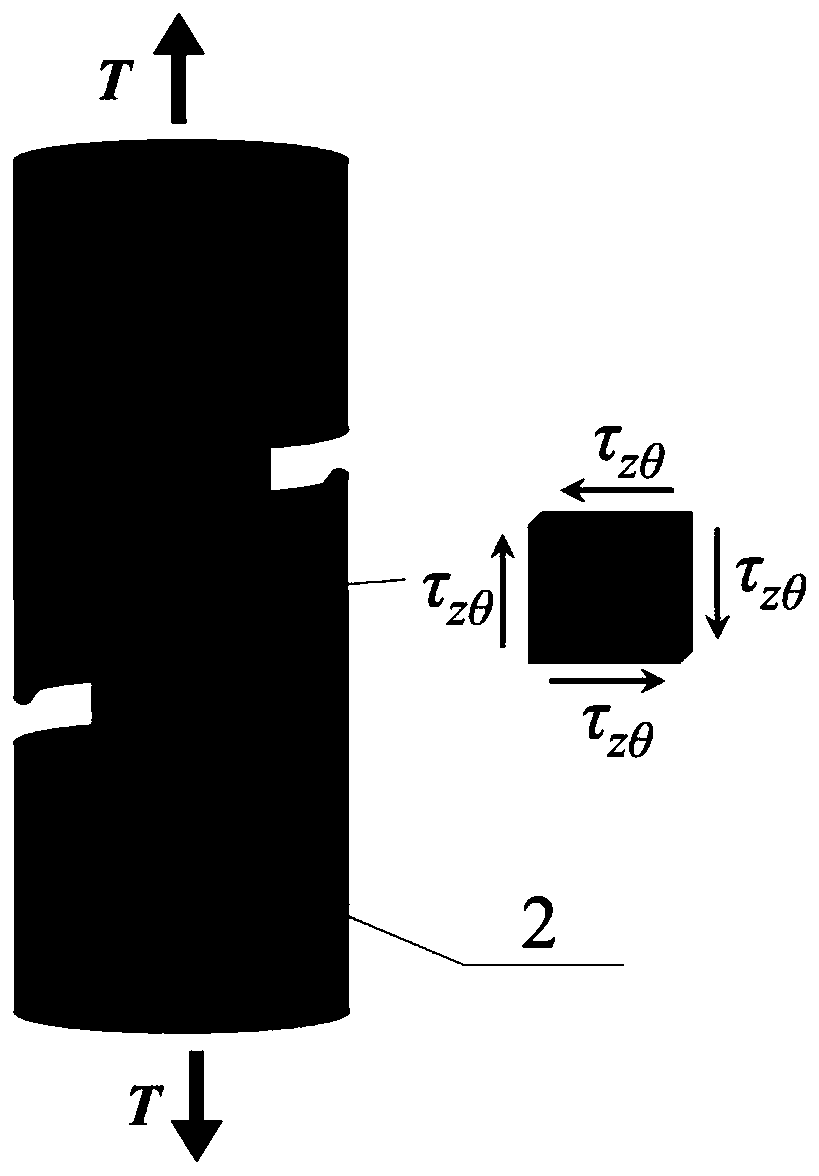

[0053] Step 1. Cut the pipe to be tested into a suitable length (length is 270mm), and carry out 9 sets of pipe bidirectional loading experiments, such as Figure 5 Shown in order to obtain the stress and strain experimental data of the pipe under the nine bidirectional stress states;

[0054] The pipe bidirectional loading experiment is carried out on a special pipe bidirectional loading experiment test device (refer to patent CN105300802B), applying a tensile or compressive load to the end of the pipe, and applying a pressure medium inside the pipe to make the pipe in the set stress path Under deformation, the experimental data (st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com